Patents

Literature

152results about How to "Avoid reprocessing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

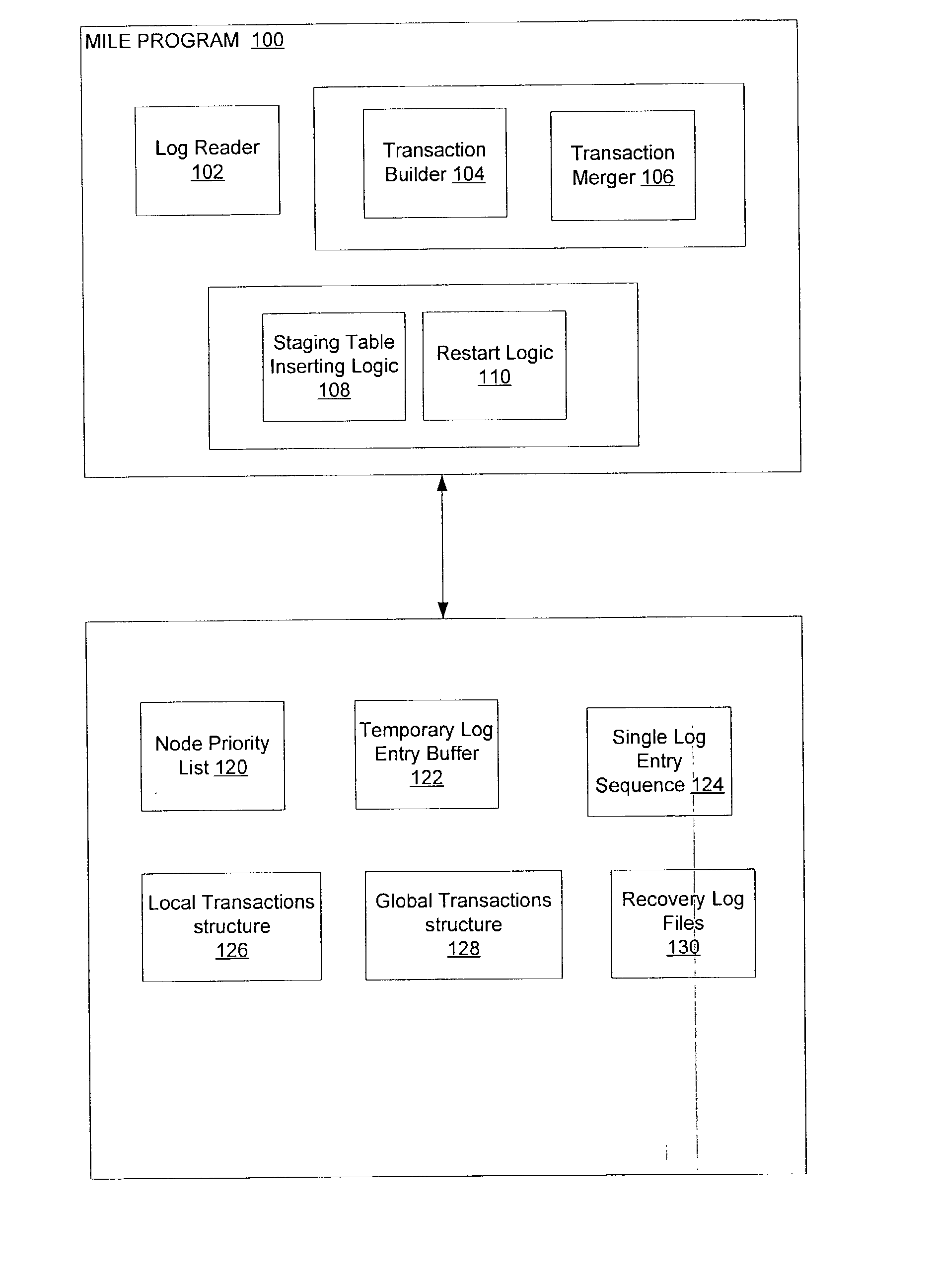

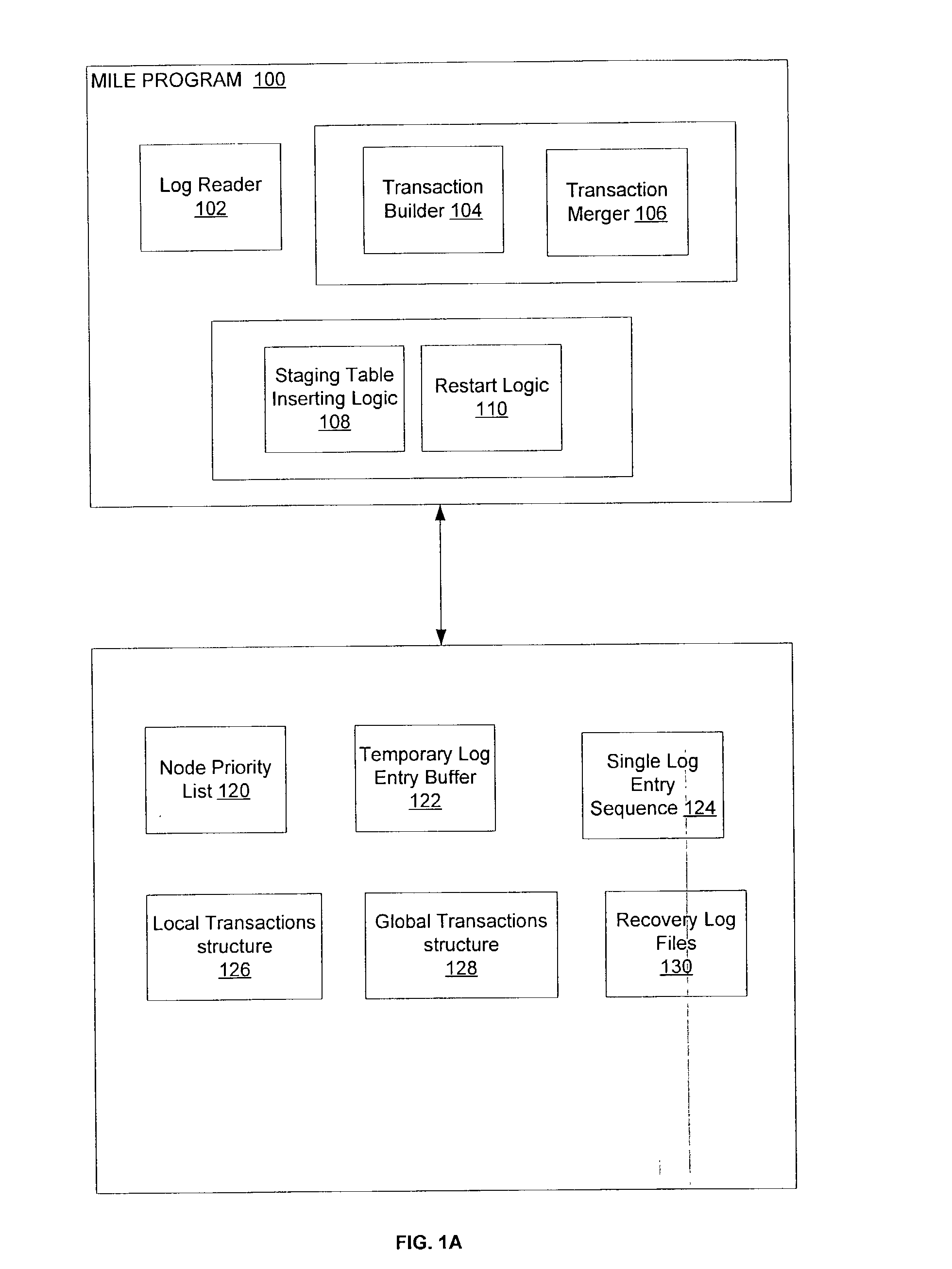

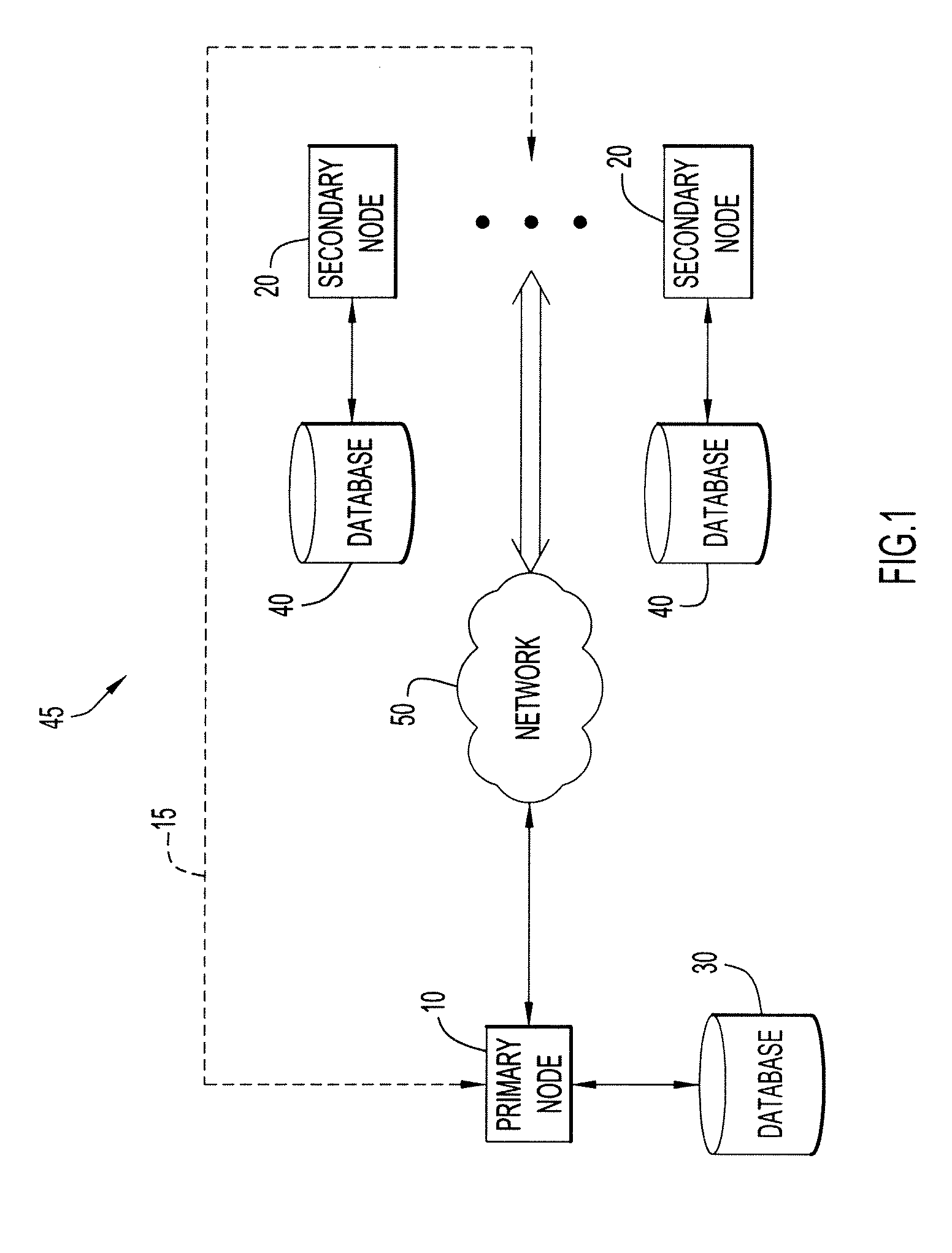

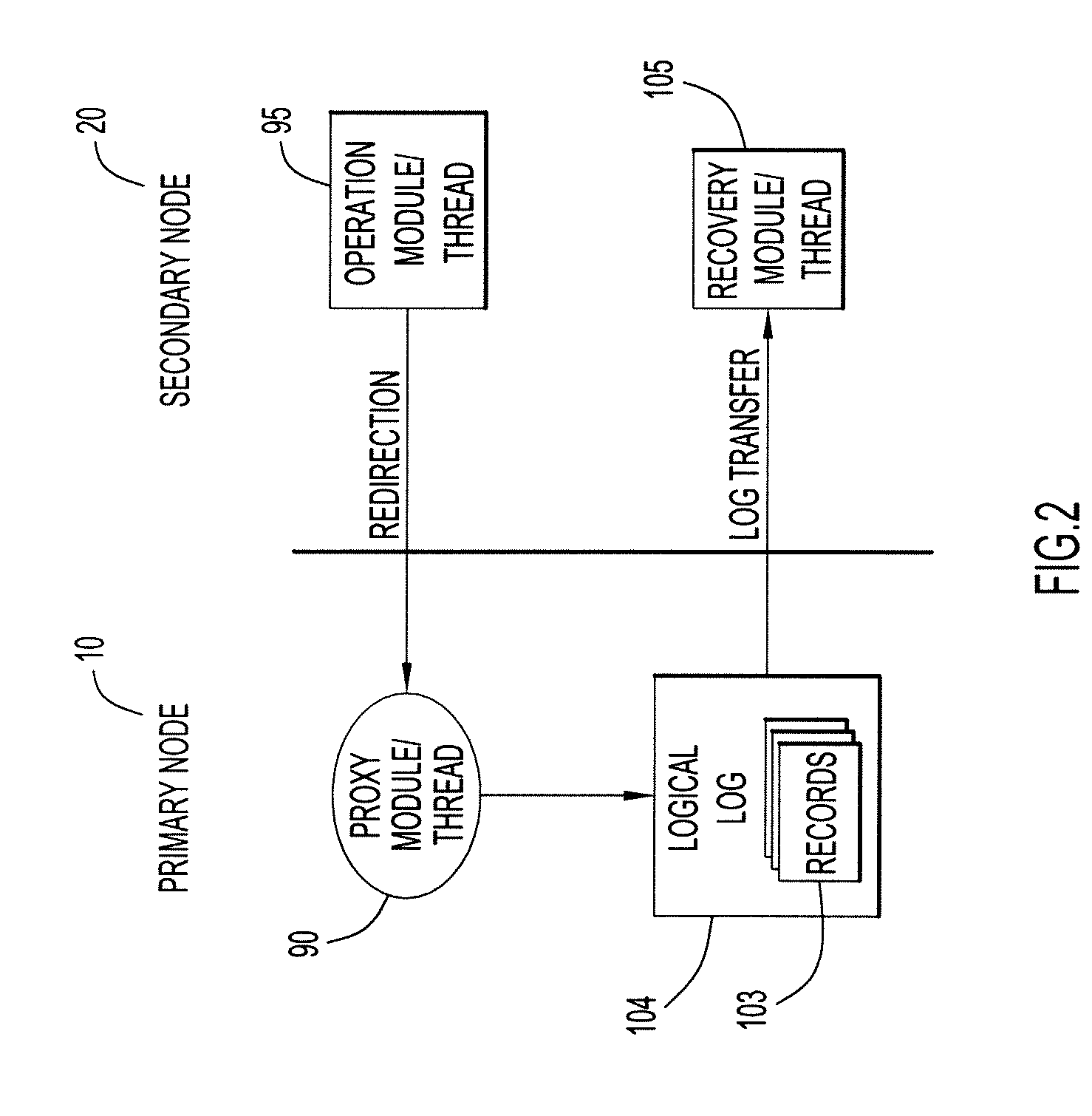

Method, system, and program for merging log entries from multiple recovery log files

InactiveUS20040030703A1Minimize overheadAvoid reprocessingData processing applicationsDigital data information retrievalDatabaseMultiple node

Provided are a method, system, and program for merging independent log entries in a multiple node shared nothing DBMS. Initially, log entries from multiple log entries are combined to form a single log entry sequence. Local transactions are generated from the single log entry sequence and stored in a local transactions structure. In particular, log entries with the same local transaction identifier form a local transaction. Then, local transactions having the same global identifier are merged to form global transactions.

