Preparation of high closeness polyacrylacid ester dispersion

A technology of polyacrylate and alkyl acrylate, which is applied in the application field of highly closed polyacrylate dispersion and its preparation, and in the preparation of water-based wood coatings, can solve the problems of easy adhesion, bleeding, yellowing, etc., and achieve The effect of low gel rate, fast drying, and small amount of emulsifier added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

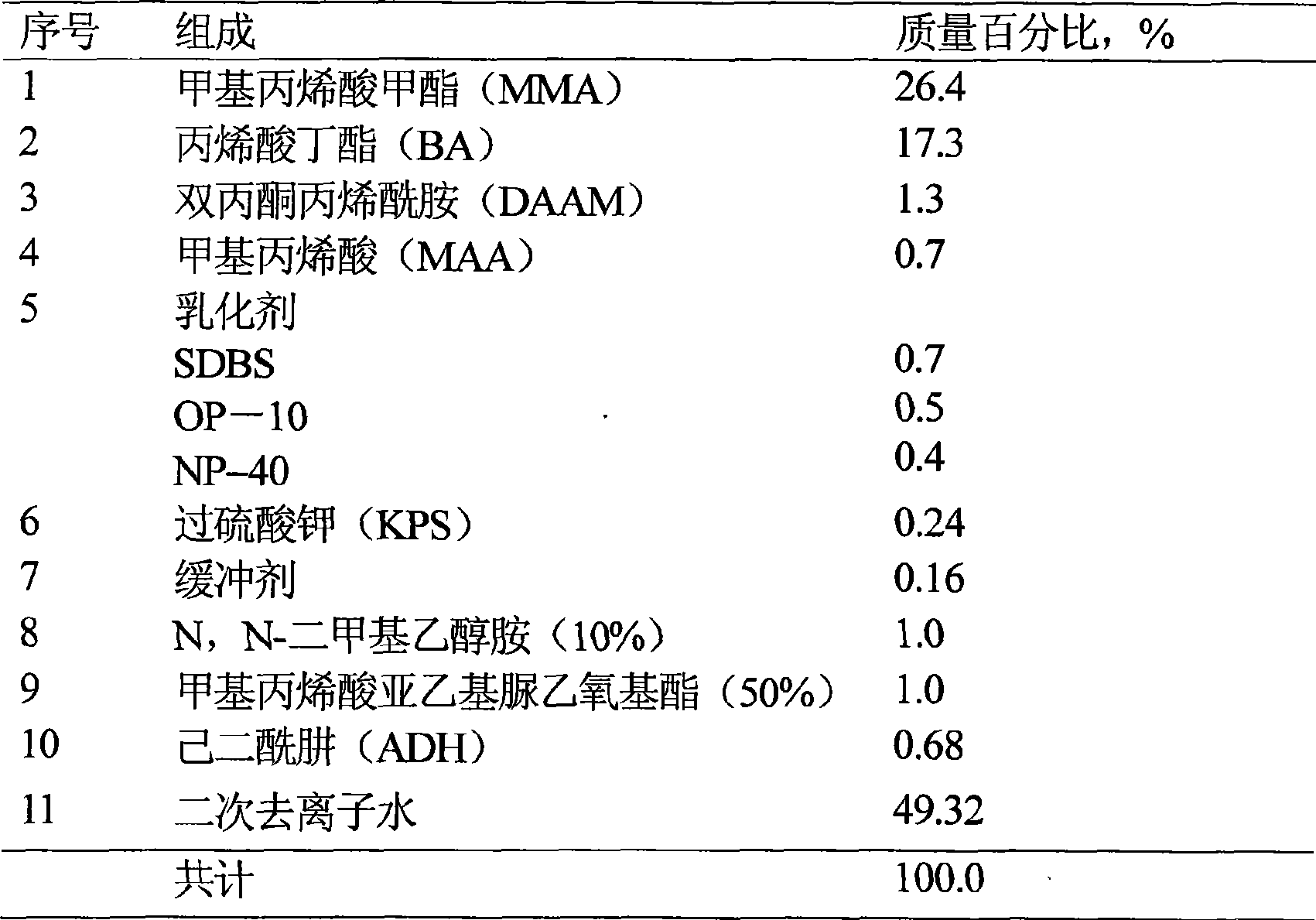

[0063] The monomer composition is butyl acrylate, methyl methacrylate, methacrylic acid, diacetone acrylamide, ethylene urea ethoxy methacrylate, and its components are listed in Table 1.

