Patents

Literature

2206 results about "Bond Force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Common to occur between Jedi Masters and their apprentices, a Force bond, also known as Force chain or Jedi kinship, was a link through which two Force-sensitives could influence each other. It allowed the communication of feelings, thoughts and images across distances and granted greater coordination in battle.

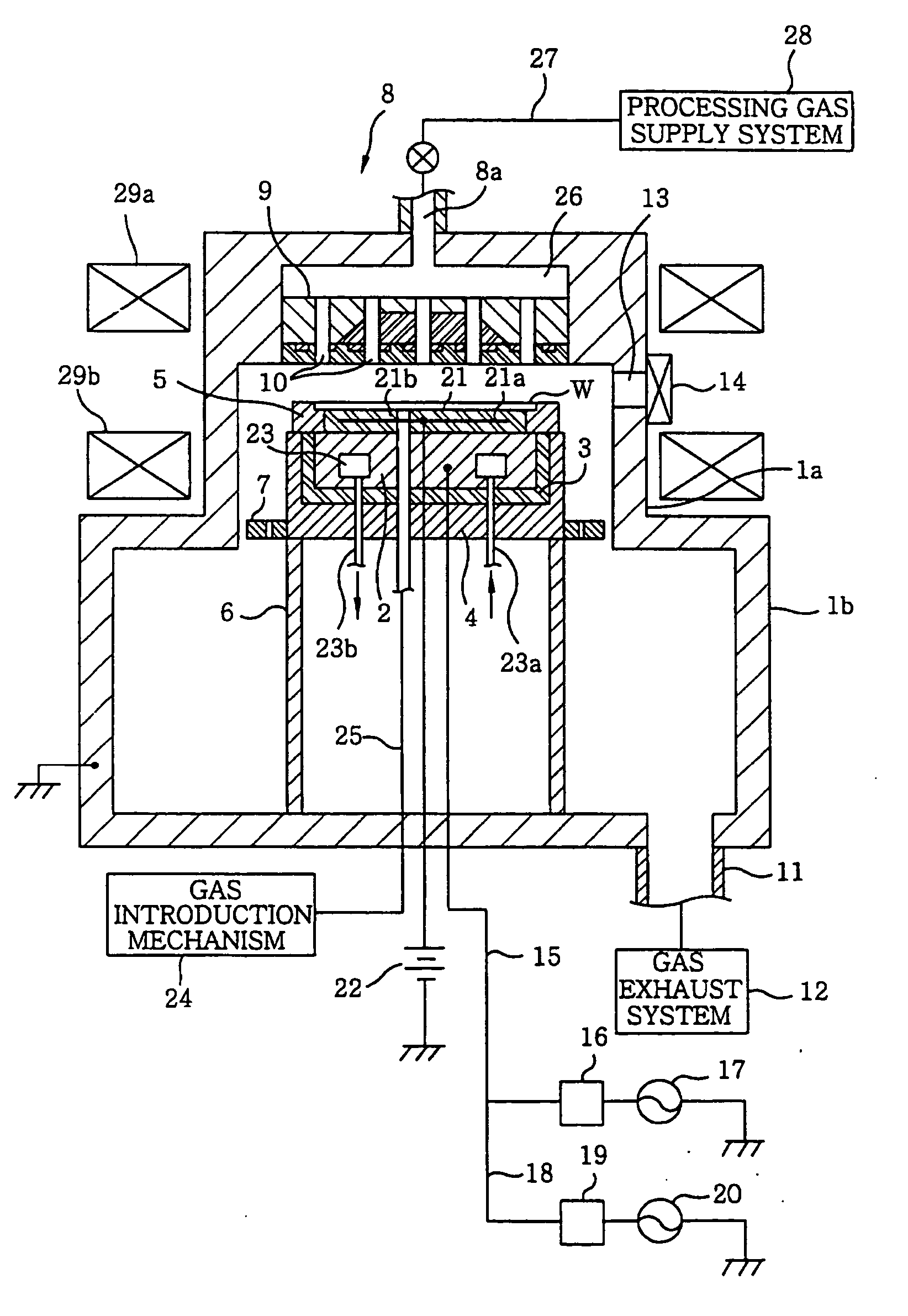

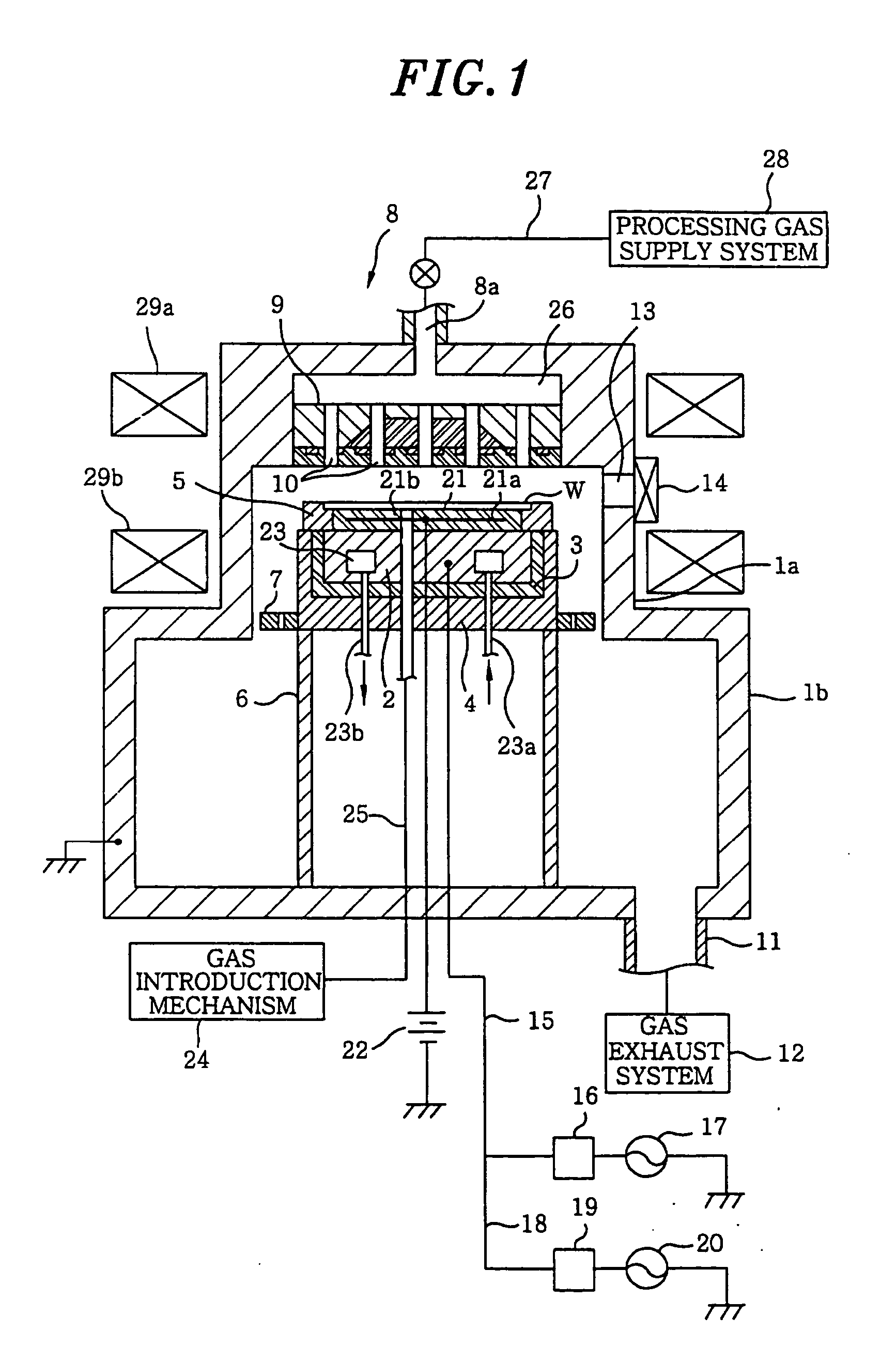

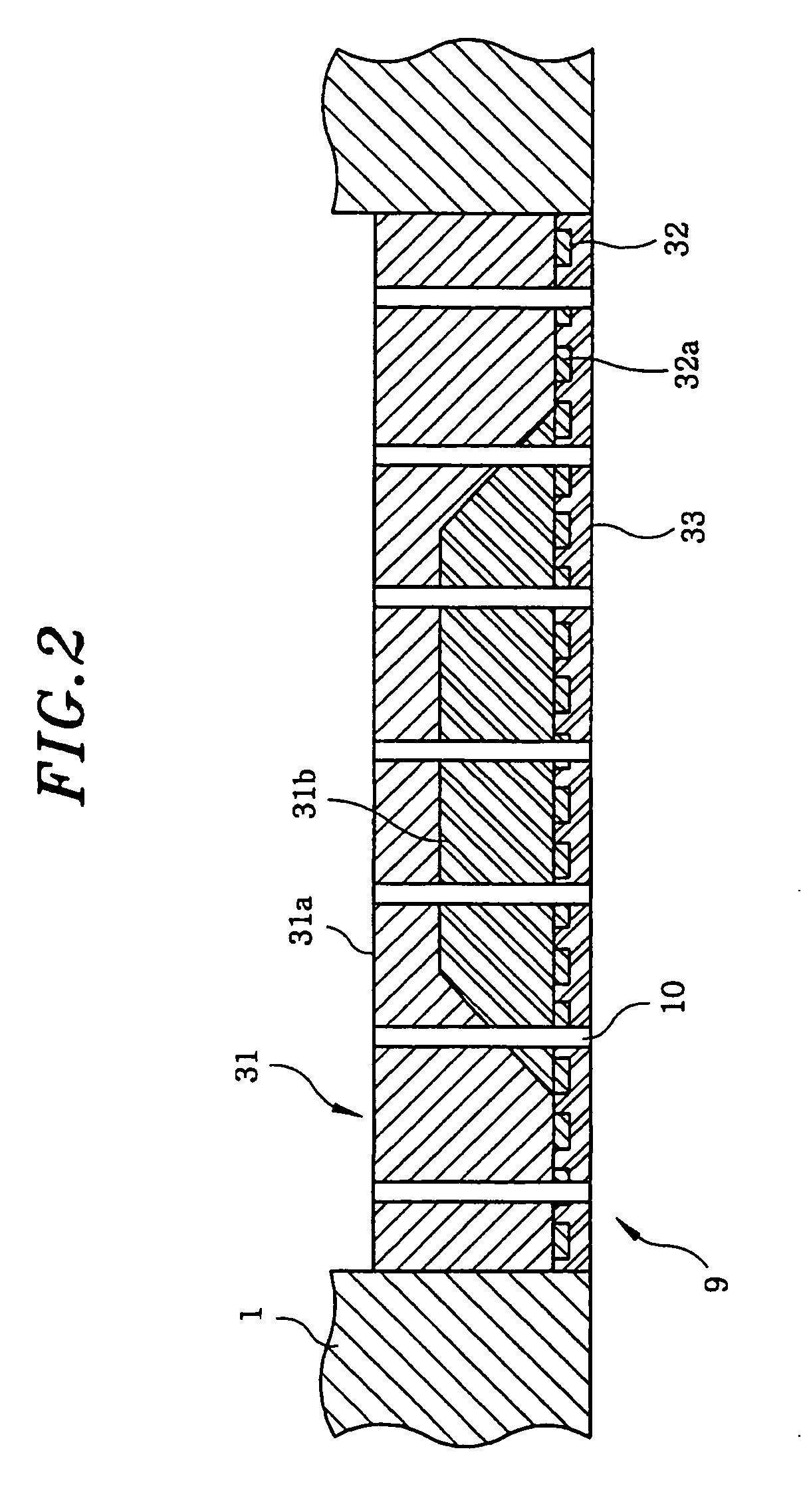

Thermally sprayed member, electrode and plasma processing apparatus using the electrode

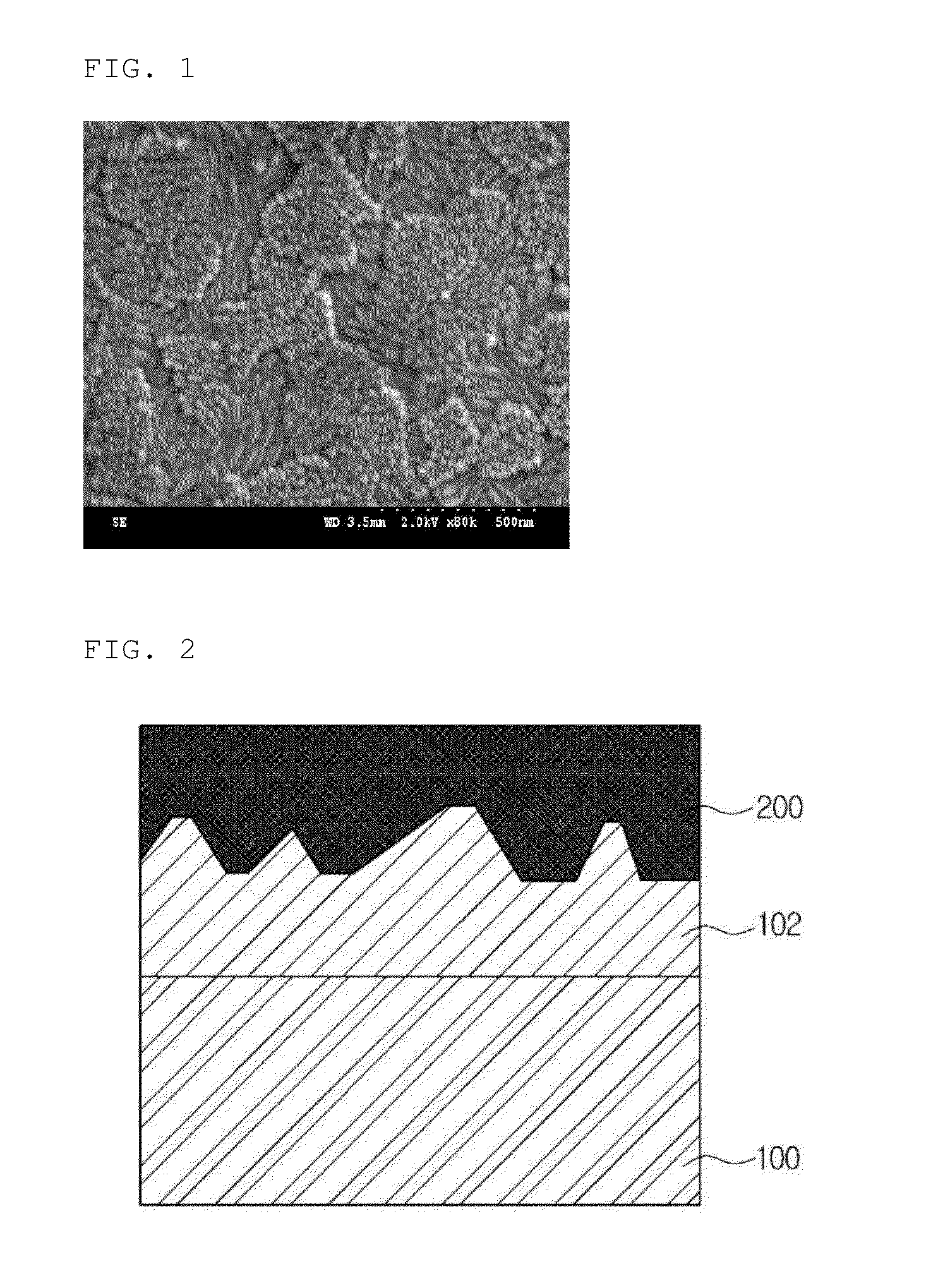

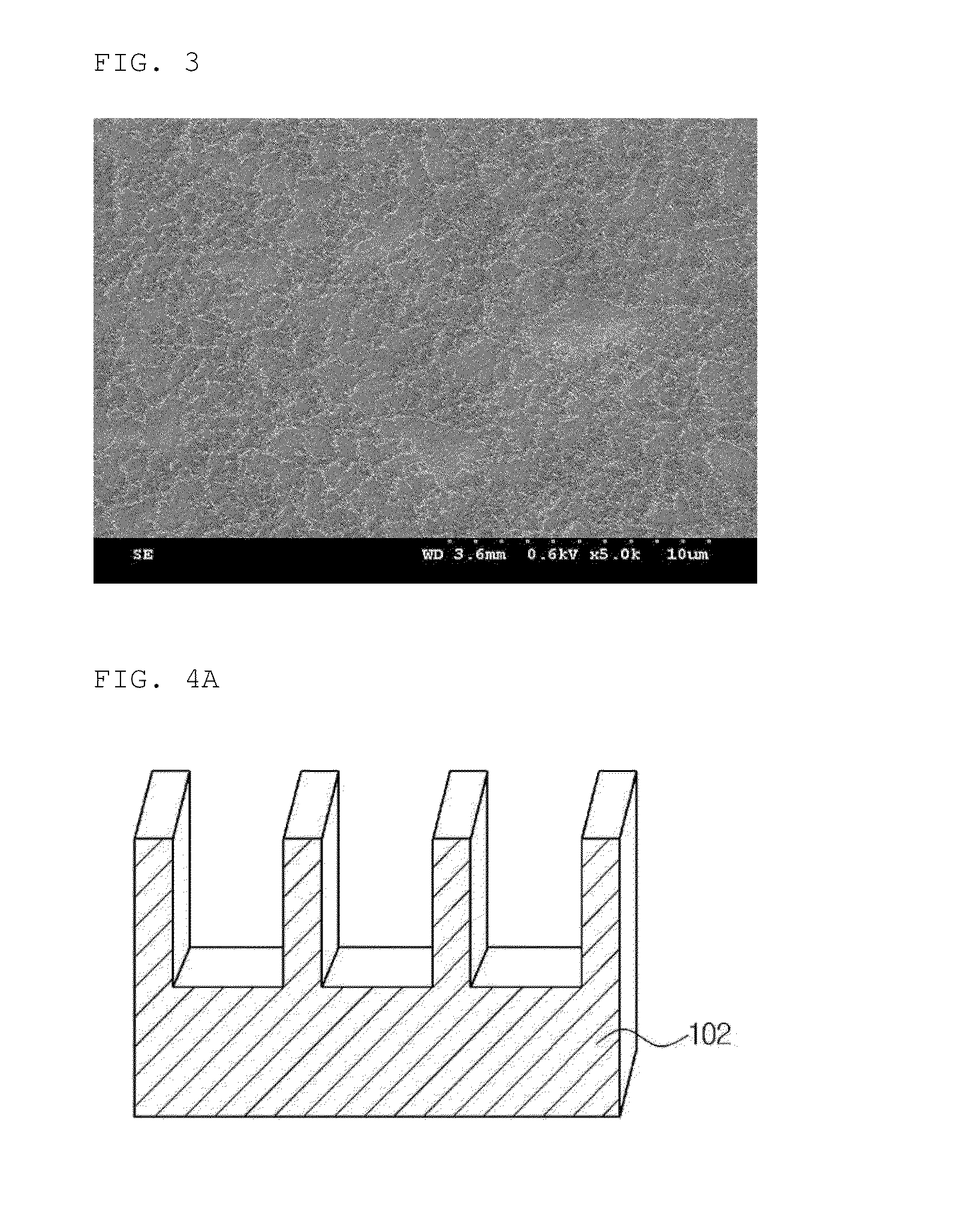

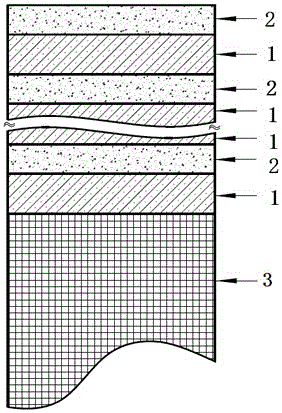

ActiveUS20050211384A1High-frequency powerAvoid flowMolten spray coatingElectric discharge tubesThermal sprayingInter layer

A thermally sprayed member or an electrode includes a basic material, a thermally sprayed film formed on the surface of the basic material, the thermally sprayed film being made of an insulating ceramic and a metallic intermediate layer provided between the basic material and the thermally sprayed film for increasing a bonding force therebetween, wherein the thermally sprayed film side of the member is exposed to a high frequency plasma atmosphere and the electrode is intended to form a high frequency plasma on the side of the thermally sprayed film. The basic material includes a base portion made of a conductive material and a dielectric portion provided to include a part of a surface of the basic material. Further, the intermediate layer is comprised of a plurality of island-shaped parts isolated from each other.

