Patents

Literature

157results about How to "Long fire resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super thin no-halogen less-smoke fire proof organic-inorganic composite paint and its prepn process

InactiveCN1974695AImprove heat resistanceImprove fire performanceFireproof paintsEpoxy resin coatingsHalogenFoaming agent

The present invention relates to one kind of super thin no-halogen less-smoke fireproof organic-inorganic composite paint and its preparation process. The composite paint is compounded with heat resistant organic and inorganic nanometer hybridized resin, organic resin, heat resistant pigment, heat resistant filler, carbon forming agent, foaming agent, catalyst, assistant, etc. In case of fire, the components of the paint synergy to swell, foam, isolate oxygen, delay heat transfer and inhibit fire spread. The fireproof paint may be used to form coating of controllable thickness in 0.2-2 mm, has fire resisting limit of 30-200 min, excellent heat resisting performance, excellent fire retarding performance, high fireproof performance, high anticorrosion performance and other advantages.

Owner:FUDAN UNIV

Fire-retardant paint with steel structure

ActiveCN101857756AExtend fire resistance timeImprove fire resistanceFireproof paintsPolyurea/polyurethane coatingsPhosphoric acidComposite substrate

The invention relates to fire-retardant paint with a steel structure, which is prepared from the following raw materials proportioning by weight: 45 to 60 of composite substrate resin, 6 to 8 of melamine, 6 to 8 of pentaerythritol, 16 to 20 of ammonium polyphosphate, 4 to 10 of expansible graphite, 2 to 5 of nano magnesium hydroxide, 1 to 3 of zinc phosphate, 1 to 3 of zinc borate, 2 to 5 of aluminum hydroxide, 3 to 5 of aluminum polyphosphate, 6 to 9 of titanium dioxide, 0.5 to 0.8 of flatting agent and 15 to 20 of acetone. The paint has excellent capabilities of fire prevention and corrosion prevention.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

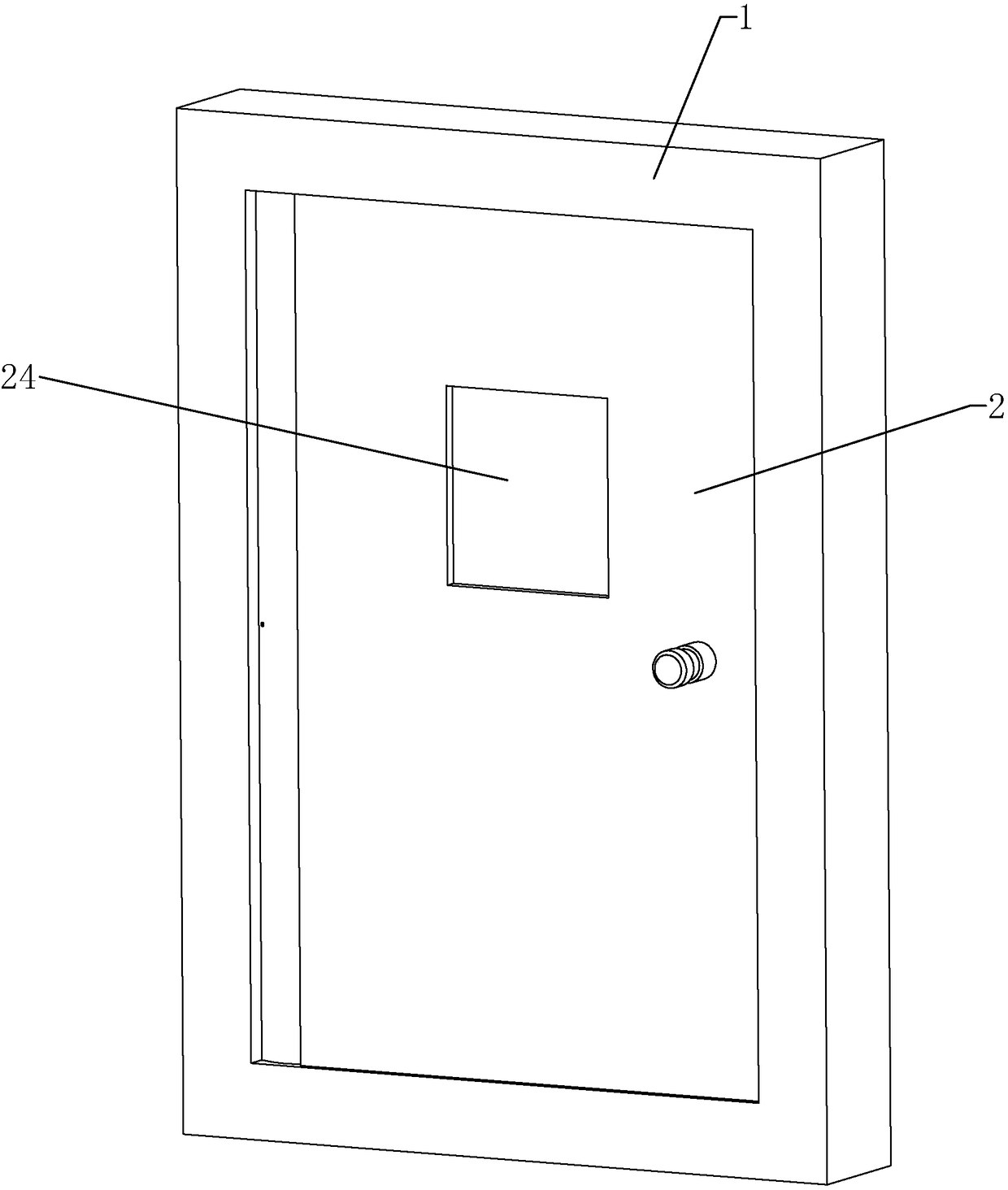

Fireproof material, preparation method thereof and fireproof door

The invention discloses a fireproof material. The fireproof material is prepared from the following raw materials in parts by weight: 35 to 70 parts of black mud powder or 10 to 45 parts of furnace slag or mixture of the black mud powder and the furnace slag, 10 to 50 parts of red silica powder or quartzitic sandstone power, 5 to 15 parts of kyanite powder or andalusite powder or sillimanite powder, 1 to 4 parts of zirconium silicate powder or yttrium-stabilized zirconia powder, 5 to 15 parts of cement, 3 to 5 parts of sodium hexametaphosphate, 3 to 5 parts of fibers, 0.5 to 1 part of aluminum sol or yttrium sol, and the balance being water and animal composite foaming agent. The invention also provides a preparation method for the fireproof material, and a fireproof door made from the fireproof material. The fireproof material is high in refractory temperature, low in manufacturing cost and simple in preparation method. The fireproof door is simple in structure, easy to produce, longin refractory time, high in refractory temperature, low in production cost and stable in quality.

Owner:汪洋

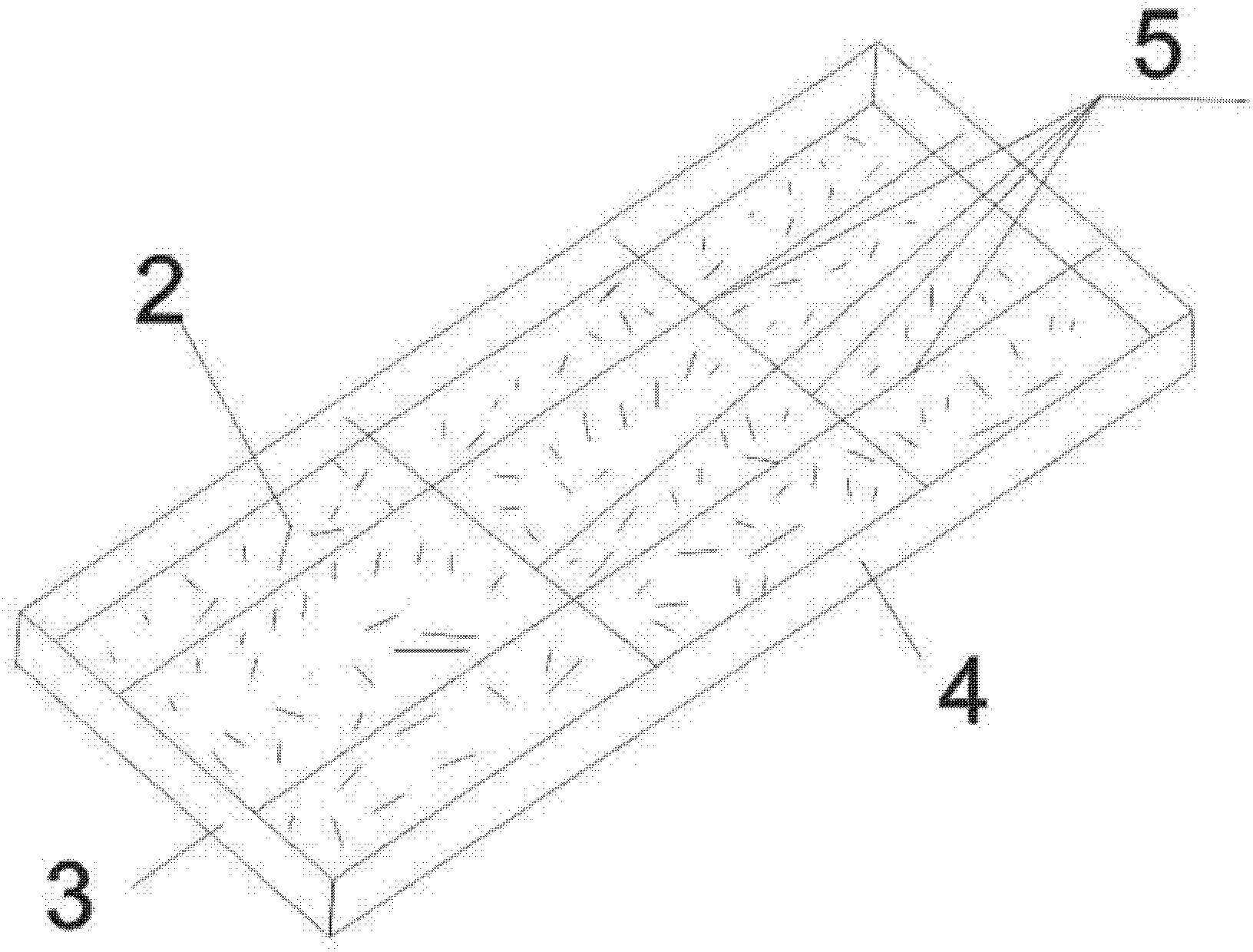

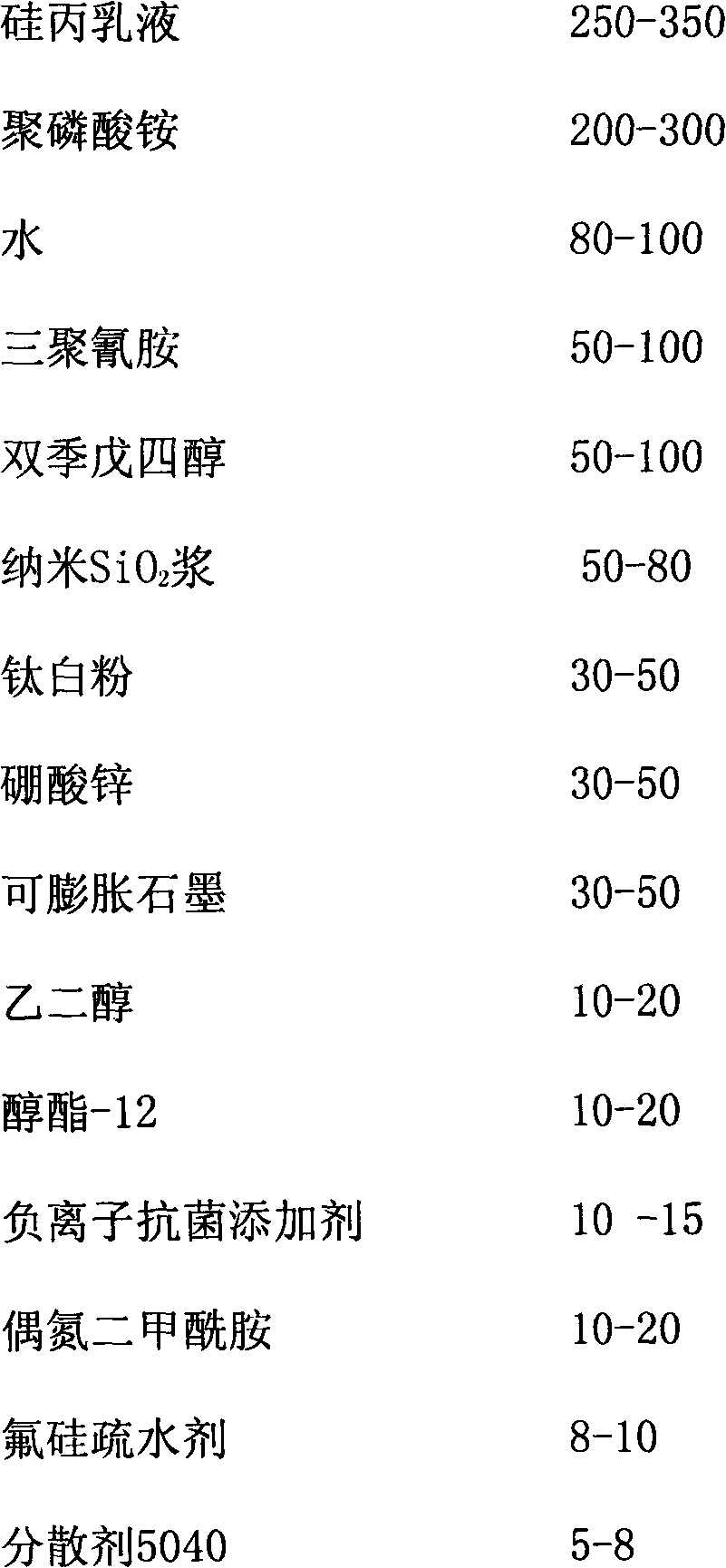

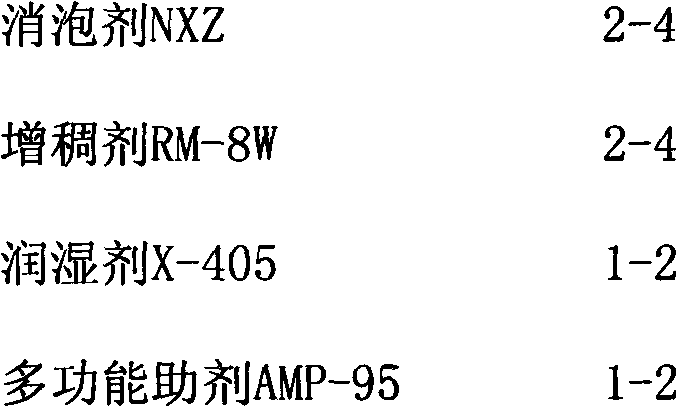

Water expansion type fire-proof mildew-proof coating for tunnels

InactiveCN102634256AWaterproof and anti-seepageLong fire resistanceFireproof paintsAntifouling/underwater paintsTunnel wallAzodicarbonamide

The invention discloses a water expansion type fire-proof mildew-proof coating for tunnels, which are prepared through conventional preparation processes with the cooperation of auxiliary agents, wherein silicone acrylic emulsion serves as a film forming matter, modified ammonium polyphosphate, melamine, dipentaerythritol and azodicarbonamide serve as fire retardants; titanium dioxide, zinc borate and expansible graphite serve as fillers; nanometer SiO2 serves as a modified material and an anion antibacterial additive serves as a mildew-proof bactericide. The mildew-proof fire-proof protective coating disclosed by the invention has the advantages of long fire-proof time limit, good adhesion property, water resistance and permeability resistance, mildew resistance and antibacterial property, environmental protection and no toxicity, good decorative effect, thinness in coating and convenience for construction and is suitable for various tunnel walls.

