Patents

Literature

866results about "Lignin material coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

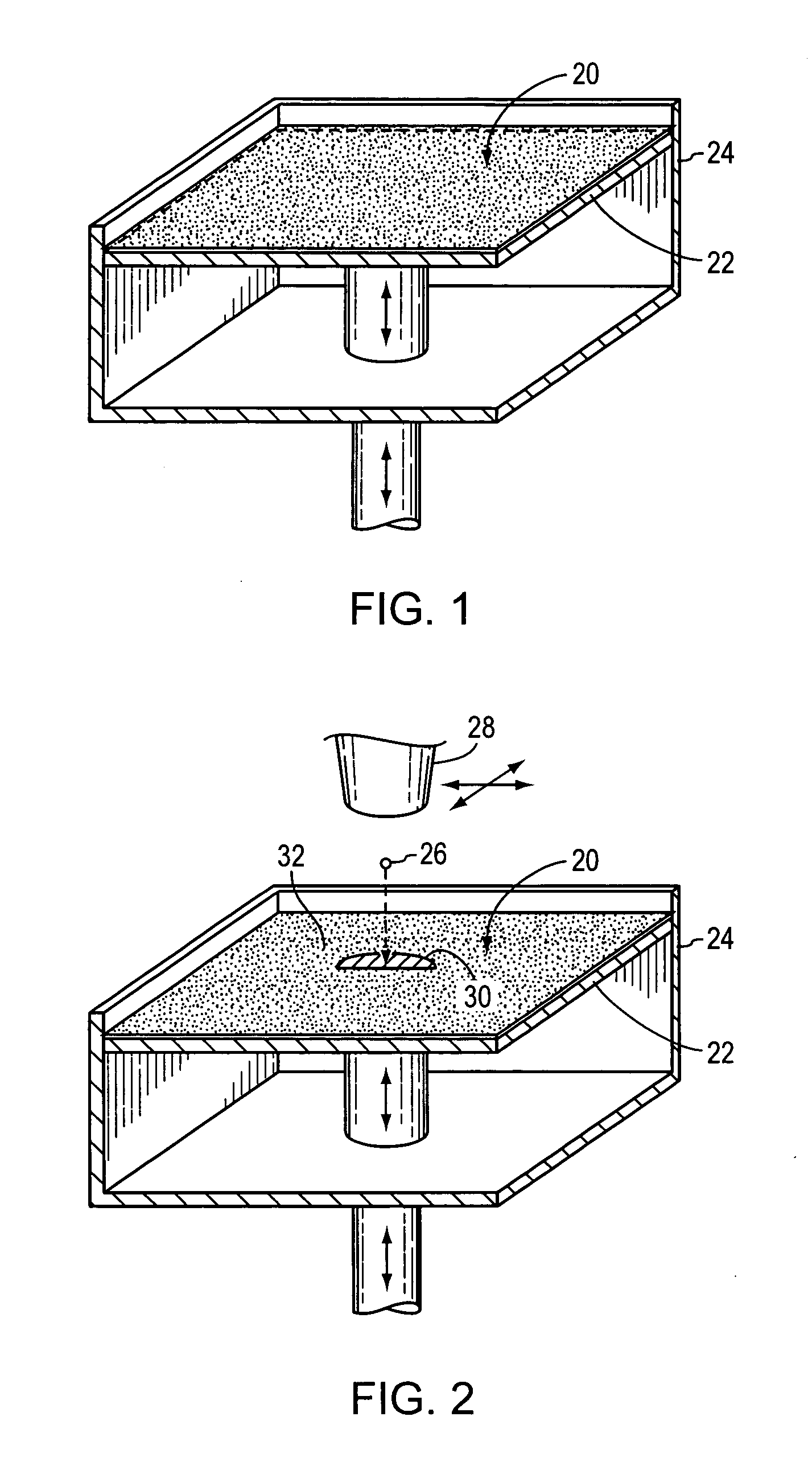

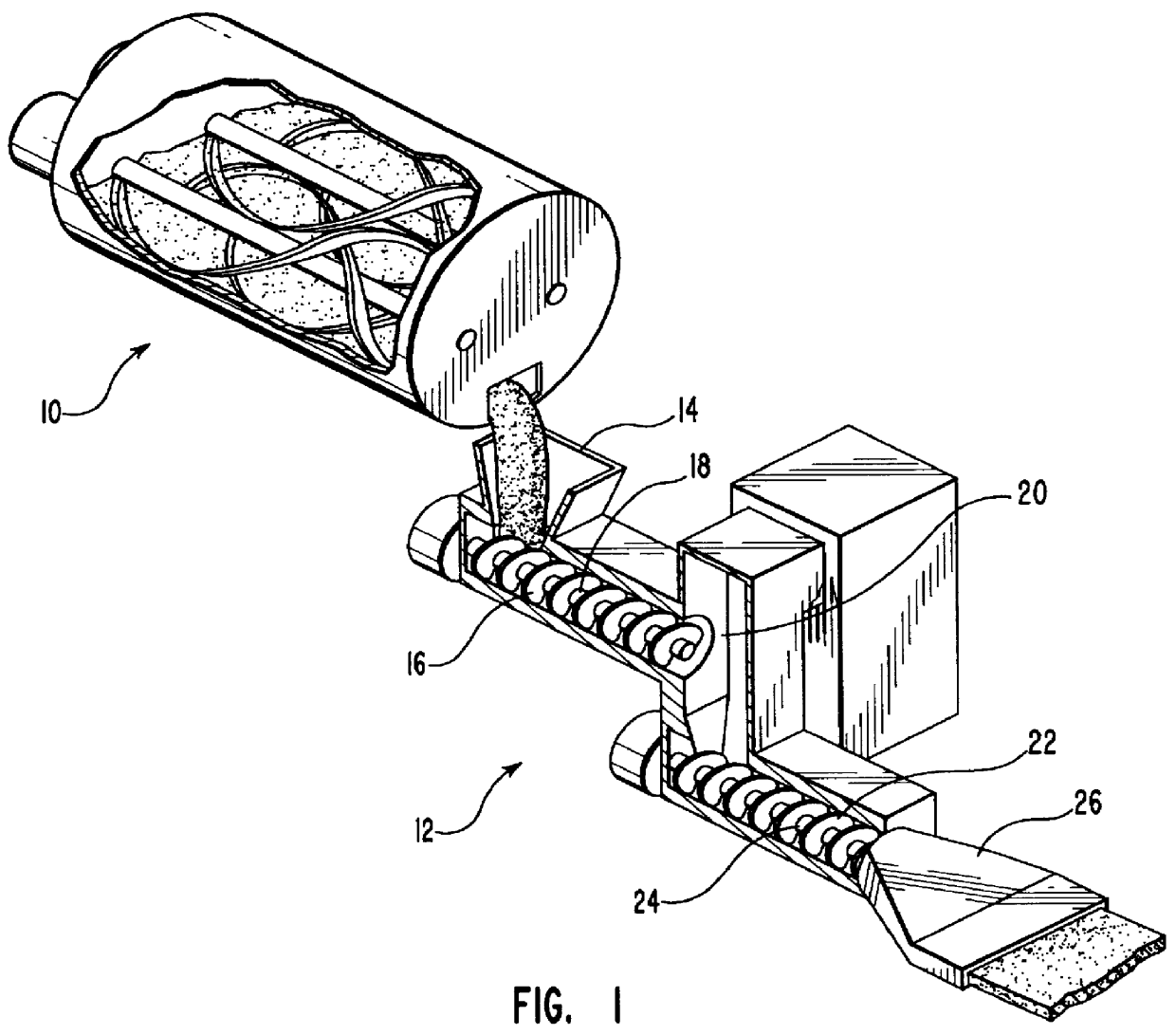

Absorbent fillers for three-dimensional printing

InactiveUS20050059757A1Quick and reliable and safe and inexpensiveSmooth surface finishPigmenting treatmentAdditive manufacturing apparatusParticulatesEngineering

A materials system and methods are provided to enable the formation of articles by three-dimensional printing. The materials system includes an absorbent particulate filler that facilitates absorption of infiltrants, thereby allowing the accurate definition of articles with enhanced mechanical and structural characteristics. The methods include the use of phase-change materials to bind a powder, as well as the formation of support structures to improve the control of the shape of the articles.

