Patents

Literature

13041results about How to "Save water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

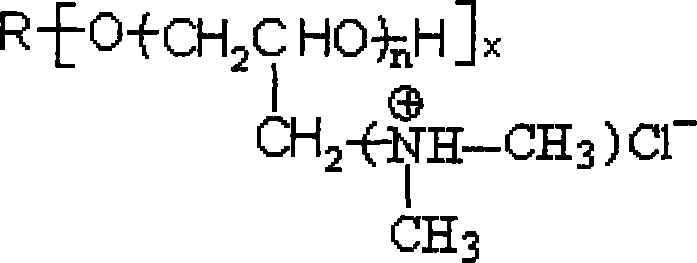

Non-phosphorus compound scale and corrosion inhibitor for treatment of circulating cooling water

ActiveCN1621362AEasy to useIncrease the concentration factorScale removal and water softeningPhosphateTungstate

The composite phosphate-free scale inhibiting corrosion inhibitor for treating circular cooling water consists of scale inhibitor and corrosion inhibitor. The scale inhibitor consists of one or several of PASP, PVA, oxidized starch, polyacrylic acid, acrylic acid / acrylate copolymer and acrylic acid / acrylate copolymer with sulfo radical. The corrosion inhibitor consists of one or several of sodium salt / potassium salt / ammonium salt of organic salt, sodium / potassium / ammonium borate, nitrous organic matter, soluble molybdenate, soluble tungstate, soluble nitrate, soluble nitrite and soluble zinc salt. The composite scale inhibiting corrosion inhibitor has excellent scale inhibiting and corrosion inhibiting performance, is environment friendly, and is especially the treatment of hard circulation water with high calcium and high alkali content.

