Patents

Literature

186results about How to "Thin coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

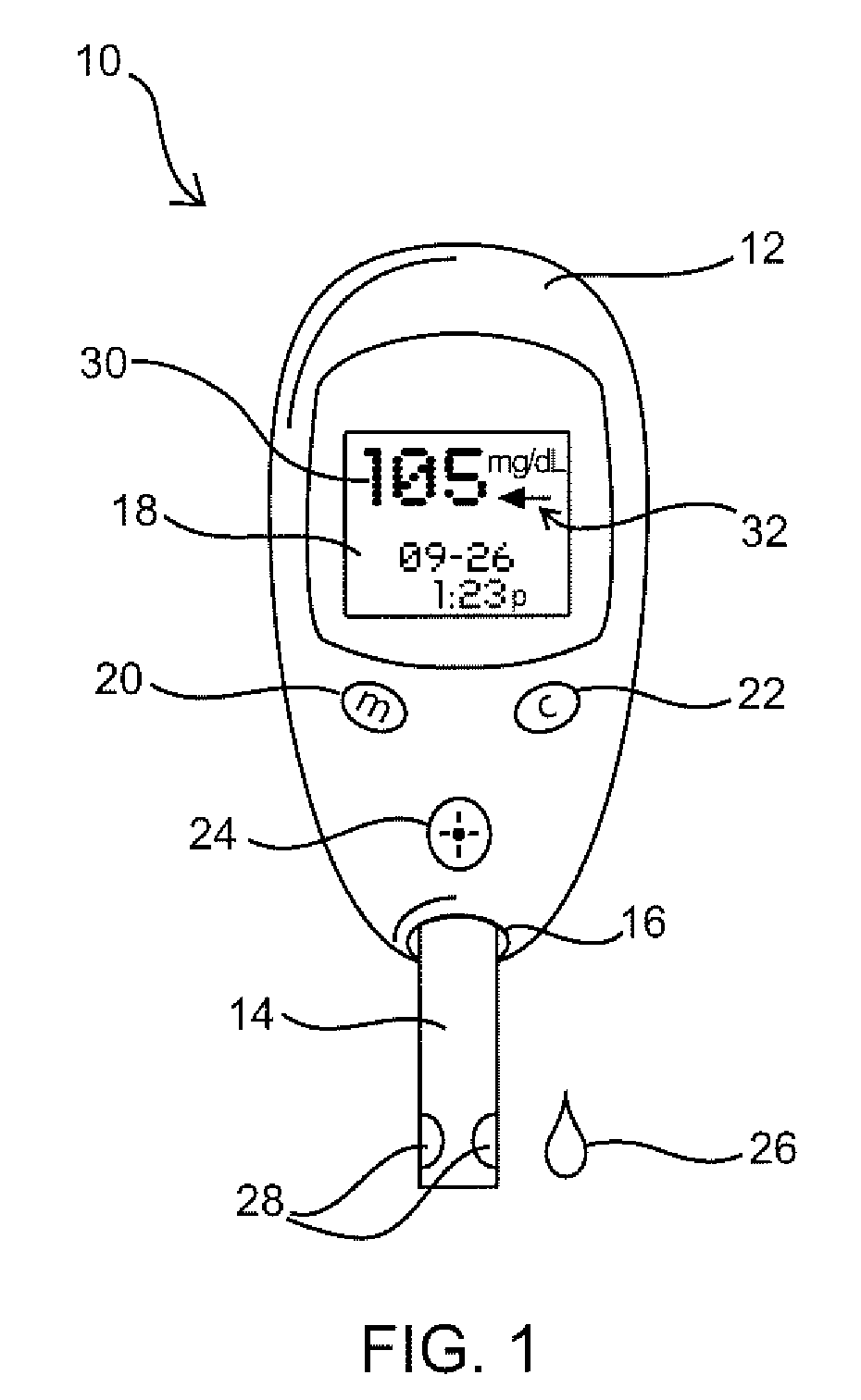

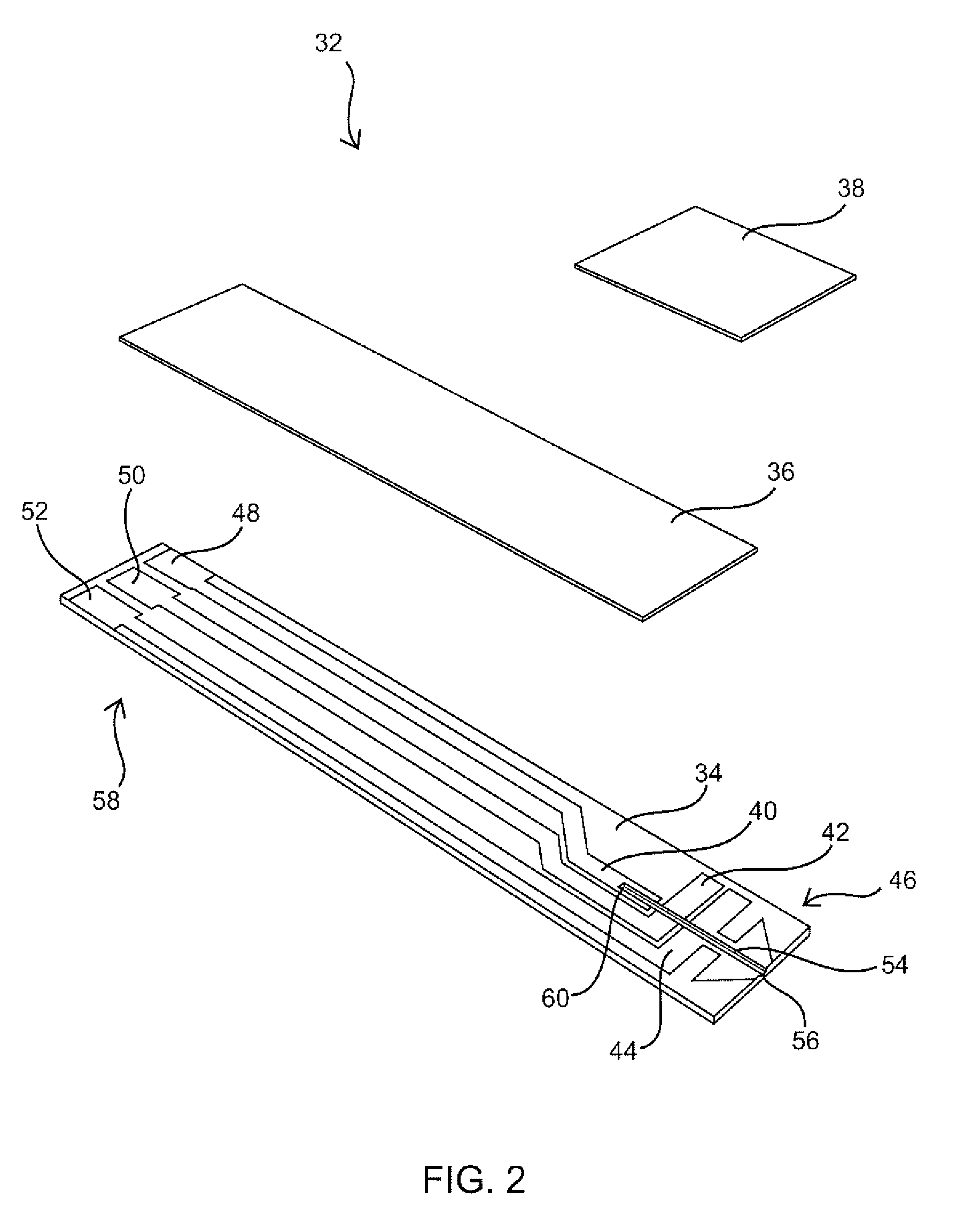

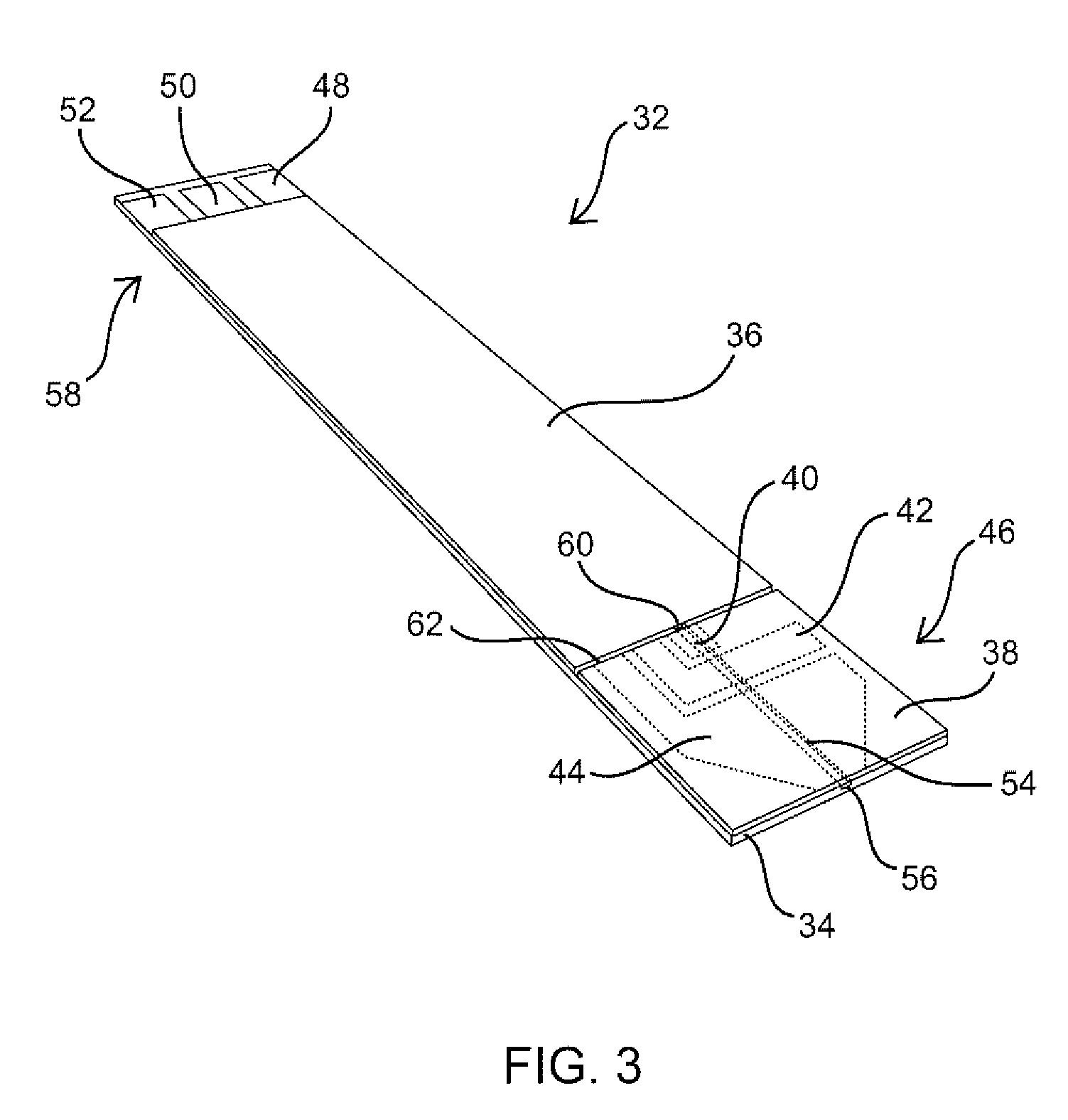

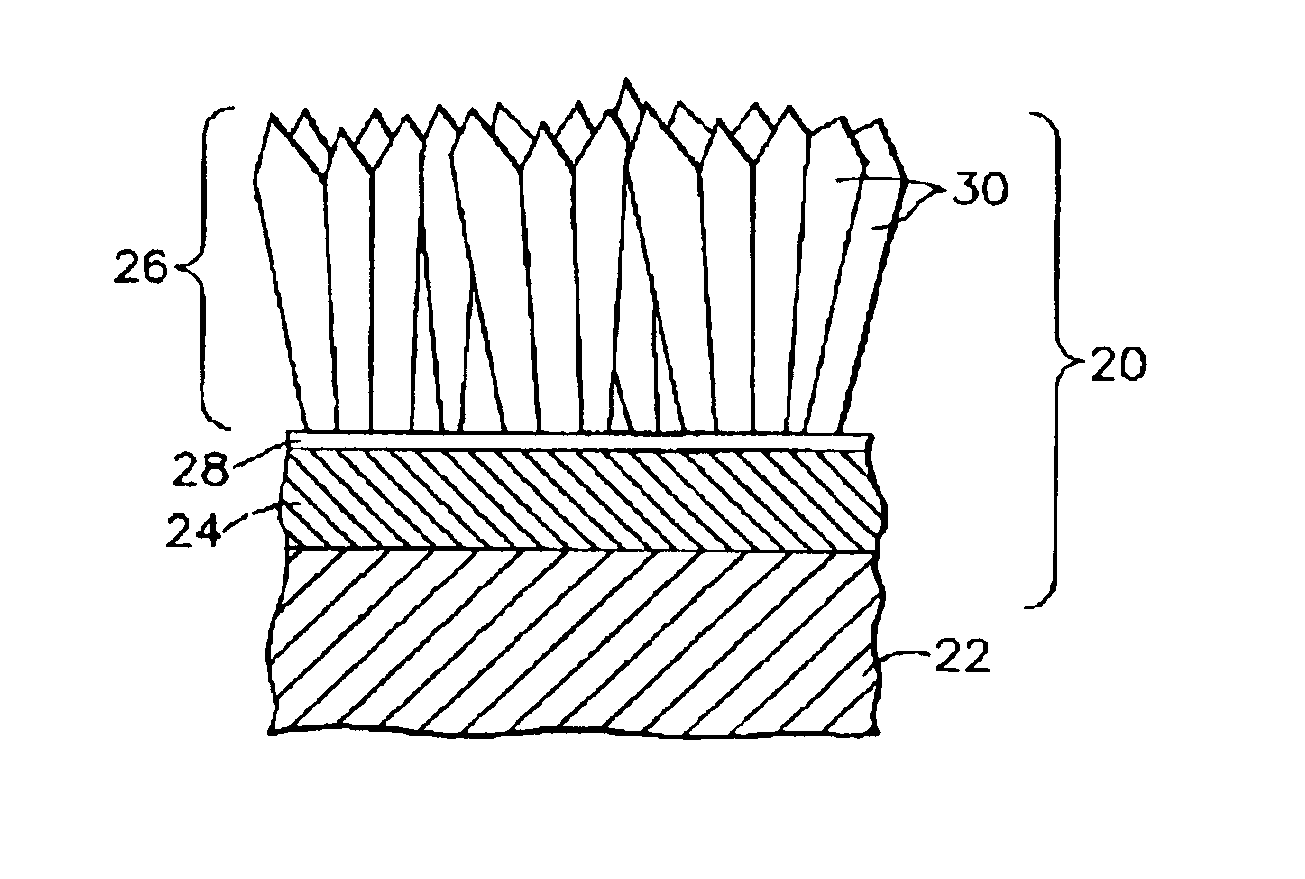

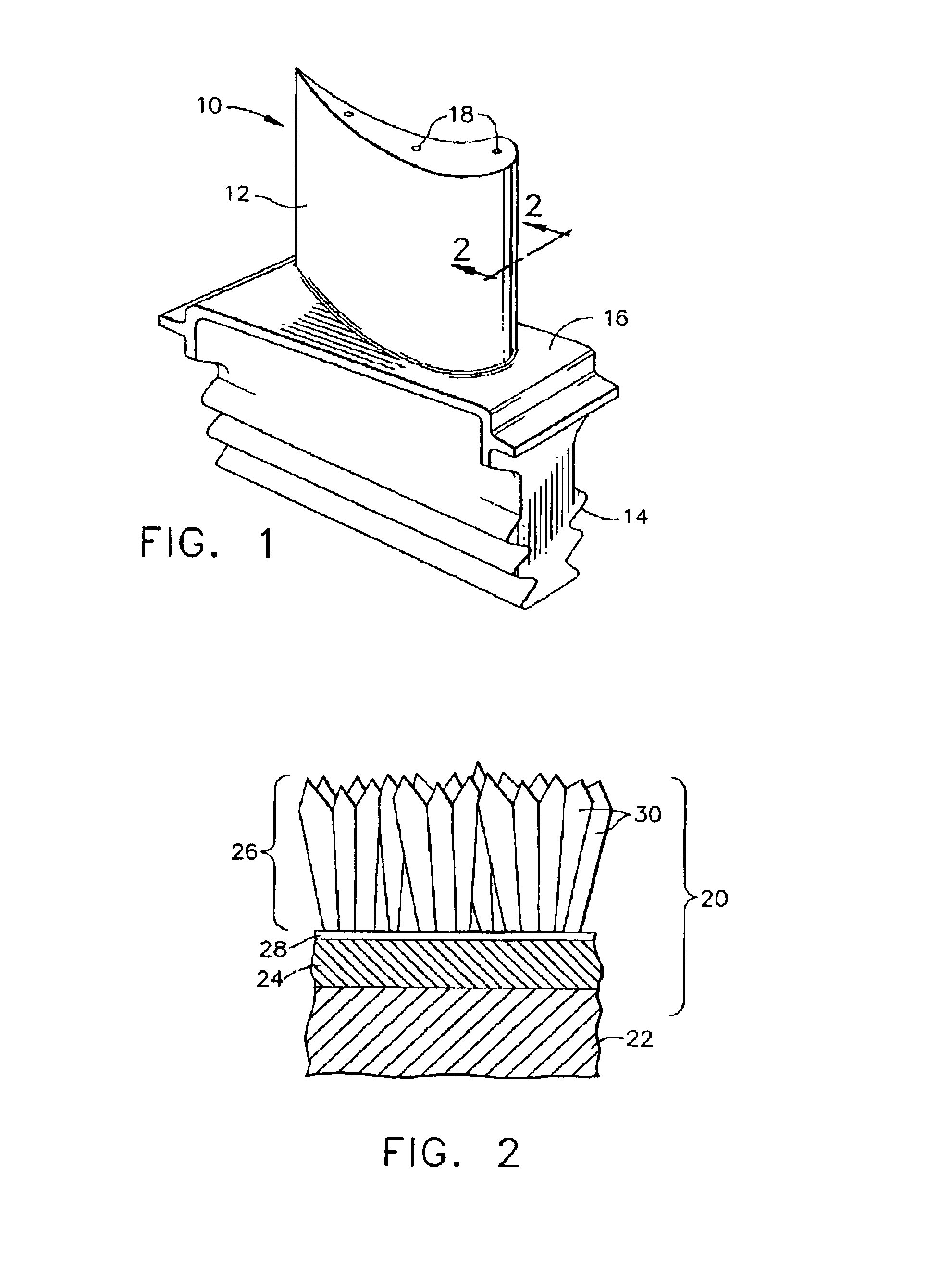

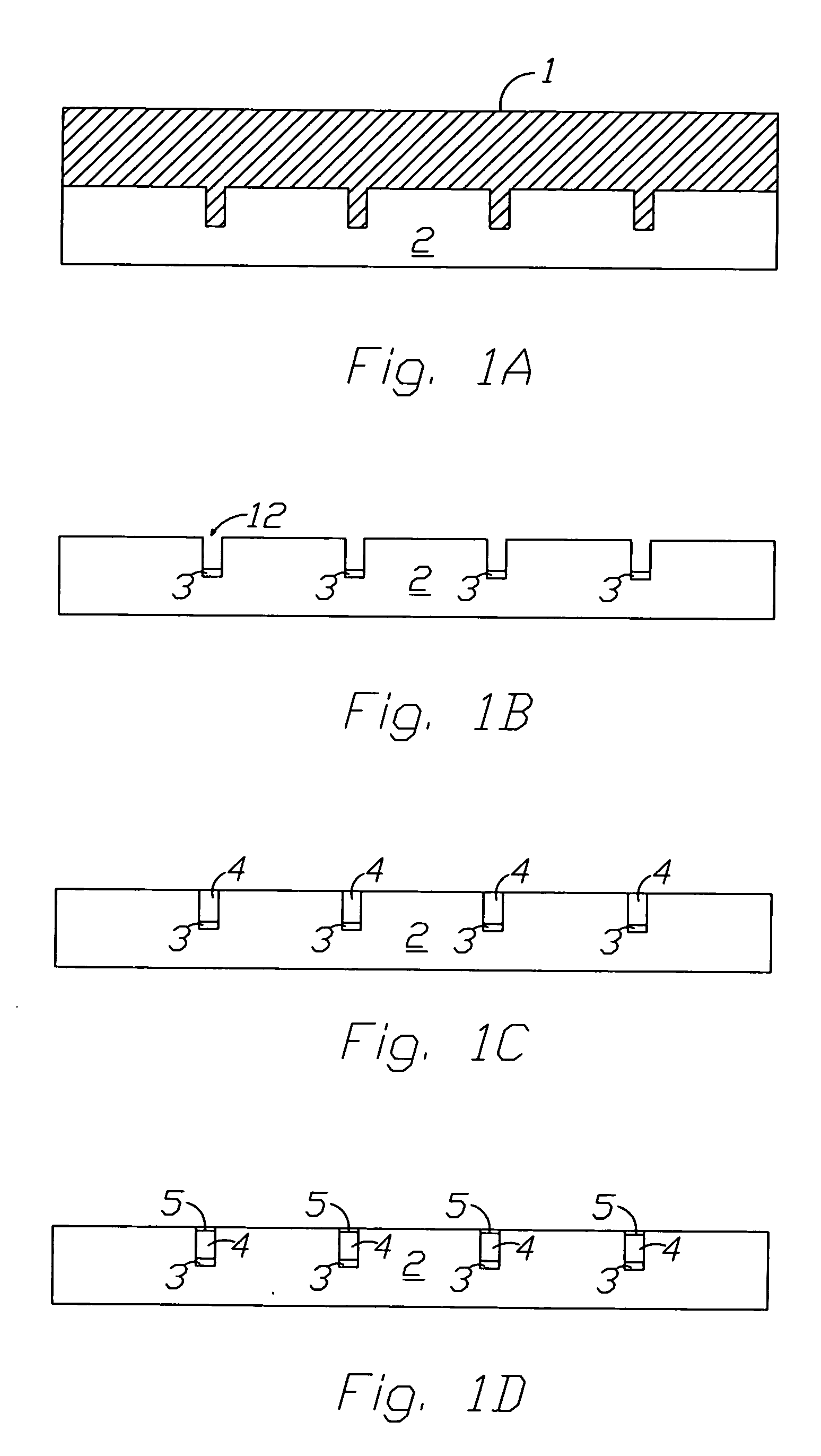

Embossed cell analyte sensor and methods of manufacture

ActiveUS7312042B1Eliminate needEasy to controlMicrobiological testing/measurementMaterial analysis by electric/magnetic meansAnalyteEngineering

An analyte measurement system is provided having sensors with embossed test chamber channels. In one embodiment, the sensors are elongate test strips for in vitro testing, each test strip having a substrate, at least one electrode, an embossed channel in the electrode, and lidding tape covering at least a portion of the embossed channel. Methods of manufacture are also disclosed for filling the sensor channels with reagent, and for trimming the ends of the sensors to eliminate the need for a calibration code during use of the sensors with a meter.

