Patents

Literature

174results about How to "Granularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

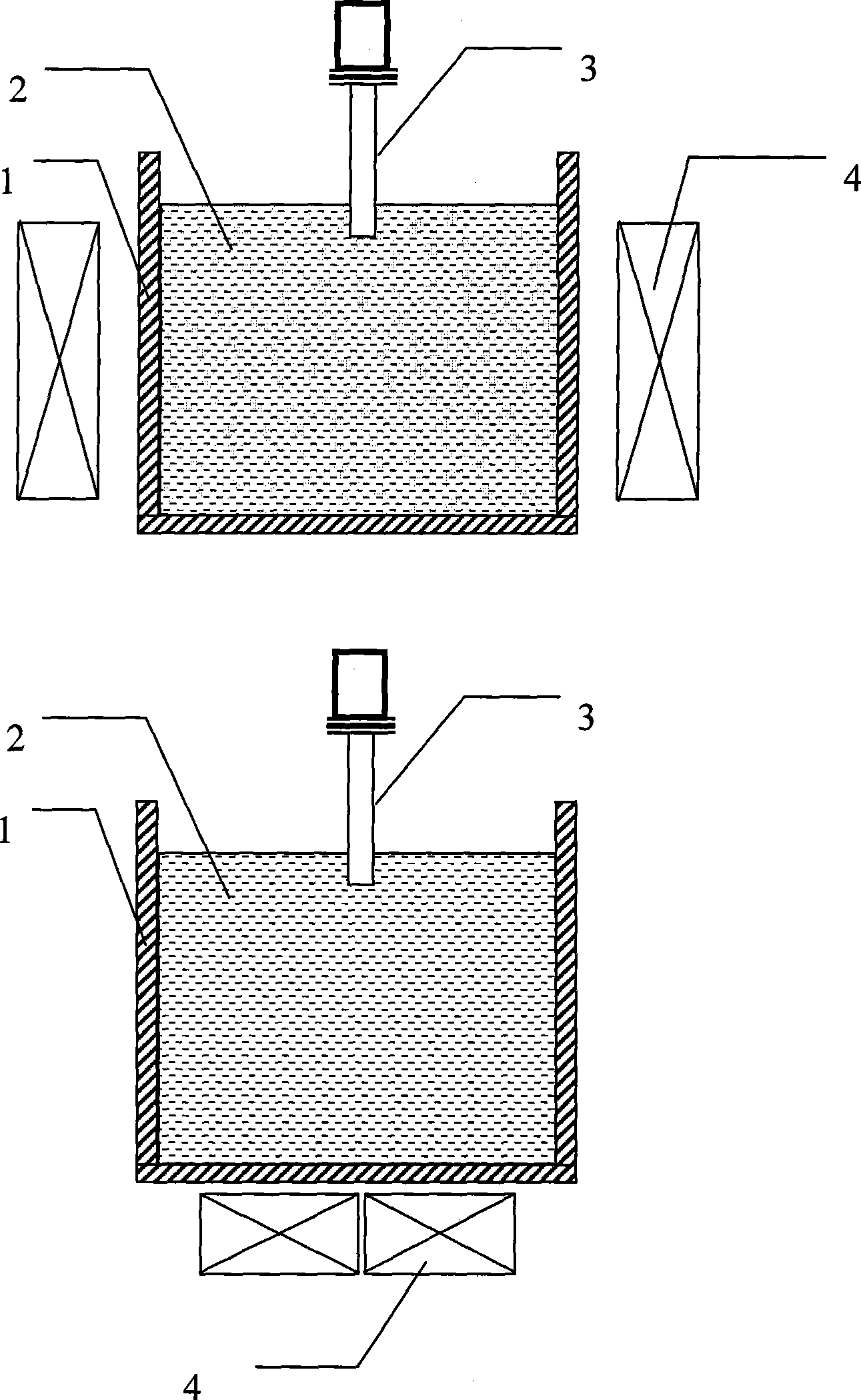

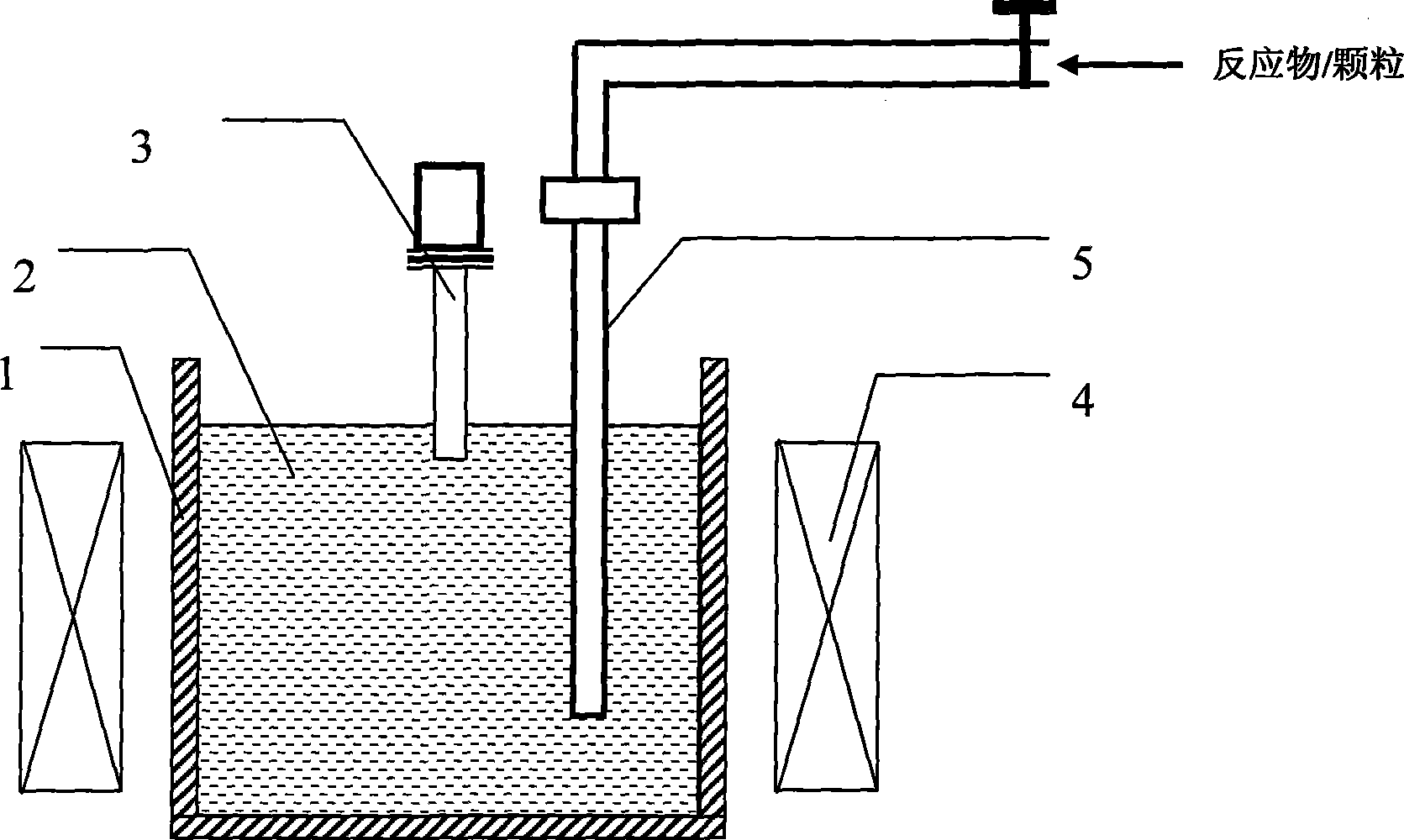

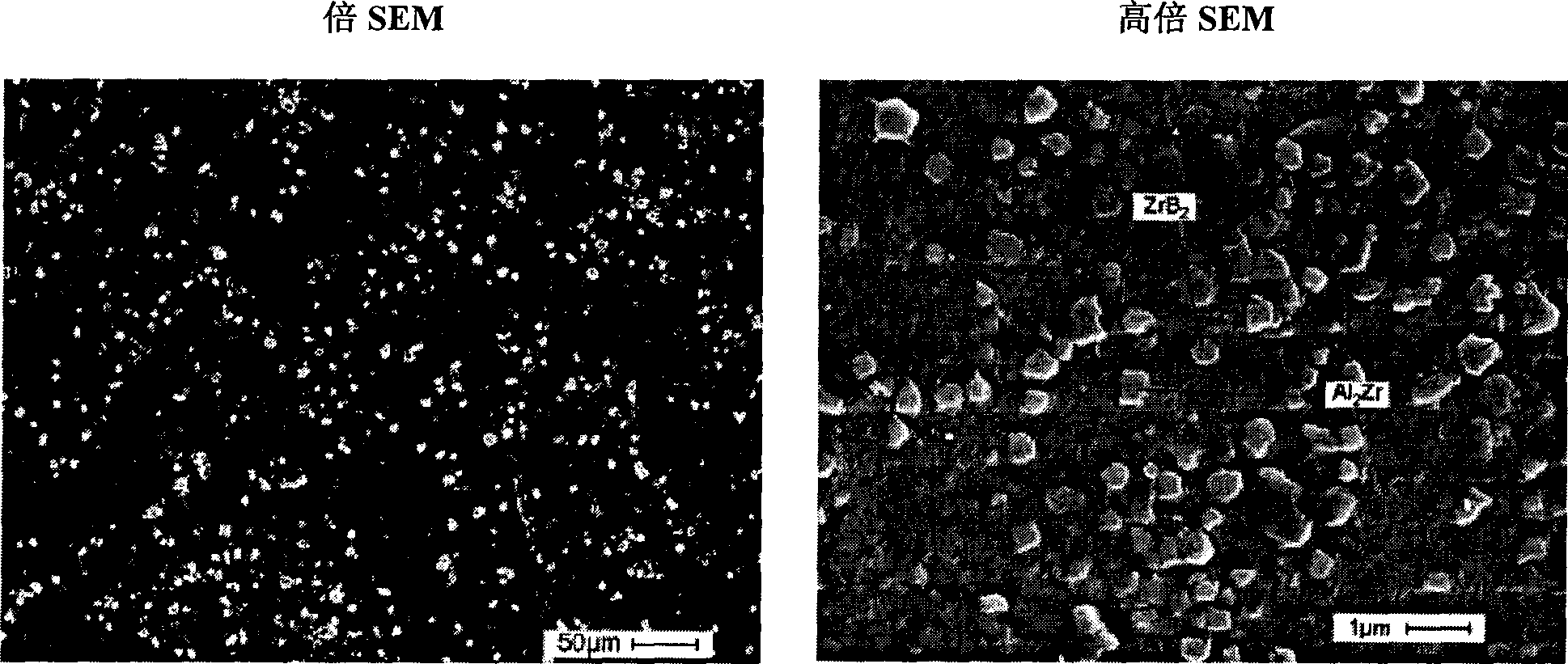

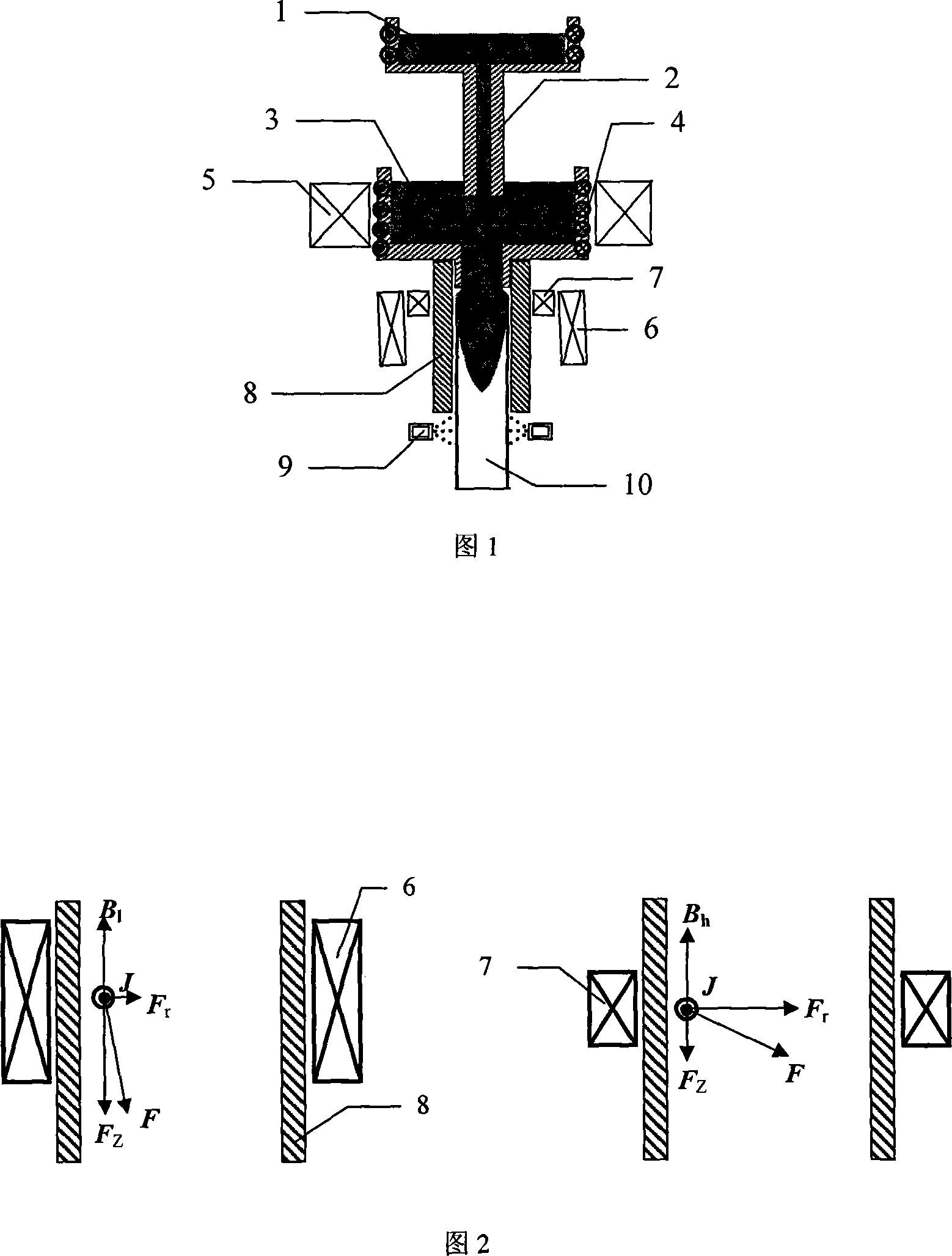

Method for synthesizing metal matrix composition using metal reaction under the coupling action of magnetic field and ultrasonic field

The invention relates to a method for preparing endogenetic particle reinforced metal matrix composites under the coupling effect of a magnetic field and supersonic waves. The method comprises: adjusting the temperature of a metal matrix fused mass to the reaction initial temperature after refining, adding a reactant which can generate a particle phase with the fused mass through the reaction in situ for implementing the synthesis reaction, standing the mixture after the reaction is over, and cooling the mixture to the pouring temperature for pouring; and the method is characterized in that: the magnetic field and the high-intensity ultrasonic field are simultaneously exerted in the reaction synthesis process to realize the synthesis of endogenetic particle reinforced metal matrix composites under the coupling effect of the magnetic field and the high-intensity ultrasonic field. The magnetic field can be an intense pulse magnetic field, a high frequency oscillation magnetic field or a low frequency alternating magnetic field. In the method, the coupling effect of the magnetic field and the ultrasonic field makes the particle sizes be thinned and dispersed evenly; the ultrasonic vibration agitation and electromagnetic stirring functions improve the composite dynamic condition, and the compounding of the particle phase and a base metal interface is better; and the co-action of magnetochemistry and sonochemistry improves the thermodynamic condition of the reaction in situ, as well as speeding up the reaction in situ and controlling the growth of the particle phase.

Owner:JIANGSU UNIV

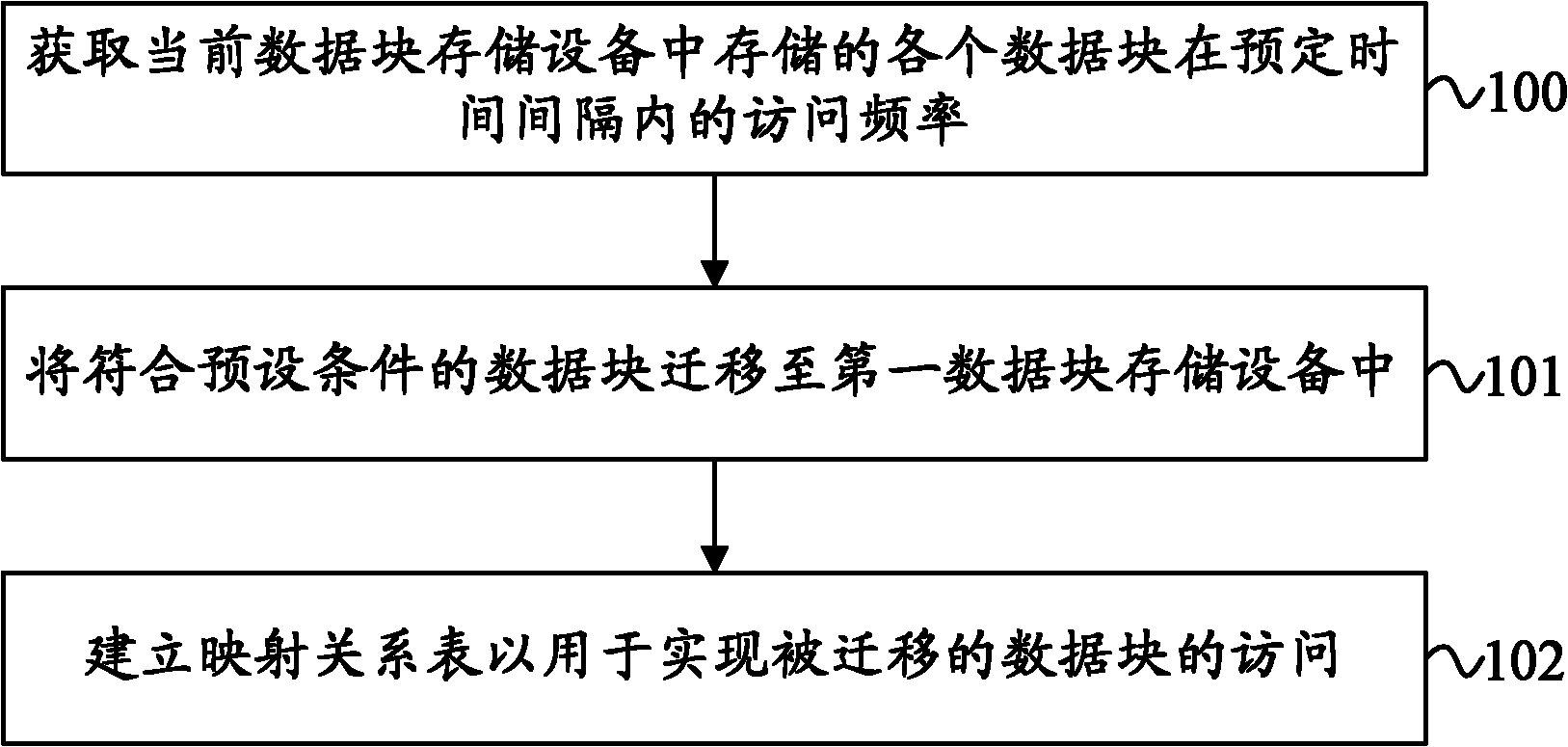

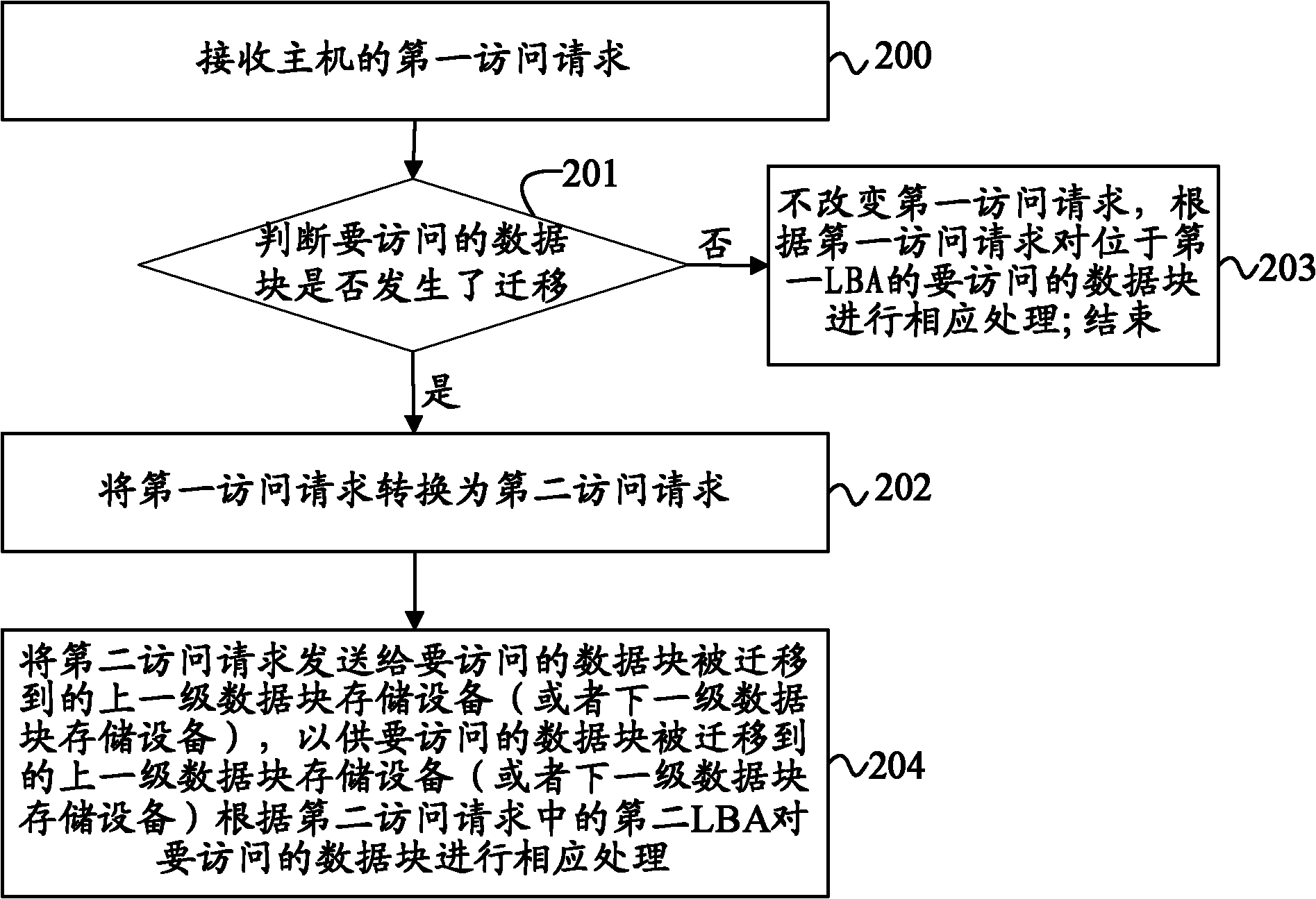

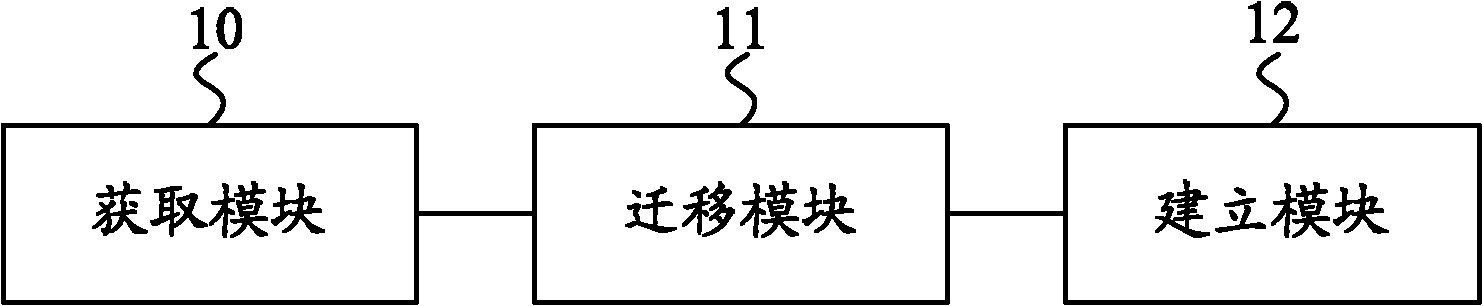

Method for processing data blocks, and data block storage equipment and system

ActiveCN102156738AGranularityImprove data migration efficiencySpecial data processing applicationsAccess frequencyDatabase

The embodiment of the invention provides a method for processing data blocks, and data block storage equipment and a data block storage system. The method comprises the following steps of: acquiring an access frequency of each data block stored in the data block storage equipment at the present within a predetermined time interval; moving the data blocks according with a preset condition to the first data block storage equipment, wherein the preset condition is that: the access frequency is less than a first preset threshold value, and the first data block storage equipment is the next data block storage equipment of the data block storage equipment at the present; and / or, the present condition is that: the access frequency is greater than a second preset threshold value, and the first data block storage equipment is the former data block storage equipment of the data block storage equipment at the present; and establishing a mapping relation table for realizing access of the moved data blocks, wherein the mapping relation table comprises a mapping relation between a logic unit address of the moved data block in the data block storage equipment at the present and a logic unit address of the moved data block in the first data block storage equipment.