Owner:Z CORPORATION

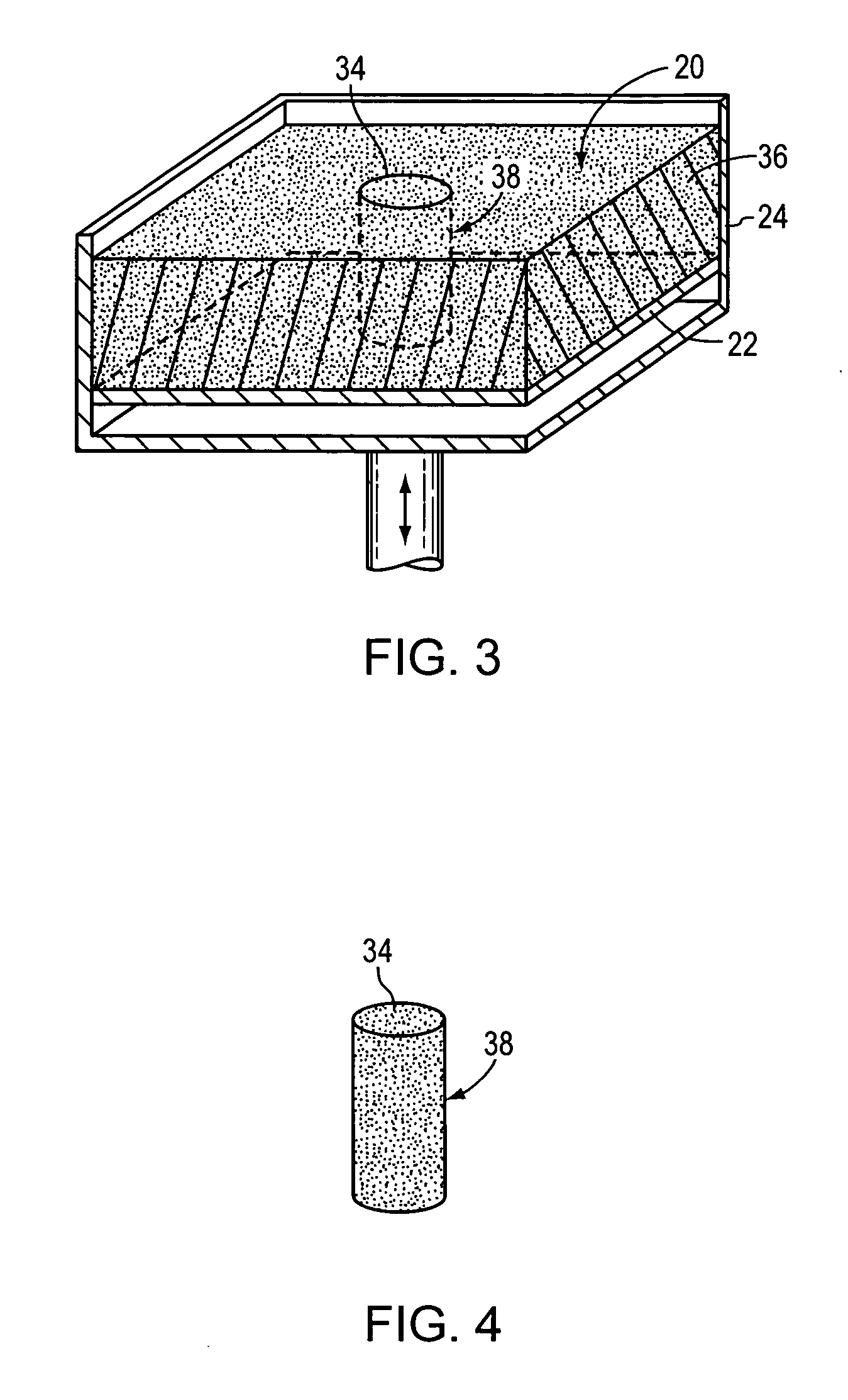

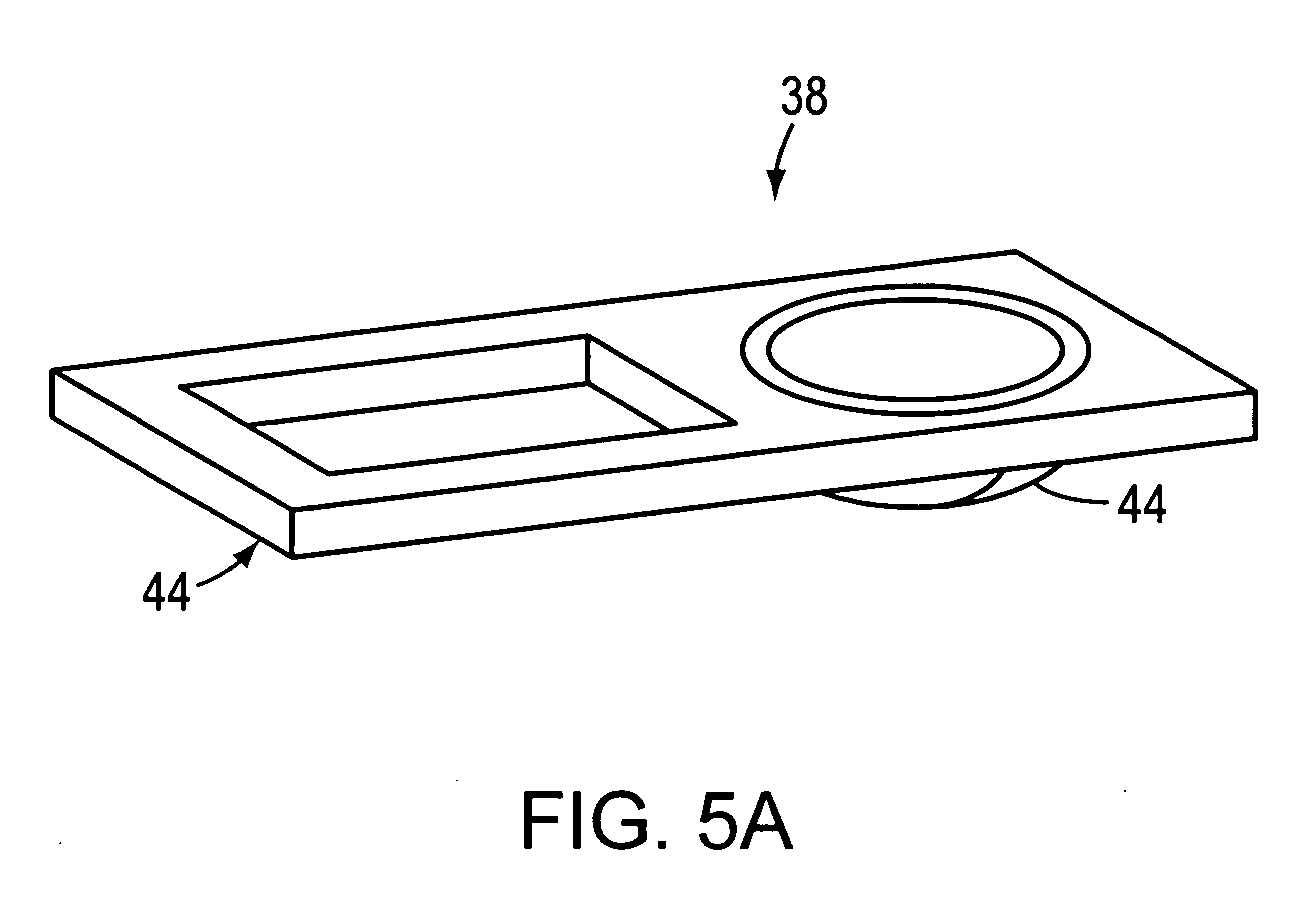

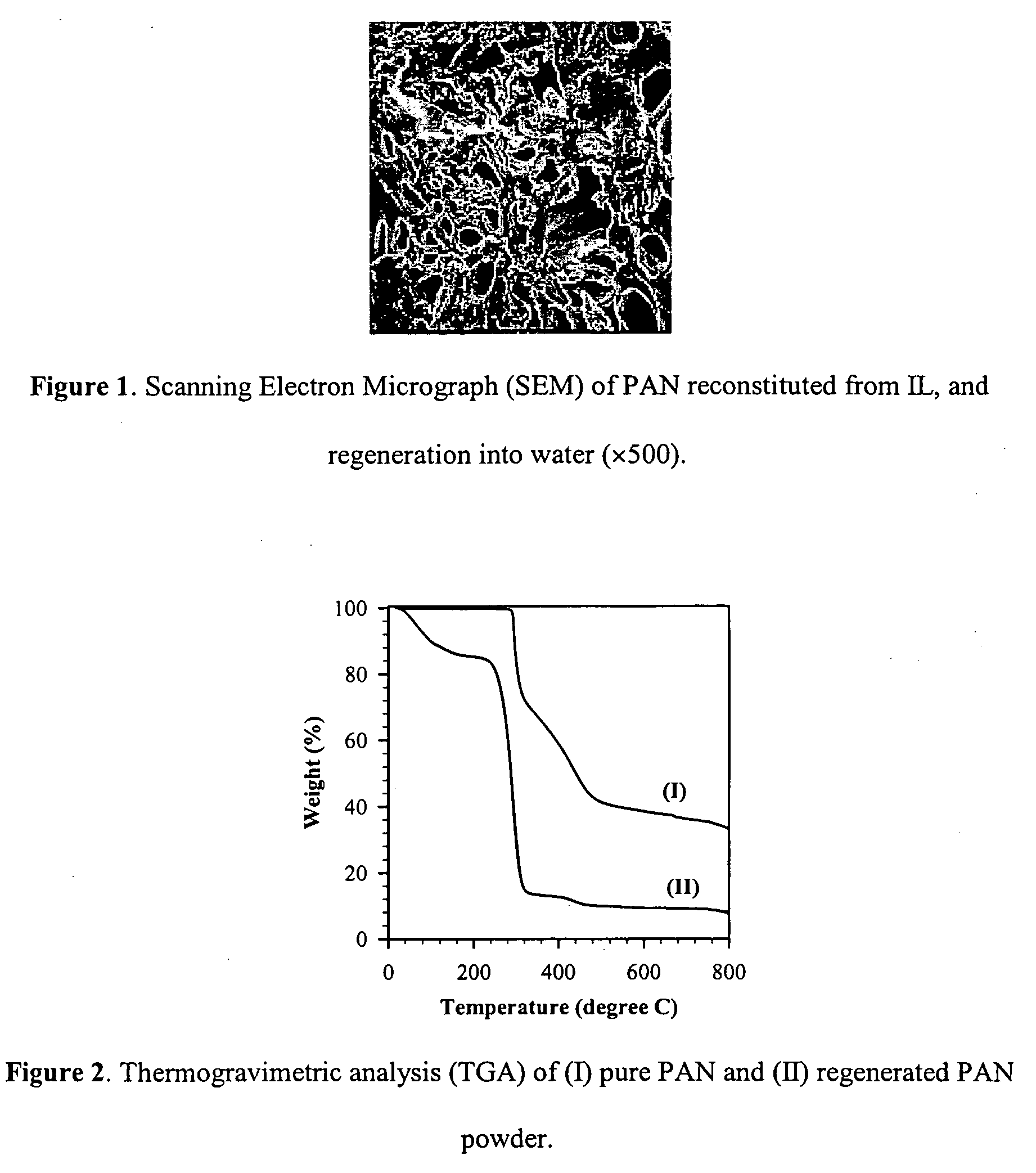

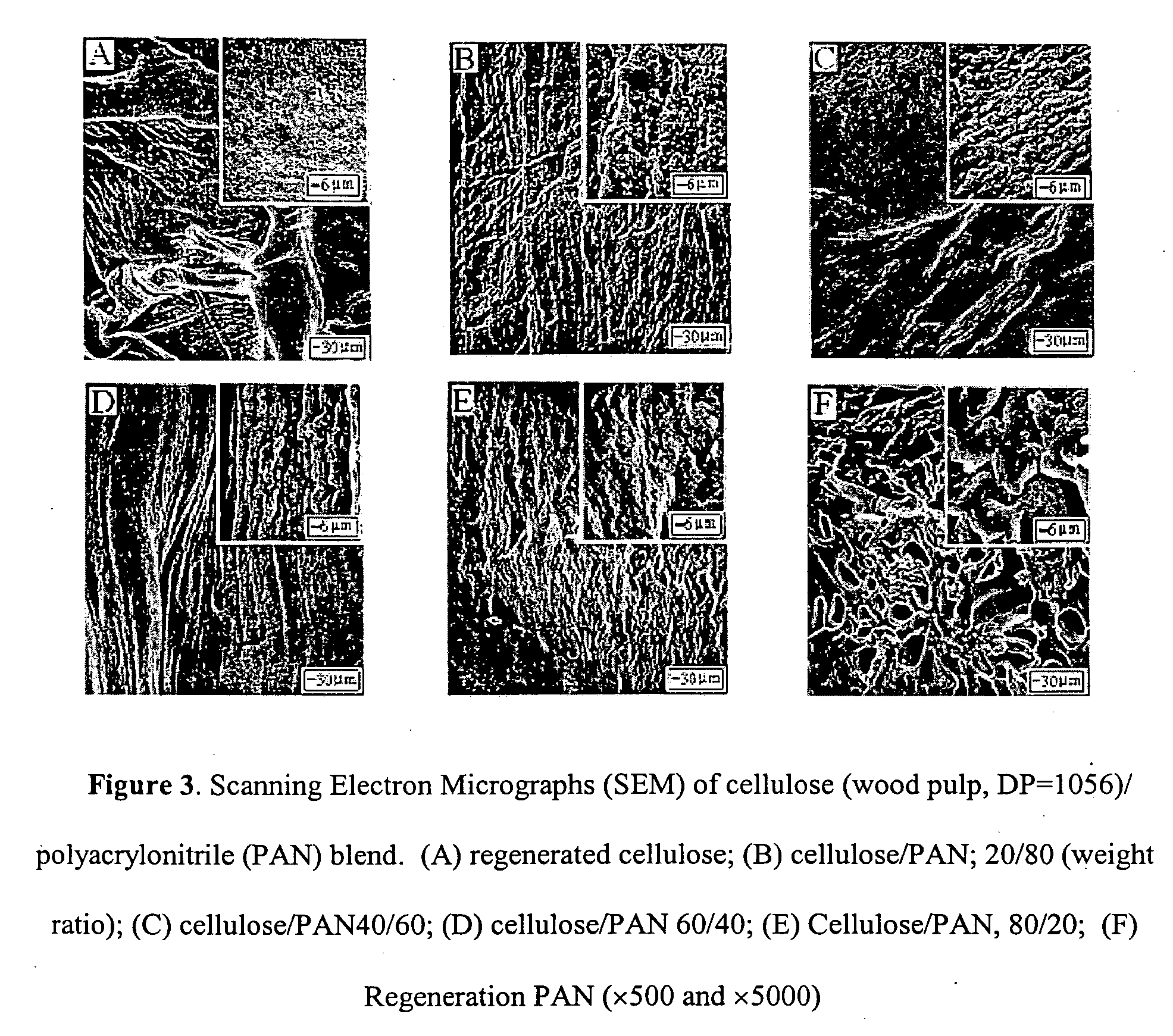

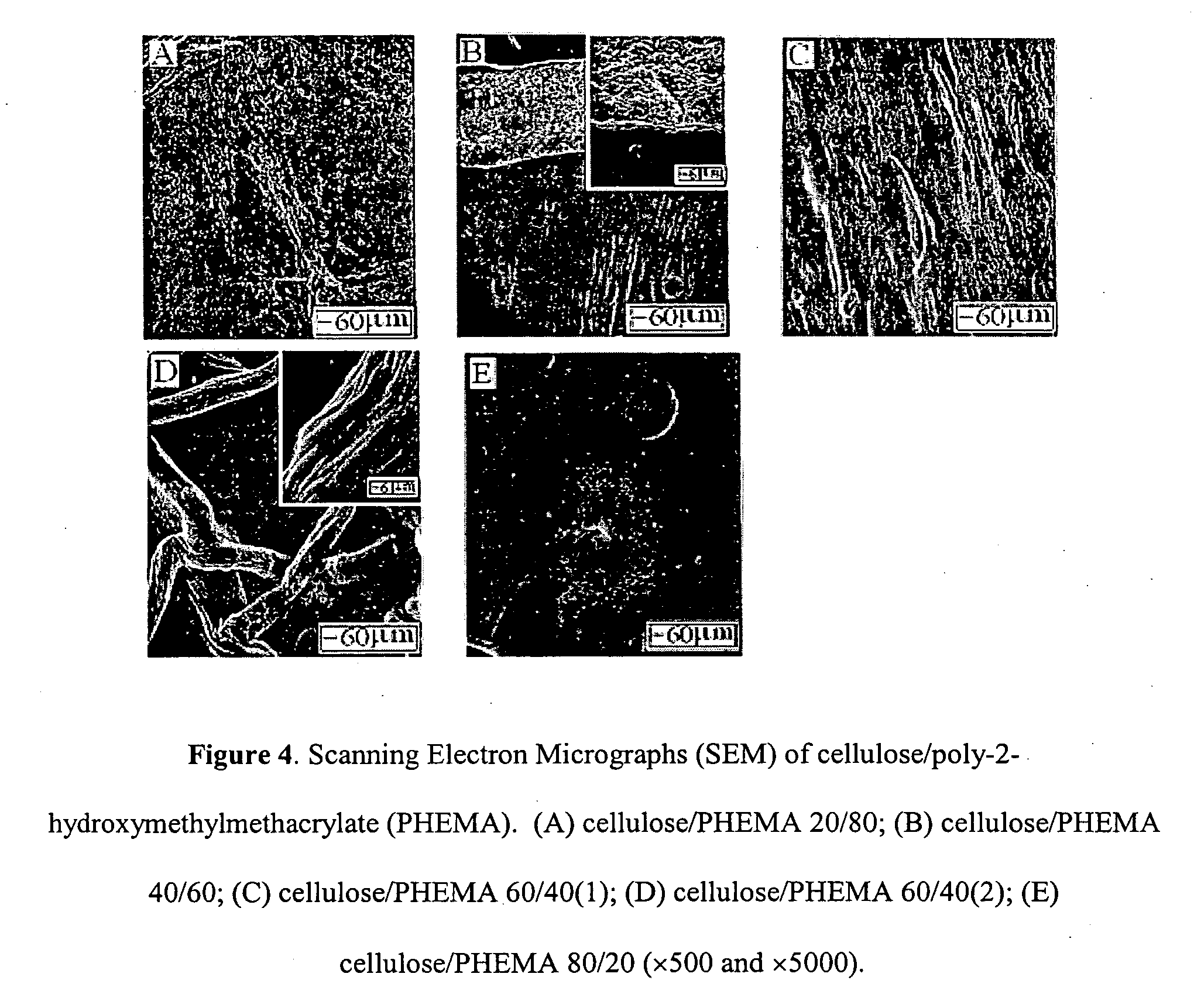

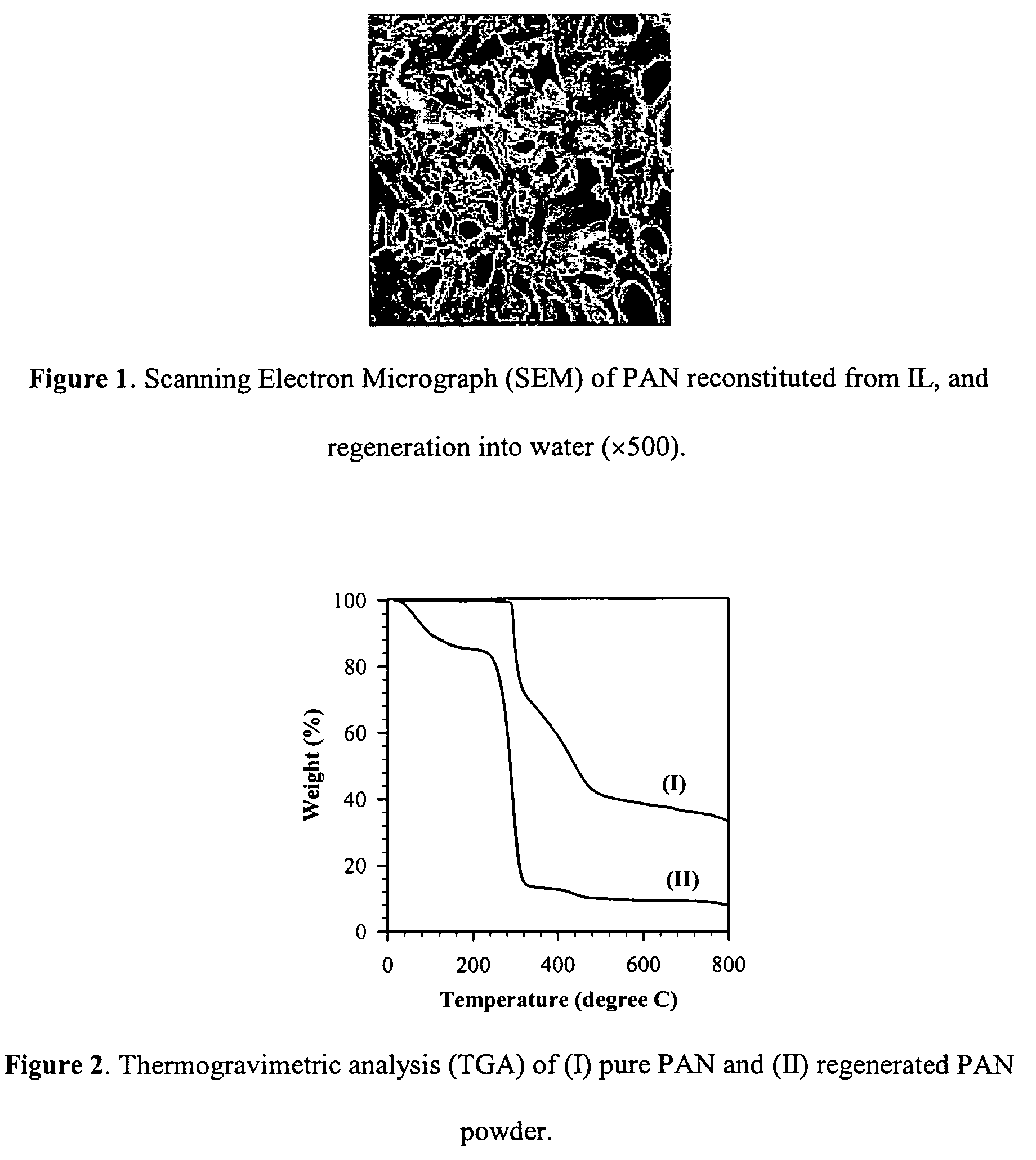

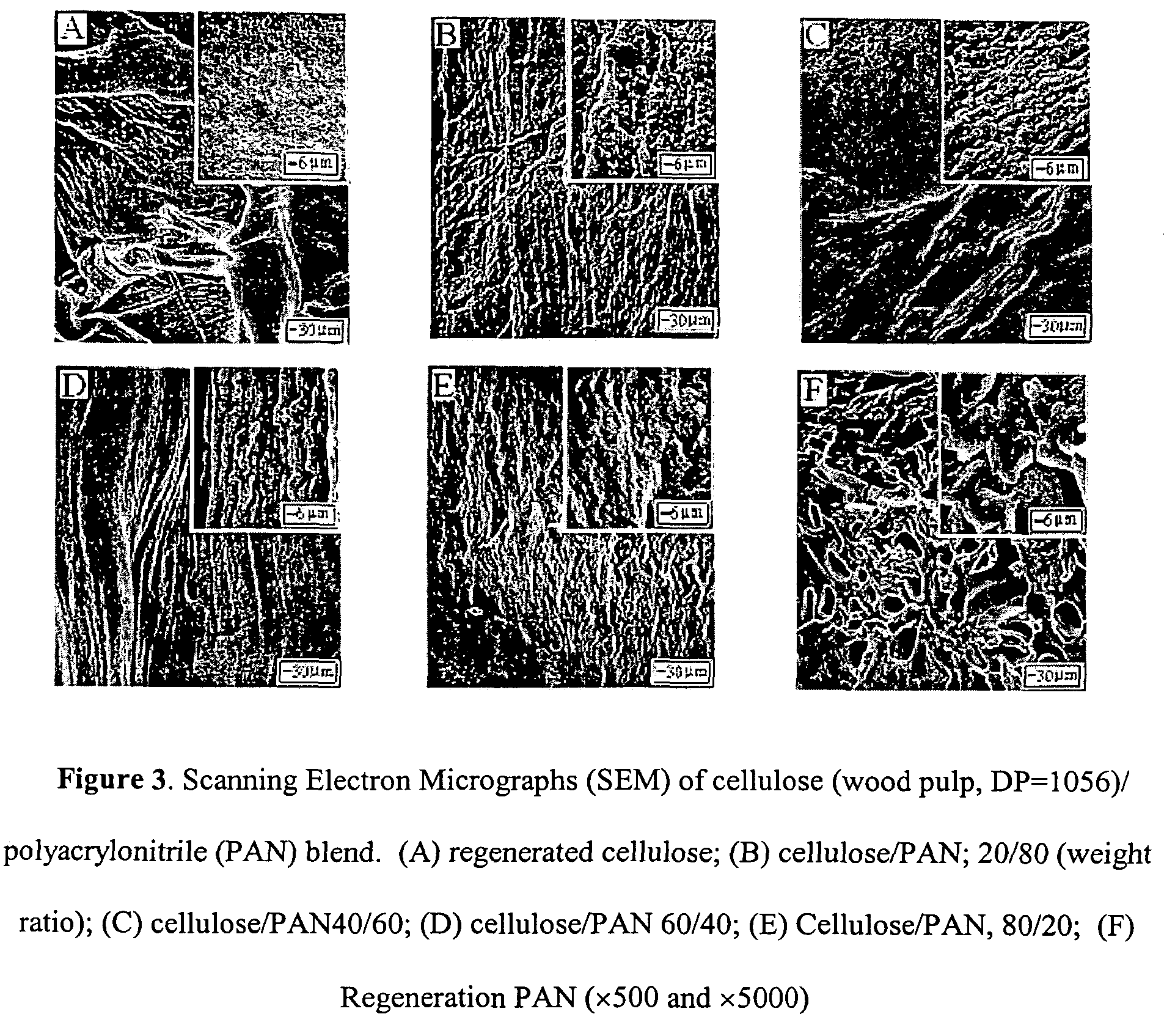

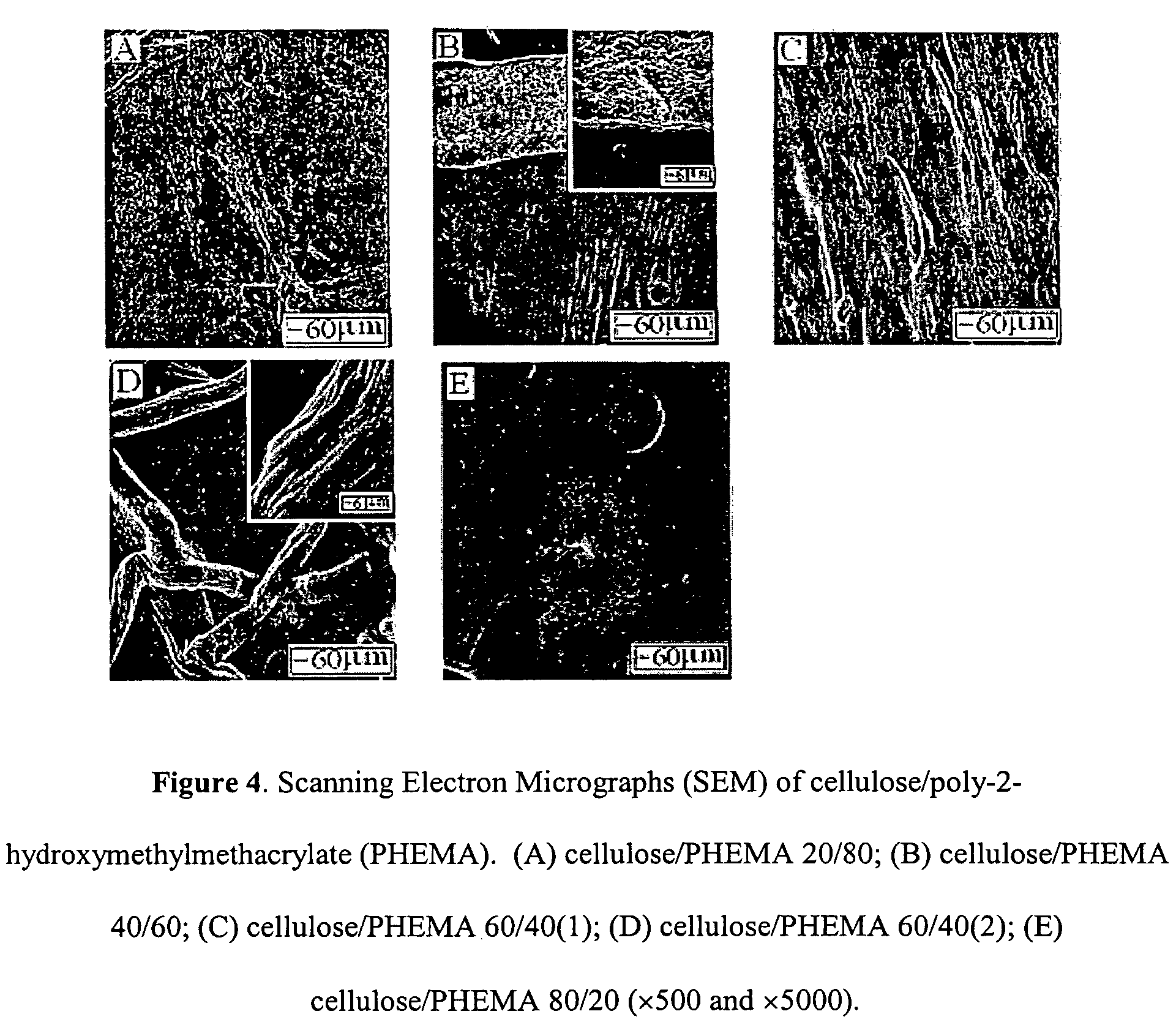

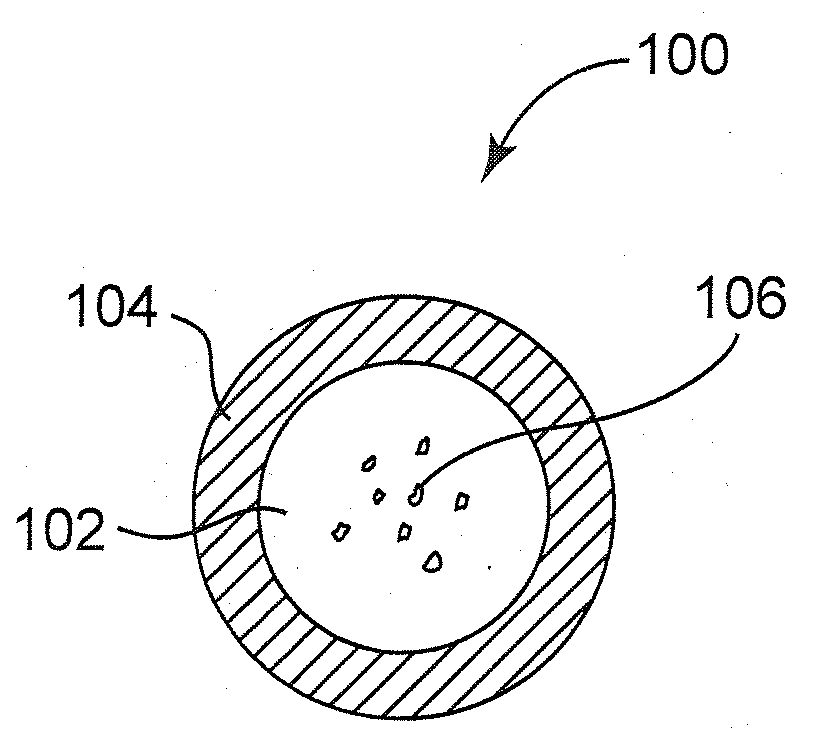

Polymer dissolution and blend formation in ionic liquids

InactiveUS20050288484A1Cosmetic preparationsToilet preparationsPolymer dissolutionAdvanced composite materials

The present invention relates to processes utilizing ionic liquids for the dissolution of various polymers and / or copolymers, the formation of resins and blends, and the reconstitution of polymer and / or copolymer solutions, and the dissolution and blending of “functional additives” and / or various polymers and / or copolymers to form advanced composite materials.

Owner:UNIVERSTIY OF ALABAMA THE

Compositions used in manufacturing articles having an inorganically filled organic polymer matrix

InactiveUS6090195AReadily and inexpensively mass producedHigh strengthClosure lidsWrappersFiberPolymer science

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more aggregate materials, fibers, and optional admixtures in the correct proportions in order to form an article which has the desired performance criteria. The inorganically filled mixtures are molded to fashion a portion of the mixture into a form stable shape for the desired article. Once the article has obtained form stability, such as by heating to remove water by evaporation, the article is removed from the mold and allowed to harden to gain strength. The articles may have properties substantially similar to articles presently made from traditional materials like paper, paperboard, polystyrene, plastic, or metal. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