Owner:BEIJING YANHUA XINGYE TECH DEV +1

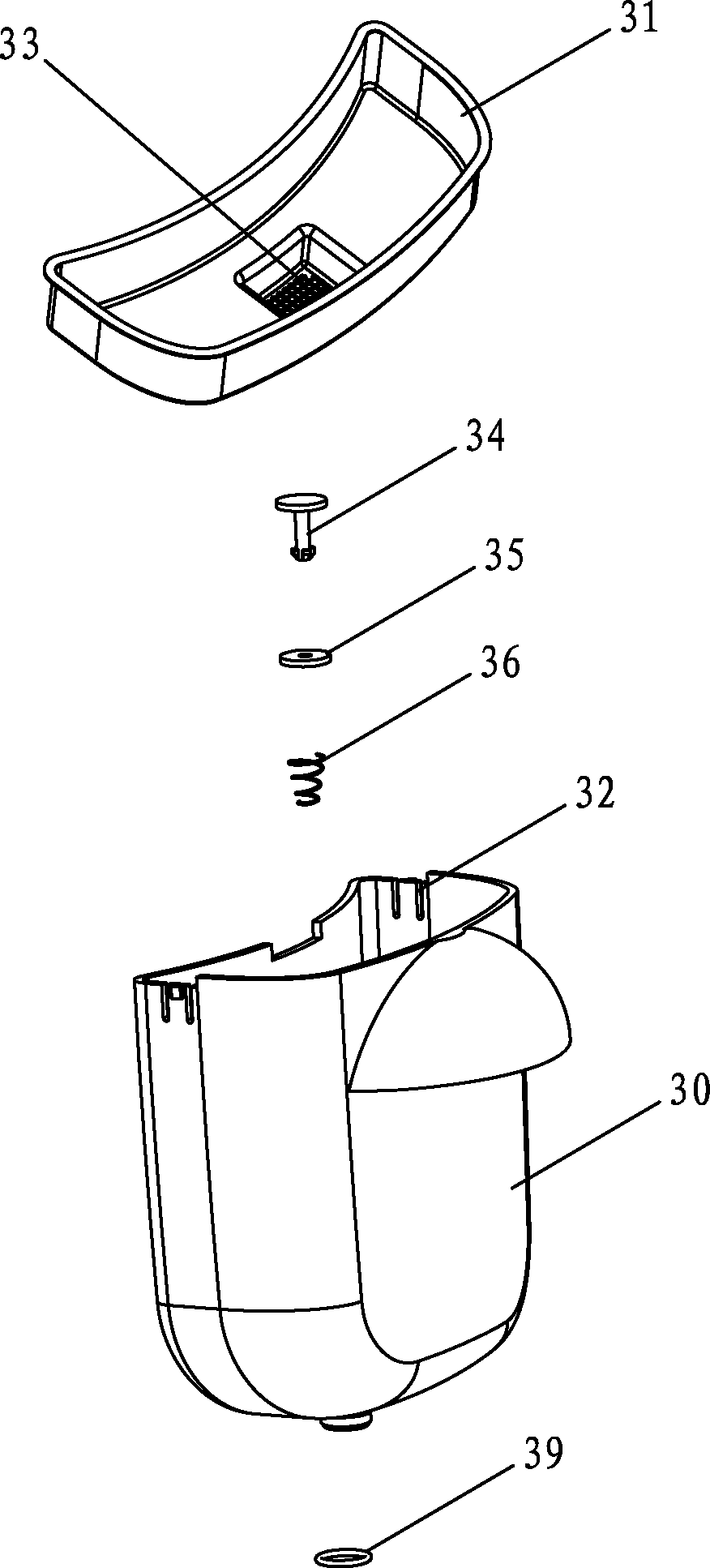

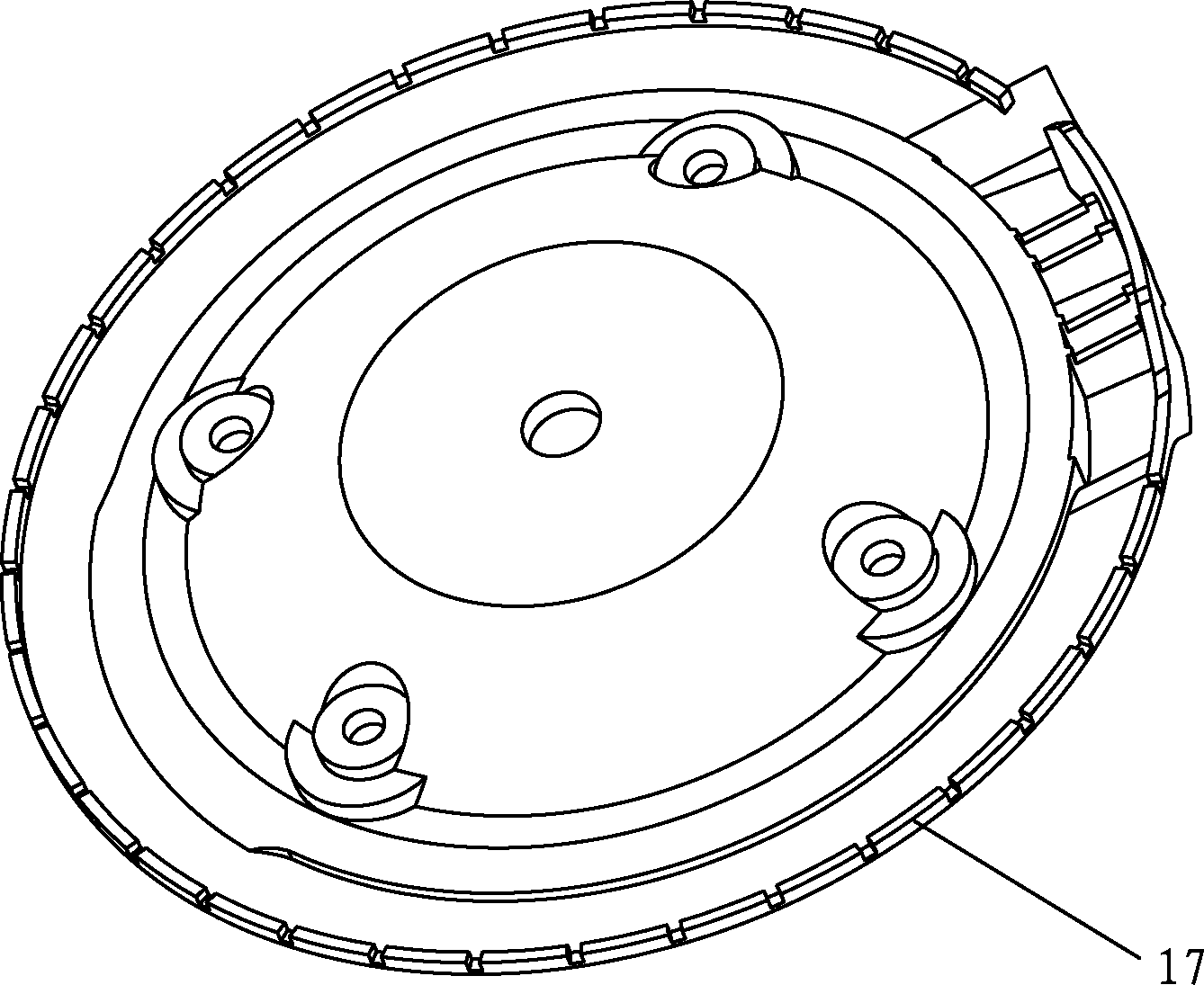

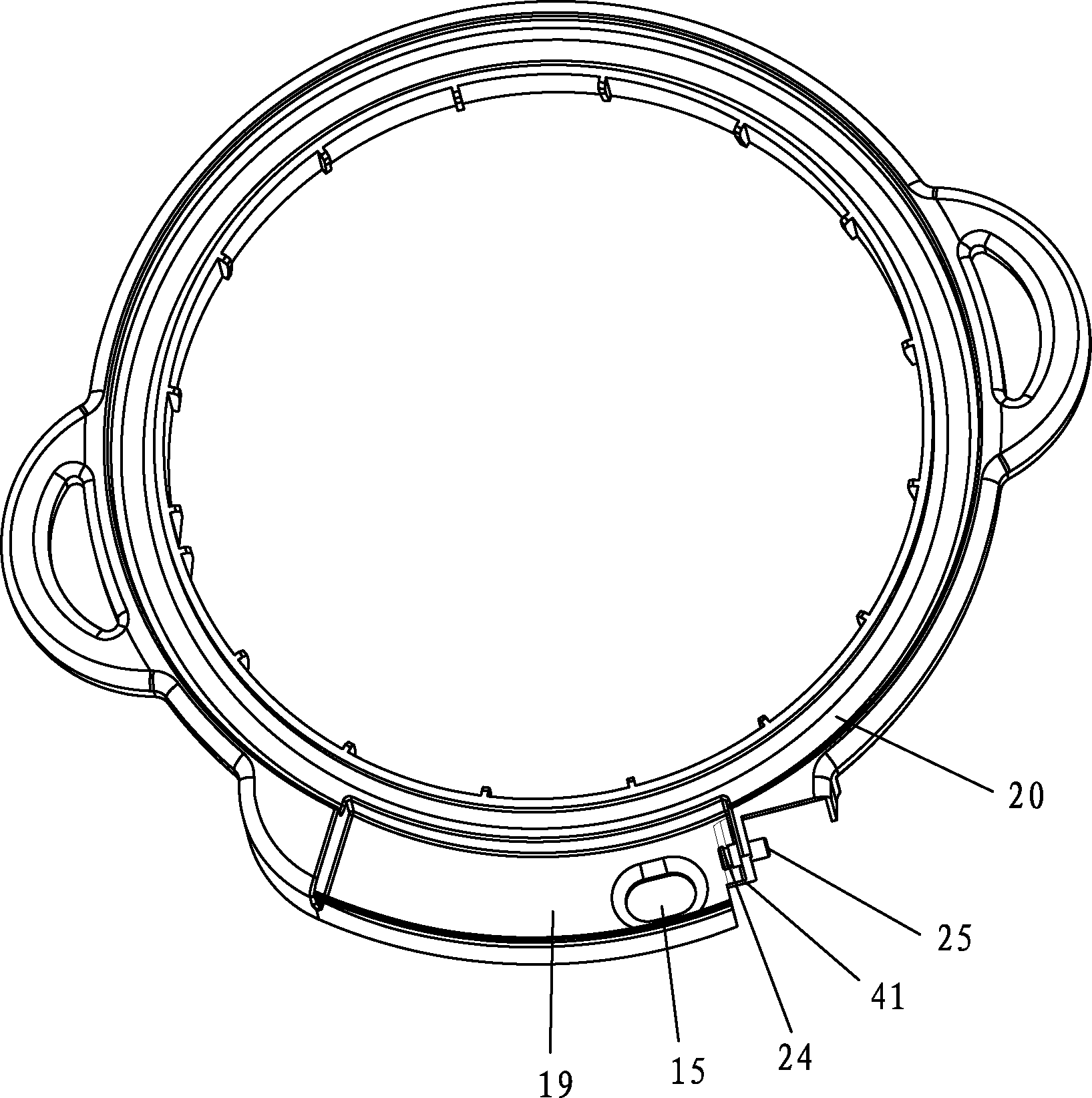

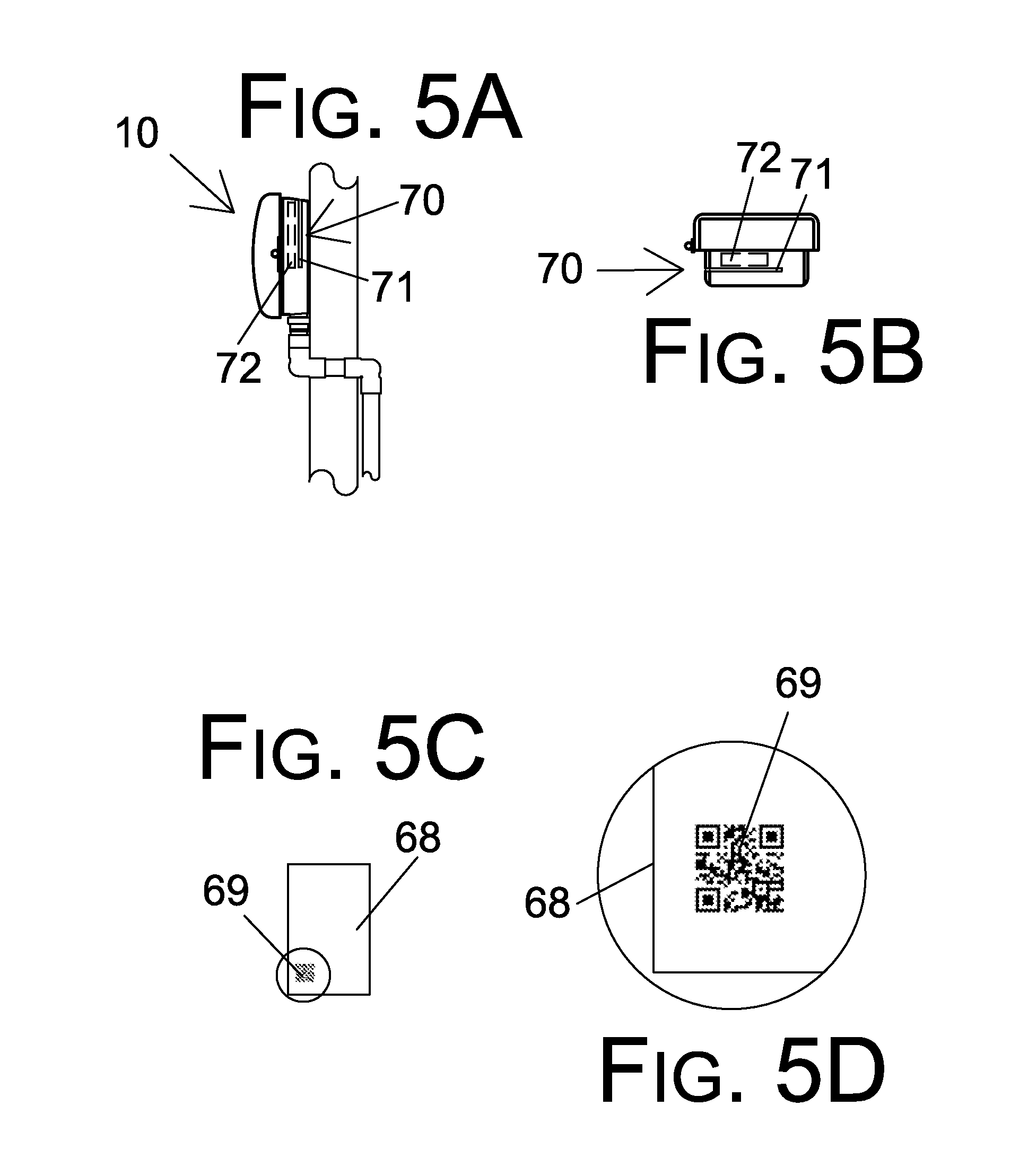

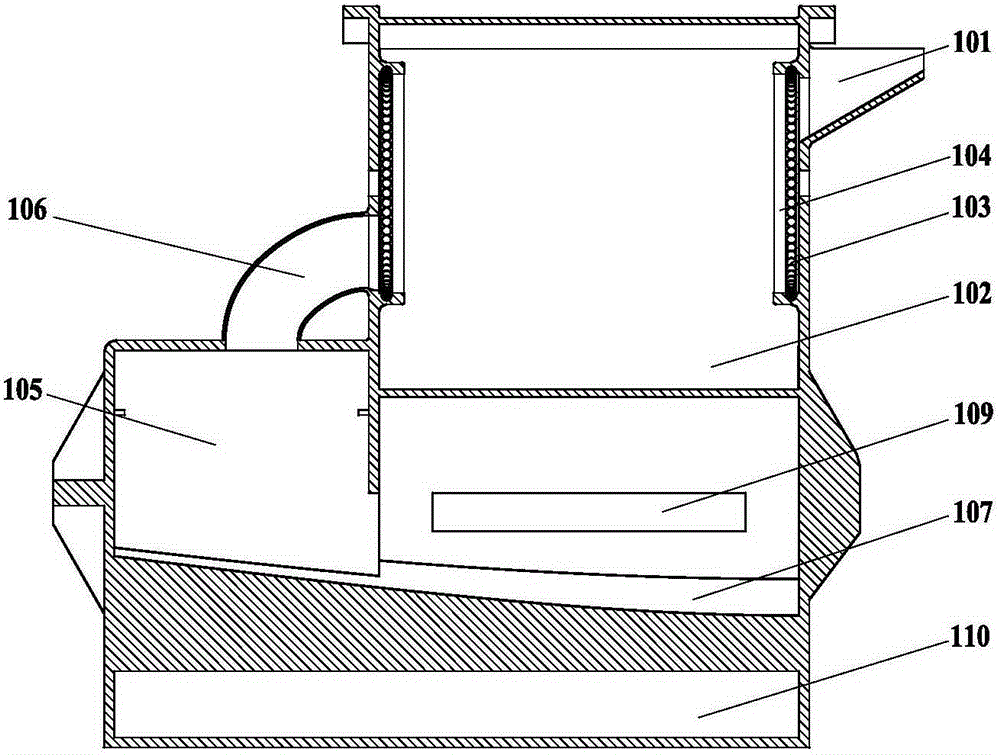

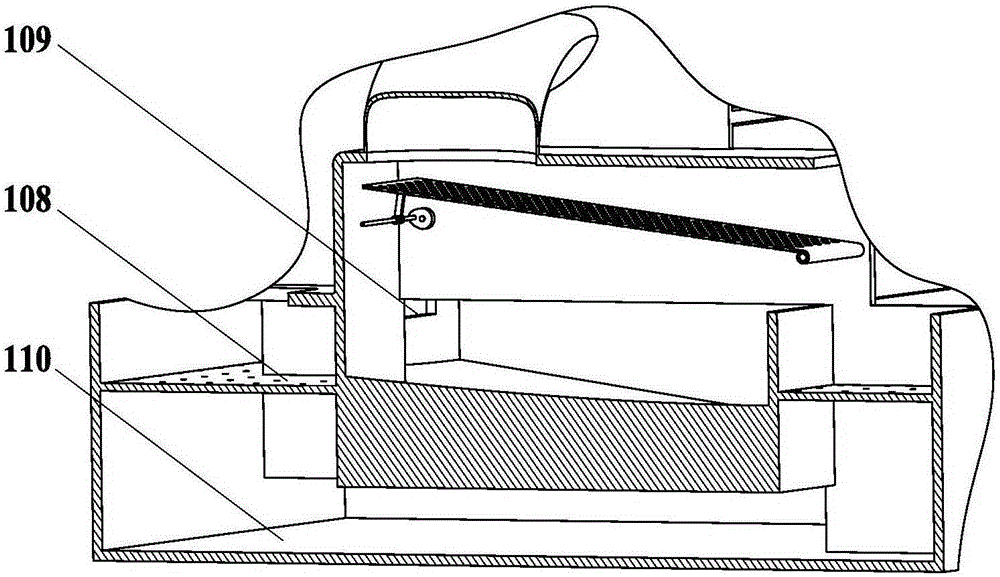

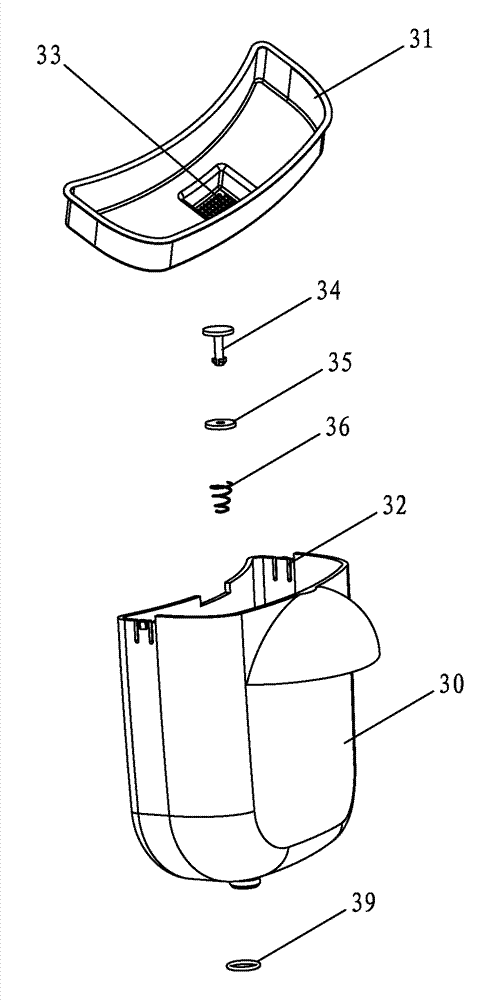

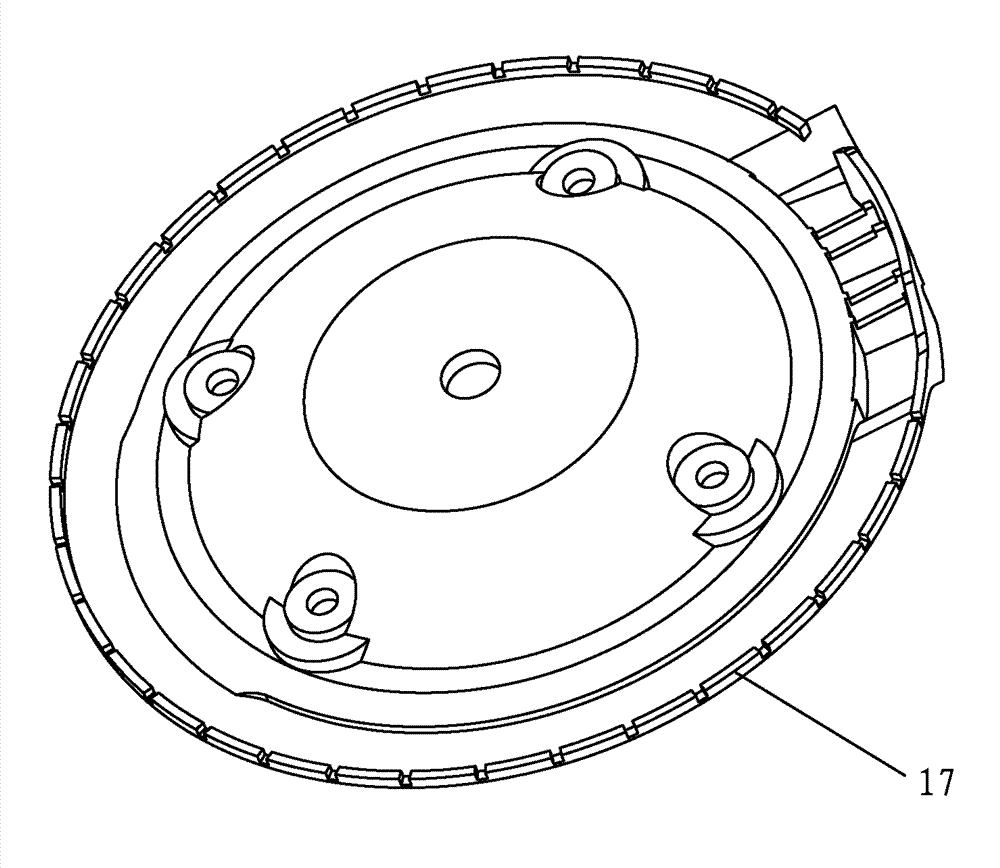

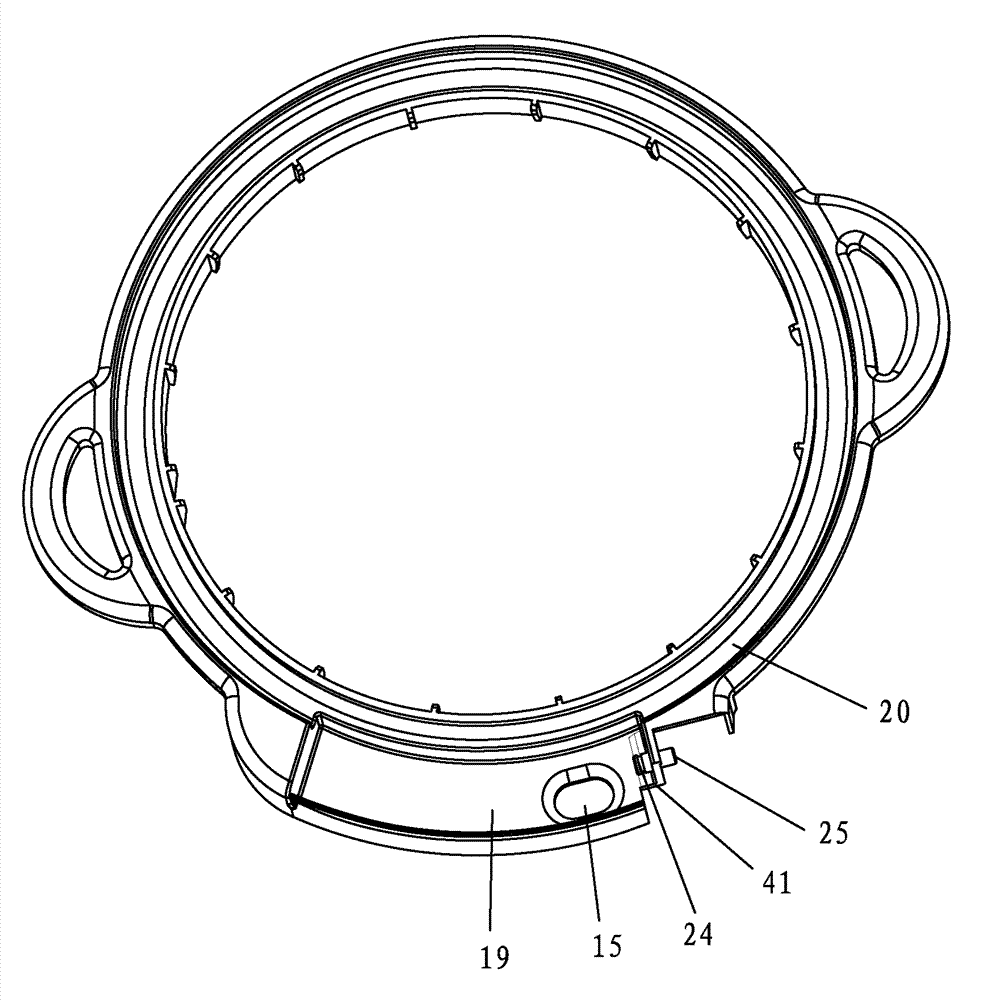

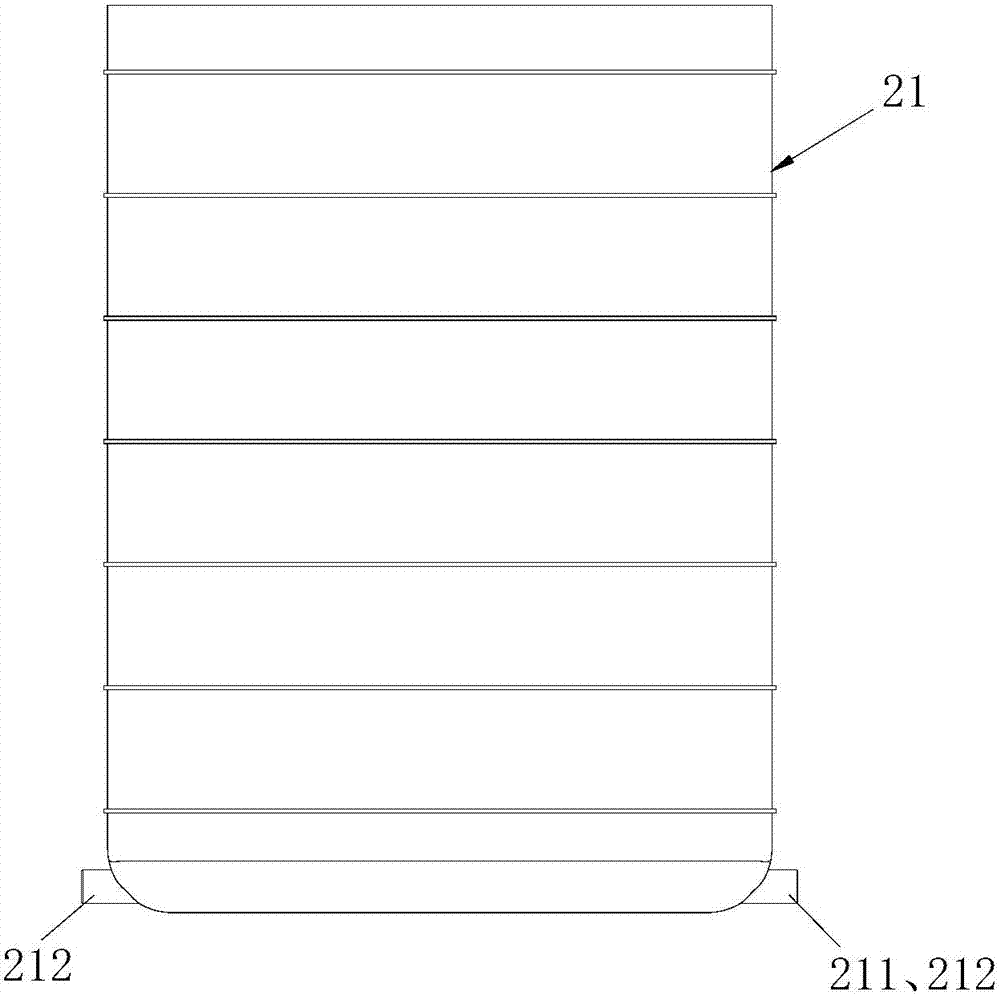

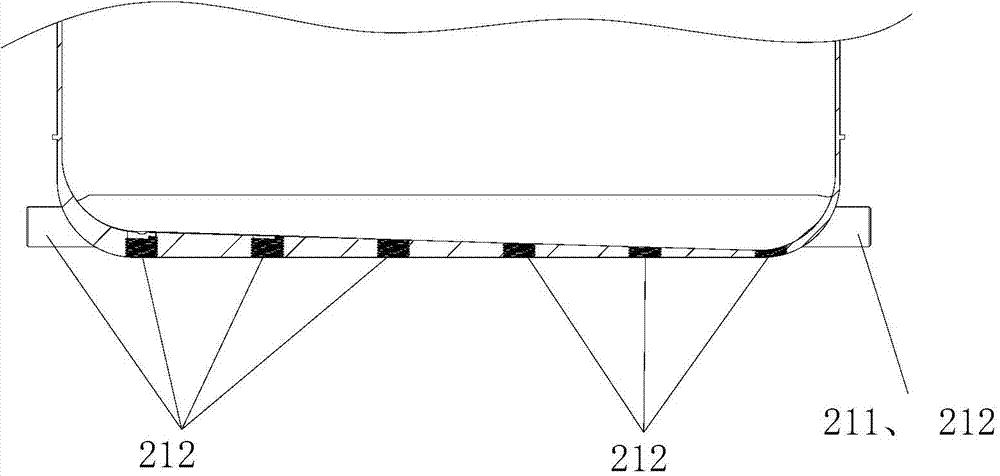

Electric pressure cooker with rapid pressure relief function

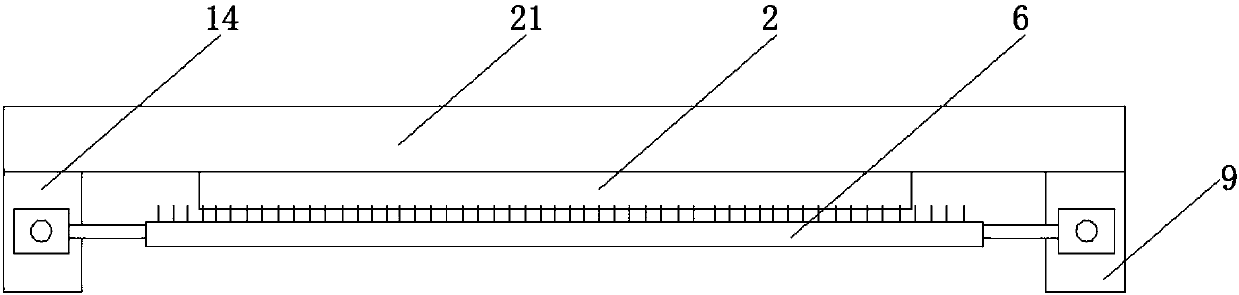

The invention relates to an electric pressure cooker with a rapid pressure relief function. The electric pressure cooker comprises a cooker cover and a cooker body, wherein the cooker cover comprises a plastic surface cover and a stainless steel cover; the cooker body comprises an upper gasket seat and a plastic shell; the electric pressure cooker also comprises a water pump and a water tank, wherein the water pump is arranged inside the cooker body, and the water tank is arranged on the lateral surface of the cooker body; the cooker cover is provided with a water spraying structure which is used for shunting water to the upper surface of the stainless steel cover; the upper gasket seat is provided with a water collecting structure which is used for receiving water flowing from the upper surface of the stainless steel cover; the bottom surface of the water collecting structure is provided with a water drainage hole; the upper end of the water tank is provided with an opening; the opening of the water tank is positioned below the water drainage hole; the water inlet of the water pump and the water outlet of the water tank are communicated; and the water outlet of the water pump and the water spraying structure are communicated. According to the electric pressure cooker disclosed by the invention, the water pump, the water tank, the water spraying structure and the water collecting structure are matched to realize circular temperature reduction of water; and the electric pressure cooker has the advantages of convenience for operation, water resource saving, good safety and high speed of temperature reduction and pressure relief.

Owner:GUANGDONG LUBY ELECTRONICS

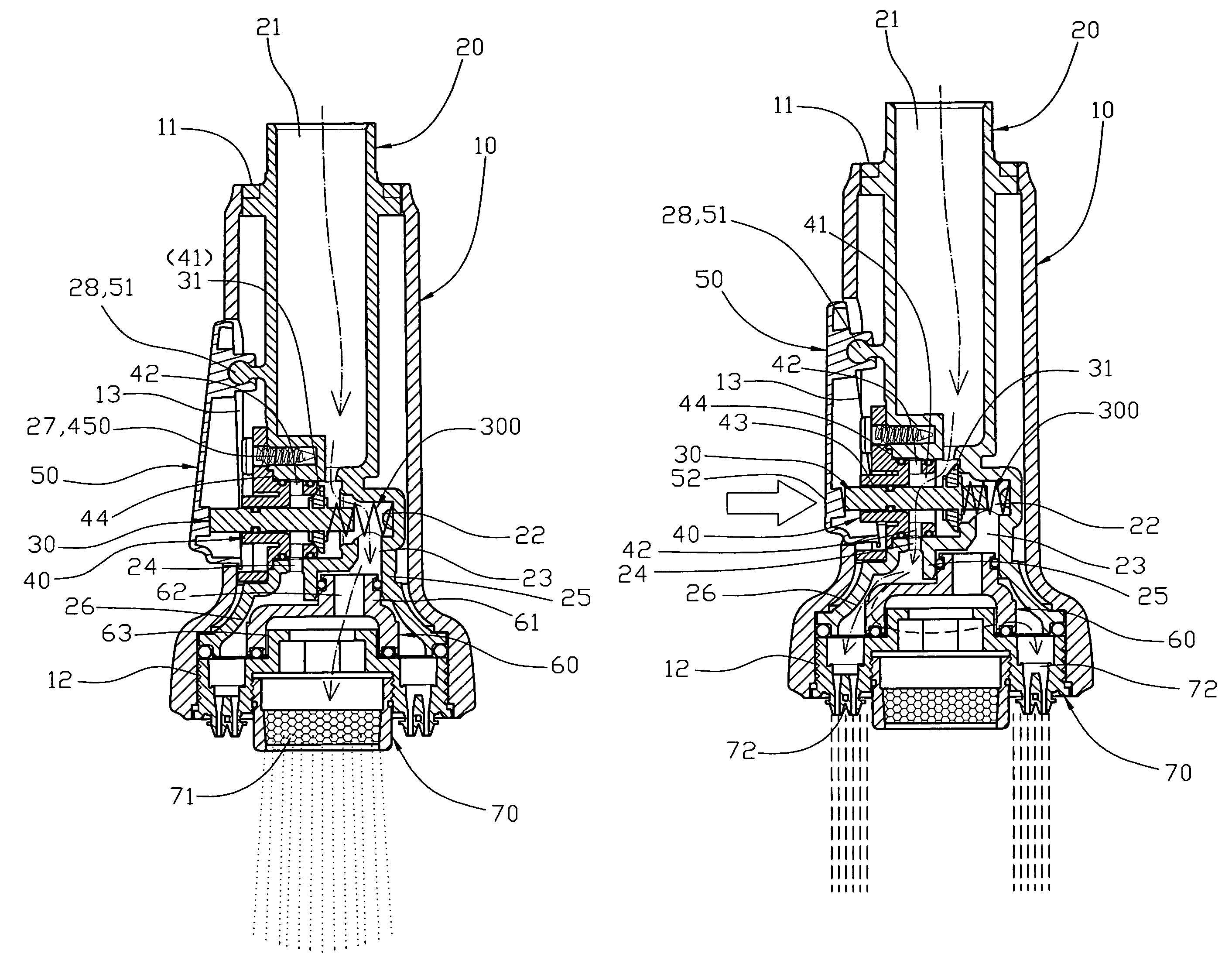

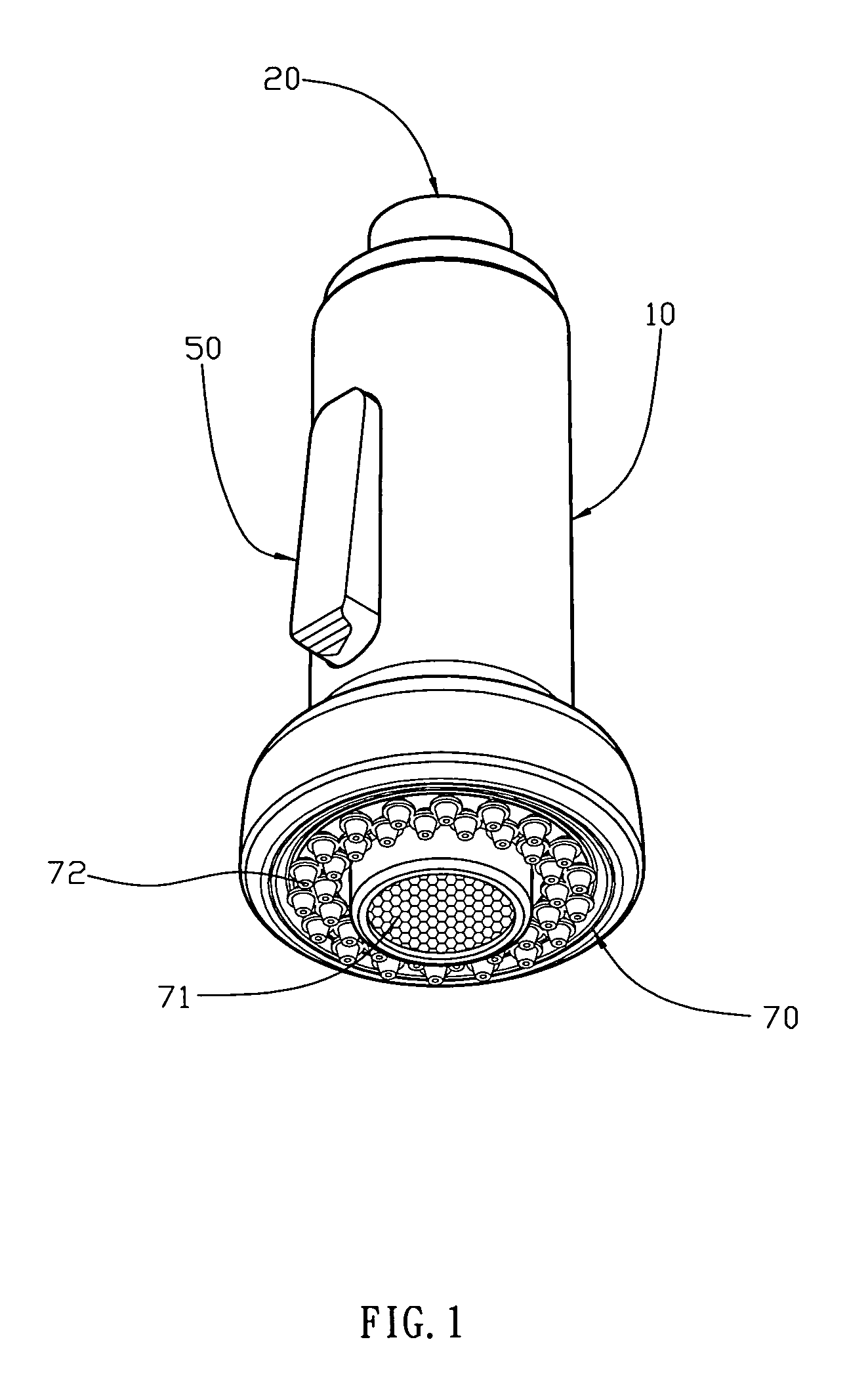

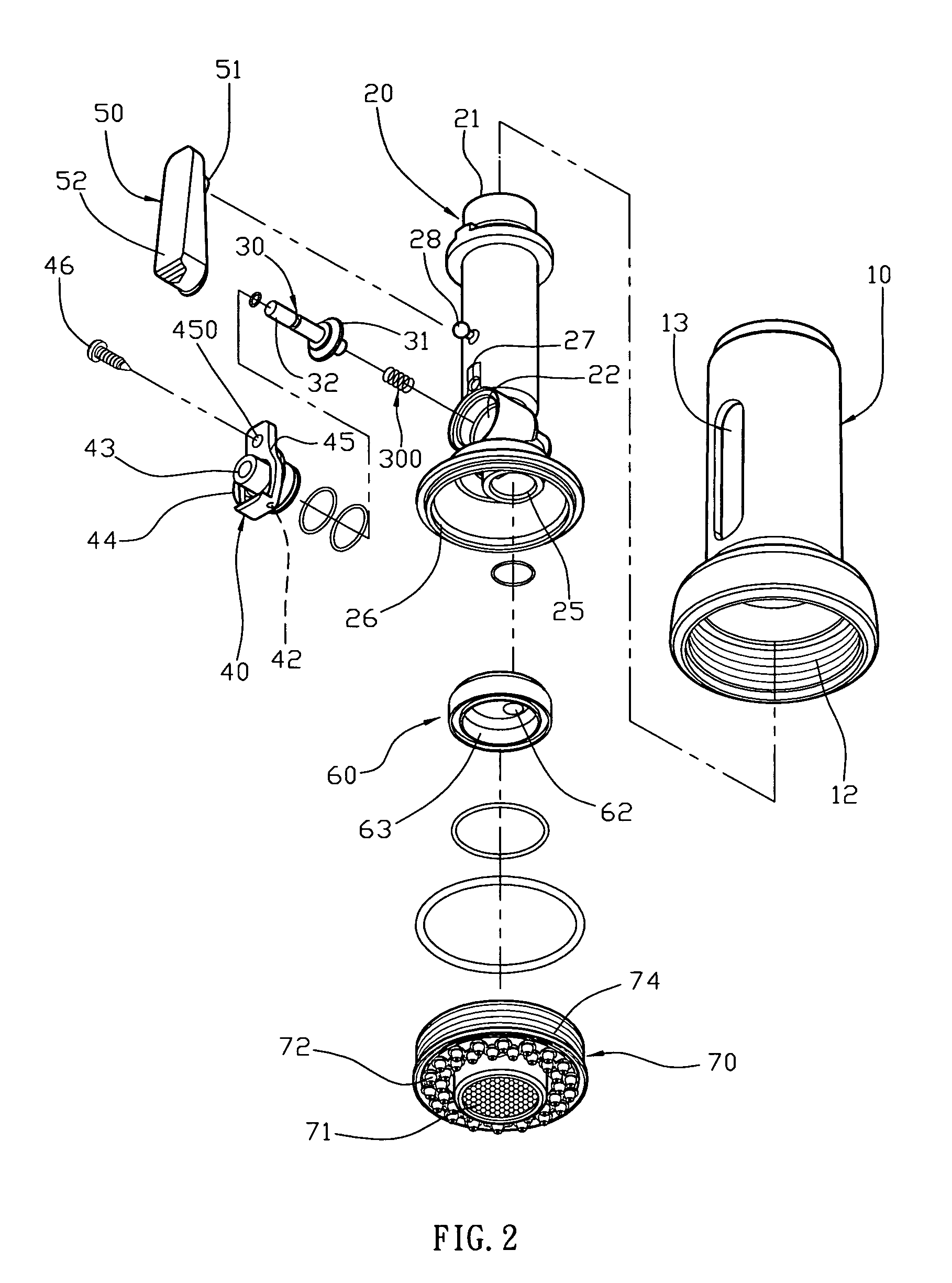

Water sprayer having two water different spraying modes

InactiveUS7380731B1Improve versatilityImprove work efficiencySpray nozzlesDomestic plumbingSpray nozzleEngineering

A water sprayer includes a housing, a control valve, a valve seat, a nozzle unit, a valve shaft, and a control button. Thus, the first nozzle and the second nozzle of the nozzle unit provide two different water spraying modes so that the water is injected outwardly from the nozzle unit in two different spraying modes according to a user's requirements, thereby enhancing the versatility of the water sprayer. In addition, the water sprayer is switched between two different spraying modes by pressing of the control button, thereby facilitating the user operating the water sprayer.

Owner:DA YUAN SHENG IND

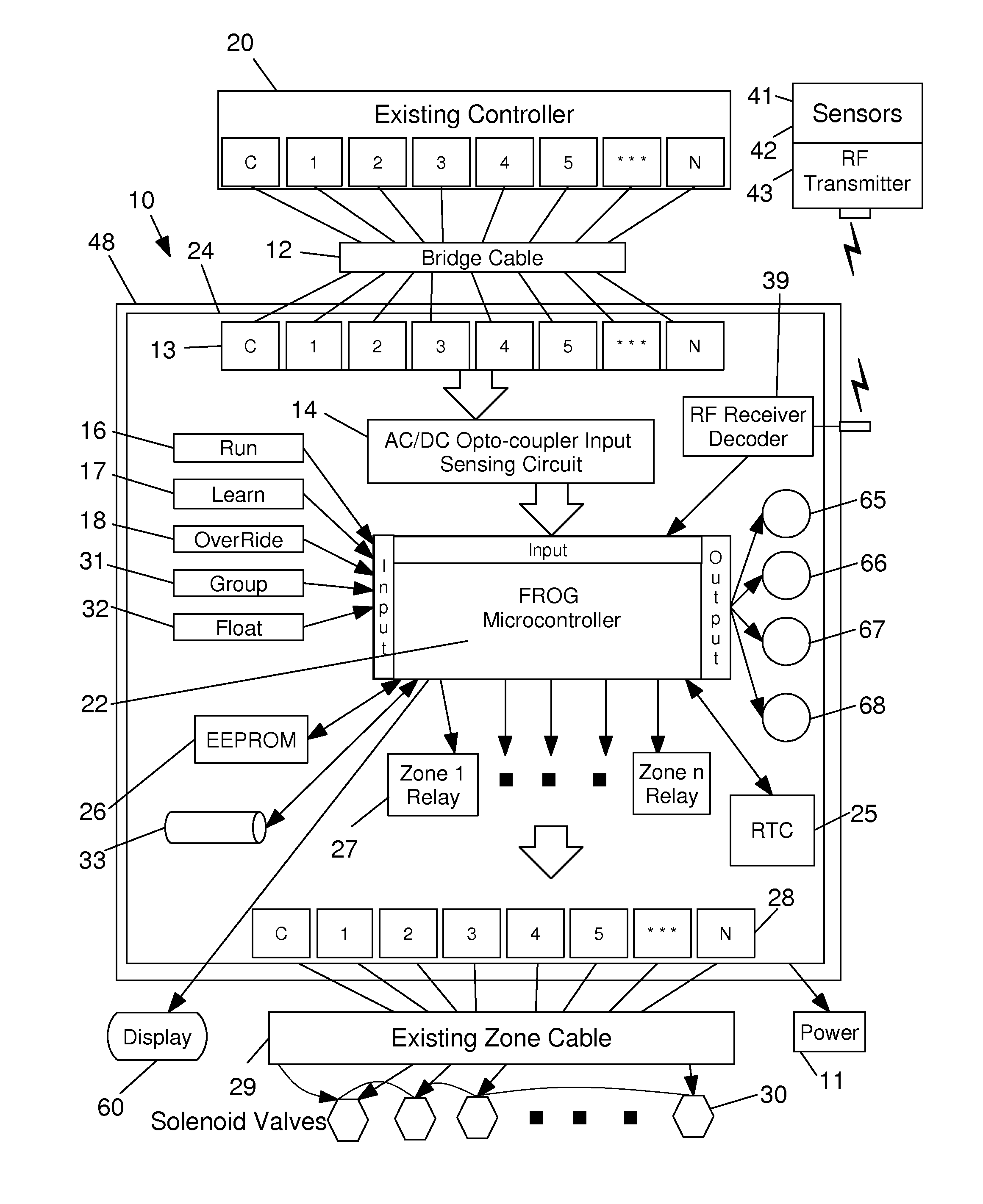

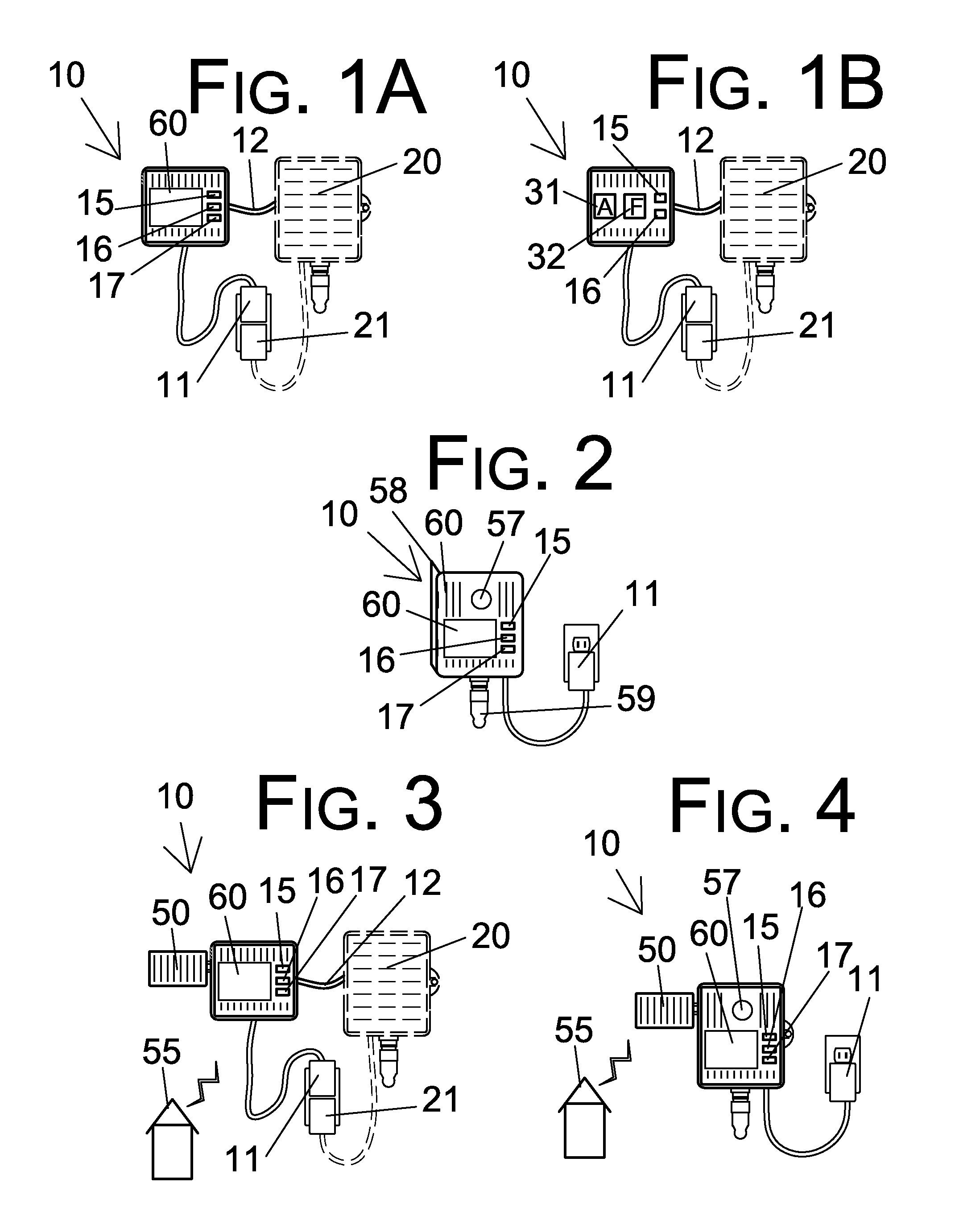

Irrigation Controller and System Integrating No-Watering Restrictions and an Empirically-Derived Evapotranspiration Local Characteristic Curve

ActiveUS20110270448A1Save waterEasy to operateProgramme controlWatering devicesWater authorityGeographic area

A convenient, easy-to-use, water-saving, and labor-saving FROG irrigation controller and system are provided, which determine the appropriate water budget and schedule for the property's landscaping based on evapotranspiration data for the geographic area, regulation data (mandated and voluntary watering restrictions), and property-specific data (such as type of plant, zone number, emitter type, and plant environment), with consideration given to reduction in watering days, increase in soil watering depth, and day of year. Once set, the FROG provides incremental adjustments over the course of the year; the homeowner no longer needs to re-set the watering program seasonally to comply with local mandated and voluntary watering restrictions. Compliance is automatic and obligatory, meeting the water saving goals of the local water authority. Optionally presented is a web-based wizard used to determine a customized water budget / schedule that is input into the FROG controller through a data storage unit or wireless input.

