Patents

Literature

175results about How to "Good dust removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

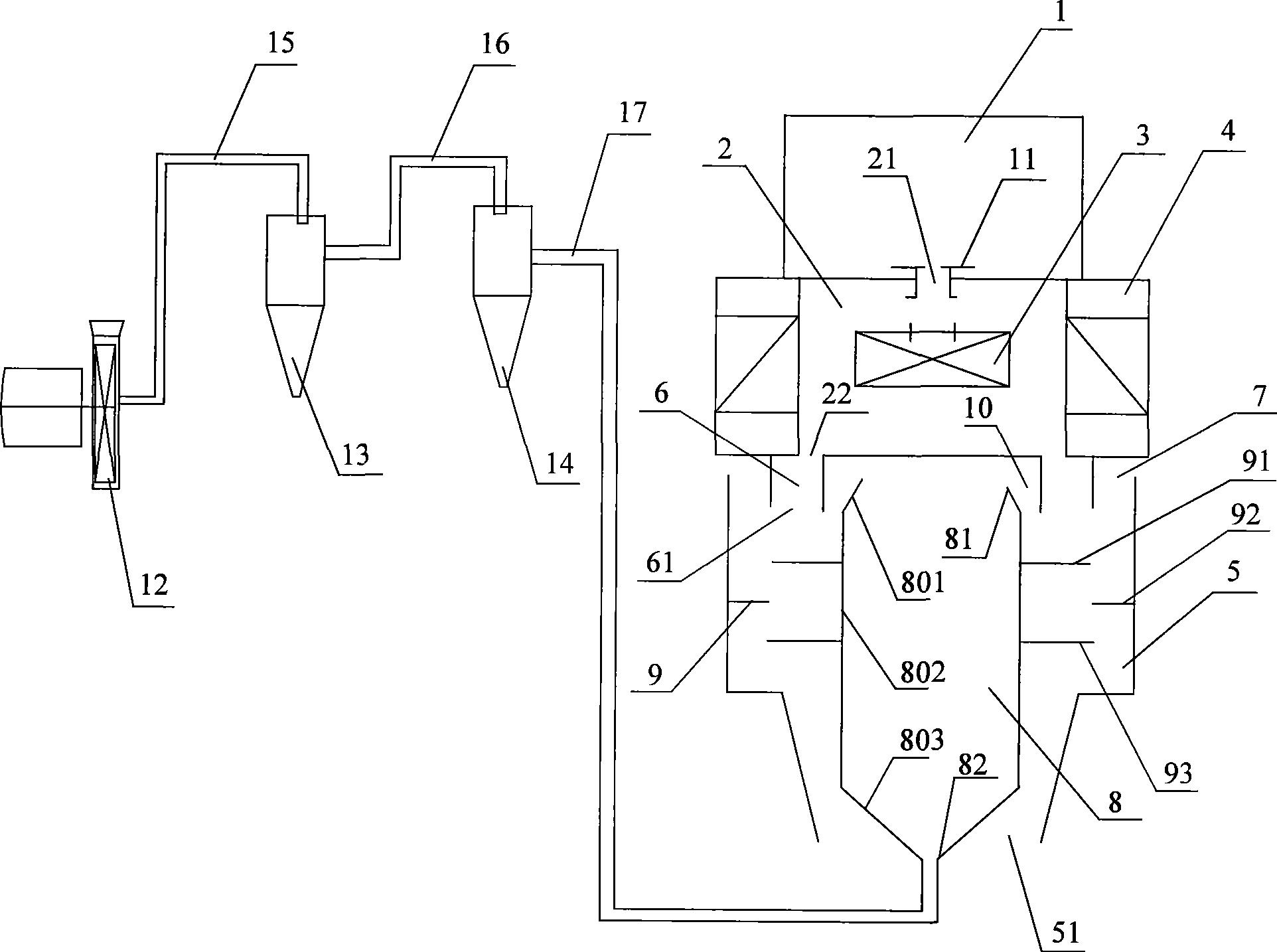

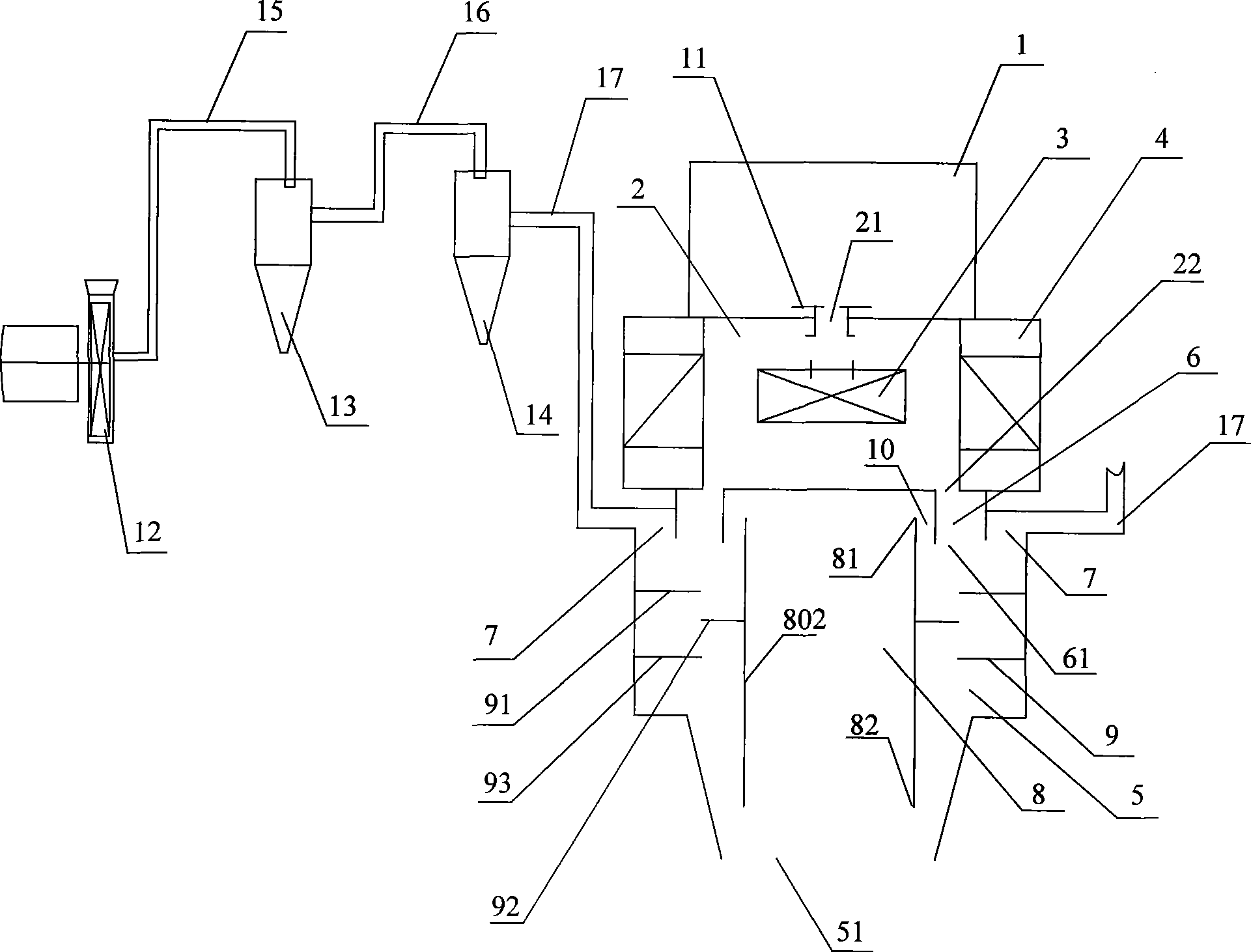

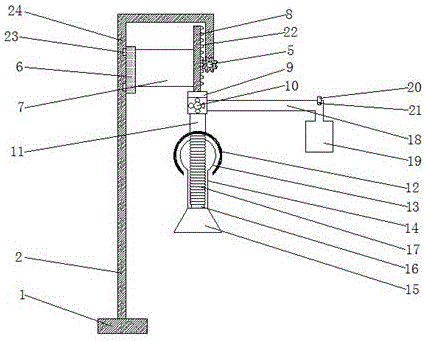

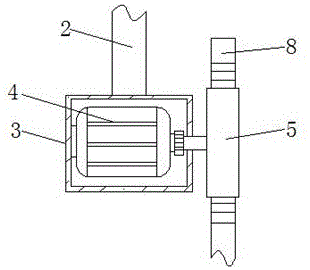

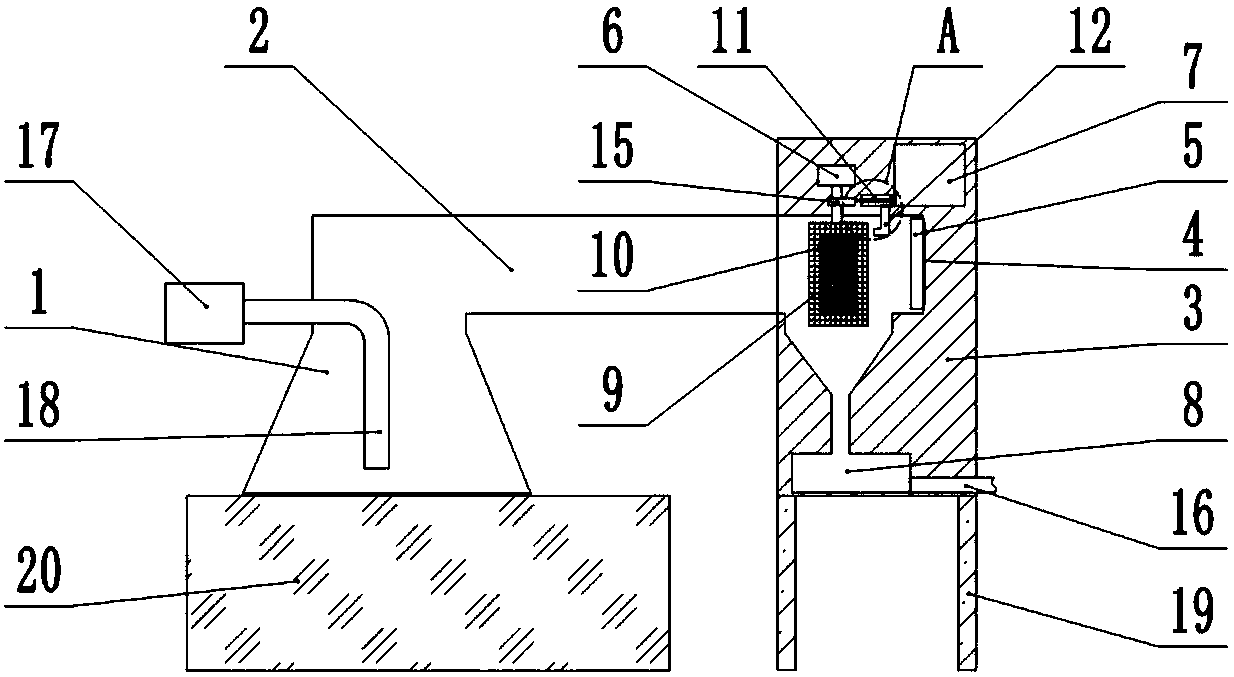

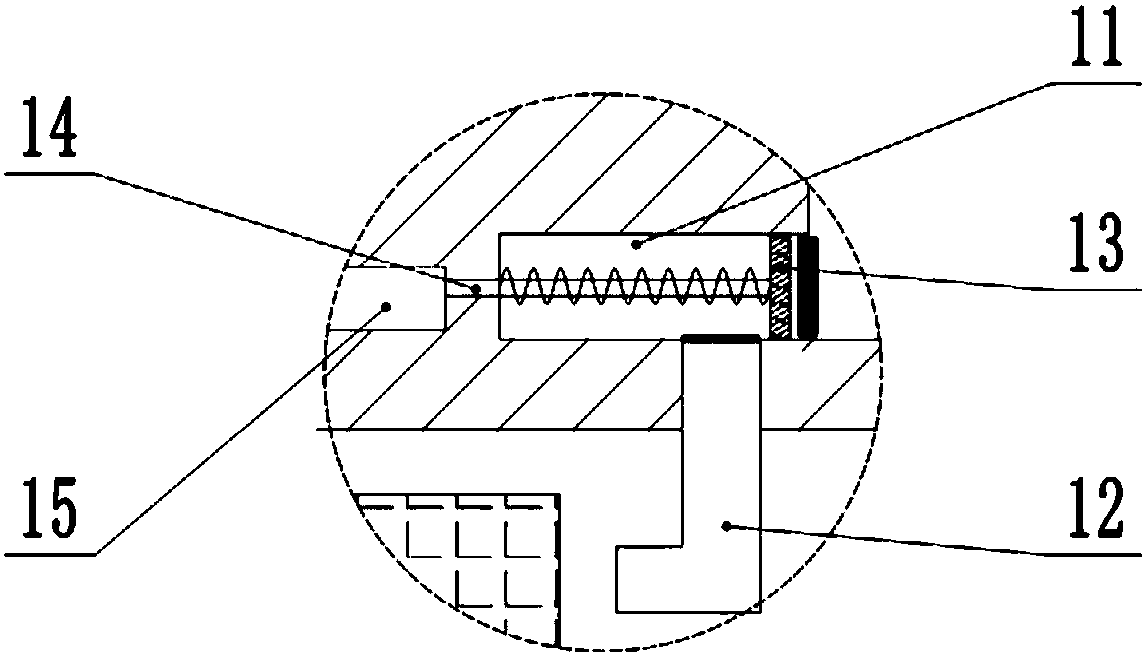

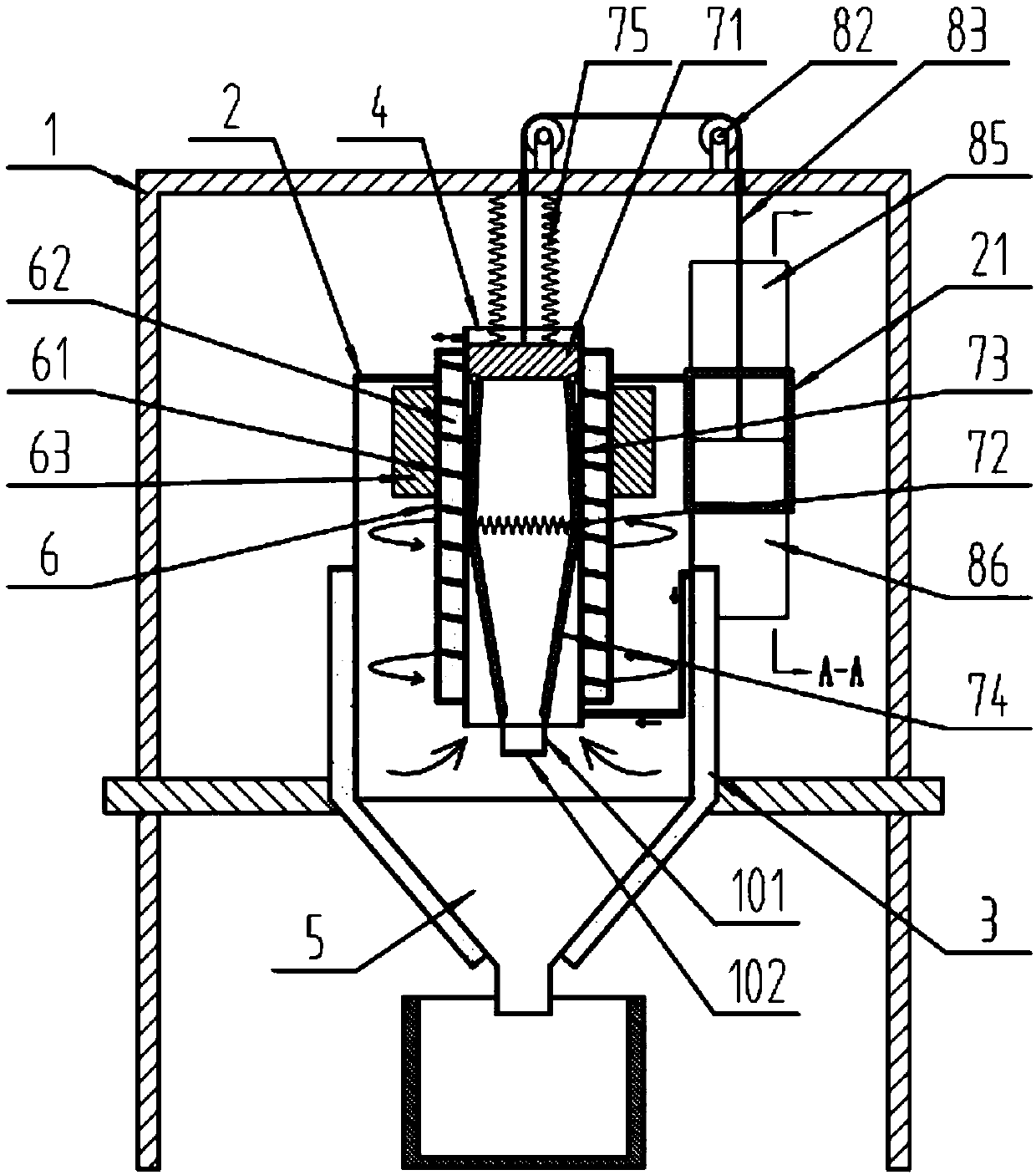

Dry-type sand making method and dry-type sand making machine thereof

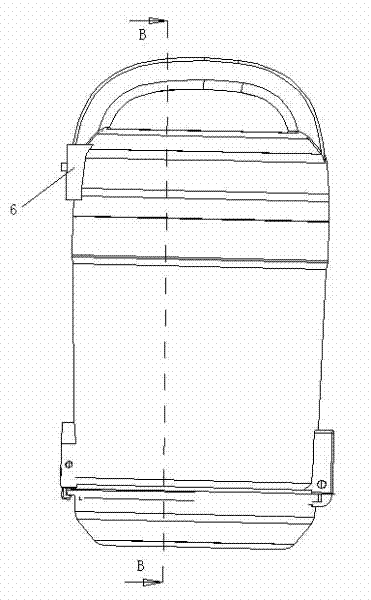

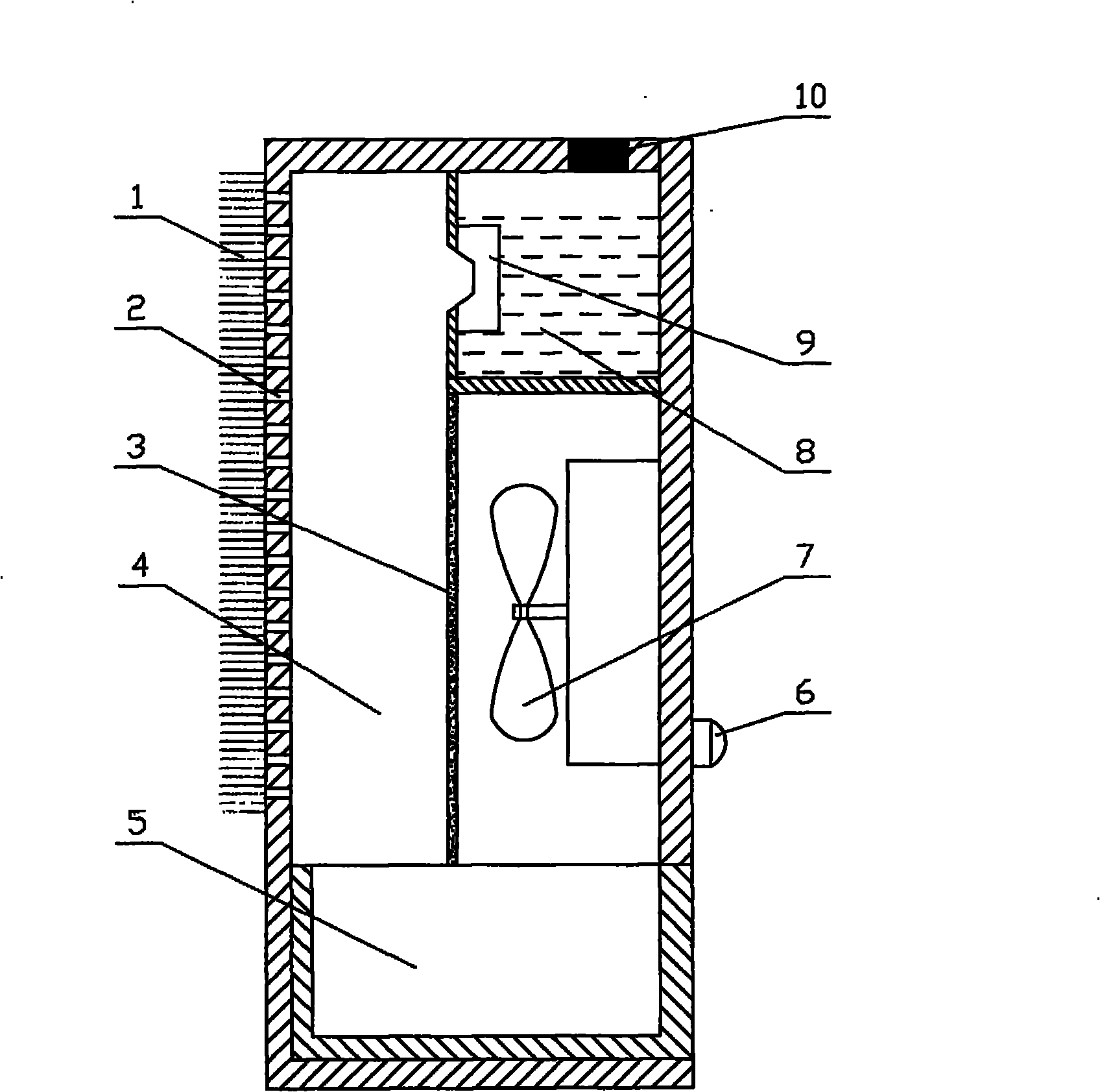

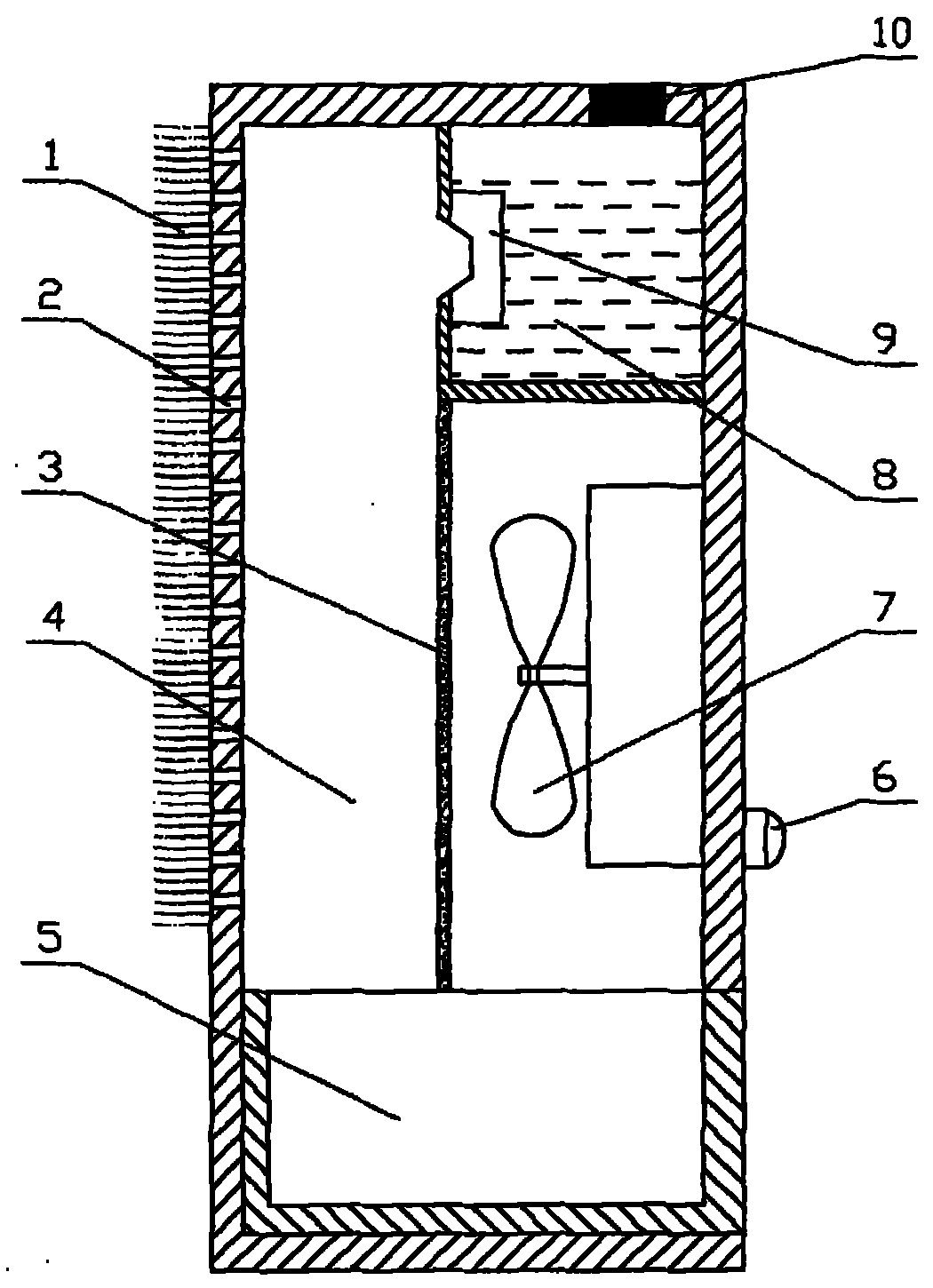

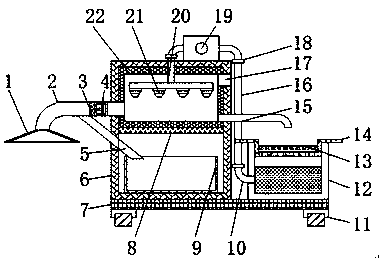

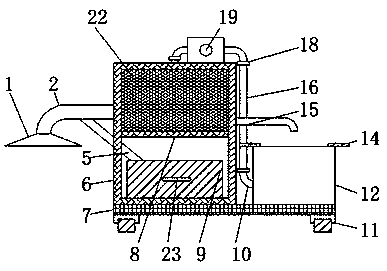

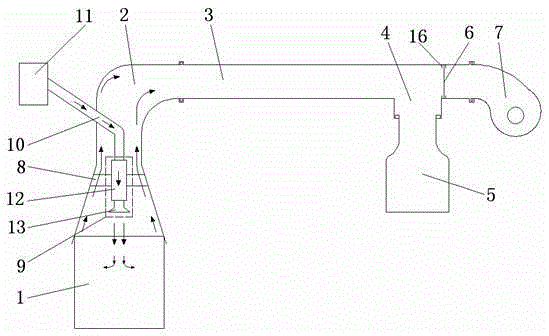

The invention discloses a dry sand maker which comprises a hollow crushing cavity (2). A hollow dust removal cavity (5) is arranged under the hollow crushing cavity (2); the upper end of a feeding channel (6) is hermetically connected with a feeding mouth (22) and the lower end (61) thereof is positioned in the dust removal cavity (5) on which an air vent (7) is also arranged; an air duct (8) is arranged in the dust removal cavity (5); the lower end (61) of the feeding channel (6) is staggered with the upper end (81) of the air duct (8) in the horizontal direction; the bottom surface of the dust removal cavity (5) is provided with an outlet (51); a dust absorption component is hermetically connected with the lower end (82) of the air duct (8) or the air vent (7) after passing through the outlet (51). The invention also provides a method for drying sand making simultaneously. By adopting the dry sand maker, the drying sand making can have the advantages of high production efficiency and low environmental pollution.

