Patents

Literature

522results about "Copper sulfides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

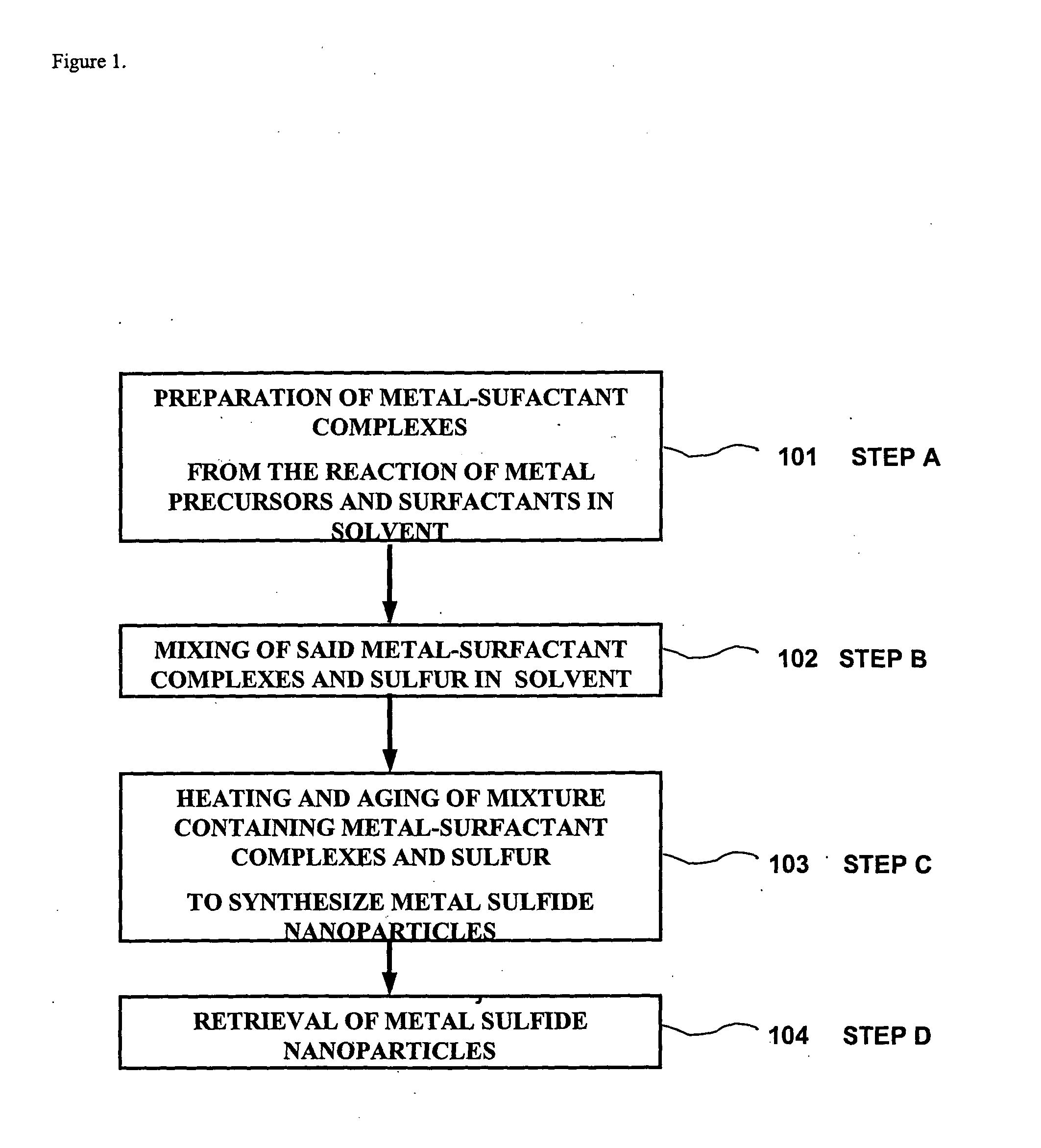

Method for synthesizing nanoparticles of metal sulfides

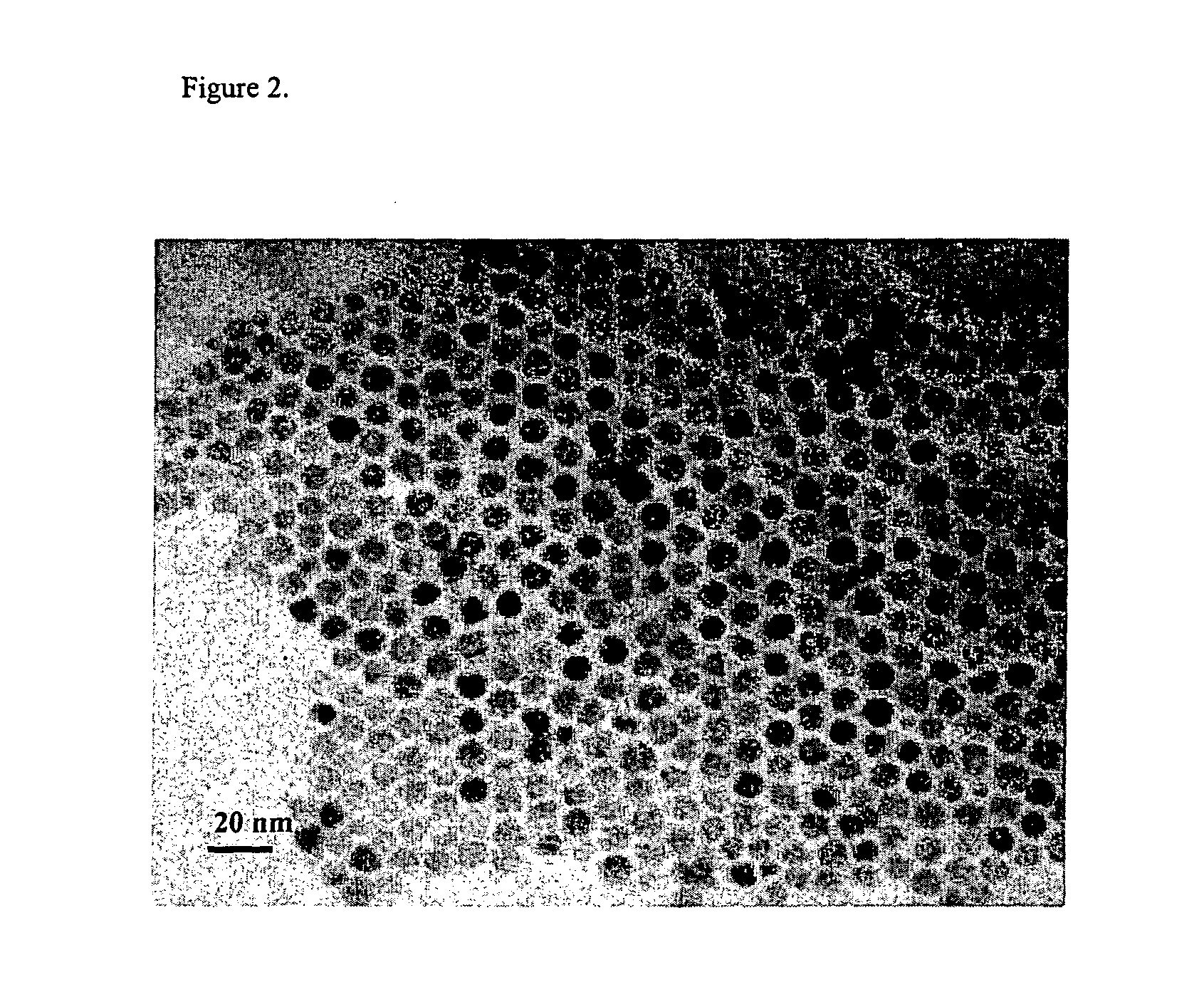

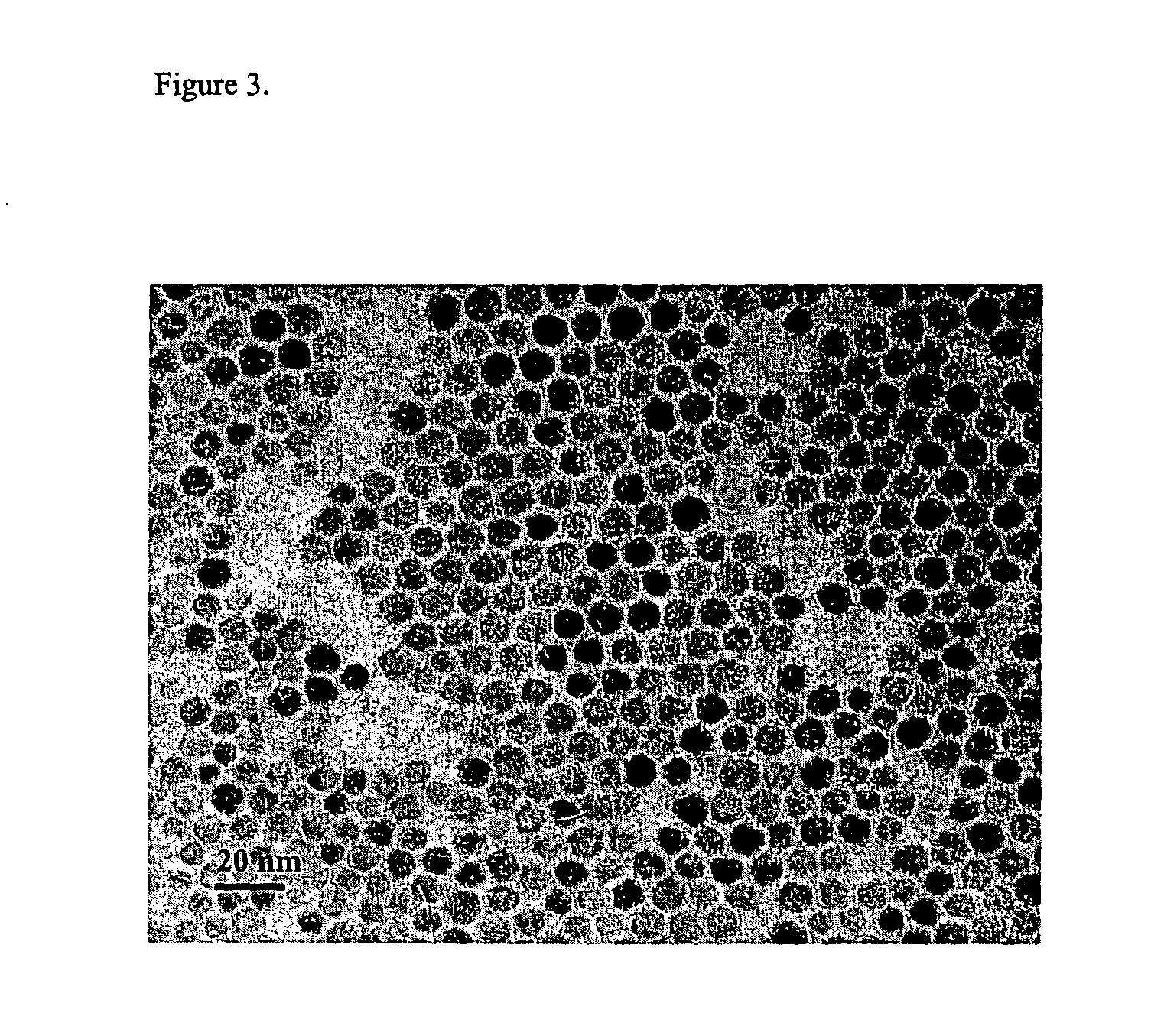

A synthetic method of fabricating highly crystalline and uniform nanoparticles of metal sulfides, doped metal sulfides, and multi-metallic sulfides disclosed, using no-toxic and inexpensive reagents. A typical synthetic method comprises the steps of, synthesis of metal-surfactant complexes from the reaction of metal precursors and surfactant, addition of sulfur reagent to the solution containing said metal-surfactant complexes followed by heating to high temperature, aging at that temperature to produce metal sulfide nanoparticles and completing the formation of synthesis of nanoparticles metal sulfides and multi-metallic sulfides by adding a poor solvent followed by centrifuging.

