Patents

Literature

749results about How to "Reduce stickiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS20070284255A1Stable cutting edgeReduce torsion fatiguePigmenting treatmentSurgeryWear resistantShape-memory alloy

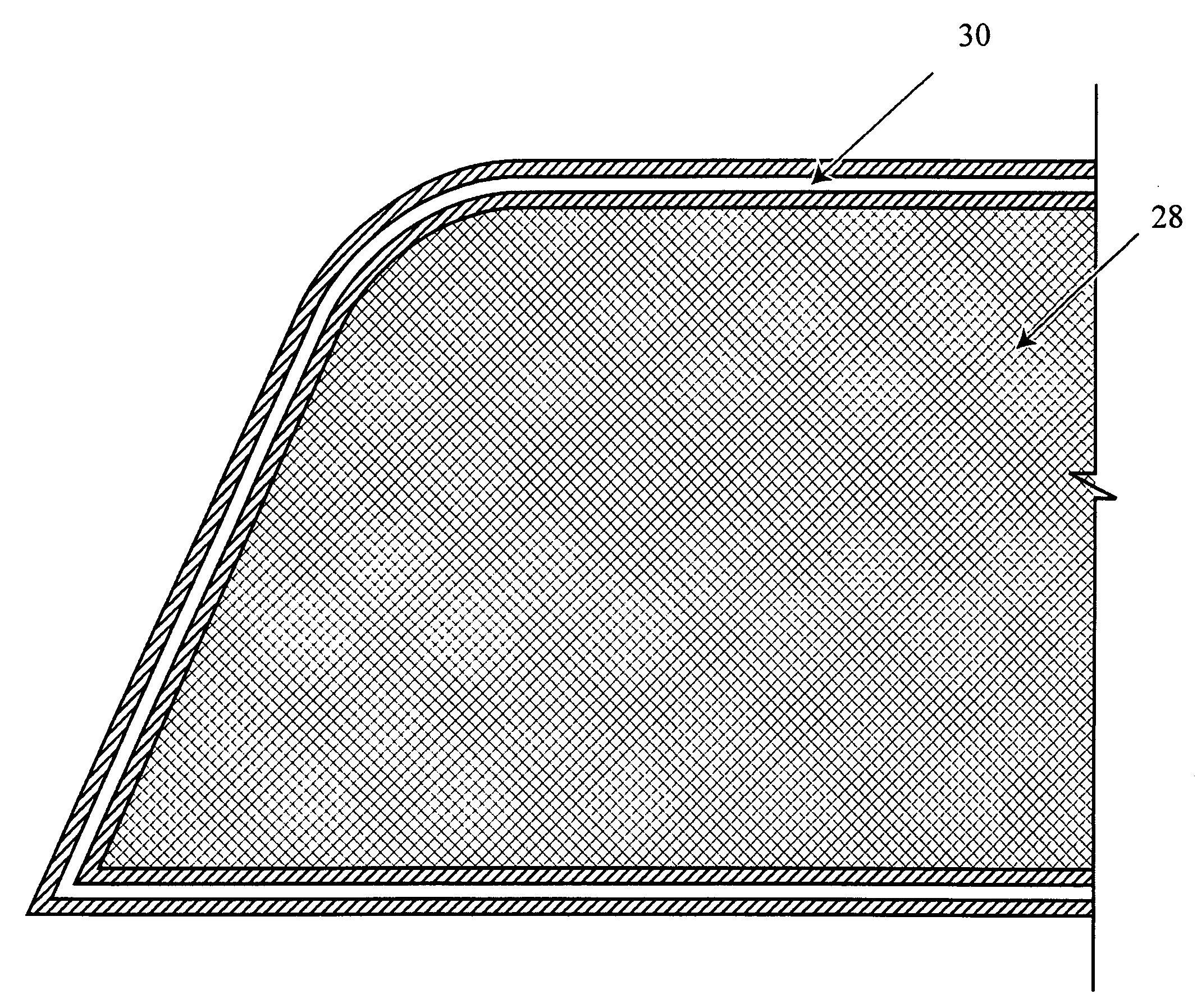

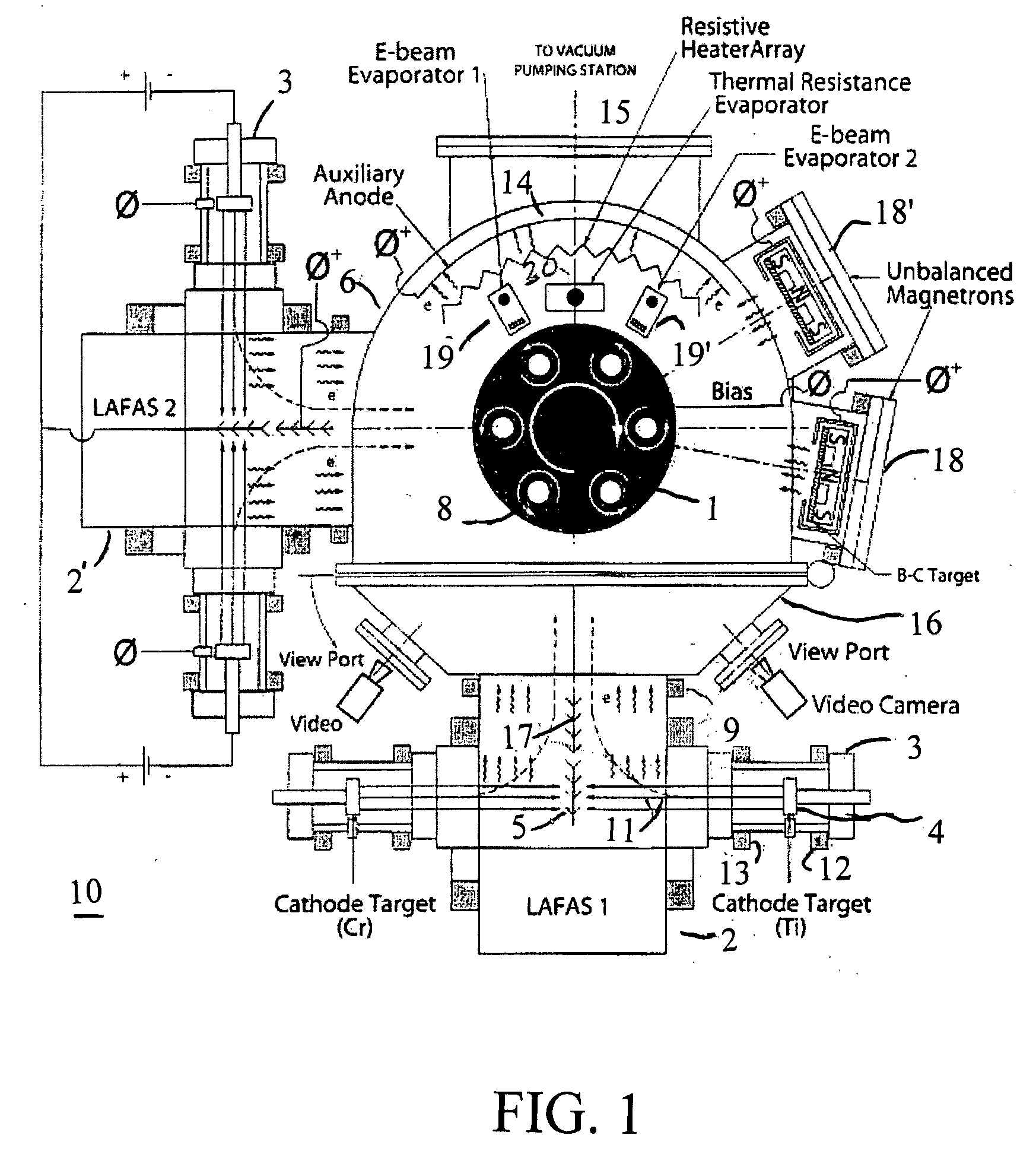

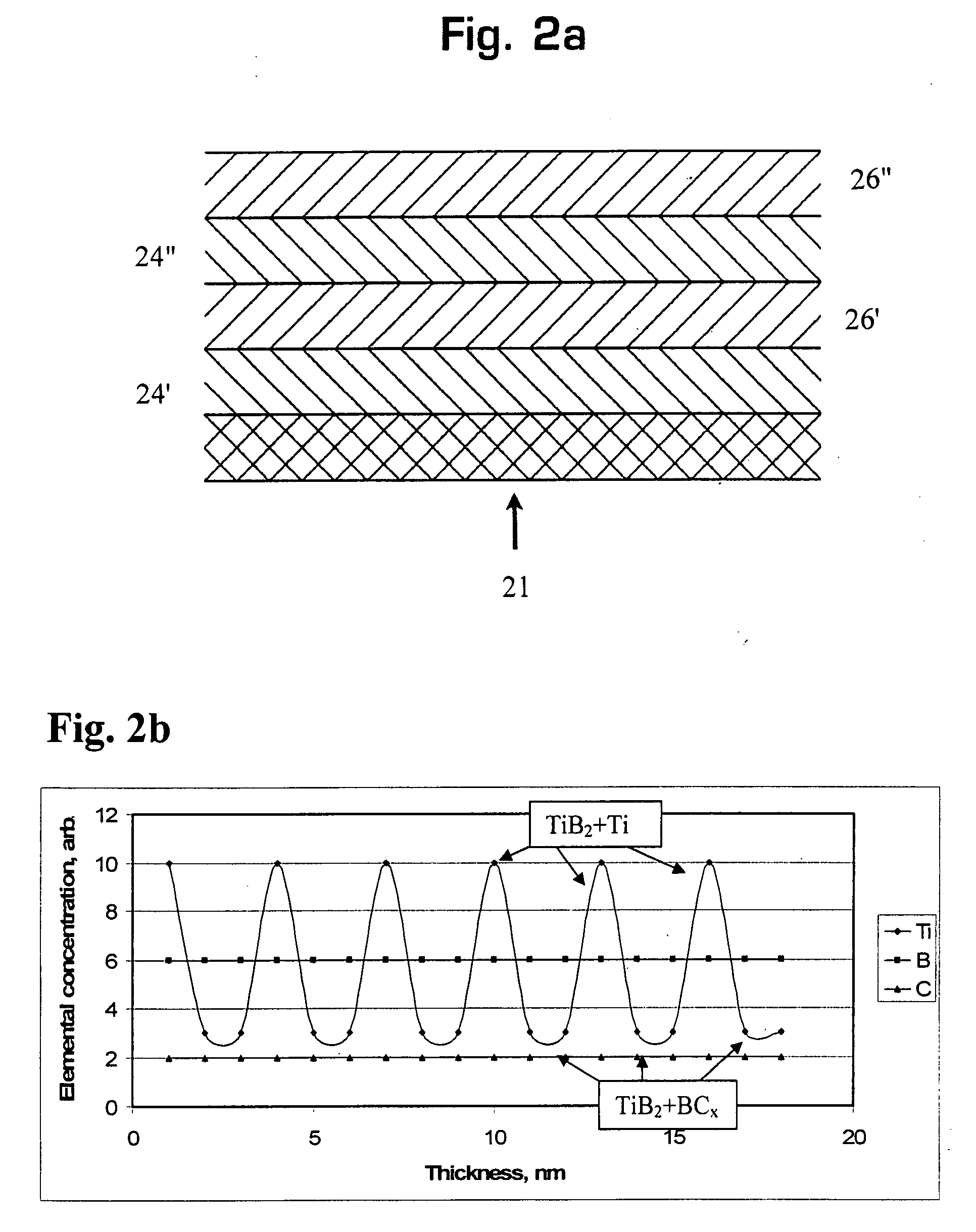

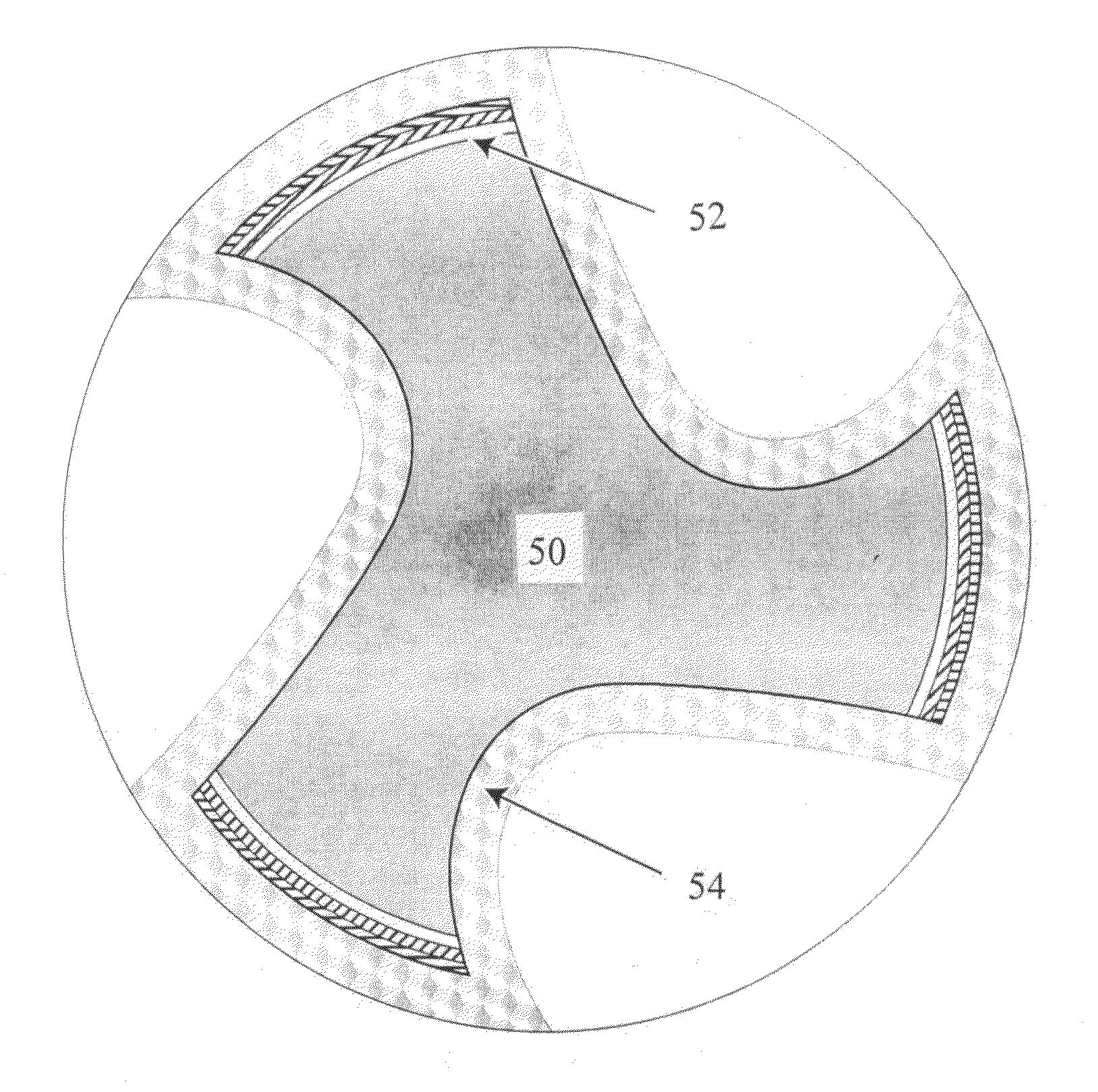

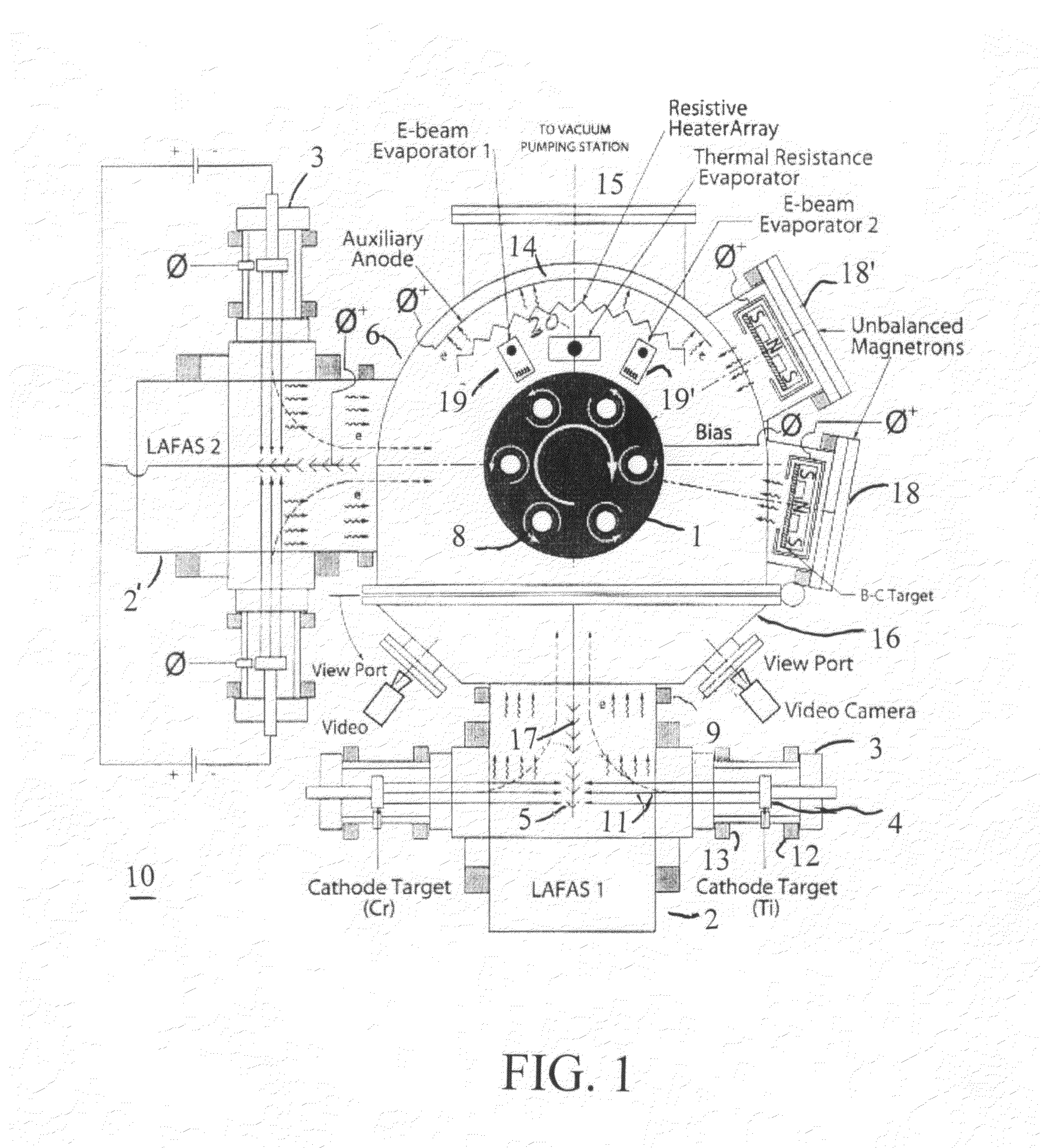

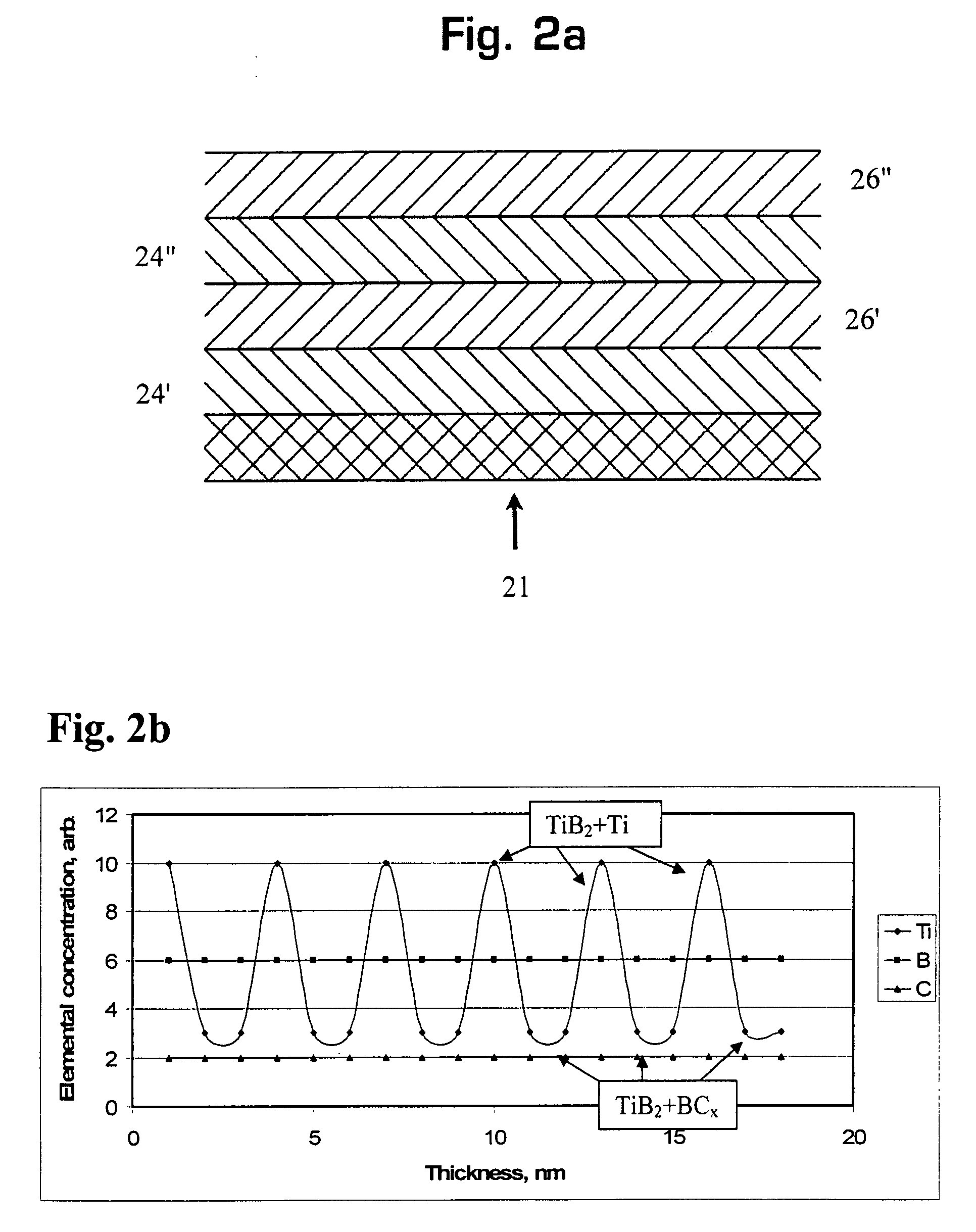

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

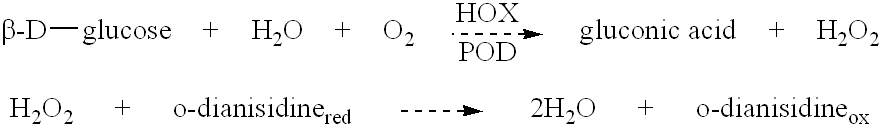

Method of improving the properties of a flour dough, a flour dough improving composition and improved food products

InactiveUS6358543B1Reduce disadvantagesReduce stickinessDough treatmentHydrolasesIridophycus flaccidumEuthora cristata

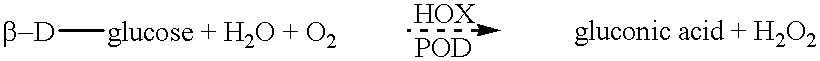

A method of improving the rheological properties of a flour dough and the quality of the finished product made from such a dough, including adding an effective amount of an oxido-reductase capable of oxidizing maltose, in particular a hexose oxidase, e.g. isolated from an algal species such as Iridophycus flaccidum, Chondrus crispus or Euthora cristata and a dough improving composition containing the oxidore-ductase.