Owner:CHENGDU HUAWEI TECH

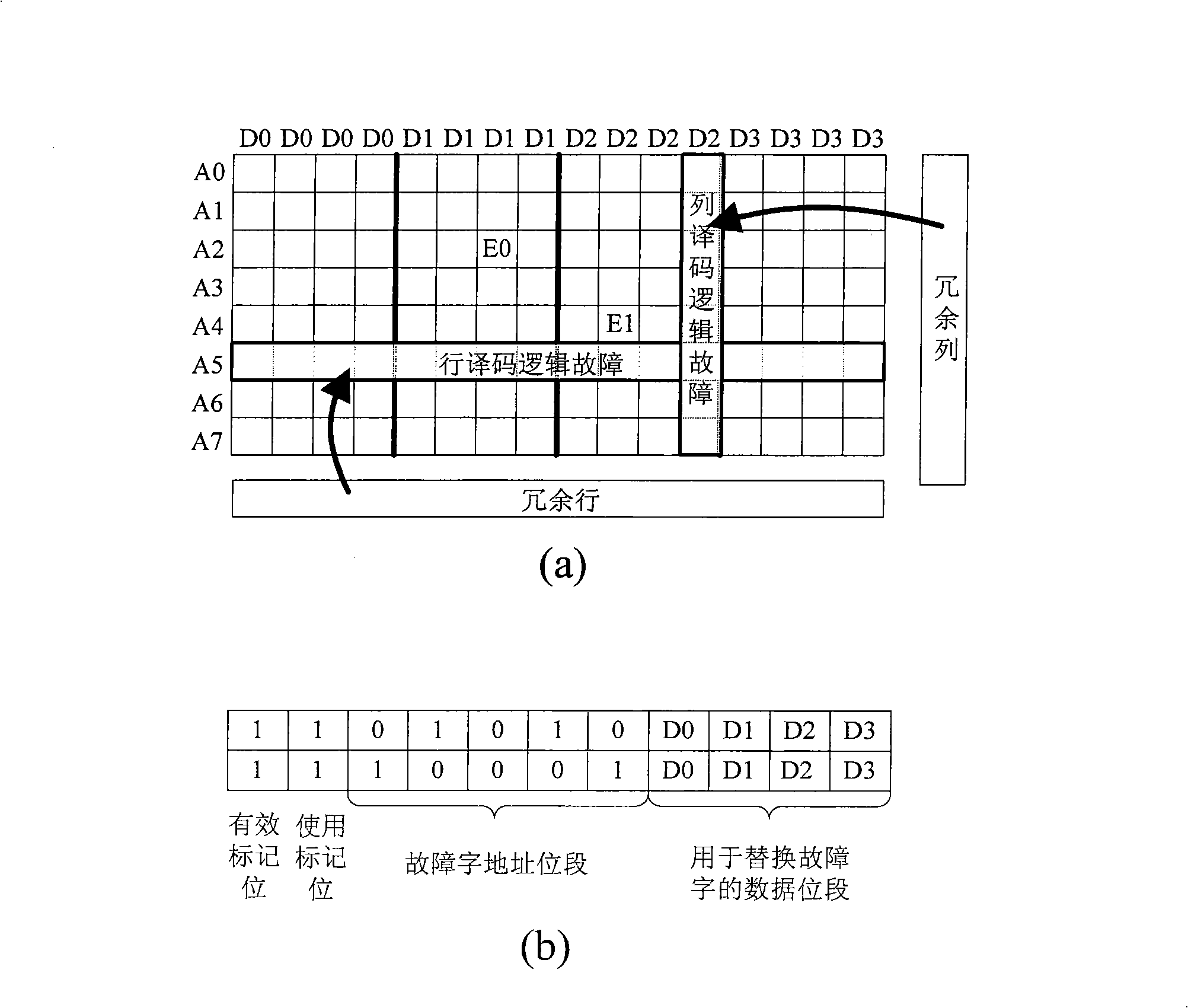

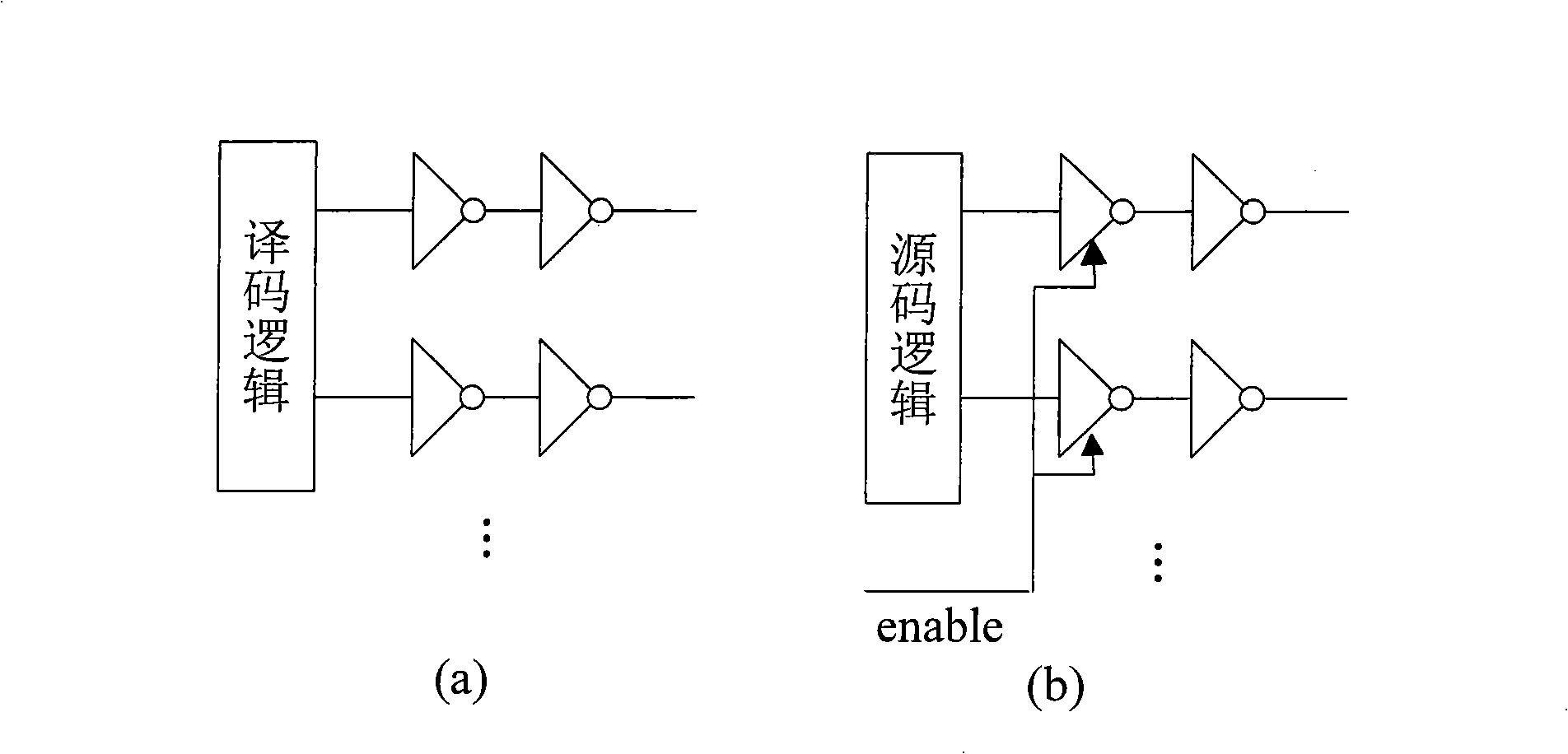

Built-in self-repairing system and method for memory

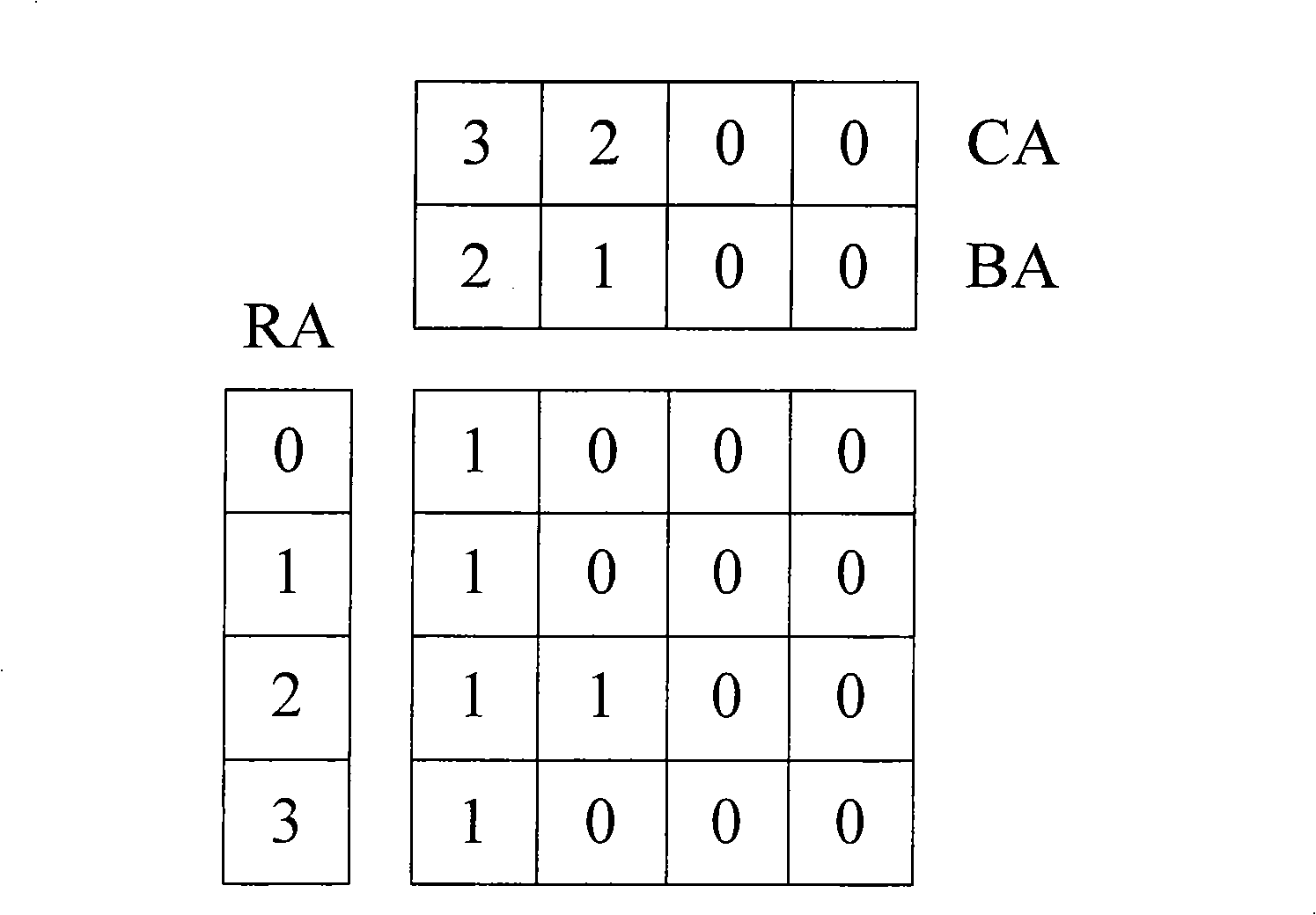

The invention provides a memory built-in self-repairing system which comprises a built-in self-testing circuit, a built-in self-diagnostic circuit, a built-in self-repairing circuit and a redundant row / column and is characterized in that: the built-in self-repairing circuit comprises a word repairing circuit provided with a redundant content addressable memory which is specially used for repairing the unit failures of a main memory; the redundant row / column is specially used for repairing the coding failures of the main memory. The invention also provides a corresponding built-in self-repairing method. The built-in self-repairing system and the built-in self-repairing method have the advantages of fining the granularity of redundant resources, increasing the utilization rate of the memory redundant resources, promoting the reliability of the memory after repairing by avoiding failed units with accessing defects, having simple default diagnosis and redundancy allocation algorithm that are easy to realize, making full use of the redundant resources and having better repairing effect.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

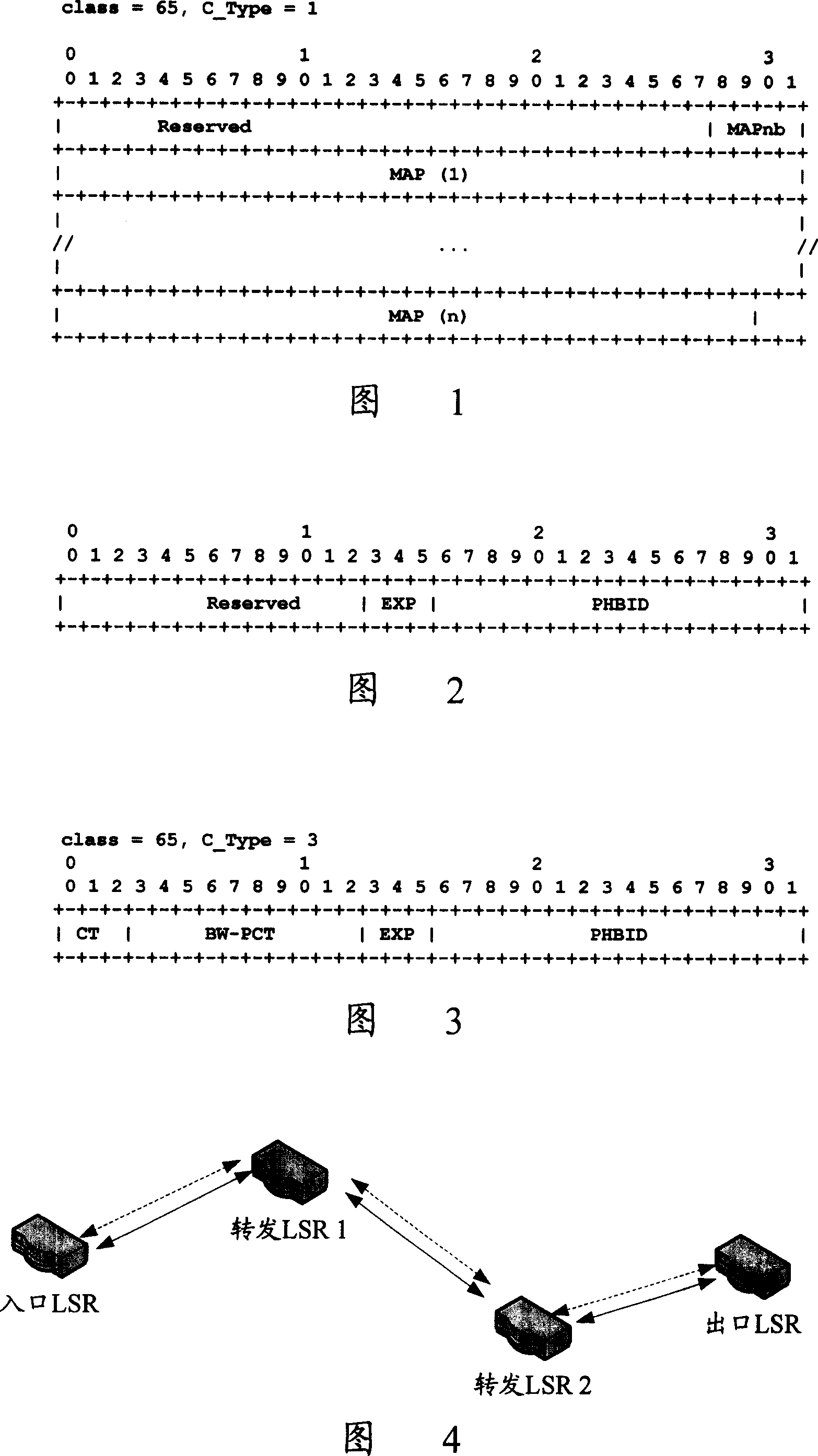

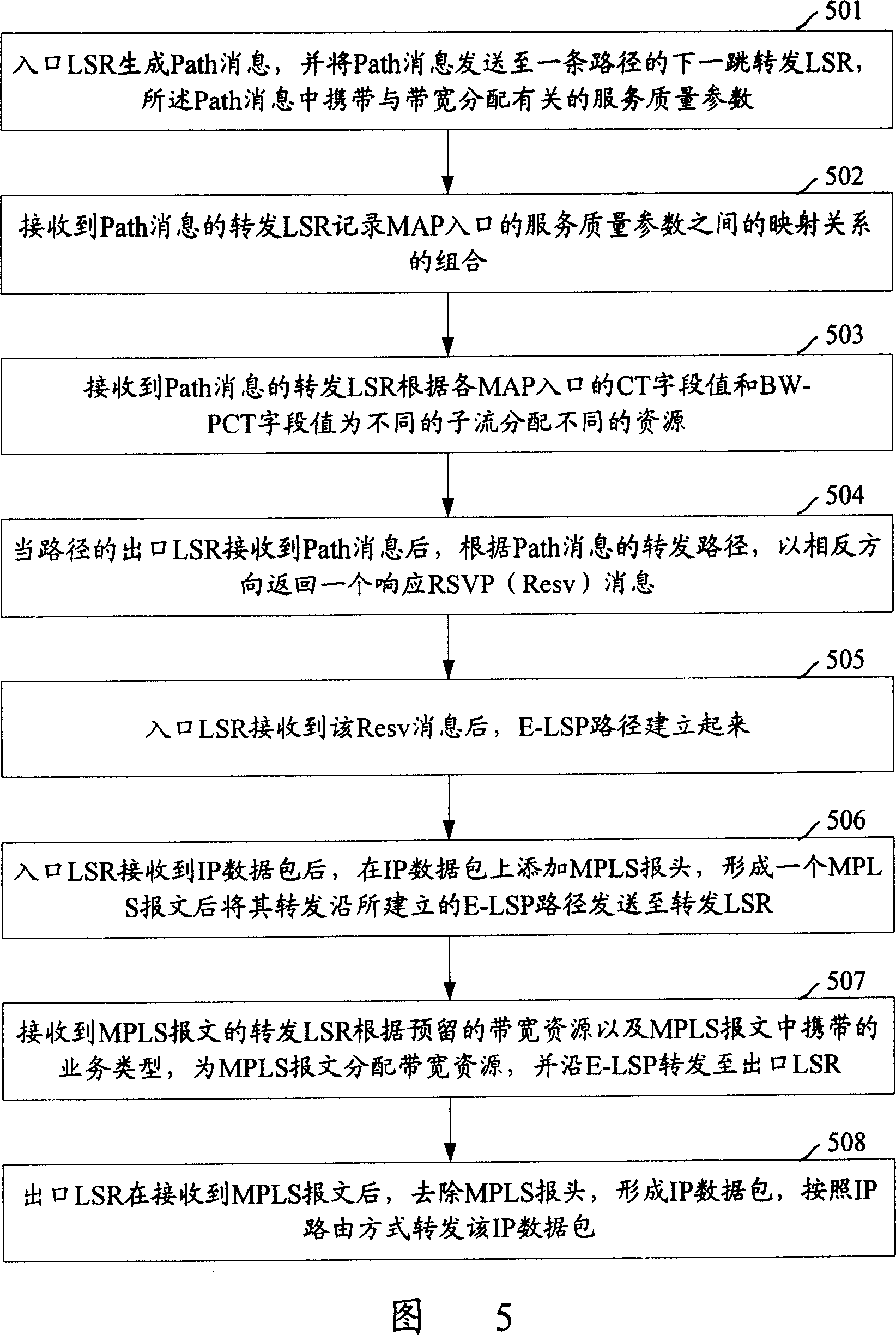

Method and system for implementing differential service flux engineering of multi-protocol label switching network

The method includes following key points: when the method establishes LSP, entrance LSR or transmit LSR carries service quality parameter (SQP) relevant to resource allocation in Path message; after receiving Path message, transmit LSR puts apart bandwidth resource for traffic flow based on SQP; after LSP is established, transmit LSR of receiving traffic flow determines bandwidth of traffic flow put apart, and forwards traffic flow according to bandwidth put apart. The invention also discloses system for implementing DS-TE of MPLS network. The system includes entrance LSR, transmit LSR, and exit LSR. Thus, the invention can allocate bandwidth resources based on different types of traffic flow, and further can thin granularity of traffic flow engineering.

