Patents

Literature

351results about How to "Short preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

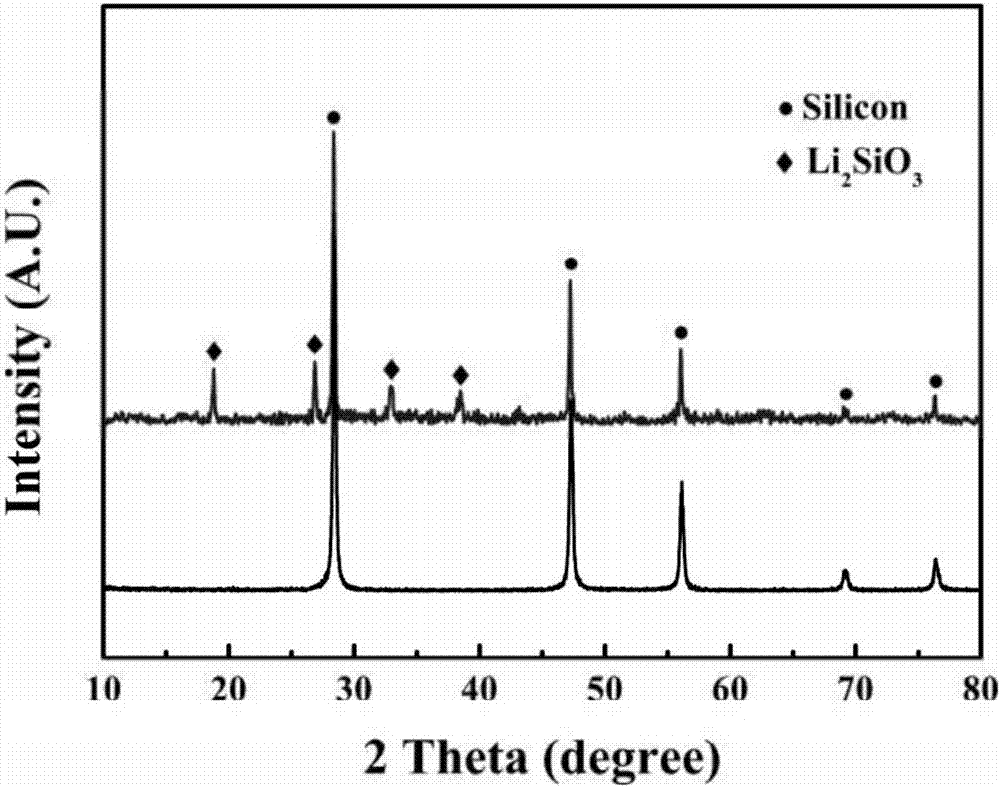

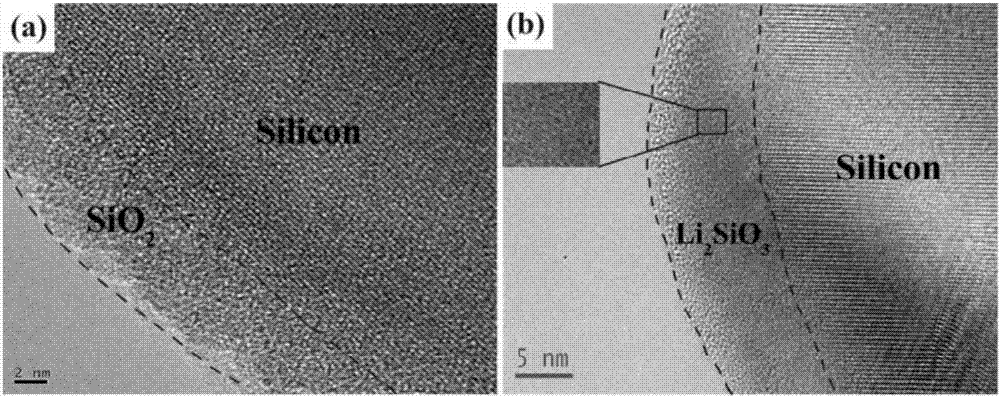

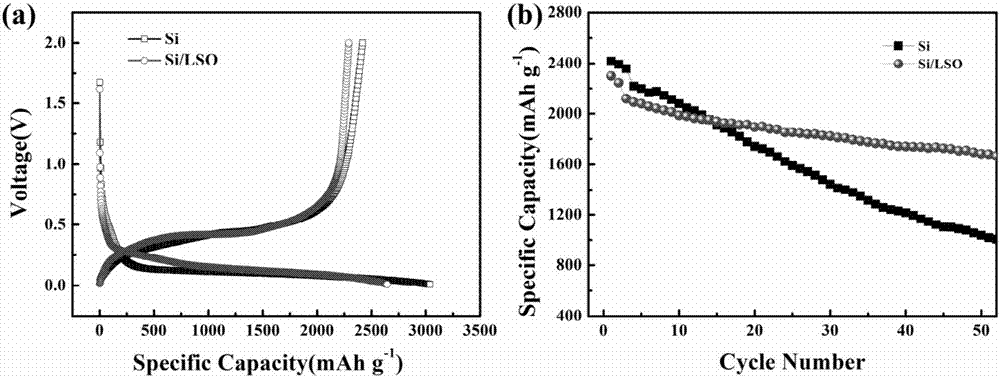

Lithium ion battery composite negative electrode material and preparation method thereof

InactiveCN107887587AImprove storage effectImprove Interface StabilityMaterial nanotechnologyCell electrodesChemical reactionSilicon dioxide

The invention discloses a lithium ion battery composite negative electrode material and a preparation method thereof. The surface of nanometer silicon is subjected to oxidization treatment to obtain nanometer silicon coated with silicon dioxide on the surface; the nanometer silicon coated with silicon dioxide on the surface is mixed with a lithium source uniformly to obtain a precursor; and the obtained precursor is placed into inert gas to be heated to obtain a nanometer silicon material coated with lithium silicate, and the product is subjected to washing, centrifugal separating and drying to obtain the lithium ion battery composite negative electrode material. By taking a uniform primary oxide layer on the surface of the nanometer silicon material as the substrate, an in-situ chemical reaction is performed to realize uniform coating of lithium silicate, so that stability between nanometer silicon and air or an electrolyte interface is improved effectively, thereby greatly improvingelectrochemical performance of the nanometer silicon material.

Owner:CENT SOUTH UNIV

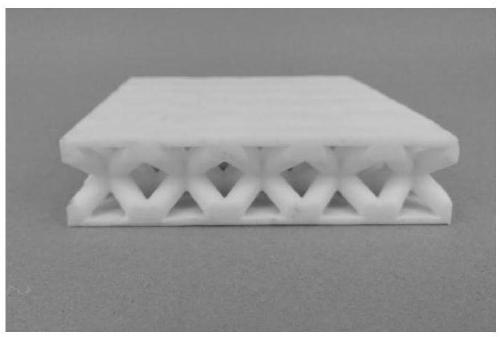

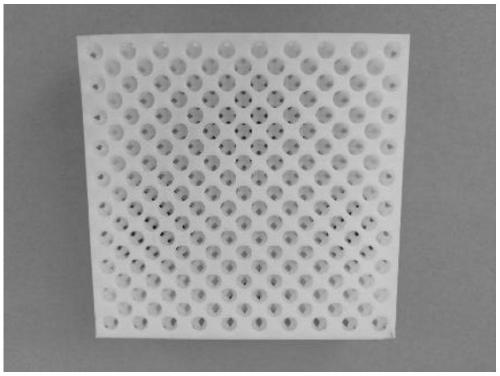

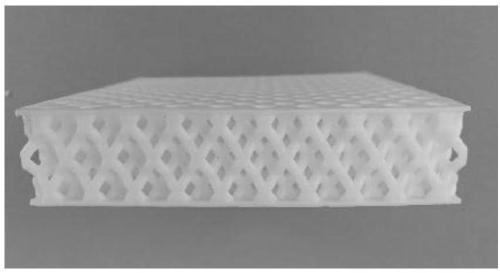

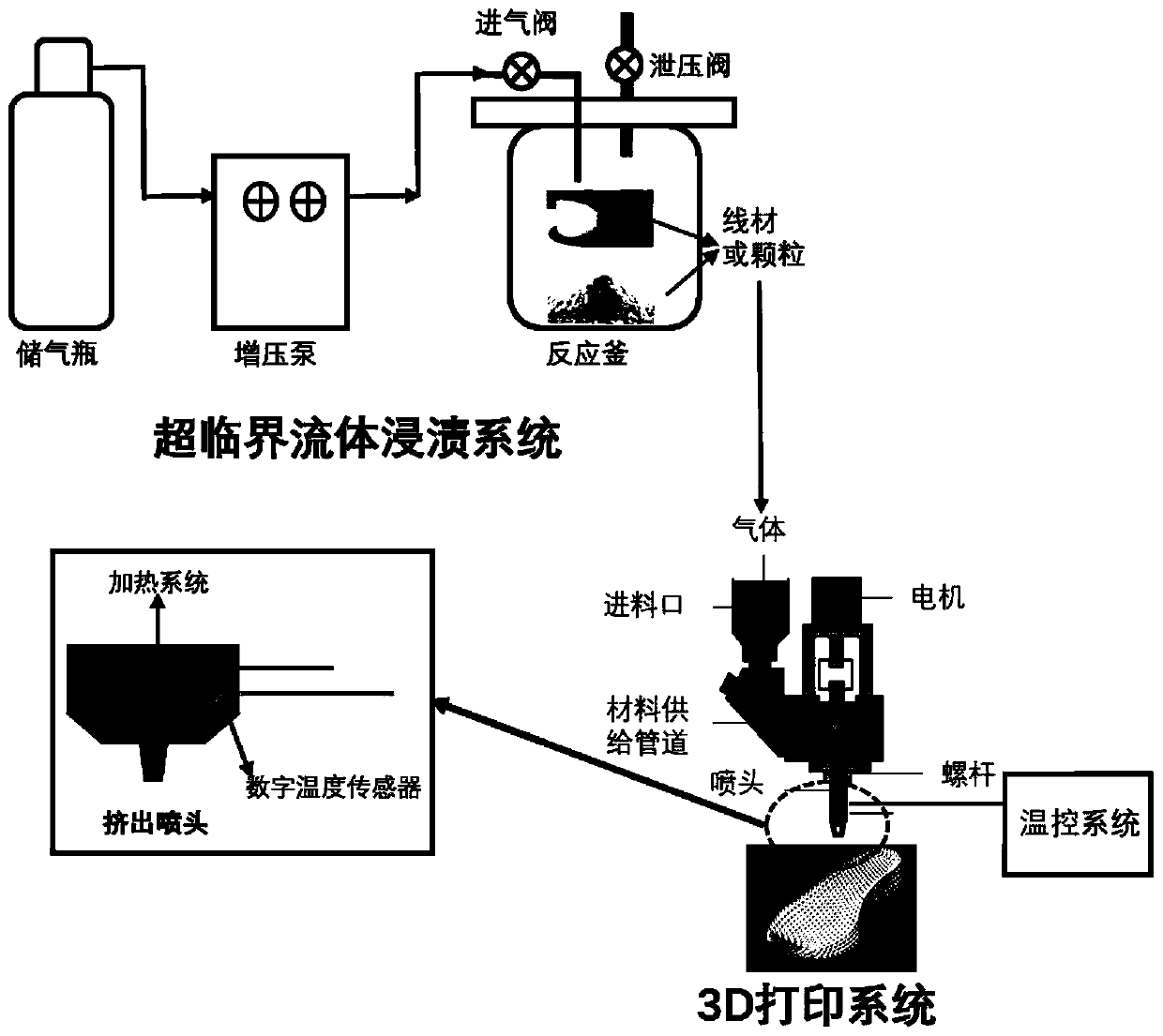

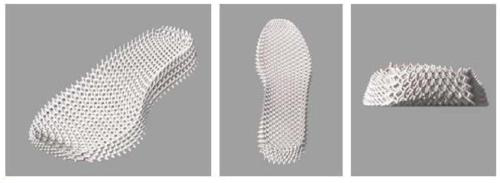

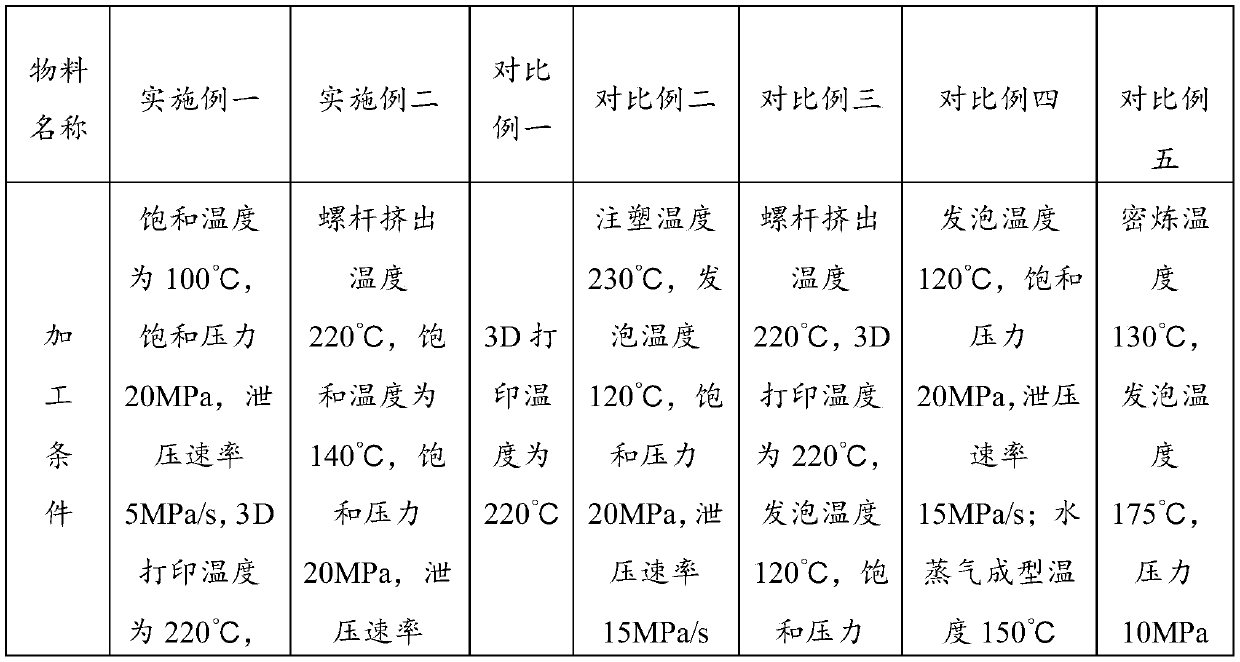

High-elastic foamed shoe insole material, and preparation method and application thereof

ActiveCN109206892AReduce weightHigh reboundAdditive manufacturing apparatusSolesCushioningThermoplastic elastomer

The invention provides a high-elastic foamed shoe insole material, and a preparation method and an application thereof, wherein the insole material is prepared by 3D-printing a thermoplastic resin compound material to form a green body, and performing supercritical fluid foaming shaping. The thermoplastic resin compound material includes: 55-100 parts of thermoplastic polyurethane resin, 0-50 parts of thermoplastic elastomer resin, 0.2-5 parts of a compatibilizer, 0.5-10 parts of a nucleating agent, 0-1.2 parts of an antioxidant, 0-1.2 parts of stearic acid, and 0-0.9 parts of a foam pore stabilizer. The insole material has a 3D structure, is light in weight, and has advantages of high resilience, low shrinking deformation and high cushioning effect. The insole material is shaped through 3D printing with the supercritical fluid impregnation and rapid pressure relief foaming. The method is green and environment-protective, is shorter in preparation process and higher in efficiency, andcan achieve customization.

