Molybdenum-base rare earth powder metallurgy forming plug and manufacturing method thereof

A manufacturing method and technology of rare earth powder, applied in manufacturing tools, metal rolling, metal rolling, etc., can solve problems such as low service life and damage, and achieve the effect of ensuring the quality of strong ultrasonic refining, dispersion and homogeneous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

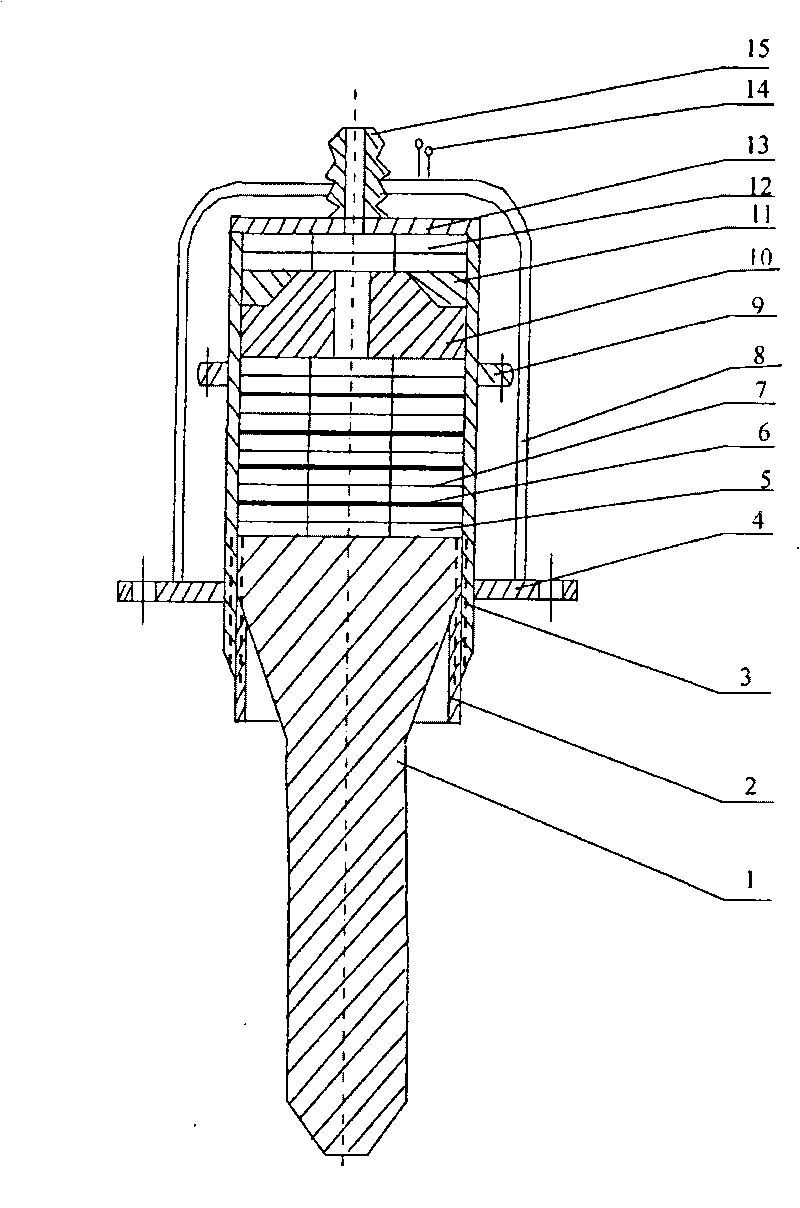

[0094] The present invention will be described in further detail below in conjunction with the accompanying drawings.

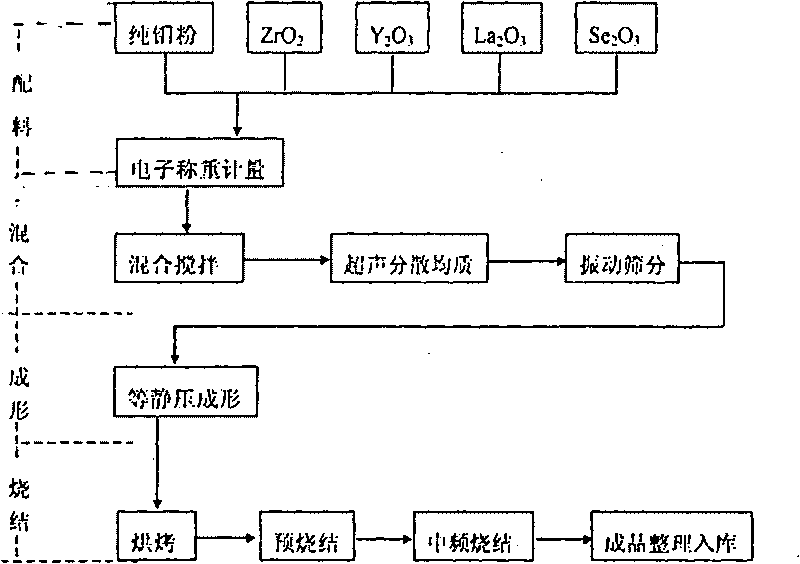

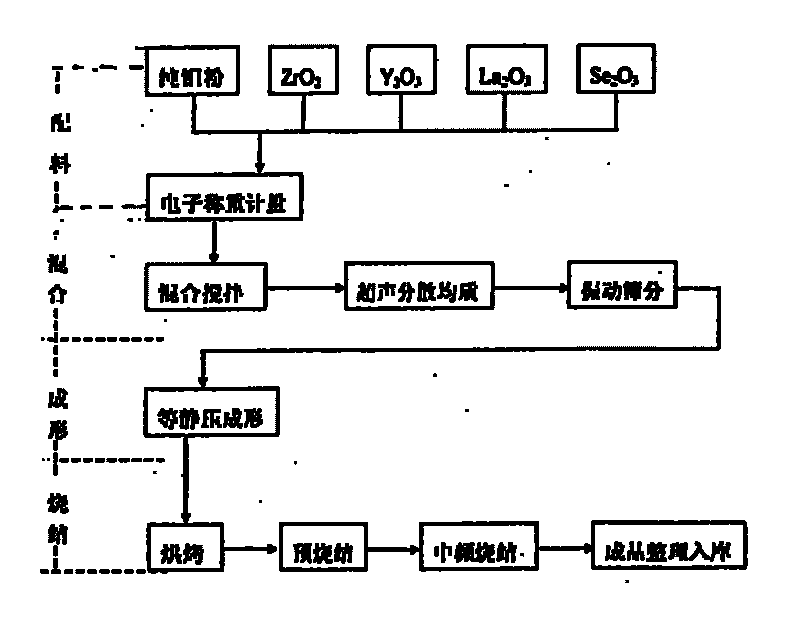

[0095] 1. Doping four kinds of rare earth oxides and a larger doping ratio into the pure phase powder at the same time,

[0096] According to the best compatibility, based on the weight of pure molybdenum powder:

[0097] ZrO 2 Mixed with 1.3~1.4% Y 2 o 3 Mixed with 0.4~0.6%

[0098] La 2 o 3 Doped with 2.4~2.6% Se 2 o 3 Mixed with 1.2~1.4%

[0099] The total blending ratio is up to 6.0%.

[0100] The basis for determining this batching and grouping technology plan is because:

[0101] A. The coefficients of thermal expansion of these four rare earth metals are very close to those of molybdenum. Under high-temperature working conditions, it can maintain the anti-deformation ability that is basically synchronized with the parent metal molybdenum.

[0102] B. These four rare earth metals have higher melting points and boiling points, ZrO 2 There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com