Owner:HUAWEI TECH CO LTD

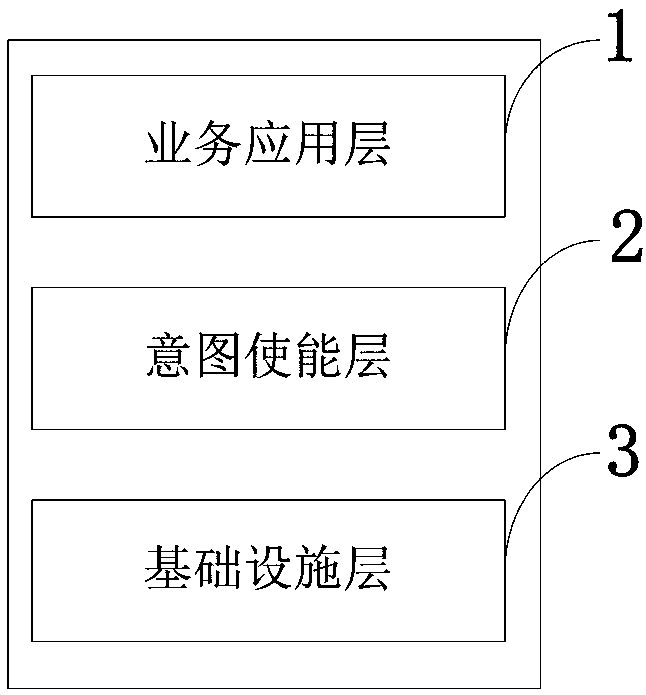

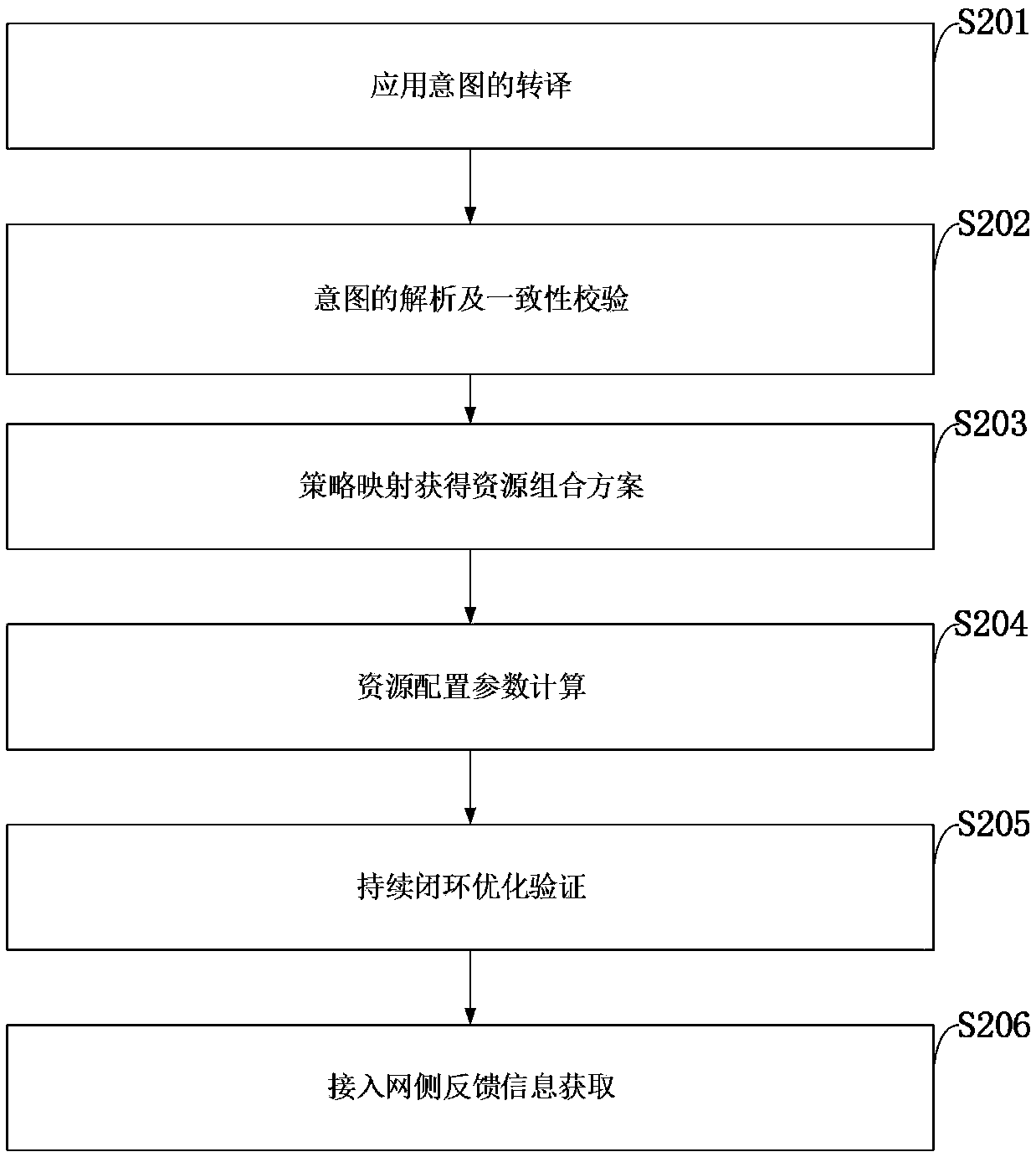

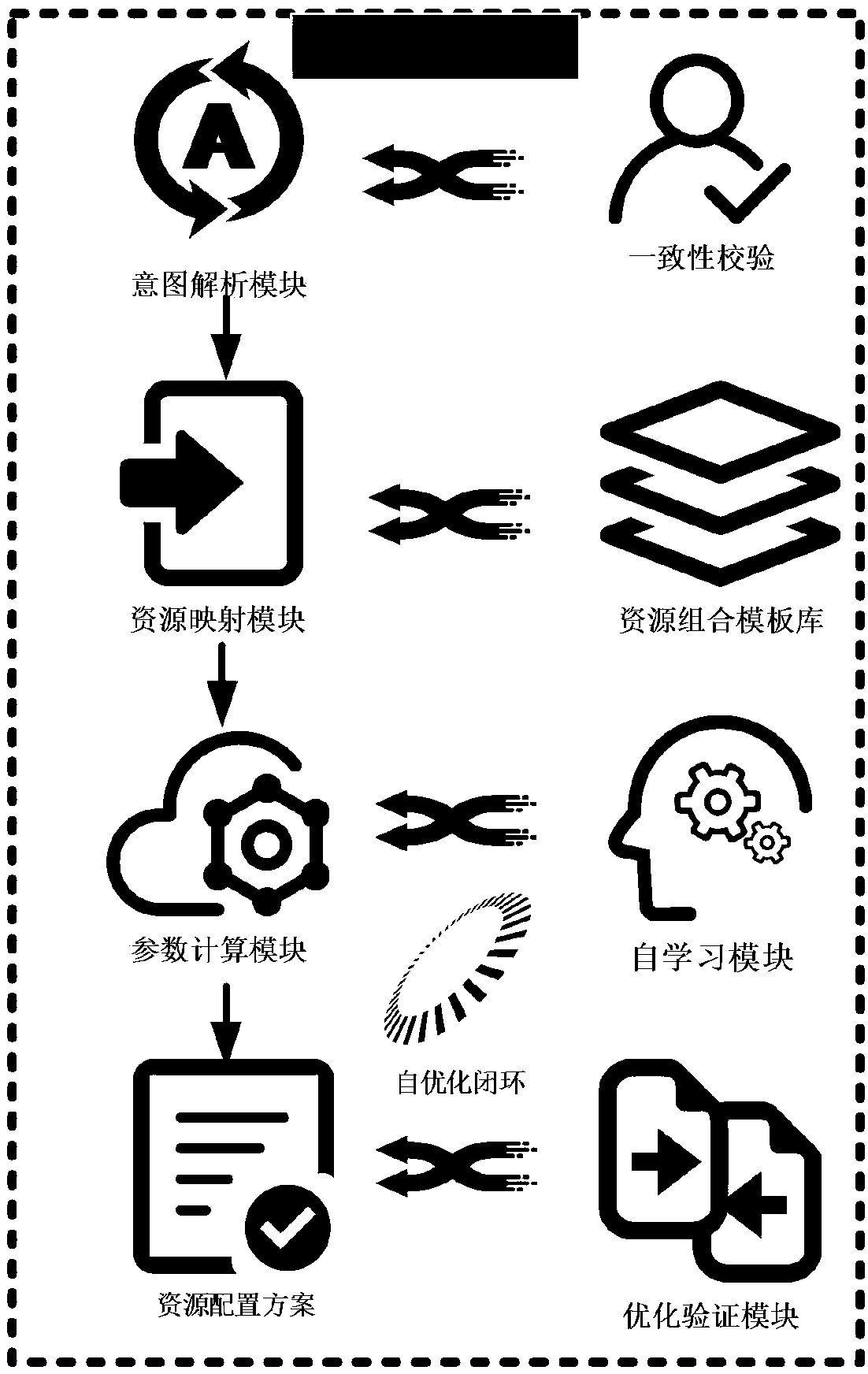

Intention-driven cloud access network system and method

The invention belongs to the technical field of wireless communication network, and discloses an intention-driven cloud access network system and method. The method comprises the steps that a businessapplication layer obtains a mobile network core application and a service complaint for a vertical industry application, and an intention northbound interface completes the transcoding; an intentionenabling layer constructs an intention-based global dynamic management and arrangement control system through a cloud network service plane, and achieves the unified planning of business intention andthe unified scheduling of resources; an infrastructure layer forms a resource pool through the resource virtualization technology, and provides a ubiquitous connection based on three big 5G application scenes. The method achieves the network cooperation, resource sharing, interface opening and management intelligentization based on an intention-driven cloud ubiquitous intelligent access network,constructs a reconfigurable resource management architecture. The invention also discloses the intention-driven cloud access network method, and the method achieves the cooperative scheduling of network resources, and guarantees the end-to-end services.

Owner:XIDIAN UNIV

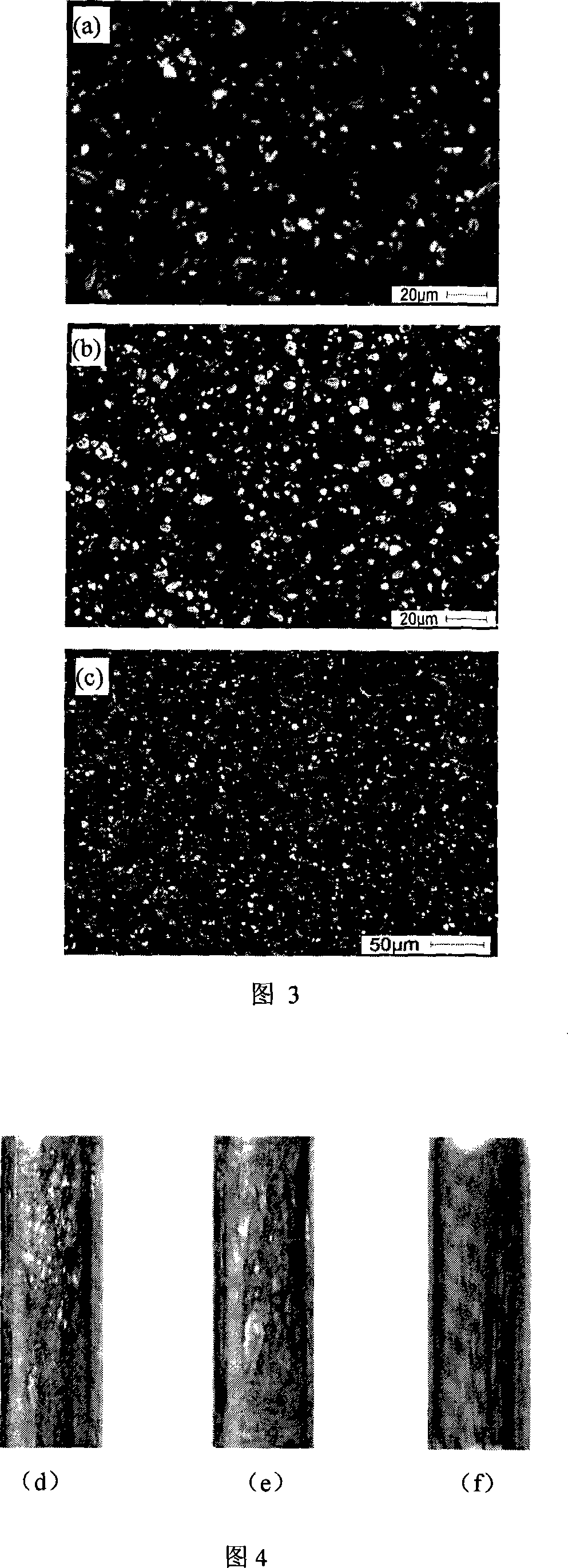

Method for preparing ultra-fine crystal grain tungsten-copper alloy and tungsten-copper alloy

A method to prepare ultra-fine grain tungsten-copper alloy and the tungsten-copper alloy, it belongs to powder metallurgy technology field. The solution of concentrated HNO3 and solution of Cu (NO3)2 will be added into the solution of (NH4)2WO4 at the condition that they are blended, the chemical deposition reaction will occur in the agitator. And then the deposit will be burned and grinded to produce the composite powder of tungsten-copper oxidate. The composite powder will be reduced at low temperature in the pipe furnace, and nanometer tungsten-copper composite powder can be gained, and then they will be pressed to take shape, the pressed compact will be sintered at the protection of H2 and ultra-fine grain tungsten-copper alloy can be gained. The weight percent of copper in a kind of tungsten-copper alloy produced according to the above method is 20%, the relative density of the alloy is 98.0%-99.7%, the average crystal grain size of the tungsten in the alloy is 0.5-1.5 mu m, the electrical resistance of the alloy is 0.035-0.041X10-6omega .m, the heat-transmit index is 200-223W.m-1.k-1. The advantage of it is that. The densification degree of the alloy is high, the tungsten crystal grain is small and uniform, the copper is highly dispersed to compose a compact net. And the flow of it is short, the technology operation is easy and reliable, the production efficiency is high, the energy and production cost is lower, and an industrial production can be carried on according the method.

Owner:UNIV OF SCI & TECH BEIJING

Aluminum-scandium alloy target blank and preparation method and application thereof

InactiveCN107841639ALow oxygenMeet the characteristic requirements of sputteringVacuum evaporation coatingSputtering coatingCrystalliteScandium

The invention relates to an aluminum-scandium alloy target blank and a preparation method and application thereof. The aluminum-scandium alloy target blank comprises, by weight part, 0.1-15 parts of scandium and 85-99.9 parts of aluminum, and the oxygen content of the aluminum-scandium alloy target blank is smaller than or equal to 160 ppm. The aluminum-scandium alloy target blank has the beneficial effects that the oxygen content is low, then the prepared target blank cannot generate abnormal discharge or particle splashing scars, and later high-quality film forming can be guaranteed; and inaddition, the aluminum-scandium alloy target blank is even in target blank crystal particle size.

Owner:GEMCH MATERIAL TECH SUZHOU

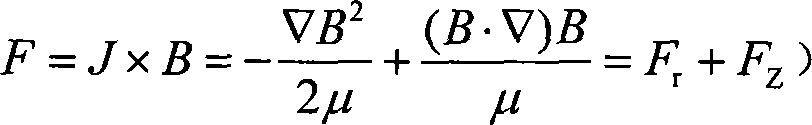

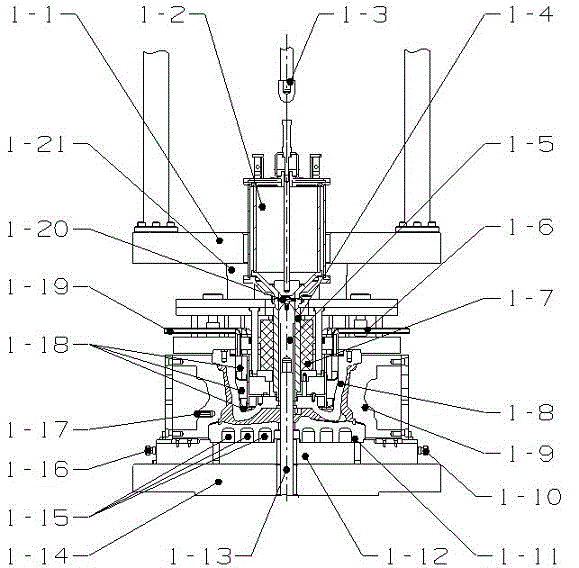

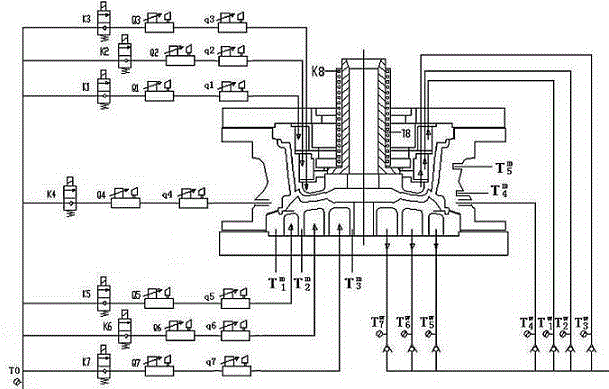

Method of continuous casting particulate reinforced metal matrix composites on different frequency multi-electromagnetic field

Disclosed is a method of particle reinforced metal matrix composite continuous casting in compound magnetic field at different frequency, relating to material processing technology field; in the process of the preparation of the composites melt, low-frequency alternating magnetic field is applied: the frequency is from 5 to 50 Hz, the power range is from 5 to 60 kW; electromagnetic stirring is carried out, making the particles to be fined and evenly distributed; in the process of continuous casting, low-frequency alternating magnetic field is applied to the crystallizer zone: the frequency is from 5 to 50 Hz, the power range is from 5 to 20 kW; electromagnetic stirring is carried out to improve the internal quality; meanwhile, the high-frequency alternating magnetic field is applied in initial solidification zone in crystallizer: the frequency is from10 to 50 kHz, the power range is from 20 to 100Kw, soft contact is applied to improve the surface quality of casting billet. The composites article reinforcement prepared by the method are evenly distributed and fined, the internal organization is compact without any structural defects such as rarefaction or shrinkage hole, the casting billet has high surface finish without any defects.