Owner:DUPONT NUTRITION BIOSCIENCES APS

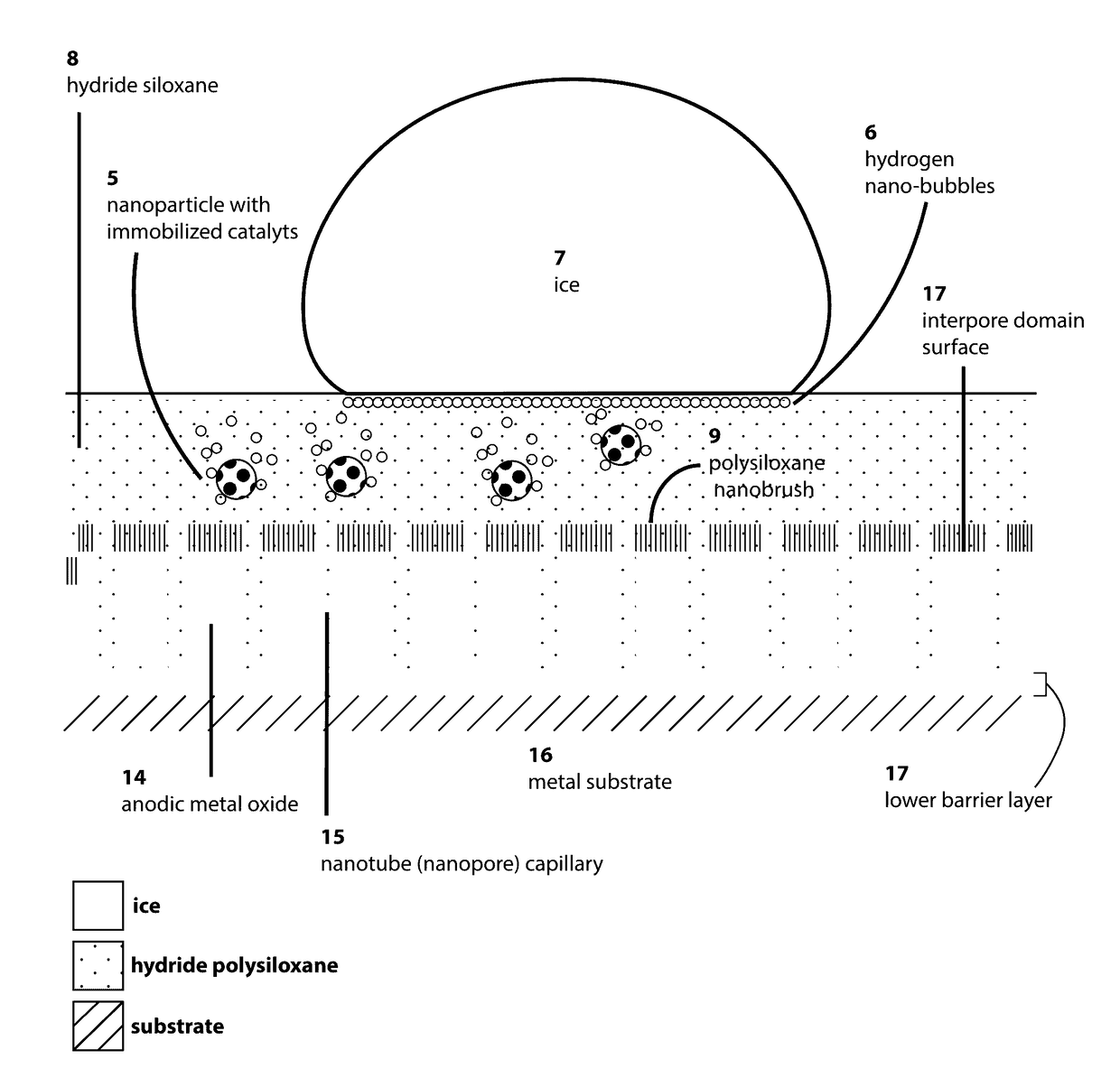

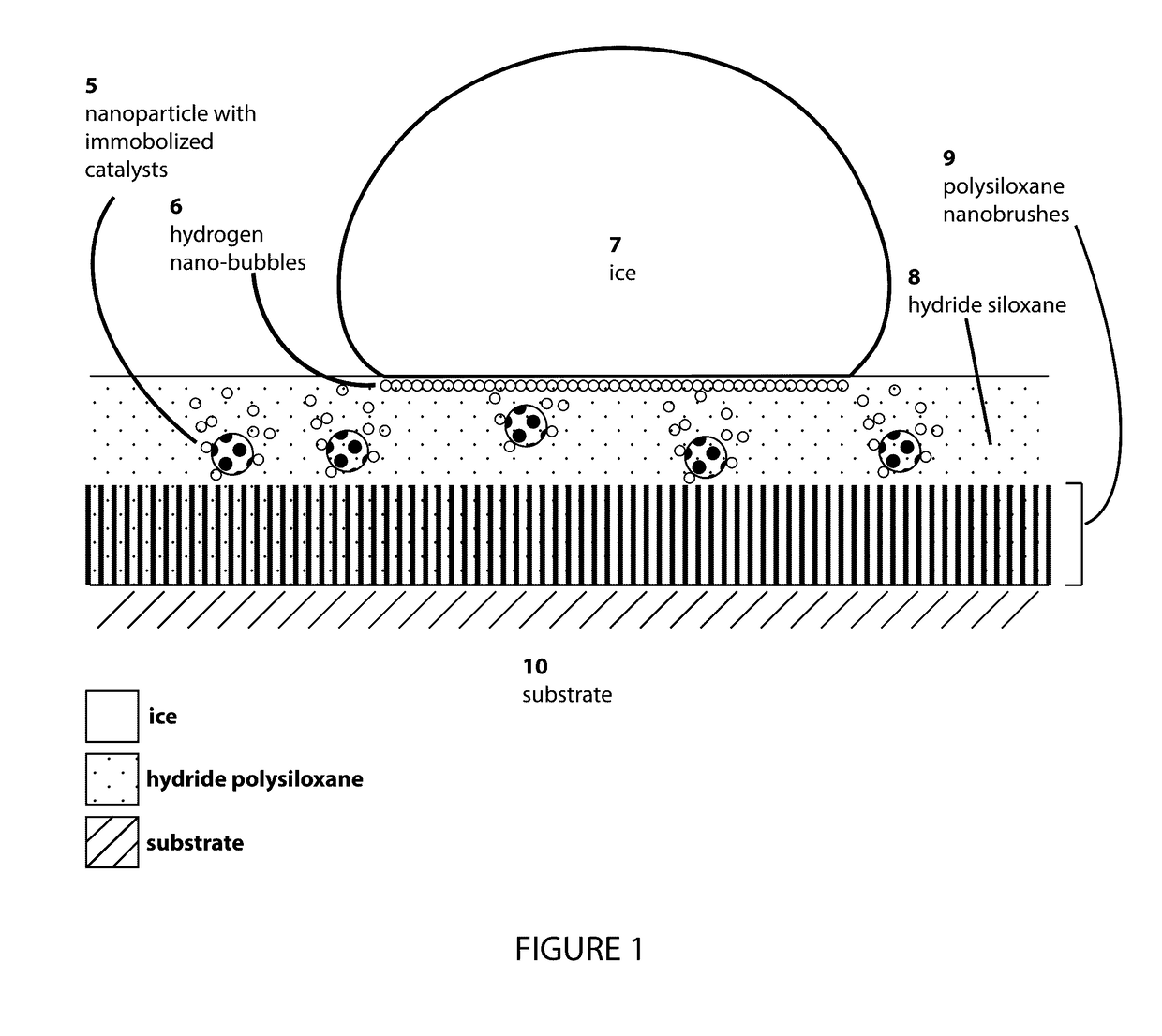

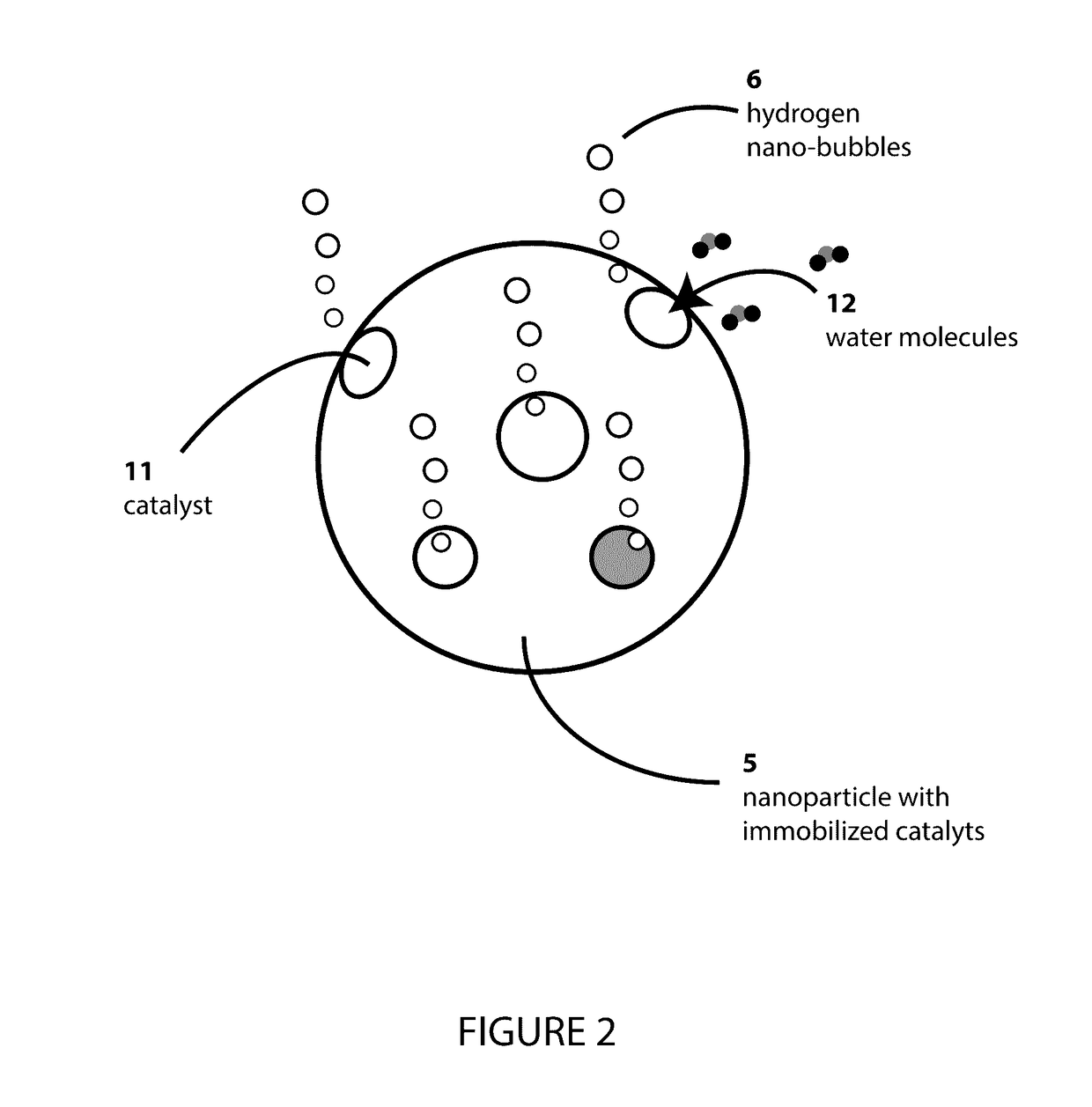

Anti-icing composition driven by catalytic hydrogen generation under subzero temperatures

InactiveUS20170107413A1Reduce hysteresisLower surface energyOther chemical processesCoatingsHydrogenOptical transparency

The present invention relates to a self-renewing, anti-icing composition driven by a dehydrogenative reaction of a reactive hydrogen-rich compound catalyzed by nanoparticle immobilized catalysts, which is active under subzero temperatures. The disclosed coating displays a variety of properties including, but not limited to hydrophobicity, anti-wetting, and resistance to ice formation and ice adhesion. The novel anti-icing coating can be used on glass surfaces requiring optical clarity and transparency and can also be applied to a variety of smooth, roughened, or porous surfaces.

Owner:WANG LIANG +1

Cosmetic or dermatologic compositions containing microspheres

InactiveUS20070224140A1Good lookingImproved performance characteristicsCosmetic preparationsHair cosmeticsMicrosphereMedicine

The invention relates to cosmetic or dermatologic compositions comprising a microsphere and a film forming component.

Owner:LOREAL SA

Method of improving the properties of a flour dough, a flour dough improving composition and improved food products

InactiveUS6936289B2Reduce certain disadvantageous effectsReduce stickinessDough treatmentHydrolasesFood productsRheology

Owner:DUPONT NUTRITION BIOSCIENCES APS

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

Pressure cast rare earth aluminum alloy with high thermal conductivity and high electrical conductivity and preparing method thereof

The invention discloses pressure cast rare earth aluminum alloy with high thermal conductivity and high electrical conductivity and a preparing method thereof. The aluminum alloy comprises 0.5-2.0 wt% of Si, 0.001-0.05 wt% of Cu, 0.2-0.6 wt% of Fe, 0.001-0.50 wt% of Mn, 0.8-3.0 wt% of Mg, 0.07-0.15 wt% of Zn, 0.001-0.05 wt% of B, 0.05-0.20 wt% of La, 0.05-0.2 wt% of Y, 0.05-0.2 wt% of Ce, and the balance Al and less than 0.1 wt% of impurities. The aluminum alloy has high castability, excellent thermal conductivity and electrical conductivity, excellent corrosion resistance and medium mechanical performance and can be applied to 3C mobile phones, notebook computer shells, communication, illumination, rail transit, civil hardware and other fields.

Owner:GAOAN JINLIANGXUAN SCI & TECH

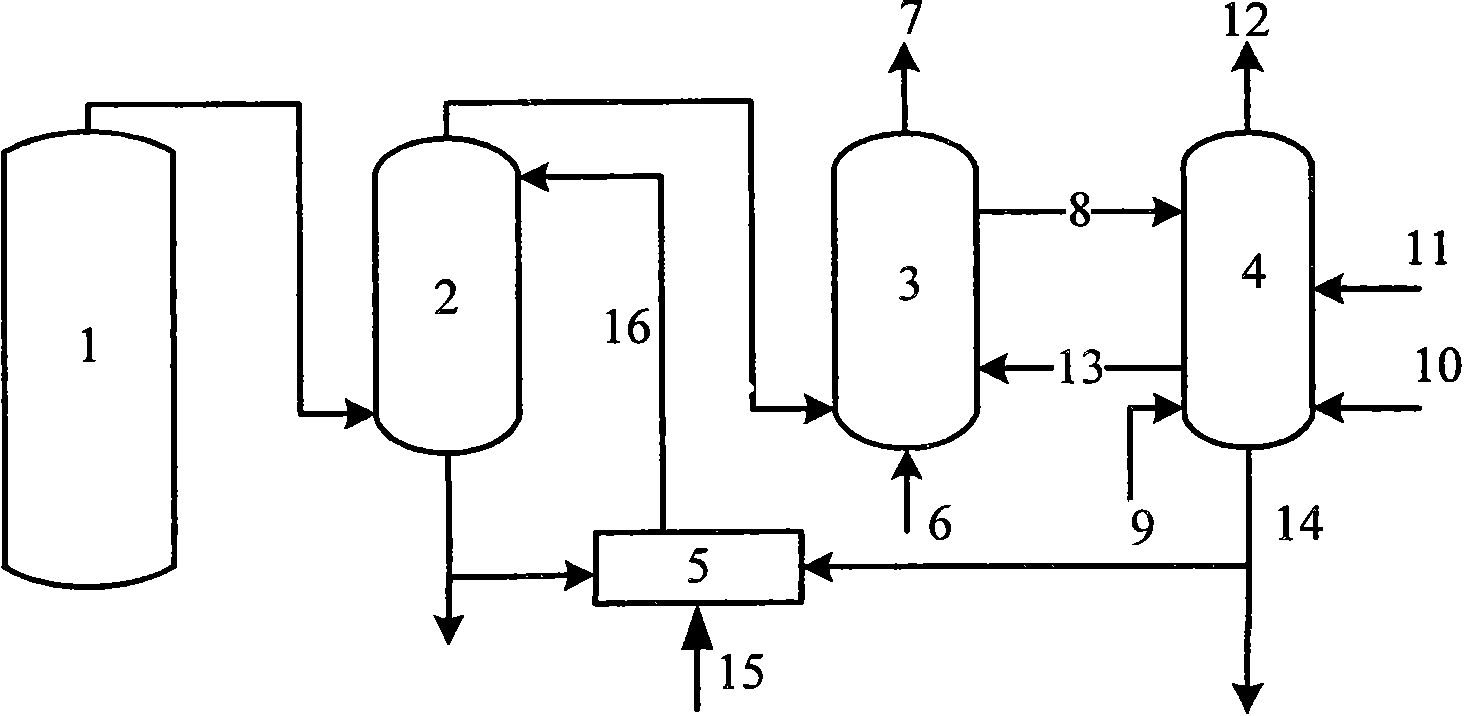

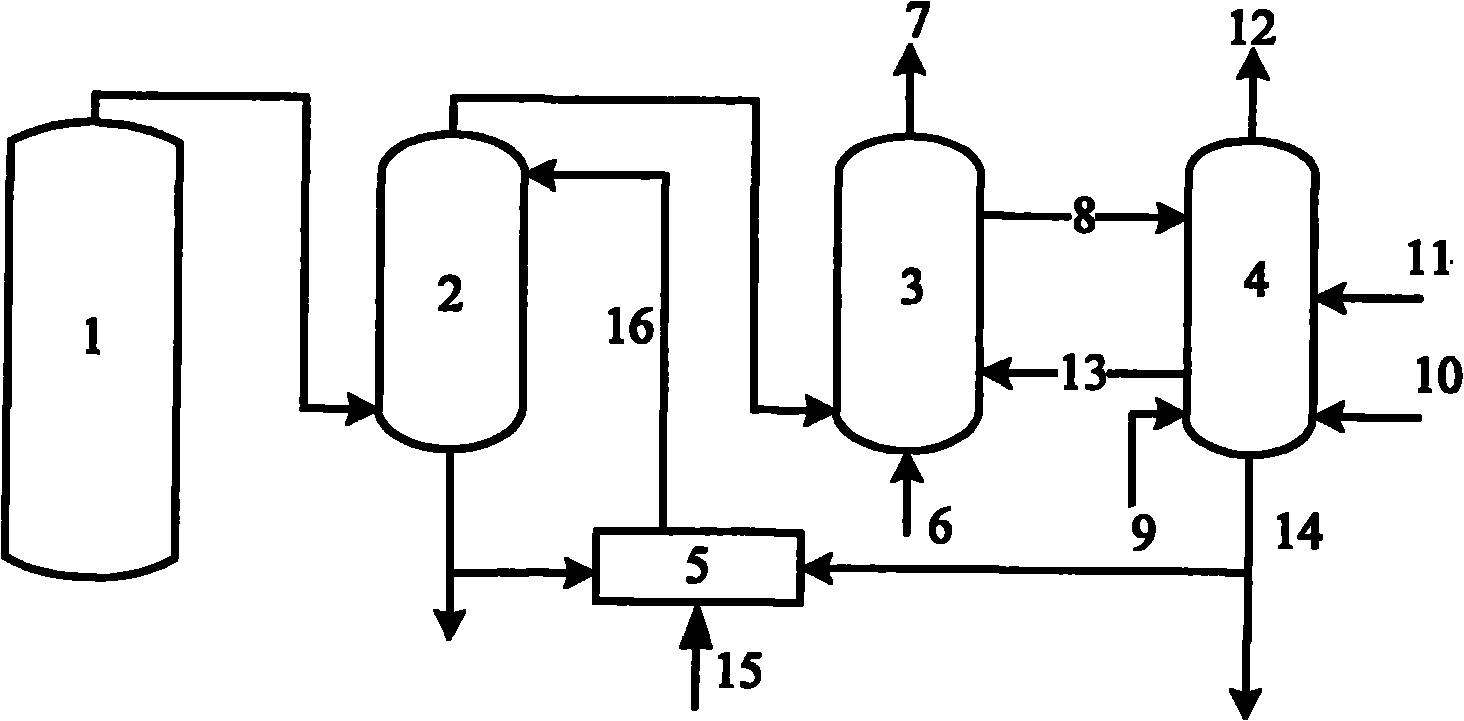

Method for circularly trapping SO2 and CO2 by using calcium-based absorbent

InactiveCN101797470AGood technical economyAvoid inputGas treatmentDispersed particle separationCarbonationCarbon dioxide

The invention provides a method for trapping SO2 and CO2 on a large scale aiming at a pulverized coal furnace of a power plant. Fume generated by the pulverized coal furnace of the power plant is desulfurized by a desulfurizing tower and then enters a fluidized bed carbonation reactor; CaO in the reactor generates solid Ca(OH)2 under the action of water vapor; Ca(OH)2 particles are subjected to a carbonation reaction to trap CO2; a product CaCO3 enters a fluidized bed calcining furnace; the CaCO3 is decomposed into CaO and CO2 by using the heat generated by oxygen enriched combustion of a biomass fuel; and the CaO is introduced into the carbonation reactor for trapping the CO2 to realize the recycling. The inactive CaO is discharged from the lower part of the fluidized bed calcining furnace, and meanwhile, the calcium-based absorbent is supplemented. Part of inactive CaO discharged from the calcining furnace is introduced into a digestion reaction to form a Ca(OH)2 solution and then enters the desulfurizing tower for desulfurization, so that the respective removal of the SO2 and the CO2 can be realized and the energy consumption of the system can be reduced.

