Patents

Literature

1481 results about "Water cooler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A water dispenser, known as water cooler (if used for cooling only), is a machine that cools and dispenses water with a refrigeration unit. It is commonly located near the restroom due to closer access to plumbing. A drain line is also provided from the water cooler into the sewer system.

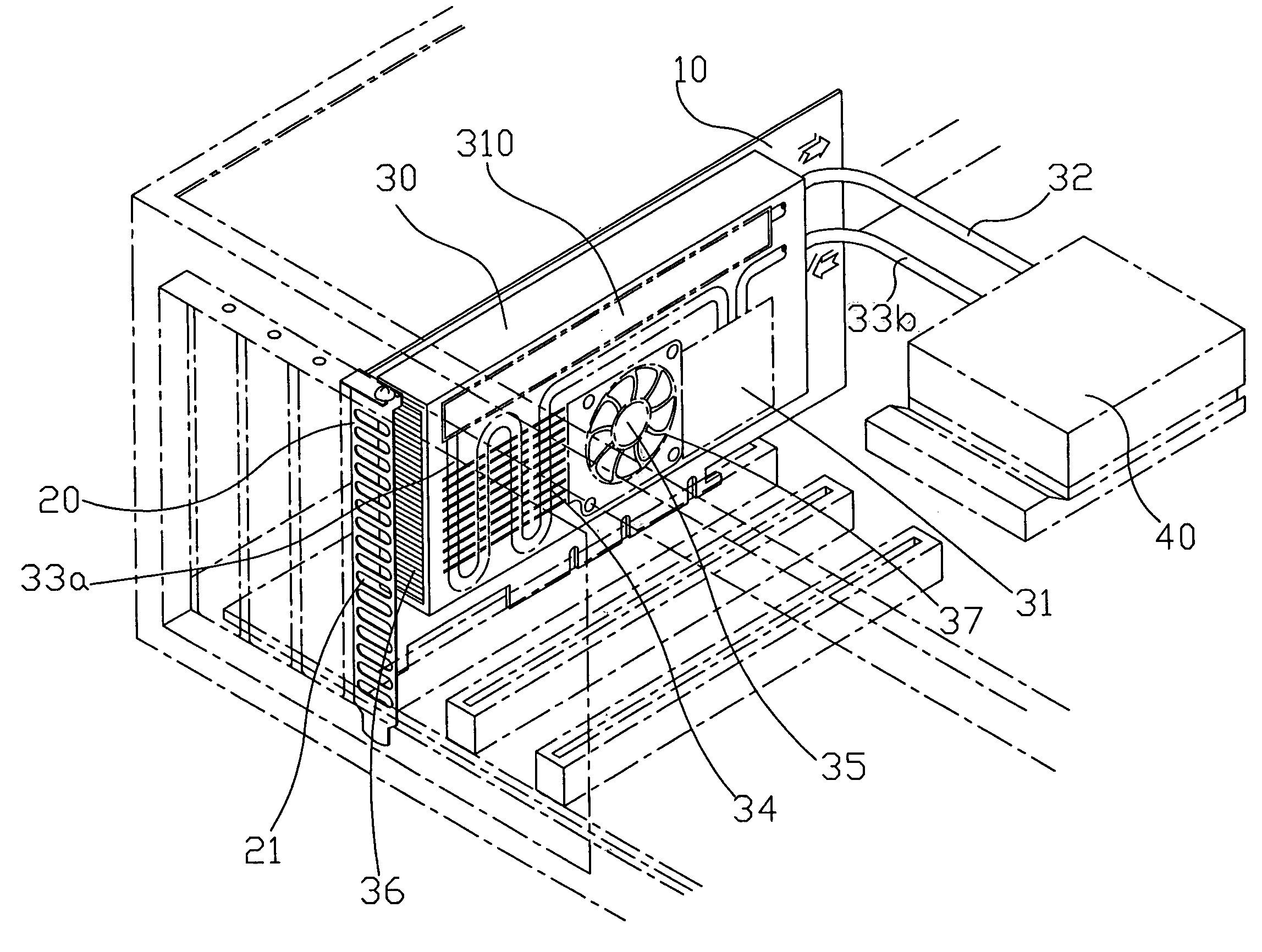

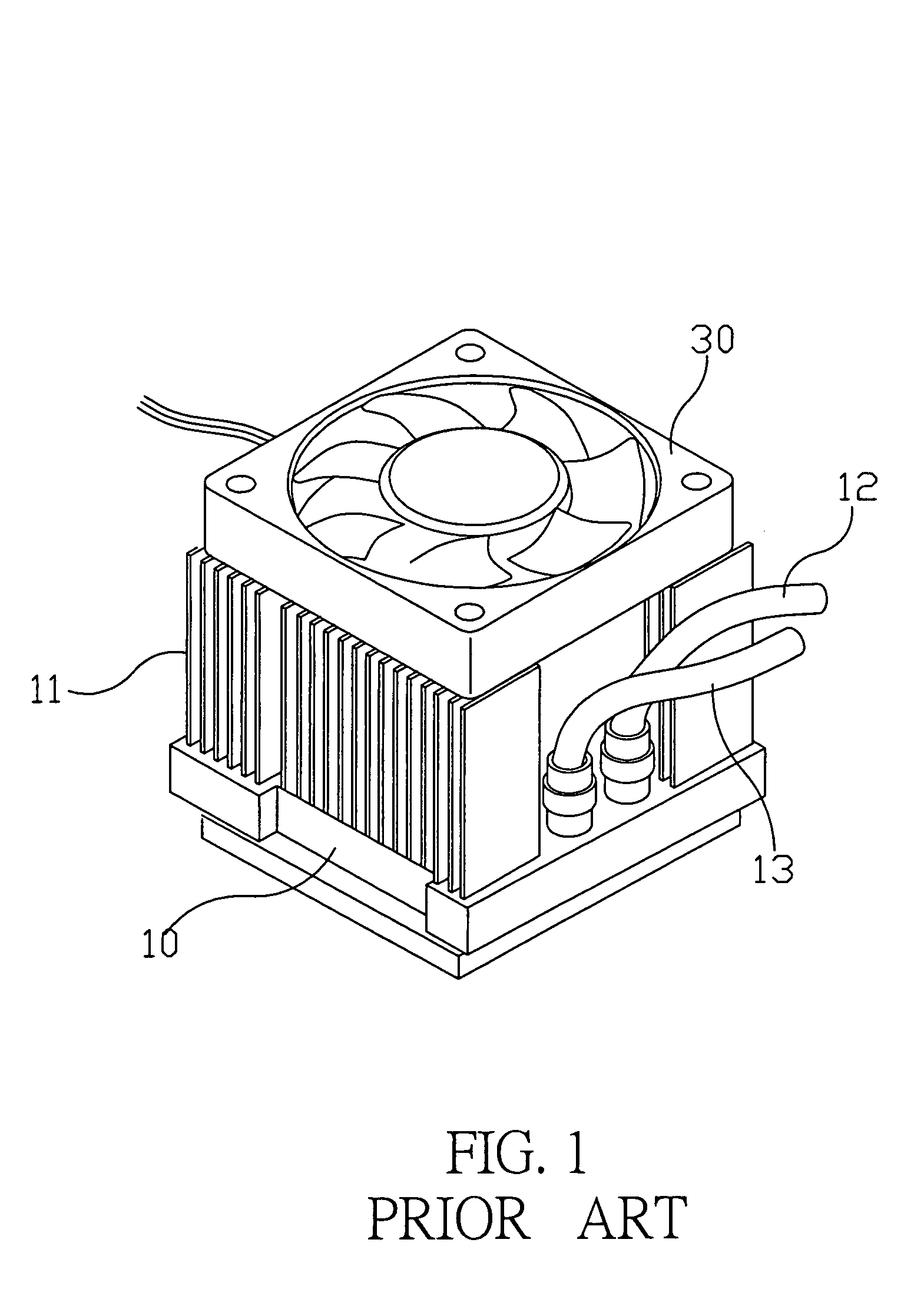

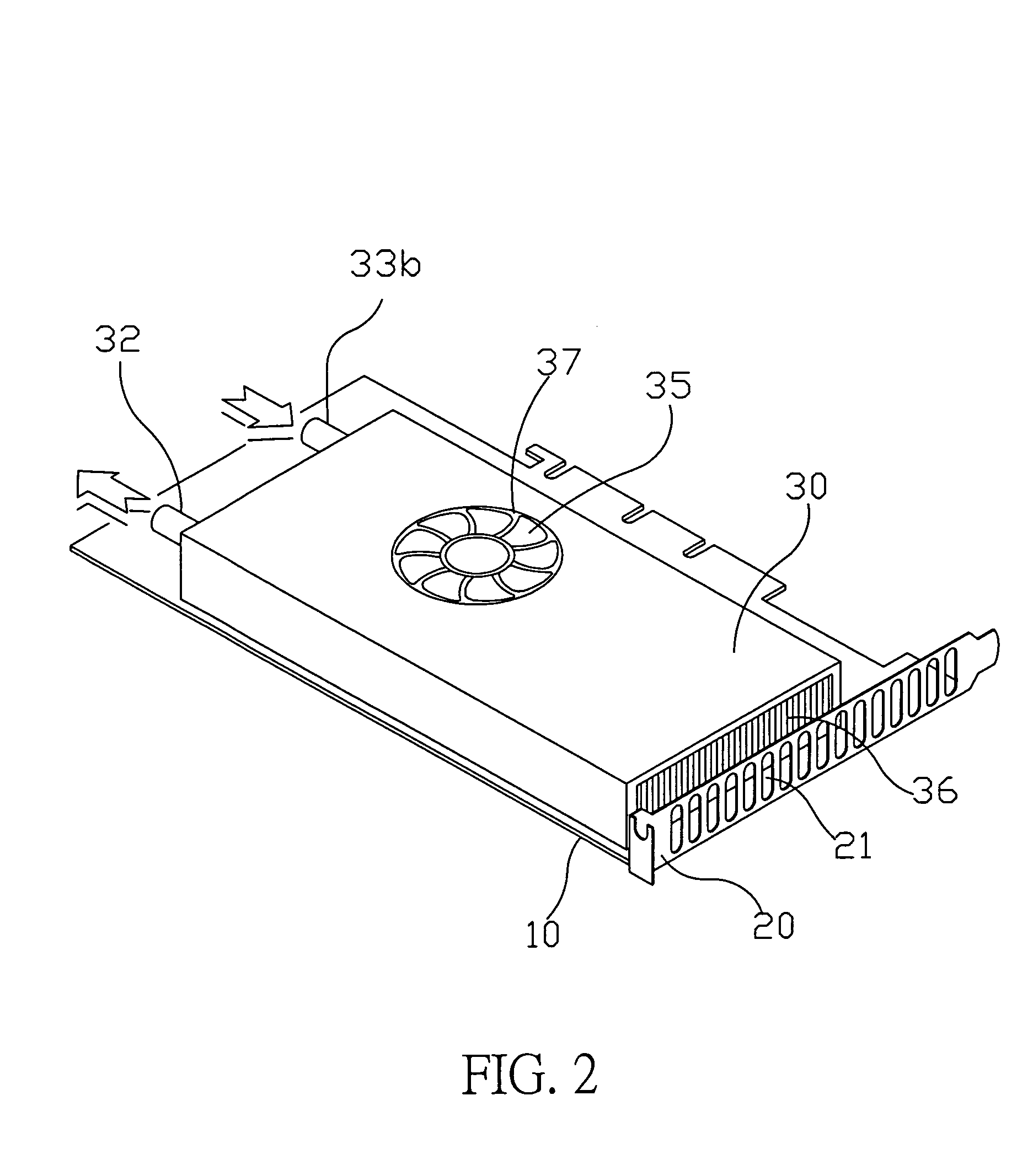

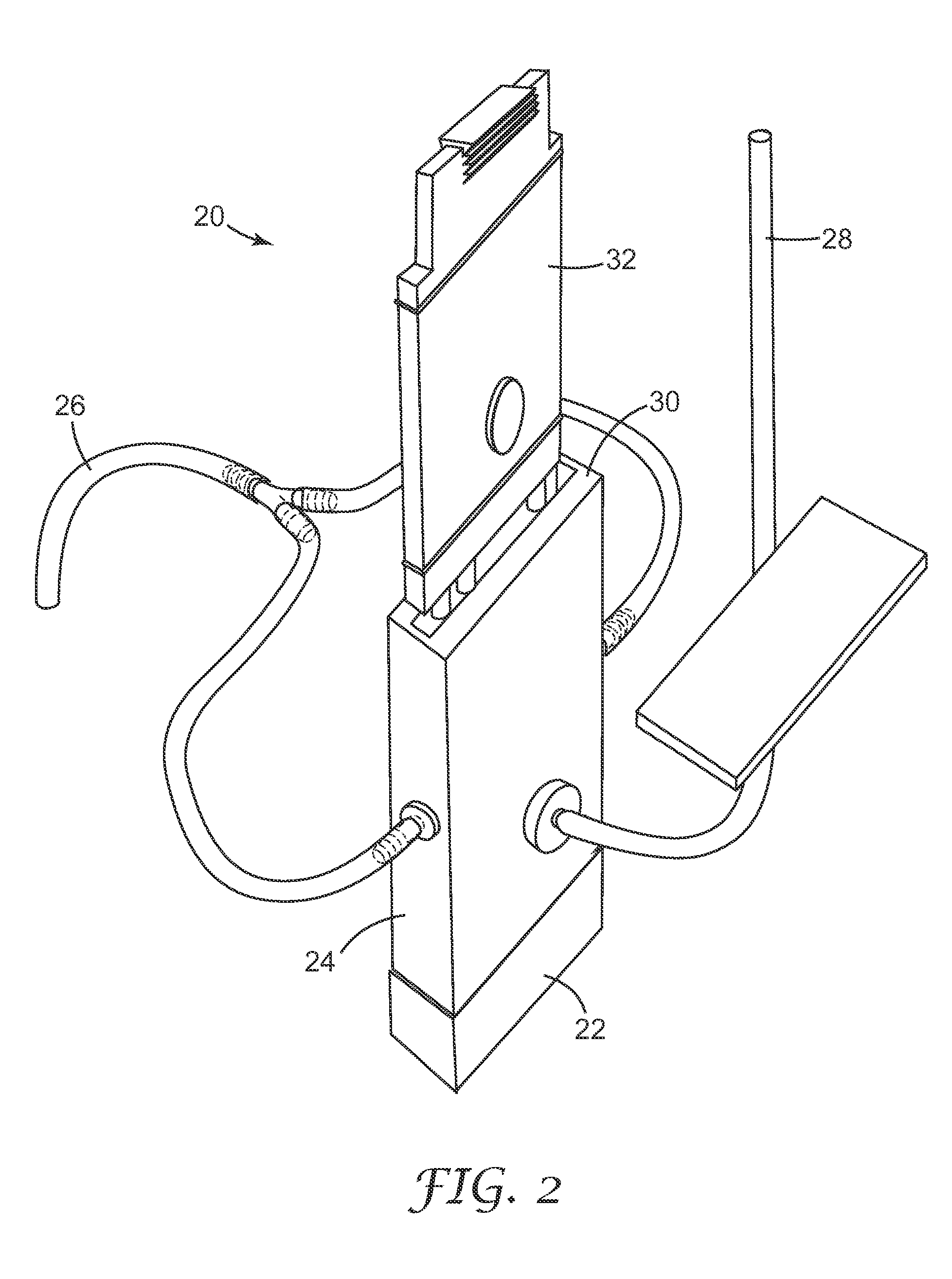

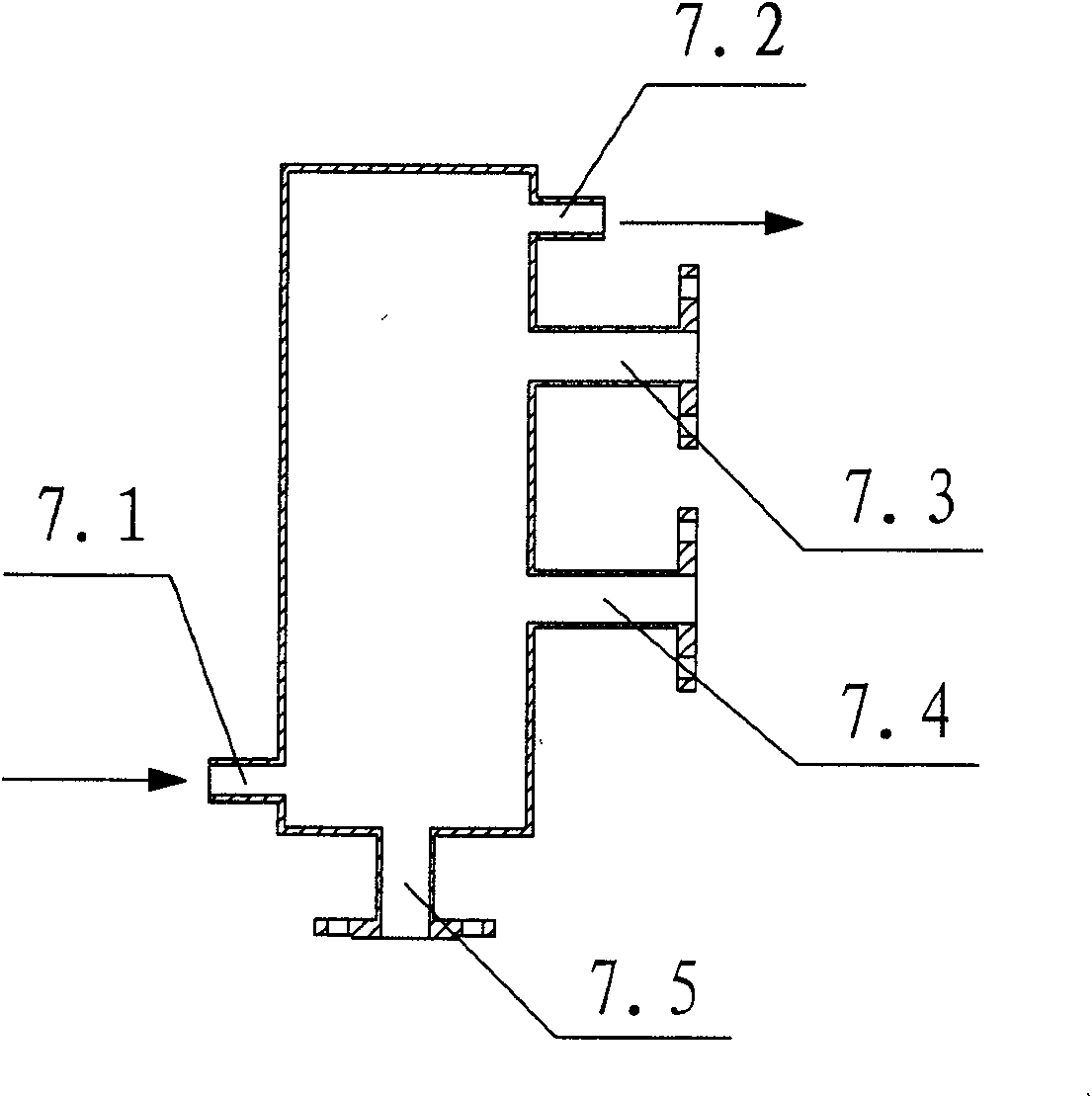

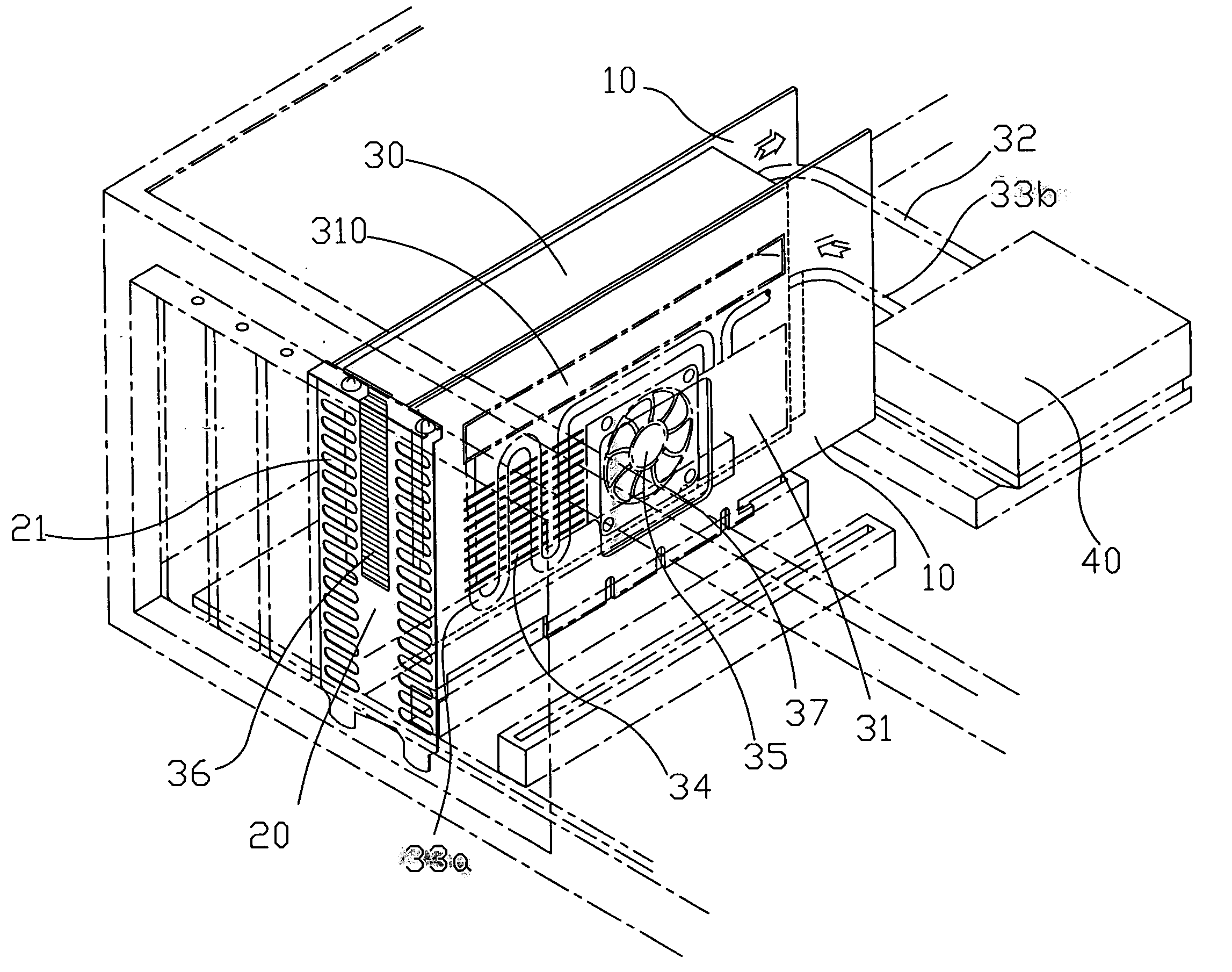

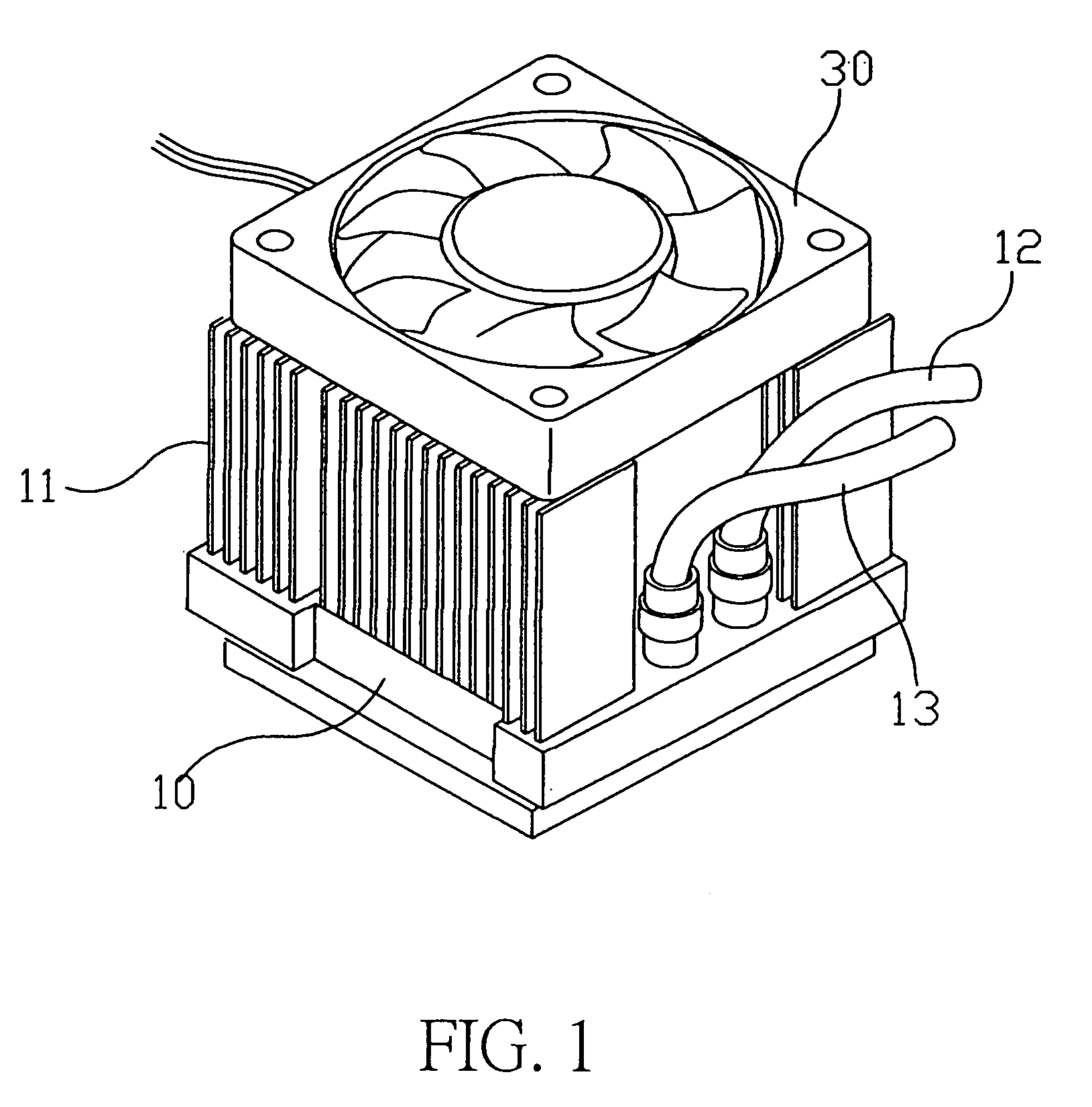

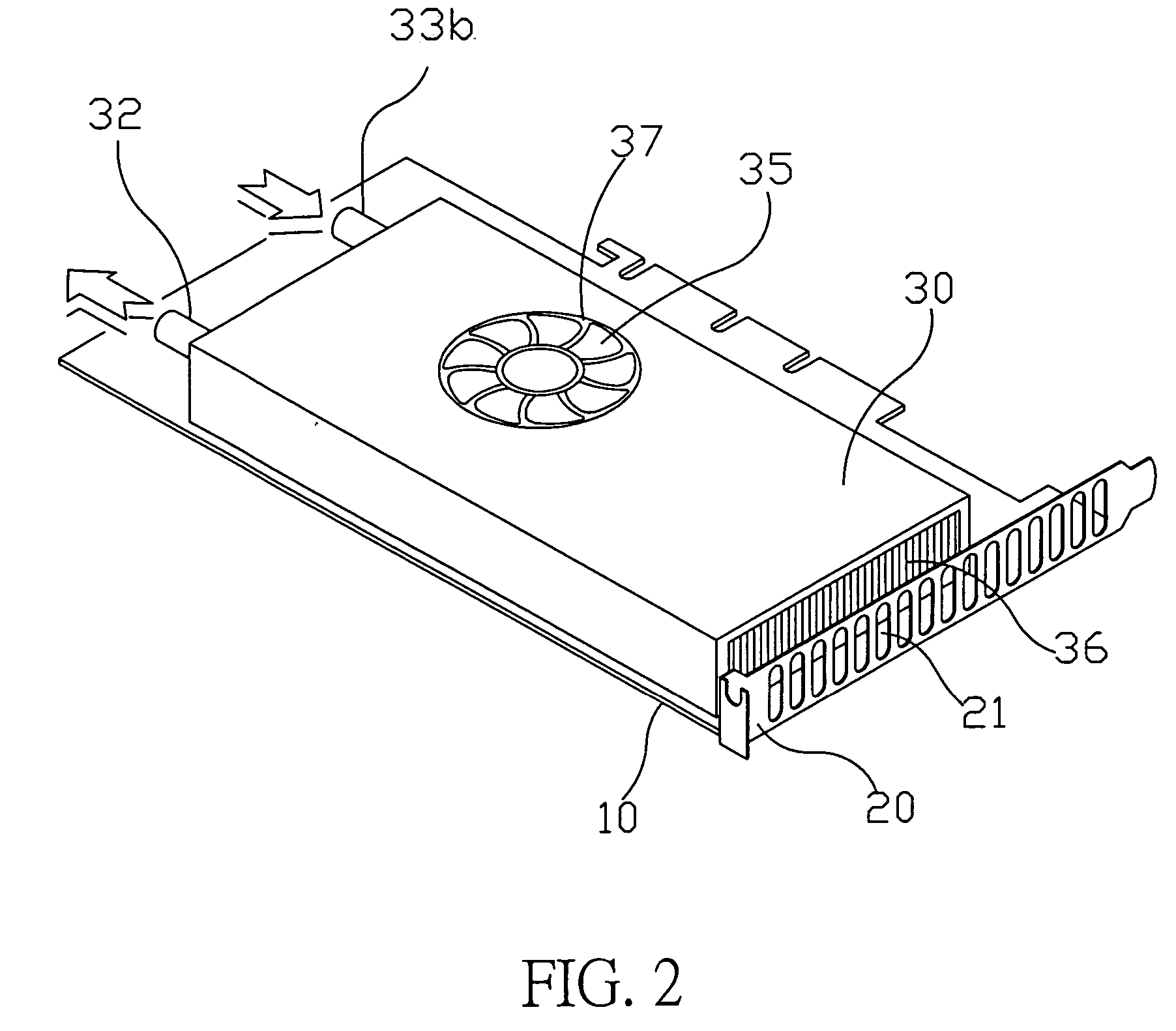

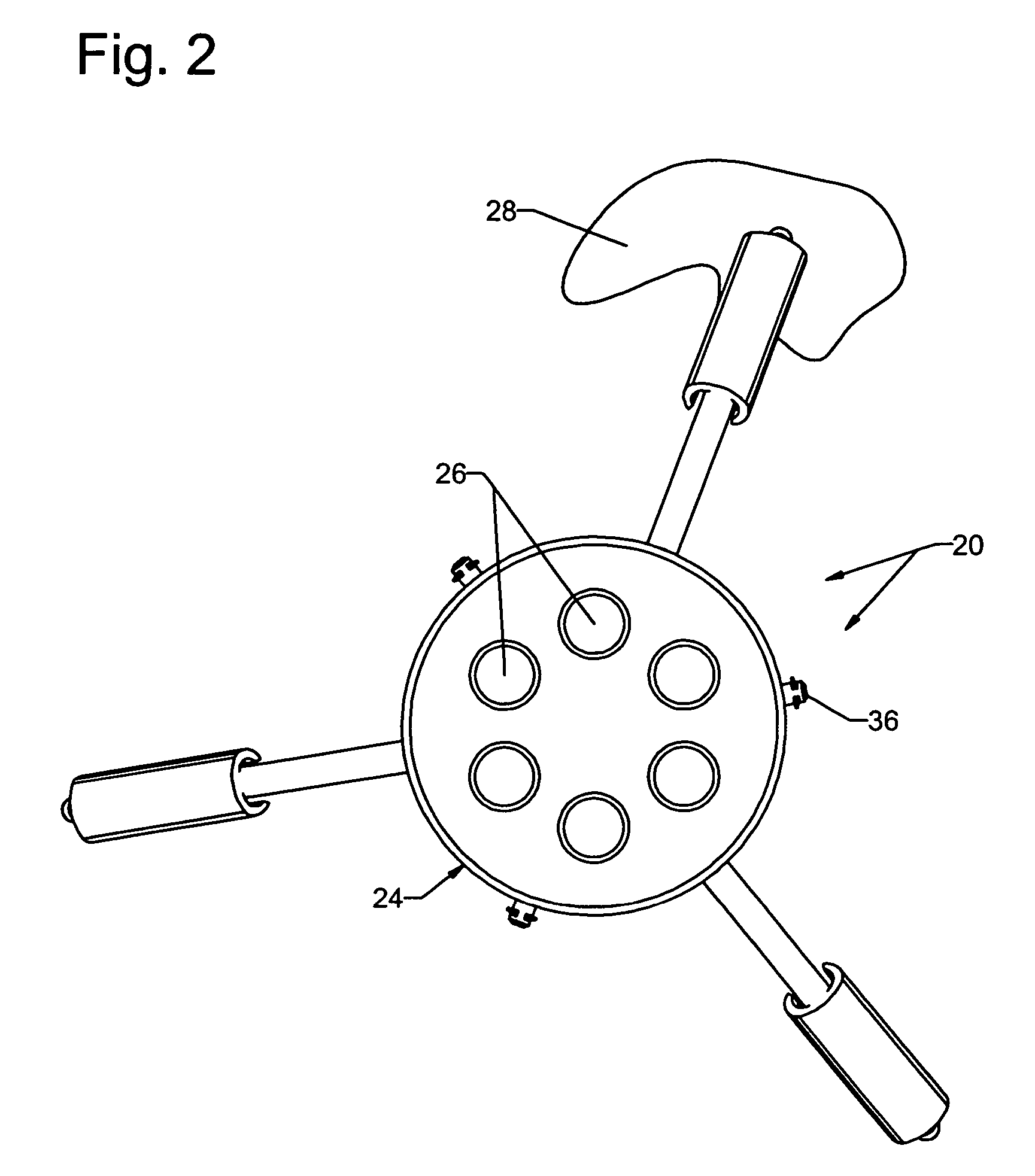

Water-cooler radiator module

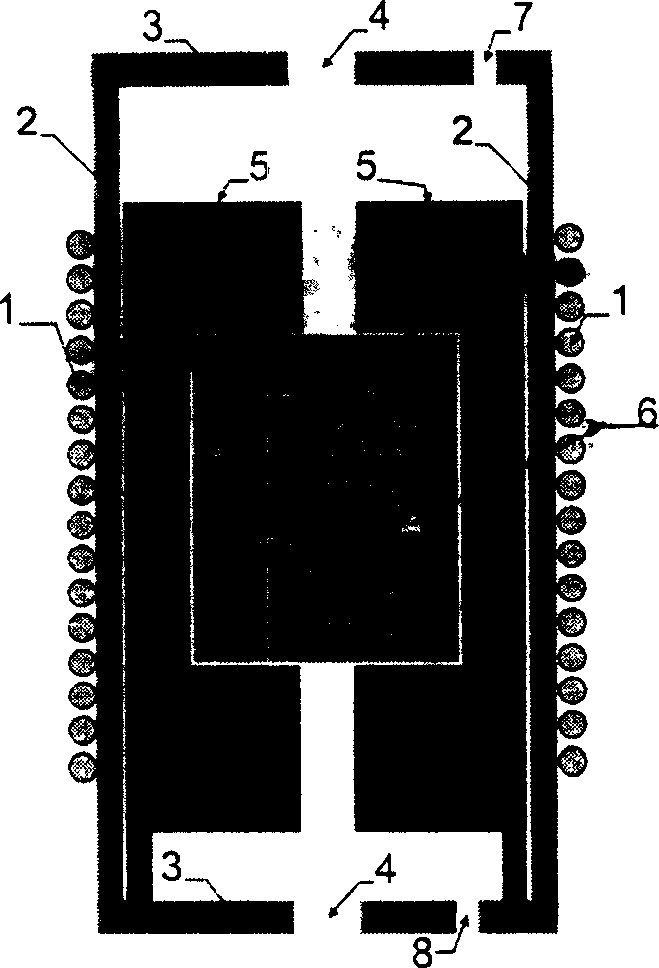

InactiveUS6955212B1Reduces possibility of any damage to heat-generatingSave spaceDigital data processing detailsSemiconductor/solid-state device detailsEngineeringElectronic component

A water-cool radiator module comes with a supporting part having a shell body; the shell body includes a fan and a water tank; the water tank is connected to a cold water pipe and a hot water pipe; an extended section of the cold water pipe and hot water pipe is connected to a cold waterhead; the shell body includes several radiating holes at one end; such that in an application, the supporting part is inserted into a slot on the computer case and the shell body is mounted onto the slot; the cold water in the cold waterhead of a heat-generating electronic component is circulated to the shell body through the hot water pipe; the fan blows air to radiate heat to the outside through the radiating holes; and the cooled fluid flows from the water tank to the cold waterhead through the cold water pipe.