Owner:ABBOTT DIABETES CARE INC

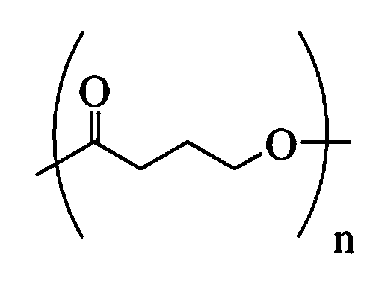

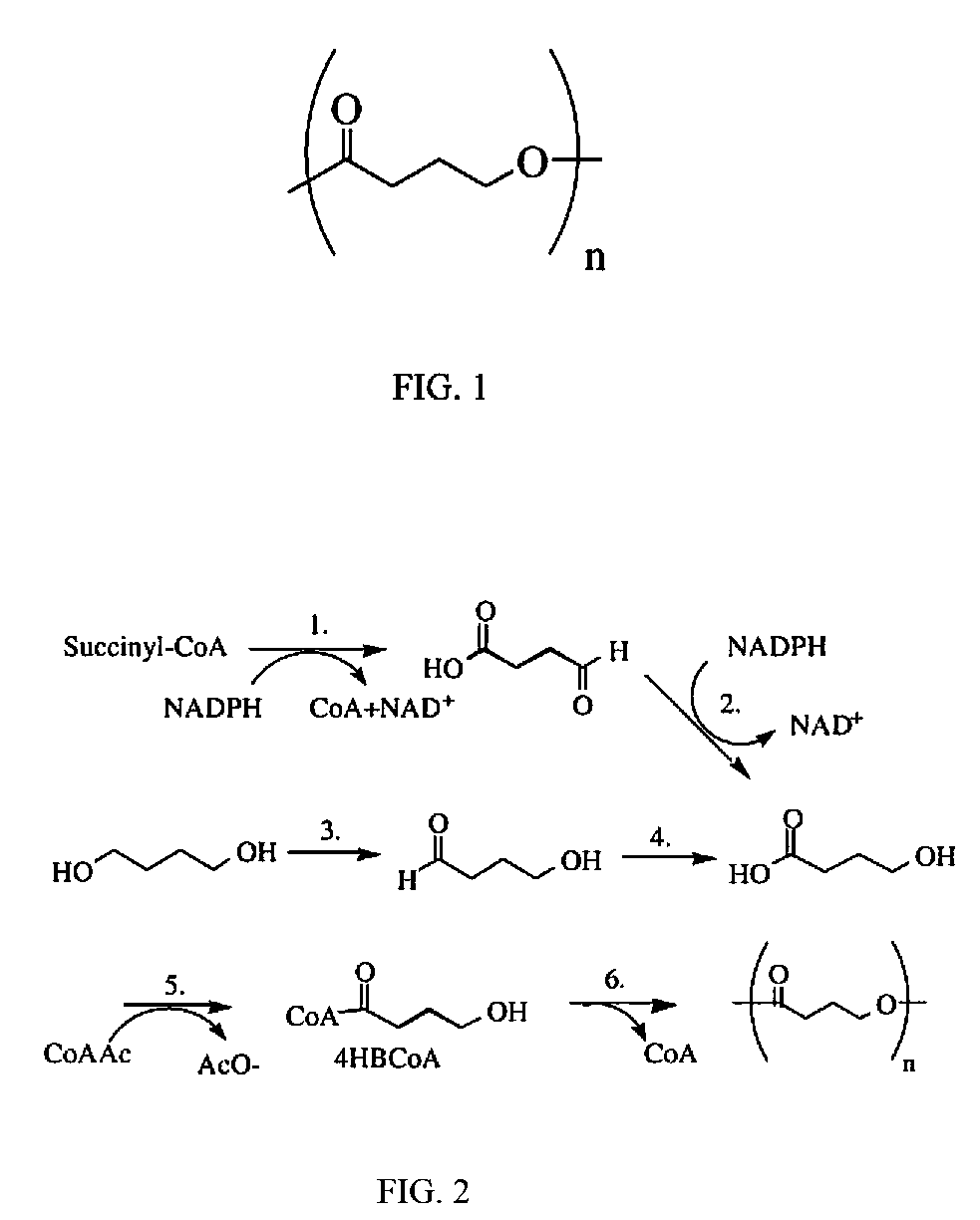

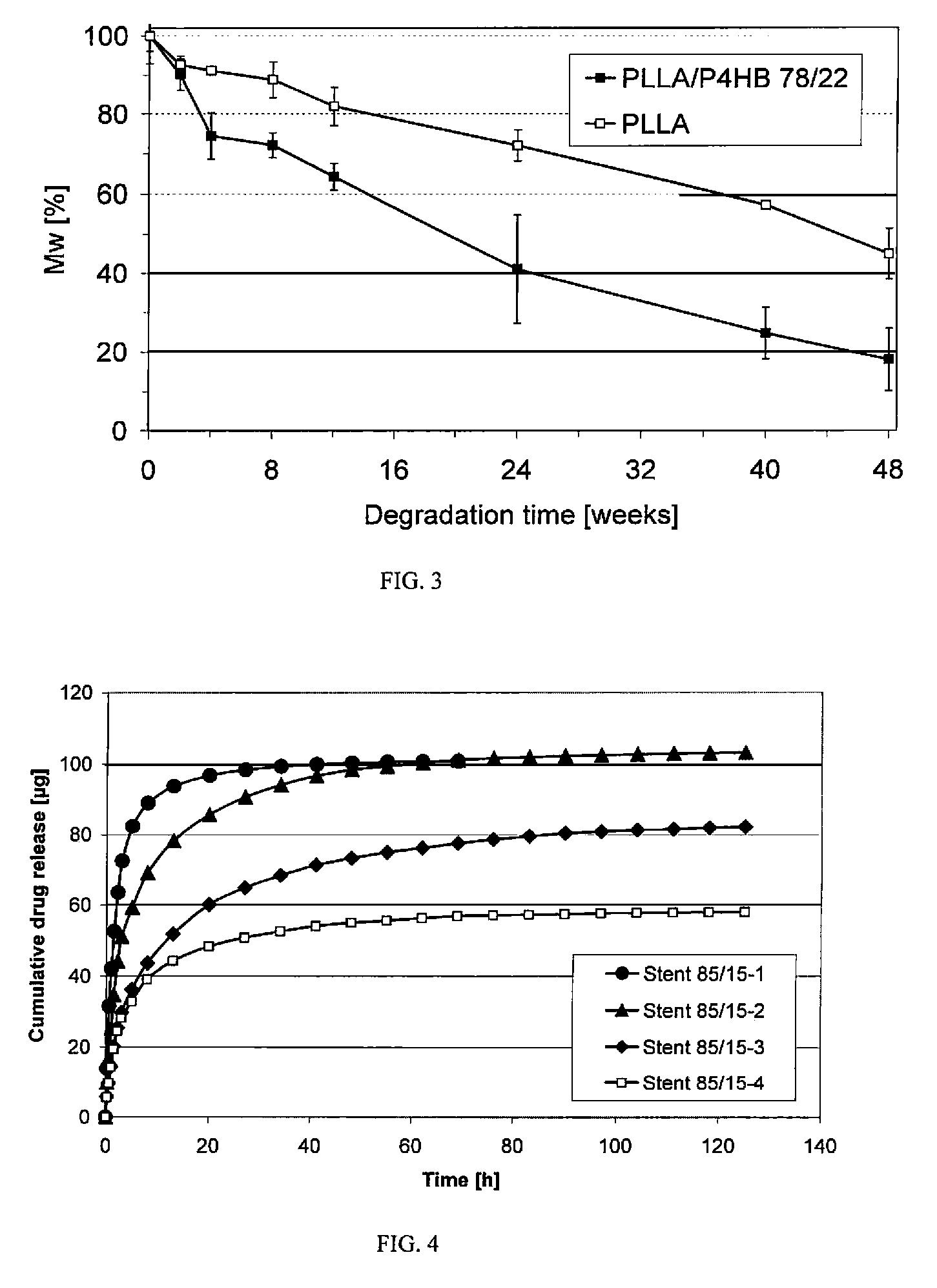

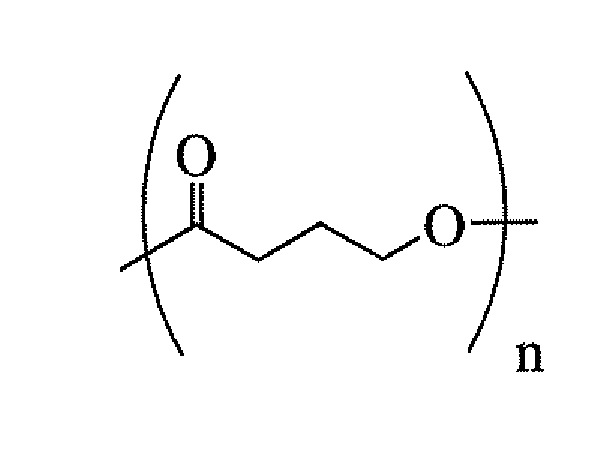

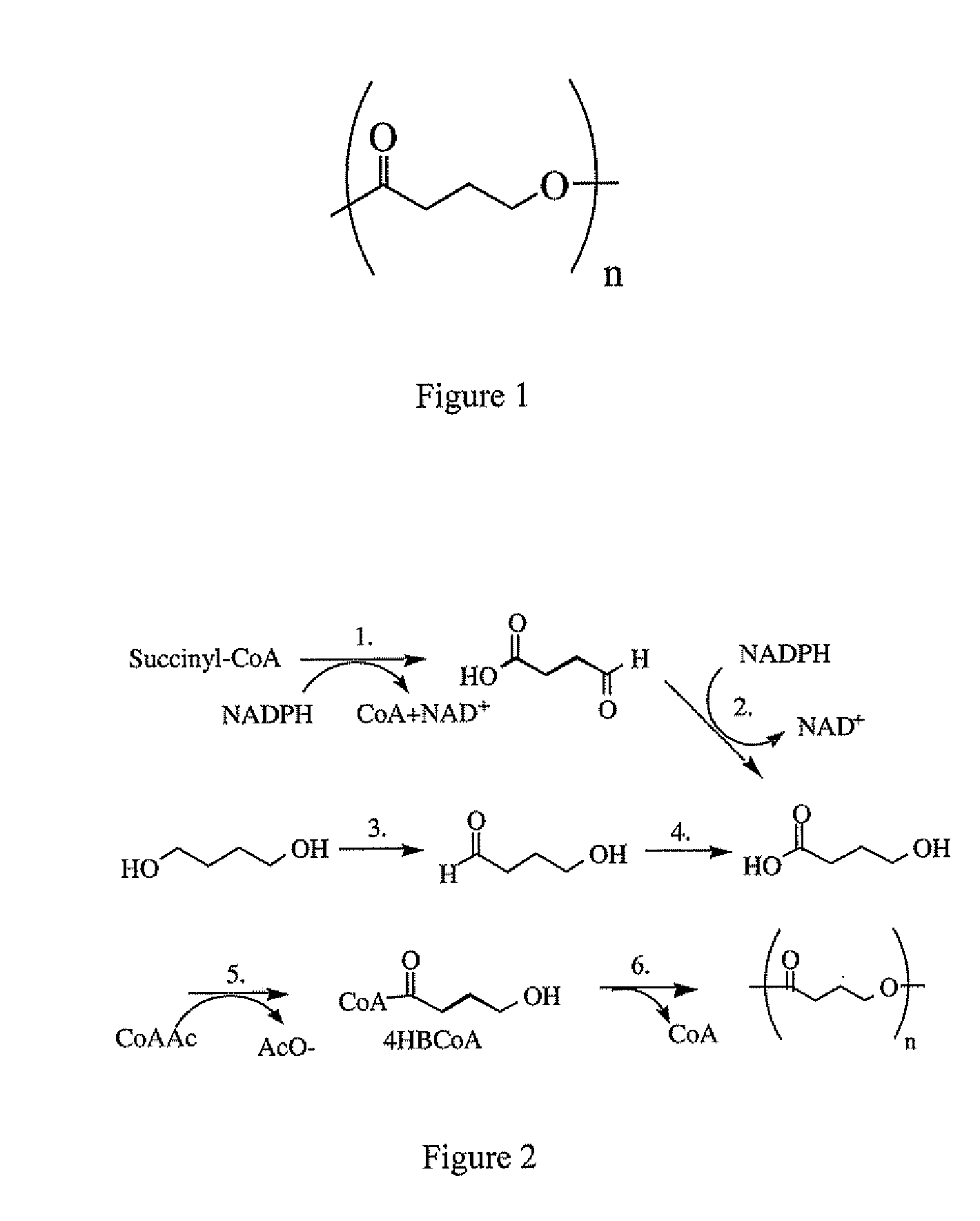

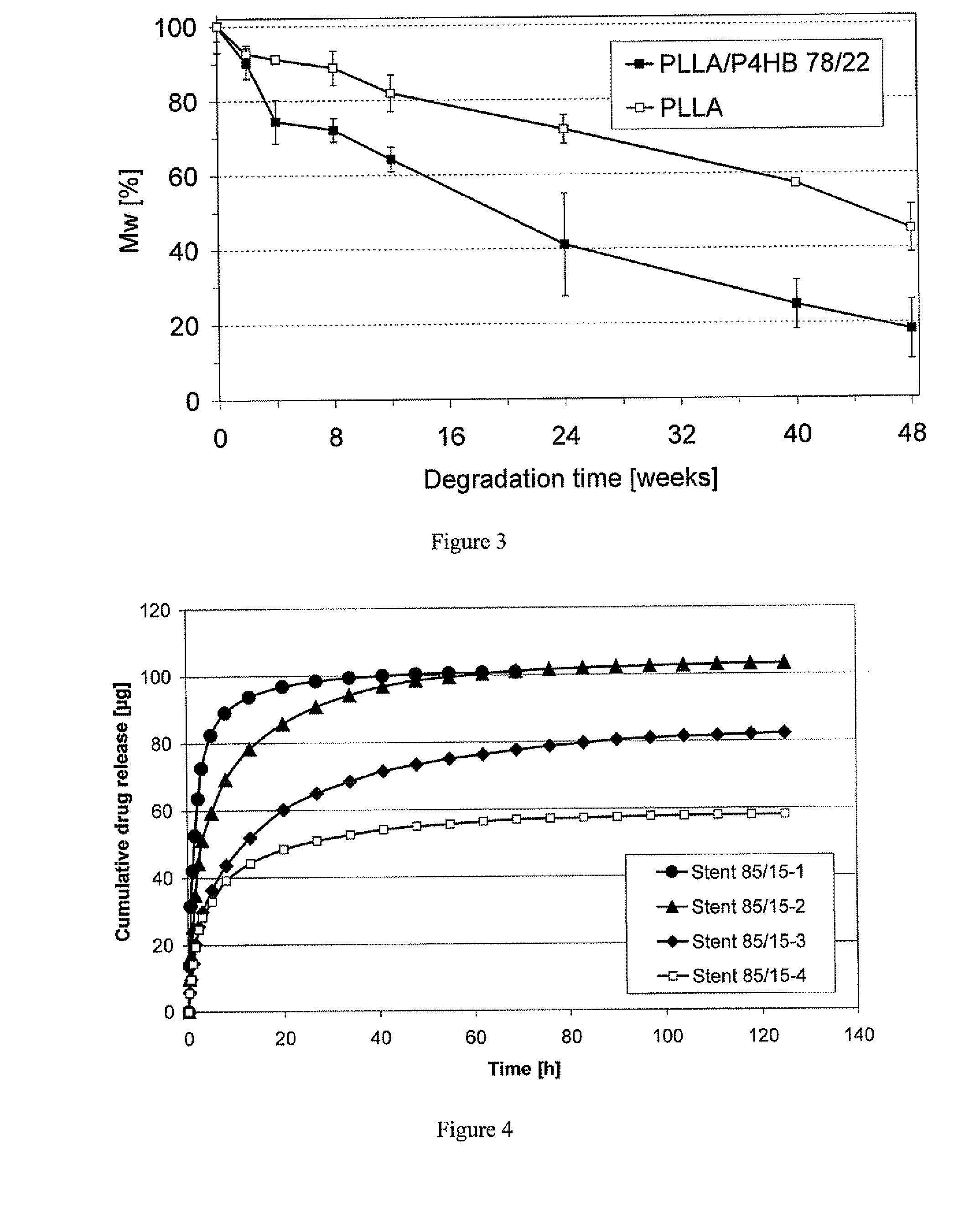

Polymeric, degradable drug-eluting stents and coatings

ActiveUS7618448B2Improve performanceImprove propertiesSuture equipmentsPharmaceutical containersAbsorbable polymersEthylene Homopolymers

Absorbable stents and absorbable stent coatings have been developed with improved properties. These devices preferably comprise biocompatible copolymers or homopolymers of 4-hydroxybutyrate, and optionally poly-L-lactic acid and other absorbable polymers and additives. Compositions of these materials can be used to make absorbable stents that provide advantageous radial strengths, resistance to recoil and creep, can be plastically expanded on a balloon catheter, and can be deployed rapidly in vivo. Stent coatings derived from these materials provide biocompatible, uniform coatings that are ductile, and can be expanded without the coating cracking and / or delaminating and can be used as a coating matrix for drug incorporation.

Owner:TEPHA INC

Thermal barrier coating material

InactiveUS6890668B2Promote thermal cycle fatigue lifeLow thermal conductivityMolten spray coatingPropellersThermal barrier coatingZirconium oxide

A coating material for a component intended for use in a hostile thermal environment. The coating material has a cubic microstructure and consists essentially of either zirconia stabilized by dysprosia, erbia, gadolinium oxide, neodymia, samarium oxide or ytterbia, or hafnia stabilized by dysprosia, gadolinium oxide, samarium oxide, yttria or ytterbia. Up to five weight percent yttria may be added to the coating material.

Owner:GENERAL ELECTRIC CO

Personal care composition in the form of an article having a hydrophobic surface-resident coating

InactiveUS20100291165A1Conveniently and quickly dissolvedEfficient use ofCosmetic preparationsHair cosmeticsPersonal careMedicine

The present invention relates to personal care compositions, especially those personal care compositions in the form of an article that is a porous, dissolvable solid structure. The article has a hydrophobic surface-resident coating that can provide enhanced deposition efficiency of hydrophobic actives contained therein.

Owner:THE PROCTER & GAMBLE COMPANY

Fire-retardant coating, method for producing fire-retardant building materials

InactiveUS20050229809A1Simple materialIncrease resistanceFireproof paintsAntifouling/underwater paintsCalcium silicateFire retardant

The present invention relates to a fire-resistant coating and method thereof, which confers enhanced flame and heat resistance to substrate such as building materials. The invented coating is especially applicable to cellulose-based building materials including but not limited to fiberboards, wallboards, roofing materials, particleboards, ceiling tiles, soundproofing boards and hardboards. This novel composition is also useful in providing a fire-resistant coating for concrete, metals, foamed polymeric materials, gypsum and other substrates. A preferred embodiment generally comprising: mono potassium phosphate, magnesium oxide, silica powder, calcium silicate, rice hull ash and water. A method for imparting fire-retardancy to substrates using the invented composition is also described

Owner:BONE SOLUTIONS INC

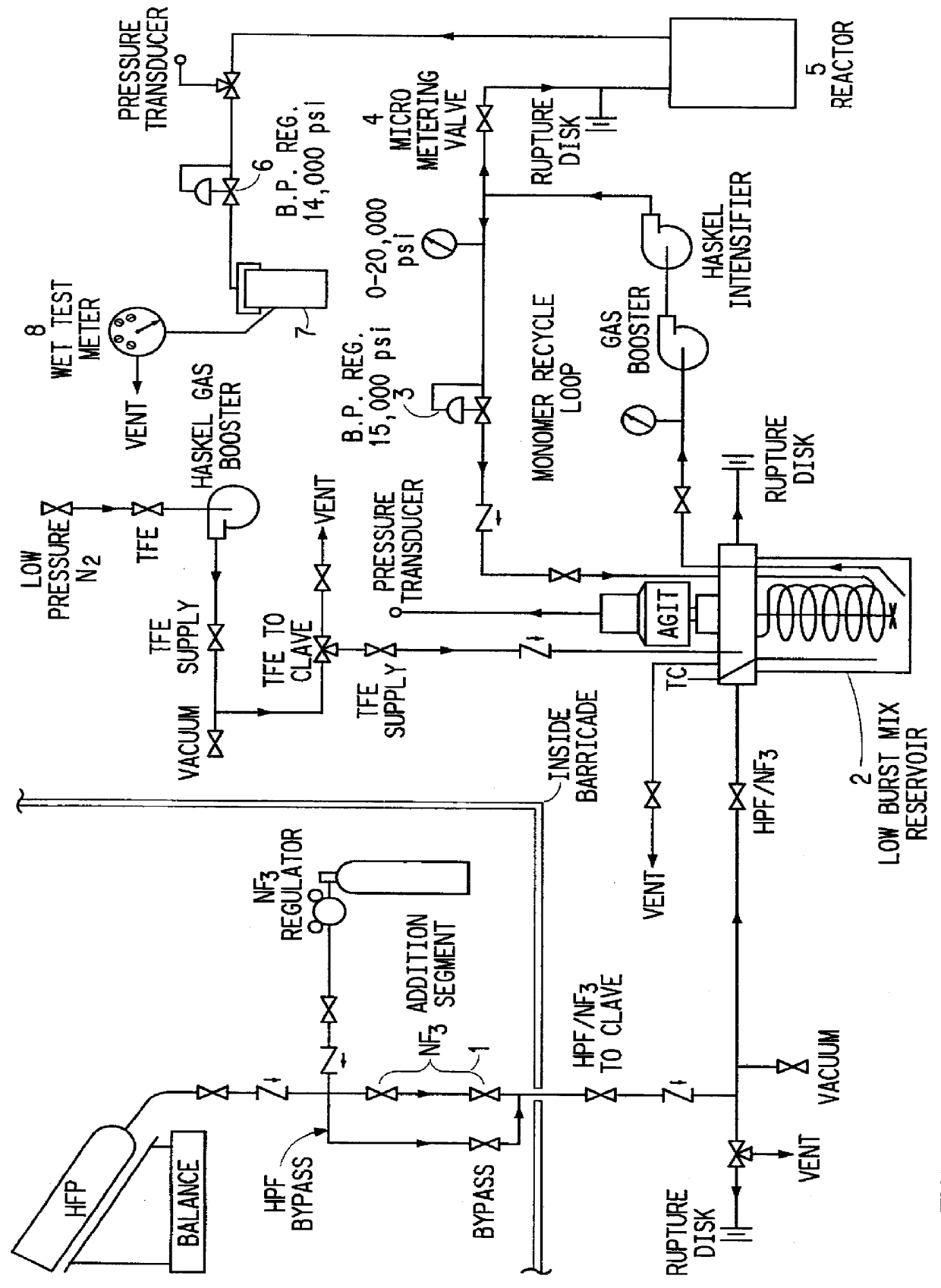

Amorphous tetrafluoroethylene-hexafluoropropylene copolymers

InactiveUS6133389AThin coatingIncrease coating thicknessOrganic chemistryCoatingsPolymer scienceHexafluoropropylene

Disclosed herein are novel amorphous tetrafluoroethylene-hexafluoropropylene (TFE-HFP) dipolymers, and other copolymers containing TFE, HFP and a third monomer, many of which are more random than previous amorphous TFE-HFP copolymers, as well as a novel high productivity continuous process for making these polymers. The polymers are particularly useful in the form of coatings, films and encapsulants.

Owner:THE CHEMOURS CO FC LLC

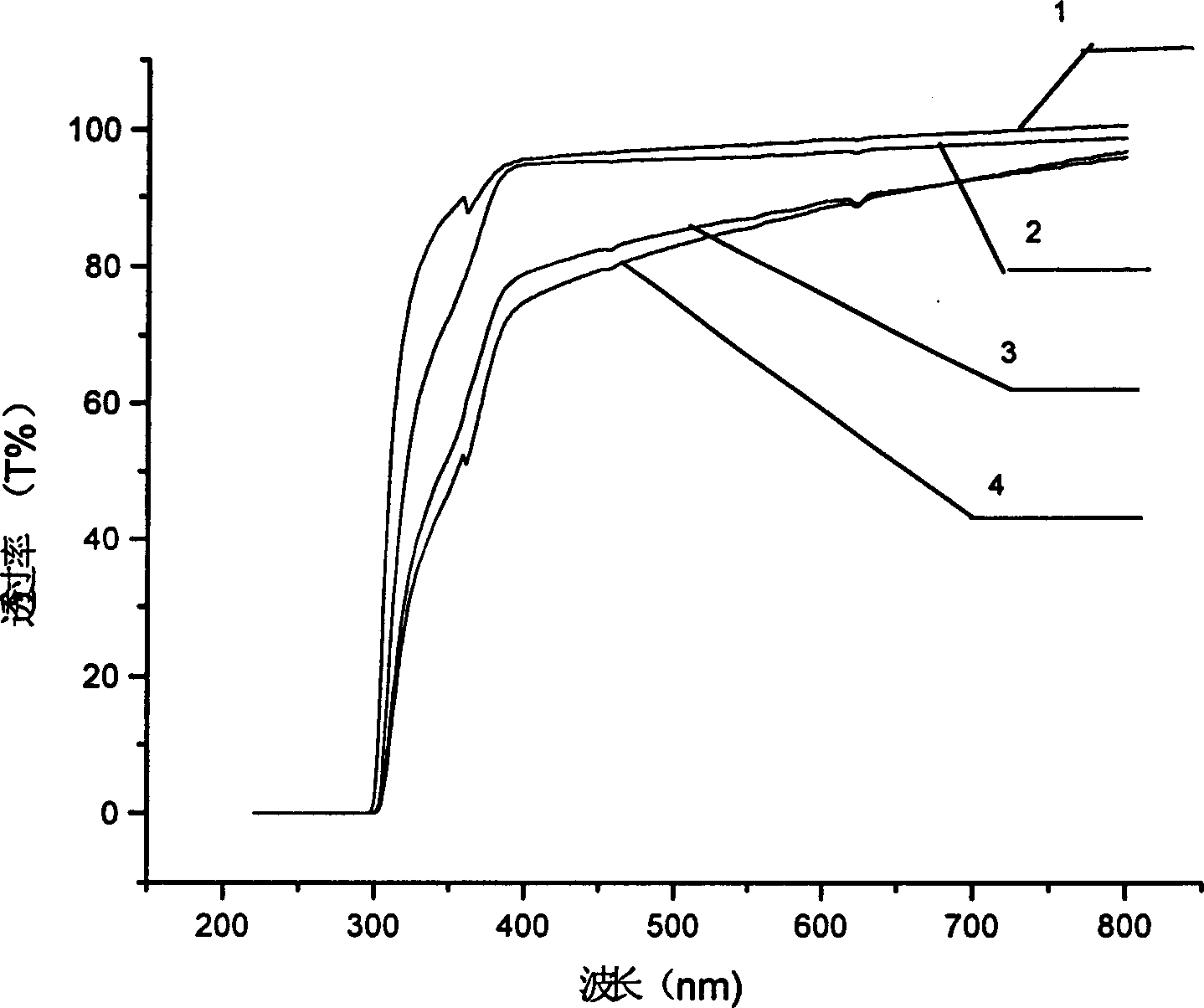

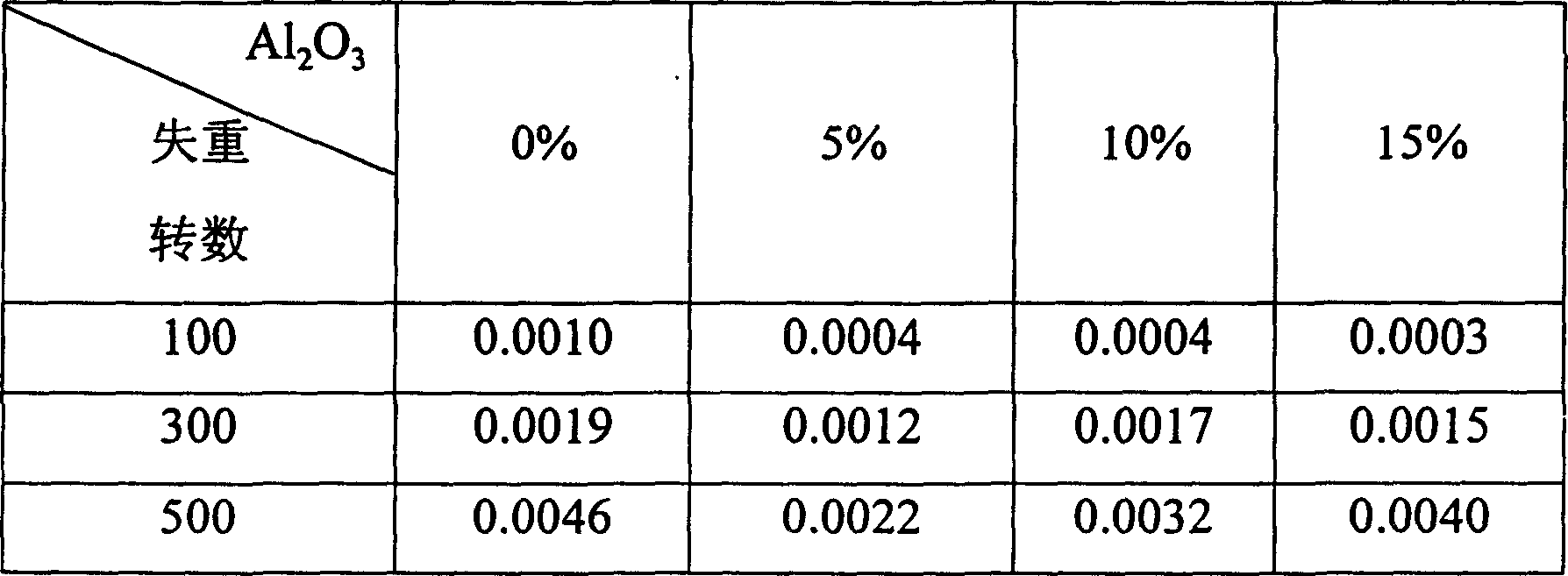

Nano transparent abrasion resistant composite paint

An antiwear transparent nano-class composite paint includes the dual-component composite paint consisting of high-molecular resin as filming material, Al2O3 nanoparticles, assistant, solvent, diluent and solidifying agent and the single-component composite paint consisting of high-molecular water resin, Al2O3 nanoparticles, assistant, and water. Its advantages are high adhesion and high ultraviolet shielding power.