Owner:BRAGG BRUCE ALLEN +2

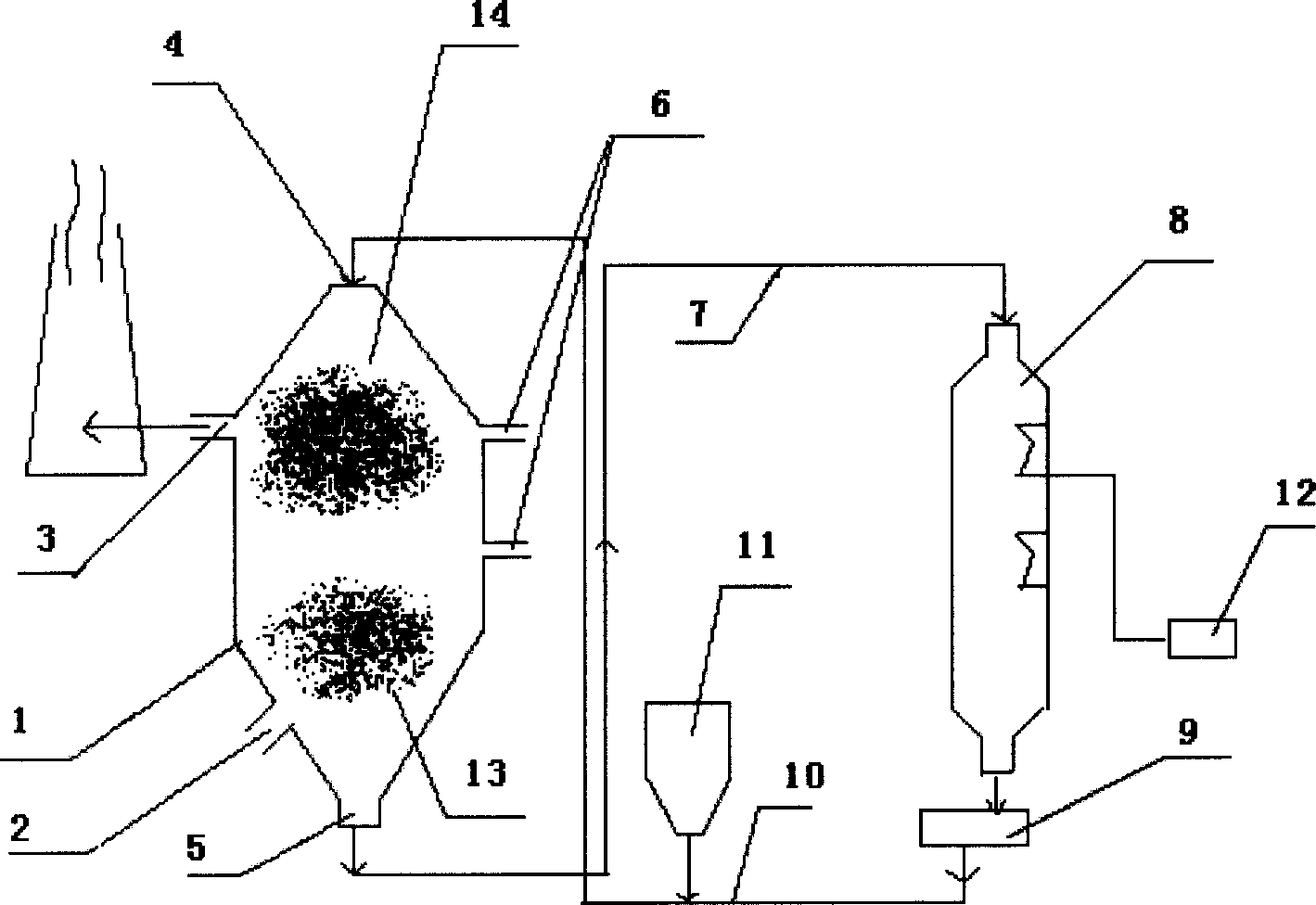

Moving bed smoke desulfur denitrate and dust removal technology

InactiveCN1911491ASimple processImprove efficiencyDispersed particle separationAir quality improvementSulfatePhysical chemistry

The present invention relates to fume desulfurizing, denitrating and dedusting process in moving bed. During the reverse contact between fume and active coke, the fume first has its adsorbed SO2 eliminated in the desulfurizing layer and then has its NOx reacted with injected NH3 to produce N2, H2O and other harmful products. The active coke after finishing desulfurization and denitration is regenerated in a regenerator physically through heating to decompose and desorb sulfuric acid and sulfate and chemically through the reaction between the created SO3 and the inner surface of the active coke to produce surface functional group. Experiment shows that the technological scheme of the present invention has the advantages of simple process, high efficiency, low cost, low power consumption, low water consumption and other advantages.

Owner:长春惠工净化工业有限公司

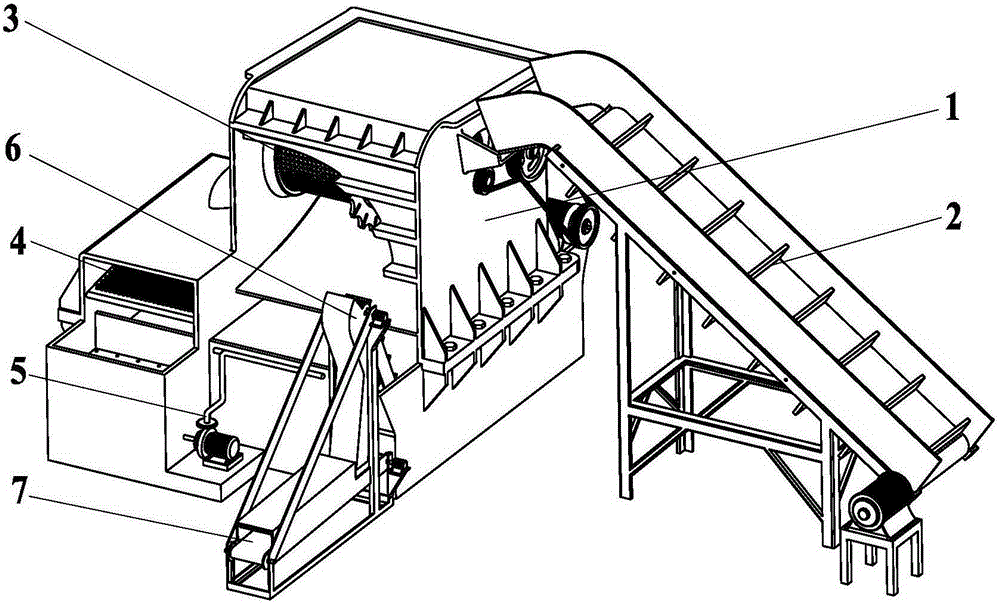

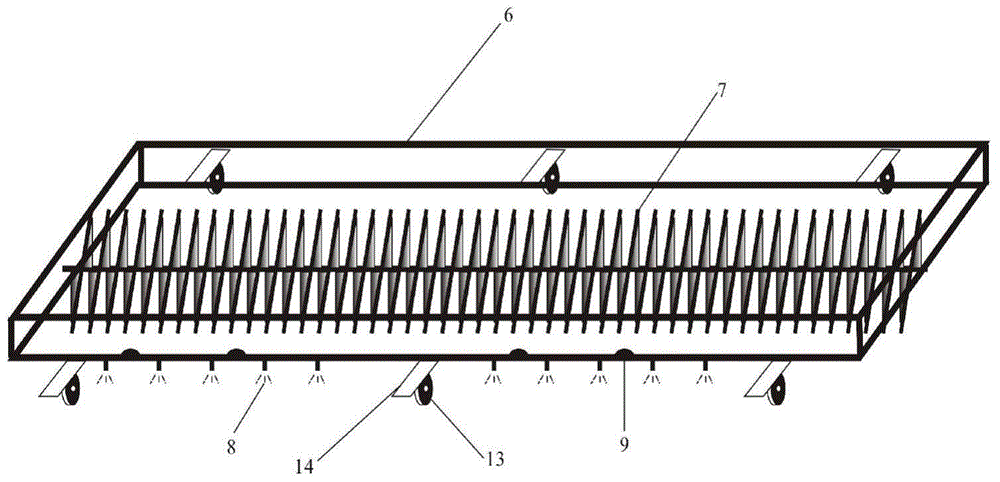

Three-time separating seed extractor for seed melons

The invention relates to the field of agricultural product processing, particularly a three-time separating seed extractor for seed melons. The seed extractor comprises a machine body, a whole seed melon transfer device, a roller separating device, a vibrating separation device, a washing device, a fishing device and a transferring and drying device, wherein the whole seed melon transfer device is positioned on the right side of the machine body for transferring the whole melon to the machine body; the roller separating device is mounted on the right side in the machine body for primarily separating the seed melon; the vibrating separating device is mounted on the left side of the roller separating device for secondarily separating the seed melon; the washing device is mounted at the front end of the machine body for separating the seed melon for the third time; the fishing device is positioned on the right side of the washing device for fishing out separated seeds; and the transferring and drying device is positioned below the front end of the fishing device for drying and transferring the seeds. The seed extractor provided by the invention can be used for separating seeds from melon pulp and melon peel for seed melons, soaking the seeds by melon juice and drying the seeds.

Owner:威海高新园区运营管理有限公司

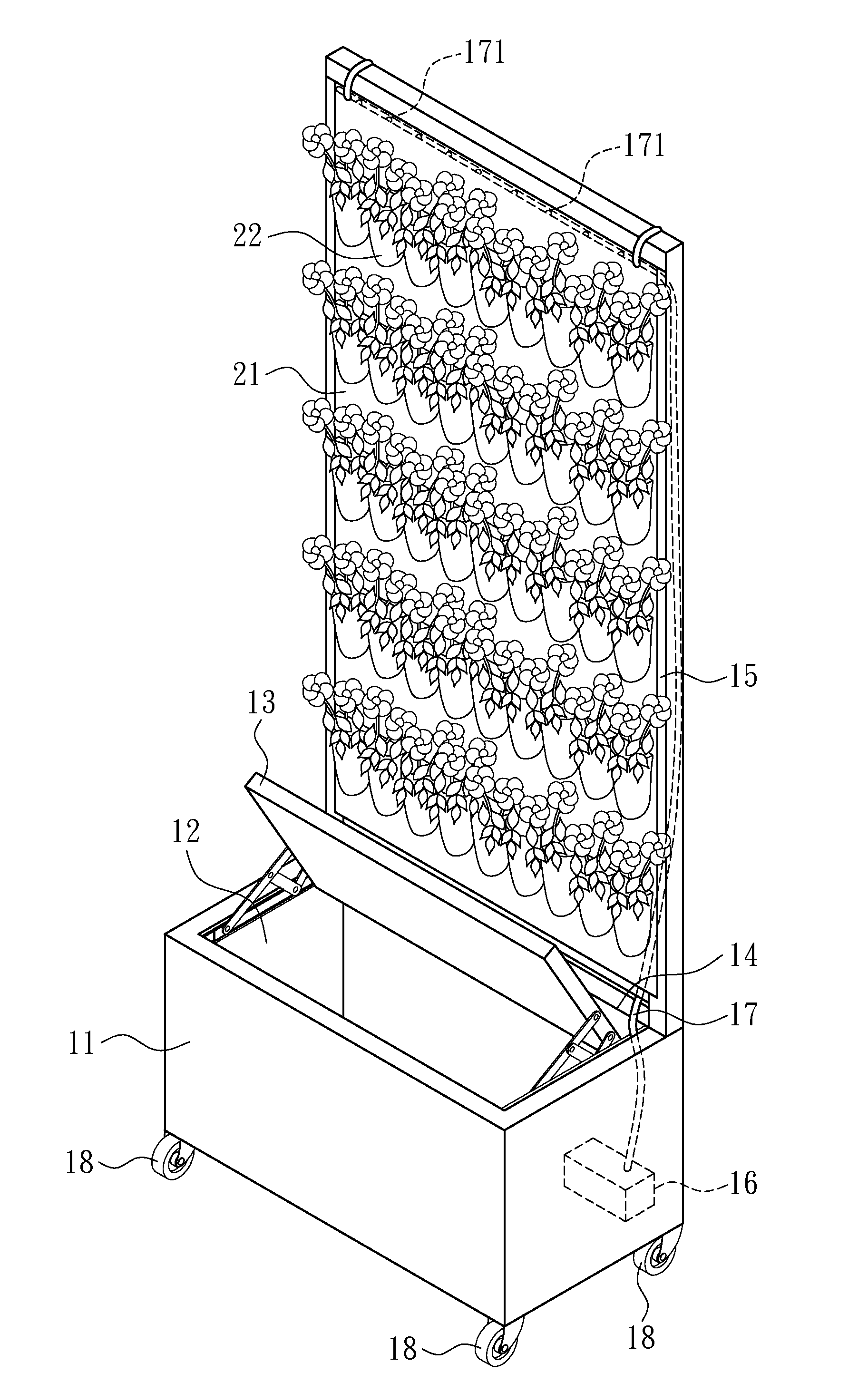

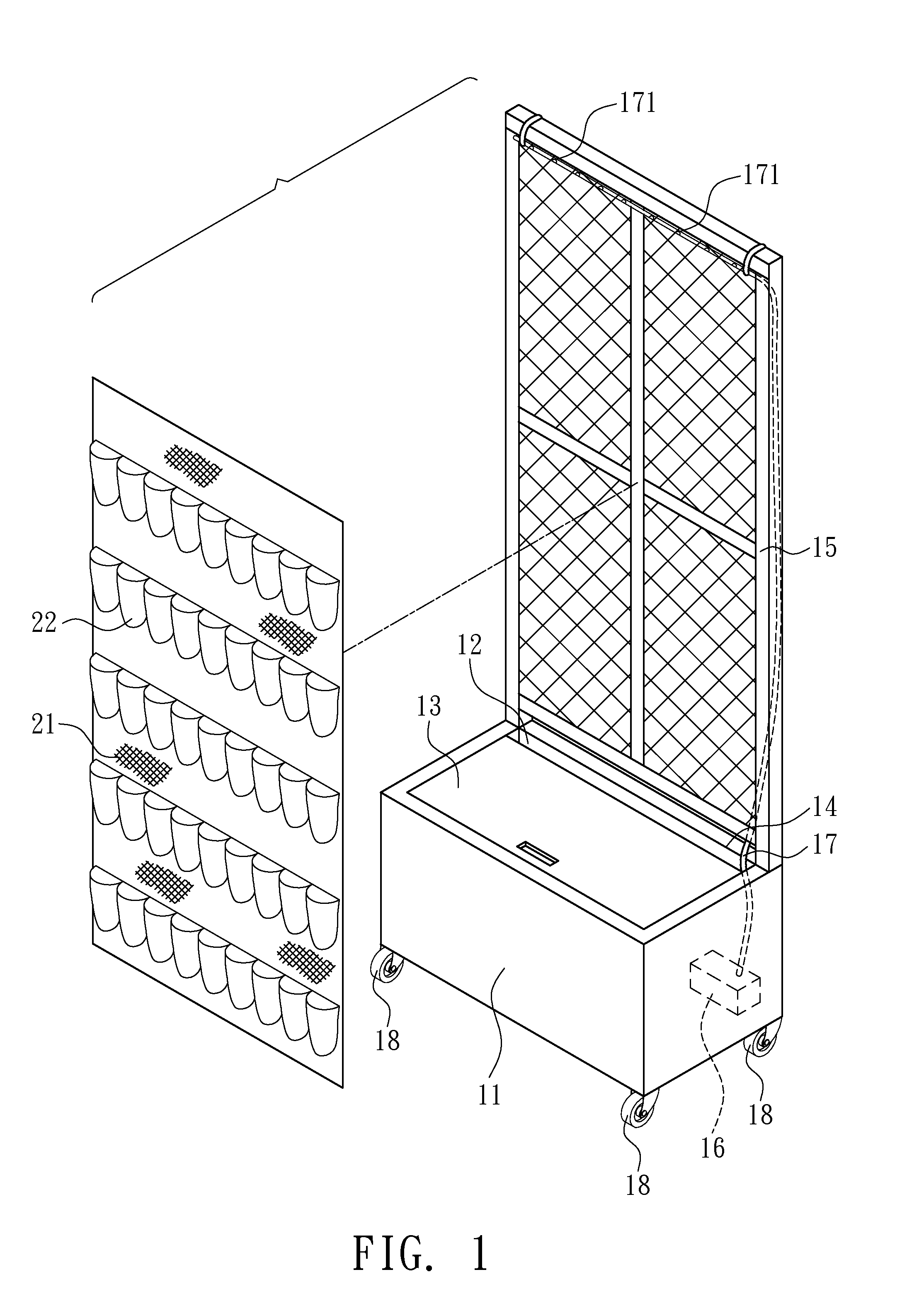

Vertical Planting Apparatus

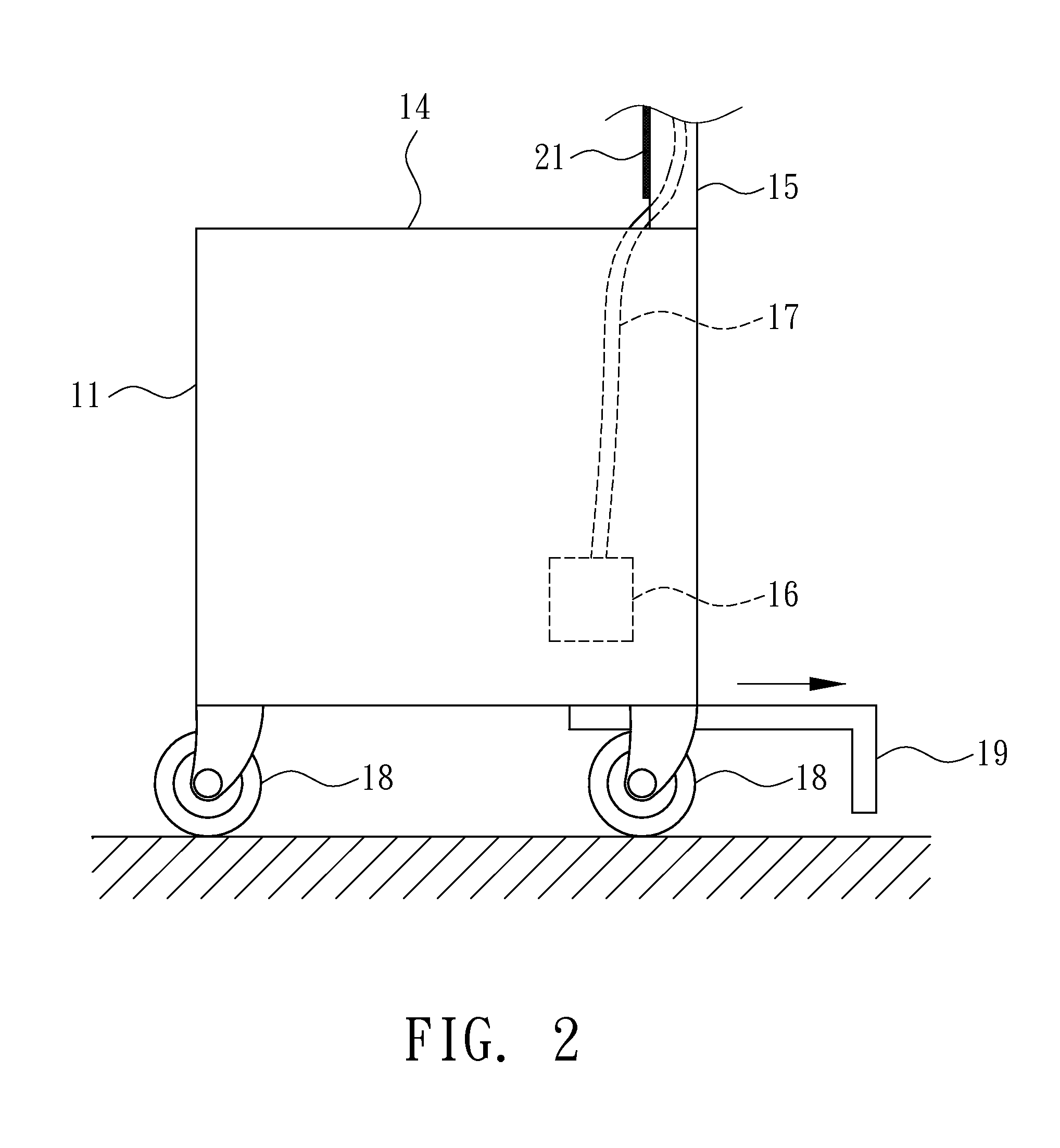

InactiveUS20120066972A1Save waterEasily transportWatering devicesCultivating equipmentsWater deliveryWater storage tank

A vertical planting apparatus includes a water storage tank, an n-shaped vertical frame extended upwardly from a side of the water storage tank, a water pump motor installed at the water storage tank for pumping irrigation water stored in the water storage tank out from the top of the n-shaped vertical frame through a water delivery pipe, a water permeating layer hanged within a range surrounded by the n-shaped vertical frame, and a plurality of bags formed on the water permeating layer and provided for growing plants, and the irrigation water outputted from the water delivery pipe enters into the permeating layer through the top of the n-shaped vertical frame and permeates sequentially from top to bottom into each of the bags.