Owner:SEOUL NATIONAL UNIVERSITY

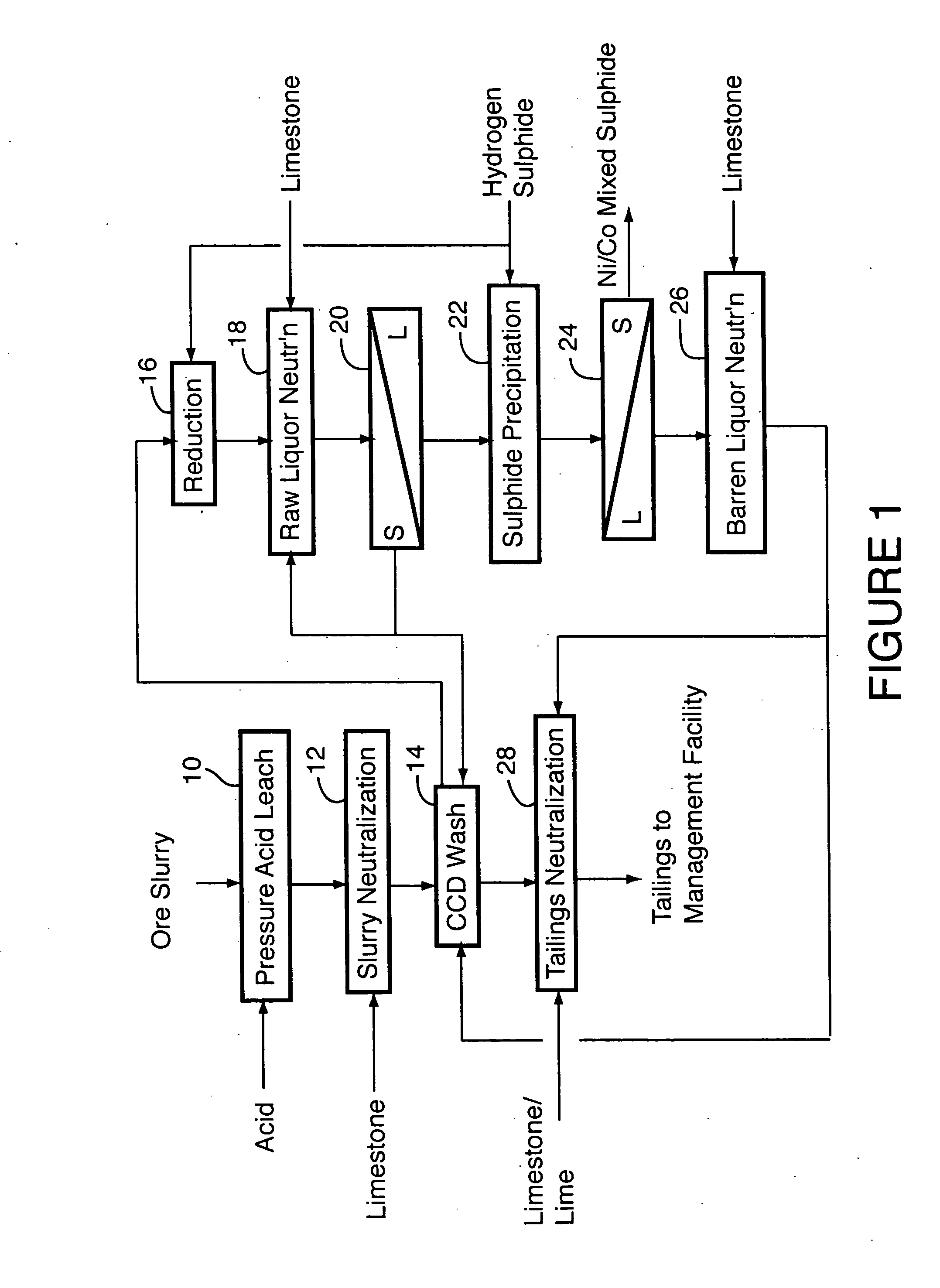

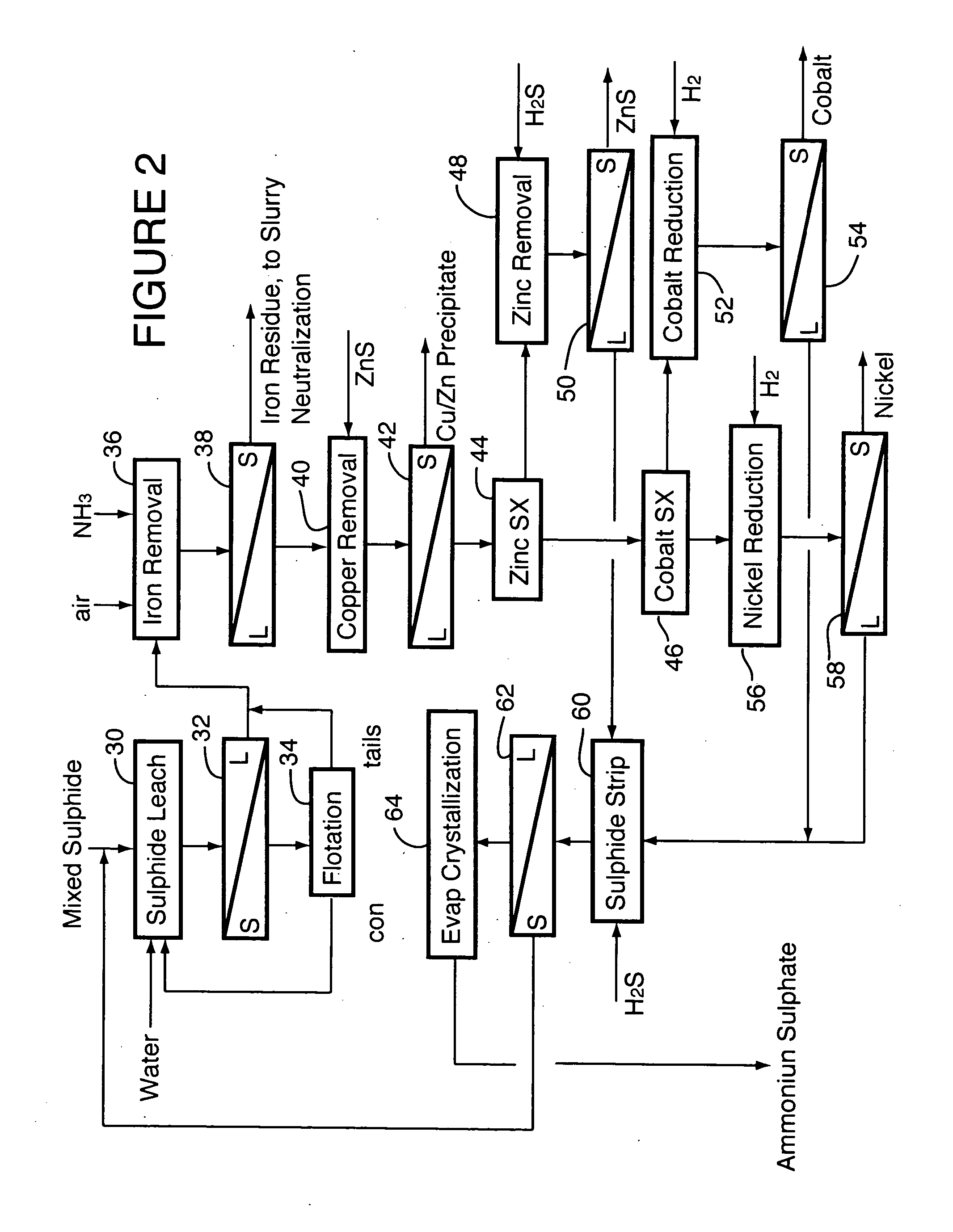

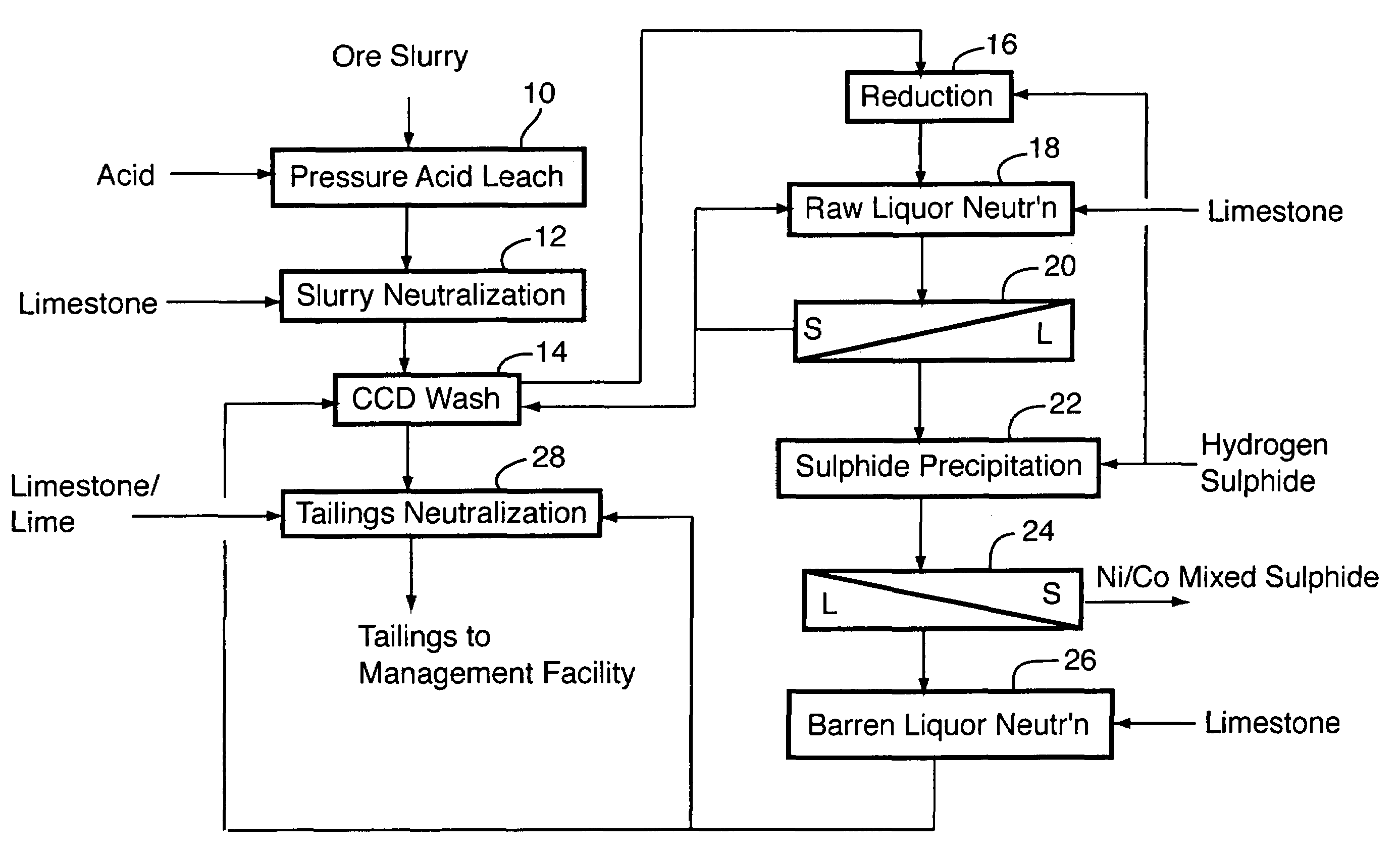

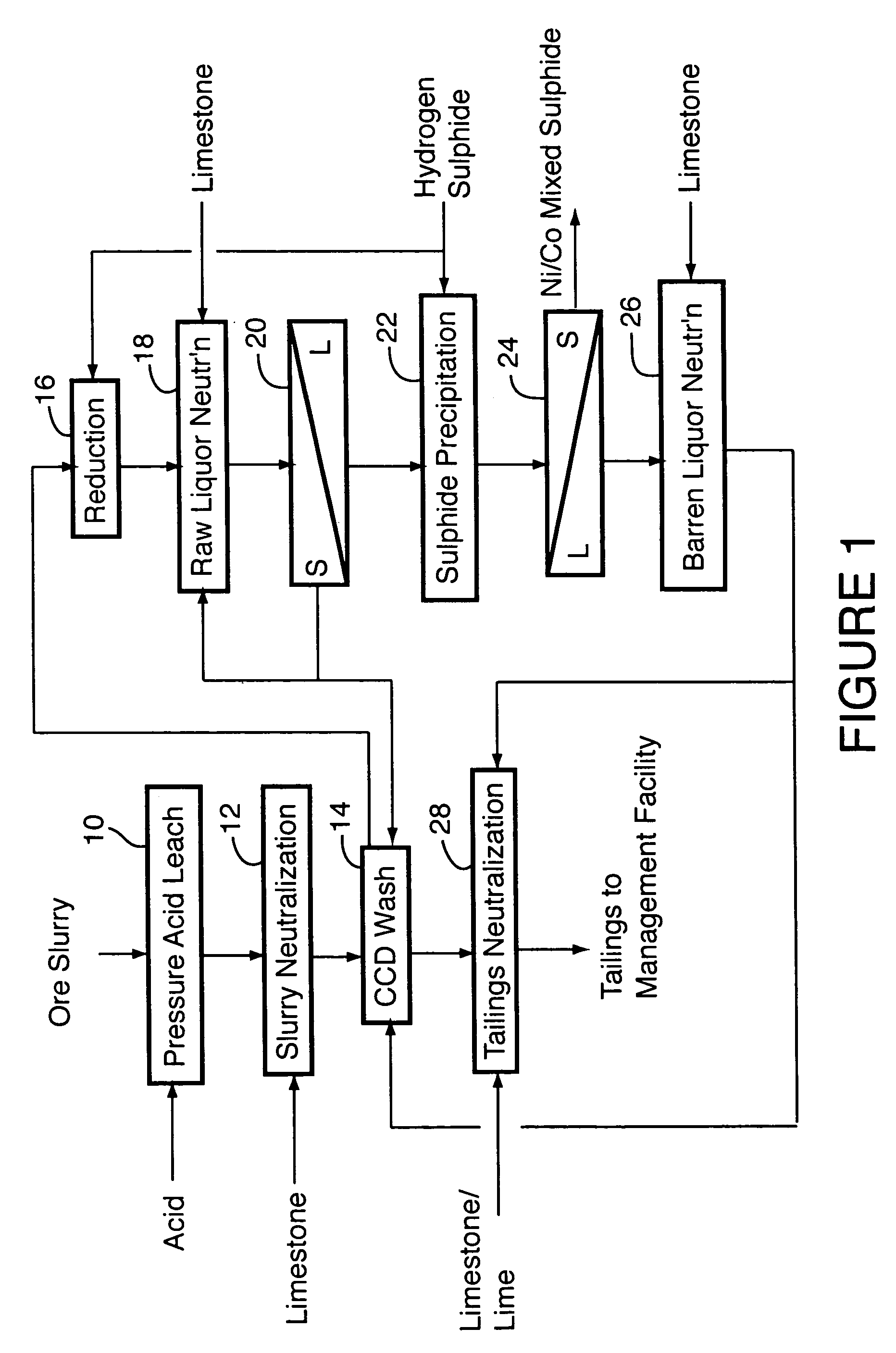

Process for recovery of nickel and cobalt from laterite ore

ActiveUS20060228279A1Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

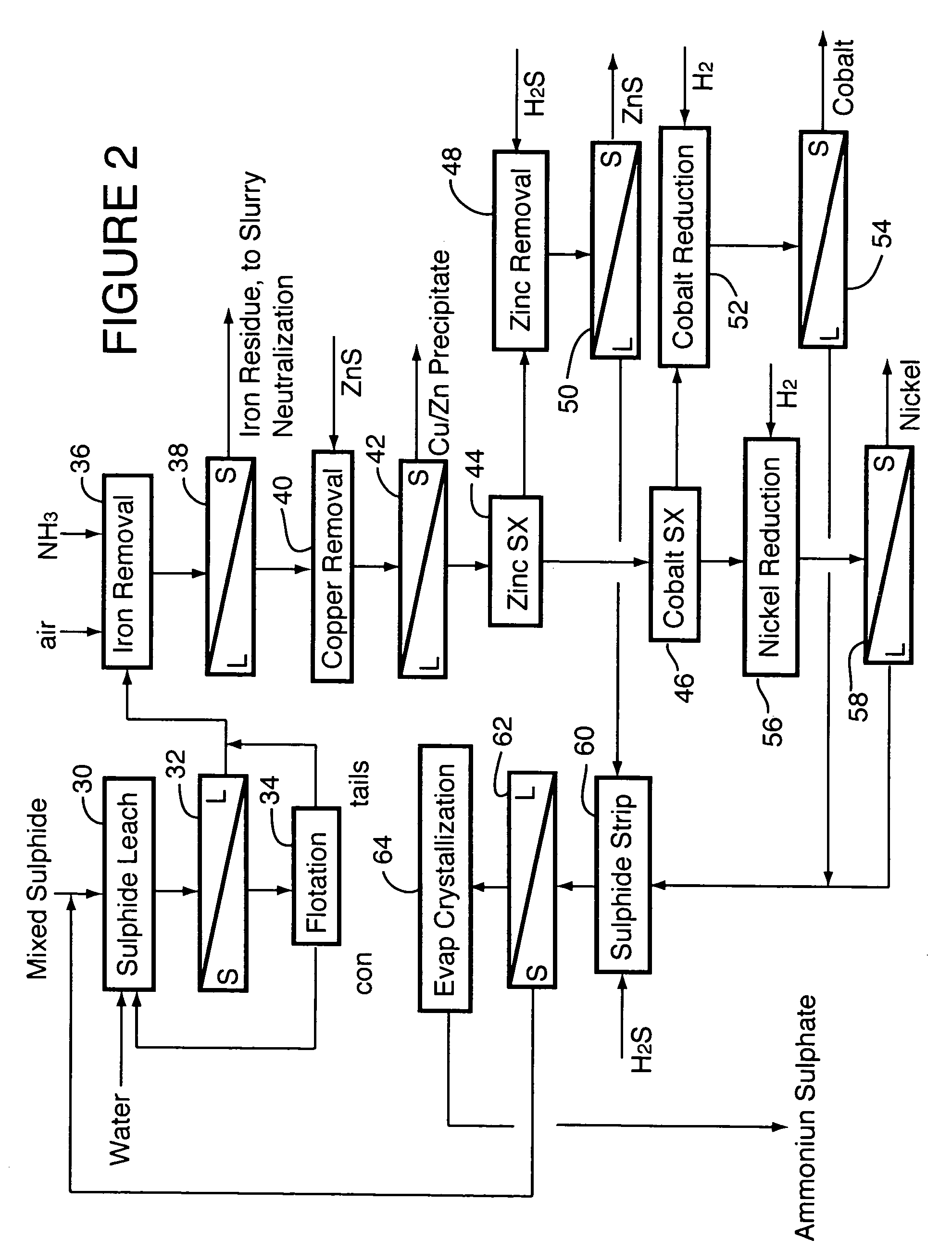

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INTERNATIONAL

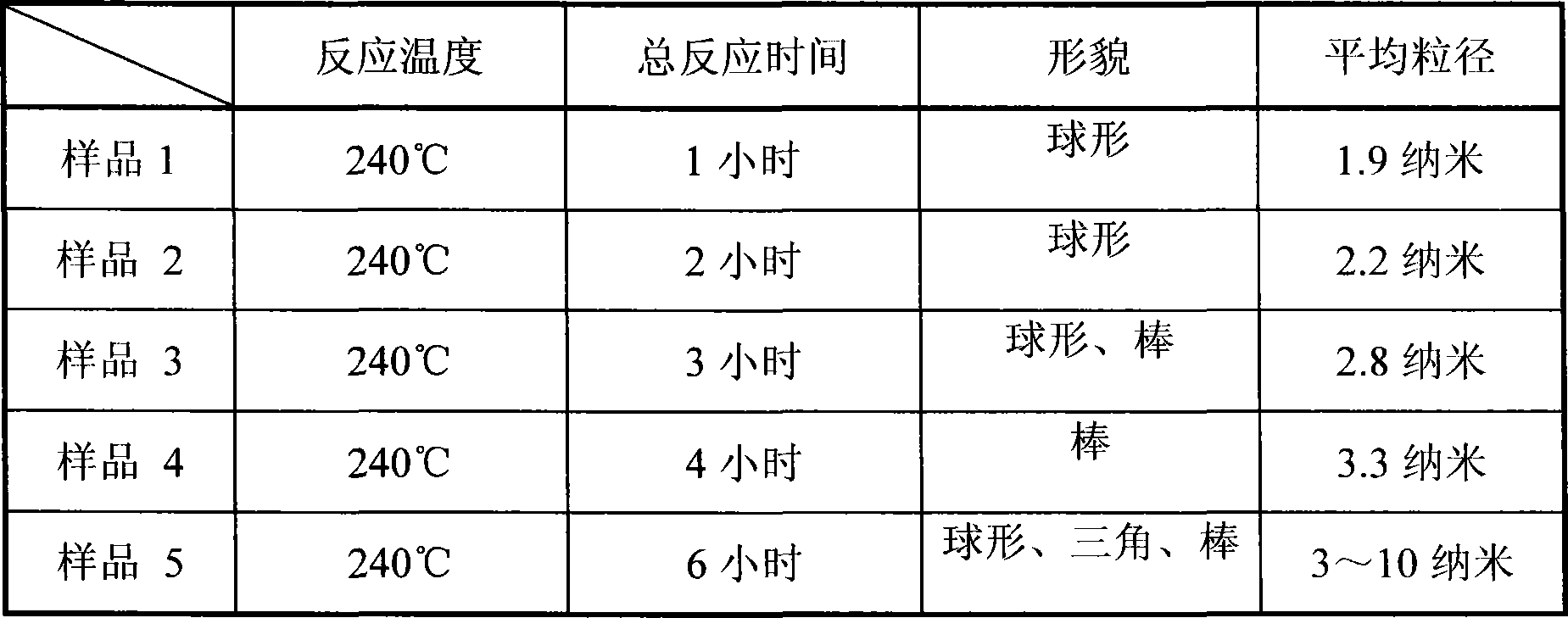

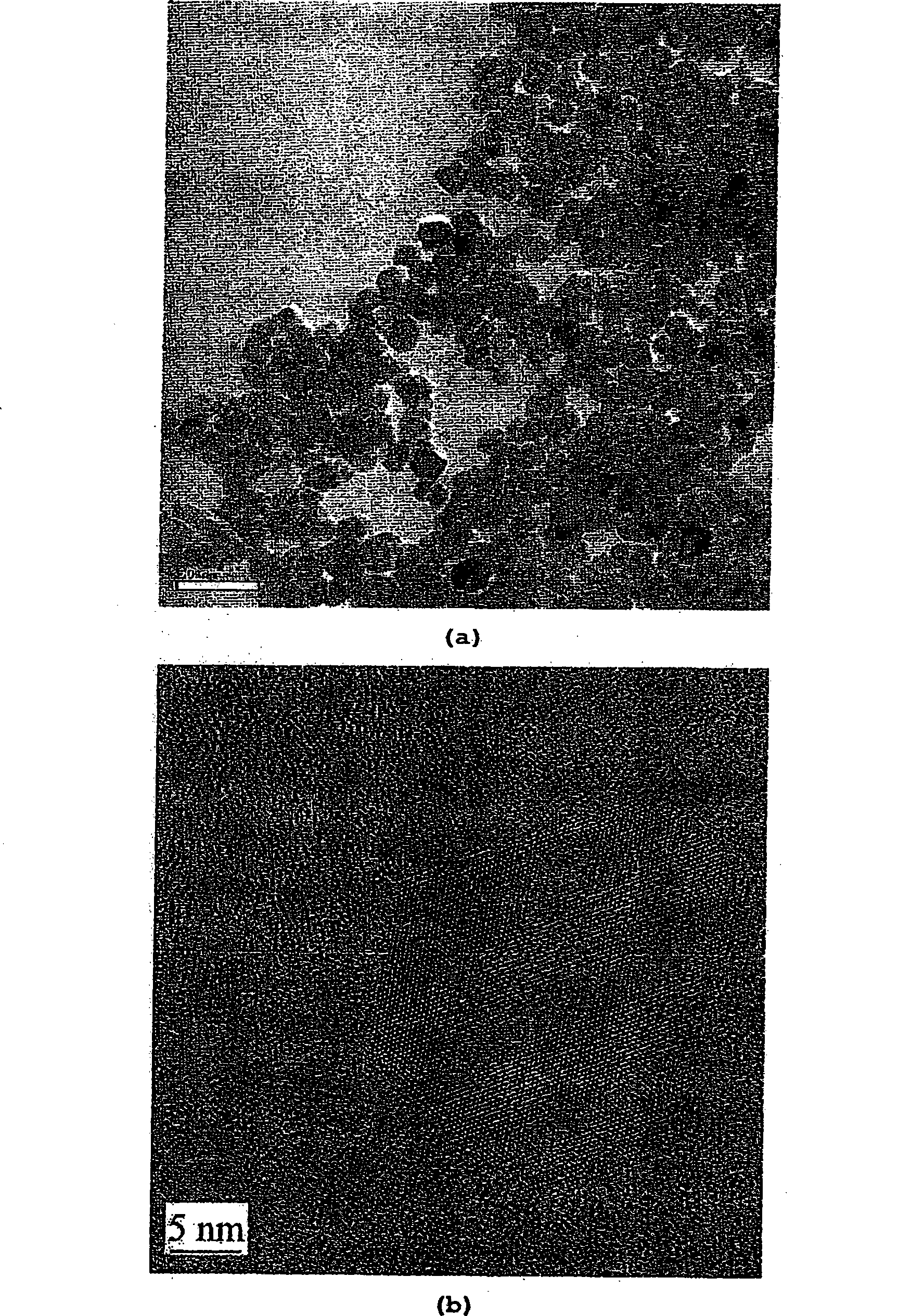

Preparation method of quantum dot self-assembling nano structural material

The invention discloses a preparation method of a super nanostructure material formed by quantum dots self-assembly. That the alcohols are used as solvent to prepare nano-metal oxides and sulphides or metal oxides and sulphides are reduced to get nano-metal is a widely used method. The super nanostructure material formed by the quantum dots self-assembly draws much attention because of the superior comprehensive properties. The application prospect is wide enough. The invention adopts a method of using the alcohols as the solvent that a super nanostructure with different appearances and is formed by the quantum dots self-assembly which is obtained by changing the condition under the existence condition of surfactant. According to the invention, precursor, namely organic metal compound is dissolved in the alcohol solvent by ultrasonic, stirring and being laid down quietly. Under the effect of the surfactant, the precursor has a nucleation and grows into a plurality of quantum dots, the size of which is similar to nano. Then the dots form a super nanostructure which has a certain shape or space structure along the defined growing direction of the surfactant.

Owner:HUAZHONG NORMAL UNIV

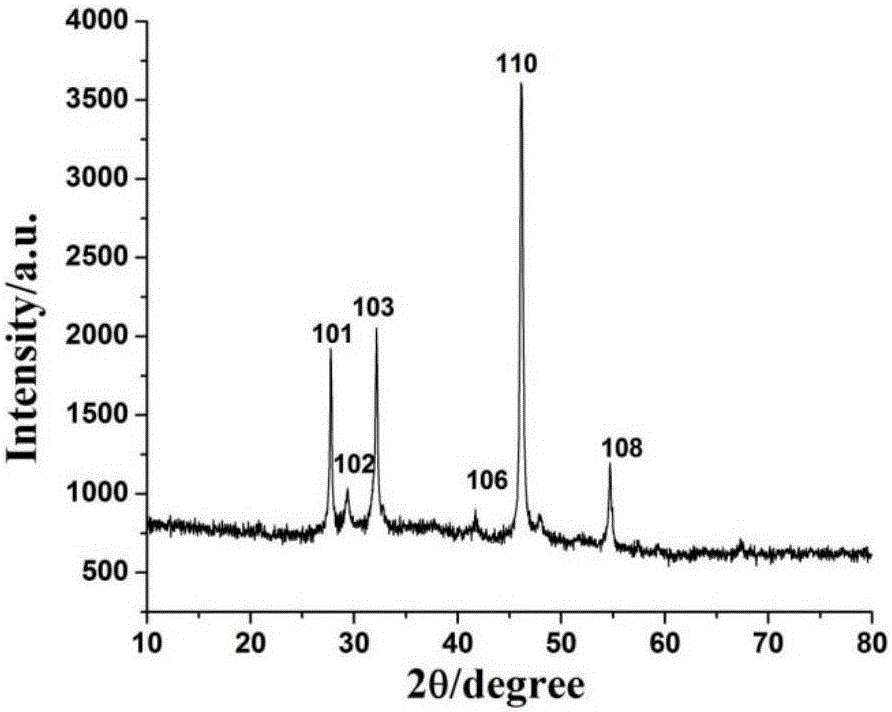

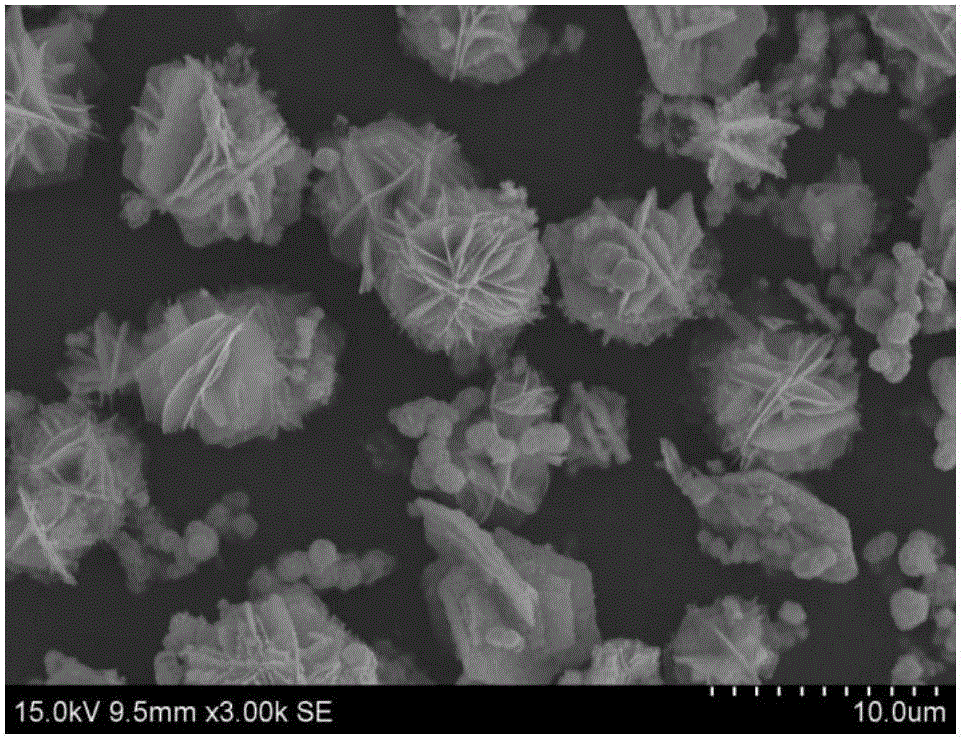

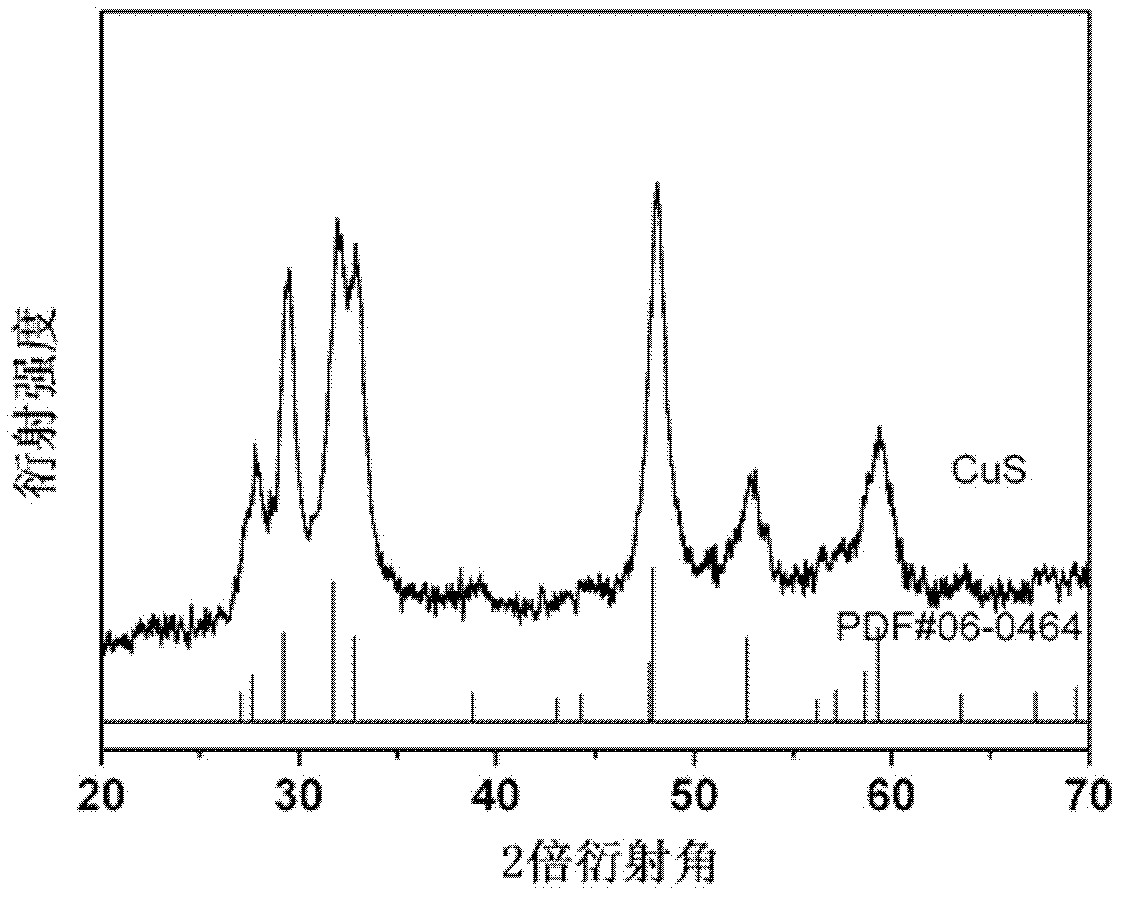

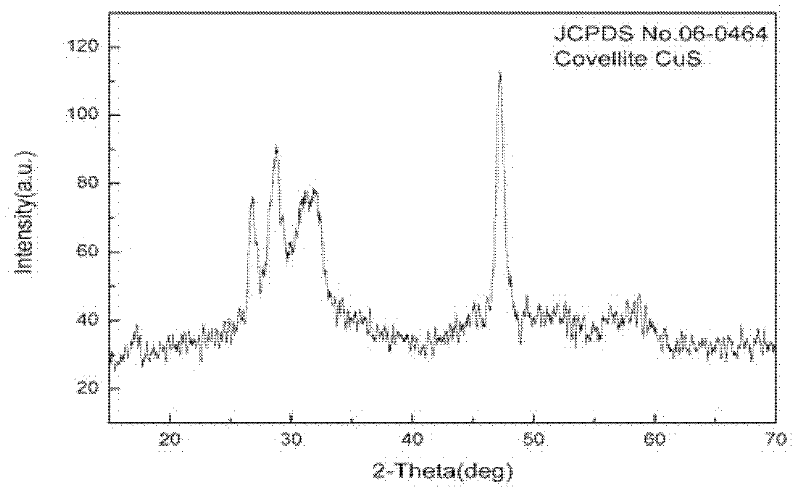

Flower-like structured CuS material as well as preparation method and application thereof

InactiveCN106082303AThe synthesis process is simpleModerate speed of self-assemblyPhysical/chemical process catalystsWater/sewage treatment by irradiationDyeing wastewaterPhotocatalytic degradation

The invention relates to a flower-like structured CuS material as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing a cupric compound and a solvent, and sufficiently stirring the components at certain temperature so as to obtain a homogeneous solution; under acute stirring, slowly adding a sulfur-containing compound into the homogeneous solution, and performing temperature-keeping treatment; transferring the solution into a hydrothermal reaction kettle, and performing a sealed heating reaction at certain temperature, performing cooling till the room temperature, performing filtration and collection, washing the product, performing filtration again, performing vacuum drying, and grinding the product, thereby obtaining a black product, that is, the flower-like structured CuS material. The flower-like structured CuS material can be applied to photocatalytic degradation dye wastewater. Compared with the prior art, the flower-like structured CuS material is wide in visible light response range of CuS, and high in visible light utilization rate.