Owner:NANJING UNIV OF TECH

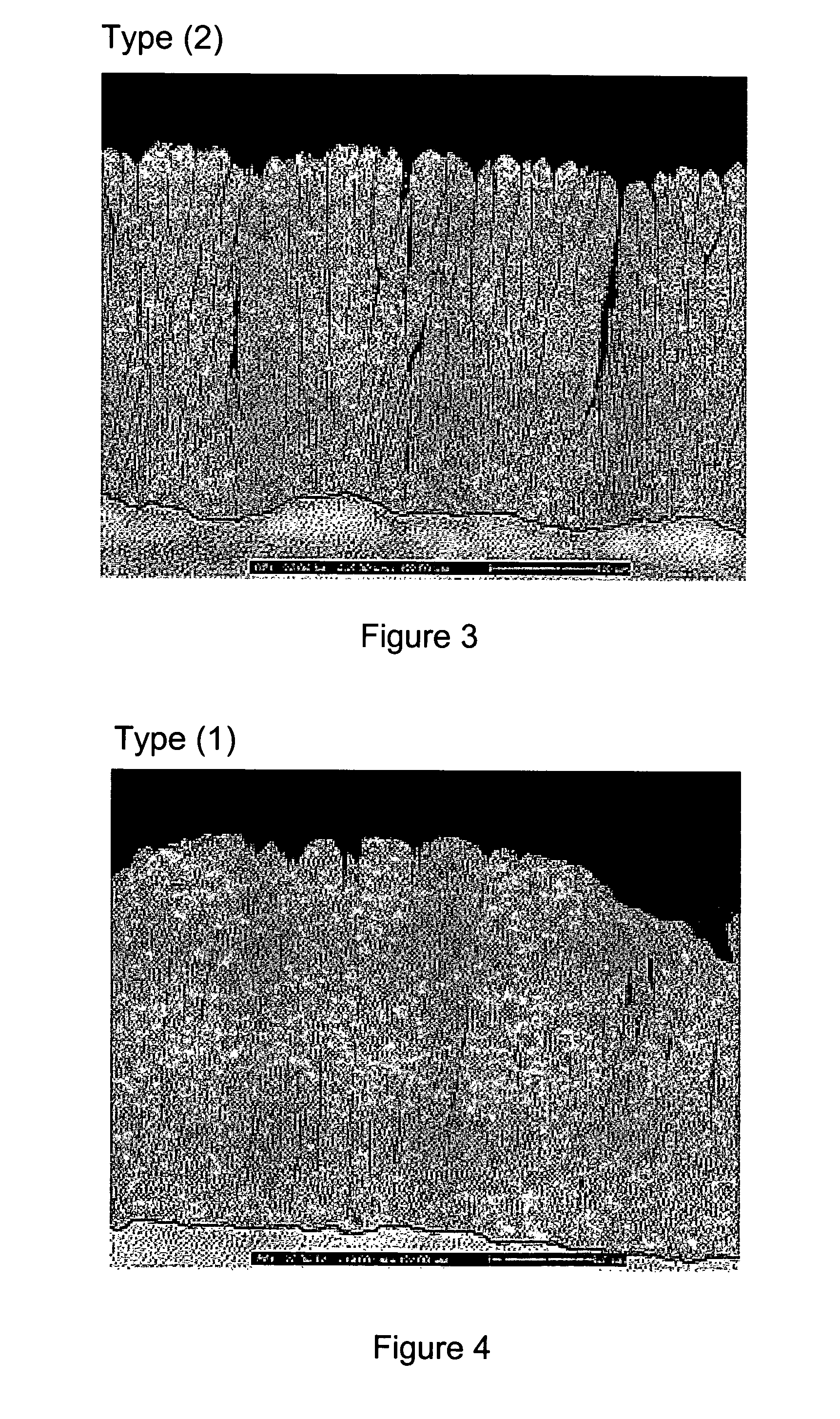

Thermal barrier coating

InactiveUS6982126B2Low thermal conductivityLess erosion-resistantPropellersVacuum evaporation coatingInterior designThermal barrier coating

A thermal barrier coating (TBC) for a component intended for use in a hostile thermal environment. The TBC has an interior region and an outer surface region on and contacting the interior region. Both regions are formed of a ceramic material, with the interior region having a lower thermal conductivity than zirconia partially stabilized by about seven weight percent yttria. The interior region constitutes more than half of the thickness of the TBC, and the outer surface region constitutes less than half of the thickness of the TBC. The TBC has a columnar microstructure whereby the interior region and the outer surface region comprise columns of their ceramic materials. The outer surface region is more erosion and impact resistant than the interior region at least in part as a result of the columns thereof being more closely spaced than the columns of the interior region.

Owner:GENERAL ELECTRIC CO

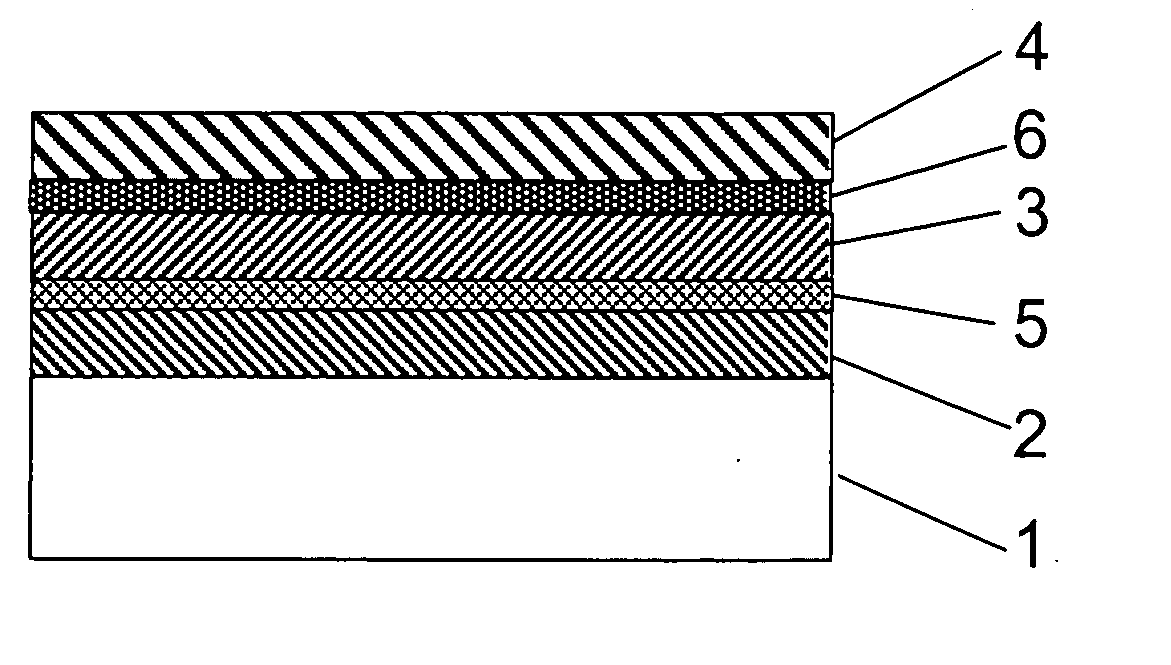

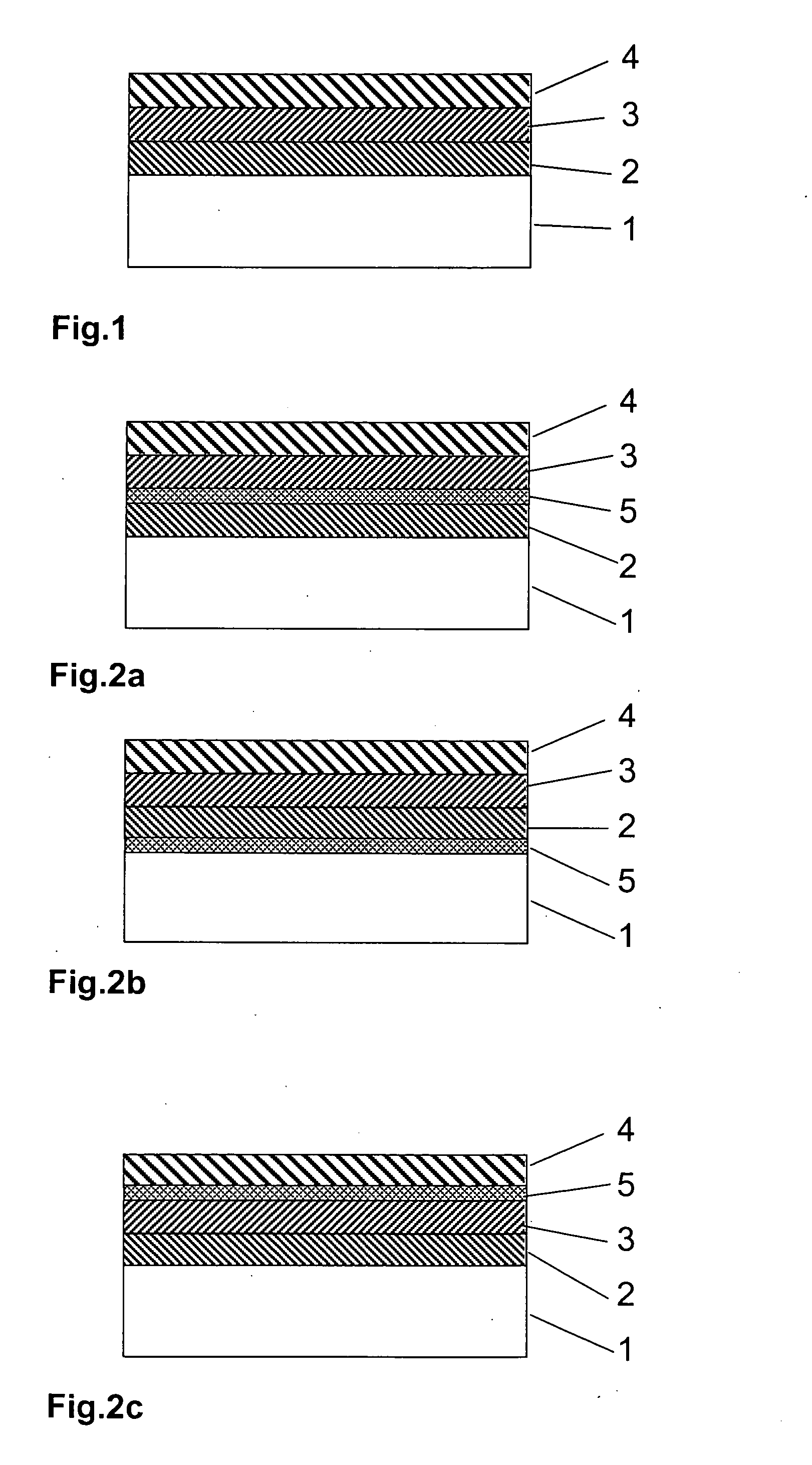

MCrAIY bond coating and method of depositing said MCrAIY bond coating

InactiveUS20050003227A1Enhanced surface roughnessReduce effectInsulating substrate metal adhesion improvementLiquid surface applicatorsBond coatingPt element

A method of depositing a bond coating to a surface of an article includes the steps of depositing an inner layer of the bond coating consisting of β-NiAl comprising Fe, Ga, Mo, B, Hf or Zr or γ / β-MCrAlY comprising Fe, Ga, Mo, B, Hf or Zr or γ / γ′- or γ-MCrAlY, and depositing an outer layer of the bond coating, which is more coarse the in the inner layer, consisting of β-NiAl comprising Fe, Ga, Mo, B, Hf or Zr or γ / β-MCrAlY comprising Fe, Ga, Mo, B, Hf or Zr or γ / γ′- or γ-MCrAlY, wherein said elements Fe, Ga, Mo, B, Hf or Zr above mentioned are present individually or in combination. The coating also includes a noble metal selected from the group consisting of platinum, palladium and rhodium in the inner and outer layer or as a separate layer.

Owner:ALSTOM TECH LTD

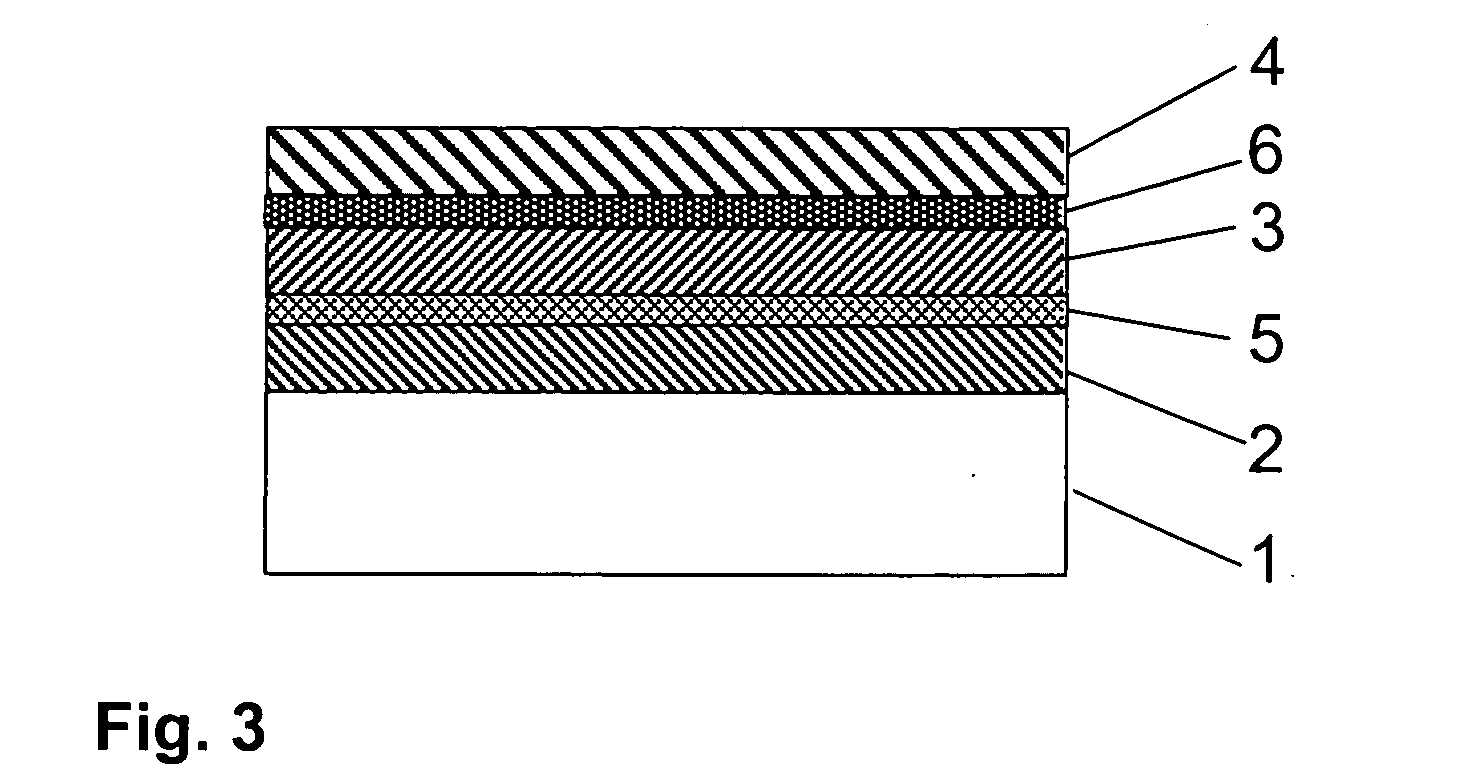

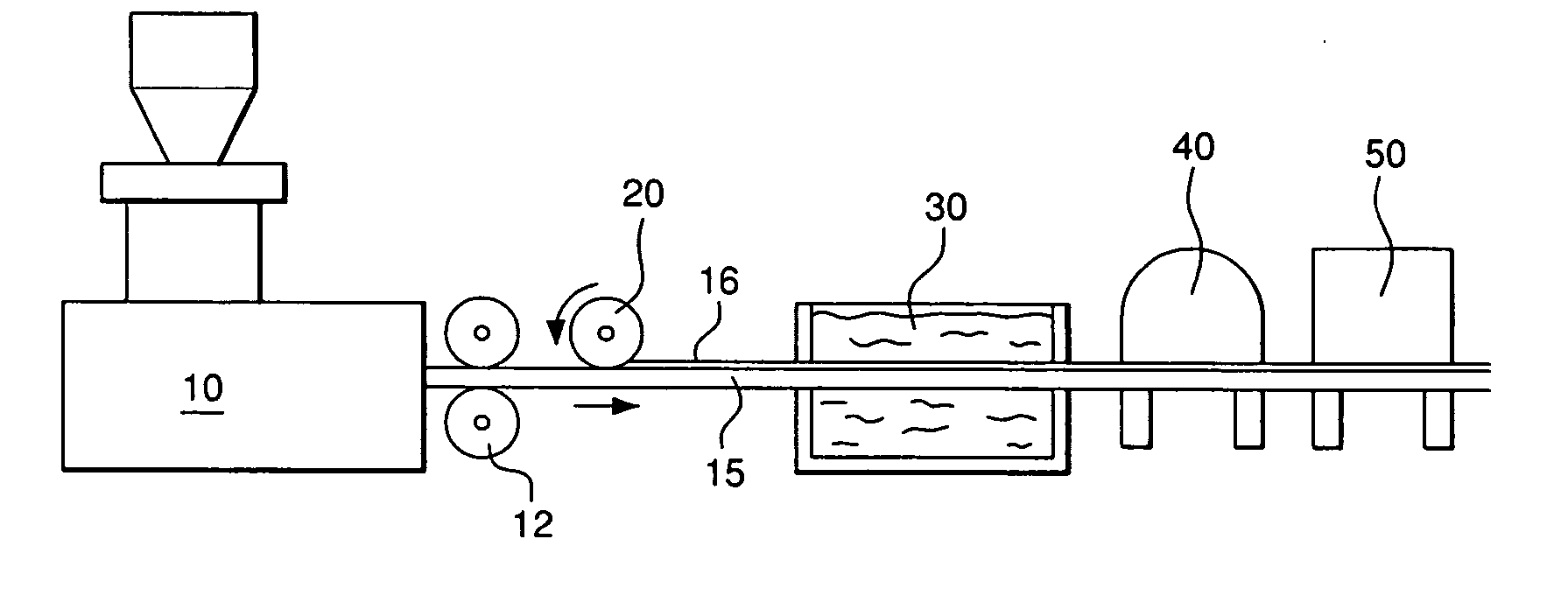

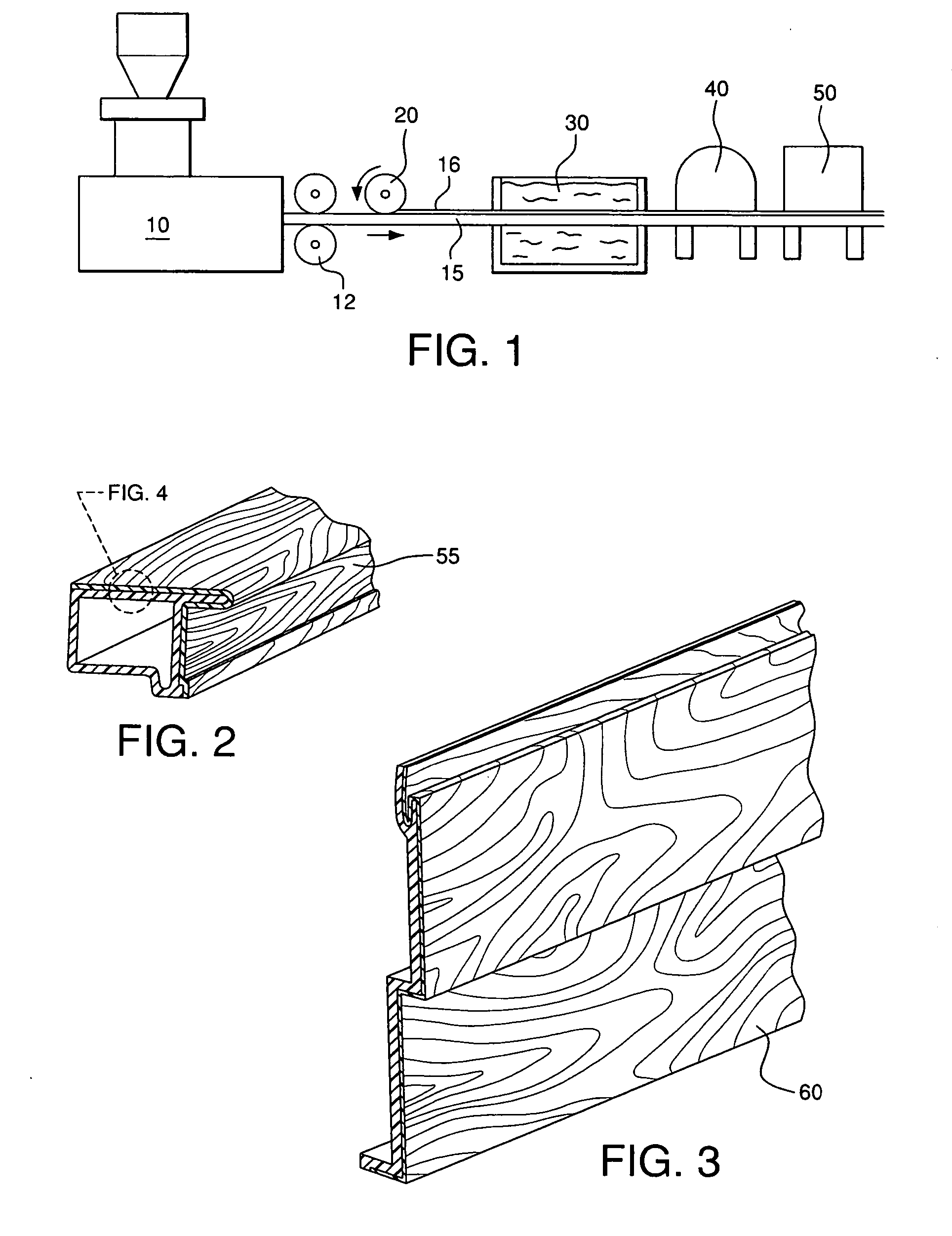

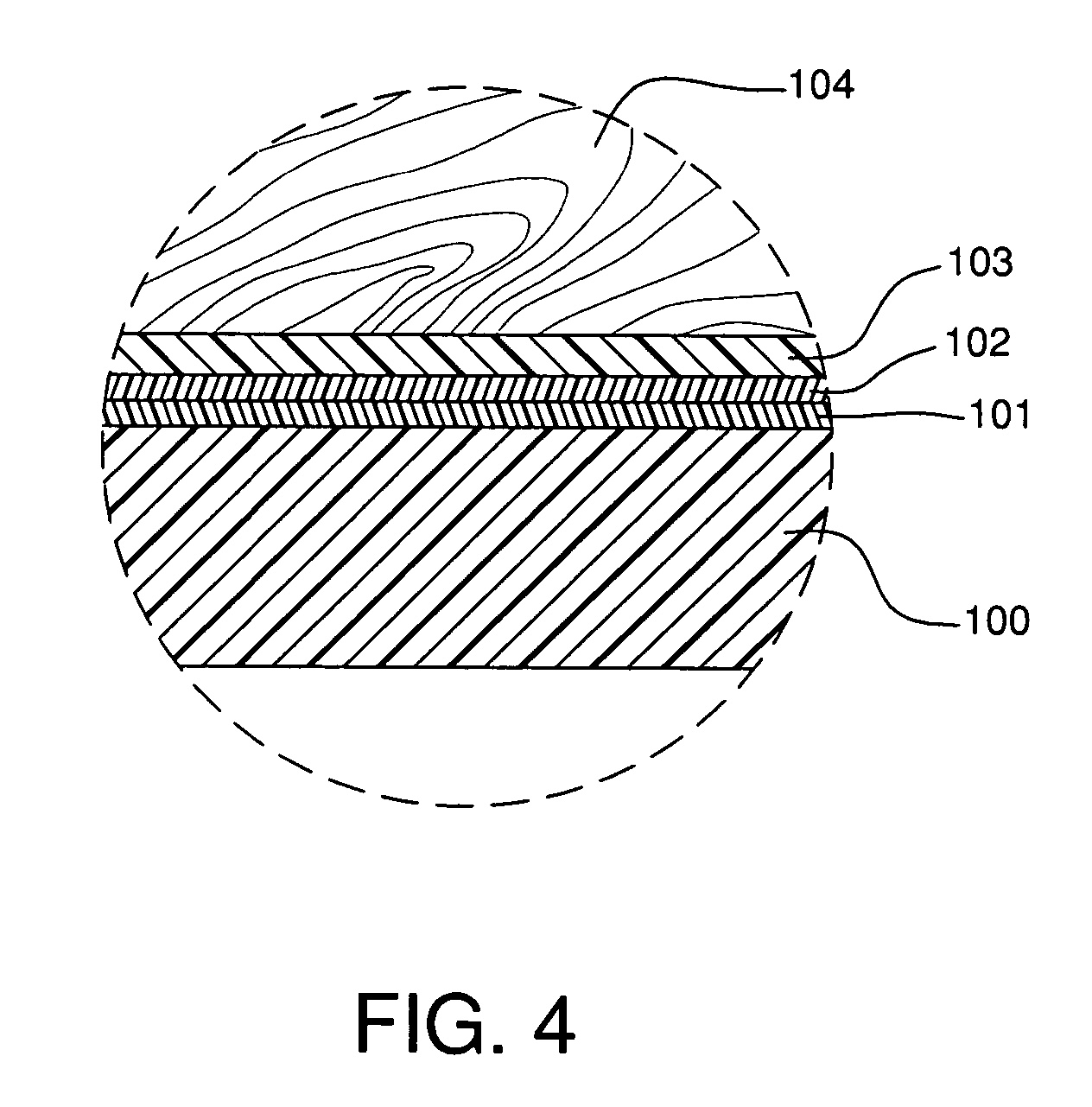

Building material having a fluorocarbon based capstock layer and process of manufacturing same with less dimensional distortion

InactiveUS20070092701A1Realistic appearanceEliminate bowingLiquid surface applicatorsCovering/liningsThermoplasticFluorocarbon

The present invention provides building materials and methods for the manufacturer which includes an extrudable thermoplastic or thermosetting substrate having a fluorocarbon-based capstock layer applied to the substrate. The fluorocarbon-based capstock layer can further include one or more top coats for providing a variegated, colored or textured pattern. The capstock layer, with or without the top coats, preferably has a thickness less than 4 mil and contains a UV-resistant PVDF resin.