Owner:JIANGSU UNIV

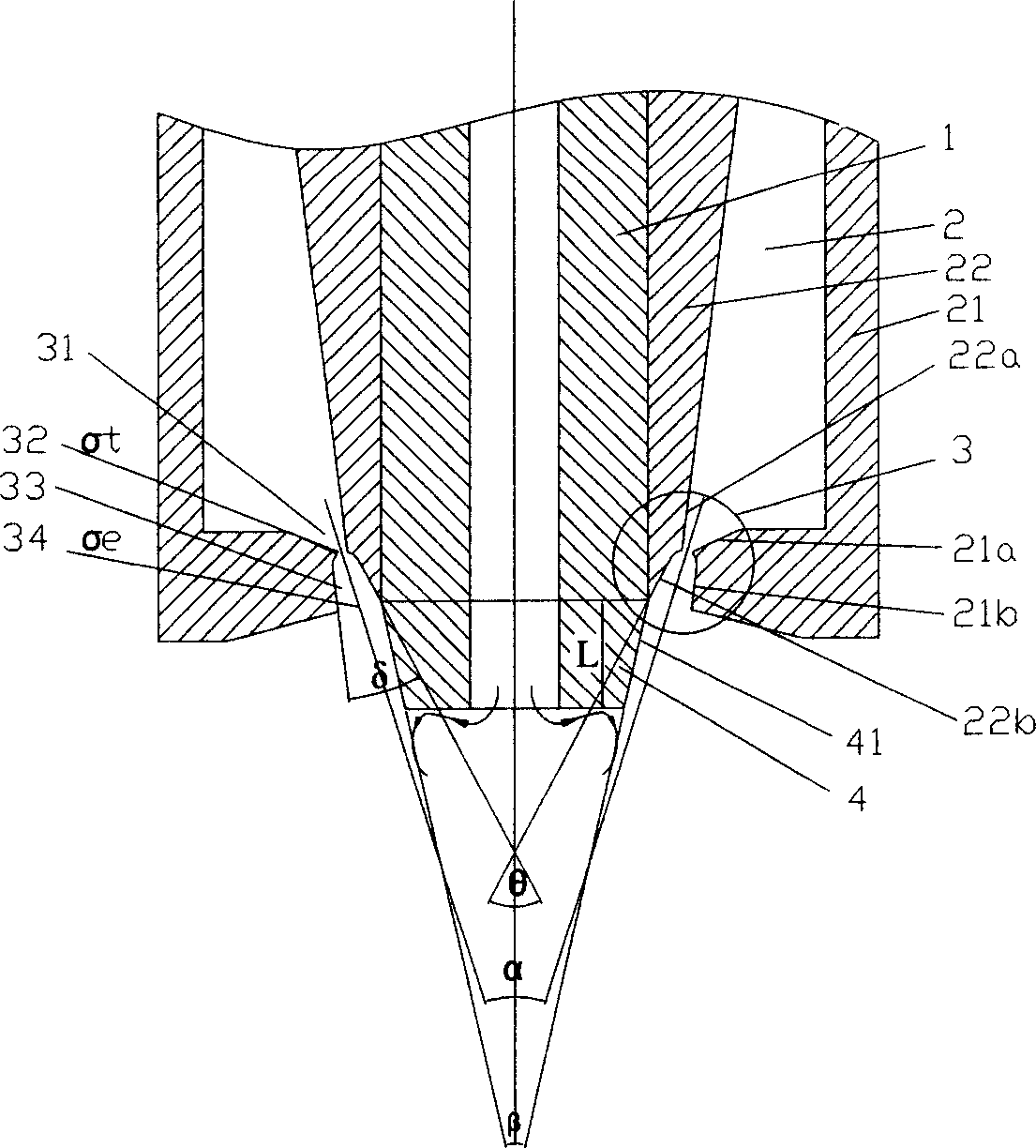

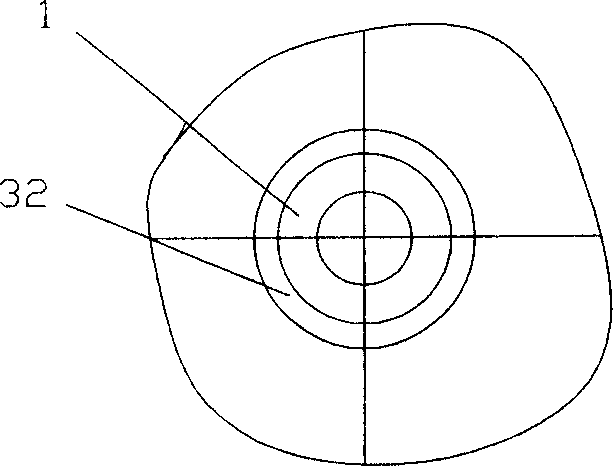

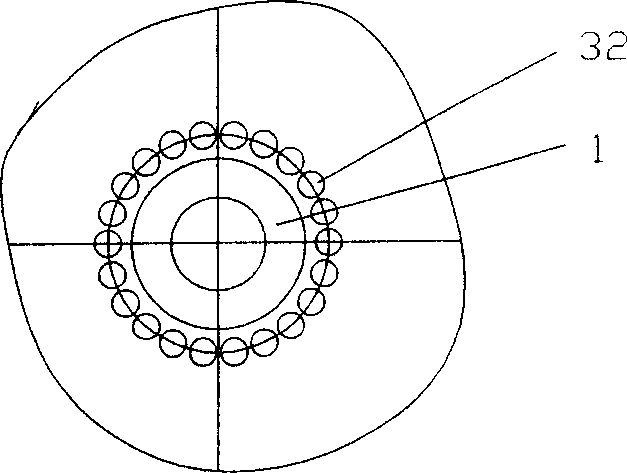

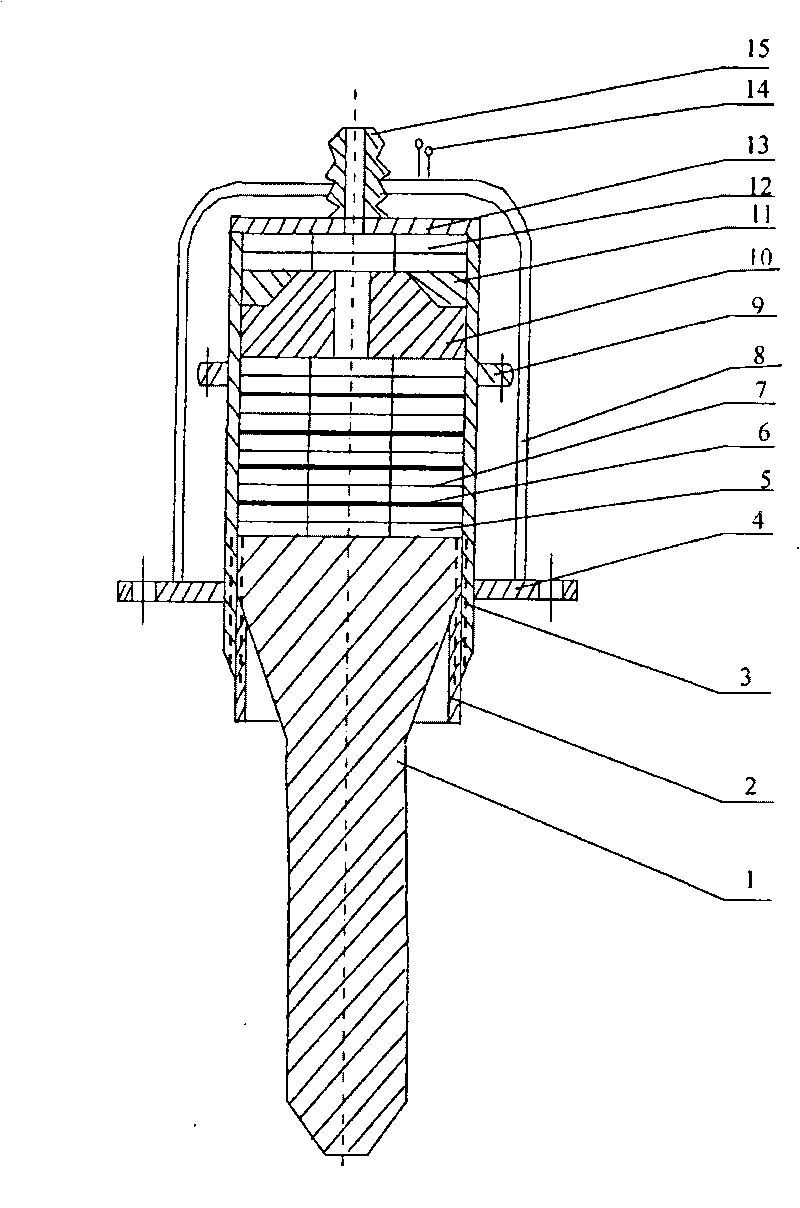

High-pressure gas atomizing nozzle

The present invention relates to the equipment using gassy pulverization high temperature coulee to make super thin powder, especially heavy-fisted gassy pulverization muzzle. It comprises guiding flow pipe outside which there is gas cavity whose ektexine and wall form Laval spout frame. The ektexine of pipes around the top of guiding flow pipe takes on taper. This invention can be applied to material with pulverization high melting point and the need to liquid's superheat temperature is not high. The air current of high-handed gas pulverizations melting liquid make super thin powder by very kinetic energy. It can not only make the most use of gas energy and make sure of the continuity on craftwork but also slender the powder and improve productivity.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

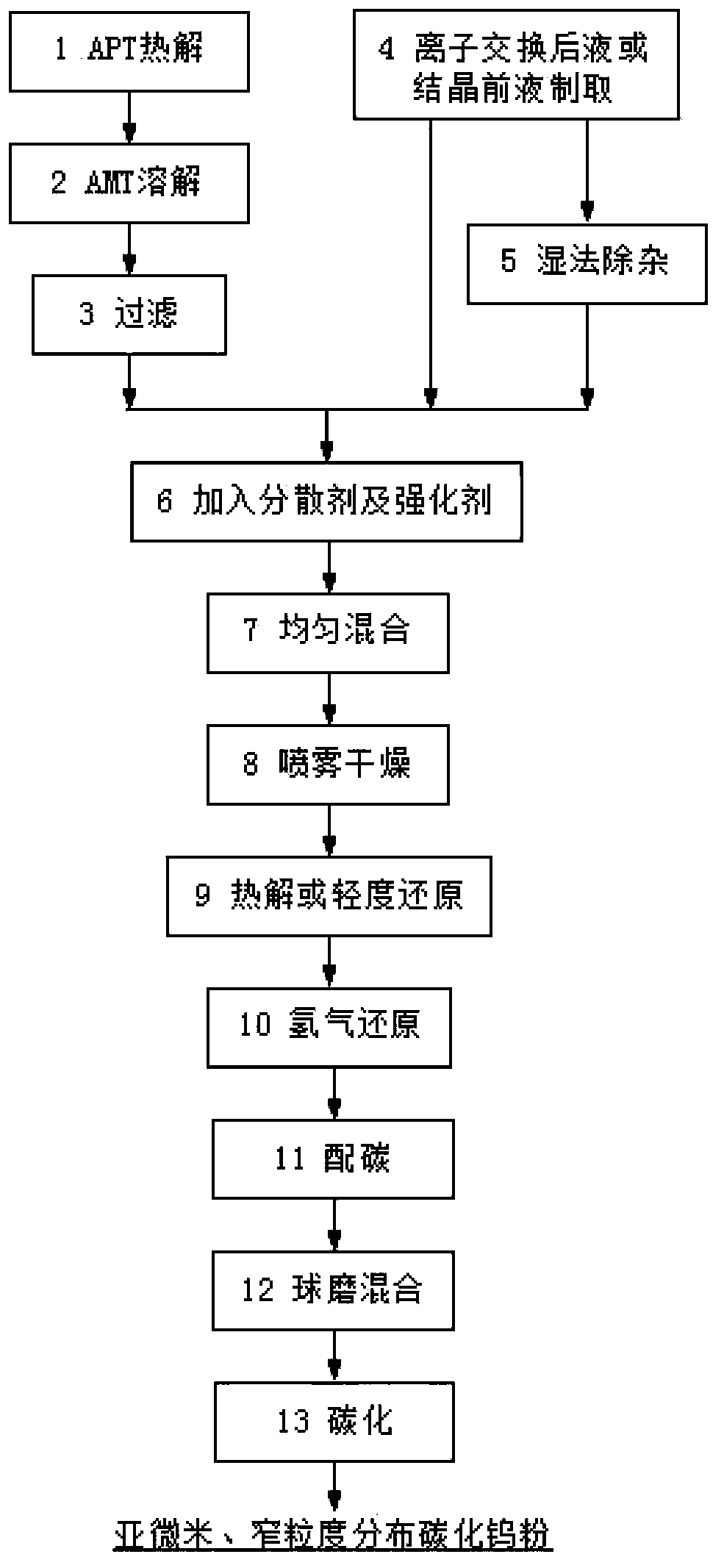

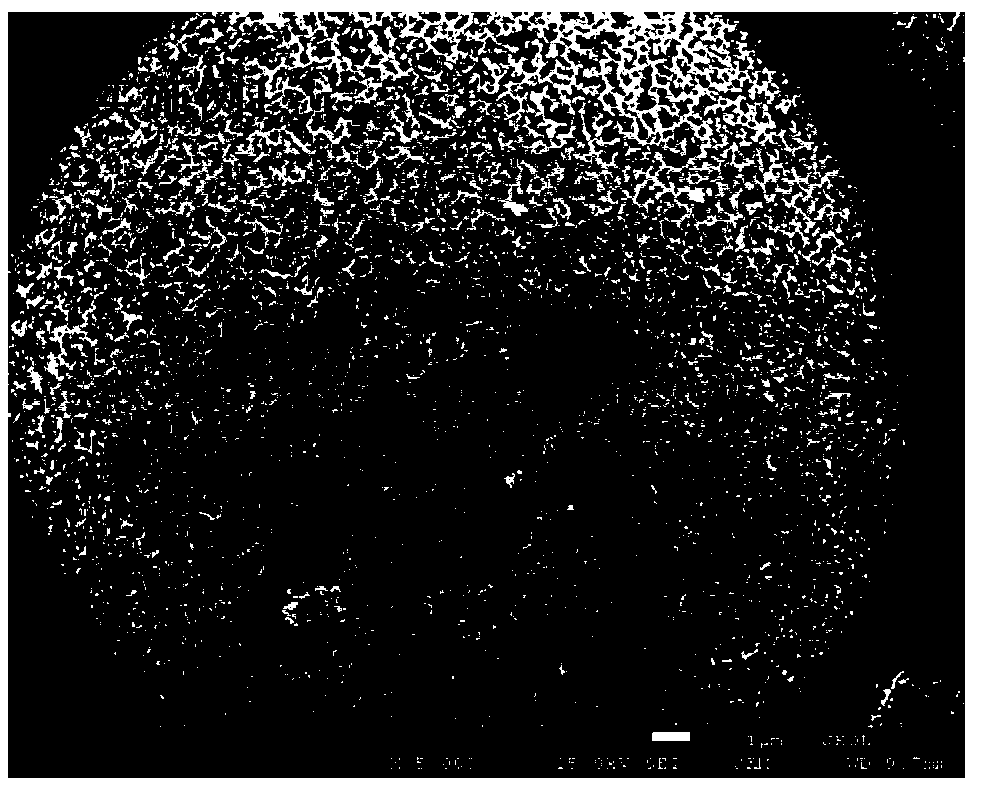

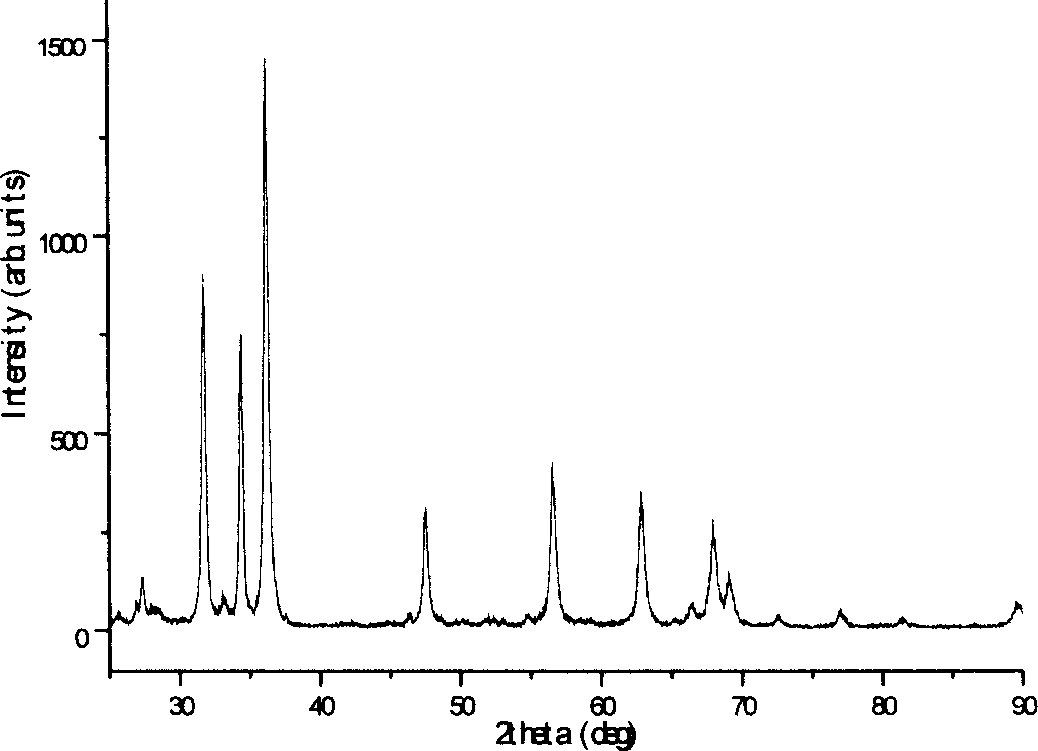

Submicron narrow particle size distribution type tungsten powder and tungsten carbide powder and preparation method thereof

ActiveCN103570020AControllable wall thicknessPurity does not affectTungsten/molybdenum carbideTungstateKetone

The invention relates to submicron narrow particle size distribution type tungsten powder and tungsten carbide powder and a preparation method thereof, and belongs to the field of metallurgic powder preparation of refractory metal powder. The submicron narrow particle size distribution type tungsten powder and tungsten carbide powder are characterized in that the average particle size is 0.1 to 1.0 micron, and the maximum particle size is not greater than twice of the average particle size. The preparation method comprises the following steps: taking an ammonium tungstate solution as a raw material and a high molecular surfactant as a dispersing agent; reinforcing the dispersion effect through alcohol or ketone; quickly crystallizing and drying by spray drying to obtain fine particle hollow thin-walled spherical ammonium tungstate crystals; and performing pyrolysis, hydrogen gas reduction and carbonizing; and then generating submicron narrow particle size distribution type tungsten powder and tungsten carbide powder in situ. According to the preparation method, the submicron narrow particle size distribution type tungsten powder and tungsten carbide powder can be prepared in situ; and the technology is reformed and upgraded on the basis of the existing production condition of the enterprise, so that the scale production is easily realized, the production efficiency is high, and the effect is great.

Owner:GRIMAT ENG INST CO LTD

Preparation and application of high-potential gradient zinc oxide piezoresistor material

This invention relates to the preparation and application of a high potential gradient ZnO piezoresistive material including: mixing raw materials in the mol ratio of ZnO: Bi2O3:Sb2O3:Cr2O3:Co2O3:MnO2=96.5:0.7:1.0:0.5:0.8:0.5 to get the product by first and second time powerful fine grindings, low temperature sinter, which is taken as the raw material to be pressed to formation, sintered at low temperature, coated with electrode Ag pulp and welded with electrode lead to get the product of high potential gradient ZnO piezoresistors. This invention greatly refines the metal oxide mixed powder grain size by twice-powerful grindings, the sintered temperature is only 900deg.C and the grain is 1.5-3.5mum.

Owner:EAST CHINA NORMAL UNIVERSITY

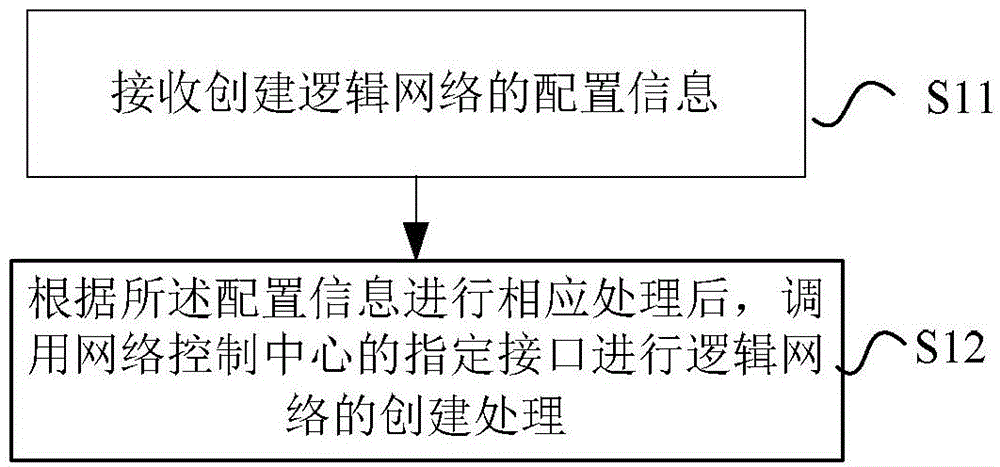

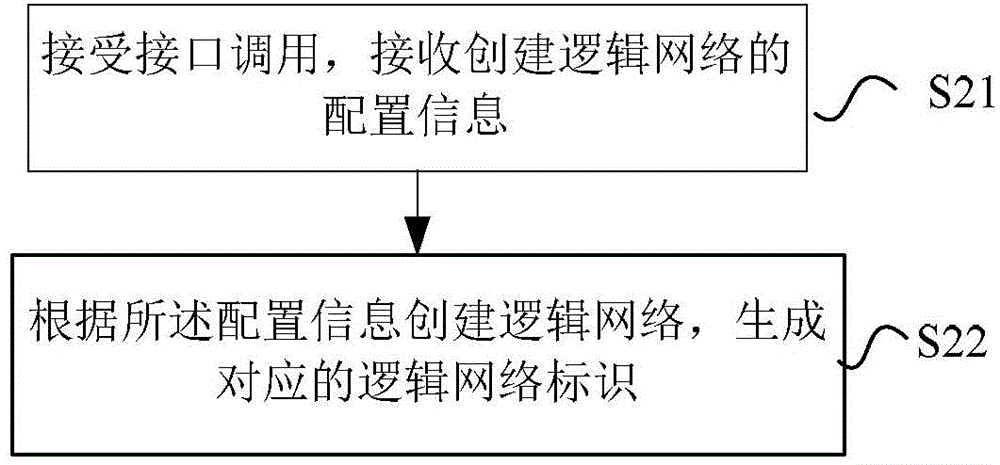

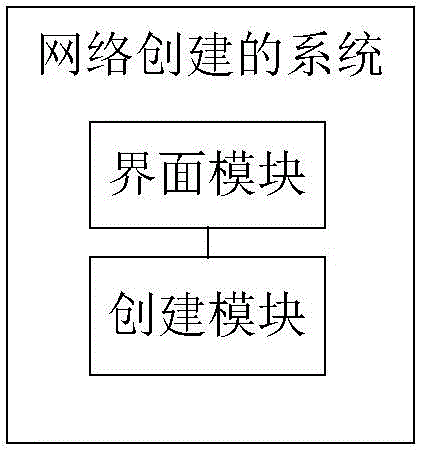

Network establishment method and system, and network control center

ActiveCN103607432AImprove automation performanceGranularityTransmissionStrategy executionNetwork control

The invention provides a network establishment method and a system, and a network control center. The method comprises the following steps of receiving configuration information used for establishing a logic network; according to the configuration information, after corresponding processing is performed, calling an assigned interface of the network control center to carry out establishment processing of the logic network. Through the method, the system and the network control center of the invention, the private and isolated logic network is established for different users; according to distribution of calculating resources owned by the user, network partition and connection are completed; network configuration is uniformly performed and strategy execution is controlled; a QOS demand needed by the user is satisfied and flexible expansion can be performed according to a need.