Owner:SHANDONG UNIV

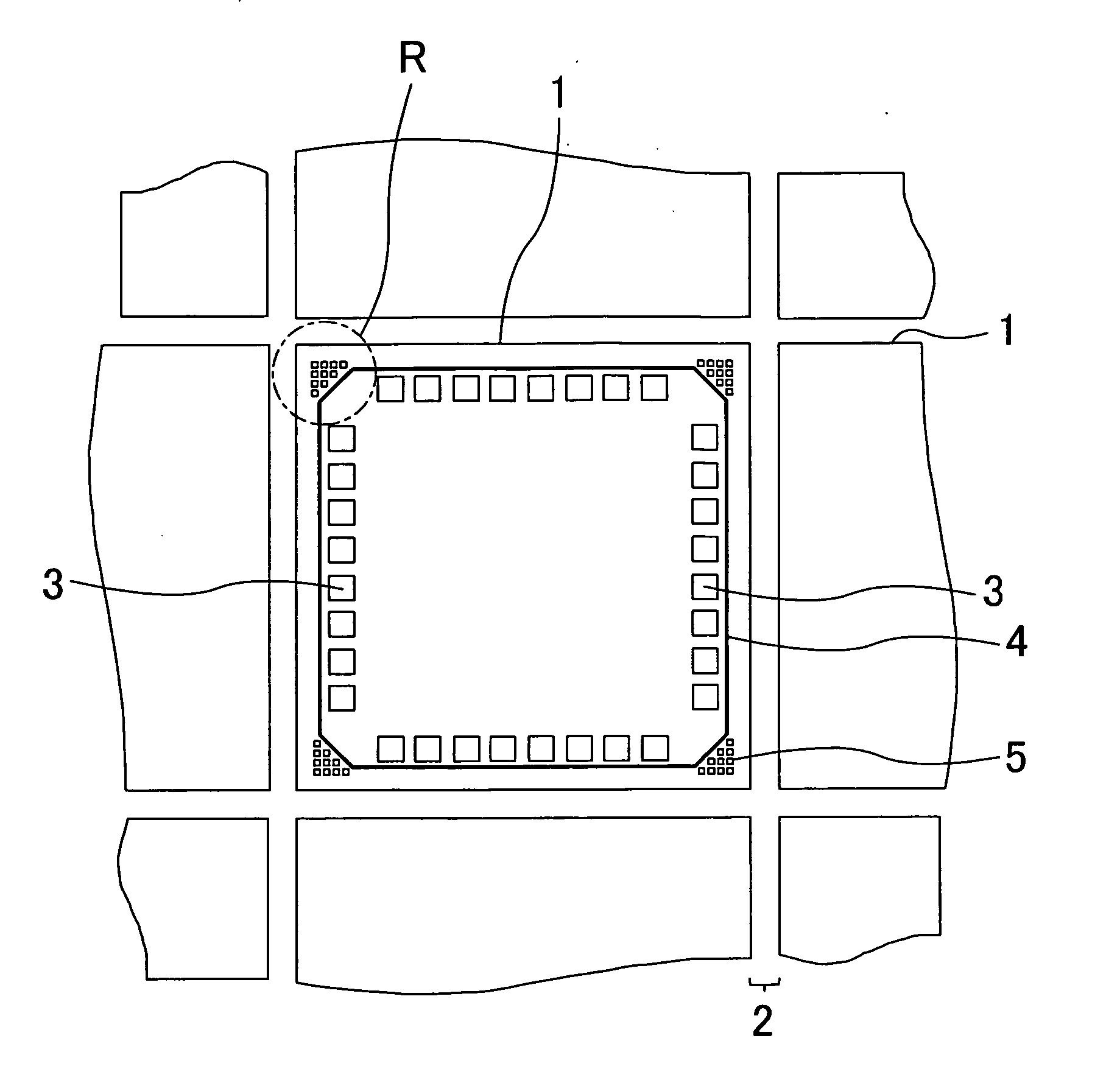

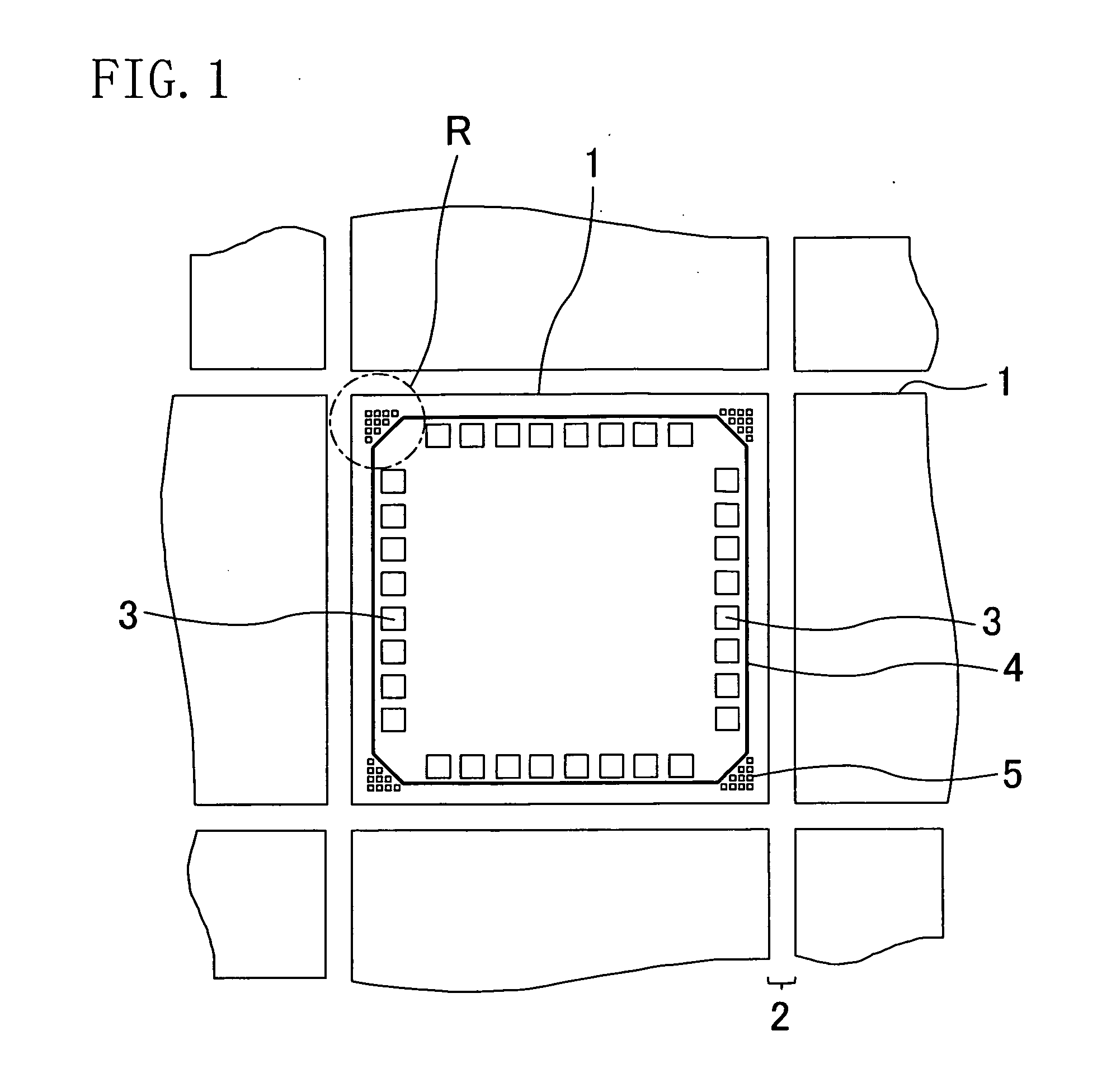

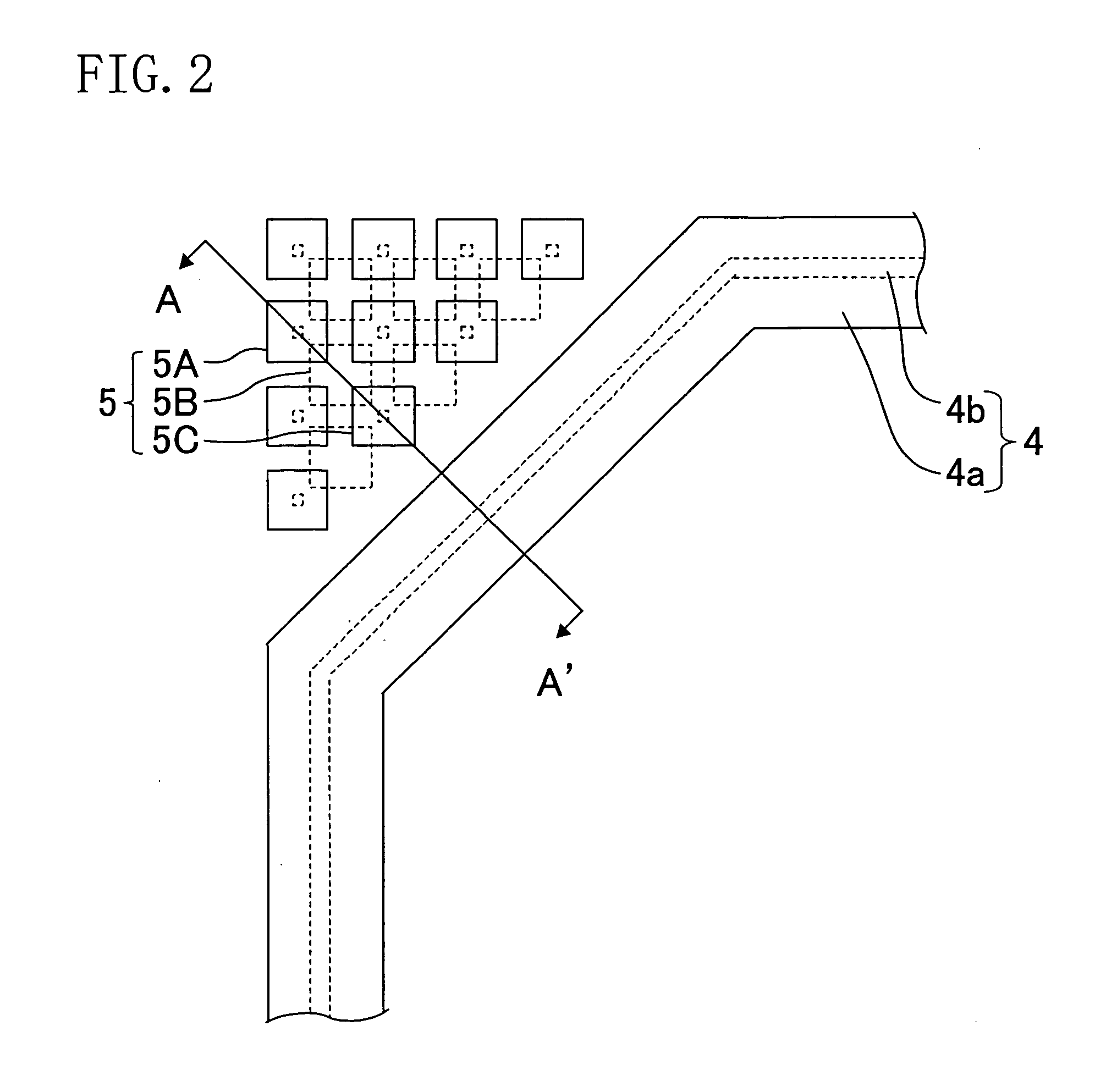

Semiconductor device

ActiveUS20070001308A1Improve mechanical strengthLow modulusSemiconductor/solid-state device detailsSolid-state devicesSemiconductorDevice material

A semiconductor device includes at least three or more wiring layers stacked in an interlayer insulating film on a semiconductor substrate, a seal ring provided at the outer periphery of a chip region of the semiconductor substrate and a chip strength reinforcement provided in part of the chip region near the seal ring. The chip strength reinforcement is made of a plurality of dummy wiring structures and each of the plurality of dummy wiring structures is formed to extend across and within two or more of the wiring layers including one or none of the bottommost wiring layer and the topmost wiring layer using a via portion.

Owner:PANASONIC CORP

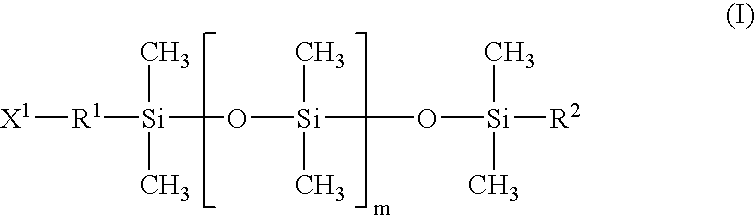

Non-aqueous liquid composition having ultraviolet-absorbing capability

InactiveUS20070098653A1Good slipperinessTransparent appearanceCosmetic preparationsHair cosmeticsPolymer scienceSilicone fluid

The present invention provides a non-aqueous liquid composition from which the coated film on the skin is transparent and slippery, does not cause stickiness and uncomfortable feeling such as creaky feeling and stretch feeling, but causes fresh feeling of use, and keeps the capability of protecting the skin from ultraviolet rays for a desired period of time even under the presence of sweat or sebum, and which is suitable for sunscreen cosmetics, a skin external preparation or a bandage preparation. The non-aqueous liquid composition comprises particles composed of at least a copolymer derived from a silicone macromer (A) and an ultraviolet-absorbing compound and silicone oil in which the particles are dispersed, wherein the silicone macromer (A) exists in the copolymer within 1 to 20 wt % of all components of the particles and orients toward the outer surface of the particle, and wherein, the ultraviolet-absorbing compound is incorporated in the polymer particle as an independent component or a part of the copolymer.

Owner:TAISEI FINE CHEM

Wear resistant vapor deposited coating, method of coating deposition and applications therefor

ActiveUS7939172B2Stable cutting edgeReduce frictionPigmenting treatmentSurgeryWear resistantShape-memory alloy

A low friction top coat over a multilayer metal / ceramic bondcoat provides a conductive substrate, such as a rotary tool, with wear resistance and corrosion resistance. The top coat further provides low friction and anti-stickiness as well as high compressive stress. The high compressive stress provided by the top coat protects against degradation of the tool due to abrasion and torsional and cyclic fatigue. Substrate temperature is strictly controlled during the coating process to preserve the bulk properties of the substrate and the coating. The described coating process is particularly useful when applied to shape memory alloys.

Owner:G&H TECH LLC

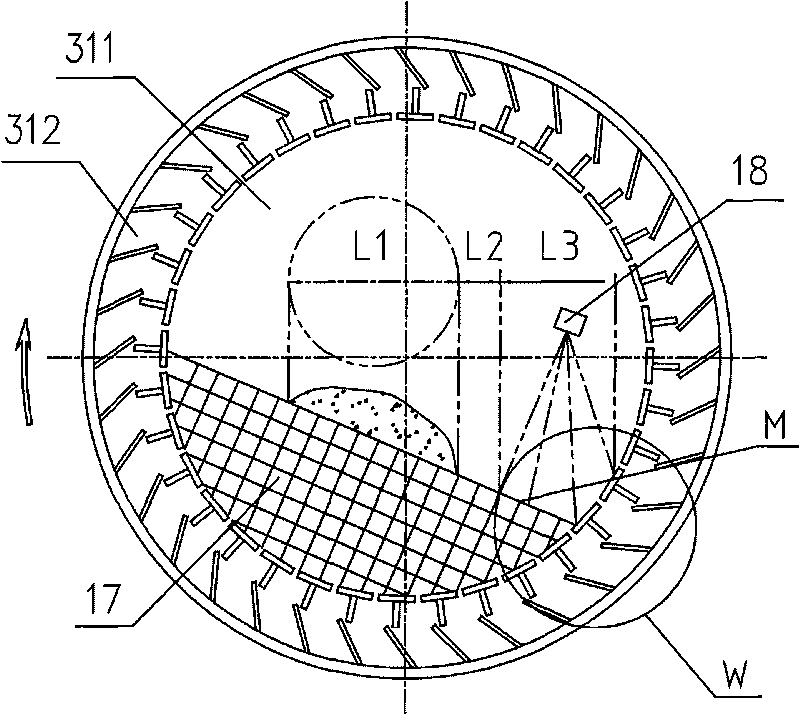

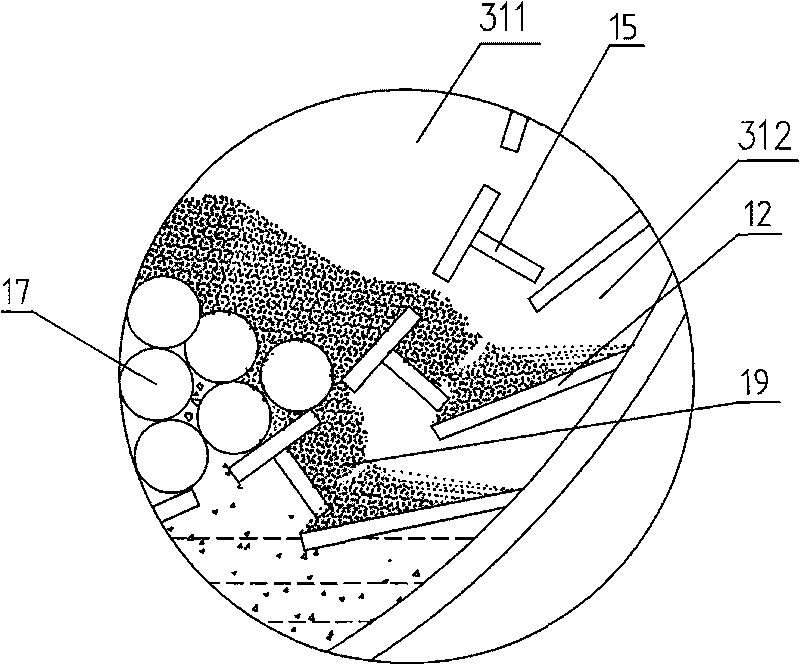

High-temperature slag handling technology by tilting roller process and device

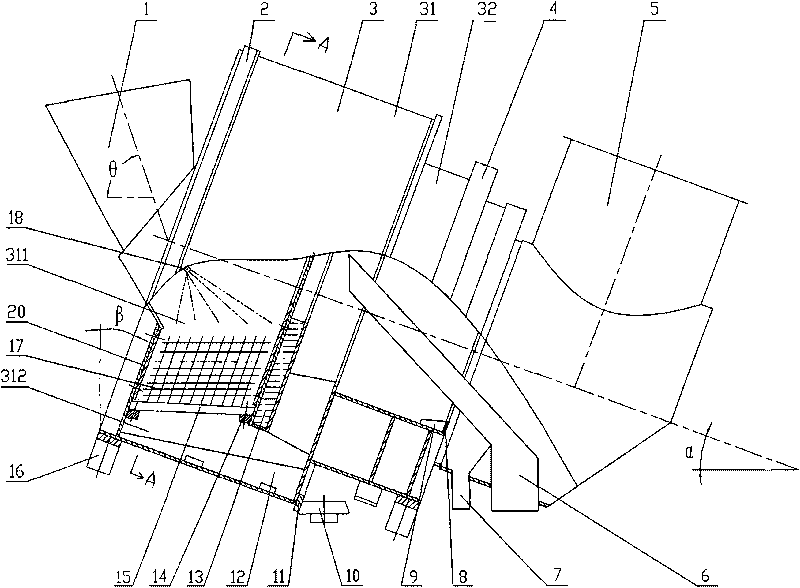

ActiveCN101760572AImprove performanceUniform particle sizeRecycling and recovery technologiesSlagWater spray

The invention discloses a high-temperature slag handling technology by the tilting roller process and a high-temperature slag handling device. The handling technology includes that high-temperature metallurgical slag is poured into a rotating working barrel body with a certain angle of inclination in the axial direction by a loading hopper; the slag in a front barrel body of the working barrel body is fast cooled by a cooling medium and the cooling water sprayed by a spray head in sequence and then crushed; the cooled and crushed slag particles are driven to drop from the gaps among cage bars and the gaps between the cage bars and a barrel body shoveling plate into a lower chamber filled with the cooling water to be cooled for the second time; along with the rotation of the working barrel body, the slag particles soaking in the cooling water in the lower chamber are carried to the upper part of the front barrel body by the barrel body shoveling plate provided with dewatering holes, poured into an open discharging chute and conveyed out of the device; the cooling water that carries fine slag particles and is separated by the barrel body shoveling plate flows to a rear barrel body, and the fine slag particles separated and intercepted by a netty slag-water separating device arranged on the rear barrel body are sent to the discharging chute and conveyed out of the device by a small shoveling plate arranged on the internal side surface of the rear barrel body.