[0064] Table 1 Polyacrylate dispersion formula

[0065]

[0066] Add 2.7 parts of compound emulsifier, buffer, and 32.92 parts of deionized water into the reaction kettle, stir at high speed for 20 minutes, and raise the temperature to 55°C, add 0.4 parts of methacrylic acid, 8.4 parts of butyl acrylate, 16 Mixed monomers of methyl methacrylate, raise the temperature of the reactor to 82°C, slowly add part of the initiator solution dropwise, wait until the seed dispersion is in a blue phase and stabilize for half an hour, add the pre-emulsified dropwise within 1.5 hours For the core monomer, continue to drop the pre-emulsified shell monomer within 2 hours after an interval of 20 minutes. After adding all the monomers, add 4 parts of 10% aqueous initiator solution, raise the temperature t...

Embodiment 2

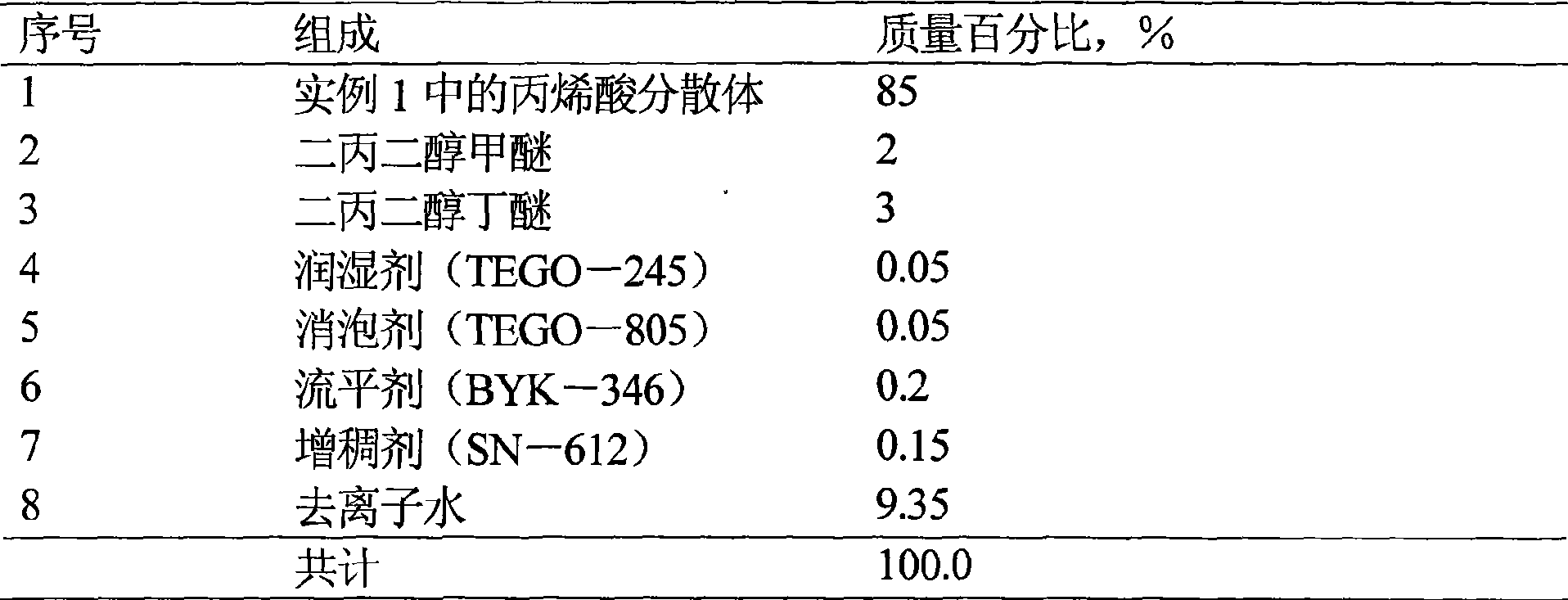

[0071] Using the acrylate dispersion prepared in Example 1, the wood coating formulation was prepared as shown in Table 2.

[0072] Table 2 Waterborne wood coating formulations

[0073]

[0074] The preparation method is as follows: firstly add raw materials No. 2-8 into the stirring tank, disperse with a high-speed disperser for 10-30 minutes, then slowly add the acrylic acid dispersion into the stirring tank, stir at a medium speed for 30-60 minutes, adjust with ammonia water The pH value of the paint, when the pH value is qualified, it is filtered, discharged and packaged. Properties of the prepared wood coating: Appearance: milky white slightly transparent liquid without mechanical impurities; pH=7-9; solid content 35-40%, viscosity 30-200cps. Wood coating film performance: Pencil hardness of coating film: HB; water resistance: no obvious change after soaking in water for 48 hours; adhesion: level 1; flexibility: level 1; excellent sealing; anti-adhesion: level A.