Owner:SHANGHAI UNIV OF ENG SCI

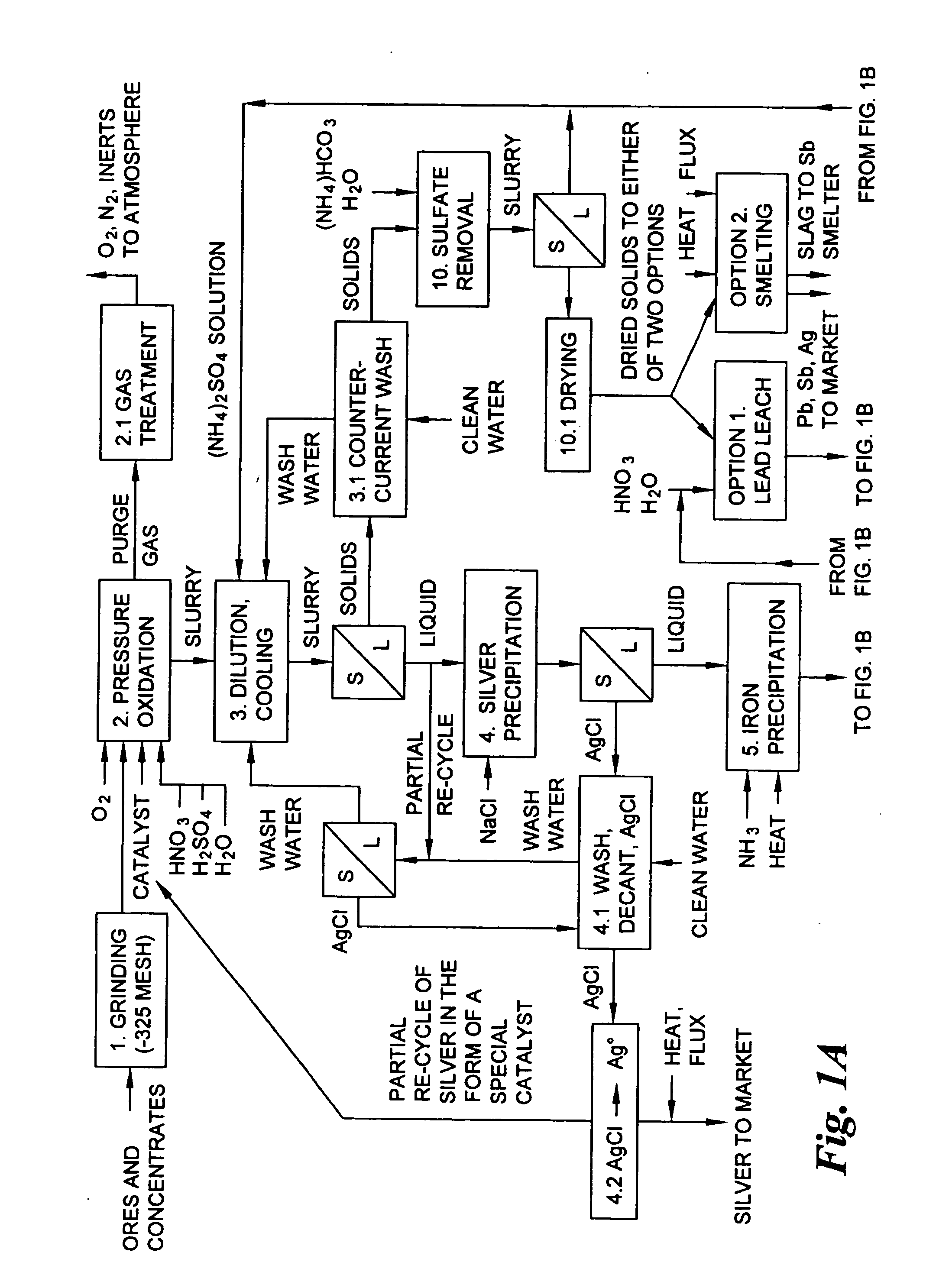

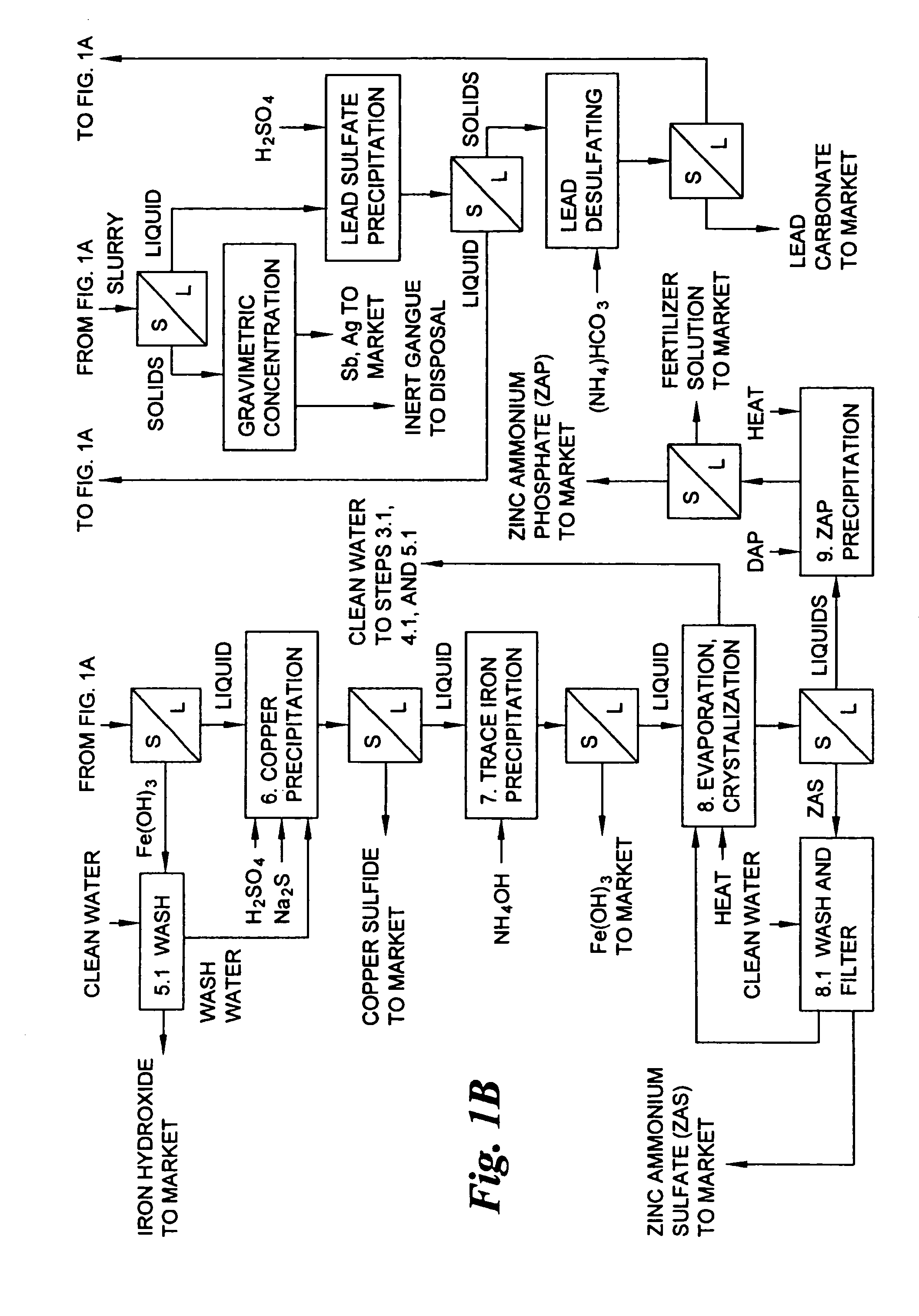

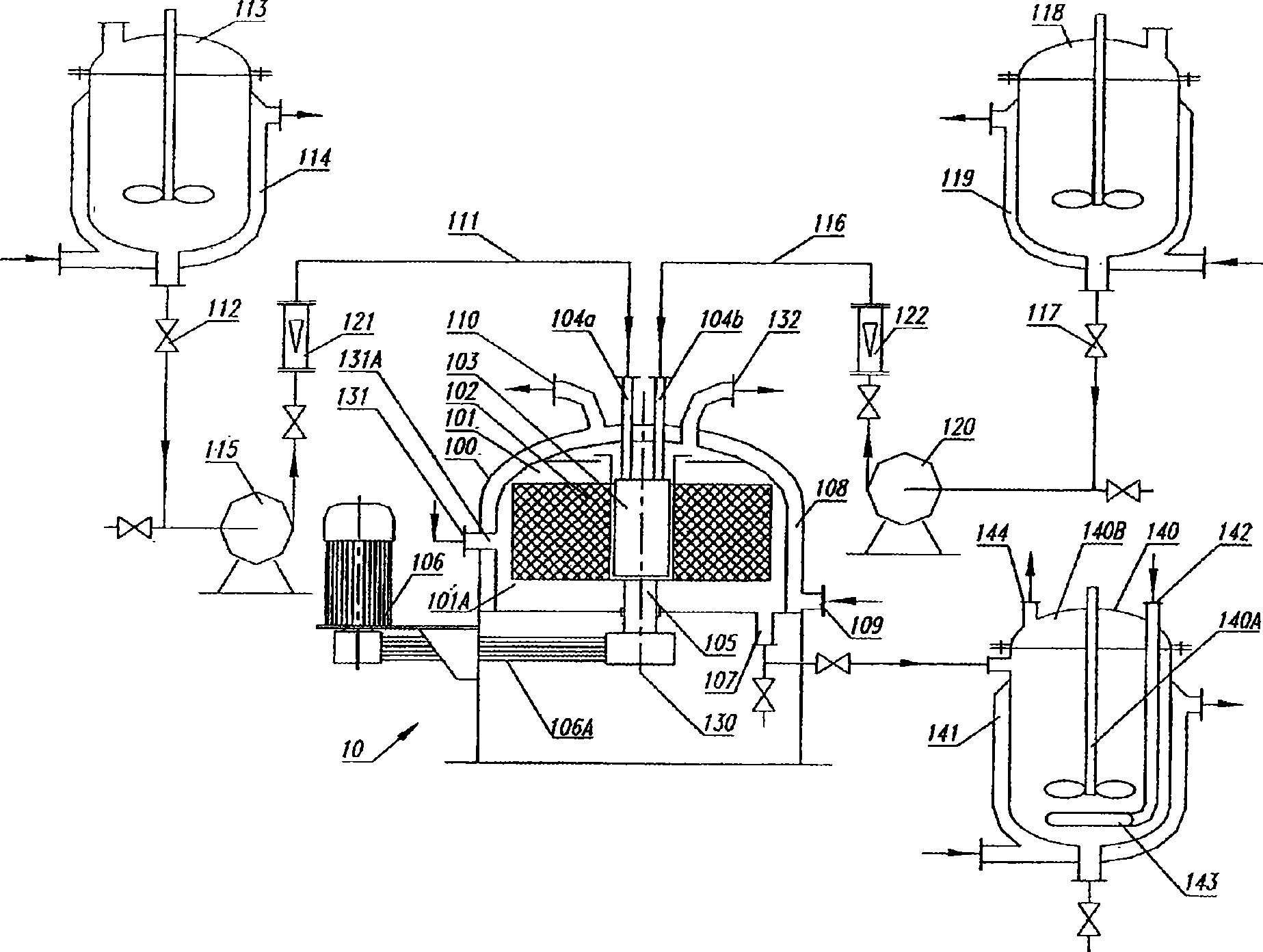

Hydrometallurgical process for the treatment of metal-bearing sulfide mineral concentrates

InactiveUS20070098609A1Improve efficiencyReduce the amount requiredSolvent extractionGold compoundsAmmonium compoundsMetallic sulfide

A hydrometallurgical process for the treatment of complex silver-bearing sulfide ores and concentrates that recovers substantially all silver, lead, antimony, zinc, copper and sulfur, along with the chemical reagents utilized during the process. Finely ground ores and concentrates are leached under heat and pressure with water, sulfuric acid, nitric acid, oxygen, and a catalyst, and are further treated to recover silver in the form of silver chloride; iron in the form of iron hydroxide; copper and all traces of soluble toxic metals as sulfides; zinc as zinc ammonium sulfate and specifically nitric acid, sulfuric acid, oxygen, ammonia, and ammonium compounds as valuable fertilizer products.

Owner:ROYAL SILVER PANAMA

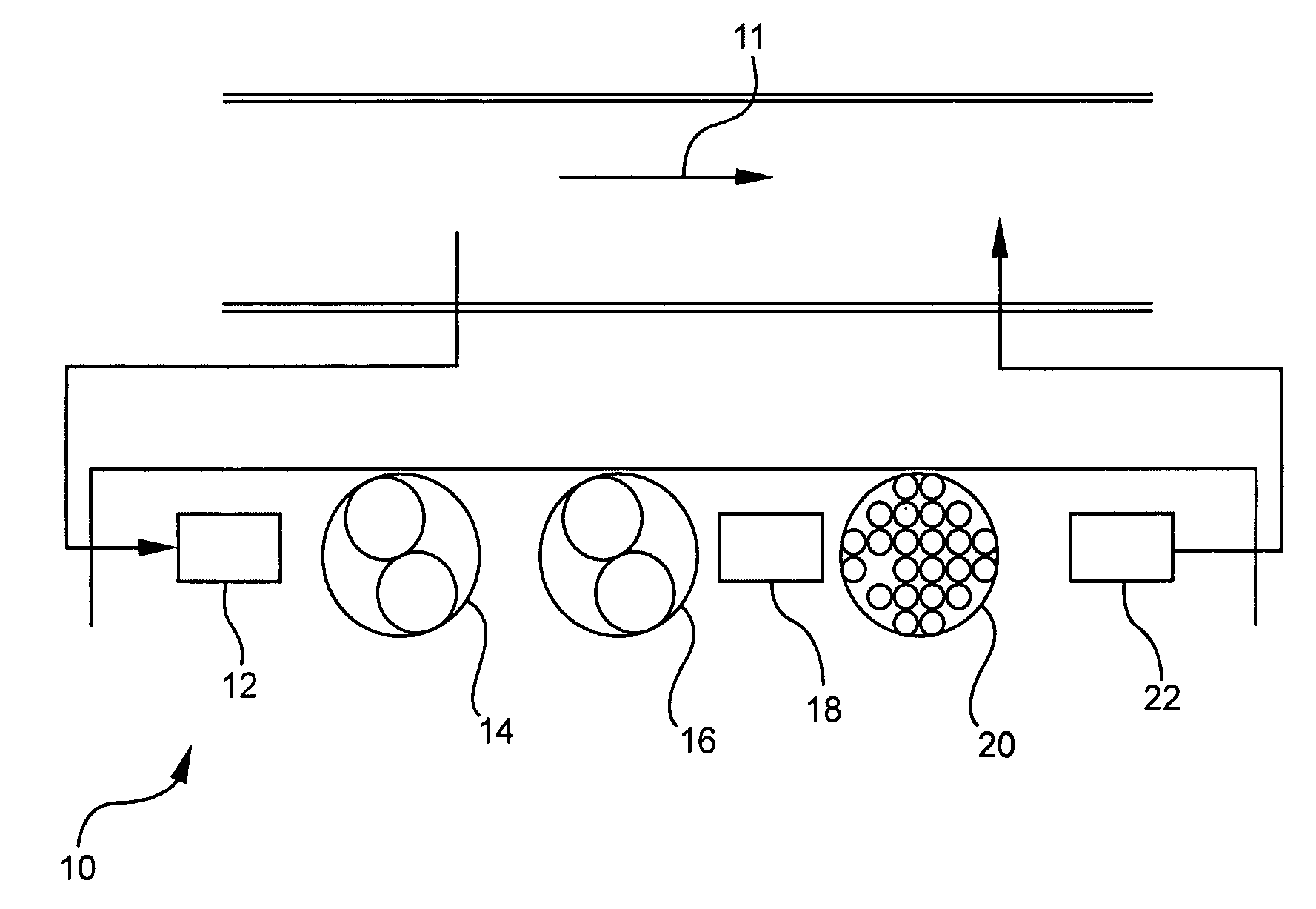

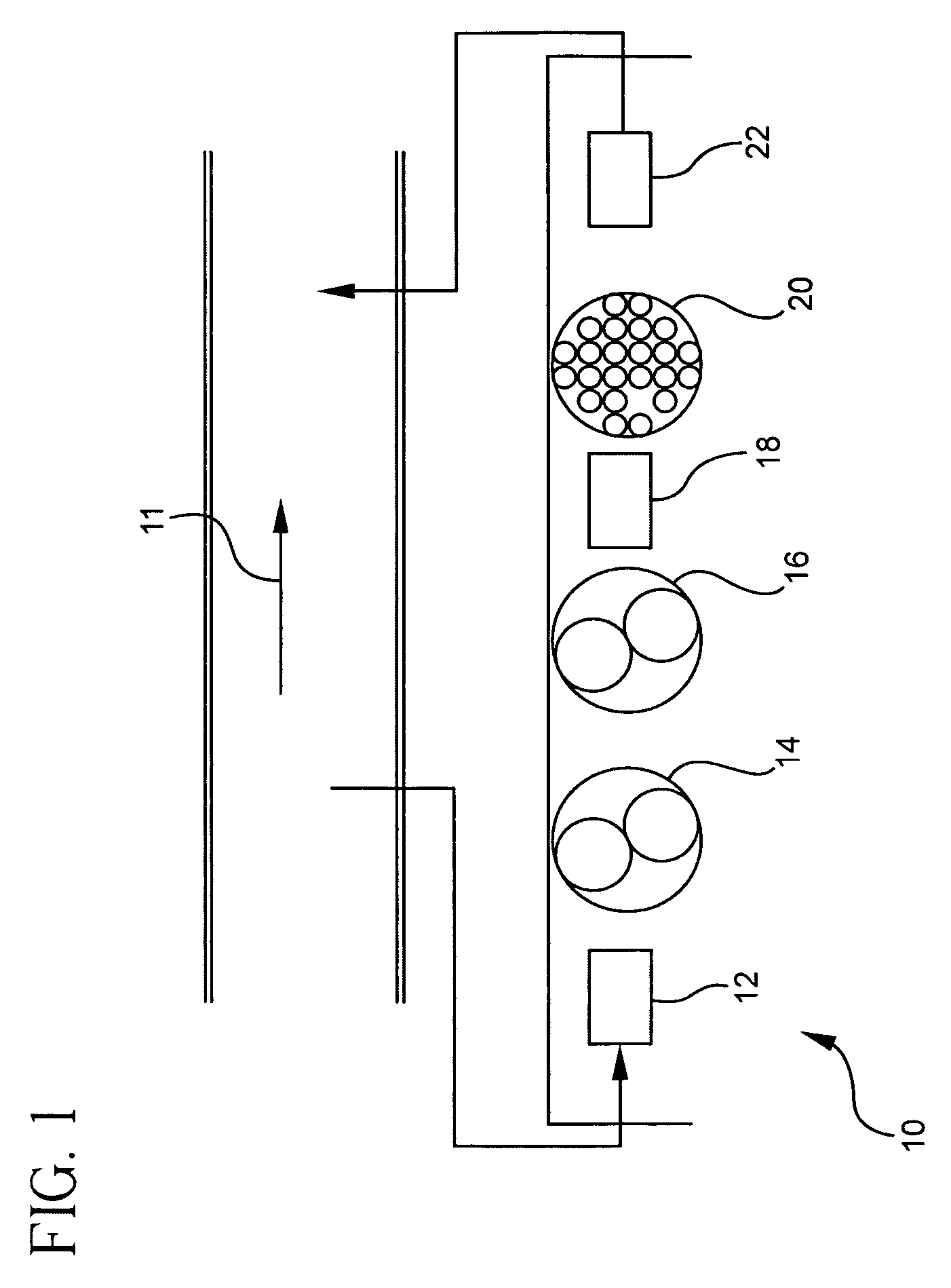

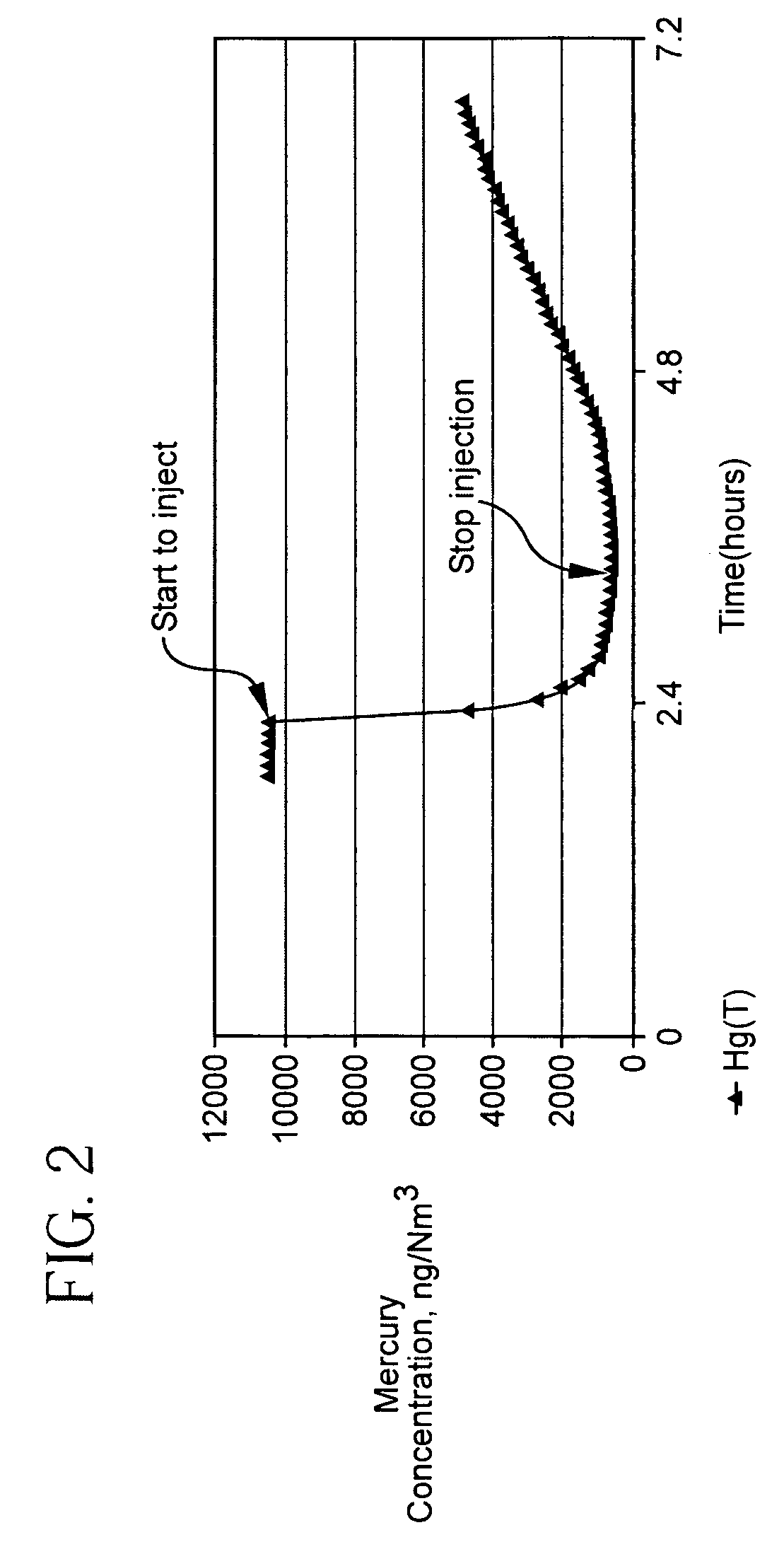

Pollutant emission control sorbents and methods of manufacture

Sorbents for removal of mercury and other pollutants from gas streams, such as a flue gas stream from coal-fired utility plants, and methods for their manufacture and use are disclosed. The methods include mixing fly ash particles with a sulfide salt and a metal salt to form a metal sulfide on the outer surface of the fly ash particles.

