Organic electroluminescence device and method for preparing same

An electroluminescent device and luminescent technology, which is applied in the manufacture of organic semiconductor devices, electric solid devices, semiconductor/solid device, etc., can solve the problems of large investment in hardware equipment, device performance degradation, high energy consumption, etc., and achieve investment and Low performance requirements, good device performance, and the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

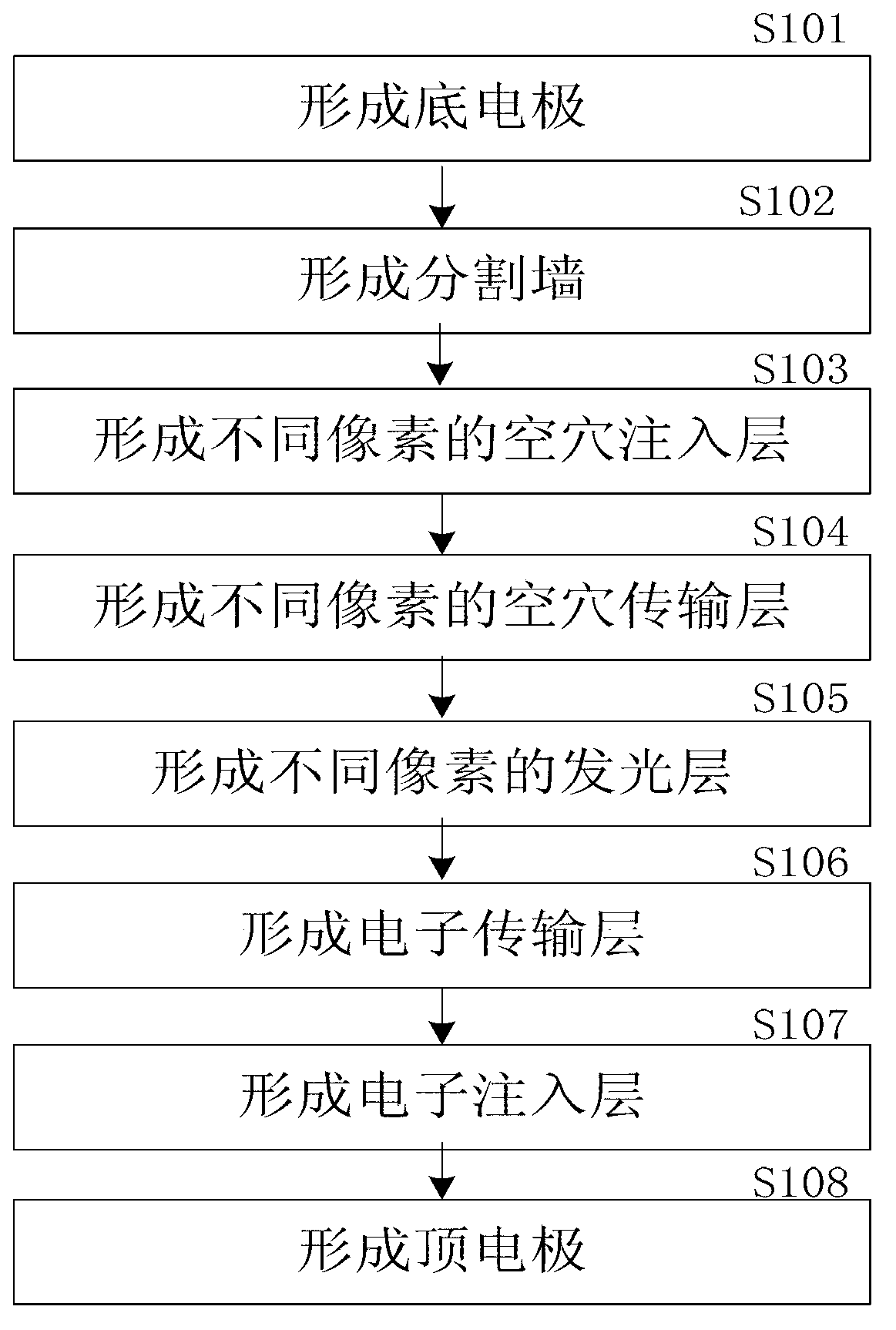

[0064] The method for preparing an organic electroluminescent device of the present invention comprises the steps of:

[0065] Step 1, depositing and patterning a bottom electrode on the substrate containing the driving transistor;

[0066] Step 2. Prepare a multi-layer pixel partition wall by coating on the above-mentioned substrate deposited with the patterned bottom electrode, and the pixel partition wall includes a lyophilic organic material separation layer and a lyophobic organic material separation layer;

[0067] Step 3, depositing and preparing a functional layer on the pixel area defined by the partition wall;

[0068] Step 4, sequentially depositing a cathode, a protection layer or an encapsulation layer on the functional layer and the pixel separation wall.

