Patents

Literature

1501 results about "Silicon tetrachloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon tetrachloride or tetrachlorosilane is the inorganic compound with the formula SiCl₄. It is a colourless volatile liquid that fumes in air. It is used to produce high purity silicon and silica for commercial applications.

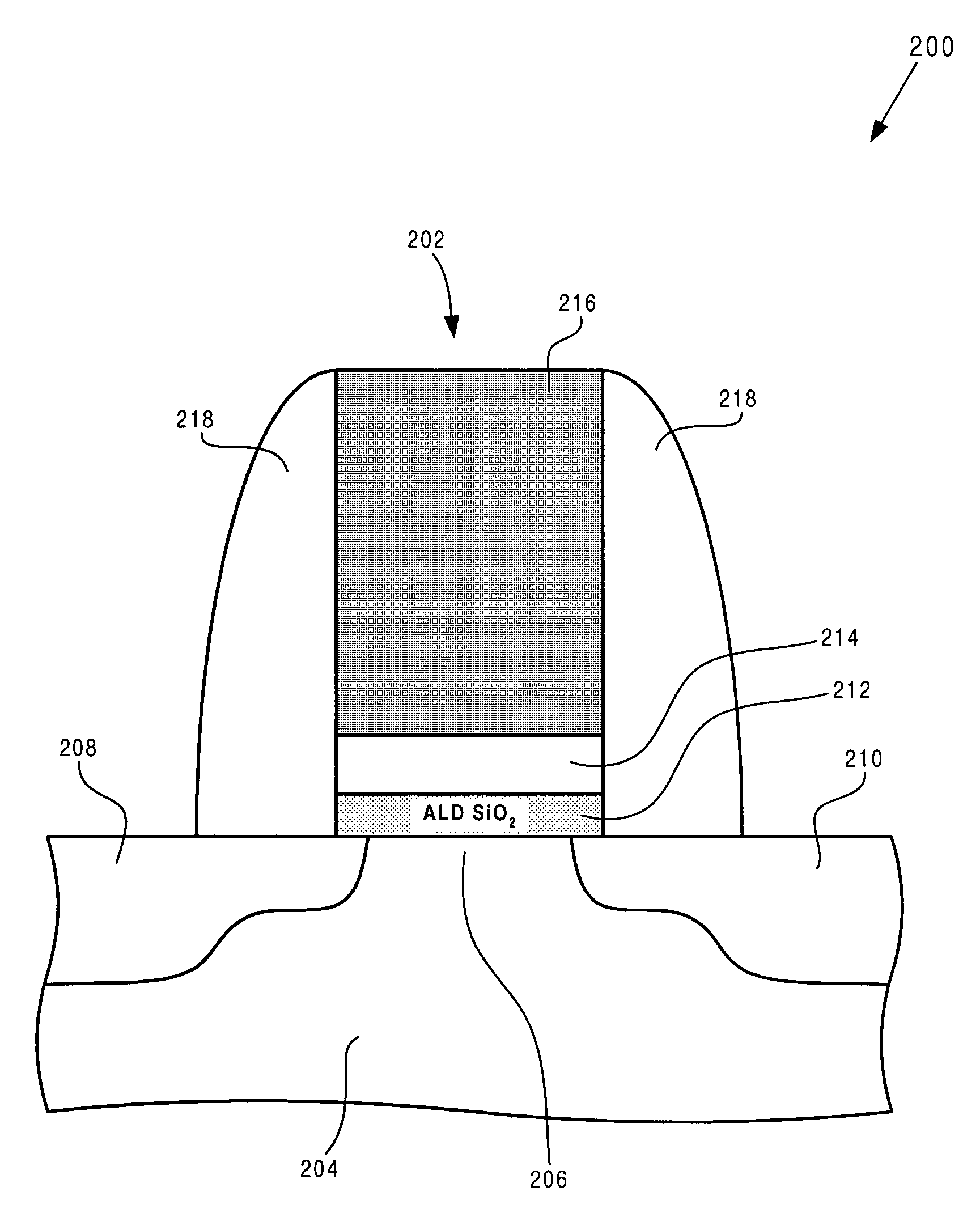

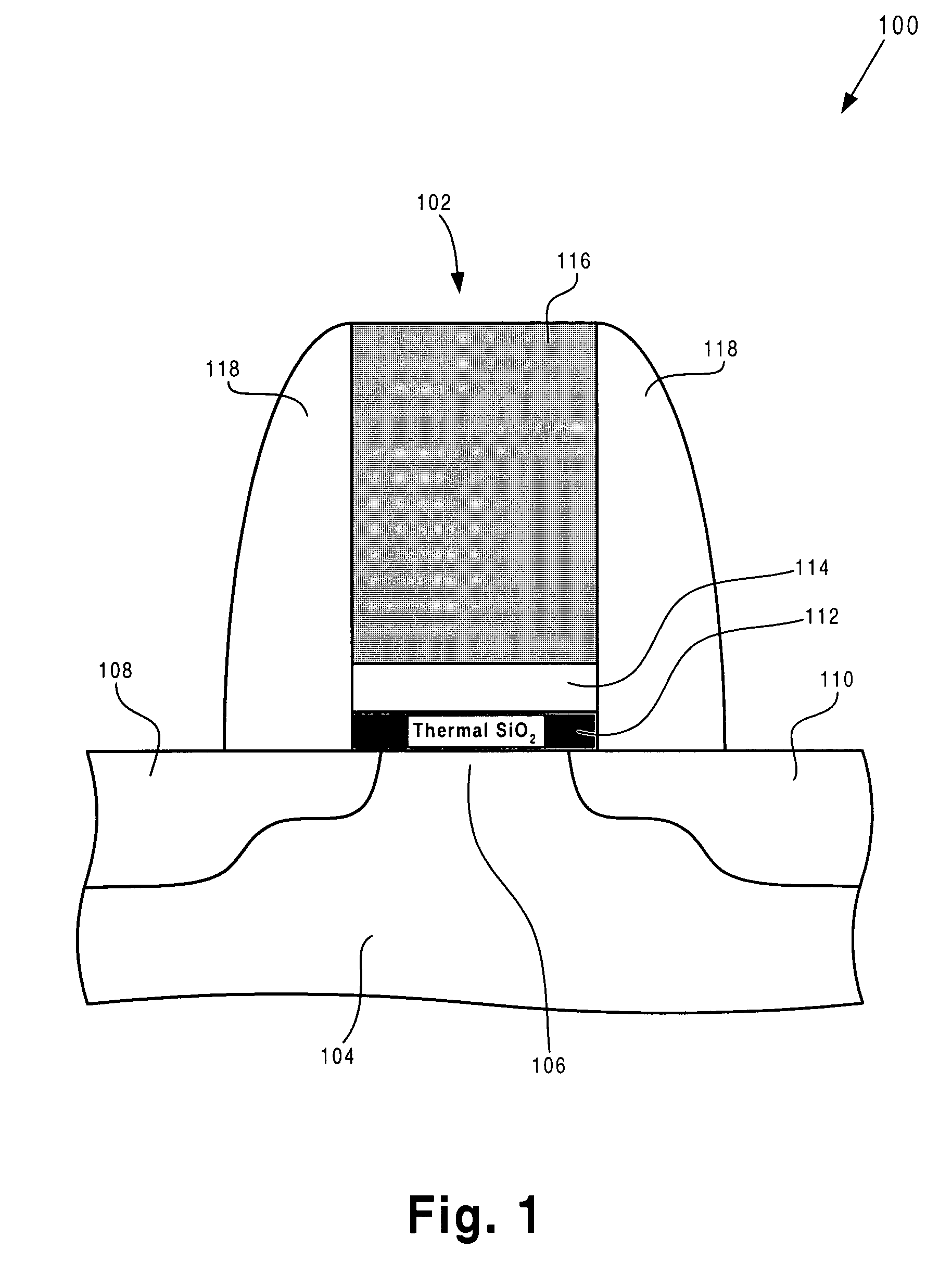

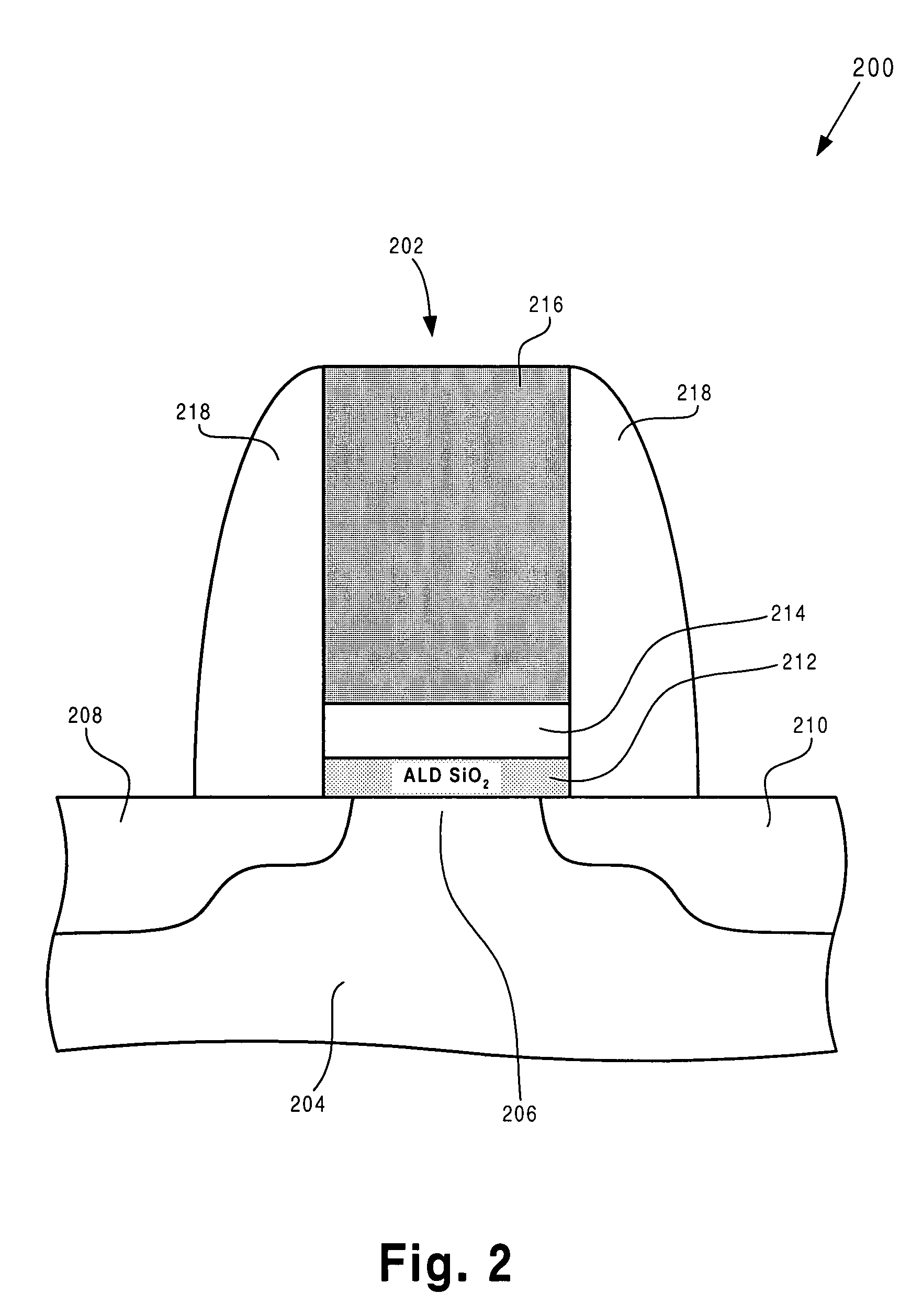

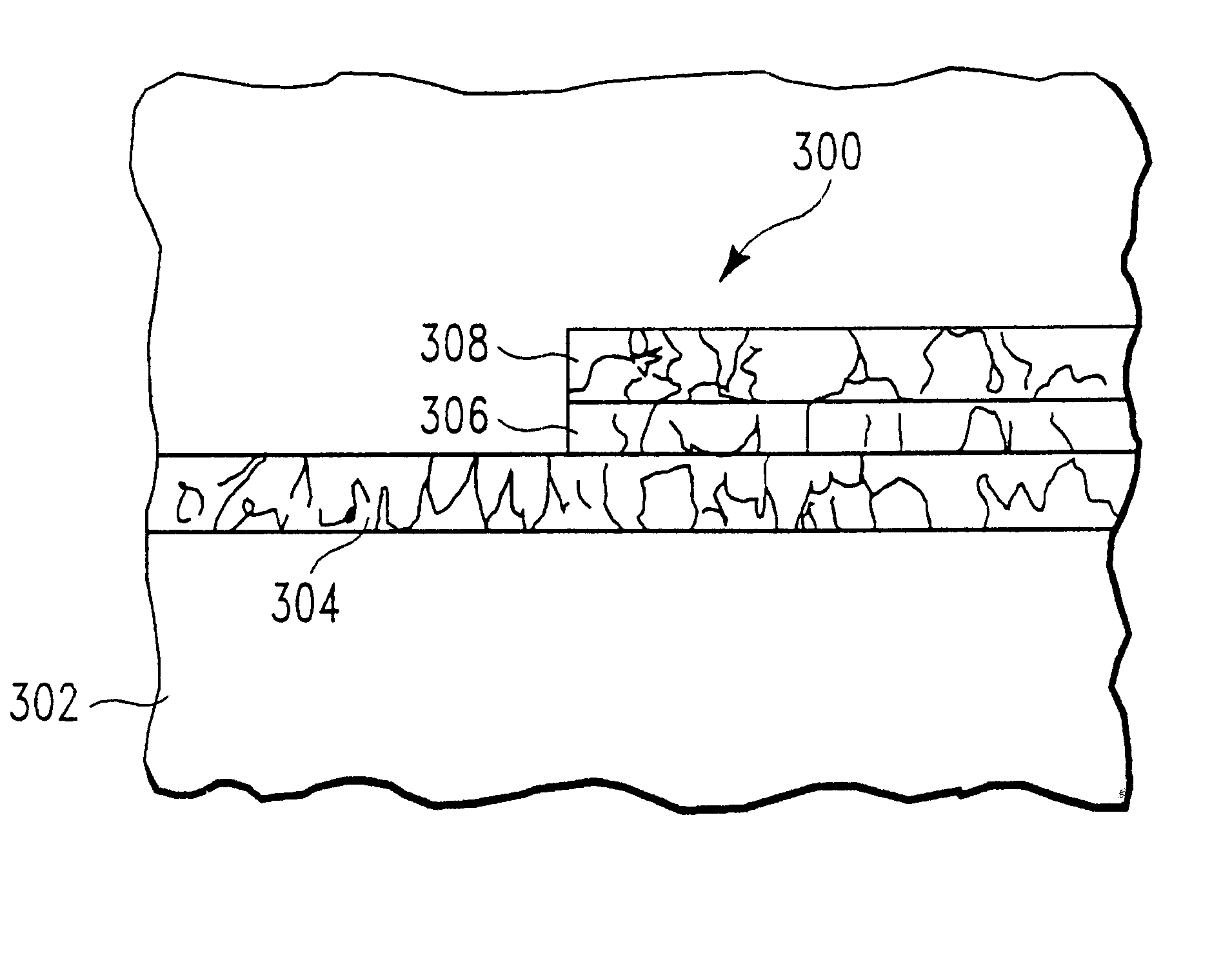

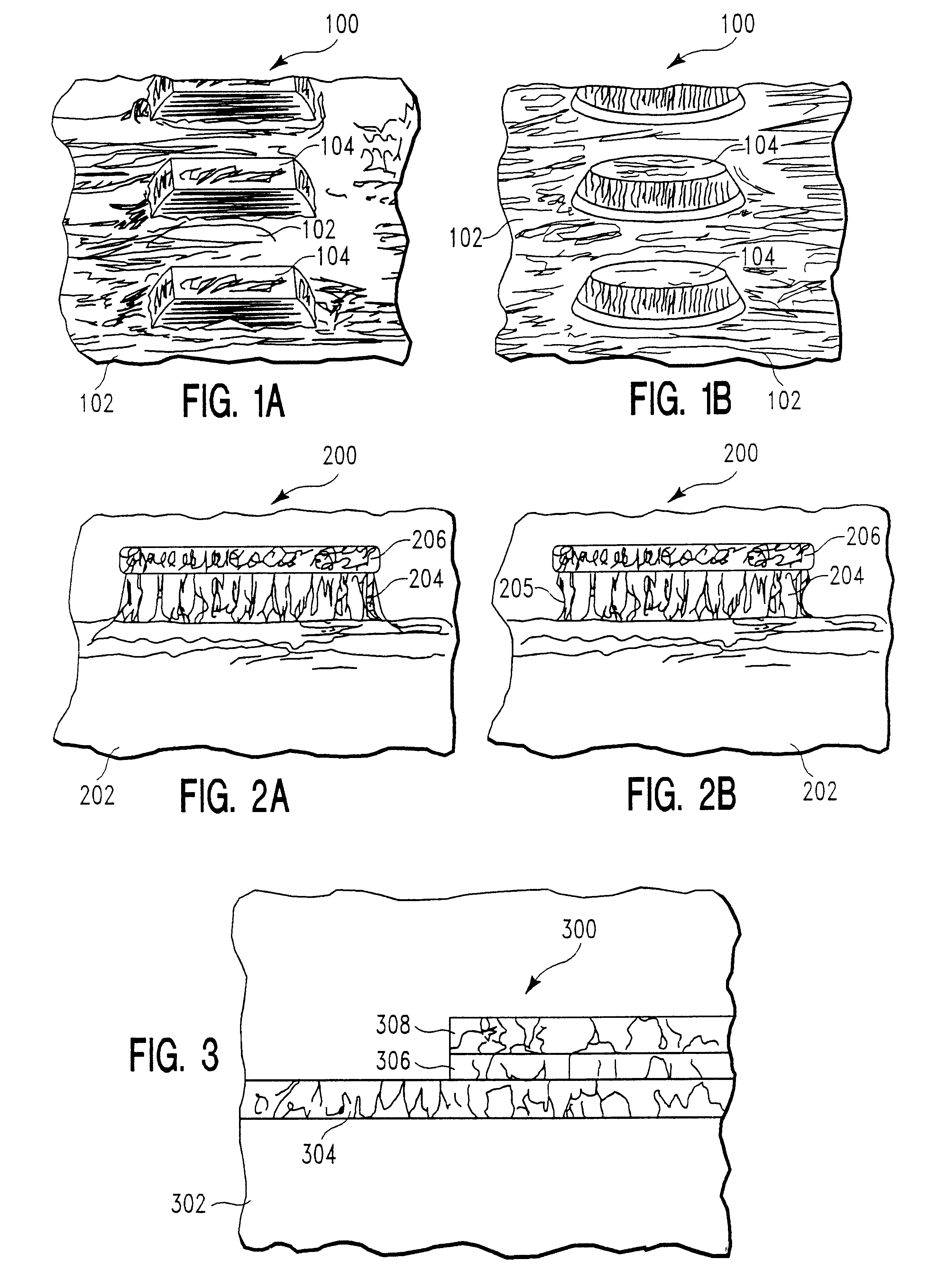

Method for forming a thin, high quality buffer layer in a field effect transistor and related structure

ActiveUS7071051B1Readily apparentSemiconductor/solid-state device manufacturingSemiconductor devicesOrganic field-effect transistorOptoelectronics

According to one exemplary embodiment, a method for forming a field-effect transistor on a substrate comprises a step of forming a buffer layer on the substrate, where the buffer layer comprises ALD silicon dioxide. The buffer layer can be formed by utilizing a silicon tetrachloride precursor in an atomic layer deposition process, for example. The buffer layer comprises substantially no pin-hole defects and may have a thickness, for example, that is less than approximately 5.0 Angstroms. The method further comprises forming a high-k dielectric layer over the buffer layer. The high-k dielectric layer may be, for example, hafnium oxide, zirconium oxide, or aluminum oxide. According to this exemplary embodiment, the method further comprises forming a gate electrode layer over the high-k dielectric layer. The gate electrode layer may be polycrystalline silicon, for example.