Owner:TOKYO ELECTRON LTD

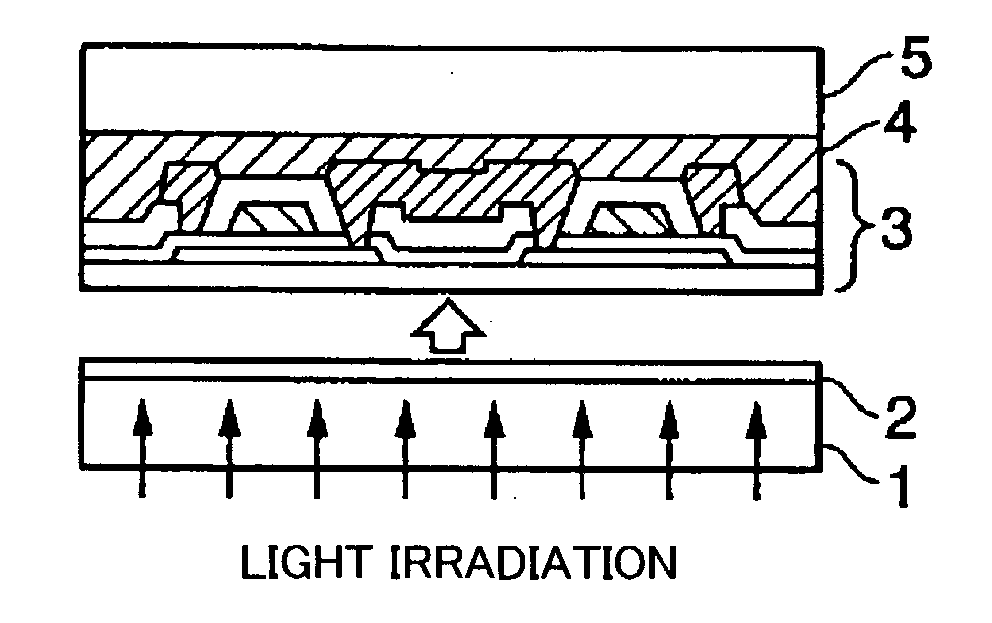

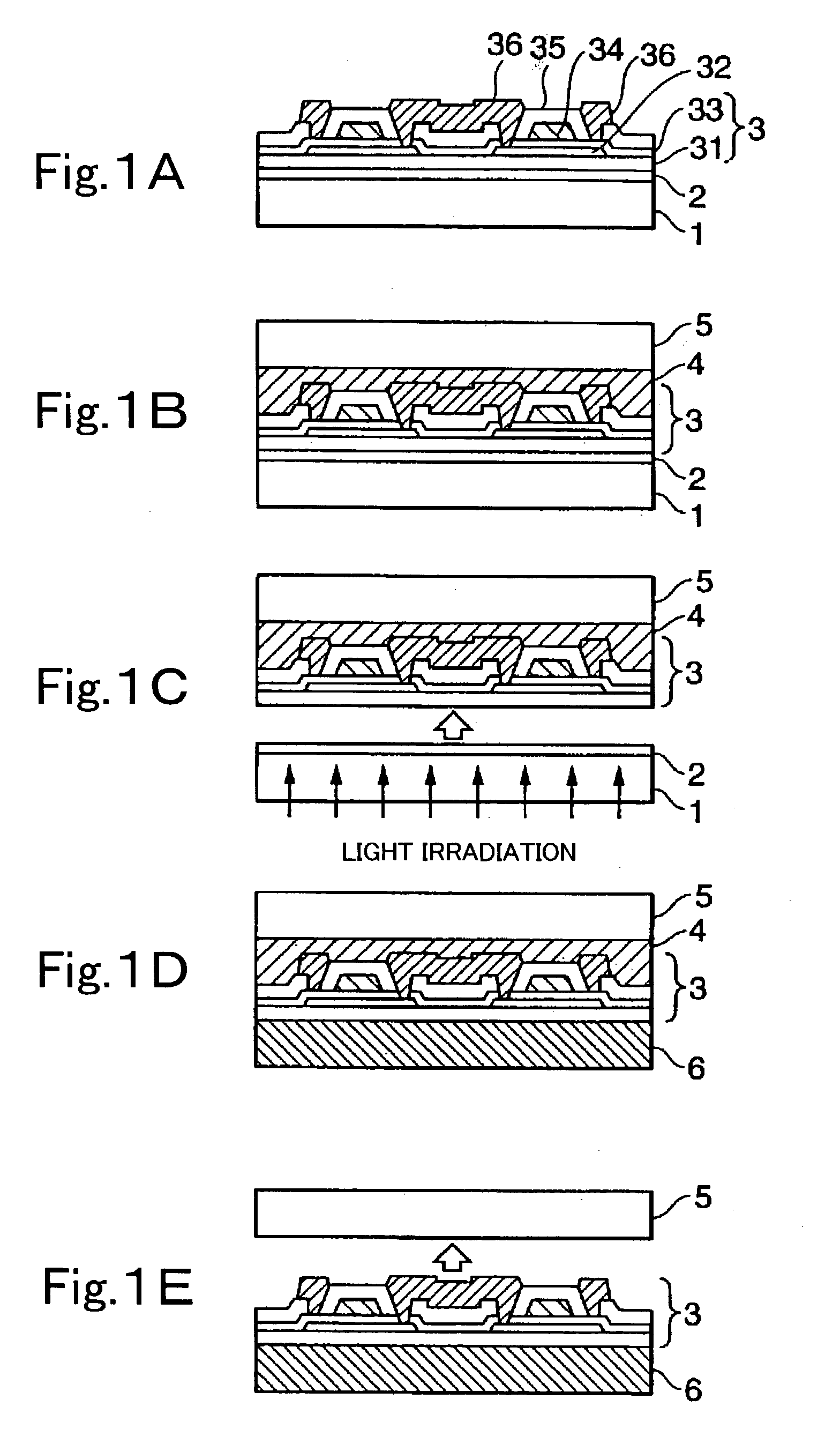

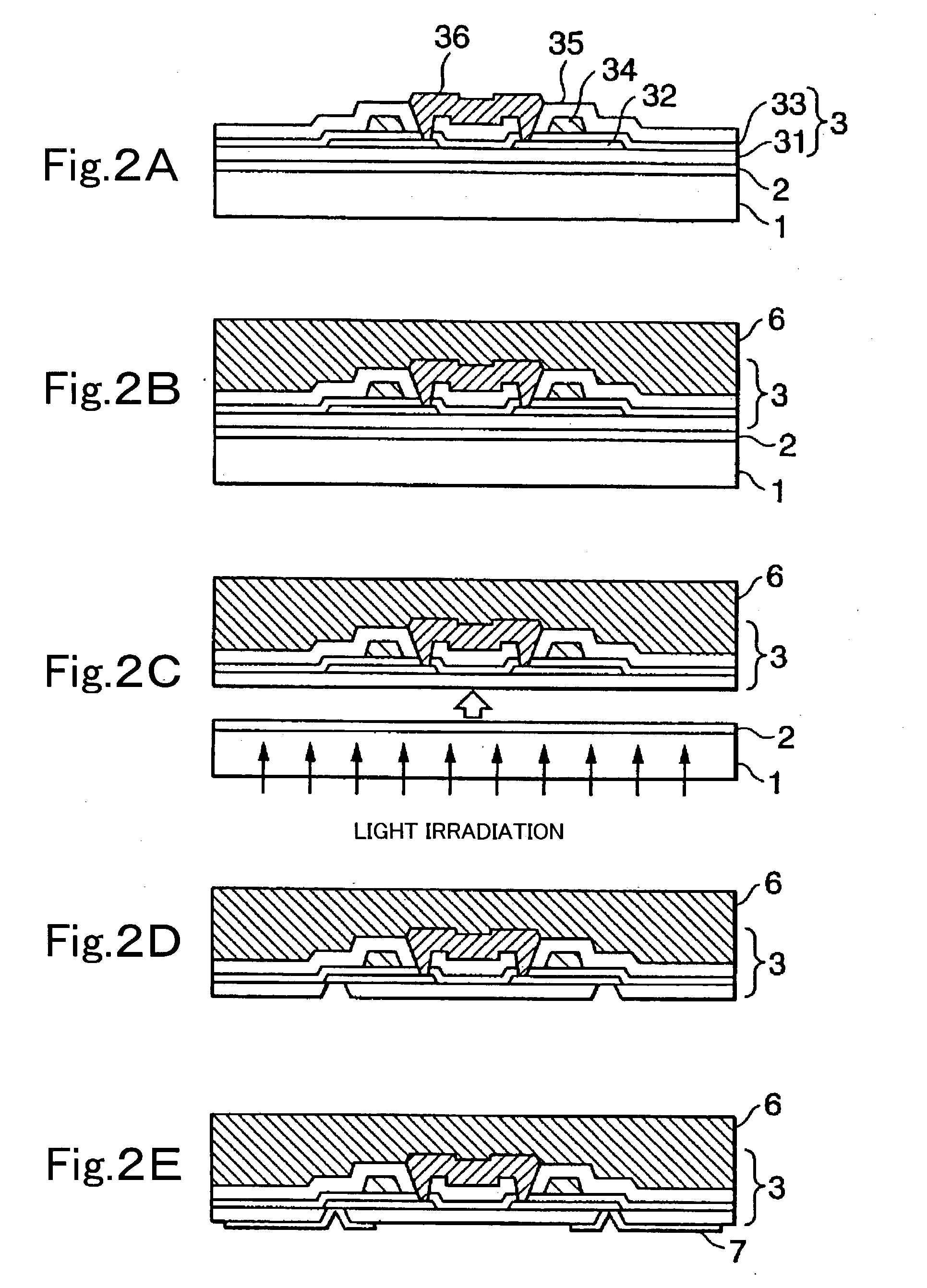

Method for transferring element, method for producing element, integrated circuit, circuit board, electro-optical device, IC card, and electronic appliance

InactiveUS20030024635A1Thinner semiconductor deviceMinimize cracksLamination ancillary operationsDecorative surface effectsDevice materialEngineering

A peeling layer 2 is formed on an element-forming substrate 1, an element-forming layer 3 including an electrical element is formed on the peeling layer, the element-forming layer is joined by means of a dissolvable bonding layer 4 to a temporary transfer substrate 5, the bonding force of the peeling layer is weakened to peel the element-forming layer from the element-forming substrate, the layer is moved to the temporary transfer substrate 5 side, a curable resin 6 is applied onto the element-forming layer 3 which has been moved onto the temporary transfer substrate 5, the resin is cured to form a transfer substrate 6, and the bonding layer 4 is dissolved to peel the temporary transfer substrate 5 from the transfer substrate 6, resulting in a structure in which a transfer substrate is formed directly on the element-forming layer 3. The separation and transfer technique can be used to form a substrate with better flexibility and impact resistance directly on a semiconductor element, without an adhesive layer on the semiconductor device that is produced.

Owner:SAMSUNG ELECTRONICS CO LTD

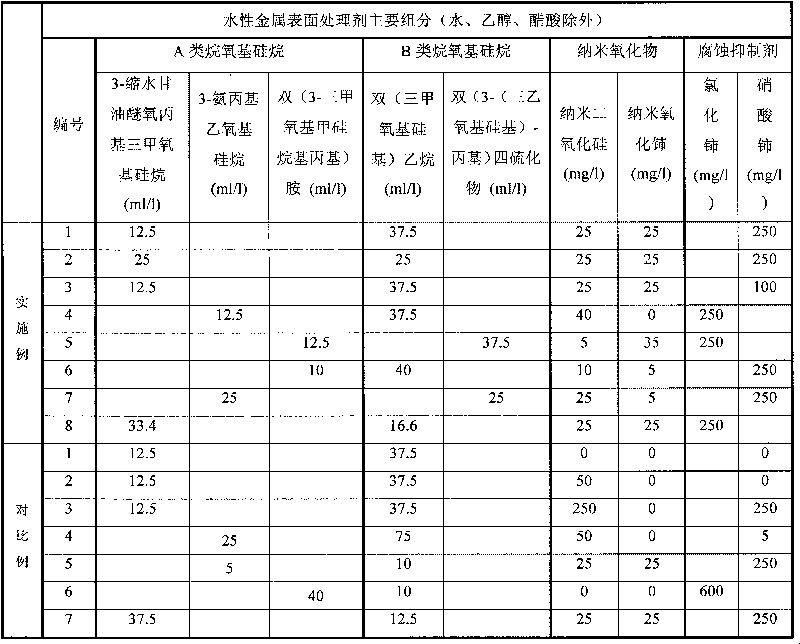

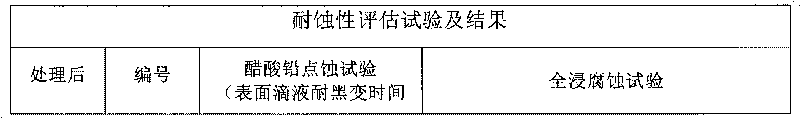

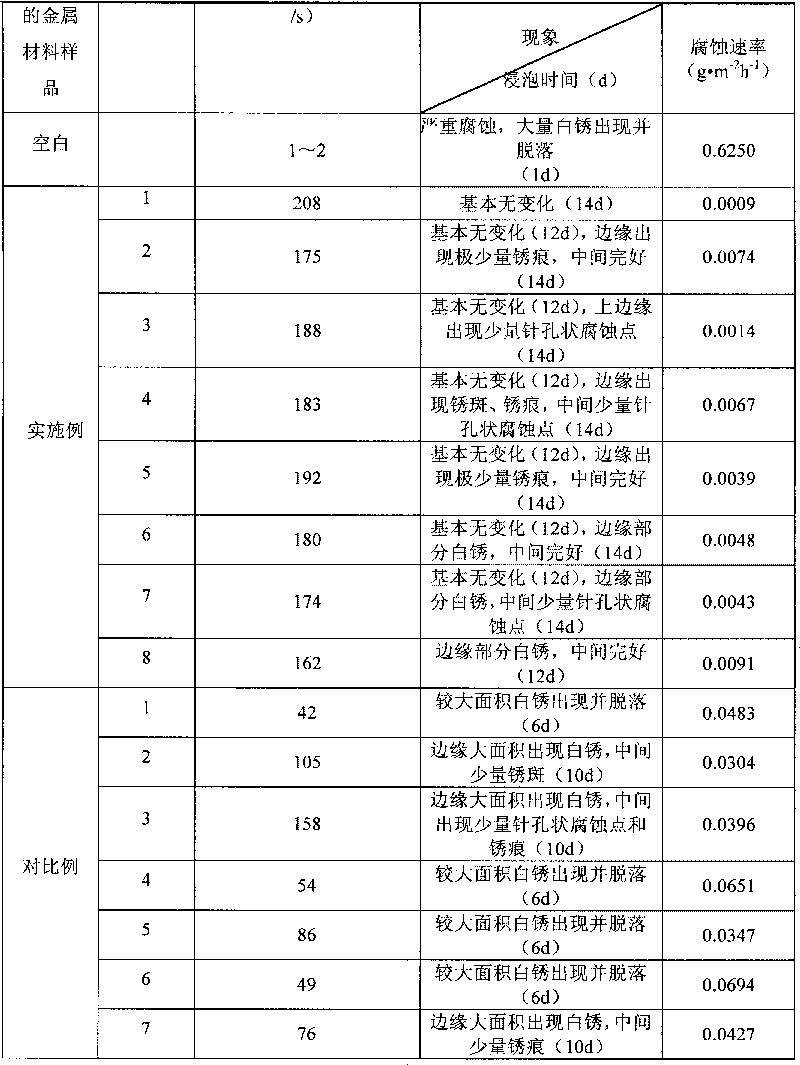

Environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface

ActiveCN101717930ASimple processApplicable industrial scaleMetallic material coating processesWater basedEpoxy

The invention discloses an environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface. The treatment agent is water-based silane solution which consists of at least one alkoxy silane containing epoxy or at least one alkoxy silane containing amino, at least one disilyl silane, nano-silicon dioxide, rare earth salt type corrosion inhibitor or rare earth salt type and rare earth nano oxide, water, or acetic acid and a small amount of ethanol. The metal material is coated by using the silane solution for impregnation, brushing, spraying or spin-coating, a siloxane layer is formed on the metal surface, then the long-acting corrosion resistance is formed by curing for 3 hours at the temperature of 100 DEG C, and a nano organic silane film which has close bonding force with a coating is formed. Nanoparticles can not only improve the corrosion resistance and enhance the mechanical strength of the silane film in a coating layer, but also realize the synergistic corrosion resistance with the corrosion inhibitor. The technology has the advantages of simple process, greenness, environmental protection and strong practicality.

Owner:HAISO TECH

Reaction bonding type node sealant and preparation method thereof

ActiveCN102911638AImprove stabilityImprove bindingNon-macromolecular adhesive additivesOther chemical processesChemical LinkagePolyvinyl chloride

The invention provides a reaction bonding type node sealant and a preparation method thereof. The sealant comprises asphalt, modifiers, an emulsifier, a crosslinking agent, thickeners, a reinforcing agent and water. In the formula system, more appropriate modifiers are adopted compared with the prior art, so that a rubber asphalt mixture can achieve good emulsification effect, elasticity and strength of a sealing layer after drying are greatly improved, and the sealing effect can be good and lasting; the chemical linkage effect with concrete is formed by using the crosslinking agent, and bonding force with the concrete is improved; and a lot of thickeners are used for adjusting the stickness of the sealant system, so that the reaction bonding type node sealant can better adhere to the surface of a pentatricopeptide repeats (PPR) or polyvinyl chloride (PVC) pipe, and good sealing at positions where PPR or PVC water supply and drainage pipes are connected with base surfaces of concrete.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Plastic composition and surface selective metallization process thereof

ActiveCN101654564AImprove bindingHigh precisionCatalyst activation/preparationLiquid/solution decomposition chemical coatingLaser etchingChemical plating

The invention provides a plastic composition and a surface selective metallization process thereof. The plastic composition comprises a high molecular polymer and a photocatalyst, wherein the mass ratio of the polymer to the photocatalyst is 1 to 100. The surface selective metallization process of the plastic composition comprises the following steps: performing laser etching on the surface of theplastic composition; putting the plastic composition after the laser etching into an aqueous solution containing a metal ion salt and a cavity sacrificial agent to perform photocatalysis reduction reaction so as to obtain a plastic composition with nanometer metal particles on the surface; and finally performing metal chemical plating. By adopting the plastic composition and the surface selectivemetallization process of the plastic composition, the bonding force of a plating layer and the chemical plating precision are very high.

Owner:BYD CO LTD

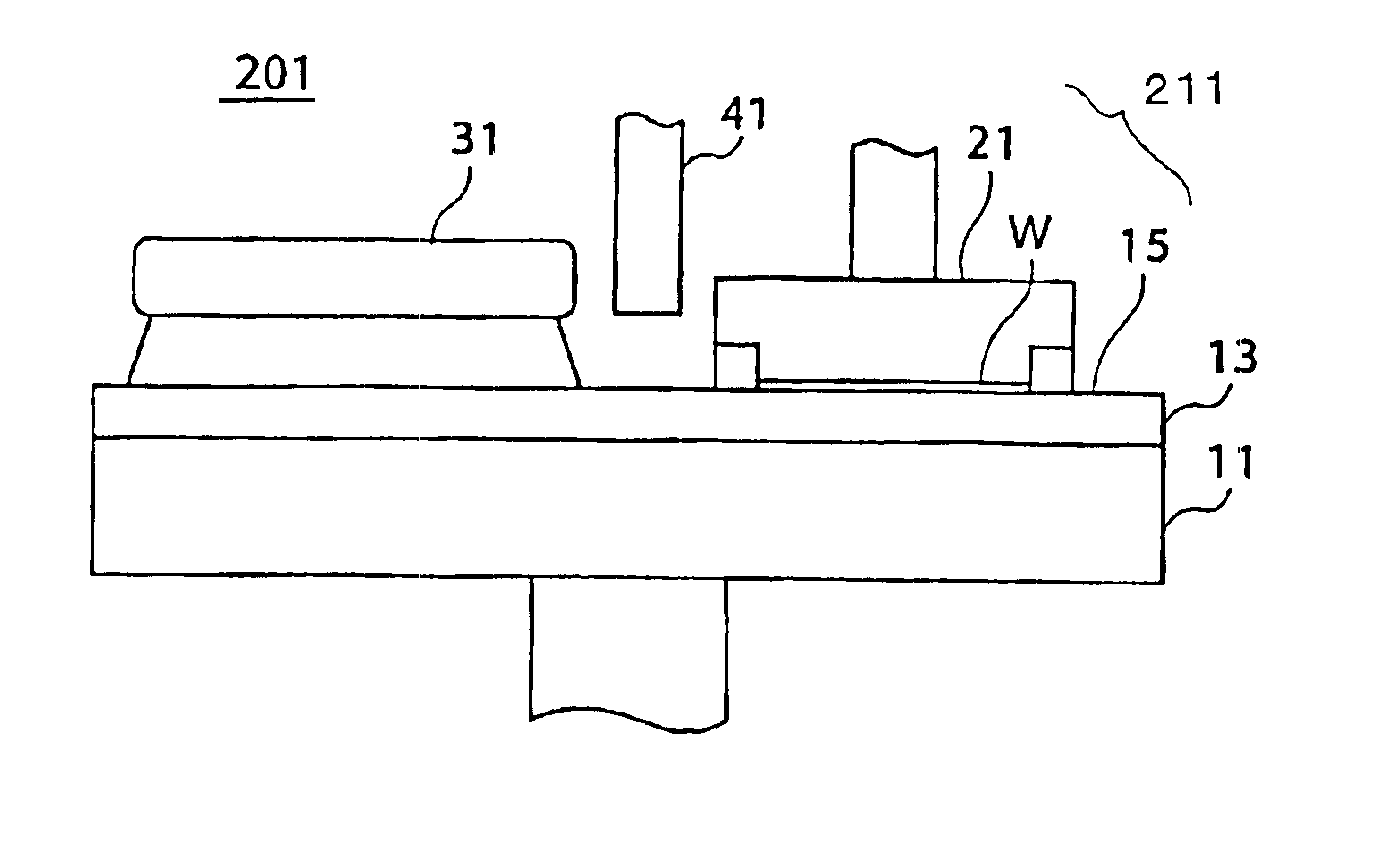

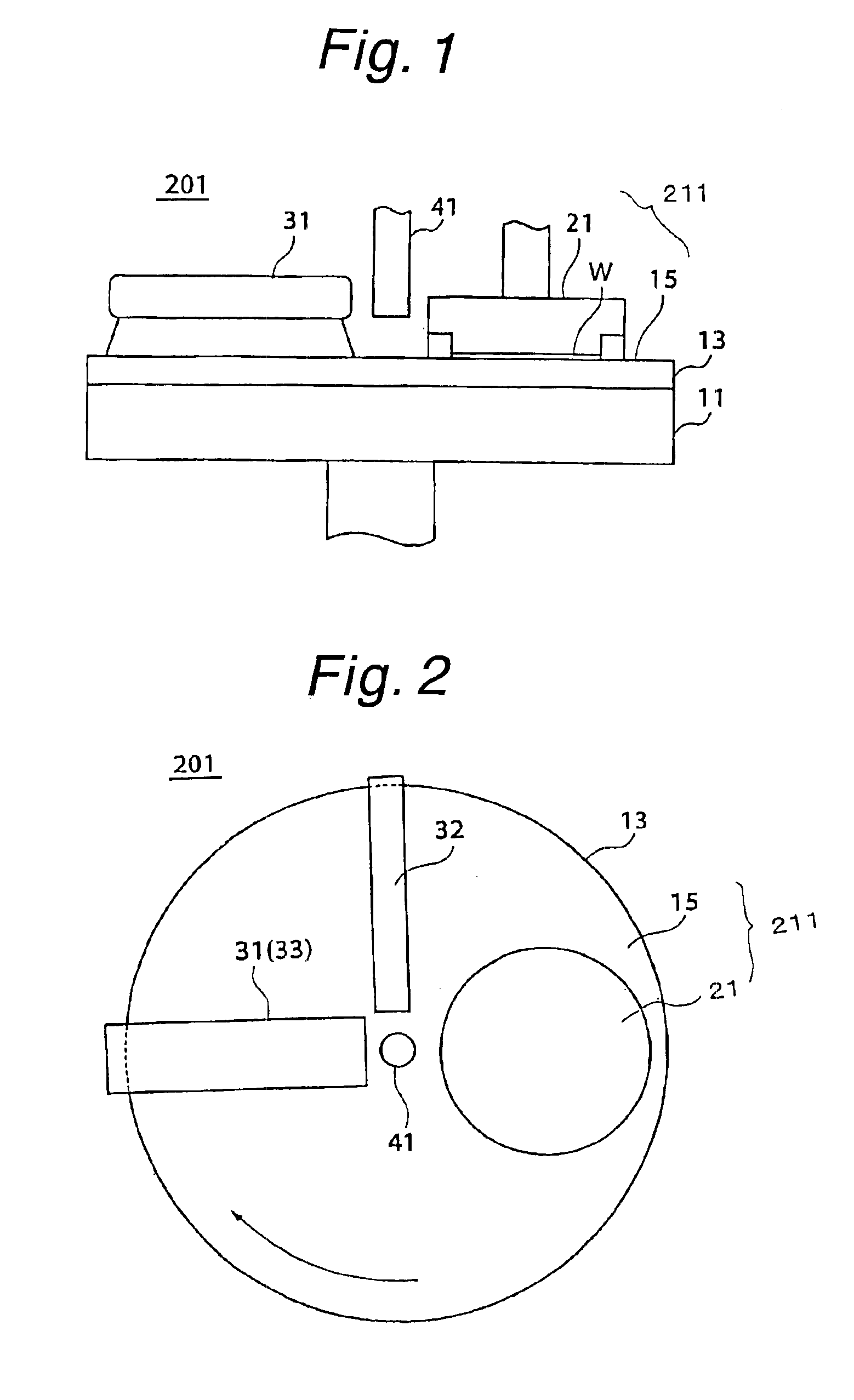

Polishing apparatus and dressing method for polishing tool

InactiveUS6899592B1Easy to dressReduce the binding forceGrinding drivesAbrasive surface conditioning devicesIrradiationBond Force

In a polishing apparatus, a polishing tool including abrasive particles and a binder for bonding together the abrasive particles is pressed against a substrate to polish the substrate. The polishing apparatus has a light source for irradiating a polishing surface with light rays for weakening a bond force of the binder for bonding together the abrasive particles, and a waste matter removing mechanism for forcefully removing waste matter produced by polishing or waste matter produced by irradiation. By irradiating the polishing surface with the light rays, dressing of the polishing surface is performed, and products resulting from dressing and the like are removed. The polishing apparatus supplies abrasive particles to the polishing surface stably by dressing and allows high-speed polishing of the substrate.