Owner:ADDA

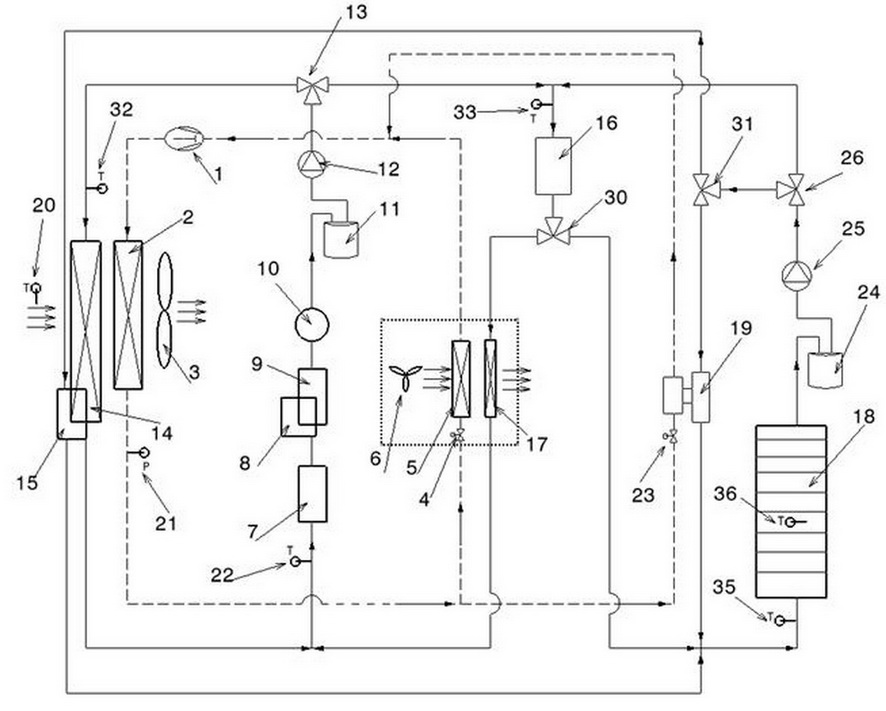

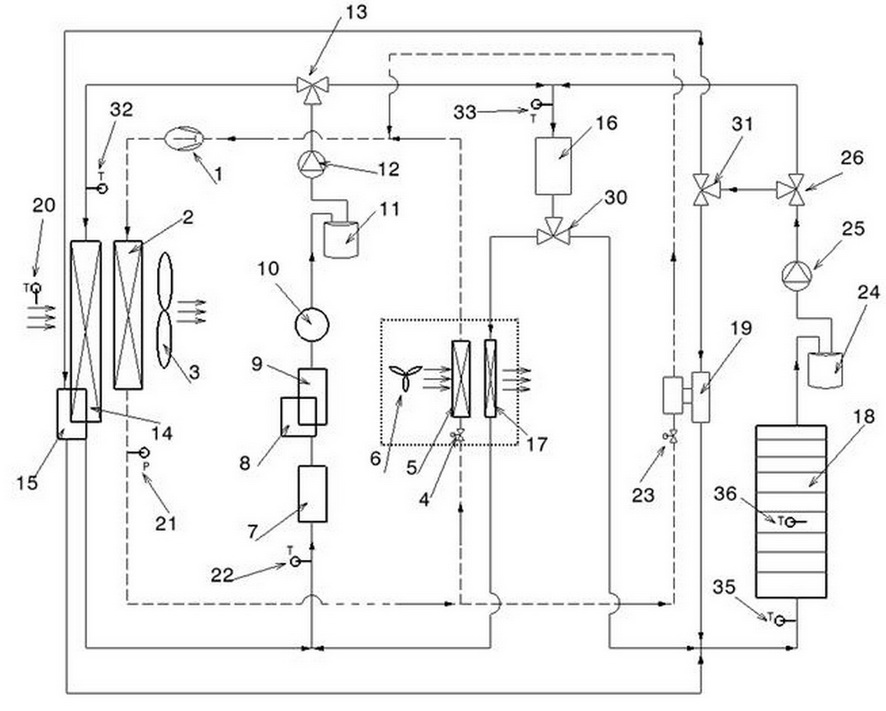

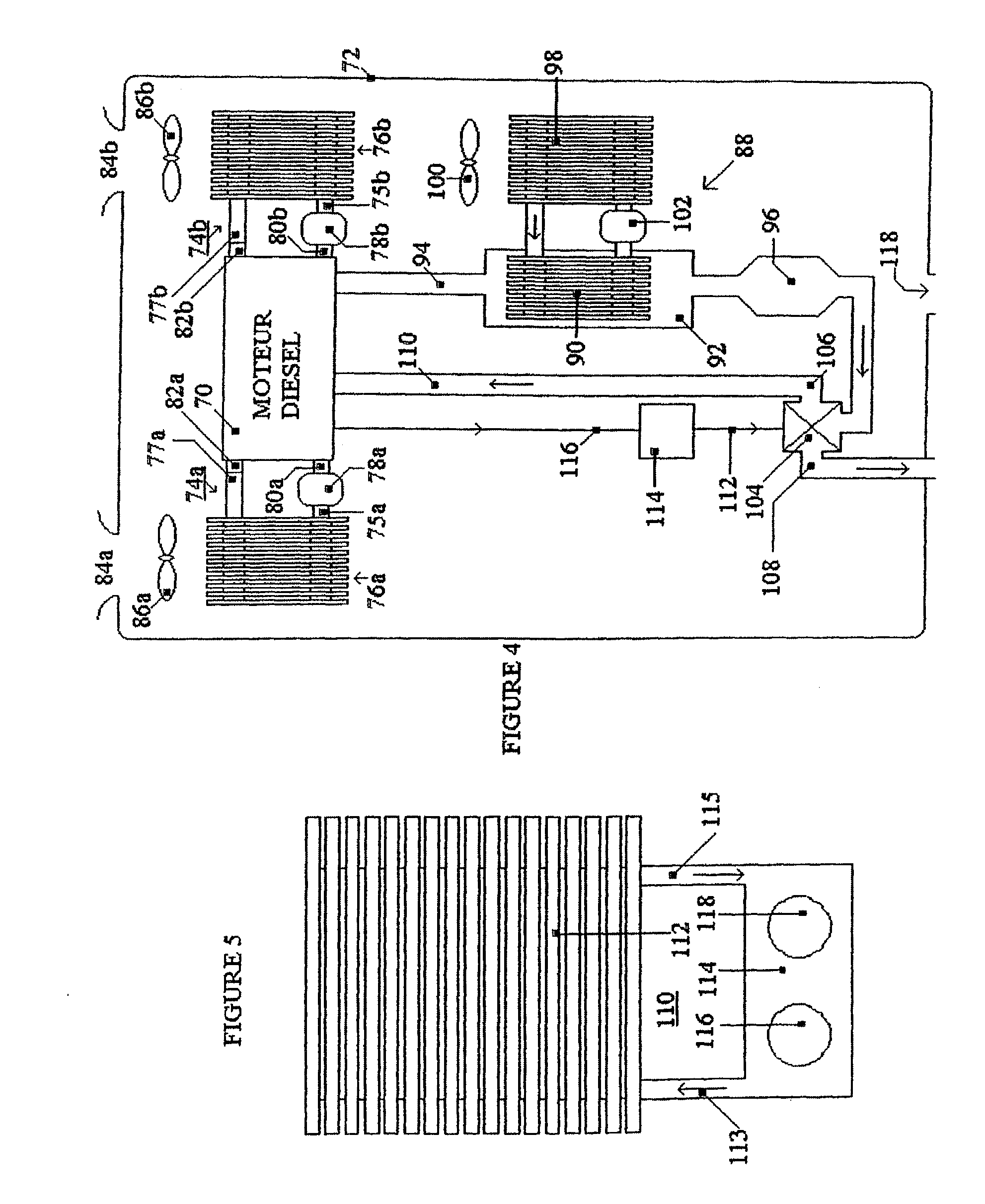

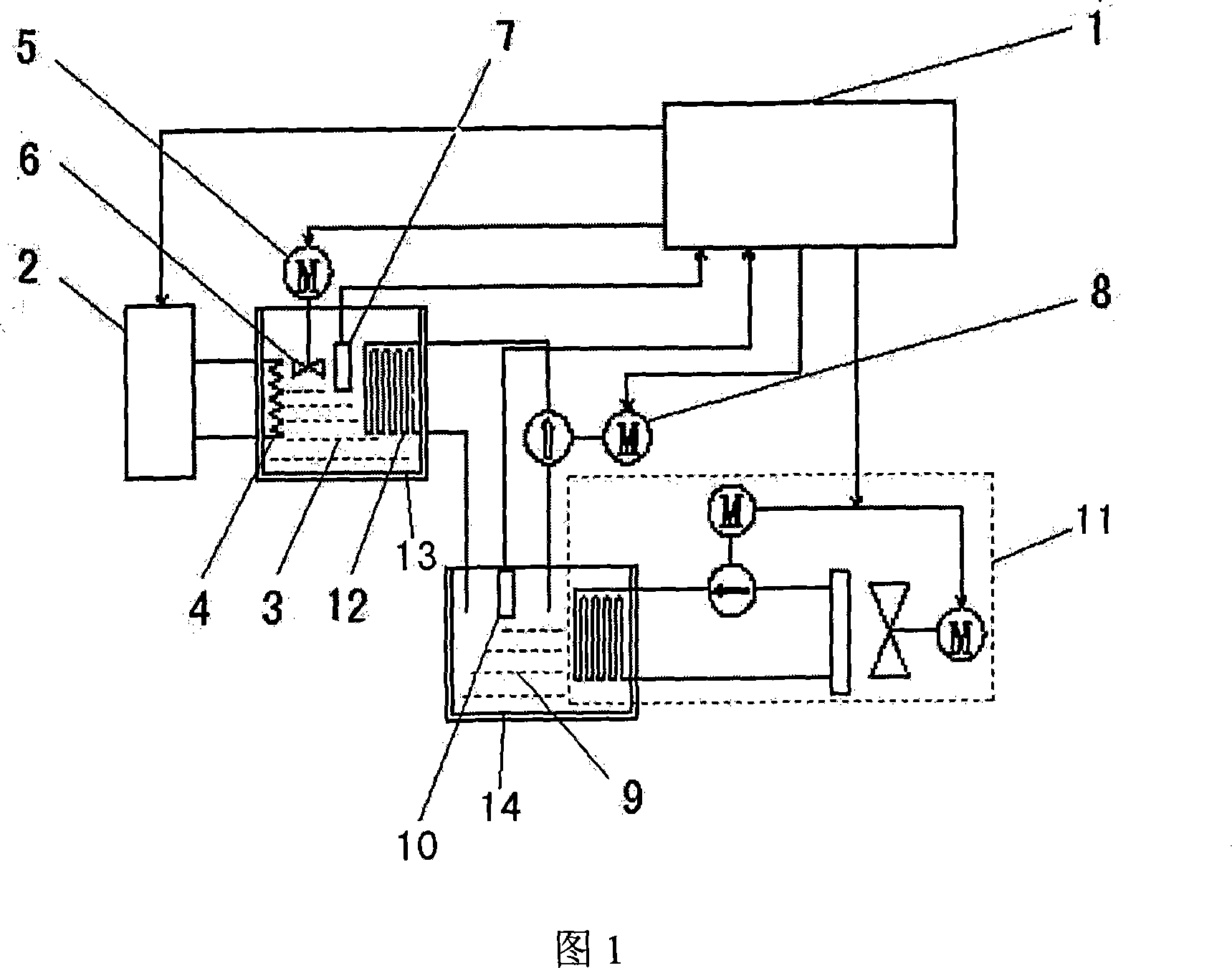

Control system for heat management of electric vehicle

InactiveCN102050007ASolve heating problemsEfficient thermal managementCompression machines with several evaporatorsComponent optimizationAutomotive batteryElectrical battery

The invention provides a control system for heat management of an electric vehicle. The control system is characterized in that the system comprises a refrigerant circulating system, a coolant circulating system and a battery pack temperature control system, wherein the refrigerant circulating system is communicated with the battery pack temperature control system via a water cooler, and the coolant circulating system is communicated with the battery pack temperature control system via a three-way water valve, so the three systems form an intercommunicating and circulating control system to control the temperature in the carriage and the working temperature of the electrical devices of the battery pack. The control system has the following positive effects: effective heat management can be carried out on each part of the electric vehicle; the problem of heating difficulty of the electric vehicle is solved by adopting the residual heat of the electrical devices in an economical and energy-saving manner; preheating and cooling of the power battery of the electric vehicle are well controlled; and the working temperature of the battery and electrical devices of the electric vehicle can be controlled, thus realizing complete heat system management of the electric vehicle.

Owner:VALEO AUTOMOTIVE AIR CONDITIONING HUBEI CO LTD

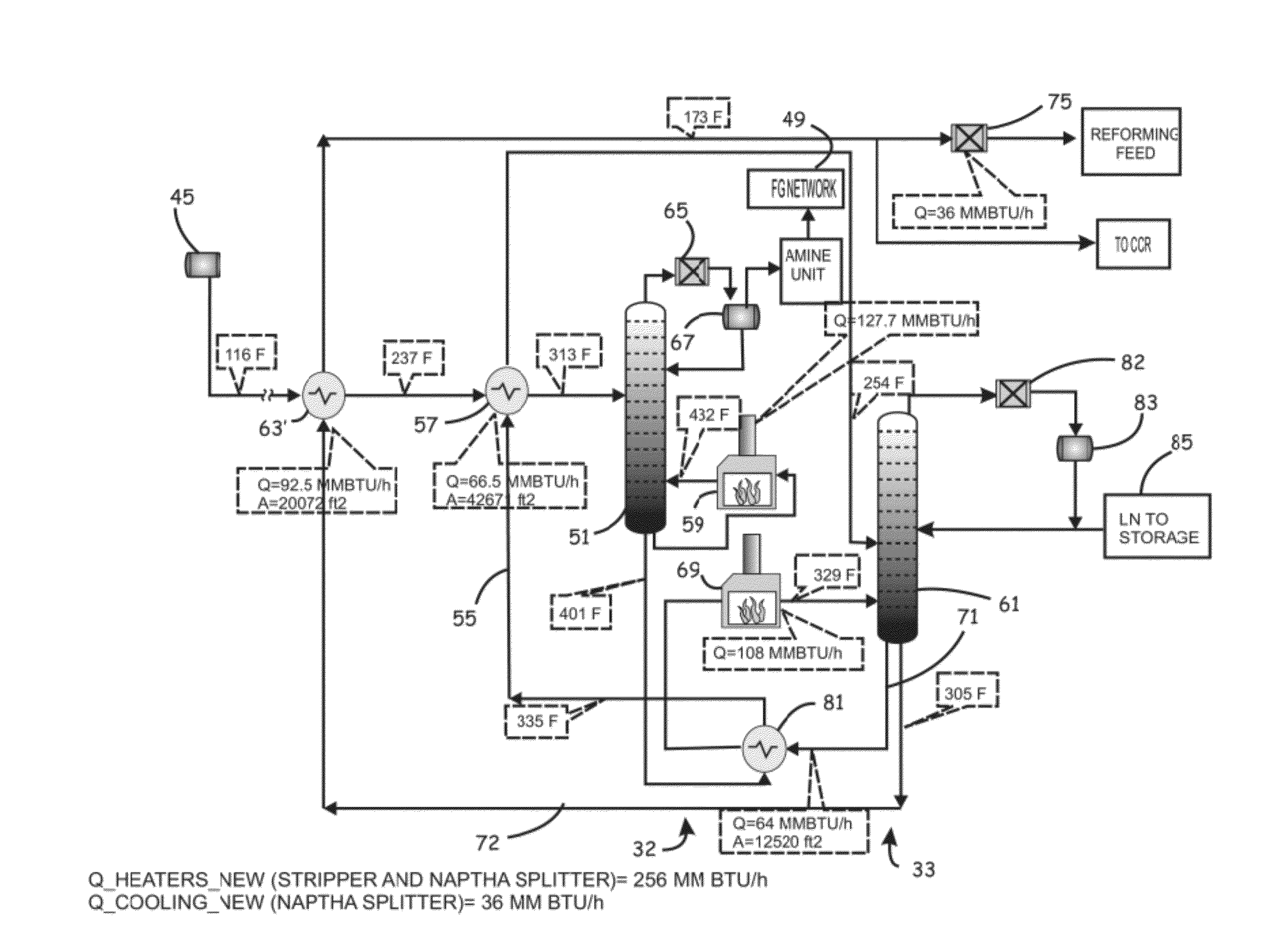

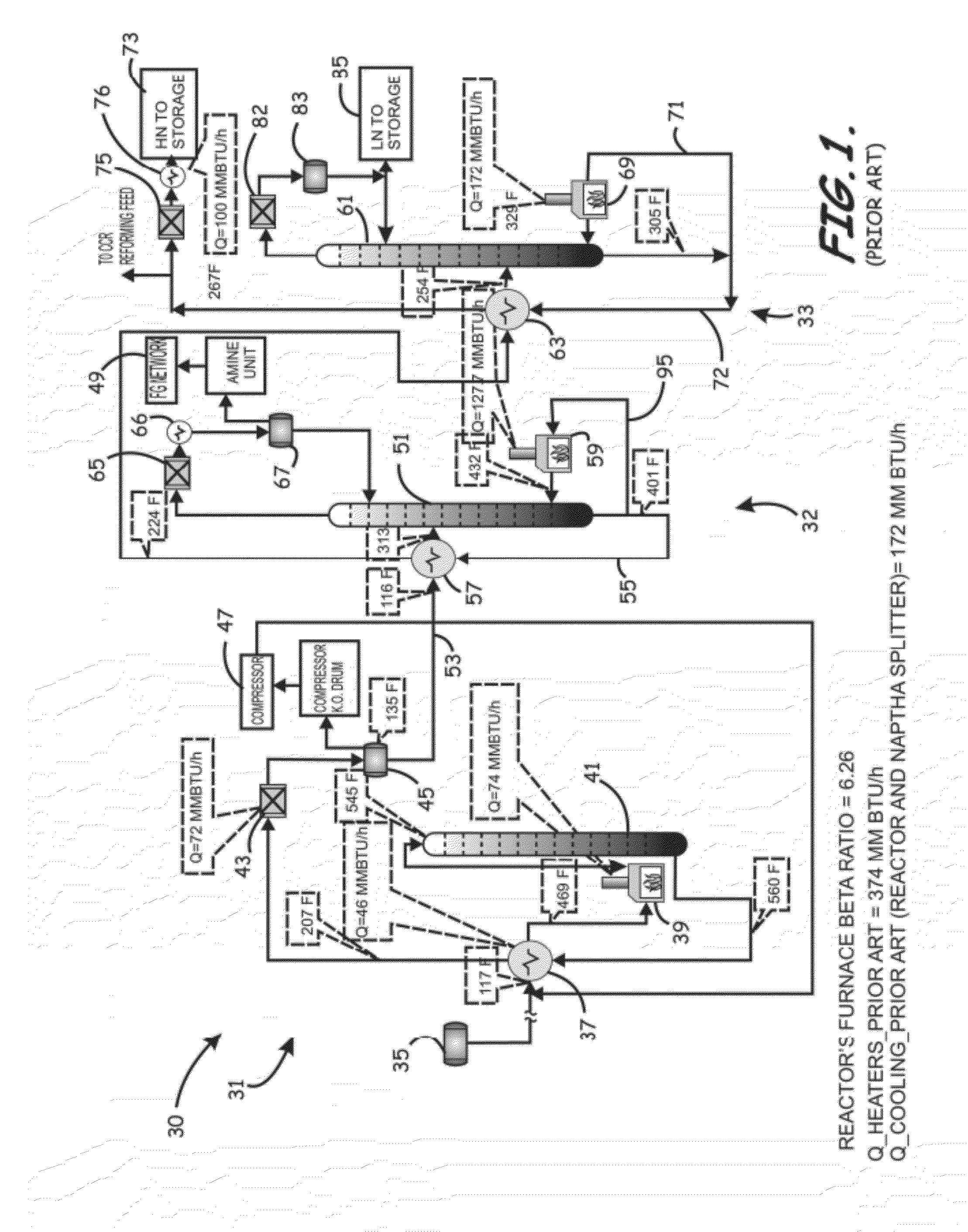

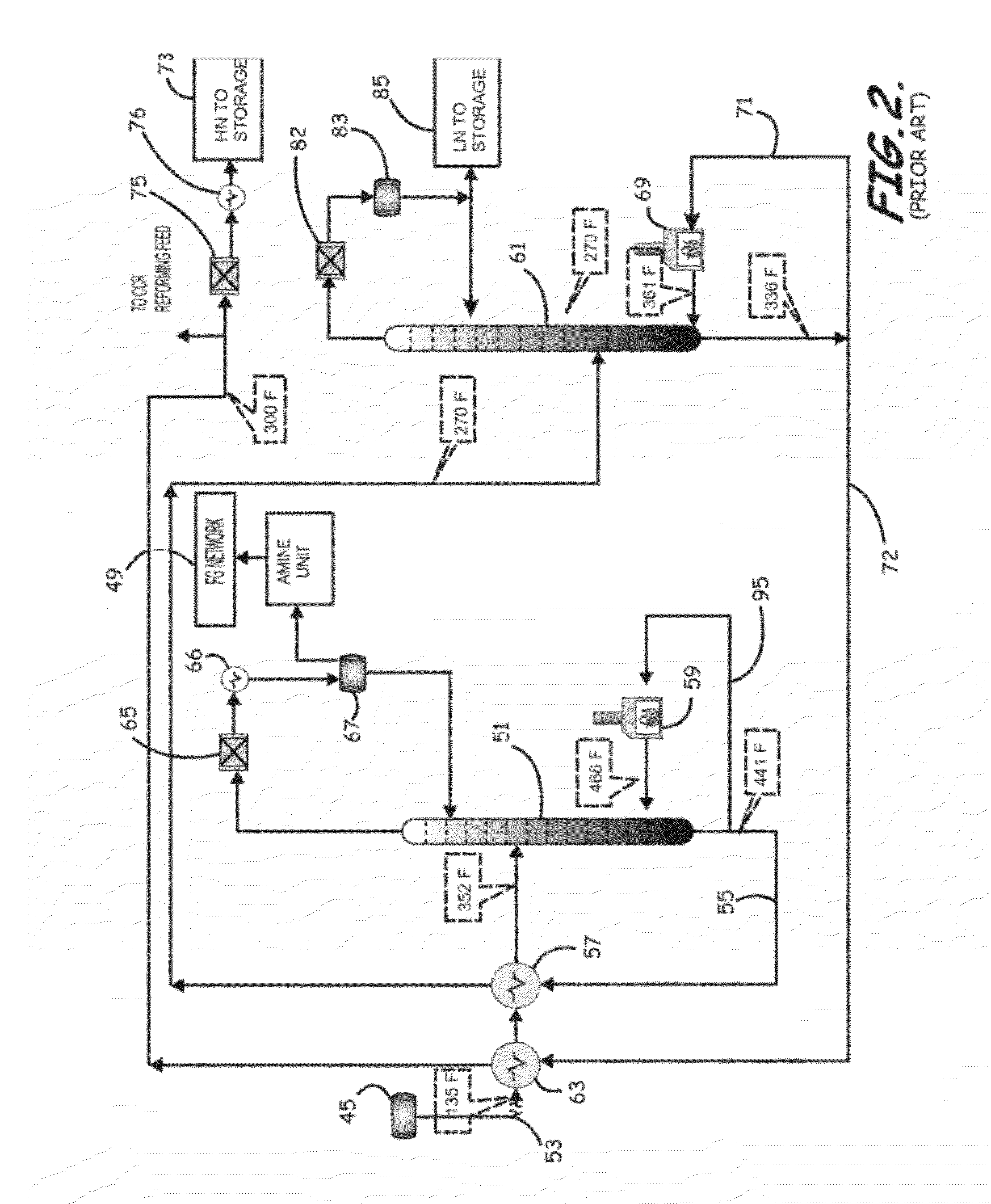

Energy-Efficient and Environmentally Advanced Configurations For Naptha Hydrotreating Process

ActiveUS20120279900A1Less emissionsLower ratioRecuperative heat exchangersThermal naphtha reformingProcess systemsNaphtha

Systems and methods of hydrotreating different naphtha feed stocks destined for a refining reforming unit and other applications with less energy consumption than conventionally possible, while producing less greenhouse gas emissions, and / or using a lesser number of heaters and correspondingly less capital investment in such heaters, air coolers, and water coolers, are provided. According to the more examples of such systems and methods, such reductions are accomplished by directly integrating a naphtha stripping process section with a naphtha splitting process section. Additional reductions can also be accomplished through directly integrating a naphtha hydrotreat reaction process section with the naphtha stripping process section.