Owner:北京国泰瑞华精藻硅特种材料有限公司

Organic-inorganic composite nanometer heat-insulating fire-retardant coating and preparation method thereof

ActiveCN104177965AImprove adhesionImprove anti-corrosion performanceFireproof paintsEpoxy resin coatingsEpoxyOrganic film

The invention discloses an organic-inorganic composite nanometer heat-insulating fire-retardant coating and a preparation method thereof. The organic-inorganic composite nanometer heat-insulating fire-retardant coating is prepared by mixing organic film-forming substance acrylic ester emulsions or styrene-acrylate emulsions, epoxide resin, organic intumescent fire-retardant system pentaerythritol, melamine and ammonium polyphosphate with inorganic fire retardant nanometer aluminum hydroxide, nanometer magnesium hydroxide, filler nanometer titanium dioxide, ceramic hollow microspheres, glass hollow microspheres and a part of auxiliary agents. The organic-inorganic composite nanometer heat-insulating fire-retardant coating disclosed by the invention not only has excellent facing property and fire-retardant property, but also achieves reflection effect on solar radiation and certain heat-insulating and heat-preserving property on a substrate, also has good adhesivity, mechanical property and hydrophobic effect, can be formed through spray coating or brush coating before being solidified, and is a novel water-based multifunctional fire-retardant material. The organic-inorganic composite nanometer heat-insulating fire-retardant coating disclosed by the invention can not only be used as a general building wall body fire-retardant coating, but also be suitable for the fire prevention of building and ornament materials, heat-insulating materials, steel structure supports, beam columns, metal roofs and the like.

Owner:山西省建筑科学研究院集团有限公司

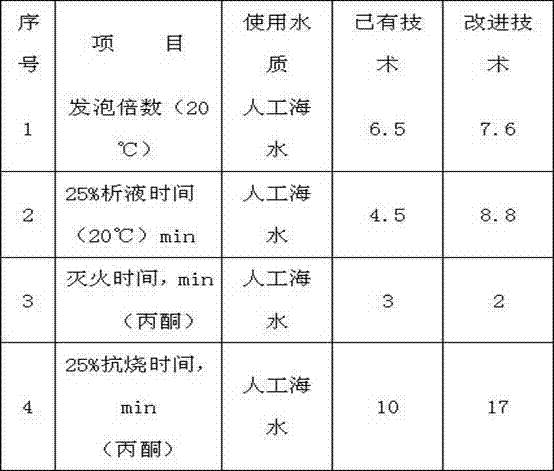

Preparation method of cold-resistant and seawater-resistant aqueous film-forming foam fire extinguishing agent

ActiveCN102284171AComprehensive performance is smallHigh foaming ratioFire extinguisherActive agentSurface-active agents

The invention discloses a novel method for preparing a cold-resistant and seawater-resistant aqueous filmforming foam extinguishing agent. According to the formula, the cold-resistant and seawater-resistant aqueous filmforming foam extinguishing agent consists of the following raw materials in part by weight: 300 to 400 parts of composite burn resistance agent, 6 to 10 parts of sodium benzoate, 50 to 100 parts of urea, 5 to 9 parts of xanthan gum, 200 to 400 parts of amphoteric hydrocarbon surfactant, 20 to 40 parts of alkyl polyglucoside (APG), 80 to 200 parts of glycol, 30 to 60 parts of butyl cellosolve, 10 to 30 parts of FC115710, 20 to 60 parts of FC120320, 20 to 40 parts of low-molecular-weight fluorinated surfactant, and 20 to 60 parts of buffering agent. The product prepared by the method is low in cost, and suitable for fresh water and seawater; and after the agent and the seawater or the fresh water are mixed in a use mixing ratio, the foam property and the extinguishment performance of the agent change slightly, the expansion rate of foam is high, 25 percent liquid drainage time is long, the foams are stable, the extinguishment speed is high and the burn resistance performance is good.

Owner:江苏江亚消防科技股份有限公司

Fireproof and pressure-resistant artificial quartz stone plate and preparation method thereof

The invention discloses a fireproof and pressure-resistant artificial quartz stone plate and a preparation method thereof. The fireproof and pressure-resistant artificial quartz stone plate is composed of the following components in parts by weight: 30-80 parts of 8-100-mesh quartz stone, 20-50 parts of 325-1250-mesh quartz powder, 5-15 parts of broken glass, 5-10 parts of unsaturated polyester resin, 10-20 parts of 50-100-mesh white afrodite powder, 10-20 parts of 100-150-mesh andalusite powder, 3-8 parts of fibers, 0.3-0.5 part of an adjuvant and 0.1-2 parts of pigment. The artificial quartz stone plate disclosed by the invention not only has excellent fireproof performance, but also has stronger breaking strength, compressive strength and bending strength; in addition, the preparation cost is low, and the preparation method is simple and is suitable for industrial production.

Owner:田忠和

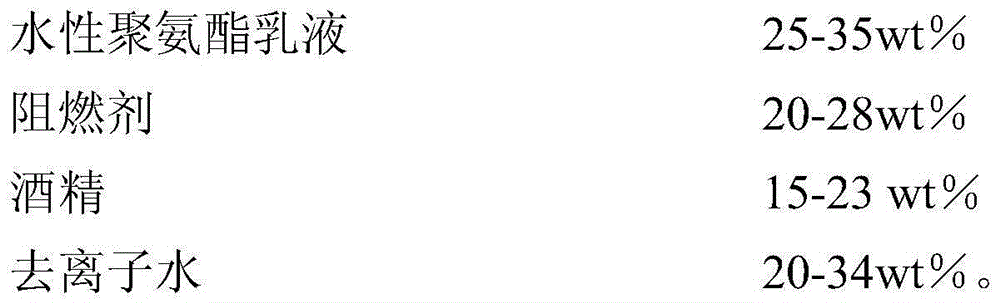

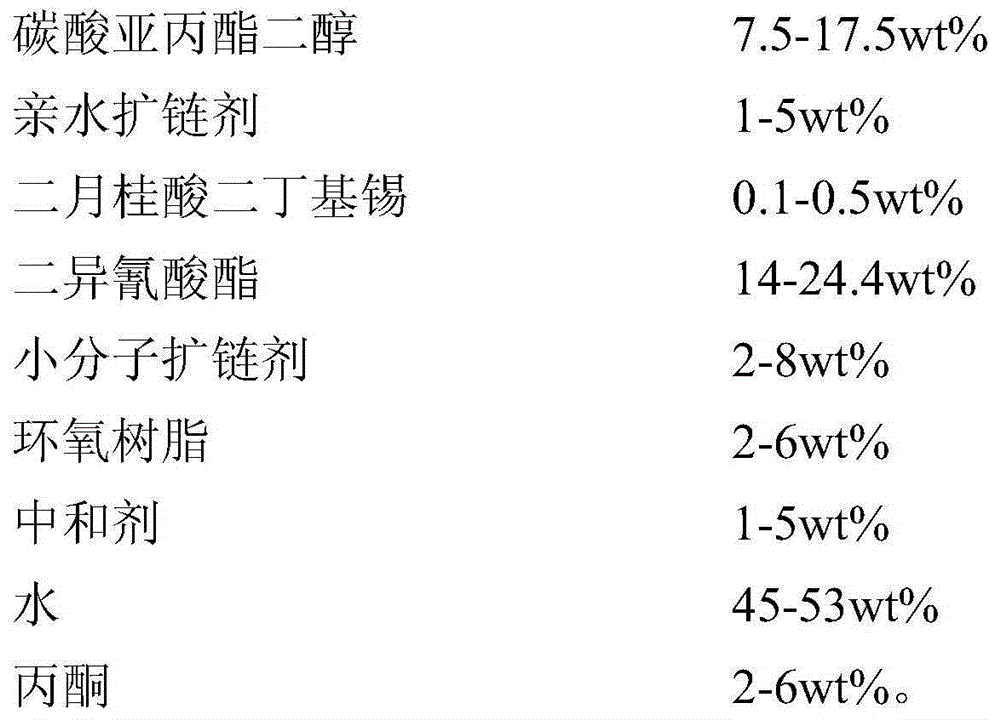

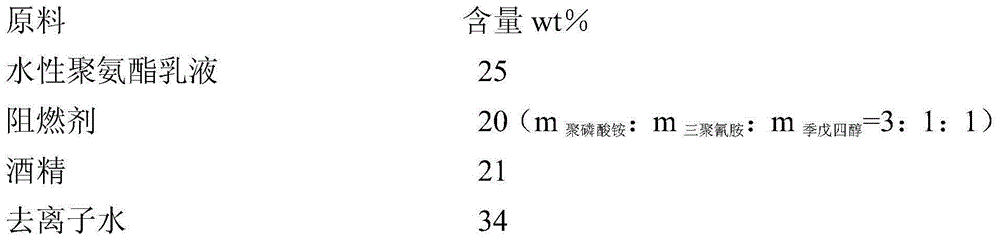

Epoxy resin modified waterborne polyurethane flame retardant paint and preparation method thereof

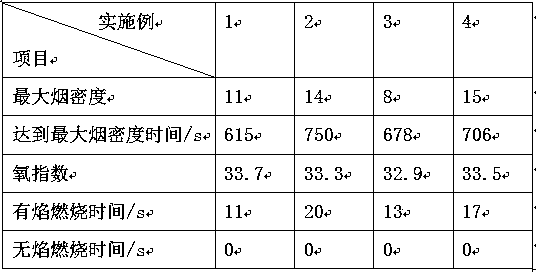

InactiveCN105238245AHigh coating hardnessImprove water resistanceFireproof paintsPolyurea/polyurethane coatingsEpoxyAlcohol

The invention relates to an epoxy resin modified waterborne polyurethane flame retardant paint, which is prepared from the following components by weight percentage: 25-35wt% of a waterborne polyurethane emulsion, 20-28wt% of a flame retardant, 15-23wt% of alcohol, and 20-34wt% of deionized water. The waterborne polyurethane flame retardant paint provided by the invention has the advantages of high film hardness and good water resistance, long fire resistance period, small smoke amount, good flame retardancy, no toxicity and no harm.

Owner:SKSHU PAINT

Artificial quartz stone sheet and preparation method thereof

The invention discloses an artificial quartz stone sheet and a preparation method thereof. The artificial quartz stone sheet comprises the following components in parts by weight: 30-90 parts of 6-80mesh calcined quartz sand, 30-70 parts of 325mesh quartz powder, 5-15 parts of broken glass, 3-10 parts of 30-50mesh tourmaline, 3-12 parts of 50-100mesh sillimanite powder, 3-12 parts of 100-200mesh zirconium silicate powder, 5-10 parts of unsaturated resin, 0.3-2 parts of a silane coupling agent, 0.3-2 parts of a curing agent and 0.1-1 part of a pigment. By the calcined quartz sand, the hardness of the artificial quartz stone sheet is increased so that the artificial quartz stone sheet resists wear and is difficult to be scratched; tourmaline is added so as to increase the antimicrobial property of the artificial quartz stone sheet and meanwhile, sillimanite powder and zirconium silicate powder are added to improve the fireproof performance of the artificial quartz stone sheet.

Owner:田忠和

Thin type fireproof glass and preparation thereof

InactiveCN101279822AImprove fire performanceGood heat insulationFireproof doorsAmide/imide polymer adhesivesFlat glassWeather resistance

The invention discloses a thin fire-resisting glass and a method for the production thereof. The thin fire-resisting glass of the invention is glued by a flat glass and compounded by pouring fire-proof transparent glue, solidifying and sealing, the compositions of the fire-proof transparent glue (W%) are: gel forming agent of 5 to 15 percent, methylene-bisacrylamide of 10 to 20 percent, initiator of 0.1 to 2.0 percent, sodium chloride of 5 to 15 percent, magnesium chloride of 5 to 30 percent, aluminum phosphate of 5 to 25 percent, boric acid of 0 to 10 percent, ethanolamine of 5 to 25 percent and water of 30 to 50 percent. The fire-resisting glass of the invention is mainly used for fireproof and soundproof building partitioning facilities such as fire-resisting and soundproof doors and fire-resisting and soundproof walls and windows, and has good sound insulation, transmittance, waterproofing and weathering resistance performances, and can meet the requirements of high-grade building fireproof materials with rather high fireproof demand.