Owner:ANTA CHINA

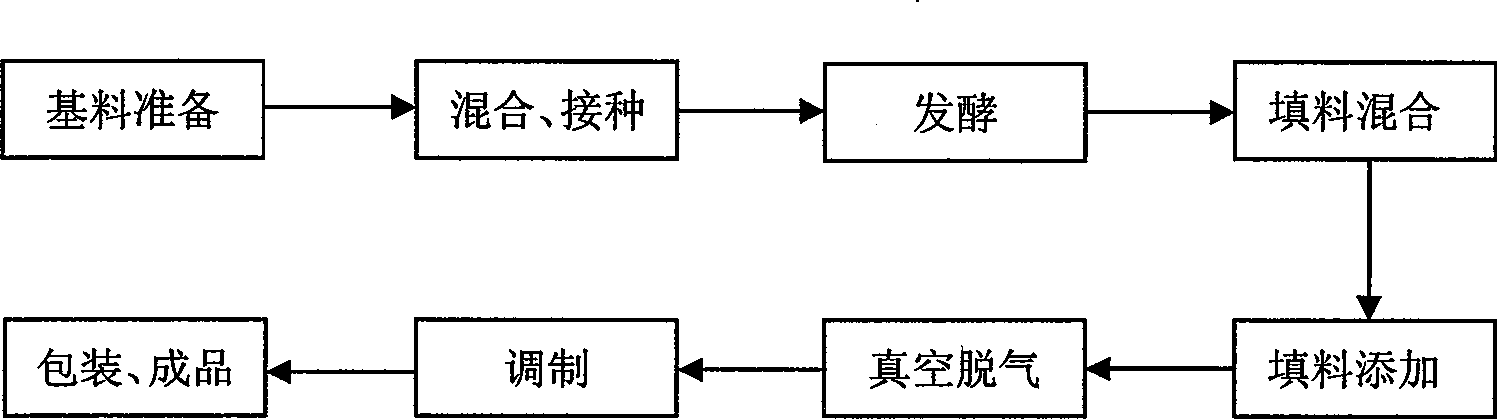

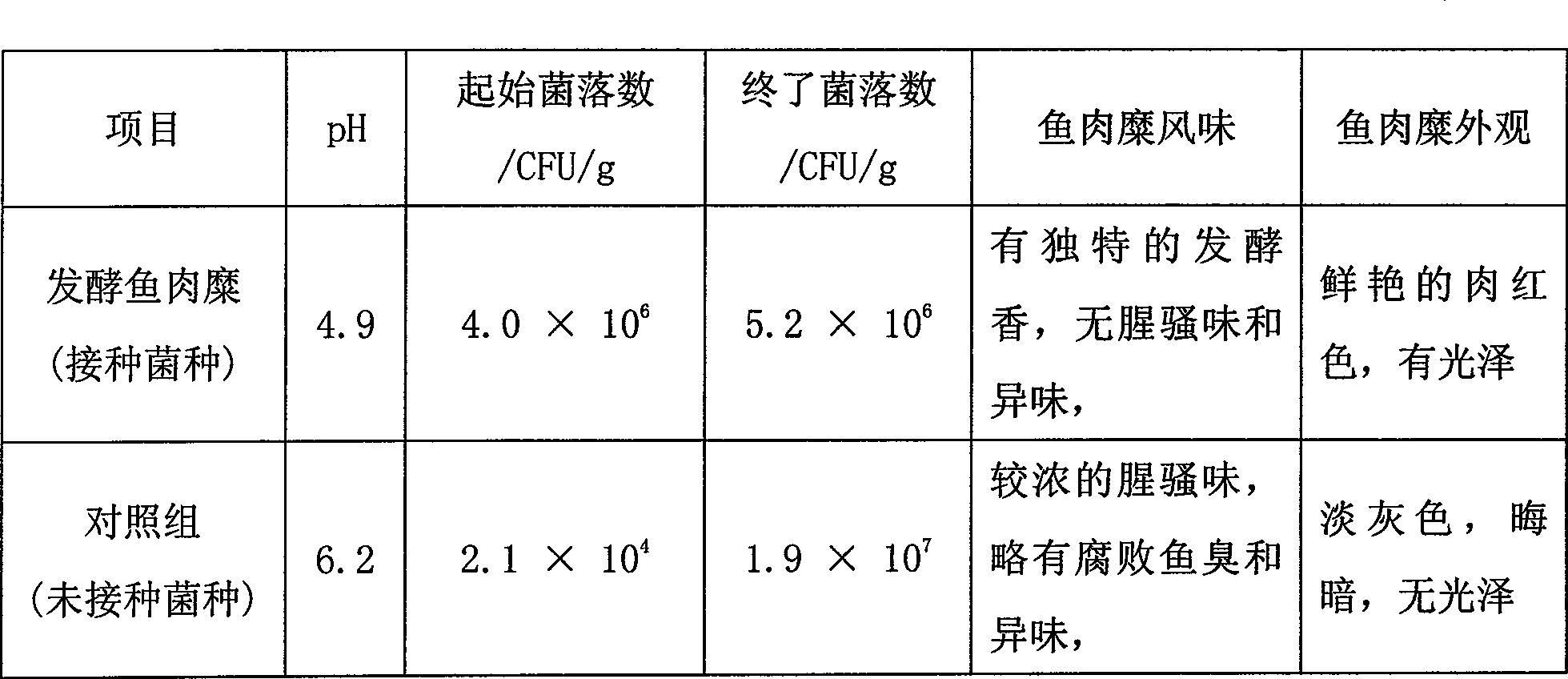

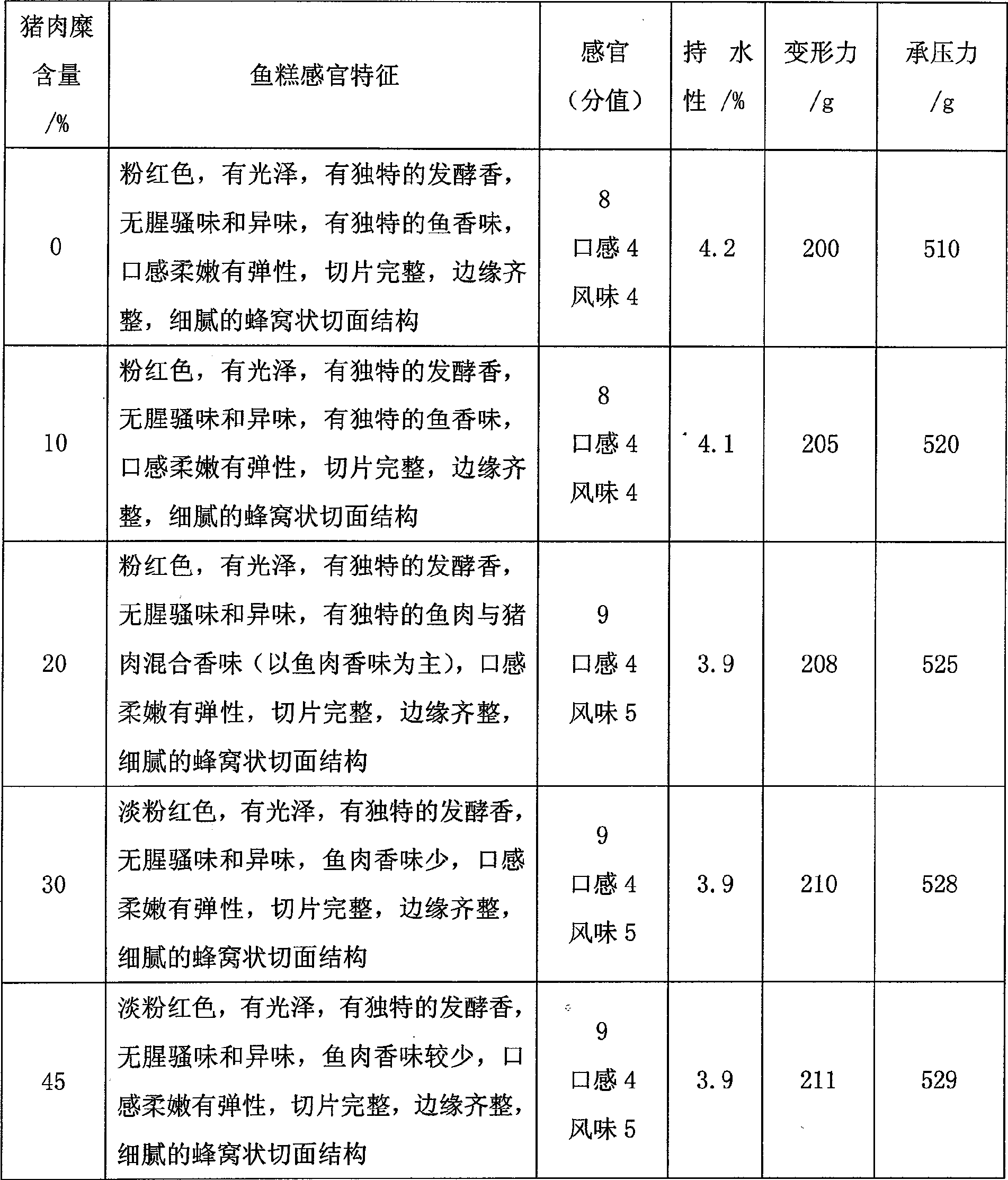

Fish meat emulsion fermented with mixed bacteria based on lactobacillus and preparation method thereof

InactiveCN101485473AAdd pure fragranceImprove gel propertiesFood preparationBiotechnologyCulture fungus

The invention discloses Lactobacillus-based mixed bacterium strains fermented minced fish. The finished product of the fish is prepared by a method comprising the steps of using minced fish as a base stock, inoculating the minced fish with mixed basic bacteria I having a colony density of 10 CFUs per gram of minced fish and mixed basic bacteria II having a colony density of 10 spores per gram of minced fish, placing the minced fished inoculated with primary cultures in a container for fermentation till the acidity reaches a standard degree, mixing the fermented mixture with a filling and adding the filling and subjecting the obtained mixture to vacuum degassing, preparation and packaging. The invention adopts a technical proposal that the minced fish is inoculated with primary cultures of the mixed basic bacteria I which are cultured by microorganic streptococcus lactis, lactobacillus bulgaricus and saccharomyces cerevisiae of the same type and have a colony density of 10 CFUs per gram of minced fish and the mixed basic bacteria II which are cultured by monascus and have a colony density of 10 spores per gram of minced fish for fermentation; the fermented mixture is mixed with a filling; the obtained mixture is added with the filling; and the final mixture is subjected to vacuum degassing and preparation. The method overcomes the drawback that natural fermentation cannot ensure the sanitation and safety, but leads to high salt content. The method can manufacture various finished products of fermented minced fish.

Owner:XIANGTAN UNIV

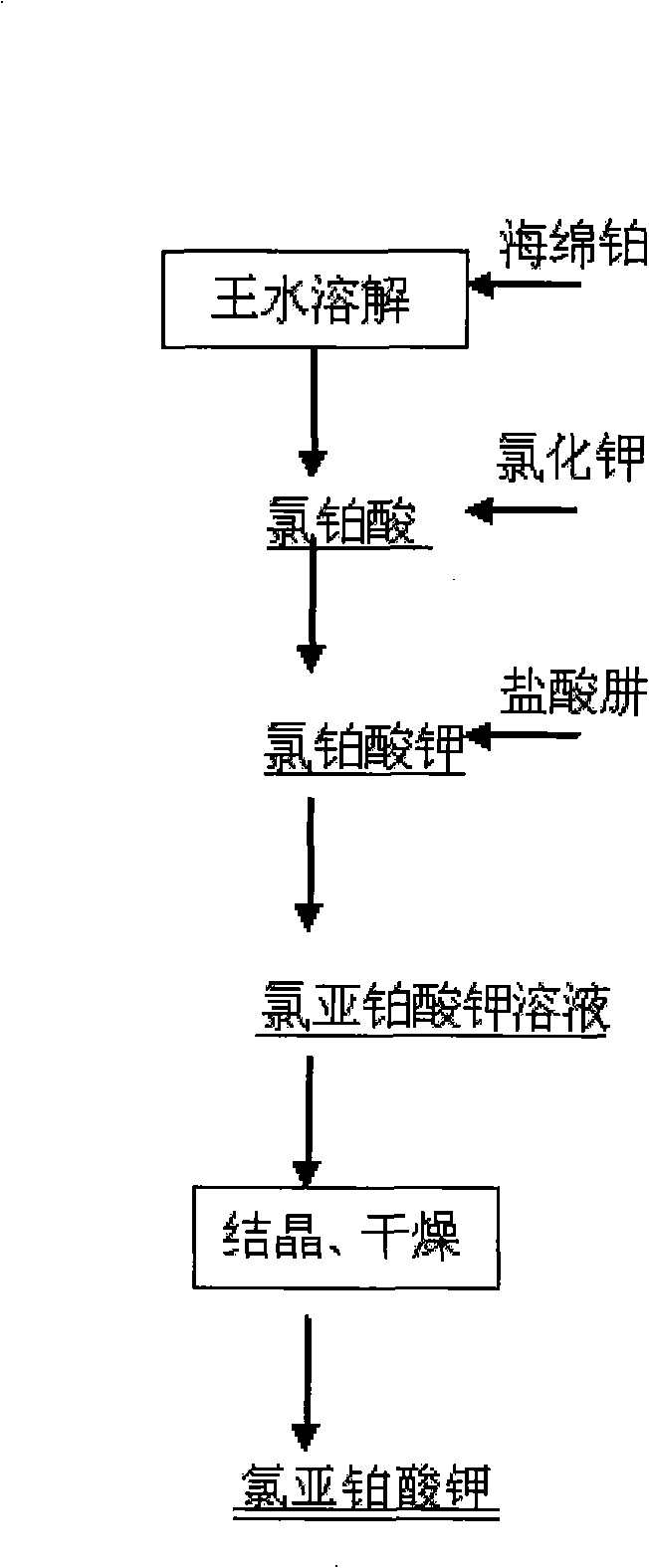

Preparation of potassium platinochloride

ActiveCN101279772AShort preparation processReduce manufacturing costRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsSodium/potassium compoundsPotassium tetrachloroplatinatePotassium

Disclosed is a method for the production of a potassium platinochloride, which relates to a process for preparing a pharmaceutical intermediate potassium platinochloride. The method of preparation is characterized in that the preparation process adopts a spongy platinum as a material to prepare a chloroplatinic acid solution which is reacted with a potassium chloride solution to prepare the potassium chloroplatinite, then a hydrazine hydrochloride is adopted as a reducing agent to reduce the potassium chloroplatinite for preparing the pharmaceutical intermediate potassium platinochloride. The product adopting the method of the invention has a platinum content of 46.9+-0.2 percent and a potassium content of 19.0+-0.2 percent through a total elemental analysis. The total content of metallic impurity is no more than 0.08 percent.

Owner:兰州金川科技园有限公司

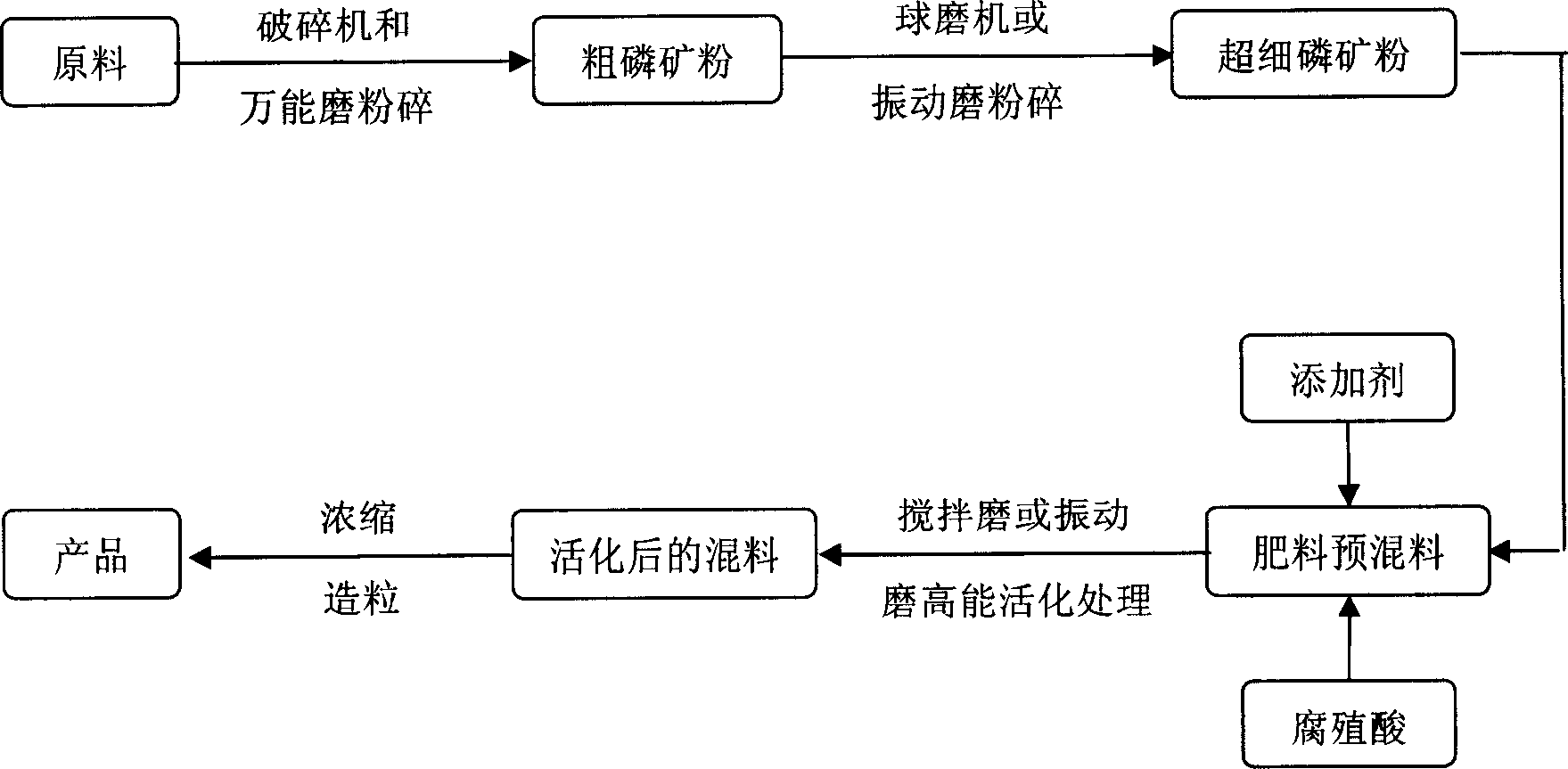

Method for preparing ultrafine activated phosphorusore compound fertilizer

InactiveCN1935749AGood effectPrevent compactionFertilisers by pryogenic processesFertilizer mixturesApatiteHigh energy

The invention is an ultrafine activated phosphorite compound fertilizer preparing method, crushing raw material into coarse powder by crusher and universal mill, and then crushing the coarse powder into ultrafine phosphorite powder as premix by ball mill or vibration mill; adding additive and humic acid in the premix and making high energy activation treatment by blending mill or vibration mill, making concentrated prilling and making the product. And the invention mechanically mills phosphorite by high input energy, improves chemical activity of apatite in phosphorite by mechano-chemical activation, and improves the releast- sustained speed of phosphor compounds in soil. And the prepared compound fertilizer has fast effect, long-time stability, and soil improving effect. And the invention is a good phosphorite compound fertilizer preparing method.

Owner:TSINGHUA UNIV

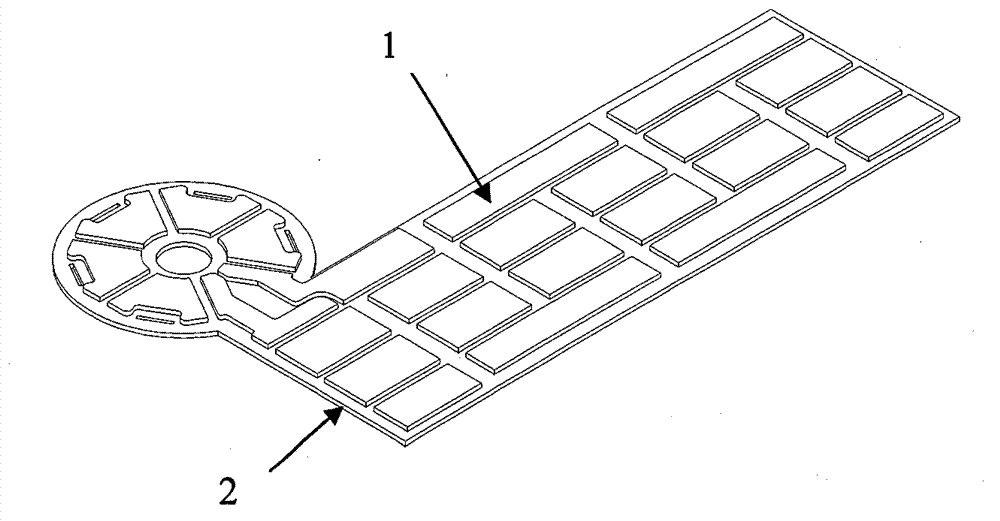

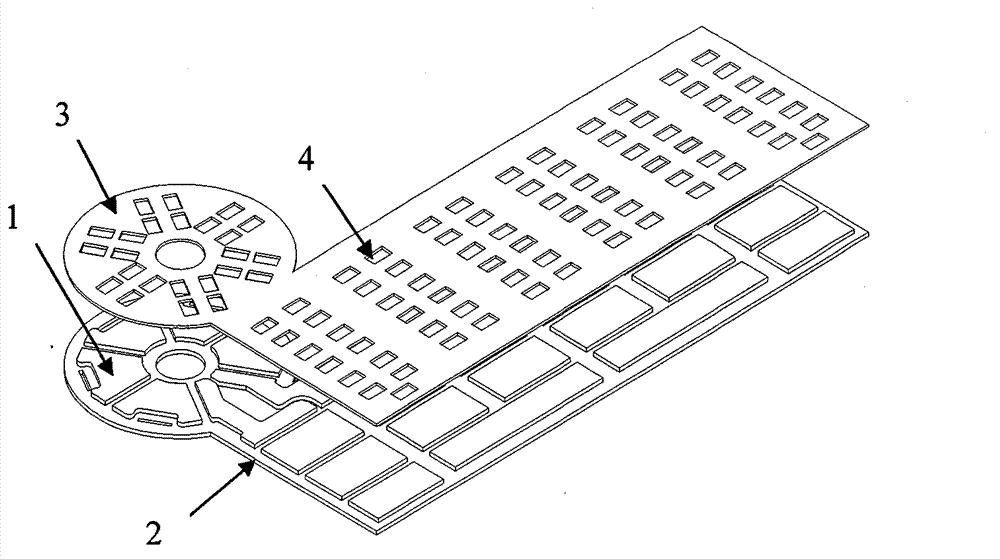

Three-dimensional luminous light emitting diode (LED) lamp bulb module and manufacturing method thereof

ActiveCN102889480AIncrease the direction of the glowHigh light efficiencyPoint-like light sourceSolid-state devicesThree-dimensional spaceEngineering

The invention provides a three-dimensional luminous light emitting diode (LED) lamp bulb module and a manufacturing method thereof. The LED lamp bulb module comprises a bendable metal-based circuit board and an LED arranged on the bendable metal-based circuit board, wherein the bendable metal-based circuit board is bent and shaped to form a lamp bulb type three-dimensional luminous structure, so that the LED lamp bulb module can irradiate in multiple directions in a three-dimensional space, and the luminous irradiation direction and the light efficiency of an LED lamp bulb are improved. The LED lamp bulb module is high in light efficiency and can irradiate in multiple directions in the three-dimensional space; and furthermore, the heat dissipation performance is high, the manufacturing flow is brief and short, the production efficiency is high, and the production cost is low.