Owner:SAUDI ARABIAN OIL CO

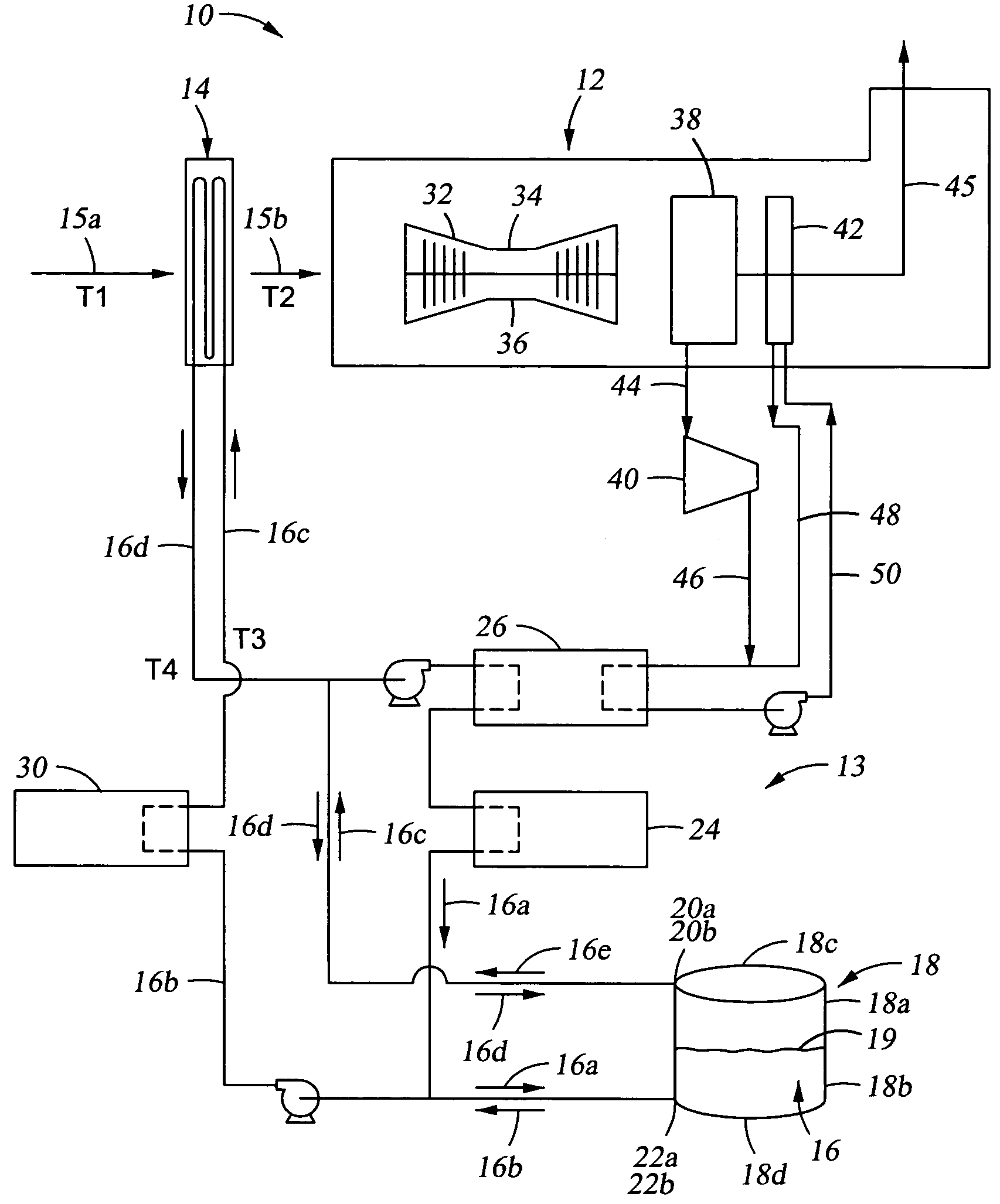

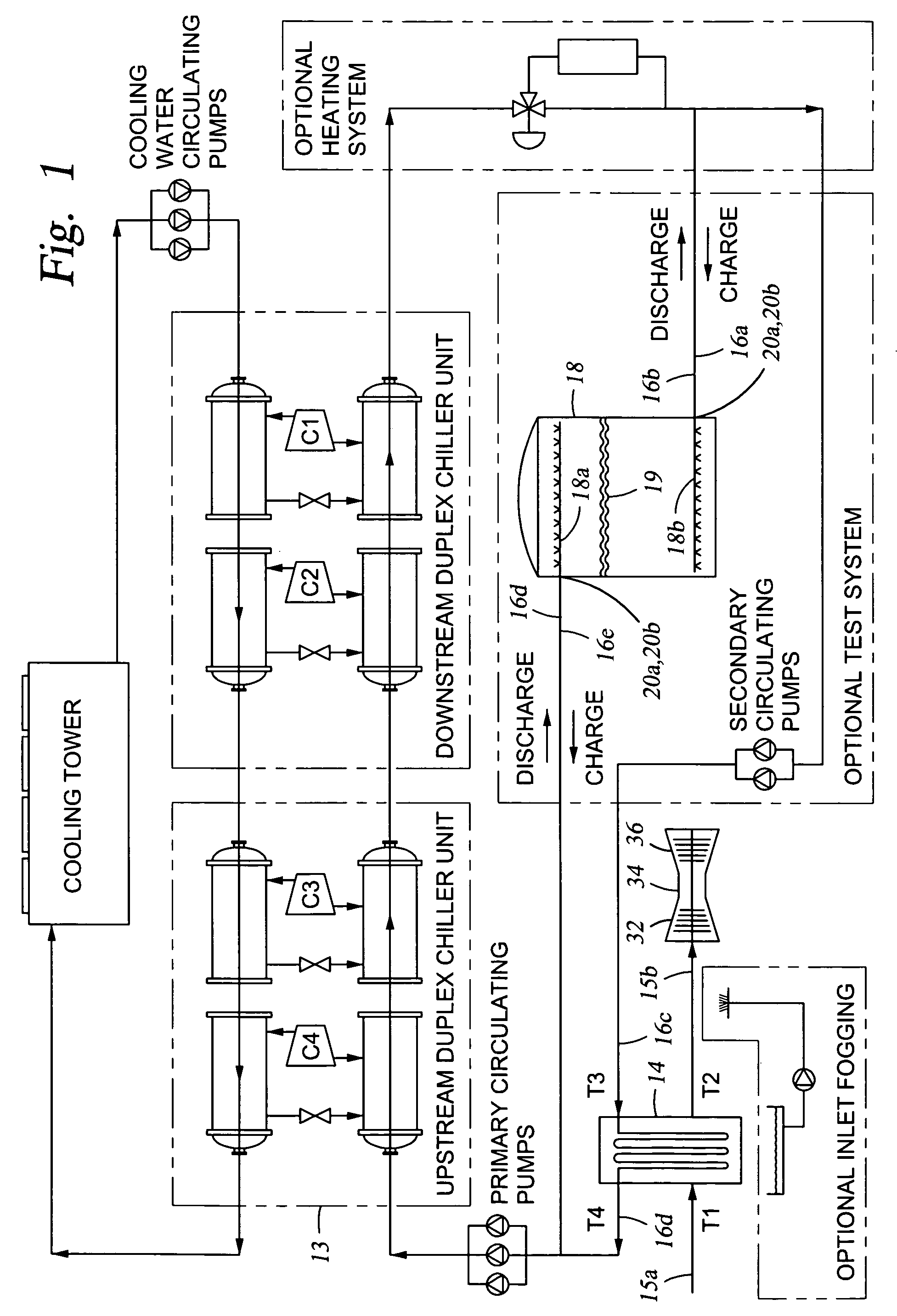

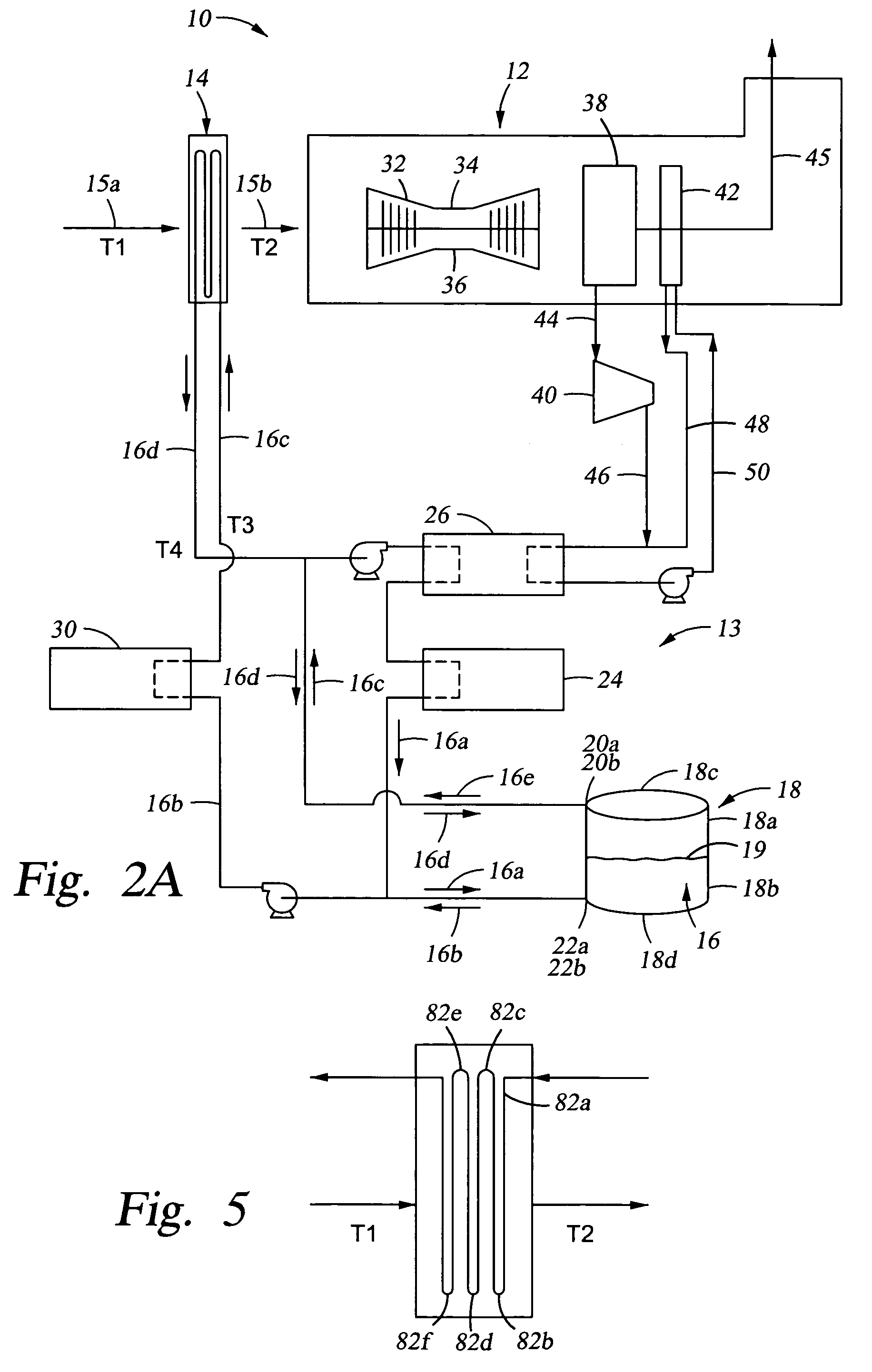

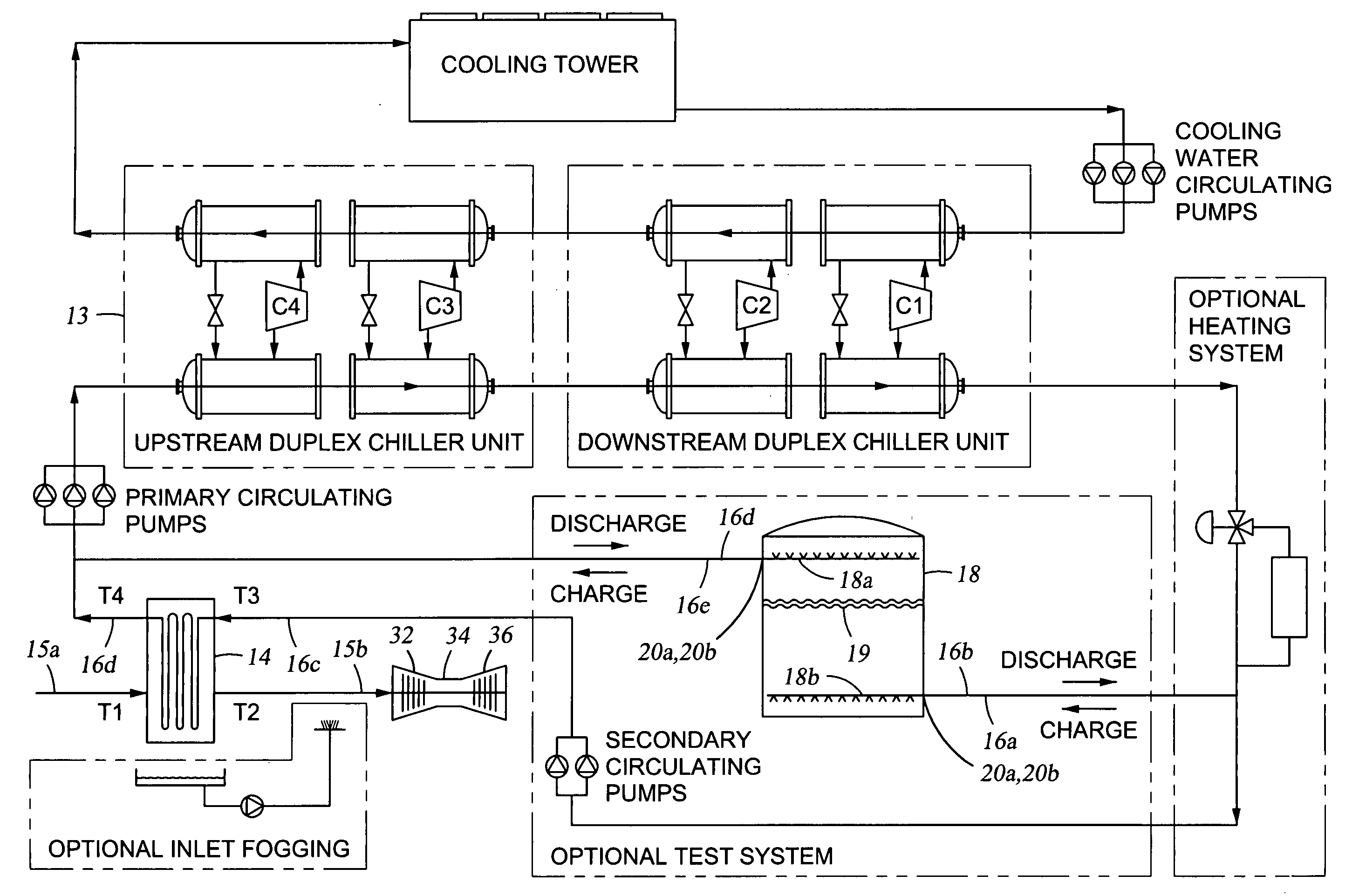

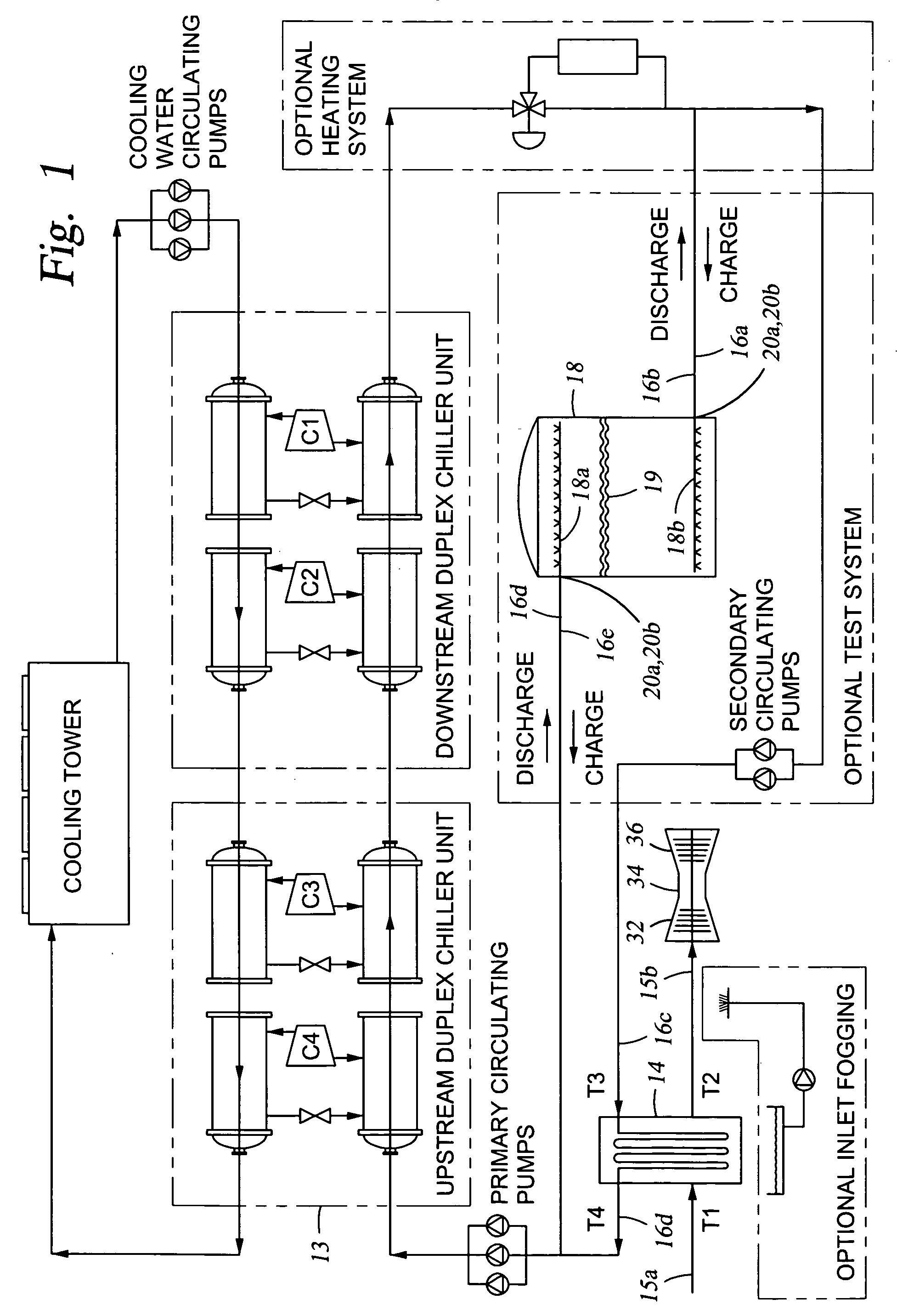

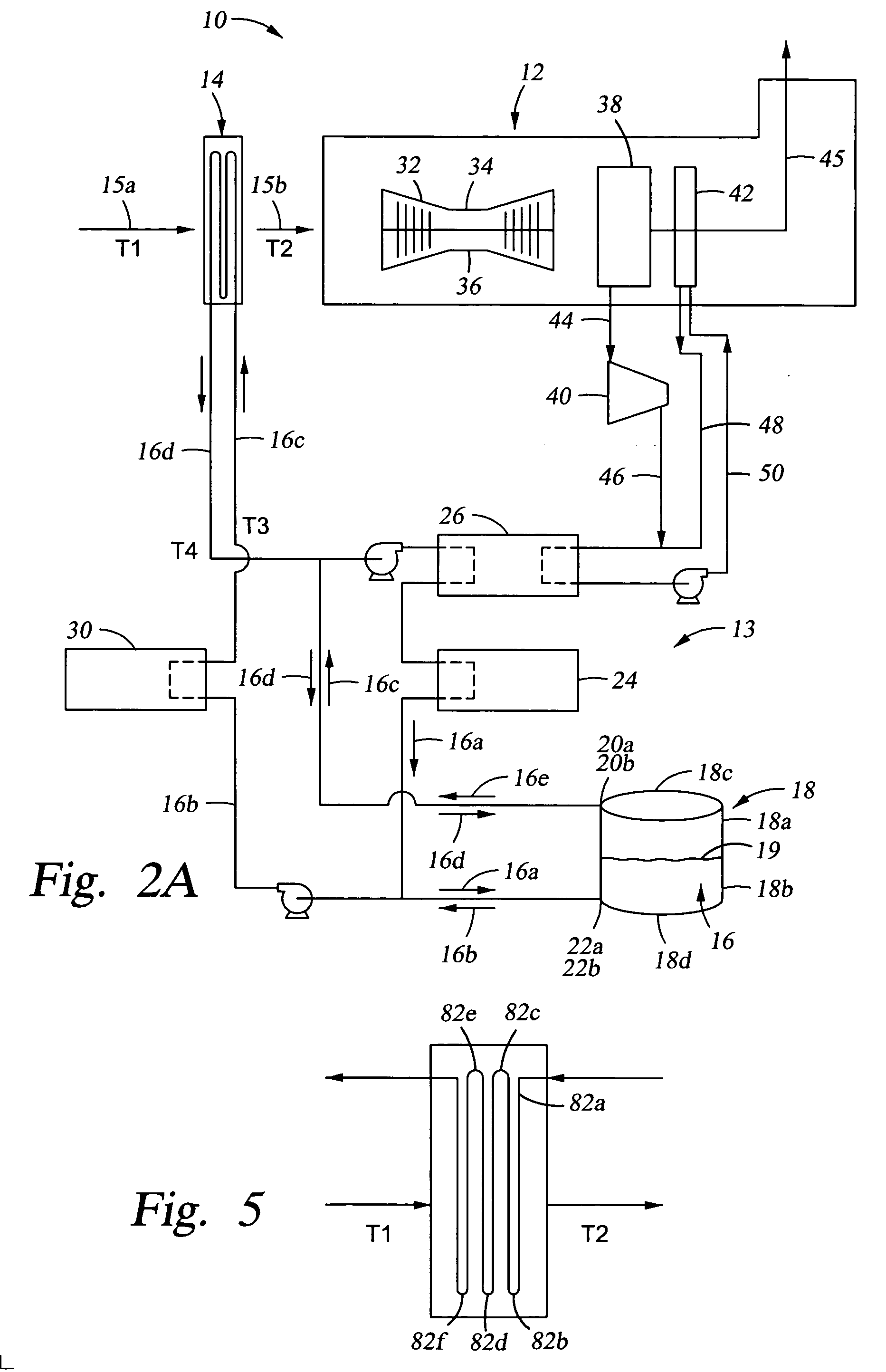

Method of chilling inlet air for gas turbines

InactiveUS7343746B2Lower the average temperature of the chilling waterLower inlet temperatureClimate change adaptationEvaporators/condensersPower stationCooling coil

A method for cooling inlet air to a gas turbine is provided. For example, a method is described including passing inlet air through a cooling coil that includes an opening for receiving the inlet air and that is operably connected to a gas turbine power plant. The gas turbine power plant may include at least one gas turbine, and at least one gas turbine inlet which receives the inlet air. The method may further include passing circulating water through a water chiller at a first flow rate to reduce the temperature of the circulating water, the water chiller including a conduit through which the circulating water is capable of passing and passing the circulating water having the first flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air. Additionally, the method may include reducing the flow rate of the circulating water passing through the water chiller, passing the circulating water through a water chiller at a second flow rate to reduce the temperature of the circulating water, the second flow rate being lower than the first flow rate, and passing the circulating water having the second flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air.

Owner:TAS ENERGY +1

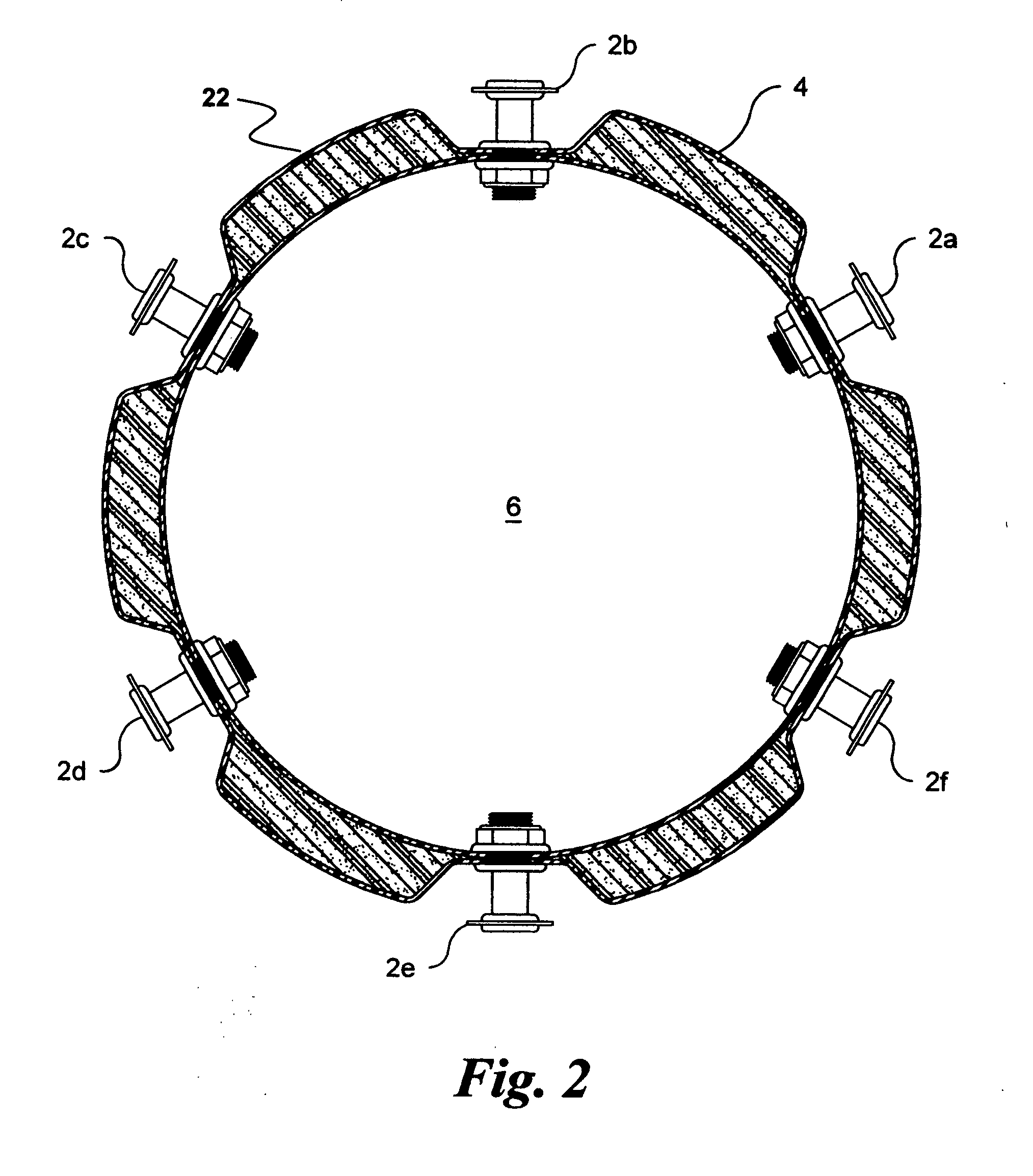

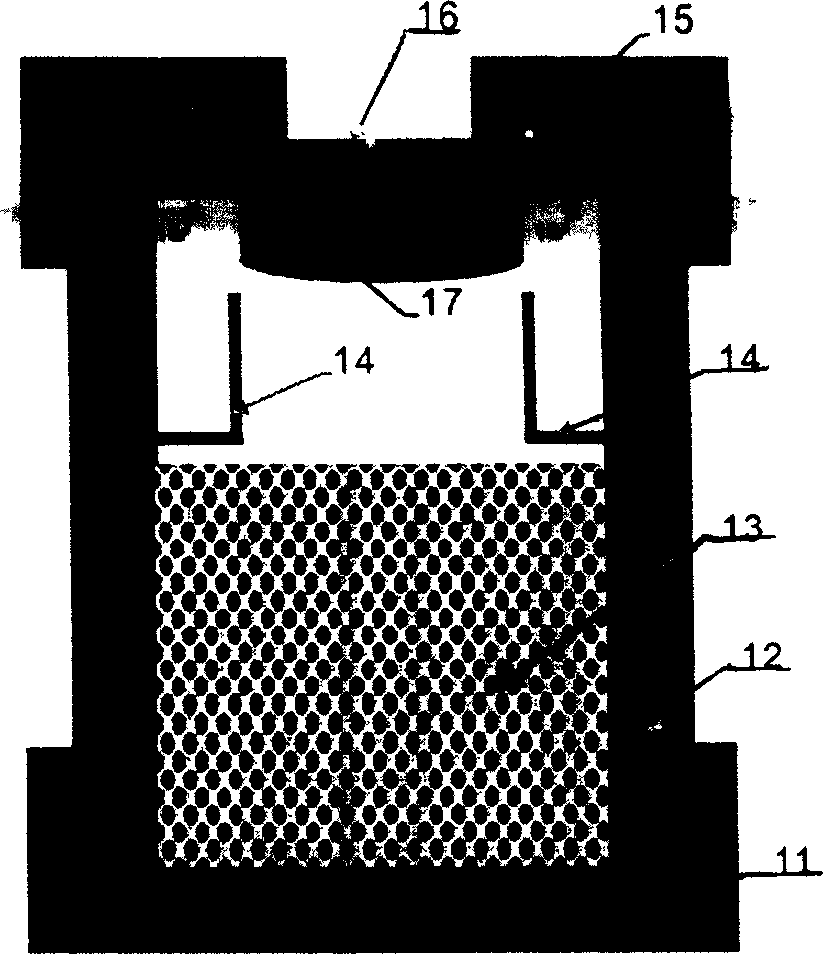

Solid-state water cooler

InactiveUS20070056295A1Operation efficiency can be improvedLow powerLiquid transferring devicesMachines using electric/magnetic effectsThermoelectric coolingWater source

In one embodiment of the invention, a system for controlling the temperature of water in a water cooler includes a water reservoir having an inlet, an outlet, and a main body, a water supply coupled to the inlet and operable to deliver water to the water reservoir, a bubbler coupled to the outlet and operable to dispense at least some of the water from the water reservoir, and a plurality of thermoelectric coolers disposed about a perimeter of the main body and operable to control the temperature of the water inside the water reservoir.

Owner:ALMONT DEV

Systems and methods of dispensing individual servings of flavored and enhanced water

Novel systems and methods for operatively utilizing nutrient / flavor impregnated media(s) operatively contained in devices, such as, for example, product structures or the like, capable of introducing the nutrients / flavors in a single serving (4-12 oz) dose packets, or multiple servings, such as, for example, a pitcher (up to 64+ oz) or a gallon or half gallon of flavored and enhanced water operatively connected to complimentary dispensing system, presently preferably, tied to a water filtration device, such as, for example, bottle less water coolers and one that could be mounted inside a refrigerator dispensing system, and the manufacture of such low cost media(s) and dispensing systems.

Owner:3M INNOVATIVE PROPERTIES CO

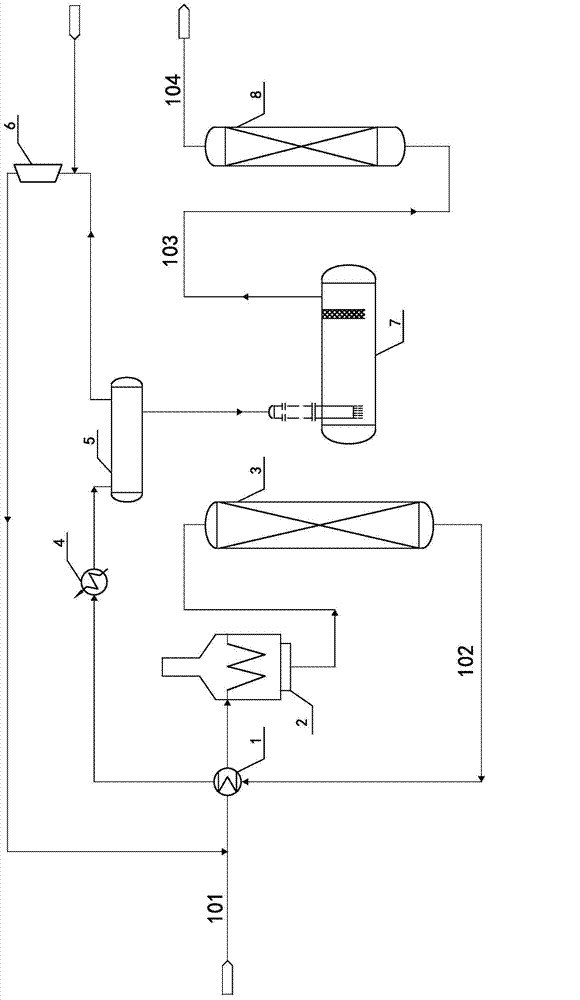

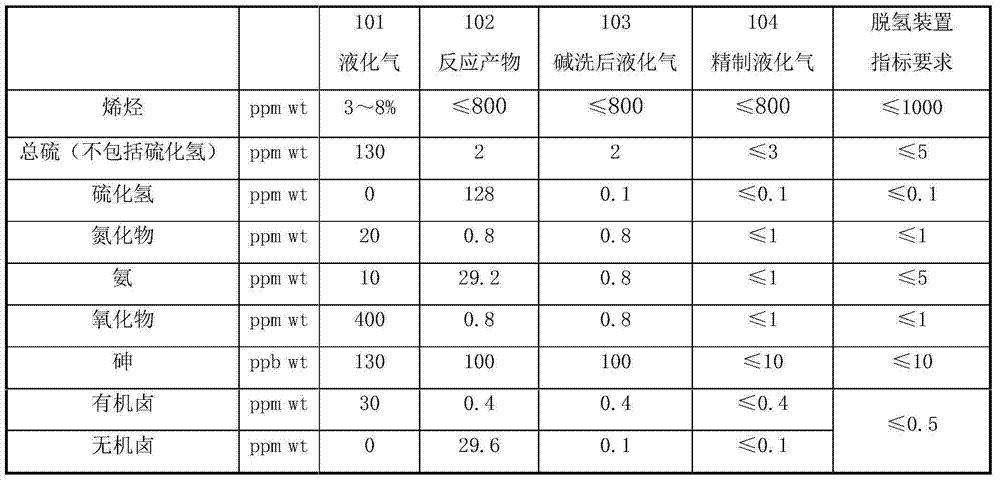

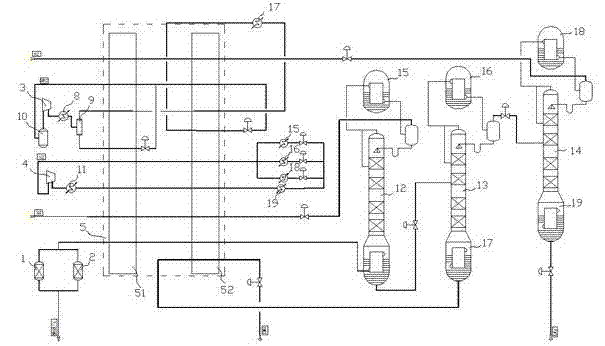

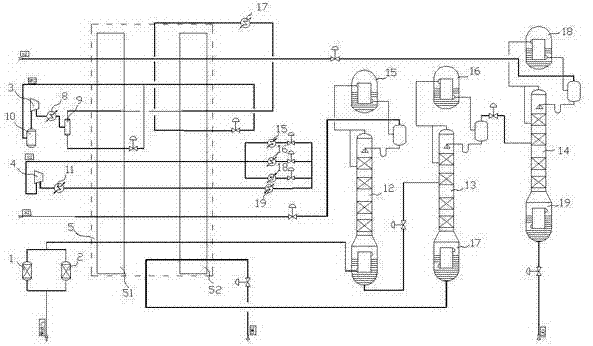

High-temperature hydrogenation and purification process for liquefied gas materials

The invention relates to a purification process of liquefied gas and particularly provides a high-temperature hydrogenation and purification process for liquefied gas materials. The high-temperature hydrogenation and purification process is characterized by comprising the following steps: (1) carrying out heat exchange on raw material liquefied gas and a reactor outlet product in a heat exchanger, heating by a heating furnace to a reaction temperature, then feeding the material into a reactor from the top, carrying out saturation hydrogenation on olefin in the material to obtain alkane, and respectively hydrogenating and converting sulfide, oxide, nitride and halide into hydrogen sulfide, water, ammonia and hydrogen halide; (2) carrying out sufficient heat exchange on the reactor outlet product and the raw material by an efficient heat exchanger, carrying out water cooling by a water cooler and enabling the material to enter a gas-liquid separation tank, compressing a flashing gas phase and fresh hydrogen by a compressor and circulating to the raw material liquefied gas; (3) enabling the flashing liquid phase to enter an alkali washing deposition tank and carrying out fiber membrane alkali washing to remove hydrogen sulfide, ammonia and hydrogen halide; (4) enabling the material which is subjected to the alkali washing to enter a dearsenicator, and removing arsenic and metal to obtain refined liquefied gas. The high-temperature hydrogenation and purification process mainly aims at a project which is very strict in requirement on the impurity content of a catalyst, and is short in flow, small in investment, low in cost and less in solid wastes.

