Patents

Literature

172 results about "Pine oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pine oil is an essential oil obtained by the steam distillation of stumps, needles, twigs and cones from a variety of species of pine, particularly Pinus sylvestris. As of 1995, synthetic pine oil was the "biggest single turpentine derivative." Synthetic pine oils accounted for 90% of sales as of 2000.

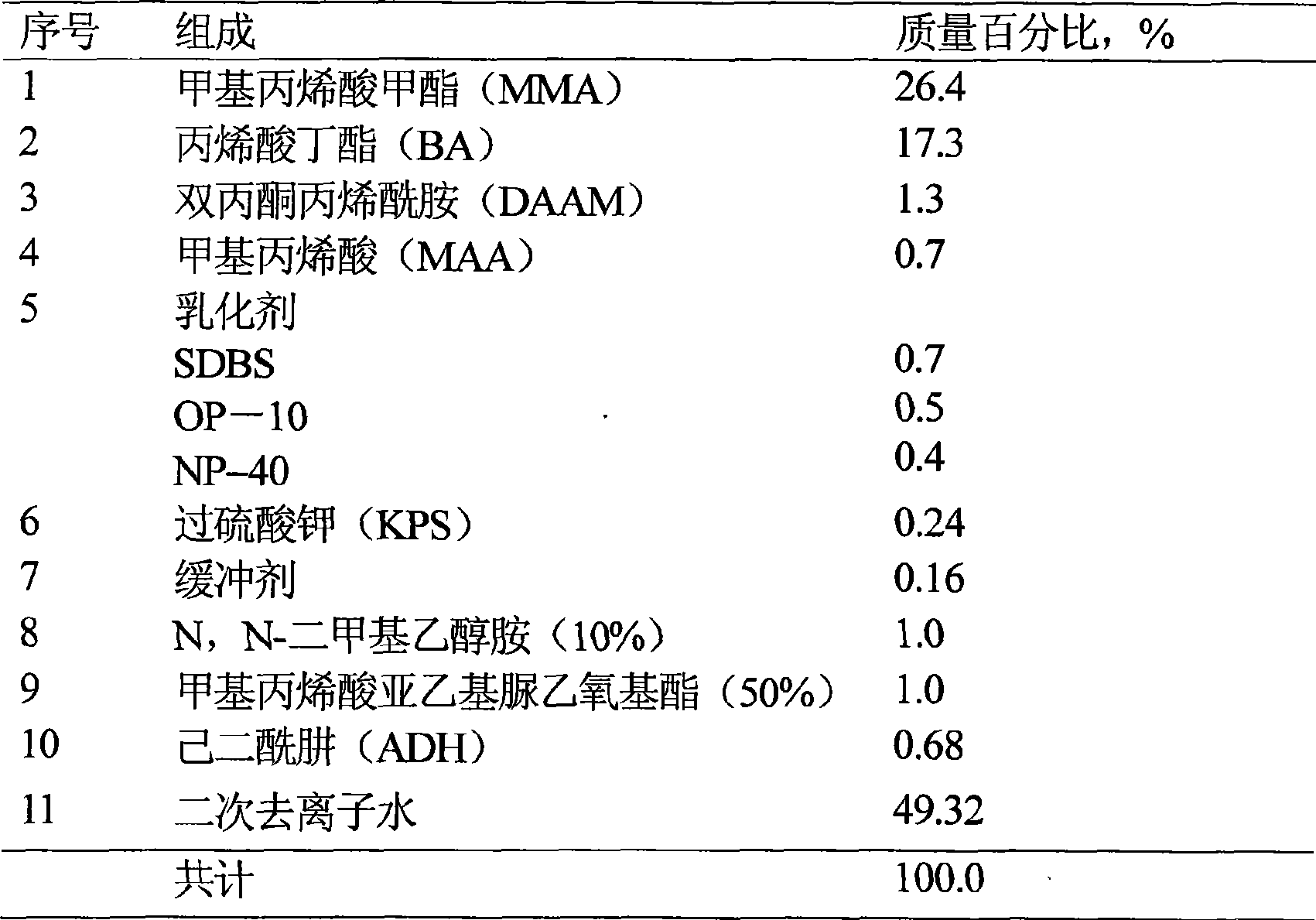

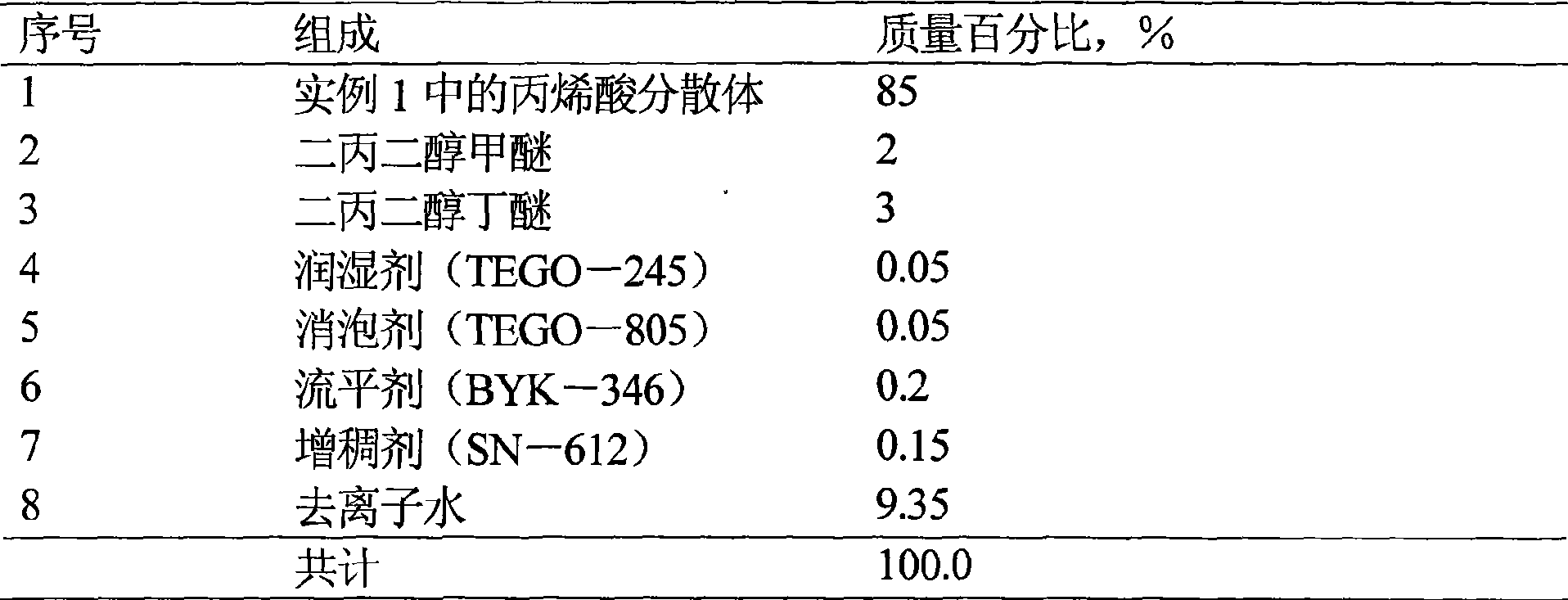

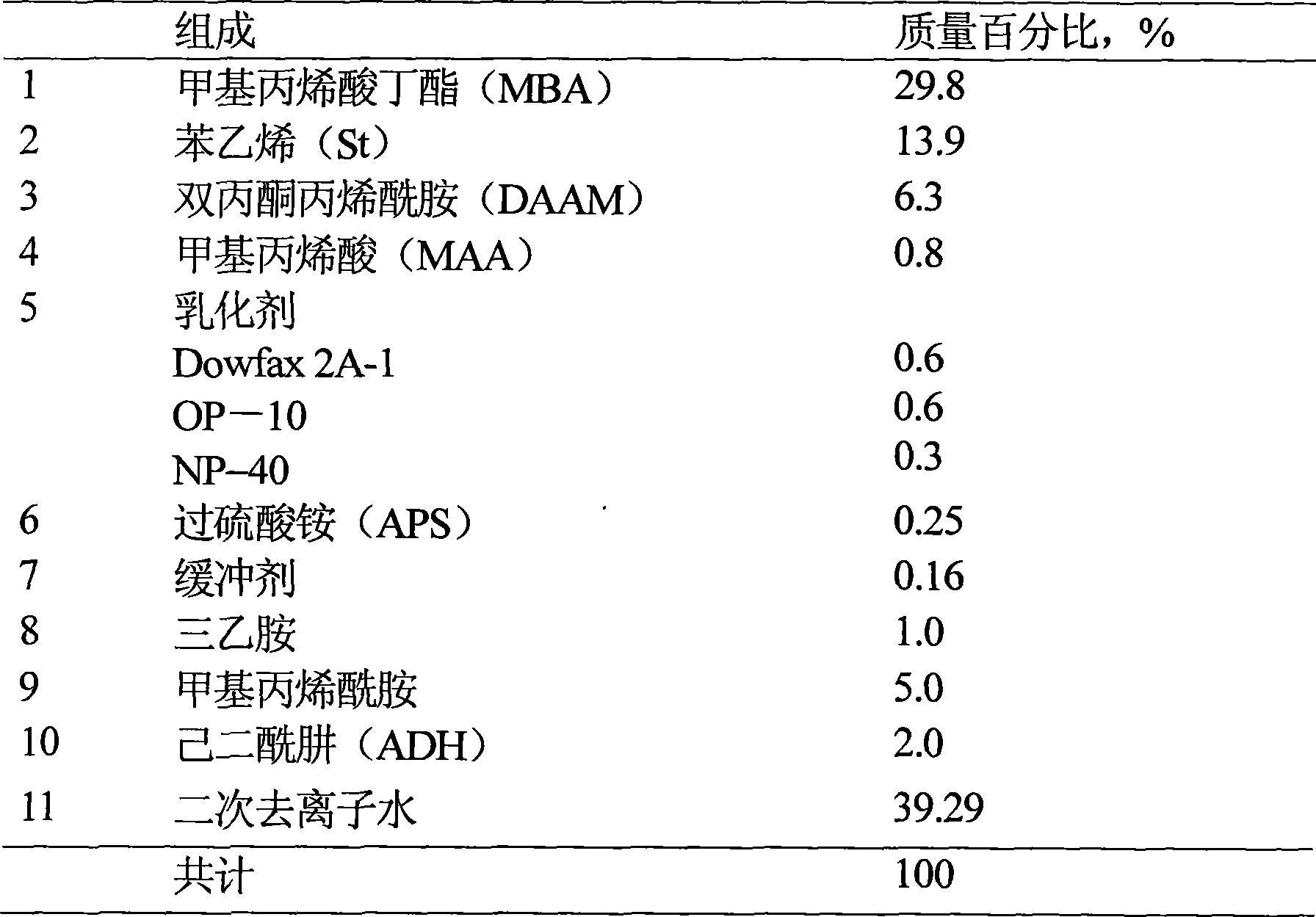

Preparation of high closeness polyacrylacid ester dispersion

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

Thin film delivery systems for volatile decongestants

A volatile decongestant delivery vehicle composition includes (i) a flowable water-soluble film-forming matrix; and (ii) a particulate volatile decongestant agent uniformly stationed therein. A useful volatile decongestant agent includes menthol, for example menthol crystals. The composition may further include a decongesting volatile oil, such as, but not limited to eucalyptus oil, menthol oil, pine oil, terpine hydrate oil, and combinations thereof. The volatile decongestant agent may be present in amounts of up to about 0.1% to about 60% by weight of the total composition.