Owner:NANJING ZHONGXING SOFTWARE

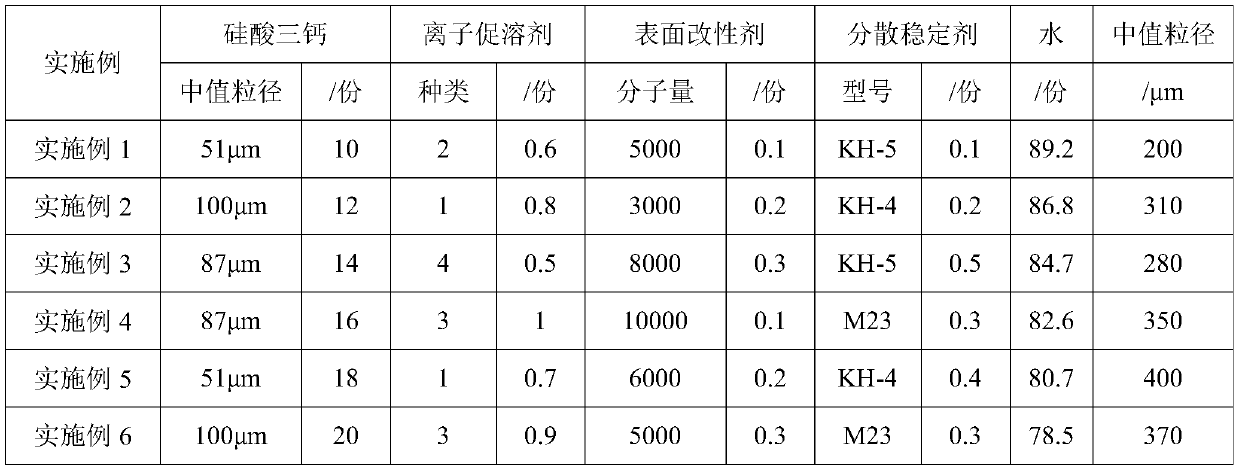

Method for realizing test exemple automation operation

Owner:STATE GRID TIANJIN ELECTRIC POWER

A high temperature resistant solder nickel zinc soft ferrite material

The invention discloses a nickel and zinc soft magnetic ferrite material and a preparation method thereof. A high-temperature-resistant soldering tin, nickel and zinc soft magnetic ferrite material comprises the following components in parts: 45-50mol percent of Fe2O3, 26-32 mol percent of ZnO, 17-21 mol percent of NiO and 4-8 mol percent of CuO, and also comprises the following components in parts: 0.2-0.5 wt percent of auxiliary material A and 0.1-0.2 wt percent of auxiliary material B, wherein the auxiliary material A is one or two of Bi2O3, SiO2 and Ta2O5, and the auxiliary material B is one or more of TiO2, ViO5 and Nb2O5. The high-temperature-resistant soldering tin, nickel and zinc soft magnetic ferrite material has the characteristics of high frequency, high magnetic conductivity,high Bs and TC (Temperature Curie).

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +2

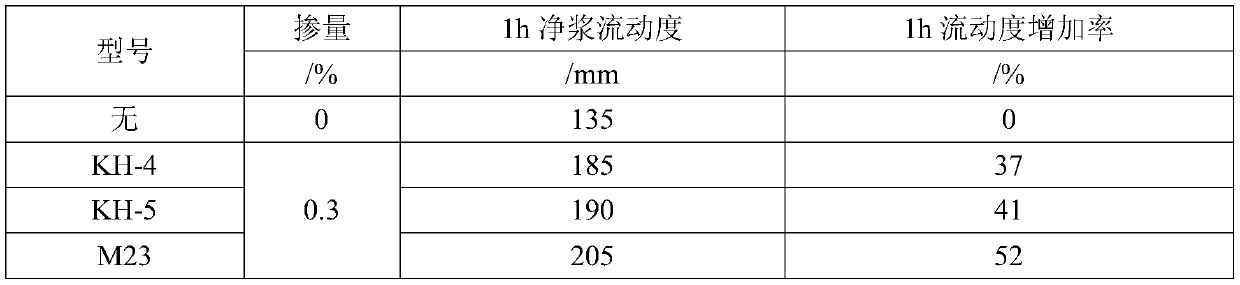

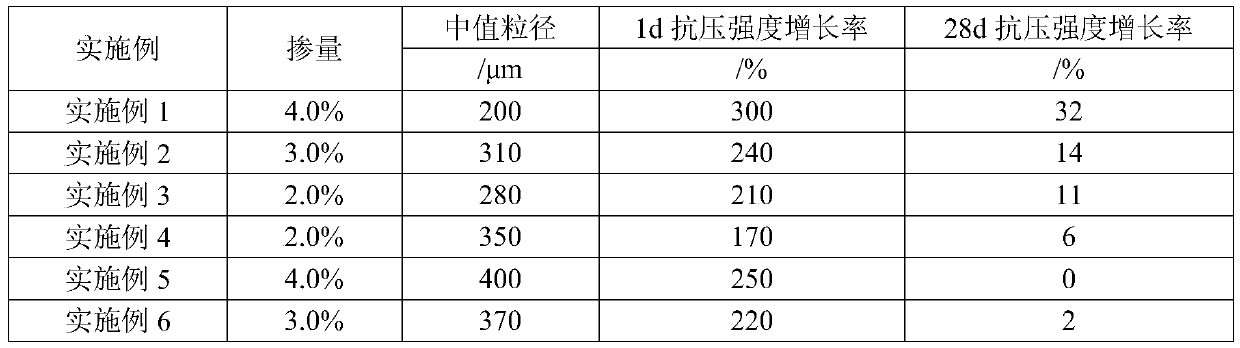

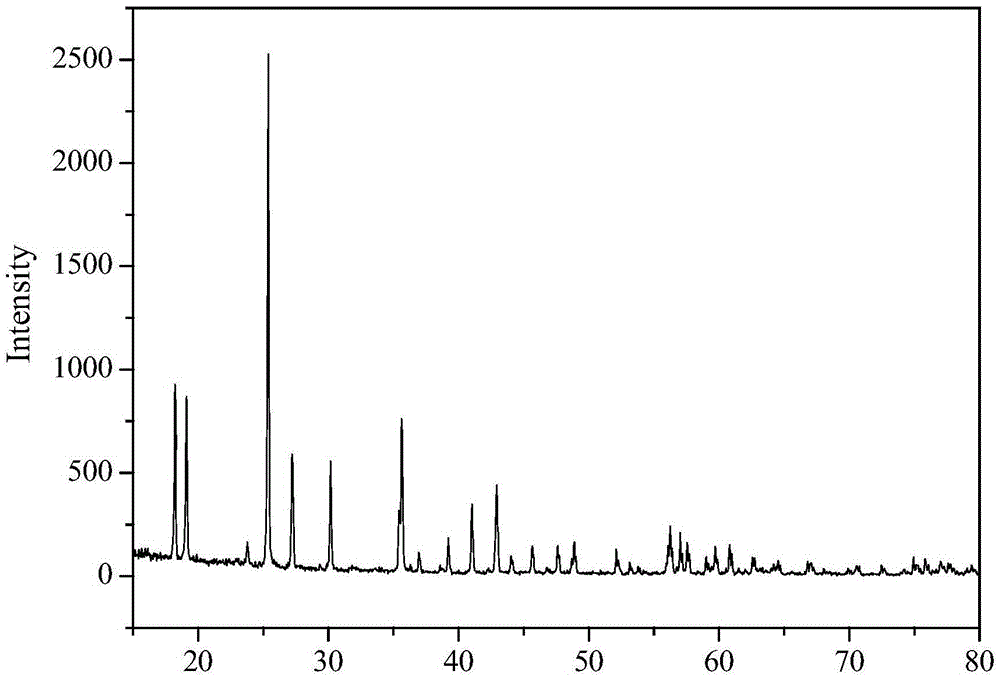

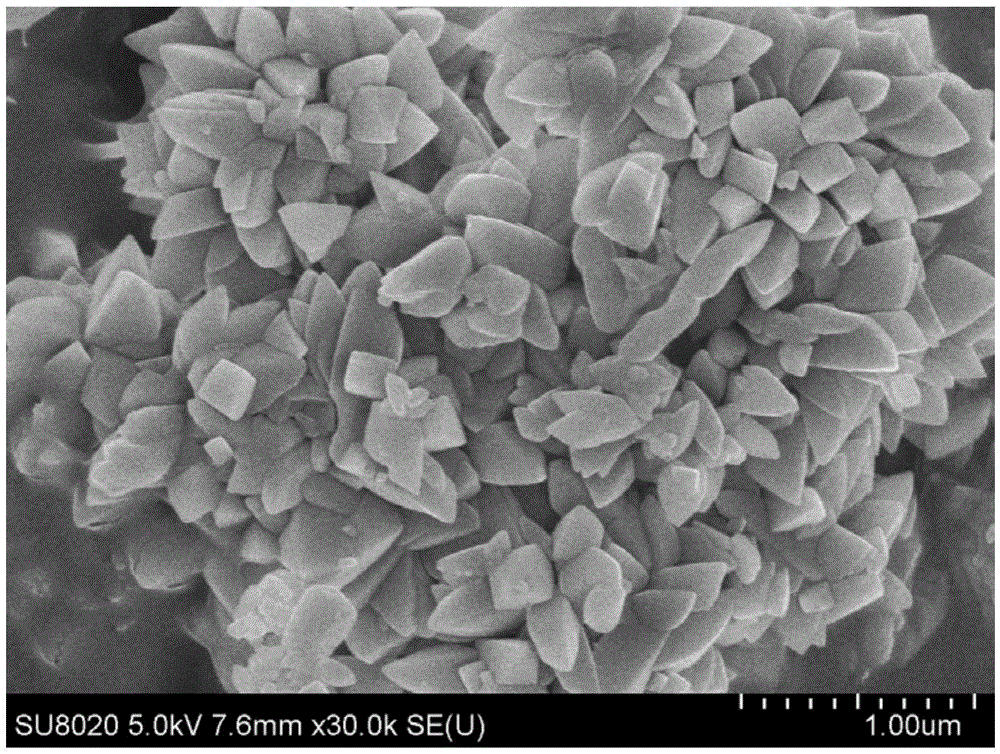

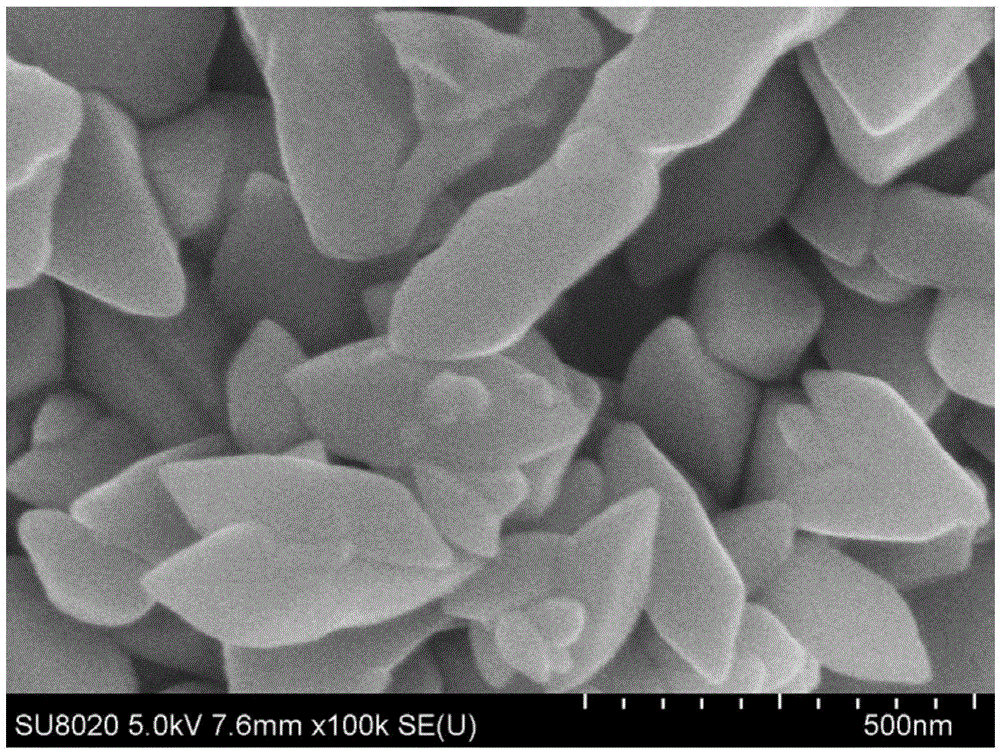

C-S-H gel nanocrystal nucleus early strength agent, preparation method and application thereof

ActiveCN110330257AAccelerated nucleation growthImprove pore structureIon acceleratorsNucleation growth

The invention provides a C-S-H gel nanocrystal nucleus early strength agent, a preparation method and application thereof. The C-S-H gel nanocrystal nucleus early strength agent is mainly prepared from the following components by weight through wet milling process: 10-20 parts of tricalcium silicate, 0.5-1 part of an ion promoter, 0.1-0.3 part of a surface modifier, 0.1-0.5 part of a dispersion stabilizer, and 78.5-89.2 parts of water. The C-S-H gel nanocrystal nucleus early strength agent provided by the invention utilizes the crystal nucleus induction effect of nano form C-S-H gel to accelerate the nucleation growth of hydration products at the early stage of hydration, and can achieve the early strength purpose from the two aspects of by improving the pore structure and inducing nucleation.

Owner:WUHAN UNIV OF TECH

Preparation method of manganese phosphate and manganese phosphate product

InactiveCN105609765AHigh purityUniform particle size distributionCell electrodesSecondary cellsManganeseSlurry

The invention discloses a preparation method of manganese phosphate and a manganese phosphate product. The method comprises the following steps: weighing a soluble phosphorus source compound and a soluble manganese source compound at the molar ratio of P to Mn being (1-2) to 1, dissolving the soluble phosphorus source compound and the soluble manganese source compound into deionized water to prepare solutions; feeding a manganese source solution to an acid-resistant reaction kettle by a metering pump, and then adding a phosphorus source solution for stirring; feeding an oxidant to the acid-resistant reaction kettle by the metering pump, and adjusting the pH value of a system; adding the organic solvent to the acid-resistant reaction kettle, and carrying out stirring reaction at 30-90 DEG C; and naturally cooling the obtained manganese phosphate slurry to a room temperature, carrying out washing, filtering and drying to obtain a manganese phosphate (MnPO<4>.H<2>O) product. According to the method, the manganese deposition rate reaches over 99%; the manganese resource is fully utilized; the product purity is high; the Mn content is greater than 32%; the P content is 18%-19%; the content of a main impurity S is smaller than 0.5%; the content of Na is smaller than 0.02%; the particle size distribution is uniform; and the mean particle size is smaller than 1micron.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

Powerful casting technology for aluminum alloy wheels

The invention discloses a powerful casting technology for aluminum alloy wheels. The powerful casting technology aims at solving the problems that in traditional low-pressure casting and gravity casting of the aluminum alloy wheels, the feeding capacity is weak, the strength of castings is low, and the ductility is low. According to the powerful casting technology for the aluminum alloy wheels, under the condition that materials are not changed, as the casting technology is changed, the application effects of increasing density, strength, the ductility, the material use rate and the production rate are achieved. The powerful casting technology is characterized in that conventional cast aluminum is smelted to be within a casting temperature range, casting is completed in an air-entrapment-free flow guide and speed-control mold filling mode, real-time powerful feeding in the solidification process is carried out on molten aluminum sealed in a cavity through a feeding pressurizing mechanism, a mold temperature control measure point and cooling-channel distribution method is given based on the sequential-solidification and rapid-cooling thought, and necessary conditions are provided for obtaining the castings with the tiny grain size and smoothly implementing powerful feeding.

Owner:秦皇岛燕大现代集成制造技术开发有限公司

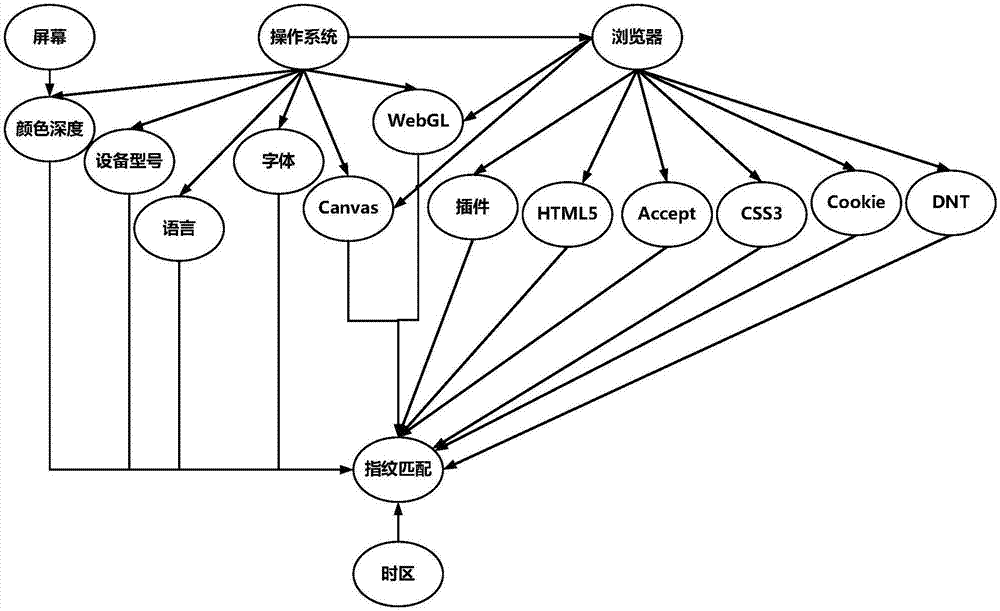

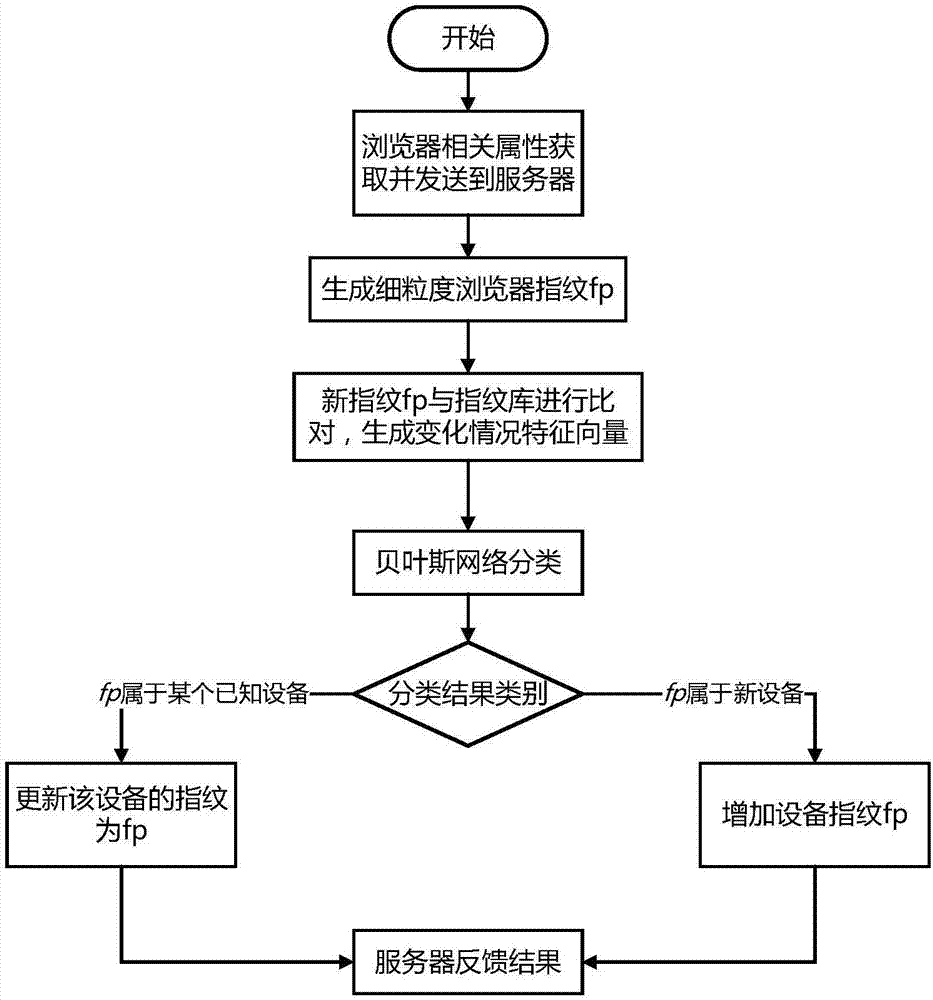

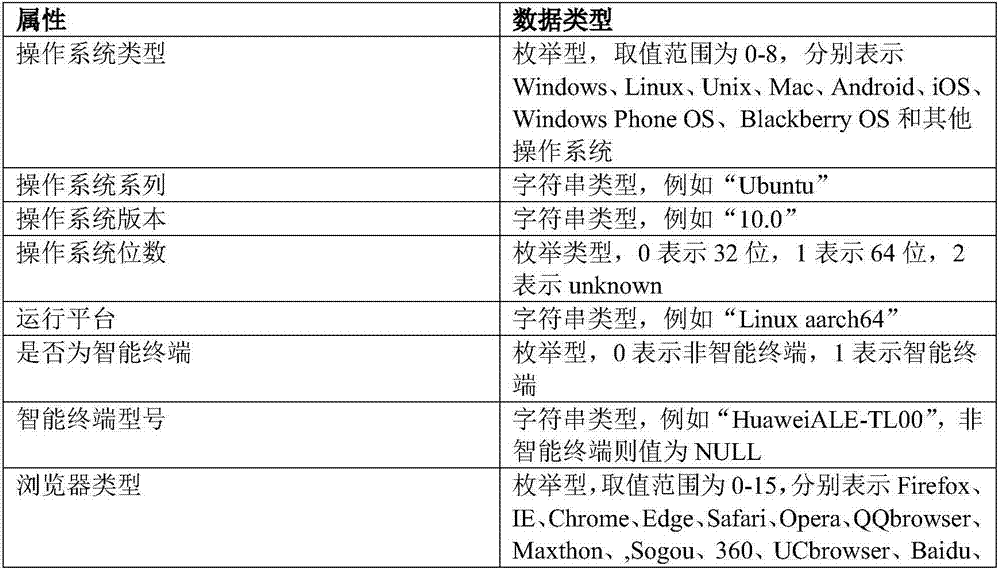

Terminal device identification method being resistant to browser fingerprint change

ActiveCN107066974AGranularityEliminate negative effectsMatching and classificationPattern recognitionTerminal equipment

The invention provides a terminal device identification method being resistant to browser fingerprint change. The invention includes I extracting a fingerprint generation scheme of forming the fine grain by means of multi-attribute features by filtering the redundant attributes and segmenting the coarse-grained attributes; II constructing the corresponding Bayesian network structure and performing parametric learning according to the mutual relation between the fingerprint attributes; and III performing fingerprint coupling classification on the unknown equipment and feeding back the result. By analyzing and filtering the relative attributes, the plurality of fine-grained attributes are extracted to form the browser fingerprint, and moreover, the mutual relation between the attributes is inferred according to the fingerprint change condition, a corresponding Bayesian network is constructed, so that the accurate identification of the terminal device under the finger change condition can be realized.