Owner:吴核明

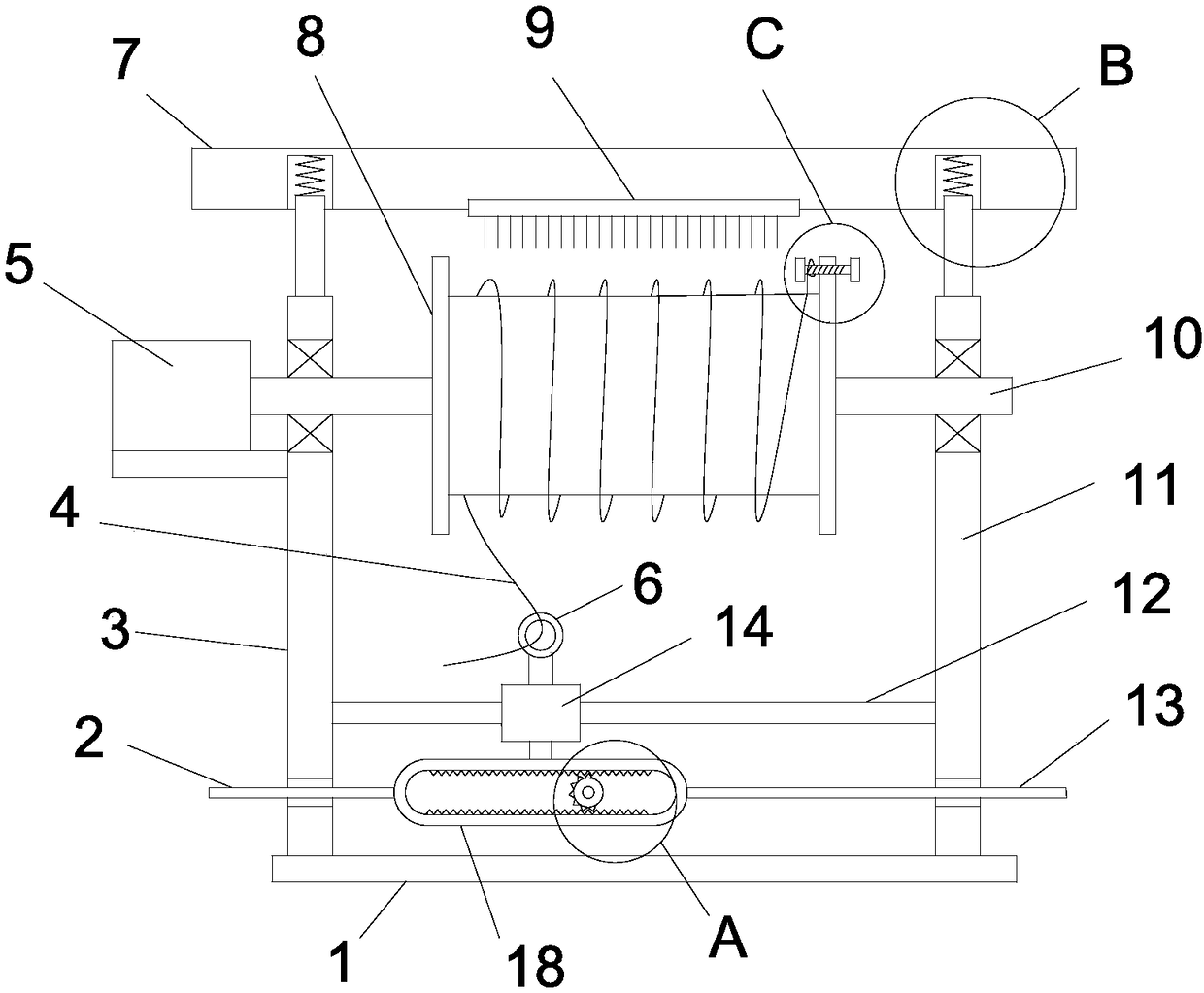

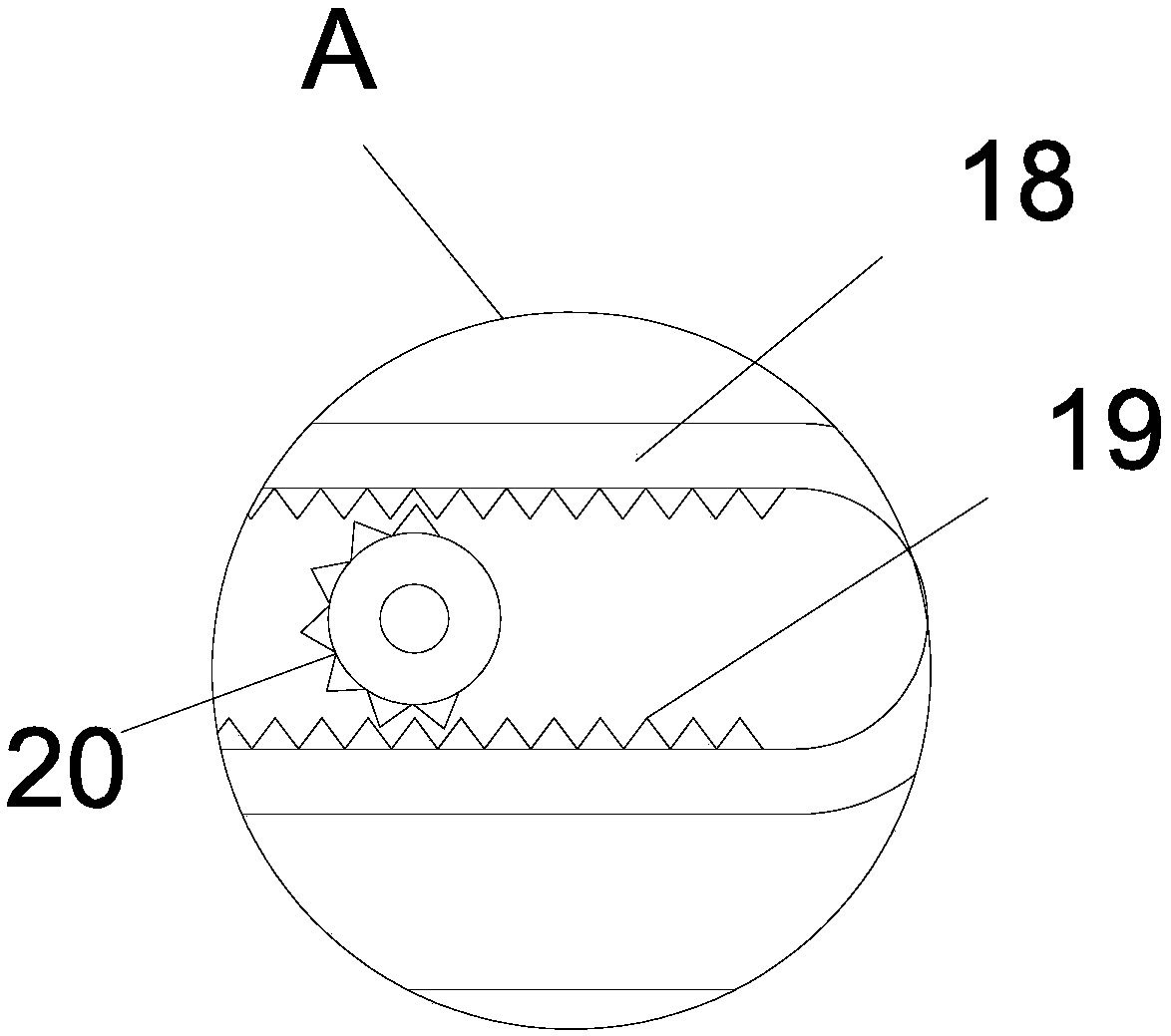

Copper wire winding device with cleaning function

InactiveCN108059032AGood dust removal effectImprove winding qualityFilament handlingCopper wireEngineering

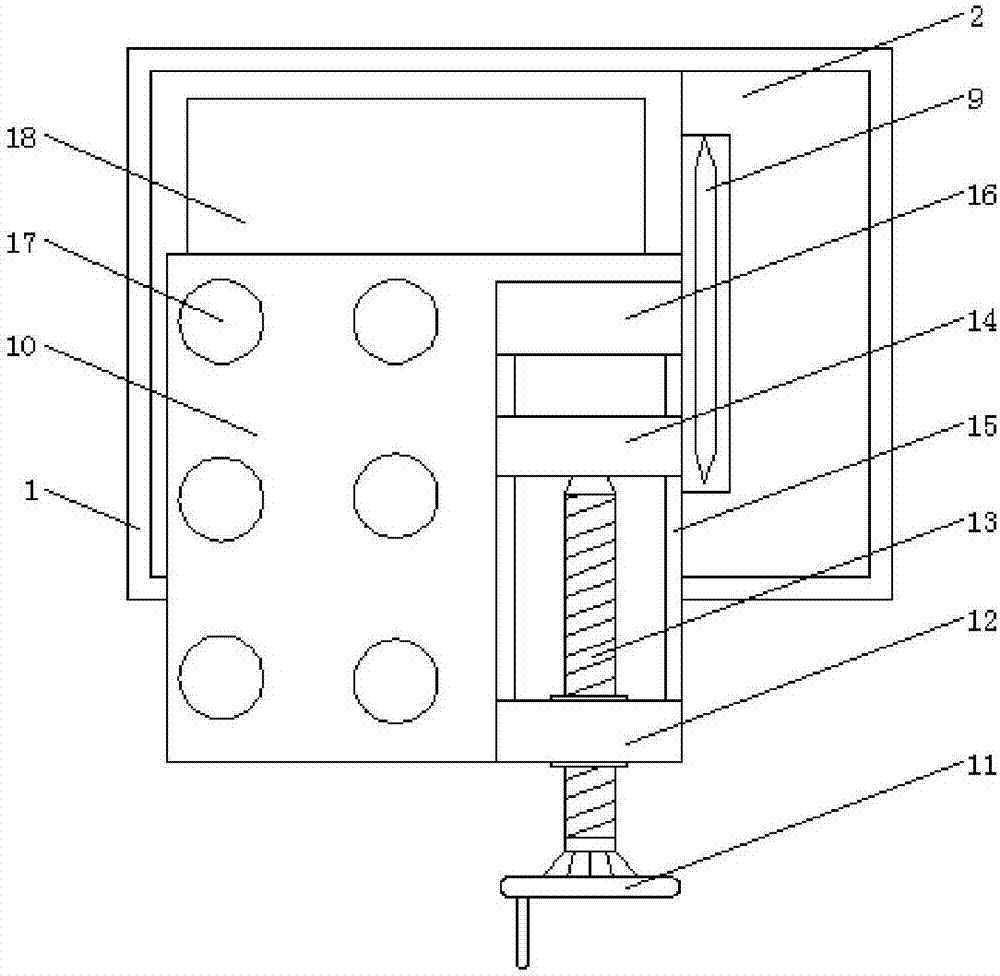

The invention discloses a copper wire winding device with a cleaning function. The copper wire winding device comprises a bottom plate. A left vertical plate and a right vertical plate are verticallyand fixedly arranged on the bottom plate. The upper end of each of the left vertical plate and the right vertical plate is vertically and fixedly provided with a vertical shaft. A pressing plate is horizontally arranged above the left vertical plate and the right vertical plate. The outer surface of a driving shaft is sleeved with and fixedly provided with a winding roller. A horizontal rod is horizontally and fixedly arranged between the left vertical plate and the right vertical plate. A sliding sleeve is fixedly provided with a limiting ring, and a copper wire penetrates the limiting ring.Straight racks are horizontally and fixedly arranged on the upper inner side wall and the lower inner side wall of a concentric-square-shaped frame. The copper wire is wound through the winding roller, the sliding sleeve is driven by the concentric-square-shaped frame to reciprocate left and right along the horizontal rod, accordingly, the limiting ring is used for driving the copper wire to reciprocate left and right, the copper wire is prevented from being excessively centralized at one position of the winding roller, and the copper wire is evenly wound around the winding roller; and a brushand the copper wire relatively rotate in the copper wire winding process, a very good dust removing effect is achieved, and the winding quality is improved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

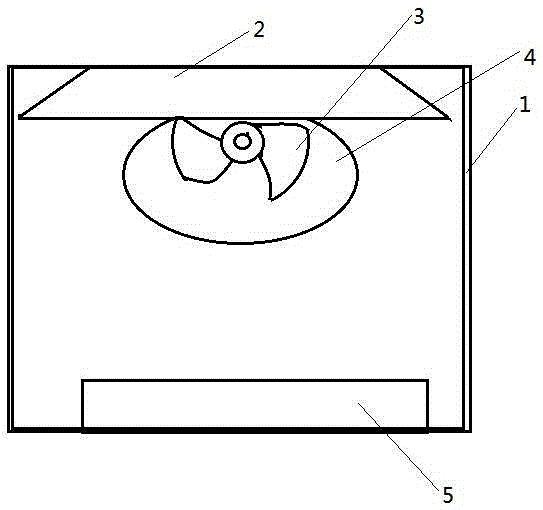

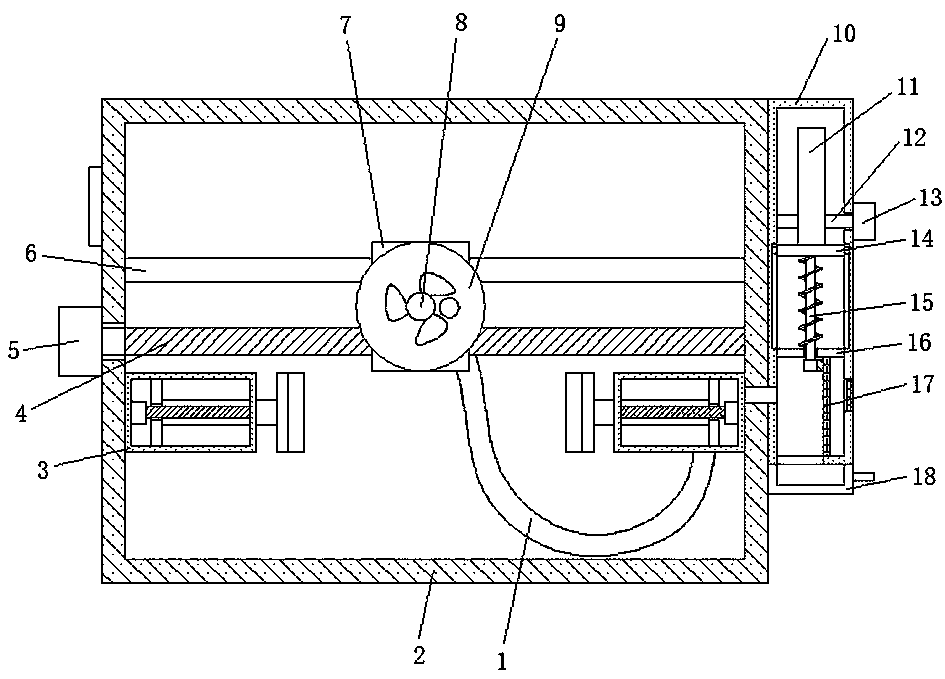

Dust remover of air conditioner

InactiveCN105268694AGood dust removal effectImprove the effectCleaning using gasesComputer caseEngineering

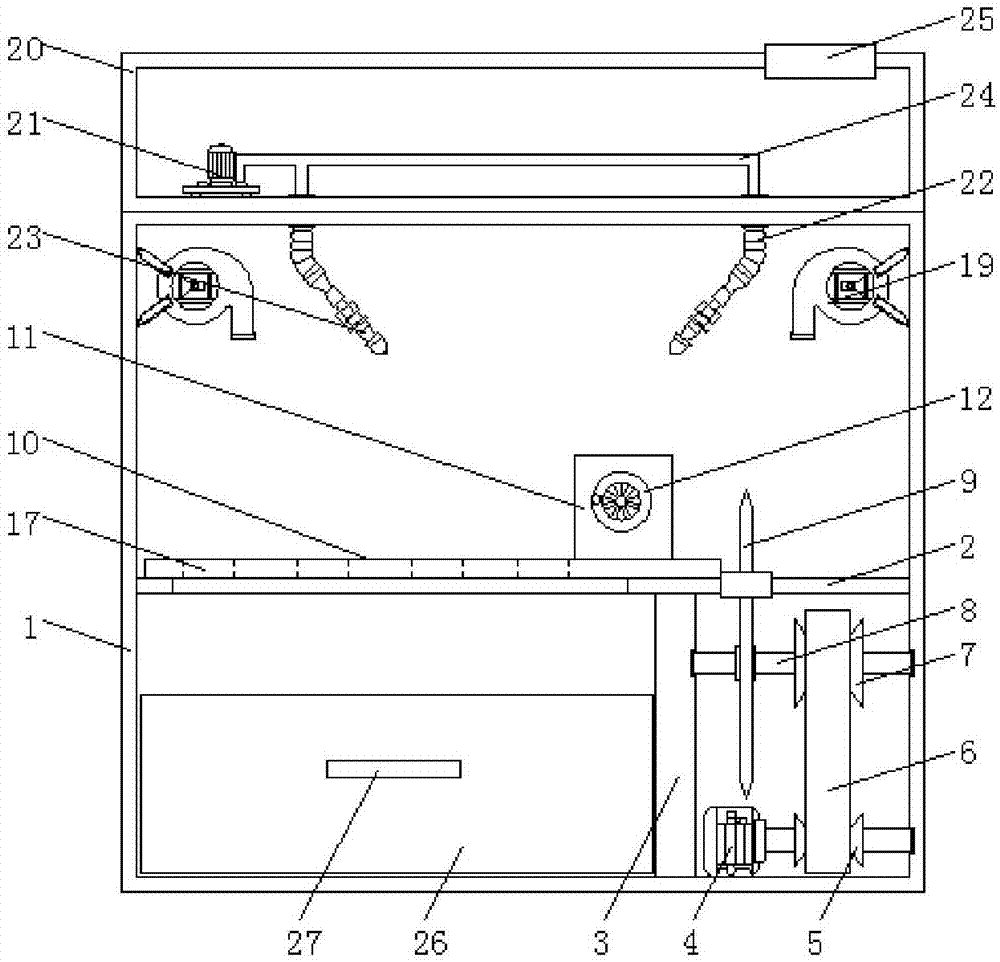

The invention discloses a dust remover of an air conditioner. The dust remover comprises a case, a dust suction device, a fan, a dust accumulation bag and a control device, wherein the dust suction device is arranged on the top of the case, the fan is arranged behind the dust suction device, the dust accumulation bag is arranged below the dust suction device, and both the dust suction device and the fan are connected with the control device. According to the dust remover of the air conditioner, the fan continuously rotates, so that dust in the air conditioner is blown, and then the blown dust is sucked by the dust suction device and then falls into the dust accumulation bag, so that a good cleaning effect on the air conditioner is achieved, a person does not need to climb high to clean the air conditioner, the operation safety of the air conditioner is increased, and the problem of difficulty in cleaning the air conditioner is preferably solved.

