Patents

Literature

86results about How to "Lower inlet temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

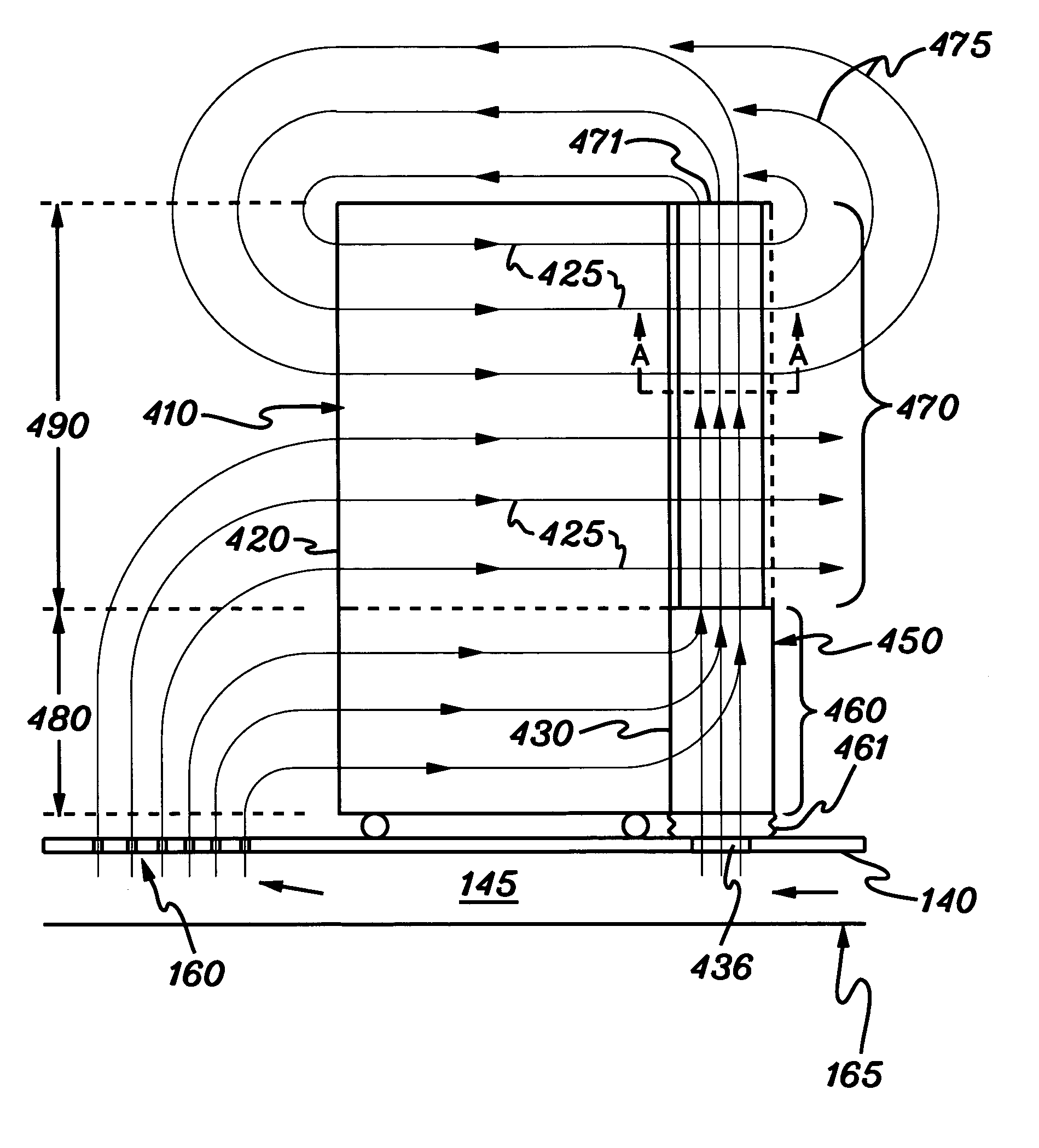

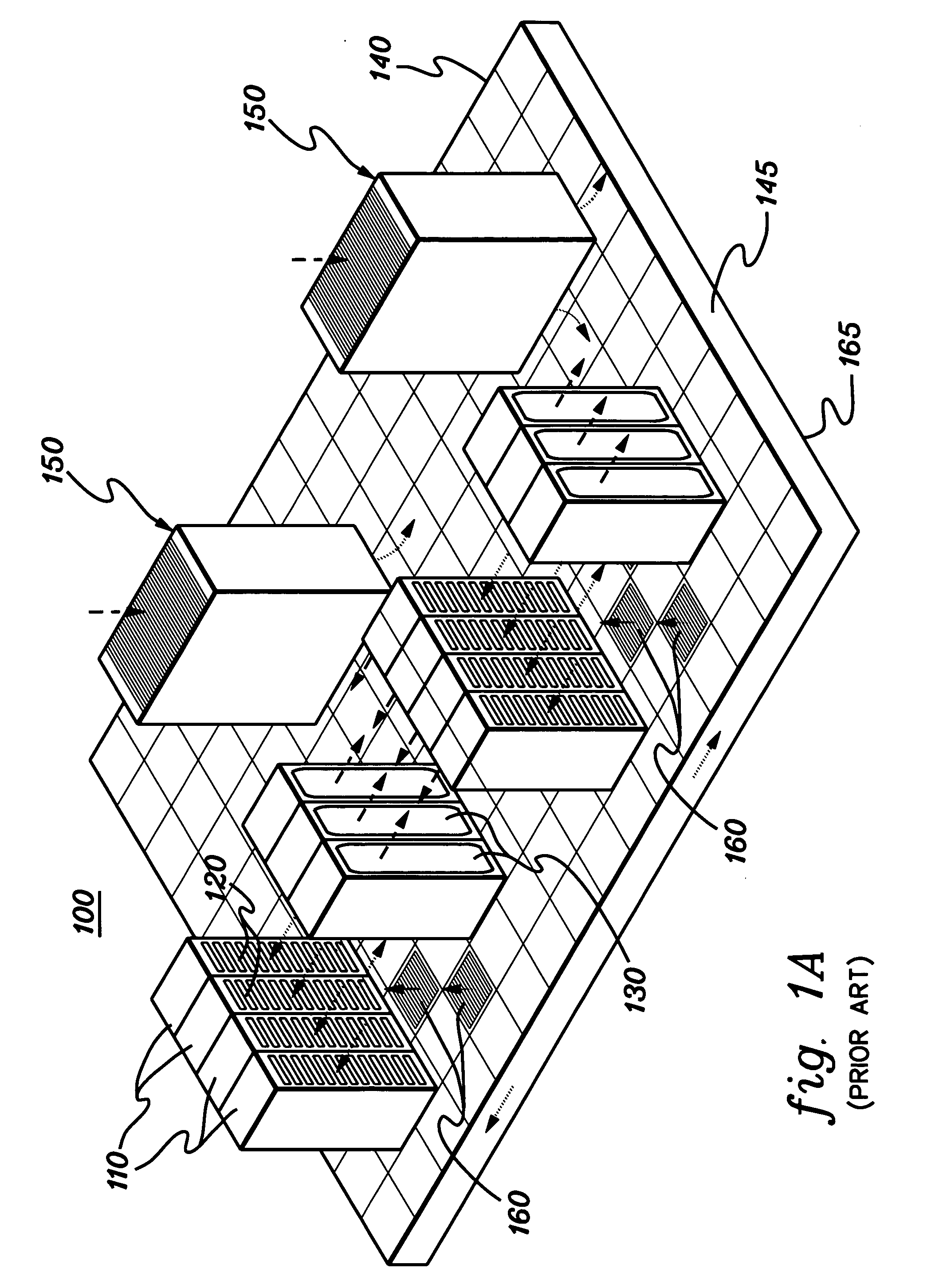

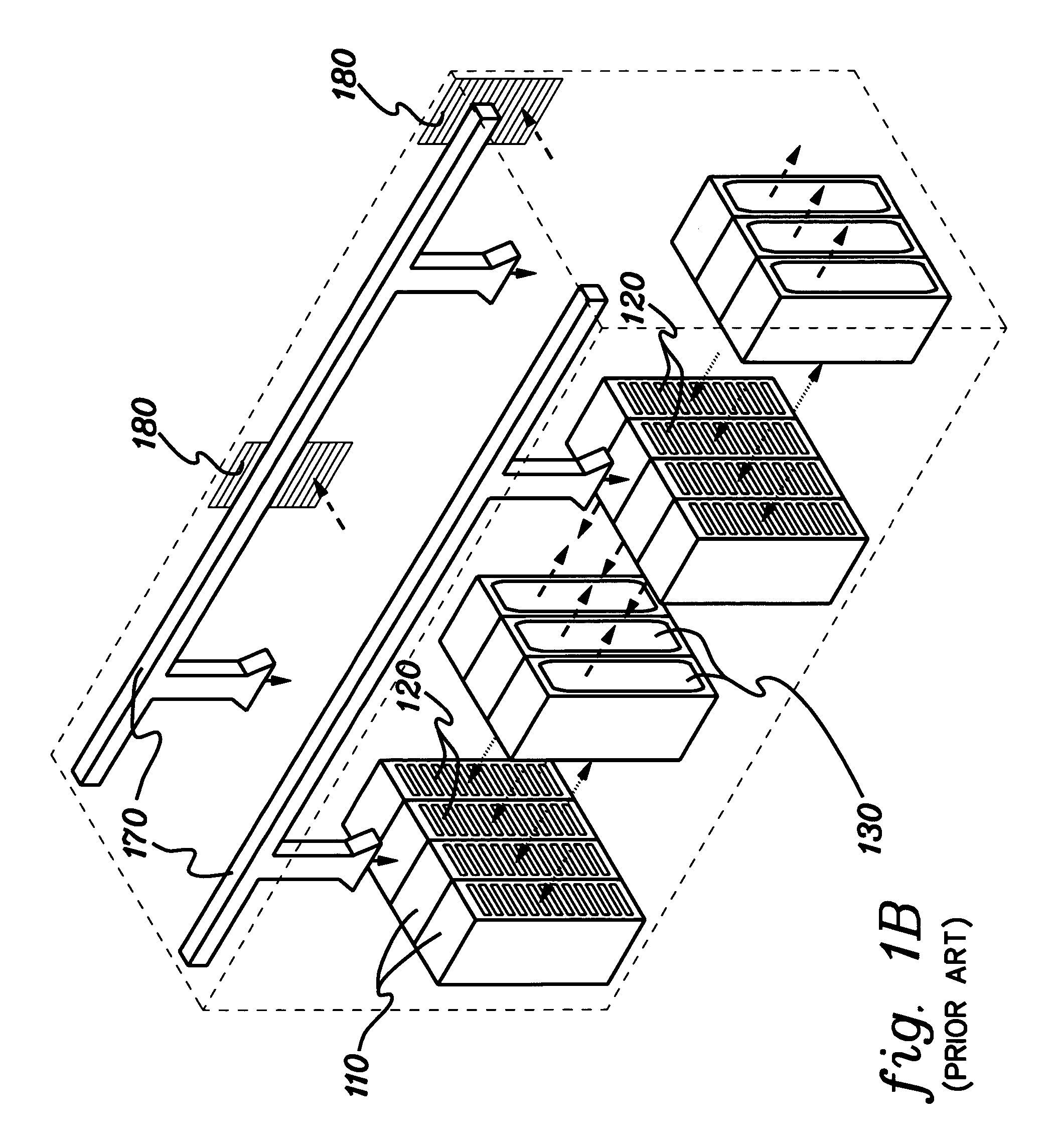

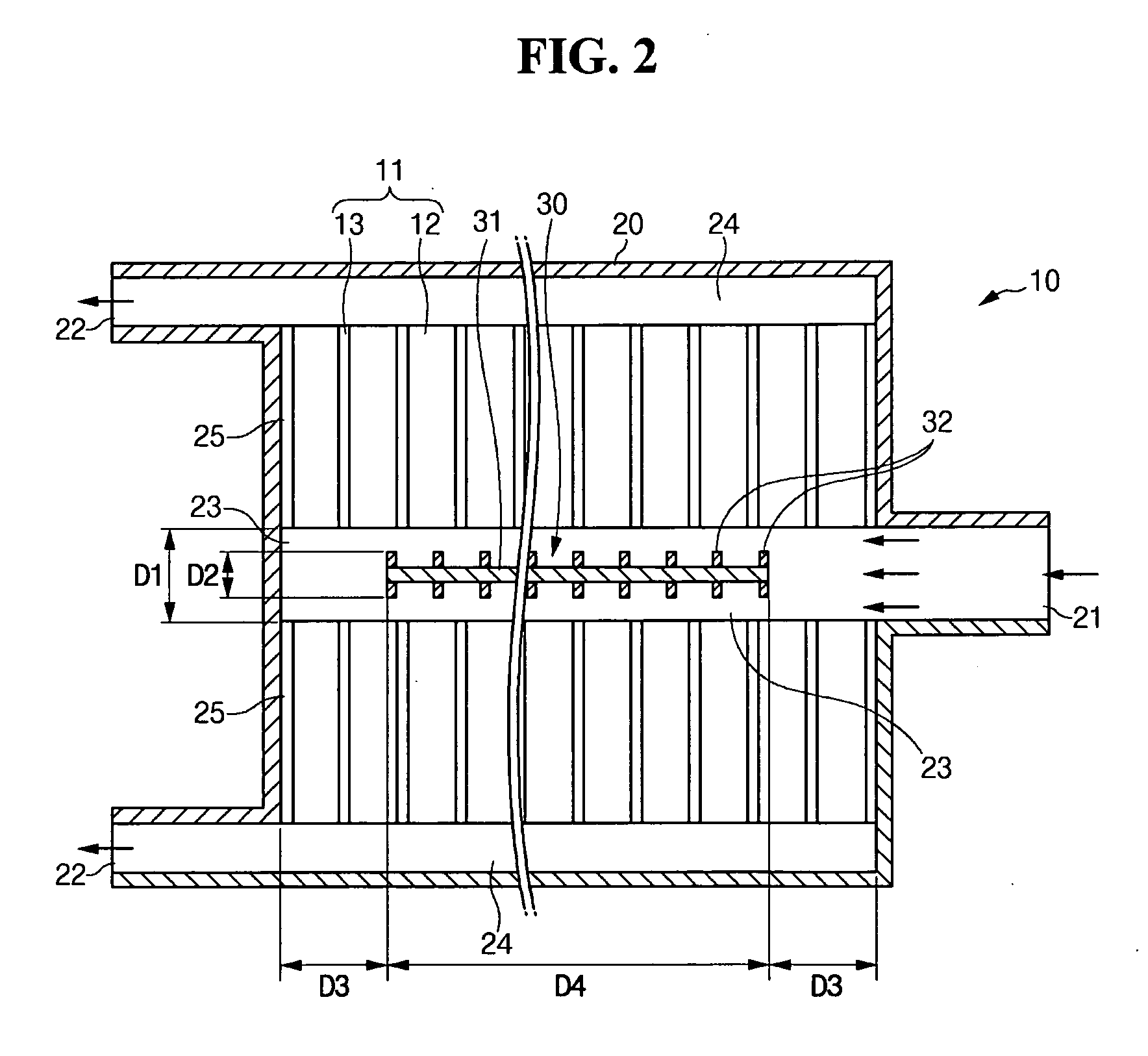

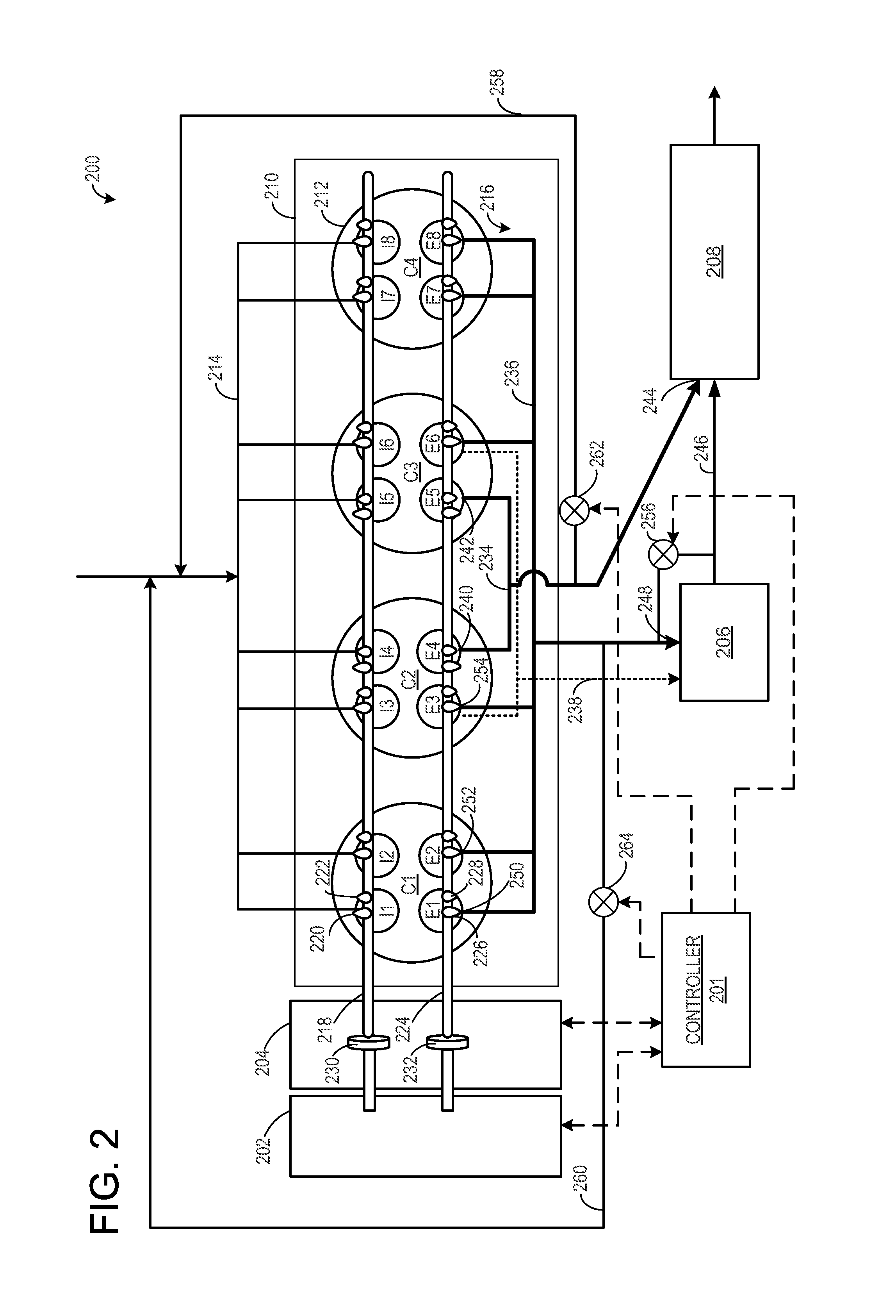

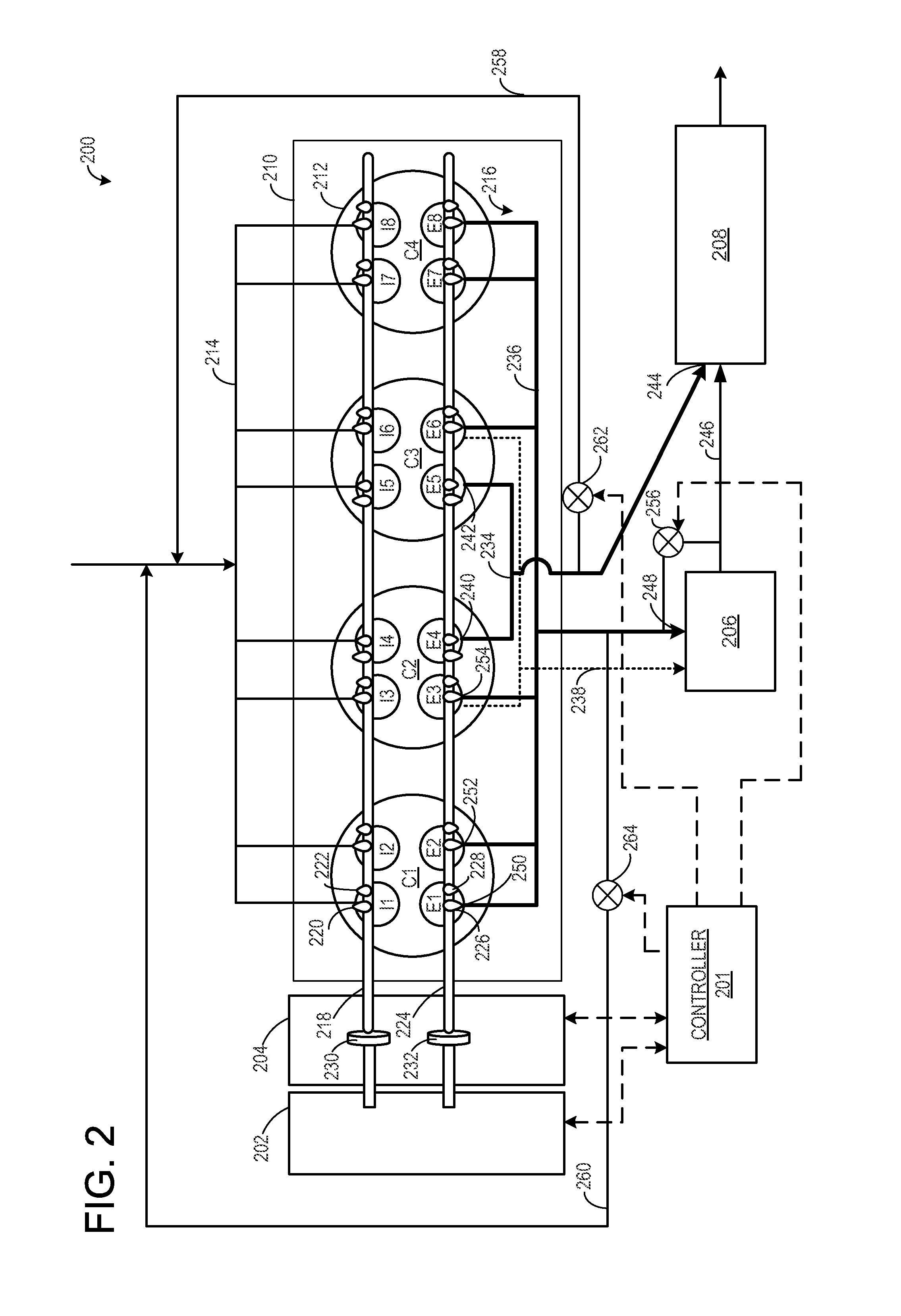

Apparatus and method for facilitating cooling of an electronics rack by mixing cooler air flow with re-circulating air flow in a re-circulation region

ActiveUS7283358B2Improve cooling effectWell mixedDucting arrangementsDigital data processing detailsRe circulationInlet temperature

Apparatus and method are provided for facilitating cooling of an electronics rack employing an air delivery structure coupled to the electronics rack. The air delivery structure delivers air flow at a location external to the electronics rack and in a direction to facilitate mixing thereof with re-circulating exhausted inlet-to-outlet air flow from the air outlet side of the electronics rack to the air inlet side thereof. The delivered air flow is cooler than the re-circulating exhausted inlet-to-outlet air flow and when mixed with the re-circulating air flow facilitates lowering air inlet temperature at a portion of the air inlet side of the electronics rack, thereby enhancing cooling of the electronics rack.