Owner:LIN PAUL

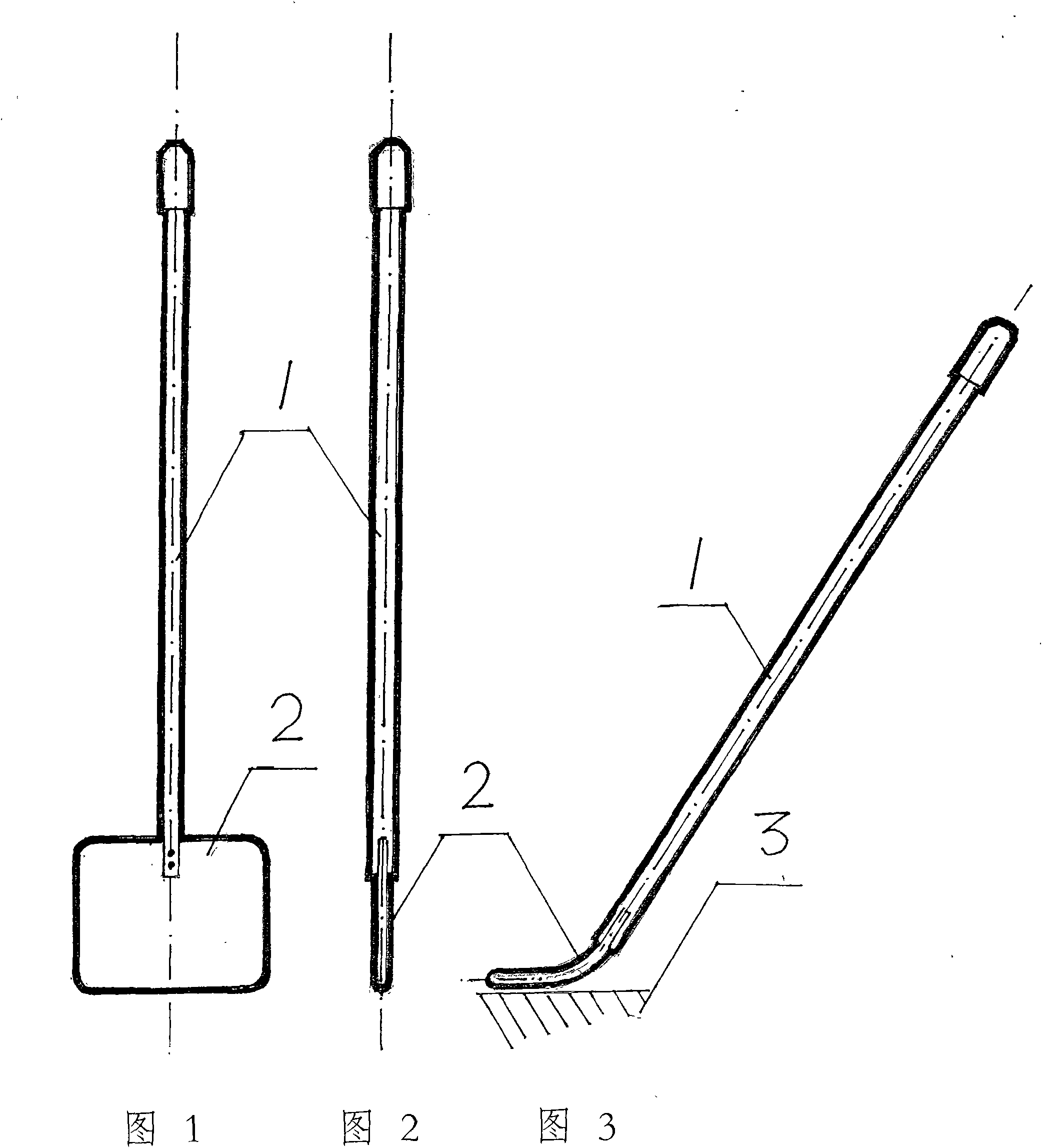

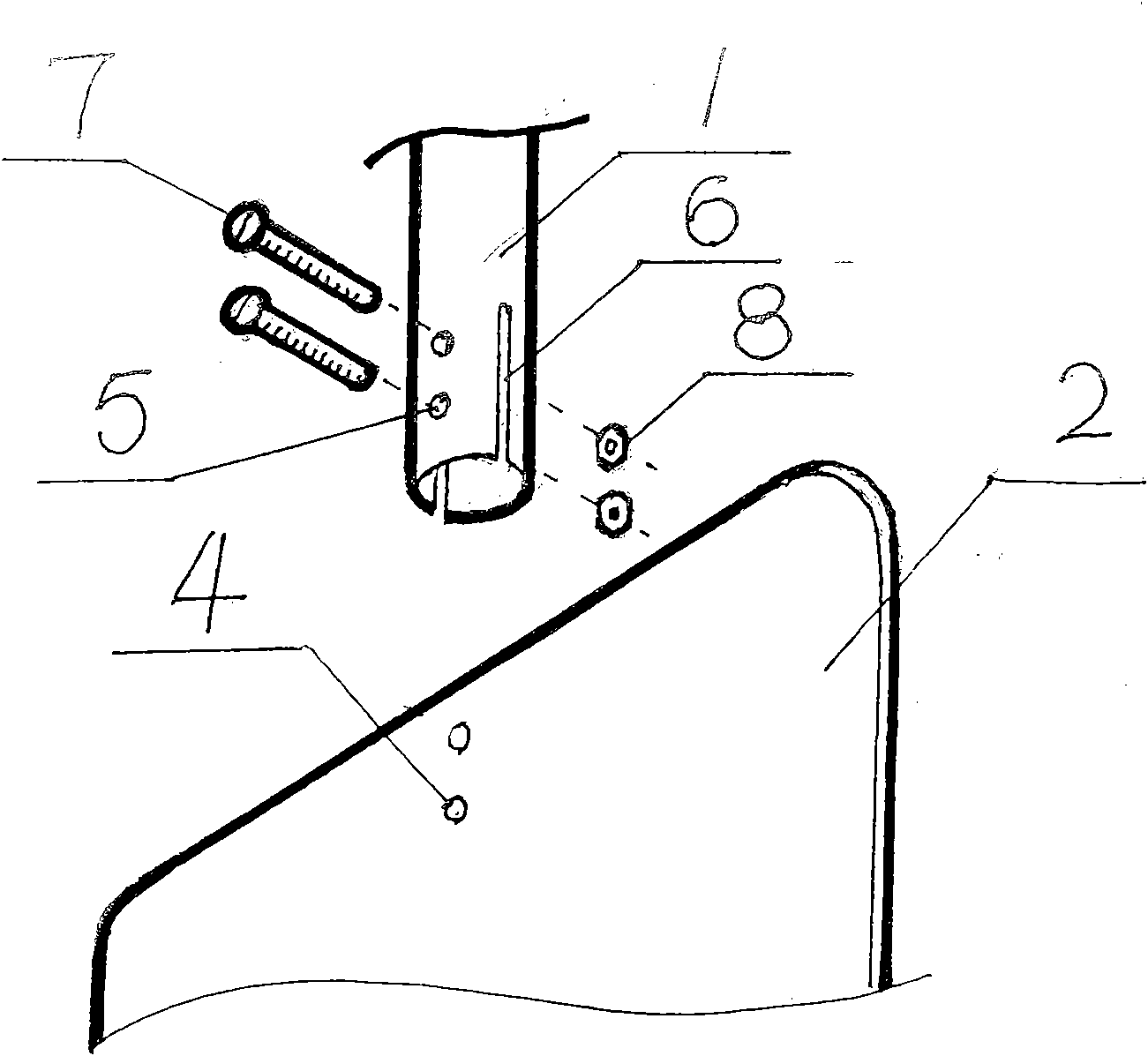

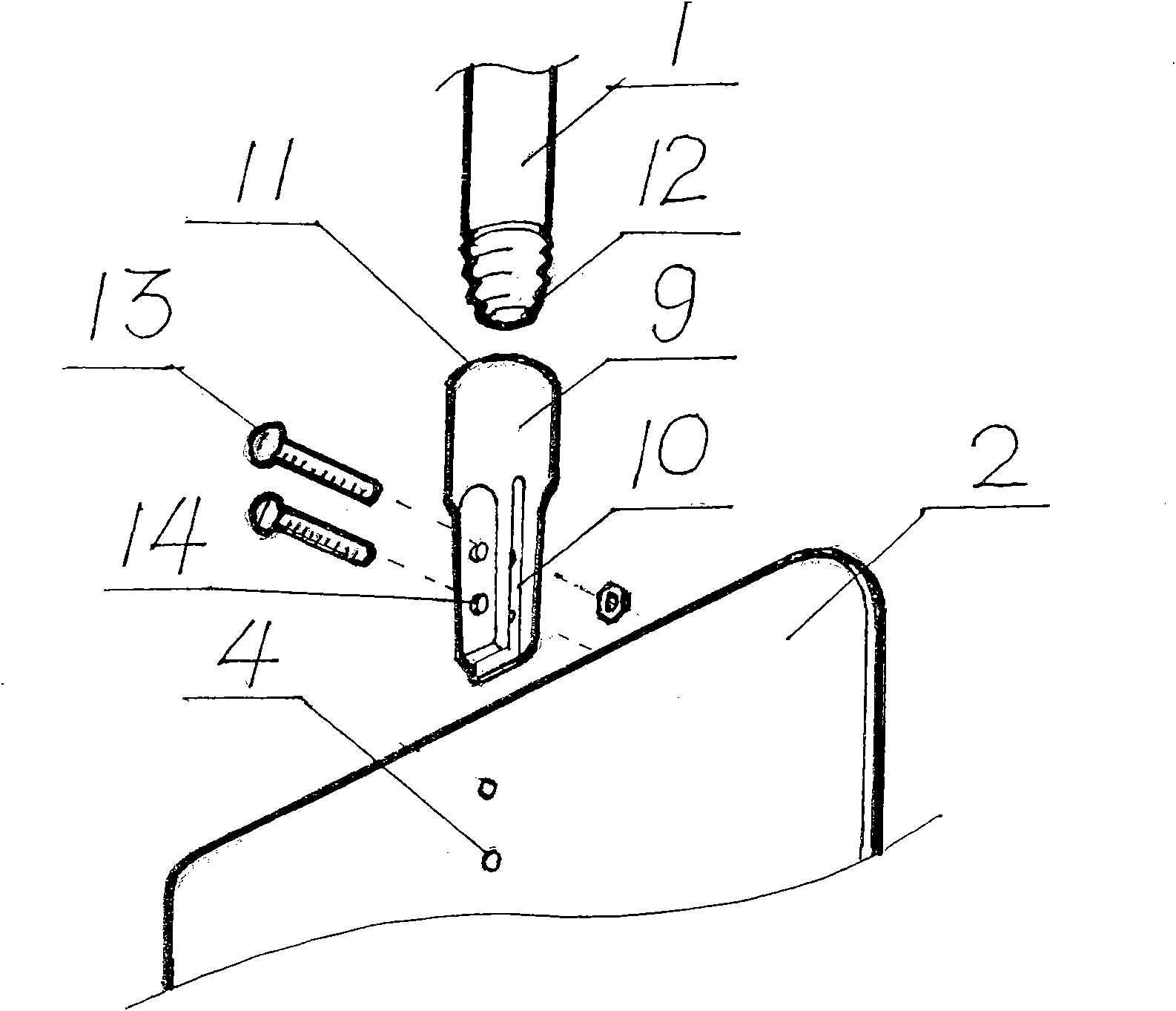

Portable mop and assorted mop barrel

The invention discloses a portable mop with simple structure, comprising a mop rod and a mop panel; the mop panel is a polygonal panel made of elastic material; an insertion connecting mechanism and a limiting device for rotating the mop panel forwardly and backwardly corresponding to the mop rod in a limiting angle are installed between the upper end of the mop panel and the lower end of the mop rod; the mop panel has straight and bent positions; in standby state, the central axis of the mop rod and the midline of the vertical section of the mop panel are located on the same straight line; in work state, the mop panel is deformed by means of external force; the upper end of the mop panel is parallel to a working surface; and the upper end of the mop panel has a crown face and can be formed into an angle with the mop rod. Meanwhile, the invention further discloses a mop barrel assorted to the portable mop. The mop barrel can remove the dirt on the mop and dehydrate the mop by means of upward and downward or forward and backward movements of the mop.

Owner:李军

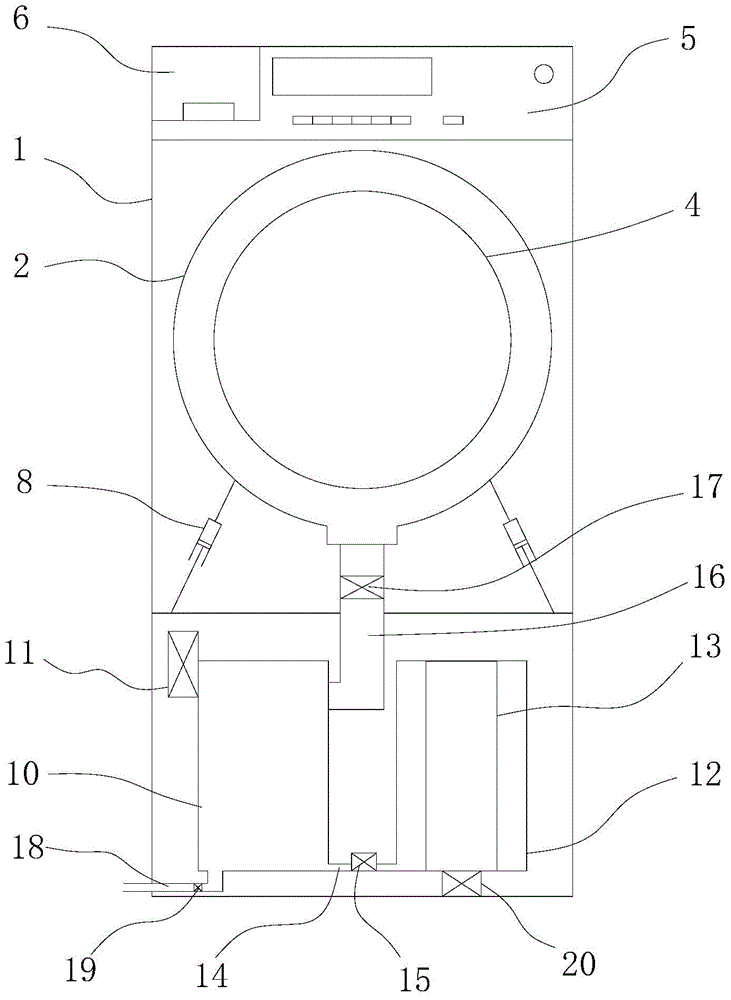

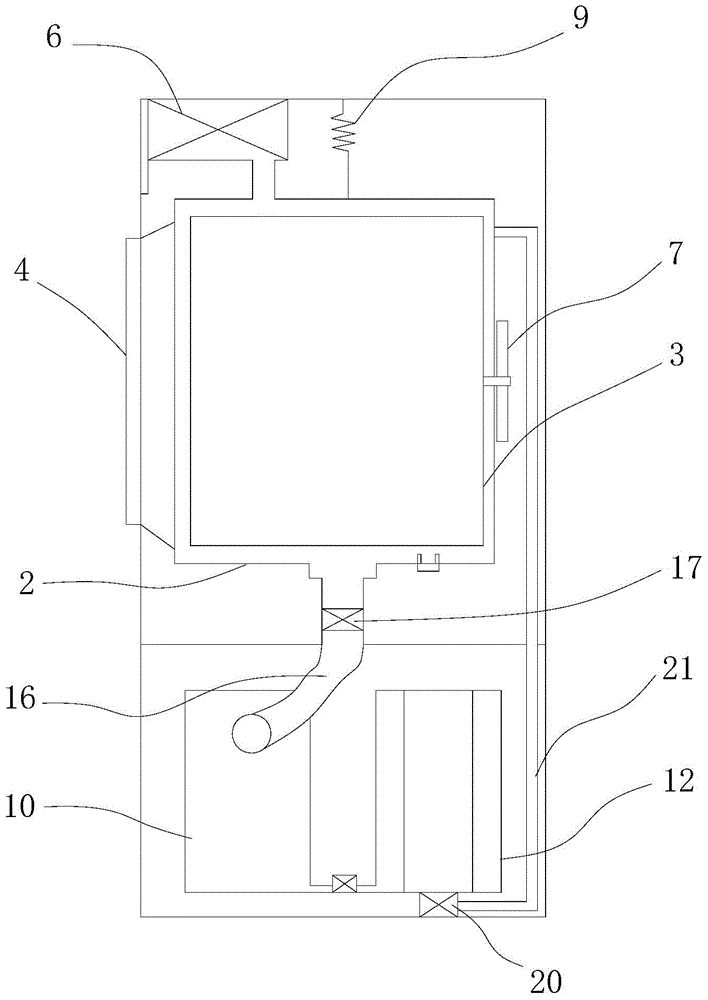

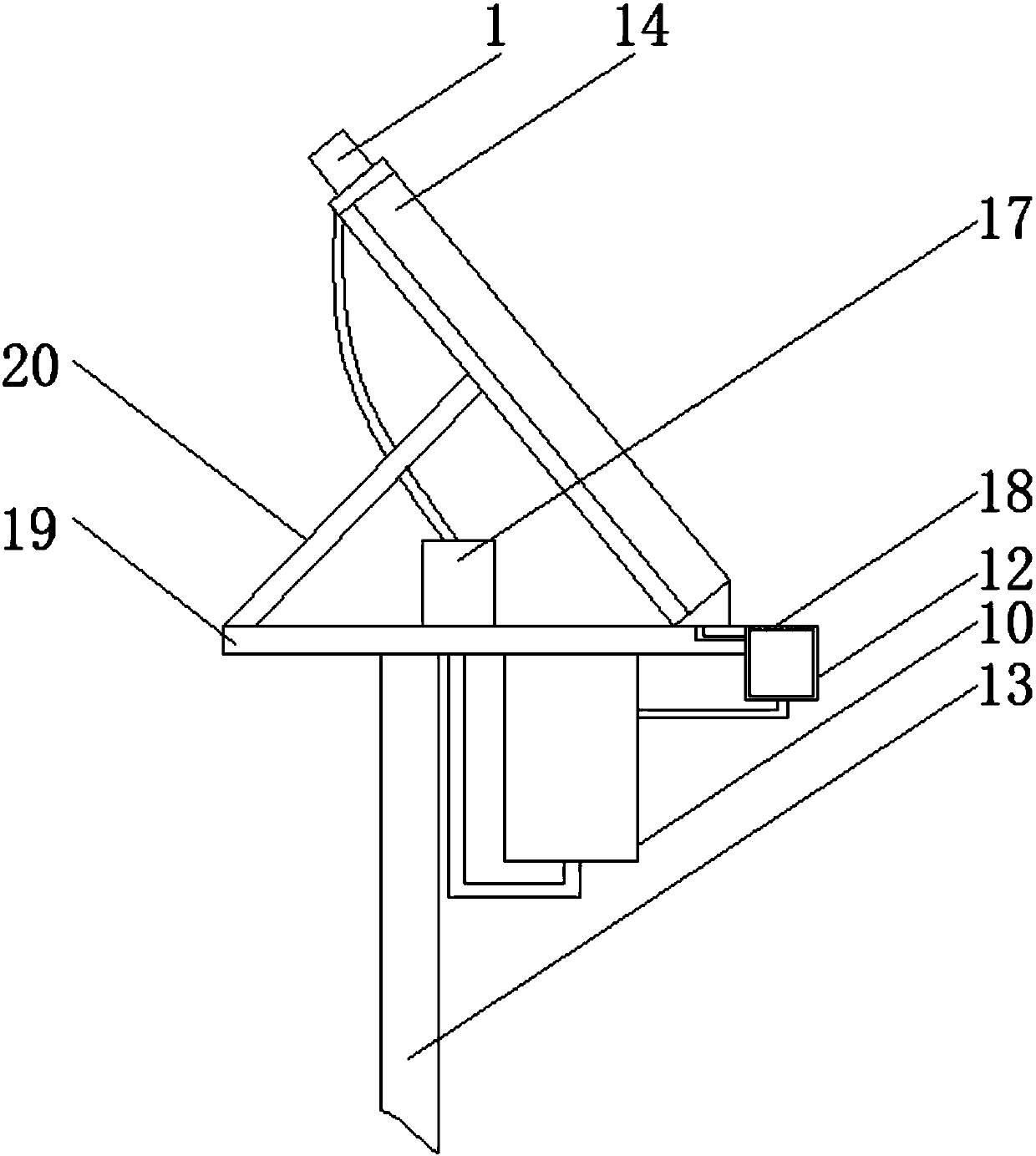

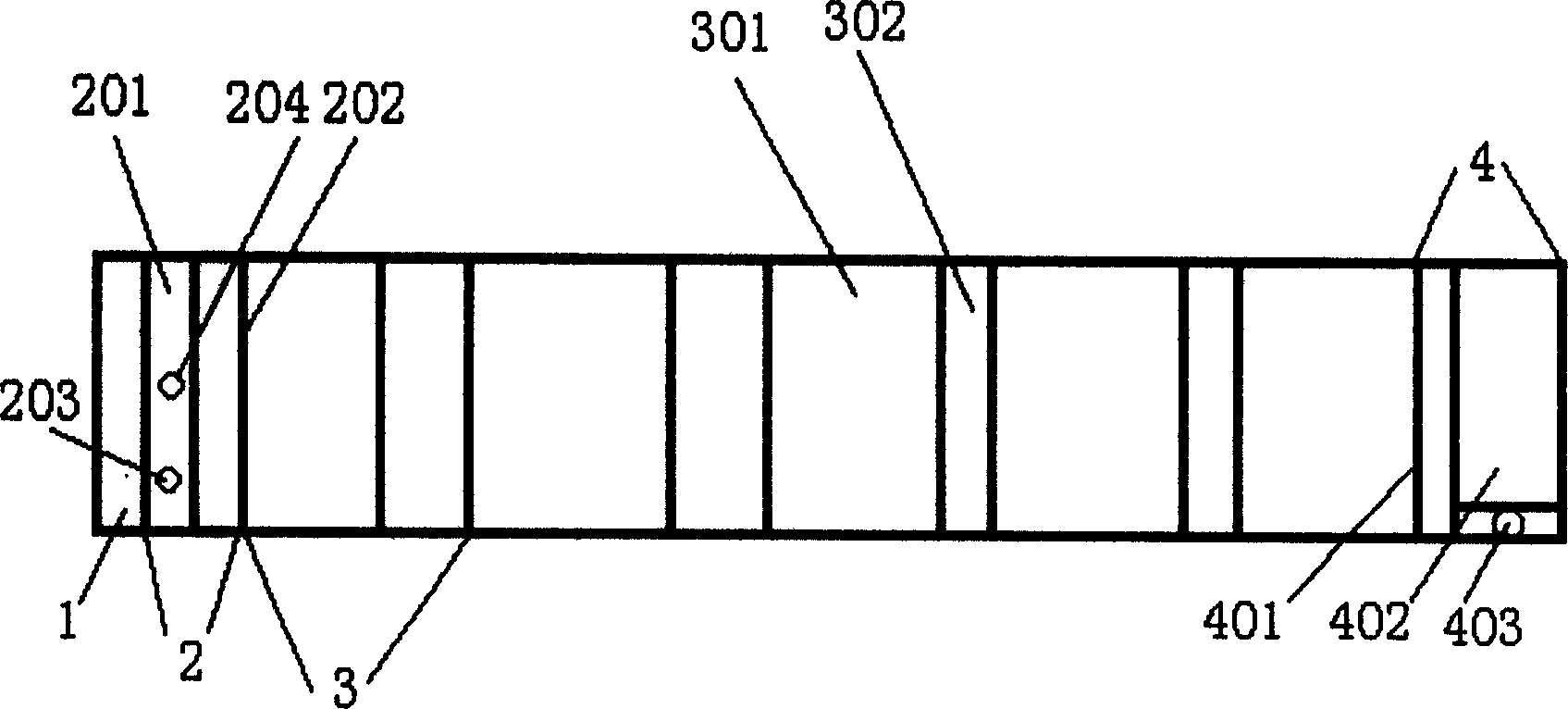

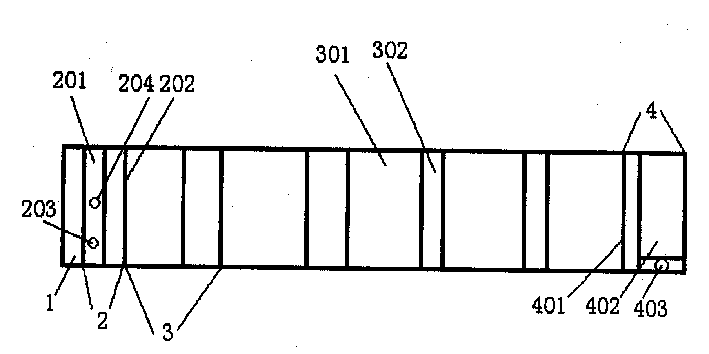

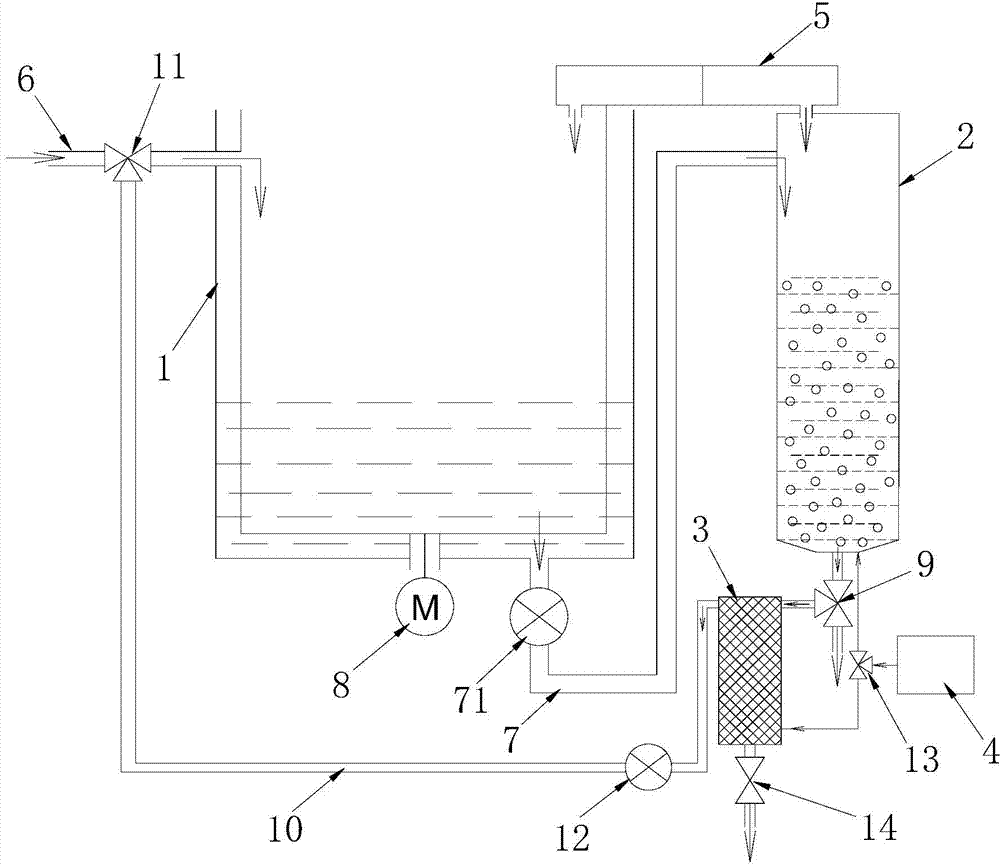

Washing machine with circulating water treatment function and control method thereof

ActiveCN104372574AGood for healthDoes not affect washing efficiencyOther washing machinesControl devices for washing apparatusFlocculationFiltration

A washing machine with a circulated water treatment function and a control method therefor. The washing machine comprises a water holding barrel (2), a washing structure arranged inside the water holding barrel (2) and a circulated water treatment device arranged under the water holding barrel (2), wherein the circulated water treatment device comprises a flocculation treatment unit and a filtering unit, the flocculation treatment unit comprises a flocculation container (10) connected to the water holding barrel (2) and a flocculation agent dosing device (11) for dosing a flocculation agent into the flocculation container (10), and water is discharged from the water holding barrel (2) to the flocculation container (10) for flocculation treatment; and the filtering unit comprises a filtering container (12) and a filter net (13) arranged inside the filtering container (12), the filtering container (12) is in communication with the flocculation container (10) and the water holding barrel (2), respectively, for filtering the water having been flocculation-treated in the flocculation container (10) and discharging same again into the water holding barrel (2) for reuse. The washing machine circularly treats water by flocculation and filtration till the end of washing, in which the water is discharged into the circulated water treatment device for purification in the flocculation treatment unit and the filtering unit and finally discharged outside. The washing machine has the advantages of saving water resources, reducing water pollution and protecting the environment.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

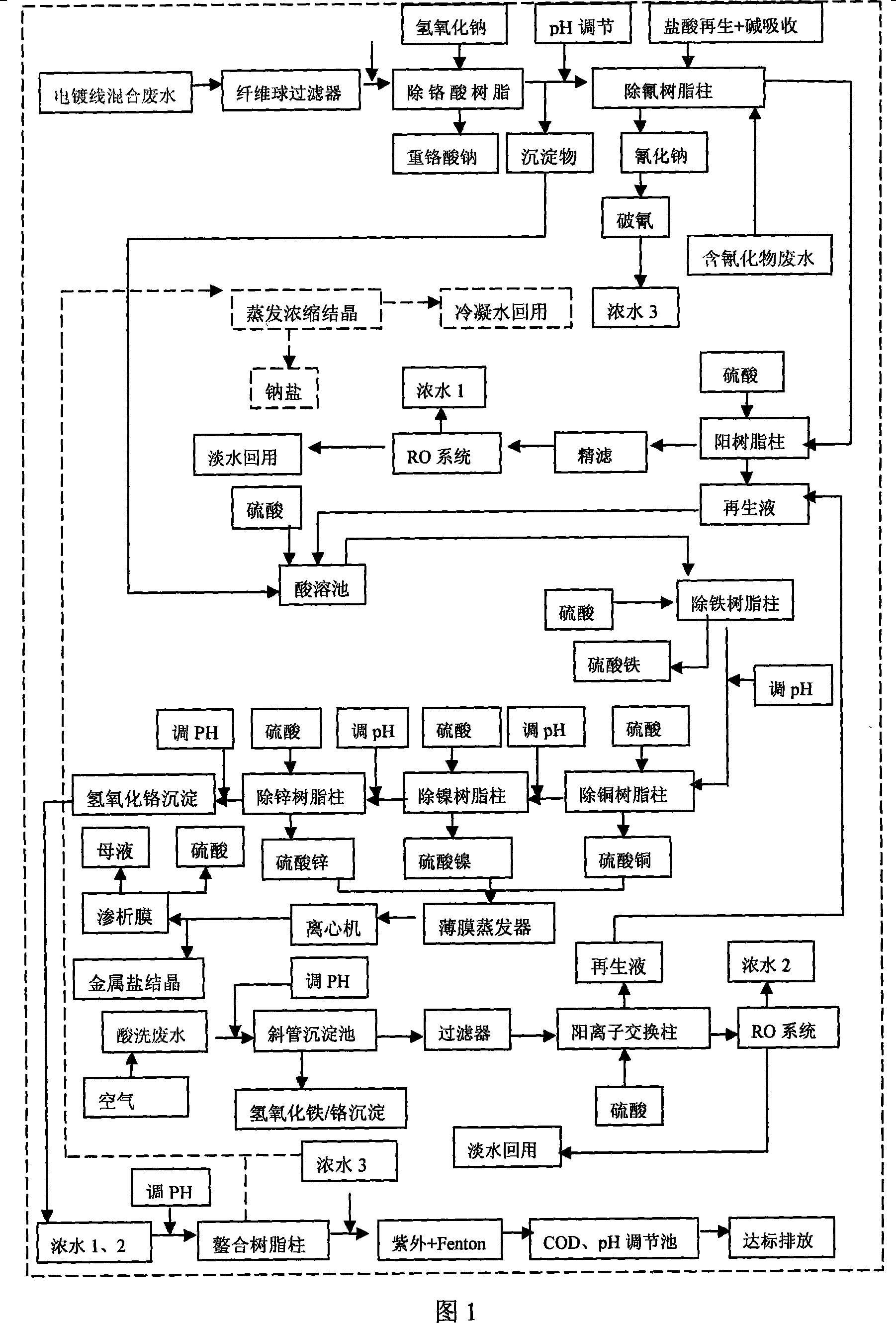

Electroplating wastewater zero-discharge or low-discharge handling method

InactiveCN101157509ASolve pollutionReduce processing costsFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationIonAutomatic control

The invention provides a processing method for zero draining or low draining of electroplating wastewater. The method adopts an integrative technique, such as barrier concentration, barrier separation, ion exchange, and ultraviolet light catalytic oxidation, etc. The following steps are adopted: the pretreatment of the electroplating wastewater; the treatment for the three types of wastewater including pickling wastewater, wastewater containing cyanide and passivating and electroplating rinsing composite wastewater; and the treatment for the wastewater in an acid-soluble pool. Compared with the wastewater in an integrative electroplating plant with universal generic multi-plating species, only the prior water separation method with no need to control the troubled water strictly can realize : first, zero draining of the electroplating wastewater is performed; second, when operating in the low energy consumption way, 65 to 85 percent of water recovery is realized, the left wastewater which can not be recovered is discharged when reaching the primary discharge standard of National Standard; third, the processing cost is reduced; fourth, the metallic ion in the wastewater can be effectively recovered and utilized, at the same time, the benefit disinvestment cost is produced; fifth, the amount for causing solid waste is reduced; sixth, the invention is advantageous to realize the automatic control and the operation.