Owner:山东海成石化工程设计有限公司

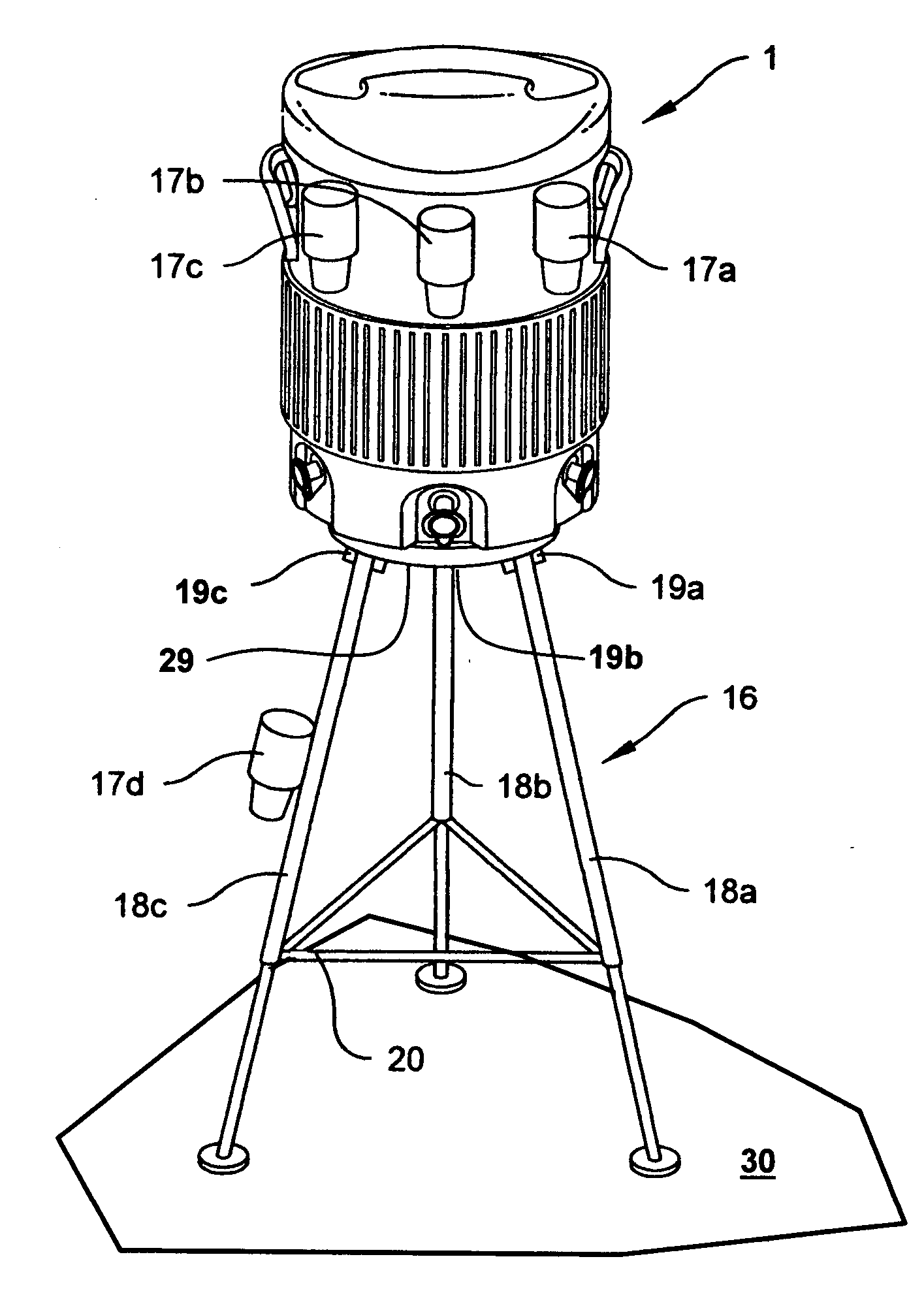

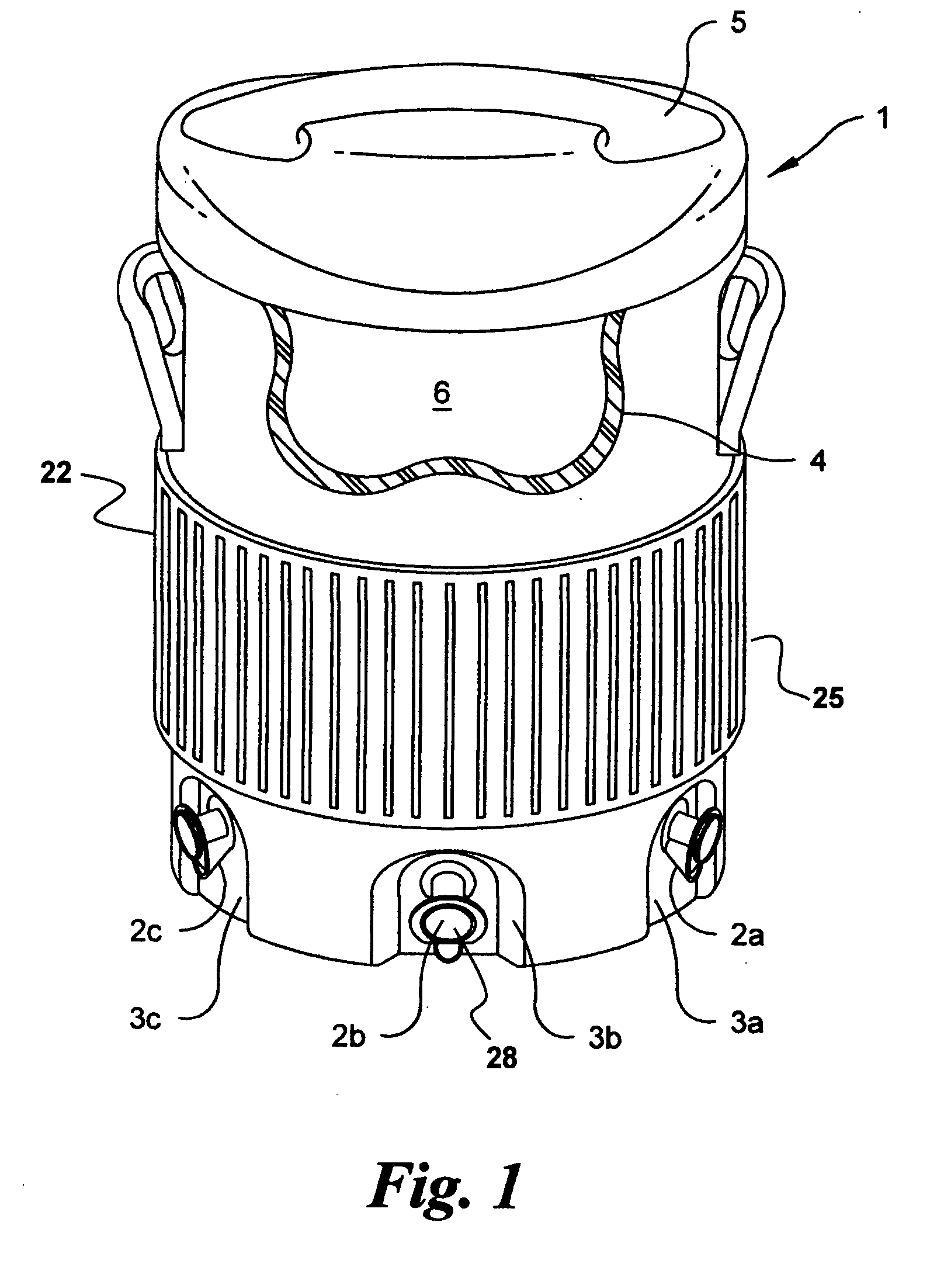

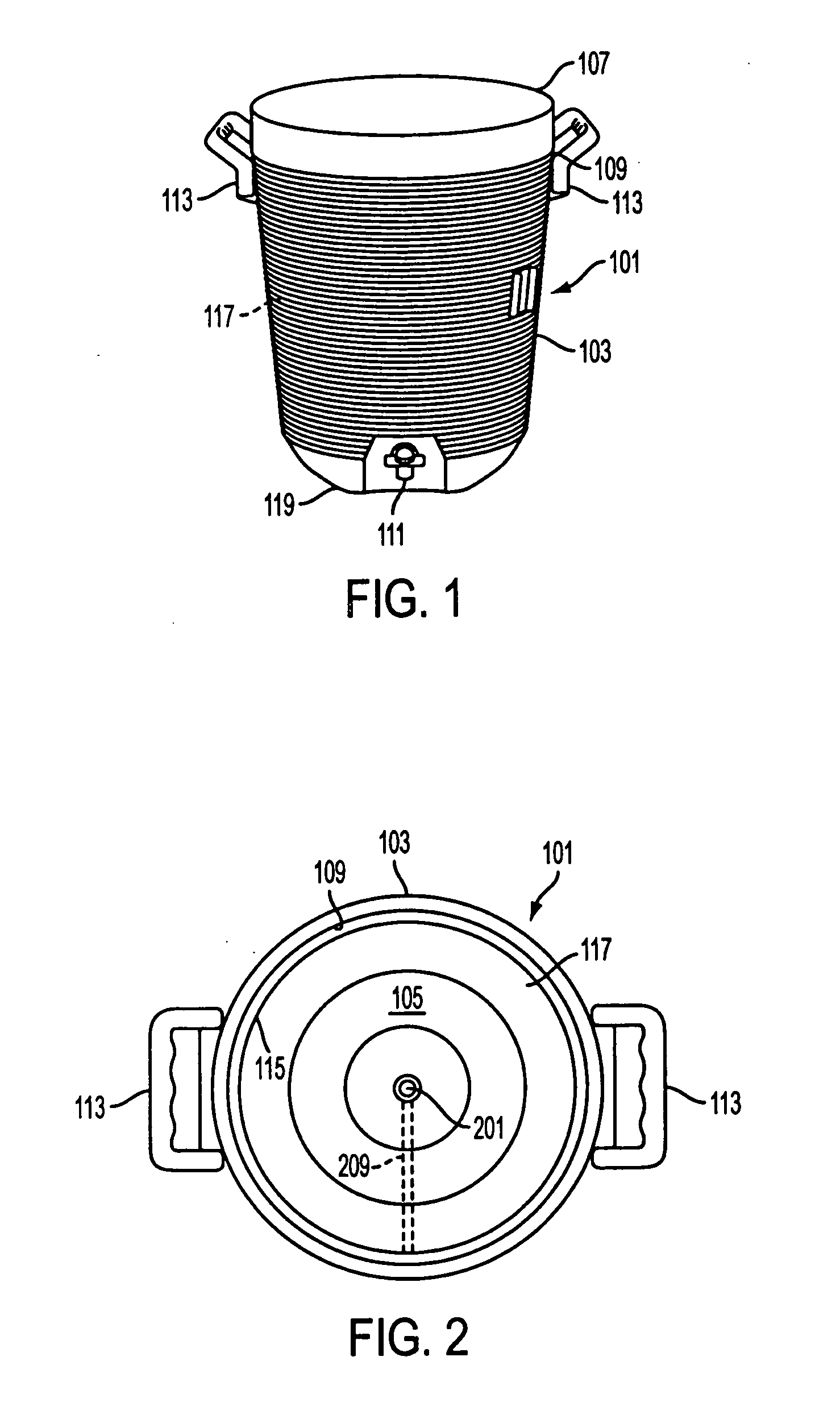

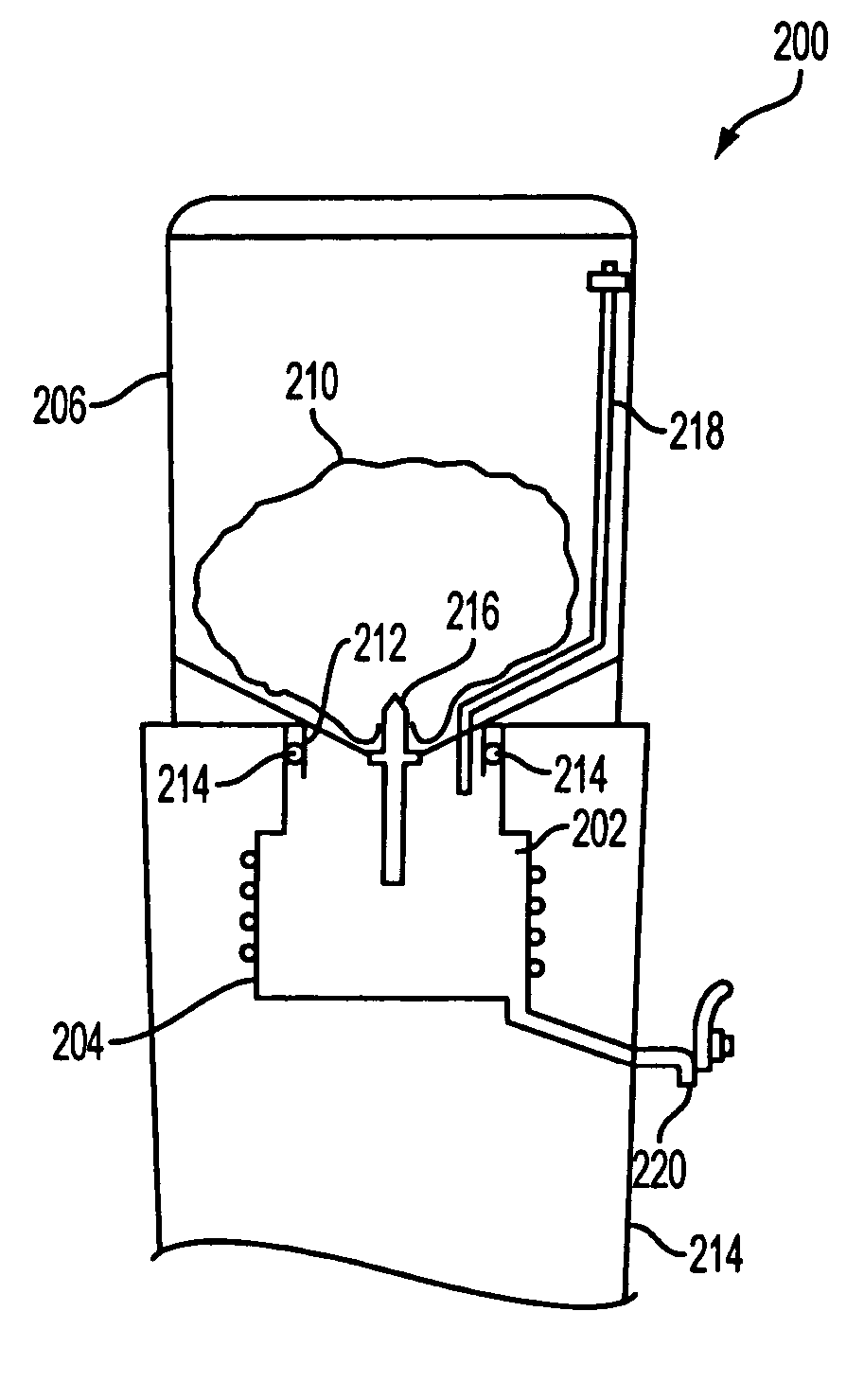

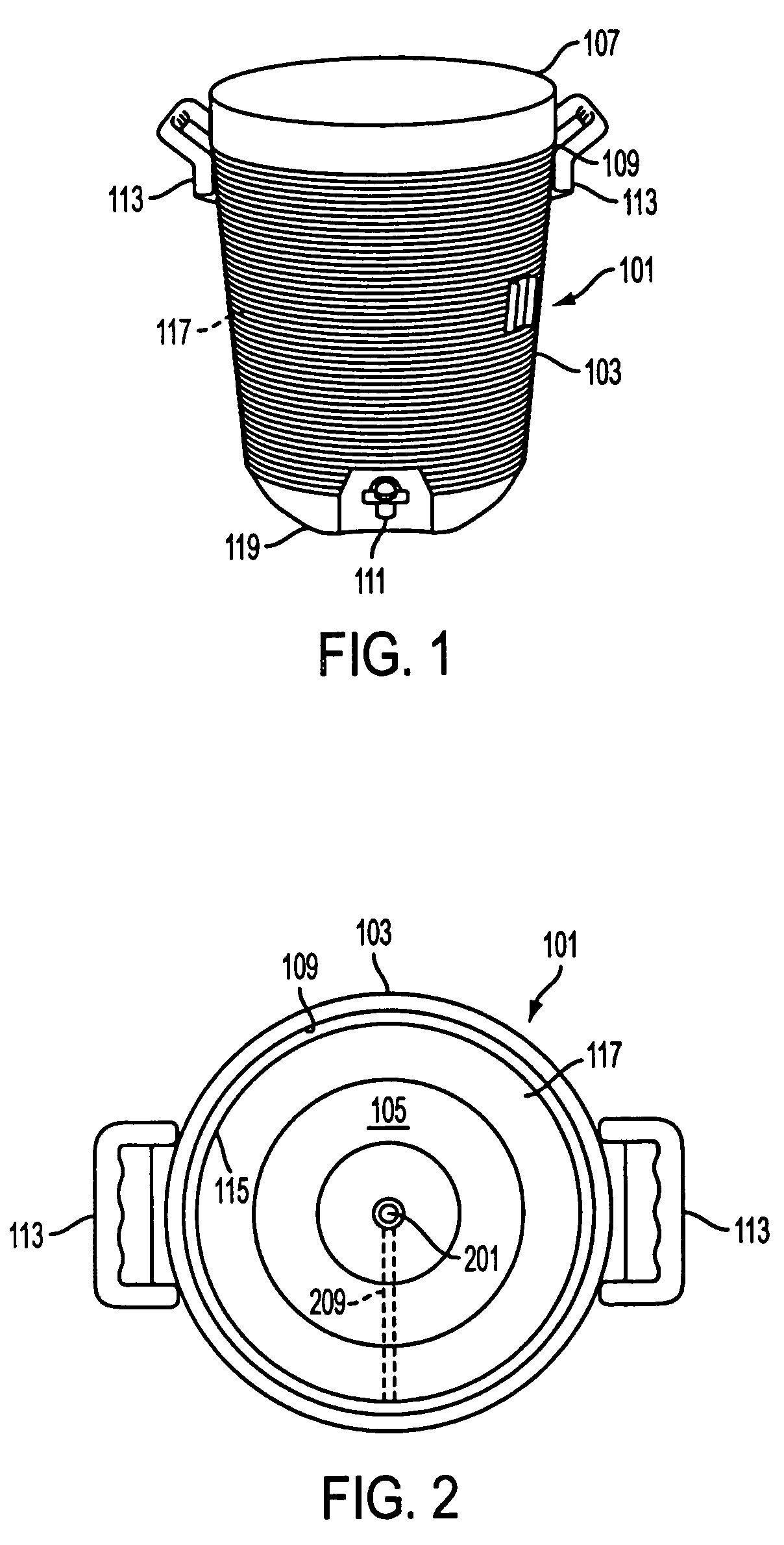

Concurrent use water cooler

InactiveUS20070187435A1Facilitates simultaneous dispensingInhibition formationLiquid flow controllersLiquid transferring devicesLine tubingEngineering

A concurrent use water cooler capable of simultaneously dispensing a single fluid to two or more users is presented. The invention includes a container having a single reservoir therein, a lid contacting and removable from the container, at least two spigots disposed about and attached to the container, a vent hole, and a plug to close the vent hole. Spigots communicate with the single reservoir and enable the gravity-fed dispensing of a single fluid. At least one spigot has a threaded spout allowing attachment of a fluid supply line. The threaded spigot is biased to resist the static pressure associated with fluid within the supply line so as to remain closed unless actuated by the user. An optional stand contacts and supports the water cooler. One or more cup dispensers may be attached to the container or stand. The present invention has immediate applicability to sports teams, military units, construction crews, and the like, where two or more persons consume a potable liquid.

Owner:QUIRK KRISTA GOULD

Method for recycling ammonia from low concentration ammonium chloride wastewater

The invention discloses a method for recovering ammonia from low-concentration ammonium chloride wastewater, which comprises the following steps that: an alkaline substance is added into the low-concentration ammonium chloride wastewater to prepare mixed slurry containing ammonia water and chloride salt; the mixed slurry is subjected to the separation and concentration of the ammonia water in an ammonia water distillation concentration tower to obtain ammonia vapor and a drained waste liquid; the ammonia vapor is conveyed to an ammonia water cooler for cooling treatment, and the ammonia water obtained by the cooling treatment is stored for standby; and the drained waste liquid is subjected to solid-liquid separation to obtain solid-phase residue and a waste liquid containing the chloride salt. The method evaporates the ammonia in the low-concentration ammonium chloride wastewater and concentrates the ammonia to an industrial grade concentration, and has the advantages of broad source of auxiliary materials, low cost, completely sealed technical process, and low energy consumption; and drained substances meet the requirement of no pollution and no nuisance.

Owner:包头市西骏环保科技有限公司

Method of chilling inlet air for gas turbines

InactiveUS20050056023A1Lower the average temperature of the chilling waterLower inlet temperatureClimate change adaptationEvaporators/condensersCooling coilInlet temperature

A method for cooling inlet air to a gas turbine is provided. For example, a method is described including passing inlet air through a cooling coil that includes an opening for receiving the inlet air and that is operably connected to a gas turbine power plant. The gas turbine power plant may include at least one gas turbine, and at least one gas turbine inlet which receives the inlet air. The method may further include passing circulating water through a water chiller at a first flow rate to reduce the temperature of the circulating water, the water chiller including a conduit through which the circulating water is capable of passing and passing the circulating water having the first flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air. Additionally, the method may include reducing the flow rate of the circulating water passing through the water chiller, passing the circulating water through a water chiller at a second flow rate to reduce the temperature of the circulating water, the second flow rate being lower than the first flow rate, and passing the circulating water having the second flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air.

Owner:TAS ENERGY +1

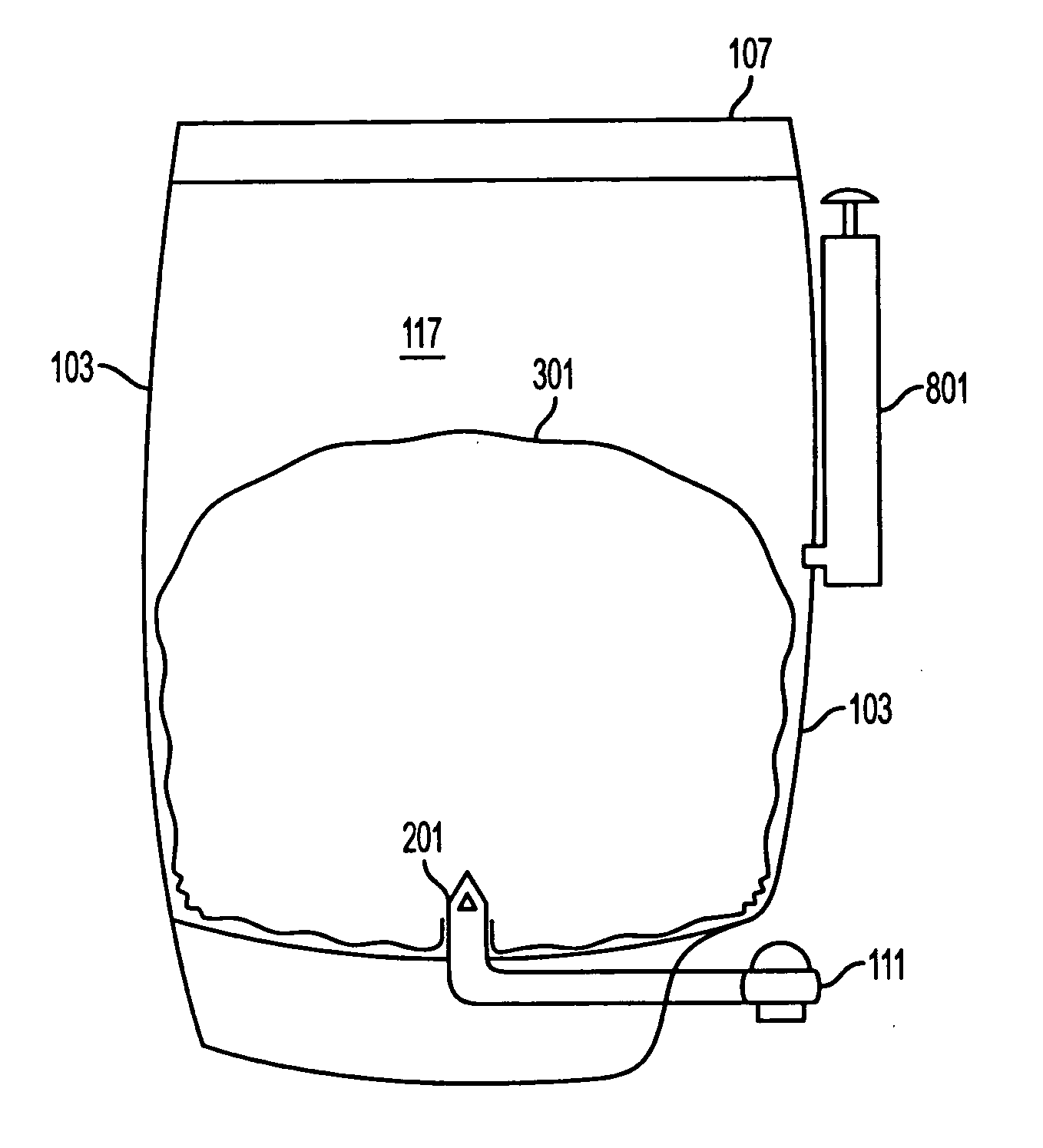

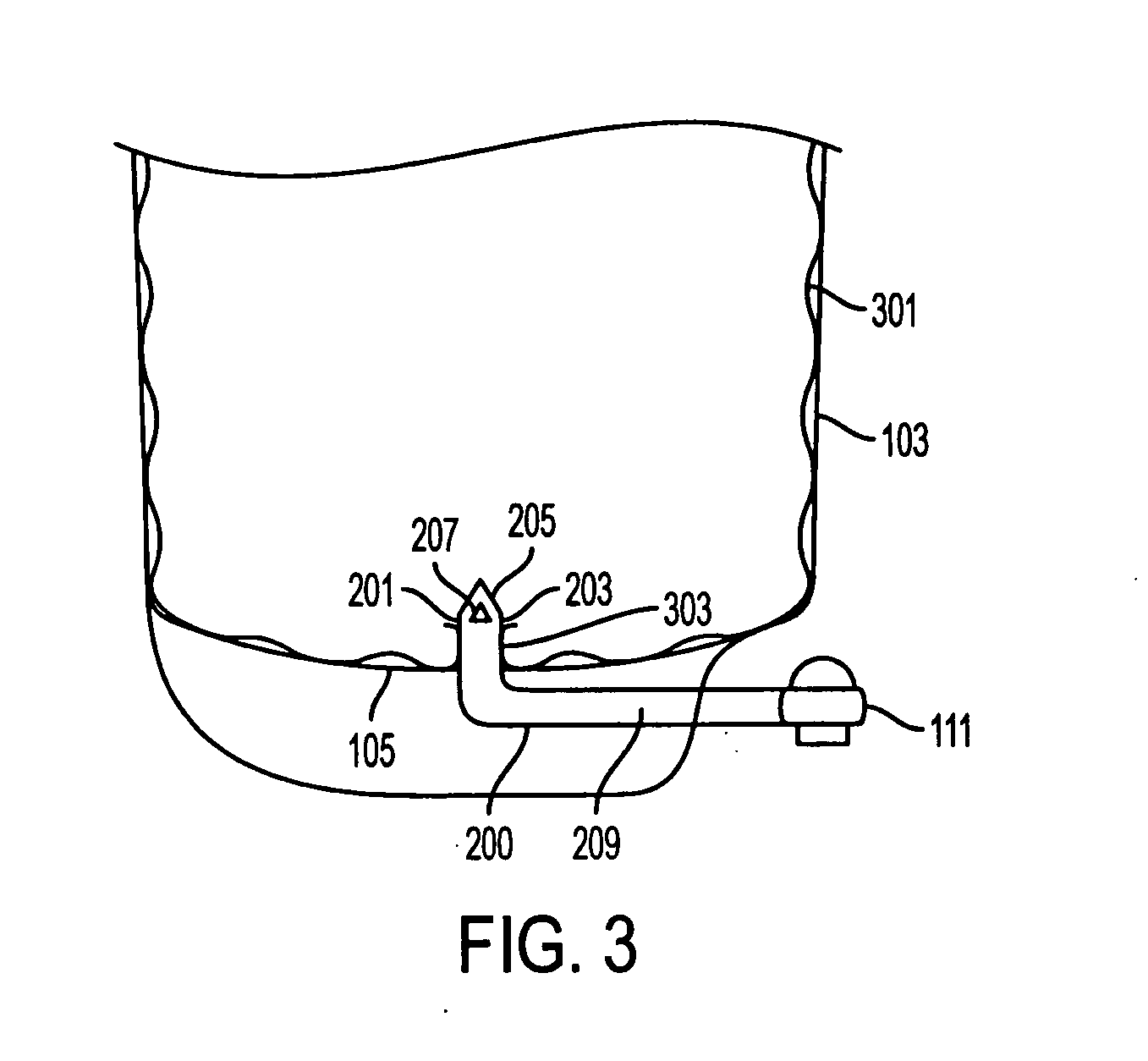

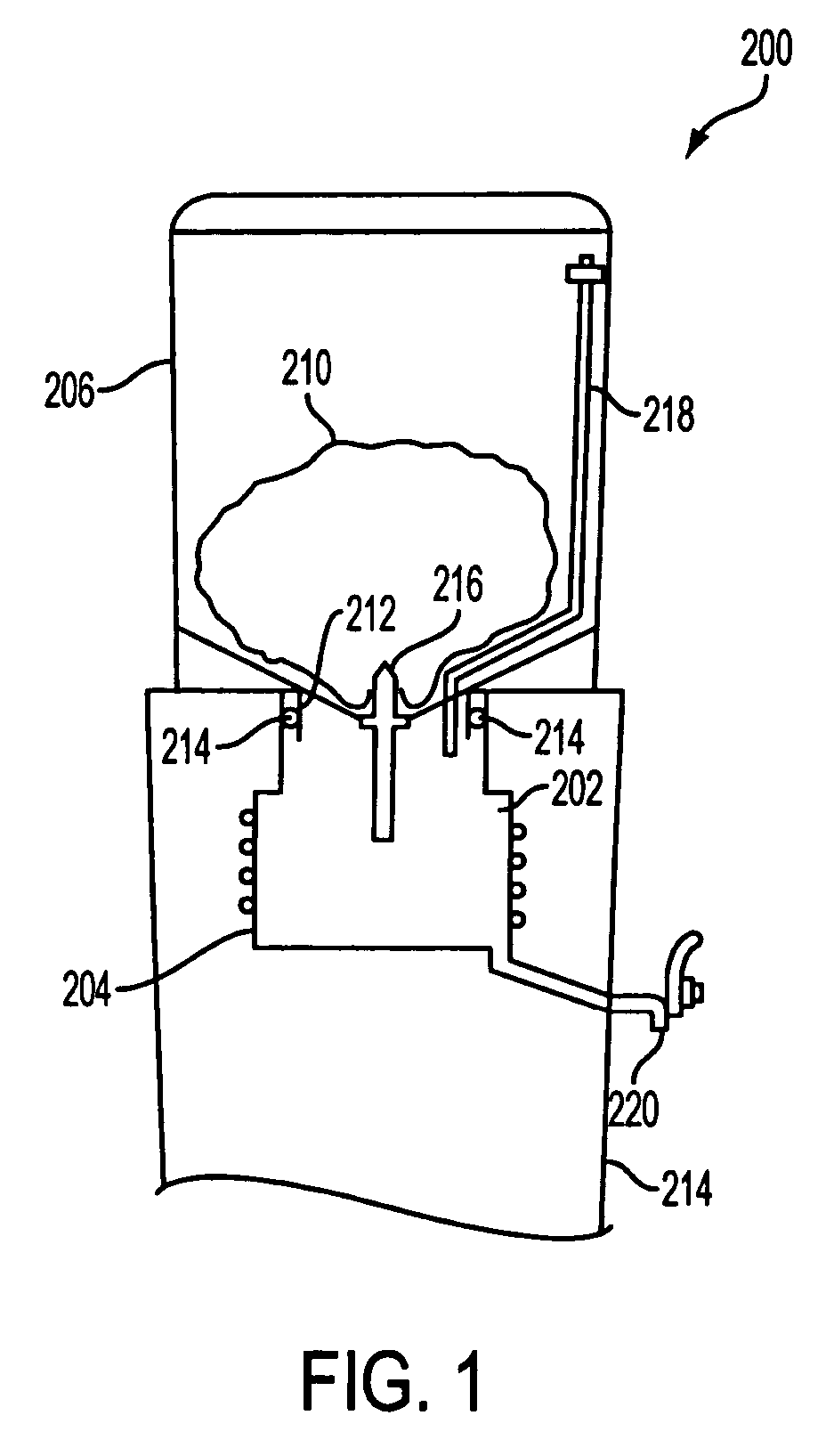

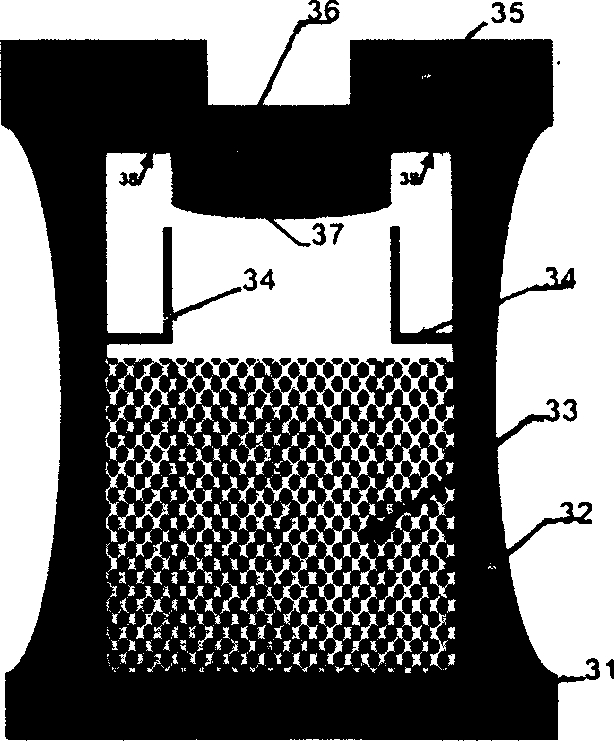

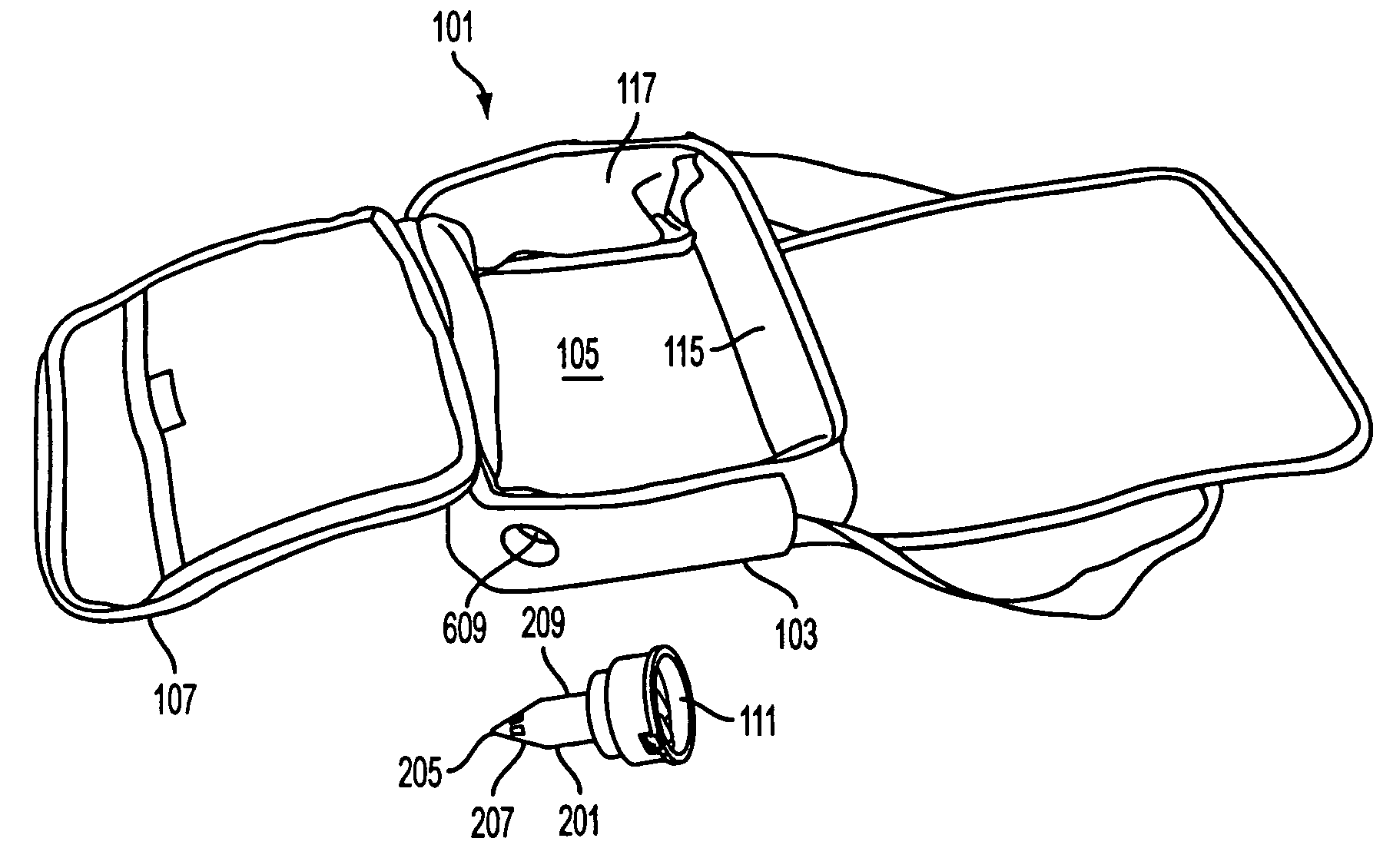

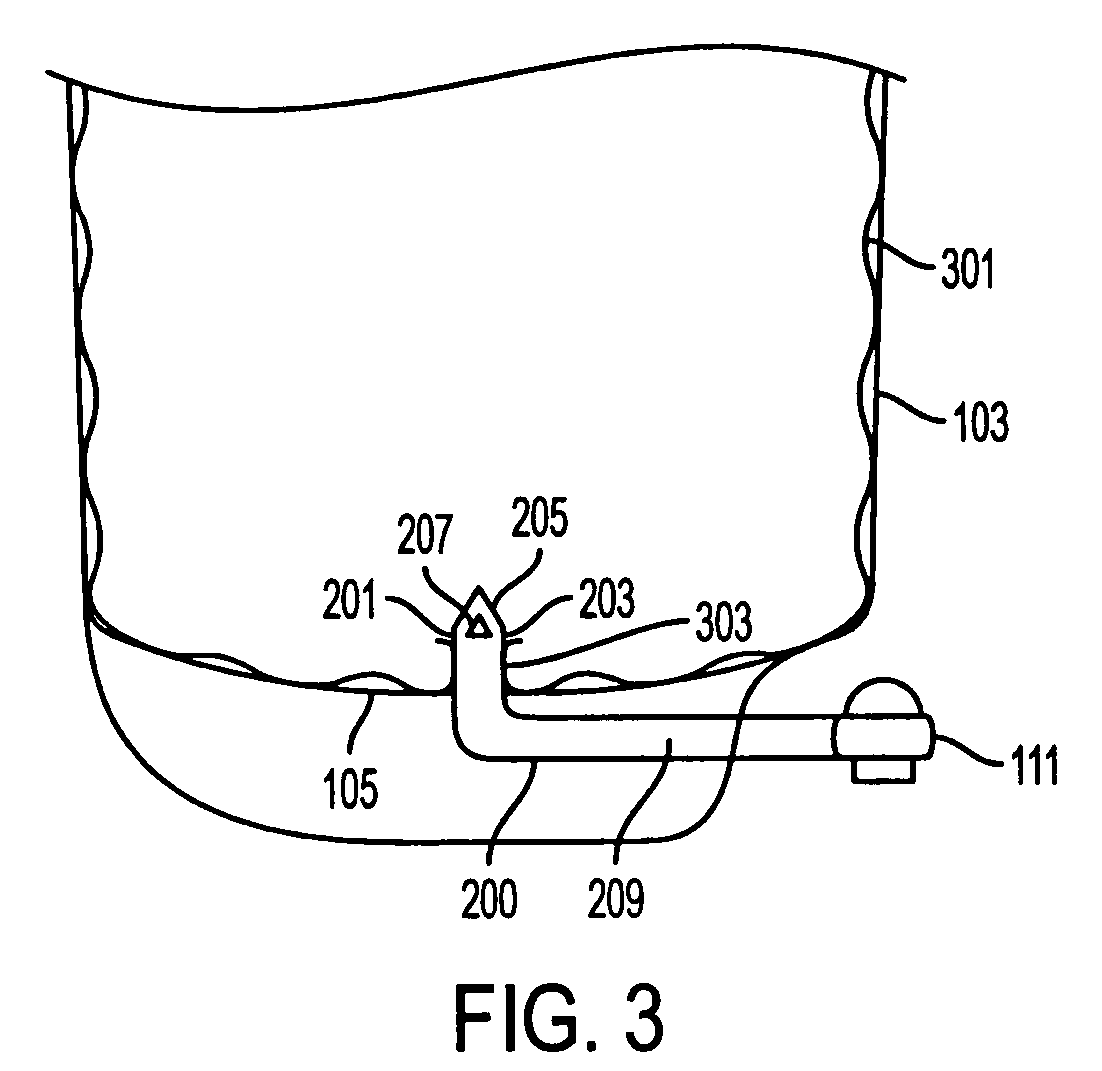

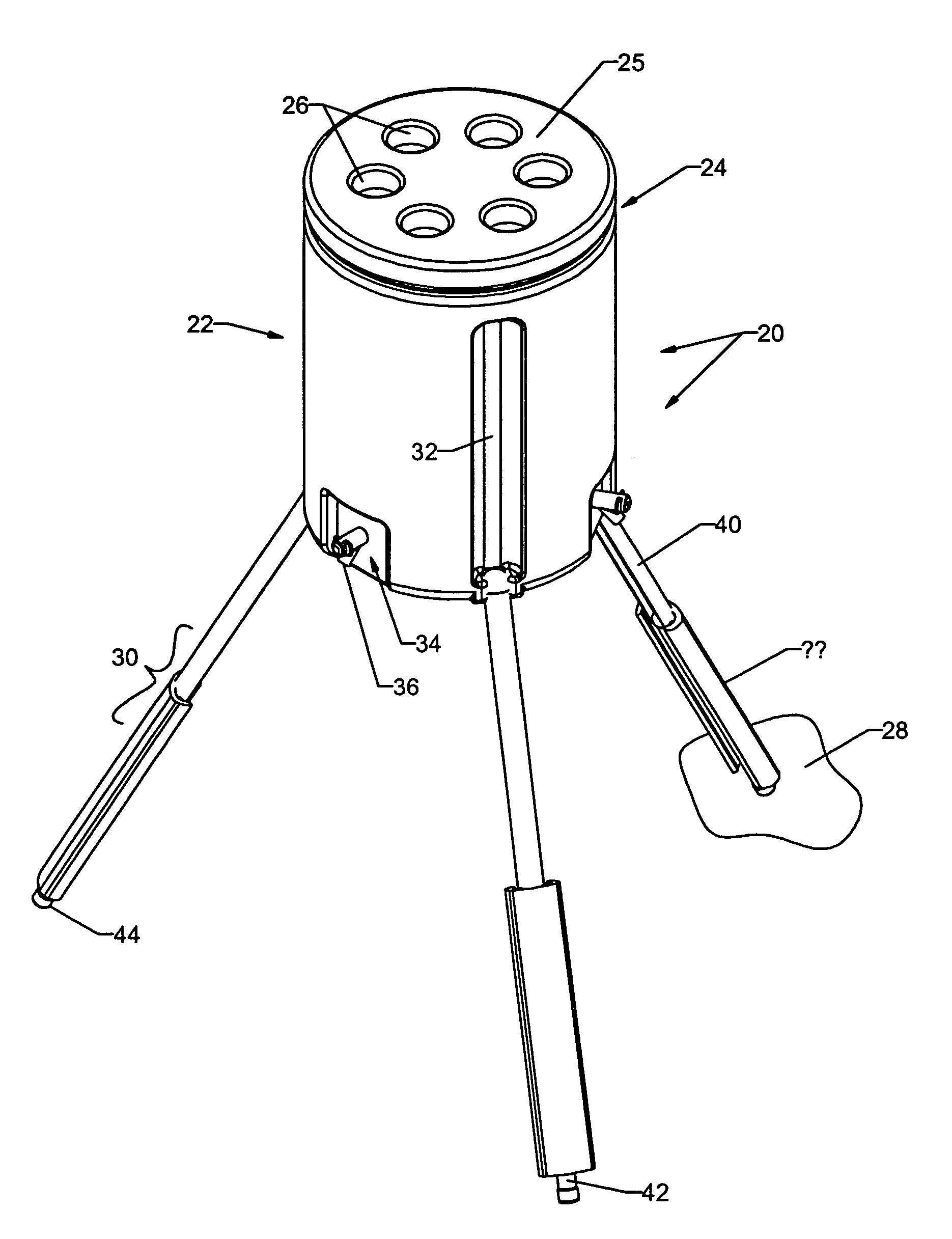

Portable water cooler for use with bagged fluids and bagged fluids for use therewith

ActiveUS20050077318A1Improved fluid controlIncrease choiceMechanical apparatusLiquid flow controllersEngineeringThermal control

A portable water cooler is designed to accept the placement of bagged fluid therein, leading to the connection of the bag of fluid to a fluid flow pathway, thereby allowing the fluid to be dispensed in a manner such that the fluid is segregated from the internal surfaces of the cooler. The portable water cooler generally includes an internal spike and external spigot through which fluid may flow. Systems and methods for dispensing bagged fluid from such a cooler, including various multi-bag systems and methods allowing for improved thermal control of fluids being dispensed, as well as increased selection of fluids dispensed from the same portable water cooler provide a high level of convenience.

