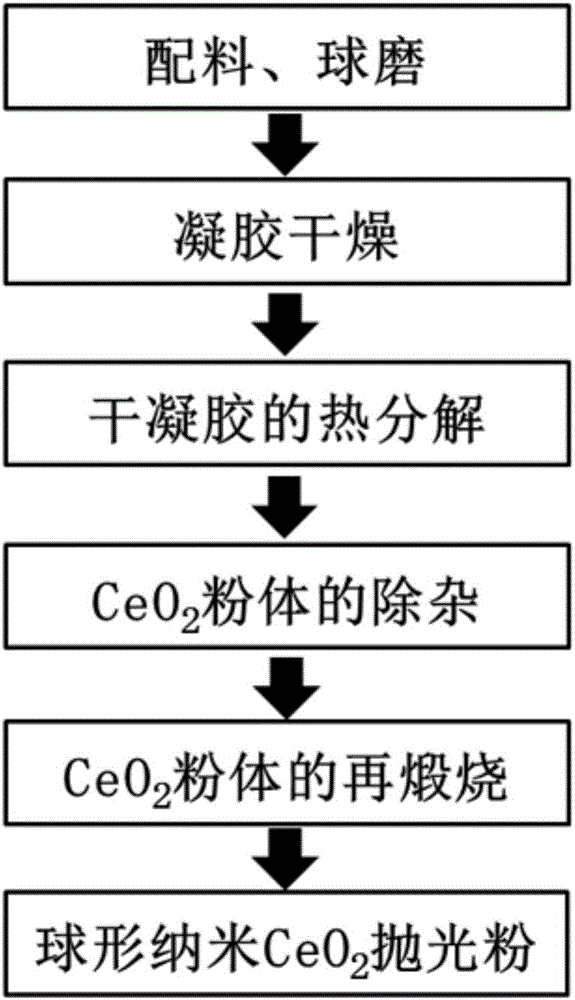

Preparation method of spherical nanometer CeO2 polishing powder

A polishing powder and nanotechnology, applied in the field of nanomaterials, can solve the problems of unsuitability for industrial production and promotion, excessive heating time for gels, severe reaction conditions, etc., and achieves good polishing performance, short gel drying time, and ingredients. The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

