Modified method and device for preparing trichlorosilane and multicrystal silicon

A technology of trichlorosilane and polysilicon, applied in chemical instruments and methods, silicon, silicon compounds, etc., can solve problems such as difficult transportation and disposal, and reduced process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

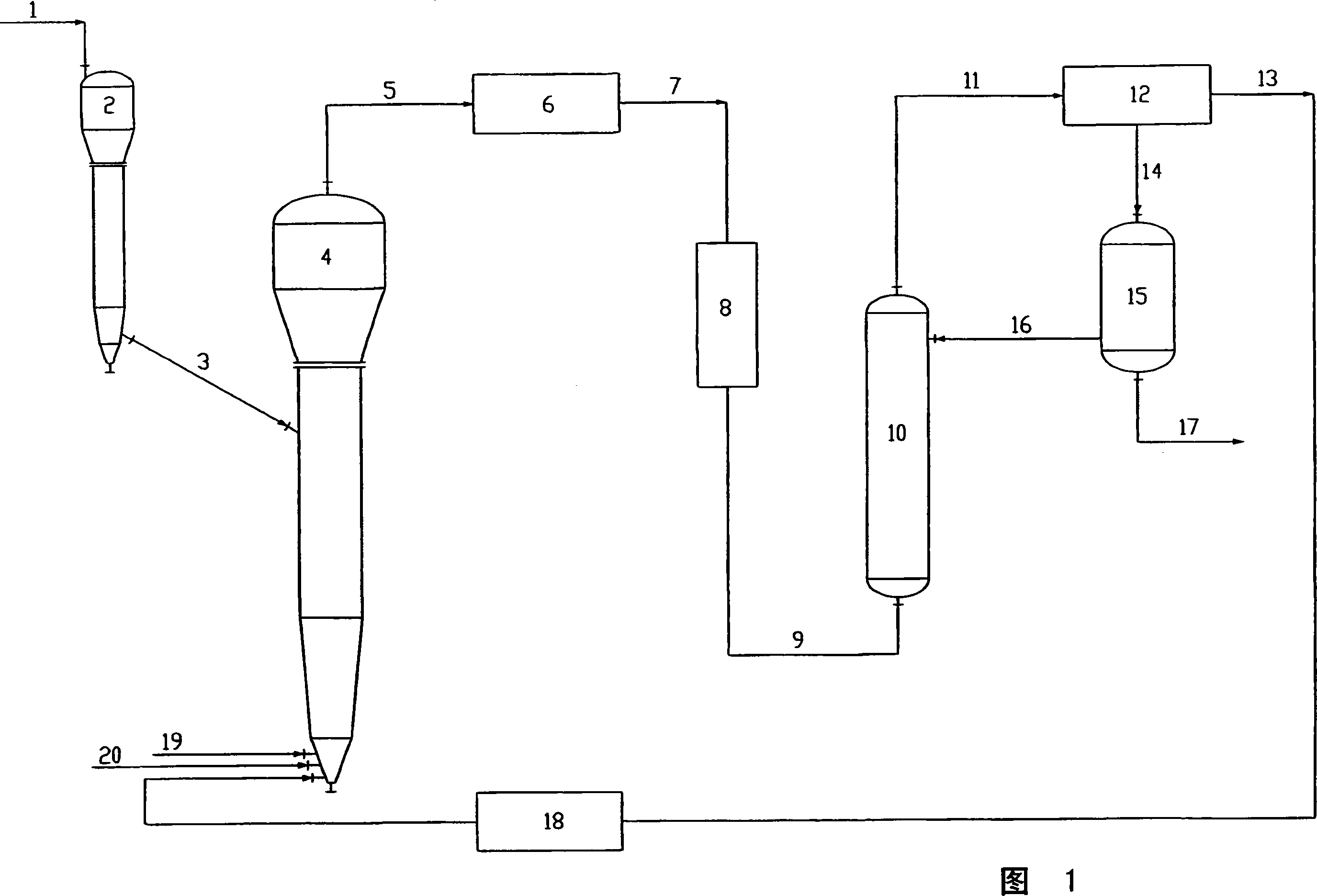

[0044] The process of the present invention for producing trichlorosilane by the hydrochlorination process will be described below with reference to FIG. 1 .

[0045] The device for preparing trichlorosilane includes a powder drying furnace 2 , an ebullated bed reactor 4 , a cyclone separator 6 , a heat recovery device 8 , a washing tower 10 and a condensation recovery device 12 .

[0046] The ebullating bed reactor 4 that is used for the present invention is generally made up of three parts, the gas separation part that is positioned at the top, the reaction part that is positioned at the middle part, and the feeding part that is positioned at the bottom, wherein the diameter of the gas separation part is greater than the diameter of the reaction part, There is a discharge port on the top, and there are hydrogen chloride gas inlet, silicon tetrachloride gas inlet, hydrogen gas gas inlet and silicon powder inlet on the feeding part, wherein the gas inlet is located under the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com