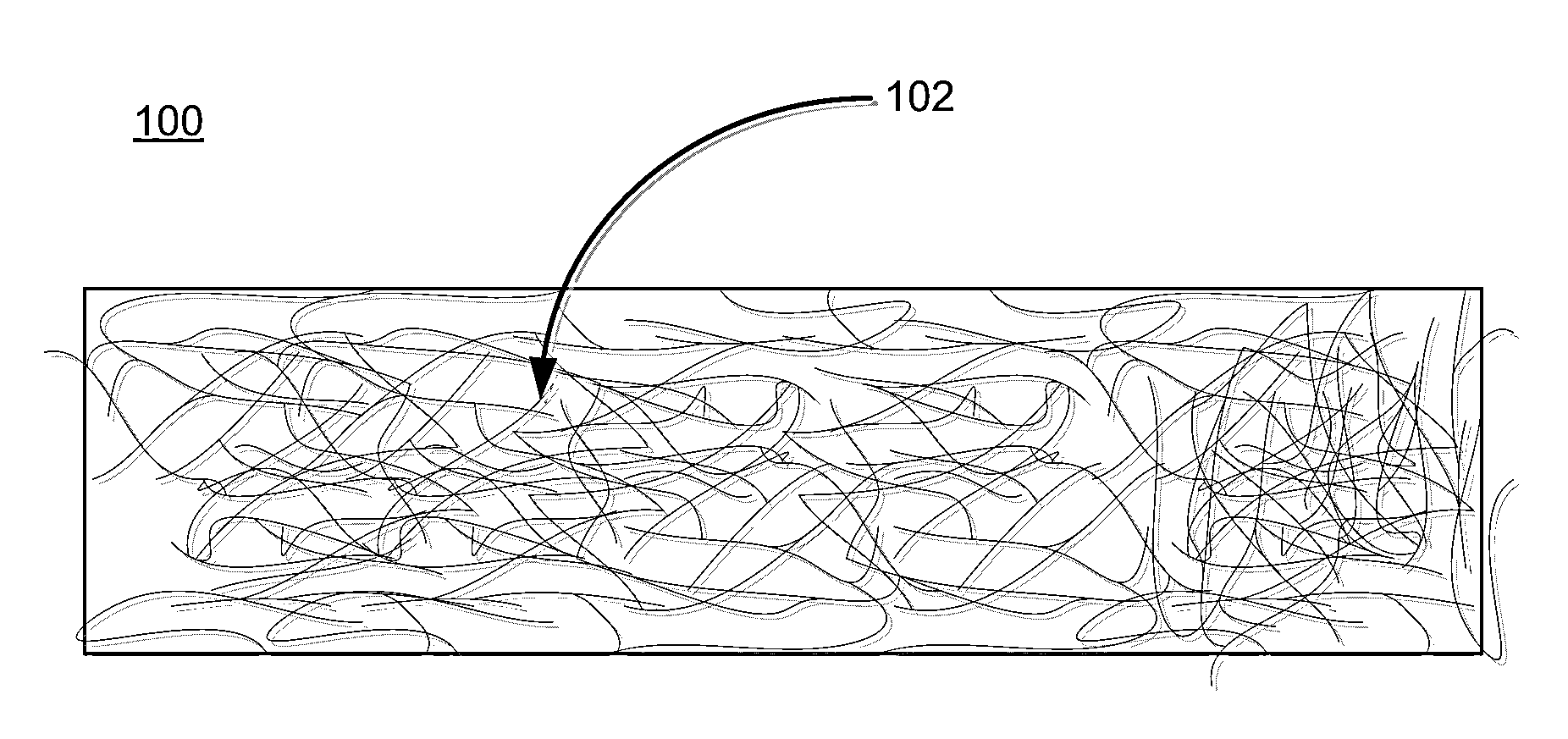

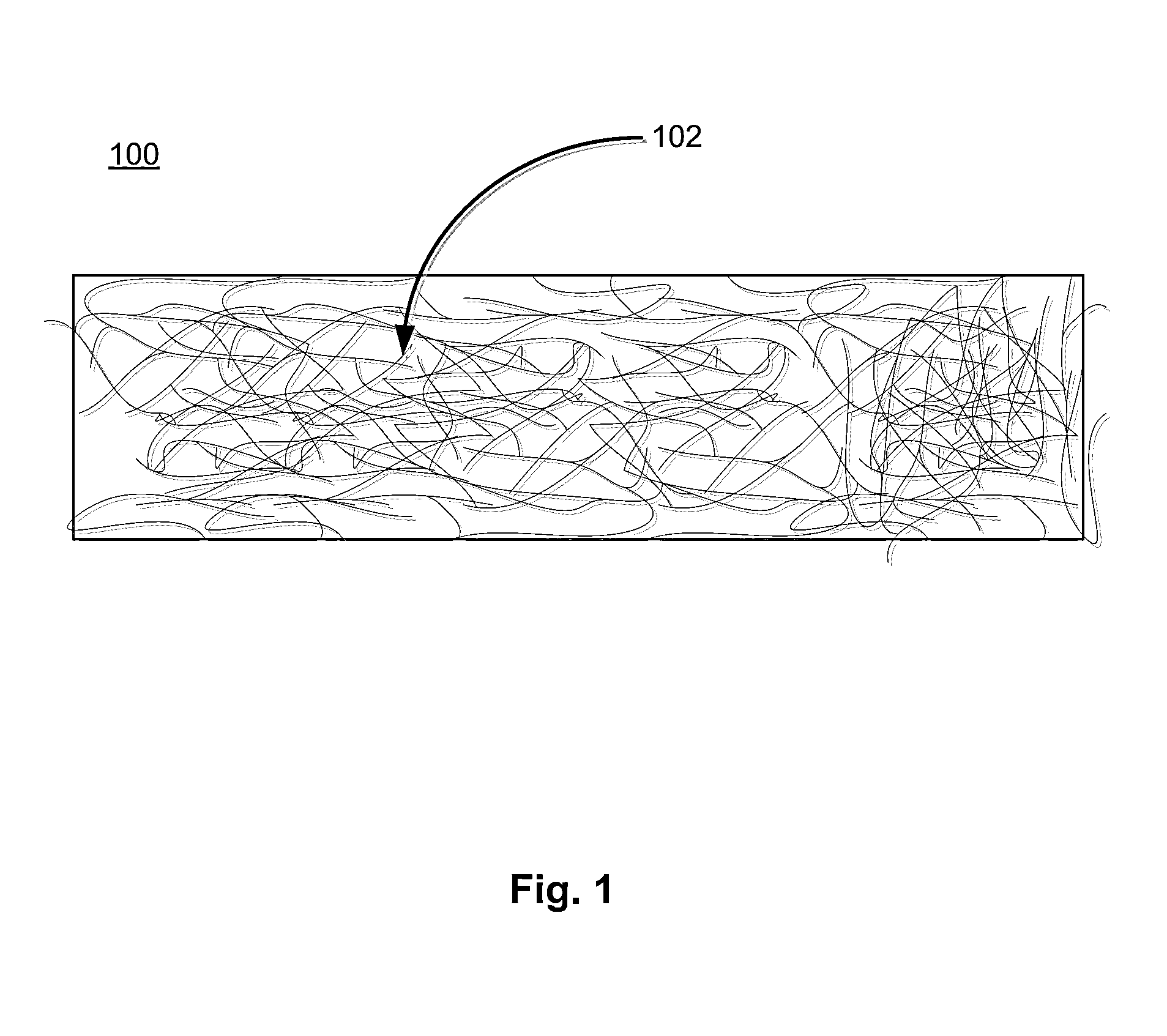

Methods for dispersing fibers within aqueous compositions

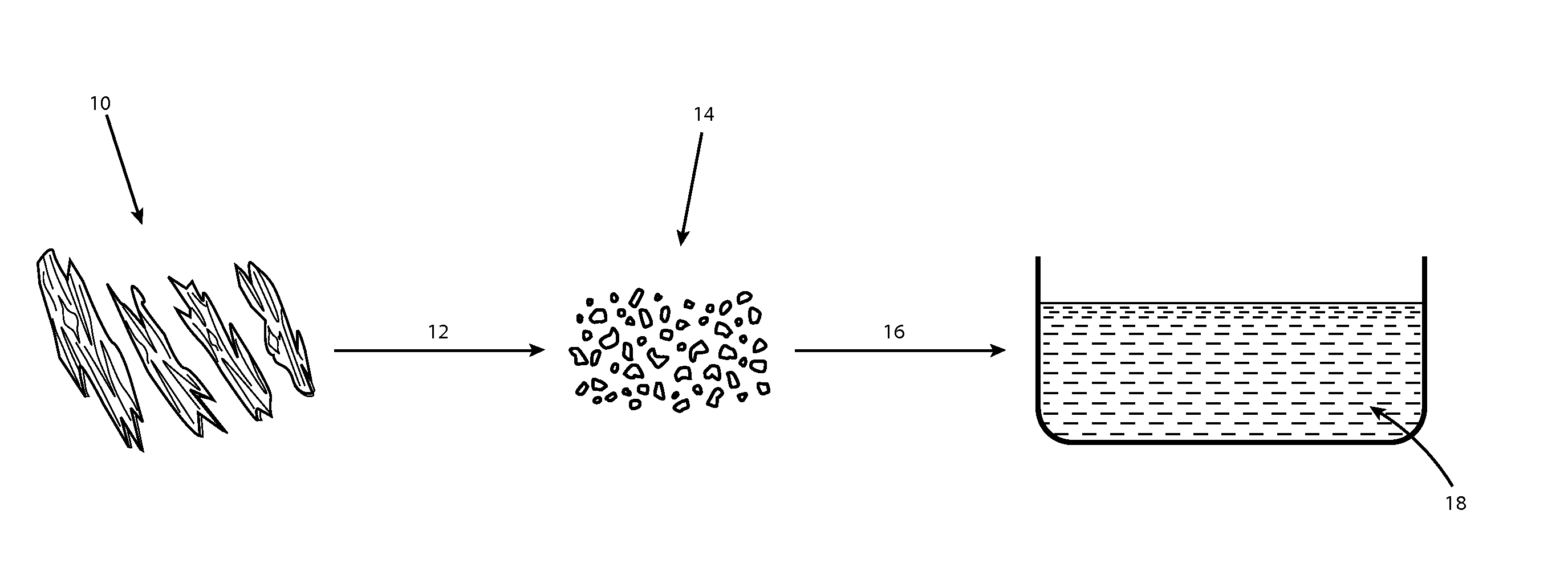

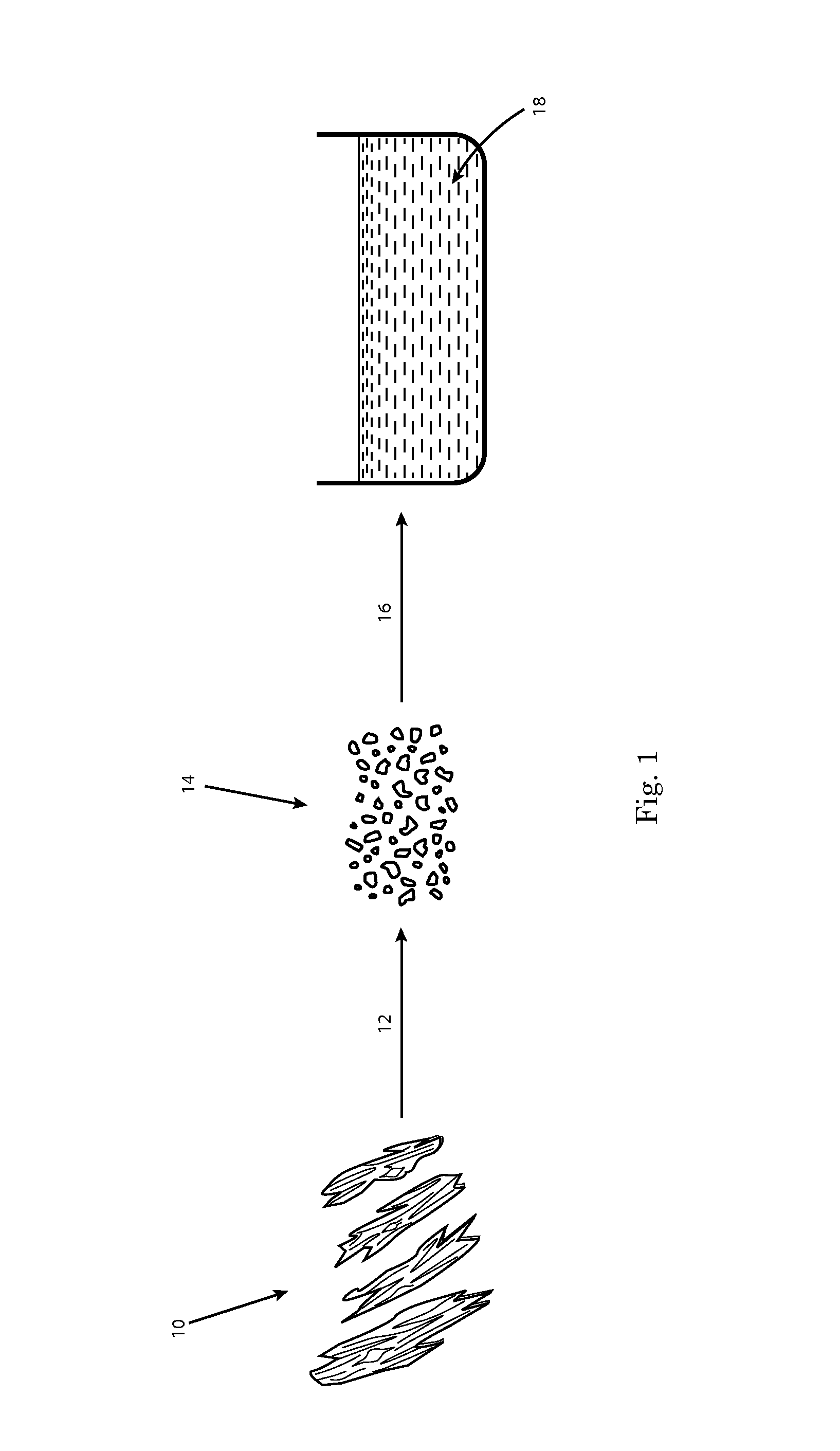

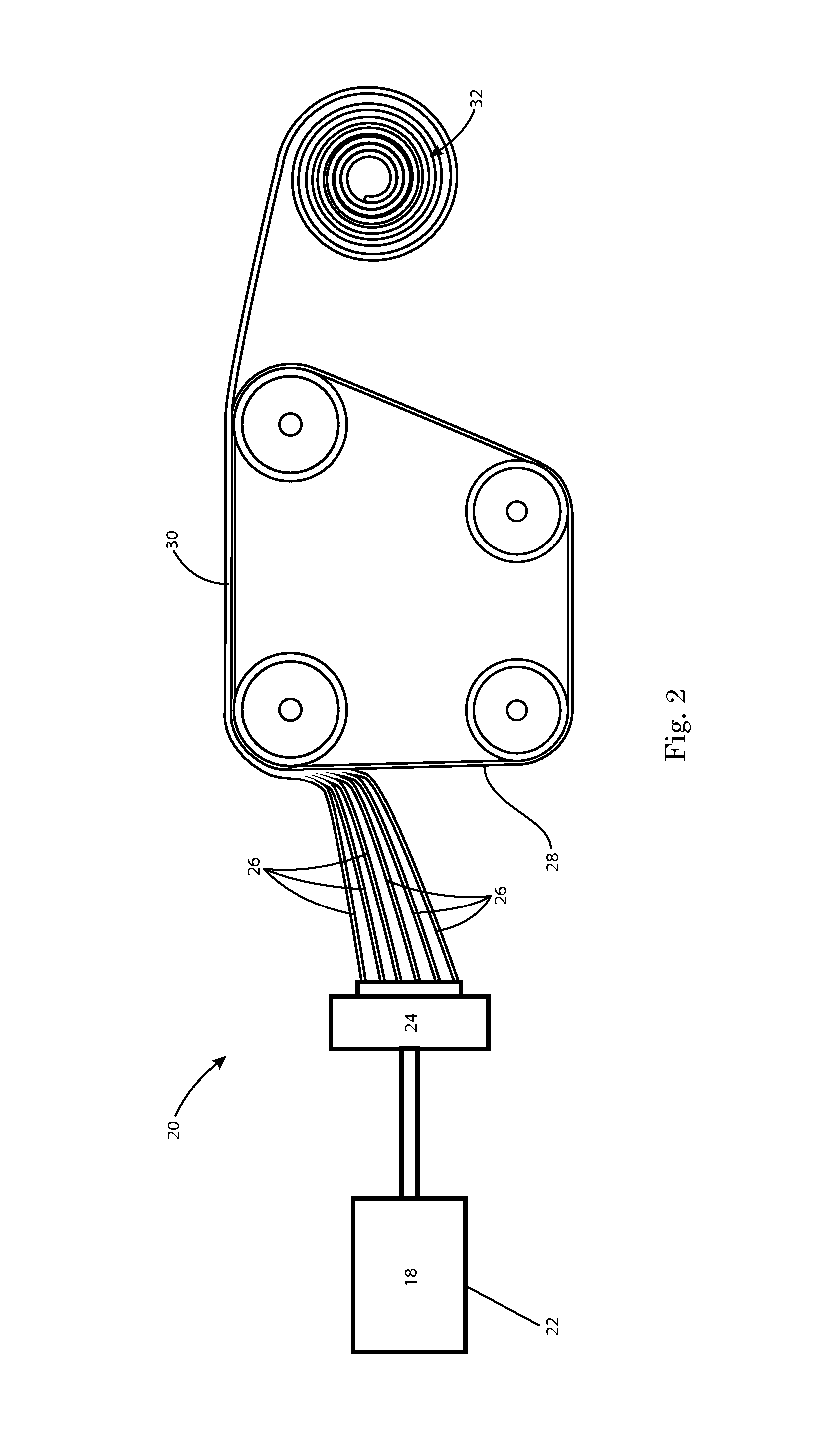

InactiveUS6379446B1Quantity maximizationMinimize interstitial spaceNon-fibrous pulp additionProtein adhesivesFiberSolid component

Compositions and methods in which dry-committed fibers are substantially homogeneously dispersed throughout a fibrous composition. The fibrous composition is characterized as having sufficient yield stress and viscosity such that the shearing forces from the mixing apparatus are effectively transferred down to the fiber level. This is accomplished by means of an appropriate thickening agent, e.g, gelatinized starch. The dry-committed fibers are exemplified by flash dry fibers or fibrous sheets that have been cut or torn into fragments less than 2 cm across. Providing fibers that have been dry-committed greatly reduces the time that it takes to obtain substantially homogeneous dispersion of the fibers throughout the fibrous composition. This, in turn, reduces the risk of mixture spoilage and mechanical or chemical damage to the solid components within the fibrous composition.

Owner:E KHASHOGGI INDS

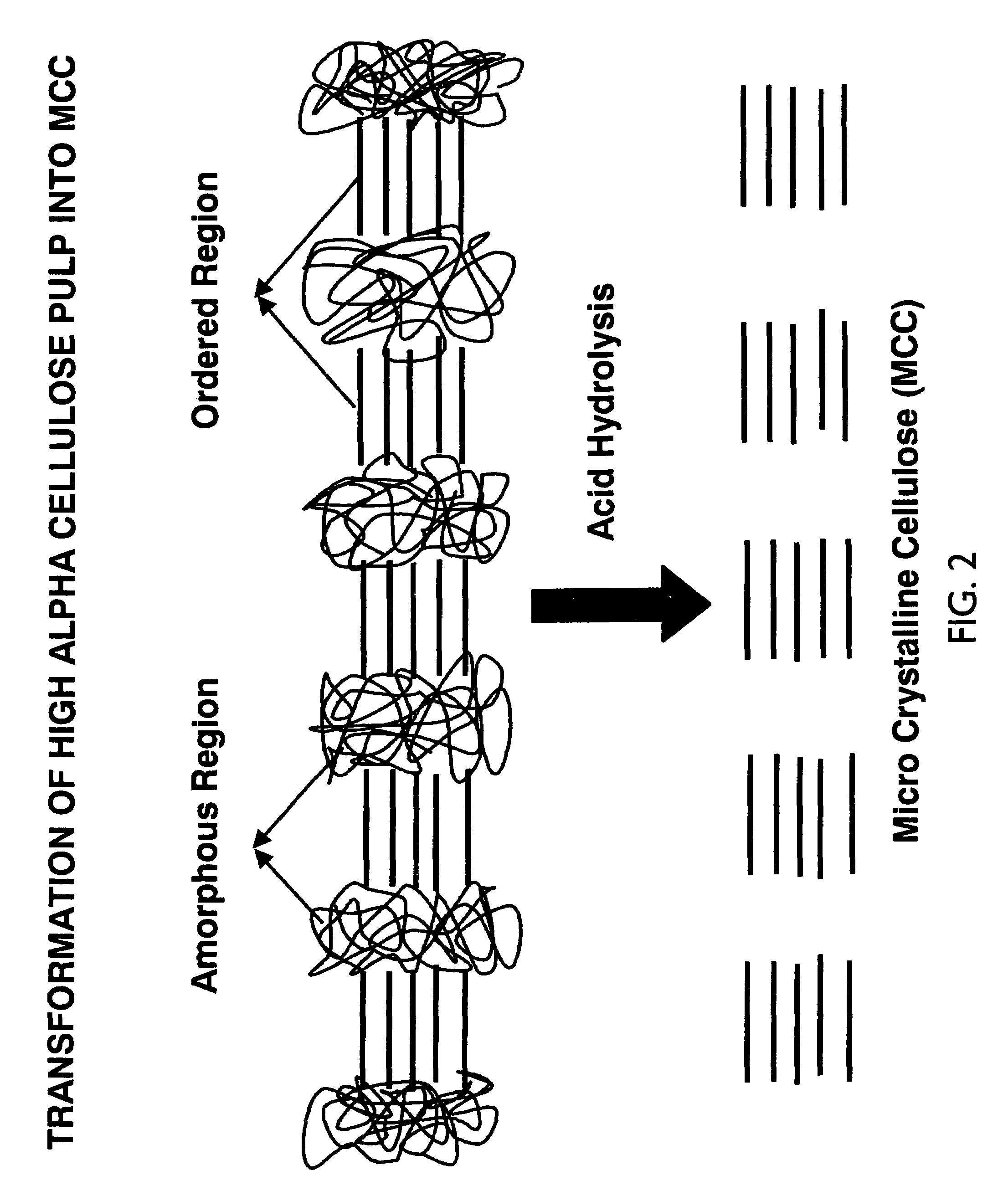

Pharmaceutical excipient having improved compressibility

InactiveUS6103219AImprove compression performanceReduce the amount requiredCosmetic preparationsPowder deliverySilica particleColloid

A microcrystalline cellulose-based excipient having improved compressibility, whether utilized in direct compression, dry granulation or wet granulation formulations, is disclosed. The excipient is an agglomerate of microcrystalline cellulose particles and from about 0.1% to about 20% silicon dioxide particles, by weight of the microcrystalline cellulose, wherein the microcrystalline cellulose and silicon dioxide are in intimate association with each other. The silicon dioxide utilized in the novel excipient has a particle size from about 1 nanometer to about 100 microns. Most preferably, the silicon dioxide is a grade of colloidal silicon dioxide.

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

Pharmaceutical excipient having improved compressibility

InactiveUS6106865AStrong and robustLess-efficient and costly tablet productionPowder deliveryCosmetic preparationsCompressibilityPharmaceutical preservatives

A composition, comprising (a) microcrystalline cellulose; and (b) a compressibility augmenting agent which (i) physically restricts the proximity of the interface between adjacent cellulose surfaces; or (ii) inhibits interactions between adjacent cellulose surfaces; or (iii) accomplishes both (i) and (ii) above, is disclosed. The composition is in the form of agglomerated particles of microcrystalline cellulose and the compressibility augmenting agent in intimate association with each other.

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

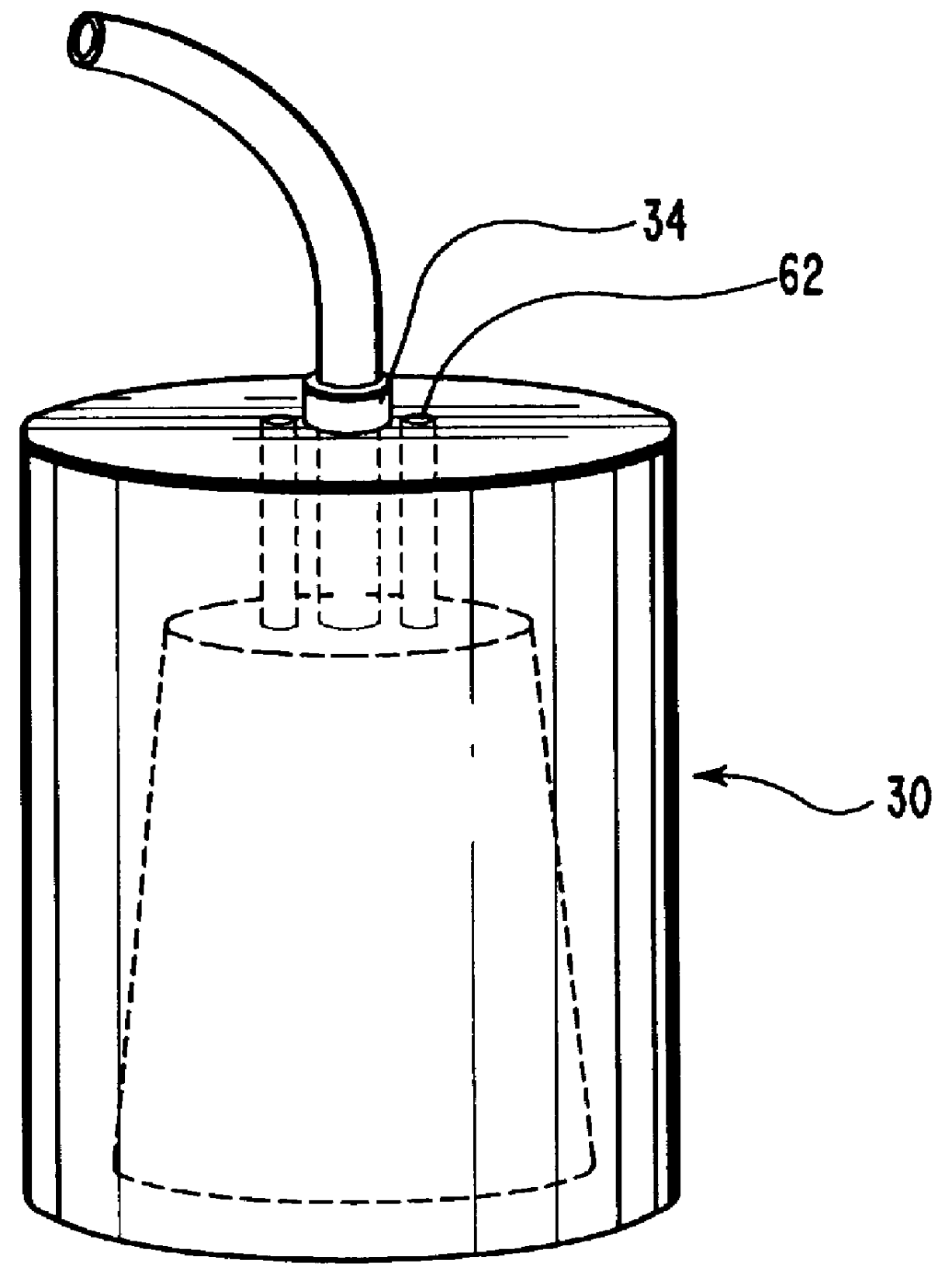

Biodegradable or compostable containers

The present invention provides an improved method and materials for forming biodegradable containers that can hold food products in dry, damp or wet conditions and provides the biodegradable containers prepared according to the disclosed process. The containers are produced through the use of a pre-gelled starch suspension that is unique in its ability to form hydrated gels and to maintain this gel structure in the presence of many other types of materials and at low temperatures.

Owner:NEW ICE LTD

Cellulosic composite

Provided is a cellulosic composite comprised of cellulosic material and a binder. The binder comprises a reaction product of an amine and a reactant in the form of an amino-amide intermediate. To the amino-amide is added an aldehyde or ketone to form a curable binder composition. The composition when mixed with cellulosic material and cured forms a cellulosic composite.