Owner:MONOSOL RX

Antimicrobial composition

InactiveUS20140322147A1Inhibiting growth)Cosmetic preparationsBiocideAdditive ingredientDisinfectant

Disclosed herein are antimicrobial compositions and methods of producing an antimicrobial effect in which a citrus extract such as Biosecur® is used in combination with benzyl alcohol and one or more additional agent selected from the group consisting of lauroyl arginate / glyceryl laurate and essential oils or constituents thereof such as galangal oil, thyme oil, thymol, cinnamon leaf oil, cinnamon bark oil, lemongrass oil, orange oil, pine oil, cedarwood oil, curry leaf oil, and rosemary oil. These compositions may be used as natural preservatives for personal care products, foods, beverages, and as topical or surface disinfectants.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Direct flotation collector of collophanite at room temperature and preparation method thereof

InactiveCN103056036ARealization of normal temperature positive flotationImprove solubilityFlotationActive agentProcess engineering

The invention belongs to collophanite flotation technology, and relates to a direct flotation collector of collophanite at room temperature and a preparation method thereof. The collector comprises ingredients with the following weight ratio: fatty acids 95-100 parts, sodium hydroxide 10-15 parts, sodium dodecyl sulfate 3-8 parts, polyoxyethylene5-10 parts and pine oil 1-3 parts. The preparation method includes: according to a certain weight ratio, heating and stirring the mixture of sodium dodecyl sulfate, polyoxyethylene pine oil, and water to obtain a novel surfactant; subjecting the fatty acid to saponification; finally, compounding the saponificated fatty acid and the novel surfactant by a certain percentage, stirring uniformly so as to obtain the collector. The direct flotation collector is not only good in solubility, but adaptable to low and medium grade collophanite and different temperature. In addition, the direct flotation collector has the advantages of good stability and simple pharmaceutical preparation process, Information about residual glue in the glue container is determined according to forming of vacuum when the vacuum generating system extracts air in the detection tube and accordingly can be widely used in the beneficiation of collophanite.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Wood wax oil and preparation technology thereof

The invention discloses wood wax oil for maintenance and decoration of buildings, furniture and the like and preparation technology thereof. The wood wax oil contains wood oil, linseed oil, catalpa oil, perilla oil, pine oil, castor oil, rosin modified resin, bee wax or wood wax and turpentine oil, wherein the content of each component is 5 to 10 percent; and each component is a pure natural extract. The preparation technology for the wood wax oil comprises the following steps: polymerizing the wood oil, the linseed oil, the catalpa oil, the perilla oil, the pine oil, the castor oil, the rosin modified resin and the bee wax or the wood wax at a high temperature of between 290 and 300 DEG; adding the turpentine oil into the polymerized product to dilute; filtering the mixture; and adding a drier into the filtered product to adjust. The wood wax oil has the advantages of natural health, good durability and permeability, and recoverability.

Owner:董学明

Herbicides

InactiveUS6759370B1Maximize productionReduce decompositionBiocideHydroxy compound active ingredientsActive agentFatty acid

The presently claimed invention is directed to agricultural compositions which find primary use as a herbicide, through may also be used for pesticidal and fungicidal roles. The presently claimed invention comprises compositions combining monterpene compounds with fatty acid soaps. In particular monterpene alcohols are preferred as a primary phytoactive agent. Preferred embodiments are based on coniferous oils, such as pine oil, in combination with a tall oil reacted with an alkali to form a fatty acid soap. Preferred methods of application include spraying in a manner in which some foaming effect is observed, which appears to confer advantage over the spray application of monoterpene compounds alone.