Owner:IBM CORP

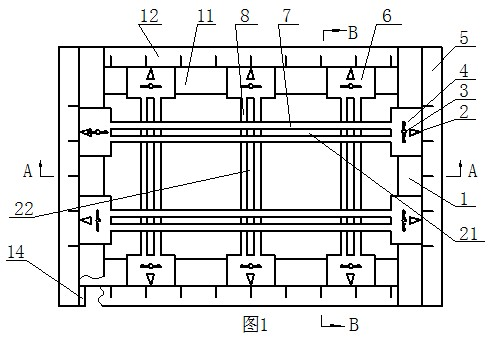

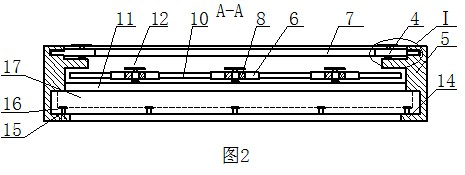

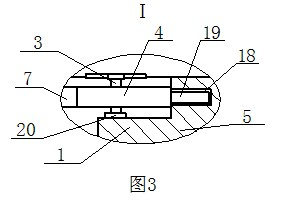

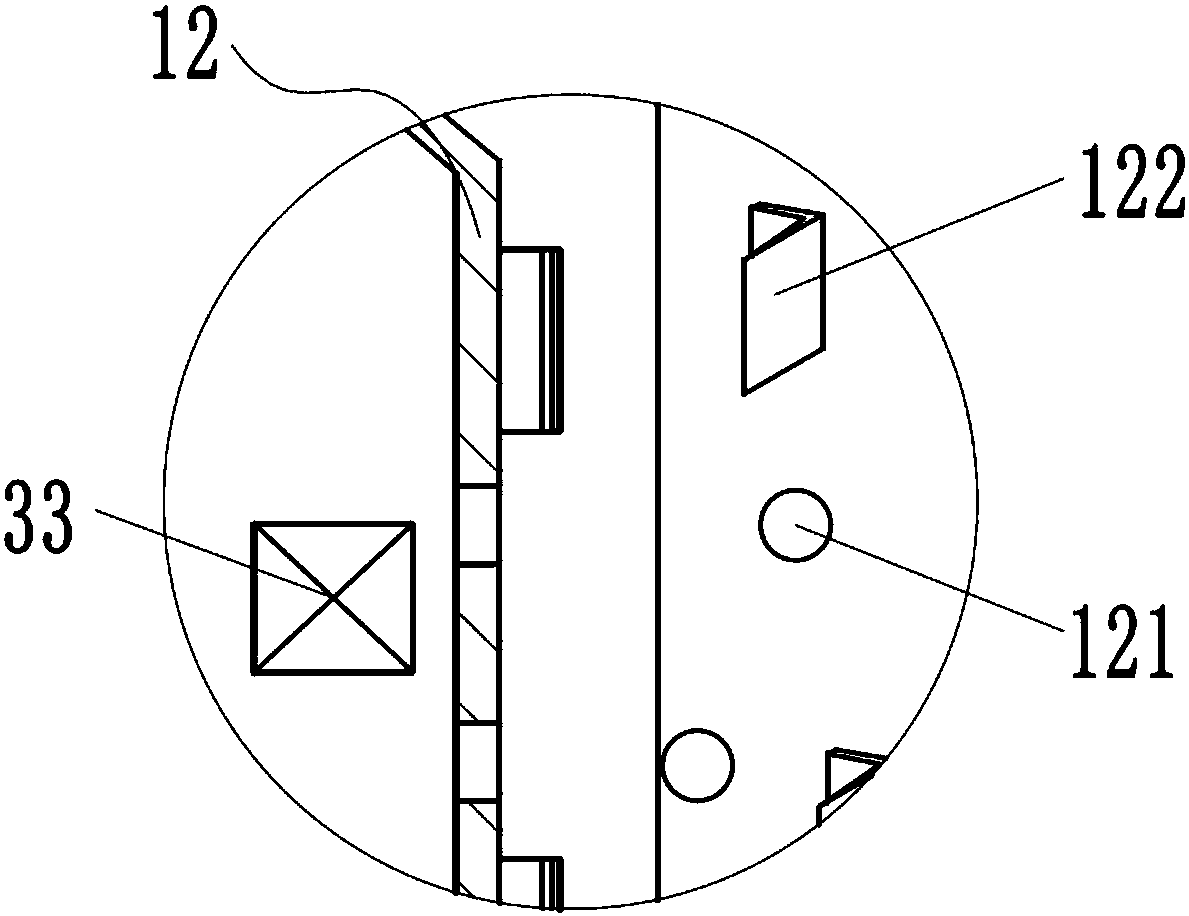

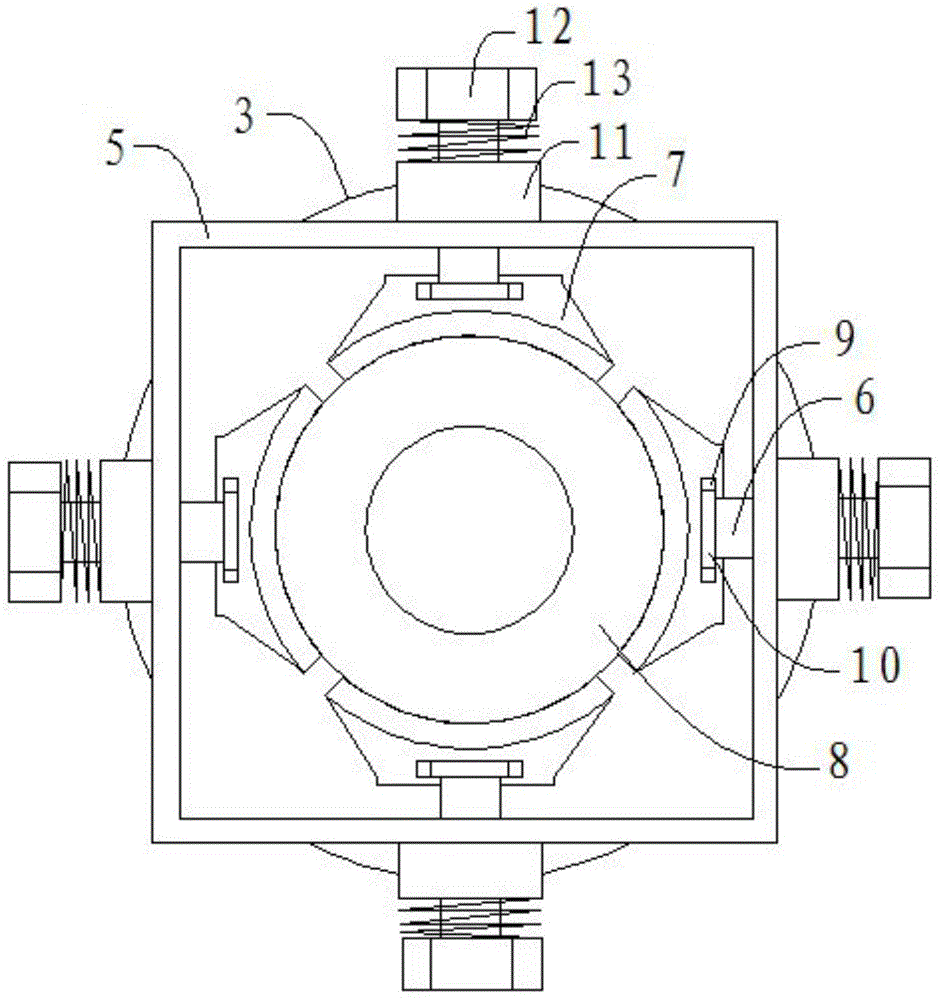

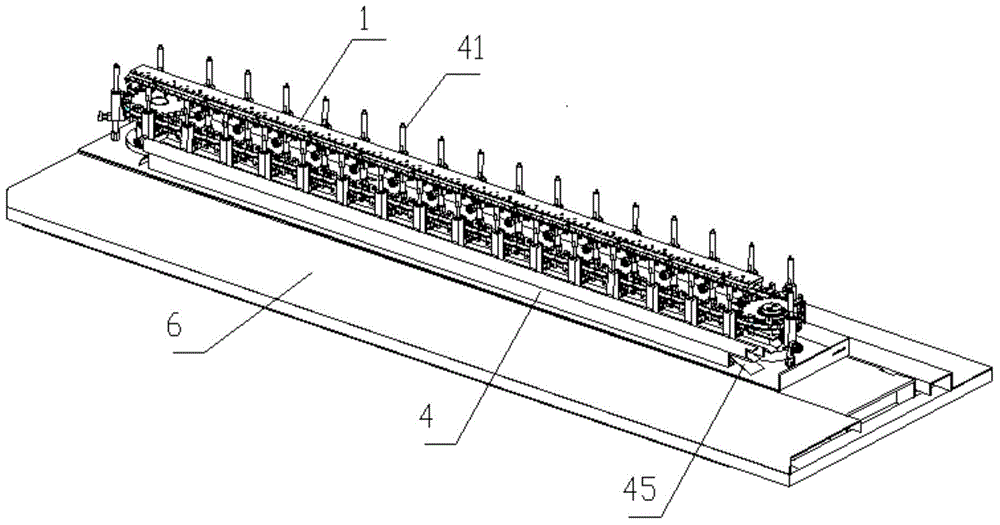

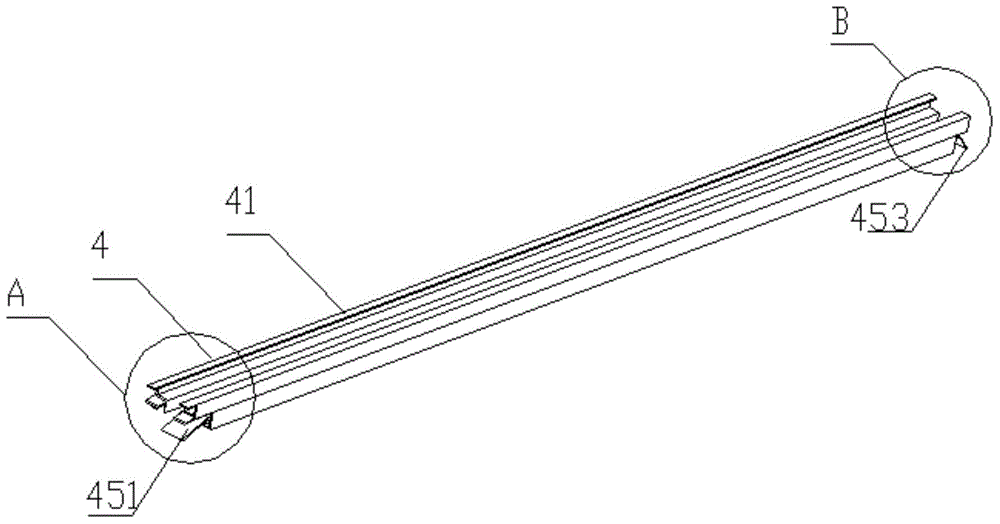

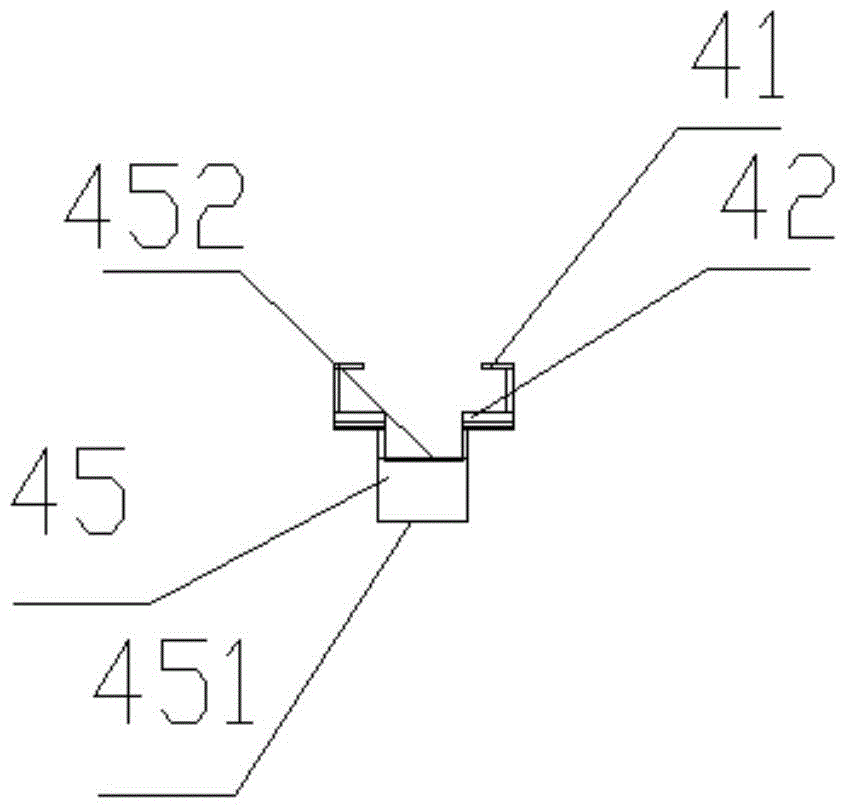

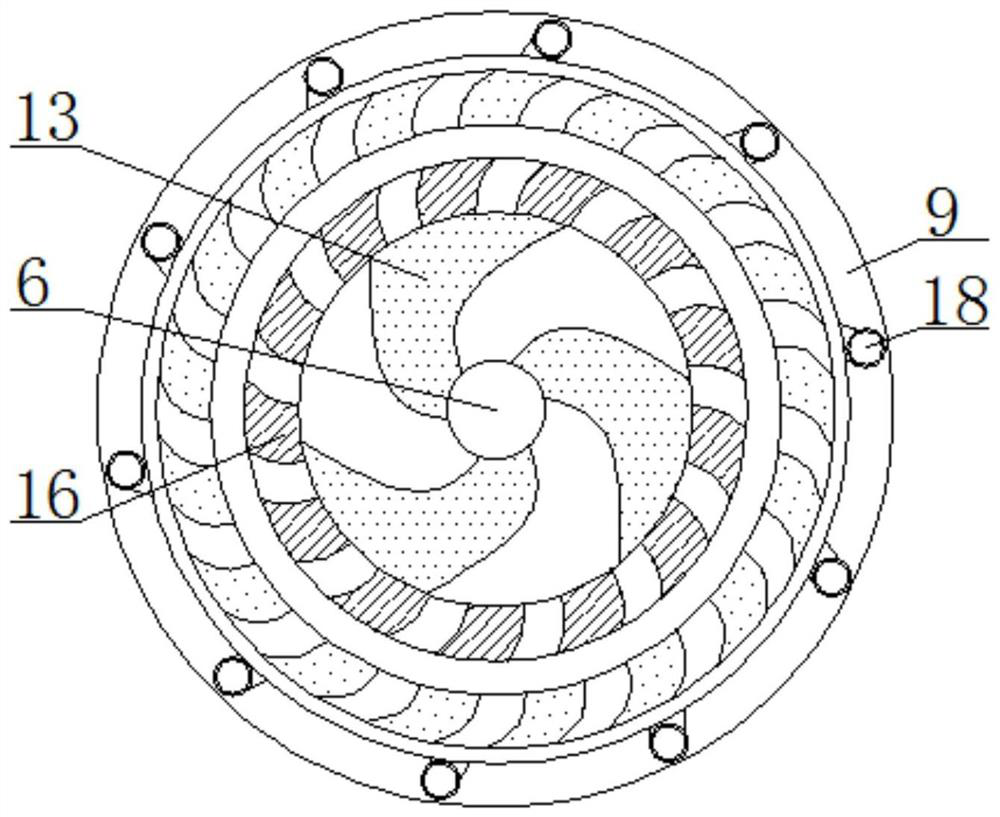

Sliding-type tool special for positioning clamp screw hole

ActiveCN102069488AAvoid reprocessingAvoid wastingOther workshop equipmentStructural engineeringEngineering

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

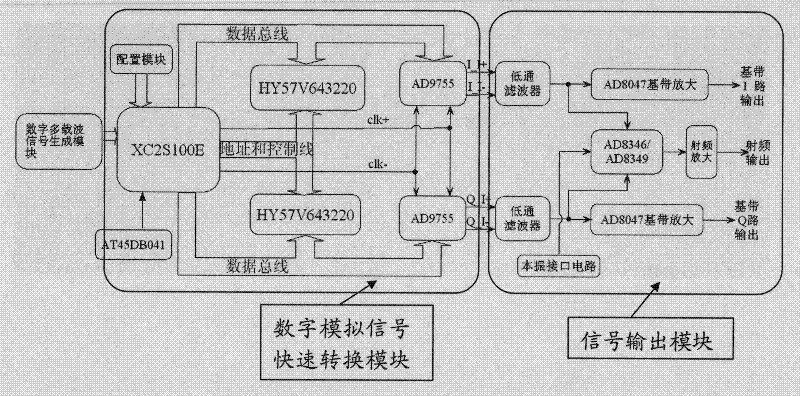

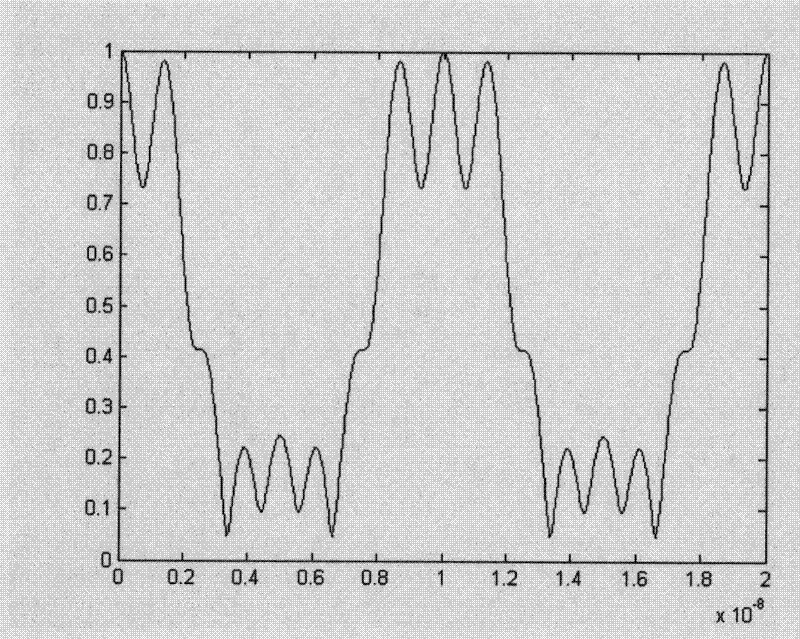

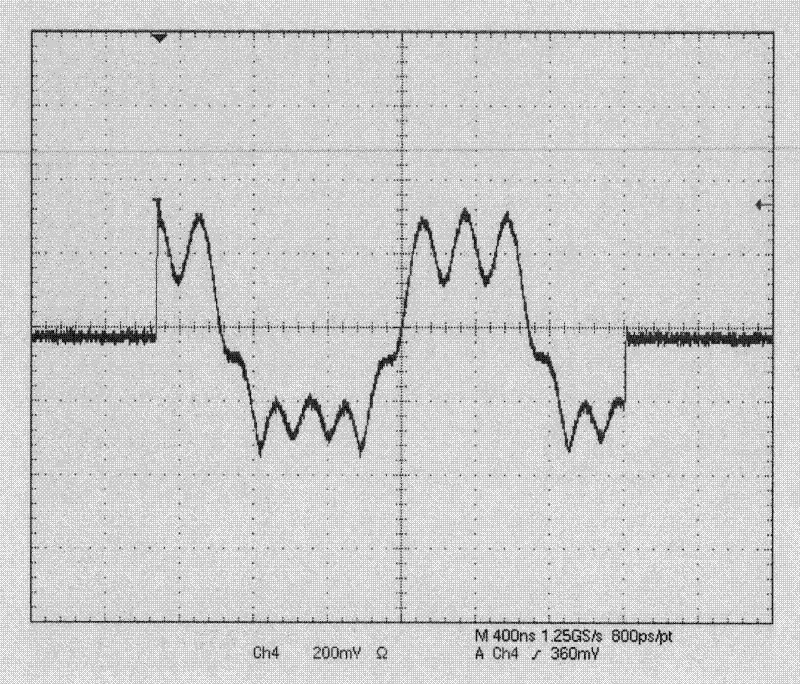

Signal source for multi-carrier micro-discharge test of spaceborne microwave component

ActiveCN102394737AAvoid reprocessingEasy to controlTransmission path multiple useDigital analogInitial phase

A signal source for a multi-carrier micro-discharge test of a spaceborne microwave component comprises a digital multi-carrier signal generation module, a digital analog signal fast conversion module and a signal output module, can directly generate multi-carrier composite signals with different initial phase distributions and different frequency distributions, and is used for a multi-carrier micro-discharge test of a spacebrone microwave component. The signal source can generate multi-carrier signal digital sampling point values together with the multi-carrier time-domain expressions with different phase distributions, and outputs the generated multi-carrier digital sampling points to the digital analog signal fast conversion module; after that, the digital analog signal fast conversion module processes multi-carrier signals into an I analog signal and a Q analog signal, and sends the analog signals to the signal output module; and the signal output module achieves low-pass filtering, baseband amplification, mixing and radio frequency output of the analog signals, and generates output baseband signals and radio frequency signals. The signal source provided by the invention dispenses with a multiplexer, does not need a phase shifter for manual phase regulation, and can accurately control the initial phases of all carriers.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

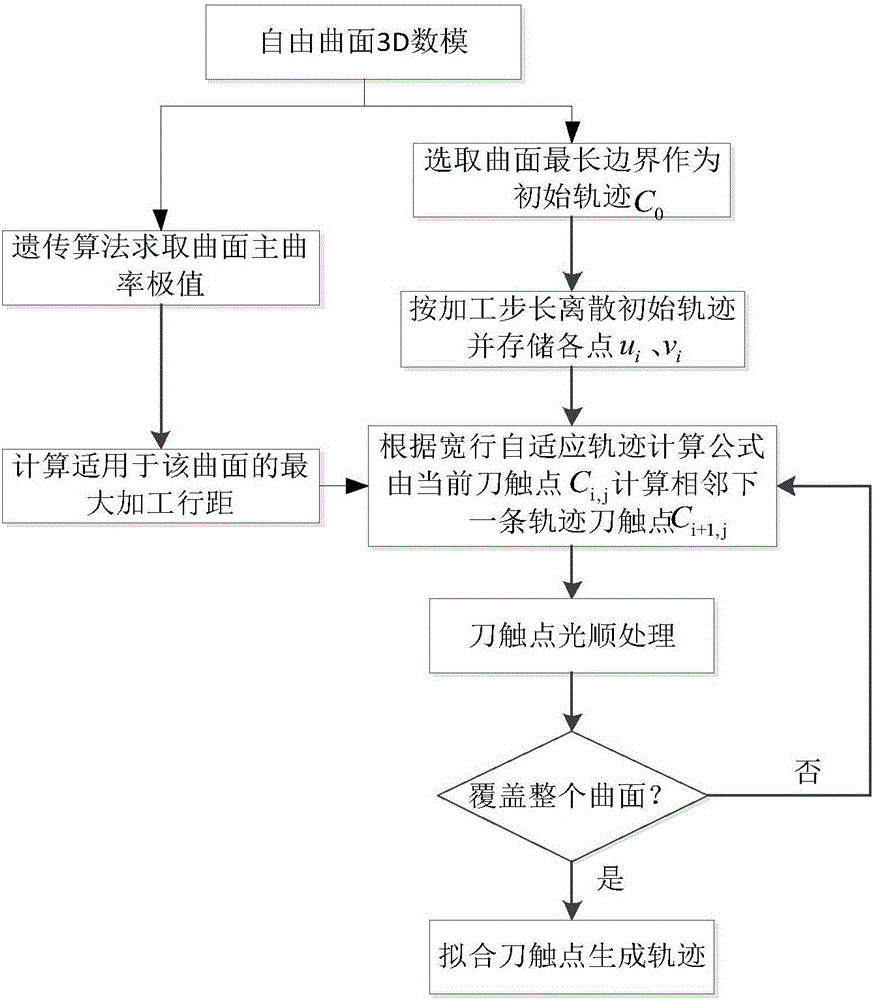

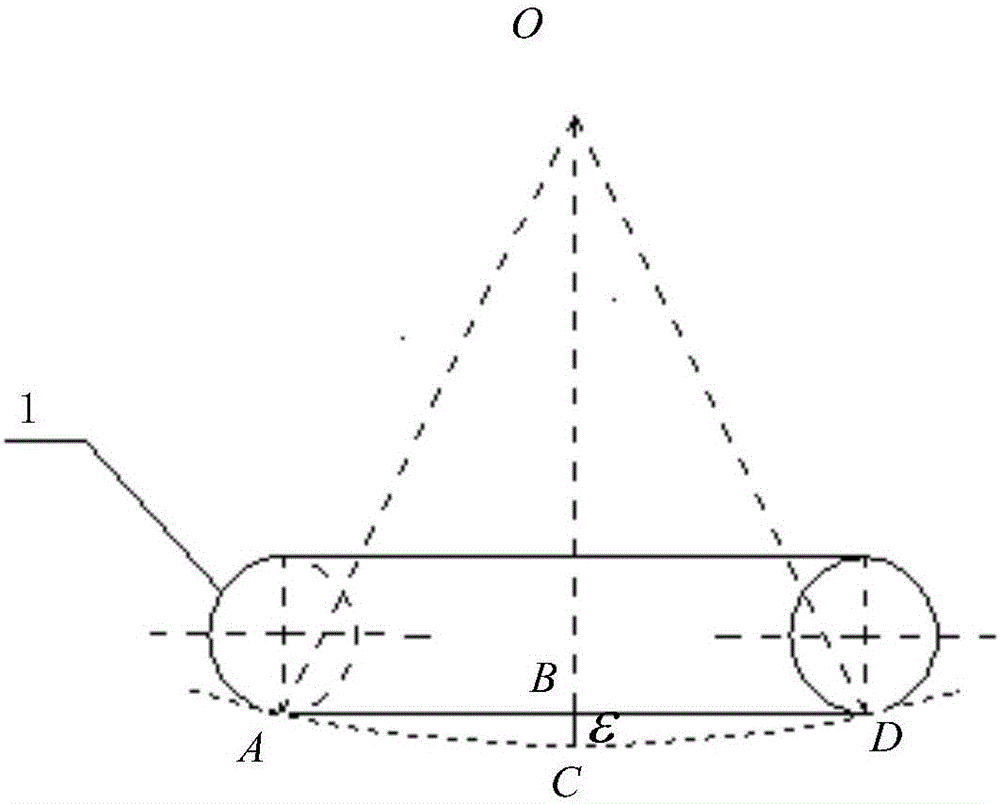

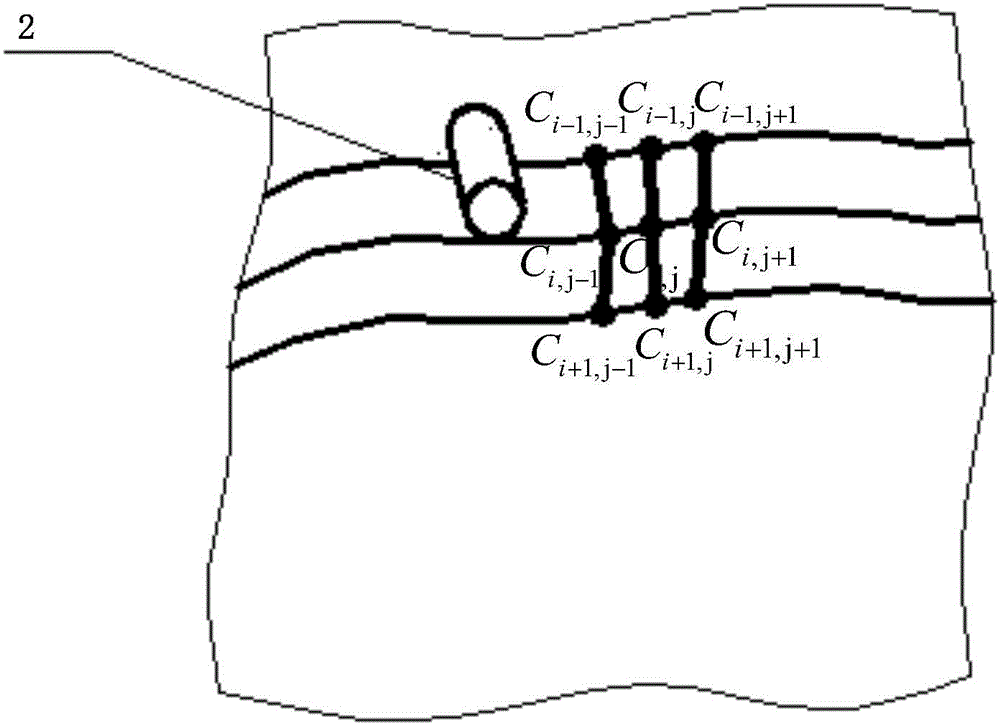

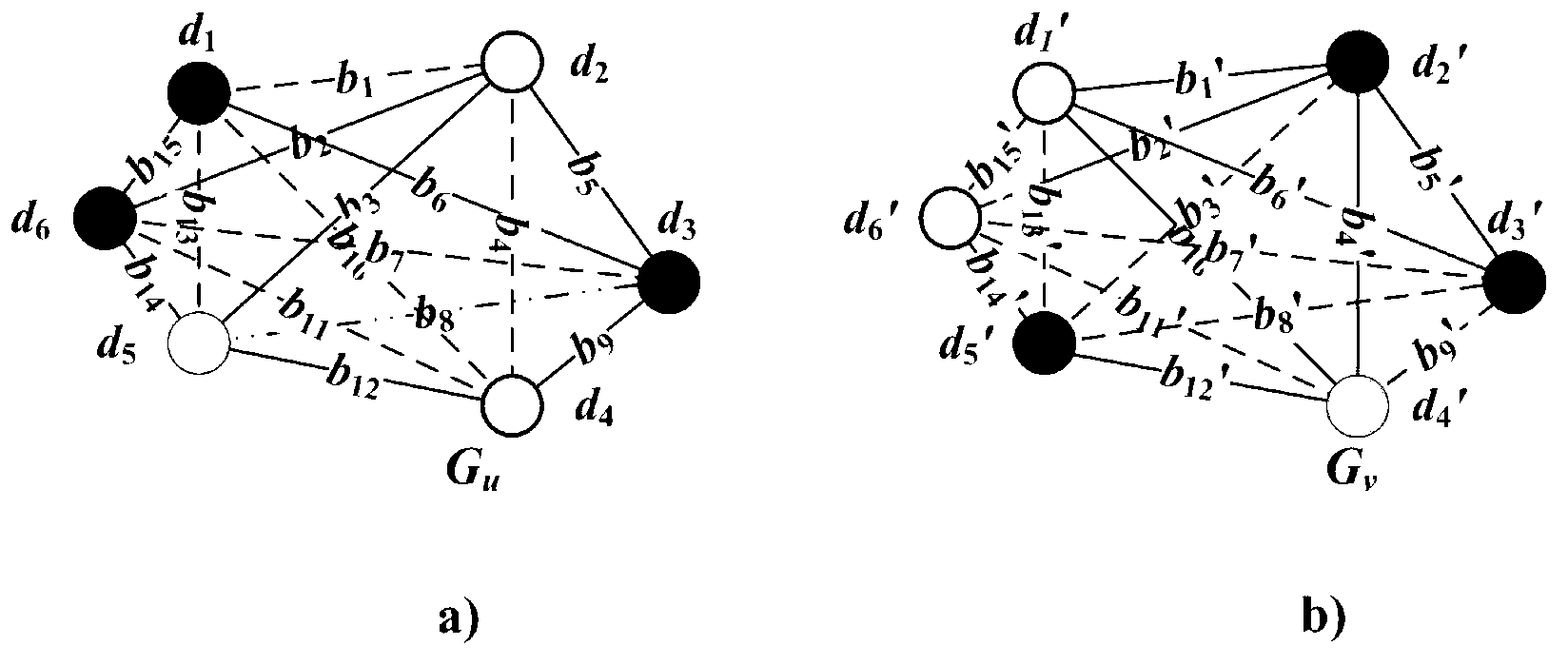

Free-form surface adaptive machining track planning method

ActiveCN106054802AReduce calculation precisionAvoid local interference problemsNumerical controlFree formGenetic algorithm

The invention discloses a free-form surface adaptive machining track planning method which is mainly used to grind free-form surface parts. The method comprises the following steps: getting the main curvature extremum of a surface through a genetic algorithm; getting the maximum line spacing suitable for surface machining according to the precision need; discretizing the longest boundary of the surface at equal step length through dichotomy; acquiring the related parameters of discrete points and calculating adjacent track cutter contacts; after traversing all newly-generated cutter contacts, performing interpolation according to the step length requirement and smoothing; and until the discrete points cover the whole surface, fitting the cutter contacts to generate a machining track. According to the invention, the maximum machining line spacing is obtained according to the machining precision requirement and the surface characteristics, and by achieving a best fitting effect between a grinding head and a surface and self-adaption of the line spacing direction, over-cutting and vibration caused by repeated grinding of a local area are avoided, and the grinding efficiency and grinding accuracy are improved. The method has great popularization and practical values.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

