Patents

Literature

245results about How to "Guaranteed washing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

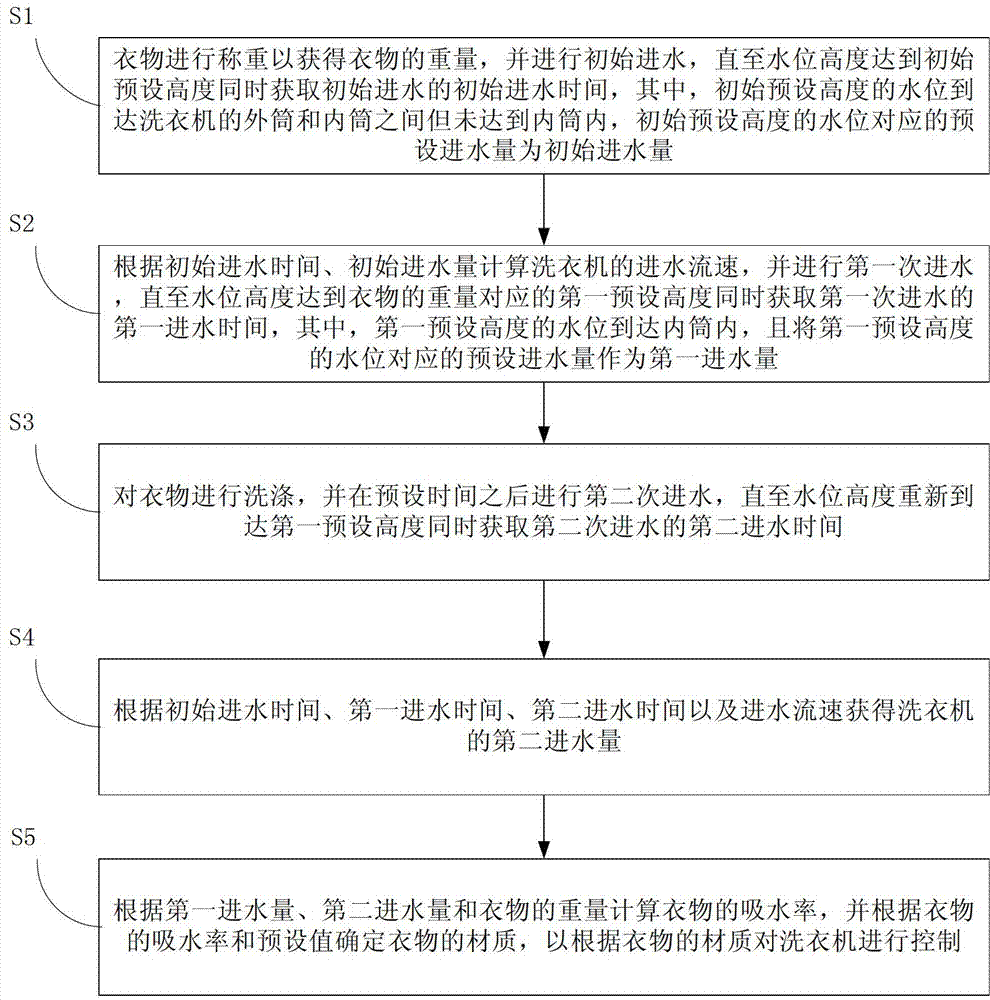

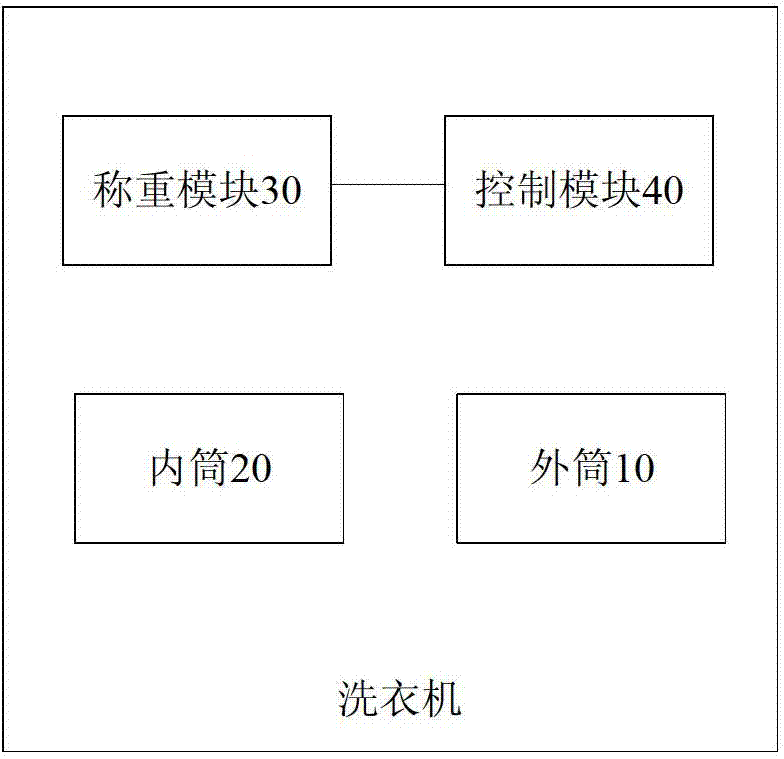

Washing machine and control method thereof

ActiveCN103485121AImprove satisfactionGuaranteed washing effectOther washing machinesControl devices for washing apparatusEngineeringWater intake

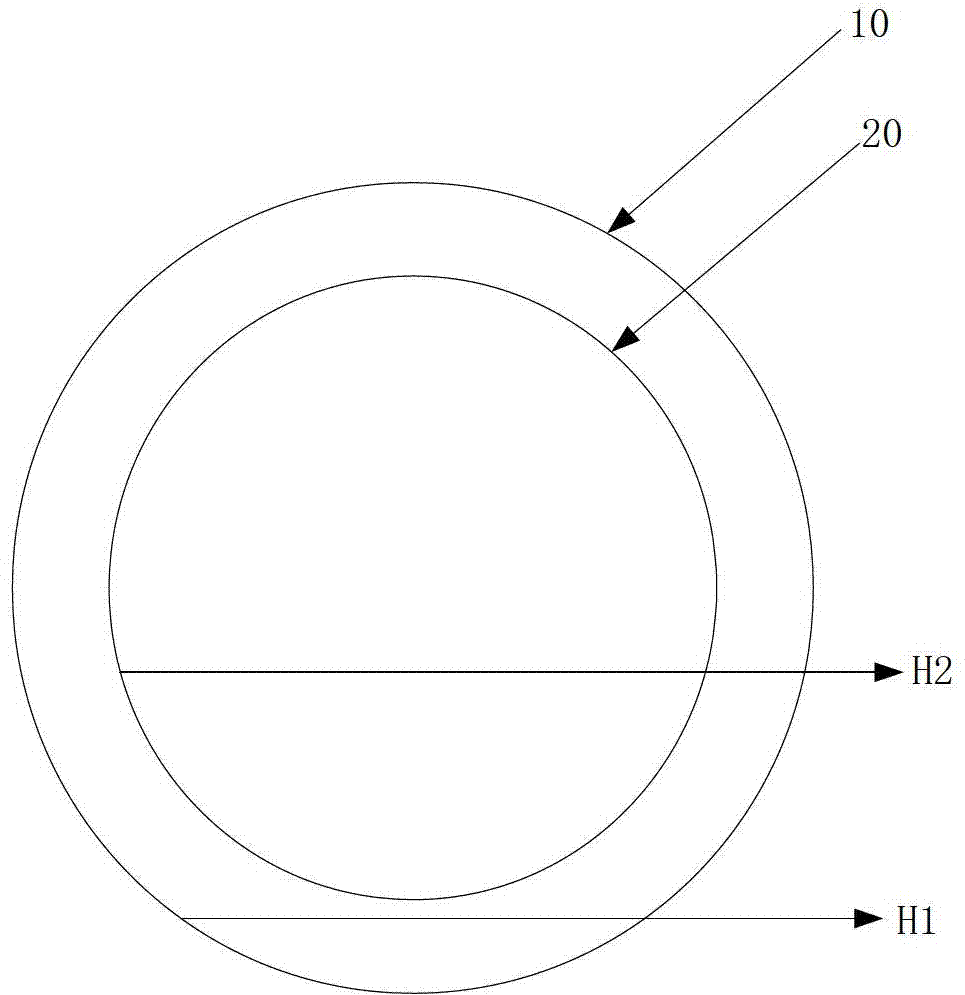

The invention discloses a washing machine and a control method thereof. The control method comprises the following steps of: weighing clothes to obtain the weight of the clothes, carrying out initial water filling until the height of water reaches an initial preset height, and acquiring initial water filling time, wherein a water intake quantity corresponding to the initial preset height represents an initial water intake quantity; calculating a water intake flow rate, carrying out primary water filling until the height of the water reaches a first preset height, and acquiring first water filling time, wherein a water intake quantity corresponding to the first preset height represents a first water intake quantity; after washing the clothes for preset time, carrying out secondary water filling until the height of the water reaches a second preset height, and acquiring second water filling time; according to the initial water filling time, the first water filling time, the second water filling time and the water intake flow rate, acquiring a second water intake quantity; and according to the first water intake quantity, the second water intake quantity and the weight of the clothes, calculating water absorption of the clothes, and determining the material of the clothes according to the water absorption of the clothes and a preset value so as to control the washing machine according to the material of the clothes. According to the invention, the material of the clothes can be identified so as to implement reasonable control on the washing machine and improve use experience of a user.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

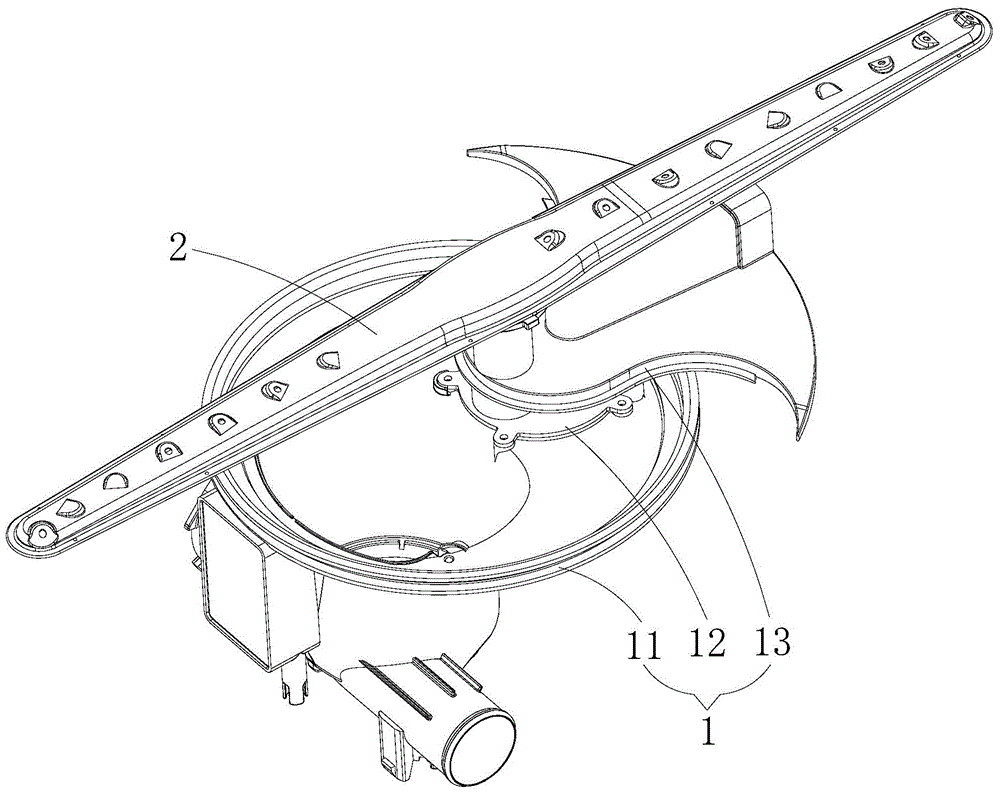

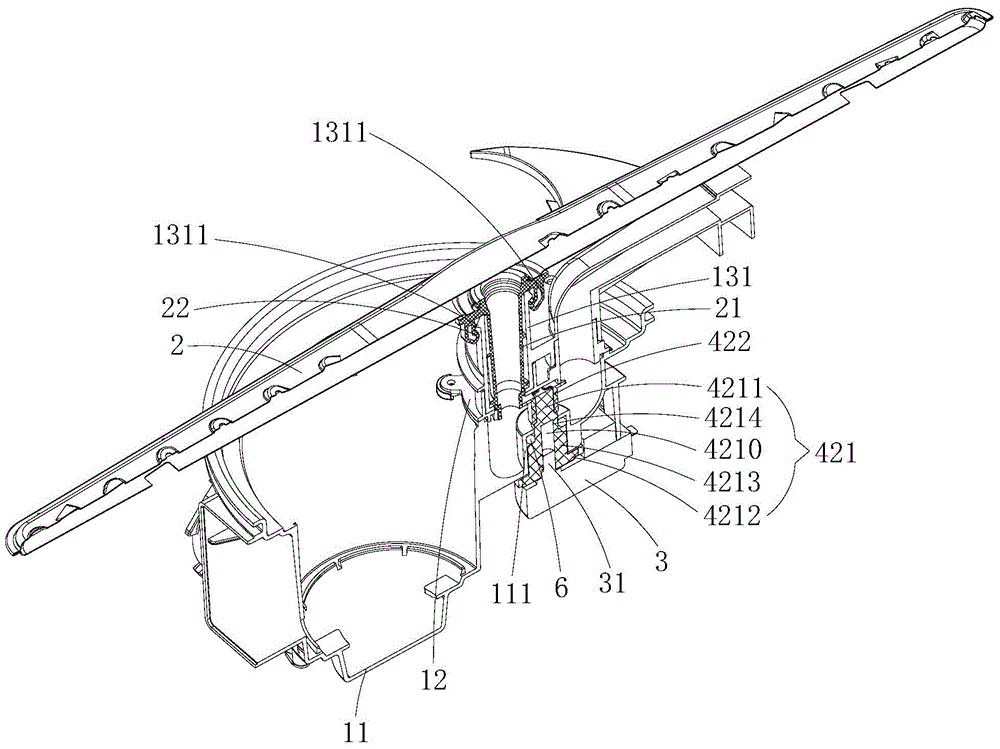

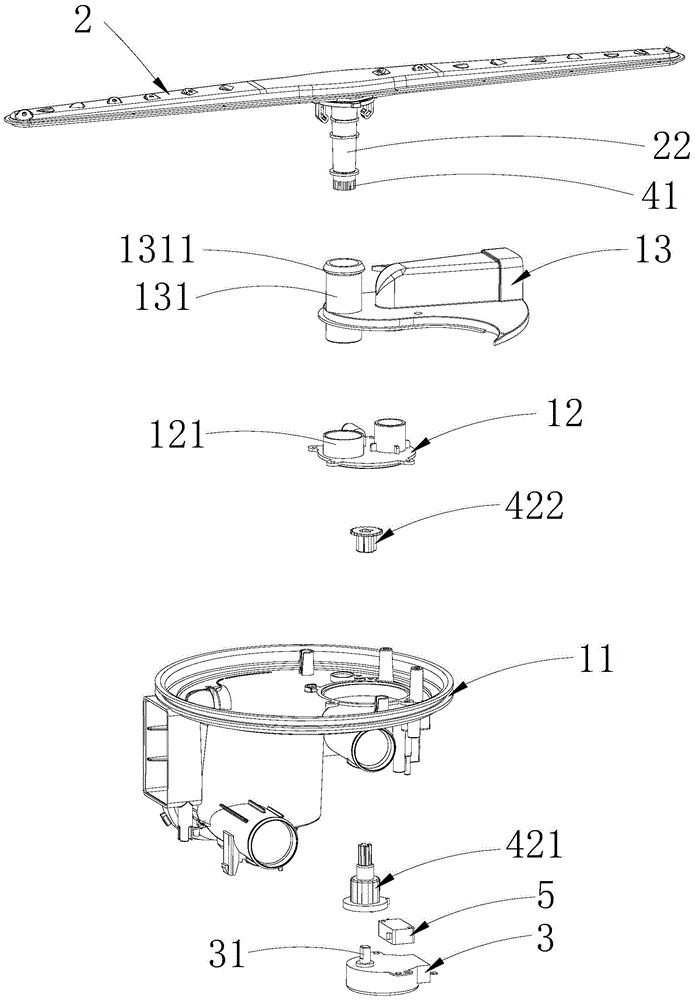

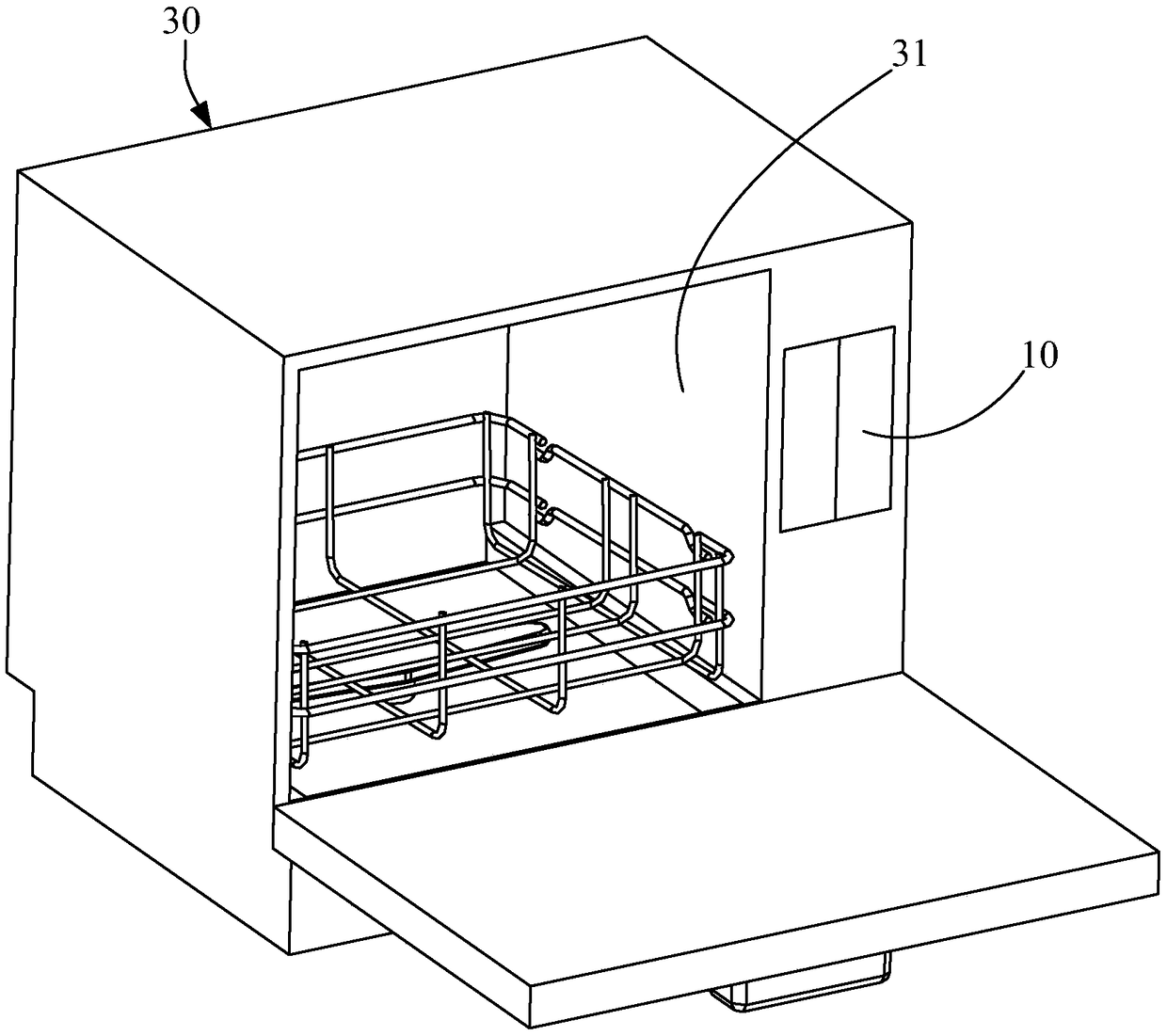

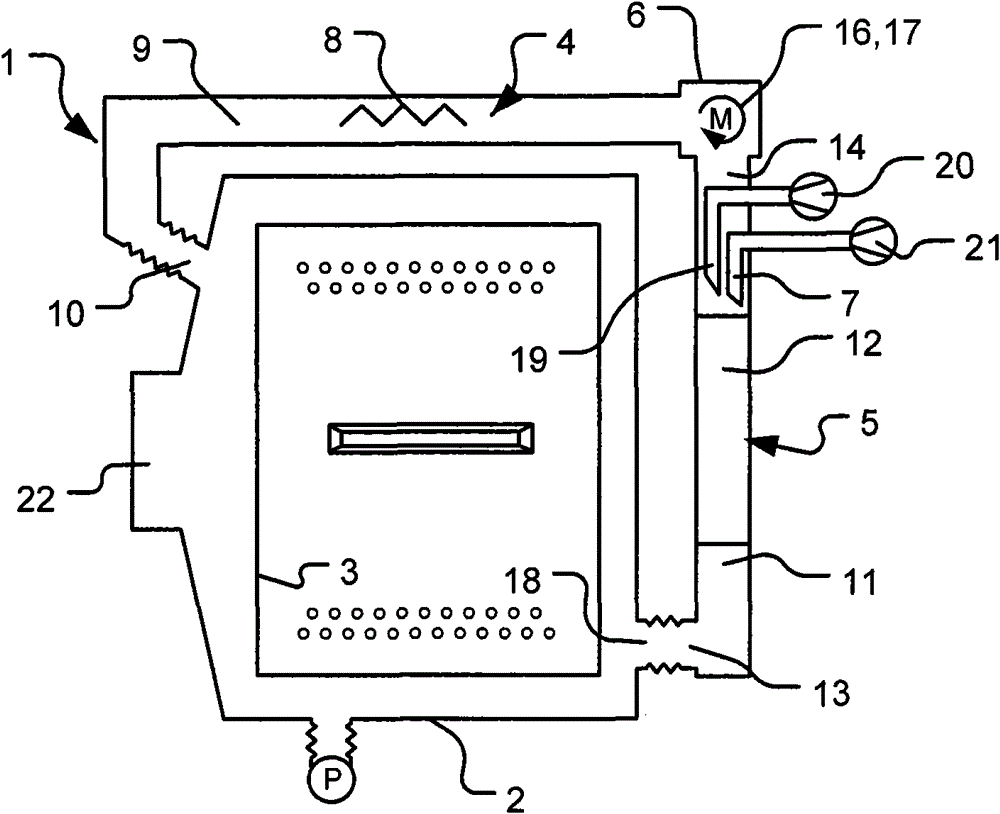

Spraying arm device and dish washing machine

ActiveCN104523208AGuaranteed stabilityImprove controllabilityTableware washing/rinsing machine detailsWater resourcesEngineering

The invention is applicable to the field of dish washing machines and discloses a spraying arm device and a dish washing machine. The spraying arm device comprises a spraying arm base assembly, a motor, a transmission structure and a spraying arm installed on the spraying arm base assembly, wherein a water cavity is formed in the spraying arm base assembly, a first connection pipe is arranged on the spraying arm in a protruding mode, penetrates through the spraying arm assembly and is communicated with the water cavity, the motor is installed on the spraying arm base assembly, and the transmission structure is connected between the first connection pipe and the motor in a transmission mode. Due to the fact that the motor and the transmission structure are matched to drive the spraying arm to rotate, the controllability of the rotational movement of the spraying arm is achieved, the spraying arm can stop at a certain position to perform reinforced washing by controlling starting and stop of the motor in the washing process, tableware which is high in fouling degree and difficult to clean can be subjected to independent prolonged washing, the washing efficiency and the washing effect of the tableware are improved, and electric energy and water resources can be saved easily; meanwhile, due to the fact that driving of the motor is stable, stability of rotation of the spraying arm is guaranteed.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

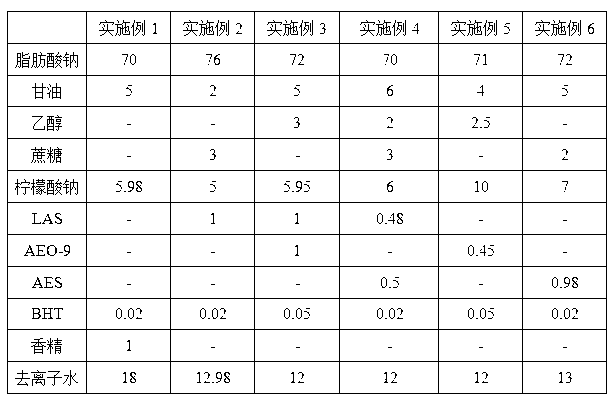

Transparent soap

InactiveCN103013715AHigh transparencyHigh hardnessSoap detergents with organic compounding agentsAlkali/ammonium soap compositionsActive agentFatty acid

The invention discloses a transparent soap, which is mainly prepared by fatty acid, a transparent reagent, sodium citrate, a surfactant and deionized water, wherein the content of sodium citrate based on weight is 0.1-15%. The transparent soap has appropriate hardness and transparency; and the washing capability is not influenced by calcium ions and magnesium ions when in use.