Owner:苏州腾辉环保科技有限公司

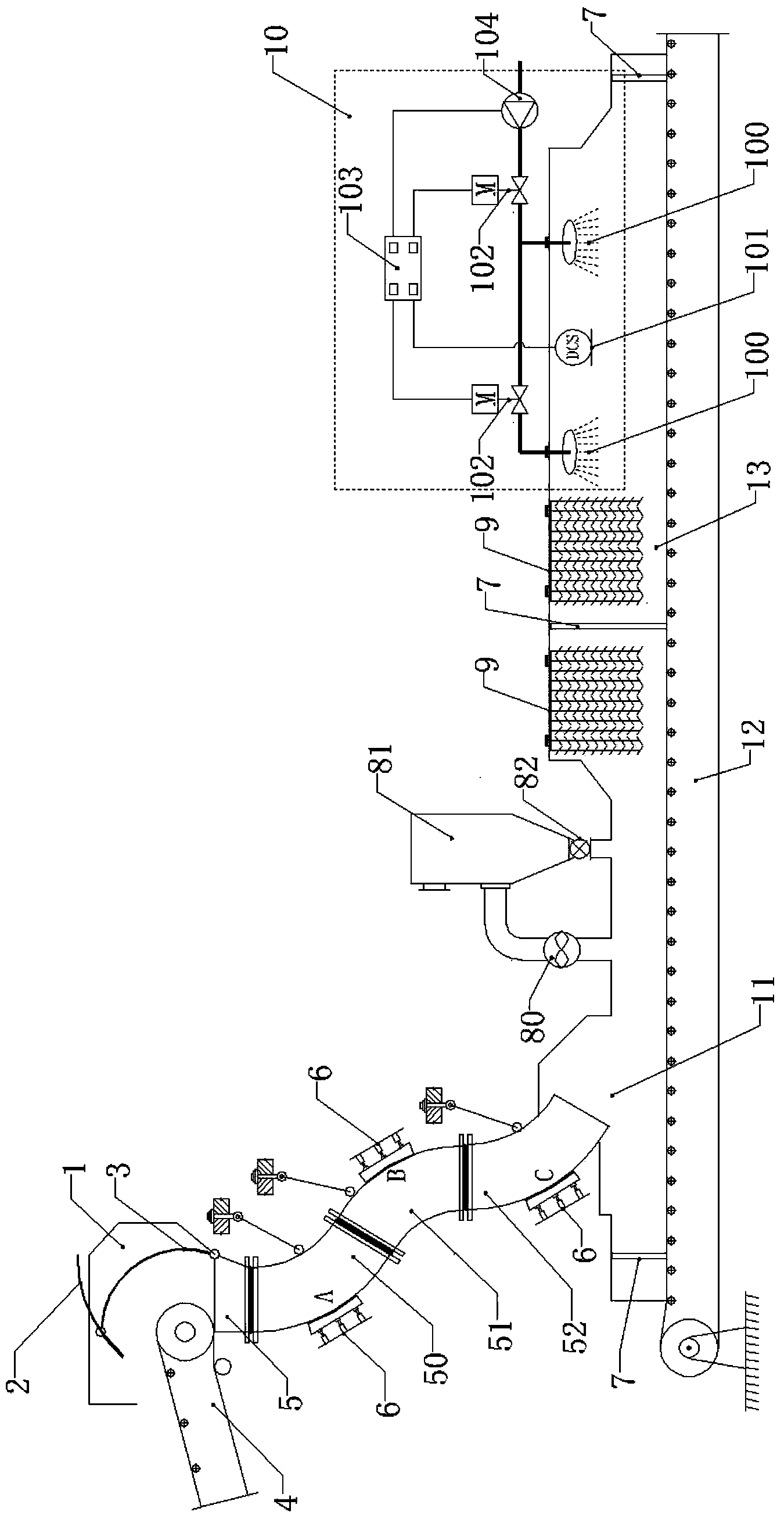

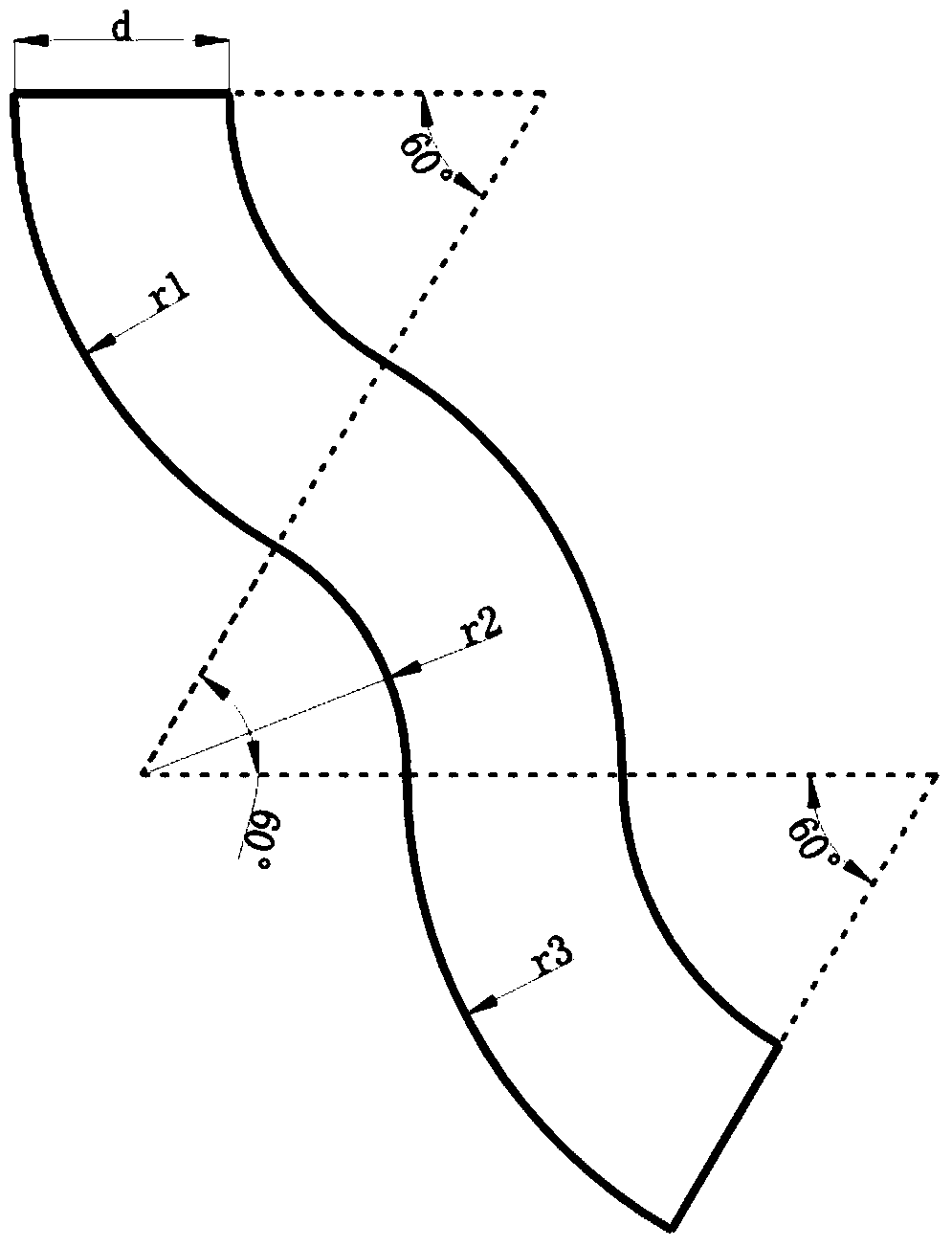

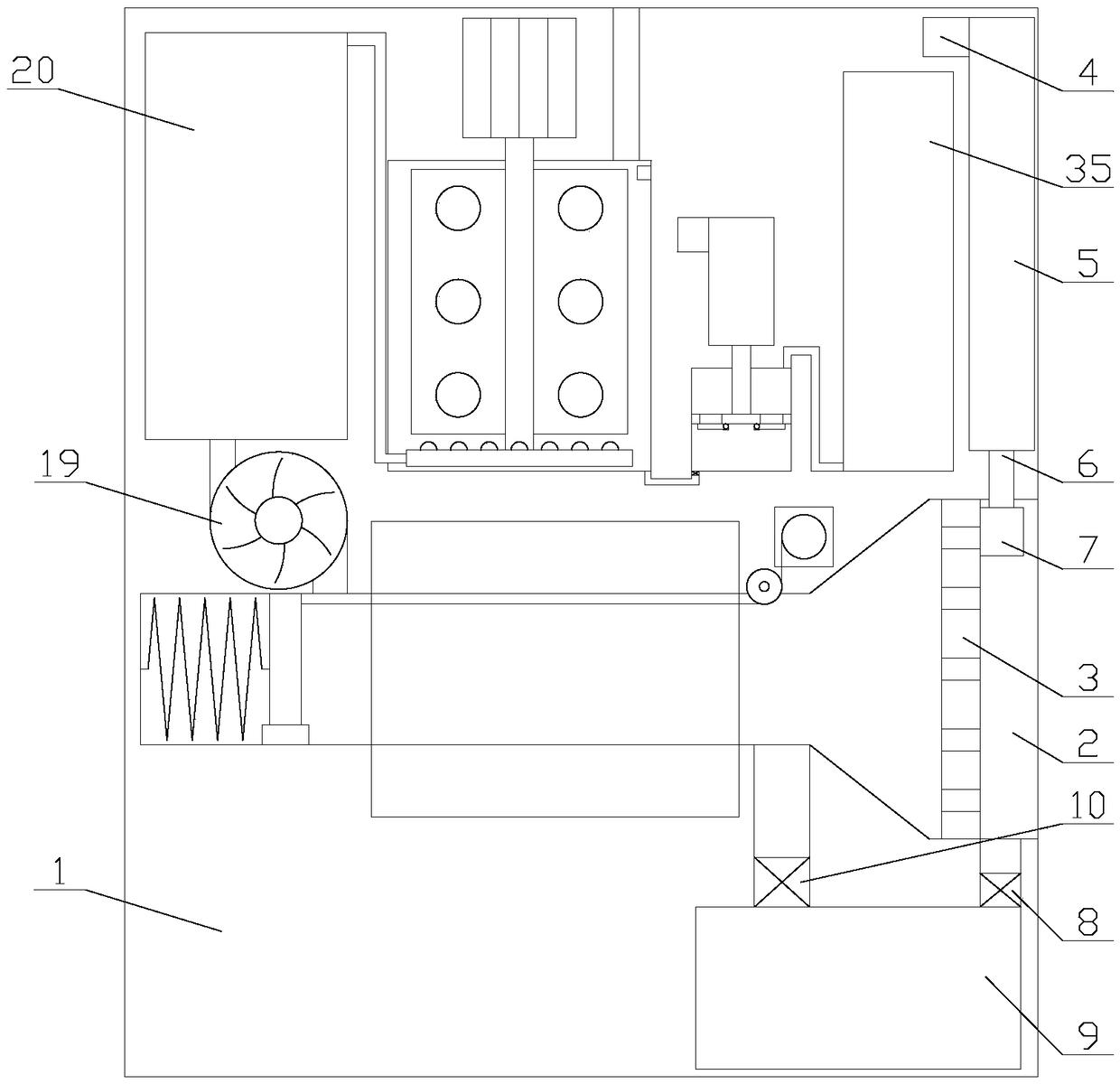

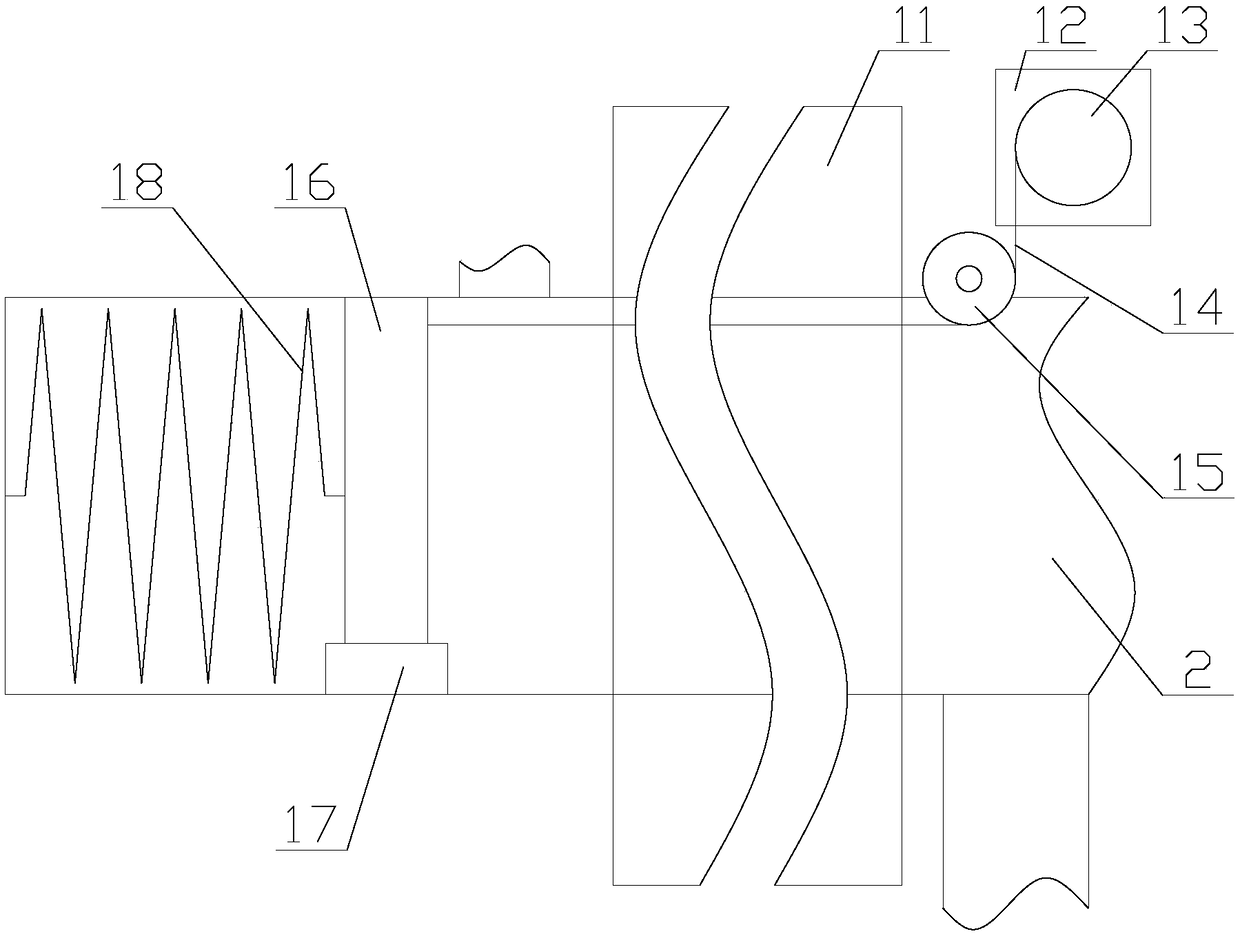

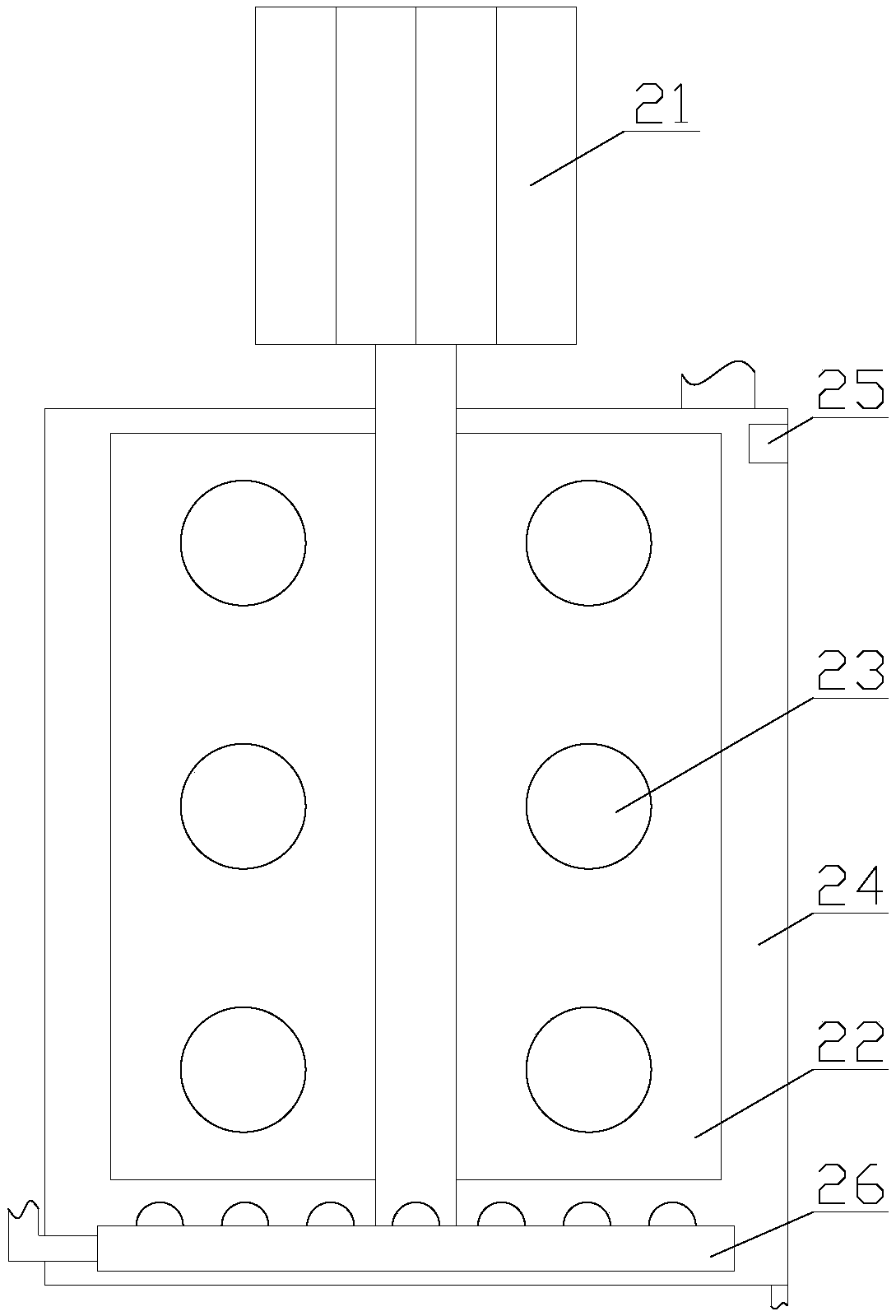

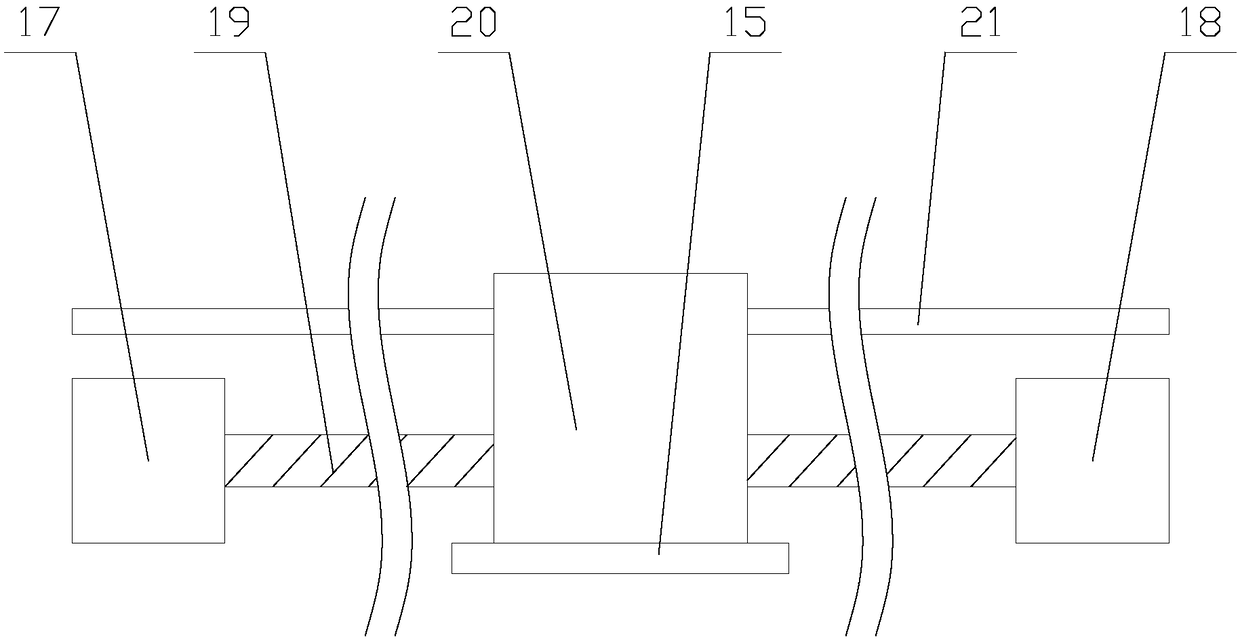

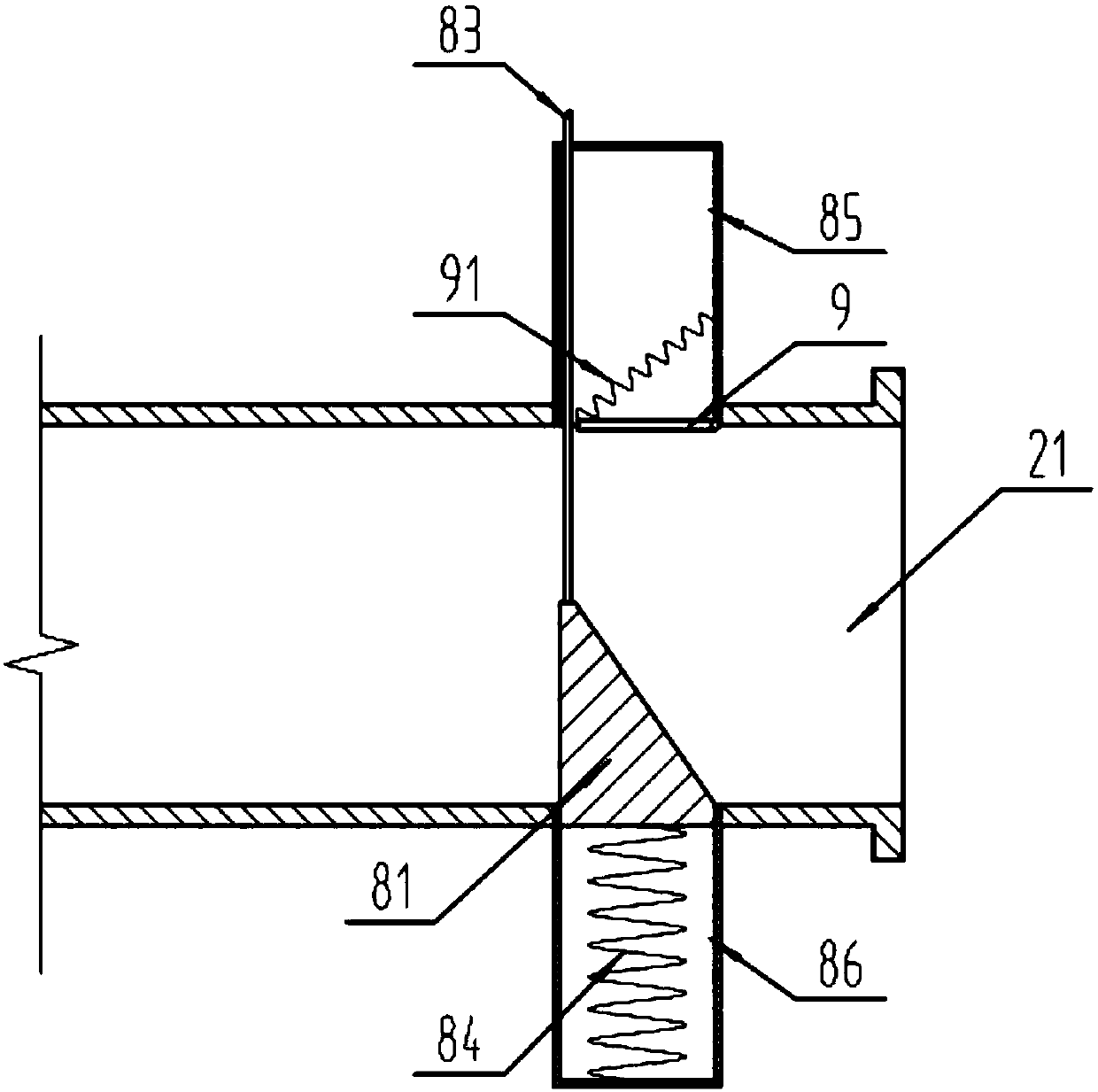

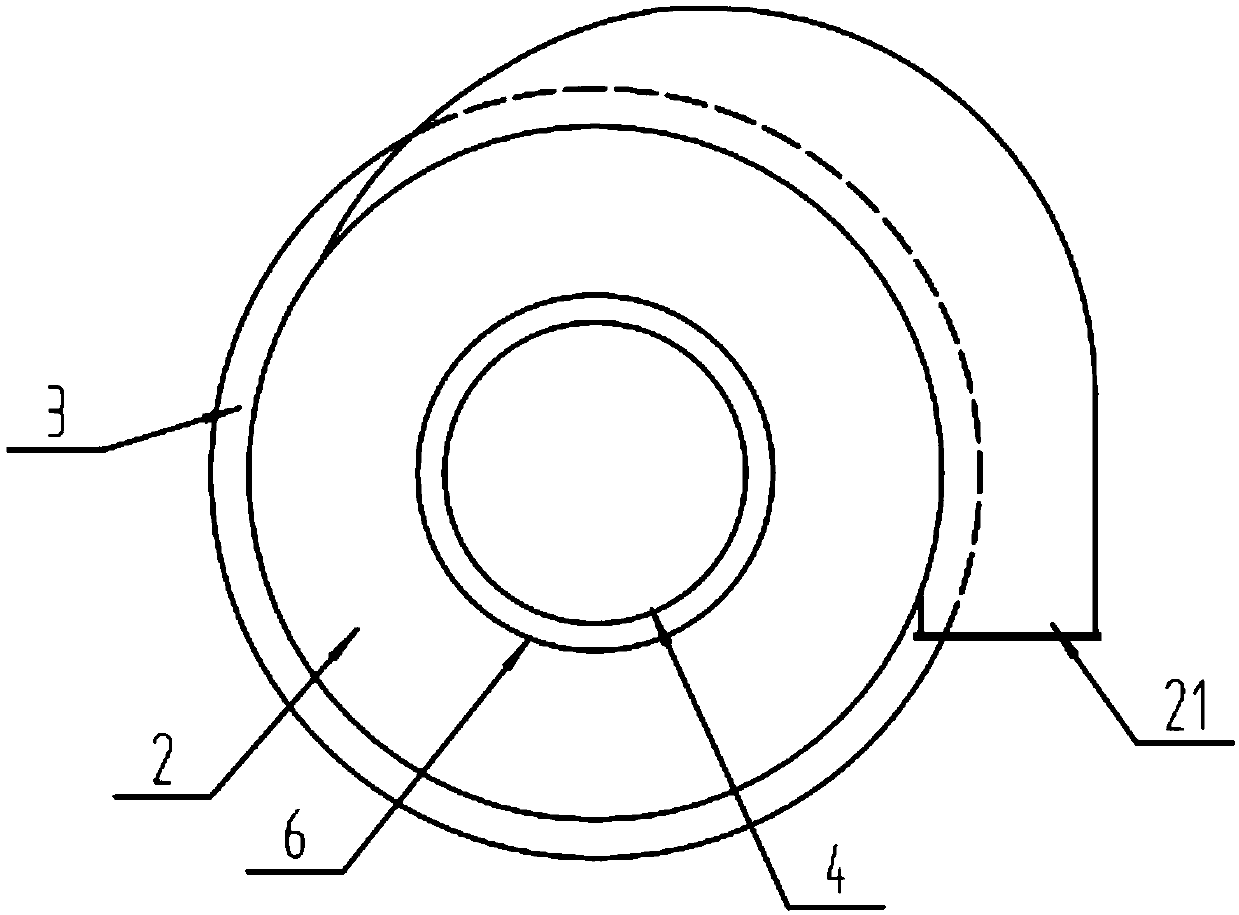

Anti-blockage, dust suppression and noise reduction coal transport system for power plant

ActiveCN104386470AGood dust removal effectEasy to remove cloth bagCleaningDiscrete element simulationThroat

The invention discloses an anti-blockage, dust suppression and noise reduction coal transport system for a power plant. The coal transport system comprises an upstream conveying device, a coal falling pipe and a downstream conveying device, wherein the discharging end of the upstream conveying device is used for feeding materials into the feeding hole of the coal falling pipe; the discharging hole of the coal falling pipe is used for feeding the materials to the feeding end of the downstream conveying device; the coal falling pipe comprises a throat hopper and a three-arc-segment coal falling pipe. The three-arc-segment coal falling pipe is designed on the basis of discrete element simulation EDEM, and has high coal type adaptability. By adopting a flow channel, the blockage of coal particles can be well prevented; meanwhile, the collision angles of the coal particles and a pipeline are reduced, and the advantage of reducing noise is realized. The three-segment coal falling pipe is spliced by adopting a deflection way, and a hydraulic damping device is arranged on a bend collision point, so that wear of the pipeline can be reduced effectively. Meanwhile, the speed of the coal particles is limited, soft landing of the coal particles and a downstream conveying belt is realized, impact on the conveying belt is reduced, and the production of dust is reduced.