Owner:GLOBALFOUNDRIES US INC

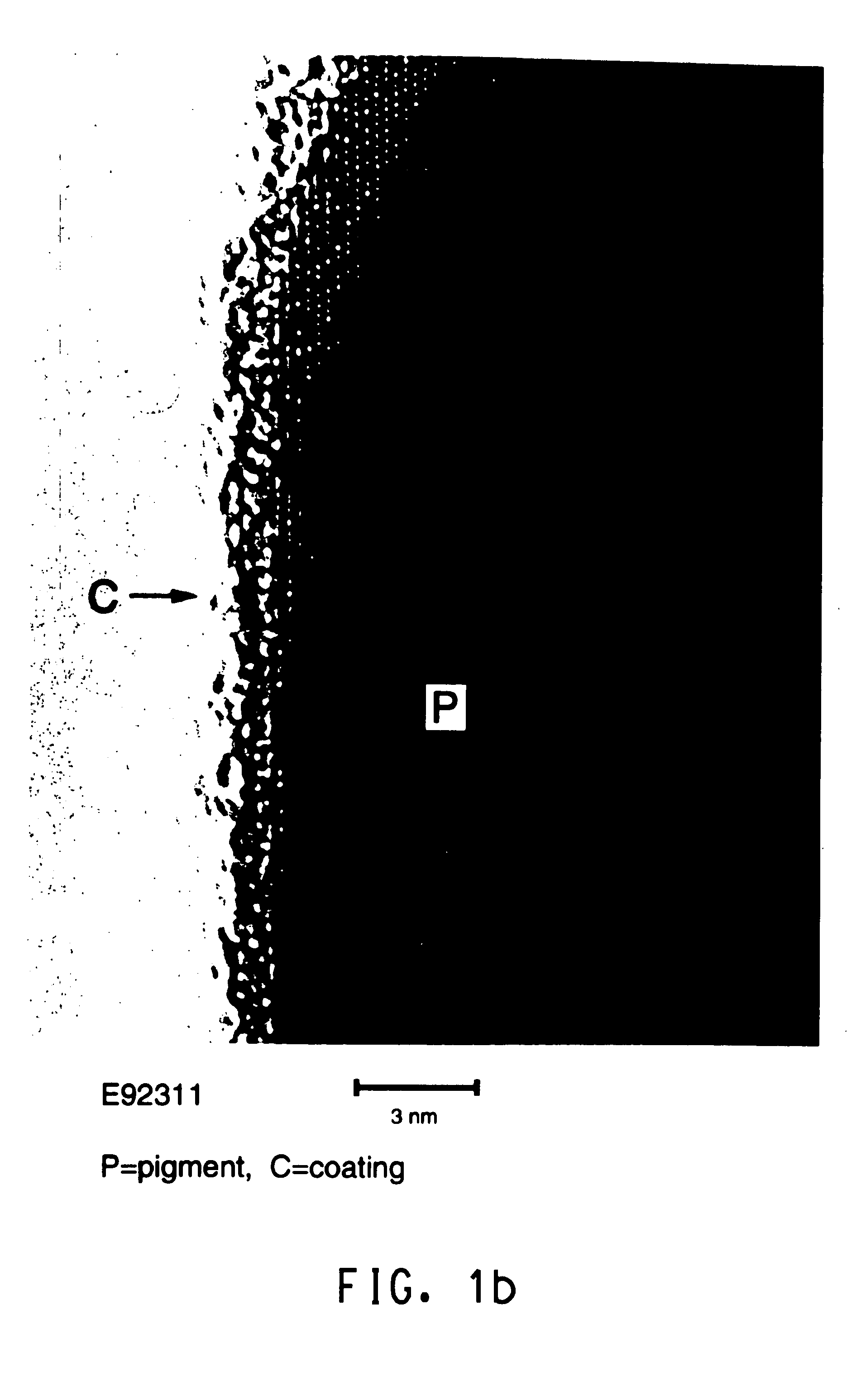

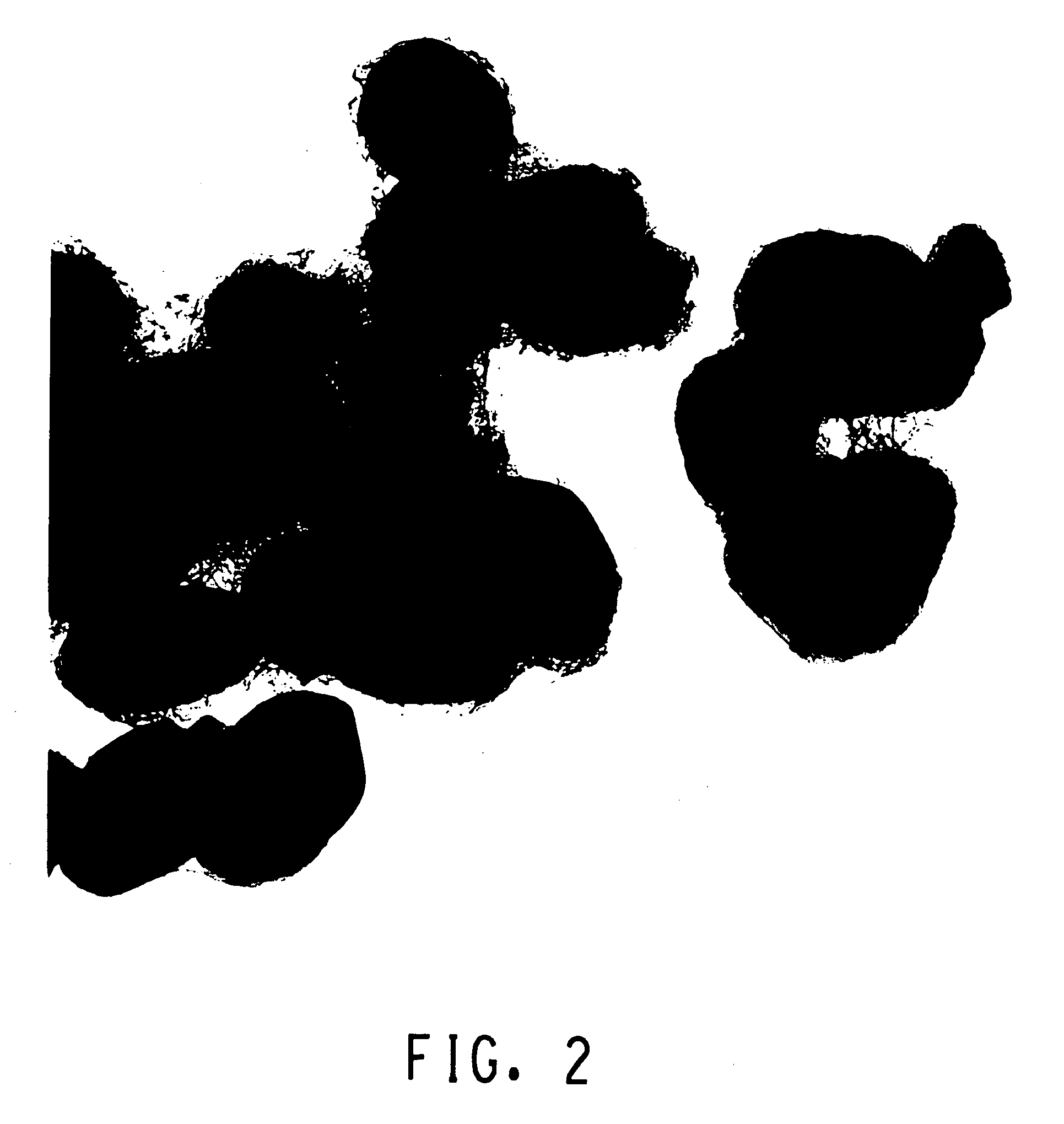

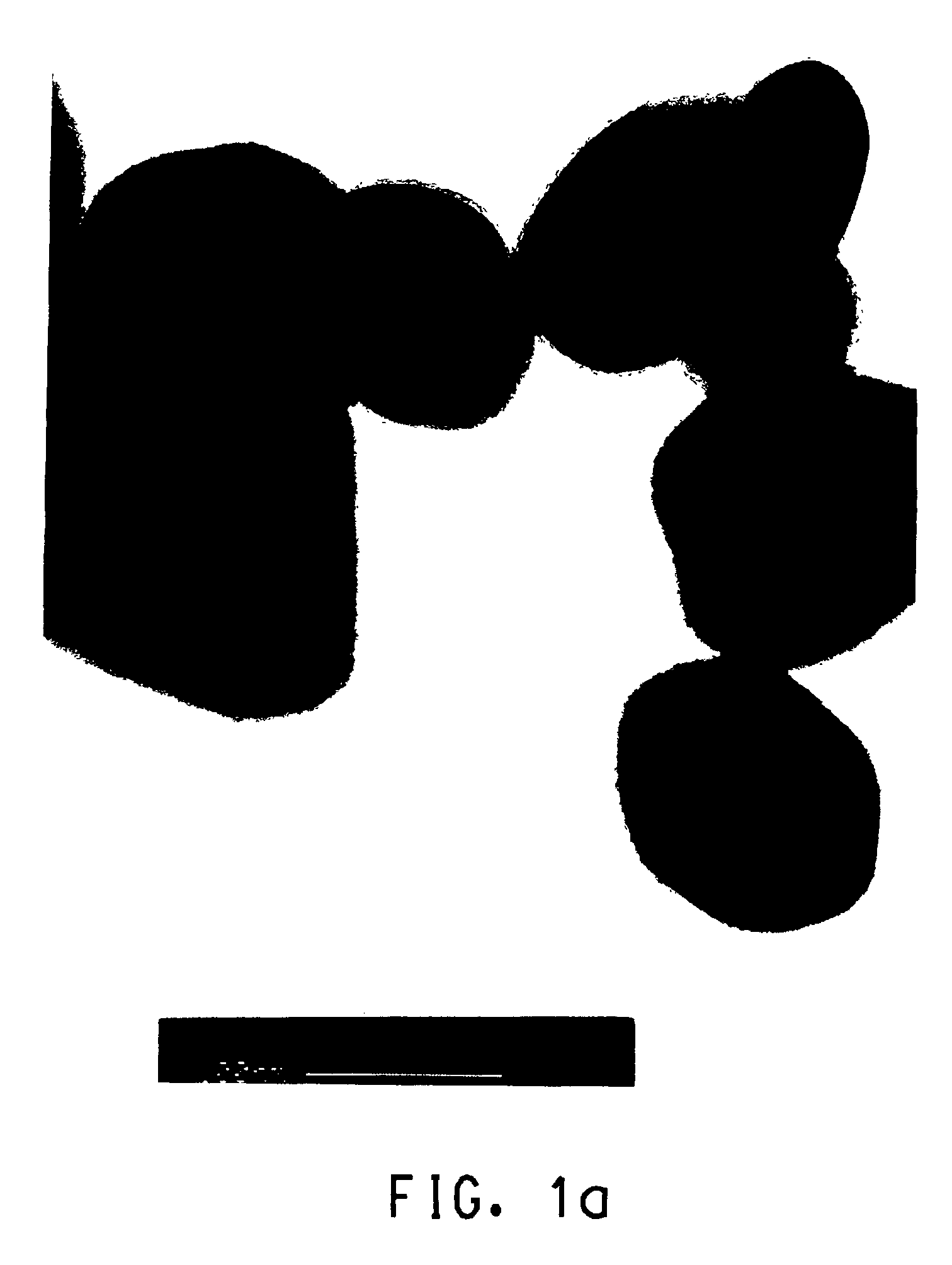

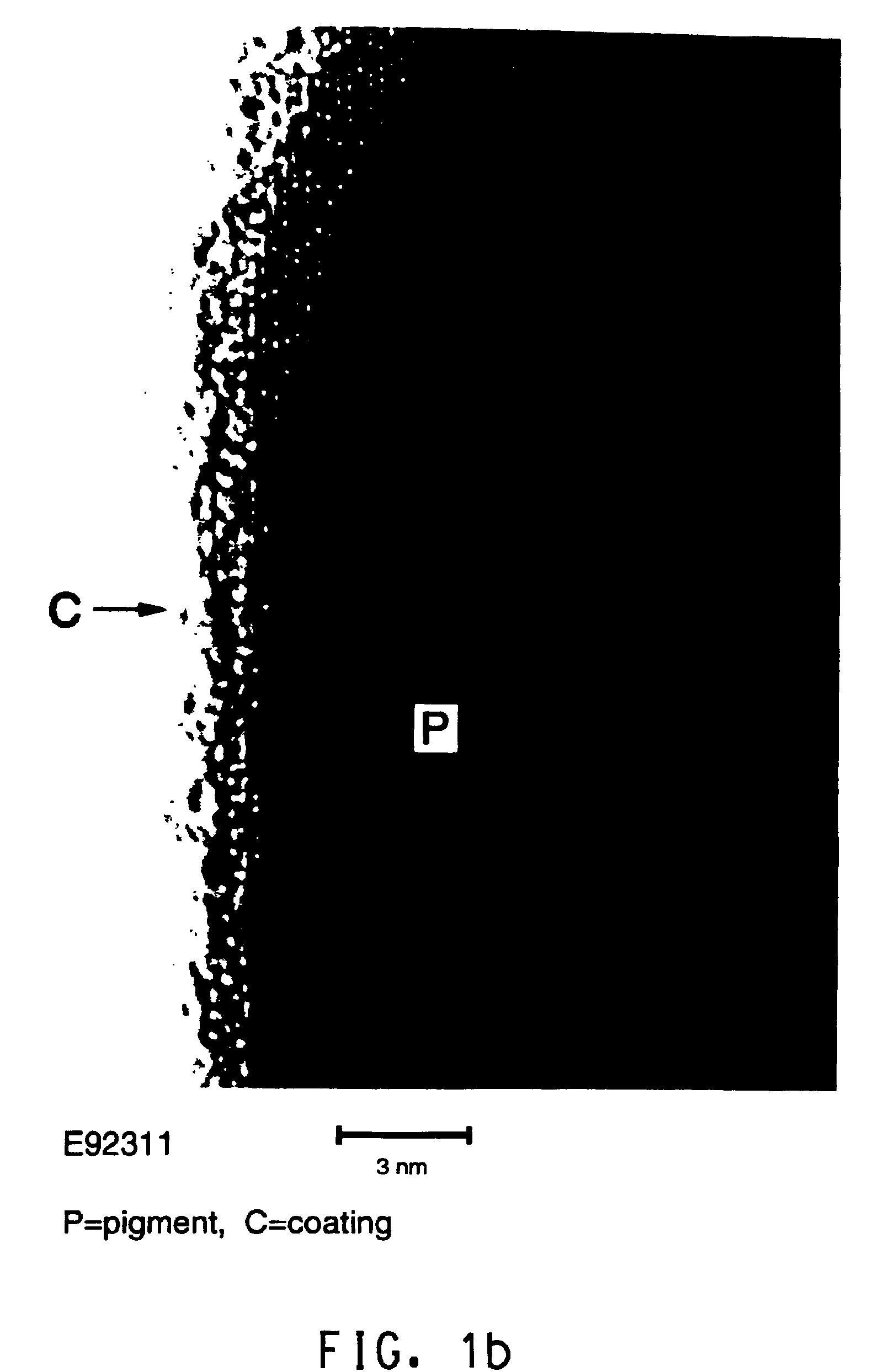

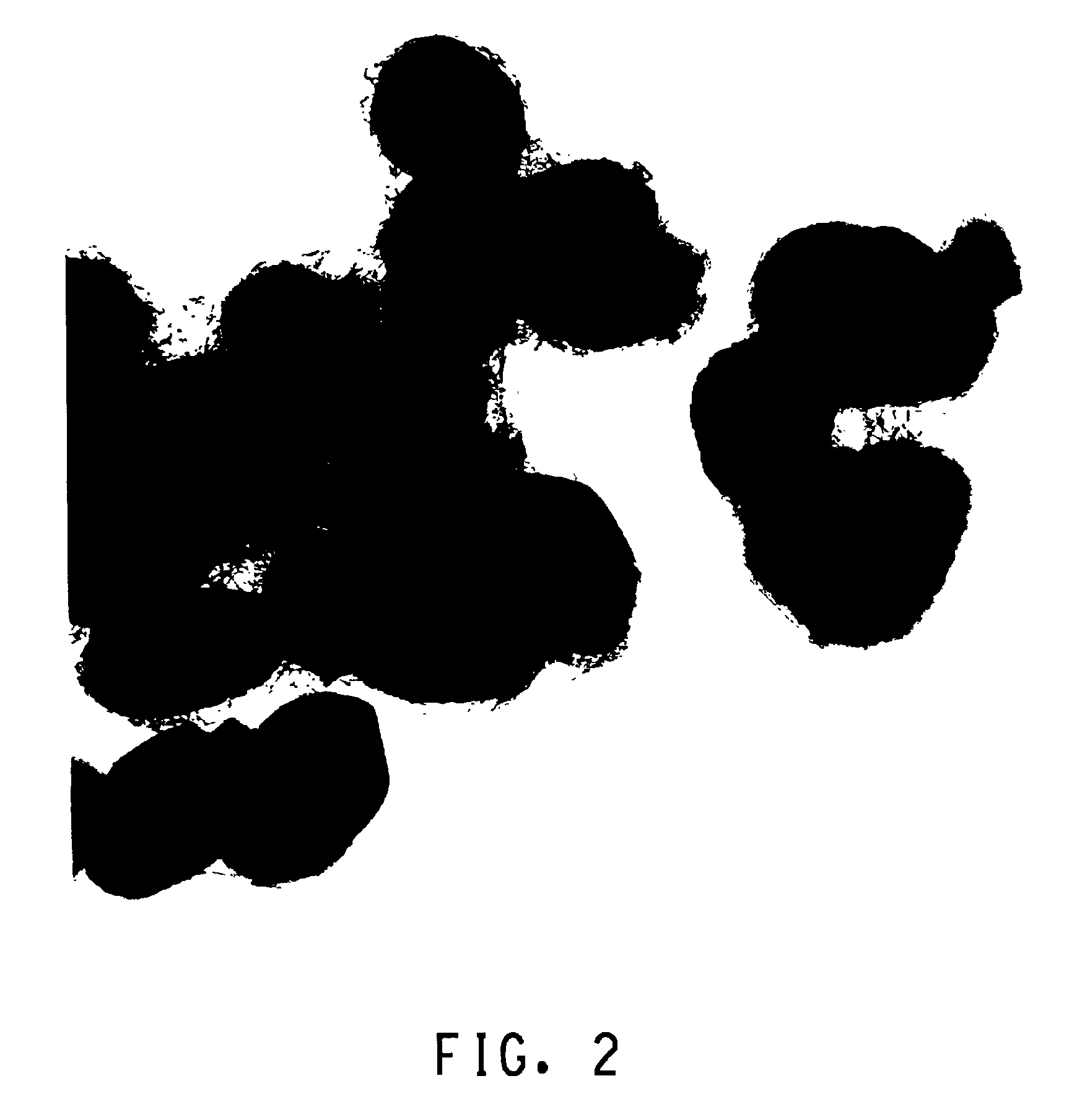

Process for making durable rutile titanium dioxide pigment by vapor phase deposition of surface treatment

The present invention relates to a process for making durable titanium dioxide pigment by vapor phase deposition of surface treatments on the titanium dioxide particle surface by reacting titanium tetrachloride vapor, an oxygen containing gas and aluminum chloride in a plug flow reactor to form a product stream containing titanium dioxide particles; and introducing silicon tetrachloride into the reactor at a point down stream of the point where the titanium tetrachloride and oxygen were contacted and where at least 97% of the titanium tetrachloride has been converted to titanium dioxide or where the reaction temperature is no greater than about 1200° C., and preferably not more than about 1100° C.

Owner:THE CHEMOURS CO FC LLC

Porous silicon/carbon composite material and preparation method thereof

ActiveCN102208634AHigh specific capacityImprove cycle stabilityCell electrodesCarbon compositesNew energy

The invention discloses a porous silicon / carbon composite material and a preparation method thereof, and belongs to the fields of electrochemistry and new energy materials. The method comprises the following steps of: preparing porous silicon dioxide by using ethyl orthosilicate, silicon tetrachloride, methyl silicone oil and sodium silicide as raw materials, reducing the porous silicon dioxide into porous silicon, coating the porous silicon by adopting an organic carbon source, and performing thermal treatment under an inert atmosphere to prepare the porous silicon / carbon composite material. The material can be directly used as the lithium ion battery cathode material, the first discharge specific capacity of the material can reach 1,245mAh / g, the specific capacity can also reach 1,230mAh / g after 30 cycles, and the material has excellent charge / discharge performance.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

Method for preparing white carbon black by utilizing silicon tetrachloride

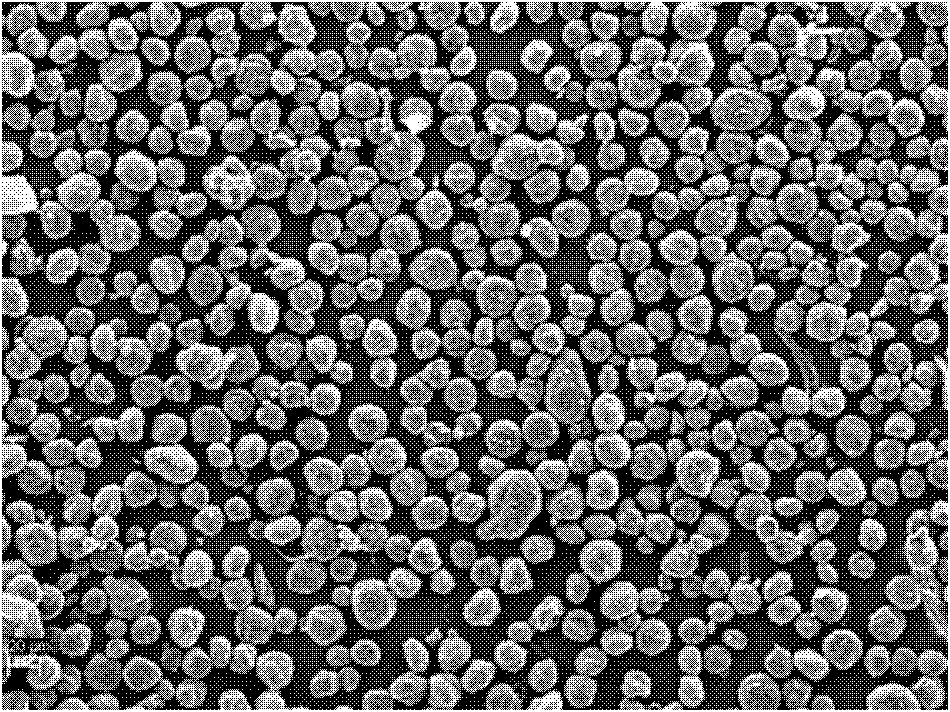

The invention discloses a method for preparing white carbon black by utilizing silicon tetrachloride. The method comprises the following steps: mixing deionized water and low molecular fatty alcohol at the molar ratio of 1:4-4:4, and adding a proper amount of surfactant; slowly adding a certain amount of the silicon tetrachloride at the room temperature; and obtaining the white carbon black through the steps of preparing reaction solution, curing the reaction solution, sedimentation and abstersion, pulpifying and spray drying, wherein the concentration of the silicon tetrachloride is controlled to be 0.2-1.0 mol.1-1, and modifiers such as 0.01-0.1mol.1-1 of Hexamethyl disilazane and the like can be added in the preparation process of the hydrophobic white carbon black. The grain diameter of the prepared white carbon black is 50-350nm and the specific surface area is 100-300m<2>.g-1; and the method has high economic value and the prepared white carbon black has good hydrophobic effect.

Owner:HENAN UNIV OF SCI & TECH

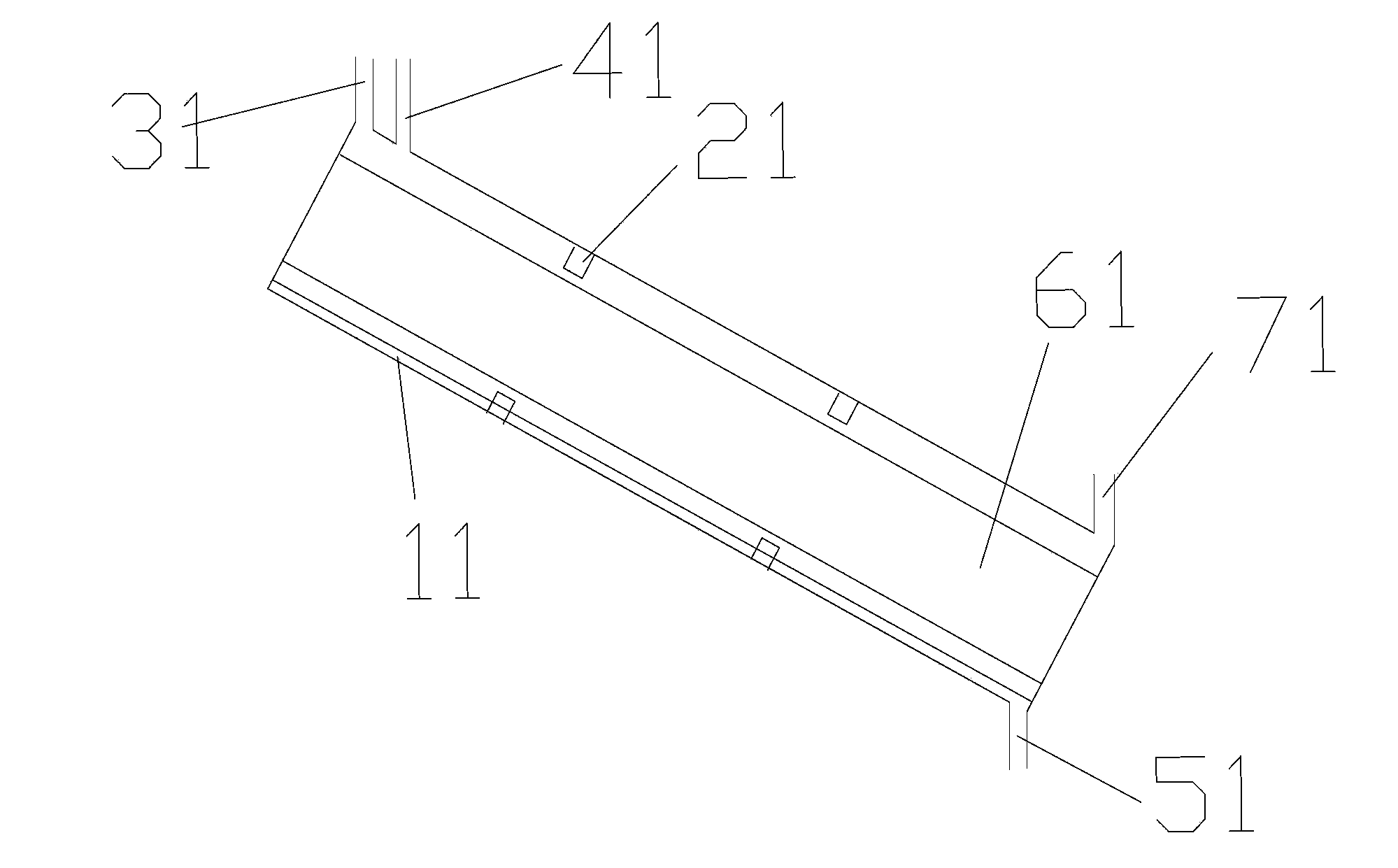

Method for preparing molecular sieve

ActiveCN103787352AFull residence timeFull contact timeCrystalline aluminosilicate zeolitesMolecular sieveGas phase

The invention relates to a method for preparing a molecular sieve, which comprises the following steps: the molecular sieve is introduced in a gas phase ultra-stable reactor, the gas phase ultra-stable reactor is capable of moving the molecular sieve from the molecular sieve inlet of the gas phase ultra-stable reactor to the molecular sieve outlet of the gas phase ultra-stable reactor under the condition that carrying gas is not used for conveying, and the molecular sieve and gas-phase silicon tetrachloride are contacted for reacting in the gas phase ultra-stable reactor. The conveying of the molecular sieve does not require inertia carrying gas, the technology flow is simplified, carrying gas amount is saved, and the consumption of silicon tetrachloride can be greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aryl silicate ester flame retardant plasticizer and preparation method thereof

InactiveCN102050961AHydrolytic activity decreasedImprove stabilitySilicon organic compoundsArylHydrogen

The invention relates to an aryl silicate ester flame retardant plasticizer and a preparation method thereof. The structure of the compound is expressed with a general formula shown in the specification, wherein R is phenyl, tolyl and benzyl, R' is hydrogen and methyl, and R'' is hydrogen and methyl or chloromethyl. The preparation method comprises the following steps: using nitrogen to protect, and reacting silicon tetrachloride with a hydroxyl compound with an aryl having the same molar ratio as that of the silicon tetrachloride to release hydrogen chloride, and then with alkylene oxide with a certain molar ratio to obtain a target product. The target product also can be obtained through changing the feeding sequence. The compound has the advantages of stable physical and chemical properties, high flame retardant performance, good plasticity, simple process and easiness of large-scale production.

