Patents

Literature

153results about How to "Clean completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

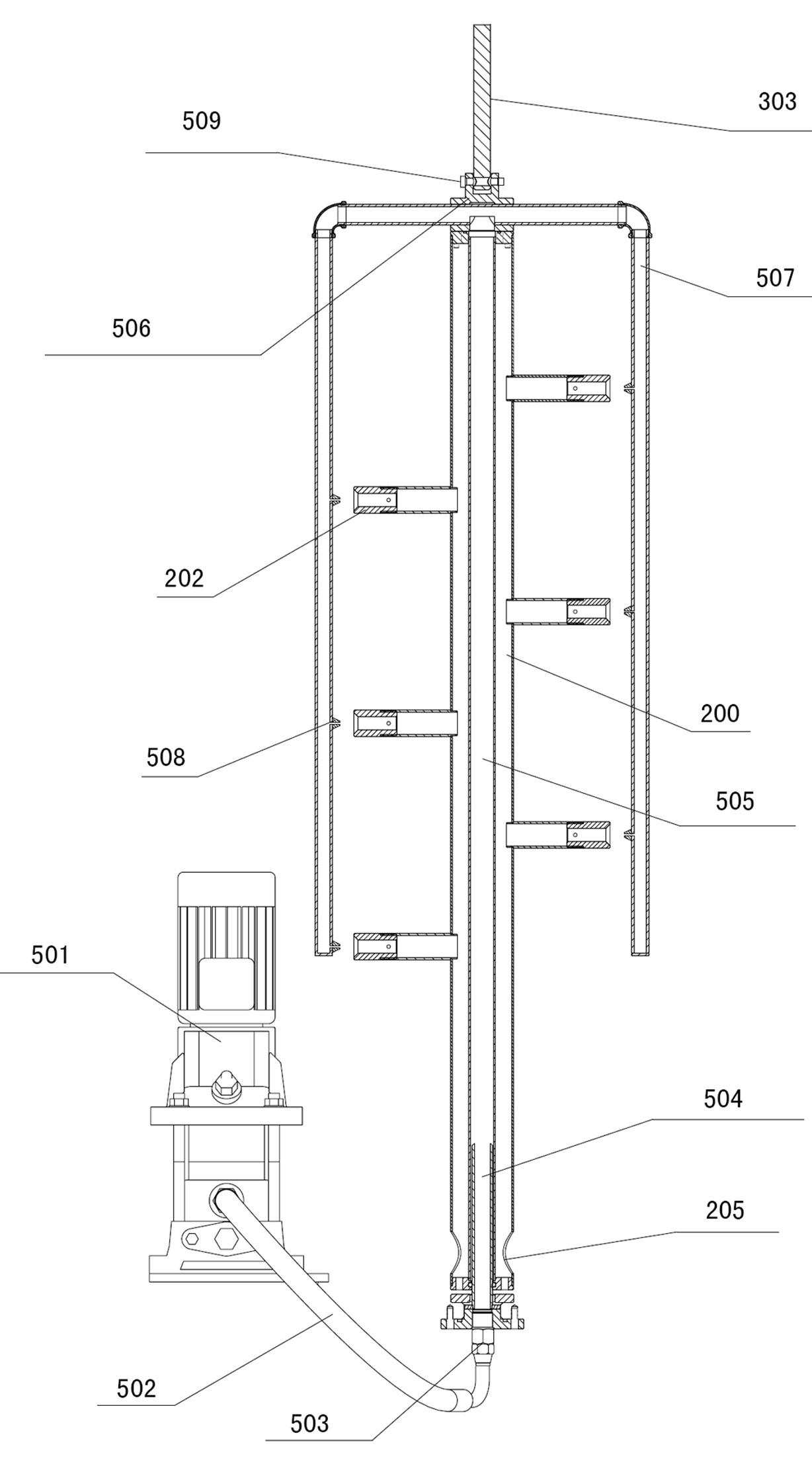

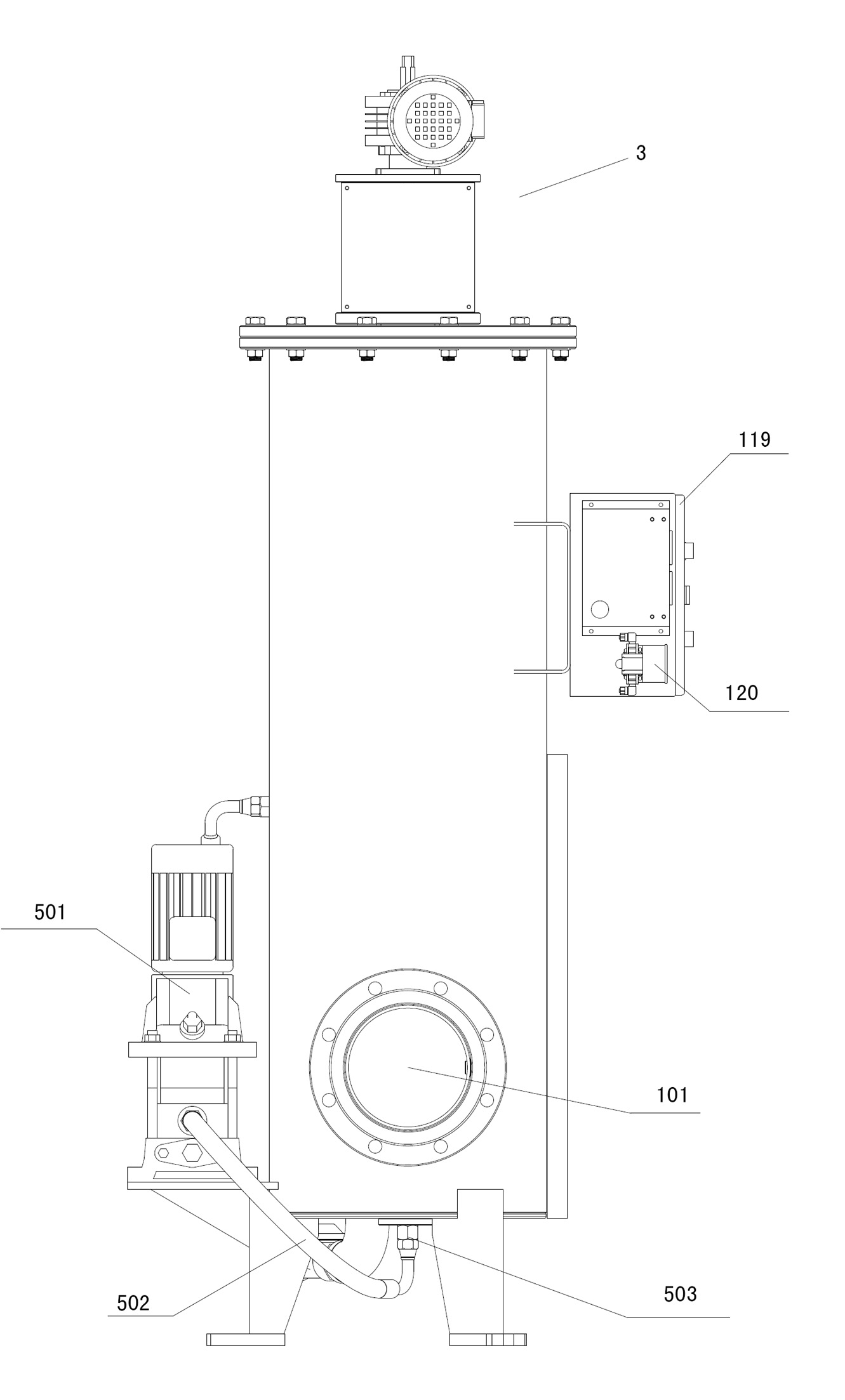

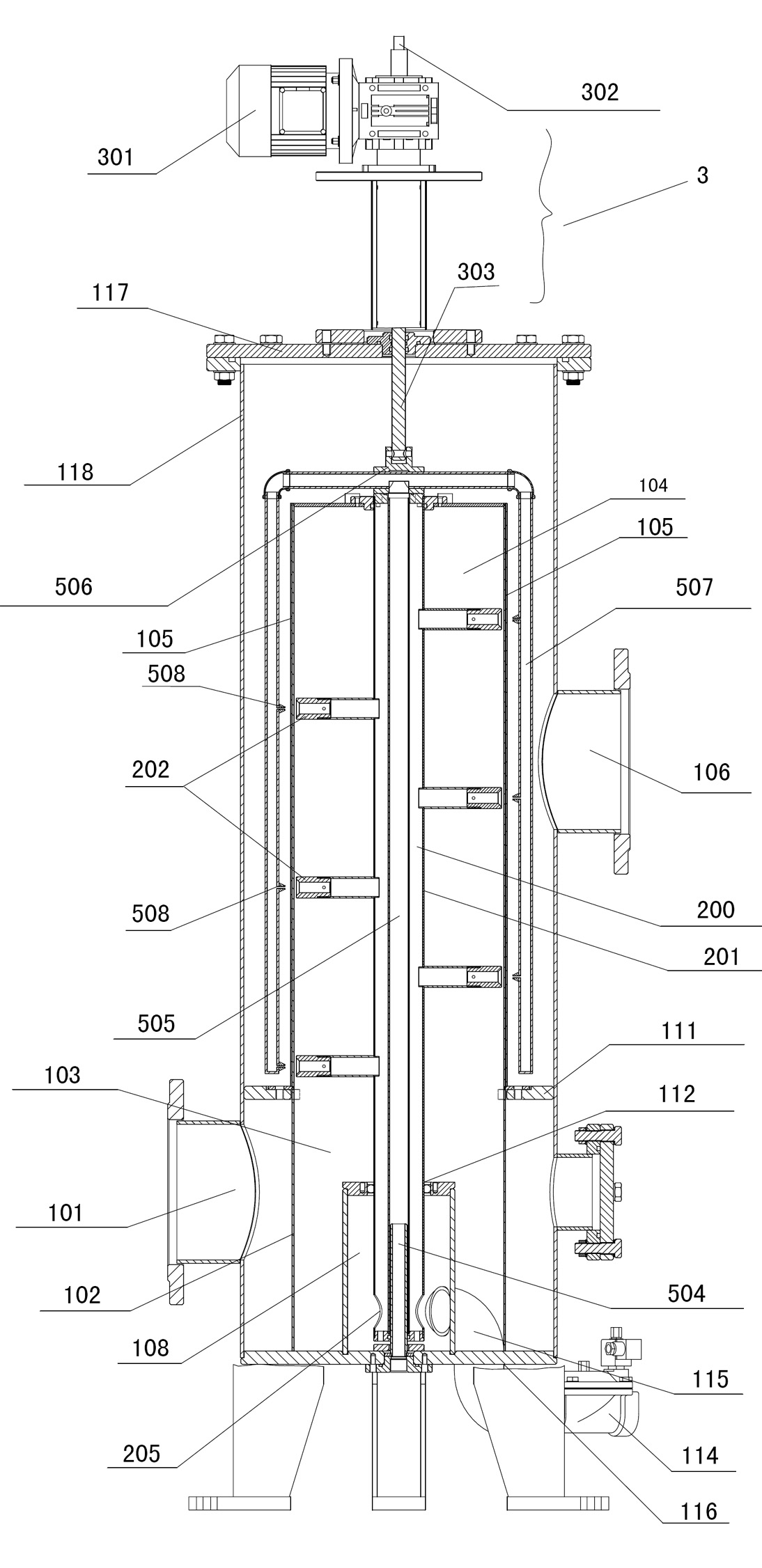

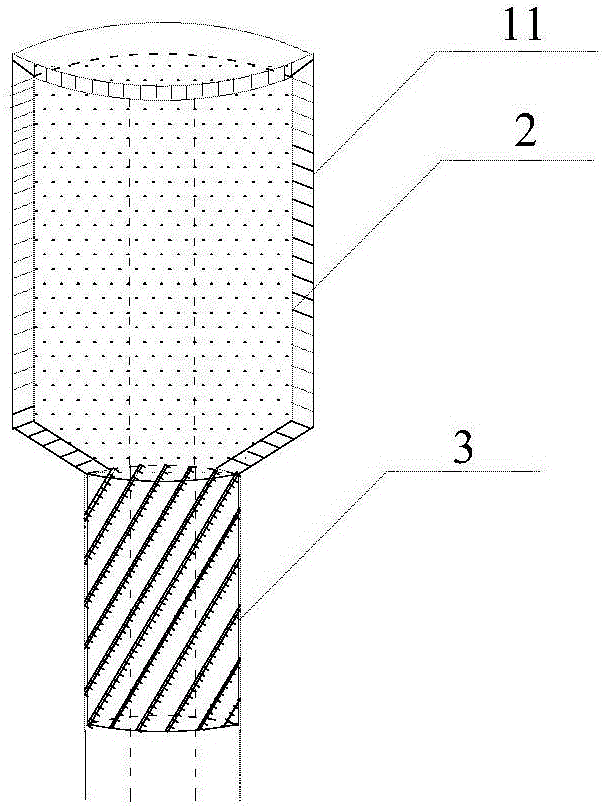

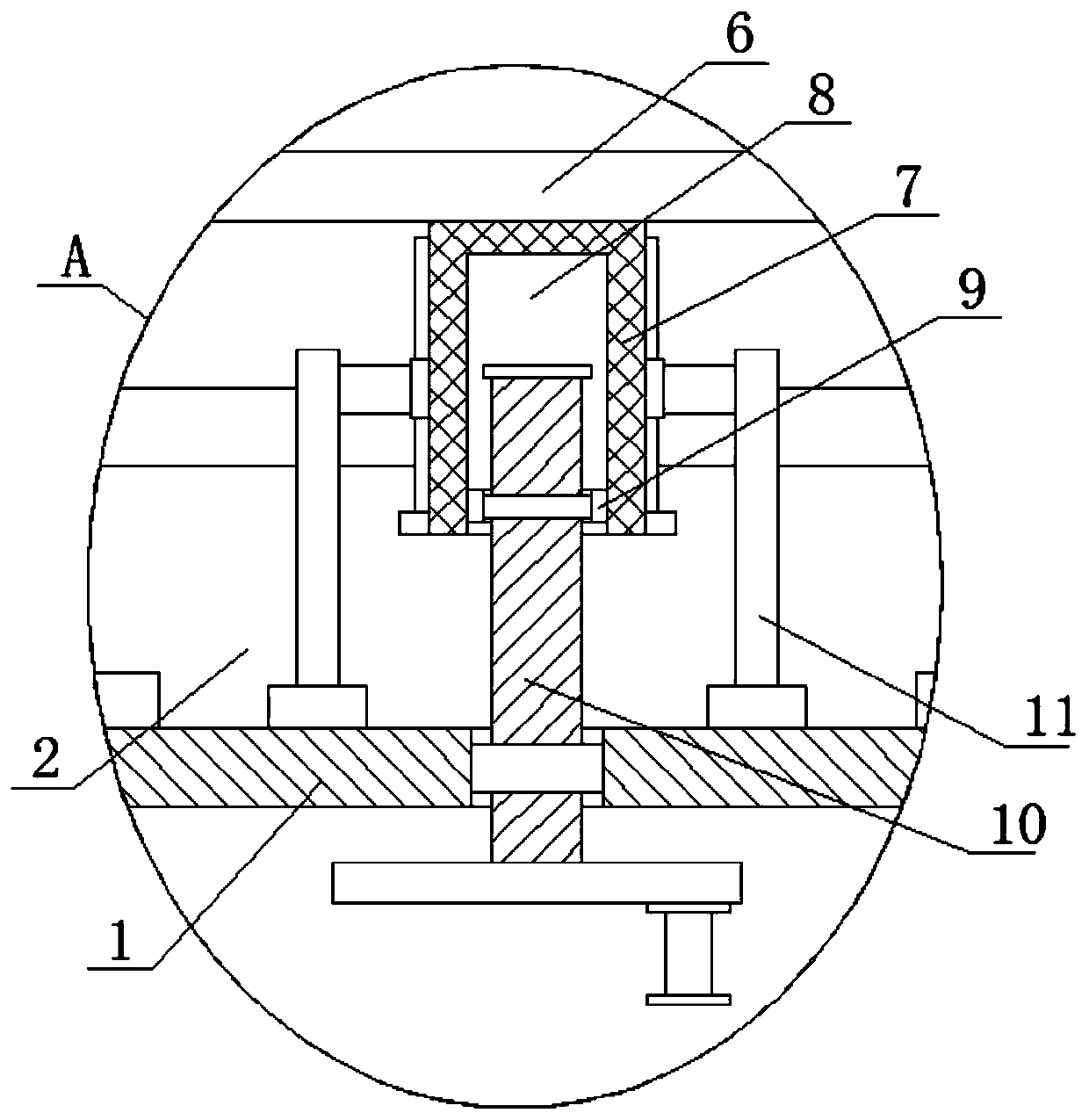

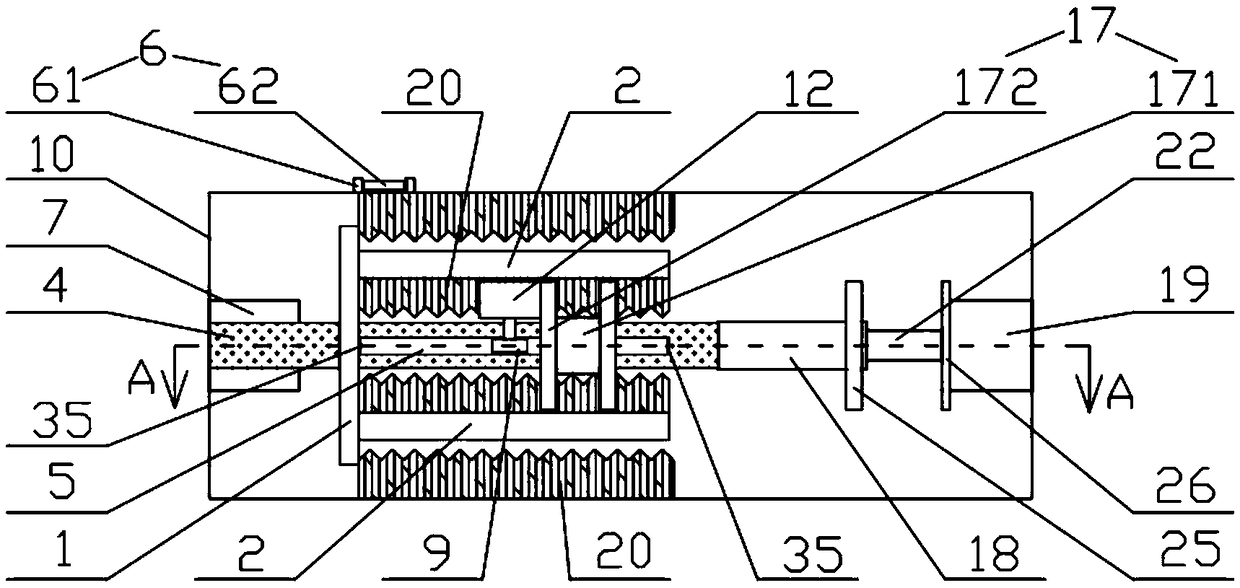

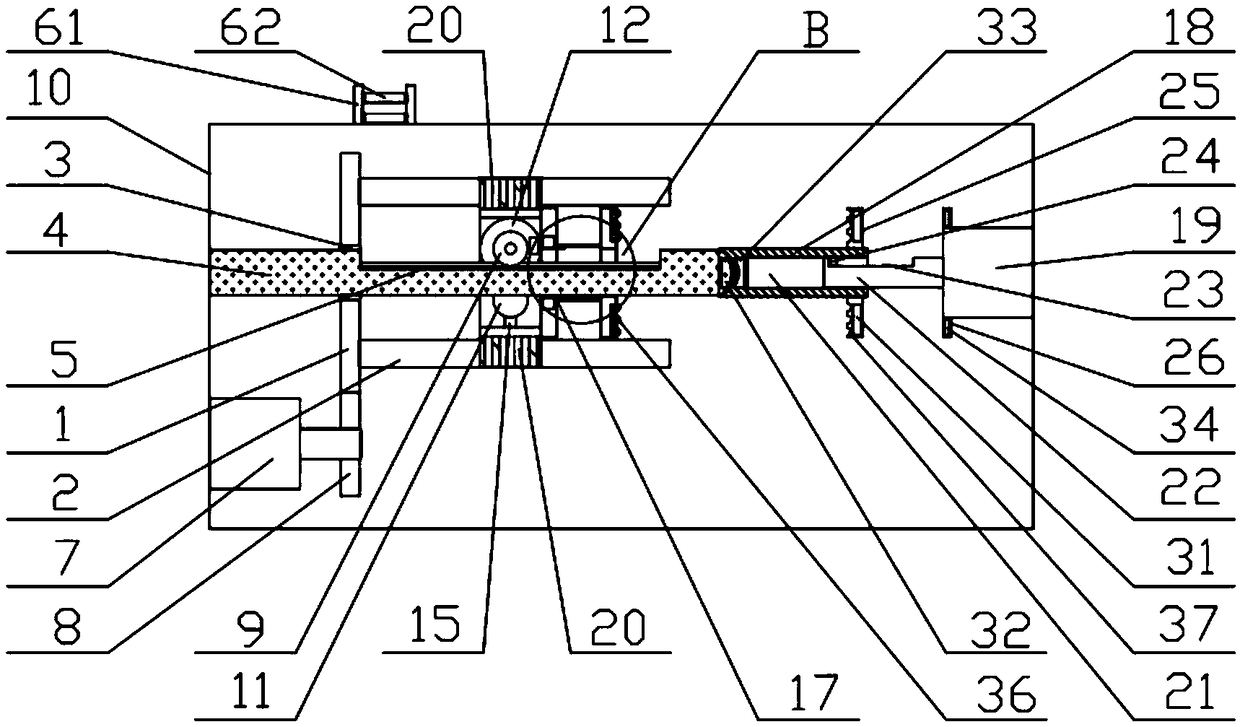

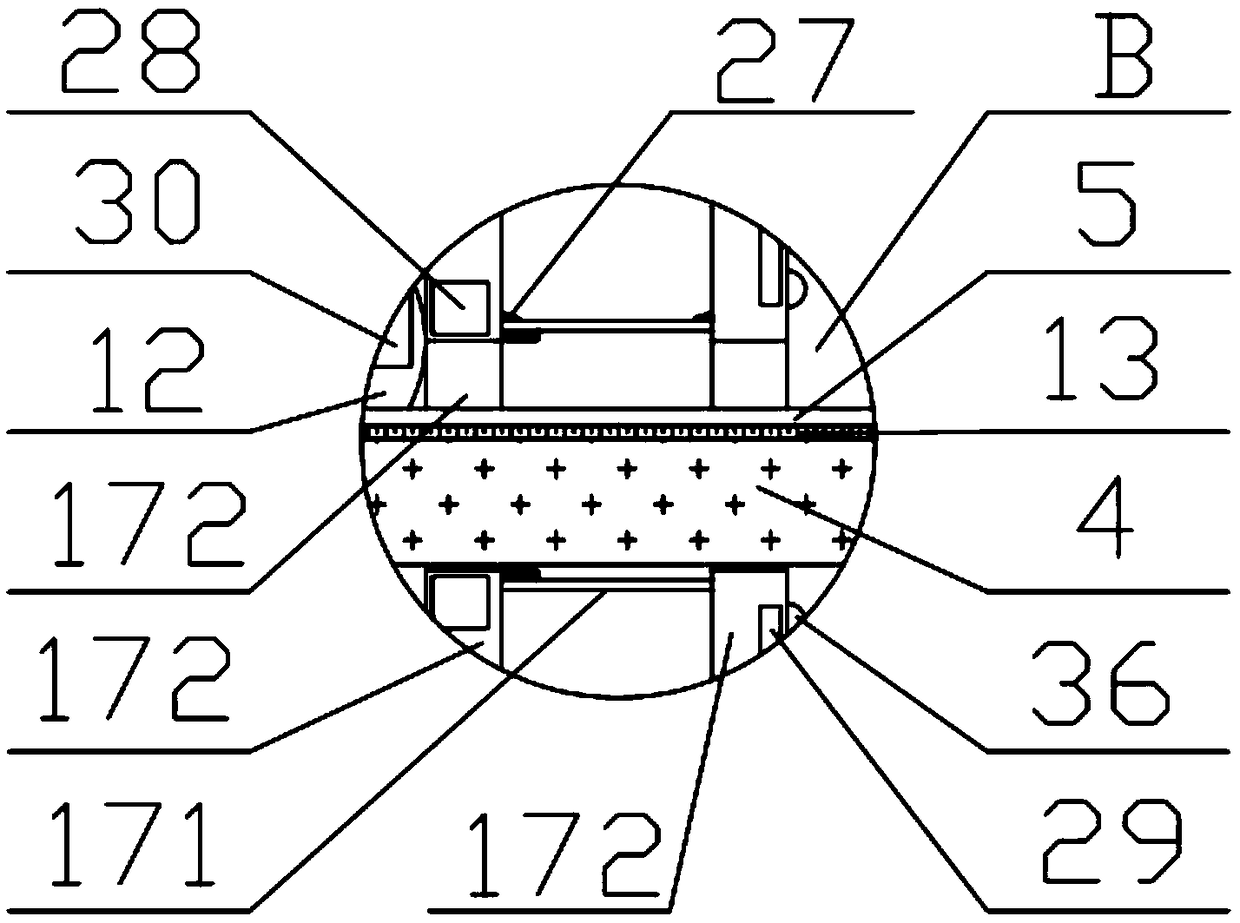

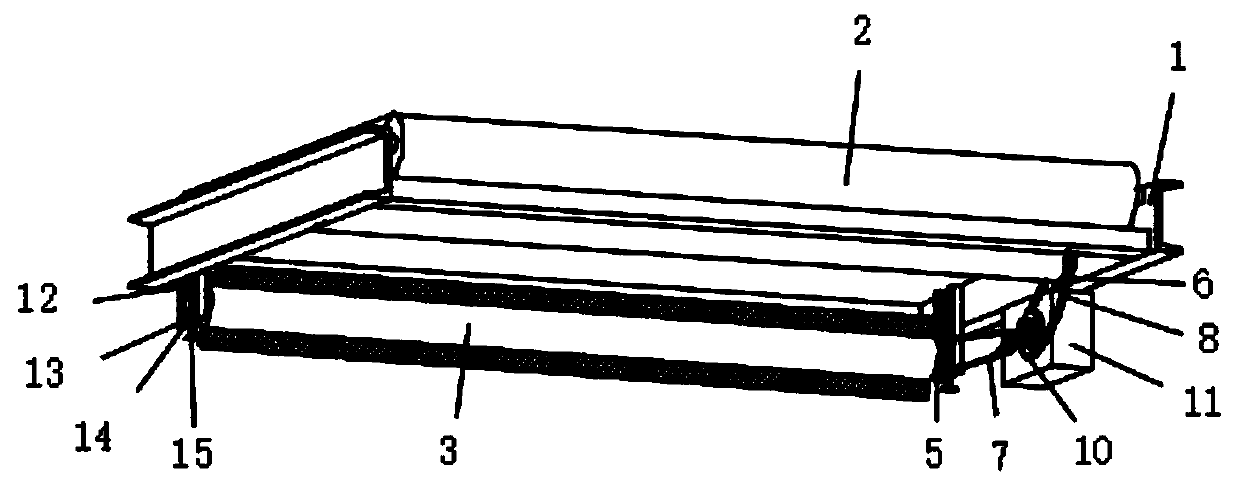

Self-cleaning filter capable of realizing double-sided backwashing

InactiveCN102580387AClean completelySuction effectiveGravity filtersStationary filtering element filtersEngineeringHigh pressure

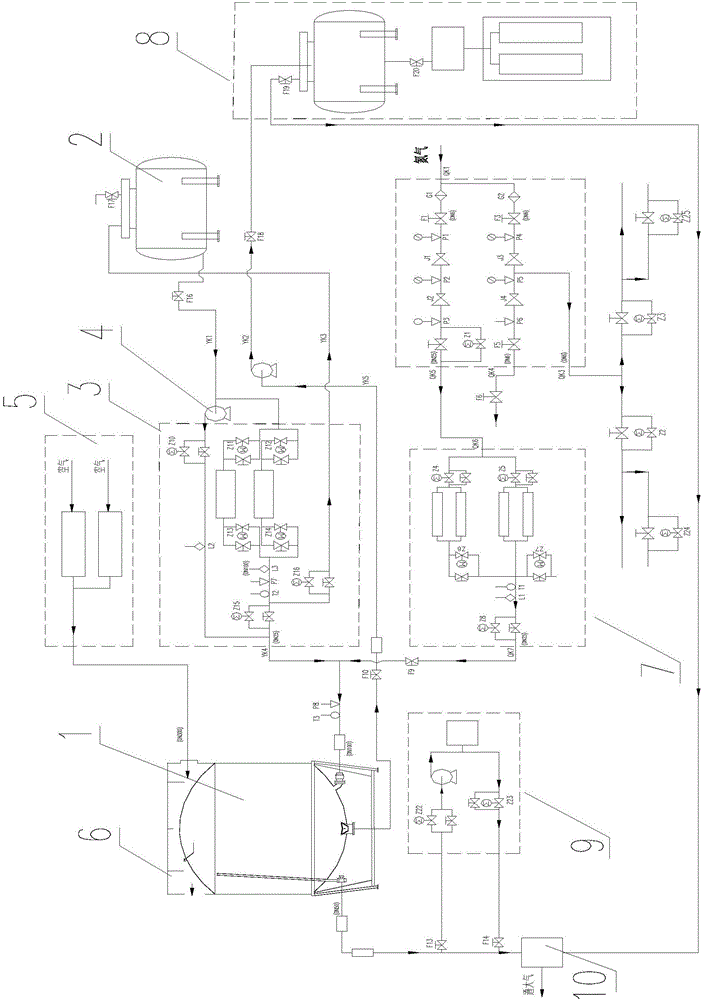

The invention relates to a self-cleaning filter capable of realizing double-sided backwashing, comprising a filtering part, a backwashing driving part for driving a dirt suction device assembly to rotate and a high-pressure washing device; the high-pressure washing device comprises a high-pressure washing pump and a high-pressure branch pipe which is arranged on the external wall of a fine filter screen of the filter and is synchronously operated with the dirt suction device assembly; the high-pressure branch pipe is provided with a plurality of nozzles at intervals over against the external wall of the fine filter screen; each nozzle corresponds to each suction nozzle arranged on a dirt suction pipe of the dirt suction device assembly, and the nozzles are oppositely arranged on the internal wall and the external wall of the fine filter screen; water discharged by the high-pressure washing pump is sprayed to the external wall of the fine filter screen via the high-pressure branch pipe and the nozzles and used for washing away or loosening dirt on the internal surface and the external surface of the fine filter screen, so that the dirt can be effectively sucked up by the suction nozzles; in combination with the rotation and translation of a dirt suction device, the internal surface and the external surface of the whole fine filter screen can be completely cleaned; and the self-cleaning filter is more suitable for online purification of a low-pressure circulating water system.

