Patents

Literature

1165results about How to "Fully cleaned" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

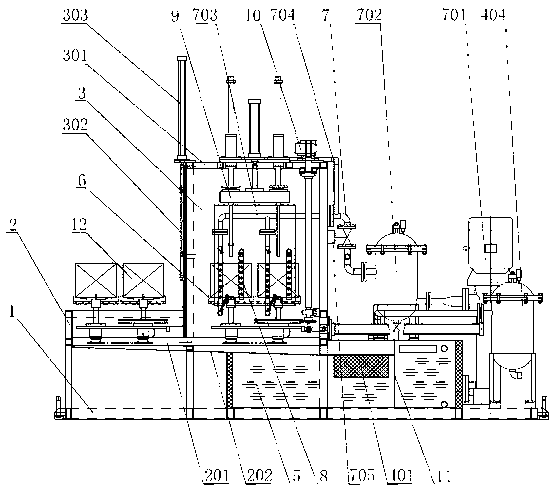

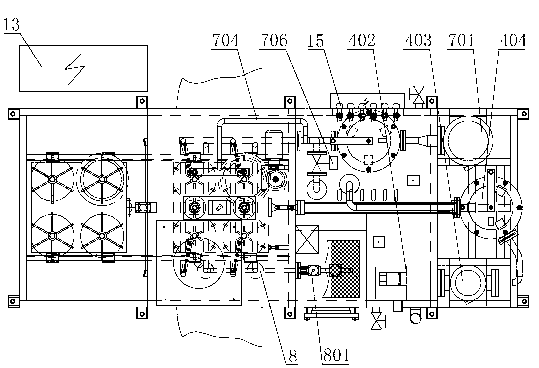

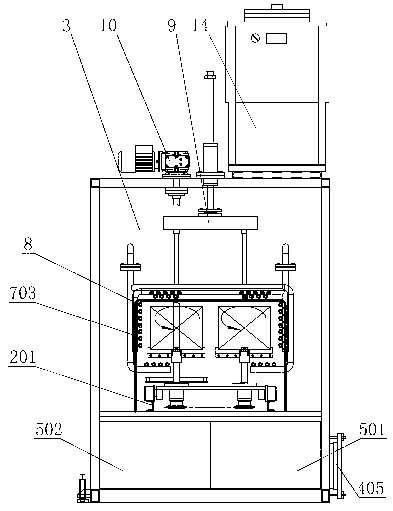

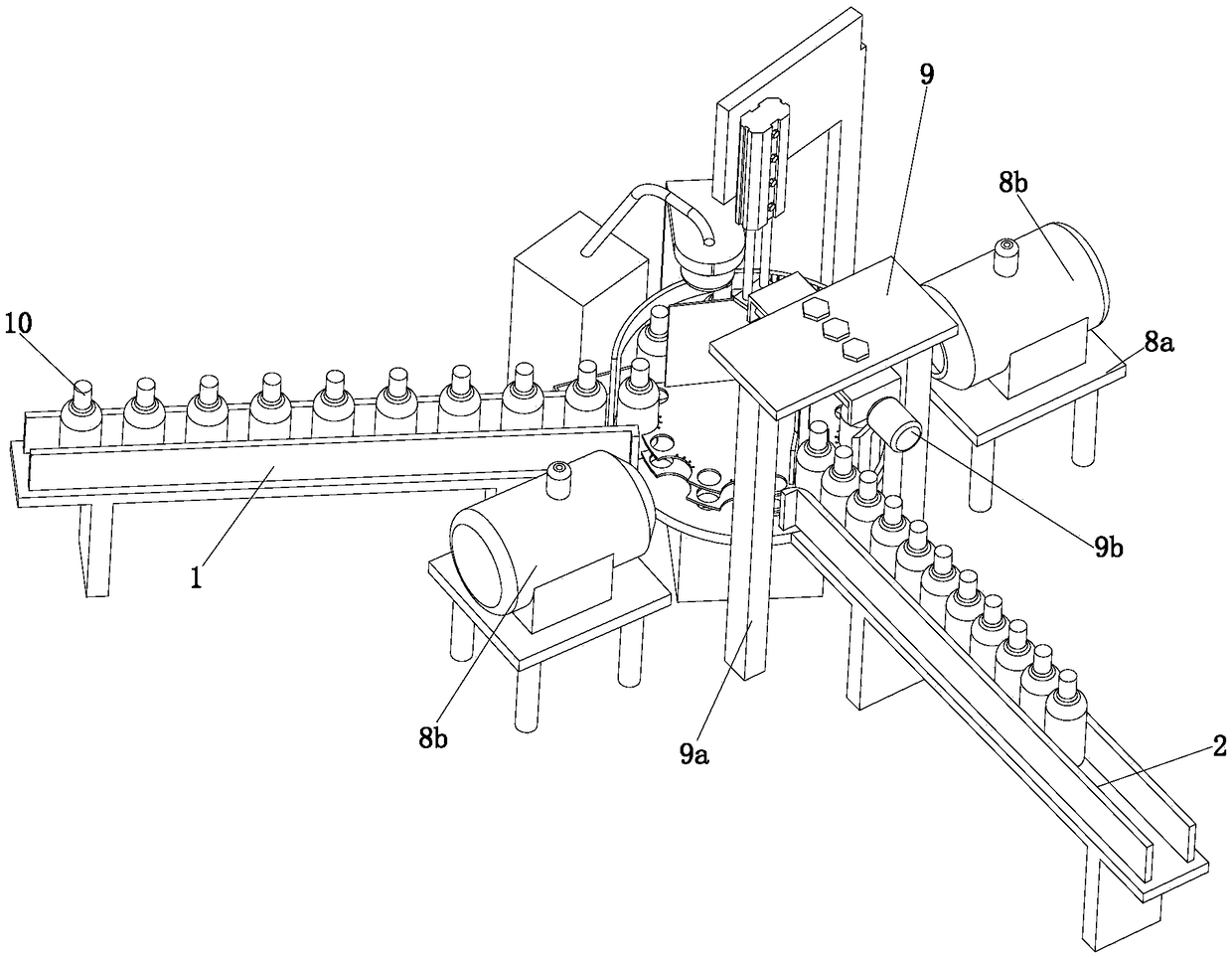

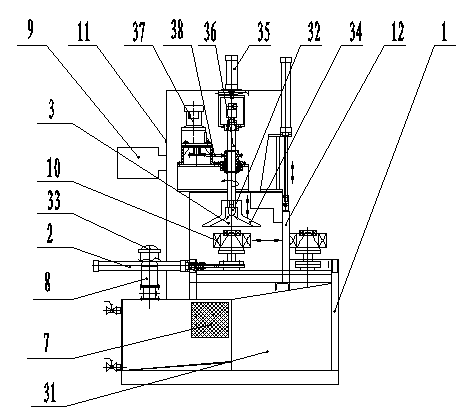

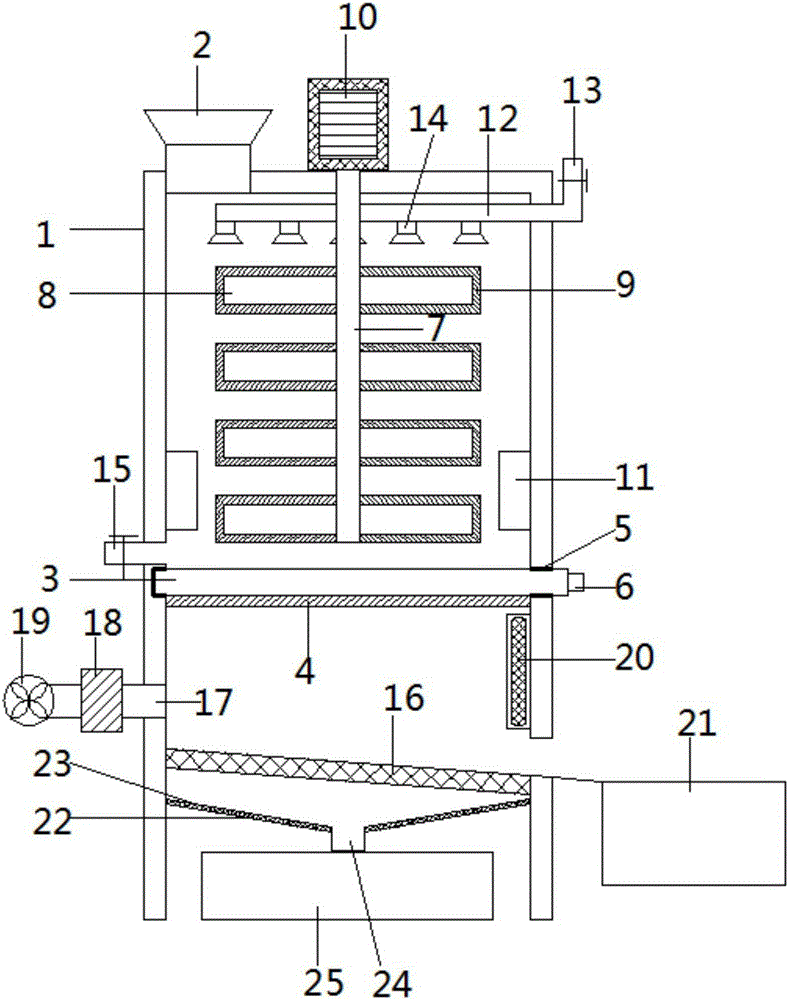

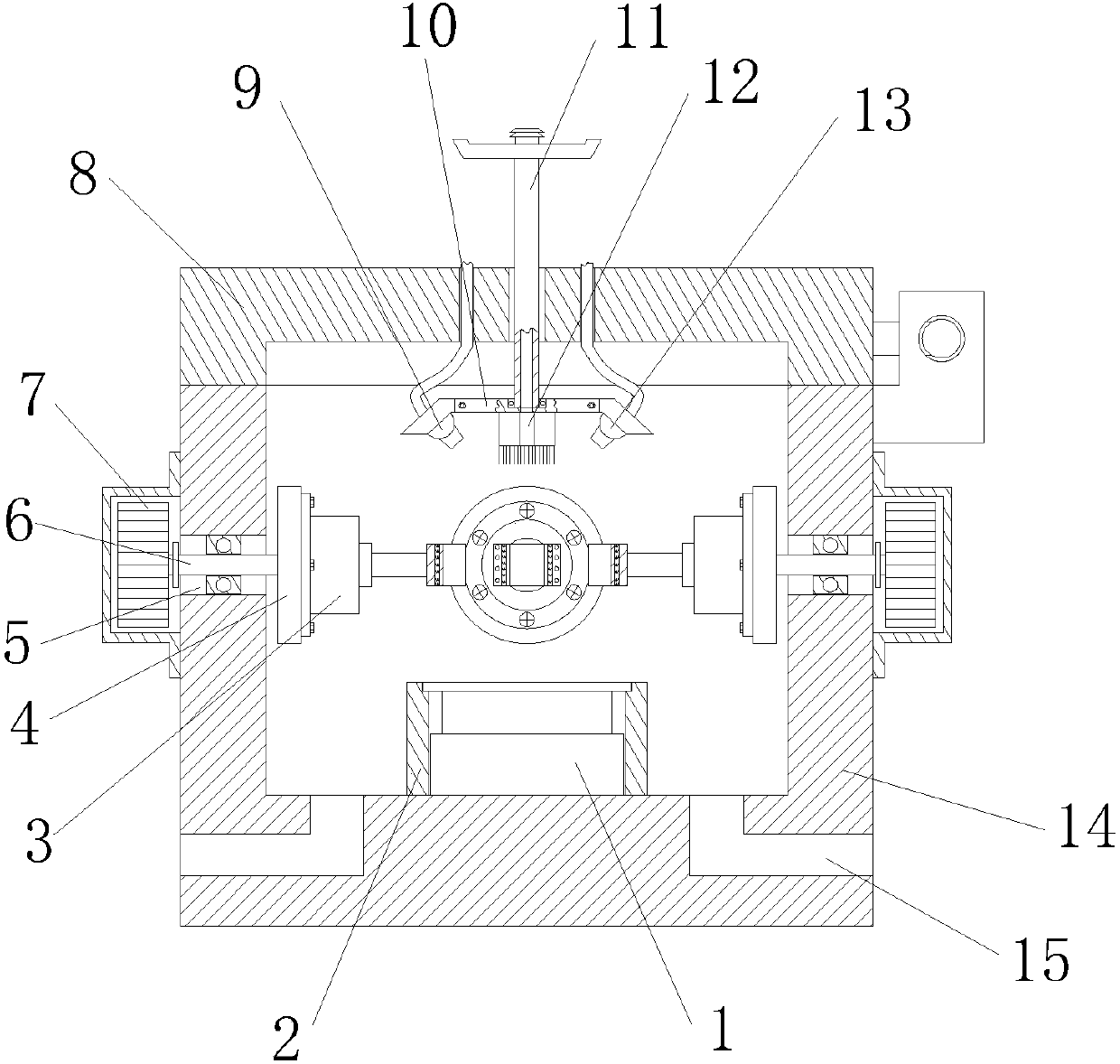

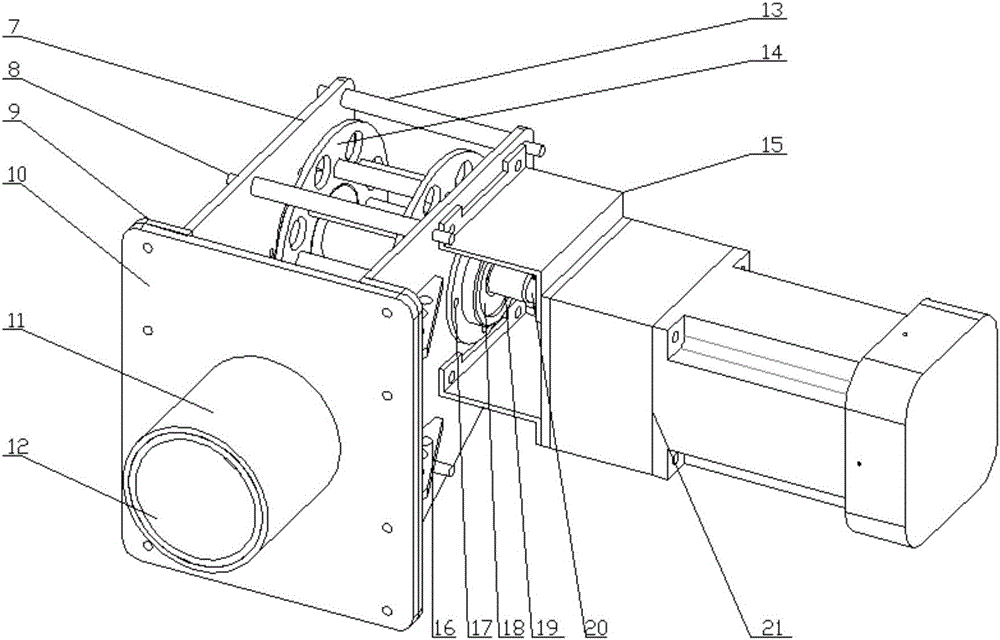

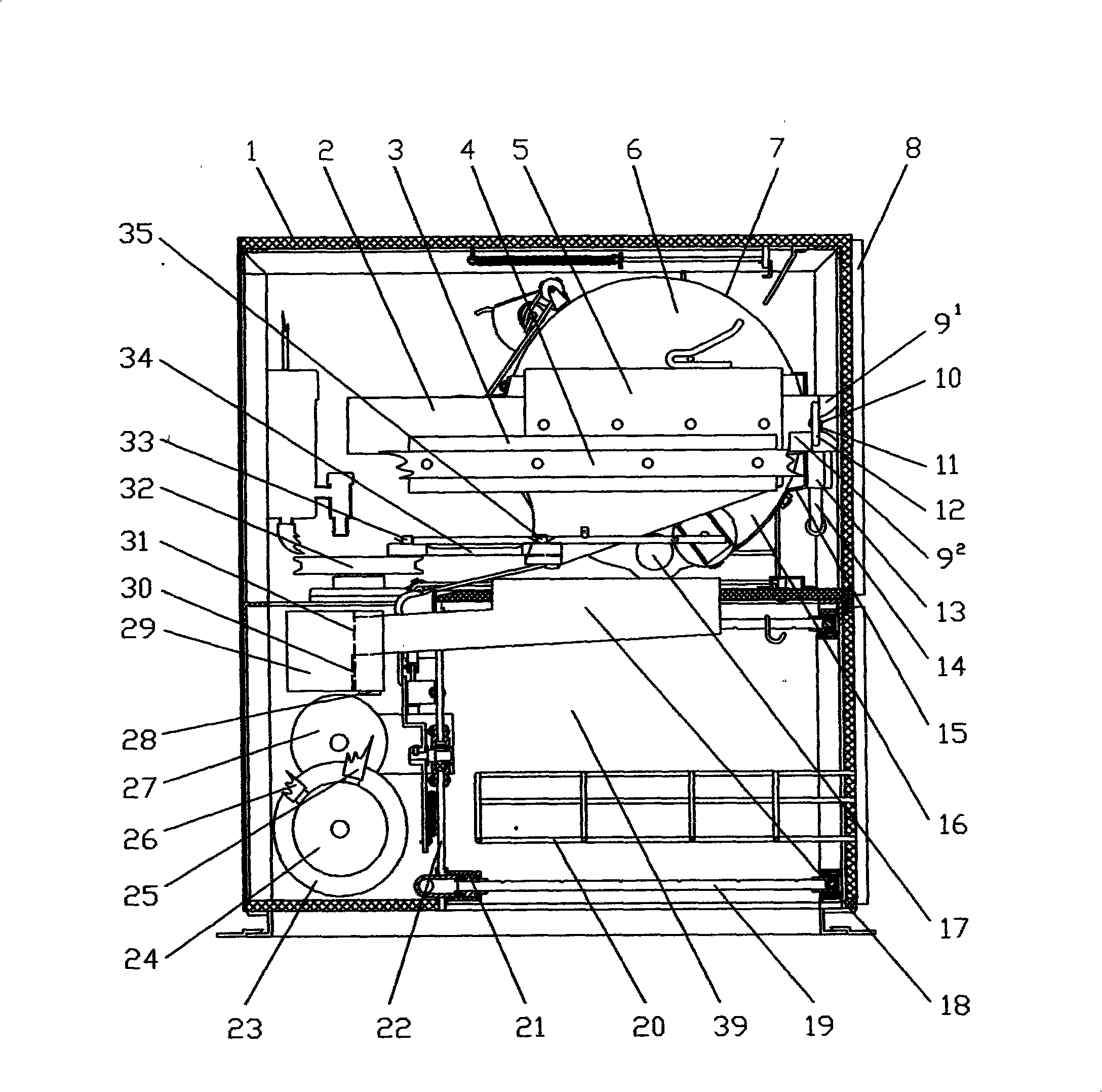

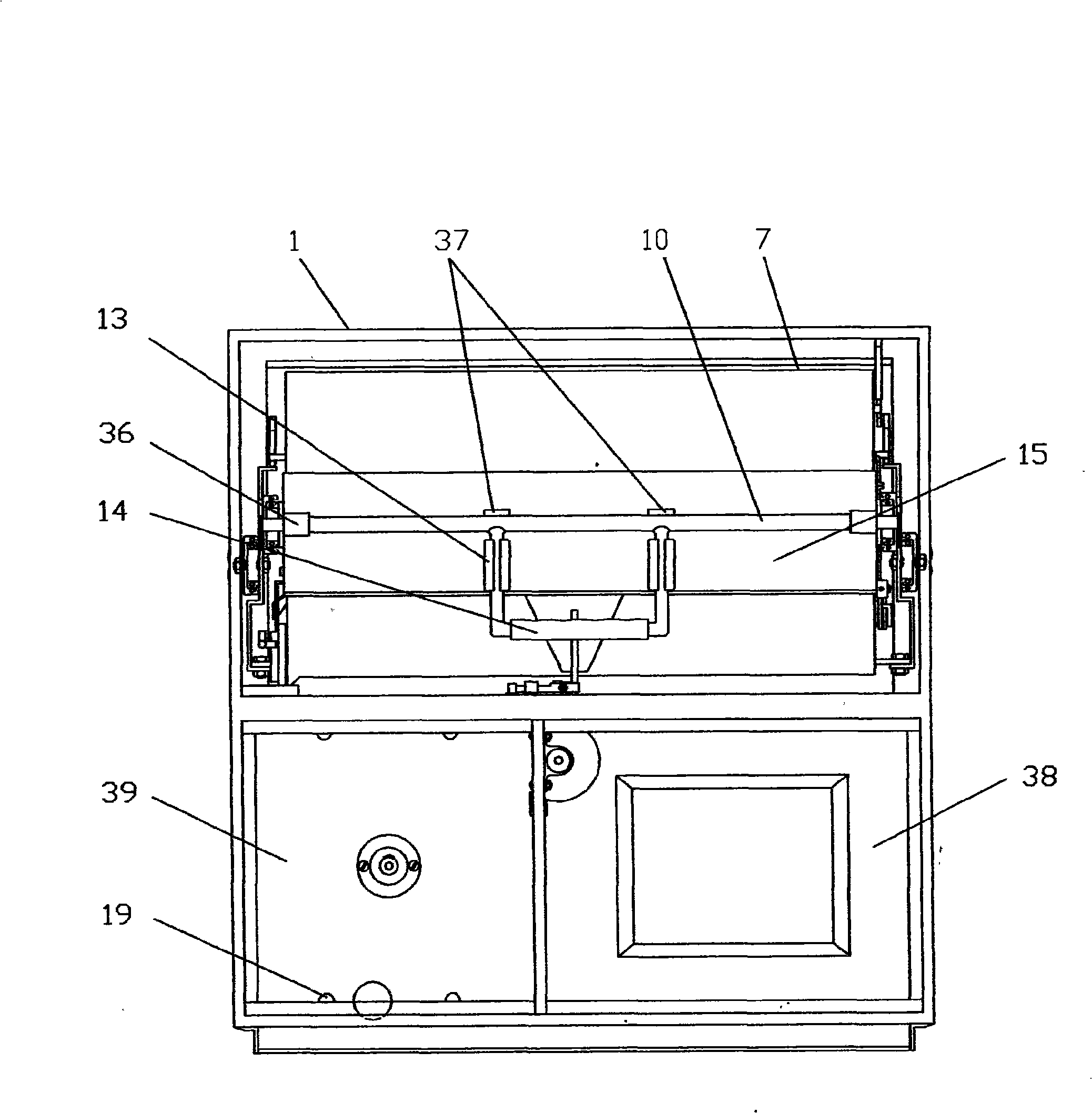

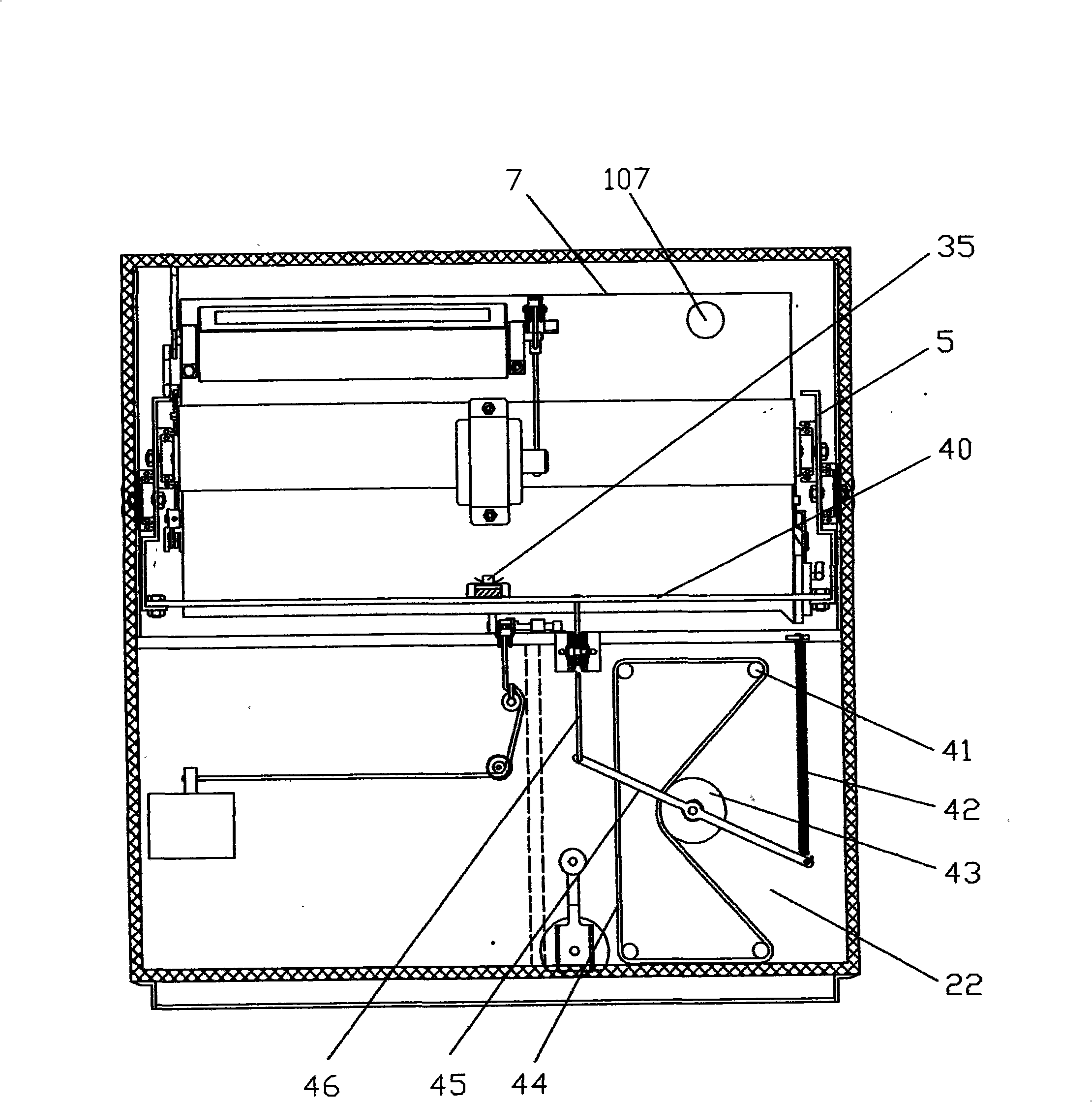

Cylinder part cleaning machine

ActiveCN103008274AImprove cleaning efficiencyRealize automatic feedingDrying gas arrangementsMultistage water/sewage treatmentElectric heatingEngineering