Owner:SOUTHEAST UNIV

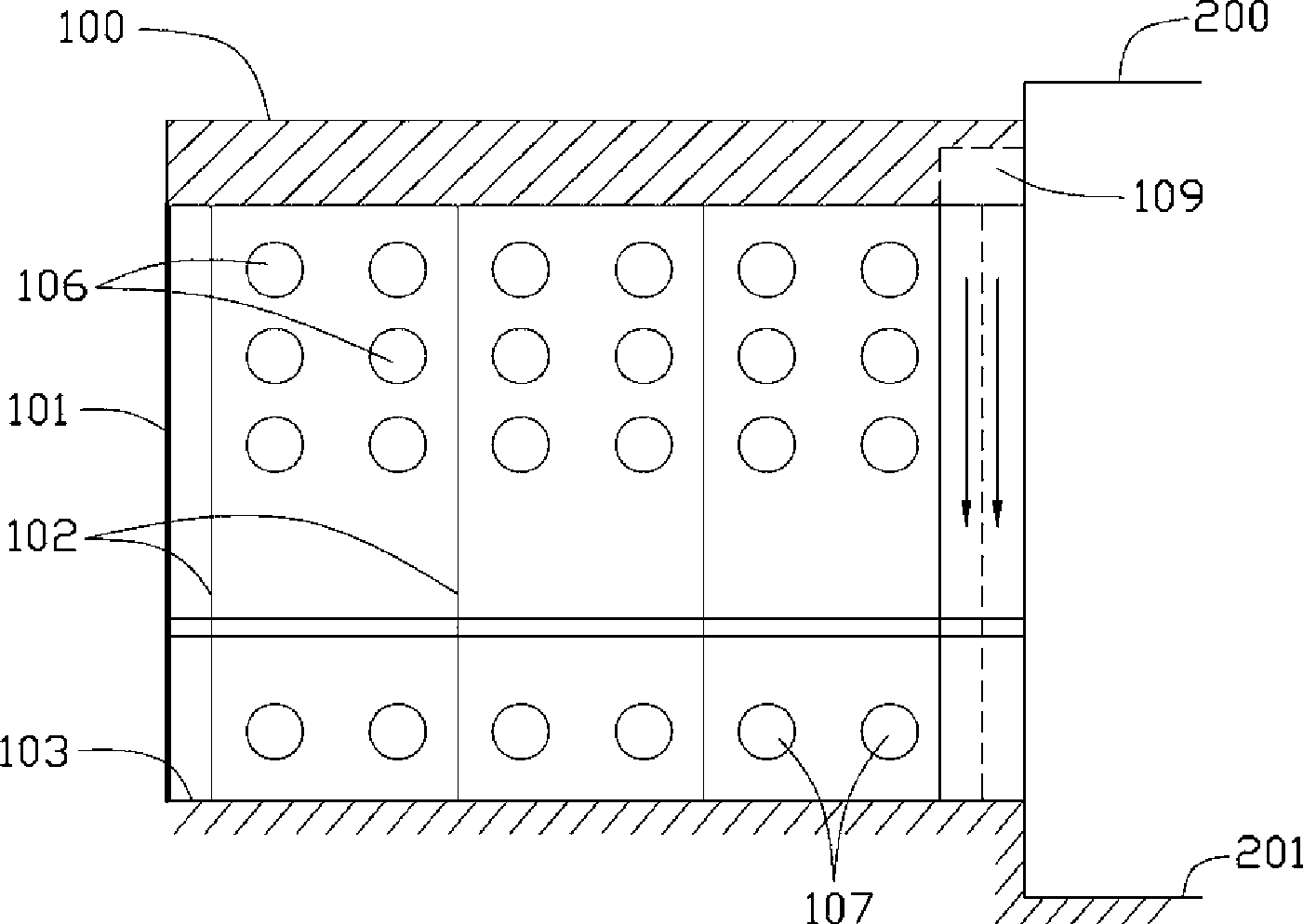

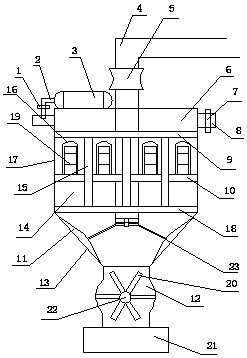

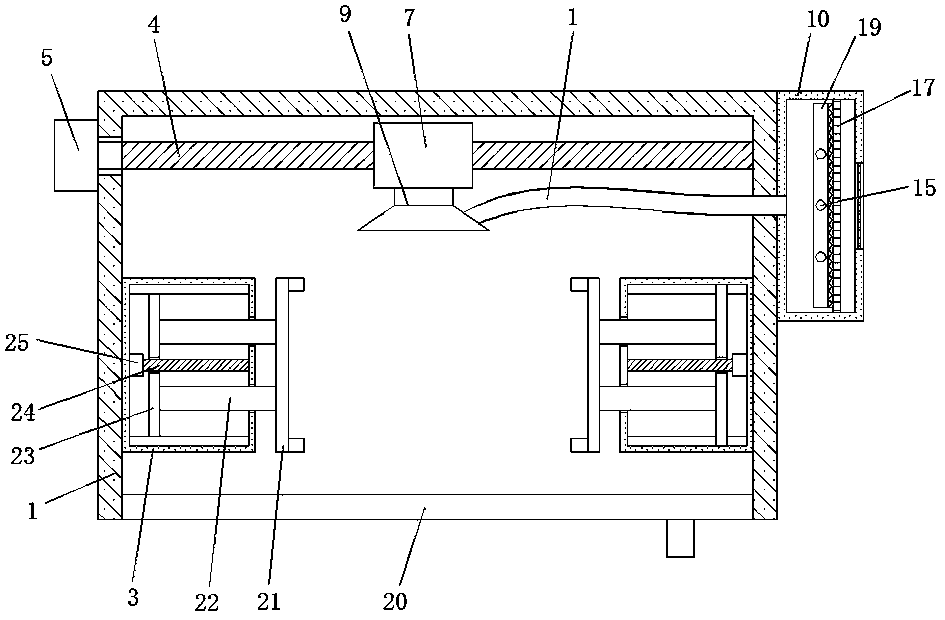

Uniform-feeding rice impurity removing equipment

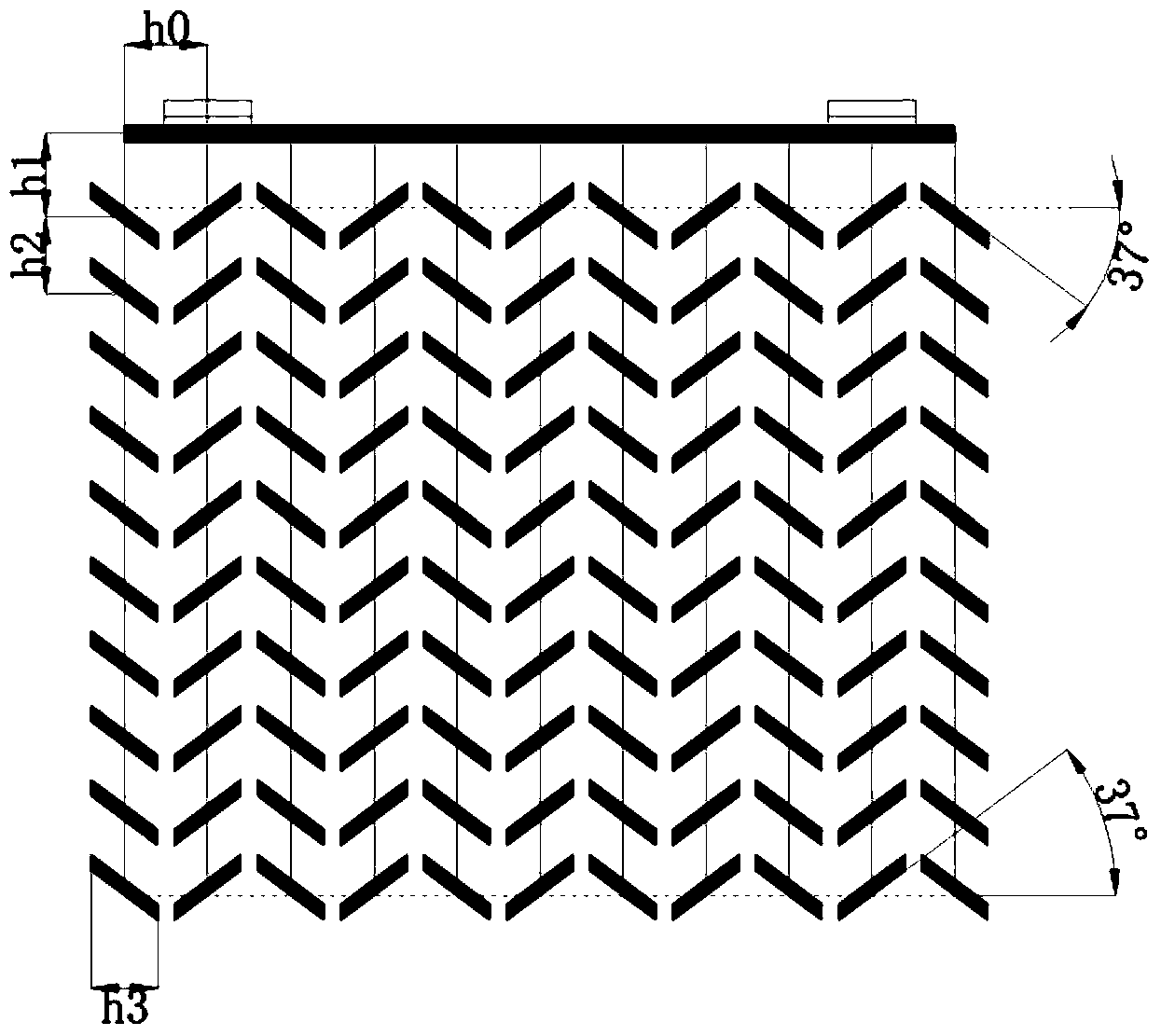

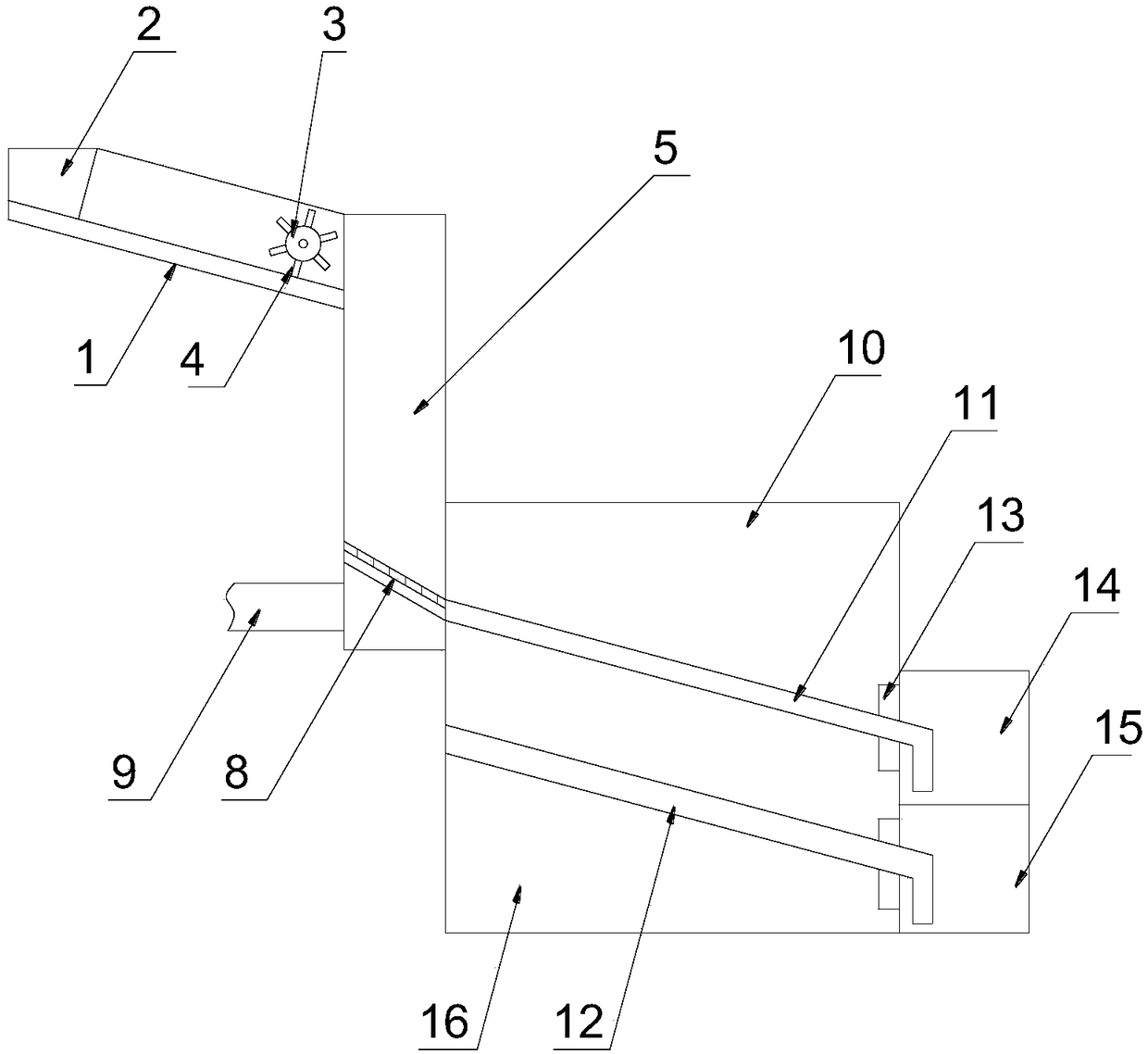

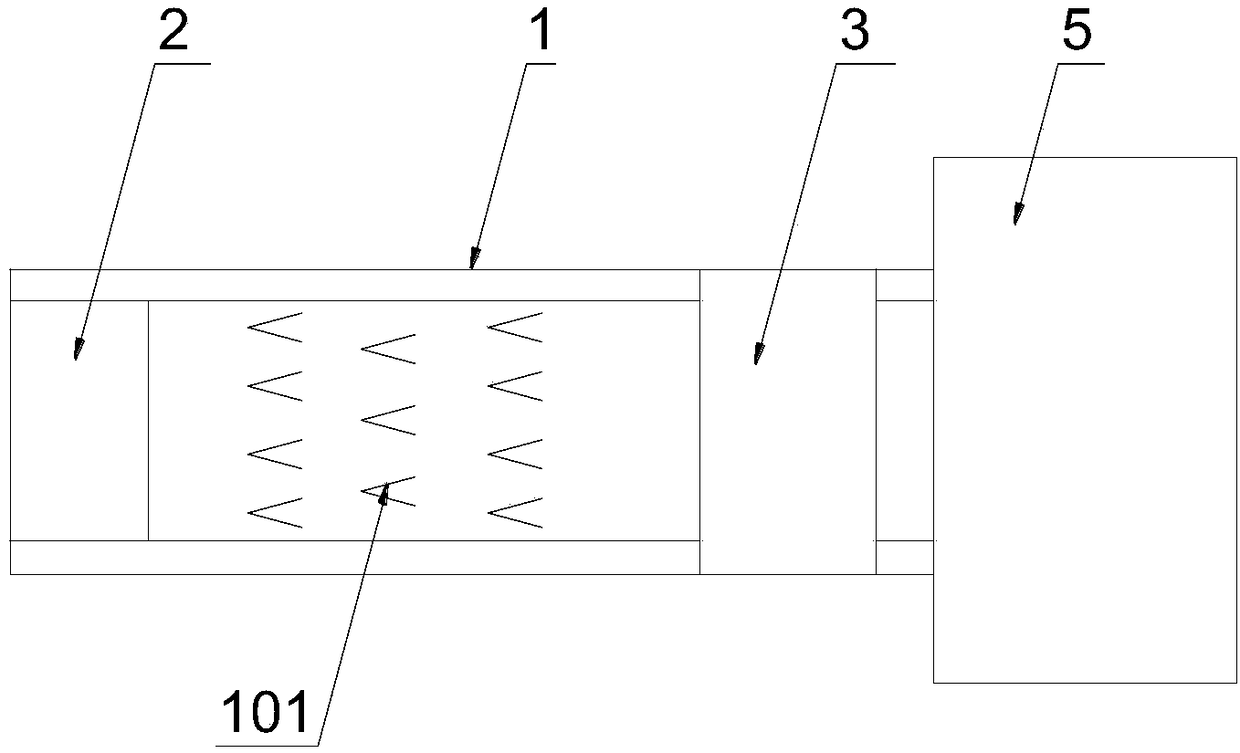

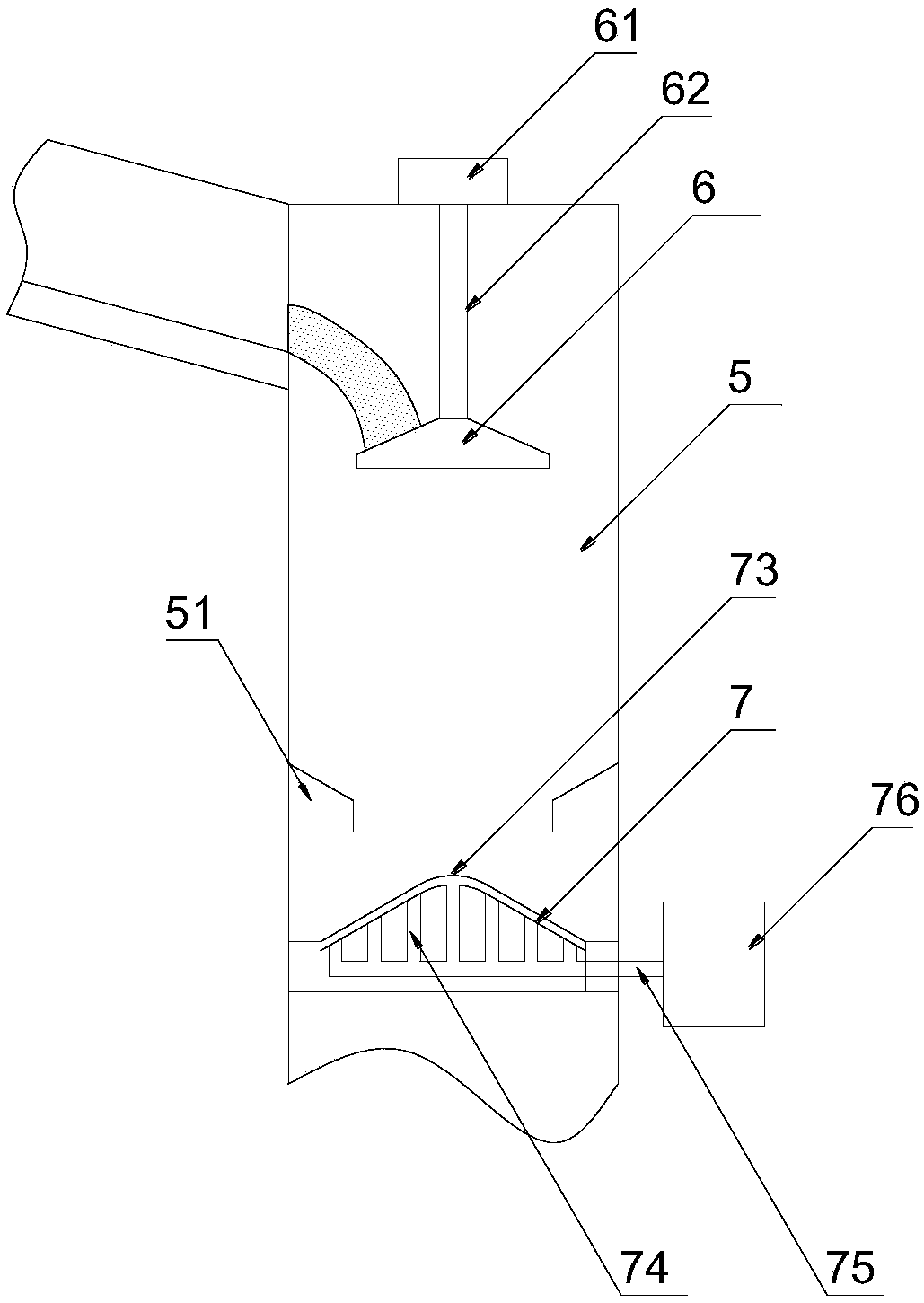

InactiveCN108339751AGood dust removal effectAvoid reprocessingSievingGas current separationEngineeringWaste management

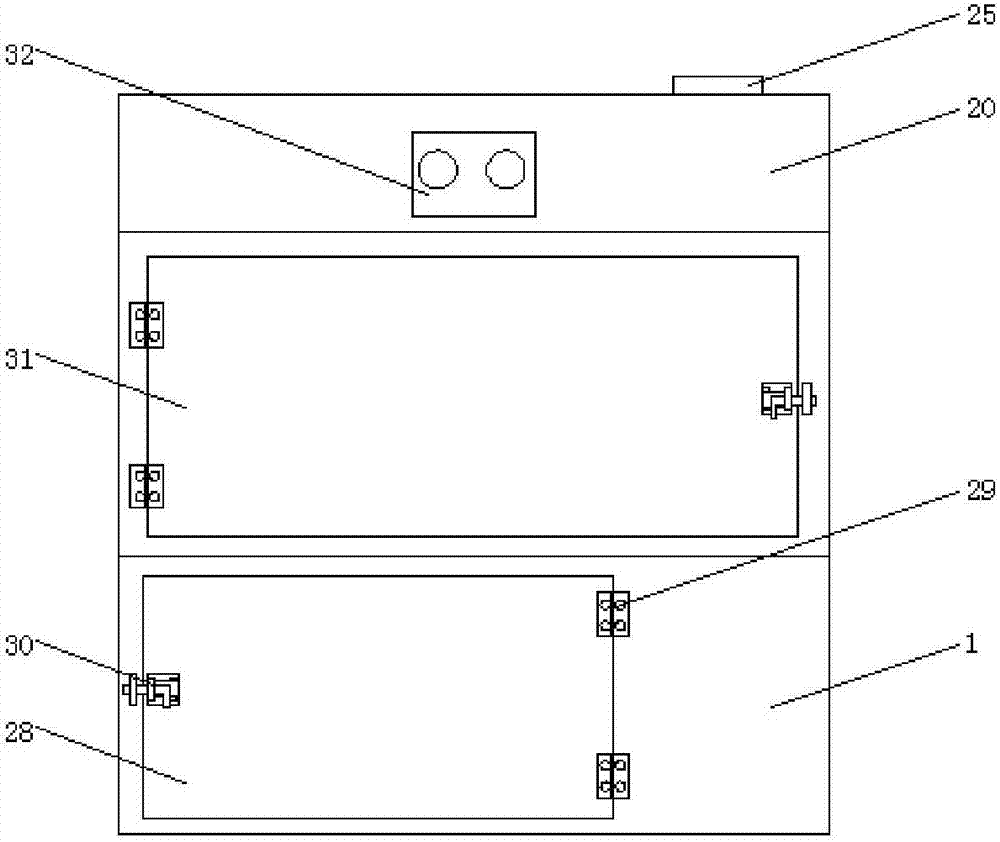

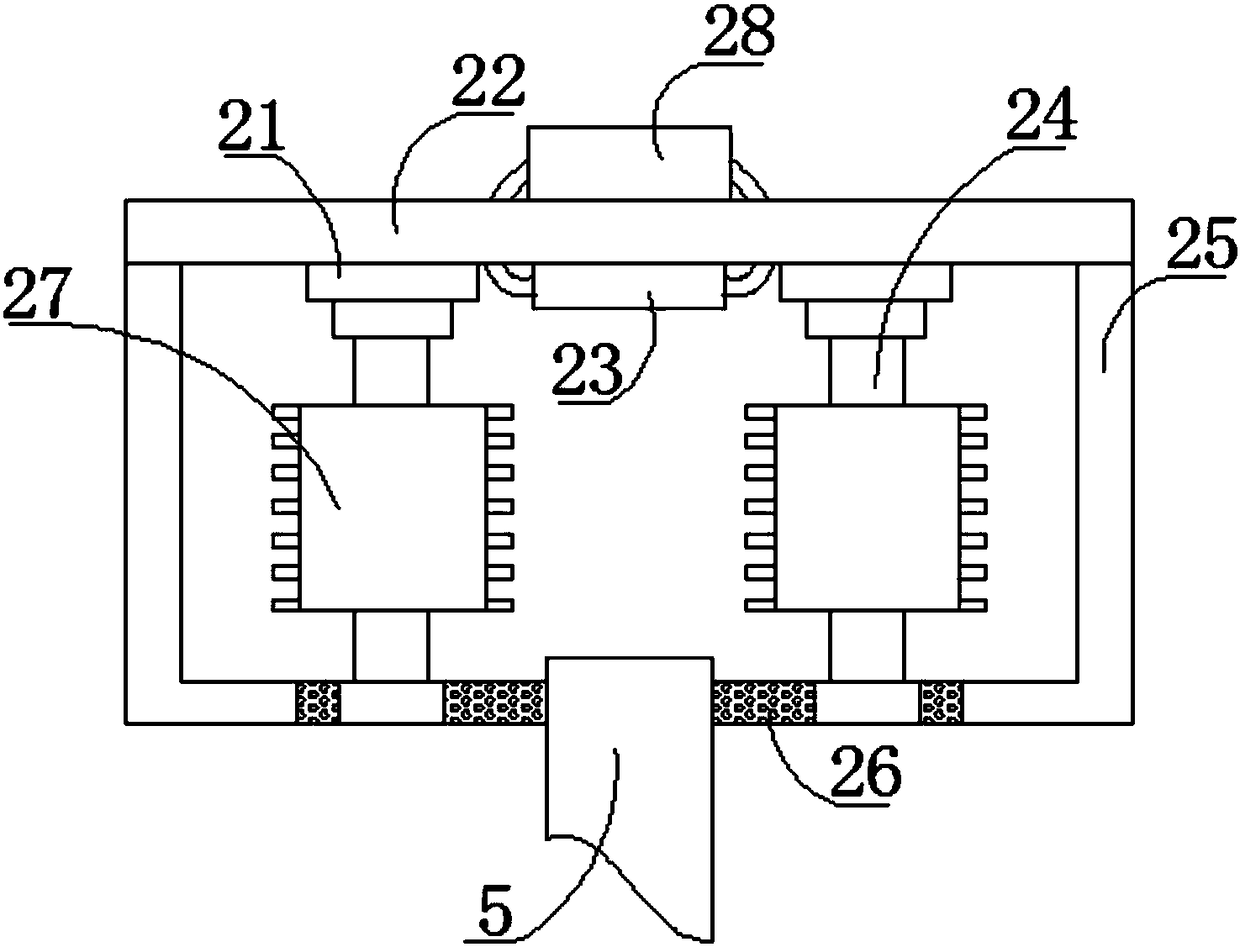

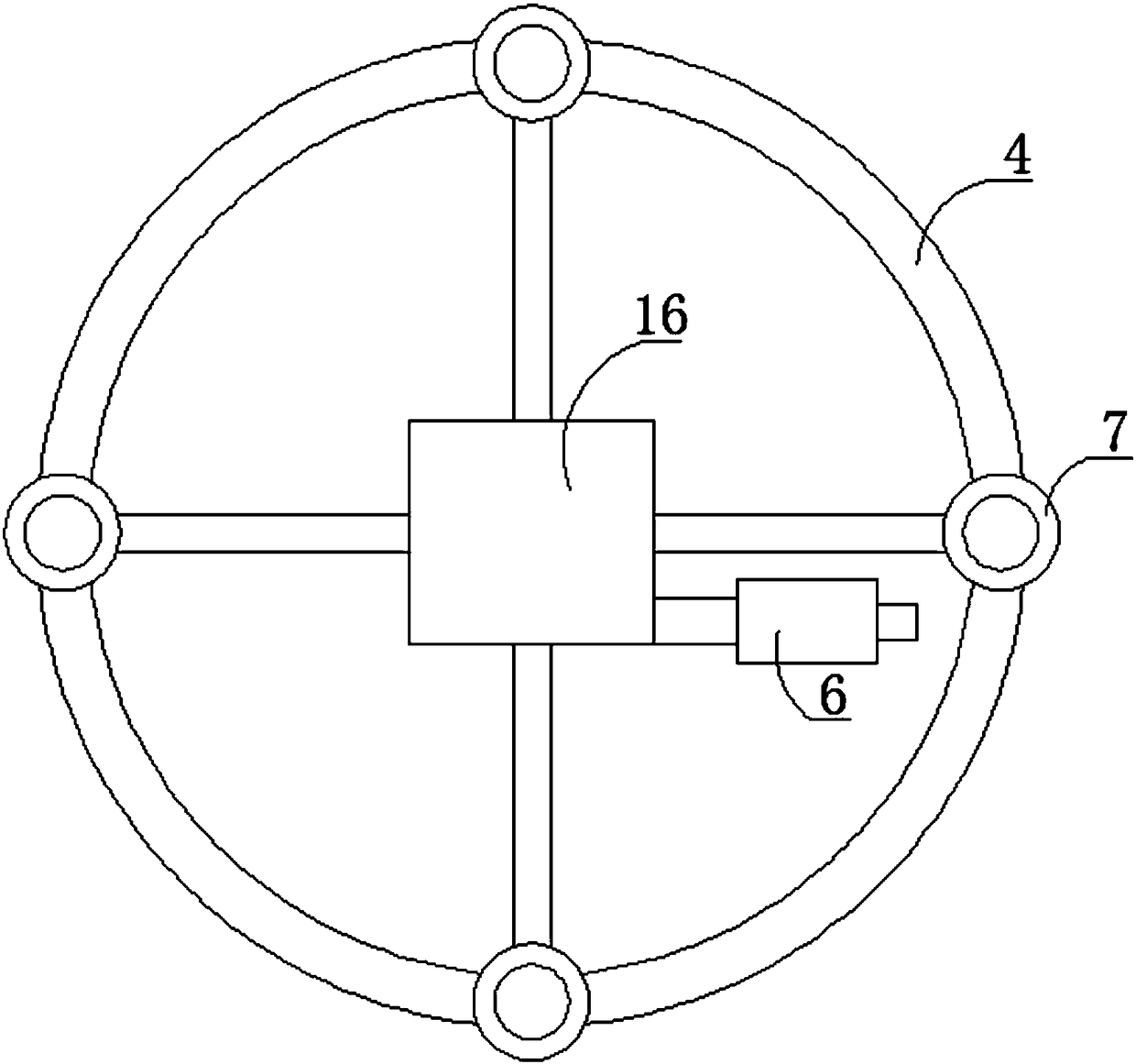

The invention discloses uniform-feeding rice impurity removing equipment. The uniform-feeding rice impurity removing equipment comprises a feeding plate, a discharging channel, a dust removing assembly, a case, a first vibration screen, a second vibration screen, a recovery box, a rice box and a waste box. The feeding plate is provided with a rotating roller, and pushing plates are uniformly arranged on the periphery of the rotating roller. A motor is installed on the outer side of the top of the discharging channel and drives a scattering disc through a rotating shaft, and the scattering discis located below a feeding inlet of the discharging channel. The dust removing assembly is installed on the lower portion of the discharging channel and comprises a dust removing disc, a filtering net, an air suction pipe and a total air pipe. A discharging outlet of the discharging channel is connected with a feeding inlet of the case, and the discharging channel is arranged close to the case sothat a partition plate can be connected with the first vibration screen. The waste box is placed on the bottom of the case and located below the second vibration screen. According to the uniform-feeding rice impurity removing equipment, rice is fed uniformly, impurities such as sand grains and dust in the rice are removed effectively, and the stone removing effect is good.

Owner:滁州广洋湖米业有限公司

Adjustable textile dust removing device

InactiveCN107175249AGood dust removal effectEliminate harm to the human bodyUsing liquid separation agentDirt cleaningEngineeringTextile

The invention discloses an adjustable textile dust removal device, comprising a base, the top of the base is fixedly connected with a support, the top of the support is provided with a drive box, and the inside of the drive box is provided with a motor, the motor The rotating shaft is connected with the gear transmission, and the inner side of the bracket is movably connected with one side of the fixed block. The adjustable textile dust removal device is provided with a drive box on the top of the bracket, the motor inside the drive box drives the gear to rotate through the rotating shaft, the gear drives the rack to move up and down, and the fixed block on one side of the rack is fixed on the bracket through the slider. Sliding up, the height of the dust cover can be adjusted according to the actual situation, and the direction can be adjusted through the rotating sphere connected to the top of the dust cover, so that the dust removal effect is better and more thorough, and the harm of residual textile dust to the human body is eliminated. The structure of the whole device is simple, Easy to operate and strong applicability.

