Vapor phase cleaning system and method of propellant storage tank

A technology for propellant storage tanks and cleaning systems, which is applied to cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc. Achieve the effect of ensuring normal operation, better cleaning effect and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

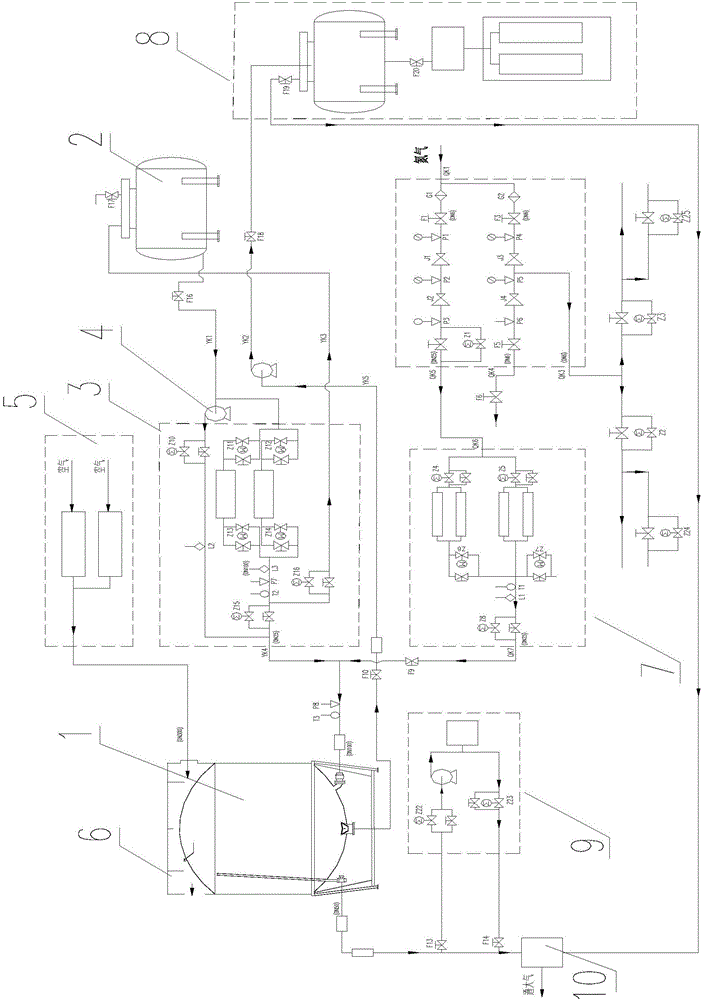

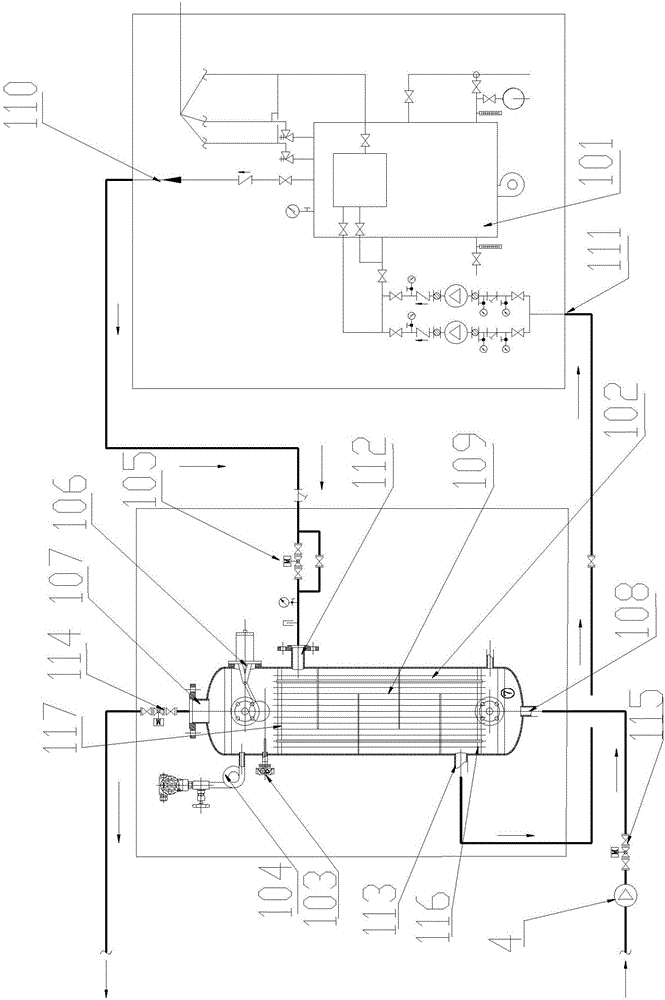

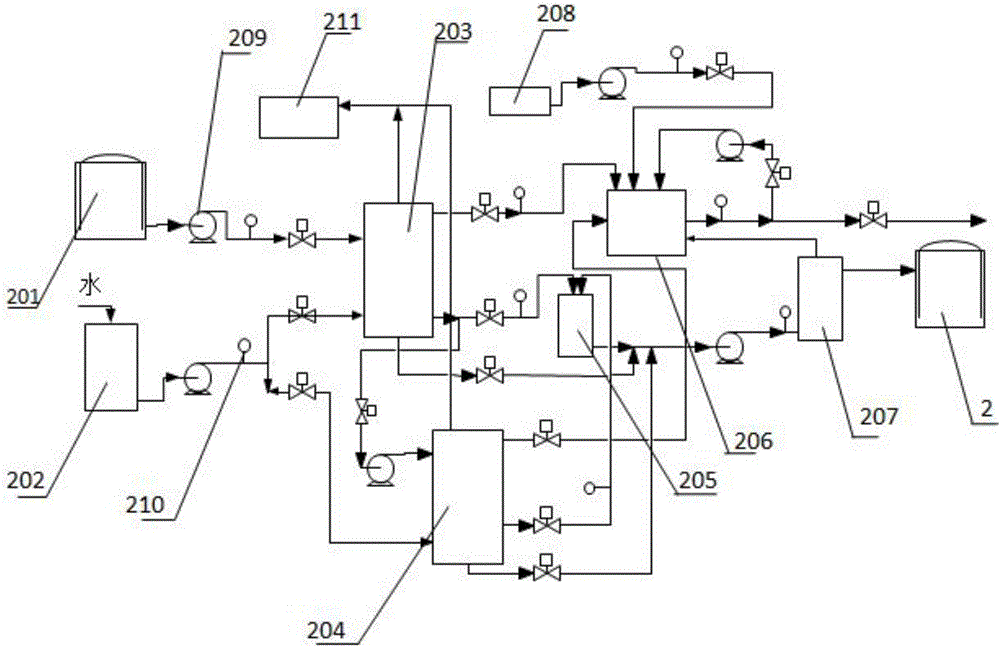

[0049] Such as figure 1 As shown, the present embodiment provides a vapor-phase cleaning system for a propellant tank, including a cleaning agent tank 2 for storing cleaning agent, a cleaning agent steam generating device 3, a delivery device 4 and a cooling system 5, wherein the delivery The input end of the device 4 is connected with the cleaning agent storage tank 2, the output end of the delivery device 4 is connected with the cleaning agent steam generating device 3, the output end of the cleaning agent steam generating device 3 is connected with the propellant storage tank 1, and the propulsion The agent tank 1 is provided with a cooling system 5 for cooling the cleaning agent vapor.

[0050] In the vapor phase cleaning system of this embodiment, the vapor phase cleaning is applied to the propellant storage tank. The cleaning agent storage tank is used to store liquid cleaning agent, and the conveying device can be a delivery pump or a lift pump, etc., which can transpo...

Embodiment 2

[0060] Such as figure 1 As shown, this embodiment is a further limitation of Embodiment 1. The vapor phase cleaning system is also provided with a nitrogen heating system 7, which includes a nitrogen heating device, and is connected to the inlet of the propellant tank through a pipeline for purging and cleaning. propellant tanks.