Owner:黄庆

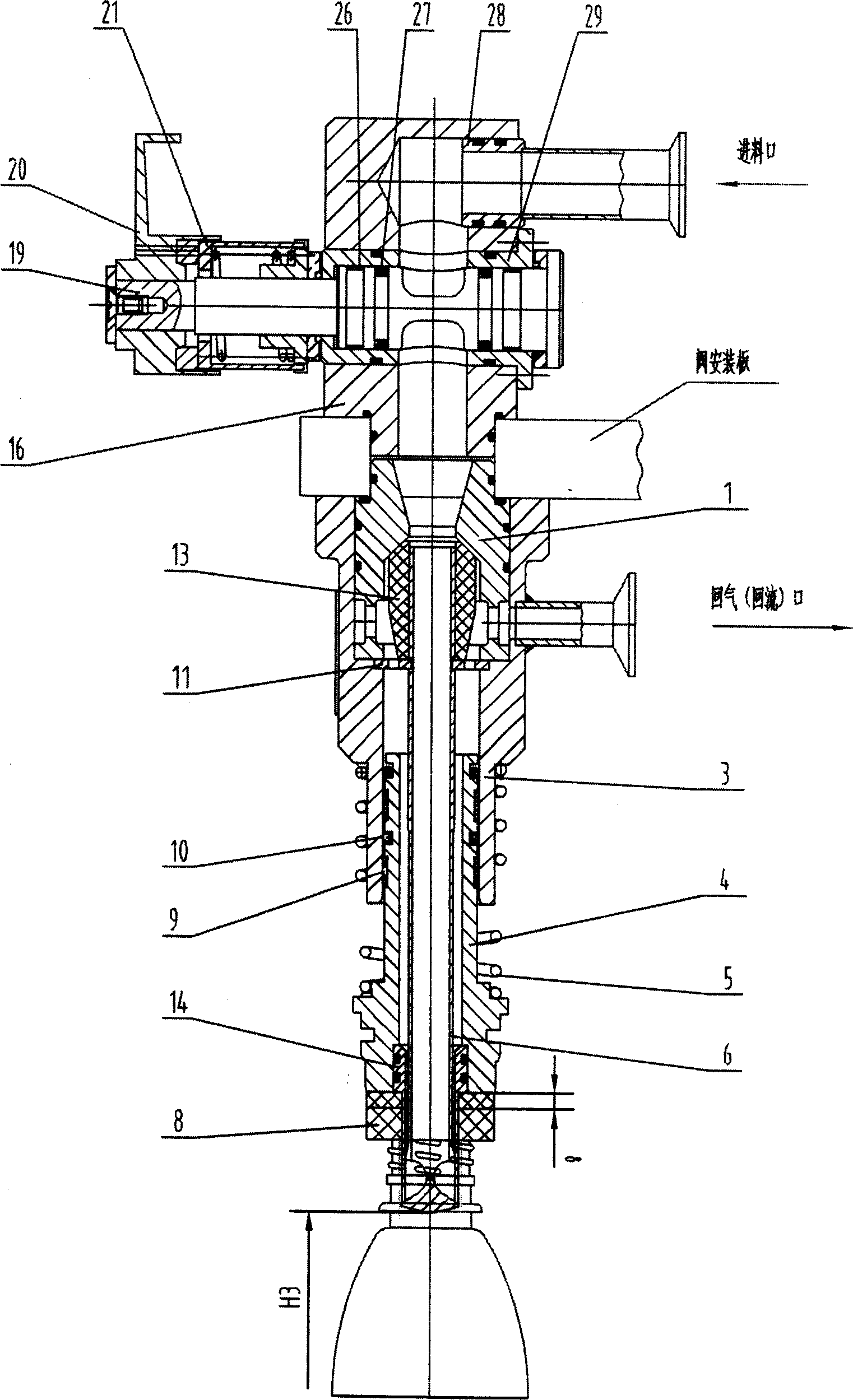

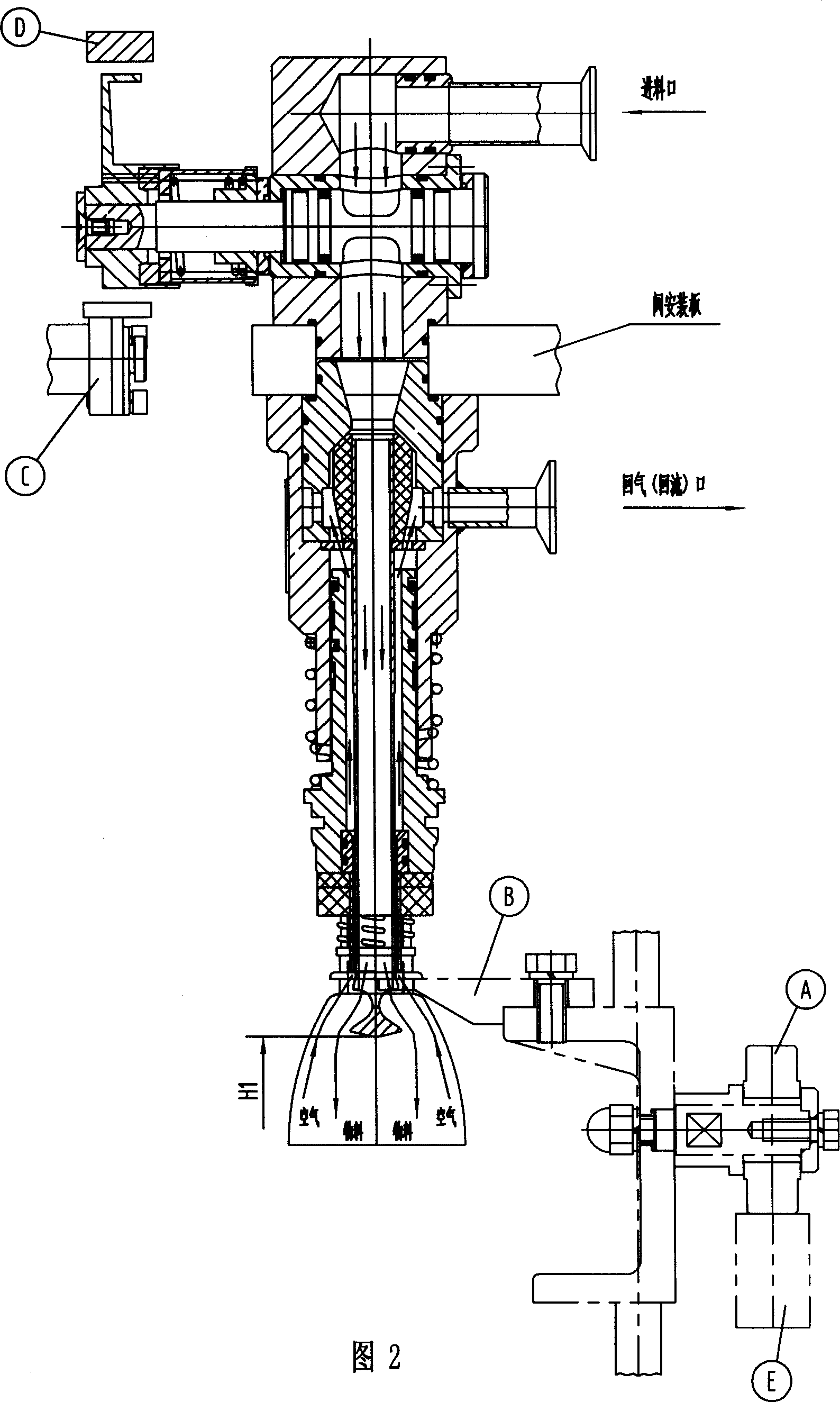

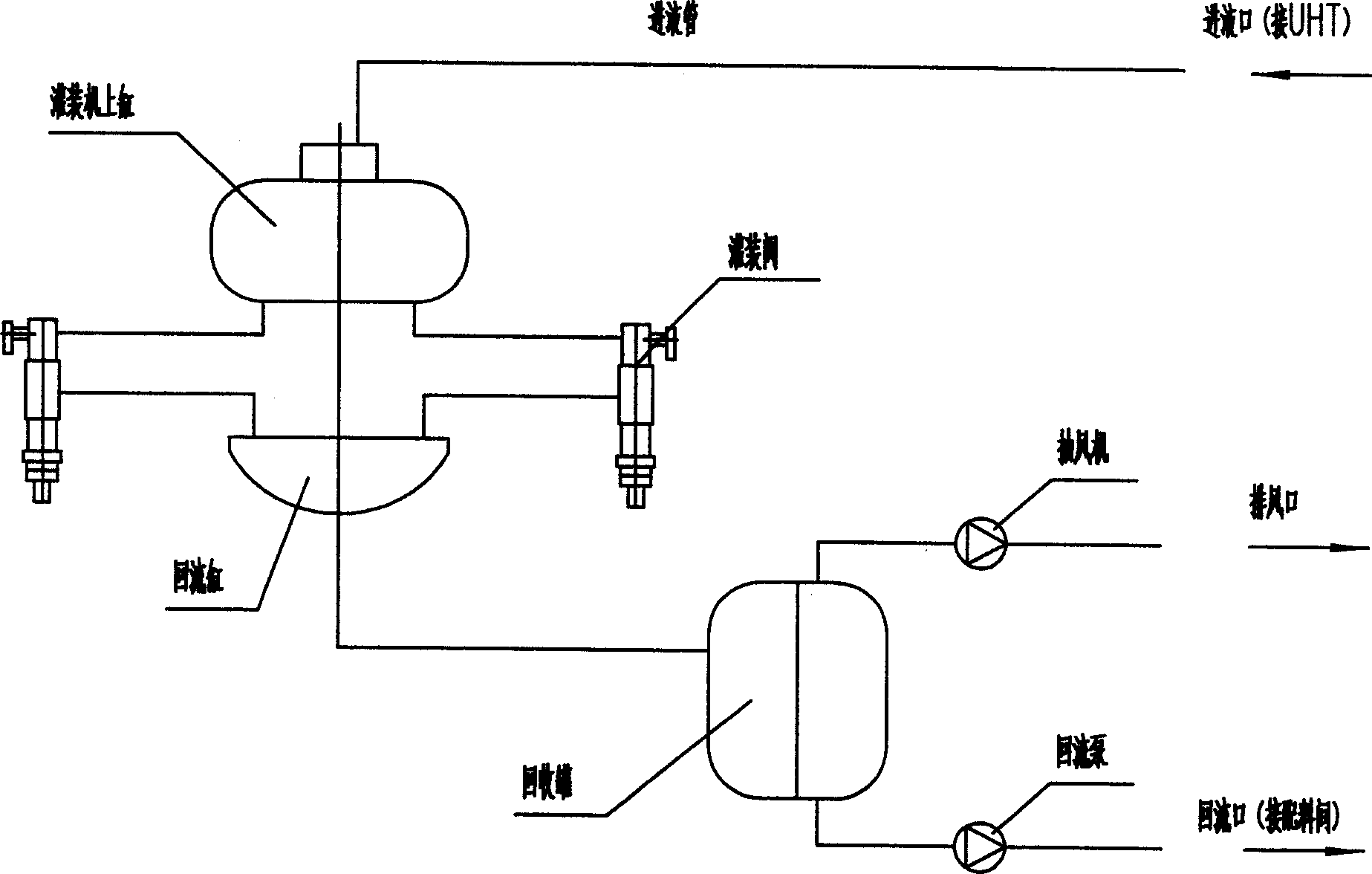

Thermal loading valve

InactiveCN1746104AAvoid problems that affect filling qualityCompact structureLiquid bottlingFeeding tube insertionEngineering

A thermal pouring valve for the beverage pouring production line based on the principle of gravitational pouring and negative-pressure reverse flow is composed of the liquid inlet tube jointer and valve body on the valve installing plate, the controller on said liquid inlet tube jointer, air returning tube jointer in the through hole on valve body, valve sleeve sleeving on the material inlet tube, spring sleeving on the lower part of material inlet tube and fixed to valve sleeve, sealing pad under the valve sleeve, reflux channel outside the material inlet tube, and a reflux hole on the valve body for connecting negative-pressure source.