Owner:EBARA CORP

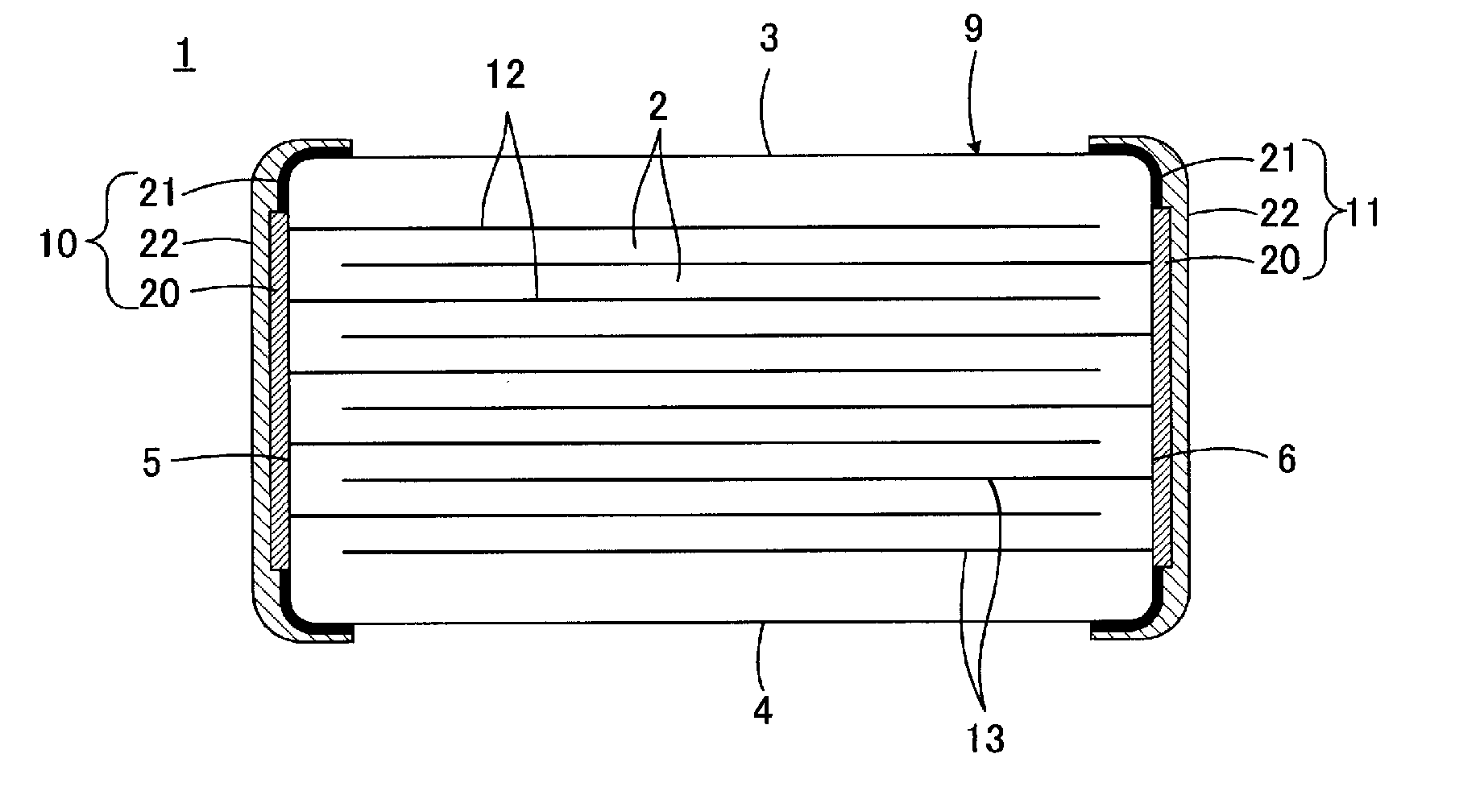

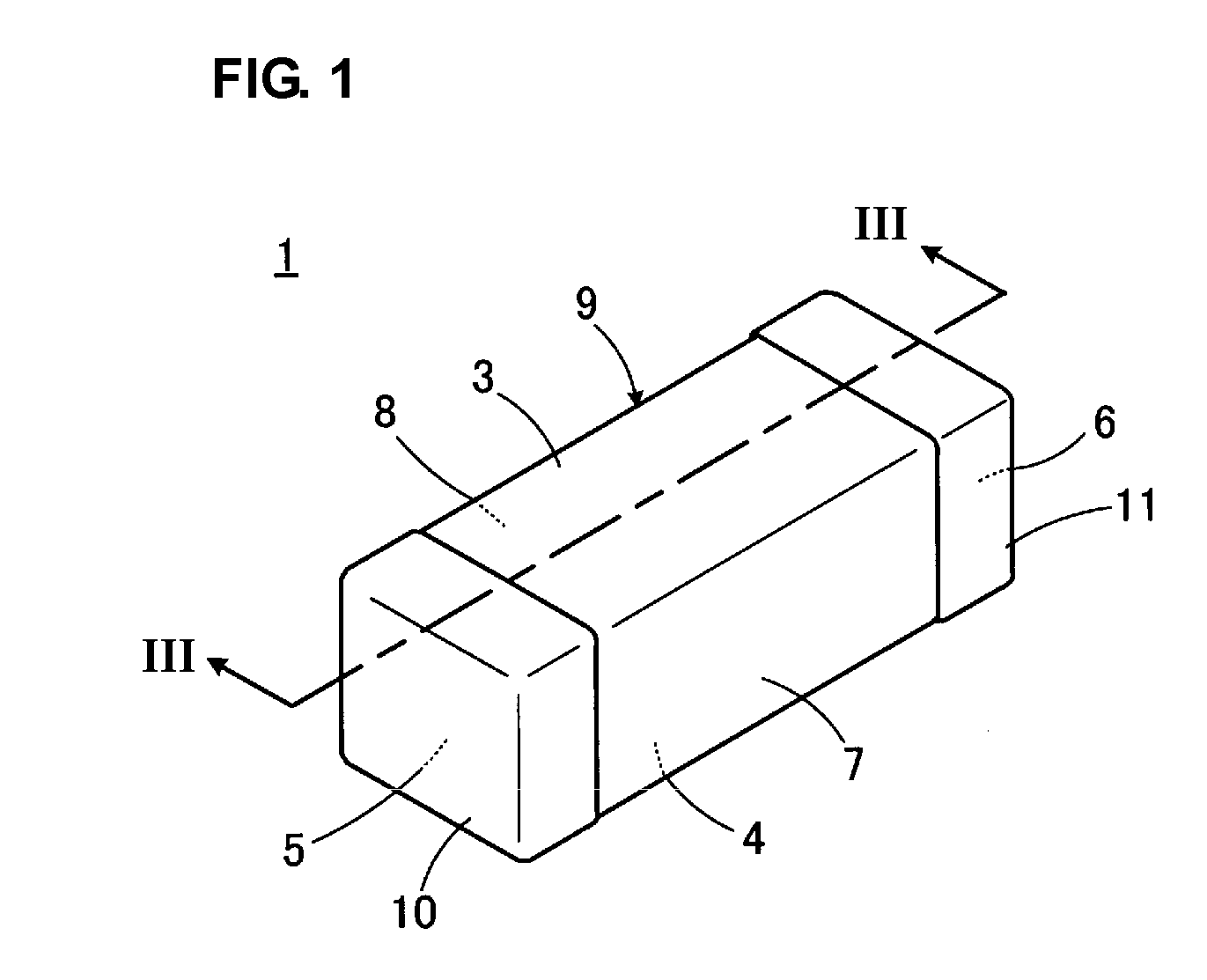

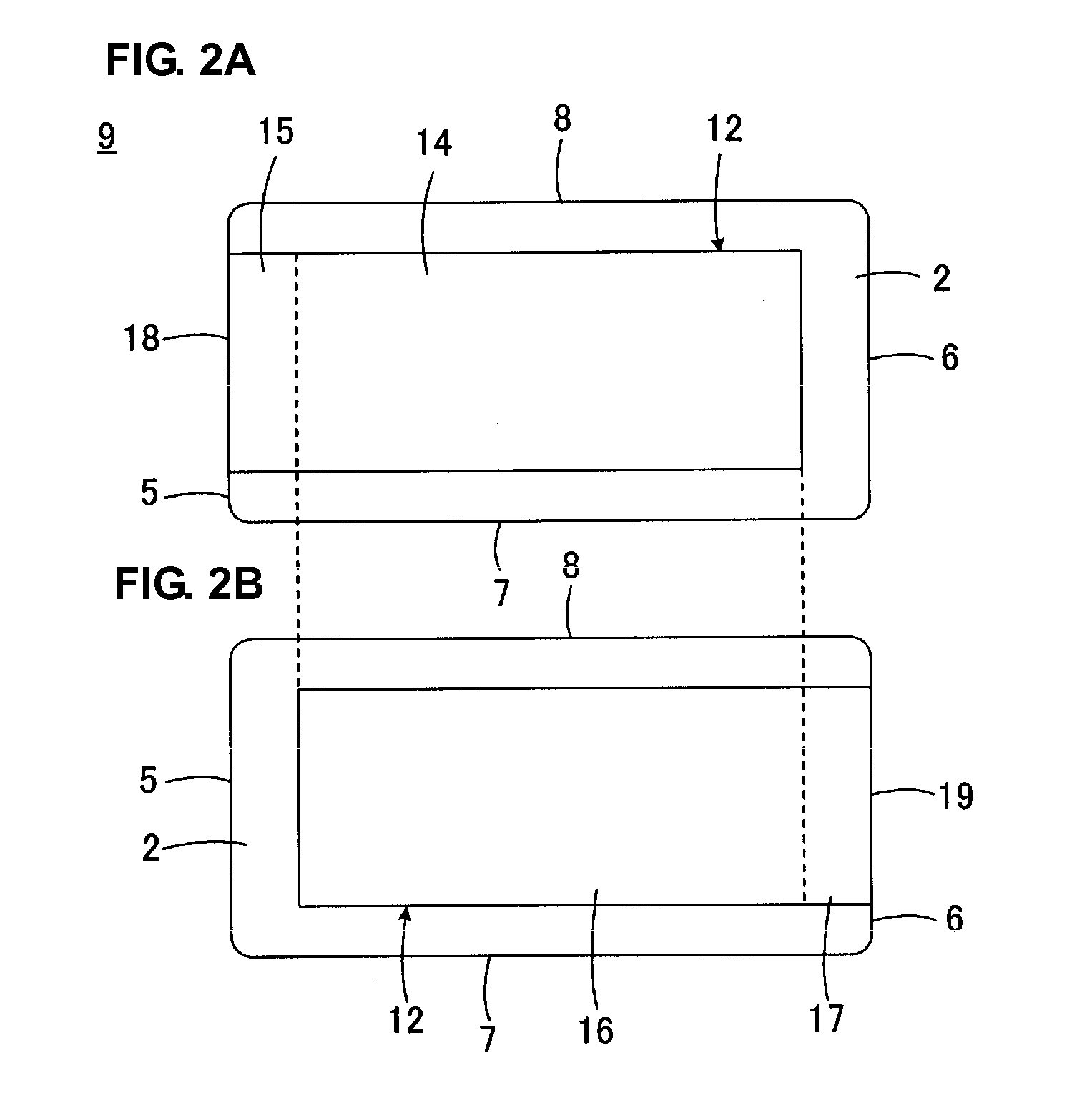

Multilayer ceramic electronic component and method for making the same

ActiveUS20090323253A1Improve bindingFixed capacitor electrodesStacked capacitorsCopper platingElectrical conductor

A multilayer ceramic electronic component includes external terminal electrodes that are formed by depositing metal plating films on exposed portions of internal conductors embedded in a ceramic body, depositing a copper plating films that cover the metal plating films and make contact with the ceramic body around the metal plating films, and heat-treating the ceramic body to generate a copper liquid phase, an oxygen liquid phase, and a copper solid phase between the copper plating films and the ceramic body. The mixed phase including these phases forms a region at which a copper oxide is present in a discontinuous manner inside the copper plating film at least at the interfaces between the ceramic body and the copper plating films. The copper oxide securely attaches the copper plating films to the ceramic body and enhances the bonding force of the external terminal electrodes.

Owner:MURATA MFG CO LTD

Method for preparing metallic organic frame films

InactiveCN101890305AEasy to separatePromote nucleationSemi-permeable membranesMetal frameworkReaction temperature

The invention belongs to the technical field of novel materials, and relates to a method for preparing metallic organic frame films(MOFs). The method is characterized in that: after a pretreated carrier is modified or not modified and coated or not coated with a crystal seed layer, the low-high temperature crystallization is performed by changing a reaction temperature; by controlling a relative speed between nucleation and crystal growth, a great deal of nuclei are formed on the surface of the carrier at the low-temperature stage, and the nuclei formed at the high-temperature stage are quickly grown; and thus, the metallic organic frame separation film which is dense, continuous, firm, free of cracks and defects and possesses higher separation performance on a micromolecular system is prepared on the carrier. The invention solves the problem that the bonding force between the metallic frame organic matters and the carrier is weak, the problem that the nucleus forming density on the carrier is so low that the continuous dense MOFs film is difficultly formed on the carrier, and provides a method for preparing the metallic organic frame films(MOFs) which are easily operated and controlled, in particular, the metallic organic frame films(MOFs) with the high separation performance prepared on the tube-shaped carrier.

Owner:DALIAN UNIV OF TECH

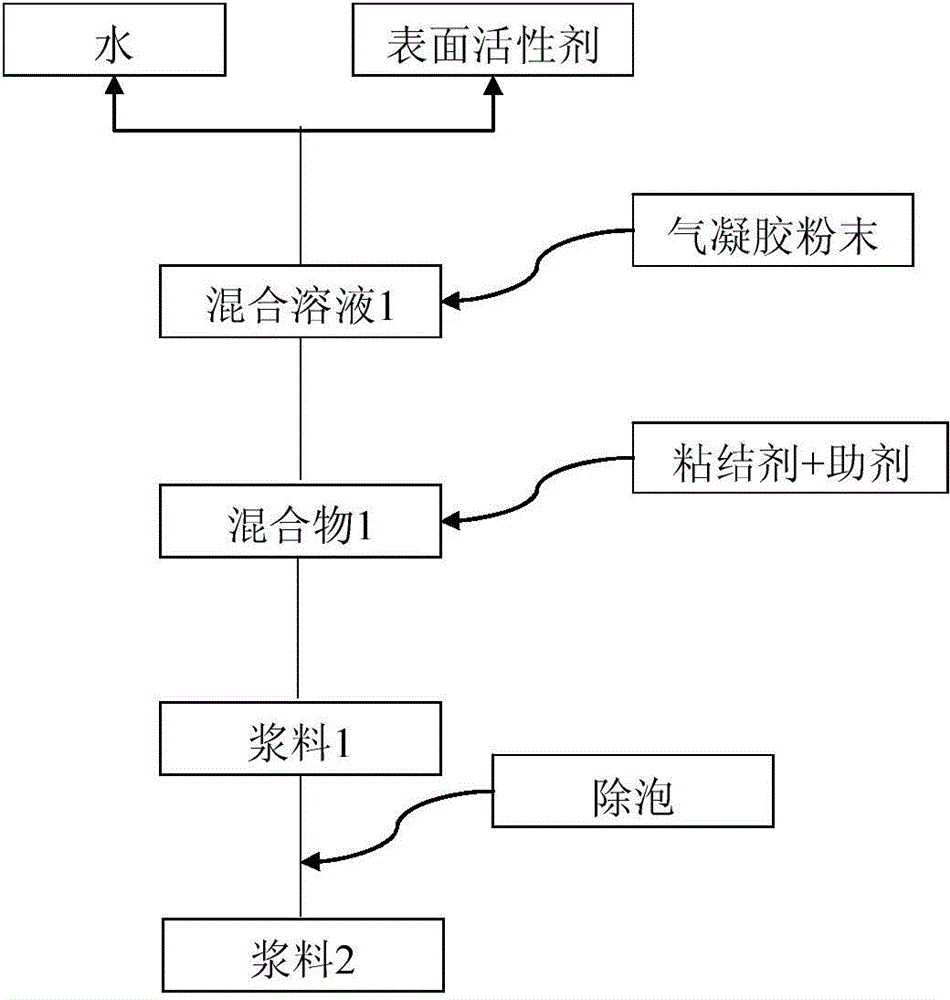

Aqueous slurry material containing silicon dioxide aerosol, preparation method and application thereof

The invention discloses an aqueous slurry material containing silicon dioxide aerosol, a preparation method and an application thereof. The aqueous slurry material is a stable dispersion system formed by uniformly mixing silicon dioxide aerosol powder, a surfactant, a bonding agent and water. The preparation method includes following steps: mixing water with the surfactant uniformly, adding the aerosol powder and mixing the mixture uniformly to obtain a suspension liquid, and adding the bonding agent and adding or not adding an additive, and uniformly mixing the mixture to obtain the aqueous slurry material. The aqueous slurry material is free of asbestos and other harmful fiber materials, is convenient to transport and construct, is free of cutting and can be easily controlled in thickness of a produced heat-insulating material, can be used through an optimized construction scheme freely, is simple in preparation process and low in cost, and is suitable for large-scale industrial production. The aqueous slurry material can be used for coating the surface of a base material and can form a coating after drying, which is flat in surface, is excellent in heat-insulating performance and is strong in bonding force, and also can be mixed with other structural materials to prepare an aqueous composite material.

