Crucible for polysilicon ingot casting, coating structure of crucible and coating preparation method

A crucible coating and polysilicon technology, which is applied to the crucible for polysilicon ingot casting, its coating structure and coating preparation, can solve the problems of sticky crucible, easy peeling of coating, weak bonding force, etc., and reduce sticking pot , not easy to fall off, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

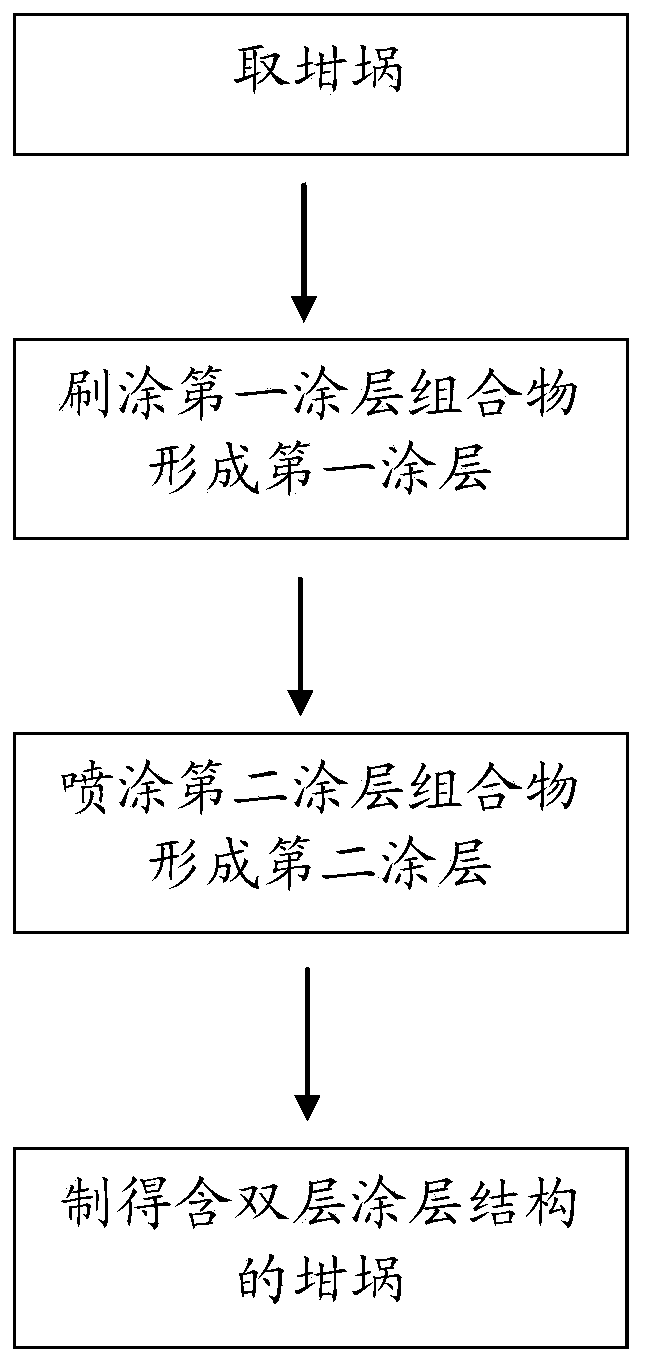

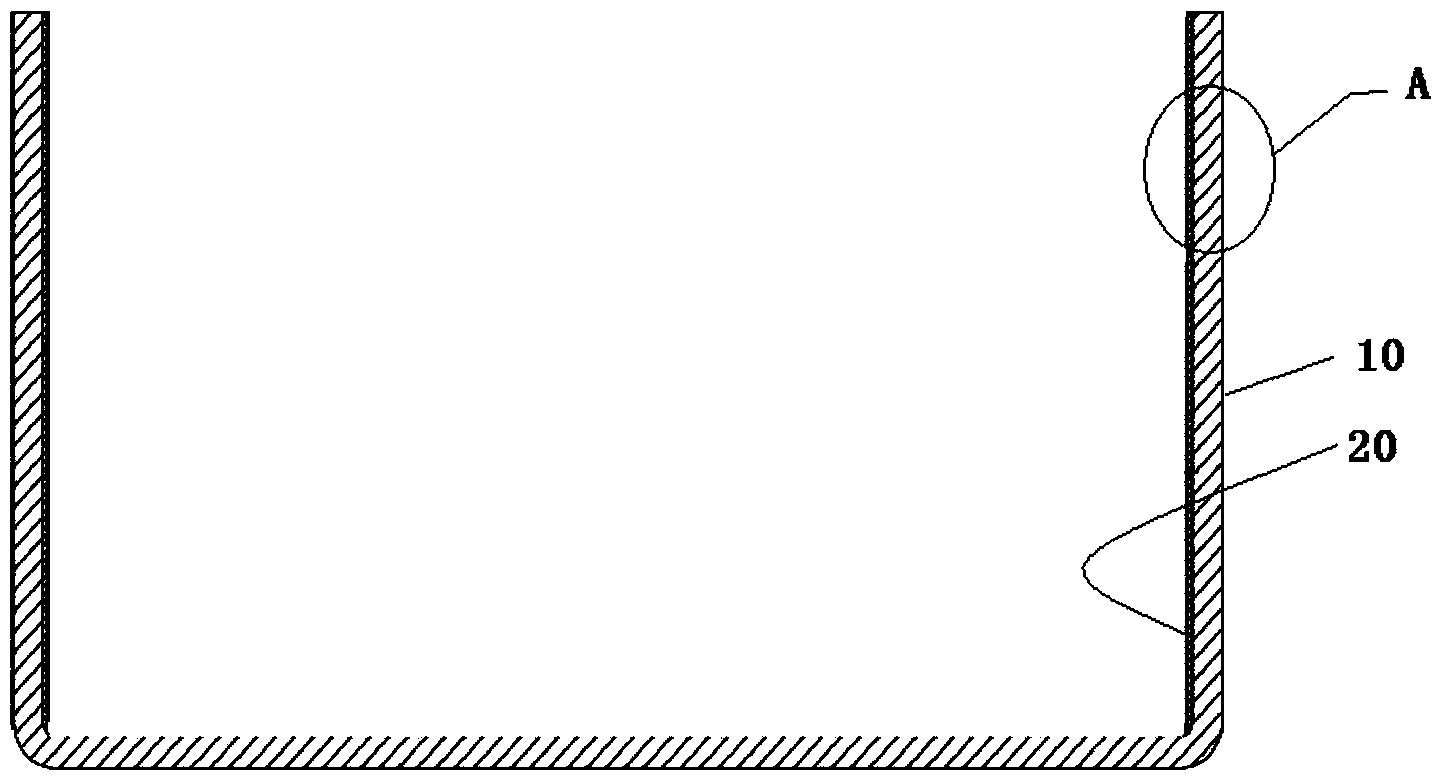

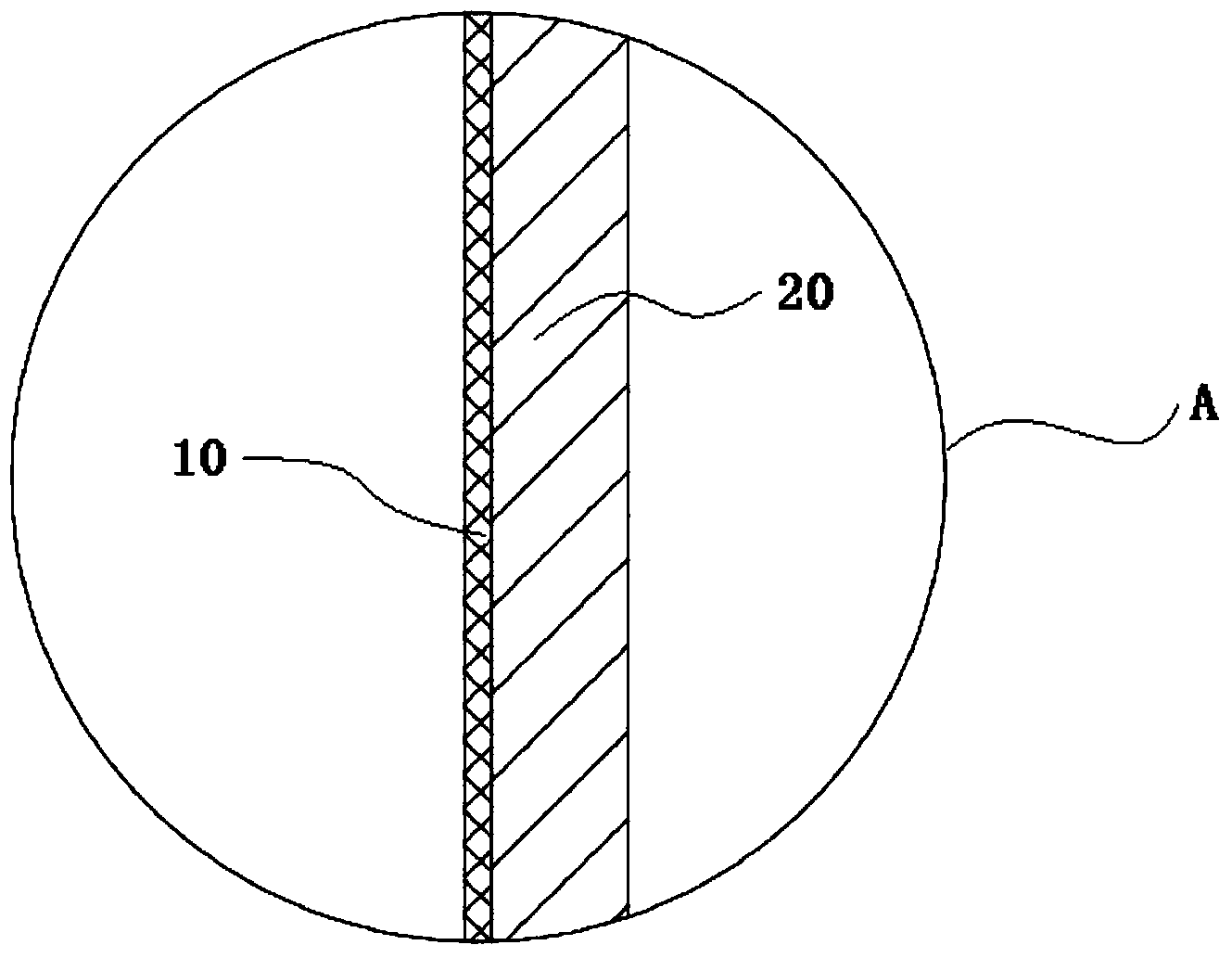

[0107] combine as figure 1 Process flow chart for the preparation of crucible coatings for polysilicon ingots shown, figure 2 The cross-sectional view of the crucible for polysilicon ingot casting and image 3 of figure 2In the partially enlarged schematic diagram of part A, this embodiment provides a coating preparation method for a crucible for polysilicon ingots, including the following steps:

[0108] 1) Take a cuboid crucible with a model size of 700mm×700mm×480mm for use, which includes a side wall 10 (if the crucible is not clean enough, you can first place the crucible to be brushed on the rotary table to blow away the sundries in the crucible);