Owner:南京轻机包装机械有限公司

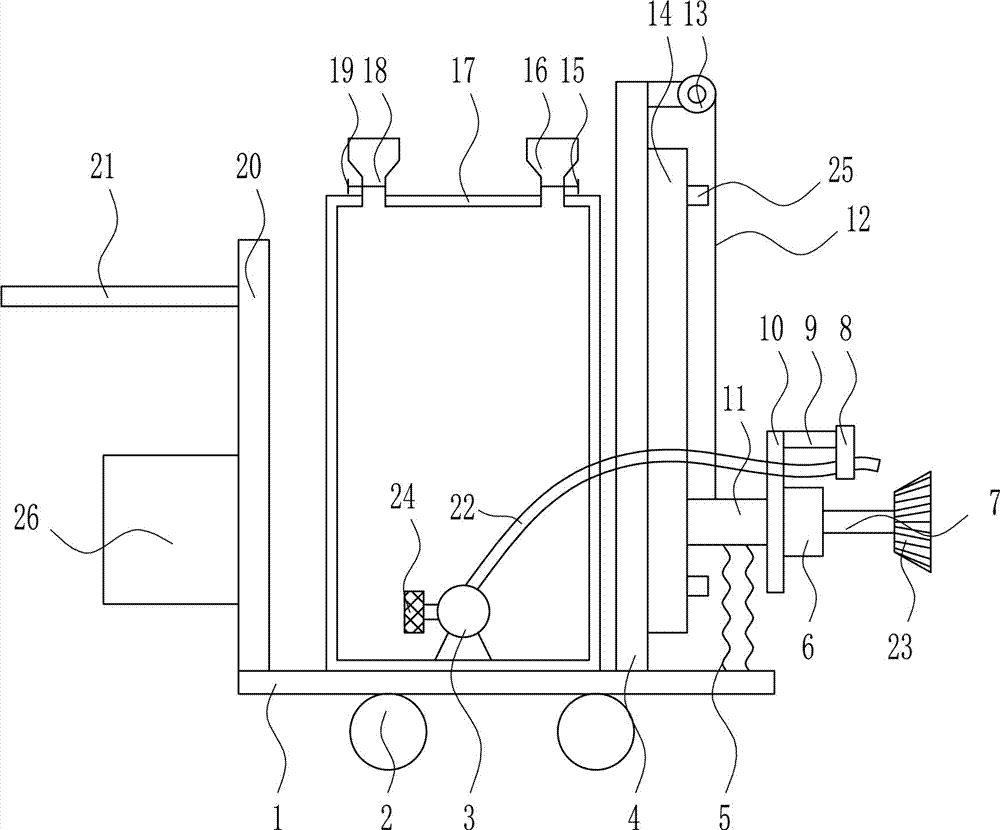

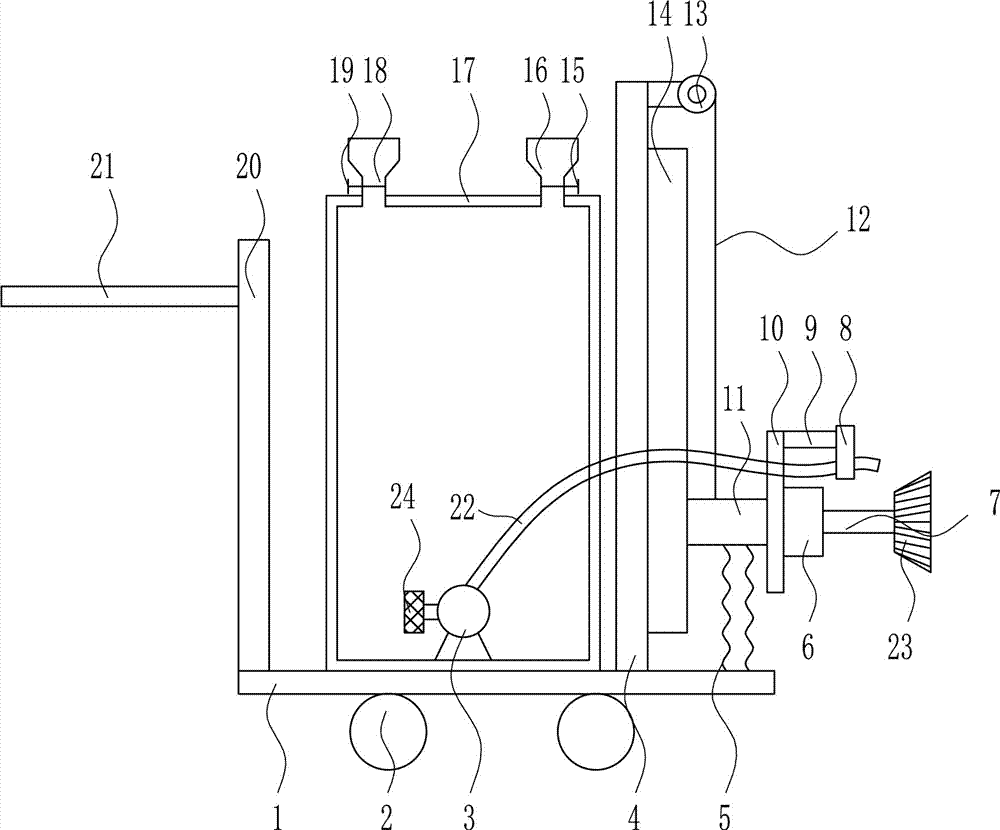

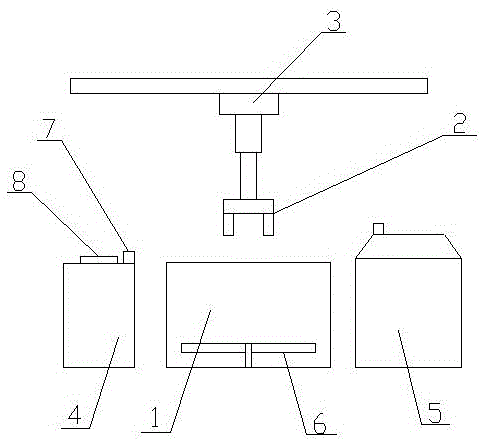

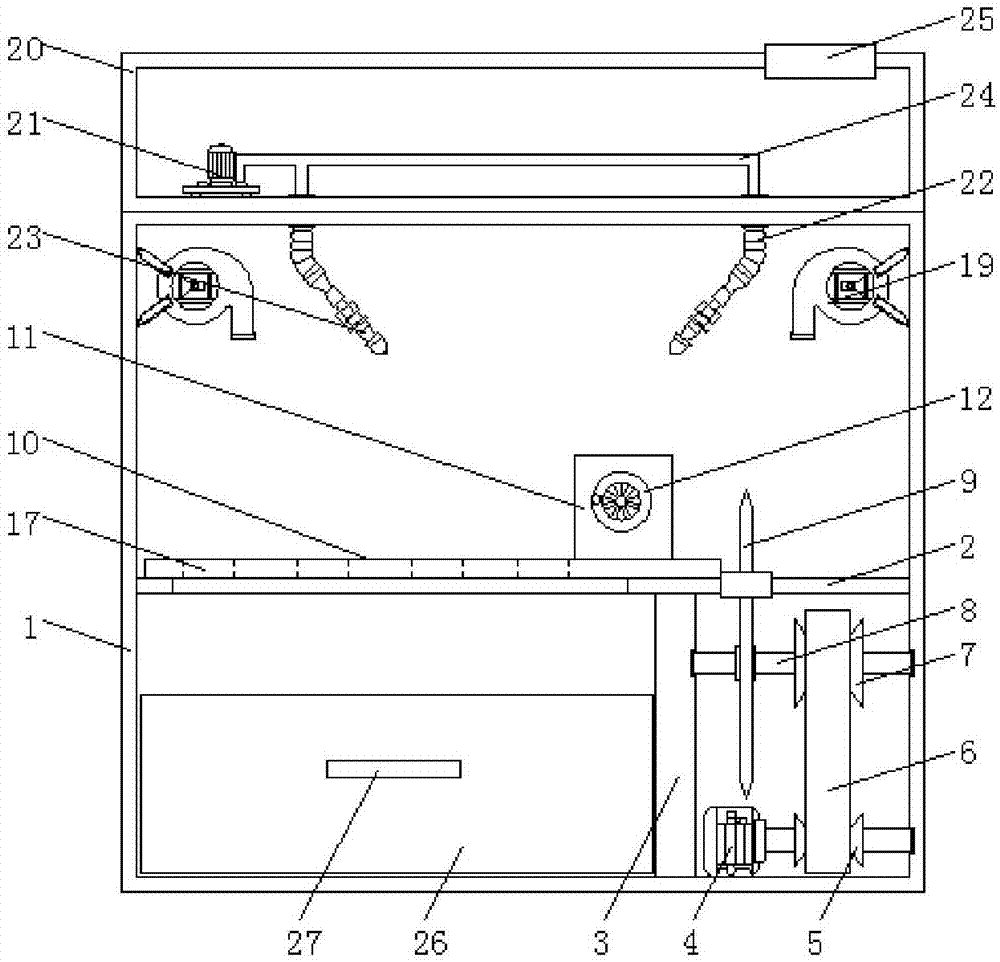

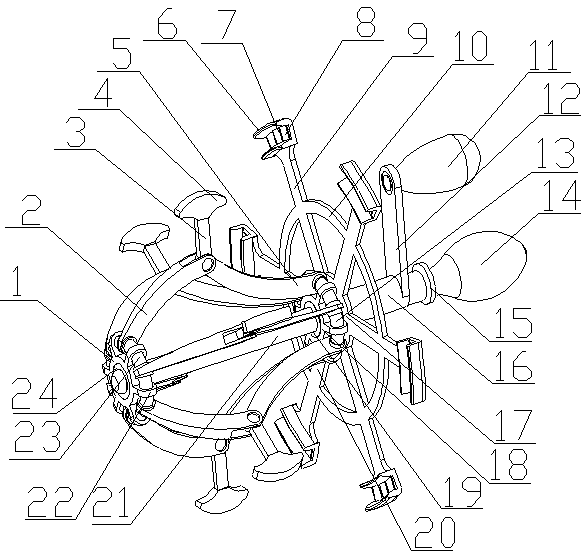

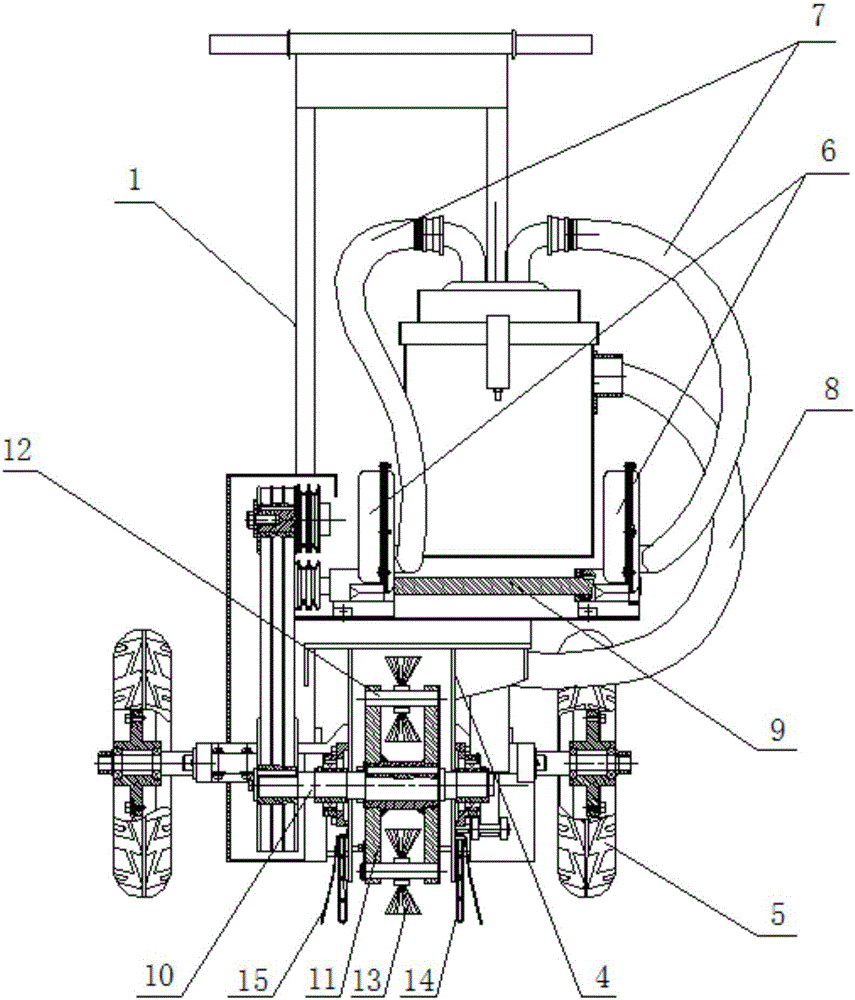

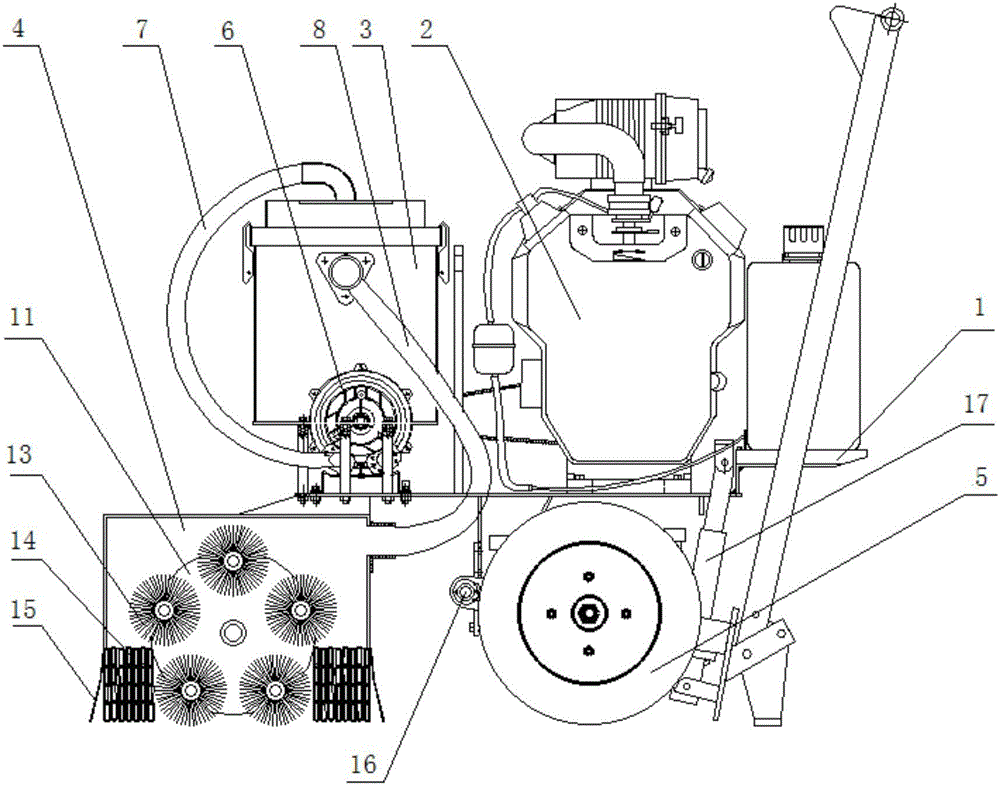

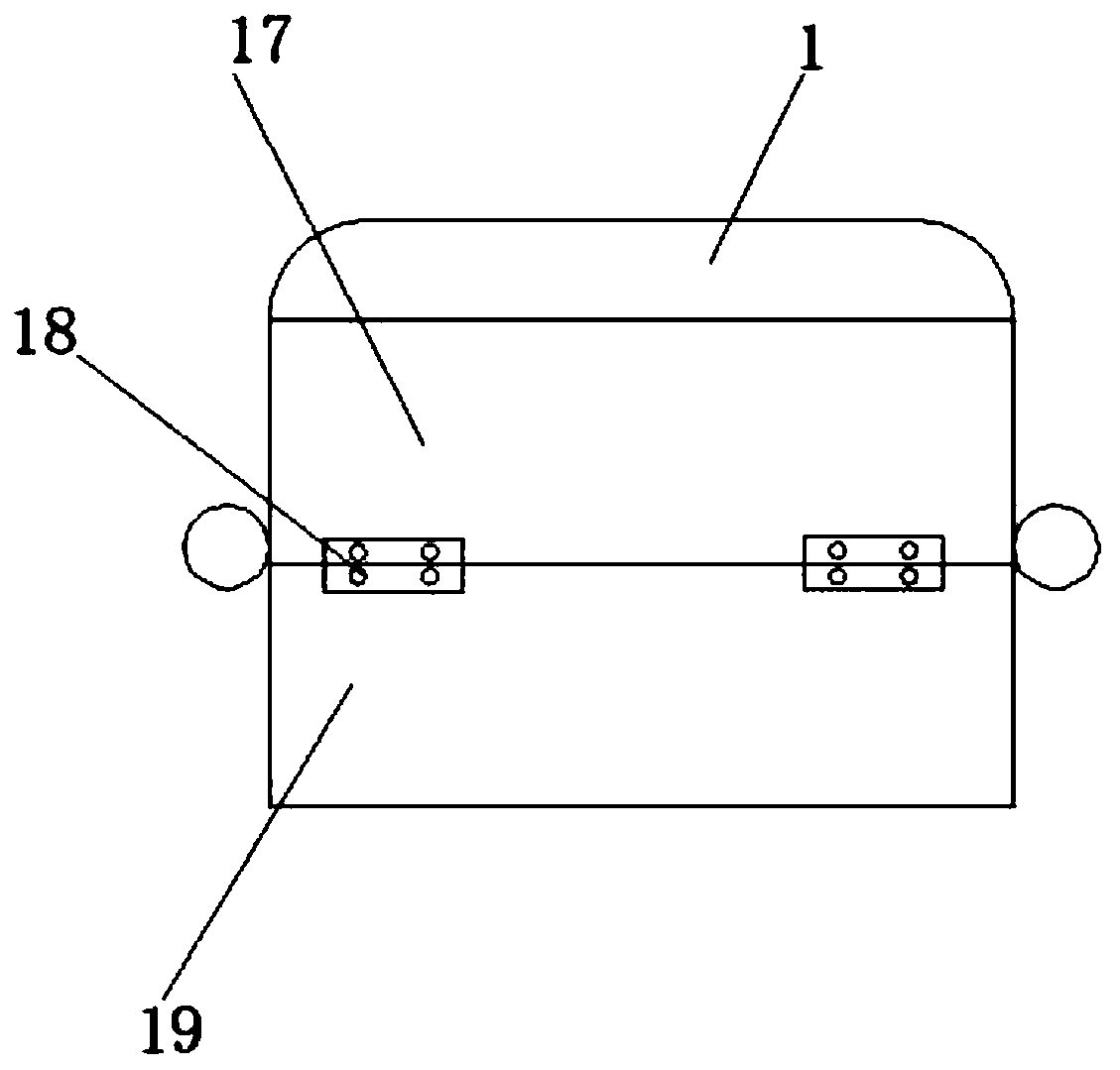

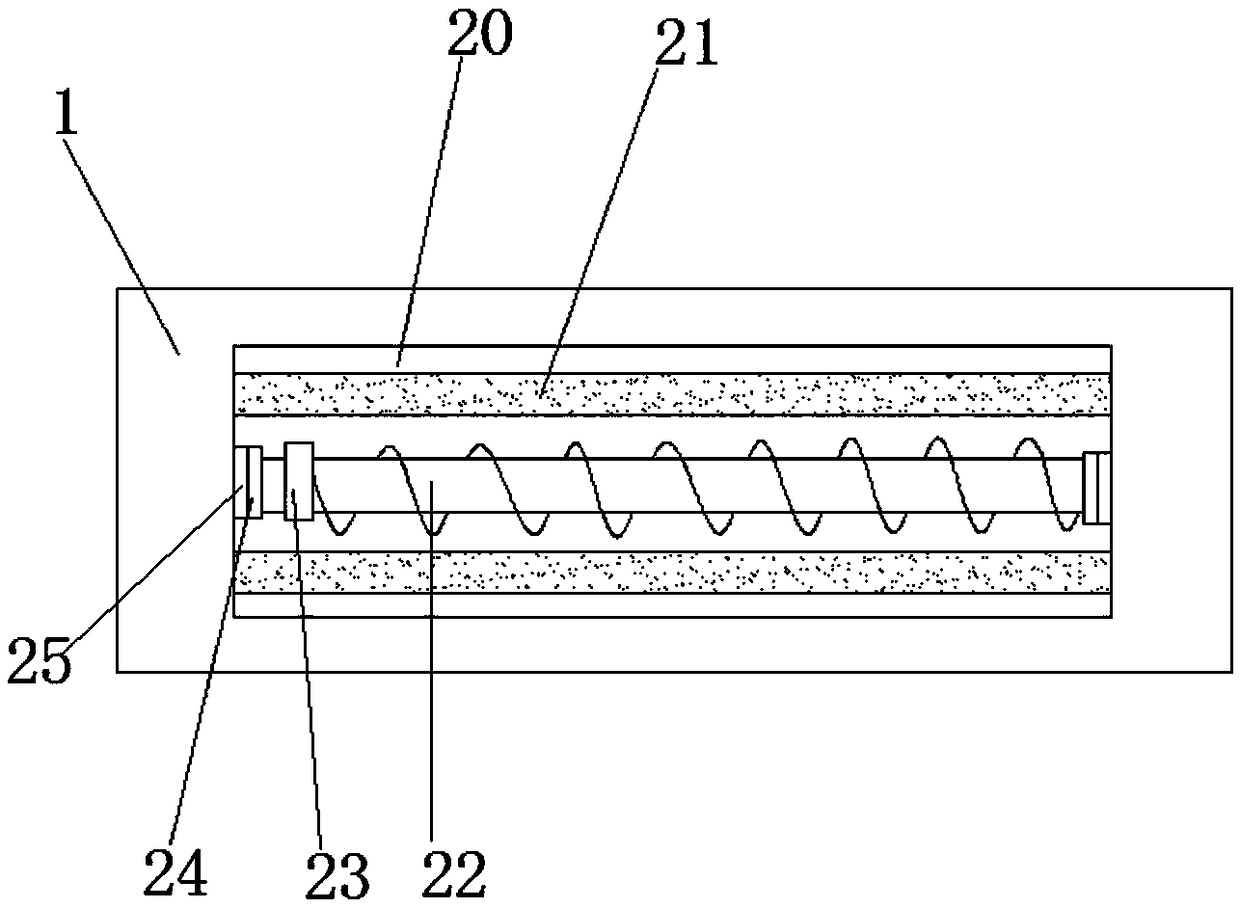

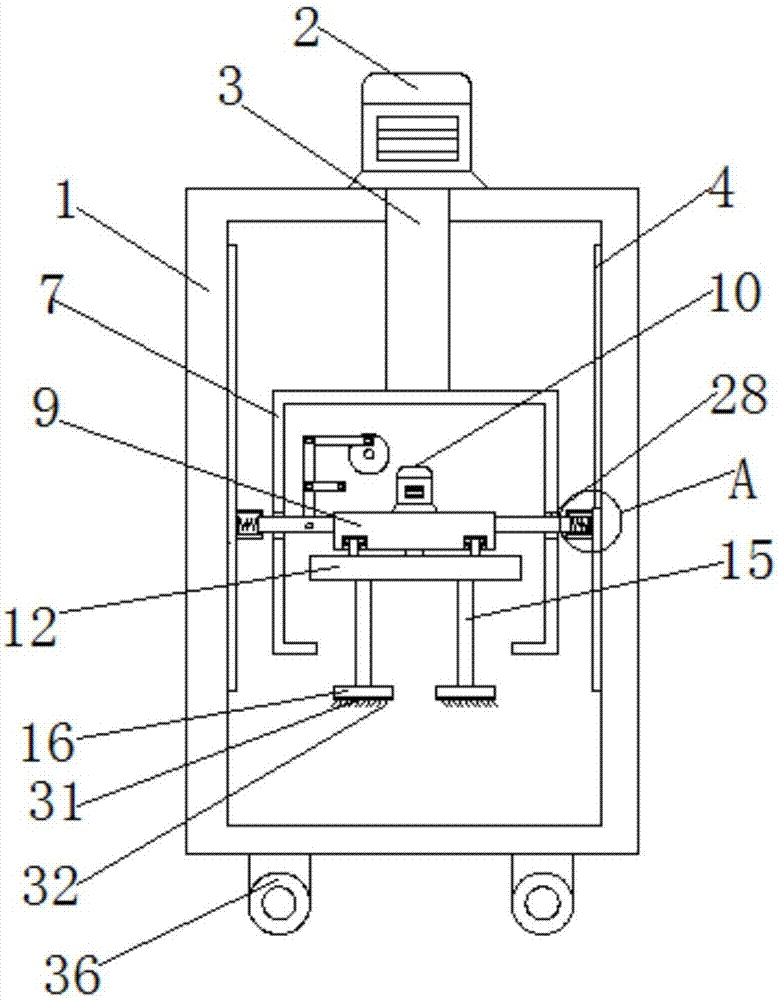

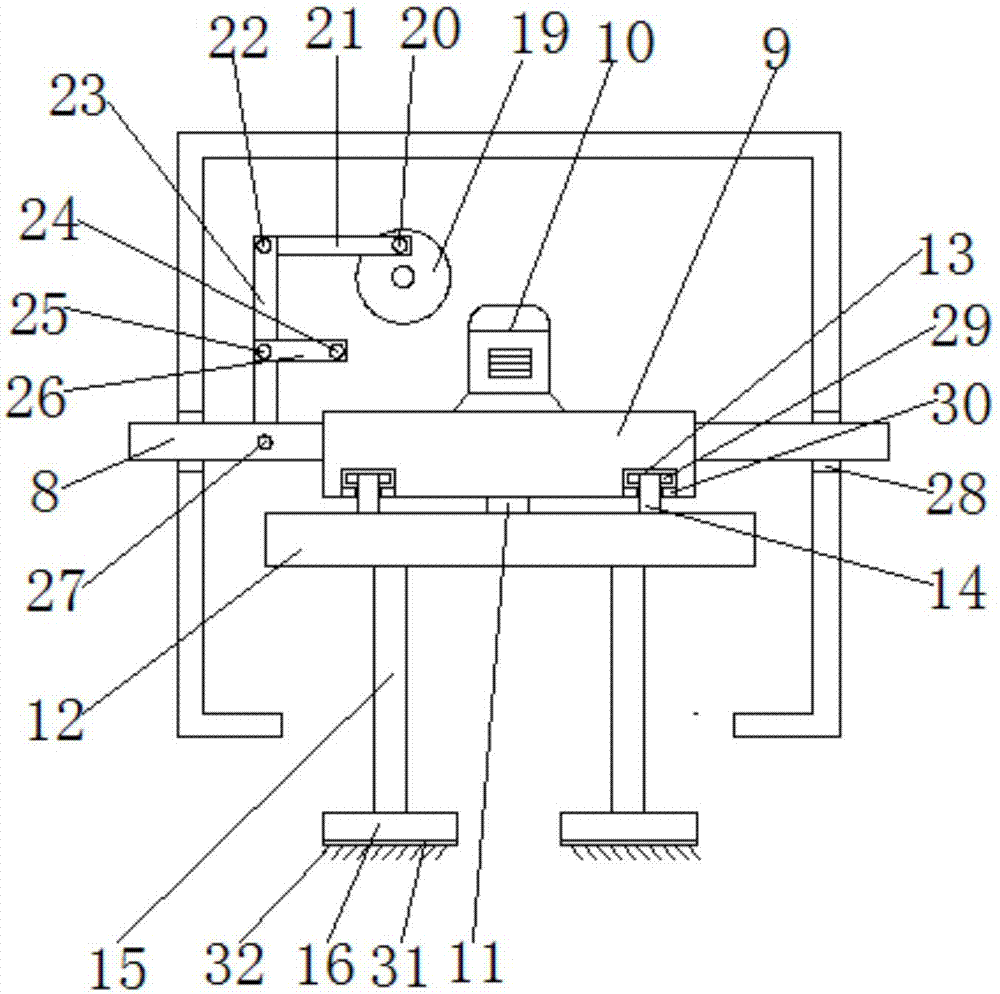

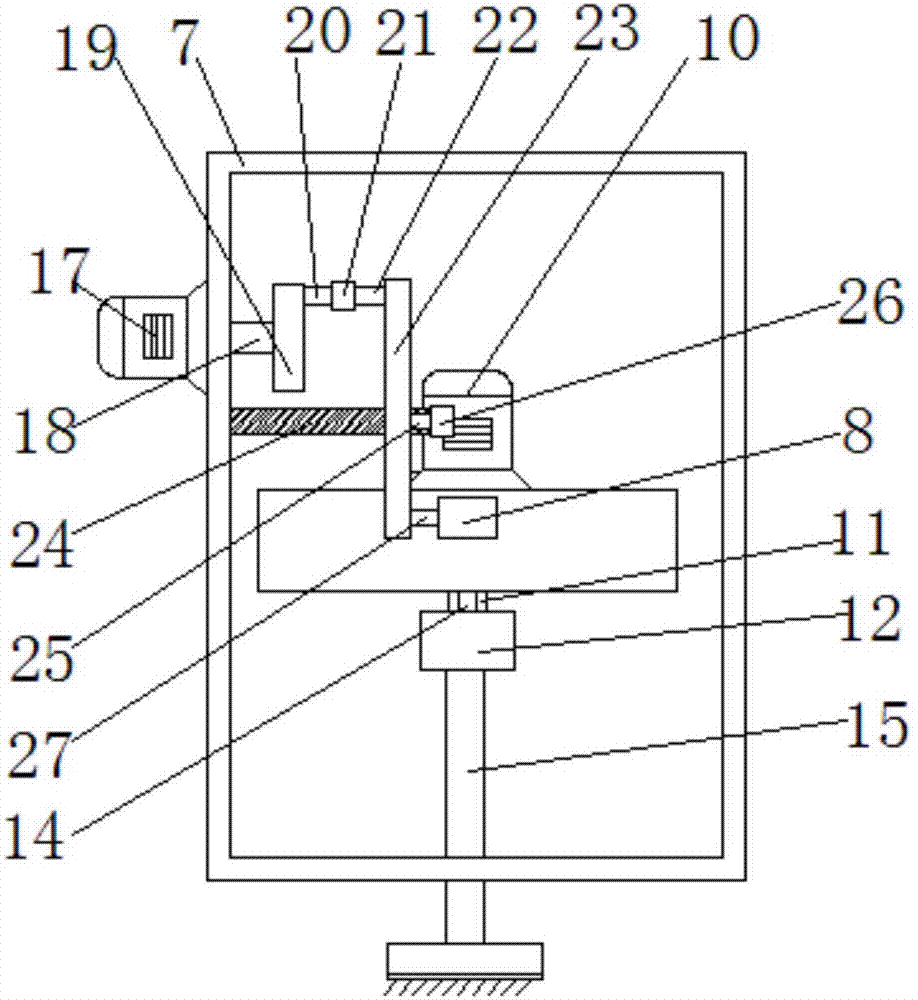

Wiping equipment of advertising board for municipal roads

ActiveCN106862126AClean completelyImprove work efficiencyTransportation and packagingRotary stirring mixersEngineeringWater tanks

The invention relates to advertising board wiping equipment, in particular to wiping equipment of an advertising board for municipal roads. According to the technical aims, the wiping equipment of the advertising board for the municipal roads is high in wiping speed and simple in wiping process. In order to achieve the technical aims, the wiping equipment of the advertising board for the municipal roads comprises a bottom board, wheels, a water pump, a first fixing board, a spring, a first motor, a rotary rod, a fixing sleeve, a second fixing rod, a second fixing board, a slide block, a pull wire and the like; a pushing handle is welded to the left side of the top of the bottom board; a sun shield is welded to the upper portion of the left side of the pushing handle; the center of the top of the bottom board is connected with a water tank in a bolt connection manner; and a first feeding opening and a second feeding opening are symmetrically formed in the top of the water tank left and right. The effects of high wiping speed and simple wiping process are achieved. The advertising board for the municipal roads is cleaned more thoroughly by controlling vertical movement of a wiping block.

Owner:广州市鑫阳交通工程有限公司

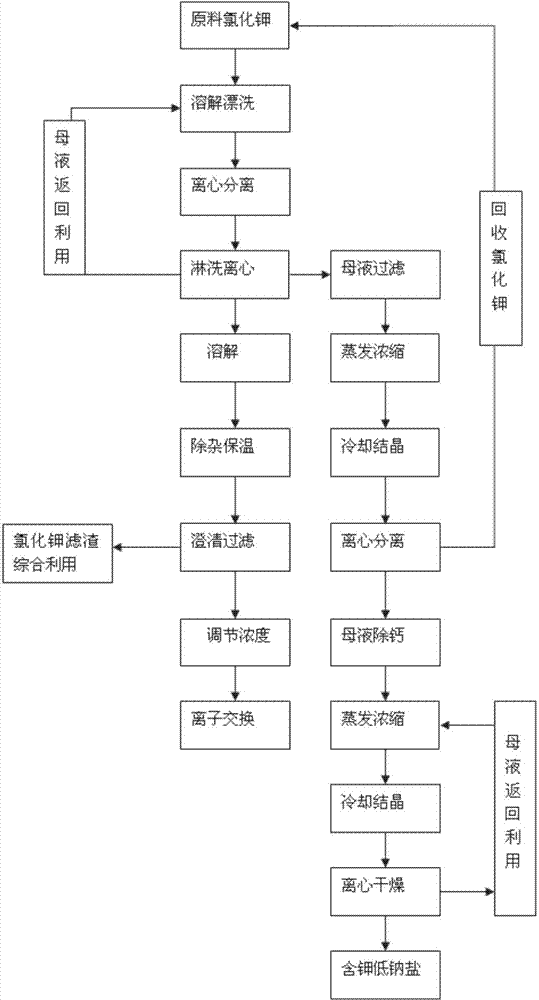

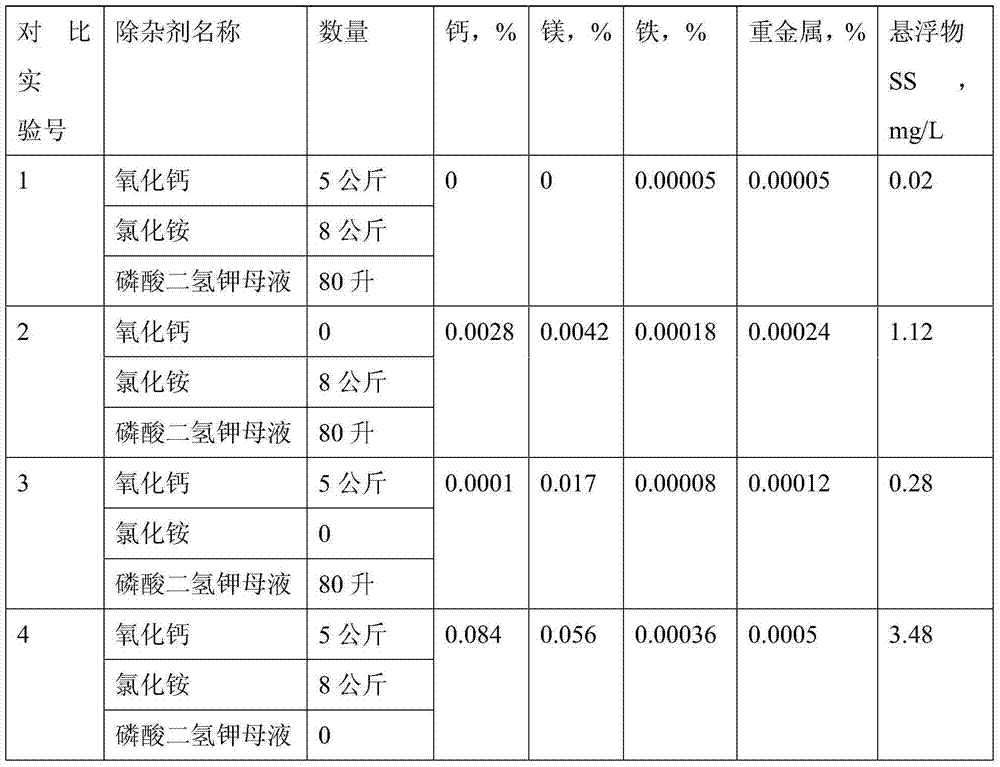

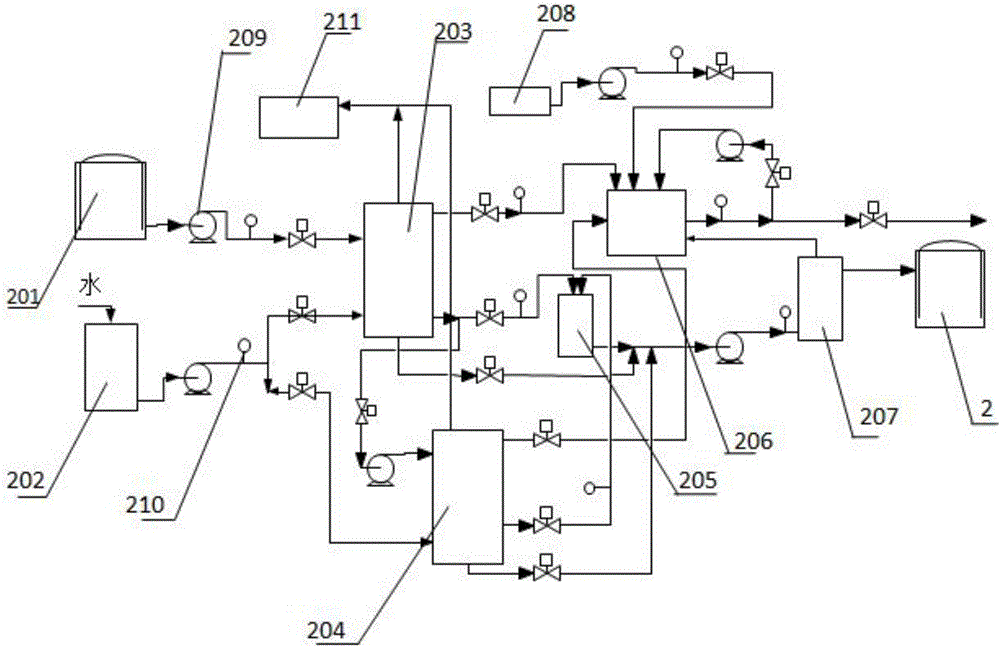

Method for producing high-purity potassium chloride solution for preparation of potassium carbonate and co-producing low sodium salt