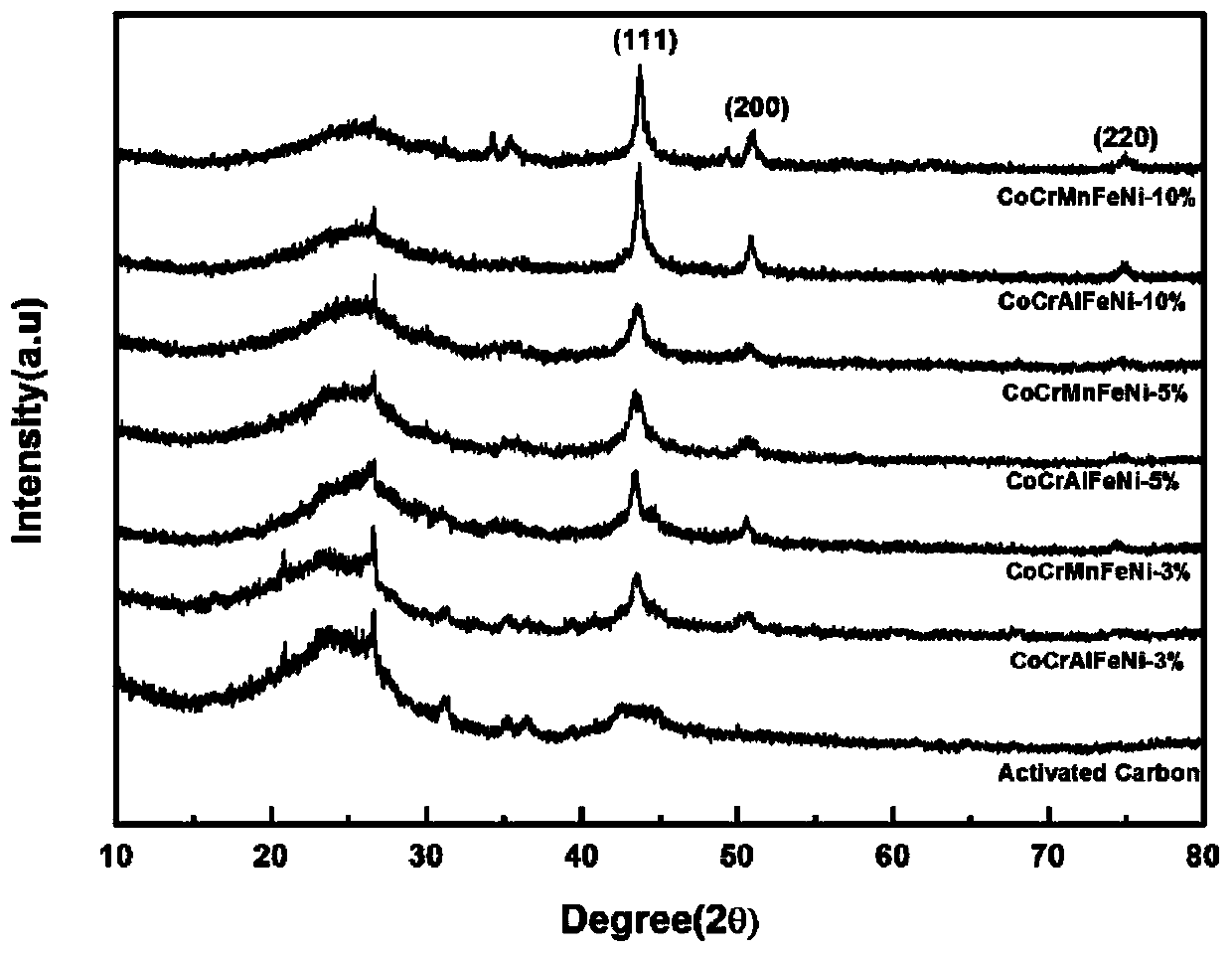

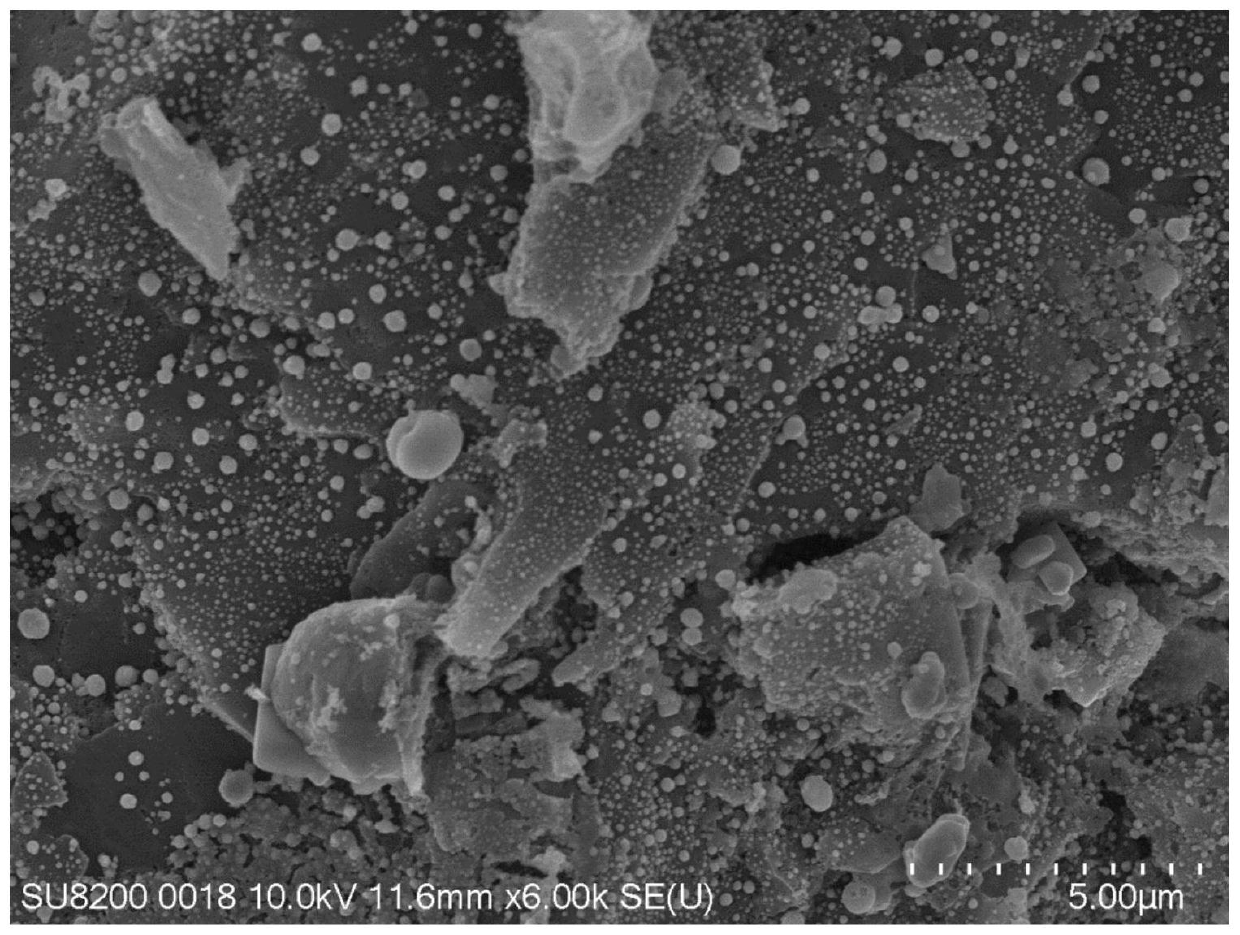

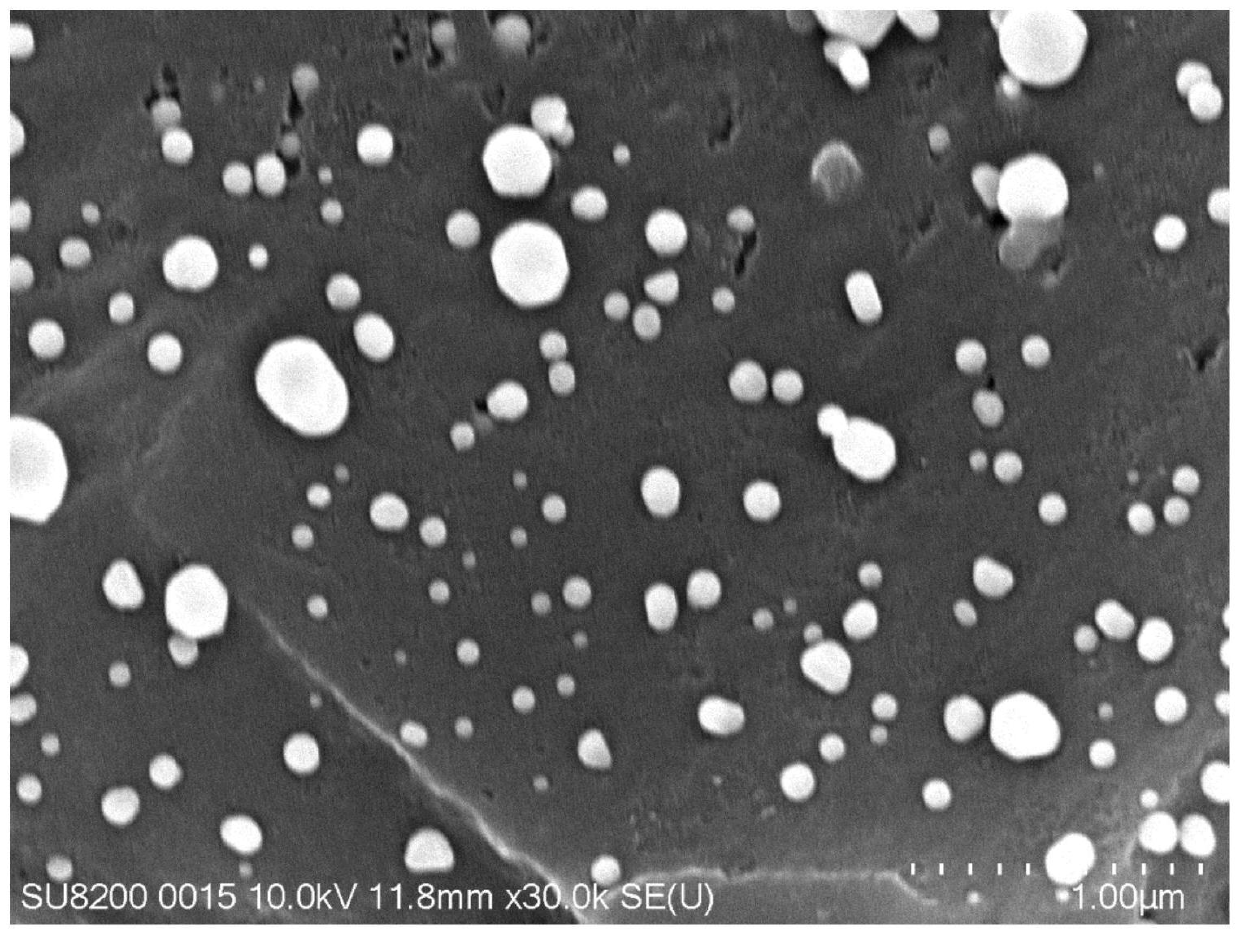

Catalyst loading CoCr(Mn/Al)FeNi high-entropy alloy nano particles and preparation method and application of catalyst

ActiveCN109999830AIncrease mixing entropyGood fade effectMaterial nanotechnologyWater contaminantsActivated carbonHigh entropy alloys

The invention discloses a catalyst loading CoCr(Mn / Al)FeNi high-entropy alloy nano particles and a preparation method and application of the catalyst. Activated carbon or a mineral material is adoptedas the matrix of the catalyst, the CoCr(Mn / Al)FeNi high-entropy alloy nano particles are loaded on the surface of the matrix, wherein the mass content of the matrix is 90-97% by weight. The CoCr(Mn / Al)FeNi high-entropy alloy nano particles loaded on the carrier are uniformly distributed, the loading capacity is controllable, the catalytic performance is excellent, and a galvanic effect can be achieved by the high-entropy alloy particles and the matrix at a nanometer scale, so that the catalytic degradation performance on azo dye is improved greatly.

Owner:CHINA UNIV OF MINING & TECH

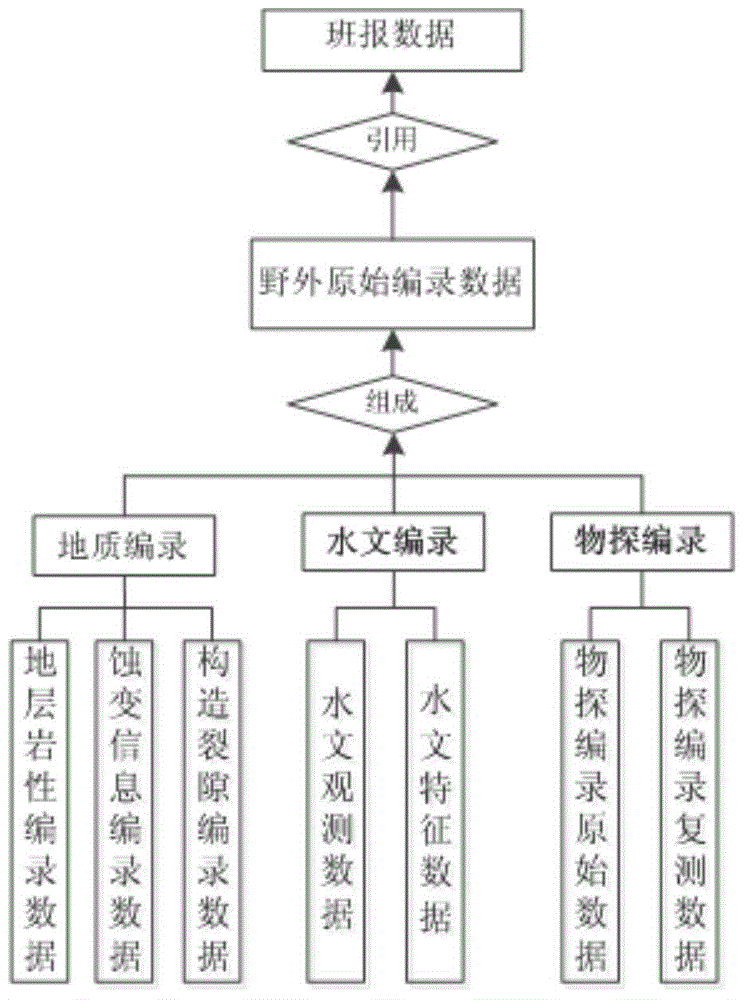

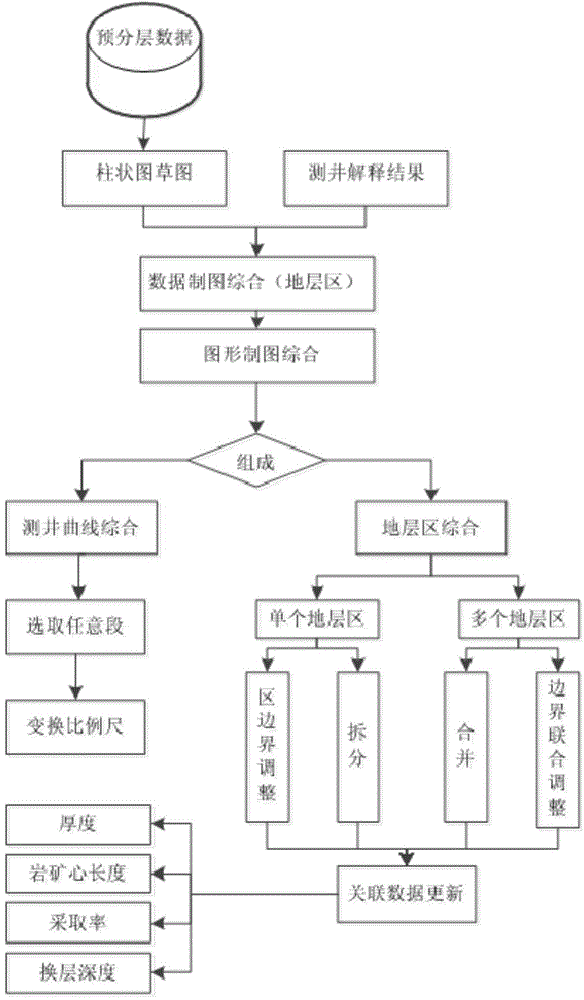

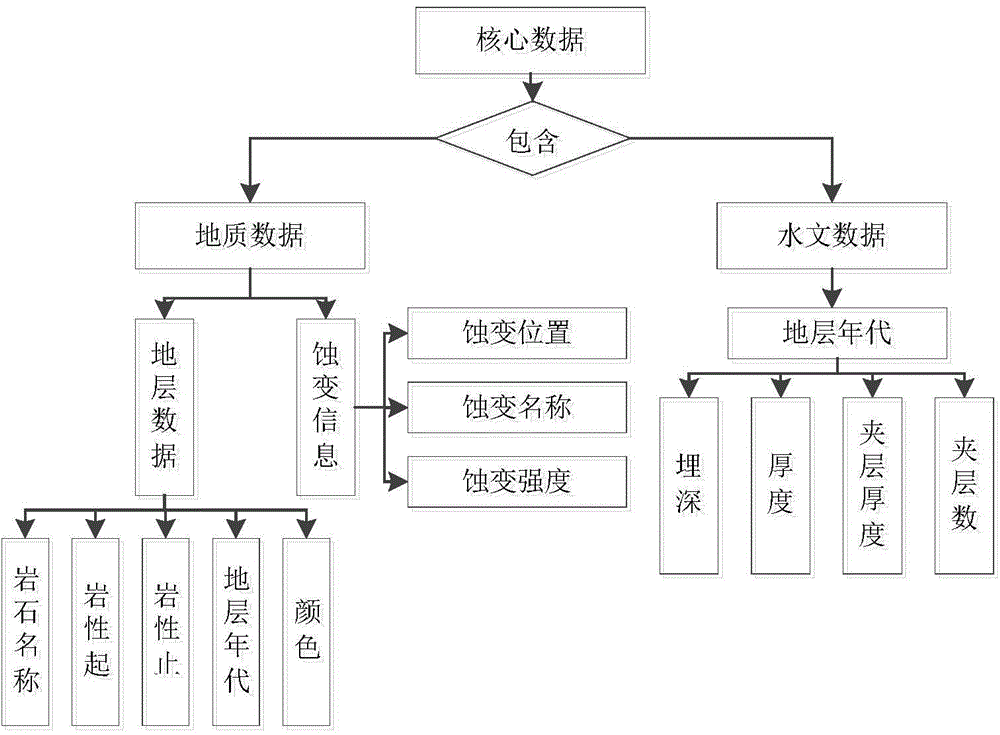

Drilling histogram compilation method based on field documentation data and automatic cartographic generalization

ActiveCN104915521AEnsure electronic unified storageEasy to storeSpecial data processing applicationsDocumentation procedureWell logging

The invention discloses a drilling histogram compilation method based on field documentation data and automatic cartographic generalization. The drilling histogram compilation method comprises the following technical modules independently used for pre-processing and storing original field data according to the rules of geological documentation and histogram drawing, combining with expertise and well logging explanation result data to carry out knowledge innervation and the cartographic generalization on the histogram, automatically classifying and archiving a comprehensive result, putting the comprehensive result into storage and carrying out user-defined printing and outputting on a result map. When a comprehensive drilling histogram is drawn through the technical system, the integral generation of the histogram can be realized, a working principle that original documentation data supports map frame generation and expert knowledge leads a final achievement can be embodied, contradiction that originally collected data is artificially tampered and industry knowledge innervation can not be carried out is avoided, the workflows of the comparison of geological documentation data and well logging data and the regulation of stratum (rock stratum) boundary line regulation can be simplified, the compilation efficiency of the drilling histogram can be greatly improved, and the drawing of the histogram can be more normative.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for removing oxytetracycline in biological medicine waste residues

ActiveCN106422152AOxidation is obviousWon't happenChemical protectionCatalytic oxidationInorganic compound

The invention relates to a method for removing oxytetracycline in biological medicine waste residues. The steps of pretreatment, catalytic oxydative degradation, bacterium inactivation, neutralizing treatment and the like are adopted, and an organic matter waste residue product containing no oxytetracycline can be formed after drying and can be used for preparing subsequent soil conditioners and organic and inorganic compound fertilizer. Compared with the prior art, purchase, use and management are easy, and hydrogen peroxide is convenient to use; and the method is used for treating the biological medicine waste residues, the oxytetracycline waste residue cost is low, the treatment process is fast, environment-friendly and small in harm, finally, the biological medicine waste residues are used as raw materials of the organic fertilizer or the soil conditioners, and the utilization value is high.

Owner:SHANGHAI RES INST OF CHEM IND

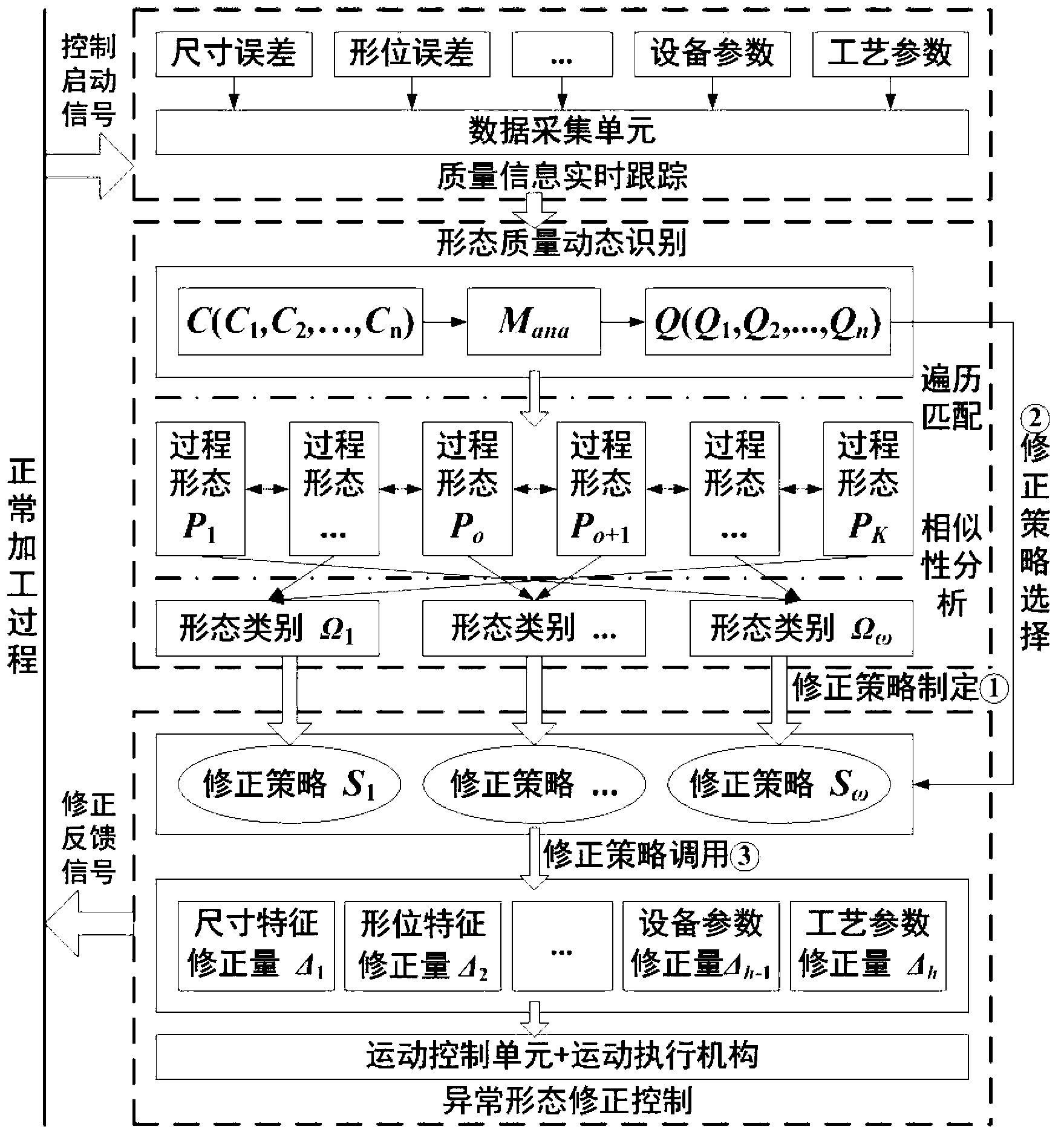

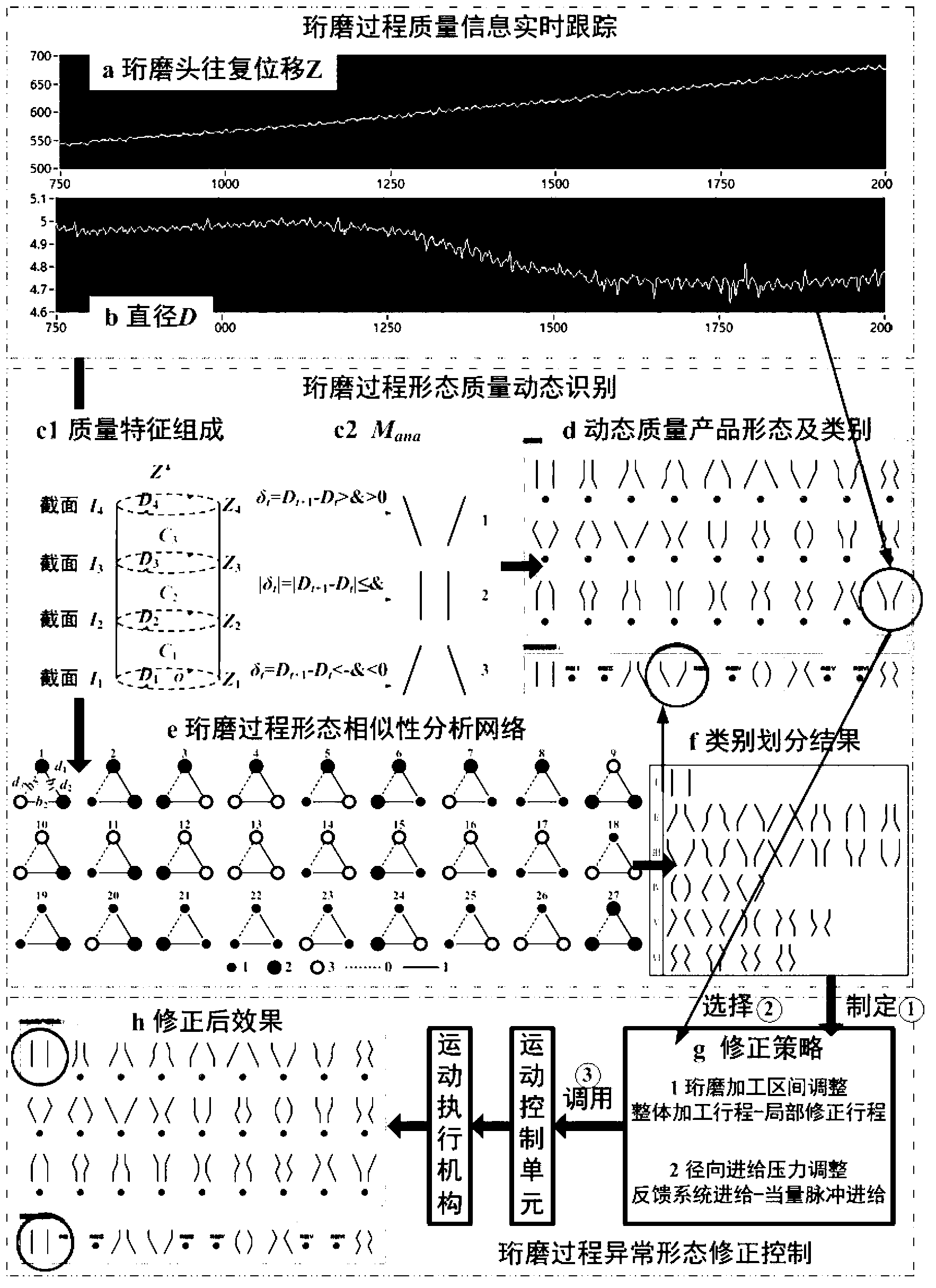

Form quality dynamic identification and modification control method in machining process

ActiveCN103257615AClear control processAvoid reprocessingProgramme controlComputer controlSimilarity analysisEconomic benefits

The invention discloses a form quality dynamical identification and modification control method in machining process. The form quality dynamical identification and modification control method in the machining process comprises the steps of (1) quality information real-time tracking, (2) form quality dynamic identification and (3) unusual form modification control, wherein the quality information real-time tracking is used for meeting the requirement that a large amount of bottom-layer data can reflect a present quality state of a workpiece form in the process of dynamic identification and modification, the form quality dynamic identification is used for carrying out data processing on acquired form quality information to acquire a dynamical quality product form, searching a form which is matched with the dynamical quality product form through an ergodic process form set and determining a belonging form type of the dynamical quality product form through similarity analysis, and the unusual form modification control is used for adopting a modification strategy ' deciding+choosing+calling' mechanism, dynamically carrying out modification control on a process exception form through a motion control unit and a motion executing mechanism. By the adoption of the form quality dynamical identification and modification control method in the machining process, the improvement of machining quality is benefited, the defects of quality is overcome in advance, quality cost is reduced, the improvement of production efficiency is benefited, off-line detection is avoided, sub-quality products can be machined again, and the economic benefit of an enterprise is improved.