Owner:INT PACKAGING INNOVATIONS

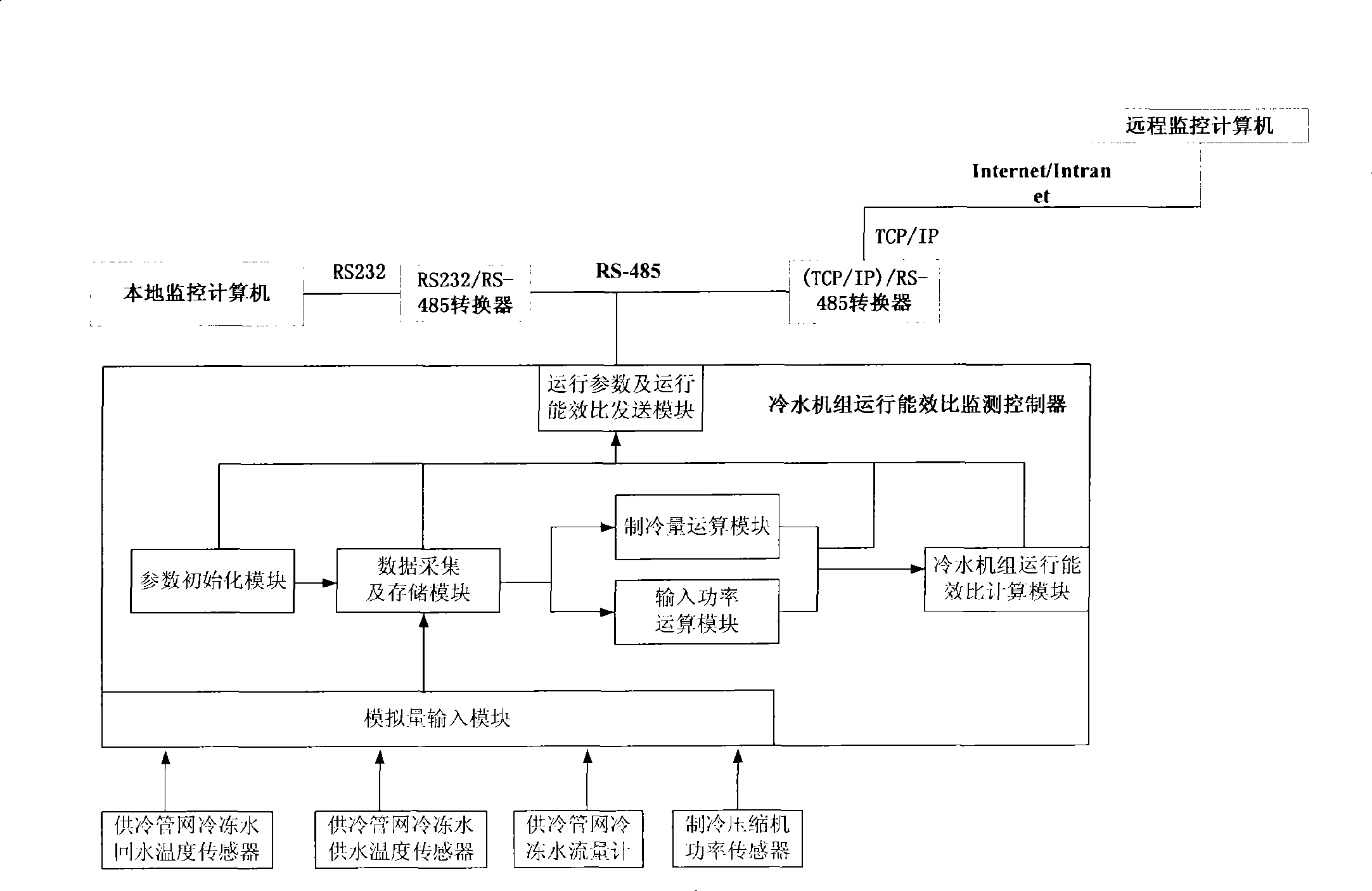

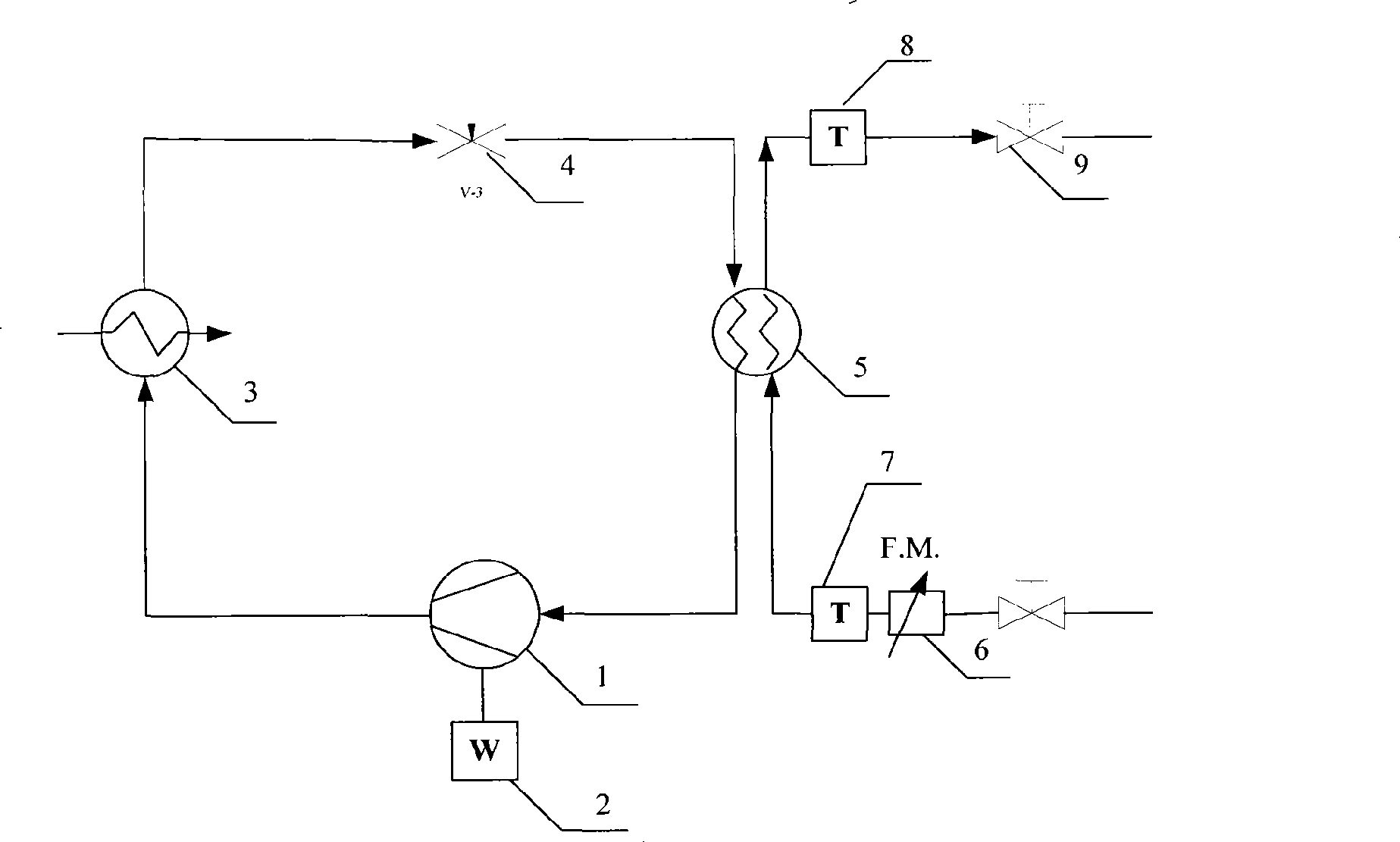

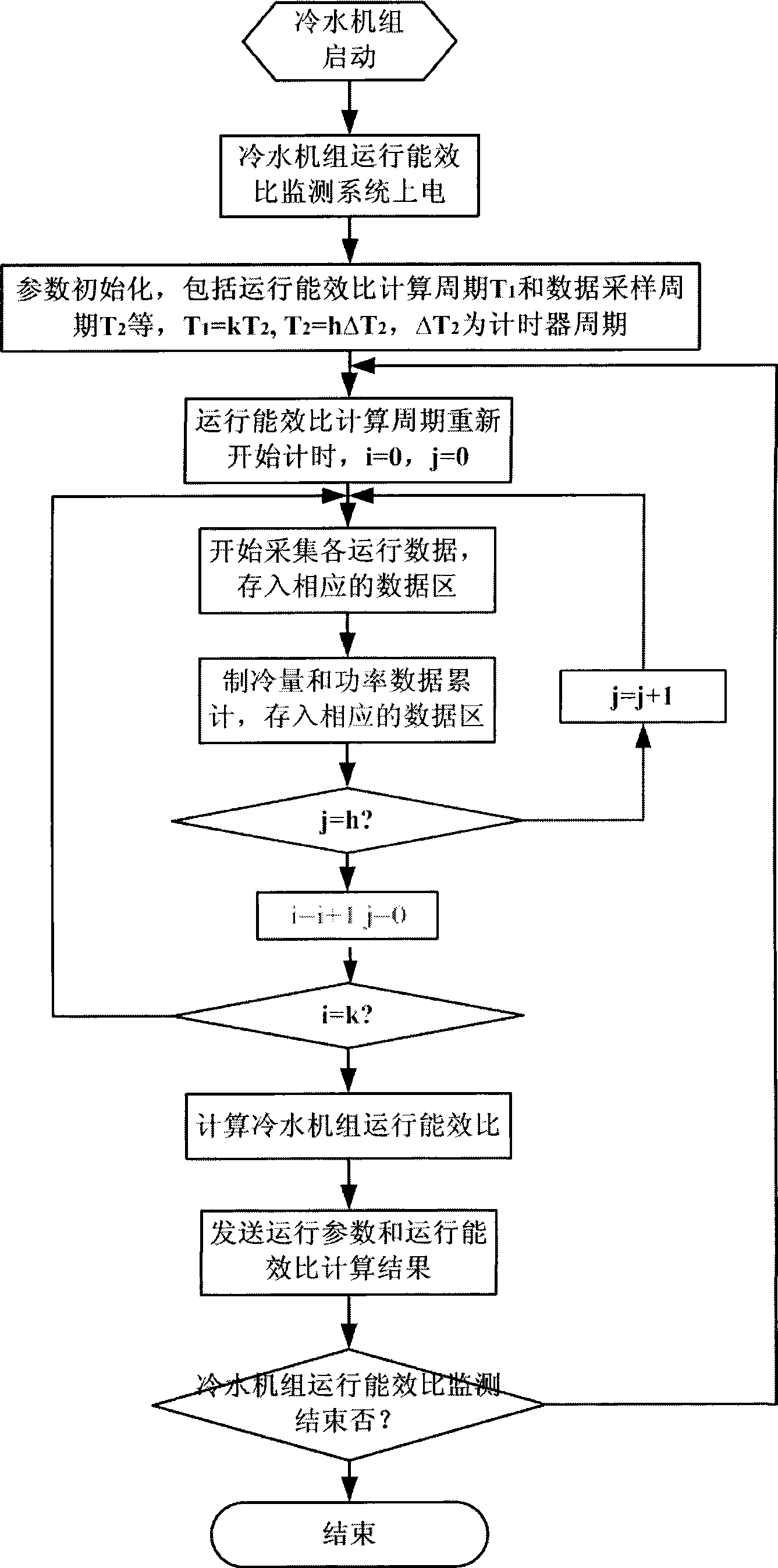

System and method for monitoring operation energy efficiency ratio of water chilling unit

ActiveCN101435643AReal-time maintenanceReduce wasteSpace heating and ventilation safety systemsSpace heating and ventilation control systemsPower sensorRefrigeration compressor

The invention relates to a system for monitoring energy efficiency ratio of operation of a water cooler set and a monitoring method thereof. The system comprises a controller for monitoring the energy efficiency ratio of operation of the water cooler set, a local monitoring computer, a remote monitoring computer and a frozen water supply temperature sensor of a cold supply pipe network, a frozen water return temperature sensor of the cold supply pipe network, a frozen water flowmeter of the cold supply network and a power sensor of a refrigeration compressor which are correspondingly connected with the water cooler set; the frozen water supply temperature sensor of the cold supply pipe network, the frozen water return temperature sensor of the cold supply pipe network, the frozen water flowmeter of the cold supply network and the power sensor of the refrigeration compressor are connected with the controller for monitoring the energy efficiency ratio of operation of the water cooler set respectively; and the local monitoring computer and the remote monitoring computer are connected with a signal of the controller for monitoring the energy efficiency ratio of operation of the water cooler set through a convertor I and a convertor II respectively. The system is suitable for the water cooler set of a central air conditioning system using electric power as primary drive energy; and the measured energy efficiency ratio of operation of the water cooler set is suitable for supervising daily energy-saving operation of the water cooler set.

Owner:GUANGZHOU YUANZHENG INTELLIGENCE TECH

Office water cooler adapter for use with bagged fluids

A fluid dispensing apparatus comprises a collapsible bag capable of being punctured by and essentially sealed about a spike that has an inlet through which fluid can flow from the bag into a conduit leading to a chamber that is situated within an enclosed chamber in a dispensing base unit. The chamber is connected to a valve positioned outside the enclosed chamber through which fluid can be dispensed from the chamber. The enclosed chamber is vented so that as fluid is dispensed from the chamber, the air pressure in the enclosed chamber is allowed to equalize with the ambient air pressure external to the chamber and the bag.