Owner:ORGANIC INTERCEPTOR PRODS

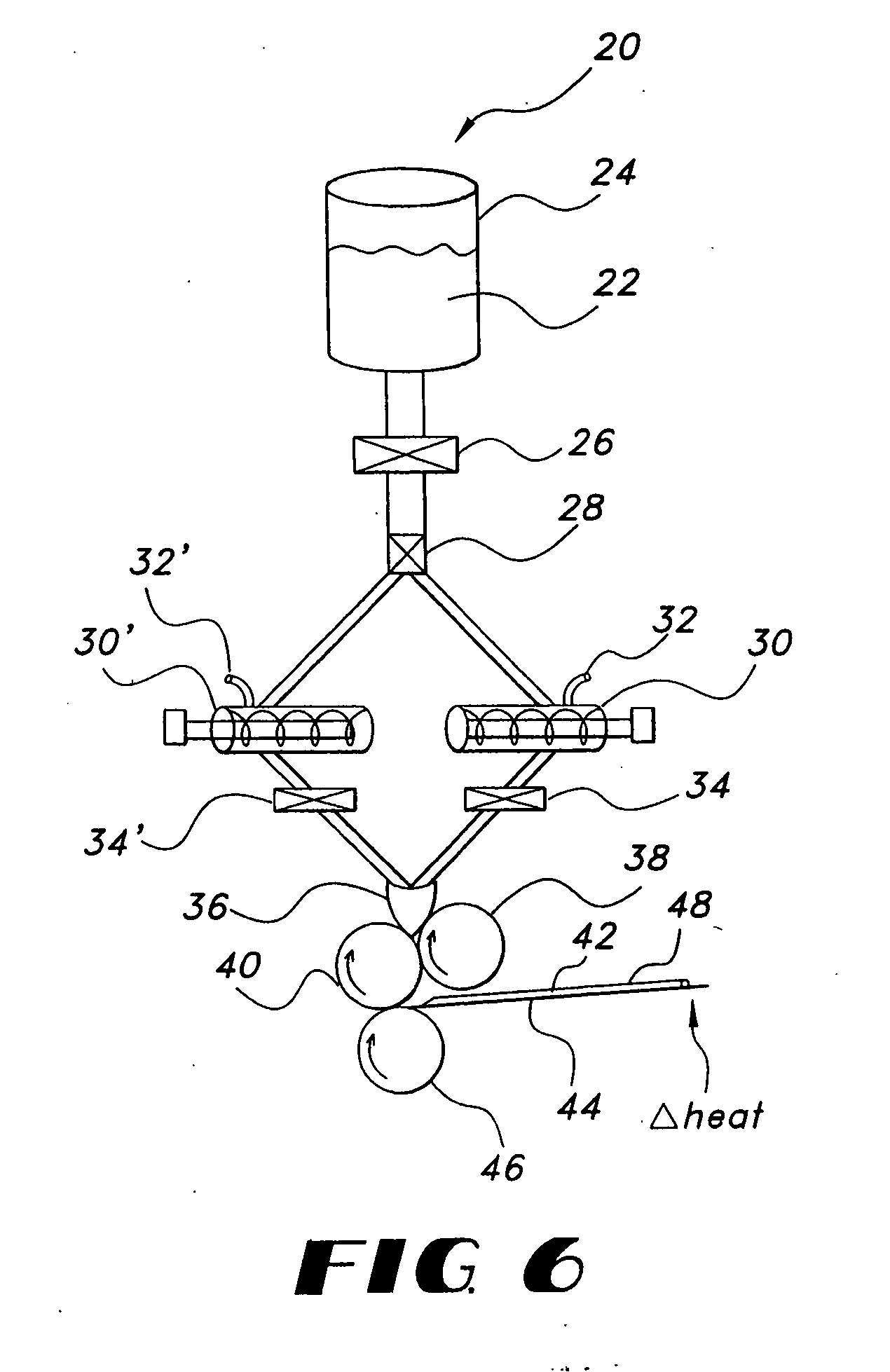

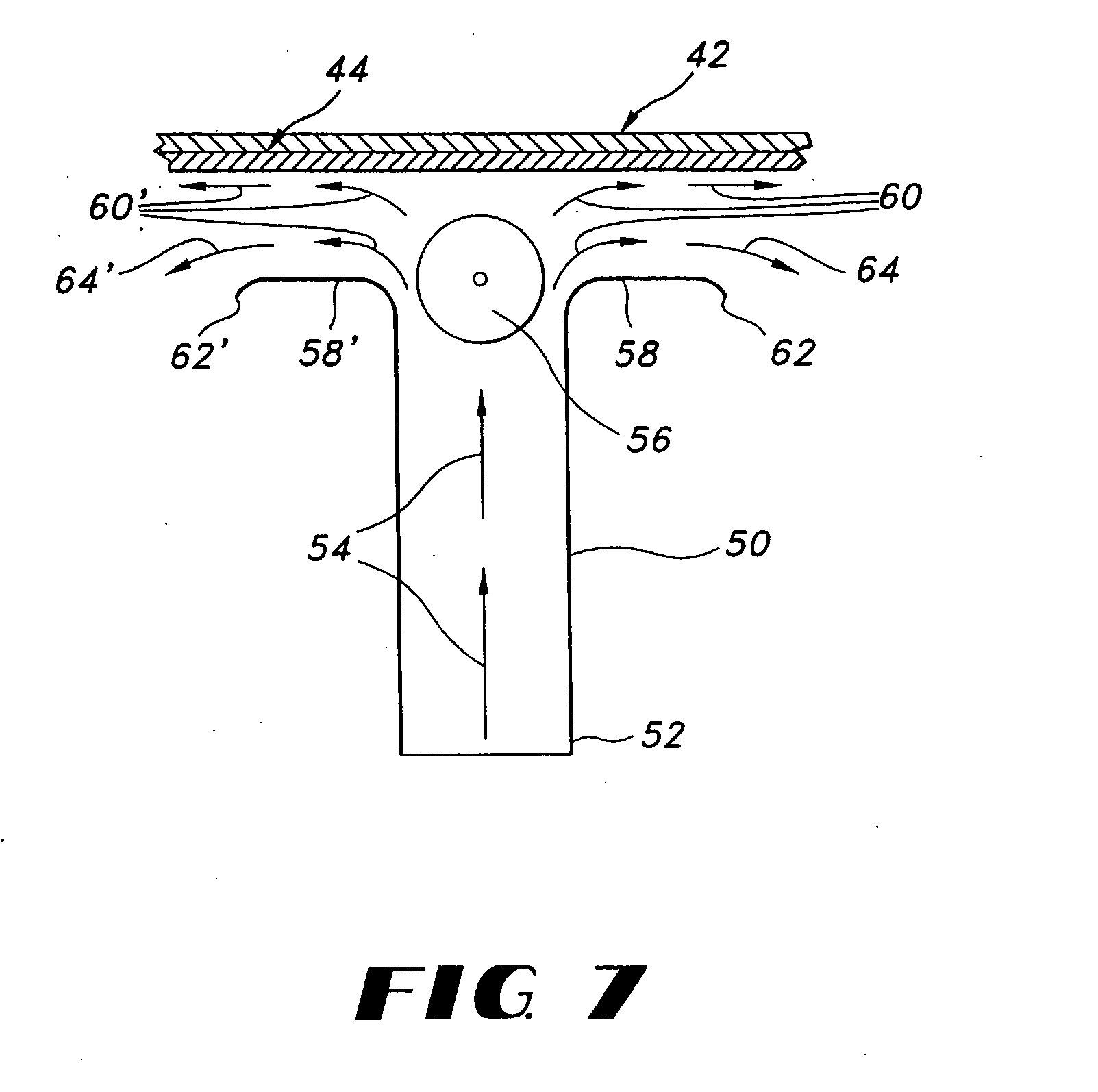

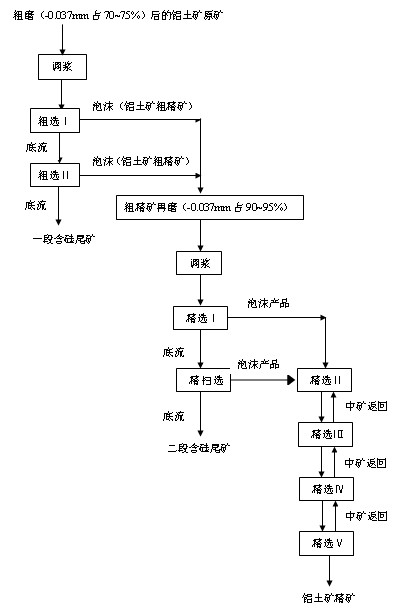

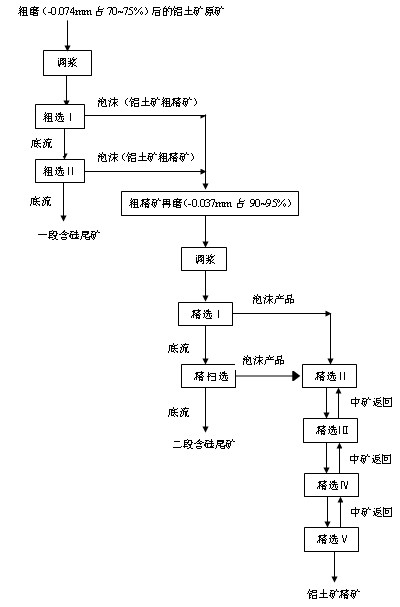

Flotation two-stage desiliconization method for high-silicon bauxite

ActiveCN102489411AReduce distractionsEfficient enrichment and recoveryFlotationSodium phosphatesEngineering

The invention relates to a flotation two-stage desiliconization method for high-silicon bauxite, which is a flotation desiliconization technology for bauxite and belongs to the technical field of mineral processing engineering. The method comprises the following steps of: coarsely grinding the bauxite into particles with certain fine granularity; under the condition of a certain ore pulp concentration, performing flotation first-stage desiliconization by using sodium carbonate as a pH regulator and a dispersing agent of the ore pulp, water glass and sodium hexametaphosphate as a combined inhibitor of gangue mineral, lead acetate as an activating agent of the bauxite, sodium oleate as a collector of the bauxite and pine oil as a foaming agent, wherein the base flow in a flotation groove is a section of silicon-containing tailings; allowing foam products to enter a grinding machine and grinding the foam products into particles with fine granularity; adding the medicaments sequentially and mixing pulp; performing flotation second-stage desiliconization, wherein the base flow in the flotation groove is a section of silicon-containing tailings; and selecting the foaming products for multiple times to form bauxite concentrate. The sectional desiliconization method for 'flotation first-stage desiliconization after coarse grinding and flotation second-stage desiliconization after regrinding rough concentrate' is utilized, so the influence of ore argillization phenomenon on desiliconization is greatly reduced, the flotation desiliconization effect on the high-silicon bauxite is obvious, the silicon dioxide content of the bauxite concentrate can be reduced greatly, the ratio of aluminum to silicon of the bauxite concentrate is increased, and the recovery rate is high.

Owner:山西道尔铝业有限公司

Floatation method of pyrites

InactiveCN101658818AImprove surface propertiesHigh recovery rateFlotationFoaming agentNonferrous metal

The invention provides a floatation method of pyrites, belonging to the field of floatation technologies. The floatation method is characterized by comprising the following steps: adding ammonium saltand sulfide as activating agents under the condition of alkaline ore pulp after the floatation of nonferrous metal sulphide ore, then adding collector xanthate and foaming agent pine oil, and stirring to float the pyrites. In the floatation process, the addition amount of the activating agent is 6-120mol / t raw ore, the addition amount of the activating agent sulfide is 6-36mol / t raw ore, the addition amount of the collector xanthate is 500g / t raw ore, and the addition amount of the foaming agent pine oil is 50g / t raw ore. The method can improve the surface properties and the floatation conditions of the pyrites, accelerate the upward-floating speed of the pyrites, improve the recovery rate and the concentrate grade of the pyrites and reduce the flotation agent consumption and the production cost.

Owner:浙江巨化化工矿业有限公司 +1

Soy protein adhesive and uses thereof

The present invention provides a soy protein-based adhesive composition and a process for making the composition that may be used in particleboards and similar wood composite systems and that is formed from an aqueous mixture of calcium oxide, pine oil, protein, lignin, and acid. The preferred protein is an enzymatically-modified soy protein and the preferred enzyme is urease.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

Novel edible vegetable oil

InactiveCN101310607ARich in nutrientsBest cooking oilEdible oils/fatsFood preparationBiotechnologyVegetable oil

The invention discloses a novel edible plant oil. The invention comprises pine nut oil and Chinese torreya oil. According to percentage by weight, the Chinese torreya oil is 5 to 20 percent and the pine nut oil is 80 to 95 percent. Compared with the prior art, the invention has the following advantages: the oil contains a plurality of nutrients which are not contained in the edible oil of other varieties; Chinese torreya and pine nut oil has more abundant nutrition components and more fragrant and mellow than single pine nut oil; the edible oil is fragrant and mellow and can leave fragrance in your mouth after being taken, thus being the best cooking oil for high-grade dishes; the oil also has effects of softening and improving blood vessel of brain and heart, promoting intelligence, relieving heart and improving eyesight, loosening bowel to relieve constipation, decreasing blood lipid, beautifying skin, prolonging life, etc.

Owner:李大健

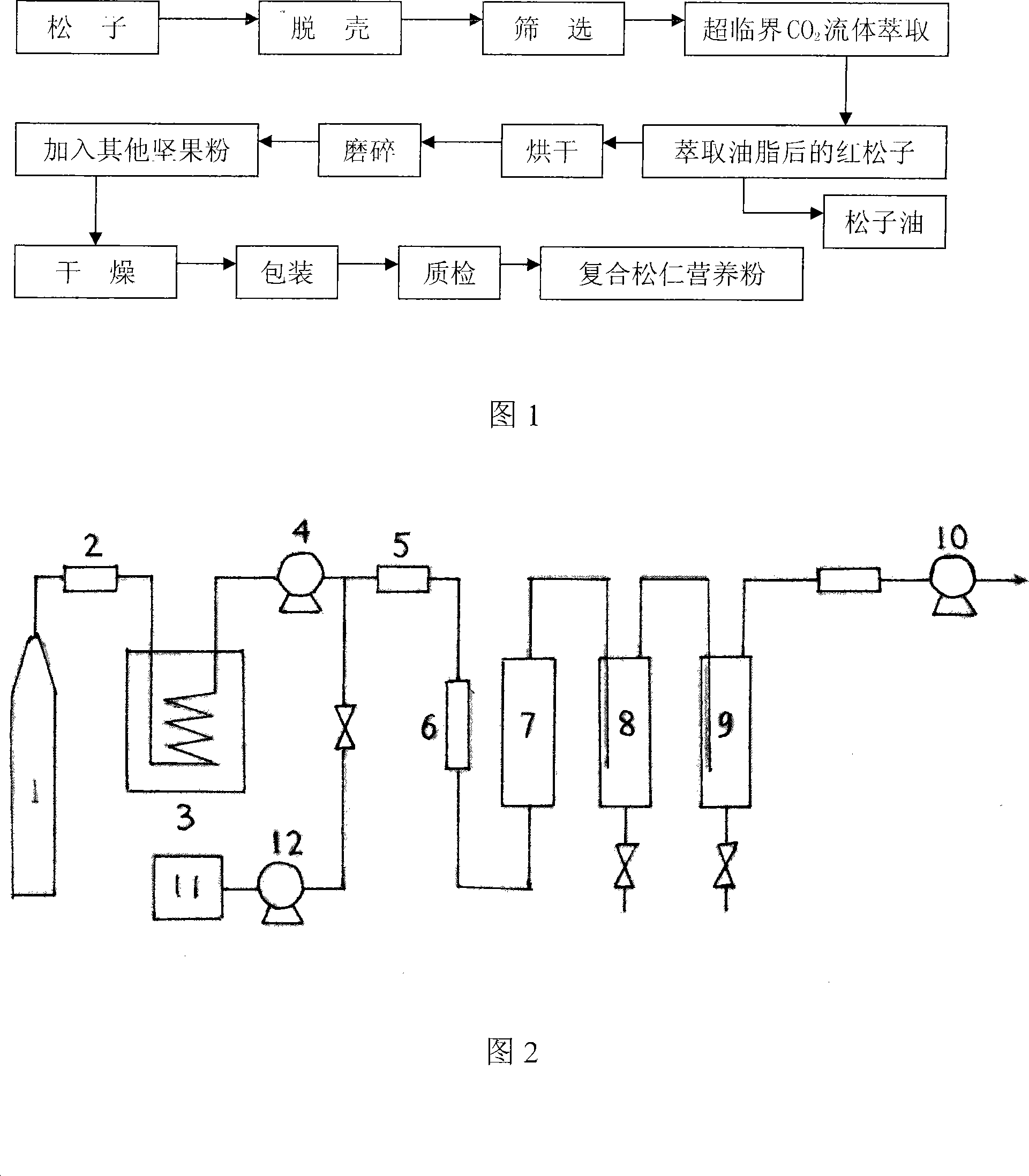

Abstraction of pine nut oil, residual oil cake food after abstracting and its preparing method

ActiveCN101161113AHigh oil extraction rateImprove oil yieldFood preparationWhole bodyGLYCYRRHIZA EXTRACT

Extraction of pine nut oil, residual oil dregs food after extraction as well as its producing method, that is obtaining pine nut after exuviating and removing skin; obtaining pine nut oil by exceed critical CO2 hydro-extraction; to get out the residual oil dregs after extraction to dry, then to grind into powder, and adding Chinese chestnut powder and walnut powder to mix as well as dry again to produce complex pine nut nutrition powder. Or using the pine nut as whole body, one-half crash, quarter crash to extract residual oil dregs, then to add into a flovoring liquid composed of common salt, liquorice, aniseed, pepertree, Chinese cinnamon, fine ginger and water to bloat, then produce dainty instant pine nut. Compared with the existing technology, the present invention improves the oil-displaced ratio, and produces dainty instant pine nut foods using extracting residual dregs, improves the using ratio of the pine nut; the line exceed critical CO2 hydro-extracting technics which takes raw ginger as anti-oxidant, ethanol as entrainer, is more advanced.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Natural plant type paint and its preparation method

The present invention relates to a natural plant type coating and its preparation method. Said coating is formed from high-molecular film-forming material, pigment, adjuvant and solvent. It is characterized by that the oil material adopted in the high-molecular film-forming material contains 30-40 portions of linseed oil, 35-45 portions of limonene, 5-15 portions of polybasic alcohol, the polybasic acid contains 8-15 portions of phthalic anhydride and 2-5 portions of trimellitic anhydride, the adjuvant is 0.02-0.1 portion of catalyst lithium hydroxide, the dryer is 1-3 portions of composite rare earth, and the solvent contains 5-10 portions of pine cone oil and 5-10 portions of terpineol, the above-mentioned raw materials are mixed to obtain the invented film-forming material. Besides, it adopts deionized water, adds 18-35 portions of pigment titanium dioxide, adds drying, dispersing, anti-freezing, defoaming, anti-corrosion and film-forming adjuvants, and adds medicinal talcum powder and natural calcium carbonate and stirs them to obtain slurry material for stand-by, then said invention utilizes 10-20 portions of film-forming material to make emulsification, adds deionized water and the above-mentioned slurry material, and adds thickening agent, mixes them so s to obtain the invented coating.