Owner:XI AN JIAOTONG UNIV

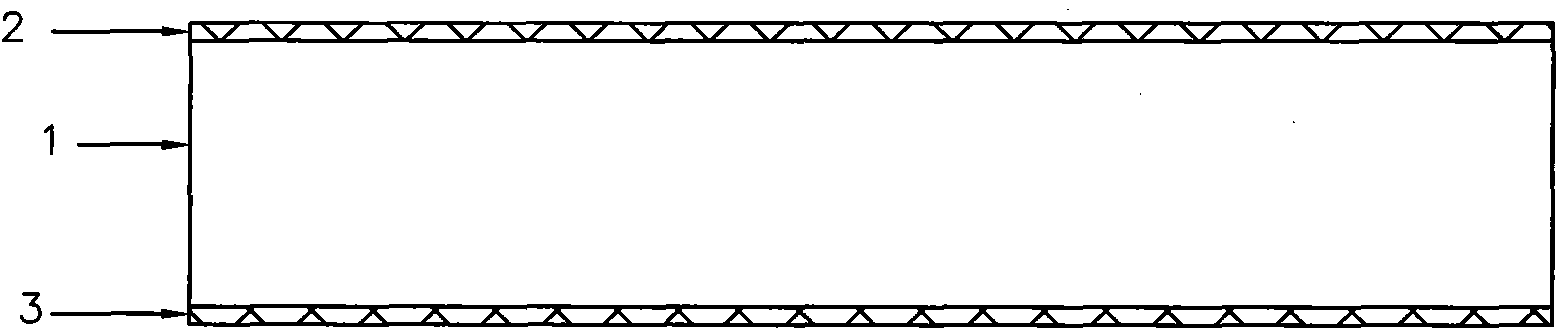

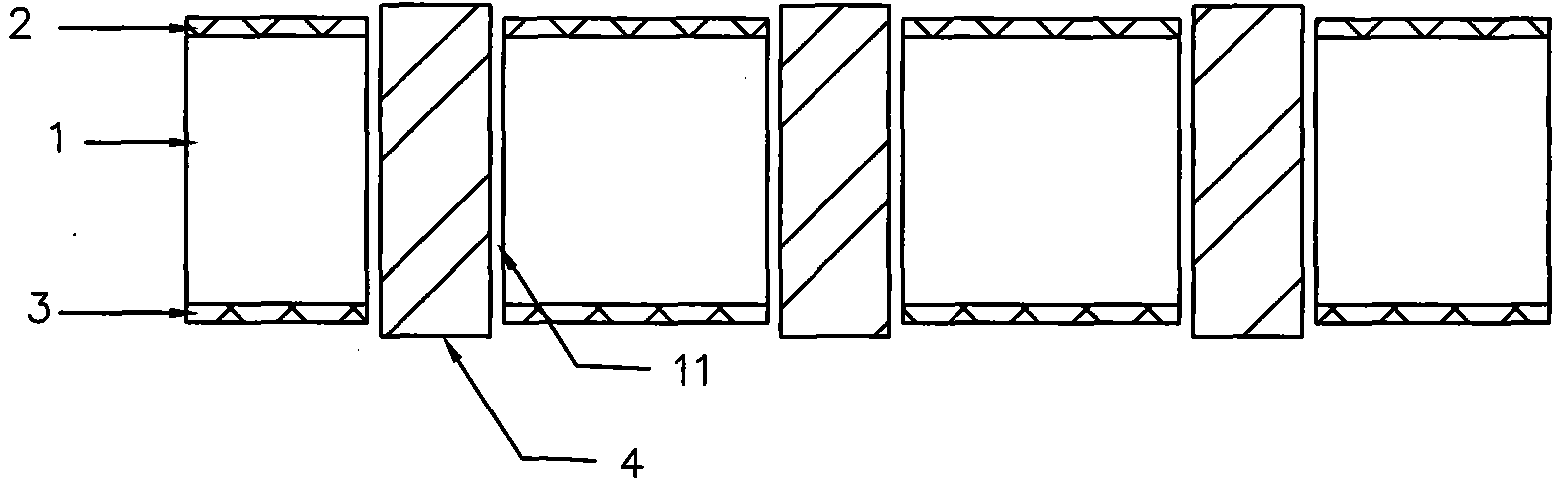

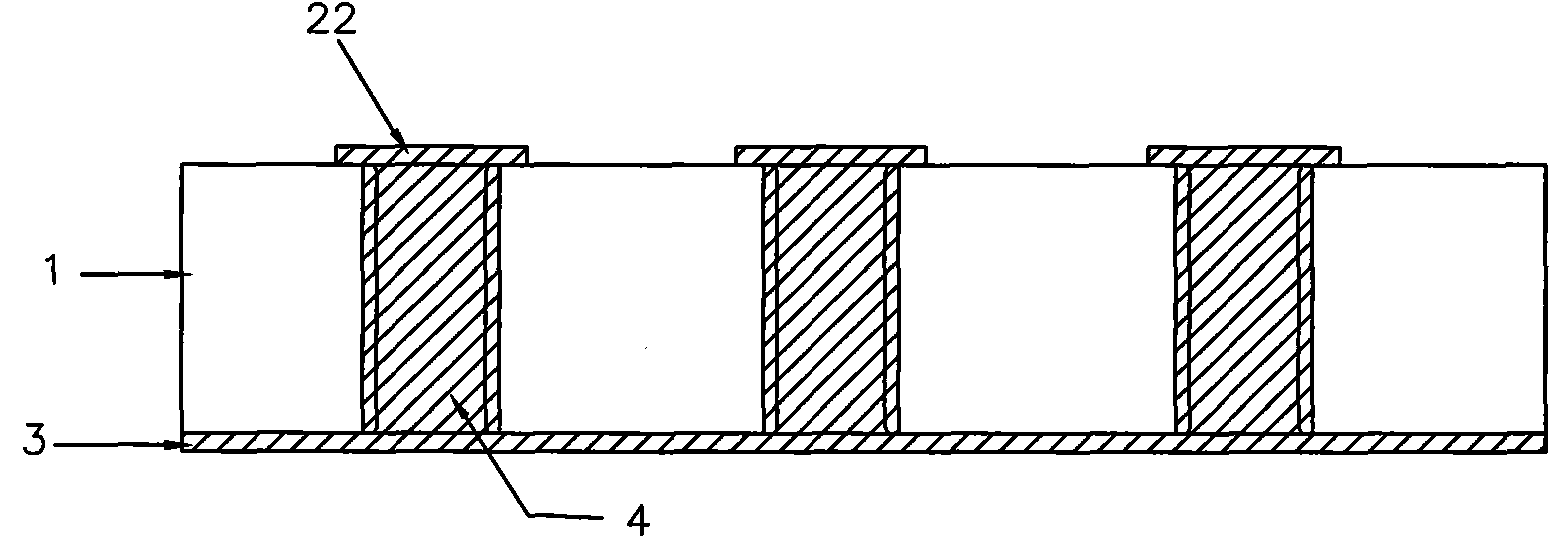

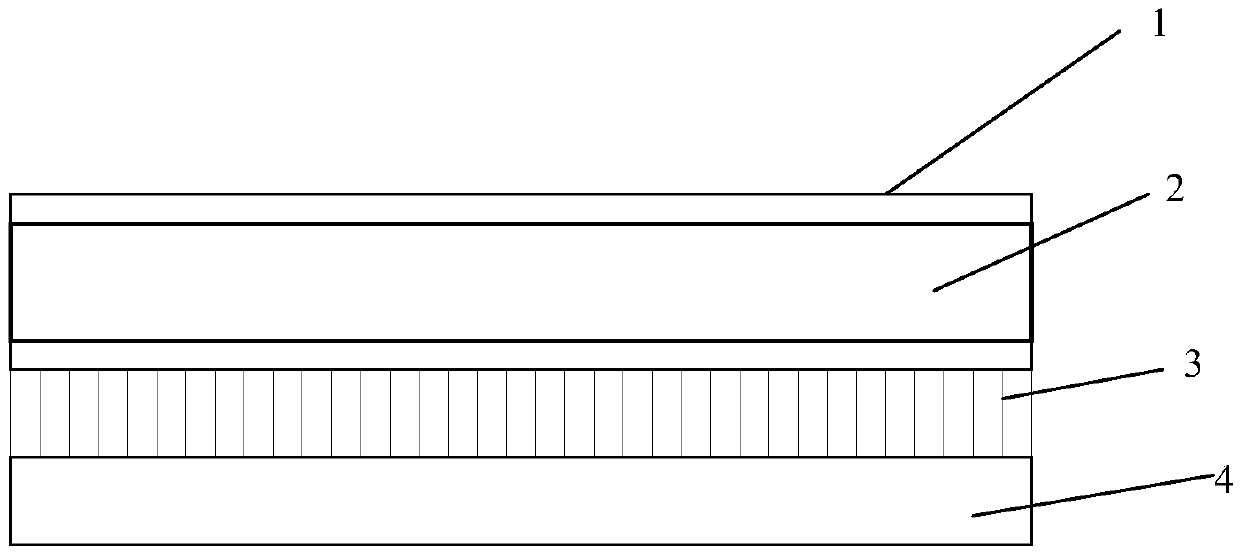

Method for manufacturing high-thermal conductivity circuit board by hot-pressing method and high-thermal conductivity circuit board

InactiveCN101841975AAvoid reprocessingDoes not affect subsequent processesPrinted circuit detailsSemiconductor/solid-state device detailsHeat conductingEngineering

The invention relates to a method for manufacturing a high-thermal conductivity circuit board and the high-thermal conductivity circuit board, which aim to solve the heat dissipation problem of heating elements on the circuit board. In the invention, by means of comprehensive consideration and overall arrangement of the implementation procedures of the high-thermal conductivity circuit board, the assembly procedures of a heat conducting column is integrated into the making process of the circuit board, which is implemented mainly as follows: before forming an electrical connecting line, the heat conducting column is assembled in a preset position of the circuit board; the method does not affect subsequent procedures and avoids reworking after the circuit board is formed; and a metal heat conducting layer can further dissipate heat on the heat conducting column, thus achieving better heat dissipation effect and having simple operation, simple structure and low cost.

Owner:ZHUHAI BONTECH ELECTRIC TECH

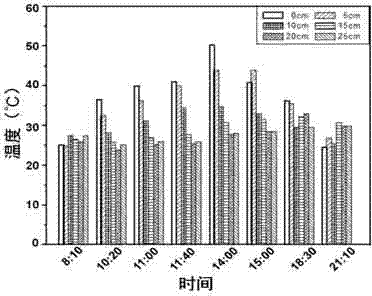

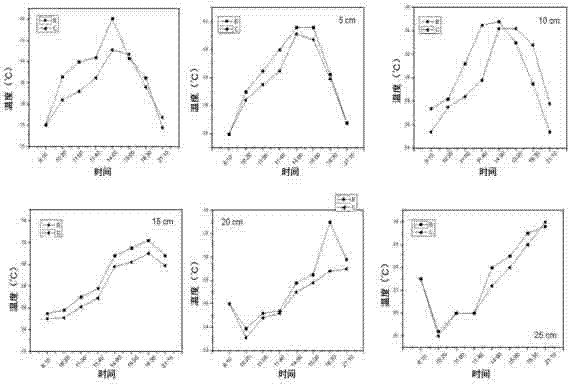

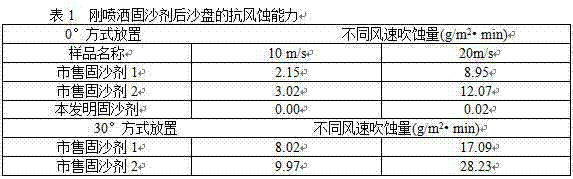

Clay-base sand stabilizing material with water-saving temperature-regulating sand stabilizing function

ActiveCN104845640ARecovery rebuilding positiveCause secondary pollutionOther chemical processesOrganic fertilisersWater savingVegetation

The invention discloses a multifunctional clay-base sand stabilizing material integrating a water saving function, a temperature regulation function and a sand stabilizing function, and belongs to the field of sand control and sand stabilization. The sand stabilizing material adopts clay, biomass waste, animal bones, animal excrement, perlite, lactic acid, potassium hydroxide, phosphoric acid, natural emulsifier and cellulose as raw materials and is prepared in a given process. When in use, the clay-base sand stabilizing material is directly sprayed onto the surface of desert by utilizing a spraying device, and the crust thickness is controlled at 5mm to 10mm. The experiment shows that the product integrates the temperature regulation function, the water saving function and the sand stabilizing function; moreover, raw materials are natural products, so that the cost is low, the preparation process is simple, secondary environmental pollution is avoided, and the clay-base sand stabilizing material plays a positive role in restoring and rebuilding vegetation of a desert area.

Owner:NORTHWEST NORMAL UNIVERSITY

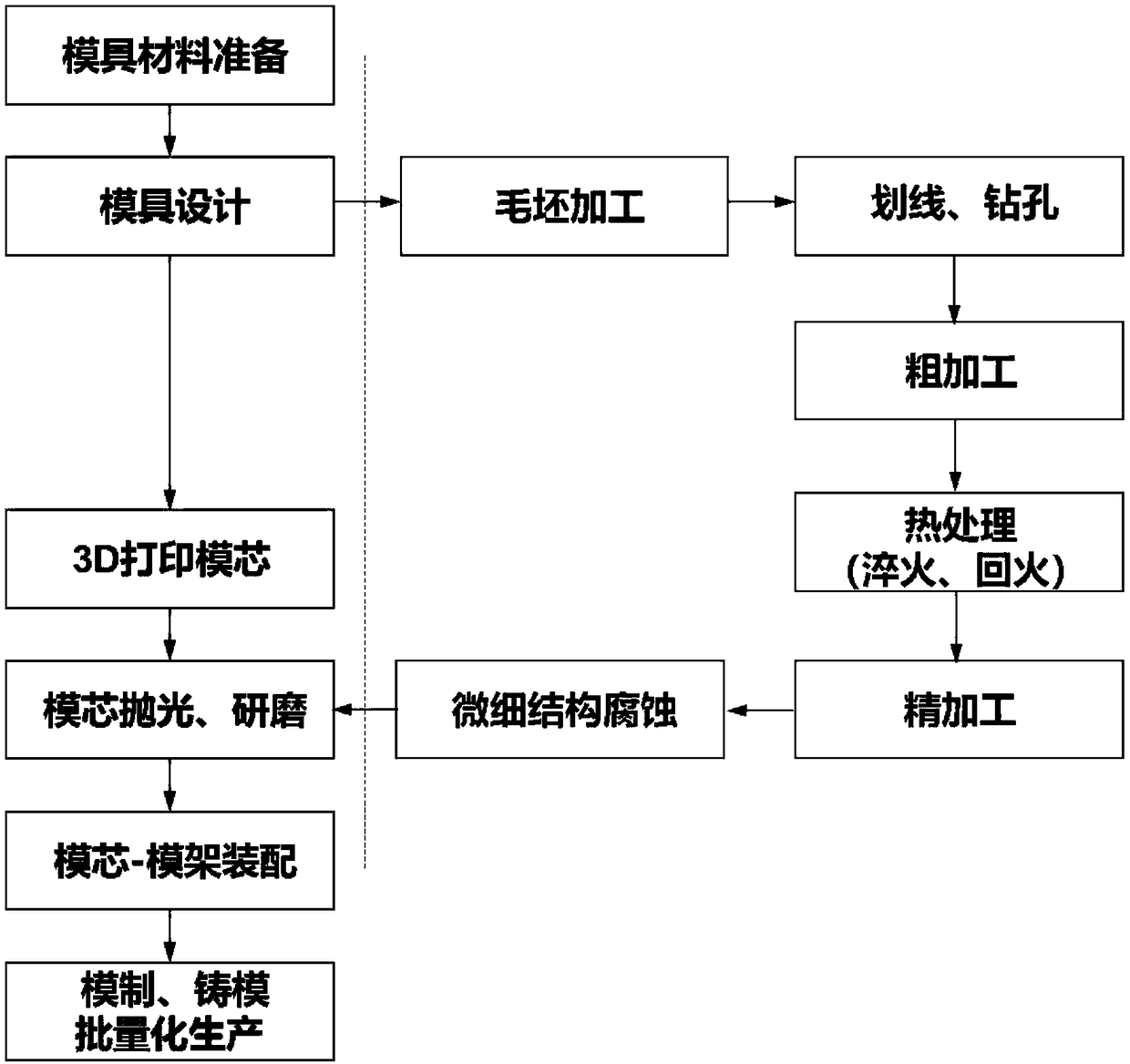

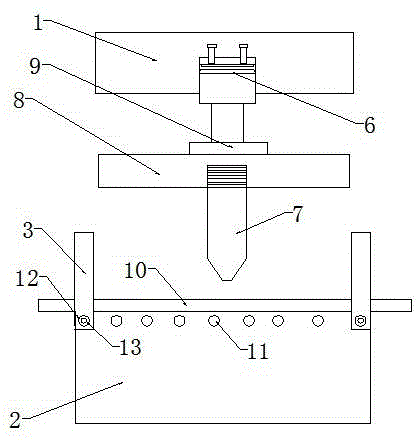

Mold rapid machining method based on 3D printing mold core

InactiveCN109128165AShorten the processing cycleRealize green and intelligent transformation and upgradingAdditive manufacturing apparatusCeramic shaping apparatusCasting moldRapid tooling

The invention discloses a mold rapid machining method based on a 3D printing mold core. The mold rapid machining method based on the 3D printing mold core is characterized by comprising the followingsteps of S1, preparing needed raw materials; S2, designing a geometric structure of the mold core, and converting the geometric structure of the mold core into a format matched with a format in a control equipment system; S3, using a 3D printing technology to print the mold core after S2 is finished; S4, polishing and grinding the mold core in S3 to a desired size and surface accuracy; S5, assembling the mold core in a mold base after S4 is finished; and S6, carrying out follow-up molding or casting mold batch production. By directly and rapidly performing 3D printing on the mold core, polishing the surface of the mold core and fastening the mold core on the mold base, the follow-up molding or casting mold batch production of the mold core is carried out and realized. According to the moldrapid machining method based on the 3D printing mold core, an optimal design is realized, the efficiency or function of a terminal product is enhanced, a difficult problem of traditional machining technologies such as CNC during machining the complicated geometric structures is solved, the design is free, the manufacturing is rapid and green, and green and intelligent transformation and upgradingof the traditional mold industry are really realized.

Owner:HUAZHONG UNIV OF SCI & TECH

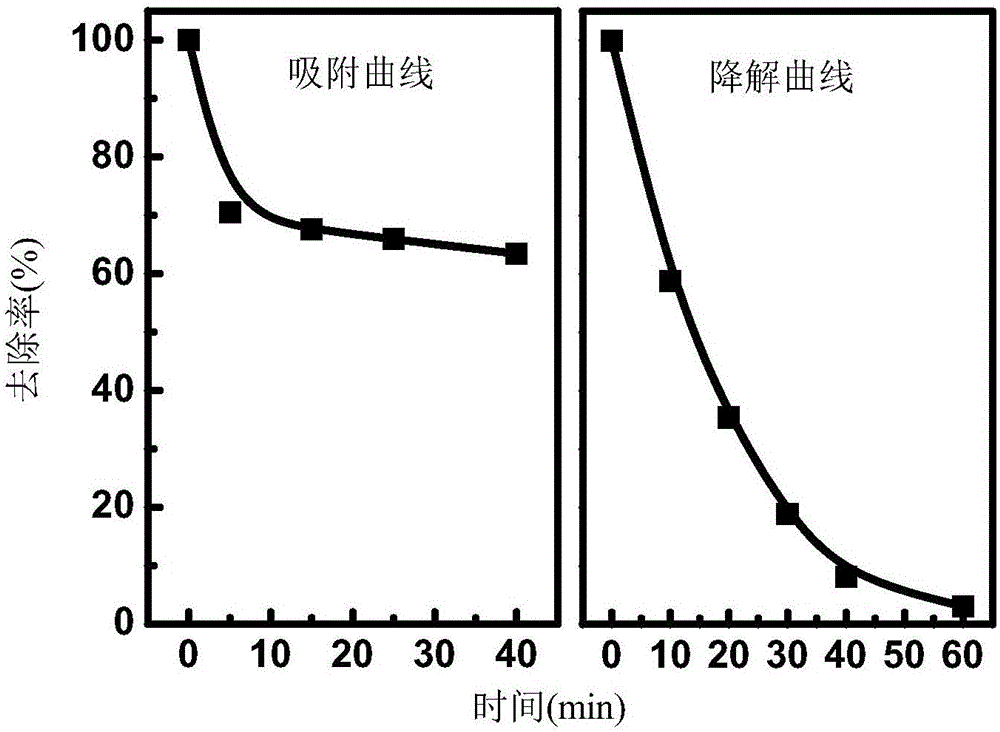

Short-hole-channel ordered mesoporous silica-sulfur-indium-zinc composite photocatalyst as well as preparation method and application thereof

ActiveCN106111053AImprove stabilityRapidly reach the active siteGas treatmentPhysical/chemical process catalystsEnvironmental resistanceIndium

The invention discloses a short-hole-channel ordered mesoporous silica-sulfur-indium-zinc composite photocatalyst as well as a preparation method and application thereof. The short-hole-channel ordered mesoporous silica-sulfur-indium-zinc composite photocatalyst is prepared through the following steps of mixing ethyl orthosilicate with ZrOCl2, zinc salt, indium salt and a reducing agent so as to obtain a mixture, in the presence of a surfactant, sequentially performing sol-gel treatment, hydrothermal treatment and alcohol ultrasonic treatment, performing sucking filtration, performing cleaning and performing drying. According to the photocatalyst, the integration of adsorption and photocatalytic oxidation is realized, the photocatalyst has high adsorption properties and high photocatalytic activity on volatile organic compounds (VOCs), and hydroxyl radicals produced on the surface of a catalyst can effectively degrade the VOCs adsorbed and enriched by materials in an in-situ manner, so that the reaction rate and the reaction efficiency of photocatalytic degradation on the VOCs can be substantially improved, the photocatalyst can be used as an adsorbent or the photocatalyst for organic contaminants in the field of environmental protection, and the photocatalyst has wide environmental protection application potential.

