Reactor with scale removing function

A reaction kettle and functional technology, applied in the field of reaction kettle with descaling function, can solve the problems of incomplete cleaning and large water consumption, and achieve the effect of sufficient cleaning and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

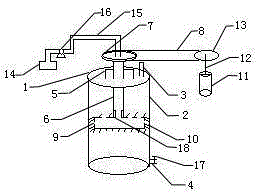

[0011] In order to further reveal the technical solutions of the present invention, the following describes the implementation of the present invention in detail in conjunction with the accompanying drawings: figure 1 As shown, a reaction kettle with descaling function includes a cover 1 and a cylinder 2, the cover 1 is provided with a feed port 3, the cylinder 2 is provided with a liquid outlet 4, and the cover 1 is provided with a liquid outlet 4. A fixing screw 5 is arranged in the middle of the outside of the cover body 1, and a hollow screw 6 is arranged on the fixing screw 5, and a pulley 7 is connected to the upper part of the hollow screw 6, and the pulley 7 is connected to the power unit through a belt 8, and the hollow The upper part of the screw 6 is connected with a liquid inlet device, the lower part of the hollow screw 6 is provided with a hollow agitator, and the upper part and both sides of the hollow agitator are respectively provided with spray holes 9 and bru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com