Owner:INT BUSINESS MASCH CORP

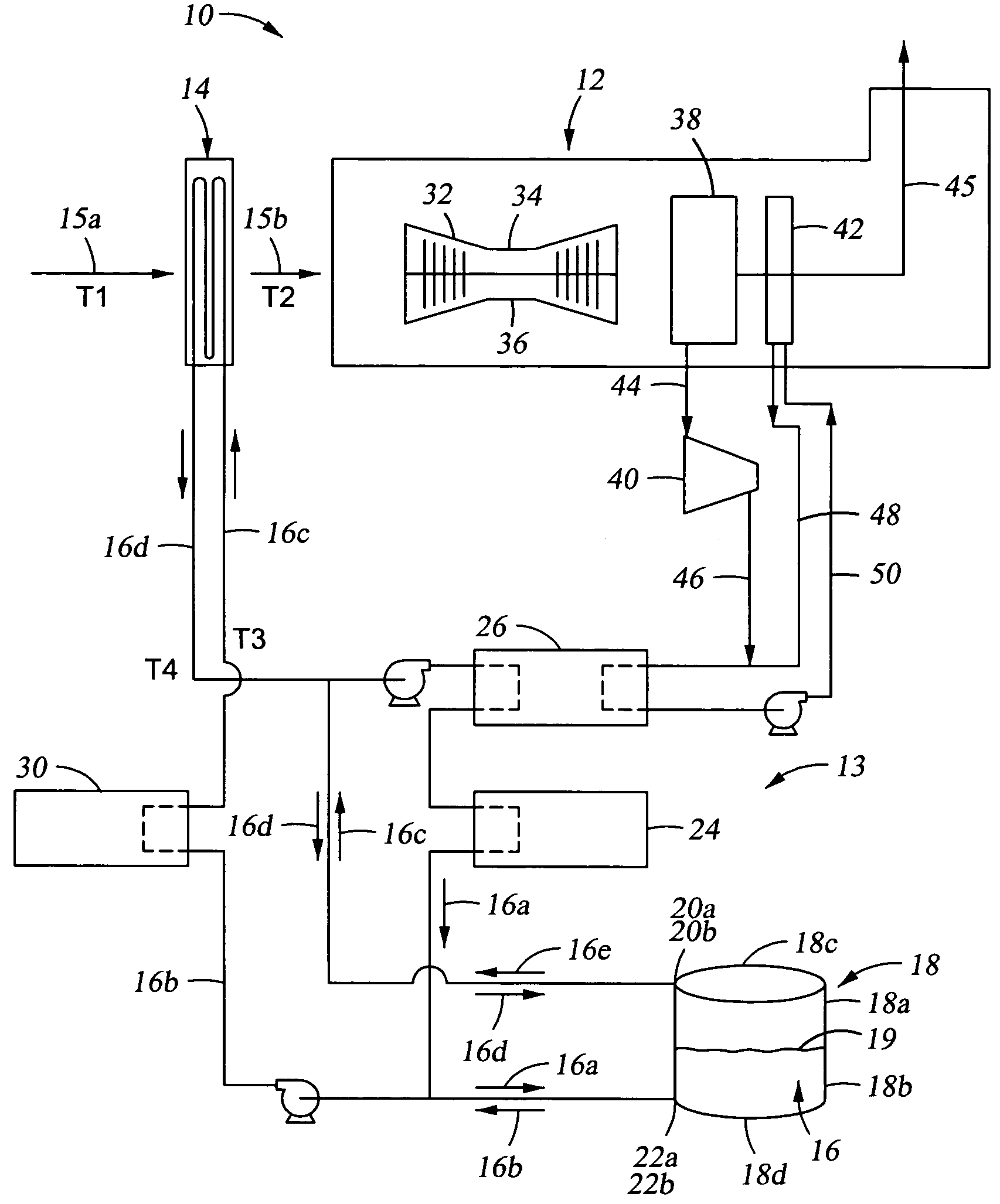

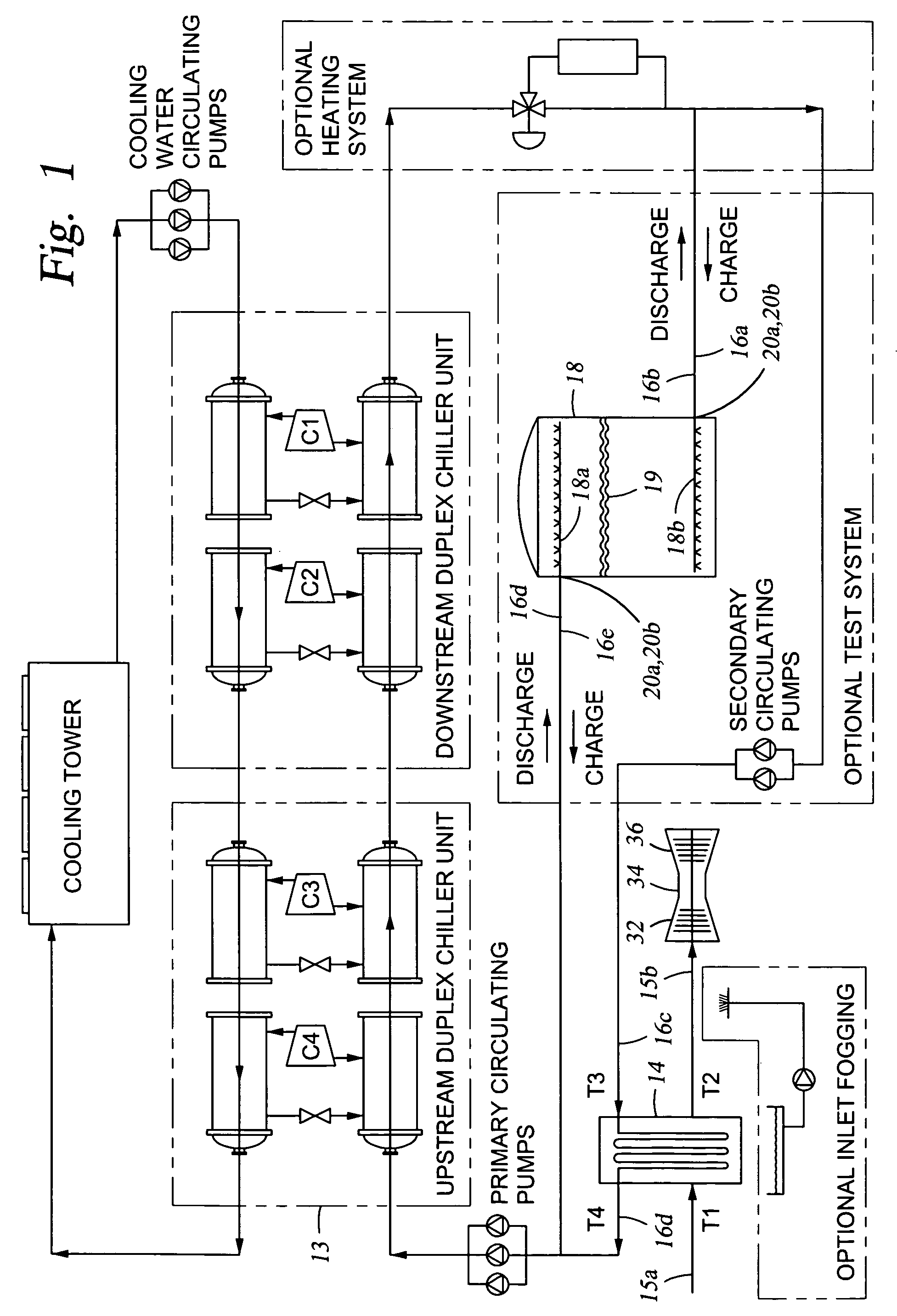

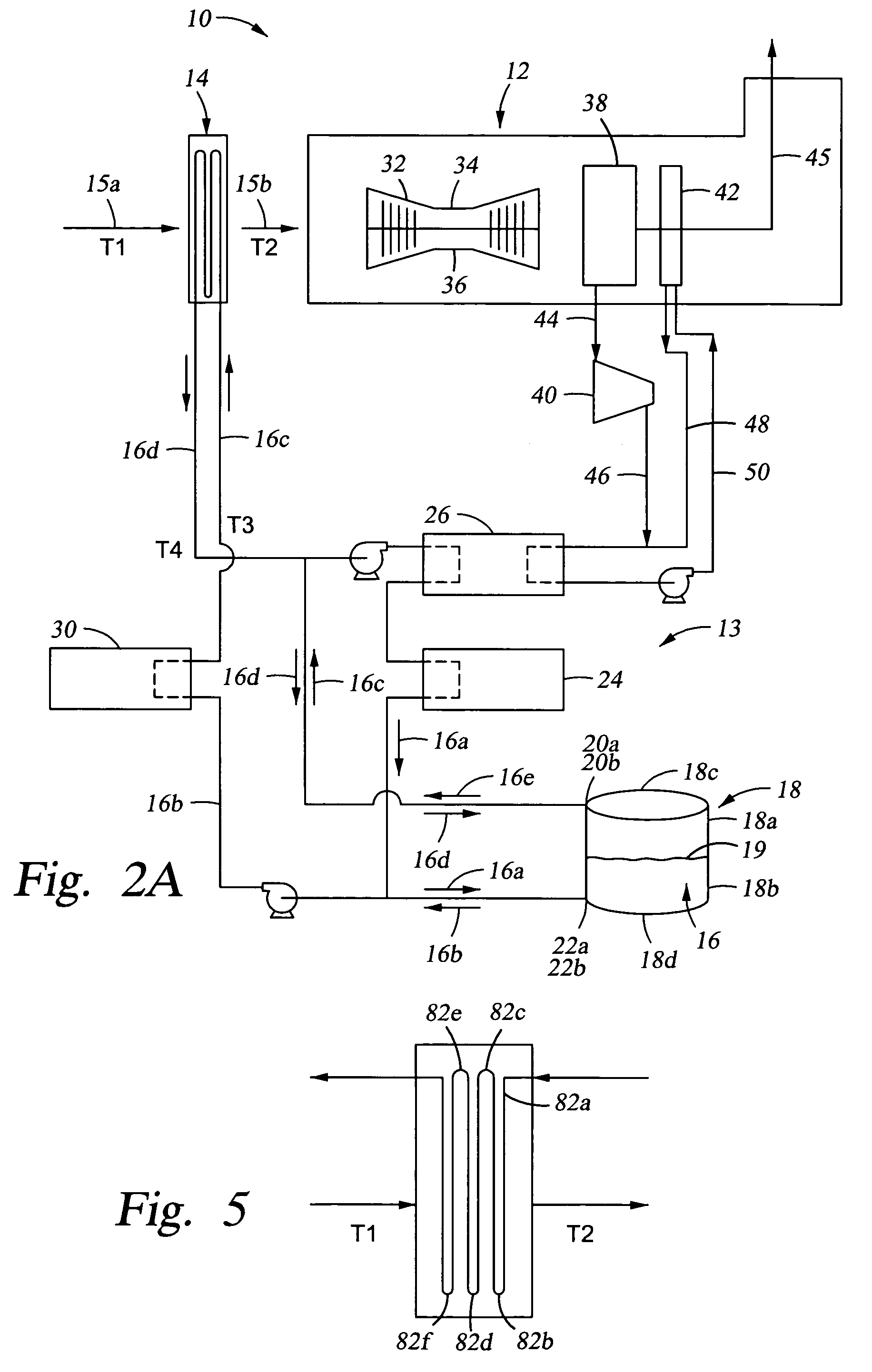

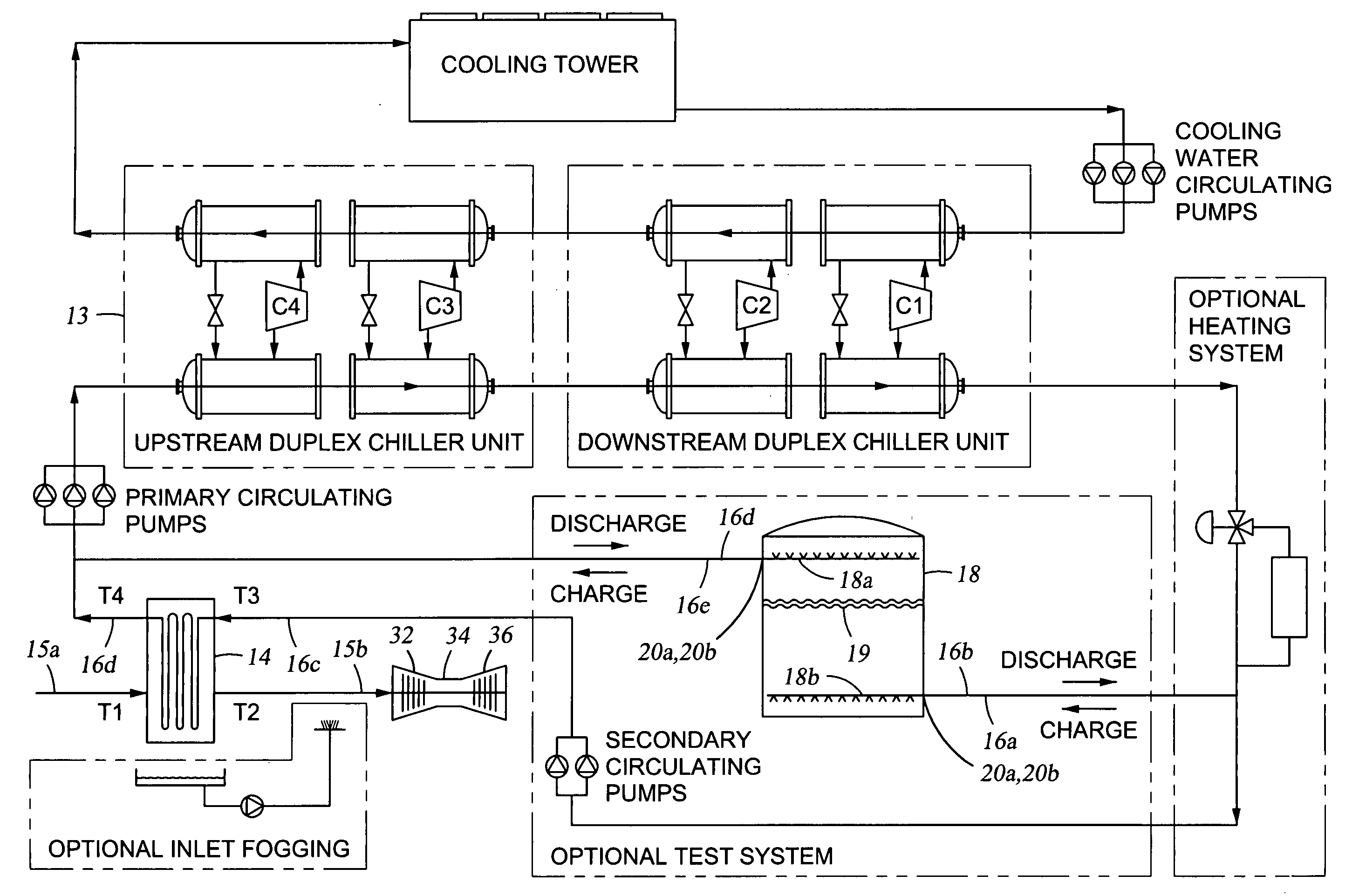

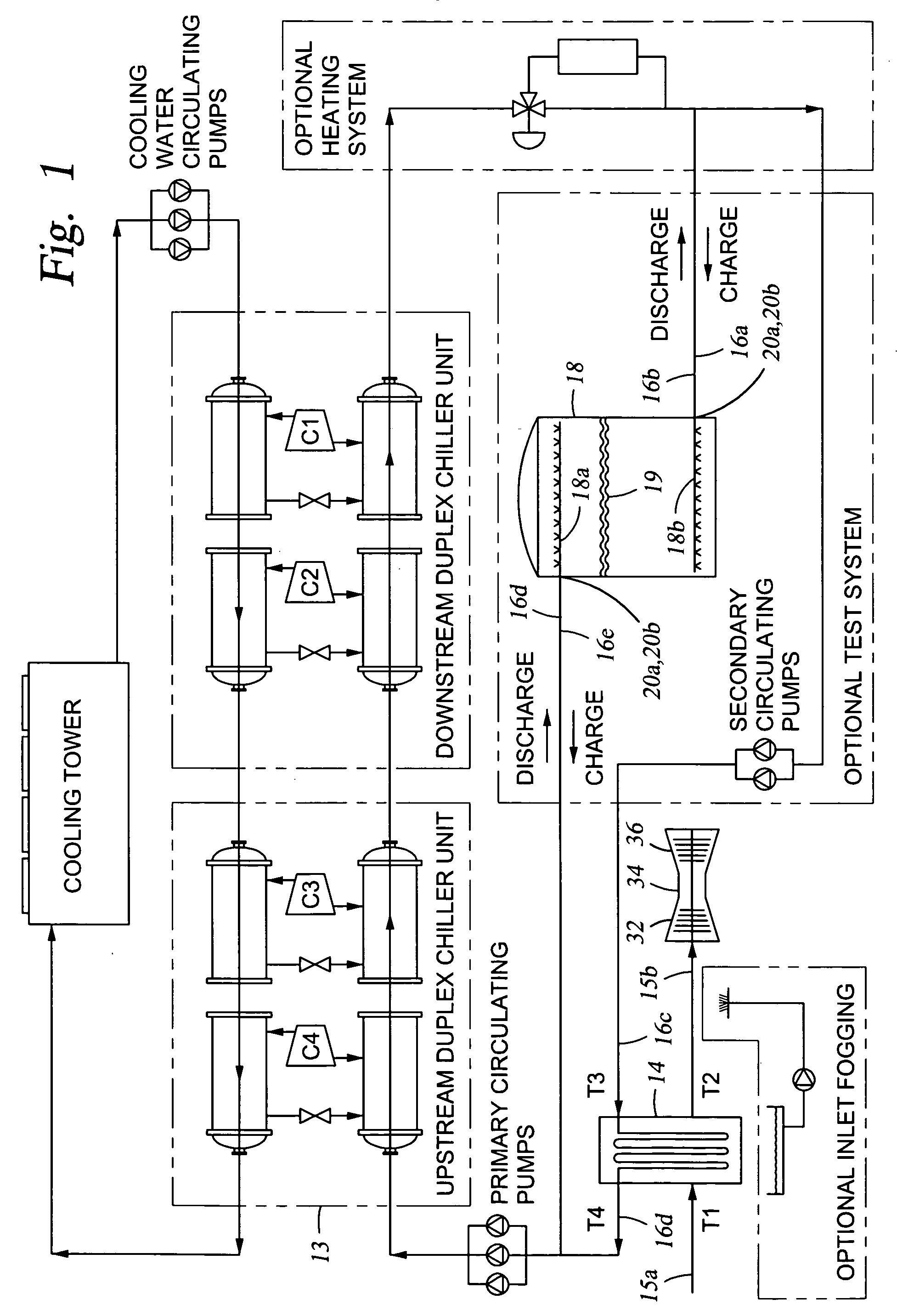

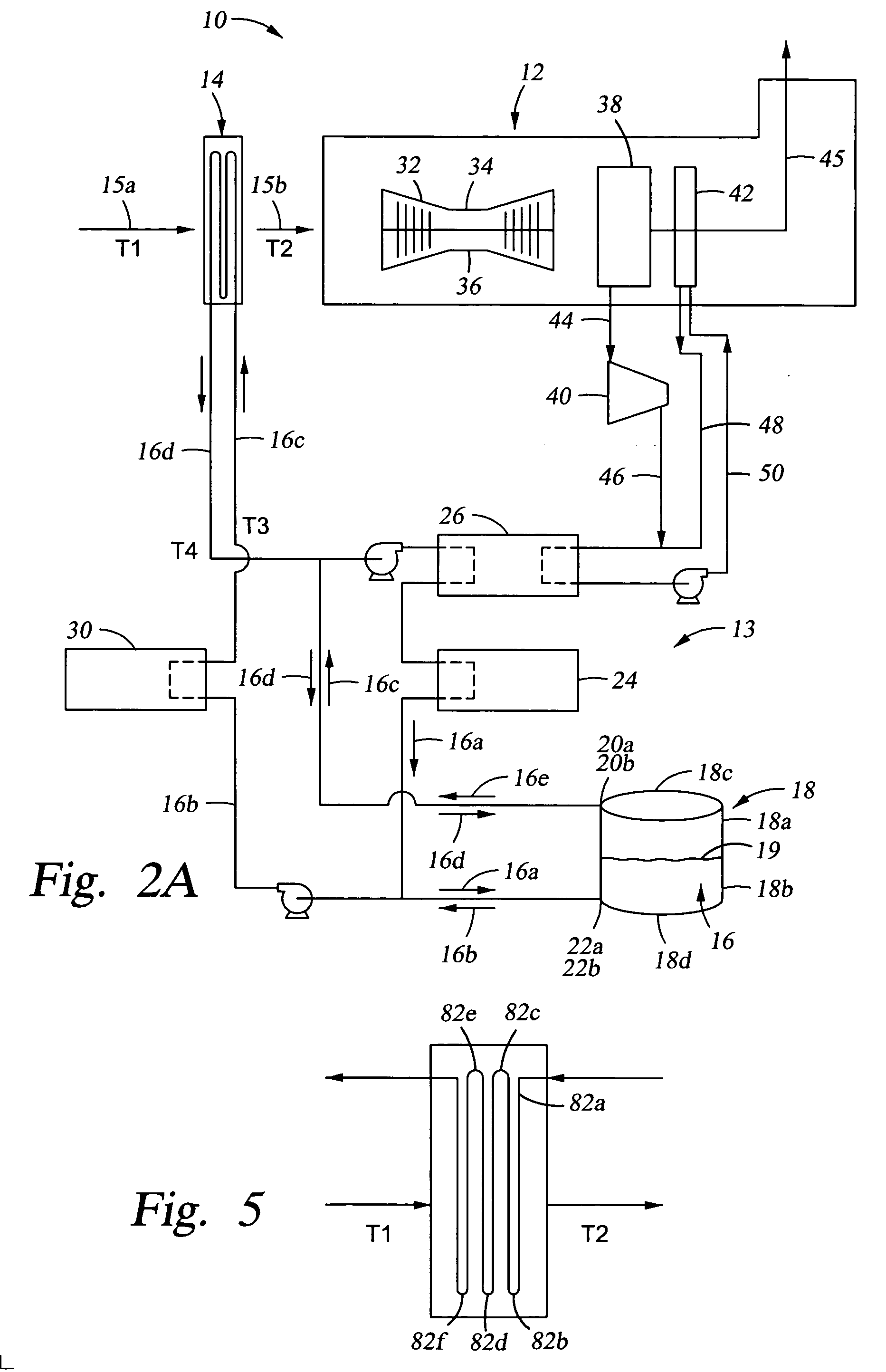

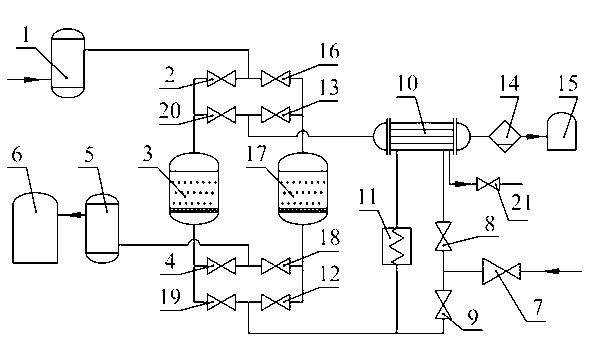

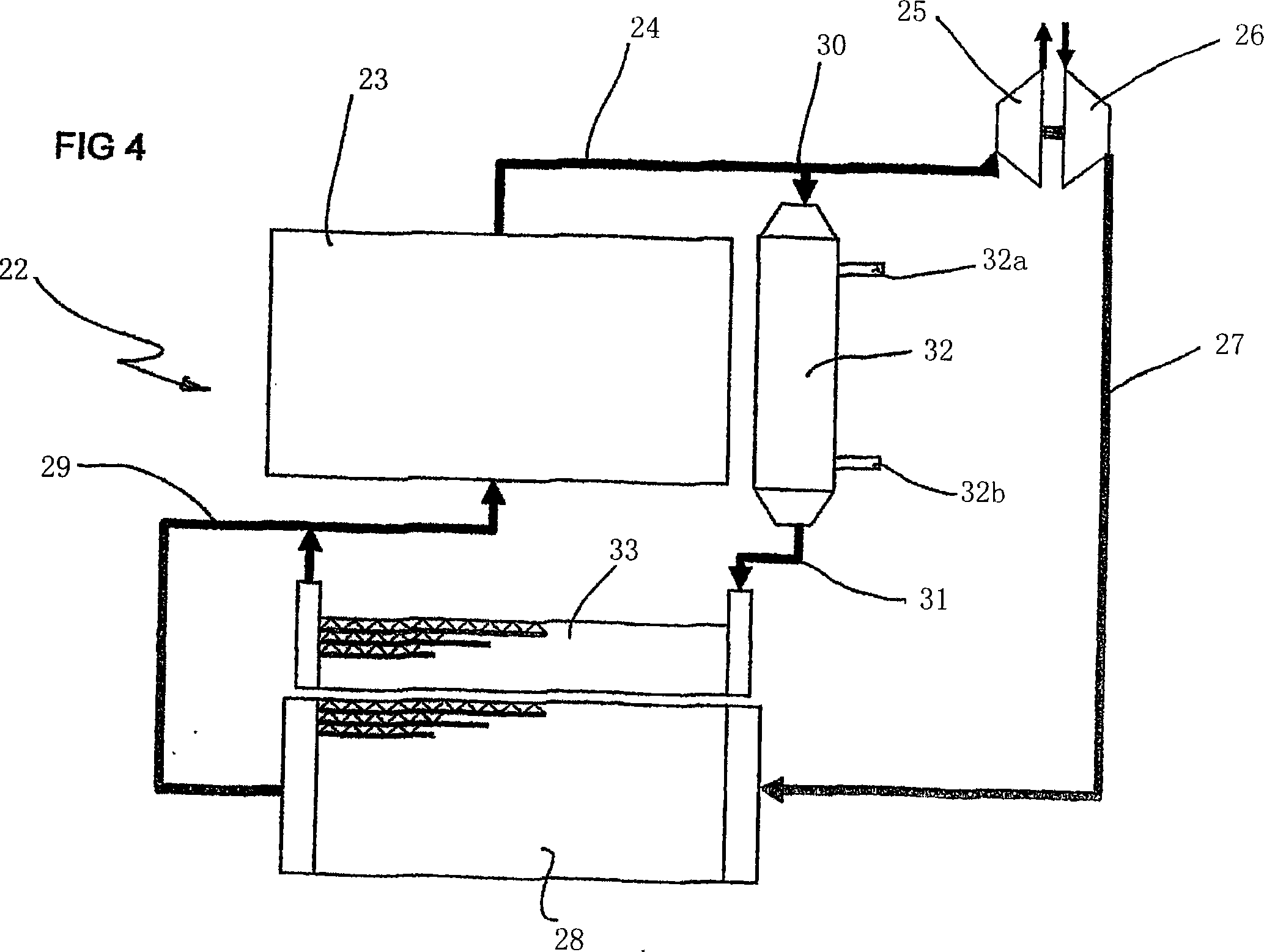

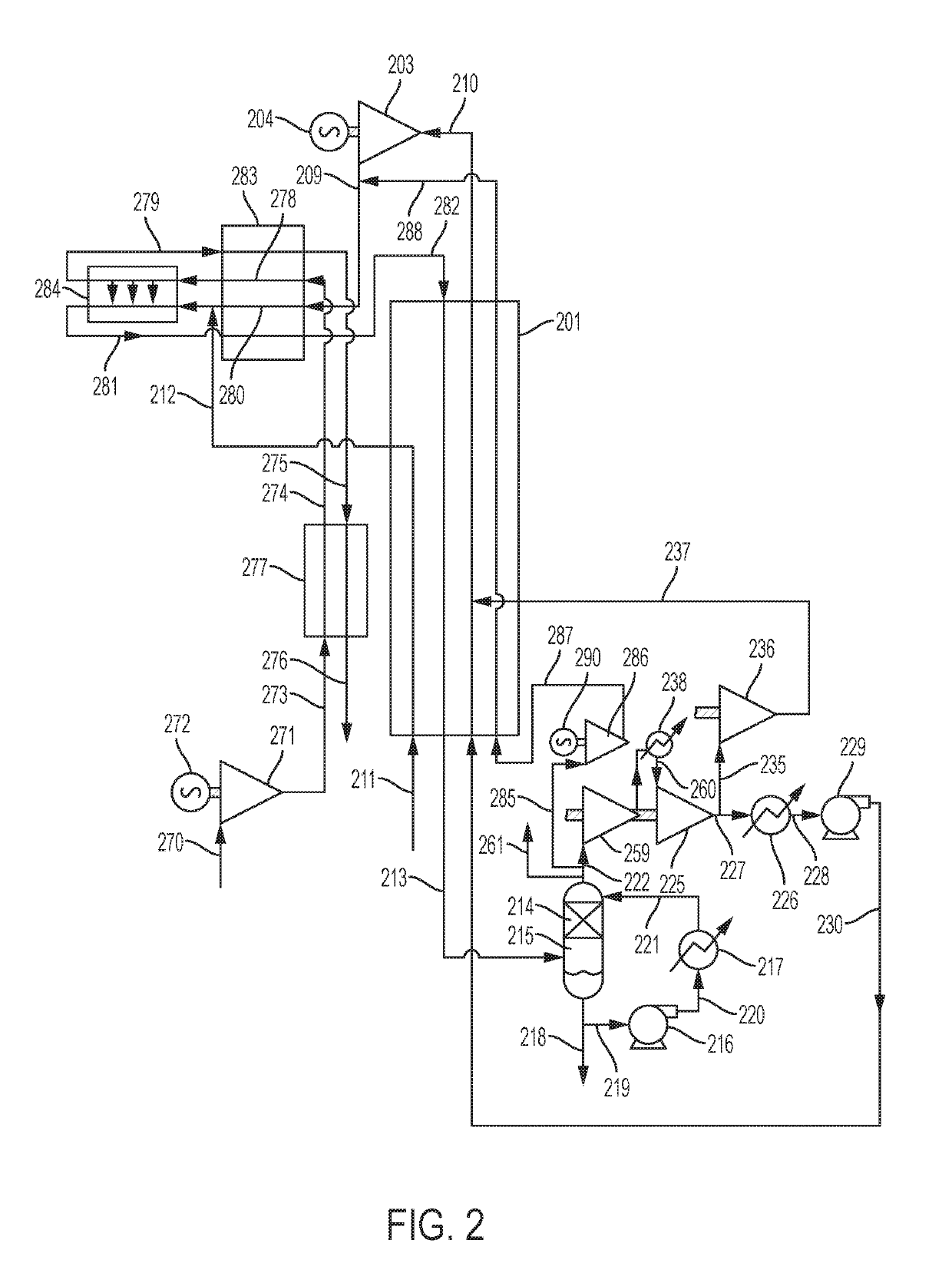

Method of chilling inlet air for gas turbines

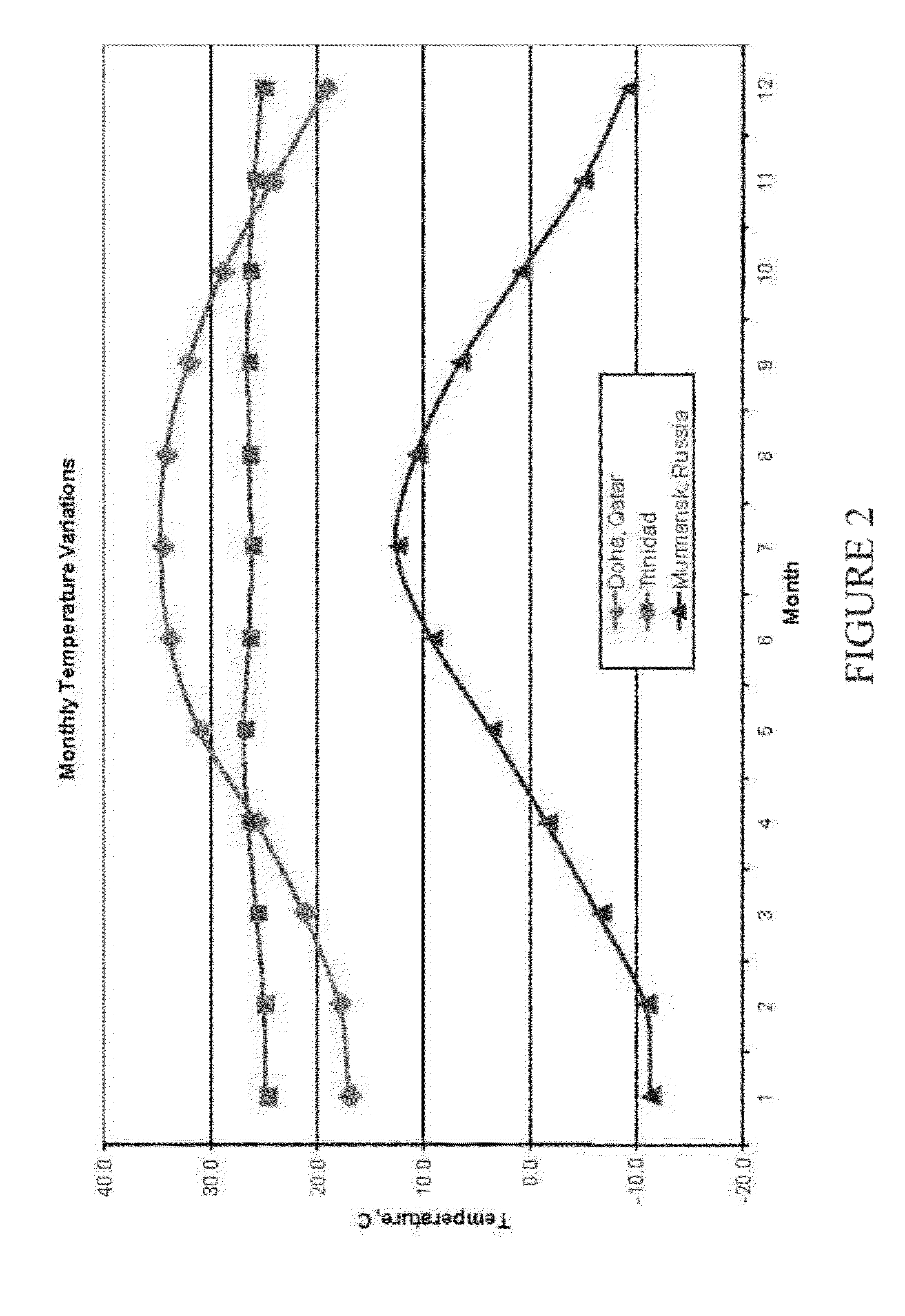

InactiveUS7343746B2Lower the average temperature of the chilling waterLower inlet temperatureClimate change adaptationEvaporators/condensersPower stationCooling coil

A method for cooling inlet air to a gas turbine is provided. For example, a method is described including passing inlet air through a cooling coil that includes an opening for receiving the inlet air and that is operably connected to a gas turbine power plant. The gas turbine power plant may include at least one gas turbine, and at least one gas turbine inlet which receives the inlet air. The method may further include passing circulating water through a water chiller at a first flow