Owner:CERTAINTEED CORP

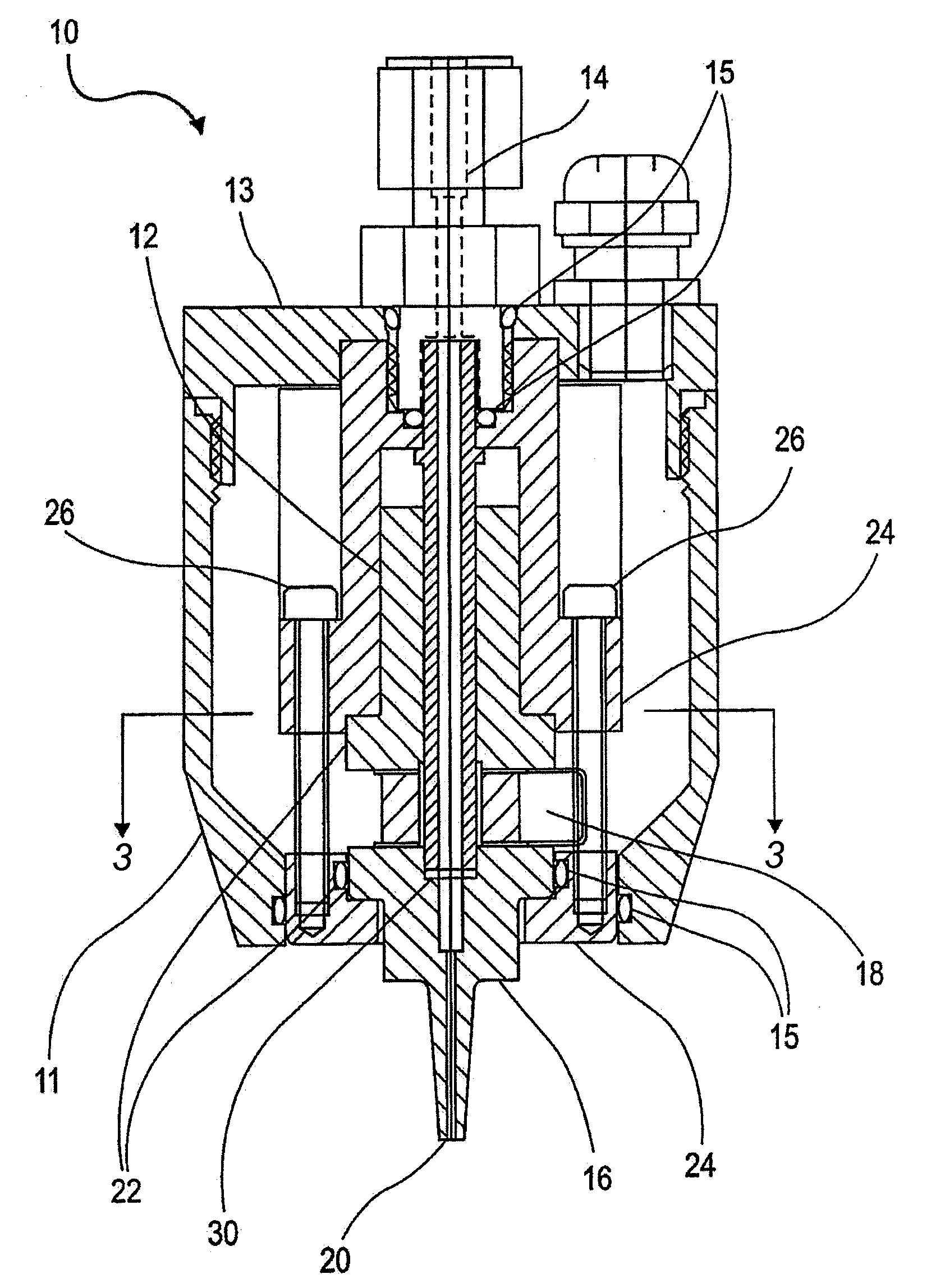

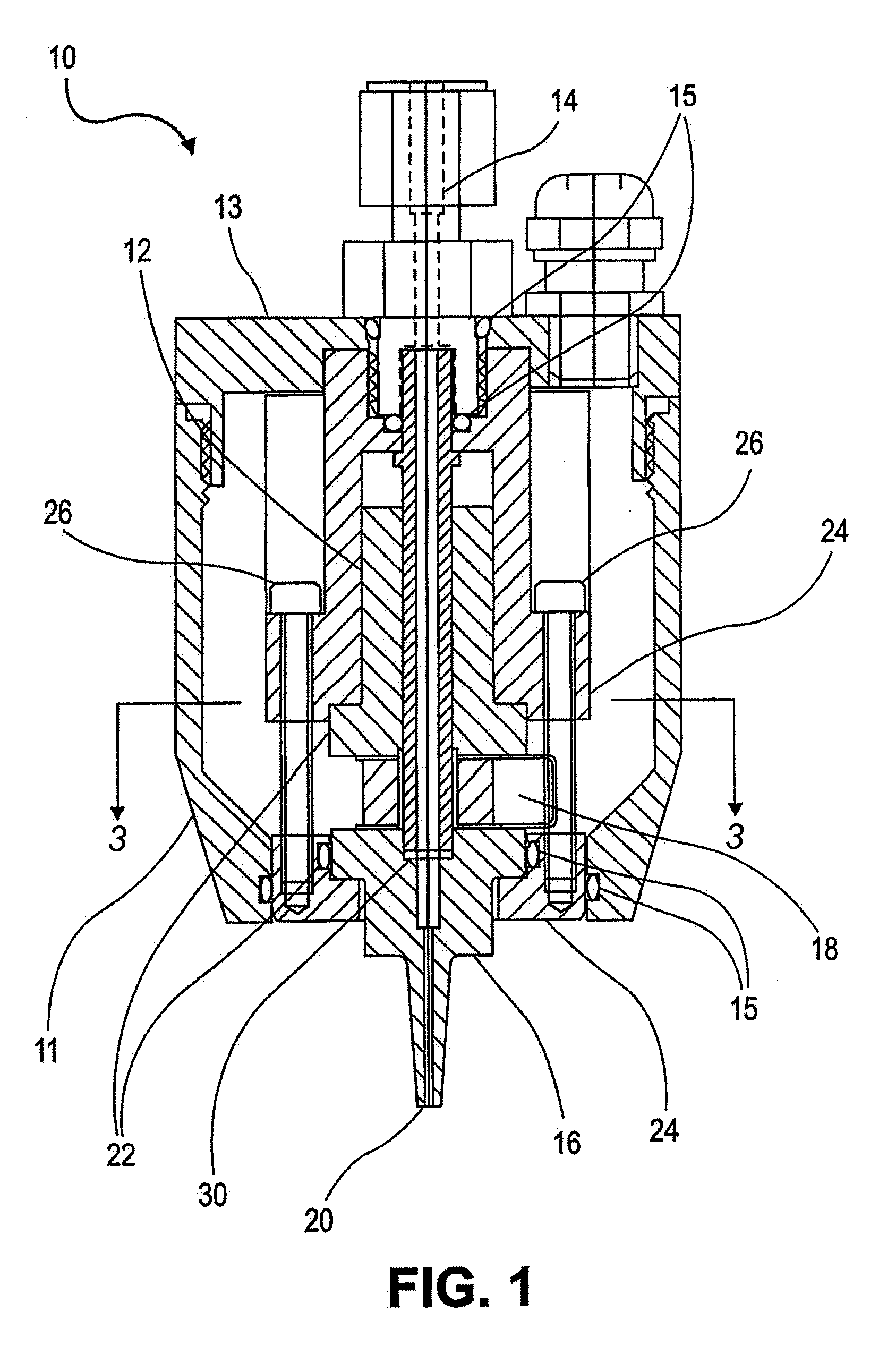

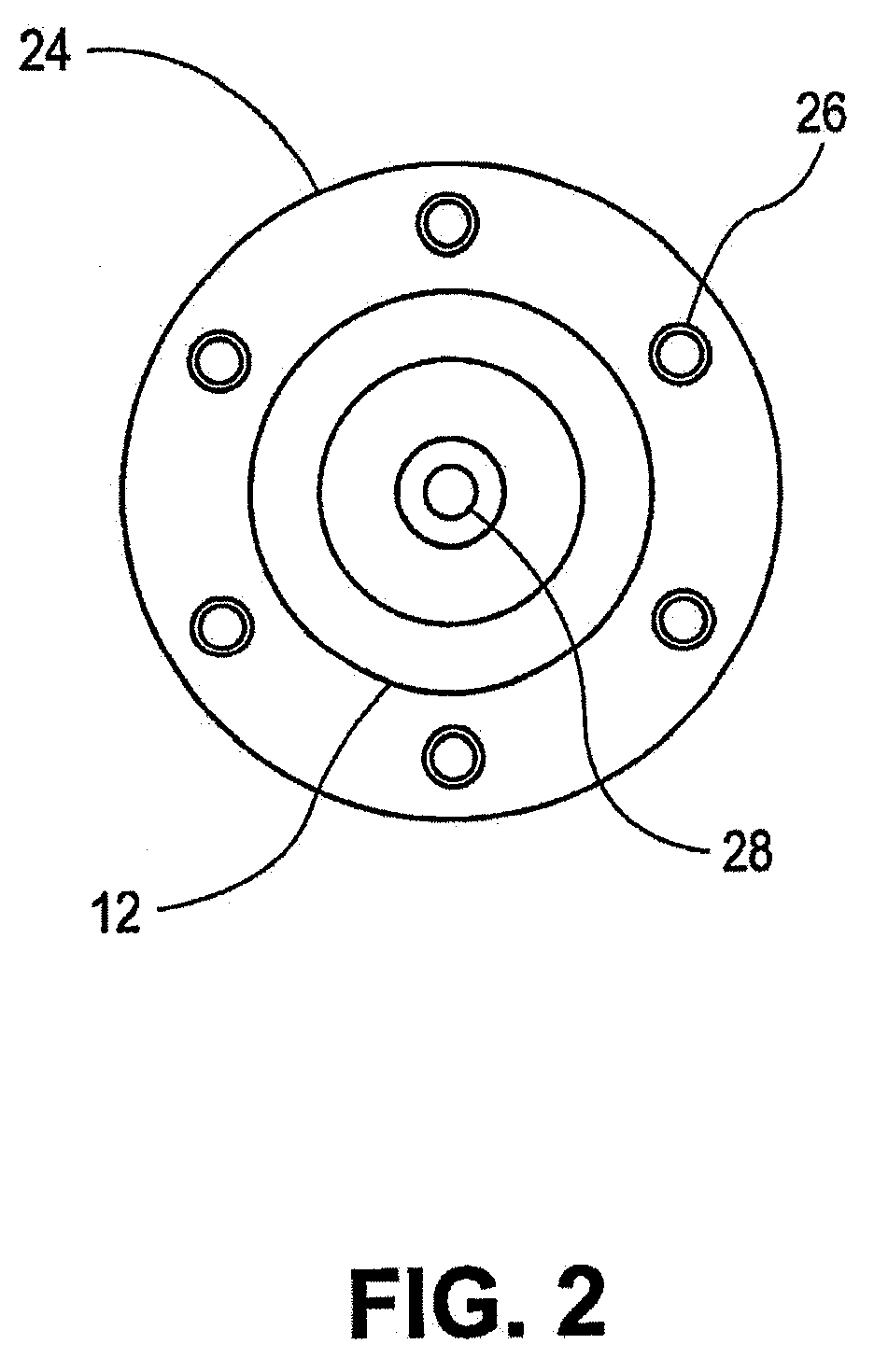

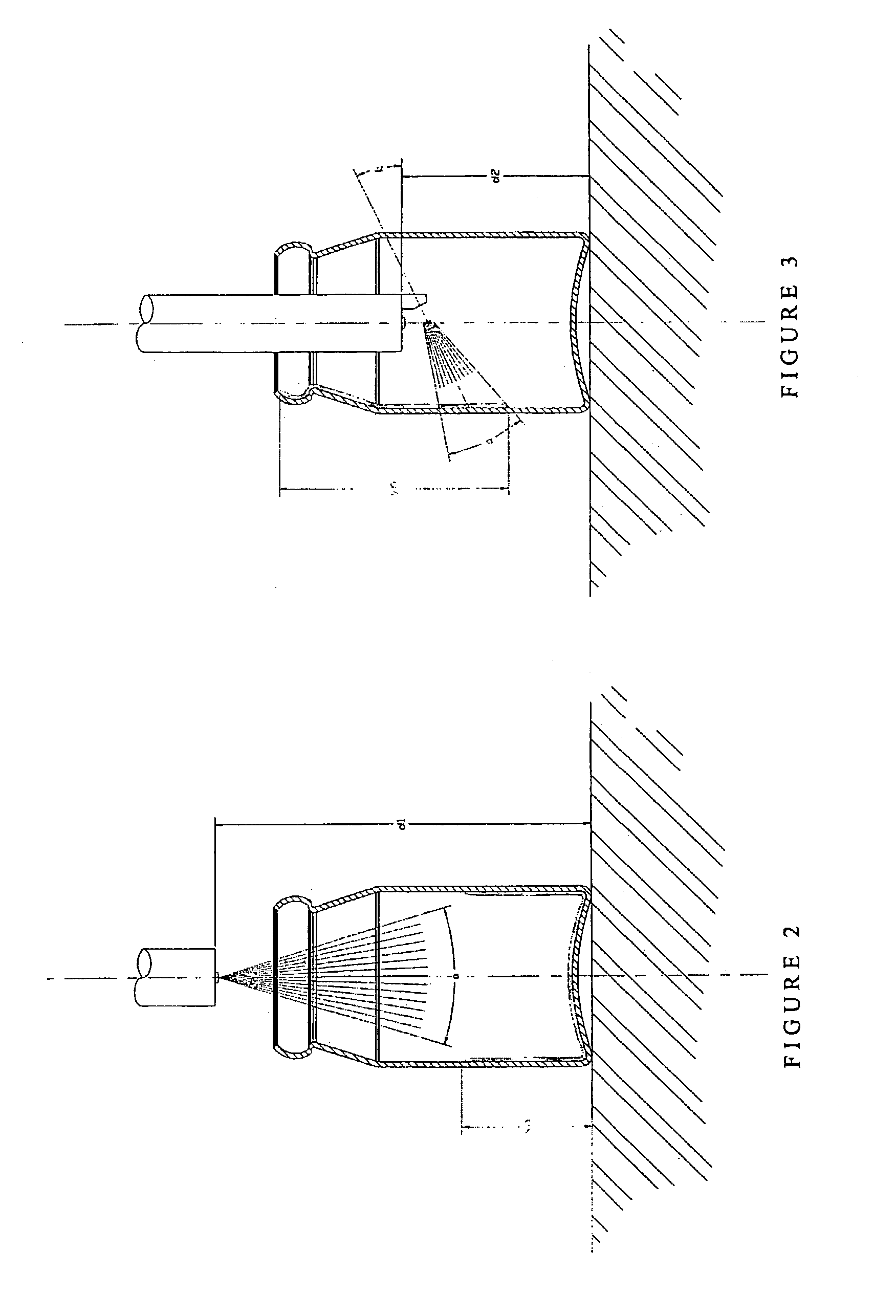

Ultrasonic atomizing nozzle methods for the food industry

ActiveUS20090224066A1Thin coatingUniform coatingLiquid surface applicatorsMovable spraying apparatusFood packagingEngineering

A spraying mechanism configured to form uniform and thin coatings on foodstuffs and food packaging materials. The spraying mechanism includes a nozzle and a surface positioned adjacent to the nozzle, wherein the surface is configured to support at least one of a foodstuff and a food packaging material. The nozzle includes an atomizing section including a ceramic material and an intermediate section configured to promote ultrasonic-frequency mechanical motion in the atomizing section.