Owner:WUJIANG YISHENG TEXTILE

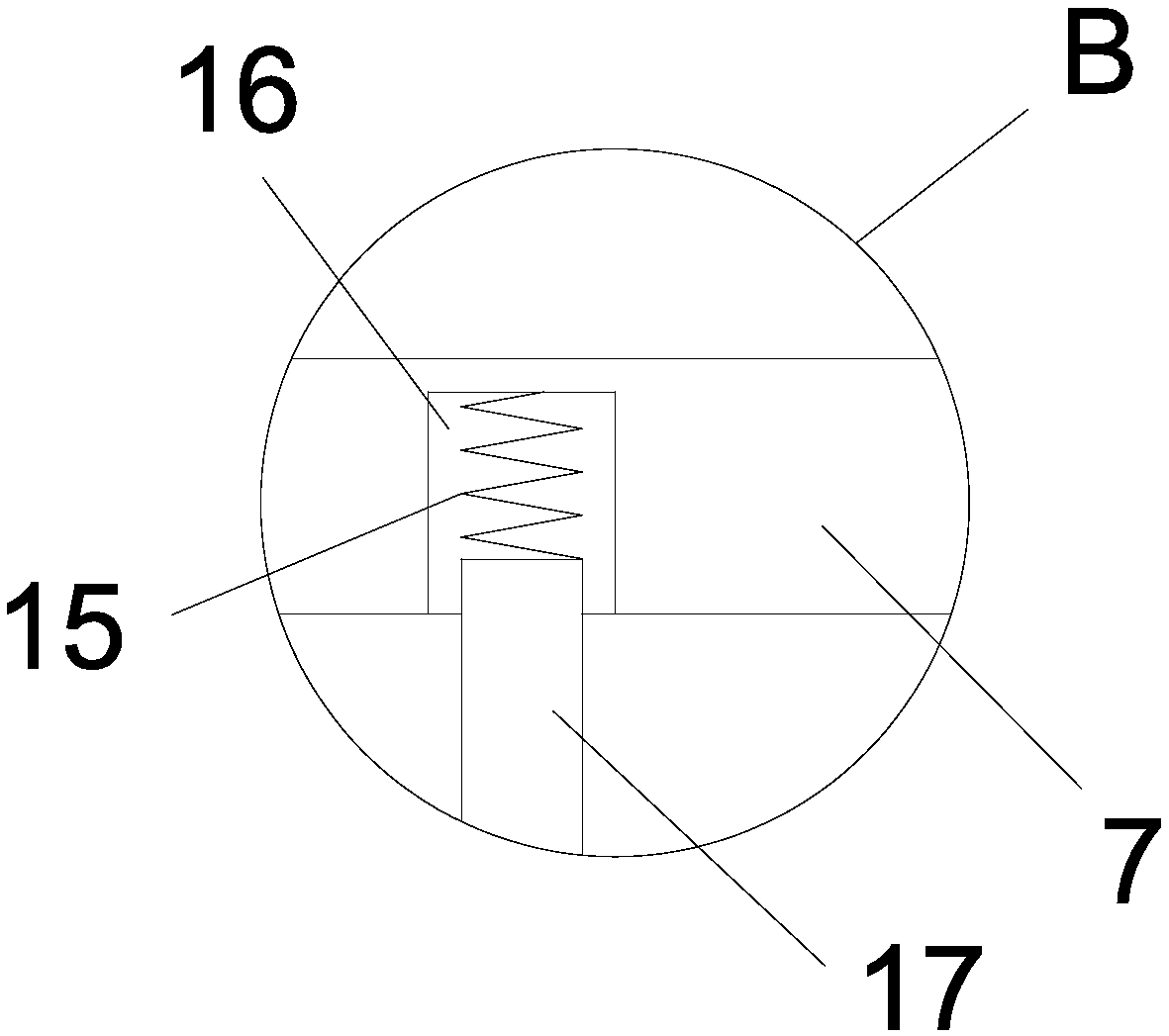

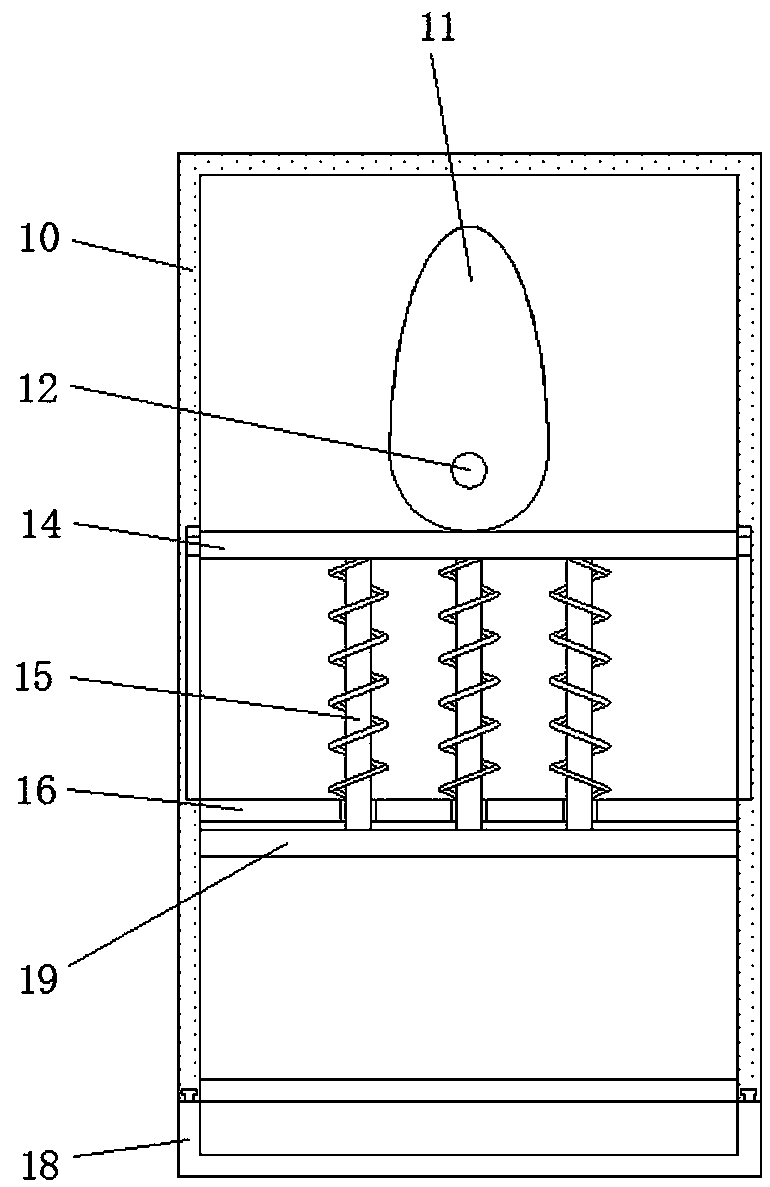

Dust removal device for industrial waste gas

InactiveCN108355417AGood dust removal effectEfficient removalDispersed particle filtrationTransportation and packagingElectric bellIndustrial waste

The invention discloses a dust removal device for industrial waste gas. The dust removal device for industrial waste gas comprises a dust removal chamber, wherein an air inlet pipe is connected onto the dust removal chamber; a spring is arranged at the bottom of the dust removal chamber; the top end of the spring is in abut joint with a dust collection chamber; a metal sheet is arranged at the bottom of the dust collection box; an insulation block is arranged at the bottom of the dust removal chamber; a first contact point and a second contact point are arranged on the insulation block; a power supply and an electric bell are arranged in the dust removal chamber; a filtering screen is arranged inside the dust removal chamber; a rotating shaft passes through the top center of the dust removal chamber; the bottom end of the rotating shaft is connected with a connecting rod; the lower end of the connecting rod is provided with bristles; the upper part of the connecting rod is provided with a scraping sheet; the outer wall of the dust removal chamber is connected with a placing plate; a fan is arranged on the placing plate; an air inlet pipe is connected onto the fan; the air inlet pipe is communicated with the main pipe; the main pipe is communicated with a sub pipe; a filtering bag is arranged on the sub pipe; the front end surface of the dust removal chamber is provided with a box door; an exhaust pipe is arranged on the top of the dust removal chamber. The dust removal device has the advantages that the dust removal effect is good; dust adhered in the device can be effectively eliminated; in addition, when the dust is accumulated to a certain amount, the warning can be provided; work personnel can be reminded of cleaning the dust.

Owner:ANHUI HANSHAN COUNTY TIANSHUN ENVIRONMENTAL PROTECTION EQUIP

Indoor air cleaning unit

InactiveCN101468208AGood dust removal effectReduce noiseDeodrantsRadiationAir cleaningActivated carbon

The present invention relates to an indoor air cleaning unit which mainly comprises a dust removing unit, an active carbon absorbing unit and an ultraviolet sterilizing unit. The dust removing unit adopts an electrostatic dust collecting structure and is provided with dust collecting plates parallel with each other and discharge electrodes distributed between the dust collecting boards. The active carbon absorbing unit is obtained by stacking a plurality of activated carbon fiber blocks. The ultraviolet sterilizing unit is provided with a plurality of photocatalytic modules which are arranged transversely and are composed of a plurality of layers of photocatalytic wire meshes. An ultraviolet lamp and an ultrasonic atomizer are installed between each photocatalytic module. The ultrasonic atomizer is provided with a water supplying device. The device has a simple structure, fully exerts the synthetic predominance of a plurality of purifying techniques and effectively settles the problem of indoor air pollution.

Owner:HAISIBOTE BEIJING SCIENE & TECH

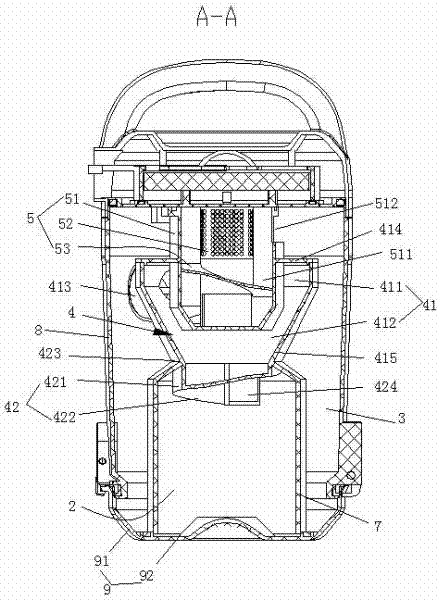

Dust cup device of dust collector and dust collector

InactiveCN102334955AAvoid dust phenomenonEasy to separateSuction filtersDust collectorWaste management

The invention discloses a dust cup device of a dust collector. The dust cup device is provided with an air inlet, a primary dust collecting chamber, a secondary dust collecting chamber, a primary cyclone separator, a secondary cyclone separator and an air outlet. The secondary dust collecting chamber surrounds the primary dust collecting chamber. The primary cyclone separator comprises a primary cyclone chamber and a primary cyclone passage. The primary cyclone passage comprises a surrounding wall and a partition plate, and the partition plate is extended from the bottom of the cyclone chamber to the crude dust receiving bottom of the primary dust collecting chamber, is spiral and forms the primary cyclone passage together with the surrounding wall. The secondary cyclone separator comprises a cyclone, a mesh filter and a flow deflector. The flow deflector is spirally extended from the bottom of the cyclone to the top of the cyclone, is positioned between the inner wall of the cyclone and the outer wall of the mesh filter and forms a spiral secondary cyclone passage together with the inner wall of the cyclone and the outer wall of the mesh filter. Because the dust cup device is provided with the primary spiral cyclone passage and the secondary spiral cyclone passage, the speed of the dust can be fully reduced, and the separation effect is good.

Owner:JIANGSU MIDEA CLEANING APPLIANCES

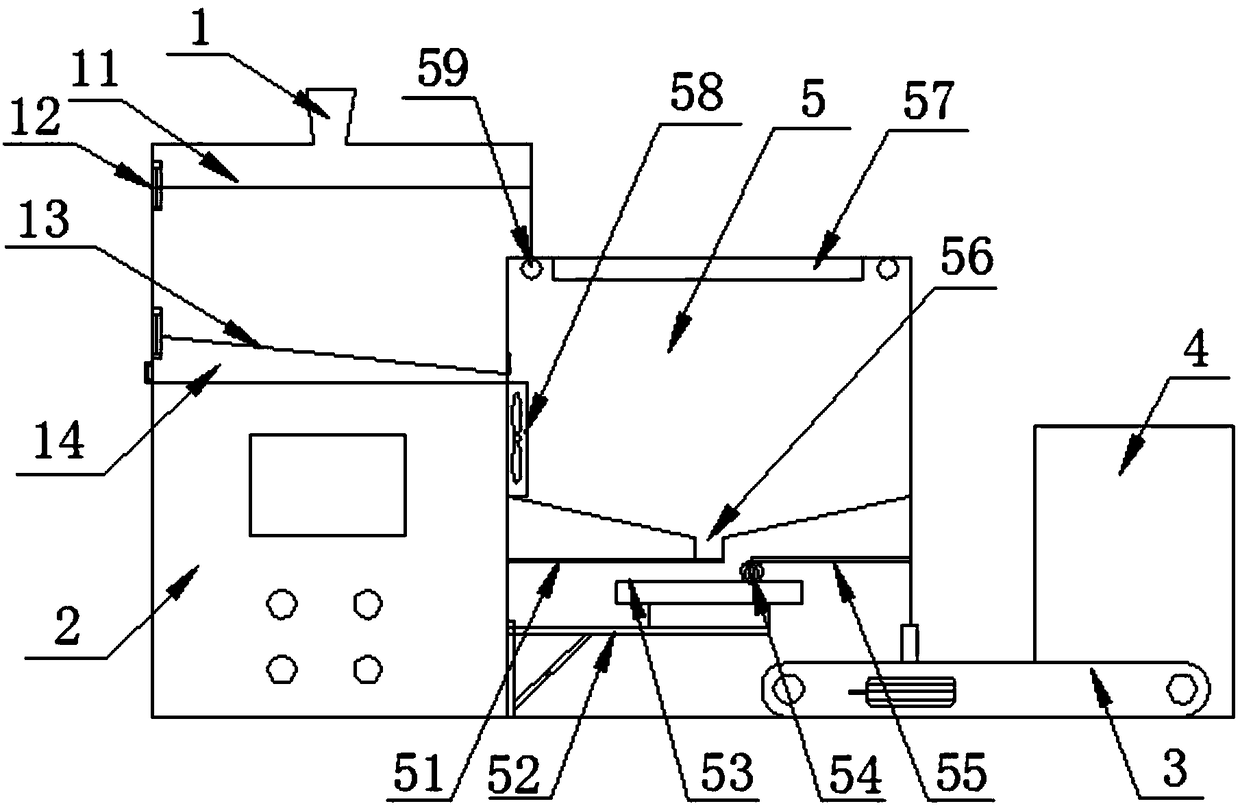

Part machining cutting device with dust removing function

InactiveCN107262811AClean completelyGood dust removal effectShearing machinesMaintainance and safety accessoriesPulleyNozzle

The invention discloses a parts processing and cutting device with the function of dust removal, which comprises a fixed box, a first partition is fixedly connected between the two sides of the inner wall of the fixed box, and the bottom of the inner wall of the fixed box and the first partition are fixed. A second partition is fixedly connected between them, the bottom of the inner wall of the fixed box is fixedly connected with a motor, and the output shaft of the motor is fixedly connected with a first pulley, and the surface of the first pulley is connected with a second belt through a belt drive. wheel, and the shaft center of the second pulley is fixedly connected with a transmission shaft, and the surface of the transmission shaft is fixedly connected with a cutting piece. The invention relates to the technical field of mechanical processing equipment. The parts processing and cutting device with the function of dust removal enables the cut dust and cuts to fall into the dust storage box through the dust leakage hole and the dust leakage hole, and the dust will be blown into the dust storage box by the wind. The dust storage box is cleaned with water by the nozzle, so that the cutting device can be cleaned quickly and completely after use, and the dust removal effect is good.

Owner:CHENZHOU JINTONG INFORMATION TECH CO LTD

Dust-free blackboard eraser

InactiveCN102029849AGood dust removal effectEasy to pourBoard cleaning devicesAbsorption effectEngineering

The invention provides a dust-free blackboard eraser, belonging to a cleaning tool. The dust-free blackboard eraser comprises felt and a box body. The felt is uniformly adhered to a surface of the box body in rows; the box body is internally provided with a dust absorption box and a fan; the dust absorption box is arranged close to the felt; a plurality of through holes are uniformly arranged on the box body wall between the dust absorption box and the felt and among the gaps of the felt; the fan is arranged at the rear of the dust absorption box; a filtering screen is arranged on the box body wall between the dust absorption box and the fan; the box body is also internally provided with a water box, a dust collection box and a switch; the water box is arranged at the rear of the dust absorption box and above the fan; a water mist generator is arranged on the shared side wall of the water box and the dust absorption box; the opening of the water mist generator faces to the interior of the dust absorption box; the dust collection box is arranged below the dust absorption box and communicated with the dust absorption box; the dust collection box can be pulled out of the box body; and the switch is arranged on the rear side surface of the box body and connected with the circuits of both the fan and the water mist generator. The dust-free blackboard eraser has the advantages of simple structure, low manufacture cost and good dust absorption effect and is convenient to use.

Owner:张文清

Airshower chamber

InactiveCN101497054AGood dust removal effectRealize dust returnDust-free enclosuresCleaning using gasesSpray nozzleEngineering

The invention discloses an air shower room, which is communicated with the outside through an air shower room inlet. The connection part of the air shower room and a dust-free room is provided with an air shower room outlet which is also a dust-free room inlet. The air shower room comprises an electrically controlled automatic door arranged at the air shower room inlet, an air shower room floor, a plurality of air spray nozzles, an air shower room wall, an infrared sensor arranged on the air shower room wall, a plurality of air holes and an air curtain. The air curtain is arranged on the top of the air shower room outlet to form a downward air flow, and the air shower room floor is 5 or more than 5 centimeters higher than the floor of the dust-free room.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

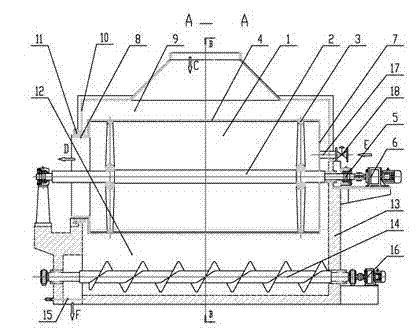

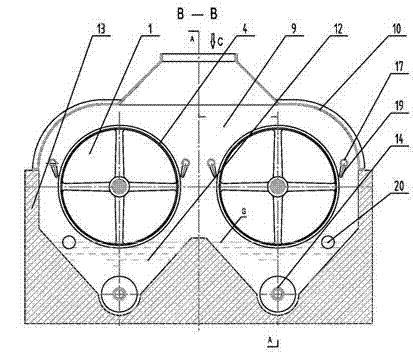

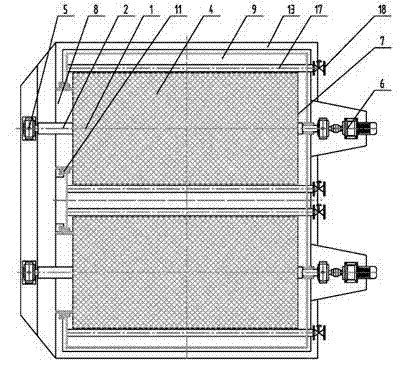

Water-washing dust-cleaning horizontal type mesh cage dust removing machine

InactiveCN102728175AGood dust removal effectSimple and novel structureCombination devicesSewage treatmentWater tanks

The invention discloses a water-washing dust-cleaning horizontal type mesh cage dust removing machine, which mainly comprises a plurality of parts, i.e., a horizontal type rotary mesh cage, a sealed type dust accumulating chamber, an automatic water mist spraying device and a helix sewage disposal device, wherein the horizontal type rotary mesh cage is a filtering unit main body which can be composed of one to more mesh cages; the mesh cages are arranged in parallel inside the dust accumulating chamber; one or more layers of filtering cloth wrap on the mesh cages; and the mesh cages are driven to rotate slowly by a transmission device. The dusty gas is led into the sealed dust accumulating chamber by a fan or a draught pipe; and during the process that the dusty gas penetrates through the filtering cloth on the mesh cages and is discharged out from a discharge port, the dust is captured by the filtering cloth, while the clean air permeates through the filtering cloth and is discharged out from ports of the mesh cages. A V-shaped water tank is arranged at the lower part of the dust accumulating chamber; a water level of certain height is maintained; and the dust accumulated on the filtering cloth is washed when the mesh cages swashes with water while rotating backwards, so that the purpose of automatic dust cleaning is achieved.

Owner:YUEYANG FOREST & PAPER CO LTD

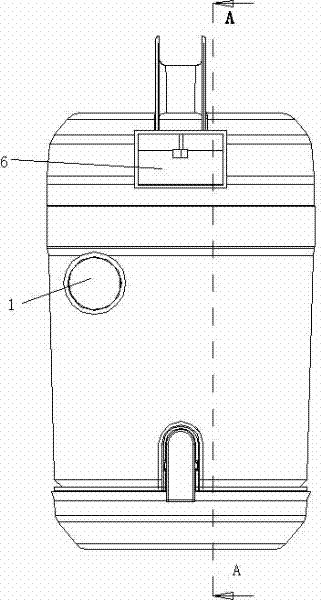

Air purifier with humidifying function

InactiveCN108758848ADust removal speed is fastGood dust removal effectMechanical apparatusLighting and heating apparatusIndoor airWater storage tank

The invention relates to an air purifier with the humidifying function. The air purifier comprises a main body, and an air inlet pipe, a dust board, an air exhauster, a purifying chamber, a dust removal mechanism, a humidifying mechanism and two electrode boards are included; a purifying mechanism is arranged in the purifying chamber, the dust removal mechanism comprises a scraping unit, a transverse moving unit, a first valve, a second valve and a storage box, the transverse moving unit comprises a drive assembly, a sliding wheel, a dust removal plate and a spring, the humidifying mechanism comprises a mixing unit and a water supplementing unit, and the water supplanting unit comprises a lifting unit, a water inlet tank, a water storage tank and a third valve. According to the air purifier with the humidifying function, the dust removal mechanism is arranged, the air purifier can clean dust in the air inlet pipe, dust is prevented from blocking the air inlet pipe, it is ensured that the air purifier can normally work, the humidifying mechanism is arranged, the air purifier can humidify the indoor air, and work and life comfort of dry space of people can be improved.

Owner:晋江市意翔环保科技有限公司

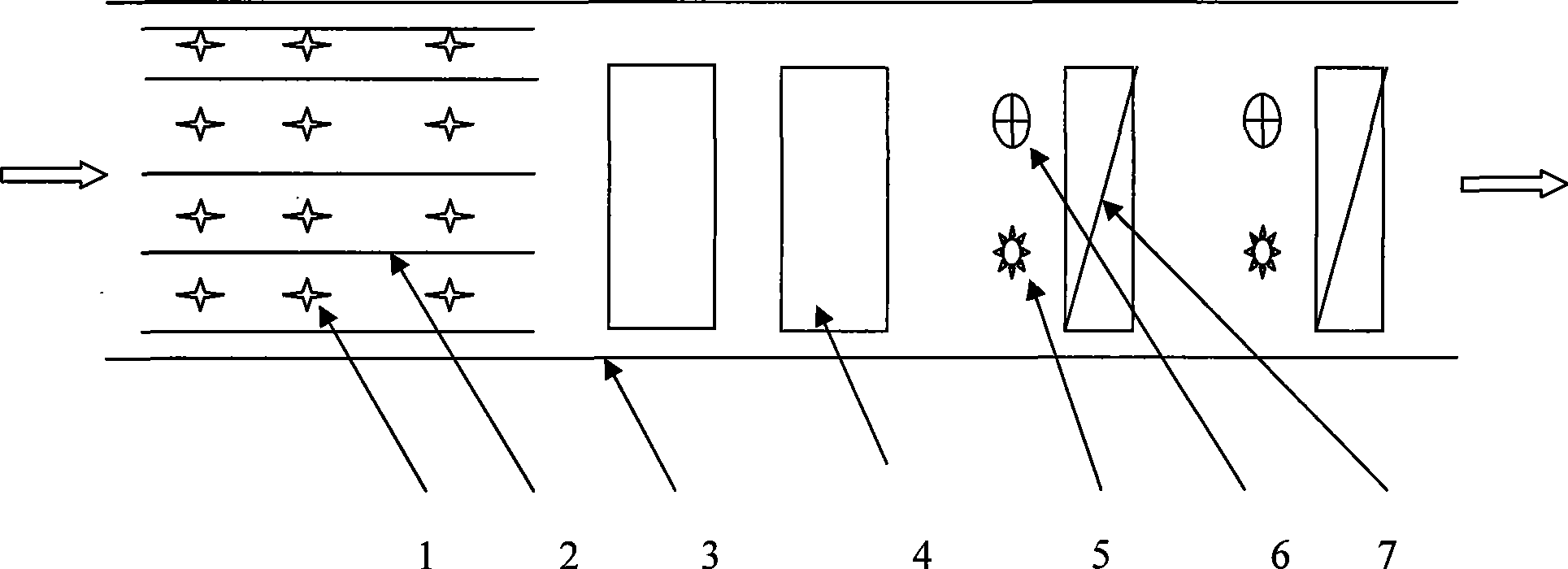

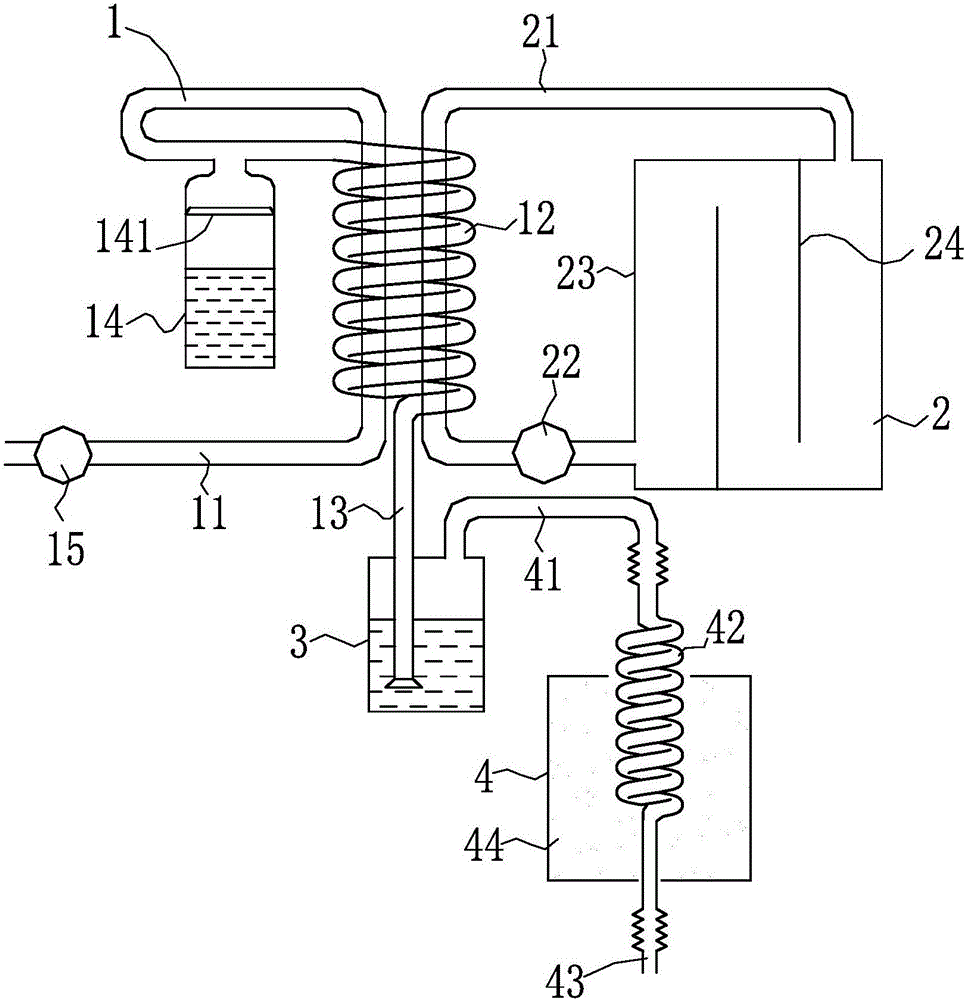

Tiny dust particle filtration and adsorption system

ActiveCN105999918AThe principle is simpleGood dust removal effectUsing liquid separation agentEngineeringDust particles

The invention relates to the field of dedusting equipment, in particular to a tiny dust particle filtration and adsorption system. The tiny dust particle filtration and adsorption system comprises an atomizing device, a circulating cooling device, an absorption device and a recooling device, wherein the atomizing device comprises an air inlet pipe, a cooling pipe, an air outlet pipe, a steam generator and an air pump, wherein the air inlet of the cooling pipe is connected with the air outlet of the air inlet pipe; the air outlet of the cooling pipe is connected with the air inlet of the air outlet pipe; the middle of the air inlet pipe penetrates through one hole of the '8'-shaped spiral cooling pipe; the output opening of the steam generator is communicated with the air inlet pipe; the steam generator is used for generating steam to be mixed with gas to be purified; the circulating cooling device is connected with the cooling pipe; the recooling device is connected with the absorption device. The tiny dust particle filtration and adsorption system imitates mist formation in meteorology, tiny dust particles serve as condensation nucleuses to form water mist first, and then the water mist is condensed into water, so that the dust particles and the water are combined and discharged. The system is simple in principle, obvious in dust removal effect, recyclable, lower in cost, and convenient to popularize.

Owner:HEBEI NAT LIGHTING PHOTOELECTRIC TECH CO LTD

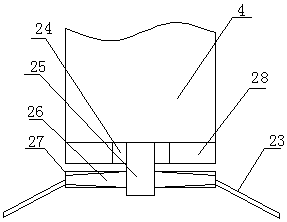

Automatic tea packaging machine

InactiveCN109131967AGood dust removal effectKeep clean and hygienicPackaging under vacuum/special atmosphereSolid materialElectrostatic precipitatorEngineering

The invention relates to an automatic tea packaging machine. The automatic tea packaging machine comprises a feeding device, a dust removal chamber and a packaging device. A primary dust removal chamber body comprises a first dust removal vibrating screen and a second dust removal vibrating screen. The first dust removal vibrating screen is horizontally arranged below a feed inlet, the second dustremoval vibrating screen is obliquely arranged below the first dust removal vibrating screen, and the inclination direction of the second dust removal vibrating screen is downward inclined from the primary dust removal device chamber body to the position of a secondary dust removal chamber body. The secondary dust removal chamber body comprises an electrostatic precipitator and a blowing system.A discharge port is formed below the electrostatic precipitator. A push plate is arranged at the bottom of the discharge port. A weighing and subpackaging device is arranged below the discharge port.A conveying belt is arranged below the weighing and subpackaging device. The tail end of the conveying belt is connected with a vacuum packaging machine. The automatic tea packaging machine has the beneficial effects that the structure is simple, the automation degree is high, and the problems of discontinuous vacuumizing operation and more tea dust residues can be effectively solved.