Owner:BASF CATALYSTS LLC

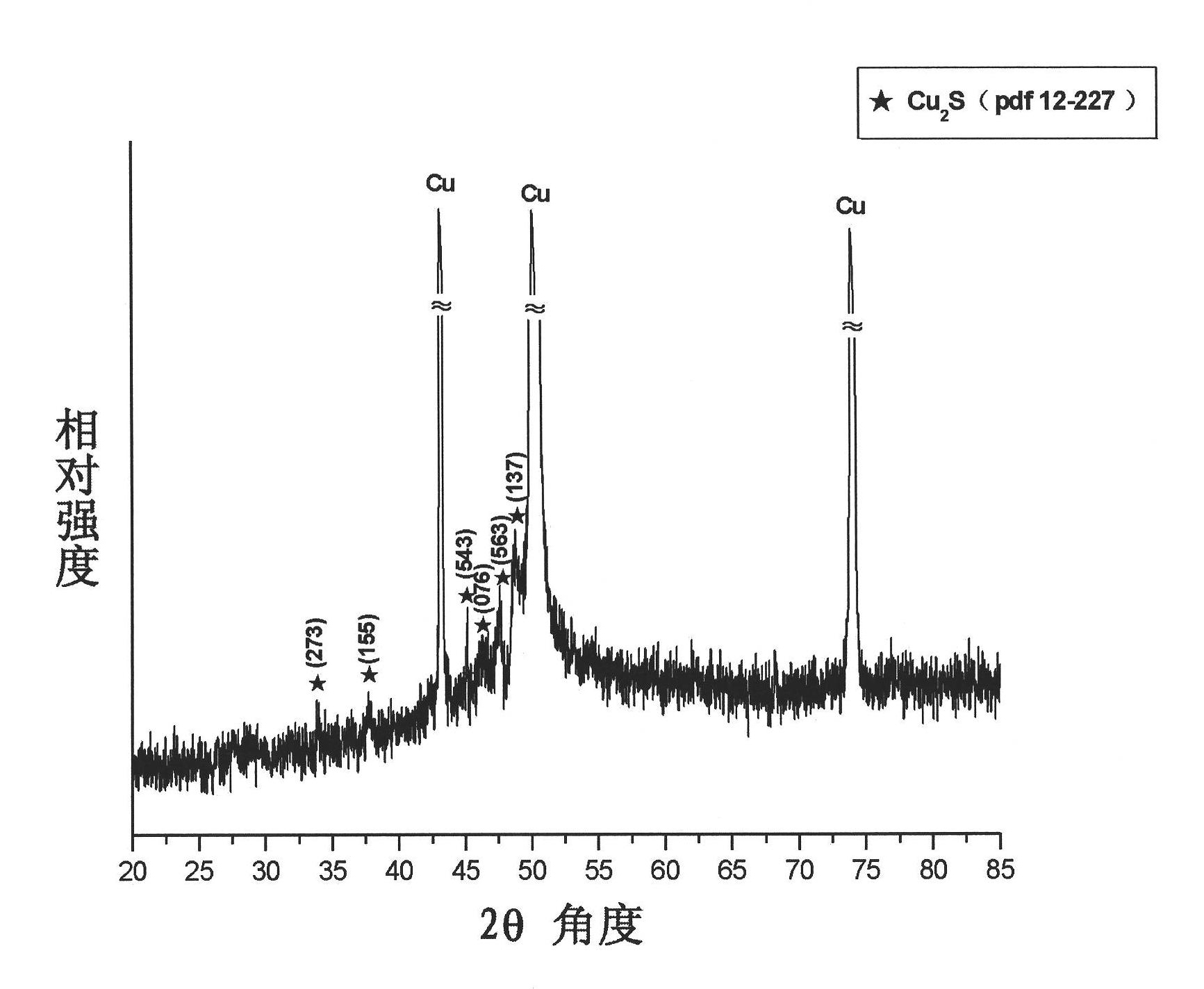

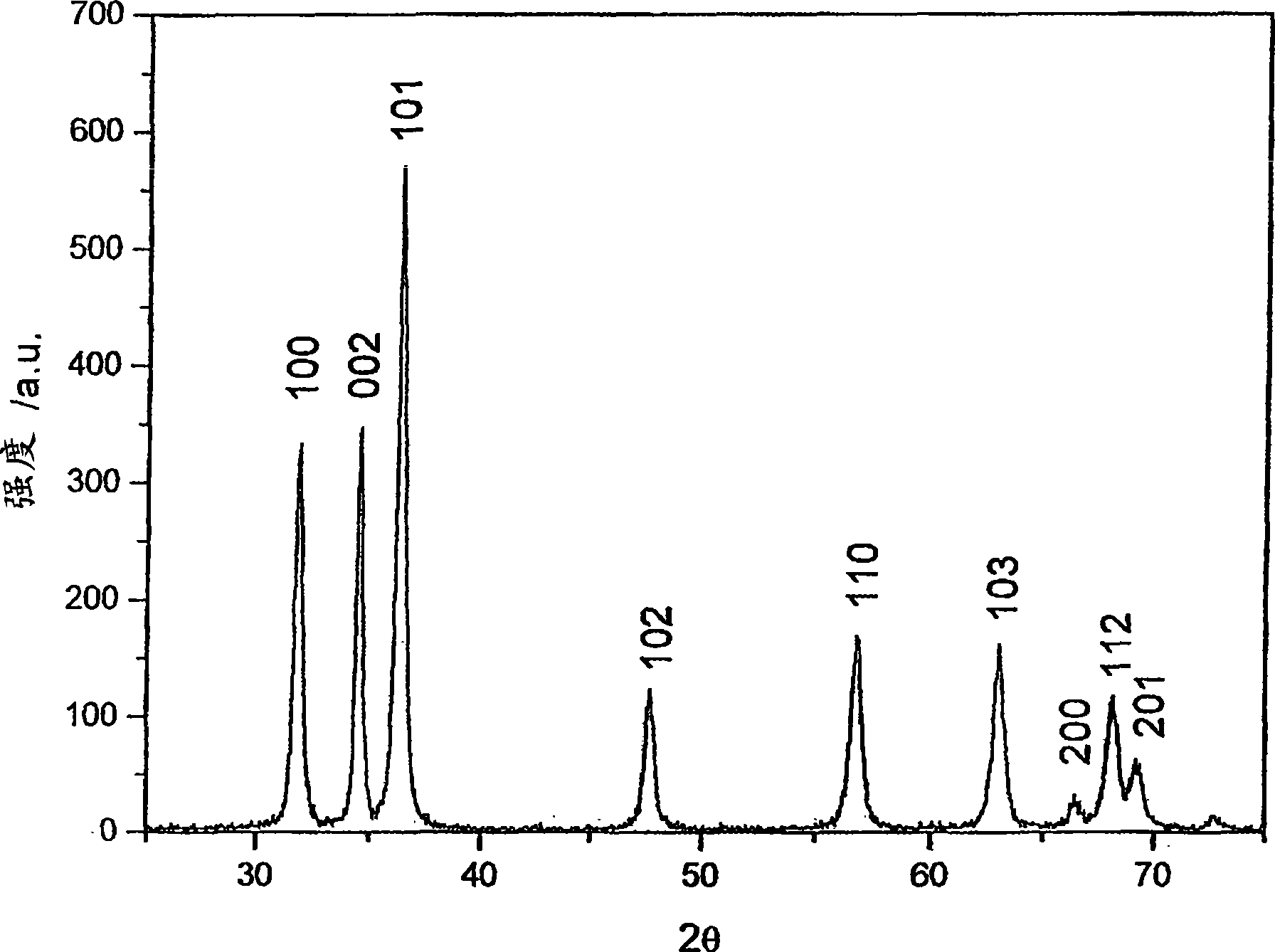

Preparation method of Cu1.8+xS binary thermoelectric material

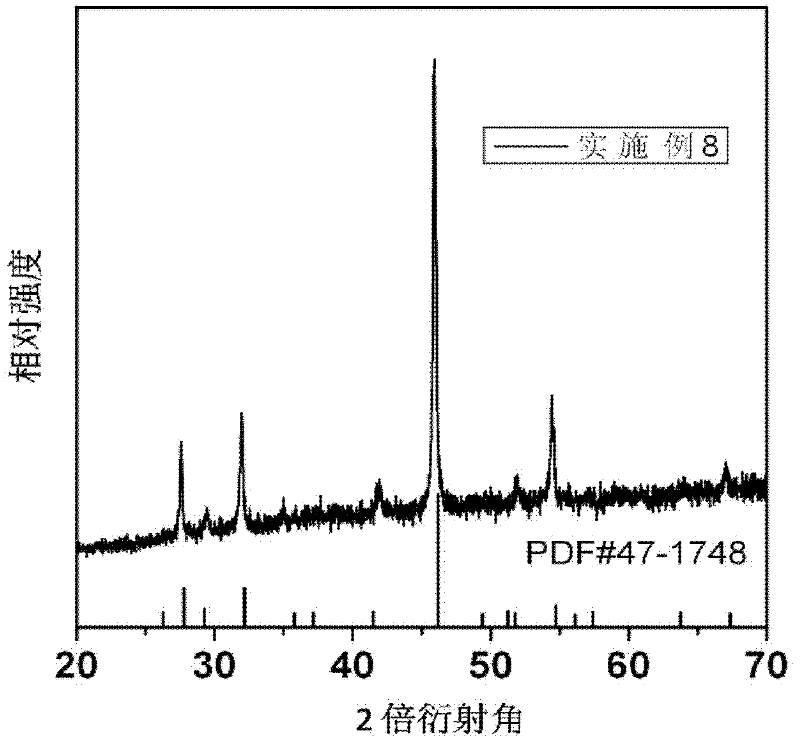

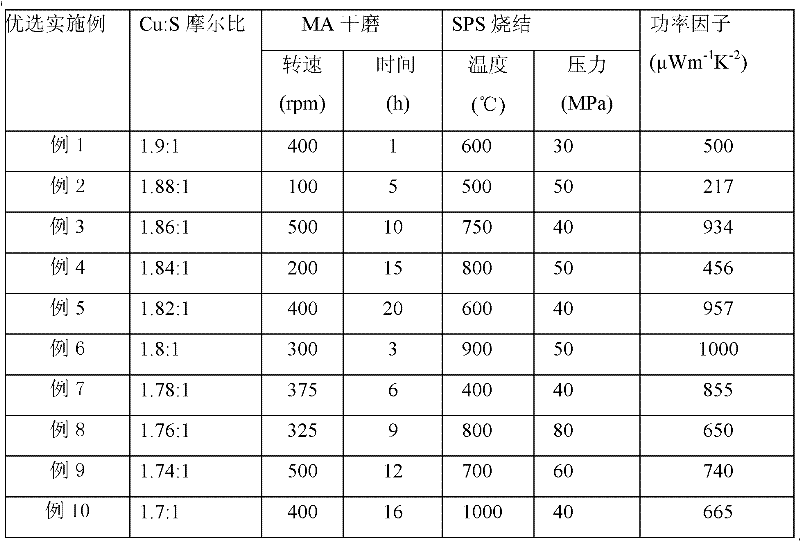

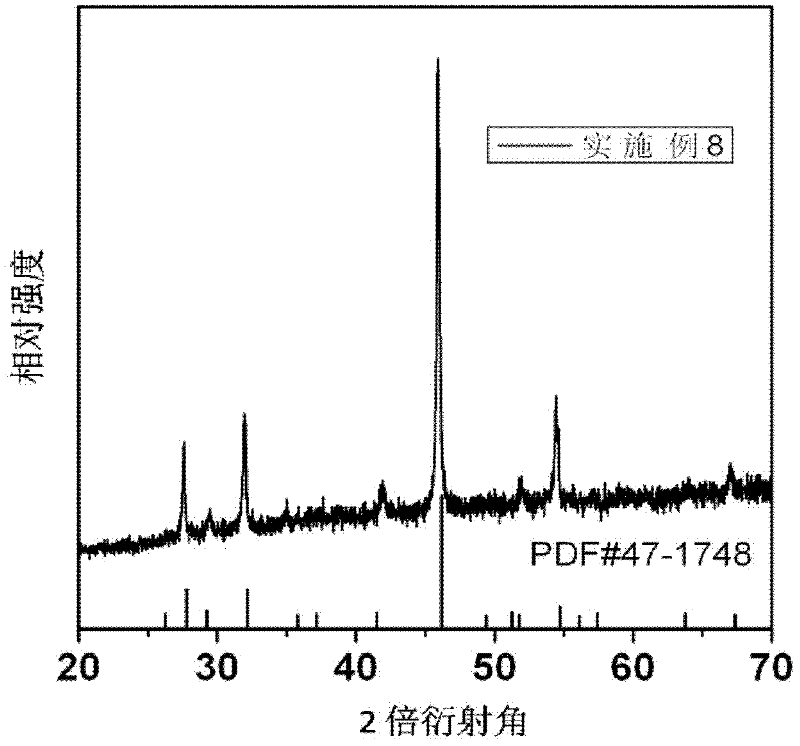

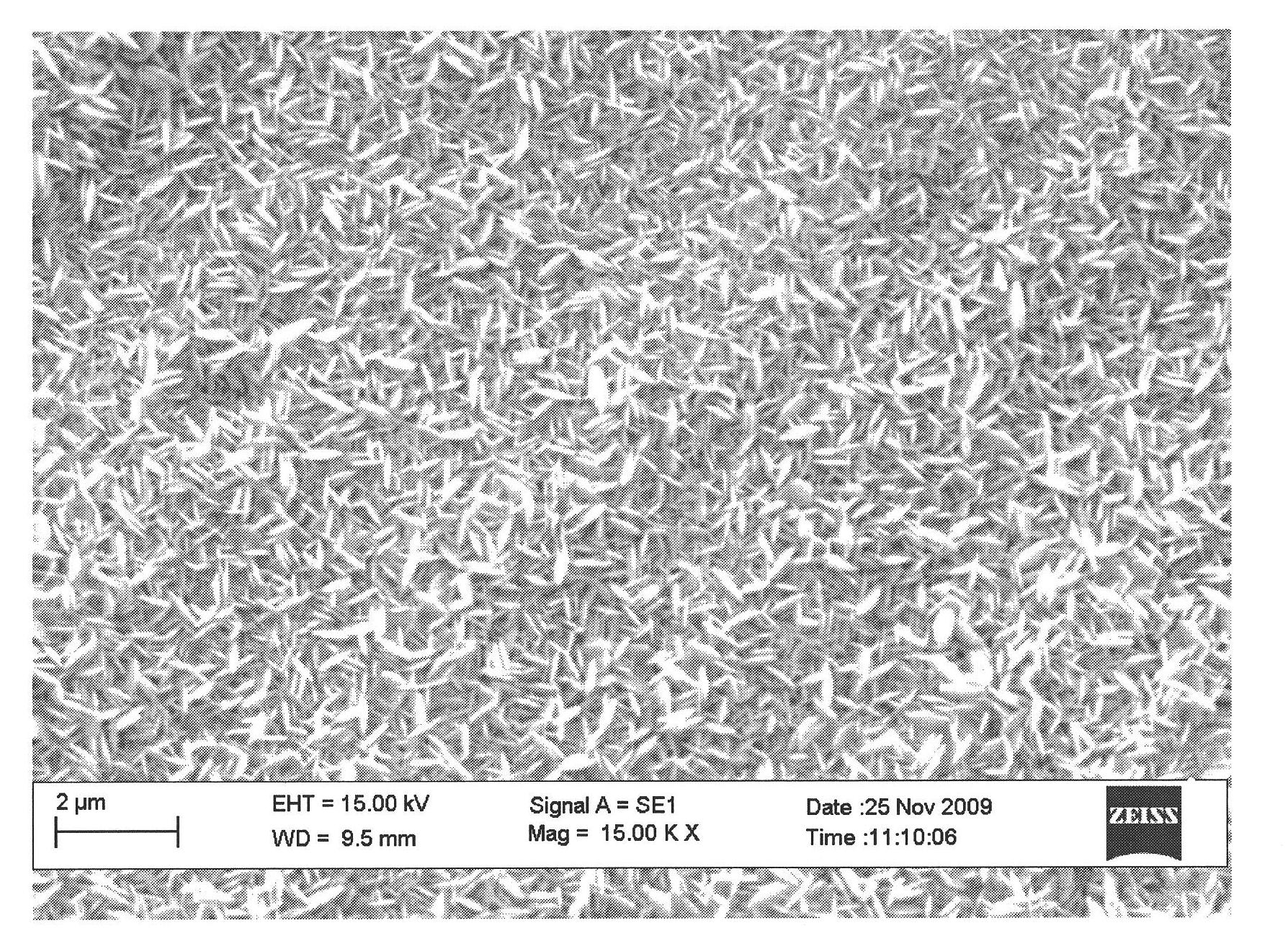

InactiveCN102363530AShort preparation processShort timeNanotechnologyCopper sulfidesThermoelectric materialsSulfur

A preparation method of a Cu1.8+xS binary thermoelectric material belongs to the technical field of energy materials, and is characterized by comprising the following steps of: using an elemental copper powder (its mass fraction is greater than 99.9%) and an elemental sulfur powder (its mass fraction is greater than 99.8%) as raw materials, preparing a compound powder by a mechanical alloying method according to the ratio of Cu1.8+xS (x is less than or equal to 0.1 and greater than or equal to minus 0.1), and preparing the Cu1.8+xS bulk thermoelectric material which has a rhombohedral structure at room temperature by the adoption of a spark plasma sintering technology. The thermoelectric material has high conductivity and good mechanical properties. The raw materials required by the preparation method are cheap and easily available. The preparation method has advantages of no pollution and short technological process, and is convenient and fast.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing copper sulfide hollow sphere

InactiveCN101054197AIncrease profitGood dispersionCopper sulfidesMicroballoon preparationReaction temperatureMaterials processing

The invention relates to a method for the preparation of CuS hollow balls in the field of inorganic materials and functional materials processing. First, a certain amount of soluble cupric salt and PVP are dissolved in the water for form clear solution, which is then added in with a certain amount of reductant to produce yellow suspending solution, and then added in with a certain amount of S source substance, reacting at the temperature of 10-90 degree for 10min to 24h to produce CuS hollow balls. The invention is characterized in soft preparation conditions, simple processing, low cost, high yield etc., which is good for industrialization production and the produced product is characterized in good dispersibility, uniform wall thickness, superior performances to the present products and wide application foreground.

Owner:QINGDAO UNIV OF SCI & TECH

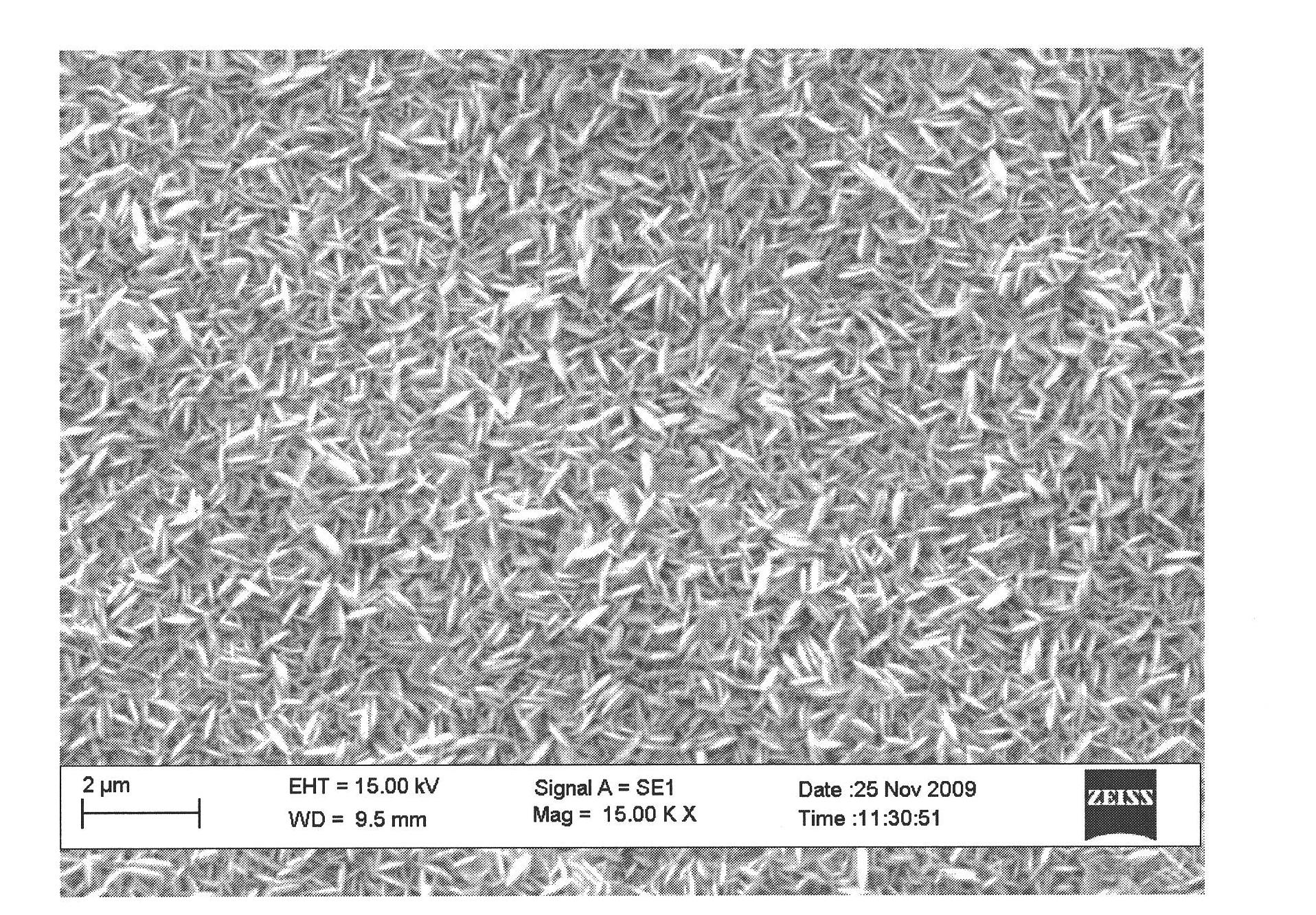

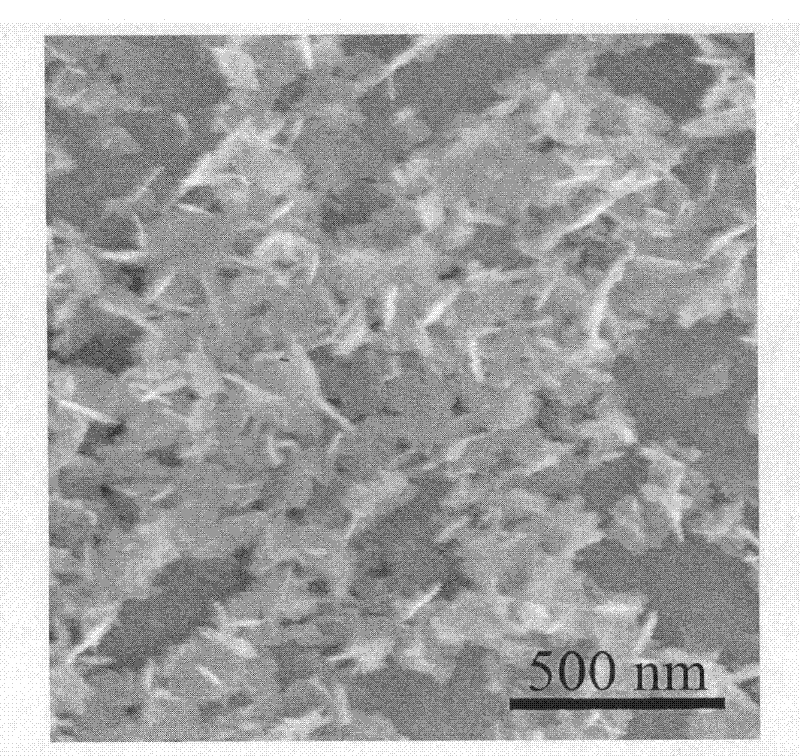

Chemical method for synthesizing flaky CuxSy nanocrystalline optoelectronic film controllably at low temperature

InactiveCN101792173ALow reaction temperatureReduce energy consumptionNanostructure manufactureCopper sulfidesN dimethylformamideFilm material

The invention provides a chemical method for synthesizing flaky CuxSy nanocrystalline optoelectronic film controllably at a low temperature. The method comprises the following steps: firstly adding sulfur powder in a container, secondly adding organic solvent N,N-dimethylformamide or absolute alcohol, wherein the volume of organic solvent is more than a half of the capacity of the container; standing at 0-60 DEG C for 1h to ensure that the sulfur powder dissolved in organic solvent is saturated, horizontally placing substrate material with a new and clean metal copper surface on the bottom of the container to avoid directly contacting with sulfur powder, reacting at 0-60 DEG C for 5-24h, cleaning the product with absolute alcohol, drying at room temperature to in-situ prepare the big area film material composed of flaky CuxSy nanocrystalline on the metal copper surface of the substrate material, wherein x:y=1-2. The method of the invention adopts low temperature, has low energy consumption, is simple, green and environmentally friendly and particularly applicable to large-area industrial production, and does not use any template, add any surfactant and perform complicated post-processing operations such as purification.

Owner:XUCHANG UNIV +1

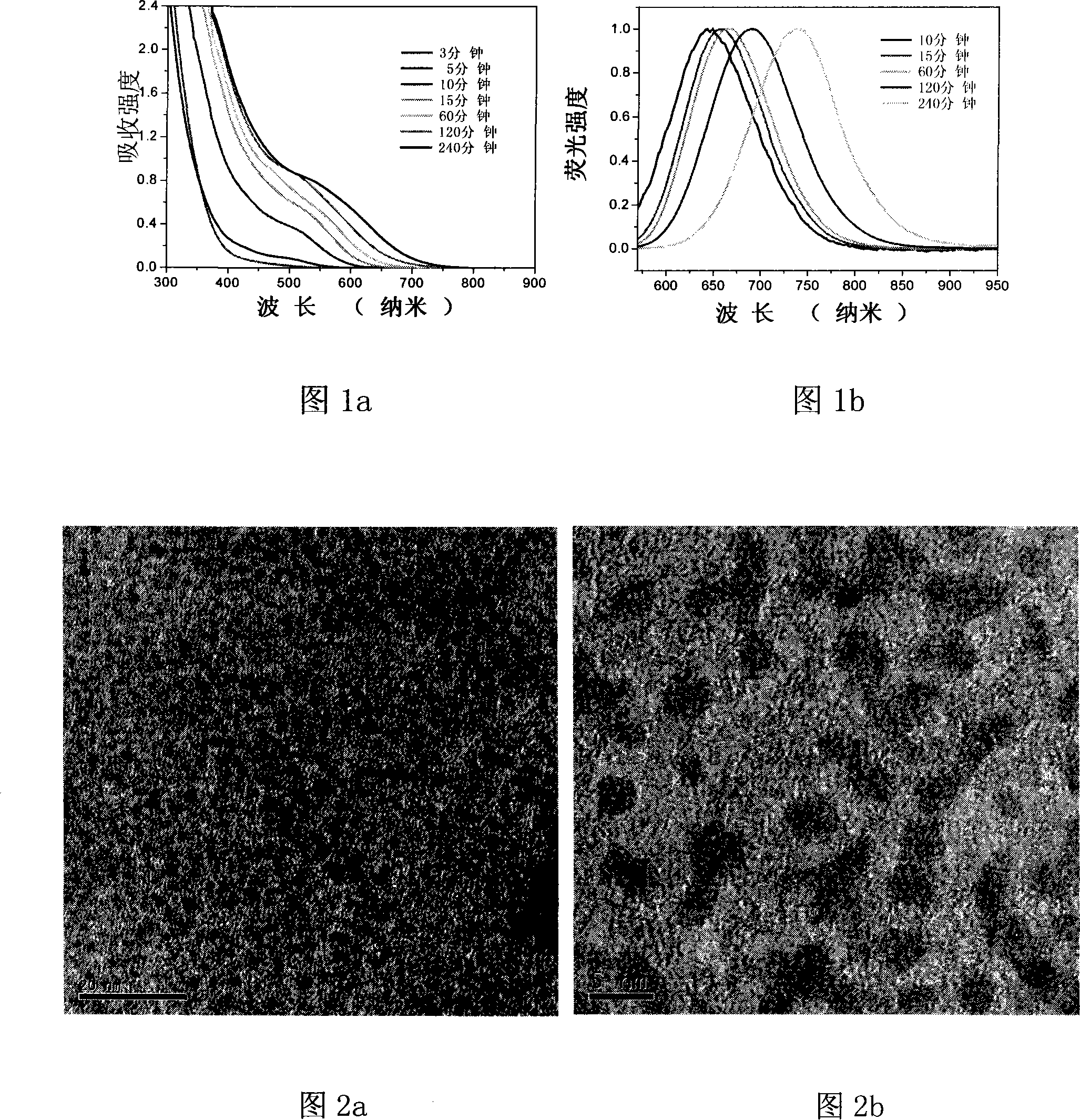

Method for preparing copper-indium-sulfur semi-conductor nano particles

InactiveCN101234779ASimple preparation processEasy to controlMaterial nanotechnologyGallium/indium/thallium compoundsIndiumSulfide

The invention relates to a method for preparing copper-indium-sulfide nano-semiconductor particle. Copper salt, indium salt and alkyl hydrosulfide are put into a reaction vessel of non-polar and high boiling organic solvent; inert gas is pumped to exclude air in the vessel; the vessel is heated, stirred and dissolved until garnet colloidal solution is obtained; the colloidal solution obtained by the step a) is cooled untill to room temperature; polar solvent is added to obtain the copper-indium-sulfide nano-semiconductor particle by centrifugal sedimentation. The copper-indium-sulfide nano-semiconductor particle can be further washed and vacuum dried to obtain copper-indium-sulfide nano-semiconductor particle powder. Particle size of the copper-indium-sulfide nano-semiconductor particle obtained by the invention is 2-10nm; morphology can be spherical, triangle, flaky and / or rod-like; productivity is up to 90 percent.