Owner:GUANGDONG UNIV OF TECH

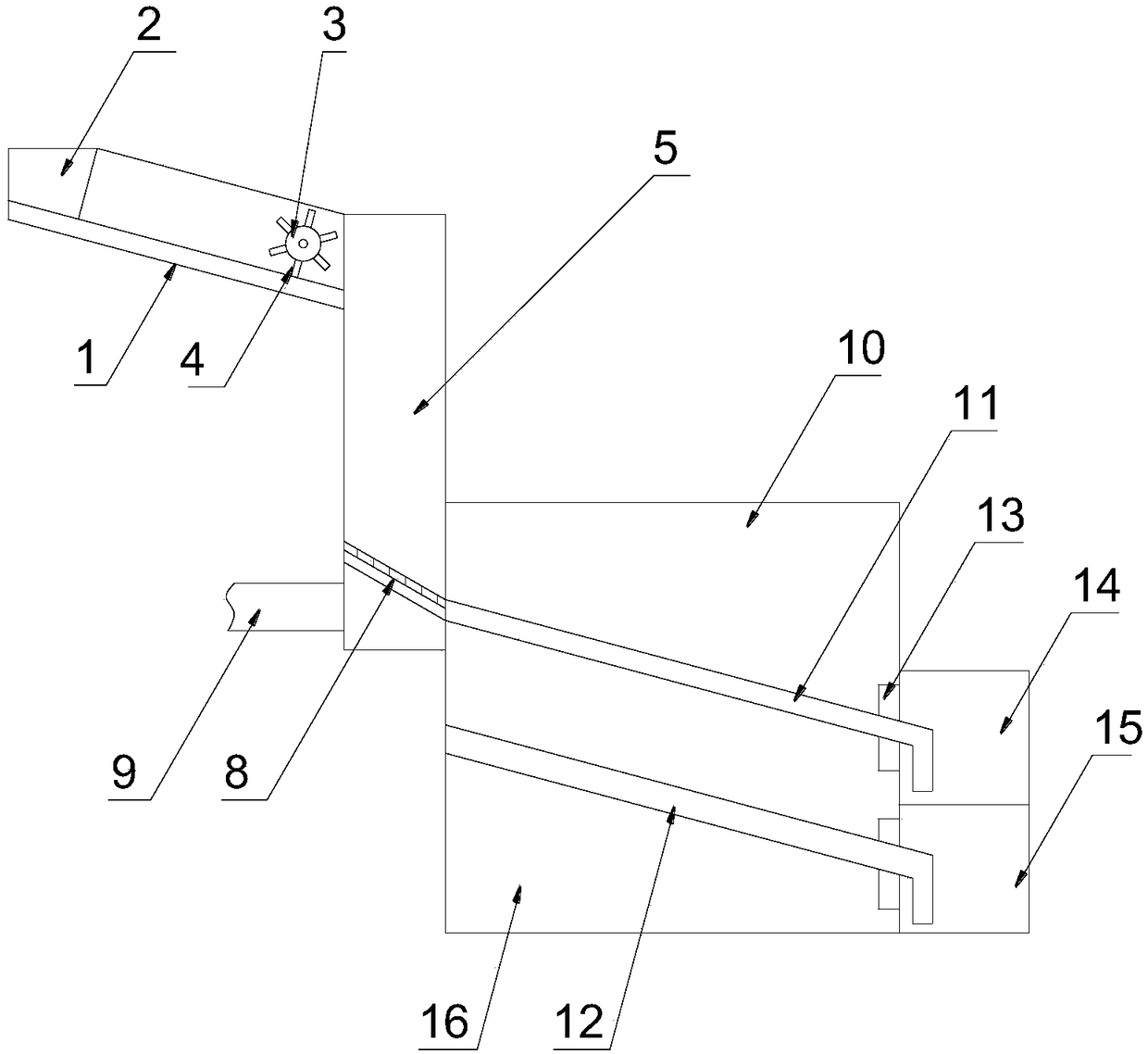

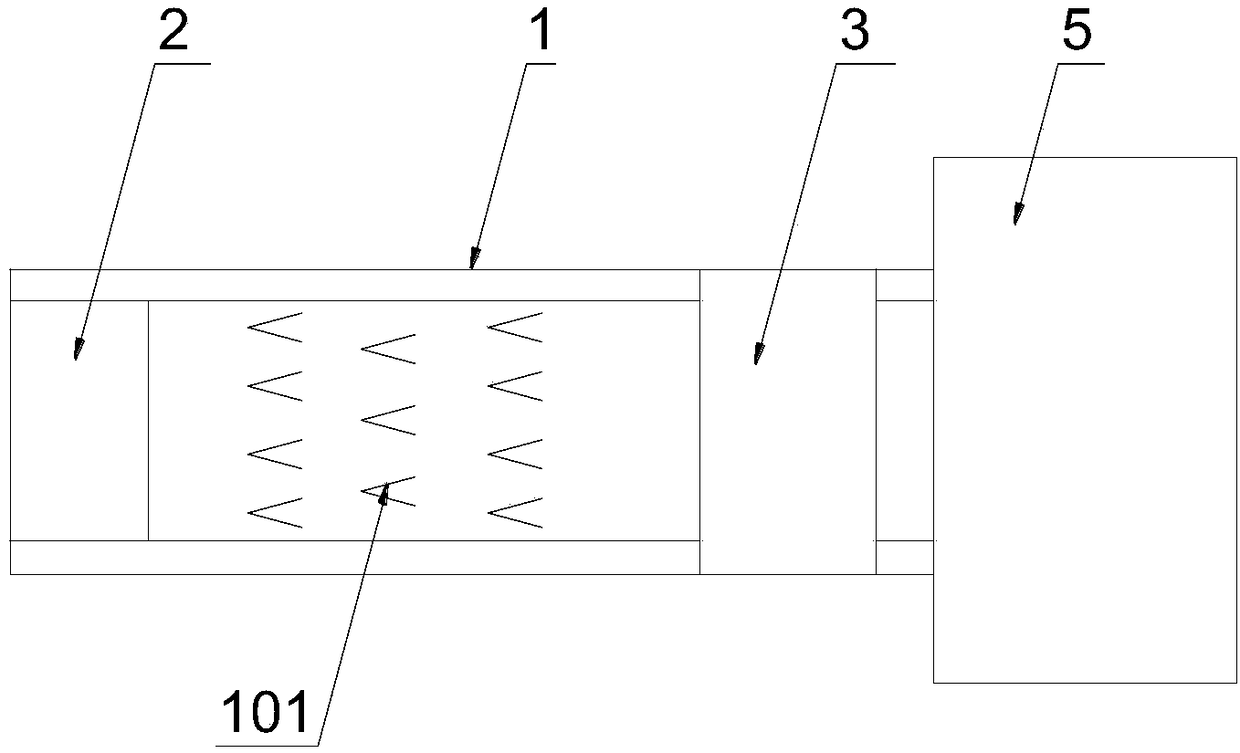

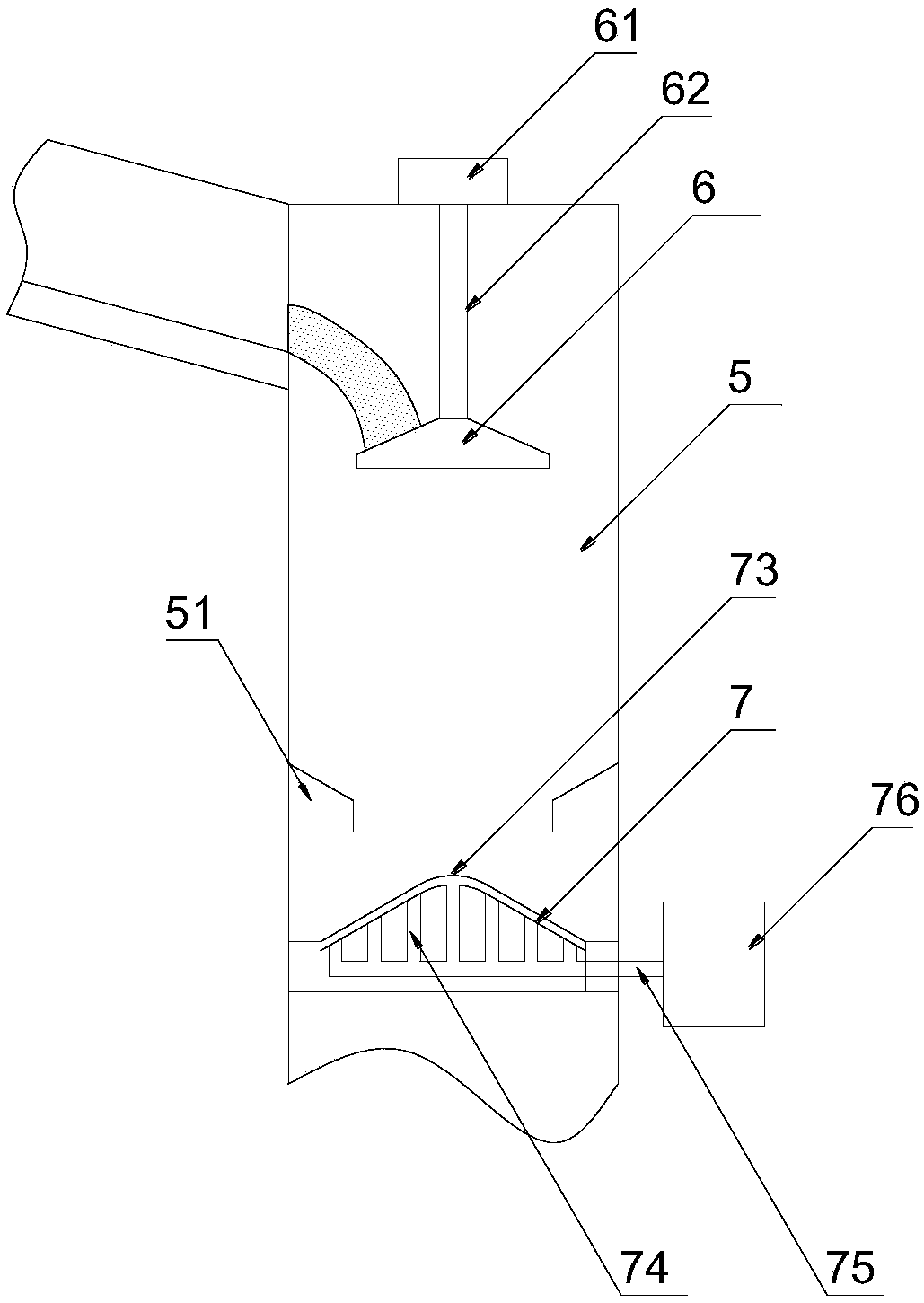

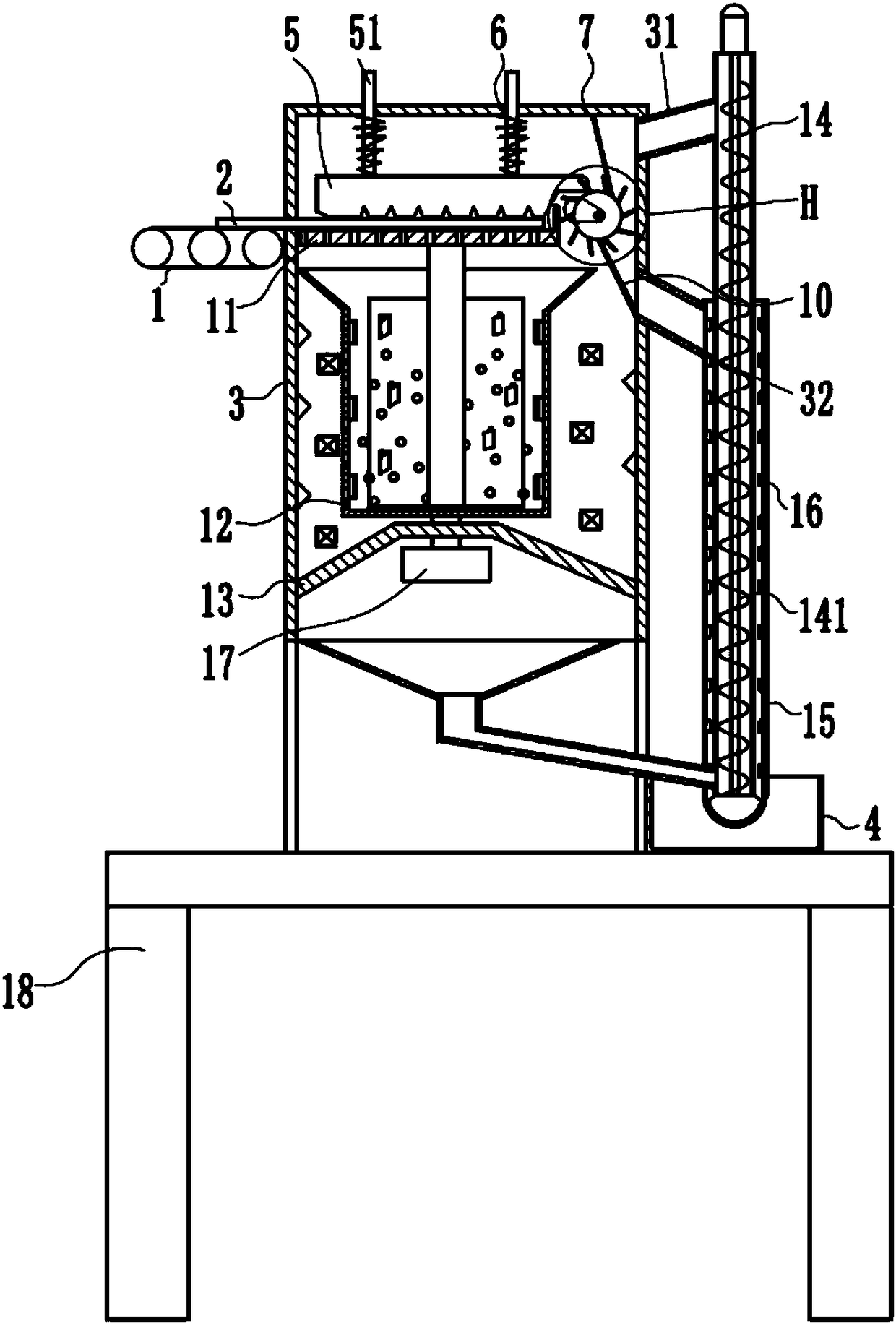

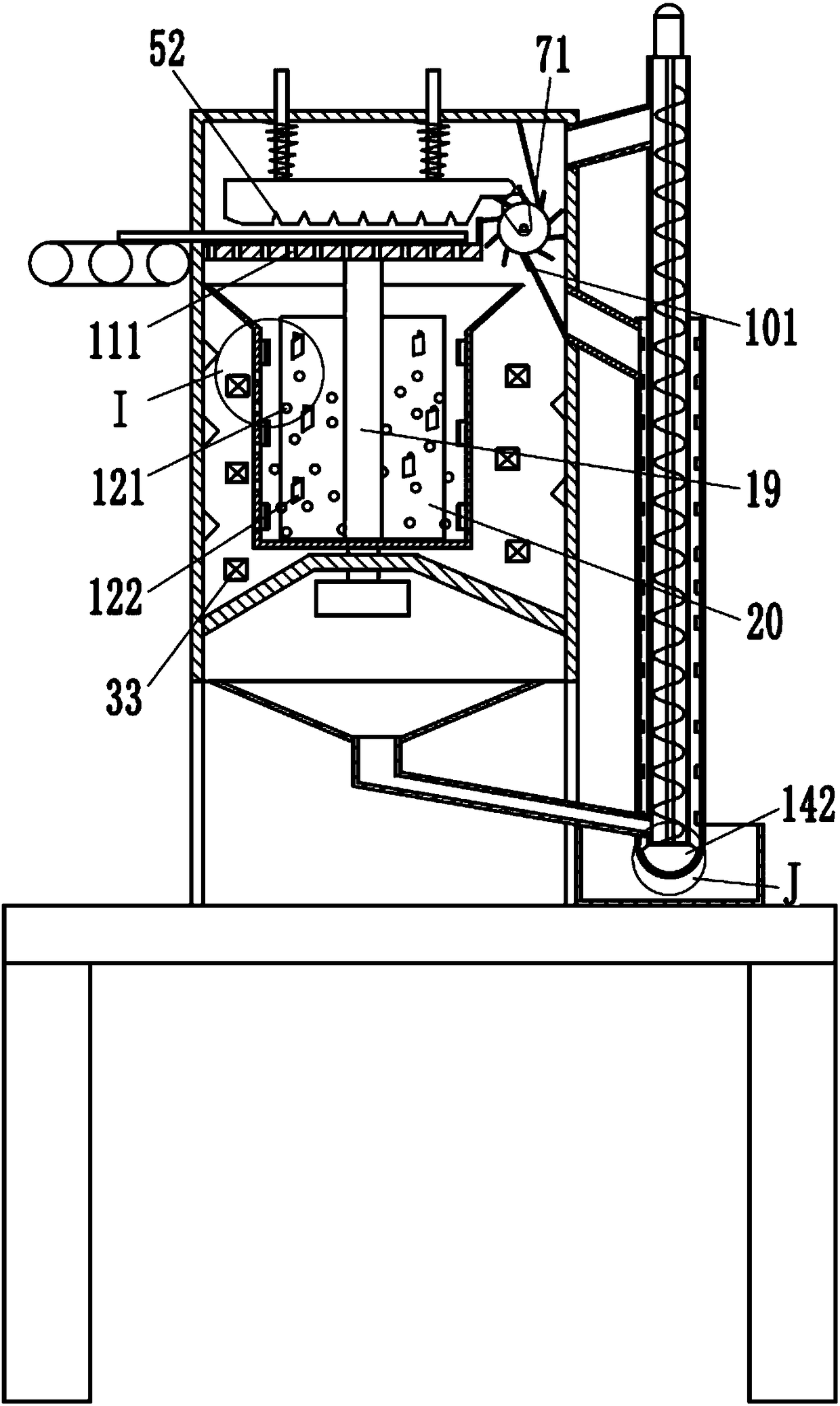

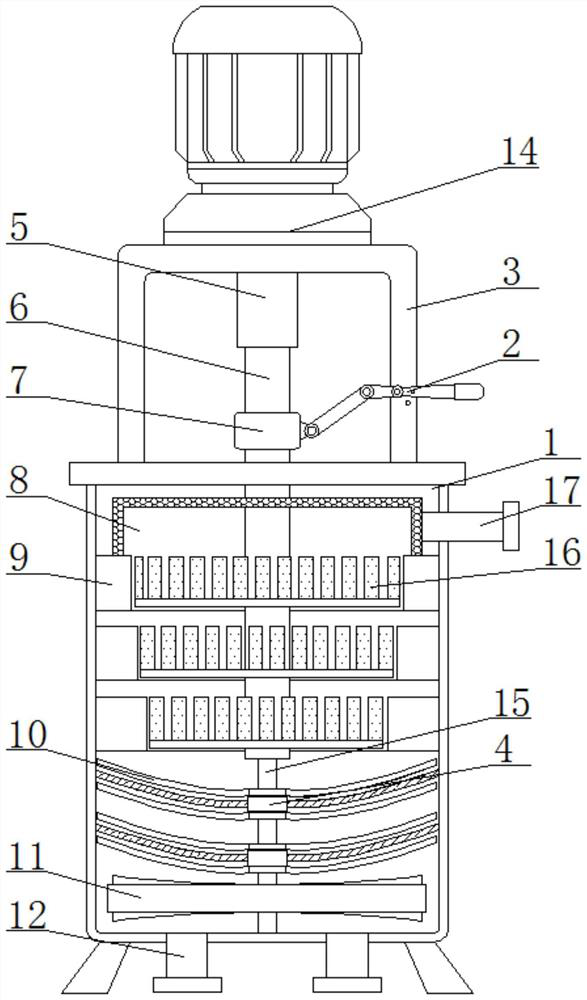

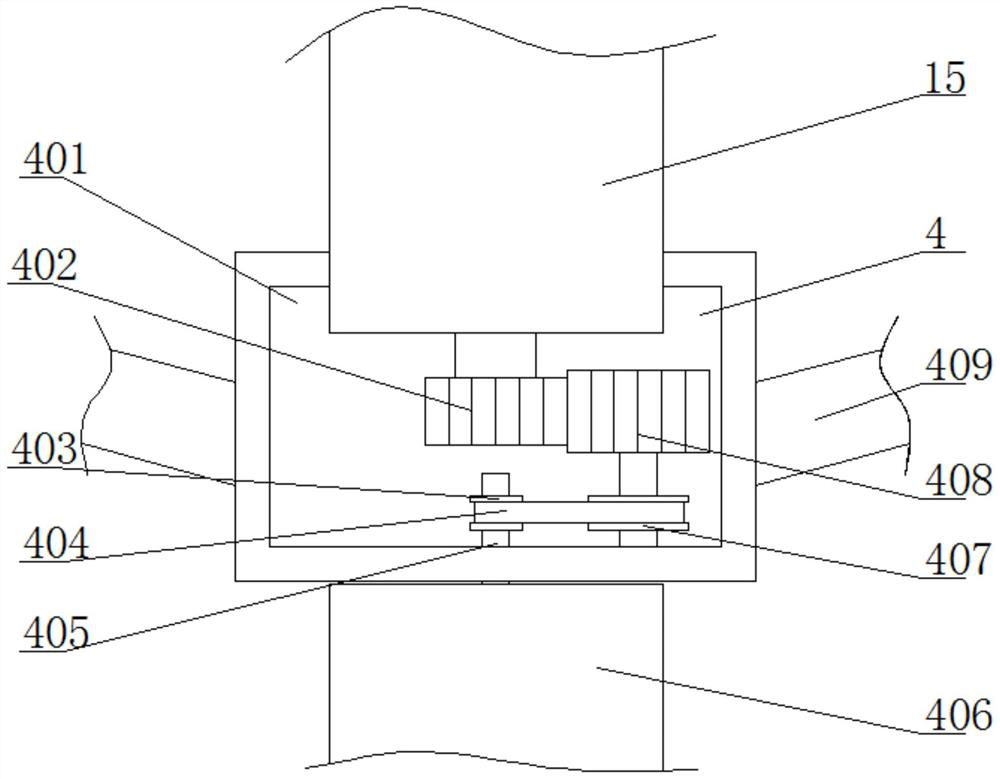

Uniform-feeding rice impurity removing equipment

InactiveCN108339751AGood dust removal effectAvoid reprocessingSievingGas current separationEngineeringWaste management

The invention discloses uniform-feeding rice impurity removing equipment. The uniform-feeding rice impurity removing equipment comprises a feeding plate, a discharging channel, a dust removing assembly, a case, a first vibration screen, a second vibration screen, a recovery box, a rice box and a waste box. The feeding plate is provided with a rotating roller, and pushing plates are uniformly arranged on the periphery of the rotating roller. A motor is installed on the outer side of the top of the discharging channel and drives a scattering disc through a rotating shaft, and the scattering discis located below a feeding inlet of the discharging channel. The dust removing assembly is installed on the lower portion of the discharging channel and comprises a dust removing disc, a filtering net, an air suction pipe and a total air pipe. A discharging outlet of the discharging channel is connected with a feeding inlet of the case, and the discharging channel is arranged close to the case sothat a partition plate can be connected with the first vibration screen. The waste box is placed on the bottom of the case and located below the second vibration screen. According to the uniform-feeding rice impurity removing equipment, rice is fed uniformly, impurities such as sand grains and dust in the rice are removed effectively, and the stone removing effect is good.

Owner:滁州广洋湖米业有限公司

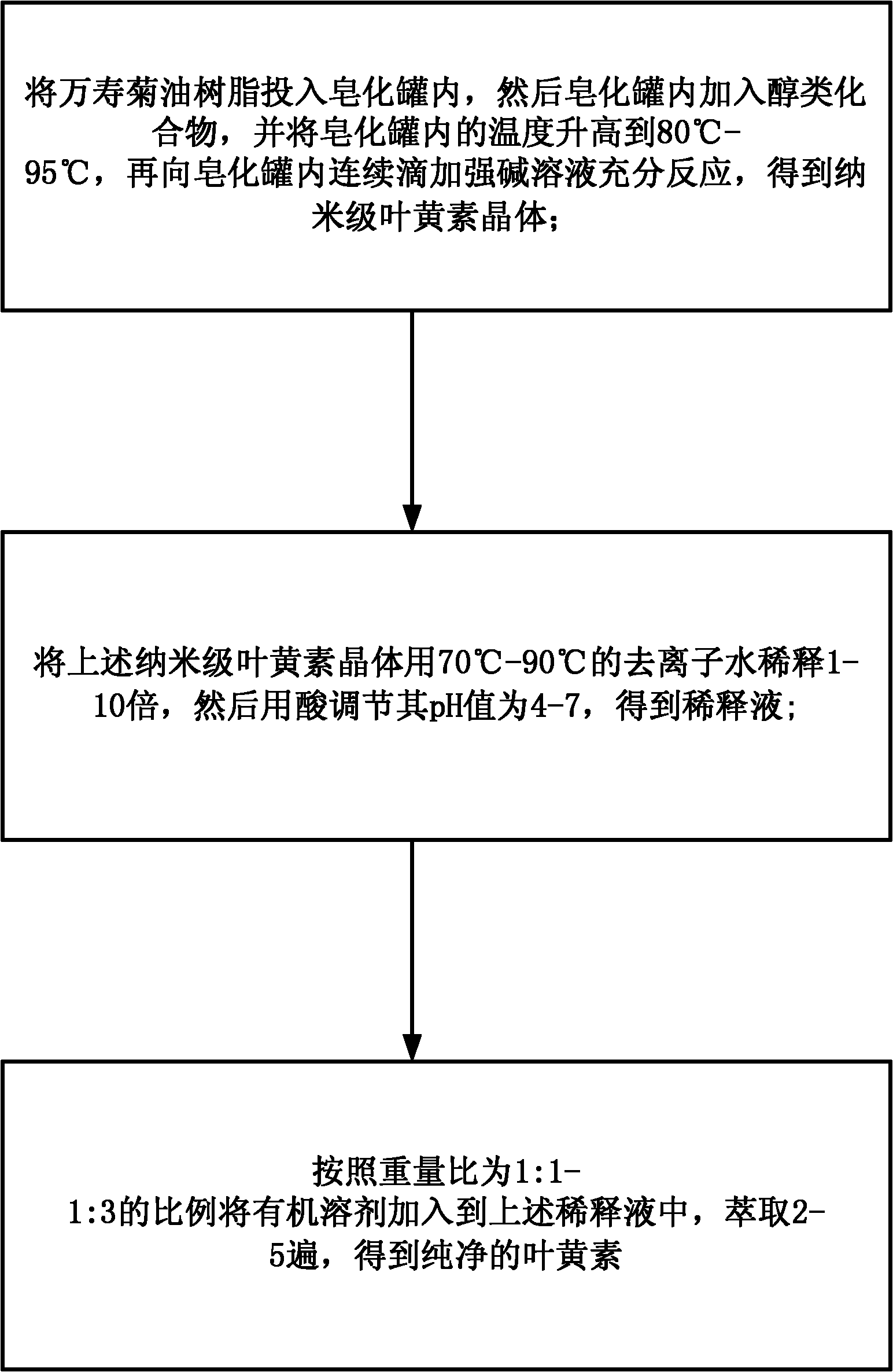

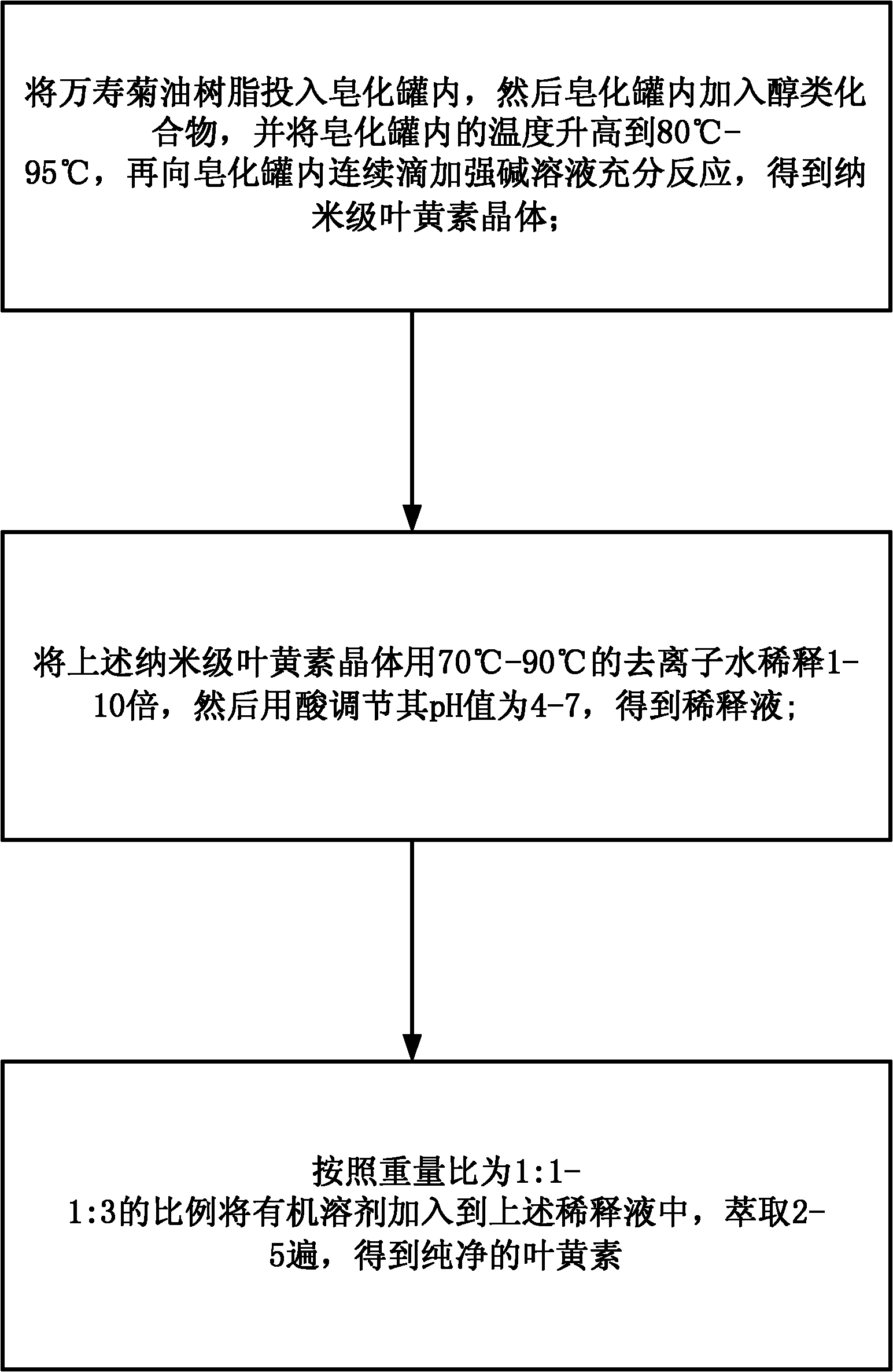

Method for preparing water-soluble lutein

InactiveCN102584662AHigh yieldImprove qualityOrganic chemistryHydroxy compound active ingredientsAlcoholHydrogen