rate to reduce the temperature of the circulating water, the water chiller including a conduit through which the circulating water is capable of passing and passing the circulating water having the first flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air. Additionally, the method may include reducing the flow rate of the circulating water passing through the water chiller, passing the circulating water through a water chiller at a second flow rate to reduce the temperature of the circulating water, the second flow rate being lower than the first flow rate, and passing the circulating water having the second flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air.

Owner:TAS ENERGY +1

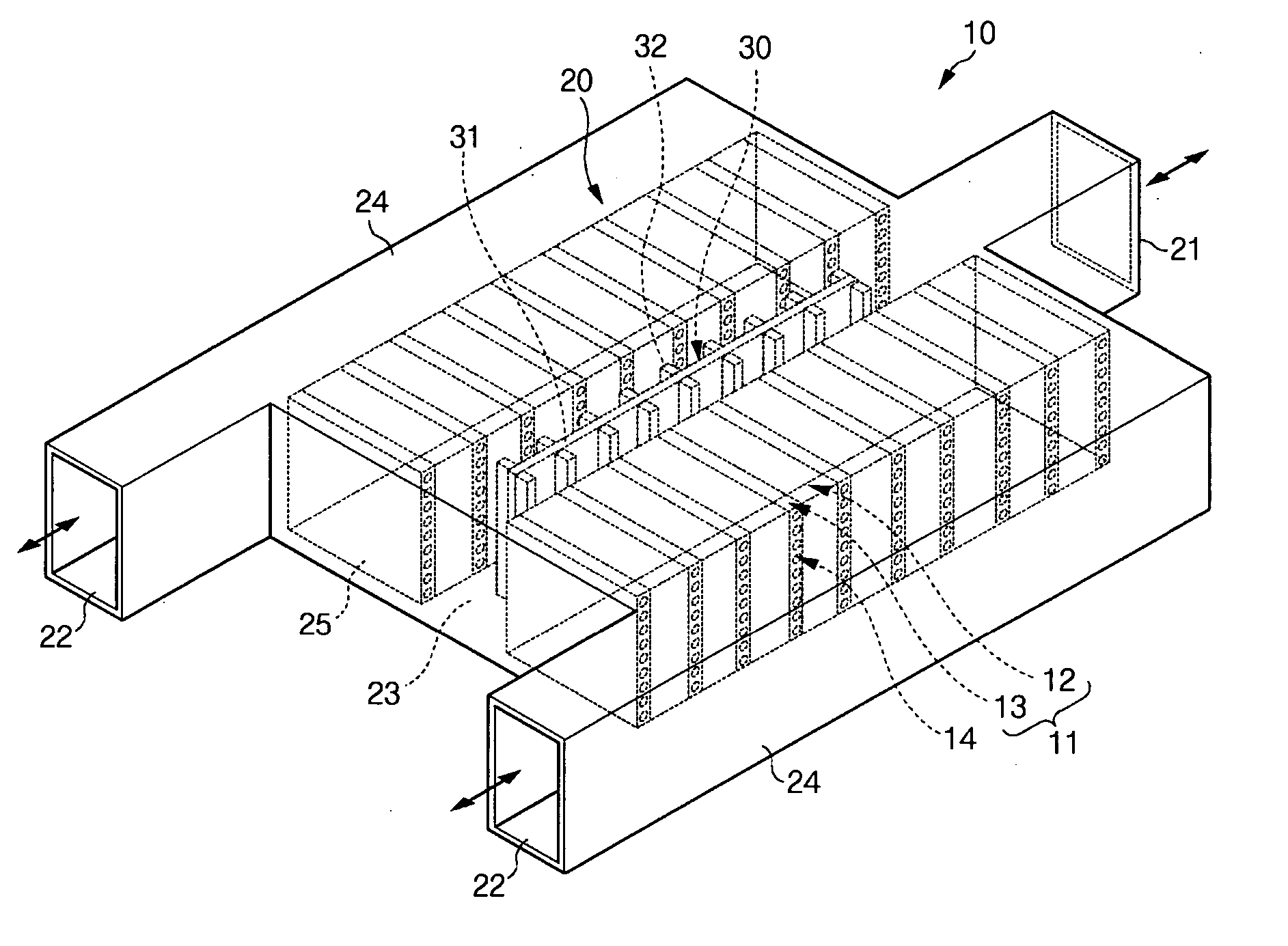

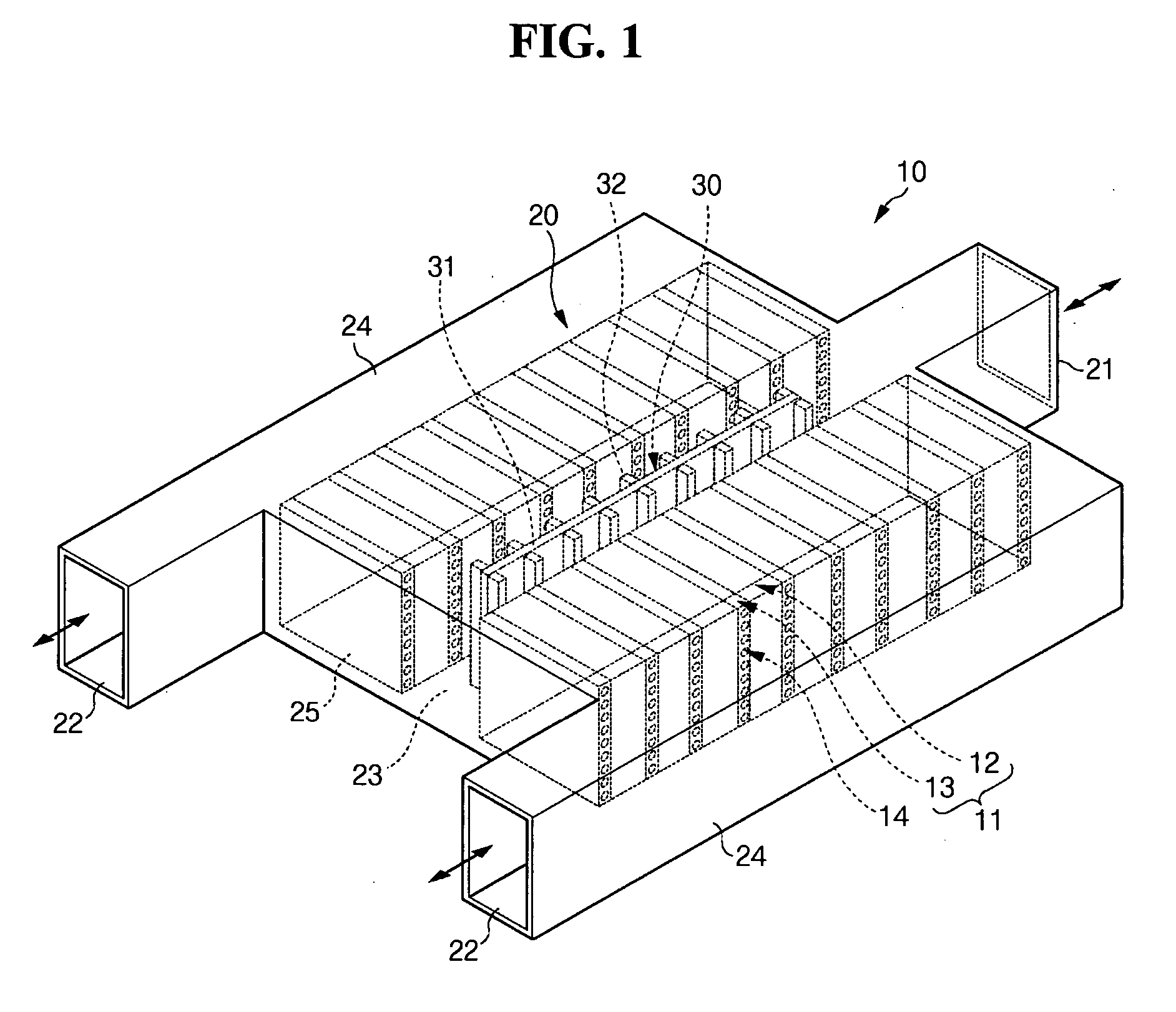

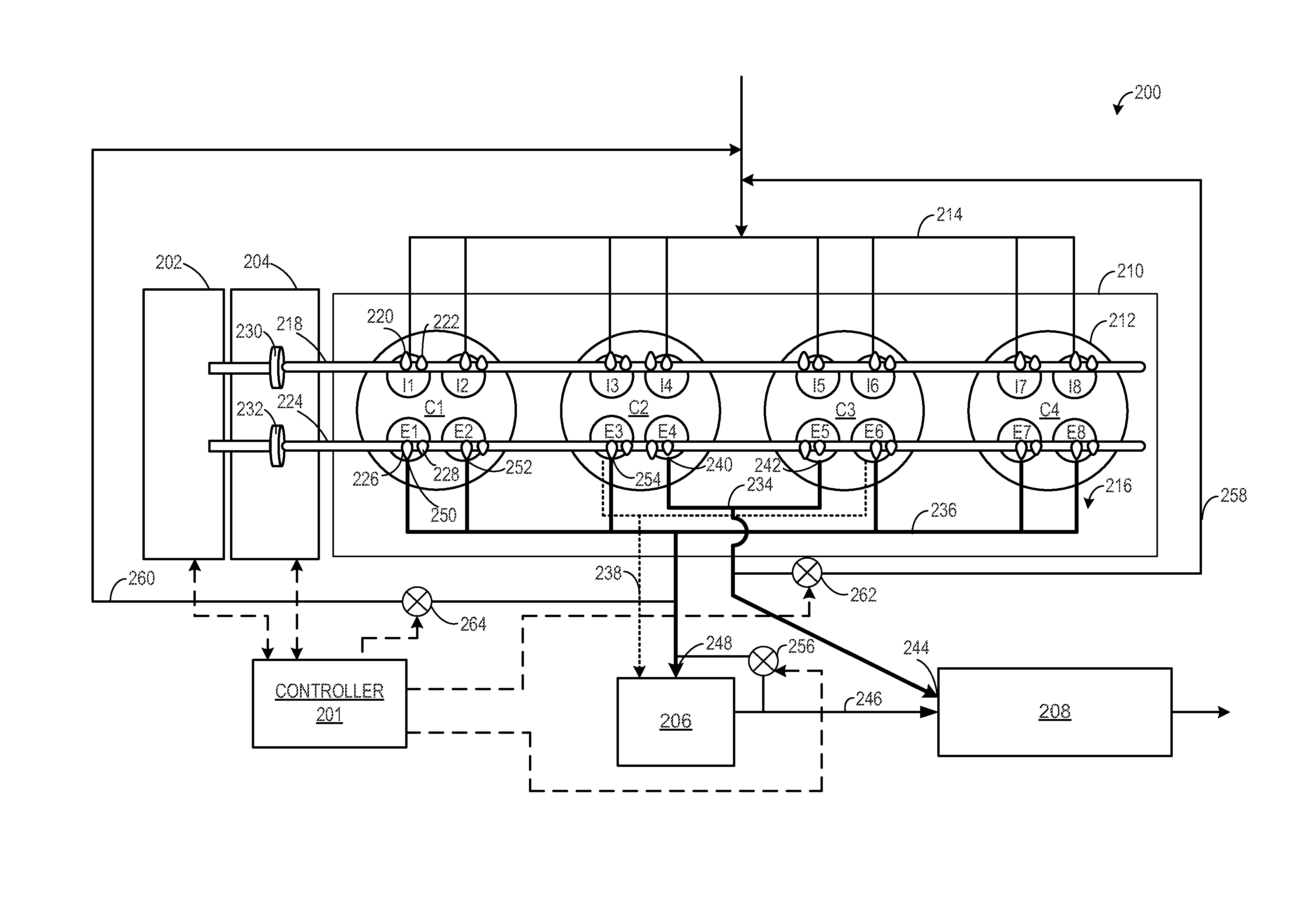

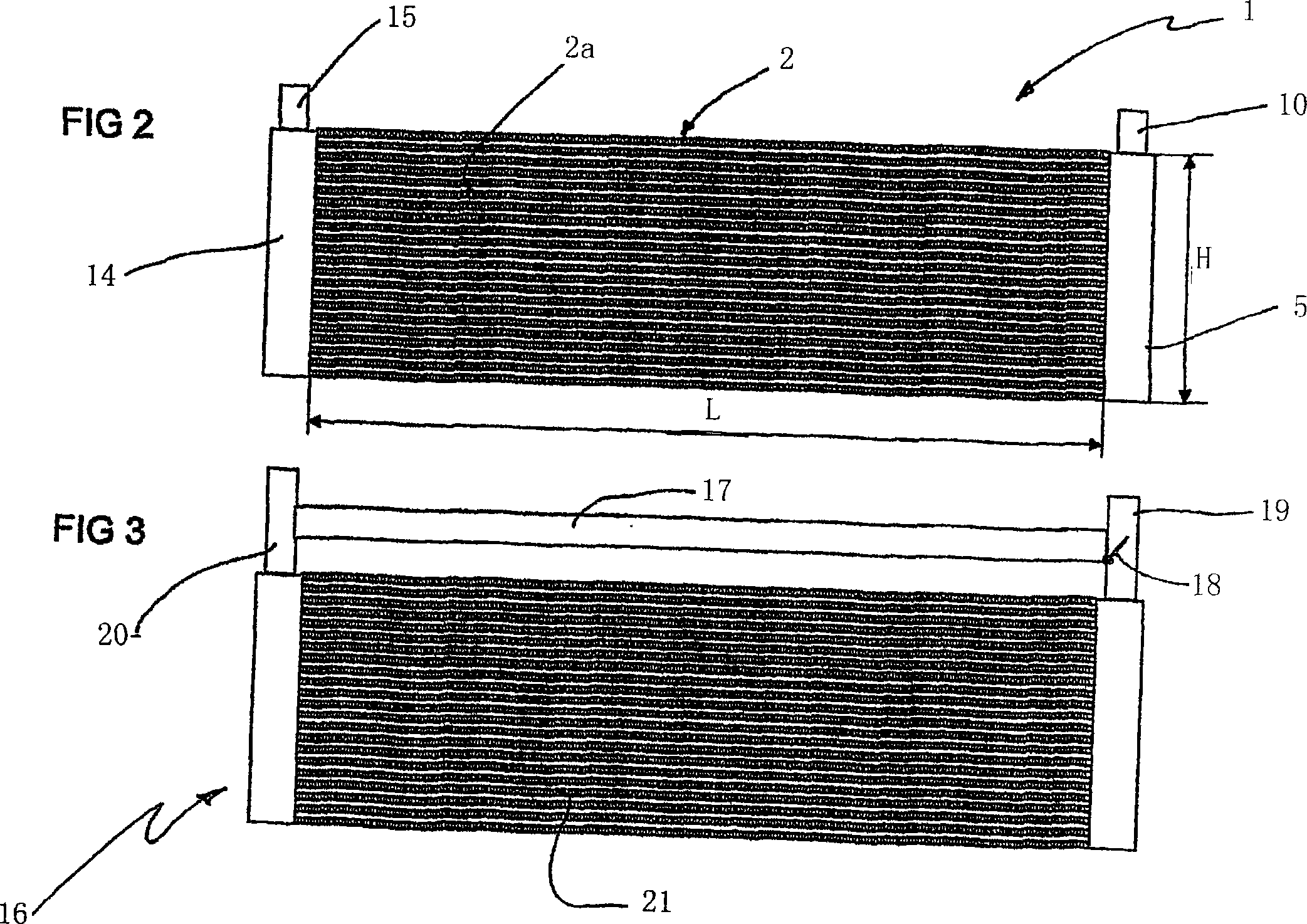

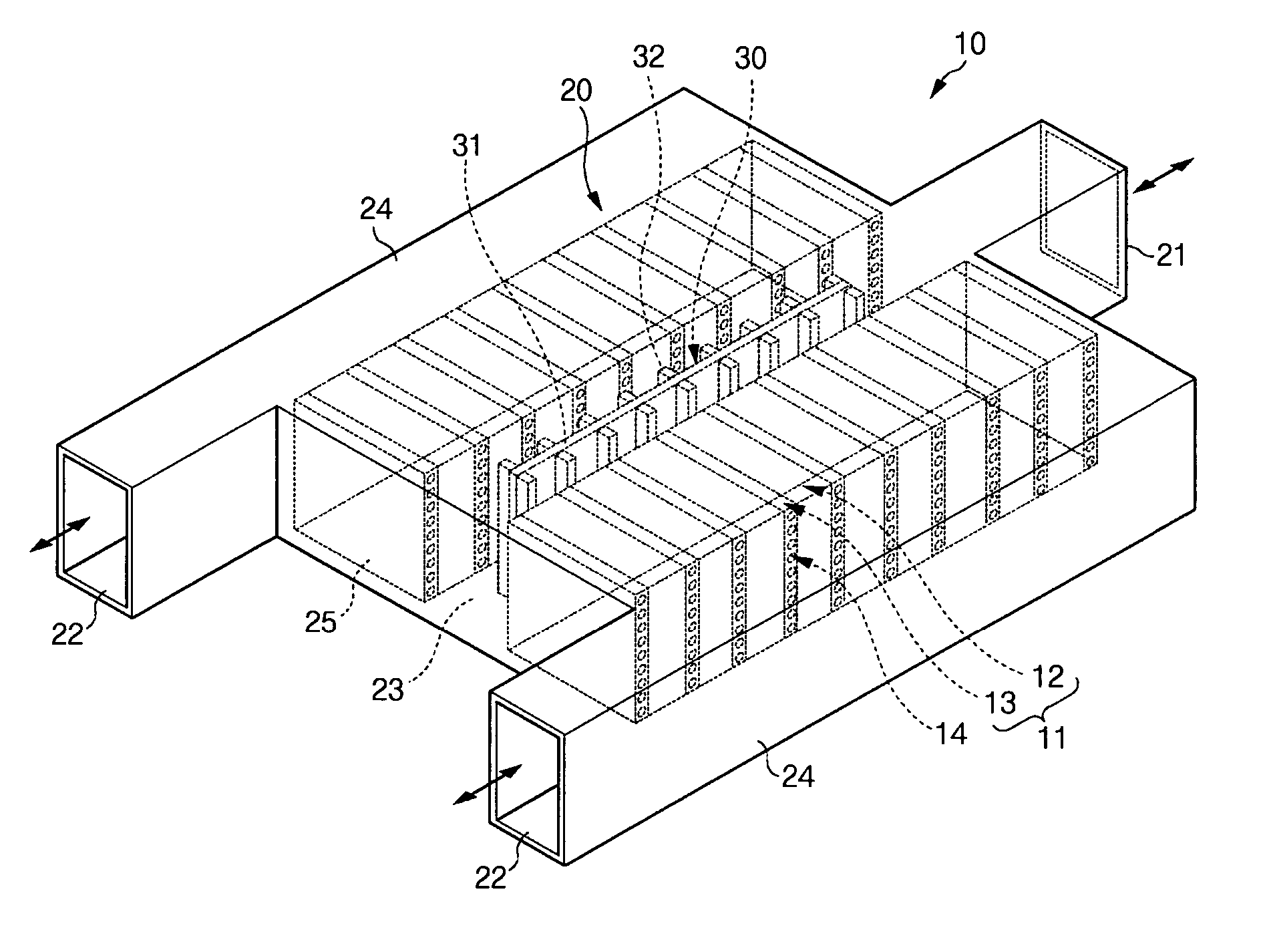

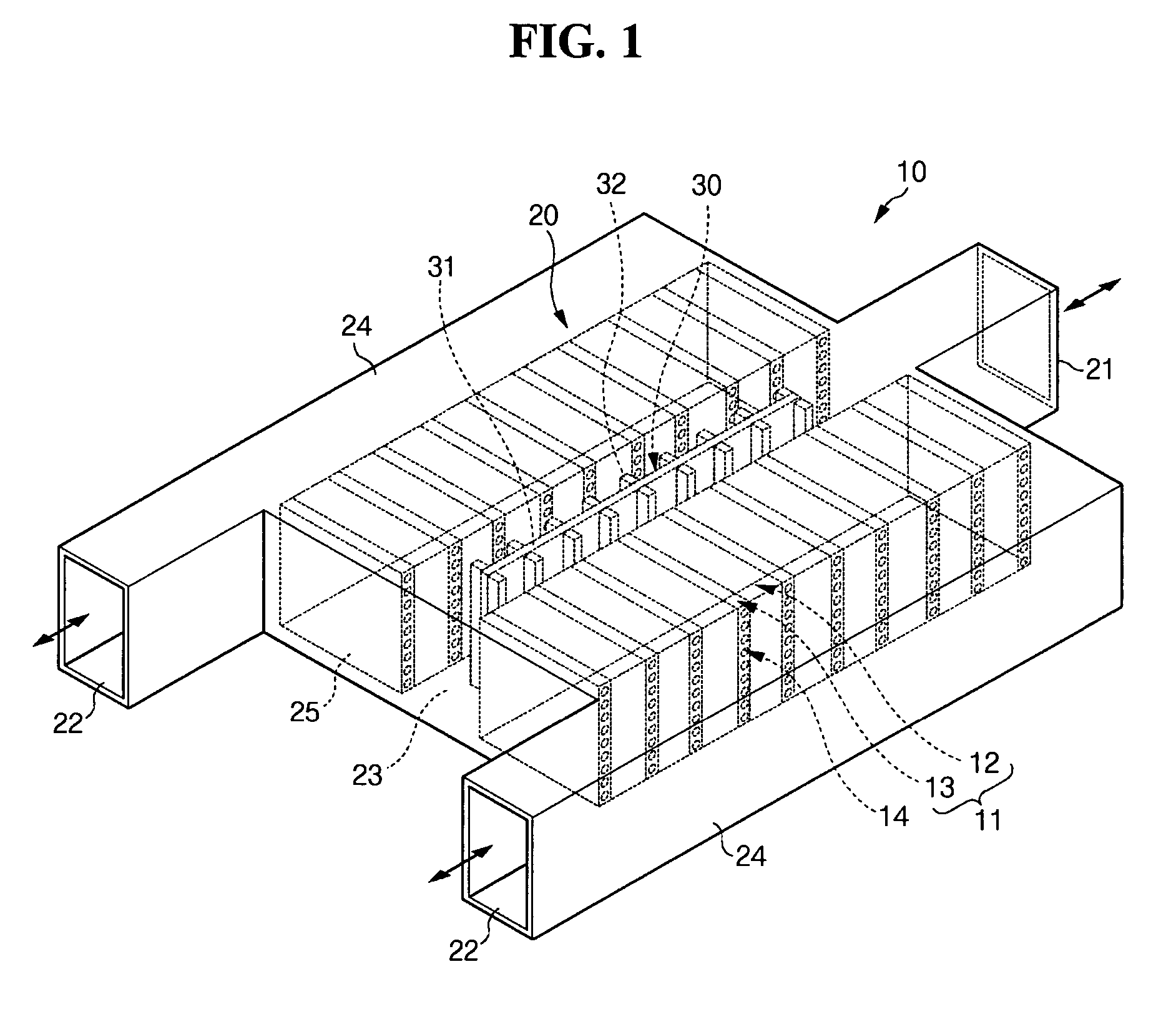

Battery module having improved cooling efficiency

ActiveUS20070031728A1Easy to optimizeEasy temperature controlPrimary cell to battery groupingCell temperature controlTemperature controlCell assembly