Owner:TONGLING GUOZHAN ELECTRONICS

Preparation method of thin-wall tubular product of particle-reinforced aluminum-based composite material

ActiveCN101737574AReduce plasticityFix production issuesRigid pipesSolution treatmentRoom temperature

The invention relates to a preparation method of a thin-wall tubular product of a particle-reinforced aluminum-based composite material, which comprises the steps of: 1, preparing a tube blank by adopting a mixing and casting process and a powder metallurgy process; 2, homogenizing the tube blank, turning and stripping, carrying out a high-temperature compression deformation test to obtain a suitable processing deformation condition; 3, spinning the tube blank for finite element number value simulation, optimizing process parameters, and thermally spinning and warmly spinning; and 4, carrying out solution treatment on the obtained tubular product, and ageing after water hardening at room temperature. The tubular product prepared by the invention has larger diameter wall thickness ratio, smooth internal surface and outer surface without defects, uniform wall thickness and better interface combination between reinforced particles and a base body of the thin-wall tubular product. The method has short procedure, labor saving of the processing mode, energy saving and environmental protection, simple process, low raw material cost, suitability for large-scale production and better popularization value, and can be widely applied to the preparation of high-strength light tubular products in the fields of aerospace, vehicles, advanced weapons and the like.

Owner:有研金属复材技术有限公司

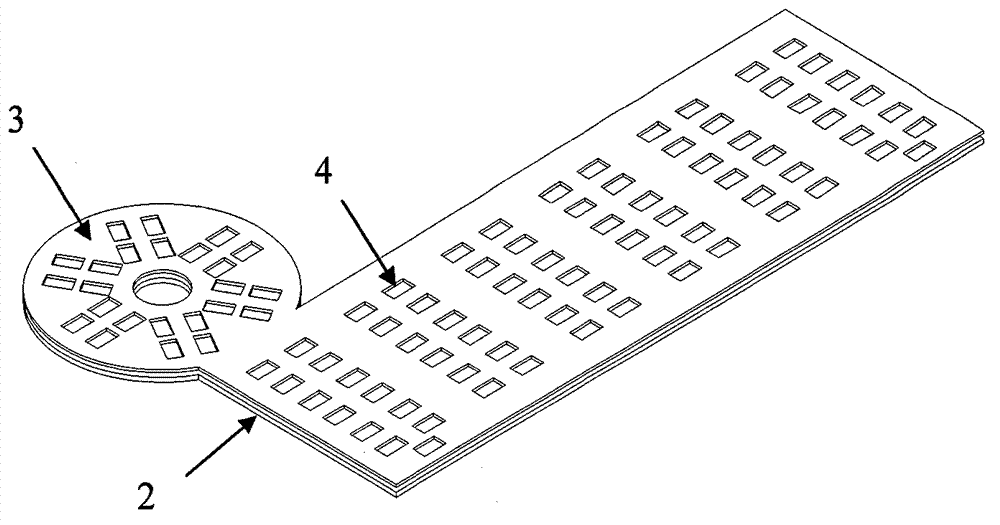

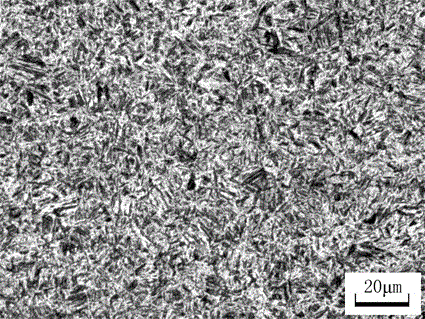

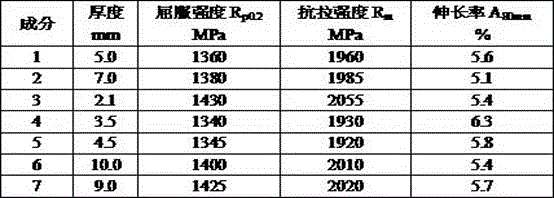

Thin hot forming steel directly rolled through thin slab and having tensile strength larger than or equal to 2100 MPa and production method

Thin hot forming steel directly rolled through a thin slab and having tensile strength larger than or equal to 2100 MPa comprises components including, by weight percent, 0.41% to 0.50% of C, 0.45% to 0.65% of Si, 1.6% to 2.0% of Mn, not larger than 0.006% of P, not larger than 0.004% of S, 0.015% to 0.060% of Als, 0.50% to 0.65% of Cr, 0.004% to 0.005% of B, 0.046% to 0.060% of Ti or 0.046% to 0.060% of Nb or 0.046% to 0.060% of V or compounding of two or more of Ti, Nb and V, 0.36% to 0.60% of Mo, 0.21% to 0.35% of Ni and not larger than 0.004% of N. Production steps comprise molten iron desulfuration, electric furnace or converter smelting and refining, continuous casting, descaling treatment before the steel enters a soaking pit furnace, uniform heating, heating, high-pressure water descaling before the steel enters a rolling mill, rolling, cooling, reeling, austenitizing, mold punching molding and quenching. The strength is high, the manufacturing flow is short, the product surface quality is good, the thickness precision can be controlled within + / -0.03 mm, energy consumption can be greatly saved, and in addition, the steel and the method have the important significance in automobile light weight.

Owner:武汉钢铁有限公司

Method for industrially preparing dimorphic hard alloy with both high strength and high tenacity

The invention discloses a method for industrially preparing a dimorphic hard alloy with both high strength and high tenacity, belonging to the technical field of hard alloys. The method comprises the following steps of: according to the content of Co in the dimorphic hard alloy, ball-milling and mixing WO2.9, Co3O4 and carbon black; coldly pressing into a billet block; preparing WC-Co composite powder in a vacuum furnace; ball-milling by taking absolute ethyl alcohol or hexane as a medium; drying to obtain the WC-Co composite powder; under the protection of argon, performing powder aggregation pre-treatment; raising the temperature to 650-950 DEG C at a speed of 5-8 DEG C per minute; keeping the temperature for 30-60 min; adding 30-80 ml of polyethylene glycol forming agent to each kilogram of powder; moulding and forming; and sintering the moulded and formed powder billet in vacuum or at low pressure. The WC-Co dimorphic hard alloy prepared by the invention has both high strength andexcellent breakage tenacity. The method is an integral industrialization preparation technology route.

Owner:BEIJING UNIV OF TECH

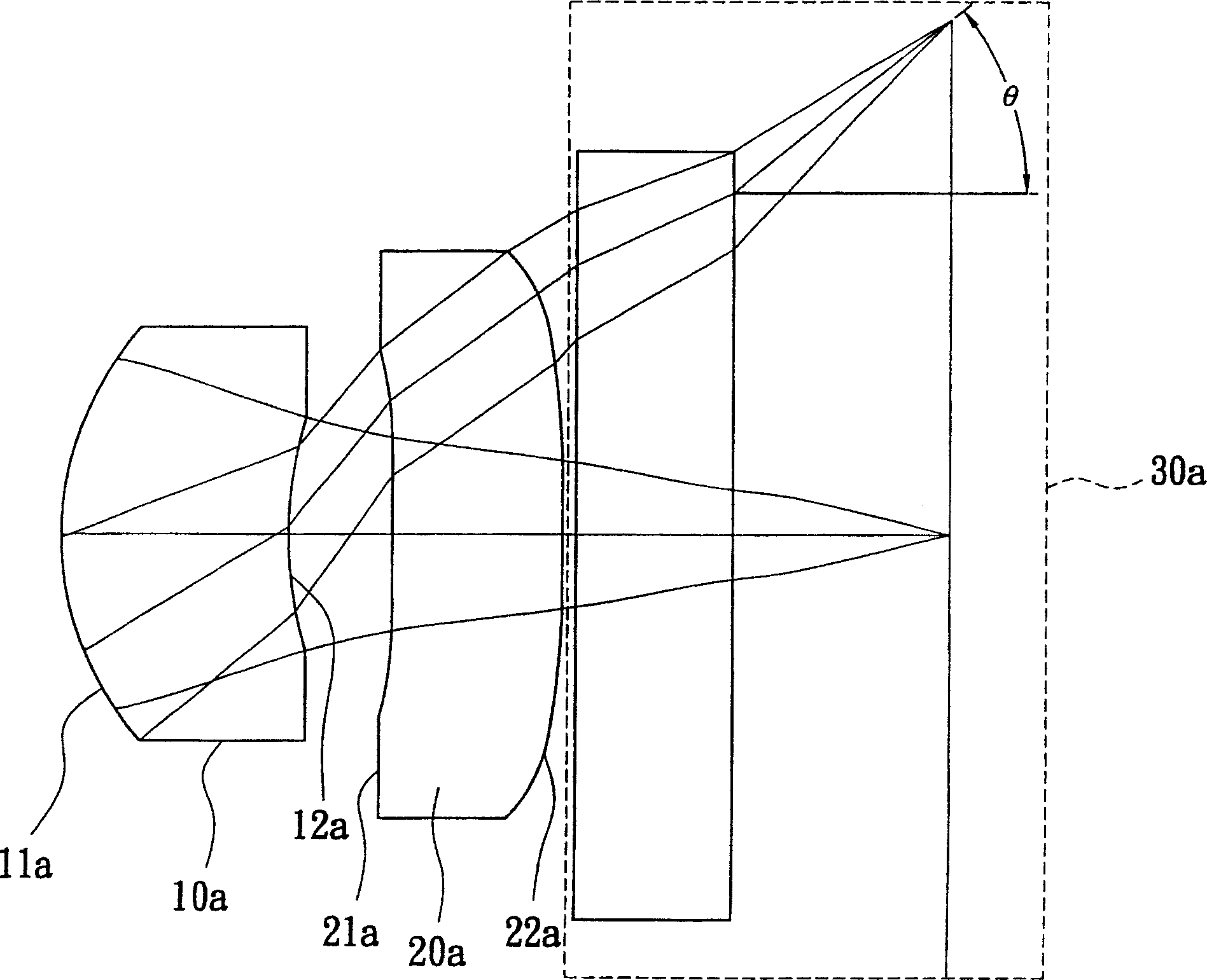

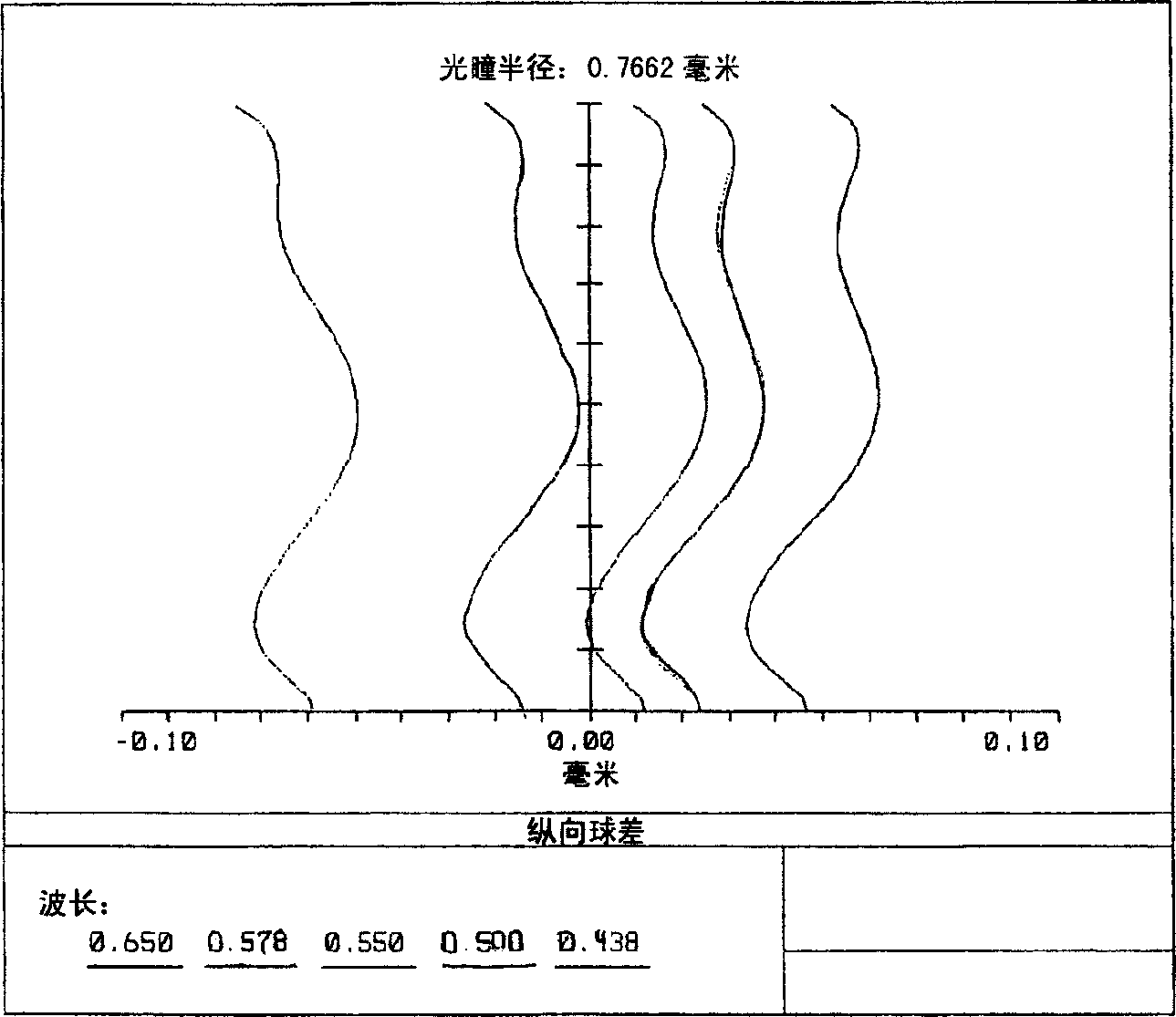

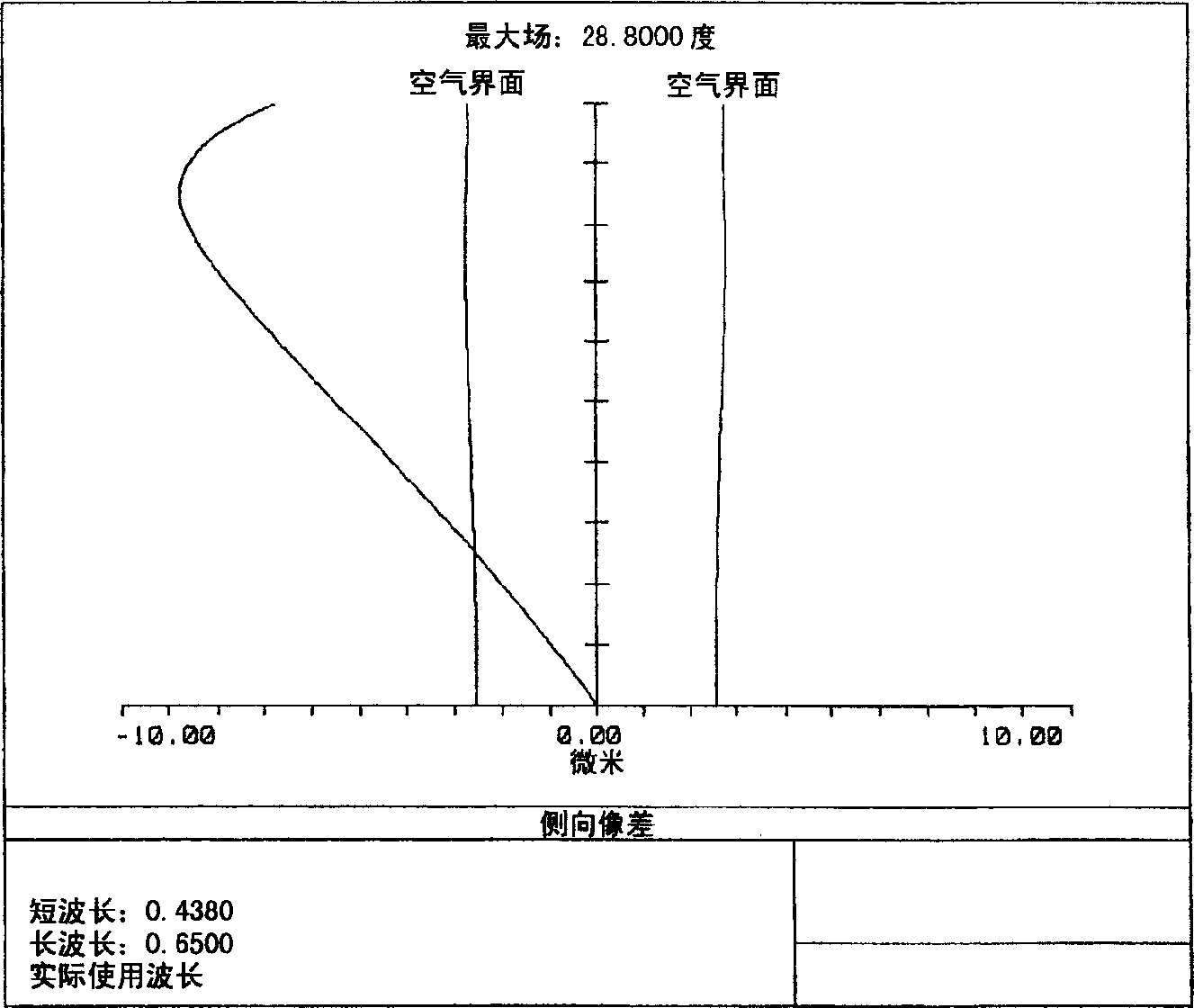

Fixed focus digital lens

InactiveCN1670560ASolve the problem of rapid light attenuationReduce image variationOptical elementsCamera lensPolyolefin

This invention discloses one stationary focus digit lens head, which comprises positive optics first lens, negative optical second lens and positive optical third lens, wherein, the first lens is made of crylic acid; the second lens is made of polycarb; the third lens is made of non-crystal polyolefin transparent plastic and the invention uses each materials to balance the temperature changes.