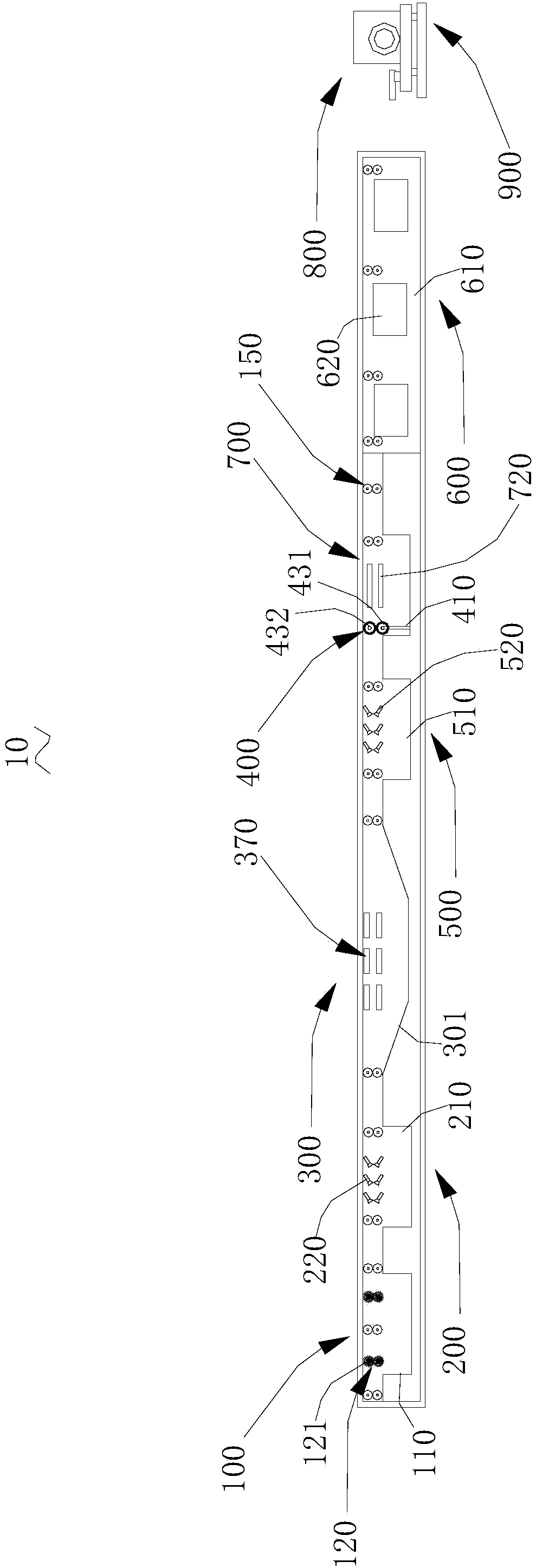

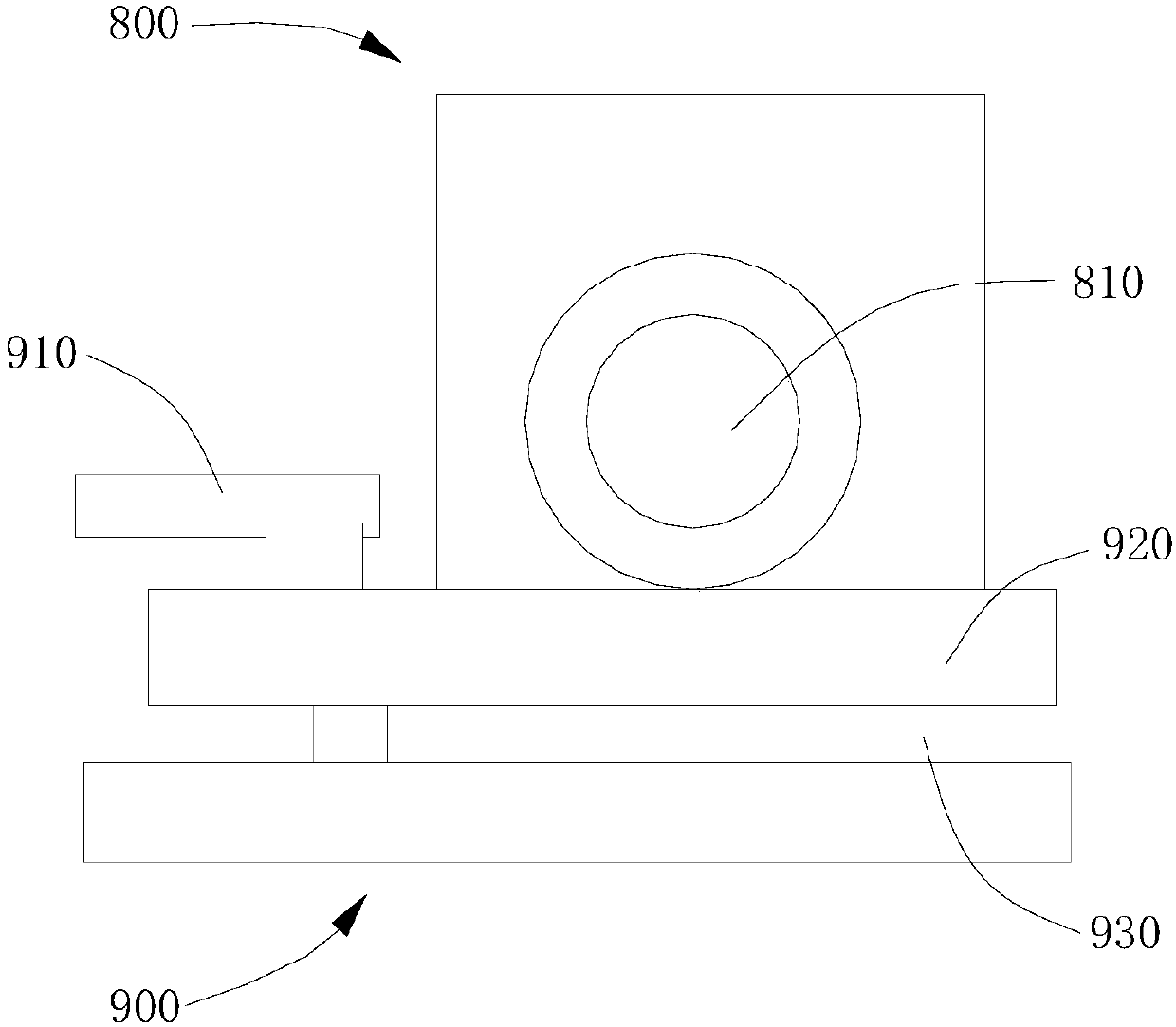

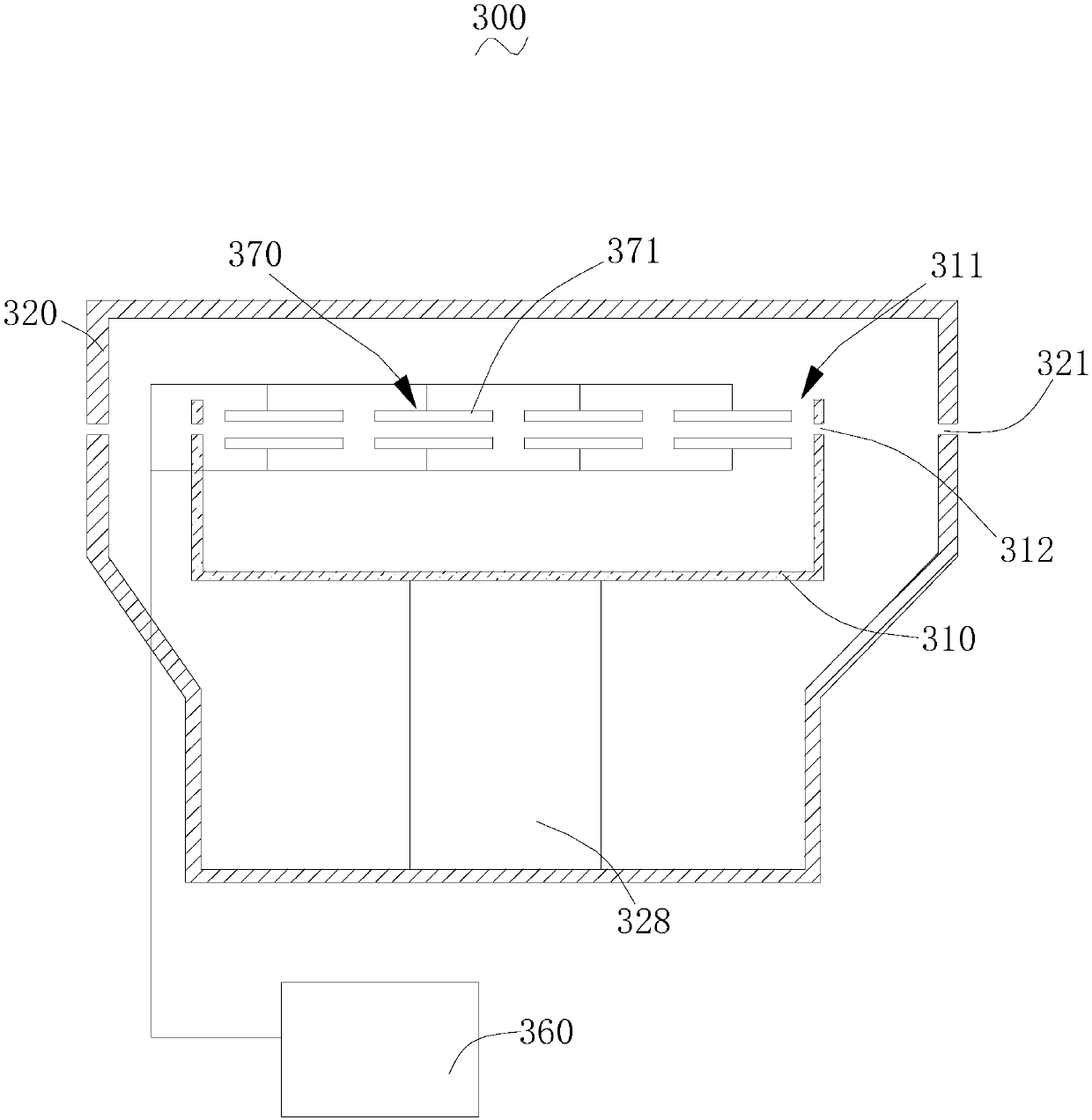

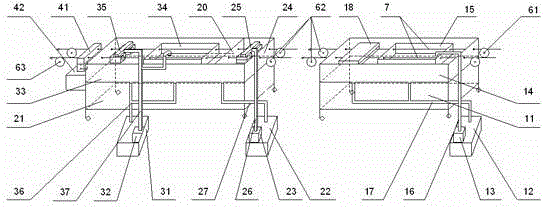

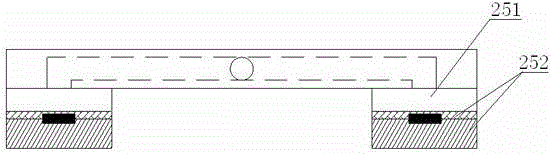

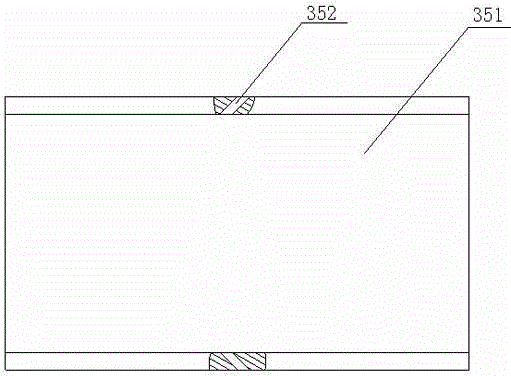

The invention discloses a cylinder part cleaning machine, which comprises a frame and an electric control cabinet, wherein the frame is horizontally provided with a workpiece station, a cleaning chamber and a water treatment system; a water tank is arranged below the cleaning chamber, extends to the water treatment system and comprises a waste water tank and a clear water tank; an electric heating tube is arranged in the clear water tank; the workpiece station is provided with a track which extends to the cleaning chamber to be fixedly connected with the inner wall of the cleaning chamber; and a guide plate is arranged below the track. The cleaning machine further comprises a conveying vehicle assembled on the track, and a cleaning pipeline, a drying pipeline, a lifting probe cleaning device and a driving device which are arranged in the cleaning chamber, wherein the conveying vehicle is provided with a plurality of bearing disks which can rotate 360 degrees; and the cleaning pipeline is divided into two paths, one of which directly leads to the cleaning chamber to clean the outer surface of a cylinder part, and the other of which enters the probe cleaning device through a pipe to clean the inner chamber of the cylinder part. The cylinder part cleaning machine can clean the inner and outer surfaces of a plurality of cylinder parts and is low in labor intensity, high in cleaning efficiency and good in cleaning effect.

Owner:安徽宝辉清洗设备制造有限公司

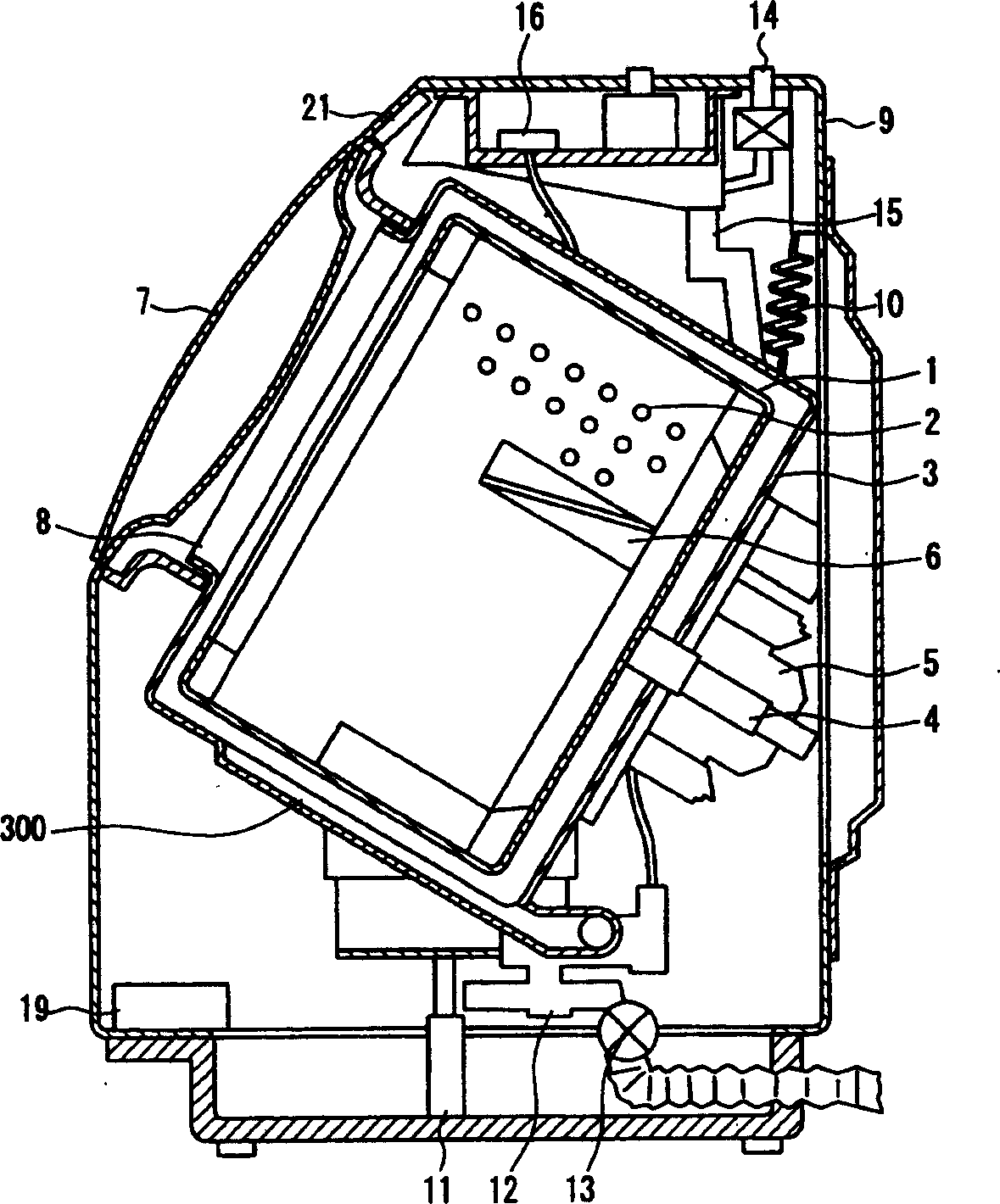

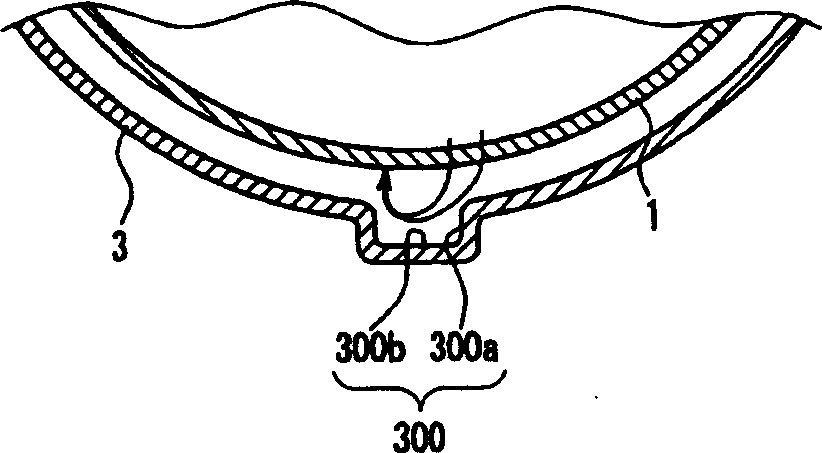

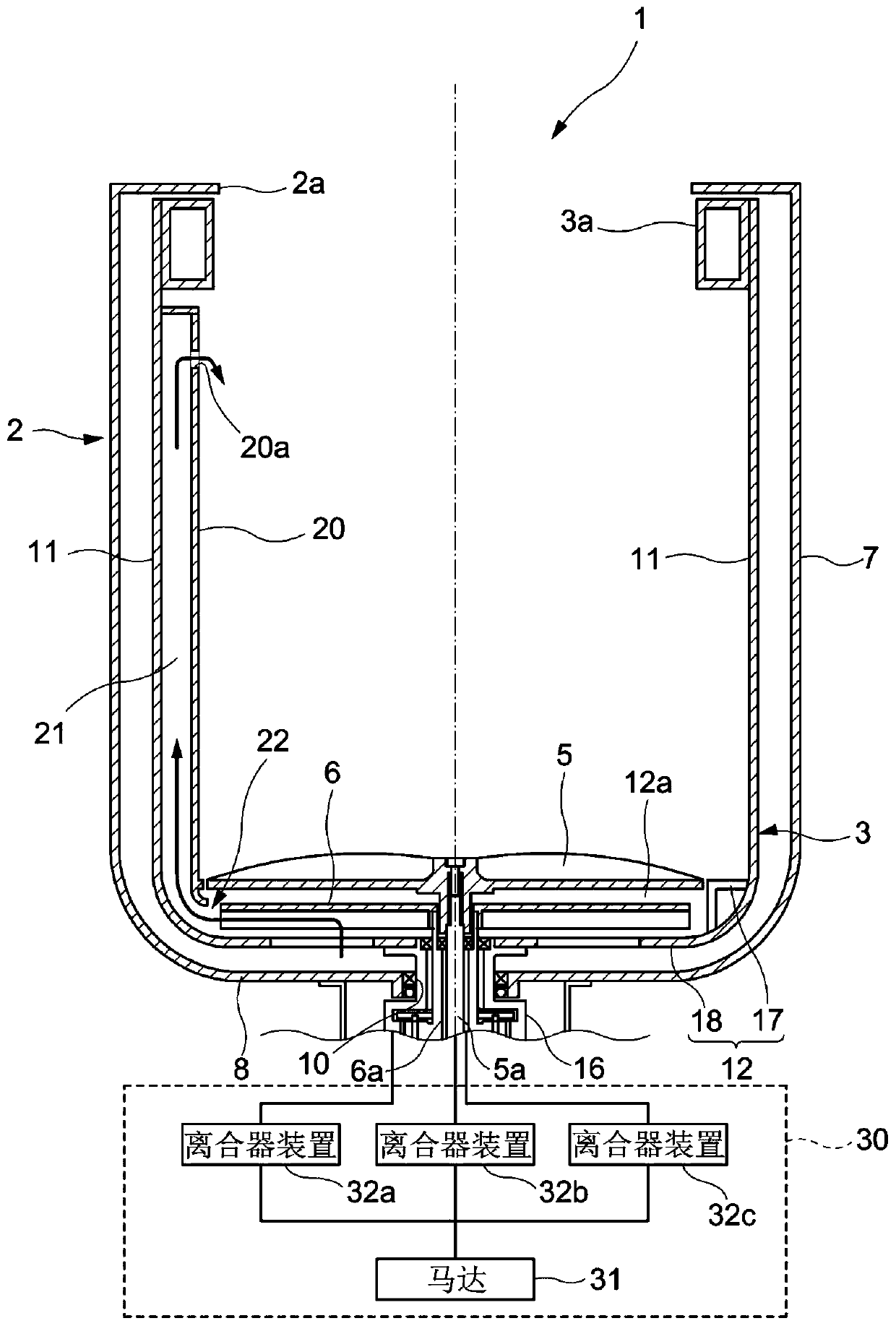

Washing machine

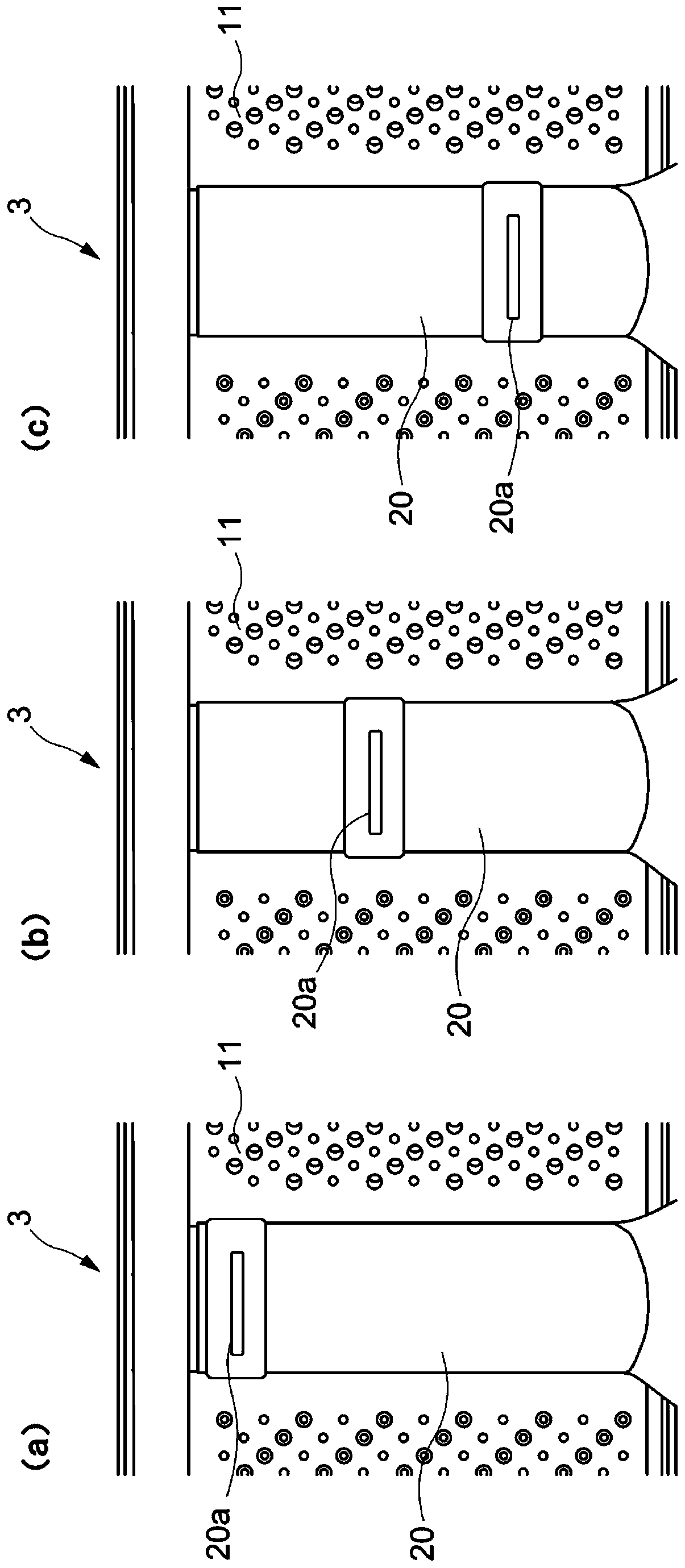

InactiveCN1611661AFully cleanedOther washing machinesControl devices for washing apparatusForeign matterElectric machinery

The invention provided a washing machine that effectively removes a foreign matter such as a detergent residue or mold sticking to the interior and exterior surface of a rotary drum having the center shaft of rotation nearly in the horizontal direction or nearly in the inclining direction and the inwall surface of a water receiving tank. The washing machine performs the combination of a first washing process in which a control means 20 rotates the rotary drum 1 at a first revolution by controlling a motor 5 after supplying water to a set water level by controlling a water supply valve 14 at a first set revolution, a second washing process in which the control means rotates the rotary drum at a second set revolution as a revolution causing a circulating stream between the outer surface of the rotary drum and an inner wall surface of the water receiving tank 3, higher than the first set revolution, and a rotation stopping process in which the control means stops the rotary drum, more than one time for a set time.