Owner:JOHNS MANVILLE CORP

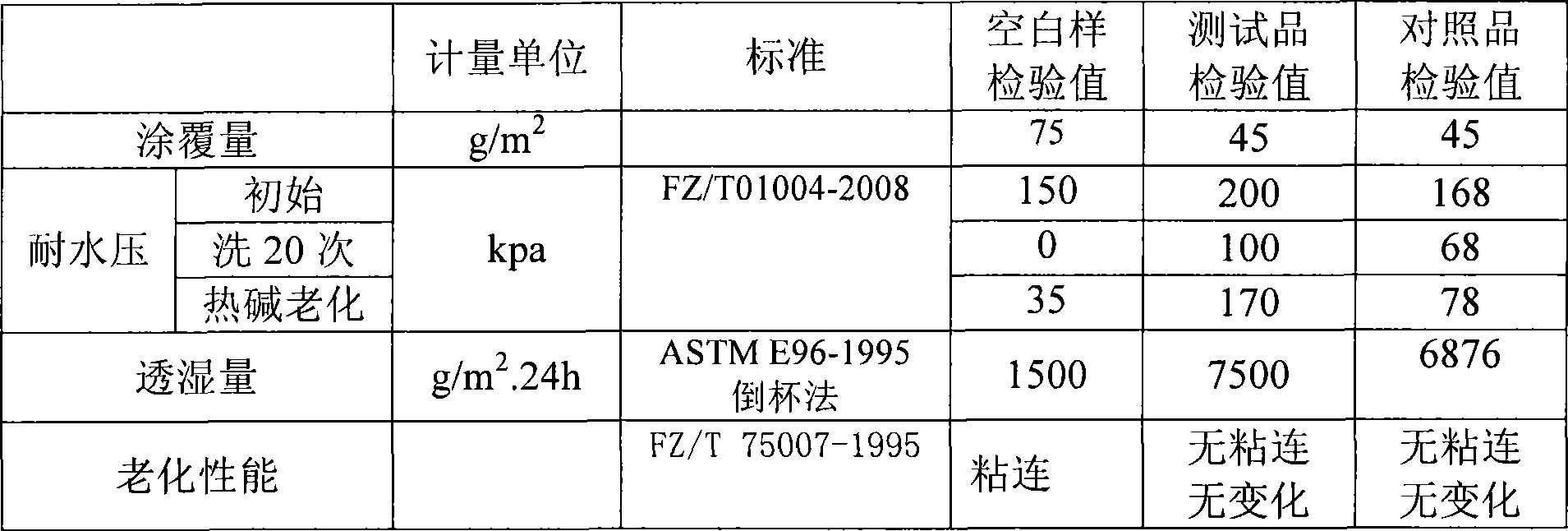

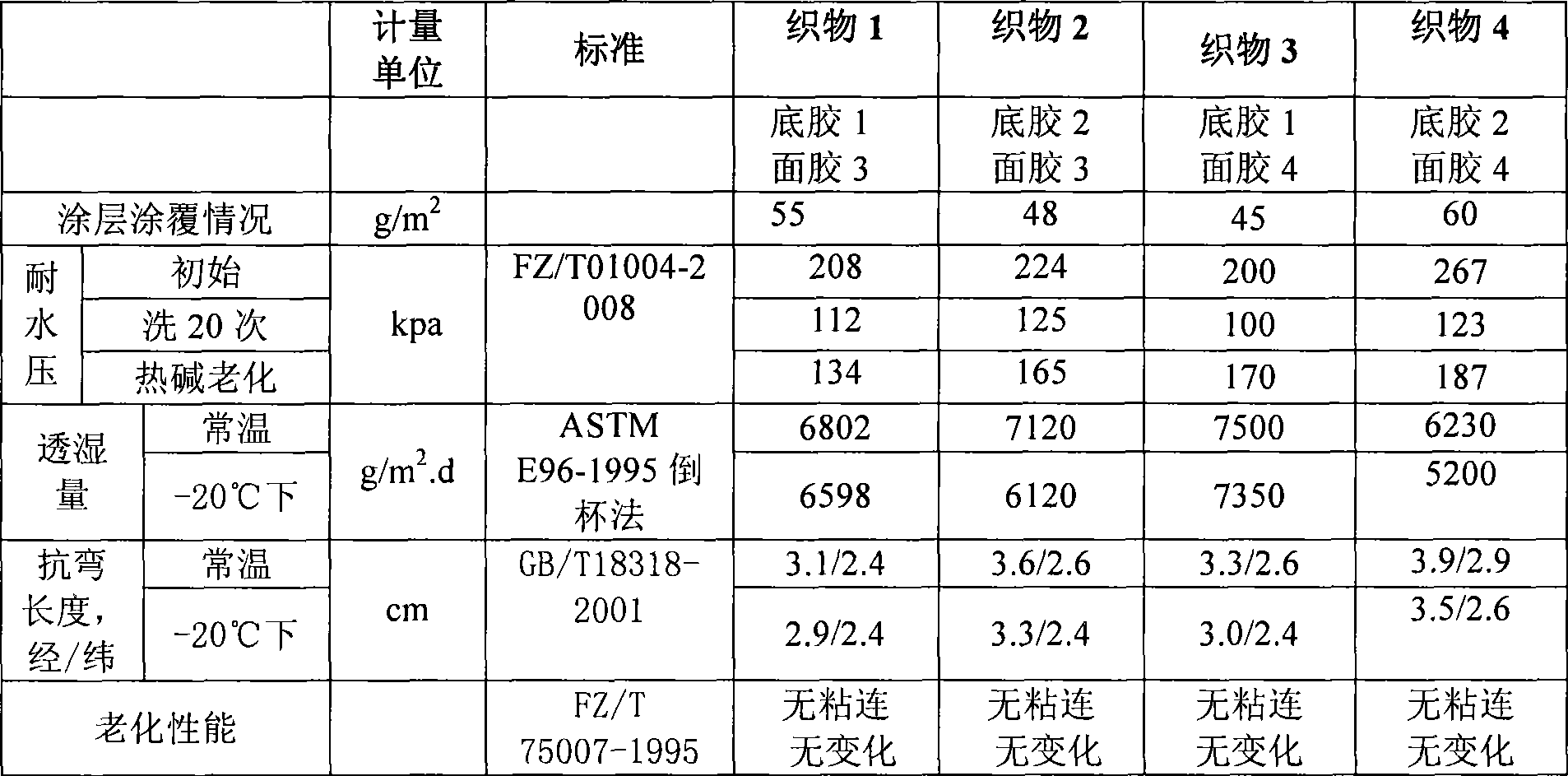

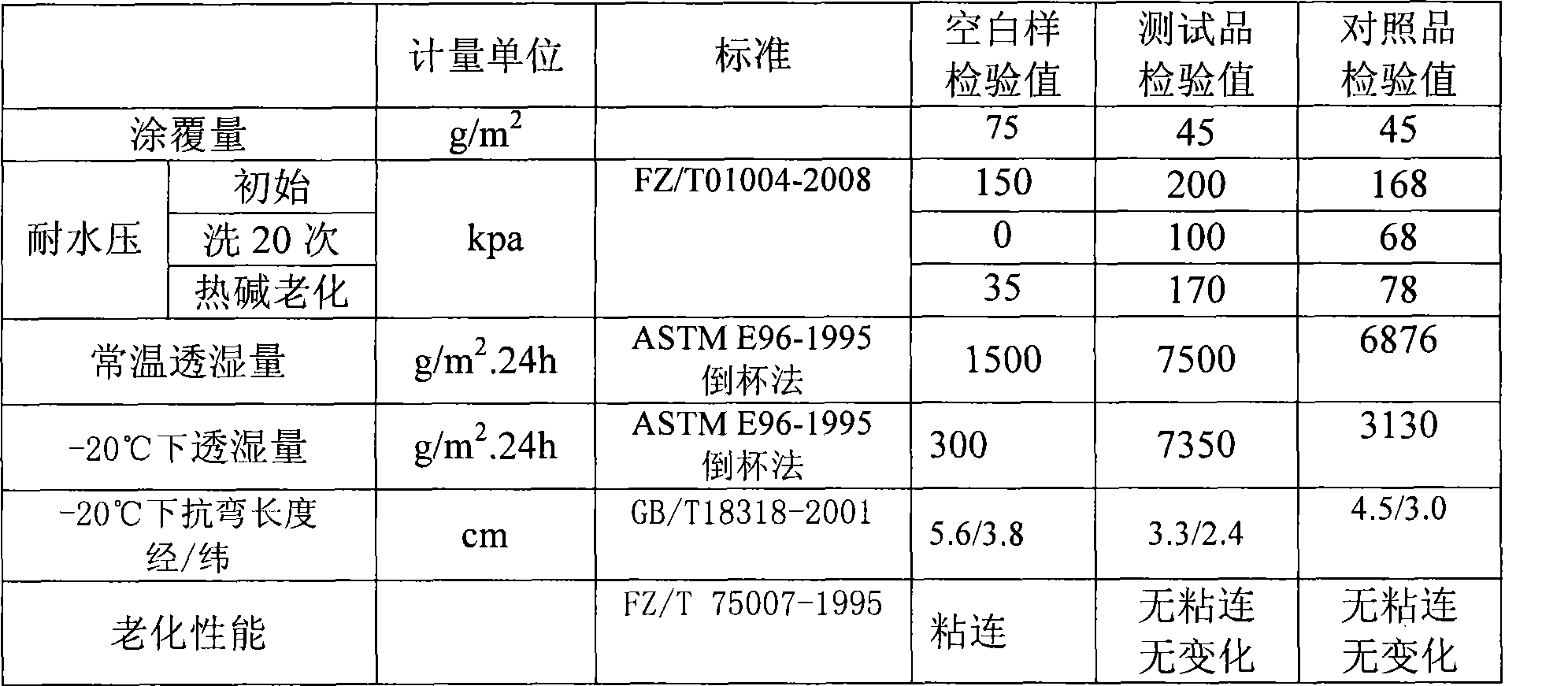

Waterproof moisture permeable modified polyurethane coating glue and preparation thereof

InactiveCN101481579AEasy to addWorkmanship is feasiblePolyurea/polyurethane coatingsTextiles and paperAdhesiveMoisture permeability

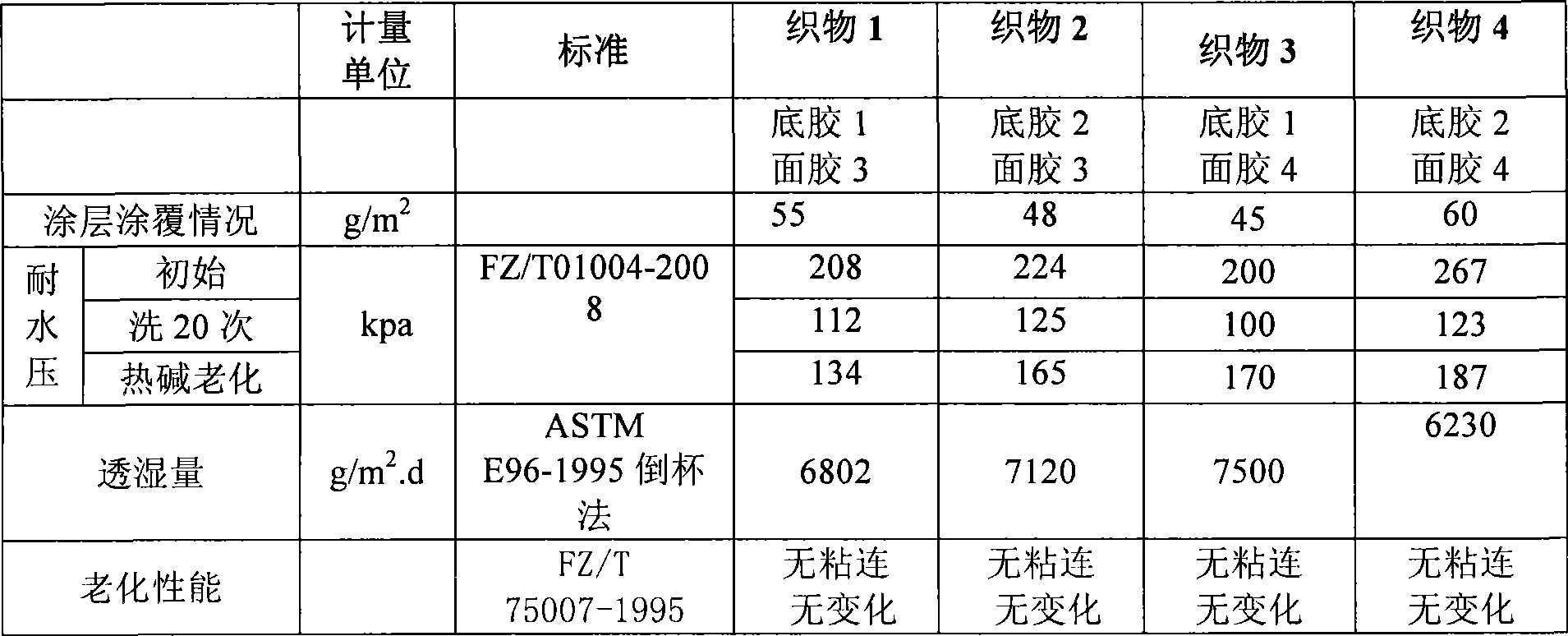

The invention provides a water-proof and moisture-permeable advanced polyurethane coating adhesive, which is prepared by mixing three components of coating agent, crosslinking agent and crosslinking promoter with a solvent when in use; the coating agent contains 500 to 1000 mesh of lignocellulose micropowder; the amounts of the crosslinking agent and crosslinking promoter are 2-5wt% of that of the coating agent; and the viscosity of the coating adhesive is 8000 to 15000 mPa.s. The advanced polyurethane coating adhesive in the invention is coated on a base fabric so as to prepare a water-proof and moisture-permeable coated fabric; the moisture permeability is greater than 7000 g / m.d; the water pressure resistance is greater than 200 kPa; the aging resistant performance is enhanced; the blocking resistance is obviously improved; and the coated fabric can be used as a coating material of clothes having water-proof and moisture-permeable functions.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +2

Cellulosic composite

Provided is a cellulosic composite comprised of cellulosic material and a binder. The binder comprises a reaction product of an amine and a reactant in the form of an amino-amide intermediate. To the amino-amide is added an aldehyde or ketone to form a curable binder composition. The composition when mixed with cellulosic material and cured forms a cellulosic composite.

Owner:JOHNS MANVILLE CORP

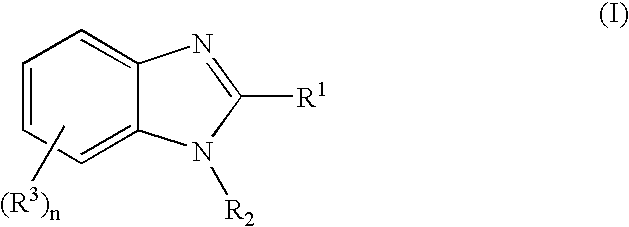

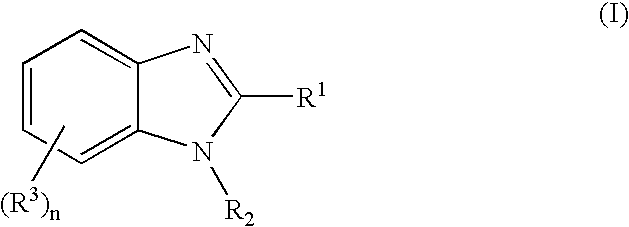

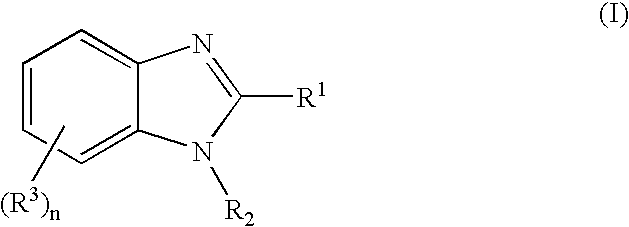

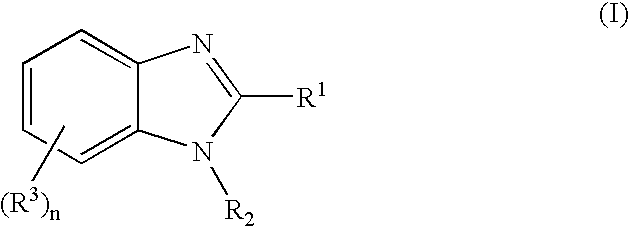

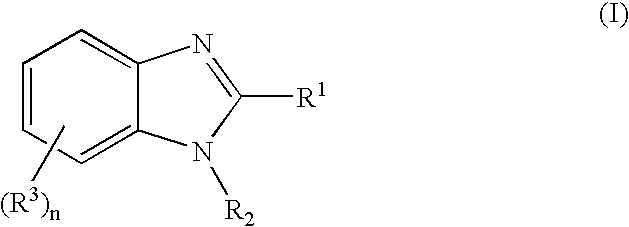

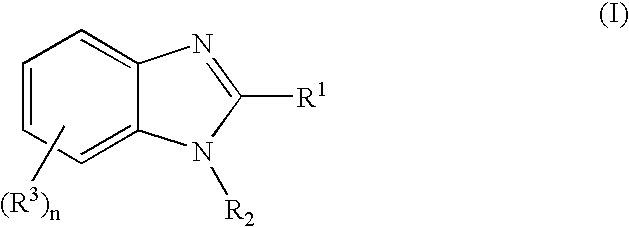

Wax emulsion preservative compositions and method of manufacture

An emulsion comprising water as the continuous phase, a wax as the discontinuous phase, an emulsifier and a preservative having the general structure:wherein R1 can be a heterocycle containing nitrogen and sulfur, such as thiazolyl, isothiazolyl, or thiadiazolyl, which can optionally be substituted with C1–C6 alkyl; R2 can be hydrogen or C1–C6 alkyl, specifically hydrogen; n is 0, 1, 2, or 3; each instance of R3 can independently be hydrogen, C1–C6 alkyl, phenoxy, C1–C6 alkoxy, halo, amino, C1–C6 alkylamino, di C1–C6 alkyl amino, imidazolyl, thiazolyl, isothiazolyl, thiadiazolyl, thienyl, furyl, pyrryl, naphthyl, phenyl, halophenyl, C1–C6 alkyl phenyl, or C1–C6 alkoxyphenyl. The preservative may be added to the emulsion after the emulsion is formed. The emulsion can be incorporated into a gypsum product such as gypsum board or gypsum wood fiber board. The gypsum product may be made by forming a slurry containing gypsum, water, and the emulsion into a solid product. A method for improving the water resistance of a lignocellulosic composite product prepared by mixing lignocellulosic material with a binder to form a mixture and solidifying the mixture in a selected configuration to form the composite product may include adding to the mixture an emulsion as described above.

Owner:MOMENTIVE SPECIALTY CHEMICALS

Nanocomposites of cellulose and clay

InactiveUS20050051054A1Improve thermal stabilityIncreased degradation temperatureMaterial nanotechnologyFibre treatmentCelluloseNanometre

This invention relates to a process of forming a nanocomposite of cellulose with a clay material that is used as the nanofiller material. The nanocomposites show significant improvements in thermal properties when compared to unbleached cotton and cotton processed under conditions for nanocomposite preparation. The degradation temperature of these nanocomposites is significantly increased over that of unbleached cotton.

Owner:US SEC AGRI

Fibers comprising hemicellulose and processes for making same

Hemicellulose fibers, more particularly to non-naturally occurring fibers incorporating hemicellulose, processes for making same and fibrous structures incorporating same are provided.

