Hydrophobic efficient fireproof coating and preparation method thereof

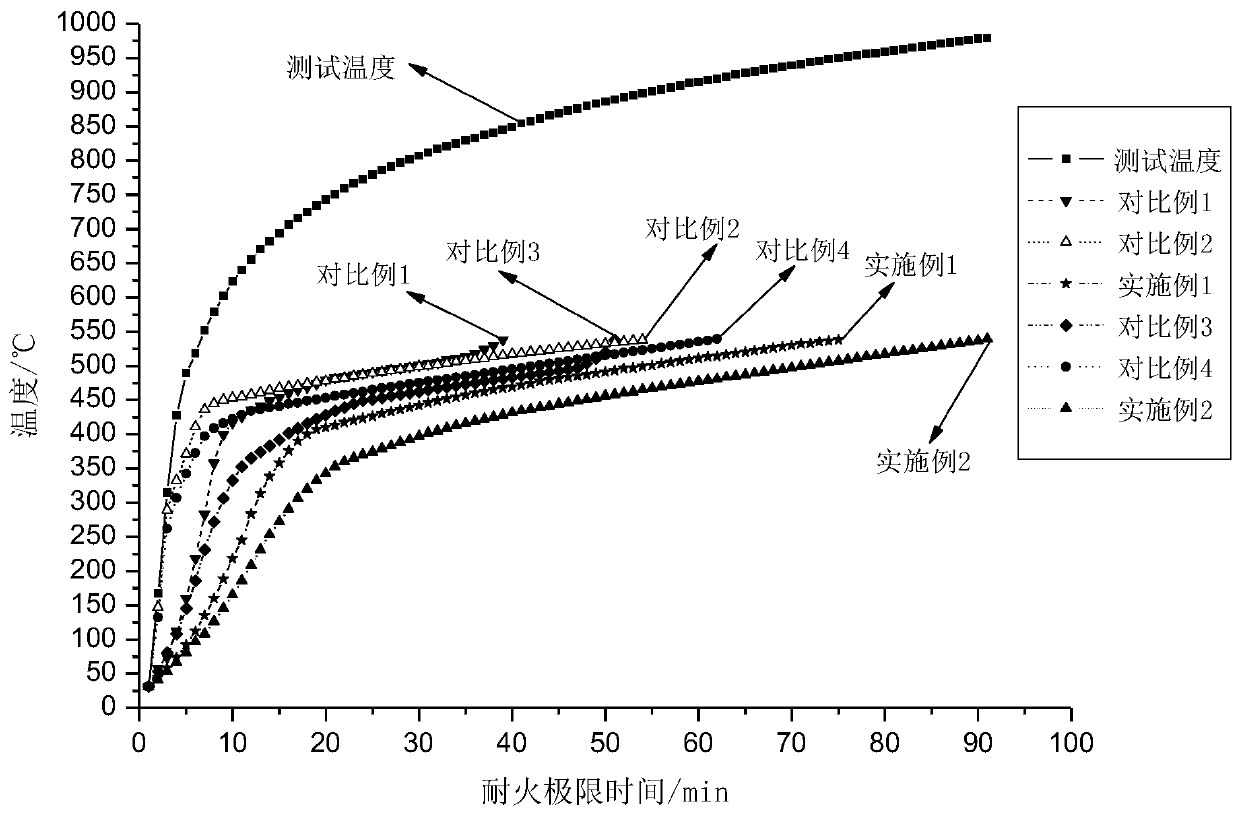

A kind of fireproof coating and high-efficiency technology, applied in the direction of fireproof coating, coating, etc., can solve the problems of aerogel dispersion, etc., to achieve the effect of improving water resistance, excellent use effect, and prolonging fire resistance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing a hydrophobic high-efficiency fireproof coating, comprising the following steps:

[0040] (1) Add the film former, modifier and airgel powder into the dispersing equipment in proportion, stir and mix evenly, and then raise the temperature to 80-100°C under stirring for 2-3h;

[0041] (2) Move the slurry prepared in step (1) into a grinding device with a cooling device, cool down to 5-10°C and then grind, and grind the slurry to a fineness of 35-45 μm;

[0042] (3) adding the pigment and filler to the slurry ground in step (2), grinding and dispersing evenly, and the slurry fineness is less than 45 μm;

[0043] (4) Move the slurry in step (3) into the dispersing equipment, cool down to 5-10°C, start to disperse and add water, flame retardant and additives in sequence, and the fineness of the slurry is less than 45 μm;

[0044] (5) the slurry obtained in step (4) is passed through a sieve of more than 100, and packed to obtain final product;

[00...

Embodiment 1

[0054] A method for preparing a hydrophobic high-efficiency fireproof coating, comprising the following steps:

[0055] (1) Add the film former, modifier and airgel powder into the dispersing equipment in proportion, stir and mix evenly, and then raise the temperature to 80°C for 3 hours while stirring;

[0056] (2) Move the slurry prepared in step (1) into a grinding device with a cooling device, cool down to 5°C and then grind, and grind the slurry to a fineness of 35-45 μm;

[0057] (3) adding the pigment and filler to the slurry ground in step (2), grinding and dispersing evenly, and the slurry fineness is less than 45 μm;

[0058] (4) Move the slurry in step (3) into the dispersing equipment, lower the temperature to 10°C, start to disperse and add water, flame retardant and additives in sequence, and the fineness of the slurry is less than 45 μm;

[0059] (5) Pass the slurry obtained in step (4) through a sieve of more than 100, and pack it to get final product.

[006...

Embodiment 2

[0077] A method for preparing a hydrophobic high-efficiency fireproof coating, comprising the following steps:

[0078] (1) Add the film former, modifier and airgel powder into the dispersing equipment in proportion, stir and mix evenly, and then raise the temperature to 90°C for 2 hours while stirring;

[0079] (2) Move the slurry prepared in step (1) into a grinding device with a cooling device, cool down to 10° C. and then grind, and grind the slurry to a fineness of 35-45 μm;

[0080] (3) adding the pigment and filler to the slurry ground in step (2), grinding and dispersing evenly, and the slurry fineness is less than 45 μm;

[0081] (4) Move the slurry in step (3) into the dispersing equipment, lower the temperature to 10°C, start to disperse and add water, flame retardant and additives in sequence, and the fineness of the slurry is less than 45 μm;

[0082] (5) Pass the slurry obtained in step (4) through a sieve of more than 100, and pack it to get final product.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com