Owner:PANASONIC CORP

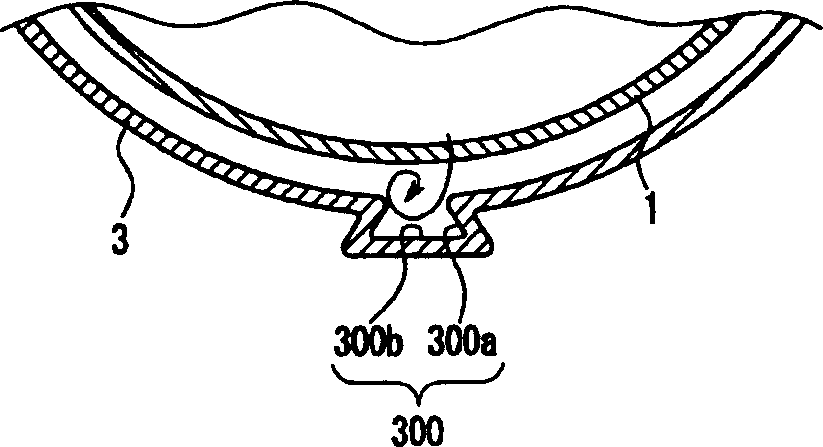

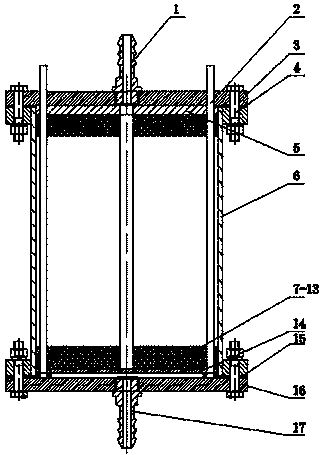

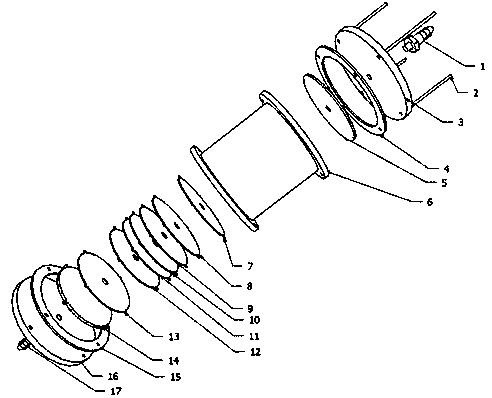

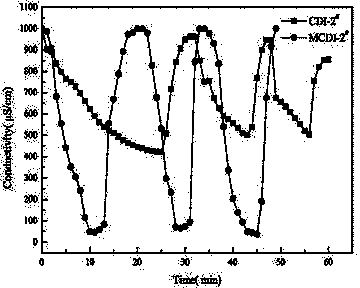

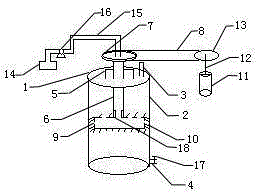

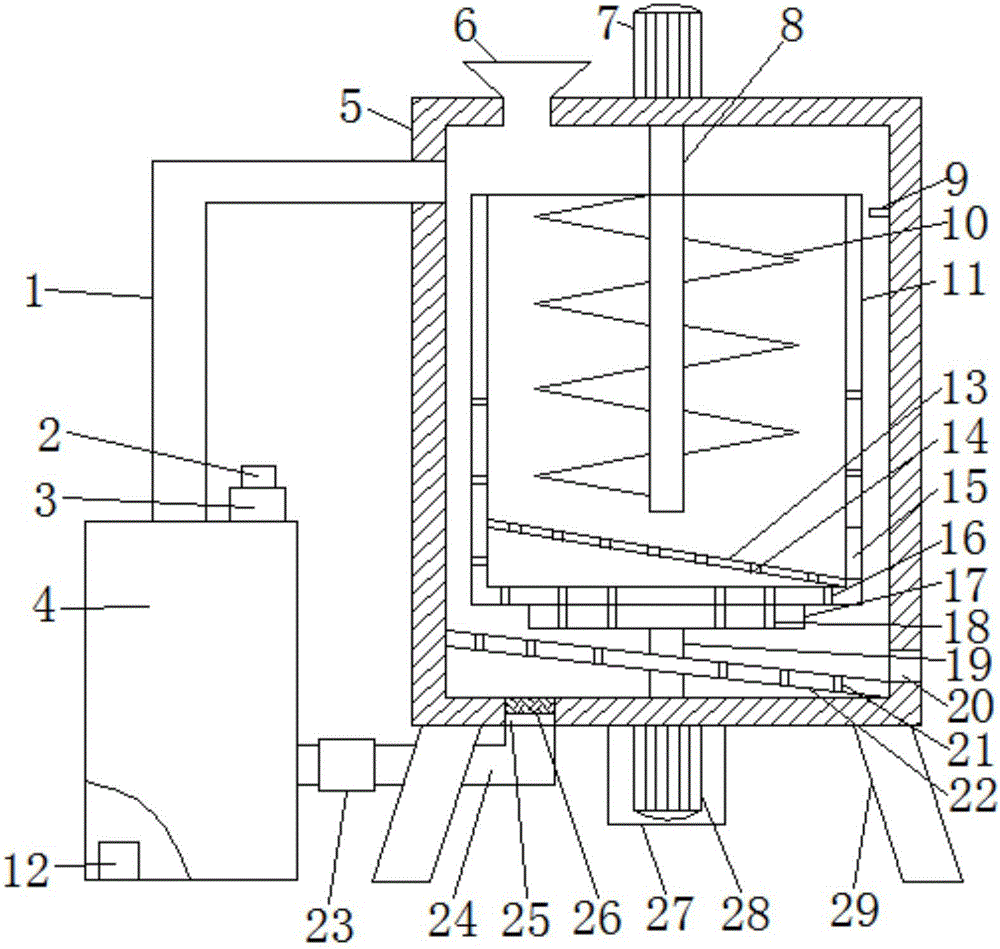

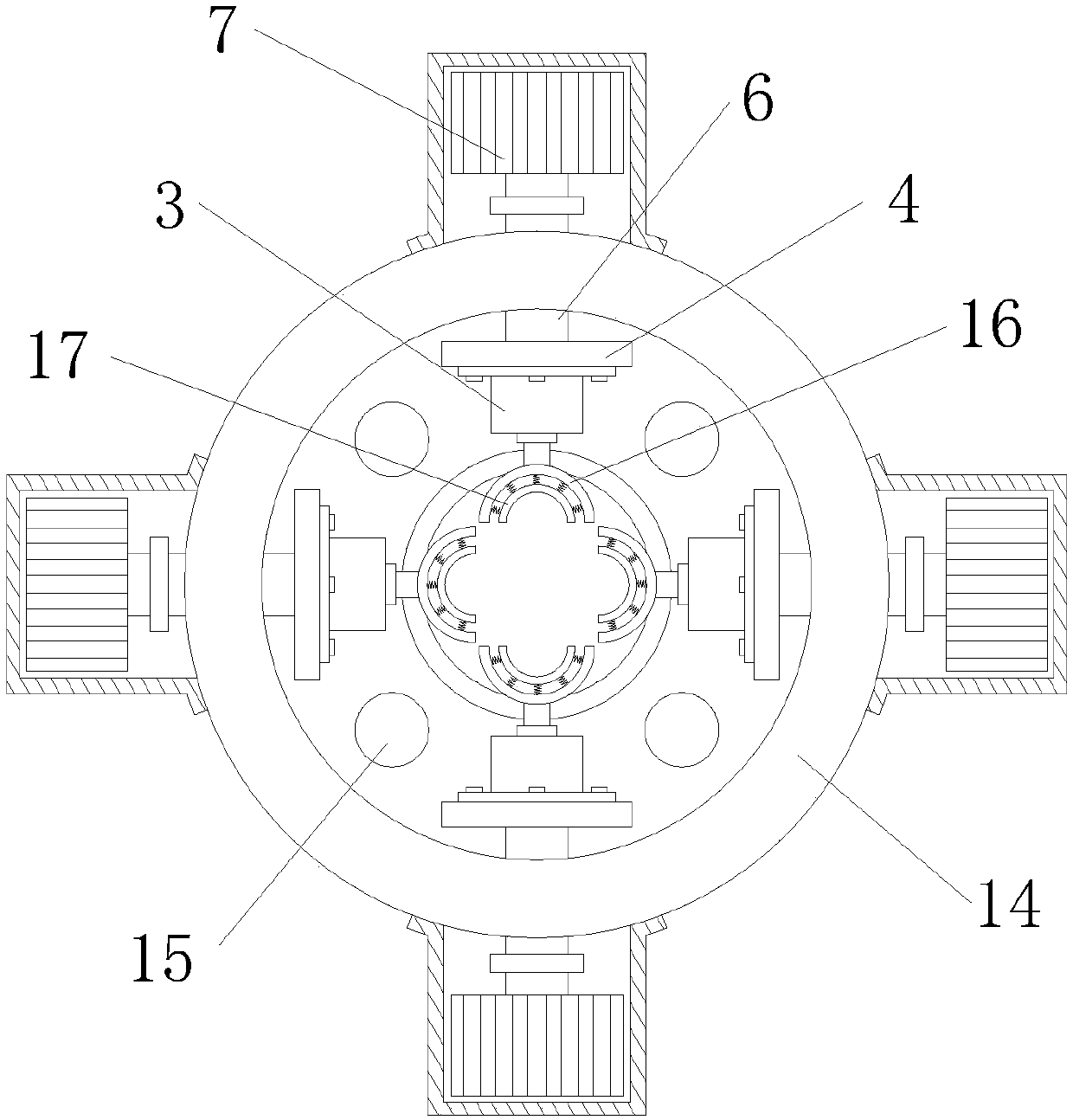

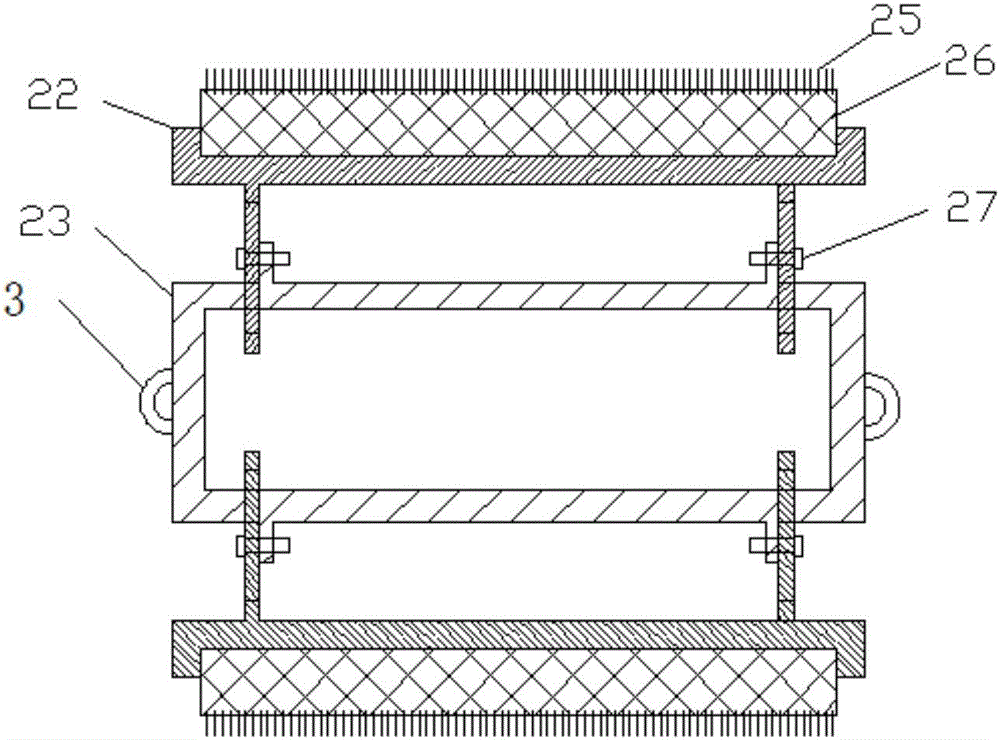

Continuous wastewater treatment device utilizing membrane capacitive deionization

ActiveCN103991937ALower resistanceLarge capacityDispersed particle separationWater/sewage treatment by ion-exchangeCapacitanceProcess module

The invention relates to a continuous wastewater treatment device utilizing membrane capacitive deionization. An upper cover plate and a lower cover plate are coaxially installed at the upper end and the lower end of a cylindrical shell, a water inlet nozzle and a water outlet nozzle which are communicated with the interior of the shell are respectively formed in the axis part of the upper cover plate and the axis part of the lower cover plate, a water collecting plate is coaxially installed on the upper cover plate in the shell, conducting rods are uniformly and axially distributed on the periphery of the shell at intervals, a lower distribution board and an upper distribution board are coaxially installed in the shell between the water collecting plate and a water distributing plate and are of a pair of metal boards, and a plurality of groups of processing module components are coaxially installed between the two distribution boards, wherein each group of processing module component comprises an upper current collecting plate, a membrane carbon positive electrode, a diaphragm, a membrane carbon negative electrode and a lower current collecting plate. According to the continuous wastewater treatment device, the membrane electrode is integral and is prepared by a carbon electrode and an ion membrane through spraying a cation exchange coating on a cathode and spraying an anion exchange coating on an anode, the thickness of the ion exchange layer is less than 10mu, and the membrane electrode has small resistance and large capacitance compared with those of a membrane electrode on which an ion membrane is directly added.