Owner:BAOSHAN IRON & STEEL CO LTD

Hair styling compositions comprising adhesive particles and non-adhesive particles

InactiveUS20060024255A1Improved hair styling propertyImprove propertiesCosmetic preparationsHair removalPolymerHair characteristics

The invention relates to a hair styling composition comprising: an effective amount of at least one adhesive particle to provide a reshapable effect, an effective amount of at least one polymeric non-adhesive particle to impart at least one of the desirable properties and / or substantially maintain said reshapable effect relative to an identical formulation without said at least one non-adhesive particles, and a cosmetically acceptable carrier. The invention also relates to a method of providing a reshapable effect to the hair, comprising applying to the hair, before, during or after shaping of the hairstyle, a hair styling composition of according to the invention. And finally, the invention also relates to a method of making a reshapable hair styling composition.

Owner:LOREAL SA

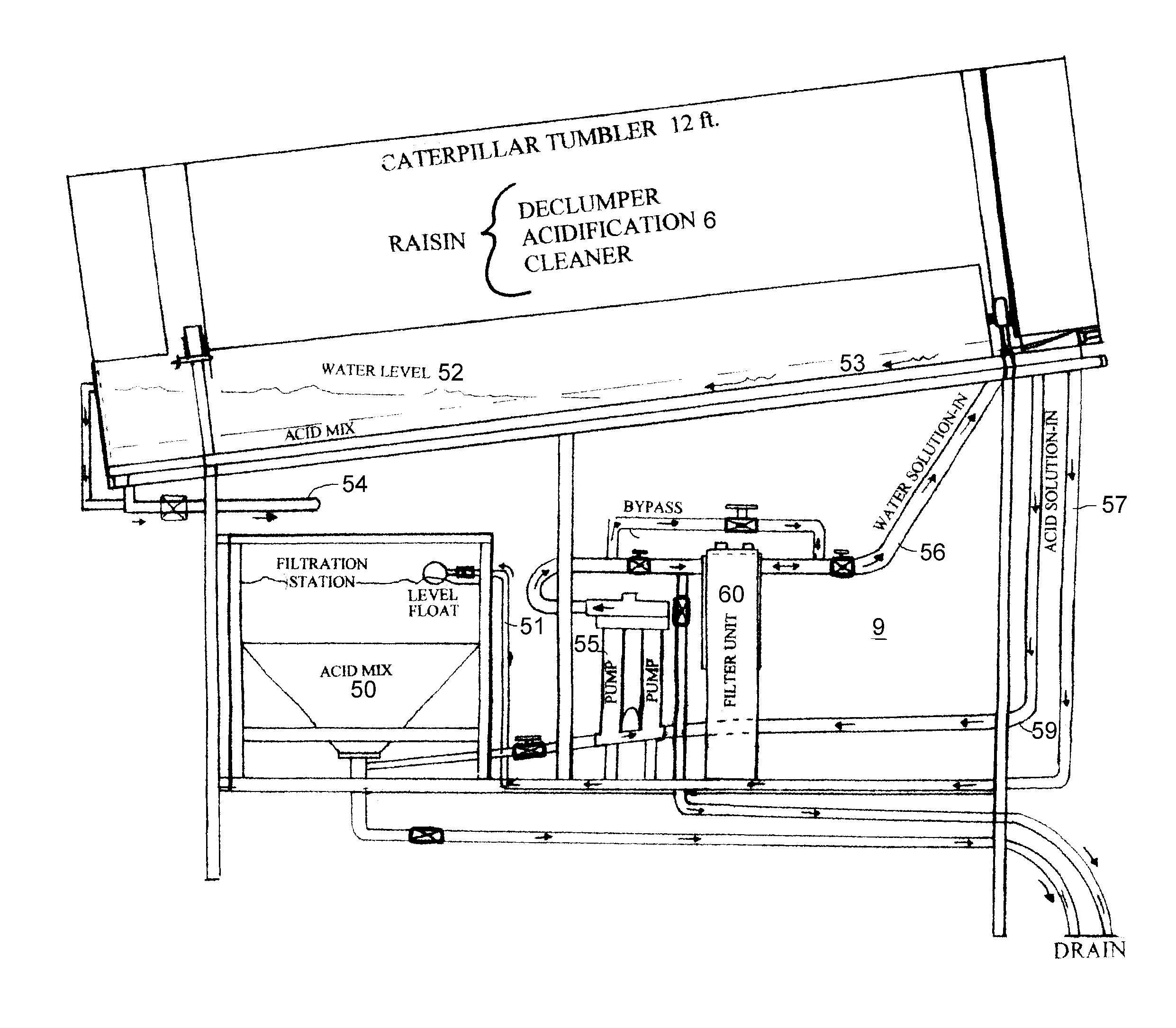

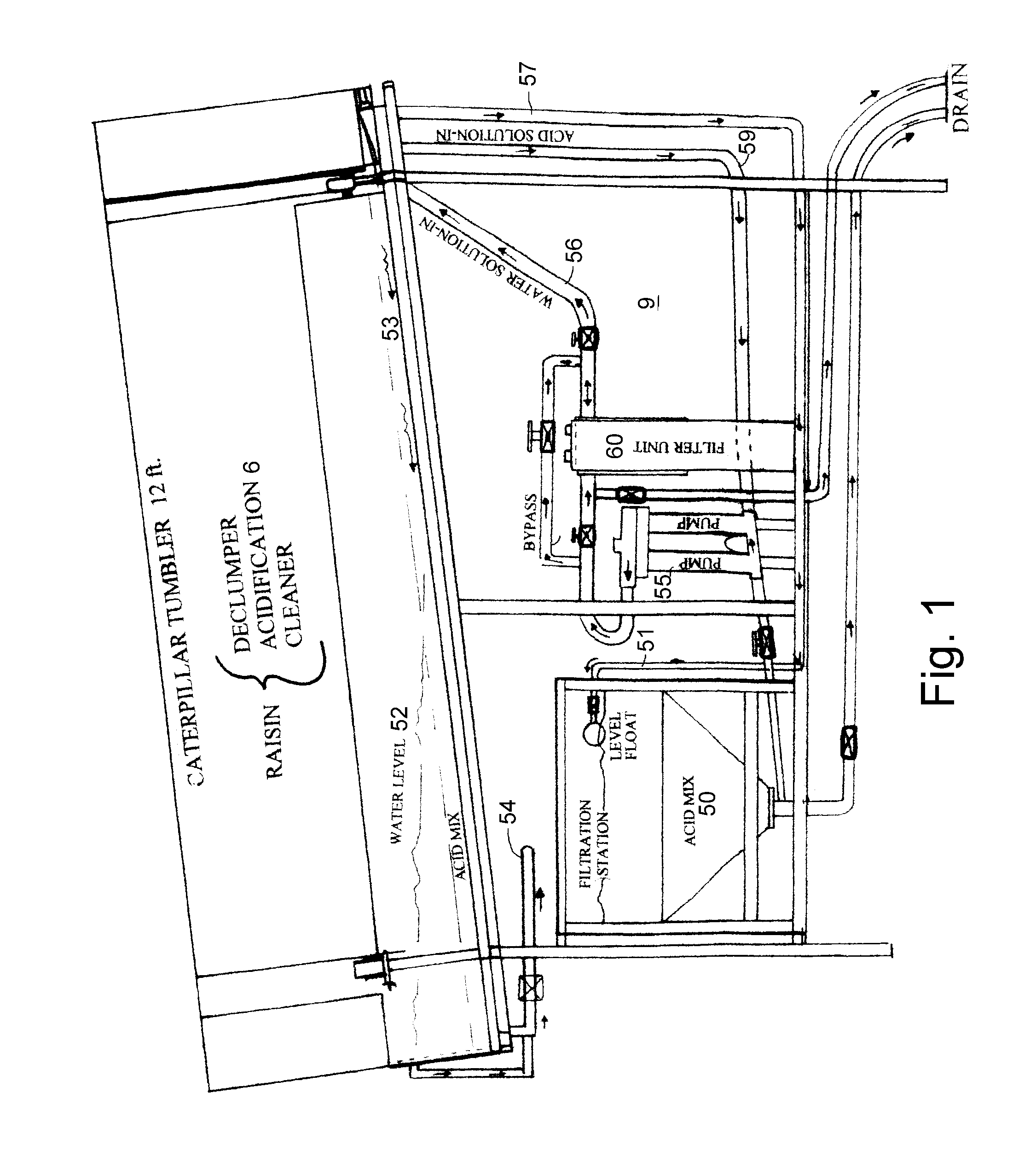

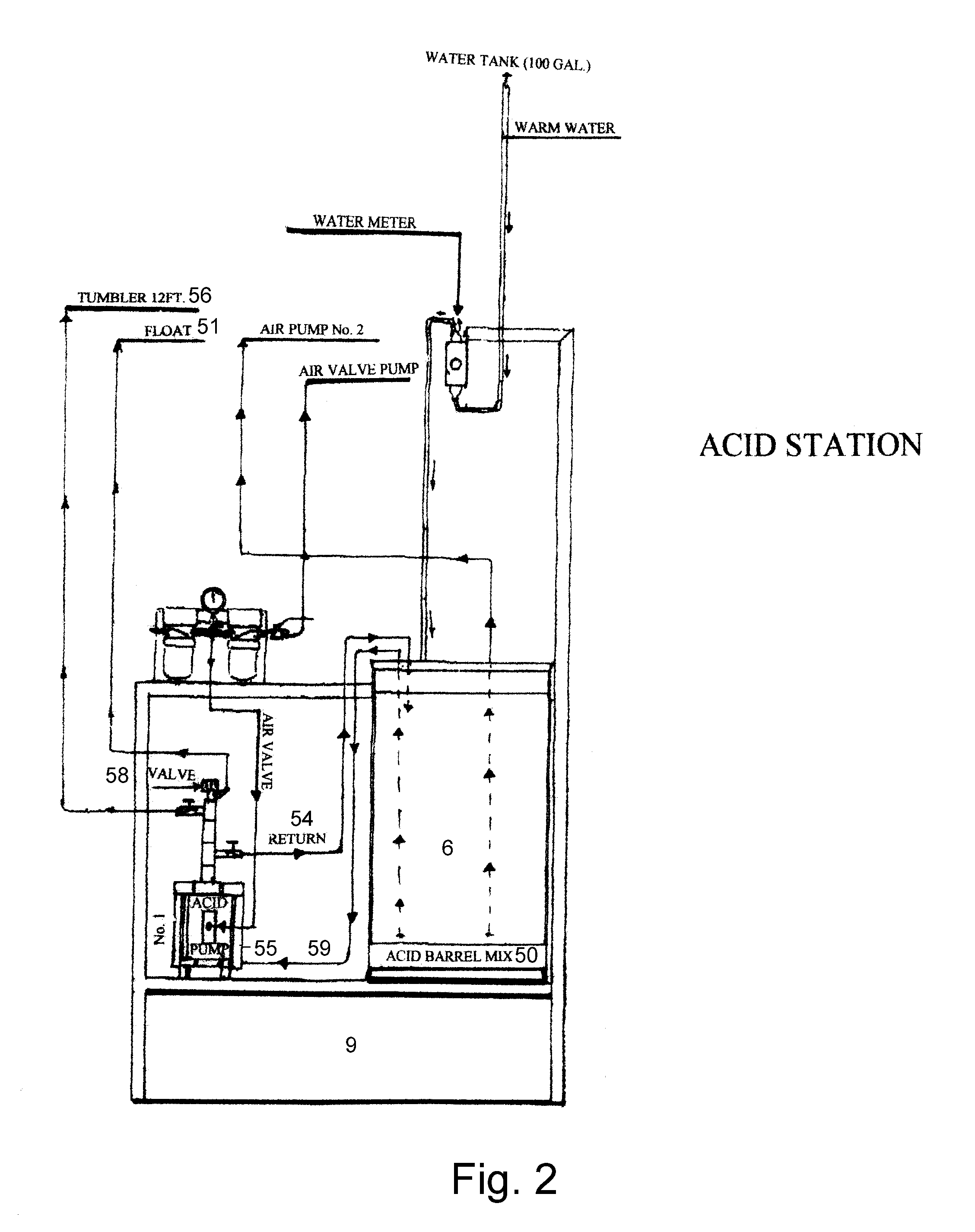

System and method for producing a dehydrated food product

ActiveUS20080274263A1Increase permeability and surface areaAvoid absorptionGrain huskingGrain polishingAcidulantDried food

A process and apparatus for preparing a dried food product said process comprising treating a dried food with an aqueous acidulant, in an amount and for a period of time which is sufficient to modify a surface of the food to increase water permeability; dehydrating the acidified food to obtain a desired moisture content with heat; cooling the heated dehydrated acidified food; and infusing the cooled dehydrated acidified food with an infusate.

Owner:MAZIN JACK G

Manufacturing method for fibrous membrane for oil-water separation

ActiveCN104313796ANot easy to slipHigh breaking strengthElectro-spinningNon-woven fabricsFiberPorosity

The invention discloses a manufacturing method for a fibrous membrane of an extremely hydrophobic organic macromolecule chemical compound with an oil-water separation function in the technical field of fibrous membrane manufacturing. The manufacturing method comprises the following steps: synthetizing a copolymer with excellent electrostatic spinnability by regulating the compounding ratio of a monomer and controlling the condition of a suspension polymerization technology and by adjusting and controlling the compositions of a solution, processing parameters and the temperature and humidity conditions of environment, and spinning a copolymer solution into the fibrous membrane with the advantages of uniform and small bore diameters, high porosity, large flux and extremely hydrophobic and oleophylic properties by using an electrostatic spinning technique. The obtained fibrous membrane has the advantages that the specific surface area is large, the patterns are large, the stacking structure is proper, and the fibrous membrane is in a three-dimensional bore channel structure. Compared with an existing polymer-based oil-water separation member, the fibrous membrane has the advantages that the bore channel structure is more reasonable, the separation capacity is stronger, the separation efficiency is higher, the anti-pollution capacity is stronger, the membrane bores are not easy to block, the oil-water selectivity is stronger, the mechanical strength is higher, the flexibility and the temperature resistance are better, the preparation process is shorter, the consumed energy is little, the filtering rate is higher, and the cost is lower, so that the fibrous membrane can better satisfy the requirements of industrial practicality.

Owner:TIANJIN POLYTECHNIC UNIV

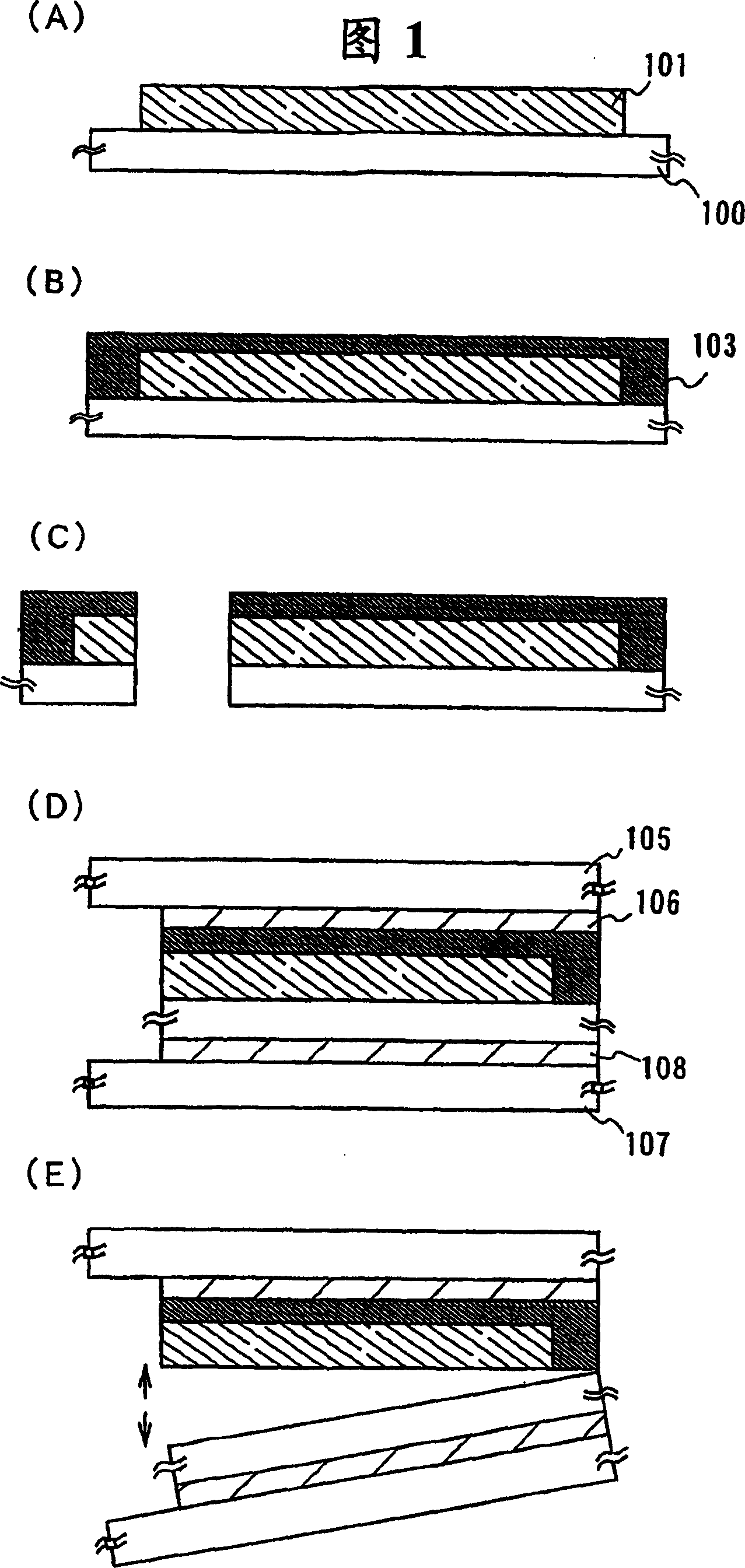

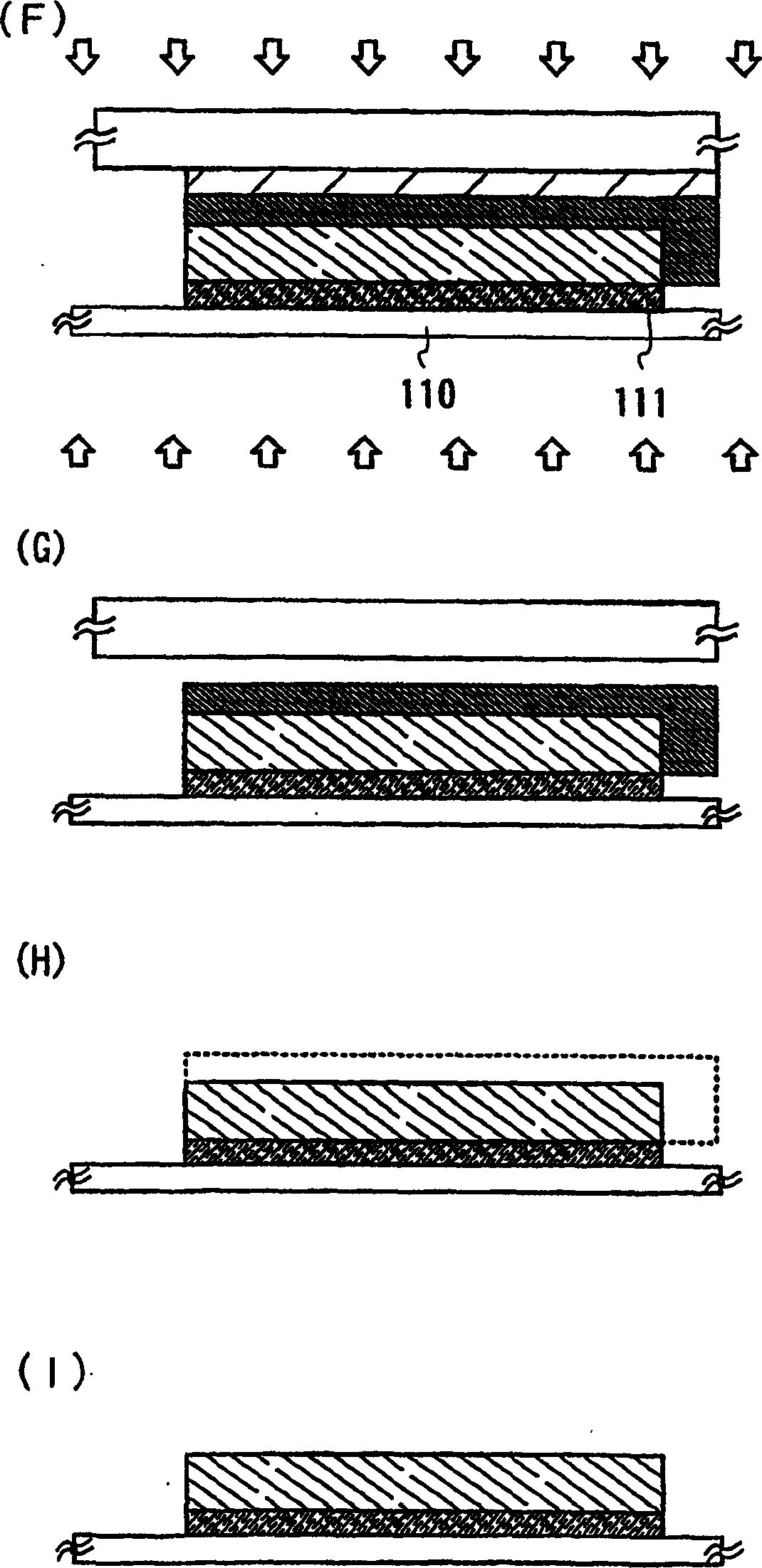

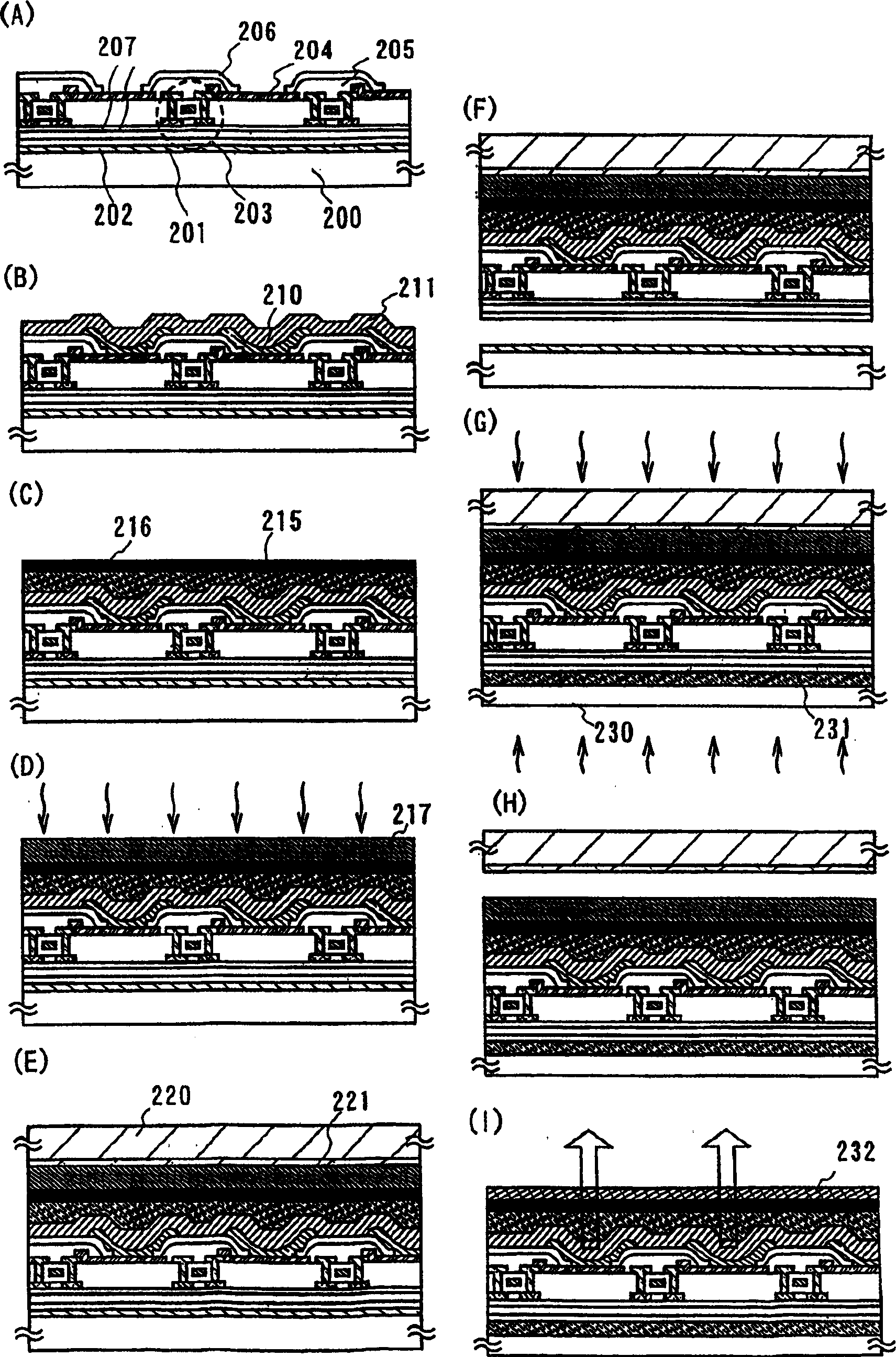

Peeling method and method for manufacturing display device using the peeling method