Owner:GUANGDONG PENGJIN INDUSTRY CO LTD

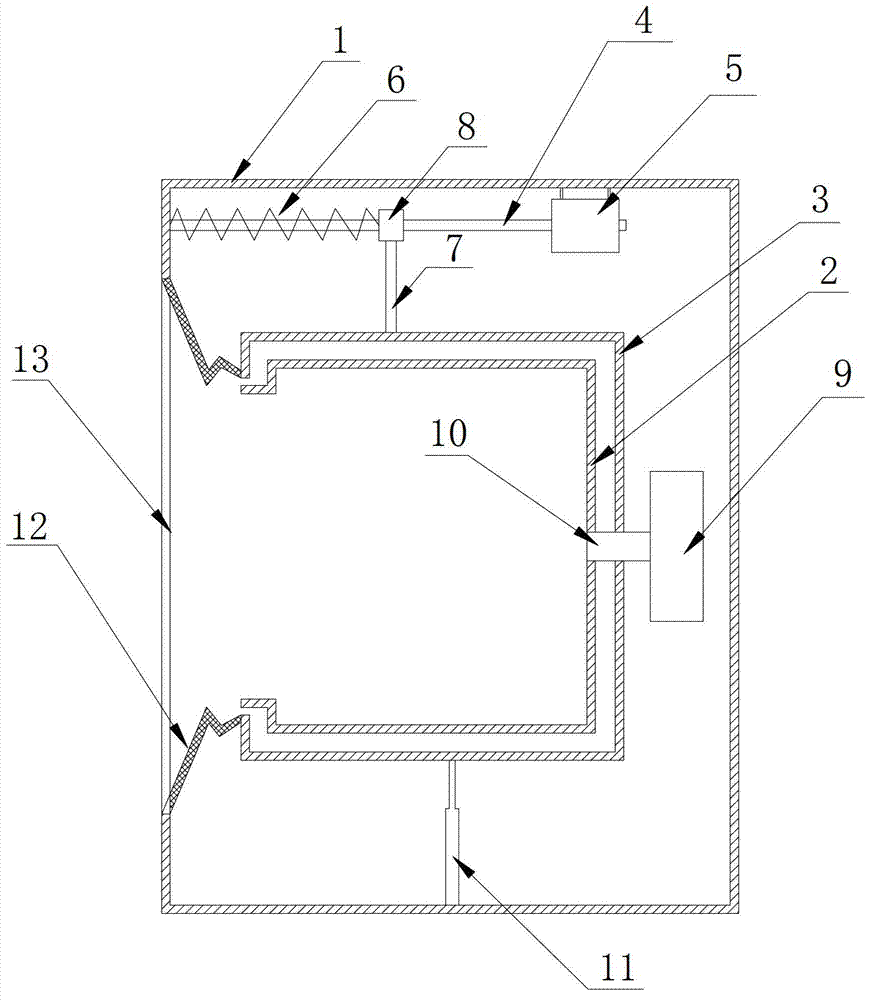

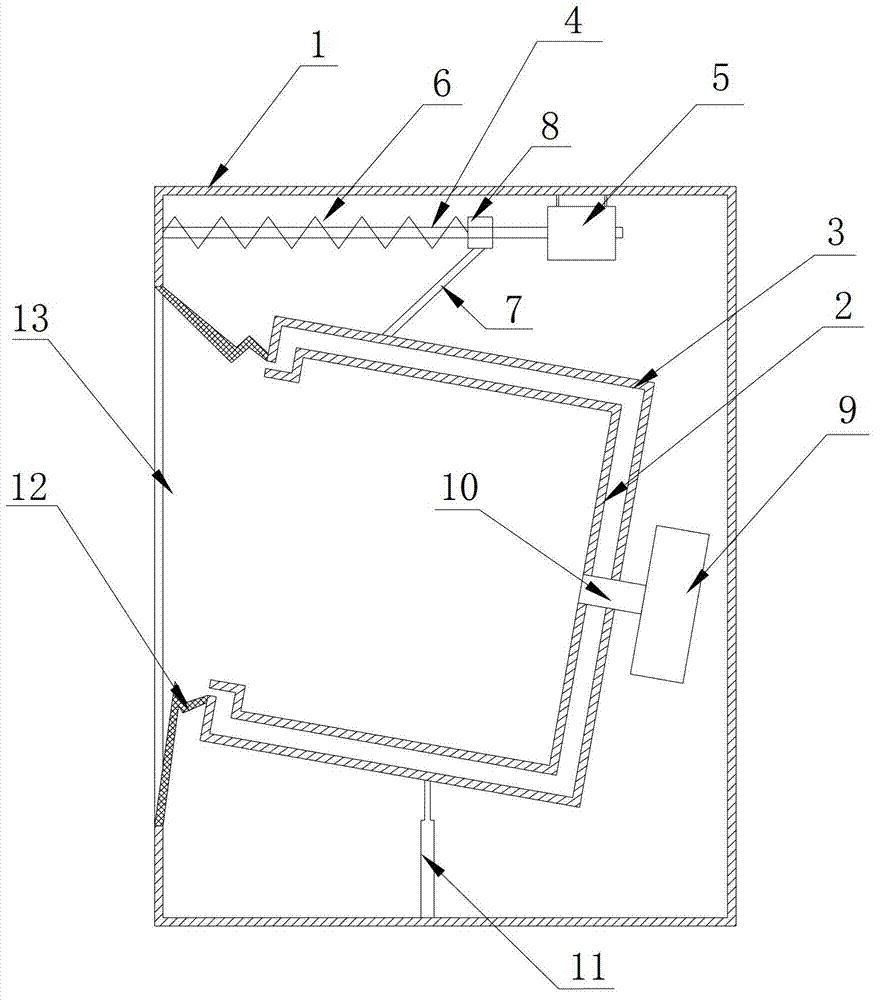

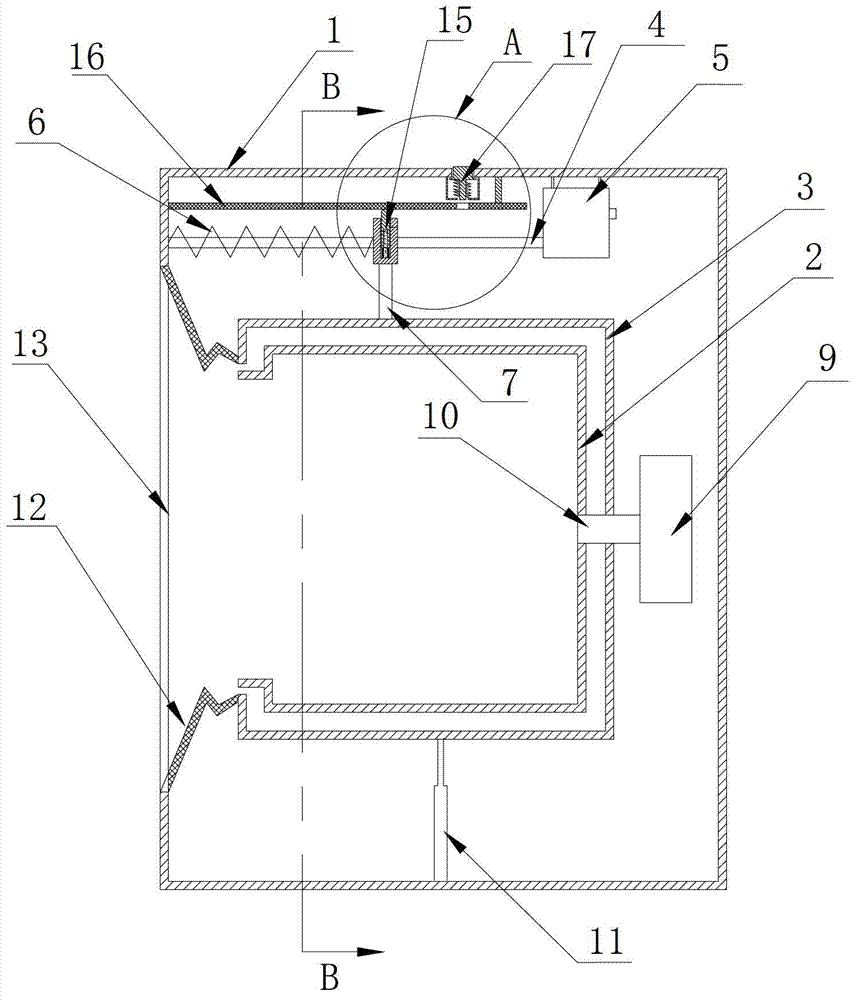

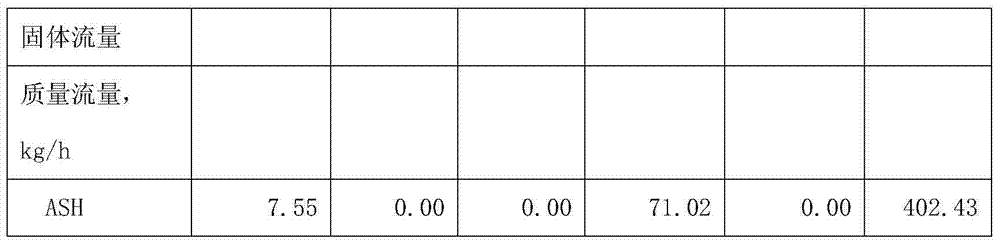

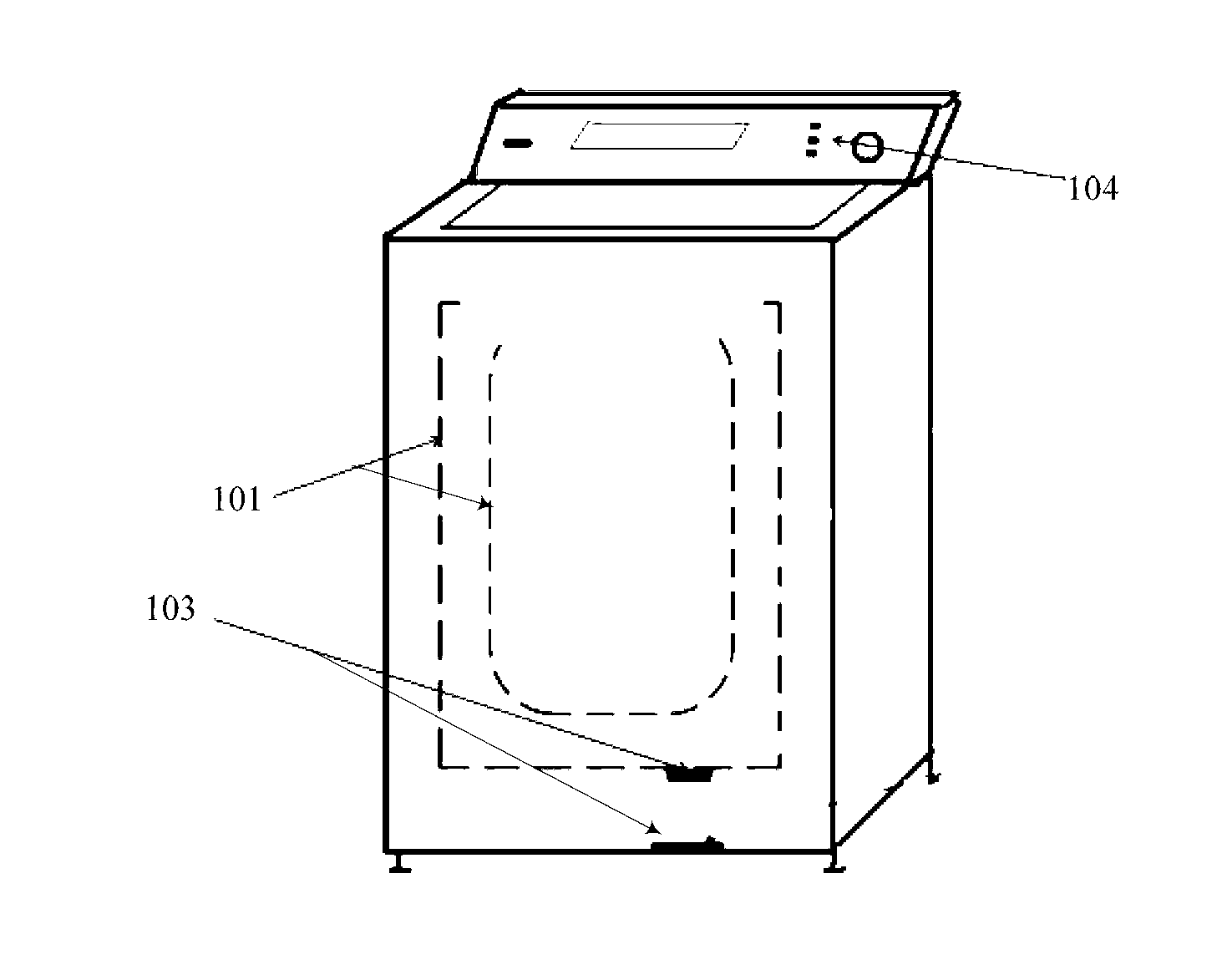

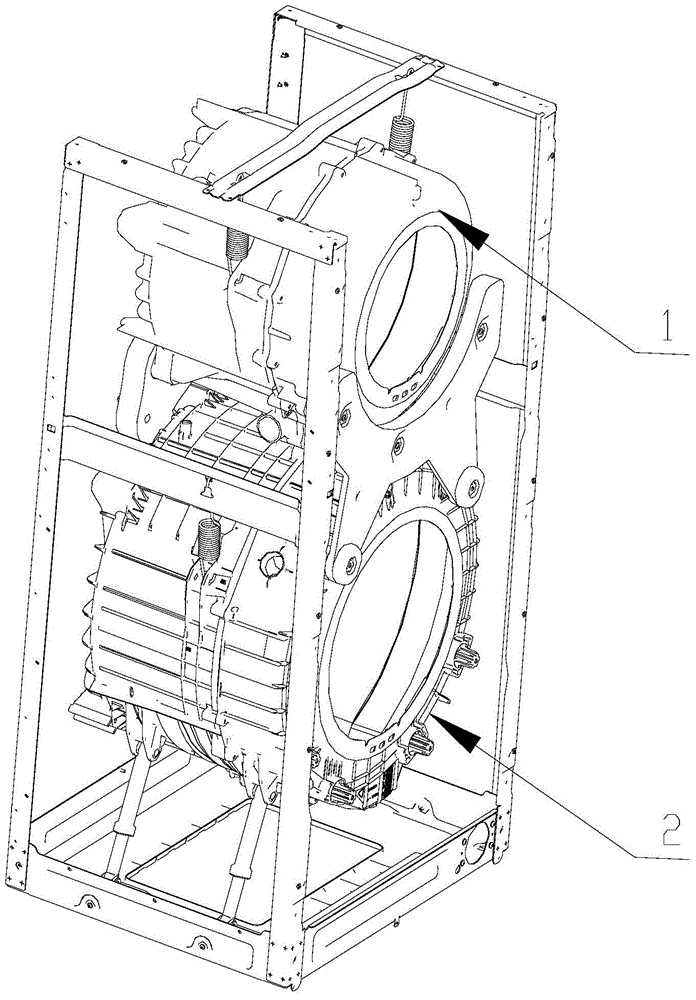

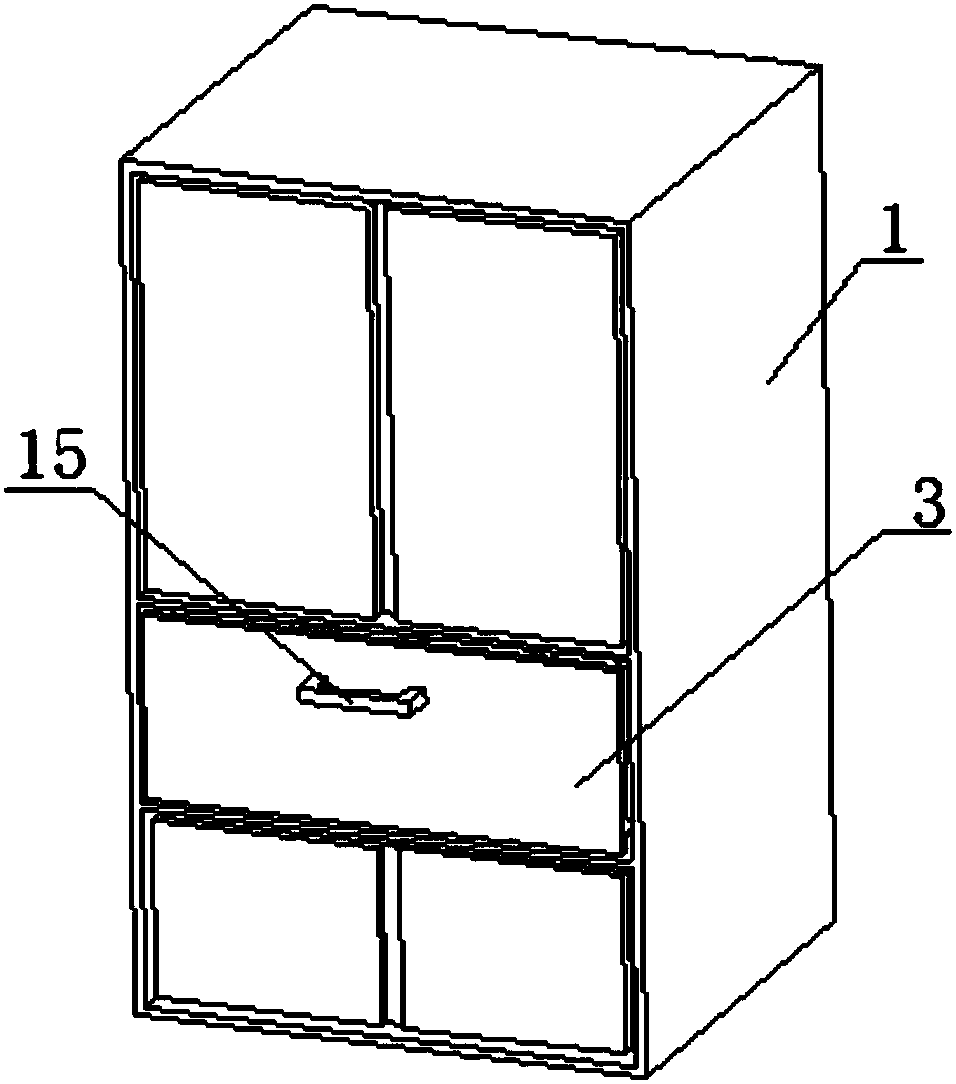

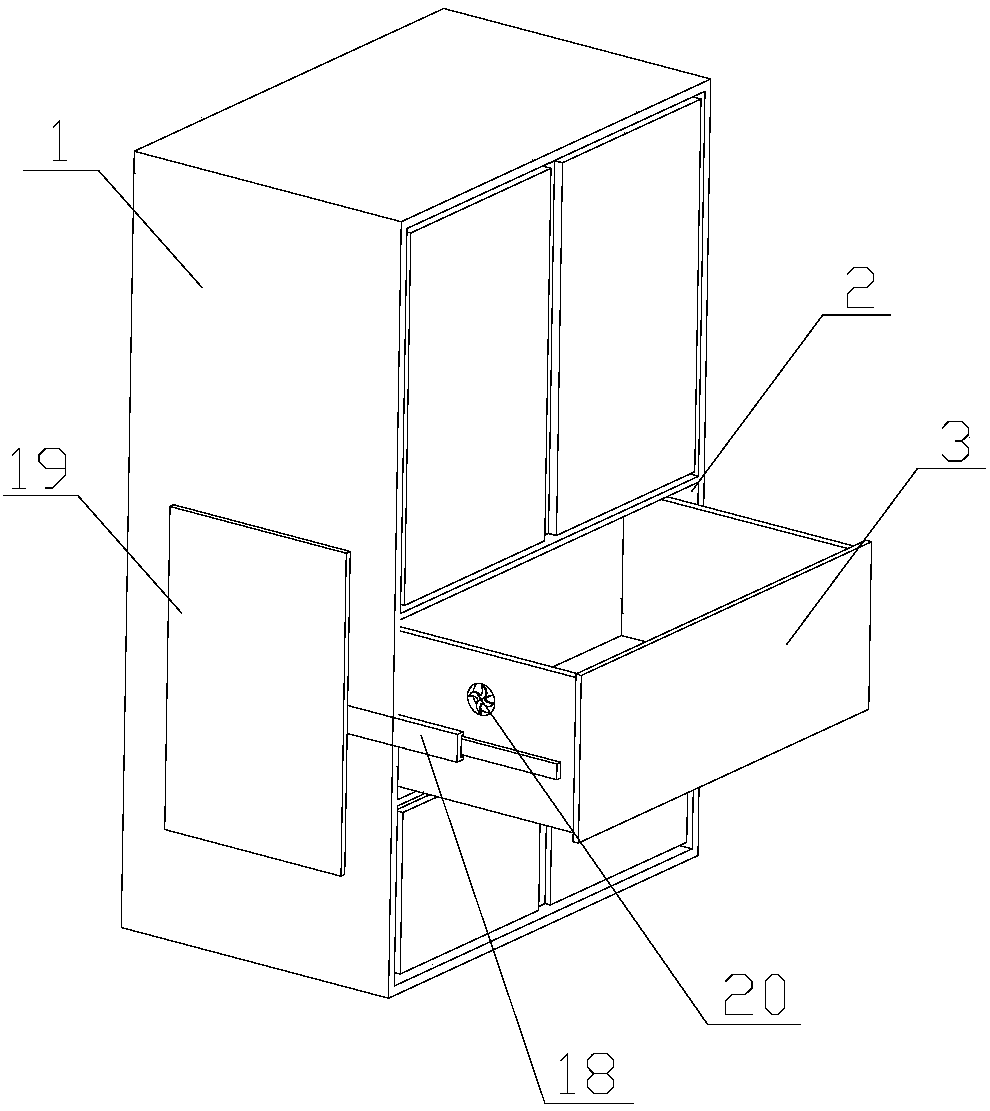

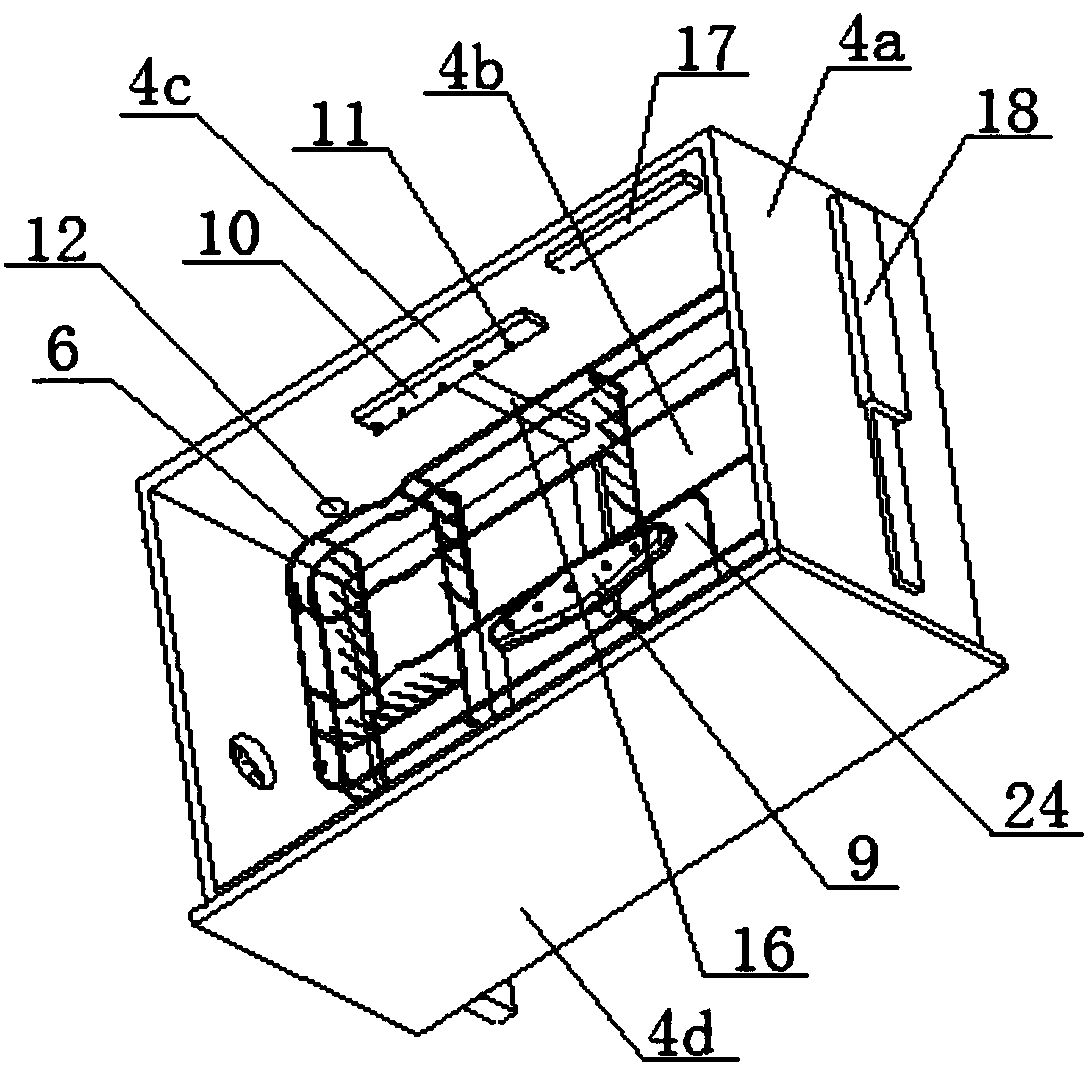

Roller washing machine with adjustable inclined angle of roller and control method thereof

ActiveCN103015119AMeet various needsEasy to operateOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The invention discloses a roller washing machine with an adjustable inclined angle of a roller and a control method thereof. The roller washing machine comprises a shell, a door body, an outer cylinder, the roller and an adjusting device for the inclined angle of the roller, wherein the door body is arranged on the front part of the shell; the outer cylinder is arranged in the shell and is filled with water; the roller is arranged in the outer cylinder and is rotatable; the adjusting device for the inclined angle of the roller is arranged above the outer cylinder; the adjusting device for the inclined angle of the roller comprises a fixed shaft, an electromagnet and a connecting part; the fixed shaft is horizontally arranged in the shell along the back-and-forth direction of the washing machine; one end of the fixed shaft is fixed on the shell; the other end is connected with the electromagnet fixed on the shell; the connecting part comprises a connecting rod and a magnetic part arranged at one end of the connecting rod; the other end of the connecting rod is fixed on an outer cylinder wall; the magnetic part is sleeved on the fixed shaft in a sliding form; and after the magnetic part is attracted by an electromagnetic force of the electromagnet, the magnetic part moves toward the electromagnet along the fixed shaft, so that the front end of the roller is pulled up and the inclined angle is formed between a rotating shaft of the roller and the horizontal direction. The roller washing machine has the characteristics of simple structure, low cost and convenience in use.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

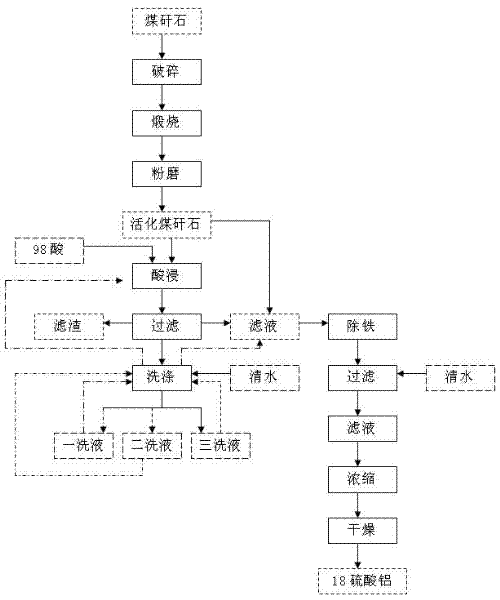

Method for producing low iron aluminum sulfate by utilization of coal gangue

InactiveCN102311136AGood slag activityUnderburn noneWaste processingSolid waste disposalSlagAluminum sulphate

The invention relates to a method for producing low iron aluminum sulfate by the utilization of coal gangue and belongs to the technical field of coal solid waste resource utilization. The method provided by the invention comprises the following steps of: carrying out calcination activation on coal gangue at the temperature of 785-850 DEG C, adjusting the pH of an aluminum sulfate solution by directly using the activated coal gangue, oxidizing divalent iron ions into trivalent ions, removing iron precipitate and a few gel in the aluminum sulfate solution by the utilization of the adsorption property of the coal gangue, producing low iron aluminum sulfate, recycling the removed iron slag, and terminating the recycling operation when the removed iron slag amount is greater than 120% of the acid-leach residue amount or the mass ratio of aluminium to iron in an iron-removing liquid is less than 160. The temperature of the calcinated coal gangue satisfies the operation condition for the boiling of a circulating fluidized bed. No addition of an auxiliary agent helps heat recovery. The activity of the coal gangue cinder is good, the grinding requirement is not high and the energy consumption is low. Hydrogen peroxide or ozone, air and variable valence element-containing hypervalent compounds KMnO4, MnO2 oxidizing agents are adopted to remove iron with less loss of aluminium. The ratio of Al2O3 to Fe in the product is greater than 160 and the quality of the product is high. The acid leaching reaction is carried out at normal pressure. And the production is easy to operate at low cost.