A battery module includes one or more cell assemblies with a plurality of unit cells, and a housing for mounting the cell assemblies therein and circulating a temperature control cooling medium through the cell assemblies. The cell assemblies are arranged in the longitudinal direction of the housing. A guidance unit is installed in a cooling medium passage formed in the longitudinal direction of the housing, and proceeds along the passage to guide cooling medium flow along the passage toward the cell assemblies.

Owner:SAMSUNG SDI CO LTD

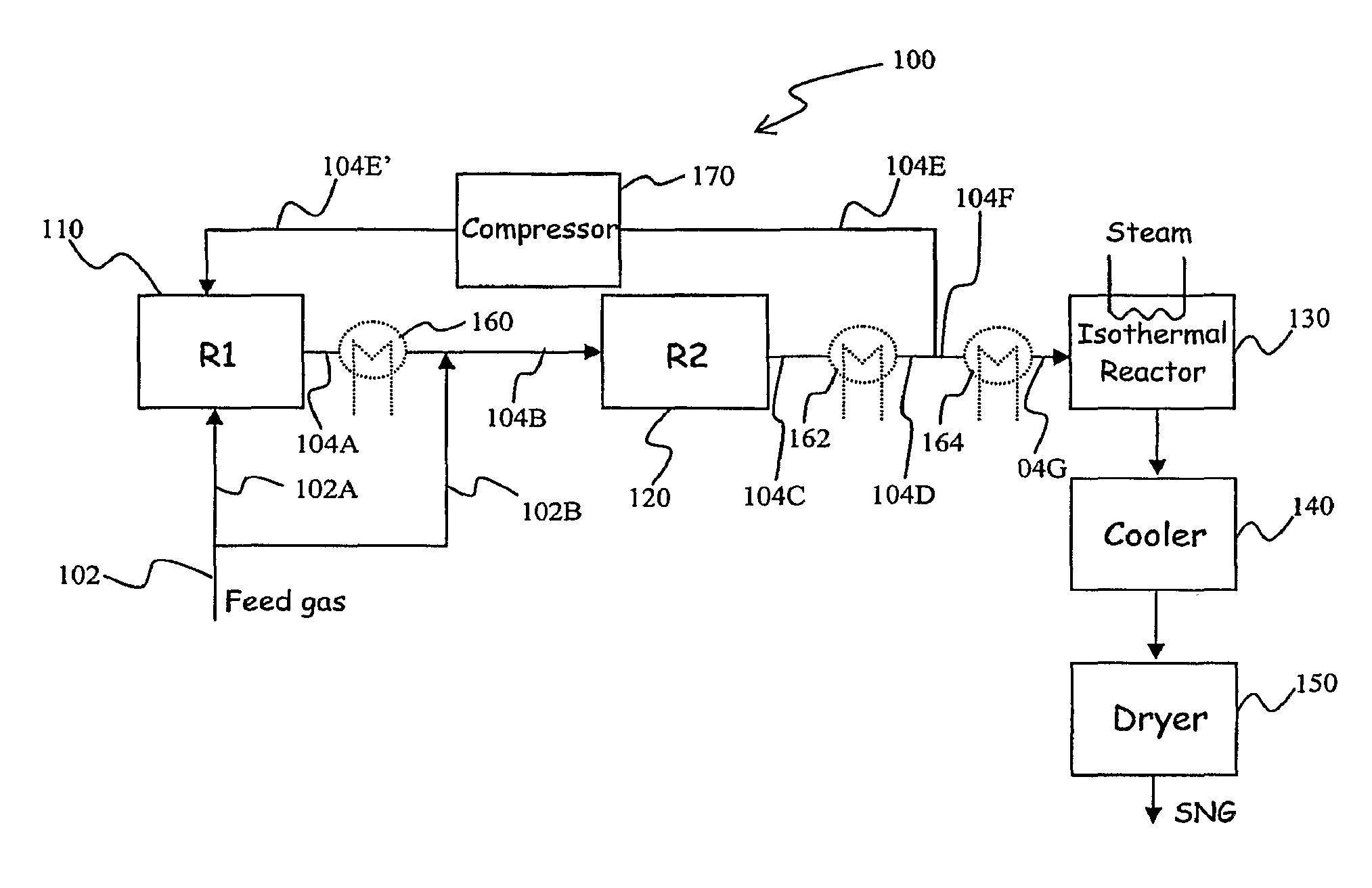

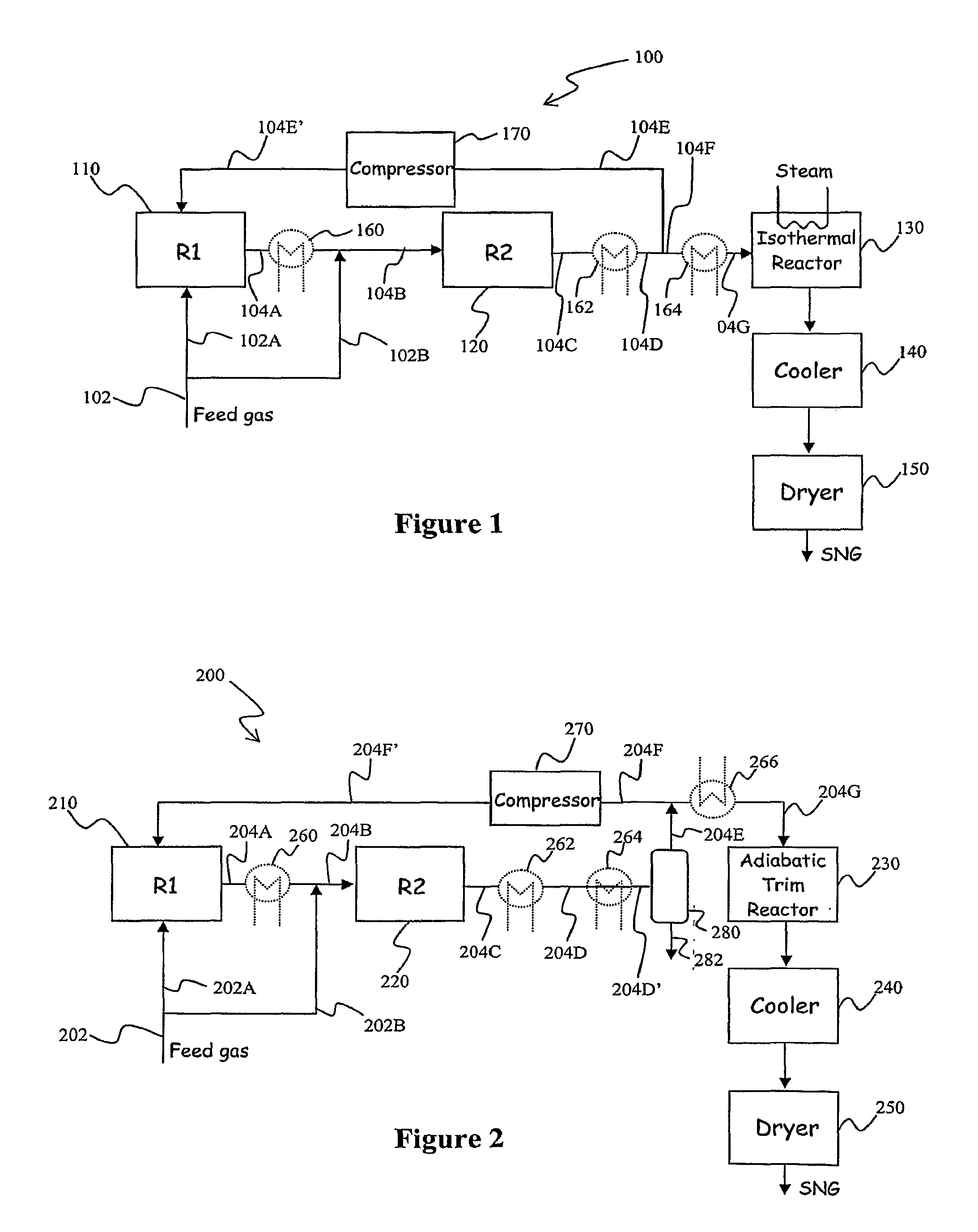

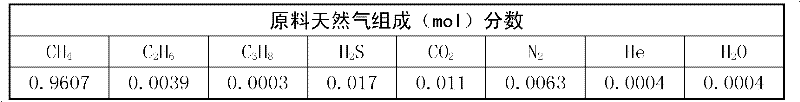

Configurations And Methods of SNG Production

InactiveUS20090247653A1Lower cost of capitalIncreased trim reactor inlet temperatureOrganic compound preparationOxygen compounds preparation by reductionMethanationSubject matter

SNG plants according to the inventive subject matter include one or more methanation reactors that produce a primary methanation product that is cooled to a temperature sufficient to condense water, which is removed in a separator. So produced dried methanation product is then split to provide a reflux stream to the methanation reactors and a feed stream to an adiabatic trim reactor. Most preferably, the plant comprises at least two methanation reactors that are operated in series, wherein the first reactor receives the recycle stream and wherein the second reactor receives a portion of the first methanation reactor effluent and a portion of the first methanation reactor feed.

Owner:FLUOR TECH CORP

Method of chilling inlet air for gas turbines

InactiveUS20050056023A1Lower the average temperature of the chilling waterLower inlet temperatureClimate change adaptationEvaporators/condensersCooling coilInlet temperature

A method for cooling inlet air to a gas turbine is provided. For example, a method is described including passing inlet air through a cooling coil that includes an opening for receiving the inlet air and that is operably connected to a gas turbine power plant. The gas turbine power plant may include at least one gas turbine, and at least one gas turbine inlet which receives the inlet air. The method may further include passing circulating water through a water chiller at a first flow rate to reduce the temperature of the circulating water, the water chiller including a conduit through which the circulating water is capable of passing and passing the circulating water having the first flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air. Additionally, the method may include reducing the flow rate of the circulating water passing through the water chiller, passing the circulating water through a water chiller at a second flow rate to reduce the temperature of the circulating water, the second flow rate being lower than the first flow rate, and passing the circulating water having the second flow rate through the cooling coil in an amount sufficient to lower the temperature of the inlet air.

Owner:TAS ENERGY +1

Dehydrogenation process with water and temperature control

ActiveUS7687676B1Long catalyst lifeLower inlet temperatureHydrocarbon by hydrogenationCatalytic naphtha reformingTemperature controlAlkane

The activity of a dehydrogenation catalyst is improved by increasing the water concentration maintained in the reactants toward the start of the catalyst's life, but after the catalyst has deactivated to the extent that the temperature required to maintain the conversion per pass of paraffinic hydrocarbon through the reaction zone increases by at least 2° C.

Owner:UOP LLC

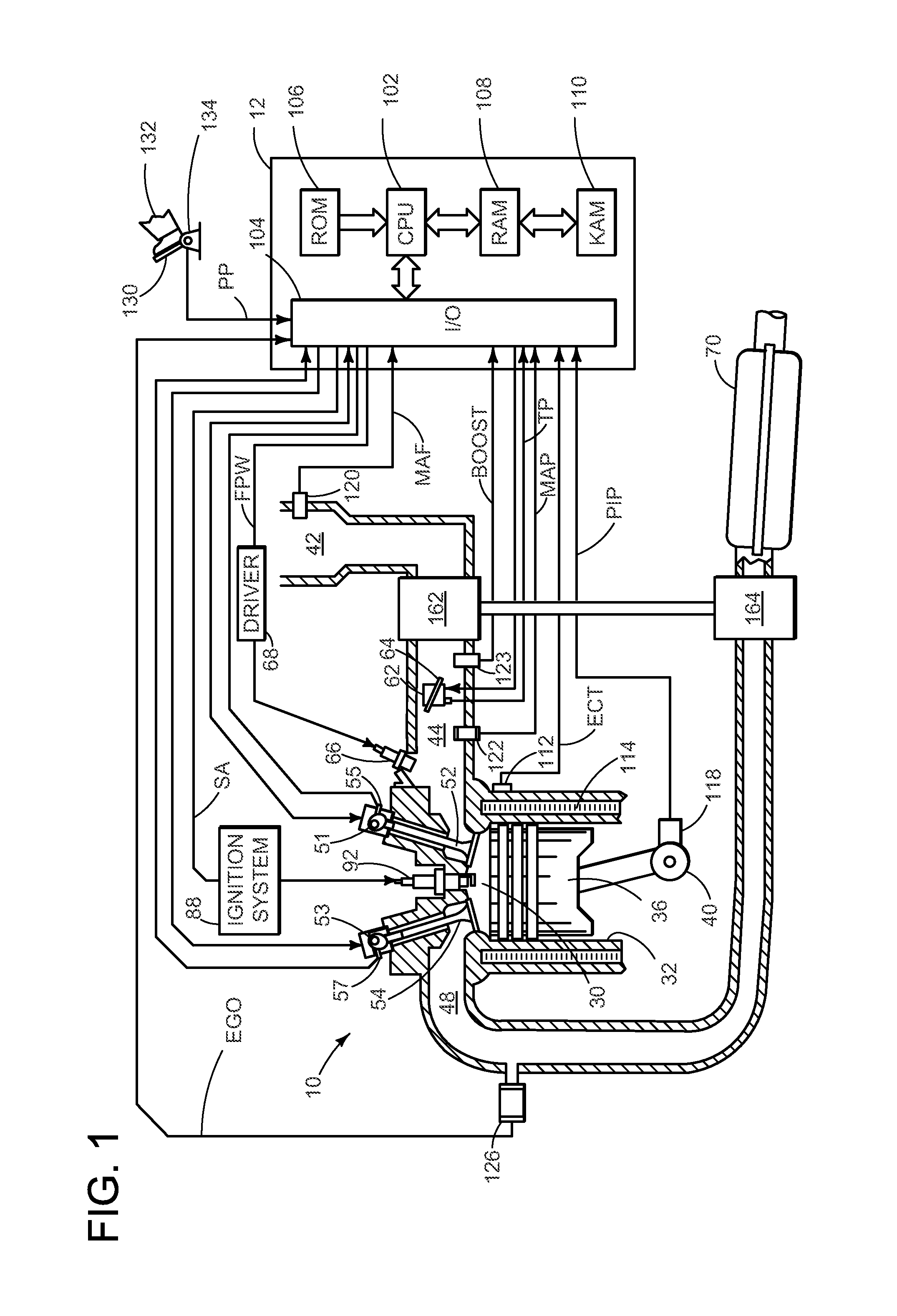

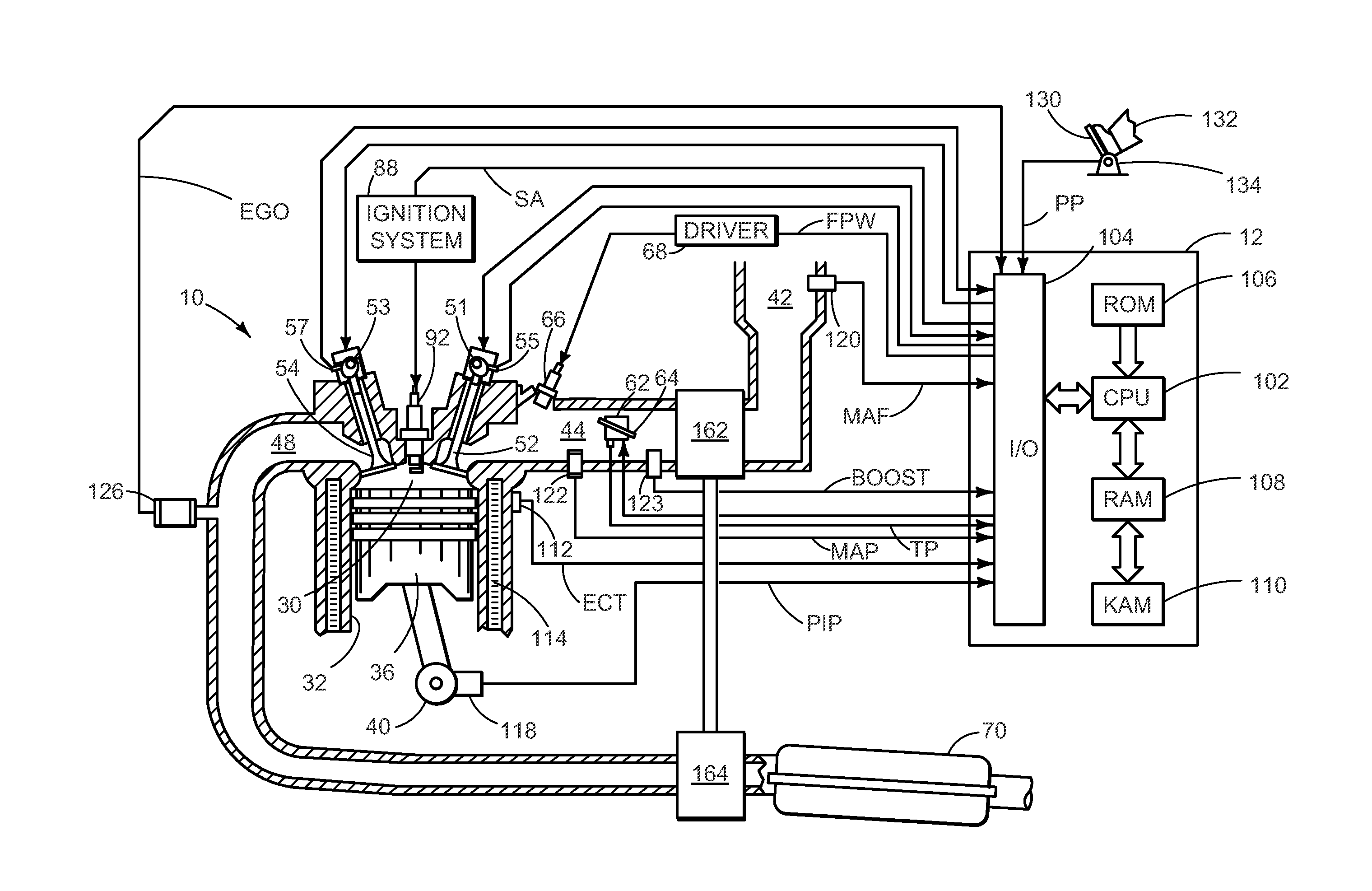

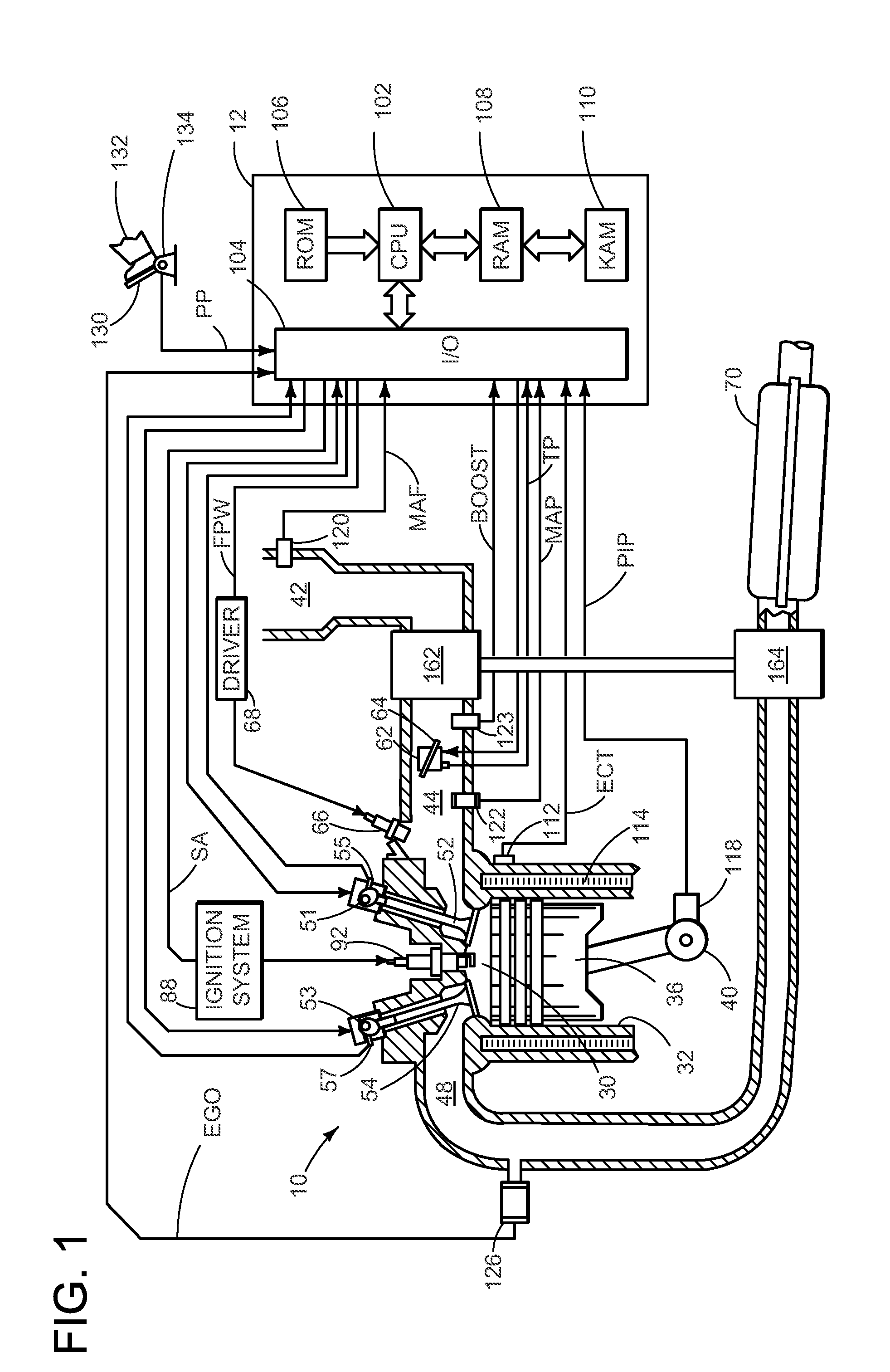

Variable valvetrain turbocharged engine

ActiveUS8833058B2Expand business scopeLower inlet temperatureElectrical controlNon-fuel substance addition to fuelTurbochargerValvetrain

Owner:FORD GLOBAL TECH LLC

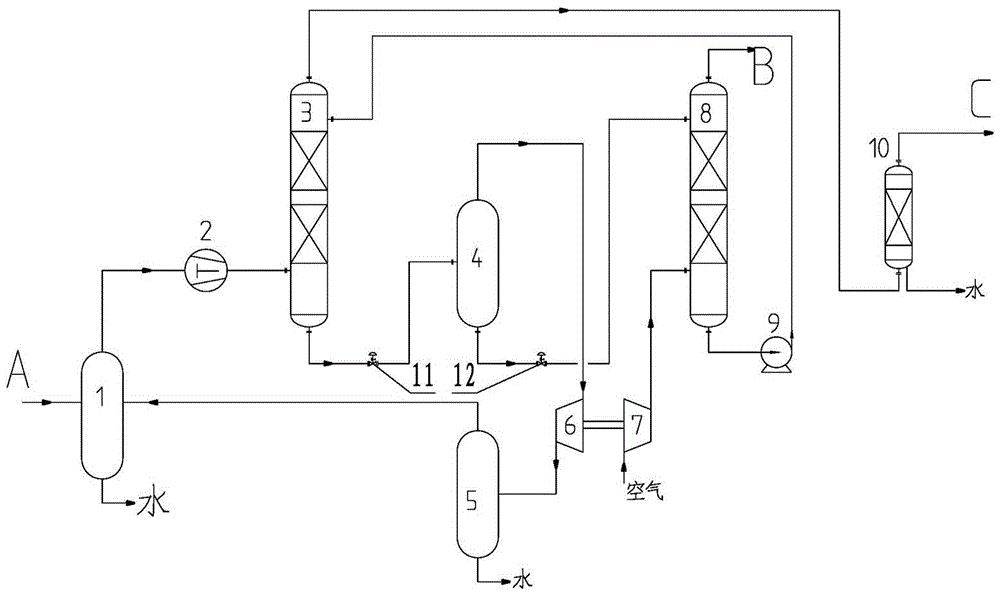

Natural gas absorbent regeneration and energy conservation technology and device

InactiveCN103071475AAvoid wastingReduce dosageGaseous fuelsCombustible gas purificationCompressed natural gasNatural gas dehydration

The invention relates to a natural gas absorbent regeneration and energy conservation technology and a natural gas absorbent regeneration and energy conservation device. The technology and the device can overcome the defects that the energy consumption is great and the heating time is long when the absorbent is regenerated. The technical scheme is as follows: a process of two towers is adopted, one tower is used for dehydration of natural gas and the other one is used for regeneration of natural gas. The two towers are switched for dehydration and regeneration of natural gas. During dehydration of natural gas, compressed natural gas first enters into the dehydration tower A to be dehydrated and obtain dried natural gas after being separated by a front filter separator, then the natural gas enters into a gas storage tank after being separated by a back filter separator; during heating and regeneration of absorbent, after flow reduction and depressurization, the regenerated natural gas is first heated in a heat exchanger and a heater and enters into the dehydration tower B to regenerate the absorbent, then, the natural gas enters into the heat exchanger to be cooled, and finally the natural gas enters into a recovery tank after being separated by a condensation separator; and during cold blowing and regeneration of the absorbent, after flow reduction and depressurization, the regenerated natural gas enters into the dehydration tower B to cold blow and reduce the temperature of the absorbent. According to the technology, complementary utilization of energy is achieved, energy consumption in absorbent regeneration is reduced, and energy-saving operation of the device is realized.