Owner:李兰敏

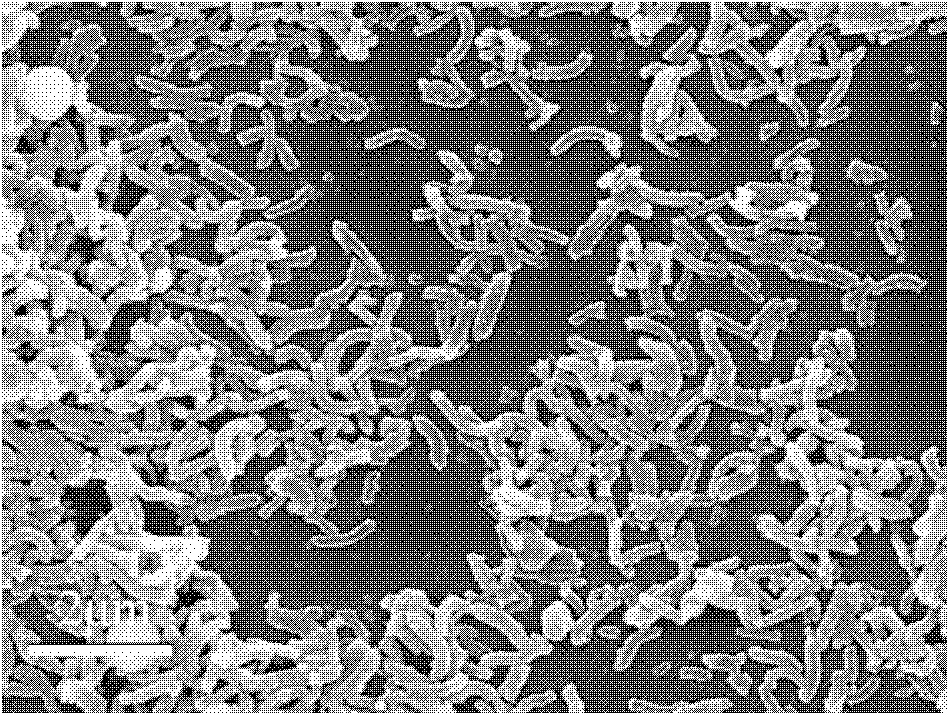

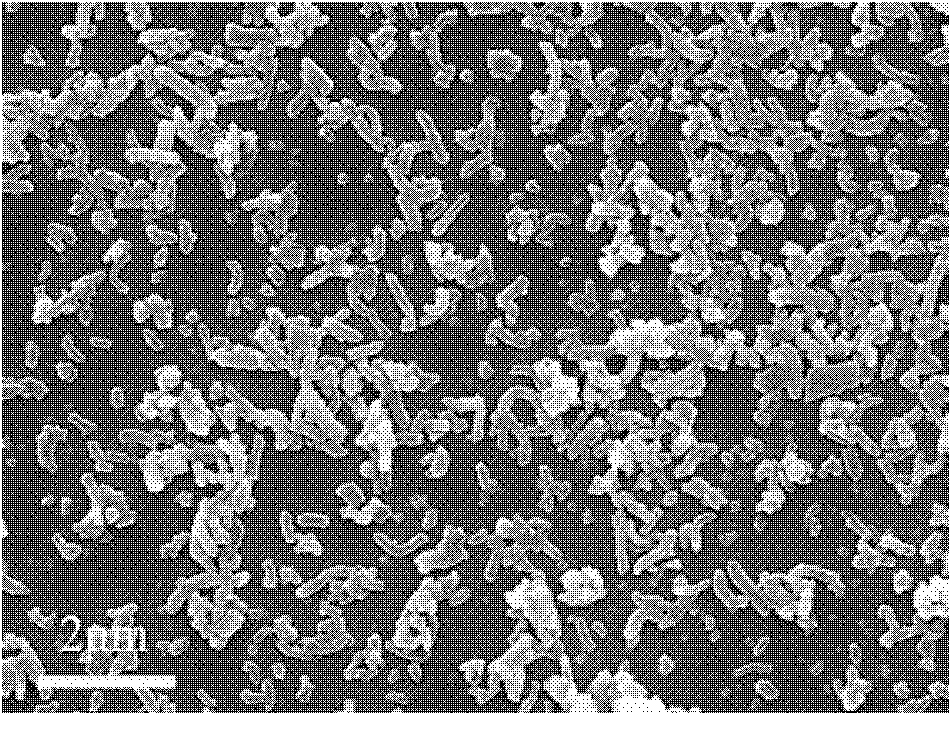

Silicon/graphene laminar composite material for lithium ion battery cathode and preparation method thereof

ActiveCN102064322ALarge active surface areaImprove cycle performanceCell electrodesSurface-active agentsElectrochemistry

The invention relates to a preparation method of a silicon / graphene laminar composite material for lithium ion battery cathode. The composite material adopts a laminar sandwich structure, silicon nano-particles are dispersed on each lamina of the grapheme, the laminas of the grapheme are separated from one another by the silicon nano-particles and the edges of the laminas are in lapped joint so as to constitute a laminar conductive network structure. The preparation method thereof comprises the steps of: formulating anhydrous silicon tetrachloride, surface active agent, sodium naphthalene and graphite oxide to tetrahydrofuran solution, adding the tetrahydrofuran solution into a reactor for reaction in vacuum at the temperature ranging from 380 to 400 DEG C, filtering the reactant to result in the product, and then washing, drying and heating the product to obtain the silicon / grapheme composite material. The preparation method of the invention has the advantages of simple preparation process and great easiness for industrial production; and the silicon / graphene laminar composite material prepared according to the method includes excellent conductivity, power performance, electrochemical activity and cycle stability, and is particularly suitable for manufacturing lithium ion battery cathode.

Owner:深圳清研紫光科技有限公司

Acid and high temperature resistant cement composites

InactiveUS20140047999A1Increase resistanceReduce resistanceSolid waste managementCement productionHigh resistanceSilicon dioxide

Process for production of acid and high temperature resistant cement composites, where the matrix is alkali activated F fly ash alone, F Fly ash combined with ground slag or ground slag alone. F-fly ash produces lower quality alkali activated cement systems. On the other hand the lack of calcium oxide results in very high resistance to medium and highly concentrated inorganic or organic acids. The high strength and low permeability of pure F-fly ash cement systems is achieved by using in the composition un-densified silica fume, the amorphous silicone dioxide obtained as by products in production of ferro-silicones. Precipitated nano-particle silica made from soluble silicates and nano-particle silica fume produced by burning silicon tetra chloride in the hydrogen stream.

Owner:RAZL IVAN

Silicon tetrachloride hydrogenating process of producing trichloro hydrosilicon

InactiveCN1436725ANo pollution in the processEasy to controlSilicon hydridesHalogenated silanesNickel catalystHydrogen atmosphere

The silicon tetrachloride hydrogenating process of producing trichloro-hydrosilicon includes: mixing powdered nickel catalyst and silicon powder in the mass ratio of 1-10 and activating the mixture in hydrogen atmosphere and at the temperature of continuously change from 20 deg.C to 420 deg.c; and making mixed gas of hydrogen and SiCl4 in the molar ratio of 1-10 pass through the activated catalyst and silicon powder layer for hydrogenating SiCl4 continuously at 400-500 deg.c temperature and 1.2-1.5 MPa pressure. The equipment, system and operation of the present invention has high once SiCl4 converting rate and low power consumption and may be used in large-scale production.

Owner:CHINA ENFI ENG CO LTD

Process for making durable rutile titanium dioxide pigment by vapor phase deposition of surface treatments

The present invention relates to a process for making durable titanium dioxide pigment by vapor phase deposition of surface treatments on the titanium dioxide particle surface by reacting titanium tetrachloride vapor, an oxygen containing gas and aluminum chloride in a plug flow reactor to form a product stream containing titanium dioxide particles; and introducing silicon tetrachloride into the reactor at a point down stream of the point where the titanium tetrachloride and oxygen were contacted and where at least 97% of the titanium tetrachloride has been converted to titanium dioxide or where the reaction temperature is no greater than about 1200° C., and preferably not more than about 1100° C.

Owner:THE CHEMOURS CO FC LLC

Method of patterning lead zirconium titanate and barium strontium titanate

In an embodiment of the present invention, a method is provided of patterning PZT layers or BST layers. For example, a PZT layer or a BST layer is plasma etched through a high-temperature-compatible mask such as a titanium nitride (TiN) mask, using a plasma feed gas comprising as a primary etchant boron trichloride (BCl3) or silicon tetrachloride (SiCi4). Although BCl3 or SiCl4 may be used alone as the etchant plasma source gas, it is typically used in combination with an essentially inert gas. Preferably the essentially inert gas is argon. Other potential essentially inert gases which may be used include xenon, krypton, and helium. In some instances O2 or N2, or Cl2, or a combination thereof may be added to the primary etchant to increase the etch rate of PZT or BST relative to adjacent materials, such as the high-temperature-compatible masking material. A TiN masking material can easily be removed without damaging underlying oxides. The selectivity of PZT or BST relative to TiN is very good, with the ratio of the etch rate of the PZT film to the etch rate of the TiN mask typically being better than 20:1. In addition, the etch rate for PZT using a BCl3-comprising plasma source gas is typically in excess of 2,000 Å per minute. A substrate bias power is applied to direct ions produced from the BCl3 or SiCl4 toward the surface to be etched. The bias power is controlled to avoid sputtering of a conductive layer or layers in contact with the PZT layer, so that the surface of the etched PZT is not contaminated by a conductive material, which can cause the semiconductor device which includes the patterned PZT to short out.

Owner:APPLIED MATERIALS INC

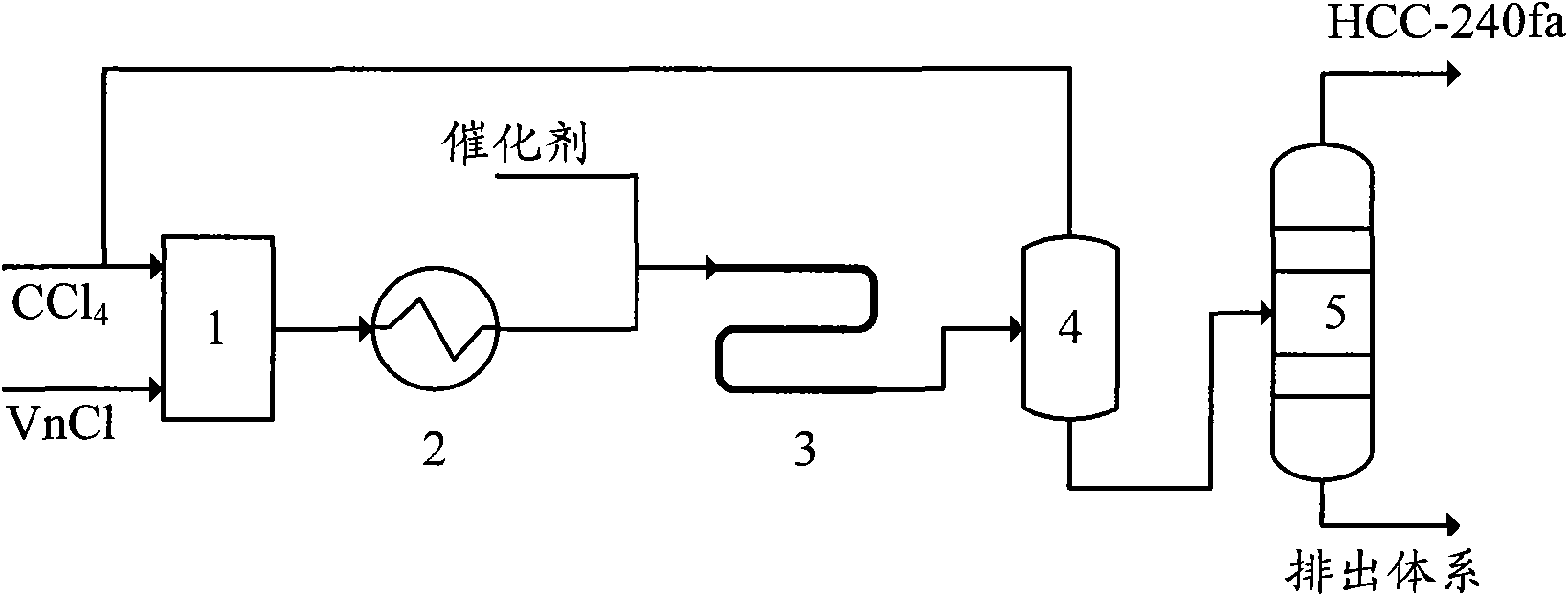

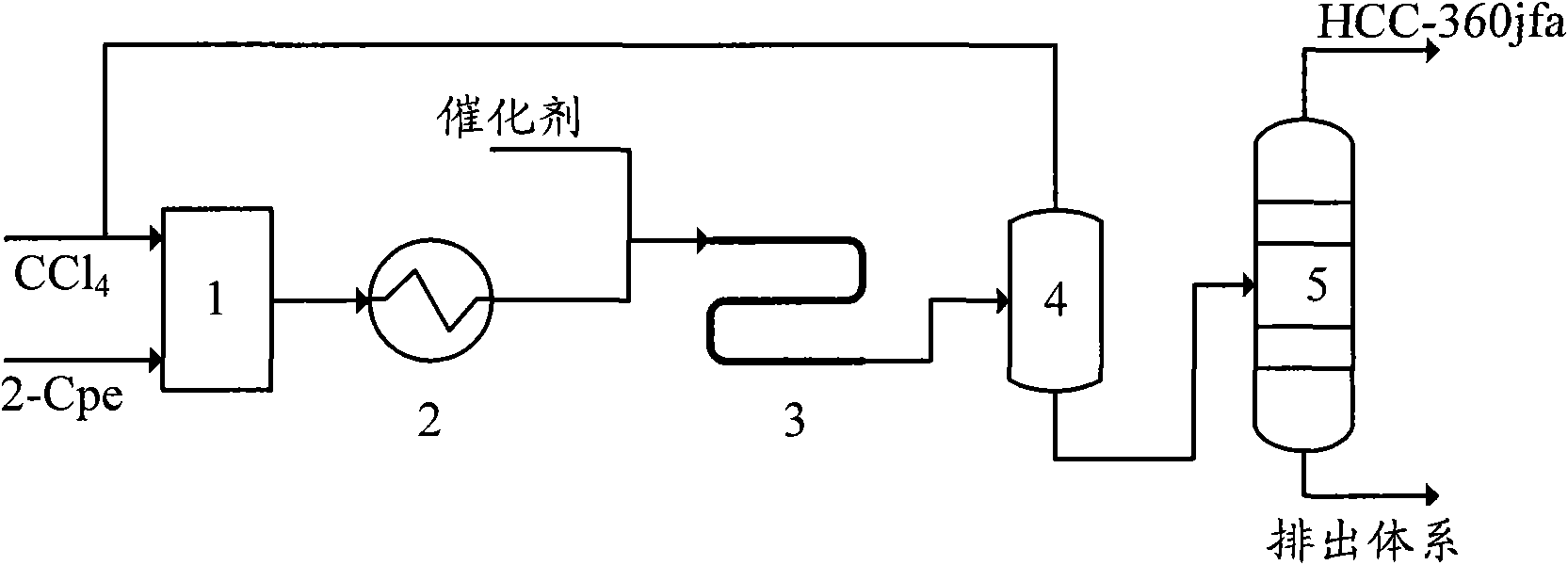

Production method of 1,1,1,3,3-pentachloropropane

InactiveCN101913980AEasy to transportAccurate measurementOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingReaction temperatureSilicon tetrachloride

The invention provides a production method of 1,1,1,3,3-pentachloropropane (HCC-240fa). The 1,1,1,3,3-pentachloropropane is synthesized by continuously reacting the materials of carbon tetrachloride and chloroethylene in a tubular reactor. The method comprises the steps of firstly mixing the carbon tetrachloride with the chloroethylene and preheating the mixture to a reaction temperature, then introducing the mixture together with a catalyst into the tubular reactor for telomeric reaction, removing the unreacted carbon tetrachloride and chloroethylene through flash evaporation, and then further distilling to obtain the HCC-240fa, wherein the unreacted carbon tetrachloride and chloroethylene are recycled and the catalyst is recycled after being subjected to the activating treatment. The invention adopts the liquid as the activated system and uses the tubular reactor for reaction, thereby ensuring simple and convenient operation as well as continuous production.