Owner:KUNMING UNIV OF SCI & TECH

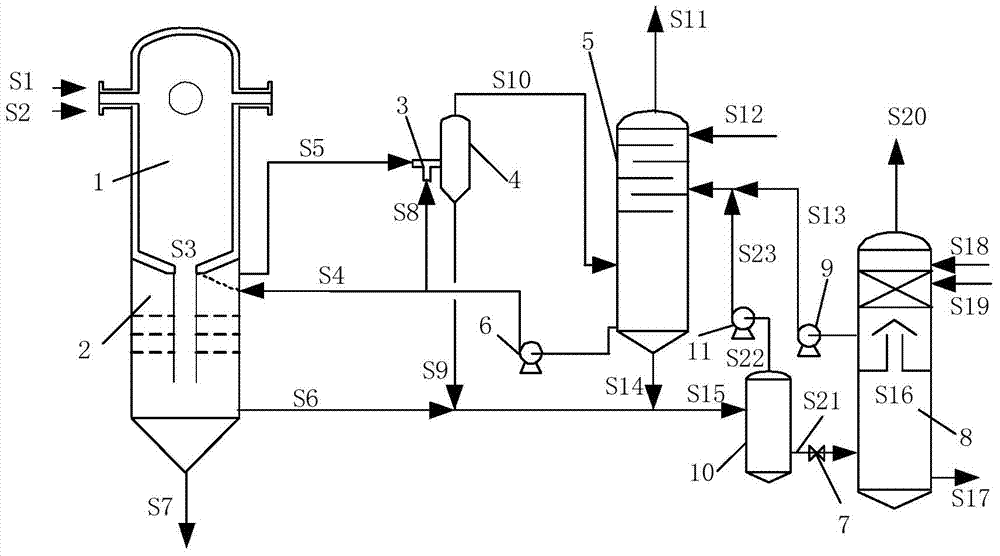

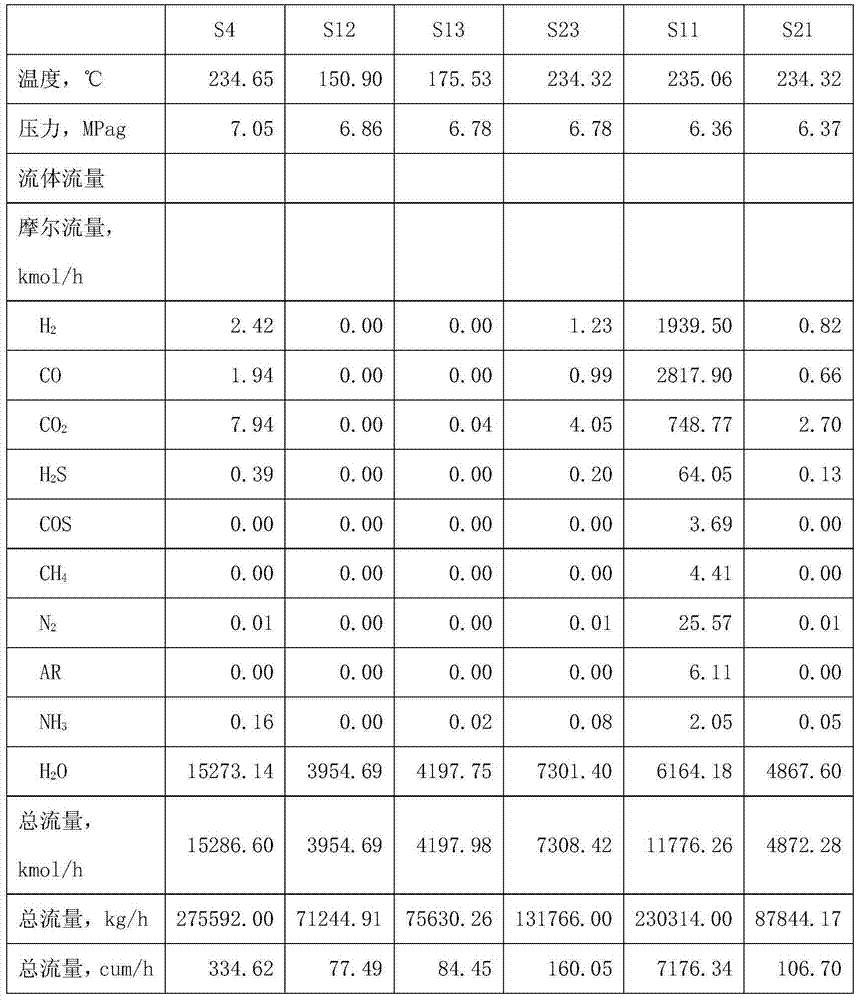

Method for treating black water of coal gasification system

ActiveCN103695041AIncrease the water-air ratioGuaranteed washing effectCombustible gas productionProcess engineeringTower

The invention discloses a method for treating black water of a coal gasification system. At least partial high-temperature black water is directly returned to a synthetic gas washing tower for being recycled after being de-ashed, and directly pumped to the synthetic gas washing tower as synthetic gas washing water after carried fine ash is separated through a solid-liquid separator. The water-air ratio of synthetic gas discharged from the gasification device is increased, the operation of a CO transformation device is facilitated, the energy of the gasification device is recycled through a byproduct steam, the CO transformation device also returns much transformation condensate to the synthetic gas washing tower, so that the washing effect of the synthetic gas discharged from the gasification device is ensured; and the amount of the black water of a black water removing treatment unit is reduced, and the power consumption, equipment size and investment of the black water treatment unit are reduced. According to the method provided by the invention, the synthetic gas in the gasification system is washed, the black water is treated, and thus the purpose of effectively utilizing materials and energy is achieved.

Owner:EAST CHINA UNIV OF SCI & TECH

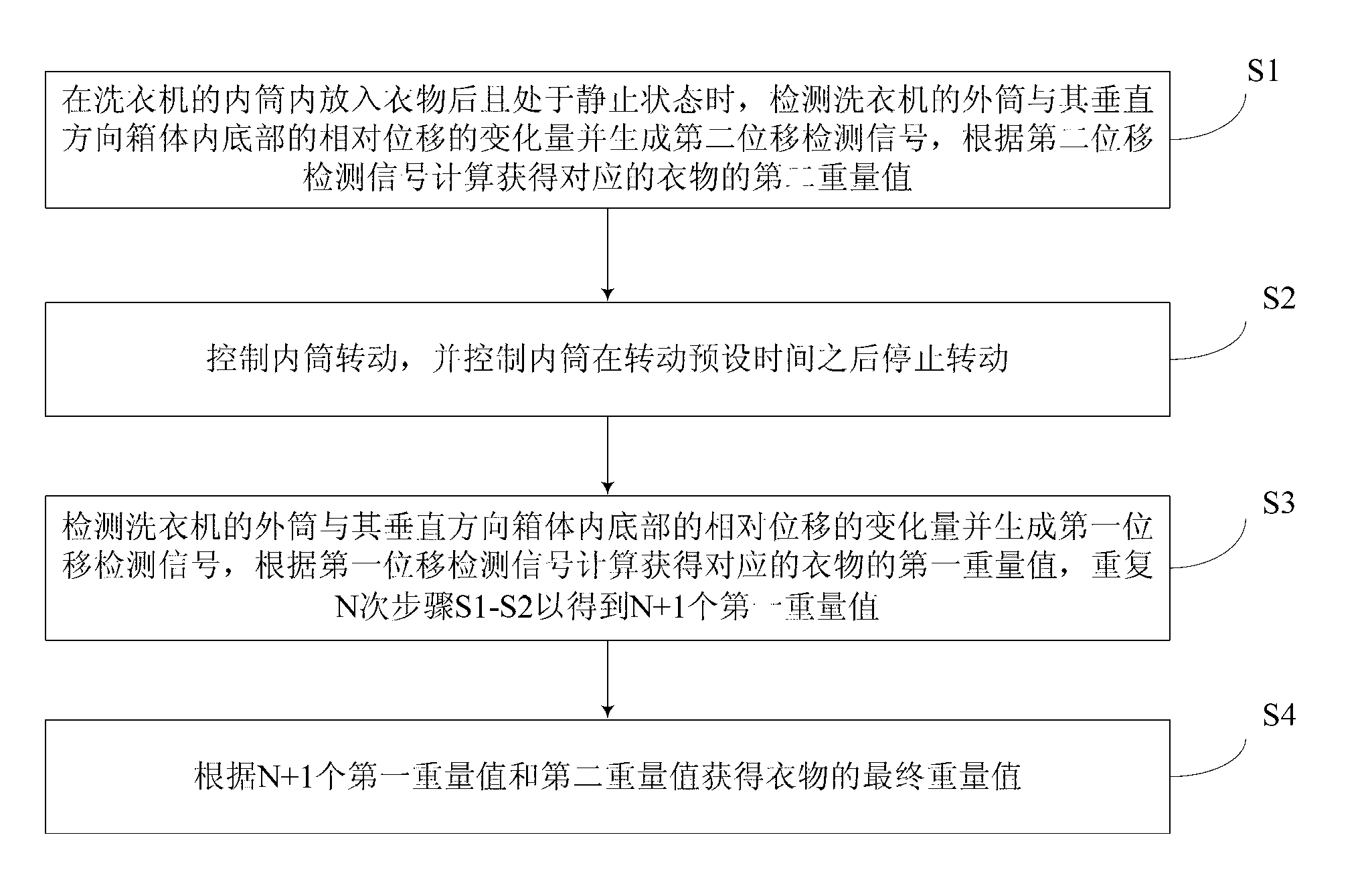

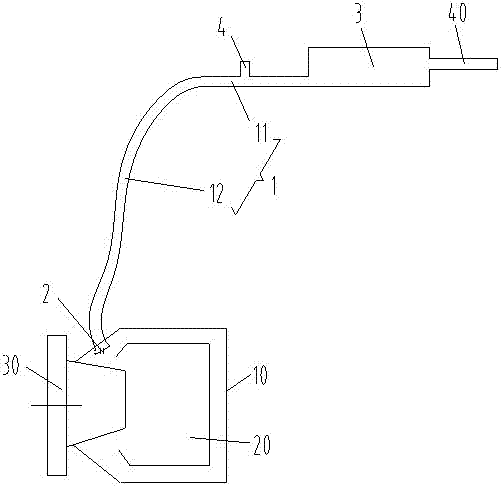

Washing machine and cloth weighing method thereof

ActiveCN103266448AAccurate weightReduce consumptionOther washing machinesTextiles and paperWater resourcesMechanical engineering

The invention discloses a washing machine and a clothes weighing method thereof. The washing machine comprises a barrel portion, a motor, at least one displacement detecting module and a controlling module. The barrel portion comprises an outer barrel and an inner barrel. The inner barrel is controlled by the motor. The displacement detecting modules are used for outputting a first displacement detecting value when clothes are in the inner barrel and after the inner barrel rotates for a preset time. The controlling module is electrically connected with the displacement detecting modules and the motor respectively, and is used for controlling the motor to start rotating the inner barrel in the preset time. N+1 first displacement detecting values are acquired by the displacement detecting module though repeating N times; N+1 first weight values are acquired according to the N+1 first displacement detecting values respectively; and the N is a positive integer. With the washing machine and the cloth weighing method thereof, water resource can be saved, and electrical energy is lowered.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

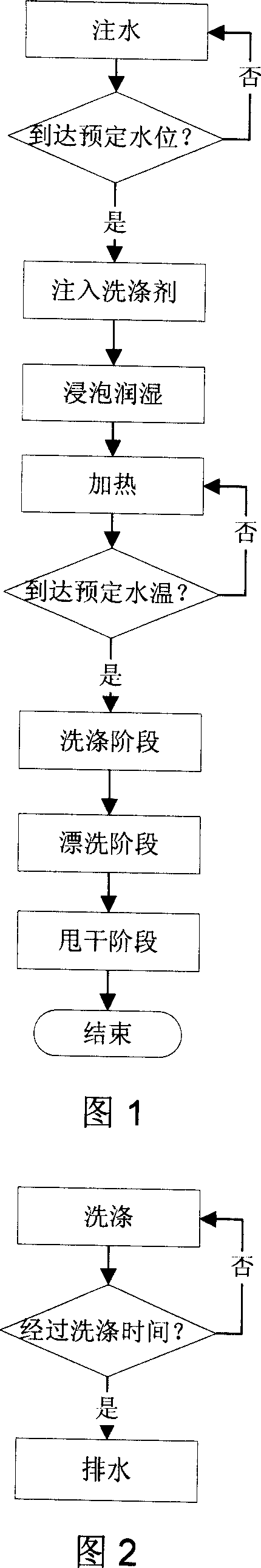

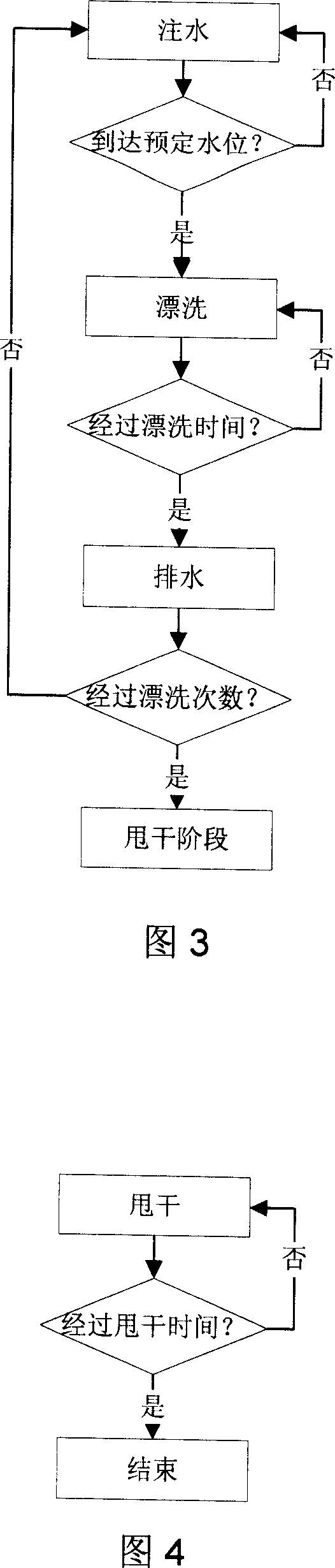

Shoe washing procedure of barrel washing machine

InactiveCN101082166AReduce wearAvoid damageControl devices for washing apparatusTextiles and paperEngineeringWater level