ActiveCN103570043AMeet quality requirementsReduce processing costsAlkali metal chloridesAlkali metal halide purificationIon exchangePotassium

The invention discloses a method for producing a high-purity potassium chloride solution for preparation of potassium carbonate and co-producing low sodium salt. The high-purity potassium chloride solution for producing potassium carbonate is prepared from agricultural grade potassium chloride serving as a raw material by the steps of rinsing, dissolving, removing impurities, settling, filtering and the like, wherein the Ca<2+> content is less than or equal to 0.0001%, the Mg<2+> content is less than or equal to 0.0001%, the Fe content is less than or equal to 0.0001%, the content of suspended solids (SS) is less than or equal to 0.1 mg / L, pH is 12+ / -0.2, and the potassium chloride content is more than or equal to 99.0%, so the quality standard of an ion exchange method for producing the potassium carbonate is complete met. Potassium chloride rinsing liquid and leachate is recycled, evaporated and concentrated, and subjected to crystallization separation according to the dissolution characteristics of the potassium chloride and sodium chloride, the potassium chloride obtained by recycling can serve as the raw materials to be reused, and the mixture containing the potassium chloride and the sodium chloride meets the quality requirement of low sodium salt.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

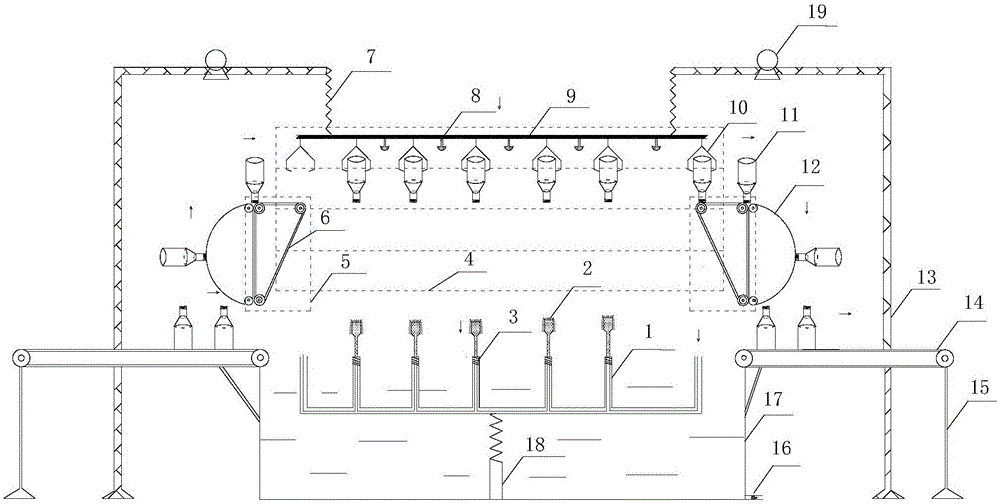

Threaded-mount bottle washing apparatus and threaded-mount bottle washing method

InactiveCN106238426AFunction as a bottle capEasy to cleanHollow article cleaningDrying gas arrangementsBrush deviceBottle

The invention relates to a threaded-mount bottle washing apparatus and a threaded-mount bottle washing method. The threaded-mount bottle washing apparatus comprises a bottle washing mechanism, a bottle conveying mechanism for conveying a to-be-washed threaded-mouth bottle to the bottle washing mechanism, and a bottle receiving mechanism for receiving a washed threaded-mouth bottle. The bottle washing mechanism comprises a first support which is fixed. A horizontal extensible track capable of moving up and down is connected to the first support. A plurality of mechanical grippers for clamping the bottoms of threaded-mouth bottles are arranged at the lower side of the extensible track and are capable of rotating around an own axis thereof and sliding along the extensible track. A water tank is arranged below the extensible track. A hollow pipe capable of moving up and down is arranged in the water tank. A plurality of vertical supporting water inlet pipes communicating with the hollow pipe are arranged on the hollow pipe. A brush device directly facing a mechanical gripper is mounted at the upper end of each supporting water inlet pipe, and comprises a screw-type brush for matching with the mouths of the threaded-mouth bottles and a cylindrical brush. The threaded-mount bottle washing apparatus is simple in structure, and is capable of effectively washing threaded-mouth bottles, and especially capable of sufficiently washing the threaded mouths of the bottles.

Owner:CHANGAN UNIV

Novel leg cleaning and dressing device for general surgery nursing

InactiveCN110236847AImprove work efficiencySimple structureCannulasEnemata/irrigatorsWorkloadNursing staff

The invention belongs to the technical field of the general surgery department, in particular to a novel leg cleaning and dressing device for general surgery nursing. For the problem that when a nurse in the existing general surgery department performs dressing treatment on a patient, a wound needs to be washed manually, then after washing is completed, a drug is sprayed on the wound, which results in that the manual operation time is longer, and the workload of the nurse is increased, the following scheme is proposed that the device comprises a workbench, wherein the workbench is provided with a mounting cavity, the inner wall of the bottom of the mounting cavity is slidably connected with two symmetrically arranged adjusting plates, the inner wall of the top of the mounting cavity is provided with through holes, and the tops of the two adjusting plates penetrate through the through holes respectively and extend to the position above the workbench. The novel leg cleaning and dressing device for general surgery nursing has the advantages that the structure is simple, the device body can adapt to the work of leg cleaning and dressing of patients of different heights and weights, the operation is simple, the manpower is liberated, the mechanical automation is strong, and the work efficiency of the nursing staff is greatly improved.

Owner:刘冬

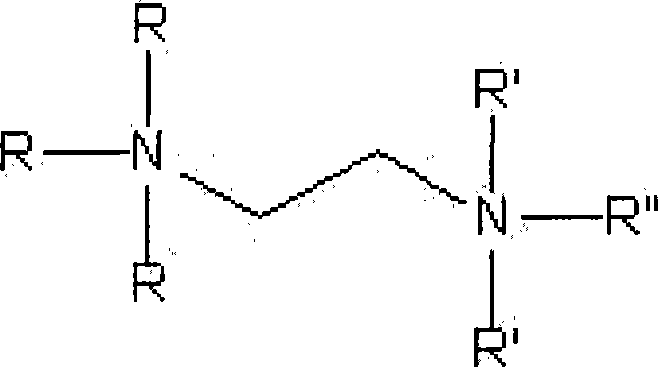

Against corrosion film stripper composition

ActiveCN101093365ARemove completelyClean completelySurface-active detergent compositionsDetergent compounding agentsDiamineSolvent

The invention relates to a photoetch-resist film used for removing the pattern of the electronic circuit or display element, a photoetch-resist film remover composition for inhibiting the corrosion to the metal wiring. The photoetch-resist film remover composition optimally comprising: a) diamine compound of 1-20 wt.%; and residual glycol ether compound. The invention may further comprise the polar solvent. The photoetch-resist film remover composition will not corrode the metal wiring in the process of removing the photoetch-resist film.

Owner:DONGJIN SEMICHEM CO LTD

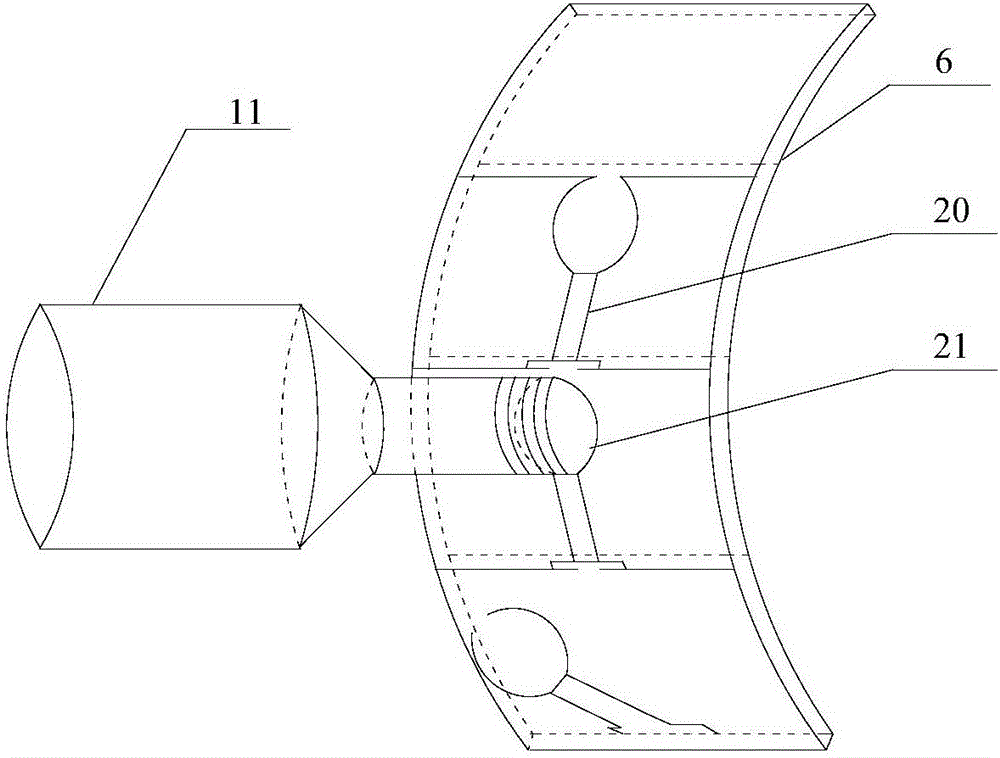

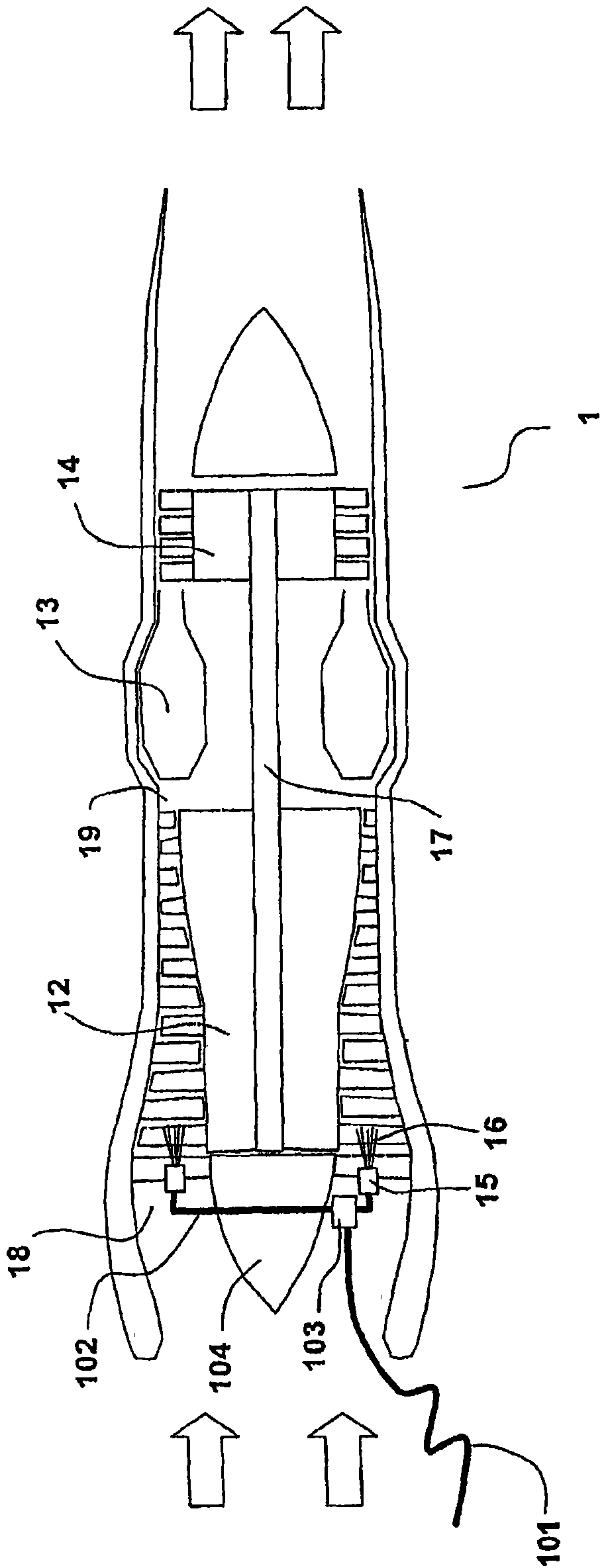

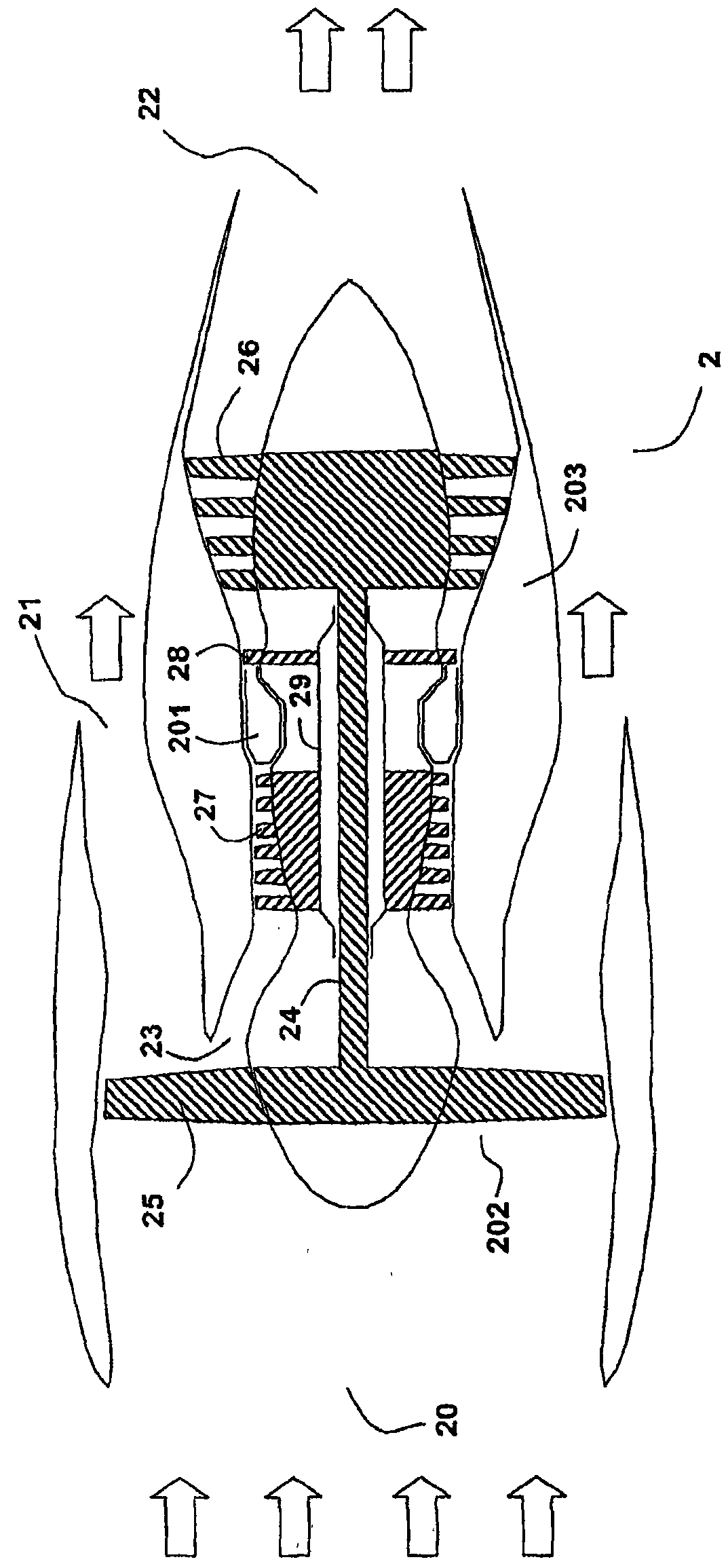

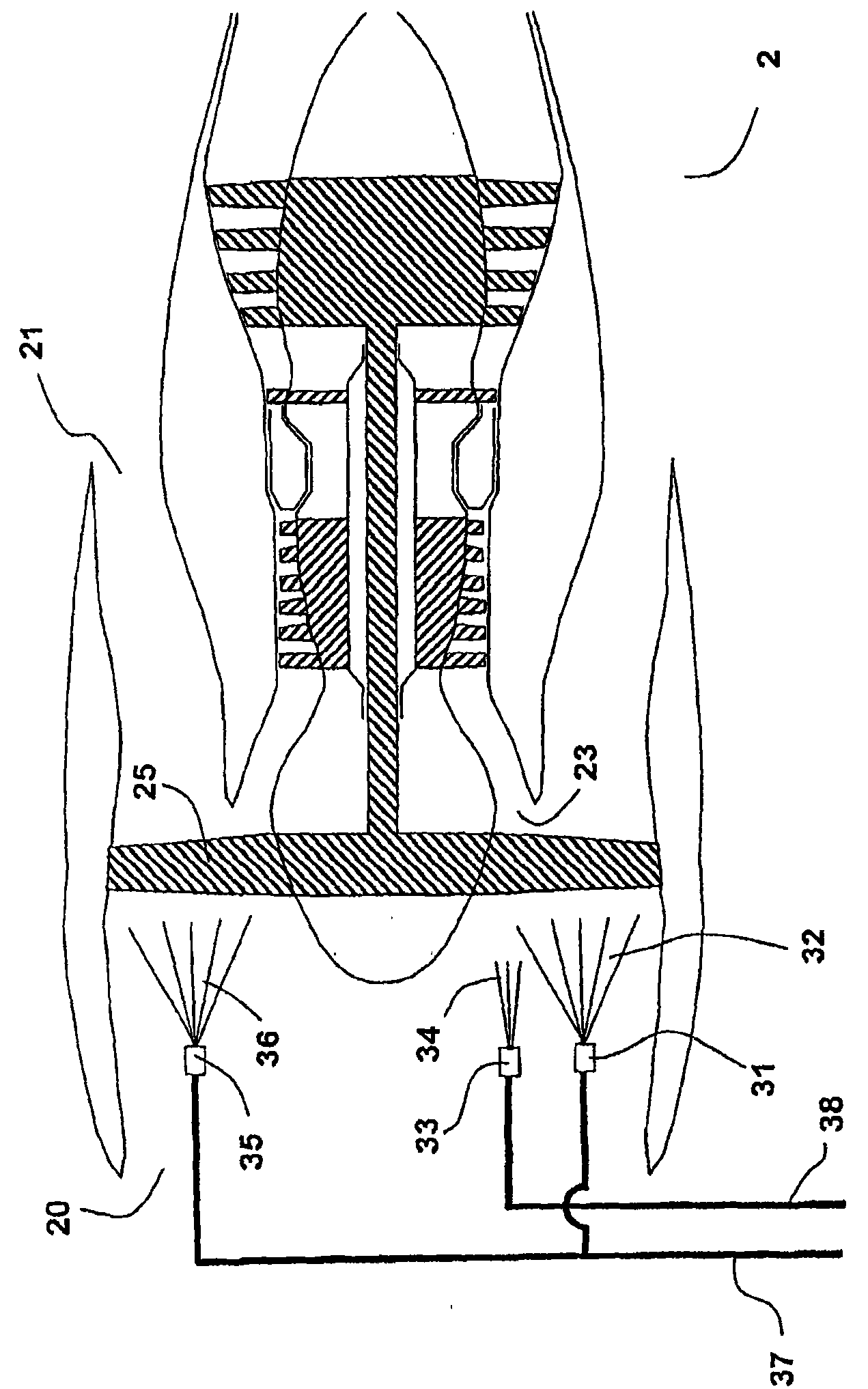

Method and equipment for cleaning turbofan gas turbine engine

The invention relates to a device for cleaning a gas turbine engine (2), in particular for cleaning an engine of a cleaning turbine fan type. The invention also relates to a method for cleaning the engine. The device comprises a plurality of spray nozzles (31, 33, 35); and the spray nozzles (31, 33, 35) are deployed at the upstream of a fan (25) of the engine (2) and at an air inlet (20) of the engine (2) so that cleaning liquid in gas flow is atomized. According to the invention, a first spray nozzle (31) is deployed at some position, so that the cleaning liquid emitted from the first spray nozzle (31) approximately impacts the surface of a blade (40) on a pressure side (53); a second spray nozzle (35) is deployed at some position, so that the cleaning liquid emitted from the second spray nozzle (35) approximately impacts the surface of the blade (40) on a suction side (54); and a third spray nozzle (33) is deployed at some position, so that the cleaning liquid emitted form the third spray nozzle (33) approximately passes through the blade (40) and enters an inlet (23) of a core engine (203). Consequently, the invention can effectively remove different types of scale found on the fan and the core engine compressor of the turbofan engine.

Owner:ECOSERVICES

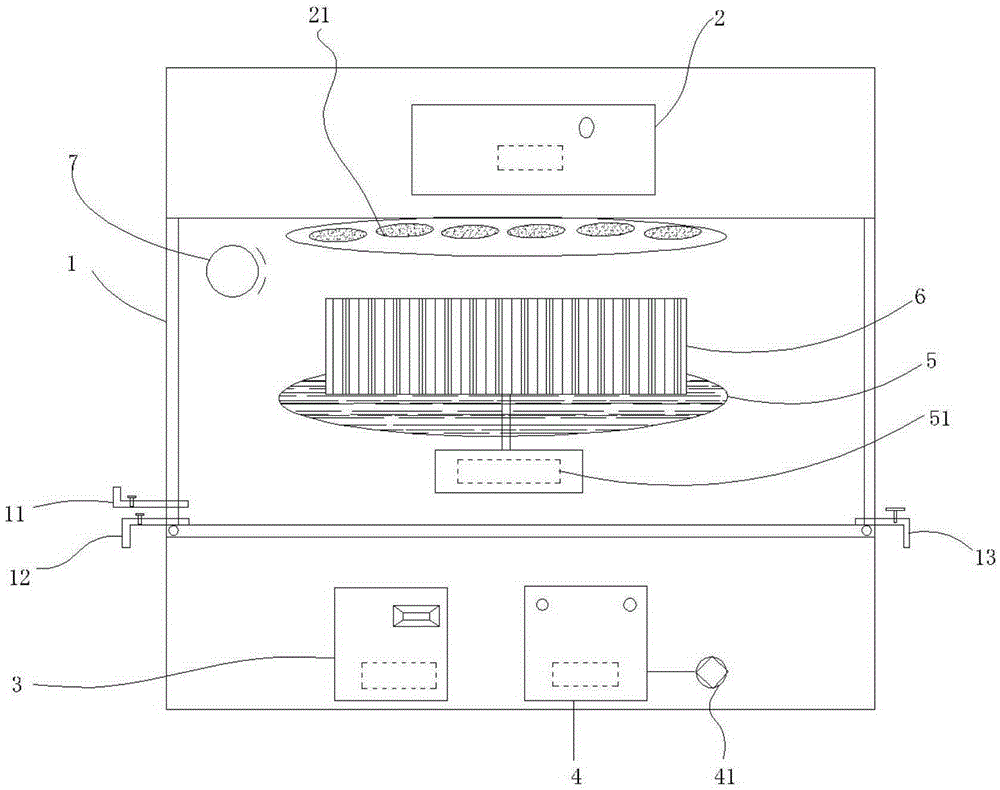

Washing device

ActiveCN104161486AWash thoroughlyClean completelyCarpet cleanersFloor cleanersMechanical engineeringComputer module

