Continuous reforming technology of hydrocarbons

A process and technology of hydrocarbons, applied in the field of continuous reforming process of hydrocarbons, can solve the problems of continuous reforming process and achieve the effect of improving reforming conversion rate and product yield, improving utilization rate and improving benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

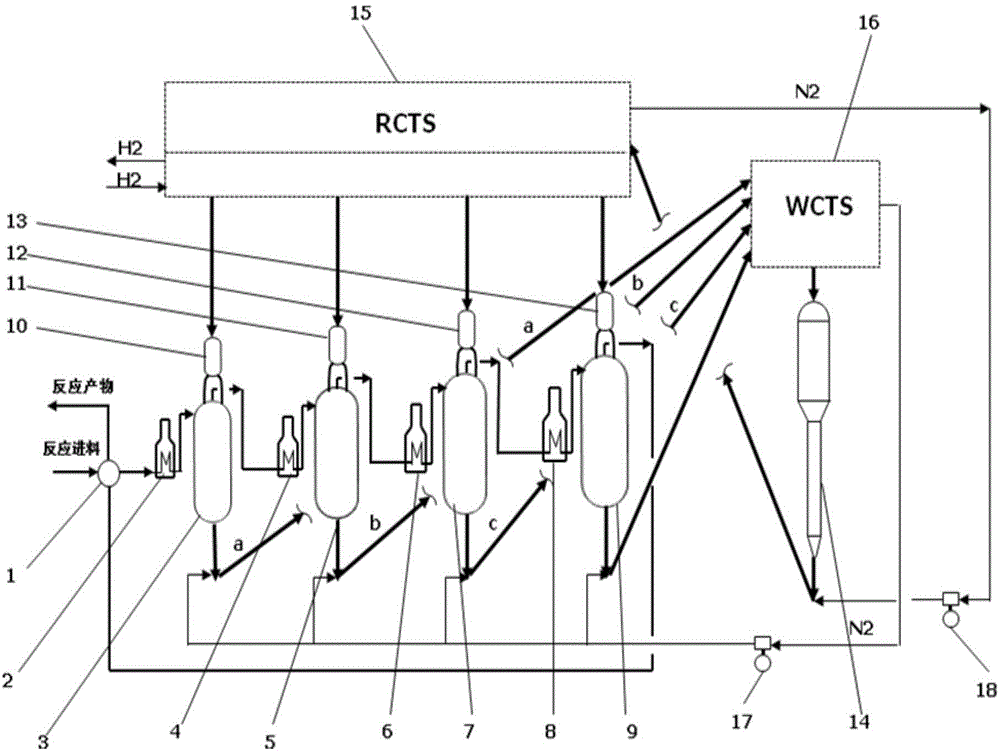

[0070] This embodiment combines the attached image 3 A specific implementation manner provided by the present invention will be described. Since what is carried out is a long-term industrial experiment, the various process operating conditions described therein allow about ±10% fluctuation.

[0071] Such as image 3 As shown, the reaction feed passes through the first reaction heating furnace 2, the first reforming reactor 3, the second reaction heating furnace 4, and the second reforming furnace successively after exchanging heat with the reaction product in the reaction feed / product heat exchanger 1. The whole reactor 5, the third reaction heating furnace 6, the third reforming reactor 7, the fourth reaction heating furnace 8 and the fourth reforming reactor 9, the reaction product leaves the reactor 9 in the reaction feed / product heat exchanger 1 to exchange heat with the reaction feed and then to the subsequent separation device for separation. The reaction material pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com