Owner:XIAN MODERN CHEM RES INST

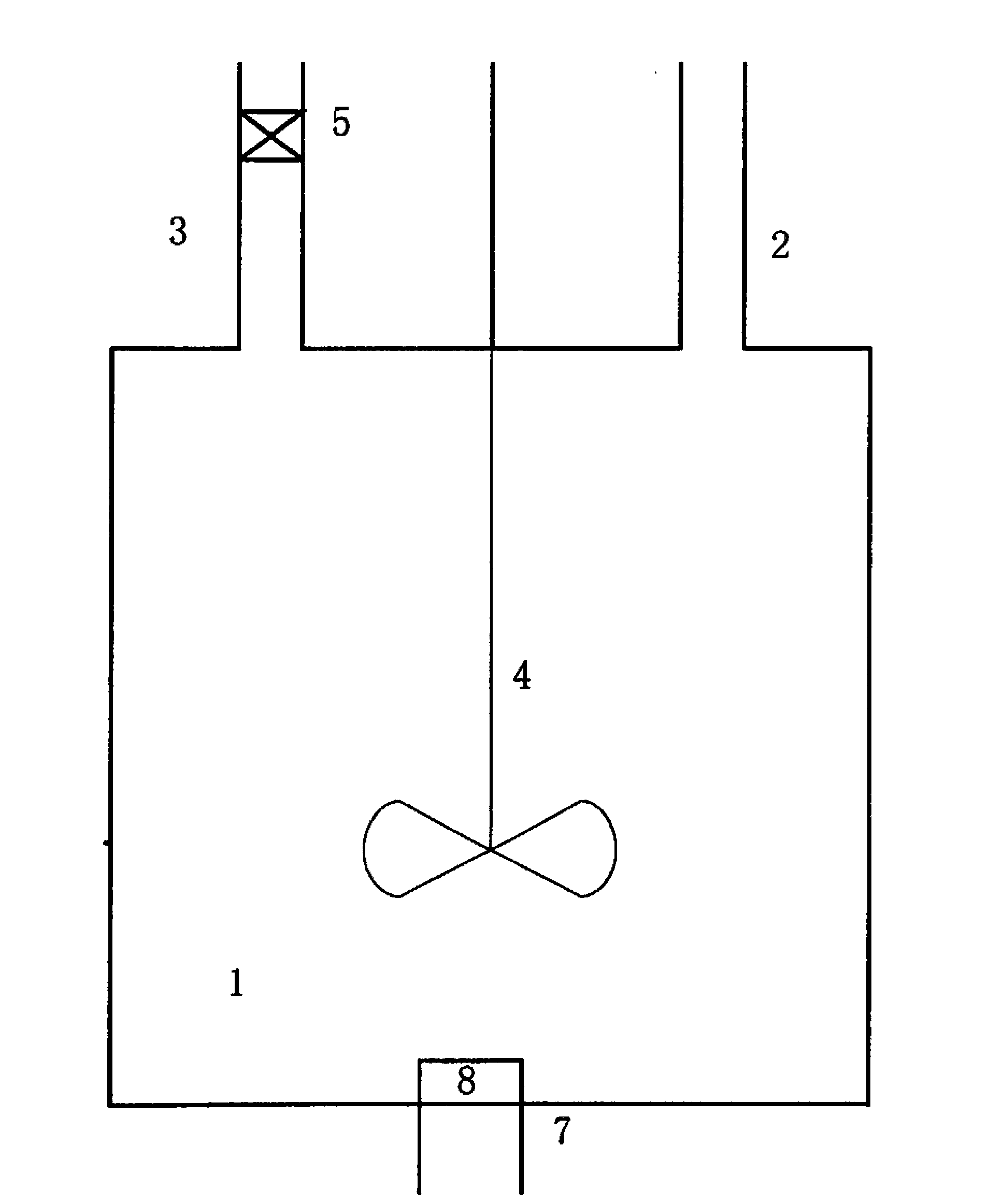

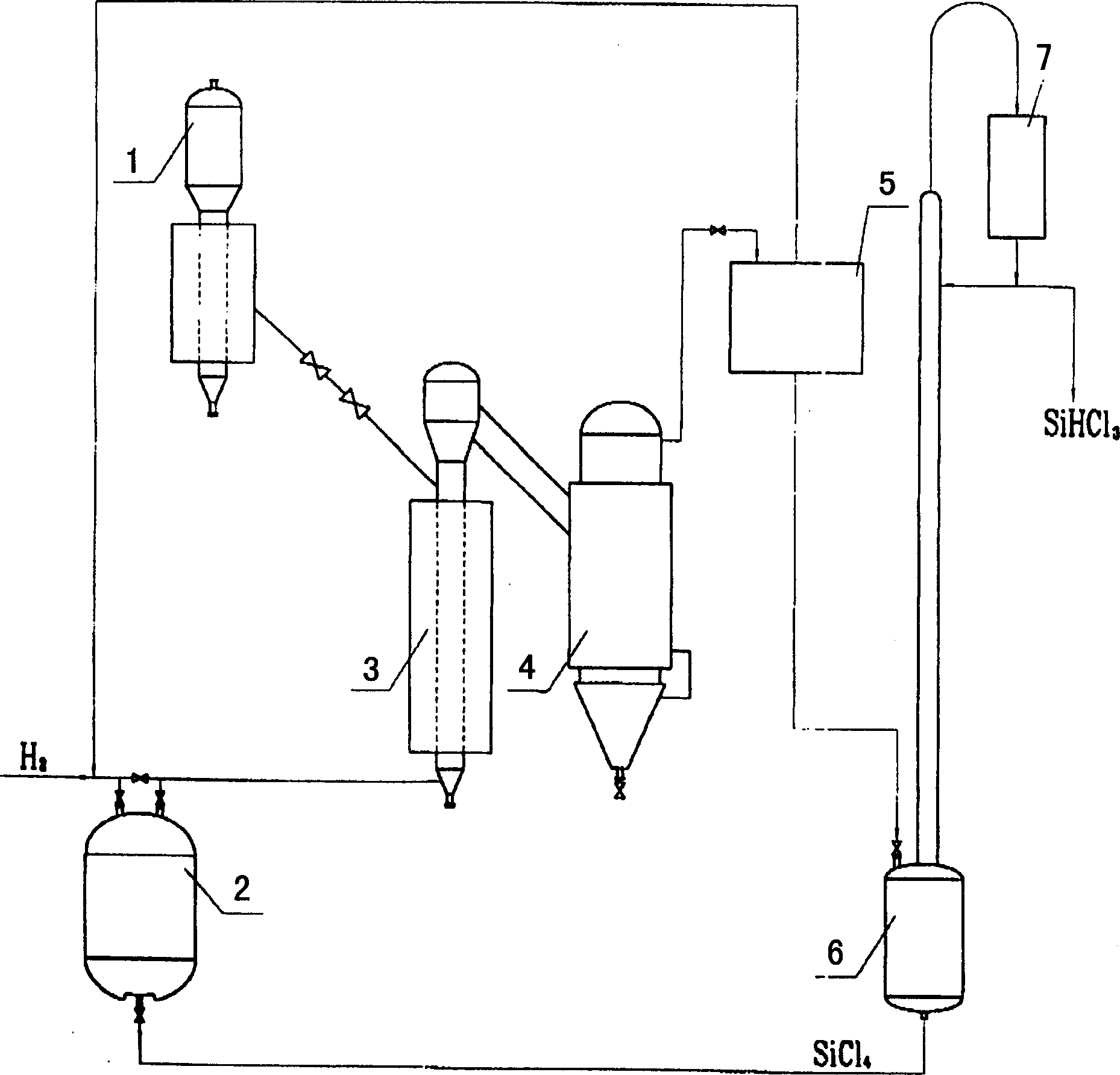

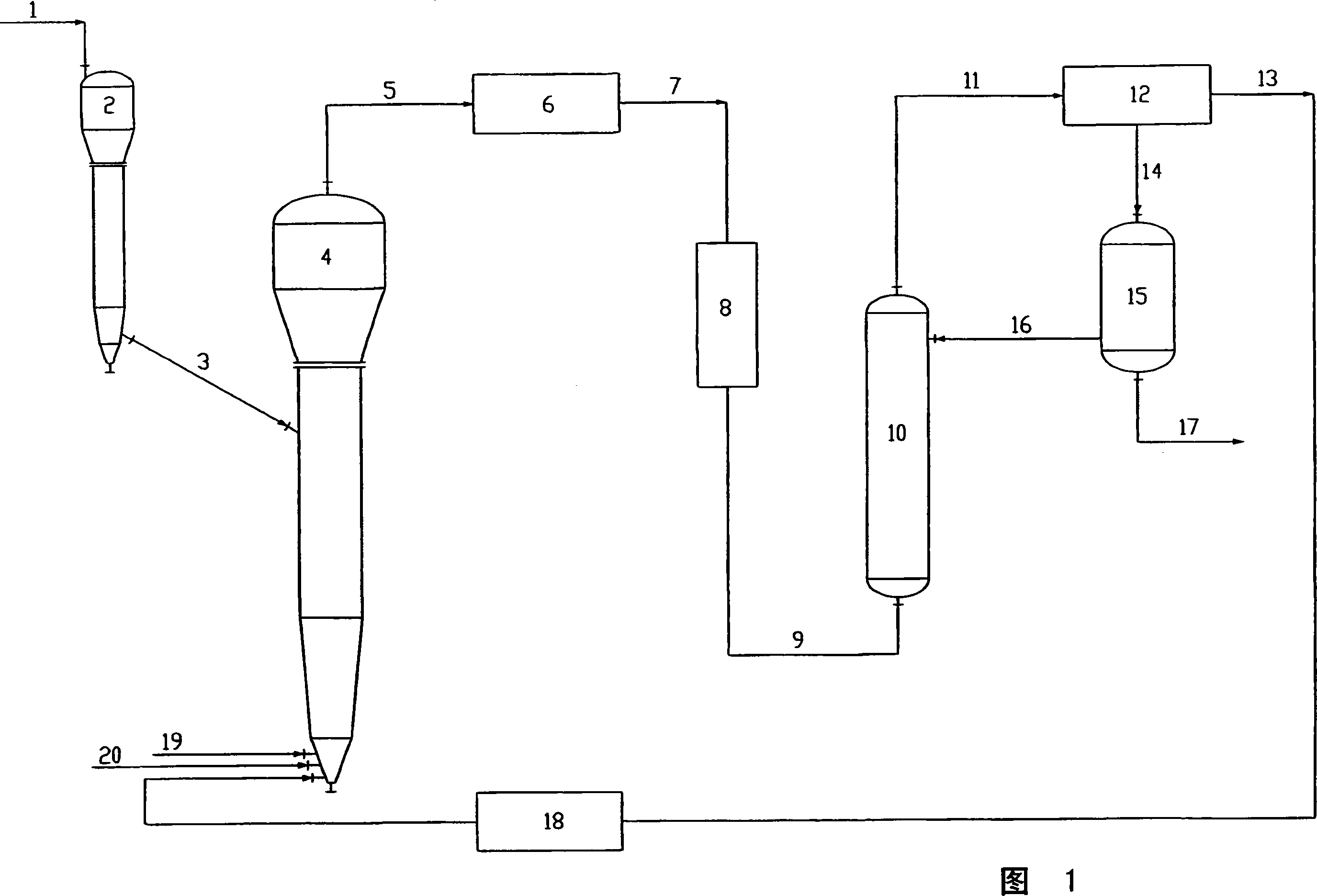

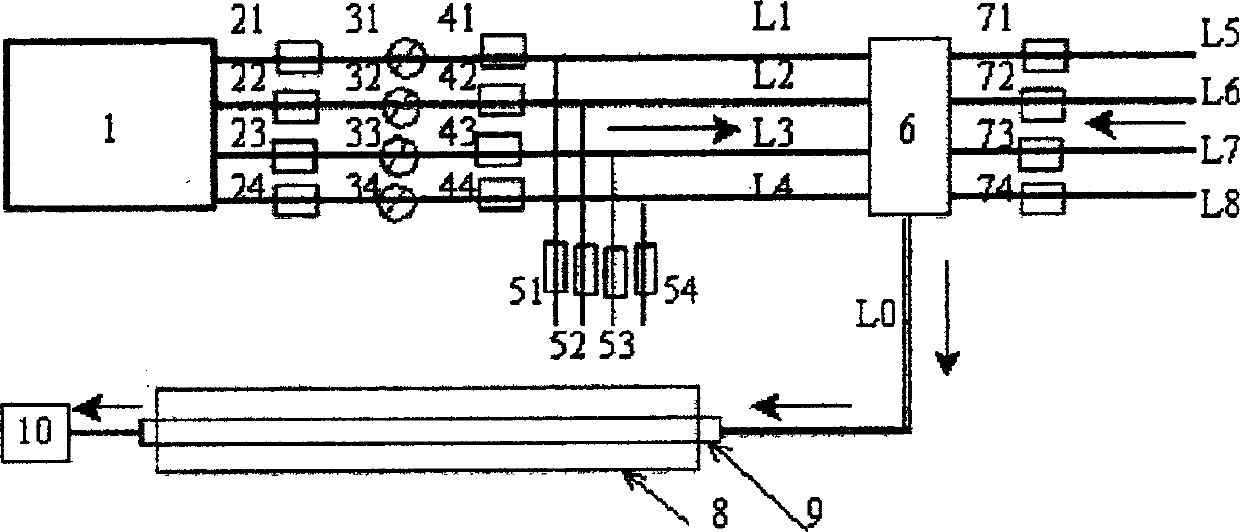

Modified method and device for preparing trichlorosilane and multicrystal silicon

The invention relates to an improved method and equipment for the preparation of trichlorosilane and polysilicon. The trichlorosilane is prepared by a chlorine hydrogenation method during the preparation process of polysilicon. The process is as follows: a) the metallurgical silicon is put into a reactor after being heated to 300-500DGE C in a powder baker; b) the silicon tetrachloride is vaporized and heated through an external heating device, which generates the silicon tetrachloride gas at the temperature of 160-600DGE C; c) the hydrogen chloride gas is preheated to 150-300DGE C through the external heating device; d) the hydrogen gas is preheated to 300-600DGE C through a heater; and e) the gases of step b), c) and d) are added into the reactor; wherein, the molar ratio between the hydrogen gas and the silicon tetrachloride is 1-5:1, the molar ratio between the hydrogen chloride gas and the silicon tetrachloride is 1: 1-20; and the temperature in the reactor is maintained at 400-600DGE C and the pressure in the reactor is kept at 1.0-3.0MPa. The method of the invention can effectively prepare the polysilicon at a low cost, which suits for semiconductor industry and solar battery.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV +1

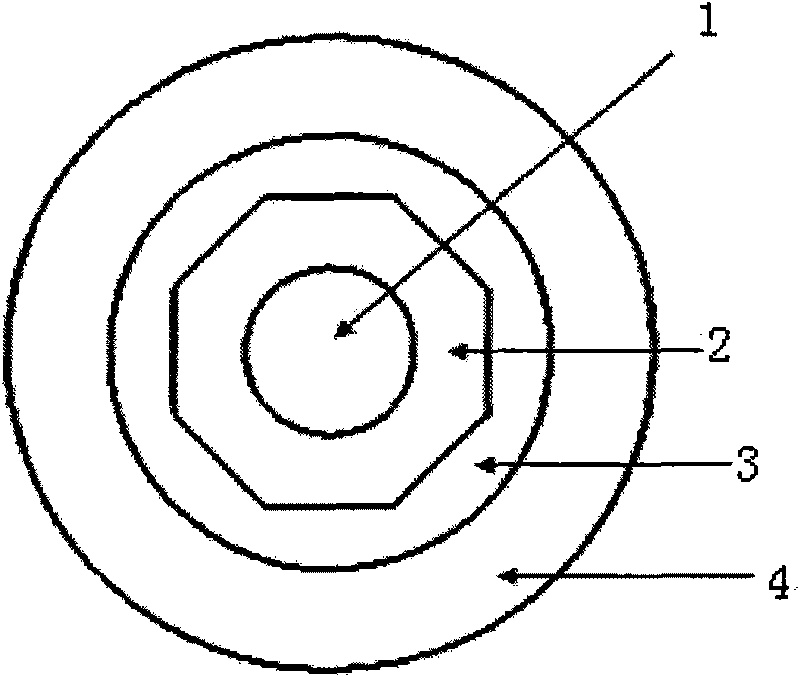

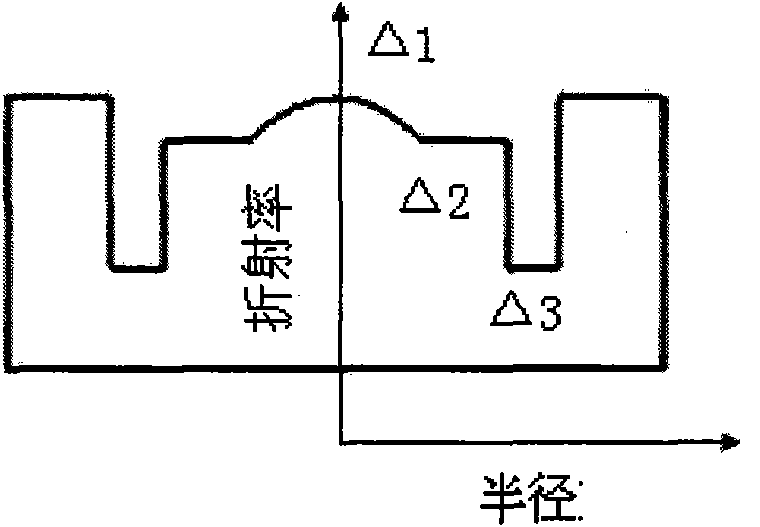

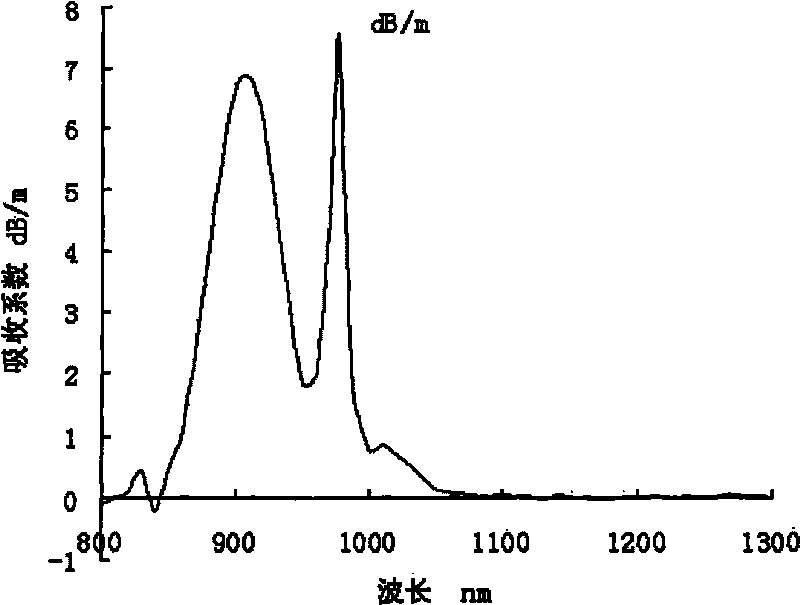

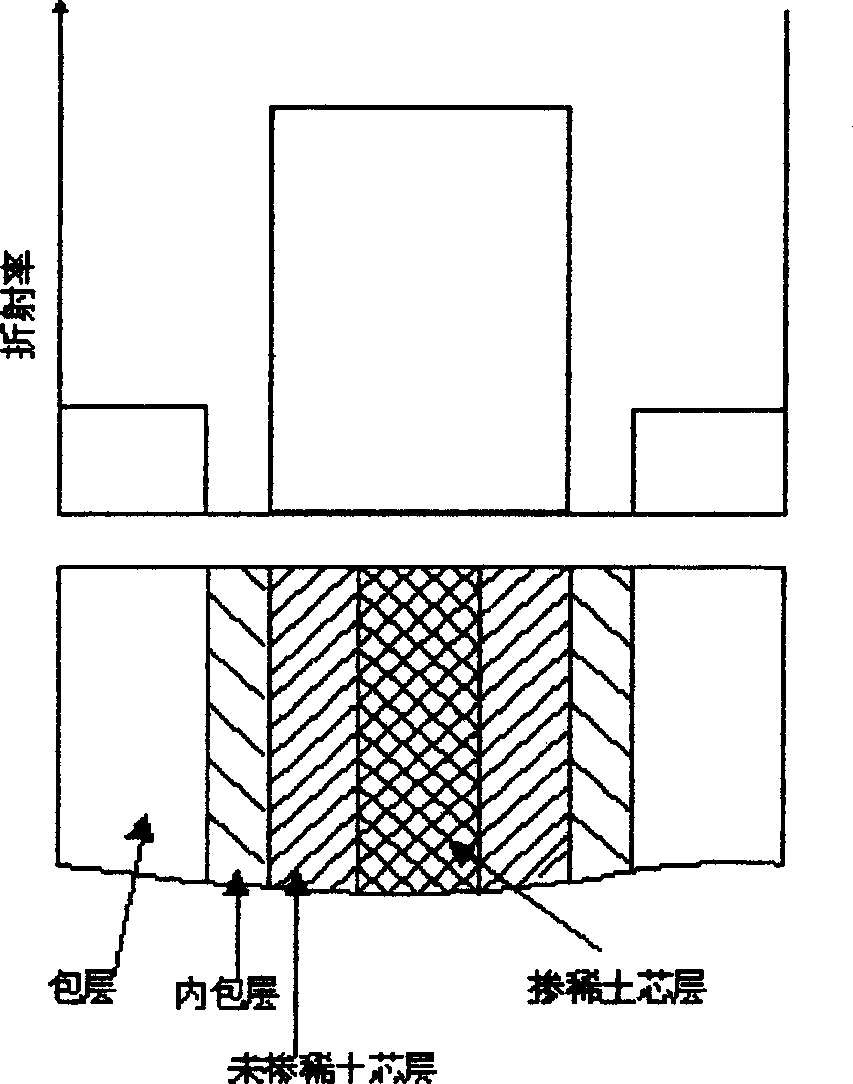

Large-mode active optical fiber and manufacture method thereof

ActiveCN101738682AIncrease powerHigh energy storage densityGlass making apparatusOptical fibre with graded refractive index core/claddingFiberRefractive index

The invention relates to optical fiber and a manufacture method thereof, in particular to large-mode active optical fiber and a manufacture method thereof. The large-mode active optical fiber is formed by drawing a fiber core and a quartz glass inner cladding, a quartz glass outer cladding and a coating which are sequentially coated on the outer surface of the fiber core, wherein the fiber core is formed by depositing, melting and collapsing silicon tetrachloride doped with rare-earth ions in a quartz glass tube; the refractive index of the fiber core is a gradually changed refractive index, and a fiber core refractive index section parameter alpha is not smaller than 1 and not larger than 3; and the appearance of the quartz glass inner cladding is in a regular gengon shape. The large-mode active optical fiber has the advantages of large mode and similar single-mode output, improves the capacity of bearing laser power and the energy storage density of the active optical fiber, improves the light beam quality of output laser, solves the problem of hollow ring of the output laser, greatly improves the reliability of high-power optical fiber laser devices and the utilization rate of raw materials and reduces the manufacture cost.

Owner:FENGHUO COMM SCI & TECH CO LTD

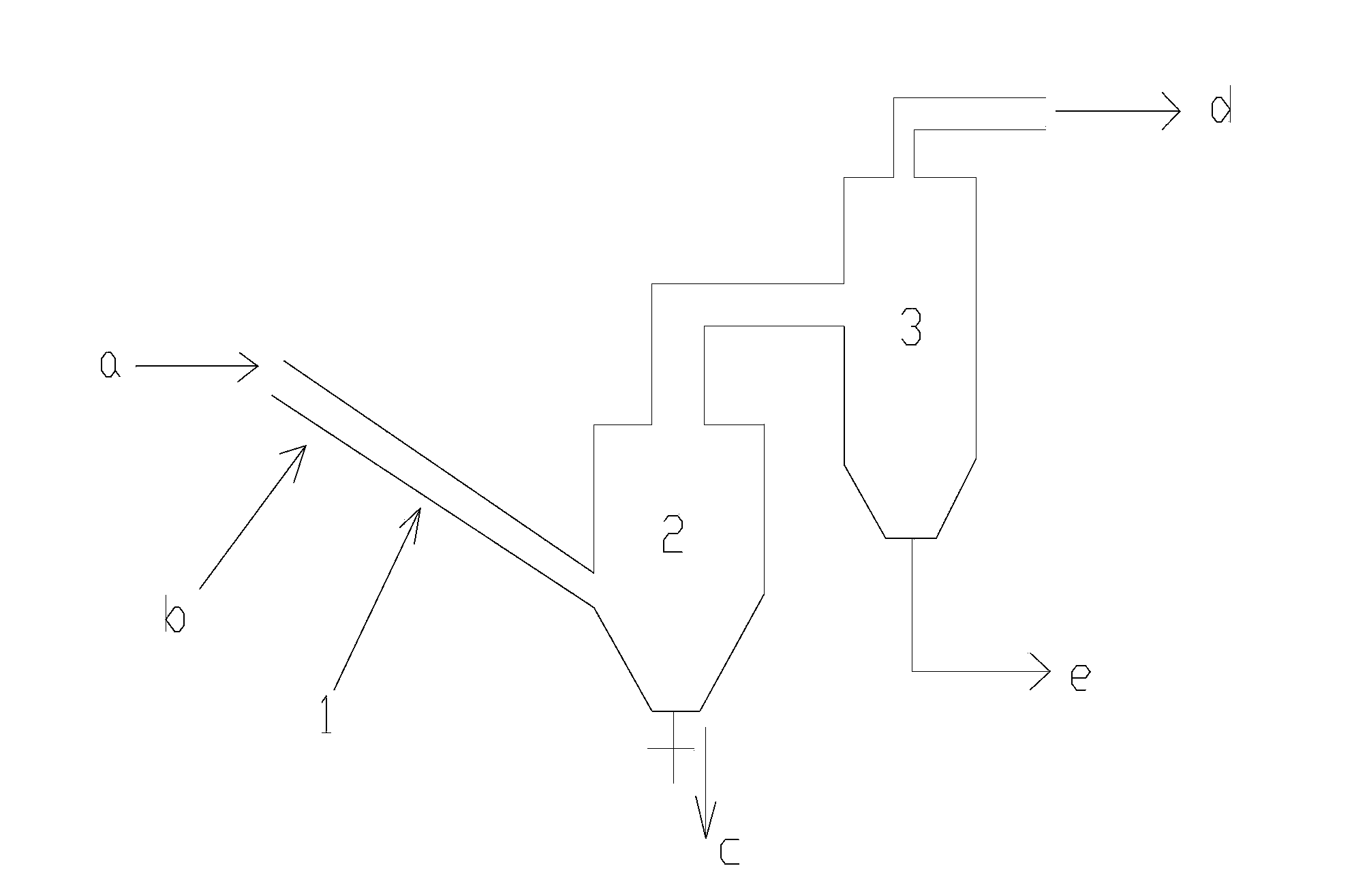

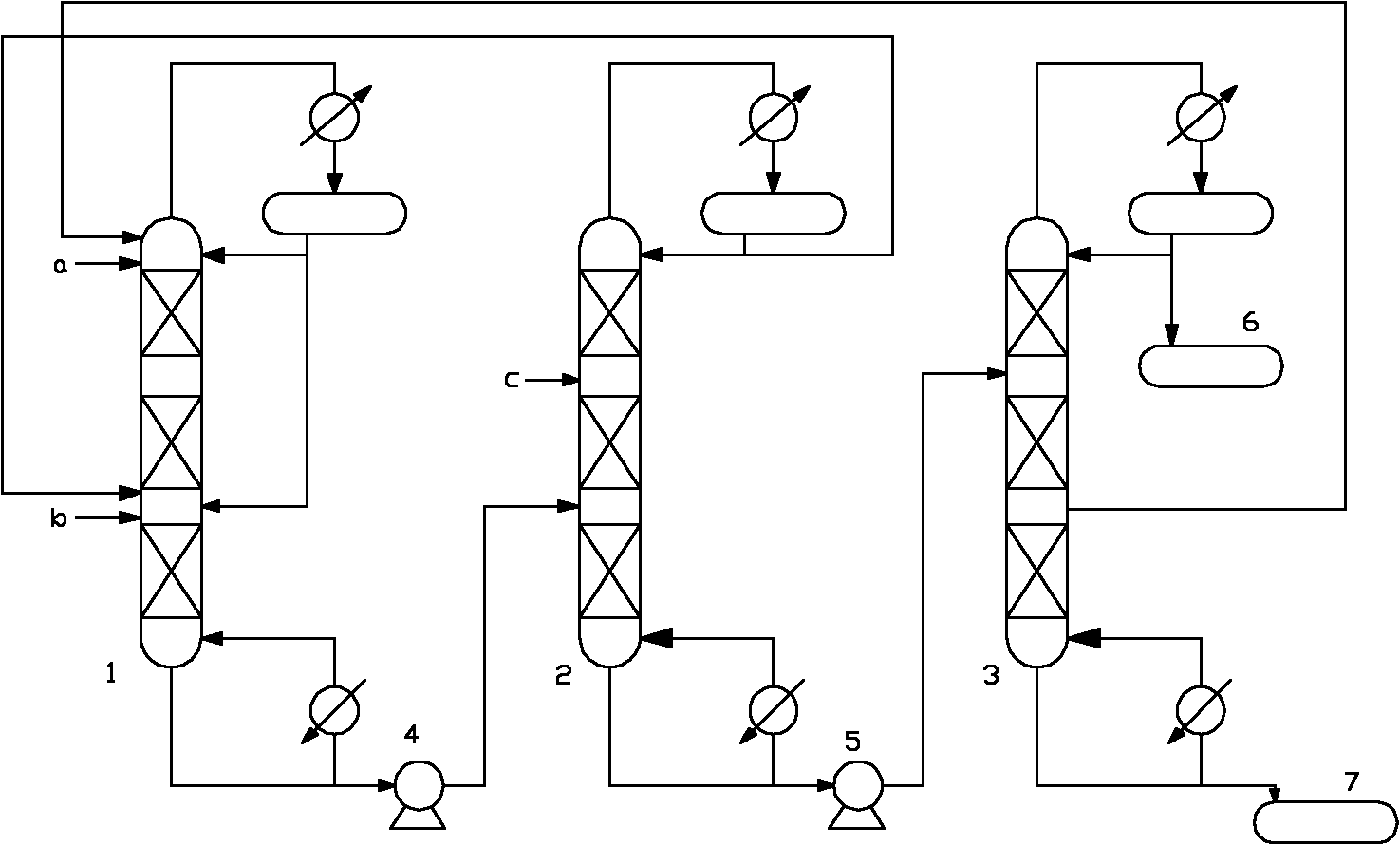

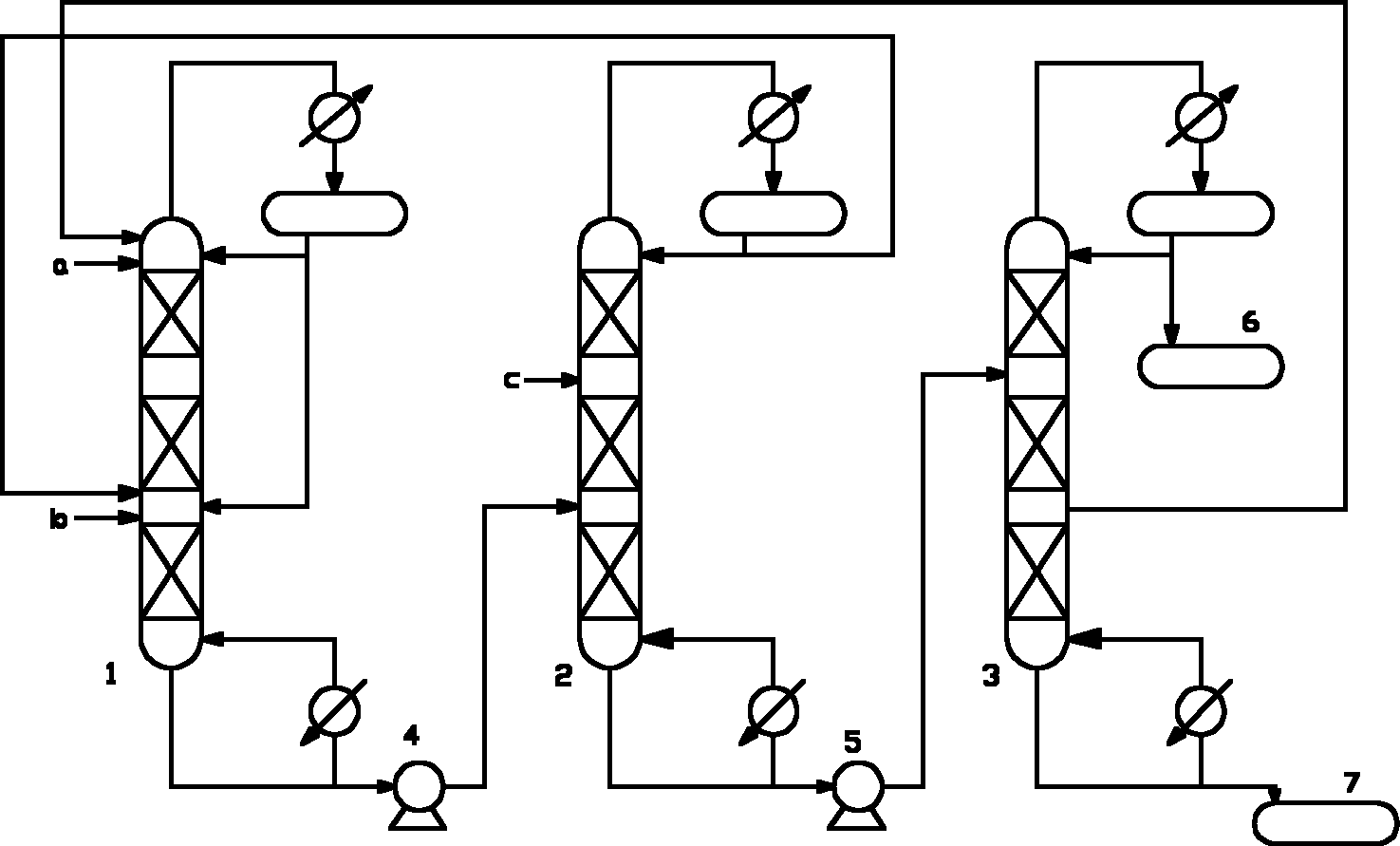

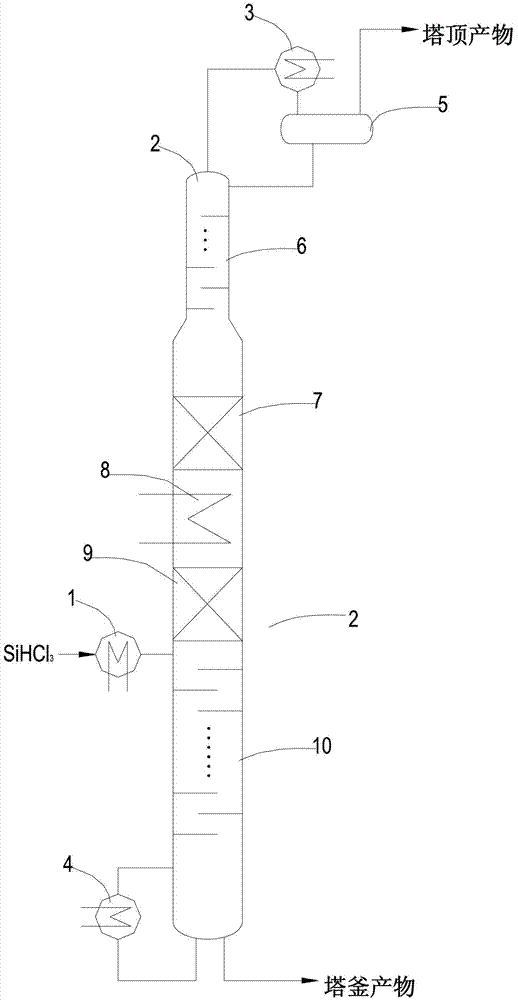

Method and apparatus for preparing trichlorosilane through reaction rectification by using proportionate reaction