Owner:TIANJIN FIRE RES INST

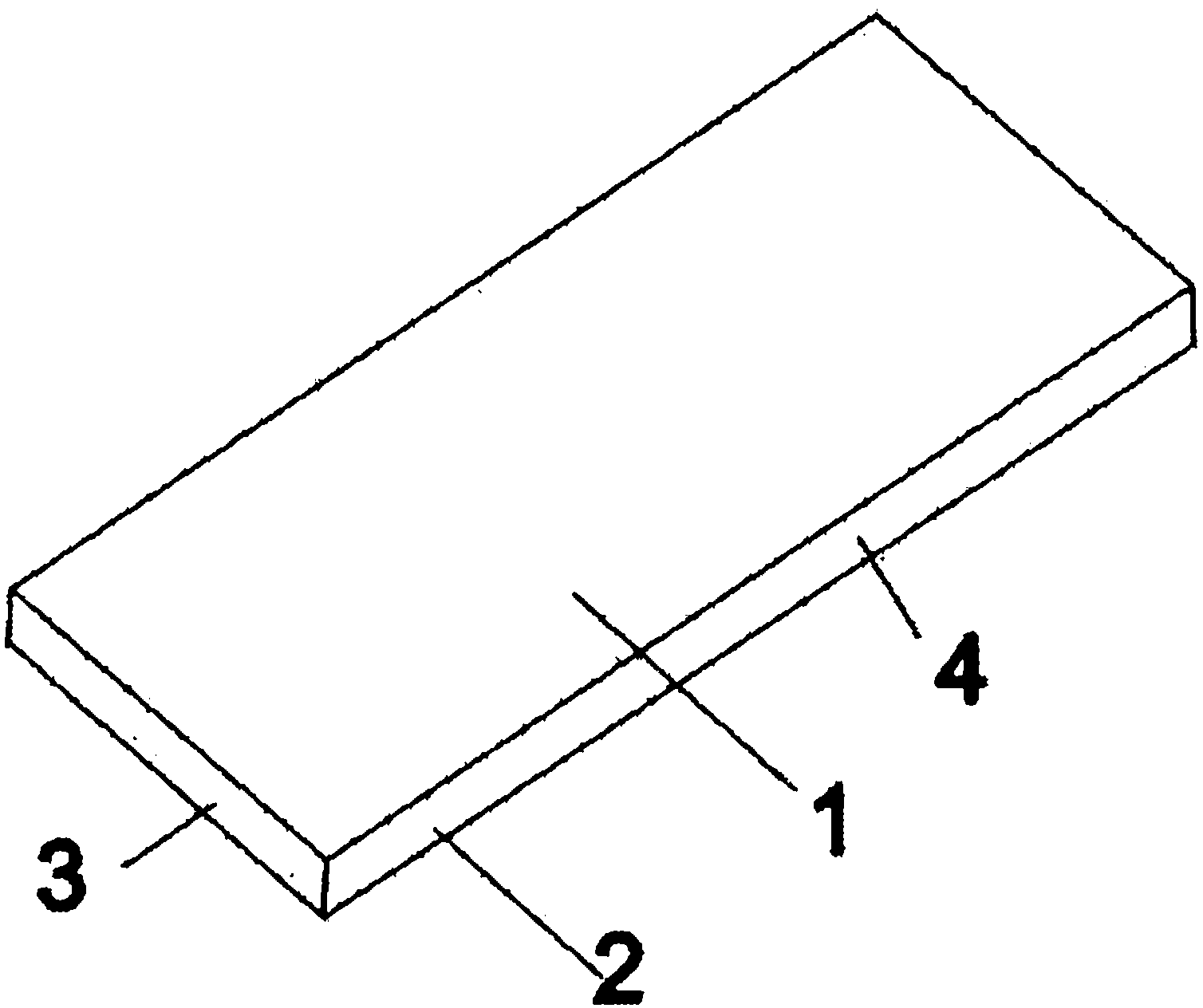

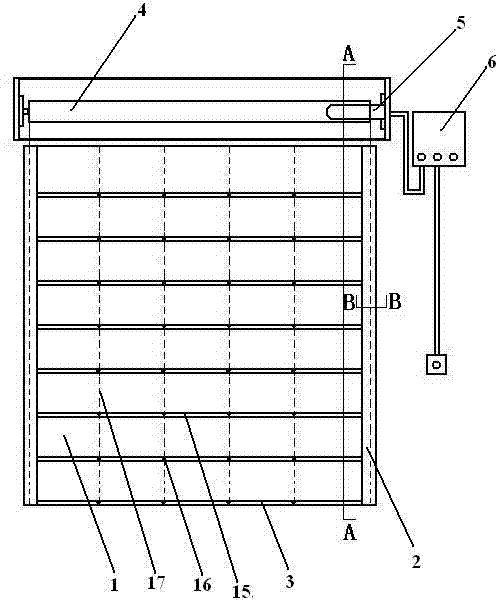

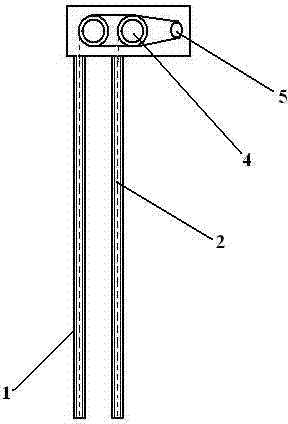

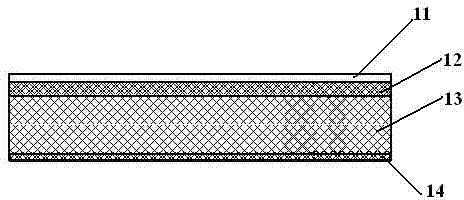

Special fireproof inorganic double-track double-shutter rolling door

ActiveCN104775737AReduce the temperatureAvoid the defect that it is not resistant to temperature and easy to break in case of fireShutters/ movable grillesFireproof doorsPulp and paper industryMultiple layer

The invention discloses a special fireproof inorganic double-track double-shutter rolling door. The rolling door comprises shutter surfaces, guide rails, a pedestal plate, rollers, a fireproof door roller and a fireproof rolling controller. The rolling door has the following beneficial effects: the shutter surfaces are formed by overlapping multiple layers of materials with corresponding functions, so that the temperature rise can be effectively reduced; the loads of the shutter surfaces are hung by steel wire ropes, so that the service life can be prolonged, and breakages caused by fire can be prevented; the installation cascade structures of the two shutter surfaces can be reversely installed, so that fire coming from different directions can be effectively prevented; the two rollers are controlled by a same shutter rolling machine, so that resources can be saved; reflecting cloth is additionally arranged in the shutter surfaces, so that heat added to the shutter surfaces can be effectively reduced; by arranging smoke control devices in the guide rails, sealing strips are swollen after heated, and gaps between the shutter surfaces and the guide rails can be extruded and eliminated; by additionally arranging expansion spray devices in the guide rails, after water which is contained in cavities of ear channels is swollen after being heated the bottom walls of small holes can be extruded and punched, so that the water in the cavities of the ear channels can be sprayed to the shutter surfaces, the temperatures of the shutter surfaces can be reduced, and the fire-resistant time can be effectively prolonged.