Owner:SOUTHWEST PETROLEUM UNIV

Variable valvetrain turbocharged engine

ActiveUS20130269315A1Expand business scopeLower inlet temperatureElectrical controlInternal combustion piston enginesTurbochargerValvetrain

Embodiments for routing exhaust in an engine are provided. In one example, an engine method comprises, during a first condition, firing a subset of cylinders and routing all exhaust from the subset of cylinders through a first exhaust manifold coupled directly to a catalyst and not a turbocharger, and during a second condition, firing all cylinders, routing a first portion of exhaust through a second exhaust manifold coupled to the turbocharger, and routing a second portion of exhaust through the first exhaust manifold. In this way, exhaust can be directly routed to a catalyst under some conditions.

Owner:FORD GLOBAL TECH LLC

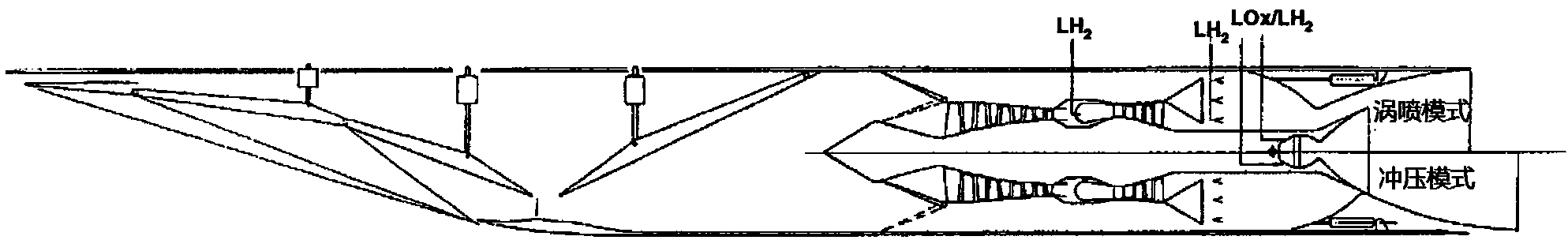

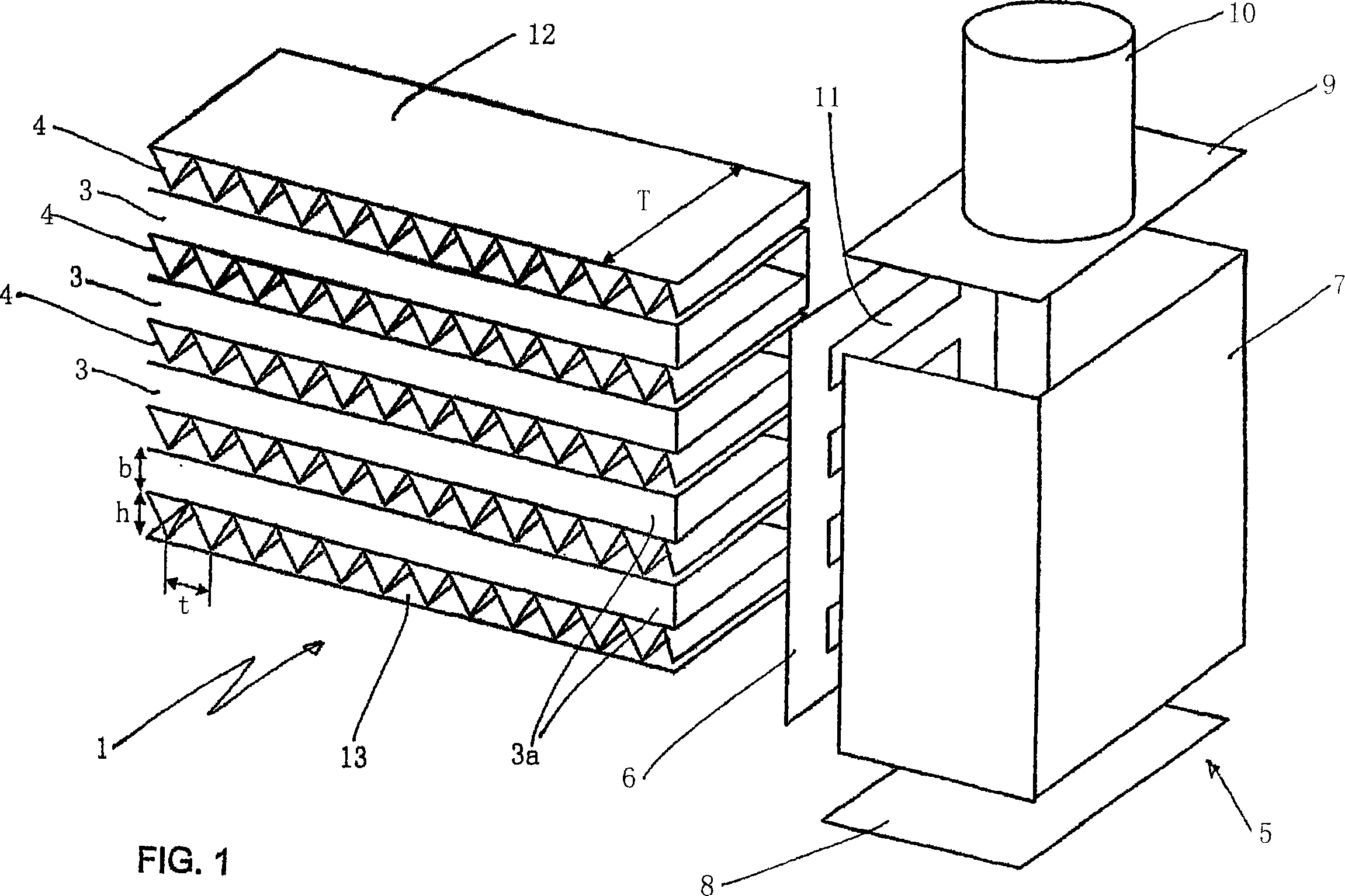

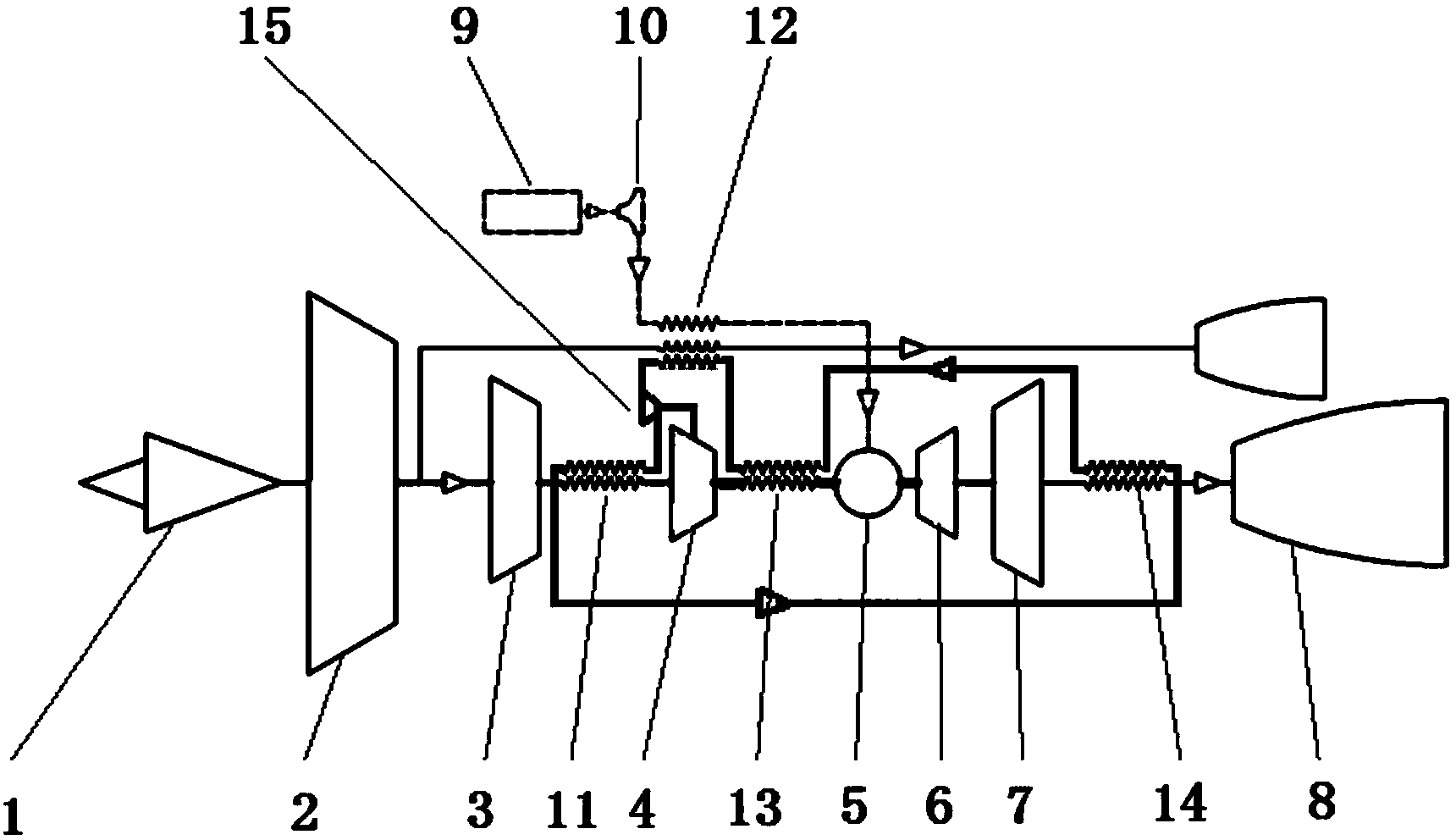

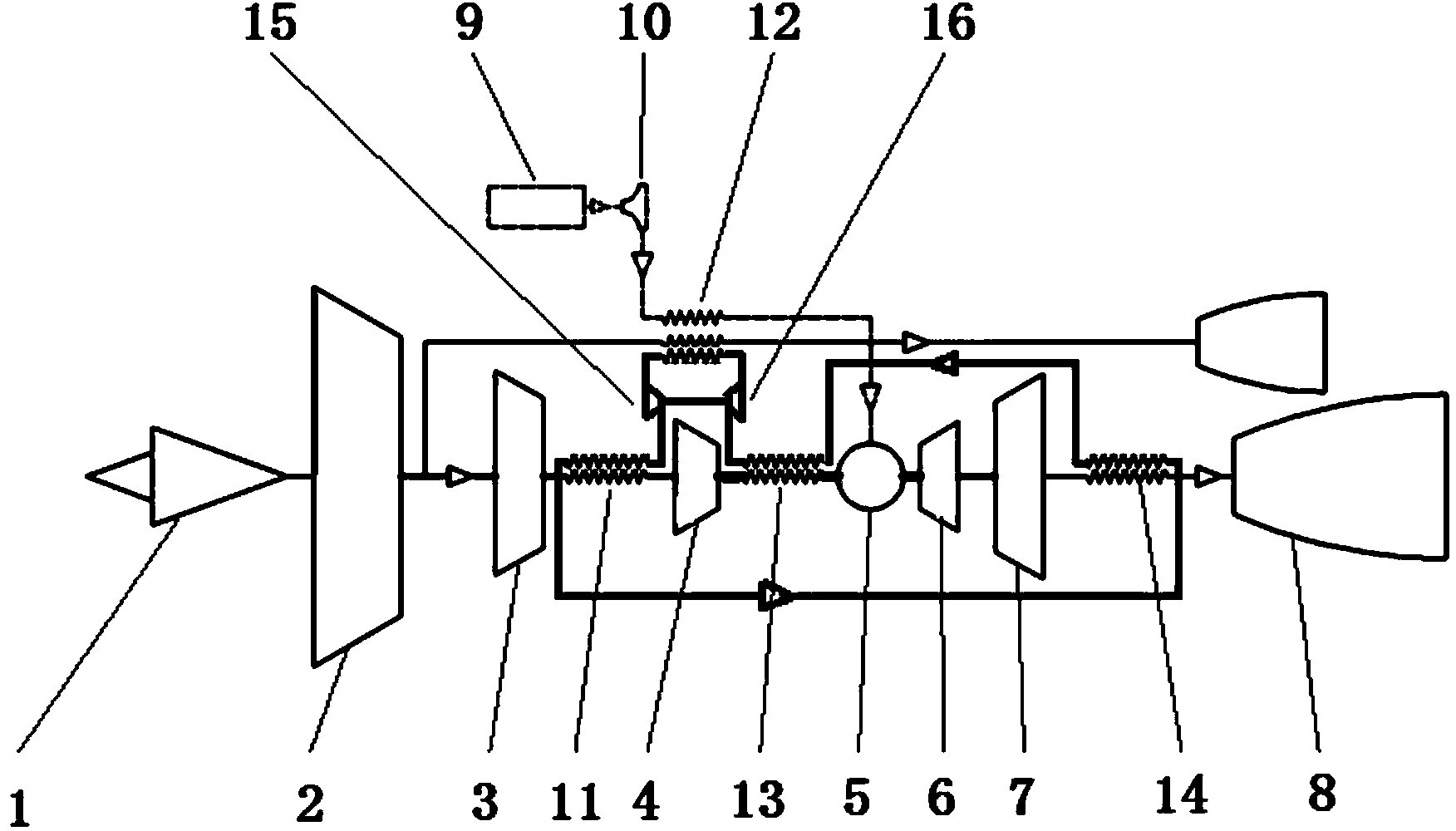

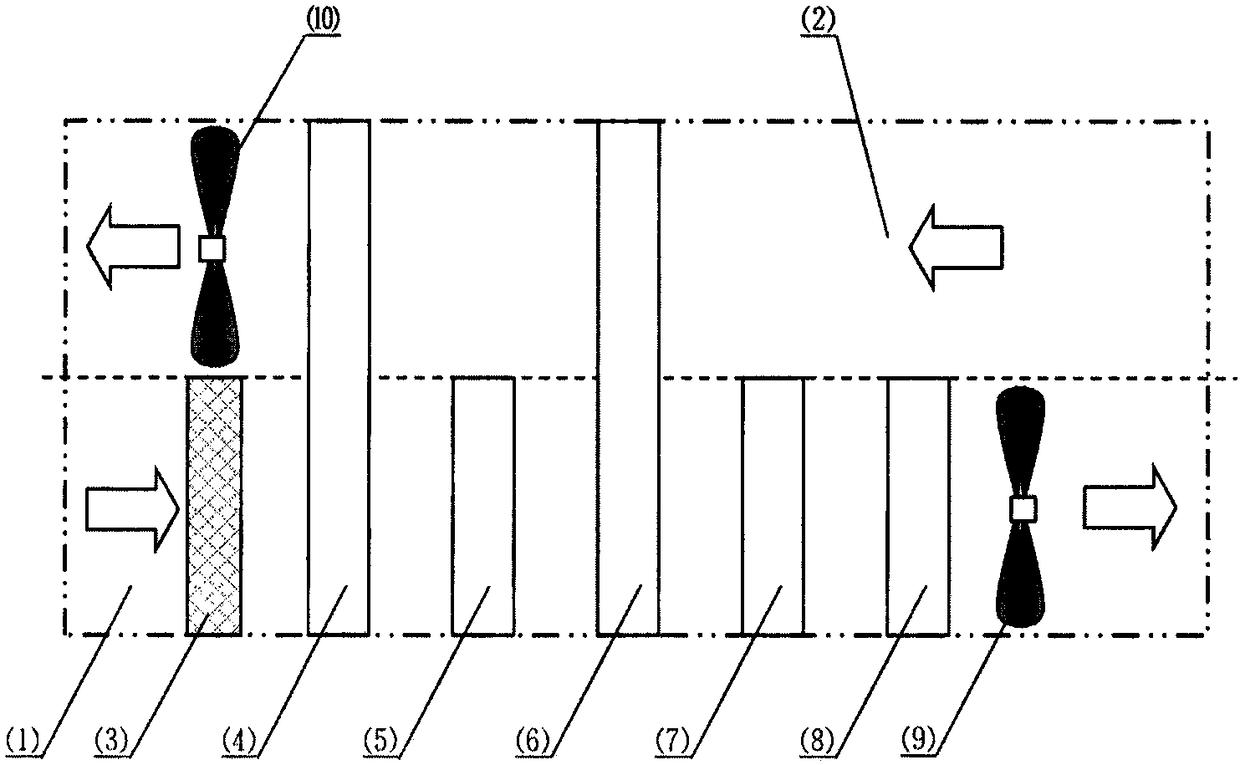

New concept high-speed aerocraft propulsion system layout method

ActiveCN104110326AEfficient cruiseLarge heat capacityRam jet enginesComposite engine plantsSpacecraft propulsionBrayton cycle

The invention provides a new concept high-speed aerocraft propulsion system layout method. Two cycles are built in a propulsion system, namely a Brayton cycle with the air as the working medium and a closed cycle with supercritical state fluid as the working medium. The two cycles are coupled through a supercritical microscopic scale heat exchange technology, a supercritical state fluid turbine and compressor power balance. By adjusting related valves, the propulsion system can be in a turbofan engine model when taking off or flying at a low speed and in a turbine rocket engine model when flying at a high Mach number, so that it is guaranteed that the aerocraft can effectively cruise for a long time in both a subsonic state and a supersonic state. Through the supercritical microscopic scale heat exchange technology, the gas flow temperature at an inlet of a compressor can be effectively reduced when the propulsion system is flying at a high speed, and when the supercritical microscopic scale heat exchange technology is applied in combination with a closed cycle technology, optical distribution of energy of the propulsion system can be achieved. By means of the method, the defects of the propulsion system of an existing high-speed aerocraft are overcome, and working performance of the high-speed aerocraft propulsion system is remarkably improved when Ma ranges from 0 to 5.

Owner:BEIHANG UNIV

Air-cooled exhaust gas heat exchanger, in particular exhaust gas cooler for motor vehicles

InactiveCN101072976AIncrease powerCompact structureInternal combustion piston enginesStationary conduit assembliesViewpointsImaging processing

To provide an image processing method which easily constructs an indoor space model of high reality in a virtual space and provides a person, who wants to buy a house, with more realistic VR pictures, and also provide a program therefor. Actual pictures of an indoor space photographed with a plurality of photographing devices are obtained, and the obtained actual pictures are compared with virtual pictures obtained by viewing the virtual model of the same indoor model from virtual viewpoints to compute a correlation between the actual pictures and the virtual model. Then, the surface area of the virtual model for mapping the textures of the actual pictures is designated, and the partial areas of the actual pictures after conversion of their forms are mapped to the surface area. Then, the VR images obtained by viewing the virtual model after the texture mapping from arbitrary viewpoints are generated and displayed on a display device.