Owner:苏州同玄新材料有限公司

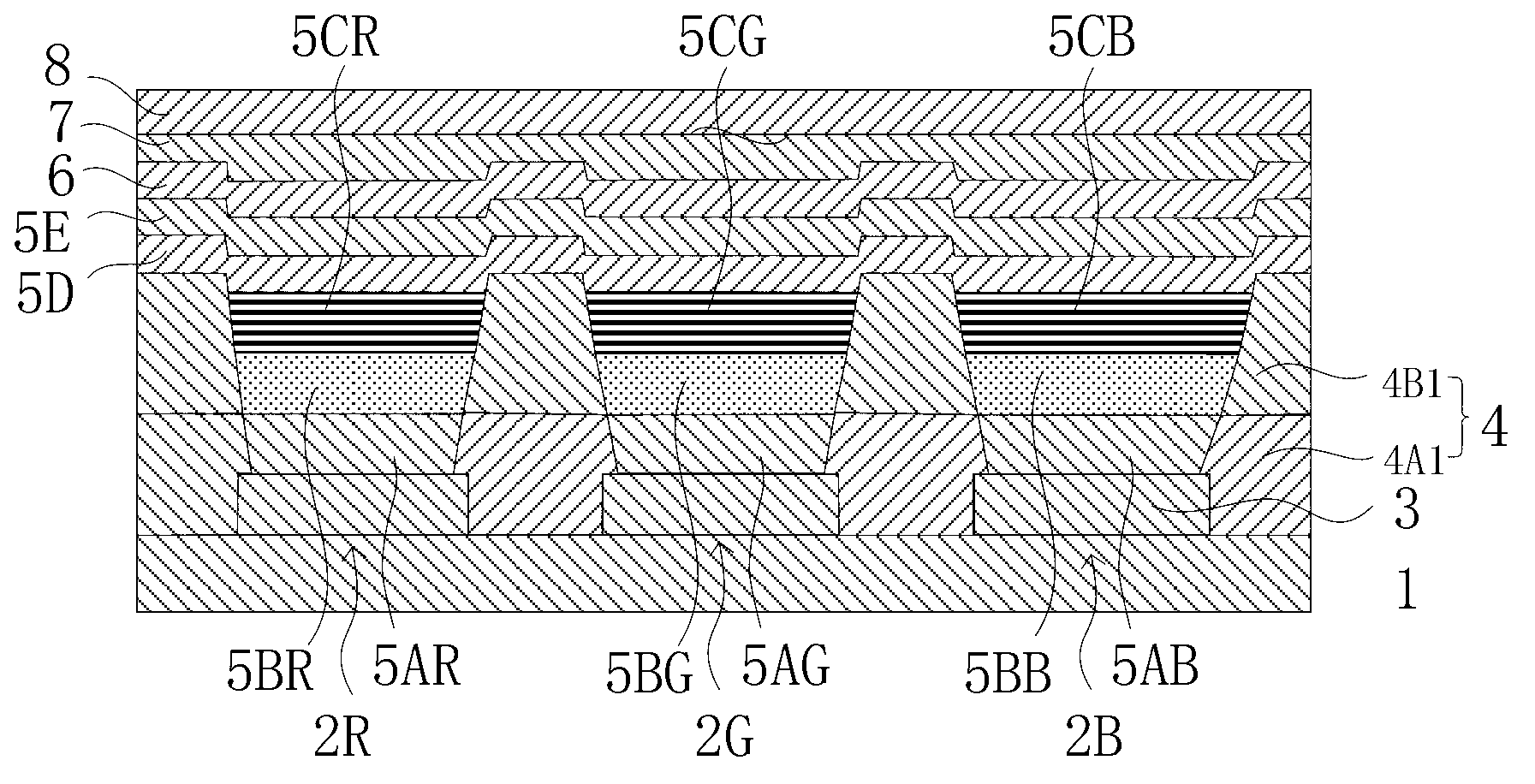

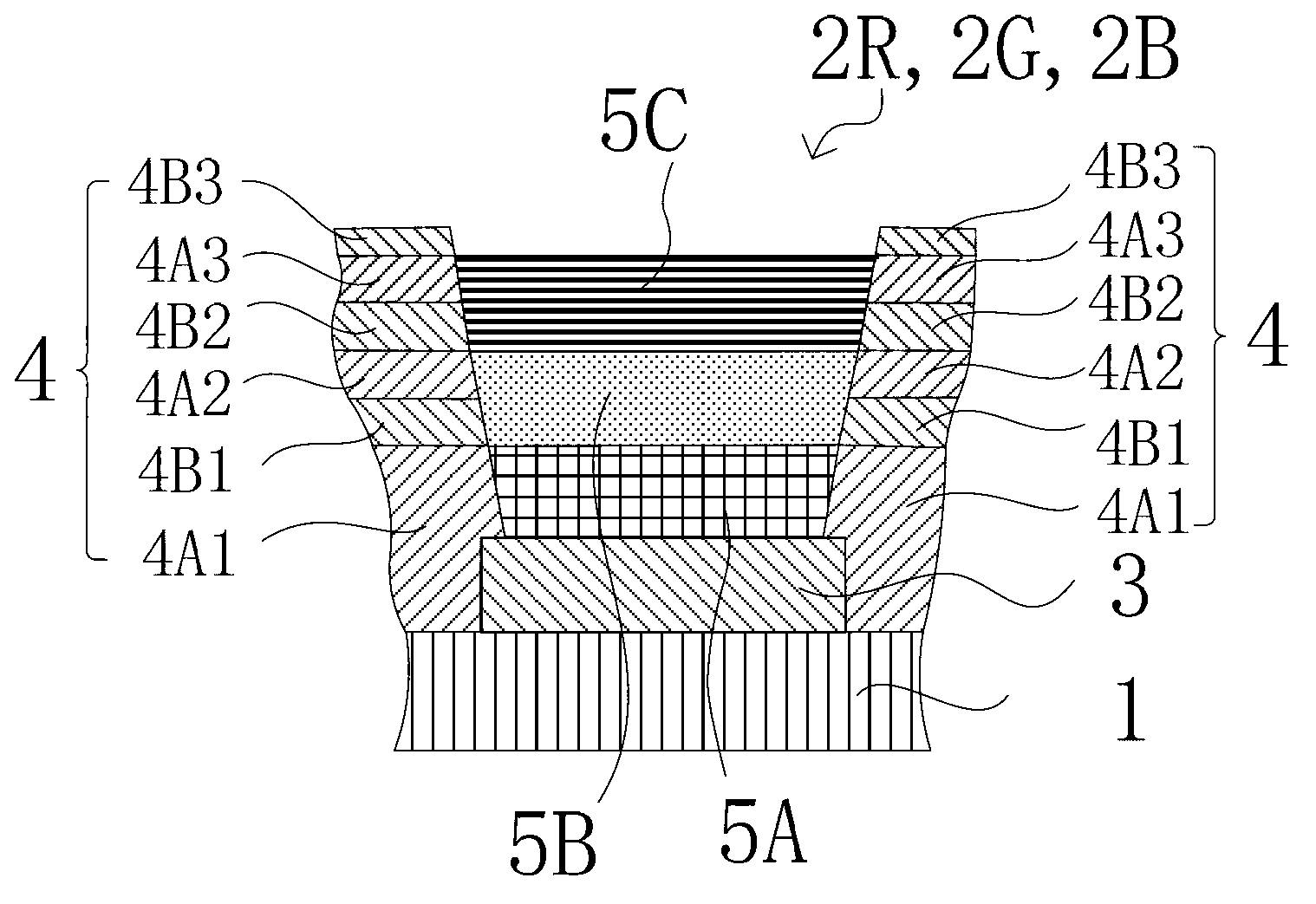

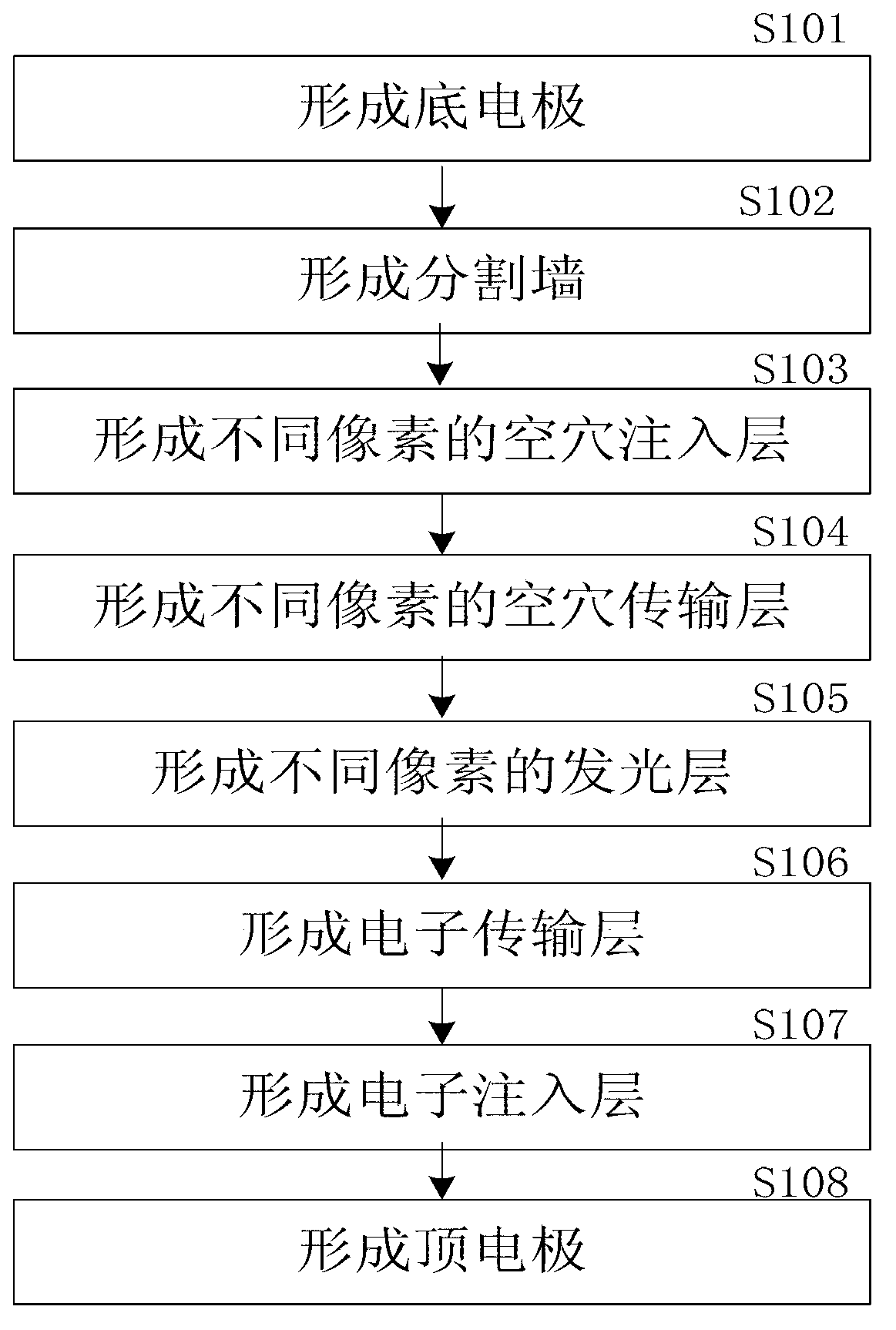

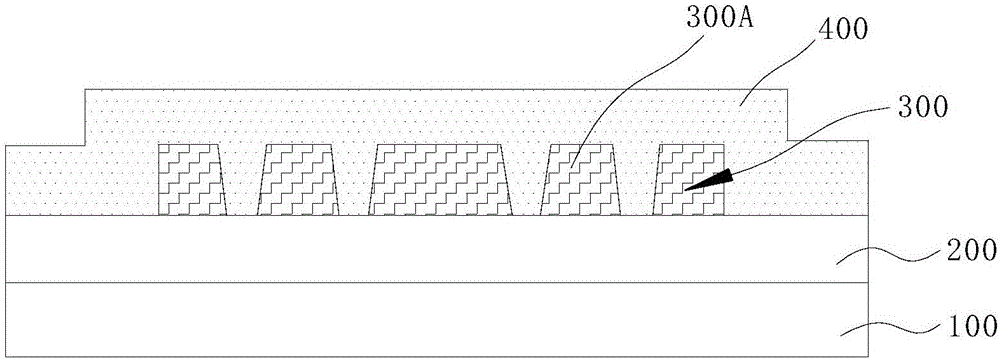

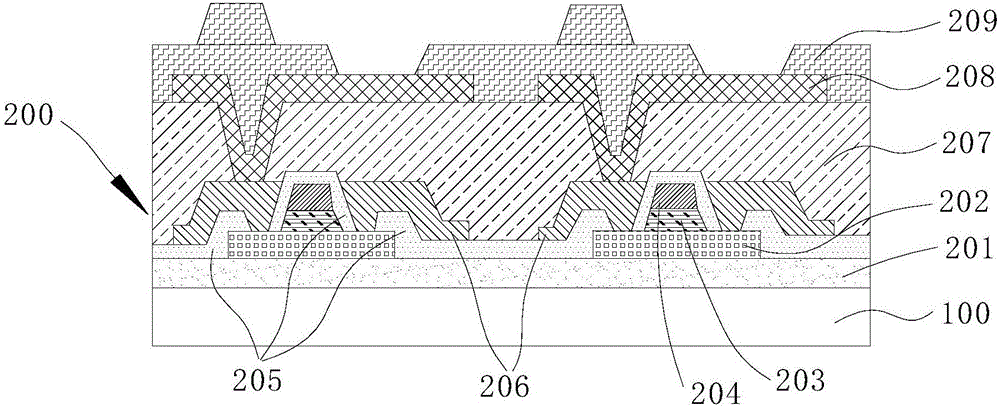

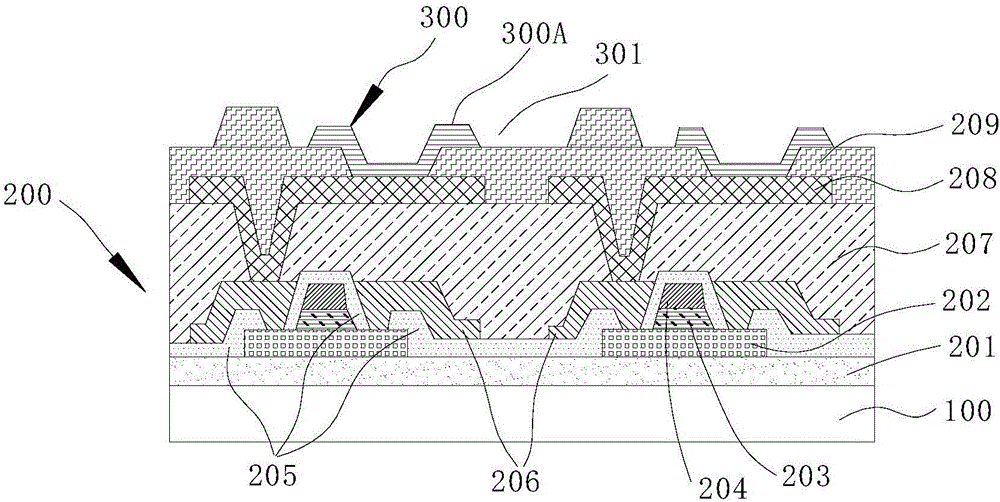

Organic electroluminescence device and method for preparing same

InactiveCN103187434AImprove performanceNo separationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOrganic electroluminescence

The invention provides an organic electroluminescence device and a method for preparing the same. The organic electroluminescence device comprises a baseplate, wherein the baseplate is provided with pixel separation walls, the pixel separation walls are composed of at least two organic material isolating layers in a stacking manner, and the wetting properties of the adjacent organic material isolating layers are different. The method for preparing the organic electroluminescence device provided by the invention comprises the following steps of: depositing a bottom electrode and a pattern, preparing two layers or multiple layers of the pixel separation walls; and depositing and preparing a functional layer, and sequentially depositing a cathode, a protective layer or a packaging layer. According to the organic electroluminescence device provided by the invention, the pixel separation walls are composed of at least two organic material isolating layers in a stacking manner, and the wetting properties of adjacent organic material isolating layers are different, the bonding force of the isolate layers in layer upon layer of organic materials is generally stronger, and the property of a device is good. The method for preparing the organic electroluminescence device provided by the invention has the advantages that the steps are simple, and therefore, the manufacturing cost is saved.

Owner:BOE TECH GRP CO LTD

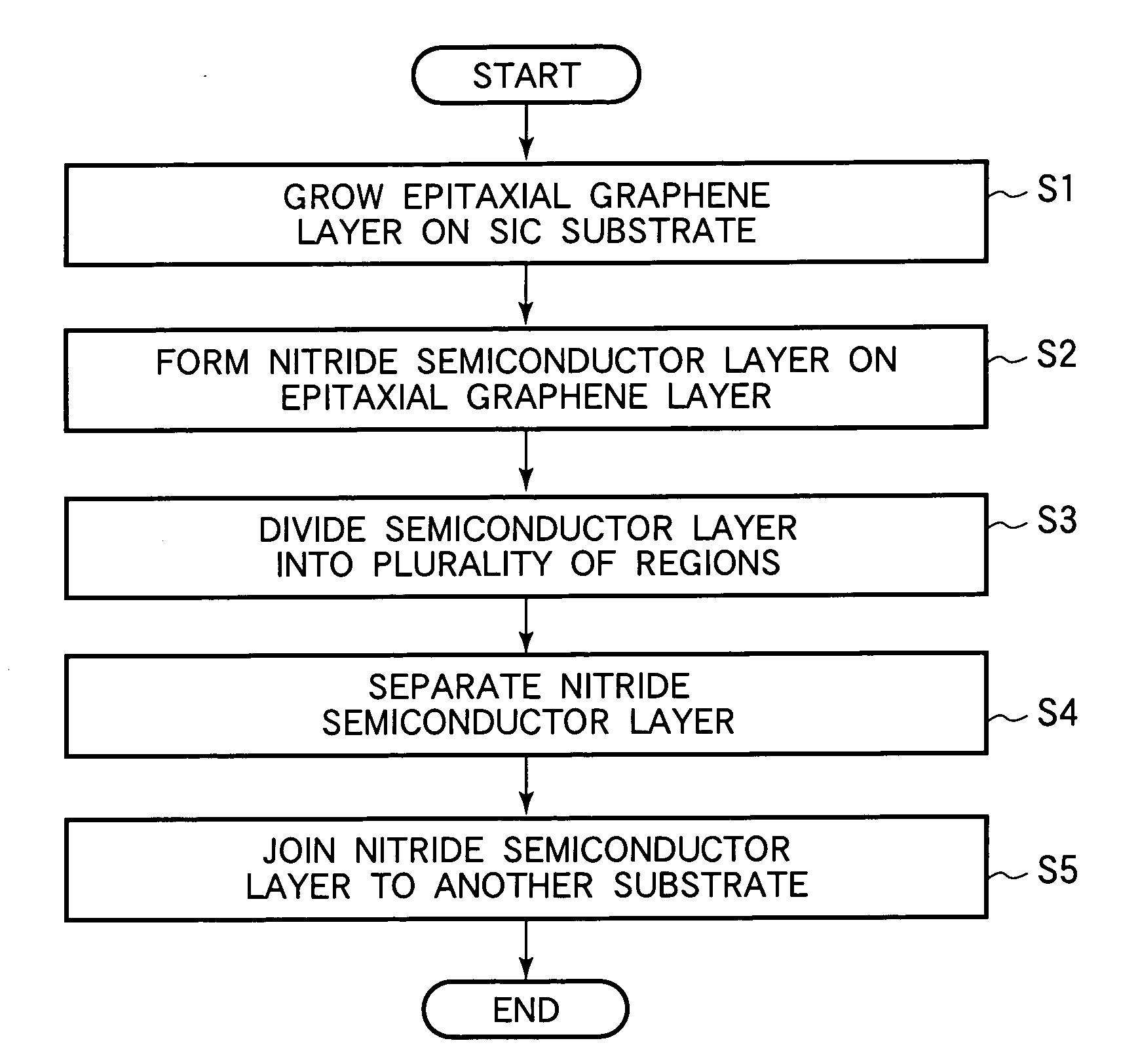

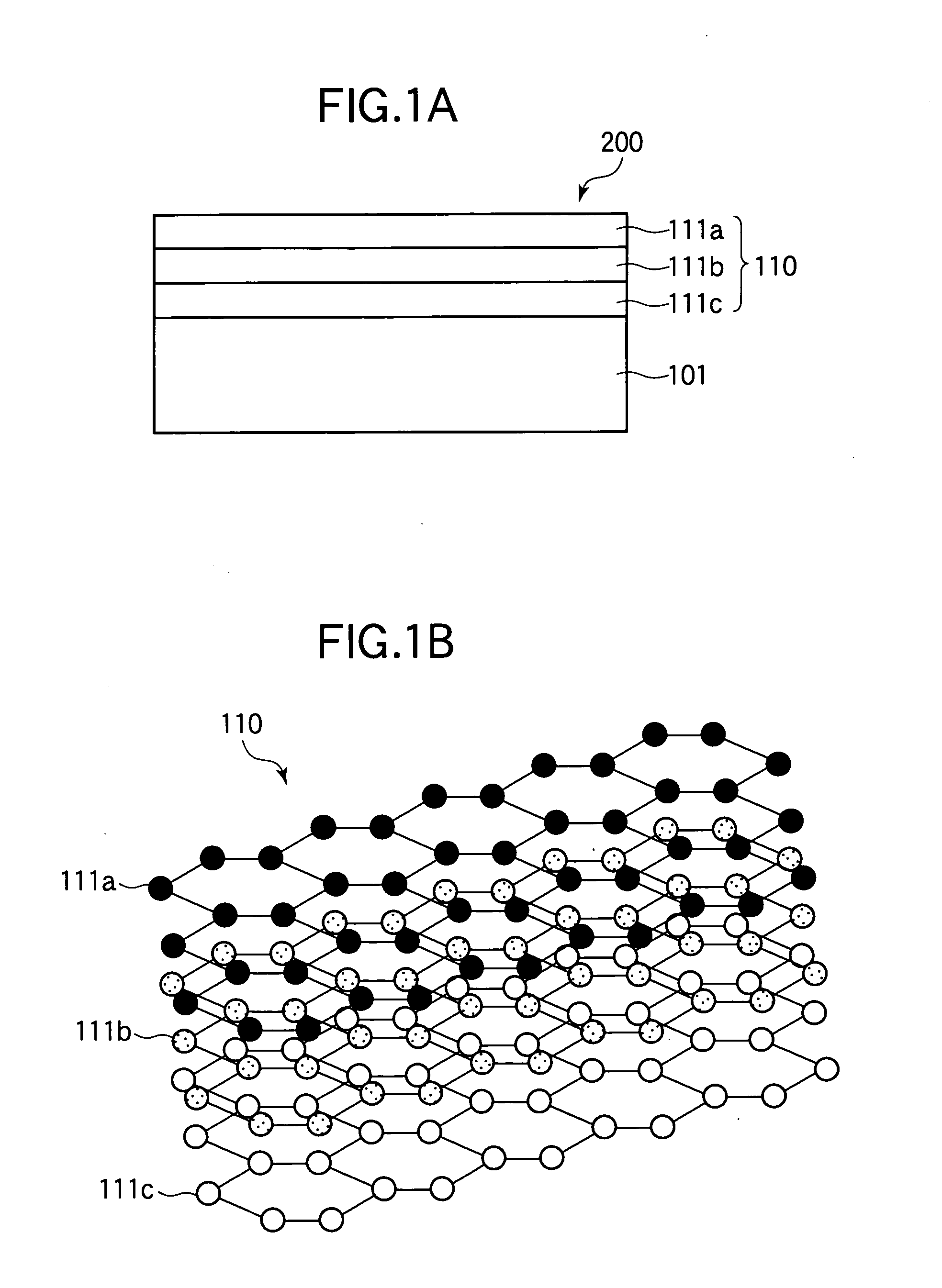

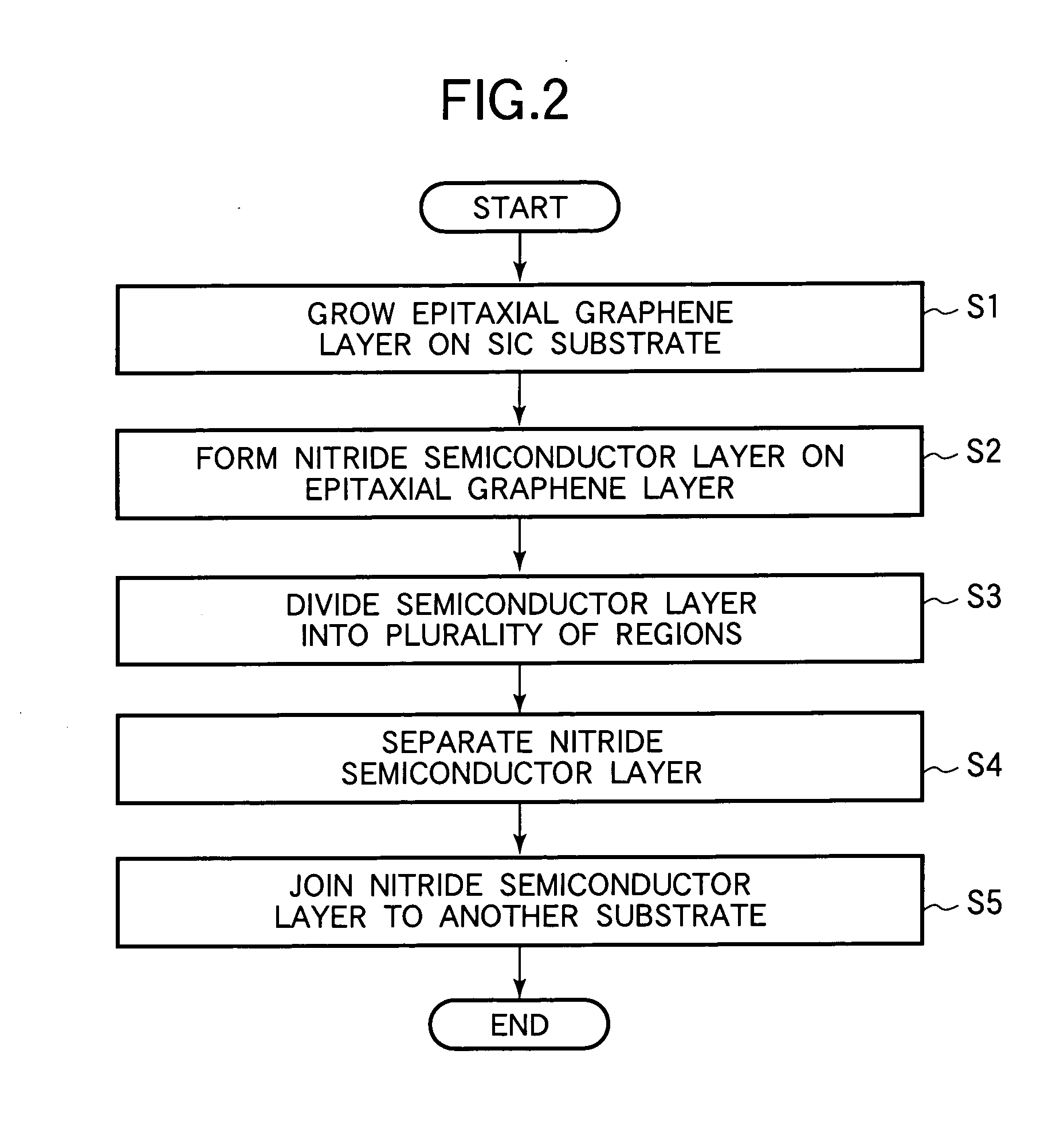

Separation method of nitride semiconductor layer, semiconductor device, manufacturing method thereof, semiconductor wafer, and manufacturing method thereof

InactiveUS20100320445A1Easy to separateQuality improvementPolycrystalline material growthSolid-state devicesGrapheneNitride semiconductors

In a separation method of a nitride semiconductor layer, a graphene layer in the form of a single layer or two or more layers is formed on a surface of a first substrate. A nitride semiconductor layer is formed on the graphene layer so that the nitride semiconductor layer is bonded to the graphene layer with a bonding force due to regularity of potential at atomic level at an interface therebetween without utilizing covalent bonding. The nitride semiconductor layer is separated from the first substrate with a force which is greater than the bonding force between the nitride semiconductor layer and the graphene layer, or greater than a bonding force between respective layers of the graphene layer.