Owner:重庆宏杰门业有限责任公司

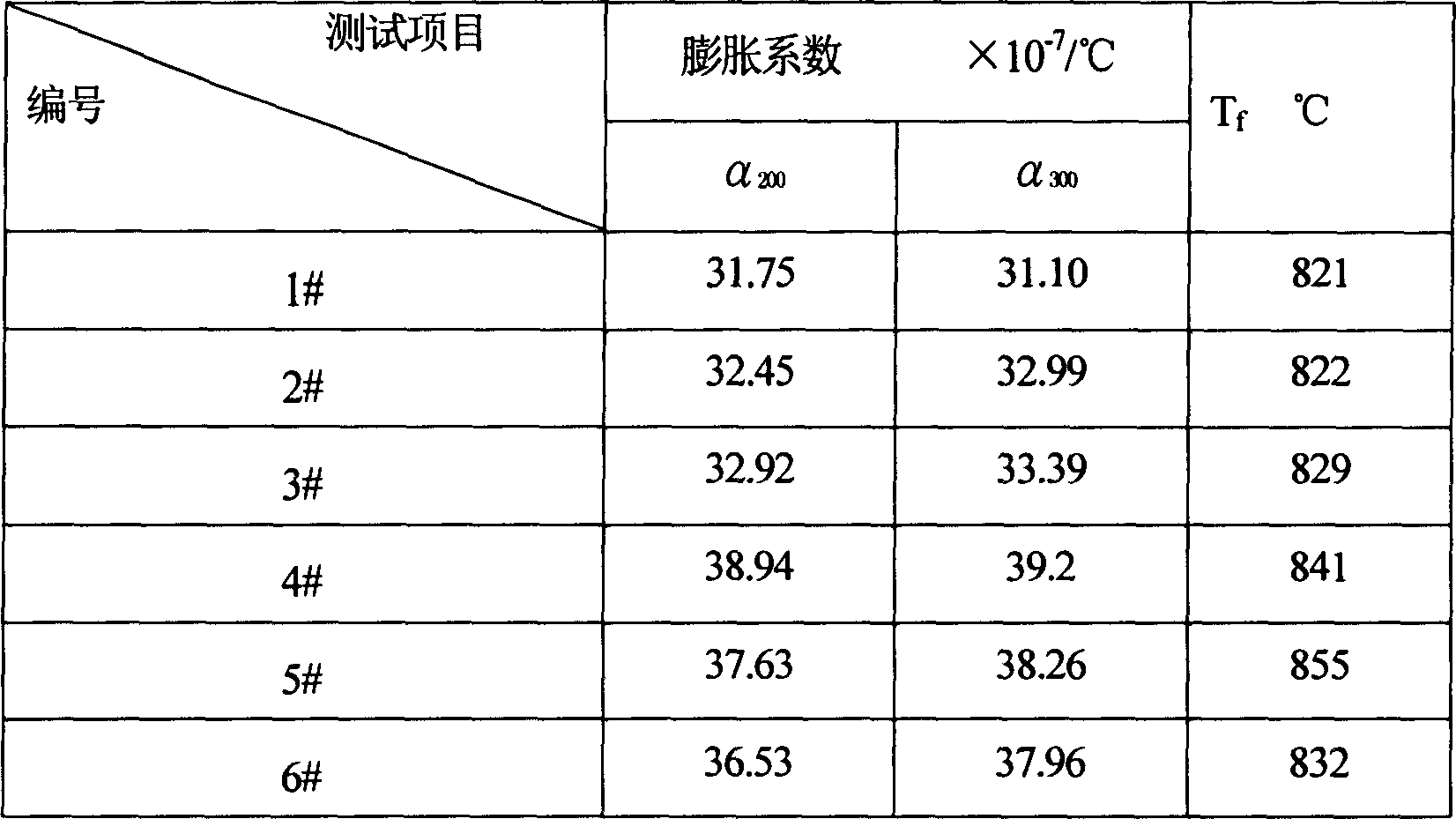

Low-expansion heat-resisting fire-retardant glass

Owner:CHINA LUOYANG FLOAT GLASS GROUP

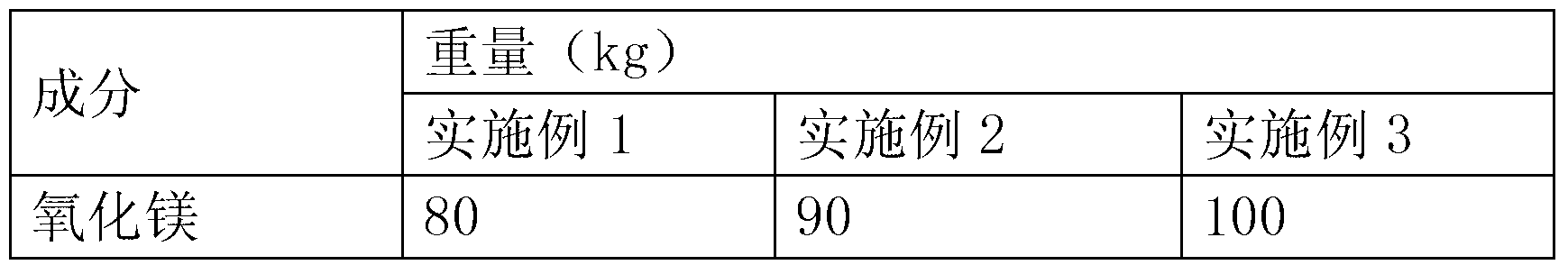

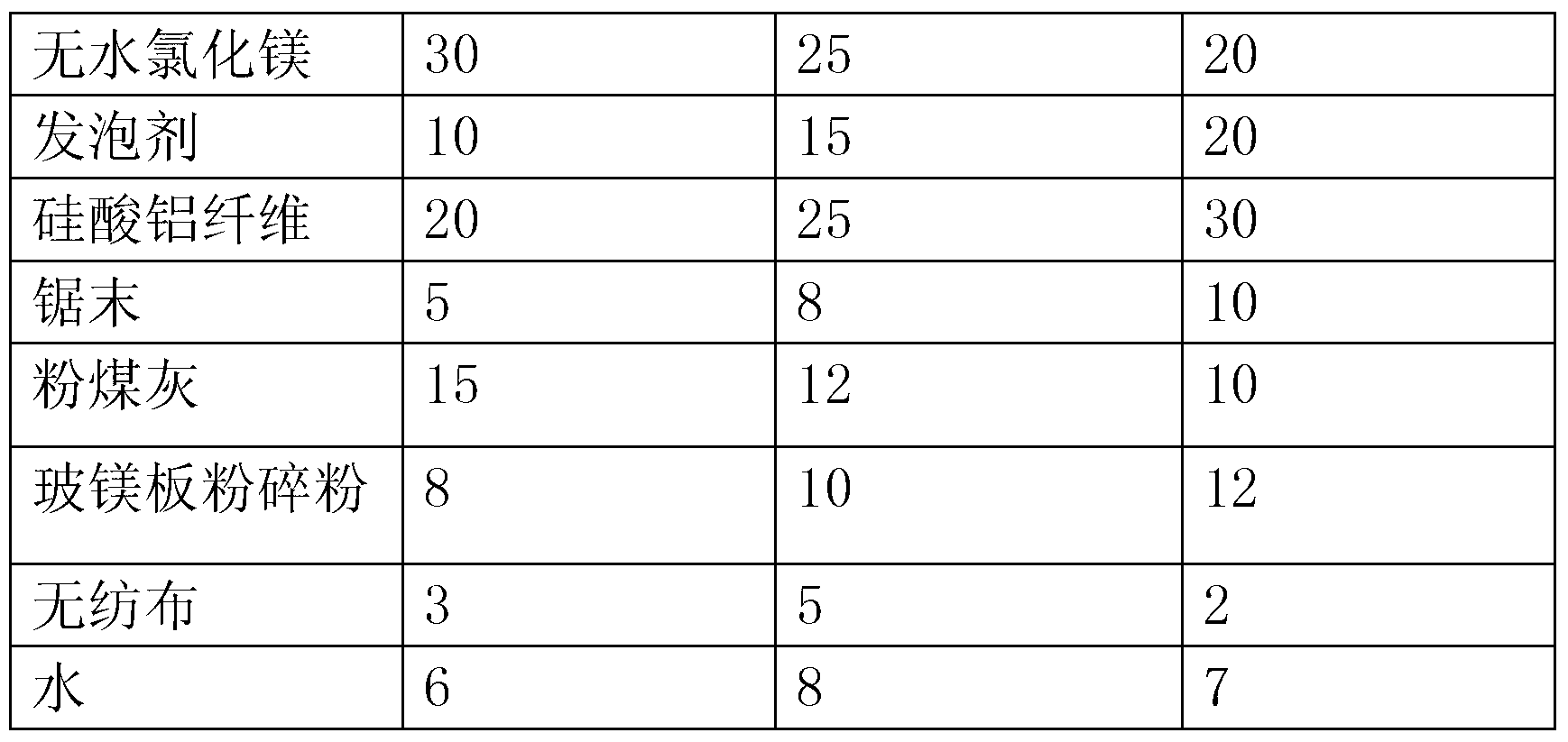

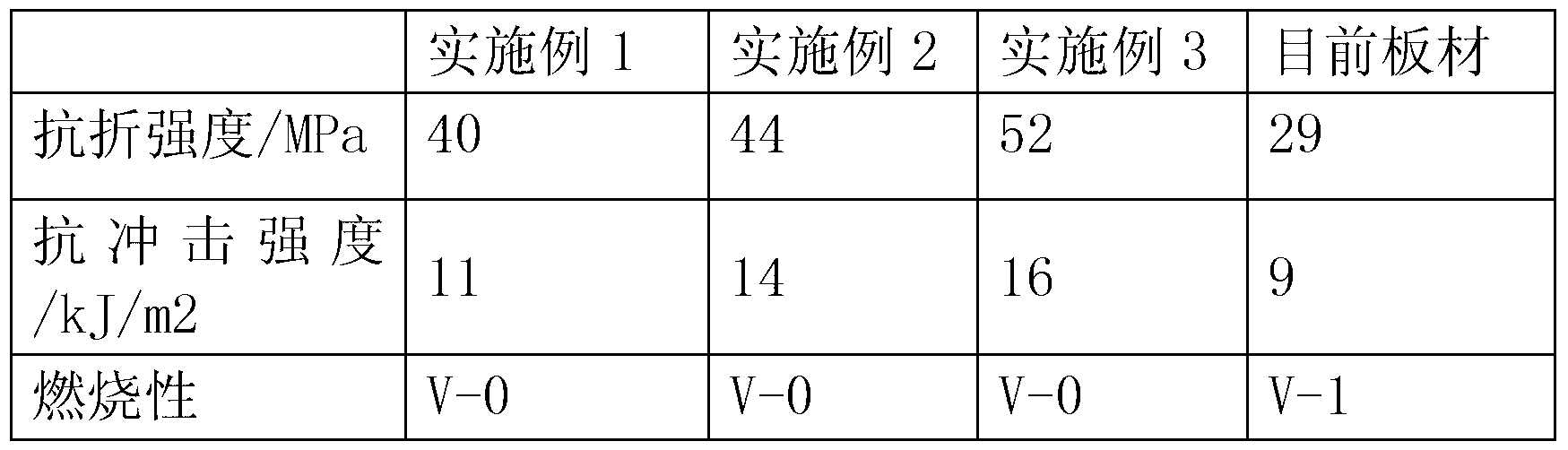

Magnesium oxide plate and manufacturing process thereof

InactiveCN103319198AImprove flame retardant performanceLong fire resistanceCeramicwareFiberAluminum silicate

The invention discloses a magnesium oxide plate and a manufacturing process thereof. The magnesium oxide plate disclosed by the invention is characterized by being prepared through mixing the following mixed raw materials in parts by weight: 80-100 parts of magnesium oxide, 20-30 parts of anhydrous magnesium chloride, 10-20 parts of foaming agent, 20-30 parts of aluminum silicate fiber, 5-10 parts of saw dust, 10-15 parts of coal ash, 8-12 parts of glass magnesium board disintegrated powder, 1.5-5 parts of non-woven fabric, and 6-8 parts of water. The magnesium oxide plate is manufactured by adding the raw materials in the parts by weight into mixing equipment and uniformly mixing the raw materials to prepare a base stock, introducing the base stock into a mold, extruding the base stock by using extrusion equipment, then molding the extruded base stock, and air-drying the molded plate. The magnesium oxide plate disclosed by the invention meets AQ1 grade safety and performance requirements; inspection according to GB24-2006 standards proves that the burning performance of the magnesium oxide plate meets A1 grade requirements; the magnesium oxide plate is smooth in surface, good in water resistance, can be applied to exterior wall decoration, and greatly expands the application space of a glass fiber and magnesium fire-proof plate.

Owner:ZHANGJIAGANG EVERNICE BUILDING MATERIALS

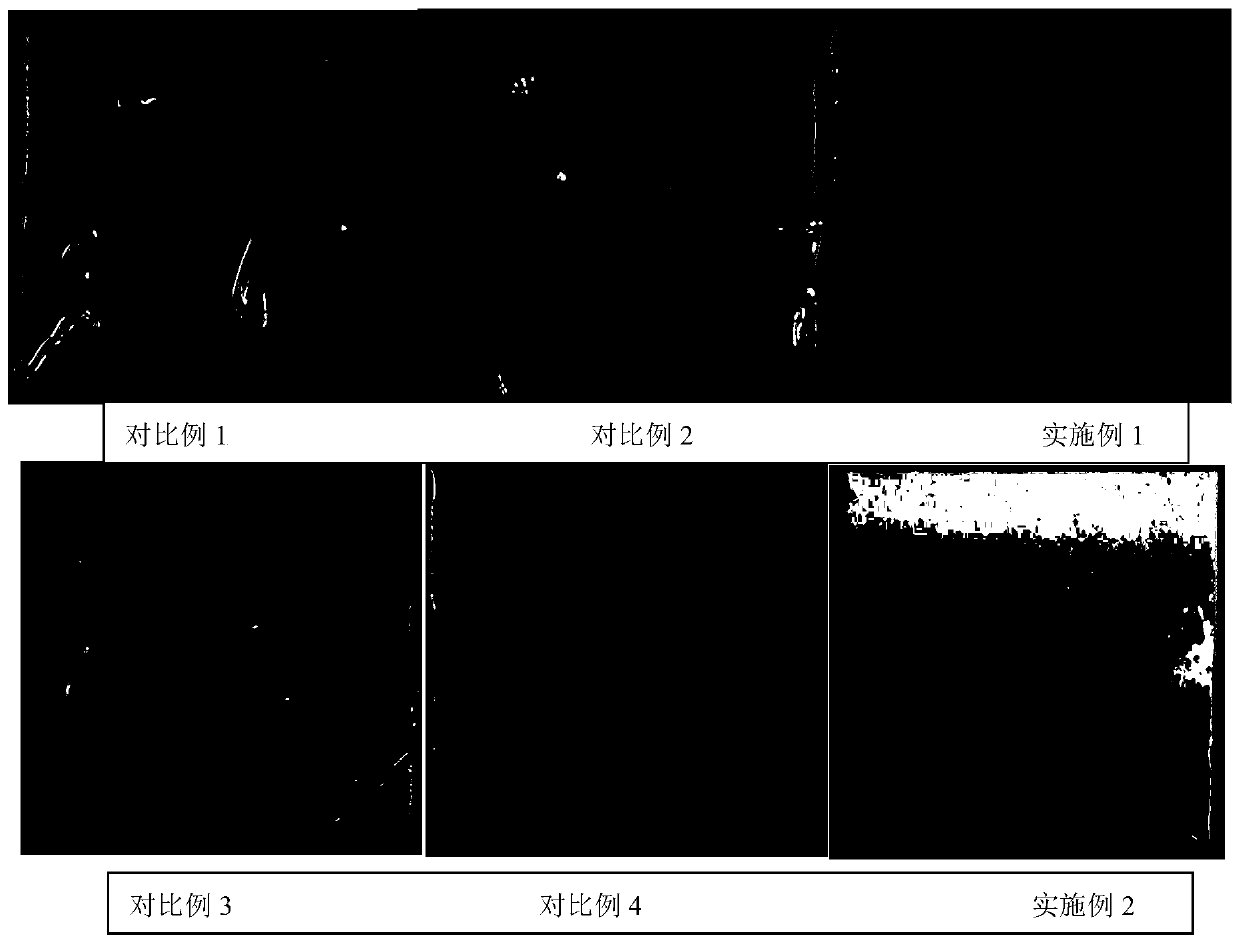

Environment-friendly fireproof material for electrical equipment and preparation method thereof

ActiveCN106497339AReduce solubilityImprove thermal stabilityFireproof paintsEpoxy resin coatingsFiberCrack resistance

The invention provides an environment-friendly fireproof material for electrical equipment and a preparation method of the environment-friendly fireproof material, and belongs to the fields of fireproof materials and preparation technologies thereof. The environment-friendly fireproof material for the electrical equipment is characterized by being prepared from the following raw materials in parts by weight: 50 to 60 parts of modified epoxy resin, 30 to 40 parts of fluorocarbon resin, 60 to 90 parts of a fire retardant, 3 to 10 parts of expanded graphite, 3 to 10 parts of alumina silicate fiber and 2 to 8 parts of molecular sieves. The fireproof material provided by the invention is applied to fire protection of the electrical equipment, and is high in crack resistance, water resistance and weather resistance and good in expansion character; meanwhile, the heat release rate of a base material in a burning condition can be obviously reduced, and the quality loss is reduced; moreover, the fireproof material is small in smoke production quantity and good in environmental protection effect.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