Owner:BEIJING BOE ENERGY TECH +1

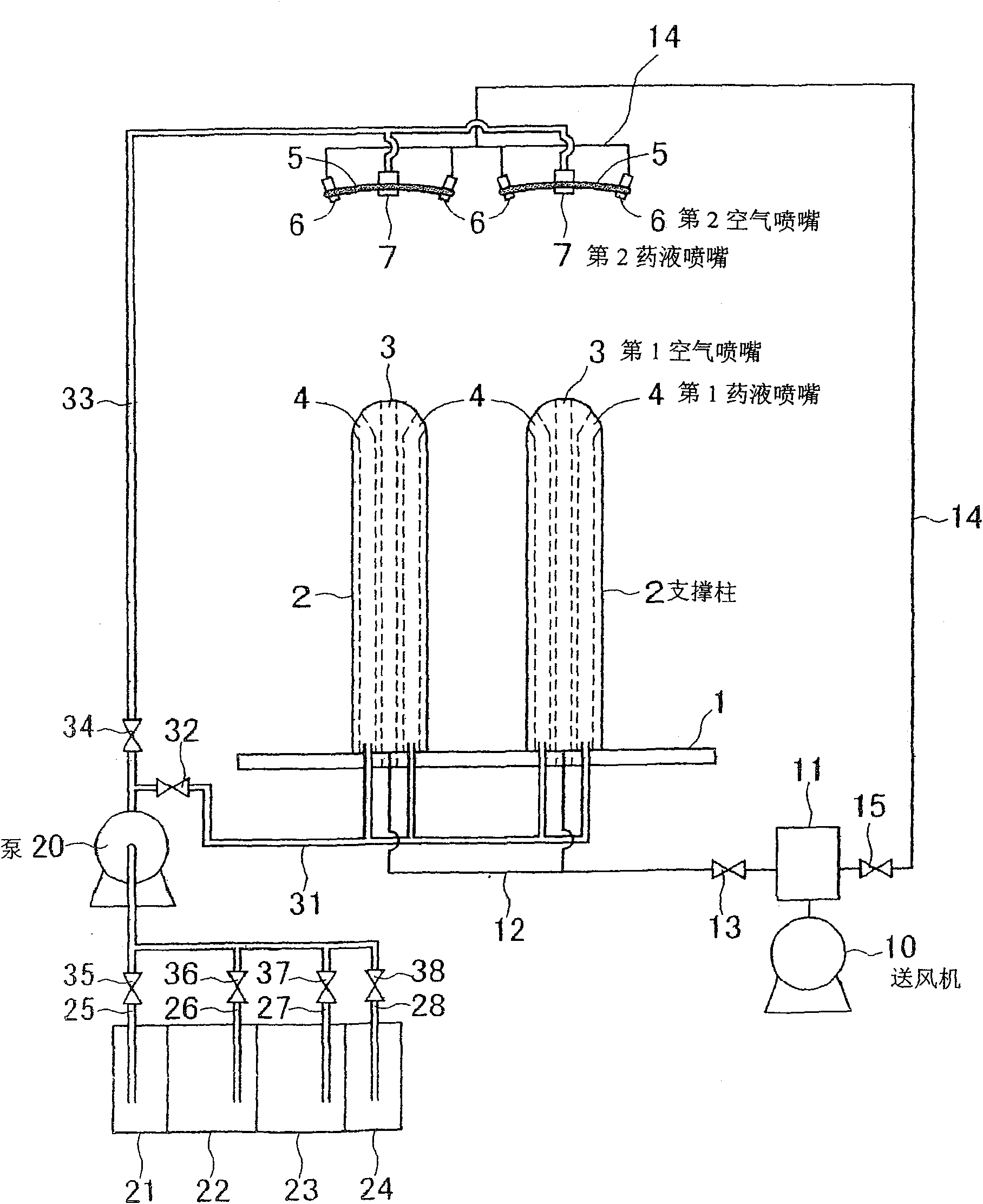

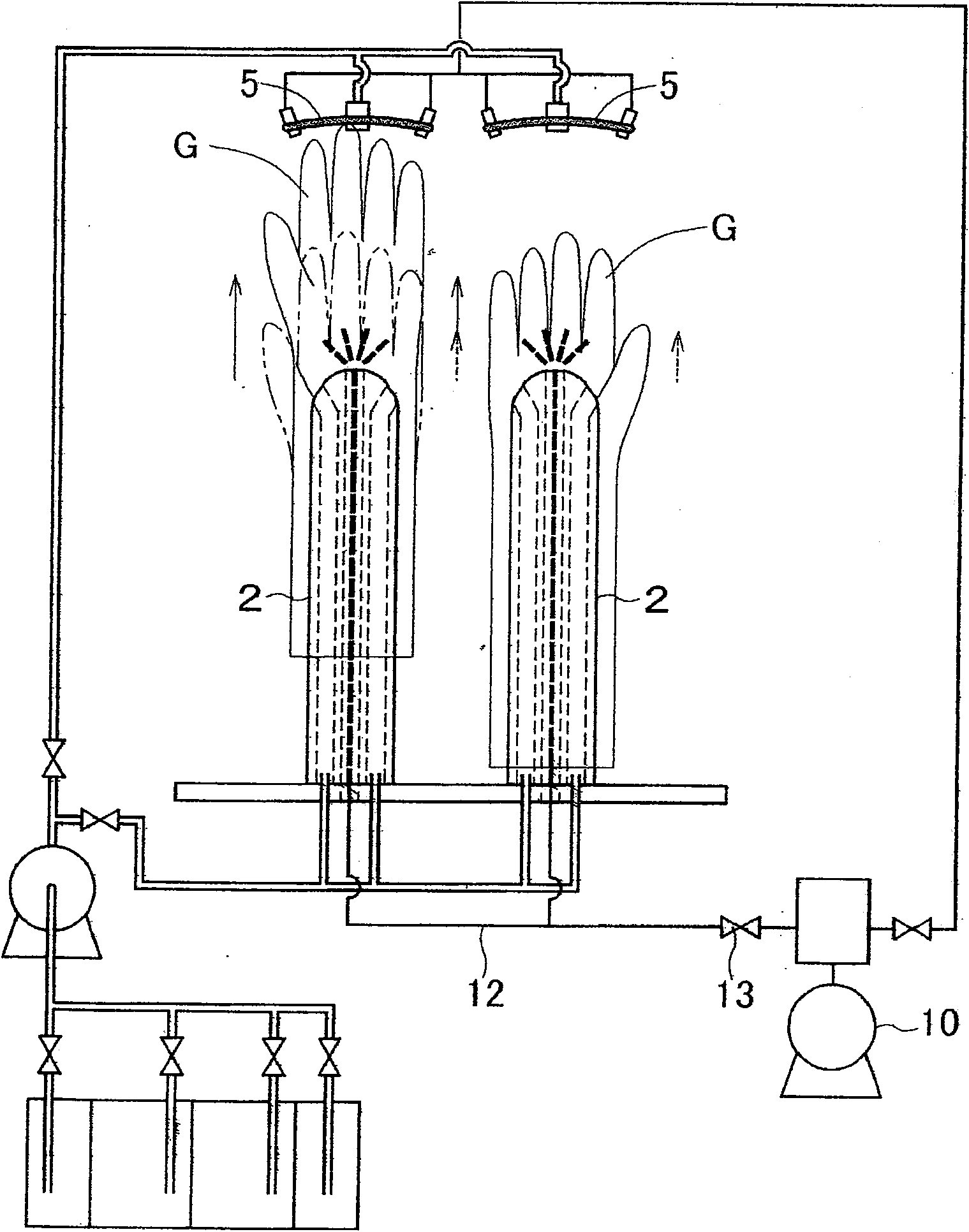

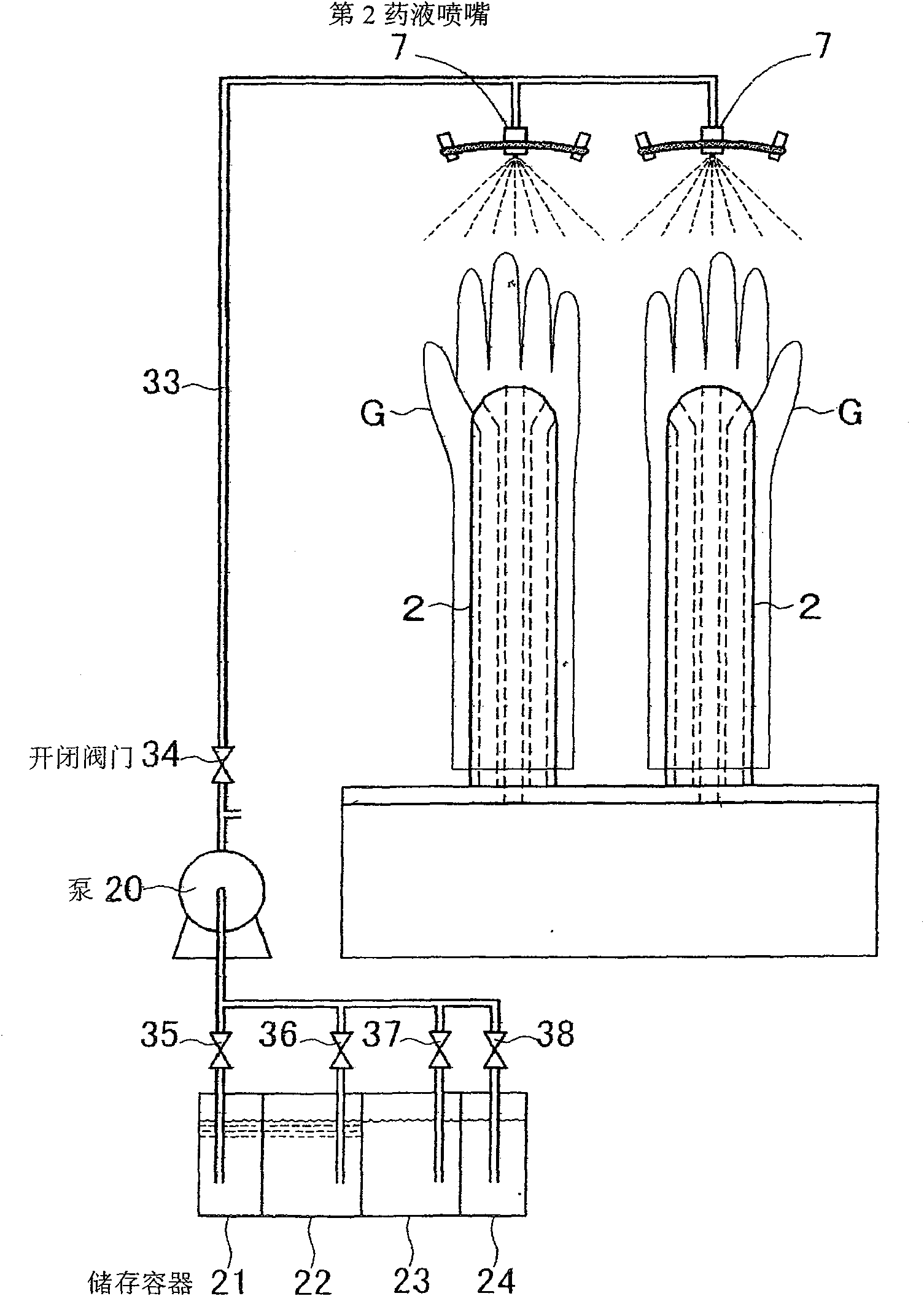

Cleaning system and method of cleaning bag-like article

InactiveCN101835545AEasy to prepareFloating and stableDiagnosticsHollow article cleaningElectrolysisCompound (substance)

A cleaning device and a cleaning method for cleanly and thoroughly cleaning the outer surface and the inner surface of a bag-like article. A support column (2) has a first air nozzle (3) for ejecting air to the inside of a bag-like article (G), a first chemical liquid nozzle (4) for ejecting chemical liquid, a second air nozzle (6) for ejecting air to the outer surface of the bag-like article (G) supported by the support column (2), and a second chemical liquid nozzle (7) for ejecting the chemical liquid. A blower (10) for supplying air and a heater (11) for heating the air supplied are connected to the first air nozzle (3) and the second air nozzle (6). A chemical liquid supply pump (20) is connected to the first chemical liquid nozzle (4) and the second chemical liquid nozzle (7), and tanks (21, 22) for containing strong alkali electrolysis water or strong acid electrolysis water as the chemical liquid are connected to the pump (20). The bag-like article is cleaned while being floated by pressure of air ejected from the first air nozzle (3) of the support column (2), and this enables the inner surface of the bag-like article to be completely cleaned.

Owner:WAKA

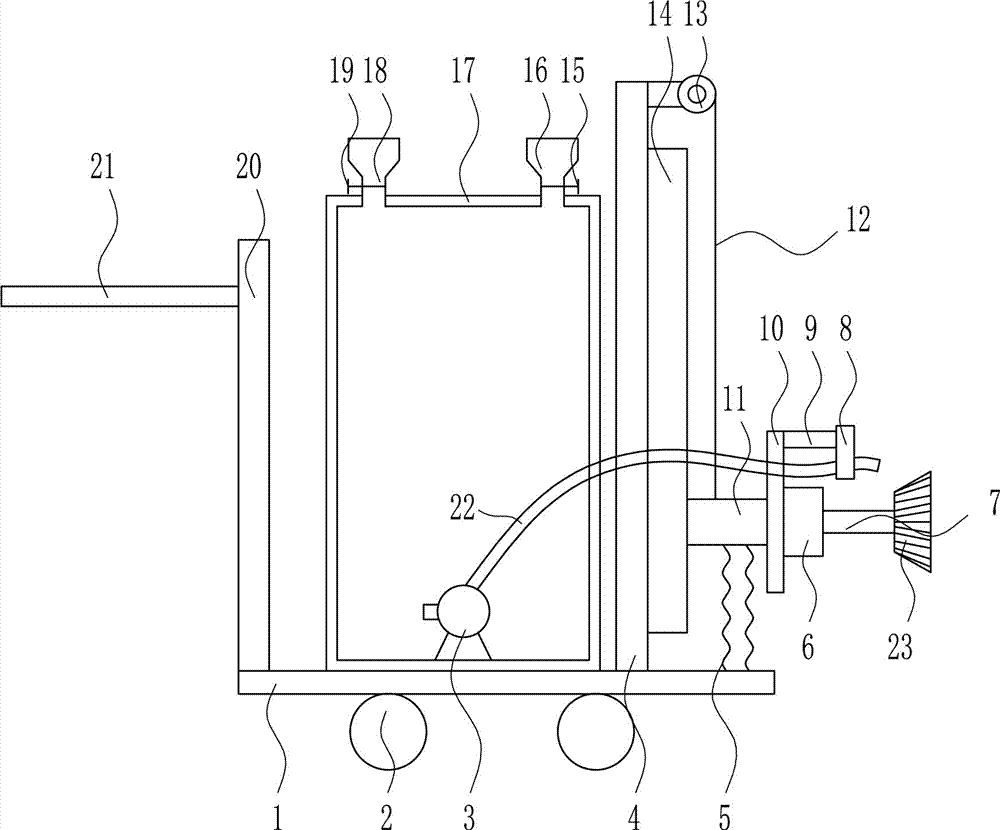

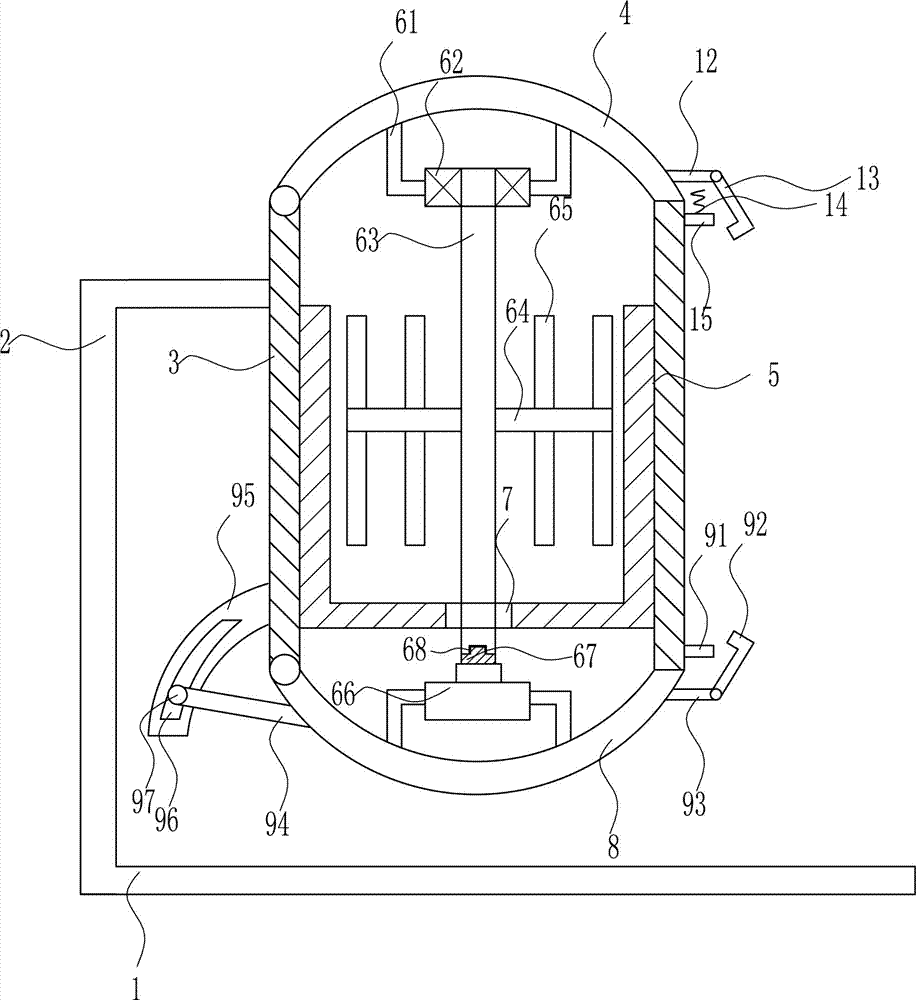

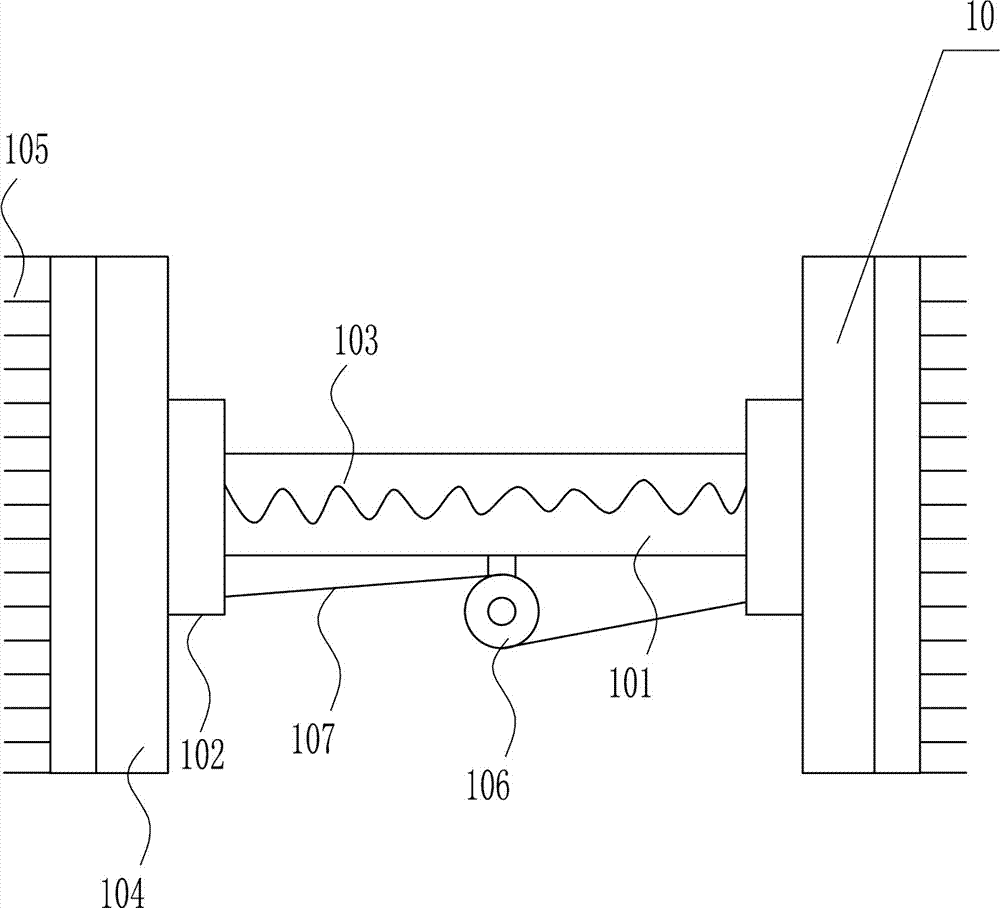

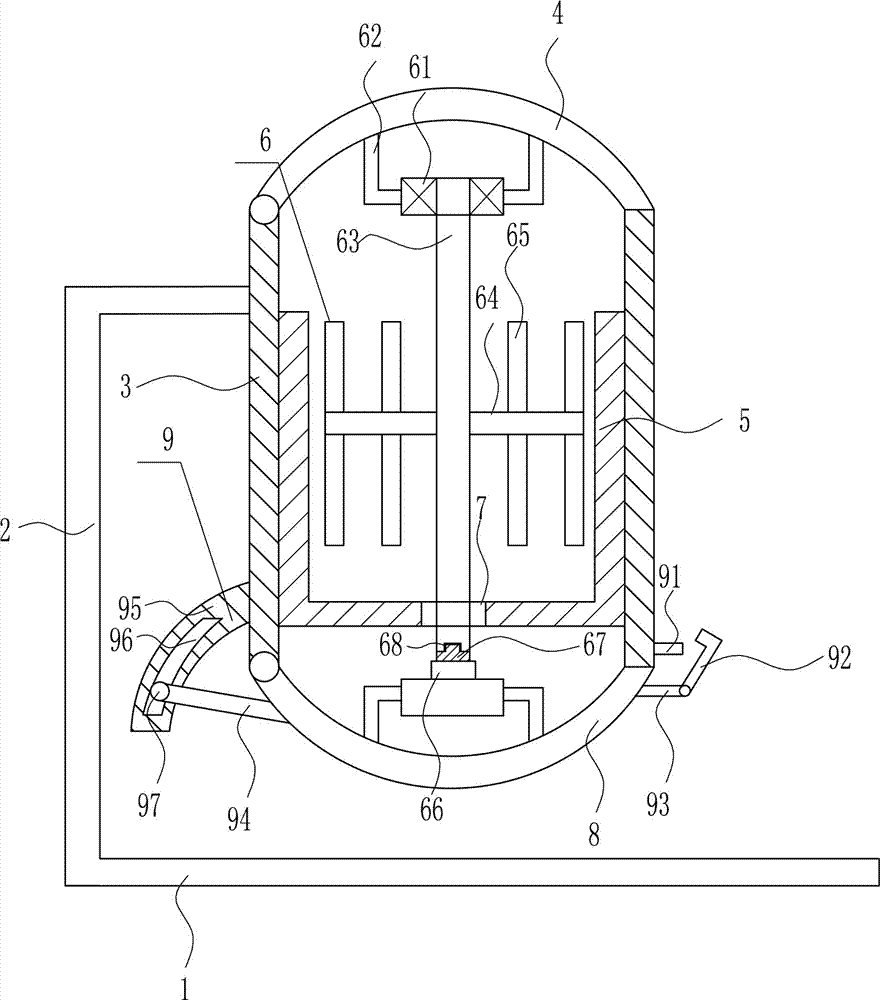

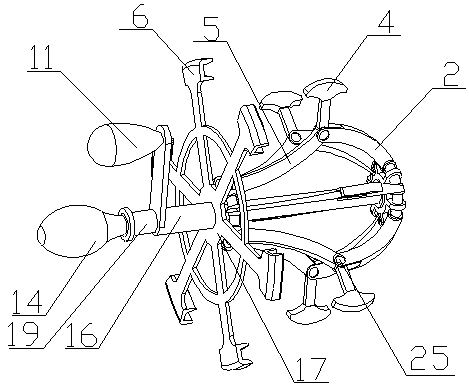

Reaction kettle for rare-earth metallurgy

ActiveCN107233856AAchieve cleaning effectImprove stirring efficiencyShaking/oscillating/vibrating mixersTransportation and packagingControl engineeringRare earth

The invention relates to a reaction kettle, particularly relates to a reaction kettle for rare-earth metallurgy, and aims at solving the technical problem of providing a reaction kettle having uniform stirring, complete washing and high work efficiency for rare-earth metallurgy. To solve the technical problem, the reaction kettle comprises a bottom plate, a left rack, a reaction kettle, an upper cover body, a mixing tank, a stirring device and the like, wherein the left rack is arranged on the left side of the top of the bottom plate, and the reaction kettle is arranged at the right end of the left rack; the upper cover body and a lower cover body are connected at upper and lower ends of the left side of the reaction kettle in a hinged manner; the mixing tank is arranged in the reaction kettle, and the stirring device is arranged in the mixing tank; a through hole is formed in the center of the bottom of the mixing tank; and a locking device is arranged at the lower part of the reaction kettle. The reaction kettle for rare-earth metallurgy has the effects of uniform stirring, complete washing and high work efficiency.

