High-speed steel roll and preparation method thereof by centrifugal compounding in electromagnetic field

A technology of centrifugal composite and centrifugal composite casting, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of coarse composite carbide, increase the cost of roll, and rare Nb element, achieve less loose defects and improve finished products. rate and pass rate, and the effect of improving the reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

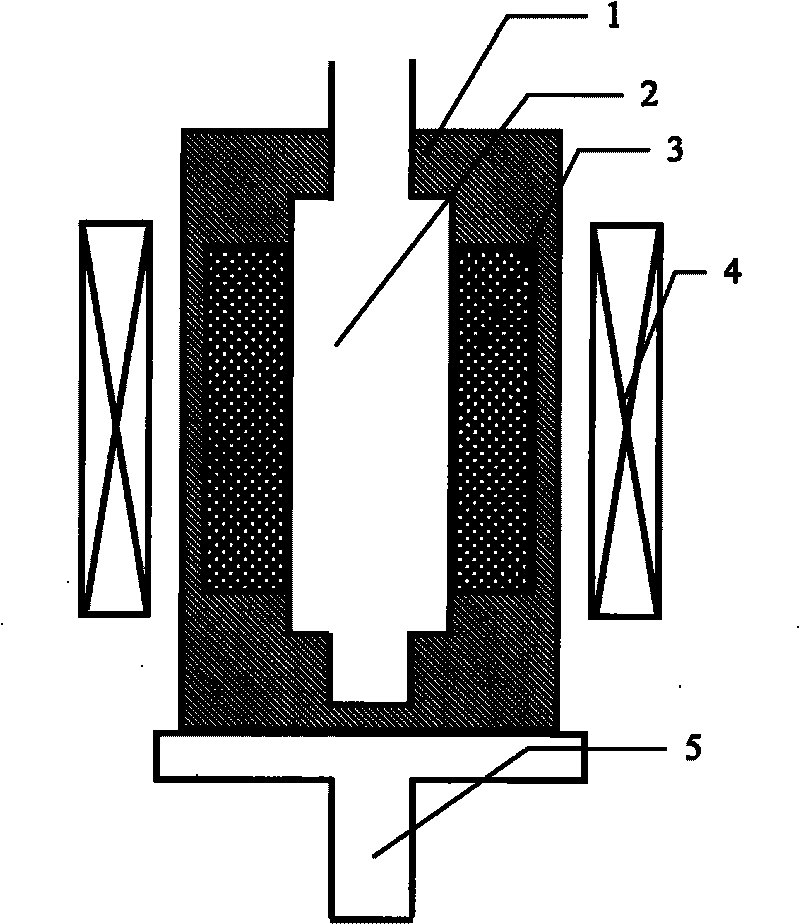

Method used

Image

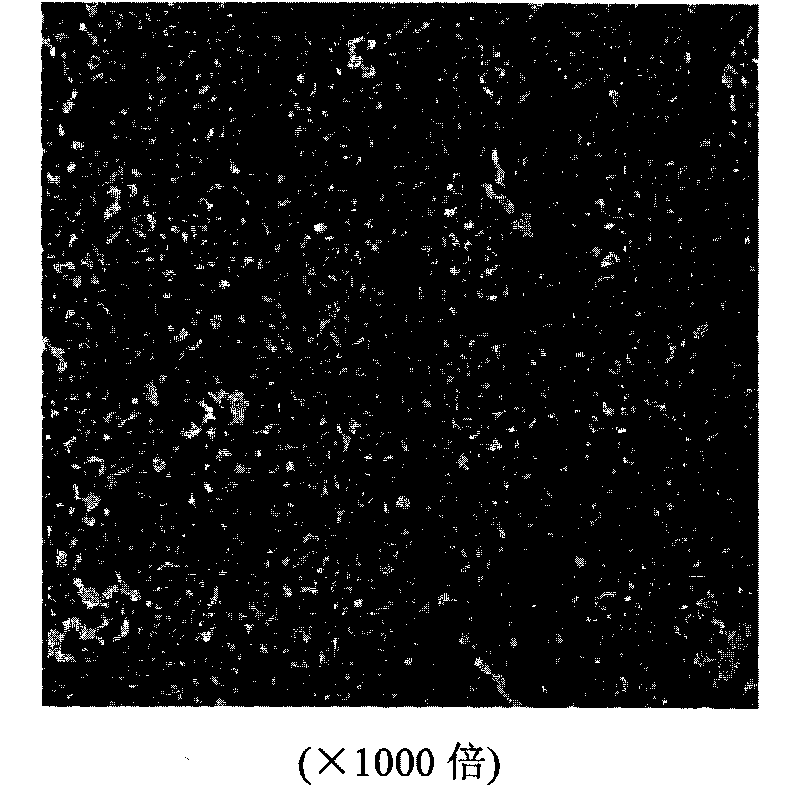

Examples

Embodiment 1

[0049] The body size of the high-performance high-speed steel composite roll in this example is φ500×1700mm. The material of the wear-resistant working layer of the composite roll and the ductile cast iron of the roll core are respectively melted in a 4t intermediate frequency induction furnace and a 5t / h cupola furnace. The manufacturing process steps are as follows :