Owner:XINYANG NORMAL UNIVERSITY

Dust collector with dust cleaning function

InactiveCN108465303AImprove filtering effectGood dust removal effectDispersed particle filtrationTransportation and packagingFlue gasEngineering

The invention discloses a dust collector with a dust cleaning function. The dust collector comprises a dust concentrator, gas filtering chambers, a flue gas input tube, a dust collector tank and a dust discharge tube. The dust collector is characterized in that the dust concentrator is welded with the bottom of the dust collector tank; the flue gas input tube is arranged in the middle of the dustcollector tank; a primary filtering net is arranged at the bottom of the dust collector tank; an efficient filtering net is arranged at the upper part of the dust collector tank; a plurality of partition plates are arranged inside the dust collector tank between the efficient filtering net and the primary filtering net; the dust collector tank is internally divided into a plurality of gas filtering chambers by the partition plates; a dust collection plate is mounted inside each gas filtering chamber; a dust collection cloth bag is connected with the upper surface of each dust collection plate;a gas outlet is formed in one side of the top of the dust collector tank; a high-pressure gas inlet is formed in a side opposite to the gas outlet; the high-pressure gas inlet is connected with a high-pressure ejection tube; the high-pressure ejection tube is connected with a high-pressure gas storage tank; the high-pressure gas storage tank is arranged at the top of the dust collector tank; a pulse electromagnetic valve is arranged on the high-pressure ejection tube.

Owner:成都奕州环保科技有限公司

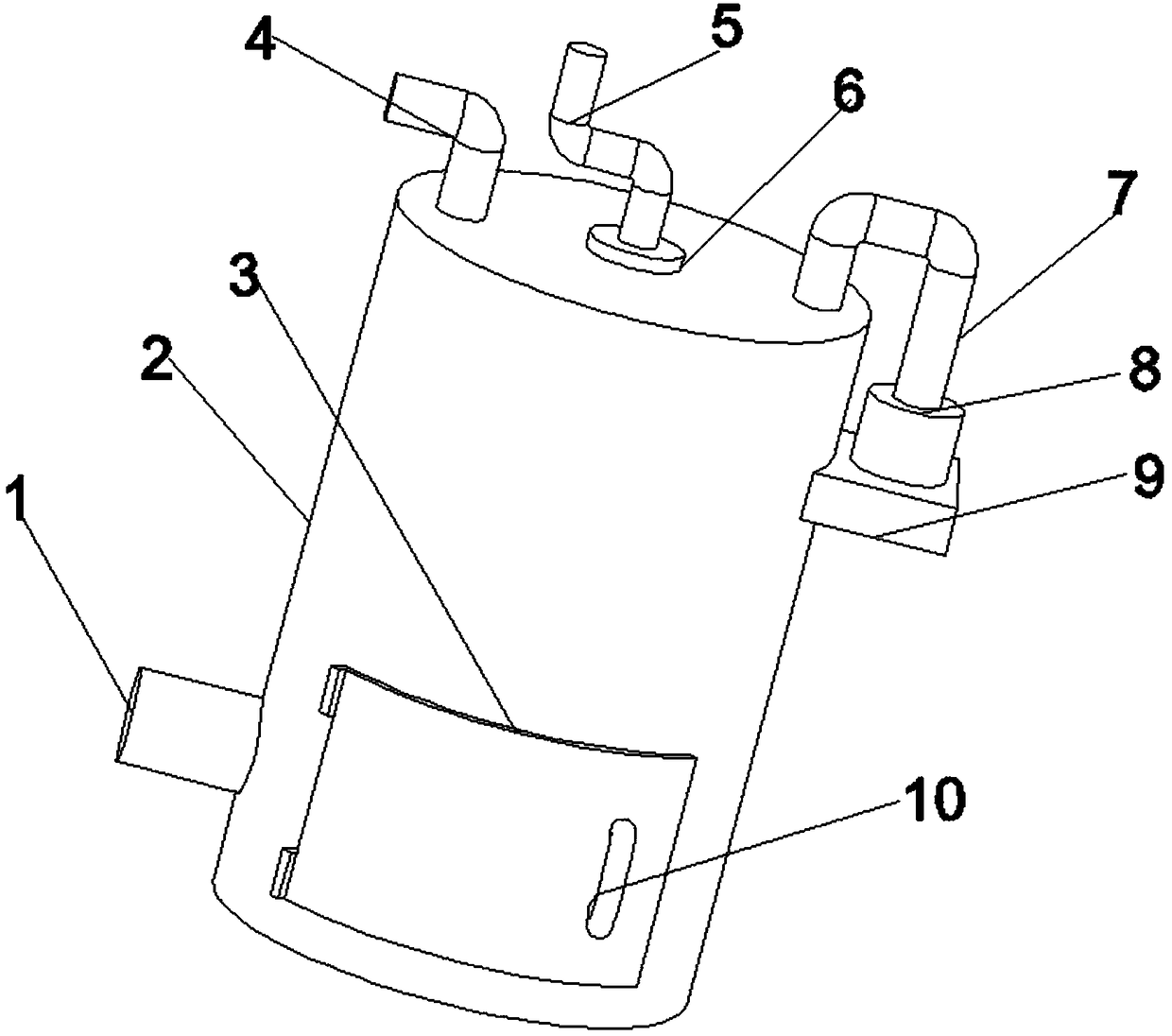

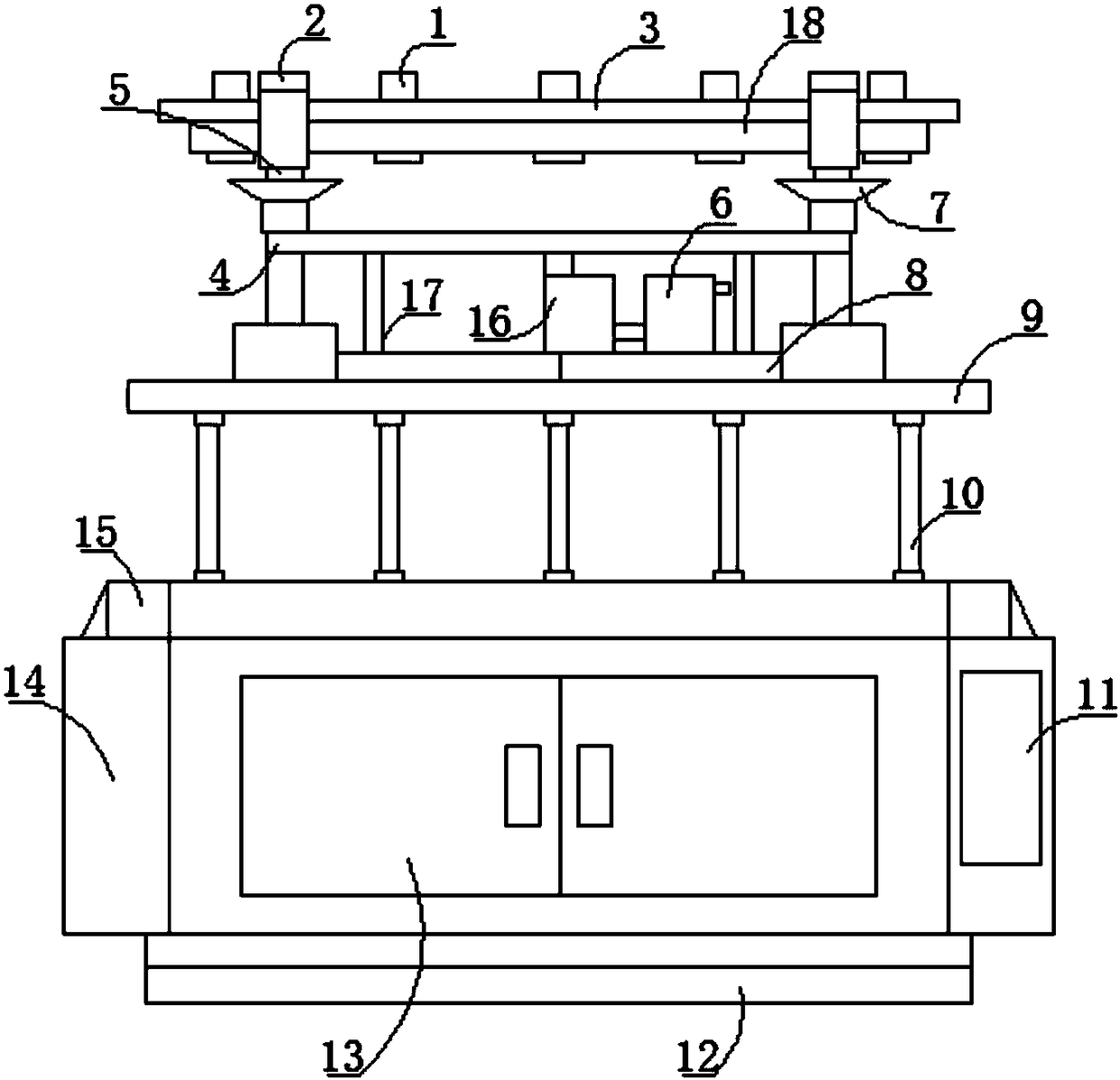

Circular knitting machine with efficient dust removal function

InactiveCN108118443AGood dust removal effectImprove efficiencyKnittingElectrostatic chargesYarnEngineering

The invention discloses a circular knitting machine with an efficient dust removal function. The circular knitting machine comprises a fixed engine base, wherein an electrical cabinet is arranged inside the fixed engine base, a cushion is arranged at the bottom of the fixed engine base, an FK-0301S controller is arranged at one side, close to the electrical cabinet, of the front surface of the fixed engine base, a fixed station is arranged at the top of the fixed engine base, the top of the fixed station is fixedly connected with a supporting frame through a support rod, a supporting seat is arranged at the top of the supporting frame, and the two sides of the top of the supporting seat are respectively fixedly connected with a cross beam by virtue of a communicating rod. The circular knitting machine disclosed by the invention has the advantages that a dust collection bucket is arranged at the bottom of a dust removal device, in a dust removal process of the dust removal device, a dust removal fan works, cotton dust and wool yarn which are produced during dust removal are sucked into the interior of the dust removal bucket through a filter screen on the dust removal device, then enter into the interior of a connecting pipe through the dust collection bucket and finally enter into the interior of a dust storage tank through the connecting pipe, the cotton dust and wool yarn which are produced during the dust removal are prevented from being suspended in the air, and an environment of a workshop is not influenced.

Owner:CHANGXING TIANSUO INTERLINING CO LTD

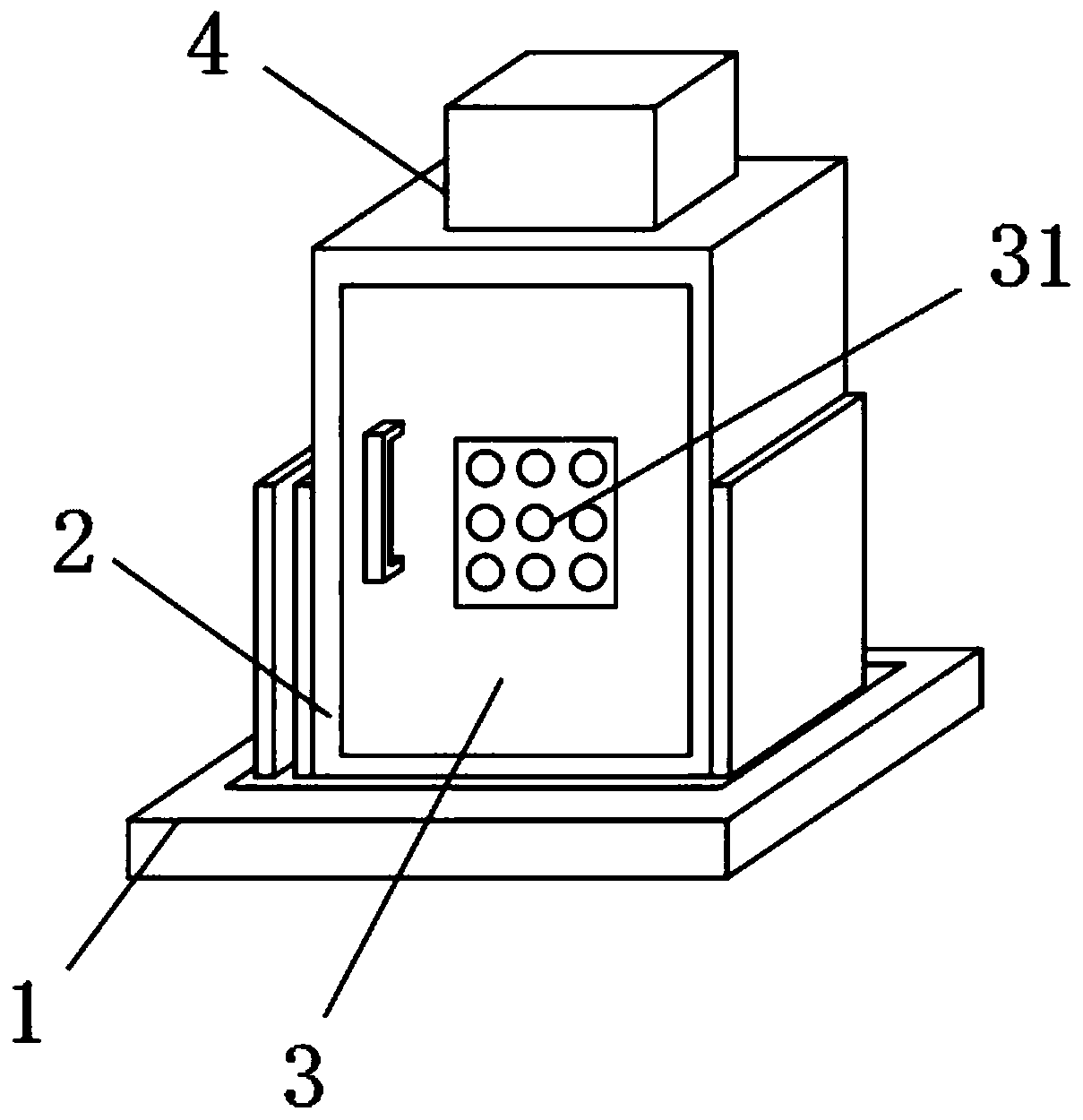

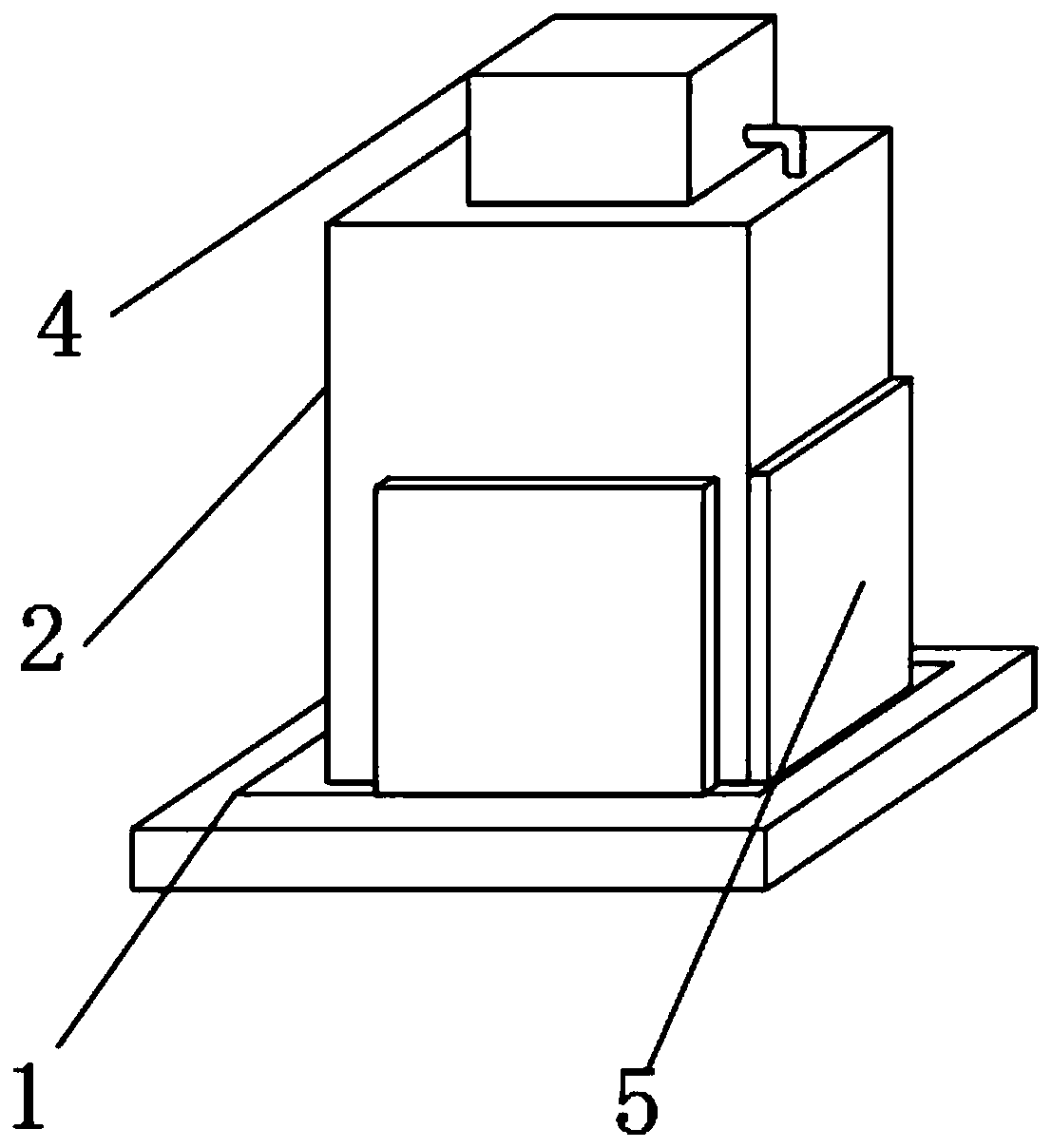

Cupboard with dust removal and humidity control functions and working method of cupboard

PendingCN110623441AGood dust removal effectEasy to useElectrostatic separationDirt cleaningControl functionEngineering

The invention discloses a cupboard with dust removal and humidity control functions and a working method of the cupboard. The cupboard comprises a base, a cupboard body, a dust removal mechanism, a clamping mechanism and a lifting mechanism, wherein the lifting mechanism is vertically mounted in the base, the clamping mechanism is mounted on the lifting mechanism, the clamping mechanism clamps thecupboard body, and the dust removal mechanism is fixedly mounted at the top of the cabinet body. Firstly, the cupboard body is placed on a support plate, one end is propped against a stop dog, then,a second knob is rotated, a third lead screw is driven to rotate, a movable plate is pushed to move and stops until second gear teeth are meshed with first gear teeth, the cupboard body is fixed, otherwise, the cupboard body can be loosened, the cupboard body is convenient to mount and dismount, replacement and maintenance of the cupboard body are facilitated, and use is facilitated; and a storageplate is driven to move up and down by a first lead screw, the height of the storage plate is adjusted, the inside space of the cupboard body is convenient to adjust, and different sizes of articlesare convenient to place.

Owner:ZBOM HOME COLLECTION CO LTD

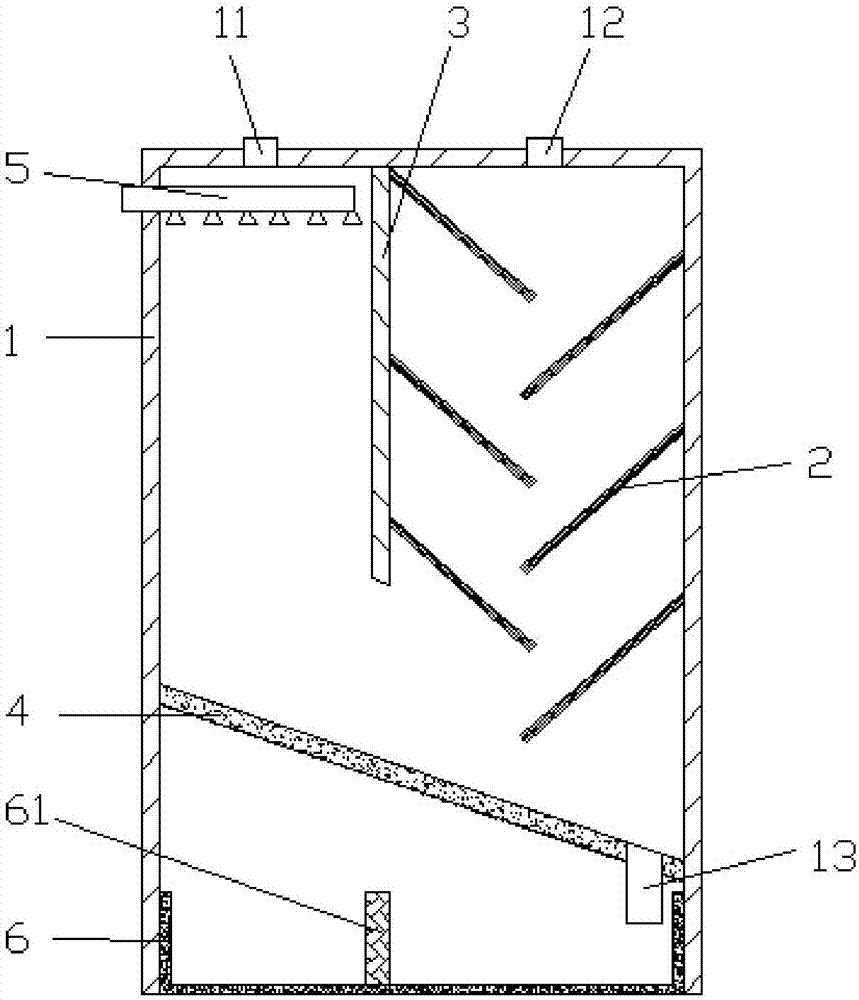

Safe and environment-friendly dust remover

The invention discloses a safe and environment-friendly dust remover. The dust remover comprises a shell and a bottom plate, wherein the shell is internally provided with a vertical division plate which divides the shell into an air inlet cavity and an air outlet cavity, and the bottom plate is arranged below the vertical division plate inside the shell; a lower part of the air inlet cavity is communicated with a lower part of the air outlet cavity to form an air flow channel, the top of the air inlet cavity and the top of the air outlet cavity are respectively provided with an air inlet and an air outlet of the air flow channel; the top of the air inlet cavity is provided with an atomizing device, the air outlet cavity is uniformly and internally provided with slantwise division plates which are arranged in a stagger manner, the high ends of the slantwise division plates are arranged on a side wall or the vertical division plate of the shell, and the low ends of the slantwise division plates are hung in the air and used for elongating the air flow channel; and the bottom plate of the shell has a slantwise shape in design, and one side wall of the shell at the low end of the bottom plate is provided with a sewage draining exit. According to the dust remover, the structure is simple, the use is safe, the requirement for conditions of usage is not high, and the dust removing effect is good.

Owner:成都智宸科技有限公司

Dust removal device for hardware mold production and processing

InactiveCN111054167ASave waterGood dust removal effectCombination devicesProcess engineeringWater storage tank

The invention discloses a dust removal device for hardware mold production and processing. The dust removal device comprises a box body, a partition plate is arranged in the box body; a dust removal bin is arranged on the upper surface of the partition plate; an air inlet pipe is arranged on one side of the inner wall of the dust removal bin; an exhaust hole is formed in the other side of the inner wall of the dust removal bin; a filter screen and a fan are arranged in the air inlet pipe; a waste barrel is arranged at the bottom of the inner wall of the box body, a base is arranged on the lower surface of the box body, a water storage tank is arranged on the upper surface of the base and located on one side of the box body, the other end of an water outlet pipe is connected with a water conveying pipe through a connector, and the other end of the water conveying pipe is connected with the water inlet end of a water pump through a connector. Through the arrangement of a series of structures, the dust removal effect is good, garbage in dust is classified and collected, water resources needed by dust removal are repeatedly utilized, and the dust removal cost is saved.