The invention discloses a method for preparing water-soluble lutein, which includes: throwing marigold oil resin into a saponification tank, adding alcohol compounds into the saponification tank, leading temperature inside the saponification tank to rise to 80-95 DEG C, and continuously dropwise adding strong alkali solutions into the saponification tank to be reacted sufficiently so as to obtain nanoscale lutein crystals; diluting the nanoscale lutein crystals for 1-10 times by aid of deionized water at temperature of 70-90 DEG C, and adjusting potential of hydrogen (pH) of the diluted nanoscale lutein crystals to be 4-7 by aid of acid to obtain diluent; and adding organic solvents into the diluent by weight ratio of 1:1-1:3, and extracting for 2-5 times to obtain the pure lutein. Through the method, the lutein crystals obtained by aid of the marigold oil resin through a special saponification process reach the nanoscale, and lutein quality and lutein production yield are improved.

Owner:青岛赛特生物科技有限公司

Glass waste and impurity recycling treatment system

The invention discloses a glass waste and impurity recycling treatment system. The system comprises an external smashing barrel, a vibration crushing device, an internal smashing barrel, a spiral material feeding back device, a grinding device and a material delivering belt; the vibration crushing device comprises a knocking hammer, a rotary wheel and a cam; the internal smashing barrel is rotatably arranged in the external smashing barrel, and the internal smashing barrel is located below a leaking plate; the spiral material feeding back device comprises an inner cylinder and an outer cylinder fixedly sleeves the inner cylinder, spiral blades are arranged in the inner cylinder, the lower part of the inner cylinder is communicated with a discharging port of the outer smashing barrel, and the upper part of the inner cylinder is communicated with a material feeding back port of the outer smashing barrel; the material located in a circular cavity can enter a grinding cavity of the grinding device, and the material being ground can enter a recycling box through a discharging hole in the outer cylinder; and the material delivering belt is used for delivering scrapped glass plates to theupper end face of the leaking plate. Due to adopting the structure, the glass waste and impurity recycling treatment system has the good smashing effect on glass, so that the treated glass can directly serve as concrete aggregate.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

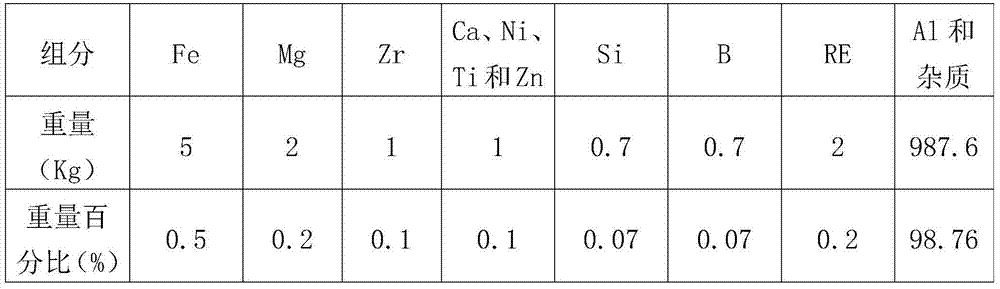

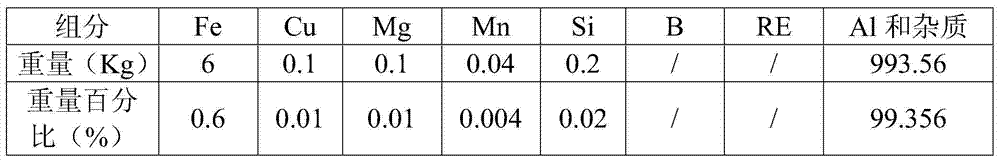

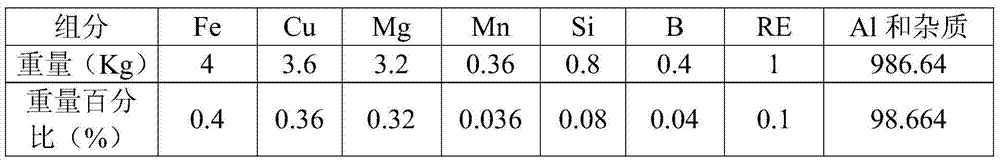

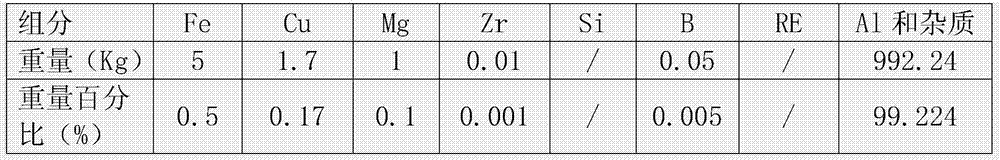

Al-Fe-Mg-Zr aluminum alloy used for coal mine cables, aluminum alloy cable and manufacturing method

PendingCN104299673AImprove performanceHigh mechanical strengthNon-insulated conductorsMetal/alloy conductorsCoalAluminium alloy

The invention discloses Al-Fe-Mg-Zr aluminum alloy used for coal mine cables. The Al-Fe-Mg-Zr aluminum alloy comprises 0.2 percent-1.1 percent of Fe, 0.01 percent-0.4 percent of Mg, 0.001 percent-0.2 percent of Zr, 0 percent-0.1 percent of Si, 0 percent-0.2 percent of B and the balance being Al and impurities, wherein the resistivity of the aluminum alloy is not larger than 0.028164 omega*mm<2> / m, the elongation at break is not lower than 10 percent, and ninety-degree fatigue bending frequency is larger than or equal to thirty. The aluminum alloy material is smelted, cast and rolled, so that an aluminum alloy rod is obtained; afterwards, the aluminum alloy rod is subjected to pulling, bunch stranding and softening, so that an aluminum alloy cable core is formed; next, the cable core is subjected to extruded insulation, cabling, sheath extrusion or armoring, so that an aluminum alloy cable is manufactured. The manufactured aluminum alloy cable has the advantages of being high in strength, high in electric conductivity, good in bending performance and the like, and therefore the requirements for cable performance in the field of coal mines can be satisfied.

Owner:ANHUI JOY SENSE CABLE

Method for manufacturing circuit board with high thermal conductivity by oil printing method and circuit board with high thermal conductivity

InactiveCN101841976AAvoid reprocessingDoes not affect subsequent processesPrinted circuit detailsPrinted circuit manufactureHeat conductingMetal

The invention relates to a method for manufacturing a circuit board with high thermal conductivity by an oil printing method and the circuit board with high thermal conductivity and aims to solve the radiating problem of a heating element on the circuit board. The assembling process of a heat-conducting post is integrated into the manufacturing process of the circuit board per se comprehensively according to the realizing process of the circuit board with high thermal conductivity and overall arrangement. The method is mainly characterized in that: before an electrically-connected circuit is formed, the heat-conducting post is assembled on a predetermined position in the circuit board, a conducting layer is printed by stencil and an electric circuit is etched, so retreatment after the circuit board is molded is avoided. An arranged metal layer can further dissipate heat on the heat-conducting post. The circuit board has the advantages of better radiating effect, simple and convenient operation, simple structure and low cost.

Owner:ZHUHAI BONTECH ELECTRIC TECH

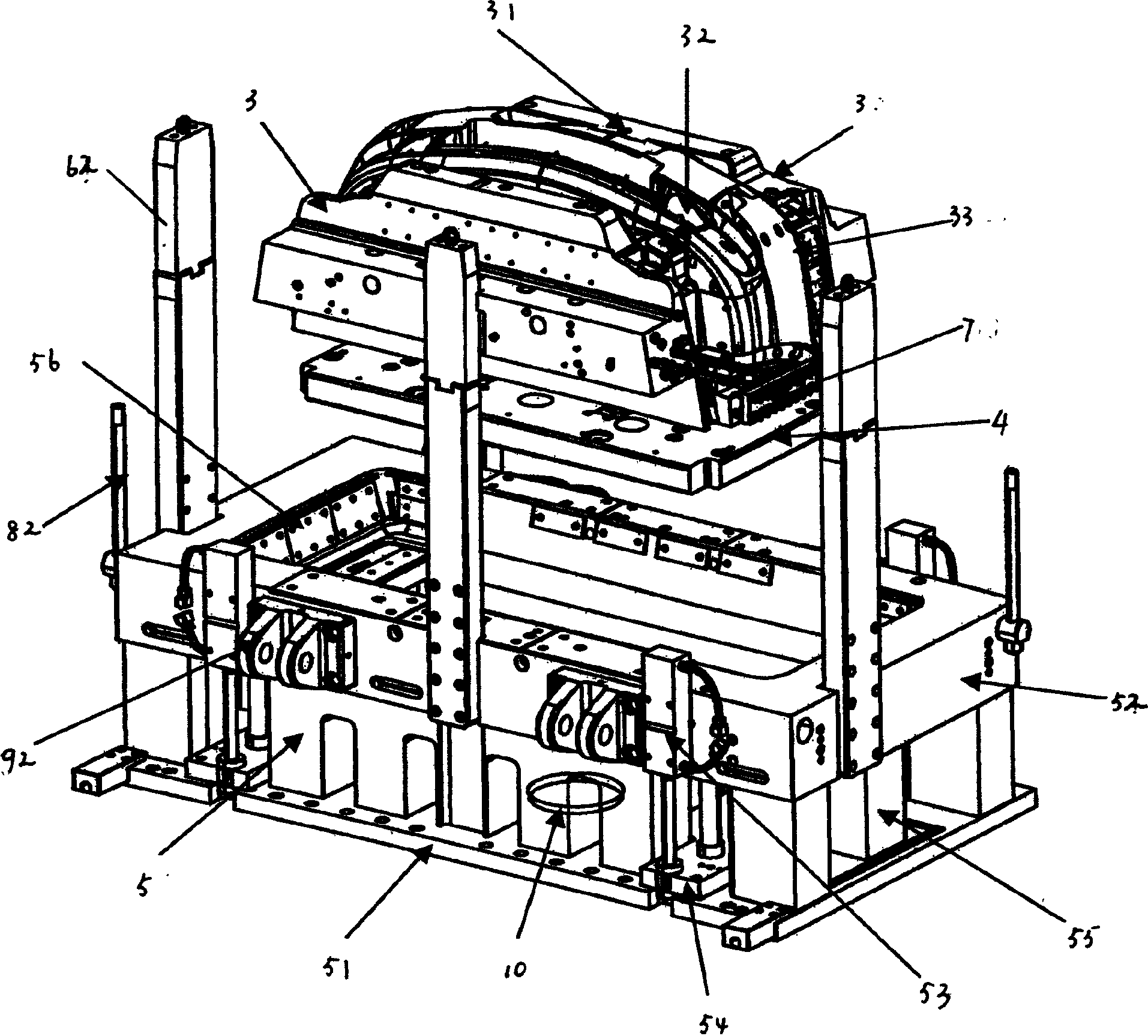

Bumper mould for realizing standardized mould frame

The present invention relates to a bomper mould capable of implementing standardized mould carrier. It includes forming portion of mould, fixed mould baseplate, flow passage portion, moving mould baseplate, knock-out system, guide system and cooling system. Said invention also provides the concrete structure and composition of the above-mentioned every portion and every system. Said invention can implement mould carrier interchangeability between bomper moulds.

Owner:JIANGNAN MOLD & PLASTIC TECH

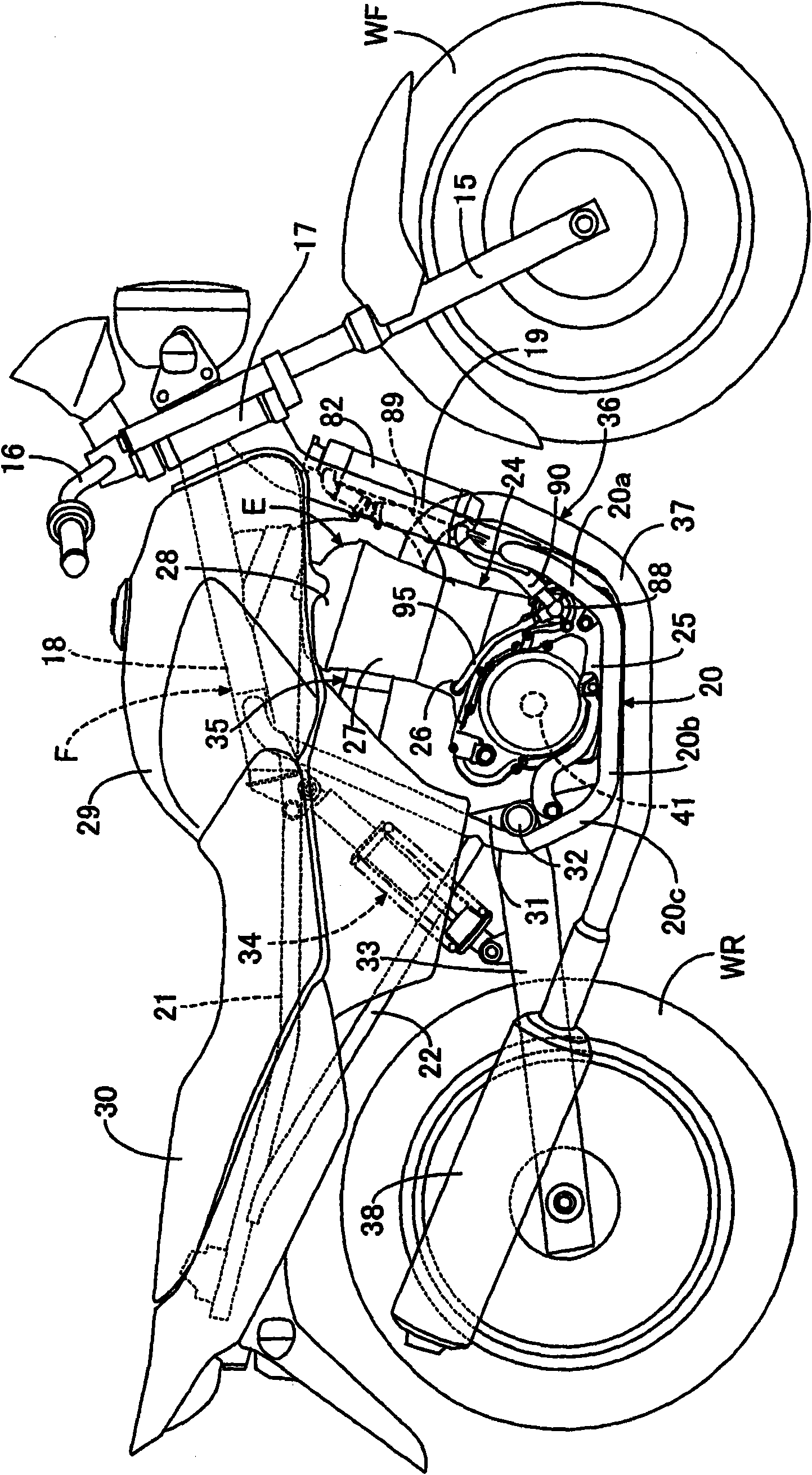

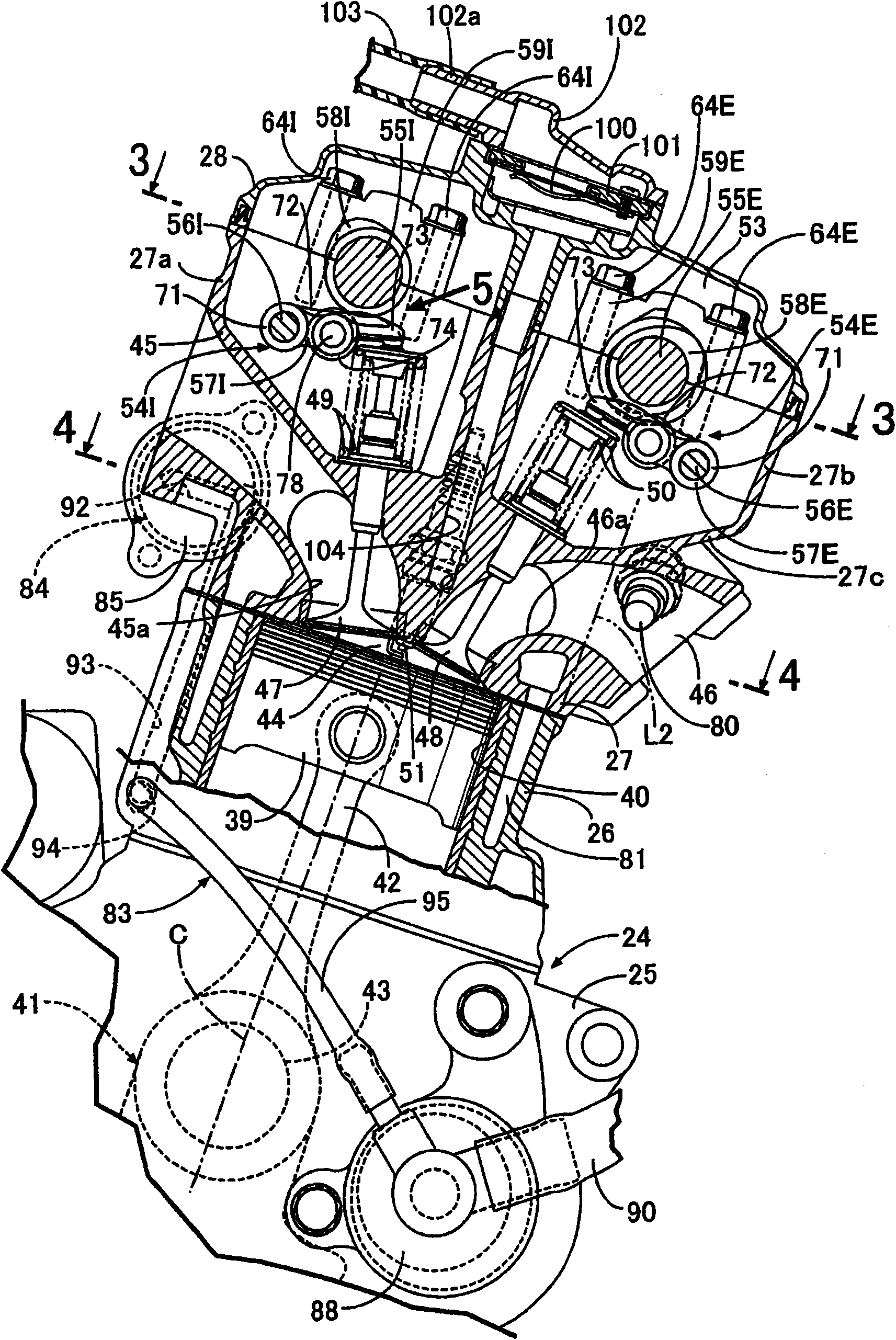

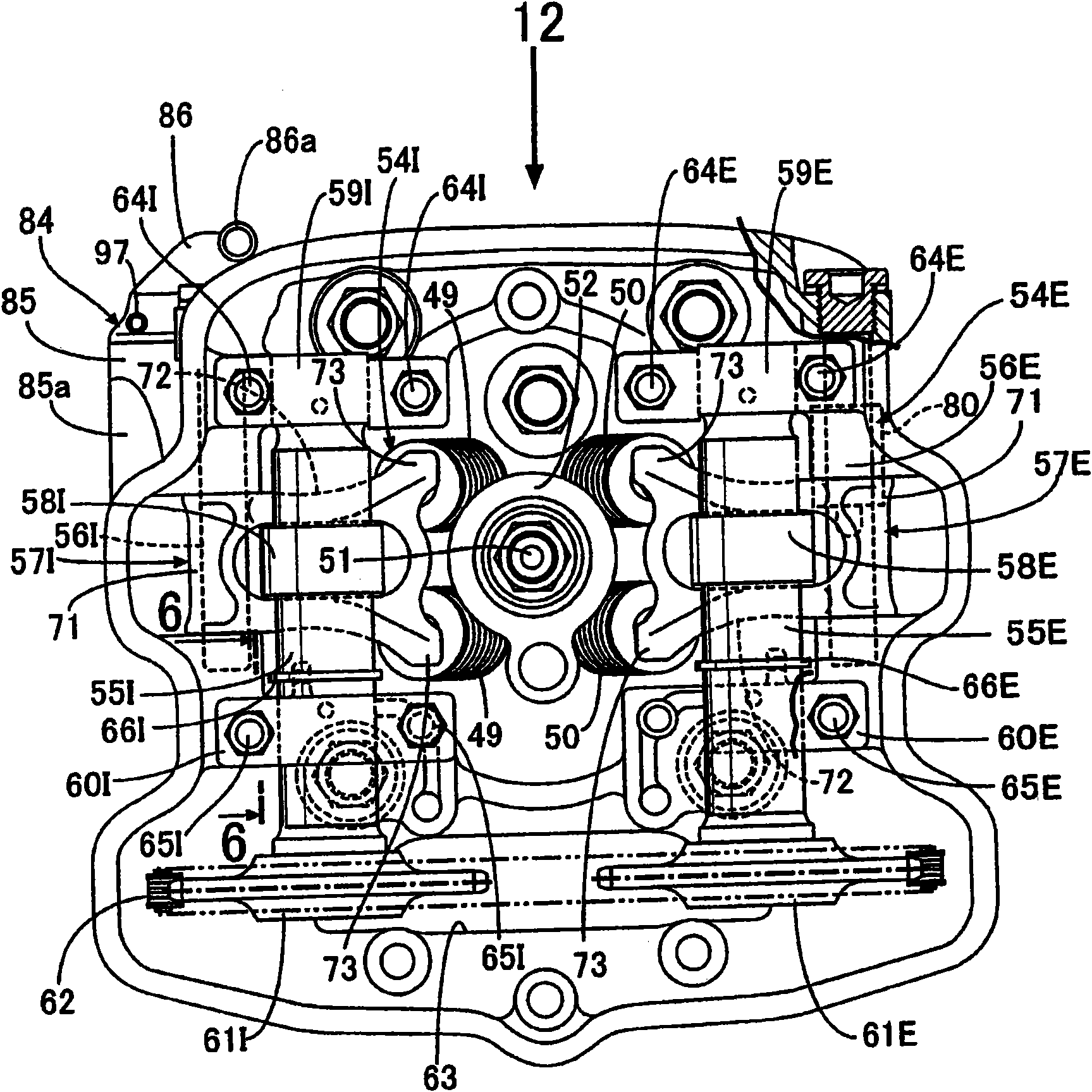

Water-cooled internal combustion engine for vehicle

ActiveCN101852119AReduce weightIncrease the number ofLiquid coolingCoolant flow controlThermal impactExternal combustion engine

The invention provides a water-cooled internal combustion engine for a vehicle. A water jacket allowing the cooling water to circulate is formed on an internal combustion engine main body having a cylinder cover. A thermostat is installed on the internal combustion engine main body and controls according to a state of the cooling water which is discharged from the water jacket and guided to a radiator side and the state of that guided to a bypass path side; the thermostat is equipped on the cylinder cover and forms at least a part of a bypass path on the internal combustion engine main body and avoids the heat from the internal combustion engine main body from influencing the cooling water circulating in the bypass path as much as possible. The thermostat (84) is equipped on the cylinder cover (27). A part of the bypass path (83) is adjacent to an air inlet (45). Viewing along the axial direction of a cylinder hole (40), a part of the bypass path (83) extends in a direction orthogonalto the air inlet (45) and the bypass path and the air inlet (45) are overlapped on the cylinder cover.