The improved shoe washing program in a washing machine includes one water feeding stage, one washing stage and one rinsing stage. The water feeding stage has one water level higher than that for washing clothes, and the washing stage and the rinsing stage have one drum rotating speed lower than that for washing clothes. The improved shoe washing program can avoid the mechanical pressure the rotating drum produces effectively and reduce the damage on the shoes and the drum during washing. By means of the improved shoe washing program, a washing machine may be applied in washing shoes without increase in the cost.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

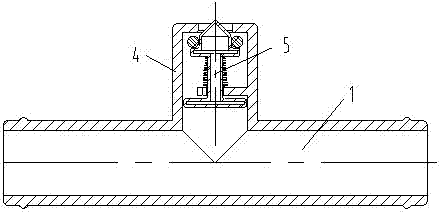

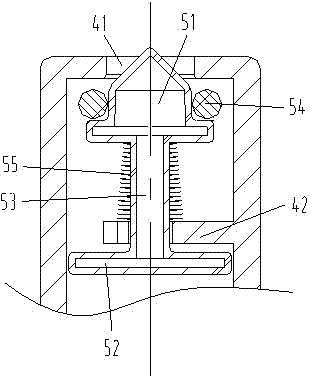

Washing machine door-end sprinkler, working method and washing machine

ActiveCN107119423ADischarge in timeAvoid influenceOther washing machinesTextiles and paperWater flowEngineering

The invention provides a washing machine door-end sprinkler, a working method and a washing machine. The door-end sprinkler comprises a sprinkling pipe communicating with a water inlet pipe, and a nozzle arranged at the tail end of the sprinkling pipe. An electromagnetic valve is arranged between the sprinkling pipe and the water inlet pipe. A ventilation pipe having a ventilation port is connected to the sprinkling pipe. A ventilation valve capable of opening and closing the ventilation port is arranged in the ventilation pipe. The ventilation valve is opposite to the electromagnetic valve in opening and closing states. The ventilation pipe and the ventilation valve are arranged, and the ventilation valve and the electromagnetic valve are opposite in opening and closing state, so that the ventilation valve is closed when the electromagnetic valve is opened; in this case, water flows through the sprinkling pipe and is ejected via the nozzle; the ventilation valve is opened when the electromagnetic valve is closed; in this case, the sprinkling pipe communicates with the external at the ventilation pipe such that water left in the sprinkling pipe flows out via the nozzle. Thus, residual water can be discharged timely, and influence of the residual water on a user and clothes is avoided; the washing effect is ensured, and the customer satisfaction is enhanced.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

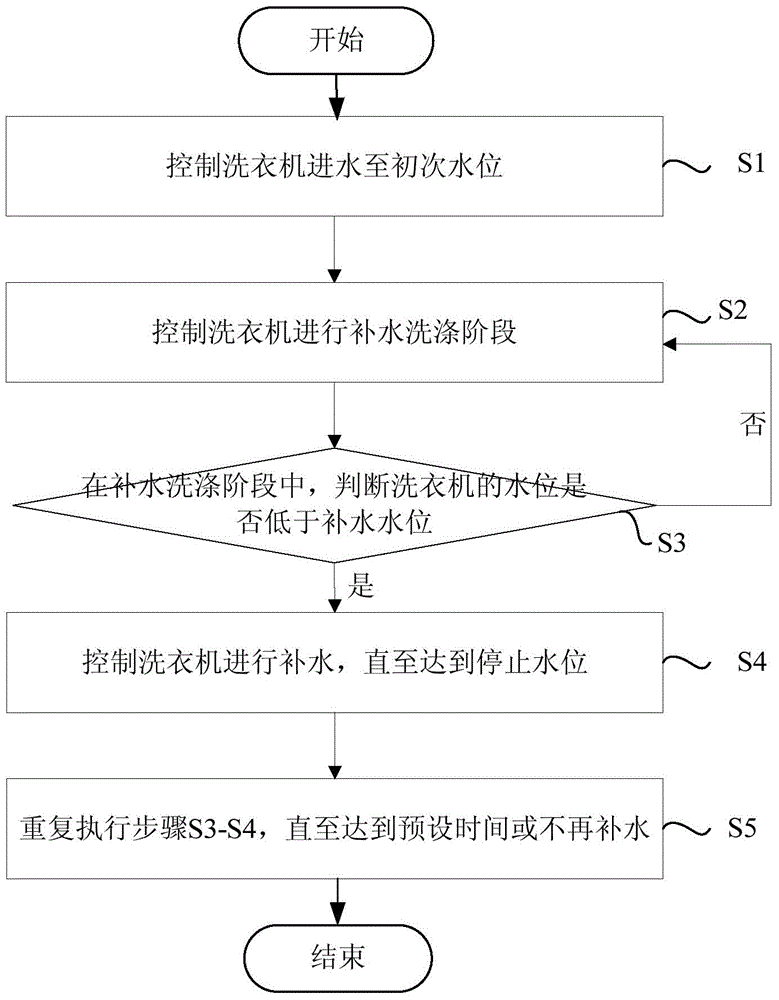

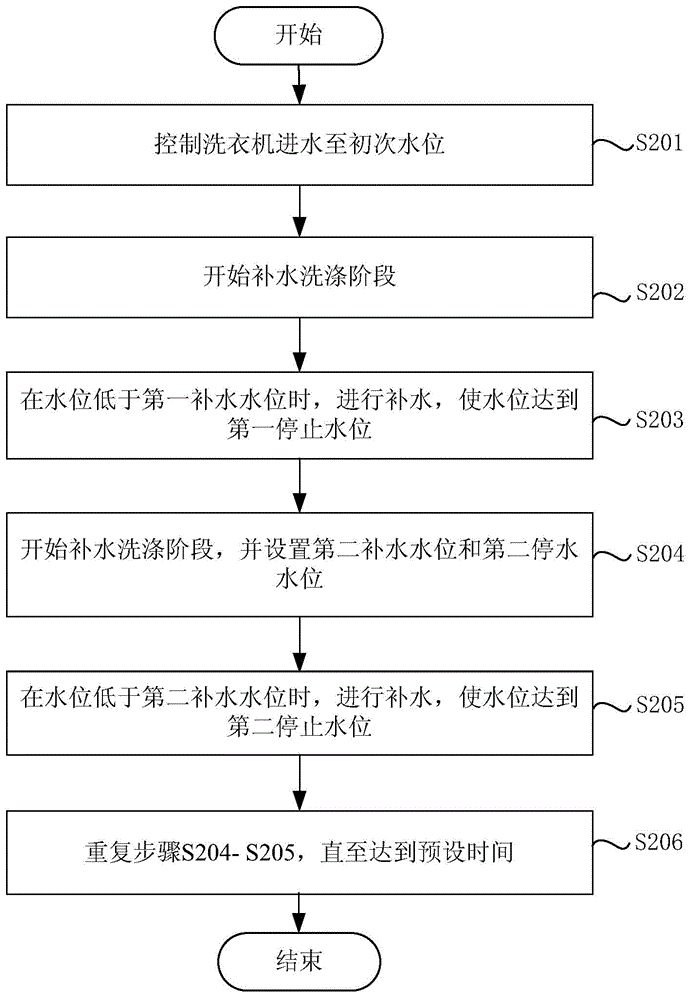

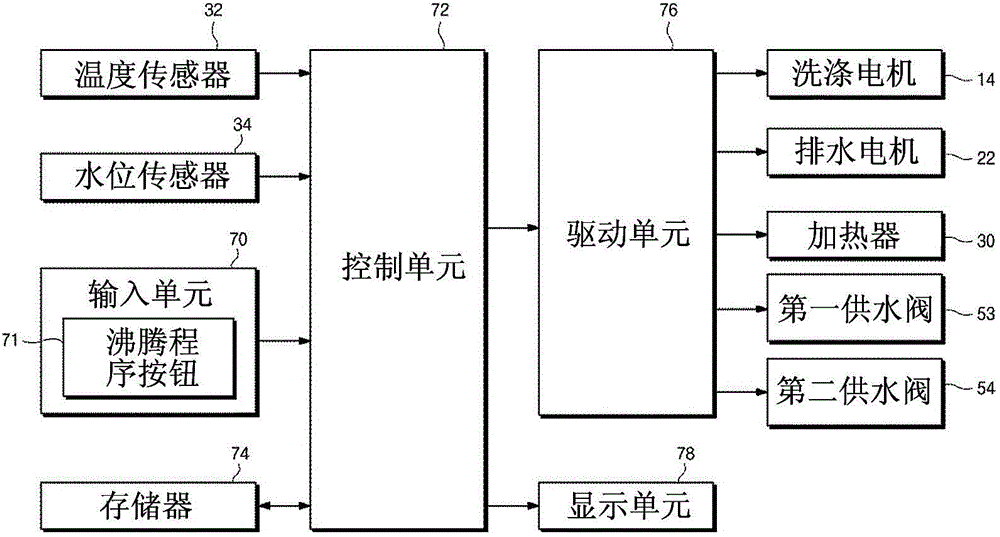

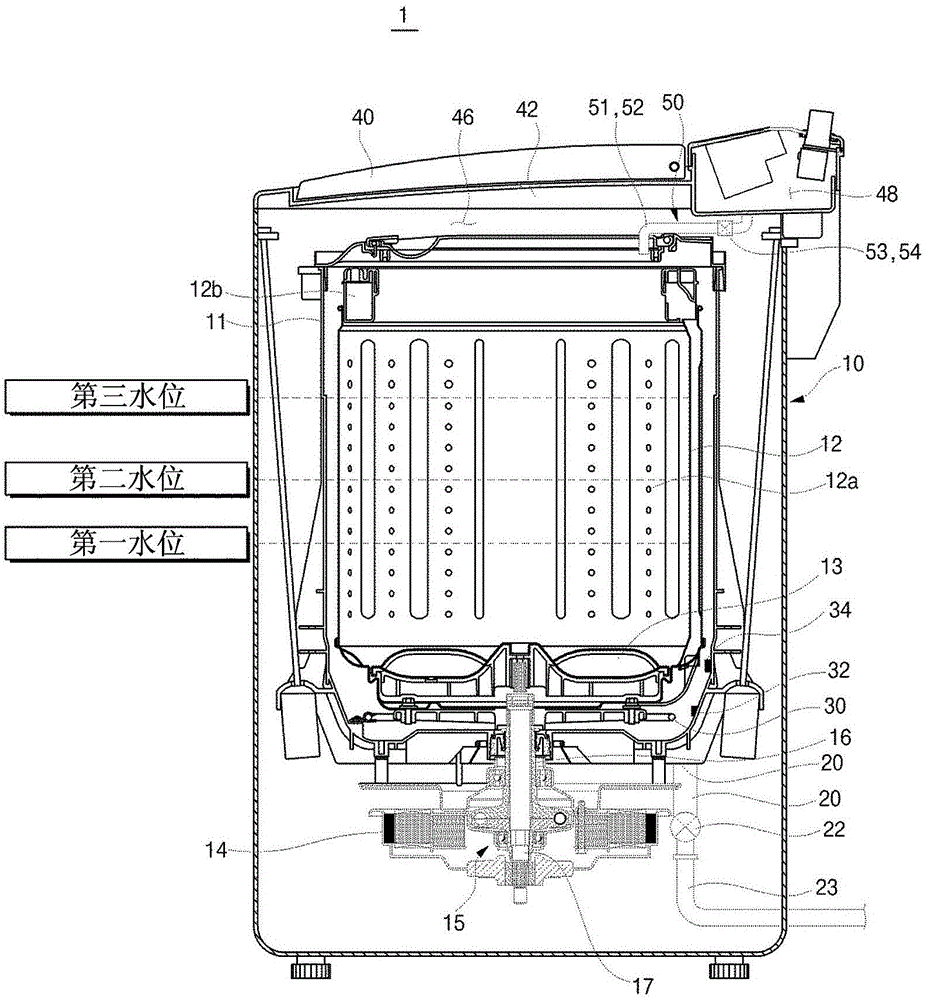

Water inflow control method and device for washing machine

ActiveCN104911865AHigh control precisionGuaranteed washing effectControl devices for washing apparatusTextiles and paperEngineeringWater level

The invention discloses a water inflow control method and device for a washing machine. The water inflow control method for the washing machine includes the steps that S1, inflow water of the washing machine is controlled to be on an initial water level; S2, the washing machine is controlled to execute the water replenishing washing stage; S3, at the water replenishing washing stage, whether the water level of the washing machine is lower than the water replenishing water level or not is judged; S4, if the water level of the washing machine is lower than the water replenishing water level, the washing machine is controlled to replenish water till the water reaches the stop water level; S5, the third step and the fourth step are executed repeatedly till preset time is reached or water is not replenished. By the adoption of the water inflow control method and device for the washing machine, the initial water level, the water replenishing water level and the stop water level are set, the initial water inflow quantity and the water replenishing quantity can be reasonably distributed, the control accuracy of the water inflow quantity is improved, water inflow time is shortened, the effective washing time is guaranteed, energy is saved, emission is reduced, and the clothes washing effect is guaranteed.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

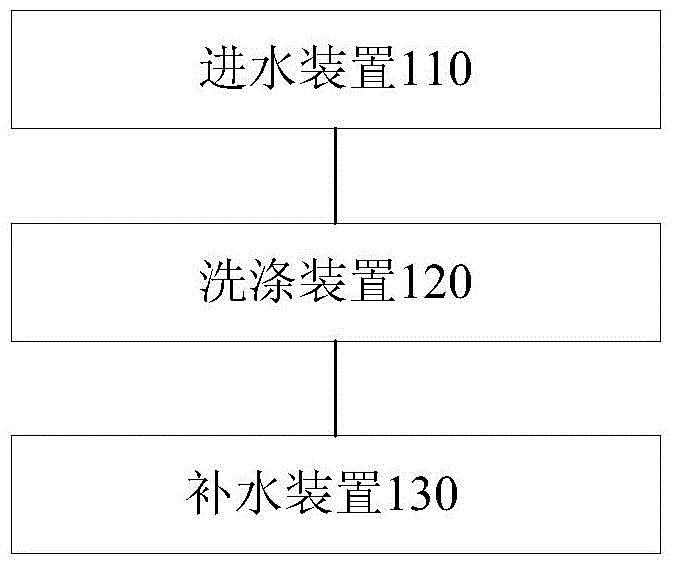

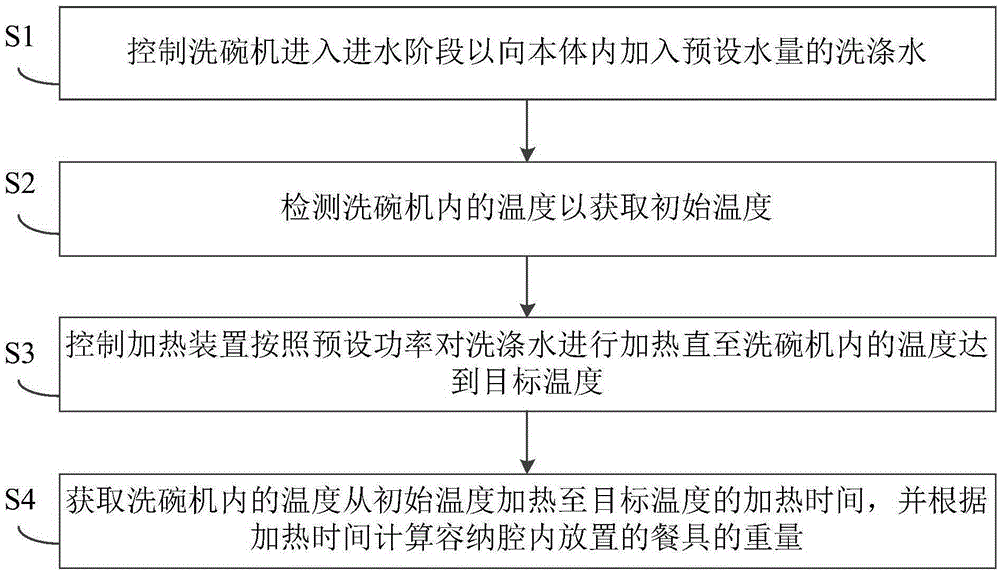

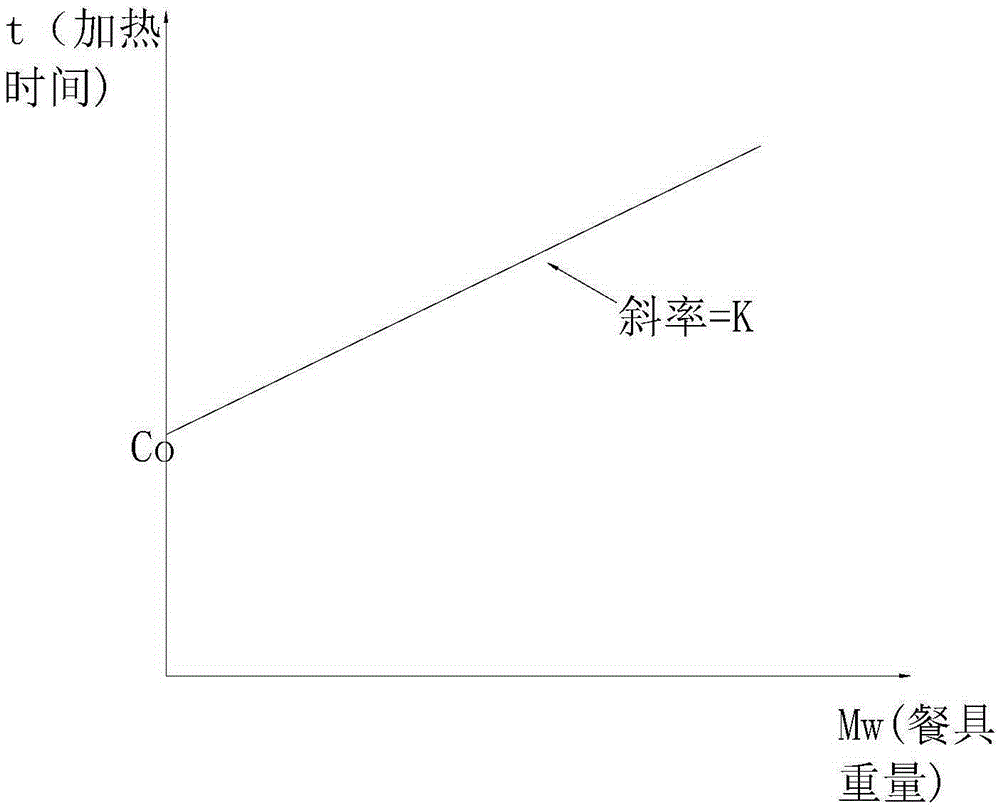

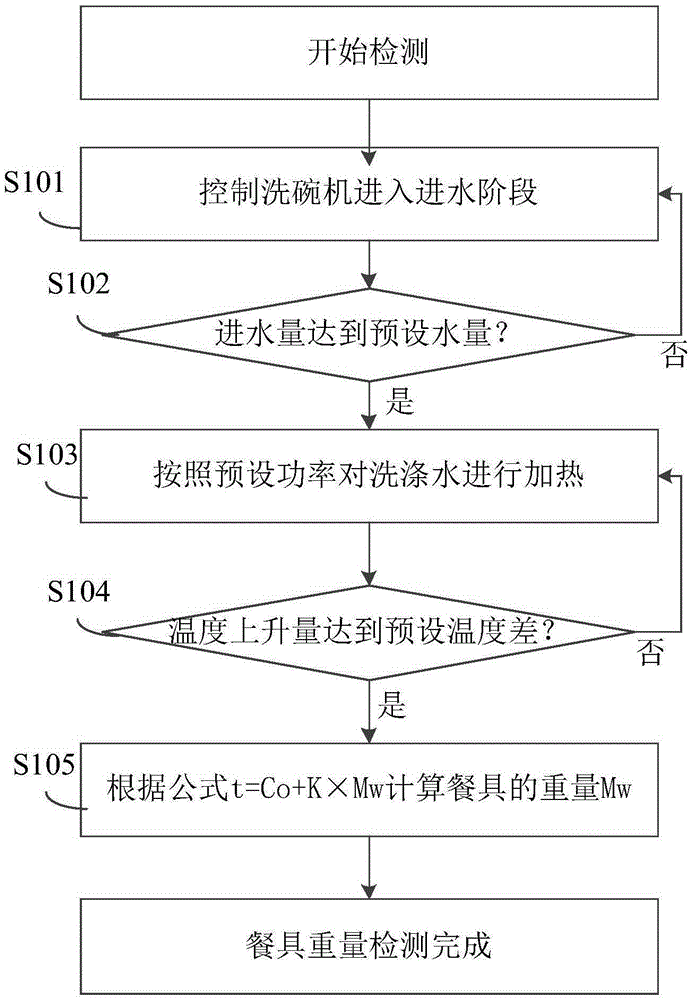

Dish washer, and method and apparatus for detecting weight of tableware in dish washer

ActiveCN105286742AGuaranteed washing effectAvoid wastingTableware washing/rinsing machine detailsHeating timeProcess engineering

The invention discloses a dish washer, and a method and apparatus for detecting the weight of tableware in the dish washer. The dish washer comprises a dish washer body, an accommodation chamber disposed inside the dish washer body and a heating device disposed inside the dish washer. The method comprises following steps: enabling the dish washer to enter a water feeding stage so as to add washing water with a preset volume into the dish washer body; detecting the temperature in the dish washer so as to obtain the initial temperature; controlling the heating device to heat the washing water according to the preset power until the temperature in the dish washer reaches the target temperature; acquiring the heating time that the temperature in the dish washer is heated to the target temperature from the initial temperature; and calculating the weight of the tableware in the accommodation chamber according to the heating time. According to the invention, the weight of the tableware actually placed by a user can be calculated just through an original temperature sensor and without additional sensing devices and detection devices, so that the dish washer can be intelligently controlled according to the weight of the tableware, washing effects can be guaranteed, and the waste of resources can be effectively avoided.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

Dishwasher consumable material dispensing device and dishwasher

PendingCN109259704APrevent leakageImprove convenienceTableware washing/rinsing machine detailsRisk strokeBiomedical engineering

The invention relates to the technical field of household appliances, in particular to a dishwasher consumable material dispensing device and a dishwasher. The dishwasher consumable material deliverydevice comprises a consumable material accommodating box; a dispensing device including a washing pipe, one end of the washing pipe communicating with a consumable outlet, the other end communicatingwith a washing chamber in the dishwasher main body, and a dosing switch arranged in the washing pipe; a dosing switch comprising a dosing chamber, a one-way valve mounted on the metering chamber inletand the metering chamber outlet, and a plunger member pullably disposed in the dosing chamber, the consumable material delivery device of the dishwasher carry out the consumable material delivery, atthis time, only control that plunger member to form a drawing stroke can realize that a fixed amount of consumables pass through a quantitative switch and enter a washing chamber through a washing pipeline, thereby improve the convenience in the process of adding consumables, avoiding the error of the adding amount of consumables and ensuring the washing effect because the quantitative consumables can be added accurately.