Owner:TIANJIN LIUHONG TECH DEV

Method for preparing gas phase absorption activated carbon from pine nut shells

InactiveCN101780399ANo pollutionHard textureOther chemical processesDispersed particle separationActivated carbonGas phase

Owner:胡志杰 +1

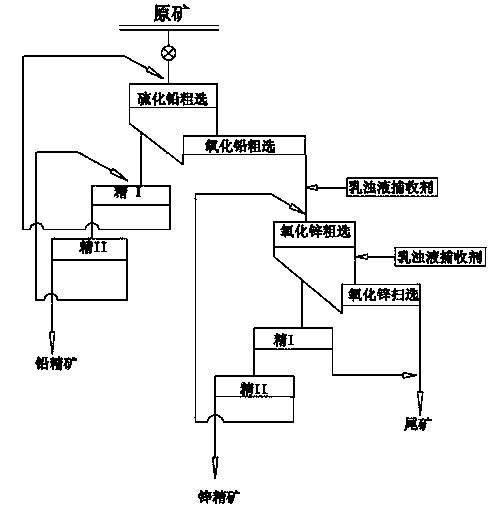

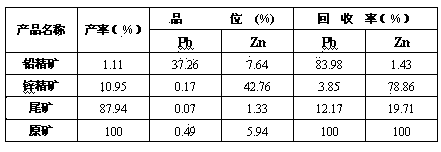

Preparation and application method of emulsion collectors for lead-zinc oxide ore difficult in selection

The invention relates to preparation and an application method of emulsion collectors for lead-zinc oxide ore difficult in selection. The preparation of emulsion collectors includes preparing amine salt, acetate and pine oil according to the proportion of 1:1:0.3, using acetate solution to dissolve amine salt to prepare mixed amine solution, and then adding pine oil to stir violently for more than 3 hours to emulsify the solution to form a novel flotation system of off-white emulsion collectors. In order to solve the technical problem that low-grate mineral is more and more in lead-zinc oxide ore and the selection is more and more difficult, a feasible flotation technical scheme is provided. The novel emulsion collectors is adopted to perform improved emulsion, recovery rate and concentrate grade of the complex and clayish lead-zinc oxide ore are improved, Pb and Zn quantity in tailings is reduced, precious metal and Pb and Zn concentrates can be recovered comprehensively, selectivity is good, medicament usage is few, and the novel emulsion collectors has important practical meaning.

Owner:YUNNAN ZHONGLIN GEOLOGIC INVESTING & DESIGN CO LTD

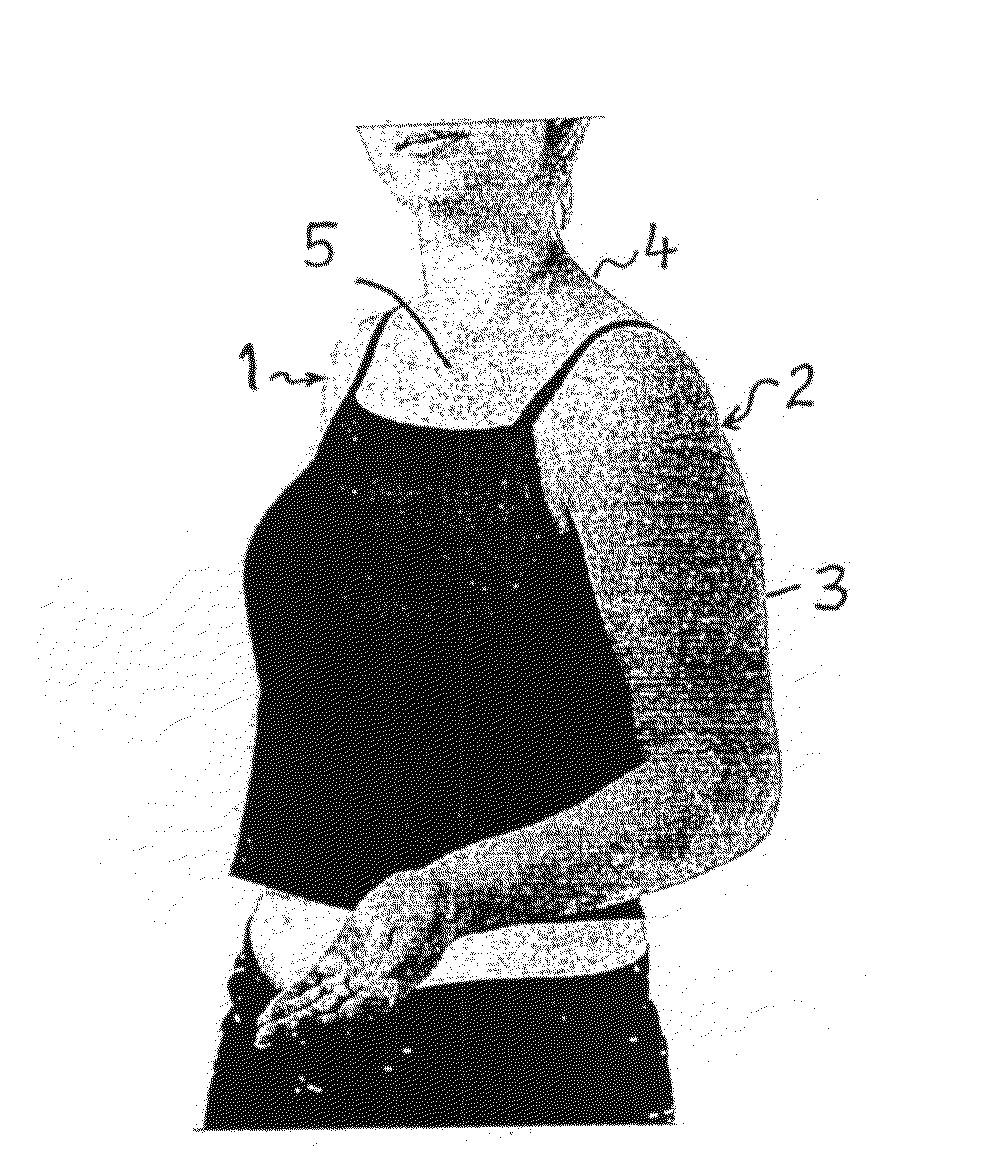

Skin Coating Composition and Uses Thereof

InactiveUS20090004252A1Increased durabilityViscosity be optimisedCosmetic preparationsMake-upShellacSunscreen agents

The present invention relates to a composition for coating the skin wherein the composition forms a water-proof flexible film on the skin. Preferably, the flexible film is durable and is capable of remaining adhered to the skin for 1 to 3 days. The composition may include (i) one or more pigments and / or dyes, or (ii) one or more sunscreen agents or (iii) one or more therapeutic agents for preventing or treating disorders of the skin. The coating composition comprises resin and flexibilizer (platicizer). Any suitable type of natural or synthetic resin may be used, preferably the resin is shellac or other natural gum derivative. A suitable flexiblizer is an animal, vegetable, mineral or synthetic oil, preferably castor oil, pine oil, rosehip oil or soya bean oil or mixture thereof. The composition optionally includes a diluent such as ethanol, a cellulosic preparation such as ethyl cellulose, an anti-agglomerating or dispersing agent and a thickener. The composition may be in the form of a paste, cream, gel, liquid or aerosol and may be used as a bandage or artificial skin.

Owner:BLONDE HLDG PTY LTD

High-temperature resistant mechanical coating

InactiveCN104371482AImprove adhesionEnsure safetyPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyPolymer science

The invention discloses a high-temperature resistant mechanical coating, comprising the following components in parts by weight: 100 parts of butylated urea resin, 36-41 parts of epoxy resin, 12-19 parts of vinylidene chloride, 3-10 parts of alkyd polyurethane and 1-5 parts of pine oil. The high-temperature resistant mechanical coating disclosed by the invention still has good caking property when being in the sun or in a high-temperature environment for a long period of time; and the operation safety of mechanical components under the high-temperature condition is ensured.

Owner:WUXI YANGGONG MACHINERY MFG

Method for preparing wax oil floor

InactiveCN105291236ASimple processAvoid local uneven moisture contentWood working apparatusCoatingsPerilla oilTurpentine

The invention relates to the field of furniture wood industries, in particular to a method for preparing a wax oil floor. Firstly, linseed oil, stillingia oil, perilla oil, pine oil, castor oil, rosin modified resins and beeswax which each account for 10%-30% of the total content of semi-finished wax oil are mixed and subjected to high-temperature polymerization at the temperature of 280-300 DEG C; turpentine is added into a polymerized mixture for dilution and filtering to form the semi-finished wax oil; a dryer is added into the diluted and filtered semi-finished wax oil for concoction, and after the concoction is finished, finished wax oil is formed; then the finished wax oil is smeared to the floor, and finally after the wax oil on the floor is blown dry, the wax oil floor is formed. The process is simple, the wax oil floor with the indexes identical to foreign indexes can be produced, the floor without harmful substances such as formaldehyde and benzene is achieved, and the requirement of environmental protection is met.

Owner:江苏徐家木业有限公司 +1

Powder for cleaning and disinfecting wooden floor

InactiveCN102443502AThe solution is not practicalSurface-active non-soap compounds and soap mixture detergentsDetergent compounding agentsSodium metasilicateSodium phosphates

The invention discloses a powder for cleaning and disinfecting a wooden floor, comprising the following components in percentage by mass: 75-80% of sodium carbonate, 10-15% of C12 branched sodium alkyl benzene sulfonate, 3-8% of sodium tripolyphosphate, 0.5-2% of pine oil, and 3-8% of sodium metasilicate (5H2O). In the invention, sodium carbonate, sodium alkyl benzene sulfonate and sodium tripolyphosphate are formulated to obtain a high-quality detergent which simultaneously has a sterilization function. The sodium metasilicate has a strong oil saponification force, as well as can remove, disperse and suspend dirt, and prevent the dirt from being redeposited. The pine oil can make the floor clean as new. The powder with the prescription is an excellent detergent for a wooden floor capable of cleaning and disinfecting the floor, and making the floor clean as new.