Owner:PROCTER & GAMBLE CO

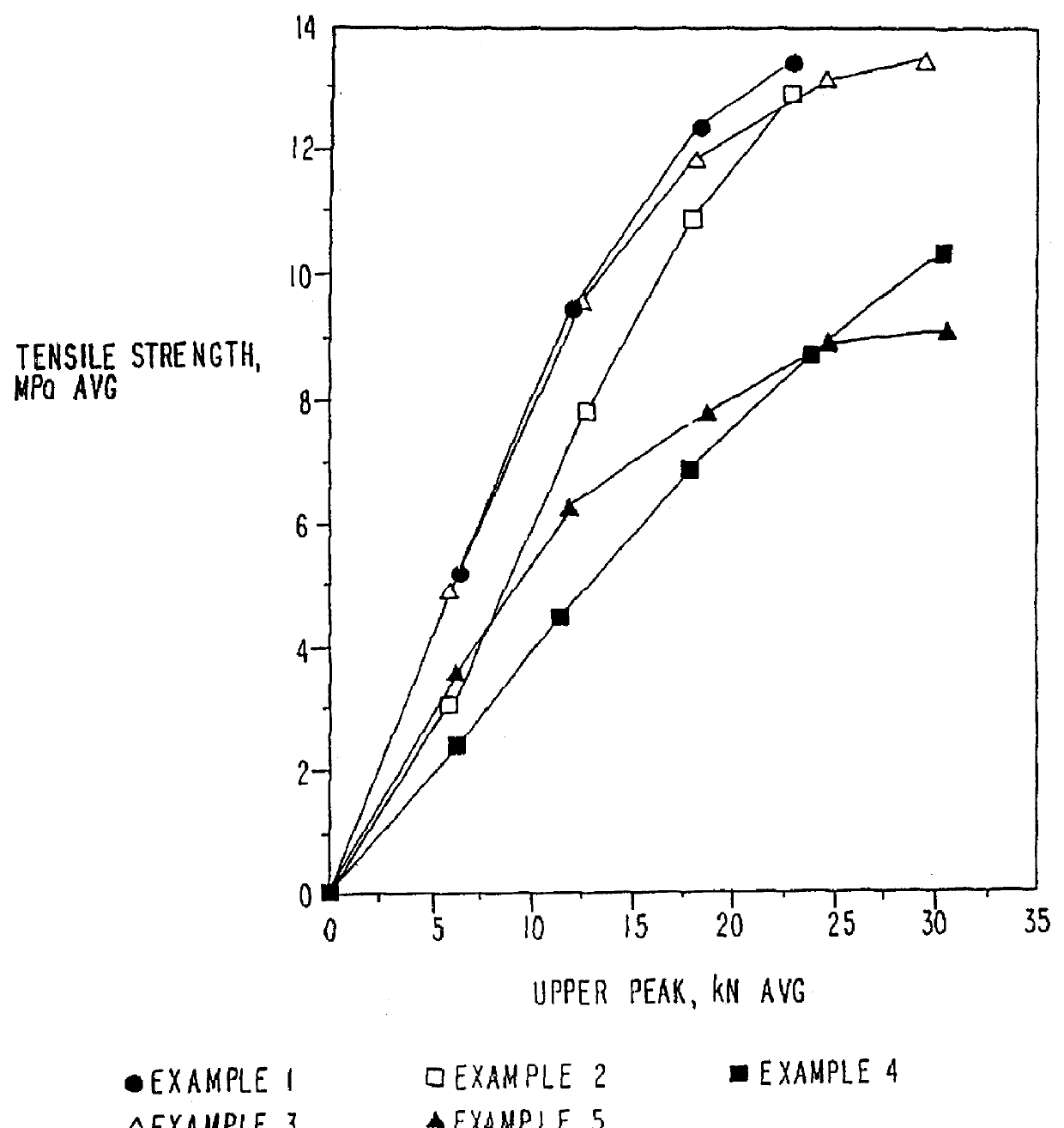

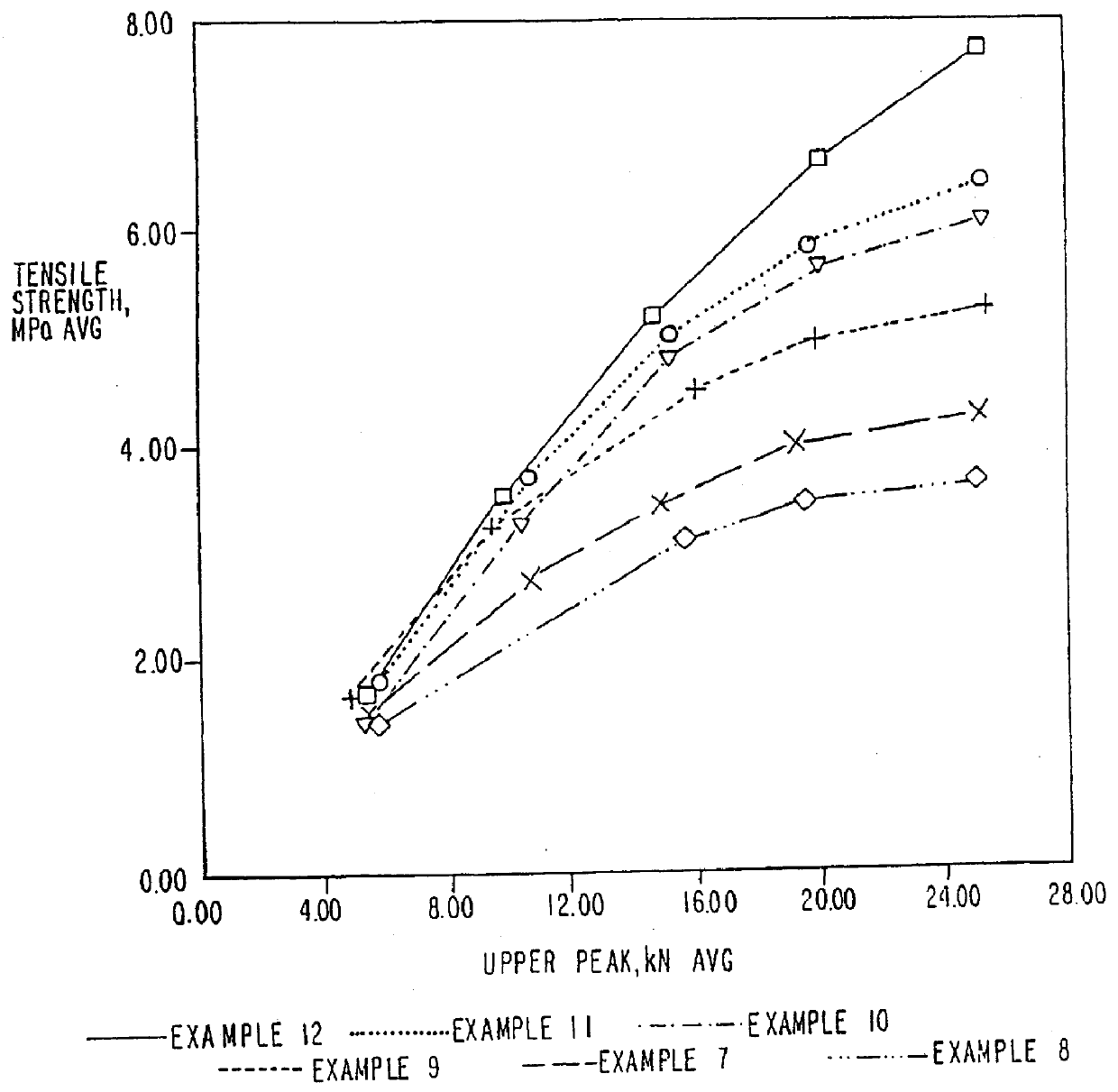

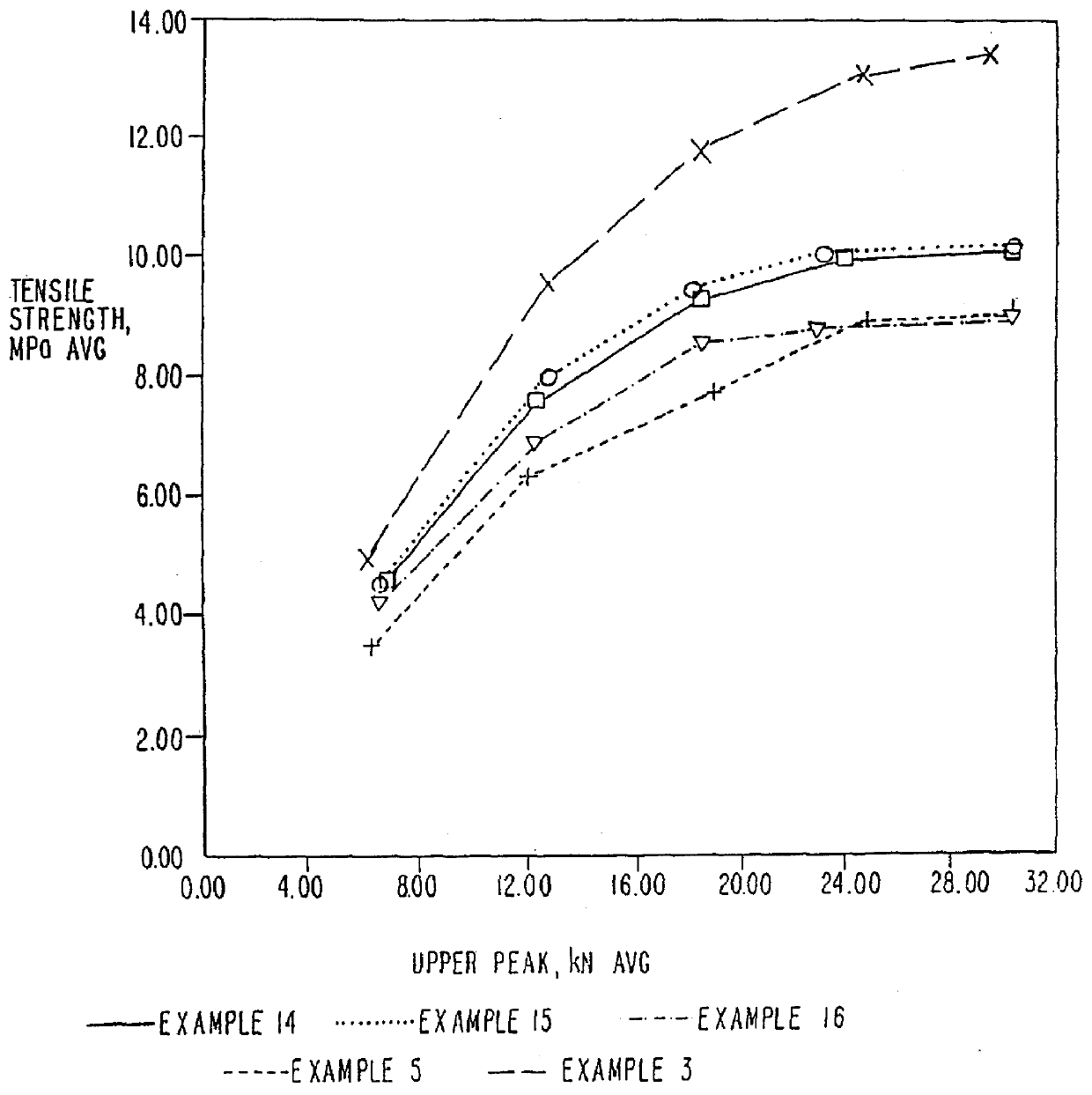

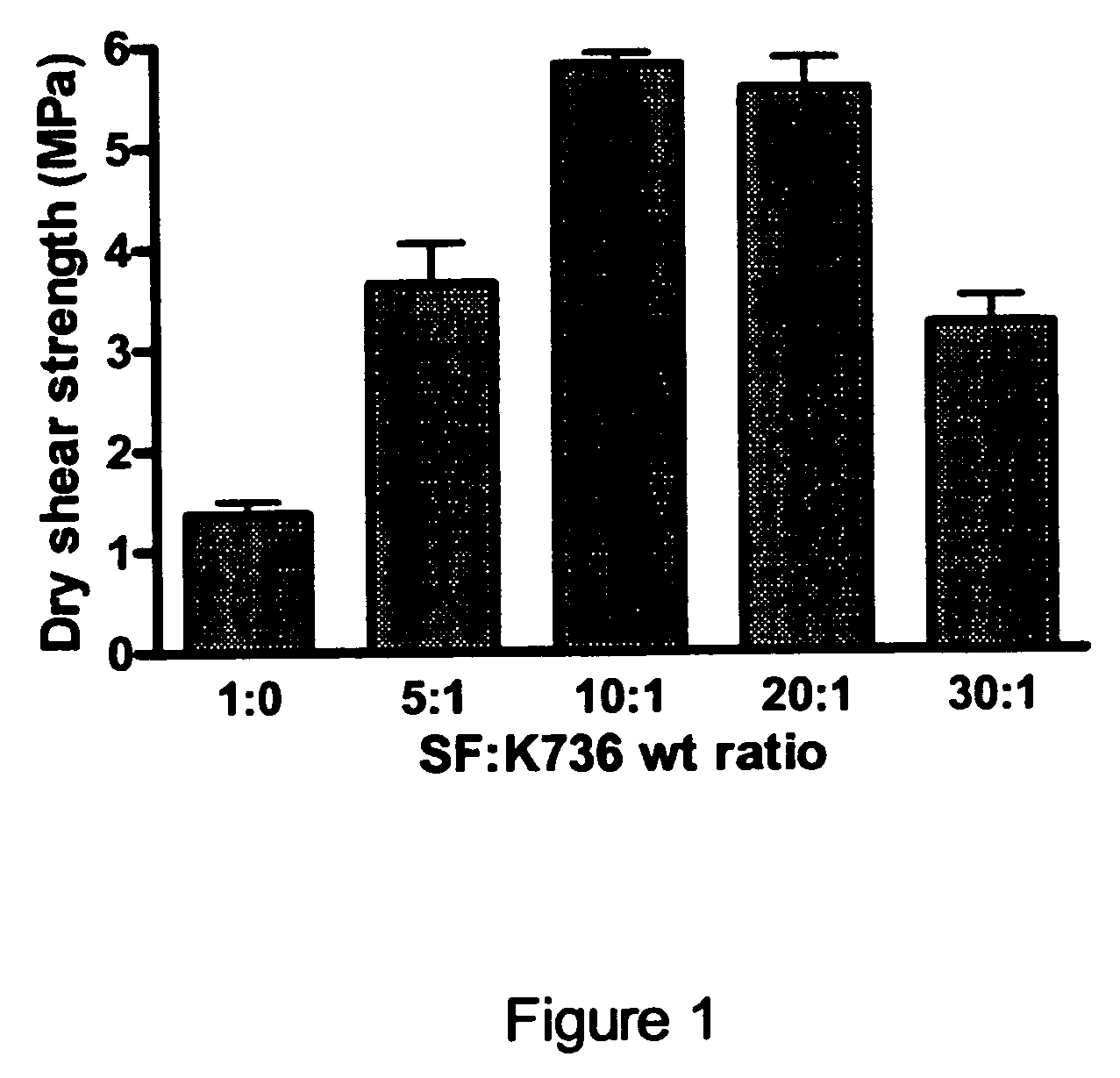

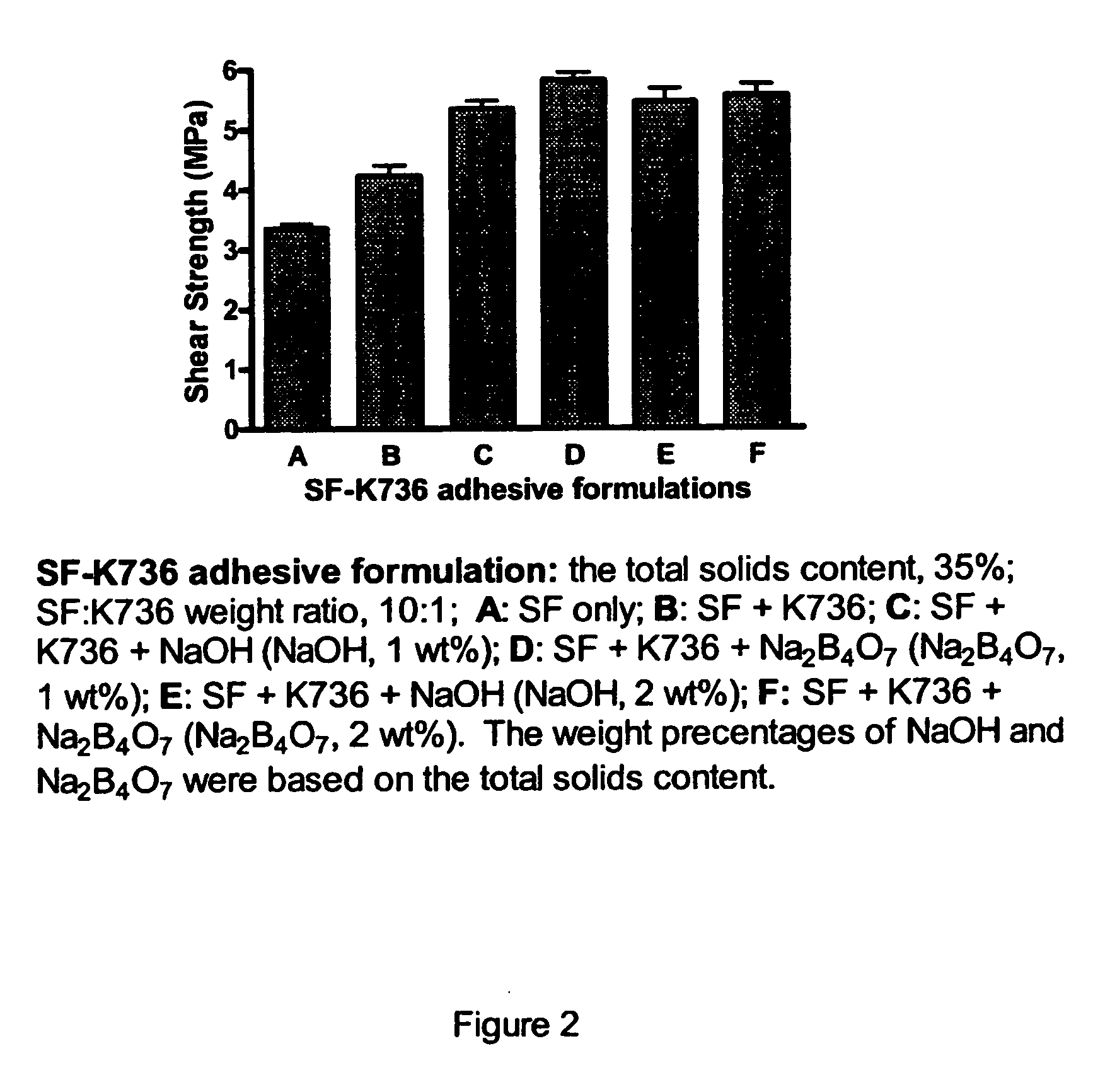

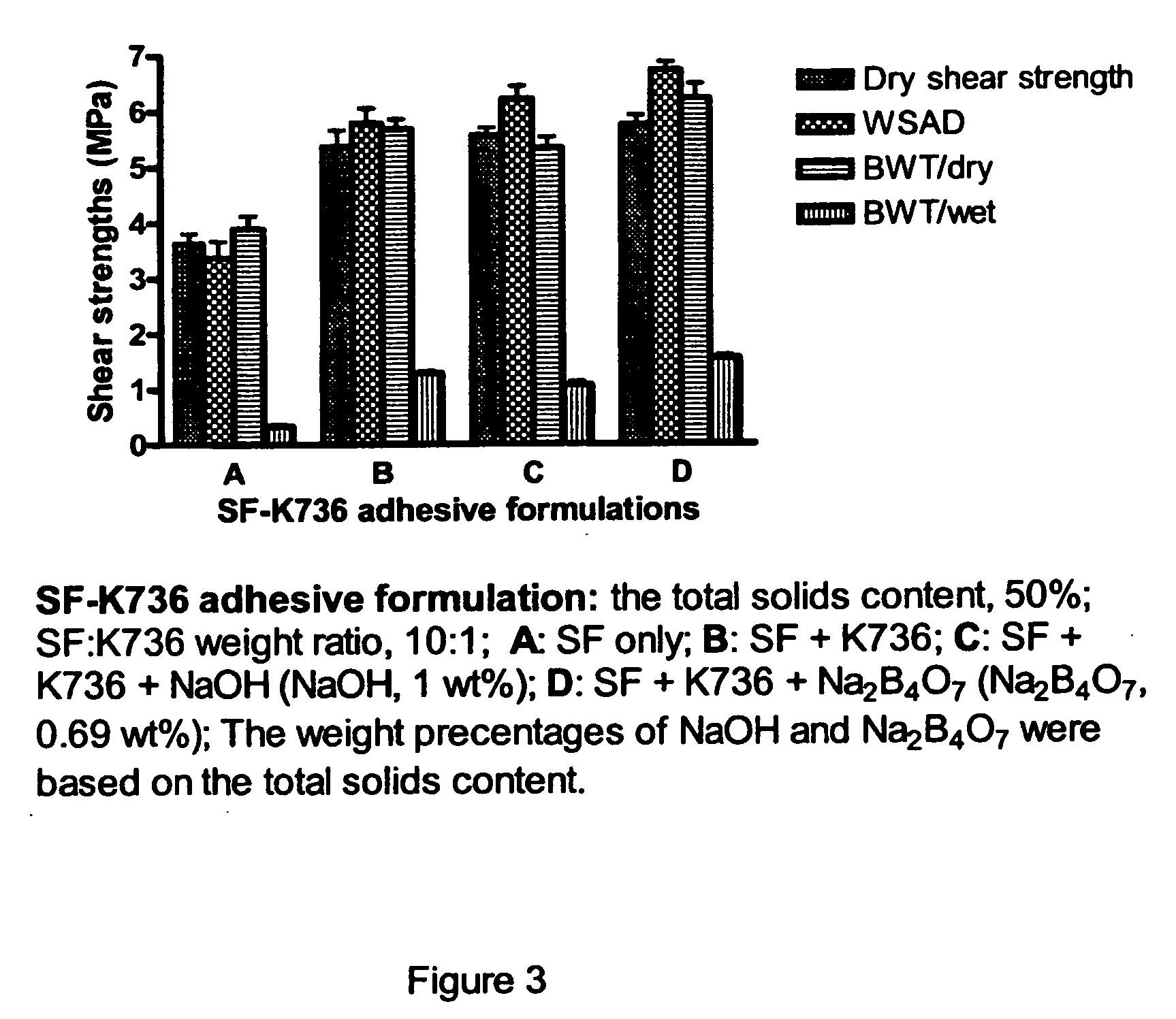

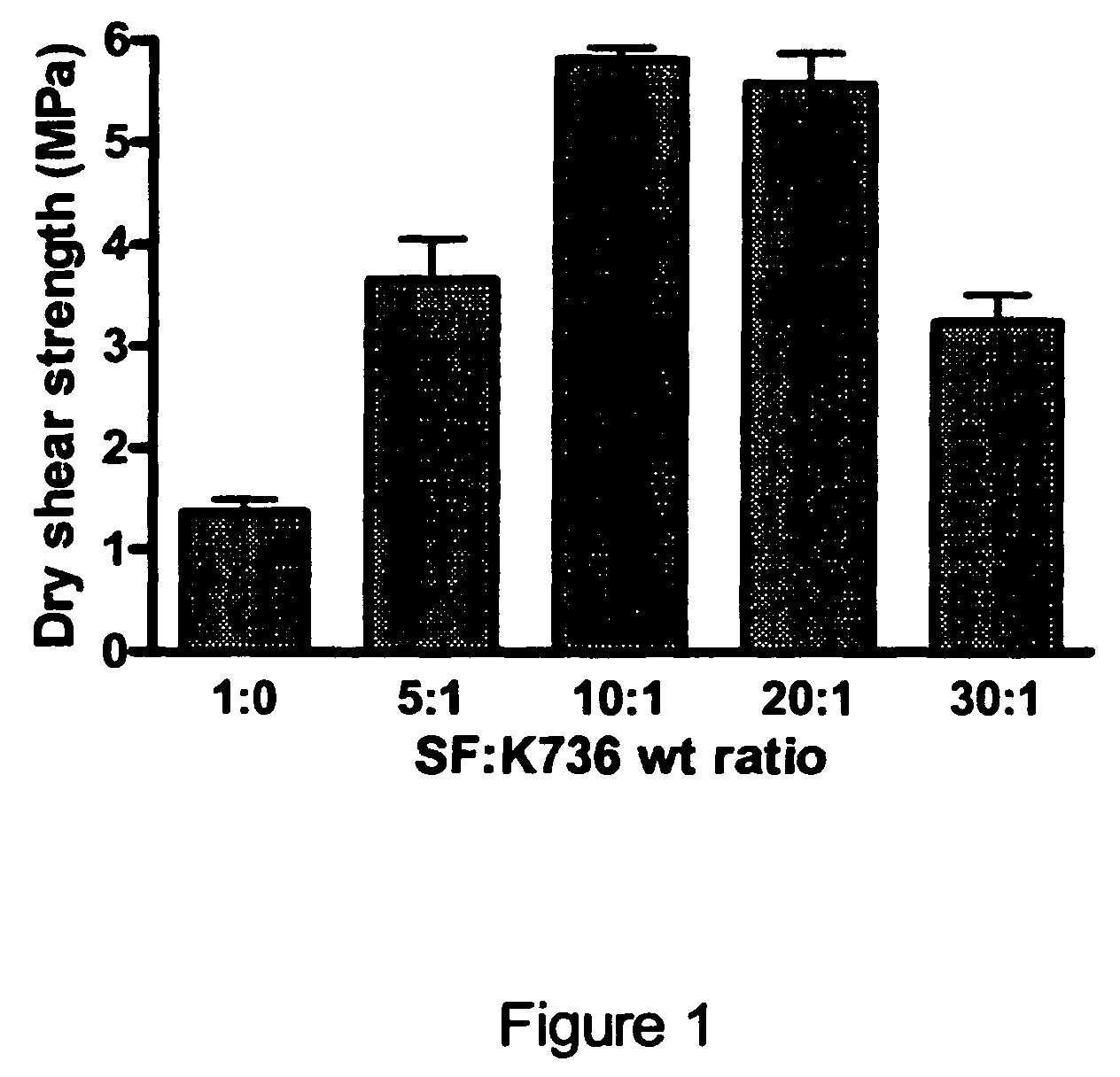

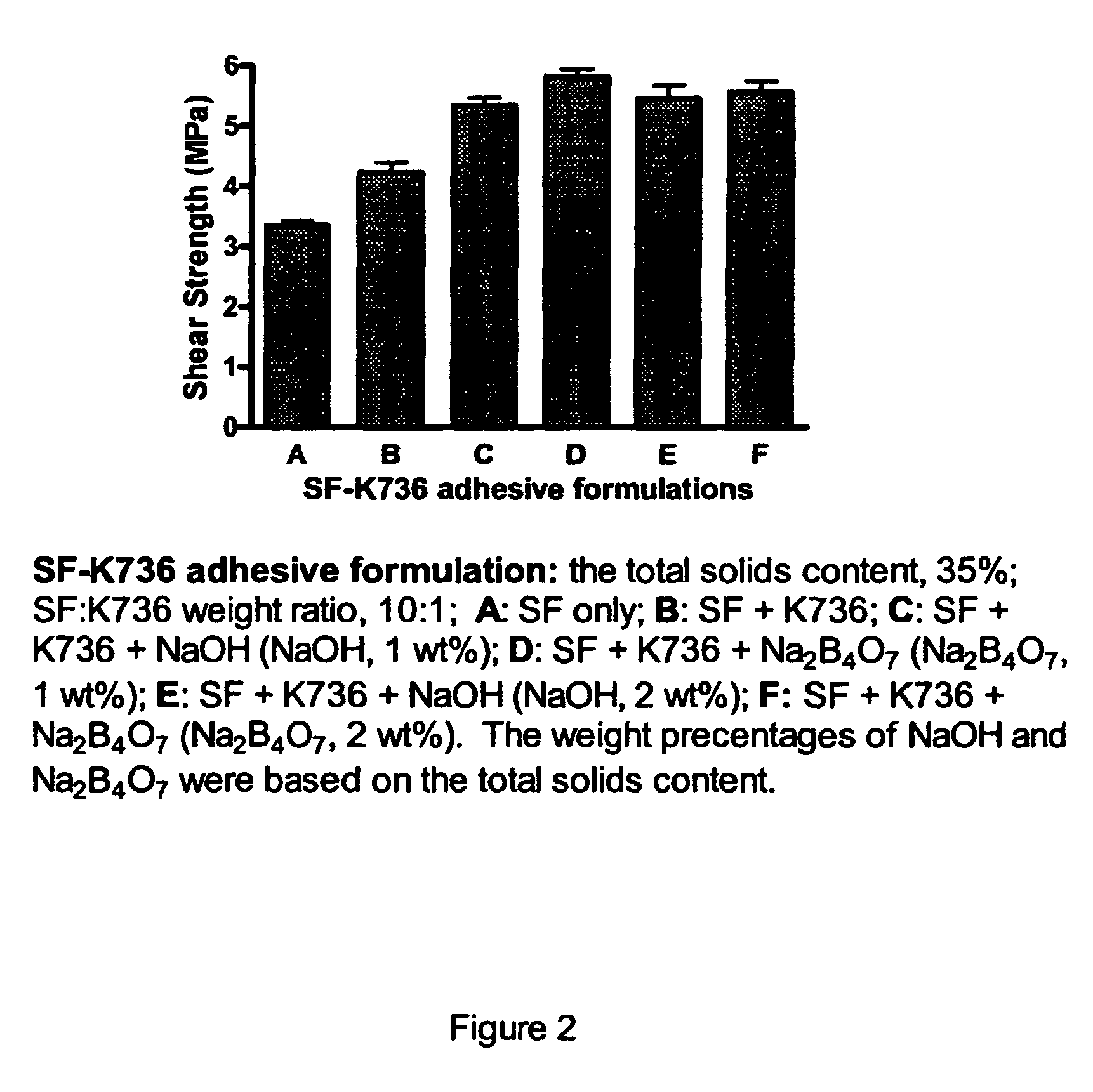

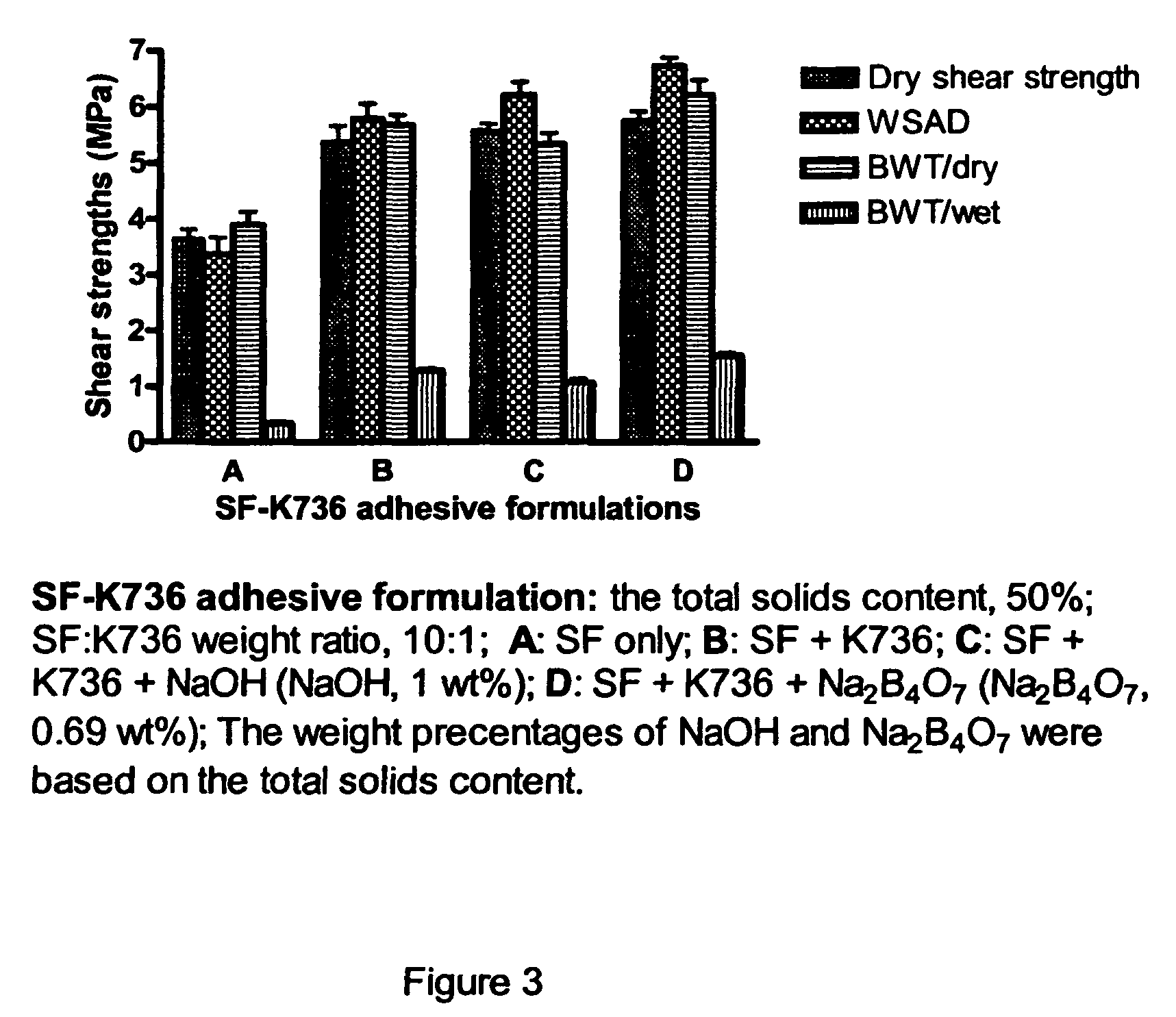

Formaldehyde-Free Adhesives and Lignocellulosic Composites Made from the Adhesives

A first variant of an adhesive composition for making a lignocellulosic composite includes soy protein and / or lignin; at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein; and at least one compound selected from a boron compound, a group IA oxide or hydroxide, or a group IIA oxide or hydroxide. A second variant of an adhesive composition includes a first component selected from soy protein and / or lignin; and at least one substantially formaldehyde-free curing agent selected from a reaction product of epichlorohydrin with ethylenediamine, a reaction product of epichlorohydrin with bis-hexamethylenetriamine, or a reaction product of epichlorohydrin with hexamethylenediamine.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

Coated substrate, a process for production of a coated substrate, a package and a dispersion coating

InactiveUS20130017349A1High strengthEasy to recycleMaterial nanotechnologyStarch dervative coatingsFiberCellulose

The present invention relates to a coated fiber based substrate comprising a dispersion coating wherein said dispersion coating comprises microfibrillated cellulose and colloidal particles of a polymer. The invention further relates to a package formed from said substrate, a dispersion coating and process for the production of mentioned substrate.