ActiveCN101955187AResolve enrichmentIncrease profitChemical industryHalogenated silanesDichlorosilaneTower

The invention relates to a method and an apparatus for preparing trichlorosilane through reaction rectification by using proportionate reaction. The method comprises the following steps of: reacting dichlorosilane with silicon tetrachloride in the upper middle part of a reaction rectification tower, obtaining incompletely reacted dichlorosilane at the top of the reaction rectification tower; reflowing at the top of the tower and in the middle of the tower, obtaining a mixture of dichlorosilane, trichlorosilane and silicon tetrachloride at the bottom of the tower, entering a light-end removal tower to remove a light component, obtaining the dichlorosilane at the top of the light-end removal tower; reflowing to the reaction rectification tower for recycling, obtaining a mixture of trichlorosilane and silicon tetrachloride at the bottom of the tower, entering a heavy-end removal tower to separate the trichlorosilane from the silicon tetrachloride, wherein the trichlorosilane at the top of the heavy-end removal tower is a product; and taking out the silicon tetrachloride at the side line of the lower part of the tower, entering the reaction rectification tower for recycling, and obtaining excessive silicon tetrachloride at the bottom of the tower. In the invention, by utilizing the proportionate reaction, the utilization ratio of the raw materials is enhanced; the problem of dichlorosilane and silicon tetrachloride enrichment is solved; and the final conversion ratio of the dichlorosilane is ensured to reach 100 percent theoretically.

Owner:TIANJIN UNIV

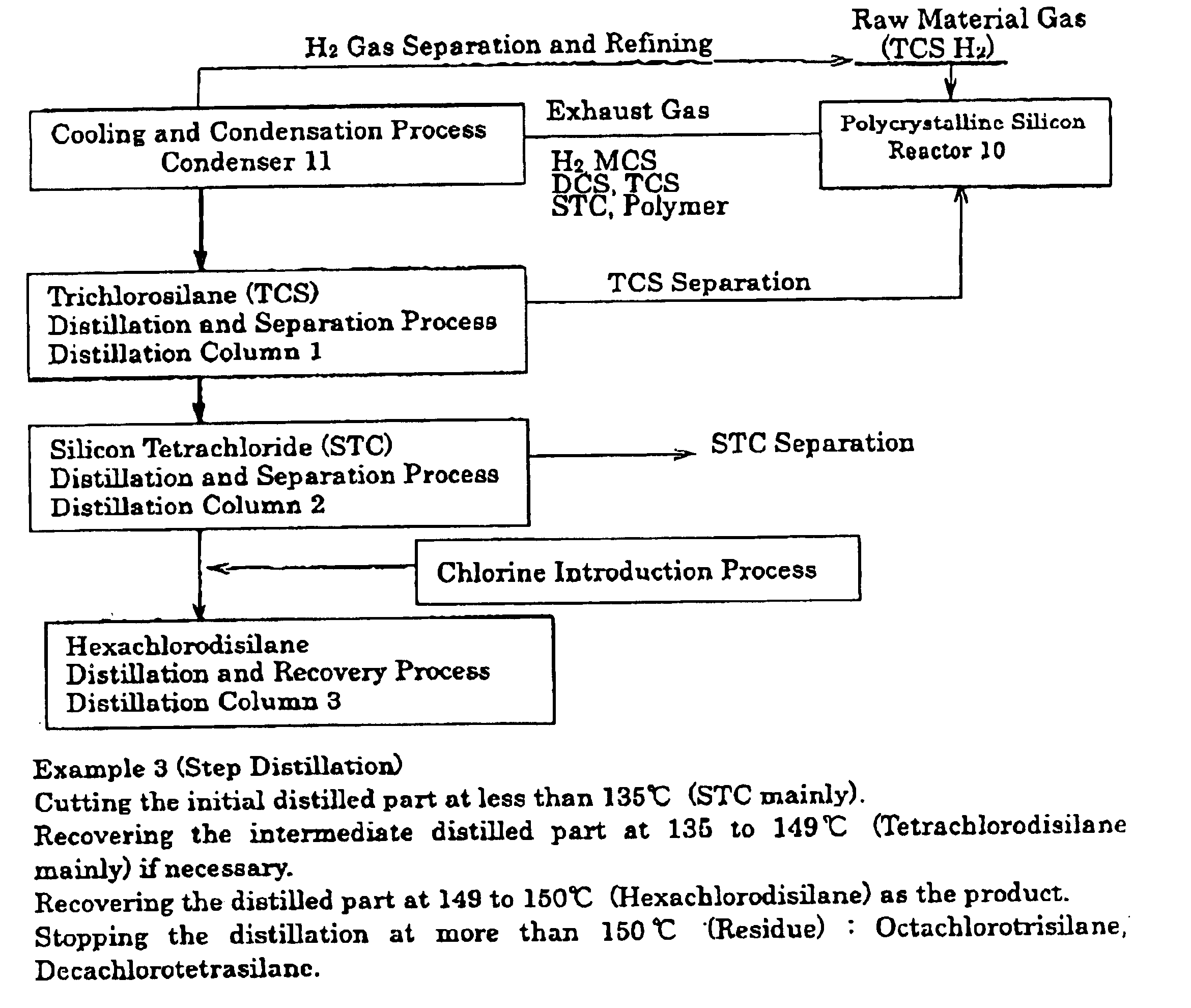

Process for producing hexachlorodisilane

InactiveUS6846473B2High purityEffective recoverySiliconDistillation separationHydrogenSilicon tetrachloride

A process for producing hexachlorodisilane comprising, condensing an exhaust gas discharged from a reactor for producing polycrystalline silicon from a chlorosilane and hydrogen to separate the hydrogen, distilling the resultant condensate to separate the unreacted chlorosilane and by-product silicon tetrachloride, and then further distilling to recover hexachlorodisilane, wherein tetrachlorodisilane can be recovered together with the hexachlorodisilane, and the hexachlorodisilane and tetrachlorodisilane recovered have a far higher purity than the conventional ones produced from metallic silicon.

Owner:MITSUBISHI MATERIALS CORP

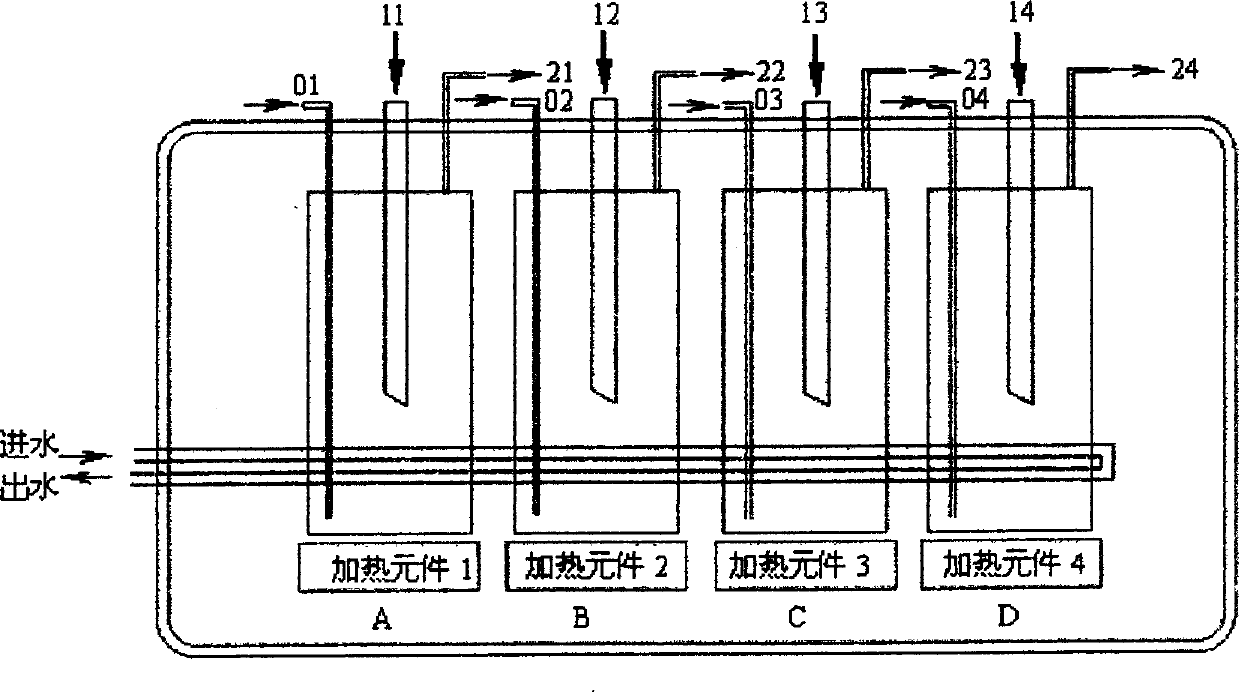

Method for manufacturing rare earth extended fibre-optical prefabricated bar

InactiveCN1490267APrecise control of doping amountImprove performanceGlass shaping apparatusGlass deposition burnersGas phaseRare earth

A process for preparing the prefabricated RE-doped optical-fibre rod features that the chemical gas-phase deposition of plasma is used to deposit the doped SiO2 layer on the inner surface of liner quartz tube and the evaporator is used to directly deliver the RE compound and other codoping agent into reaction tube for direct deposition without pollution.

Owner:FENGHUO COMM SCI & TECH CO LTD

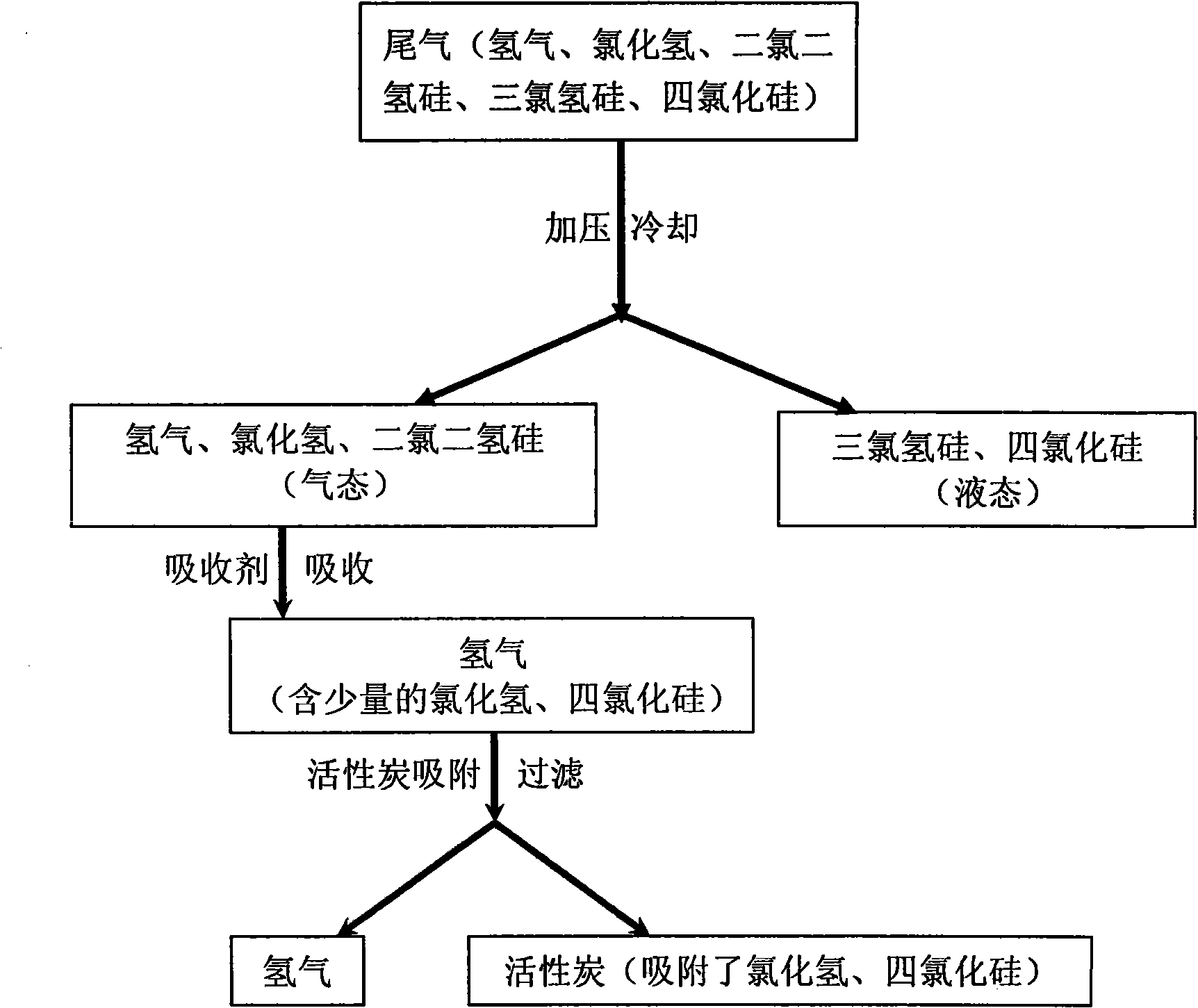

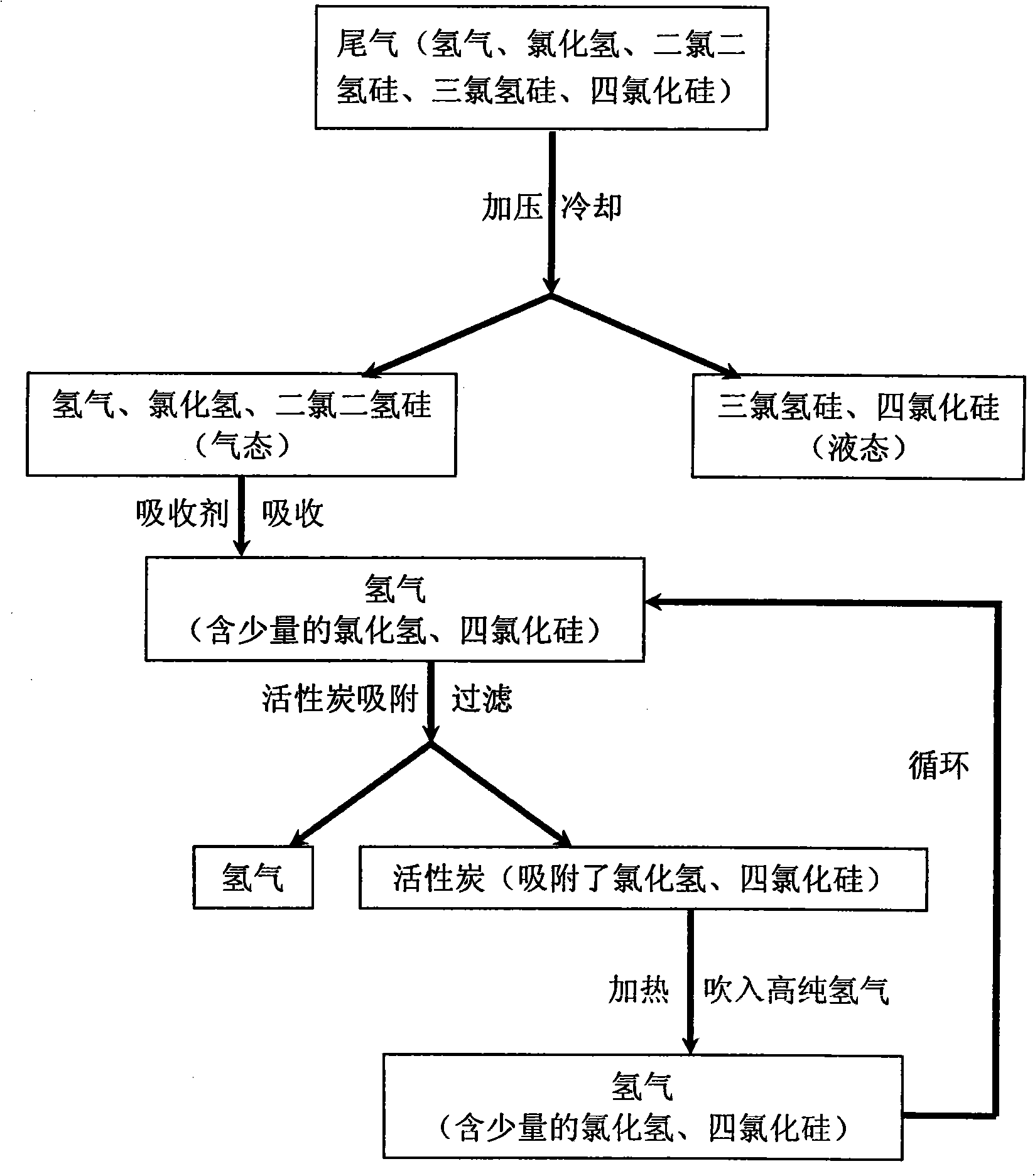

Method for reclaiming hydrogen from tail gas from polysilicon production

ActiveCN101327912AOvercome and eliminate the disadvantages of recycling technologyOvercome and eliminate shortcomingsHydrogen separation using liquid contactDispersed particle separationRecovery methodLiquid state

The invention relates to a hydrogen recovery method in the exhaust generated by producing polysilicon. The exhaust mainly comprises hydrogen, chlorine hydride, dichlorosilane, trichlorosilane and tetrachlorosilane. The method comprises the following steps: pressurizing and cooling the exhaust in order to turn trichlorosilane and tetrachlorosilane to liquid state while hydrogen, chlorine hydride and dichlorosilane still being gas state, so that the gas hydrogen, chlorine hydride and dichlorosilane can be separated from the liquid trichlorosilane and tetrachlorosilane by gas liquid separation; dissolving the gas chlorine hydride and dichlorosilane into the liquid tetrachlorosilane by passing gas hydrogen, chlorine hydride and dichlorosilane through the liquid tetrachlorosilane, so that separating the hydrogen from chlorine hydride and dichlorosilane. The invention recovers the hydrogen in the exhaust by dry treatment and the hydrogen can be reused in the polysilicon production, which makes good use of the material, reduces pollutants, settles the problem of environmental pollution, improves the product quality and reduces the cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