Owner:HONDA MOTOR CO LTD

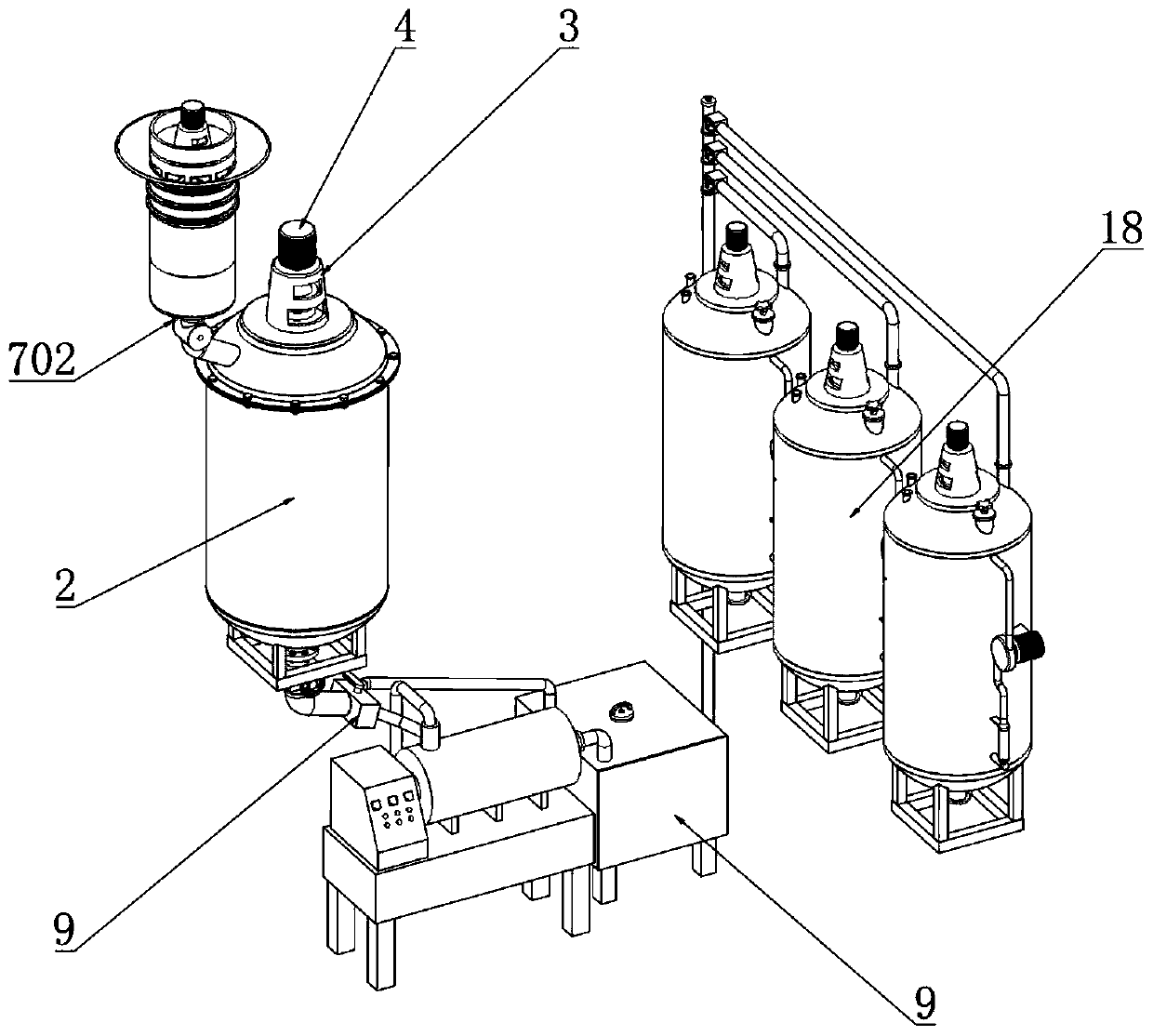

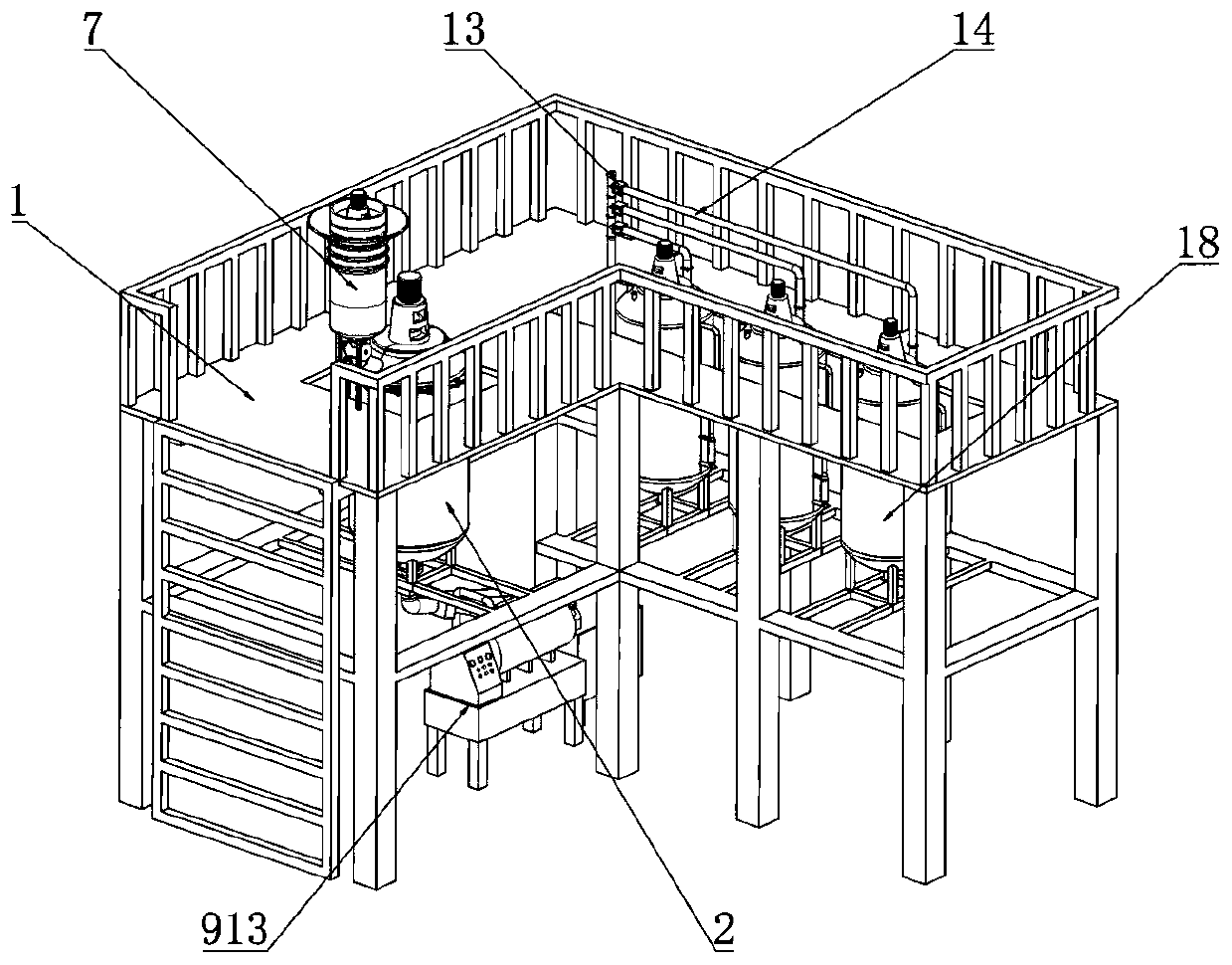

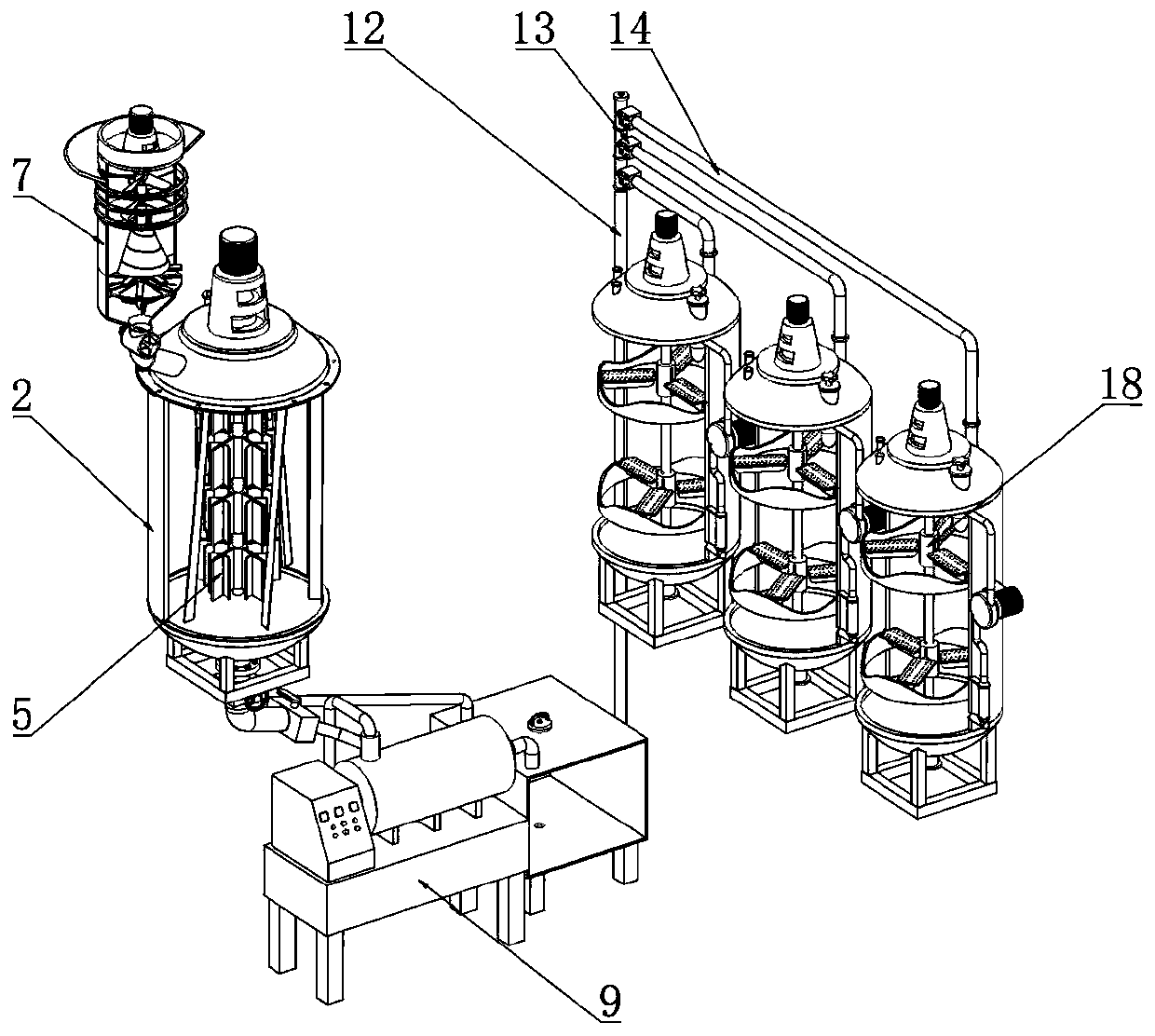

Manufacturing device for producing weather-resistant environment-friendly anticorrosive coating

ActiveCN111569760AScientific and reasonable structureEasy to useTransportation and packagingMixer accessoriesWeather resistanceElectric machine

The invention discloses a manufacturing device for producing a weather-resistant environment-friendly anticorrosive coating. The manufacturing device comprises a mounting support, wherein a dispersingbarrel is fixedly connected to one end of the top of the mounting support; a fixed mounting rack is fixedly connected to the middle part of the top end of the dispersing barrel; a dispersing motor isfixedly connected to the middle part of the top end of the fixed mounting rack; the input end of the dispersing motor is electrically connected with the output end of a mains supply; and an efficientdispersing and discharging mechanism is arranged on the inner side of the dispersing barrel. According to the invention, powdery raw materials are added into the dispersing barrel through a materialadding port; under the action of a driving gear and a rotating gear ring, the rotating gear ring, a connecting inclined rod, a mounting ring and a dispersing rotating shaft are driven to rotate in opposite directions, and therefore, stirring vertical plates, stirring arc plates and a mounting ring on the dispersing rotating shaft rotate in opposite directions in the dispersing barrel at the same time; and thus, efficient stirring in the dispersing barrel is achieved, the mixing rate of raw materials in the dispersing barrel is increased, the mixing time of anticorrosive paint is shortened, andthe processing efficiency of the anticorrosive paint is improved.

Owner:丹阳市美尔鑫化工有限公司

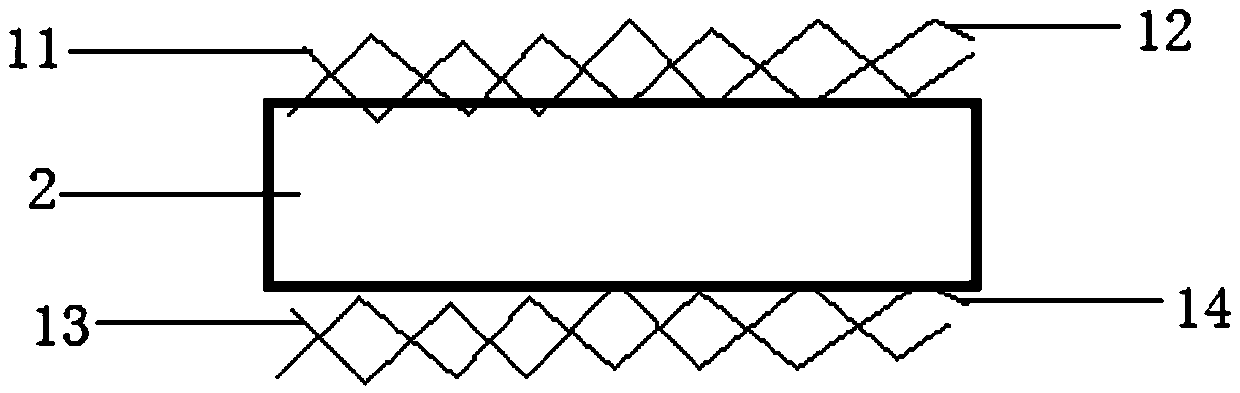

Machining method of breathable steel ring strap

The invention relates to a machining method of a breathable steel ring strap. The breathable steel ring strap comprises an upper woven strap and a lower woven strap, wherein the upper woven strap is connected with the lower woven strap through a fishing wire; the upper woven strap has a partial hollow structure and the partial hollow structure is a steel wire hole; and the fishing wire is one of a nylon monofilament and a polyester monofilament. According to the machining method, a breathable layer structure is arranged in the steel ring strap, so that the air permeability of the steel wire strap is improved, compression on chest tissue structures, caused by a dense textile structure, is avoided, and a condition that an airtight textile structure stops the conveying of water and gas of tissue cells is avoided; meanwhile, a grid-shaped breathable structure layer has certain stretchable elasticity and has the effect of relieving pressure on the chest tissue structures of human bodies in a use process, and the comfort of users is improved; and meanwhile, the breathable steel ring strap is formed by integrally weaving and has no cutting thread residues and sewing incisions, so that procedures including reprocessing and the like are avoided, and the wearing comfort and artistic feeling can be improved.