Owner:BAYER TECH & ENG SHANGHAI

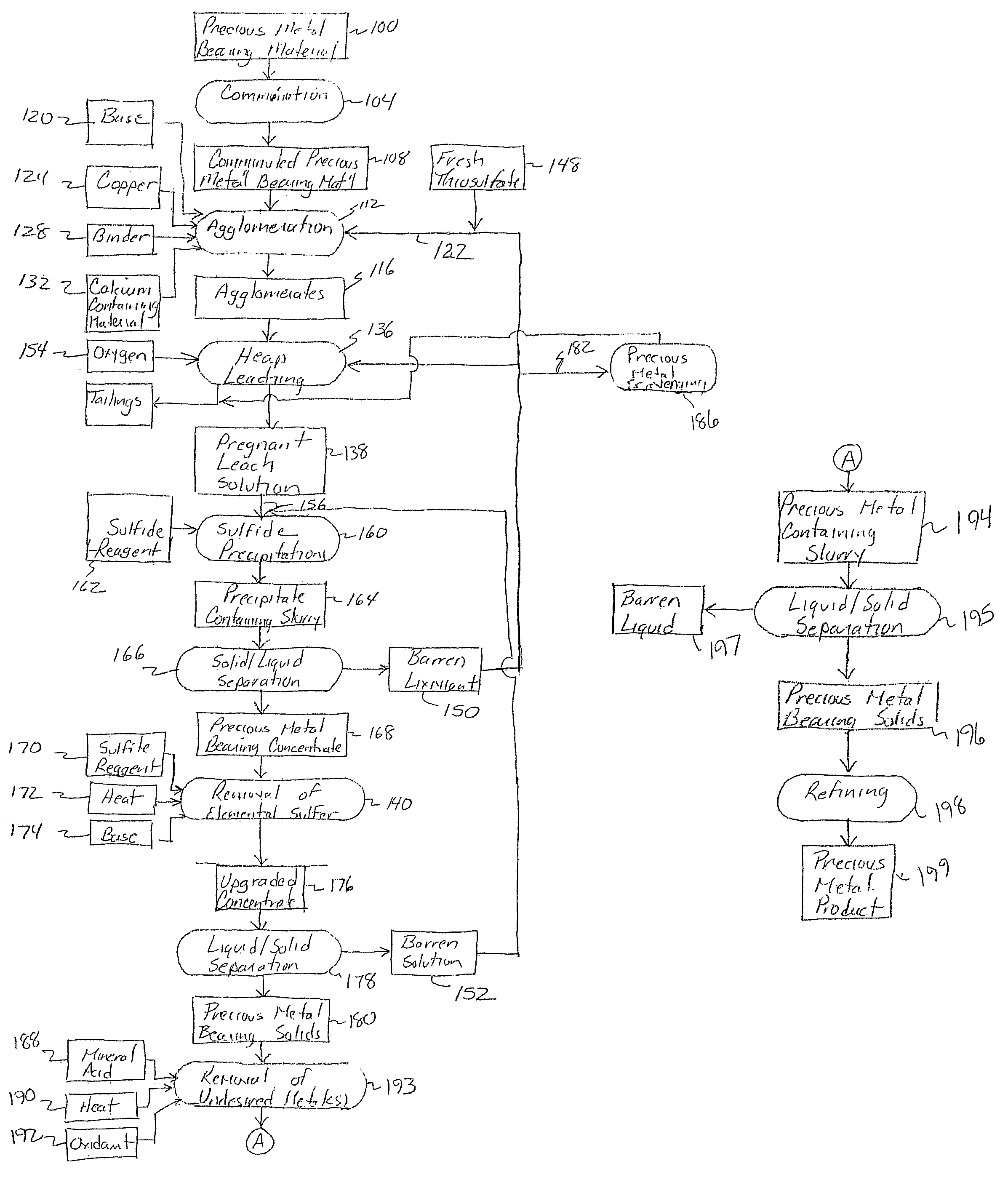

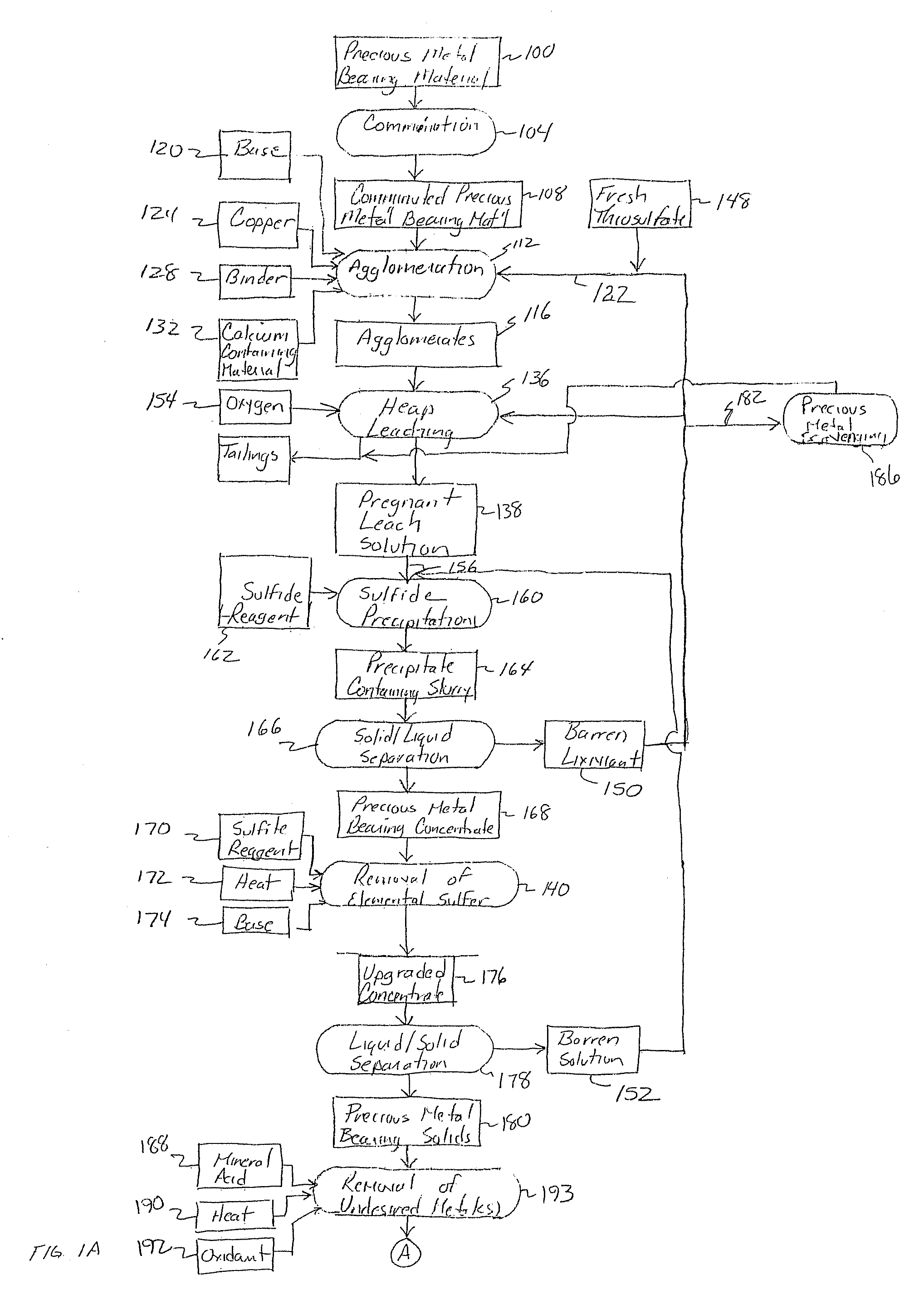

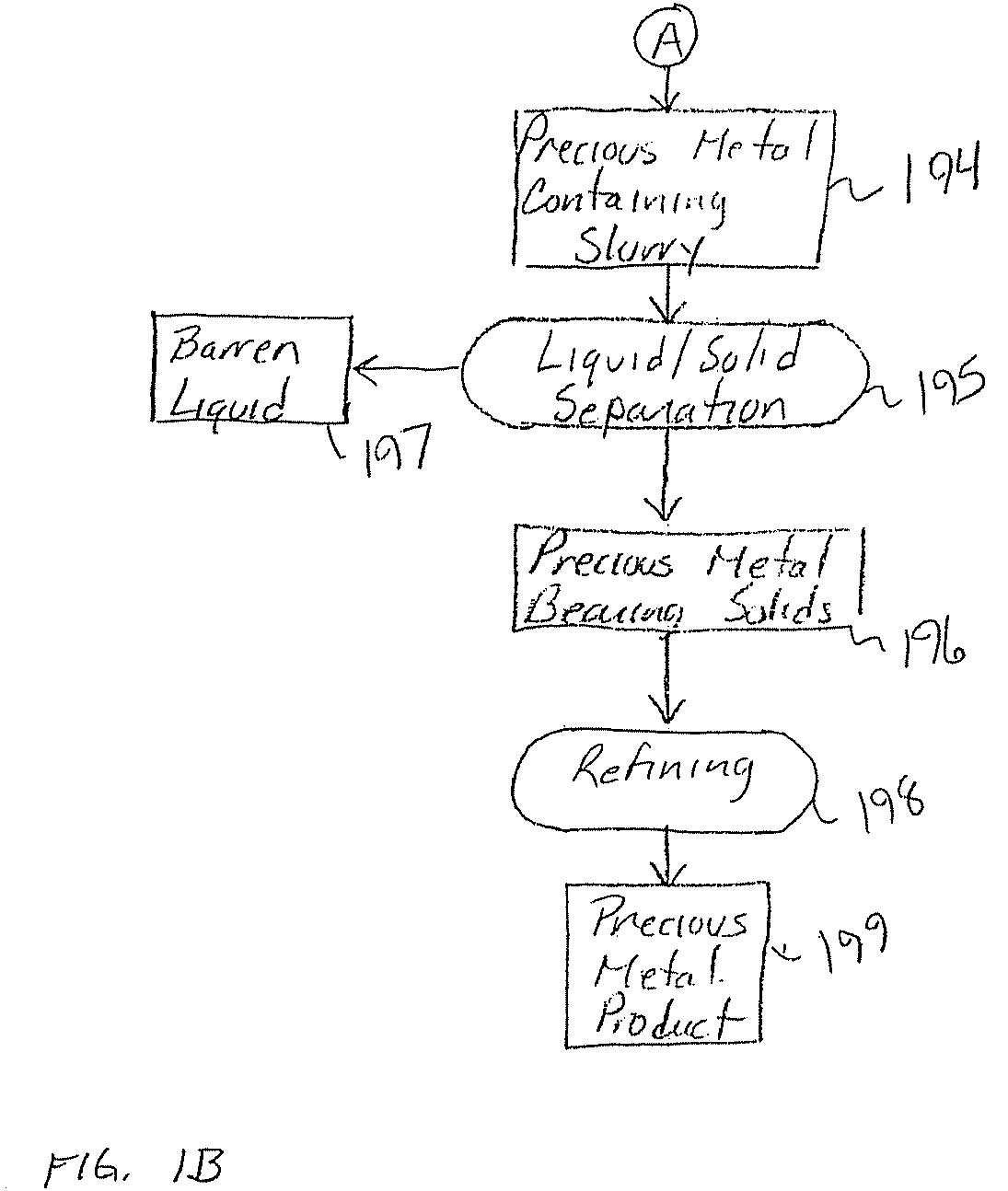

Method for thiosulfate leaching of precious metal-containing materials

InactiveUS7544232B2Avoid the needLow costCopper sulfidesProcess efficiency improvementLixiviantRefractory

Processes are provided for recovering precious metals from refractory materials using thiosulfate lixiviants. The processes can employ heap leaching or lixiviants that include one or more blinding agents.

Owner:PLACER DOME TECHN SERVICES

Circuit board acid-base etching waste liquid recycling treatment technology

InactiveCN108862365AImprove protectionEasy to operateCopper sulfidesCopper sulfatesEconomic benefitsCopper oxide

The invention discloses a circuit board acid-base etching waste liquid recycling treatment technology. Acidic etching waste liquid and alkaline etching waste liquid are neutralized to generate copperoxychloride, copper oxychloride reacts with an alkaline solution to generate copper oxide, copper oxide reacts with concentrated sulfuric acid to generate copper sulfate, and filtrate and washing water in the reactions are collected. The circuit board acid-base etching waste liquid recycling treatment technology makes copper ions precipitate to generate different copper-containing products througha plurality of steps, operation is easy, the cost is low, etching waste liquid ca be treated on a large scale, meanwhile, the treated filtrate is sufficiently utilized to prepare etching liquid again, the economic benefit is enhanced, emission is reduced, and environmental protection is facilitated.

Owner:广东省博罗县湘澧精细化工有限公司

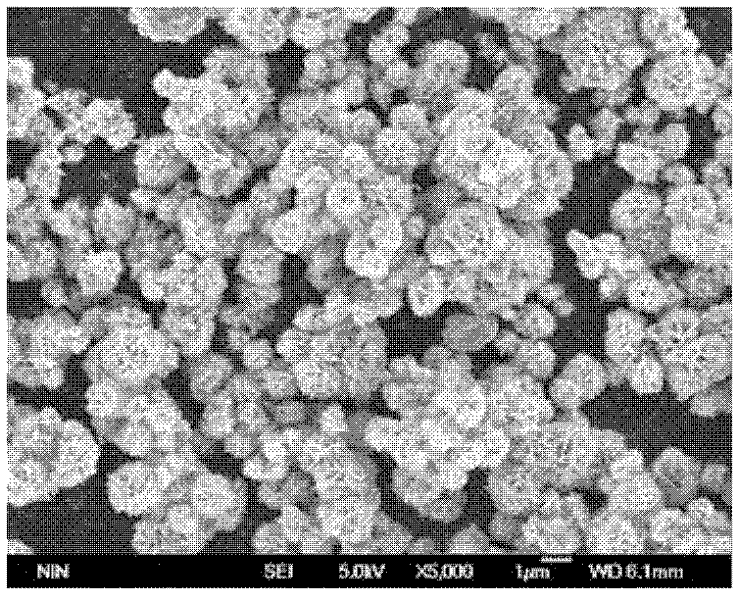

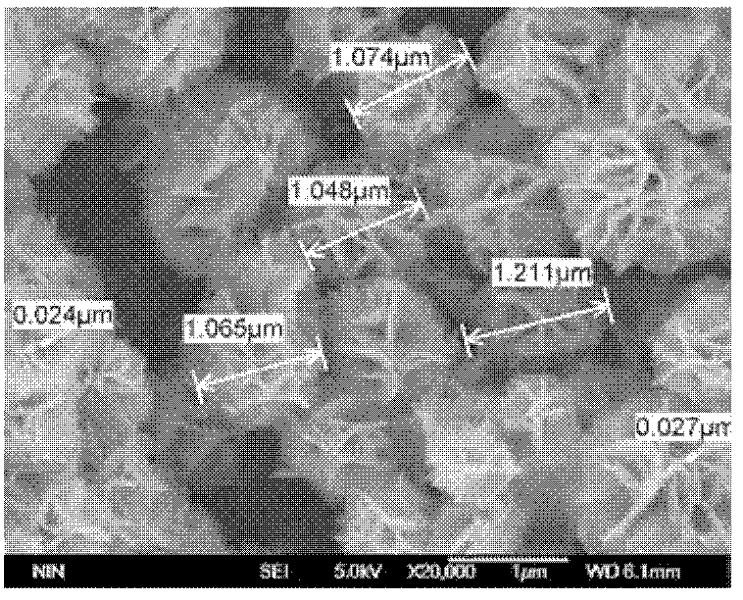

Preparation method of copper sulphide nano-powder with different stoichiometric ratios

InactiveCN102320647AStoichiometric ratio is easy to controlRaw materials are easy to getNanotechnologyCopper sulfidesArgon atmospherePhysical chemistry

The invention discloses a preparation method of copper sulphide nano-powder with different stoichiometric ratios, and belongs to the technical field of nanometer materials. The preparation method is characterized in that elemental copper powder (having a mass fraction above 99.9%) and elemental sulfur power (with a mass fraction above 99.8%) are utilized as raw materials and mixed according to a general chemical formula of Cu2-xS, wherein x is great than or equal to -0.5 and less than or equal to 1.5; and the mixture is subjected to ball-milling at a ball-milling rate of 100 to 425rpm in an argon atmosphere for 5 to 600 minutes to obtain stoichiometric ratio-adjustable single-phase copper sulphide nano-powder with particle sizes of 1 to 500 nanometers. The preparation method has the advantages of cheap and easily available raw materials, simple equipment, good operability of equipment, short process flow, convenience and quickness of large-scale production of copper sulphide nano-powder with different stoichiometric ratios, and wide application prospects.

Owner:UNIV OF SCI & TECH BEIJING

Recovery of nickel, cobalt, iron, silica, zinc and copper from laterite ore by sulfuric acid leaching

ActiveUS7387767B2Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INC

Preparation method of copper sulfide nano material

InactiveCN101559971AUniform sizeGood biocompatibilityNanostructure manufactureCopper sulfidesSulfurCopper sulfide

The invention relates to a preparation method of copper sulfide nano material, belonging to the technical field of nano composite material. The preparation method comprises the following steps of: preparing copper ion protein mixed solution; preparing copper-sulfur protein mixed solution; and carrying out centrifuge treatment and vacuum drying treatment. The method has simple and novel technique, little equipment quantity and low energy consumption and is environment-friendly.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing copper sulphide nanosheet

The invention discloses a method for preparing a copper sulphide nanosheet, comprising the following steps of: dissolving copper chloride and surfactant in deionized water to prepare a solution A; and dissolving thioacetamide in the deionized water to prepare a solution B; 2) mixing two solutions, i..e. the solution A and the solution B serving as a reaction solution to carry out water bath reaction to prepare a hexagon copper sulphide nanosheet; and controlling the side length of the copper sulphide nanosheet to be between 55 and 140nm and the thickness to be between 8 and 20nm through controlling a reaction condition. The method has the characteristics of easiness in acquisition of raw materials, simple equipment, low cost, simplicity in operation, effectiveness, quickness and the like; and the prepared copper sulphide nanosheet is ordered in appearance, high in dispersibility, yield rate and stability, controllable in sizes and suitable for large-scale industrial production. The prepared copper sulphide nanometer material has wide application prospect in the fields of light-emitting diodes, photochemical catalysts, flourescent materials, electrochemical batteries, sensors, lasers, solar batteries and the like.

Owner:CHONGQING UNIV OF ARTS & SCI

Process for making nano-sized and micro-sized precipitate particles

Owner:XIAMEN NANOTECH

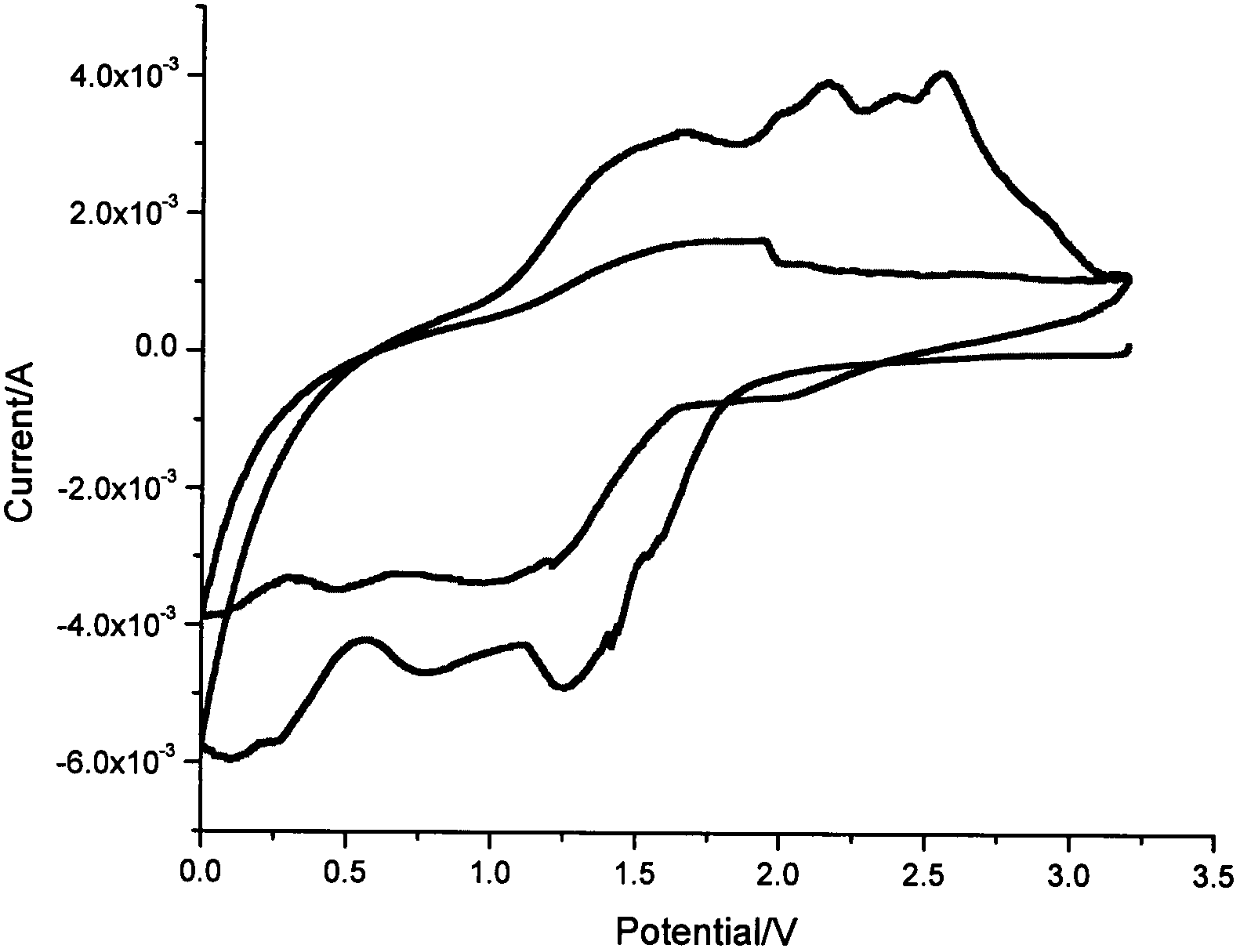

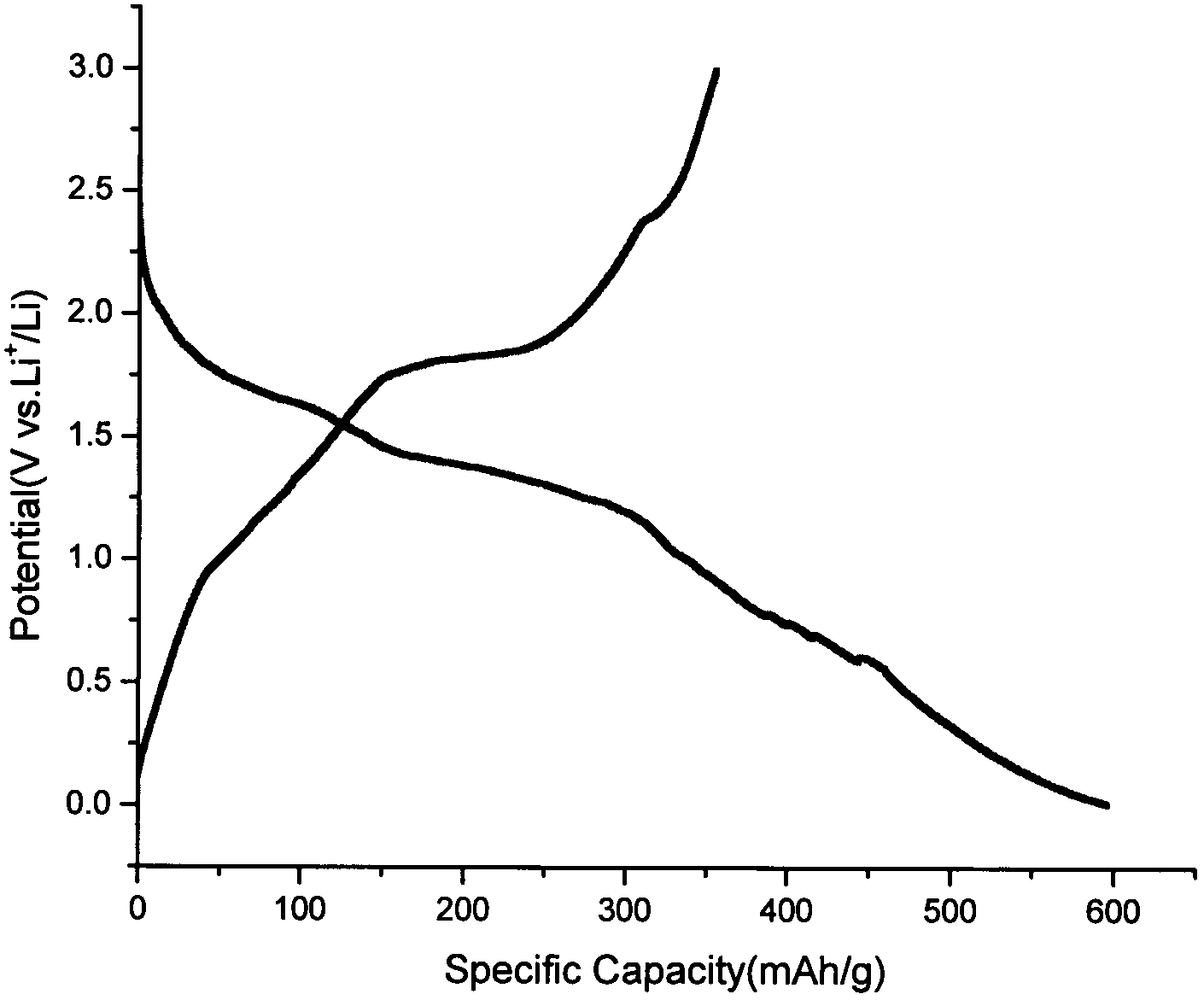

Cathode active substance for lithium ion battery, cathode material containing cathode active substance and lithium ion battery

InactiveCN102701160AHigher quality than capacityImprove conductivityTin compoundsCell electrodesAluminium-ion batterySodium-ion battery

The invention discloses a cathode ternary compound CuxMySz active substance for a lithium ion battery, a cathode material containing the substance and the lithium ion battery using the cathode material as a cathode. M in the chemical formula CuxMySz belongs to an IVB group, a VB group, a VIB group, a VIII group, an IIB group and an IVA group in a fourth period and a fifth period in periodic table of chemical element and is any one in metal elements of an IIIA group in third, fourth, fifth and sixth periods, such as Ti, Cr, Mo, Fe, Al, Ga, In, Tl, Sn and the like. The active substance has higher charge-discharge capacity which is about two times that of commonly used graphite material in the charge-discharge capacity, thereby being a novel lithium ion battery cathode material with good application prospect and high capacity.