Owner:PREMIER IMAGE TECH

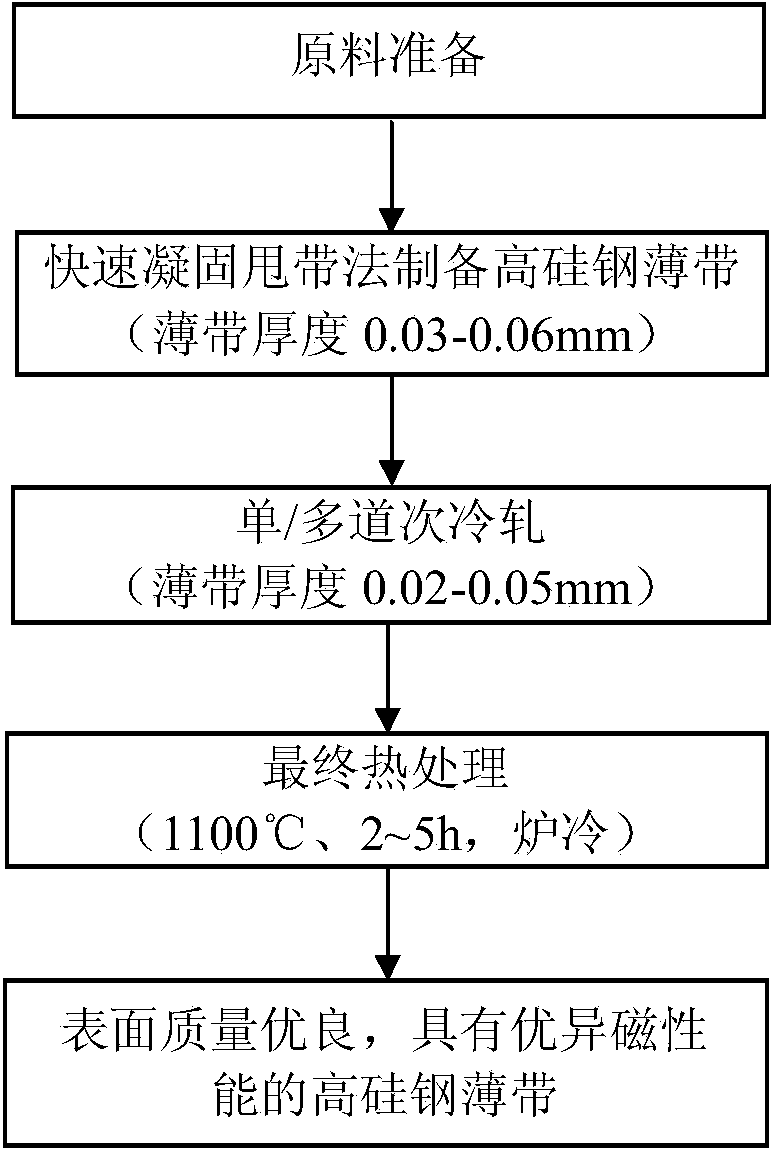

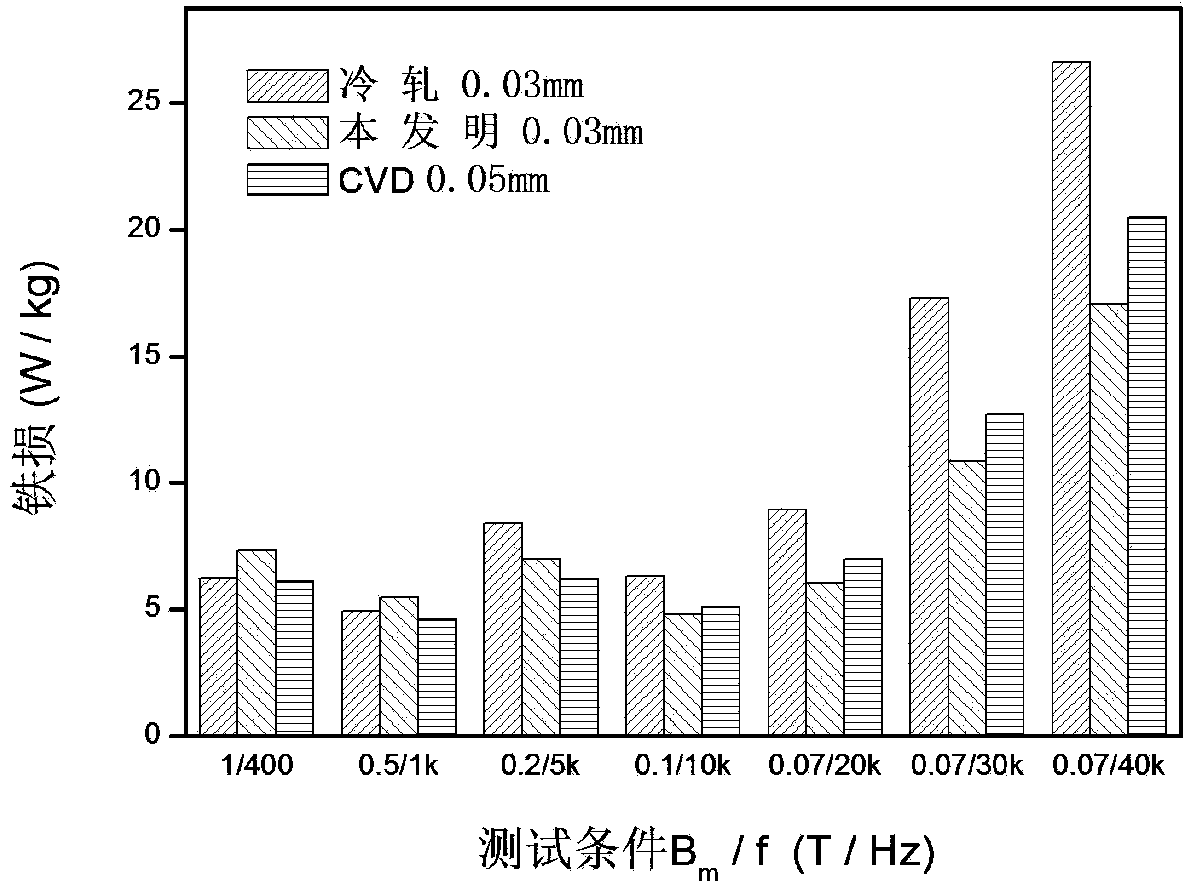

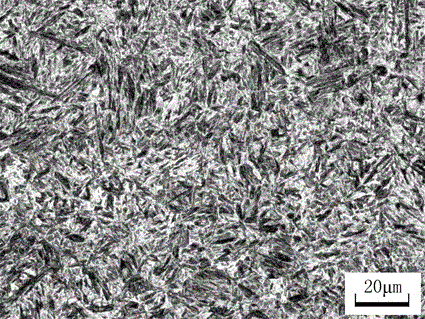

Short-process efficient cold-rolling preparation method of high-silicon steel thin strip

The invention aims at providing a short-process efficient cold-rolling preparation method of a high-silicon steel thin strip. The preparation method is characterized in that the high-silicon steel thin strip is prepared by using a rapid solidification method, and the thickness of the high-silicon steel thin strip is reduced by using a cold rolling method, the surface quality is improved, and the high-frequency magnetic performance is improved; due to rapid solidification, the plasticity of high-silicon steel can be improved, and the thin strip with certain plasticity is obtained and can be wound into a coil; then, cold rolling is carried out, so that the degree of order of the high-silicon steel is further lowered, the plasticity of the high-silicon steel is improved, and a high-silicon steel thin strip coil is obtained; the thin strip obtained through rapid solidification has the advantages that the crystal grain size is obviously reduced, the degree of order is obviously lowered, and the microhardness change is not great, so that next-step cold rolling is facilitated; during cold rolling, the rolling reduction of first-time rolling is controlled, and then, the plasticity is further improved, so that the thin strip with the thinnest thickness of 0.02mm can be obtained. According to the preparation method, the production efficiency of the prepared high-silicon steel thin strip is high, and the product quality of the prepared high-silicon steel thin strip is good, so that the method can be widely implemented industrially and accordingly has a broad application prospect.

Owner:UNIV OF SCI & TECH BEIJING

Lightweight decorative acrylic sheet and its preparation method

The invention relates to a lightweight decorative acrylic sheet and its preparation method. The method comprises the steps of: dissolving waste organic glass powder by an acrylic acid monomer to obtain a slurry A, dissolving an ethylene-vinyl acetate copolymer by the acrylic acid monomer to obtain a slurry B, pouring the slurry B into the slurry A and stirring them uniformly to obtain a slurry C, then adding solid waste powder, a fly ash based paraffin composite phase change material, a pigment, magnesium hydroxide and dibenzoyl peroxide, stirring them evenly to obtain a hyperviscous slurry D; adding an organic solvent into the hyperviscous slurry D, conducting stirring, then placing the mixture into a steel die, performing cold press molding by a thermocompressor, then implementing heating at 70-80DEG C to carry out polymerization foaming for 2-4h; and conducting cooling and die release to obtain the lightweight decorative acrylic sheet. The method disclosed in the invention makes use of waste to prepare the lightweight decorative acrylic sheet and reduces environmental pollution. The obtained acrylic sheet has small density, high gloss, great hardness, good heat insulation and flame retardant effects and a high additional value, and can be widely applied in construction and decoration industries.