Owner:STORA ENSO OYJ

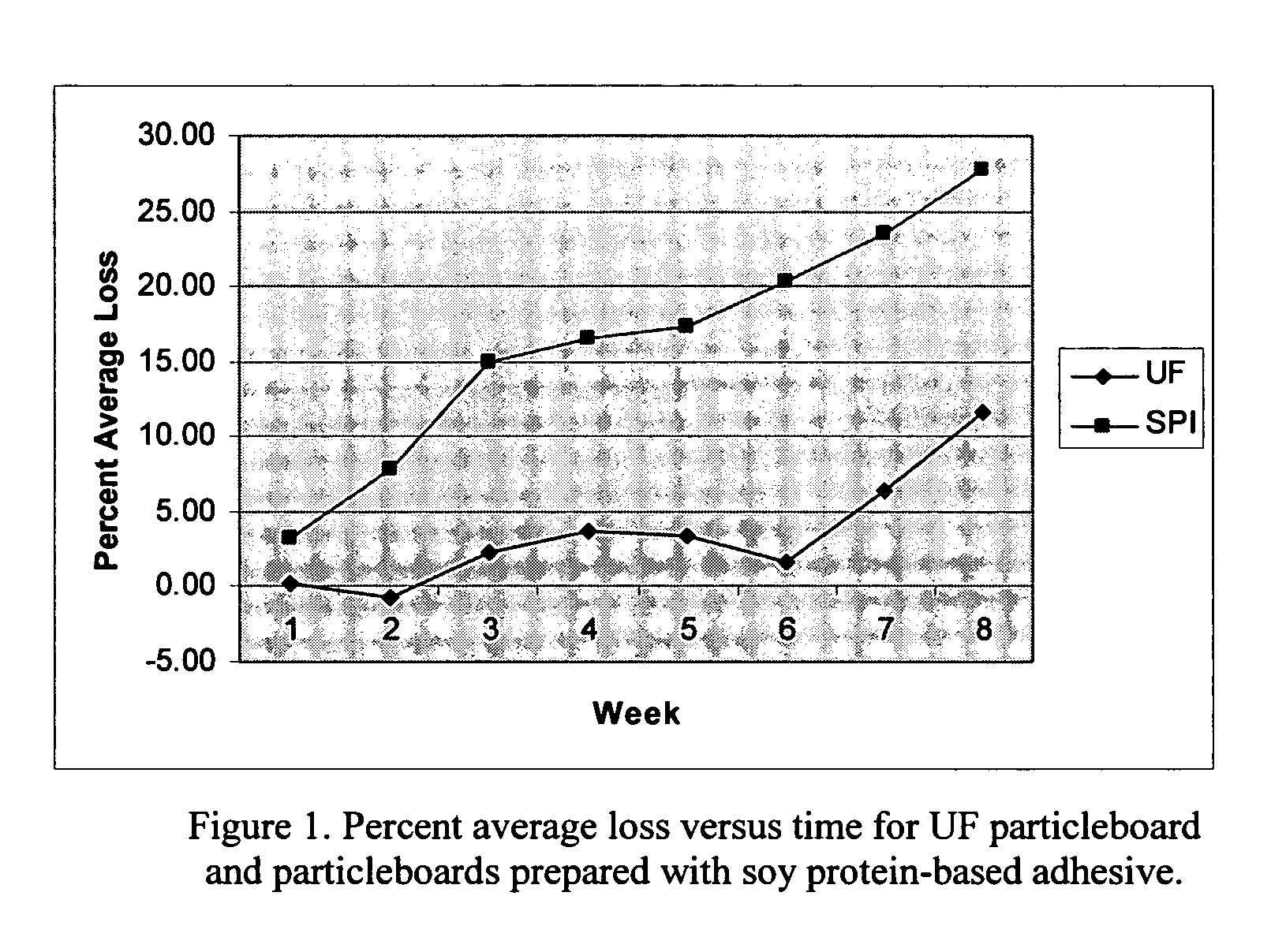

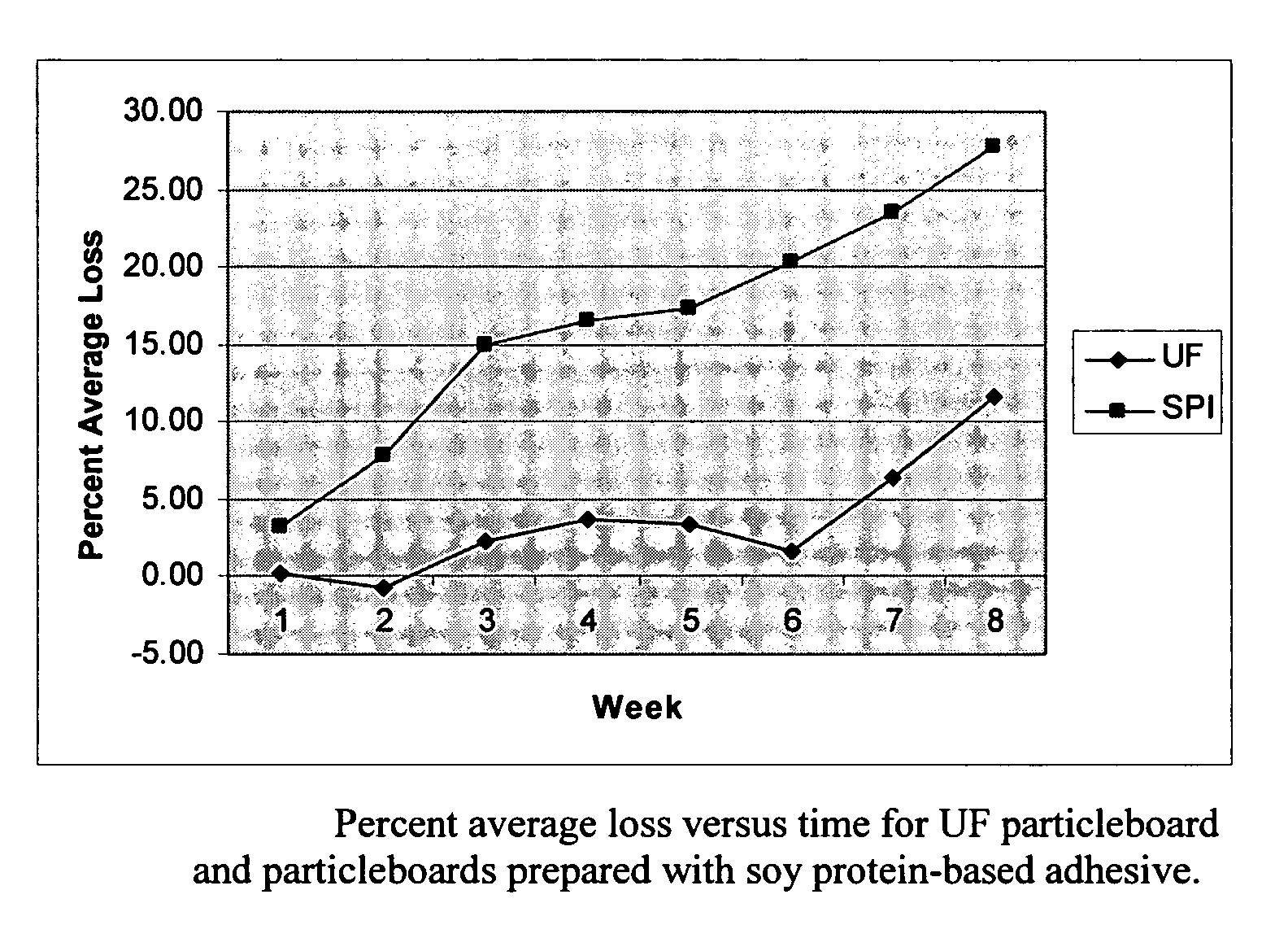

Soy protein based adhesive and particleboard

An adhesive composition that can be used in particleboards and other composites is formed from an aqueous mixture of soy protein, zinc sulfate heptahydrate, calcium oxide, sodium benzoate, pine oil, wax emulsion and non-sulfonated kraft lignin. In a second embodiment the composition further includes an acid.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

Graphene-modified fluororesin coating material

The present invention discloses a graphene-modified fluororesin coating material, which comprises a film forming substance, commonly used additives, a solvent and graphene, wherein the amount of the added graphene is 0.001-10% of the mass of the fluororesin coating material, the fluororesin coating material is further added with the first additive and the second additive, and the addition amount of the first additive and the second additive is 0.1-3.5% of the mass of the fluororesin coating material. According to the present invention, the graphene is adopted to improve the strength of the fluororesin coating material, wherein the friction resistance, the adhesion of the fluororesin coating material and the substrate, the impact resistance and the thermal conductivity of the fluororesin coating material are significantly increased; and the fluororesin coating material has characteristics of low cost, less use amount, durable effect and simple and convenient use, and can be used in a plurality of fields of building industry, household non-stick cookware, marine life fouling resistance fields, high temperature resistance fields, national economy and national defense construction fields and the like.