[0061] After cleaning the propellant tank with cleaning agent steam, there will be residual cleaning agent liquid, which can generally be purged with nitrogen. In this embodiment, the heated nitrogen gas can dry the inner wall of the propellant tank more quickly and improve the cleaning effect. . Among them, the heating of nitrogen can be realized by explosion-proof nitrogen heater, and nitrogen can also provide gas source for each valve.

[0062] In a further solution, the vapor-phase cleaning system is also provided with a waste liquid recovery treatment system 8 and a waste gas treatment system 10, and the waste liquid recovery treatment system...

Embodiment 3

[0069] This embodiment provides a method for cleaning a propellant tank using a vapor phase cleaning system, comprising the following steps:

[0070] (1) The delivery device 4 transports the cleaning agent to the cleaning agent steam generating device 3 to generate cleaning agent steam;

[0071] (2) The cleaning agent steam enters the propellant storage tank 1 for vapor-phase cleaning. At the same time, the cleaning agent steam is liquefied under the action of the cooling system 5 and washes down the inner wall of the propellant storage tank.

[0072] The conveying device is opened, and the liquid cleaning agent in the cleaning agent storage tank is delivered to the opened cleaning agent steam generating device to generate cleaning agent steam; the cleaning agent steam enters the lower end of the propellant storage tank, climbs upward, and enters the propellant storage tank At the same time, the cleaning agent vapor condenses and liquefies under the action of the cooling syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com