Embodiment 3

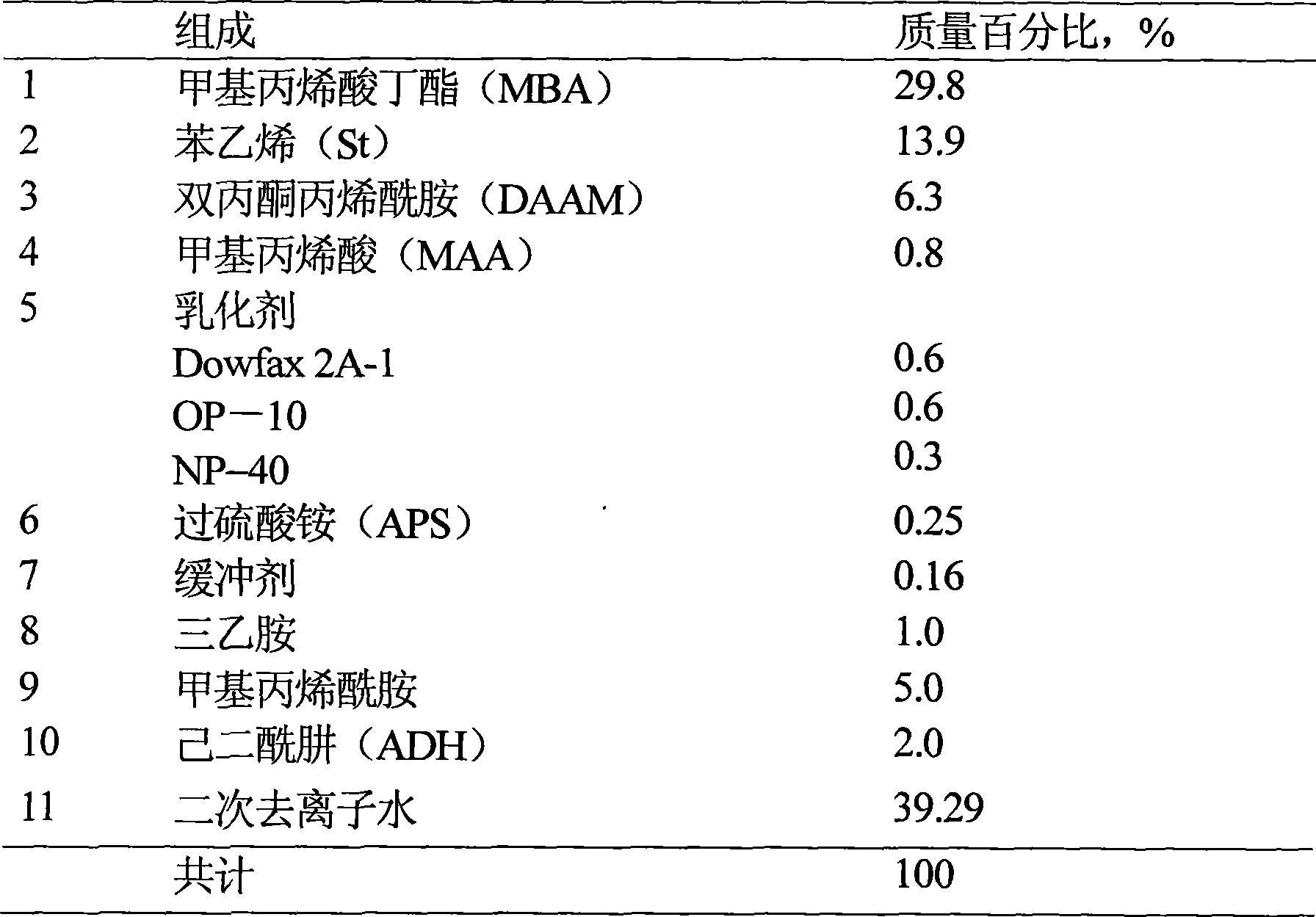

[0076]The monomer composition is butyl acrylate, methyl methacrylate, methacrylic acid, diacetone acrylamide, and methacrylamide, and its component formula is shown in Table 3:

[0077] Table 3 Polyacrylate dispersion formula

[0078]

[0079] Add 4.0 parts of compound emulsifier, buffer, and 51.92 parts of deionized water into the reactor, stir at high speed for 20 minutes, and raise the temperature to 55°C. Within 20 minutes, 0.5 parts of methacrylic acid, 10.5 parts of styrene, 22.5 Part of butyl methacrylate mixed monomer, raise the temperature of the reactor to 82°C, slowly add part of the initiator solution dropwise, wait until the seed dispersion is in a blue phase and stabilize for half an hour, drop the pre-emulsified solution within 1.5 hours For the core monomer, continue to drop the pre-emulsified shell monomer within 2 hours after an interval of 20 minutes. After adding all the monomers, add 4 parts of 10% aqueous initiator solution, raise the temperature to 85...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com