Owner:开化祥盛磁业有限公司

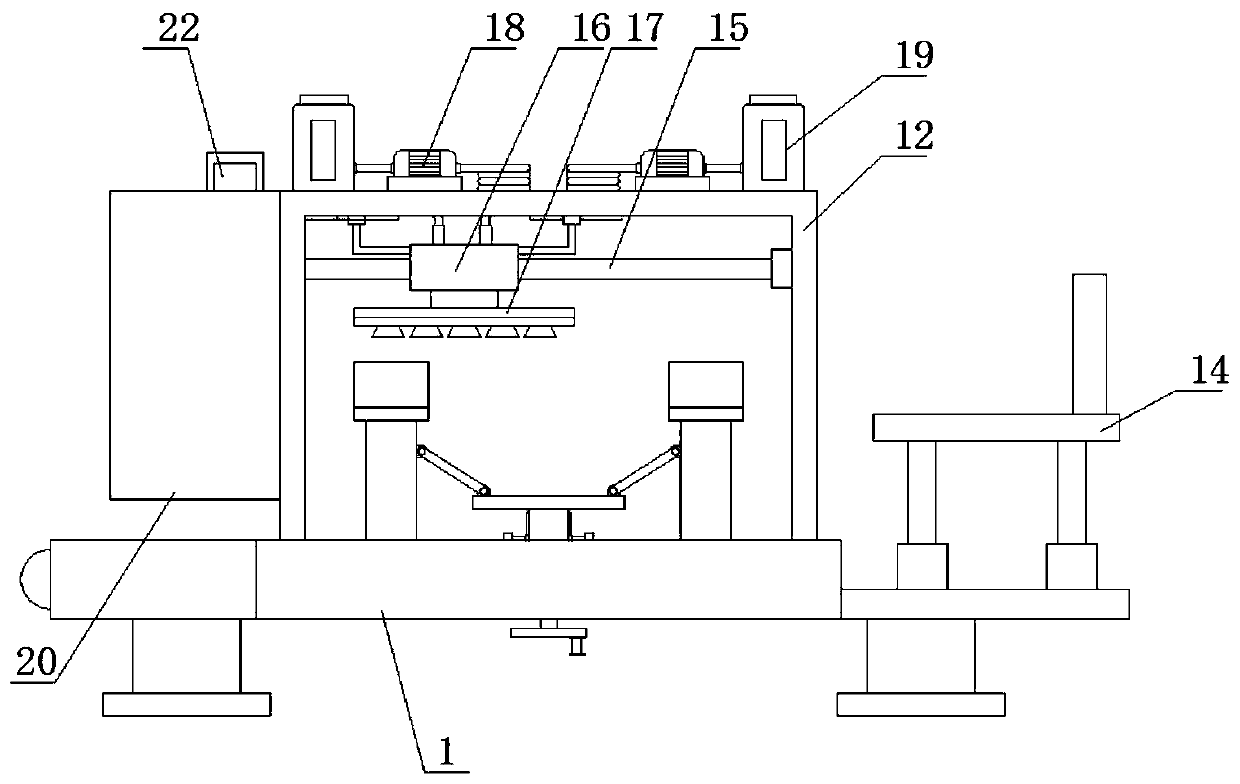

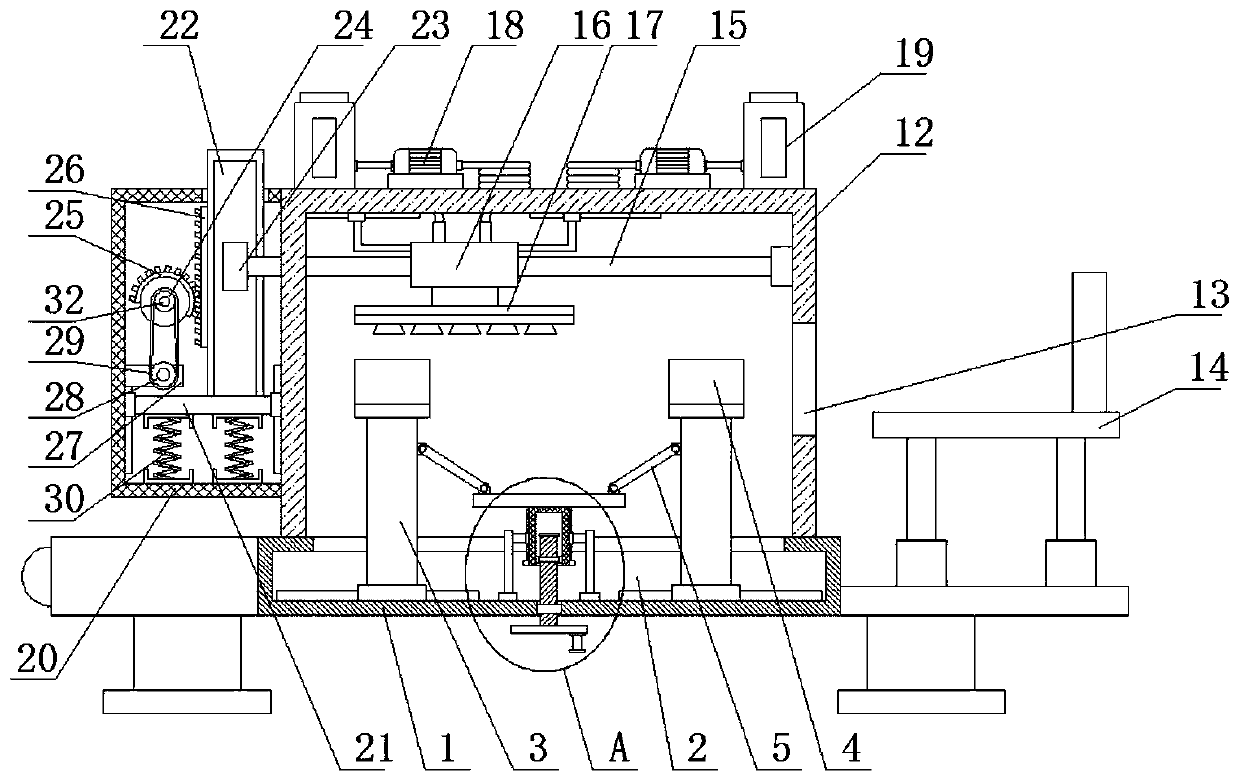

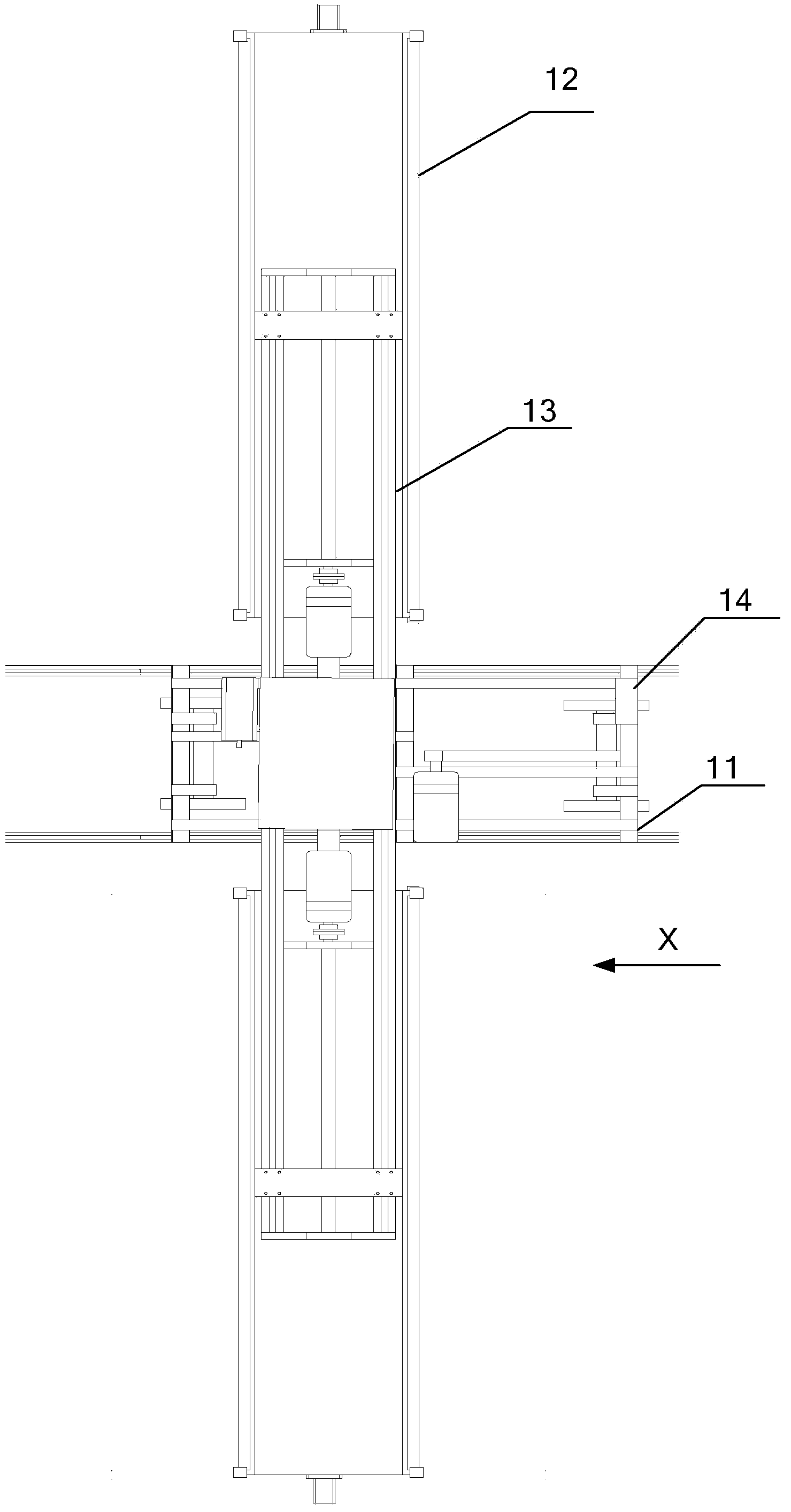

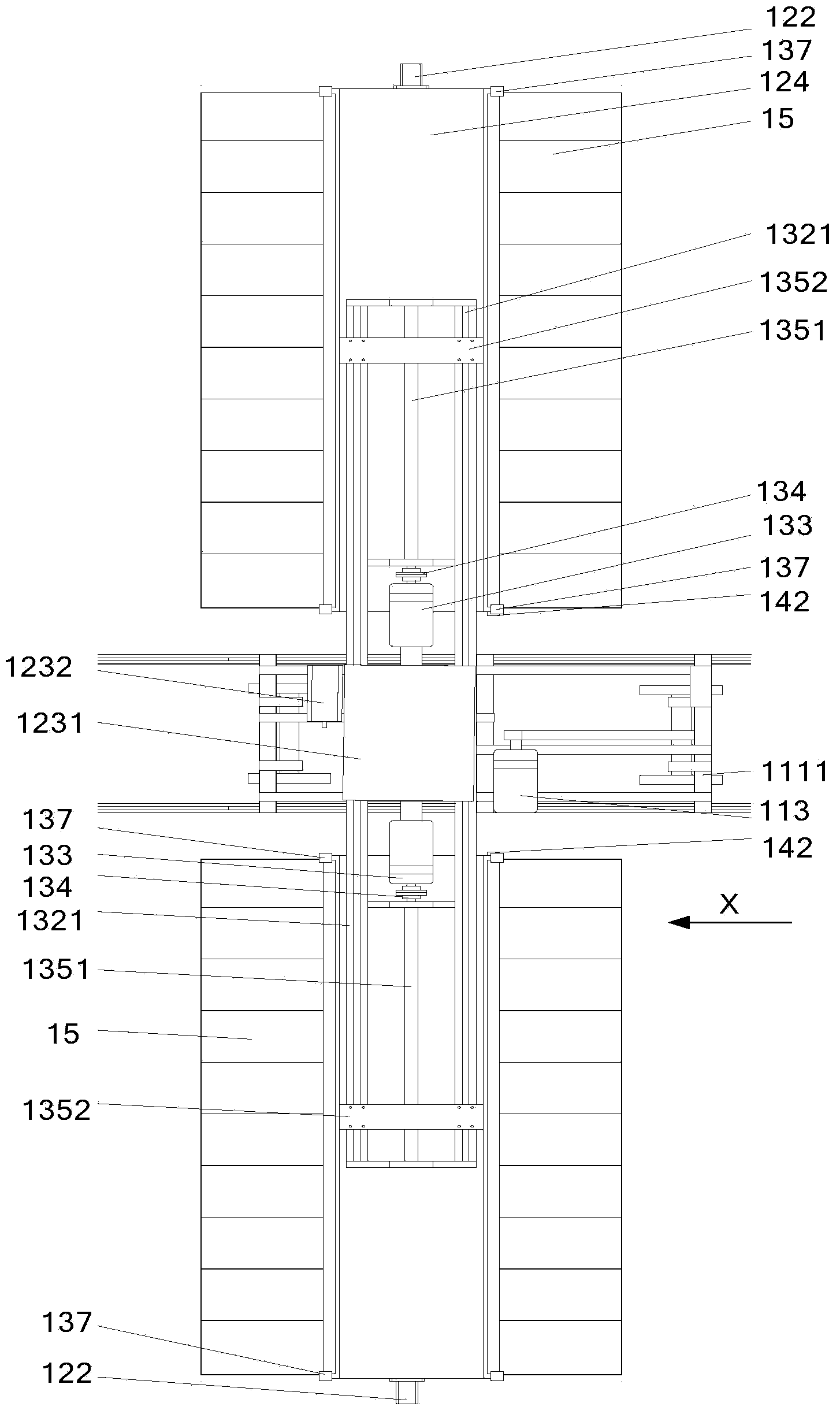

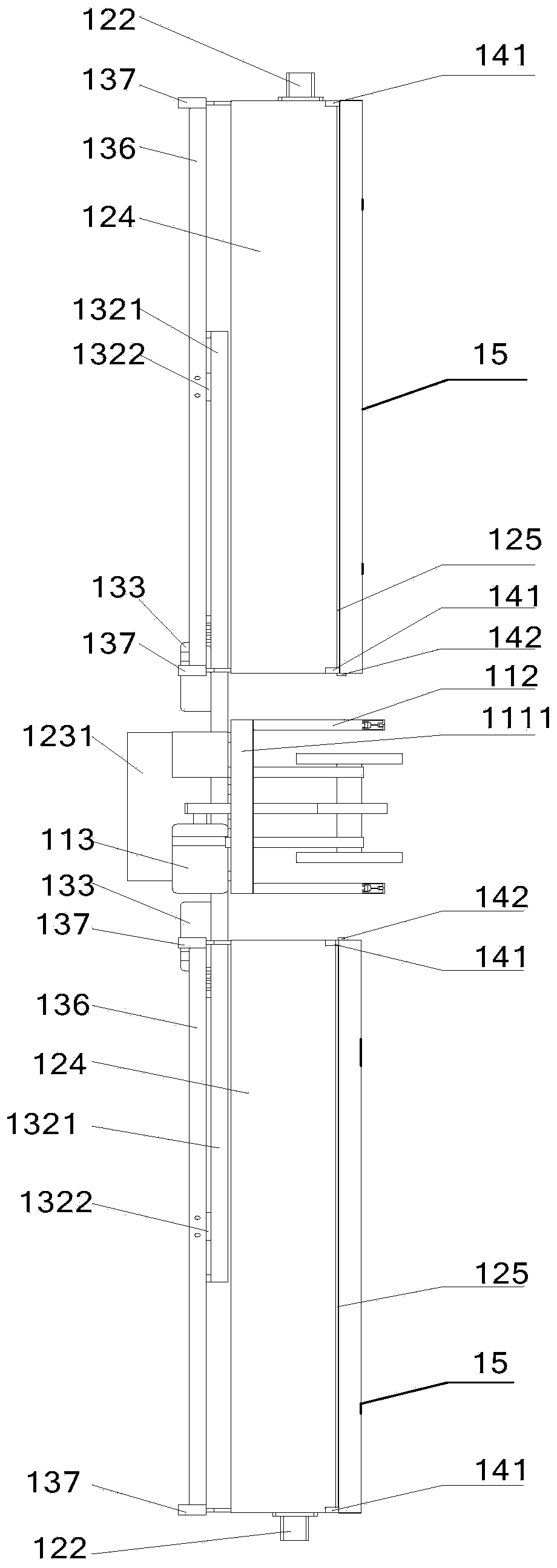

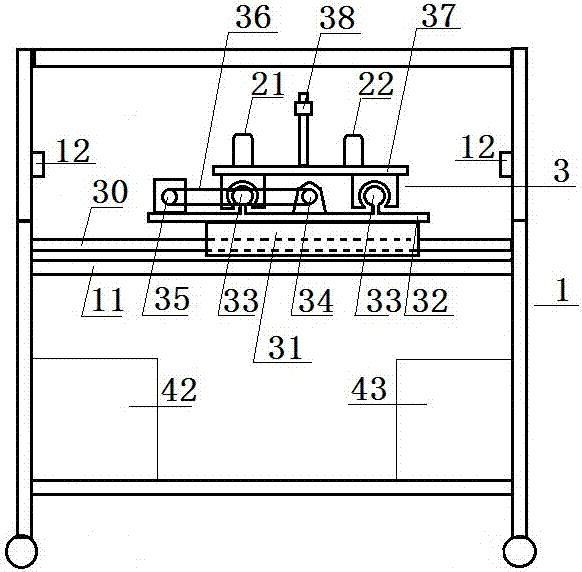

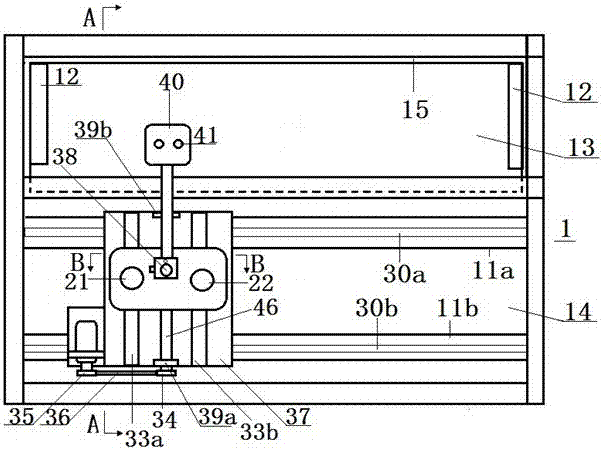

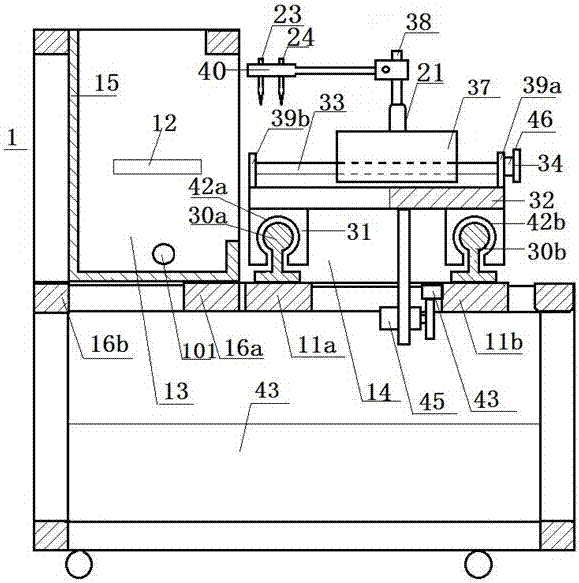

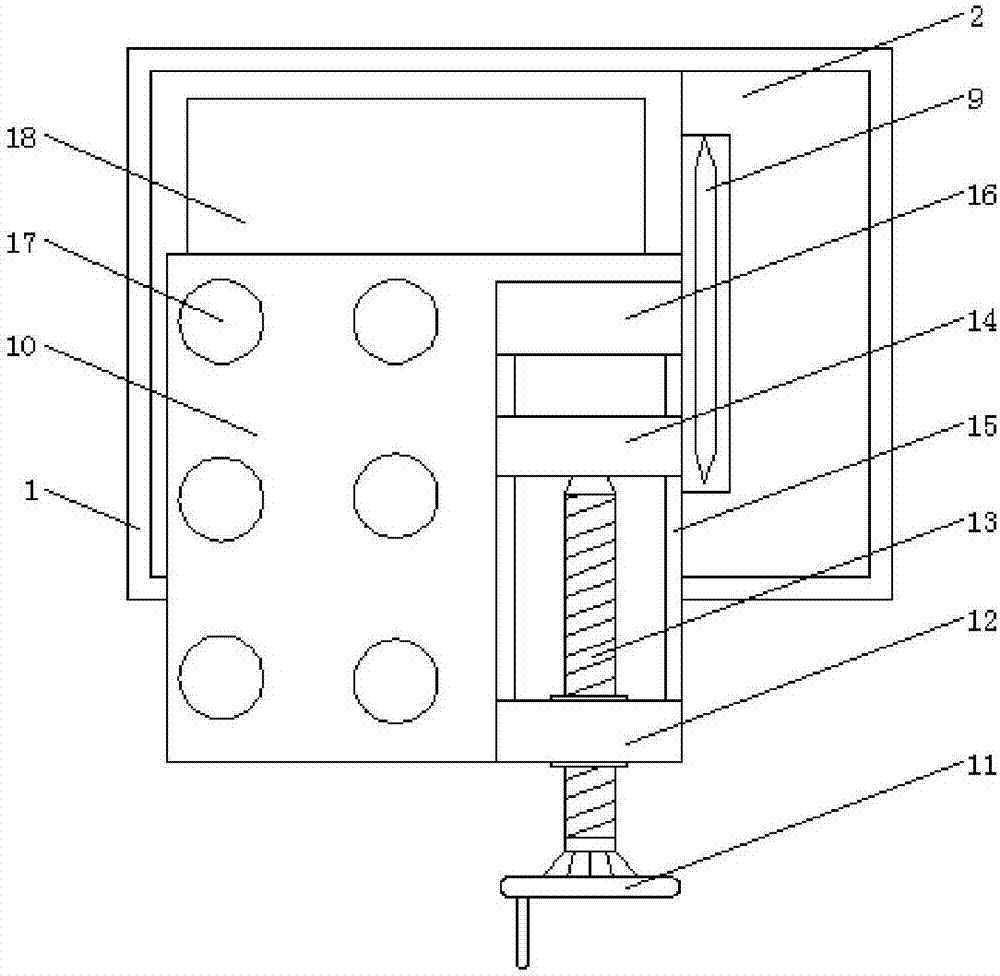

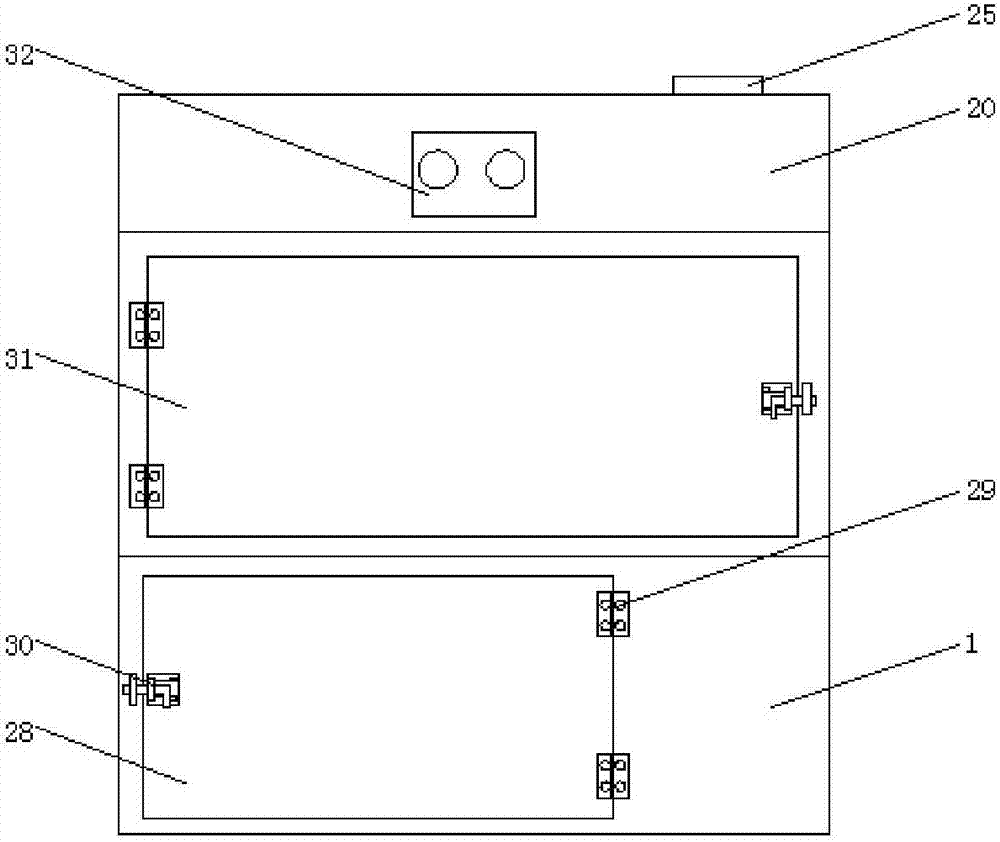

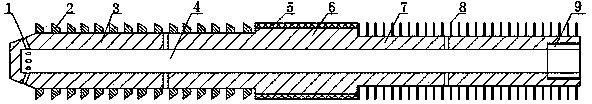

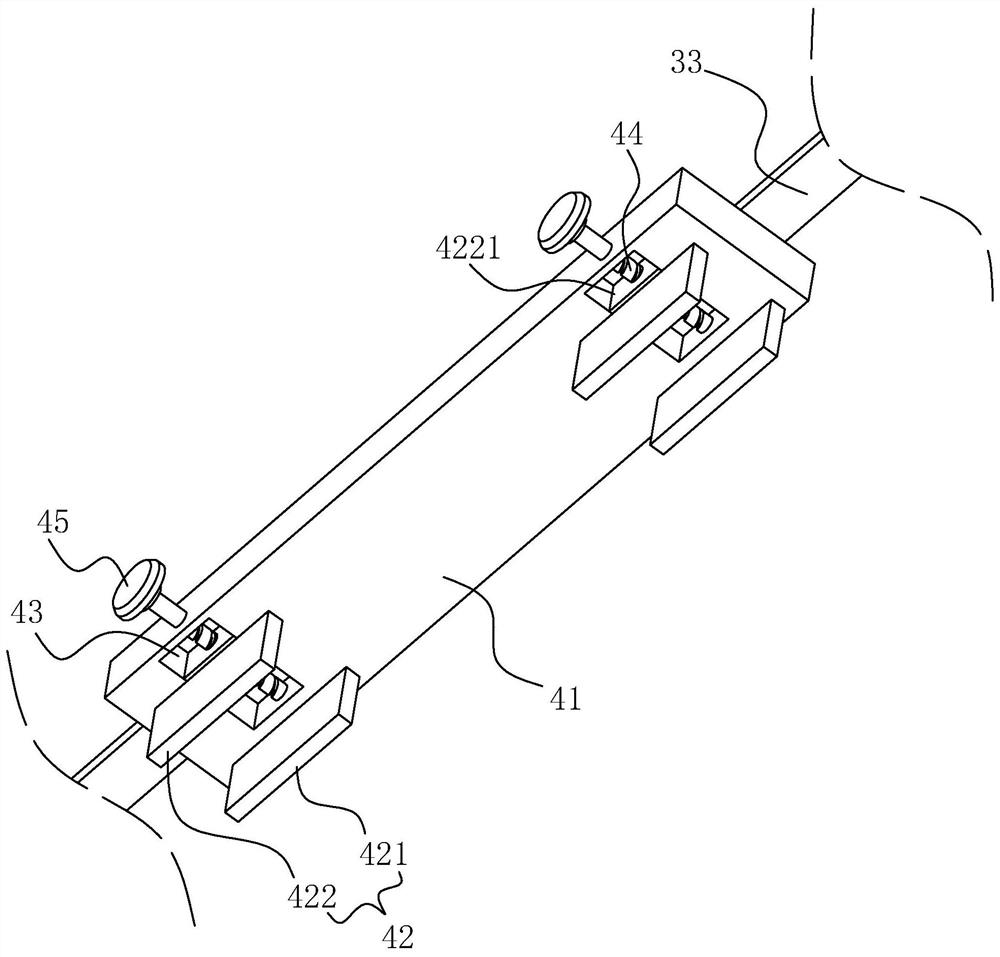

Automatic through hole cleaning equipment for spinneret components

PendingCN107513768APrecise and controllable displacementPrecise and controllable positioningSpinnerette packsSurface layerJet flow

The invention relates to automatic through hole cleaning equipment for spinneret components. The automatic through hole cleaning equipment comprises a support provided with a cleaning area and a displacement control area, and the cleaning area is provided with a high-pressure water cleaning system and an object bearing table which is used for bearing the spinneret components; the high-pressure water cleaning system generates high-pressure water jet flow above or / and below the spinneret components, and the jet flow is used for cleaning attachments on the surface layers of the spinneret components or / and in the spinneret holes; the displacement control area is internally provided with a displacement control mechanism and a control system, and the displacement control mechanism is used for driving the high-pressure water jet flow to conduct reciprocating displacement motion in the horizontal direction or the longitudinal direction of the spinneret components. The control system comprises a touch display screen and a PLC, and the PLC is connected with the displacement control mechanism and the high-pressure water cleaning system separately. Besides, a high-pressure gas system which is used for generating high-pressure gas flow and is connected with the PLC and the displacement control mechanism separately can be further arranged, and is used for cleaning the attachments attached to the surface layers of the spinneret components or / and in the spinneret holes.