Owner:SURFACE & INTERFACE CHEM ENG TECH RES CENT NANJING UNIV +1

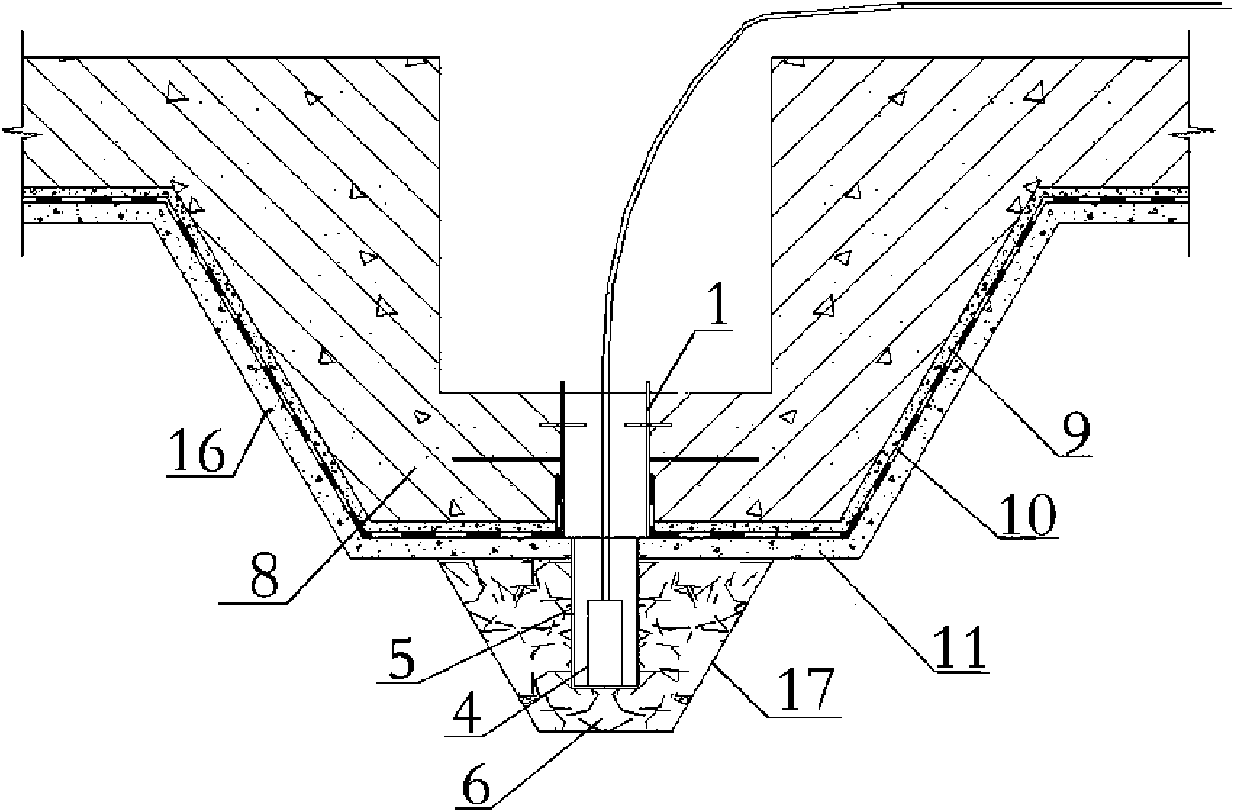

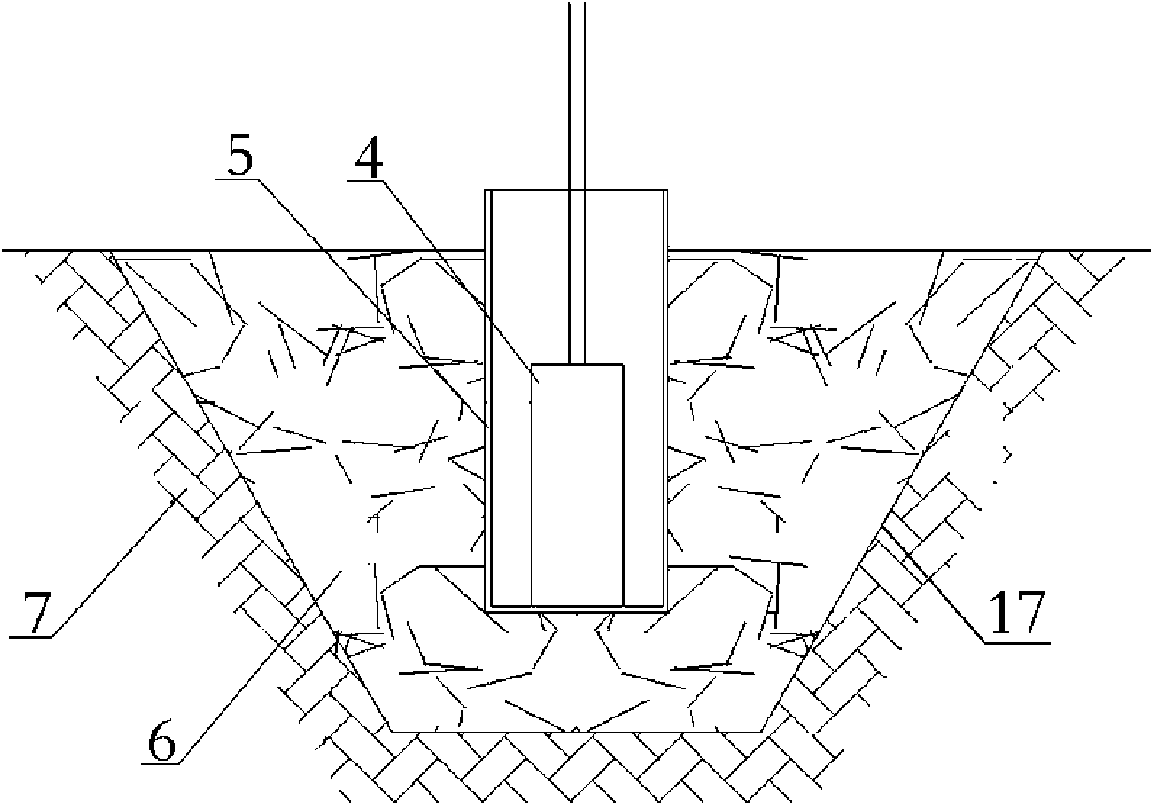

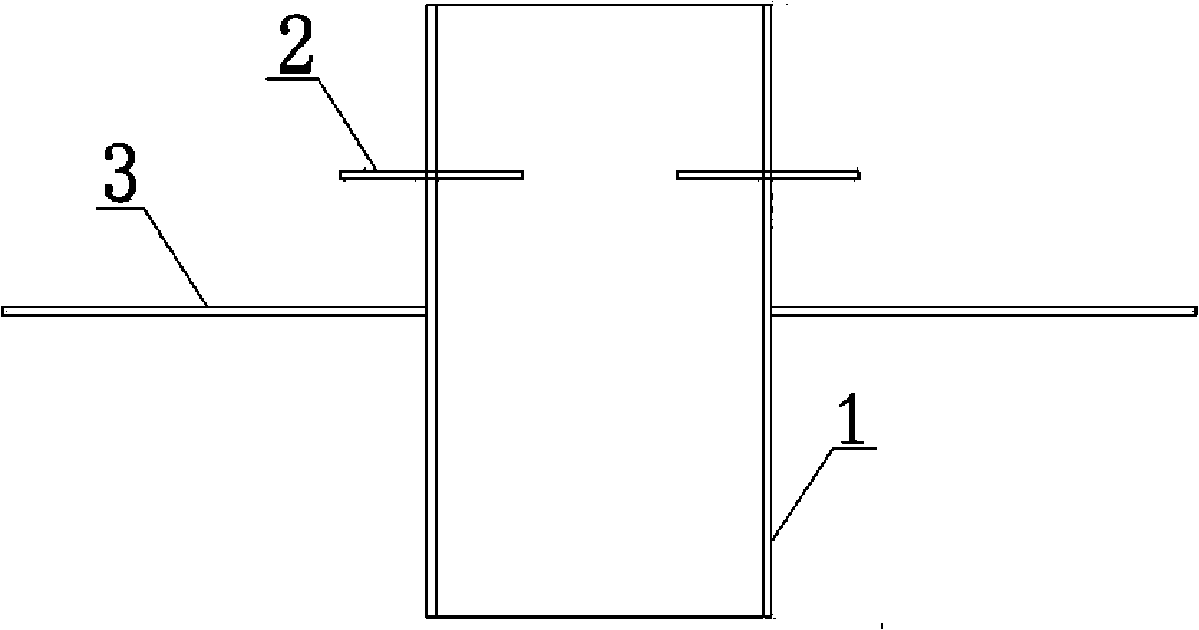

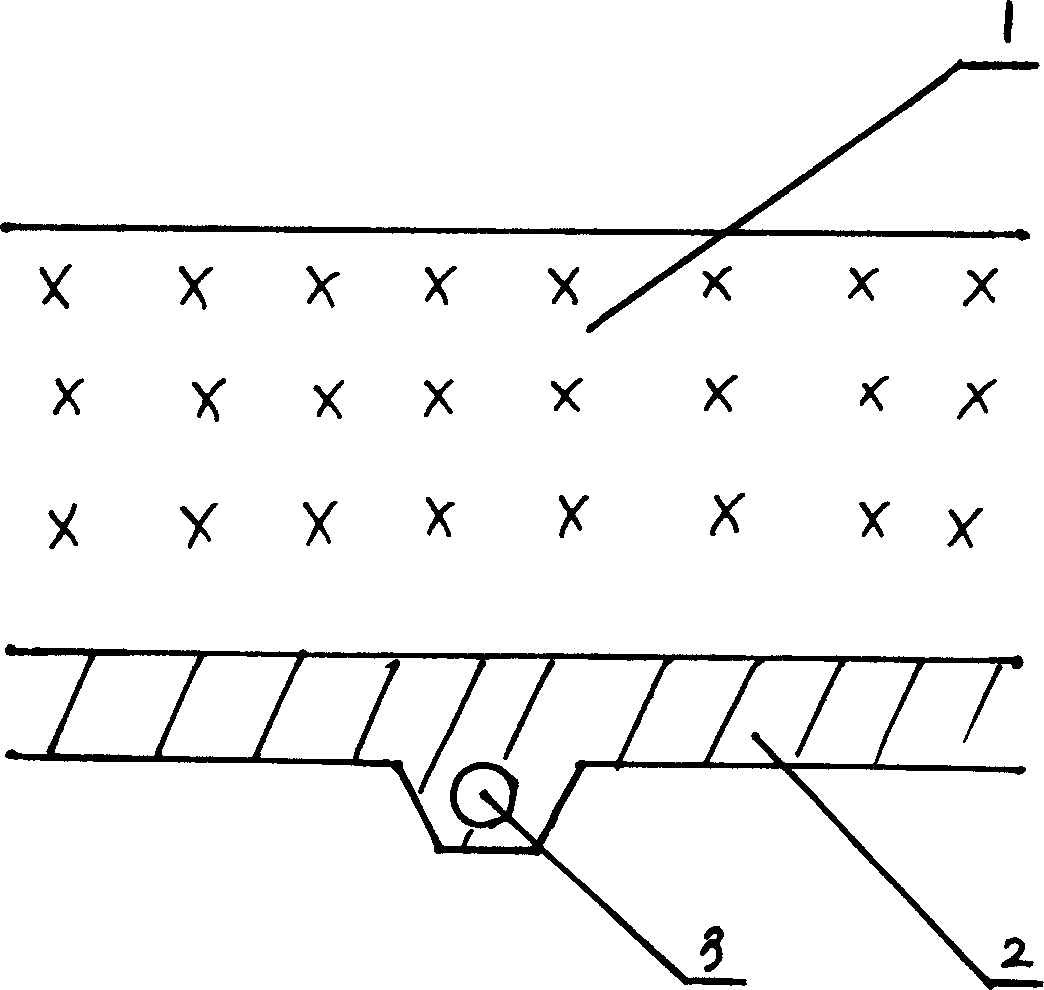

Base pit dewatering and water saving device and construction method thereof

InactiveCN101768976ASolve the precipitation problemEfficient use ofProtective foundationExcavationsWater savingBaseboard

The invention relates to a base pit dewatering and water saving device and a construction method thereof. The middle part of the base pit of a baseboard structure is provided with a well pit; the well pit is internally and vertically provided with a no-sand tube; pebbly sand is filled between the bottom and periphery of the no-sand tube; the top of the no-sand tube is higher than the top surface of the well pit; a water pump is arranged in the no-sand tube; blinding layer concrete is poured at the top surface of the well pit which is at the periphery of the no-sand tube and the side wall of the base pit of the baseboard structure; and the top elevation of the no-sand tube is flush with the elevation of a blinding layer; a dewatering conduit is pre-buried in a base pit baseboard right above the no-sand tube, a waterproof layer is paved on the blinding layer concrete, a layer of waterproof and protective concrete is poured on the waterproof layer, and the base pit baseboards are poured above the waterproof and protective concrete and at the periphery of the dewatering conduit. The method of the invention has lower investment, saved cost and less amount of dewatering amount, thereby reducing the loss of underground water and protecting water resource; and the method can be adopted for a project in which the well point dewatering method is not ideal for dewatering or a project in which the underground water is near the base pit elevation.

Owner:CSCEC CITY CONSTR DEV +1

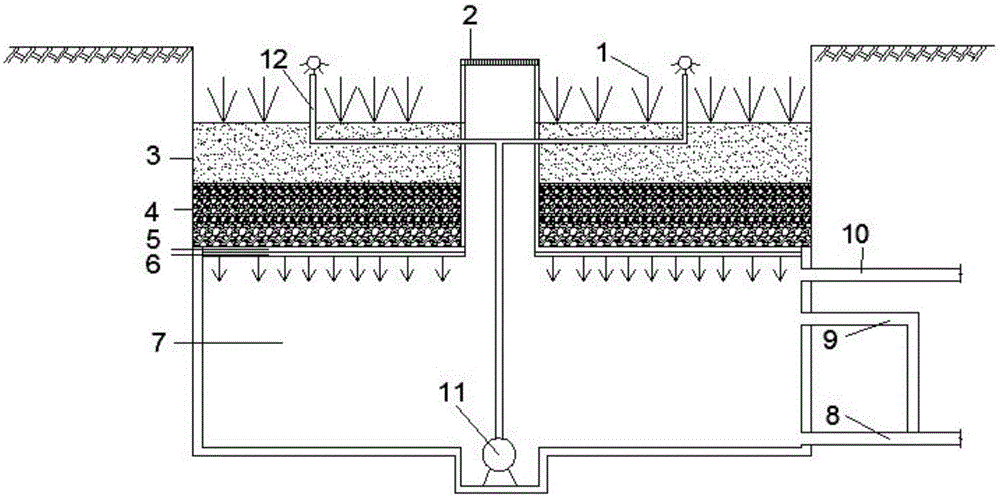

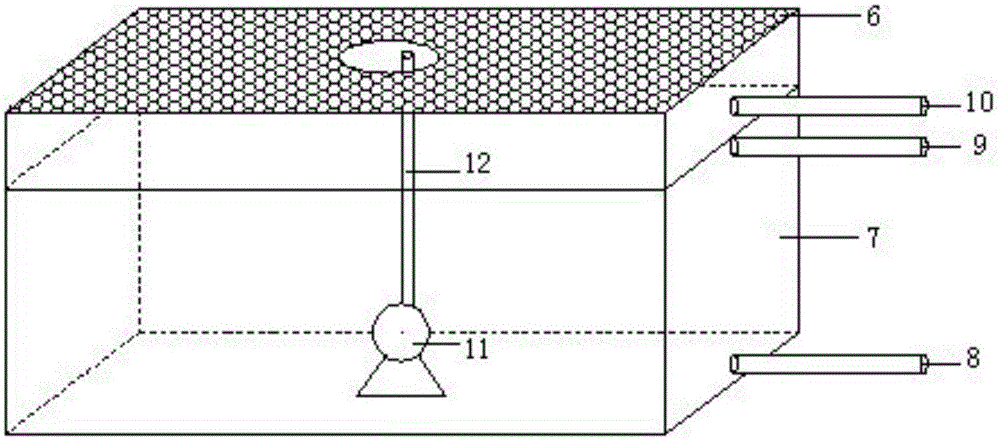

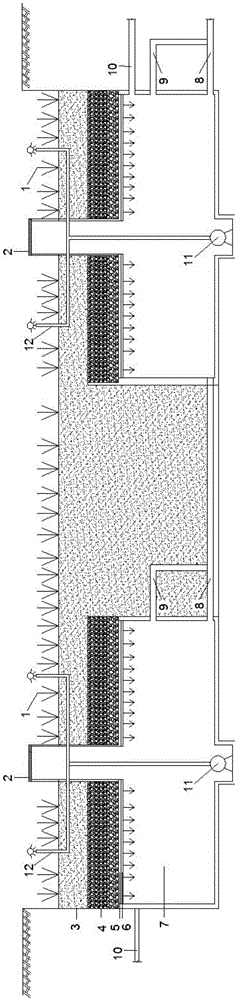

Low elevation greenbelt rainwater regulation scheduling pool and distributed rainwater regulation scheduling pool system

InactiveCN105089142AReduce waterloggingReduce runoff pollution loadSewerage structuresSewage drainingWater storageRainfall runoff

The present invention discloses a low elevation greenbelt rainwater regulation scheduling pool and a distributed rainwater regulation scheduling pool system. The distributed rainwater regulation scheduling pool system comprises a low elevation greenbelt (1), a rainwater overflow well (2) and a rainwater regulation scheduling pool (7), and water storage, drainage and supply which are integrated with a rainwater pipe network or a sewage pipe network are achieved. Compared with the prior art, rainfall runoff and flood detention can be effectively adjusted, runoff pollution can be reduced, and purification, storage and utilization functions of rainwater are fulfilled; and the system is tightly combined with the rainwater and sewage pipe networks of a city, the problems of urban inland inundation caused by rainstorm, the runoff pollution caused by rain wash, and rainwater resource utilization are solved, water storage is scheduled according to drainage ability of drainage pipelines, an important means is provided for sponge urban construction, and the system has outstanding social, environmental and economic benefits.