Owner:SOUTHEAST UNIV

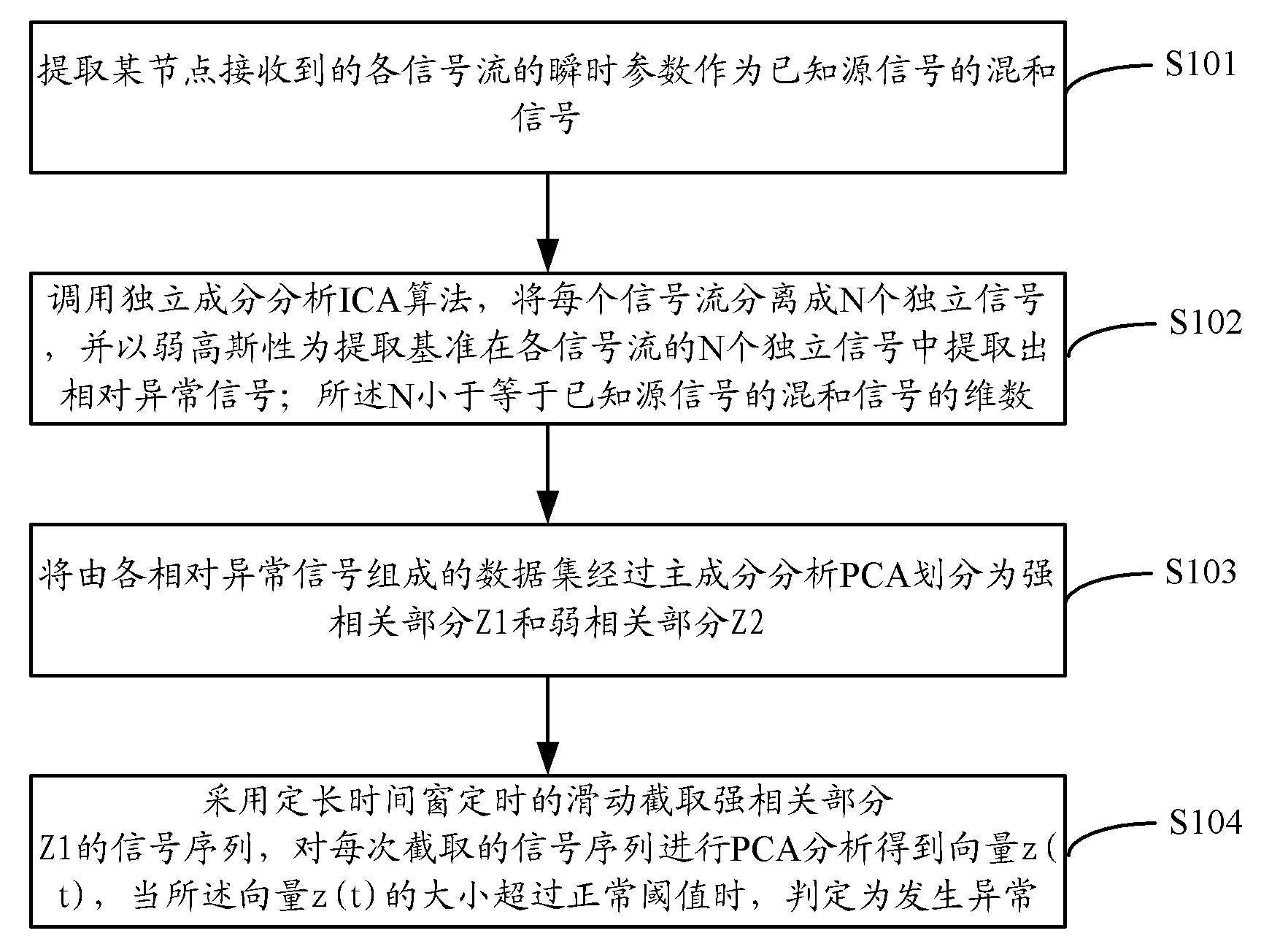

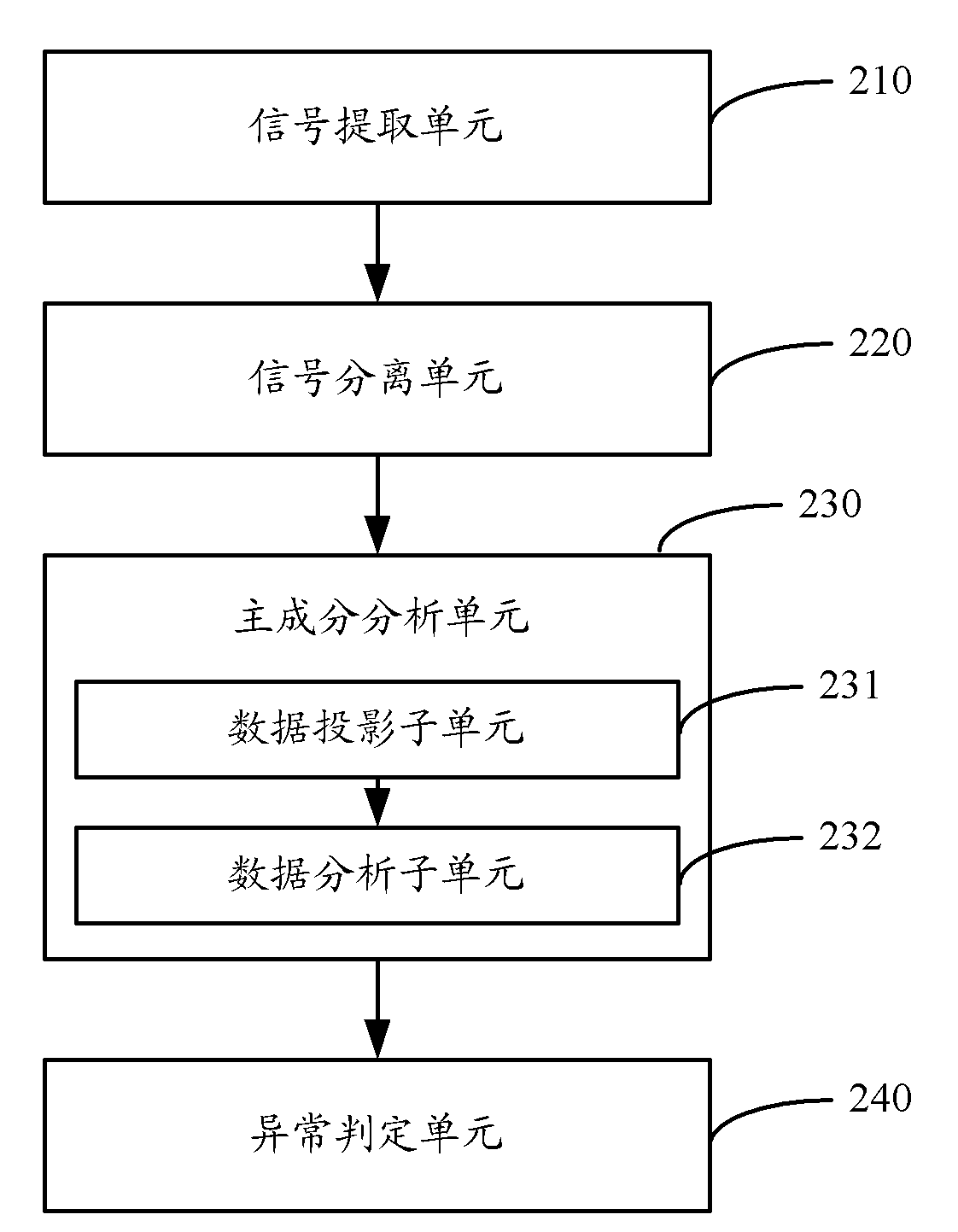

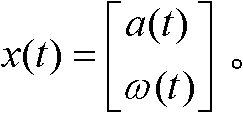

Method and device for detecting multidimensional flow anomalies of distributed network

The invention discloses a method and device for detecting multidimensional flow anomalies of a distributed network. The method comprises the following steps: extracting instantaneous parameters of each signal flow which is received by a certain node as mixed signals of a given source signal; calling an independent component analysis (ICA) algorithm to divide each signal flow into N independent signals, and taking weak Gaussianity as extraction reference to extract relative abnormal signals in the N independent signals of each signal flow, wherein N is less than or equal to the dimensionality of the mixed signals of the given source signal; dividing a data set Y constituted by the relative abnormal signals into a strongly correlated portion Z1 and a weakly correlated portion Z2 by virtue of principle component analysis (PCA); adopting timed sliding of a fixed-length time window to capture the signal sequence of the strongly correlated portion Z1, and carrying out PCA on the captured signal sequence each time so as to obtain a vector z1(t); and when the size of the vector z1(t) exceeds a normal threshold value, judging that anomalies exist. According to the invention, the ICA is utilized to separate out abnormal portions from the frequency domain and time domain of each flow signal, thus eliminating influences caused by similar characters among the normal flows.

Owner:NO 30 INST OF CHINA ELECTRONIC TECH GRP CORP

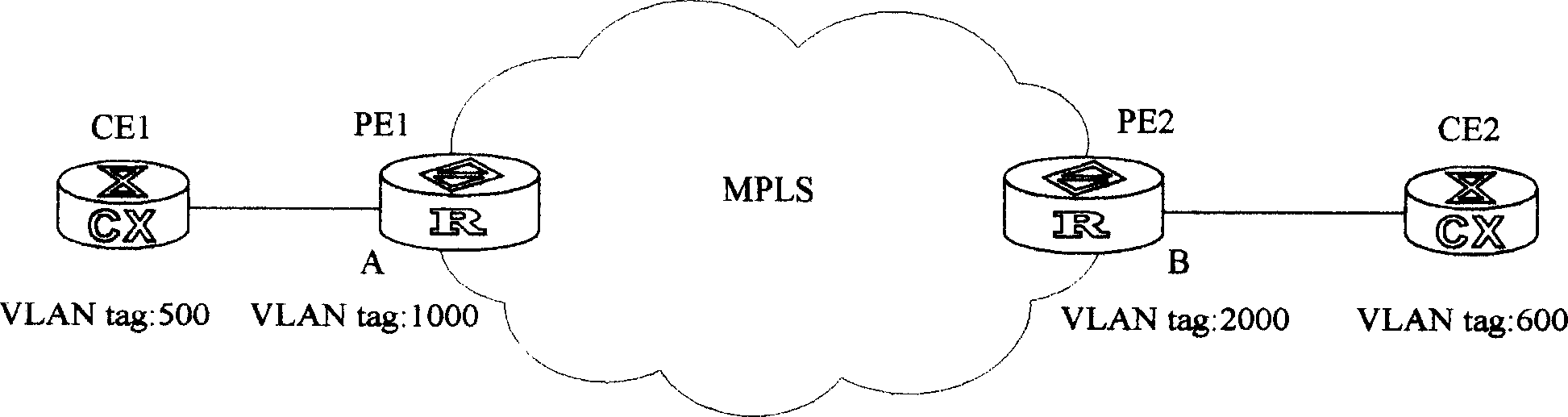

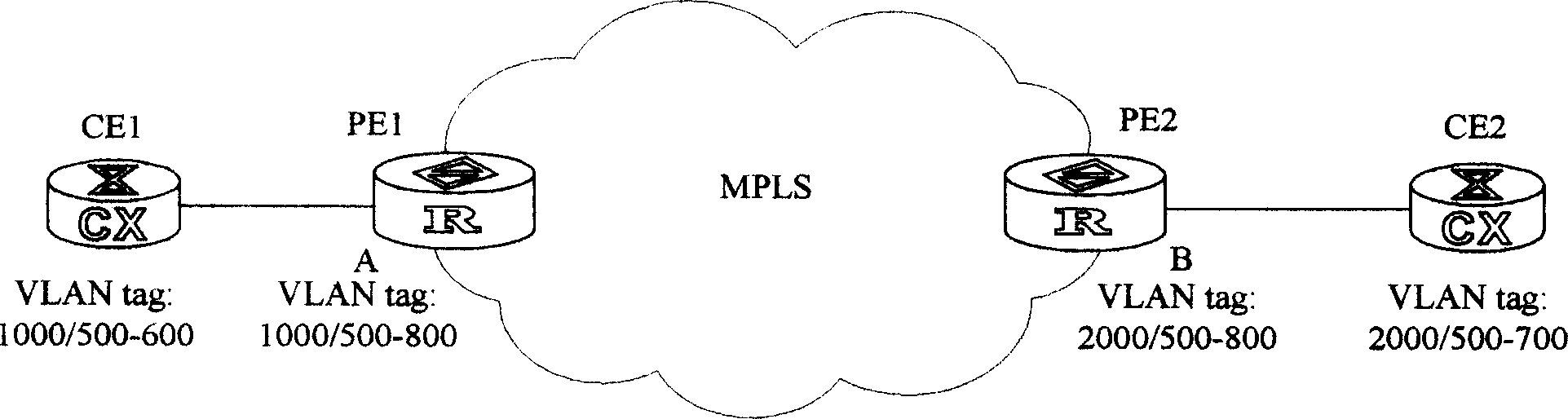

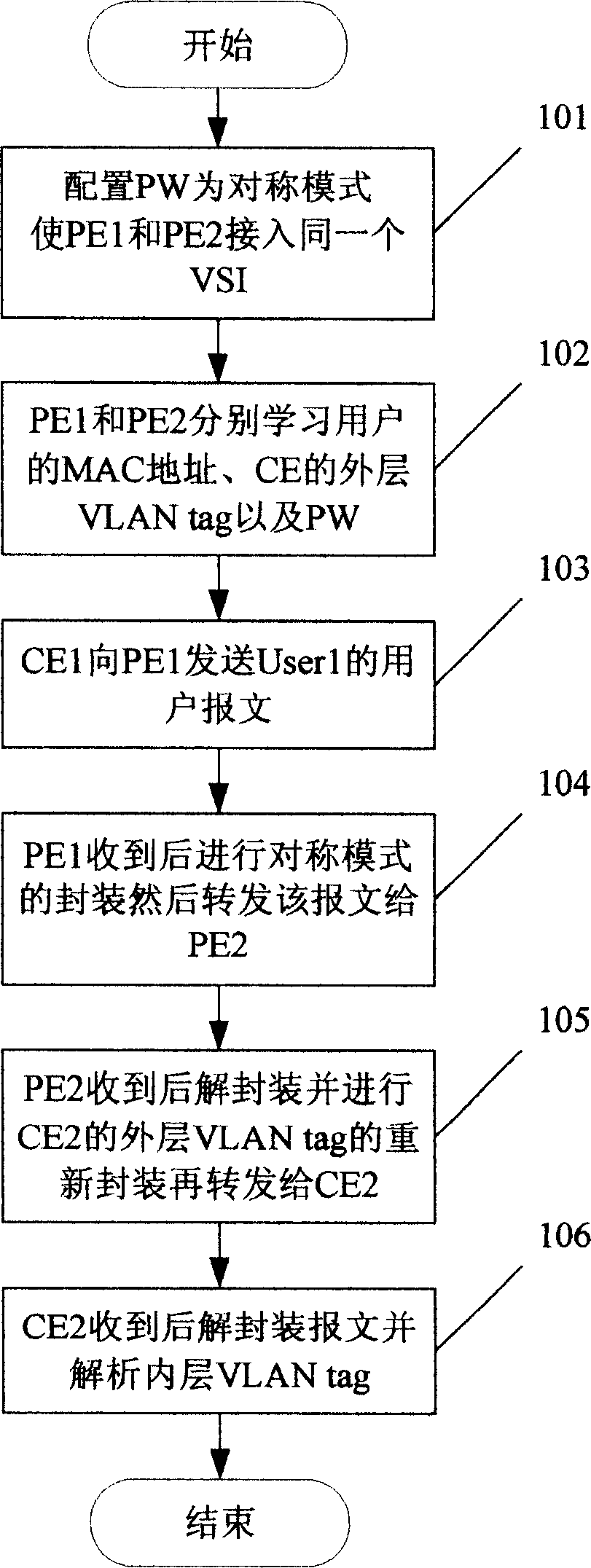

Method and system of user access virtual special LAN service

InactiveCN1905509AGranularityAchieve isolationNetworks interconnectionComputer scienceVirtual Private LAN Service

The invention provides a method and system to connect to VLAN services for a user, belonging to communication technical field. And it provides a method for a user to connect to VLAN services, comprising the steps of: setting symmetrical or unsymmetrical mode as working mode of PW; and packing and unpacking according to the working mode of PW and packing mode. And it also provides a corresponding system. And it implements intercommunication between users on two ends whose VLAN tag values are not equal and also fines the grain size that a user connects to VPLS. And it can implement VLAN isolation between partial users in the same VSI, achieving an effect of flexible control.

Owner:HUAWEI TECH CO LTD

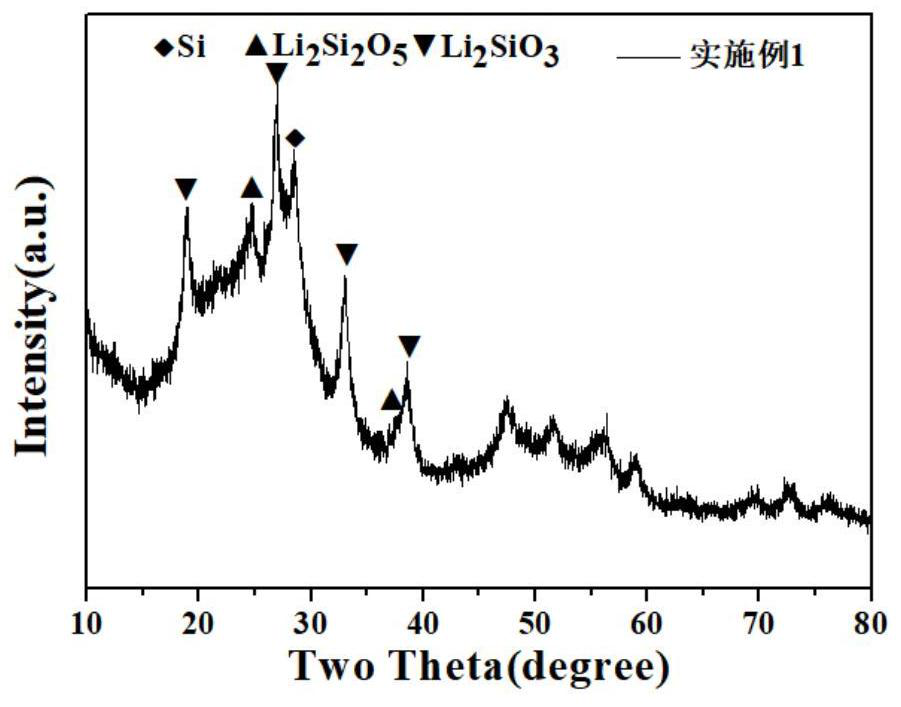

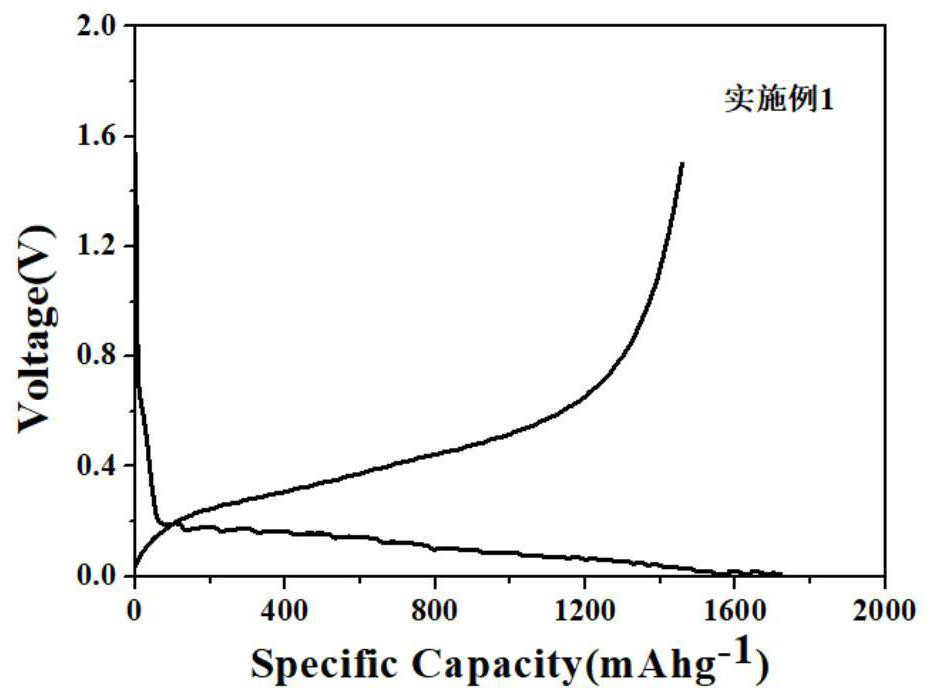

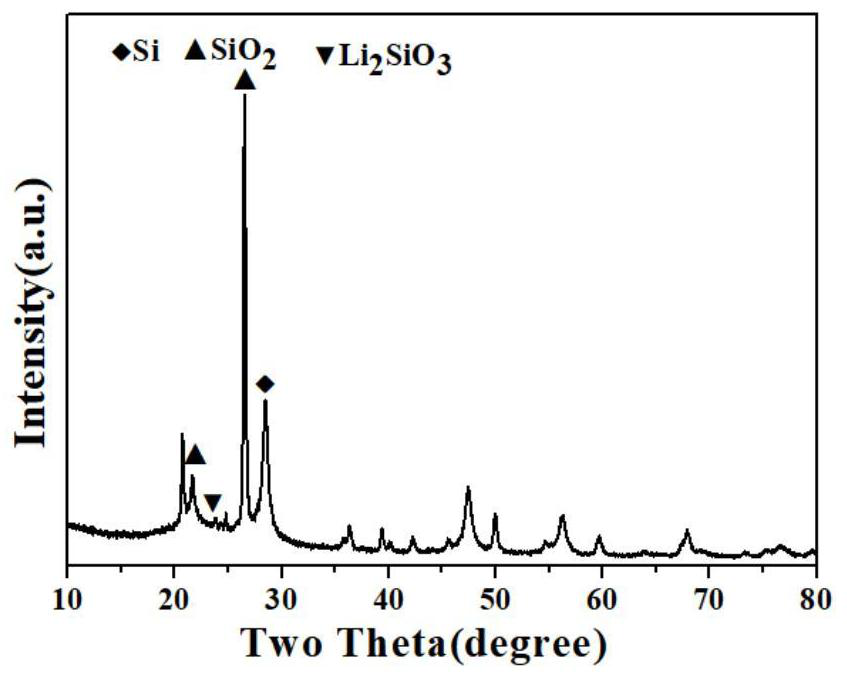

Pre-lithiated silicon monoxide/carbon composite material, and preparation method and application thereof

InactiveCN112289999AImprove electrochemical performanceAchieve lithium supplementationSecondary cellsNegative electrodesCarbon compositesMetallic lithium

The invention discloses a pre-lithiated silicon monoxide / carbon composite material, and a preparation method and application thereof, and belongs to the technical field of silicon monoxide materials.The preparation method comprises the following steps: performing vapor deposition on a silicon monoxide material to coat a carbon layer to prepare a silicon monoxide / carbon composite material; crushing a lithium salt to a proper particle size, and uniformly mixing the crushed lithium salt with silicon monoxide / carbon; and heating the mixed material to a certain temperature, and keeping the temperature for a period of time in a reducing atmosphere to obtain the pre-lithiated silicon monoxide / carbon composite material. According to the present invention, with the simple and efficient preparationmethod, a negative electrode material with characteristics of high first effect and good cycle performance can be effectively prepared, the negative electrode material can be well used for preparingthe lithium ion battery negative electrode material, and the method has advantages of low cost and easy scale-up production compared to the lithium supplementing through the metal lithium.