Owner:NINGBO MORSH NEW MATERIALS

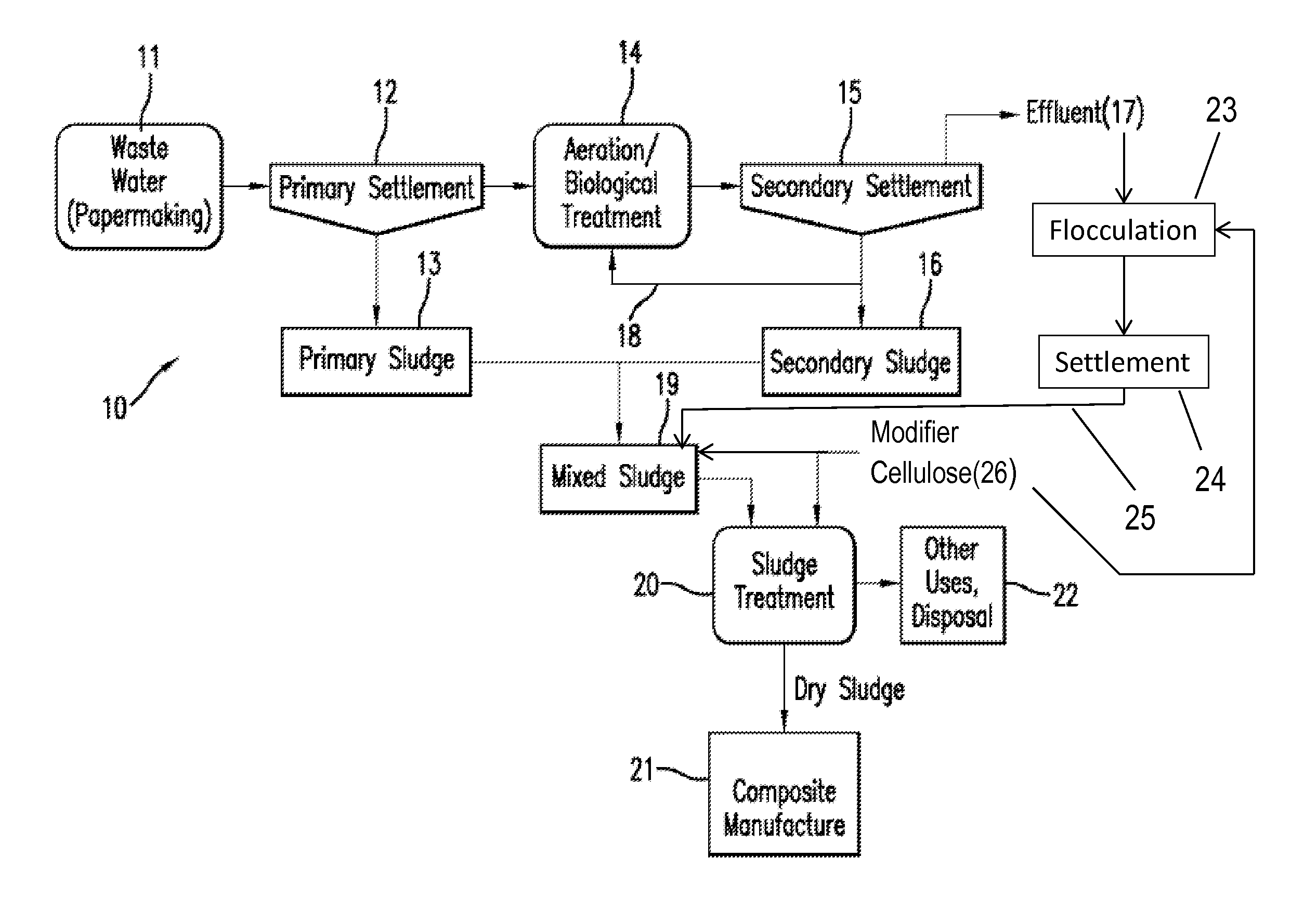

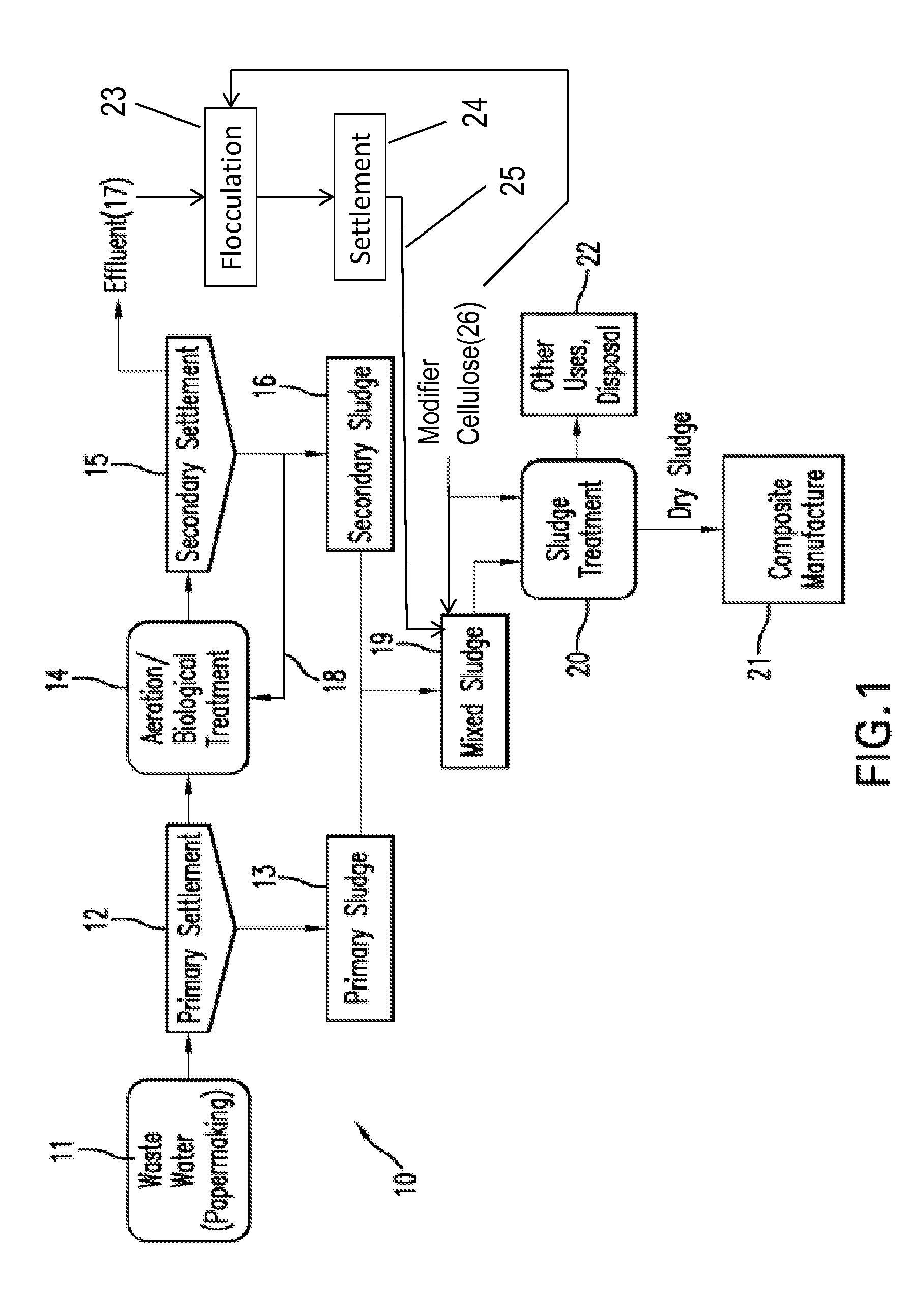

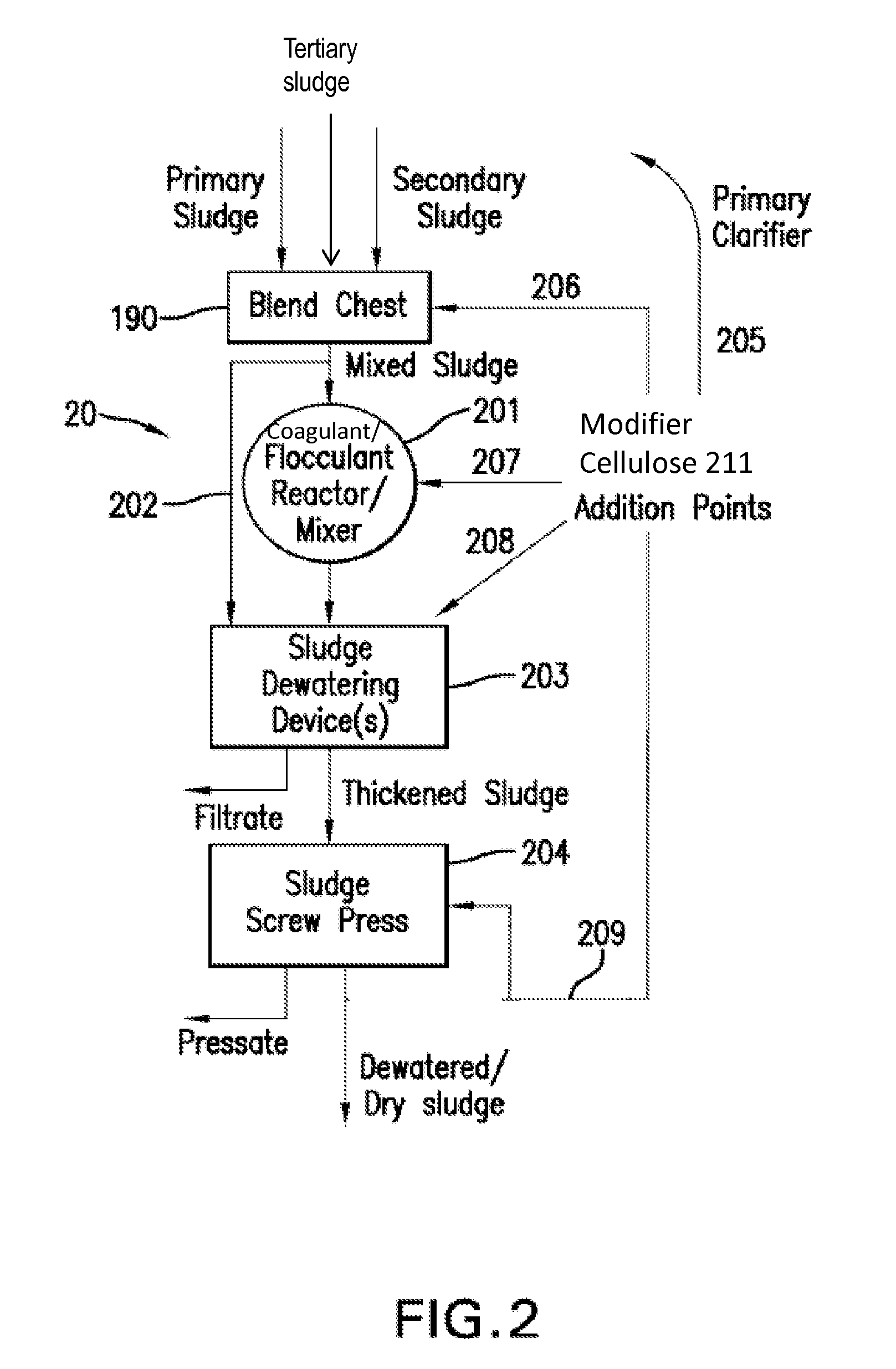

Use Of Celluloses In Sludge Dewatering, And Sludge Products Thereof

InactiveUS20150197439A1Accelerates the dehydration processNon-macromolecular adhesive additivesInksParticulatesPrill

Methods to improve dewatering in industrial and municipal sludges are described. One method involves admixing sludge from a papermaking process and modified cellulose to provide modified sludge with the modified cellulose present in an effective amount to improve dewatering in the treated sludge, such as in allowing use of reduced amounts of coagulant and / or reducing dewatering times, increased dewatered volumes, and reduced sludge product moisture contents, and the like. The dewatered sludge may be formed into a dried particulate, and may be used as filler or other component of concrete, rubber, asphalt, plastics, resin-wood composite products, and other composite products.

Owner:BUCKMAN LAB INT INC

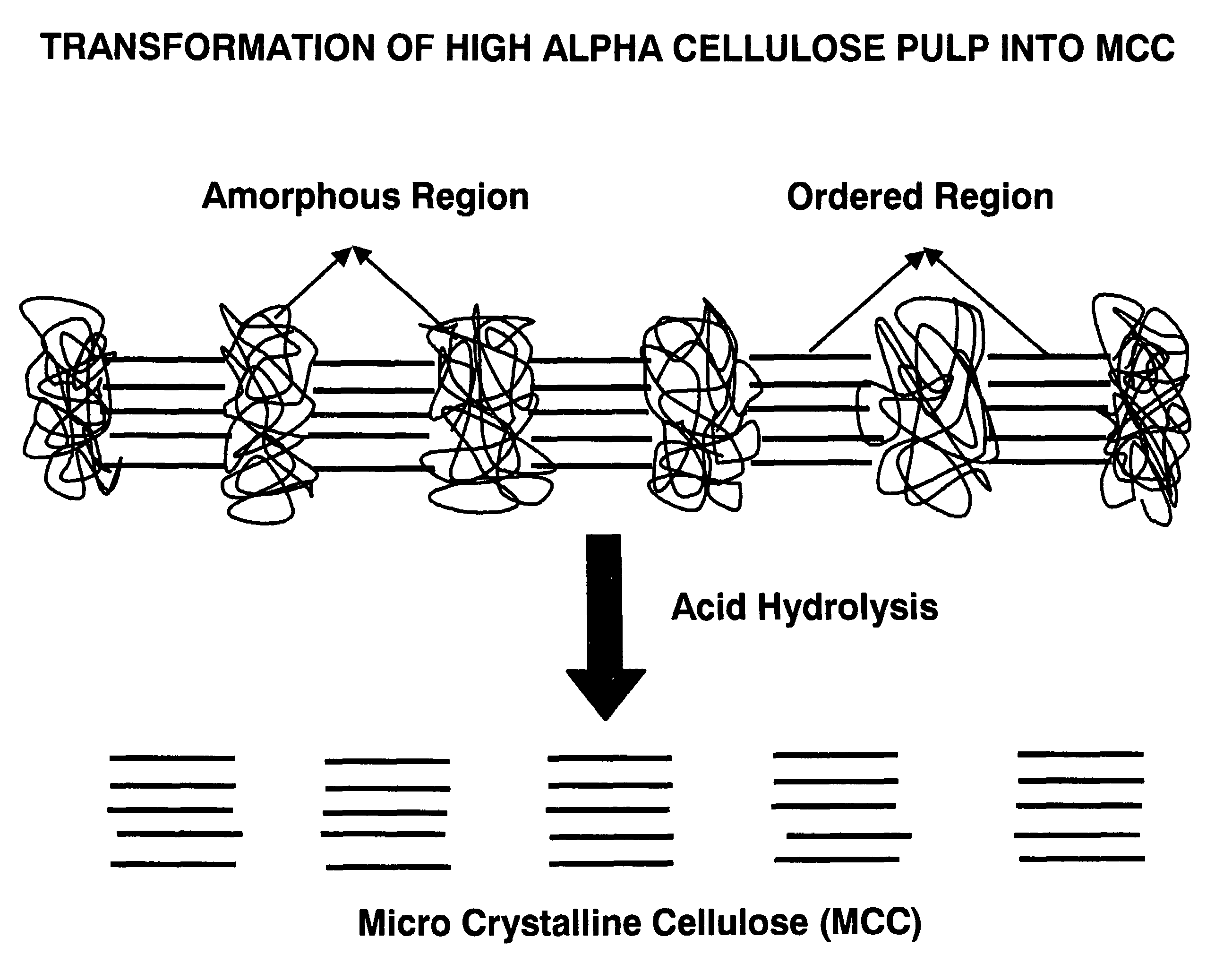

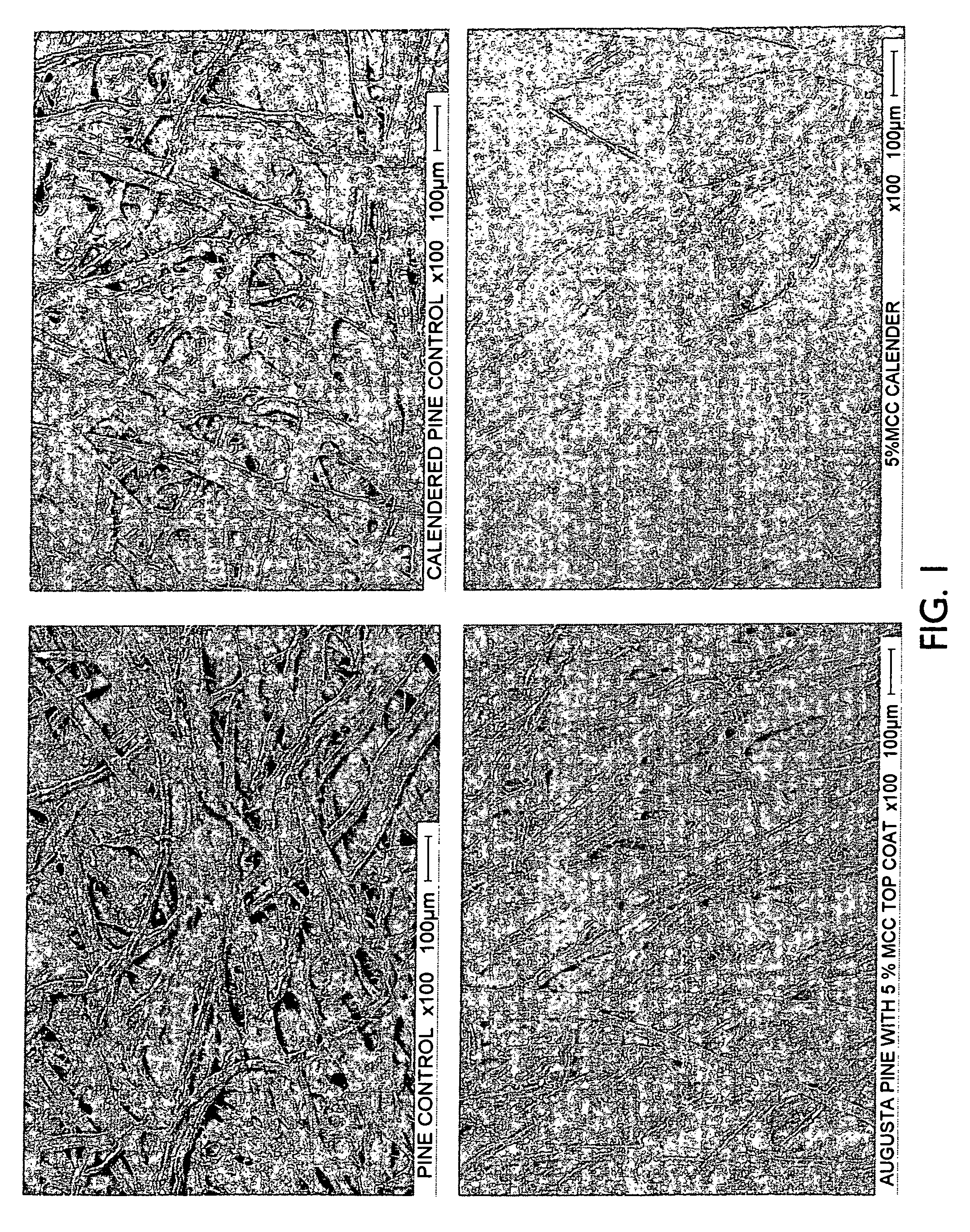

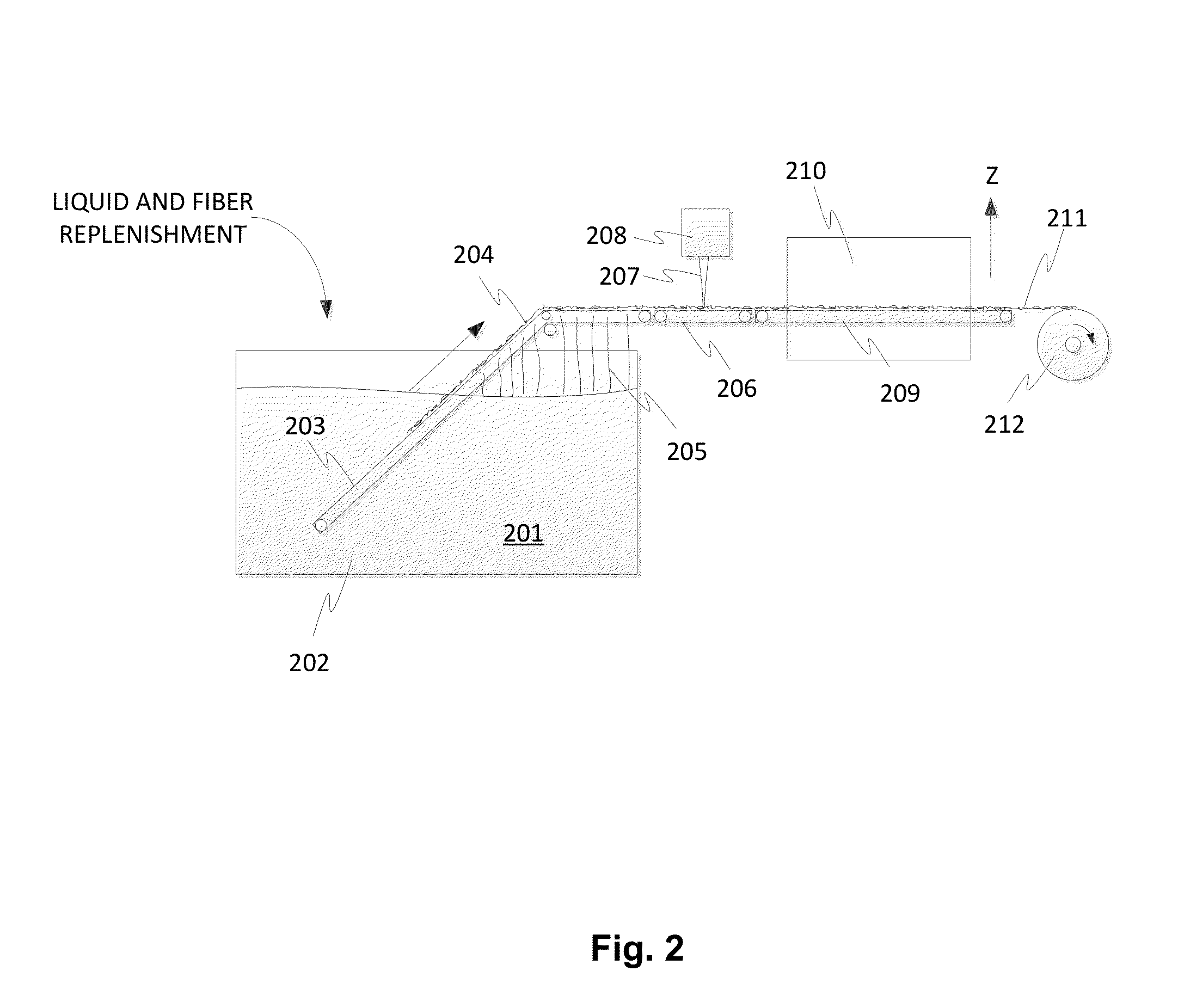

Surface treatment with texturized microcrystalline cellulose microfibrils for improved paper and paper board

The present invention relates to the production of texturized microcrystalline cellulose from raw pulp material. This texturized microcrystalline cellulose can then be used for surface treatment of paper or paper board. Additionally, the texturized microcrystalline cellulose may be used as a starting material for production of paper or paper board.

Owner:INT PAPER CO

Viscosity modified formaldehyde-free binder compositions

ActiveUS20140134909A1High viscosityLaminate strength deterioratesNon-fibrous pulp additionNon-macromolecular adhesive additivesGuar gumHydroxyethyl cellulose

Viscosity-modified carbohydrate binder compositions are described. The binder compositions may include a carbohydrate, a nitrogen-containing compound, and a thickening agent. The binder compositions may have a Brookfield viscosity of 7 to 50 centipoise at 20° C. The thickening agents may include modified celluloses such as hydroxyethyl cellulose (HEC) and carboxymethyl cellulose (CMC), and polysaccharides such as xanthan gum, guar gum, and starches.

Owner:JOHNS MANVILLE CORP

Polymer dissolution and blend formation in ionic liquids

InactiveUS7888412B2Cosmetic preparationsToilet preparationsPolymer dissolutionAdvanced composite materials

The present invention relates to processes utilizing ionic liquids for the dissolution of various polymers and / or copolymers, the formation of resins and blends, and the reconstitution of polymer and / or copolymer solutions, and the dissolution and blending of “functional additives” and / or various polymers and / or copolymers to form advanced composite materials.

Owner:UNIVERSTIY OF ALABAMA THE

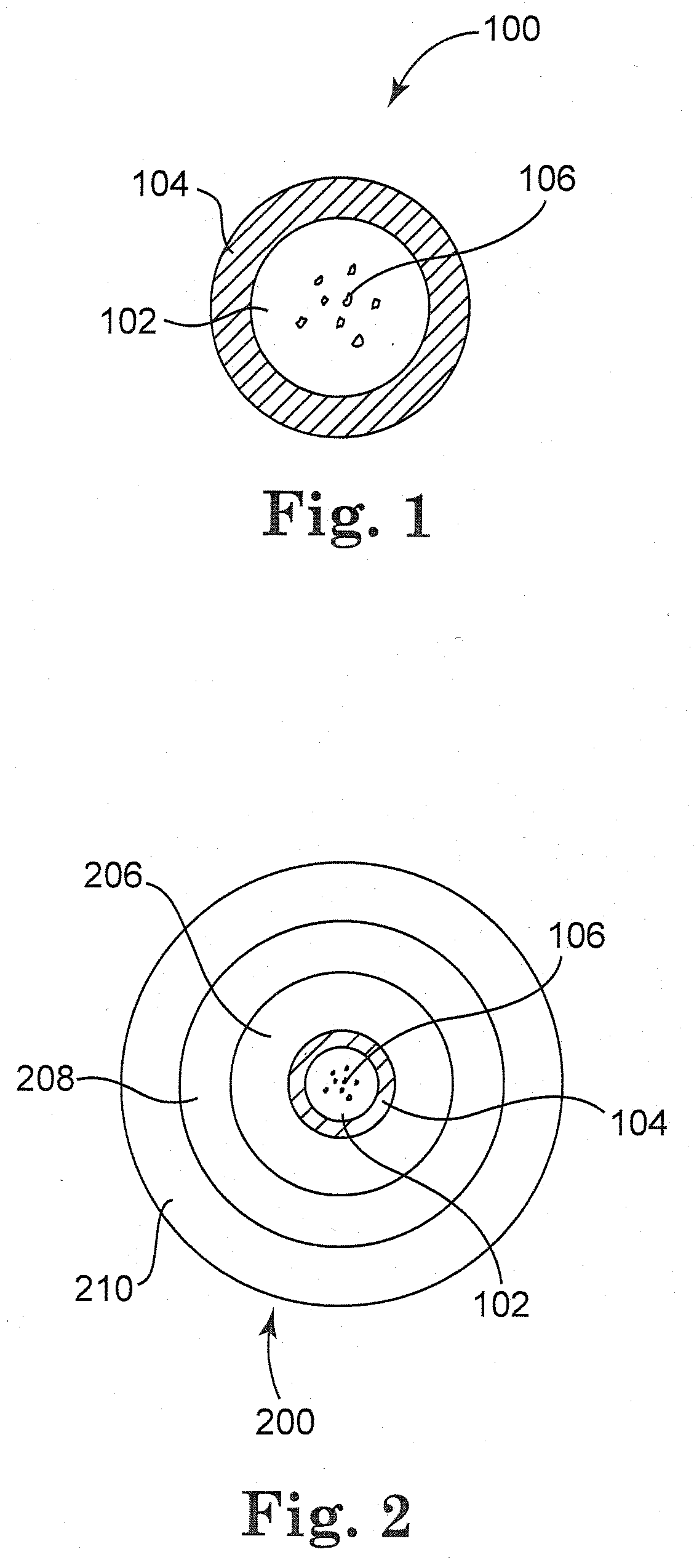

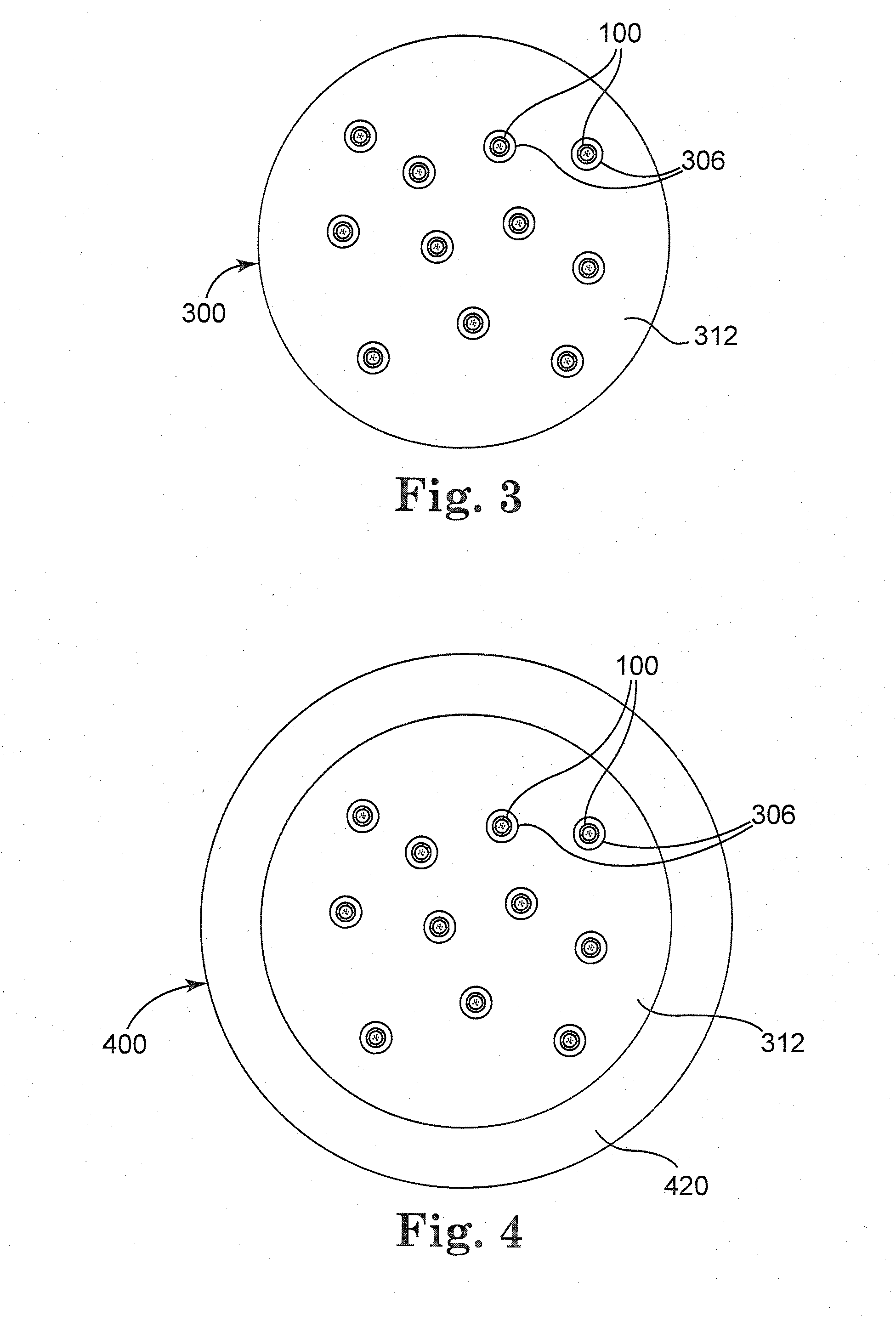

Encapsulation of oxidatively unstable compounds

InactiveUS20110052680A1Improve Oxidation StabilityDry powder formImmobilised enzymesOrganic active ingredientsPhospholipidPhytosterol

An encapsulated material containing an oxidation-sensitive core is covered by at least a dried phospholipid layer, and contains at least one phytosterol in the core, the phospholipid layer or in a further layer or layers. By using microencapsulation, oxidatively unstable materials may be provided with a synthetic protective barrier and rendered less susceptible to oxidative degradation.