Owner:TIANJIN UNIV

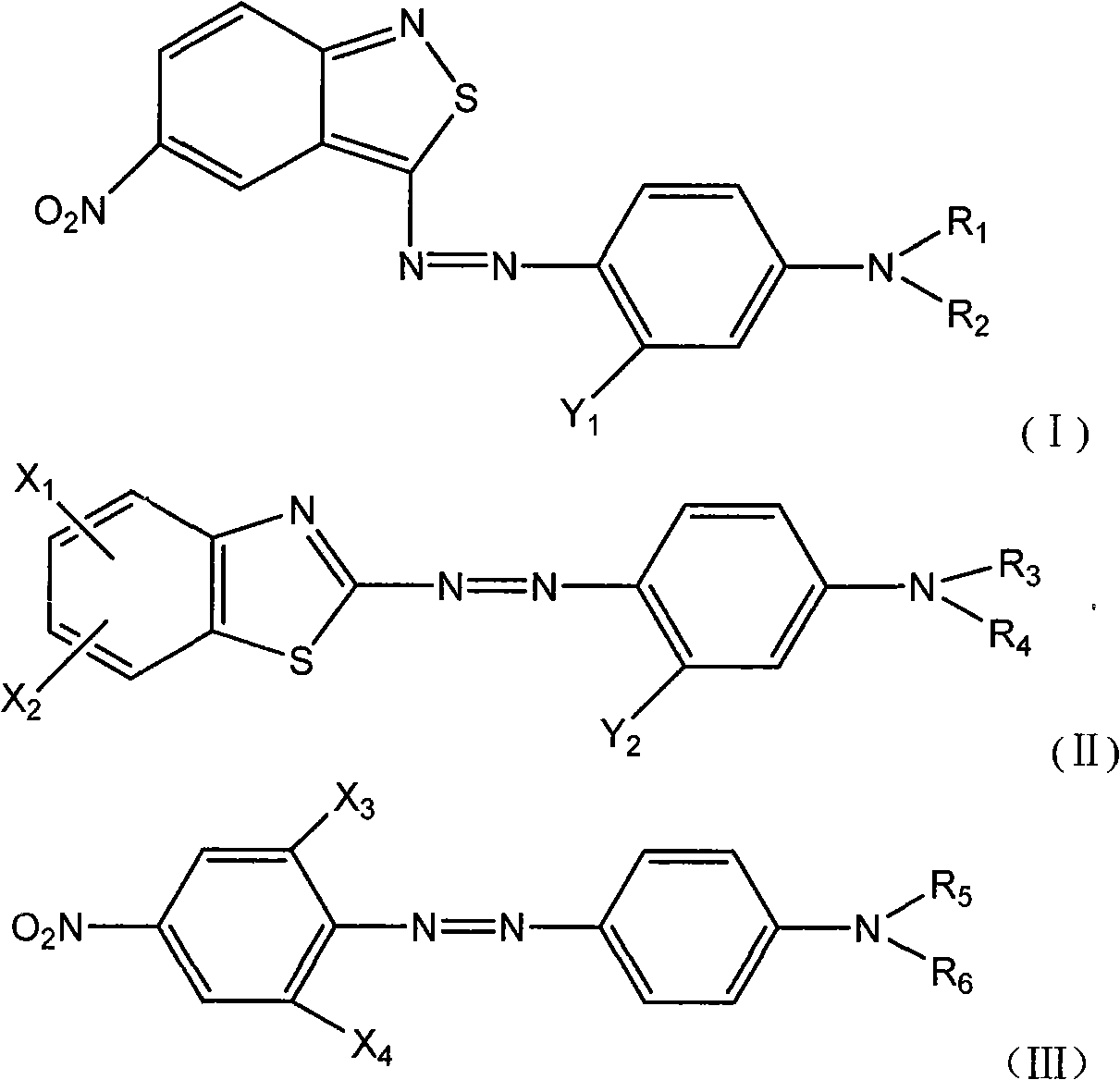

Disperse dye composition suitable for basic dyeing

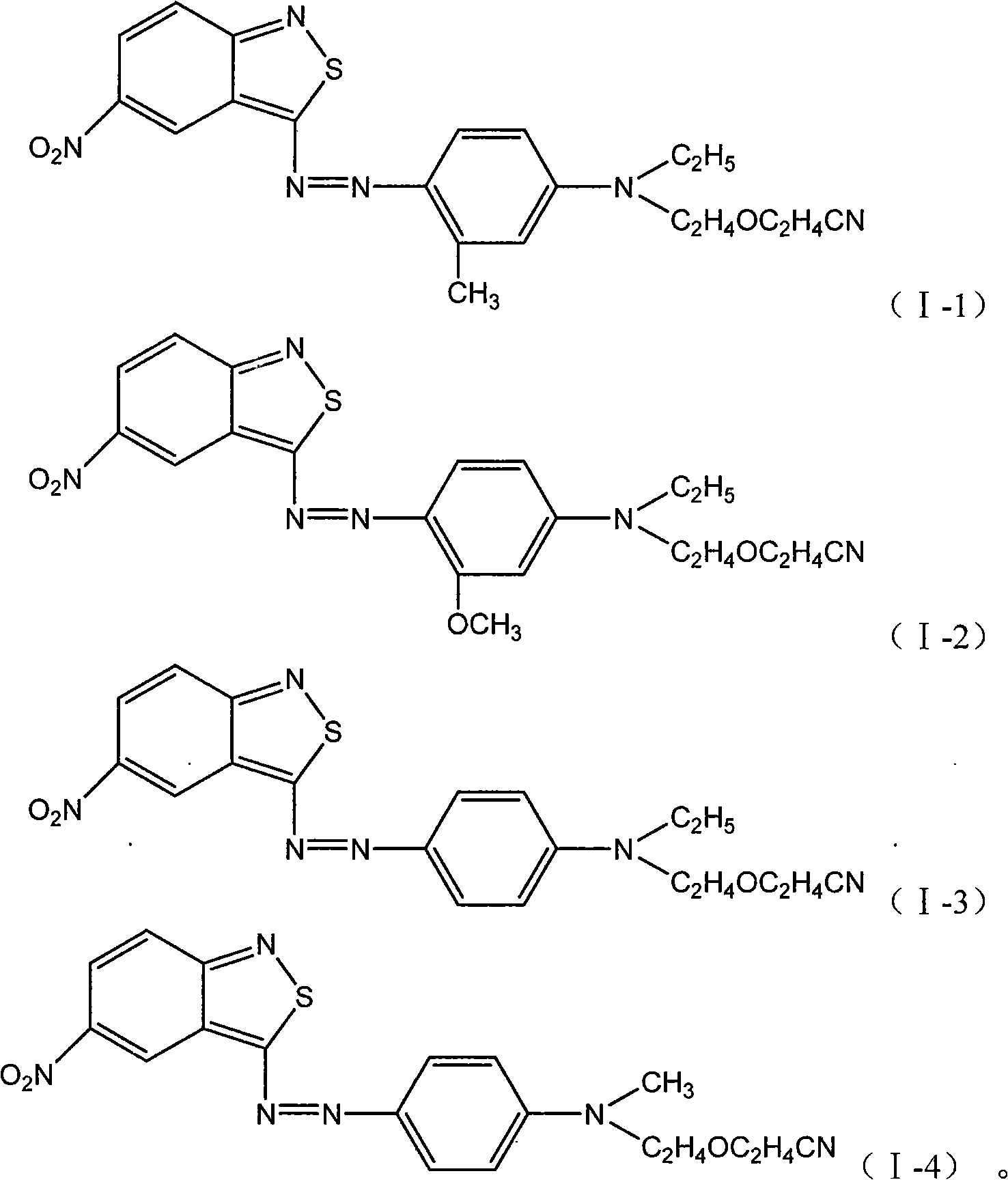

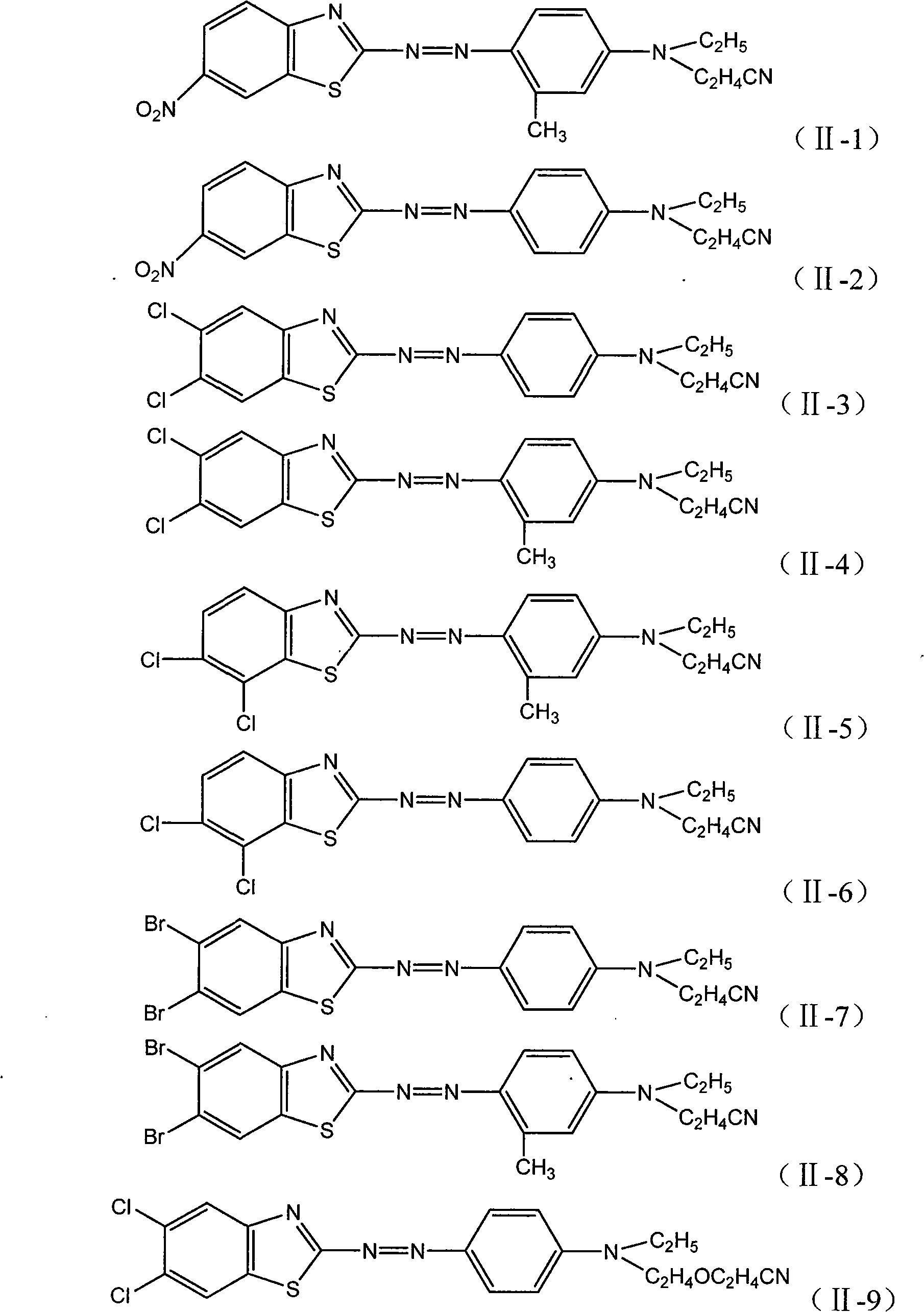

ActiveCN101649129AAvoid problems such as contaminationGuaranteed stabilityOrganic dyesDyeing processDisperse dyeColour fastness

The invention provides a disperse dye composition suitable for basic dyeing, mainly comprising the following raw materials in percentage by weight: 40-95 percent of one or a plurality of blue dyeing components A with a structural formula (I), 1-25 percent of one or a plurality of red dyeing components B with a structural formula (II) and 4-50 percent of one or a plurality of orange dyeing components C with a structural formula (III). The disperse dye composition has a wide dependency range of pH values, and can dye in a pH value ranging from 4.0 to 10; dyed and woven fabrics with predominant color-fastness performance, such as full hues, washing fastness, and the like, can be obtained.

Owner:浙江龙盛染料化工有限公司

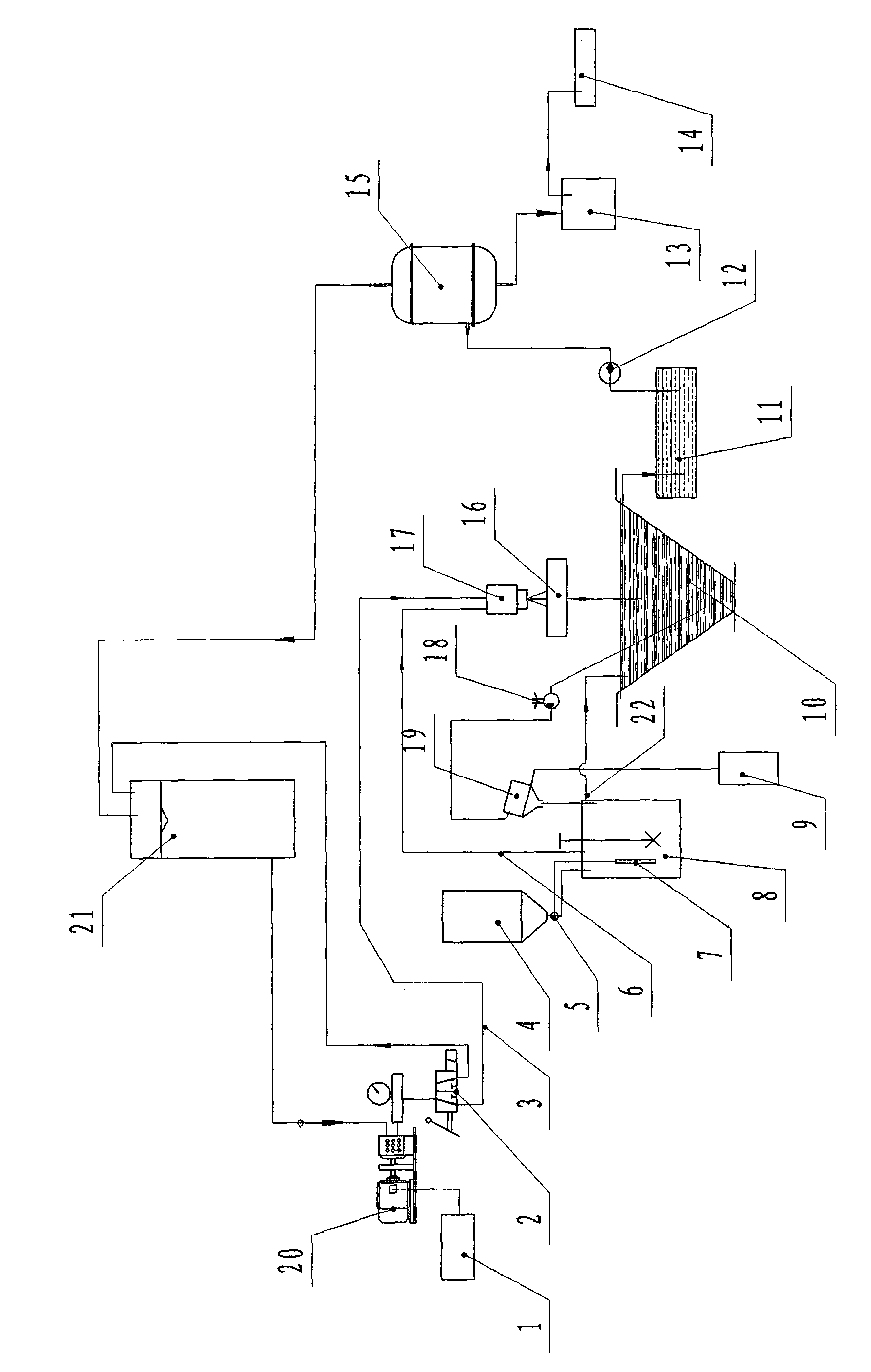

Online high-pressure water-jet blasting surface cleaning system

ActiveCN101633154AUniform supplyGuaranteed uptimeAbrasive feedersAbrasive machine appurtenancesSlagSurface cleaning

An online high-pressure water-jet blasting surface cleaning system comprises a high pressure water feed mechanism, an abrasive material feed mechanism and a spray nozzle. The high pressure water feed mechanism and the abrasive material feed mechanism are communicated with an input end of the spray nozzle, an abrasive material collecting pit is arranged below the spray nozzle, an output end of the abrasive material collecting pit is divided into two paths, one path is connected with an input end of an abrasive material sorting device by an abrasive material cyclical feeding device and a pipeline, and the other path is connected with an input end of a waste water treatment circulating mechanism by a pipeline, an output end of the waste water treatment circulating mechanism is connected with the high pressure water feed mechanism by a pipeline, an output end of the abrasive material sorting device is divided into two paths, one path is connected with the abrasive material feed mechanism, and the other path is connected with a slag collection barrel by a pipeline. The online high-pressure water-jet blasting surface cleaning system has the advantages of simple and compact structure, low energy consumption, good environmental protection, good operational reliability and stability, and recycled water and abrasive materials.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

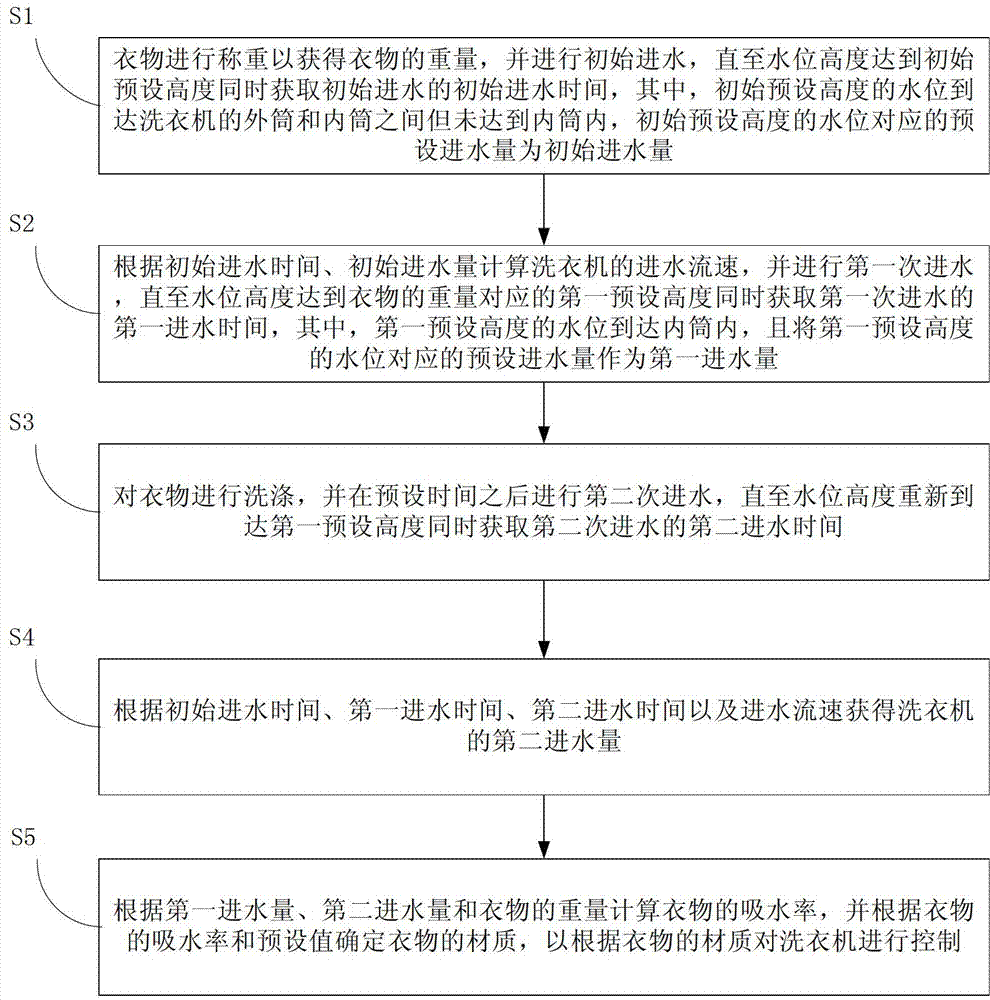

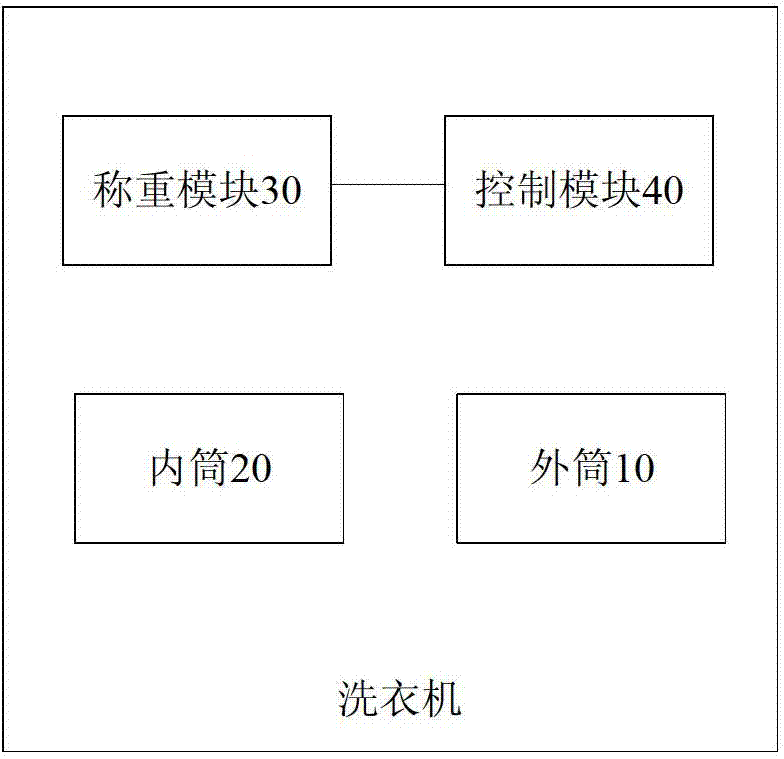

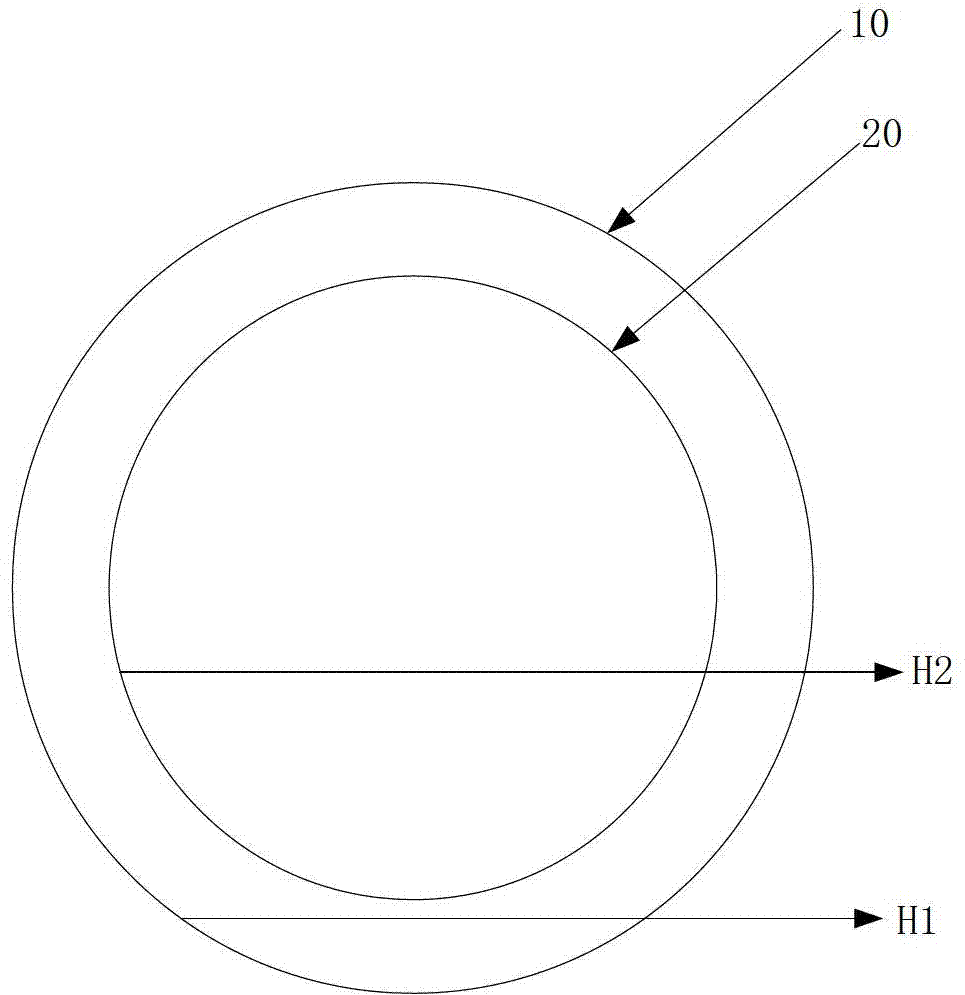

Washing machine and control method thereof

ActiveCN103485121AImprove satisfactionGuaranteed washing effectOther washing machinesControl devices for washing apparatusEngineeringWater intake

The invention discloses a washing machine and a control method thereof. The control method comprises the following steps of: weighing clothes to obtain the weight of the clothes, carrying out initial water filling until the height of water reaches an initial preset height, and acquiring initial water filling time, wherein a water intake quantity corresponding to the initial preset height represents an initial water intake quantity; calculating a water intake flow rate, carrying out primary water filling until the height of the water reaches a first preset height, and acquiring first water filling time, wherein a water intake quantity corresponding to the first preset height represents a first water intake quantity; after washing the clothes for preset time, carrying out secondary water filling until the height of the water reaches a second preset height, and acquiring second water filling time; according to the initial water filling time, the first water filling time, the second water filling time and the water intake flow rate, acquiring a second water intake quantity; and according to the first water intake quantity, the second water intake quantity and the weight of the clothes, calculating water absorption of the clothes, and determining the material of the clothes according to the water absorption of the clothes and a preset value so as to control the washing machine according to the material of the clothes. According to the invention, the material of the clothes can be identified so as to implement reasonable control on the washing machine and improve use experience of a user.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

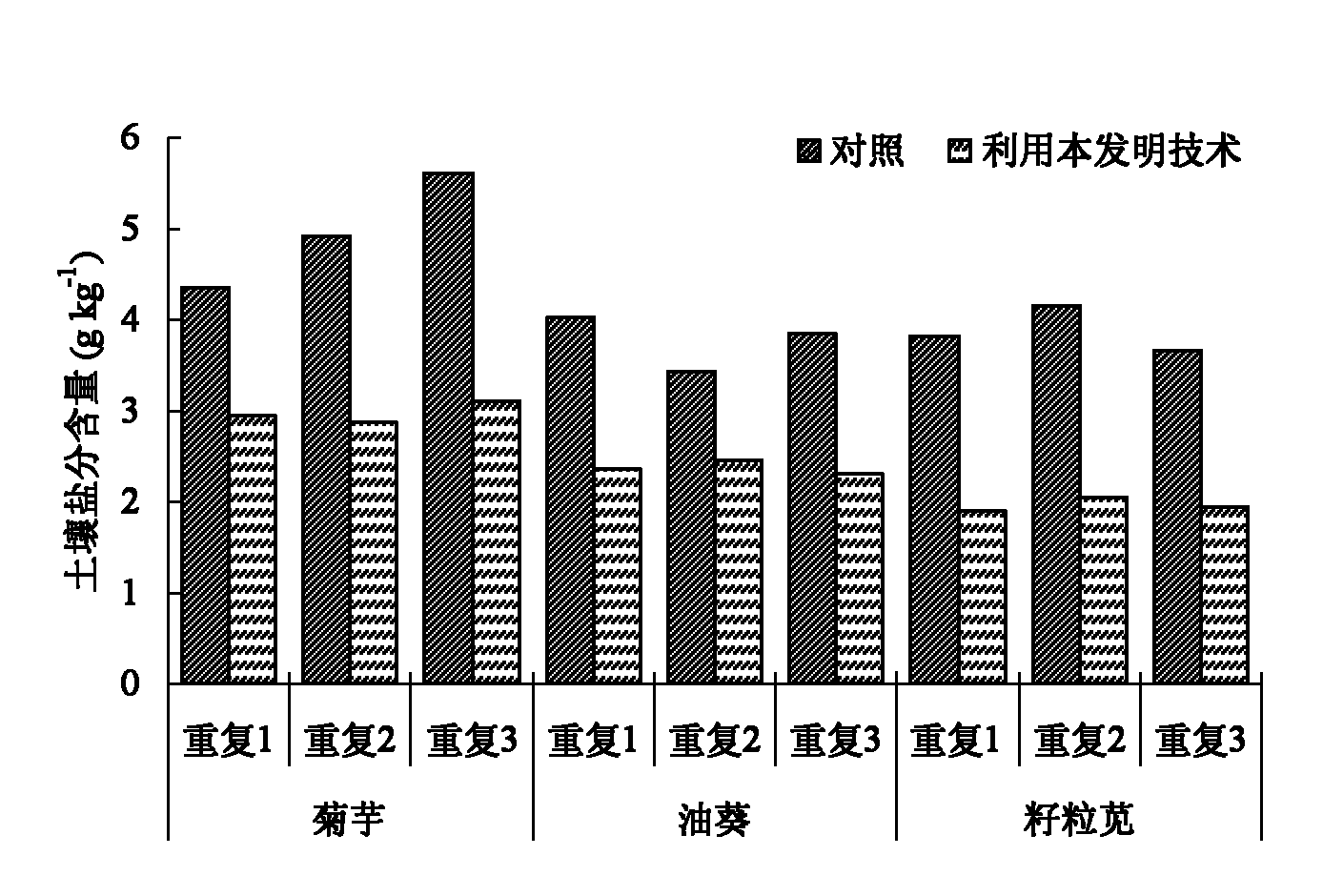

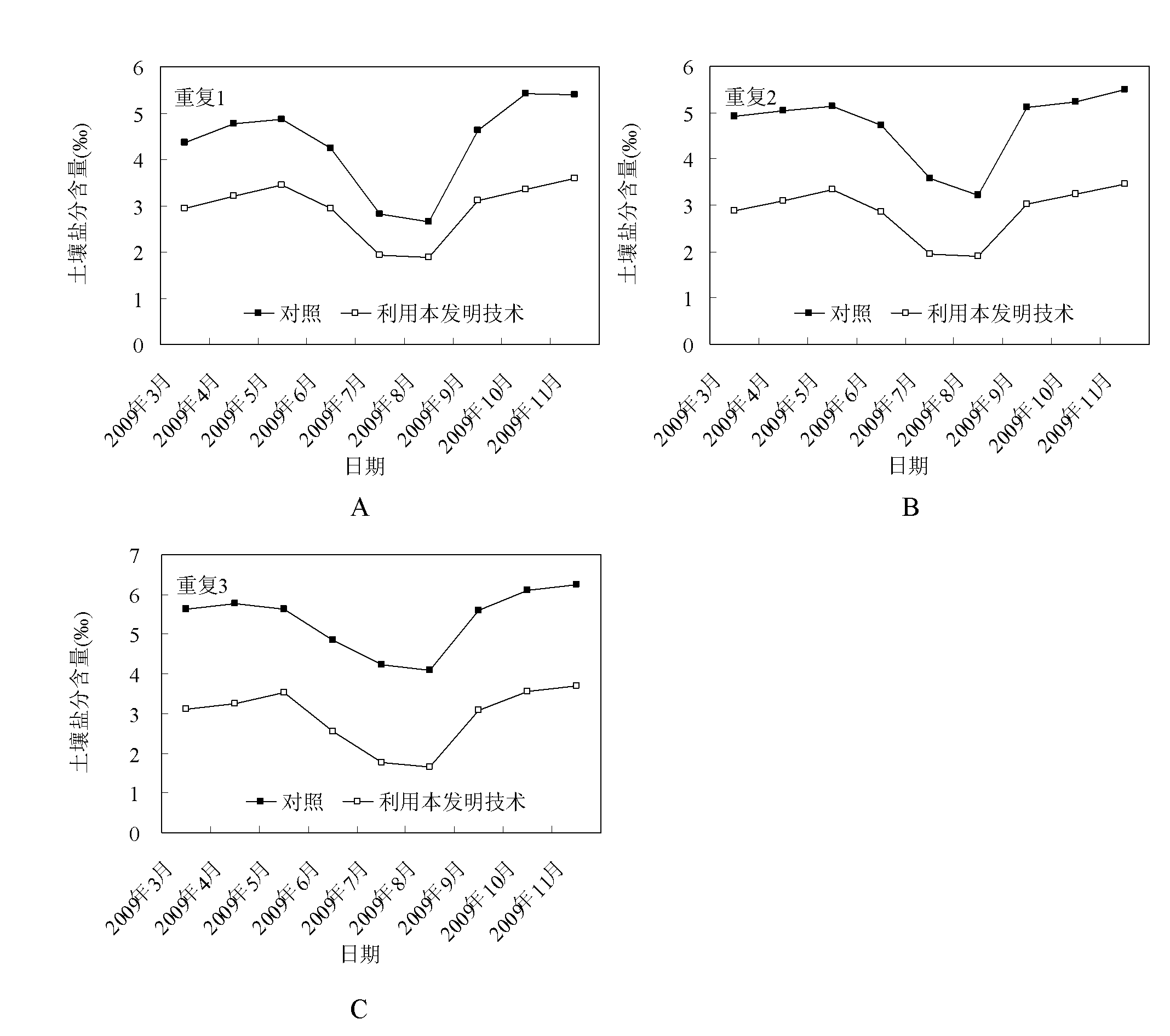

Controlled-salinity cultivation method for plating crop on moderate and medium and severe saline-alkali soil

InactiveCN102057775AImprove germination rateImprove irrigation and drainage efficiencyClimate change adaptationSoil-working methodsSoil scienceAlkali soil

The invention discloses a controlled-salinity cultivation method for plating crop on moderate and medium and severe saline-alkali soil, comprising: before sowing, irrigating saline-alkali soil for pressing salt and making soil moisture with fresh water; applying base fertilizer based on the principal of organic fertilizer into the saline-alkali soil; meanwhile, applying compound fertilizer suitable for the saline-alkali soil as the assistant material; then, ploughing soil, and raking with a leveller to preserve soil moisture; furrowing and making a ridge; covering films and sowing on the high position of the ridge; carrying out close planting; and spraying growth regulator. The cultivation method has the advantages of strong adaptability and high crop output, can be used for improving the utilization ratio of the fertilizer, quickeing the soil fertility cultivation process and bringomg high agricultural use benefits.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Electric pressure cooker with rapid pressure relief function