Owner:扬州起航机械有限公司

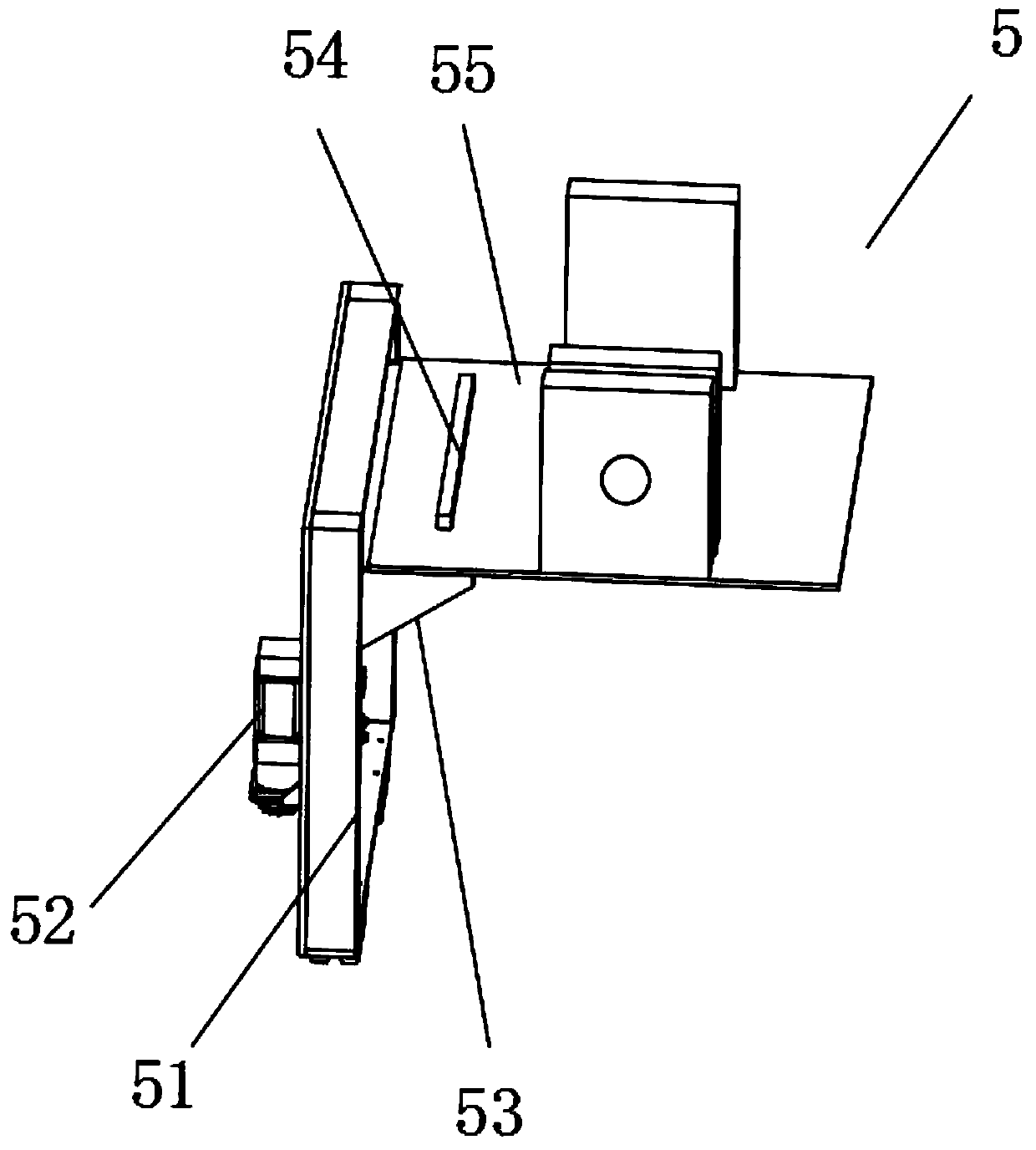

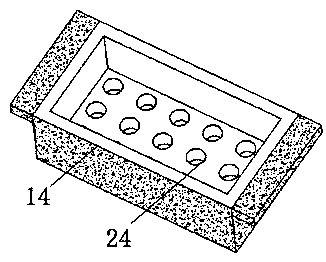

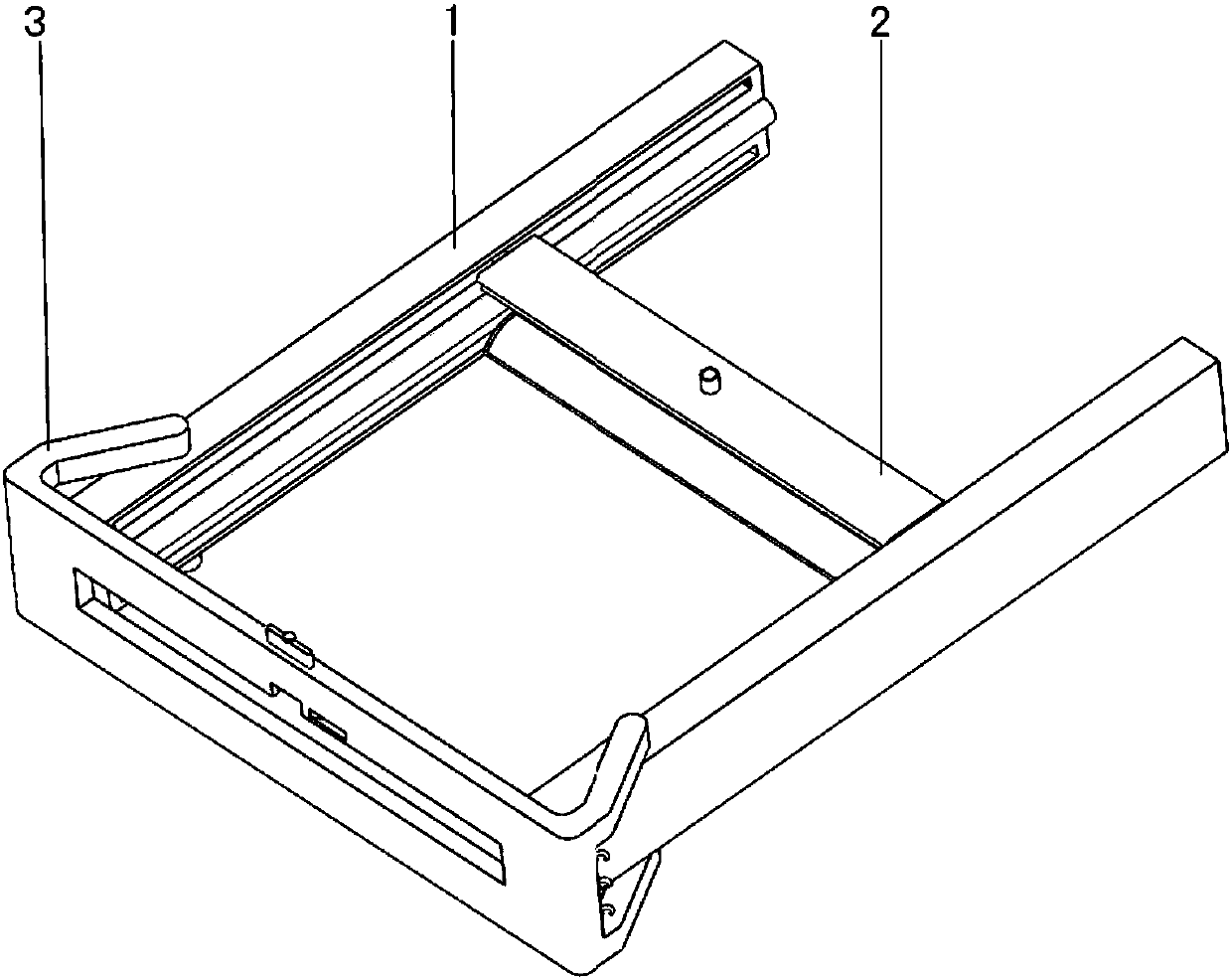

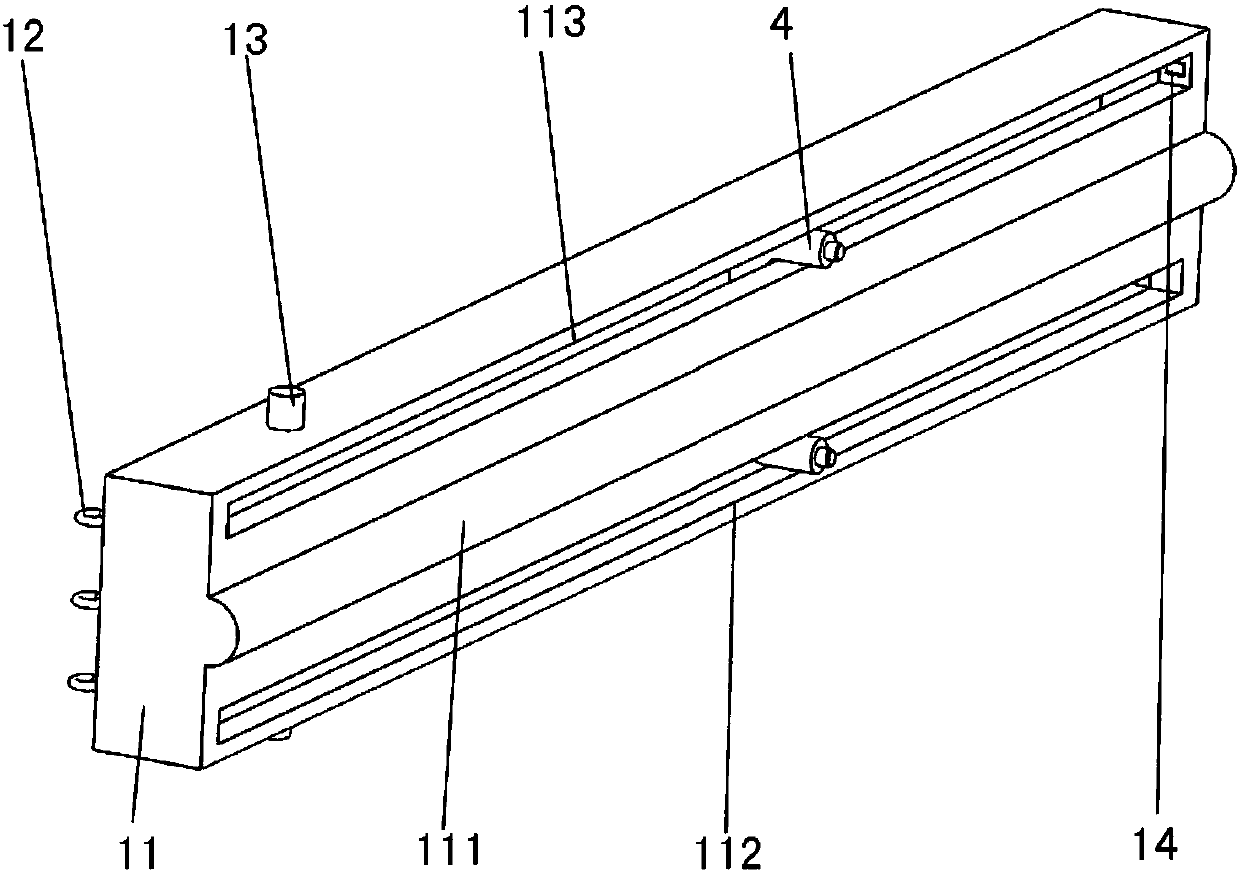

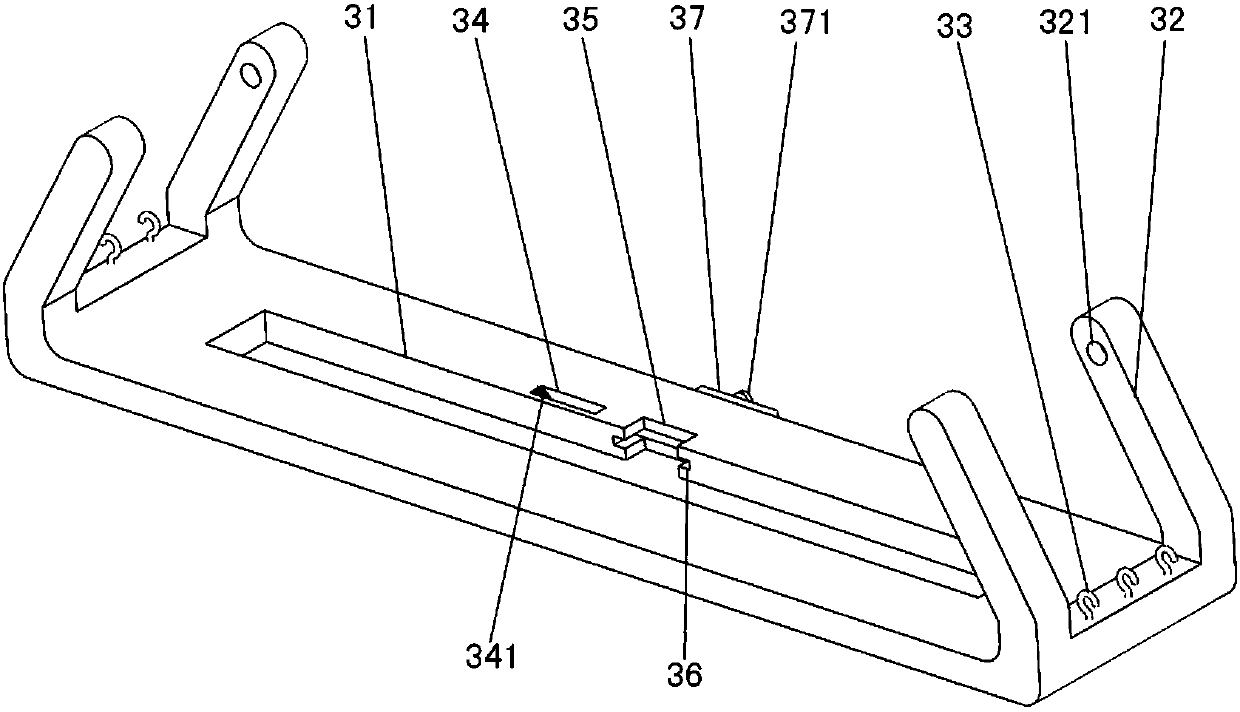

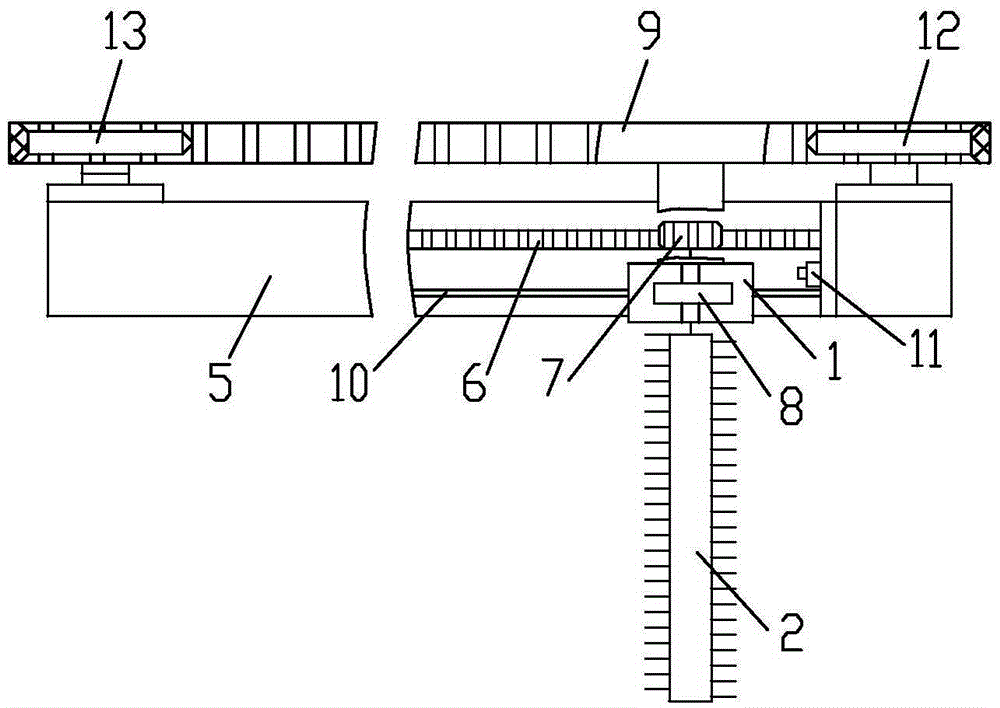

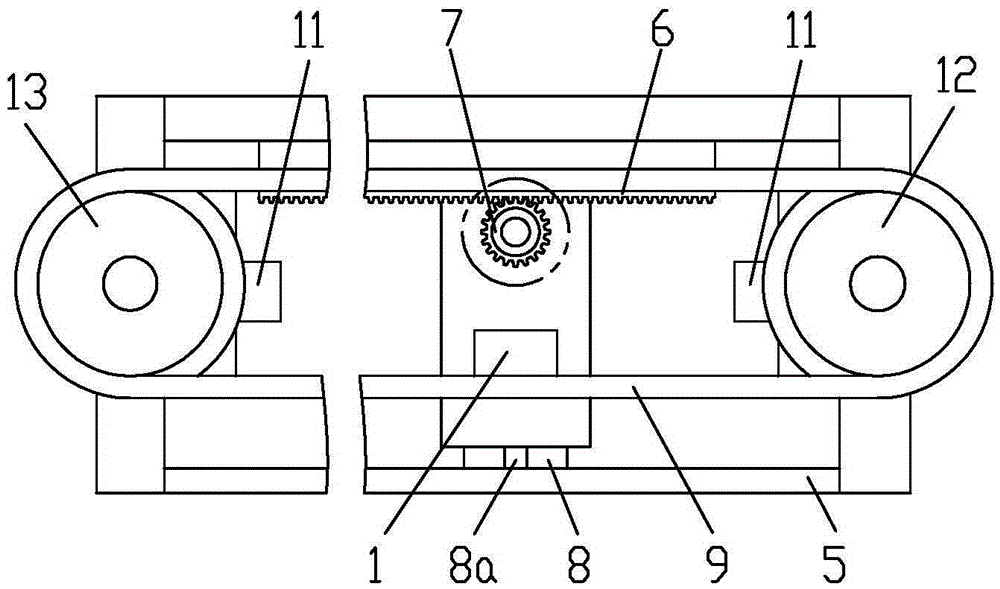

High altitude glass dust collector capable of scrubbing double sides of glass

The invention discloses a high altitude glass dust collector capable of scrubbing double sides of glass. The dust collector comprises two clamping slide seats and a fixed seat, wherein the two clamping slide seats are rotatably connected to two ends of the fixed seat and separately clamp two sides of a glass window; a mobile connecting device capable of moving automatically is arranged in each clamping slide seat; a pair of dust collecting seats is arranged between the mobile connecting devices; and a plurality of notches are formed in the bottom of the fixed seat for locking the glass window.The dust collector has the advantages that by means of the characteristics of a common glass window structure on a building at present, the two clamping slide seats are clamped in the grooves in twosides of the glass window, and by means of the structural characteristics of a switch handle of the glass window, the switch handle is locked into an inclined notch of the fixed seat, so that the whole device is fixed on the glass window; and the mobile connecting devices capable of moving automatically are arranged between the two clamping slide seats to move to drive a dust collecting seat to move so as to scrub double sides of the glass window.

Owner:HUZHOU YOUCHUANG TECH CO LTD

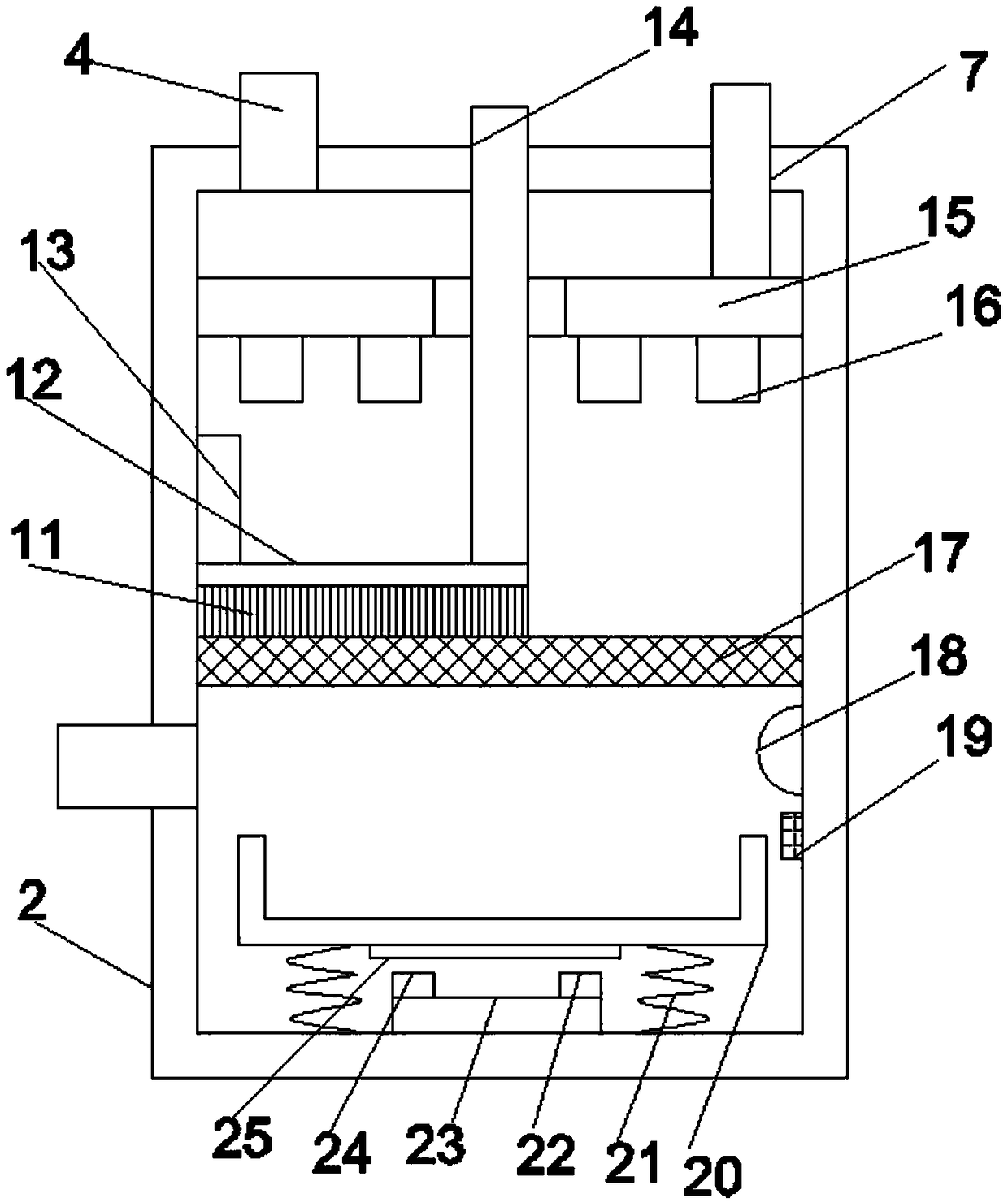

Spinning dust collection device

InactiveCN108442024AGood dust removal effectAvoid secondary dustCombination devicesUsing liquid separation agentEngineeringCam

The invention discloses a spinning dust collection device. The spinning dust collection device comprises a first dust collection pipe, a second dust collection pipe and a dust collection box, whereina motor and a water tank are fixed in the dust collection box, an adsorption cylinder is connected on an output shaft of the motor, a sponge block is fixedly connected in the adsorption cylinder, a wastewater pool is arranged at the lower portion of the adsorption cylinder and is communicated with the second dust collection pipe, a water absorption pipe is communicated on the side wall, close to the motor, of the water tank, a water spraying pipe is communicated to one end, close to the water tank, of the water absorption pipe, the communication portion between the water tank and the water absorption pipe and the communication portion between the water absorption pipe and the water spraying pipe are each provided with a one-way valve, a piston is slidingly connected in the water absorptionpipe, a piston rod is connected on the piston, the part, located in the water absorption pipe, of the piston rod is sleeved with a tension spring, a cam is connected on the output shaft of the motor,the piston rod abuts against the cam, and a first negative-pressure draught fan is fixed at the end of the second dust collection pipe. By means of the spinning dust collection device in the technical scheme, the problems that the dust collecting device needs to be manually cleaned, and the dust collecting and cleaning effect is poor are solved.