Owner:AVEKA INC

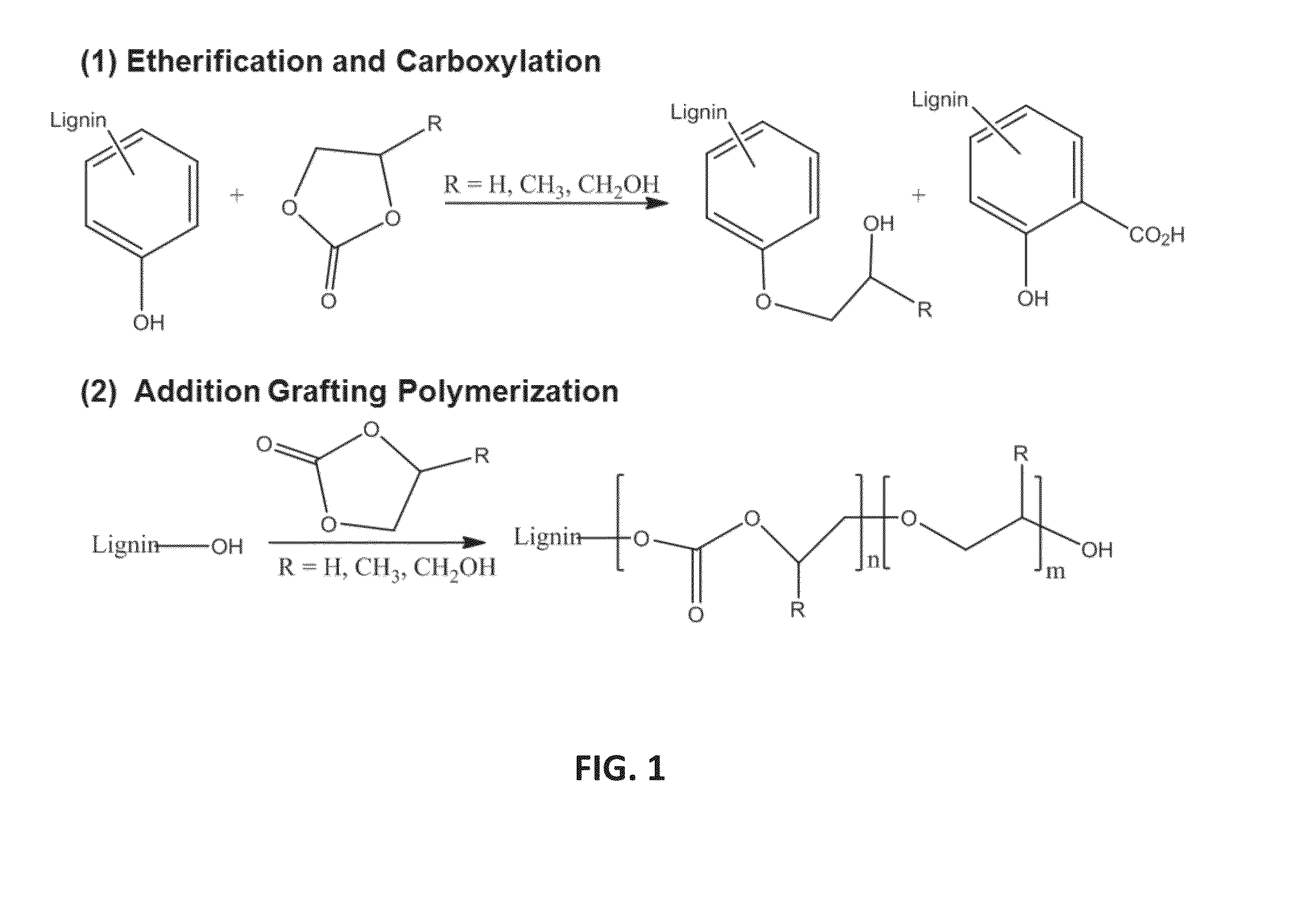

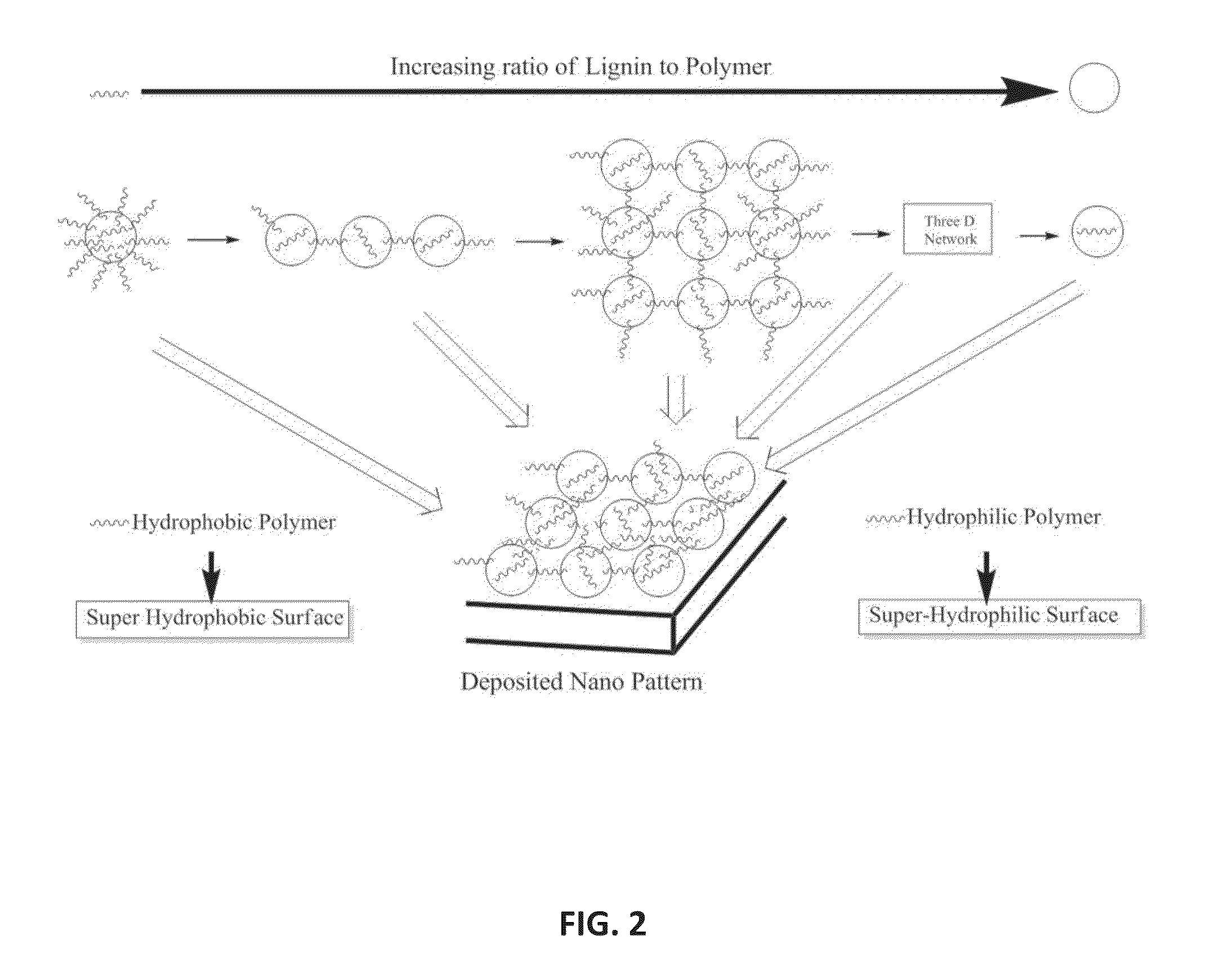

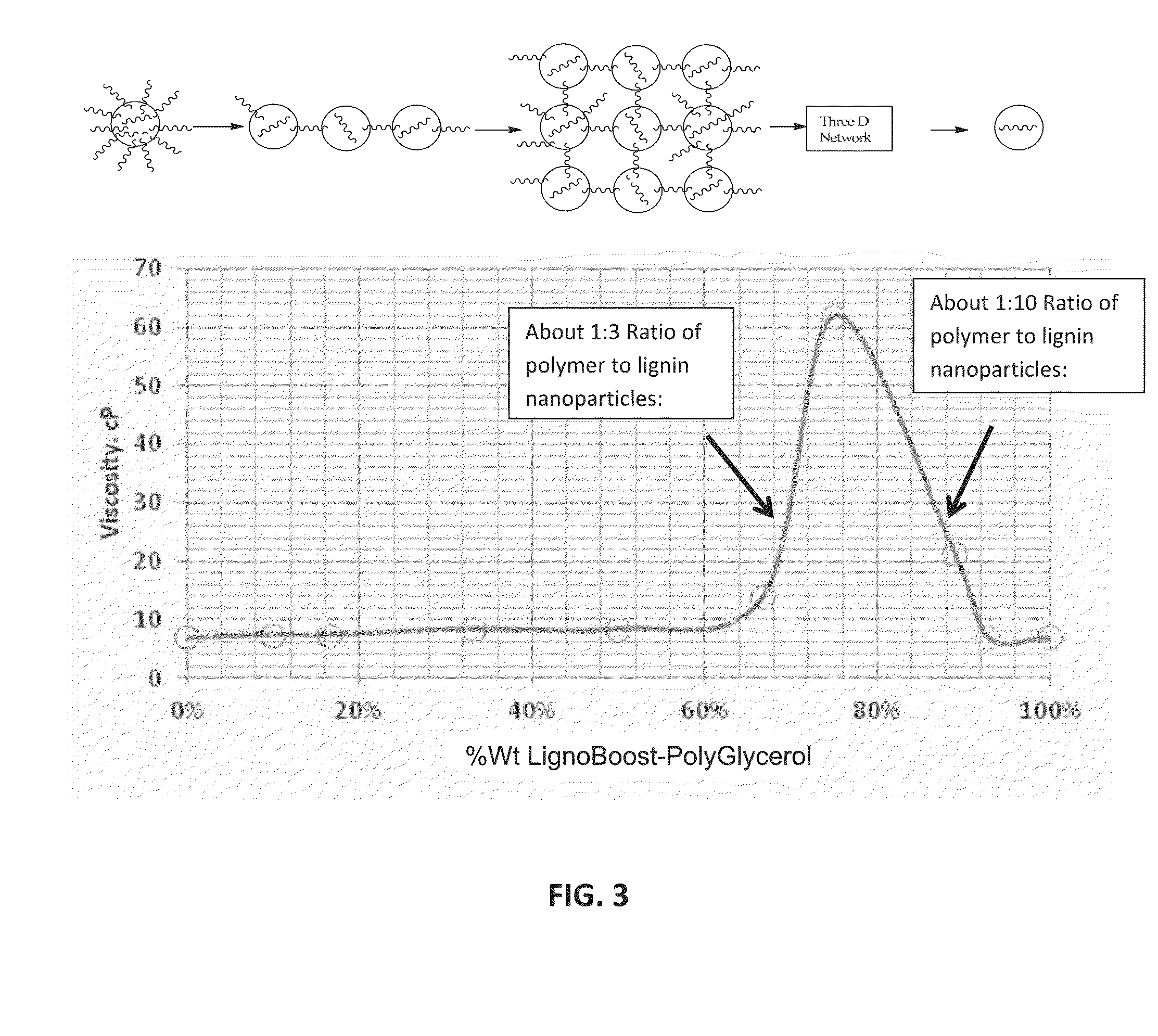

Lignin nanoparticle dispersions and methods for producing and using the same

A mild, simple process of preparing lignin nanoparticle dispersions is disclosed. Additionally, compositions and methods of making lignin nanoparticle-polymer complexes comprising derivatized and / or non-derivatized lignin nanoparticle dispersions and water soluble and / or water dispersible polymers are disclosed. Further, methods of using at least one of the lignin nanoparticle dispersions, derivatized lignin nanoparticle dispersions, and / or the lignin nanoparticle-polymer complex to impart rinse-resistant properties, such as hydrophilic properties, to substrates, or function as tunable nanoparticle surfactants are disclosed.

Owner:SOLENIS TECH CAYMAN

Soy protein based adhesive and particleboard

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

Waterproof, low temperature resistant, soft and moisture permeable coating glue and preparation thereof

InactiveCN101481580AGood flexibilityImprove waterproof performancePolyurea/polyurethane coatingsTextiles and paperCelluloseAdhesive

The invention provides a water-proof, cold-resistant, flexible and moisture-permeable coating adhesive, which is prepared by mixing three components of coating agent, crosslinking agent and crosslinking promoter with a solvent when in use; the coating agent is organosilicone polyurethane copolymer containing 500 to 1000 mesh of advanced lignocellulose micropowder; the amounts of the crosslinking agent and crosslinking promoter are 2-5wt% of that of the coating agent; and the viscosity of the coating adhesive is 8000 to 15000 mPa.s. The advanced organosilicone polyurethane coating adhesive in the invention is coated on a base fabric so as to prepare a coated fabric; the moisture permeability is greater than 5000 g / m.d; the water pressure resistance is greater than 100 kPa; the aging resistant performance is good; the blocking resistance is obviously improved; the moisture permeability is less than 20% reduced and the bending length is basically unchanged at a low temperature; and the coated fabric has good flexibility and very good low temperature resistant characteristic, and is in particular applied to being used as a coating material of clothes having water-proof and moisture-permeable functions at a low temperature.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +2

Wax emulsion preservative compositions and method of manufacture

InactiveUS20060009535A1Economical to useImprove the immunityNon-fibrous pulp additionNatural cellulose pulp/paperFiberCellulose

An emulsion comprising water as the continuous phase, a wax as the discontinuous phase, an emulsifier and a preservative having the general structure: wherein R1 can be a heterocycle containing nitrogen and sulfur, such as thiazolyl, isothiazolyl, or thiadiazolyl, which can optionally be substituted with C1-C6 alkyl; R2 can be hydrogen or C1-C6 alkyl, specifically hydrogen; n is 0, 1, 2, or 3; each instance of R3 can independently be hydrogen, C1-C6 alkyl, phenoxy, C1-C6 alkoxy, halo, amino, C1-C6 alkylamino, di C1-C6 alkyl amino, imidazolyl, thiazolyl, isothiazolyl, thiadiazolyl, thienyl, furyl, pyrryl, naphthyl, phenyl, halophenyl, C1-C6 alkyl phenyl, or C1-C6 alkoxyphenyl. The preservative may be added to the emulsion after the emulsion is formed. The emulsion can be incorporated into a gypsum product such as gypsum board or gypsum wood fiber board. The gypsum product may be made by forming a slurry containing gypsum, water, and the emulsion into a solid product. A method for improving the water resistance of a lignocellulosic composite product prepared by mixing lignocellulosic material with a binder to form a mixture and solidifying the mixture in a selected configuration to form the composite product may include adding to the mixture an emulsion as described above.

Owner:MOMENTIVE SPECIALTY CHEMICALS

Formaldehyde-free adhesives and lignocellulosic composites made from the adhesives

A first variant of an adhesive composition for making a lignocellulosic composite includes soy protein and / or lignin; at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein; and at least one compound selected from a boron compound, a group IA oxide or hydroxide, or a group IIA oxide or hydroxide. A second variant of an adhesive composition includes a first component selected from soy protein and / or lignin; and at least one substantially formaldehyde-free curing agent selected from a reaction product of epichlorohydrin with ethylenediamine, a reaction product of epichlorohydrin with bis-hexamethylenetriamine, or a reaction product of epichlorohydrin with hexamethylenediamine.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

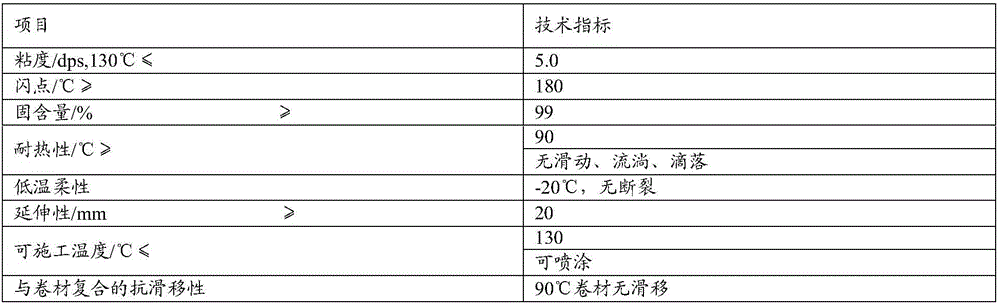

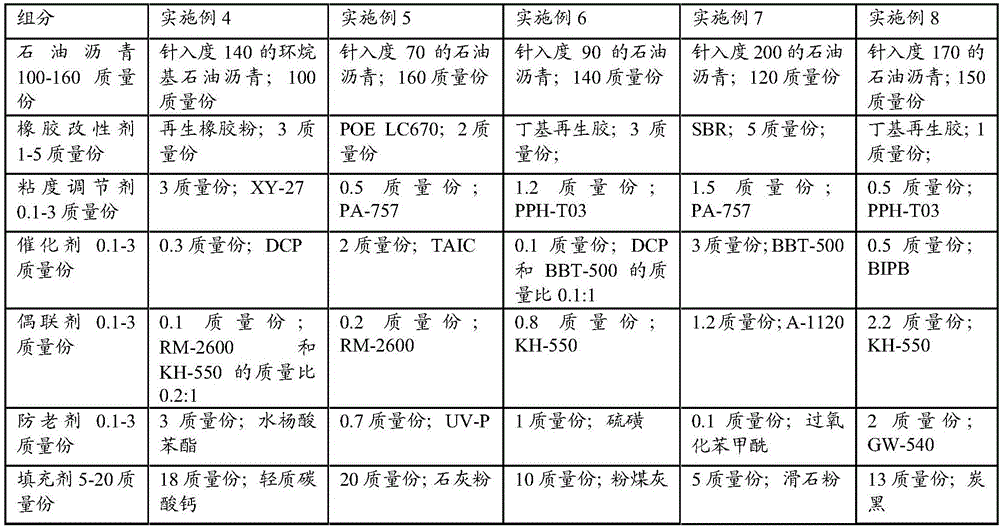

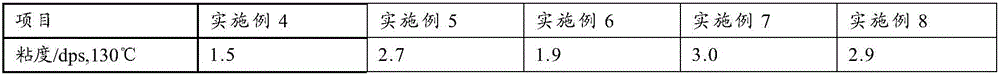

Non-curable rubber asphalt waterproof coating and preparation method and composite waterproof roll material thereof

ActiveCN105885693AImprove heat resistanceLow viscosityFireproof paintsConjugated diene hydrocarbon coatingsBituminous waterproofingElastic plastic

The invention provides a non-curable rubber asphalt waterproof coating and a preparation method and a composite waterproof roll material thereof. The non-curable rubber asphalt waterproof coating is prepared from, by mass, 100-160 parts of petroleum asphalt, 1-5 parts of rubber modifier, 0.1-3 parts of viscosity regulator and 0.1-3 parts of a catalyst. The chemical crosslinking reaction of the petroleum asphalt and the rubber modifier is achieved by adding the viscosity regulator and the catalyst in the petroleum asphalt and the rubber modifier of the non-curable rubber asphalt waterproof coating, so that the non-curable rubber asphalt waterproof coating has high heat resistance (greater than or equal to 90 DEG C) and low viscosity (smaller than or equal to 5.0 dps), can be sprayed or scraped at the low temperature (sprayable at the temperature of 130 DEG C) and also has energy saving and consumption reducing properties and other special properties on the basis that the common properties of an elastic-plastic paste body are kept within the service life, the comprehensive performance of the non-curable rubber asphalt waterproof coating is improved, and the service life of the non-curable rubber asphalt waterproof coating is prolonged.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD +1

Process for the production of a composition comprising fibrillated cellulose and a composition

ActiveUS8728273B2Produced in advanceImprove propertiesCellulosic pulp after-treatmentNon-fibrous pulp additionCellulose fiberPre treatment

The present invention relates to a process for the production of a composition wherein the process comprises pre-treating cellulosic fibers by mechanical, chemical and / or enzymatic treatment, mixing the pre-treated cellulosic fibers with pigments forming a dispersion and dispersing the dispersion of pre-treated cellulosic fibers and pigments whereby a composition comprising microfibrillated cellulose is formed. The invention further relates to a composition produced according to the process.

Owner:STORA ENSO OYJ

Process for the production of a composition comprising fibrillated cellulose and a composition

ActiveUS20130053454A1High dry contentIncrease productionCosmetic preparationsBiocideCellulose fiberPre treatment

The present invention relates to a process for the production of a composition wherein the process comprises pre-treating cellulosic fibers by mechanical, chemical and / or enzymatic treatment, mixing the pre-treated cellulosic fibers with pigments forming a dispersion and dispersing the dispersion of pre-treated cellulosic fibers and pigments whereby a composition comprising microfibrillated cellulose is formed. The invention further relates to a composition produced according to the process.

Owner:STORA ENSO OYJ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com