Owner:BEIJING HUA YAN BANG SCI & TECH +1

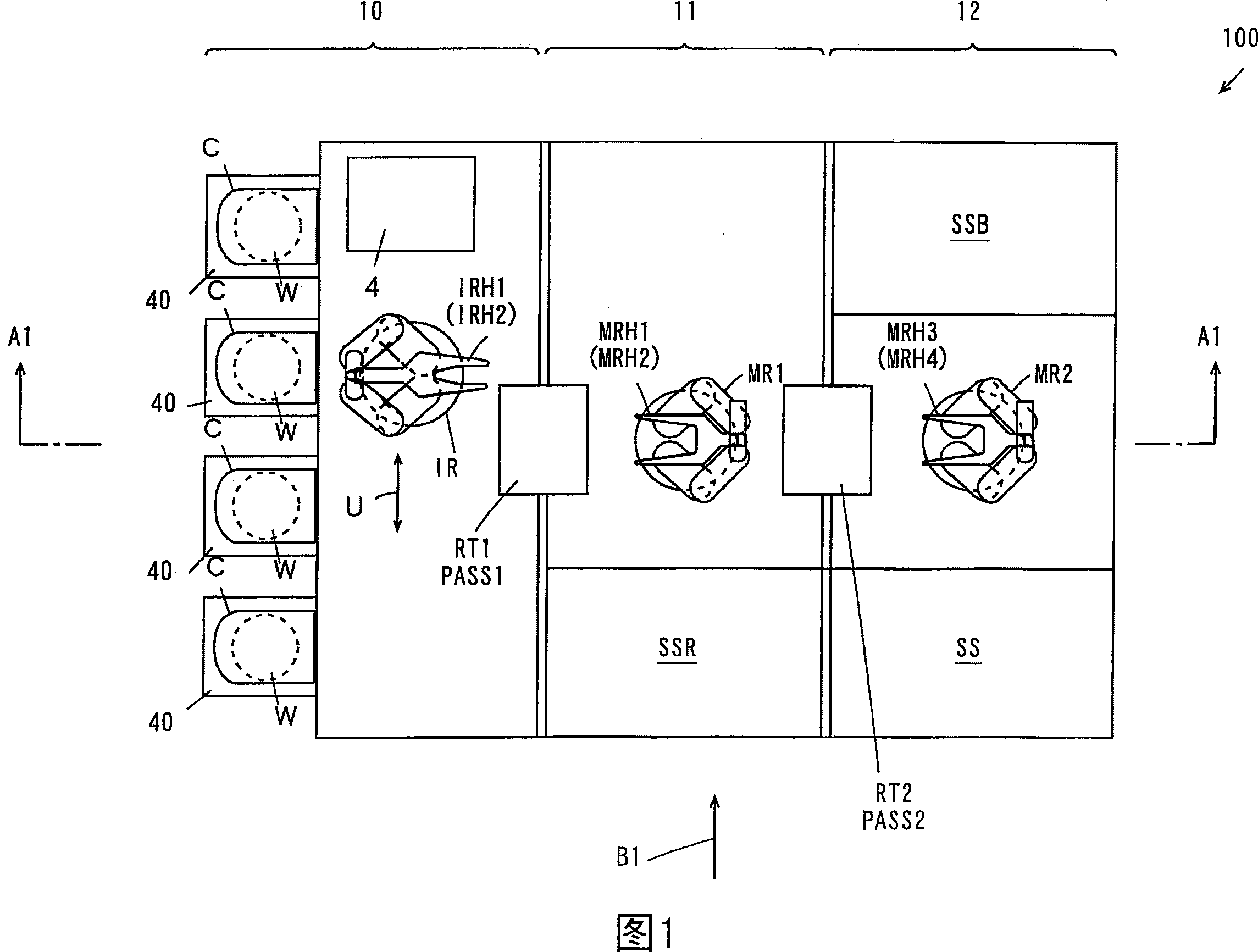

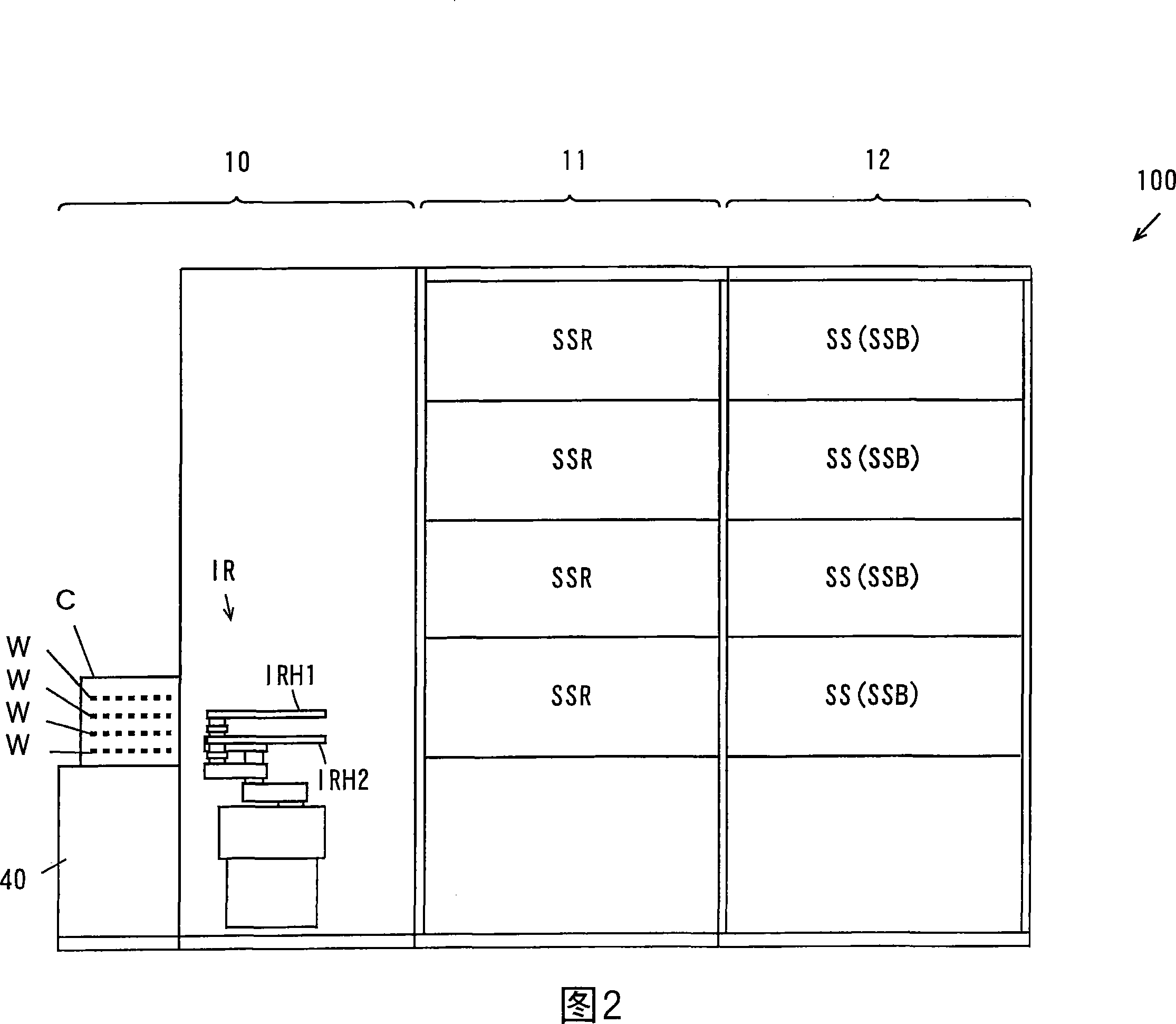

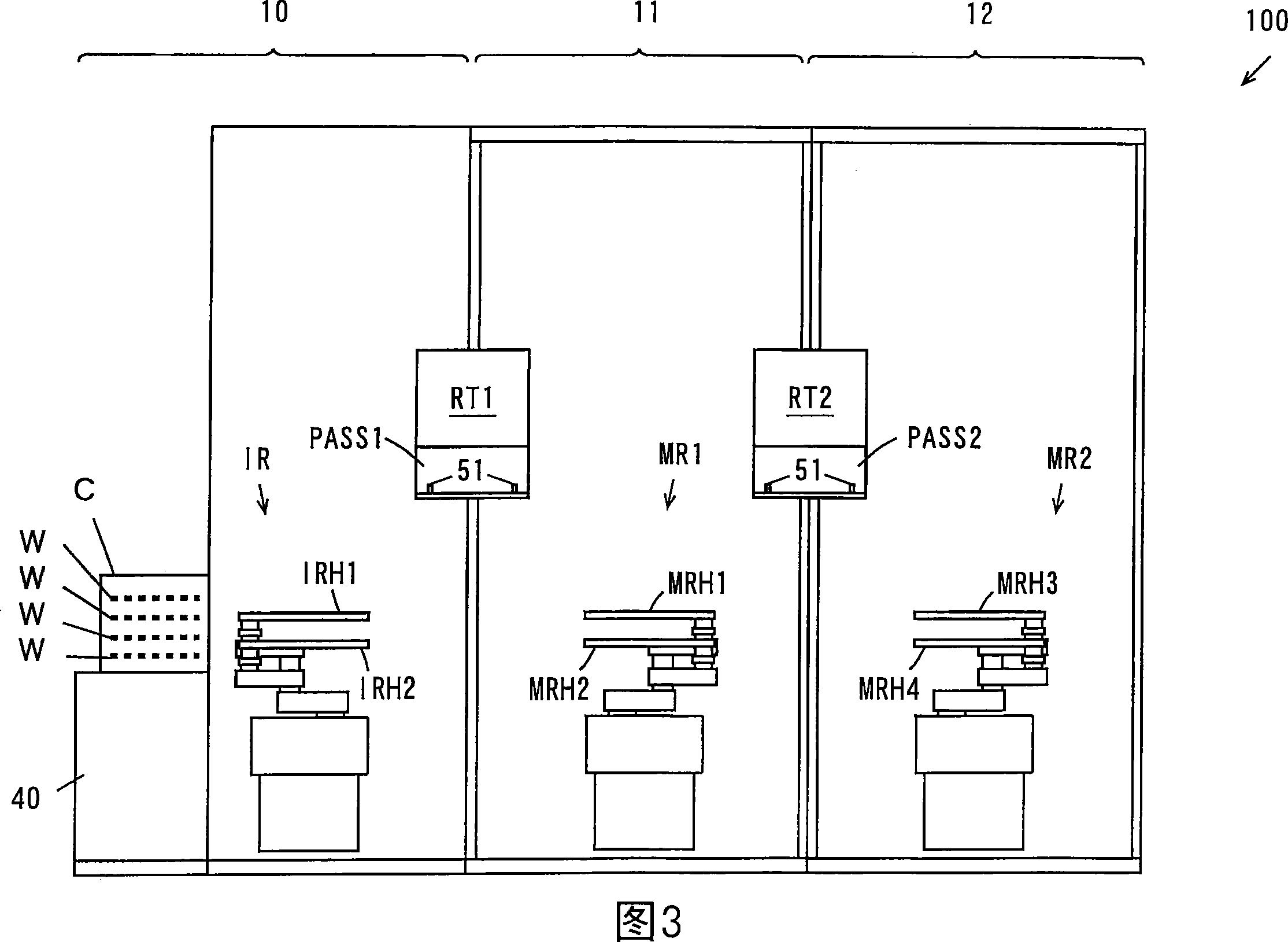

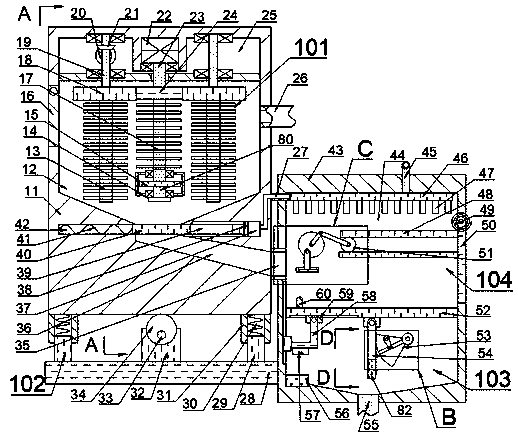

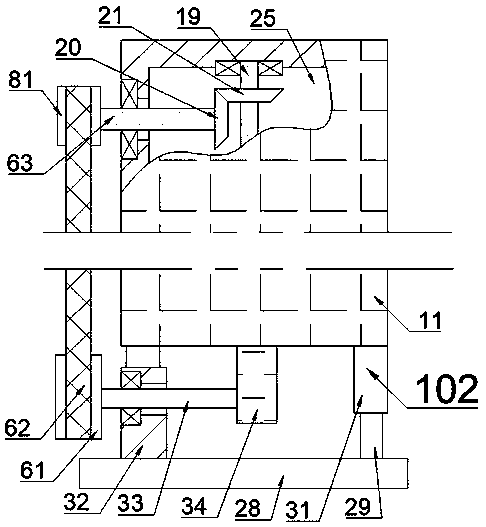

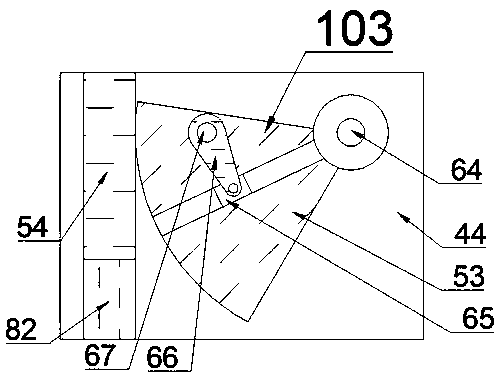

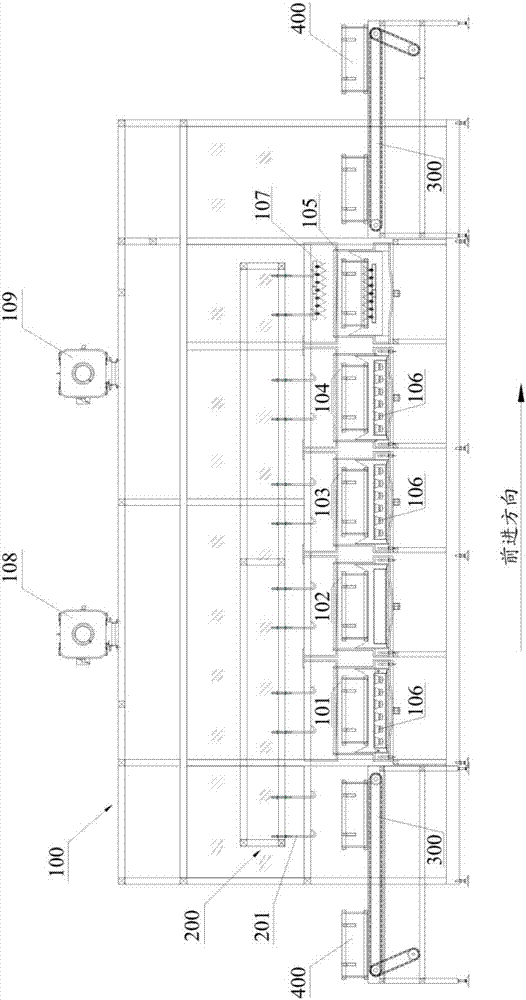

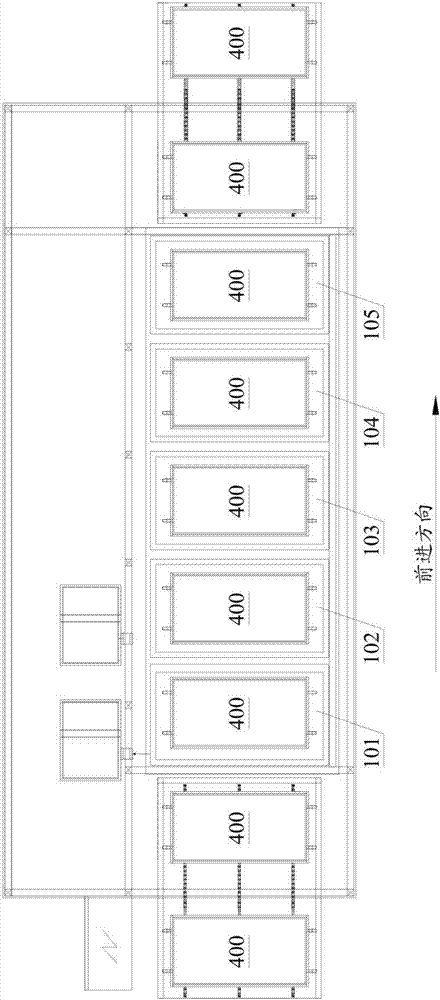

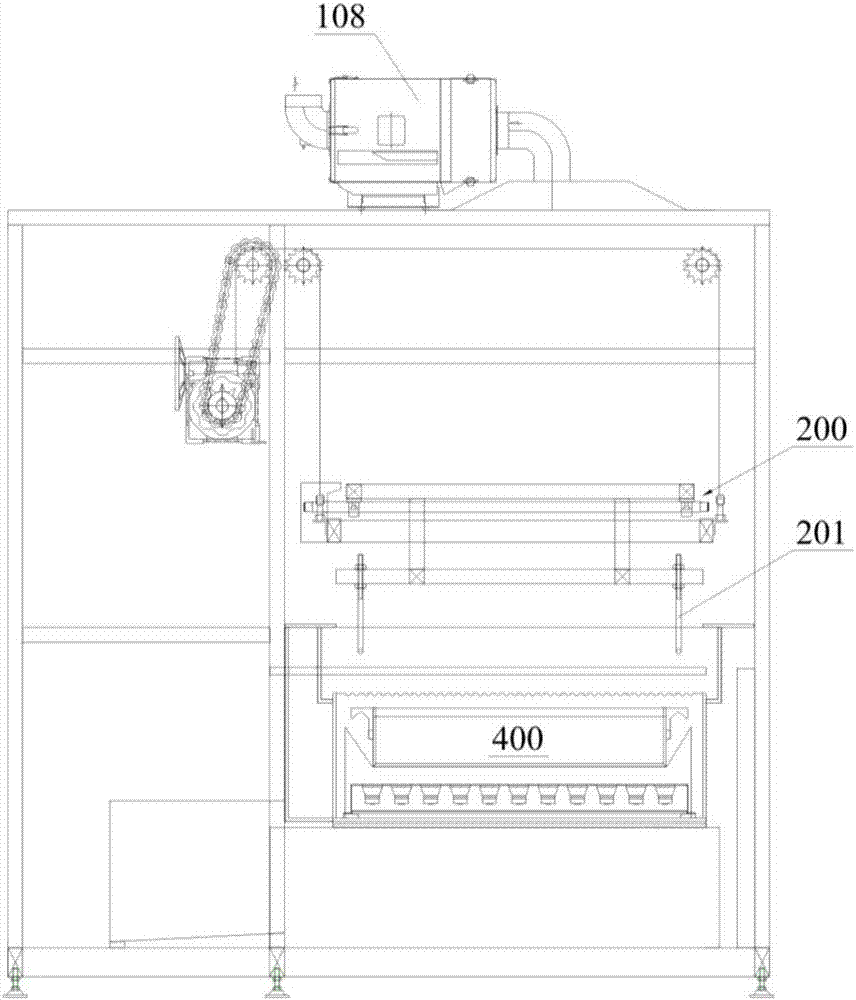

Substrate processing apparatus

ActiveCN101246812AFully cleanedSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEngineeringBiomedical engineering

PROBLEM TO BE SOLVED: To provide a substrate-treating device capable of improving throughput. ŽSOLUTION: The substrate-treating device 100 comprises indexer blocks 10 provided in parallel mutually and first and second treatment blocks 11, 12. In the indexer block 10, there is an indexer robot IR. In the first treatment block 11, there are a plurality of rear cleaning units SSR and a first main robot MR1. In the second treatment block 12, there are a plurality of end face cleaning units SSB, a plurality of front cleaning units SS, and a second main robot MR2. Ž

Owner:DAINIPPON SCREEN MTG CO LTD

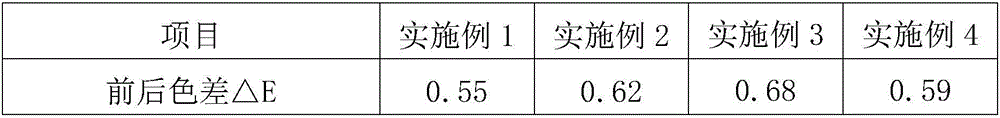

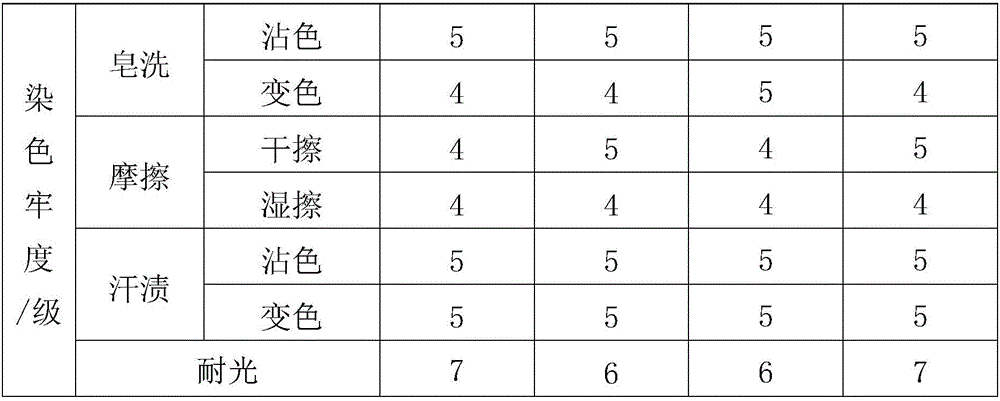

Dyeing and finishing process for polyester blended fiber fabric

ActiveCN106223003ASoft touchImprove water absorptionHeating/cooling textile fabricsHeat resistant fibresDisperse dyeAfter treatment

The invention discloses a dyeing and finishing process for a polyester blended fiber fabric. The process comprises the following steps of 1, pretreatment, wherein the polyester blended fiber fabric is sequentially subjected to scouring, bleaching and enzyme washing; 2, mercerizing and sizing, wherein the fabric is subjected to padding of alkali liquor under the room temperature for pre-sizing; 3, dyeing, wherein the fabric is soaked into dye liquor formed by disperse dyes, dyeing is performed under the temperature of 30-40 DEG C, temperature is increased to 90-110 DEG C at the heating rate being 0.8-1 DEG C / min, washing is performed through warm water, infrared ray pre-heating is performed, and then hot-blast air drying is performed; padding is performed again under the room temperature to reduce the suspended solid dye liquor formed by dyes, a reduction solution is subjected to padding, steam reduction and oxidation are performed, washing is performed through warm water, soaping is performed, and then washing and drying are performed; 4, after-treatment, wherein soft and flame-proof treatment is performed in sequence. According to the dyeing and finishing process for the polyester blended fiber fabric, the touch feeling, elasticity and other properties of the fabric are improved remarkably, dyeing is uniform, the color fastness is high, and the color is full.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