InactiveCN1739129ASimplify the manufacturing processImprove pass rateElectroluminescent light sourcesSolid-state devicesAdhesiveDisplay device

The present invention provides a simplifying method for a peeling process as well as peeling and transcribing to a large-size substrate uniformly. A feature of the present invention is to peel a first adhesive and to cure a second adhesive at the same time in a peeling process, thereby to simplify a manufacturing process. In addition, the present invention is to devise the timing of transcribing a peel-off layer in which up to an electrode of a semiconductor are formed to a predetermined substrate. In particular, a feature is that peeling is performed by using a pressure difference in the case that peeling is performed with a state in which plural semiconductor elements are formed on a large-size substrate.

Owner:SEMICON ENERGY LAB CO LTD

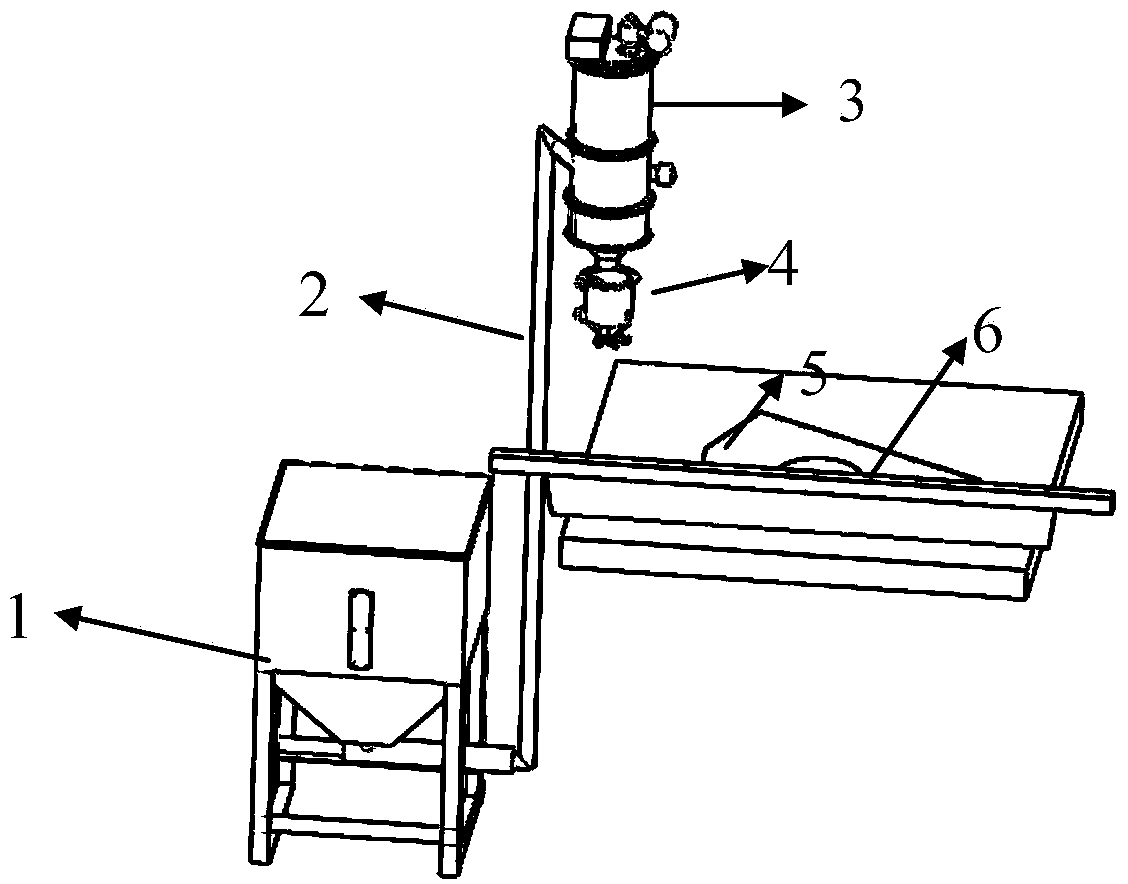

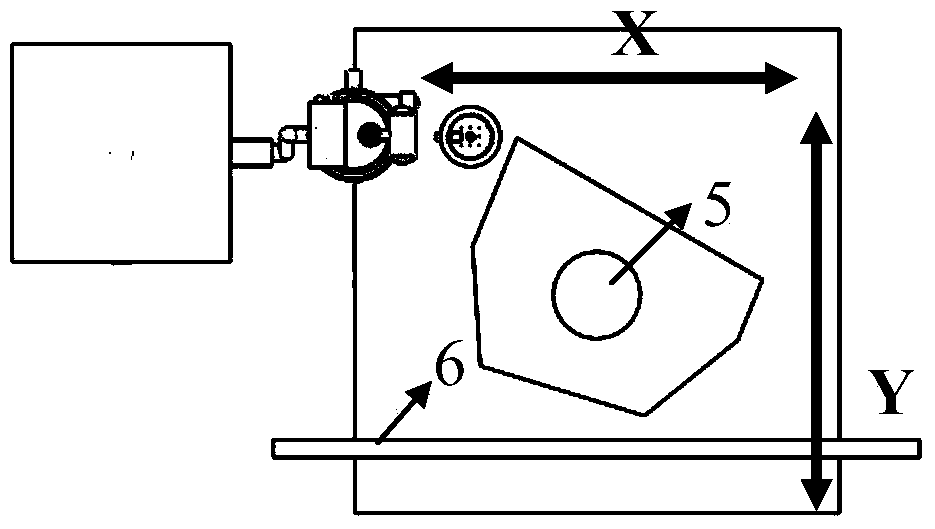

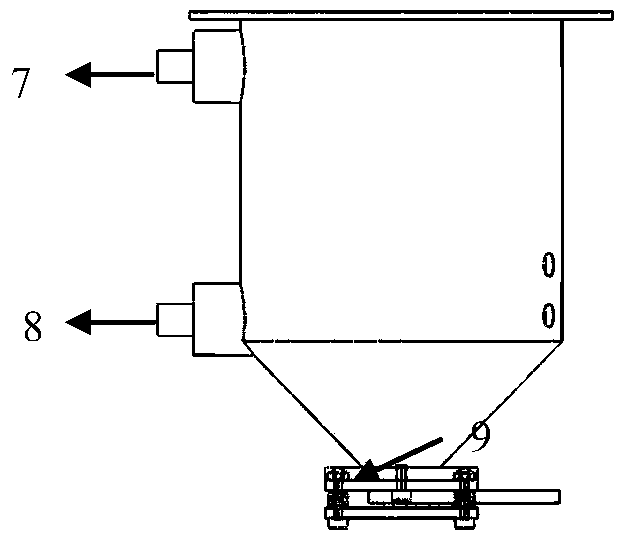

Movable hopper type powder bed powder laying device and method

ActiveCN103738747AImprove process performanceShorten the timeLoading/unloadingLevel sensorEngineering

The invention discloses a movable hopper type powder bed powder laying device. The powder bed powder laying device mainly comprises a feeding device, a movable (discharging) funnel, a powder laying device, a related transmission mechanism device and the like. The amount of powder needed by each layer is calculated, and the feeding device is controlled to accurately feed the powder to the movable funnel by using a powder level sensor in the movable funnel. The powder is discharged rapidly and evenly through control over left-and-right moving speed of the discharging funnel, the bore diameter of a discharging opening and the opening and closing degree of the discharging opening, and then the discharged powder is slicked through front and back movement of a powder slicking plate to finish the powder laying process. The powder is discharged rapidly and evenly, the usage amount of the powder is saved, the machining efficiency of rapid forming equipment is increased, and cost is reduced.

Owner:DALIAN UNIV OF TECH

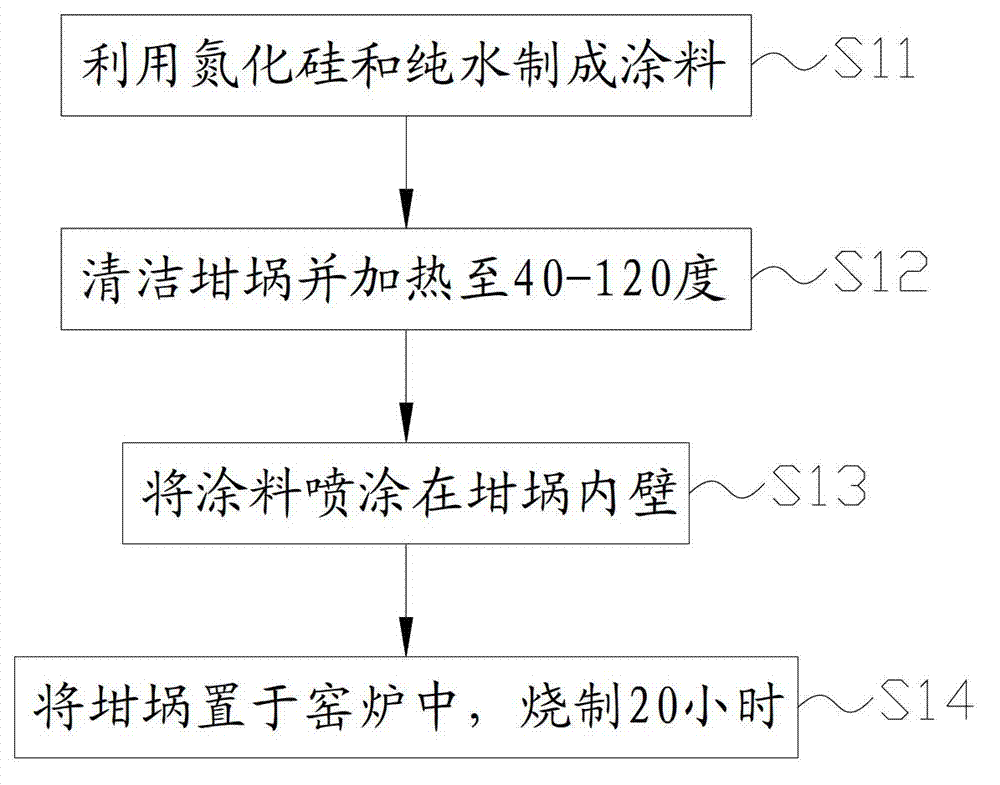

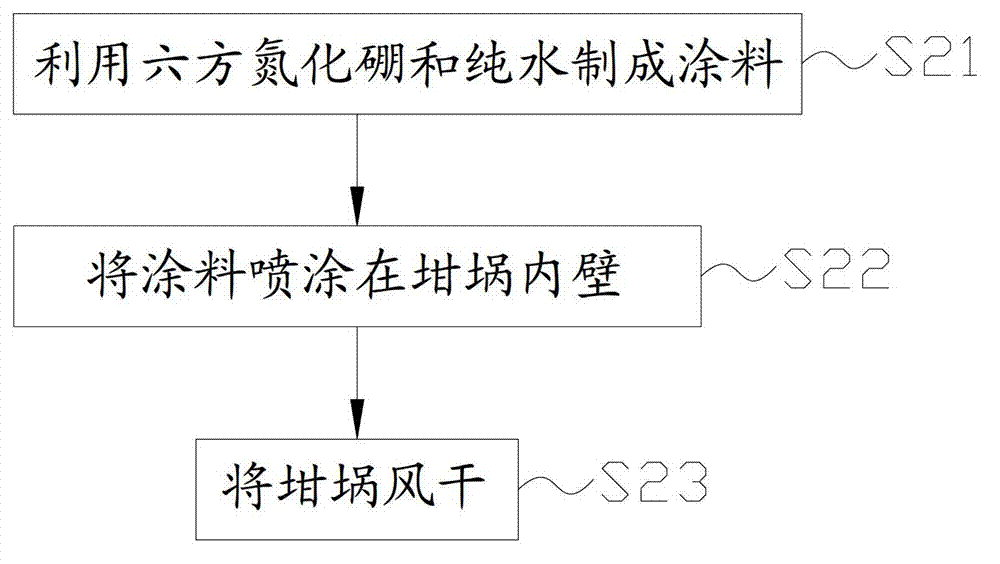

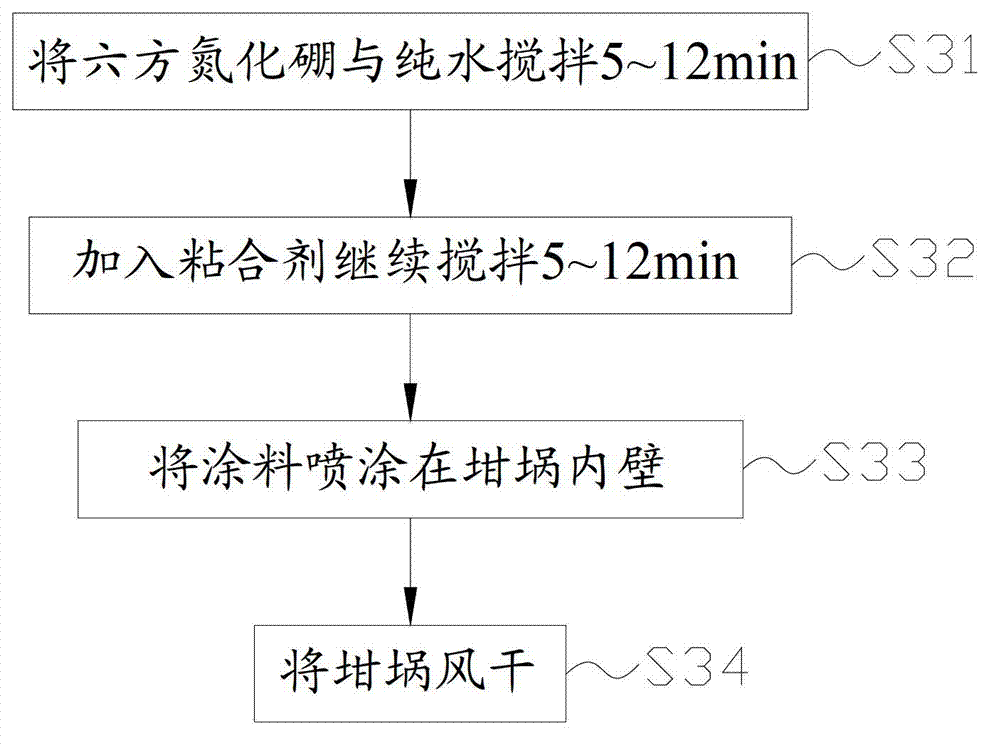

Crucible and coating method thereof

InactiveCN103084325AImprove coating efficiencyIncrease productivityAfter-treatment apparatusPretreated surfacesHexagonal boron nitrideCrucible

The invention discloses a crucible and a coating method of the crucible. The disclosed coating method of the crucible comprises the following steps: coating paint is manufactured, and the coating paint comprises hexagonal boron nitride and pure water; the coating paint is coated on the inner wall of the crucible in a spraying mode; and the crucible is aired to be dry. The possibility of the reaction between the crucible and the hexagonal boron nitride is small, silicone material is not prone to stick to the crucible, the possibility of occurrence of leakage is obviously lowered, and therefore the safety and reliability in the process of production of the silicone material are improved. Meanwhile, a coating is poor in wettability with liquid silicone and is not prone to stick to the silicone materials under the condition of carrying the liquid silicone. In addition, due to the fact that the hexagonal boron nitride has good wettability, demolding of a silicone ingot is good. The coating enables the heat conduction to be more uniform in the growth process of the silicone ingot, so that the interior quality of the silicone ingot is improved. Therefore, the coating method of the crucible is capable of reducing the sticking and permeation between the crucible and the liquid silicone material, plays a role in a protective layer, has the functions of lubrication and demolding, and improves the production quality of the silicone material and production efficiency.

Owner:TIANJIN YINGLI NEW ENERGY RESOURCES

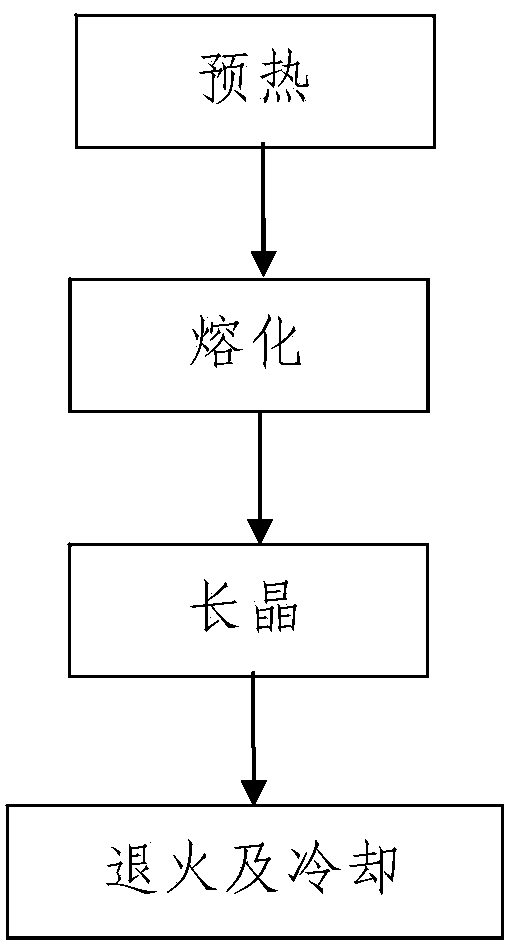

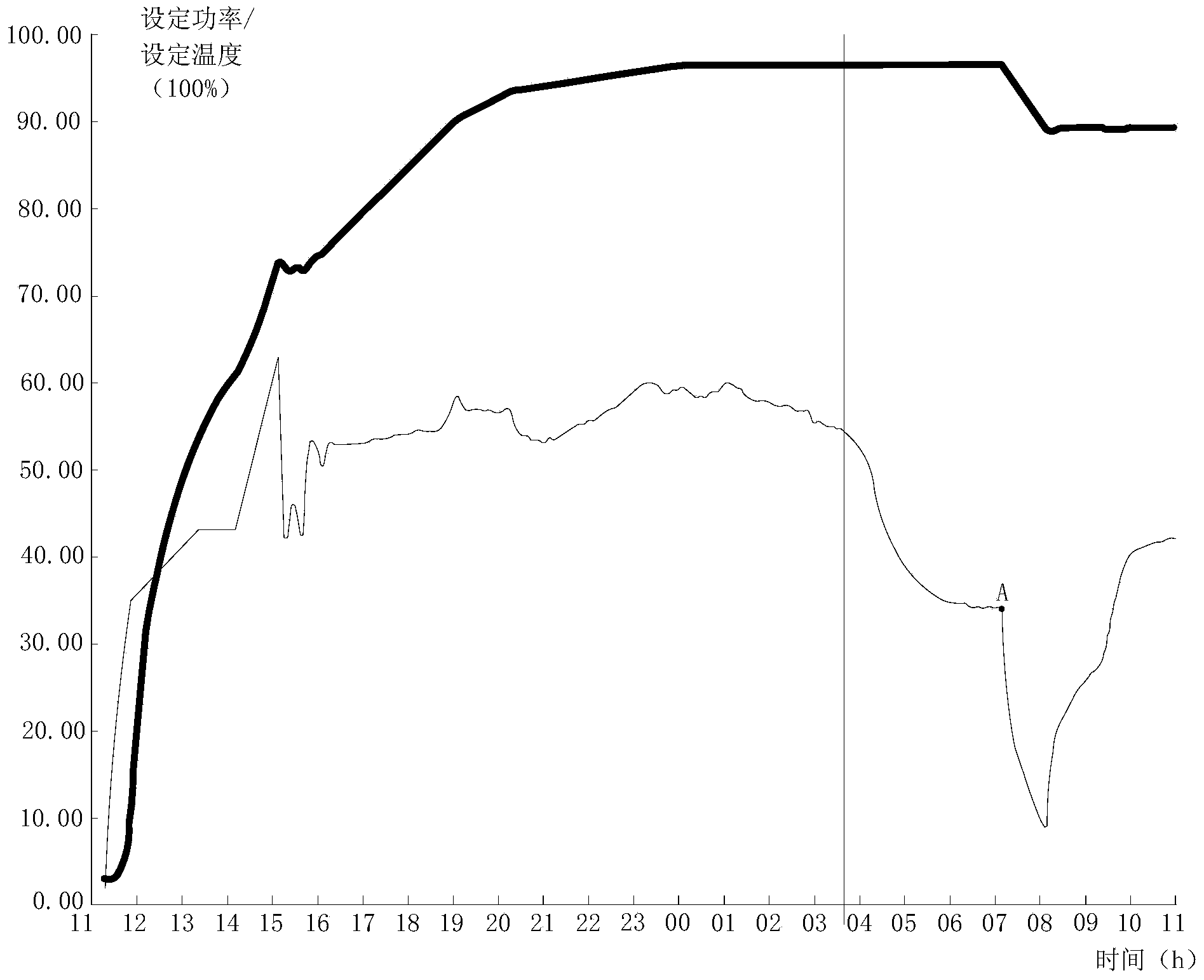

Polycrystalline silicon ingot casting process

InactiveCN103741214AReasonable designSimple processing stepsPolycrystalline material growthSingle crystal growth detailsPolycrystalline siliconMetallurgy

The invention discloses a polycrystalline silicon ingot casting process. The process comprises the following steps: 1, preheating; 2, melting; 3, growing crystal: the temperature is controlled to T6 and is preserved for 1h, and T6=1420 DEG C; the hoisting height of a heat insulation cage is 90mm; the temperature is controlled to T6 and is preserved for 2h, and the hoisting height of the heat insulation cage is not changed; the temperature is controlled to T6 and is preserved for 3h, and the hoisting height of the heat insulation cage is 110mm; the temperature is gradually lowered from T6 to T7, the temperature lowering time is 7-9h, and the hoisting height of the heat insulation cage is 210mm; T7=1405 DEG C; the temperature is controlled to T7 and is preserved for 7-9h, and the hoisting height of the heat insulation cage is not changed; the temperature is controlled to T7 and is preserved for 7-9h, and the hoisting height of the heat insulation cage is not changed; the temperature is gradually lowered from T7 to T8, and the hoisting height of the heat insulation cage is not changed; T8=1395 DEG C; 4, annealing and cooling. The polycrystalline silicon ingot casting process has the advantages of simple steps, reasonable design, convenience in realization, easiness in grasp and good using effect and can reasonably control the ingot casting crystal growth process.