Owner:BEHR GMBH & CO KG

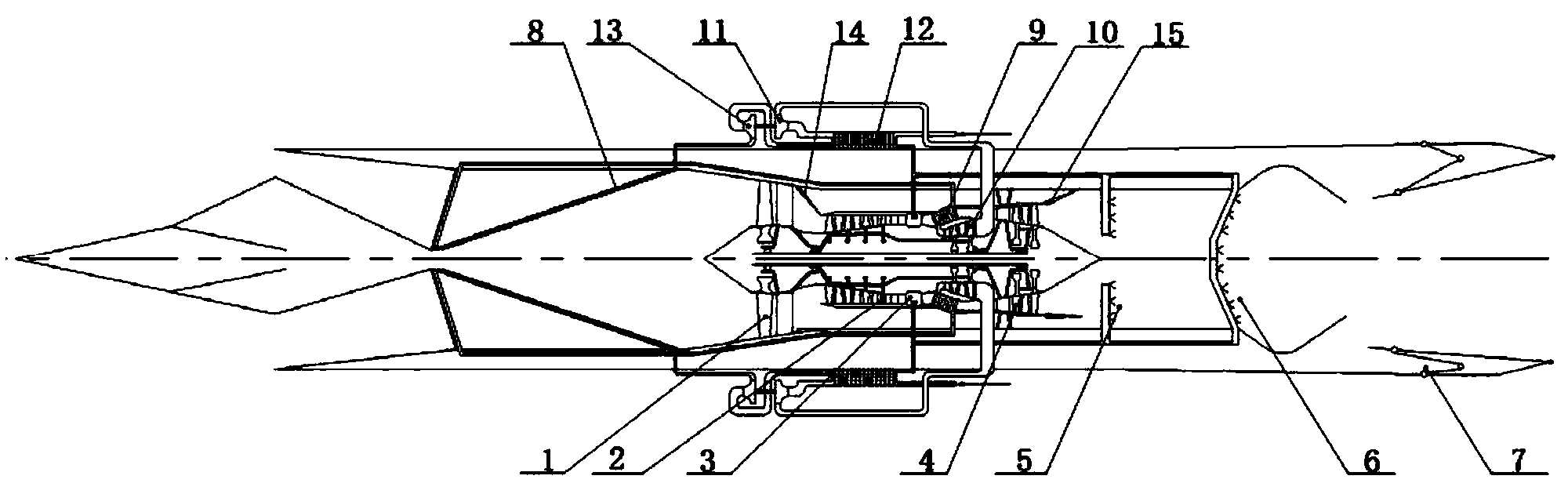

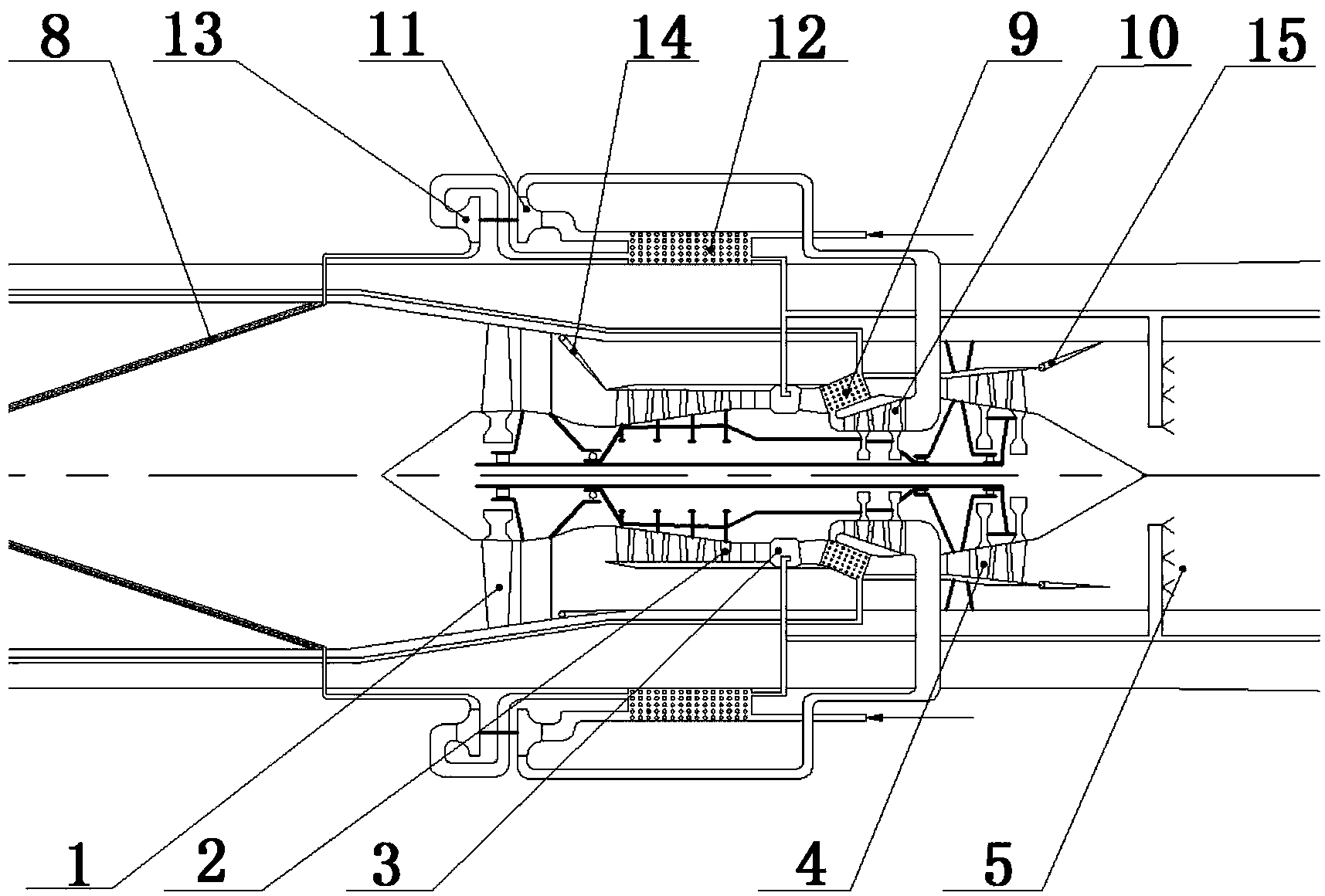

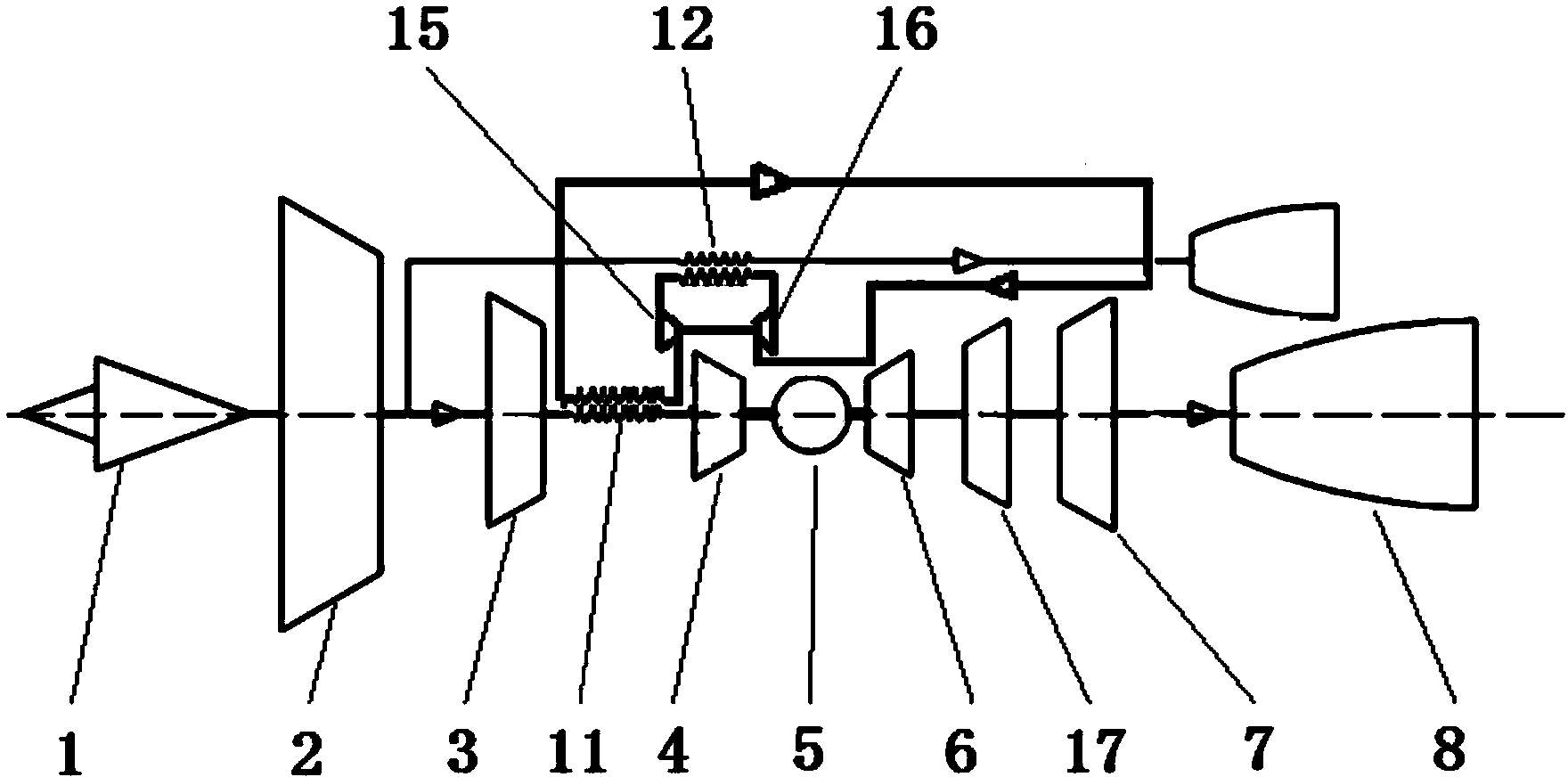

Intercooling or intercooling recuperating layout for aero-engine

ActiveCN104110309AAvoid losses along the wayLarge heat capacityTurbine/propulsion engine coolingGas turbine plantsBrayton cycleEngineering

The invention provides an intercooling or intercooling recuperating layout for an aero-engine. The layout comprises a Brayton cycle in a main flow path and a supercritical state fluid cycle, wherein the two cycles are mutually independent and are coupled through a micro-scale heat exchanger. The micro-scale heat exchanger is a supercritical micro-scale compact rapid heat exchanger comprising a heat exchanging element and two working mediums, wherein the two working mediums exchange heat through the heat exchanging element. The micro-scale heat exchanger is characterized in that one of the working mediums employs a supercritical state fluid, the other working medium is not limited, the size of the heat exchanging element is in a micro-scale range, the critical pressure of the supercritical state fluid is at least 0.5 MPa, the temperature of the supercritical state fluid is at least 200 DEG C higher than critical temperature, and micro-scale refers to that the geometric scale of the basic heat exchanging element is no more than 2 mm. The intercooling or intercooling recuperating layout provided by the invention overcomes the disadvantages of conventional intercooling or intercooling recuperating layouts, improves the cycle efficiency of the aero-engine and reduces the oil consumption rate of the aero-engine.

Owner:BEIHANG UNIV

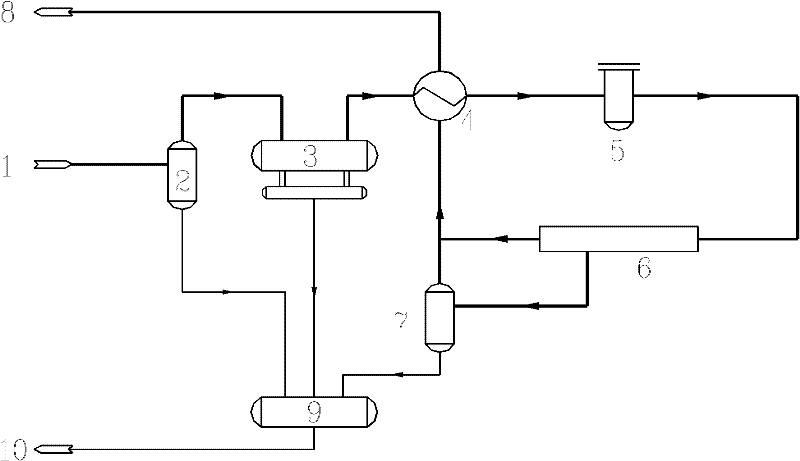

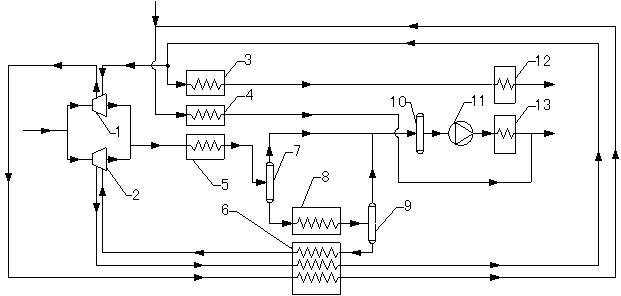

Gas dehydration and dealkylation method for supersonic vortex tube

ActiveCN102389690AAvoid cloggingLow hydrocarbon dew pointCombination devicesGaseous fuelsProcess engineeringDry gas

The invention relates to a gas dehydration and dealkylation method for a supersonic vortex tube, wherein the feed gas enters a separator and a filter separator to separate large particles out, the filtering separated feed gas and a dry gas are cooled in a first level gas-to-gas heat exchanger, and enter a first level prewhirling pre-nucleation supersonic vortex tube to be dehydrated after fine and small solid particles are separated out through a fine filter, and are separated into a first level dry gas and a gas-liquid mixture; the gas-liquid mixture enters a first level gas-liquid separatorto be separated; the separated gas phase flows into the first level dry gas to enter a second level gas-to-gas heat exchanger; the cooled first level dry gas enters a second level prewhirling pre-nucleation supersonic vortex tube to be dehydrated, and is separated into a second level dry gas and the gas-liquid mixture; the gas-liquid mixture enters a second level gas-liquid separator to be separated; the separated gas phase is interflowed with the second level dry gas to enter the second level gas-to-gas heat exchanger and the first level gas-to-gas heat exchanger for exchanging heat with thefirst level dry gas and the feed gas for temperature rise, and the heated dry gas is exported; and the high water dew point and blockage problems of hydrocarbon are solved, the dehydration and the dealkylation of the feed gas are realized, and a purification device is ensured to stably operate.

Owner:PETROCHINA CO LTD

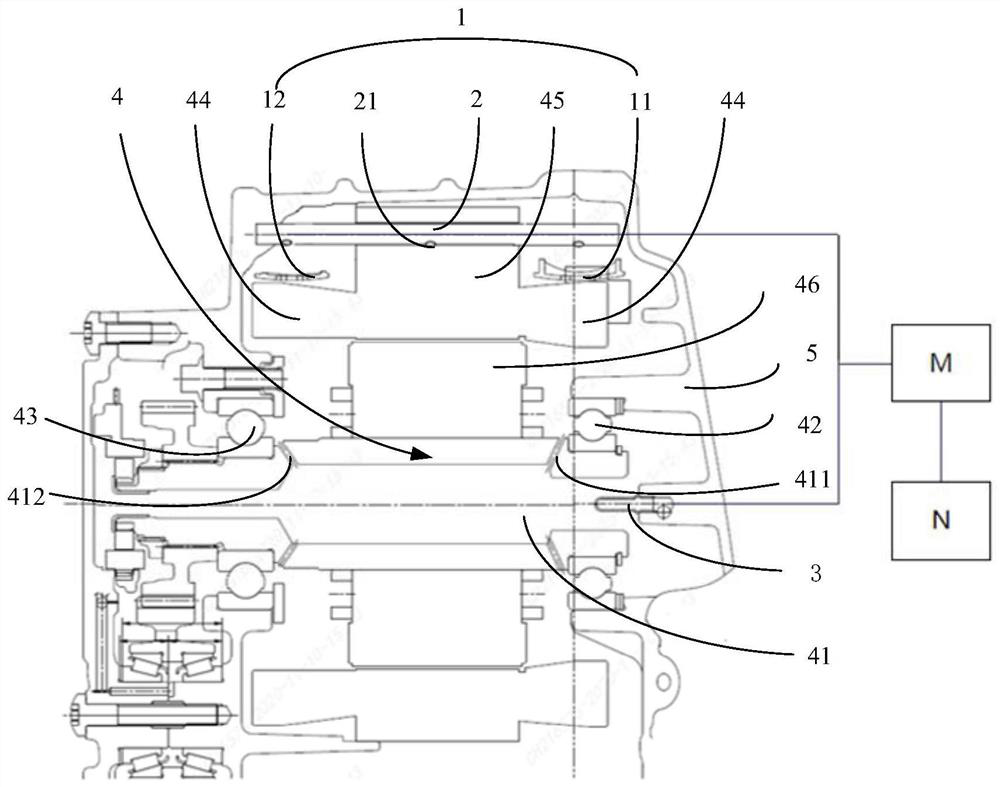

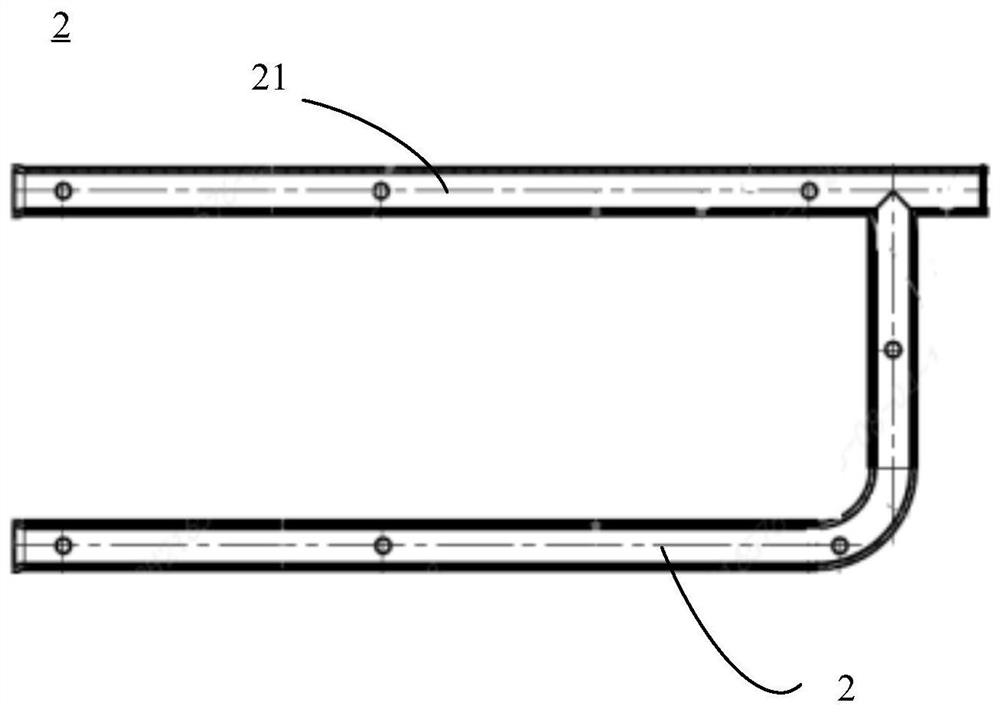

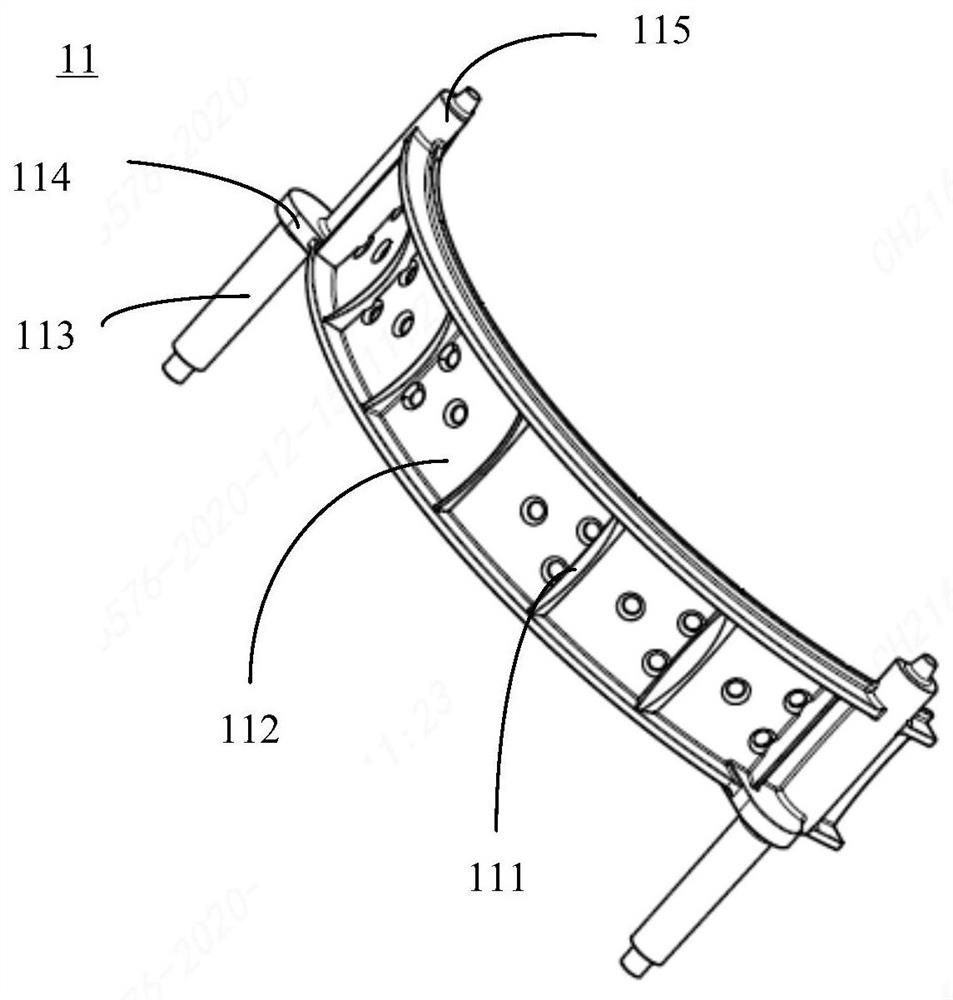

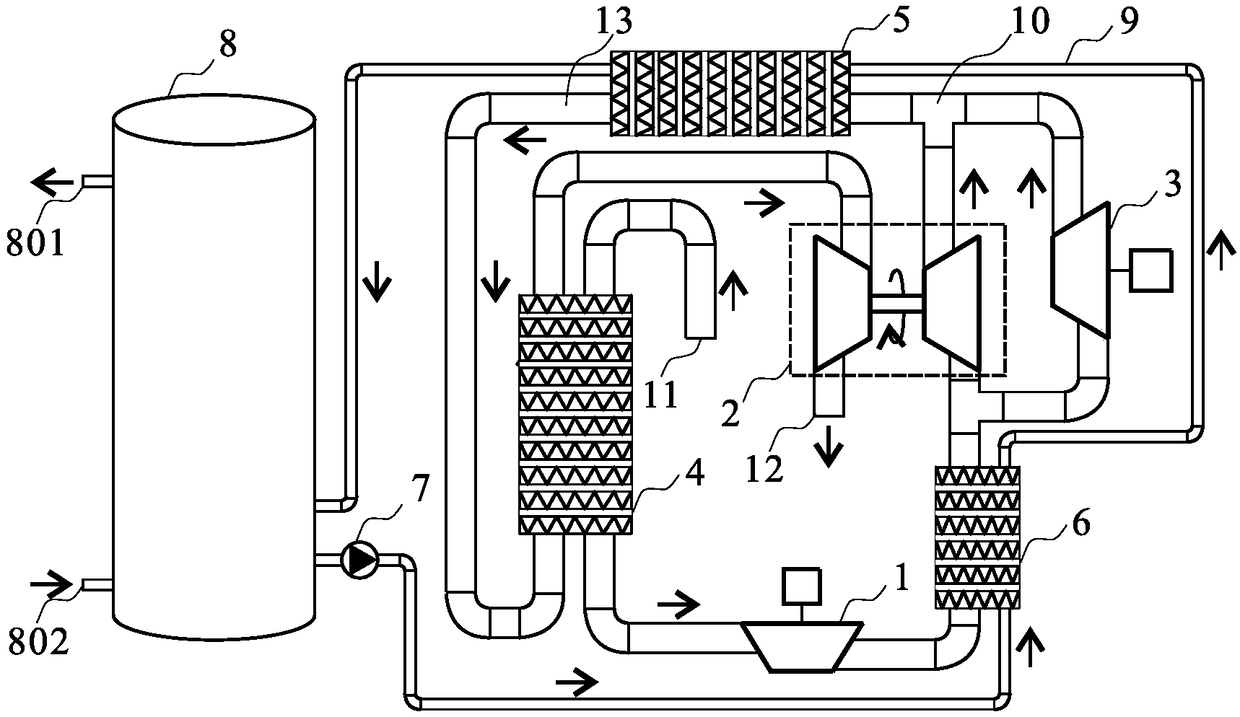

Oil-cooled motor cooling system

ActiveCN112701856AAchieve coolingAvoid accumulationMechanical energy handlingCooling/ventillation arrangementThermodynamicsElectric machine

The invention discloses an oil-cooled motor cooling system. The system comprises an oil collecting assembly, an oil spraying pipe, an oil guiding pipe and a motor. A plurality of oil throwing holes are formed in a rotor shaft of the motor, and when the rotor rotates, cooling oil injected through the oil guide pipe is thrown and splashed to the inner sides of bearings on the two sides of the rotor shaft through the oil throwing holes in the rotor shaft and then rebounded to the inner side of a stator winding and a rotor iron core. A plurality of oil spraying holes are formed in the oil spraying pipe, so that cooling oil in the oil spraying pipe can be sprayed to the oil collecting assembly. The oil collecting assembly comprises a first oil collecting disc and a second oil collecting disc which are arc-shaped and provided with a plurality of through holes, and cooling oil in the oil collecting discs is dripped on the stator winding and the stator iron core through oil holes. According to the system, the oil collecting assembly, the oil spraying pipe and the oil guiding pipe which are simple in structure are utilized, cooling of the inner side and the outer side of the stator winding, the stator iron core, the rotor and the inner sides of the bearings on the two sides of the rotor shaft is achieved through the two oil cooling paths, the cooling range is wide, and the cooling effect is good.

Owner:CHERY AUTOMOBILE CO LTD

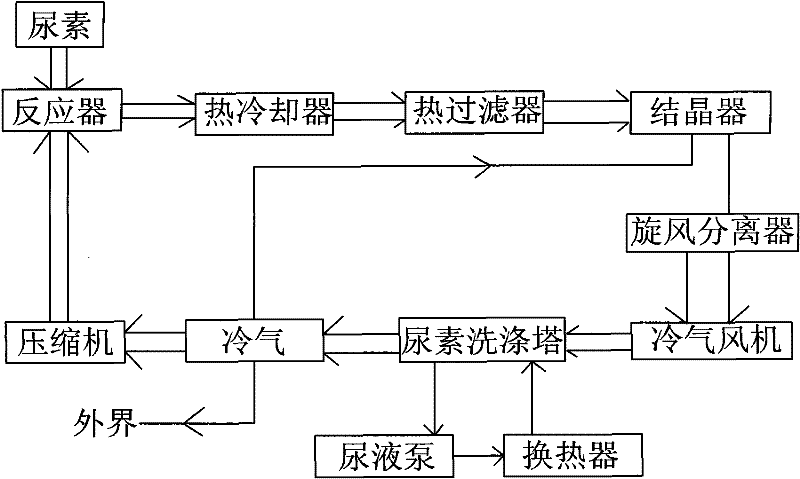

Energy-saving process for producing melamine

InactiveCN102452992APrevent spoilagePrevent melting point riseOrganic chemistryChemical industryComing outCatalytic function

The invention relates to an energy-saving process for producing melamine, comprising the following steps: using urea as the raw material, and producing melamine, ammonia and carbon dioxide in a reactor under the catalytic function of a catalyst at 350-420 degrees centigrade and a pressure of 0-1.5 MPa through reaction, wherein material gas from the reactor enters a hot-gas cooler, and the cooled hot technological gas enters a filter to be filtered, and the filtered technological gas containing melamine enters a crystallizer, and the melamine after crystallization enters a cyclone separator, and the separated solid triamine is sent to a storage bin to be packaged, and the gas coming out from the cyclone separator enters a heat exchanger; cooling the gas containing ammonia and carbon dioxide at about 200-220 degrees centigrade by water to about 30-145 degrees centigrade, and purifying the technological gas in an urine liquid washing tower; separating urine liquid fog drops carried in the purified gas by a separator, wherein the gas after separation is divided into three ways: one way gas is compressed into the reactor by the compressing machine, and one way gas enters the crystallizer by a cool air fan through pressure boosting to be used as cool air, and one way is a tail gas exhaust system for other purposes. The process disclosed by the invention has characteristics of compact equipment, simple technology, less energy consumption, cost saving and so on.