Owner:李荣春

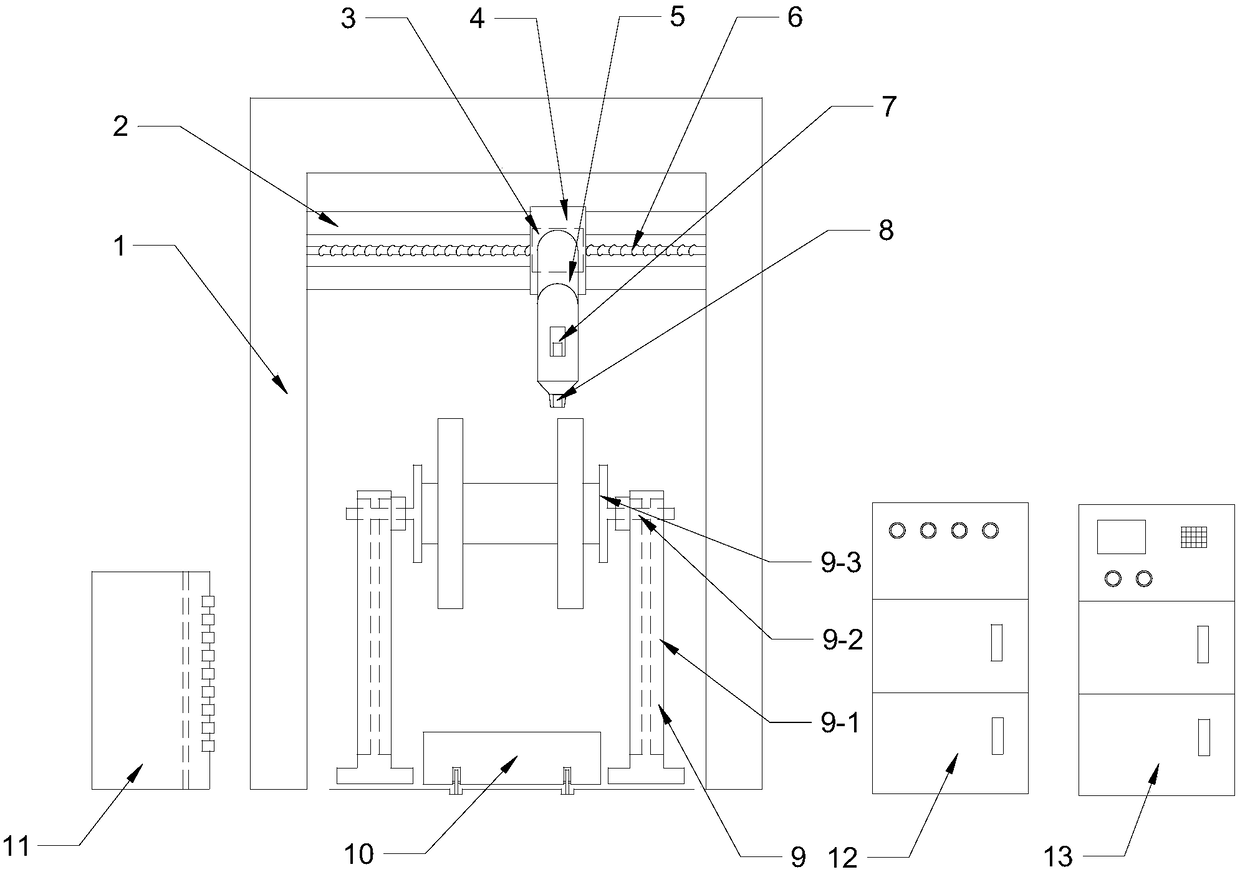

Intelligent laser washing system for wheel sets and bogies

PendingCN108435710AHigh degree of automationReduce work intensityCleaning processes and apparatusTruckRail traffic

The invention relates to the field of rail traffic washing equipment, in particular to an intelligent laser washing system which is used for washing metal components such as wheels sets and bogies oftrucks, passenger cars, metros, bullet trains and locomotive inspection and repair bases. The intelligent laser washing system comprises a portal frame. A linear rolling guide rail pair and a horizontal ball screw pair are installed on the portal frame. A fixing box is fixed on a moving part of the rolling guide rail pair. A ball screw nut is installed on the ball screw pair. The ball screw nut isfixedly connected with a back plate of a robot through the fixing box. A machine vision system is installed on an arm of the robot. A laser head is installed on the portion under the wrist joints ofthe robot. According to the system, the automation degree is improved, working intensity of workers is reduced, operation efficiency is improved, a sewage treatment system is not needed, consumable items are not needed during operation, return on investment can be obtained fast, the operation and maintenance cost is reduced, long-distance operation is achieved, the parts which cannot be reached easily through the traditional washing method can be washed, and the system is suitable for being popularized in the field of the rail traffic washing equipment.

Owner:德阳瑞方智能交通设备科技有限公司

Cleaning device for live line tool

The invention provides a cleaning device for a live line tool. The cleaning device comprises a water tank, a clamping manipulator is arranged on the water tank, a rotating cylinder is arranged at the upper end of the clamping manipulator, the clamping manipulator is driven by the rotating cylinder to rotate, a placing table is arranged on the left side of the water tank, a drying device is arranged on the right side of the water tank, the clamping manipulator grabs the tool from the placing table and puts the tool into the water tank for cleaning, and the tool is placed into the drying device for drying at last. The clamping manipulator clamps the live line tool and put the live line tool into the water tank, and cleaning is conducted on the live line tool with cleaning fluid in the water tank; the drying device is arranged, drying is conducted on the live line tool, and rusting caused by water on the surface of the live line tool is avoided; stirring blades are arranged to stir the cleaning fluid in the water tank, and cleaning on the live line tool in the water tank is more complete; a contact sensor is arranged, and it is avoided that the clamping manipulator conducts idle work.

Owner:HUBBELL ELECTRIC WUHU

Part machining cutting device with dust removing function

InactiveCN107262811AClean completelyGood dust removal effectShearing machinesMaintainance and safety accessoriesPulleyNozzle

The invention discloses a parts processing and cutting device with the function of dust removal, which comprises a fixed box, a first partition is fixedly connected between the two sides of the inner wall of the fixed box, and the bottom of the inner wall of the fixed box and the first partition are fixed. A second partition is fixedly connected between them, the bottom of the inner wall of the fixed box is fixedly connected with a motor, and the output shaft of the motor is fixedly connected with a first pulley, and the surface of the first pulley is connected with a second belt through a belt drive. wheel, and the shaft center of the second pulley is fixedly connected with a transmission shaft, and the surface of the transmission shaft is fixedly connected with a cutting piece. The invention relates to the technical field of mechanical processing equipment. The parts processing and cutting device with the function of dust removal enables the cut dust and cuts to fall into the dust storage box through the dust leakage hole and the dust leakage hole, and the dust will be blown into the dust storage box by the wind. The dust storage box is cleaned with water by the nozzle, so that the cutting device can be cleaned quickly and completely after use, and the dust removal effect is good.

Owner:CHENZHOU JINTONG INFORMATION TECH CO LTD

Inner-oil-tube cleaning tool

The invention discloses an inner-oil-tube cleaning tool. The inner-oil-tube cleaning tool sequentially comprises a tool body section (3), a polishing section (6) and a hairbrush section (7) from left to right, a plurality of annular scrapers (2) are arranged on the circumference face of the outer side of the tool body section (3), a polishing layer (5) is arranged on the circumference face of the outer side of the polishing section (6), the outer lateral side of the hairbrush section (7) is covered with a steel wire hairbrush (8), and an inner thread connector (9) is further arranged on the end portion of the right side of the hairbrush section (7). The inner-oil-tube cleaning tool in the design is complete and thorough in cleaning, low in cost and long in service life, and brings convenience to cleaning.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

Hydraulic pipe orifice cleaning device

ActiveCN107617610ASo as not to damageEasy to useEdge grinding machinesHollow article cleaningEngineeringScrew thread

The invention discloses a hydraulic pipe orifice cleaning device, in particular a device for cleaning pipe orifices and the inner and outer walls of the pipe orifices through internal support of hydraulic pipes and rotation of multiple clamping blocks along the pipe orifices. The hydraulic pipe orifice cleaning device is characterized in that a fixed handle is positioned at one end of a fixed shaft; a thread is arranged on the surface of the fixed shaft; a thread sleeve sleeves the fixed shaft, and is matched with a thread on the surface of the fixed shaft; a retainer ring sleeves one end of the thread sleeve; a rotating ring is positioned at the other end of the thread sleeve; a main support ring is connected with a rotating ring through multiple fixed lugs; the distances between two adjacent fixed lugs on the main support ring are the same; a connecting ring is positioned at the other end of the fixed shaft through a bearing; an auxiliary support ring is connected with the connectingring through multiple fixed lugs; the multiple fixed lugs on the auxiliary support ring are corresponding to the multiple fixed lugs on the main support ring one to one; one ends of multiple transmission rods are positioned on the auxiliary support ring at equal intervals; and one ends of the transmission rods are positioned between two adjacent fixed lugs on the auxiliary support ring.

Owner:江苏华淼电子科技有限公司

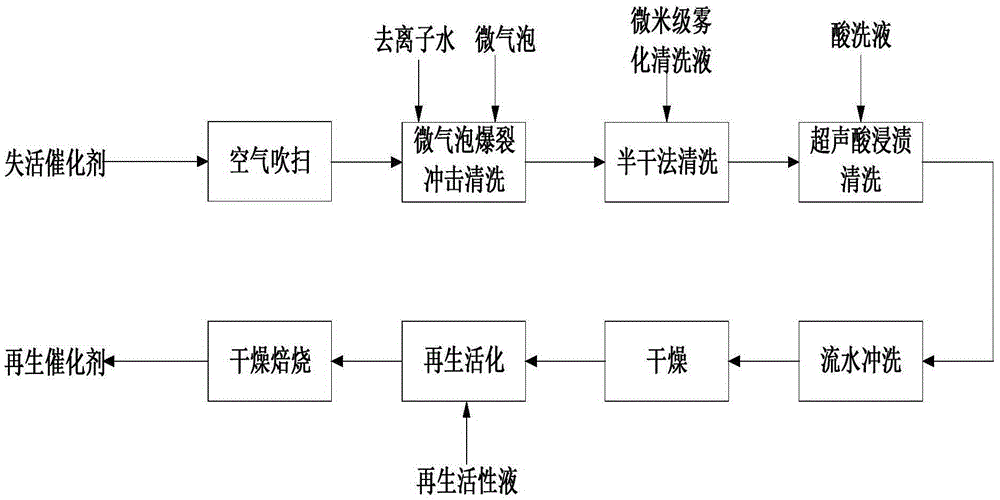

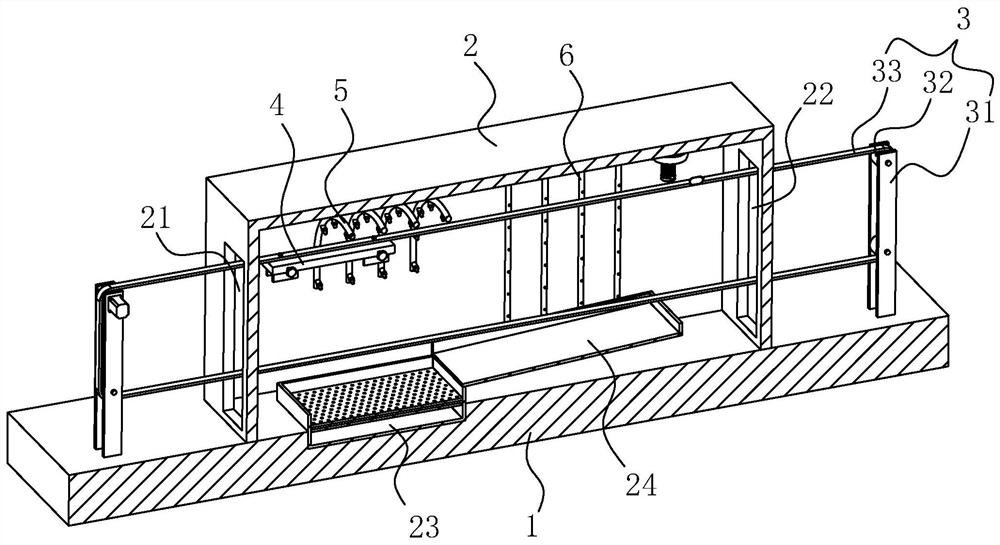

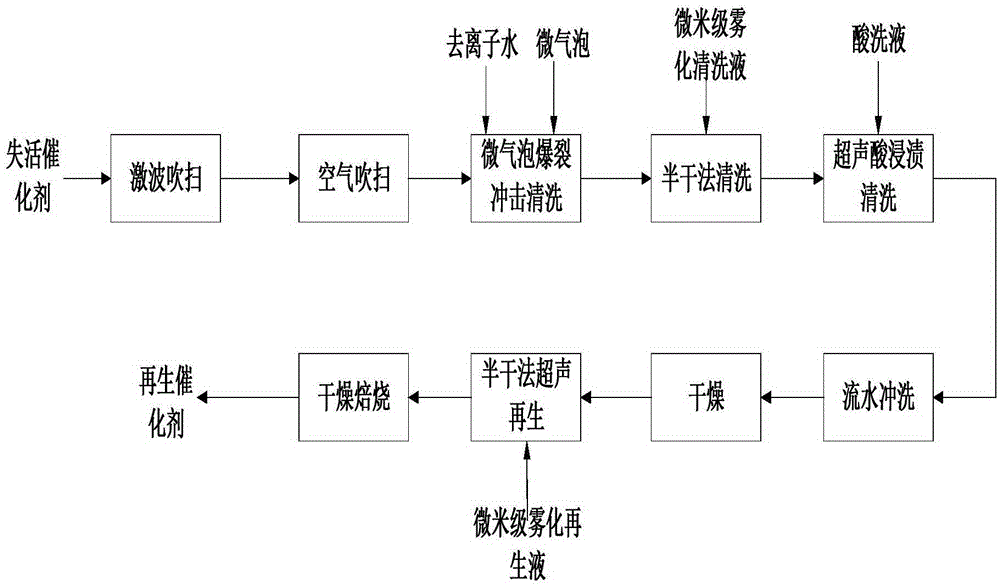

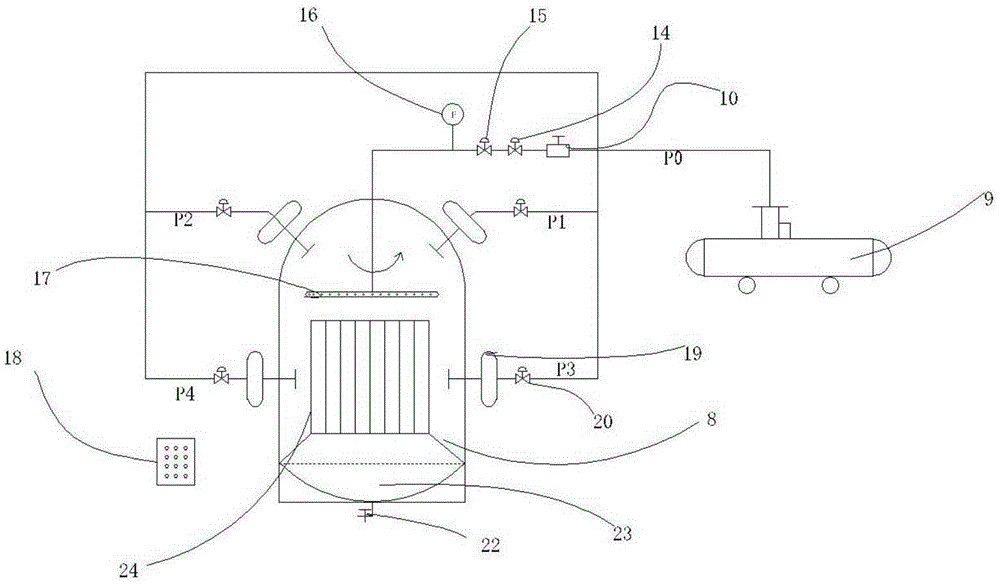

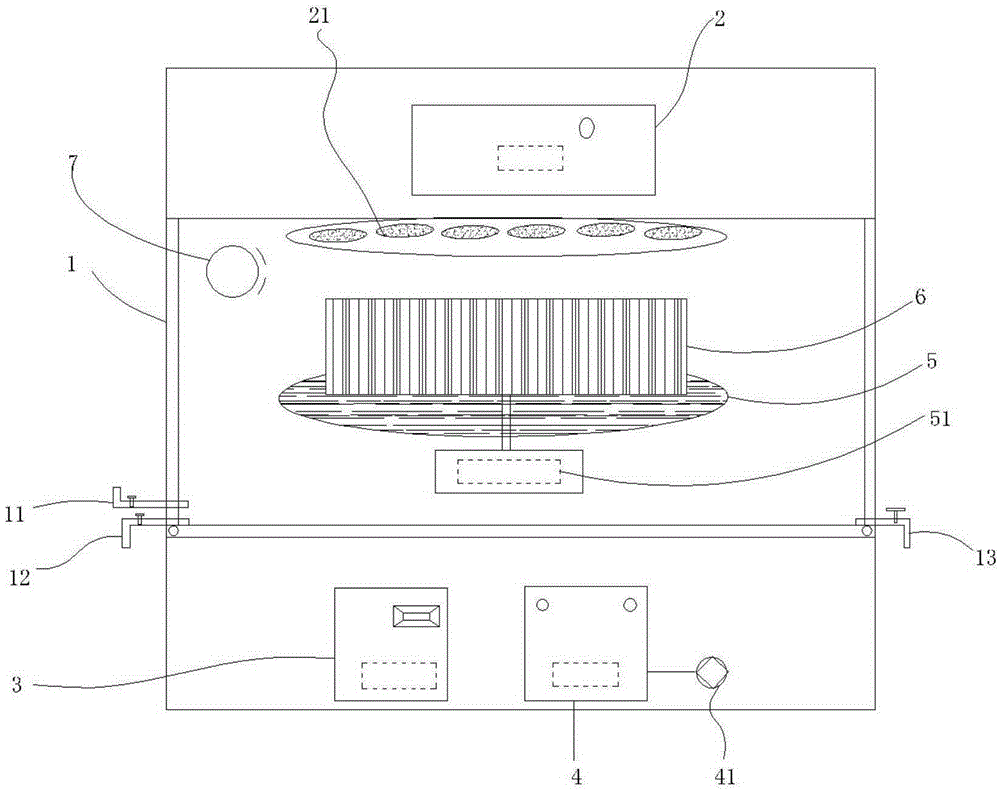

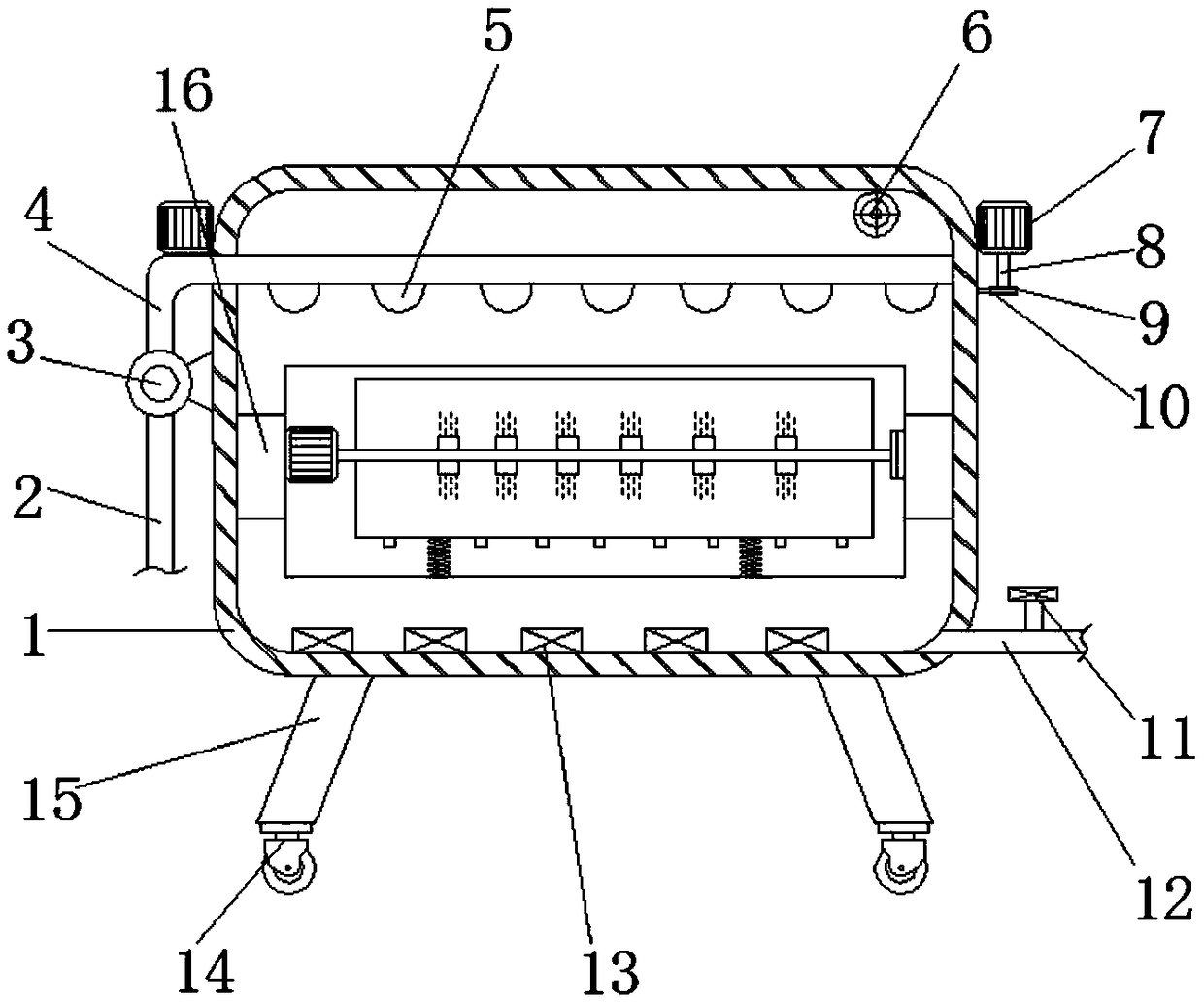

Closed cleaning device and method for inactivate SCR denitration catalyst and regeneration system and method

InactiveCN105363500AIncrease profitRestore surface structureDispersed particle separationCatalyst regeneration/reactivationBiological activationRegenerative system

The invention relates to a closed cleaning device and method for an inactive SCR denitration catalyst and a regeneration system and method. The closed cleaning device comprises a cleaning body box, an ultrasonic atomizer, an ultrasonic washing machine, a microbubble generator, a catalyst cleaning rotary plate and a micro negative-pressure suction device. The regeneration method includes the following steps that firstly, air blowing and sweeping are carried out; secondly, the inactivative SCR denitration catalyst is flushed and processed through running water by means of the microbubble explosive burst impact cleaning method, semi-dry method cleaning and acid steeping cleaning; thirdly, drying is carried out; fourthly, regeneration and activation are conducted to obtain a regenerated denitration catalyst. Regeneration of the inactive catalyst can be achieved. Compared with the common regeneration technology, cleaning achieved through the technology is thorough. Meanwhile, the utilization rate of a cleaning solution can be greatly increased, and the surface and the porous structure of the inactive catalyst can be restored to the largest extent.

Owner:FUJIAN ZIJIN ENVIRONMENT ENG TECH +1

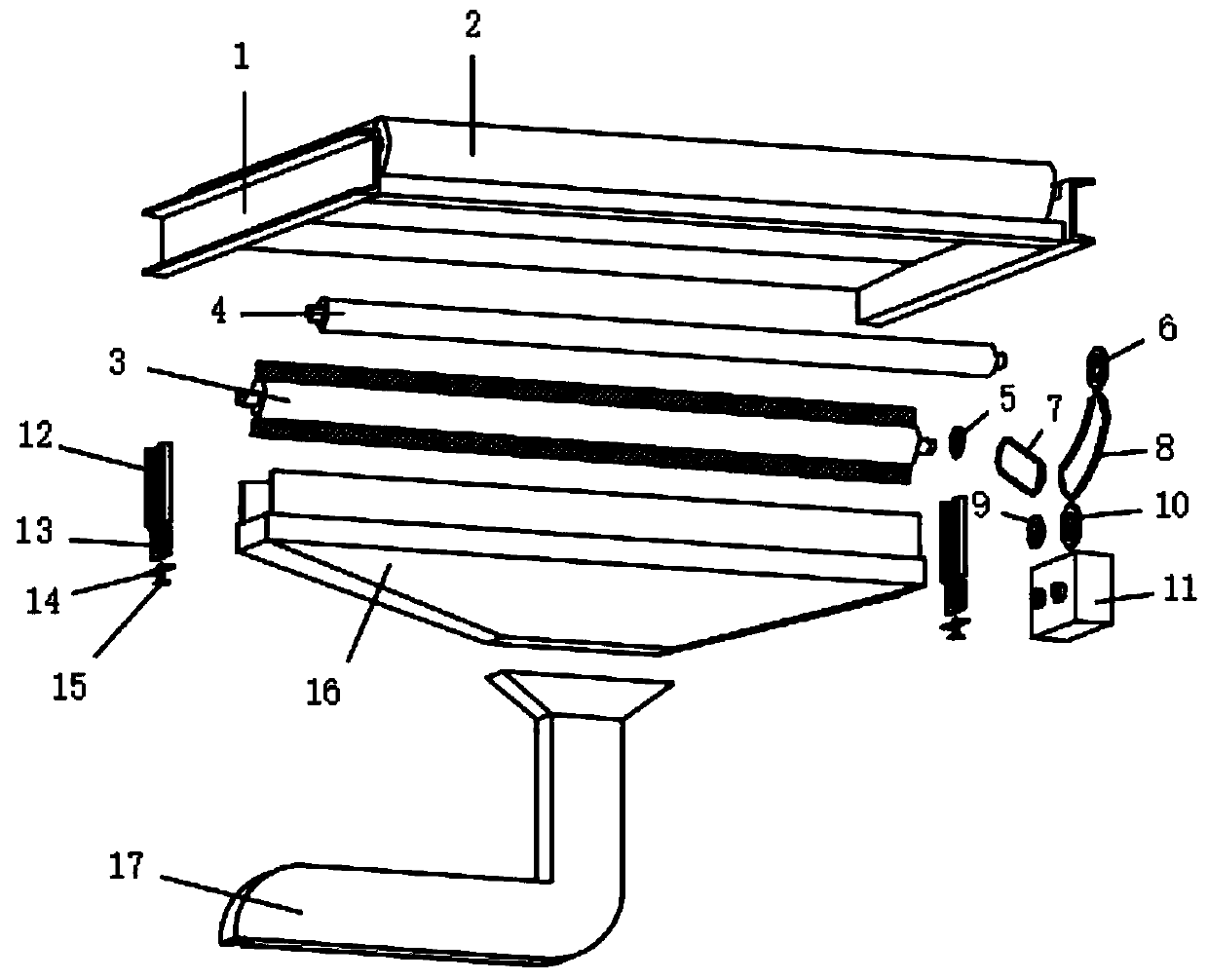

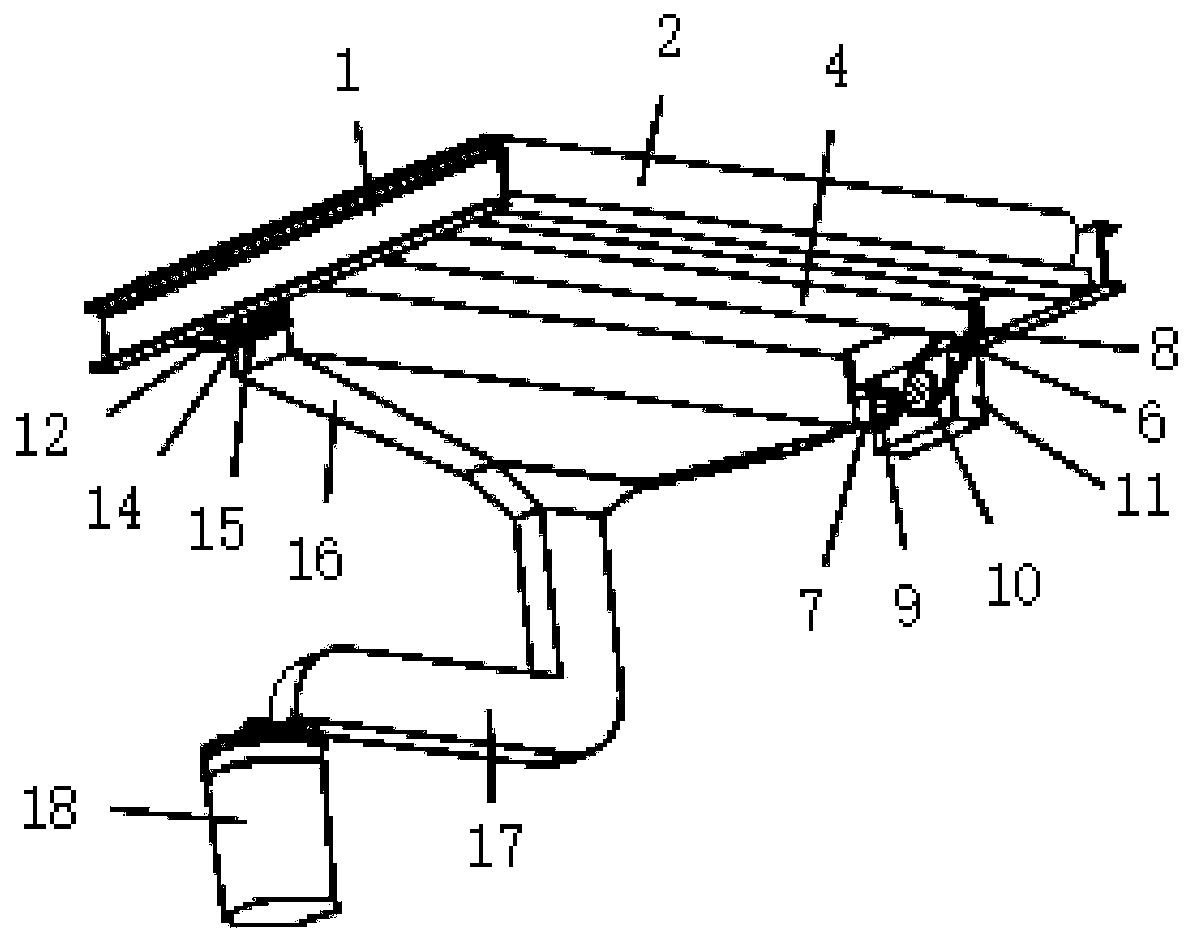

Aluminum veneer cleaning equipment

InactiveCN112427371AClean completelyReduce moistureDrying gas arrangementsCleaning using liquidsSingle plateEngineering

The invention relates to aluminum veneer cleaning equipment, and belongs to the field of aluminum veneer manufacturing. The equipment comprises a base; a cleaning box is arranged on the base; a feeding opening is formed in one side wall of the cleaning box; a discharging opening is formed in the side wall, opposite to the feeding opening, of the cleaning box; the feeding opening and the discharging opening communicate with the interior of the cleaning box at the same time; a conveying frame is arranged on the base; a conveying belt is arranged on the conveying frame; the conveying belt is arranged in the cleaning box in a penetrating mode through the feeding port and the discharging port; a fixing device used for fixing an aluminum veneer is arranged on the conveying belt; when the fixingdevice fixes the aluminum veneer, the aluminum veneer is in a vertical state, and the plate face of the aluminum veneer is parallel to the conveying direction of the conveying belt; cleaning devices used for cleaning the aluminum veneer are arranged on the inner side walls, located on two sides of the conveying belt, of the cleaning box; and a water collecting tank is arranged at the bottom of thecleaning box. The aluminum veneer cleaning equipment has the effect that aluminum veneers can be cleaned more completely.