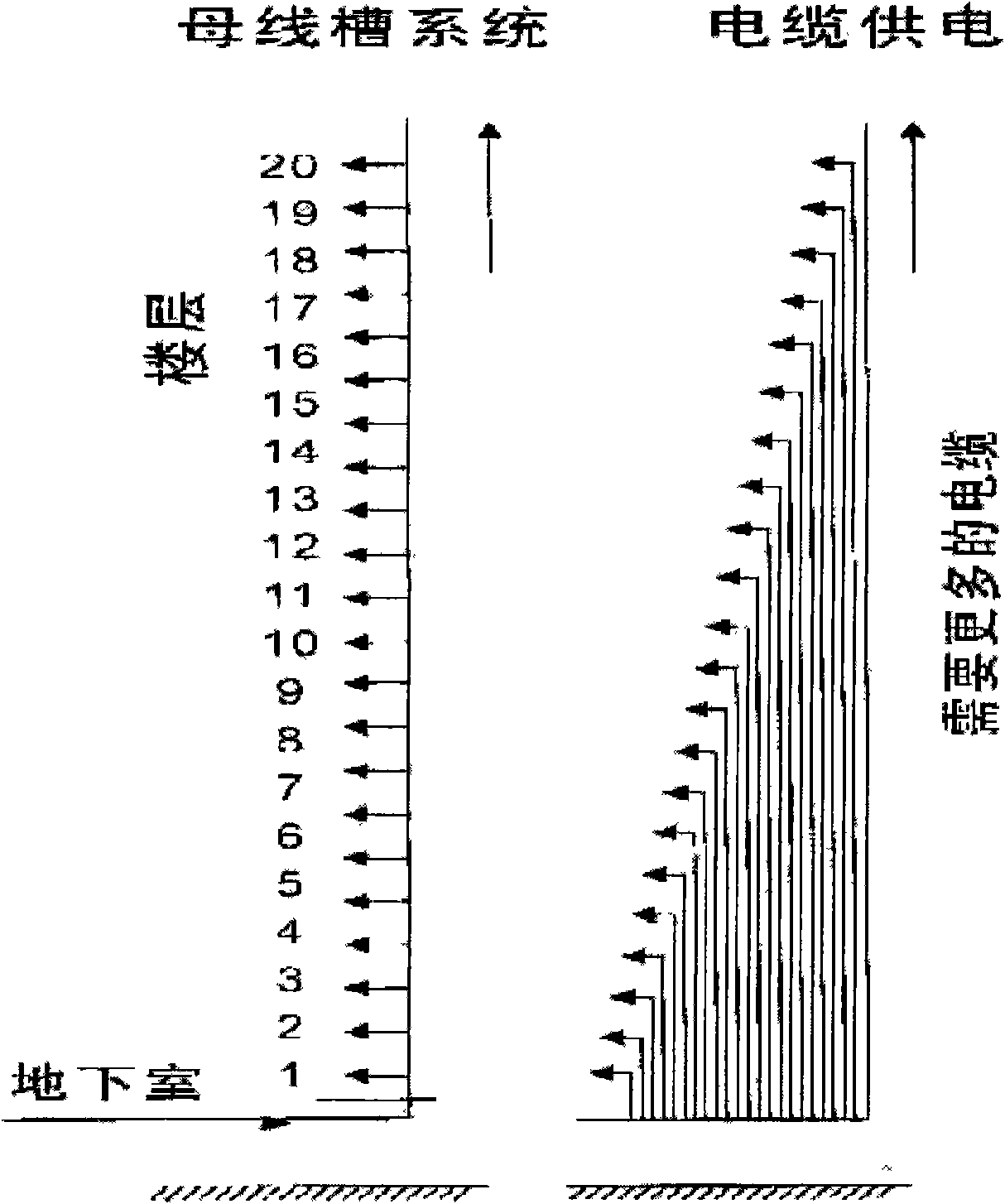

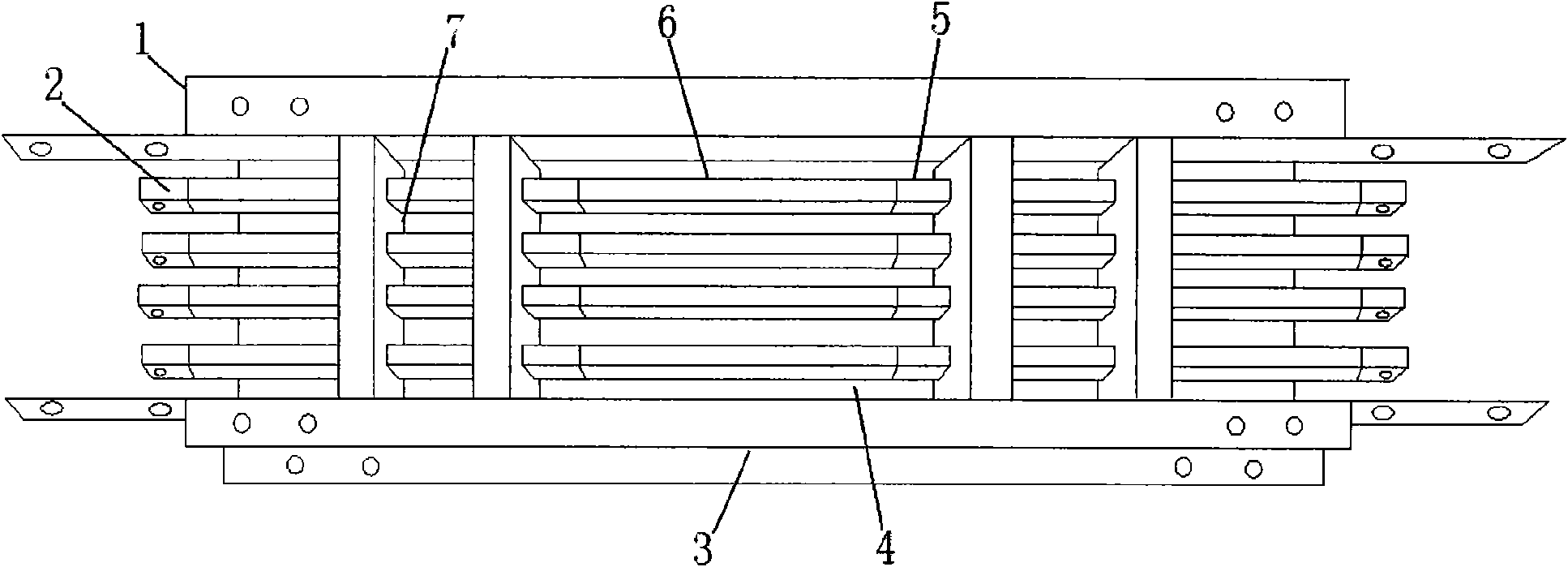

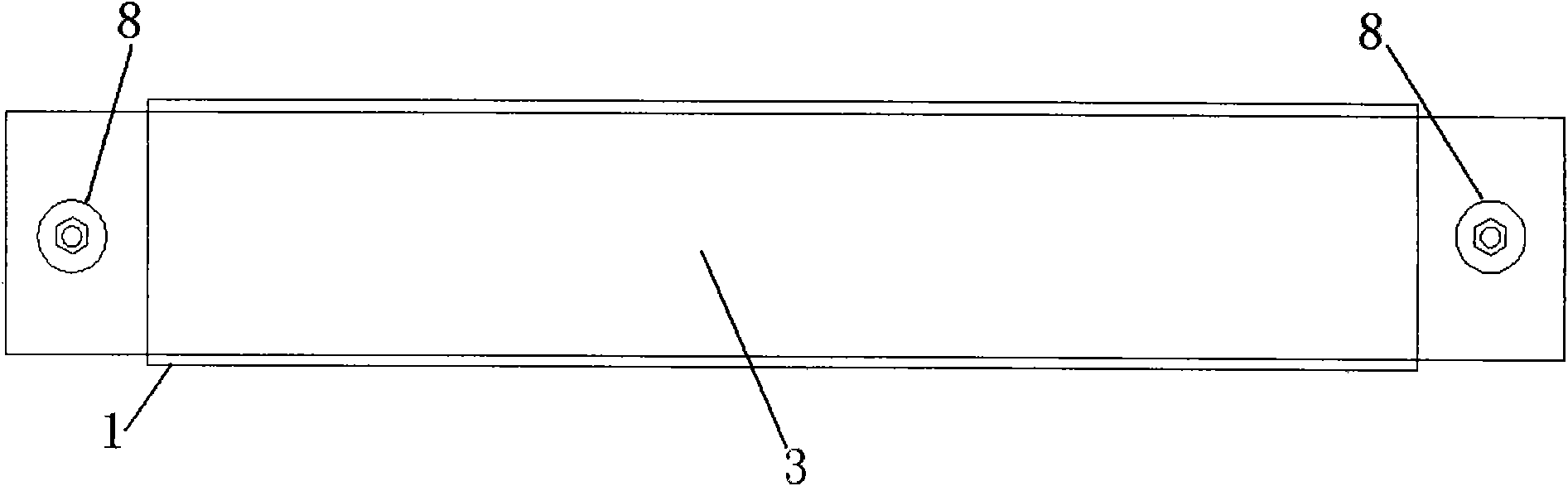

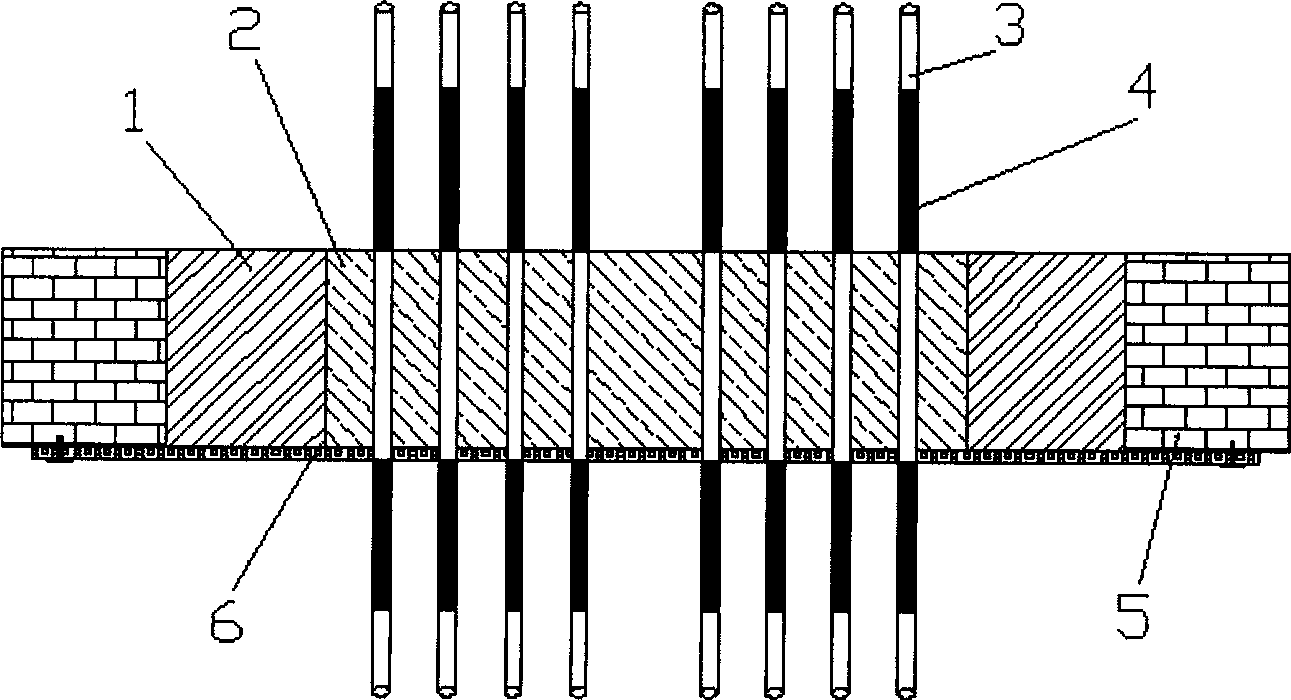

Insulated fireproof bus duct

InactiveCN101567536AHigh mechanical strengthLower backfire temperatureTotally enclosed bus-bar installationsElectrical conductorEngineering

The invention discloses an insulated fireproof bus duct, which comprises a shell and a conductor, wherein the shell consists of a side plate and a cover plate which are connected with each other through a fastener to clamp the conductor; the inner wall of the shell is sprayed and coated with fireproof materials; the conductor is coated by a high temperature resistant reinforced mica tape and externally coated by an insulator heat shrinkage sleeve; an interphase and a terminal are provided with spacer blocks made of inorganic glass fiber reinforcing materials; and the side plate and the conductor are riveted and fixed on a joint through a butterfly spring. The insulated fireproof bus duct can be fireproof for a long time, and the conductor is coated by the high temperature resistance reinforced mica tape and externally coated by the insulator heat shrinkage sleeve; the spacer blocks are made by pressing the inorganic glass fiber reinforcing materials, so that the spacer blocks are noncombustible and inexplosive and have good mechanical property; the inner wall of the shell is sprayed and coated with the fireproof materials, so that the back-fire temperature is reduced or the fireproof time is prolonged; and the butterfly spring has the function of automatic regulation to make the pressure uniformly applied to the contact surface, so that the contact resistance and the temperature rise are reduced. Moreover, the insulated fireproof bus duct has large capacity, low line loss, high short-circuit strength and good heat dispersion.

Owner:KUNSHAN POWER SUPPLY CO LTD OF JIANGSU ELECTRICPOWER +1

Preparation method for novel high temperature resisting organic fire prevention heat insulating material

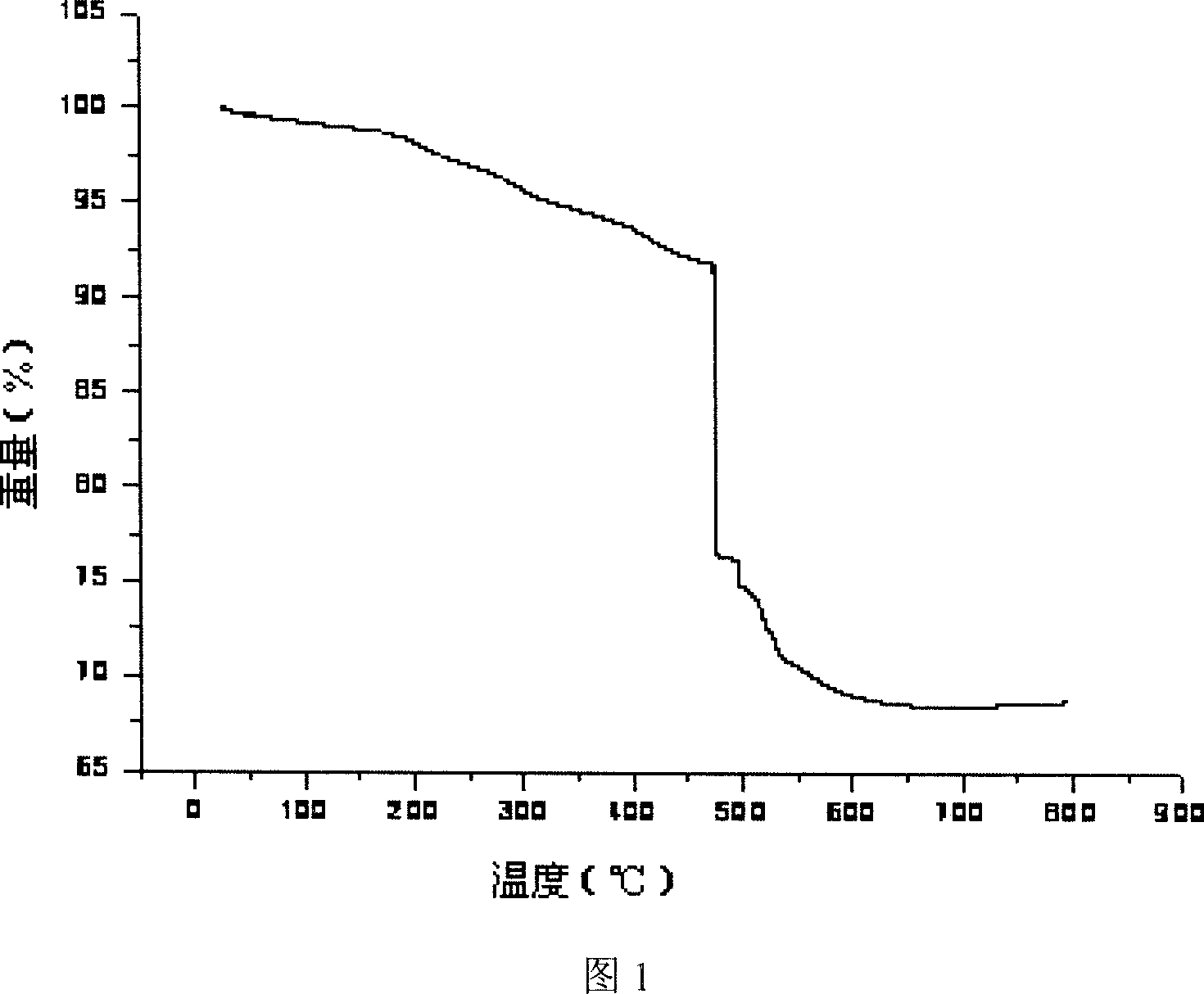

InactiveCN101544014AHigh temperature resistantDimensionally stableCeramic shaping apparatusMass ratioSolvent

The invention provides a preparation method for novel high temperature resisting organic fire prevention heat insulating material. The preparation method comprises the following steps: mixing an organic silicon resin and alumina micropowder according to the mass ratio of 25-35:75-65, adding an organic solvent so as to make the raw materials be evenly mixed, adding the mixture into a 110 to 130 DEG C constant temperature oven and performing heating preservation for 3 to 12 hours so as to remove the solvent, transferring the mixture into a heating die while the mixture is still hot, carrying out the forming according to a staged temperature rise die stamping process system, and adding the material into a constant temperature oven at 200 to 250 DEG C after decompression and die ejection and carrying out the treatment for 5 to 10 hours. The prepared organic fire prevention heat insulating material has the advantages of conventional inorganic and organic fire prevention materials. The material shows the characteristics of resin material and has enough mechanical strength at a room temperature; and the material is converted into ceramic material at a high temperature, still meets the requirement of enough mechanical strength, and has stable external dimensions without deformation in the heating process. The material has a simple preparation process, and can be used for making covers and protecting cases meeting various requirements on the shape through die stamping. The method is suitable for the industrialized production.

Owner:WUHAN UNIV OF TECH

Artificial quartzite plate and manufacturing method thereof

InactiveCN104496273AImprove antioxidant capacityImproves UV protectionAntioxidantAntibacterial property

The invention discloses an artificial quartzite plate and a manufacturing method thereof. The artificial quartzite plate is composed of the following components in parts by weight: 30-90 parts of 3-80-mesh quartzite, 30-70 parts of 325-mesh quartz powder, 5-15 parts of cullet, 3-10 parts of 30-50-mesh tourmaline, 3-12 parts of 50-100-mesh sillimanite powder, 3-12 parts of 100-200-mesh zirconium silicate powder, 0.1-2 parts of antioxidant, 5-10 parts of unsaturated resin, 0.3-2 parts of silane coupling agent, 0.3-2 parts of curing agent and 0.1-1 part of pigment. The antioxidant is added to the raw materials, thereby enhancing the oxidation resistance and ultraviolet resistance of the artificial quartzite plate. The tourmaline is added to the raw materials to effectively enhance the antibacterial property of the artificial quartzite plate, and thus, the artificial quartzite plate has long antimicrobial effect. The sillimanite powder and zirconium silicate powder, which are favorable refractory materials with very high melting point and hardness, can enhance the refractory temperature of the artificial quartzite plate, prolong the refractory time and increase the compression strength.

Owner:田忠和

Foamed brick and processing method thereof

The invention relates to a foamed brick and a processing method thereof. The foamed brick is prepared from the following raw materials in parts by weight: 20-30 parts of fine stone sand, 10-20 parts of coal ash, 20-30 parts of 42.5-grade rapid hardening portland cement, 15-20 parts of quick lime, 10-15 parts of general coal ash ceramisite, 6-10 parts of sodium silicate, 1-3 parts of a concentrated high foam agent, 2-5 parts of calcium chloride, 5-8 parts of reinforcing glass fiber silks, 2-3 parts of an organic silicone water repellent, 0.2-0.3 part of vermiculite, 0.6-0.8 part of graphite and a proper amount of water. The processing method comprises the following steps: (1) mixing the materials and stirring to form mortar; (2) performing injection molding. The foamed brick is low in cost, very good in heat insulation property, sound insulation property and fire prevention property, and relatively high in strength.

