High-CO high-conversion-rate isothermal shift reactor

A technology of isothermal conversion and reactor, which is applied in chemical instruments and methods, bulk chemical production, inorganic chemistry, etc., can solve the problems of easy aging of reaction catalysts, high conversion rate requirements, and large thermal stress of pipelines, etc., to achieve high conversion High efficiency, simple process, and the effect of less cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

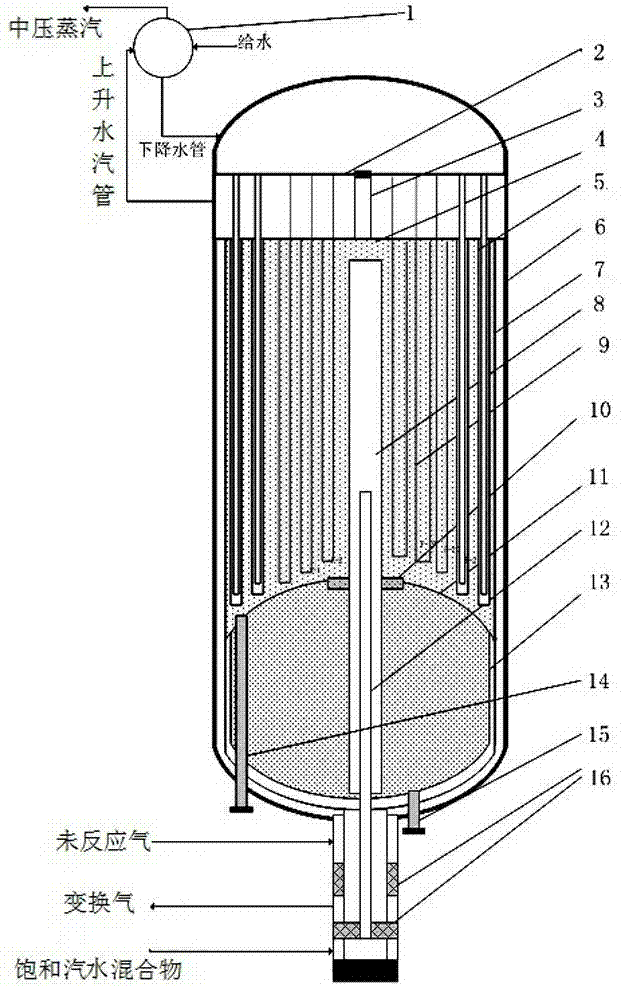

[0077] The CO in the unreacted gas of the present invention can be as high as 85% or more, and the CO in the shifted gas can be reduced to 0.4%. The shift reactor catalyst is a sulfur-resistant cobalt-molybdenum catalyst composed of MOS and COS. The temperature of the catalyst bed in the present invention is within the low-end range of the active temperature (230°C- 310°C), the maximum temperature difference between the axial and radial directions of the reaction bed is only within 3°C to 8°C.

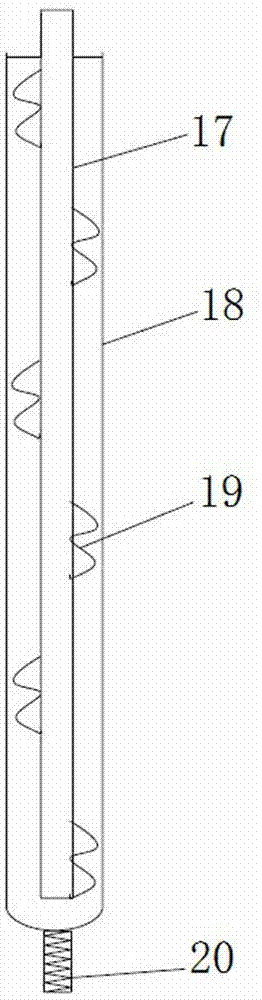

[0078] The isothermal shift reactor 5 is cylindrical as a whole, such as image 3 As shown, by upper tube plate 2, charging tube 3, lower tube plate 4, double sets of water vapor pipes 5, shell 6, upper radial catalytic bed 7, center pipe 8, U-shaped water vapor pipe 9, annular communicating hole 10, The support head 11, the steam-water mixture nozzle 12, the lower radial catalytic bed 13, the upper discharge pipe 14, the lower discharge pipe 15, the sealing packing 16, the bottom tee...

Embodiment 2

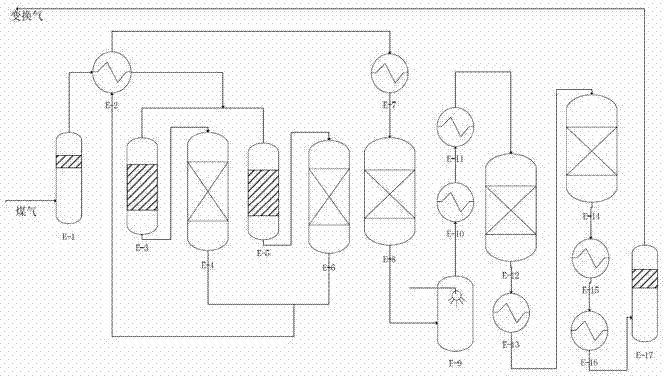

[0090] Such as Figure 4 As shown, the CO volume concentration matched with the isothermal shift reactor of the present invention is 40% to 70%, and the gas shift process flow of water-gas ratio is 1.3 to 1.6, which consists of the first water separator E-41, the heat exchanger E -42, purification and detoxification devices E-43, E-44, isothermal shift reactor E-45, first waste heat boiler E-46, second waste heat boiler E-47, second water separator E-48, Boiler feed water heater E-49, water cooler E-410, third water separator E-411. During operation, the coal containing CO passes through the first water separator E-41 and enters the heat exchanger E-42. The unreacted gas is heated to 230°C-240°C and enters the purification and detoxification devices E-43, E-44, Chlorine, phosphorus, oxygen, and hydrocarbons in the gas are removed here, and a small amount of CO is also converted. After the gas temperature rises to 255 ° C ~ 265 ° C, it enters the isothermal shift reactor E-45,...

Embodiment 3

[0093] Such as Figure 5 As shown, the CO 50%-85% industrial furnace gas (such as acetylene furnace gas, steelmaking converter, yellow phosphorus furnace gas) conversion process flow matched with the isothermal shift reactor of the present invention.

[0094] Industrial furnace gas is characterized by high C0% content (40% to 85%), basically no water vapor, basically no sulfur, but high dust content, high oxygen content, and acetylene furnace gas also contains unsaturated hydrocarbons.

[0095] Such as Figure 5 As shown, the isothermal transformation process is used to match the process by E-51 washing tower, E-52 water separator, parallel filters E-53, E-54, compressor E-55, oil remover E-516, purification and removal Poison E-56, E-57, Hydrogenation Converter E-517, Isothermal Shift Reactor E-58, Steam Dryer E-59, Heat Exchanger E-510, Boiler Desalination Water Heater E-511, Desalination Composed of oxygen water heater E-512, air cooler E-513, fifth water separator E-514,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com