Owner:SHAANXI COAL & CHEM TECH INST

Macromolecule network preparation method for high-purity ultra-fine aluminum nitride ceramic

The invention relates to a macromolecular network preparation method for high-purity superfine aluminum nitride ceramic powder, which comprises the following steps: (1) preparing materials; (2) preparing mixed powder of aluminum nitride (Al2O3) and carbon (C); (3) synthesizing AlN powder; and (4) decarburization, wherein main raw materials are sugar, aluminum nitrate, acrylamide, N, N'-methylene acrylamide and ammonium persulphate. The key point of the macromolecular network preparation method for the high-purity superfine aluminum nitride ceramic powder is to form a macromolecular network structure by macromolecular polymerization. The high-purity superfine aluminum nitride ceramic powder has the characteristics of fine granularity, high purity and low cost, and is suitable for industrial mass production.

Owner:SHENYANG UNIV

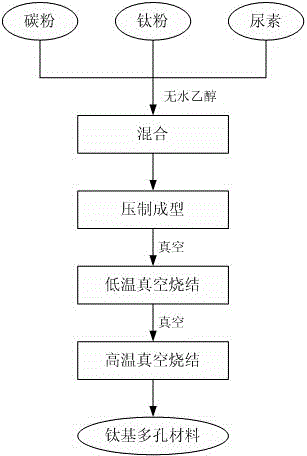

Preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials

The invention discloses a preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials. A powder metallurgy pore forming substance technology is used, and urea, carbon powder and titanium powder are used for being subjected to mixing, pressing forming and sintering to prepare the titanium-based multi-hole composite materials. The urea is used as a pore forming substance. Absolute ethyl alcohol is used as binding agents. Components of the titanium-based multi-hole materials are easy to control. Meanwhile, the advantage that raw material cost is low is achieved. A two-stage type sintering process is used for reducing energy consumption, equipment cost is lowered, and benefit is improved. In addition, the titanium-based multi-hole composite materials prepared with the preparing method of the in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials are high in intensity, good in comprehensive mechanical property and high in anti-corrosion performance, the durability of the titanium-based multi-hole composite materials is improved, a new technology path is provided for sewage purification, biology implant materials and the like, and great application prospect is achieved.

Owner:CHONGQING UNIV

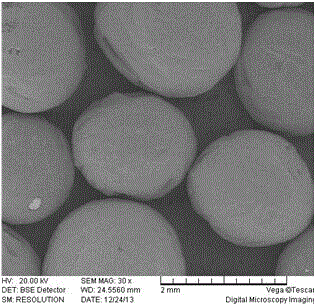

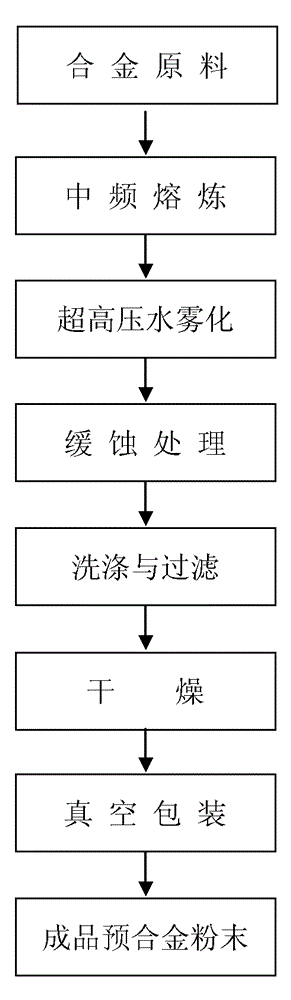

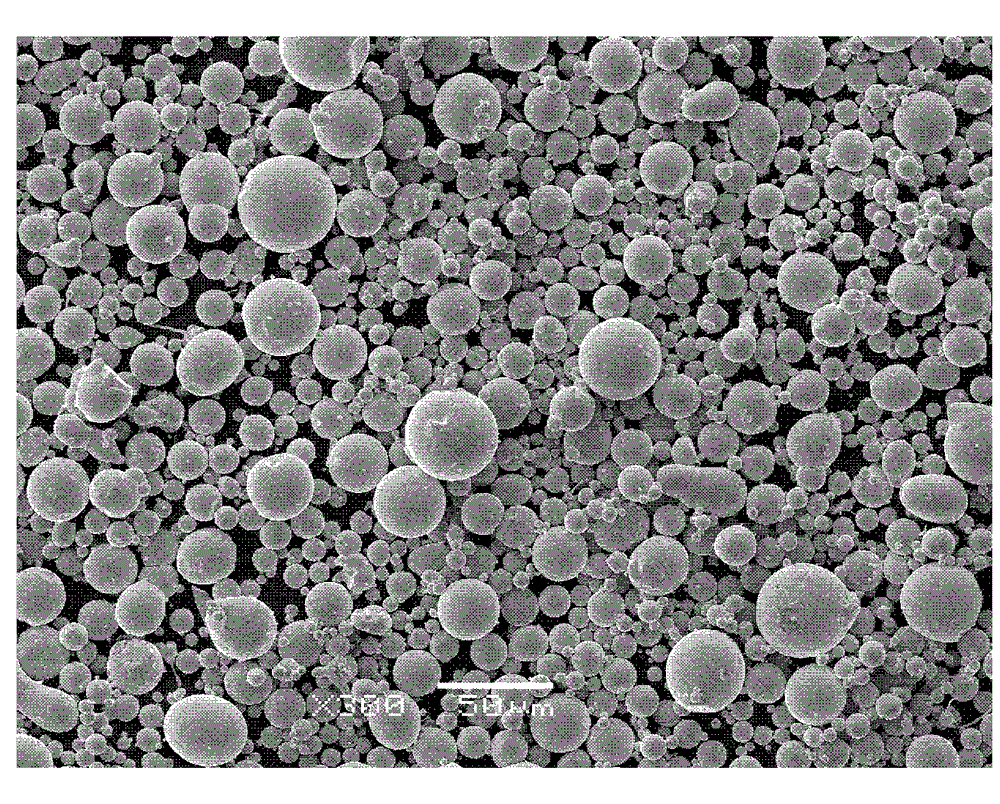

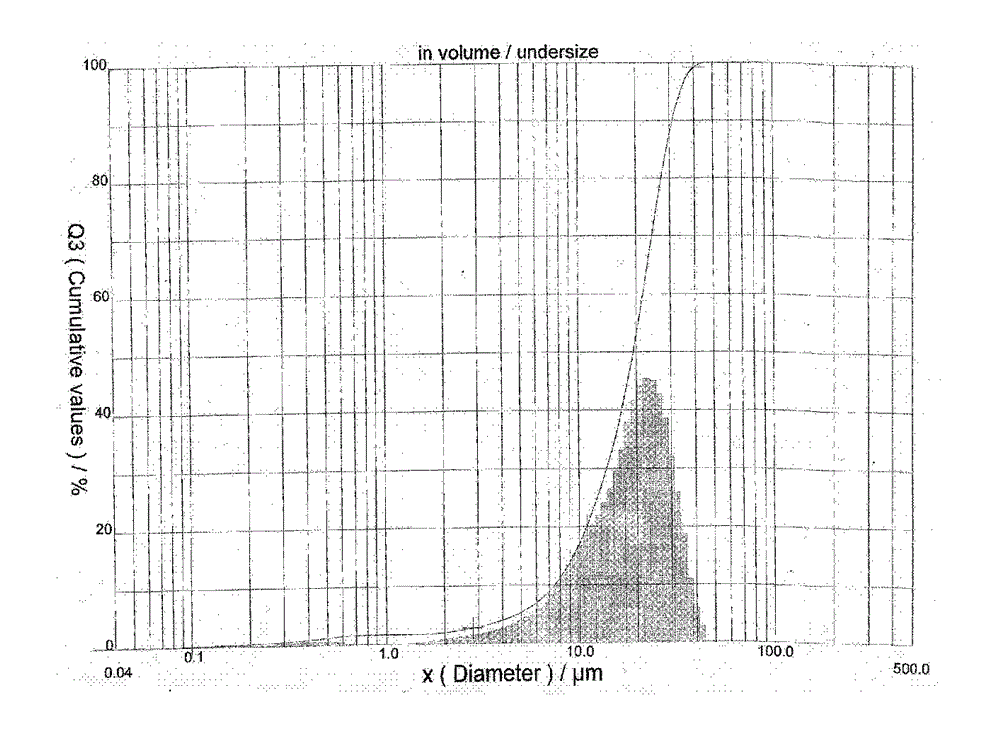

Method for preparing prealloy powder for low-oxygen-content micro-diamond product and using ultrahigh-pressure water atomization

The invention relates to a method for preparing prealloy powder for a low-oxygen-content micro-diamond product and using ultrahigh-pressure water atomization. The method comprises the technological processes of prealloy smelting, ultrahigh-pressure water atomization, quick solidification, cooling, powder corrosion inhibition process, powder collection, powder drying, powder property detection, product packaging and the like. The method has the advantages that the product is low in oxygen content, fine in granularity, controllable in particle morphology, and even and non-segregation in component, prealloy of powder elements is achieved, production process device and technology are simple, and operation is convenient.

Owner:HUNAN METALLURGY MATERIAL RES INST

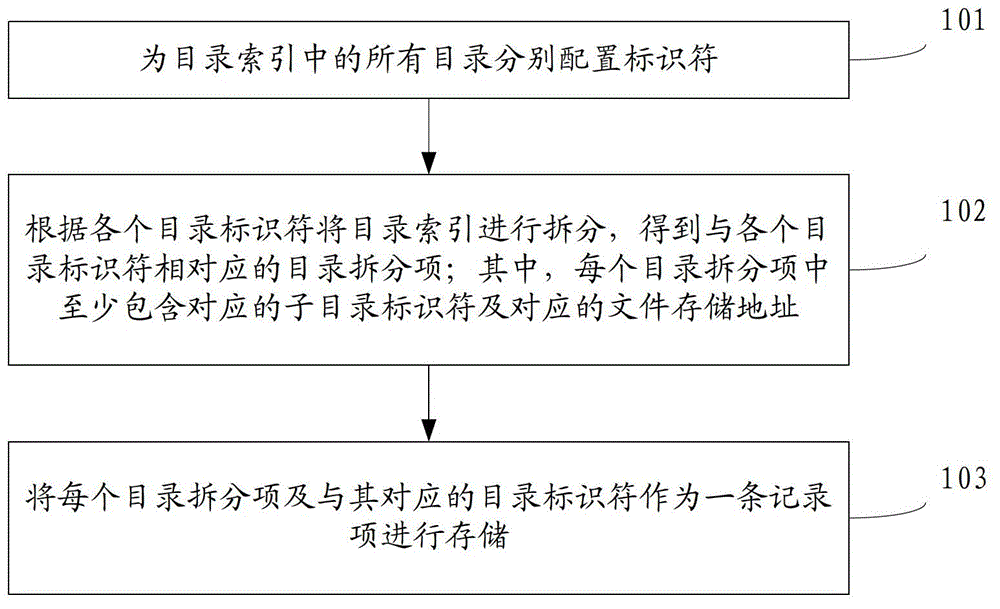

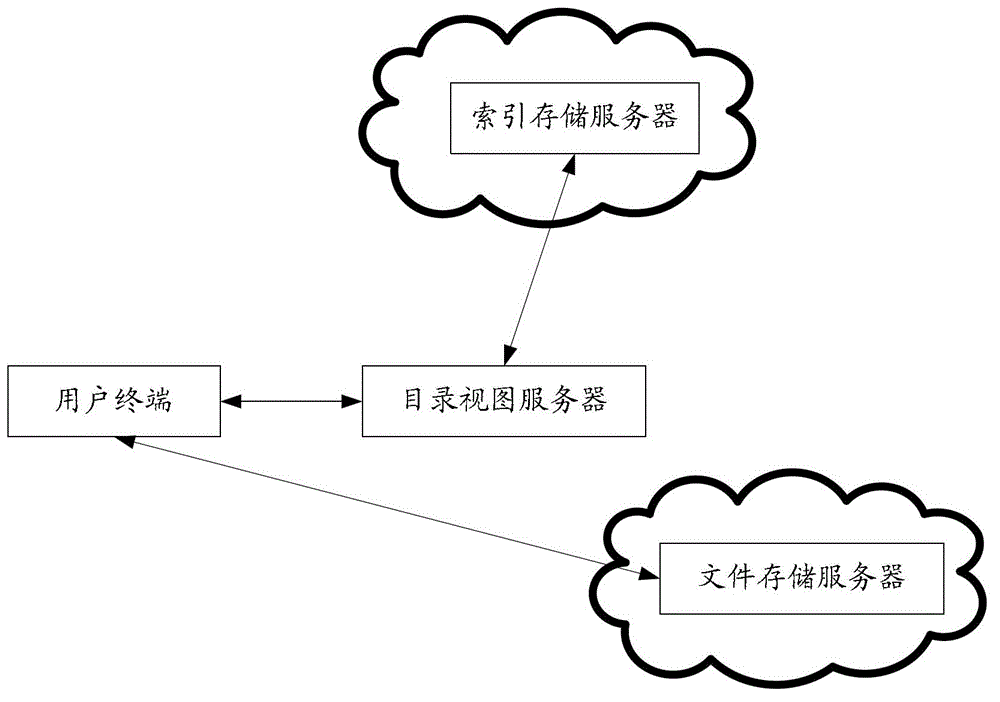

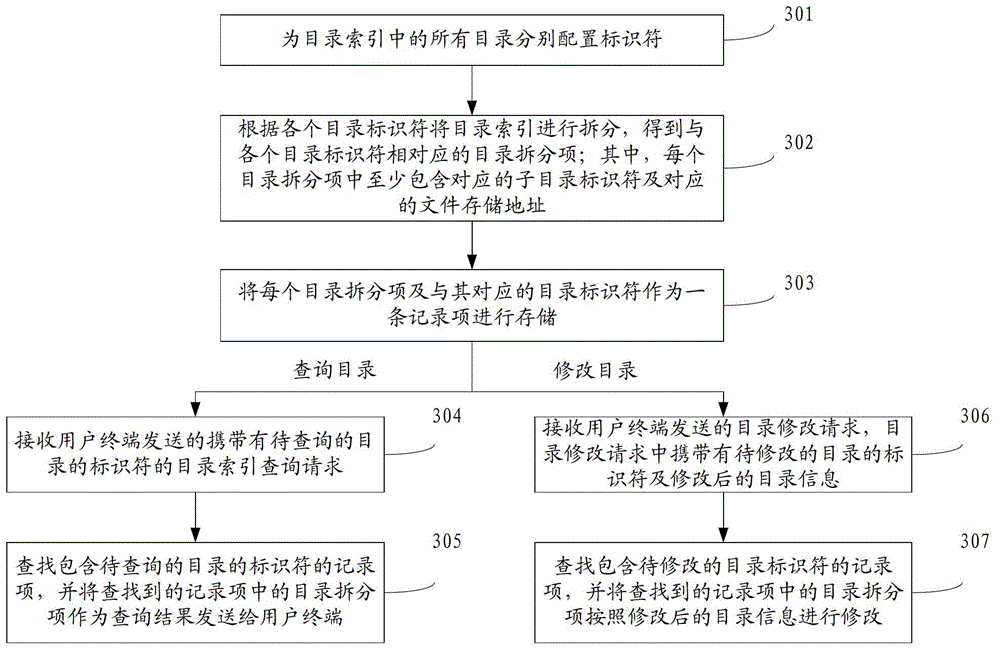

Method, device and system for storing and reading catalogue index

ActiveCN103942205AGranularityImprove access performanceFile access structuresSpecial data processing applicationsGranularityLibrary science

The invention discloses a method, device and system for storing and reading a catalogue index and belongs to the technical field of computers. The method for storing the catalogue index includes the steps that identifiers are configured to all catalogues in the catalogue index; the catalogue index is split according to the identifiers of the catalogues, and catalogue split items corresponding to the catalogue identifiers are obtained; each catalogue split item and the corresponding catalogue identifier of the catalogue split item serve as one record item to be stored, wherein each catalogue split item at least comprises a corresponding sub catalogue identifier and a corresponding file storage address. According to the method, device and system for storing and reading the catalogue index, the identifiers are configured to all the catalogues in the catalogue index, the catalogue index is split according to all the catalogue identifiers, after the catalogue split items corresponding to the catalogue identifiers are obtained, and each catalogue split item and the corresponding catalogue identifier of the catalogue split item serve as one record item to be stored. Thus, the granularity of the catalogue index is refined, and therefore the access performance of the catalogue index is improved.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

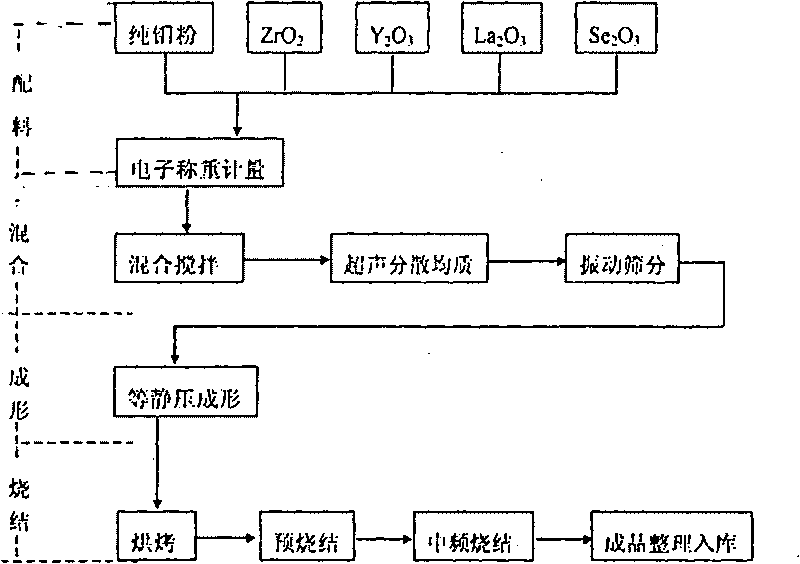

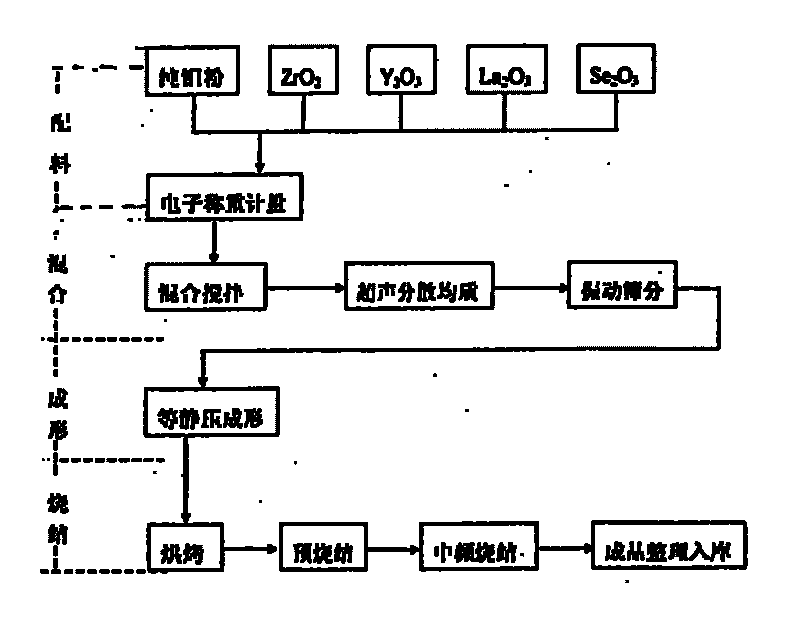

Molybdenum-base rare earth powder metallurgy forming plug and manufacturing method thereof

ActiveCN101722308ARaise the recrystallization temperatureHigh tensile strengthMandrelsMetal rolling arrangementsChemical industryAviation

The invention relates to a seamless steel tube, in particular to a molybdenum-base rare earth powder metallurgy forming plug used by a high nickel-chromium stainless steel seamless pipe and a manufacturing method thereof. The manufacturing method of the molybdenum-base rare earth powder metallurgy forming plug comprises the following steps of: simultaneously mixing four rare earth oxides of ZrO2, Y2O3, La2O3 and SC2O3 in pure molybdenum powder; mixing molybdenum-base material to prepare powder by using an ultrasound characteristic; packaging the powder into a vane mixing blender, dispersing mixed molybdenum-base rare earth powder by primary refining; dispersing homogenized molybdenum-base rare earth powder by ultrasound refining through an ultrasound transducer; screening by a 180-mesh equalizing screen in accordance with a configured Tyler standard in a 'vibrating screen classifier' to obtain screen under flow, namely blended qualified molybdenum-base rare earth powder; and manufacturing the molybdenum plug by an isostaticmoulding mold, demolding and cleaning, and finishing the manufacturing in a configured hydrogen atmosphere roaster, a hydrogen atmosphere pre-sintering furnace and a hydrogen atmosphere horizontal intermediate frequency furnace. The molybdenum-base rare earth powder metallurgy forming plug and the manufacturing method thereof can be widely applied to chemical industry, metallurgy, machinery, aviation, national defense and other industrial departments.