Owner:贵州省恒威新型建材有限责任公司

Sound-absorbing type tunnel fireproof paint

A sound-absorbing type tunnel fireproof paint is mainly prepared by stirring the following raw materials in parts by weight: 70-78 parts of sulphoaluminate cement, 30-38 parts of AEC expansive cement, 20-30 parts of portland cement, 30-35 parts of methyl methacrylate, 10-18 parts of vinyl acetate resin emulsion, 12-14 parts of aluminium hydroxide, 4-8 parts of starch, 3-6 parts of ammonium bichromate, 10-18 parts of light calcium carbonate, 10-15 parts of polypropylene short fiber, 8-10 parts of carboxymethyl cellulose, 10-16 parts of fly ash glass microsphere, 5-9 parts of kaoline, 5-9 parts of vermiculite and 5-7 parts of ammonium polyphosphate. The product provided by the invention is long in fireproof time, good in adhesive property and convenient to construct, is applicable to various tunnel walls, and has the sound absorbing function based on the fireproof function.

Owner:上海世范乐建新材料有限公司

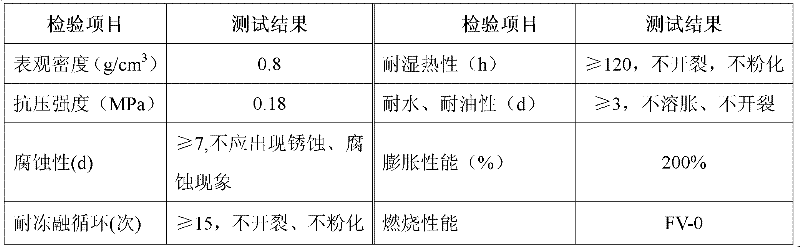

Environment-friendly fire-retardant module

The invention discloses an environment-friendly fire-retardant module. The environment-friendly fire-retardant module consists of 40 to 90 weight parts of expanded vermiculite, 10 to 60 weight parts of flame-retardant resin, 5 to 30 weight parts of expanded graphite, and 5 to 30 weight parts of magnesium oxide. The environment-friendly fire-retardant module has the advantages that: the plasticity is high, and the module contributes to opening pores and cutting; the module has high performance such as water resistance, oil resistance, alkali resistance and the like, and does not have the defects of swelling, deformation and cracking; the weight is light, the actual density is 0.8g / cm<3>, and the load of blocking materials on cable bridges and buildings can be effectively lightened; the fire-resistant time is long, namely the fire-resistant time is prolonged to be more than 5 hours, and the module is a national first-class fireproof product; the module cannot produce toxic gas when encountering with fire, does not contain halogen components, cannot release toxic gas when encountering with fire hazards, and is environment-friendly; the period of validity of the product is long, namely the period of validity is over 15 years, and the repetitive investment and construction are avoided; and the module can be widely applied to the fireproof blocking of wires, cable and electrical equipment of large-scale industrial and mining enterprises in the fields of electric power, petrochemistry, metallurgy and steel, communication, national defense and the like.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

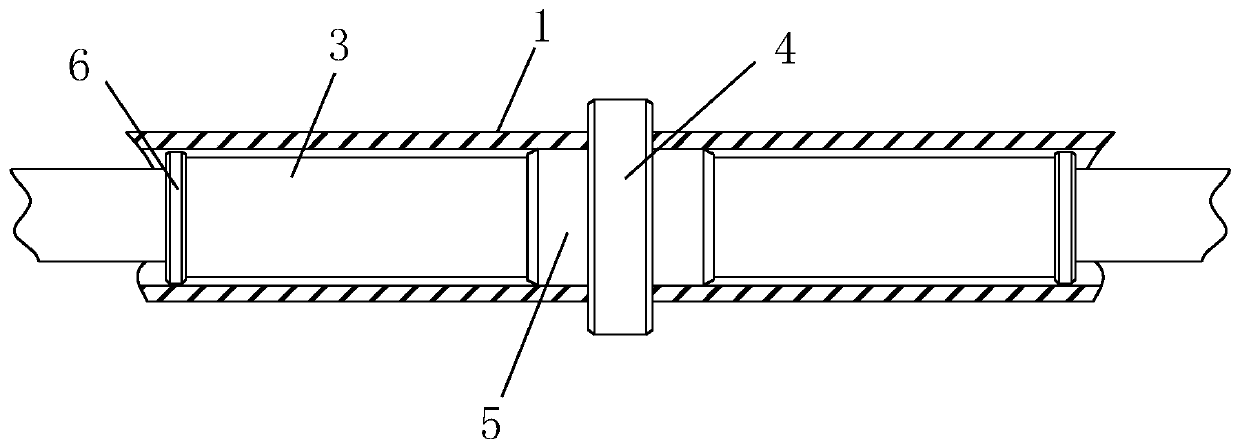

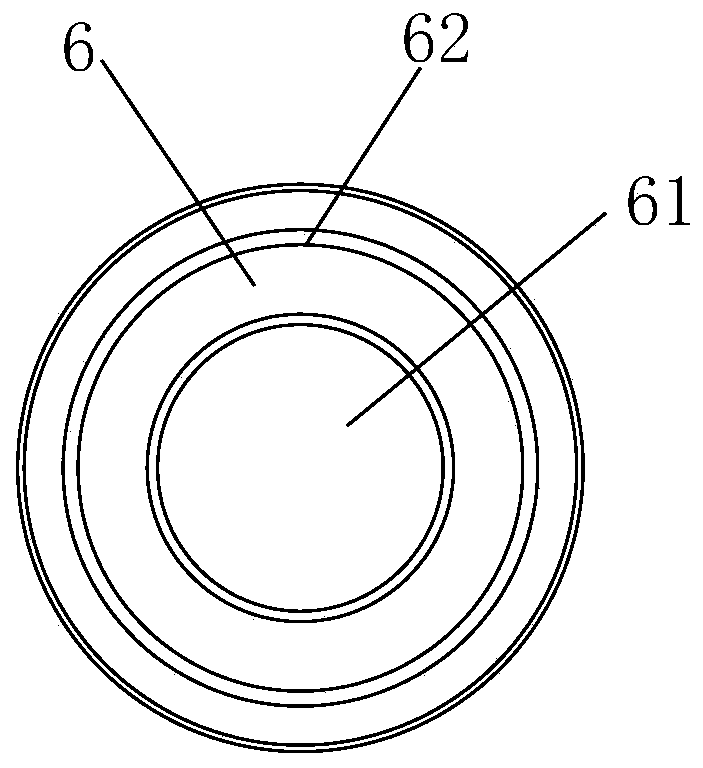

Fire stopping ring core material and preparation method and use thereof

The invention discloses a fire stopping ring core material and a preparation method and use thereof. The fire stopping ring core material consists of a core material solidifying agent, a flame-retarding agent, a carbonizing agent, a carbonization catalyst, a foaming agent, an expansible material, a reinforcing body, glue and other materials. The fire stopping ring core material disclosed by the invention has the advantages of environment protection, convenience and low cost; and at a certain temperature, the fire stopping ring core material can be used for quick plugging, the expansion factor of the fire stopping ring core material is high and the fire resistant time is long.

Owner:GUANGDONG LIANSU TECH INDAL

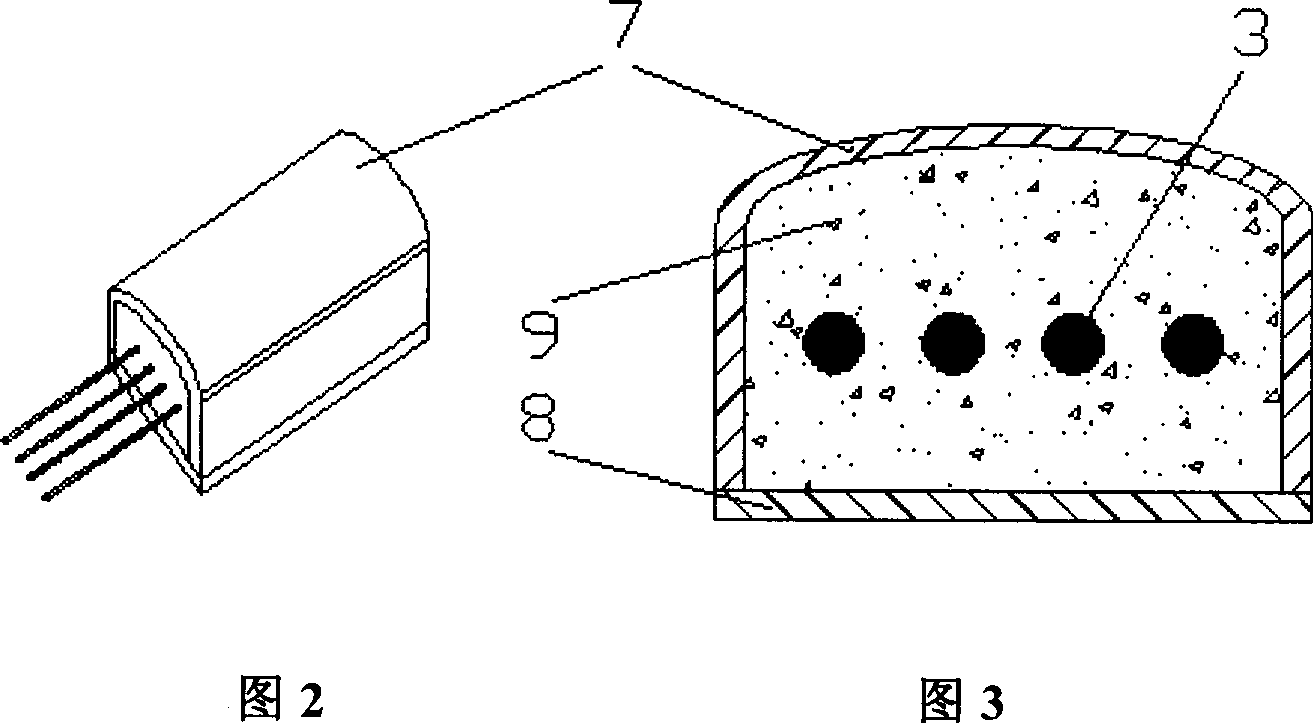

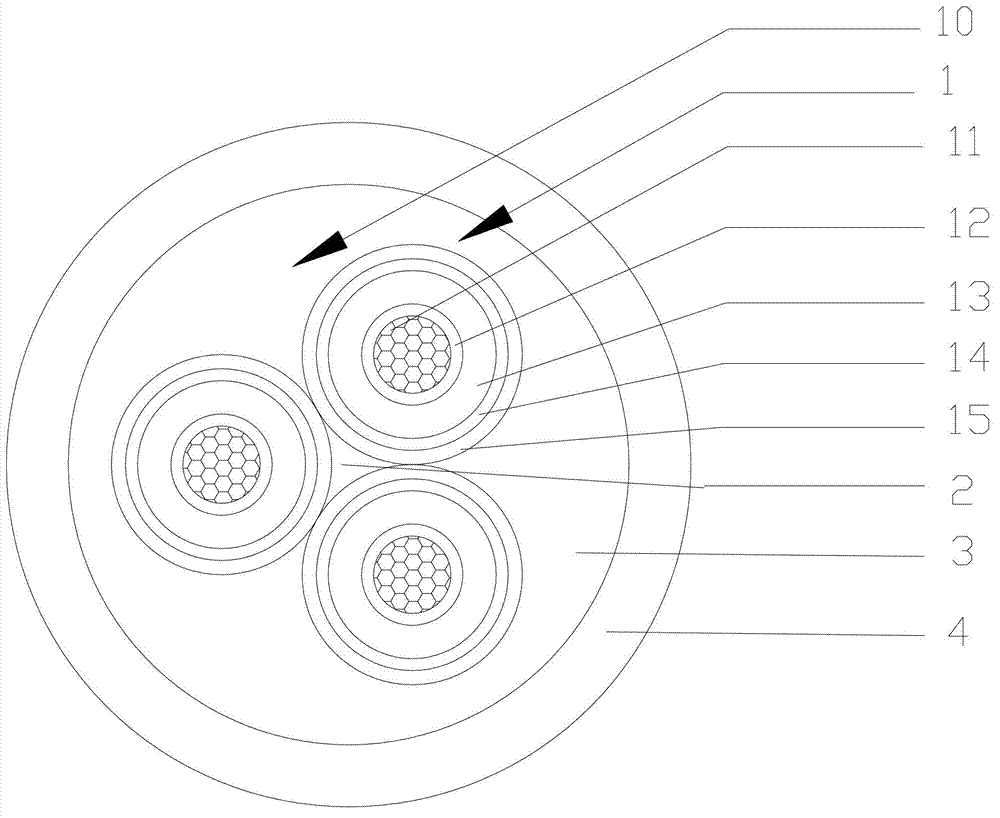

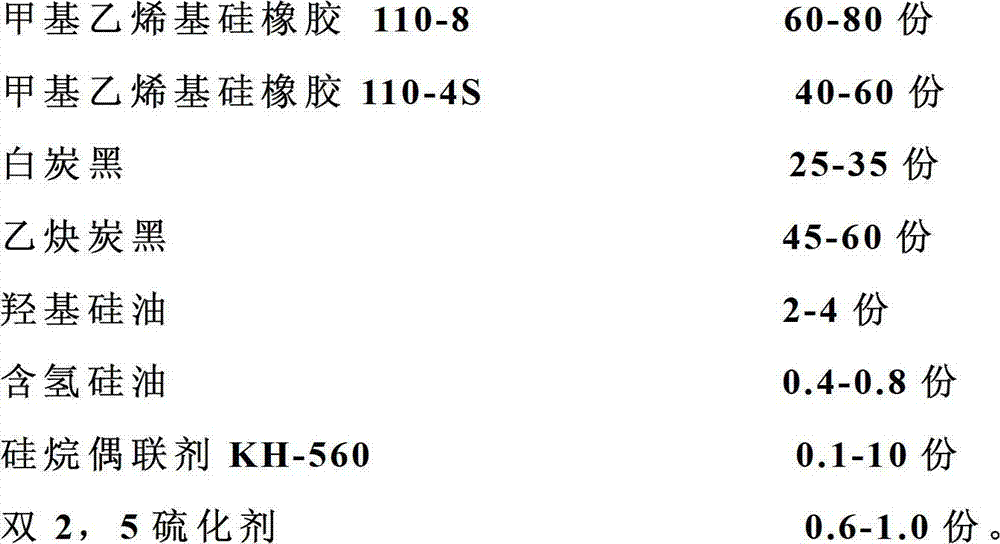

Ceramic silicon rubber insulation medium-voltage fire-resistant cable with rated voltage of 6-35kV and machining process thereof

ActiveCN102760526ASimple structureSmall outer diameterPower cables with screens/conductive layersCable/conductor manufactureCombustionElectrical conductor

The invention discloses a ceramic silicon rubber insulation medium-voltage fire-resistant cable with rated voltage of 6-35kV and a machining process thereof. A semiconductor taking silicon rubber as a base material or an insulating screen shielding material is adopted, so that a process of simultaneously extruding three layers, namely a semiconductor shielding layer which takes the silicon rubber as the base material, a ceramic silicon rubber insulating layer and a semi-conductive insulating shielding layer which takes the silicon rubber as the base material, is designed; the ceramic silicon rubber serves as an insulating layer and a fire-resistant layer, and the structure of the medium-voltage cable is simplified, the cable is small in outer diameter, light in weight, low in manufacturing cost, long in fire-resistant time, high in fire-resistant temperature and high in non-secondary combustion or flame retardancy, and the defects that in the prior art, the medium-voltage cable is not fire-resistant or low in fire resistance can be well overcome.