Owner:XIAN HUAJING ELECTRONICS TECH

Apricot solid drink and preparation method thereof

InactiveCN101536805AIncrease the juice yieldGood instant solubilityFood preparationCarboxymethyl celluloseAdditive ingredient

The invention relates to an apricot solid drink and a preparation method thereof. The ingredients of the apricot solid drink are 10-50% of apricot powder, 20-60% of maltodextrin, 10-30% of saccharose, 0.05-0.10% of citric acid, 0.1-0.2% of xanthan gum, 0.1-0.3% of sodium carboxymethyl cellulose, 0.03-0.1% of sodium alginate and 0.5-1.4% of amorphous silicon dioxide. The preparation method comprises the steps of pre-treating, washing and colour-protecting, blanching and cooling, pulping, zymohydrolysis, glue milling, homogenizing, spray drying, material mixing and granulating, packaging, and sterilizing. The solid drink has high fruit content, natural flavour, excellent stability, and convenient carry and use, thereby meeting requirements of modern consumption and having broad market prospect.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

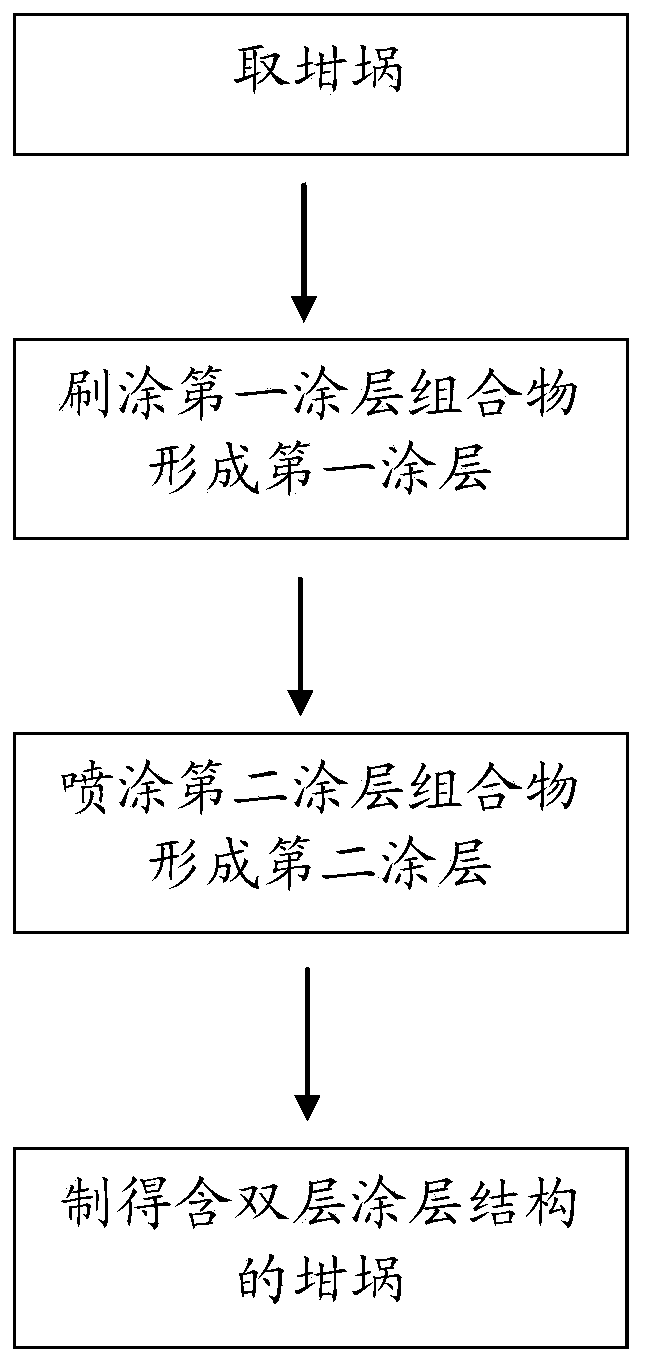

Crucible for polysilicon ingot casting, coating structure of crucible and coating preparation method

InactiveCN104109902AImprove bindingNot easy to fall offPolycrystalline material growthSingle crystal growth detailsCrucibleIngot casting

The invention provides a crucible for polysilicon ingot casting, a coating structure of the crucible and a coating preparation method. The coating structure of the crucible for polysilicon ingot casting comprises a first coating arranged on the inner side wall of the crucible and a second coating arranged on the first coating. The first coating is formed from a first coating composition by brush coating. The first coating composition comprises silicon nitride and a solvent. The second coating is formed from a second coating composition by spray coating. The second coating composition comprises silicon nitride and a solvent. The coating structure of the crucible for polysilicon ingot casting has uniform thickness, does not crack easily, has high bonding force to the inner wall of the quartz ceramic crucible, and strong bonding force between silicon nitride particles, does not spall easily in an ingot casting technology and has a low rate of adhesion to the crucible.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

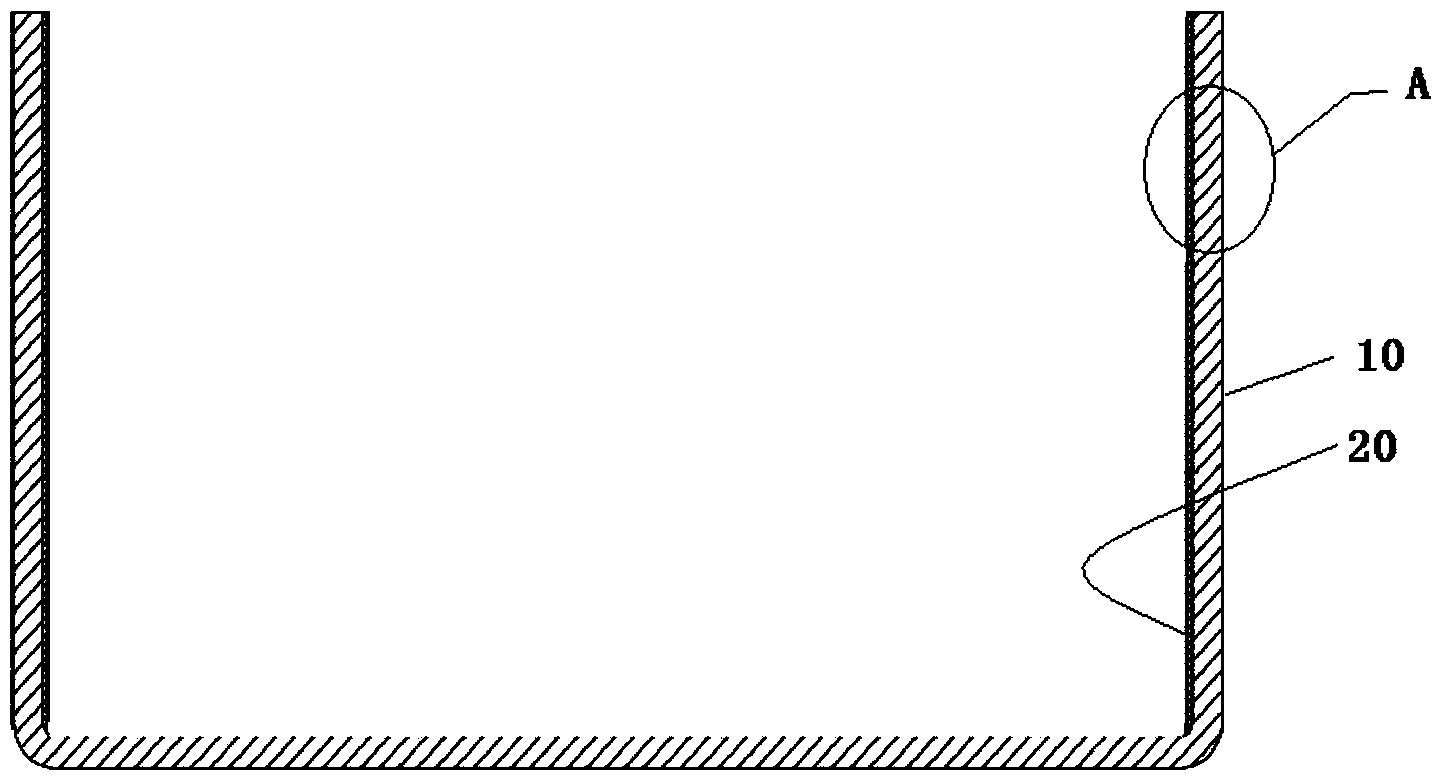

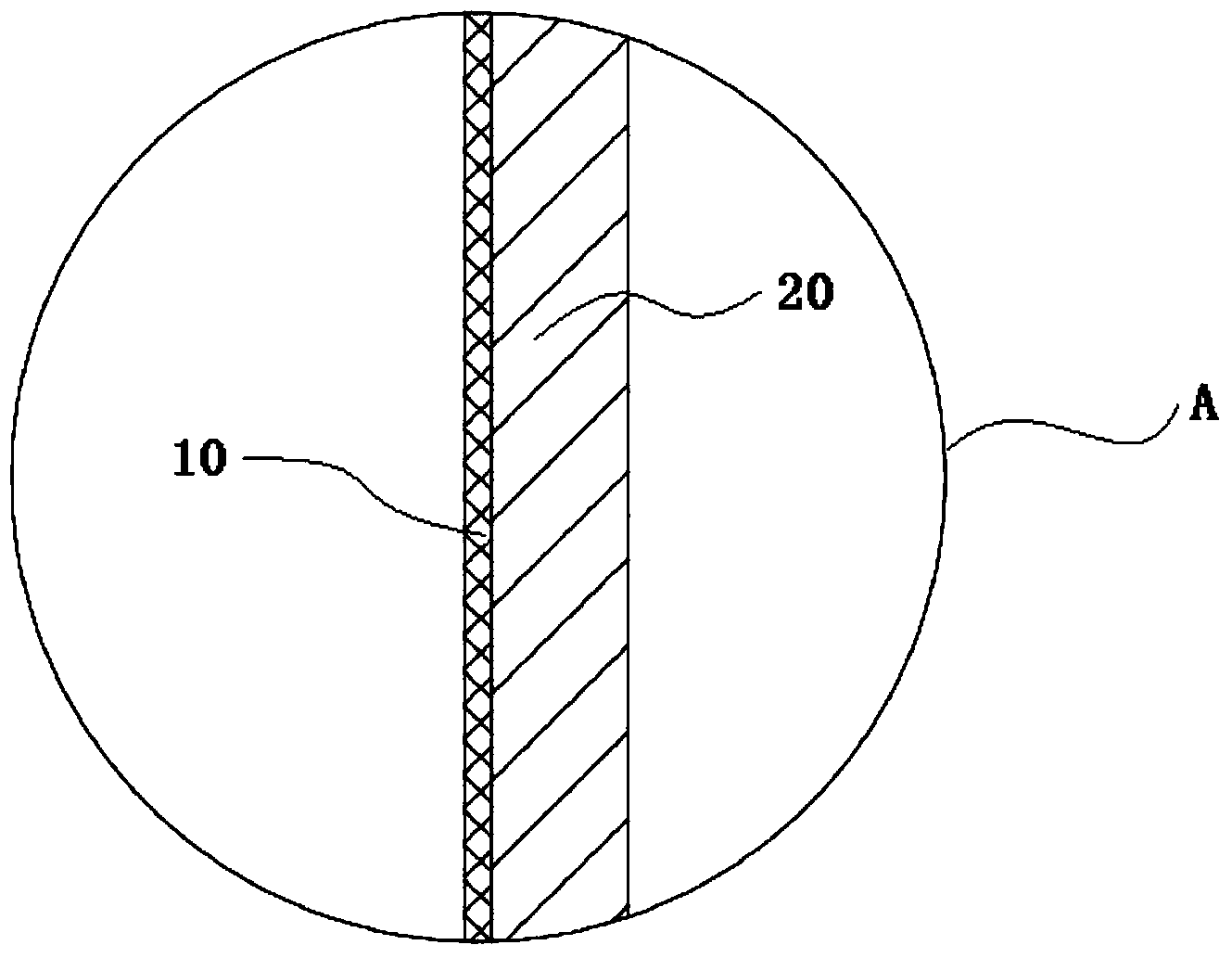

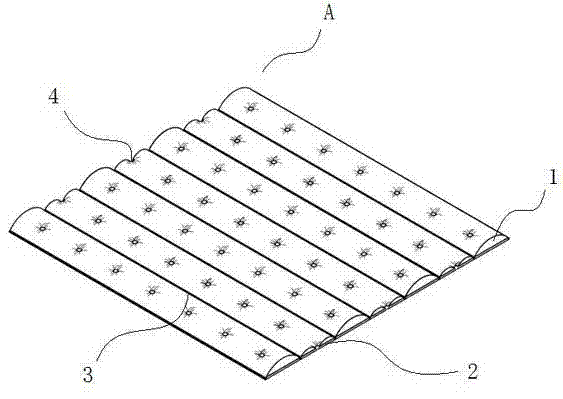

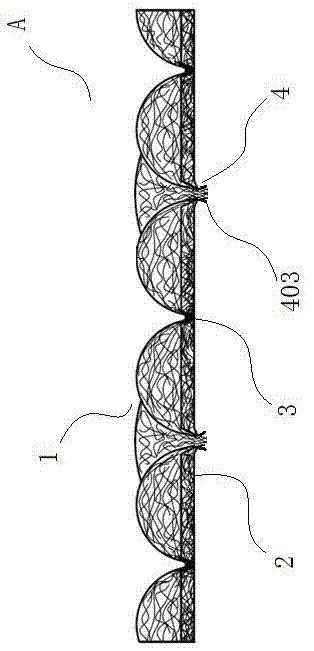

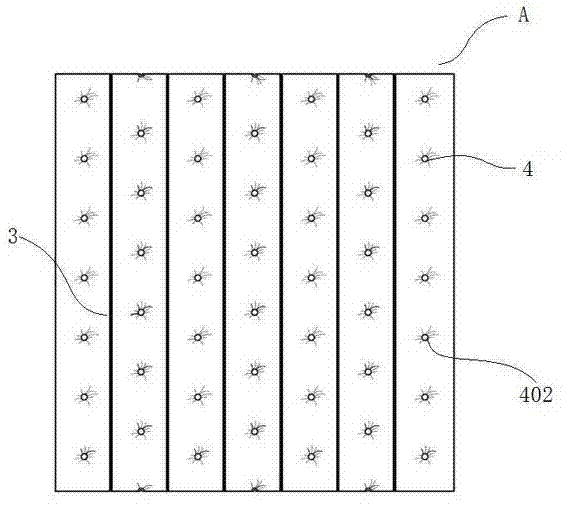

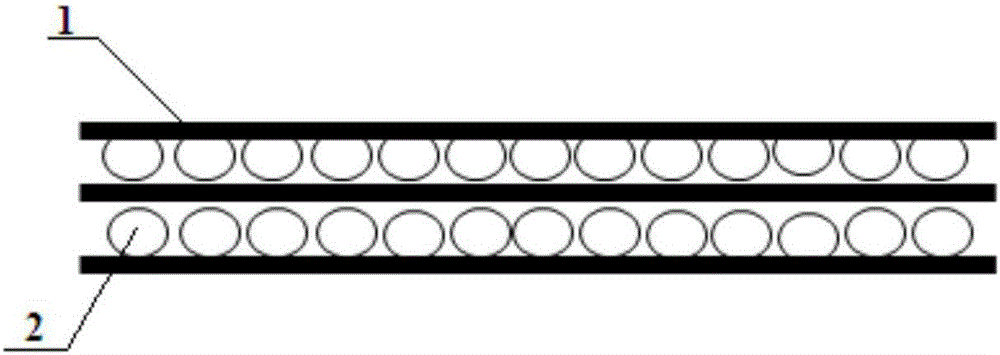

Liquid permeability clad sheet, manufacturing device thereof and manufacturing method thereof

The invention discloses a liquid permeability clad sheet, a manufacturing device of the liquid permeability clad sheet and a manufacturing method of the liquid permeability clad sheet. The liquid permeability clad sheet comprises a first layer sheet and a second layer sheet, the liquid permeability clad sheet is provided with strip-shaped grooves, and cone-shape and three-dimensional openings are formed between the strip-shaped grooves in a horizontal mode. The first layer sheet is bonded with the second layer sheet through the strip-shaped grooves, the cone-shape and three-dimensional openings are provided with flowers hanging on heads, and the flowers hanging on the heads extend towards the lower portion of the second layer sheet. The manufacturing device comprises a punching needle roller, a cooperating roller and a composite punching roller, and heaters are arranged on both the punching needle roller and the composite punching roller. The manufacturing method is adopted by the manufacturing device and carries out the following steps: heating the composite punching roller through the heater, conveying the second layer sheet between the punching needle roller and the cooperating roller to be punched, and conveying the second layer sheet and the first layer sheet between the composite punching roller and the cooperating roller to be punched to composite. By the adoption of the clad sheet, liquid is convenient to seep downwards, the sticky and wet feeling of the skin is reduced, the structure of the manufacturing device is concise in structure and convenient to use, production efficiency of the manufacturing method is good, manufacturing cost is low and effect is good.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

Leave-on compositions for personal care

InactiveUS7235230B2Improve aestheticsLeave less visibleCosmetic preparationsHair cosmeticsPersonal careEmulsion

The present invention relates to leave-on compositions for personal care comprising trimethylsilylalkylsilsesquioxanes, particularly trimethylsilyl-n-octylsilsesquioxanes (Caprylyl Trimethicones). Said trimethylsilylalkylsilsesquioxanes are especially useful in formulating emulsions.

Owner:CLARIANT LIFE SCI MOLECULES SPA

Dental curable composition and composite resin using the same

ActiveUS20110257292A1Excellent light diffusionHigh transparencyImpression capsOther chemical processesInorganic particleRefractive index

The present invention provides a dental curable composition exhibiting both excellent light diffusion and excellent transparency, and having high mechanical strength and surface smoothness and gloss after polishing as a cured product as well as good handling properties as a paste. The present invention is a dental curable composition including: a polymerizable monomer (A) having a refractive index of 1.52 to 1.58 after polymerization; inorganic particles (B) having a refractive index of 1.43 to 1.50; and inorganic particles (C) having a refractive index of 1.52 to 1.58. The inorganic particles (B) are aggregates of inorganic fine particles having an average primary particle size of 2 to 50 nm, and the content of the inorganic particles (B) is 0.1 to 10% by weight.