Owner:GREE ELECTRIC APPLIANCES INC

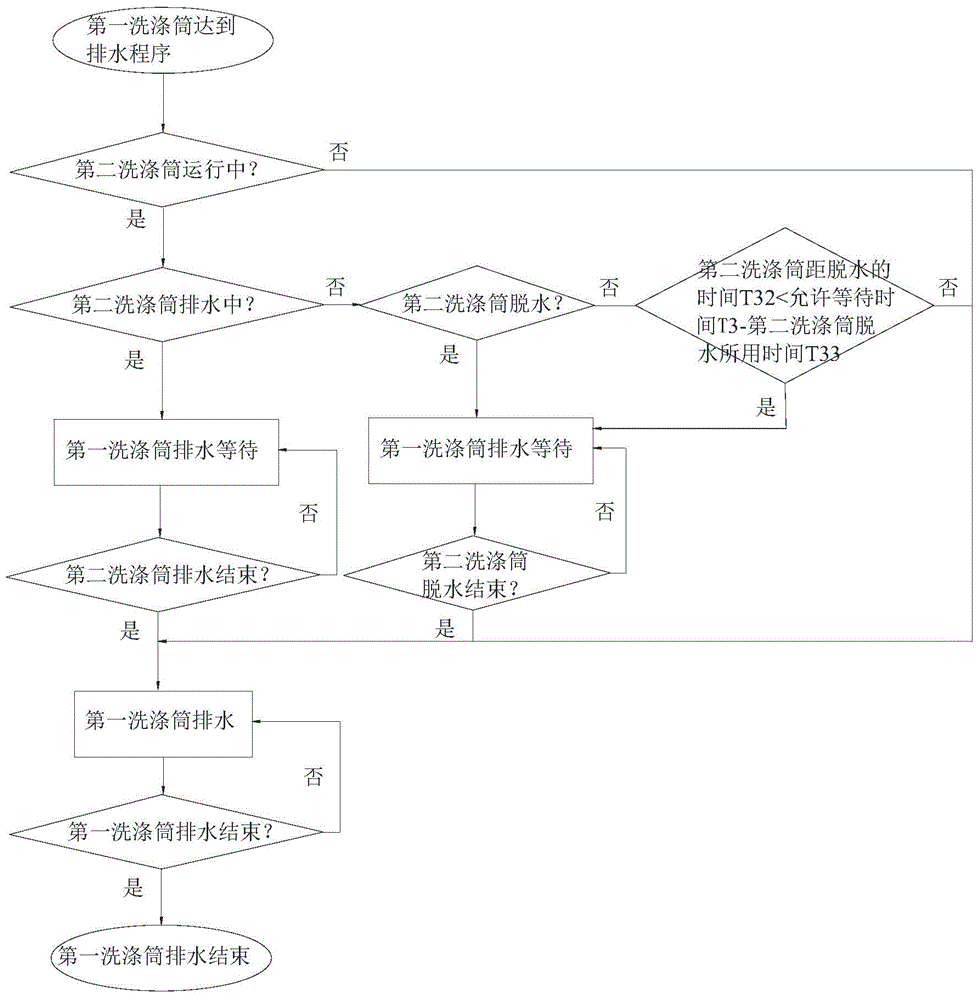

Draining control method for multi-drum washing machine

ActiveCN105734894AWeight increaseRealize the shock absorption effectControl devices for washing apparatusTextiles and paperEngineeringMechanical engineering

The invention relates to a draining control method for a multi-drum washing machine. The multi-drum washing machine at least comprises a first washing drum and a second washing drum. When the first washing drum reaches a draining program, whether the second washing drum is carrying out dewatering at the moment or not is judged; if yes, the first washing drum waits to carry out draining until the second washing drum completes dewatering; if not, whether the first washing drum needs to wait to carry out draining until the second washing drum completes dewatering or not is judged. The process of judging whether the first washing drum needs to wait to carry out draining until the second washing drum completes dewatering or not comprises the steps that it is determined that the time, from the current moment to the dewatering moment, of the second washing drum is T32 and the dewatering time of the second washing drum is T33, and an allowable waiting time T3 is set; if T32+T33<T3, the first washing drum waits to carry out draining until the second washing drum completes dewatering; otherwise, water in the first washing drum is directly drained.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

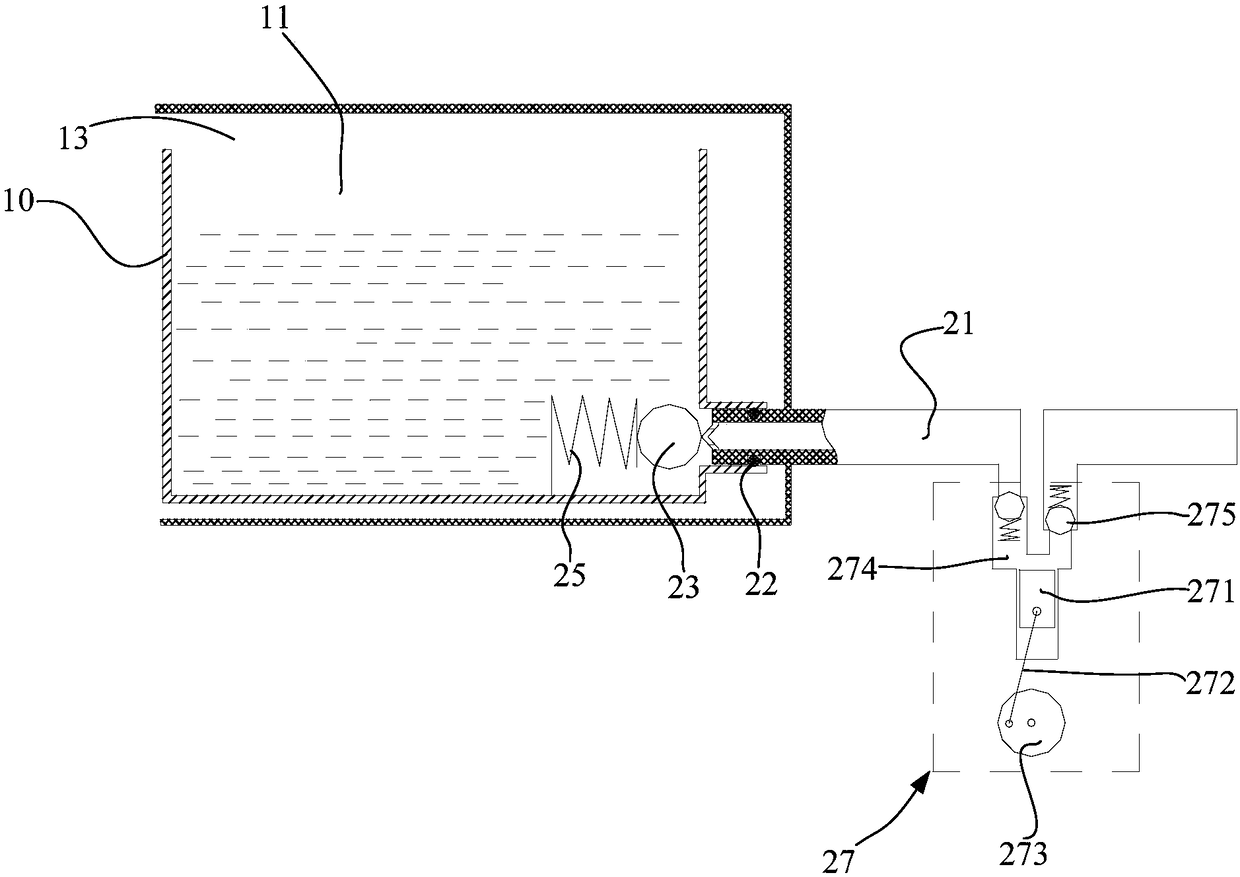

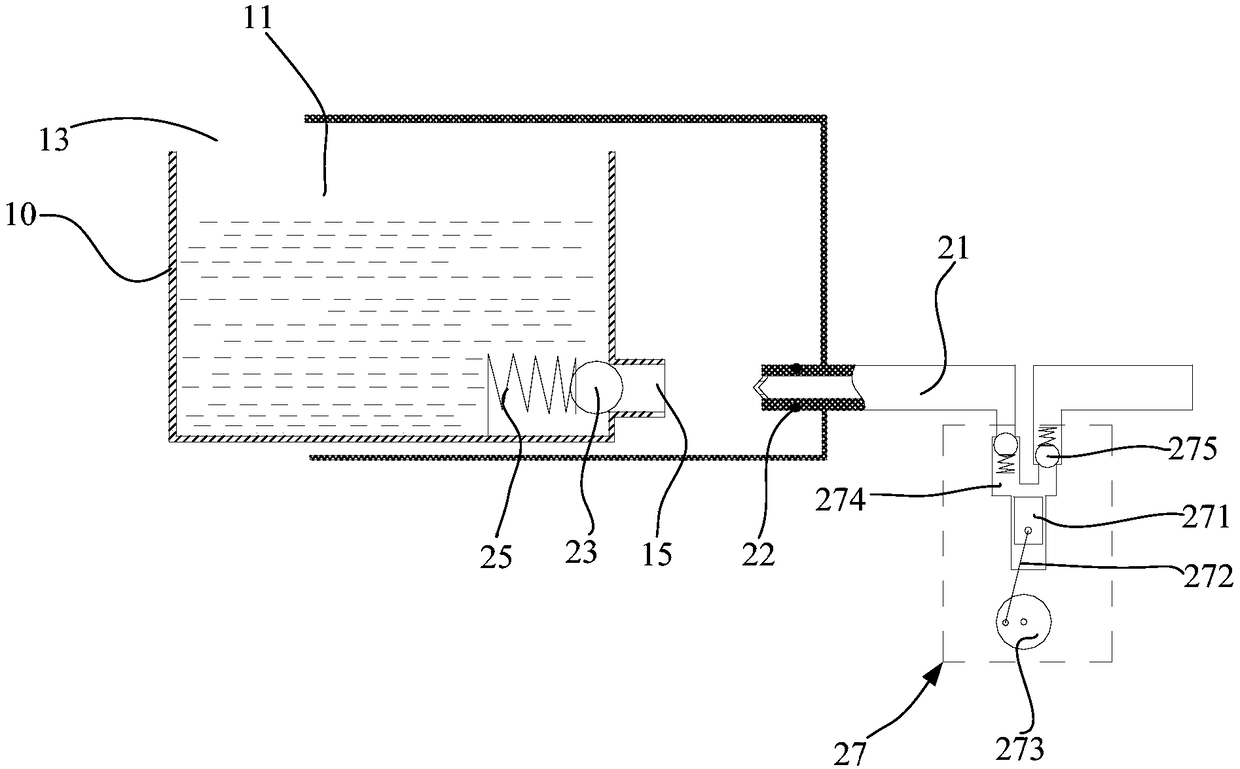

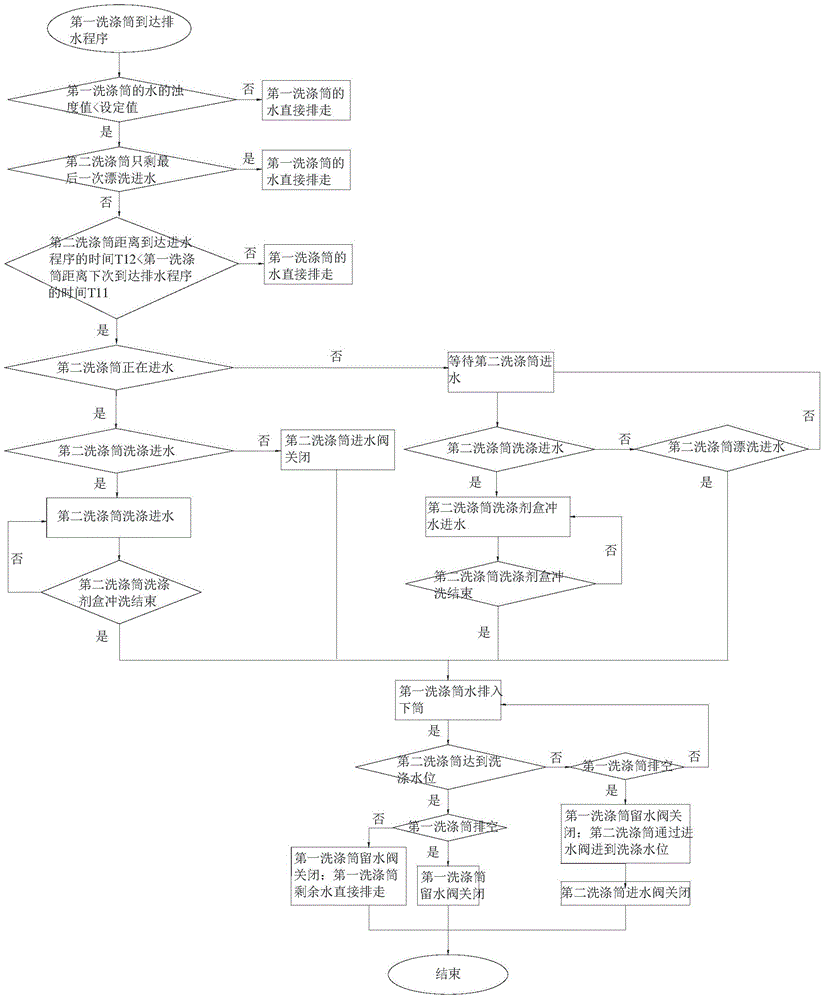

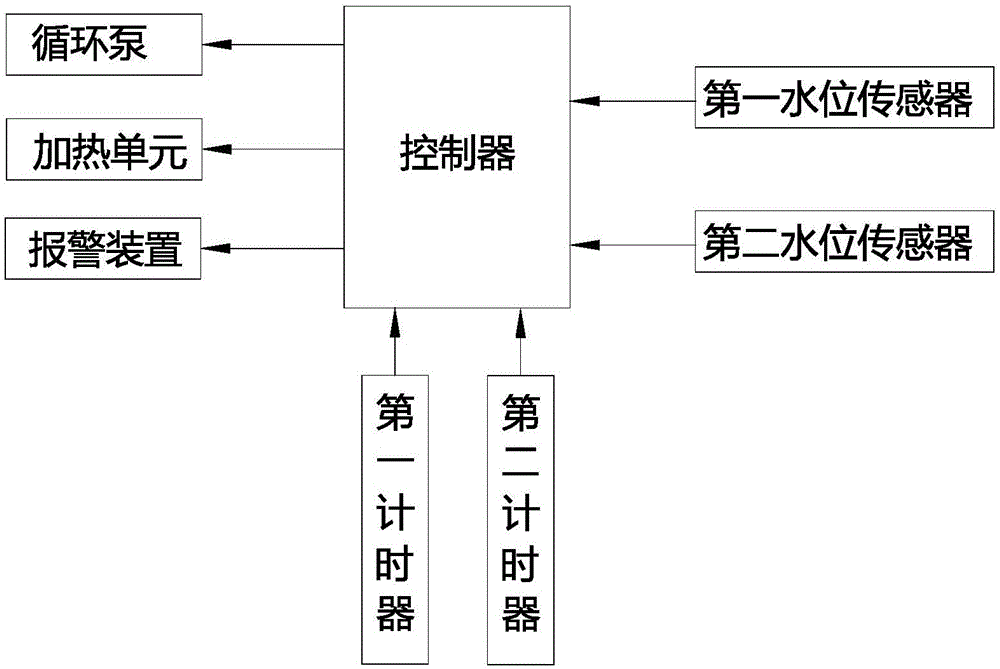

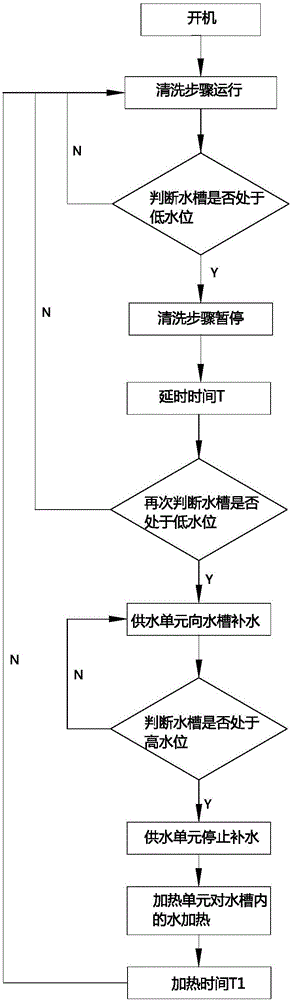

Dish washing machine and washing control method thereof

ActiveCN106725181AReduce the number of power on and offExtended service lifeTableware washing/rinsing machinesEngineeringWater level

The invention discloses a dish washing machine and a washing control method thereof, and belongs to the technical field of kitchen electric appliances, which solves the technical problem of false shutdown and alarming due to poor reliability of low water level detection in a dish washing machine in the prior art. The dish washing machine comprises a water tank, a water supply unit and a first water level sensor, wherein the water supply unit is used for supplying water to the water tank; the first water level sensor is used for detecting the low water level of the water tank. The washing control method of the dish washing machine comprises washing steps; the washing steps comprise a water level delay detection step: when the first water level sensor detects the low water level of the water tank, entering the water level delay detection; after set delay time T is reached, judging whether the actual water level of the water tank is in the low water level or not. The dish washing machine can be use to operate the washing control method.

