Method for treating black water of coal gasification system

A treatment method and coal gasification technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of low water vapor in syngas, large amount of circulating cooling water, and large material flow, so as to improve the water-gas ratio, reduce power consumption, The effect of efficient use of matter and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

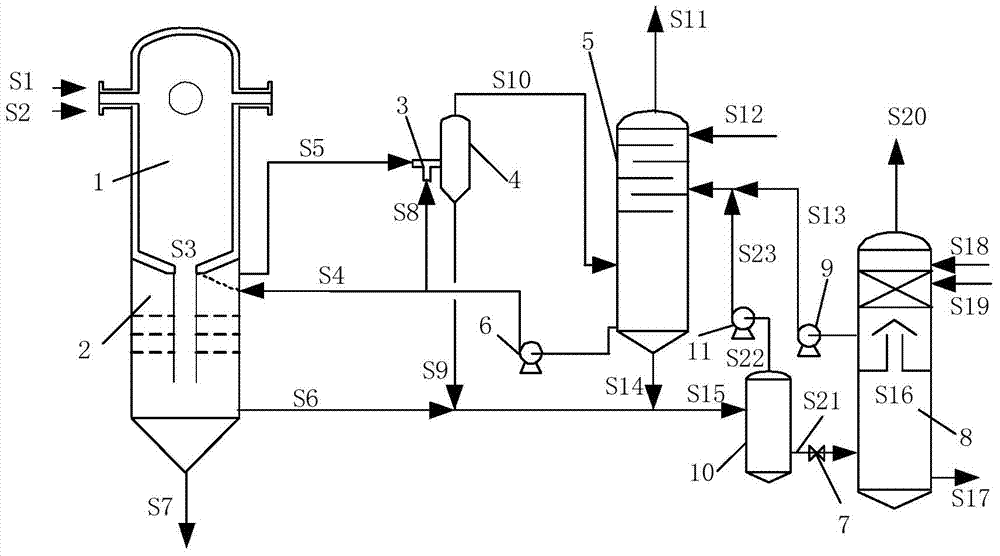

Method used

Image

Examples

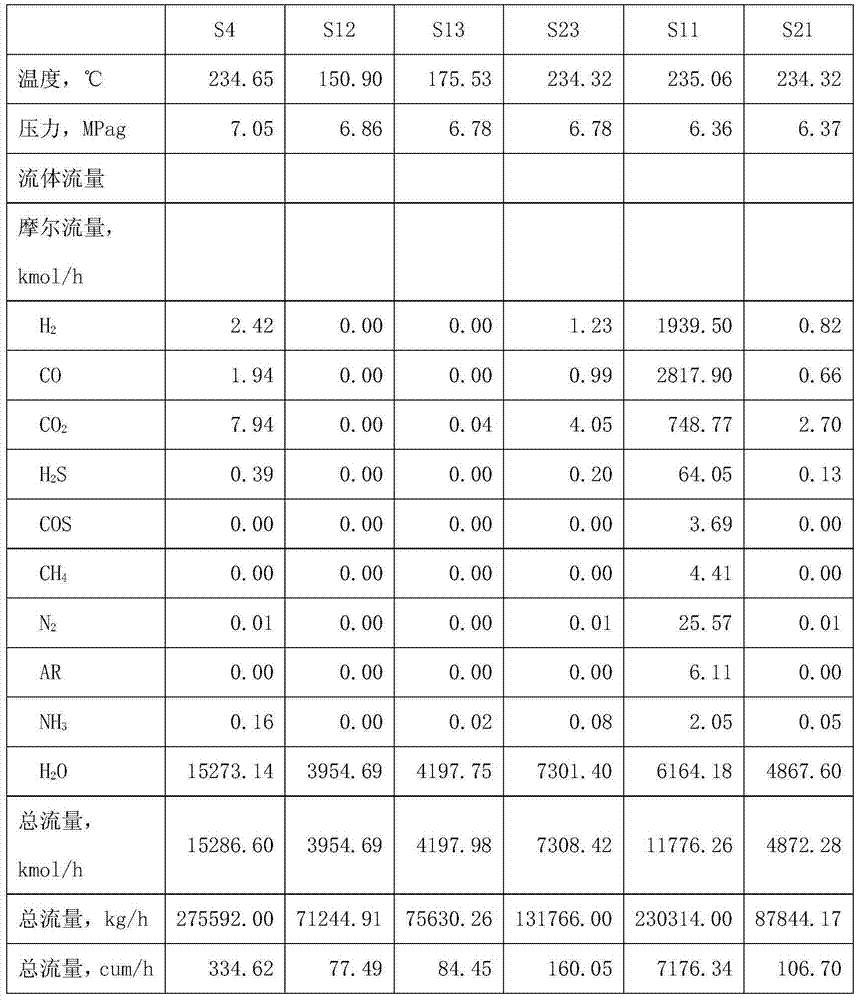

Embodiment 1

[0043] For hydrogen production units that use a mixture of petroleum coke and coal as raw materials, wet-feed gasification technology is used. The pressure of the gasifier is 6.5MPaG, the temperature is 1300°C, the slurry concentration is 63%, and the effective gas (CO+H 2 ) output is 100000Nm 3 / h, the gasifier is lined with refractory bricks. Table 1 shows the analytical data after mixing petroleum coke and coal. Table 2 is the main gasification process indicators.

[0044] Table 1 Analytical data after mixing petroleum coke and coal

[0045] Industrial Analysis

Mar,wt%

10.63

FCd,wt%

85.93

Vd,wt%

11.24

Ad,wt%

2.84

Cd,wt%

84.58

Hd,wt%

4.13

[0046] Nd,wt%

1.40

Sd,wt%

4.16

Od,wt%

2.88

[0047] Table 2 Main gasification process indicators

[0048] carbon conversion rate

%

97

Effective gas...

Embodiment 2

[0058] For hydrogen production units that use coal as raw material, dry feed gasification technology is used. The pressure of the gasifier is 4.0MPaG, the temperature is 1344°C, the pulverized coal uses nitrogen as the transport medium, and the effective gas (CO+H 2 ) output is 60000Nm 3 / h, the gasifier adopts water-cooled wall lining. Table 5 is the analysis data of pulverized coal into the furnace, and Table 6 is the main gasification process indicators.

[0059] Table 5 Pulverized coal analysis data

[0060] Industrial Analysis

[0061] Table 6 Main gasification process indicators

[0062] carbon conversion rate

[0063] Using the solid-liquid separator of the treatment method of the present invention to separate black water, the high-temperature gray water flow rate for direct reuse is 50% of the total amount of black water in the chilling chamber, cyclone separator, and water washing tower, and the solid separation efficiency is 85%. Table 7 and T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com