Owner:GUANGDONG LUBY ELECTRONICS

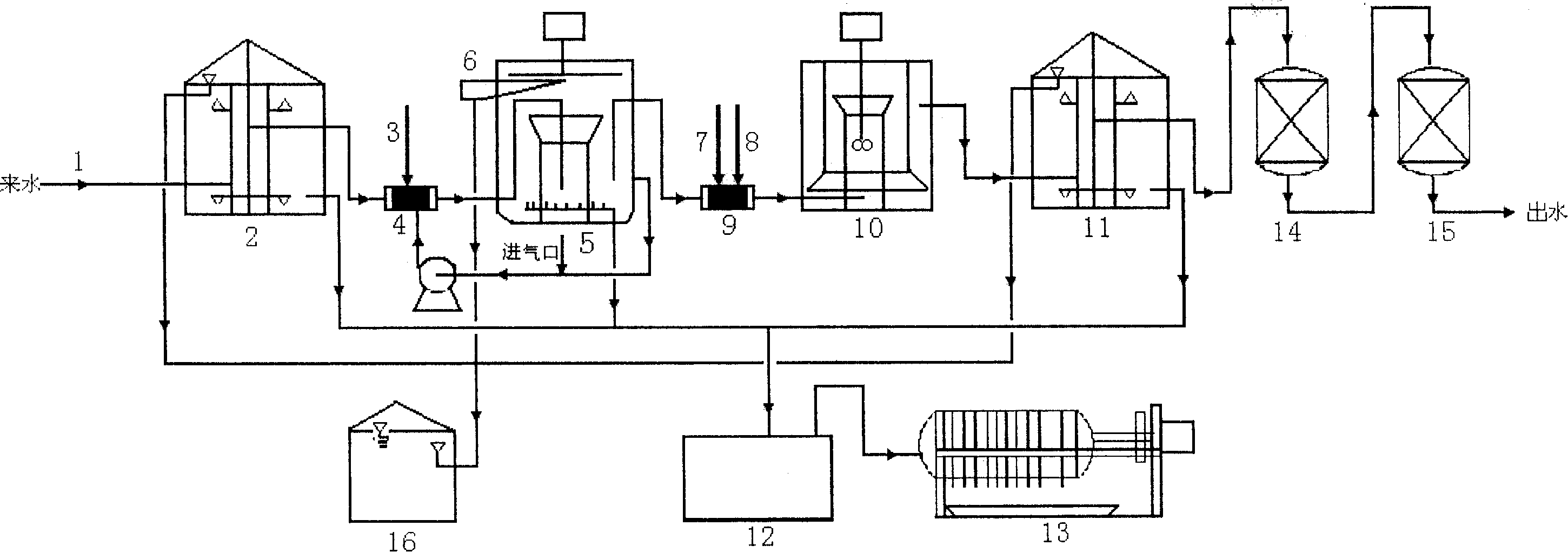

Ternary combination flooding produced liquid oil-containing sewage treatment technique

ActiveCN101125717AImprove processing efficiencyReduce processing costsFatty/oily/floating substances removal devicesMultistage water/sewage treatmentFiltrationPolymer

The invention discloses a treatment technique for oil sewage in produced liquid in 3-dimension complex drive in oil fields. The produced liquid in 3-dimension complex drive in oil fields contains a mass of polymers, alkali and surfactant, thus water-in-oil emulsion formed in the sewage is quite stable and treatment of the oil and suspended substances is quite difficult. The technique uses methods of natural sedimentation, oil removal by floatation, coagulation sedimentation and mechanical filtration by adding oil removal agent, flocculant and coagulant aid to treat the oil sewage in the produced liquid in 3-dimension complex drive, so as to realize that oil content in the water after the treatment of the sewage is less than 20 mg / L and the content of the suspended substances is less than 20 mg / L to meet the standards of injection water of the 3-dimension complex drive in the oil fields. The technique solves the problems of the oil sewage treatment in the produced liquid in 3-dimension complex drive in the oil fields and has effective economic and social benefits for saving water resource, reducing tertiary recovery cost and protecting the environment.

Owner:PETROCHINA CO LTD

Process method for rapidly fermenting chopped hot peppers

InactiveCN101982104AShort fermentation timeReduce churnClimate change adaptationFood preparationAllium sativumWater content

The invention mainly relates to a process method for rapidly fermenting chopped hot peppers, and mainly relates to the field of food processing application. The process method comprises the following steps: washing, soaking and disinfecting the fresh hoppers; draining and removing the water content on the surface of the fresh hoppers; directly chopping by a chopper mixer; adding 2% of salt, 0.5% of calcium chloride, 0.05% of citric acid; inoculating 0.05% of lactobacillus plantarum, and 0.05% of lactobacillus fermentium cultured in high density, wherein, the number of the lactic acid bacteria is 1010cfu / g and the amount of the ester-producing yeast is over 107cfu / m; fermenting for 48h in a sealing mode at the temperature of 37 DEG C; filtering, wherein, the filter pulp can be used as the strain water of the next batch; adjusting the salt concentration of the filtered and fermented hot peppers according to the different tastes to 8%; adding spices, such as white wine, Liuyang brown bean and garlic and the like; encapsulating after evenly stirring; and pasteurizing to obtain the finished product.

Owner:HUNAN AGRICULTURAL UNIV

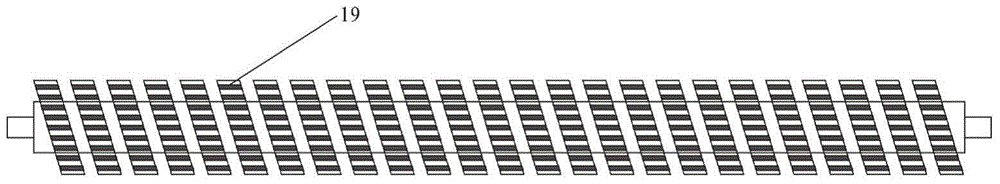

Self-navigation full-automatic cleaning device for photovoltaic cell panel

InactiveCN103599907AReduce labor intensityImprove work efficiencyCleaning using toolsCleaning using liquidsFixed bearingCells panel

The invention discloses a self-navigation full-automatic cleaning device for a photovoltaic cell panel. The device has the full-automatic functions of automatically navigating travelling, automatically regulating a cleaning state, automatically selecting a cleaning mode and automatically charging an accumulator. The load-bearing trolley of the device realizes the automatic travelling function of a fixed route by utilizing a self-navigation sensing system and detecting characteristic markers previously placed on site; the lifting platform, telescopic link, brush roller bracket and fixed bearing of the device can completely substitute for the design of a mechanical arm to realize the automatic real-time control of the angle height of the brush roller bracket and realize the function of automatically regulating the cleaning state according to pressure sensing data; a photoelectric sensing system can feed back the dust dirty degree of the surface of the photovoltaic cell panel in real time so as to regulate the travelling speed of the load-bearing trolley and the rotation speed of a brush roller and determine whether a water spray cleaning mode is adopted or not. The self-navigation full-automatic cleaning device disclosed by the invention is simple in structure, can not only save the cost, but also increase the cleaning efficiency, and is very suitable for large-area popularization and usage.

Owner:邵俊松 +1

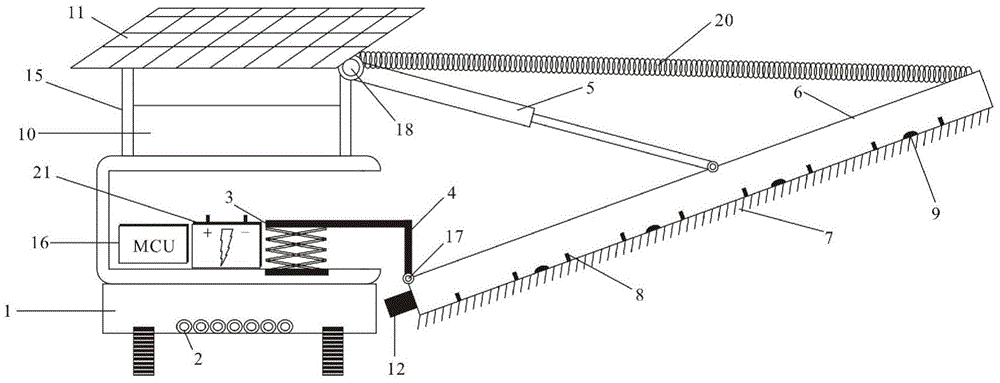

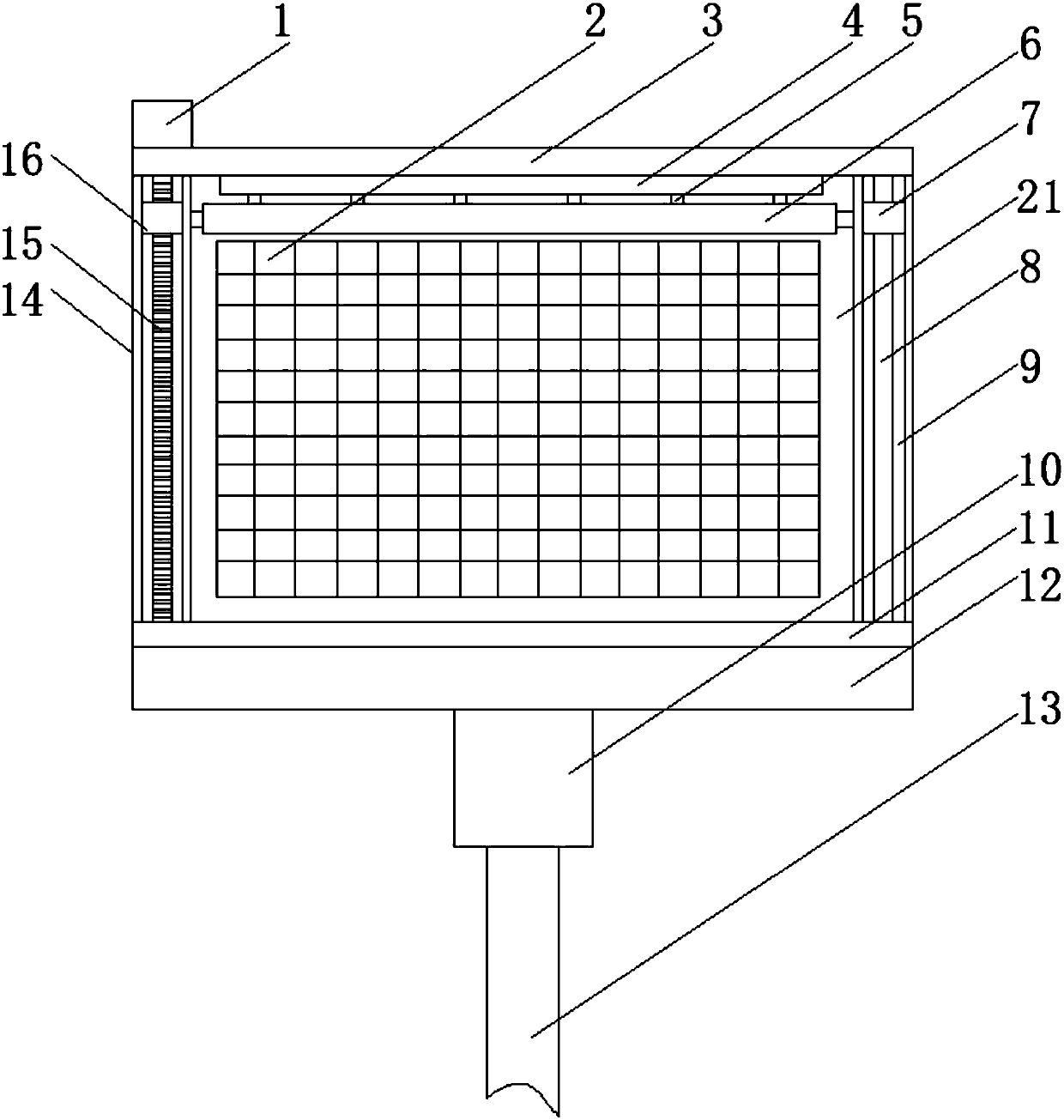

Cleaning device for solar photovoltaic panel

InactiveCN108043762ASimple structureEasy to usePhotovoltaicsCleaning using toolsMotor driveWater storage tank

The invention discloses a cleaning device for a solar photovoltaic panel. The cleaning device for the solar photovoltaic panel comprises a solar photovoltaic panel, a spraying pipe, a scrubbing plate,a water storage tank, a second sliding groove, a threaded rod, a threaded sleeve and a water pump, the cleaning device for the solar photovoltaic panel is characterized in that the bottom of a supporting rod is fixed on the ground, a bottom plate is fixedly arranged at the top of the supporting rod, the water storage tank is fixedly arranged at the bottom of the bottom plate and is close to the left side position, the water pump is fixedly arranged at the top of the bottom plate, and a fixing plate is obliquely arranged at the top of the bottom plate through a fixing rod; and the left side ofthe fixing plate is fixedly provided with the second sliding groove, the right side of the fixing plate is fixedly provided with a first sliding groove, a rectangular sliding cavity is formed in eachof the first sliding groove and the second sliding groove, and strip-shaped grooves communicating with the sliding cavities are formed in the opposite surfaces of the first sliding groove and the second sliding groove. According to the cleaning device for the solar photovoltaic panel, the structure is simple, the use is convenient, a motor drives the scrubbing plate, and so that the solar photovoltaic panel can be cleaned; and meanwhile, water can be collected, so that the cleaning efficiency is high, and water resources are saved.

Owner:ZHONGHUI ELECTROMECHANICAL TECH

High density aquatic plant ditch sewage treatment system

InactiveCN1533990ASimple processAchieve reuseSustainable biological treatmentBiological water/sewage treatmentNatural ecosystemHazardous substance

A system and method for treating sewage features that a high-density hydrophyte ditch is used to simulate a natural ecological system, which can absorb the nutrients from sewage, adsorb heavy metals and toxic and hamful substance, and remove nitrogen from sewage. Its advantages are high effect and low cost.

Owner:邱江平

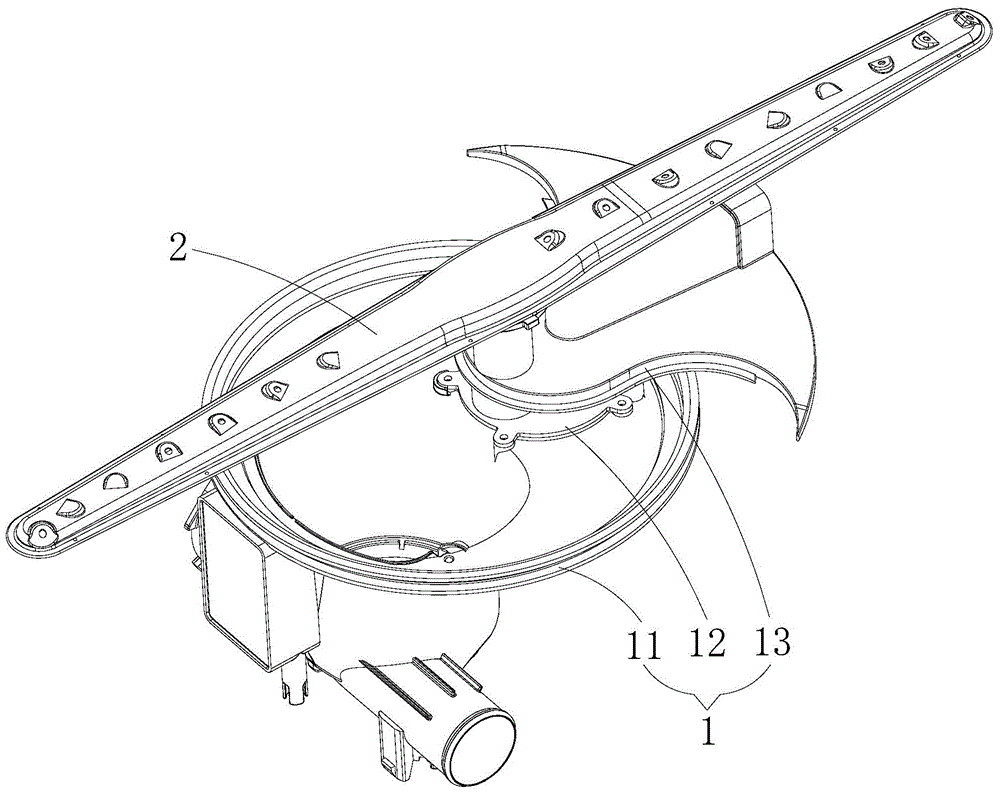

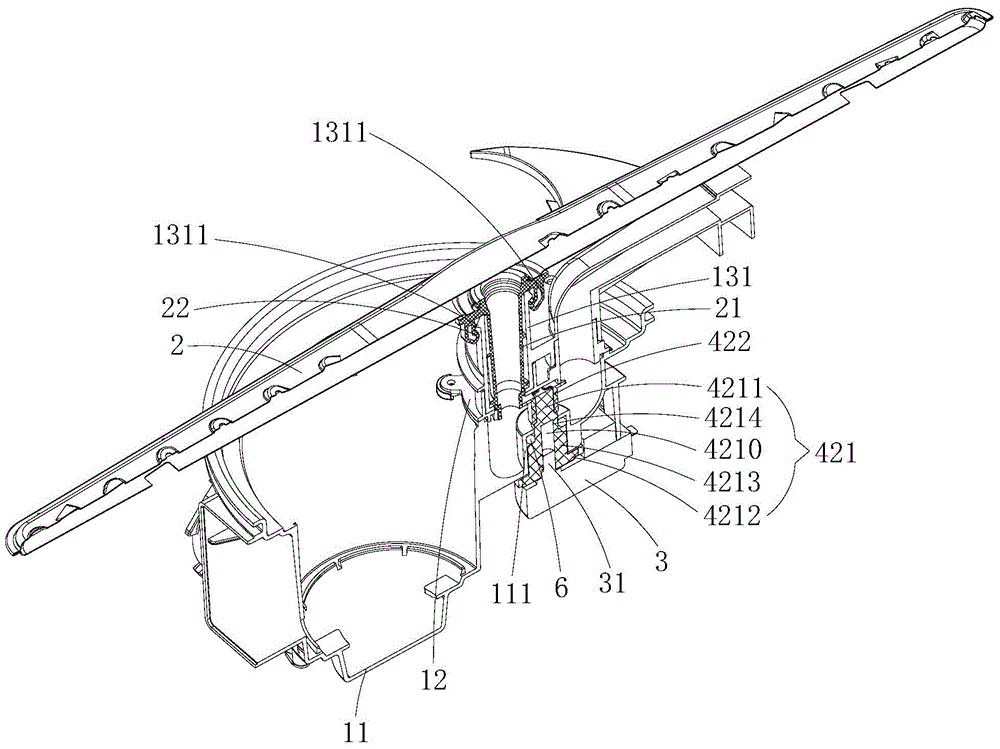

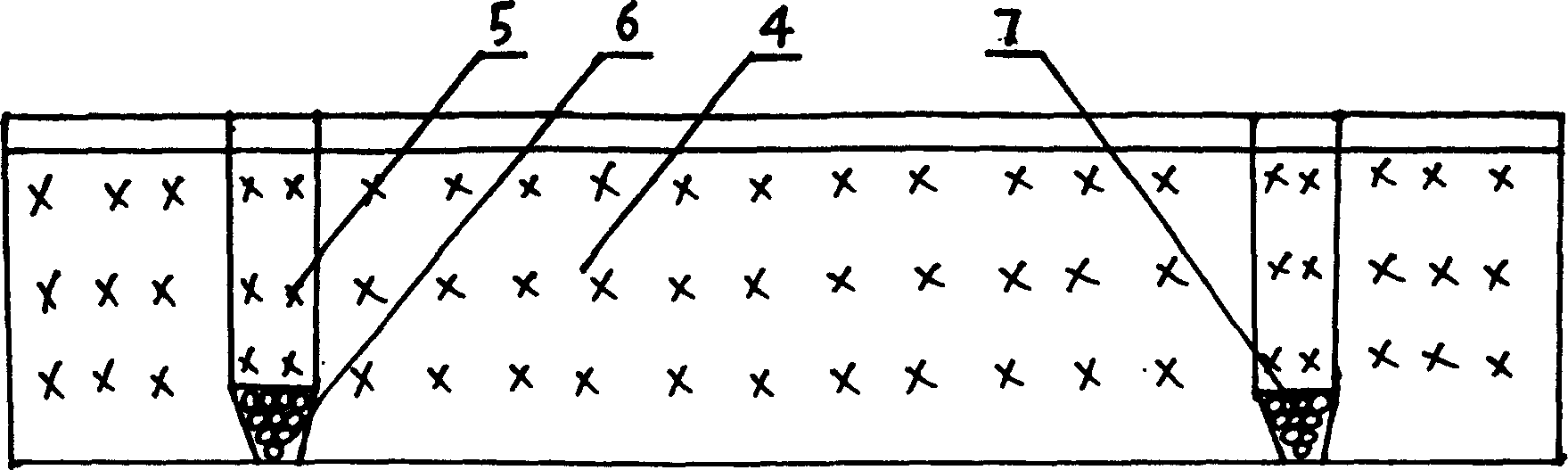

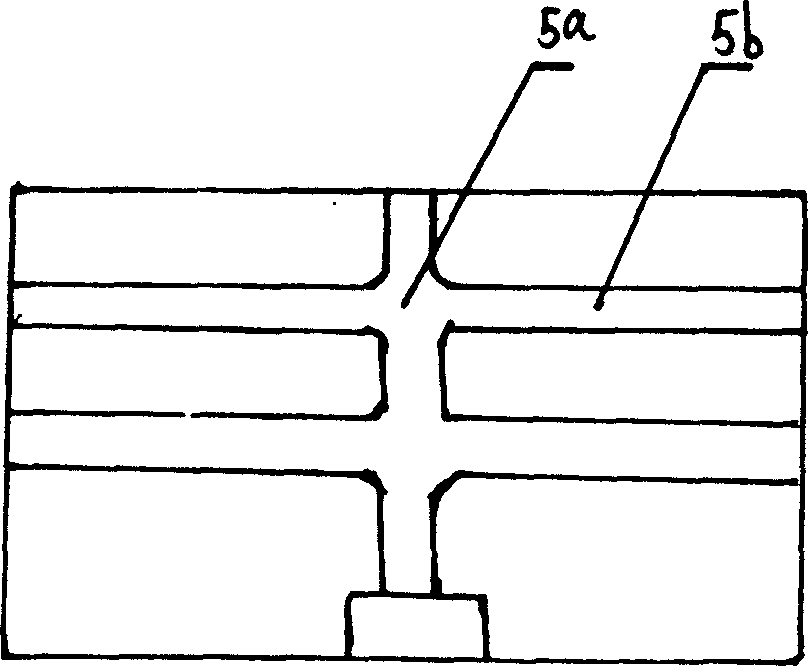

Spraying arm device and dish washing machine

ActiveCN104523208AGuaranteed stabilityImprove controllabilityTableware washing/rinsing machine detailsWater resourcesEngineering

The invention is applicable to the field of dish washing machines and discloses a spraying arm device and a dish washing machine. The spraying arm device comprises a spraying arm base assembly, a motor, a transmission structure and a spraying arm installed on the spraying arm base assembly, wherein a water cavity is formed in the spraying arm base assembly, a first connection pipe is arranged on the spraying arm in a protruding mode, penetrates through the spraying arm assembly and is communicated with the water cavity, the motor is installed on the spraying arm base assembly, and the transmission structure is connected between the first connection pipe and the motor in a transmission mode. Due to the fact that the motor and the transmission structure are matched to drive the spraying arm to rotate, the controllability of the rotational movement of the spraying arm is achieved, the spraying arm can stop at a certain position to perform reinforced washing by controlling starting and stop of the motor in the washing process, tableware which is high in fouling degree and difficult to clean can be subjected to independent prolonged washing, the washing efficiency and the washing effect of the tableware are improved, and electric energy and water resources can be saved easily; meanwhile, due to the fact that driving of the motor is stable, stability of rotation of the spraying arm is guaranteed.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