[0109] 2) Silicon nitride (Si 3 N 4 ), silica sol, and pure water are mixed and poured into a measuring cup according to the weight ratio of 3:1:5. The amount of silicon nitride in each crucible is 60g, and stirred with a mixer for 10 minutes to make it evenly mixed to obtain the first coating combination wherein, the...

Embodiment 2

[0116] This embodiment provides a coating preparation method for a crucible for polysilicon ingots, comprising the following steps:

[0117] 1) Take a cuboid crucible with a model size of 840mm×840mm×480mm for use, which includes side walls 10 (if the crucible is not clean enough, you can first place the crucible to be brushed on the rotary table to blow away the sundries in the crucible);

[0118] 2) Silicon nitride (Si 3 N 4 ), polyvinyl alcohol, and absolute ethanol are mixed and poured into a measuring cup according to a weight ratio of 4:1:5. The amount of silicon nitride in each crucible is 80g, and stirred with a mixer for 15 minutes to make it evenly mixed to obtain the first coating Layer composition, wherein the silicon nitride is silicon nitride particles with a particle size of 50um, which is a product produced by Japan UBE Company, wherein the nitrogen content is >38wt%, and the oxygen content is <2.0wt%;

[0119] 3) Take off the measuring cup after stirring, a...

Embodiment 3

[0126] This embodiment provides a coating preparation method for a crucible for polysilicon ingots, comprising the following steps:

[0127] 1) Take a cuboid crucible with a model size of 1040mm×1040mm×480mm for use, which includes a side wall 10 (if the crucible is not clean enough, you can first place the crucible to be brushed on the rotary table to blow away the sundries in the crucible);

[0128] 2) Silicon nitride (Si 3 N 4 ), polyvinylpyrrolidone, and isopropanol were mixed and poured into a measuring cup according to a weight ratio of 5:1:5. The amount of silicon nitride in each crucible was 100g, and stirred with a mixer for 20 minutes to make it evenly mixed to obtain the first coating Layer composition, wherein the silicon nitride is silicon nitride particles with a particle size of 50um, which is a product produced by Starck Company in Germany, wherein the nitrogen content is >38wt%, and the oxygen content is <2.0wt%;

[0129] 3) Take off the measuring cup after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com