Owner:EAST CHINA UNIV OF SCI & TECH

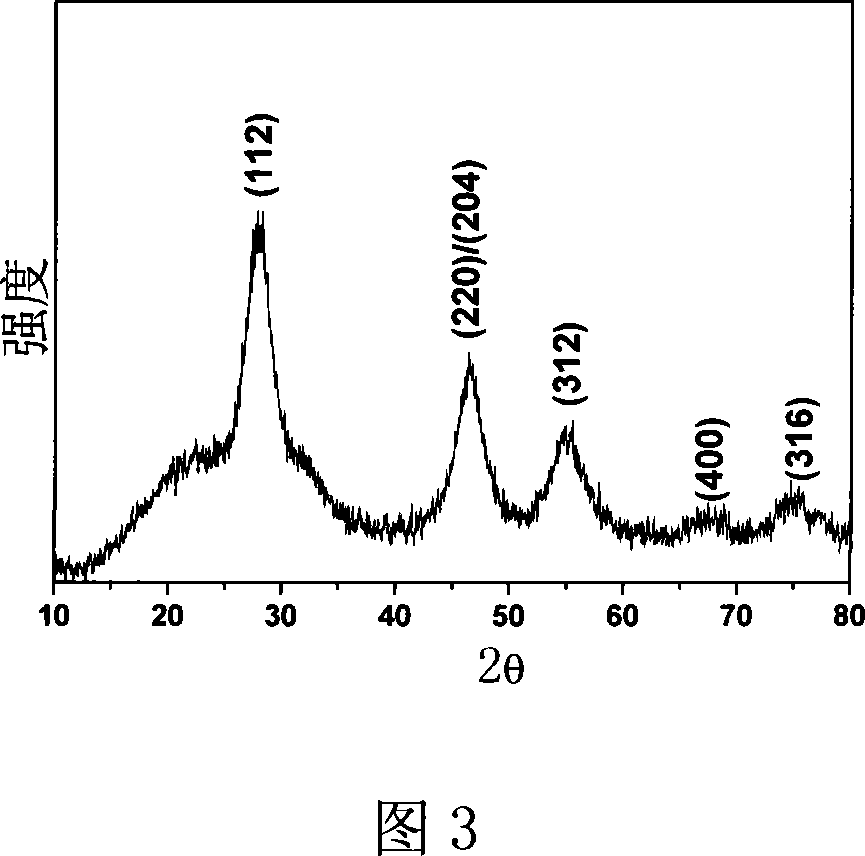

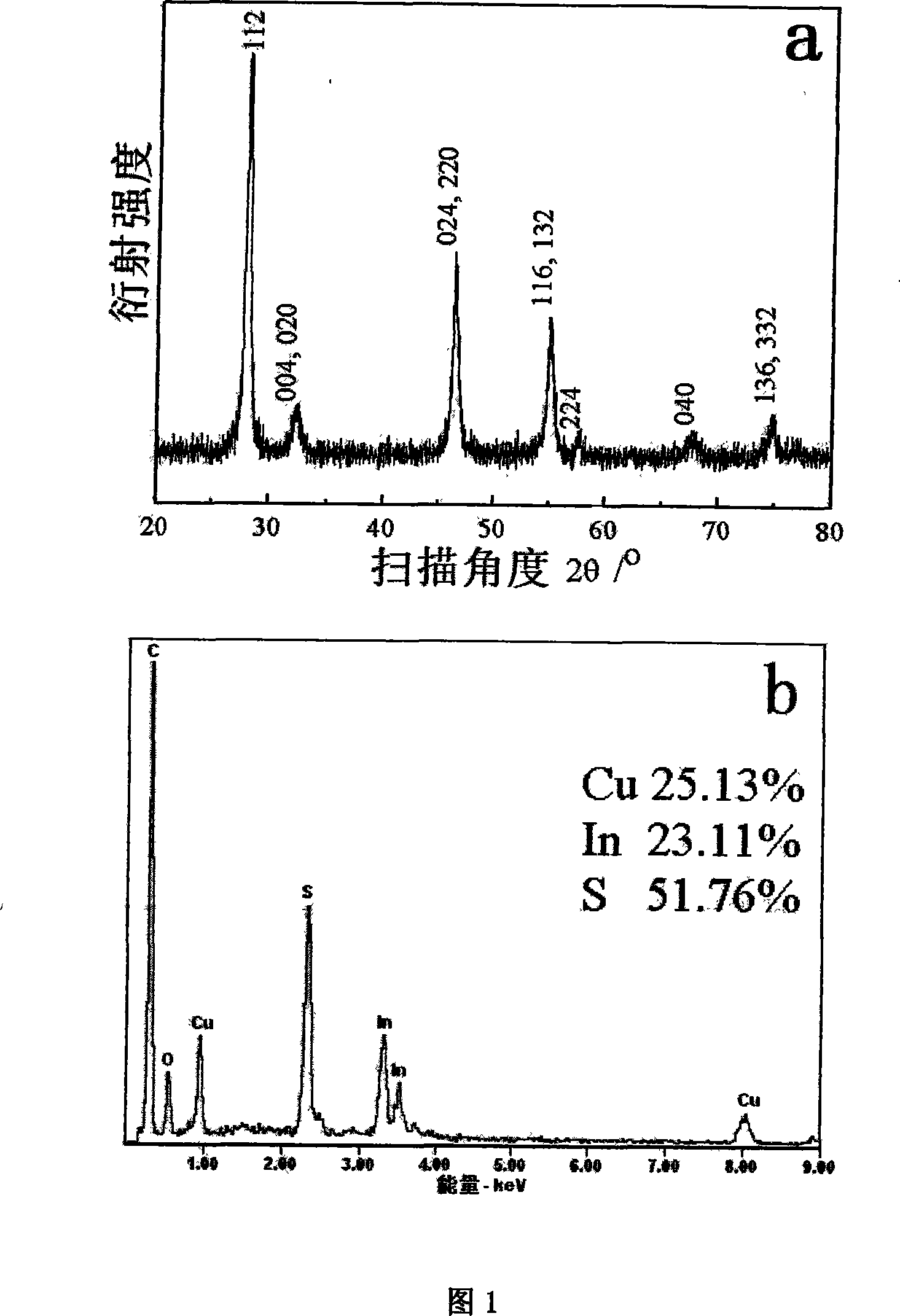

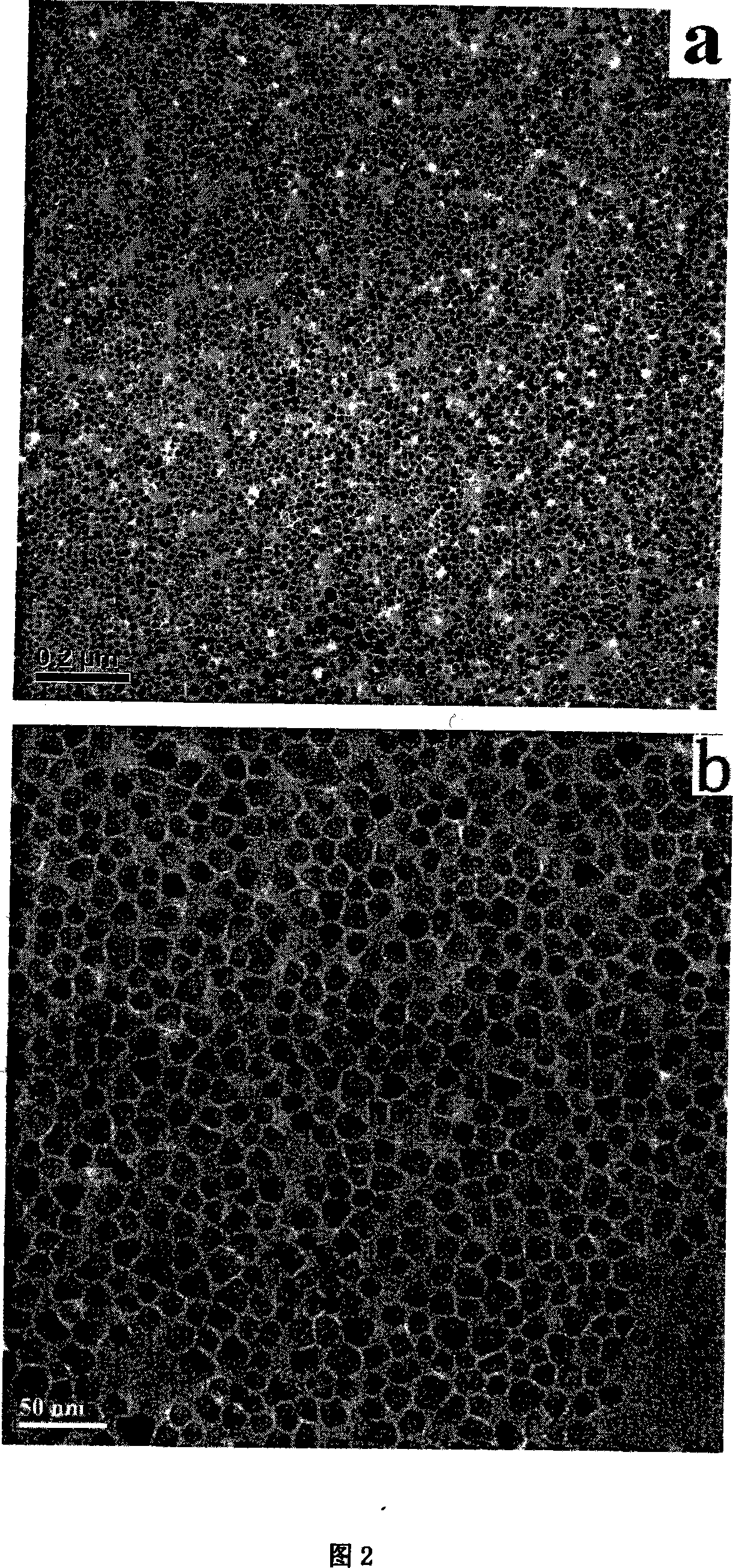

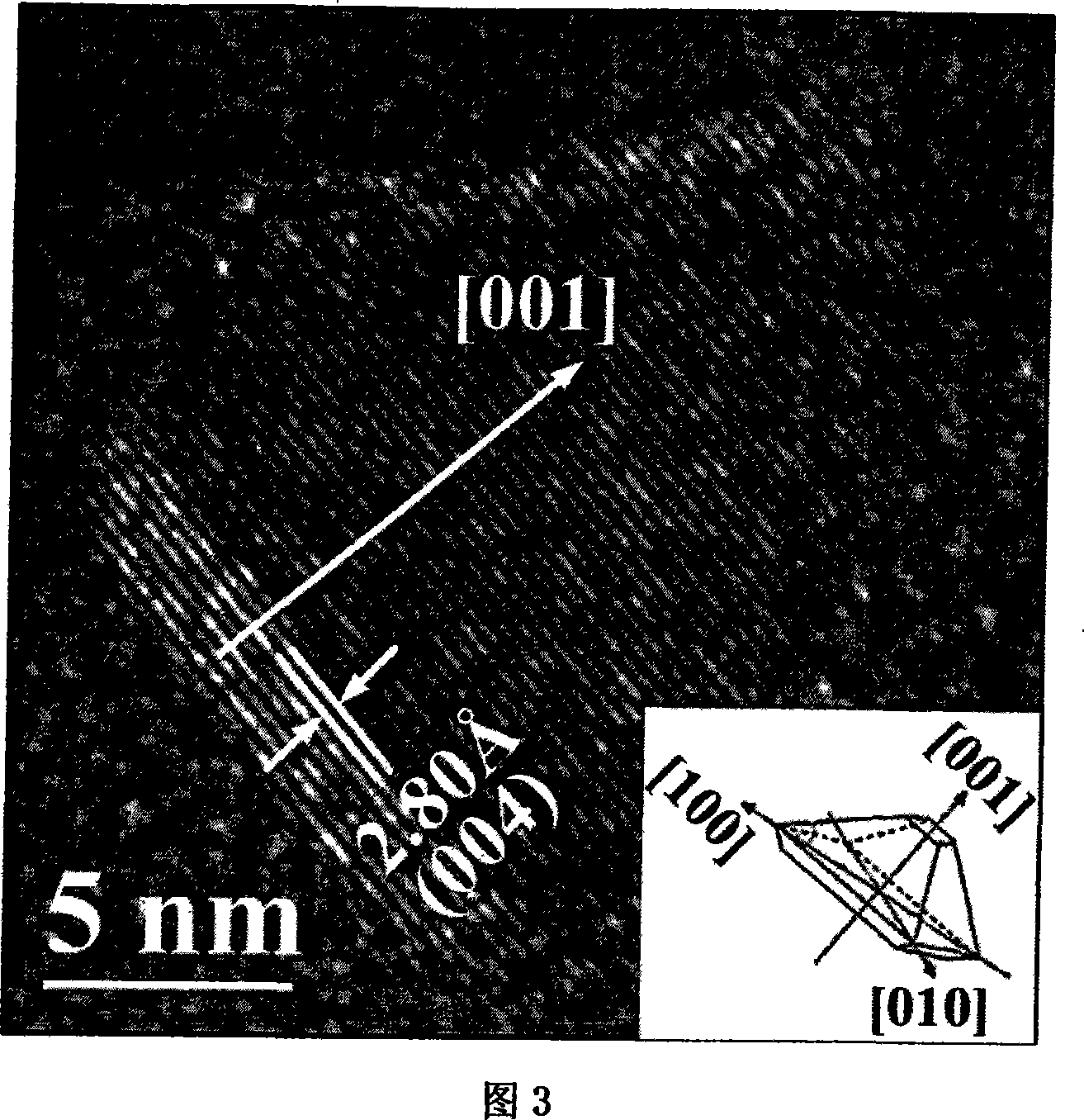

Method for preparing monodisperse ternary sulfide CuInS2

InactiveCN101054198ASave raw materialsEasy to operateNanostructure manufactureGallium/indium/thallium compoundsIndiumChemical solution

The invention relates to a method for preparing single-dispersive 3D sulfide CuInS2, which belongs to the field of nano-materials preparation. Chemical solution method is used to prepare the single-dispersive 3D sulfide CuInS2 nano-crystal by using alkylamine as the surfactant. First, cupric salt, indium salt, sulfer source and alkylamine are dispersed in the solvent to prepare the reaction solution, which is for solvent heat treatment to produce single-dispersive 3D sulfide CuInS2 nano-crystal with uniform shape. The invention is characterized in simple preparation, low cost and capable of synthersizing the single-dispersive 3D sulfide CuInS2 nano-crystal in large scale. And the prepared CuInS2 nano-crystal is of polyhedron shape, which is of 13-17nm in size and capable of self assembly in a wide range to produce single-layer nano-superlattice.

Owner:SHANGHAI JIAO TONG UNIV

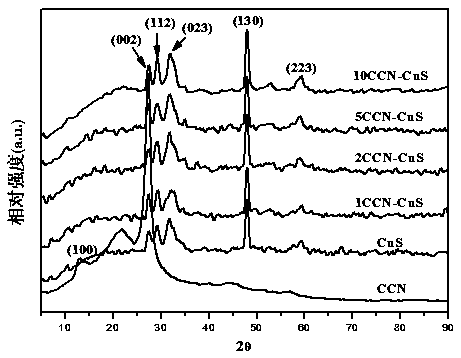

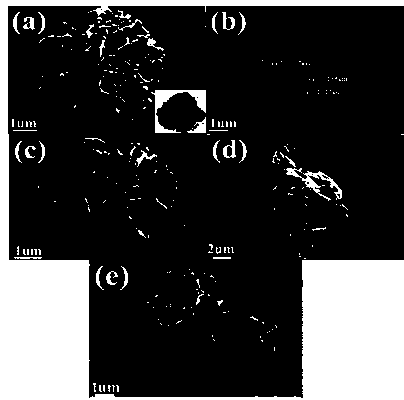

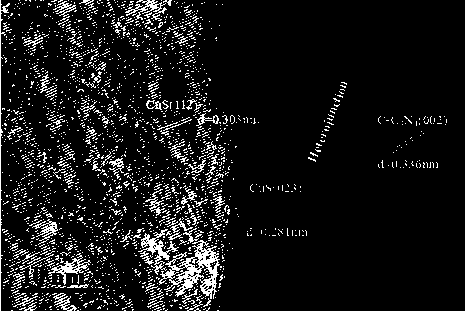

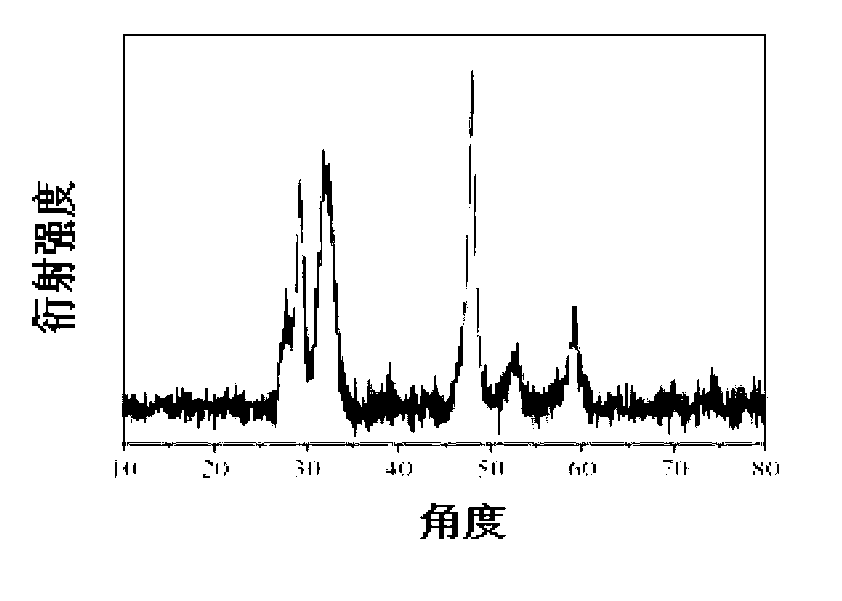

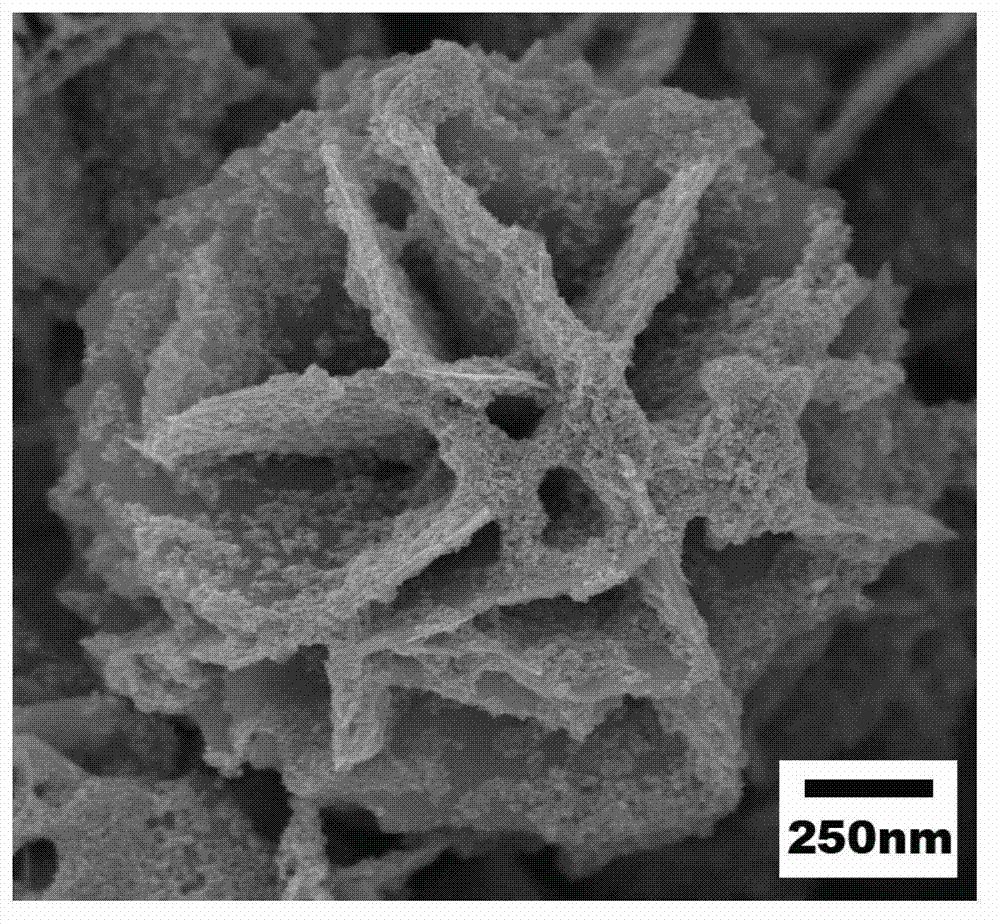

Preparation and application of carnation-shaped p-n heterojunction copper sulfide nanometer material

InactiveCN105502475ALower transfer resistanceEfficient separationPhysical/chemical process catalystsCopper sulfidesHeterojunctionThiourea

The invention provides preparation of a carnation-shaped p-n heterojunction copper sulfide nanometer material, and belongs to the technical field of nanometer materials. The preparation includes the steps that melamine is used as a raw material, carbon-doped graphene carbon nitrogen C-g-C3N4(CCN) is synthesized through hydro-thermal treatment and high-temperature calcination, and the carbon-doped graphene carbon nitrogen, copper chloride dihydrate and thiourea are further subjected to a hydrothermal reaction to synthesize a CCN-CuS p-n heterojunction; the p-n heterostructure reduces charge transfer resistance, enables photoinduced charges to be effectively separated and can effectively improve activity of photocatalyst. It is indicated through experiments that the prepared CCN-CuS p-n heterojunction nanometer material shows excellent visible-light catalytic activity and good cycling stability, and the degradation rate of rhodamin B can reach 92.6%. Therefore, the nanometer material can be used for degradation treatment on organic dyestuff waste water.

Owner:NORTHWEST NORMAL UNIVERSITY

Synthesis process of nanometer silver sulfide/copper sulfide in controlled shape

InactiveCN1887719ALower decomposition temperatureHigh yieldCopper sulfidesSilve compoundsReaction temperatureAmmonium bromide

The synthesis process of nanometer silver sulfide / copper sulfide in controlled shape relates to shape controlling synthesis technology of silver sulfide / copper sulfide in nanometer structure. The present invention aims at lowering the synthesis temperature of silver sulfide / copper sulfide, and raising the yield and structure controllability. The technological scheme is that under magnetic stirring, silver nitrate or copper chloride solution of 6-15 mmol / L concentration is drop-by-drop added into sodium thiosulfate solution of 9-52.5 mmol / L concentration, cetyl trimethyl ammonium bromide in 2.0-3.5 mmol is then added into the solution, the solution is stirred strongly at 30-60 deg.c for 30 min, acid is added to regulate pH to 1-5, and through further heating at the same temperature for 1-8 hr and natural cooling, the product is obtained.

Owner:HARBIN NORMAL UNIVERSITY

Method for preparing hierarchical floriform hollow-structure CuS

InactiveCN102795655AImprove surface roughnessImprove stabilityMaterial nanotechnologyCopper sulfidesAlcoholSulfur

A method for preparing hierarchical floriform hollow-structure CuS relates to a method for preparing nano-CuS. The method aims to solve the technical problem of low photocatalytic activity of the CuS nano-material prepared by the prior art due to small specific surface area. The method comprises the following steps of: firstly, completely dissolving inorganic copper salt into alcohol; secondly, adding a sulfur source for dissolving and then performing aging; thirdly, adding the aged solution to a high-pressure reaction kettle lined with polytetrafluoroethylene for solvent thermal reaction, and then naturally cooling until the temperature reaches the room temperature; and finally, orderly performing separation, washing and drying, thereby obtaining the hierarchical floriform hollow-structure CuS. The hierarchical floriform hollow-structure CuS prepared by the method can be applied to the fields such as solar cells, electrochemistry, gas-sensitivity, catalysis and the like.