Owner:SONO TEK CORP

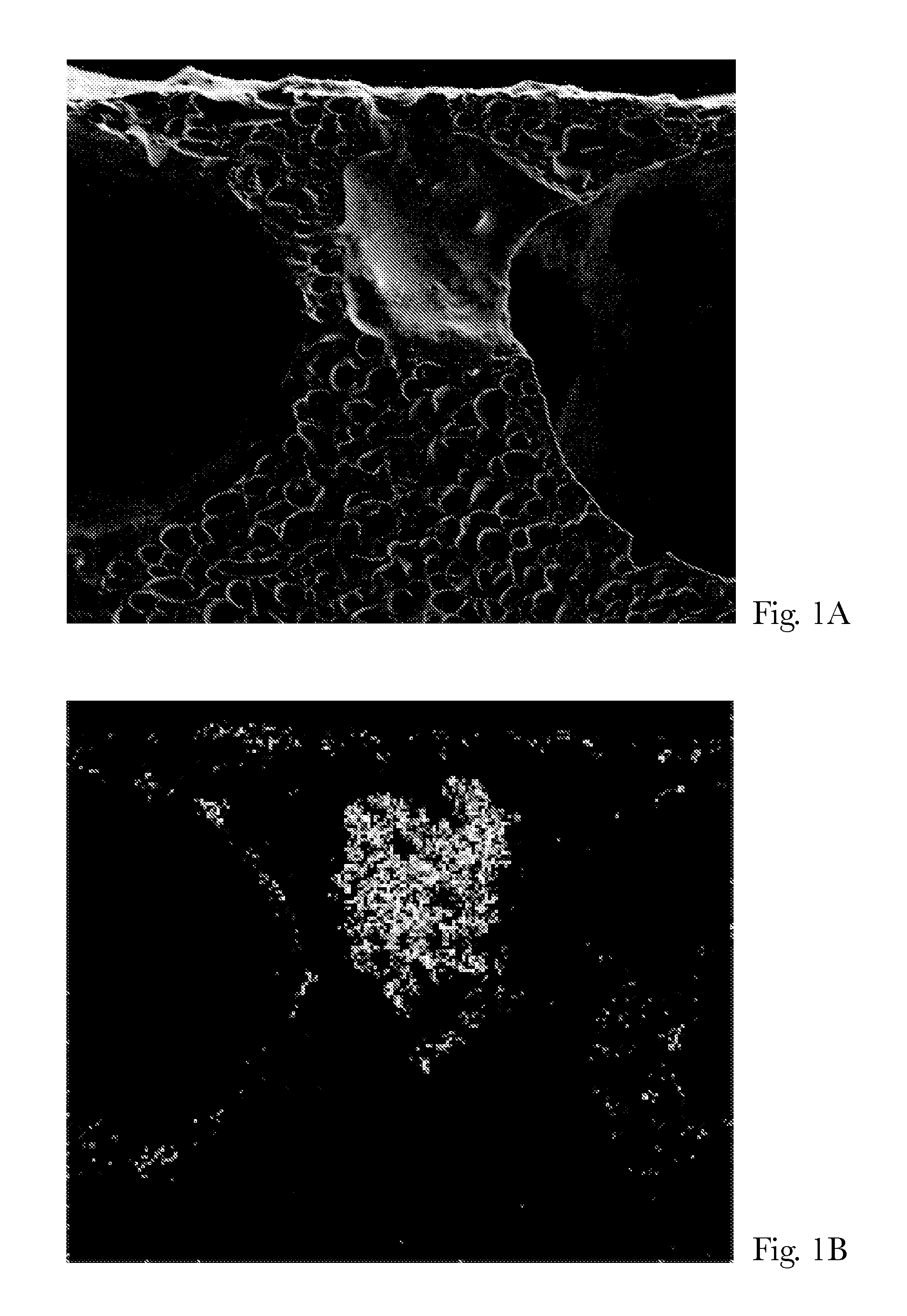

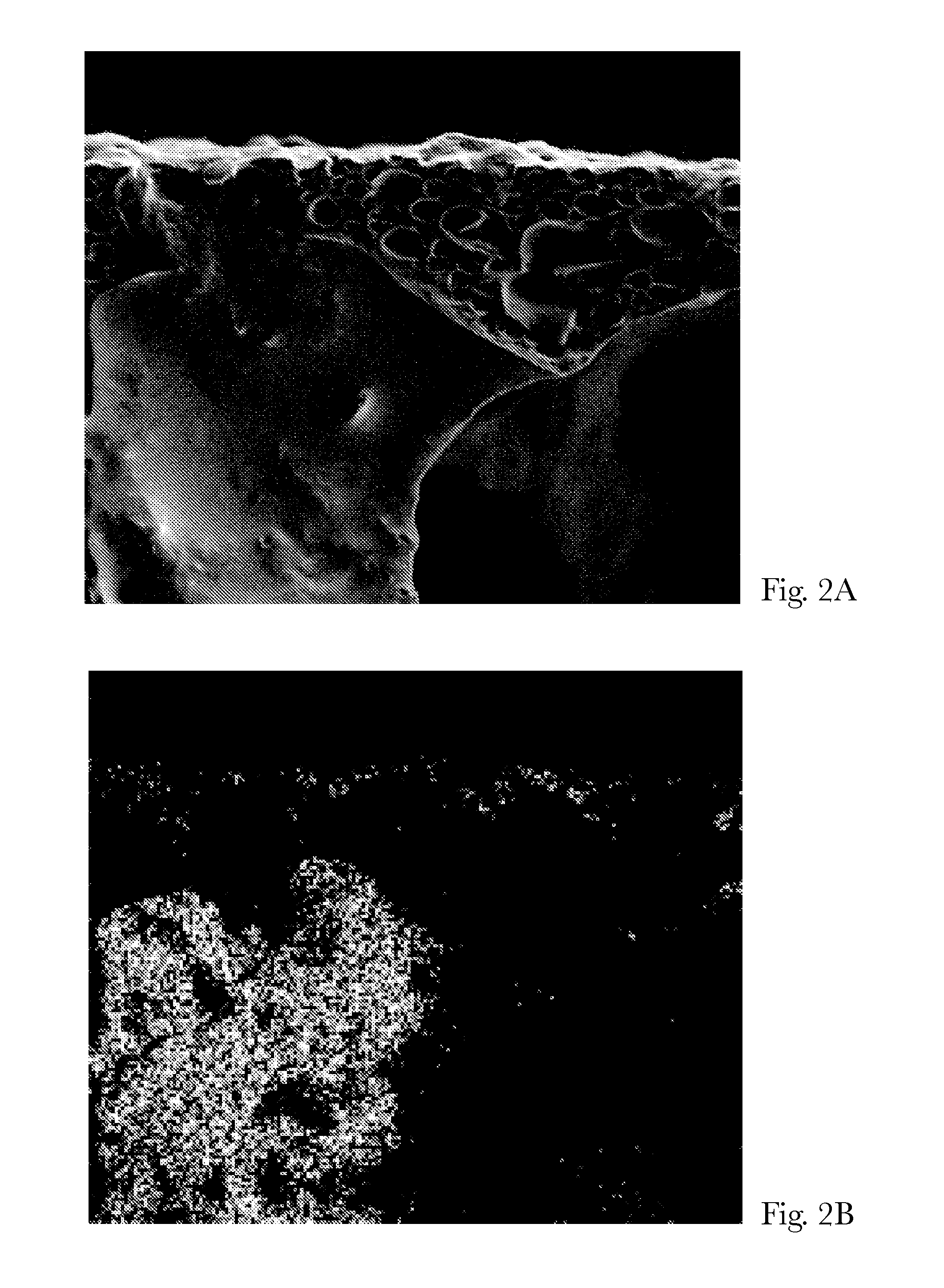

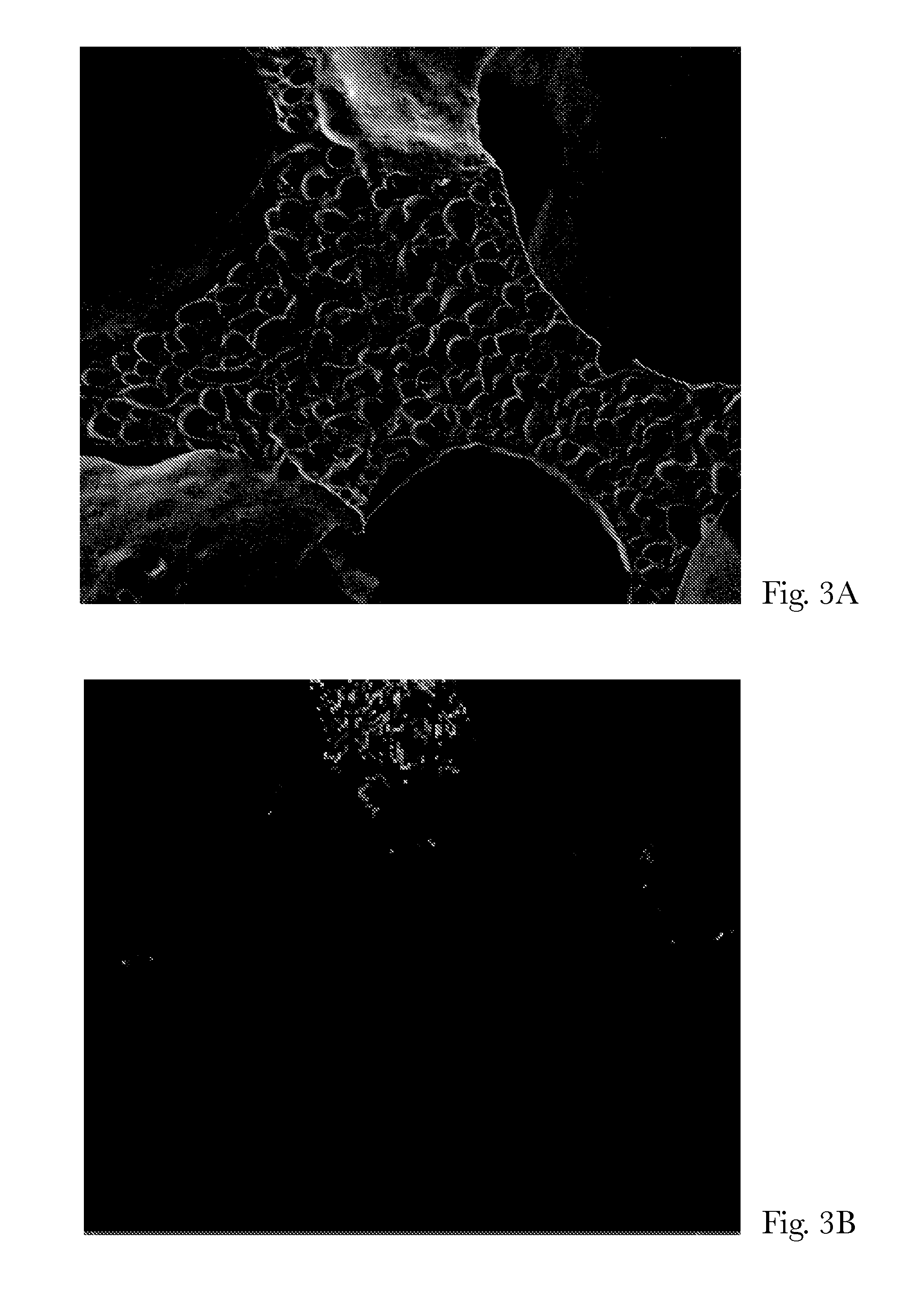

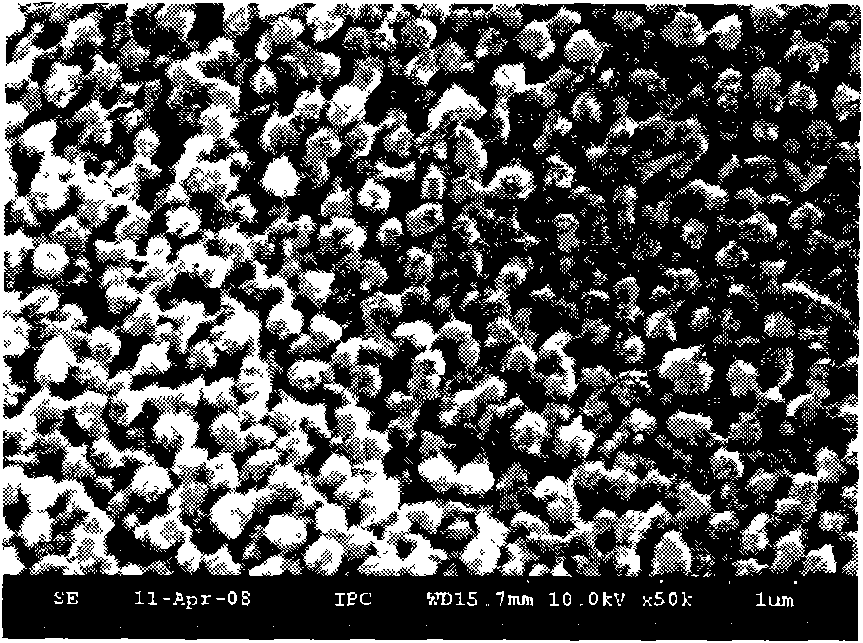

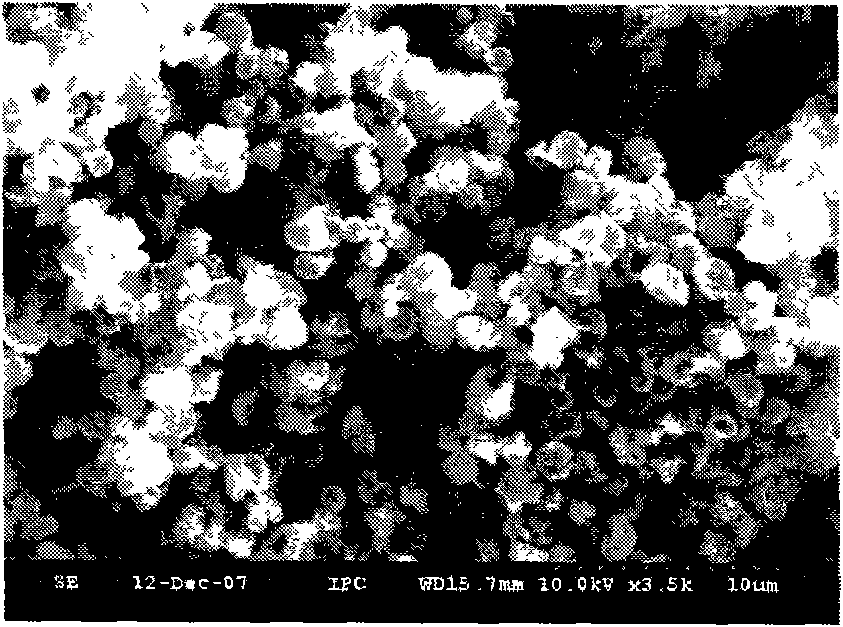

Catalytic devices and method of making said devices

InactiveUS6953554B2Thin coatingFaster lightoffNitrous oxide captureCombination devicesMicrometerEngineering

The invention is a catalytic device comprised of a catalyst support of fused ceramic grains and a catalyst that is surface-bound to at least a portion of the ceramic grains, incorporated into at least a portion of the ceramic grains or combinations thereof, wherein the grains and catalyst form a surface structure that has a box counting dimension of greater than 1.00 or the box counting dimension has at least one step change when measured from a box size “d” of at least about 1 micrometer to at most about 1 millimeter. The invention is particularly useful in making a catalytic converter or catalytic converter-soot trap.

Owner:DOW GLOBAL TECH LLC

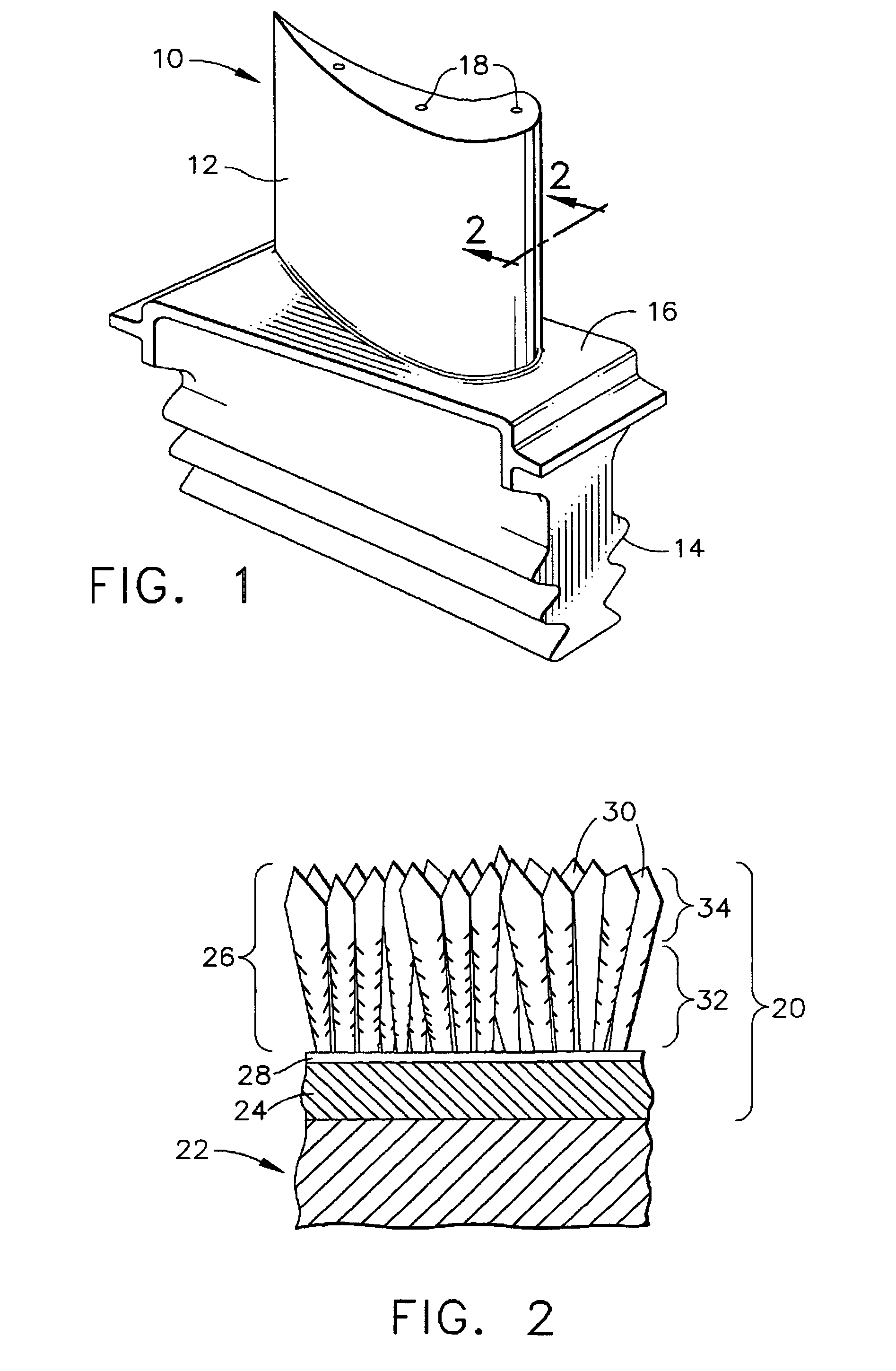

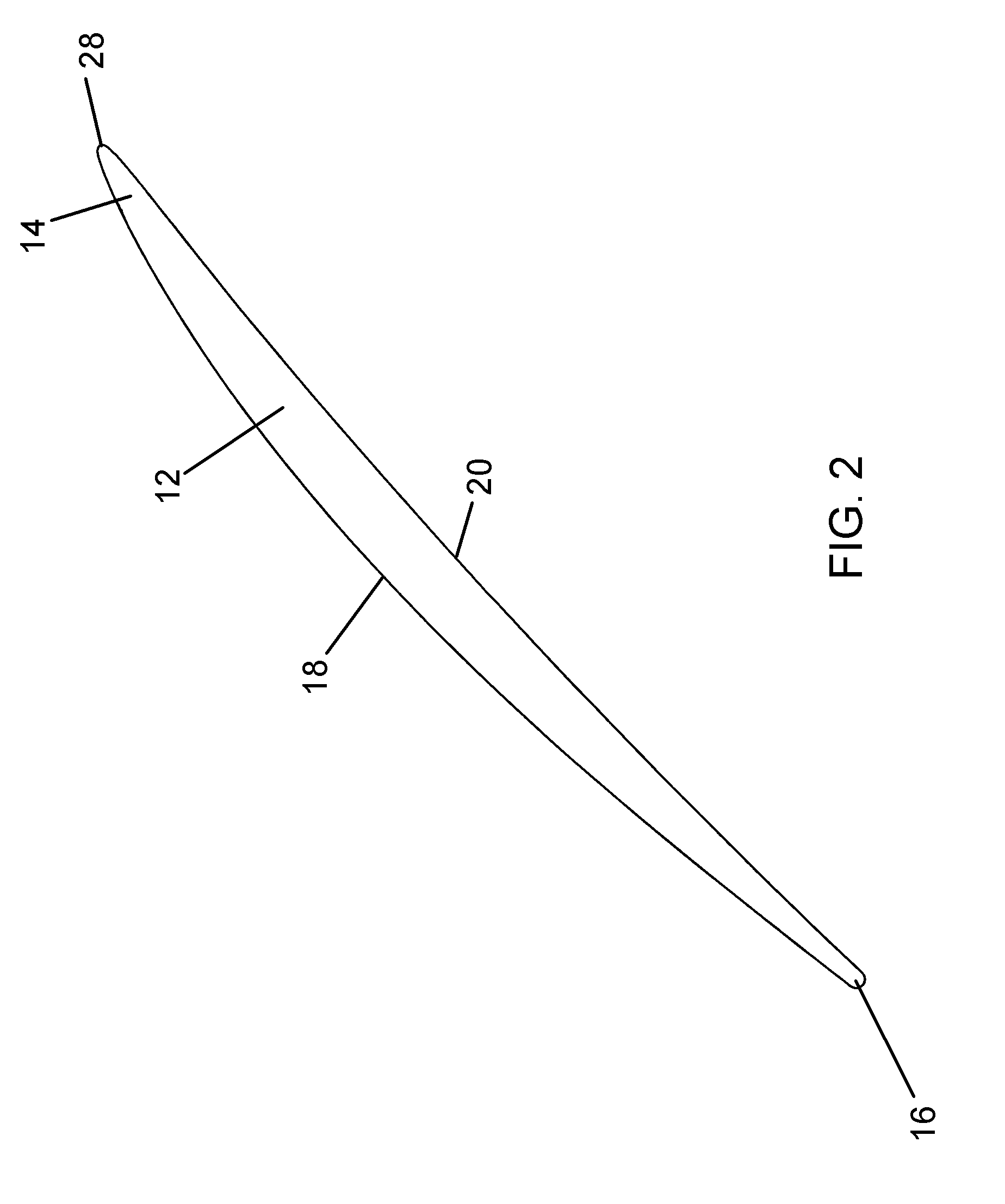

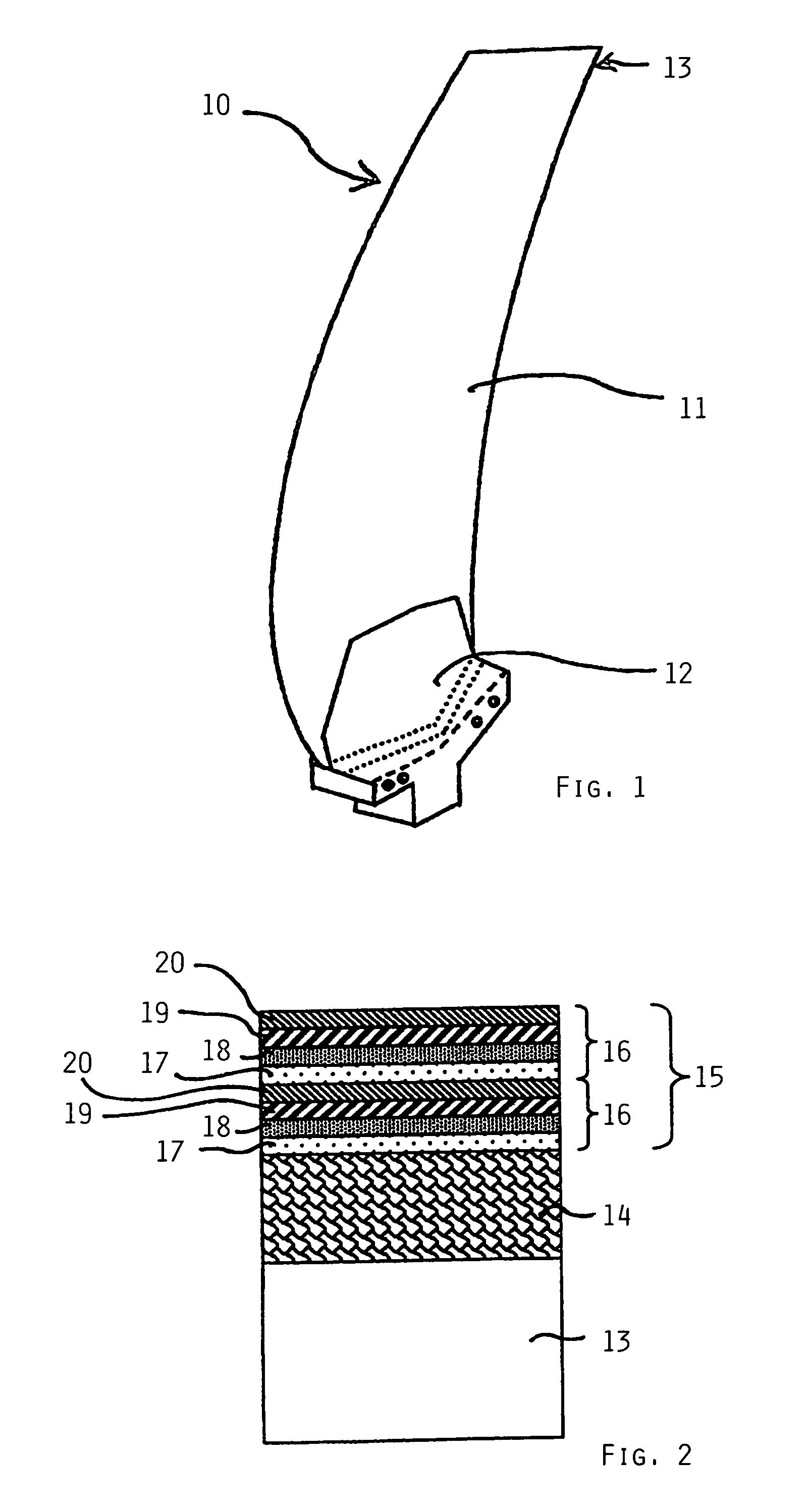

Airfoil and process for depositing an erosion-resistant coating on the airfoil

InactiveUS20110052406A1Thin coatingPrevent surfacePropellersPump componentsLeading edgeTrailing edge

A process for depositing coatings, and particularly erosion-resistant coatings suitable for protecting surfaces subjected to collisions with particles, such as a compressor blade of a gas turbine engine. The blade has an airfoil comprising oppositely-disposed convex and concave surfaces, oppositely-disposed leading and trailing edges defining therebetween a chord length of the airfoil, and a blade tip. An erosion-resistant coating is present on at least the concave surface, but not on the convex surface within at least 20% of the chord length from the leading edge.