Owner:ANHUI XINTAO OPTOELECTRONICS TECH CO LTD

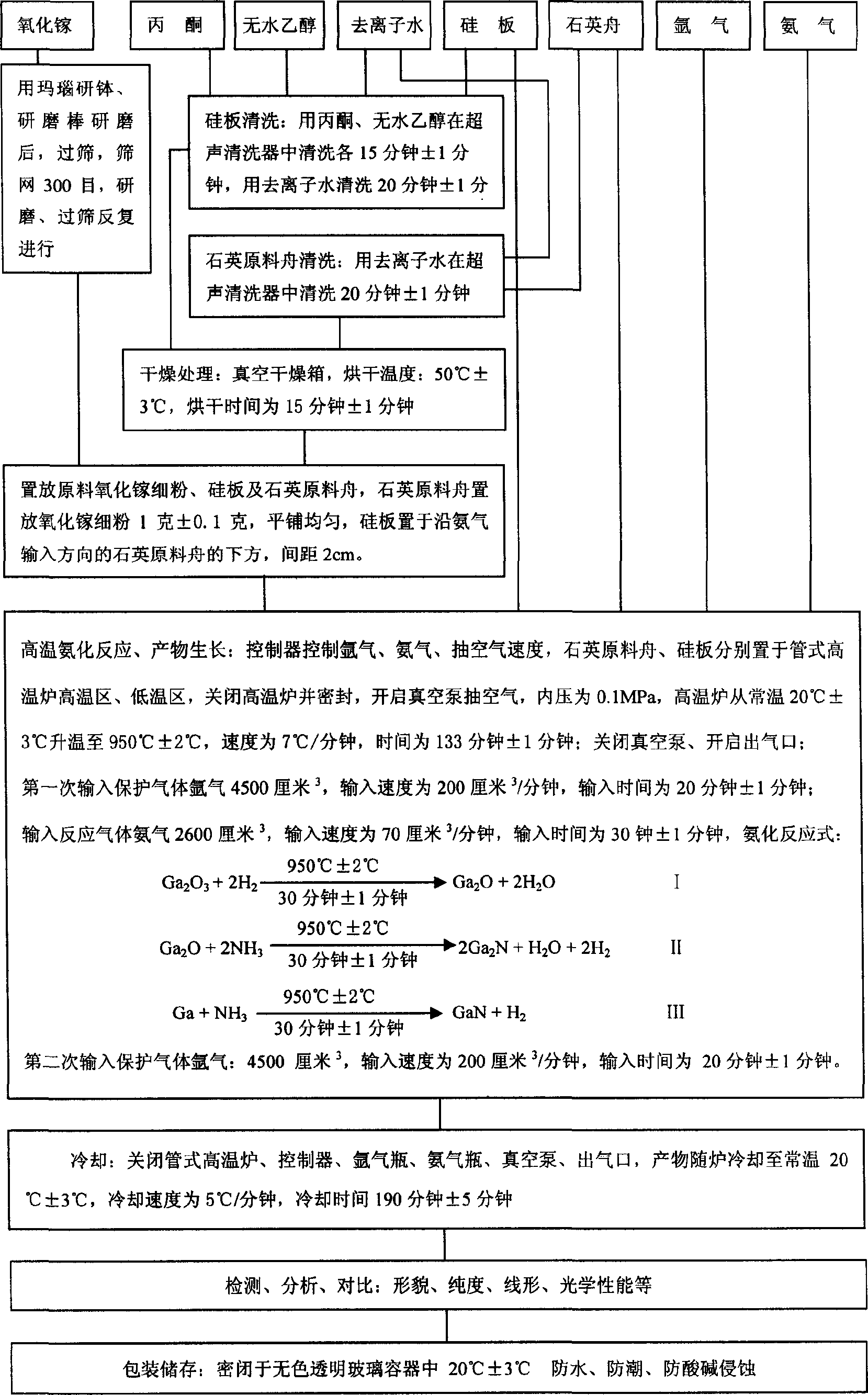

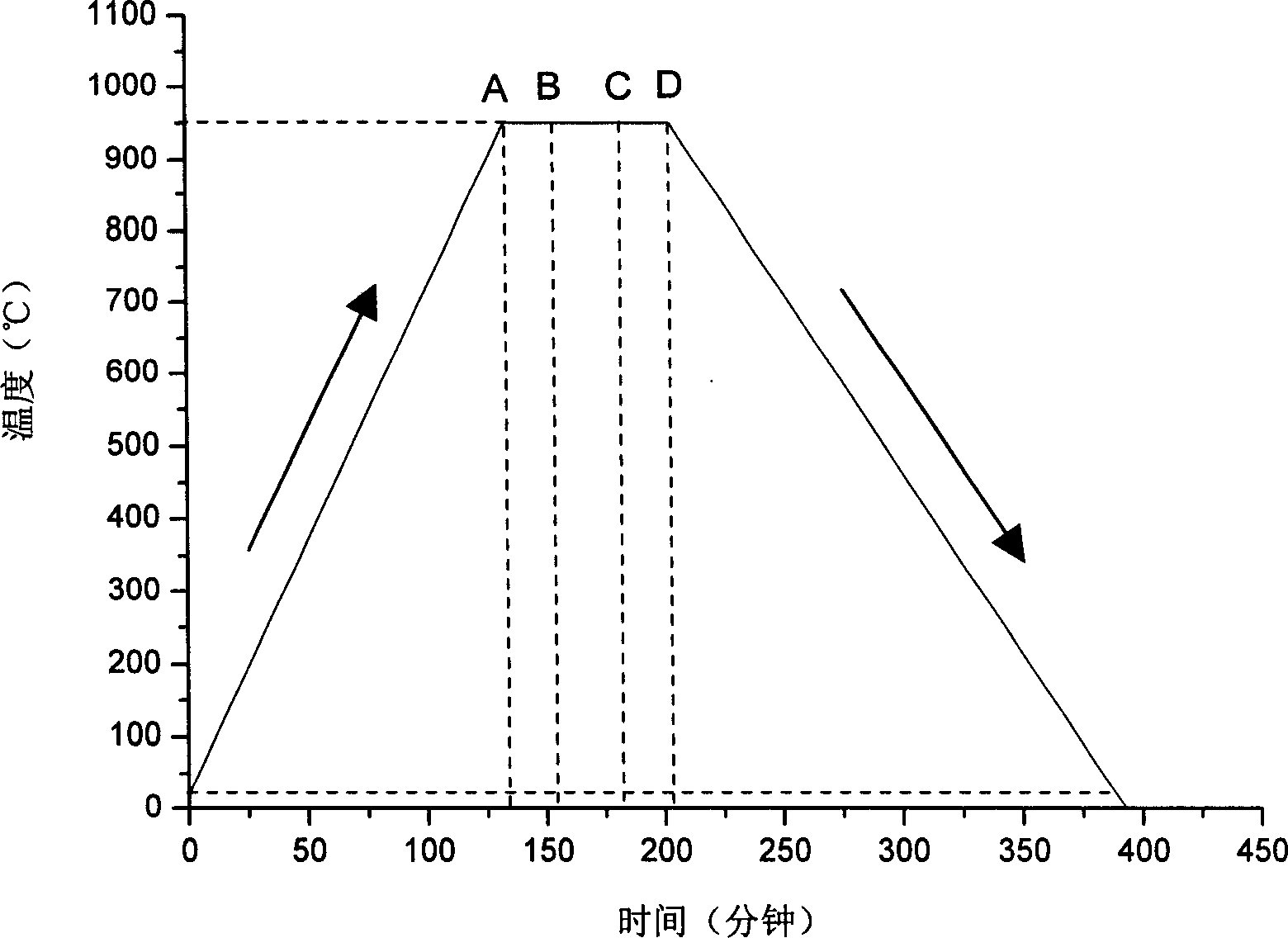

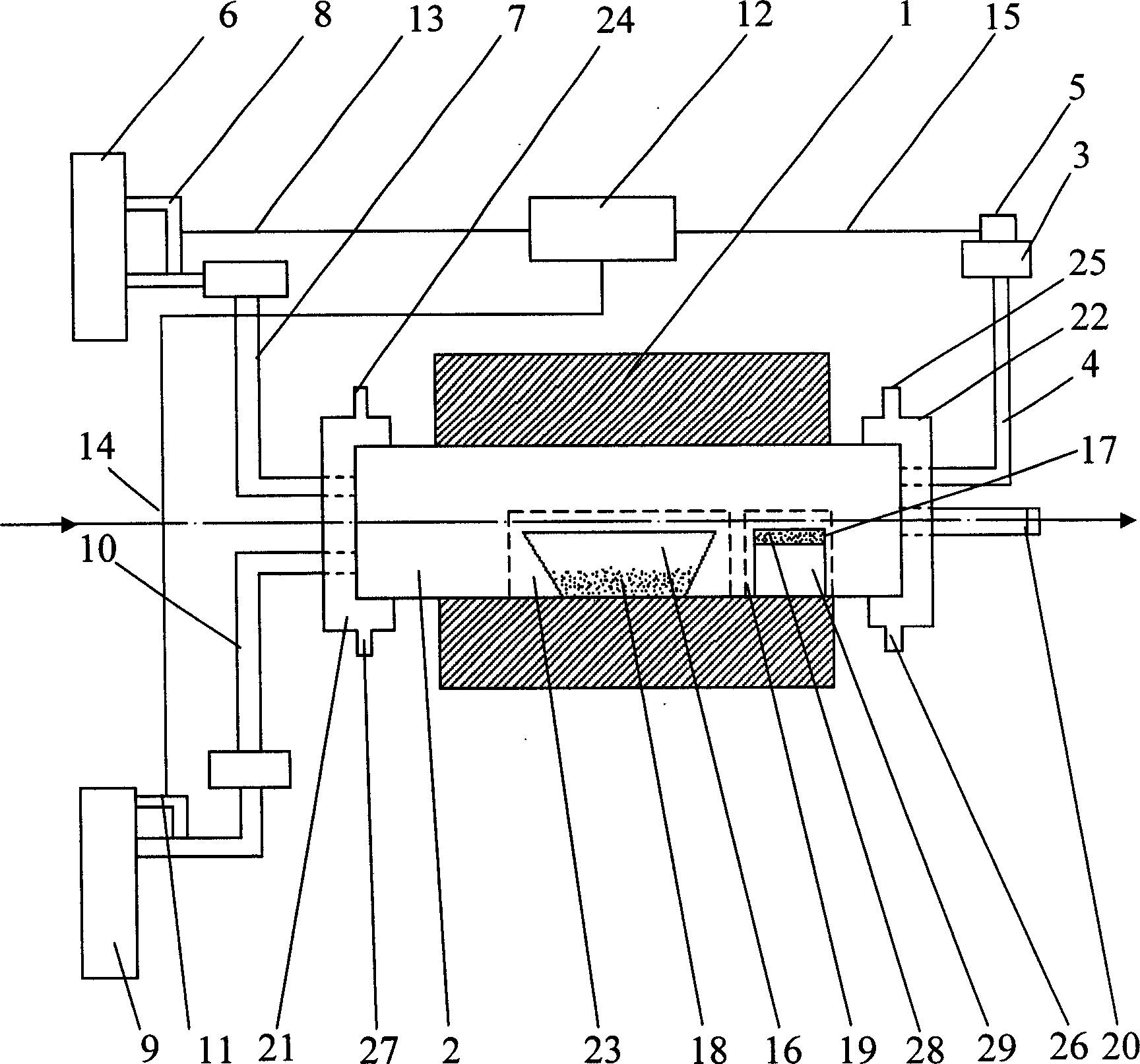

High purity gallium nitride nanometer line preparation method

InactiveCN1789114AHigh purityHigh precisionLighting and heating apparatusNitrogen-metal/silicon/boron binary compoundsNanowireShielding gas

The invention discloses a process for preparing a kind of gallium nitride nanoline of high purity, which employs gallium oxide (Ga2O3) as raw material, alkaline air (NH3) as reacting gas, inert gas argon gas (Ar) as protective gas, silicon board as base carrier for product growing, absolute ethyl alcohol, acetone and deionized water as cleaning agent for the sicicon board, and employs no accelerating agent; the gallium nitride nanoline grows out under the temperature of 950 Deg C and on the silicon board through ammonification reaction; the preparing process is simplified by grinding, sifting the raw material, cleaning the silicon board and quartz material, controlling the air extraction, argon gas and alkaline air inputting by tubing high temperature furnace control device procedurally, which prevents the side product generating effectively and increases the product outcome, purity and quality and finally getting the gallium nitride nanoline of light yellow, solid and in linary shape; the product is characterized by the uniform shape, order arrangement, and stable optical, chemical and physical property; the invention is characterized by the short preparing process, high yield (reaching to 95%), high purity (reaching to 98.6%) and the high linary accuracy, with the diameter being 5-20 cm, the average length of the monoline 30-50 ª–m.

Owner:TAIYUAN UNIV OF TECH

6-8mm TMCP on-line quenching low-yield-ratio high-strength wear-resistant steel NM400 coiled plate and production method thereof

The invention discloses a 6-8mm TMCP on-line quenching low-yield-ratio high-strength wear-resistant steel NM400 coiled plate and a production method of the 6-8mm TMCP on-line quenching low-yield-ratiohigh-strength wear-resistant steel NM400 coiled plate. According to the chemical components of the coiled plate, the coiled plate comprises, by mass percentage, 0.18%-0.22% of C, 0.30%-0.50% Si, 1.30%-1.45% of Mn, smaller than or equal to 0.012% of P, smaller than or equal to 0.003% of S, 0.015%-0.025% of Nb, 0.010%-0.025% of Ti, 0.25%-0.40% of Cr, 0.0005%-0.0020% of B, 0.0010%-0.0030% of Ca, 0.020%-0.050% of Al, smaller than or equal to 2ppm of H, smaller than or equal to 30ppm of O, smaller than or equal to 50ppm of N and the balance Fe and inevitable impurities. The provided coiled plate has excellent mechanical properties, a metallographic structure is a ferrite and martensite two-phase structure, and the application prospect is wide.

Owner:BAOTOU IRON & STEEL GRP

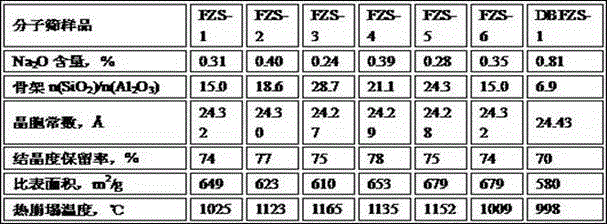

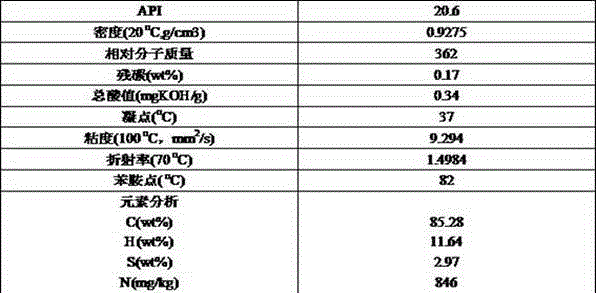

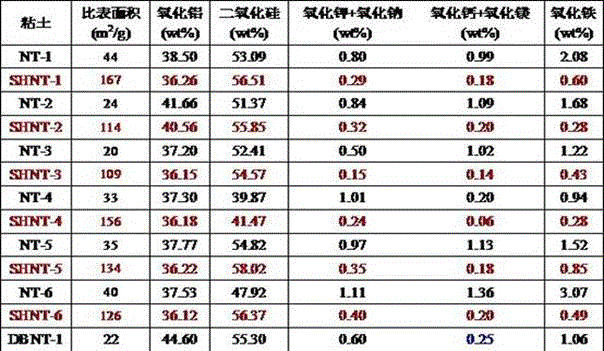

Preparation method of catalytic cracking catalyst

ActiveCN106732745AHigh crystallinity retentionImprove thermal stabilityCatalytic crackingMolecular sieve catalystsHigh concentrationGas phase

The invention relates to a preparation method of a catalytic cracking catalyst. According to the method, the NaY molecular sieve raw powder and halogen-containing gas are contact to perform gas phase ion exchange reaction; the sodium reduction and the ultra-stabilization of the NaY molecular sieve raw powder are completed in one step; the low-sodium high-silica-alumina-ratio molecular sieve is prepared. According to the method, different kinds of clay raw ores are compounded and are treated by high-concentration acid to obtain acid active composite clay; then, the low-sodium high-silica-alumina-ratio molecular sieve, the acid active composite clay, bonding agents, rare earth and decationized water are mixed and pulped; then, spraying granulation is performed; roasting and curing are performed; washing and drying are not needed; a finished product of the catalytic cracking catalyst is obtained. The catalytic cracking catalyst has the advantages that the olefin content in the gasoline can be obviously reduced; the light oil yield is improved; the preparation flow process of the catalyst is short; no ammonia and no nitrogen are discharged.

Owner:REZEL CATALYSTS CORP

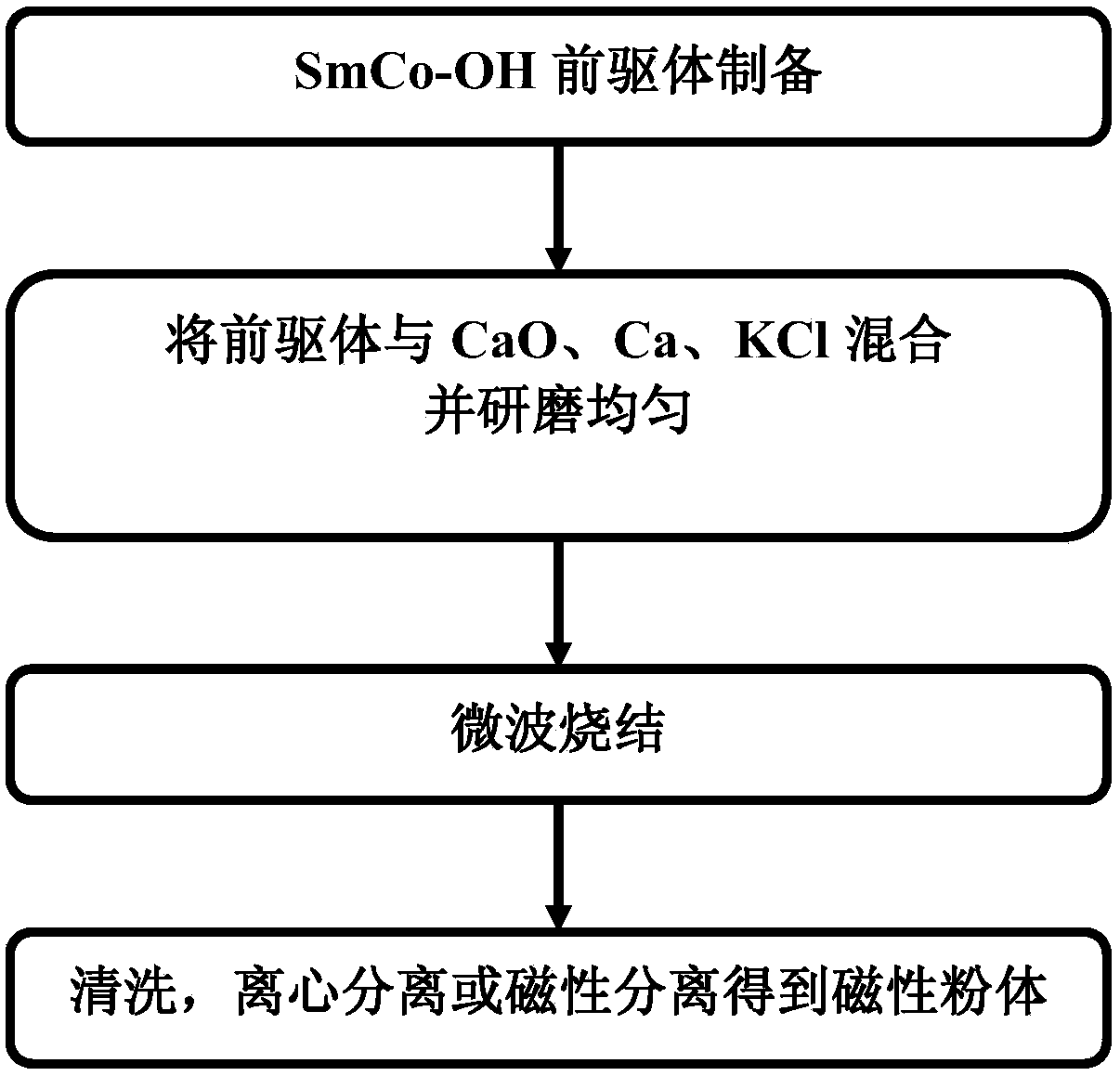

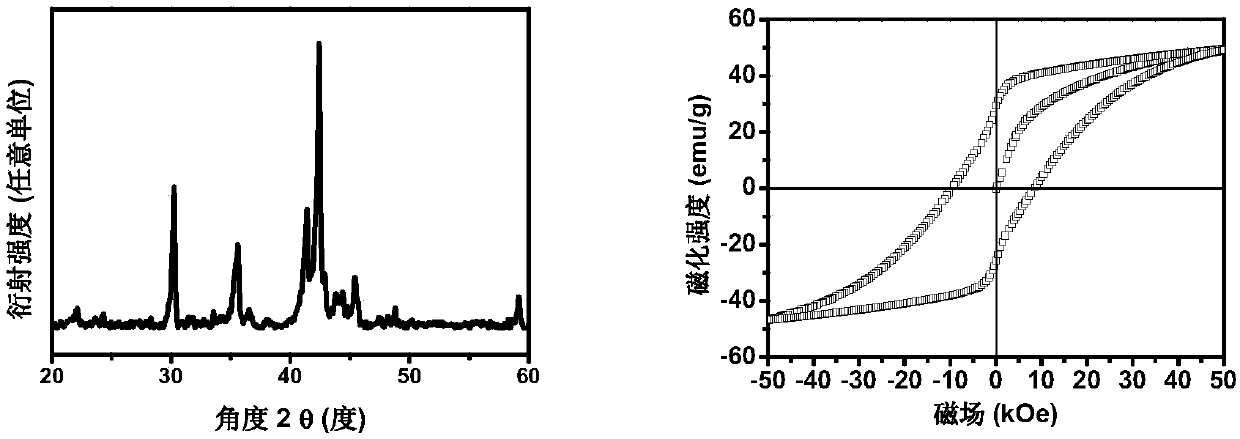

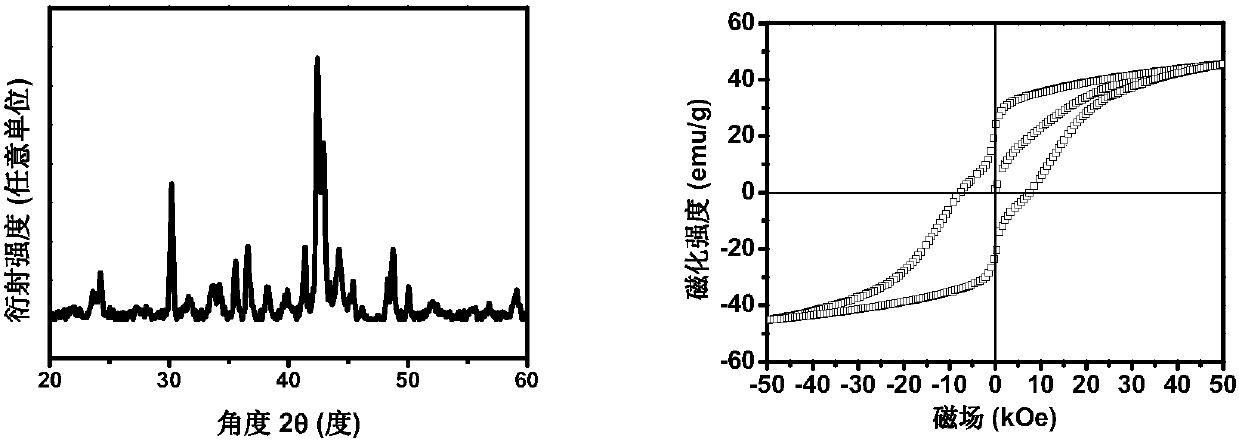

Method for preparing SmCo/ Co nano-composite magnetic material through microwave calcium thermal reduction

ActiveCN107799252AImprove magnetic propertiesShort preparation processInductances/transformers/magnets manufactureMagnetic materialsMagnetic phaseMicrowave

The invention relates to a method for preparing an SmCo / Co nano-composite magnetic material through microwave calcium thermal reduction, and belongs to the field of magnetic materials. The method ischaracterized in that an SmCo-OH precursor is prepared by using an ultrasonic co-precipitation method, and then the SmCo / Co nano-composite magnetic material is prepared by adopting the microwave calcium thermal reduction method, a hard magnetic phase is SmCo5 and Sm2co17, a soft magnetic phase is Co, and an exchange coupling effect exists between the hard magnetic phase and the soft magnetic phase. Compared with samples prepared without a microwave auxiliary under the same temperature, the magnetic performance is greatly improved. The method is simple in technology, and provides a new approach for preparing the nano-composite magnetic materials.