Owner:JIANGSU HENGTONG POWER CABLE

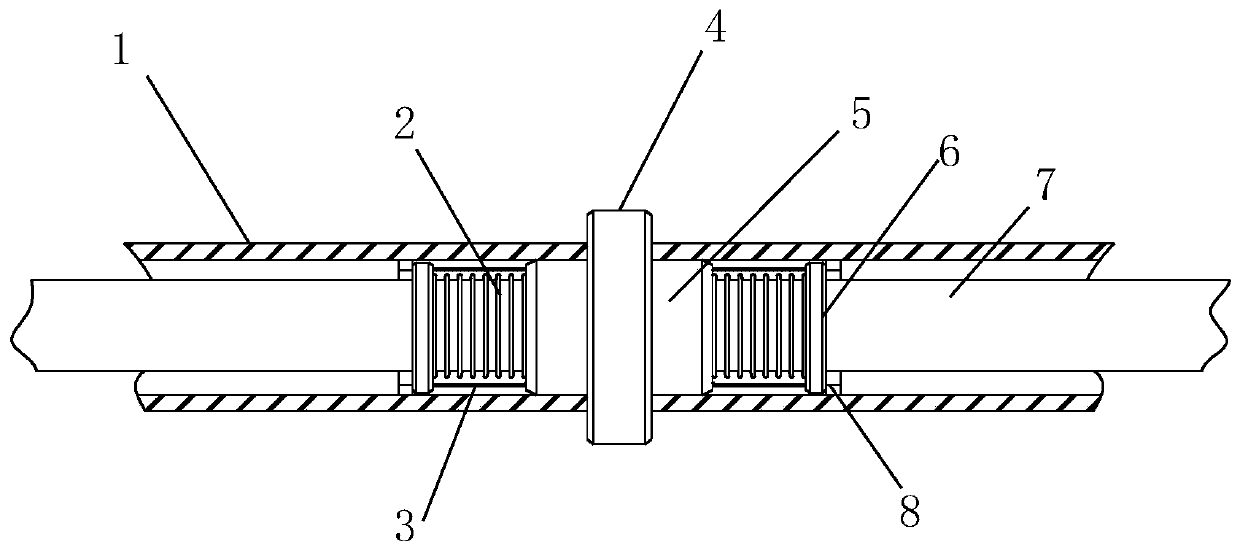

Fire resistant cable

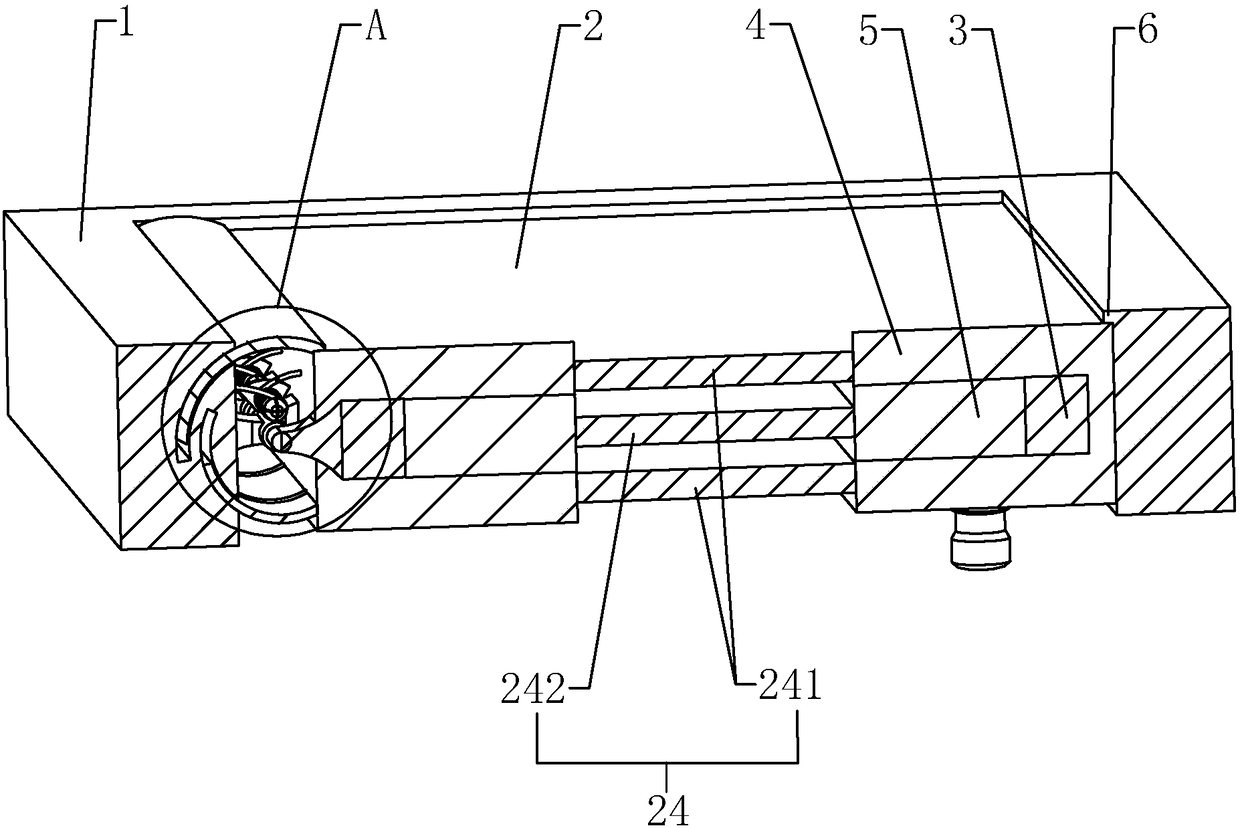

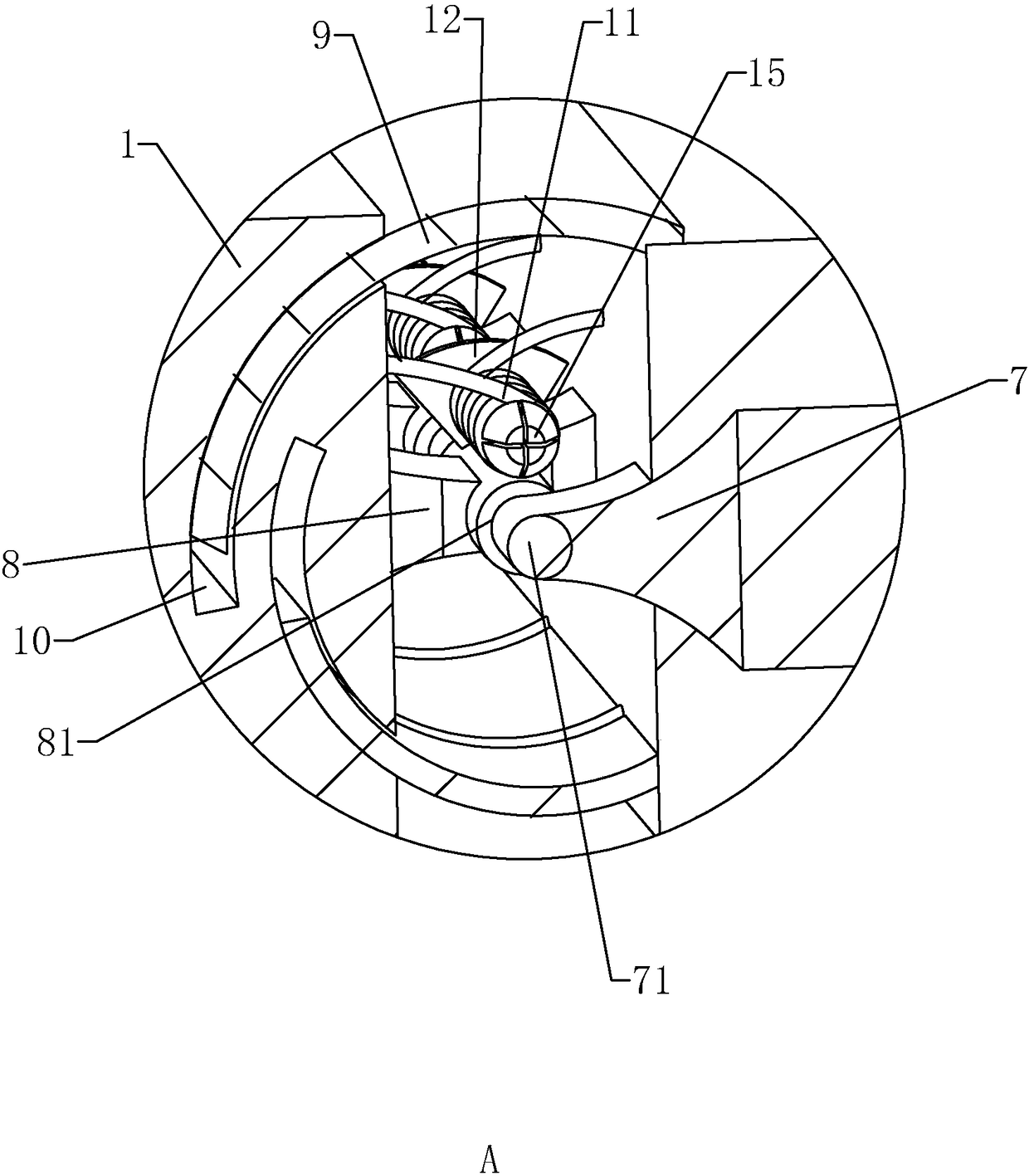

ActiveCN110164615ALong fire resistanceFire fastInsulated cablesInsulated conductorsEngineeringFire resistance

The invention discloses a fire resistant cable, which comprises more than one connector, wherein both sides of each connector are provided with an assembly protrusion, the part between two adjacent connectors is sleeved with a cable outer protective sleeve, two ends of the cable outer protective sleeve are open and respectively sleeve the assembly protrusions between two connectors, the middle ofeach connector is provided with a through hole in a penetrating mode, and core wires of the cable pass through the through hole in the middle of each connector. The composite cable disclosed by the invention has excellent fire resistance, can quickly extinguish the fire by using a slip ring in an emergency while guaranteeing the heat dissipation requirements, and forms a secondary fireproof layeroutside the core wires of the cable so as to increase the flame retardant time.

Owner:海盐爱德森特种线缆有限公司

Fireproof plugging module

The invention discloses a fireproof plugging module, which consists of 40 to 90 weight parts of expanded vermiculite, 10 to 60 weight parts of acrylic acid emulsion, 5 to 30 weight parts of expanded graphite and 5 to 30 weight parts of zinc oxide. The fireproof plugging module has high plasticity and is convenient for opening a hole and cutting; the water resistance, oil resistance, alkaline resistance and other performances of the fireproof plugging module are high, and drawbacks of swelling, deformation and cracking are avoided; the weight is light, the actual density is 0.8g / cm<3>, and the load of a plugging material on a cable bridge frame and a building can be reduced effectively; the fireproof time is long and is increased to more than 5 hours, so the module is a product with national grade one fireproof product; toxic gases are not generated upon contact with fire, halogen components are avoided, and as toxic gases are not released upon contact with fire, the module is environment-friendly; the effective period of the module is long and can reach more than 15 years, so repeated investment and construction are avoided; and the module can be widely used as wire, cable and electric fireproof plug in large industrial and mining enterprises such as power plants, petrochemical enterprises, metallurgical steel enterprises, communication emprises and national defense enterprises.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

Fireproof manmade quartz stone slab with superhardness and manufacturing method of fireproof manmade quartz stone slab

The invention discloses a fireproof manmade quartz stone slab with superhardness and a manufacturing method of the fireproof manmade quartz stone slab. The manmade quartz stone slab is manufactured from the following components in parts by weight: 30-80 parts of 6-80-mesh calcined quartz stones, 30-60 parts of 325-mesh quartz powder, 5-10 parts of cullet, 10-20 parts of 50-100-mesh red-silica powder or quartzitic sandstone powder, 5-15 parts of 100-150-mesh kyanite powder or andalusite powder or sillimanite powder, 1-10 parts of 100-200-mesh zirconium silicate or yttria-stabilized zirconia powder, 5-10 parts of unsaturated resins, 0.3-0.5 part of auxiliary, and 0.3-0.8 part of pigment. According to the fireproof manmade quartz stone slab, the red-silica powder, quartzitic sandstone powder, kyanite powder or andalusite powder or sillimanite powder, and zirconium silicate or yttria-stabilized zirconia powder is added in a manufacturing process, so that the compressive property and the fireproof flame retardant performance of the manmade quartz stone slab are improved; meanwhile, by using the calcined quartz stones, the hardness of the manmade quartz stone slab is improved, so that the fireproof manmade quartz stone slab with superhardness is relatively wearproof, difficult to scratch and long in service life.

Owner:田忠和

Wooden fireproof door and manufacturing process thereof

ActiveCN108104690ANot easy to damageNot easy to failFireproof doorsBuilding braking devicesFire - disastersEngineering

The invention discloses a wooden fireproof door and a manufacturing process thereof. According to the technical scheme, the wooden fireproof door is characterized in that the wooden fireproof door comprises a door frame and a door leaf rotatably connected to the door frame; connecting plates are arranged on the side, rotatably connected to the door frame, of the door leaf; the ends, away from thedoor leaf, of the connecting plates are provided with rotating shafts; the ends, rotatably connected with the door leaf, of the door frame are provided with rotating seats; shaft holes matched with the rotating shafts are formed in the rotating seats; the positions, located on the two sides of the connecting plates, of the door leaf are provided with protective plates correspondingly, and the section of each protective plate is in an arc shape; arc-shaped grooves allowing the arc-shaped plates to be inserted into are formed in the door frame; and door closing devices for closing the door leafon the door frame are arranged on the rotating seats. When a fire disaster occurs, connecting pieces such as the connecting plates, the rotating seats and the door closing devices are not liable to bedirectly affected by fire behavior and thus not liable to lose efficacy, thus the fire-resistant time is long, the door leaf is not liable to be disengaged from the door frame when the fire disasteroccurs, and use reliability and safety are high.