Owner:JOYOUNG CO LTD

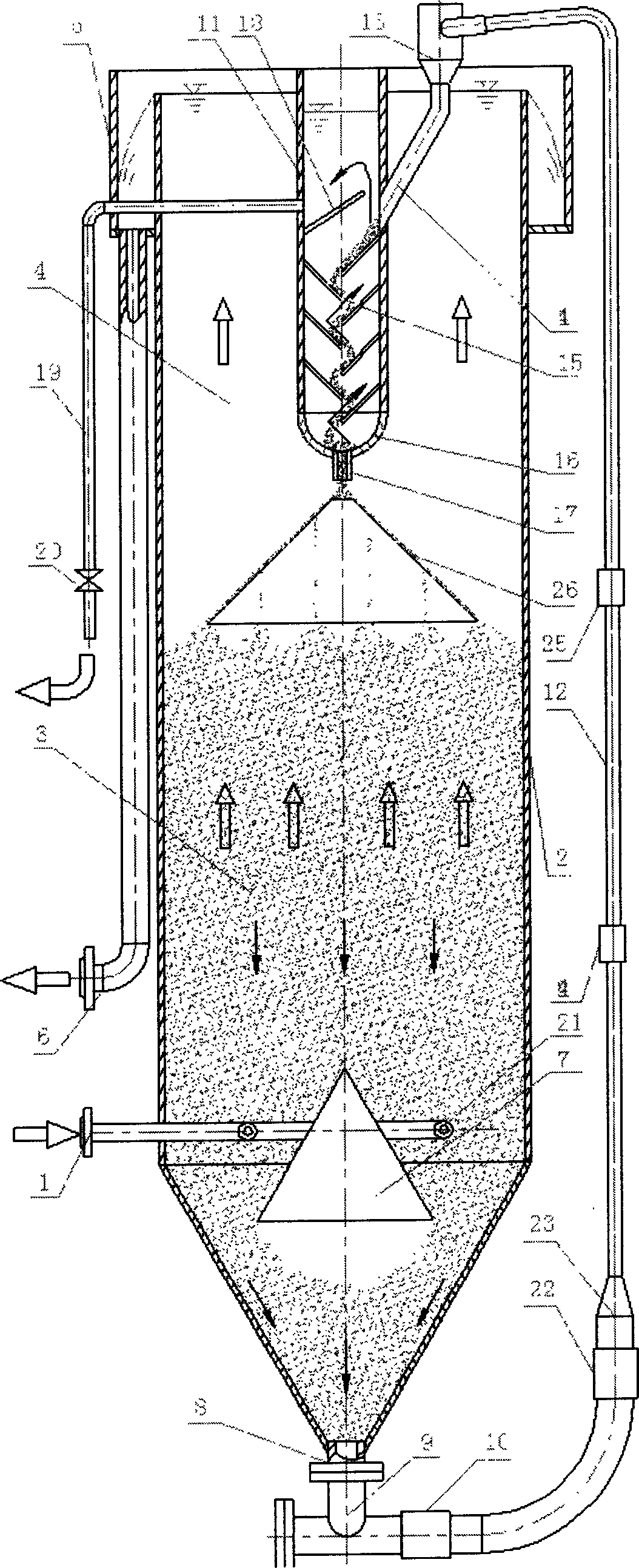

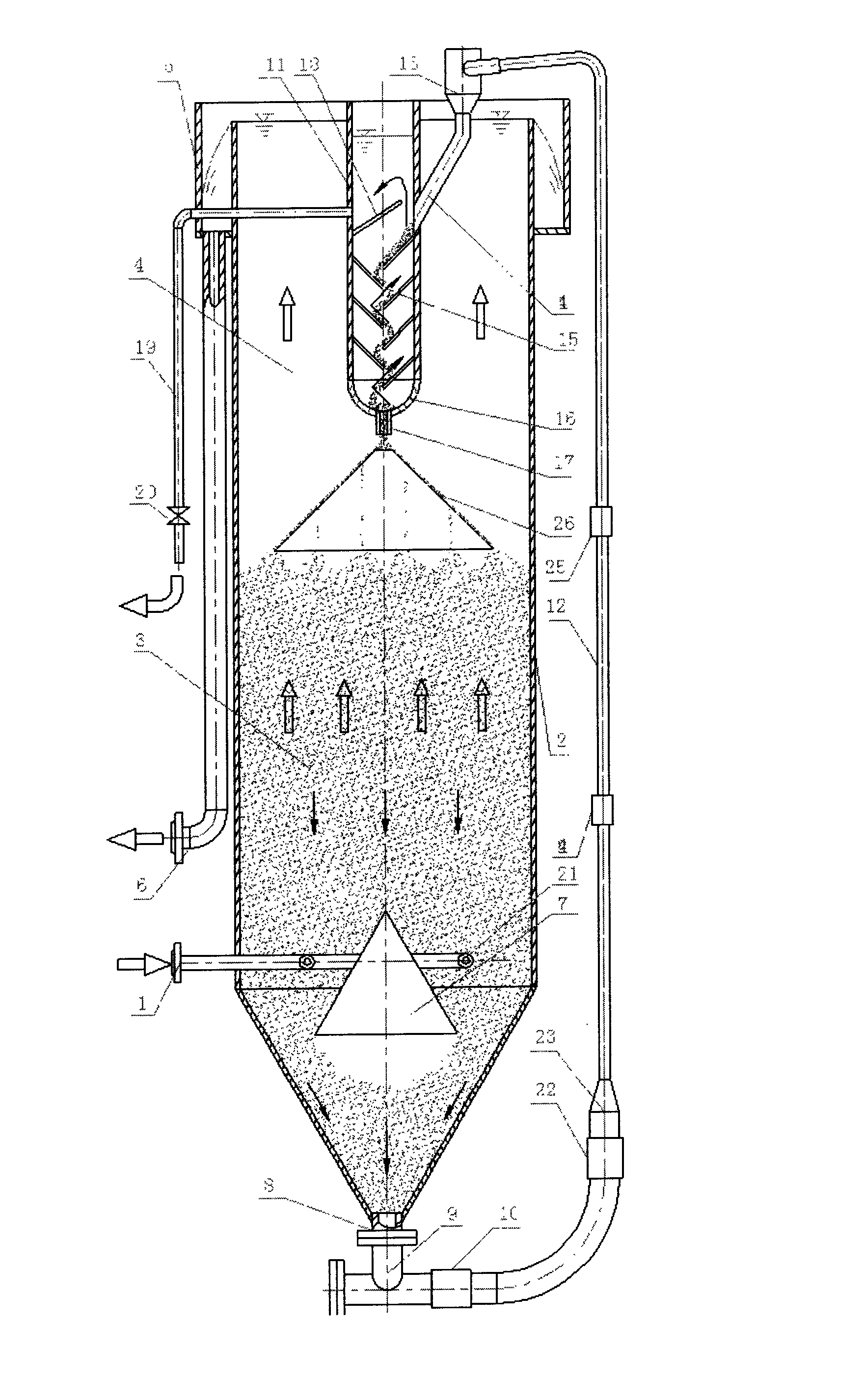

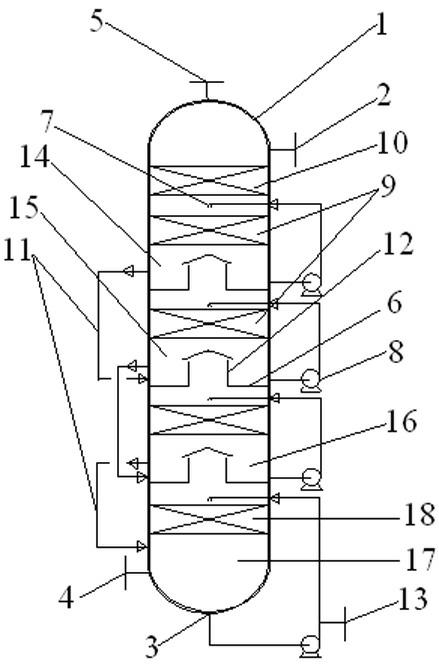

Moving bed filter

InactiveCN1597042AEasy to operateIncrease the chance of frictionLoose filtering material filtersGravity filtersWater qualityFilter material

A moving-bed filter able to continuously run for treating water is composed of cylindrical tank, water distributor, filtering bed, fairing unit, air distributor, filtering material delivering pipe, gas separator, washer, filtering material distributor and the regulating valve for the washing water.

Owner:CHINA PETROLEUM & CHEM CORP +1

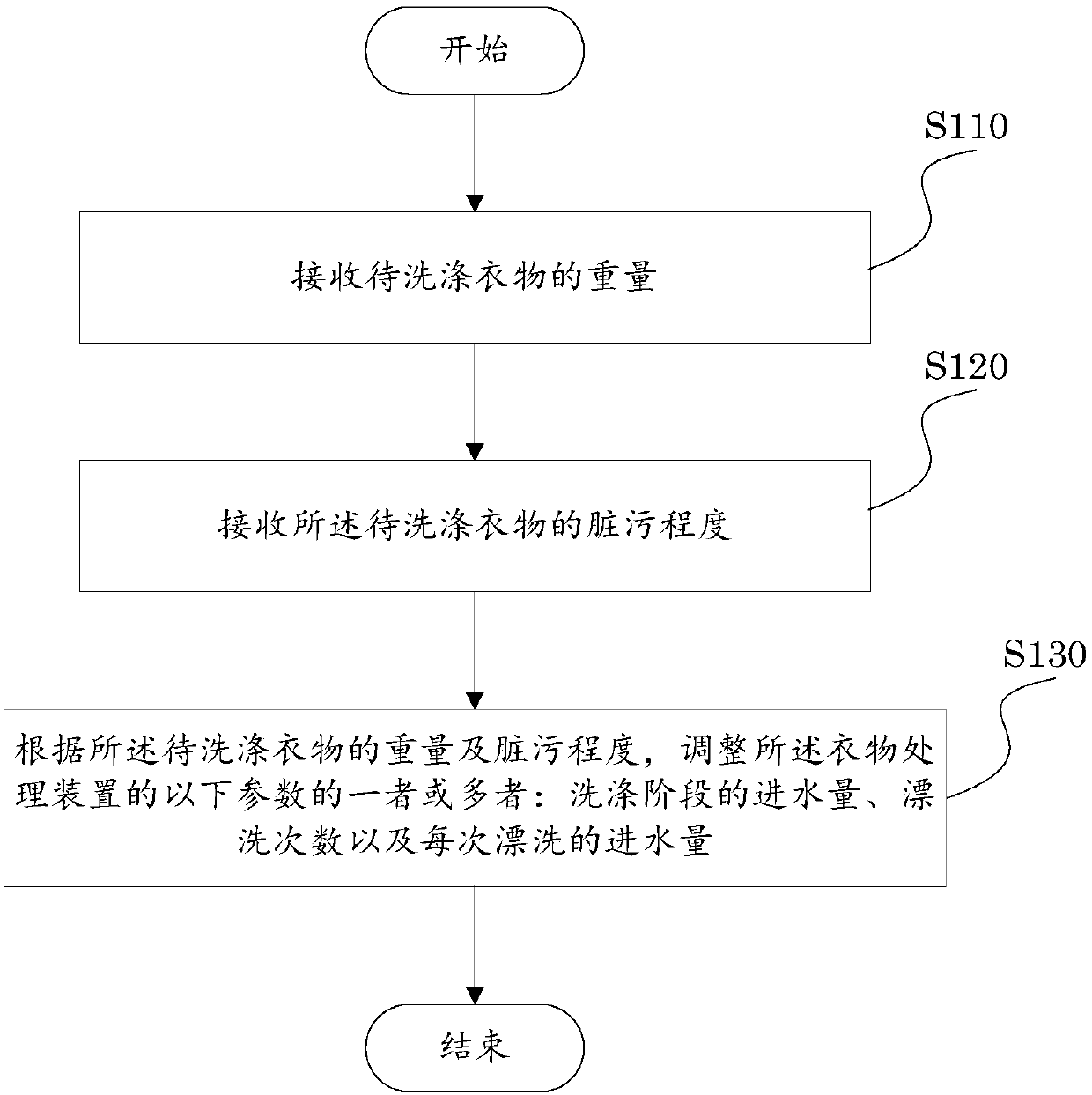

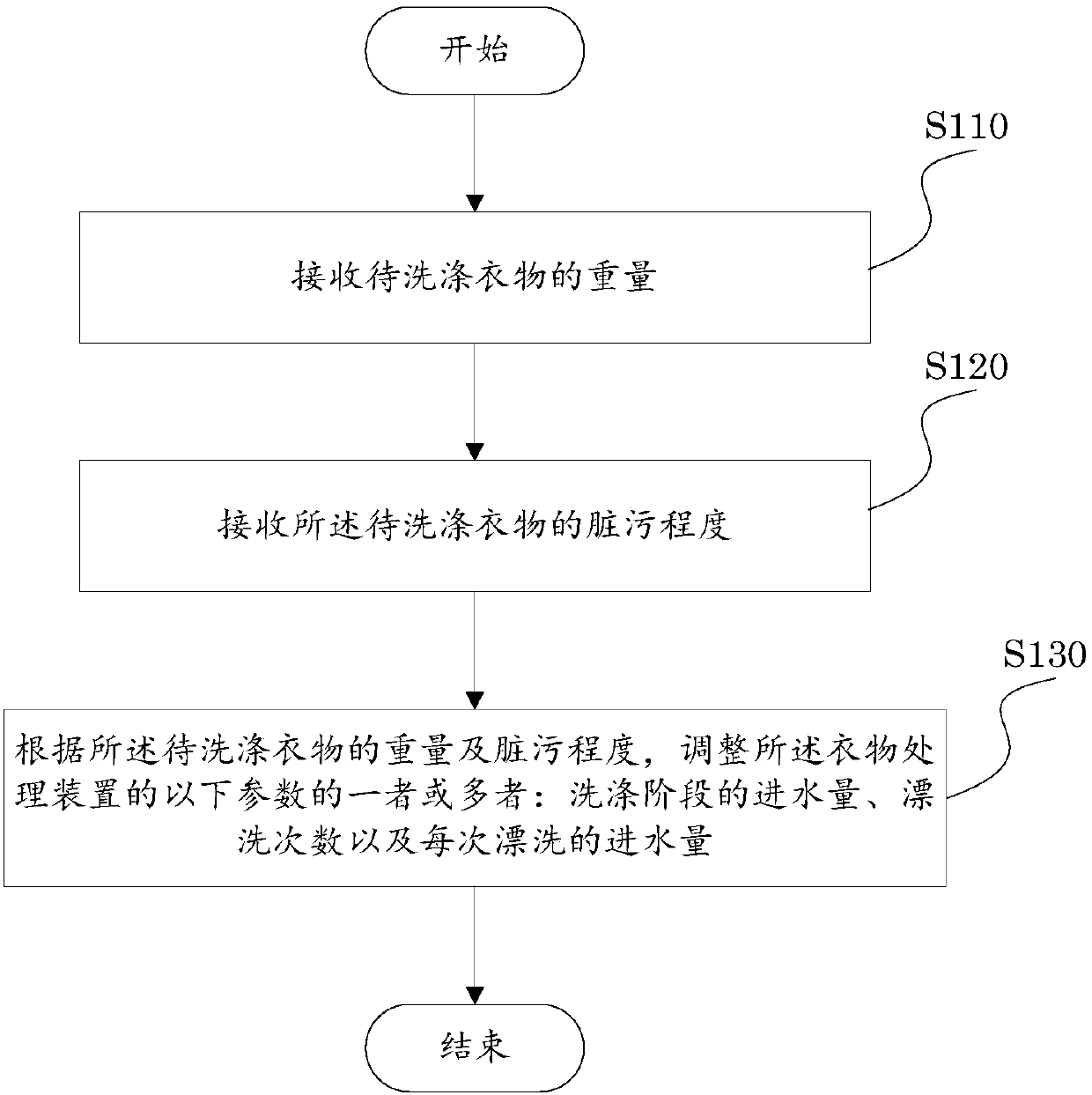

Clothes treating device and control device and method for clothes treating device

PendingCN109706687AGuaranteed washing effectControl devices for washing apparatusTextiles and paperEngineeringControl equipment

The embodiment of the invention provides a clothes treating device and a control device and method for the clothes treating device, and belongs to the field of household appliances. The control methodfor the clothes treating device comprises the steps that the weight of to-be-washed clothes is received; the dirty degree of the to-be-washed clothes is received; according to the weight and dirt degree of the to-be-washed clothes, one or more of the following parameters of the clothes treating device are adjusted, wherein the parameters include the water inlet amount in the washing stage, the number of times of rinsing and the water inlet amount of each time of rinsing. By means of the technical scheme, according to the weight and dirt degree of the to-be-washed clothes, one or more of the following parameters of the clothes treating device are adjusted, wherein the parameters include the water inlet amount in the washing stage, the number of times of rinsing and the water inlet amount of each time of rinsing; then the washing process is optimized, and therefore washing parameters can be automatically adjusted according to the weight and dirt degree of the to-be-washed clothes, and the washing effect is ensured.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

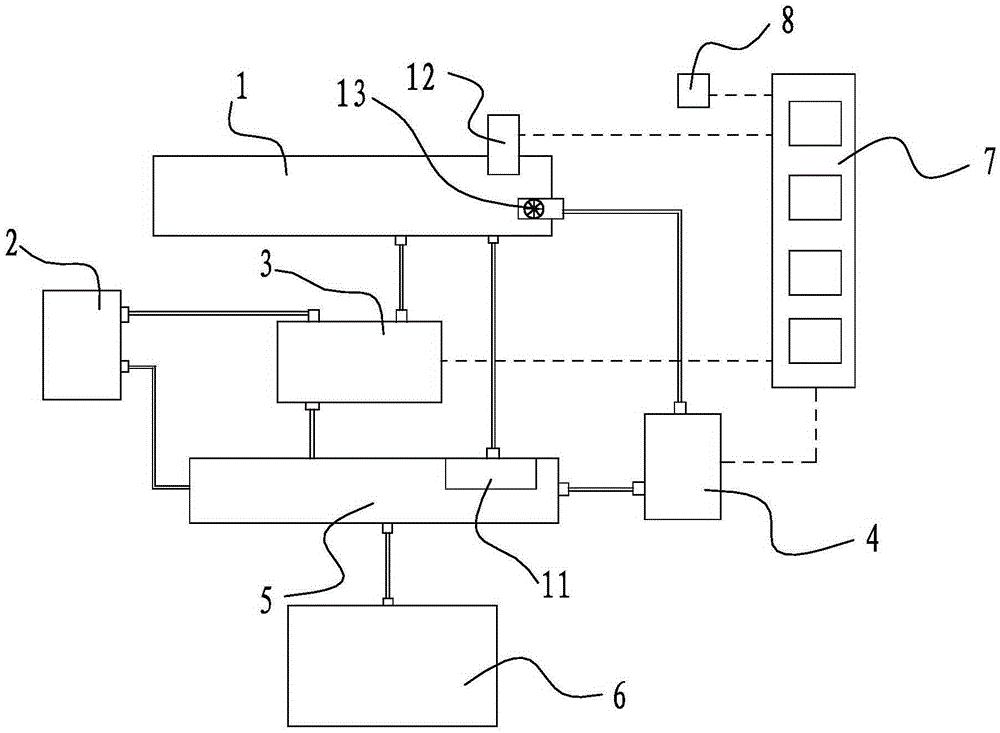

Laundry detergent casting system and washing machine

InactiveCN105401383AIncrease the amount addedGuaranteed washing effectOther washing machinesControl devices for washing apparatusDisinfectantInlet valve

The invention provides a laundry detergent casting system comprising a laundry detergent box, a disinfectant box, a water inlet valve, a metering pump, a water box, a washing barrel and a controller. The laundry detergent box is connected with a liquid injection port via a first pipeline and connected with the metering pump via a second pipeline; the water inlet valve is connected with the disinfectant box via a third pipeline and connected with a water box via a fourth pipeline; the water inlet valve is connected with the controller via a first line signal; the disinfectant box is connected with the water box via a fifth pipeline; the metering pump is connected with the water box via a sixth pipeline; the metering pump is connected with the controller via a second line signal; and the water box is connected with the washing barrel via a seventh pipeline. The beneficial effects of the laundry detergent casting system are that various demands for laundry detergent casting amount is considered according to cloth smudginess degree, so the laundry detergent can be prevented from blocking the pipelines; the barrel body of the washing barrel and clothes in the barrel can be disinfected; and after the laundry detergent in the laundry detergent box is used up, the laundry detergent box and post pipelines can be automatically cleaned.

Owner:QINGDAO AUCMA WASHING MACHINE

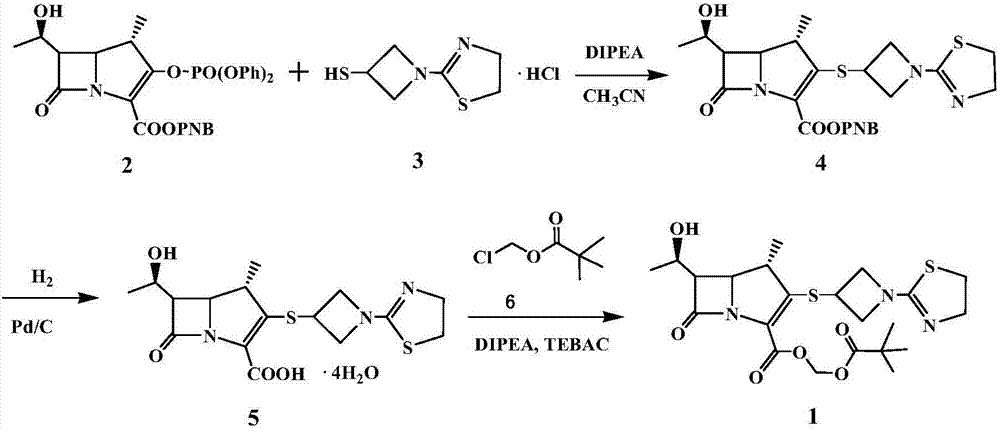

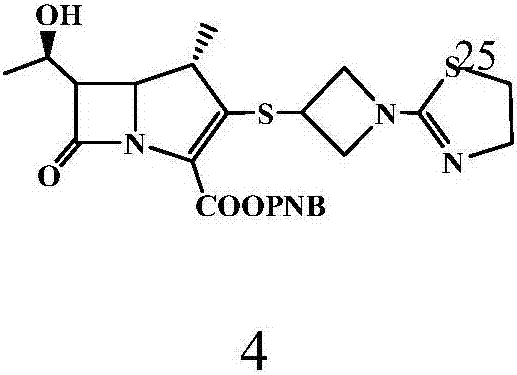

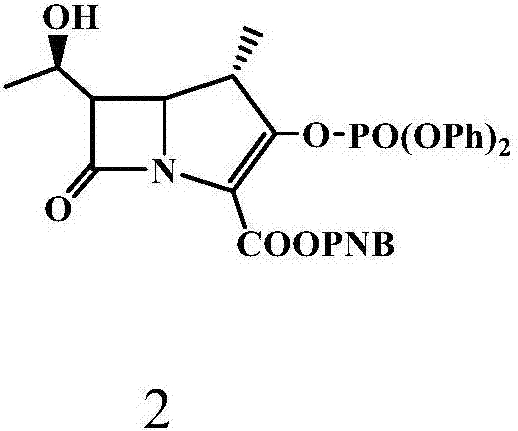

Preparation method of tebipenem pivoxil and intermediate thereof

ActiveCN107501268AHigh purityMild reaction conditionsOrganic chemistryReaction temperatureTEBIPENEM PIVOXIL

The invention provides a preparation method of tebipenem pivoxil. A three-step method synthesis route taking MAP (compound 2) and TAT (compound 3) as starting raw materials is adopted. The preparation method is characterized in that in the first step, the temperature of reaction for preparing an intermediate compound 4 of the tebipenem pivoxil from the MPA and the TAT is -4 to 5 DEG C. Compared with the preparation method using the three-step method synthesis route in the prior art, the preparation method has the following advantages: the step avoids ultralow reaction temperature, so that the method is mild in reaction condition, easy to implement and suitable for industrialized production; furthermore, the reaction yield in each step is increased and the purify of reactants is improved.

Owner:ZHEJIANG HISOAR CHUANNAN PHARMA +1

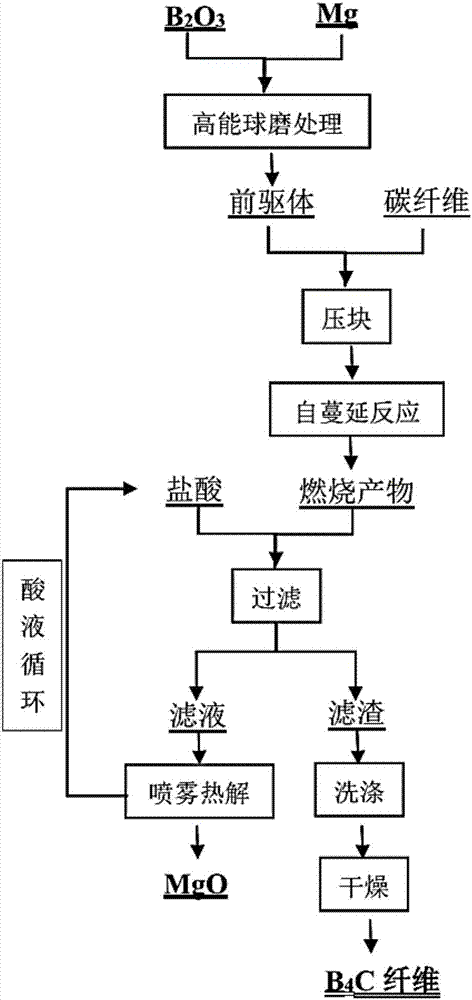

Method for preparing B4C fiber through in-situ combustion

The invention discloses a method for preparing B4C fiber through in-situ combustion, and belongs to the technical field of ceramic fibers. The method comprises the following steps: mixing boric oxide and magnesium powder according to a mole ratio, and performing mechanical activation treatment in a high-energy ball mill; further uniformly mixing with a carbon fiber according to a mole ratio, putting into a mold, pressing at 10-60MPa so as to obtain a blocky blank, and performing self-propagating reaction; soaking a product into diluted hydrochloric acid, performing intensified leaching in a sealed reaction kettle, and finally performing spray thermal decomposition, thereby obtaining a high-purity boron carbide fiber product. By adopting the method, a two-dimensional ceramic fiber material which is high in purity, high in activity and good in sintering property is prepared. The method is low in raw material cost, low in energy consumption, simple to operate and low in process condition and instrument equipment requirement, and the situations that a conventional two-dimensional fiber structure is high in energy consumption for producing B4C and low in yield are changed. Due to high-energy ball milling activation, defects of a conventional magnesiothermic reduction method are alleviated; and due to a self-propagating powdering technique, the prepared product has the advantages of being high in purity, controllable in granularity distribution and high in powder activity.