Owner:BEIHANG UNIV

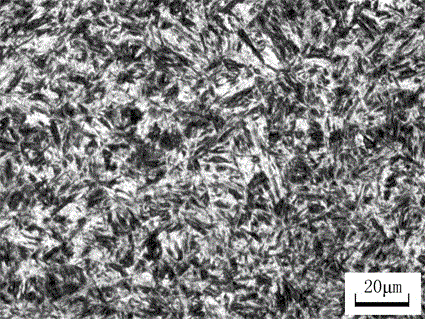

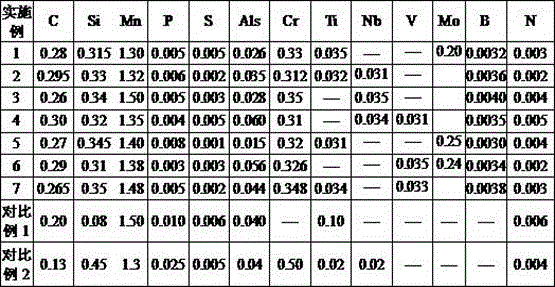

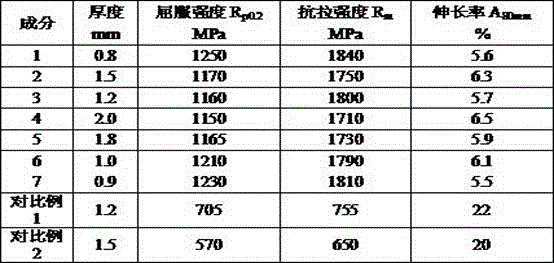

Thin thermoformed steel with tensile strength being not lower than 1700 MPa directly rolled by sheet billet and production method of thin thermoformed steel

The invention provides thin thermoformed steel with tensile strength being not lower than 1700 MPa directly rolled by a sheet billet. The thin thermoformed steel with tensile strength being not lower than 1700 MPa directly rolled by the sheet billet comprises the following components, in percentage by weight, 0.26-0.30% of C, 0.31-0.35% of Si, 1.3-1.5% of Mn, not higher than 0.008% of P, not higher than 0.005% of S, 0.015-0.060% of Als, 0.31-0.35% of Cr, 0.031-0.035% of Ti or 0.031-0.035% of Nb or 0.031-0.035% of V or a mixture mixed by more than two of the three components in any proportion, 0.003-0.004% of B, 0.20-0.25% of Mo, 0.06-0.10% of Ni and not higher than 0.005% of N. The production method of the thin thermoformed steel comprises the steps of desulfurizing molten iron; smelting the molten iron by an electric furnace smelting or a rotating furnace and refining the molten iron; performing continuous casting; performing descaling treatment before putting the molten iron into a soaking pit furnace; performing soaking; performing heating; performing high pressure water descaling before putting the molten iron into a rolling mill; performing rolling; performing cooling; performing coiling; performing austenitizing; performing mould stamping forming; and performing quenching. The steel is high in strength, short in manufacture process and good in quality of product surface, the accuracy of thickness can be controlled within + / -0.03mm and the energy consumption can be greatly reduced; moreover, the steel has great significance to realize automobile lightweight.

Owner:武汉钢铁有限公司

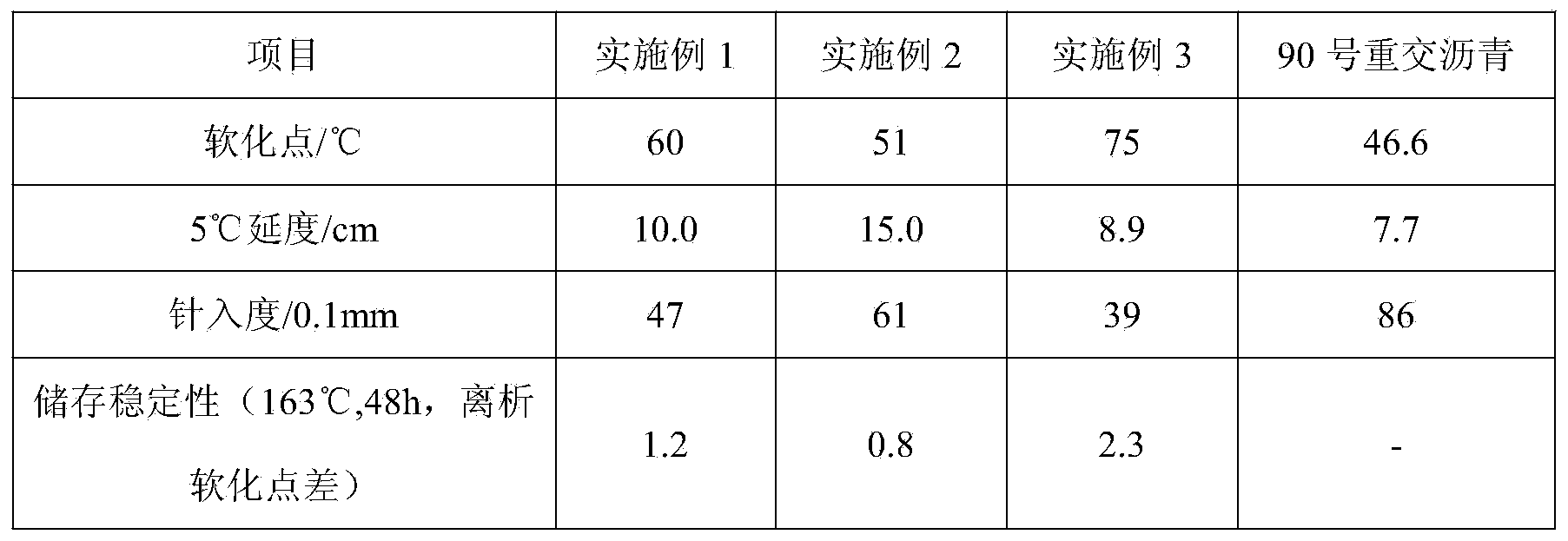

Polyethylene/rubber powder blend modified asphalt and preparation method thereof

InactiveCN103709770AReasonable priceEasy to operateBuilding insulationsCrack resistanceAging resistance

The invention provides a polyethylene / rubber powder blend modified asphalt which is composed of a matrix asphalt and a polyethylene / rubber powder blended substance, wherein the polyethylene / rubber powder blended substance is composed of the following components in percentage by weight: 40-52% of polyethylene, 45-59% of rubber powder and 1-3% of crosslinking agent; and the weight ratio of the polyethylene / rubber powder blended substance to the matrix asphalt is (5-15):100. According to the polyethylene / rubber powder blend modified asphalt, the softening point is enhanced, the penetration degree is lowered, and the anti-rut property of the asphalt mixture is enhanced; the ductility is enhanced, and the low temperature ductility is improved; the aging resistance is improved; and the storage stability of the modified asphalt is enhanced, and the storage and transportation properties of the modified asphalt are improved. The polyethylene / rubber powder blend modified asphalt provides flexibility, fatigue resistance and cracking resistance for the asphalt pavement, thereby prolonging the service life of the pavement.

Owner:中华人民共和国泰州出入境检验检疫局

Hot forming steel directly rolled through medium and thin slab and having tensile strength larger than or equal to 1900 MPa and production method

ActiveCN106119694AMeet quality requirementsReduce consumptionWork treatment devicesFurnace typesPunchingThin slab

Hot forming steel directly rolled through a medium and thin slab and having tensile strength larger than or equal to 1900 MPa comprises components including, by weight percent, 0.31% to 0.40% of C, 0.36% to 0.44% of Si, 1.6% to 2.0% of Mn, not larger than 0.006% of P, not larger than 0.004% of S, 0.015% to 0.060% of Als, 0.36% to 0.49% of Cr, 0.036% to 0.045% of Ti or 0.036% to 0.045% of Nb or 0.036% to 0.045% of V or mixing of two or more of Ti, Nb and V with the any proportion, 0.004% to 0.005% of B, 0.26% to 0.35% of Mo, 0.11% to 0.20% of Ni and not larger than 0.005% of N. Production steps comprise molten iron desulfuration, electric furnace or converter smelting and refining, continuous casting, descaling treatment before the steel enters a soaking pit furnace, uniform heating, heating, high-pressure water descaling before the steel enters a rolling mill, rolling, cooling, reeling, austenitizing, mold punching molding and quenching. The flow is short, the product surface quality is good, the thickness precision is high, the quality requirement of a cold rolled product can be met, complex deformation can be smoothly completed, not springback exists after deformation, the size precision of parts is high, and the steel and the method have the important significance in automobile light weight.

Owner:武汉钢铁有限公司

3D printing method for high-performance foam shoe midsole

InactiveCN110193931ALow densityFast preparationAdditive manufacturing apparatusDomestic footwearWater vaporThermoplastic elastomer

The invention provides a 3D printing method for a high-performance foam shoe midsole. The method comprises the following steps that shoes are saturated through thermoplastic elastomer resin particlesor wires by using supercritical state gas, after slow pressure relief by a certain time, a treated material is obtained; and the treated material is extruded after melting, and meanwhile, the treatedmaterial is printed and foamed according to a three-dimensional digital model of the midsole through a fusion deposition forming mode to obtain the 3D printing high-performance foam shoe midsole. According to the method, the ultra-light high-resilience shoe midsole material can be rapidly prepared, the midsole material can be directly formed through 3D printing, rear-end mold pressing molding andwater vapor forming process are not needed, the preparation process is short, the efficiency is higher, and personalized customization can be realized. Meanwhile, the midsole prepared by the method has the characteristics of low density, good physical property and durability, and better wearing and running experience is provided for a wearer.

Owner:ANTA CHINA

Short-flow preparation method for Cu-Nb composite material

The invention discloses a short-flow preparation method for a Cu-Nb composite material. The method comprises the following steps of: drawing a Cu / Nb single core wire, straightening, and performing fixed-length cutting; acid-washing, dehydrating and drying an oxygen-free copper tube and the Cu / Nb single core wire; assembling the Cu / Nb single core wire into the oxygen-free copper tube to obtain a primary composite rod; drawing the primary composite rod, straightening, and performing fixed-length cutting to obtain a composite wire; acid-washing, dehydrating and drying the composite wire and another oxygen-free copper tube; assembling the composite wire into the oxygen-free copper tube to obtain a secondary composite rod; and repeatedly processing the secondary composite rod twice according to the processing method of the primary composite rod twice, and drawing until the secondary composite rod has a final size to obtain the Cu-Nb composite material. In the method, the process is simple, and the preparation period is short; and the prepared Cu-Nb composite material has the characteristics of high strength, high electric conductivity, steady performance and strong practicability, can meet the need of pulse magnets, and can be applied to the field of pulsed magnetic fields.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

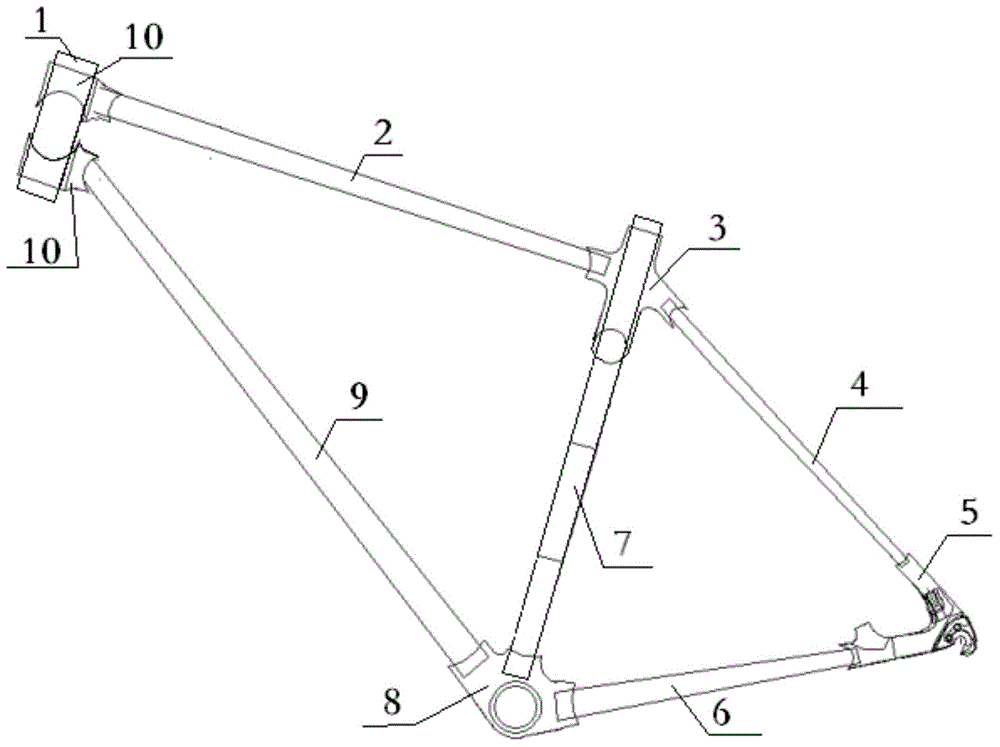

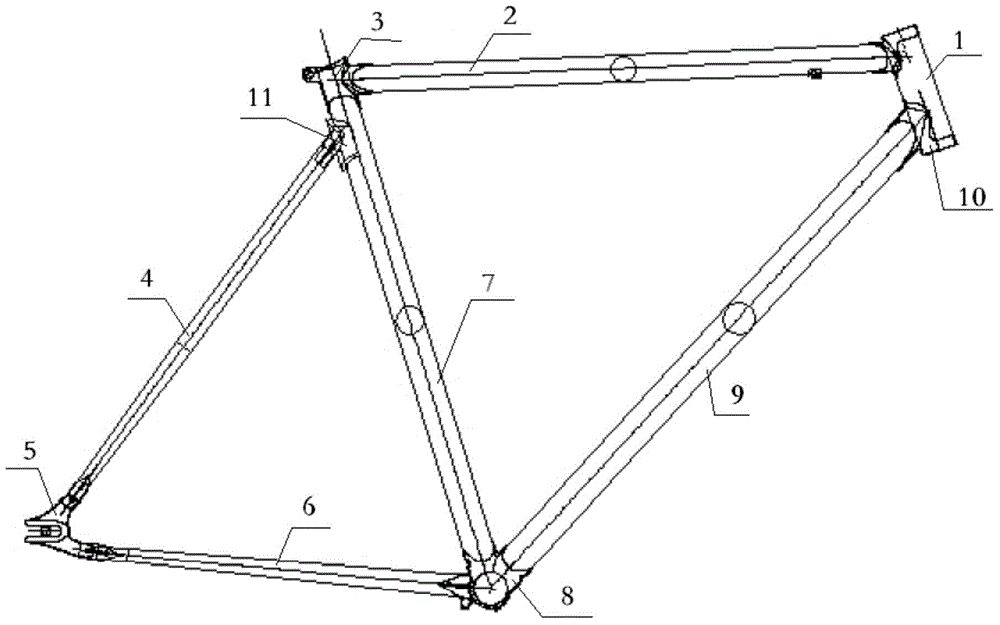

Bicycle frame and manufacturing process thereof

InactiveCN104029776AGuaranteed quality strengthReduce manufacturing costCycle framesVehicle frameSizing

The invention provides a bicycle frame. The bicycle frame comprises hollow tubes and metal connecting pieces, wherein the metal connecting pieces comprise a five-way connecting piece, a claw connecting piece, a seat tube connecting piece and two bicycle head connecting pieces; a bicycle head is connected with an upper tube through one bicycle head connecting piece; the bicycle head is connected with a lower tube through one bicycle head connecting piece; the upper tube, a middle tube and an upper fork are connected together through the seat tube connecting piece; the lower tube, the middle tube and a lower fork are connected together through the five-way connecting piece; the upper fork and the lower fork are connected with each other through claws; the hollow tubes and the metal connecting pieces are glued into a frame body. A process for manufacturing the bicycle frame comprises the following steps: customizing the metal connecting pieces and the claws on a large scale, performing sand blasting and cleaning for later use; performing sand blasting on hollow tubes including the bicycle head, the upper tube, the middle tube, the lower tube, the upper fork and the lower fork, and cleaning for later use; gluing spare metal connecting pieces, claws and hollow tubes into a frame body; entering a baking procedure, and baking at the temperature of 140-160 DEG C for an hour for sizing; after baking, cooling to obtain the bicycle frame.

Owner:TIANJIN JIAHAO BICYCLE +1

Magnesium-lithium alloy foil and preparation method and application thereof

ActiveCN111004951AShort preparation processImprove efficiencyTemperature control deviceMetal rolling arrangementsIngotAluminum foil

The invention belongs to the technical field of magnesium-lithium alloy materials, and particularly relates to a magnesium-lithium alloy foil and a preparation method and application thereof. A magnesium-lithium alloy cast ingot is coiled into an alloy coiled tape with the thickness of 1.5-3.5 mm through large-deformation hot extrusion cogging, then, multi-pass coiling type cooling rolling is conducted through a four-roller aluminum foil rolling mill provided with a tension roller set and a coiling machine, and thus the magnesium-lithium alloy foil is obtained, wherein the minimum thickness ofthe magnesium-lithium alloy foil can be rolled to 0.014 mm. The foil is short in preparation process, high in efficiency, small in residual stress, fine in grain, smooth, free of burrs and high in yield, and the yield can reach 80% or above. The magnesium-lithium alloy foil is used for preparing a vibrating diaphragm or a vibrating diaphragm dome base material, and has good shock absorption performance and high fidelity.