Owner:HEILONGJIANG UNIV

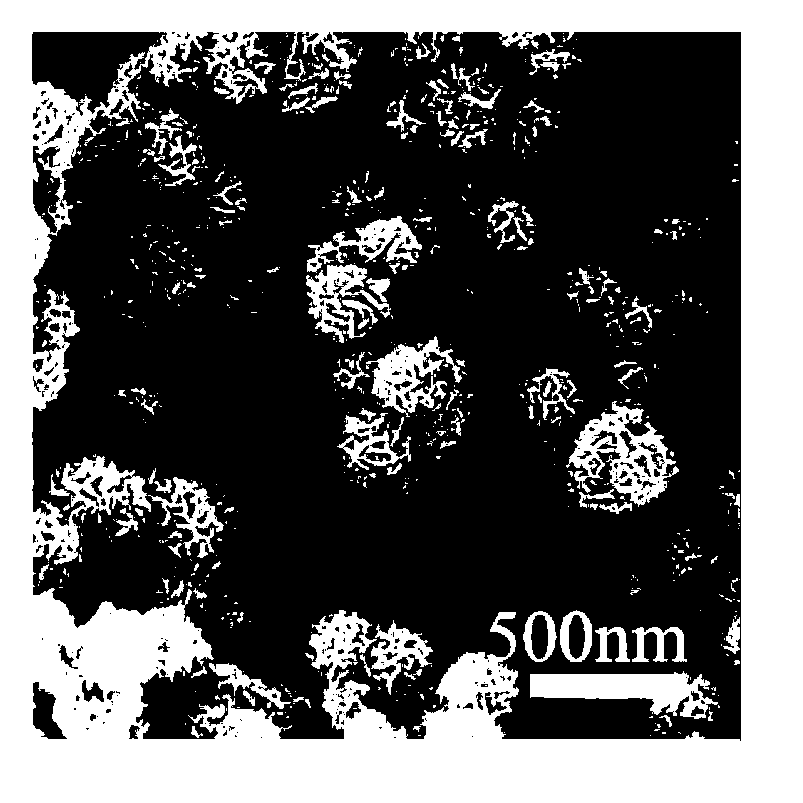

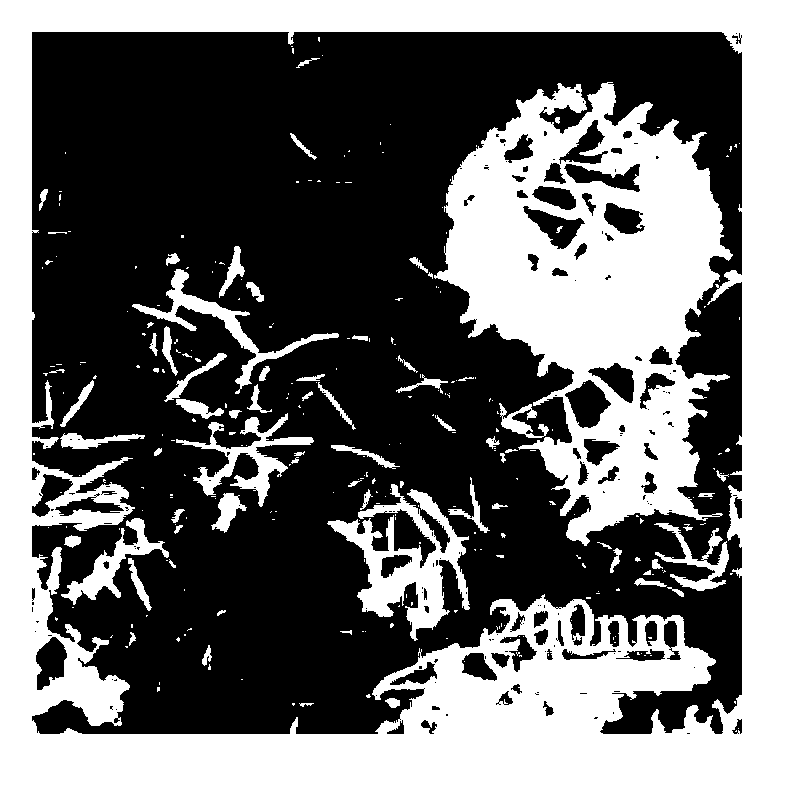

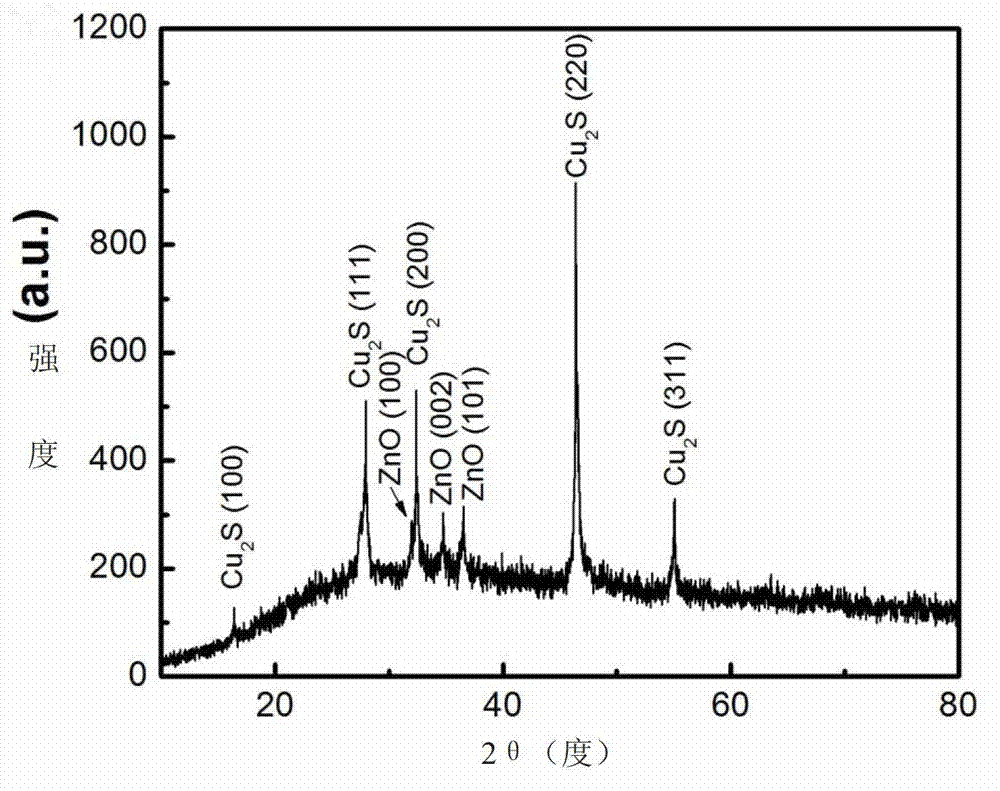

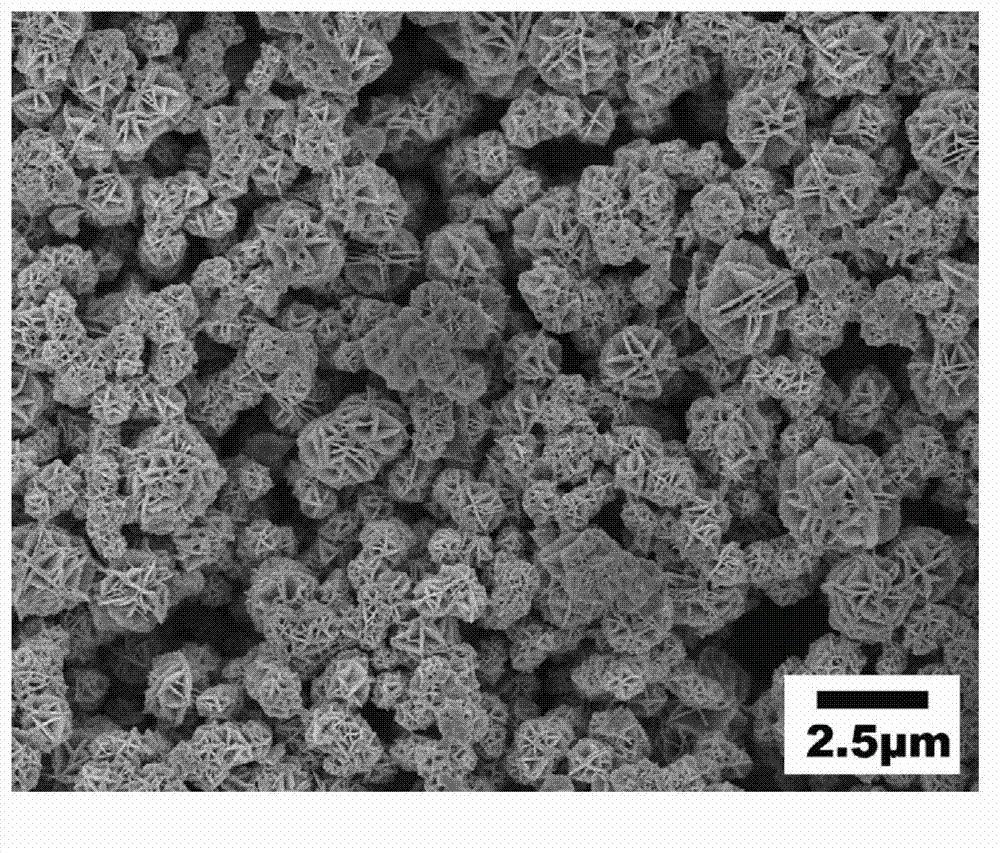

Three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material and preparation method thereof

InactiveCN103204536ARapid annealingPromote recrystallizationMaterial nanotechnologyPhysical/chemical process catalystsImideSemiconductor materials

The invention discloses a three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material. The three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material comprises ZnO nanometer-particle crystals and a CU2S nanometer-flower structure substrate material, wherein the ZnO nanometer-particle crystals are uniformly covered on the CU2S nanometer-flower structure substrate material; the CU2S nanometer-flower structure substrate material consists of Cu2S nanometer-sheets; and a P-N junction is formed at the interface of the ZnO nanometer-particle crystals and the Cu2S nanometer-flower structure. The invention further discloses a preparation method of the three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material. The preparation method comprises the following steps of: synthesizing the Cu2S nanometer-flower crystals and ZnO nanometer-particle crystals by adopting a hydrothermal synthesis method, respectively; and uniformly compounding the ZnO nanometer particles on the Cu2S nanometer-sheets by using PEI (Polyether Imide) as an auxiliary material to obtain the three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material. The three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material has the advantages of being low in cost, low in growth temperature, high in repeatability and the like, and also has great development application potential in the on-spot emission field and the photo-catalysis field.

Owner:EAST CHINA NORMAL UNIV

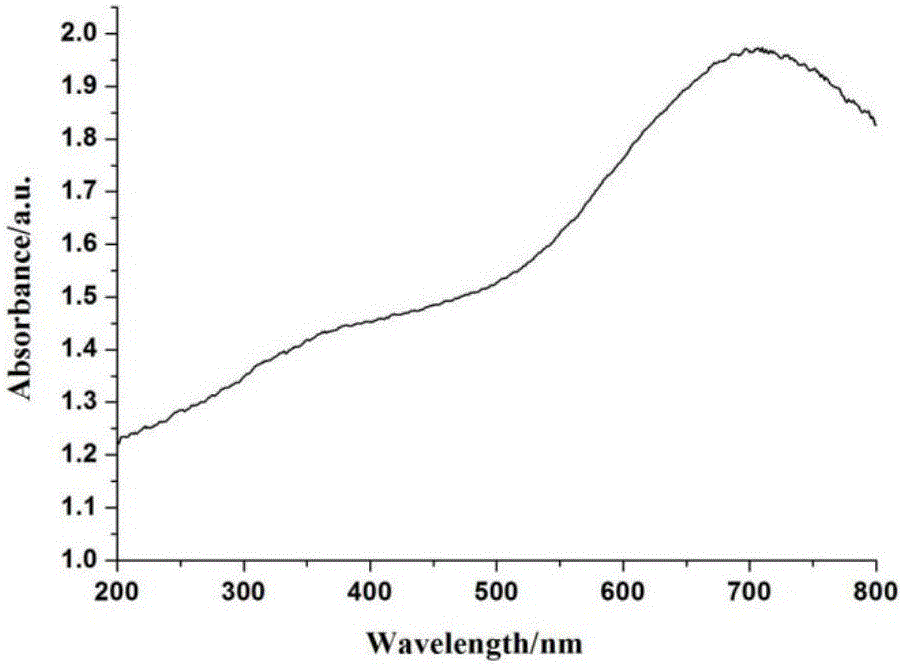

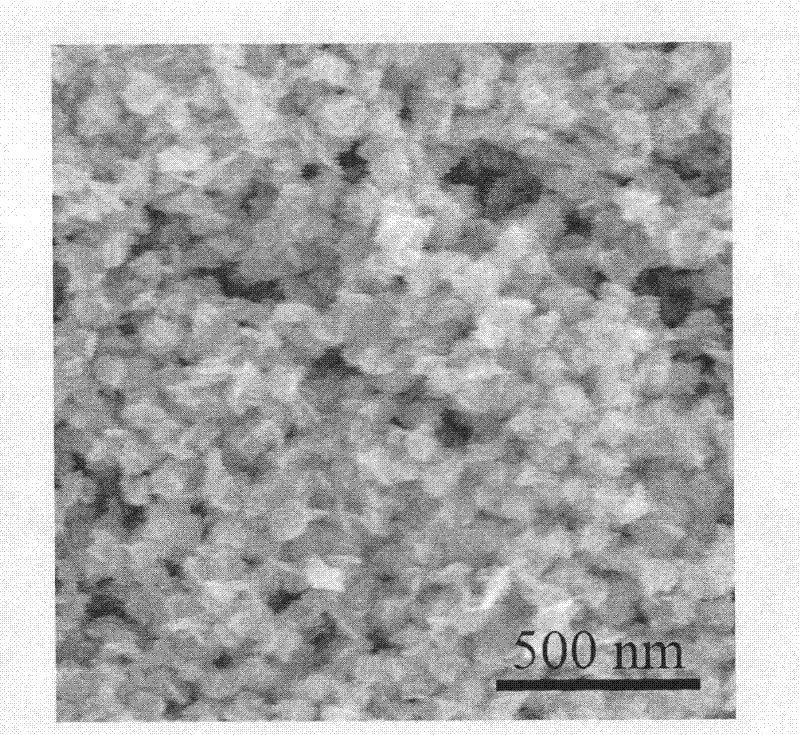

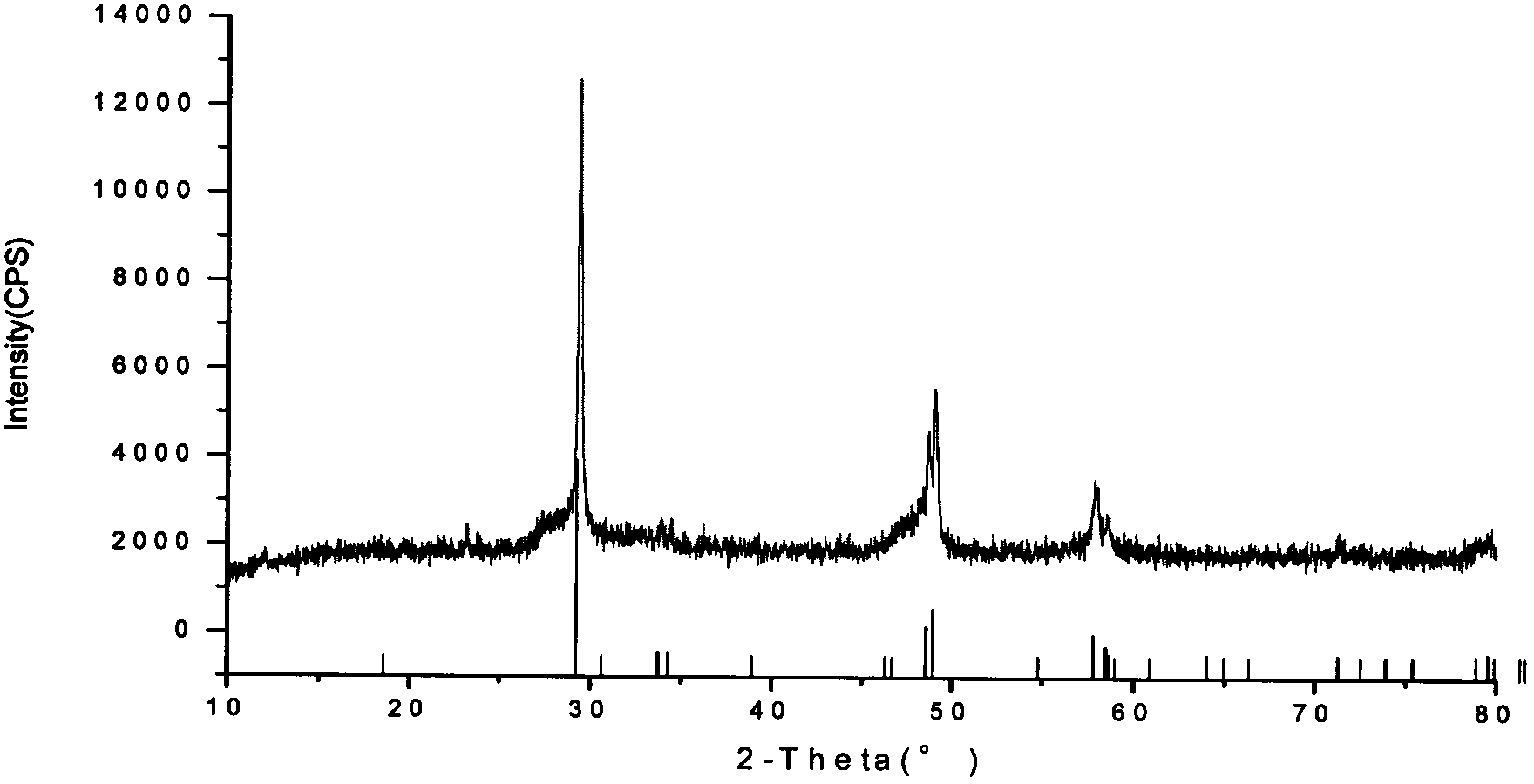

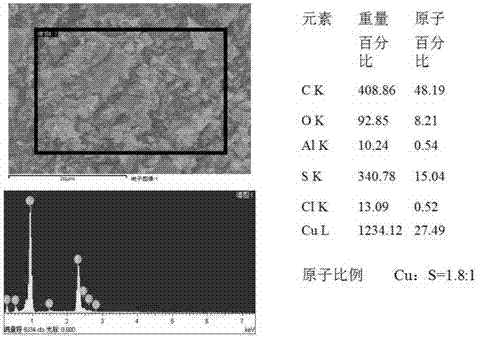

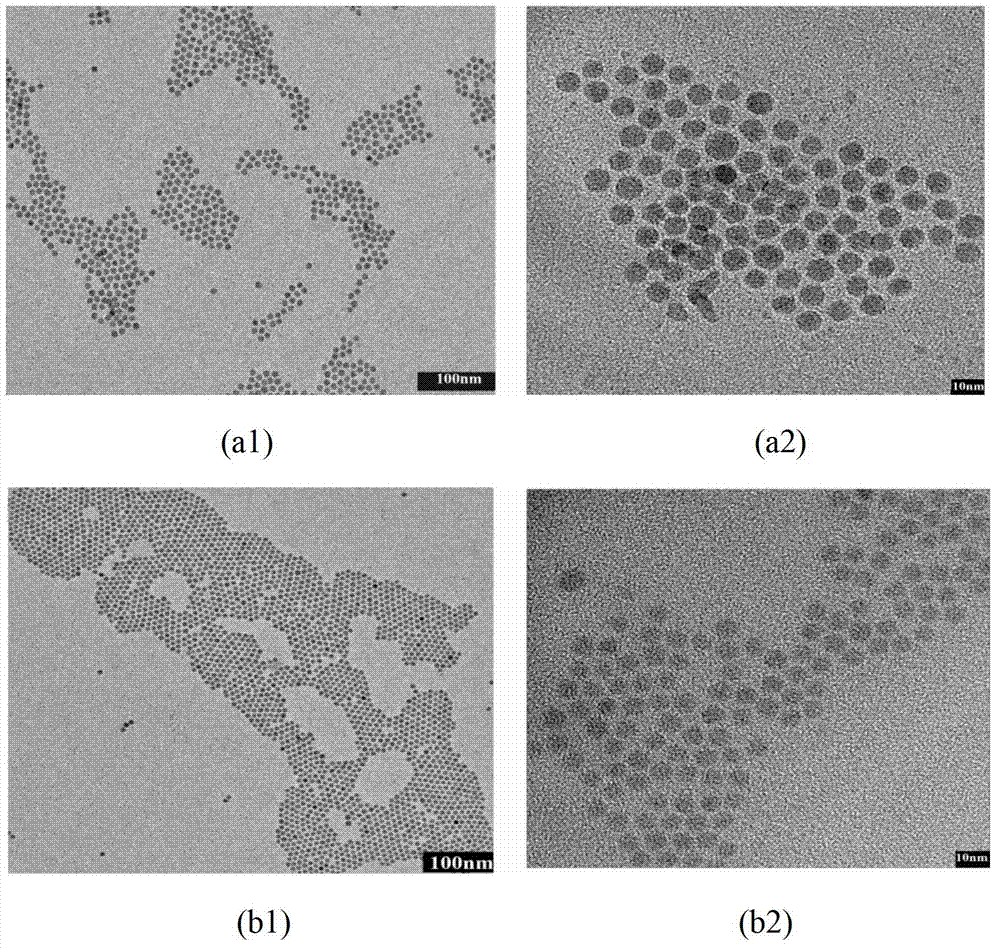

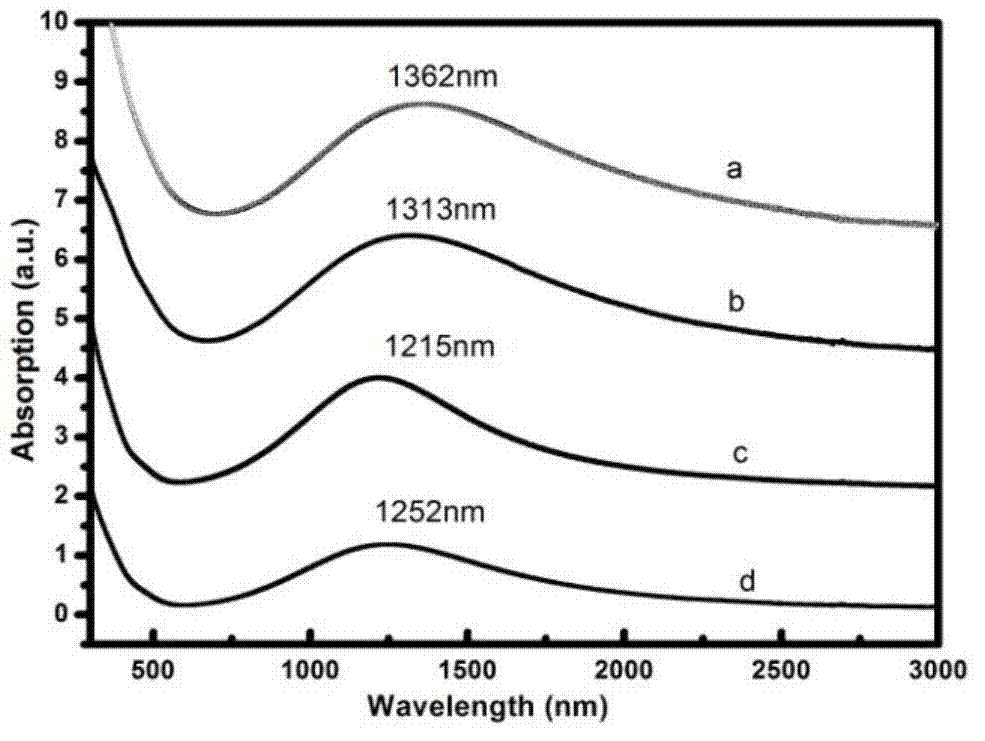

P-type CuxSy semiconductor nanocrystalline, preparation method and application thereof

InactiveCN102774871ASingle crystal phaseGood dispersionFinal product manufactureSolid-state devicesCharge carrier mobilityTemperature resistance

The invention discloses a p-type CuxSy semiconductor nanocrystalline, a preparation method and an application thereof and belongs to the fields of nanometer material preparation and applications. X / y of the nanocrystalline CuxSy is 1.8, the nanocrystalline is spherical, and the particle size of the nanocrystalline is 6-12nm. The preparation method includes preparing a copper source, preparing a sulfur source, injecting the copper source to the sulfur source, subjecting the solution to heating reaction to obtain a colloidal solution and subjecting the colloidal solution to washing and centrifugal sedimentation to obtain the nanocrystalline. The nanocrystalline is single in crystalline phase, good in dispersibility, controllable in size and morphology, good in electrical conductivity, high in carrier mobility and good in high temperature resistance and stability, the nanocrystalline is high in absorption ability in the whole near infrared area, and the absorption peak is 1100-1500nm. The preparation method is high in productivity and applicable to large-scale production. When the nanocrystalline is applicable to hole transport layers of thin-film solar cells, transport abilities of the hole transport layers can be obviously improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

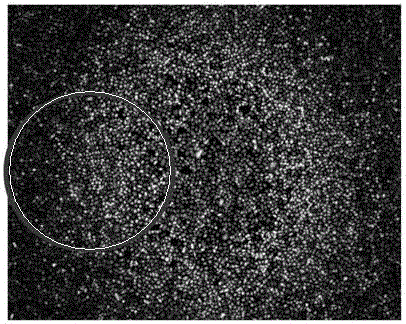

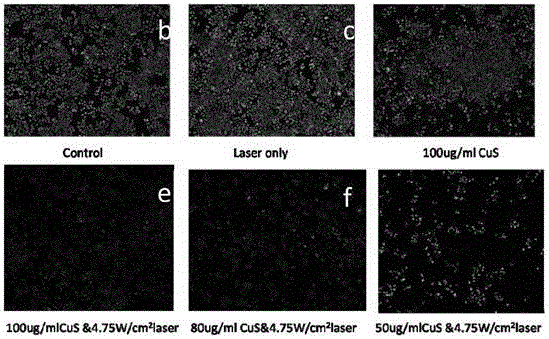

Ultra-small metal chalcogenide compound nano crystal and biological synthesis method and application thereof

InactiveCN106315663AMild reaction conditionsEasy to operateMaterial nanotechnologyEnergy modified materialsSynthesis methodsFluorescence

The invention discloses an ultra-small metal chalcogenide compound nano crystal and a biological synthesis method and application thereof. In one embodiment, the synthesis method is as follows: a protein with the isoelectric point PI lower than 9.0 and a metal salt are mixed with water evenly to form a mixed solution, the mixed solution is adjusted to alkaline, a reducing agent and a sulfur source are added for reaction to form the ultra-small metal chalcogenide compound nano crystal with the particle size less than 10nm. The method has the characteristics of mild reaction conditions, simple operation, direct use of particles without additional surface modification in biological photothermal therapy, and the like, the prepared ultra-small metal chalcogenide compound nano crystal is uniform in size, good in dispersion and high in stability, and the prepared ultra-small metal chalcogenide compound nano crystal has very good bio-compatibility without any surface modification, also has the photothermal effect, and is a great-application-prospect nano material used for photothermal therapy and biological fluorescence imaging.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

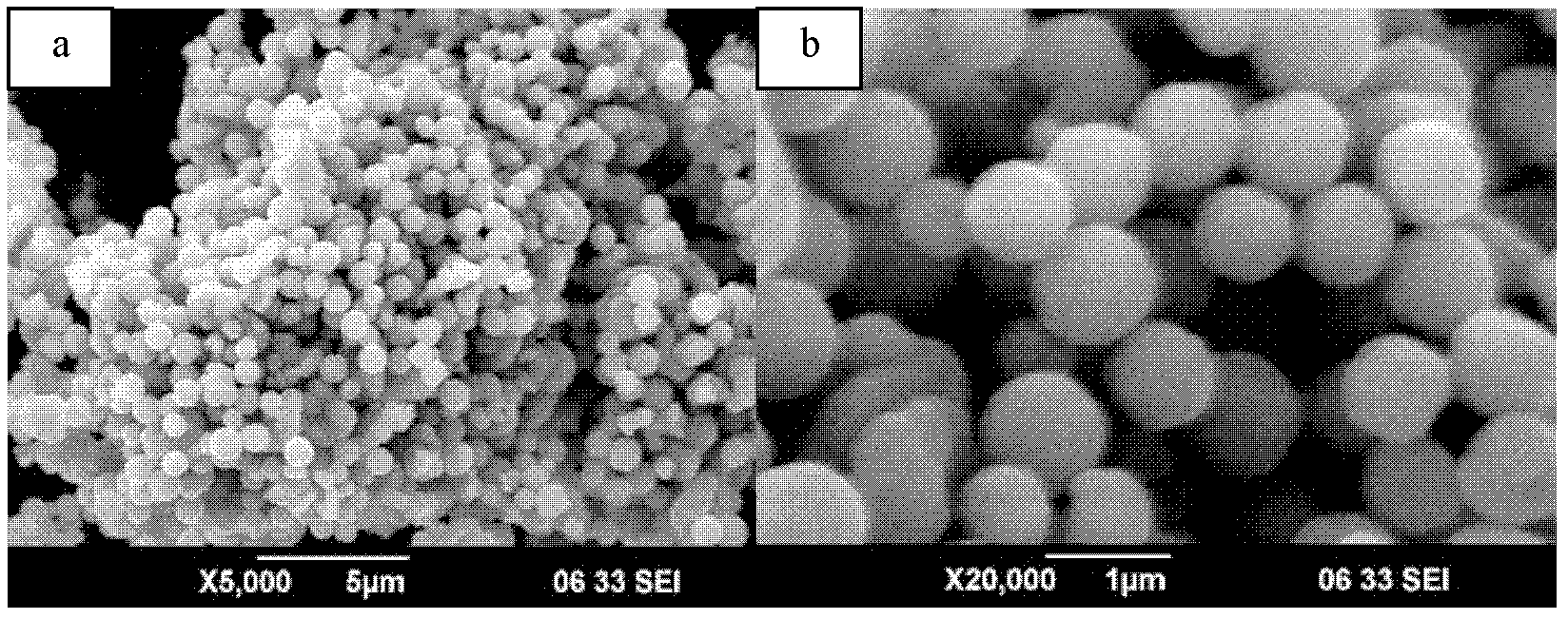

Preparation method of spherical copper sulphide (CuS) particles

The invention relates to a preparation method of spherical (CuS) particles. The preparation method comprises the steps that: copper nitric acid trihydrate is added into a mixed solvent consisting of de-ionized water and ethylene glycol to obtain solution A; thiourea is added into the solution A to obtain solution B; polyvinylpyrrolidone K30 is added into the solution B to form precursor solution C; the precursor solution C is poured into a microwave hydrothermal reaction kettle, then, the reaction kettle is sealed and is put into a temperature and pressure dual-control microwave hydrothermal reaction instrument, a temperature control mode or a pressure control mode is selected for reaction, and the solution is naturally cooled to the room temperature after reaction completion; and the hydrothermal reaction kettle is opened, products are respectively washed by the de-ionized water and absolute ethyl alcohol after centrifugal collection, and final products of spherical CuS particles are obtained after drying. The method has the advantages that a simple microwave hydrothermal method preparation process is adopted, the reaction period is short, the energy consumption is low, the reaction is completed in one step in liquid phases, and the later-period treatment is not needed. The prepared CuS particles have regular sphere shapes and uniform size.

