Aldehyde-free vegetable protein-based wood adhesive as well as preparation and application methods thereof

A wood adhesive and vegetable protein technology, applied in the design and development of environmental protection chemical materials, can solve the problems of poor initial viscosity, unfavorable coating, high viscosity, etc., and overcome the problems of poor water resistance, check strength and high water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

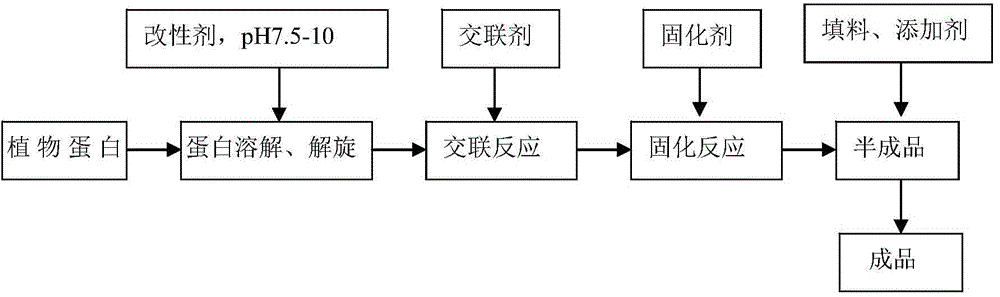

Method used

Image

Examples

Embodiment 1

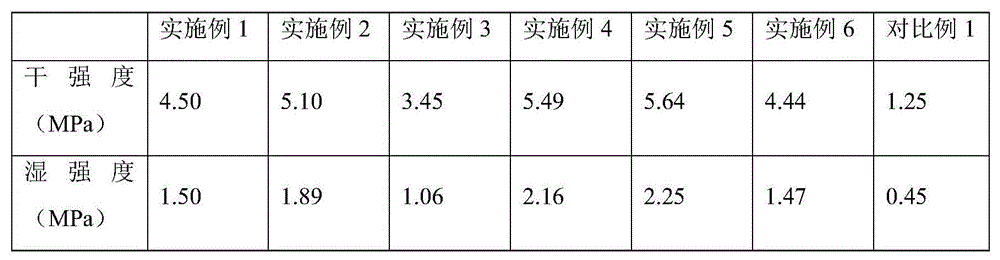

[0020]Embodiment 1. Add 100 g of water and 0.35 g of sodium hydroxide into a 500 mL three-necked flask, stir to dissolve the sodium hydroxide, then add 3 g of sodium sulfite to the alkali solution, stir well, and prepare a modifier solution. Then add 30 g of defatted soybean flour (50% by weight of protein) to the modifier solution, stir at room temperature for 0.5 h, and stir evenly to obtain a viscous paste. Then add 20g modified polyvinyl alcohol solution (mass concentration 25%) in this viscous paste, stir at room temperature for 10 minutes, then react for 1h; then add 3g polyamide polyamine-epichlorohydrin solution (mass concentration Concentration 12.5%), continue to stir for 10 minutes, until stirring evenly. Finally, 1 g of sodium-based montmorillonite and 3 g of micro-nano fibrils were added, and stirred for 10 minutes to obtain a formaldehyde-free vegetable protein-based wood adhesive. The prepared adhesive was used for the bonding of three-layer poplar boards, and ...

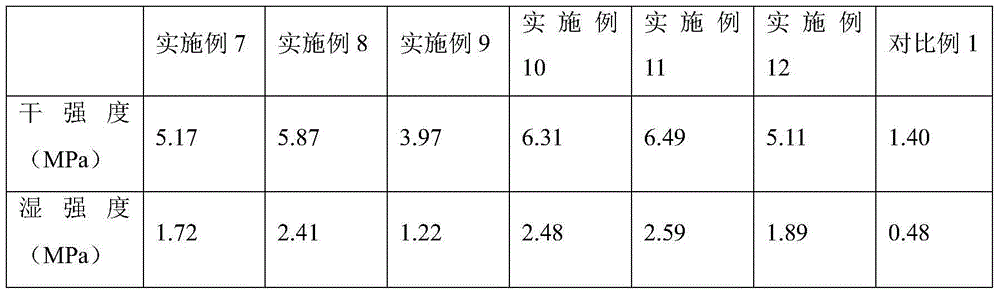

Embodiment 2

[0021] Embodiment 2, preparation method are the same as embodiment 1, difference is that described modifying agent is 0.35g sodium hydroxide and 3g urea. The prepared adhesive was used for the bonding of three-layer poplar boards, and the dry strength and wet strength were tested. The dry strength was 5.10MPa and the wet strength was 1.89MPa, respectively.

Embodiment 3

[0022] Embodiment 3, preparation method is the same as embodiment 1, and difference is that described modifying agent is 0.35g sodium hydroxide and 1g sodium lauryl sulfate. The prepared adhesive was used for the bonding of three-layer poplar boards, and the dry strength and wet strength were tested. The dry strength was 3.45MPa and the wet strength was 1.06MPa, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com