Owner:郑州轻研合金科技有限公司

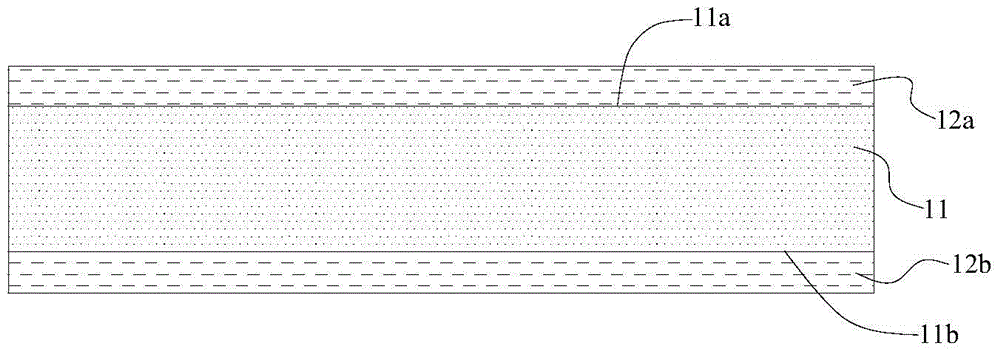

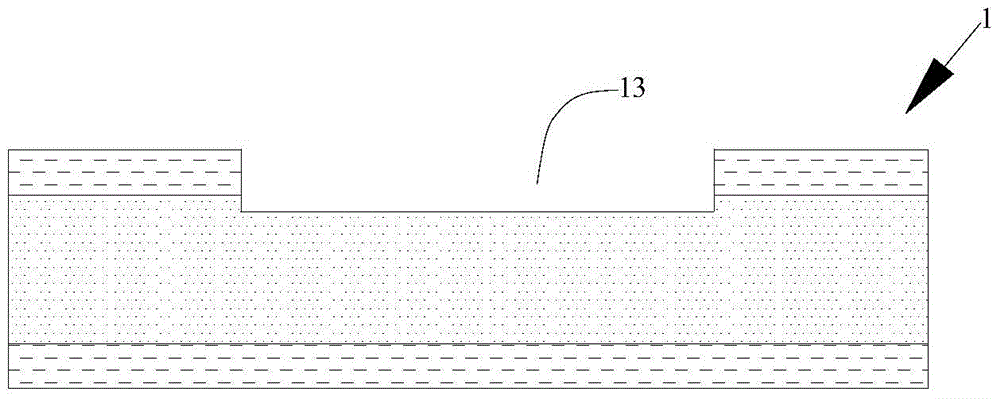

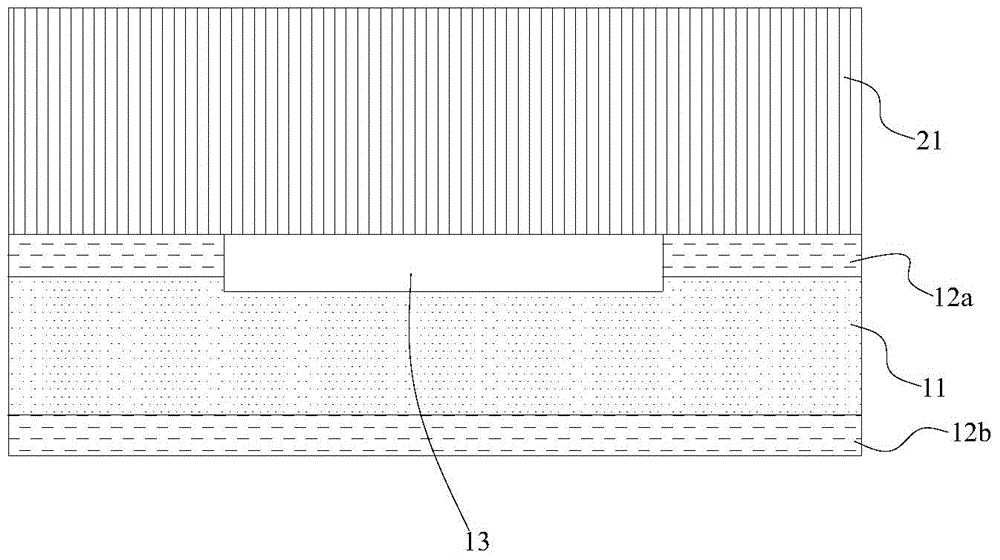

Chip scale packaged MEMS (Micro-Electro-Mechanical Systems) chip with multifunctional cover board and manufacturing method of chip scale packaged MEMS chip with multifunctional cover board

ActiveCN105668501AImprove performanceImprove reliabilityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectricityAccelerometer

The invention discloses a chip scale packaged MEMS chip with a multifunctional cover board. The MEMS chip comprises the cover board, an MEMS structure layer and a base board underlayer; the cover board comprises a cover board underlayer, an upper cover board insulation layer, a first metal layer pattern, an intermetallic insulation layer and a second metal layer pattern; through holes are arranged in the intermetallic insulation layer; the second metal layer is filled in the through holes; the cover board are bonded with the MEMS structure layer and the upper cover board insulation layer through a sealing ring; and a first bonding block is located on the upper surface of an MEMS signal export part. According to the MEMS chip, the electric signals on the MEMS structure is leaded to the cover board through a metal wire bonded between the first bonding bloc and a second bonding block; then crossover wiring is finished on the cover board; moreover, a constant temperature heater and a thermal convection accelerometer for leakage detection can be manufactured by utilizing the first metal layer pattern and the second metal layer pattern on the cover board; according to the manufacturing method provided by the invention, electric connection between the MEMS structure layer and a base board is unnecessary; it is unnecessary to electrically connect the MEMS structure and the cover board through a TSV (Through Silicon Via); it is unnecessary to carry out crossover wiring in the MEMS structure layer or on the base boar; the process is short; the cost is low; and the yield is high.

Owner:ANHUI BEIFANG XINDONG LIANKE MICROSYST TECH

Preparing method for noble metal catalyst for proton exchanging film fuel cell

ActiveCN1979930AHigh catalytic activityPrecise size controlCell electrodesCatalyst activation/preparationMicroparticleSurface-active agents

The method includes steps: (1) adding water solution of noble metal compounds, and water solution of reducing agent to non aqueous solution of surface active agent respectively, and then stirring them evenly so as to obtain two inverse micellar solutions; (2) mixing the obtained two inverse micellar solutions, making the mixed solution contact with carrier of catalyst, and stirring them to make grains of noble metal be loaded to carrier of catalyst, obtaining catalyst grains of noble metal. Controlling size of fluid drop i.e. water content, the method can control size of grain of noble metal catalyst. Thus, the invention can obtain catalyst with high catalytic activity and smaller grain size so as to raise use ratio of noble metal, lower cost. Features are: simple method, controllable technical condition, and no pollution of reducing agent on environment.

Owner:BYD CO LTD

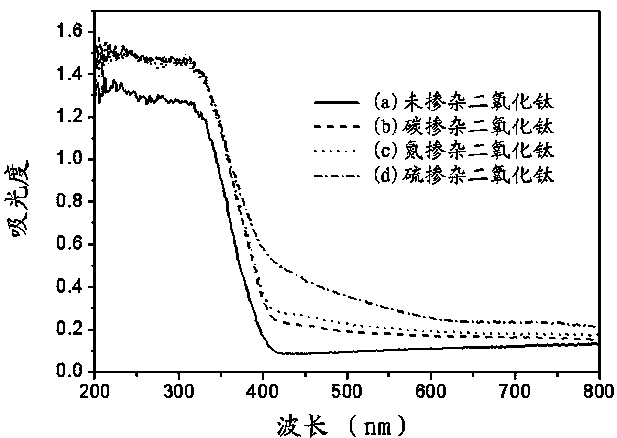

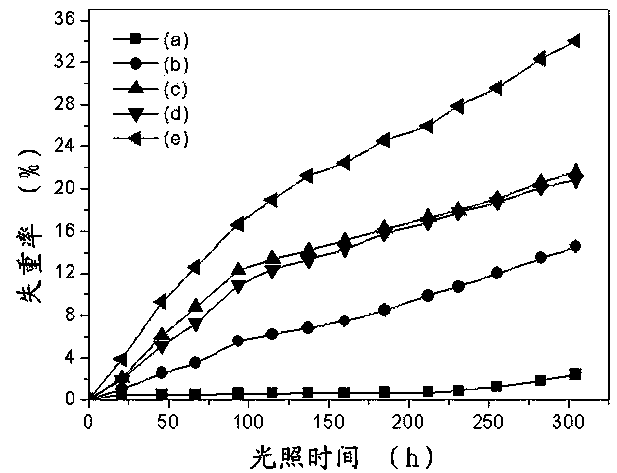

Nonmetal-doped titanium dioxide, preparation method thereof and degradable plastic film

The invention discloses nonmetal-doped titanium dioxide, a preparation method thereof and degradable plastic film. The nonmetal-doped titanium dioxide is prepared by high-energy ball milling of nano titanium dioxide and a nonmetal doping source, wherein the weight of the nonmetal element is 0.1%-5.0% of the weight of the titanium element. The degradable plastic film can be prepared by subjecting the nonmetal-doped titanium dioxide and a polyolefin resin to belt blending and extrusion-blown molding, wherein the weight of the nonmetal-doped titanium dioxide is 0.1%-10.0% of the weight of the polyolefin resin. The nonmetal-doped titanium dioxide has characteristics of simple production technology, easily available raw materials, high photocatalytic activity, wide light absorption range, and the like. The degradable plastic film prepared by the nonmetal-doped titanium dioxide has characteristics of short degradation time, controllable stable periods, wide application range, and the like.

Owner:SOUTH CHINA AGRI UNIV

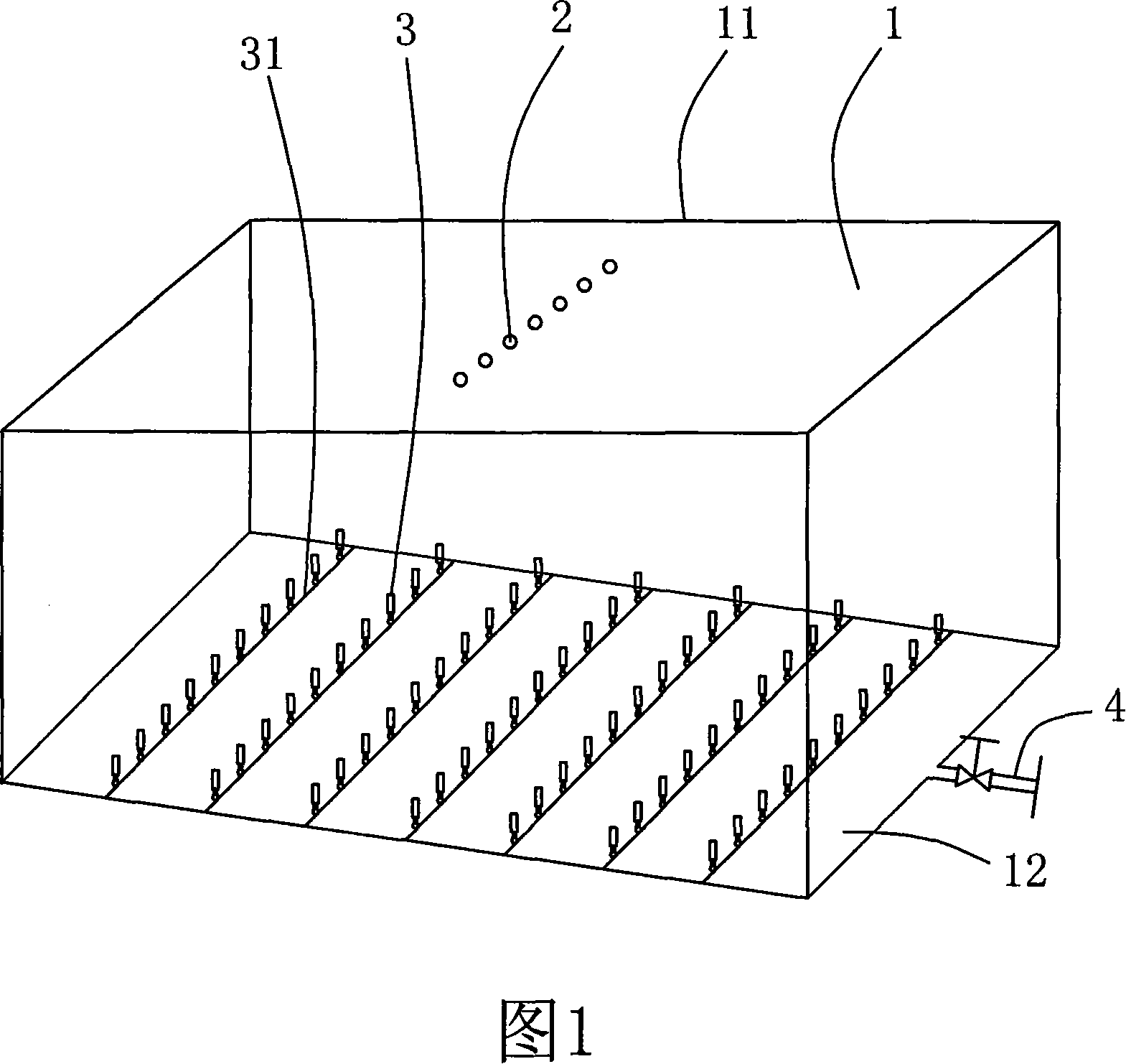

Preparation method and device of high-concentration whole tailings slurry

InactiveCN101139178AShort preparation processSimplify process and equipmentHigh concentrationEnergy consumption

The present invention discloses a preparation method and device for high-concentration whole tailings slurry for mine filling. The preparation method comprises the processes such as dehydration, drainage, storage, mud making, etc applied to the low-concentration whole tailings. The processes are accomplished in the same sand silo according to the following steps: the low-concentration whole tailings discharged from mills are directly delivered into the sand silo to be dehydrated; the stationary primary water at the upper part of the sand silo is discharged from top to bottom layer by layer; when the tailing content in the discharge water reach the preset index ranging from 0.1 to 10g / l, the water discharge is stopped and the whole tailings in the sand silo are stored locally in the silo to be prepared for use; the comprehensive fluidization slurry making is applied to the whole tailings slurry in the sand silo through pressure gas so as to form the high-concentration slurry, the mass fraction of the tailings in which reaches 70 to 75 percent; then the high-concentration slurry is discharged into a mixing equipment to be mixed with the cementing material so as to prepare the binding backfill slurry. The present invention integrates the processes such as the dehydration, drainage, storage, slurry making, etc in a device to accomplish them, thus greatly shortening the preparation process, simplifying the technique and equipments and lowering the preparation energy consumption and cost.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

NaxMnO2 anode material, preparation method and application thereof

ActiveCN107045948AHigh Na contentHigh specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureNanoparticleSupercapacitor

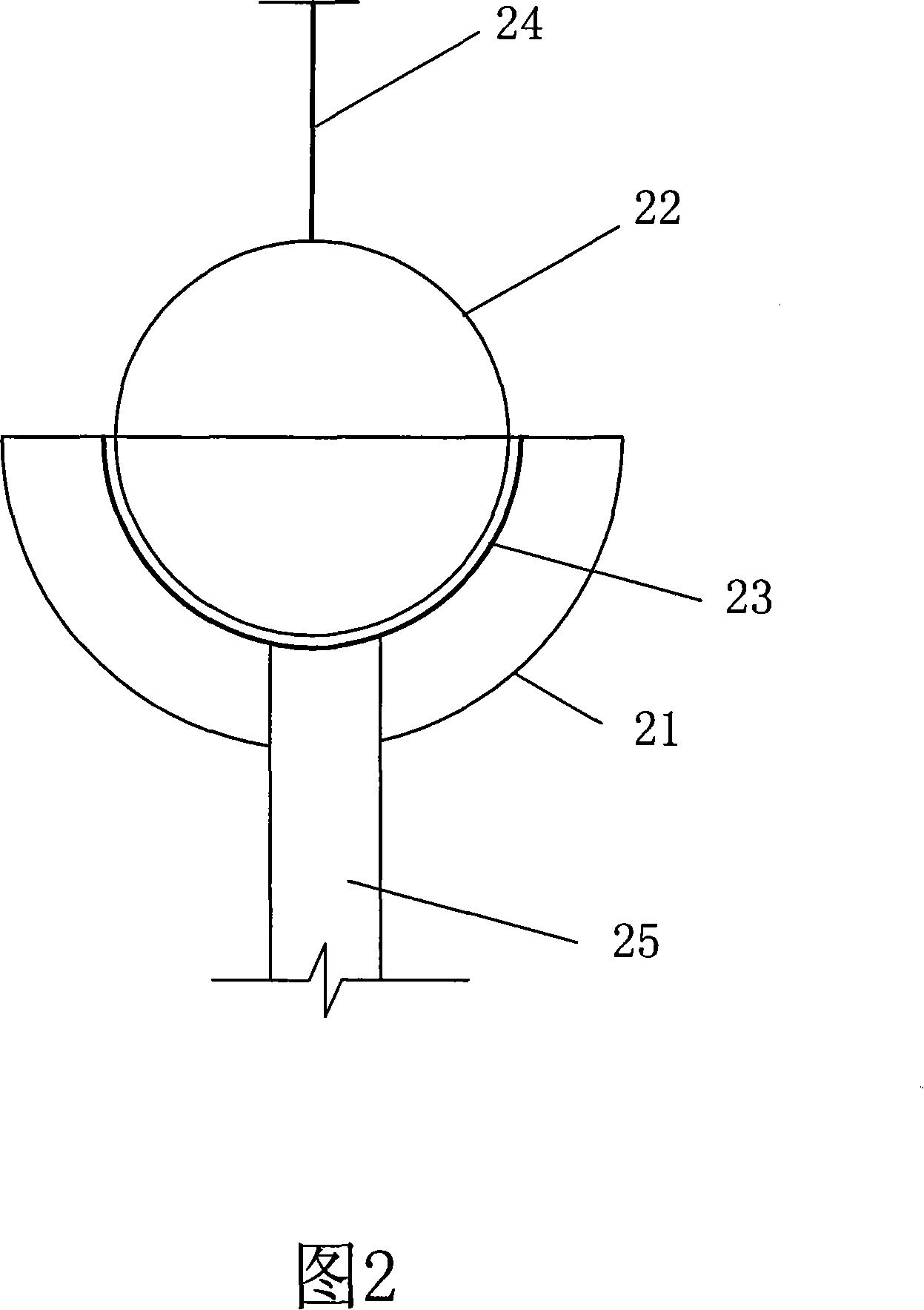

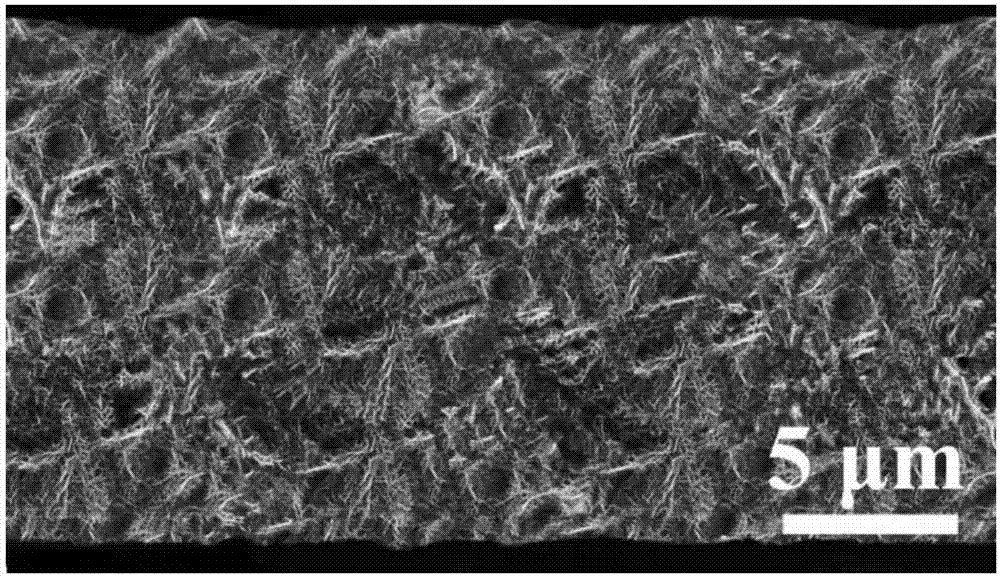

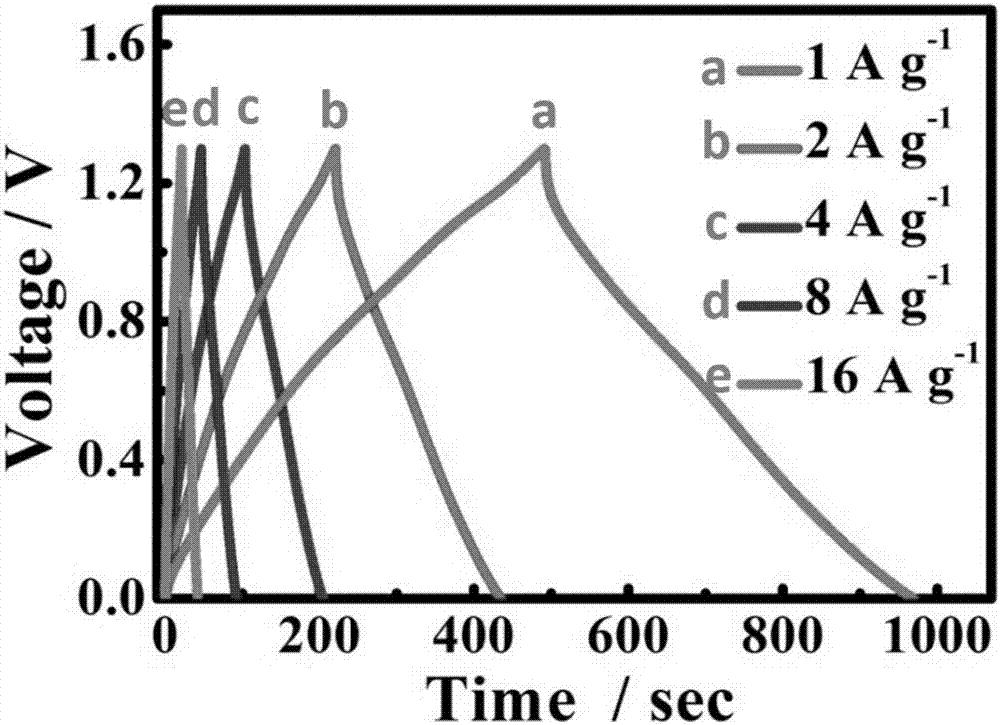

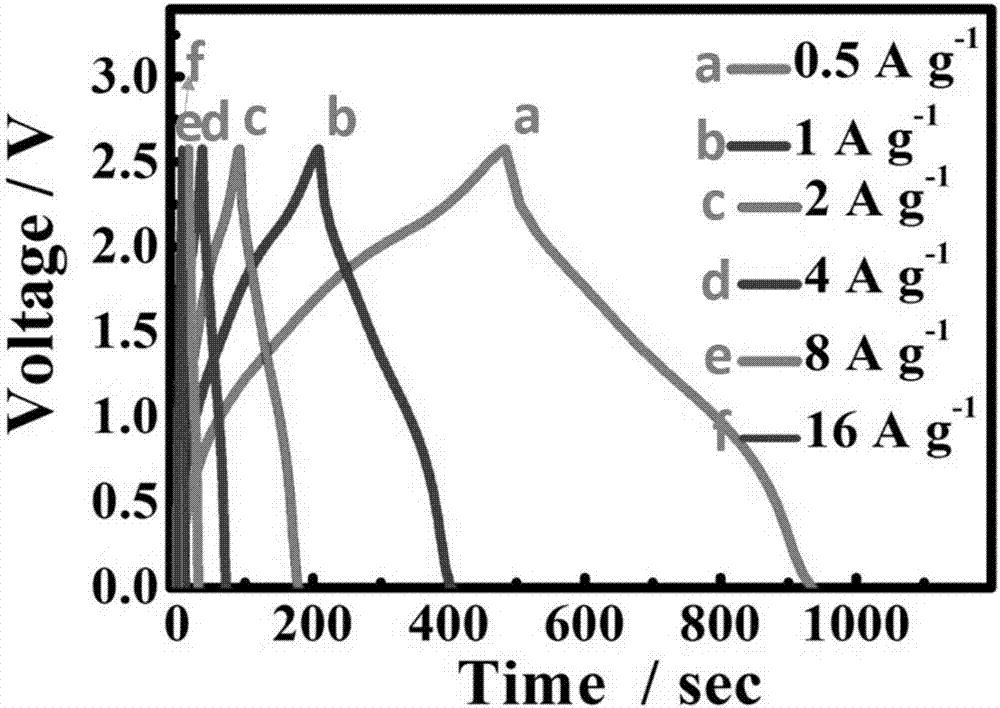

The invention discloses a NaxMnO2 anode material, a preparation method and application thereof. The method comprises: hydrothermal processing is carried out on a nano-wall array formed by self assembling of Mn3O4 nanoparticles growing on a piece of carbon cloth, thereby forming a high-Na-content nano-wall array based on self assembling of Na0.55MnO2 nanosheets. The working potential window of the Na0.55MnO2 nano-wall array can be extended to 0 to 1.3V (vs. Ag / AgCl); and the specific capacity can reach 366F g<-1>. A Na0.55MnO2 / / Fe3O4@C water-system asymmetric super capacitor with a 2.6-V ultra-wide working potential window is prepared by using the Na0.55MnO2 as an anode material and a Fe3O4 nanorod array coated with carbon as a cathode. The super capacitor not only has the general characters of the common super capacitor but also has advantages of high power density and ultra long cyclic service life. Moreover, the super capacitor has a2.6-V ultra-wide working potential window and the ultra high power density (87 Wh kg<-1>).

Owner:NANJING UNIV OF SCI & TECH

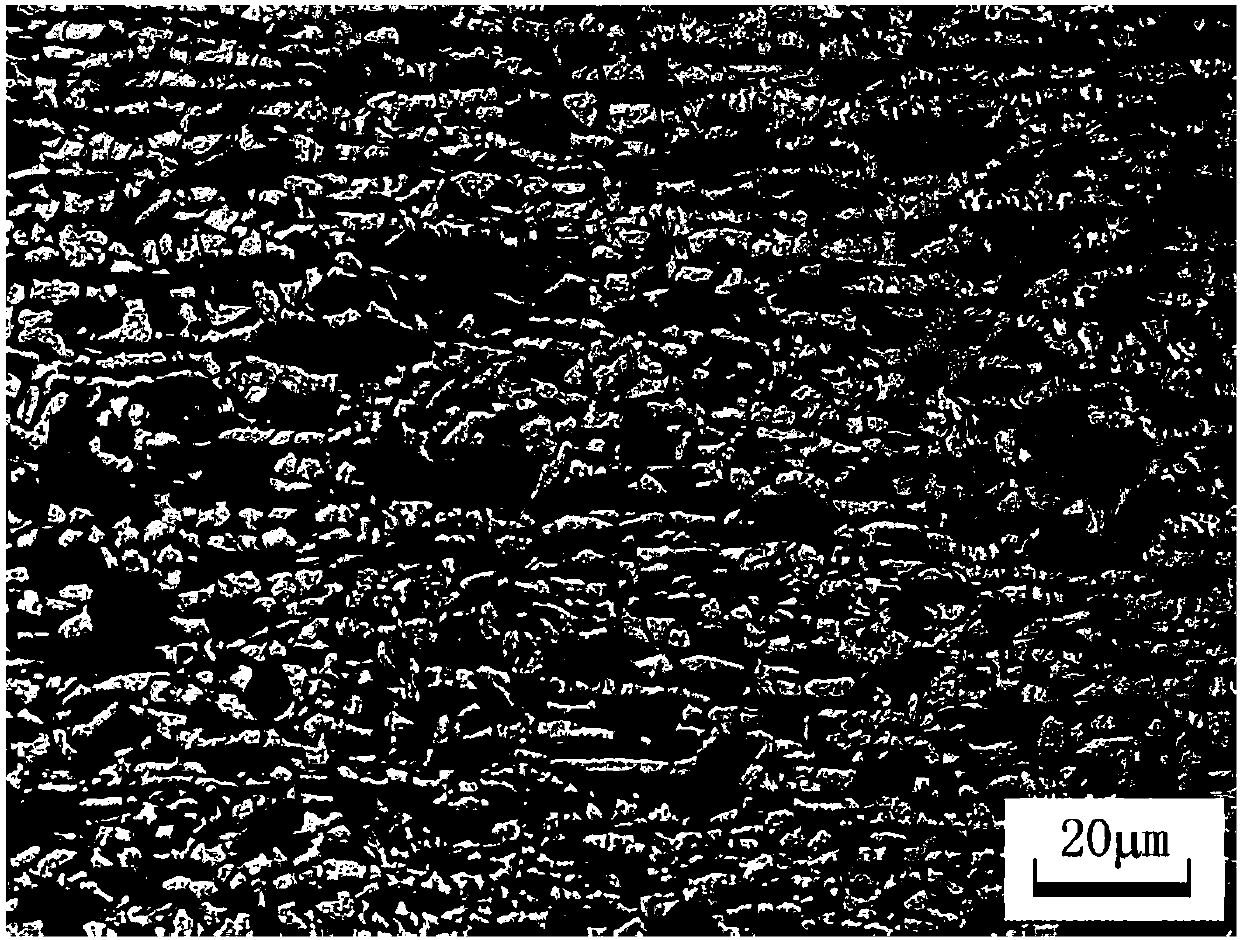

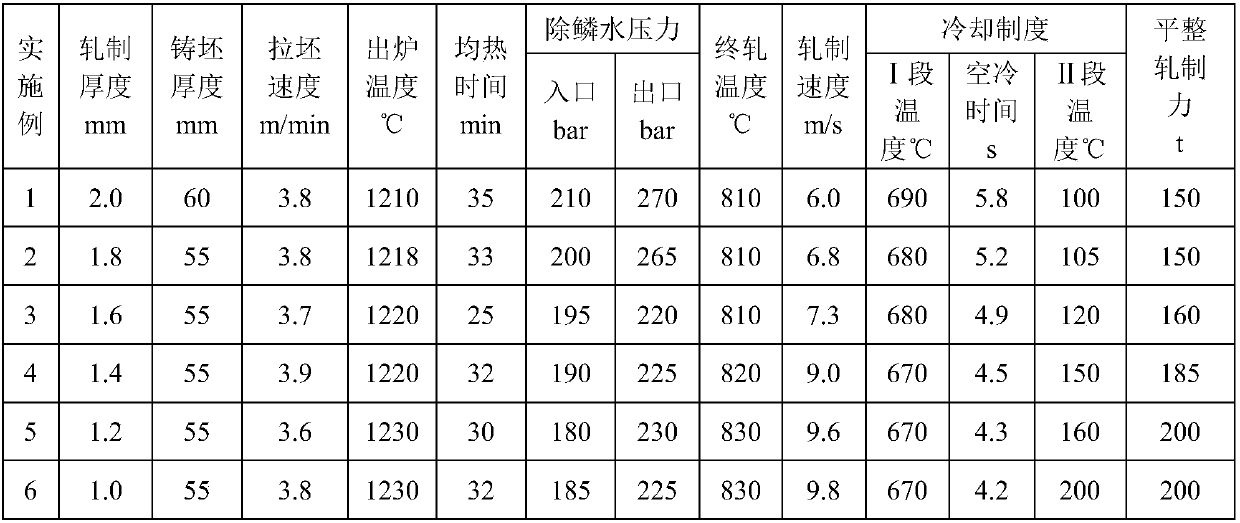

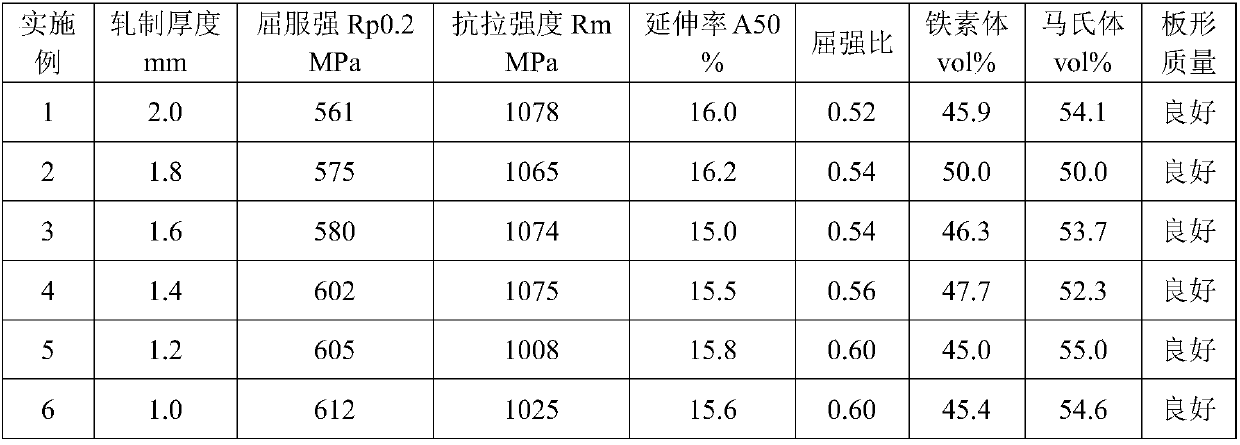

Method for producing thin-gauge hot-rolled DP980 steel based on CSP process

ActiveCN107716551AThin profile highThin Gauge High Strength High StrengthWork cooling devicesMetal rolling arrangementsThin slabHigh pressure water

The invention discloses a method for producing thin-gauge hot-rolled DP980 steel based on a CSP process. The method comprises the following steps that (1) components of molten iron are regulated; (2)continuous casting of a thin slab is conducted, specifically, the thickness of the cast slab is controlled to be 55-60 mm, and the slab drawing speed is 3.6-3.9 m / min; (3) conventional soaking is conducted, specifically, the tapping temperature is controlled to be 1210-1230 DEG C, and the soaking time is 25-35 min; (4) high-pressure water descaling is conducted; (5) finish rolling is conducted forseven passes, specifically, the finished rolling temperature is 810-830 DEG C, and the rolling speed of a tail rack is 6.0-9.8 m / s; (6) two-stage type cooling and reeling are conducted, specifically,water cooling at the first stage is conducted till the temperature reaches 670-690 DEG C, then air cooling is conducted for 4.2-5.8 s, and water cooling at the second stage is conducted till the temperature reaches 100-200 DEG C; and (7) flattening is conducted. The manufacturing process is short, product performance is stable, the plate shape quality is good, and thickness precision is high; thecharacteristics of low cost, high strength, thin gauge and low yield ratio are achieved; and the quality requirement of cold-rolled products can be met, and the method has great significance for achieving the light weight of automobiles and promoting the progress of replacing cold rolling with hot rolling in the automobile industry.

Owner:武汉钢铁有限公司

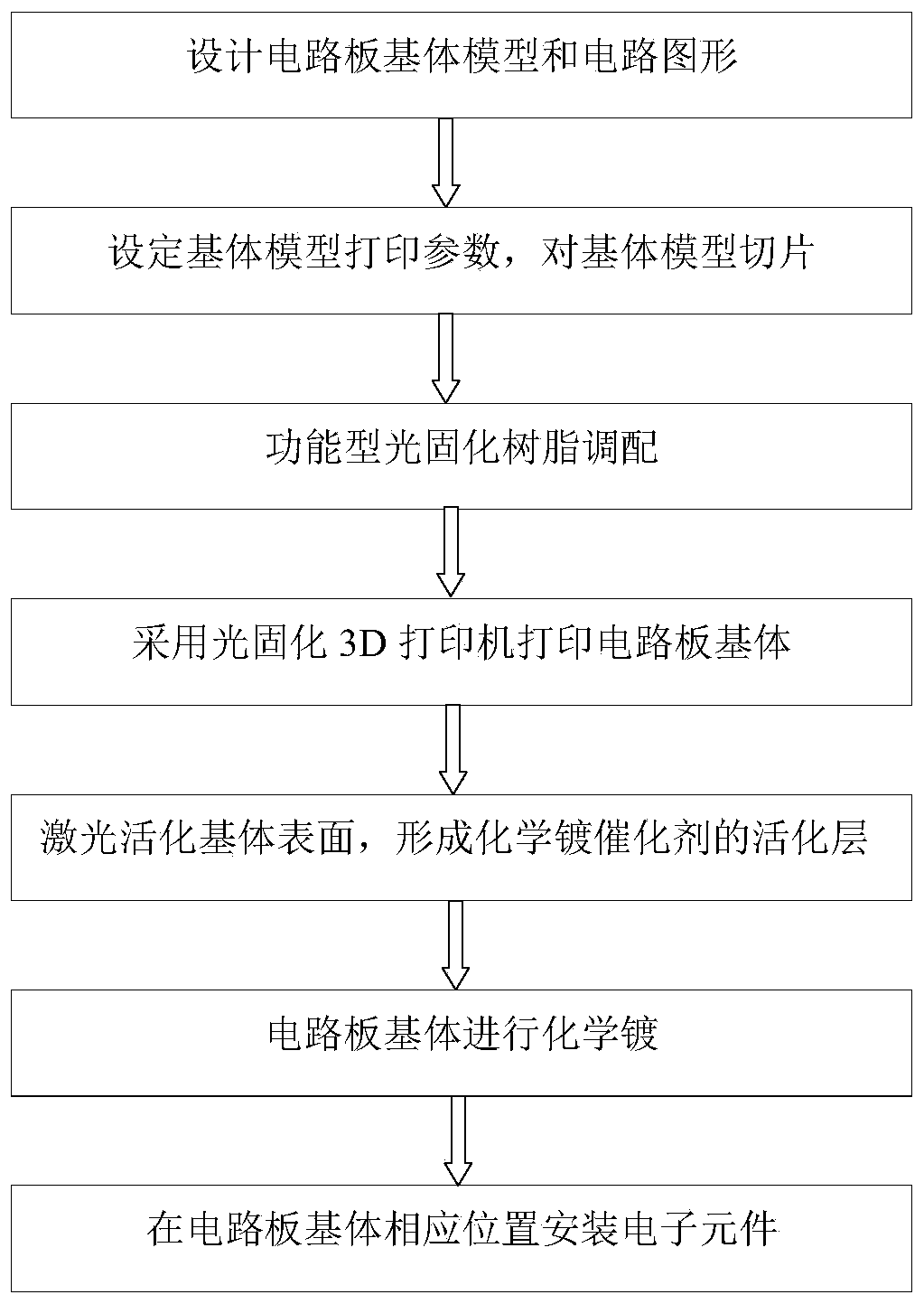

Manufacturing method based on photocuring 3D printing technology and used for circuit board

InactiveCN109774132AShorten the production cycleReduce production equipment and mold investmentAdditive manufacturing apparatus3D object support structuresChemical platingEngineering

The invention discloses a manufacturing method based on a photocuring 3D printing technology and used for a circuit board. The manufacturing method based on the photocuring 3D printing technology andused for the circuit board comprises the following steps: (1) designing a matrix model and a circuit pattern of the circuit board; (2) setting the printing parameters of the matrix model, and slicingthe matrix model; (3) blending functional photocuring resin; (4) printing a circuit board matrix through a photocuring 3D printing machine; (5) activating the surface of the matrix through laser to form an activated layer attached with a chemical plating catalyst; (6) carrying out chemical plating on the circuit board matrix; and (7) installing electronic components at the corresponding positionsof the circuit board matrix. The manufacturing method is high in machining degree of freedom, and capable of being applied to manufacturing for a three-dimensional circuit and manufacturing for a two-dimensional circuit board. The manufacturing method is capable of conveniently designing the circuit board and the circuit pattern according to the actual user need, and efficiently manufacturing thecircuit board, low in manufacturing cost, short in process flow, and green and environment-friendly.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com