Owner:吴克

Stain resistant coating material

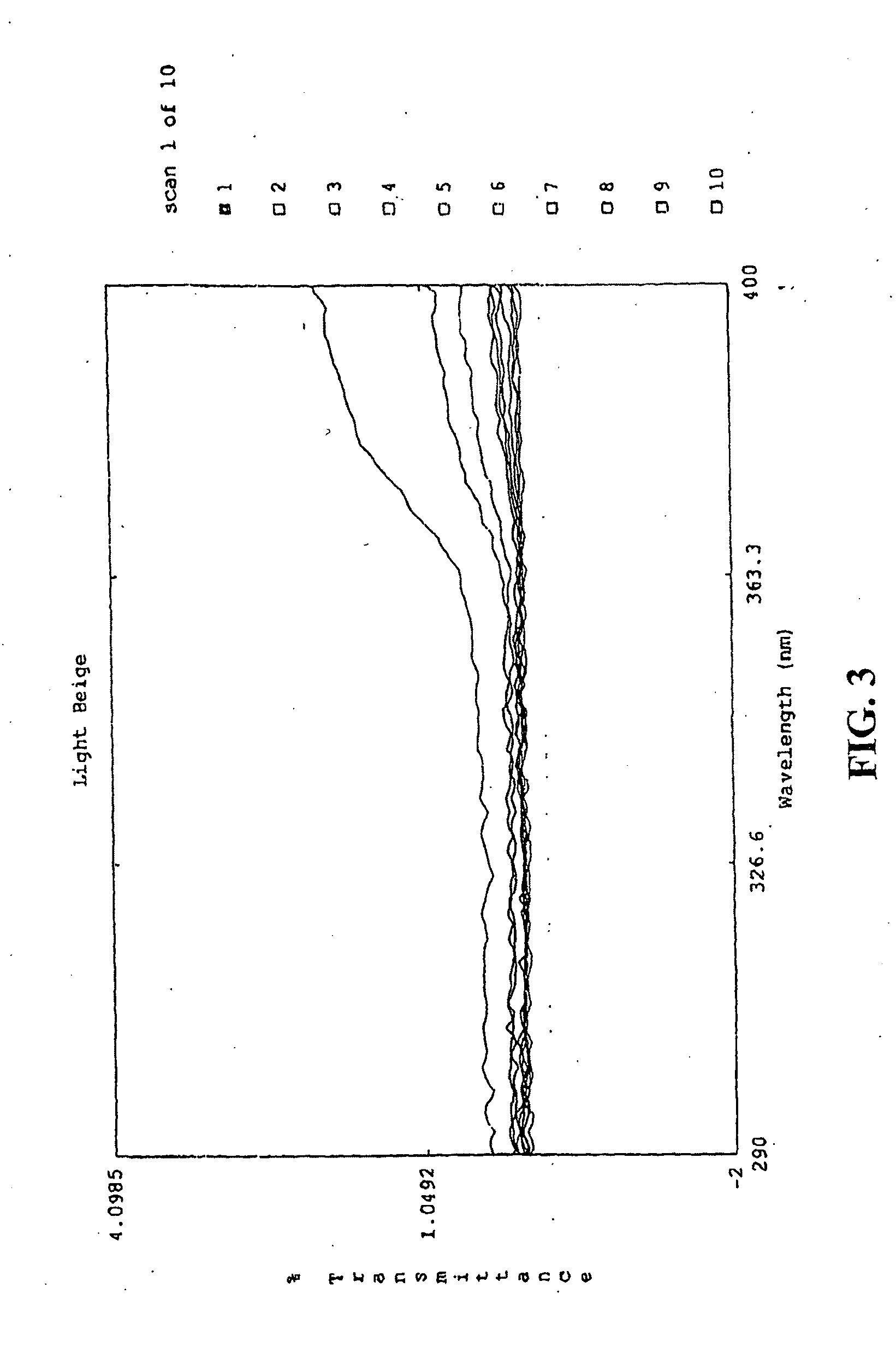

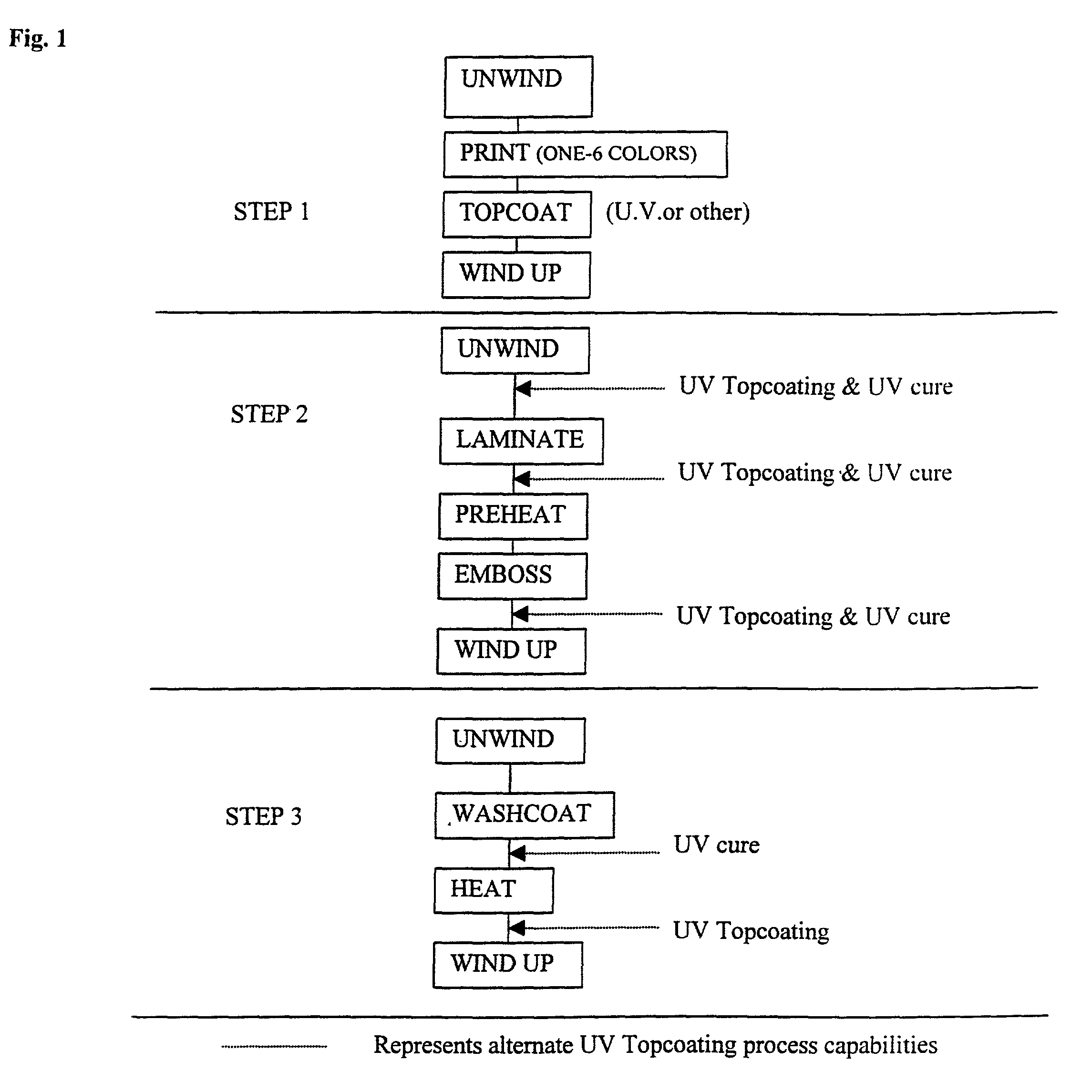

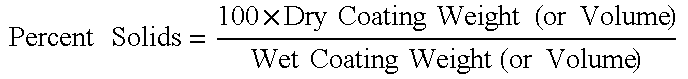

InactiveUS20010010254A1Low costReduce speedAdhesive processesDecorative surface effectsPolymer scienceHeat sensitive

Application of radiation curable coatings to a flexible vinyl web, which is usually printed with a decorative pattern. This printed vinyl may be laminated to a backing for support and is often embossed. The actinically irradiated coated vinyl surface has improved stain resistance and is resistant to chemical attack by common as well as aggressive household cleaning solvents such as pine oil cleaners and nail polish remover. The coating is essentially free of hazardous volatile organic compounds and does not pose a toxicological threat to humans nor does it contaminate the atmosphere. These surface coated, actinically crosslinked vinyl laminates can be used in the manufacture of wallcoverings, automotive interiors, upholstery, tablecloths and other such applications especially where heat sensitive plastics are employed.