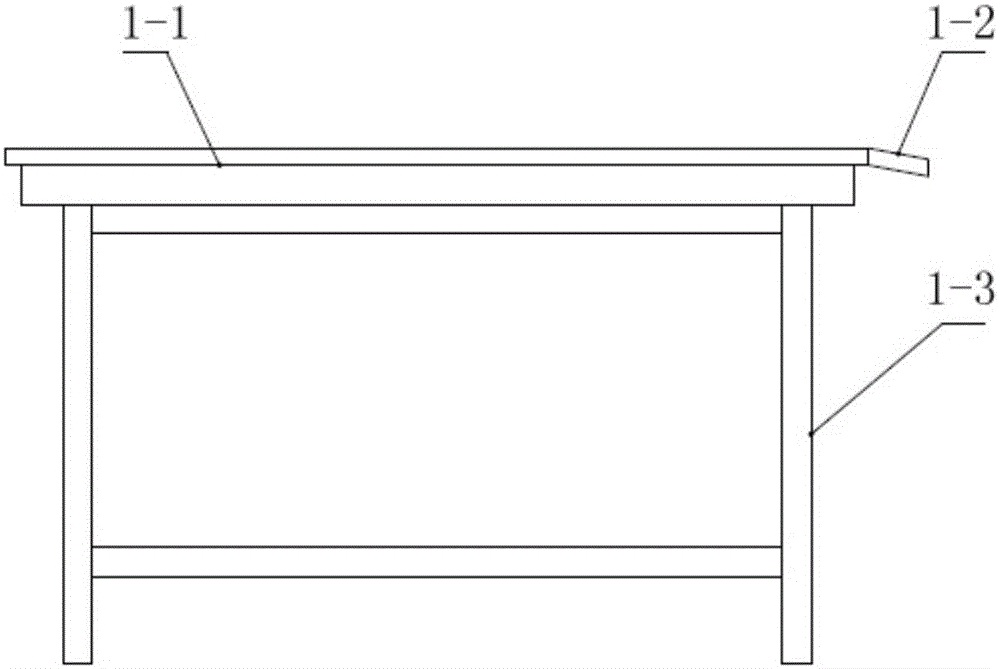

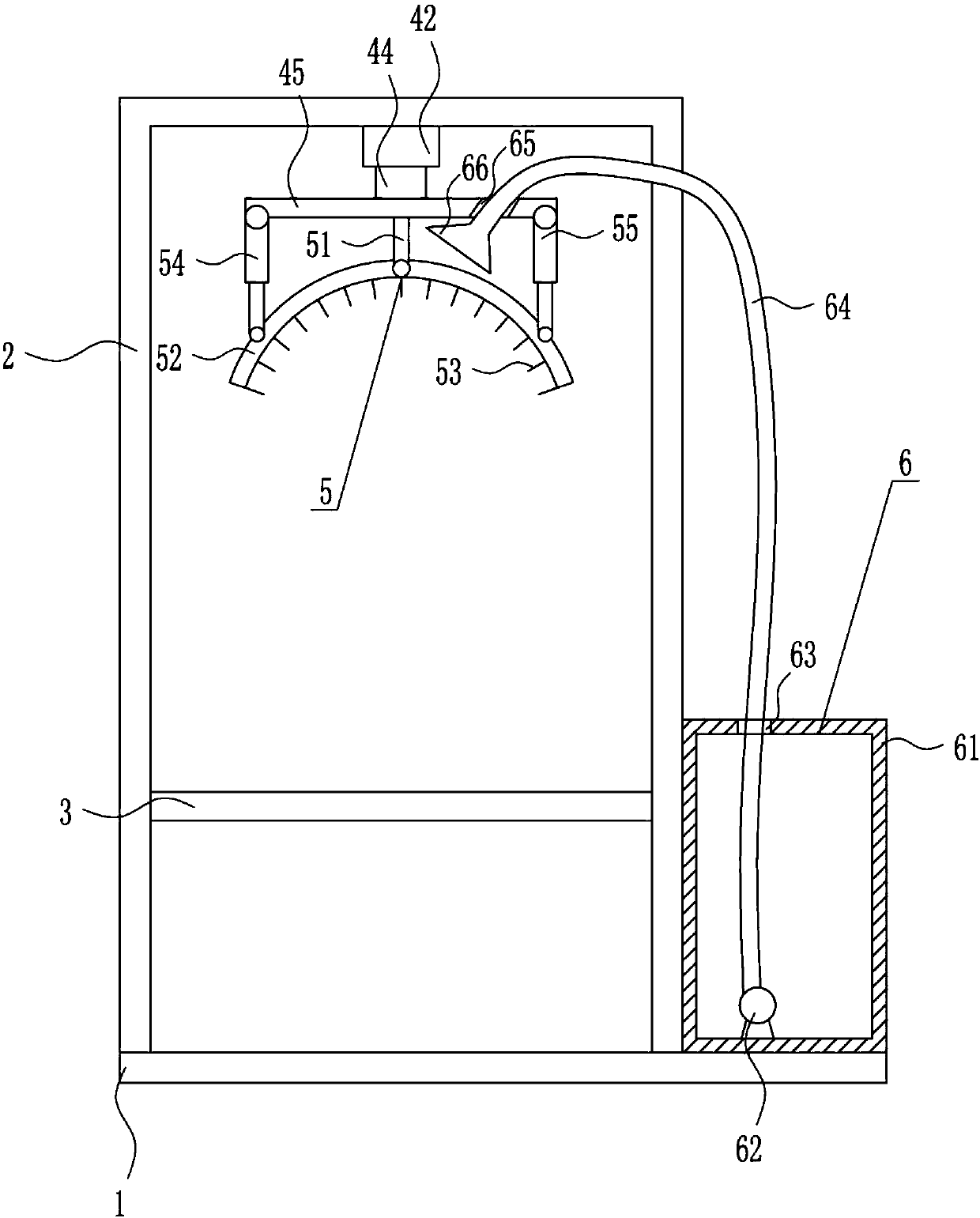

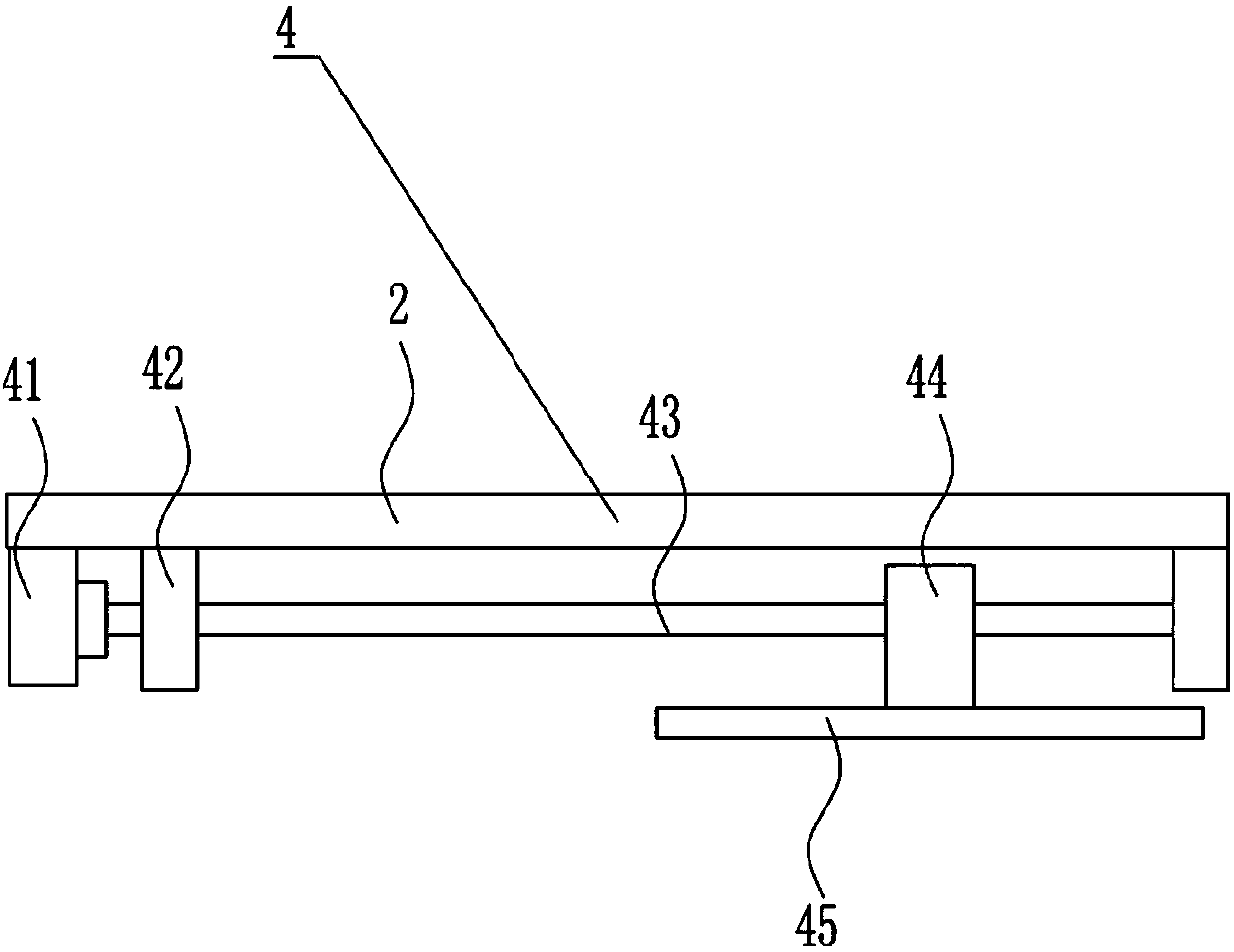

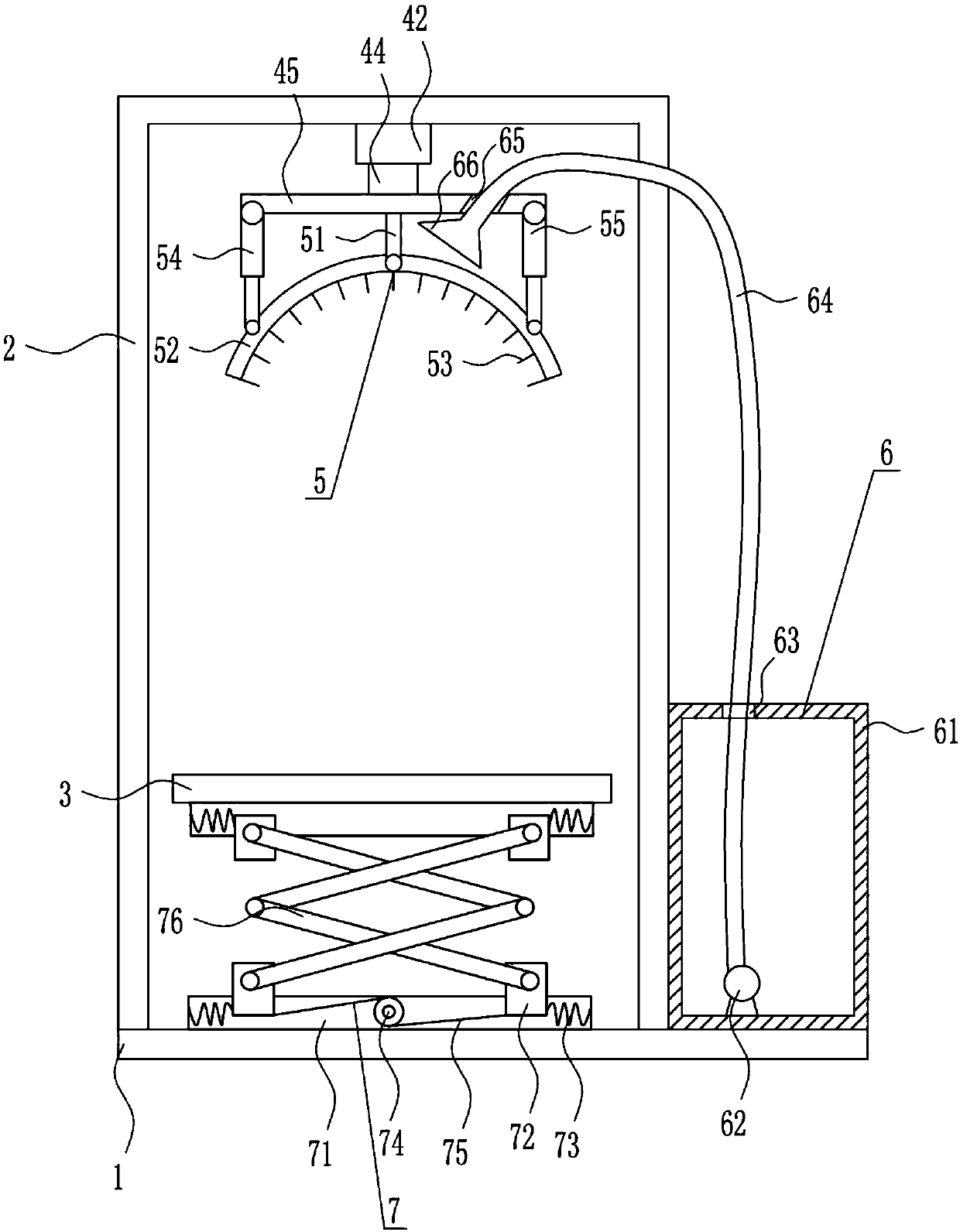

Medical medicine bottle cleaning equipment

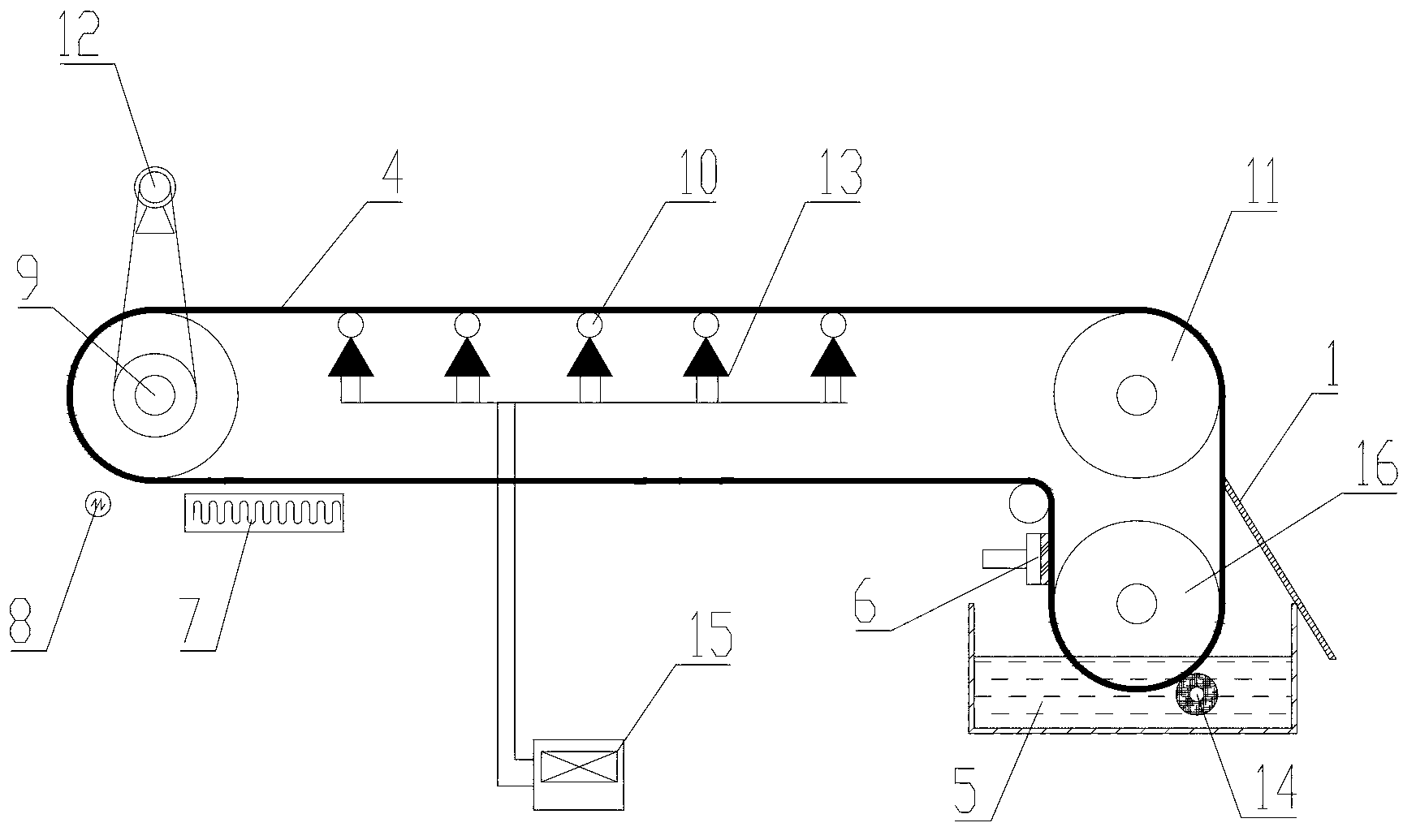

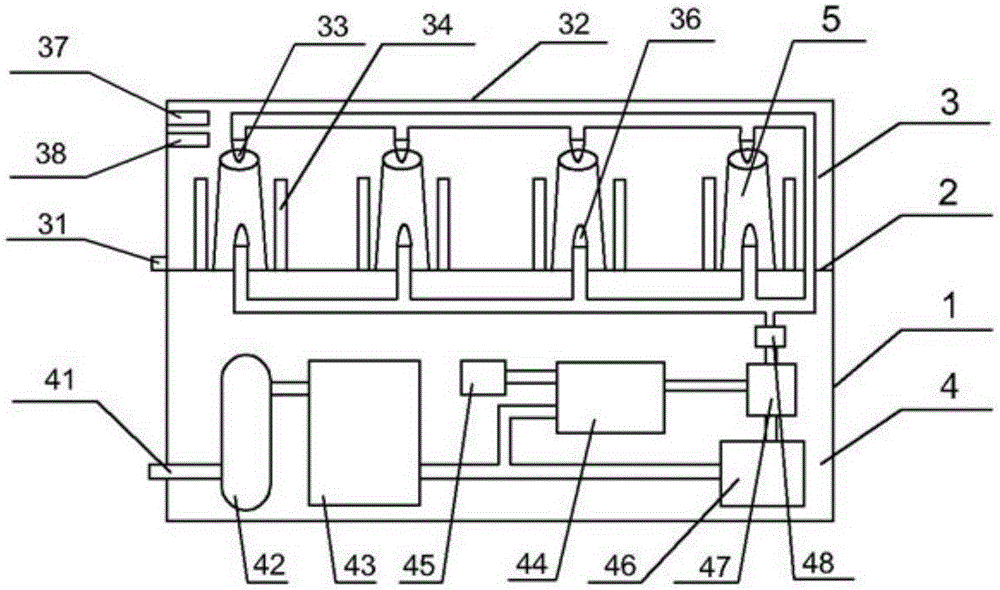

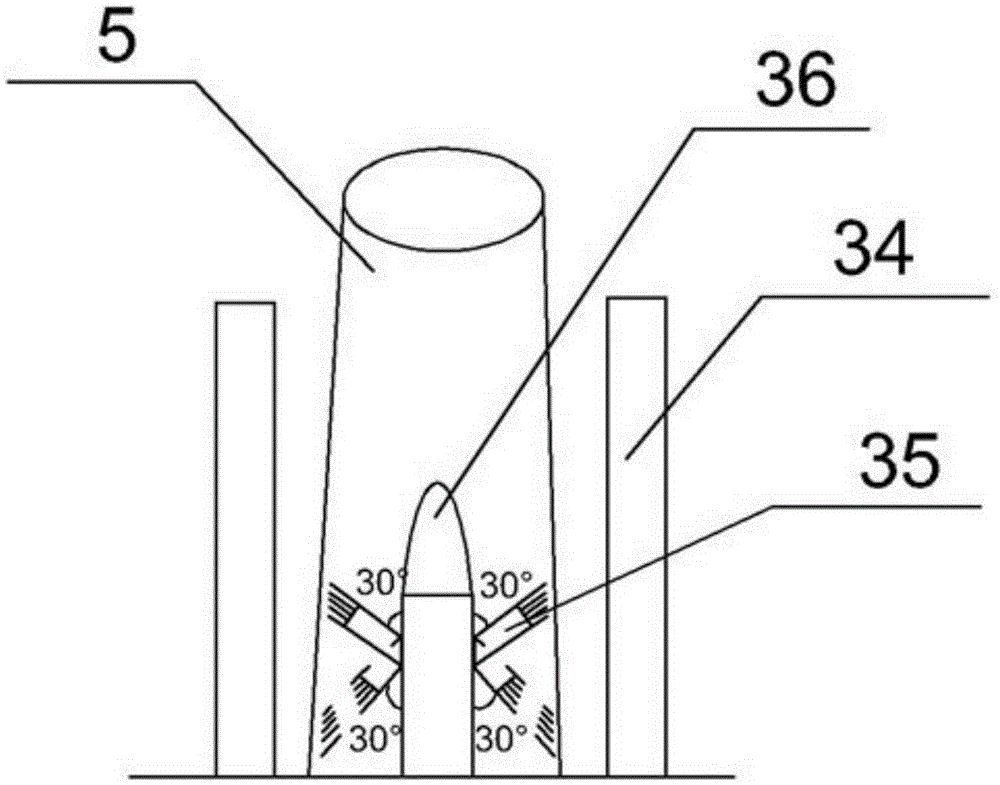

InactiveCN108325981AEasy to get wetFully cleanedHollow article cleaningConveyor partsWater storage tankWater supply

The invention relates to the technical field of cleaning equipment, in particular to medical medicine bottle cleaning equipment. The medical medicine bottle cleaning equipment comprises a feeding conveying belt and a discharging conveying belt. The medical medicine bottle cleaning equipment further comprises a flow guiding platform, a cleaning assembly, an isolation assembly, a first drying assembly and a second drying assembly. The discharging end of the feeding conveying belt and the feeding end of the discharging conveying belt are both connected with the flow guiding platform. The cleaningassembly comprises a water storage tank, a water supply pipe, a water pump and a spray head. The spray head is mounted above the flow guiding platform through a first mounting block. One end of the water supply pipe is connected with the spray head. The water pump is arranged at the other end of the water supply pipe, and the end, provided with the water pump, of the water supply pipe communicates with the water storage tank. Two shifting discs are arranged at the top of the flow guiding platform. An arc-shaped plate is arranged at the edge of the top of the flow guiding platform. By means ofthe medical medicine bottle cleaning equipment, outer wall cleaning can be conducted on medicine bottles effectively and automatically; after being cleaned, the medicine bottles can be dried rapidlyand delivered to the incasement procedure directly; and production efficiency of an enterprise is improved.

Owner:孙磊 +2

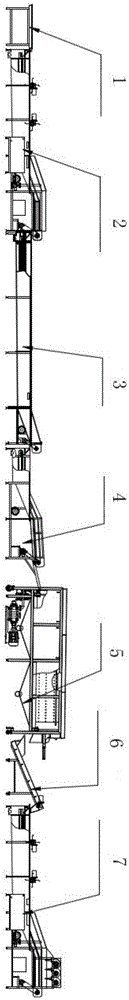

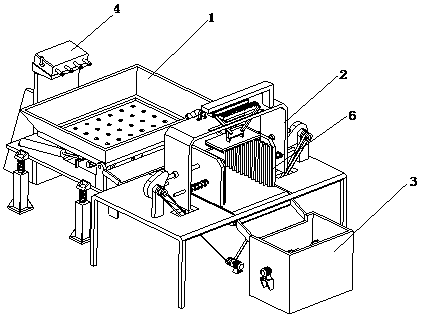

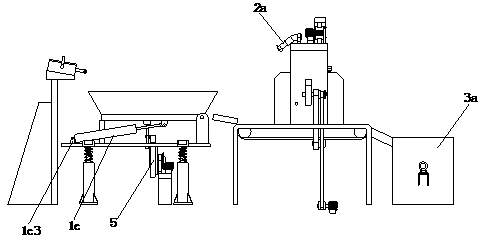

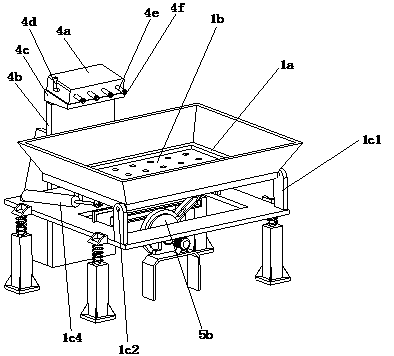

Automatic rhizome peeling and washing assembly line and method

ActiveCN105124725APeeling SatisfactionMeet cleaningVegetable peelingFood treatmentAssembly lineProcess engineering

The invention discloses an automatic rhizome peeling and washing assembly line. According to a material processing flow, the assembly line comprises an unpacking platform, a wind remover bubble washer, a cooking machine, a cooling machine, a roller peeling machine, a belt conveyor, a bubble washer and a control cabinet in sequence, wherein the unpacking platform, the wind remover bubble washer, the cooking machine, the cooling machine, the roller peeling machine, the belt conveyor and the bubble washer are connected with the control cabinet. The invention also discloses an automatic rhizome peeling and washing method. The assembly line and the method have the beneficial effects that according to peeling and washing design of rhizomatic Chinese herbal medicine materials and subsidiary agricultural products, the assembly line and the method comprise material washing, material cooking, material cooling, material peeling and secondary washing, are automatic in control of the whole process and satisfy peeling and washing of different materials; and the whole assembly line saves time and labor and is energy-saving and efficient.

Owner:HANGZHOU FUYANG KANGHUA PHARMA MACHINERY CO LTD

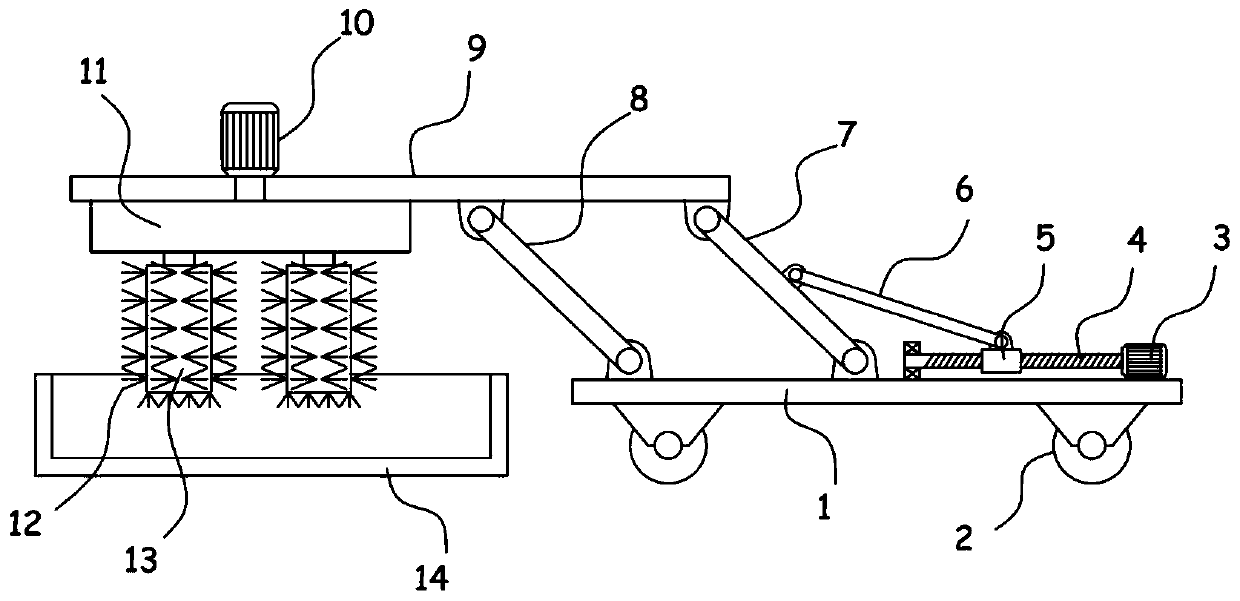

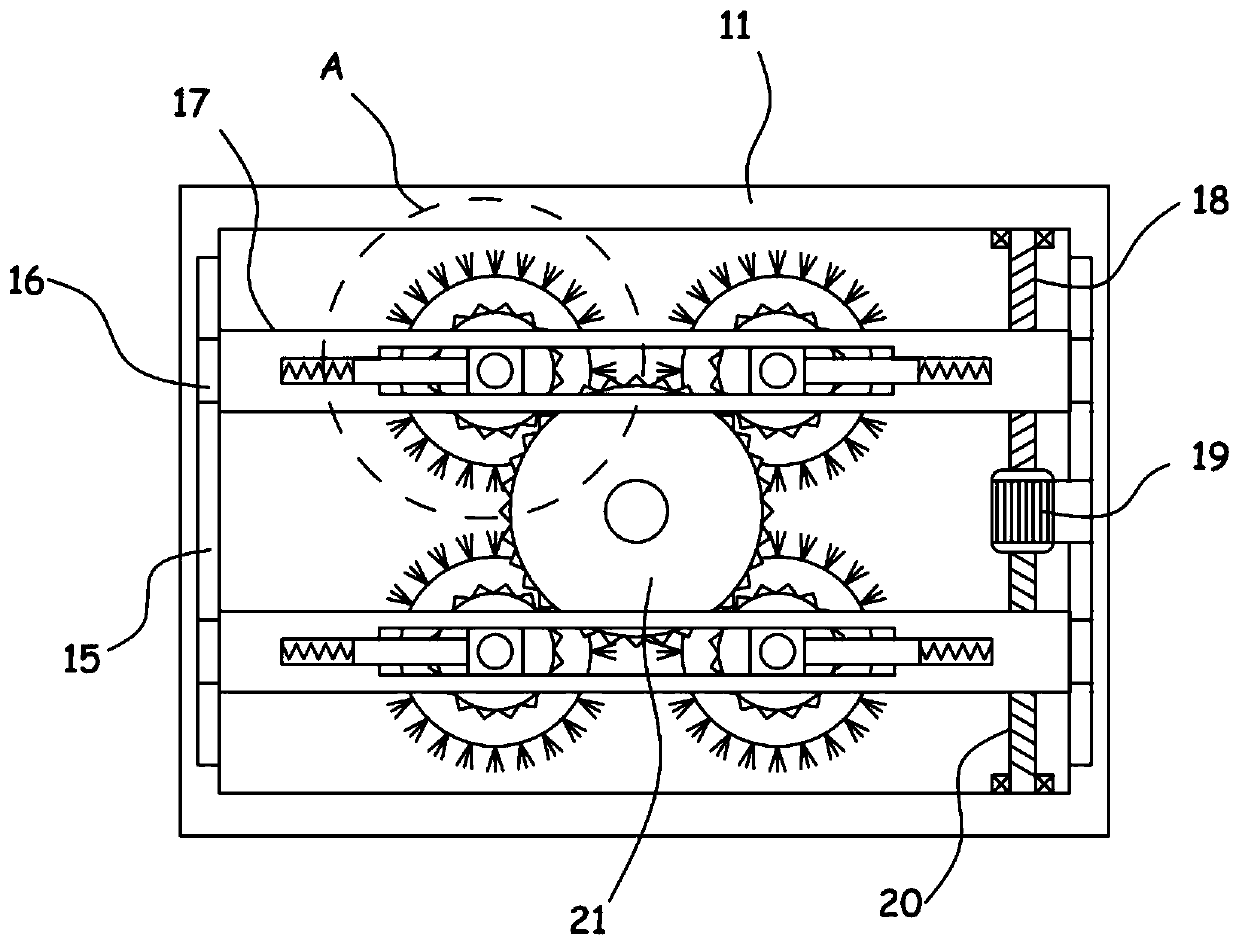

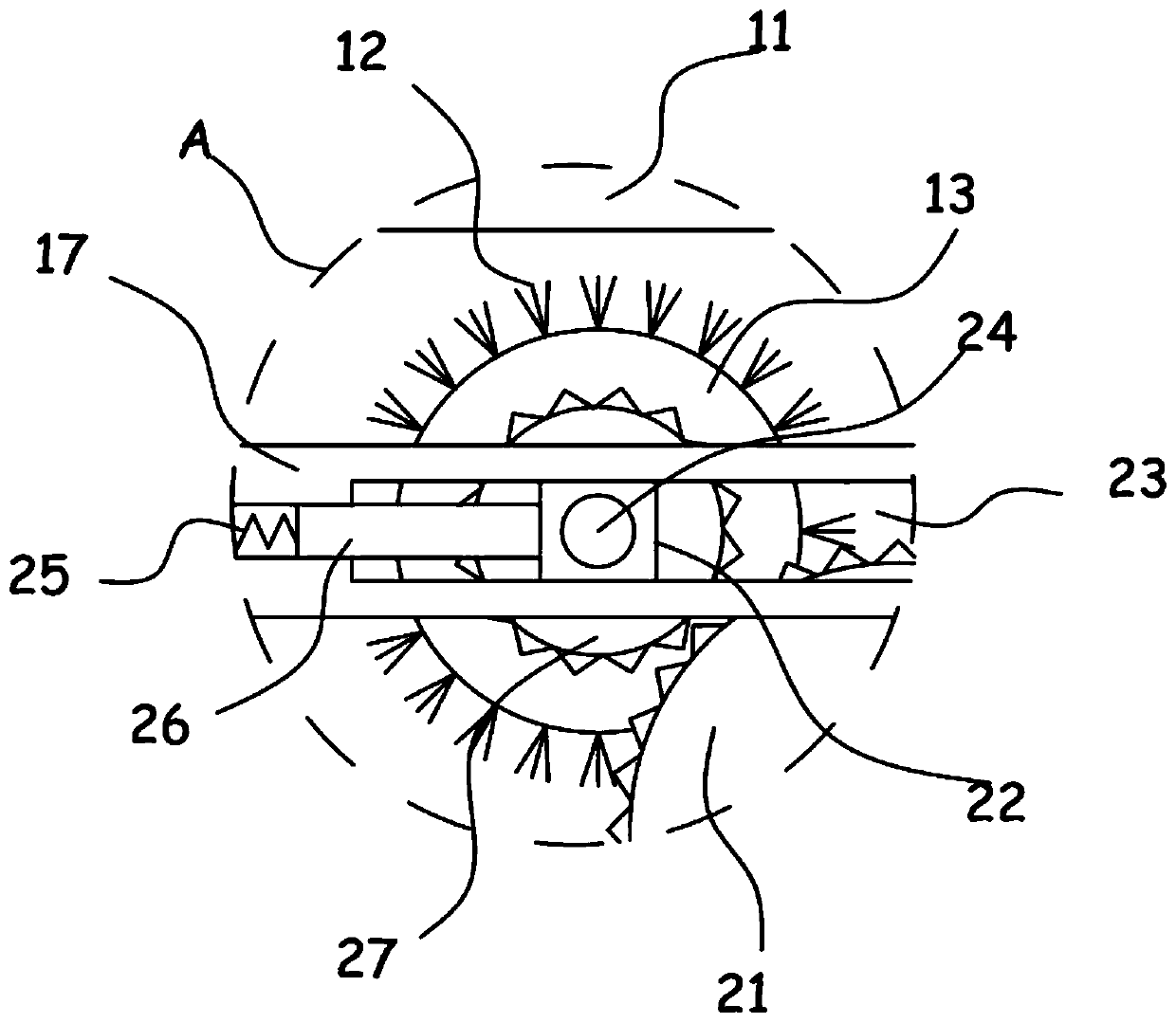

Pet dog cleaning device for veterinarian

InactiveCN107821208AComprehensive cleaningFully cleanedVeterinary instrumentsGrooming devicesEngineeringCanis lupus familiaris