Owner:NORTHEASTERN UNIV

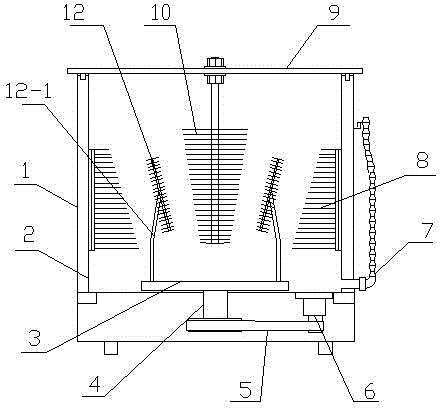

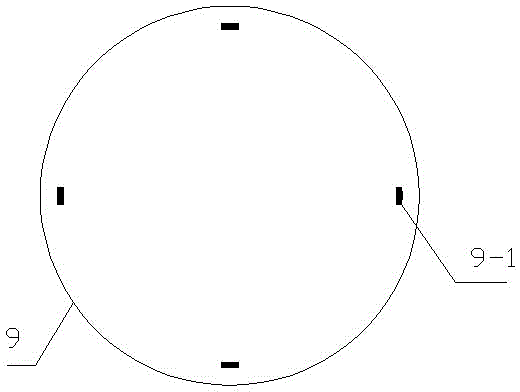

Shoe washing machine

InactiveCN104799798AImprove use reliabilityGuaranteed washing effectFootwear cleanersMechanical engineering

The invention discloses a shoe washing machine. The shoe washing machine comprises a washing barrel, a shell, a cover body and a rotating mechanism, the washing barrel is firmly connected with the shell, the rotating mechanism comprises a rotating plate and a drive mechanism for driving the rotating plate to rotate, the rotating plate is arranged in the washing barrel and extends to the outside of the washing barrel from the bottom of the washing barrel through a rotating shaft, the rotating shaft is driven by the drive mechanism, 3 to 5 side brushes are uniformly arranged at the upper side of the rotating plate along the circumference, the side brushes are provided with cylindrical brush bodies, and the central axial lines of the side brush bodies incline towards the outside in the same angle from the central axial line of the rotating plate; a vertically downward central brush is arranged on the cover body, the brush body of the central brush is cone shape of which the upside is large while the downside is small, and the height of the central brush is correspondingly matched with the height of each side brush of the rotating plate; the cover body is relatively static to the washing barrel under the working state. The shoe washing machine is reliable to use, good in washing effect, simple in structure, low in cost and good for popularization.

Owner:LUOYANG INST OF SCI & TECH

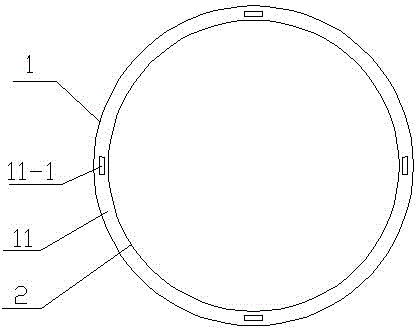

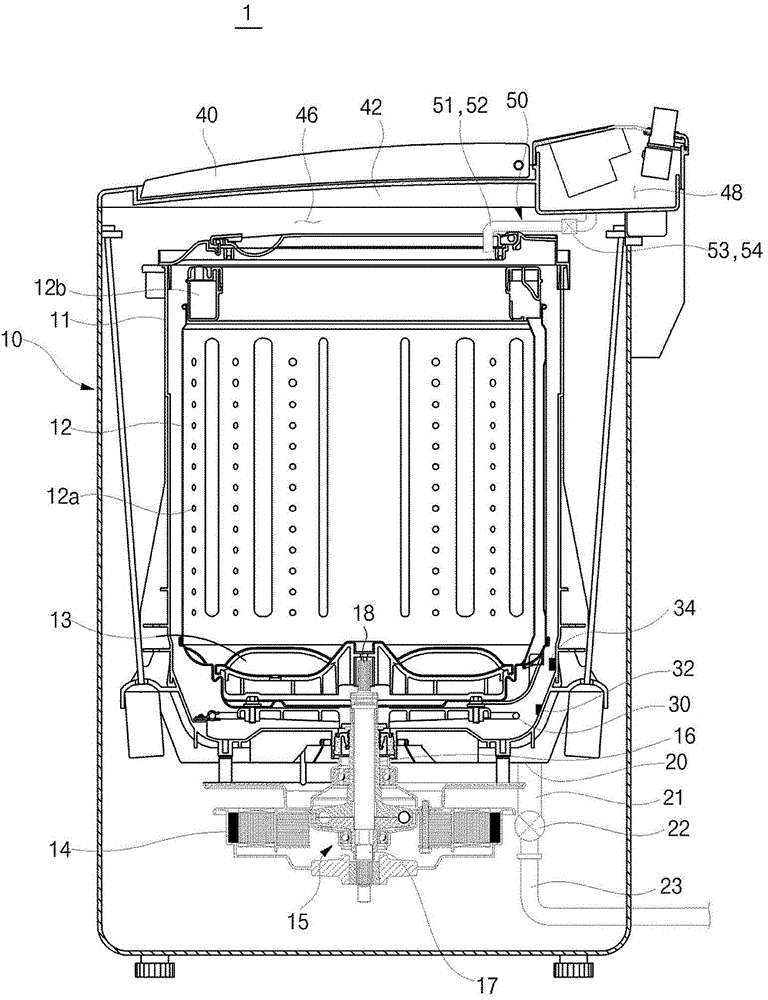

Washing machine and control method thereof

InactiveCN104420120ALower the water levelImprove washing effectOther washing machinesControl devices for washing apparatusEngineeringProcess engineering

A washing machine having a boiling washing course function to perform washing by heating water to increase a washing effect, and a control method thereof. In the washing machine and control method, it is possible to increase a washing effect by heating water for a predetermined time according to the temperature of the initially supplied water, draining the water if the temperature of the heated water is less than the set temperature, and maintaining the amount of the initially supplied water without draining the water if the temperature of the water is equal to or greater than the set temperature. Further, by allowing the water to reach the target temperature of a high temperature within a predetermined washing time while maintaining the amount of the initially supplied water, it is possible to maintain a washing effect due to a washing temperature thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

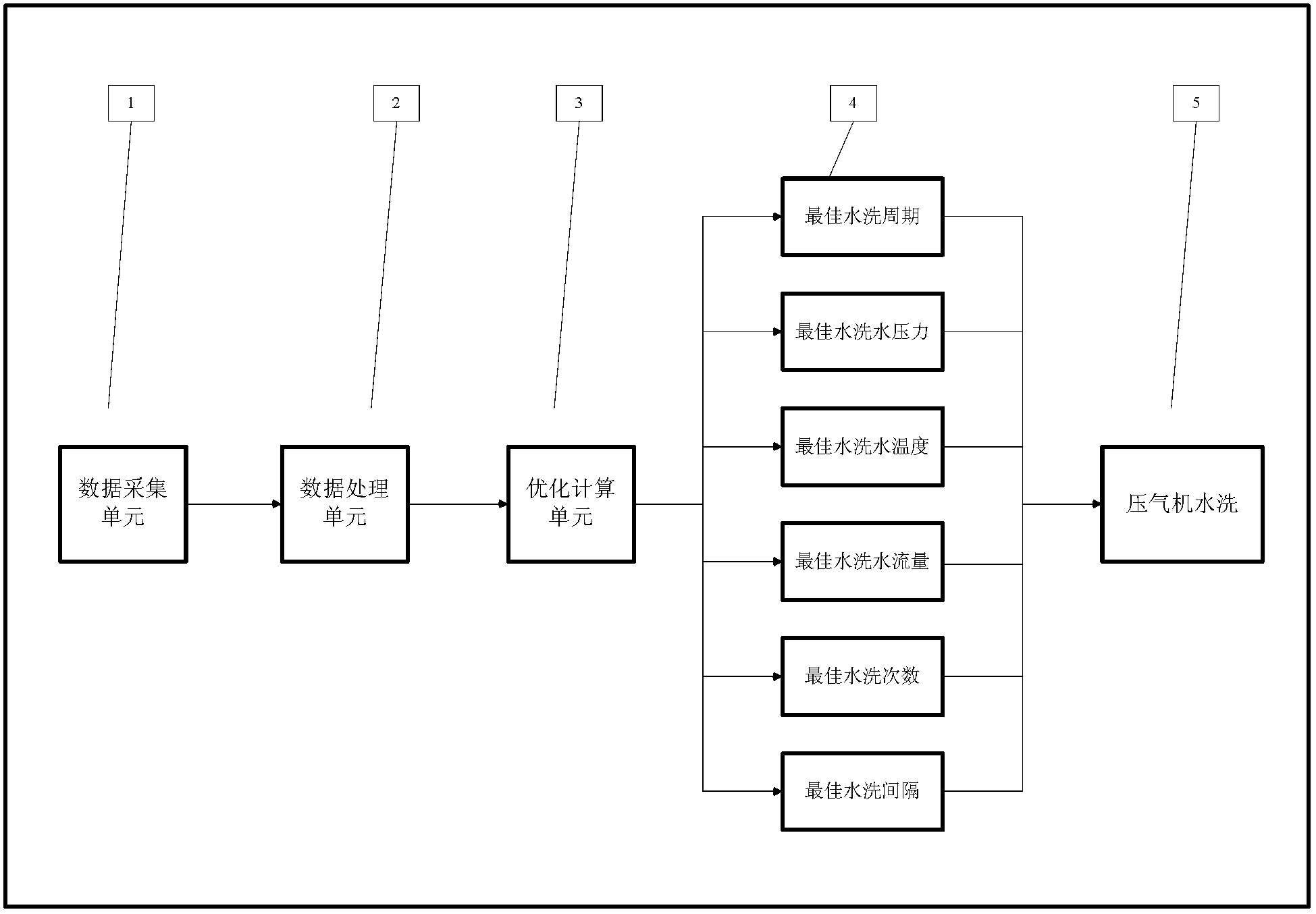

Method and device for washing compressor flow passage of gas-steam combined generating set

InactiveCN103212547AImprove work efficiencyGuaranteed accuracyEnergy industryCleaning using liquidsHardware structureData accuracy

The invention relates to a method and a device for washing a compressor flow passage of a gas-steam combined generating set. The method is characterized in that 1, according to an operating manner and an operating state of the gas-steam combined generating set, a data acquisition unit automatically leads out start-stop times, operating time and compressor efficiency from an SIS (Supervisory Information System of whole plant) system and summarizes the start-stop times, the operating time and the compressor efficiency into a basic data table; 2, the SIS system is connected with a field unit DCS (Distributed Control System) to acquire field data; 3, the basic data table is applied to complete a decline curve of working efficiency of a compressor by an optimization computation unit and by comparing historical data of washing the compressor and according to the historical data of washing the compressor, the optimal washing water pressure, washing water temperature and washing water flow of the compressor flow passage are formulated; and 4, by comparing the historical data of washing the compressor and according to the historical data of washing the compressor, washing operating detailed rules of the compressor flow passage are made, so that the method for washing the compressor flow passage of the gas-steam combined generating set is determined. The method and the device have the characteristic of simple hardware structure; the condition of an unstable data source can be avoided; data accuracy is ensured; and a good washing effect is ensured.

Owner:SHENZHEN GUANGQIAN ELECTRIC POWER

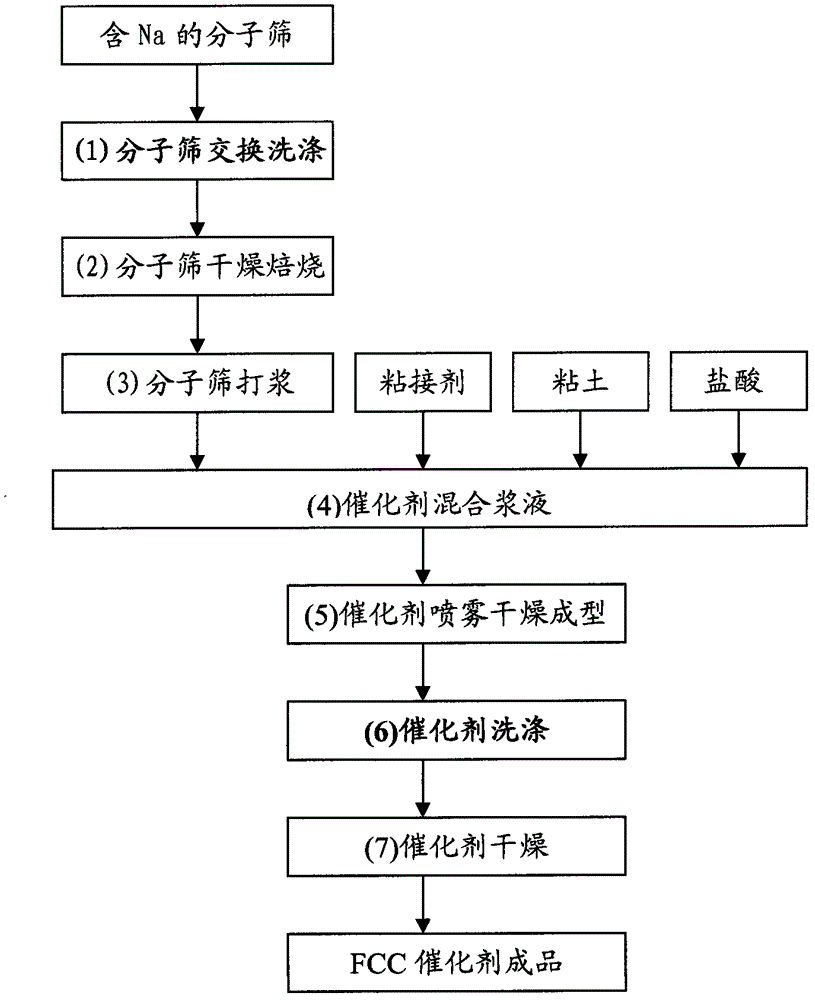

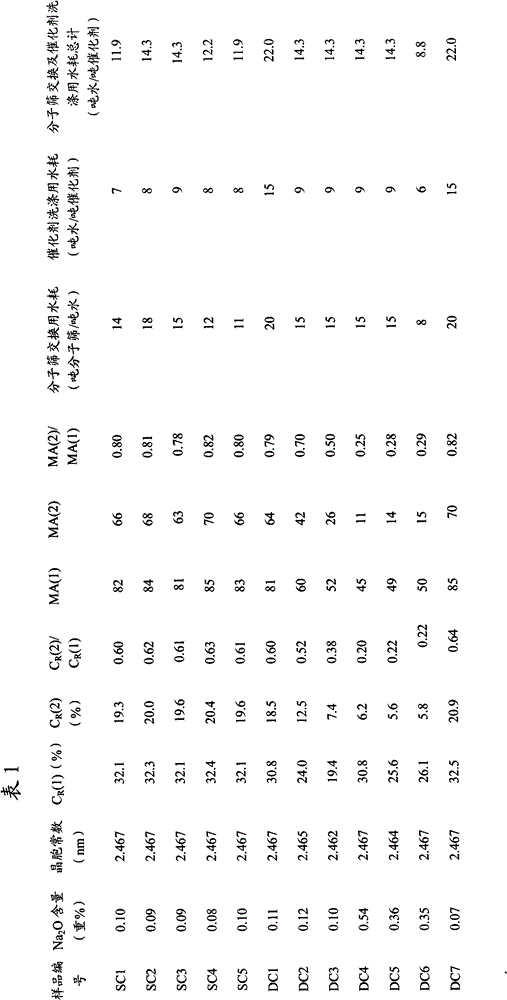

Method for preparing catalytic cracking catalyst

ActiveCN102794191AReduce sodium oxide contentReduce water consumptionMolecular sieve catalystsCatalyst activation/preparationMolecular sieveOrganic acid

The invention discloses a method for preparing a catalytic cracking catalyst. The method comprises the following steps of: performing molecular sieve exchange, preparing the catalyst, and washing the catalyst and is characterized in that the step of performing molecular sieve exchange comprises the following substeps of: contacting a molecular sieve and an aqueous solution containing organic acid and inorganic acid at the temperature of between 0 and 5 DEG C for 0.5 to 3 hours, wherein the weight ratio of H2O to the molecular sieve is (11-18):1; the step of washing the catalyst comprises the following substeps of: contacting the catalyst and the aqueous solution containing the organic acid and the inorganic acid at the temperature of between 0 and 5 DEG C for 10 to 30 minutes, wherein the weight ratio of H2O to the catalyst is (7-9):1; and based on the amount of H<+>, the concentration of the organic acid in the aqueous solution is 0.0001 to 0.2 mol / L, and the concentration of the inorganic acid is 0.0001 to 0.1 mol / L. According to the method, ammonium salt is not completely used in the preparation process of the catalyst, the problem of ammoniac nitrogen pollution can be solved from the source, and water consumption and the discharge of wastewater in the preparation process are reduced obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

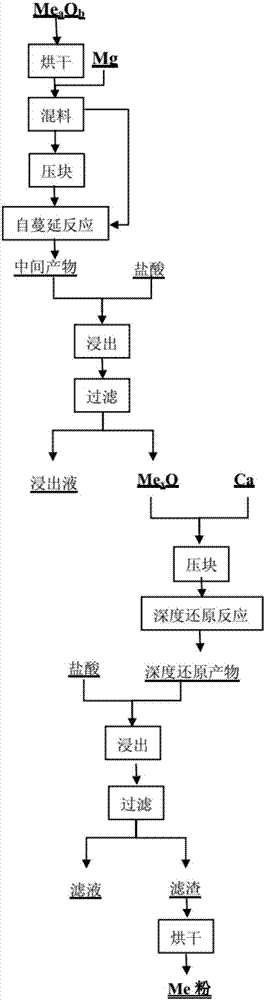

Method for preparing high-melting-point metal powder through multistage depth reduction

ActiveCN107236868AHigh activityRaise the temperature gradientProcess efficiency improvementGranularityMetal powder

The invention discloses a method for preparing high-melting-point metal powder through multistage depth reduction, and belongs to the technical field of powder preparing. The method comprises the steps that dried high-melting-point metallic oxide powder and magnesium powder are mixed and then subject to the self-propagating reaction, and high-melting-point metal Me is one or several of W, Mo, Ta, Nb, V, Zr, Hf or Re; intermediate products are placed in a seal reaction kettle, hydrochloric acid serves as a leaching agent to carry out leaching, and low-valence oxide MexO precursor of low-valence high-melting-point metal is obtained; the precursor is evenly mixed with calcium powder to be pressed, a mixture is placed in a vacuum reduction furnace, heating is carried out to enable the temperature to rise to 700 DEG C to 1200 DEG C, deep reduction is carried out for 1 h to 6 h, hydrochloric acid serves as the leaching agent to carry out leaching on a deep reduction product, and through treatment, high-melting-point metal powder is obtained. The method is low in raw material cost, easy to operate, and low in requirement for process and instrument equipment, the foundation is laid for industrial production, and the high-melting-point metal powder has the beneficial effects of being high in purity, controllable in granularity distribution, high in powder activity and the like.

Owner:NORTHEASTERN UNIV LIAONING

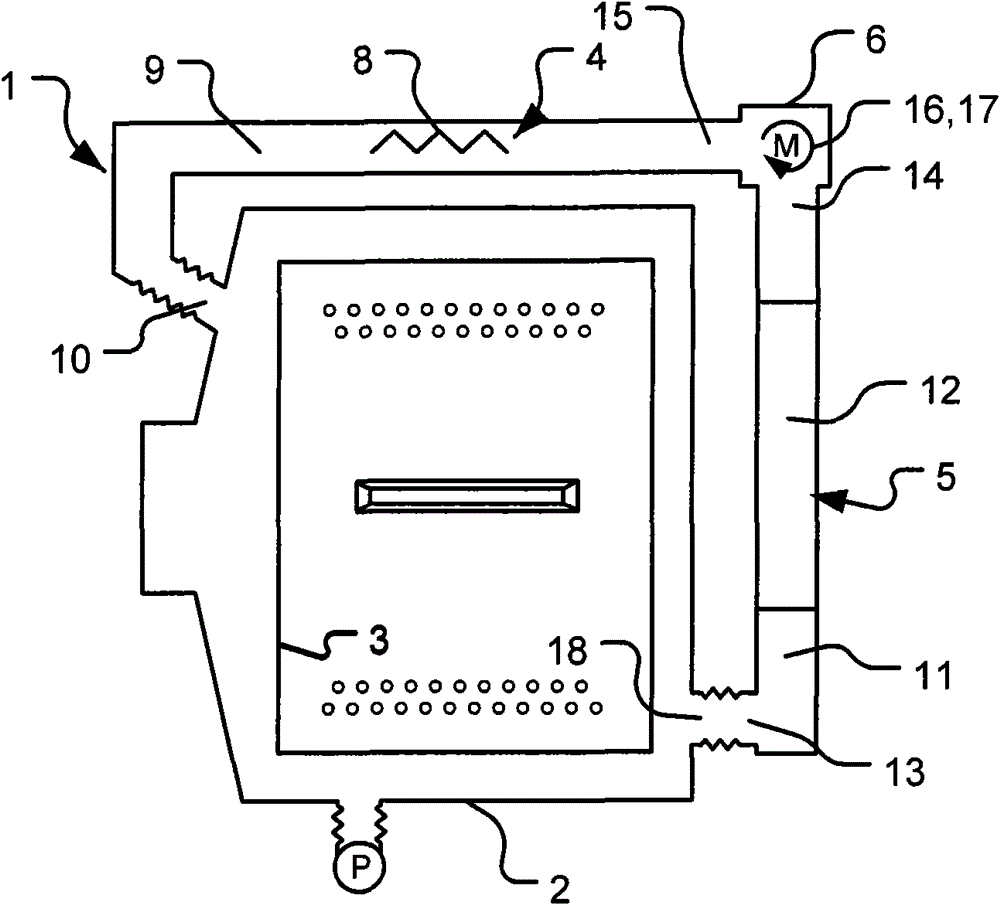

Cleaning machine heating method, cleaning machine and refrigerator with same

PendingCN109425187AImprove functionalityImprove space utilizationDomestic cooling apparatusLighting and heating apparatusProcess engineeringRefrigerated temperature

The invention relates to a cleaning machine heating method, a cleaning machine and a refrigerator with the same. Heat of a radiator of the refrigerator is blown into the cleaning machine to be used for heating washing water which enters the cleaning machine before washing and / or heating tableware after washing to realize drying of the tableware. By adopting the cleaning machine heating method, thecleaning machine and the refrigerator with the same, combination of the refrigerator with the cleaning machine is realized, and the space utilization rates of a kitchen and the refrigerator are increased, so that the functionality of the refrigerator is improved, and the space is saved; and meanwhile, by blowing the heat produced by the radiator of the refrigerator into the cleaning machine through a heat transferring device, the heat is used for heating the washing water and drying the tableware, so that energy consumption is reduced to the maximum, and the purposes of energy conservation and environmental protection are achieved.