Owner:LANDAU ARTHUR +1

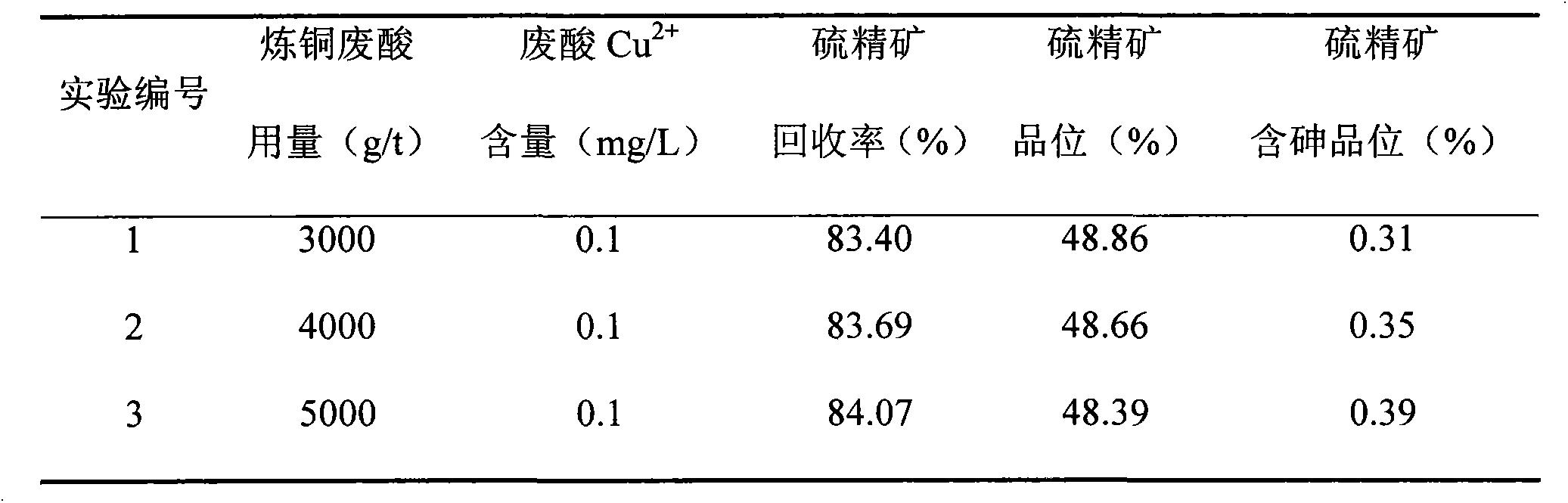

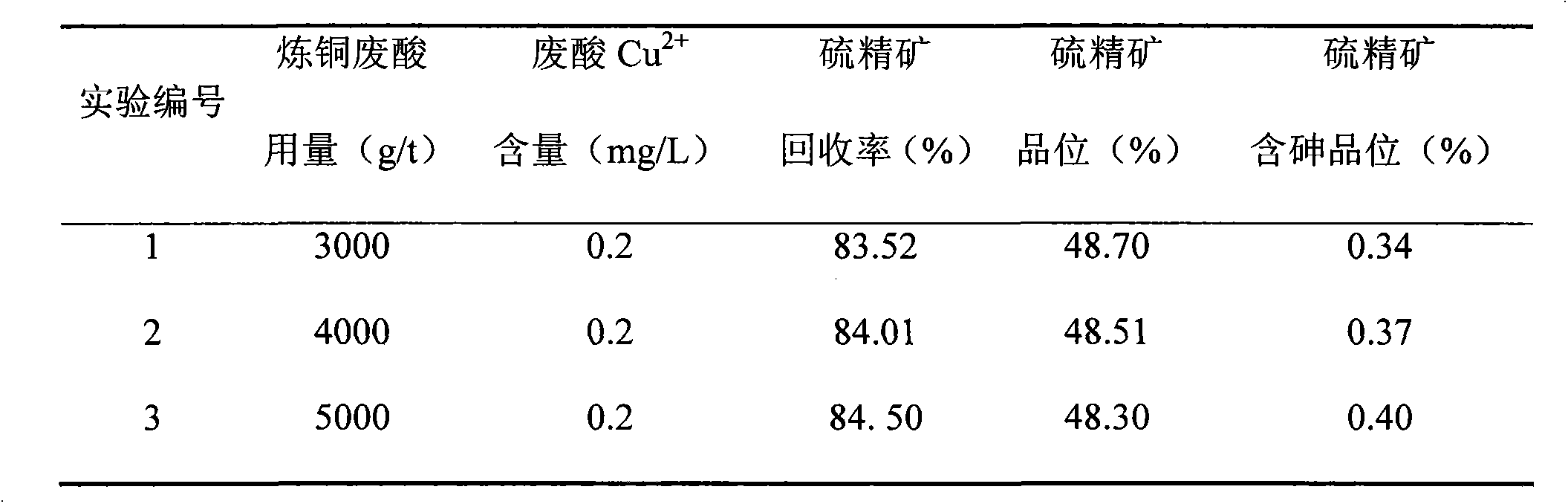

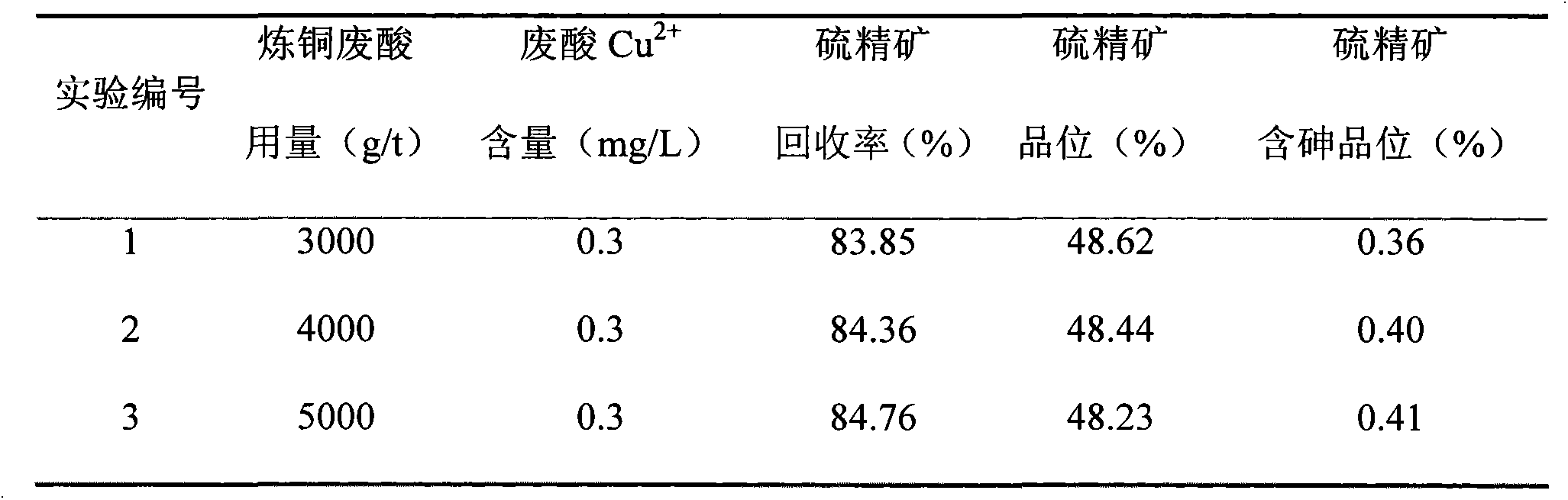

Flotation process for arsenic-containing pyrite

InactiveCN103212481ASimple systemSulfur and arsenic separation effect is goodFlotationHydrogenSulfur

The invention relates to a flotation process for arsenic-containing pyrite. The method comprises the following steps: grinding ore through an ore mill until monomer separation and then entering a flotation process; adding copper smelting waste acid as an activator of pyrite; adjusting the pH (Potential of Hydrogen) value to be 6-7; and adding an arsenopyrite inhibitor, a collector and pine oil to perform pyrite flotation so as to obtain low-arsenic sulfur concentrate. The copper smelting waste acid adopted by the flotation process is waste acid stock solution of a copper smelting plant, and the using amount is 3,000-5,000 g / t; and Cu<2+> included in the copper smelting waste acid is 0.1-0.3 mg / L. The process has the advantages of simple flow, low medicament cost, capability of recycling the copper smelting waste acid of the copper smelting plant, low-arsenic high-sulfur sulfur concentrate can be obtained by the process, and the process has good industrialapplicationprospect.