Owner:KURARAY NORITAKE DENTAL

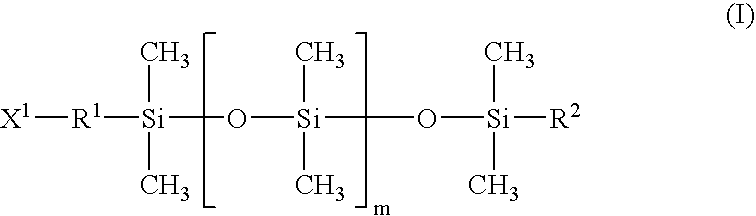

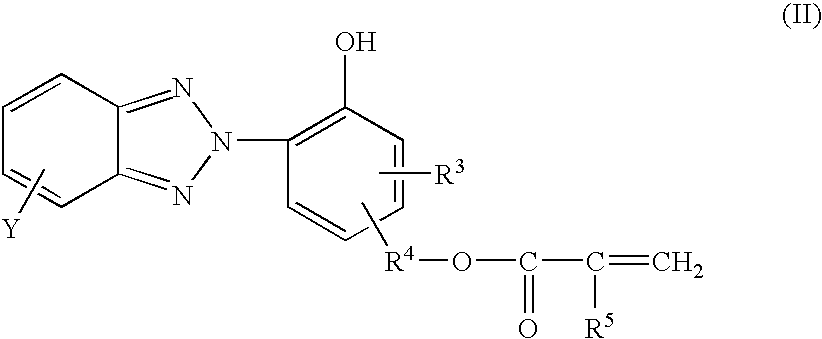

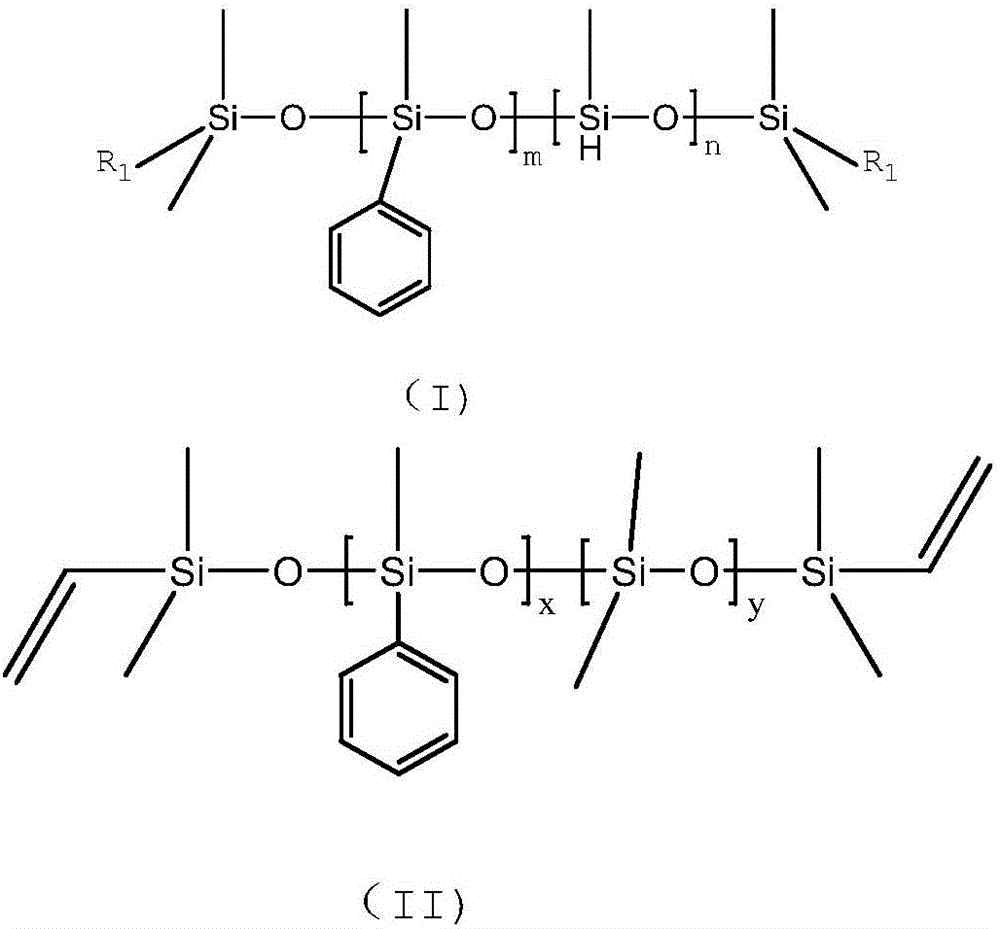

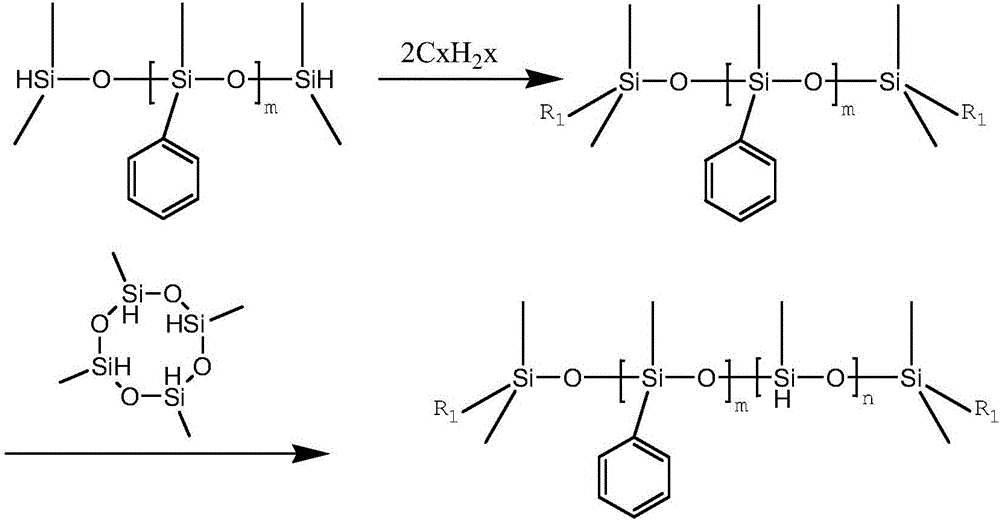

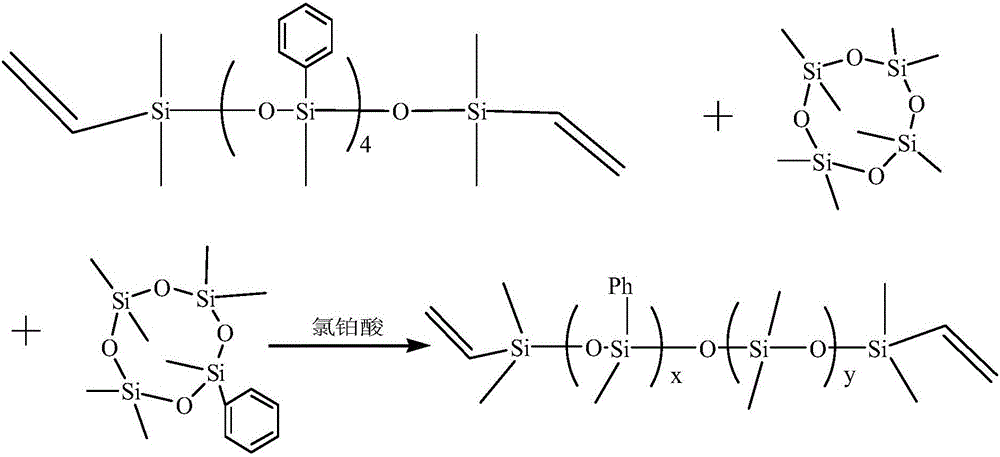

Organic silicone elastomer gel and preparation method thereof

ActiveCN106633076AImprove stabilityGood compatibilityCosmetic preparationsMake-upPolymer scienceWhitening Agents

The invention relates to the field of high polymer materials, in particular to organic silicone elastomer gel and a preparation method thereof. The organic silicone elastomer gel is prepared from a copolymer of a first polymer and a second polymer as well as a carrier fluid, wherein the structural formula of the first polymer is (I), the structural formula of the second polymer is (II), R1=CzH2z+1, z=8-18, m, n=8-15, x=10-20 and y=15-25. The organic silicone elastomer gel is well compatible with most oil and active ingredients (such as essence, sun-screening agents, skin whitening agents, vitamin and vitamin derivatives), is easy to add and is used as a thickener for water-in-oil and anhydrous formulas. The invention further provides the preparation method of the organic silicone elastomer gel to facilitate industrial production.

Owner:湖南斯洛柯有机硅有限公司

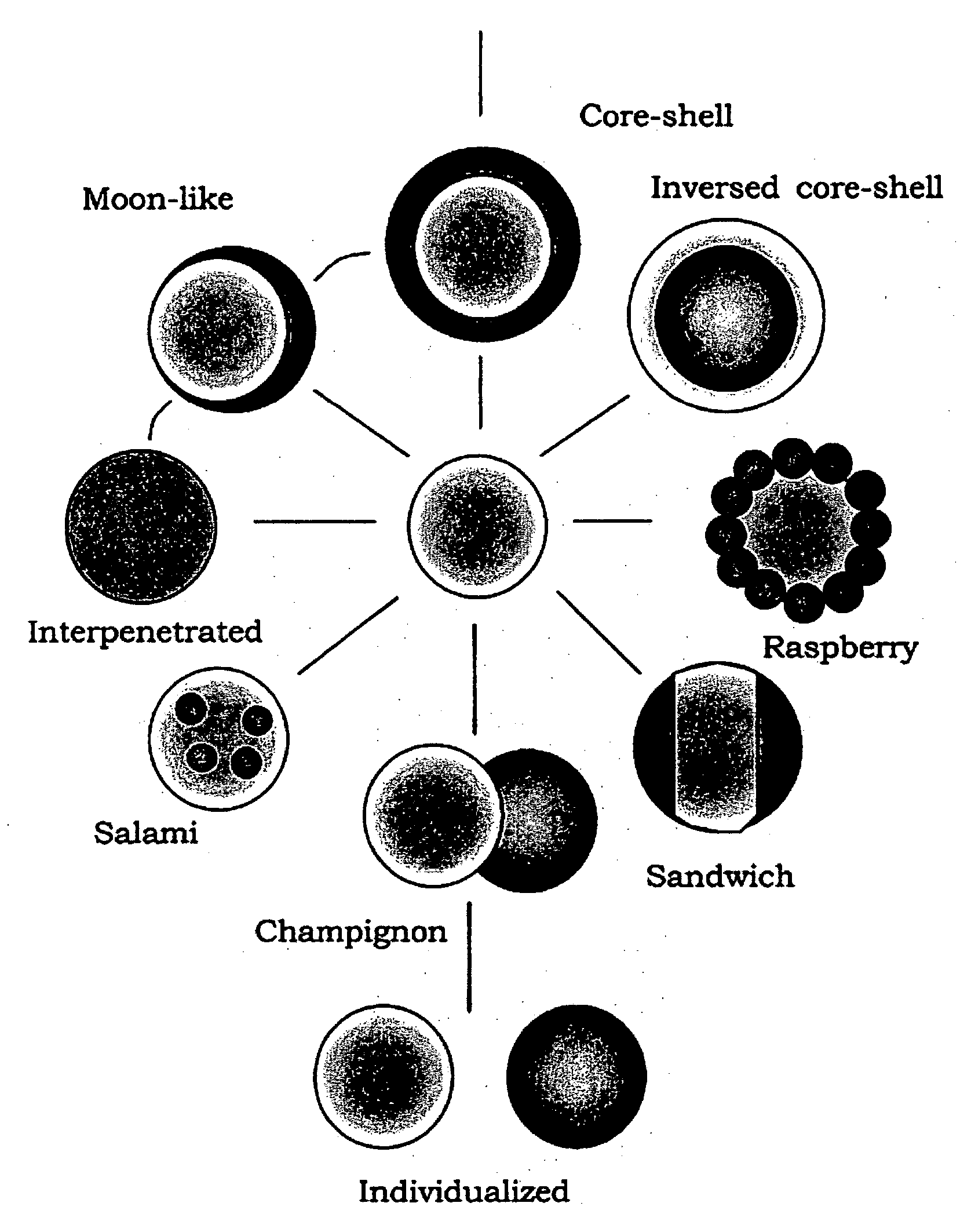

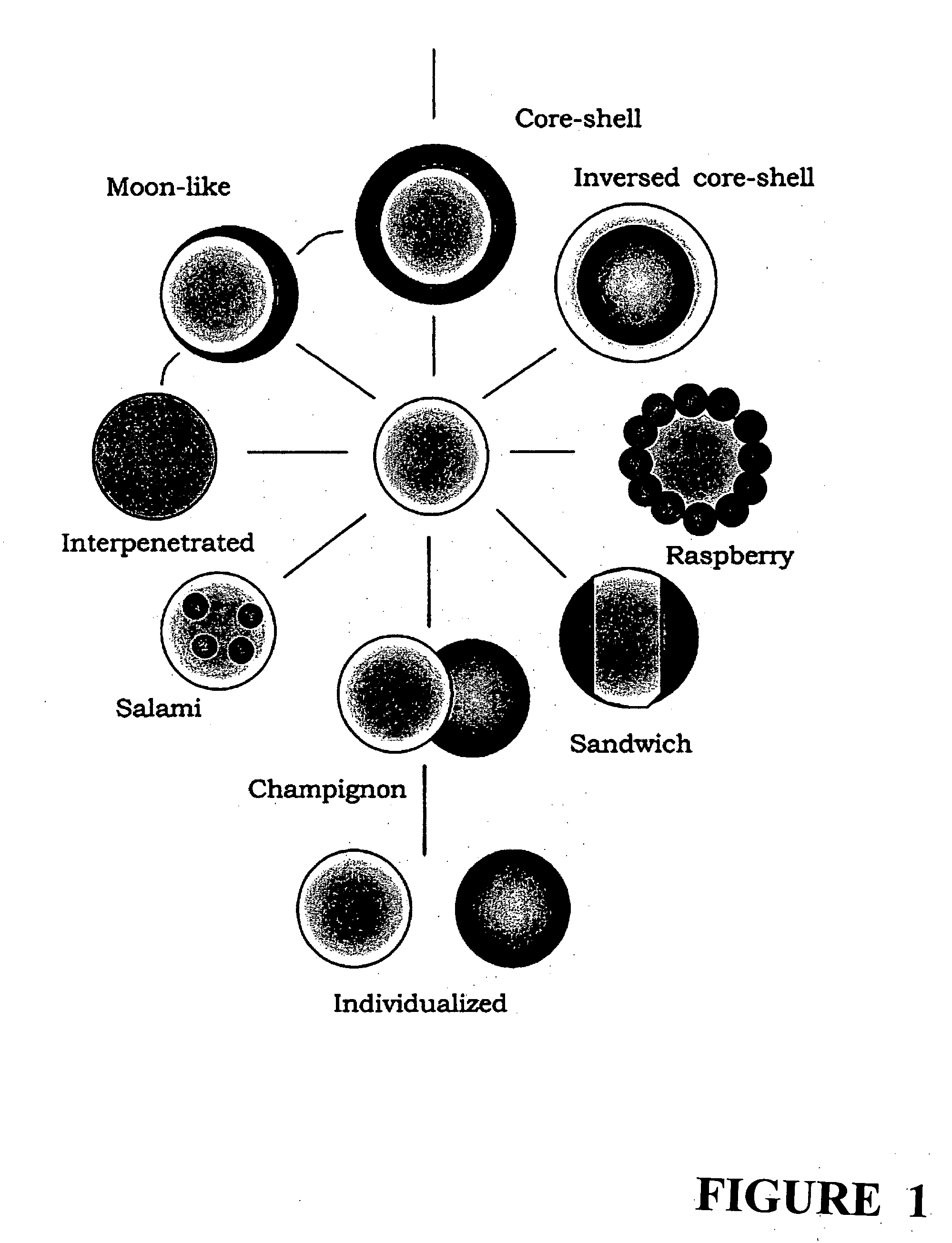

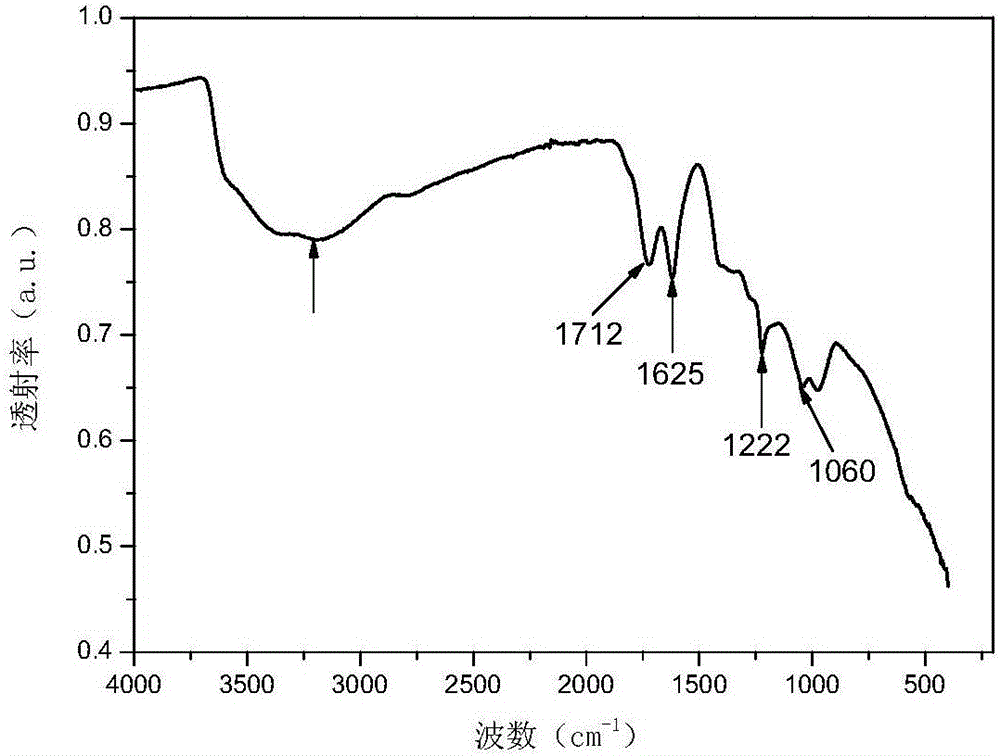

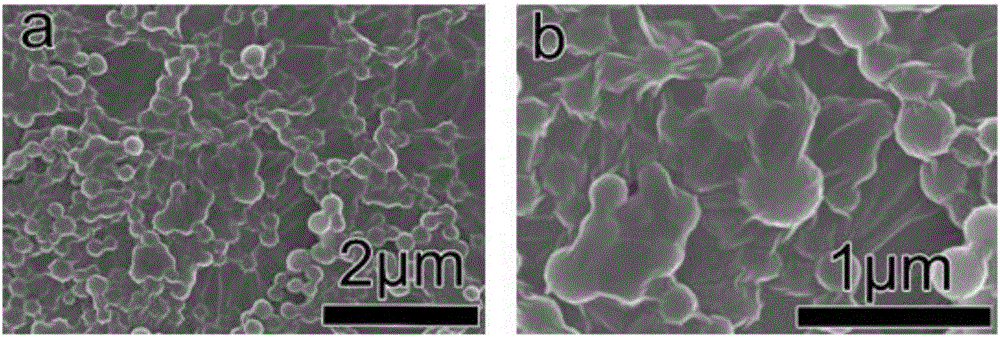

Graphene oxide-polymeric microsphere water-based lubricant additive and preparation method thereof

The invention belongs to the field of lubricant additives, and particularly relates to a graphene oxide-polymeric microsphere water-based lubricant additive as well as a preparation method of the lubricant additive. The preparation method comprises the following steps: preparing graphene oxide powder and a polymeric microsphere emulsion, wherein the polymeric microsphere emulsion is the polyacrylate microsphere emulsion or polystyrene microsphere emulsion; adding the graphene oxide powder into the polymeric microsphere emulsion, conducting ultrasonic vibration until the graphene oxide powder is completely dispersed to obtain a graphene oxide-polymeric microsphere compound emulsion, and diluting the graphene oxide-polymeric microsphere compound emulsion to be with the mass fraction of 0.1-2% through the deionized water, so as to obtain the graphene oxide-polymeric microsphere water-based lubricant additive. The graphene oxide-polymeric microsphere water-based lubricant additive is adopted to replace the conventional oil-based lubricant, so that the friction coefficient can be reduced, the abrasion resistance can be improved, the environmental pollution can be reduced, the cost can be reduced, the use stability can be improved, and meanwhile, various efficacies of cooling, rust prevention, corrosion inhibition and the like can be achieved.

Owner:WUHAN UNIV OF TECH

Method of improving the properties of a flour dough, a flour dough improving composition and improved food products

InactiveUS20020064577A1Reduce disadvantagesReduce stickinessDough treatmentHydrolasesIridophycus flaccidumOxidoreductase

A method of improving the rheological properties of a flour dough and the quality of the finished product made from such a dough, comprising adding an effective amount of an oxidoreductase capable of oxidizing maltose, in particular a hexose oxidase, e.g. isolated from an algal species such as Iridophycus flaccidum, Chondrus crispus or Euthora cristata and a dough improving composition comprising the oxidoreductase.