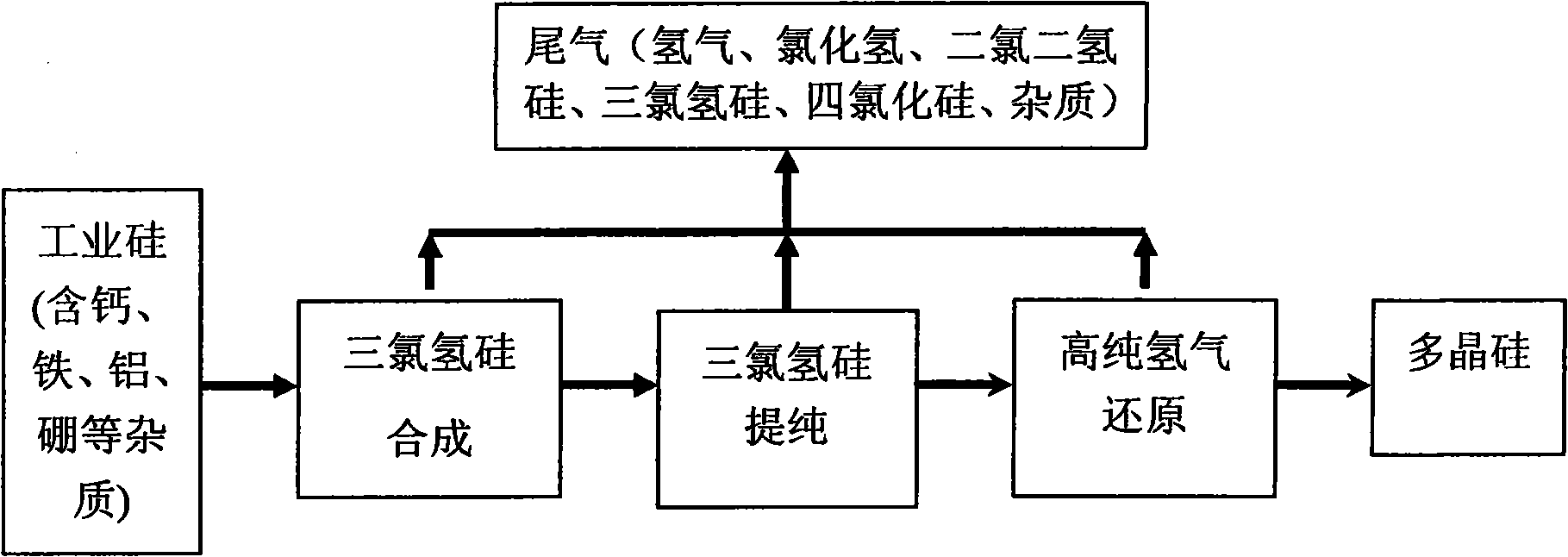

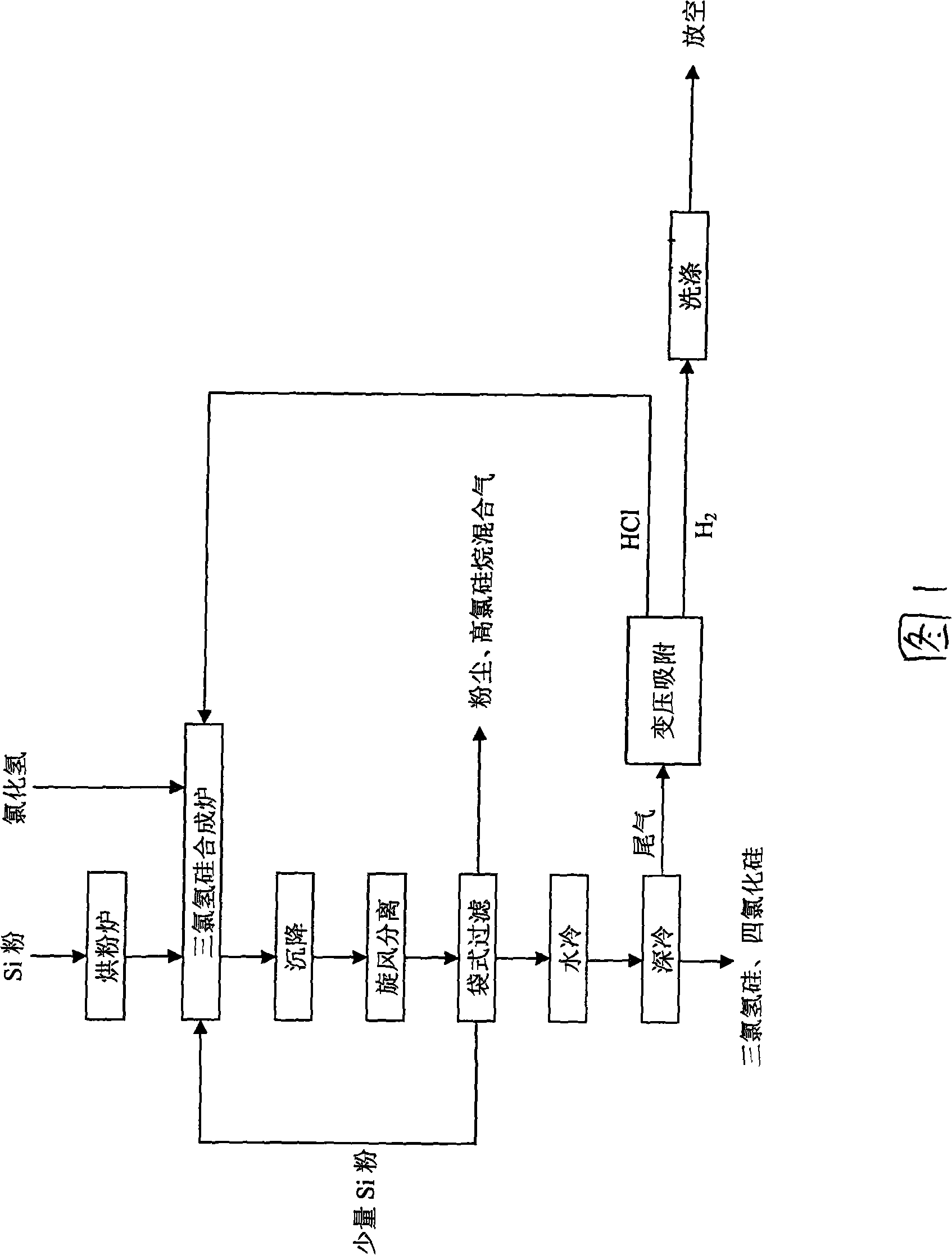

Method for synthesizing polysilicon raw material trichlorosilane

The invention discloses a method for the synthesis of a polysilicon raw material trichlorosilane. The method comprises the following steps: A) silica powder is conveyed to a trichlorosilane synthesis furnace by dried hydrogen chloride gas; B) hydrogen chloride for reaction is input into the synthesis furnace from the bottom of the trichlorosilane synthesis furnace proportionally and proper amount of hydrogen and silicon tetrachloride are added in the synthesis furnace at the same time; C) silica powder and hydrogen chloride react at the temperature of 280-310 DEG C to generate mixing gas containing trichlorosilane and silicon tetrachloride; D) the mixing gas of dust and high chlorosilane is removed, after water cooling and pressuring by a diaphragm compressor, trichlorosilane and silicon tetrachloride are condensed into liquid by a refrigerant with -40 DEG C, wherein, noncondensable gas containing H2 and HCI is separated. The method of the invention can improve the yield of trichlorosilane from 82 percent to more than 88 percent.

Owner:HUBEI HUIFU NANOMATERIAL CO LTD

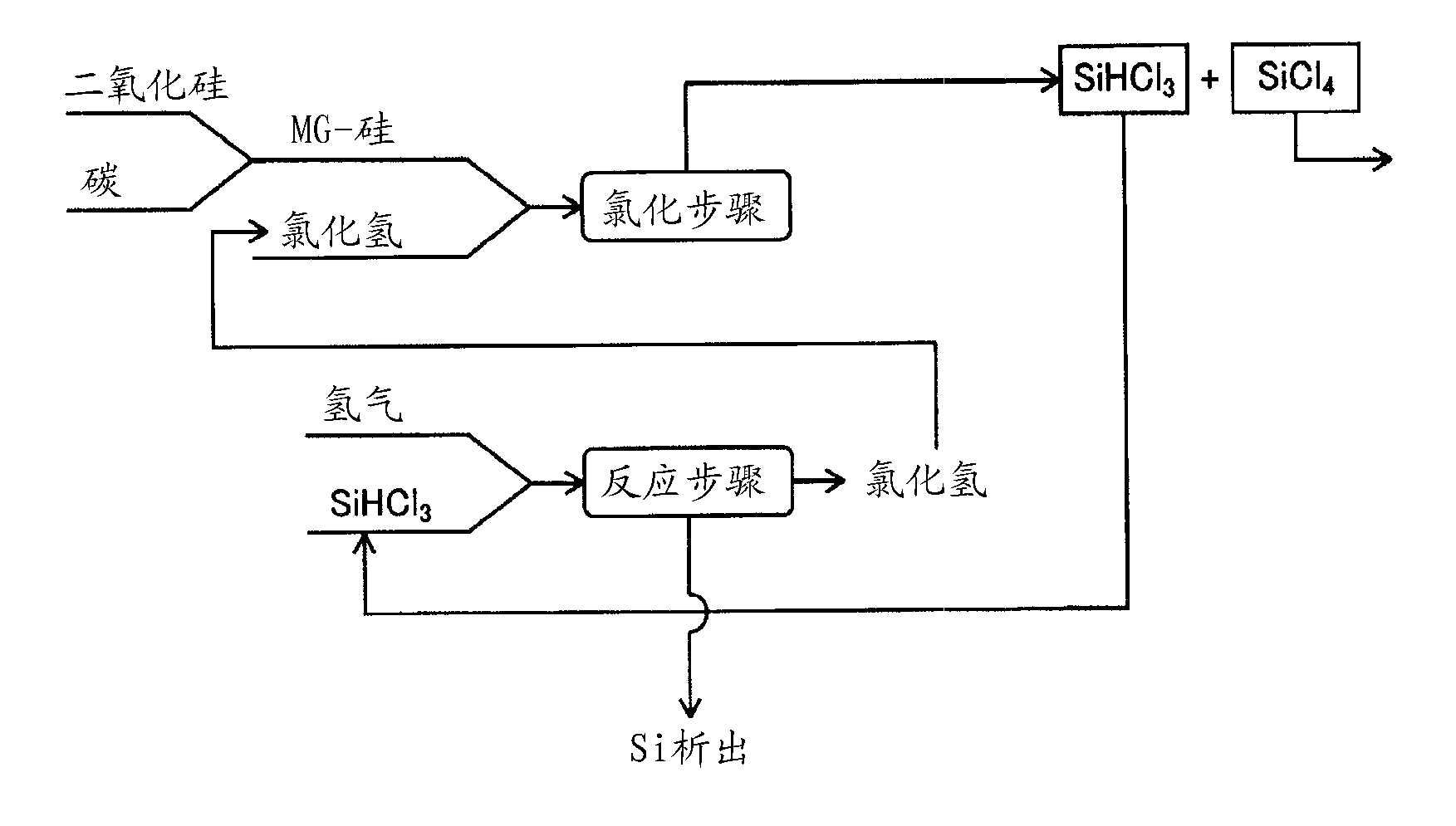

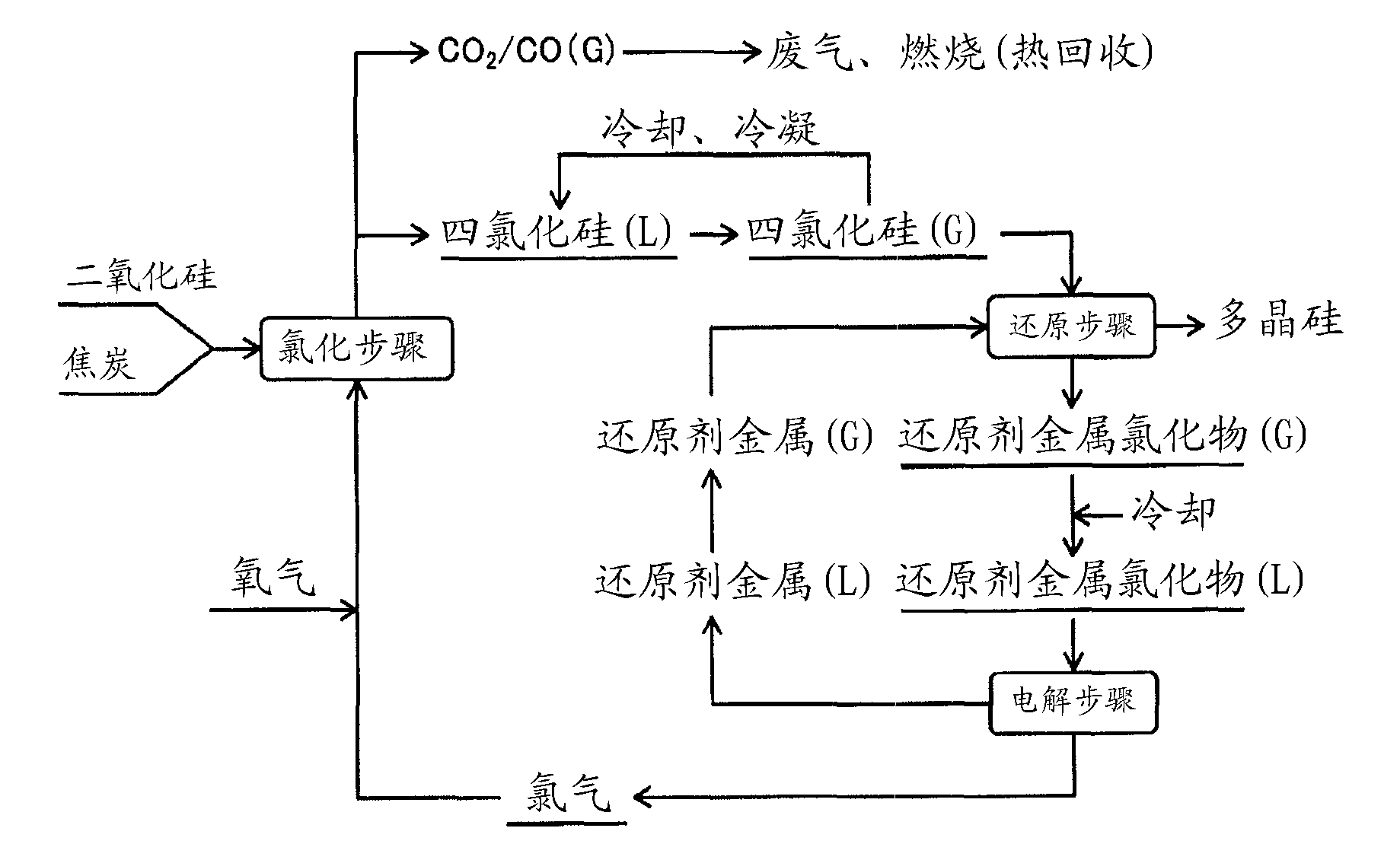

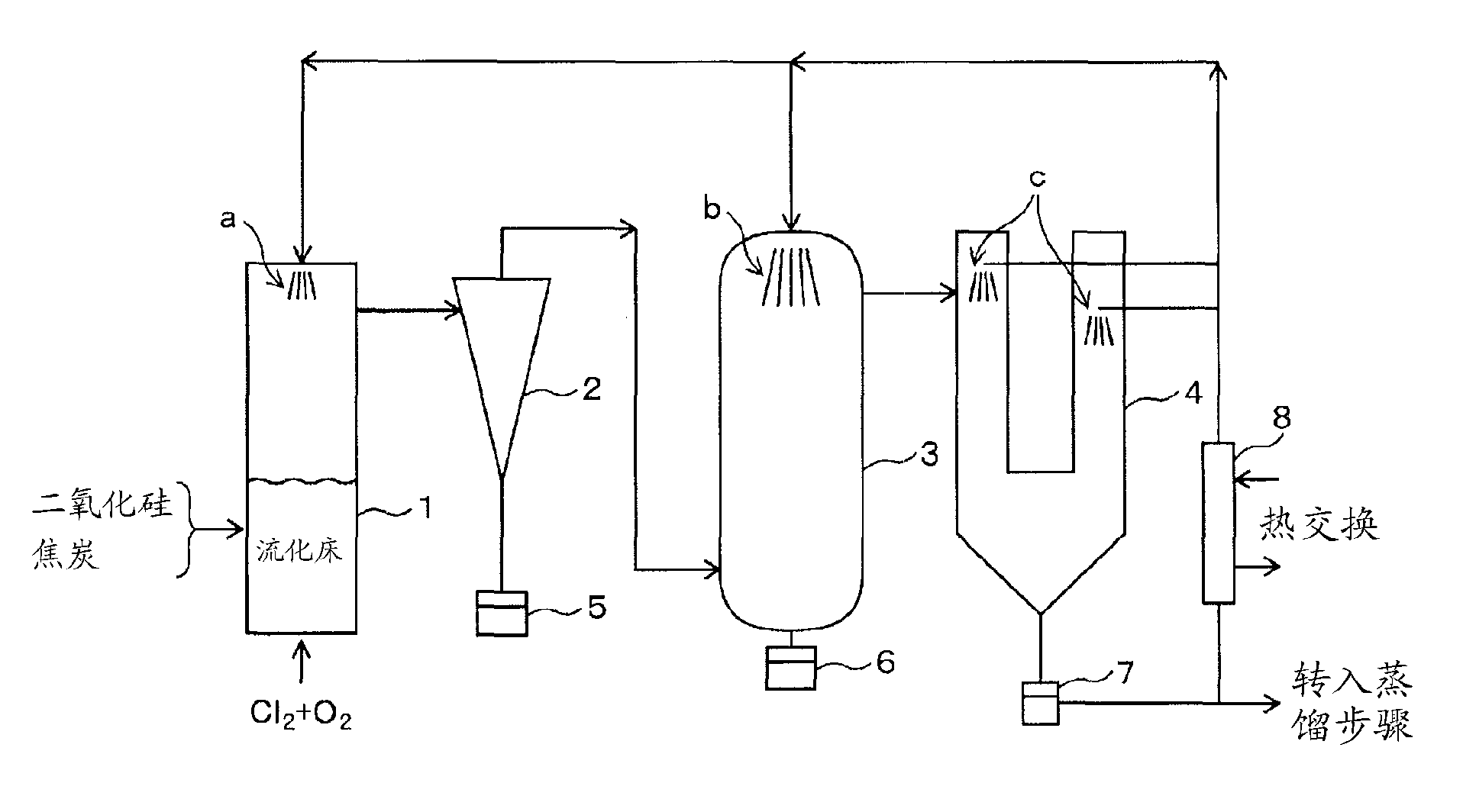

Method for manufacturing polysilicon and method for manufacturing silicon tetrachloride

InactiveCN102686514AEfficient use ofCheap manufacturingSiliconHalogenated silanesElectrolysisSilicon dioxide

Provided is a method for manufacturing polysilicon and silicon tetrachloride. The polysilicon manufacturing process used in said method is energy-efficient and can use an inexpensive raw material, the supply of which is stable. The chlorination reaction in said process proceeds smoothly and post-chlorination impurities are minimized. The provided method comprises: a chlorination step which generates silicon tetrachloride by chlorinating granules comprising silicon dioxide and a carbon-containing substance; a reduction step which generates polysilicon by using a reducing metal to reduce the silicon tetrachloride; and an electrolysis step which generates chlorine gas and a reducing metal by performing molten-salt electrolysis on a reducing metal chloride generated as a by-product from the reduction step. In the chlorination step, chlorine gas is supplied to the silicon dioxide and the carbon-containing substance in the presence of oxygen gas in order to react said substances. The reducing metal generated in the electrolysis step is reused as the reductant for the silicon tetrachloride in the reduction step, and the chlorine gas generated in the electrolysis step is reused in the chlorination step.

Owner:JNC CORP +2

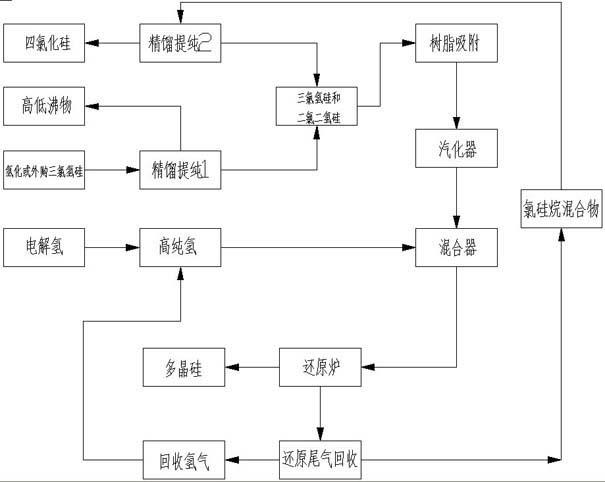

Method adopting trichlorosilane and dichlorosilane mixed raw materials to produce polycrystalline silicon

InactiveCN102642834ASolve processing problemsReduce investmentSiliconPhysical chemistryMixed materials

The invention discloses a method adopting trichlorosilane and dichlorosilane mixed raw materials to produce polycrystalline silicon. After trichlorosilane produced by hydrogenation of silicon tetrachloride or purchased outside is rectified and purified, the rectified and purified trichlorosilane is mixed with recycled trichlorosilane and dichlorosilane mixed materials, the volume percent of dichlorosilane in the mixed raw materials is controlled to be between 3% and 15%, preferably between 5% and 10%, then impurity removal by adsorption and vaporization operation are performed, vaporized chlorosilane mixed gas and high-purity hydrogen are mixed according to mole ratio of 1:2 to 1:10, preferably 1:4 to 1:6, and finally the vaporized chlorosilane mixed gas and the high-purity hydrogen enter into a reduction furnace to produce the polycrystalline silicon. After reactions, tail gas undergoes low-temperature condensation recycle, chlorosilane obtained by recycle is sent to a rectification process to perform separation of silicon tetrachloride and impurities, and the trichlorosilane and dichlorosilane mixed raw materials are obtained. The method makes full use of byproduct dichlorosilane in the polycrystalline silicon production process to improve sedimentation velocity of silicon and reduce power consumption and material consumption, simultaneously can reduce treatment cost and loss of silicon, and improves trichlorosilane utilization rate.

Owner:雅安永旺硅业有限公司

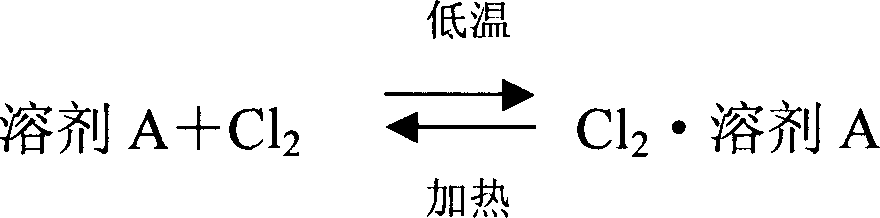

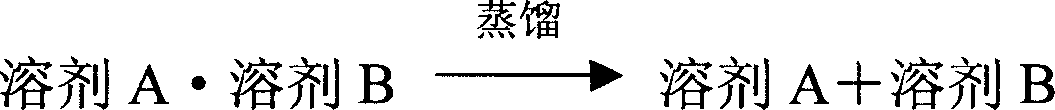

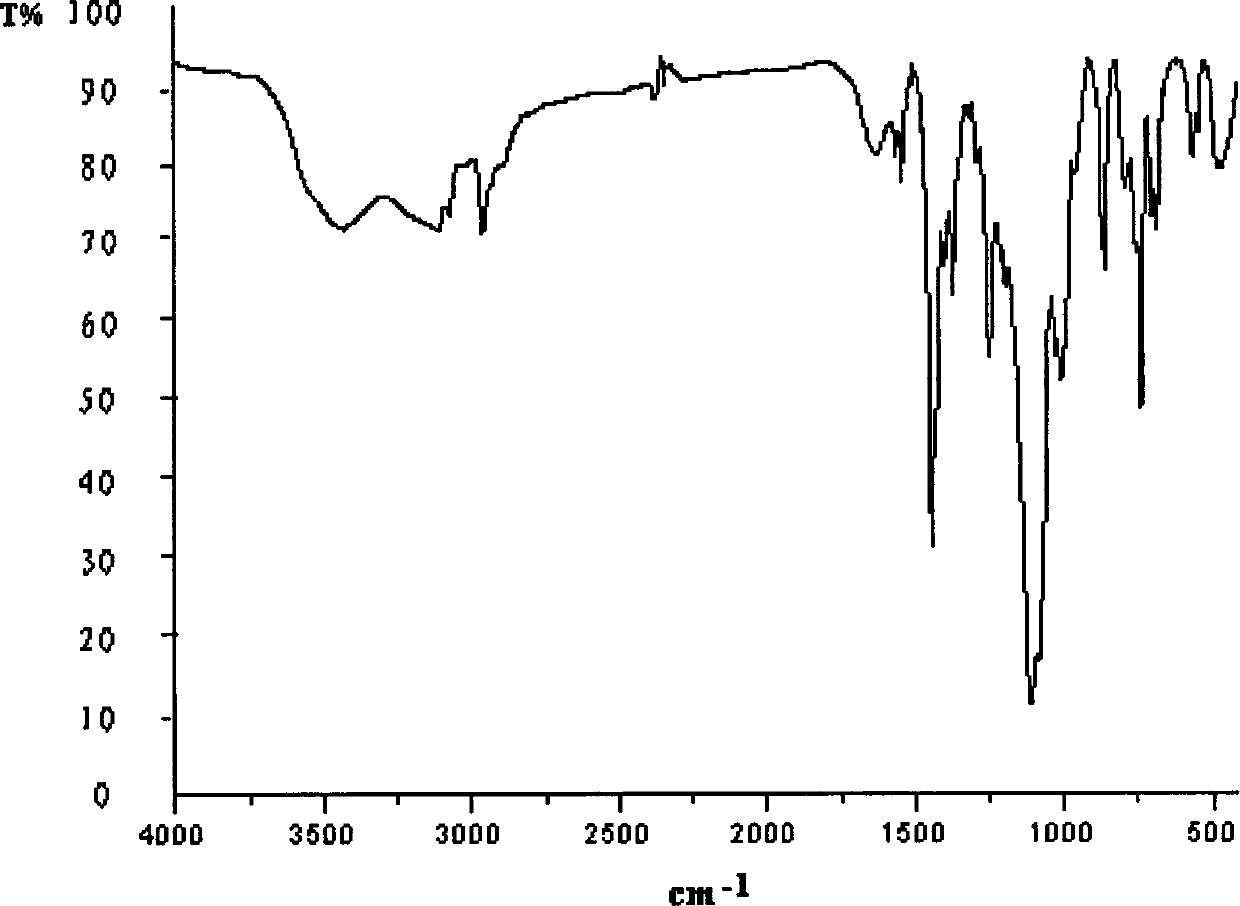

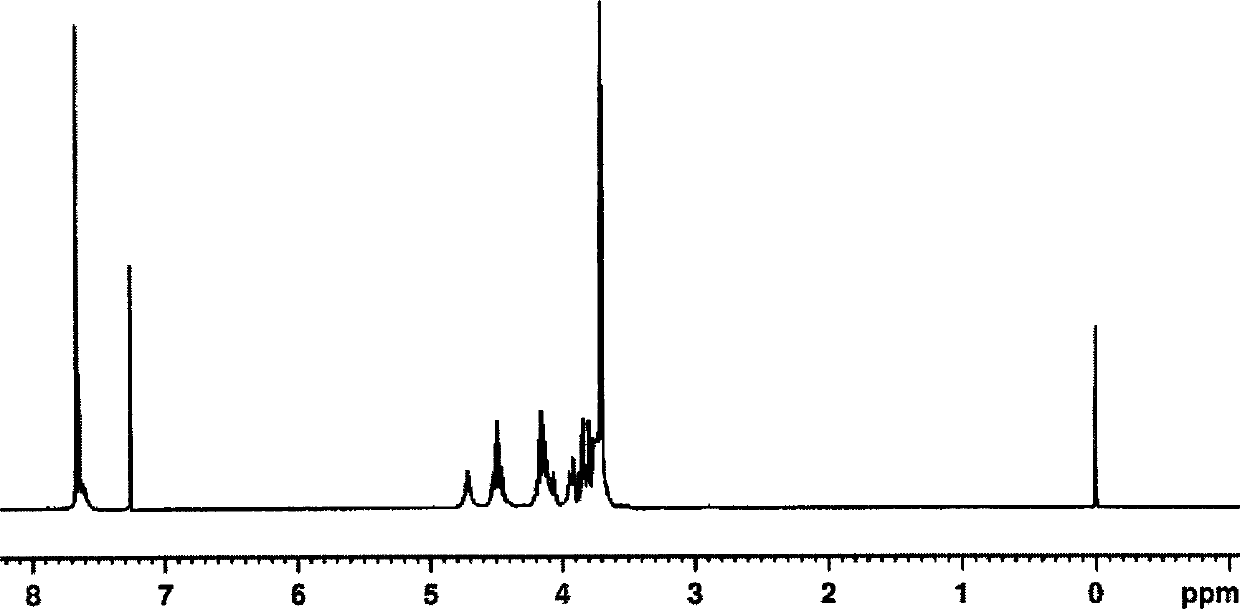

Separation and purification method of mixed waste gas containing chlorine and hydrogen chloride

InactiveCN1865127ARealize recycling of resourcesHigh recovery rateChlorine/hydrogen-chloride purificationPurification methodsGas phase

This invention relates to a method for separating and purifying mixing exhaust gas of chlorine and hydrochloride, comprising: absorb the chlorine in the mixing exhaust gas using solvent A to separate from gas phase hydrochloride, the chlorine can be obtained after solvent A desorption, the hydrochloride can be obtained by removing solvent A in the gas phage hydrochloride using solvent B, wherein: solvent A is one of benzene, silicon tetrachloride, nonyl hydride, sulfur monochloride, carbon tetrachloride and chlorosulfonic acid, and solvent B is one of cyclopentadiene and hexachlorobutadiene. By washing with concentrated hydrochloric acid to remove trace amount of organic compounds, and chemical washing to remove heavy metal elements, the hydrochloride is absorbed by water to make hydrochloric acid. This invention is characterized of efficient separation of chlorine and hydrochloride, high efficiency of separation, low cost, high-usage of resources, high purity of chlorine up to 99%, recycling use, and the purity of hydrochloride meets the requirement of producing industrial hydrochloride and hydrochloride regent .