Owner:GENERAL ELECTRIC CO

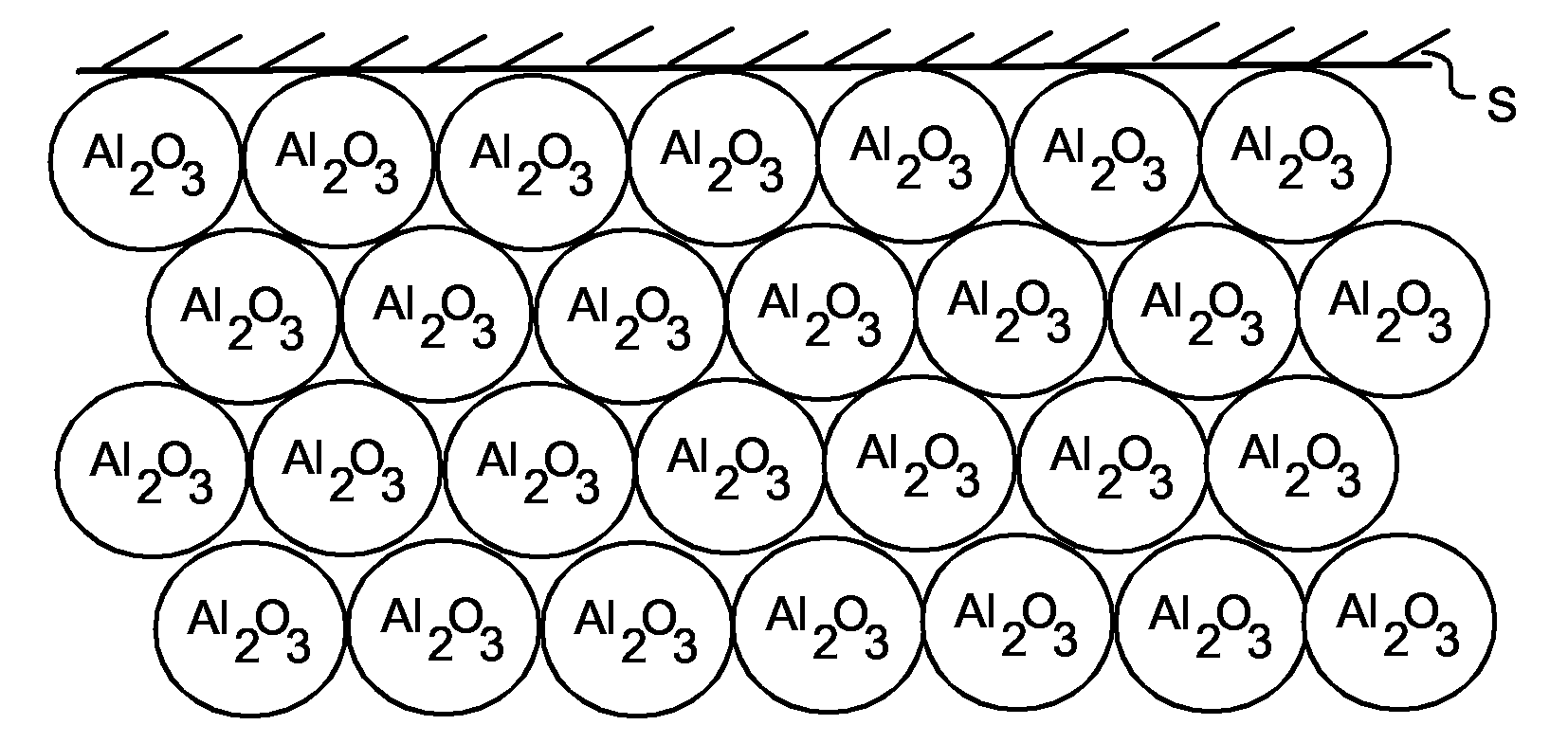

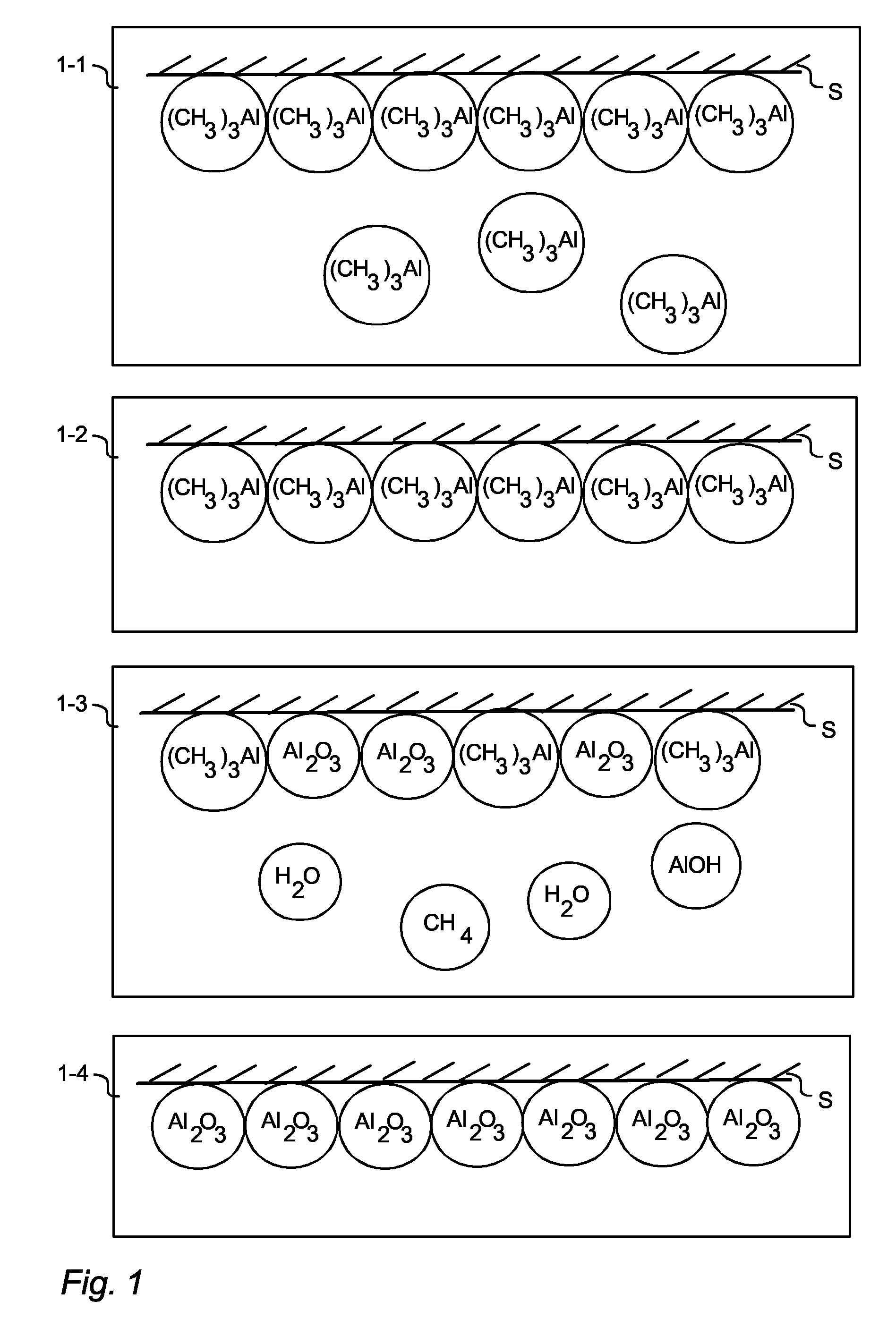

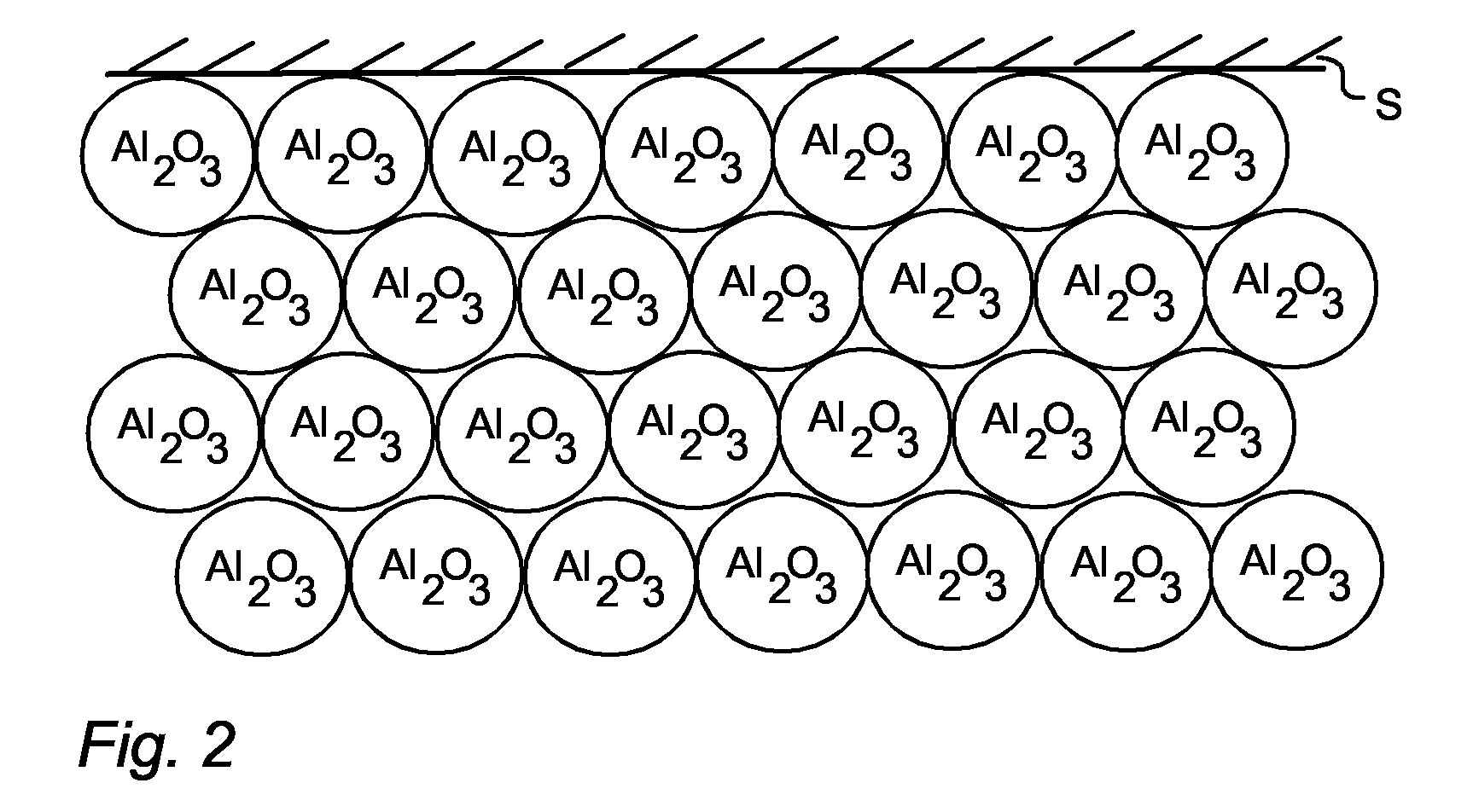

Protective Coating of Silver

ActiveUS20090004386A1Avoid tarnishingThin coatingJewelleryChemical vapor deposition coatingAtomic layer depositionFilm-coated tablet

In the method, silver is protected against tarnishing using an Atomic Layer Deposition method. In the Atomic Layer Deposition method, a thin film coating is formed 5 on the surface of silver by depositing successive molecule layers of the coating material. For example aluminium oxide (Al 2O3) or zirconium oxide may be used as the coating material.

Owner:BENEQ OY

Natural Water-Insoluble Encapsulation Compositions and Processes for Preparing Same

InactiveUS20080160084A1Prevent degradationHigh dye concentrationPowder deliveryBiocideWater insolubleFine particulate

The present invention relates to dry particulate encapsulation compositions comprising a water-insoluble matrix comprising at least 70% by weight of proteins, based on the total weight of the matrix and a moisture content of about 5 to 10% by weight, based on the total weight of the matrix and an encapsulate encapsulated in the matrix, wherein the matrix once wetted in a clear colorless aqueous solution or in mineral oil has a lightness value (L*) greater than about 40, a color vividness or Chroma (C*) lower than about 33 and a hue angle between about 70 and 90. The encapsulation compositions of the present invention are useful in encapsulating dyes, medications and vitamins. Fine particulate encapsulation compositions comprising natural dyes can be used in lieu of artificial lakes in confectionery, cosmetics and caplets color coatings.

Owner:COLAROME

Fire-retardant coating, method for producing fire-retardant building materials

InactiveUS7429290B2Simple materialIncrease resistanceFireproof paintsAntifouling/underwater paintsCalcium silicateCardboard

The present invention relates to a fire-resistant coating and method thereof, which confers enhanced flame and heat resistance to substrate such as building materials. The invented coating is especially applicable to cellulose-based building materials including but not limited to fiberboards, wallboards, roofing materials, particleboards, ceiling tiles, soundproofing boards and hardboards. This novel composition is also useful in providing a fire-resistant coating for concrete, metals, foamed polymeric materials, gypsum and other substrates. A preferred embodiment generally comprising: mono potassium phosphate, magnesium oxide, silica powder, calcium silicate, rice hull ash and water. A method for imparting fire-retardancy to substrates using the invented composition is also described.

Owner:BONE SOLUTIONS INC

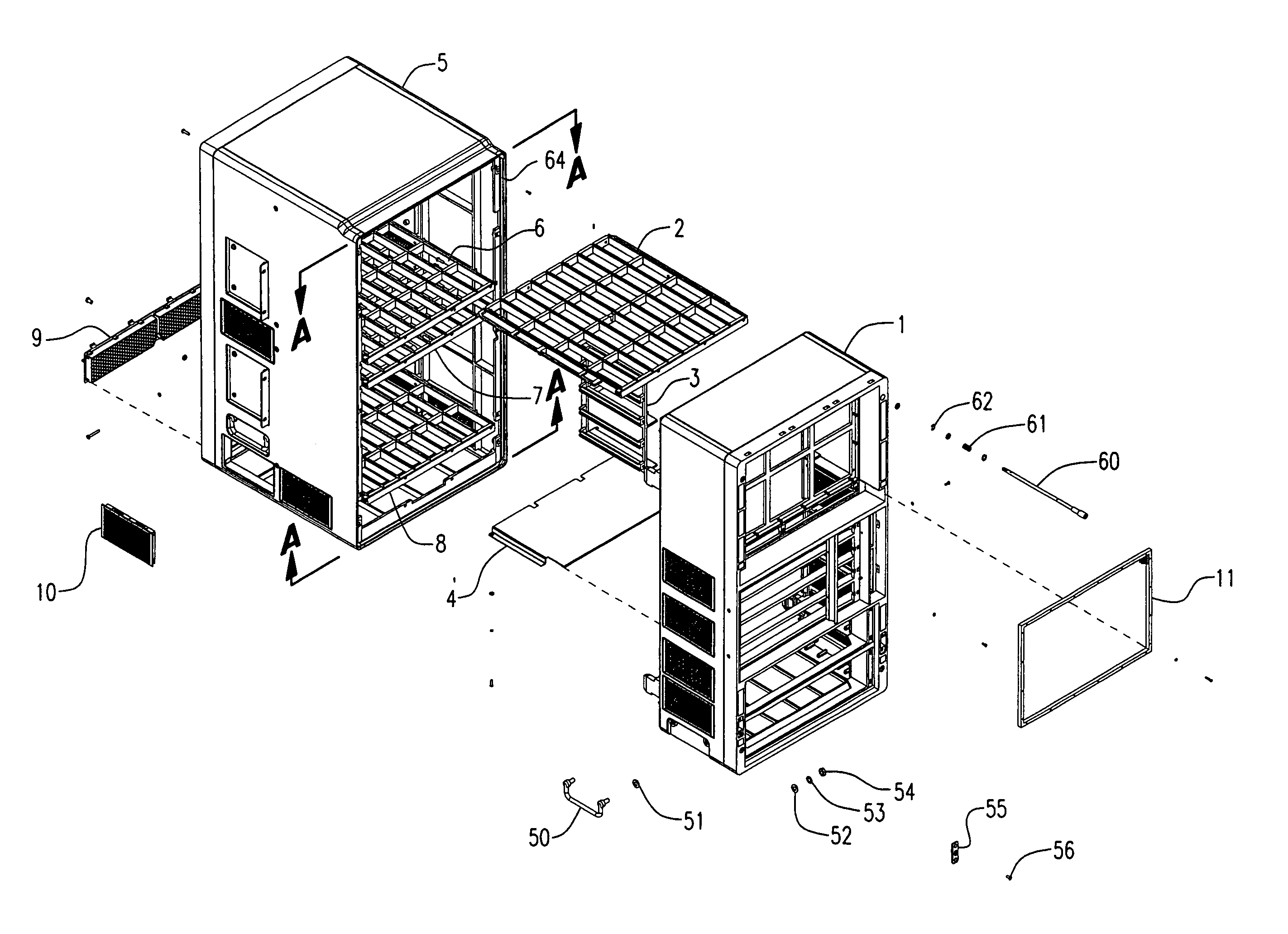

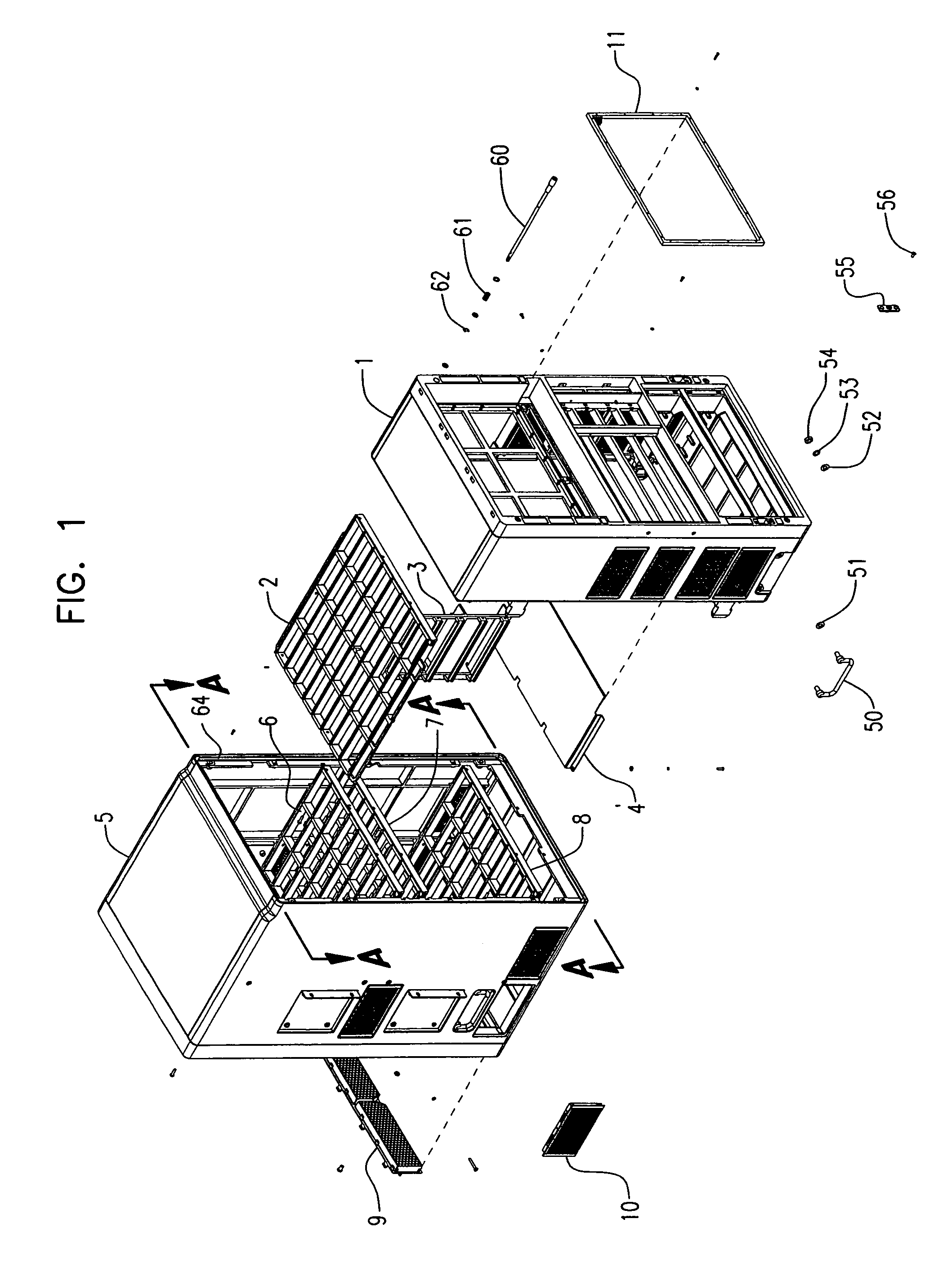

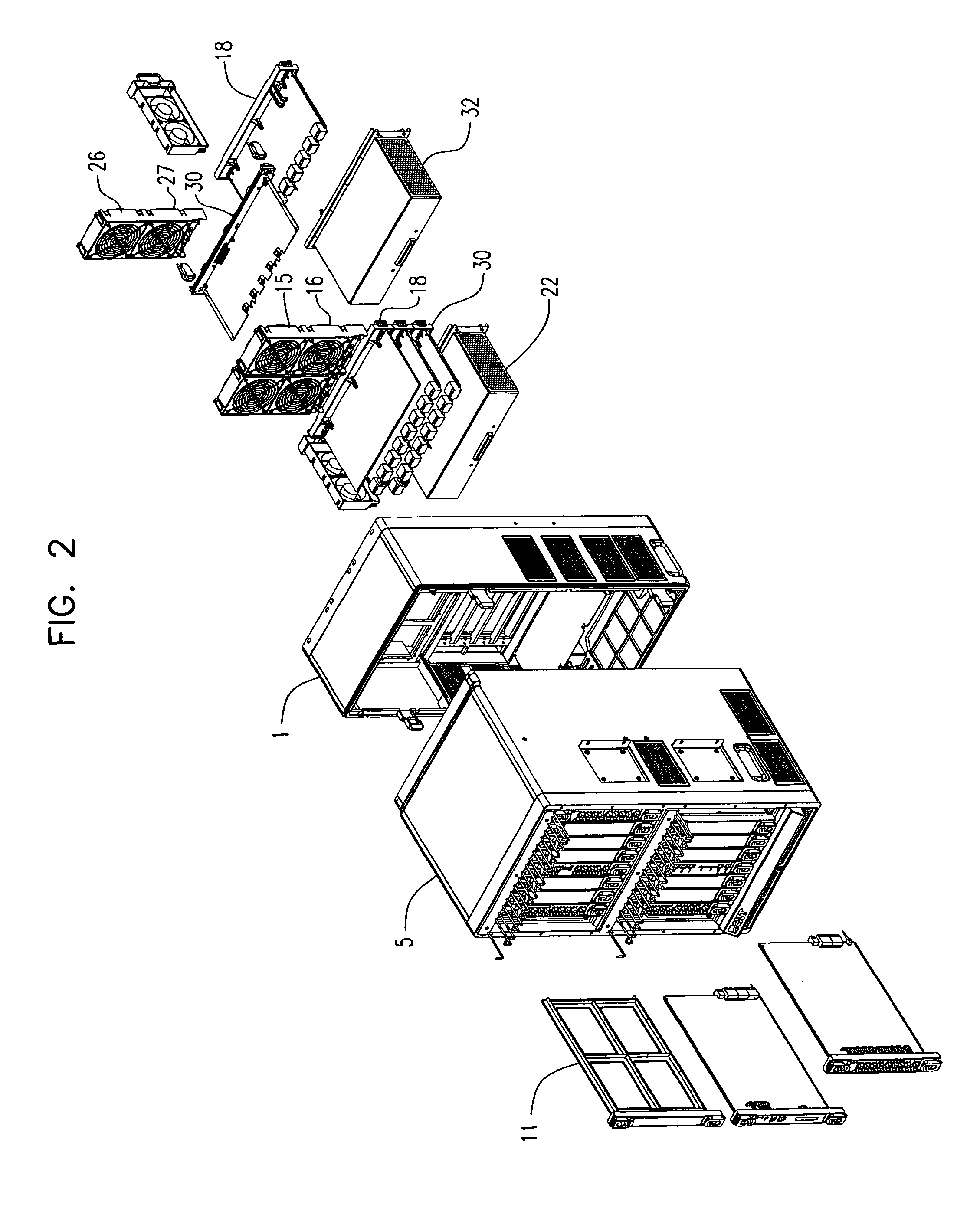

EMI shielded chassis for electrical circuitry

InactiveUS6963495B1Improve serviceabilityEMI suppressionElectrostatic discharge protectionCoupling device detailsElectromagnetic interferenceEngineering

An enclosure for computer-based telephone switching equipment that suppresses the radiation of electromagnetic interference through the use of multiple overlapping seals and apertures.

Owner:MCDATA SERVICES CORP

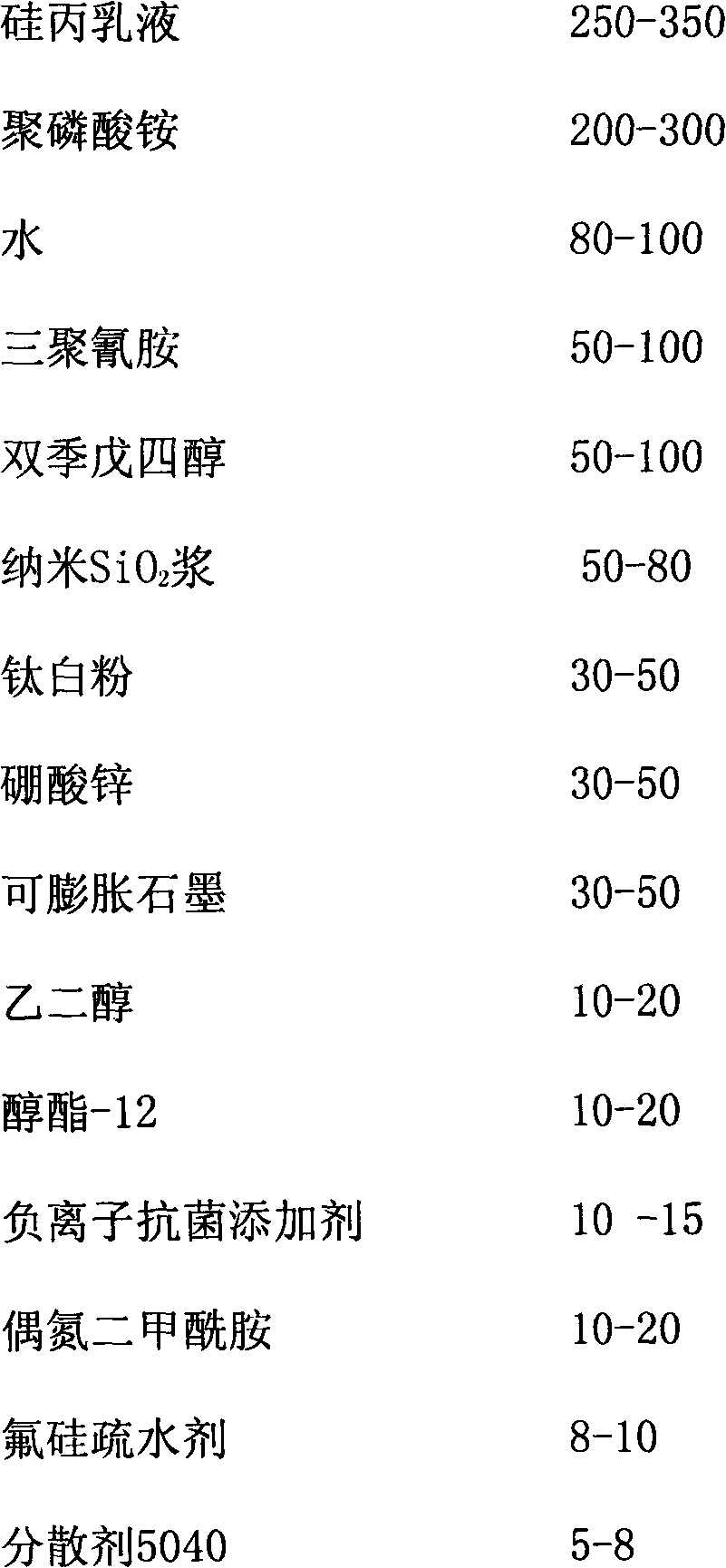

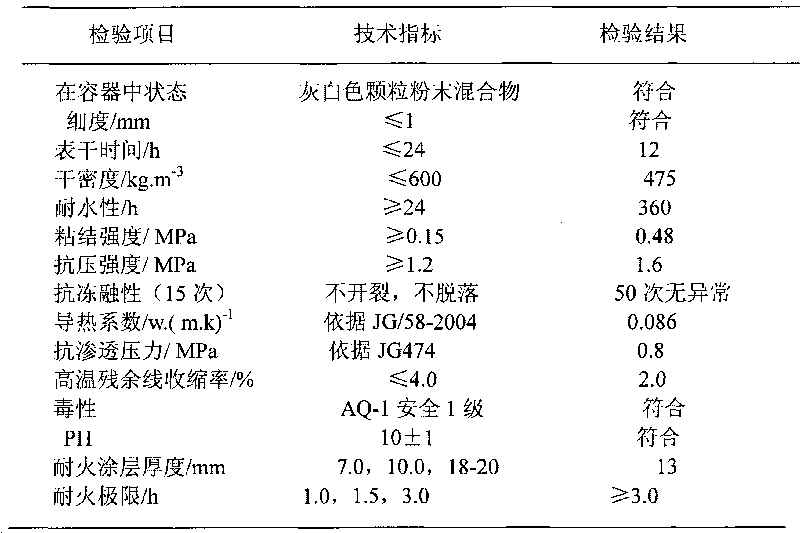

Water expansion type fire-proof mildew-proof coating for tunnels

InactiveCN102634256AWaterproof and anti-seepageLong fire resistanceFireproof paintsAntifouling/underwater paintsTunnel wallAzodicarbonamide

The invention discloses a water expansion type fire-proof mildew-proof coating for tunnels, which are prepared through conventional preparation processes with the cooperation of auxiliary agents, wherein silicone acrylic emulsion serves as a film forming matter, modified ammonium polyphosphate, melamine, dipentaerythritol and azodicarbonamide serve as fire retardants; titanium dioxide, zinc borate and expansible graphite serve as fillers; nanometer SiO2 serves as a modified material and an anion antibacterial additive serves as a mildew-proof bactericide. The mildew-proof fire-proof protective coating disclosed by the invention has the advantages of long fire-proof time limit, good adhesion property, water resistance and permeability resistance, mildew resistance and antibacterial property, environmental protection and no toxicity, good decorative effect, thinness in coating and convenience for construction and is suitable for various tunnel walls.

Owner:北京国泰瑞华精藻硅特种材料有限公司

Positive electrode active material for lithium secondary battery and method for producing same

InactiveUS20070117014A1Improve securityLarge capacityNon-aqueous electrolyte accumulatorsActive material electrodesParticulatesLithium-ion battery

It is to provide a cathode active material for a lithium ion secondary battery, which has high safety, a high discharge voltage, a large capacity and excellent cyclic durability, and a process for producing it. A cathode active material for a lithium secondary battery, characterized by comprising a particulate lithium cobalt composite oxide represented by the formula LiaCobAlcMgdAeOfFg (1) (wherein A is Ti, Nb or Ta, O.90≦a≦1.10, 0.97≦b≦1.00, 0.000l≦c≦0.02, 0.000l≦d≦0.02, 0.000l≦e≦0.01, 1.98≦f≦2.02, 0≦g≦0.02, and 0.0003≦c+d+e≦0.03).

