Al-Fe-Cu-Mg aluminum alloy for cables for coal mines, aluminum alloy cable and preparation method of alloy cable

An al-fe-cu-mg, aluminum alloy technology, used in cable/conductor manufacturing, metal/alloy conductors, circuits, etc., can solve the problem of poor mechanical properties and corrosion resistance, electrical conductivity and mechanical strength properties that cannot meet coal mines. Using cables and other issues to achieve the effect of improving yield strength and elongation, improving age hardening characteristics, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

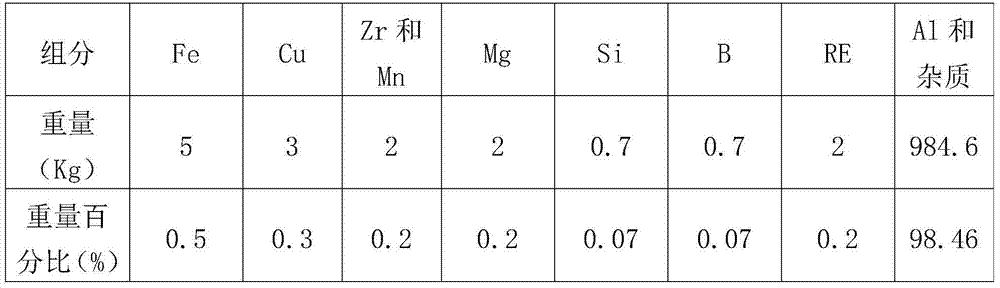

[0041] An aluminum alloy for coal mine cables, the components and the weight percentages of each component are as follows (total weight: 1T):

[0042]

[0043] Wherein, the rare earth element RE includes Ce, La and Pr, wherein the content of Ce and La accounts for 50% of the total content of the rare earth element, and the weight ratio of Zr and Mn is 1:1.

[0044] The method for making Al-Fe-Cu-Mg aluminum alloy cables for coal mine cables by using the above-mentioned aluminum alloys, the processing technology includes the following steps:

[0045] a. Obtain casting material by casting the above-mentioned aluminum alloy: add the aluminum alloy components mentioned in the present invention in proportion, carry out the smelting process at a temperature of 700°C, and then cast at a temperature of 650°C to obtain an ingot ;

[0046] b. The ingot obtained in step a is solution treated at 500° C. for 4 hours, and then rapidly quenched in cooling water at 30° C.;

[0047] c. ag...

Embodiment 2

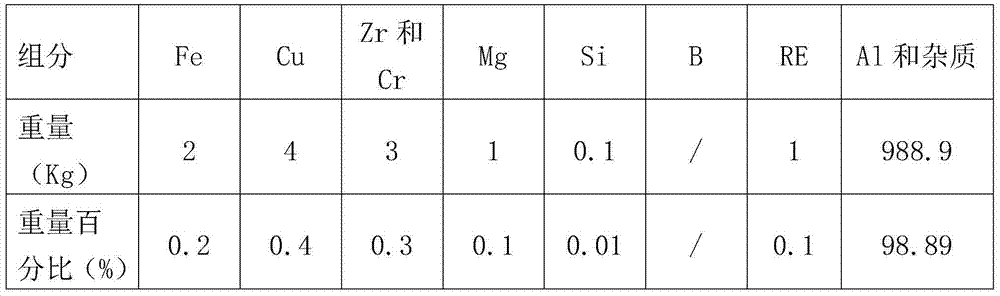

[0057]

[0058] Wherein, the rare earth element RE includes Ce, La and Er, wherein the content of Ce and La accounts for 60% of the total content of the rare earth element, and the weight ratio of Zr and Cr is 1:1.

[0059] The method for making Al-Fe-Cu-Mg aluminum alloy cables for coal mine cables by using the above-mentioned aluminum alloys, the processing technology includes the following steps:

[0060] a. The casting material is obtained by casting the above-mentioned aluminum alloy: add the aluminum alloy components mentioned in the present invention in proportion, carry out the melting process at a temperature of 800°C, and then cast at a temperature of 680°C to obtain an ingot ;

[0061] b. Solid solution treating the ingot obtained in step a for 6 hours at 460°C, and then rapidly quenching in cooling water at 20°C;

[0062] c. aging the ingot obtained in step b for 6 hours at 250°C, and then raising the temperature to 400°C and rolling it into an alloy rod;

[0...

Embodiment 3

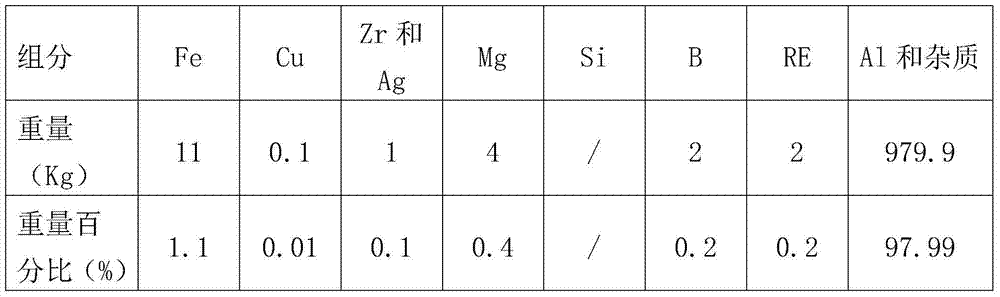

[0071]

[0072] Among them, the rare earth element RE is Ce, La, and the weight ratio of Zr and Ag is 1:1.

[0073] The method for making Al-Fe-Cu-Mg aluminum alloy cables for coal mine cables by using the above-mentioned aluminum alloys, the processing technology includes the following steps:

[0074] a. The casting material is obtained by casting the above-mentioned aluminum alloy: add the aluminum alloy components mentioned in the present invention in proportion, carry out the melting process at a temperature of 750°C, and then cast at a temperature of 650°C to obtain an ingot ;

[0075] b. Solid solution treating the ingot obtained in step a for 2 hours at 550°C, and then rapidly quenching in cooling water at 100°C;

[0076] c. aging the cast ingot obtained in step b for 10 hours at 200°C, and then raising the temperature to 300°C and rolling it into an alloy rod;

[0077] d. Under the temperature condition of 300°C, the alloy rod rolled in step c is subjected to draw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Average creep speed | aaaaa | aaaaa |

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com