Owner:OKI DATA CORP

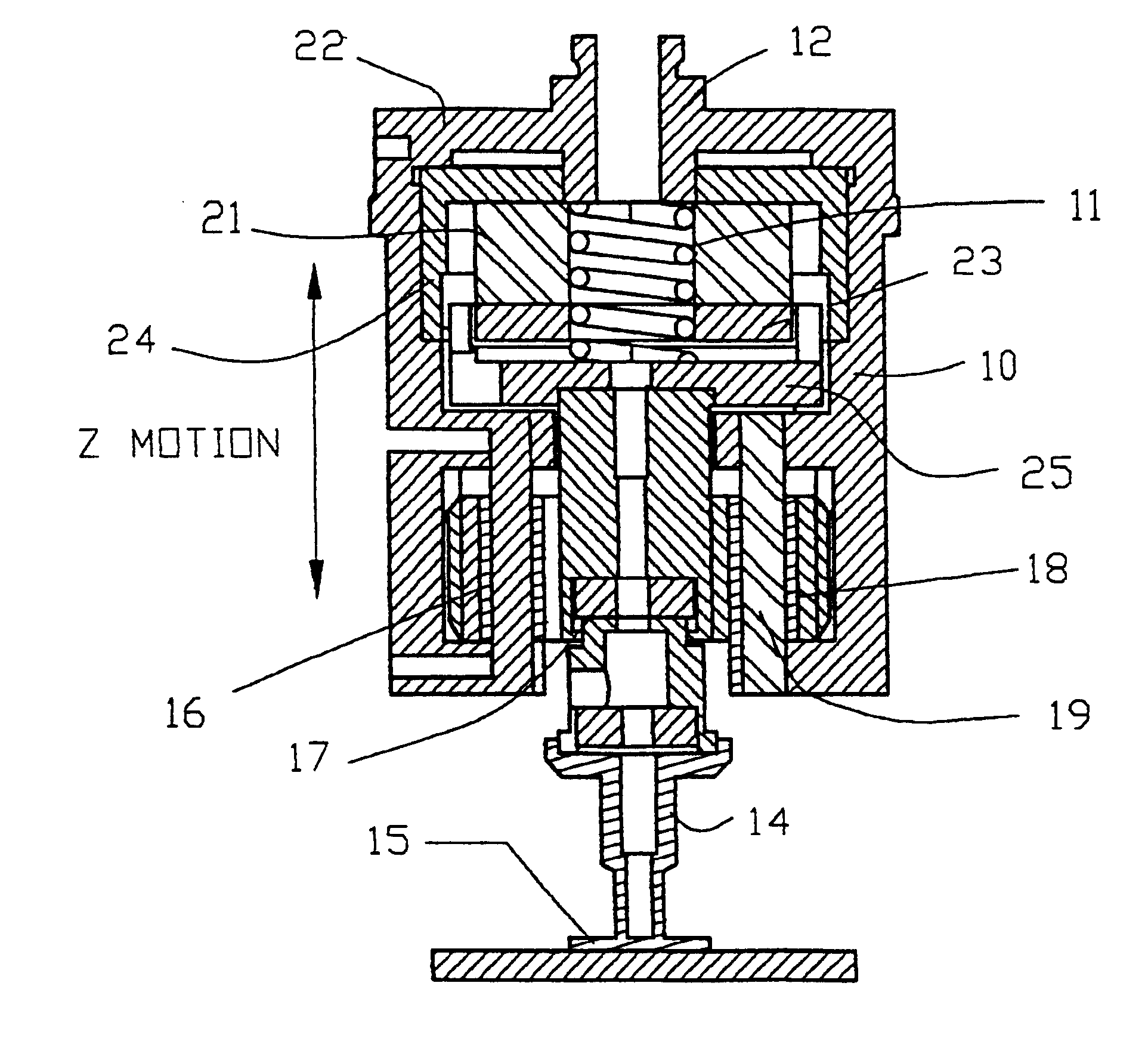

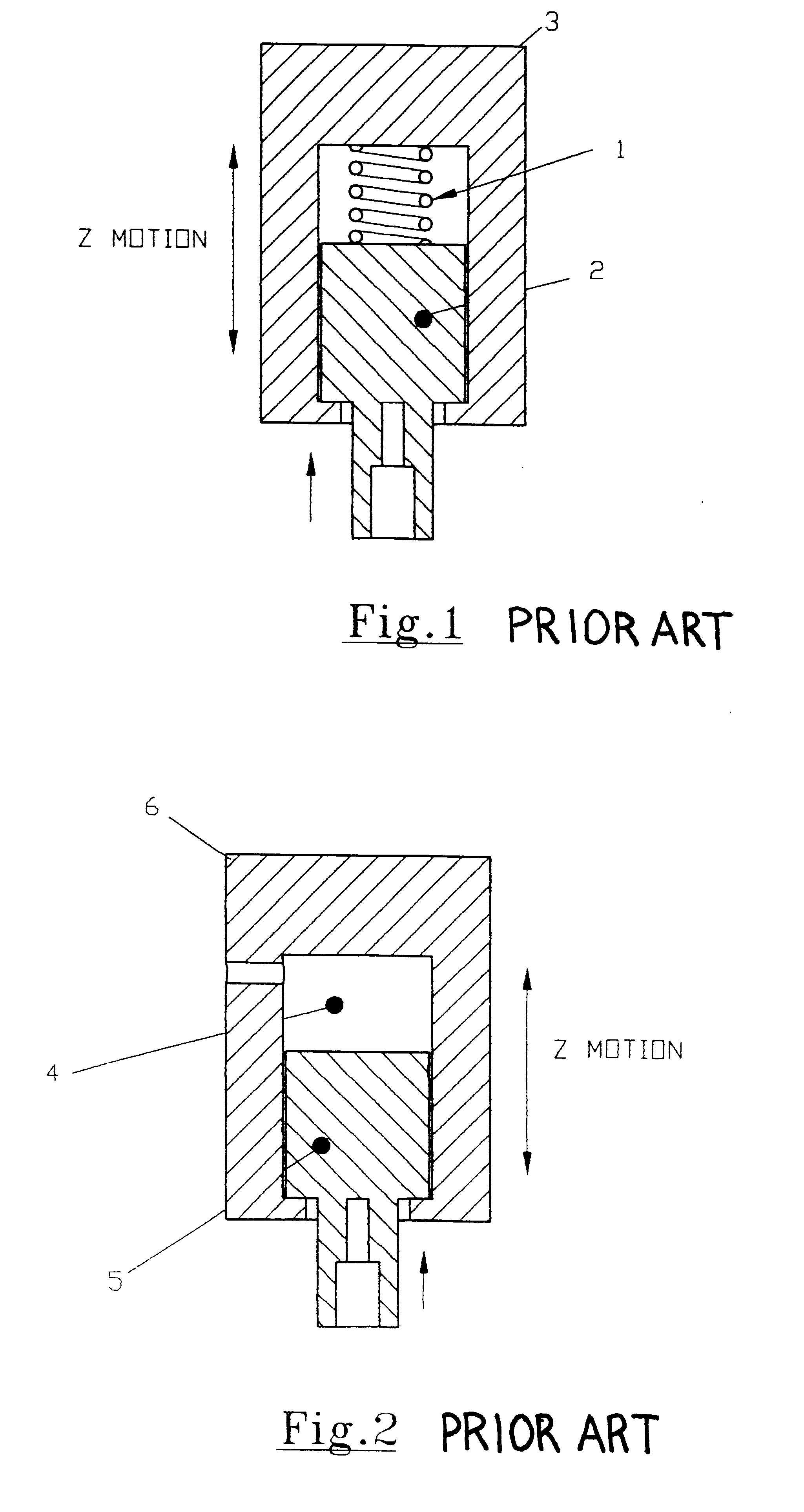

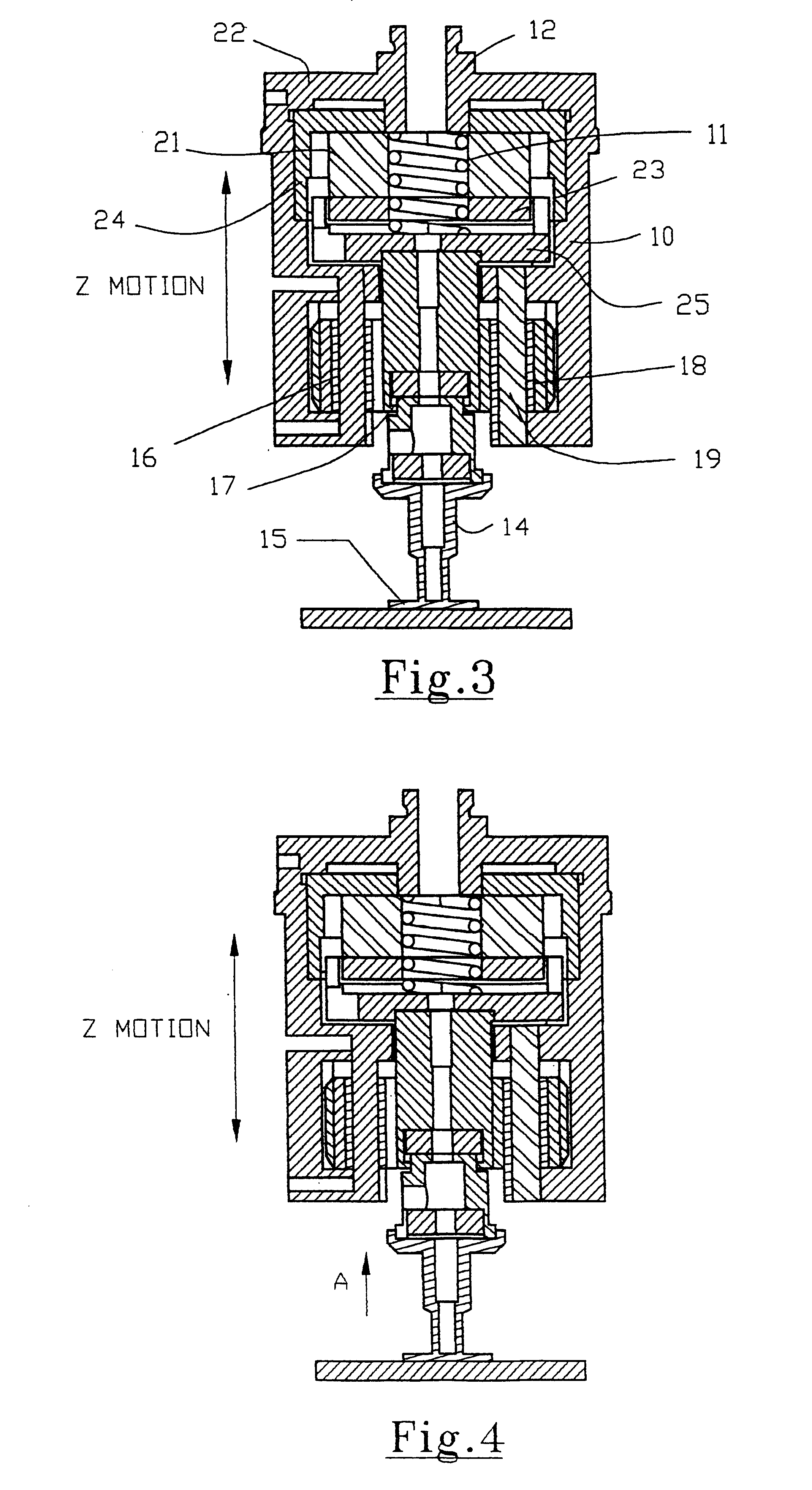

Apparatus and method for bond force control

InactiveUS6616031B2Avoid assemblyAutomatic control devicesPrecision positioning equipmentEngineeringDie bonding

An apparatus and method are disclosed for providing bond force in a die bonding operation. The apparatus comprises means such as a compression spring for generating a primary bond force, and additionally means such as a voice coil for generating a compensatory bond force. The compensatory bond force can be controlled by varying the current to the voice coil so as to add to or reduce the bond force whereby a bond force comprising the sum of the primary bond force and the compensatory bond force may be controlled.

Owner:ASM ASSEMBLY AUTOMATION LTD

Supporting substrate for manufacturing flexible information display device, manufacturing method thereof, and flexible information display device

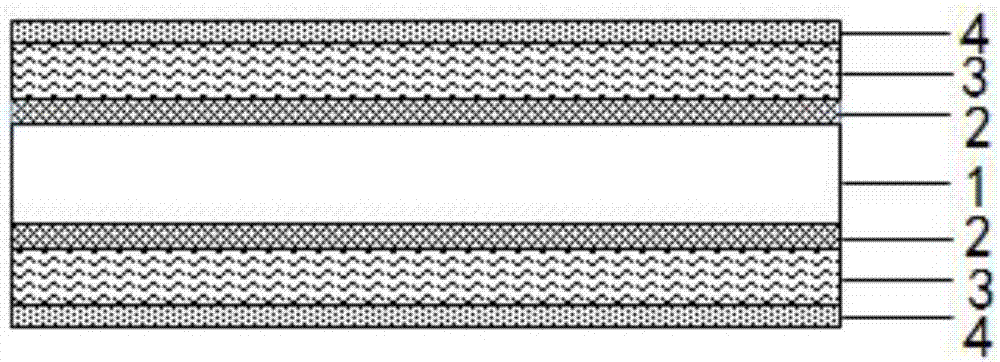

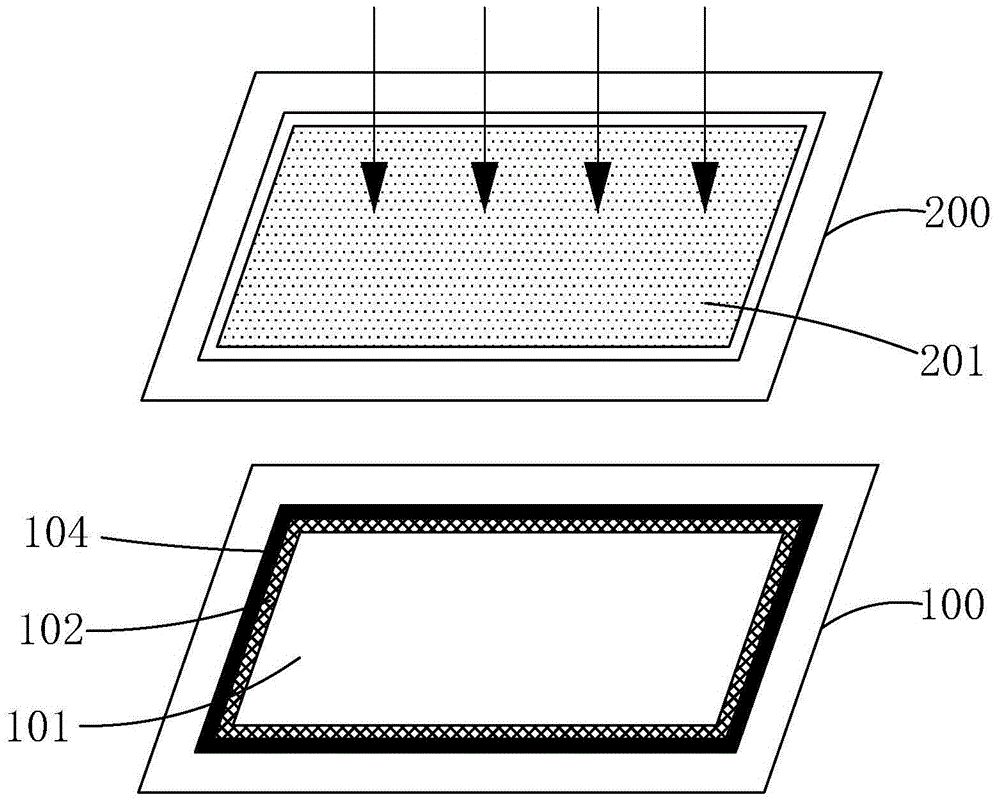

InactiveUS20150060870A1Low investment costIncrease equipment costLamination ancillary operationsLayered product treatmentDisplay deviceEngineering

Disclosed are a supporting substrate for manufacturing a flexible information display device capable of easily separating the flexible information display device from the supporting substrate without deforming or damaging the flexible information display device, a manufacturing method thereof, and a flexible information display device manufactured thereby. The supporting substrate for manufacturing a flexible information display device includes: a coating layer formed therein with a plurality micro-protrusions formed on the supporting substrate; and a temporary bonding / debonding layer formed on the coating layer and including an adhesive material mechanically interlocked with and bonded to the supporting substrate through Van der Waals bonding force. The method provides a method capable of economically manufacturing the display device having a high resolution while reviewing a cost competitive force by reducing a device investment cost and improving the yield rate in the flexible flat panel information display device.

Owner:LEE KEUN SOO +2

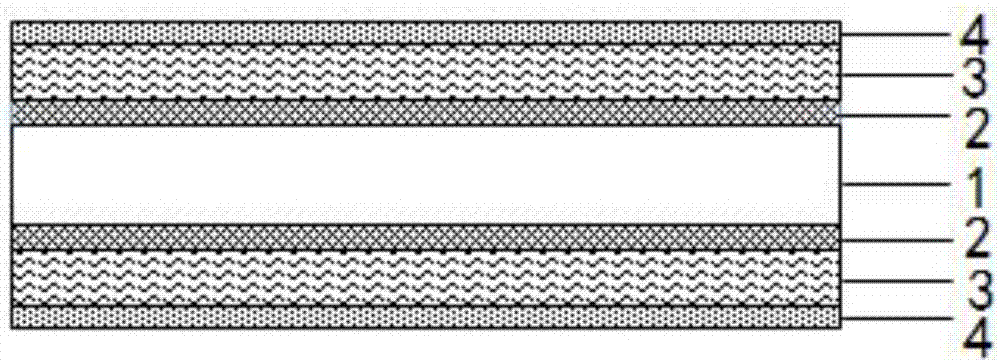

Positive electrode current collector and preparation method and application thereof

ActiveCN107123812AIncrease energy densityReduce thicknessFinal product manufactureElectrode carriers/collectorsEvaporationAluminum metal

The invention discloses a positive electrode current collector and a preparation method and an application thereof. The positive electrode current collector is of a multilayered structure and comprises a plastic thin film, wherein the upper and lower surfaces of the plastic thin film are coated with a bonding force enhancement layer, an aluminum metal coating layer and an anti-oxidization layer in sequence. The preparation method comprises the steps of coating the bonding force enhancement layer, the aluminum metal coating layer and the anti-oxidization layer through an evaporation film-coating process in sequence. The application of the positive electrode current collector mainly refers to an application in a lithium ion battery. By virtue of the positive electrode current collector, light weight of the battery can be realized, energy density can be improved, the aluminum coating layer does not fall off easily, and easy oxidization can be avoided.

Owner:CONTEMPORARY AMPEREX TECH CO +1

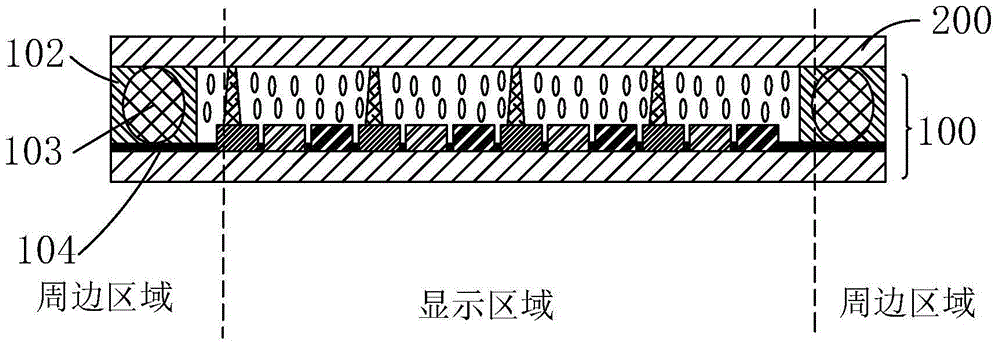

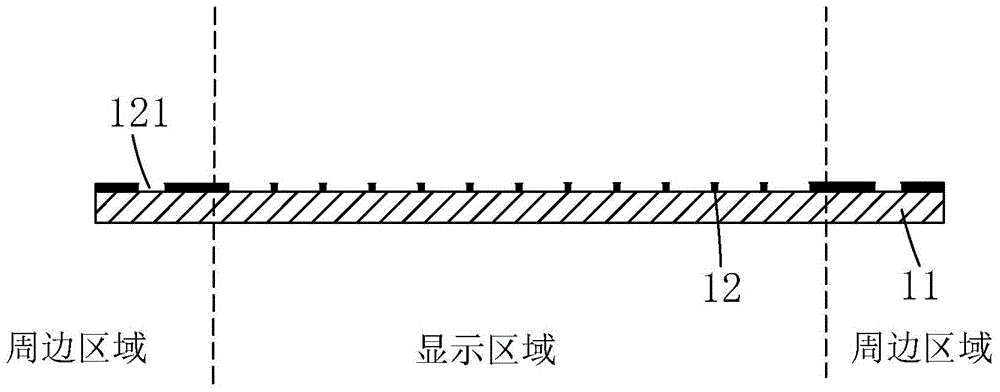

Manufacturing method for liquid crystal display panel

ActiveCN105242446AAvoid exposure to contaminationEliminate uneven brightnessNon-linear opticsLiquid-crystal displayAdhesive

The invention provides a manufacturing method for a liquid crystal display panel. According to the method, while black matrixes are formed, grooves are formed in black matrixes of peripheral areas; or while color blocking layers or spacers are formed, color blocking retaining walls or spacer retaining walls are formed on the black matrixes of the peripheral areas, a gluing area is formed between the grooves and the color blocking retaining walls or spacer retaining walls in a defined mode so as to isolate frame adhesive from a liquid crystal, and therefore the problem that due to contamination of contact between the frame adhesive and the liquid crystal, the peripheral areas of the liquid crystal display panel are uneven in brightness can be eliminated; the manufacturing process is simple, and an additional photomask and an additional exposure manufacturing process are not needed; the color blocking retaining walls or the spacer retaining walls can have an effect of supporting upper and lower substrates, and the production cost is reduced; in addition, as the grooves are formed in the black matrixes of the peripheral areas and filled with the frame adhesive, bonding force between the black matrixes and the upper and lower substrates is increased indirectly, and the stripping phenomenon is avoided; the width of the frame adhesive is adjustable, and therefore diversity requirements of narrow frame design are met.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