[0050] The first stage: smelting of high-speed steel and smelting of roll core ductile iron

[0051] Note: The smelting of high-speed steel and the smelting of ductile iron of the roller core are carried out at the same time

[0052] The melting process of high-speed steel is:

[0053] 1. by composition requirement of the present invention, scrap steel 1390kg, pig iron (4.2%C) 1700kg, ferrochrome (50%Cr) 200kg, molybdenum iron (60%Mo) 100kg), tungsten iron (70%W) 260kg are mixed, in Compact the block on the press, put it into the smelting furnace and heat it to melt. After the molten steel is melted, when th...

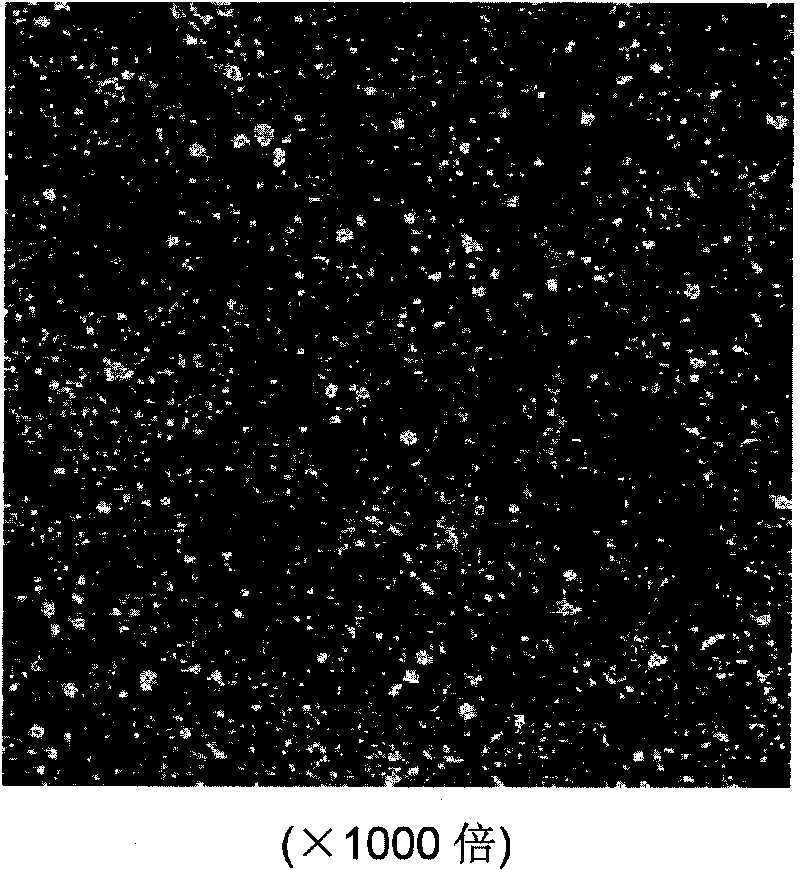

Embodiment 2

[0073] The size of the high-performance high-speed steel composite roll in this embodiment is φ600×1400mm. The wear-resistant working layer material of the composite roll and the nodular cast iron of the roll core are smelted in a 4t intermediate frequency induction furnace and a 5t / h cupola respectively. The manufacturing process steps are as follows :

[0074] The first stage: smelting of high-speed steel and smelting of roll core ductile iron

[0075] Note: The smelting of high-speed steel and the smelting of ductile iron of the roller core are carried out at the same time

[0076] The melting process of high-speed steel is:

[0077] 1. by composition requirement of the present invention, scrap steel 1000kg, pig iron (4.2%C) 1600kg, ferrochrome (50%Cr) 290kg, molybdenum iron (60%Mo) 290kg), tungsten iron (70%W) 340kg are mixed, in Compact the block on the press, first put 30kg of recarburizer (95%C) into the furnace, then put the pressed block into the smelting furnace to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com