Owner:四川成功新型材料科技有限公司

Automatic cleaning and reeling device for fire hose

The invention discloses an automatic cleaning and reeling device for a fire hose, and belongs to the field of fire protection equipment. The automatic cleaning and reeling device comprises a box bodyinternally containing water. A cleaning mechanism and a reeling mechanism are arranged in the box body. The cleaning mechanism comprises a sizing assembly, a walking assembly and cleaning brushes. Thereeling mechanism comprises an I-shaped winding disc, a rotation shaft and a reeling motor. The sizing assembly comprises a rotary disc and at least three winding rods fixed to the rotary disc. A fixing shaft penetrates the center position of the rotary disc and is provided with a walking groove for the walking assembly to move. A drive gear driven by a rotation motor and externally engaged withthe rotary disc is arranged beside the rotary disc. The cleaning brushes are fixed to the top and the bottom of a forward and reverse rotation motor, the sides, towards the fixing shaft, of the winding rods, and the inner wall of the box body. The I-shaped winding disc sleeves the fixing shaft or the rotation shaft, and the rotation shaft is connected to a drive shaft of the reeling motor througha key groove. The automatic cleaning and reeling device can integrally clean the hose, the cleaning stroke can be increased, cleaning is sufficient and complete, the cleaning effect is good, and watercan be saved as well.

Owner:张丽华

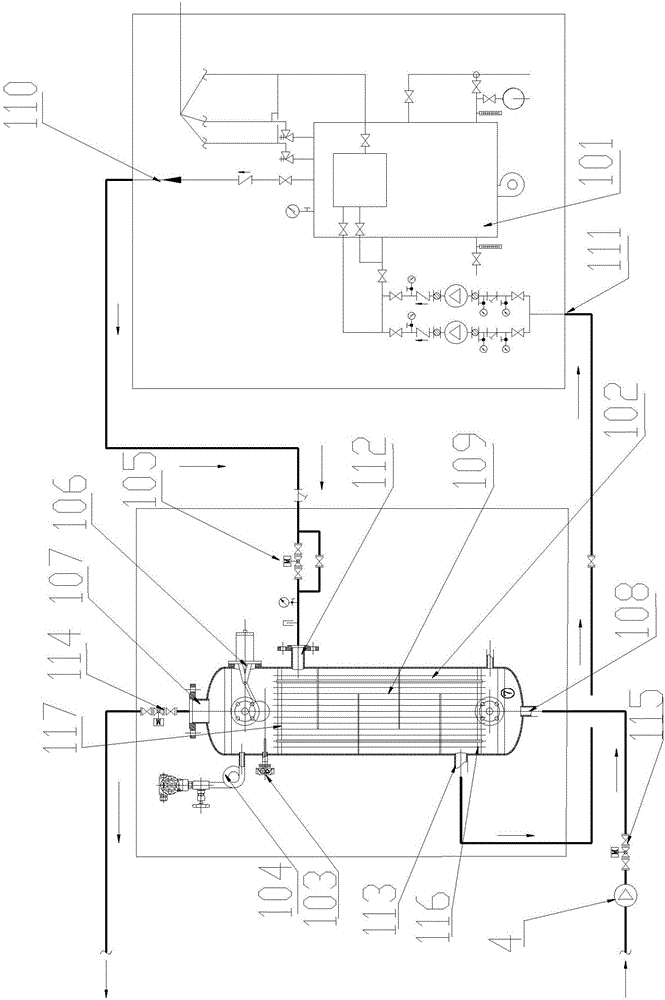

Vapor phase cleaning system and method of propellant storage tank

The invention discloses a vapor phase cleaning system of a propellant storage tank. The vapor phase cleaning system comprises a cleaning agent storage tank used for storing a cleaning agent, a cleaning agent steam generation device, a conveying device and a cooling system, wherein the input end of the conveying device is connected with the cleaning agent storage tank; the output end of the conveying device is connected with the cleaning agent steam generation device; the output end of the cleaning agent steam generation device is connected with the propellant storage tank; and the propellant storage tank is provided with the cooling system used for cooling steam of the cleaning agent. The vapor phase cleaning system is applicable to the propellant storage tank, can be automatically controlled, and is safe and reliable; the cleaning agent is small is dosage and can be repeatedly utilized multiple times, and cost is reduced; and in the propellant storage tank, the dissolution effect of the vaporous cleaning agent is combined with the flushing effect of the liquid cleaning agent, so that the propellant storage tank is cleaned more completely, and the cleaning effect is better.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

Garbage cleaning equipment for daily maintenance of V-shaped adhesive tape of bridge expansion joint

The invention discloses a garbage cleaning equipment for daily maintenance of a V-shaped adhesive tape of a bridge expansion joint. The garbage cleaning equipment for daily maintenance of the V-shaped adhesive tape of the bridge expansion joint comprises a frame, an engine, a dust collection box, a dust collection cover and a chassis, wherein the engine is mounted at the upper part of the frame; the dust collection box is mounted at the front end of the frame; the dust collection cover is mounted on the lower side of the front end of the frame; and the chassis is mounted at the bottom of the frame. A fan is also mounted on the side wall of the dust collection box; an air inlet pipe is mounted between the fan and the dust collection box; and a dust collection pipe is mounted between the dust collection box and the dust collection cover. According to the garbage cleaning equipment for daily maintenance of the V-shaped adhesive tape of the bridge expansion joint, the engine drives a transmission shaft in the dust collection cover to rotate so that mounting discs and a steel brush are driven to rotate so as to clean sundries in the expansion joint; meanwhile, the fan is opened to suck the cleaned sundries into the dust collection box from the dust collection cover so that the interior of the V-shaped adhesive tape of the expansion joint can be effectively cleaned.

Owner:JIANGSU PINGSHAN TRANSPORTATION FACILITIES CO LTD

Liquid phase plasma surface cleaning method for tungsten-rhenium wire

The invention discloses a liquid phase plasma surface cleaning method for a tungsten-rhenium wire. Equipment comprises a control power supply, an output power supply, a cleaning tank, a first electrode and a second electrode. According to the liquid phase plasma surface cleaning method, the tungsten-rhenium wire is taken as the first electrode, the tungsten-rhenium wire is matched with the second electrode and a neutral salt cleaning solution, plasma can be produced on the surface of the tungsten-rhenium wire after electrification, ultrasonic oscillation is taken as assistance for removing greasy dirt and impurities on the surfaces of parts, and the liquid phase plasma surface cleaning method has the characteristics of thorough and complete cleaning and bright and tidy smooth; the cleaning solution selects a sodium bicarbonate solution which does not contain acid and alkali, the treatment of the waste solution is not required, and the harm to an environment can also be avoided; and the tungsten-rhenium wire is rolled up for batch cleaning, the cleaning quantity is large, and the cleaning efficiency is high.

Owner:CHONGQING ACADEMY OF SCI & TECH

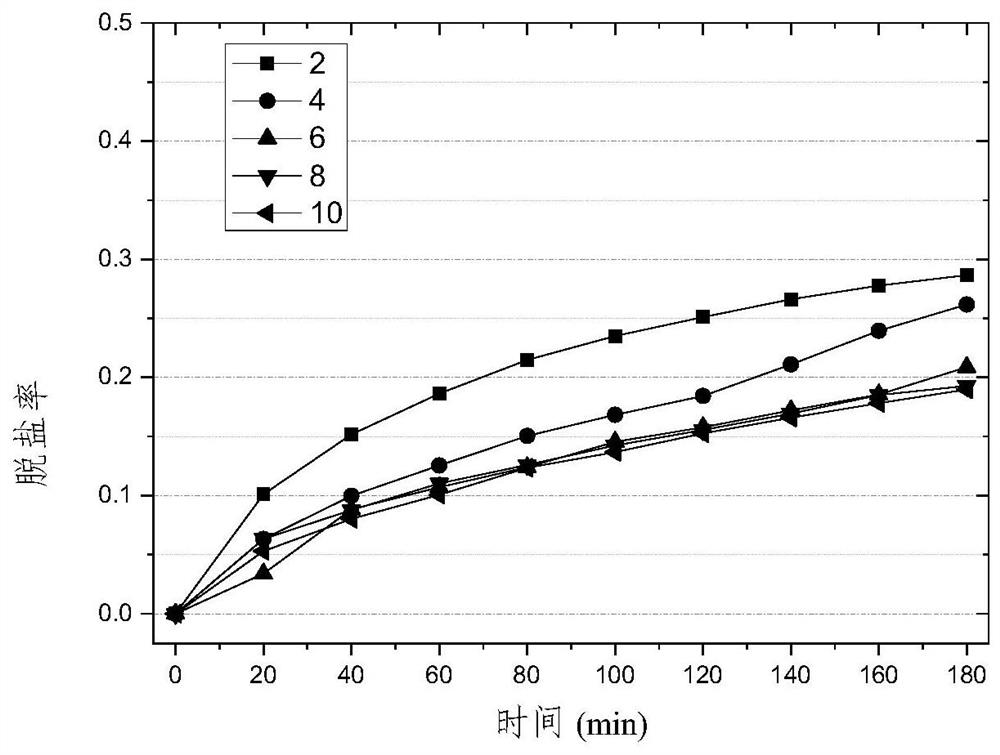

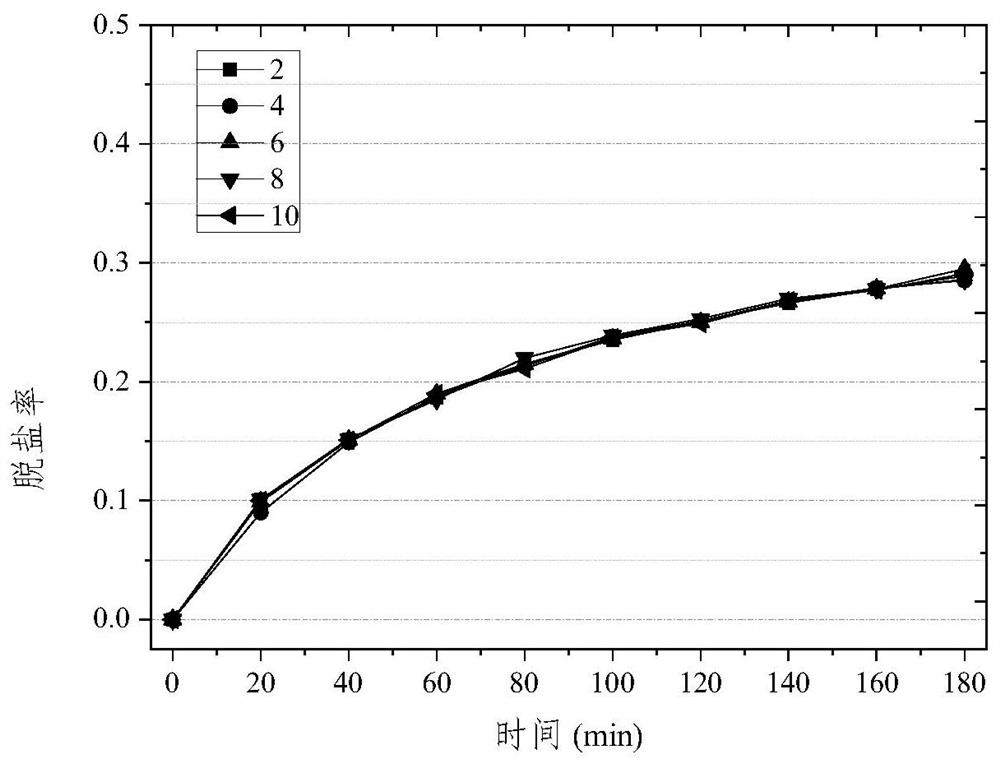

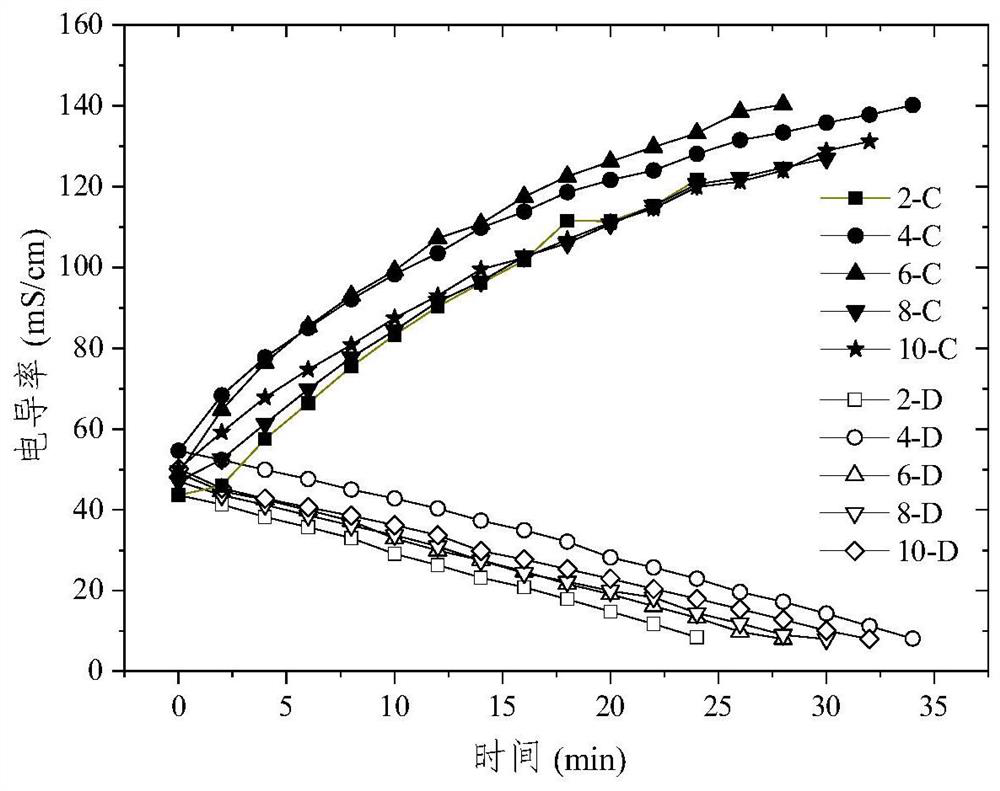

Method for cleaning membrane pollution in process of electrodialysis treatment on paper-making reconstituted tobacco extract liquor

InactiveCN111672326AImprove the effect of alkaline cleaning processRestore fluxTobacco preparationTobacco treatmentMembrane foulingProcess engineering

The invention discloses a method for cleaning membrane pollution in the process of electrodialysis treatment on paper-making reconstituted tobacco extract liquor, which is used for cleaning an electrodialysis system generating membrane pollution through the cleaning processes of primary water washing, reversed-pole alkaline washing, secondary water washing, reversed-pole acid washing and tertiarywater washing in sequence. According to the cleaning method, membrane pollution in the electrodialysis process can be effectively solved, the desalination rate of an electrodialysis system is remarkably recovered, and reliable operation guarantee is provided for the process of treating the paper-making process reconstituted tobacco extracting solution through electrodialysis.

Owner:CHINA TOBACCO ANHUI IND CO LTD

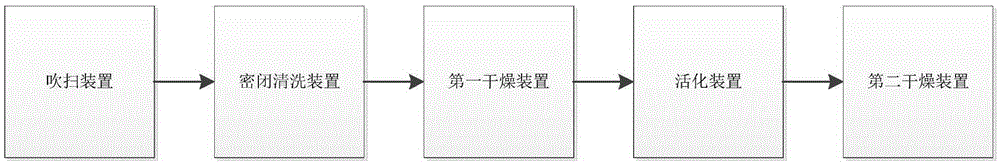

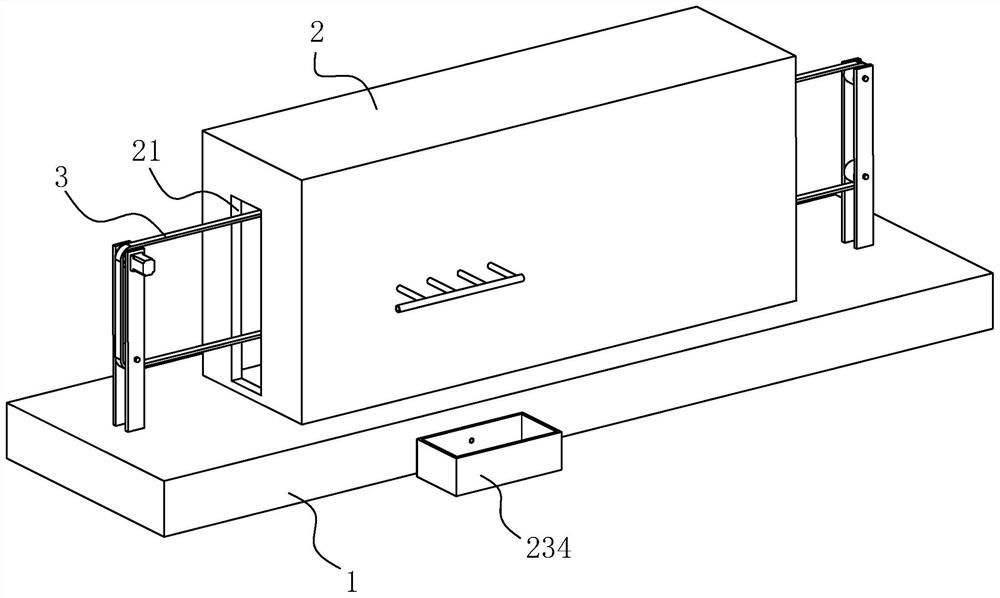

Deactivated SCR denitration catalyst purging device, activation device and regeneration system and corresponding methods

InactiveCN105381716AAchieve activationAchieve regenerationDispersed particle separationCatalyst regeneration/reactivationEngineeringBiological activation

The present invention relates to a deactivated SCR denitration catalyst purging device, an activation device and a regeneration system and corresponding methods, the activation device includes a regeneration main body tank, an ultrasonic atomization device, a catalyst rotating turntable and a micro negative pressure suction device; and the regeneration system includes the purging device, a cleaning device, a first drying device and the activation device which are connected in turn. The regeneration system can achieve deactivated catalyst regeneration, and compared with the normal regeneration process, the process is more thorough in purging and more complete in cleaning, also greatly improves the utilization ratio of a cleaning solution and a regeneration solution, and maximizes recovery of surface and pore structure of a deactivated catalyst.

Owner:FUJIAN ZIJIN ENVIRONMENT ENG TECH +1

Disinfecting and soaking device for medical drug storage instrument

InactiveCN108815539AClean completelyEasy to cleanHollow article cleaningLavatory sanitoryMedicineDrug Storage

The invention belongs to the technical field of medical equipment, and particularly relates to a disinfecting and soaking device for a medical drug storage instrument. The disinfecting and soaking device for the medical drug storage instrument aims to solve the problems that an existing disinfecting and soaking device for a medical drug storage instrument is poor in mobility and poor in convenience and inconvenient to use. The disinfecting and soaking device is characterized by comprising a soaking box, four supporting rods are fixed to the outer wall of the bottom of the soaking box through bolts and are located at four corners of the outer wall of the bottom of the soaking box, universal wheels are fixed to the outer walls of the bottoms of the supporting rods through bolts, and heaterswhich are distributed at equal intervals are fixed to the inner wall of the bottom of the soaking box through bolts. The disinfecting and soaking device has the advantages that a second motor can be enabled to well drive a second transmission rod and brushes to rotate to clean the medical drug storage instrument, meanwhile, through the cooperative use of the vibration of vibrators and the brushes,cleaning is more complete, and therefore the cleaning capacity of the device is improved, the medical drug storage instrument can be well sterilized and disinfected, bacteria on the surface of the medical drug storage instrument can be prevented from breeding, and the sterilization and disinfection capability of the device is improved.

Owner:郑州莉迪亚医药科技有限公司

Cleaning agent for antireflective coating of organic light-emitting micro-display and cleaning process

ActiveCN103242985AReduced electrical performanceNot corrosiveOrganic non-surface-active detergent compositionsCleaning using liquidsDisplay deviceCleansing Agents

The invention relates to the field of organic light emitting, and in particular relates to a cleaning agent used in a stripping and cleaning technique and a photoetching reworking technique in the process of manufacturing an organic light-emitting display. The cleaning agent is formed by mixing N-methylpyrrolidone, isopropanol and an organic amine solution according to the volume ratio of 15:4:1 to 15:4:4. A method for cleaning by the cleaning agent for an antireflective coating of the organic light-emitting micro-display comprises the following steps of: preparing the cleaning agent, soaking an IC (Integrated Circuit) wafer of the anode-stripped organic light-emitting diode or a to-be-reworked wafer in the cleaning solution for the antireflective layer for 3-15 minutes at 15-25 DEG C to dissolve the antireflective layer, soaking the IC wafer of the anode-stripped organic light-emitting display or the to-be-reworked wafer in isopropanol for 5-20 minutes to remove residual photoresist, N-methylpyrrolidone, and organic amine, and cleaning the IC wafer of the organic light-emitting display or the to-be-reworked wafer sequentially by isopropanol, pure water and mega sound. The cleaning agent has the advantages of complete cleaning, no corrosion and no residue, and is especially suitable for cleaning of the anode antireflective layer of the organic light-emitting display.

Owner:YUNNAN NORTH OLIGHTEK OPTO ELECTRONICS TECH

Automatic cleaning device for annular conveying belt

InactiveCN111232596ASolve efficiency problemsFix security issuesCleaningTransmission beltEngineering

The invention discloses an automatic cleaning device for an annular conveying belt. The automatic cleaning device comprises two main body brackets, the top between the two main body brackets is rotationally connected with a conveying belt, a driven roller is rotationally connected to the position, below the conveying belt, between the two main body brackets, the driven roller makes contact with the conveying belt, one end of the driven roller is fixedly connected with a second chain wheel, the bottoms of the main body brackets are fixedly connected with a gearbox, and the input end of the gearbox is fixedly connected with a fourth chain wheel. A cleaning part of the device rotates through power provided by the conveying belt, the power does not need to be additionally provided, the cleaning process operates automatically, the conveying belt can be cleaned at any time without shutdown, manual assistance is not needed, the problems that as for an existing cleaning conveying belt, the production efficiency is affected, and potential safety hazards exist can be well solved, and the brushing intensity of a cleaning roller brush can be adjusted through rotation of a threaded rod, so thatdust is cleared more completely.

Owner:青岛宝井钢材加工配送有限公司

Spinneret or metal sintering net cleaning method

The invention specifically relates to a spinneret or metal sintering net negative pressure cleaning method characterized by comprising the following steps: 1, heating up a to-be-cleaned spinneret; 2, placing the spinneret of the step 1 into liquid nitrogen for cooling; 3, carrying out ultrasonic cleaning for the spinneret; 4, placing the spinneret into a negative pressure environment so as to separate and precipitate attachments on the spinneret surface and feed hole inner wall surfaces from the spinneret, thus realizing thoroughly cleaning effect. The whole spinneret or metal sintering net cleaning method is very concise in process, can completely and fully clean the surface and each ultra-small hole of the spinneret, and secondary pollution is prevented.

Owner:上海志骑信息科技有限公司

Cleaning device inside high-voltage switch cabinet

InactiveCN107994492AClean completelyFull Coverage GuaranteedCleaning using toolsSwitchgearEngineeringLinear motor

The invention discloses a cleaning device inside a high-voltage switch cabinet. The cleaning device includes the high-voltage switch cabinet. The top of the high-voltage switch cabinet is fixedly connected with a linear motor, an output shaft of the linear motor is fixedly connected with a connecting rod, the connecting rod passes through the high-voltage switch cabinet and extends into the insideof the high-voltage switch cabinet, the left side and the right side of the inner wall of the high-voltage switch cabinet are fixedly connected with sliding grooves, the sliding grooves each are fixedly connected with a fixed block, the left side and the right side of the fixed block are fixedly connected with first limiting blocks, and the bottom of the connecting rod is fixedly connected with acleaning box cover. The cleaning device can move up and down in the cabinet through the linear motor. Through a rotating motor and a rotary motor in the cleaning device, a sweeping rod can rotate orperform left-right sweeping inside, so that the sweeping is safer, the sweeping rod moves back and forth inside to perform cleaning in multiple directions, and the full coverage of cleaning is ensuredto the maximum extent.

Owner:上力电力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com