Owner:NINGBO WENZE TEXTILE CO LTD

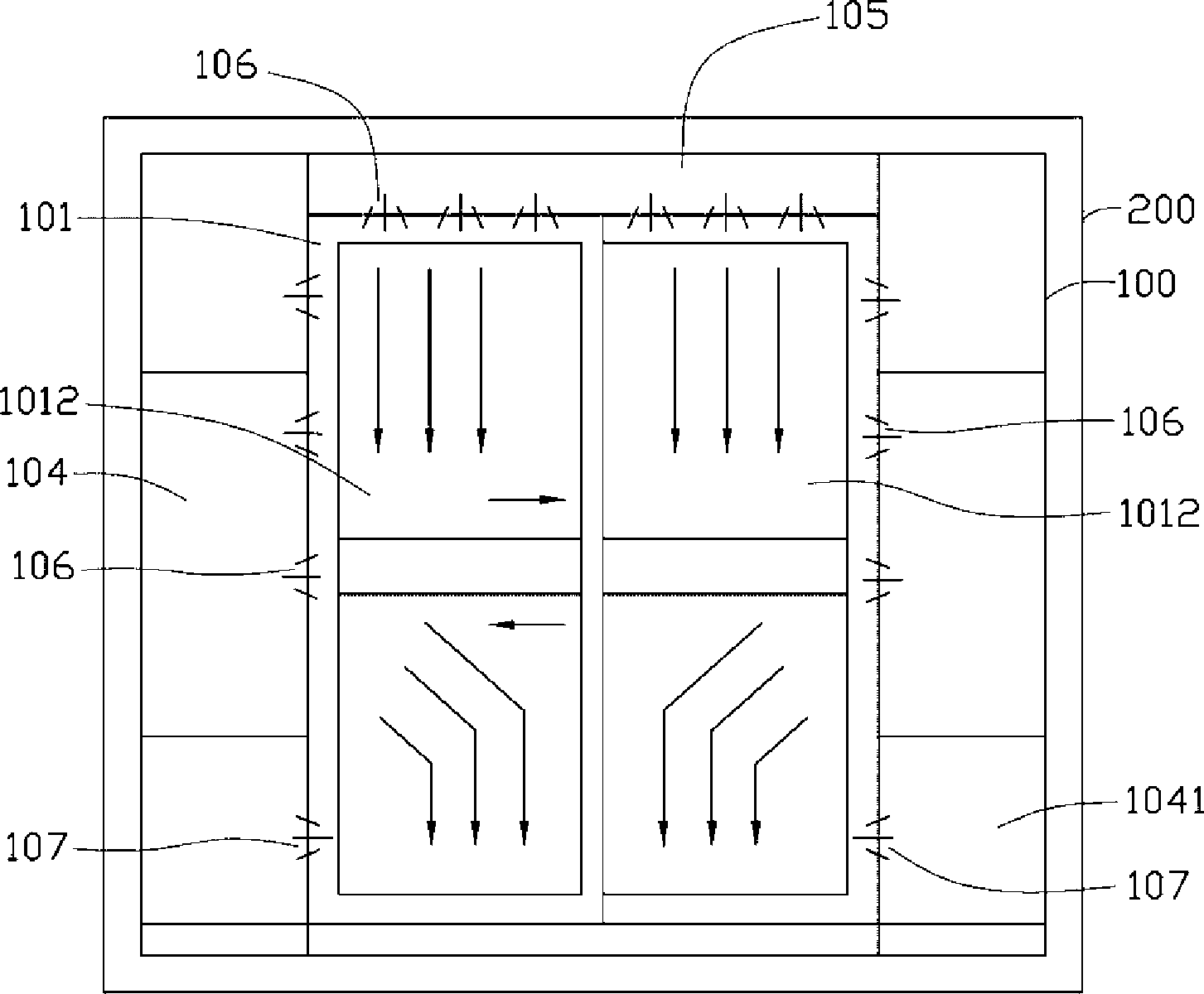

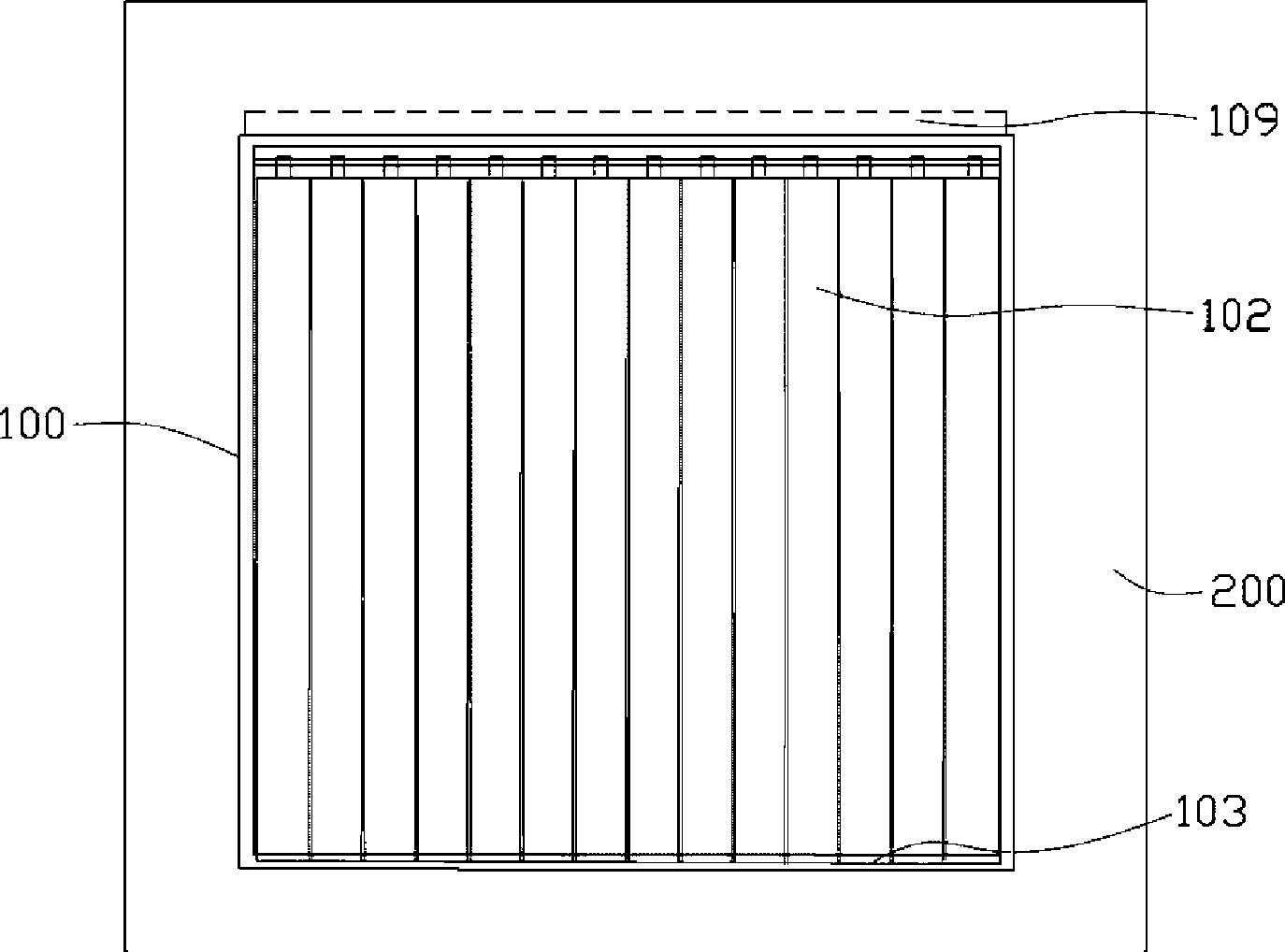

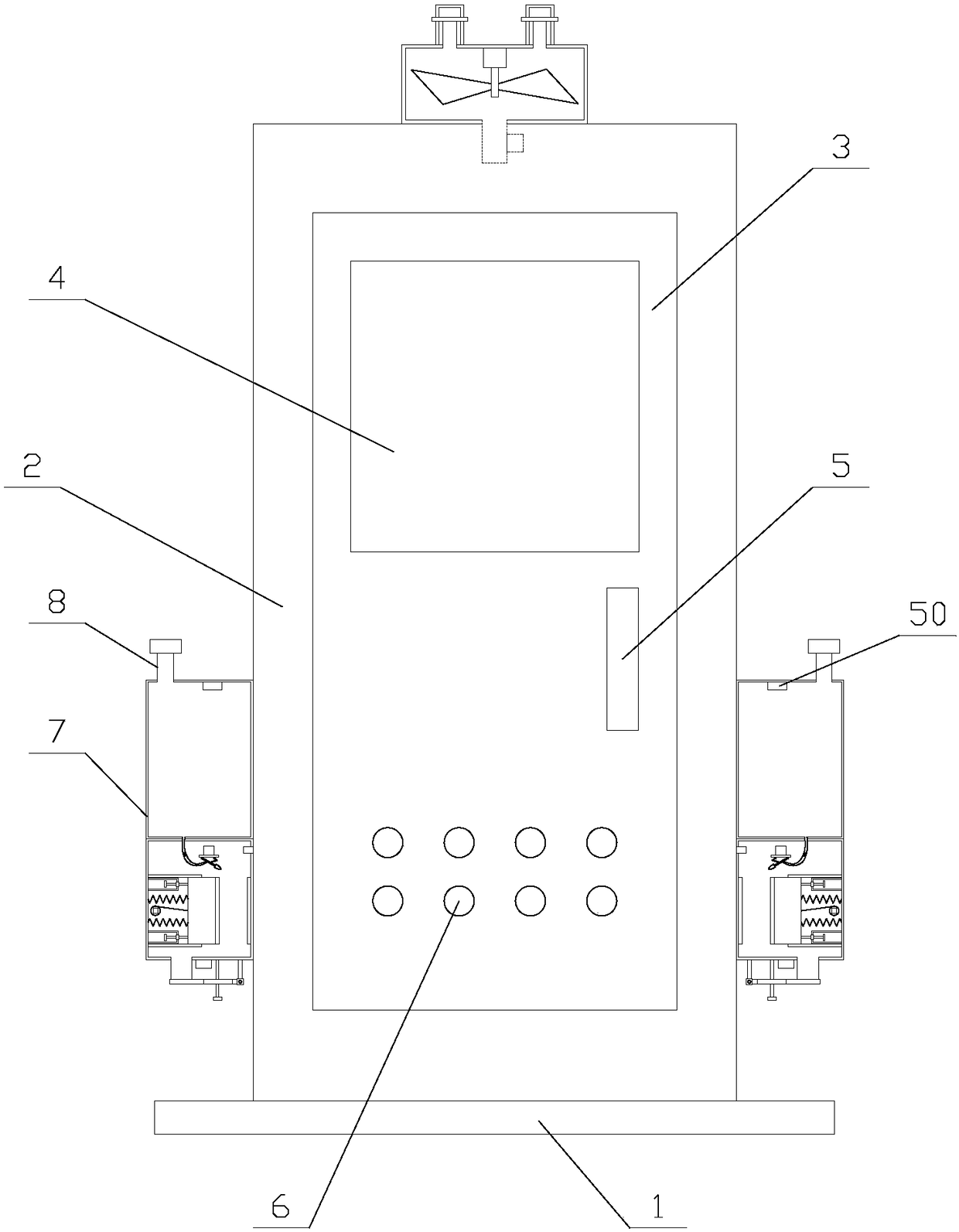

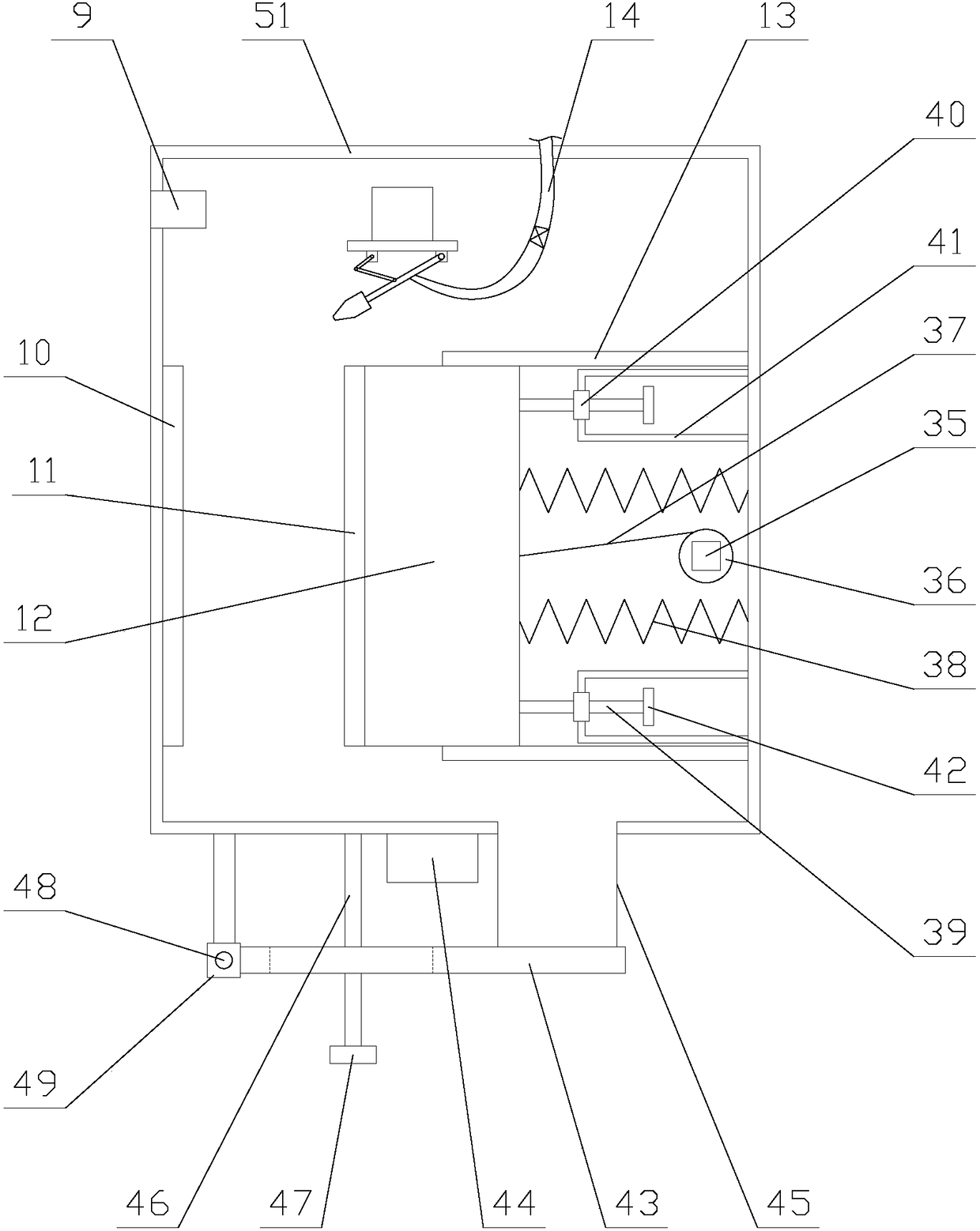

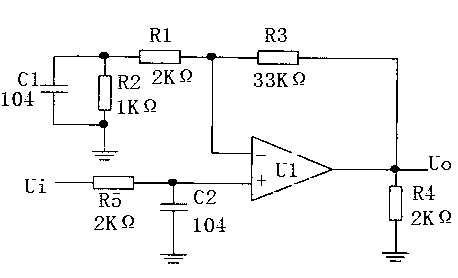

Intelligent switch cabinet with high temperature reduction effect for electric power system

InactiveCN108376919AGood dust removal effectIncrease the electric field strengthBoards/switchyards circuit arrangementsSubstation/switching arrangement cooling/ventilationAir changeEngineering

The invention relates to an intelligent switch cabinet with high temperature reduction effect for an electric power system. The intelligent switch cabinet comprises a cabinet body, an air guiding mechanism, a cabinet door and two air changing devices. The air changing device comprises an alcohol box and a dust eliminating device. The dust eliminating device comprises a dust eliminating chamber anda sealing assembly. The dust eliminating chamber is internally provided with an air inlet pipe, a dust eliminating mechanism and a cleaning mechanism. The dust eliminating mechanism comprises an anode plate, a cathode plate, a translation assembly and two transverse plates. The cleaning mechanism comprises a connecting pipe, a moving assembly, a moving board, an adjusting assembly and a nozzle. The moving assembly comprises a first motor, a bearing, a first driving shaft, a moving block and a guiding rod. The intelligent switch cabinet with high temperature reduction effect for the electric power system attracts dust in the air which is sucked into the cabinet body through a dust attracting mechanism, thereby ensuring entering of clean air into the cabinet body, and realizing the high dust eliminating effect. Furthermore alcohol is flushed to the surface of the anode plate through the cleaning mechanism for cleaning, thereby ensuring dust attracting capability of the anode plate and improving practicability of the intelligent switch cabinet.

Owner:南安市瑞欣生物科技有限公司

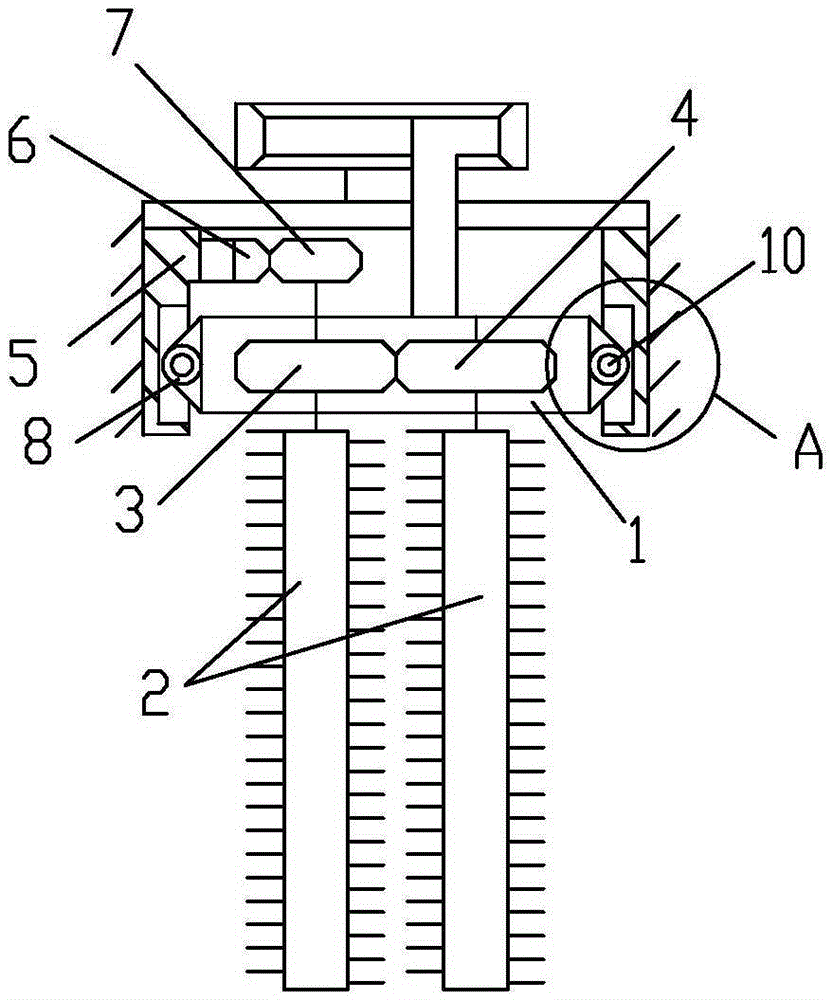

Brush roll dedusting device for negative ion emission rows

InactiveCN105363559AGood dust removal effectSimple structureElectrodes cleaningEngineeringIon emission

The invention discloses a brush roll dedusting device for negative ion emission rows. The brush roll dedusting device comprises two rotatably suspended brush rolls through a mounting element; the two brush rolls form paired rollers through a driving gear and a driven gear at the upper ends of the brush rolls; the driving gear is fixedly connected with an input gear coaxially; the input gear is meshed with a tooth rack on a machine frame; or the driving gear is meshed with the tooth rack on a machine frame; the mounting element is connected to the machine frame through a guide rail pair structure formed by two cooperated circular guide sleeves and a guide post, and is connected with and fixed to a synchronous belt which reciprocates under the driving of a motor; the two guide sleeves are fixedly connected to the two sides of the mounting member respectively; the guide post is fixedly connected with the machine frame; the tooth numbers of the driving gear and the driven gear are the same. The brush roll dedusting device has the benefits that a cleaning effect on emission heads is good, moreover, the structure is simple, the operation is reliable, the manufacturing cost is low, and maintenance and repair are convenient.

Owner:重庆松池科技有限公司

Computer equipment maintenance box

InactiveCN108941054AGood dust removal effectVersatileDispersed particle filtrationTransportation and packagingComputer equipmentEngineering

The invention discloses a computer equipment maintenance box which comprises a maintenance box body. A box door is arranged on one side of the maintenance box body. A first motor is fixed to the middle position of the outer wall of the side, away from the box door, of the maintenance box body. An output shaft of the first motor is connected with a first lead screw. One end of the first lead screwpenetrates through the outer wall of the maintenance box body to be rotationally connected to the inner wall of the maintenance box body. A moving seat is in threaded connection to the first lead screw. A dust suction cover is arranged on the side wall of the side, close to the box door, of the moving seat. An exhaust fan is arranged in the dust suction cover. The maintenance box can have the maintenance function, effective dust removal can be carried out on computer equipment according to needs, and functions are diversified; dust is sucked out of the maintenance box in an air draft manner, the situation that normal work of the computer equipment is influenced by too much dust is avoided, and the dust removal effect is good; and when repaired and maintained, the computer equipment can beeffectively fixed, and the situation that the computer equipment moves, and consequently normal repair and maintenance of the computer equipment are influenced is avoided.

Owner:合肥锦和信息技术有限公司

Cyclone mechanical cooling equipment

ActiveCN108671640AGood cooling effectGood dust removal effectDispersed particle separationMoving conduit heat exchangersProduct gasEngineering

The invention belongs to the technical field of environment protection equipment and in particular discloses cyclone mechanical cooling equipment. The cyclone mechanical cooling equipment comprises asupporting frame, wherein an outer barrel is arranged on the supporting frame; an air inlet pipe is arranged at the upper part of the outer barrel; a cooling barrel sleeves the outer barrel; a liquidinlet pipe is arranged at the bottom of the cooling barrel; a hole is formed in the top of the outer barrel; the outer barrel is internally provided with an air outlet pipe which stretches out of thetop of the outer barrel; a dust removing ash bucket is arranged at the bottom of the outer barrel; a rotary barrel sleeves the air outlet pipe; the rotary barrel is sealed and is connected onto the air outlet pipe in a horizontal sliding manner; a liquid feeding spiral is arranged on an inner side wall of the rotary barrel; a cooling chamber is formed between the rotary barrel and the air outlet pipe; the bottom of the cooling chamber is communicated with the top of the cooling barrel; a liquid outlet pipe, which is communicated with the cooling chamber, is arranged at the upper part of the air outlet pipe; a rotary blade is arranged at the upper part in the peripheral direction of the rotary barrel. The cooling equipment has a relatively good cooling effect on dust-containing gas and a relatively excellent dust-containing effect.

Owner:GUIZHOU HUANKE ENVIRONMENT ECOLOGICAL RES & DEV CO LTD

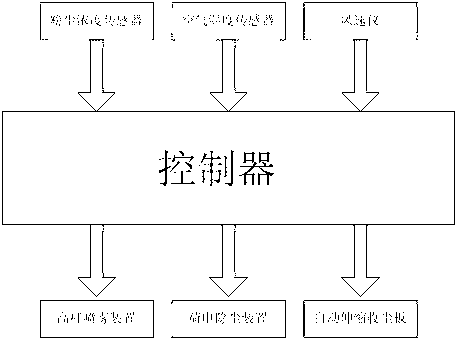

Open-air dust-removal system

ActiveCN103285698AGood dust removal effectSmall water lossCombination devicesAtmospheric dustElectricity

The invention discloses an open-air dust-removal system, which comprises a high rod atomizing device, a charging demisting dust-removal device, a dust concentration sensor, an air humidity sensor, an anemometer, a controller and an automatic retractable dust collecting plate, wherein signals acquired by the dust concentration sensor, the air humidity sensor and the anemometer are transmitted to the controller; the controller calculates the atmospheric dust concentration, the air humidity and the outside wind speed at the moment according to the received data; the controller controls the high rod atomizing device and the charging demisting dust-removal device according to the calculated atmospheric dust concentration, air humidity and outside wind speed, and controls the automatic retractable dust collecting plate to be unfolded or folded. The open-air dust-removal system can fulfill the purpose of dust removal in a safe, energy-saving, high-efficiency and self-adapting to external environment manner.

Owner:QINHUANGDAO CAPITAL STARLIGHT ENVIRONMENTAL TECH CO LTD

Textile machine with dust collecting device

InactiveCN105414143AGood dust removal effectGuaranteed cleanlinessDirt cleaningProcess engineeringDust control

The invention discloses a textile machine with a dust collecting device. The textile machine comprises a textile machine body and a dust collecting mechanism, wherein the dust collecting mechanism comprises a first dust suction pipe, the inlet end of the first dust suction pipe is located above the textile machine, the outlet end of the first dust suction pipe is connected with a second dust suction pipe, a dust outlet is formed in the lower part of the outlet side of the second dust suction pipe, the dust outlet of the second dust suction pipe is connected with a dust collecting box, the second dust suction pipe is internally provided with a screen mesh, and the outlet end of the second outlet suction pipe is connected with an air suction device; the lower part of the first dust suction pipe is shaped like a horn mouth, the upper part of the first dust suction pipe is L-shaped, and a damping frame is arranged on the horn mouth position in the first dust suction pipe and is fixedly provided with an air cannon which is connected with an air compressor through a pipeline; and the air cannon is composed of a buffer chamber and an air nozzle, wherein the air nozzle is located below the buffer chamber which is of a cylindrical structure. The textile machine has the characteristics of relatively good dust collecting effect, dust collecting thoroughness and relatively good flexibility.

Owner:HUZHOU NANXUN SHICONG SHENGYAN SILK

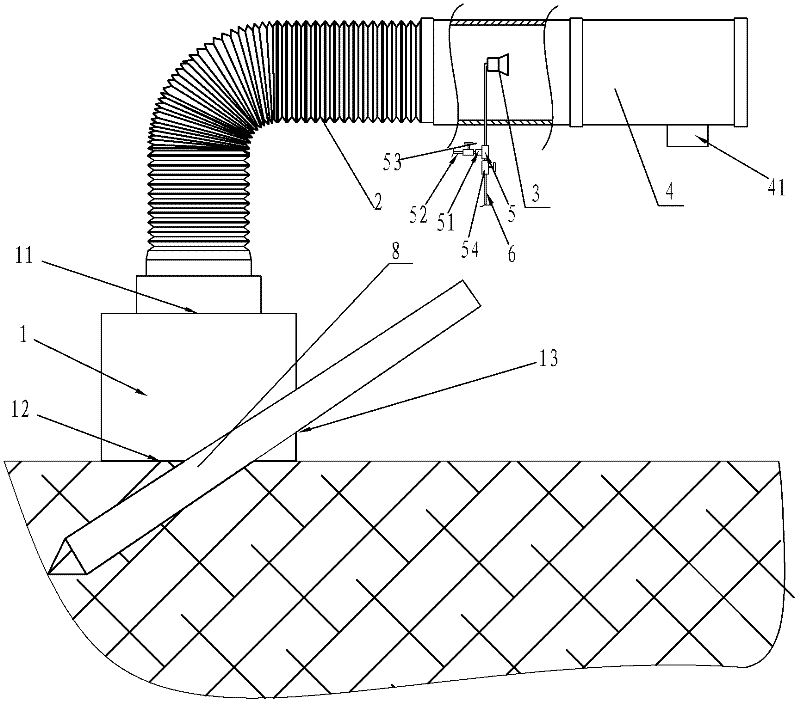

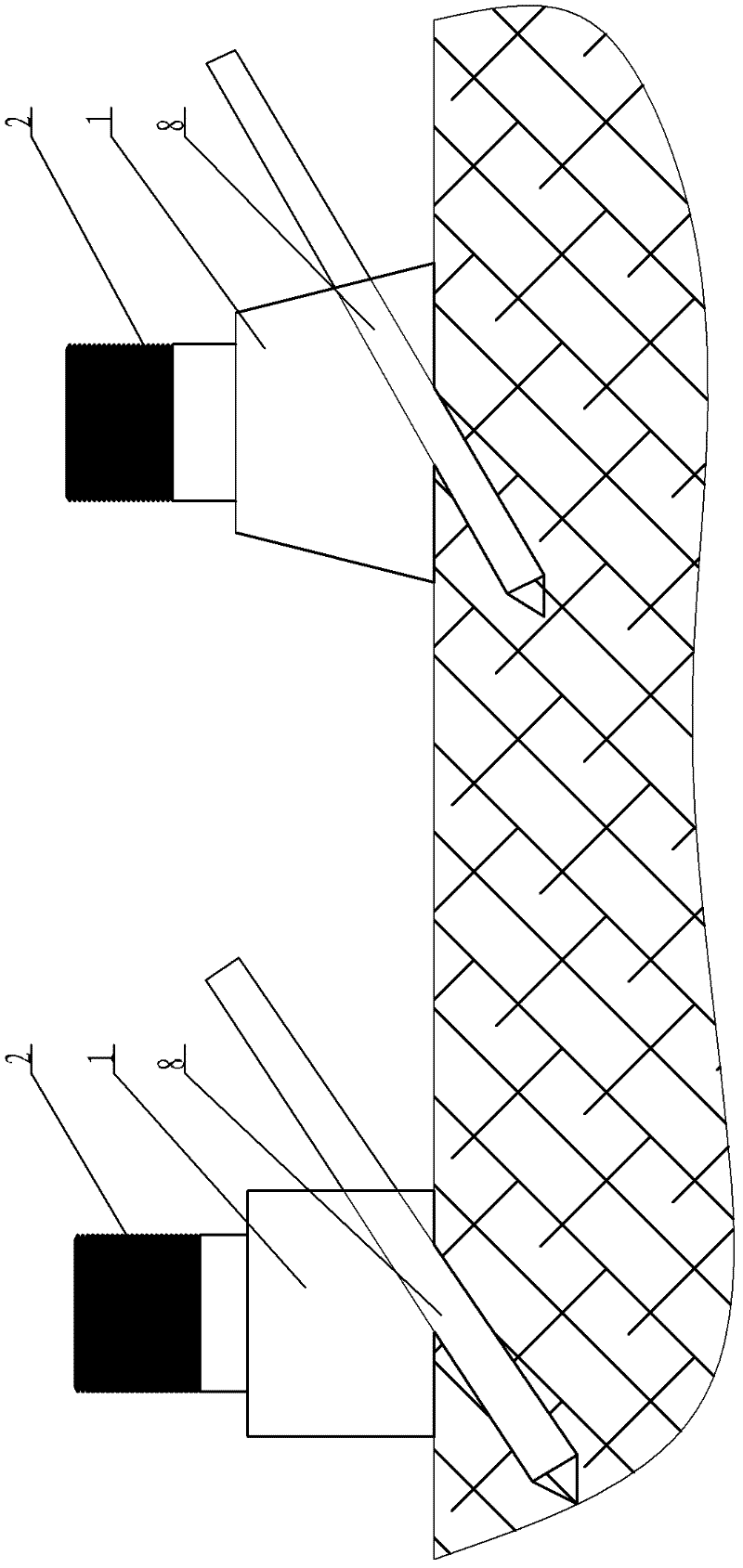

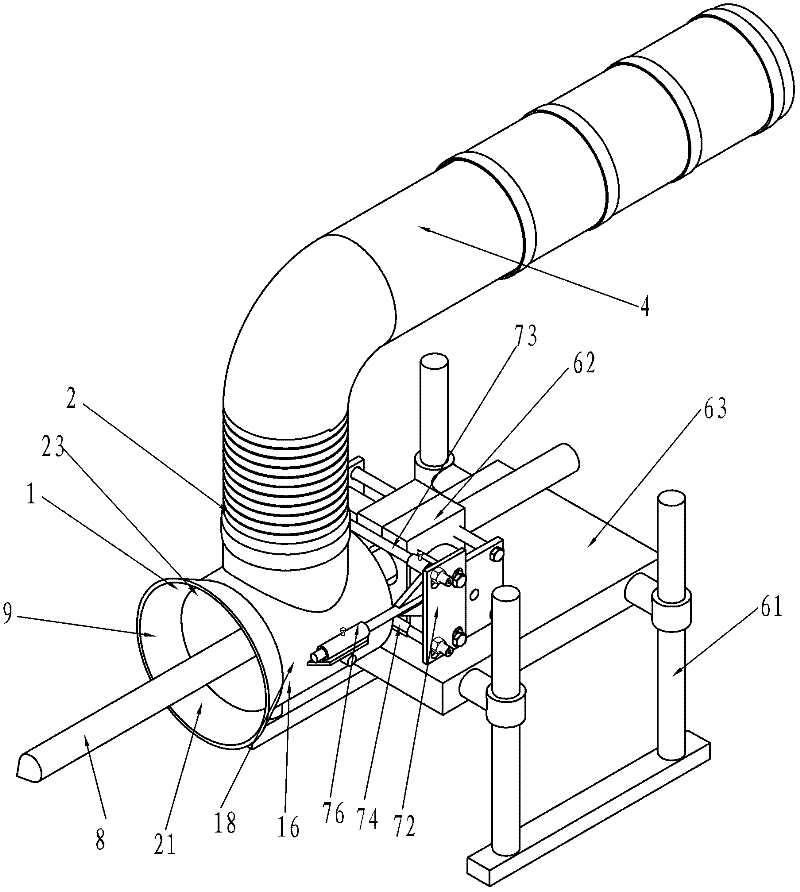

Coal mine down-hole drill hole water jet negative-pressure dedusting device

InactiveCN102518404AImprove efficiencyGood dust removal effectSpray nozzlesFlushingSpray nozzlePiping

The invention discloses a coal mine down-hole drill hole water jet negative-pressure dedusting device, which comprises a guide hood, a guide hose, a negative-pressure dedusting pipe, a fog-spray nozzle, a high pressure water inlet pipe, a three-way pipe, wherein the guide hood is provided with an inlet, an outlet and a drill rod through hole; the outlet of the guide hood is connected with the guide hose and the negative-pressure dedusting pipe in turn; the water outlet of the high pressure water inlet pipe extends into the negative-pressure dedusting pipe; the water outlet of the high pressure water inlet pipe is connected with the fog-spray nozzle; the high pressure water inlet pipe is fixedly connected with the pipe wall of the negative-pressure dedusting pipe; the water inlet of the high pressure water inlet pipe is communicated with a down-hole high pressure water pipe; the high pressure water inlet pipe is connected in series with the three-way pipe and a water inlet valve; another inlet of the three-way pipe is connected with a high pressure air inlet pipe; an air intake valve is arranged on the high pressure air inlet pipe; the high pressure air inlet pipe is communicated with a down-hole high pressure air pipe; the bottom at the rear end of the negative-pressure dedusting pipe is provided with a drain hole; and the drain hole is communicated with a drainage hose.

Owner:淮南同正科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com