Owner:FUJIAN BAIKAI ELASTIC WEAVING

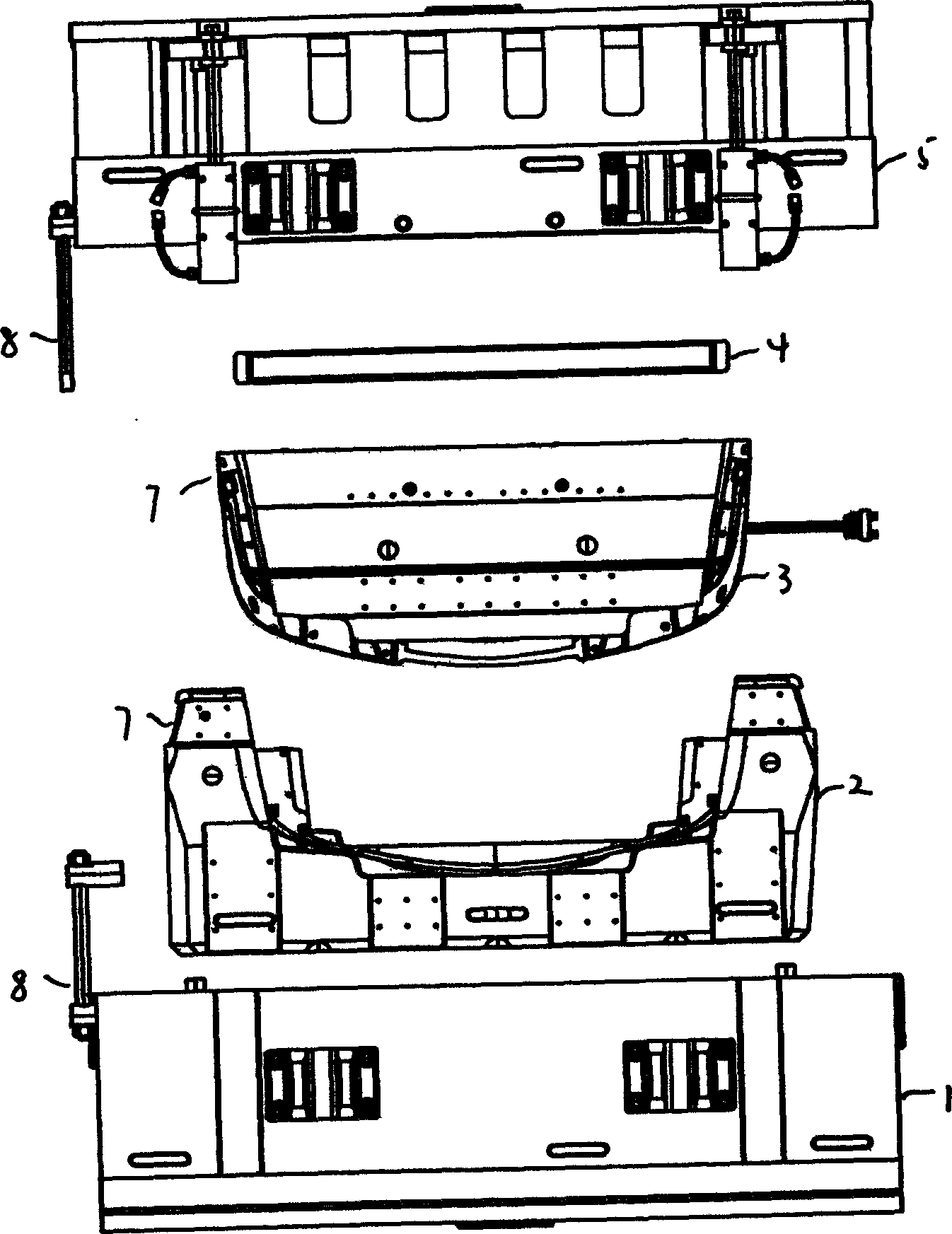

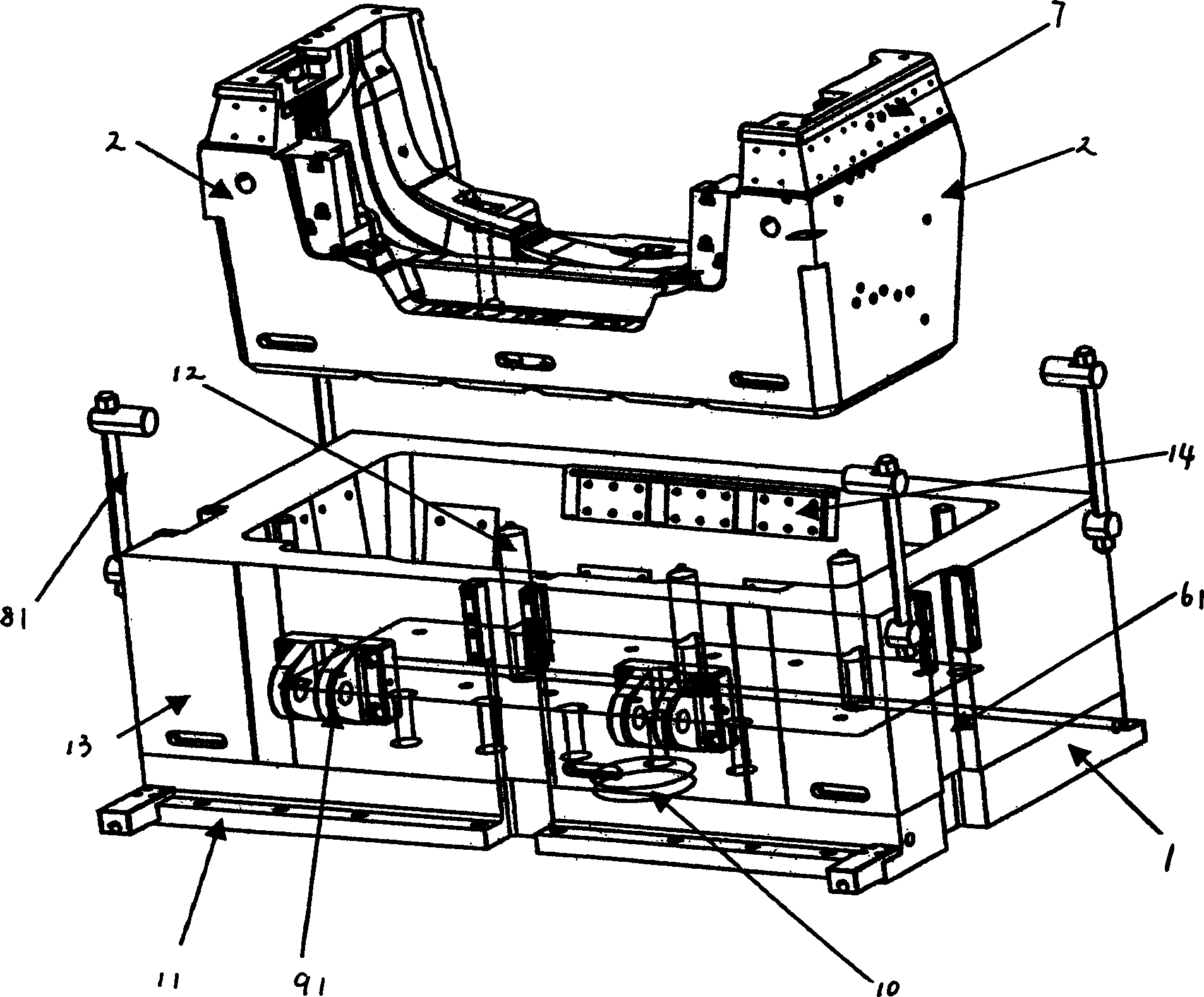

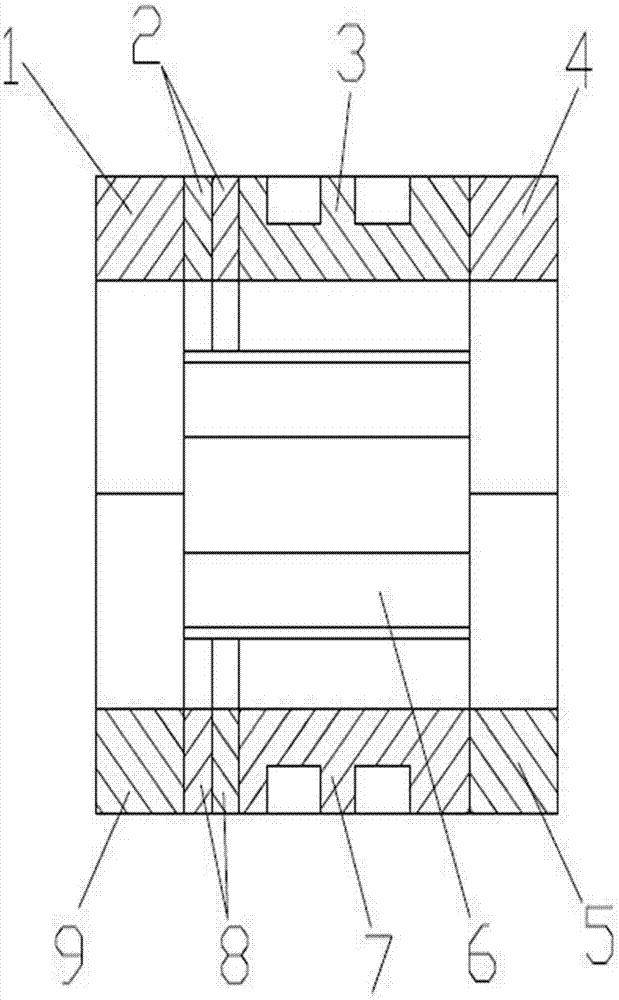

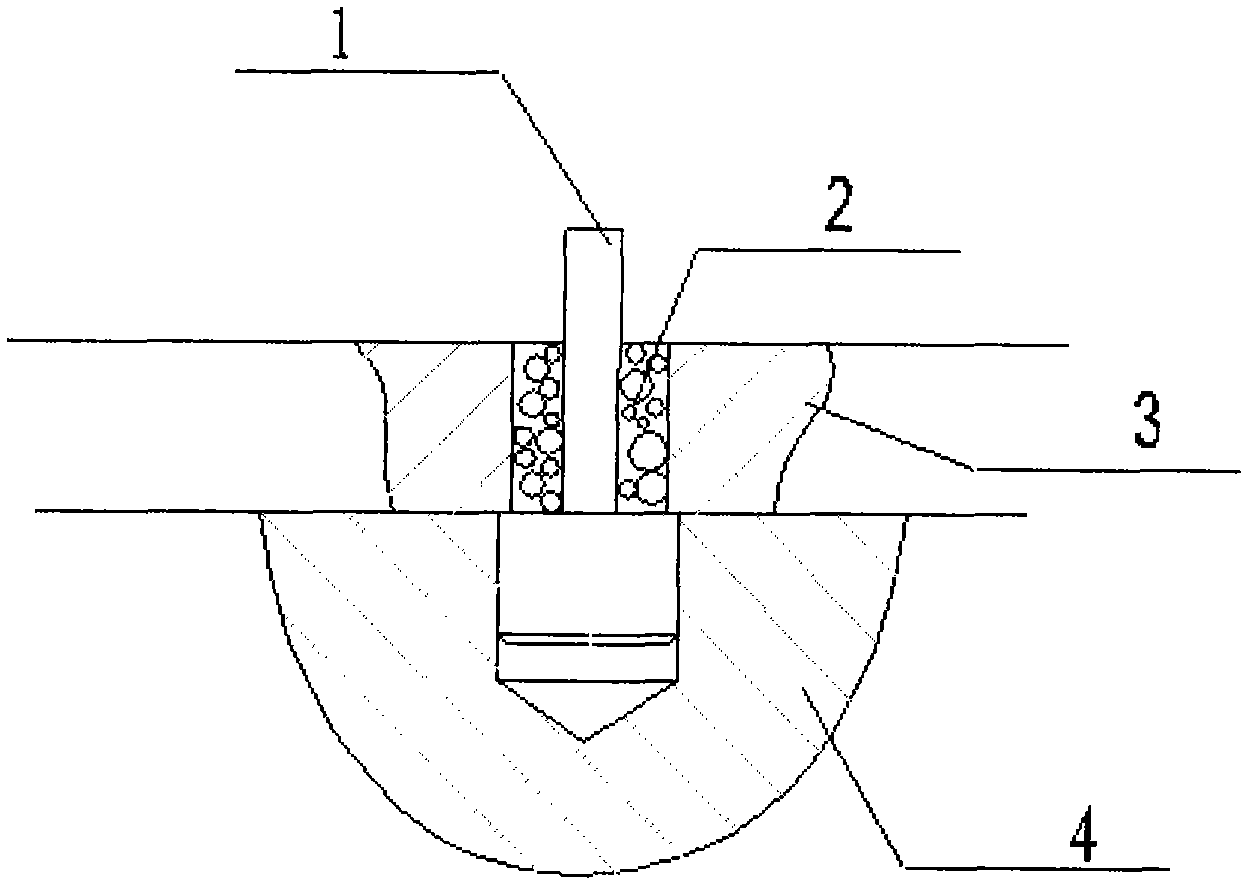

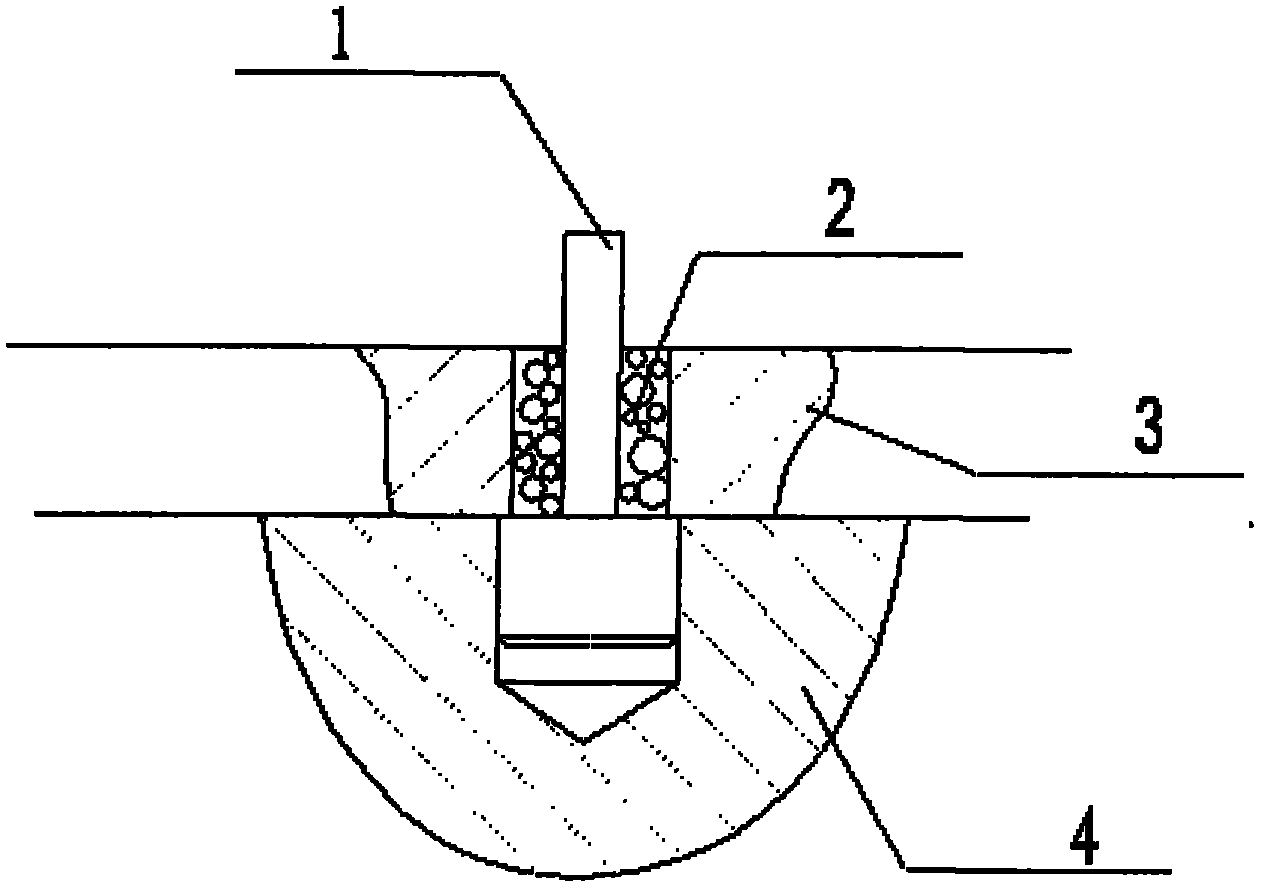

Method for expanding use of middle die device of copper rotor die-casting die

The invention relates to a method for expanding the use of a middle die device of a copper rotor die-casting die and belongs to the technical field of die-casting dies. The middle die device is the middle die device of a conventional copper rotor die-casting die. According to the method, different upper cushion blocks (2), supporting columns (6) and lower cushion blocks (8) are replaced to adjust the total length, wherein the upper cushion block (2) and the lower cushion block (8) are processed to be as long as each other, or to be composed of two or more cushion blocks; the cushion blocks are the same or different in thickness, and the thickness can be decided according to the change of the product length; each part is formed and fixed by use of the overall dimension or by use of a positioning pin. The method is simple and convenient to operate; the repeated machining of the middle die is avoided; the free change of different iron core lengths of the same product can be realized; the die machining cost can be greatly reduced; the inventory pressure is reduced.

Owner:云南铜业压铸科技有限公司

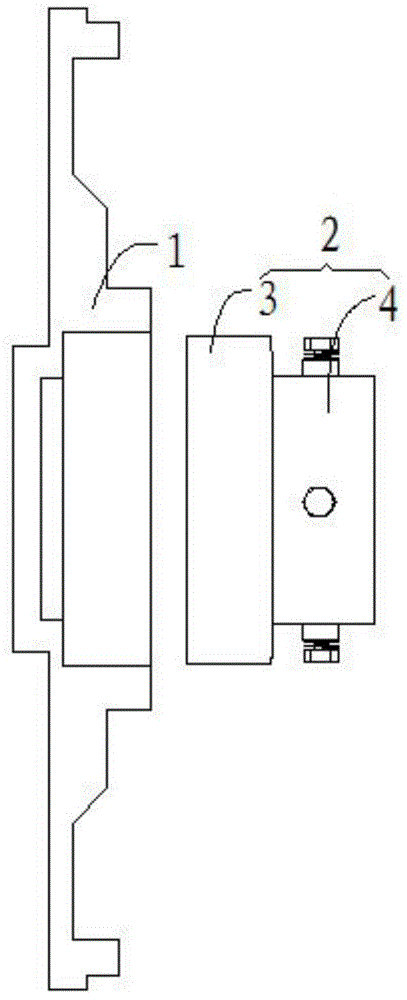

Motor end cap

InactiveCN104901463AAvoid reprocessingEasy to replaceSupports/enclosures/casingsEngineeringMechanical engineering

The invention discloses a motor end cap comprising an end cap body and a bearing installing base. The bearing installing base is arranged in the internal part of the end cap body. The bearing installing base comprises a connecting part and an installing part. The connecting part and the end cap body are detachably connected. The installing part comprises a shell, multiple spiral push rods and multiple clamping blocks which are corresponding to the spiral push rods in a one-to-one way. A circular arc shape used for clamping a bearing is formed by the internal sides of the multiple clamping blocks. The external side of each clamping block is provided with an open cavity. One end of each spiral push rod is connected with the open cavity in a clamping way via a connector. The spiral push rods outwardly extend to the external part of the shell from the connectors and are connected with the shell via threads. The motor end cap can be adjusted according to the sizes of different bearings so that only the size of the clamping circular arc formed by all the clamping blocks requires to be adjusted when the bearing is replaced, and reprocessing of a bearing cavity is avoided. Besides, the replacing process is more convenient and rapid and processing cost is reduced.

Owner:遵义天义利威机电有限责任公司

Multidirectional locating and stamping die

The invention discloses a multidirectional locating and stamping die which comprises an upper die base, a lower die base for placing products, a stamping assembly arranged on the upper die base, a locating assembly arranged on the lower die base, and a fixing assembly enabling the locating assembly to be connected to the lower die base. The locating assembly comprises a locating rod detachably fixed to the lower die base, a telescopic piece fixed to the locating rod and perpendicular to the products, and a pressing plate arranged below the telescopic piece and pressing the products. According to the locating and stamping die, the locating assembly is detachably fixed to the edge of the lower die base, the products are pressed to the lower die base stably, the products are prevented from generating displacement in the stamping process, and the quality of the products is improved, remachining is avoided, and cost is reduced.

Owner:昆山—邦泰汽车零部件制造有限公司

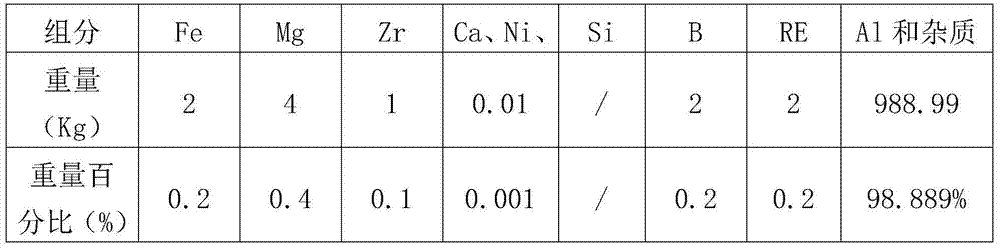

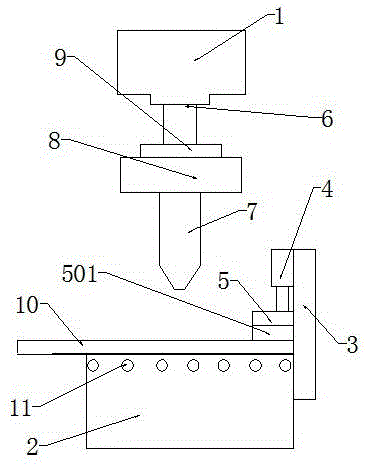

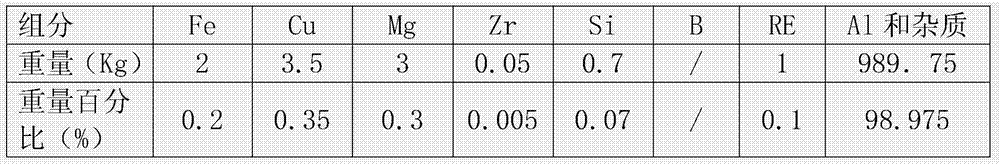

Al-Fe-Cu-Mg-Mn aluminum alloy used for coal mine cables and aluminum alloy cable

ActiveCN104299669AExtended service lifeImprove performanceNon-insulated conductorsMetal/alloy conductorsElectrical conductorImpurity

The invention discloses Al-Fe-Cu-Mg-Mn aluminum alloy used for coal mine cables and an aluminum alloy cable. The aluminum alloy material comprises, by weight, 0.2 percent-1.1 percent of Fe, 0.01 percent-0.4 percent of Cu, 0.01 percent-0.4 percent of Mg, 0.001 percent-0.1 percent of Mn, 0 percent-0.1 percent of Si, 0 percent-0.2 percent of B and the balance being Al and impurities. The aluminum alloy material is smelted, cast and rolled, so that an aluminum alloy rod is obtained; afterwards, the aluminum alloy rod is subjected to pulling, bunch stranding and softening, so that an aluminum alloy cable core is formed; next, the cable core is subjected to extruded insulation, cabling, sheath extrusion or armoring, so that the aluminum alloy cable is manufactured. The Al-Fe-Cu-Mg-Mn aluminum alloy used for the coal mine cables has the advantages of being high in strength, high in electric conductivity, good in bending performance and the like; the aluminum alloy cable made of the aluminum alloy can meet the requirements for cable performance in the field of coal mines.

Owner:安徽中青欣意铝合金电缆有限公司

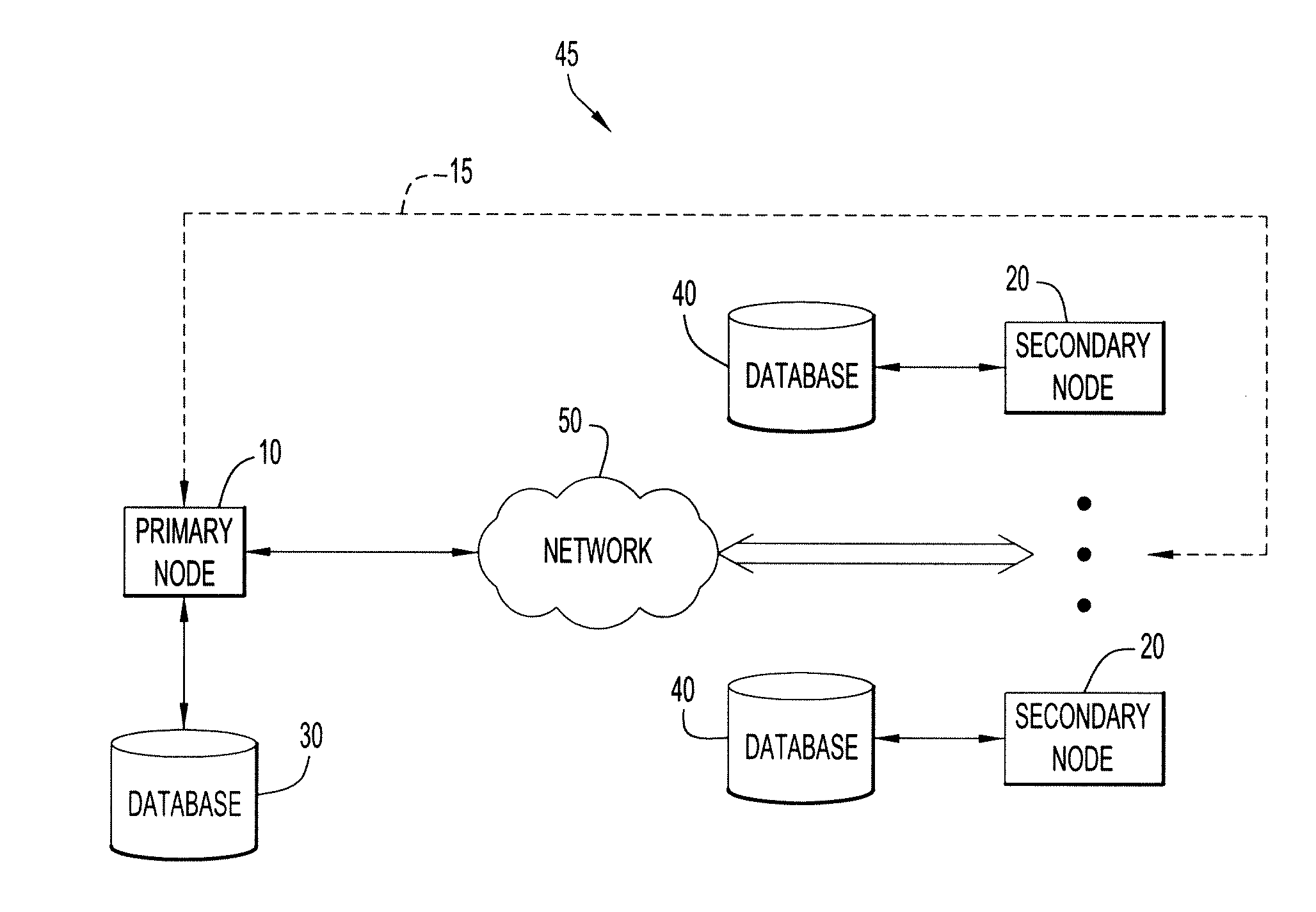

Eliminating Redundant Processing of Data in Plural Node Systems

InactiveUS20110320416A1Avoid duplicationAvoid reprocessingDigital data information retrievalDigital data processing detailsData operationsComputerized system

According to a present invention embodiment, a system avoids duplicate processing of database objects to ensure operation integrity in a database system including a plurality of nodes. The system comprises a computer system including at least one processor. The computer system receives a data operation from a secondary node, executes the received data operation, and identifies each database object that is relocated based on the executed data operation. The computer system communicates to the secondary node operations performed by the computer system for execution of the data operation and an indication of each relocated database object. The secondary node stores an identifier reflecting the relocation for each relocated database object to prevent re-processing of the relocated database objects for the data operation. Embodiments of the present invention further include a method and computer program product for avoiding duplicate processing of database objects in substantially the same manner described above.

Owner:IBM CORP

Feeding mechanism of sewing machine

ActiveCN105002664AAvoid reprocessingVersatilityWork-feeding meansEngineeringElectrical and Electronics engineering

The invention relates to a feeding mechanism of a sewing machine. The feeding mechanism comprises a rack, a cloth hanging plate, a driving belt, a limiting rail, ramps, a plurality of thimbles and two driving roller wheels. The two driving roller wheels are rotatably connected with the rack and are connected in a transmission manner through the driving belt. The limiting rail and a high end, and the ramps connected with two ends of the limiting rail, are arranged on a side of a close-loop transmission chain. The plurality of thimbles respectively slide up and down and are elastically arranged on the driving belt. The cloth hanging plate is provided with a spliced eye, and the cloth hanging plate is arranged above the driving belt. Beneficial effects are that the cloth hanging plate which is provided with cloth can be directly driven to do rectilinear motion to feed. Compared with a fell seam machine, the feeding mechanism prevents manual feeding, and positions of cloth hung on cloth hanging needles are relatively fixed, and a water gap can be controlled, and the front end and the rear end of the cloth can be effectively sewed, and a reprocessing program is prevented.

Owner:程林森

Method for processing locating hole of product locating piece in forming mould

The invention relates to a method for processing a locating hole of a product locating piece in a forming mould, relating to the technical field of processing of locating holes of product locating pieces in forming moulds. The method comprises the following steps of: manufacturing a small hole which is smaller than a final hole at the approximate position of the locating piece; manufacturing a step pin and pressing the step pin in the locating hole of a mould body; fixing the locating piece at the correct position by utilizing a connecting piece; filling epoxy resin mixed glue in the gap between the locating piece and the step pin; after a colloid is thoroughly dried, taking down the locating piece; centring the hole moulded by the mixed glue; and expanding the hole to form the required locating hole. According to the method for processing the locating hole of the product locating piece in the forming mould disclosed by the invention, the locating hole position of the locating piece to be repaired is taken out from the mould body; simultaneously, the bottom hole of the mould body cannot be damaged; the mould is prevented from being returned and processed again; the repairing time of the mould is shortened; and the labour production efficiency is increased.

Owner:HARBIN

High-speed shearing, homogenizing and emulsifying device

ActiveCN111644089AAvoid reprocessingOrderly feeding emulsificationTransportation and packagingMixing methodsElectric machineryEngineering

The invention relates to the technical field of emulsifying equipment, and discloses a high-speed shearing, homogenizing and emulsifying device. The device includes an outer cartridge, a supporting seat is fixedly mounted at the top of the outer cylinder, a high-speed motor is fixedly mounted at the top of the supporting seat, and the output end of the high-speed motor extends into the supportingbase and is fixedly connected to a hollow connecting shaft, a rotating shaft is movably clamped to the bottom of the hollow connecting shaft, a lifting apparatus is movably installed on the outer surface of the rotating shaft, the bottom of the rotating shaft extends into the outer cylinder, and the outer surface of the rotating shaft is fixedly sleeved with rotors. When the high-speed shearing, homogenizing and emulsifying device is used, the situation that a traditional emulsifying machine needs to be placed in a charging barrel, so that materials in the charging barrel flow into the emulsifying device disorderly is changed, repeated processing of the materials by the emulsifying device is prevented, with the device, materials can be fed and emulsified orderly and then flow out, and theemulsifying efficiency is improved.

Owner:浙江巨邦高新技术有限公司

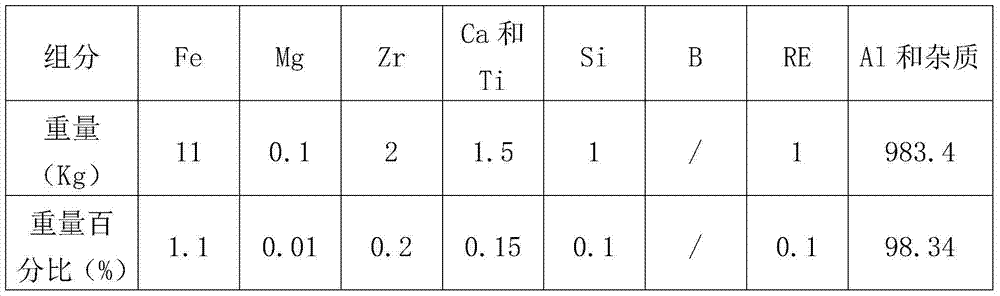

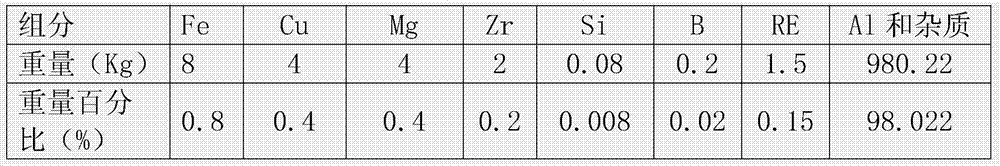

Al-Fe-Cu-Mg-Zr series aluminum alloy for cables for coal mines and aluminum alloy cable

ActiveCN104294089AImprove performanceHigh mechanical strengthFlexible cablesMetal/alloy conductorsElectrical conductorAdditive ingredient

The invention discloses an Al-Fe-Cu-Mg-Zr series aluminum alloy for cables for coal mines and an aluminum alloy cable. The aluminum alloy contains the ingredients in percentage by weight: 0.2-1.1% of Fe, 0.01-0.4% of Cu, 0.01-0.4% of Mg, 0.001-0.2% of Zr, 0-0.1% of Si, 0-0.2% of B and the balance of Al and impurities. The aluminum alloy cable is produced through enabling the aluminum alloy to be subjected to the processes of melting, casting and rolling, so as to obtain aluminum alloy rods, then, carrying out drawing, stranding and softening, so as to form aluminum alloy conductor wire cores, and then, carrying out extruded insulation, cabling and extruded sheathing or armoring on the conductor wire cores. The Al-Fe-Cu-Mg-Zr series aluminum alloy for the cables for the coal mines, disclosed by the invention, has the characteristics of high strength, high conductivity, good bending property and the like; the aluminum alloy cable produced from the aluminum alloy can meet the requirements on the properties of the cable in the field of the coal mines.

Owner:林泽民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com