Owner:DUPONT NUTRITION BIOSCIENCES APS

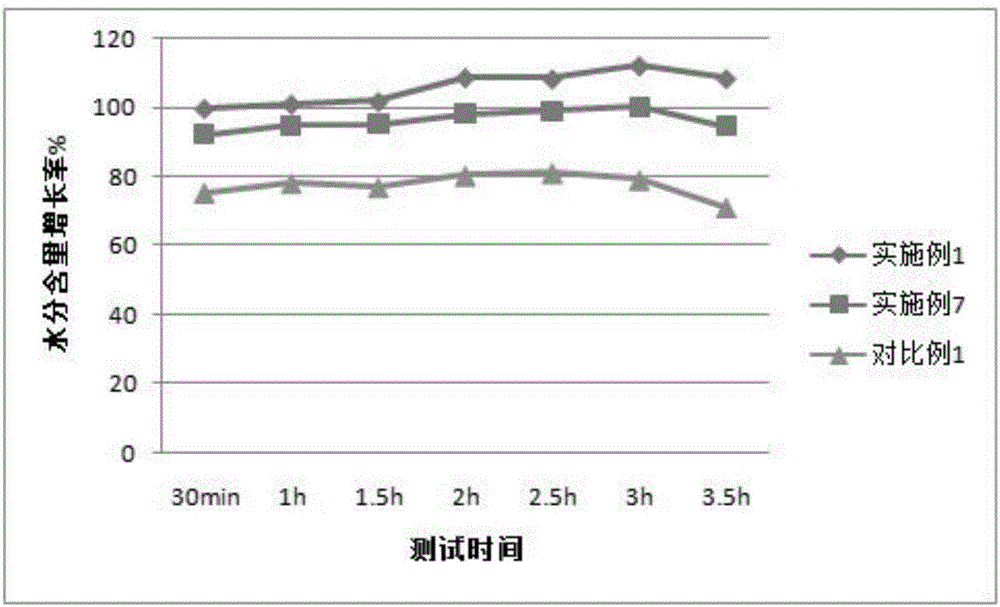

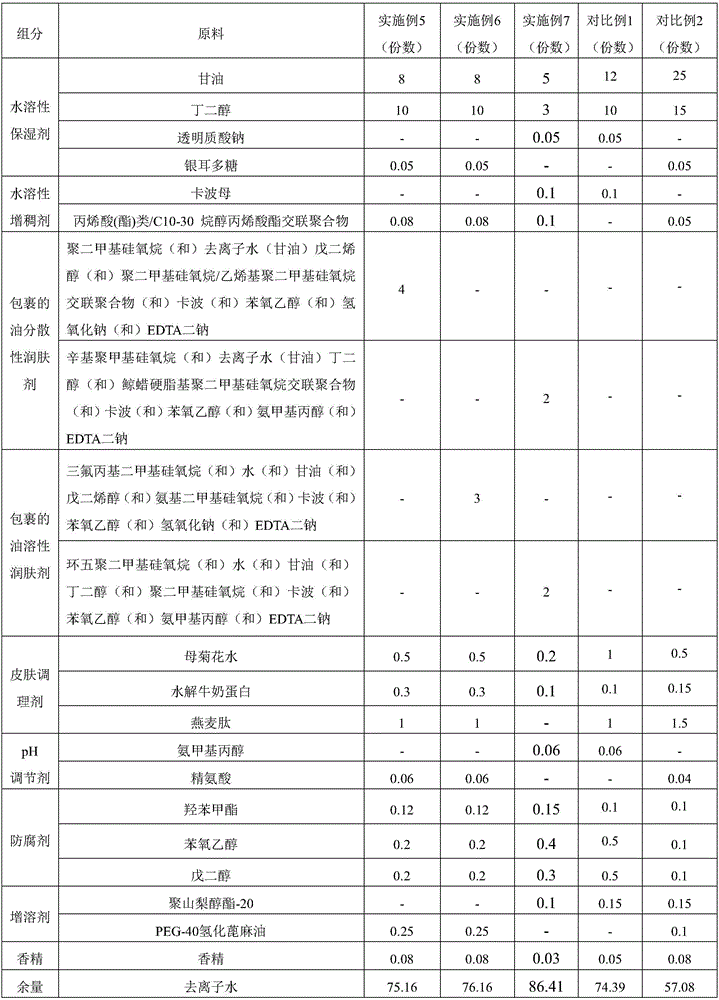

Moisturizing toning lotion and preparation method thereof

ActiveCN106726920AReduce stickinessStay hydratedCosmetic preparationsToilet preparationsMedicineTouch Senses

The invention provides moisturizing toning lotion and a preparation method thereof. The moisturizing toning lotion contains the following components in percentage by weight: 1-15%, preferably 3-12%, of a wrapped oil-dispersible emollient and / or wrapped oil-soluble emollient, 5-40%, preferably 8-31%, of a water-soluble moisturizing agent, 0.05-0.5%, preferably 0.08-0.3%, of a water-soluble thickening agent, 0.1-5%, preferably 0.3-3%, of a skin conditioner, 0.05-0.8%, preferably 0.05-0.5%, of a solubilizing agent, 0.001-0.2%, preferably 0.005-0.1%, of a pH regulator and 45-93%, preferably 55-88%, of water. The moisturizing toning lotion contains the wrapped oil-dispersible emollient and / or wrapped oil-soluble emollient, so that the moisturizing toning lotion has soft touch sense and smooth texture and stickiness of the moisturizing toning lotion also can be reduced.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

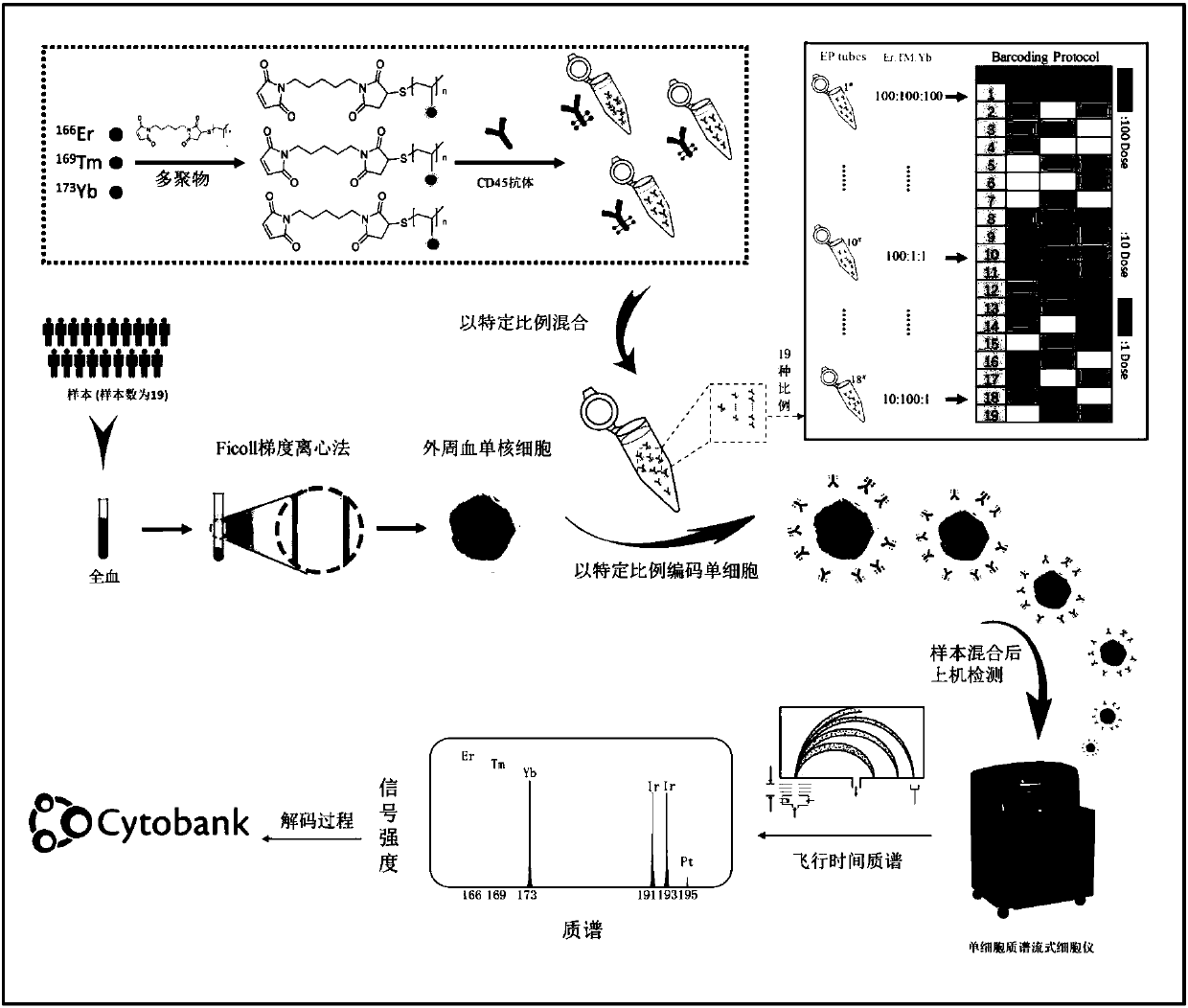

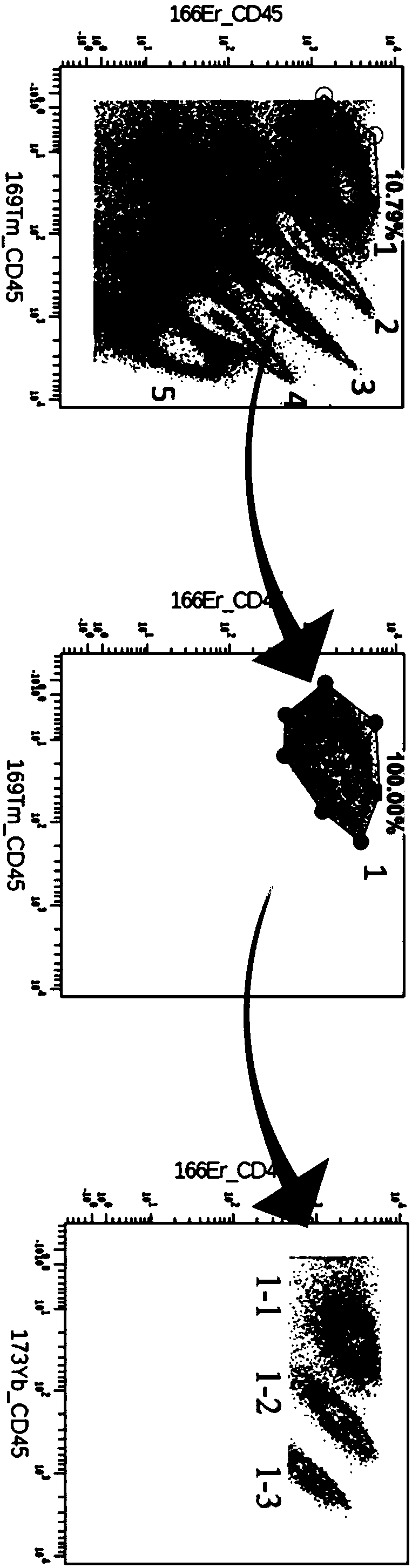

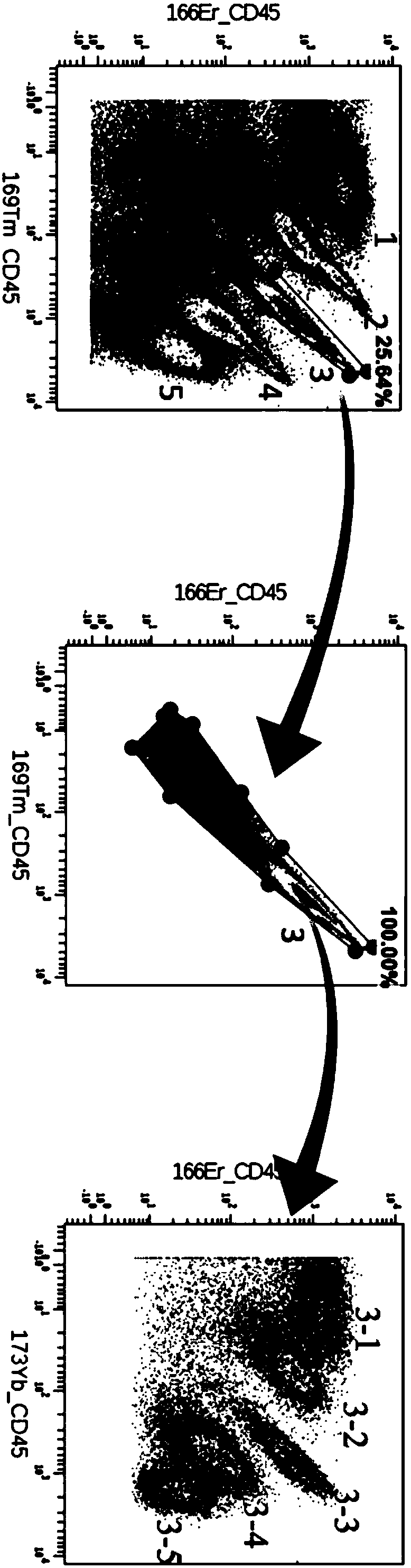

Detecting method for unicellular mass spectrum flow cytometry

InactiveCN107796748AImprove efficiencyLow costIndividual particle analysisConcentration ratioIsotope

The invention discloses a detecting method for unicellular mass spectrum flow cytometry. A novel encoding method of an isotope metal concentration ratio marking antibody is applied, metals with different ratios is used, thus a new label combination is structured; thus a detecting channel of the mass spectrum flow cytometry is expanded by a few metal label number, a Barcoding technology which moreefficient than the existed technology is developed.

Owner:SHANGHAI JIAO TONG UNIV

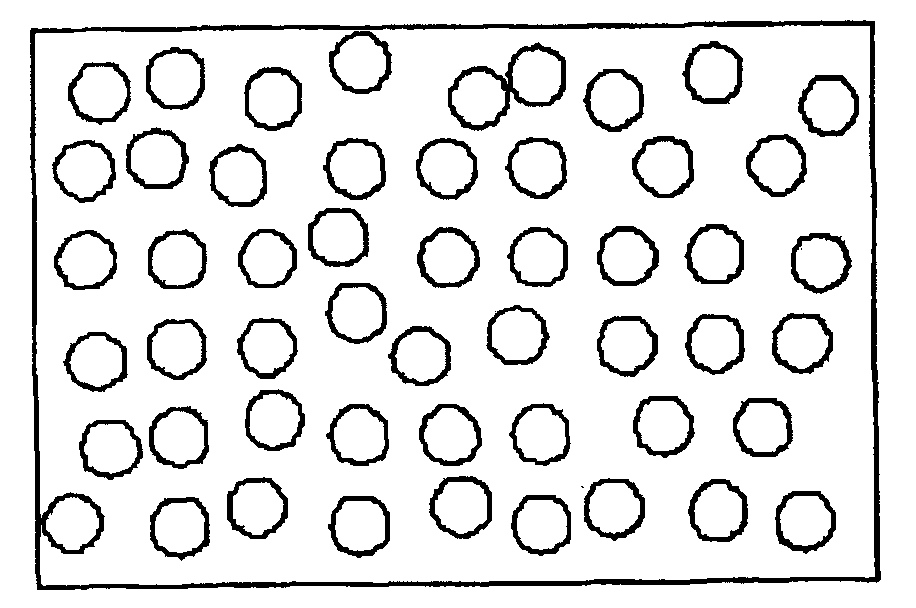

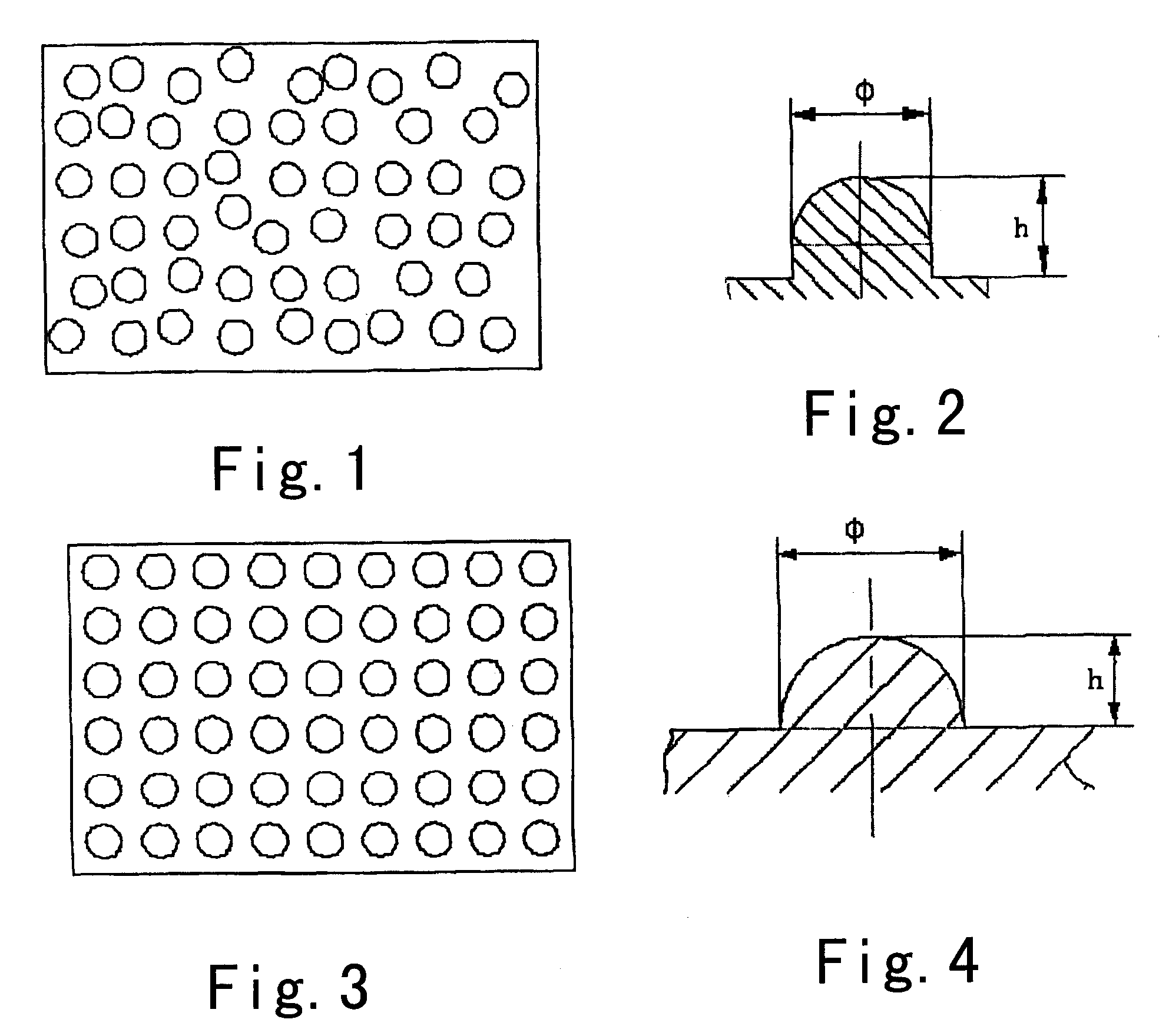

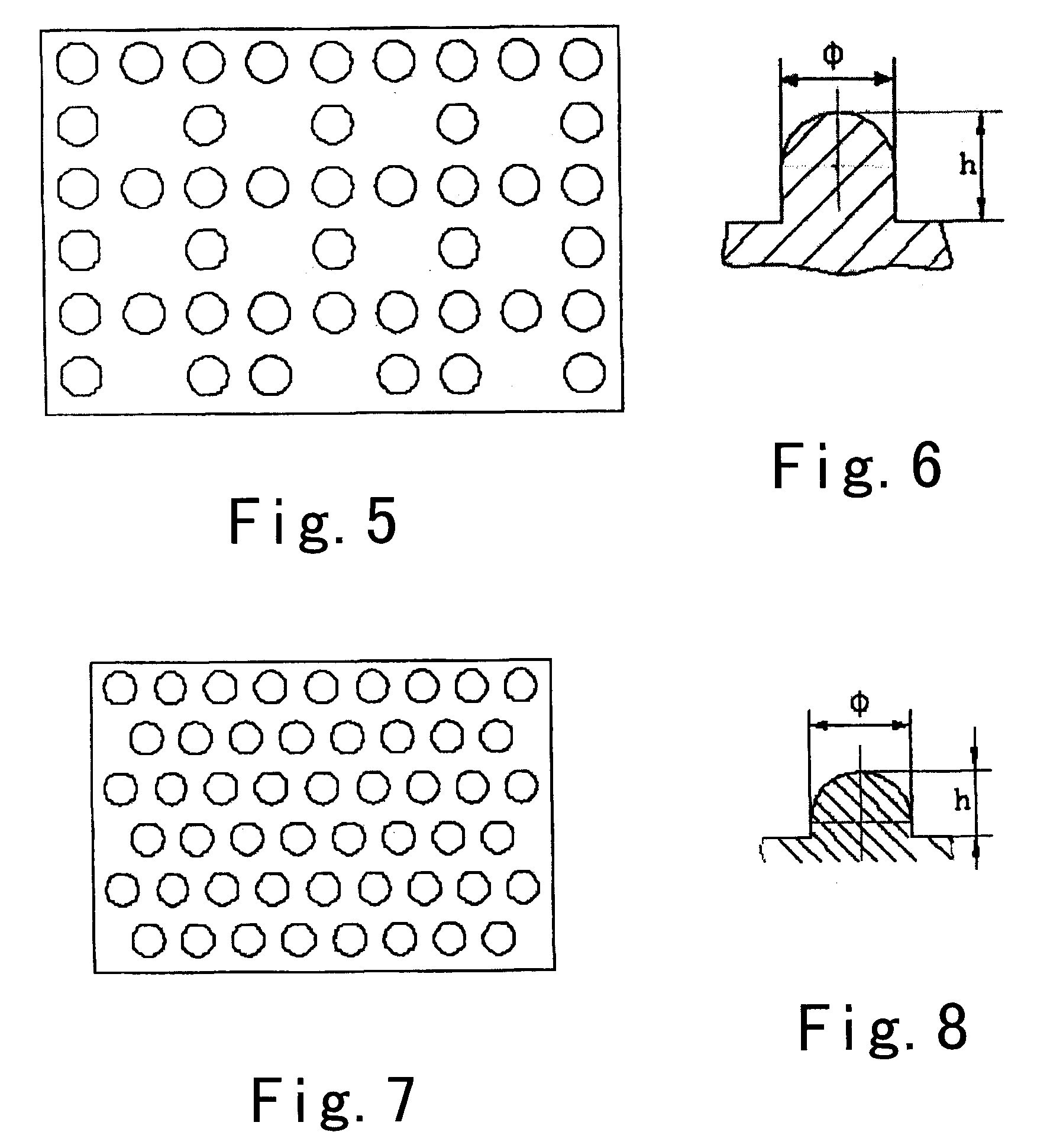

Non-Stick Cooking Utensil

InactiveUS20080105689A1Efficient reductionImprove waterproof performanceRecord information storageMagnetic recordingBiomedical engineeringCooker

The invention relates to a non-stick cooking utensil, wherein protrusions are arranged on interior wall of the utensil to form a non-smooth surface, said protrusion has a height of 20-999 μm and a projection area of 314-783431 μm2 with respect to the interior surface of the utensil, the protrusions are so distributed that the total projection area of protrusions on the surface of the interior wall is about 10%-60% of the surface area, a coating film is formed on said non-smooth surface with protrusions. As compared with utensils with smooth surface, the sticking intensity and stickiness between foods and the utensil of present invention may be decreased by 60%-80%.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com