Owner:INT PACKAGING INNOVATIONS

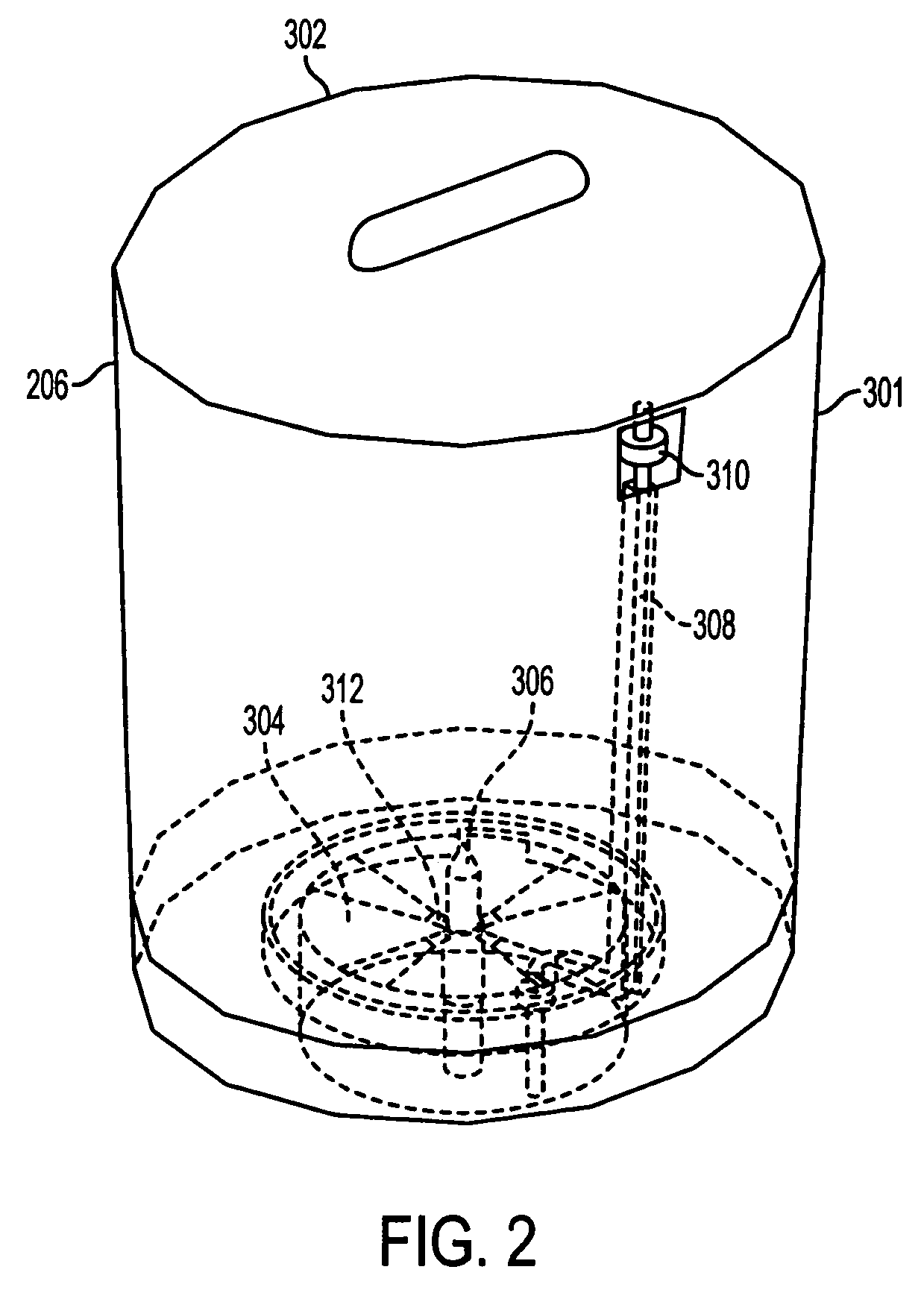

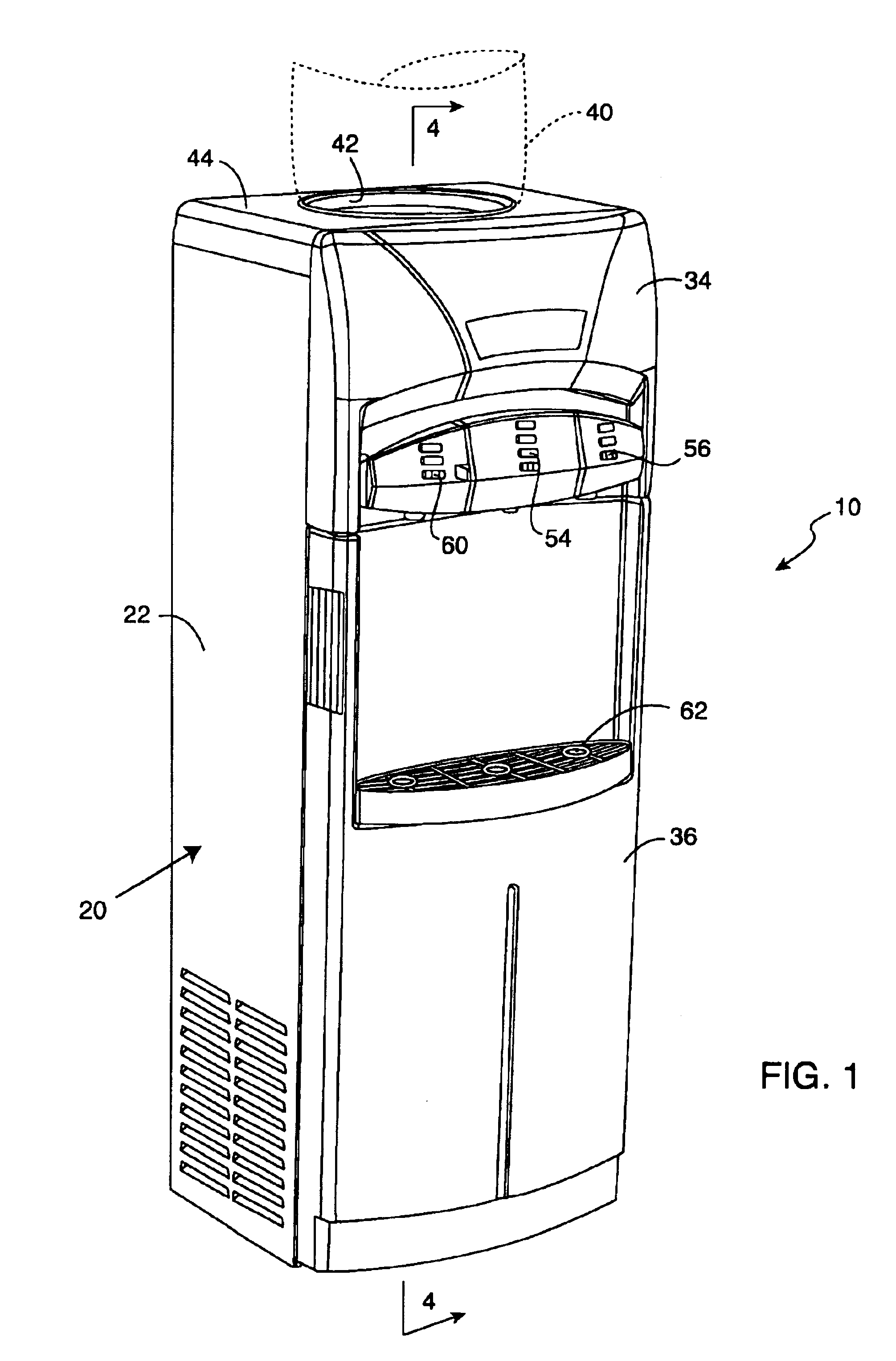

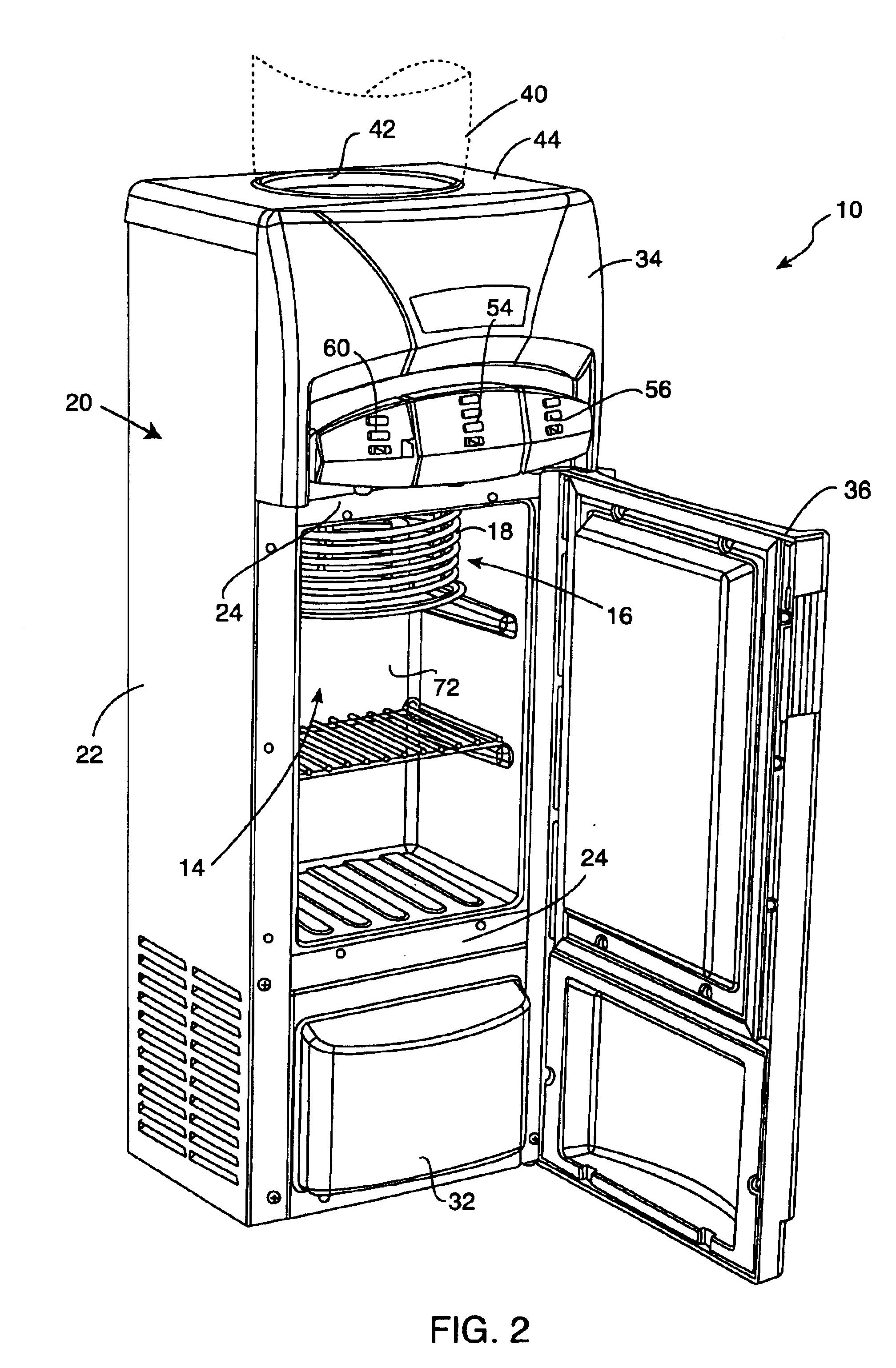

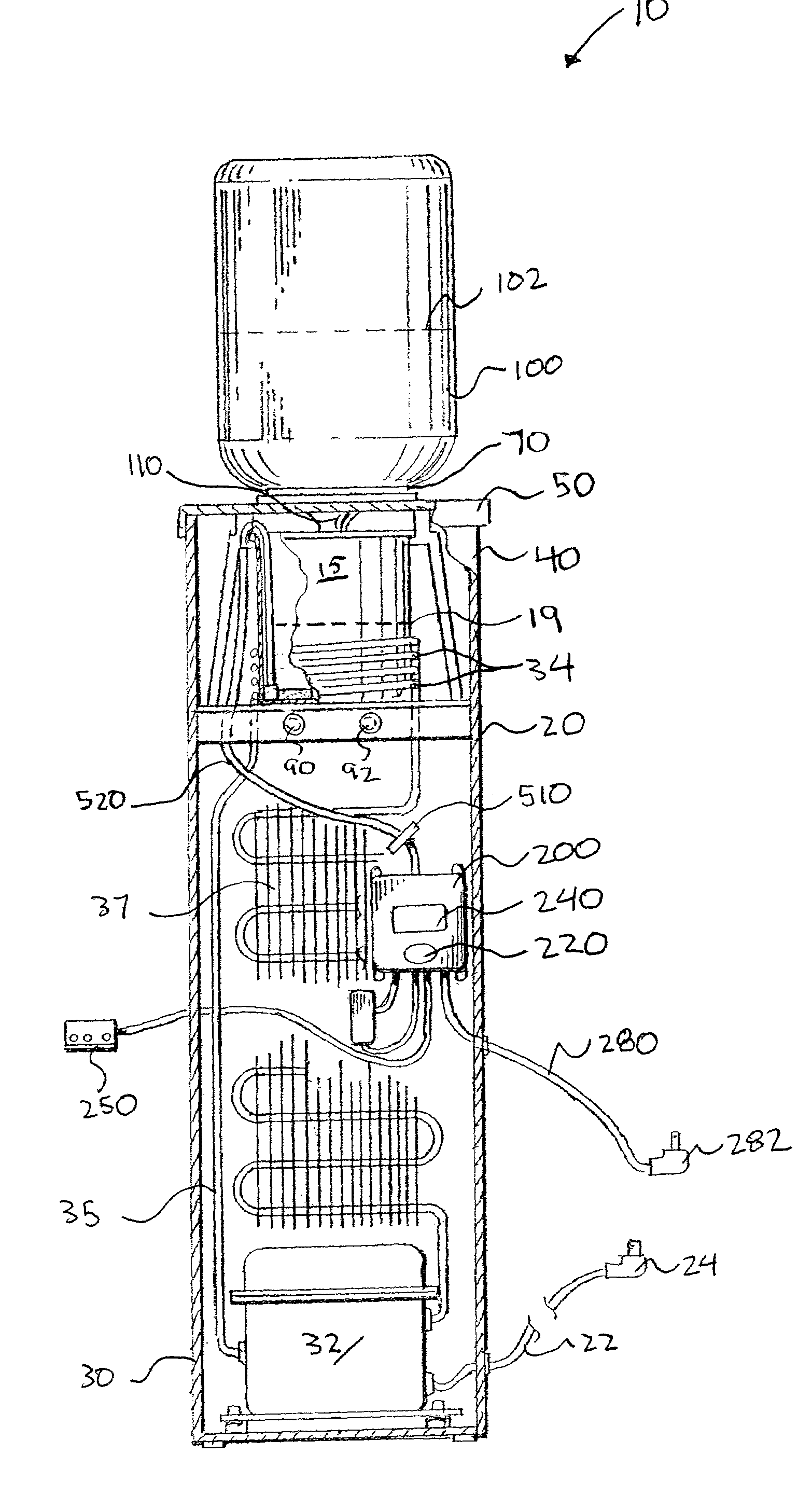

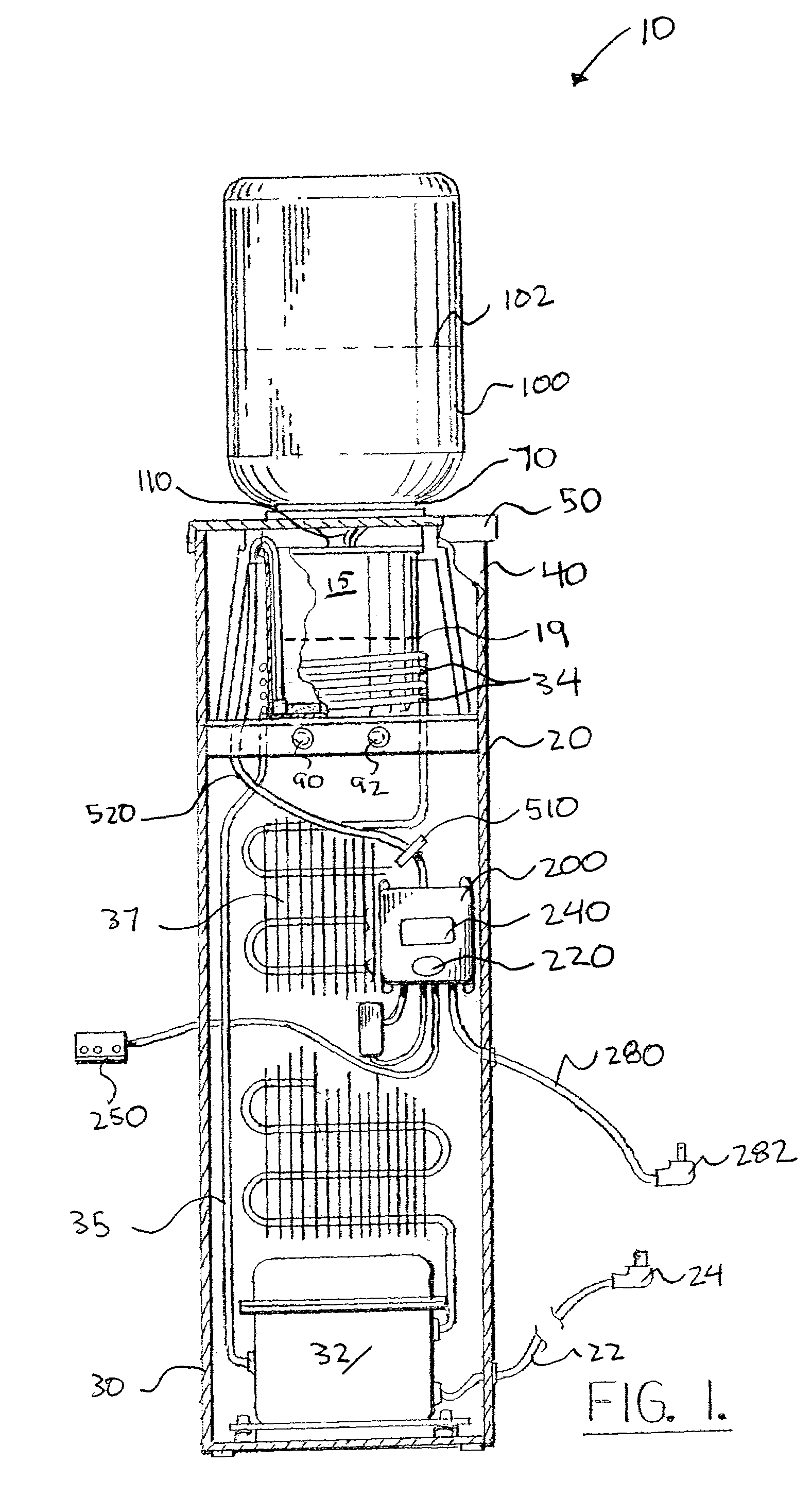

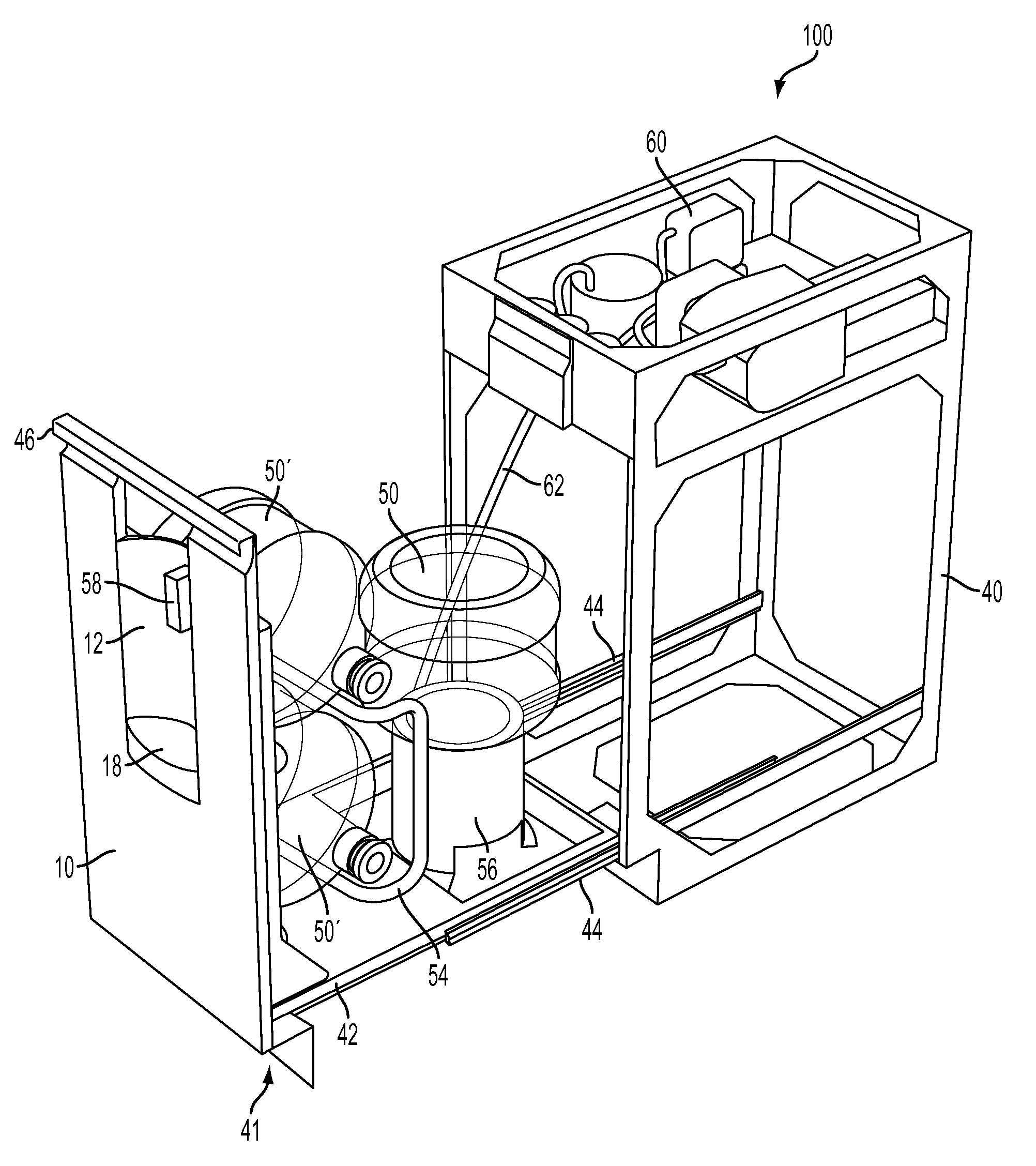

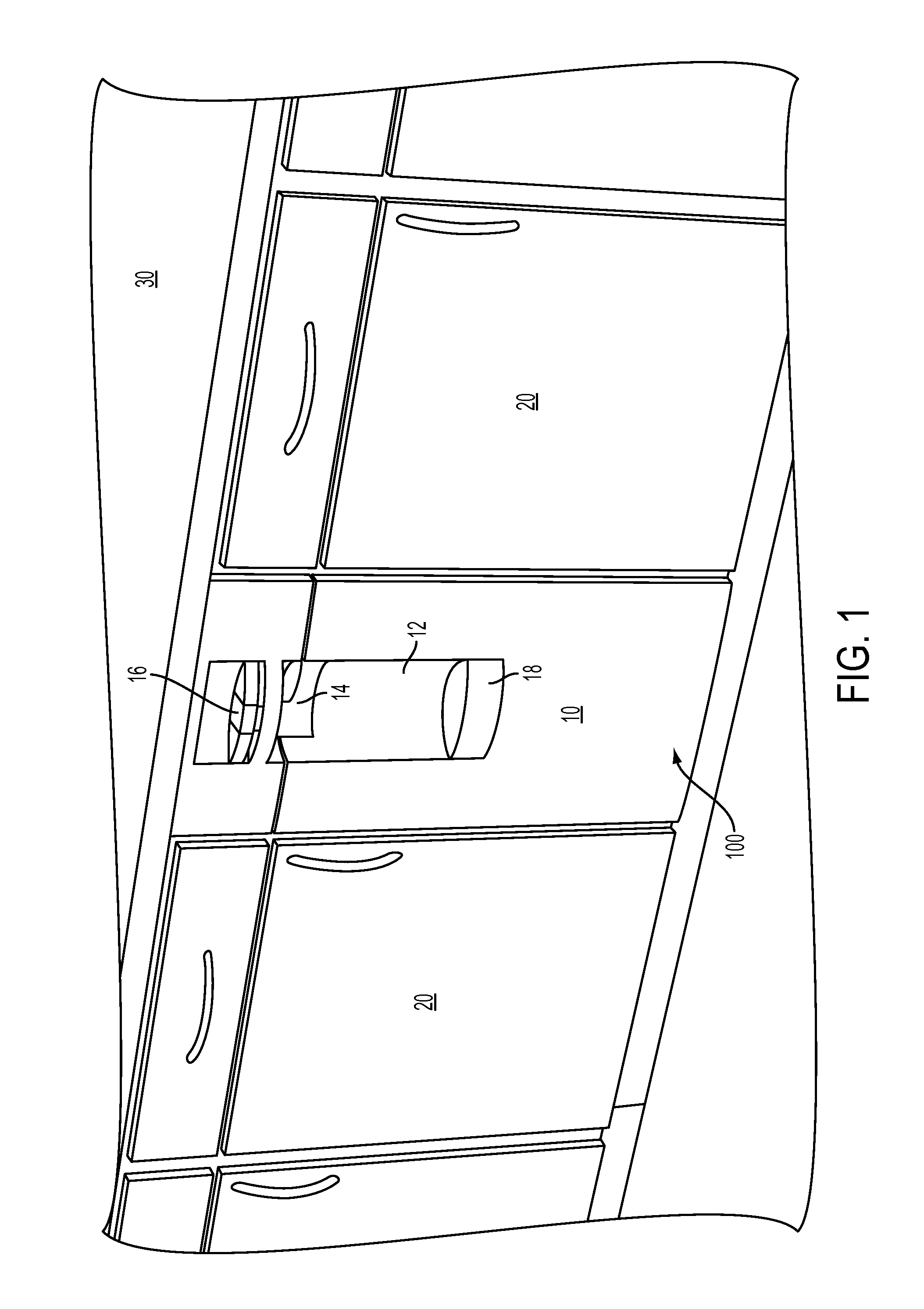

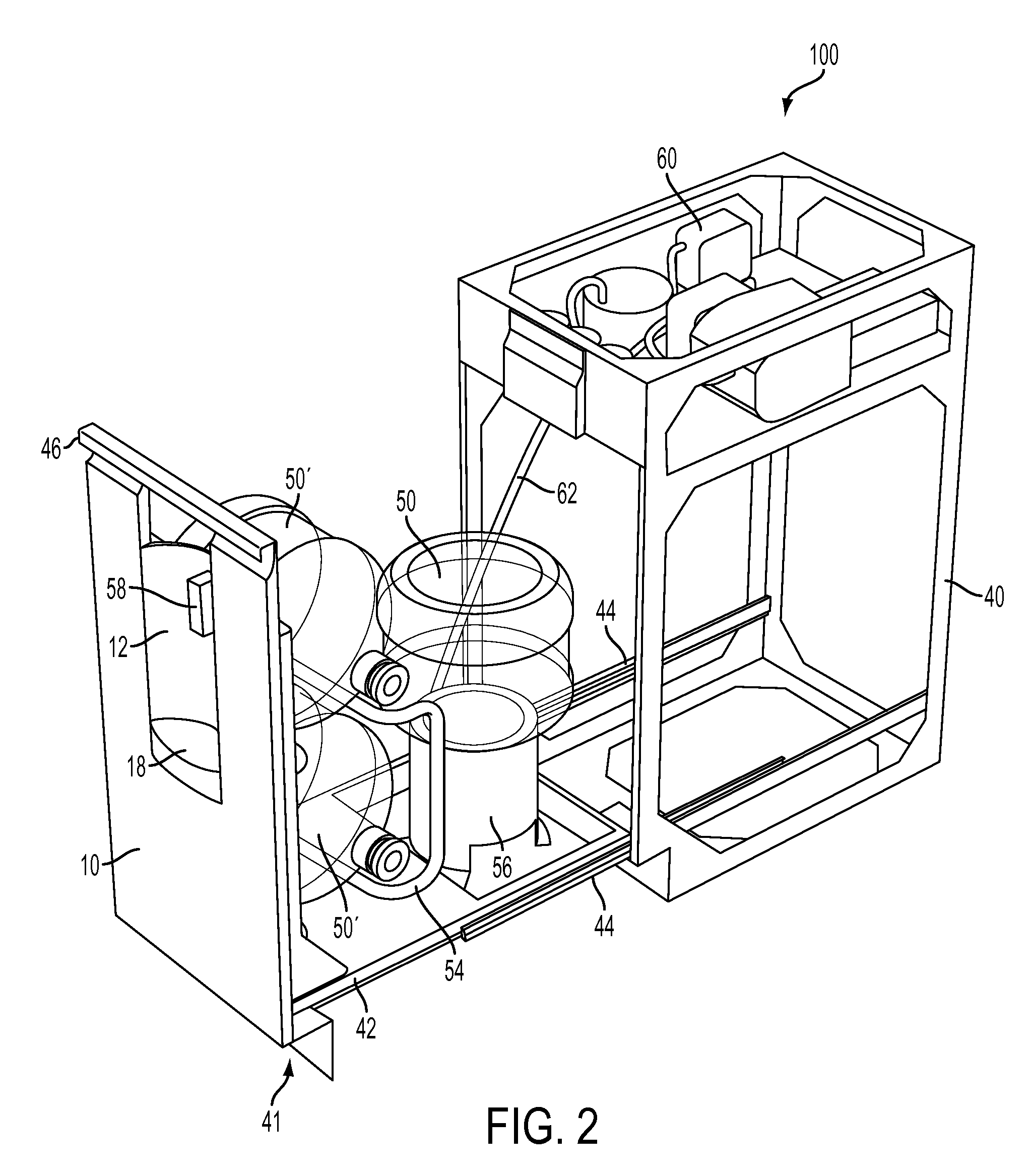

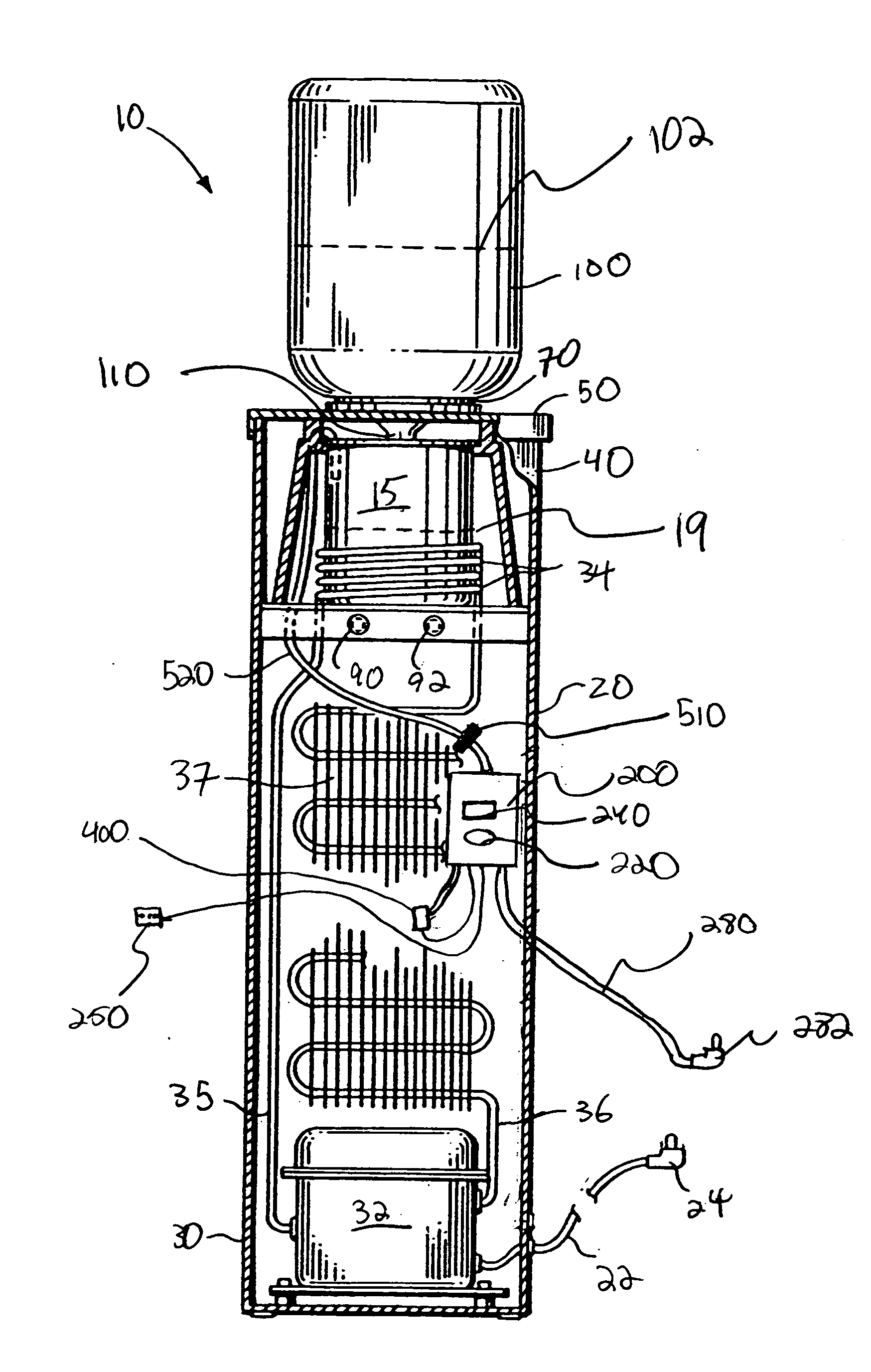

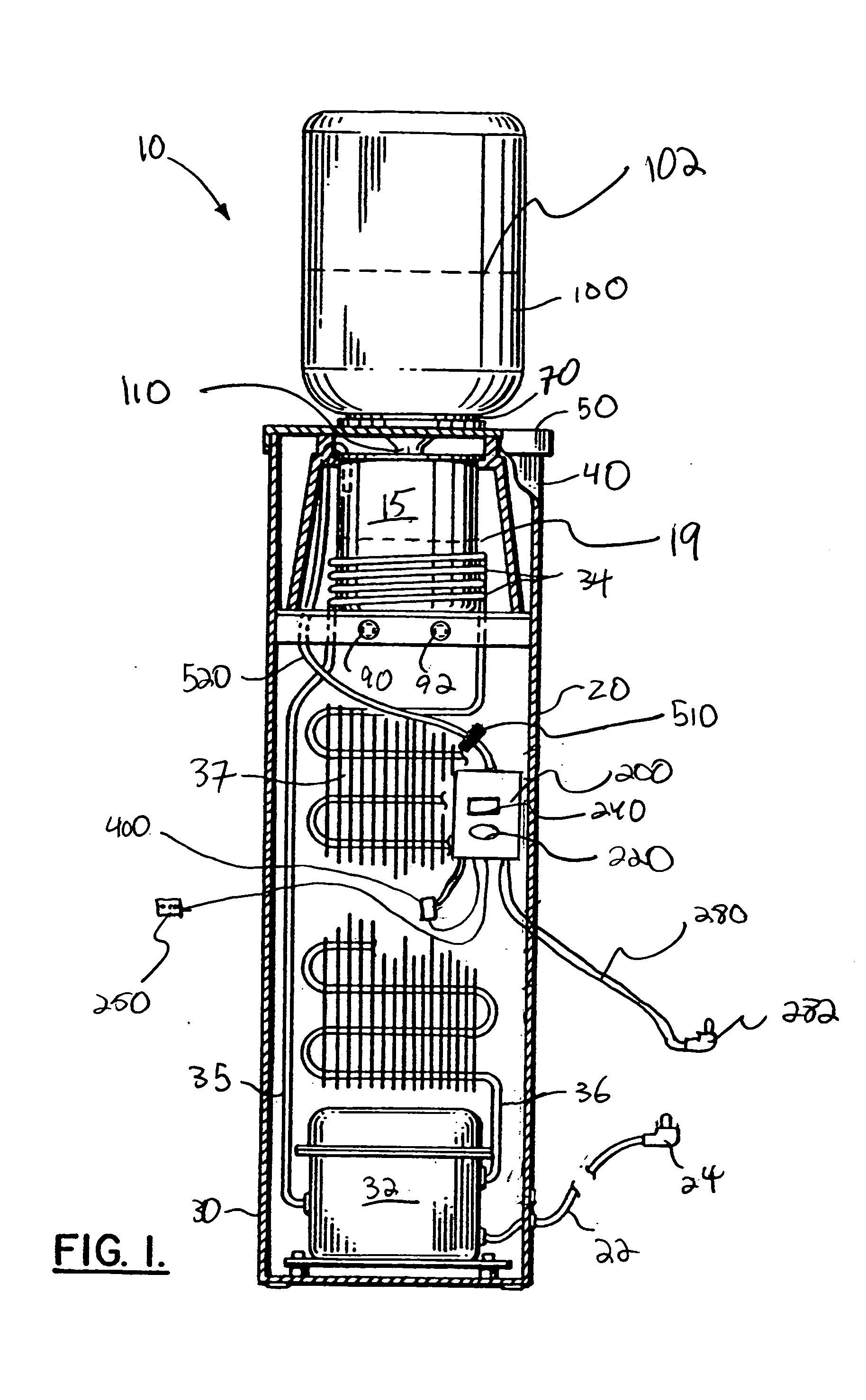

Combined water cooler and refrigerator unit

InactiveUS6912867B2Prevent overcoolingEliminate riskLighting and heating apparatusDomestic refrigeratorsTemperature controlWater source

A combination water cooler and refrigerator unit is provided including a lower cabinet defining a refrigerated compartment, and an upper water reservoir for receiving a supply of water from a water source, such as an inverted water bottle. A refrigeration system mounted within the cabinet includes a chiller coil having a first segment for chilling the refrigerated compartment, and a second segment for chilling water within the water reservoir. In addition, a lower end of the water reservoir is positioned in heat transfer relation with an upper region of the refrigerated compartment, and a single thermostatic temperature control sensor is mounted within the refrigerated compartment for regulating the refrigeration system for substantially eliminating risk of reservoir or refrigerator freeze up.

Owner:ZOHAR WATERWORKS

Separation and recycling device and recycling method for methane and argon in synthetic ammonia relief gas

ActiveCN102419071ARealize separation and recoveryImprove heat transfer efficiencySolidificationLiquefactionDehydrogenationProcess engineering

The invention relates to the technical field of recycling of a synthetic ammonia relief gas, and discloses a separation and recycling device and a recycling method for methane and argon in the synthetic ammonia relief gas. The device comprises a cooling box, a virgin gas pipeline, a water cooler, a gas-liquid separator, a gas-liquid balancing tank, a throttling reducing valve, a purification system, a refrigeration system and a rectifying system, wherein the refrigeration system comprises a mixed refrigerant circulating compressor, a medium-pressure circulating nitrogen compressor and a main heat exchanger; the medium-pressure circulating nitrogen compressor is connected with the water cooler and the main heat exchanger through a pipeline respectively; the rectifying system comprises a dehydrogenation tower, a methane rectifying tower and an argon rectifying tower; and the main heat exchanger, the dehydrogenation tower, the methane rectifying tower and the argon rectifying tower are connected through pipelines. By the device and the method for separating and recycling the methane and the argon from the synthetic ammonia relief gas by utilizing the mixed refrigerant and argon double-refrigeration system, high-purity methane and high-purity argon can be obtained, and nitrogen with relatively higher purity and hydrogen with relatively higher purity can be obtained at the same time.

Owner:HANGZHOU ZHONGTAI CRYOGENIC TECHNOLOGY CORPORATION

Device and method for growng large diameter 6H-SiC monocrystal with semiconductor property

ActiveCN1554808ALarge crystalsFor the purpose of dopingPolycrystalline material growthFrom condensed vaporsEngineeringSingle crystal

The present invention relates to apparatus and method of growing great diameter 6H-SiC monocrystal with semiconductor characteristic and belongs to the field of crystal growing technology. The apparatus includes growing chamber, water cooler on the side wall of the growing chamber, graphite crucible, heat insulating material, induction heating system, cylindrical vapor guiding plate of Ta inside the crucible, and cylinder. Regulating the position of the crucible relative to the inducing coil can minimize the temperature at the crystal seed inside the crucible and increase the temperature field distribution in the growing direction. Altering the atmosphere composition or material compounding can obtain great diameter SiC monocrystal with n-type, p-type or semi-insulating type semiconductor characteristic. By means of selecting the Si plane of the crystal seed and growing temperature, the crystal form may be controlled and 6H-SiC may be obtained.