Owner:四平市北威钼业有限公司

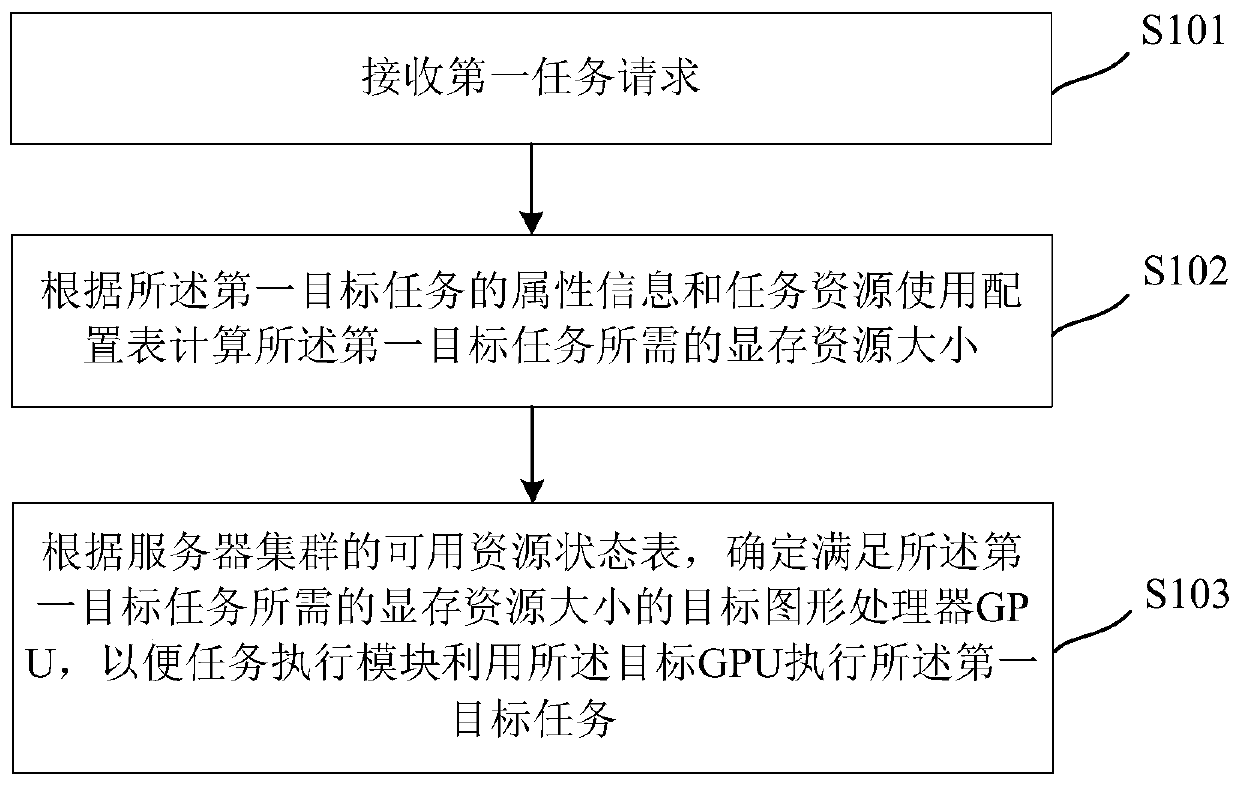

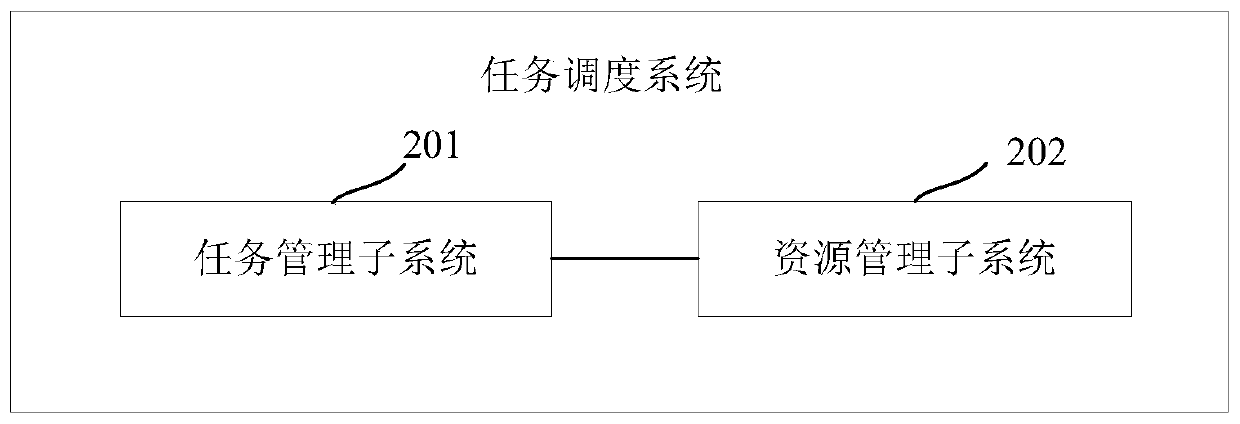

GPU resource-oriented task scheduling method, device and system

InactiveCN109992422AIncrease profitGranularityProgram initiation/switchingResource allocationVideo memoryGranularity

The embodiment of the invention discloses a GPU resource-oriented task scheduling method. . The method comprises the following steps of when a task (such as a first target task) needs to be executed by using a video memory resource in a server cluster, calculating the size of a video memory resource required by the first target task according to the attribute information of the first target task included in the first task request and a task resource use configuration table, and then, according to the available resource state table of the server cluster, determining the GPU meeting the video memory resource size required by the first target task, so that the task execution module executes the first target task by utilizing the target GPU. According to the scheme, when the task request is received, video memory resource estimation of the task is carried out, the available GPU is selected with the video memory resource as the minimum unit to complete the task, and the granularity of resource management and task scheduling is refined. If the video memory resources in one GPU meet the task requirements, the purpose that one GPU executes multiple tasks in parallel can be achieved, and the utilization rate of the video memory resources in the GPU is increased.

Owner:北京朗镜科技有限责任公司

Software security enhancing method based on binary rewrite and dynamic randomization

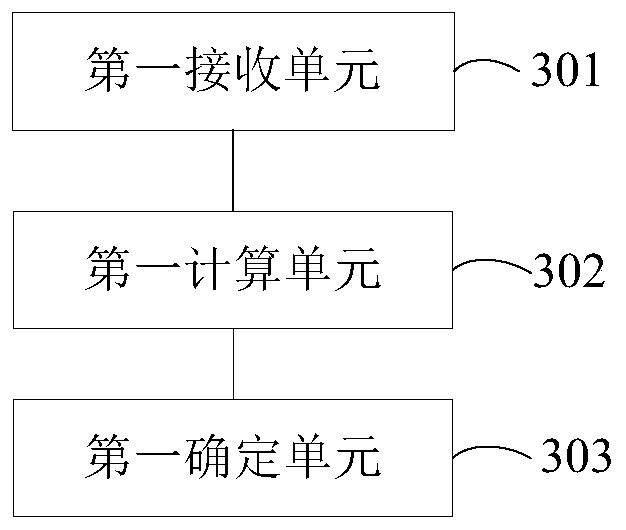

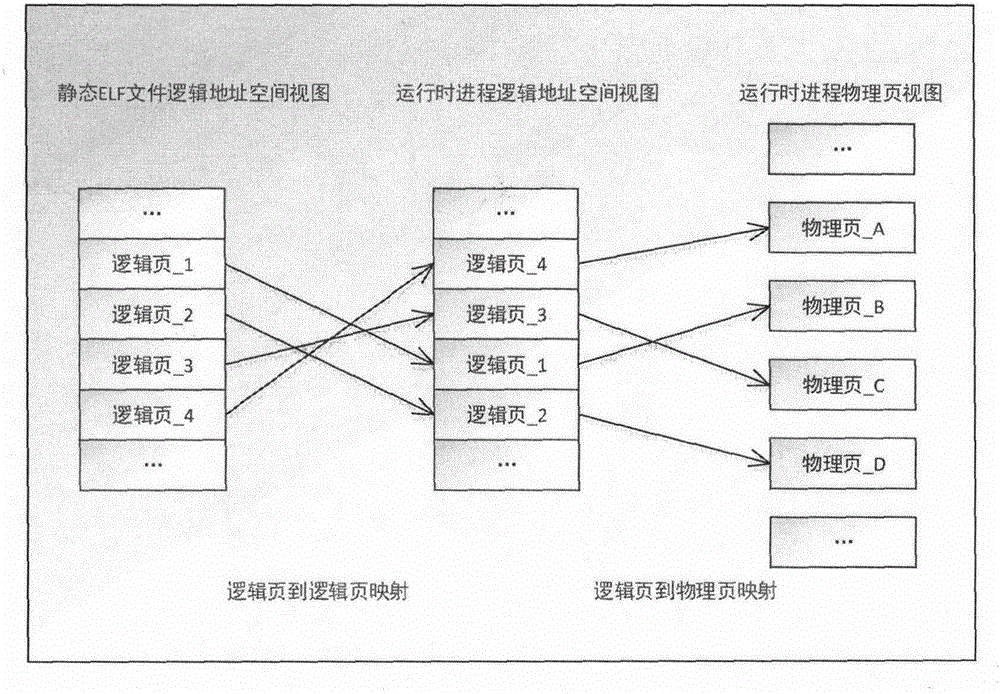

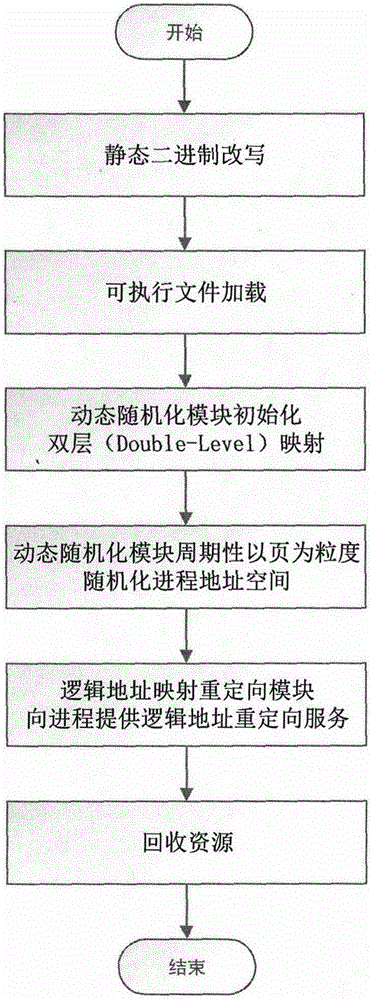

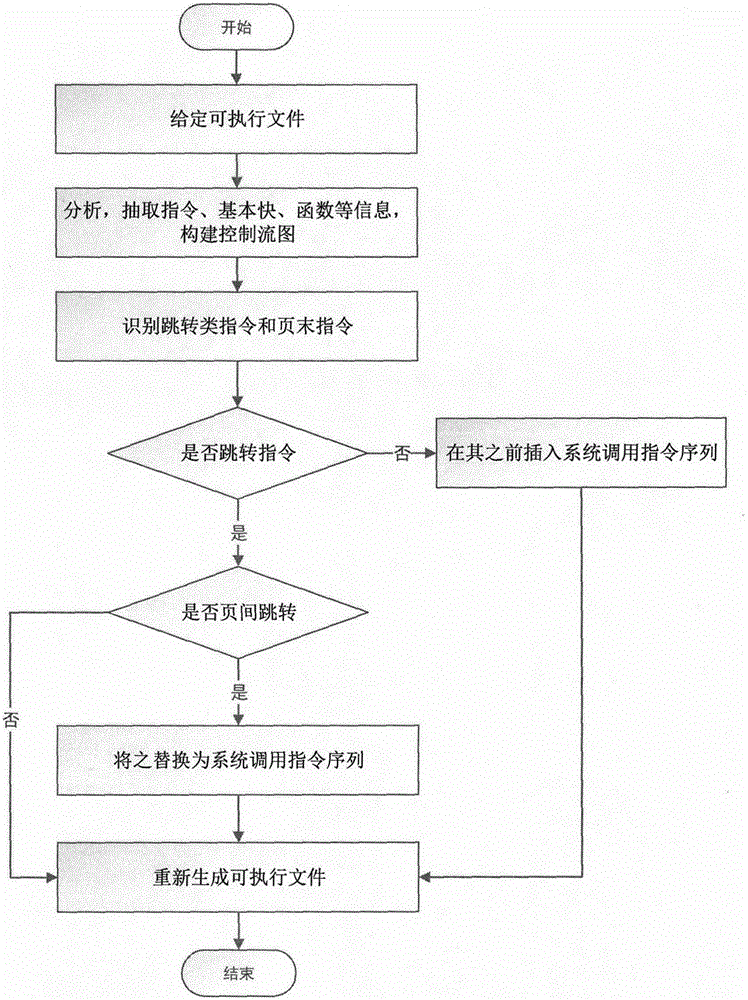

InactiveCN105335656ARandomization granularity refinementRandomization Entropy IncreasePlatform integrity maintainanceAddress spaceLogical address

The invention provides a software security enhancing method based on binary rewrite and dynamic randomization, comprising the following modules: 1) static binary rewrite; 2) double-level mapping, namely from a process logical page to a logical page and from the logical page to a physical page; 3) a dynamic randomization mechanism periodically randomizes a process address space by taking pages as granularities; 4) a logical address mapping redirecting mechanism provides the logical address mapping a redirecting service for a process. According to the software security enhancing method based on the binary rewrite and the dynamic randomization, the randomization entropy of the process address space is remarkably improved through the fine granularity dynamic cyclical randomization, the successful probability of attacking of an attacker is lowered, and the security of the a computer system and software is improved.

Owner:NANJING UNIV

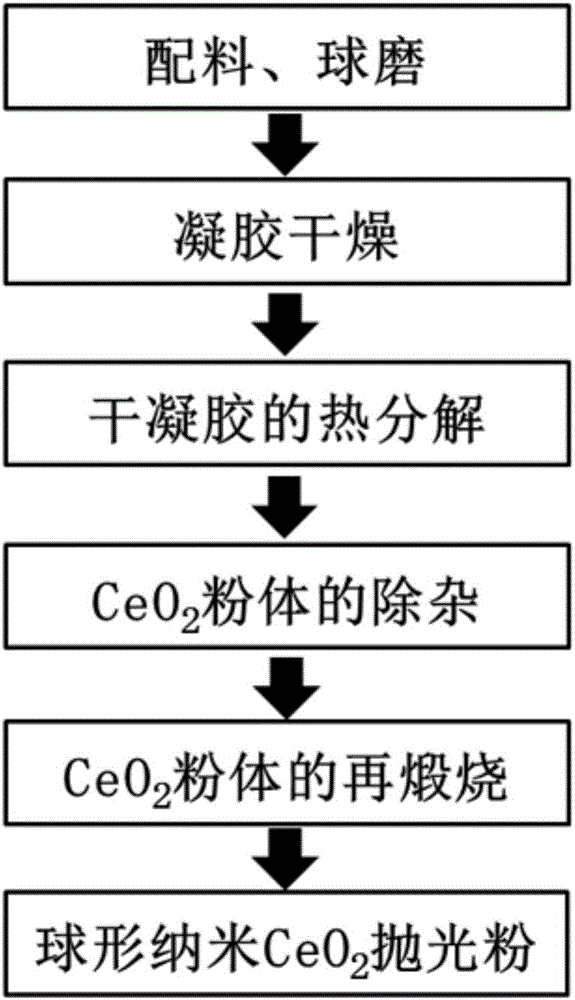

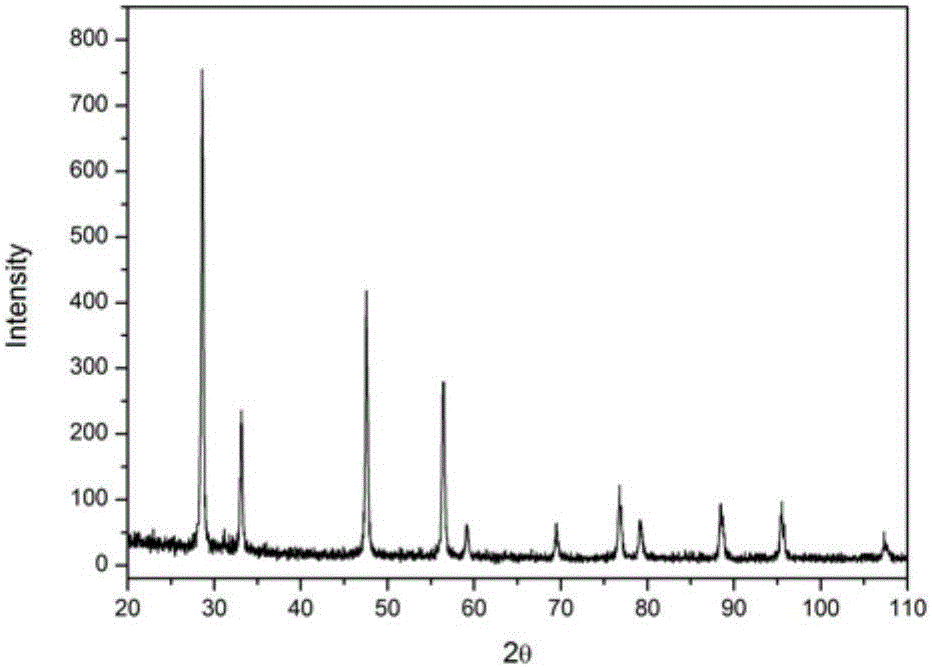

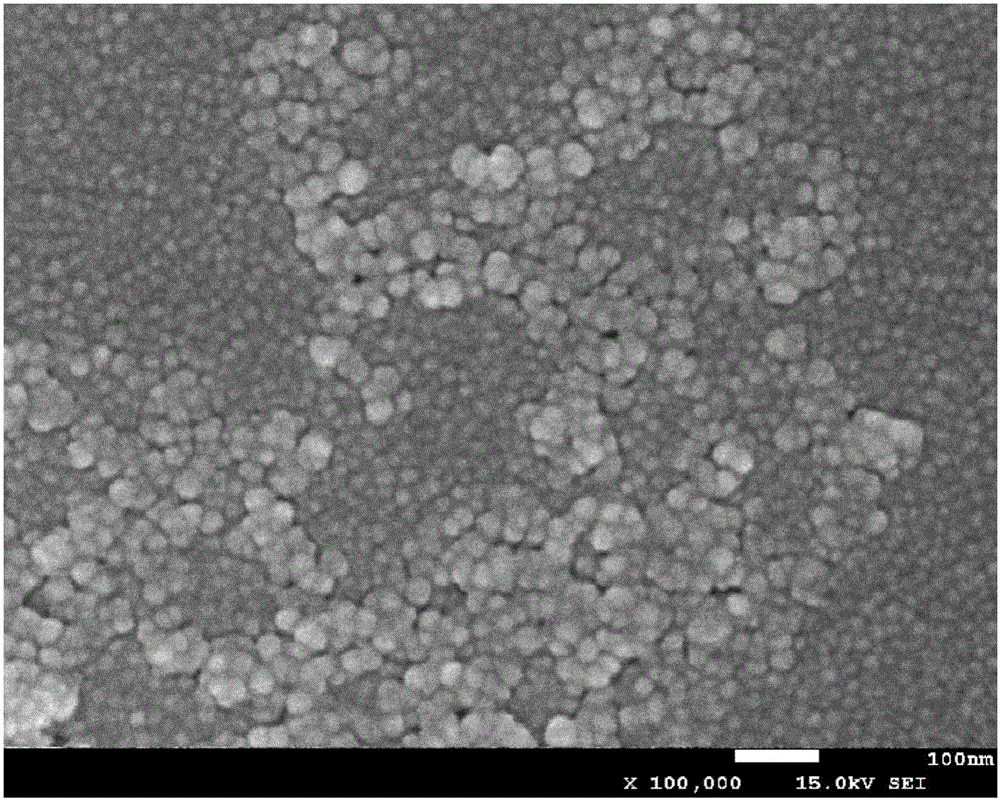

Preparation method of spherical nanometer CeO2 polishing powder

ActiveCN106587131AGranularityUniform particle sizeRare earth metal oxides/hydroxidesPolishing compositions with abrasivesChemical reactionCerium

The invention discloses a preparation method of spherical nanometer CeO2 polishing powder and belongs to the field of nanometer material research. The preparation method utilizes a crystal water-containing cerium salt and citric acid as raw materials, a proper amount of ethanol as a lubricant and the ball milling mechanical force to refine the raw materials so that reaction efficiency is improved. Crystal water released by the raw materials and the lubricant ethanol form a liquid film and precursor gel is directly prepared so that a ball milling solid-phase chemical reaction method and a sol-gel method are combined. The gel can effectively inhibit the agglomeration and growth of cerium oxide particles in later calcination processes so that the pherical nanometer CeO2 polishing powder with uniform particle sizes, good dispersibility and good polishability are prepared. The pherical nanometer CeO2 polishing powder has uniform particle sizes, good dispersibility and good polishability. The preparation method has the advantages of simple processes, high efficiency, no pollution and good reproducibility, and is suitable for industrial mass production.

Owner:SICHUAN UNIV

Cold fresh pulp preparation method

The present invention relates to a cold fresh pulp preparation method. The technical problem solved by the present invention is to reduce oxidation during a fresh keeping process, improve pulp freshness and improve original taste. A super micron fiber fruit dissolving technology is adopted, such that the pulp is instantly dissolved in water, layering and precipitation are not easily generated, and nutrition is easily absorbed by human body. The preparation method comprises the following steps: 1) preparing a material; 2) adopting a colloid mill to prepare a coarse pulp; 3) preparing fruit dissolving fibers, wherein the coarse pulp is grinded into fruit dissolving fibers through a super high pressure homogenizer, a particle size is less than or equal to 800 nm, super high pressure homogenizer working pressure is 60-80 Mpa, and a grinding temperature is controlled to less than or equal to 20 DEG C; 4) carrying out vacuum liquid state sub-packaging; 5) carrying out super high pressure low temperature sterilization; 6) carrying out low temperature quick partial-freezing, wherein the sterilized pulp is placed into a low temperature quick partial-freezing machine, a freezing temperature is -30 to -35 DEG C, and a freezing time is 6-15 min; and 7) carrying out low temperature cold preservation, wherein a temperature is less than or equal to -18 DEG C.

Owner:叶波 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com