Owner:SHAANXI UNIV OF SCI & TECH

Reduced copper sulphide sorbent for removing heavy metals

InactiveUS20110226700A1Avoid problemsUsing liquid separation agentSolid sorbent liquid separationSorbentCadmium Cation

A sorbent, suitable for removing heavy metals, particularly mercury, from fluid streams containing a reductant such as hydrogen and / or carbon monoxide, is in the form of a shaped unit containing ≦0.1% by weight in total of heavy metal selected from mercury, arsenic, lead, cadmium and antimony, and 4-75% by weight of copper in the form of one or more reduced copper sulphides which have a sulphur to copper atomic ratio of ≦0.6:1.

Owner:JOHNSON MATTHEY PLC

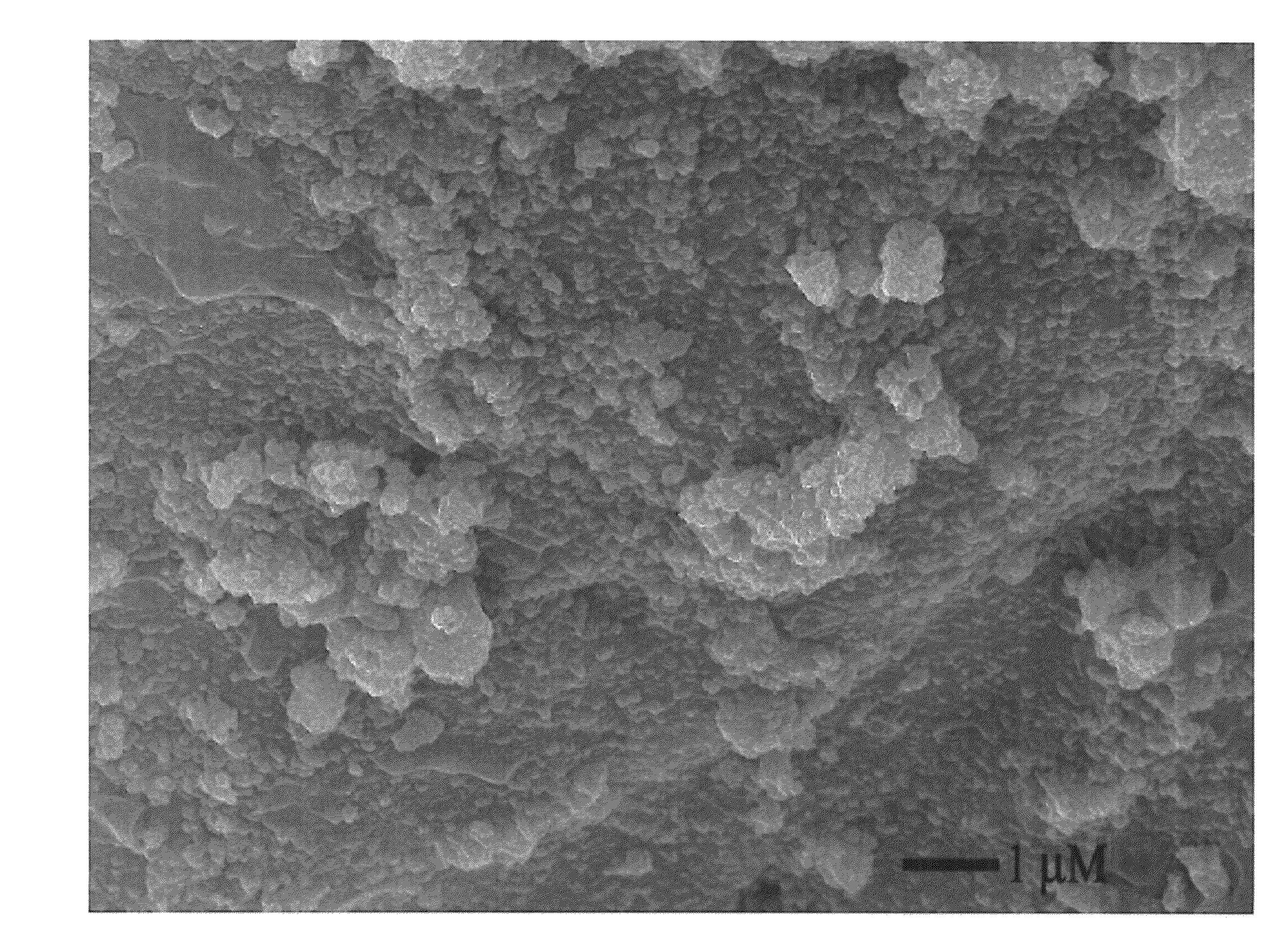

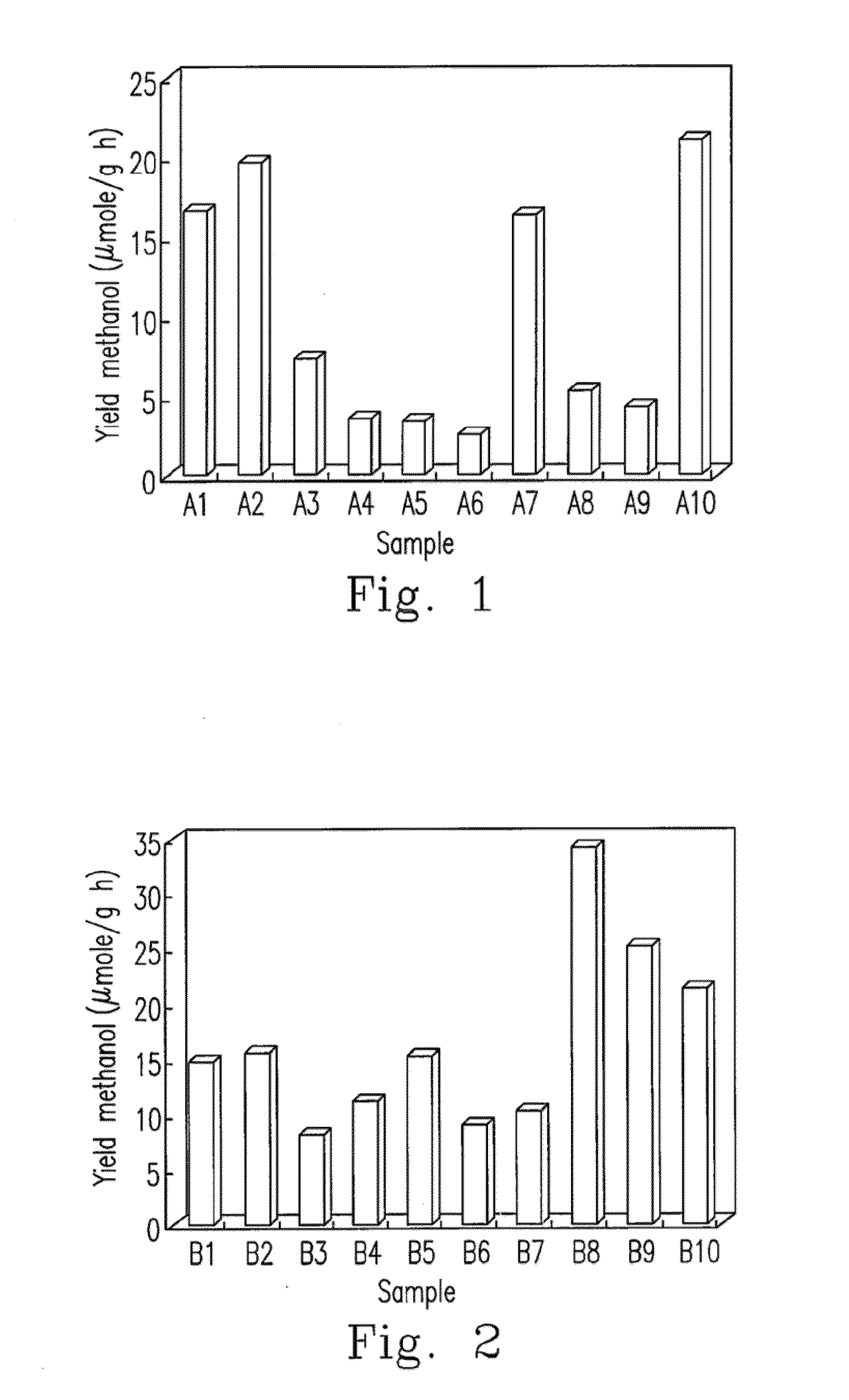

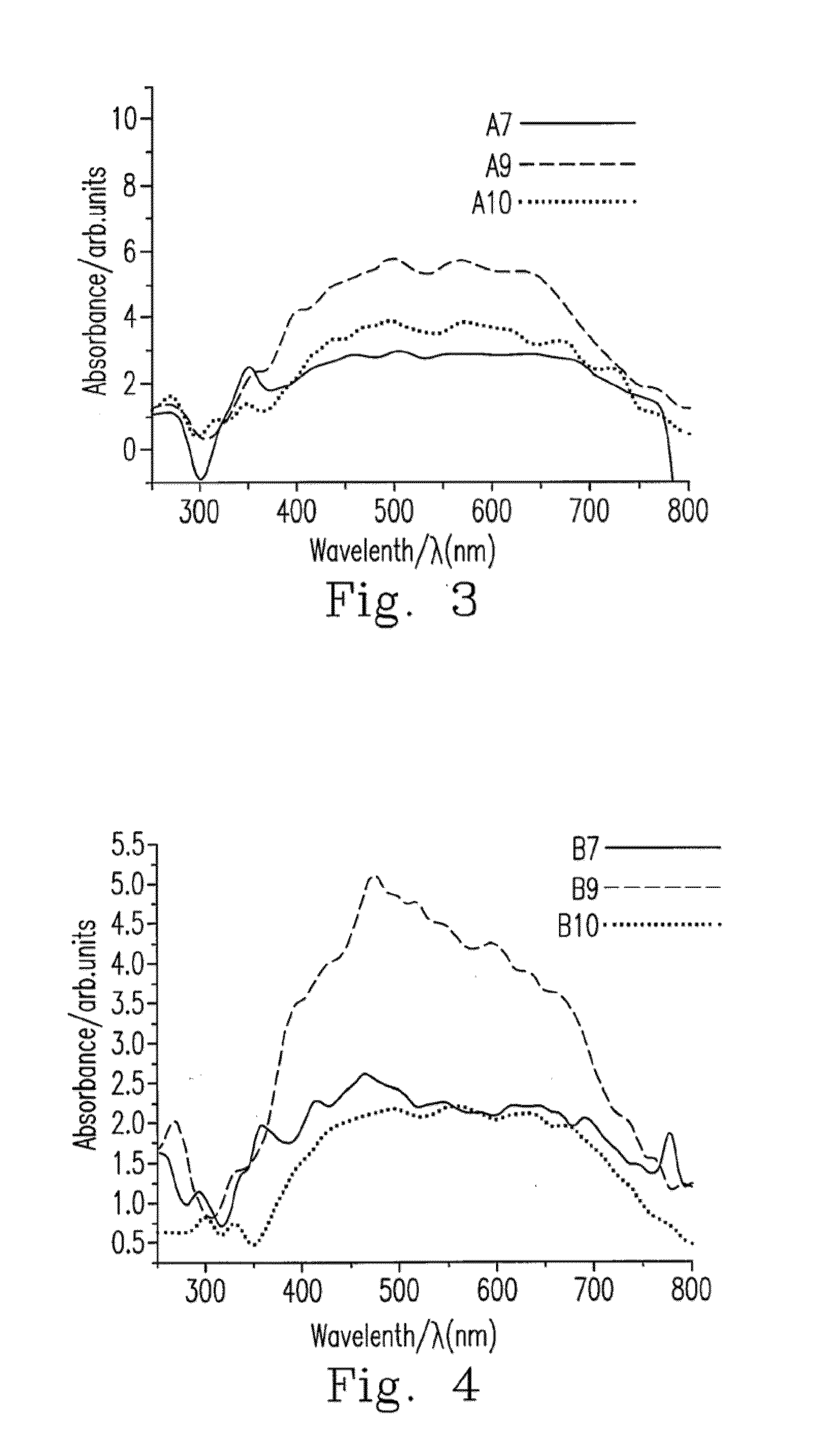

Metallic sulfide photocatalyst for carbon dioxide reduction and the preparation for the same

InactiveUS20130252798A1Readily apparentCell electrodesHydroxy compound preparationOxidation stateMetallic sulfide

Disclosed are the metallic sulfide photocatalyst and its preparation method. The photocatalyst includes at least one soluble metallic salt and a sulfide with the oxidation state of S atom ≦+4. The photocatalyst is afforded by reacting the sulfide with the at least one soluble metallic salt dissolved in the complexing agent. Additionally, the photocatalyst further is customized with co-catalyst such as RuCl to form Ru-carried metallic sulfide photocatalyst. The metallic sulfide photocatalyst and Ru-carried metallic sulfide photocatalyst are capable of effectively reducing CO2 to CH3OH under the visible light illumination.

Owner:NATIONAL TSING HUA UNIVERSITY

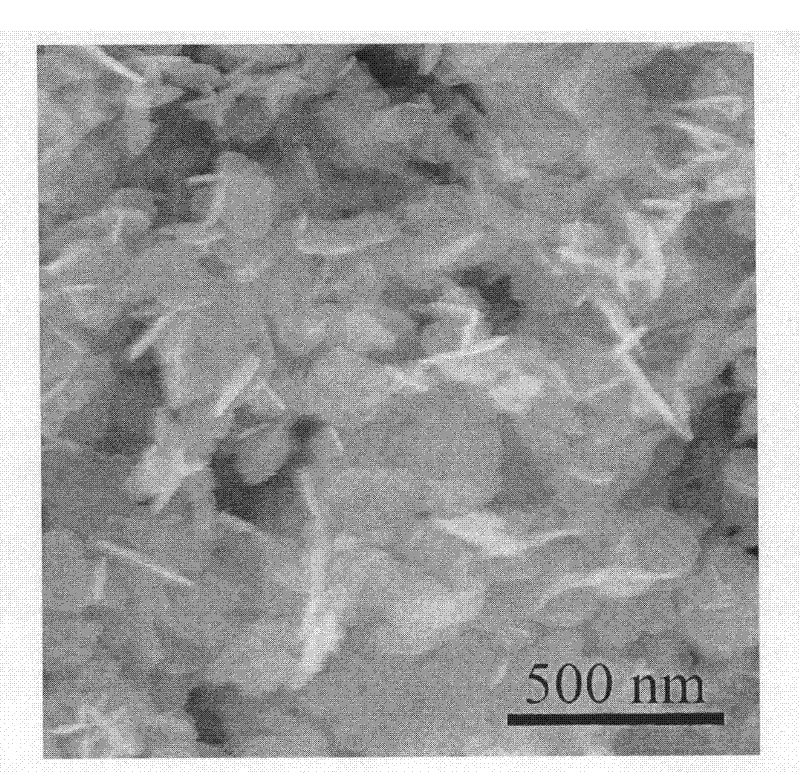

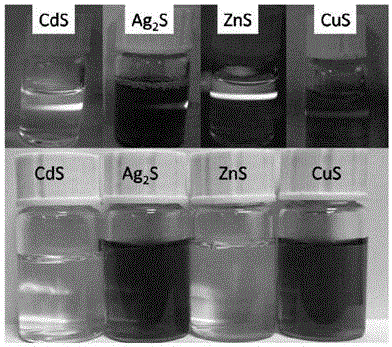

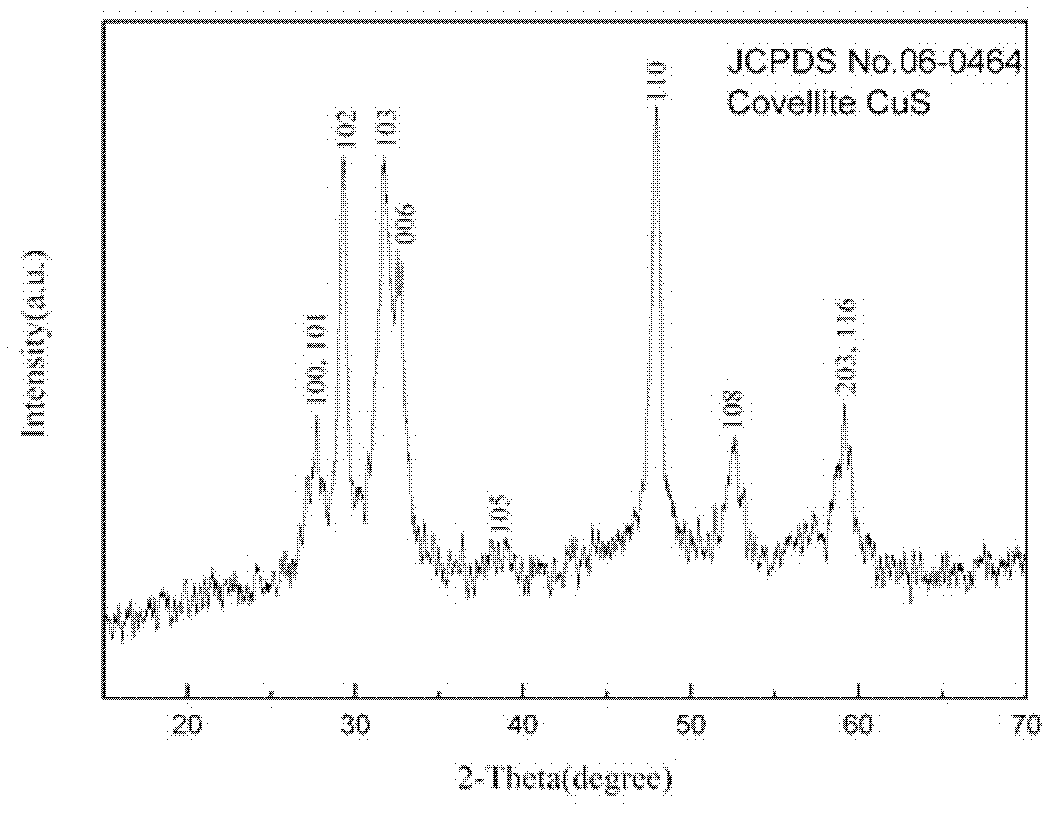

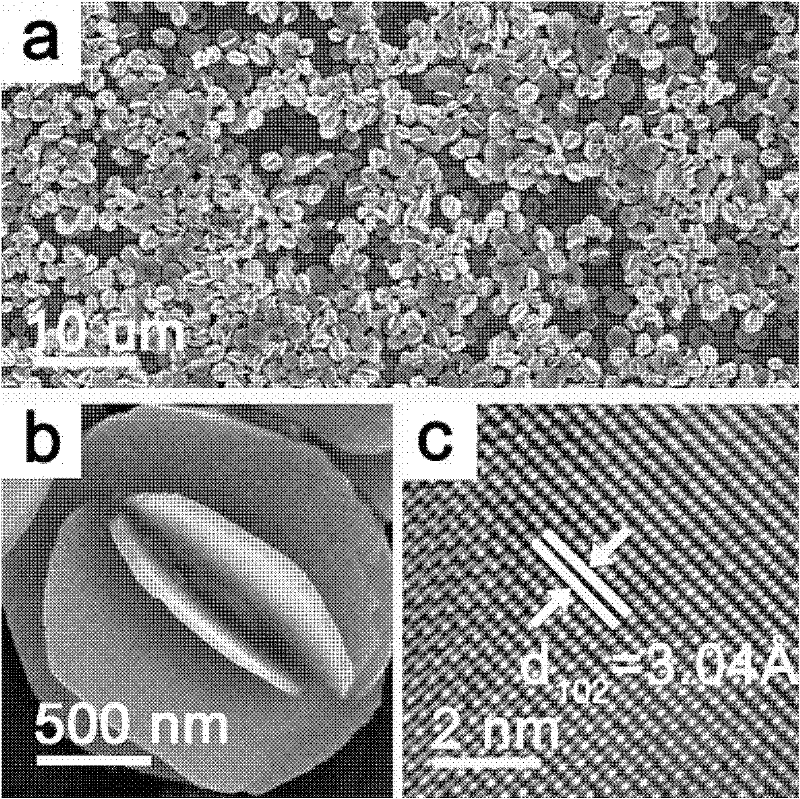

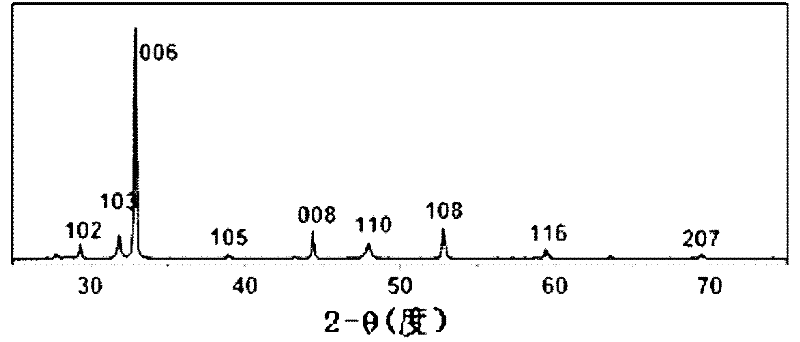

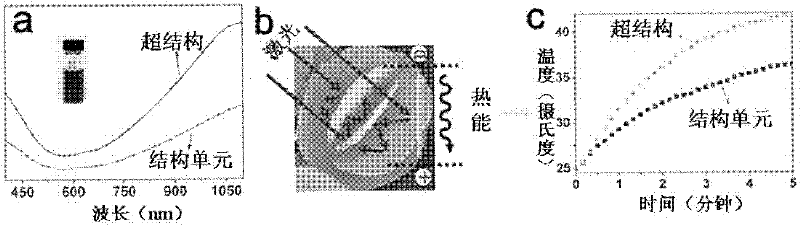

Copper sulfide superstructure and its application in improving near infrared thermal conversion efficiency

The invention relates to a copper sulfide (CuS) superstructure, and its application in improving near infrared thermal conversion efficiency. The CuS superstructure is composed by orderly arranged CuS sheet-shaped nano-units with particle sizes of 1 to 2000nm. The CuS superstructure can be well dispersed in water or phosphate buffer solution. The CuS superstructure is applied in near infrared thermotherapy. The CuS superstructure has advantages of simple preparation method, low cost, and good stability. With an internal reflection effect, the CuS superstructure can effectively adsorb near infrared, such that the utilance of near infrared is improved. Therefore, the CuS superstructure can be applied in the preparation of materials for improving near infrared thermal conversion efficiency, and has good application prospect in the field of near infrared thermotherapy.

Owner:DONGHUA UNIV

Method for preparing flower-shaped copper sulfide (CuS) nanocrystal

InactiveCN102557107AShort reaction cycleReduce energy consumptionNanotechnologyCopper sulfidesSemiconductor materialsThiourea

The invention relates to a method for preparing a flower-shaped copper sulfide (CuS) nanocrystal, which comprises the following steps of: dissolving a dissoluble copper salt into deionized water to obtain a solution A; adding sulfourea into the solution A to obtain a solution B; adding hexadecyl trimethyl ammonium bromide into the solution B to form a precursor solution C; pouring the precursor solution C into a microwave hydrothermal reaction kettle, sealing the reaction kettle, putting the reaction kettle into a temperature and pressure dual-control microwave hydrothermal reactor, and carrying out natural cooling to room temperature after the reaction is finished; and opening the hydrothermal reaction kettle, carrying out centrifugal collection on a product, then, washing the production by respectively using deionized water and absolute alcohol, and drying to obtain the flower-shaped copper sulfide nanocrystal. According to the method for preparing the flower-shaped copper sulfide nanocrystal, flower-shaped copper sulfide nanocrystals with different grain sizes are prepared through changing the concentration of an added surfactant, i.e. the hexadecyl trimethyl ammonium bromide, the grain size controllable preparation of the flower-shaped copper sulfide nanocrystals is achieved, and then, copper sulfide semiconductor materials with different optical and electrical properties are prepared; and CuS grains prepared by the method are of a flower-shaped structure formed by assembling flake-shaped crystals with the thickness of 20-50 nm, so that the CuS grains have larger surface areas and can be applied to the catalytic field.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com