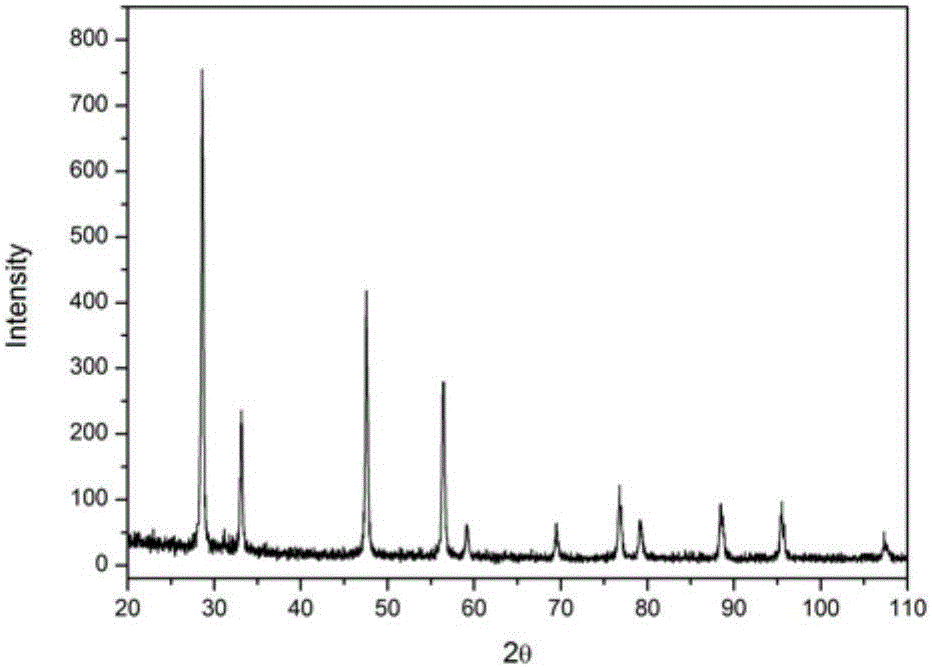

Embodiment 1

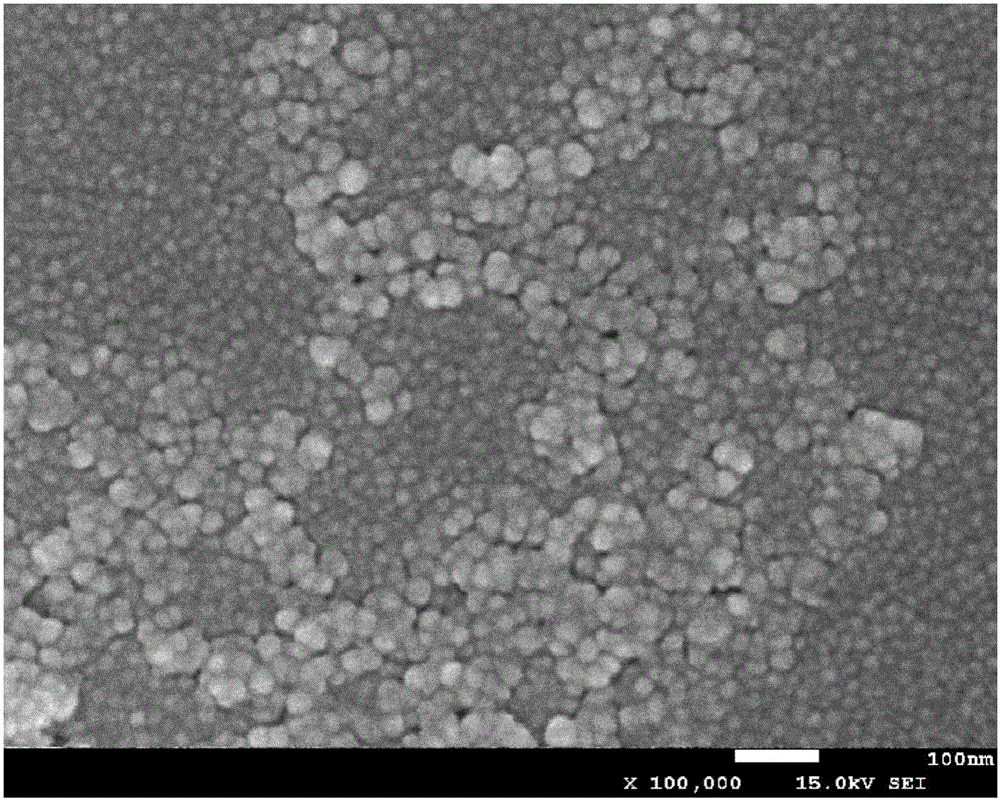

[0024] Weigh cerium chloride heptahydrate and anhydrous citric acid according to the molar ratio of cerium salt and citric acid as 1:1.5, place in a ball mill jar, add absolute ethanol as lubricant, and ball mill at room temperature for 2.5 hours in a planetary ball mill, Add absolute ethanol during ball milling so that the mixed powder is fully lubricated; the gel obtained from ball milling is placed in a drying oven, and dried at 70°C for 6 hours to form a xerogel; then the xerogel is placed in a muffle furnace and heated at 400 Thermally decompose at ℃ for 2 hours; then grind the powder obtained by thermal decomposition, wash with deionized water and ethanol three times respectively, put it into a drying oven, and dry it at 60°C; then put it in a muffle furnace, at 800 Calcined at ℃ for 1 hour; the final spherical nano-CeO 2 Polishing powder. The resulting CeO 2 Polishing powder is pure CeO 2 Phase, high crystallinity, average particle size is 40nm, particle size is very...

Embodiment 2

[0026] Weigh cerium nitrate hexahydrate and citric acid monohydrate according to the molar ratio of cerium salt to citric acid as 1:2, place them in a ball mill jar, add absolute ethanol as a lubricant, and ball mill at room temperature for 3 hours in a planetary ball mill. When adding absolute ethanol to make the mixed powder fully lubricated; the gel obtained by ball milling was placed in a drying oven and dried at 60°C for 8 hours to form a xerogel; then the xerogel was placed in a muffle furnace and heated at 500°C Thermally decompose for 1.5 hours; then grind the powder obtained by thermal decomposition, wash three times with deionized water and ethanol respectively, put it in a drying oven, and dry it at 60°C; then place it in a muffle furnace at 800°C Calcined for 1 hour; finally spherical nano-CeO 2 Polishing powder; resulting CeO 2 The average particle size of the polishing powder is 60nm, the primary particle size is within 10-20nm, the particle size is very uniform...

Embodiment 3

[0028] Weigh cerium nitrate hexahydrate and citric acid monohydrate according to the molar ratio of cerium salt to citric acid as 1:2, place them in a ball mill jar, add absolute ethanol as a lubricant, and ball mill at room temperature for 3 hours in a planetary ball mill. When adding absolute ethanol so that the mixed powder is fully lubricated; the gel obtained by ball milling is placed in a drying oven, and dried at 50°C for 10 hours to form a xerogel; then the xerogel is placed in a muffle furnace and heated at 600°C Thermally decompose for 1 hour; grind the powder obtained by thermal decomposition, wash with deionized water and ethanol three times respectively; then put it in a drying oven to dry at 70°C, and place it in a muffle furnace for calcination at 800°C for 1 hour; The final spherical nano-CeO 2 Polishing powder. The resulting CeO 2 The average particle size of the polishing powder is 70nm, the particle size is relatively uniform, and the dispersion is good. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com