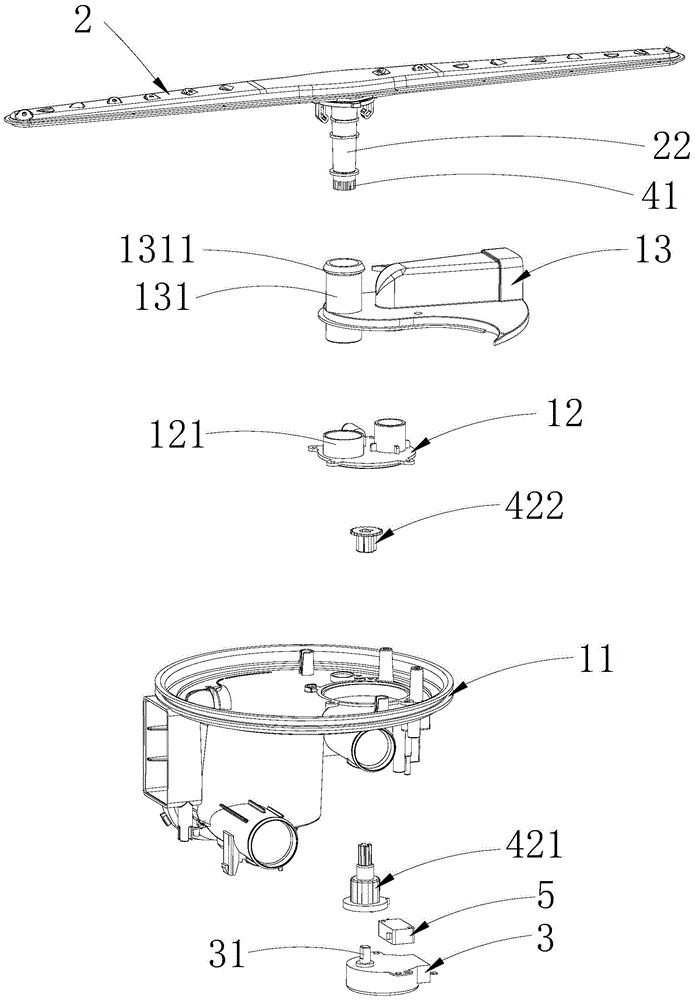

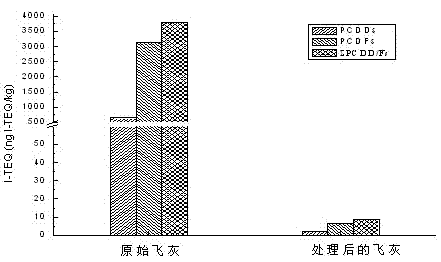

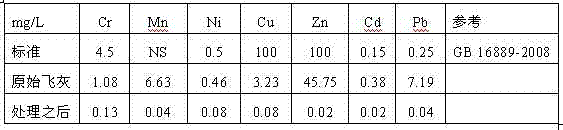

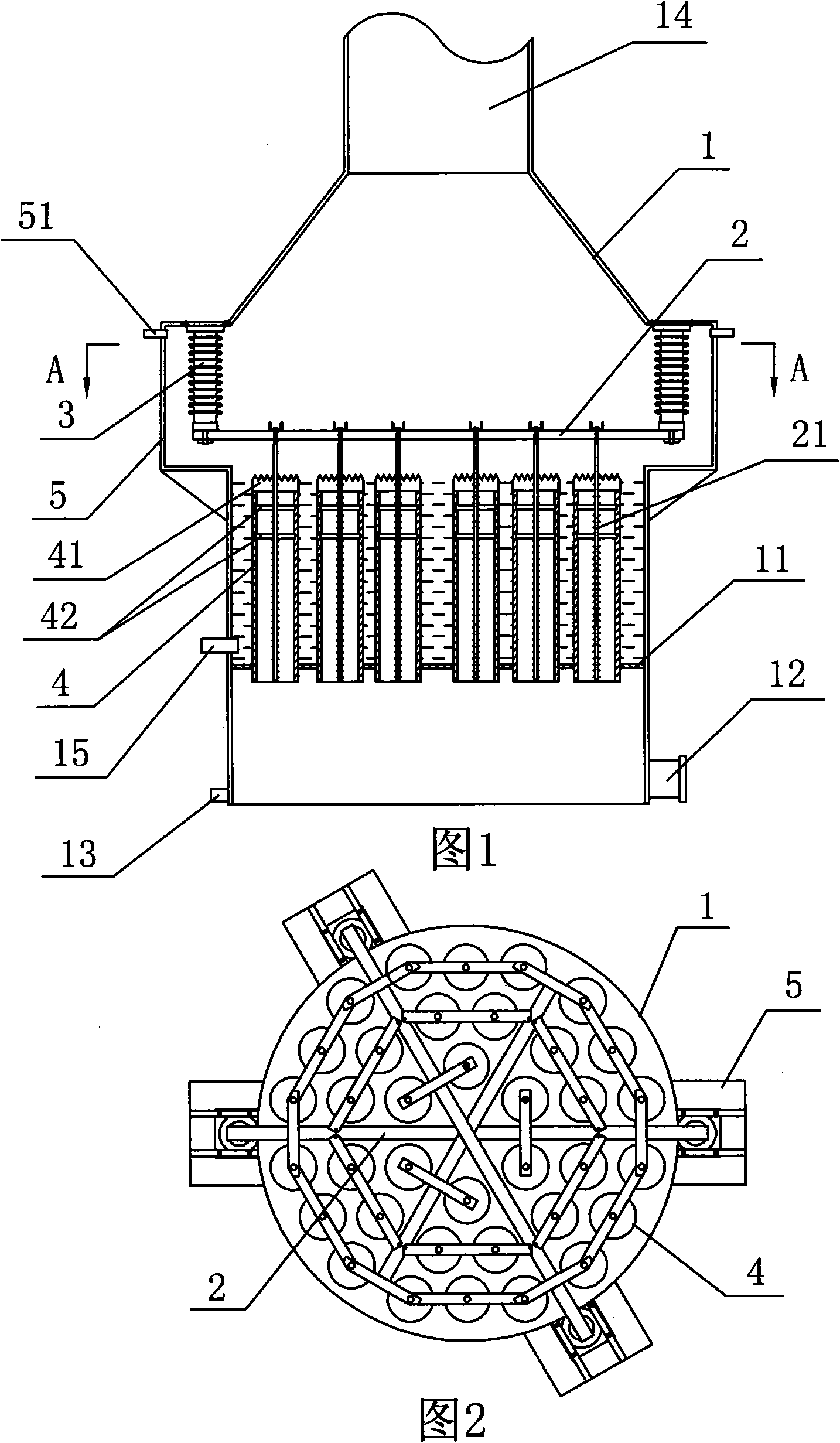

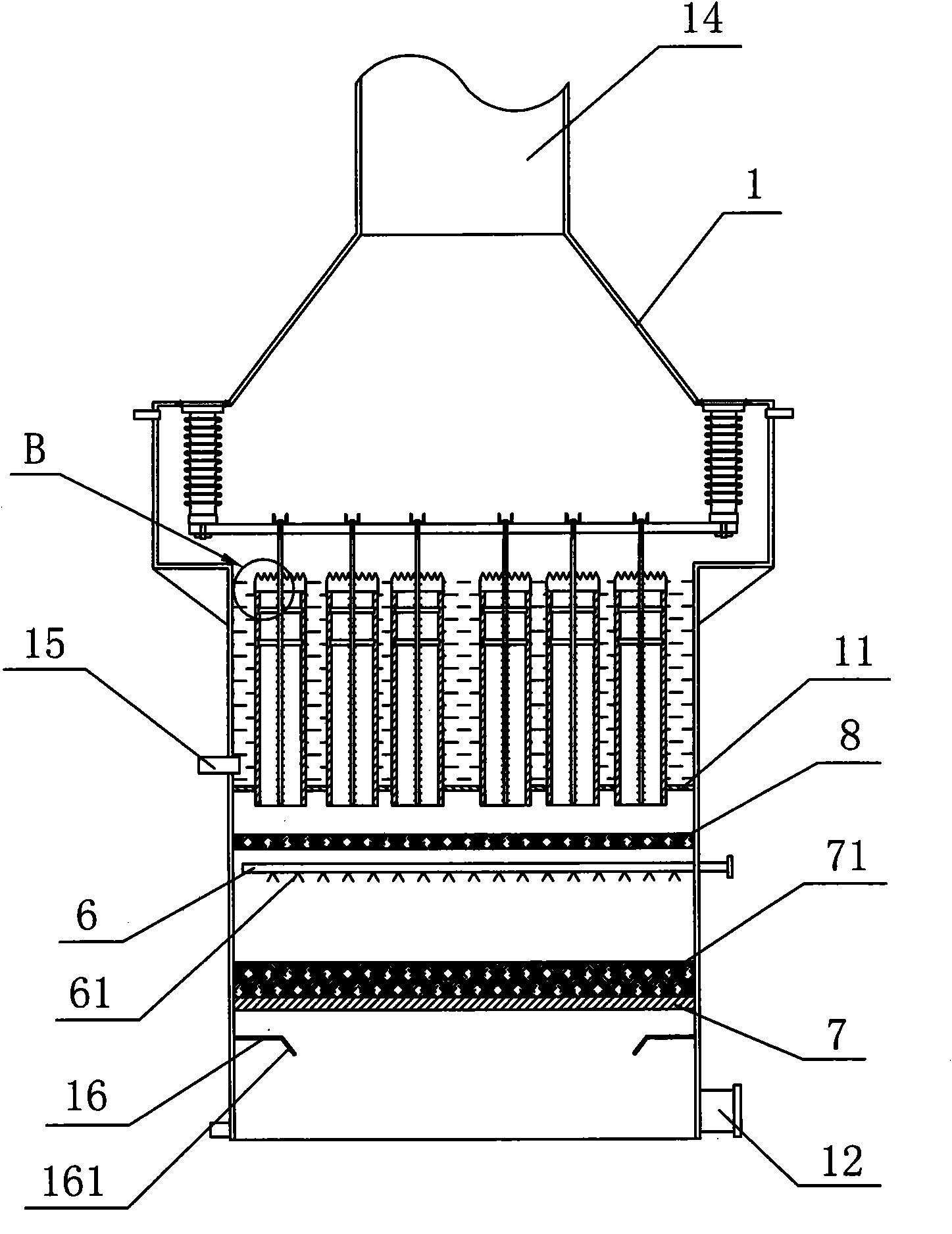

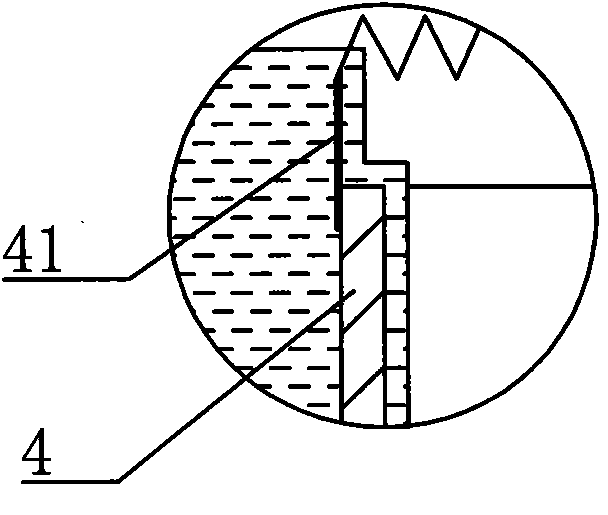

Harmless treatment method for urban garbage incineration fly ash

The invention discloses a harmless treatment method for urban garbage incineration fly ash. Due to the adoption of a treatment system and a method disclosed by the invention, heavy metals in incineration fly ash can be effectively stabilized and dioxin can be degraded; the leaching toxicity of heavy metals is fully accordant with the national standard; the toxicity of dioxin is removed by 99.9 percent; and meanwhile, the chloride ions in fly ash can be effectively removed, salt substances are recovered, and zero discharge of waste liquids is ensured. A process and the method have the remarkable characteristics of energy saving, environmental friendliness, remarkable economic benefit and remarkable social benefit; and meanwhile, the treated fly ash has novel physicochemical properties, canbe applied to the industries of environmental protection, construction and the like, and has application and popularization values.

Owner:ZHEJIANG UNIV

Method for dyeing and finishing pure-cotton high-count high-density fabric

ActiveCN101532230AReduce trafficEmission reductionTextile storage in superimposed formSingeingHigh densityMoisture absorption

The invention discloses a method for dyeing and finishing pure-cotton high-count high-density fabric, which includes steps of singeing, cold dome, desizing and boiling-off, bleaching, mercerization, dyeing, moisture absorption and breath, no-iron sorting, tentering, pre-shrinking and packaging. The fabric dyed and finished by the present invention has advantages of high rebound, moisture absorption and breath, crease-resistance and soft feel.

Owner:SUNTEX

Wet static dedusting device

InactiveCN101780435AAvoid failureExtended service lifeExternal electric electrostatic seperatorHazardous substanceEngineering

The invention discloses a wet static dedusting device which comprises a tower body, an electrode support and an insulated pillar, wherein the electrode support is installed in the tower body. The wet static dedusting device is characterized in that a plurality of suspended electrode rods are fixedly arranged on the electrode support; a hollow condenser tube is sleeved outside the electrode rods; a clapboard is sealed and fixedly arranged in the tower body; the condenser tube is fixedly arranged on the clapboard, with the lower end running out of the clapboard; a water inlet is arranged on the tower body; one end of the insulated pillar is fixedly connected with the electrode support, and the other end of the insulated pillar is fixedly connected with the tower body; a waste gas inlet and a dirt drain port are arranged at the lower end of the tower body; and a gas exhaust port is arranged at the upper end of the tower body. The wet static dedusting device has the advantages that a uniform water film renewed constantly is formed on the inner wall of the condenser tube and serves as a dust collecting electrode when the electrode rods discharge so that a uniform electrostatic field can be formed in the condenser tube; charges of the high voltage electrostatic electrons generated by the electrode rods adhere to the harmful particles in the exhaust gas, and under the action of the high voltage electric field, the harmful particles directionaly migrate to the wall of the condenser tube and then flow down with the water film to be drained; the ozone or plasma free radicals generated when the electrode rods discharge can oxidize and remove the fetid substances in the exhaust gas, so the exhaust gas can get deep purification treatment; and the wet static dedusting device has good dedusting and purifying effects and the whole equipment can operate safely for a long period.

Owner:NINGBO UNIV

Vat dye dyeing method using supercritical CO2 fluid

The invention is applicable to the field of dyeing technologies, and provides a vat dye dyeing method using a supercritical CO2 fluid. The vat dye before a reduction reaction is dissolved by a supercritical CO2 fluid; polyester fiber, cellulosic fiber, protein fiber and fabric thereof are dyed; meanwhile, a cosolvent is added to improve the solubility of the vat dye in the supercritical CO2 fluid, the dyeing depth and the like; moreover, a natural fiber swelling agent is added for the vat dye to enter the fiber for dyeing, thereby greatly saving the water resources and realizing a perfect dyeing effect.

Owner:CHENGDU TEXTILE COLLEGE

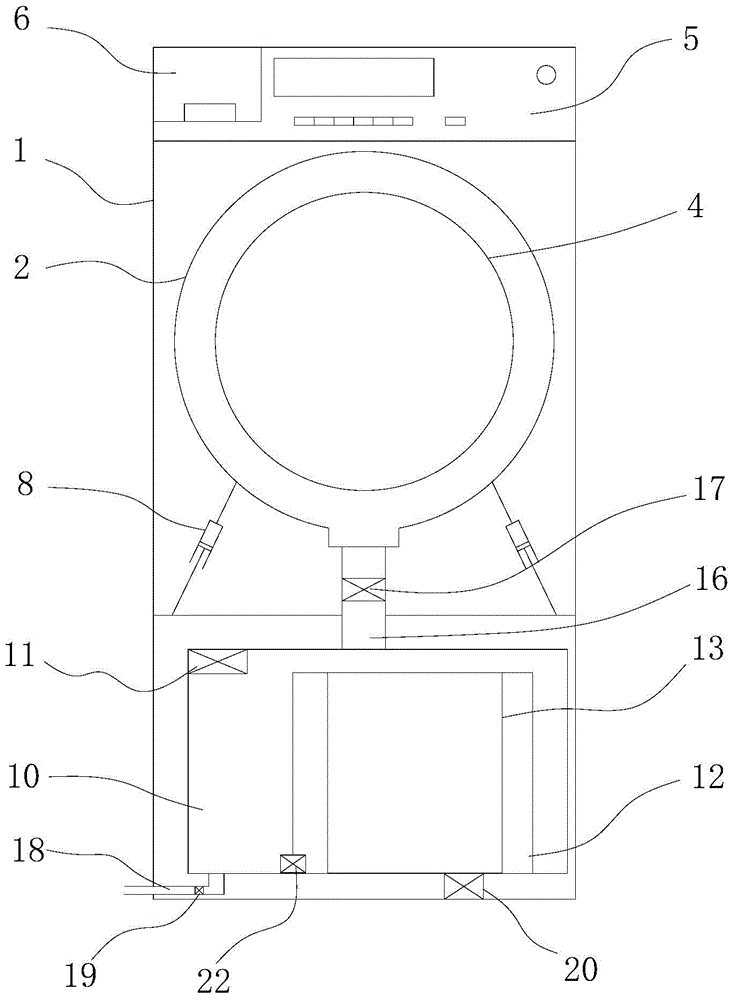

Flocculation washing machine

ActiveCN104514122ARealize self-cleaningBlow evenlyOther washing machinesTextiles and paperFlocculationFilter effect

The invention discloses a flocculation washing machine. The flocculation washing machine comprises an outer barrel, a flocculation unit and a filtering unit which are circularly communicated in a sequence through pipelines. The washing machine further comprises an air pump which is respectively communicated with the flocculation unit and the filtering unit. According to the flocculation washing machine, air generated by the air pump is conveyed into a flocculation container through the same air pump so as to generate a mass of bubbles in the water into the flocculation container, thus the water fully flow to enable fully mixing of a flocculant and washed water to achieve flocculation reaction; in addition, the air exhausted by the air pump can be conveyed into a filtering container during washing a filtering unit to generate bubbles to drive water in the filtering container to fully flow as well as generating an instantaneous impact force to act on the surface of a filtering screen, so as to separate dirt attached on the surface of the filtering screen, and as a result, the filtering effect of the filtering screen can be improved. The flocculation washing machine is high in automation degree and simple in structure and saves the production cost.

Owner:HAIER GROUP TECHN R&D CENT +1

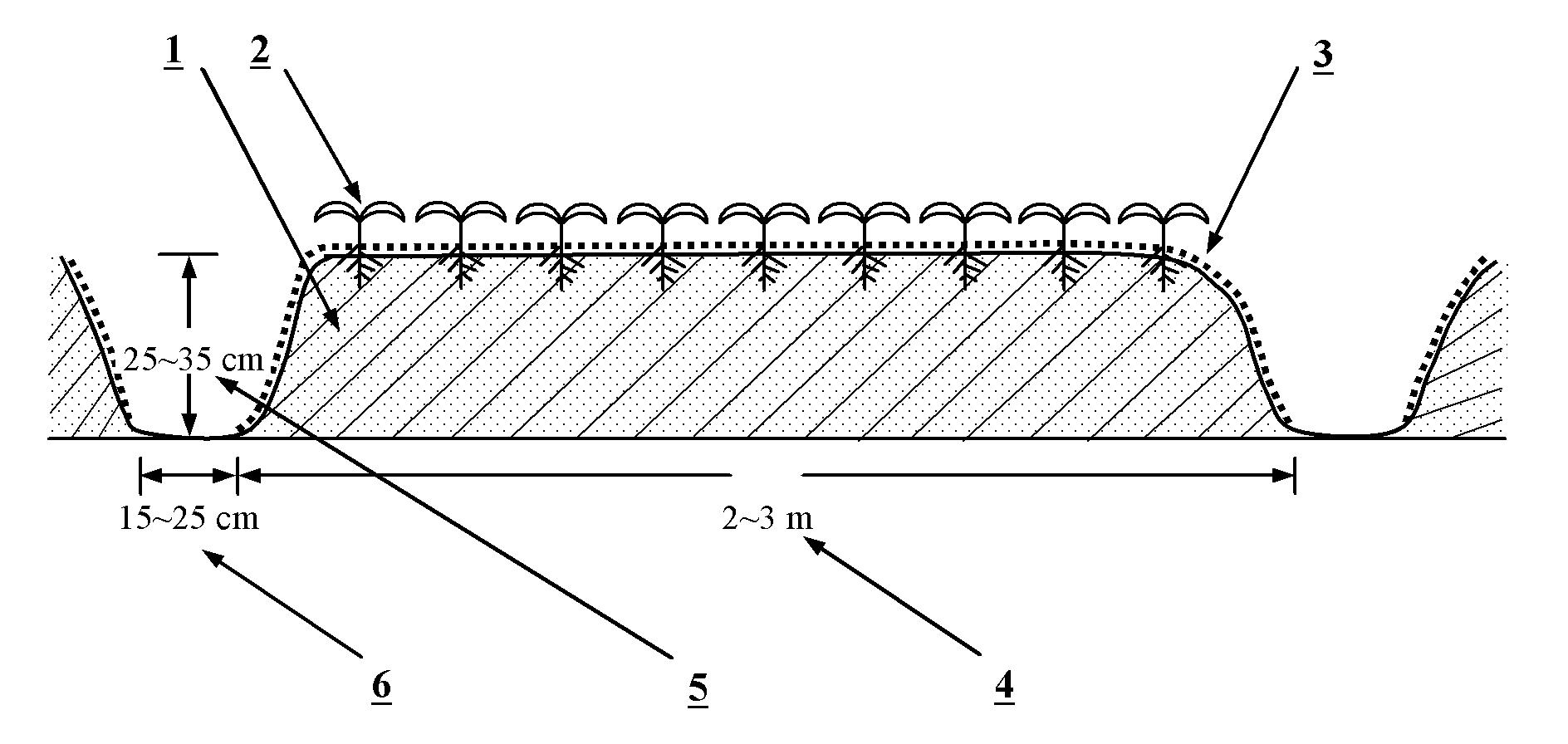

Water-saving type salina physics-chemistry-biology comprehensive improvement and vegetation construction technique

ActiveCN1765531ASave waterGuaranteed normal growthContaminated soil reclamationEuryhalinePrecipitation

The invention discloses a water-saving salt marsh physic-chemical-ecological integrated modification and vegetation construction technique. The invention firstly digs a dripping slot at the ground needed reconstructed, and lays the material which is anti-corrosion and permeable in said dripping slot and lays a certain depth of stones above this; covers the stones with the material which is anti-corrosion and permeable to construct the dripping blind slot; backfills the soil excavated from said dripping slot; fills the acid organic manure above said backfilled soil surface; processes deep tillage on the manure soil to laid acid organic manure; and constructs the salt-extract permeable channel. The invention also has an automatically precipitation system. The invention has the advantages that: it avoids dig slot, remove soil, lays dripping layer, lays blind pipe, changes planting soil, which can confirm the normal growth of nursery-grown plant and avoid the destroy on the infield.

Owner:TIANJIN HAILIN GARDENING ENVIRONMENTAL PROTECTIONTECH ENG

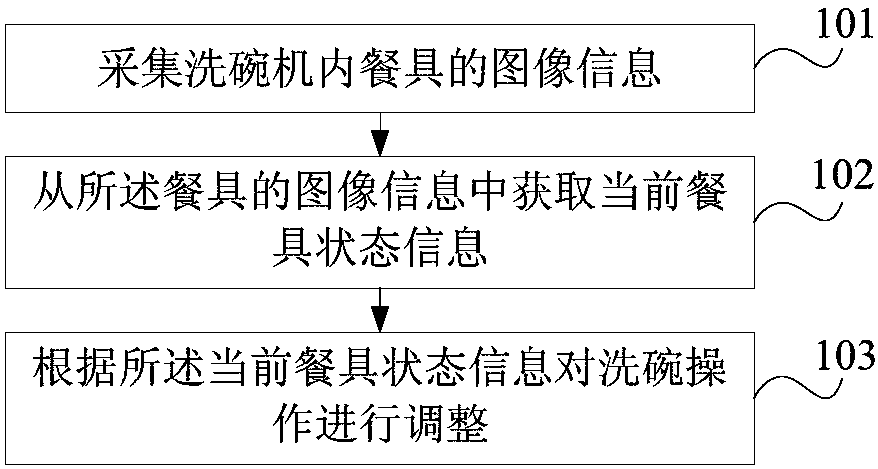

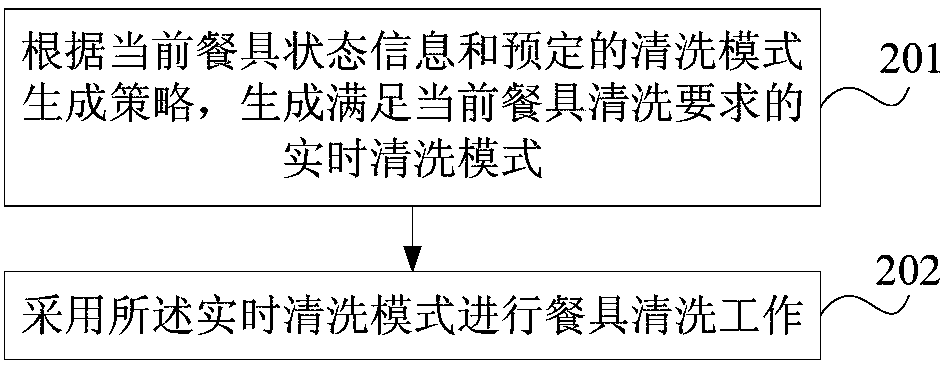

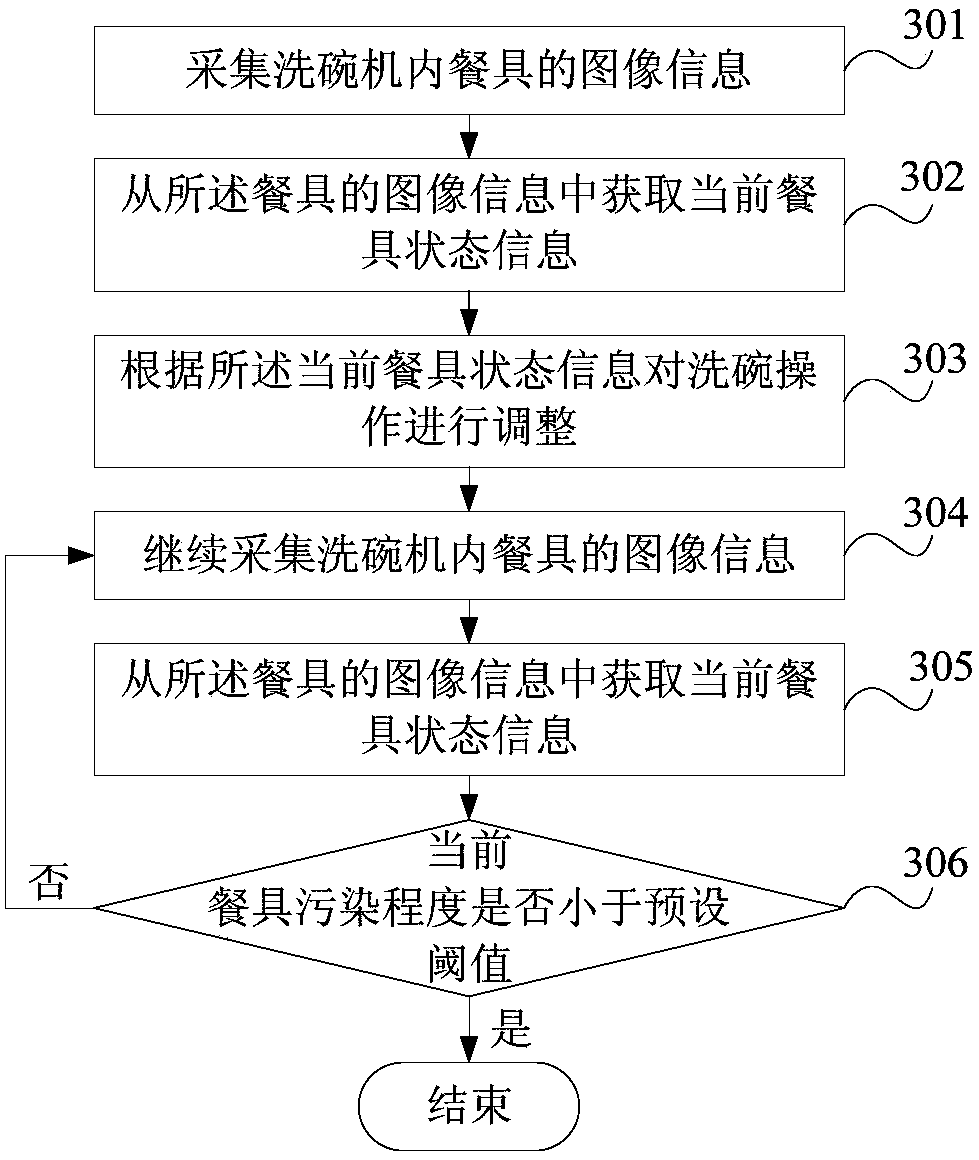

Dish-washing machine control method and device, dish-washing machine and computer readable storage medium

InactiveCN108577730ASolve the cleaning rateSolve efficiency problemsWashing controlling processesHome appliance efficiency improvementMachine controlEnergy consumption

An embodiment of the invention discloses a dish-washing machine control method and device, a dish-washing machine and a computer readable storage medium, relates to the field of intelligent householdelectrical appliances and can solve the problems of low washing rate and working efficiency of existing dish-washing machines. The dish-washing machine control method comprises steps as follows: acquiring image information of tableware in the dish-washing machine; acquiring current tableware state information from the image information of the tableware; adjusting dish-washing operation according to the current tableware state information. The washing rate and washing efficiency of the dish-washing machine can be improved, the cleaning time is saved, energy consumption and water consumption arereduced, and the dish-washing machine control method and device are applicable to various dish-washing machines.

Owner:KINGSOFT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com