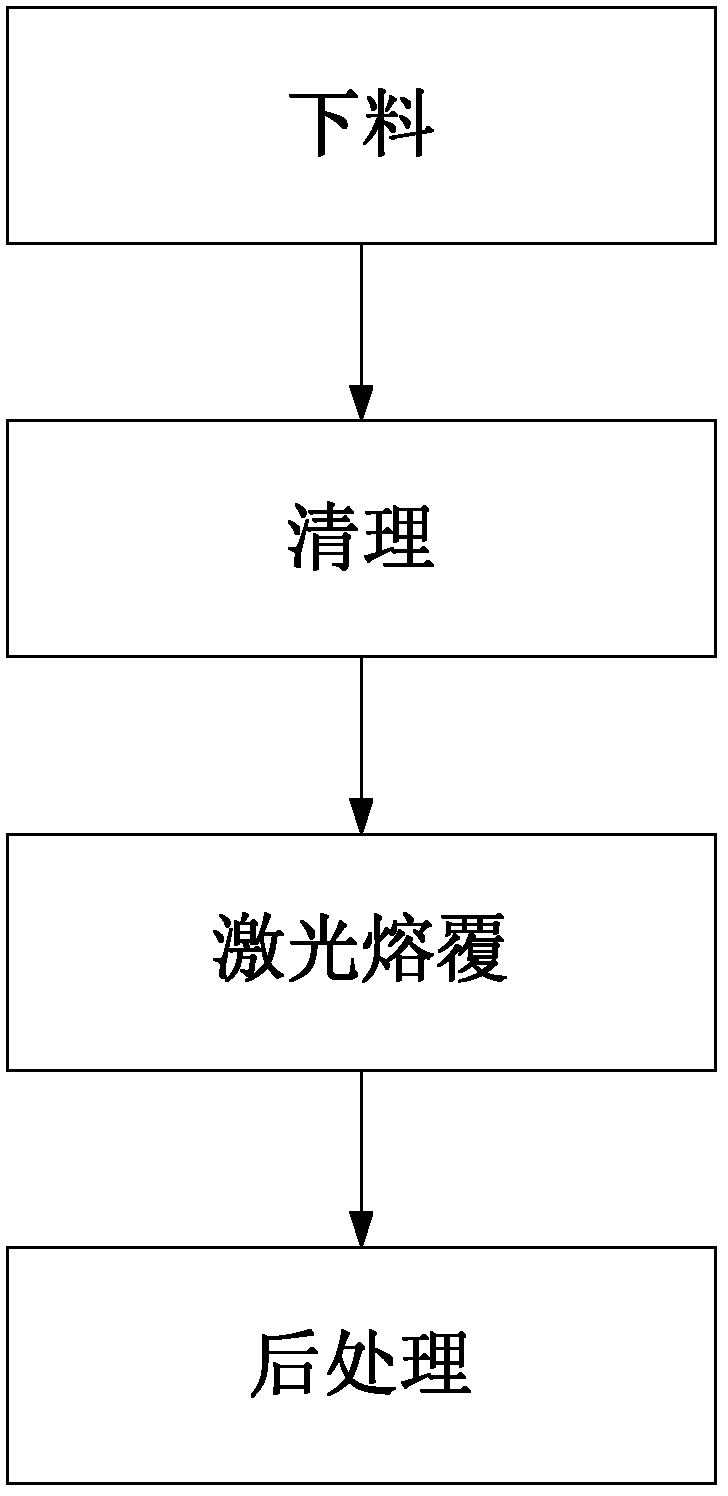

Laser cladding method

ActiveCN102560478AQuality controllableSmall heat affected zoneMetallic material coating processesHeat-affected zoneOptoelectronics

The invention provides a laser cladding method which comprises the steps of: blanking, preparing cladding material according to a workpiece to be cladded; and laser cladding, melting parent material by laser, fusing the cladding material and the melted parent material onto the parent material and forming a cladding layer. According to the laser cladding method, the cladding layer is bonded with the parent material in a metallurgical bonding way; and the cladding speed is rapid, the heat affected zone is small, and the quality of the cladding layer is more easily controlled, so that quality defect such as a brittle point or a crack is not easily caused, and the bonding force between the cladding layer and the parent material is strong.

Owner:ZOOMLION HEAVY IND CO LTD

Method for increasing retention rate of calcium carbonate in paper-process reconstituted tobacco sheets

The invention relates to a method for increasing the retention rate of calcium carbonate in paper-process reconstituted tobacco sheets. The purpose of the invention is to solve the problems that: since the prior art directly adds calcium carbonate, the bonding force between the calcium carbonate and tobacco fibers is weak, as a result, loss is severe, the material utilization rate is low, the amount of waste water to be treated is large, and the treatment cost is high. The technical point is that: needed chemical constituents are extracted from tobacco material, residue is ground into pulp after extraction, and the concentration of the pulp is regulated between 3 percent and 25 percent; the solution of soluble carbonate accounting for 4 percent to 40 percent of the weight of dry fibers in the pulp is added into the pulp, and is fully stirred and uniformly mixed, and impregnation is then carried out for 20 to 150 minutes, so that the fibers of the pulp can be impregnated with the soluble carbonate; the solution of soluble calcium salt, the molar mass of which is approximately equal to the molar mass of the soluble carbonate, is added into the impregnated pulp, and is fully stirred and uniformly mixed, static reaction is then carried out for 30 to 180 minutes, and the reaction temperature is controlled at 5 DEG C to 50 DEG C; and after the static reaction, the pulp is made into reconstituted tobacco sheets by papermaking equipment.

Owner:GUANGDONG JINKE REFORGING TOBACCO LEAF CO LTD

Anti-icing composite coating and manufacturing method thereof

ActiveCN102205680AImprove bindingFast heat conductionSynthetic resin layered productsEpoxy resin coatingsEpoxyHigh pressure

The invention discloses an anti-icing composite coating and a manufacturing method thereof. The anti-icing composite coating comprises three layers, wherein an inner layer is an organic silicon modified epoxy resin layer, a middle layer is a polyelectrolyte salt layer and an outer layer is a fluorine-silicon modified acrylic ester layer. The anti-icing composite coating is coated on the surfaces of components, such as high-voltage cables, iron towers, communication lines, aircrafts and the like, the adhesive force between the inner layer and a substrate can be increased due to the inner layer, icing can be slowed down due to ions ionized by the middle layer, and the adhesive force of ice on the surface and the icing quantity of the surface can be reduced due to the super hydrophobicity of the outer layer. The anti-icing composite coating has excellent bonding force on the substrate and higher heat conductivity, the surface of the outer layer has low surface tension, high hydrophobicity and high icing resistance, and the adhesive force of water and ice can be reduced to the maximum, thus the water and the ice can be easily removed; meanwhile, the middle layer can ionize ions to delay the adhesion of the ice under severe environment, thus the purposes of icing prevention and ice removal are realized. The manufacturing method disclosed by the invention has the advantages of easiness, feasibility, convenience for control, lower cost, and excellent use effect during engineering.

Owner:WUHAN UNIV +1

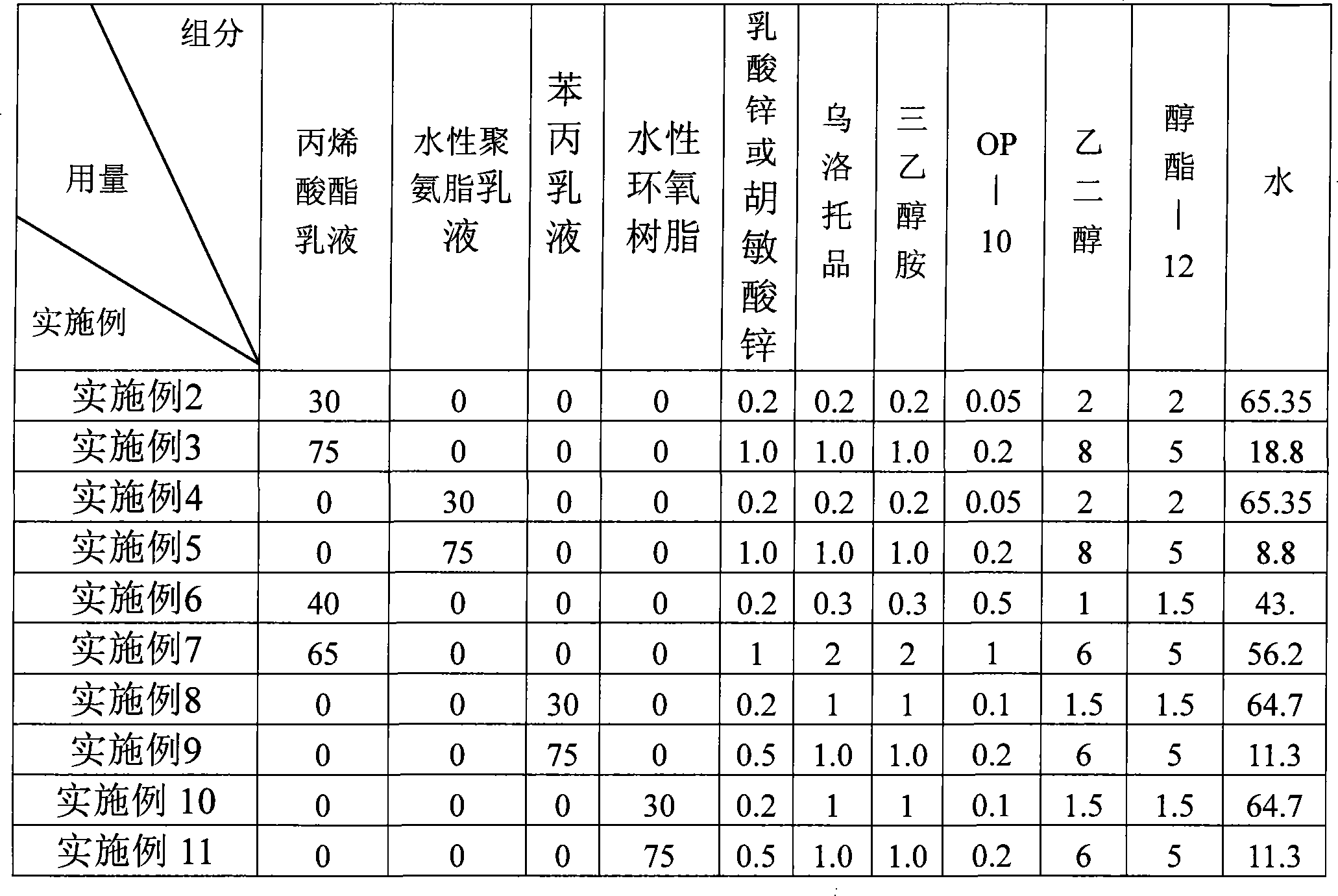

Water-based antirust agent

InactiveCN101240141AImprove bindingStay the sameLiquid surface applicatorsAnti-corrosive paintsWater basedWater vapor

The invention discloses a water-base anti-rust agent composed of 30% to 75% film-forming agent, 0.5% to 6.0% inhibitor, 2% to 16% accessory ingredient and water. Bonding force of film layer to basal body is improved by adopting acrylic ester emulsion or water-base polyurethane emulsion as film-forming substance associated with components of inhibitor, accessory ingredient, etc. The water-base anti-rust agent is brushed on steel surface to form continuous compact protection layer, isolating steel surface from oxygen and water vapor effectively, for long lasting rust prevention. The anti-rust period of steel piece might be more than one year. The protecting film is quite compact, which maintains fundamental color of steel piece invariable. User can process next step of treatment directly without removing the protecting film, which reduces tiresome process of removing anti-rust coat. Operation modes include soaking, spraying, brush coating, etc. The invention is incombustible, nontoxic and environment-friendly. Contents of free formaldehyde, heavy metal and volatile organic meet qualified criteria. Bond strength of twice-brushed deformed steel bar to concrete is more than non-brushed test piece.

Owner:焦占付

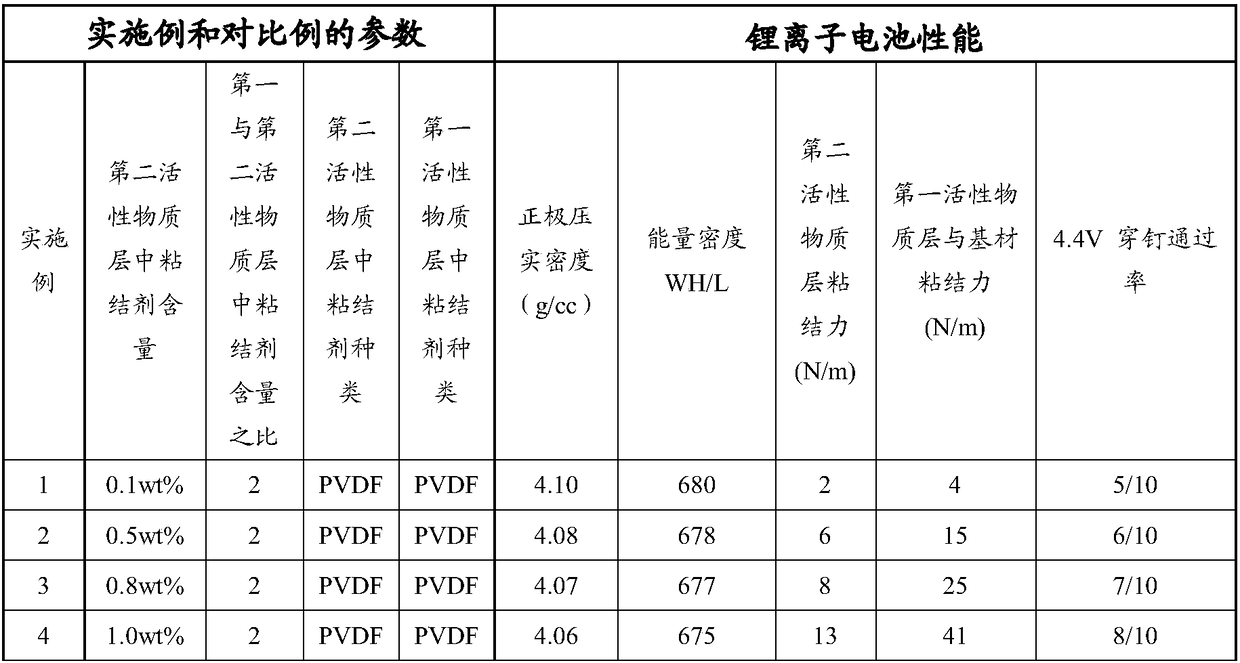

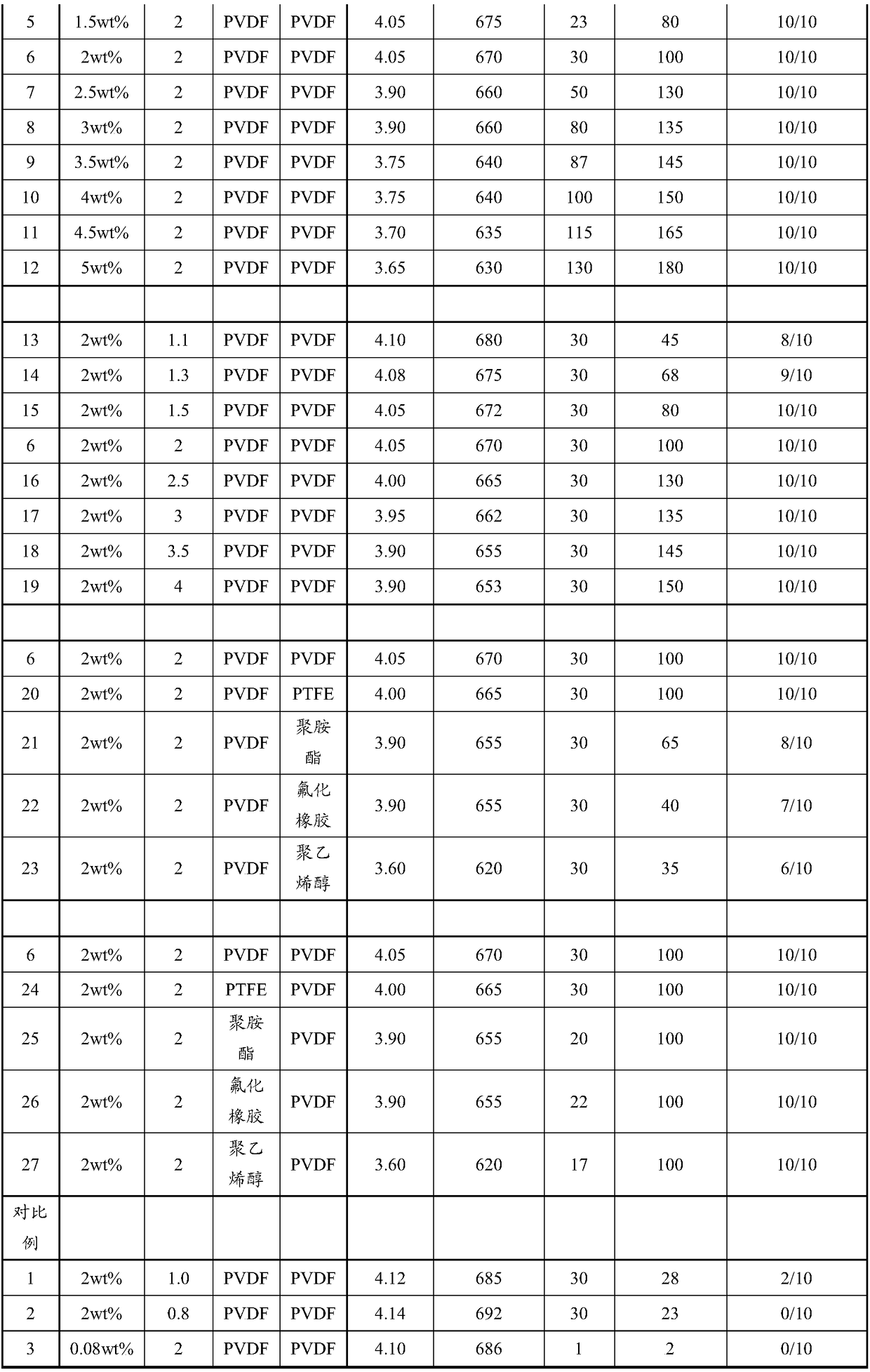

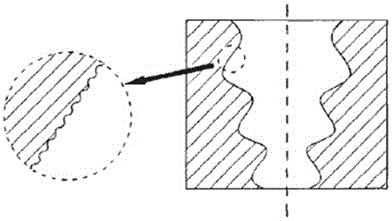

A positive electrode plate and a lithium ion battery

InactiveCN109004171AGuaranteed Energy DensityImprove nail penetration safety performanceFinal product manufactureNon-aqueous electrolyte accumulator electrodesElectrical batteryEngineering

A positive electrode sheet and a lithium ion battery are provided. A positive electrode sheet includes: a current collector; A first active material layer; And a second active material layer; Whereina first active material layer is disposed between the current collector and the second active material layer, the first active material layer and the second active material layer each comprising a binder, and the binder content in the first active material layer is greater than the binder content in the second active material layer. In the present application, the active material in the positive electrode sheet adopts a two-layer design, and the content of the binder in the first active material layer is higher than that in the second active material layer, so that the energy density of the lithium ion battery is ensured, and the purpose of improving the bonding force of the active material layer and the safety performance of the lithium ion battery is achieved.

Owner:NINGDE AMPEREX TECH

Preparation process of TiCN multilayer composite coating layer on slotting cutter surface of steam turbine rotor

ActiveCN105154880AImprove performanceExtend your lifeVacuum evaporation coatingSputtering coatingMilling cutterHardness

The invention relates to a preparation process of a TiCN multilayer composite coating layer on a slotting cutter surface of a steam turbine rotor; and the preparation process comprises surface pretreatment of a cutter basal body, cleaning, cutter clamping and loading, preparation of the multilayer composite coating layer, cooling and discharge, and aftertreatment. The multilayer structure formed by the coating layer preparation process uses TiN and TiCN as alternating coating layers to prepare 50 TiN and TiCN alternating coating layers on the slotting cutter surface; TiN is the backing layer; and TiCN is the outermost layer. The coating layer prepared by the method relieves the residual stress of the coating layer and the cutter basal body, so that the bonding force of the basal body and the coating layer is larger, the bonding degree of the coating layer is higher, and the coating layer is not easy to be stripped off. In addition, C atoms are introduced based on TiN to cause the lattice distortion and the solid solution strengthening effect, so that the surface hardness of the cutter basal body can reach HV3500, the cutter wear resistance is improved, the cutter service life is prolonged, the machining quality of the steam turbine rotor is guaranteed, and the production cost is reduced.

