Preparation method of catalytic cracking catalyst

A catalytic cracking and catalyst technology, applied in the field of radiation, can solve the problems of molecular sieve bed overheating, direct discharge of saline waste water to pollute the environment, excessive sulfate radicals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

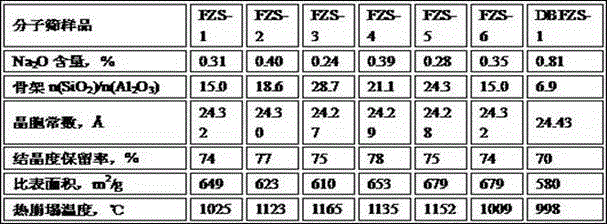

[0118]Embodiment 1: Get the former powder of NaY molecular sieve (sodium oxide content 10.3wt%, unit cell constant 24.64Å, skeleton n (SiO 2 ) / n(Al 2 o 3 ) is 5.3, crystallinity 92%), according to the weight ratio of halogen-containing gas phosphorus trichloride:molecular sieve powder=0.6:1, contact with halogen-containing gas phosphorus trichloride carried by carrier gas oxygen to carry out gas phase ion exchange reaction , reacted at a constant temperature of 530°C for 1 hour, and the reaction product was washed to prepare a low-sodium, high-silicon-aluminum ratio molecular sieve FZS-1, whose physical and chemical indicators are shown in Table 2.

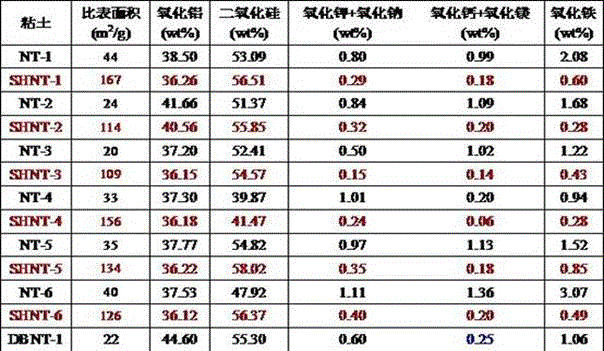

[0119] Composite clay was prepared by mixing Suzhou kaolin and Xuyi attapulgite, denoted as NT-1. The composite clay contained 80.0wt% of Suzhou kaolin and 20.0wt% of Xuyi attapulgite on a dry basis. The obtained composite clay and hydrochloric acid solution with a mass fraction of 15% were fully slurried at 60°C, the liquid-sol...

Embodiment 2

[0121] Embodiment 2: Get the former powder of NaY molecular sieve (sodium oxide content 11.8wt%, unit cell constant 24.67Å, skeleton n (SiO 2 ) / n(Al 2 o 3 ) is 5.4, crystallinity 93%), according to the weight ratio of halogen-containing gas dichloromethane:molecular sieve powder=0.7:1, contact with the halogen-containing gas dichloromethane carried by carrier gas water vapor to carry out gas phase ion exchange reaction, And at a heating rate of 10°C / min, rise to 440°C within 0.5h, then react at a constant temperature for 2.5h, and the total reaction time is 3h. After washing the reaction product, a low-sodium high-silicon-aluminum ratio molecular sieve FZS-2 is prepared. Table 2.

[0122] Maoming kaolin and Lingshou halloysite were mixed to obtain a composite clay, which was designated as NT-2. The composite clay contained 60.0wt% of Maoming kaolin and 40.0wt% of Lingshou halloysite on a dry basis. The obtained composite clay and sulfuric acid solution with a mass fraction ...

Embodiment 3

[0124] Embodiment 3: Get the former powder of NaY molecular sieve (sodium oxide content 11wt%, unit cell constant 24.66Å, skeleton n (SiO 2 ) / n(Al 2 o 3 ) is 5.4, crystallinity 92%), according to the halogen-containing gas CH 3 SiCl 3 : Molecular sieve raw powder = 0.4:1 weight ratio, and the halogen-containing gas CH carried by the carrier gas oxygen 3 SiCl 3 Contact for gas phase ion exchange reaction, and rise to 402.7°C within 0.45h at a heating rate of 3.8°C / min, then react at a constant temperature for 0.9h, and then rise to 543.1°C at a heating rate of 0.5°C / min, and the reaction product is prepared after washing The low-sodium high-silicon-aluminum ratio molecular sieve FZS-3 was obtained, and its physical and chemical indicators are shown in Table 2.

[0125] Mix Longyan kaolin and Lingshou rectorite to obtain a composite clay, which is designated as NT-3. The composite clay contains 94.0wt% of Longyan kaolin and 6.0wt% of Lingshou rectorite on a dry basis. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com