Owner:ZHEJIANG WEIHUA CHEMICAL CO LTD

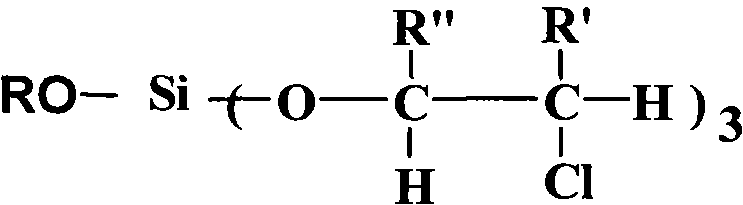

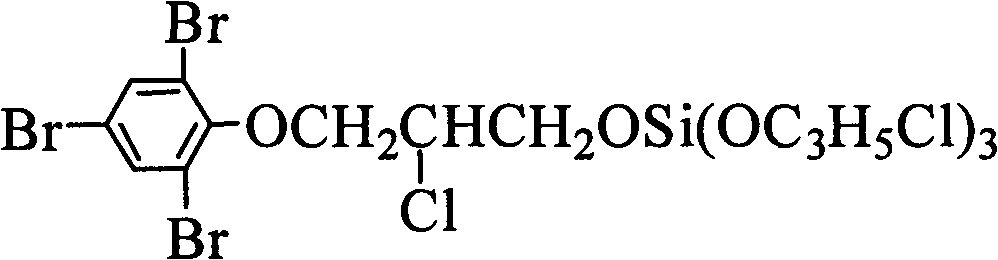

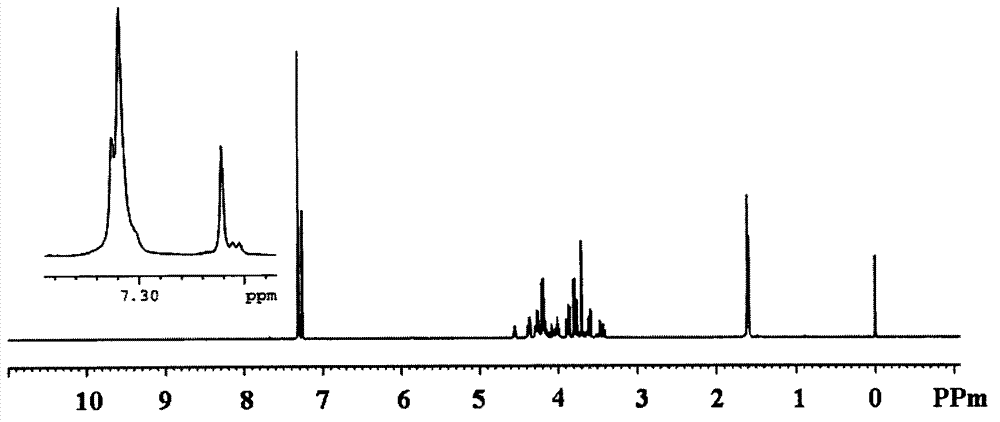

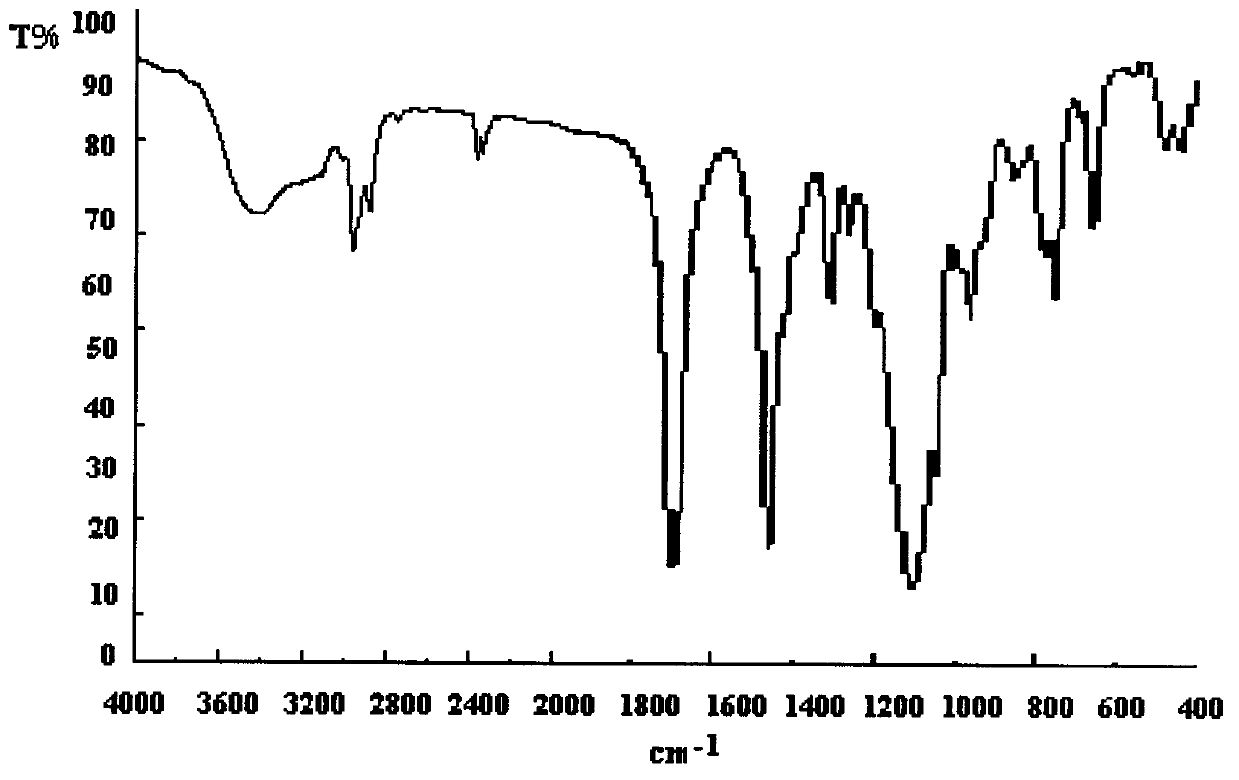

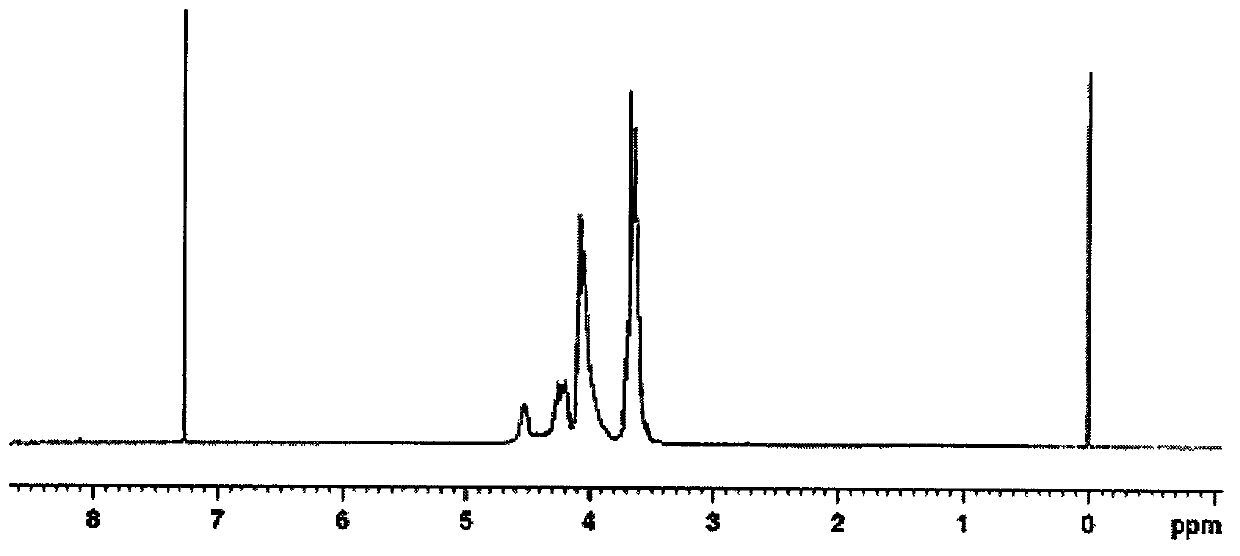

Tris(dichloropropyl) tribromophenoxy chloropropyl silicate compound and preparation method thereof

ActiveCN102731553AGood symmetryPhysicochemically stableSilicon organic compoundsOrganic solventHalogen

The invention relates to a tris(dichloropropyl) tribromophenoxy chloropropyl silicate compound which is a silicon-halogen synergistic fire retardant, and a preparation method of the compound. The compound has a structure shown in a formula described in the specification; and in the formula, OC3H5Cl2 is OCH2CHClCH2Cl or OCH (CH2Cl) 2. The preparation method of the compound comprises the following steps: reacting tribromophenyl glycidyl ether and silicon tetrachloride according to the same molar ratio in an organic solvent for 4-6h at 60-80 DEG C; then dropwise adding dichloropropanol according to a certain molar ratio, reacting for 4-8h at 50-100 DEG C; and finally purifying to obtain faint yellow liquid which is the tris(dichloropropyl) tribromophenoxy chloropropyl silicate. The compound is applicable to fire retardants for polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and other materials; and the production process is simple, low in equipment investment and cost, and suitable for industrial production.

Owner:张家港市乐余科创园投资发展有限公司

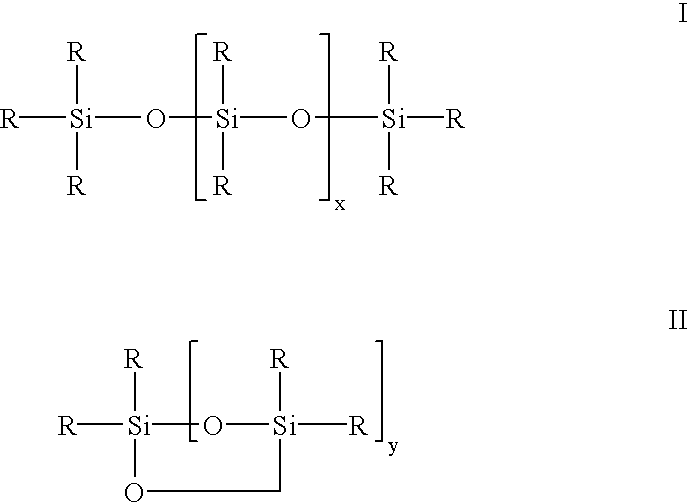

Siloxane oligomers, a process for their production and their use

Siloxane oligomers of the general formula I or II wherein at least one functionalized alkyl group is present per oligomer molecule. The siloxane oligomers are produced by oligomerization of halogenalkyltrihalogensilanes, and co-optionally co-oligomerized with (C1-C18)-alkyl-, phenyl-, aryl- or aralkyl-trihalogensilanes and / or silicon tetrachloride, in the presence of alcohol and water, following which the halogenalkyl function is optionally modified in a further step. The siloxane oligomers can be used as coupling agents in rubber mixtures or as building preservation agents.