Owner:郗运柱

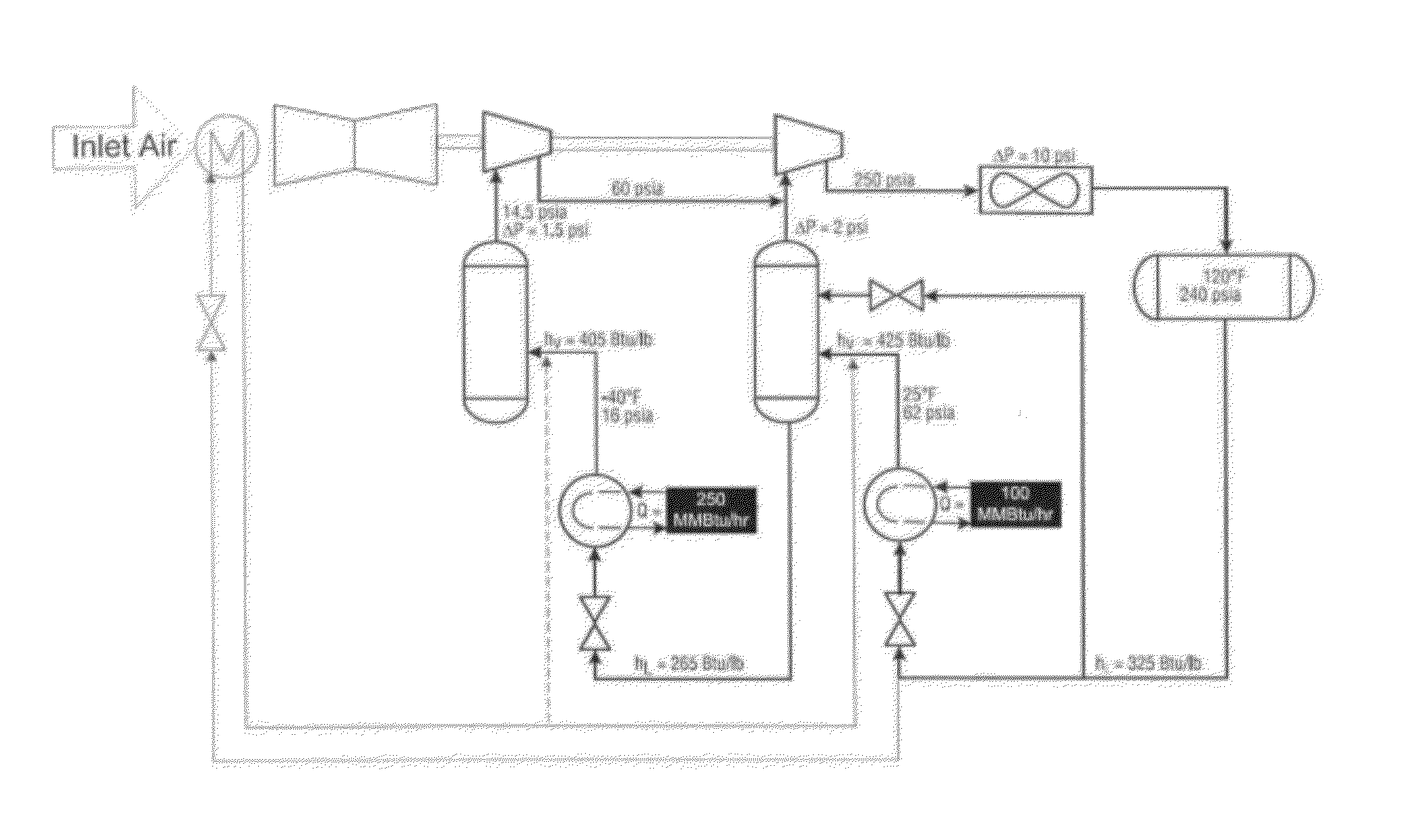

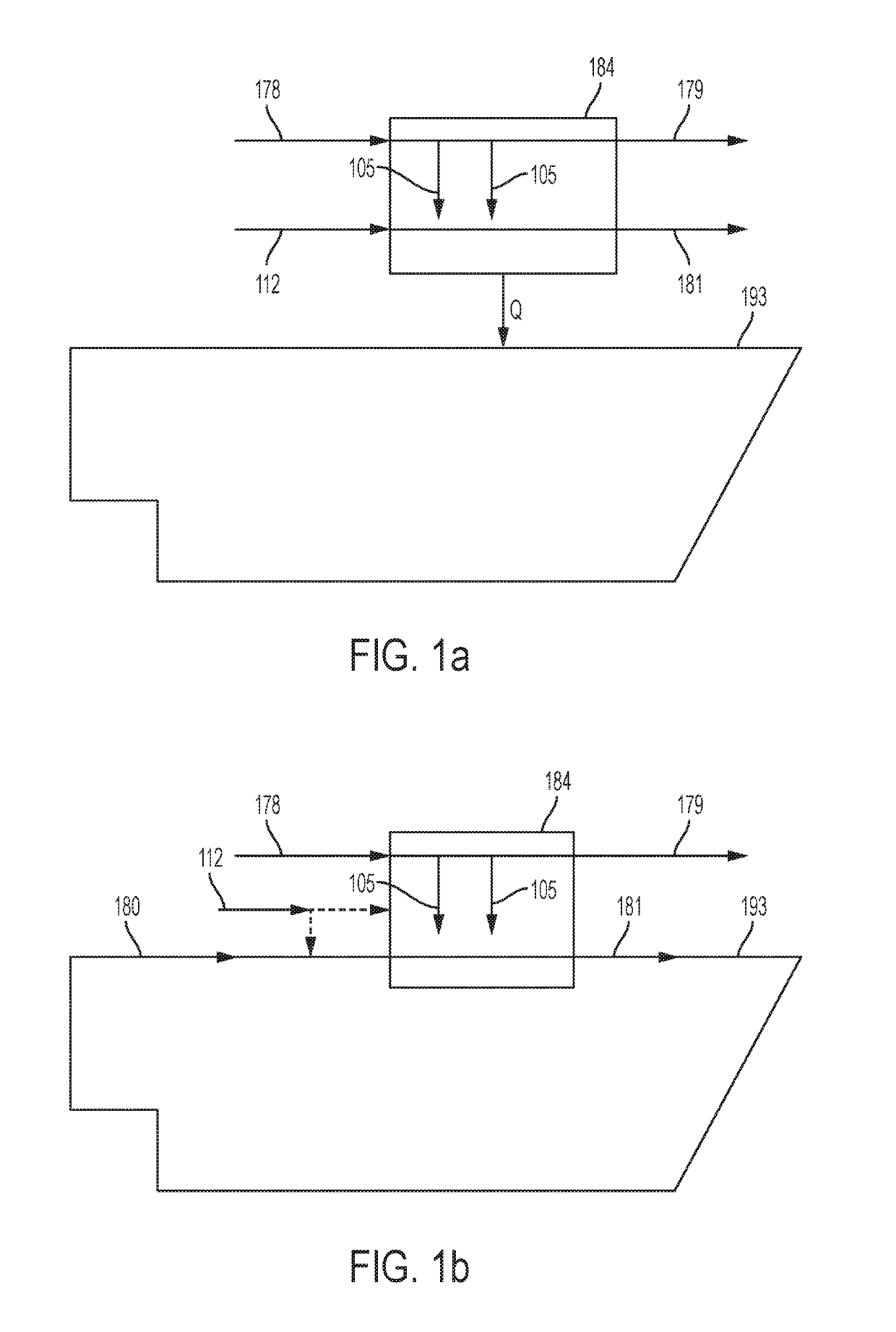

Use of refrigeration loops to chill inlet air to gas turbine

InactiveUS20120167618A1Reduce the temperatureOutput maximizationSolidificationLiquefactionPresent methodEngineering

As described herein, a method and system for operating a refrigeration system are provided. In the present methods and systems, a portion of the refrigerant from the refrigeration system is used for reducing the temperature of inlet air entering the gas turbine. The refrigeration system disclosed herein can be used for LNG production, air separation, food storage, or ice-making.

Owner:CHEVROU USA INC

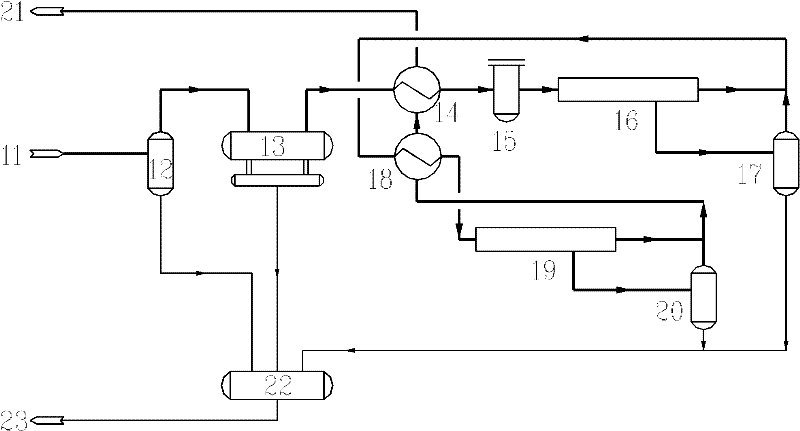

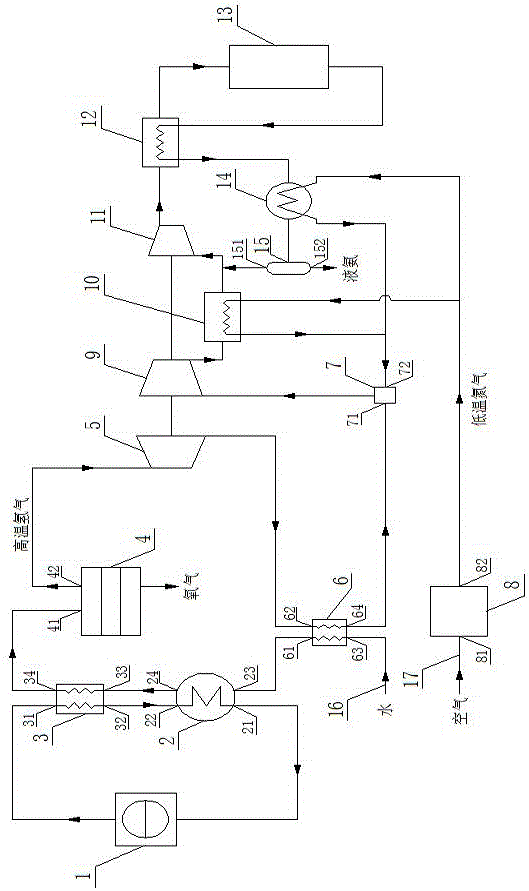

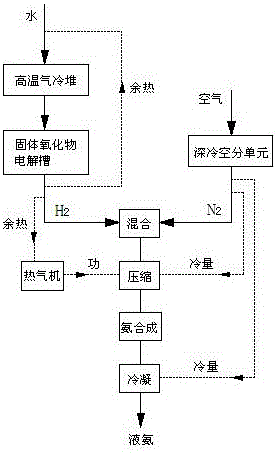

Ammonia carbon-free synthesis system by means of nuclear energy and method thereof

InactiveCN105836759AGet rid of dependenceLower fuel costsEnergy inputAmmonia preparation/separationIntercoolerSuperheater

The invention discloses an ammonia carbon-free synthesis system by means of nuclear energy and a method thereof .The system comprises a high-temperature gas cooled reactor, a steam generator, an overheater, a solid oxide electrolytic cell, a Stirling hot air engine, a heater, a mixer, a deep cooling air separation unit, a low-pressure compressor, an intercooler, a high-pressure compressor, a preheater, an ammonia synthesis tower, an ammonia condenser, an ammonia separator, a water supply pipeline and an air pipeline .The nuclear energy serves as fuel, air and water serve as raw materials, and the ammonia synthesis system which does not depend on fossil energy or generate pollutants is achieved jointly through the high-temperature gas cooled reactor in cooperation with a steam electrolysis method and a deep cooling air separation method .Waste heat of high-temperature hydrogen generated through the steam electrolysis method is used for driving the Stirling hot air engine to drive the compressors to act, low-temperature nitrogen of the deep cooling air separation unit serves as a cooling medium of the ammonia condenser and the intercooler, the advantages of comprehensively utilizing energy, saving water, simplifying the technological process and the like are achieved, and therefore high economic and environment-friendly value and good application prospects are achieved .

Owner:陈志强

Dehydrogenation process with water control

InactiveUS20090275792A1Long catalyst lifeReduced reactor inlet temperatureCatalystsHydrocarbon preparation catalystsAlkaneWater concentration

The activity of a dehydrogenation catalyst is improved by increasing the water concentration maintained in the reactants toward the start of the catalyst's life, but after the catalyst has deactivated to the extent that the temperature required to maintain the conversion per pass of paraffinic hydrocarbon through the reaction zone increases by at least 2° C.

Owner:UOP LLC

Systems and methods for power production including ion transport components

ActiveUS10260416B2Improve efficiencyHigh puritySolidificationLiquefactionIon transferProcess engineering

The present disclosure relates to systems and methods for power production utilizing an ion transfer membrane (ITM) unit. An air stream and a fuel stream can be passed through the ITM unit so that the fuel is at least partially oxidized or combusted to form an outlet stream comprising CO2. The CO2 stream can be compressed and expanded to generate power.

Owner:8 RIVERS CAPTTAL LLC

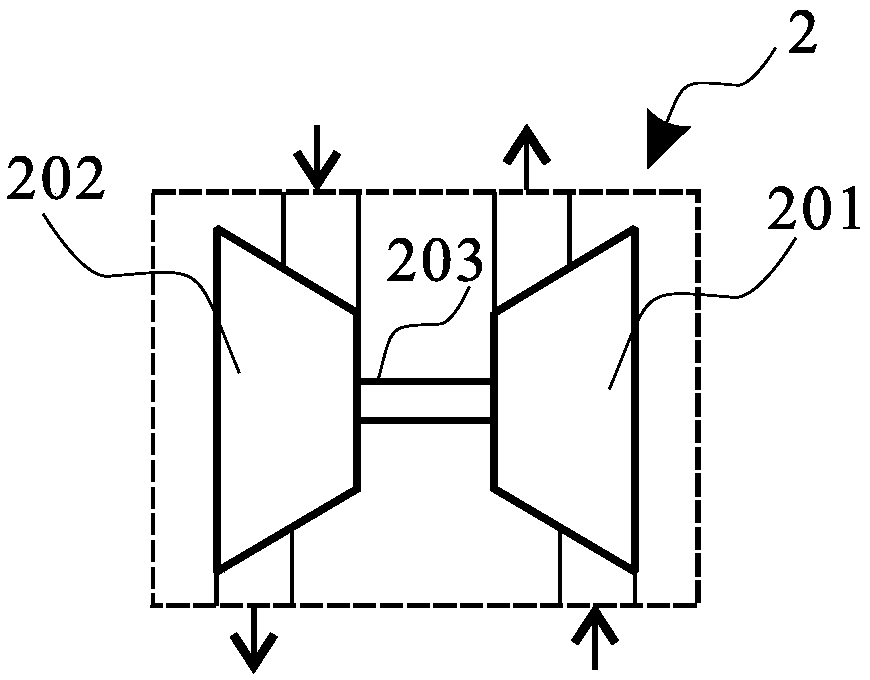

Constant-temperature and constant-humidity air treatment equipment provided with two stages of heat recovery devices

PendingCN108105931ALower inlet temperatureReduce the temperatureEnergy recovery in ventilation and heatingLighting and heating apparatusAir treatmentFresh air

The invention relates to constant-temperature and constant-humidity air treatment equipment. The constant-temperature constant-humidity air treatment equipment has the function of conventional constant-temperature and constant-humidity air treatment equipment and is provided with two stages of heat recovery devices, and the stage of heat recovery device close to a fresh air inlet is a full heat recovery air-air heat exchanger. The constant-temperature constant-humidity air treatment equipment has the advantages of excellent energy-saving performance and the flexible control means; compared with a traditional system without a heat recovery device, the full heat recovery air-air heat exchanger of the system can effectively reduce the temperature and humidity of fresh air under a summer working condition, and energy consumption required by a cold coil is greatly reduced; and compared with a system only adopting one stage of full heat recovery air-air heat exchanger, the system is providedwith the second stage of heat exchanger, namely the sensible heat recovery air-air heat exchanger, heat in exhausted air is recovered, energy consumption for reheating the coil is reduced, the freshair reduces the temperature of the exhausted air through the cold amount brought by transition cooling of the cold coil after dehumidification, and the cooling and dehumidification capacity of the fresh air at an inlet is further improved.

Owner:廊坊康平空调制造有限公司

Double-turbine boosting expansion machine propane dehydrogenation cold box separation system and technique

ActiveCN104296499ALower inlet temperatureHigh recovery rateSolidificationLiquefactionDehydrogenationProcess engineering

The invention discloses a double-turbine boosting expansion machine propane dehydrogenation cold box separation system and technique. After being connected in parallel, a low-pressure expansion machine and a high-pressure expansion machine are connected with an inlet of a high-temperature separator via a third cold-mixing feeding heat exchanger. A gas outlet of the high-temperature separator is connected with an inlet of a medium-temperature separator via a second expansion heat exchanger, a liquid outlet of a high-temperature separator, a flash tank, a liquid pump and a second feeding quencher are connected sequentially, a liquid outlet of the medium-temperature separator is connected with an inlet of the flash tank, a gas outlet of the medium-temperature separator, a first expansion heat exchanger and an inlet of the high-pressure expansion machine are connected, an outlet of the high-pressure expansion machine is connected with the first expansion heat exchanger to be divided into two ways, one way is connected with a first feeding quencher via the first cold mixing feeding heat exchanger while the other way is connected with the inlet of the low-pressure expansion machine, and the outlet of the low-pressure expansion machine, the first expansion heat exchanger and the second cold-fixing feeding heat exchanger are connected. The system is reliable in equipment, high in safety, low in cost and high in recovery rate of reactor effluent.

Owner:HANGZHOU ZHONGTAI CRYOGENIC TECHNOLOGY CORPORATION

Graft copolymer latex and method for preparing dried powder thereof

Owner:LG CHEM LTD

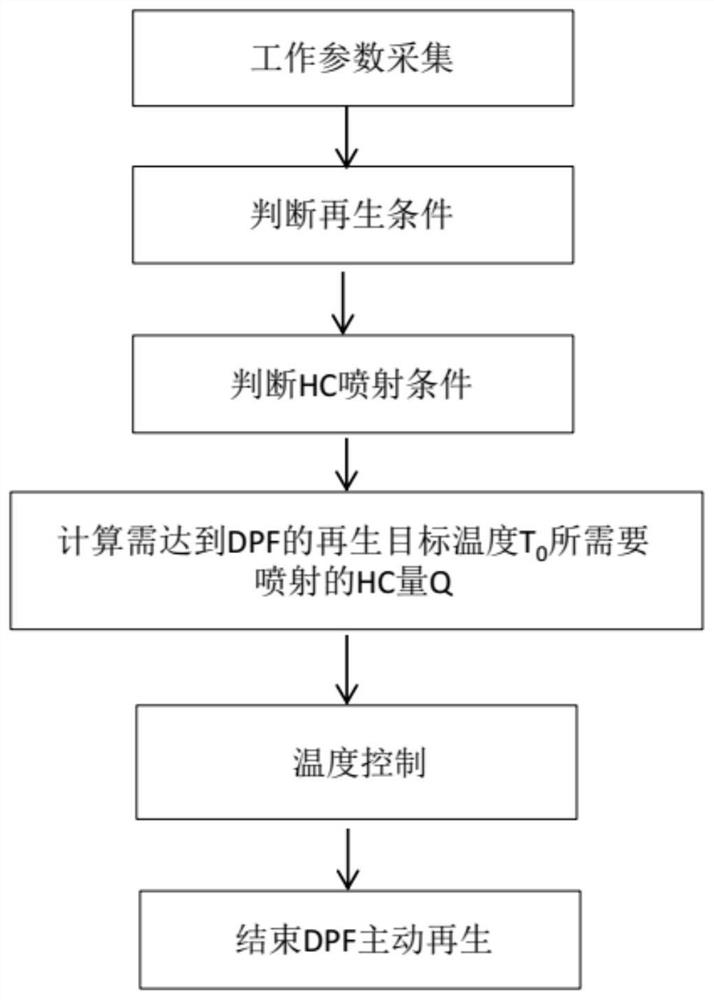

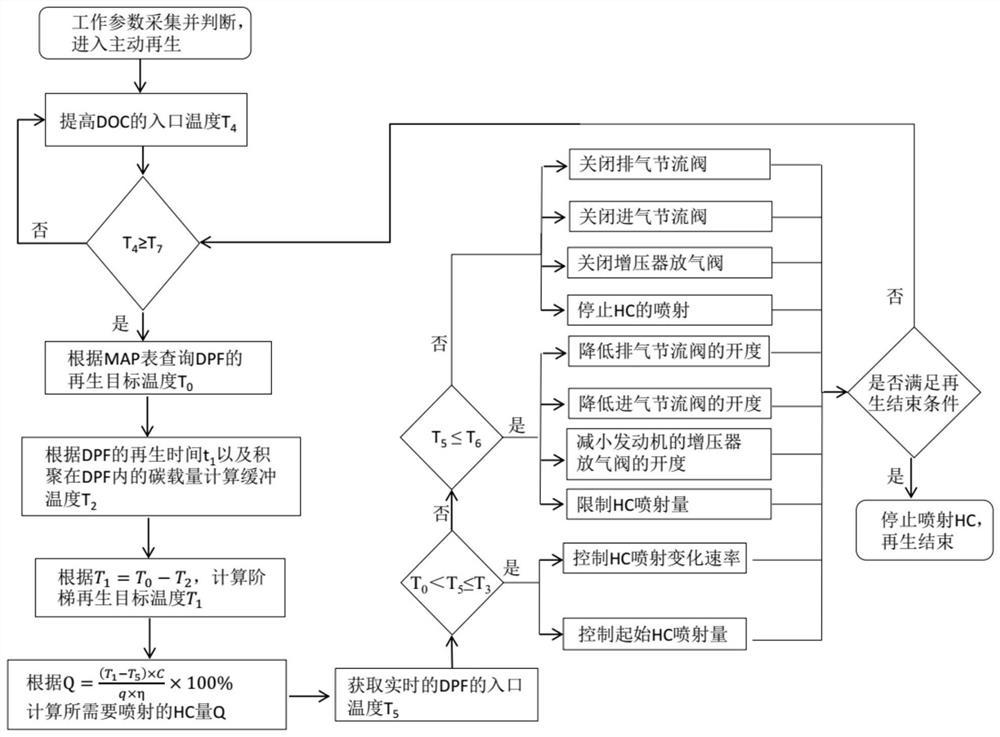

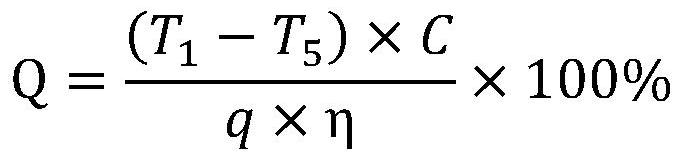

DPF active regeneration safety control method

ActiveCN112963226ARaise the inlet temperatureCarbon load guaranteeInternal combustion piston enginesExhaust apparatusTemperature controlBiochemical engineering

The invention discloses a DPF active regeneration safety control method, and belongs to the technical field of regeneration safety. The DPF active regeneration safety control method comprises the following steps that S10, regeneration conditions are judged; S20, the HC injection condition is judged; S30, the amount of HC needing to be injected to reach T0 is calculated, T1=T0-T2, T2 is the buffer temperature, and T2 is gradually reduced to 0 along with reduction of the carbon loading amount and increase of the regeneration time t1; and S40, temperature control is conducted. In the step S10, when one of operation condition parameters of an engine reaches a regeneration threshold value corresponding to the parameter, a DPF enters active regeneration; in the step S20, when T4 is greater than or equal to T7, the HC injection condition is met; and in the step S40, when T5 is greater than T0 and less than or equal to T3, the initial HC injection amount is reduced, the change rate of HC injection is reduced, when T5 is greater than T3 and less than or equal to T6, the injection amount of HC is reduced, and the amount of tail gas exhausted into the DPF by the engine is increased, and when T6 is less than T5, HC injection is stopped, and the amount of the tail gas exhausted into the DPF by the engine is increased. The DPF active regeneration safety control method has the following beneficial effect that the safety of active regeneration of the DPF can be high.

Owner:FAW JIEFANG AUTOMOTIVE CO

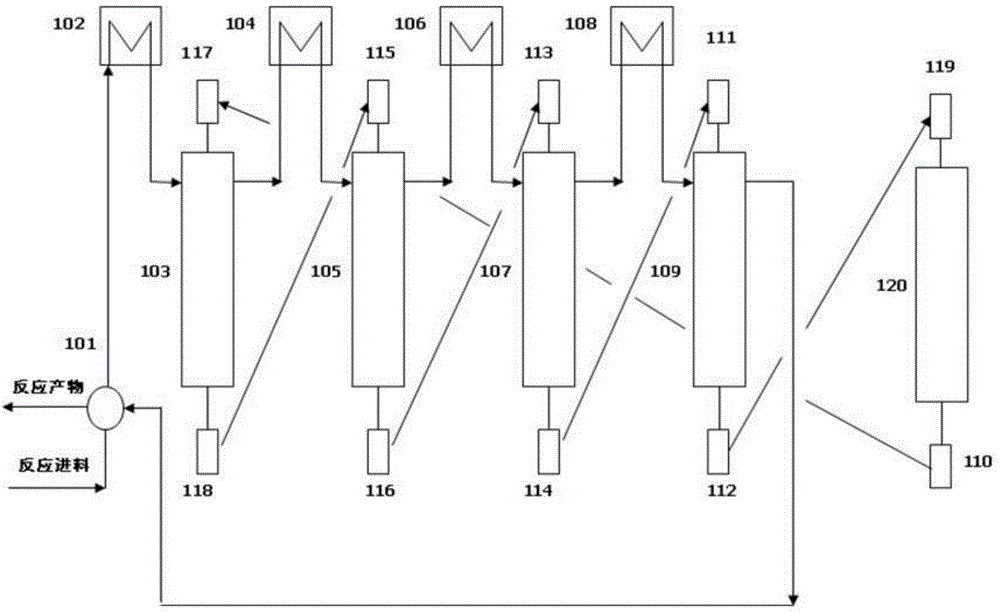

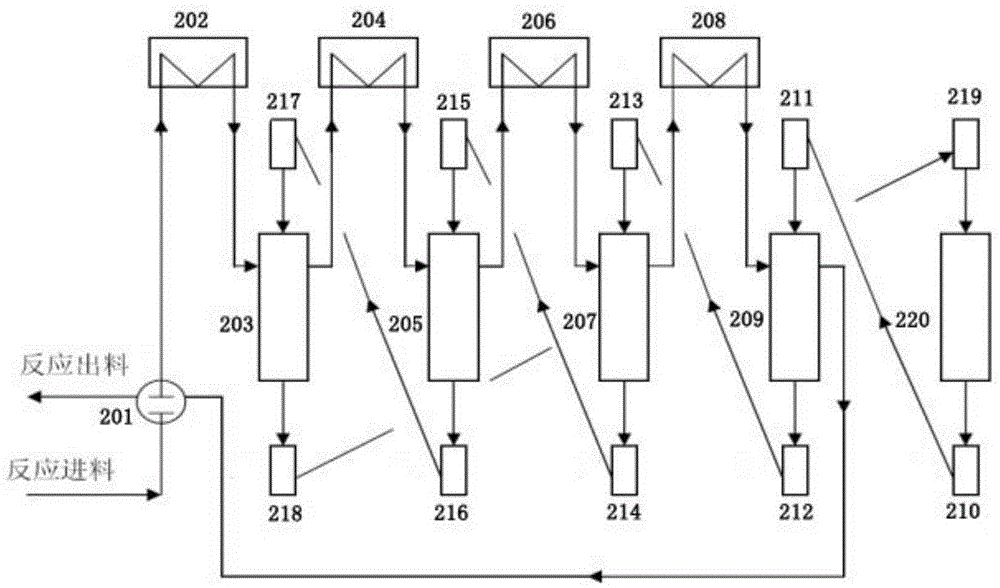

Continuous reforming technology of hydrocarbons

ActiveCN105349180AFully activeReduce carbon depositionNaphtha treatmentProcess engineeringHigh activity

The invention discloses a continuous reforming technology of hydrocarbons. According to the technology, at least two reforming reactors and at least one catalyst regenerator are arranged. The technology is characterized in that conveying of reaction feedstock to each reforming reactor is carried out in series, and circulation conveying of a catalyst between the reactors and the regenerator is carried out in parallel. According to the invention, all the reactors can use fresh high-activity catalysts and independently adjust and change catalyst flow according to needs, catalyst activity can be fully performed, utilization rate of catalysts can be raised, and reforming conversion rate and product yield can be enhanced.