Owner:QINGDAO HAIER DISHWASHER

Clothing drying equipment having drying program and control method thereof

ActiveCN101988260BGuaranteed washing effectGuaranteed drying effectTextiles and paperLaundry driersAir cycleProcess engineering

A clothes washing device 1 with a drying procedure and a method of controlling the same are provided. The clothes washing device 1 includes a water tub 2, a drum 3 rotatably disposed in the water tub 2 to receive clothes of a user, a heating member 4 for heating air to perform drying operation on the clothes, and a blower for driving air circulation. The clothes washing device 1 is provided with a washing procedure for performing washing operation on the clothes placed in the drum 3 by the user, and further provided with a cleaning procedure for performing cleaning operation by intermittently driving the blower 6. Through the cleaning procedure, the lint generated during the washing procedure and drying procedure can be washed away, thus ensuring a washing effect and drying effect of the device.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

Environment-friendly household clothes/dish washing bag

The invention discloses an environment-friendly household clothes / dish washing bag which comprises a liquid clothes / dish washing liquid and a solid clothes / dish washing sheet, wherein the liquid clothes / dish washing liquid is packaged by a water soluble film material, and the liquid clothes / dish washing liquid and the solid clothes / dish washing sheet are then placed in a packaging bag made from the water soluble film material. The solid clothes / dish washing sheet comprises a single layer or a layer overlaid by two layers. The bag disclosed by the invention is reasonable in formula and multiple-effective, and various active components coexist in the packaging bag made from the water soluble film material in liquid and solid states, so that the bag is not only strong in greasy dirt removing capacity, but also is energy-saving and environment-friendly. The bag is suitable for rinsing common colored or white clothes and cleaning tableware, tea sets, wine glass and the like.

Owner:YUYAO DEPAI COMMODITY LTD

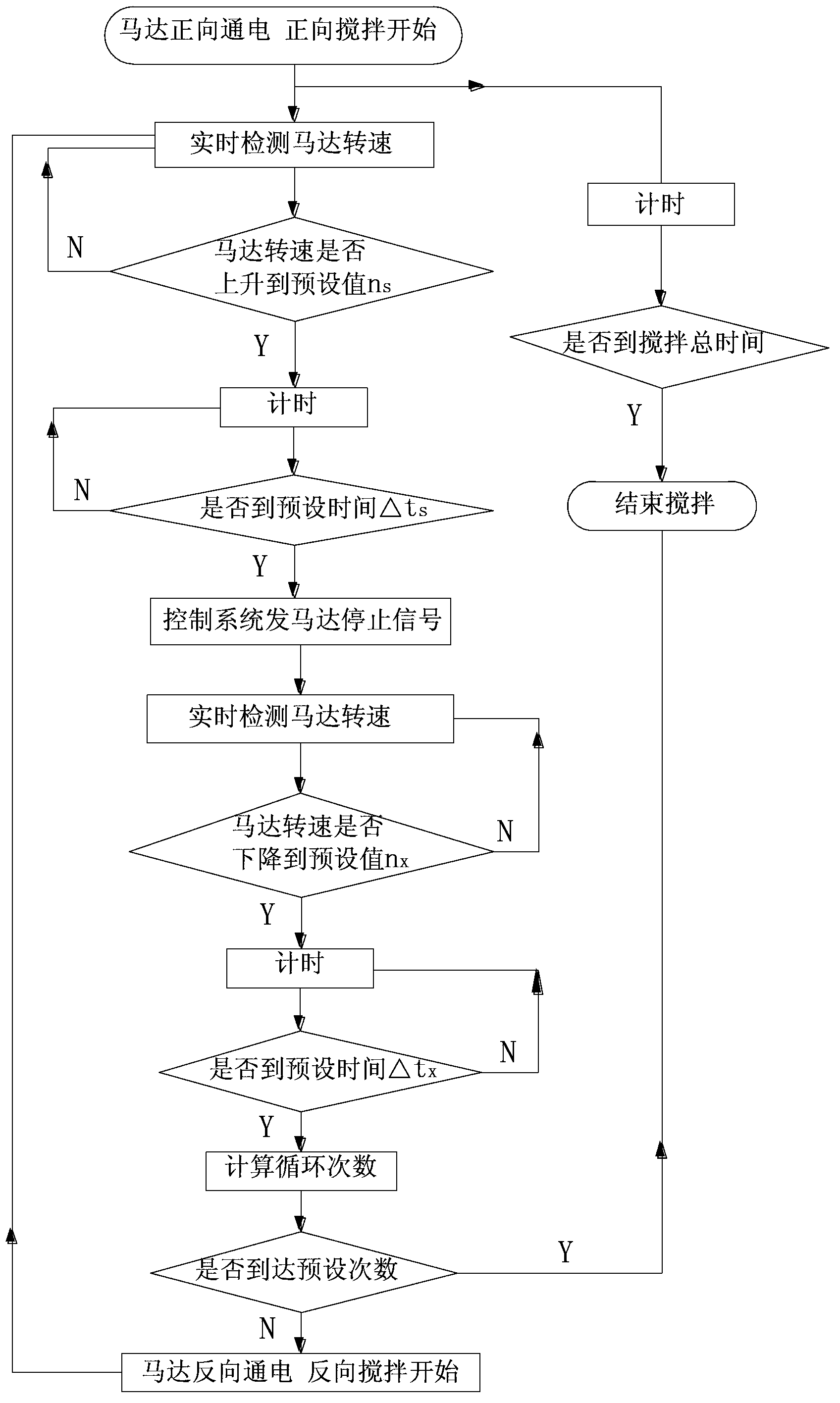

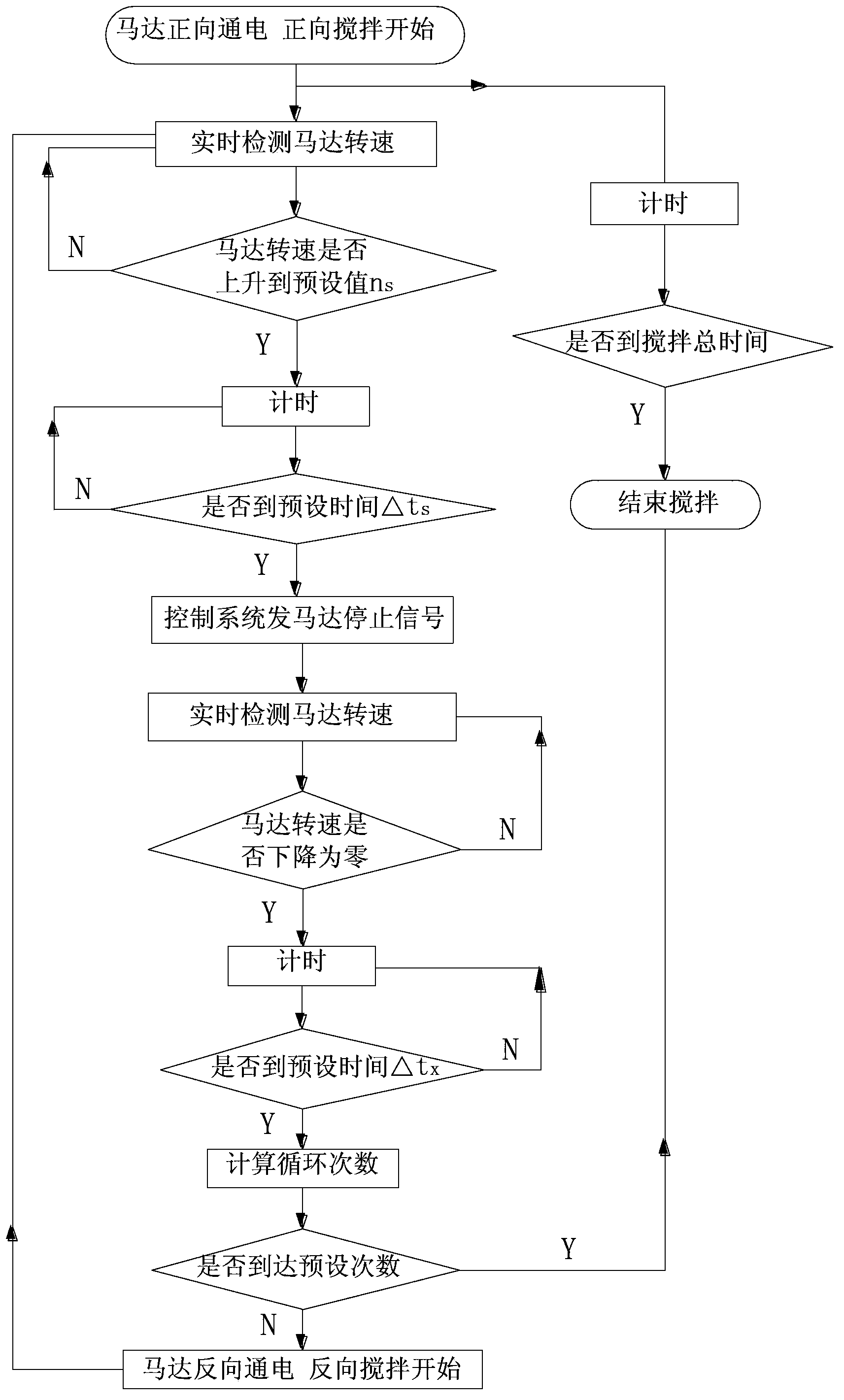

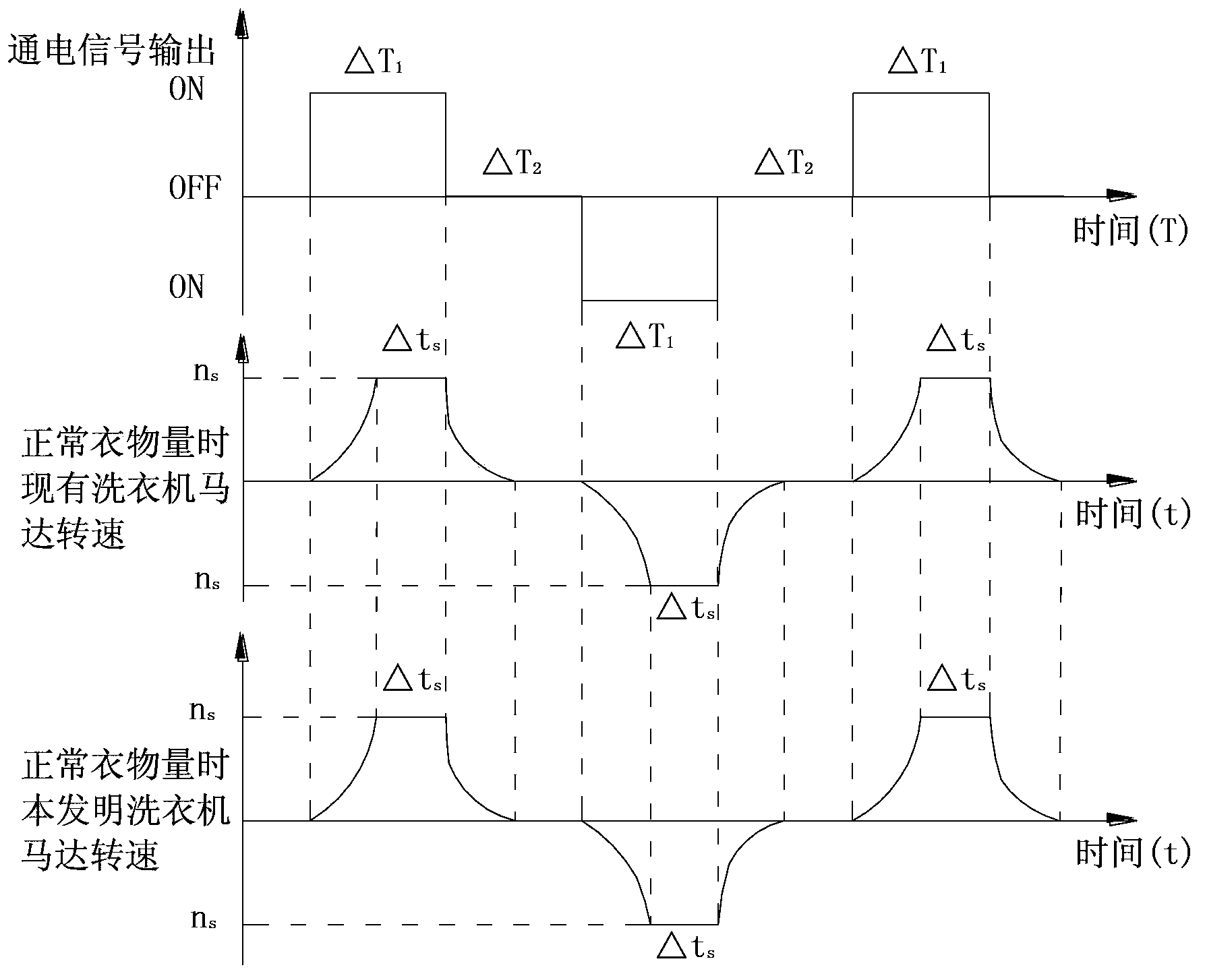

Method for controlling clothes stirring of washing machine

InactiveCN103409967AIntelligently adjust working statusGuaranteed washing effectControl devices for washing apparatusTextiles and paperMotor speedMode control

The invention discloses a method for controlling clothes stirring of a washing machine. When a control system controls a motor to begin to run according to a selected washing mode, a motor rotating speed detection device detects the rotating speed of the motor in a real-time mode. The control system further controls the motor according to one or two preset conditions that in any rotating speed ascending stage of the motor stirring motion, when the motor rotating speed detection device detects that the rotating speed of the motor ascends to the preset rotating speed ns, the control system controls the motor to run for delta ts seconds under the state that the rotating speed is not less than the rotating speed ns, and then the motor enters the rotating speed descending stage; in any rotating speed descending stage of the stirring motion, when the motor rotating speed detection device detects the rotating speed of the motor descends to the preset rotating speed nx, the control system begins to keep time for delta tx seconds, and the control system begins to execute the motion of the next step after the preset delta tx seconds are reached. According to the control method, when the number of washed clothes is large, the washing effect of the clothes is ensured, and when the number of the washed clothes is small, electric energy can be saved.

Owner:PANASONIC HOME APPLIANCES R&D CENT HANGZHOU +1

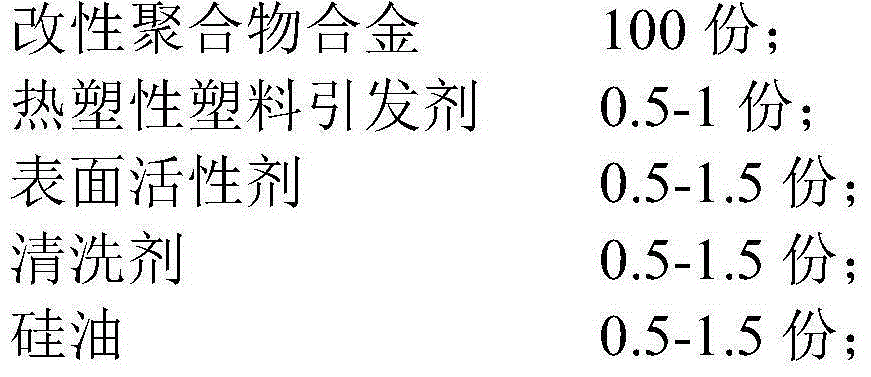

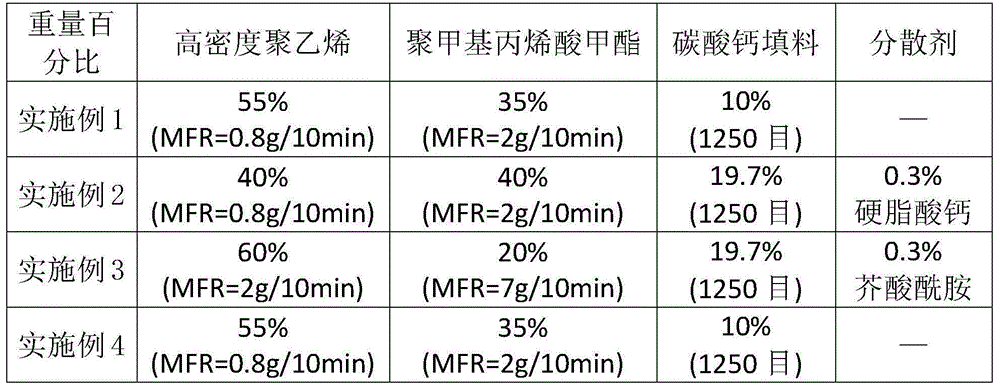

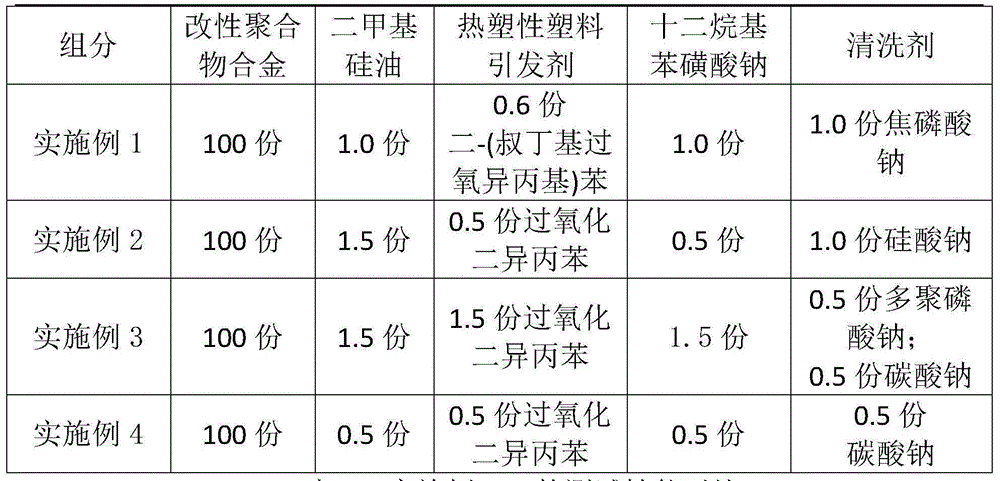

Special general polymer material for machine cleaning and preparation method thereof

The invention provides a special general polymer material for machine cleaning and a preparation method thereof. The special general polymer material comprises, by weight, 100 parts of modified polymer alloys, 0.5-1 part of thermoplastic plastic initiator, 0.5-1.5 parts of surface active agents, 0.5-1.5 parts of cleaning agents and 0.5-1.5 parts of silicon oil. The modified polymer alloys comprise, by weight, 40-60% of high-density polyethylene, 20-40% of polymethyl methacrylate and 10-20% of calcium carbonate filling. The special general polymer material has the advantages of being high in machine cleaning efficiency, environmentally friendly, safe, high in generality and easy to use, store and transport.

Owner:TIANJIN KINGFA NEW MATERIAL

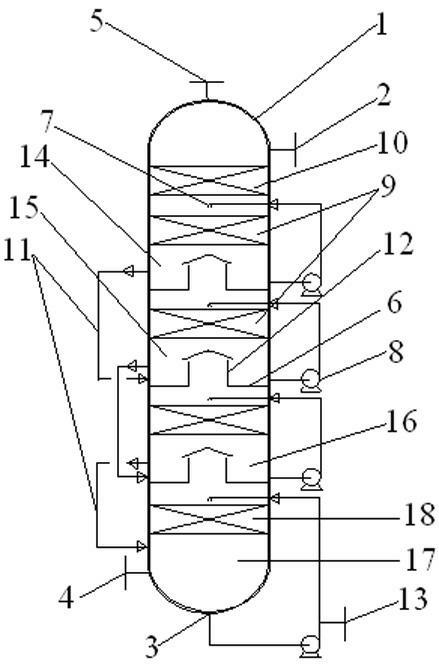

Circulating washing tower

InactiveCN102430304AReduce concentrationConcentration does not exceedUsing liquid separation agentEngineeringTower

The invention relates to a circulating washing tower, which comprises a tower body, wherein a liquid sprayer is arranged above tower plates; liquid storage space is connected with the liquid sprayer by a circulating pump in at least a primary gas-liquid exchange unit and a secondary gas-liquid exchange unit; the adjacent gas-liquid exchange spaces are connected by a downcomer; a unit filling bed is arranged below the liquid sprayer and above the tower plates transversely; a first filling bed is transversely arranged above the highest liquid sprayer and at the position which is lower than a liquid inlet; a second filling bed is arranged in the gas-liquid exchange space at the bottommost part of the tower body, and the liquid sprayer is arranged above the second filling bed; a liquid outlet is connected with the liquid sprayer in the space to which the liquid outlet belongs by the circulating pump; an effluent outlet capable of being opened and closed is formed on a liquid inlet pipe at the bottommost part of the tower body; a gas ascending pipe of which the opening is upward is arranged on each tower plate, and the top of the gas ascending pipe is higher than that of the downcomer arranged in the gas-liquid exchange unit to which the gas ascending pipe belongs; and the liquid flow of the circulating pump is 20 to 25 times that of the liquid inlet.

Owner:陕西煤业化工技术开发中心有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com