Owner:SICC CO LTD

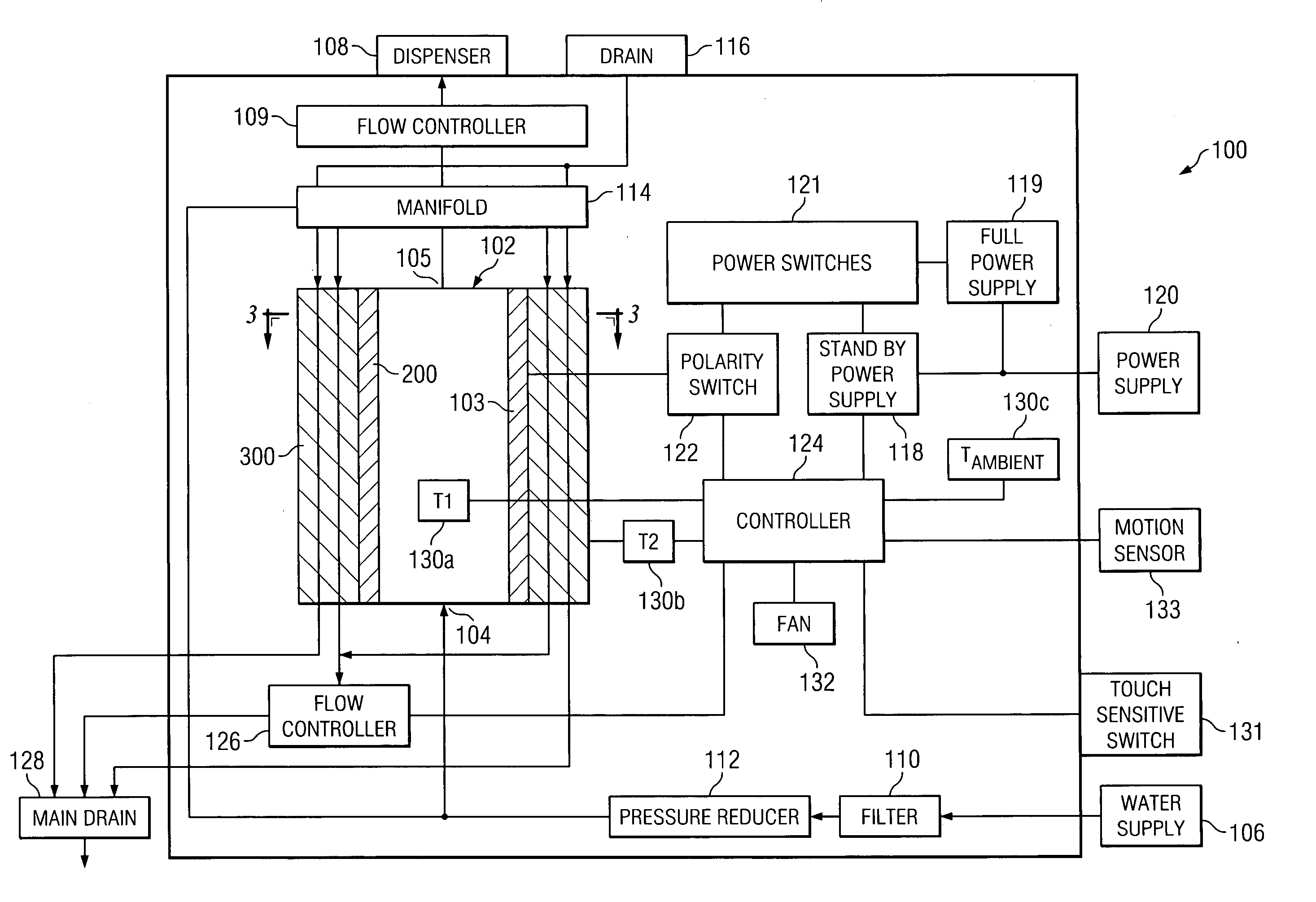

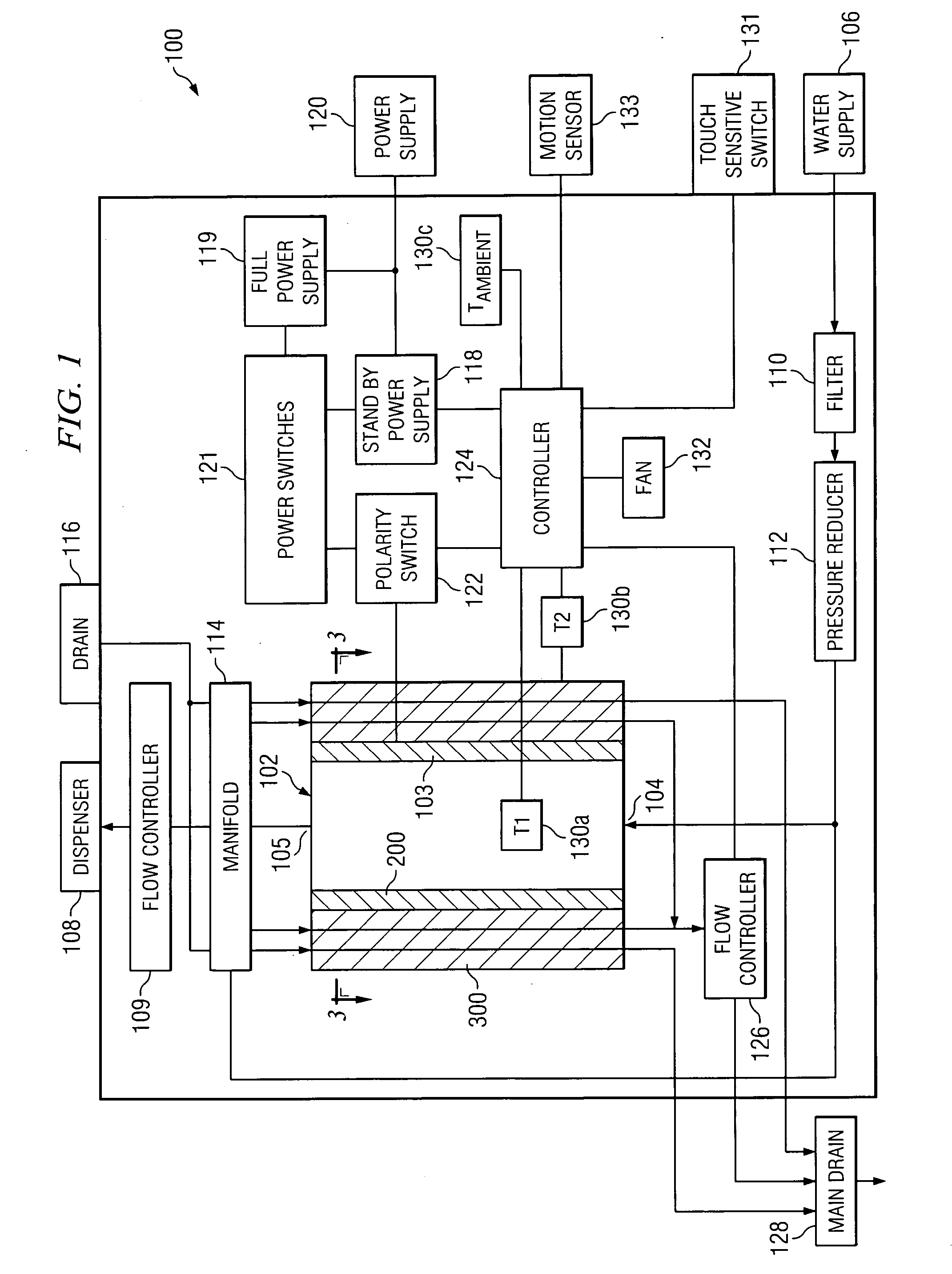

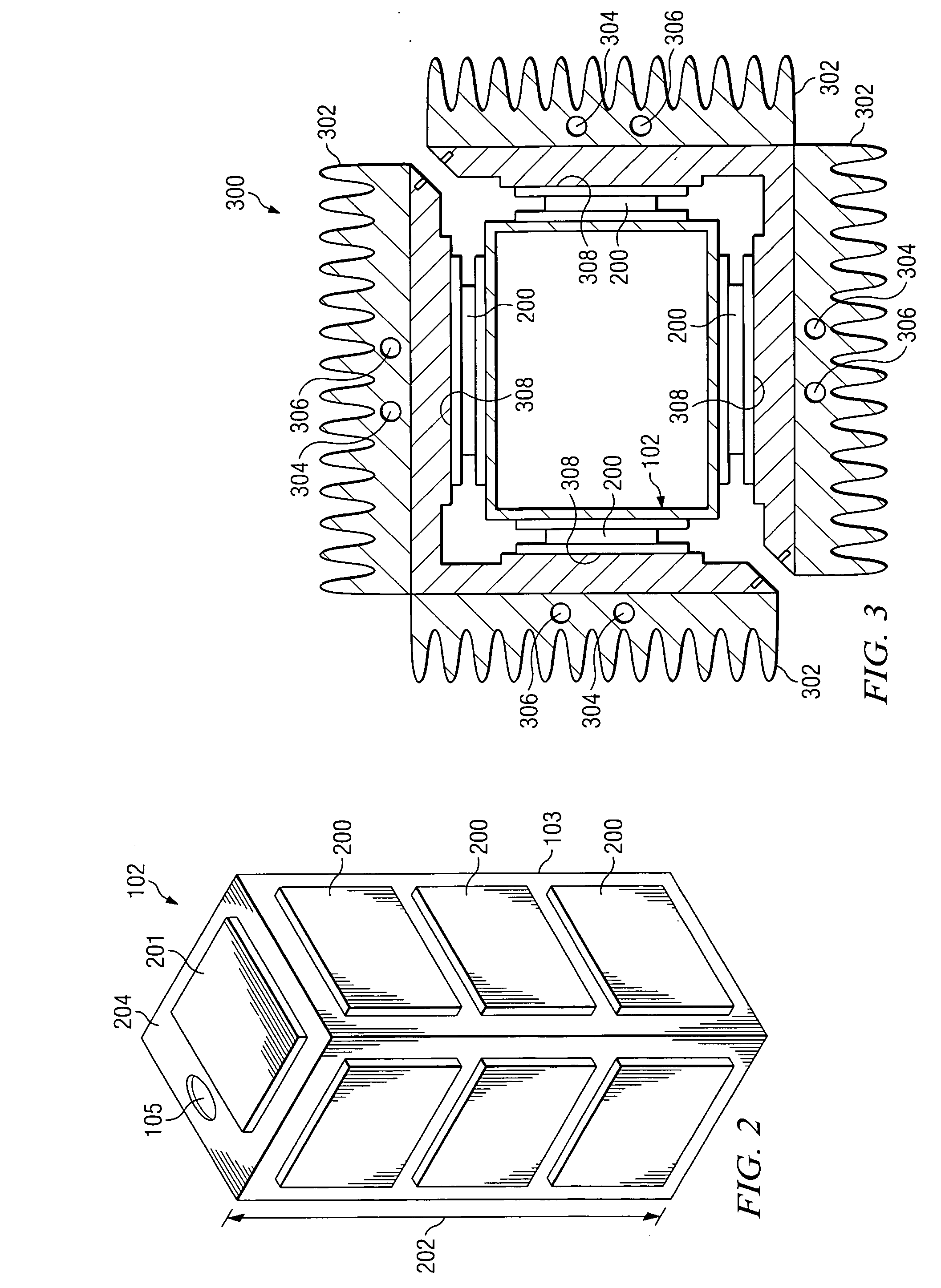

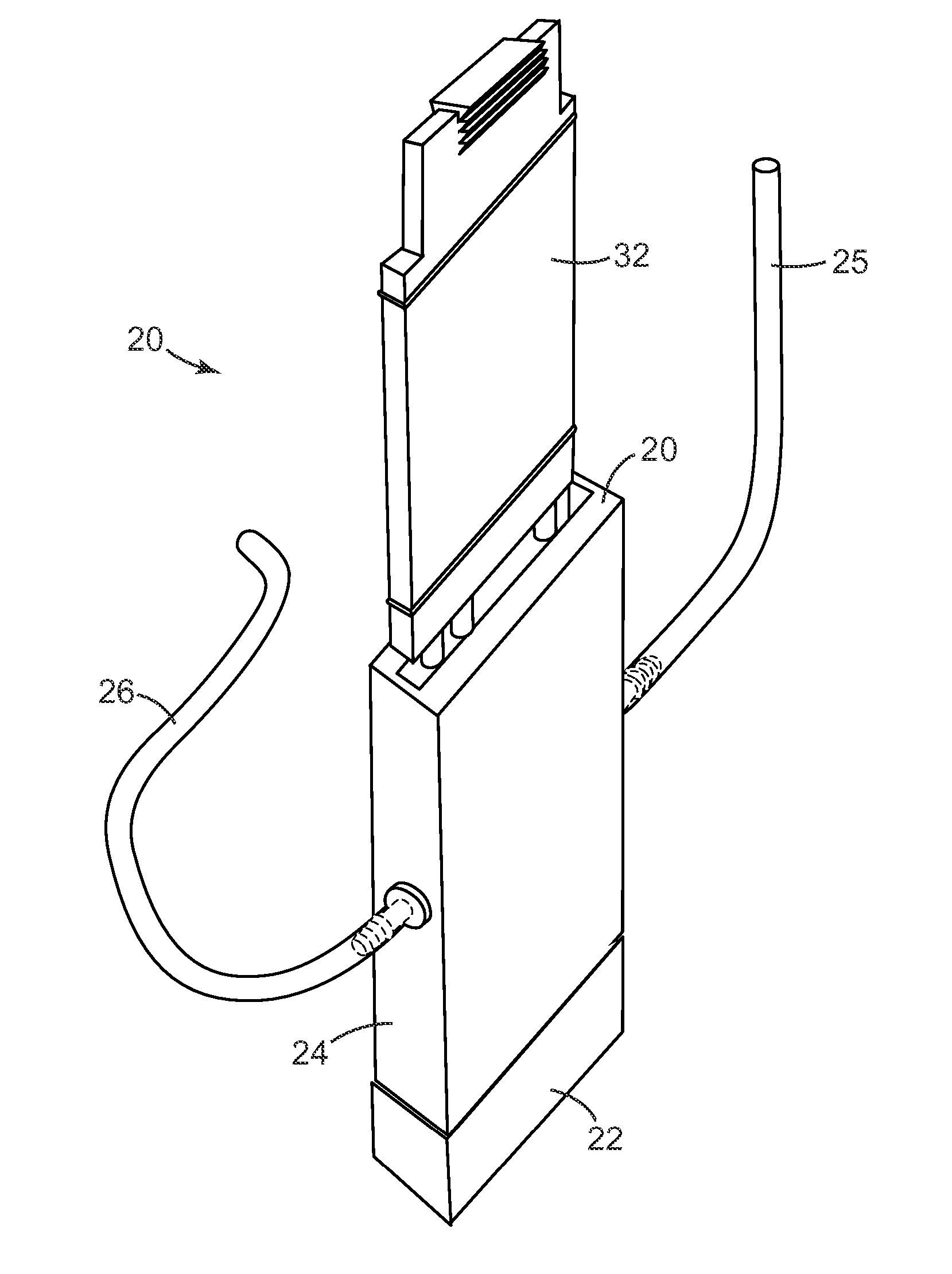

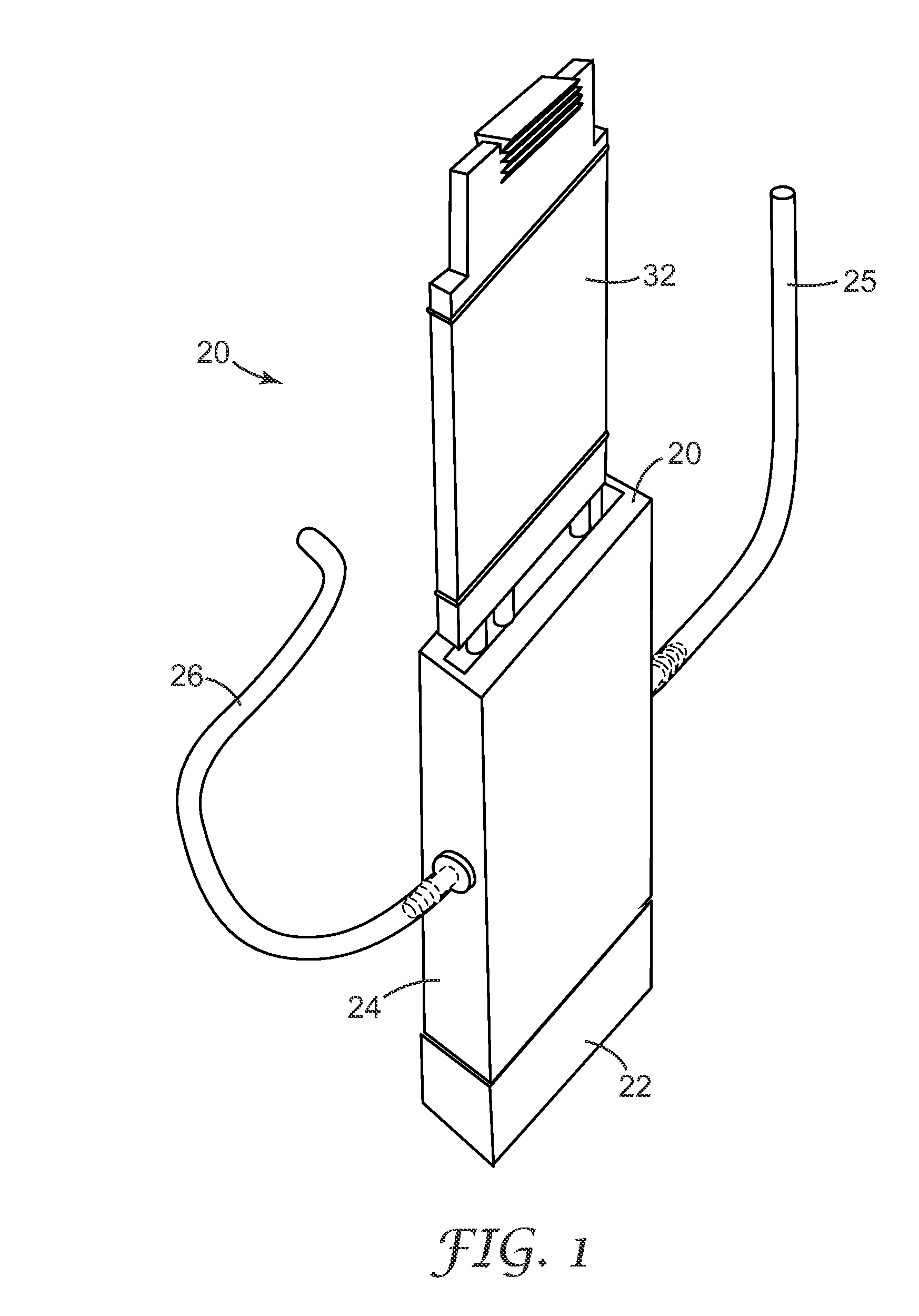

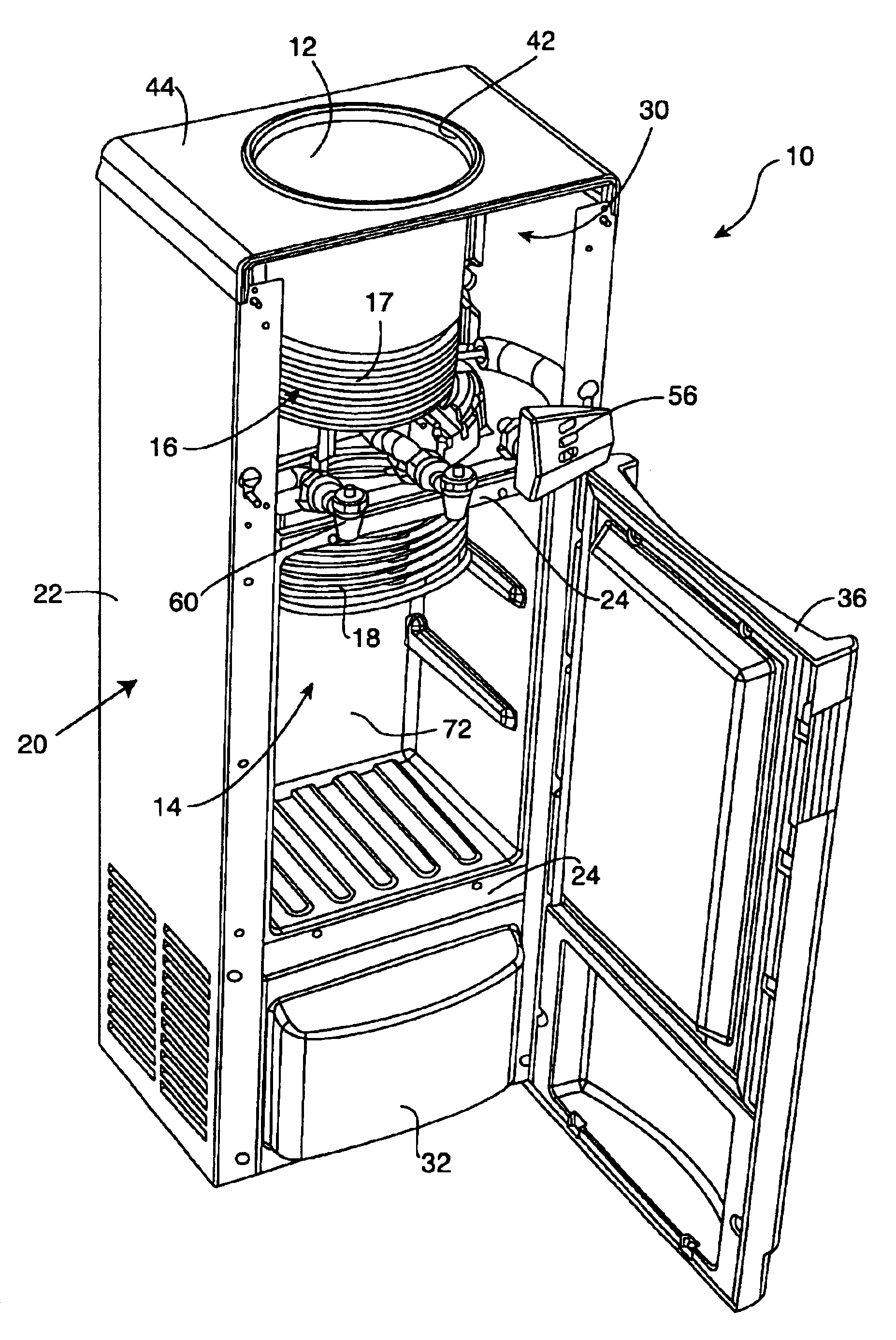

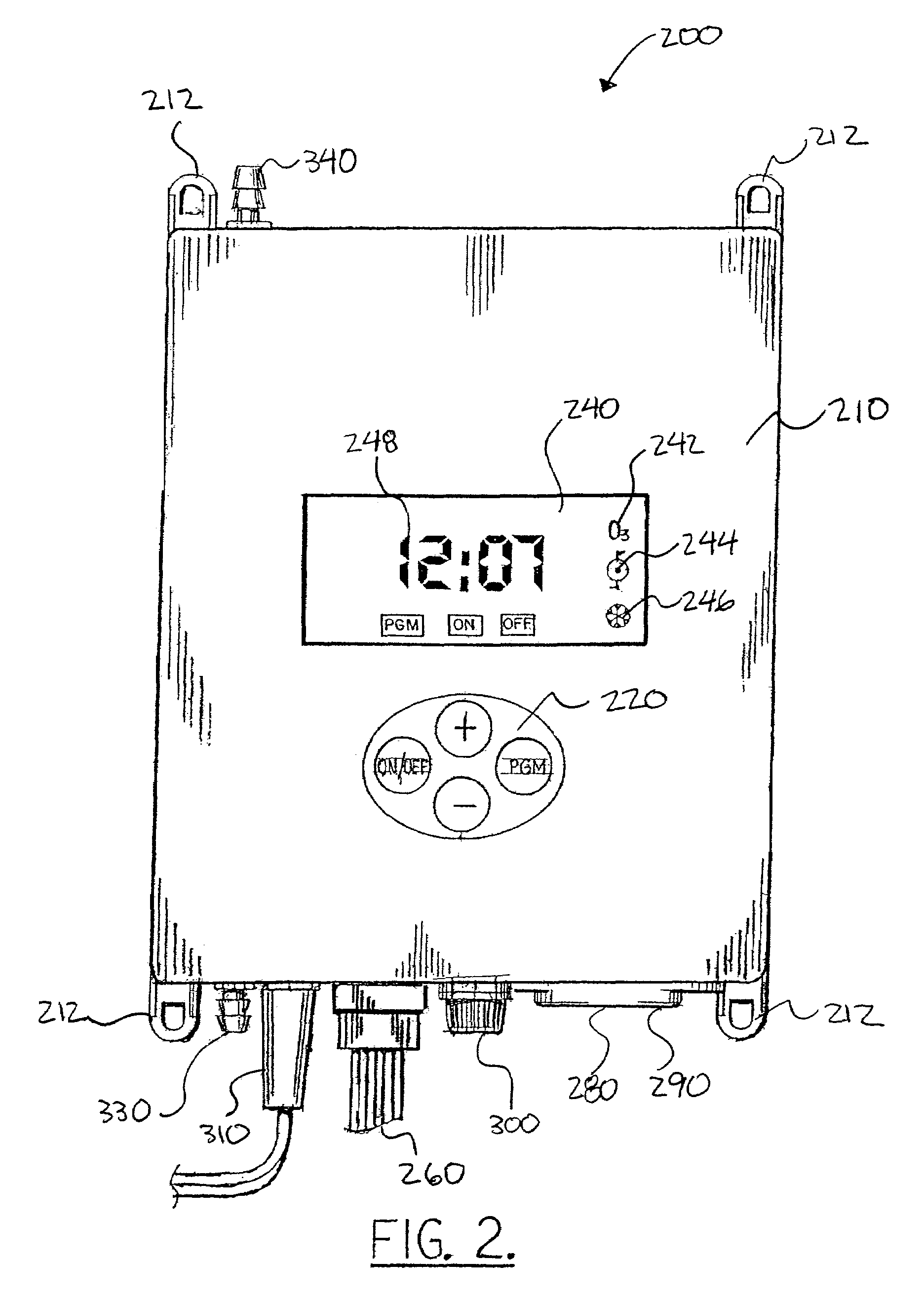

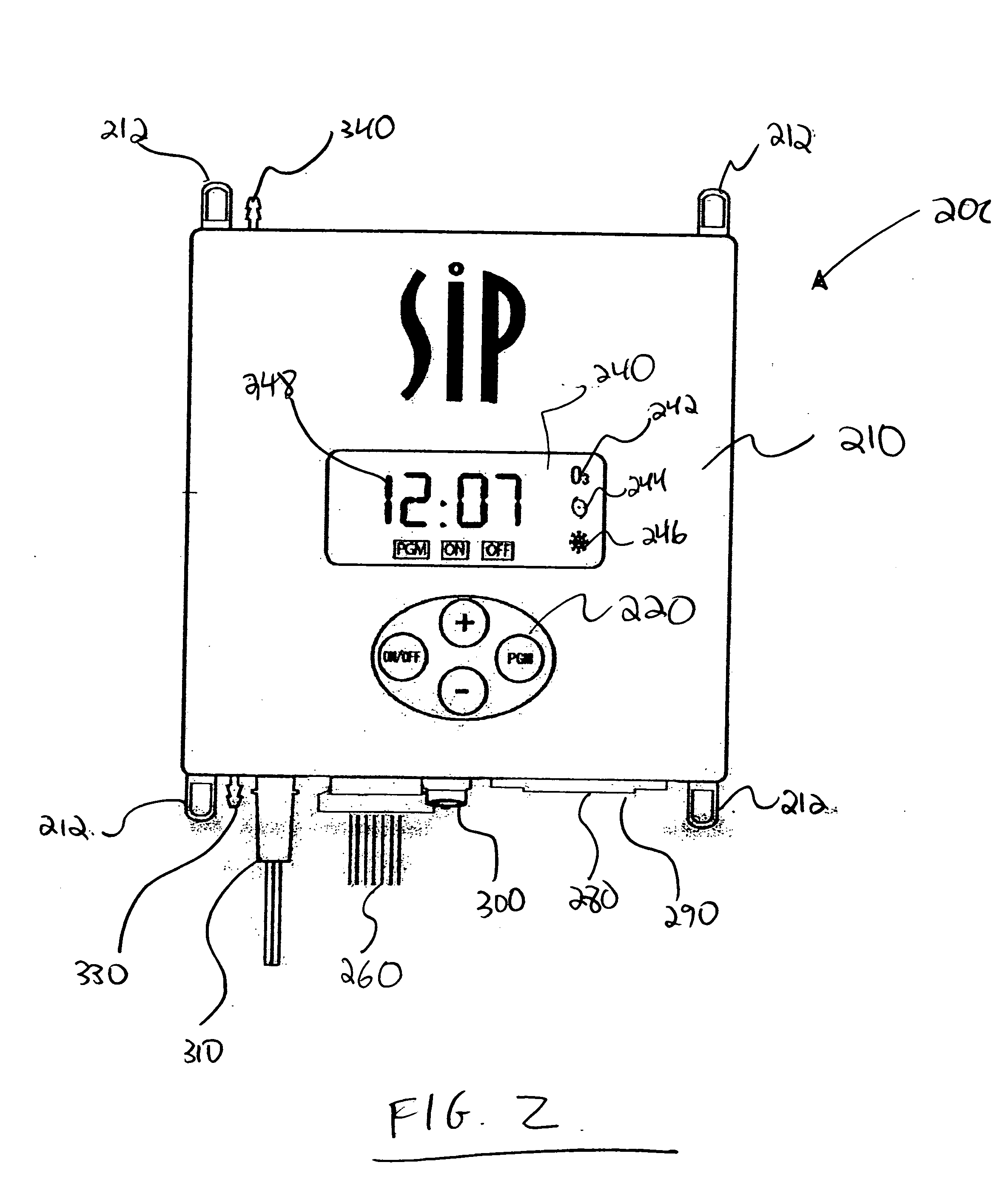

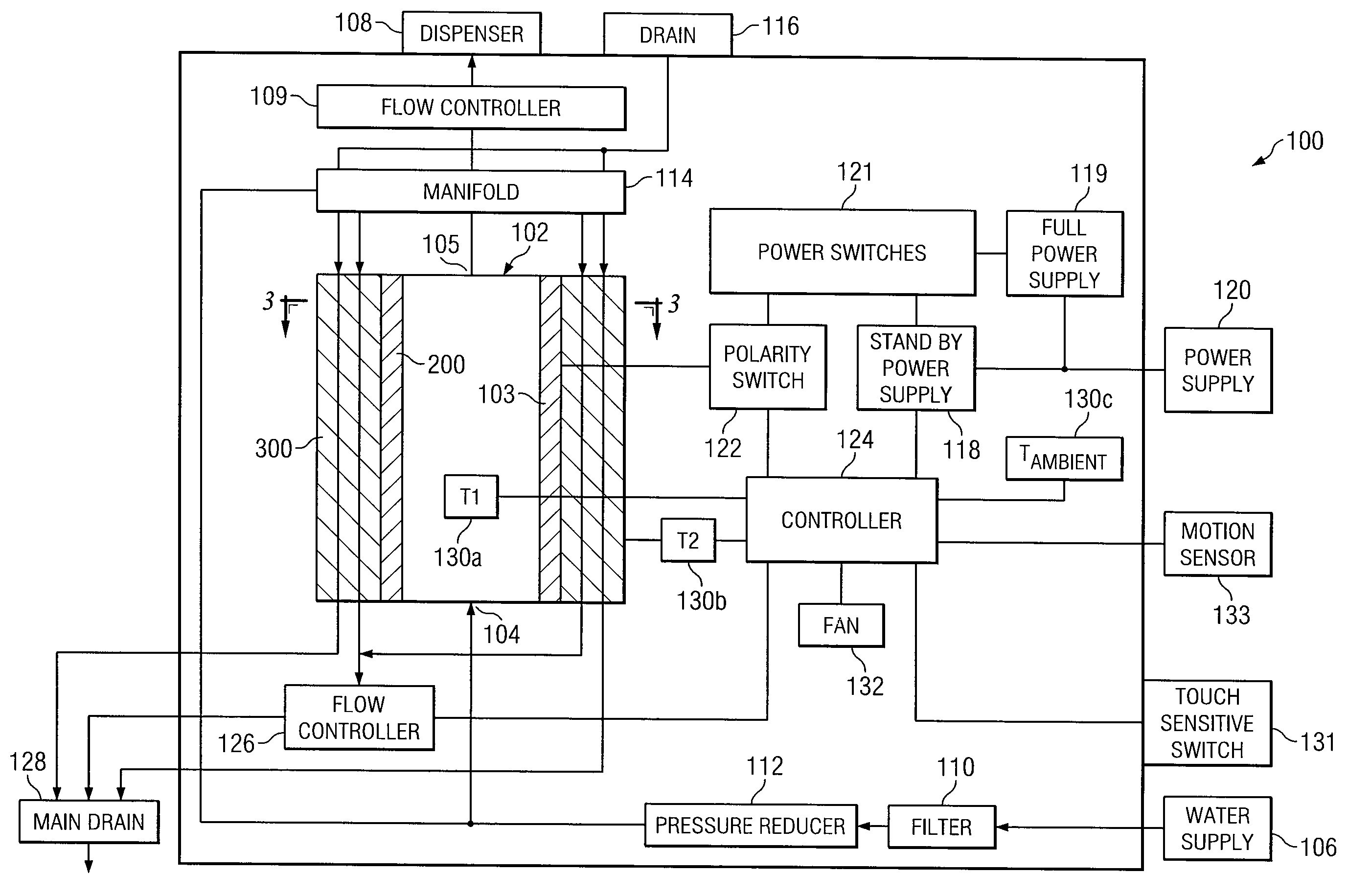

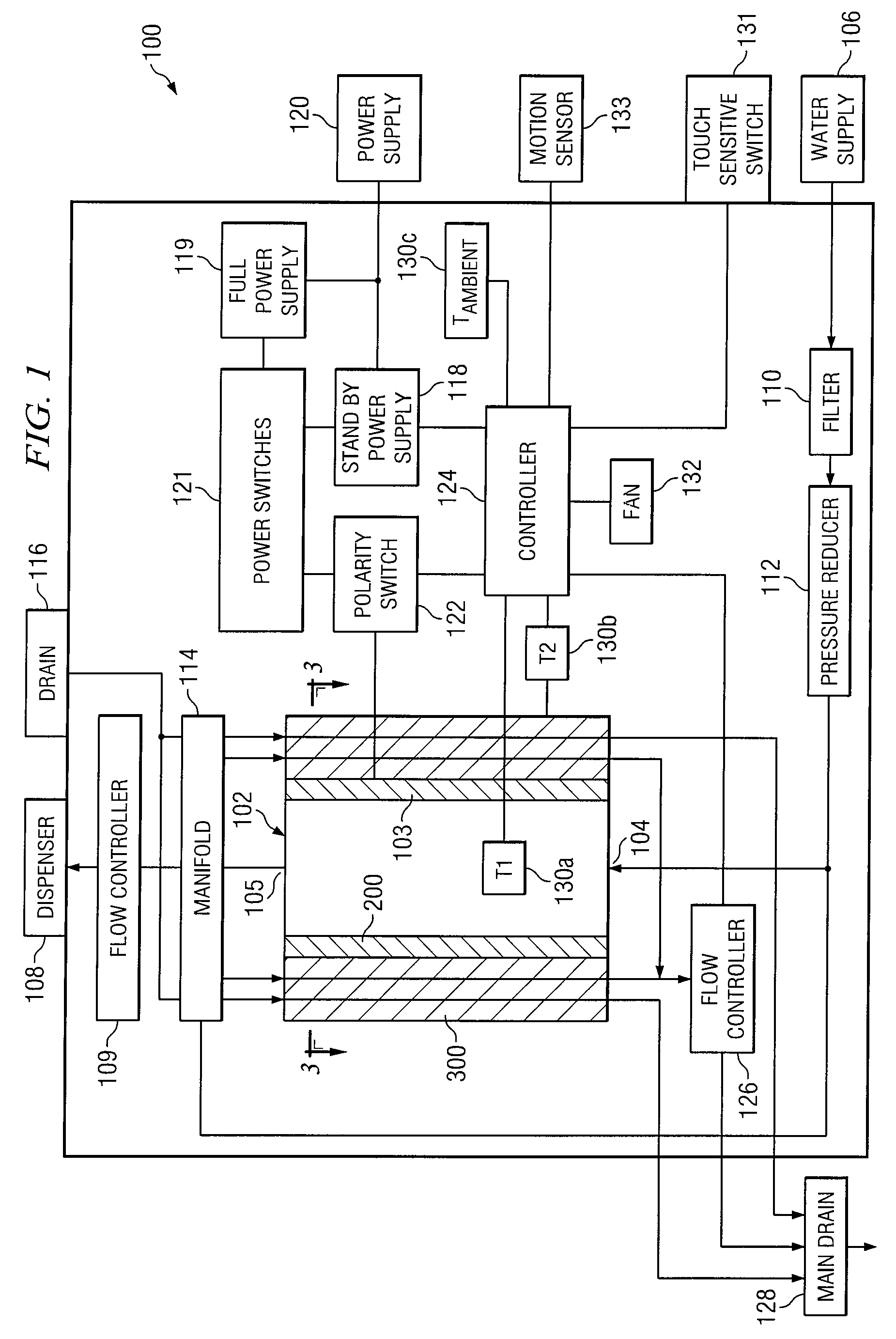

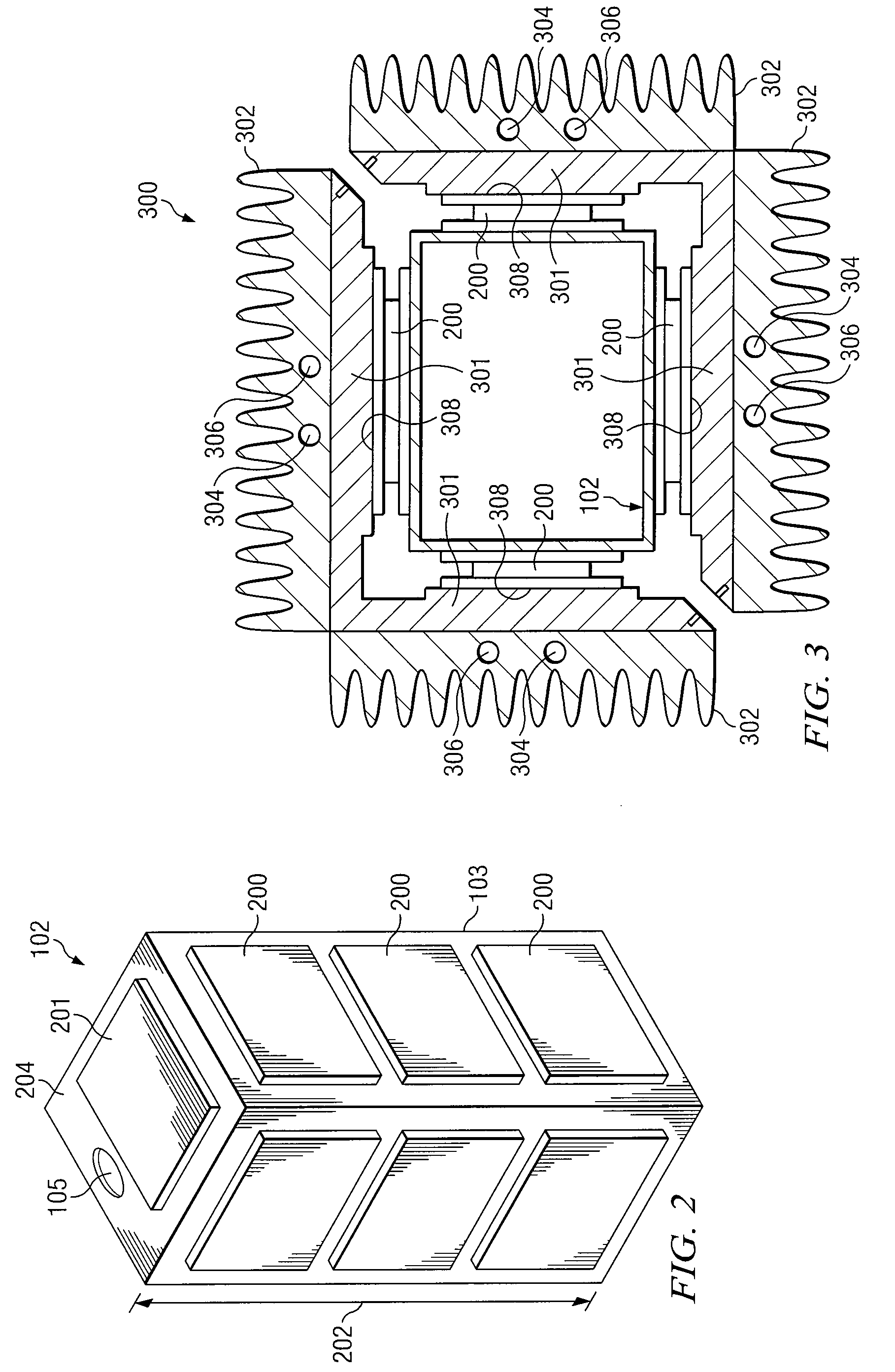

Method and apparatus for programably treating water in a water cooler

ActiveUS7114637B2Water treatment parameter controlLighting and heating apparatusEnvironmental engineeringDigital computer

An apparatus for a programmable self sanitizing water dispenser apparatus with a digital computer as well as a programmable method for generating ozone for cleaning the reservoir and the water contained within it.

Owner:S I P TECH L L C

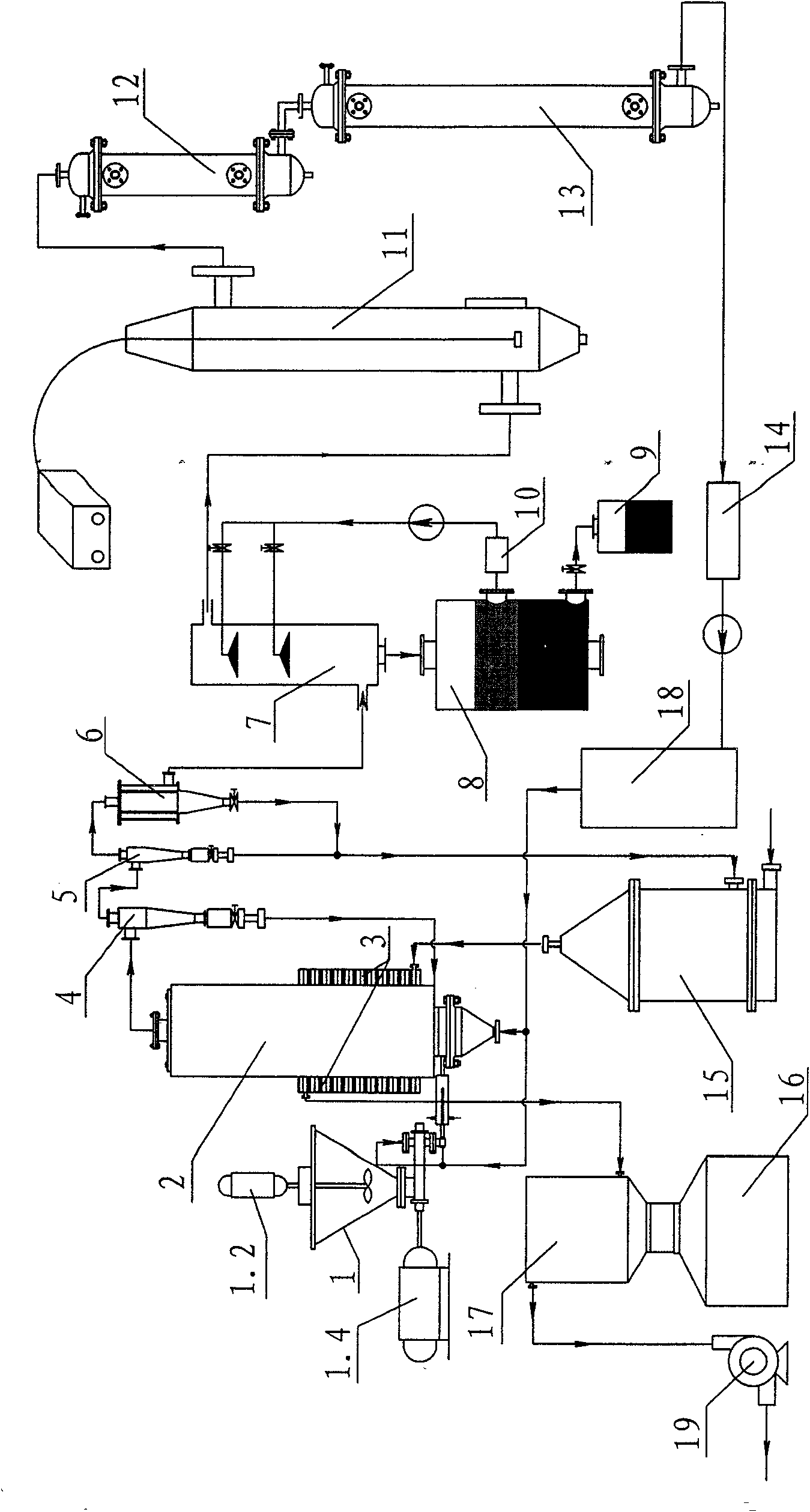

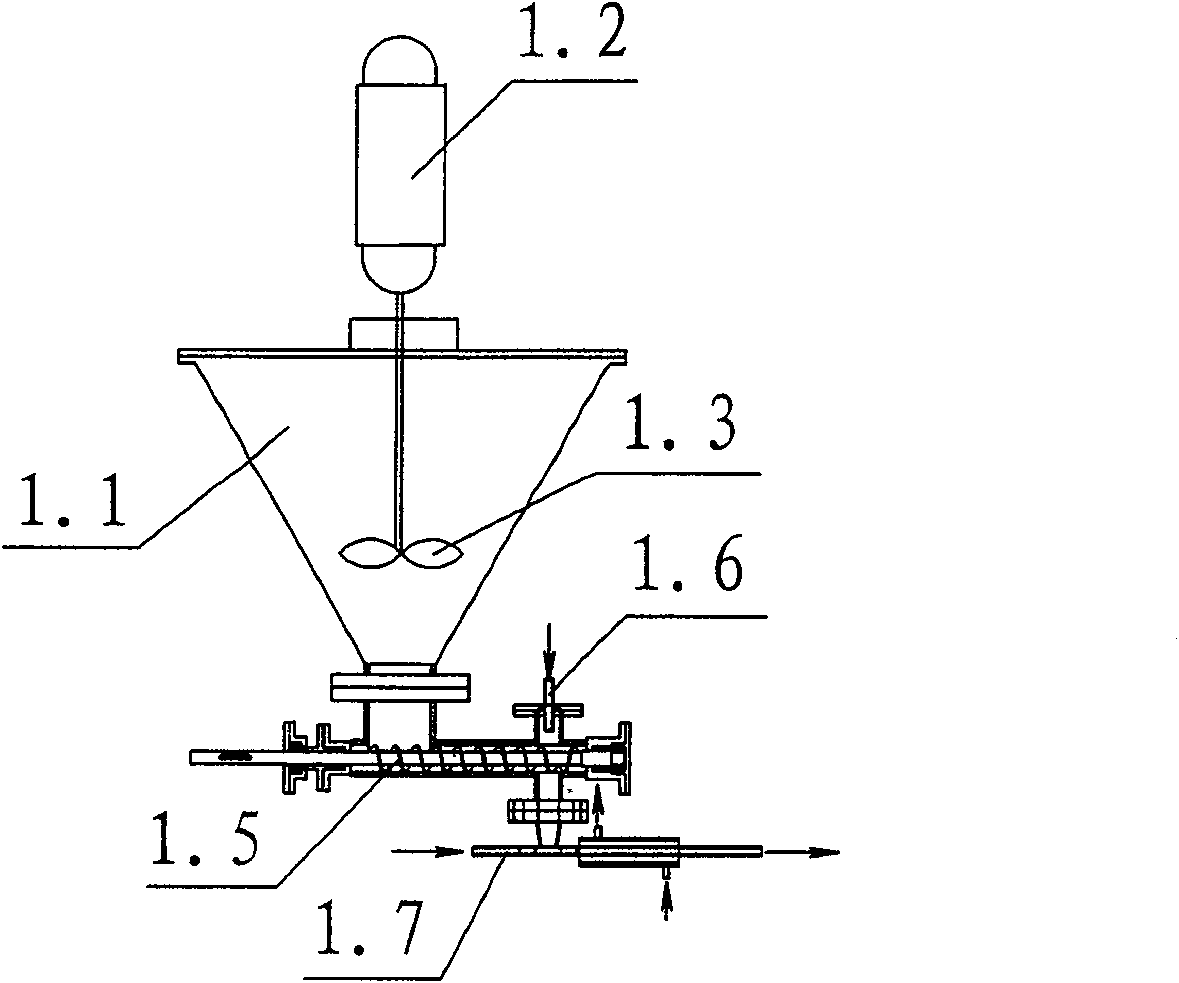

Method for preparing liquid fuels by self-heating self-circulating thermal cracking of biomass and device thereof

InactiveCN101560405ARealize self-heatingAvoid secondary reactionsLiquid hydrocarbon mixture productionCycloneElectricity

The invention relates to a method for preparing liquid fuels by self-heating self-circulating thermal cracking of biomass and a device thereof. Solid substances and carbon can be effectively reclaimed through a two-stage cyclone separator and a carbon filter, most of heavy oil components in thermal cracking volatile components are collected by adopting spray condensing, micro oil drops in the volatile components are further caught by electric catching, light oil components are complementally collected by cooling through a final dividing wall type water cooler, the volatile components are gradually cooled at an inlet of a cooling system at a temperature of 200 DEG C to collect biological oil, and finally, condensable parts in the volatile components are basically collected at an outlet at a temperature of below 30 DEG C. Through quick thermal cracking technology and stepped cooling and collecting processes, cellulose biomass wastes are converted into the liquid fuels of different levels, and simultaneously, volatile gas and coke products in the thermal cracking process are reclaimed and utilized to realize self-heating for a complete thermal cracking system and save cost.

Owner:顾赛 +1

Under-counter water cooler appliance

InactiveUS20100116847A1Liquid flow controllersLiquid transferring devicesLiquid storage tankEngineering

An appliance for dispensing a liquid to a user, including an appliance base cabinet comprising an enclosure positioned under a counter that is fixed to a wall. The appliance base cabinet having a support member that is moveable relative to the counter. At least one dispenser spigot is coupled to the appliance base cabinet at a suitable distance below the counter to allow a user dispense water via the at least one dispenser spigot. At least one liquid storage tank is supported by the support member having an opening for out-flow of the liquid. The at least one liquid storage tank is accessible for removal or installation when the support member is moved away from the kitchen counter. The appliance further includes an intermediate reservoir within the appliance base cabinet under the kitchen counter coupled to the opening of the at least one liquid storage tank through which the liquid out of the at least one liquid storage tank is channeled to the at least one dispenser spigot.

Owner:DESIGN BY PARI

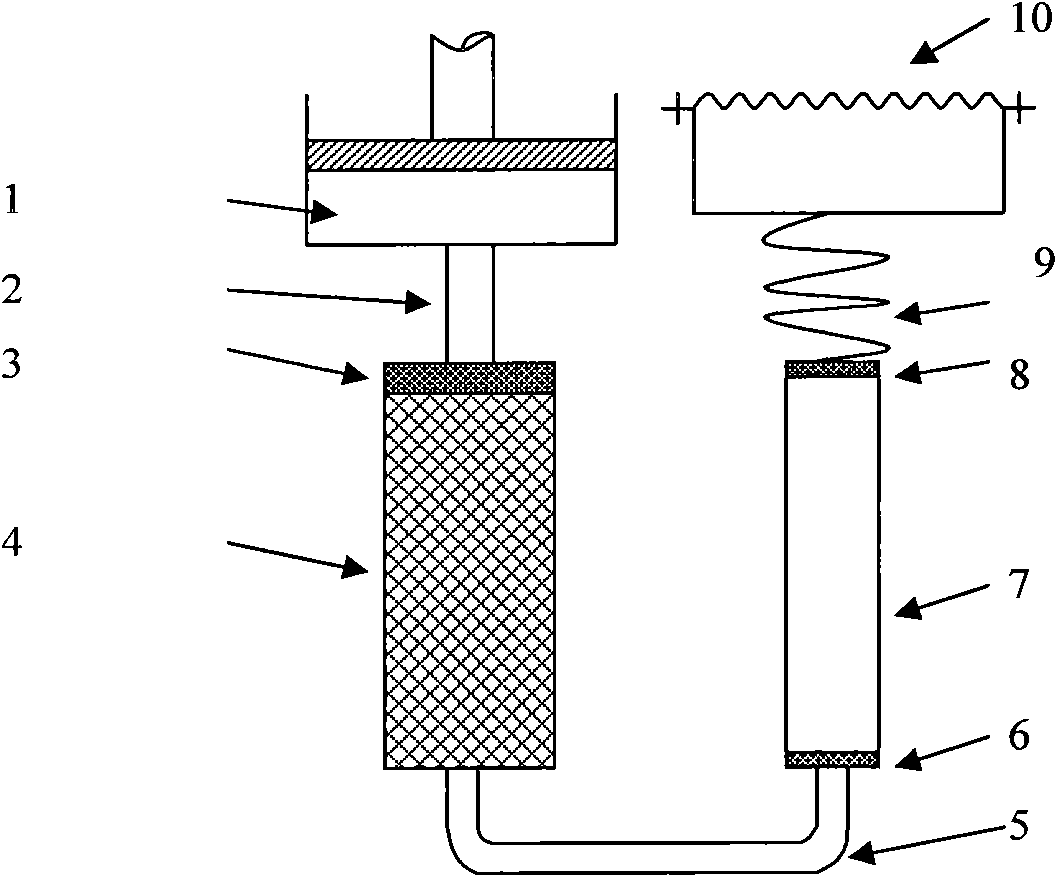

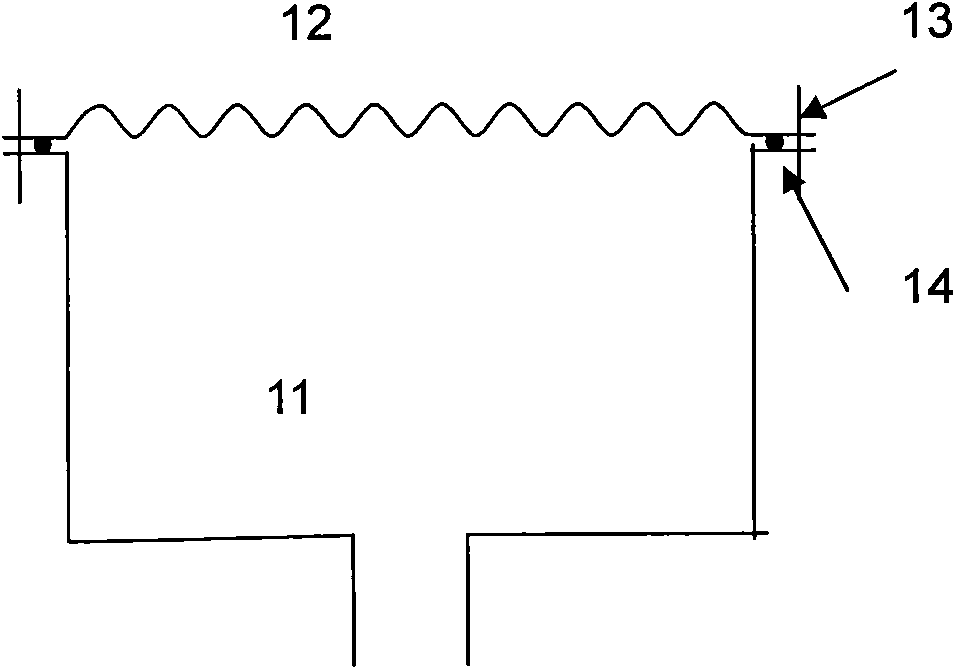

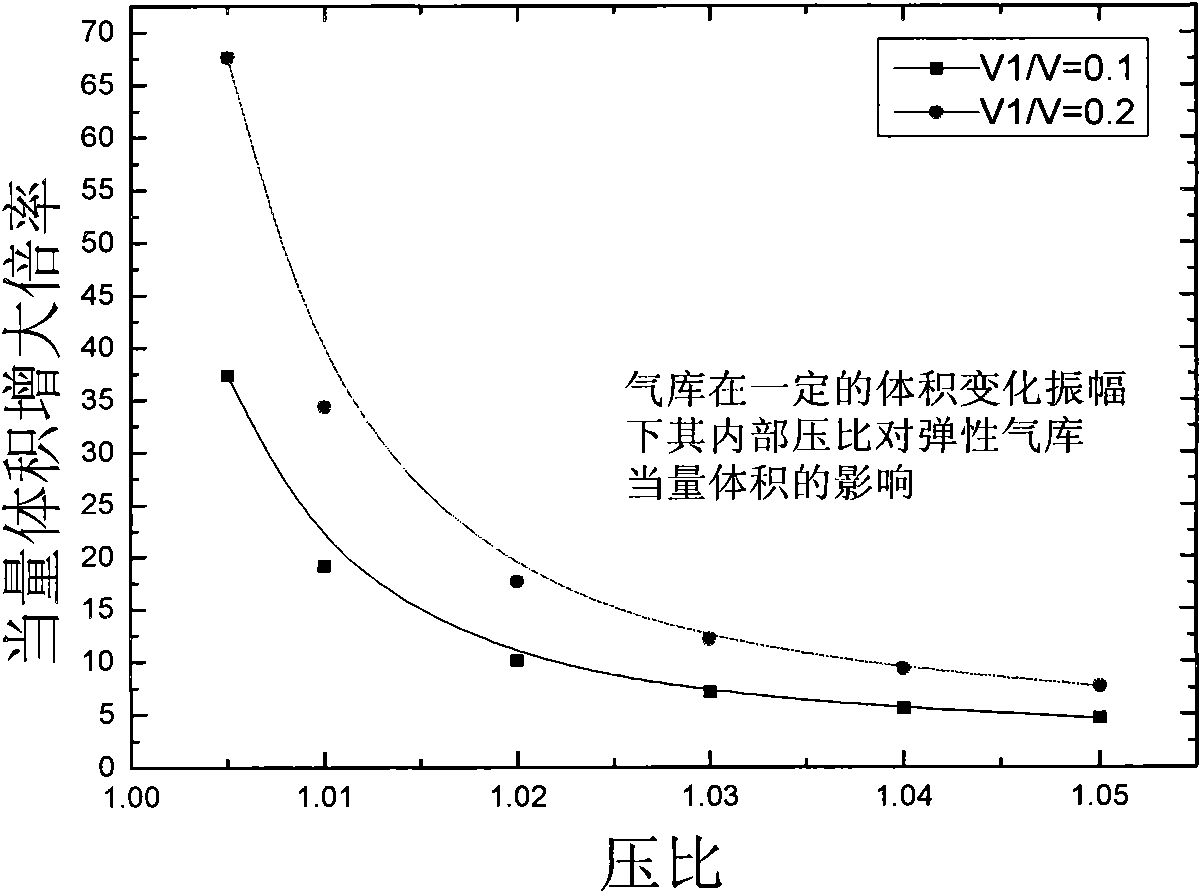

Pulse tube refrigerator with elastic air reservoir

InactiveCN101832675AShorten pre-cooling timeReduce chargeCompression machinesGas cycle refrigeration machinesPulse tube refrigeratorEngineering

The invention discloses a pulse tube refrigerator with an elastic air reservoir. The pulse tube refrigerator comprises a compressor, a transport tube, a water cooler, a heat regenerator, a cold end connecting pipe, a cold end heat exchanger, a pulse tube, a hot end heat exchanger, an inertance tube and an elastic air reservoir. The compressor is sequentially connected with the transport tube, thewater cooler, the heat regenerator, the cold end connecting pipe, the cold end heat exchanger, the pulse tube, the hot end heat exchanger, the inertance tube and the elastic air reservoir. A pulse tube refrigerator is usually provided with a huge air reservoir to obtain a better performance. The pulse tube refrigerator with the elastic air reservoir can obtain the same phase modulation effect with just a few percent of a common air reservoir in volume after employing the elastic air reservoir, so that the whole system becomes compact, and the charging quantity of working medium is reduced, which is particularly important for rare helium-4 and helium-3. As for the air reservoir in low temperature, the elastic air reservoir can shorten the cooling time and accelerate the cooling speed of a system.