Owner:DEGUSSA AG

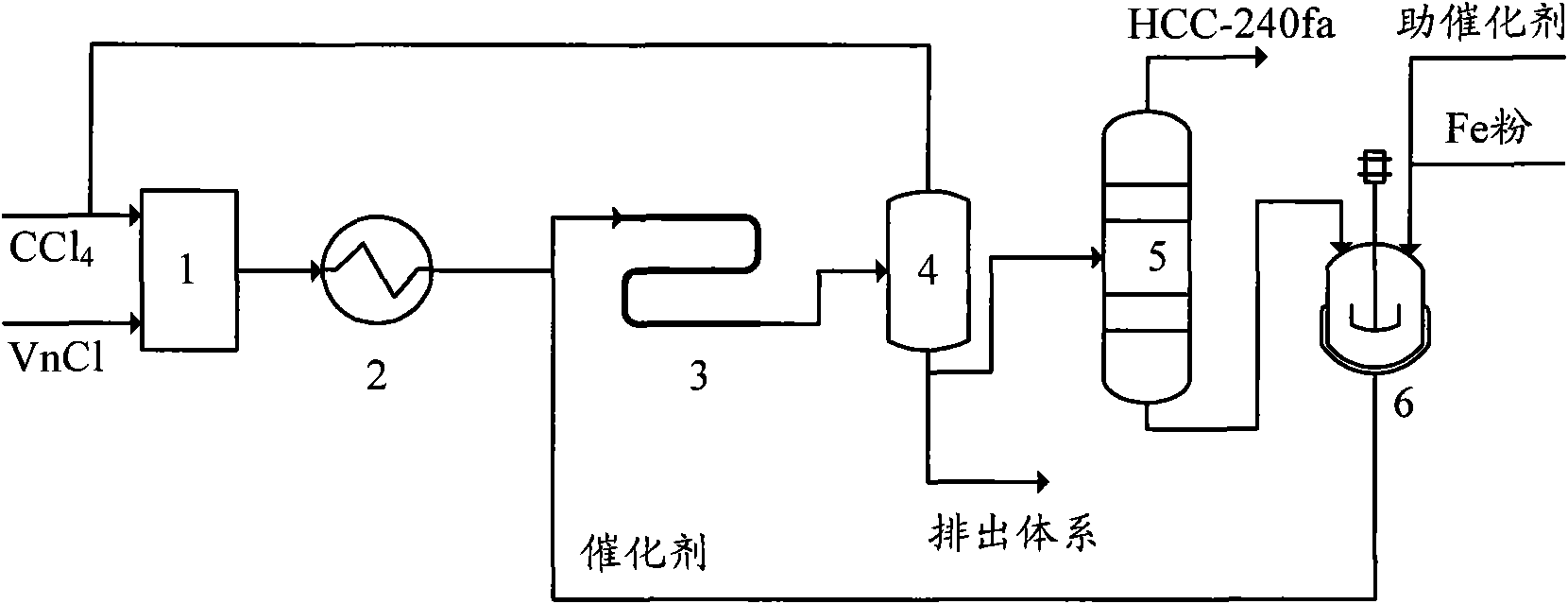

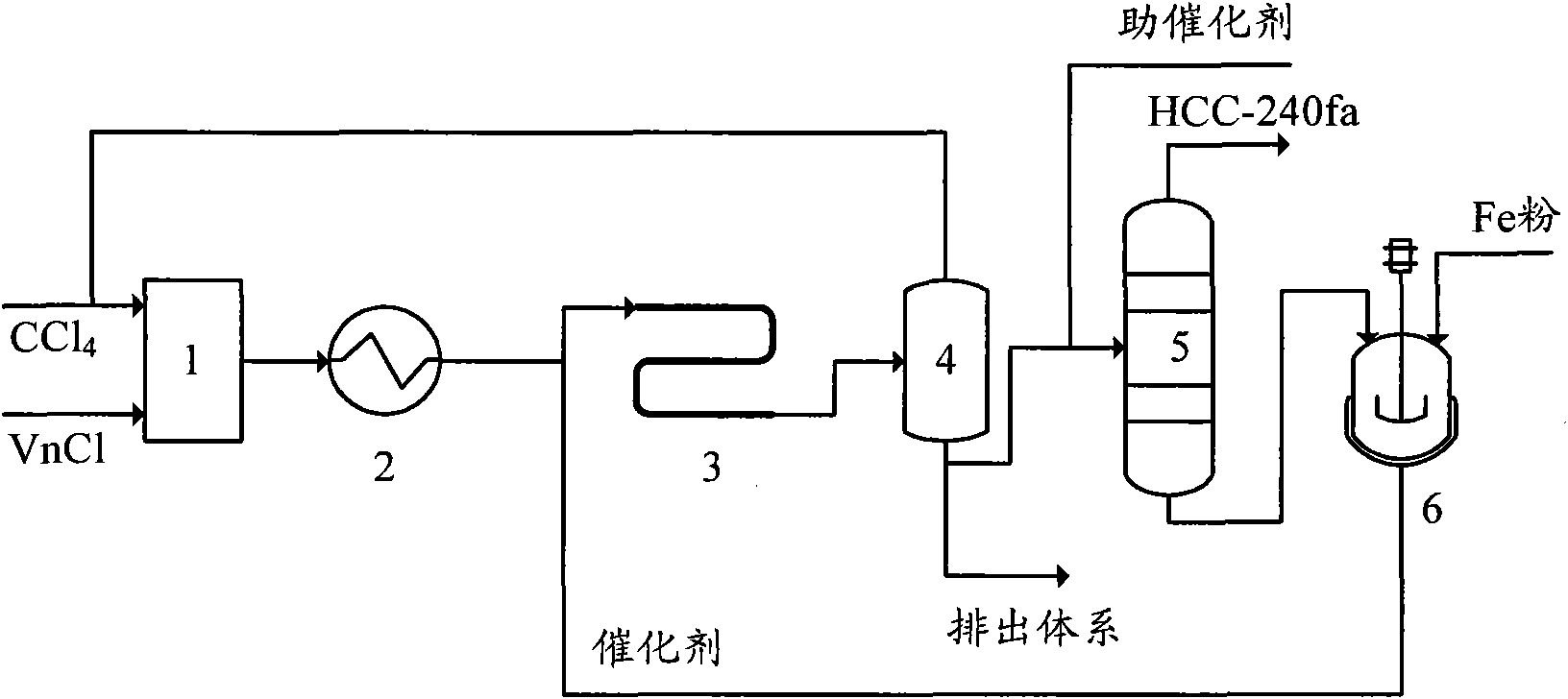

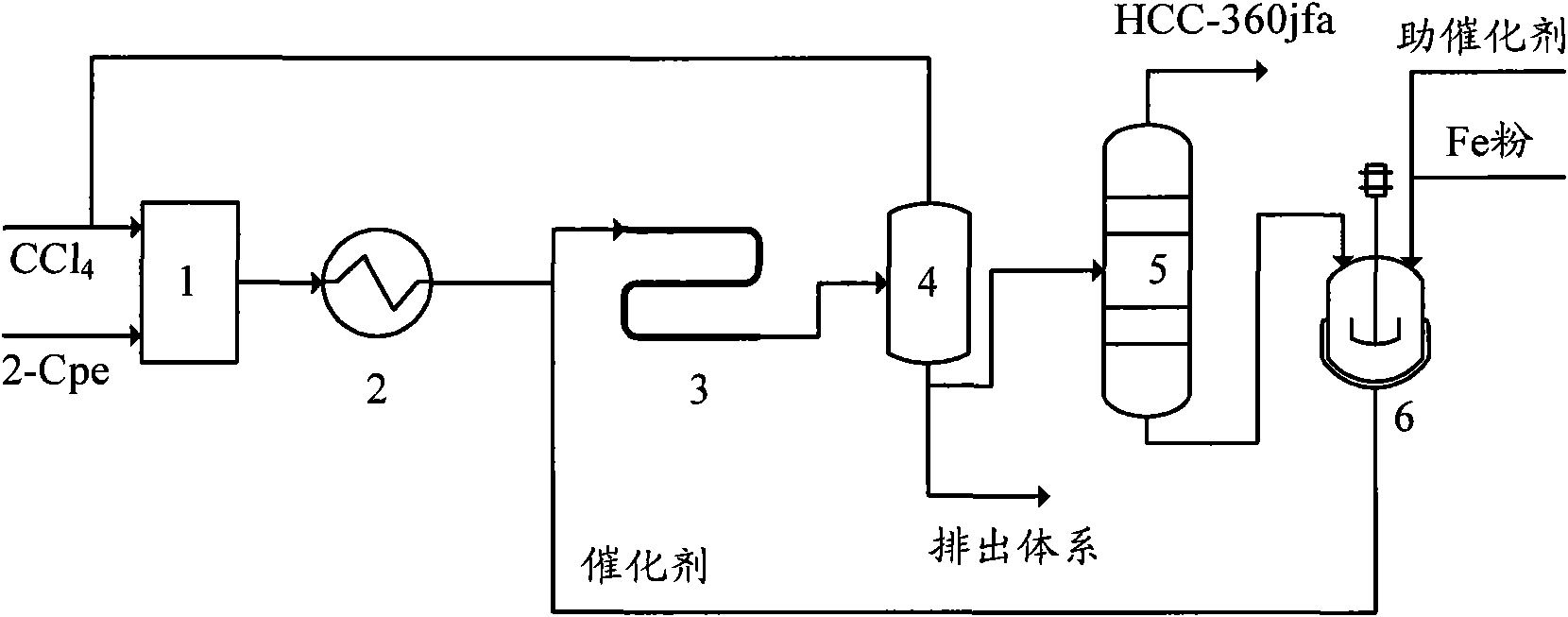

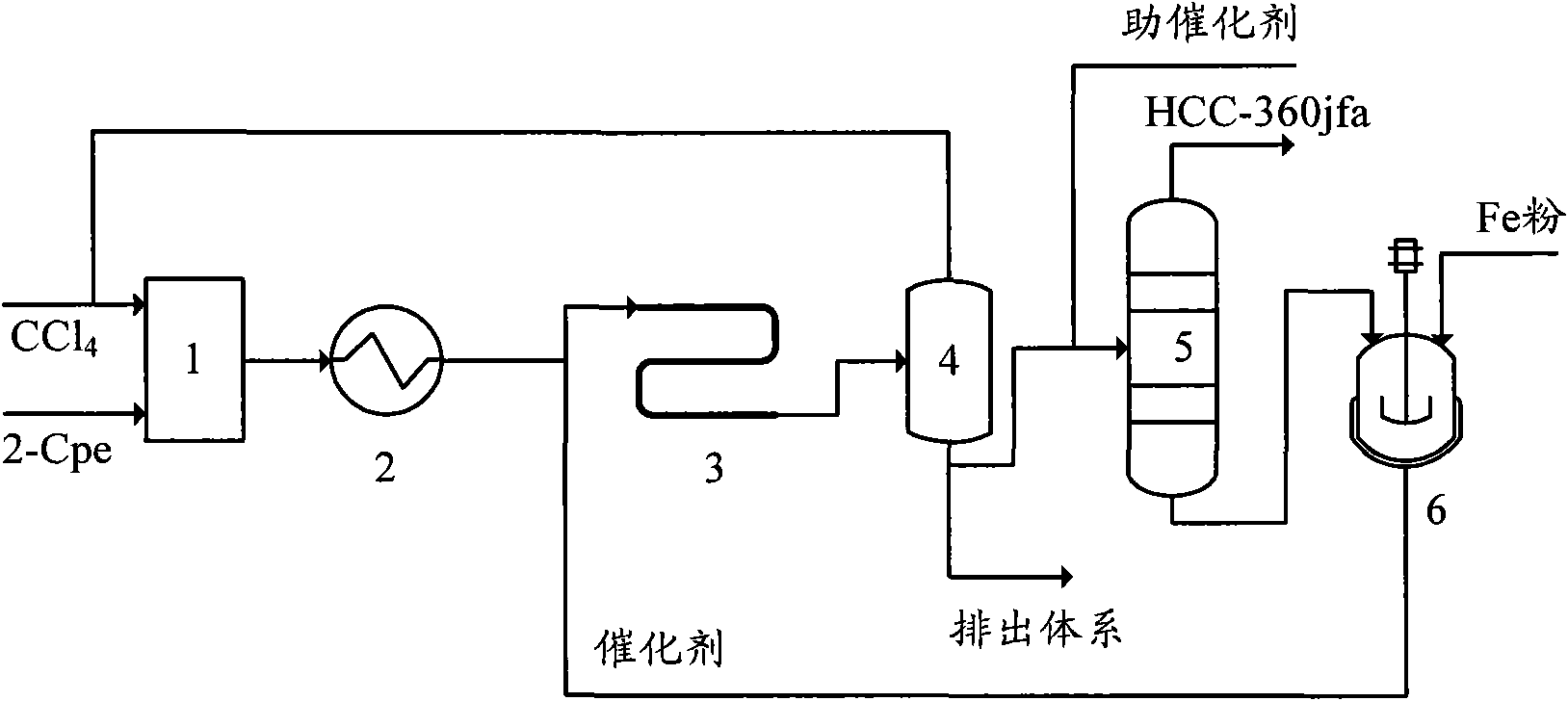

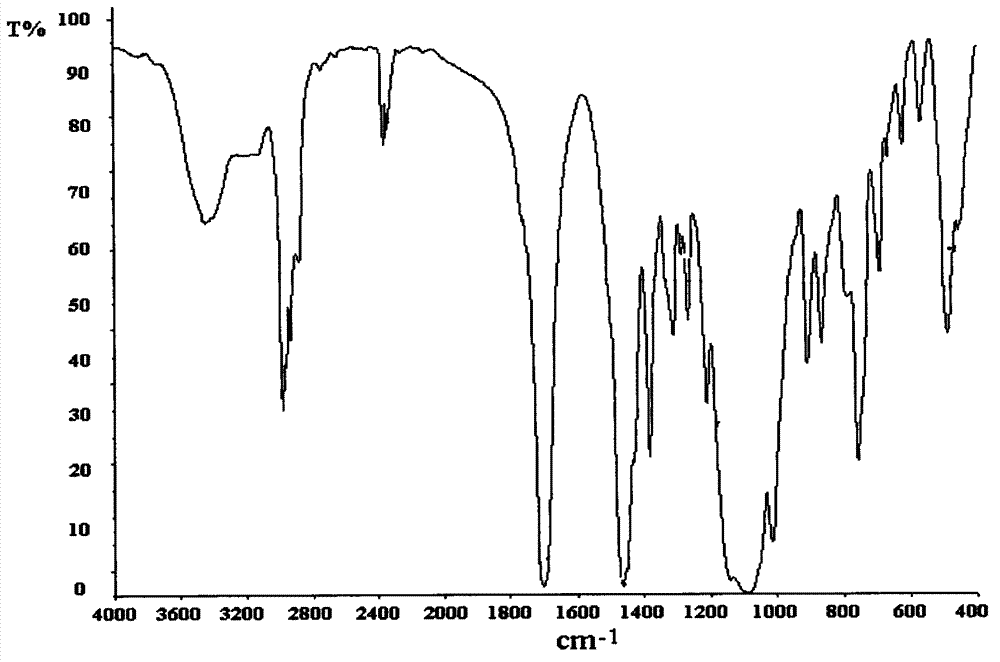

Production method of 1,1,1,3,3-pentachlorobutane

InactiveCN101913979ASuitable for continuous productionEasy to useOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingReaction temperatureTelomerization

The invention provides a production method of 1,1,1,3,3-pentachlorobutane (HCC-360jfa), in which carbon tetrachloride and 2-chloropropene are taken as raw materials for continuous reaction in a tubular reactor to synthesize the 1,1,1,3,3-pentachlorobutane. In the method, the carbon tetrachloride and 2-chloropropene are firstly mixed and preheated to reaction temperature; the carbon tetrachloride and 2-chloropropene enter the tubular reactor with a catalyst for telomerization; a product undergoes flash evaporation to remove the un-reacted tetrachloride and 2-chloropropene and then is further distilled to obtain the HCC-360jfa product; the un-reacted tetrachloride and 2-chloropropene are recycled; and the catalyst undergoes activating treatment for recycle. The catalyst used by the invention is liquid, no solid exists in the reaction product, and the tubular reactor is used for reaction, so that the invention is convenient for operation and easy for continuous production.

Owner:XIAN MODERN CHEM RES INST

Silicon and catalyst material preparation in a process for producing trichlorosilane

InactiveUS20090060818A1Reduce size requirementsReduce yieldSiliconHalogenated silanesMaterials preparationHydrogen

A process for preparing trichlorosilane by reacting silicon with hydrogen chloride, or silicon tetrachloride with hydrogen in the presence of silicon, and catalysts where the silicon and catalysts are laminated together and reduced in particle size prior to reaction.

Owner:DYNAMIC ENG

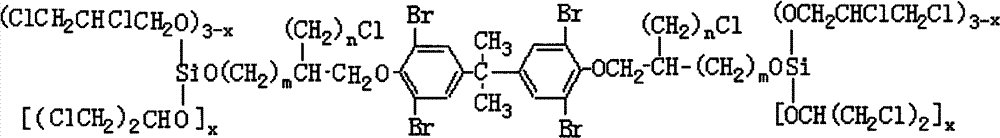

Novel coordinate flame retardant compound of three elements silicon, chlorine and bromine, and preparation method thereof

ActiveCN102775431AGood structural plasticityHigh synergistic flame retardant performanceSilicon organic compoundsTetrabromobisphenol APolyvinyl chloride

The invention relates to a novel coordinate flame retardant compound of three elements silicon, chlorine and bromine, and a preparation method thereof, and in particular relates to a silicon halide coordinate flame retardant plasticizer tetrabromobisphenol A bi[tri(dichloropropoxy) silicon acyloxy chloropropyl] ether compound and a preparation method. The structure of the compound is expressed by the following formula: n is equal to 1 when m is 0, the n is equal to 1 when the m is 1, and x is 0, 1, 2 or 3. The preparation method comprises the following steps of: under stirring, dissolving tetrabromobisphenol A bisepoxy propyl ether in an organic solvent; dropping the mixture in silicon tetrachloride at the temperature of 25 DEG C; after dropping, carrying out insulation reaction for 3-4 hours at the temperature of 70-80 DEG C; dropping epoxychloropropane according to a certain mole ratio; reacting for 7-8 hours at the temperature of 80-100 DEG C; and carrying out purification treatment to obtain the tetrabromobisphenol A bi[tri(dichloropropoxy) silicon acyloxy chloropropyl] ether. The product isa good flame retardant plasticizer, and is suitable for being used as a flame retardant plasticizing additive such as epoxy resin, polyvinyl chloride, unsaturated polyester resin, and polyurethane.

Owner:SUZHOU UNIV OF SCI & TECH

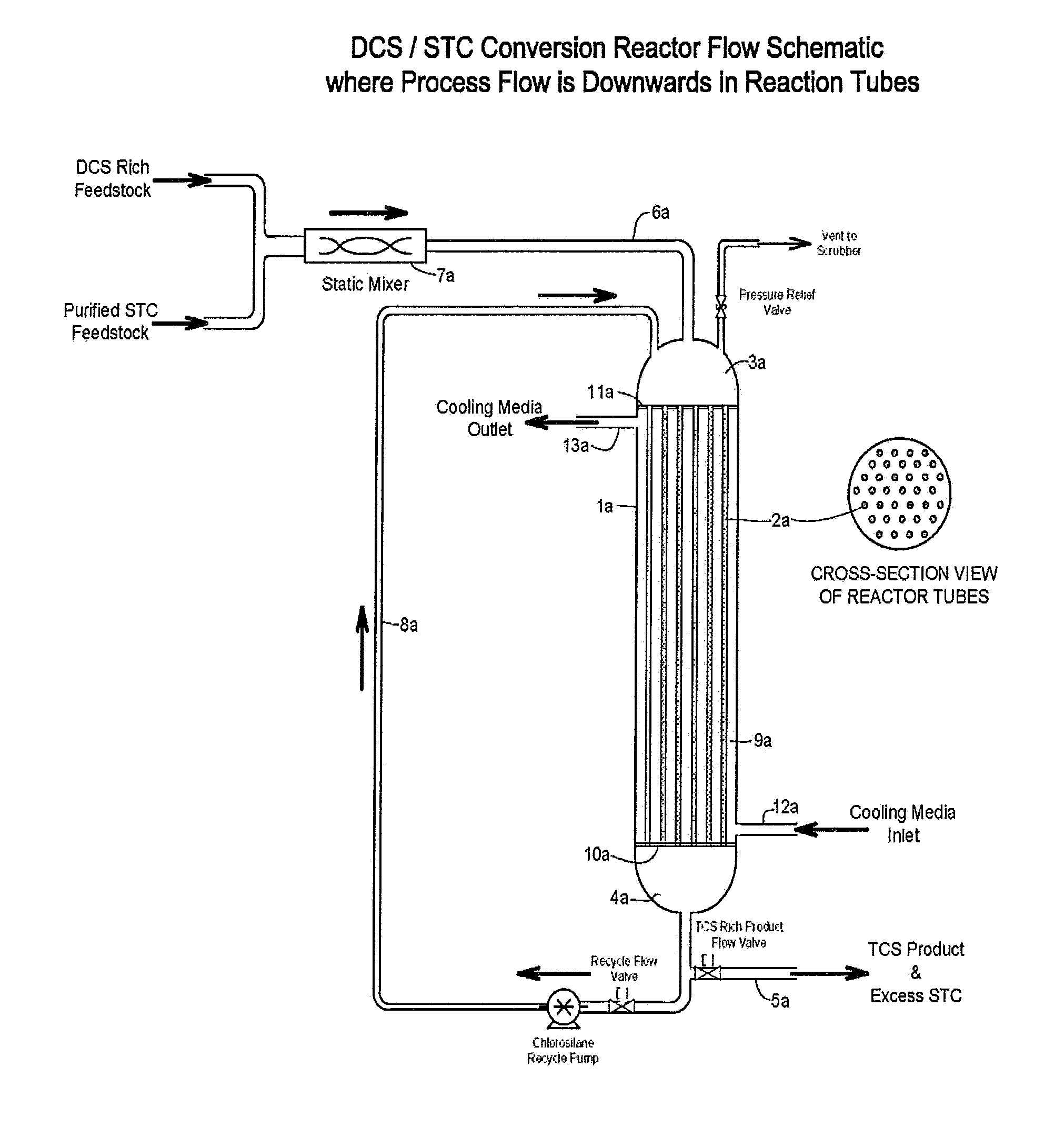

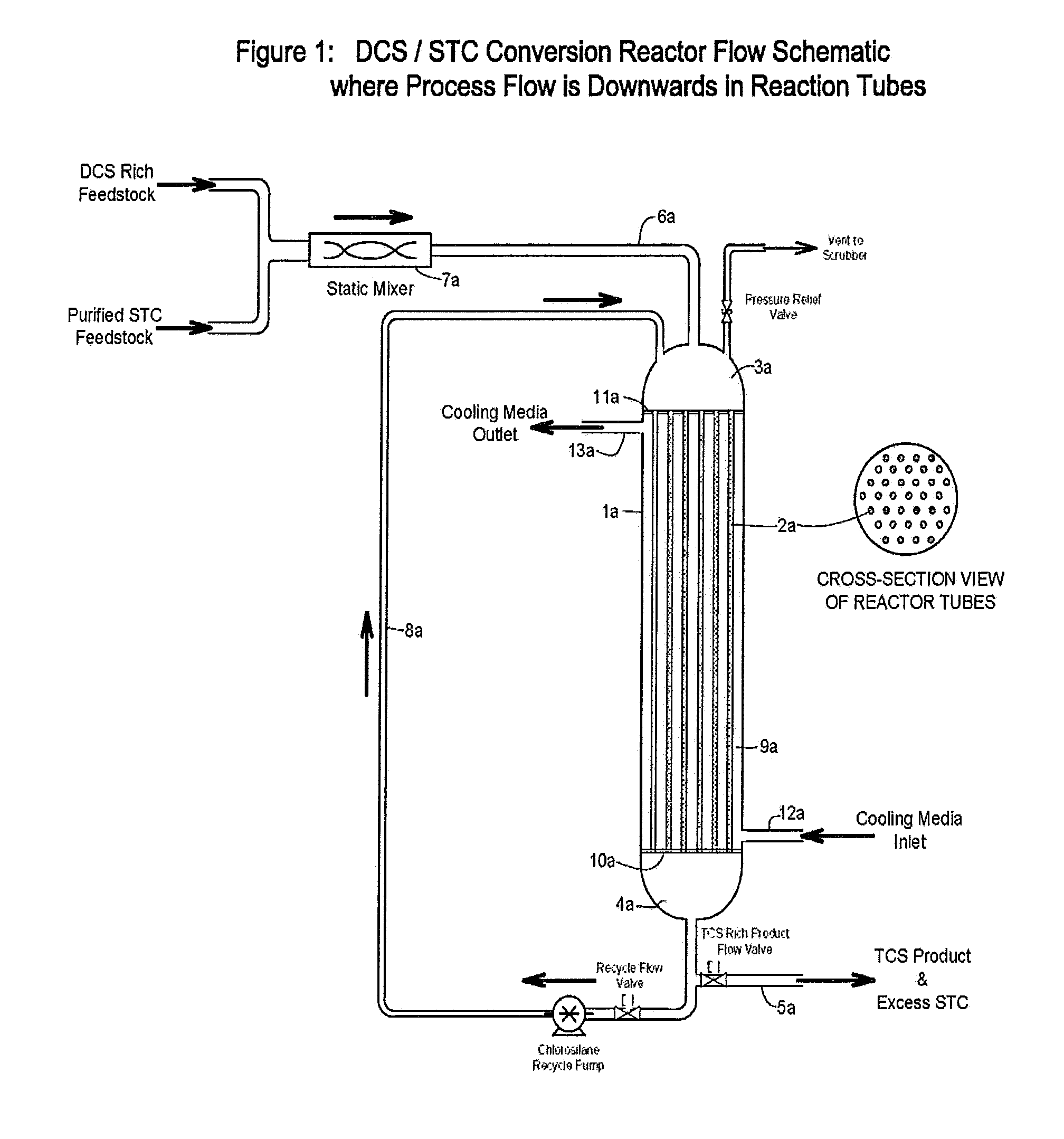

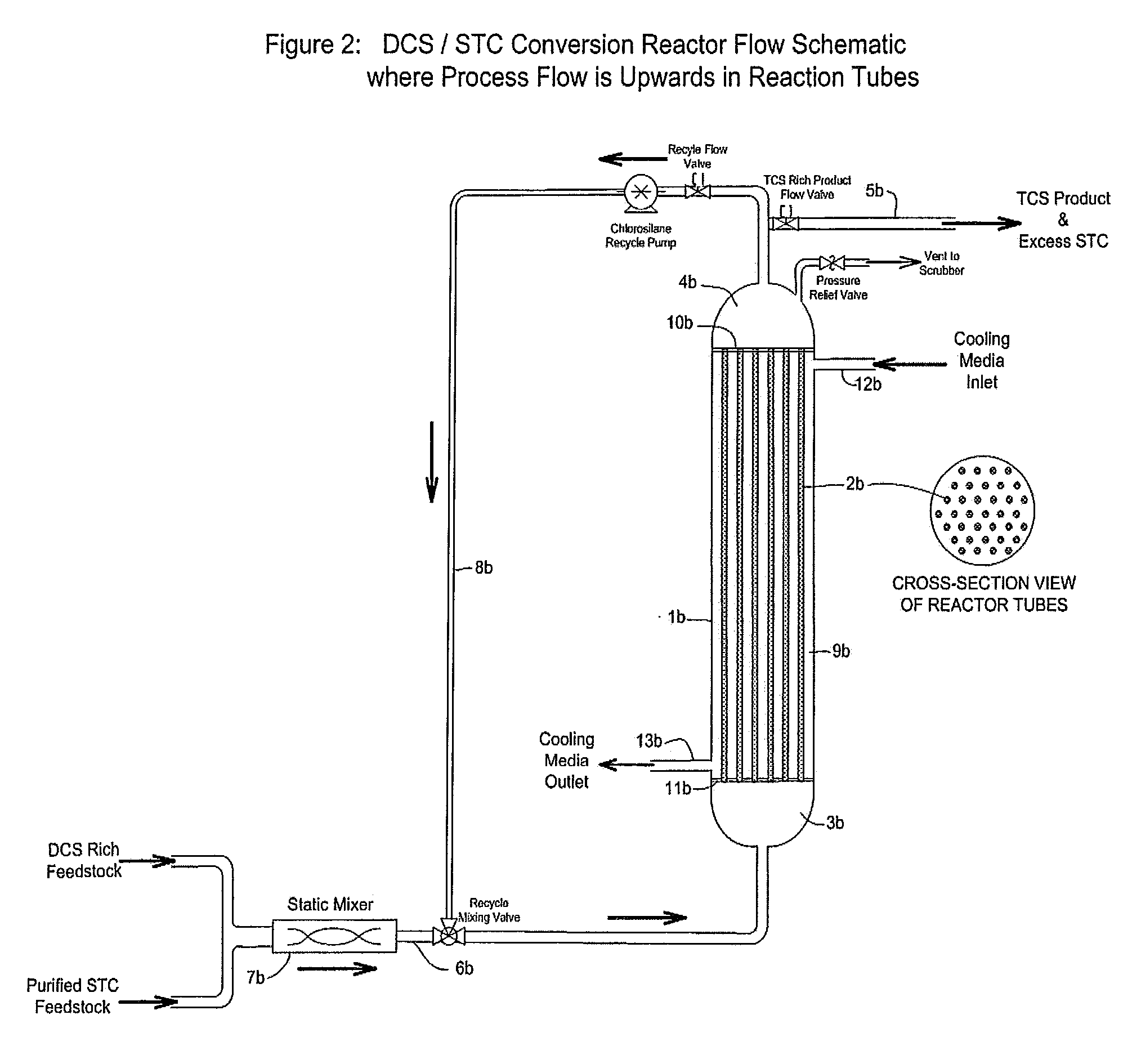

Enhancements for a chlorosilane redistribution reactor

The present invention includes a process and means for using two isolated by-products from the reaction of at least one of metallurgical silicon and silicon tetrachloride with at least one of anhydrous hydrogen chloride and hydrogen to produce trichlorosilane. The two isolated by-products are dichlorosilane and silicon tetrachloride. The present process reduces chlorosilane waste and improves efficiency of overall process for production of trichlorosilane for use in chemical vapor deposition of polysilicon for electronic and solar applications. The present invention further includes a chemical reactor for the reacting dichlorosilane with silicon tetrachloride to produce additional trichlorosilane.

Owner:DYNAMIC ENG

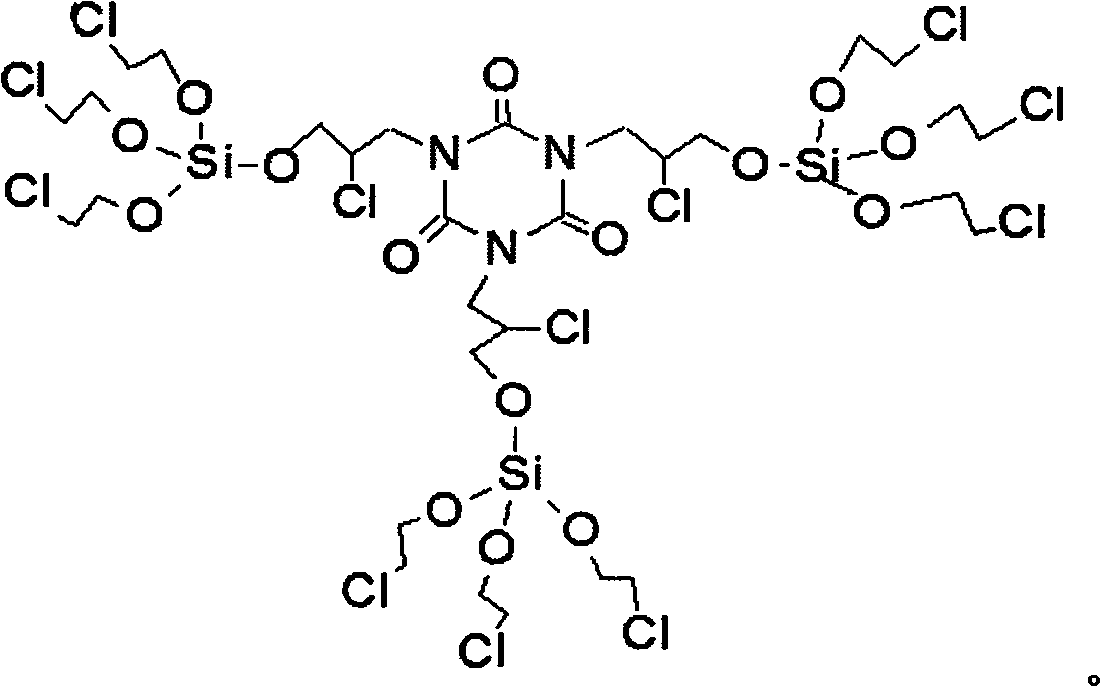

Isocyanurate chloropropyl chloroethyl silicate and preparation method thereof

ActiveCN102731545AGood compatibilityHigh synergistic flame retardant performanceSilicon organic compoundsEpoxyPolyvinyl chloride

The invention relates to a nitrogen, silicon and chlorine thee-element synergic flame retardant tri{2-chloro-3-[tri(chloroethoxy)silicon acyloxy]propyl}isocyanurate compound and a preparation method thereof. The structure of the compound is shown as a formula in the specification. The preparation method comprises the following steps: dripping organic solvent solution of triglycidyl Isocyanurate into silicon tetrachloride, and reacting for 4 to 6 hours at a temperature of between 50 and 70 DEG C; and cooling to 30 DEG C, introducing ethylene oxide under the liquid surface, reacting for 2 to 3 hours at a temperature of between 45 and 55 DEG C, and purifying to obtain the tri{2-chlor-3-[tri(chloroethoxy)silicon acyloxy]propyl}isocyanurate. The compound has good flame retardant plasticization, and is suitable for flame retardant plasticizer such as polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like; and the method has simple production process and low cost, and is easy for industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

Production method of silane

The invention discloses a production method of silane. The production method comprises the following steps of: heating trichlorosilane to 70-90 DEG C by using a preheater; feeding heated trichlorosilane into a first reaction region of a reaction rectifying tower, and performing a first step catalytic disproportionation reaction of trichlorosilane in the first reaction region to generate dichlorosilane and silicon tetrachloride; feeding silicon tetrachloride generated in the first reaction region into the stripping section of the reaction rectifying tower, separating, purifying and discharging from a tower kettle; raising dichlorosilane generated in the first reaction region to a second reaction region of the reaction rectifying tower, and performing a second step catalytic disproportionation reaction to generate trichlorosilane and silane; refluxing the trichlorosilane generated in the second reaction region into the first reaction region, mixing with trichlorosilane heated by using the preheater, and continually performing the first step catalytic disproportionation reaction; and raising silane generated in the second reaction region into the rectifying section of the reaction rectifying tower, separating, purifying and discharging from the tower top of the reaction rectifying tower to obtain silane.

Owner:覃攀

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com