Owner:SHANGHAI INST OF TECH +1

Flexible display panel and manufacturing method thereof

InactiveCN106783881AImprove bindingAvoid partial peelingSolid-state devicesSemiconductor/solid-state device manufacturingPath lengthContact position

The invention discloses a flexible display panel. The flexible display panel comprises a flexible substrate layer, an array substrate layer, an organic light emitting diode layer and a thin film encapsulation layer which are sequentially overlapped in the longitudinal direction. The effective display area of the organic light emitting diode layer comprises a luminous area with sub-pixels and a non-luminous area beside the luminous area, wherein the non-luminous area is provided with a recess unit, and the thin film encapsulation layer is deposited on the surface of the organic light emitting diode layer and inside the recess unit. The invention also discloses a manufacturing method of the flexible display panel. By increasing the contact area and the contact positions between the TFE (thin film encapsulation) layer and the Array layer, the flexible display panel can effectively enhance the bonding force between the TFE layer and the Array layer, avoids local peeling of the OLED (organic light emitting diode) layer of a screen under external force and further improve the impact resisting and bending resisting performance of the screen. Besides, the applied encapsulation manner of the flexible display panel can effectively release the internal stress of the TFE layer to further improve the bending resisting performance of the screen; meanwhile, the TFE structure prolongs the path length of water permeation and further enhances the encapsulation effects.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Water-based surface treatment agent for color coating pretreatment of galvanized plates

ActiveCN102070927AImprove bindingGood coating effectAnti-corrosive paintsMetallic material coating processesWater basedPre treatment

Owner:马鞍山市安工大智能装备技术研究院有限公司

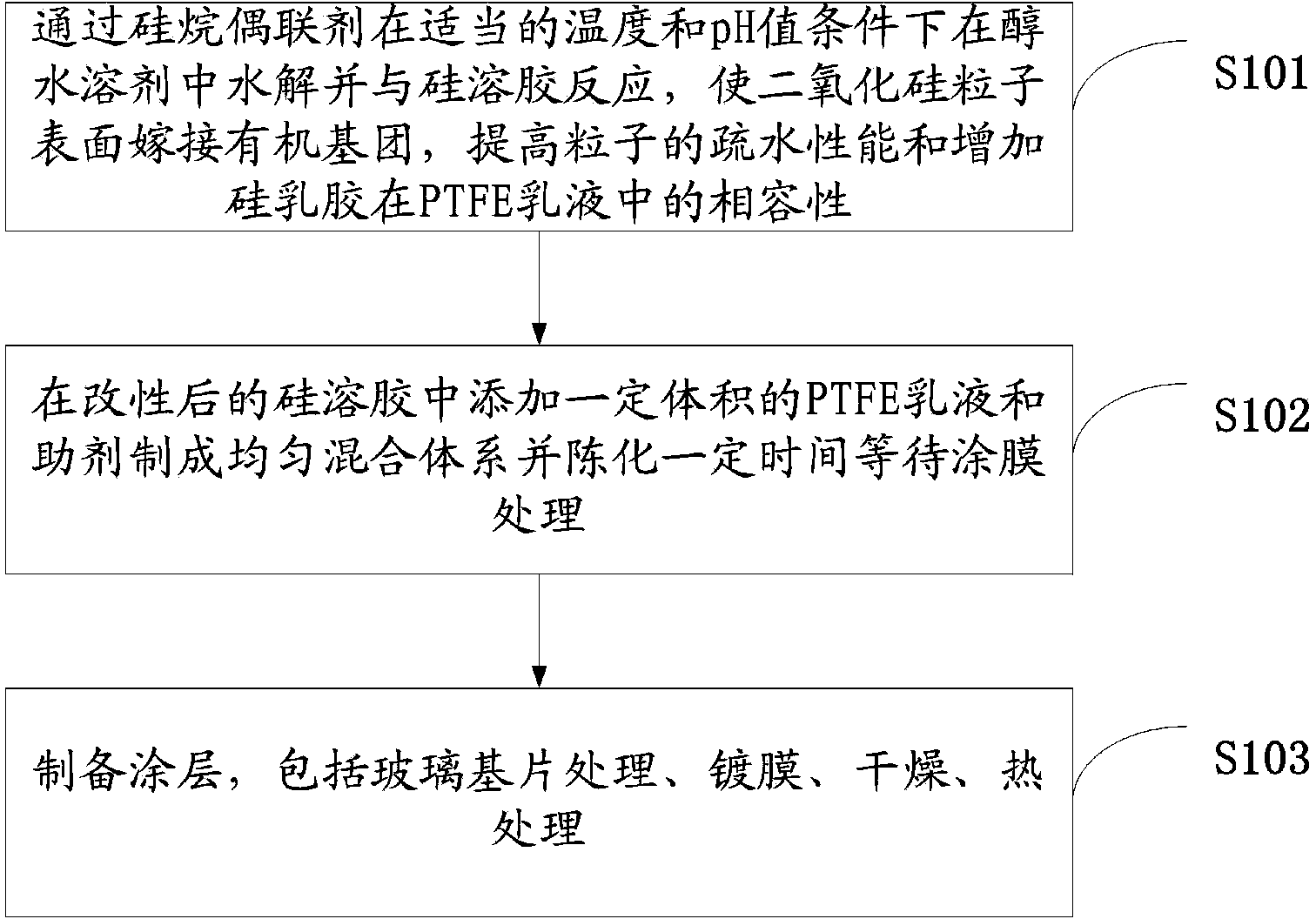

Preparation method of SiO2/polytetrafluoroethylene hybridized super-hydrophobic coating

The invention discloses a preparation method of a SiO2 / polytetrafluoroethylene hybridized super-hydrophobic coating. The preparation method comprises the following steps: hydrolyzing a silane coupling agent in an alcohol-water solvent at appropriate temperature and pH value, allowing the solution to react with silicon sol, enabling the surface of silicon dioxide particles to be grafted with organic radicals, adding a certain volume of PTFE (Polytetrafluoroethylene) emulsion and an auxiliary in the modified silica solution to prepare a uniformly-mixed system, ageing for a certain time, performing coating treatment, and preparing the coating. The preparation method of the SiO2 / polytetrafluoroethylene hybridized super-hydrophobic coating is to utilize the silane coupling agent to modify the silica solution, enable the silanol structures on the surface of the SiO2 particles to be grafted with part of hydrophobic groups, in the meantime improve the dispersibility of the particles, utilize a sol-gel method to enable the modified silica solution and the PTFE emulsion to be hybridized to form the uniformly-mixed system to prepare the super-hydrophobic coating. Therefore, the bonding force between polytetrafluoroethylene and the base material can be effectively improved, the rigidity and the abrasive resistance can be improved, the roughness of the coating surface can be constituted, and furthermore the contact angle on the surface can be increased.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

Composite metal carbide wear-resistant coating and preparation process thereof

The invention relates to a composite metal carbide wear-resistant coating and a preparation process thereof, and belongs to a wear-resistant coating and a preparation process thereof. The composite metal carbide wear-resistant coating consists of adhesive coated tungsten carbide and other carbides, wherein the adhesive coated tungsten carbide has the grain size of WC-Co or WC-Ni; and the other carbides comprise chromium carbide, vanadium carbide, iron carbide, titanium carbide and the like. The preparation process comprises the following steps of: mixing the adhesive coated tungsten carbide and one or more kinds of the carbide powder; and performing spray coating (welding) or plasma spray coating (welding) on the surface of a medium-carbon steel part through supersonic flame to form the wear-resistant coating, wherein the carbon content of the medium-carbon steel is 0.35 to 0.55 weight percent (wt); the medium-carbon steel is subjected to the thermal refining state of quenching and high-temperature tempering; and the supersonic flame spray coating (welding) or plasma spray coating (welding) process sequentially comprises steps of performing sand blasting and rust removal on the surface of the medium-carbon steel, spraying a Ni-5 percent Al alloy adhesive coating and spraying a composite carbide wear-resistant coating. The composite carbide wear-resistant coating has Vickers hardness (HV) of 1,200 to 1,800, bonding force of more than 60 Mpa, and high mechanical property, wear resistance and corrosion resistance.

Owner:CHINA UNIV OF MINING & TECH +1

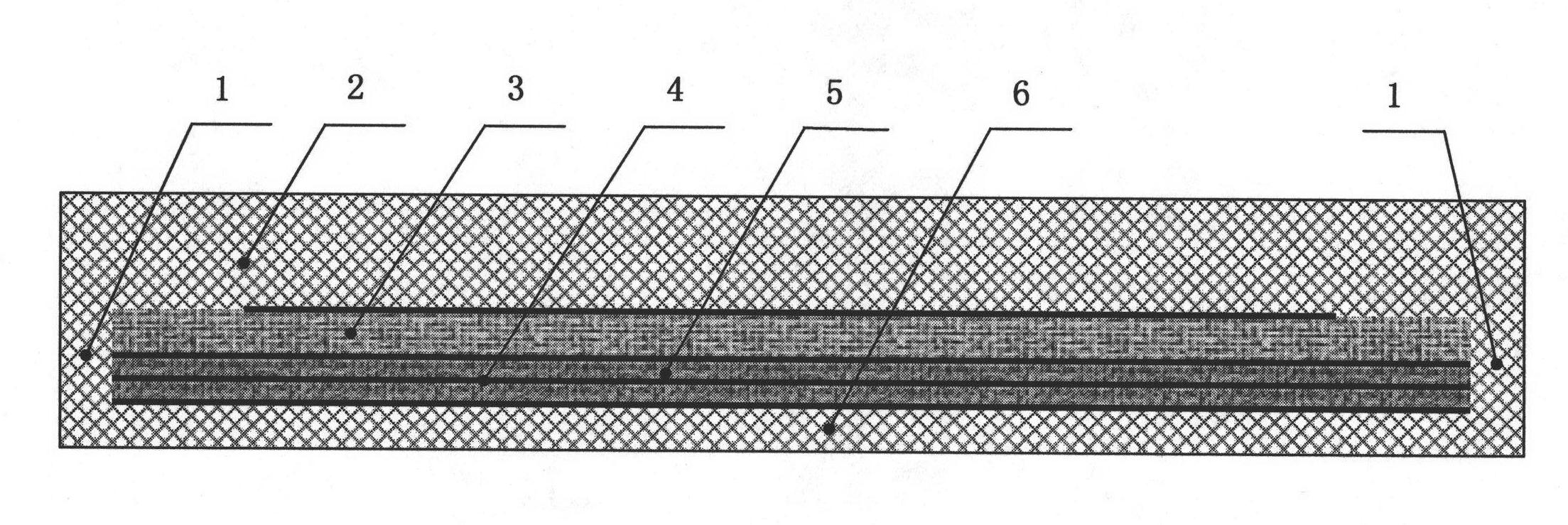

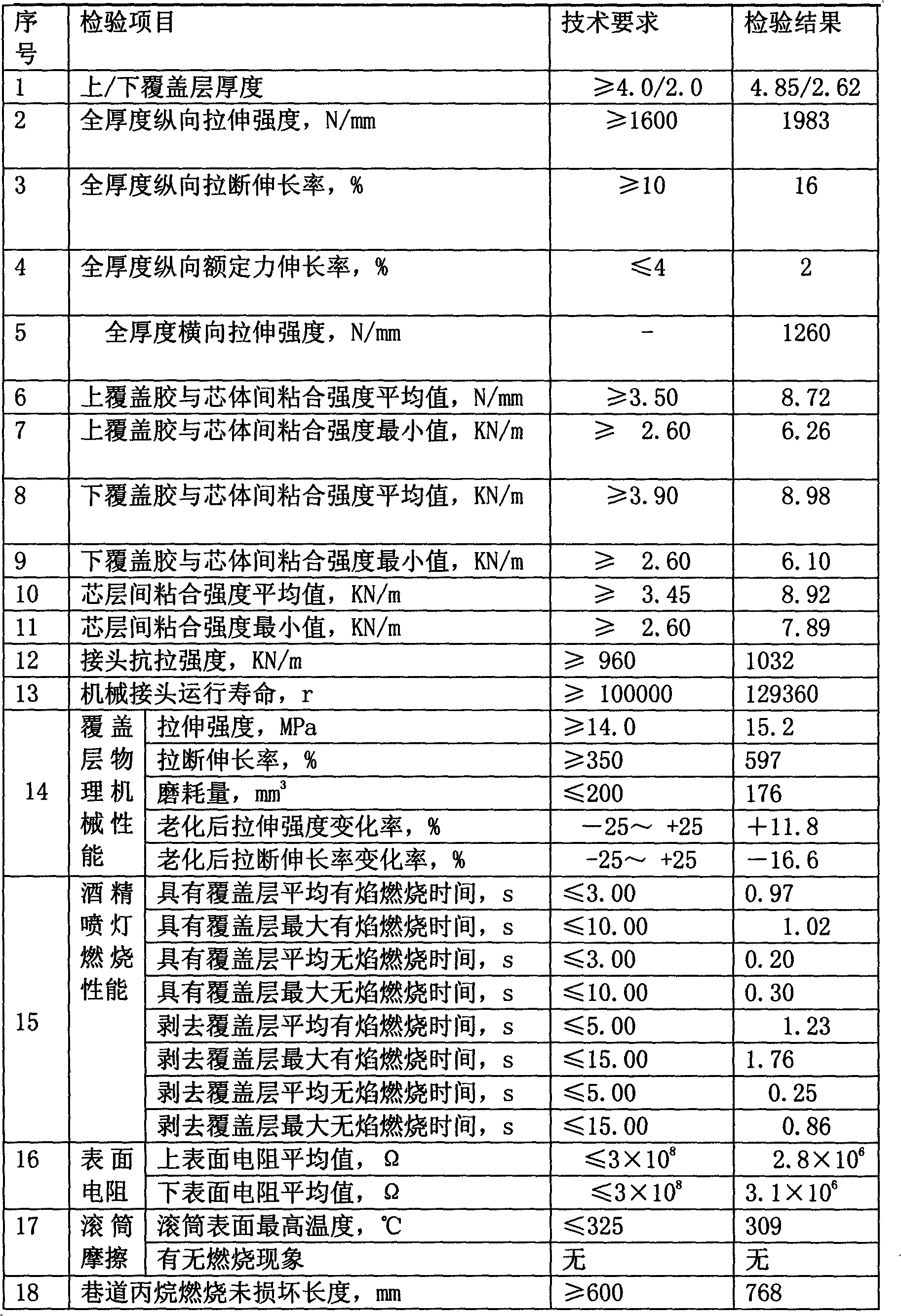

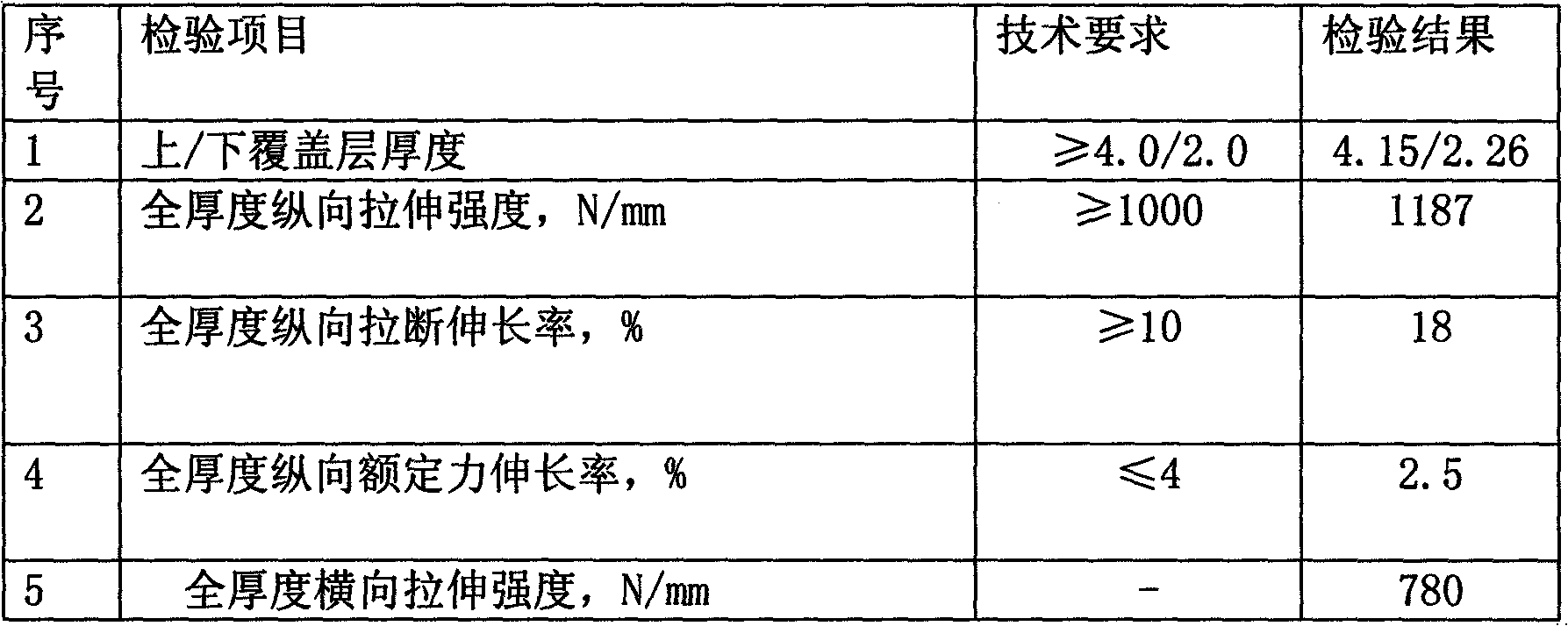

Tube-shaped flame retardant conveying belt with fabric laminations for coal mine

InactiveCN102642693AOptimizing process designReduce dosageNatural rubber adhesivesConveyorsEngineeringFire retardant

The invention discloses a tube-shaped flame retardant conveying belt with fabric laminations for a coal mine, which solves the problem that exiting products are not suitable for usage for underground conveying belts with laminations for coal mines. The conveying belt is characterized by comprising an upper flame retardant covering adhesive layer, a lower flame retardant covering adhesive layer, a side adhesive, skeleton layers, a flame retardant bonding layer and a buffering layer. A flame retardant bonding adhesive is used for bonding among the skeleton layers, among the skeleton layers and buffering layer and between the buffering layer and the upper flame retardant covering adhesive layer to form a whole, and formulas of the flame retardant bonding adhesive and a flame retardant covering adhesive are designed. Flame retardant epoxide resin (EP) canvas which is subjected to flame retardant impregnation processing serves as a skeleton, produced conveying belts have high pipe forming capability, conveying belt bodies have suitable softness, and produced conveying belts can meet turning requirements of tube-shaped conveying belts at different levels and requirements of tube-shaped conveying machines on physical mechanical properties of tube-shaped conveying belts; a flame retardant bonding adhesive material has high infiltration capacity on skeleton materials, after sulfuration, the bonding force of the flame retardant bonding adhesive material is large, dynamic heat is small, and the flame retardant bonding adhesive material has repeated bending fatigue resistance; and abrasion resistant and yielding resistant performance of the flame retardant bonding adhesive material is improved, and the flame retardant performance meets underground flame retardant requirements for coal mines.

Owner:胡世献

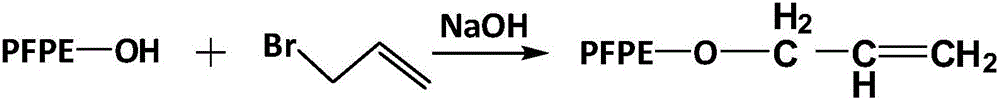

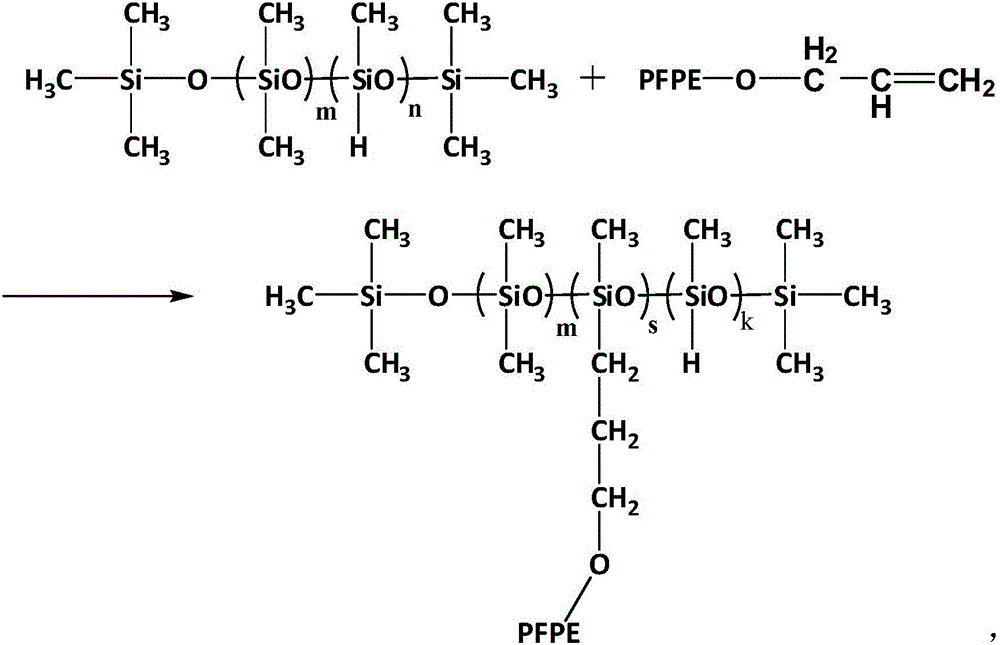

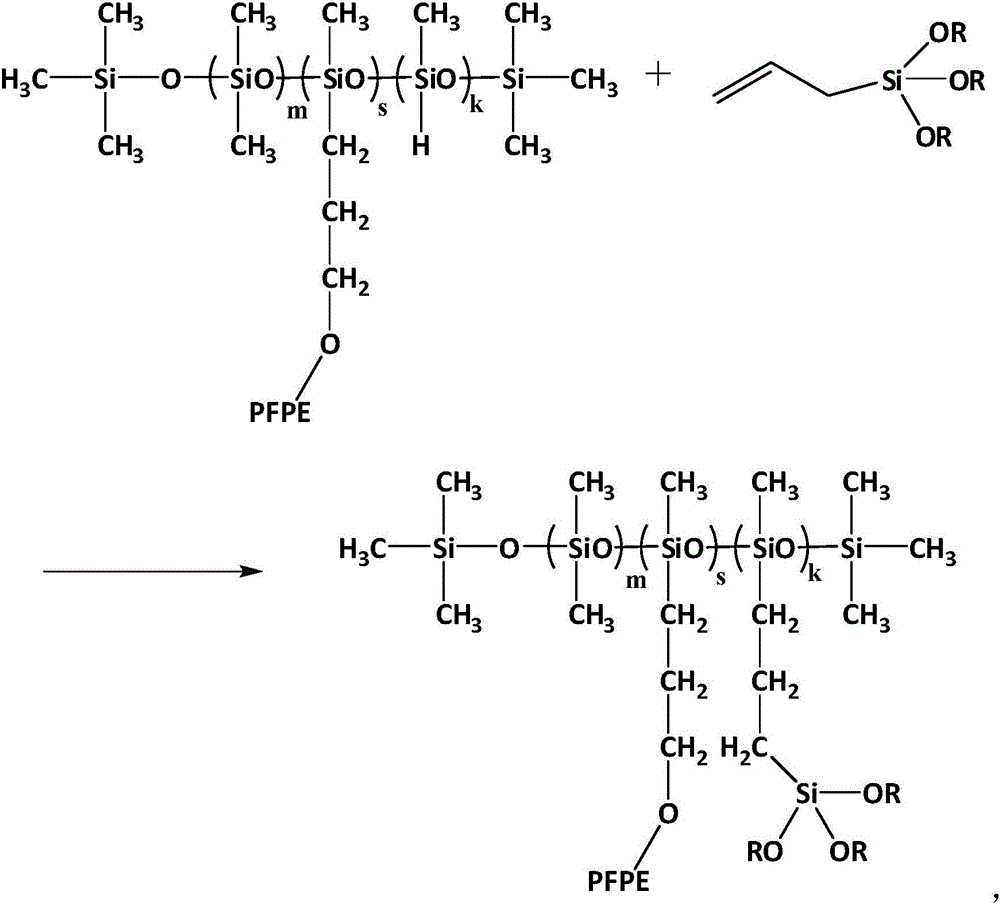

Preparation method of high-performance fingerprint-resistant agent

ActiveCN106085227AHigh hardnessImprove wear resistanceAntifouling/underwater paintsPaints with biocidesHydrogenPerfluoropolyether

The invention discloses a preparation method of a high-performance fingerprint-resistant agent. The preparation method includes the following steps that hydroxyl-terminated perfluorinated polyether and allyl bromide react to obtain allyl-terminated perfluorinated polyether; allyl-terminated perfluorinated polyether and hydrogen-containing silicone oil are subjected to a layer adding reaction through silicone hydrogen, and perfluorinated polyether-hydrogen-containing silicone oil (unreacted hydrogen still exists in silicone oil) is obtained; the obtained product and allyl siloxane continue to be subjected to a silicone hydrogen water adding reaction to obtain a needed target product pectinate perfluorinated polyether-siloxane; then pectinate perfluorinated polyether-siloxane is prepared into the fingerprint-resistant agent. The prepared fingerprint-resistant agent has the advantages of being good in hydrophobic and oleophobic performance, excellent in anti-fouling property and good in fingerprint easy-to-move property, a fingerprint-resistant coating and a glass base material are high in bonding force, the product is good in abrasion resistance, and compared with the prior art, the durability and abrasion resistance of the fingerprint-resistant agent are greatly improved.