Owner:JIANGXI UNIV OF SCI & TECH

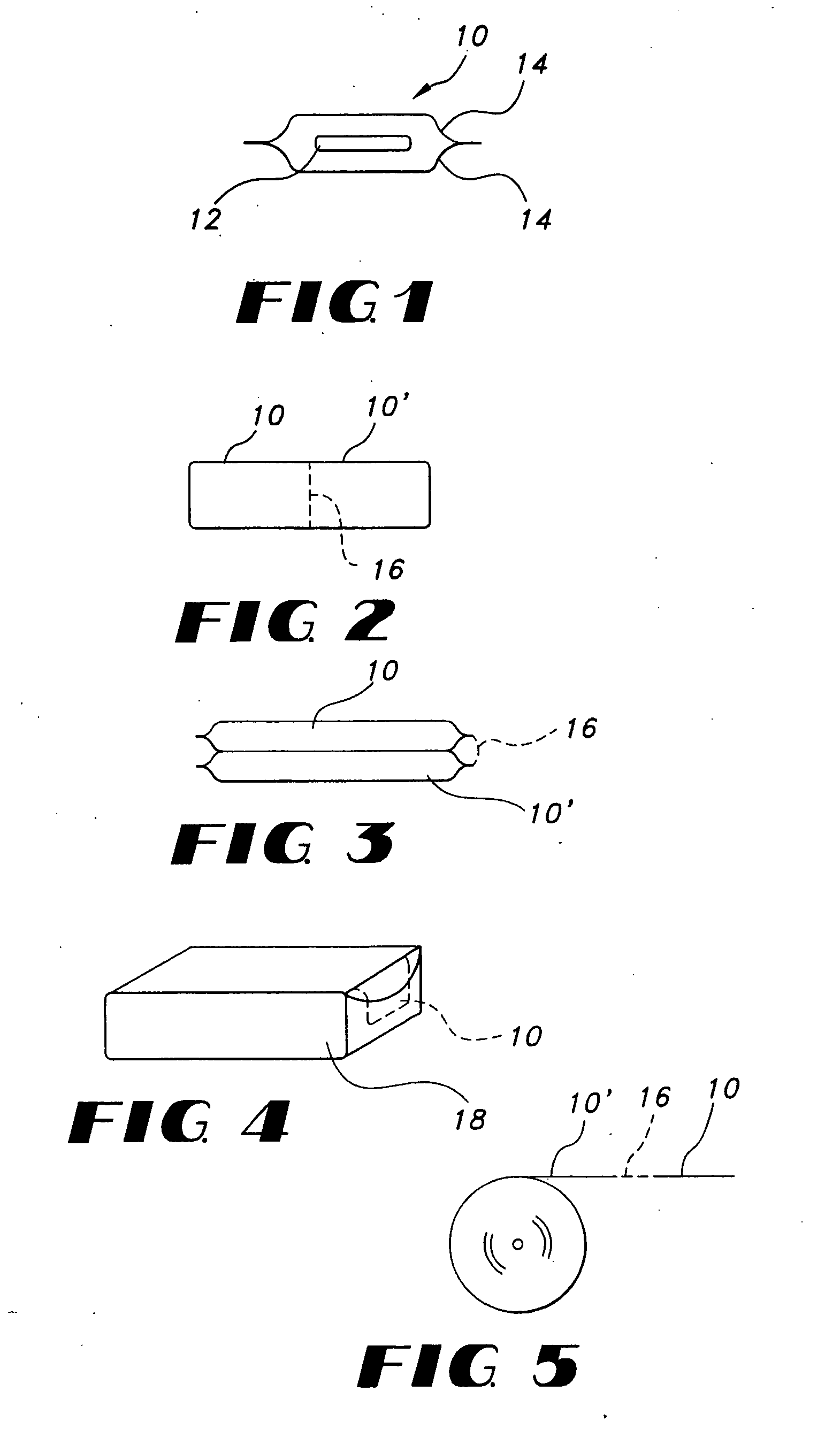

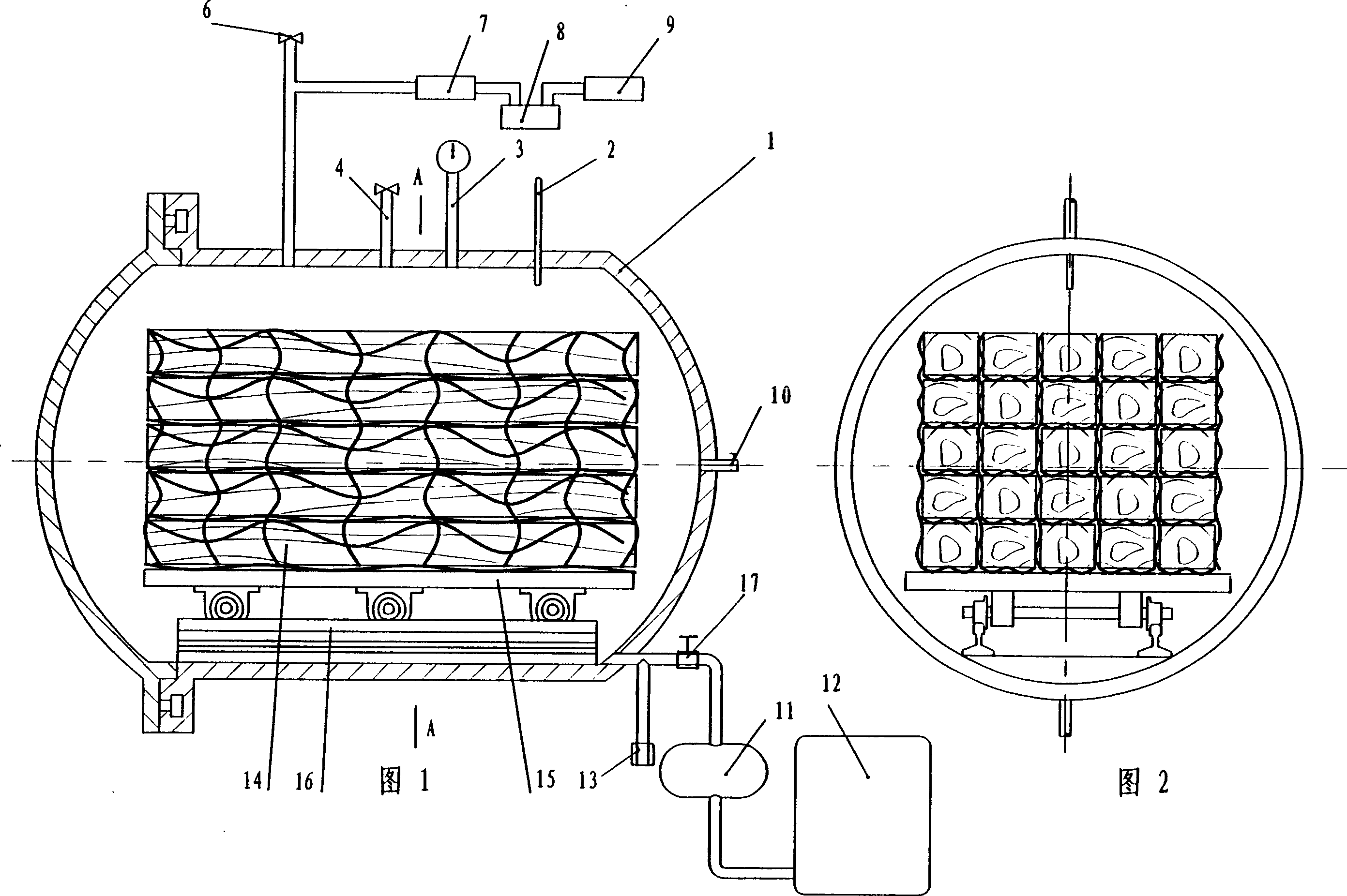

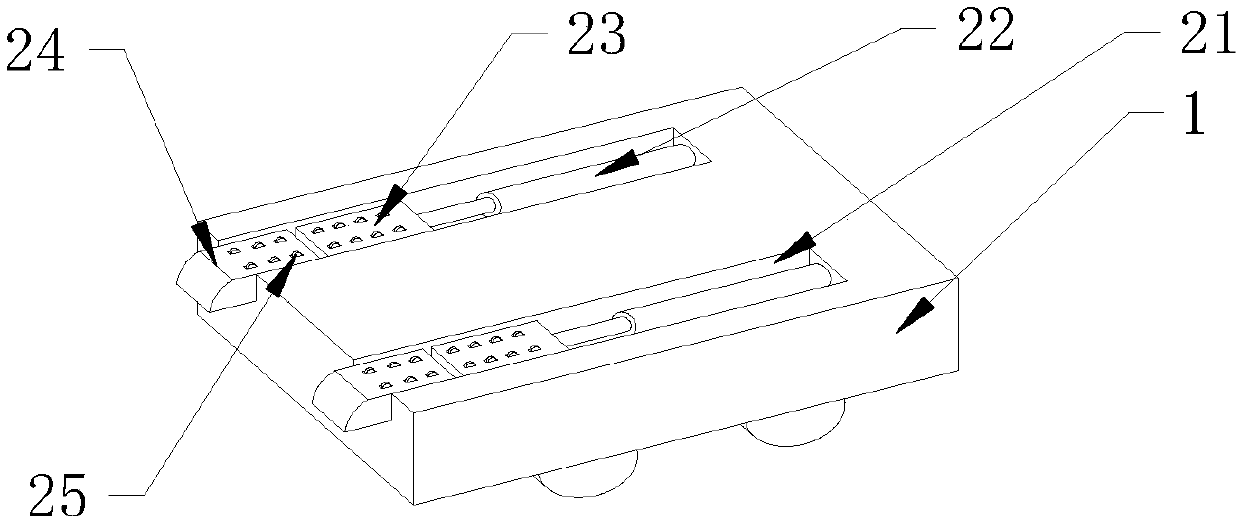

Vacuum pine oil-eliminating method and apparatus

InactiveCN1810469AGuaranteed anti-corrosion performanceExtended service lifePressure impregnationVacuum pumpingBogie

The pine oil eliminating method includes timber stacking, injecting oil eliminating agent, high temperature and high pressure steaming, extracting oil eliminating agent, spraying steam, cooling, draining, vacuum pumping, and relieving pressure and discharging. The relevant oil eliminating apparatus includes a horizontal high pressure tank with rotary sealing cover, bogies for stacking timber on the tracks inside the tank, a liquid storage for oil eliminating agent, a pipeline with pump and valve as well as draining valve communicated to the bottom of the tank, a vacuum pump connected with buffering tank and condenser, safety steam valve, and a heat supply unit communicated with the tank through pipeline with steam valve. The present invention can separate pine oil from timber while leaving rosin in timber to maintain the anticorrosive performance and prolong the service life.

Owner:黄豹

Health edible pine nut oil

InactiveCN1421145AEasy to prepareNo pollution in the processEdible oils/fatsAnimal scienceProtein molecules

The present invention is health edible pine nut oil. After pine nut kernal is crushed and milled into milk and silky fowl egg white is stirred to homogeneous, silky fowl egg white is mixed with pine nut kernel milk, so that silky fowl egg white is combined with protein molecule in pine nut kernel milk to separate oil molecule from pine nut kernel milk. Separated pine nut primary oil is heated to eliminate water, filtered and sterilized to obtain pine nut oil. Pine nut oil is added into peanut oil or sunflower oil to obtain the health edible pine nut oil with pine nut oil content of 5-10%. Thehealth edible pine nut oil has rice nutrients, including oleic acid, linolenic acid, vitamins, folic acid, etc. and has the functions of strengthening physique and resisting diseases.

Owner:吉林省巨龙高科技术开发有限责任公司

Preparation method of traditional Chinese medicine black hair dye added with natural transdermal absorption penetration enhancers as dye penetrants

InactiveCN110731940ASimple manufacturing processImprove permeabilityCosmetic preparationsHair cosmeticsBiotechnologyOrganic dye

The invention discloses a traditional Chinese medicine black hair dye adopting natural transdermal absorption penetration enhancers such as oleum menthae, pine oil, eucalyptus oil and cinnamyl alcoholas dye penetrants. Chinese herbal medicines and natural plant extracts are adopted as raw materials and are divided into two agents; the hair dye selects tannic acid in a galla chinensis extract as adyestuff, and a surface active agent as an emulsifying agent, is added with one or multiple combination of the oleum menthae, the pine oil, the eucalyptus oil and the cinnamyl alcohol as the dye penetrant(s), and is prepared through deionized water; and a dye mordant selects green-vitriol as a color developing agent, a surface active agent as an emulsifying agent, sodium hydroxide as a pH regulator, and iron powder as a reducing agent, and is prepared through deionized water. The traditional Chinese medicine black hair dye provided by the invention adopts the natural plant extracts and is free from organic dyestuff so as to be poisonless and harmless, incapable of hurting hair, appropriate in hair dyeing temperature, and durable in white hair black-dyeing effect.

Owner:NANTONG UNIVERSITY

Local cock breeding method

InactiveCN105145480ALess prone to diseaseHigh nutritional valueFood processingAnimal feeding stuffPinus thunbergiiNutritive values

The invention discloses a local cock breeding method. The local cock breeding method comprises the following steps: feeding cocks in a pine forest; opening grooves in pines and putting pine oil storage bags for receiving pine oil flowing out from the grooves under the grooves, wherein the cocks in the pine forest eat pine oil in the pine oil storage bags, and pine needles and pine leaves which fall off from the pines; and putting corns, rice husks and water into the pine forest for the cocks to eat. The cocks are bred in the pine forest, and eat the pine oil flowing out from the pines and the pine needles and pine leaves which fall off from the pines; and chicken has a high nutritive value and relatively good meat quality, and the cocks does not easily have diseases.

Owner:WUHU SHIBA FREE RANGE BREEDING CO LTD

Paint cleaner for fabric

InactiveCN103666874AEfficient removalChemical paints/ink removersSurface-active non-soap compounds and soap mixture detergentsPhosphoric Acid EstersPolyvinyl alcohol

The invention relates to a paint cleaner for fabric, which comprises the following components in parts by mass: 0.5-7 parts of pine oil, 13-24.6 parts of naphtha, 0.2-0.48 parts of tetradecyl benzyl dimethyl ammonium chloride, 0.03-0.05 parts of polyvinyl alcohol, 0.01-0.022 parts of dodecyl phosphate salt, 3.25-9.25 parts of sodium percarbonate, 0.1-0.35 parts of essence and 159-183 parts of water. The invention provides the paint cleaner for the fabric, which can effectively remove paint and other stains from the fabric, kill bacteria on the fabric and allows the cleaned fabric to become soft and antistatic.

Owner:南通信一服饰有限公司

Edible blend oil based on pine nut oil and preparation method thereof

The invention relates to an edible blend oil based on pine nut oil and a preparation method thereof. The edible blend oil based on pine nut oil comprises the following components in percentage by mass: 20-50% of pine nut oil, 10-40% of soybean oil, 10-40% of colza oil, 5-20% of peanut oil, 5-20% of sunflower seed oil, 2-10% of sesame oil, 2-10% of linseed oil and 0.02-0.08% of antioxidant. The preparation method comprises the following steps: proportionally adding the components into a mixing tank, adding a specified amount of antioxidant, slowly stirring uniformly, and filtering to remove solid suspended substances, thereby obtaining the edible blend oil finished product based on pine nut oil. The edible blend oil provided by the invention has the advantages of wide component sources, reasonable price and cost and high polyunsaturated fatty acid content, and conforms to the human body diet fatty acid equilibrium principle; and the technique is simple, thus being beneficial to popularization of edible oil based on pine nut oil.

Owner:XIJING UNIV

Method for manufacturing pine picture

InactiveCN101633285AAvoid pollutionColorful worksDecorative surface effectsSpecial ornamental structuresEngineeringTwig

The invention discloses a method for manufacturing a pine picture, which comprises the following steps: preparing pine oil; collecting natural raw materials from pins such as pine braches, pin barks, pine nuts, pine cones, pine needles and the like, and trimming the raw materials properly; sticking the trimmed raw materials onto a bottom board coated with the pine oil to form a picture; and coating a pine oil protective layer on the surface of the stuck picture. The method for manufacturing the pine picture fully avoids pollution because all the manufacturing raw materials are from the natural parts of the pines. The raw materials are selected from various components of the pines such as braches, twigs, leaves (needles), nut, shell and the like, so the works are colorful, real, natural, vivid and strong in third dimension, have natural rosin smell slowly releasing for a long period, and can prevent moths.