Owner:AGC SEIMI CHEM CO LTD

Water-based fluorocarbon heat insulation coating and preparation method

InactiveCN102585626AImprove reflectivityLow thermal conductivityReflecting/signal paintsWater basedInsulation system

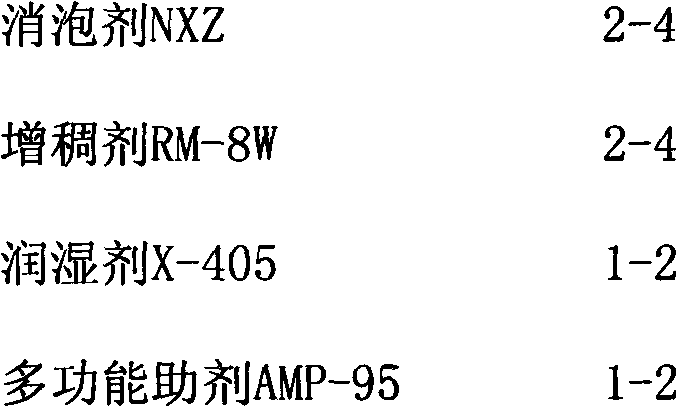

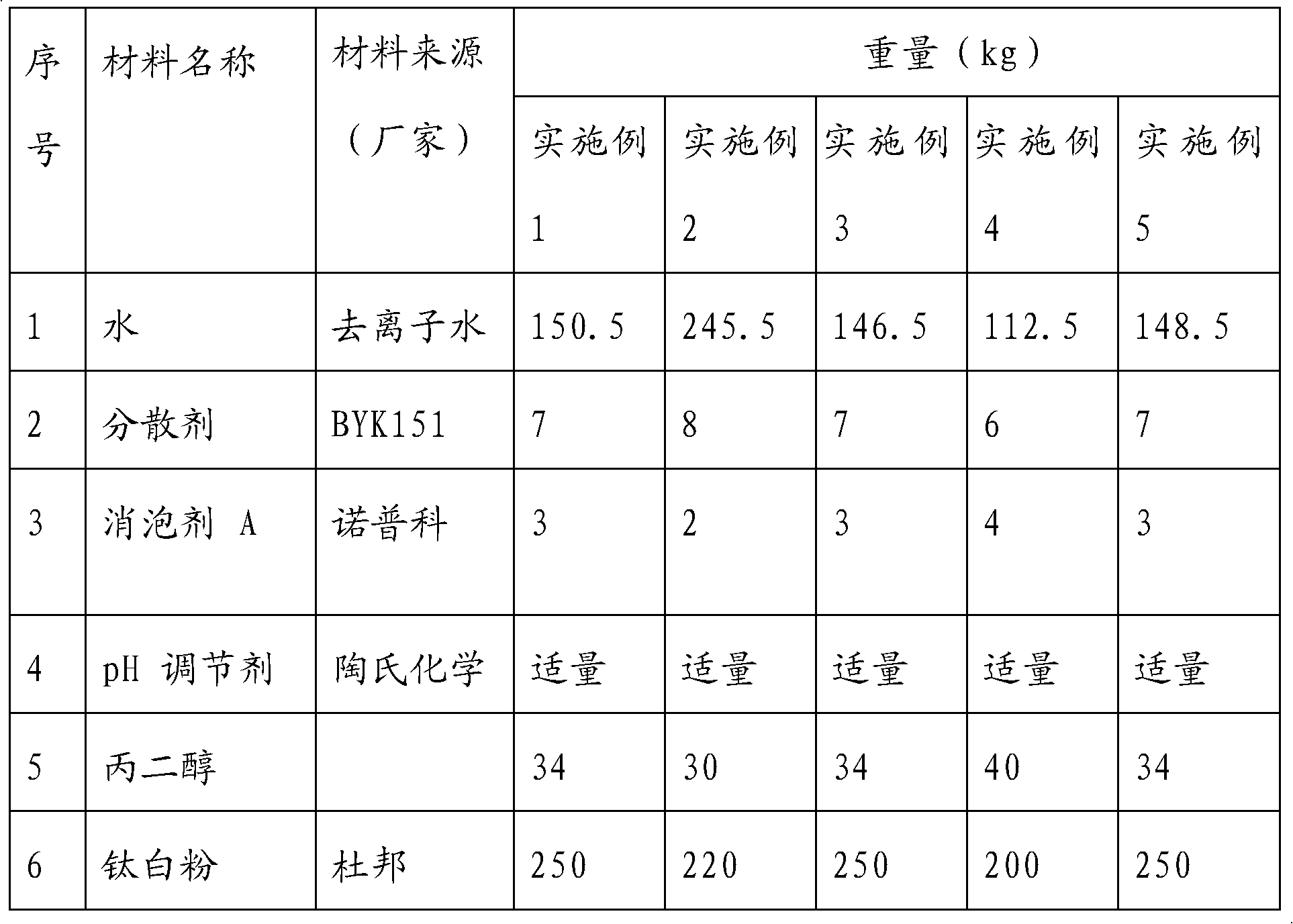

A water-based fluorocarbon heat insulation coating is prepared by the following components by weight: 100 to 250 parts of water, 6 to 8 parts of dispersing agent, 2 to 4 parts of defoamer A, pH regulators of right amount, 30 to 40 parts of propylene glycol, 200 to 250 parts of titanium dioxide powder, 4 to 7 parts of mildew preventive, 2 to 4 parts of defoamer B, 400 to 500 parts of water-based fluorocarbon emulsion, 28 to 40 parts of film-forming assistant, 15 to 30 parts of heat insulation material A, 25 to 40 parts of heat insulation material B, 6 to 10 parts of flatting agent, 6 to 10 parts of thickening agent and 2.5 parts of preservative. A product of the water-based fluorocarbon heat insulation coating has various performances, can achieve the effect of oil-based fluorocarbon coating, can overcome the shortcomings of the oil-based fluorocarbon coating, and can meet requirements of an external wall heat insulation system in addition.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Polymeric, degradable drug-eluting stents and coatings

ActiveUS20090012604A1Improve radial strengthRisk minimizationSurgeryCoatingsAbsorbable polymersEthylene Homopolymers

Absorbable stents and absorbable stent coatings have been developed with improved properties. These devices preferably comprise biocompatible copolymers or homopolymers of 4-hydroxybutyrate, and optionally poly-L-lactic acid and other absorbable polymers and additives. Compositions of these materials can be used to make absorbable stents that provide advantageous radial strengths, resistance to recoil and creep, can be plastically expanded on a balloon catheter, and can be deployed rapidly in vivo. Stent coatings derived from these materials provide biocompatible, uniform coatings that are ductile, and can be expanded without the coating cracking and / or delaminating and can be used as a coating matrix for drug incorporation.

Owner:TEPHA INC

Braze foil for high-temperature brazing and methods for repairing or producing components using a braze foil

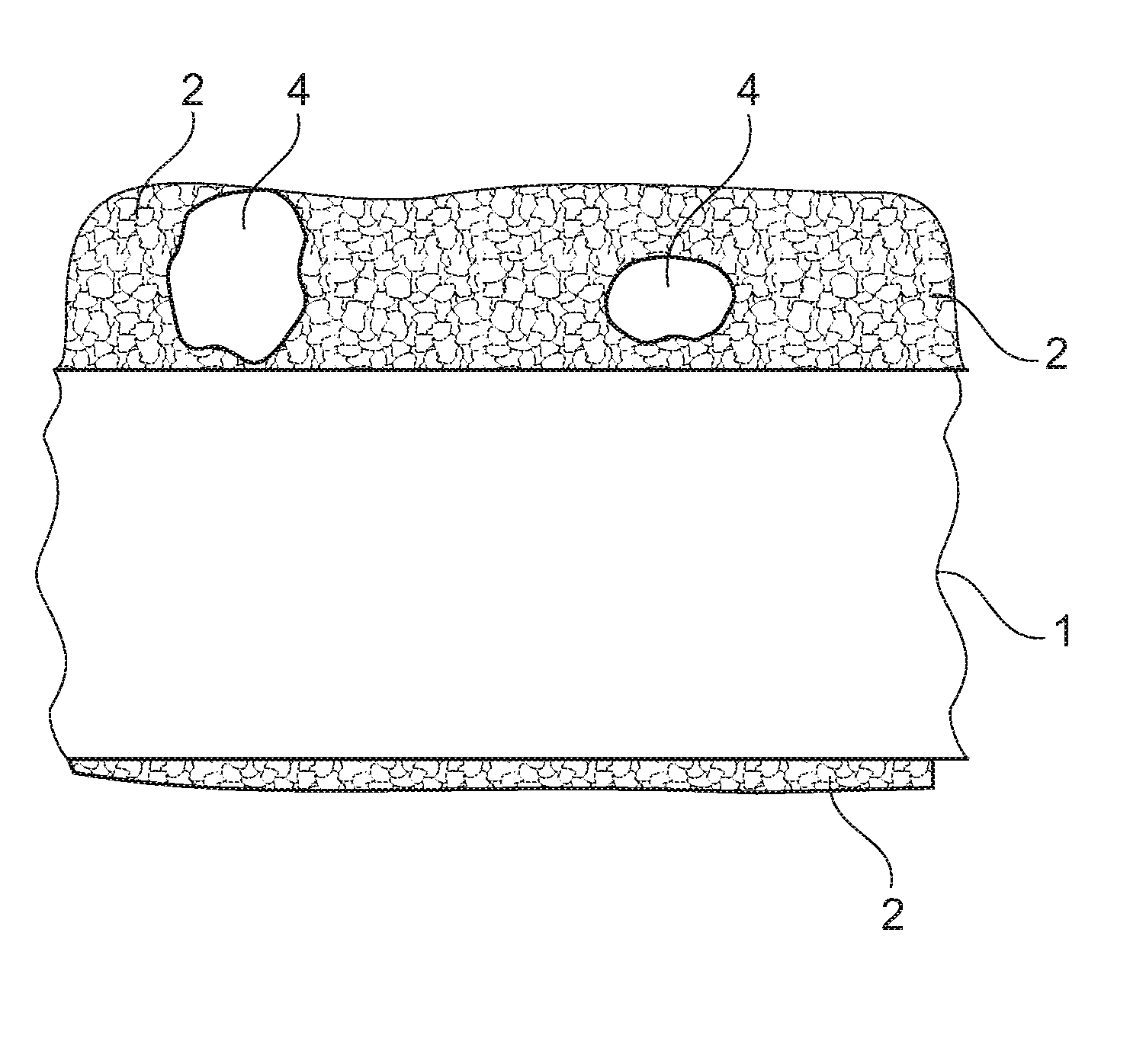

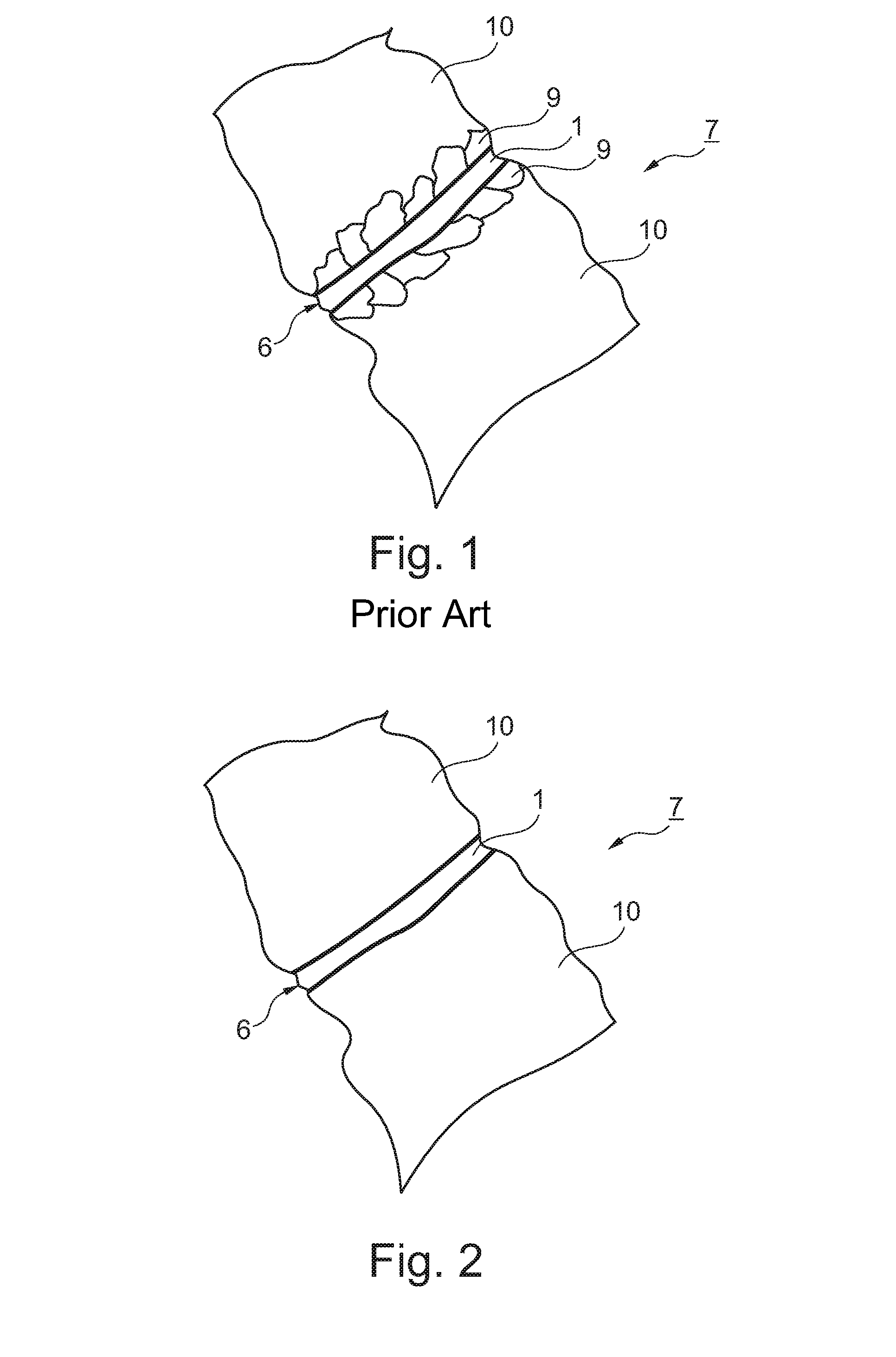

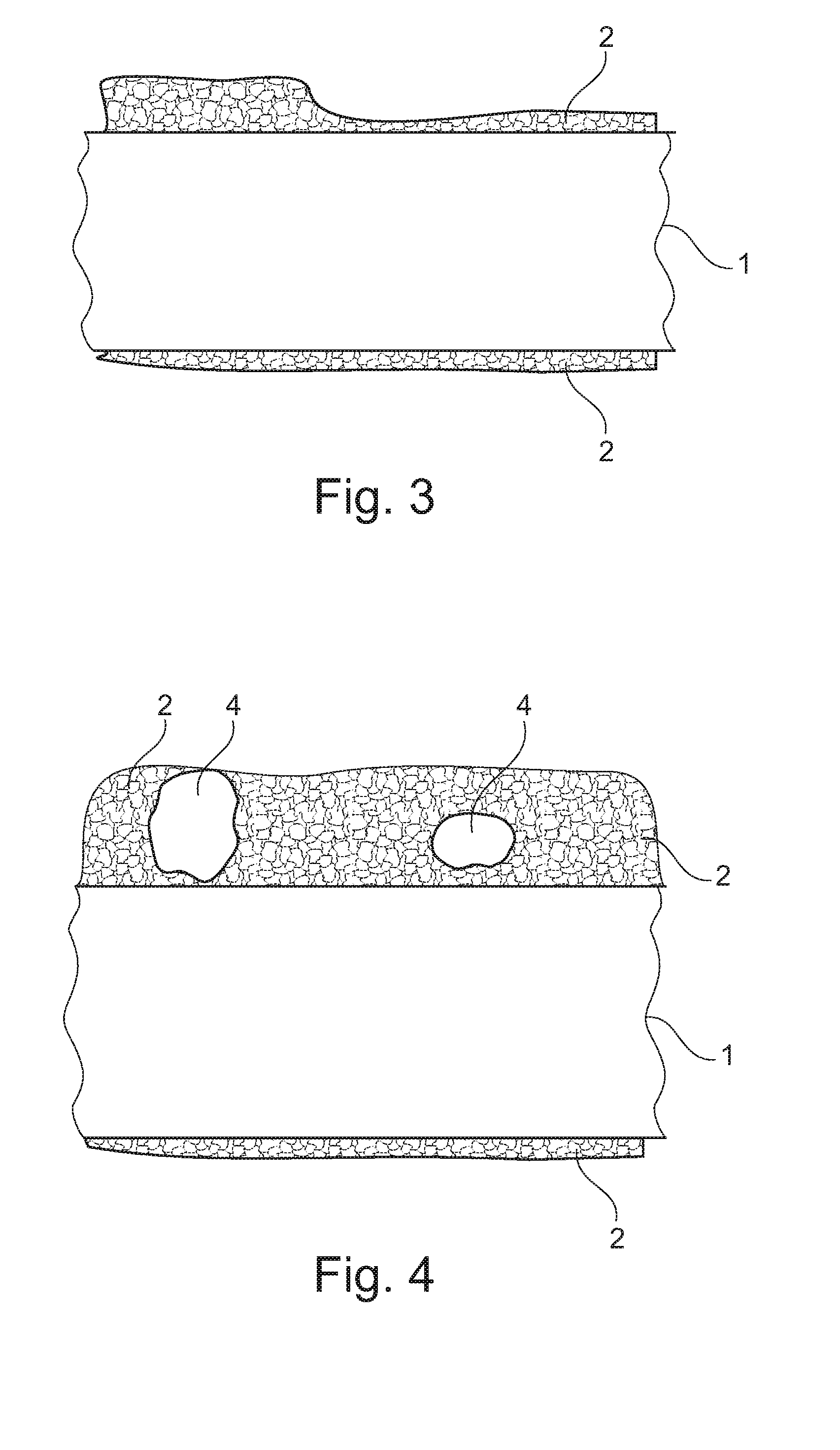

An amorphous braze foil (1) produced by a melt-spin process has an upper side and a lower side. The upper side and the lower side are thinly coated with a film of metallic Ni-based, Co-based, or Ni—Co-based braze powder (2) with a particle size in the nanometer range, wherein both the braze foil (1) and also the braze powder (2) additionally include grain boundary stabilizing elements as alloying elements. In addition, melting point depressants can be present in the braze foil or in the nano braze powder (2) in a commercially common quantity or with a considerably increased proportion. With the braze foil (1) coated in this manner, both the melting temperature of the braze material and also the probability of recrystallization are advantageously reduced when brazing in the adjacent base material (10).

Owner:ANSALDO ENERGIA IP UK LTD

Fireproof and waterproof coating for tunnel

The invention discloses a fireproof and waterproof coating for tunnel. The coating comprises composite binder, refractory insulating material, expansion and foaming material and flame-resistant and smoke-eliminating material. The preparation method of the fireproof and waterproof coating for tunnel comprises the following steps: 1. screening, mixing and dispersing; and 2. mixing and the like. The invention has the advantages of thin coating, high fire endurance and bonding strength, excellent flexibility and crack resistance and good water resistance and waterproof property; and the coating is resistant to freezing and thawing, is environmentally friendly and nontoxic, has low cost, is convenient to popularize and use, and is applicable to the coating protections of various tunnels, underground projects, petrochemical devices, and buildings and steel structures which have demands of fire resistance, water resistance and thermal insulation.

Owner:唐山市思远涂料有限公司

Protein-Containing Food Product and Coating for a Food Product and Method of Making Same

InactiveUS20080113067A1Thin coatingHigh in proteinEdible oils/fats ingredientsConfectioneryLipid formationNutritive values

A method for forming a complex of a protein-containing material and a lipid-based material comprises the steps of admixing said protein-containing material into said lipid material, applying heat and a shear force to said admixture to form an emulsion of protein material in said lipid material, and cooling said admixture to form a lipid-protein complex. Optionally, a liquid grinding step also may be used. The complex comprises at least about 10-50 net weight % protein, preferably no more than about 1% of an emulsifier, and an amount of a lipid-containing material sufficient to form an emulsion with the protein containing material. It is believed that higher proportions of protein could be obtained in the emulsion with high capacity pumps and shear apparatus. The complex can be used as a coating composition for a food product, or as an ingredient in a coating composition for a food product, or as an ingredient in a food article. When used as or in a coating for a snack food item such as a protein-containing energy bar, the coating can add to the nutritive value of the bar, and maintain the moisture content of the bar.

Owner:BUNGE OILS INC

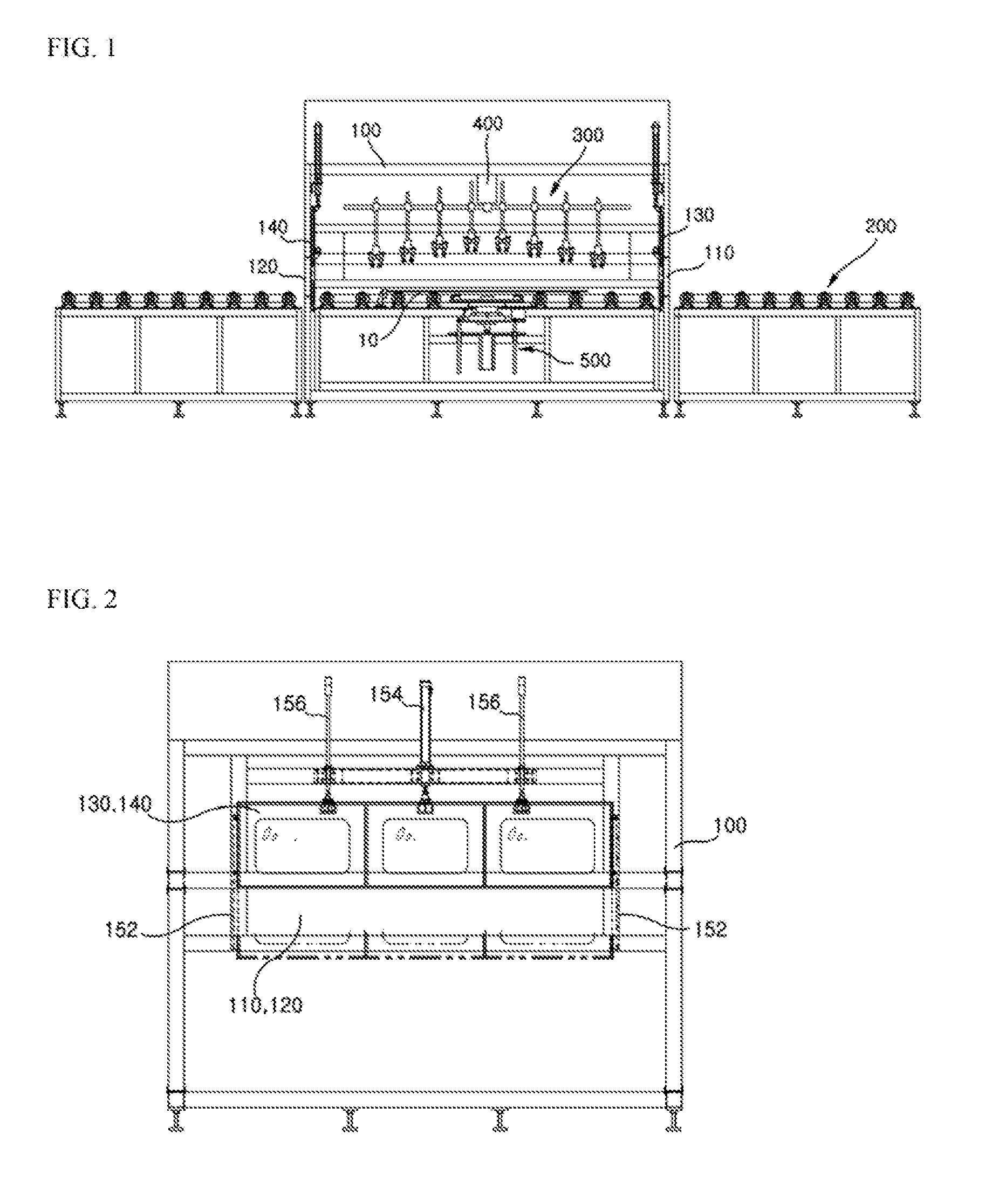

Silver thin-film spead apparatus by means of deposition of NANO metallic silver

ActiveUS20120085280A1Increasing film compactnessImprove reflectivityLiquid surface applicatorsMovable spraying apparatusConstant frequencyDevice form

Disclosed is a silver thin film spread apparatus by means of deposition of nano metallic silver, the apparatus comprising: a treatment booth formed at one side with an inlet for inputting a substrate, and formed at the other side with an outlet for discharging the substrate; a transfer device formed at a lower side of the treatment booth for transferring the substrate; a spray device formed at an upper side of the treatment booth for spraying silver solution on a surface of the substrate; a moving device for linearly reciprocating the spray device; and a rotation device formed at the lower side of the treatment booth for rotating the substrate, whereby reflectivity can be enhanced by increasing film compactness and coating uniformity of thin film, where the substrate is rotated at a predetermined constant speed to allow the spray guns to linearly reciprocate and to allow the nano silver thin film to be uniformly spread and deposited on the surface of the substrate at a predetermined constant frequency.