Owner:ZHEJIANG UNIV

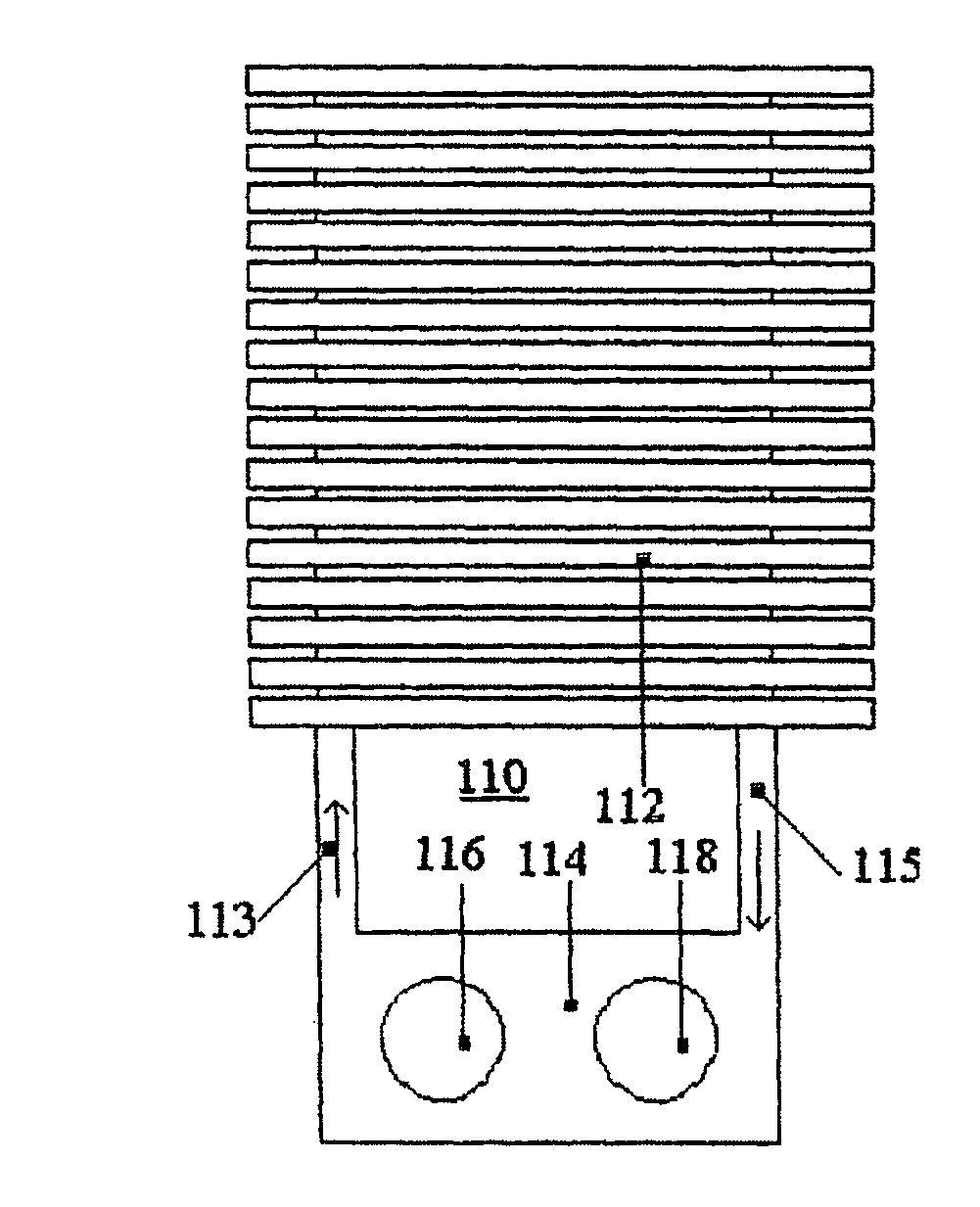

Cooling devices for various applications

InactiveUS20070184320A1Effective, not bulky, and inexpensivePoor heat resistanceInternal combustion piston enginesFuel cells groupingHeat fluxMicroheater

The figure displays the diagram of a laminar flow water cooler (110) for a microprocessor comprising an integral radiator (112) provided with thin-walled and hollow fins which are produced by controlled compression of double convex bellows of a polymer or glass hot-blown blank. In order to form a closed circuit filled with water at the atmospheric pressure, the manifolds (113, 114, 115) of the radiator (112) are connected to the manifolds of an original component (114) formed by a mini heater (116) provided with a copper heating plate with internal grooved face and a mini pump (118) provided with a brushless electric motor devoid of a centrifugal turbine, wherein said mini heater and mini pump are disposed in a rigid small-sized moulded polymer hose. The total thermal resistance of said cooler can be equal to 0.15° / W that is of interest, in particular for high performance microprocessors for dissipating more than 200 W through the very hot central area of 1.5 cm2 of the heat dissipating surface thereof. The concept of the production of the inventive cooler makes it possible to design efficient and low-cost cooling devices which are usable for microprocessors, high-power electronic devices, thermal engines or fuel cells, in particular mounted in a motor vehicle. Said invention can be used for cooling any component dissipating a given thermal flux within the determined power and temperature limits.

Owner:TECH DE LECHANGE THERMIQUE TET

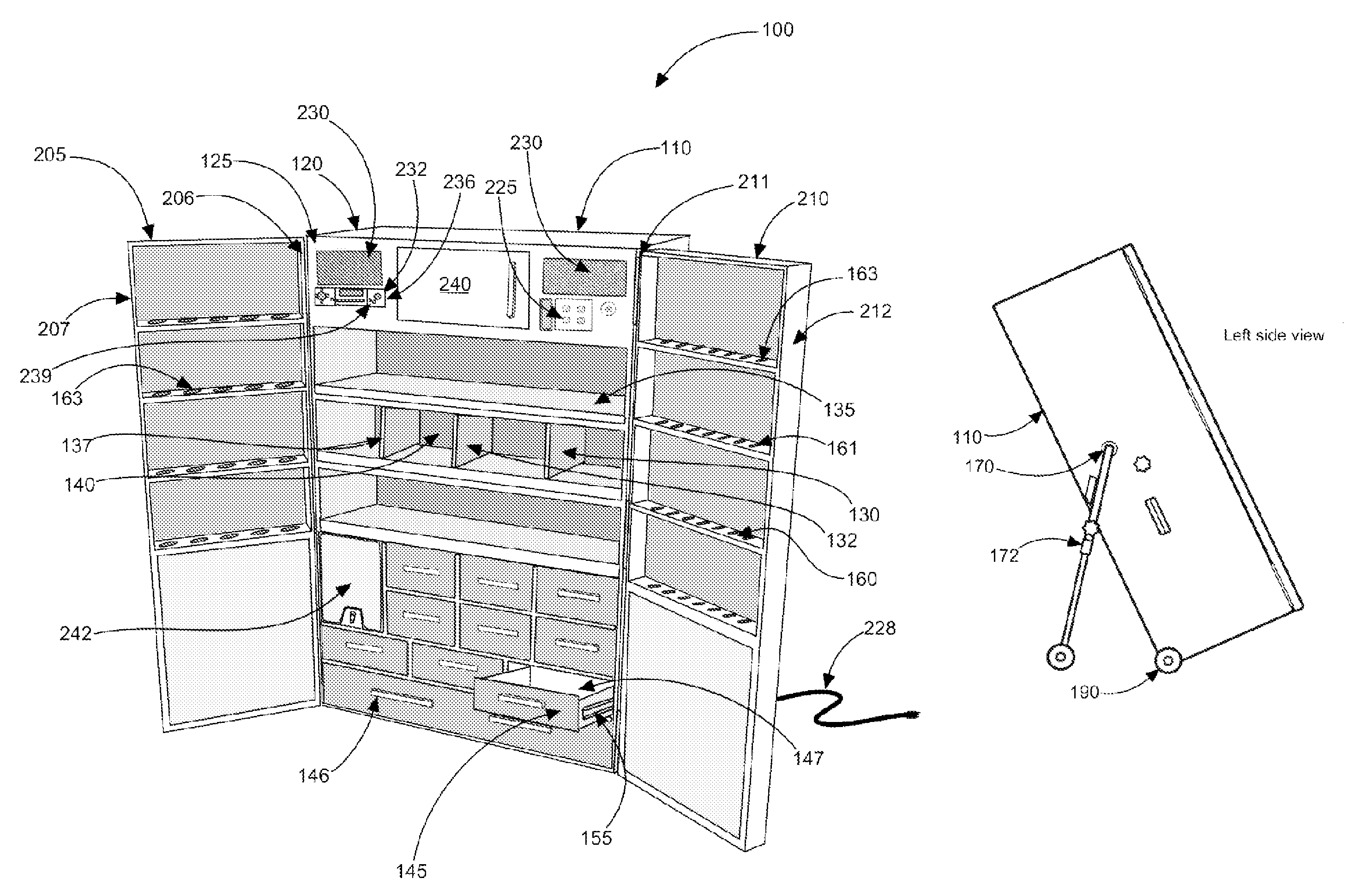

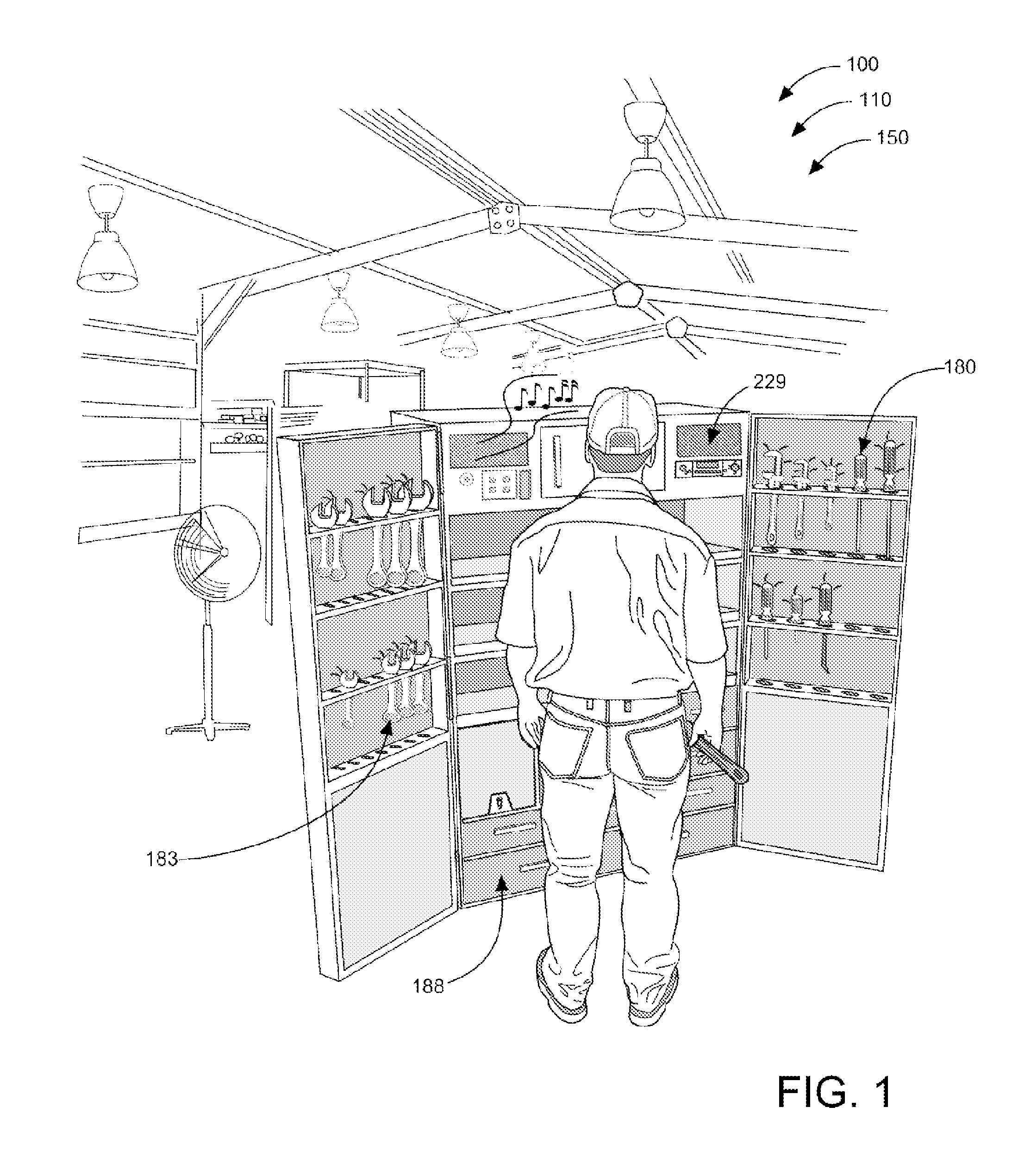

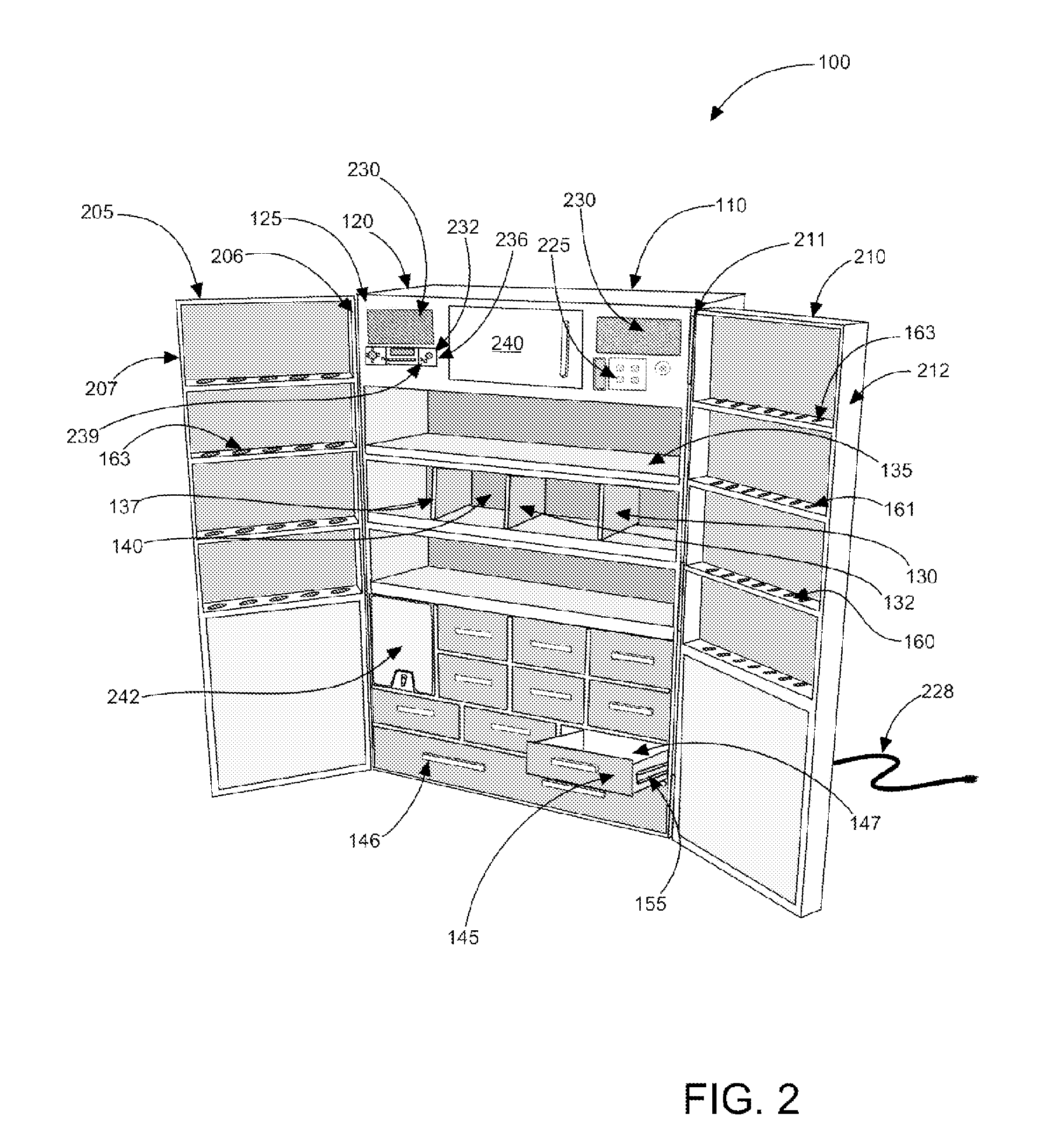

Portable modular tool cabinet systems

ActiveUS8668209B1Precise positioningWork lessCarriage/perambulator with single axisHand carts with one axisPickup truckElectric power system

An apparatus for organizing and storing tools, related work materials, and convenience items such as a music system with speakers, a radio, a digital CD-player, and a MP3 adapter, as well as a compact refrigerator and a water cooler in a tool cabinet that is modular and easily transportable between work sites. The portable modular tool cabinet provides an electrical power system, shelving units and sliding drawers for holding tools and two lockable doors that hold additional hand tools and can be secured when the user is ready to transport the portable modular tool cabinet to another work site. The entire unit is transportable by using two base wheels and a pivotable-dolly-system with telescoping rod and wheel combinations that allow easy rolling to a transport vehicle such as a pickup truck for loading and transporting to another location.

Owner:ANZIVINO MARY SUE +1

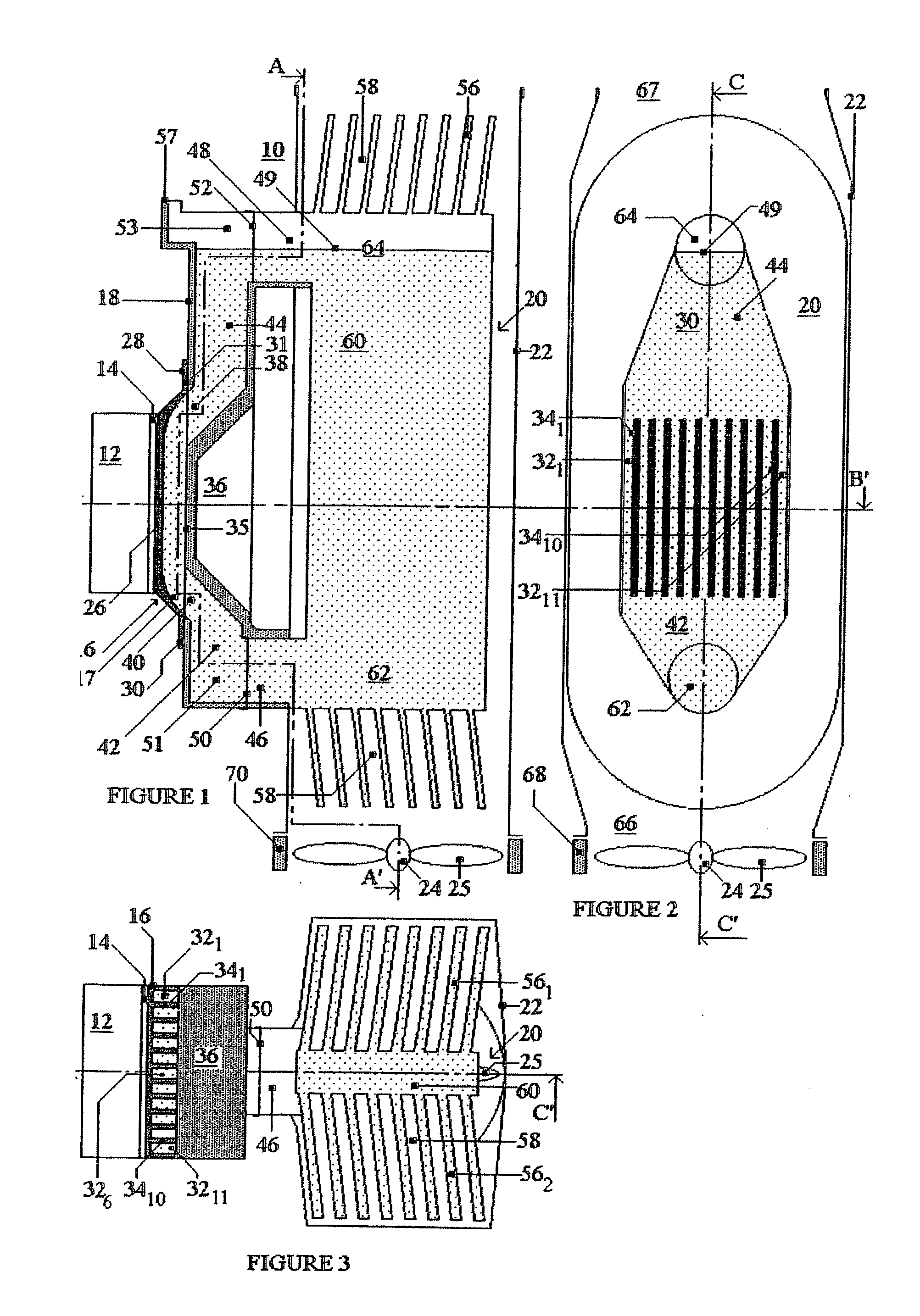

Water-cooler radiator module

InactiveUS20050230083A1Reduces possibility of any damage to heat-generatingSave spaceDigital data processing detailsSemiconductor/solid-state device detailsEngineeringElectronic component

A water-cool radiator module comes with a supporting part having a shell body; the shell body includes a fan and a water tank; the water tank is connected to a cold water pipe and a hot water pipe; an extended section of the cold water pipe and hot water pipe is connected to a cold waterhead; the shell body includes several radiating holes at one end; such that in an application, the supporting part is inserted into a slot on the computer case and the shell body is mounted onto the slot; the cold water in the cold waterhead of a heat-generating electronic component is circulated to the shell body through the hot water pipe; the fan blows air to radiate heat to the outside through the radiating holes; and the cooled fluid flows from the water tank to the cold waterhead through the cold water pipe.

Owner:ADDA

Liquid cooling cooling-down type thermostatic bath system and intelligent temperature control method

InactiveCN101219403AShorten the timeIncrease freedomWater/sand/air bathsTemperature controlEngineering

The invention relates to a liquid cooling temperature thermostatic bath system and an intelligent temperature control method thereof, comprising a cooling water tank and a cooling liquid, a liquid bath and a working liquid, and an intelligent temperature controller. The cooling water tank is provided with a water tank temperature sensor and a refrigerator, an electrical heater connected with an electrical heating executor, and a water cooler, a stirrer, a liquid bath temperature sensor, and a water inlet pipe and a water outlet pipe of the water cooler that are connected with the cooling water tank; the other end of the water inlet pipe is connected with a cooling water pump, a signal input end of the intelligent temperature controller is respectively connected with the temperature sensor of the cooling water tank and the temperature sensor of the liquid bath, while the output end is respectively connected with the electrical heating executor, a stirrer engine, the cooling water pump and the refrigerator. The system and the method can drop the temperature at a speed higher than the natural cooling by near 20 times through forced liquid cooling, and can effectively avoid the over regulating of temperature and reduce the negative impact of thermal inertia, thus greatly shortening the precision temperature controlling process and cutting down power consumption.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

Method and apparatus for programably treating water in a water cooler

ActiveUS20050236432A1Water treatment parameter controlLighting and heating apparatusEngineeringEnvironmental engineering

An apparatus for a programmable self sanitizing water dispenser apparatus with a digital computer as well as a programmable method for generating ozone for cleaning the reservoir and the water contained within it.

Owner:S I P TECH L L C

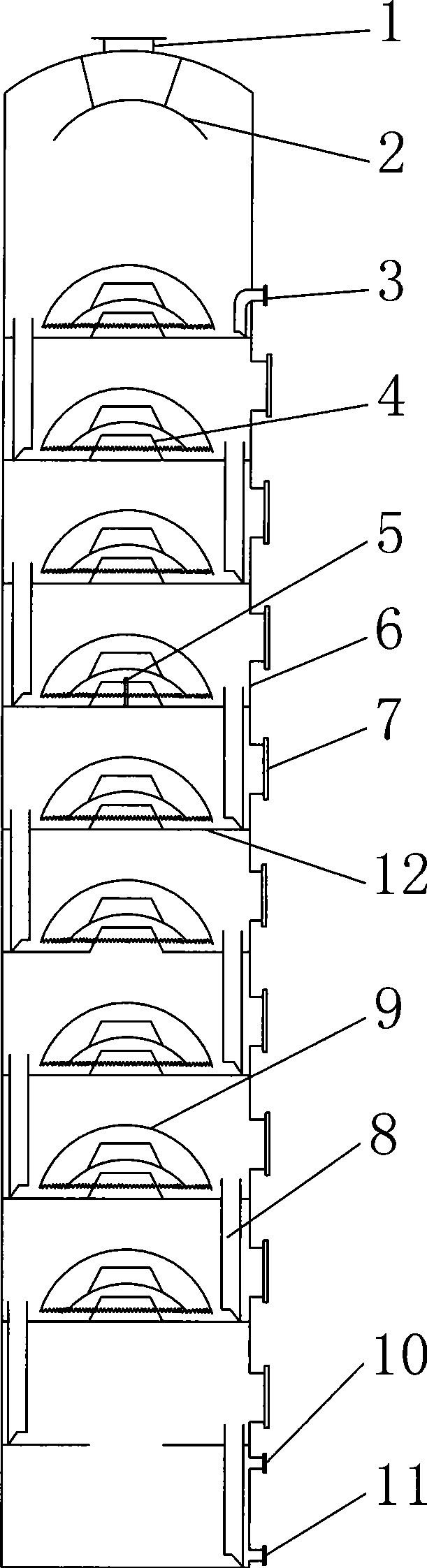

Multistage Thermoelectric Water Cooler

InactiveUS20080184710A1Operation efficiency can be improvedReduce energy billDomestic cooling apparatusLiquid transferring devicesThermoelectric coolingEngineering

In one embodiment of the invention, a system for controlling the temperature of water in a water reservoir includes a water reservoir, an inlet operable to deliver water to the water reservoir, an outlet operable to dispense at least a portion of the water from the water reservoir, and a staged water cooler having a first thermoelectric cooler stage coupled to a second thermoelectric cooler stage, the staged water cooler operable to control the temperature of the water in the water reservoir.

Owner:ALMONT DEV

Portable water cooler for use with bagged fluids and bagged fluids for use therewith

ActiveUS7165700B2Easy to controlIncrease choiceMechanical apparatusLiquid flow controllersEngineeringThermal control

A portable water cooler is designed to accept the placement of bagged fluid therein, leading to the connection of the bag of fluid to a fluid flow pathway, thereby allowing the fluid to be dispensed in a manner such that the fluid is segregated from the internal surfaces of the cooler. The portable water cooler generally includes an internal spike and external spigot through which fluid may flow. Systems and method for dispensing bagged fluid from such a cooler, including various multi-bag systems and methods allowing for improved thermal control of fluids being dispensed, as well as increased selection of fluids dispensed from the same portable water cooler provide a high level of convenience.

Owner:INT PACKAGING INNOVATIONS

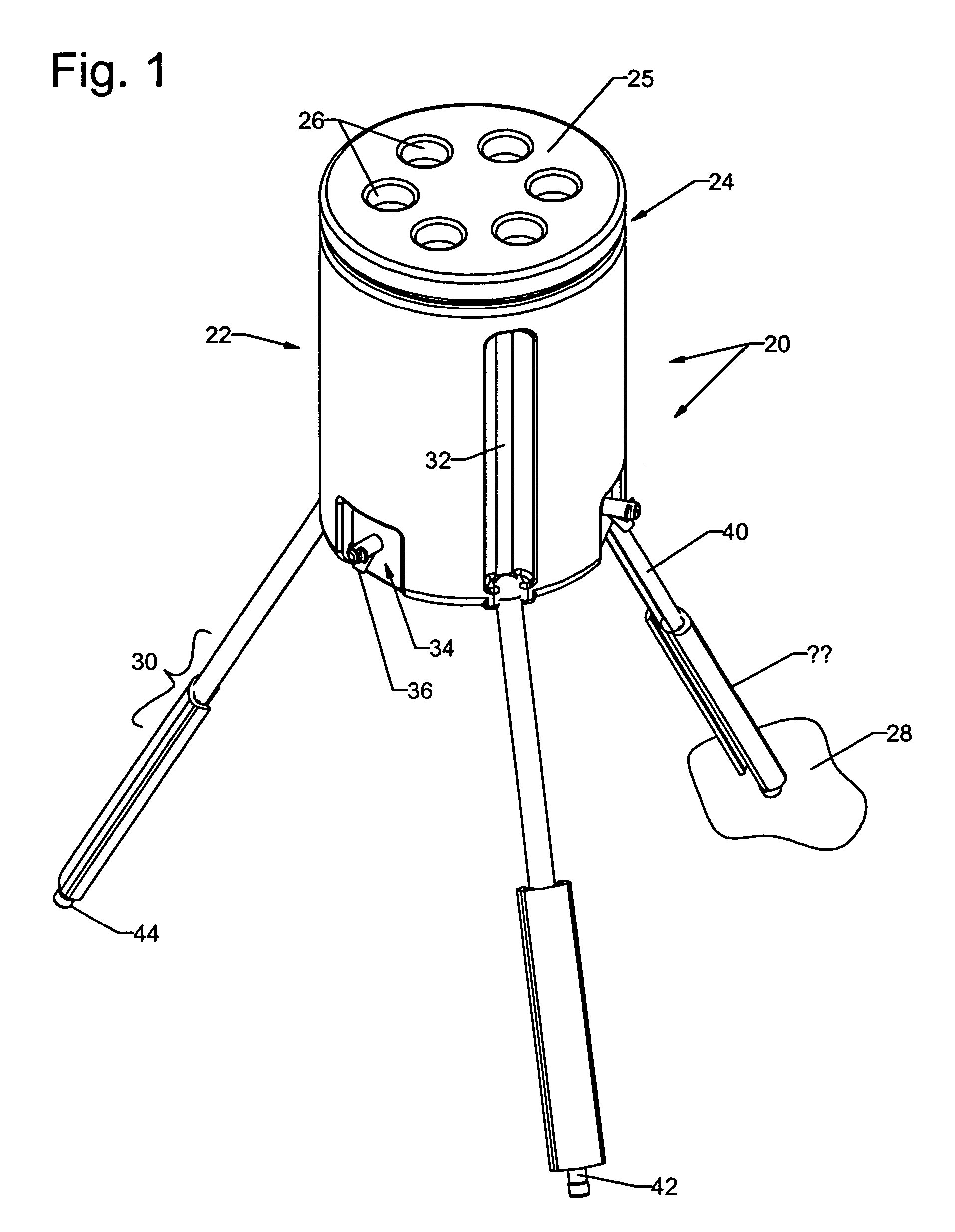

Multi-user transformable water cooler

ActiveUS7350671B2Easy to transportLess likely to collide with other objectLiquid flow controllersLiquid transferring devicesEngineeringMechanical engineering

Owner:HOSPITEC

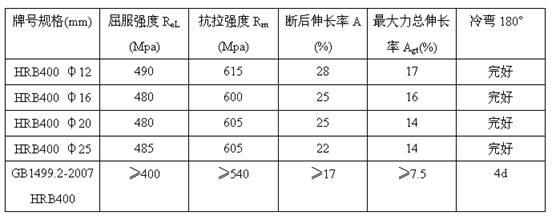

Controlled rolling and controlled cooling production process of HRB400 (Hot-rolled Ribbed-steel Bar 400) steel bar

The invention relates to a controlled rolling and controlled cooling production process of an HRB400 (Hot-rolled Ribbed-steel Bar 400) steel bar, which is characterized by comprising the following steps of: heating a 150*150*6,000 mm or 165*165*6,000 mm continuous casting by a three-section continuous pusher-type heating furnace and then rolling into the hot-rolled ribbed-steel bar with the diameter of Phi10 to Phi32 mm, wherein the start rolling temperature is controlled to be 1,050-1,150 DEG C and the final rolling temperature is controlled to be 930-970 DEG C; setting a three-section water cooler after the final rolling, wherein the temperature after water cooling is 680-760 DEG C; and adjusting cooling rates of the hot-rolled ribbed-steel bars of various specifications through cooling, reheating, cooling, reheating and cooling to obtain a needed sorbite so that the steel bar is reinforced. Under the premise of ensuring the comprehensive mechanical property of the steel bar, the invention can remarkably reduce the use level of main alloys and greatly reduce production cost.

Owner:福建三宝钢铁有限公司

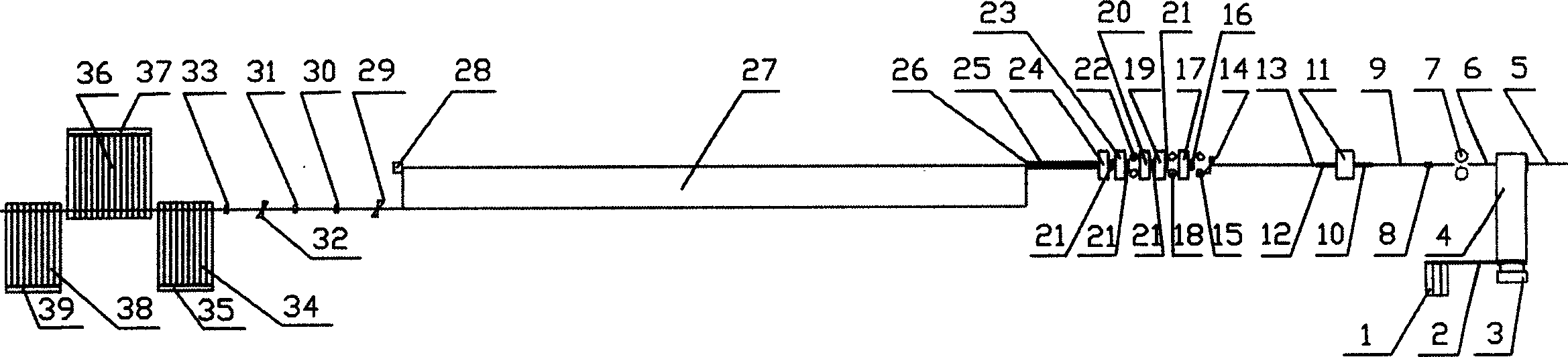

Hot rolling process of wide flat bar steel

InactiveCN1857807AImprove cleanlinessExact widthWork treatment devicesRoll mill control devicesHeating furnaceWater cooling

The hot rolling process of wide flat bar steel includes the following steps: heating continuously cast rectangular steel billet at 1050-1150 deg.c inside heating furnace, coarse edge rolling in an edger, descaling in a descaling unit, repeated rolling in a two-roller reversing mill, cutting ends in a hot shearing machine, finish rolling in a finishing mil group, chilling to 475-525 deg.c in a water cooler, cooling to below 200 deg.c in a cooling bed, cutting ends in a cold shearing machine, lengthing in a shear gauge, shearing to certain length in a cold shearing machine, collecting and baling. The present invention provides wide flat bar steel in certain sizes for building and bridge.

Owner:江阴博丰钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com