Owner:QUZHOU FLUORIDE & SILICON RES INST

Cathode current collector, and preparation method and application of cathode current collector

ActiveCN107369810AIncrease energy densityHigh tensile strengthNitrogen-metal/silicon/boron binary compoundsElectrode carriers/collectorsCopper platingEvaporation

The invention discloses a cathode current collector, and a preparation method and an application of the cathode current collector. The cathode current collector is in a multilayer structure, and comprises a plastic film, wherein the upper and lower surfaces of the plastic film are sequentially coated with bonding force reinforcement layers, copper coating layers and antioxidation layers. The preparation method comprises the steps of coating the bonding force reinforcement layers on the plastic film by utilizing a magnetron sputtering coating technology, coating the copper coating layers by utilizing an evaporation coating technology, and coating the antioxidation layers by utilizing an electron beam evaporation coating technology or the magnetron sputtering coating technology. The application of the cathode current collector is mainly in a lithium ion battery. The cathode current collector can realize lightweighting of the battery, improves the energy density, lowers the cost, and can reduce the possibility of falling and oxidation of the copper coating layers.

Owner:CONTEMPORARY AMPEREX TECH CO

Method for preparing modified urethane elastomer

InactiveCN101333280AGood dispersionImprove the interface binding forcePolyurethane elastomerOligomer

The invention discloses a method for preparing polyurethane elastomer modified by a carbon nano-tube. After acidification and acylchlorination at the surface, the carbon nano-tube reacts with polyhydroxy compound or oligomer to produce a carbon nano-tube with functionalized hydroxyls; one or more hydroxyls are connected to the surface of the functionalized carbon nano-tube through covalent bonds and have certain crosslinking and chain extension functions if being applied in the synthesis of polyurethane, thus greatly increasing the bonding force between the interfaces of the carbon nano-tube and the polyurethane base body, and meanwhile, the existence of hydroxyls improves the dispersibility of the carbon nano-tube in the polyurethane base body, which greatly improves the mechanical properties in all aspects of the functionalized carbon nano-tube / polyurethane composite material as compared the original carbon nano-tube / polyurethane composite material. Furthermore, the carbon nano-tube is capable of changing the dielectric property of the polyurethane composite material or even producing conductive polyurethane, thus enlarging the application range and field of polyurethane.

Owner:TONGJI UNIV

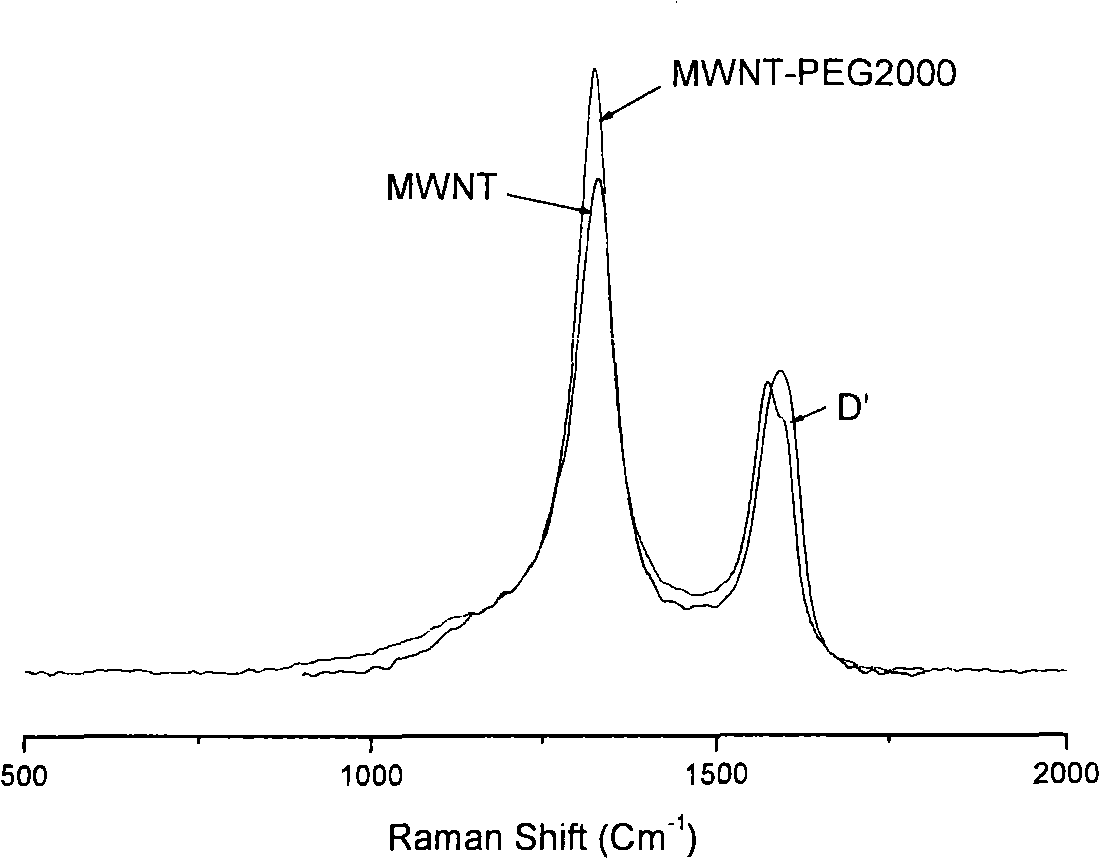

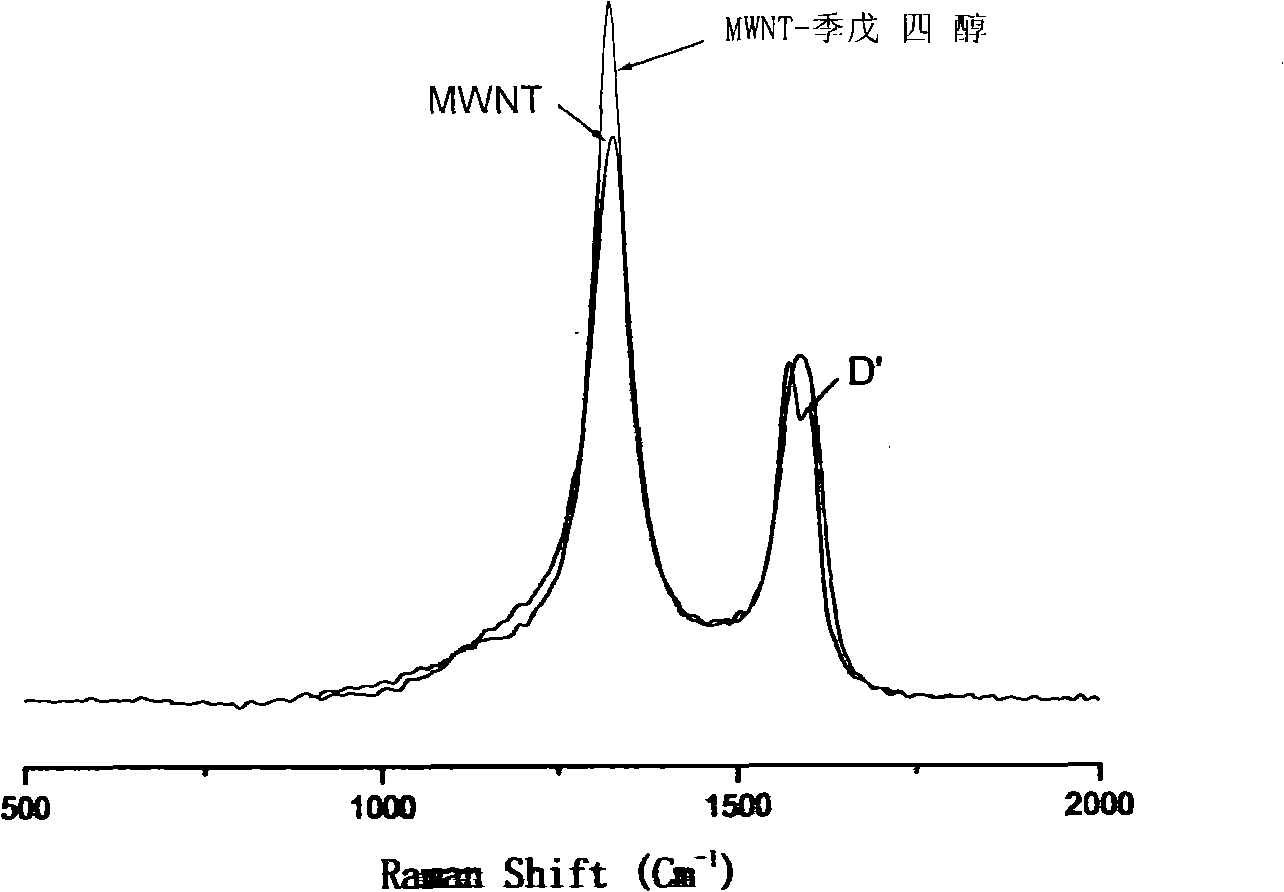

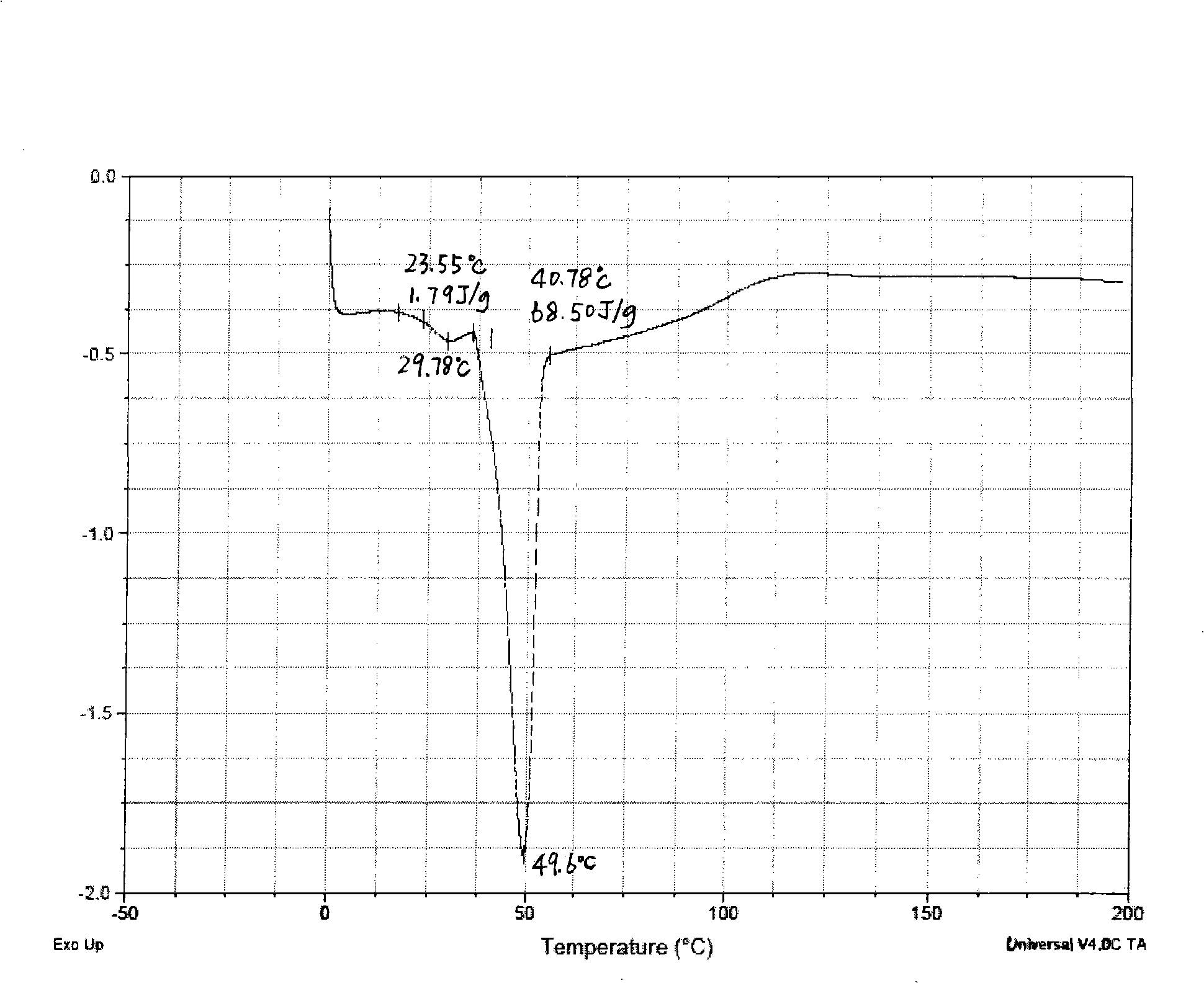

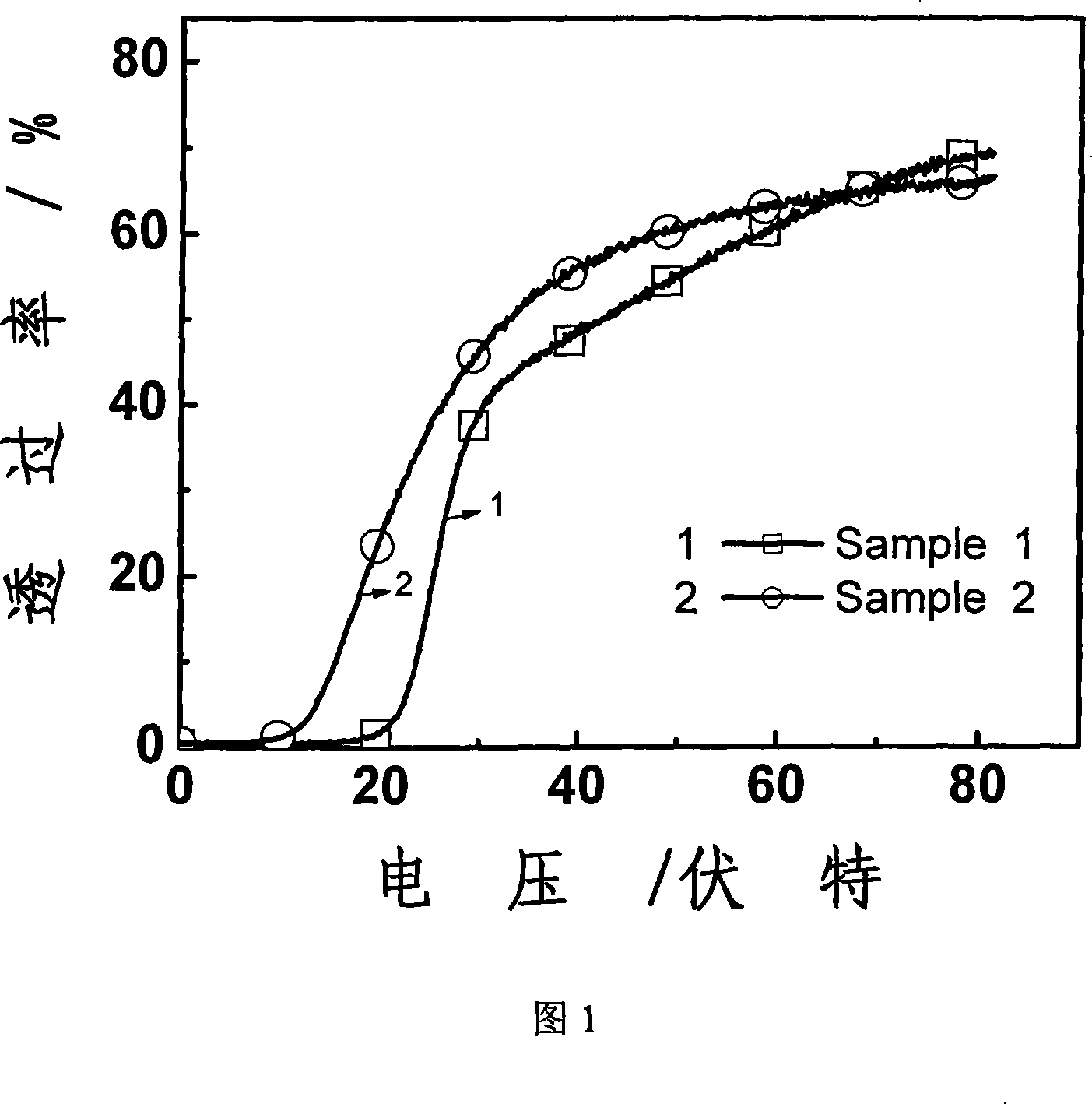

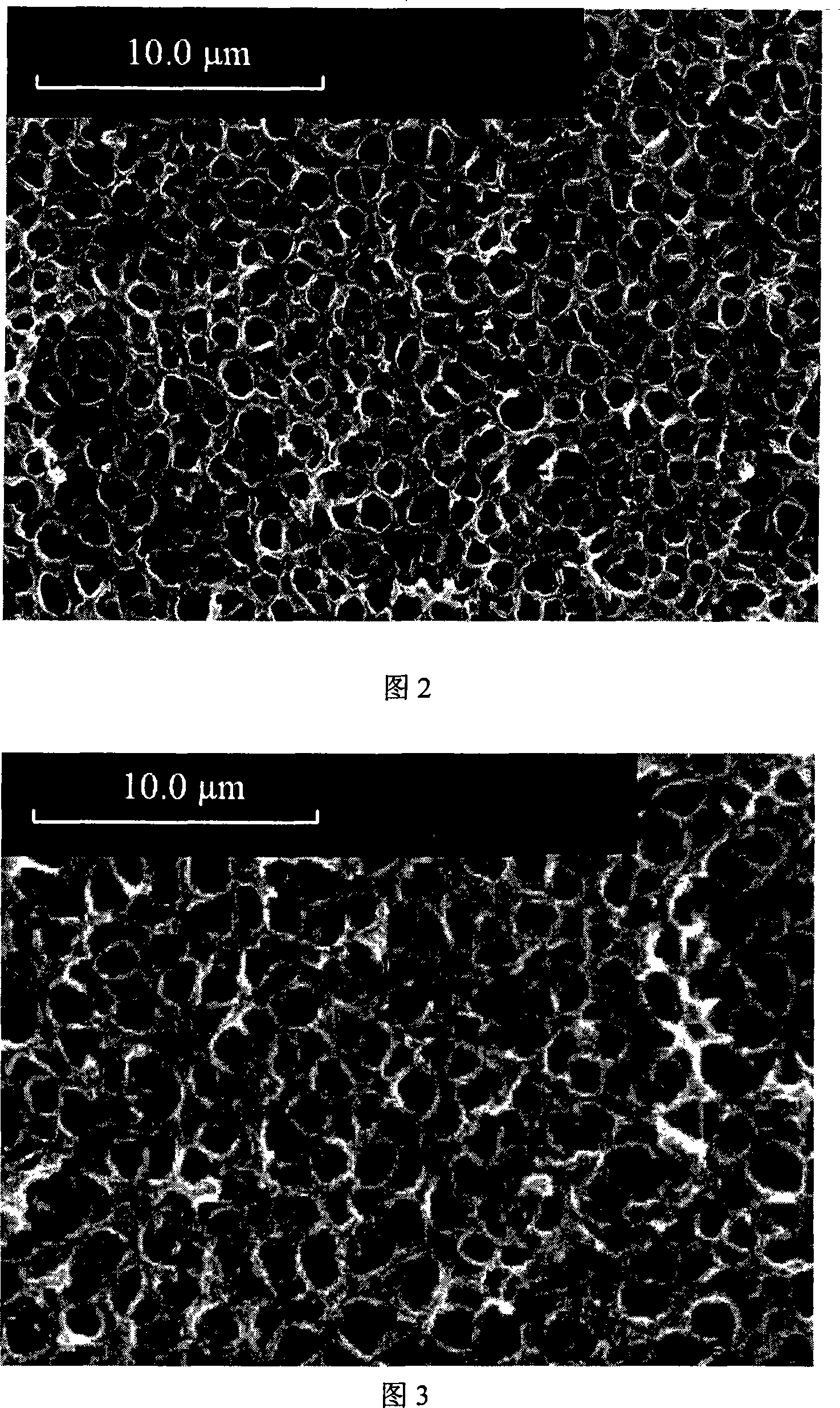

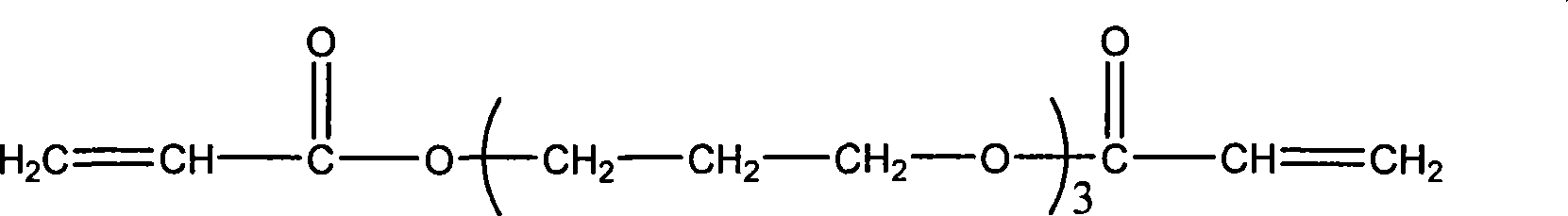

Method for preparing polymer dispersion liquid crystal material by ultraviolet-heating step-polymerization process

ActiveCN101225308AIncrease crosslink densityImprove interfacial adhesionLiquid crystal compositionsUltraviolet lightsPolymer network

The invention in particular relates to a preparation method of polymer dispersing liquid crystal film by an ultraviolet irradiating-heating plus stepwise initiated polymerization and phase separation method, belonging to the functional material field, which is applied in the preparation of electric controlled intelligent glass. The preparation method is characterized in that: the nematic liquid crystal, the monomer which can be polymerized under ultraviolet light, the light initiator, the thermal polymerized monomer and the glass microsphere is blended and then are clipped between two pieces of transparent conductive film plated with indium tin oxide, and then film with the thickness of 20 Mum if formed and is irradiated by the ultraviolet light with the wavelength of 365nm at 0 to 25 degrees; the intensity of the ultraviolet light is 20.0mW / m<2> and the illumination time is 1 to 10 minutes; the thermal polymerization temperature is 60 to 100 degrees, the holding time is 5 to 8 hours, at last the PDLC film is prepared by solidification. The polymer dispersing liquid crystal film has the advantages that: because of the stepwise polymerization crosslinking reaction which is carried out by selecting the monomer polymerized by ultraviolet and thermal polymerized monomer and irradiating and heating under ultraviolet light, the electro-optic performance the PDLC film is improved, the network strength of the polymer is enhanced, meanwhile, the bonding force of the interface between the polymer network and the ITO film are reinforced.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com