Owner:白巧英

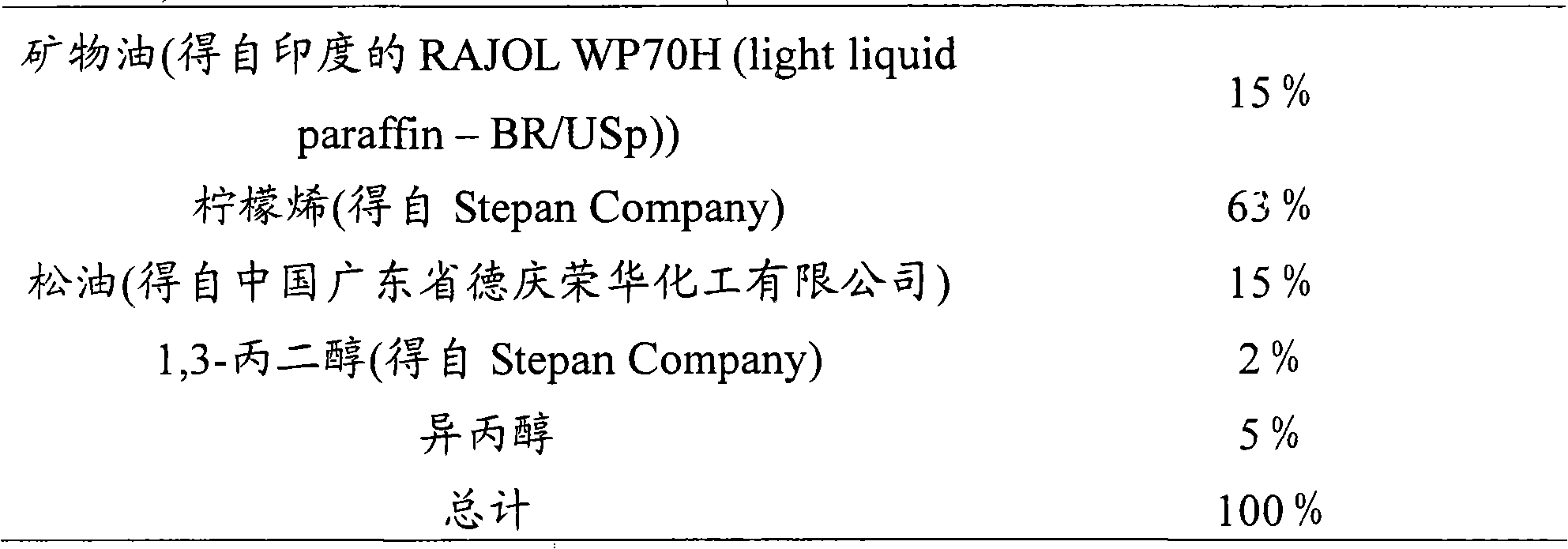

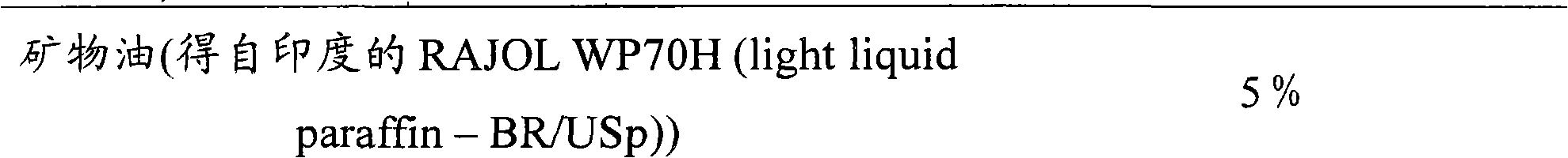

Nonaqueous organic composition and application thereof

InactiveCN101921543AIncrease non-greasyRich lusterBiocideAntifouling/underwater paintsPolyolNonferrous metal

The invention relates to a nonaqueous organic composition and an application thereof. The composition comprises the following components: 5-50 wt% of mineral oil, 1-10 wt% of cosolvent, 30-70 wt% of limonene, 5-25% of pine oil and 0-5 wt% of polyalcohol. The composition is a blended mixture of organic compositions, which can be locally applied on log, wood with permanent coatings, ceramics, stainless steel, non-ferrous metal or other hard surface objects, plays the roles of disinfectors, sterilizers, mildew preventives, insecticides, deodorants, degreasing agents and lubricants, simultaneously maintains excellent gloss and performs excellent protection on avoiding damages due to oxidation and sunlight. The composition is locally applied to wood or other objects through superior rag, dry napkin or dry sponge and the like.

Owner:梁伟贤

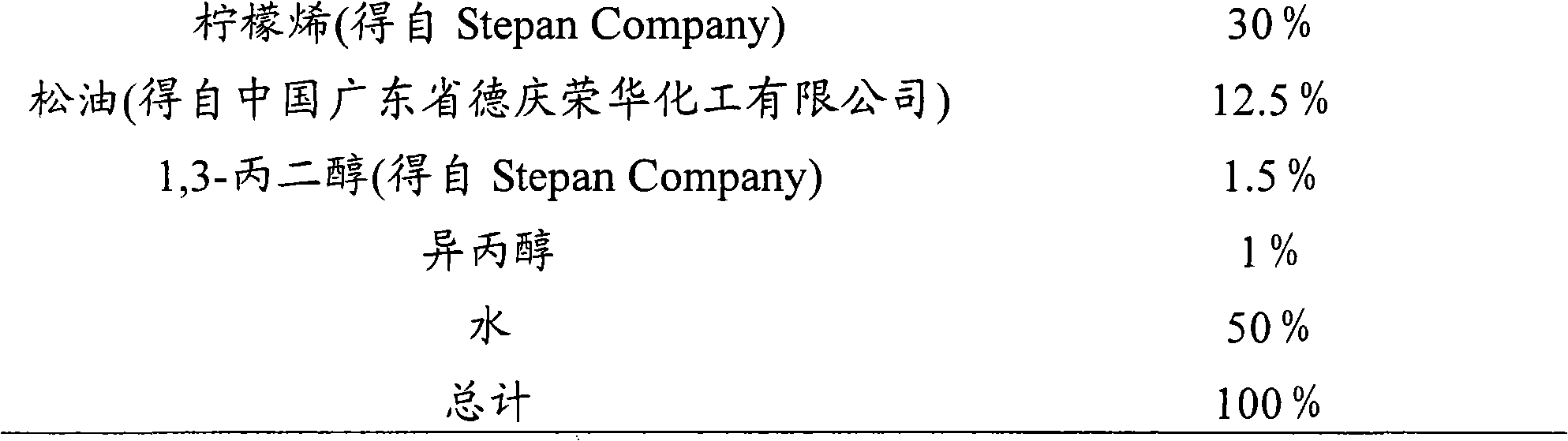

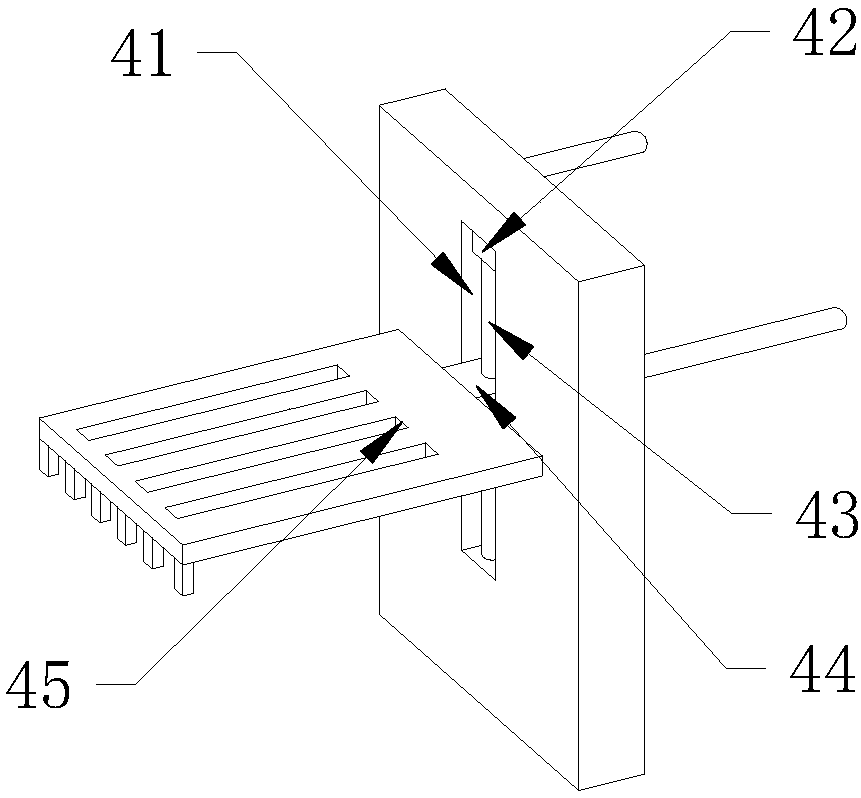

Vertical carrying equipment for pine oil barrels

PendingCN108100000ASave human effortEasy loadingHand carts with multiple axesPine oilMechanical engineering

The invention provides vertical carrying equipment for pine oil barrels. The equipment comprises a loading platform, a side baffle, first grooves, electric retractable rods, first supporting plates, second supporting plates, rolling wheels, a second groove, a servo motor, a screw rod, a bearing base and a clamping plate; the first grooves are formed in the upper end faces of the bearing platform,the electric retractable rods are assembled on the rear walls of the interiors of the first grooves, the first supporting plates are installed at the front ends of the electric retractable rods, the second supporting plates are assembled at the front ends of the first supporting plates, the rolling wheels are installed on the upper end faces of the first supporting plates and the upper end faces of the second supporting plates respectively, and therefore the function of conveying the pine oil barrels is achieved through the design; the second groove is formed in the front end face of the sidebaffle, the servo motor is assembled at the top of the interior of the second groove, the screw rod is installed at the lower end of the servo motor, the bearing base is assembled on the annular sidesurface of the screw rod, the clamping plate is fixed at the front end of the bearing base, and therefore the function of fixing the pine oil barrels is achieved through the design. The equipment is easy to operate, high in safety, stable, reliable and capable of saving manpower and fixing the pine oil barrels conveniently.

Owner:江西松源林产高科有限公司

Dining table capable of repelling mosquitoes

InactiveCN105534034AUnmolestedGood mosquito repellentBiocidePest repellentsSandalwood oilParaffin wax

The invention discloses a dining table capable of repelling mosquitoes. The dining table includes a body and a mosquito repelling coating coated on the surface of the body. The mosquito repelling coating is formed by mixed compression of paraffin, stearic acid and mosquito repelling essential oil; the mosquito repelling coating includes, by mass percent, 42-48% of the paraffin, 12-18% of the stearic acid, and the balance mosquito repelling essential oil; and the mosquito repelling essential oil includes, by mass percent, 45-48% of peppermint oil, 6-10% of lemon grass oil, 12-16% of spearmint oil, 15-21% of pine oil, and the balance sandalwood oil. Through this way, the dining table has a good mosquito repelling effect, and can ensure that people cannot be invaded by the mosquitoes during dining at the dining table, and the dining comfort can be ensured.

Owner:SUZHOU BOLANG FURNITURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com