Owner:郑诗青

Self-cleaning efficient stirrer

InactiveCN105056808AAvoid Stirring Dead AngleEasy to moveRotary stirring mixersHollow article cleaningHydraulic cylinderPulp and paper industry

The invention discloses a self-cleaning efficient stirrer. The self-cleaning efficient stirrer comprises a stirrer body, a heat insulation material layer and hydraulic cylinders; a heating cavity is formed in the lower side of the stirrer body and internally provided with a heating furnace, the outer wall of the stirrer body is covered with the heat insulation material layer, a control panel is arranged on the outer wall at the left side of the stirrer body, a stirring rotating shaft is vertically arranged in the stirrer body, and stirring paddles are symmetrically arranged on outer walls at the two sides of the bottom end of the stirring rotating shaft. The self-cleaning efficient stirrer is good in lifting stirring effect and high in efficiency, in the stirring process, materials at the bottom in the stirrer are circularly pumped into the top to be mixed, the stirring effect and efficiency are greatly improved, and no dead angle exists in the stirring process; the materials are heated in the stirring process, the heat efficiency is high, the heat insulation effect is good, after stirring is finished, a nozzle is driven by a motor to rotate to clean the inside of the stirrer, the cleaning effect is good, and manual operation difficulty and intensity are reduced; in addition, the stirrer is convenient and fast to move and high in convenience.

Owner:岑立强

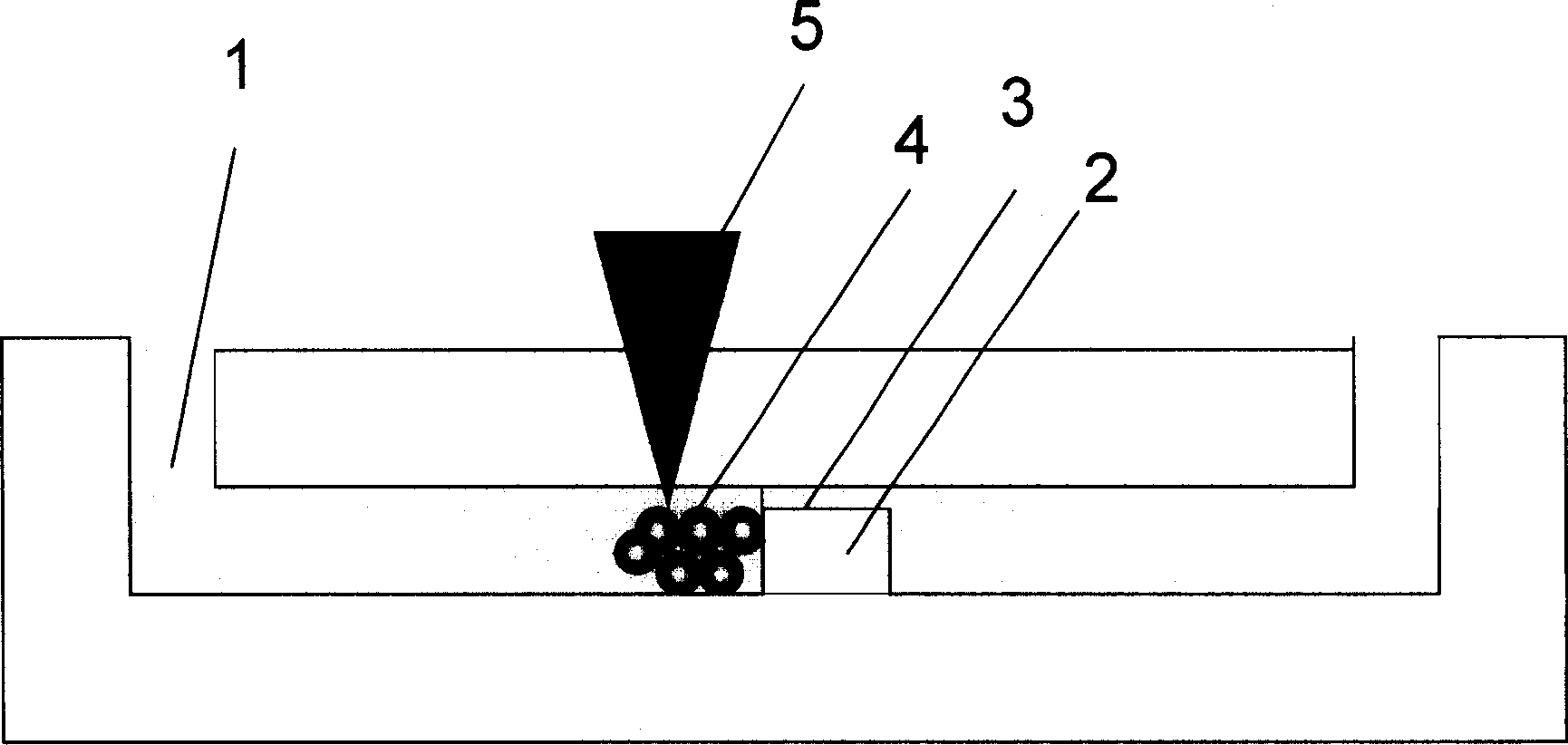

Special washing machine for low-noise and high-strength roller bearings

InactiveCN104307791AImprove cleanlinessWon't scratchDrying gas arrangementsCleaning using liquidsLow noiseControl system

The invention discloses a special washing machine for low-noise and high-strength roller bearings. The special washing machine comprises a framework, a conveying mechanism, a spray-wash system and an electric control system. The spray-wash system comprises a liquid storage tank, a ball nozzle and a liquid delivery pipe, the liquid storage tank is arranged below a machine body, the ball nozzle is arranged above a conical apex, the liquid delivery pipe is connected with the liquid storage tank and the ball nozzle, a washing pump is arranged at the liquid delivery pipe, a conical compression cover is further arranged at the ball nozzle, the conveying mechanism comprises a worktable cylinder, the worktable cylinder is horizontally arranged on the framework, the tail end of a piston rod of the worktable cylinder is fixedly connected with a worktable, and the worktable can horizontally move under the control of the worktable cylinder. The special washing machine has the advantages that the ball nozzle can be directly aligned with the insides of the bearings, so that the bearings can be washed while rotating, grooves in collars can be washed, dirt between rollers and retainers also can be thoroughly washed, the cleanliness of the bearings can be improved, and requirements of the bearings on low noise and vibration can be met.

Owner:JIANGSU TWB BEARINGS CO LTD

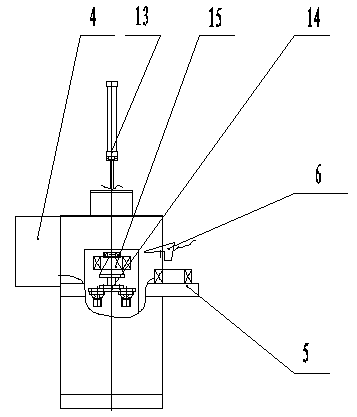

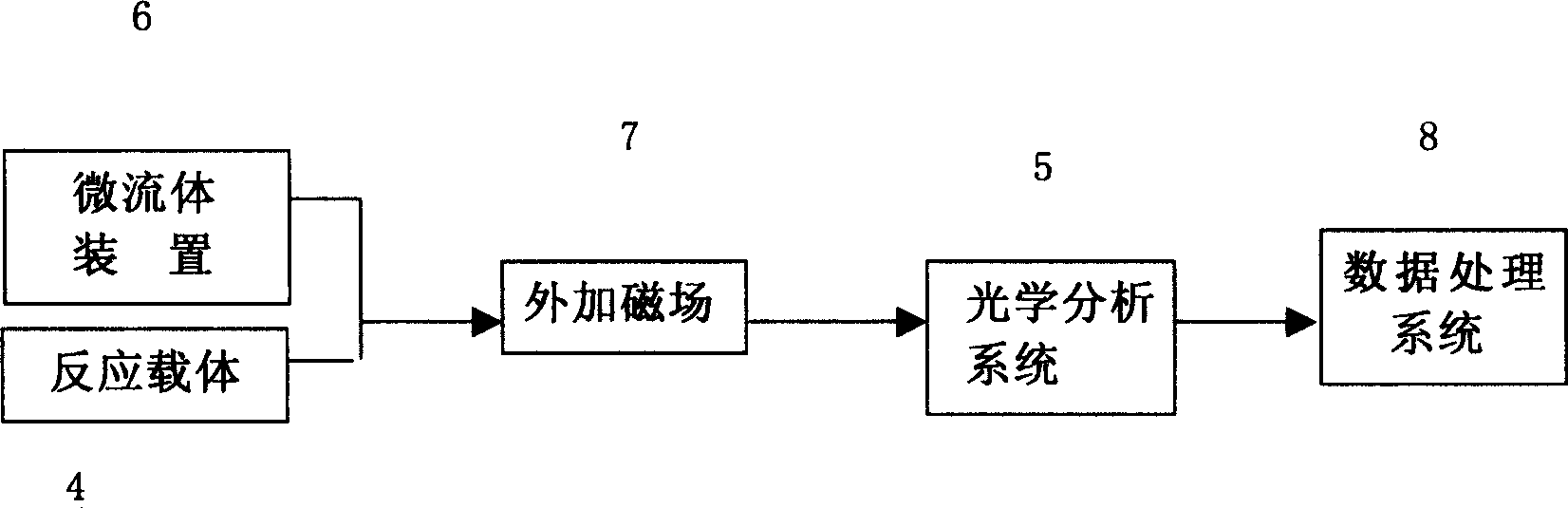

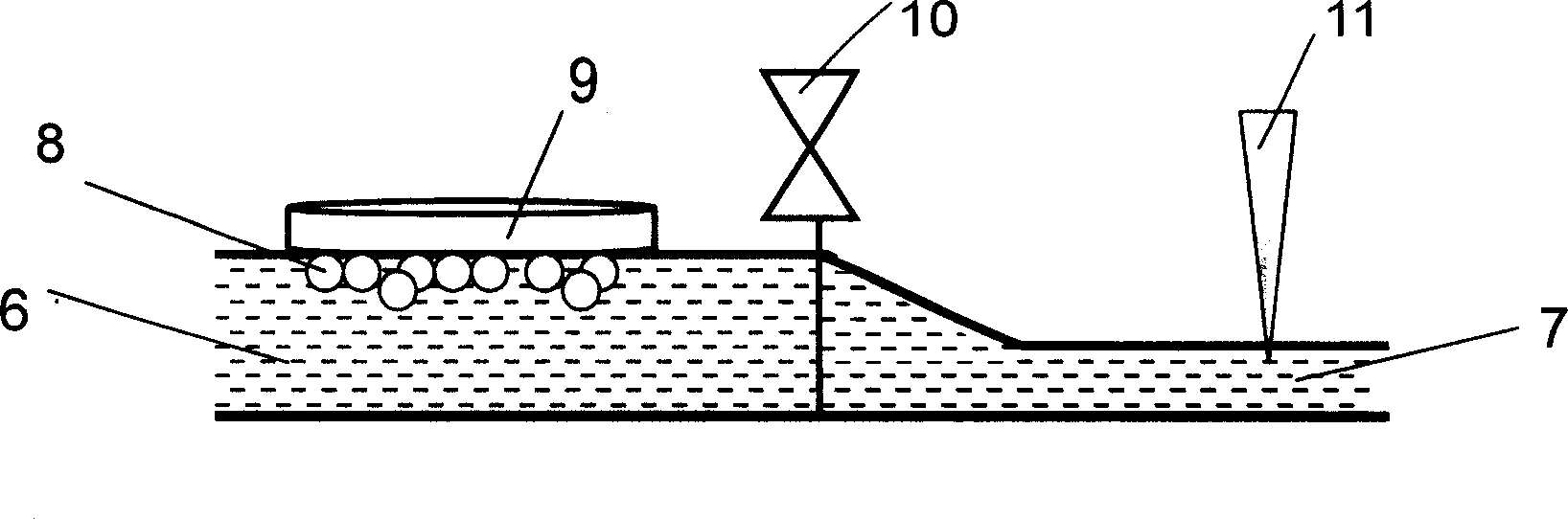

Microfluid analytical system using magnetic microsphere as medium and ivestigating method thereof

ActiveCN1598579AFull responseFully cleanedColor/spectral properties measurementsBiological testingEngineeringLight source

The invention discloses a micro fluid analysis system which is leaded by magnetic microsphere, the system includes micro fluid analysis system equipment, optic analysis system and data analysis system which is set in the output end of the optic analysis system, reaction carrier is in the micro fluid equipment, the optics analysis system includes detector, reaction aisle and detector aisle joint where has valve; the reaction carrier is magnetic microsphere or magnetic fluorescent microsphere. The invention can control the course to process truly, using the magnetism of magnetic microsphere during reaction and cleanout; because the process can be controlled, the reaction carrier can select different radius magnetic microsphere or magnetic fluorescent microsphere. The detector can be set at different position according to the demand, and it can analyze the result by CCD shooting method, color testing by spectroscope, the invention can also test the result of magnetic fluorescent microsphere and fluorescence signal of the tiny surface by laser lamp-house system.

Owner:XIAN GOLDMAG NANOBIOTECH

Cleaning equipment for removing pesticide residues of traditional Chinese medicinal materials

InactiveCN110369363AGood cleaning effectImprove cleaning efficiencyCleaning using toolsCleaning using liquidsInsecticide residueVertical vibration

The invention discloses cleaning equipment for removing pesticide residues of traditional Chinese medicinal materials. The cleaning equipment comprises a cleaning tank, wherein a cleaning cavity witha leftward and downward opening is formed in the cleaning tank, and a cleaning device used for cleaning the traditional Chinese medicinal materials is arranged in the cleaning cavity; a vibration device used for realizing vertical vibration cleaning is arranged on the lower end surface of the cleaning cavity, a filtering tank is fixedly connected to the right end surface of the cleaning tank, anda filtering cavity with a right opening is formed in the filtering tank; and an auxiliary tank door is rotationally connected to the opening in the right side of the filtering cavity, a filtering device is arranged in the filtering cavity, and an opening device which is positioned on the upper side of the filtering device and is used for opening and closing the auxiliary tank door is arranged in the filtering cavity. The device for cleaning the traditional Chinese medicinal materials is composed of a brush cleaning mechanism, a stirring mechanism and a vibration cleaning mechanism, and combined cleaning can be conducted no the traditional Chinese medicinal materials, so that dirt attached to the surface of the traditional Chinese medicinal materials can be effectively removed, the cleaningeffect is good, and the cleaning efficiency is high.

Owner:JINHUA KAISEN INTELLIGENT TECH CO LTD

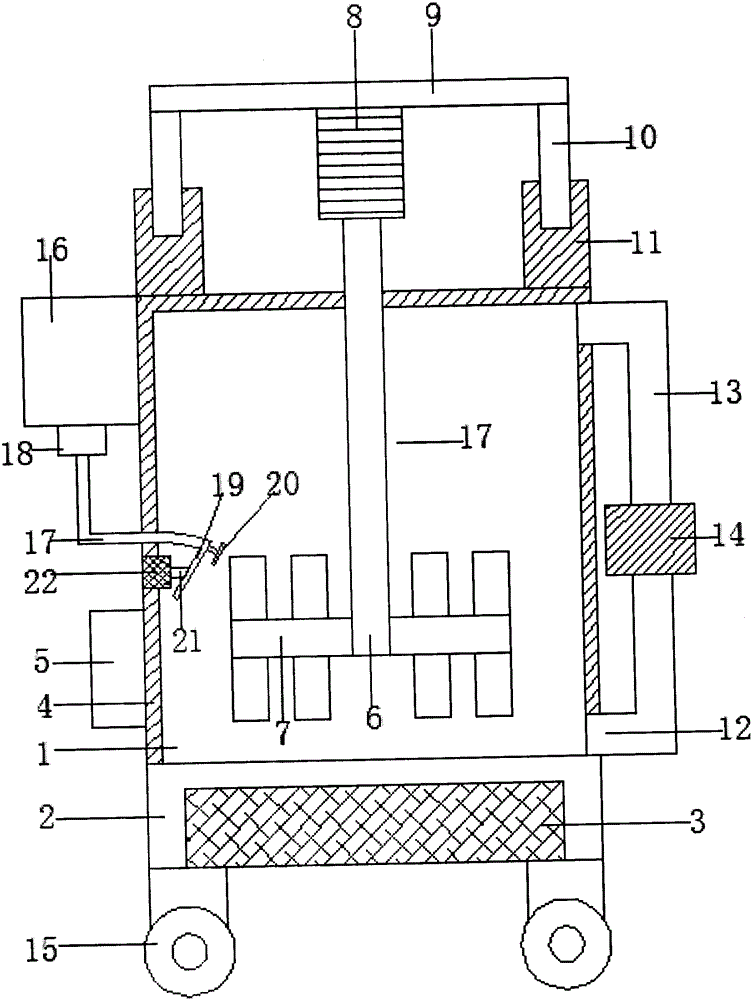

Waste automobile part recycling and processing equipment

InactiveCN110420936AReduce labor intensityAvoid affecting recycling efficiencyTransportation and packagingSolid waste disposalMotor vehicle partInjection air

The invention discloses waste automobile part recycling and processing equipment, and belongs to the field of automobile part recycling. The waste automobile part recycling and processing equipment comprises a dirt clearing mechanism, a compression crushing mechanism and an acid liquid processing mechanism, wherein the compression crushing mechanism comprises compression components on both sides,an air injection component, a workbench and a top crushing component; a conveyor belt is arranged on the workbench; the dirt clearing mechanism comprises a cleaning component, a knocking vibration component, a mounting frame and a turning component; and a filter screen is horizontally arranged in the mounting frame. The dirt clearing mechanism can be used for shaking automobile parts and clearingthe dirt on the automobile parts so as to prevent the incomplete disposal of thedirt on the automobile parts from affecting the recycling efficiency; and the compression components on the both sides can be used for compressing the automobile parts on the conveyor belt, so that the automobile parts can be fully compressed, and are prevented from occupying relatively large space of a processing box.

Owner:冯云

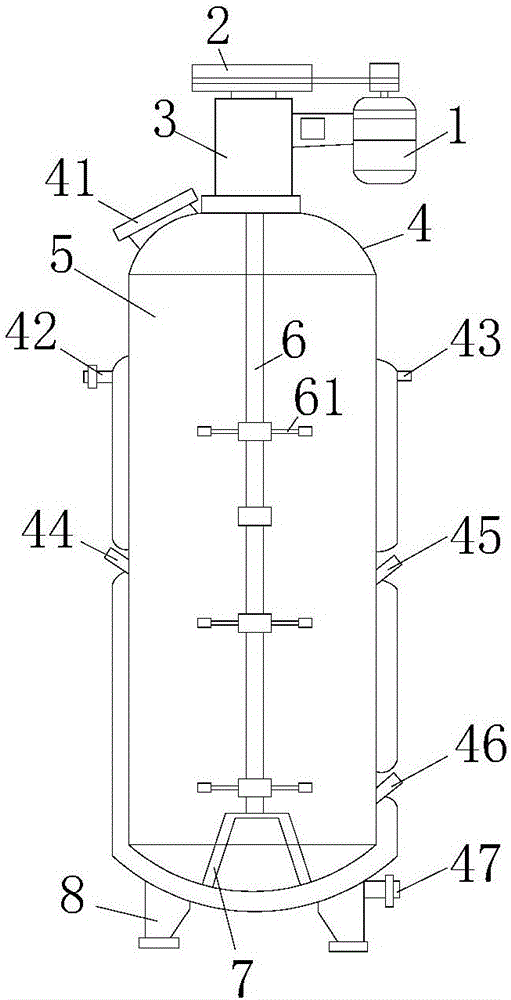

Reactor with scale removing function

InactiveCN105289449AAchieve cleaningSave waterHollow article cleaningChemical/physical/physico-chemical stationary reactorsWater sourceEngineering

The invention discloses a reactor with a scale removing function. The reactor comprises a cover and a cylinder; a material inlet is arranged in the cover, a liquid outlet is arranged in the cylinder, a fixing screw is arranged in the middle of the exterior of the cover, a hollow screw rod is arranged on the fixing screw, the upper part of the hollow screw rod is connected to a belt wheel, the belt wheel is connected to a dynamic device through a belt, the upper part of the hollow screw rod is also connected to a liquid feeding device, the lower part of the hollow screw rod is provided with a hollow stirrer, and the upper part and two sides of the hollow stirrer are respectively provided with a spray orifice and a hairbrush. The reactor has the advantages that the upper part and two sides of hollow stirrer are provided with a spray orifice and a hairbrush respectively, so when the washing liquid is sprayed, the stirring can be carried out, and the water source is saved. The hollow stirrer is arranged on the hollow screw rod, so when the screw rod rotates through the threads, the hollow stirrer can be moved up and down, the washing becomes more sufficient, and the whole reactor is washed.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

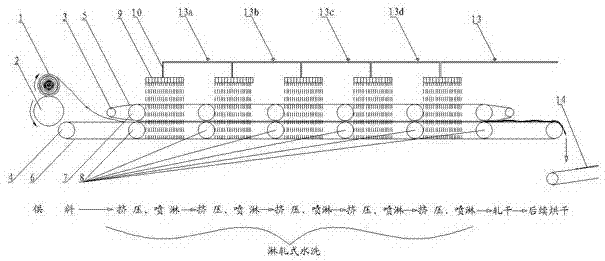

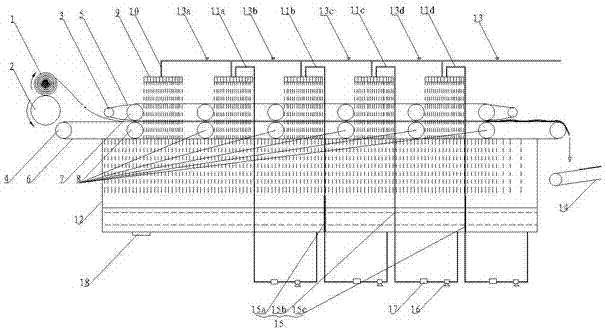

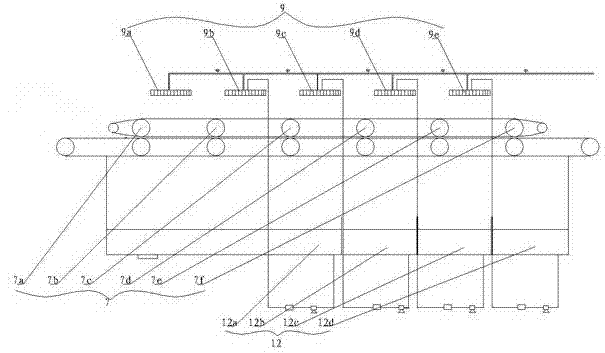

Spray-rolling type loose fiber washing process

ActiveCN103774362ALow water consumptionLow costLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsDyeingFiber

The invention relates to a spray-rolling type loose fiber washing process, and belongs to the technical field of loose fiber dyeing. Dyed loose fibers are conveyed to a spray-rolling type washing device, while the loose fibers are horizontally clamped by a guide belt to be conveyed, a plurality of groups of spray-rolling type washing with alternative squeezing and spraying is carried out on the loose fibers, and the loose fibers are washed, rolled to be dry, and output. The spray-rolling type loose fiber washing process has the advantages that dyeing is even, water consumption is small, and the working procedure is simple.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

High-efficiency cleaning machine for processing nectarines

InactiveCN105212242AImprove processing efficiencyUse full cleaningFood treatmentUv disinfectionMegasonic cleaning

The invention discloses a high-efficiency cleaning machine for processing nectarines. The high-efficiency cleaning machine comprises a body and a material inlet bucket. The material inlet bucket is arranged at the upper left end of the body. The middle segment in the body is provided with a drawing-pulling separator plate in a horizontal direction. The drawing-pulling separator plate divides the body into an upper chamber and a lower chamber, namely a cleaning chamber and a screening chamber. After cleaning, just through drawing out the drawing-pulling separator, screening can be performed, thereby realizing simple operation and high convenience in use. A nectarine cleaning function and a nectarine screening function are integrated. A processing efficiency of the nectarine is effectively improved. Three cleaning modes of ultrasonic cleaning, brushing by a cleaning rod and clear water flushing are combined, thereby effectively improving cleaning efficiency and ensuring high cleaning effect. In screening, hot-air drying and ultraviolet sterilization can be performed on the nectarines. Furthermore later storage and transportation are facilitated.