Owner:安徽中特门业有限公司

Flame-retardant building coating and production method

InactiveCN107793914AHighlight substantive featuresSignificant progressFireproof paintsAntifouling/underwater paintsPorosityFire resistance

The invention discloses a flame-retardant building coating and a production method. The flame-retardant building coating is prepared from the following raw materials: polyurethane, an emulsion, glassfiber, water, a composite coupling agent, a flame retardant, pigment, an antifoaming agent, a wetting agent and a leveling agent. The flame-retardant building coating disclosed by the invention can improve such performance of a film as surface performance, mechanical and optical performance, corrosion resistance, dirt clearing performance and flame retardance, enhances the water repellency, dustadsorption preventing performance and self-repairing function of the coating, and further improves the film in density, toughness, weather resistance, permeation resistance, fire resistance, expansionproperty and the like; moreover, the flame-retardant building coating prolongs the fire-resistant time, reduces the porosity of the film, prevents bacteria from adhering to the film, and clears pollutants on the film surface so as to purify the environment.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

Hydrophobic efficient fireproof coating and preparation method thereof

InactiveCN110698926AImprove water resistanceSolving Dispersion ProblemsFireproof paintsSlurryFire retardant

The invention relates to the technical field of fireproof coatings, in particular to a hydrophobic efficient fireproof coating and a preparation method thereof. The preparation method of the fireproofcoating comprises the following steps: adding a film forming matter, a modifier and aerogel powder into dispersion equipment, carrying out uniform mixing under stirring, performing heating to 80-100DEG C in a stirring state, and keeping the temperature for 2-3 hours; transferring dispersed slurry into a grinding device, performing cooling to 5-10 DEG C, and performing grinding until the finenessof the slurry reaches 35-45 microns; adding pigments and fillers into the ground slurry, and carrying out grinding and dispersing uniformly; transferring the slurry into the dispersion equipment again, performing cooling to 5-10 DEG C, sequentially adding water, a flame retardant and an assistant, and carrying out dispersion; and stopping dispersing, and carrying out sieving and packaging. According to the invention, the film forming matter, the modifier and the aerogel powder are mixed, then heated and dispersed, and then cooled and ground, so the surface of the aerogel powder is coated andmoisture or other small molecular substances are prevented from entering holes of the aerogel powder; and thus, the problems that the aerogel powder is poor in dispersity and prone to losing efficacywhen applied in coatings are solved, the heat conductivity coefficient of the fireproof coating in an earlier stage of heating is obviously reduced, and fireproof time is prolonged.

Owner:QINGYUAN MEINUOKE NEW MATERIAL +1

Artificial quartz stone panel and preparation method thereof

The invention discloses an artificial quartz stone panel and a preparation method thereof. The artificial quartz sand panel is prepared from the following components in parts by weight: 30-90 parts of 3-80mesh quartz stones, 20-60 parts of 325mesh quartz powder, 5-15 parts of cullet, 3-10 parts of shells, 3-10 parts of fibers, 3-10 parts of 30-50mesh tourmaline, 3-12 parts of 50-100mesh sillimanite powder, 3-12 parts of 100-200mesh zirconium silicate powder, 5-10 parts of unsaturated resin, 0.3-0.5 part of auxiliaries and 0.3-0.8 part of pigments. According to the artificial quartz stone panel disclosed by the invention, in the preparation process, the fibers and tourmaline are added, so that the compressive property and the antibacterial property of the artificial quartz stone panel are improved and meanwhile, the sillimanite powder and the zirconium silicate powder are added, so that the fireproof performance of the artificial quartz stone panel is improved.

Owner:田忠和

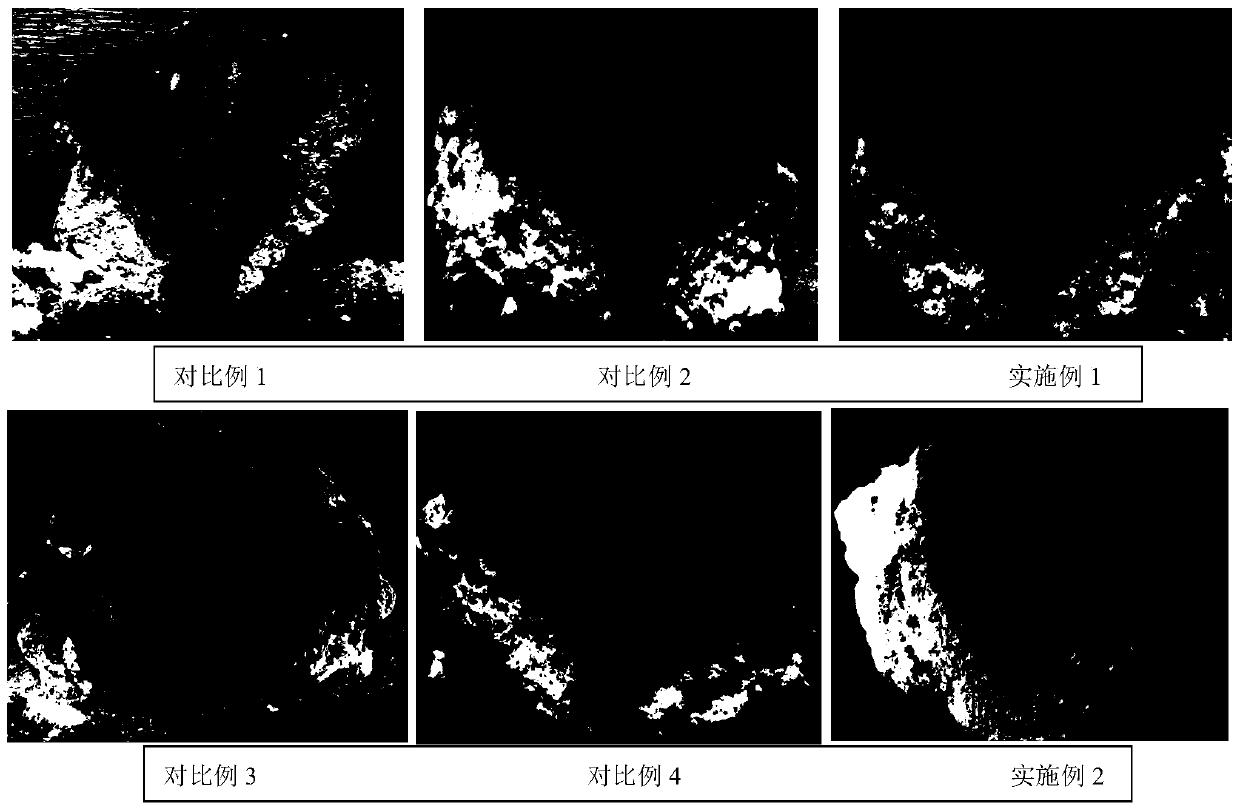

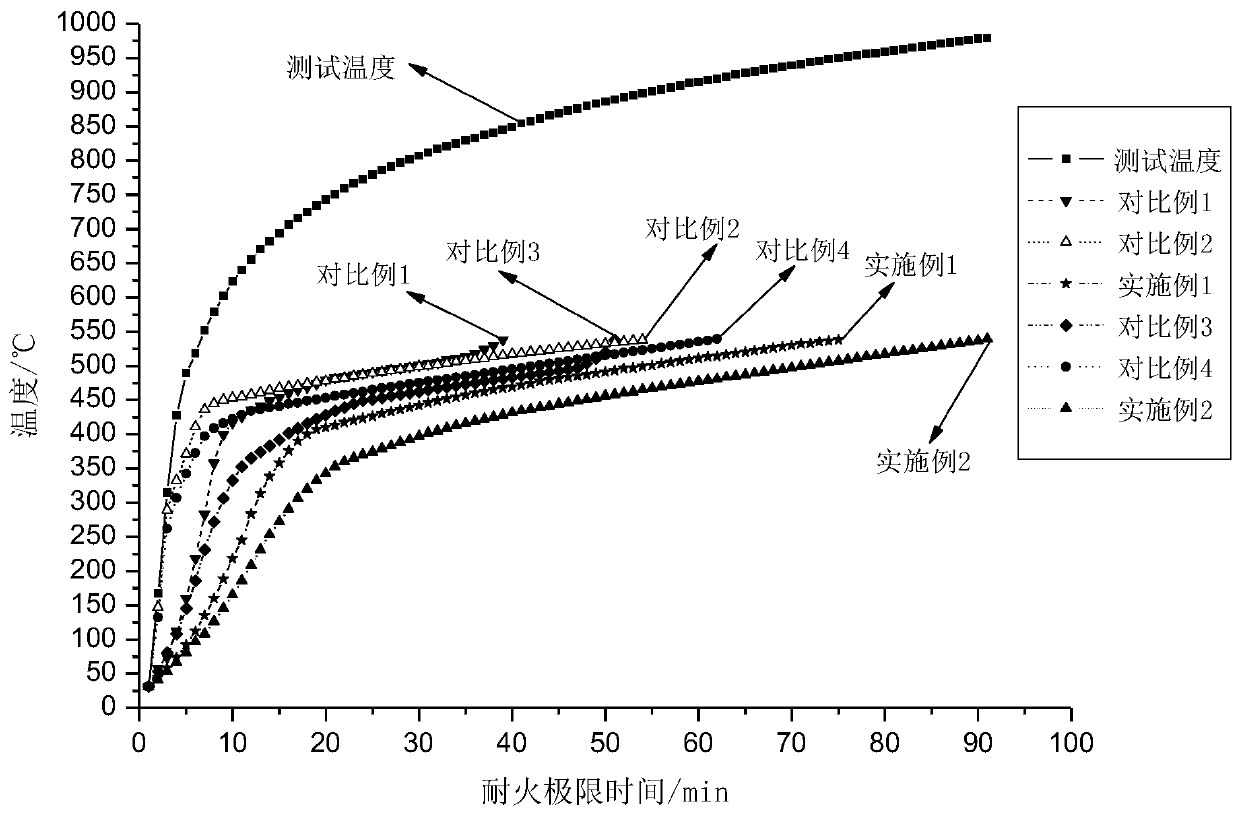

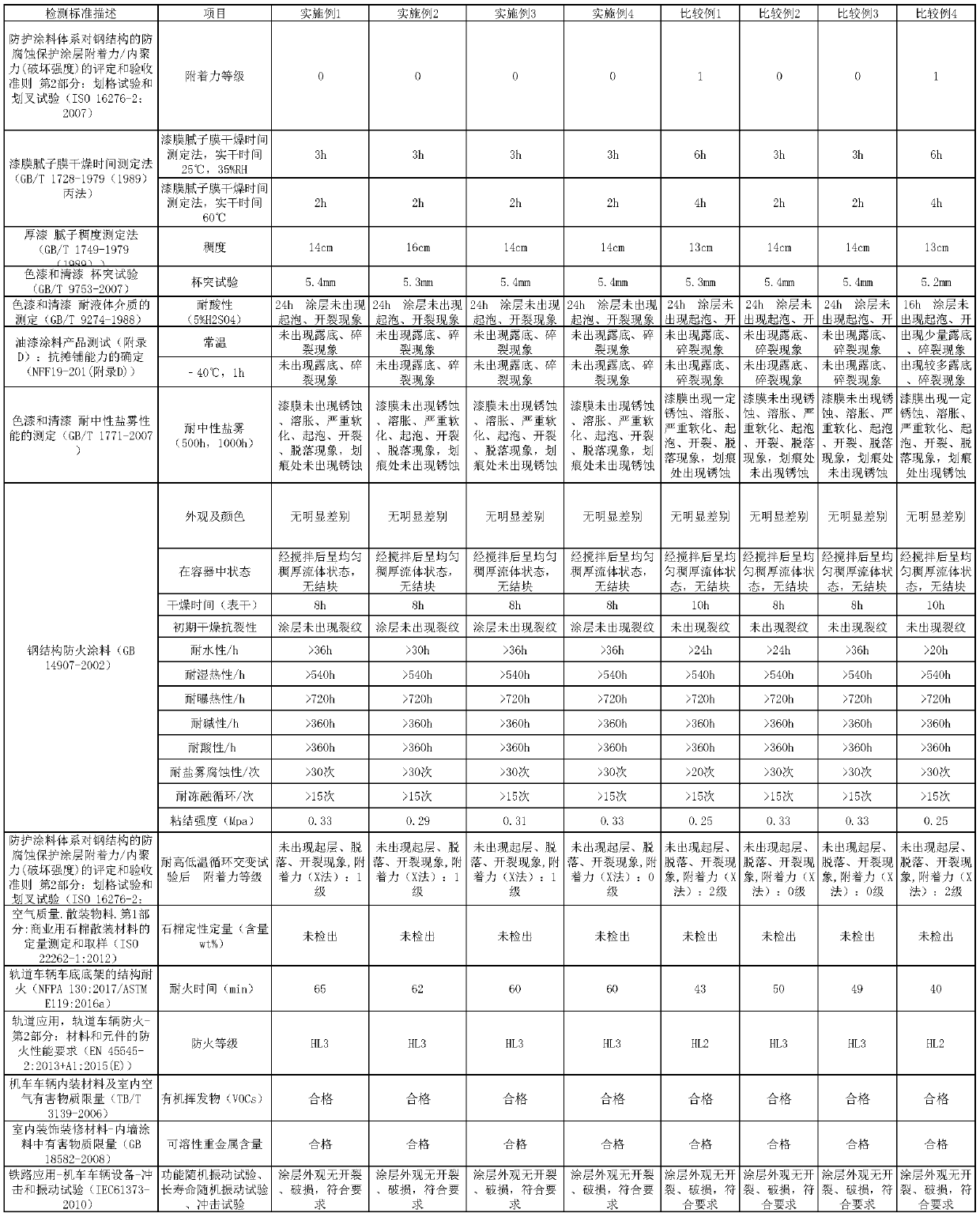

Water-based fireproof coating suitable for railway vehicle chassis and preparation method thereof

InactiveCN110591509AHigh expansion factorStable structureFireproof paintsEpoxy resin coatingsWater basedMelamine phosphate

The invention relates to a water-based fireproof coating suitable for railway vehicle chassis and a preparation method thereof, and belongs to the field of water-based fireproof coating. The water-based fireproof coating disclosed by the invention is prepared from the following substances in parts by mass: 20-30 parts of a film-forming substance, 40-60 parts of an intumescent flame-retardant system, 5-8 parts of titanium dioxide, 2-4 parts of nano magnesium aluminum hydroxide, 1-2 parts of organic bentonite, 1-3 parts of expandable graphite, 9-17 parts of deionized water, 0.8-1.3 parts of a film-forming aid, 0.2-0.5 part of a dispersing agent and 0.2-0.5 part of a defoaming agent; the intumescent flame-retardant system is prepared from melamine phosphate, dipentaerythritol and melamine, and the mass part ratio of the melamine phosphate to the dipentaerythritol to the melamine is 1.8-2.3: 0.8-1.2: 0.8-1.2. The water-based fireproof coating can met structure fire-resistant requirement of the chassis of the railway vehicles; no volatilization of harmful substances such as organic solvents is caused in the construction and drying processes; the occupational health and safety of constructors are guaranteed; equipment can be flexibly selected for use according to different scenes; investment of special equipment is reduced; and production cost is reduced.

Owner:河北萨迪科轨道交通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com