Owner:NANOCMS

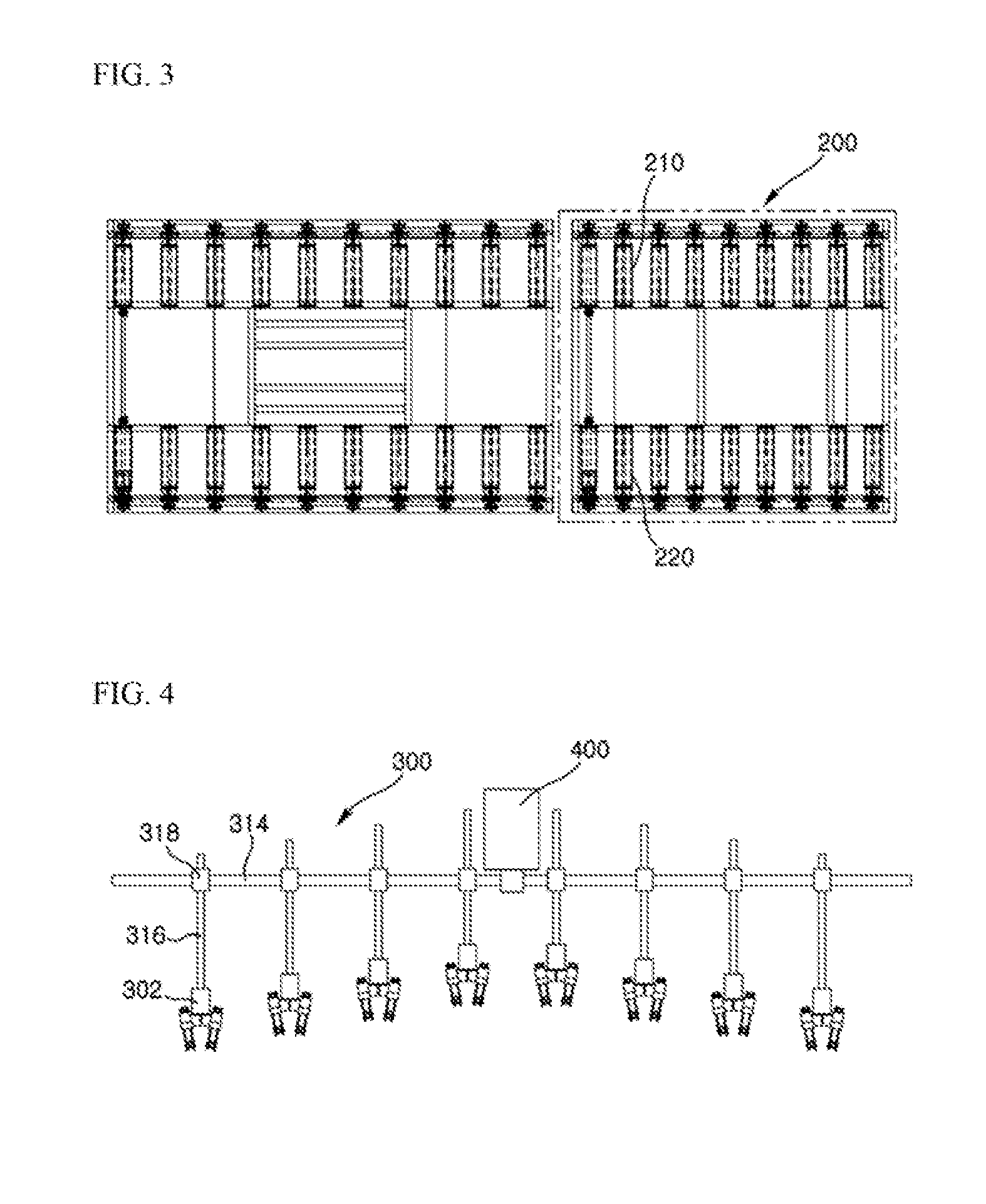

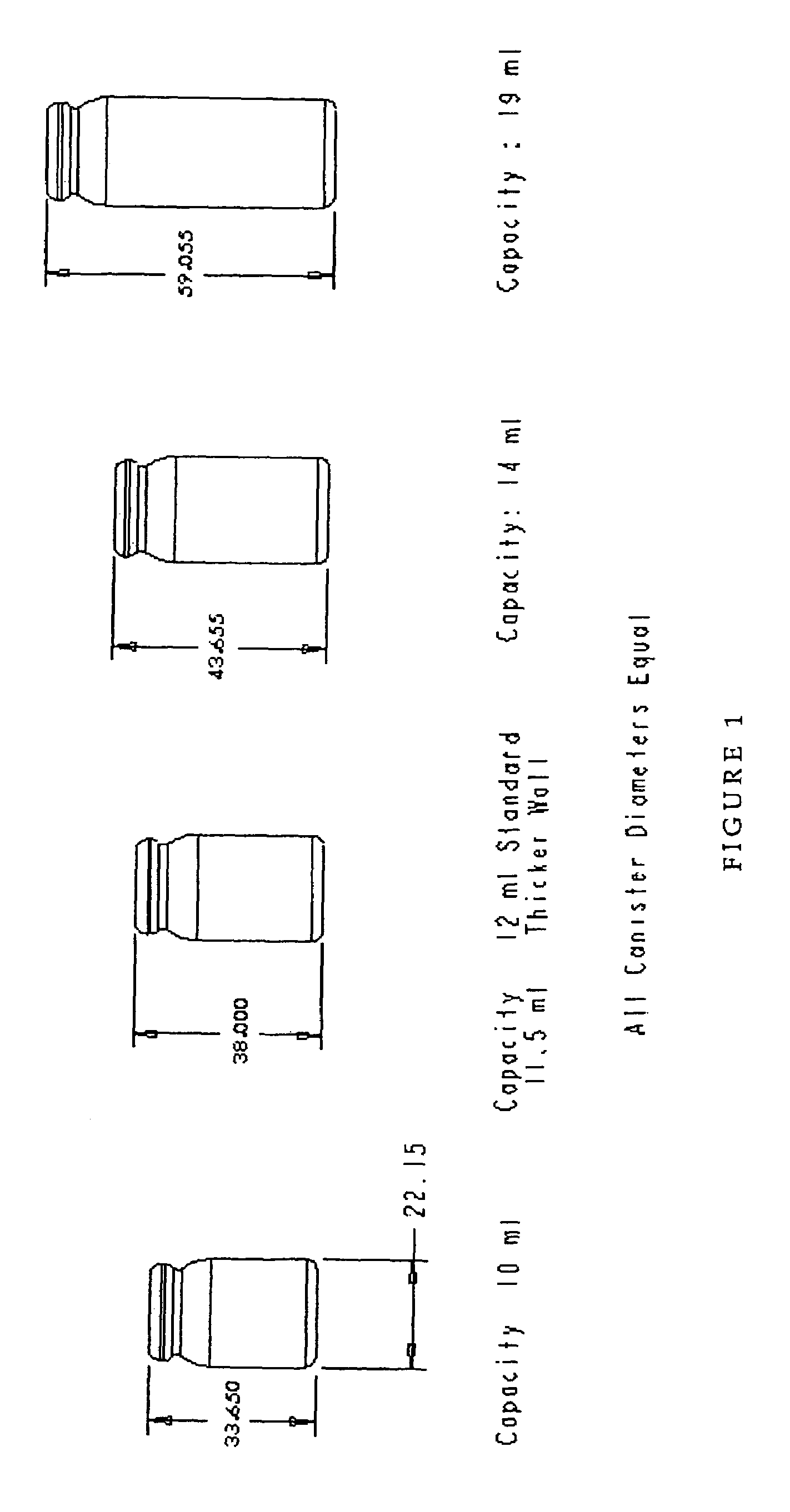

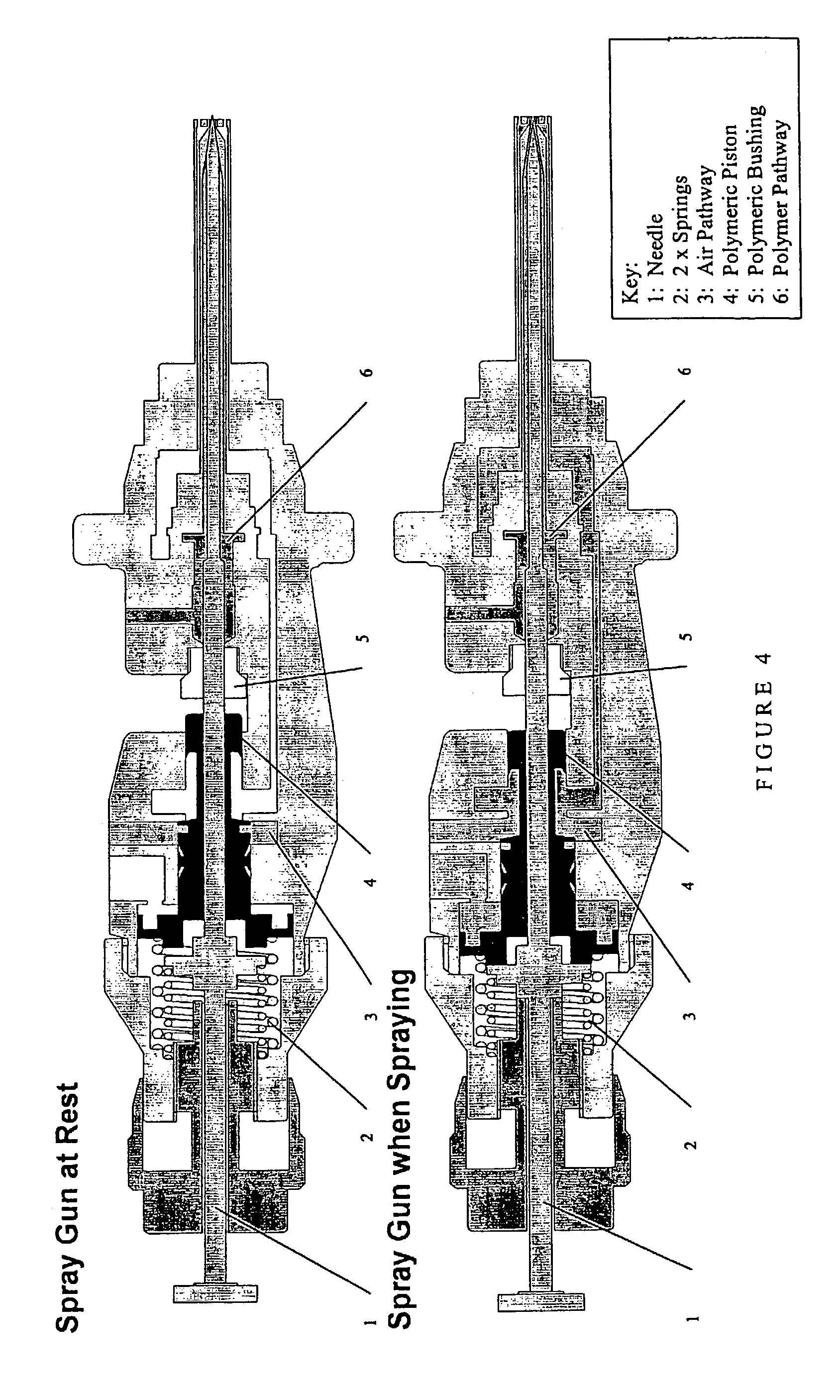

Method for applying a polymer coating to the internal surface of a container

InactiveUS7205026B2Avoids long-term extractionConvenient coatingPretreated surfacesLiquid/solution decomposition chemical coatingPolymer coatingsEngineering

Provided is a method for the application of a polymer coating to an internal surface of a container, which method comprises: (a) heating the inside surface of the container to be coated; (b) spraying an aqueous suspension of a fluorine-containing polymer onto the surface to form a coating on the surface; and (c) sintering the coating; wherein the container comprises a base and one or more side walls defining a container opening and is suitable for storing a medicament, and wherein the spraying step is conducted with a first spraying means configured to produce an axial spray pattern that is substantially conical about an axis perpendicular to the container base.

Owner:ASTRAZENECA AB

Conductive polymer wave-absorbing material

InactiveCN101585959AThin coatingReduce weightNon-conductive material with dispersed conductive materialFrequency bandPolymer chemistry

The invention belongs to the technical field of wave-absorbing materials, and in particular relates to a conductive polymer wave-absorbing material. The material consists of poly(3,4-ethylenedioxythiophene) (PEDOT) microspheres and epoxy resin or organic binder such as polyurethane and the like, wherein the content of the conductive polymer poly(3,4-ethylenedioxythiophene) microspheres in the conductive polymer wave-absorbing material is 20 to 80 percent by mass percentage. The conductive polymer wave-absorbing material has the remarkable advantages of thin coating, light weight and the like, has good wave-absorbing performance on a frequency band of between 2 and 18GHz, has the maximum absorption of 21dB at the frequency of 16GHz particularly, and has good prospect as a radar wave-absorbing material.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

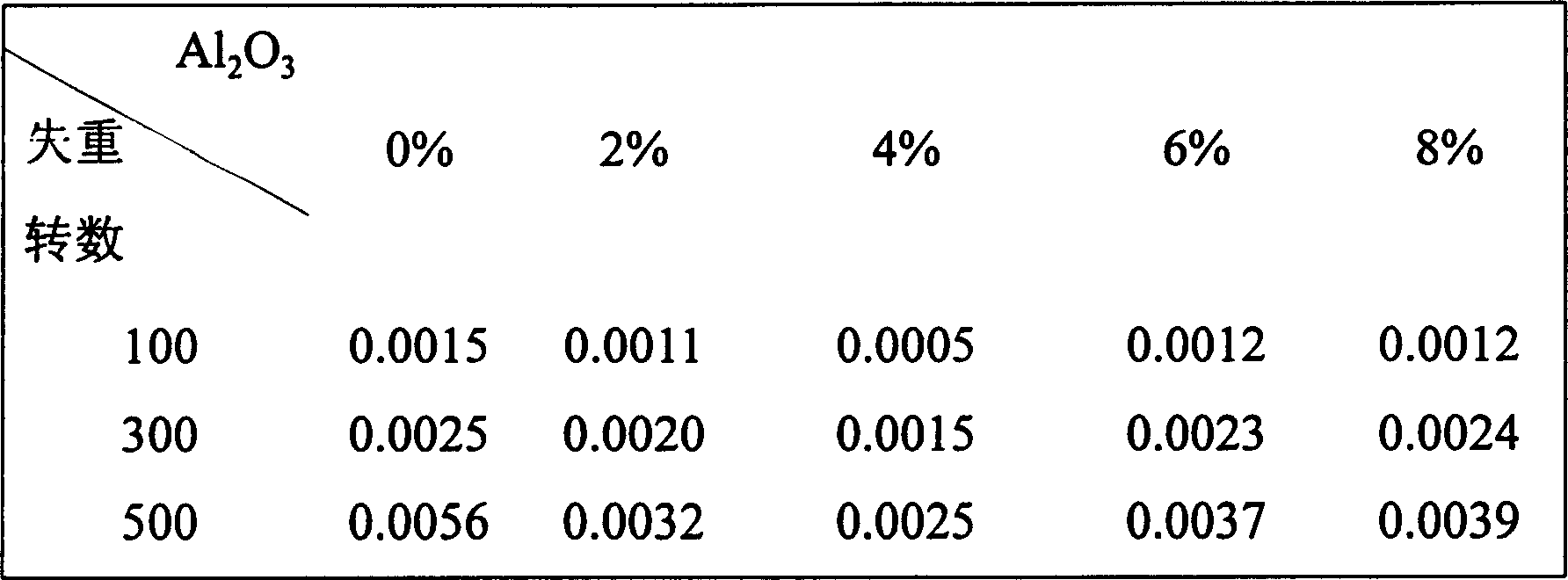

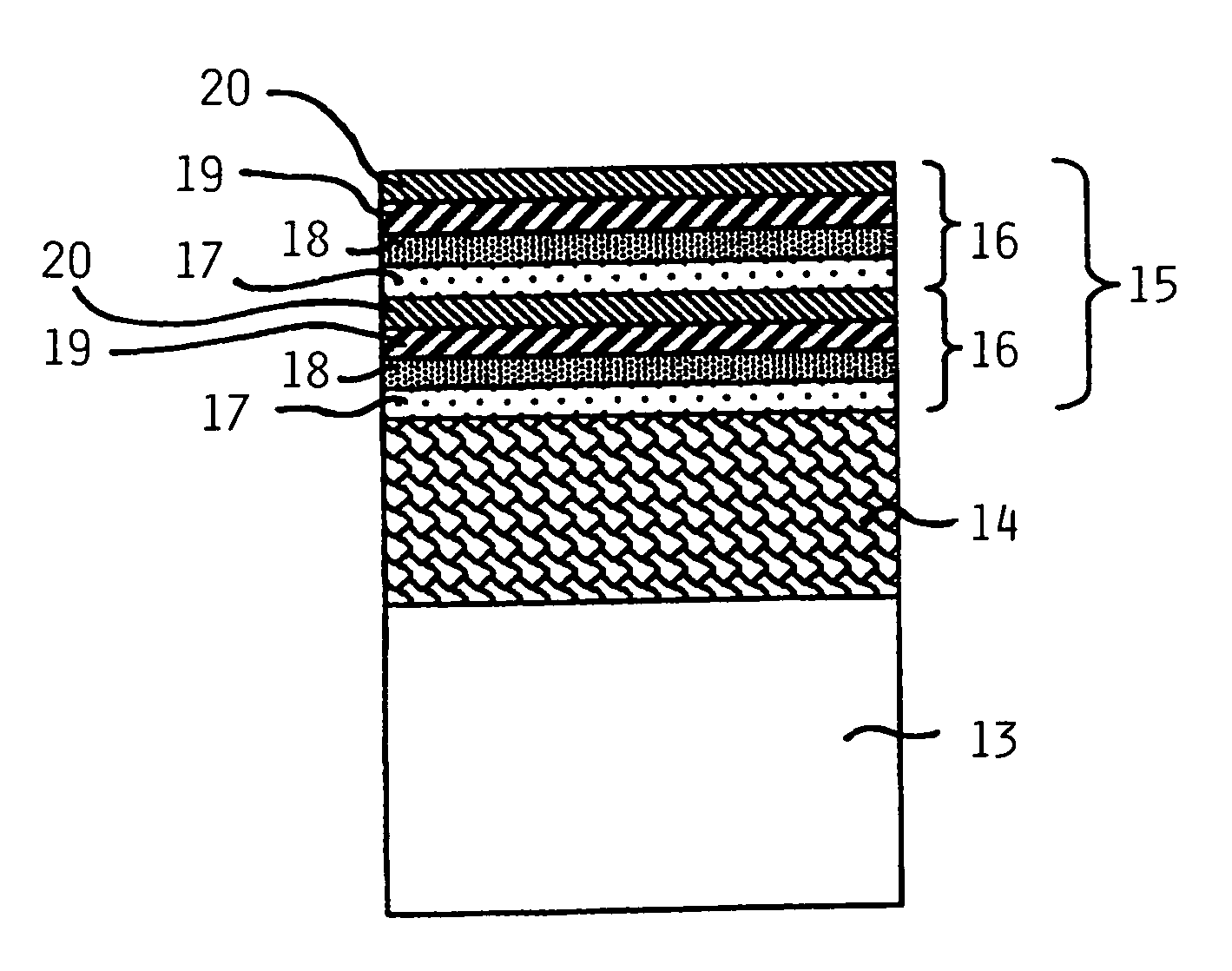

Turbomachine blade with a blade tip armor cladding

ActiveUS7942638B2Not easy to wearIncreased durabilityPropellersRotary propellersCoating systemTurbine blade

A blade of a turbomachine such as a gas turbine includes a blade vane with a blade tip and a blade base. A blade tip armor cladding is applied on the blade tip. A coating covers at least the armor cladding and includes at least one multilayer coating system, and preferably plural such coating systems stacked repetitively on one another. Each coating system includes at least two different layers stacked successively on one another, with one layer of a metal material closer to the blade tip and one layer of a ceramic material farther from the blade tip.

Owner:MTU AERO ENGINES GMBH

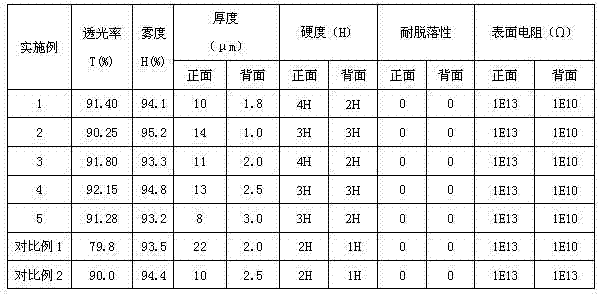

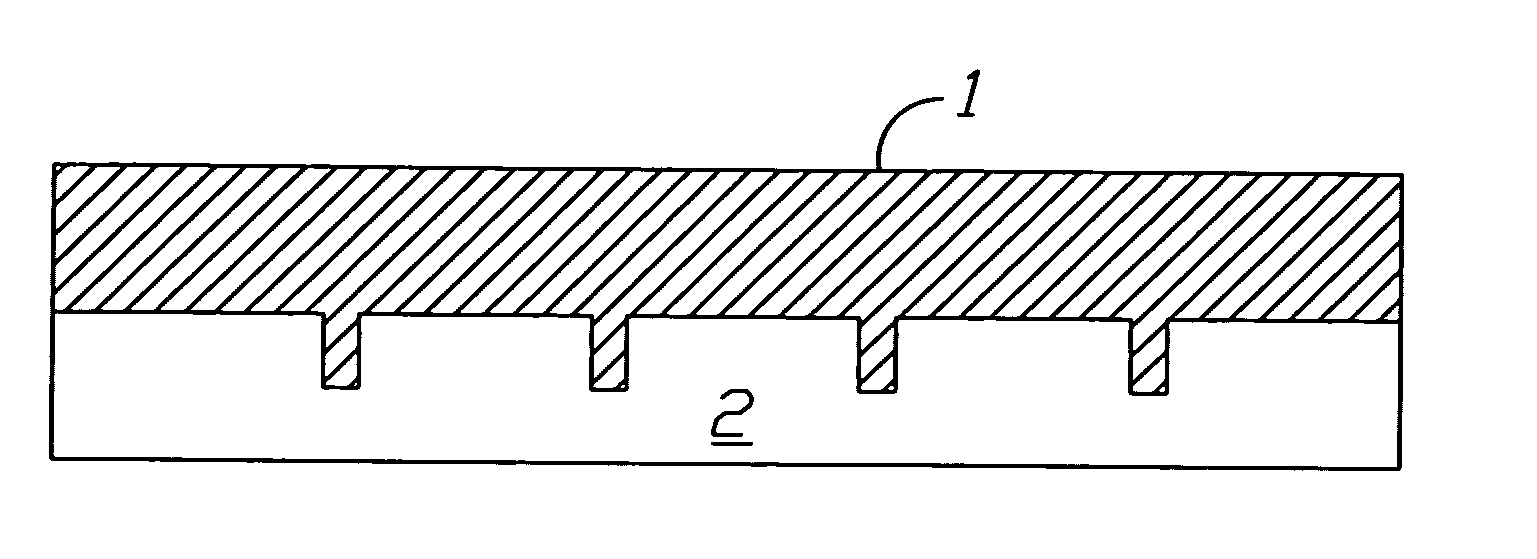

Optical diffusion barrier

ActiveCN102778712AHigh hardnessThin coatingDiffusing elementsSynthetic resin layered productsDisplay deviceFlat panel display

The invention relates to an optical diffusion barrier which comprises a substrate, a diffusion layer and a back layer, wherein the diffusion layer is ultraviolet-cured on any one of the surfaces of the substrate by coating solution comprising optical diffusion particles A, resin A and photo-initiator, wherein the resin A consists of epoxy acrylate resin and urethane acrylate with 8 degrees of functionality in the weight ratio of 1:9-9:1; the back layer is ultraviolet-cured on the other surface of the substrate by coating solution comprising optical diffusion particles B, resin B, photo-initiator and antistatic agent, wherein the resin B consists of pentaerythritol triacrylate and caprolactone modified dipentaerythritol penta / hexa-acrylate in the weight ratio of 1:9-9:1; the optical diffusion particles A consist of high polymer micro-spheres in particle sizes of 10-25 microns and inorganic particles in the particle sizes of 1-4 microns, in the weight ratio of 2:1-4:1; the optical diffusion particles B are inorganic particles in the particle sizes of 2-4 microns; and the diffusion barrier has high hardness, thin coating layer and high transmittance, full diffusion performance and good antistatic property and can meet the development direction of a flat panel display in large size, thinning, light weight and low cost.

Owner:昆山乐凯锦富光电科技有限公司

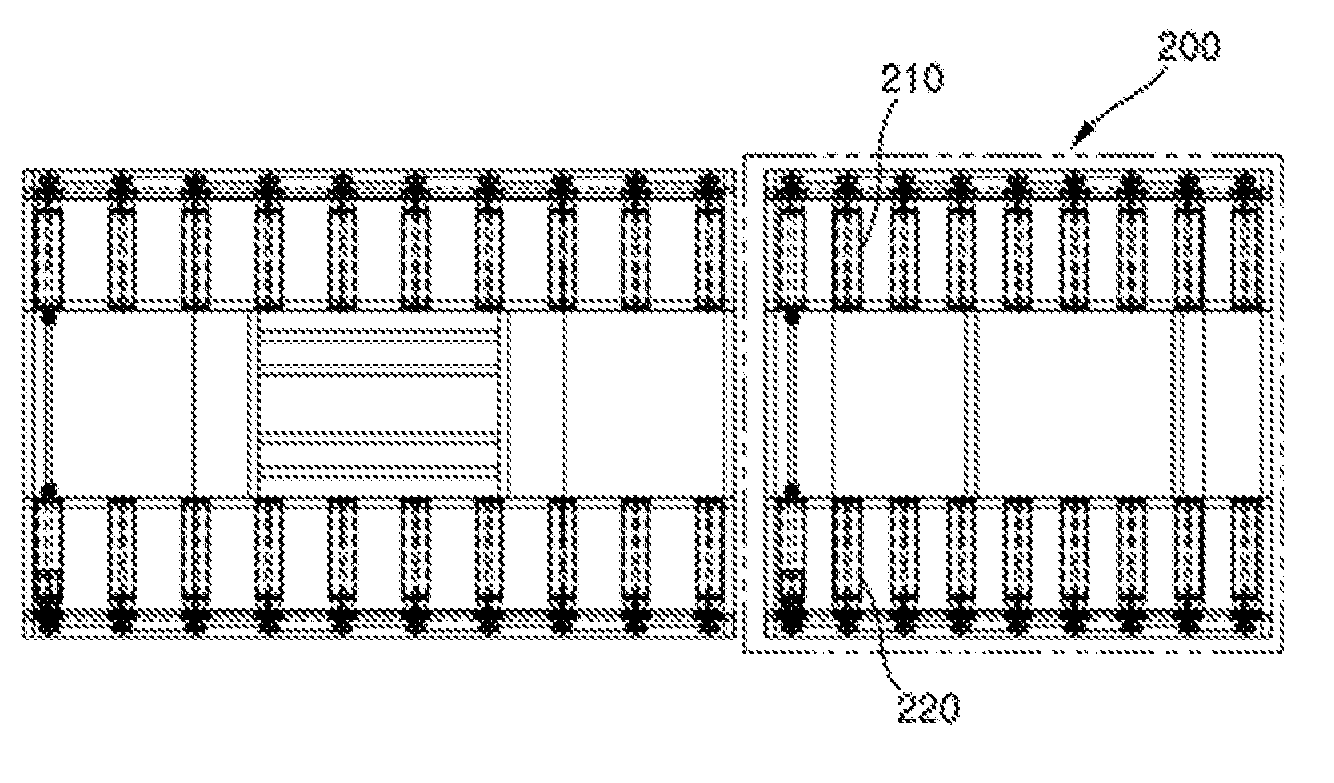

Structure of an electromagnetic shield layer for a plasma display panel and method for manufacturing the same

InactiveUS20070128412A1Avoid influenceGood light transmissionElectric discharge tubesMagnetic/electric field screeningDisplay boardPlastic materials

A structure of an electromagnetic shield layer for a plasma display panel and a method for manufacturing the same. The manufacturing method of the electromagnetic shield layer uses integrated technologies of hot embossing, coating, and electroplating. The structure according to the present invention is a metal layer with an electromagnetic-wave shielding effect and is built in a plastic material. The aspect ratios of the geometric patterns on the metal layer are above 75%.

Owner:NAT CHUNG SHAN INST SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com