Owner:SINOPEC ENG +1

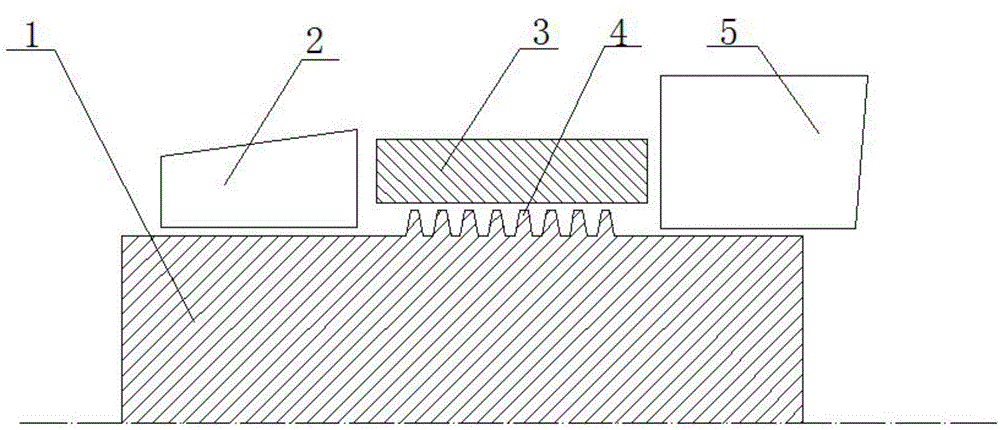

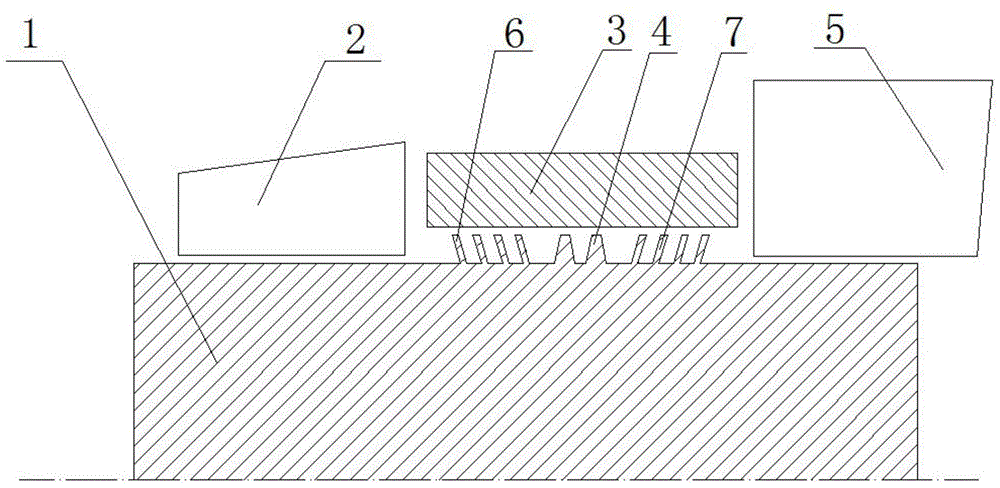

Spiral multi-section combined type sealing labyrinth

InactiveCN104929700AImprove performanceIncrease stability marginLeakage preventionMachines/enginesCombustionEngineering

The invention belongs to rotary sealing devices, and particularly relates to a device which can prevent labyrinth seal structure media from being leaked. The device is particularly applied to the fields of aero-engines, combustion gas turbines and steam turbines. The invention provides a spiral multi-section combined type sealing labyrinth which can improve the sealing effect at all the rotating speed stages and lower the requirement for the air entraining content of a compressor outlet. The spiral multi-section combined type sealing labyrinth comprises a rotating shaft with common labyrinth bodies and a static ring face. The left side and the right side of the common labyrinth bodies are provided with left section spiral labyrinth bodies and right section spiral labyrinth bodies respectively. The rotating direction of the left section spiral labyrinth bodies is opposite to the rotating direction of the right section spiral labyrinth bodies. The static ring face abuts against the common labyrinth bodies, the left section spiral labyrinth bodies and the right section spiral labyrinth bodies to form a sealing face. The spiral multi-section combined type sealing labyrinth has the beneficial effects that a traditional sealing labyrinth is optimized to be the spiral multi-section combined type sealing labyrinth, so that the sealing effect is improved at all the rotating speed stages, and meanwhile the requirement for the air entraining content of the compressor outlet is lowered.

Owner:赵军

Battery module having improved cooling efficiency

ActiveUS8617735B2Simple structureEasy temperature controlPrimary cell to battery groupingCell temperature controlTemperature controlEngineering

A battery module includes one or more cell assemblies with a plurality of unit cells, and a housing for mounting the cell assemblies therein and circulating a temperature control cooling medium through the cell assemblies. The cell assemblies are arranged in the longitudinal direction of the housing. A guidance unit is installed in a cooling medium passage formed in the longitudinal direction of the housing, and proceeds along the passage to guide cooling medium flow along the passage toward the cell assemblies.

Owner:SAMSUNG SDI CO LTD

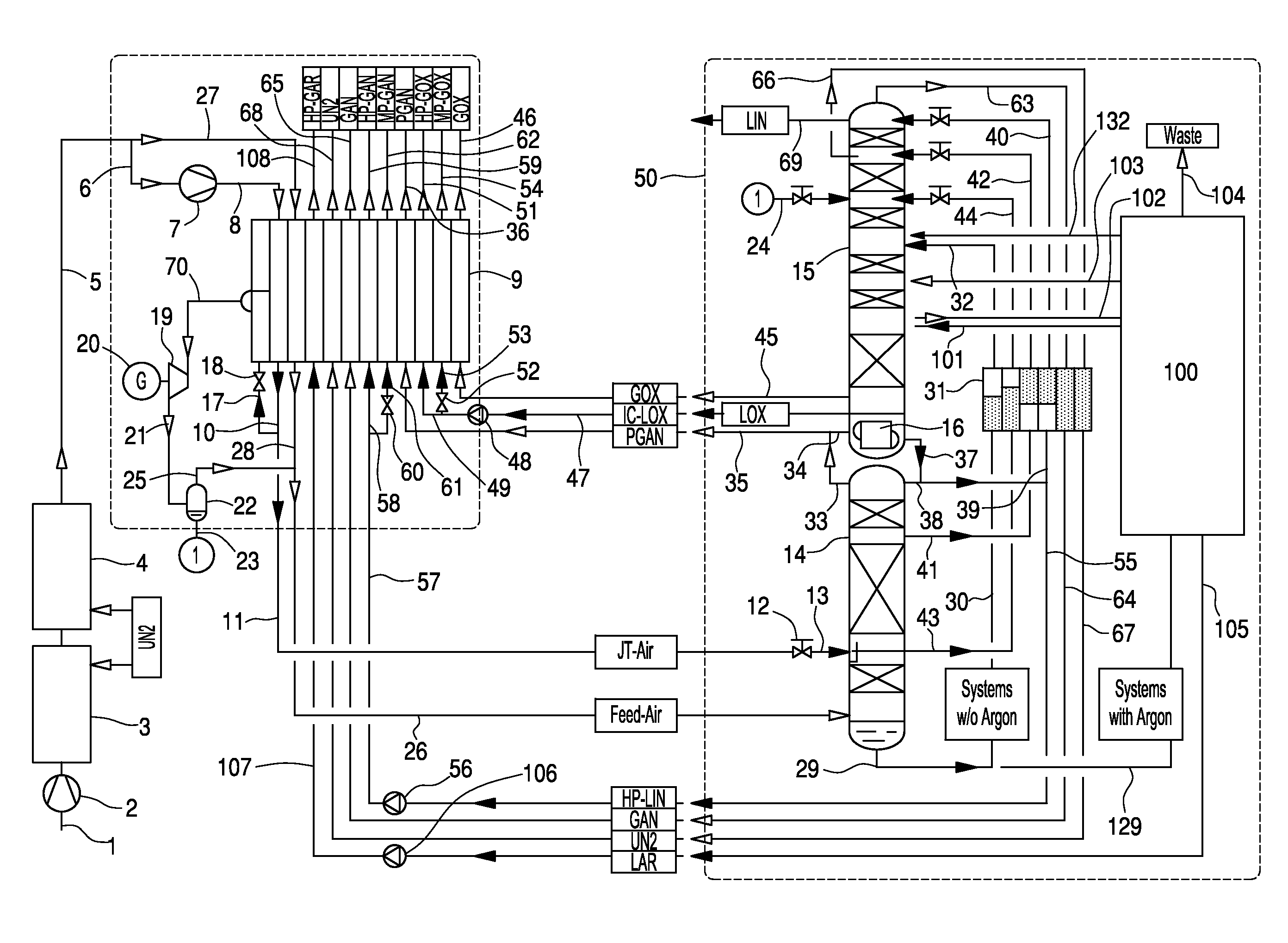

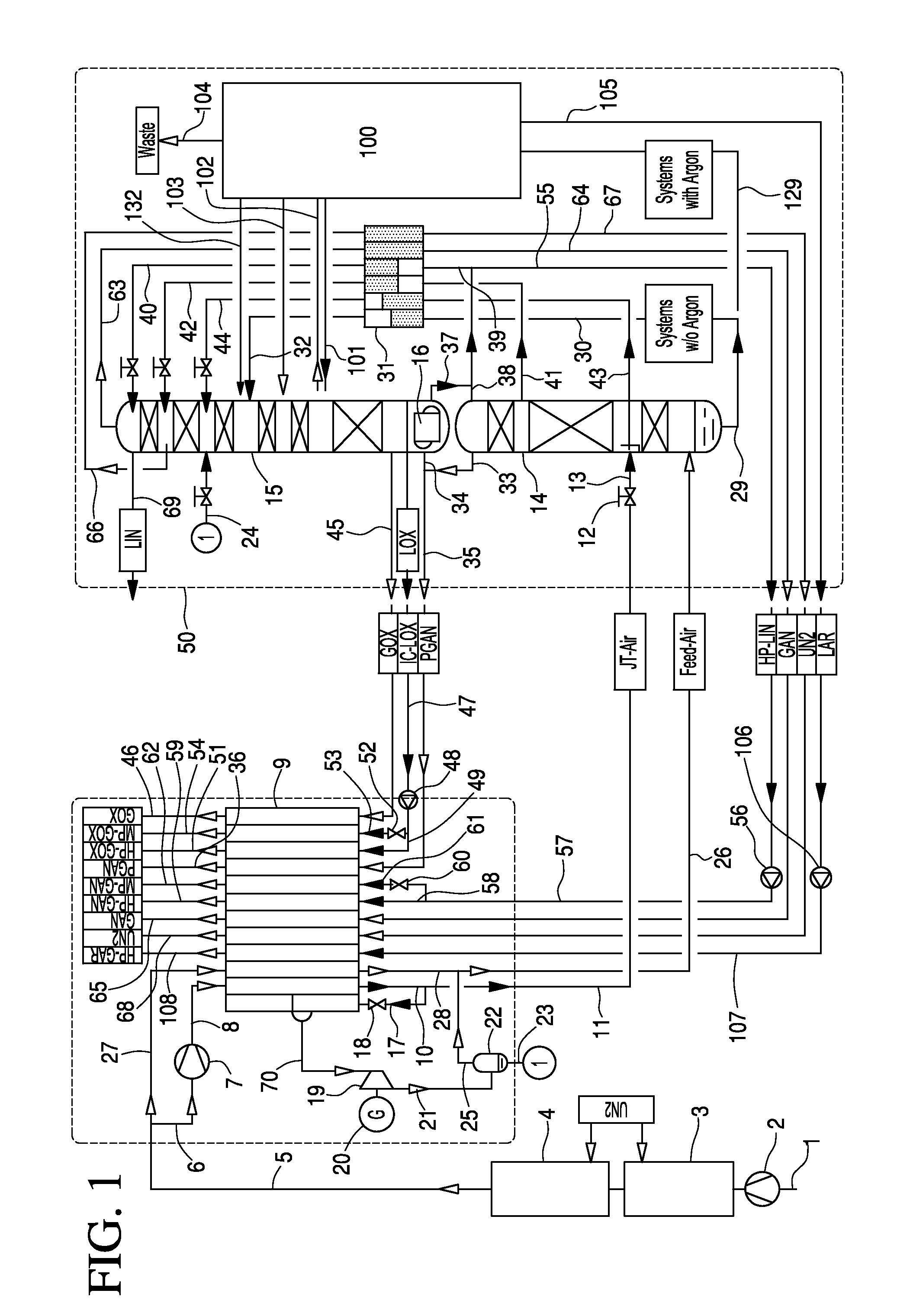

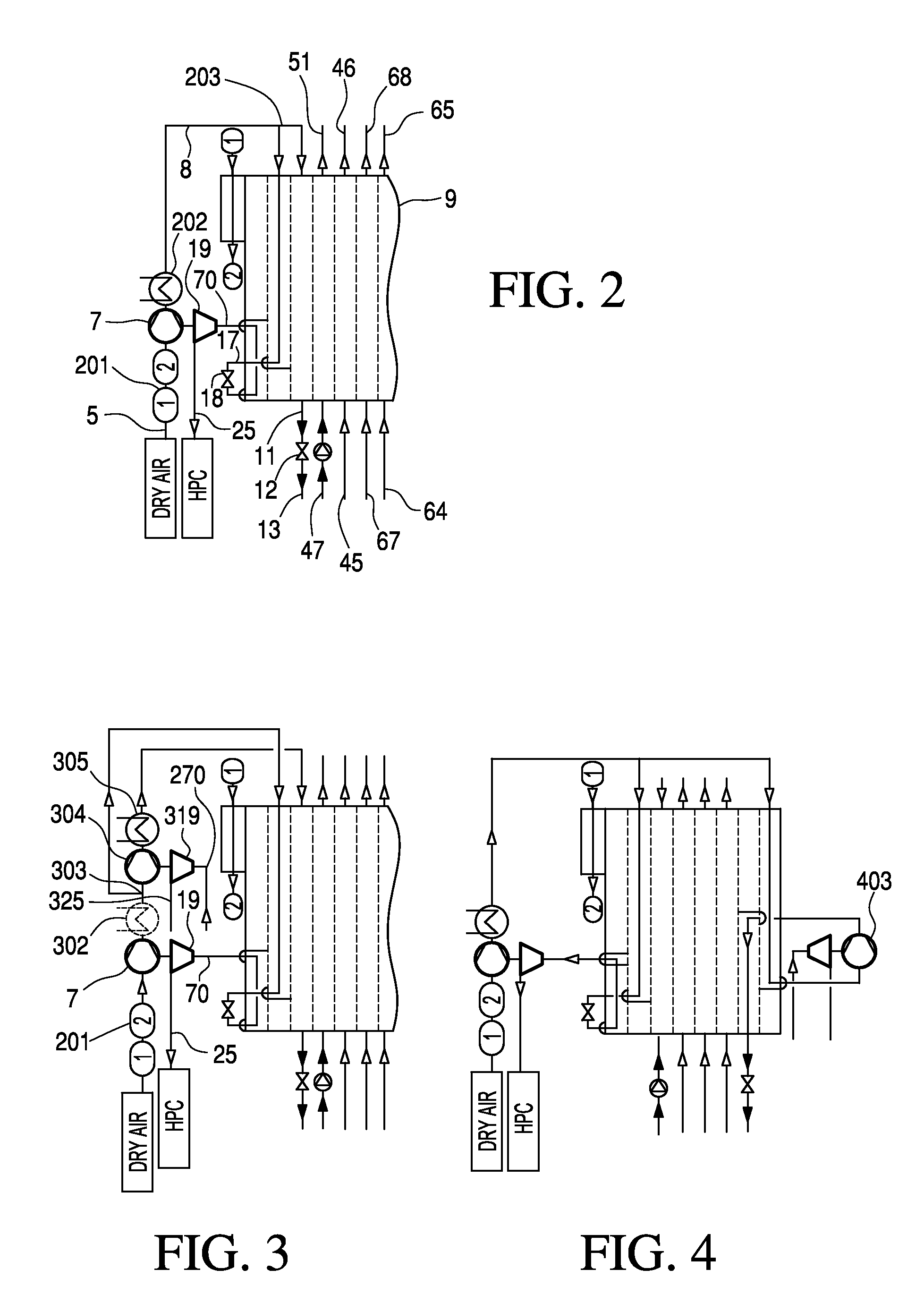

Processes and Device for Low Temperature Separation of Air

InactiveUS20110067444A1Low equipment costImprove efficiencySolidificationLiquefactionFractionating columnEngineering

The process and device serve for the low-temperature separation of air in a distillation-column system includes at least one separation column. A main air stream is compressed in an air compressor at a first pressure and is then purified. A first air stream, which is formed from at least one part of the purified main air stream, is further compressed at a second pressure that is higher than the first pressure. From the further compressed first air stream, a throttling stream and a turbine stream are branched off. The throttling stream is cooled down and liquefied or pseudo-liquefied in a main heat exchanger and is then passed on to expansion equipment. The expanded throttling stream is conducted into the distillation-column system. The turbine stream is cooled down in the main heat exchanger and under an intermediate temperature of the main heat exchanger is conducted into an expansion machine.

Owner:LINDE AG

Preparation method of hot water by using open type heat pump via air circulation

ActiveCN108954821ALower inlet temperatureImprove operating conditionsFluid heatersHeat pumpsIntermediate heat exchangerEngineering

The invention discloses a preparation method of hot water by using an open type heat pump via air circulation. According to the preparation method, after air is subjected to primary preheating by a reheater, a first air compressor, the air is subjected to two-stage compression by a first air compressor, a second air compressor and a turbine air compressing component for preparation of high-temperature air, circulating water is heated by two times of heat exchange by an intermediate heat exchanger and an air / water heat exchanger, and water above 60 DEG C for building heating and domestic hot water can be prepared in cold and severe cold areas.

Owner:DALIAN NATIONALITIES UNIVERSITY

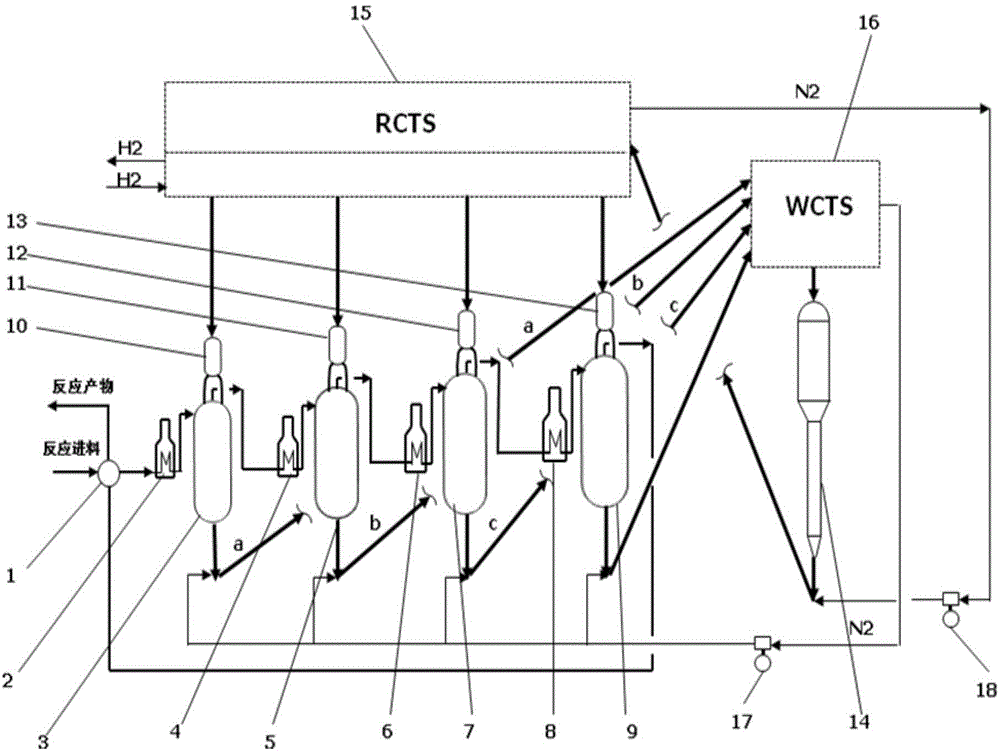

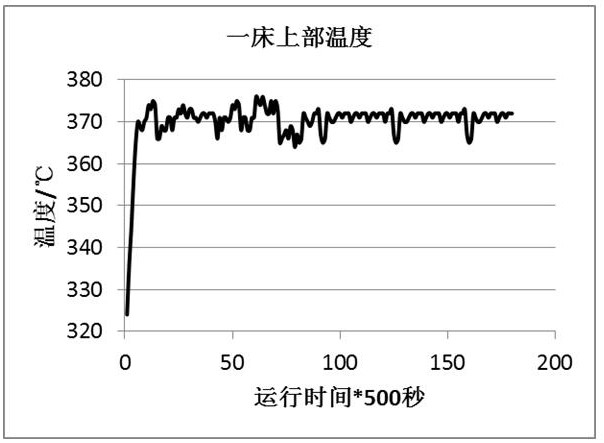

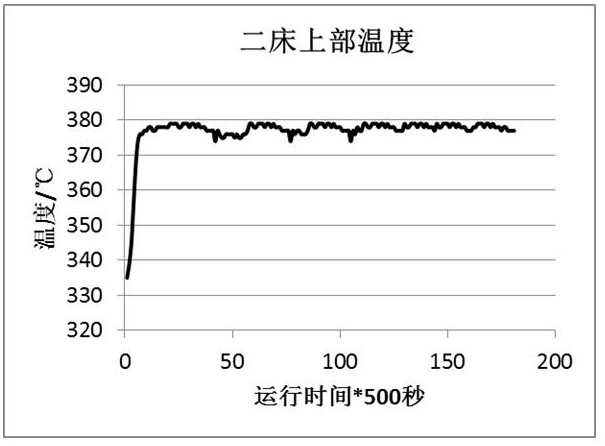

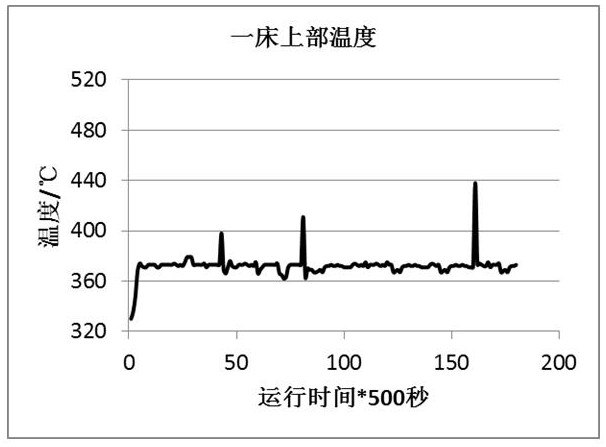

Up-flow residual oil hydrogenation reaction system and residual oil hydrotreatment method

ActiveCN112063414AImprove conversion abilityImprove catalytic performanceHydrocarbon oils treatmentRefining to eliminate hetero atomsPtru catalystFluid phase

The invention discloses an up-flow residual oil hydrogenation reaction system and a residual oil hydrotreatment method. The system comprises at least one up-flow hydrogenation reactor, wherein at least two catalyst bed layers are arranged in each up-flow hydrogenation reactor, and the activity of a hydrotreating catalyst is reduced from high to low along the direction of a liquid-phase reactant flow. The invention also discloses a residual oil hydrotreatment method, which is characterized in that residual oil feed and hydrogen pass through the up-flow residual oil hydrogenation reactor systemdisclosed by the invention to obtain a hydrotreatment product. According to the invention, the method overcomes the defects that the temperature of the catalyst bed layer in the existing up-flow reactor is unstable and is not easy to control, has good hydrogenation performance and capacity of removing metal, and has certain desulfurization and carbon residue and asphaltene conversion capacity, sothat the up-flow process has the advantages of high hydrogenation activity and long service cycle.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for removing acidic gas from natural gas

ActiveCN104359286AReduce power consumptionLower inlet temperatureSolidificationLiquefactionWater useWater resources

The invention relates to a method for efficiently utilizing a water absorption method to remove acidic gas from natural gas. A device comprises a raw natural gas feeding pipe, an expansion machine, a brake fan, a compressor set, a separating tank, an absorbing tower, an air stripping tower, a flash tank, a water pump and a dryer, wherein a feeding pipe of the expansion machine is connected with a gas discharging pipe of the flash tank; a discharging pipe of the expansion machine is connected with a feeding pipe of the separating tank behind the expansion machine; a discharging pipe of the brake fan of the expansion machine is connected with a gas-loading port of the air stripping tower; a feeding pipe of the brake fan of the expansion machine is connected with atmosphere. The invention provides the method for utilizing the water absorption method to efficiently remove the high-content acidic gas from the natural gas; the method has the advantages of convenience in material taking, recycling, water-saving property, environmental protection and zero three-waste discharge; the method is simple in flow structure, low in energy consumption and low in cost.

Owner:LIAONING CIMC HASHENLENG GAS LIQUEFACTION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com