[0069] The method for preparing an organic electroluminescent device of the present invention, wherein, comprises the following steps:

[0070] Step 1. Prepare the bottom layer of the partition wall by coati...

Embodiment 1

[0078] Example 1. Organic electroluminescent device with double-layer pixel partition walls

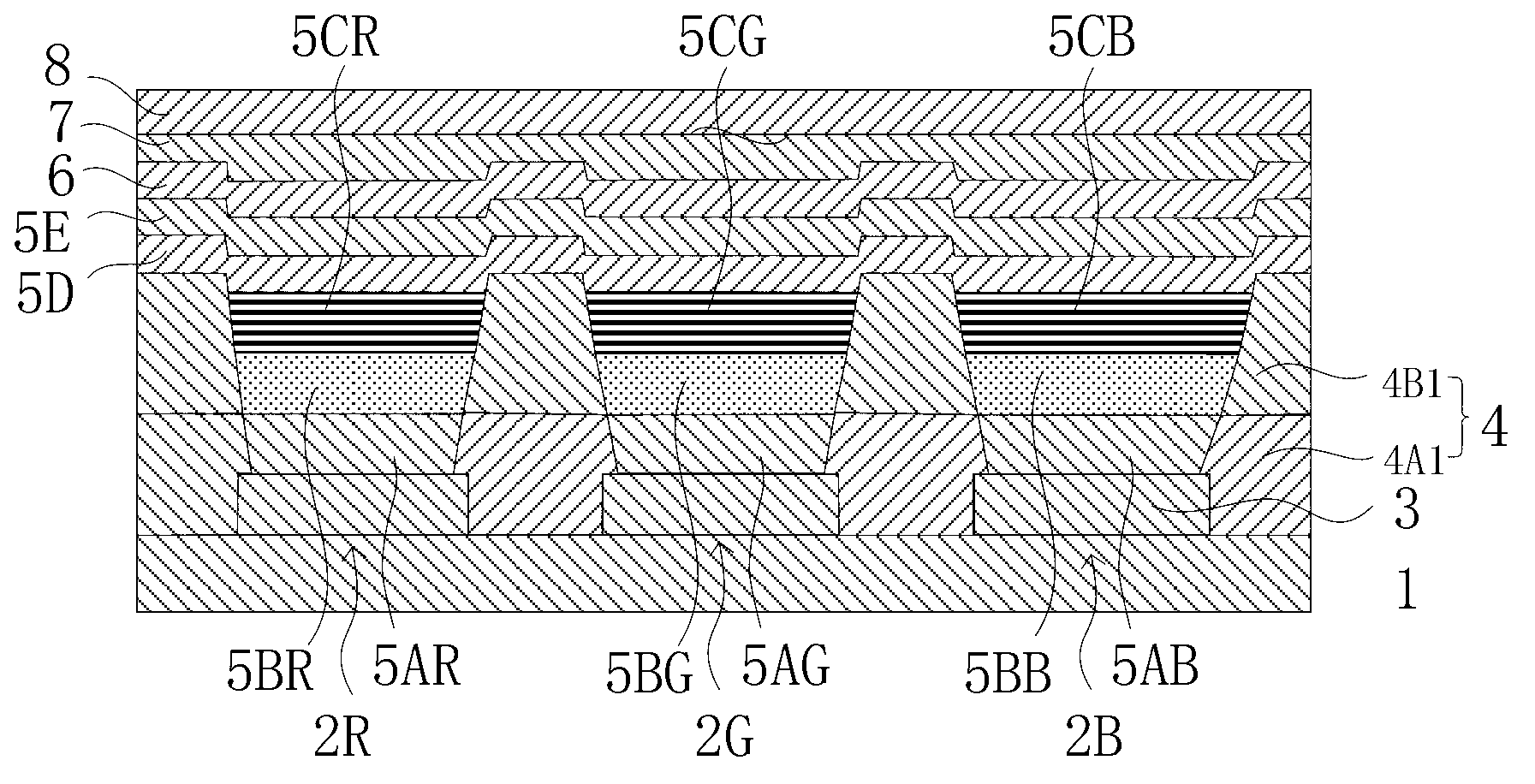

[0079] figure 1 A cross-sectional view of one example of the organic electroluminescence device of the present invention is shown. The organic electroluminescent device is composed of the following parts: substrate 1 (carrying light-emitting units 2R, 2G, 2B), bottom electrode 3 (anode referred to in this embodiment) deposited sequentially on the substrate, and pixel separation wall 4 (first separation layer 4A1 and second separation layer 4B1), hole injection layer 5A, hole transport layer 5B, light emitting layer 5C, electron transport layer 5D, electron injection layer 5E, top electrode 6 as a cathode, protective layer 7 and package substrate 8 .