Owner:徐州市贾汪区滨农农业科技发展有限公司

Silicon block cleaning and drying device

ActiveCN107363034AFully cleanedReduce waiting time for cooling downAfter-treatment detailsFlexible article cleaningEngineeringSilicon

The invention provides a silicon block cleaning and drying device. The silicon block cleaning and drying device comprises a cleaning unit, a drying unit and a cooling unit, wherein the cleaning unit is used for conducting cleaning treatment on the surface of a silicon block after being broken, the drying unit is used for conducting drying treatment on the silicon block after cleaning is completed, and the cooling unit is used for conducting cooling treatment on the silicon block after drying is completed. According to the silicon block cleaning and drying device, the silicon block can be sufficiently cleaned to remove residue and scratches on the surface of the silicon block.

Owner:新疆新特新能材料检测中心有限公司

Efficient cleaning device for soybeans

InactiveCN106539106AReasonable structureInnovative design ideasFood treatmentEngineeringRotating drum

The invention discloses an efficient cleaning device for soybeans. The device comprises a box body. A first rotating shaft is fixedly connected to the output end of a first motor, a spiral stirring rod is fixedly connected to the surface of the first rotating shaft, and a supporting frame is fixedly connected to each of the four corners of the bottom end face of the box body. A second rotating shaft is fixedly connected to the output end of a second motor. A rotating disk is fixedly connected to the upper end face of the second rotating shaft. Third through holes are evenly formed in the rotating disk. A rotating drum is fixedly connected to the upper end face of the rotating disk. Second through holes are evenly formed in the bottom end and side walls of the rotating drum. A second electromagnetic valve is arranged on the side, close to the bottom end of a second tilting plate, of an inner cavity of the box body. The efficient cleaning device for the soybeans is reasonable in structure, novel in designing thought and better in cleaning effect; by using a robot to replace human power, labor intensity is lowered, and cleaning efficiency is improved; and cleaned water can be recycled, and resources are saved.

Owner:CHONGQING XINRUN AGRI DEV

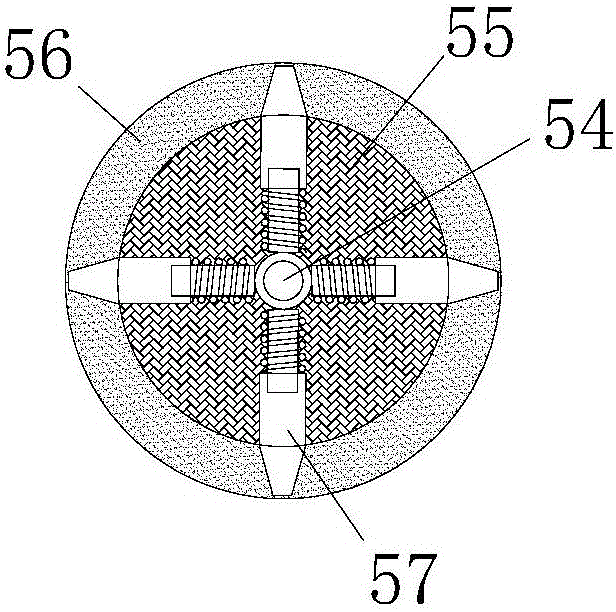

Greasy dirt cleaning device for surface of metal part before heat treatment

InactiveCN107899983AConducive to closed cleaningEasy to cleanDrying gas arrangementsCleaning using toolsHydraulic ramImpurity

The invention discloses a greasy dirt cleaning device for the surface of a metal part before heat treatment. The greasy dirt cleaning device comprises a hydraulic pushing rod, a mounting seat, an electric pushing rod, a bearing round plate, a mounting hole, a rotating rod, a motor, a sealing cover, a water spraying head, a fixing plate, an outer threaded pipe, a cross-type brush, a gas spraying head, a cylinder body, a fluid flowing hole, arc-shaped blocks and a rubber block. According to the greasy dirt cleaning device for the surface of the metal part before heat treatment, the design is reasonable, closed cleaning treatment is conducted on the metal part advantageously, dust impurities are avoided from falling in, the metal part is cleaned and air-dried again advantageously, and the greasy dirt cleaning device is suitable for greasy dirt cleaning of metal parts of various kinds of different specifications; the cleaning effect is improved, artificial operation is reduced, and subsequent heat treatment of the metal parts is facilitated; the rotating metal part is subjected to greasy dirt cleaning through the cross-type brush with cleaning fluid, and full using and saving of cleaning are facilitated; and through the four arc-shaped blocks located the same plane and arranged between the fixing plate and a placing round plate, the four arc-shaped blocks clamp the metal part through the electric pushing rod advantageously.

Owner:张粉银

Cleaning device of fermentation tank

InactiveCN106424040AGuaranteed sterilityPromote fermentationWater/sewage treatment by irradiationHollow article cleaningMotor driveWater flow

The invention discloses a cleaning device of a fermentation tank. The cleaning device comprises a tank body and a cleaning device, wherein the cleaning device is arranged inside the tank body; the cleaning device comprises a water pipe, a fixed block, a second motor, a second rotating shaft, an elastic body, cleaning cotton, water nozzles, water outlet pipes and springs; the top of the second rotating shaft is connected with the water pipe through a bearing; a water pump is mounted on the water pipe; a second rotating wheel is connected with the second motor through a belt; and the second motor is mounted on the fixed block through a supporting block. According to the cleaning device of the fermentation tank, during cleaning, water passes through ultraviolet lamps, the ultraviolet lamps sterilize and disinfect water, and water flowing out of the water outlet pipes is guaranteed to be sterile; and the second motor drives the second rotating shaft to rotate, water flows towards the bottom of the second rotating shaft under the actions of gravity and pressure, the cleaning cotton is in full contact with the tank body, the tank body can be fully cleaned, the inner wall of the tank body is guaranteed to be clean, and cleanliness of the tank body is guaranteed.

Owner:弘毅天承知识产权股份有限公司

Livestock breeding livestock watering trough inner wall cleaning device

ActiveCN110404905AImprove the cleaning effect of the inner wallIncrease cleaning rateAnimal watering devicesHollow article cleaningEngineeringMoving frame

The invention discloses a livestock breeding livestock watering trough inner wall cleaning device, and relates to the technical field of livestock breeding. The livestock breeding livestock watering trough inner wall cleaning device comprises a moving frame. A lifting plate which is parallel to the moving frame is connected to the moving frame in a driving mode through an extending mechanism. A cleaning assembly which is used for a watering trough is coaxially fixed to the bottom of each rotating shaft. An adjusting mechanism which is used for conducting separation distance adjustment on the cleaning assemblies is arranged on a surrounding plate. According to the livestock breeding livestock watering trough inner wall cleaning device, by means of the arranged adjusting mechanism, the cleaning assemblies which are used for cleaning the watering trough can be adjusted, and therefore the situation that brushes on rotating rollers can be well pressed and attached to the inner wall of the watering trough can be guaranteed, and the watering trough inner wall cleaning effect is greatly improved. An arranged gear disc and four driven gears are connected in a meshing mode to achieve the synchronous rotation of the four rotating rollers, and therefore the cleaning speed of the watering trough is remarkably increased, and the cleaning adequacy of the watering trough is remarkably improved. An arranged extending assembly can drive the cleaning assemblies to be subjected to the adjustment of the vertical height, and therefore the inner wall, with the different depths, of the watering trough can be fully cleaned, and the cleaning process is efficient and comprehensive.

Owner:山东千禧农牧发展有限公司

Steel sheet cleaning device

InactiveCN107597642AFully cleanedEasy to dryDrying gas arrangementsCleaning using toolsMegasonic cleaningEngineering

The invention relates to a steel sheet cleaning device comprising a scrubbing cleaning mechanism, a spraying cleaning mechanism, an ultrasonic cleaning mechanism, a sprinkling mechanism, a water scrapping mechanism and a drying mechanism, wherein the scrubbing cleaning mechanism, the spraying cleaning mechanism, the ultrasonic cleaning mechanism, the sprinkling mechanism, the water scrapping mechanism and the drying mechanism are sequentially arranged on one straight line. A steel sheet sequentially passes through the scrubbing cleaning mechanism, the spraying cleaning mechanism, the ultrasonic cleaning mechanism, the sprinkling mechanism, the water scrapping mechanism and the drying mechanism. Through scrubbing cleaning of scrubbing cleaning rollers, spraying cleaning of spraying heads and ultrasonic cleaning, surface oil stains and impurities of the steel sheet are fully removed, clean water is sprinkled to the surface of the steel sheet through the sprinkling mechanism, so that thesurface of the steel sheet is cleaner, then through a first squeezing wheel and a second squeezing wheel of the water scrapping mechanism, residual water on the surface of the steel sheet is scrappedoff, a trace amount of water remains on the surface of the steel sheet, and then the steel sheet can be rapidly dried after entering a drying box. By the adoption of the process, the steel sheet is more fully cleaned and is cleaner, the drying efficiency is effectively improved, and the overall cleaning efficiency of the steel sheet is effectively improved.

Owner:深圳市志虹供应链有限公司

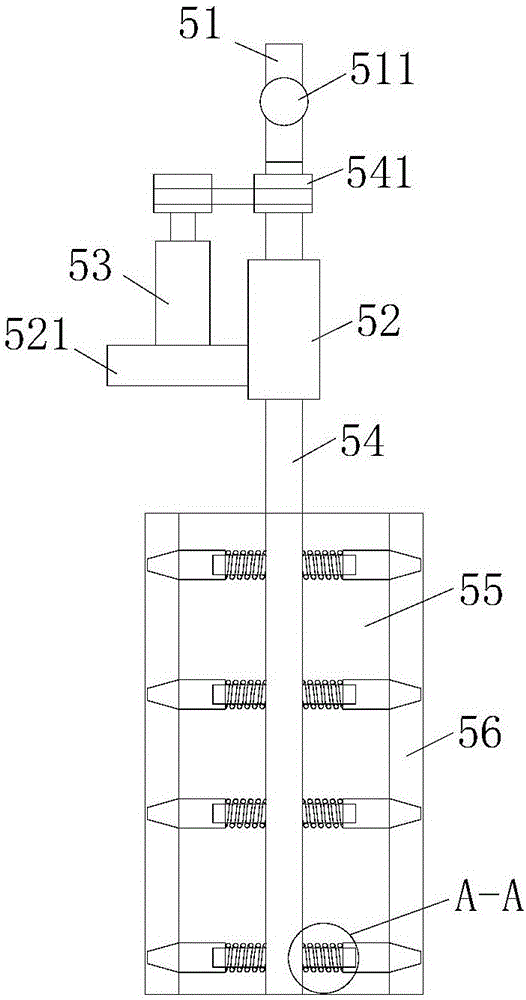

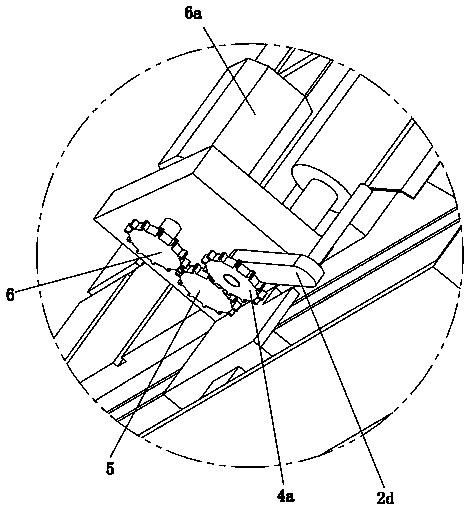

Portable pipeline interior washing device

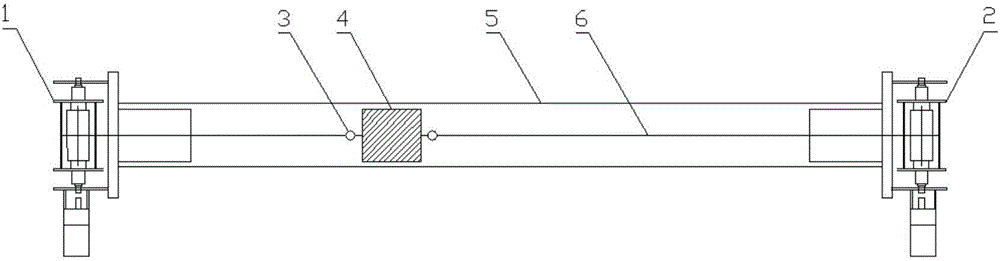

ActiveCN106583361ALow working environment requirementsTotal light weightHollow article cleaningBristleEngineering

The invention discloses a portable pipeline interior washing device. The portable pipeline interior washing device comprises a first power working device, a second power working device, a brush head used for pipe interior washing and two sections of steel wire ropes connected with the two sides of the brush head, wherein the first power working device and the second power working device are arranged at the two ends of a pipeline; one ends of the two sections of steel wire ropes are connected to the first power working device and the second power working device, and the other ends of the two sections of steel wire ropes are connected with the two ends of the brush head; the structure of the first power working device and the structure of the second power working device are the same, the steel wire ropes are wound through a gear motor, the brush head is pulled to do back-and-forth motion in the pipeline, and therefore the pipeline washing work is done; and the installation positions of a brush bristle barrel and a brush bristle body are changed so that pipelines with different diameters can be washed. The portable pipeline interior washing device is simple in structure, easy to disassemble and maintain and low in environmental requirement; the brush head is adopted for washing, damage to a pipeline inner bore is avoided, and meanwhile washing of the pipelines with different diameters can be completed.

Owner:NANJING UNIV OF SCI & TECH

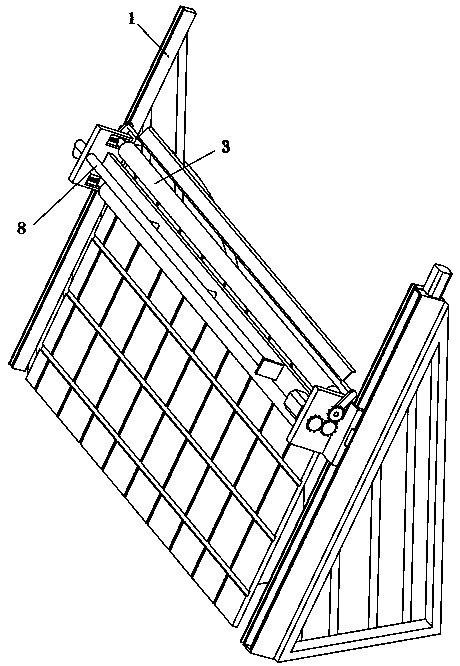

Rapid intelligent synchronous cleaning device for photovoltaic solar cell panel

ActiveCN108282149AFully cleanedSimple structurePhotovoltaicsPhotovoltaic energy generationDrive motorEngineering

The invention discloses a rapid intelligent synchronous cleaning device for a photovoltaic solar cell panel, which comprises a cleaning piece, a left side lead rail and a right side lead rail; the left side lead rail and the right side lead rail are slant and arranged at left and right sides of the solar cell panel; the cleaning piece comprises a guide part and at least two rollers; outer surfacesof the rollers are provided with brushes, both ends of the guide part are glidingly fitted with the left side lead rail and the right side lead rail; the side of the right side lead rail is providedwith a driving motor, two rollers are arranged at both sides of the guide part, a conveying pipeline is arranged between two rollers, the lower part of the conveying pipeline is provided with at leastthree nozzles connected with it; a scraper plate is arranged between the left side lead rail and the right side lead rail. The rapid intelligent synchronous cleaning device for the photovoltaic solarcell panel can replace manual work to automatically clean the solar cell panel; the cleaning device is simple in structure and low in input cost; through the cooperation of the scraper plate, the secondary pollution after brushing can be avoided.