[0080] The substrate 1 mainly carries the red organic electroluminescent unit 2R, the green organic electroluminescent unit 2G and the blue organic electroluminescent unit 2B thereon. The substrate material of the substrate may be qua...

Embodiment 2

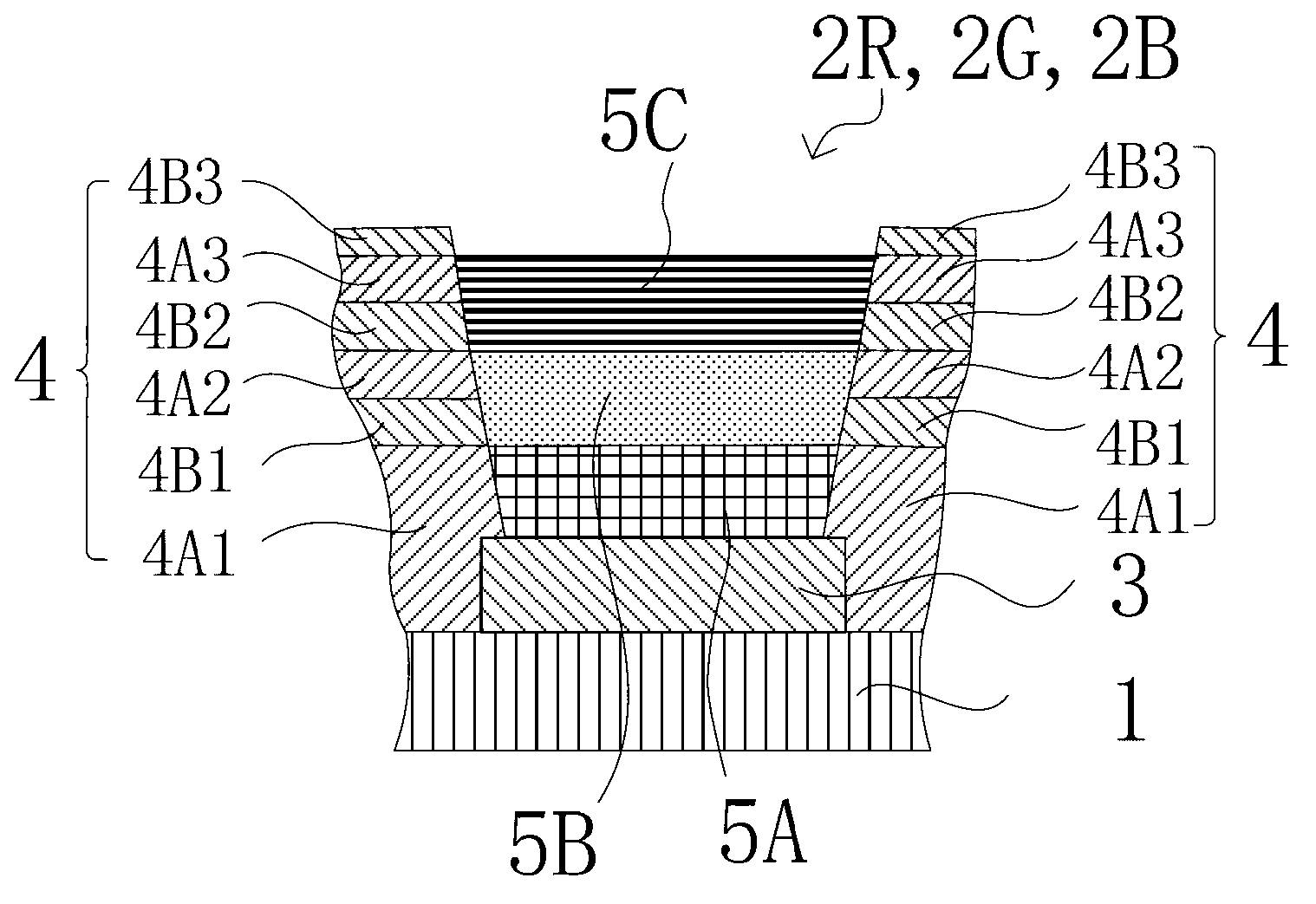

[0093] Example 2. Organic electroluminescent device with multi-layered pixel partition walls

[0094] figure 2 A schematic diagram of an organic electroluminescence device having a multilayered pixel partition wall as the present embodiment is shown. The organic electroluminescent device in this embodiment is the same as the organic electroluminescent device in the first embodiment, the difference is that the pixel partition wall 4 is composed of more than two (multiple) separation layers stacked, each separation layer Using organic materials, the wettability of adjacent separation layers is different, the same components are designated with the same reference numerals, the details of which are not described again.

[0095] In the multi-layer pixel partition wall structure shown in this embodiment, each layer ( 4A1 , 4B1 , 4A2 , 4B2 , 4A3 and 4B3 ) constituting the pixel partition wall is composed of organic materials, such as polymer materials. The wettability of adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com