Owner:西安华凌新能源科技有限公司

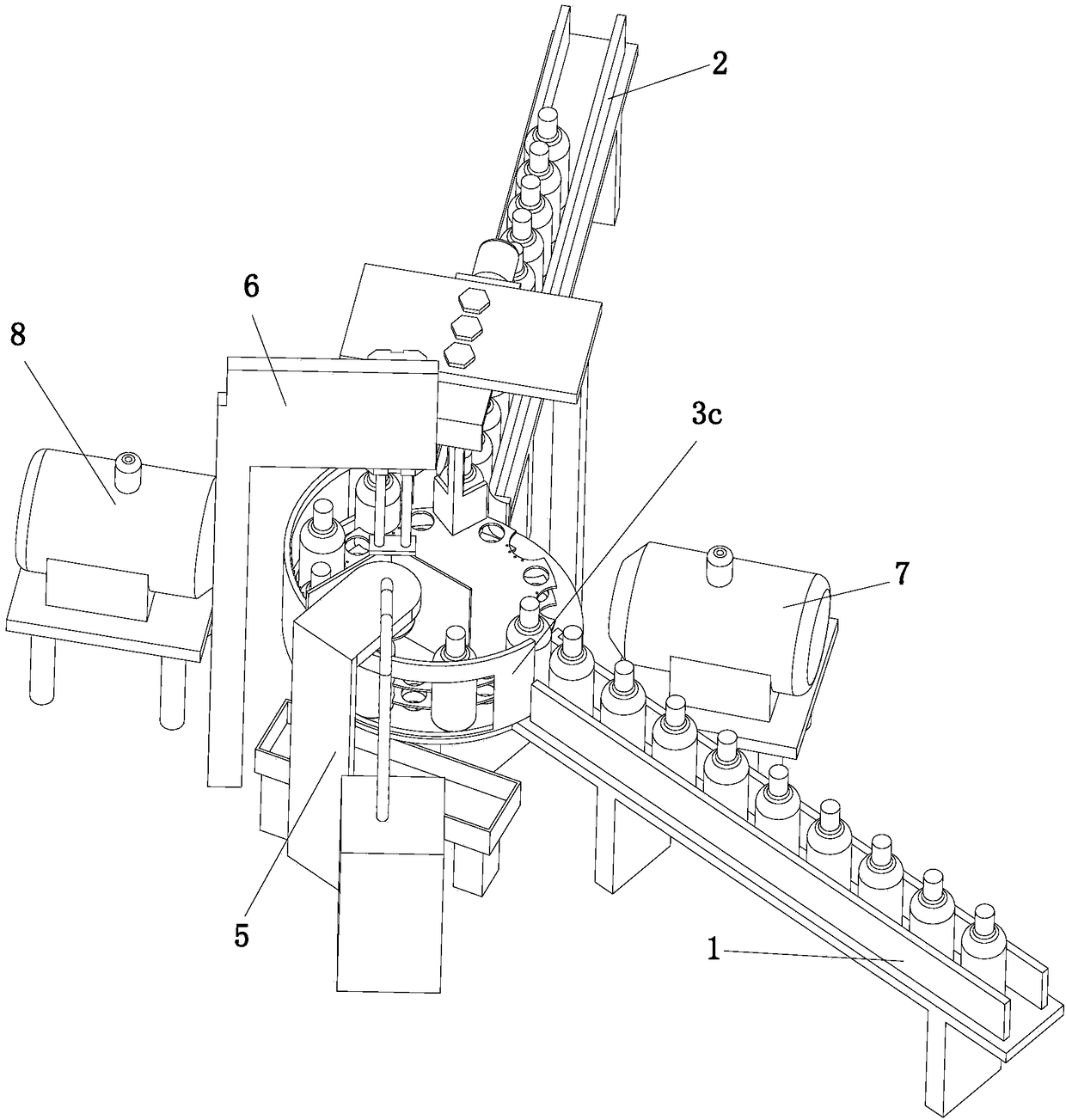

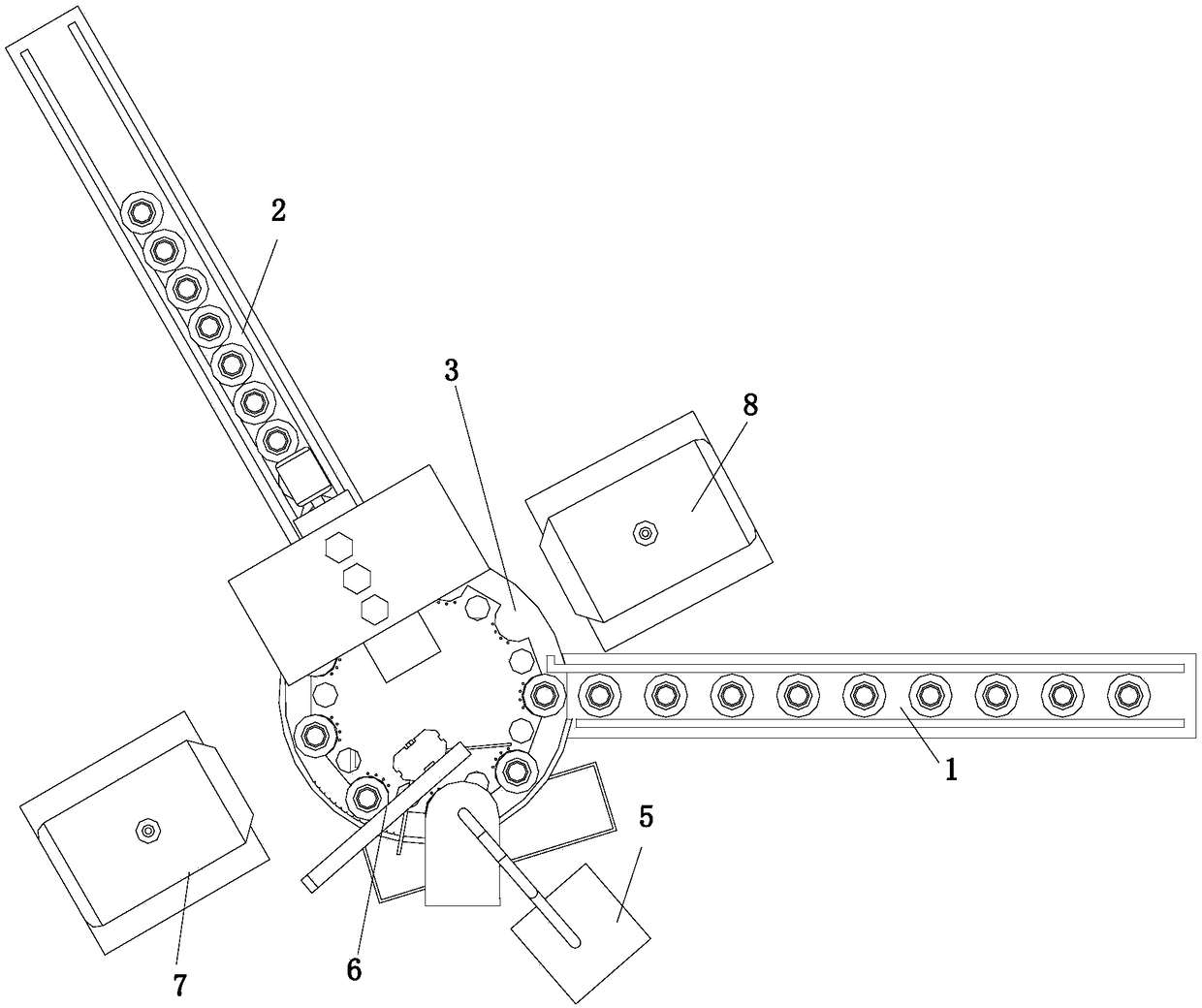

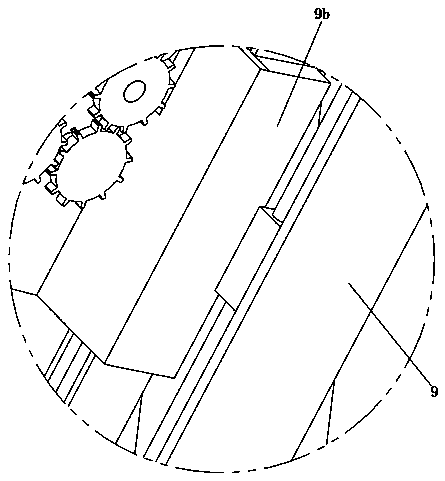

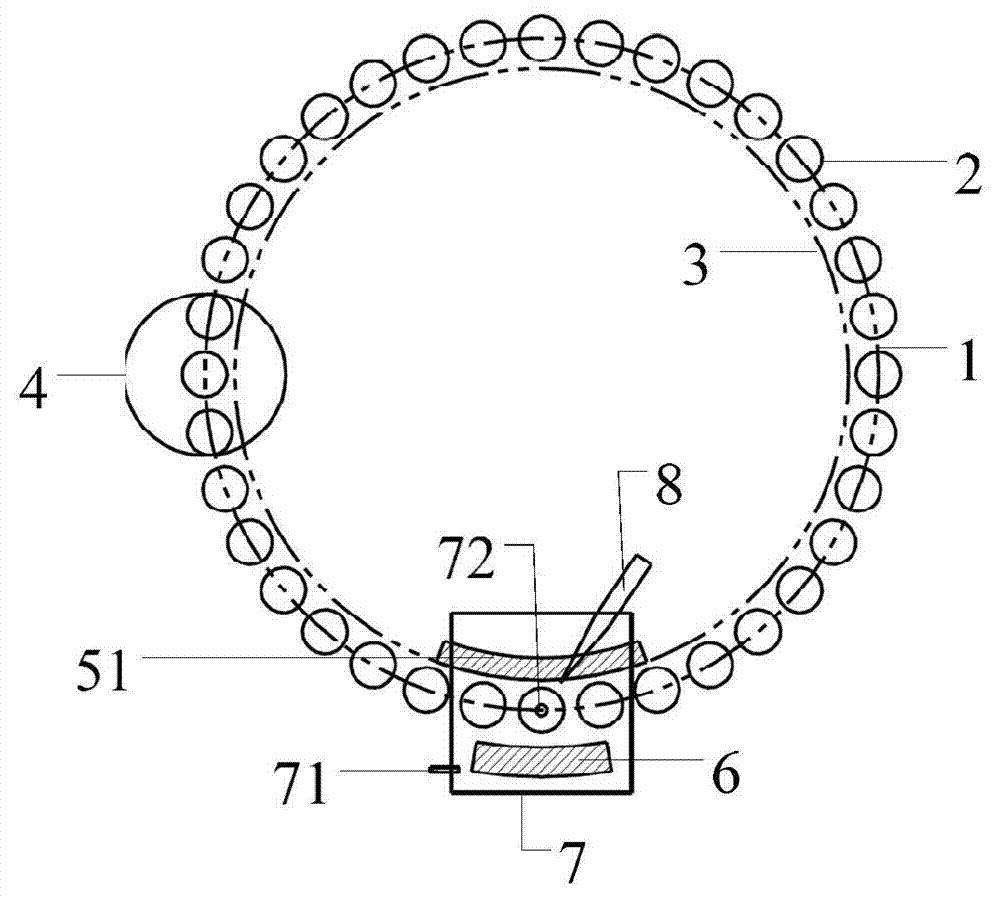

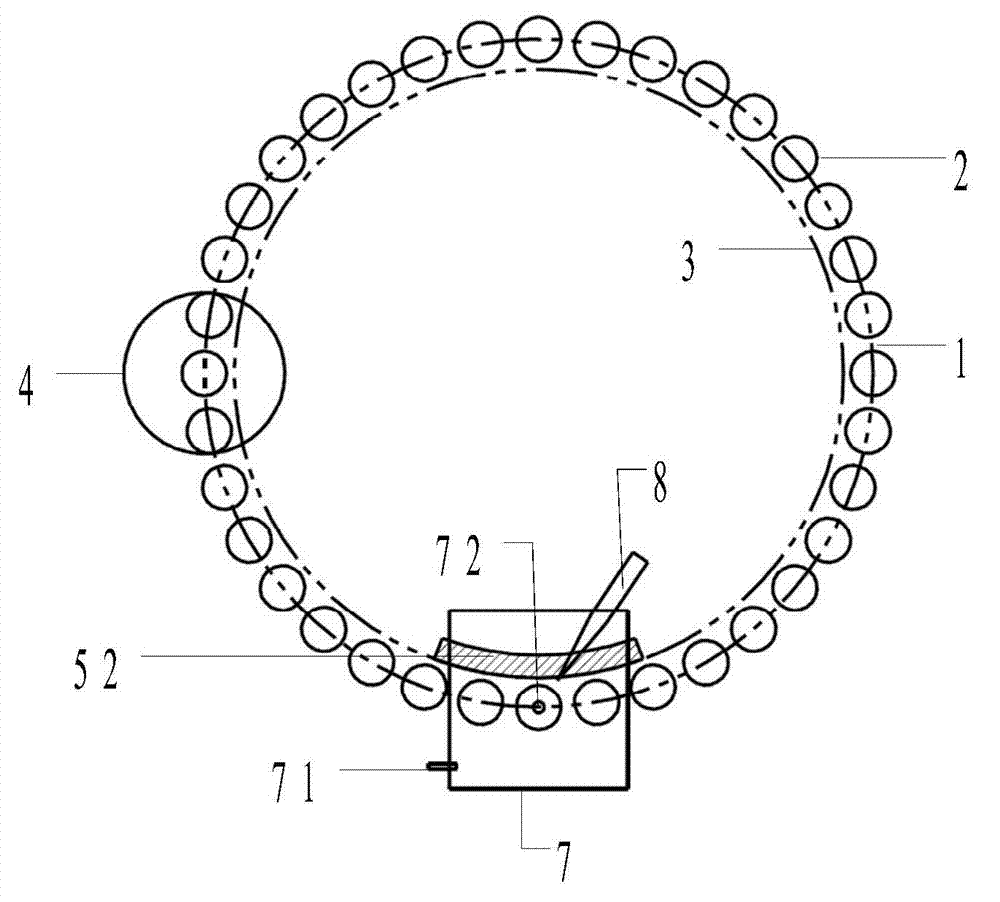

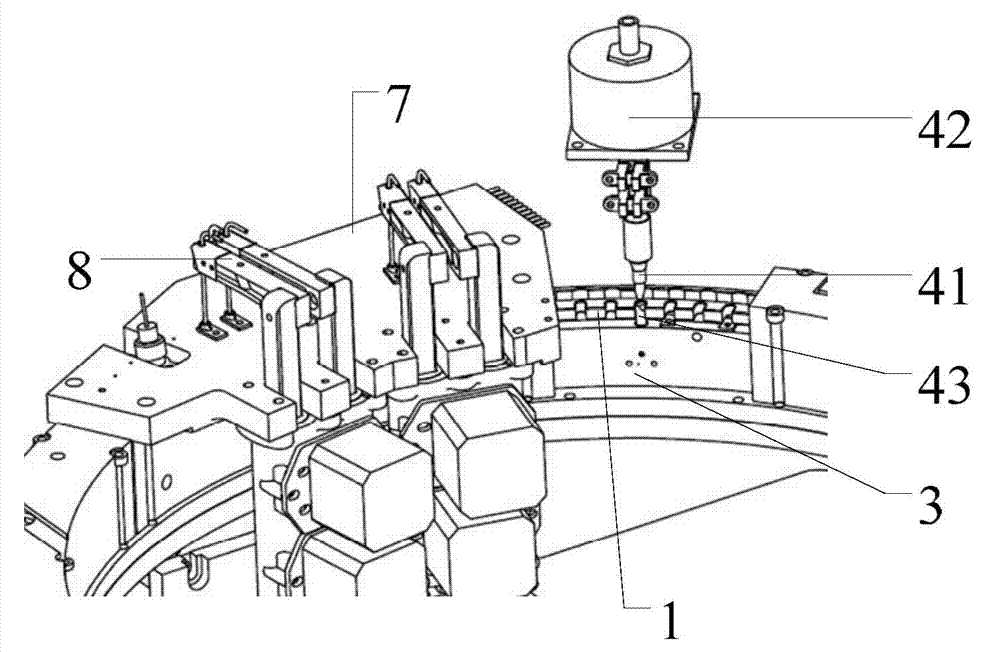

Magnetic microsphere cleaning device for full-automatic chemiluminescent immunoassay instrument

ActiveCN103920675ASimplify the electronic control structureSmall impurity interferenceCleaning using liquidsMaterial analysisDislocationMicrosphere

The invention discloses a magnetic microsphere cleaning device for a full-automatic chemiluminescent immunoassay instrument. The magnetic microsphere cleaning device comprises an outer ring, an inner ring, a dislocation mechanism, an electromagnet, a cleaning part and a controller. A plurality of reaction cups arrayed at intervals are arranged around the outer ring, and magnetic microspheres used for attracting a to-be-detected sample are placed in the reaction cups; the inner ring is coaxially arranged on the inner side of the outer ring, and a permanent magnet is arranged on one side of the inner ring; the electromagnet is positioned on one side of the outer ring and opposite to at least one of the reaction cups of the outer ring; the cleaning part is arranged above the outer ring and opposite to at least one of the reaction cups of the outer ring; the controller is used for controlling power on and off of the electromagnet and the dislocation mechanism. The cleaning device enables a magnetic field to be easily mastered by the aid of the electromagnet, the magnetic field can be automatically removed or adjusted when cleaning solution is injected, and consequently the magnetic microspheres can be completely cleaned to reduce impurity interference, and test precision of the instrument can be improved.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Enameled copper wire cleaning device and method of using enameled copper wire cleaning device for cleaning copper wires

ActiveCN104128326AEasy to cleanImprove surface qualityDrying gas arrangementsCleaning using toolsCopper wireSoft water

An enameled copper wire cleaning device comprises an alkali liquid cleaning device, a clear water cleaning device, a soft water cleaning device and a copper wire blow-dry device in sequential placement. Alkali liquid cleaning is a chemical action while ultrasonic cleaning is a physical action, the two actions are combined with soft water to thoroughly clean articles, and the defect that continuity and uniformity in cleaning of the copper wires cannot be guaranteed due to singleness of existing cleaning techniques is overcome. When the enameled copper wire cleaning device is used, the surfaces of the copper wires are flushed by means of combination of chemical alkali liquid cleaning and physical ultrasonic cleaning, residual alkali liquid is flushed away by clear water, then physical ultrasonic cleaning with soft water serving as a medium is carried out, finally oil stains, copper powder and residual alkali liquid on the surfaces of the copper wires are flushed away by means of high-pressure water flushing, and a high-pressure vortex pump presses air flows into a copper wire blow-dry pipe for drying the surfaces of the cleaned copper wires by blowing. Cleaning liquids flow into cleaning liquid tanks through bottoms of cleaning liquid storage tanks after the copper wires are flushed, and the cleaning liquids are recycled for effectively cleaning the copper wires.

Owner:广东松田科技股份有限公司

Automatic cleaning colony house

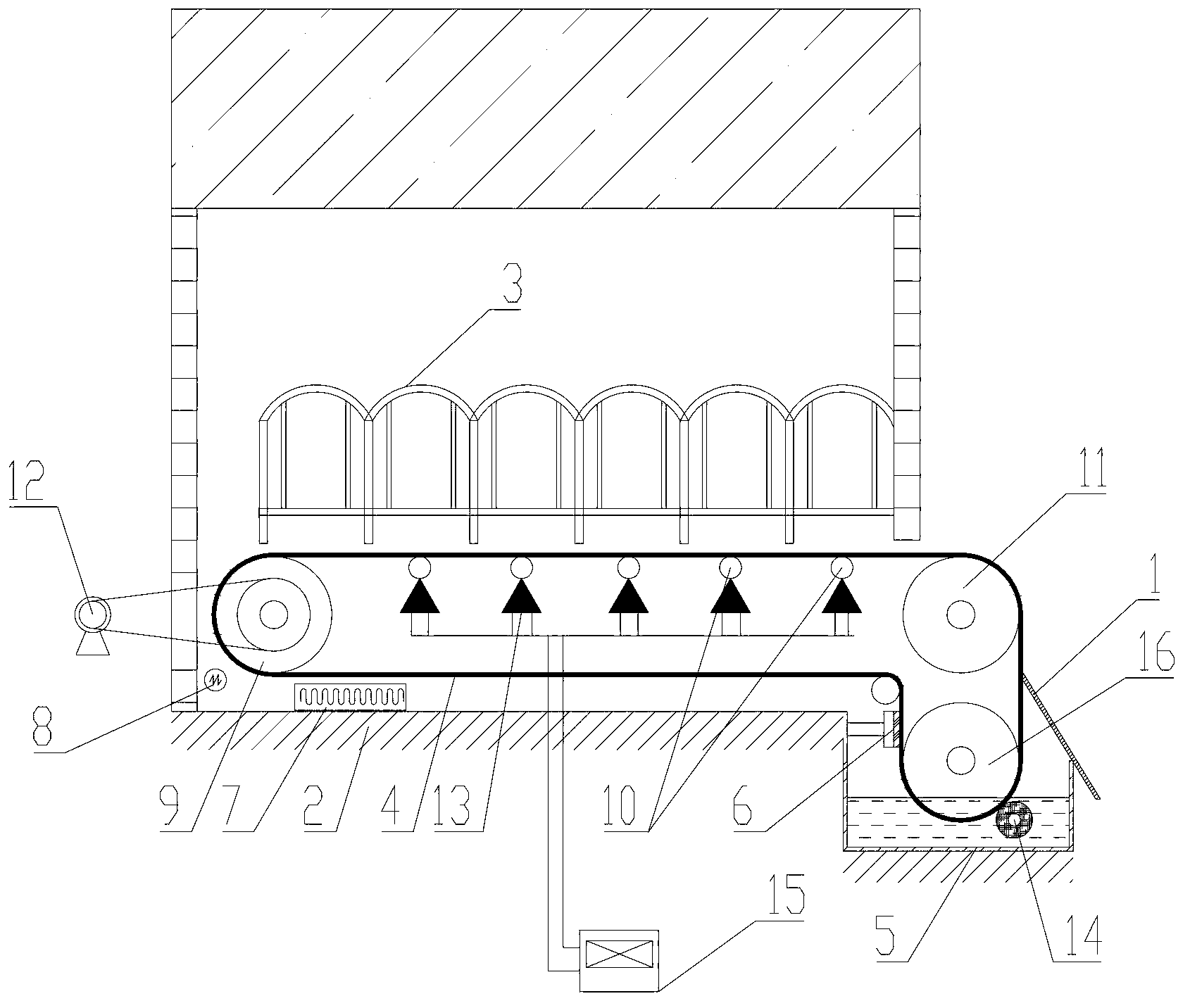

The invention discloses an automatic cleaning colony house, which comprises a belt conveyer and a manure scraping plate, wherein the belt conveyer is arranged on the ground of the colony house; an animal guardrail is arranged above the belt conveyer; and one end of the manure scraping plate is in close fit with the belt surface of the belt conveyer. The automatic cleaning colony house can be cleaned automatically, no manual labor is needed in the whole cleaning process, and the cleaning water is reduced, so that the labor cost is greatly reduced. In addition, a belt has a very good heat preservation effect, so that animals sleeping on the belt can grow fast, the breeding income is increased and a remarkable progress is made.

Owner:巫溪县银龙畜禽养殖有限公司

Spraying type water cup cleaning integrated device

InactiveCN105411497AEfficient separationGuaranteed clean spaceTableware washing/rinsing machine detailsElastic componentSpray nozzle

The invention discloses a spraying type water cup cleaning integrated device which comprises a shell. A horizontal separation plate is arranged in the shell and divides the shell into a cleaning part and a device part. The device part comprises a purifying device, a main water tank, a water dividing tank, a cleaning agent box, an evaporator, an injection pump, a heating device and a water dividing pipe. One side of the cleaning part is connected with a cover capable of being opened / closed through hinges, and the cover is provided with a plurality of rotatable first nozzles in multiple rows and lines. The cleaning part comprises a plurality of cup holders vertically arranged on the horizontal separation plate in multiple rows and lines, the periphery of a second water outlet end is in pin joint with a brush through an elastic component, the brush is driven by a motor to periodically swing to form the angle of 30 degrees to 150 degrees with the vertical direction, and rotatable second nozzles are arranged at the second water outlet end. According to the spraying type water cup cleaning integrated device, purified cleaning water can be used for comprehensively and fully cleaning a cup mouth and a cup bottom, cleanliness and cleaning efficiency are improved, and manpower and material resources are saved.

Owner:梁进球

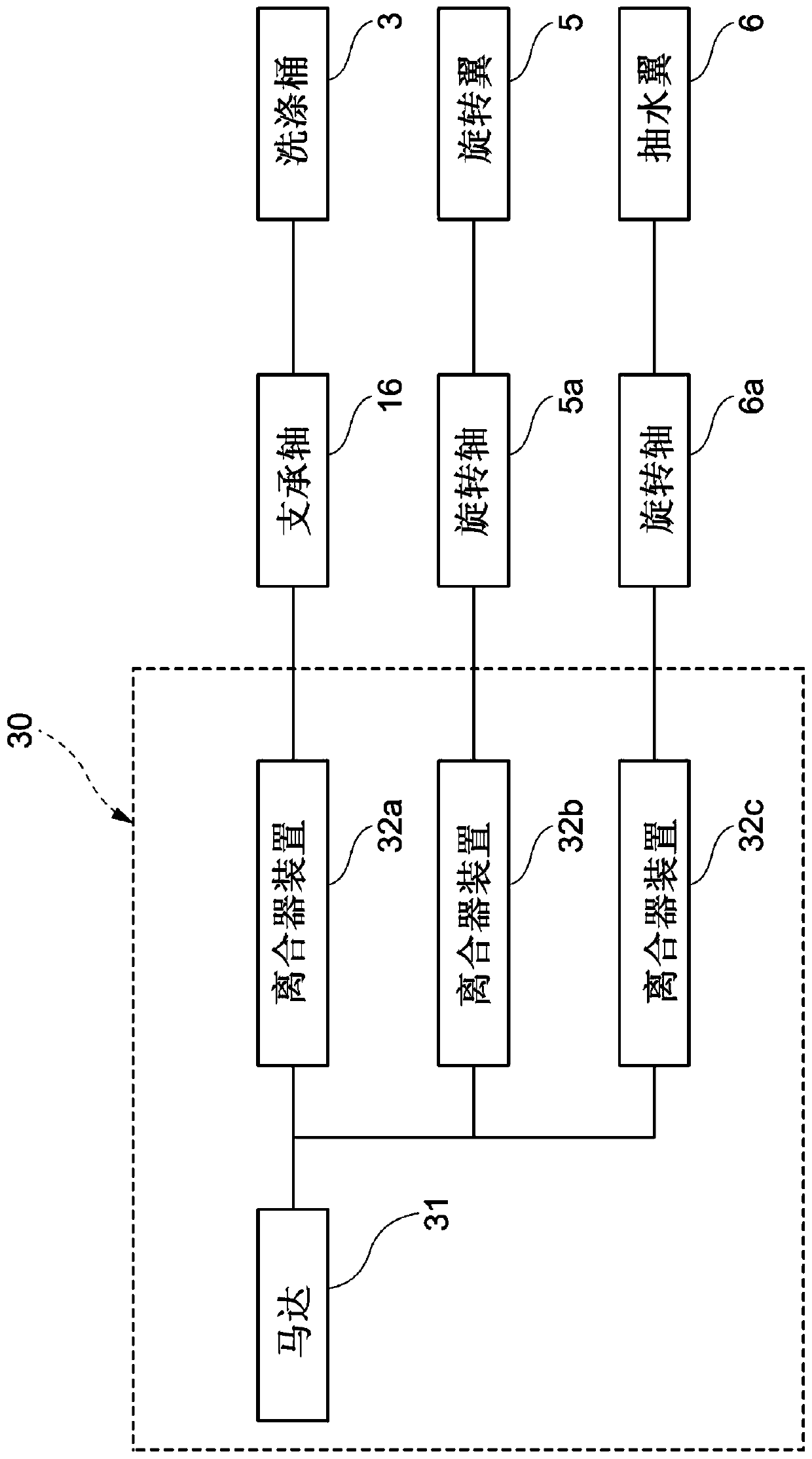

Washing machine

InactiveCN109863265AFully cleanedAvoid damageOther washing machinesControl devices for washing apparatusPulp and paper industryRotary wing

A vertical washing machine which prevents the washings in the washing and dewatering tub from being damaged by the friction generated by the rotation of the rotary wing during the washing process. Thevertical washing machine of the present invention comprises: an outer tub; a washing and dewatering bucket rotatably disposed in the outer tub and containing the laundry; and a pumping road disposedin the washing and dewatering bucket for extracting the washing and dewatering bucket from the bottom of the washing and dewatering bucket The washing liquid is returned to the washing and dewateringbarrel; a discharging port which discharges the washing liquid from the pumping road to the washing and dewatering barrel; a rotating wing, which is disposed at the bottom of the washing and dewatering bucket, and stirs objects in the washing and dewatering bucket through rotation; a pumping wing, which is disposed between the bottom wall of washing and dewatering and the rotating wing, and transmits washing liquid in a washing barrel from the bottom of a dewatering barrel into a dewatering bucket through rotation; a driving unit, which can be used for conducting rotation drive respectively onthe washing and dewatering bucket, the rotating wing and the pumping wings are independently driven to rotate independently; and a control unit controlling the drive unit.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Full-automatic swiftly moving and spraying type bowl washing machine

InactiveCN101301187ASolve the phenomenon of clogged drainFully cleanedTableware washing/rinsing machinesOzone generatorElectrical connection

A full-automatic sprinkling-turbulent type dish washing machine is provided with a turbulent washing chamber and a sprinkling washing chamber therein. The turbulent washing chamber is provided with a self-rotating type ozone generator, an auto-controlled water-level probe, a dish auto-fastening device, an auto-washing chopsticks box, and a washing tank with an automatic device capable of automatically opening, closing, and fastening the groove cover; the washing tank moves turbulently on the sliding rail between two ends driven by a motor, and the washing water in the washing tank generates inertial impulsive force and thrust force to be gathered into strong rinsing force for washing dish; for cleaning irregular dishes, the sprinkling washing chamber is additionally provided, comprising a dish shelf, a plurality of self-rotating sprinkling tubes, a sterilization device, a boosting device, and a drain outlet, which can simultaneously carry out complete cleaning, washing, and sterilization for various dishes. The inventive full automatic device adopts electrical connection and non-electrical connection, can be operated conveniently, and has good performance.

Owner:施兆登

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com