Patents

Literature

2114 results about "Inorganic layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

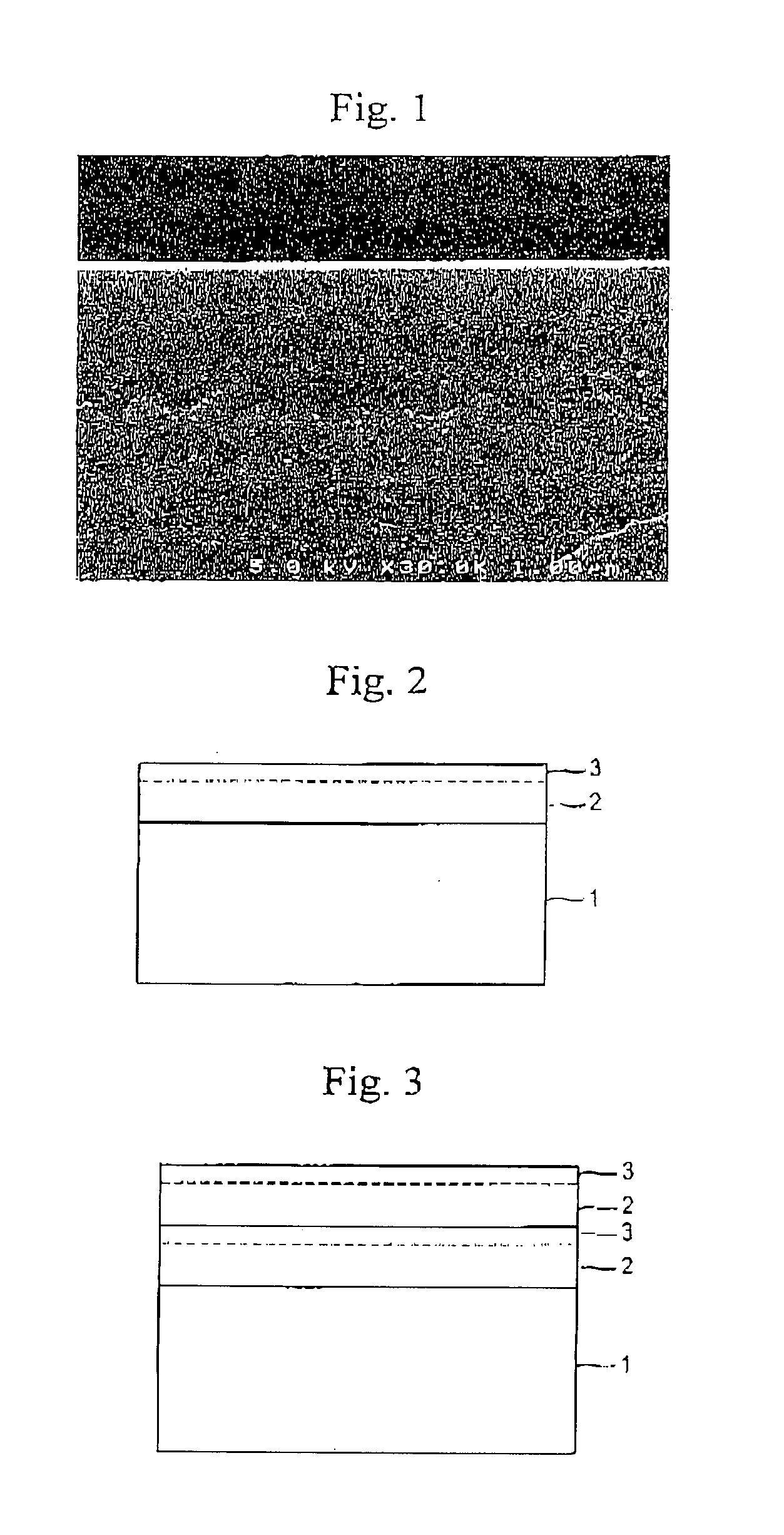

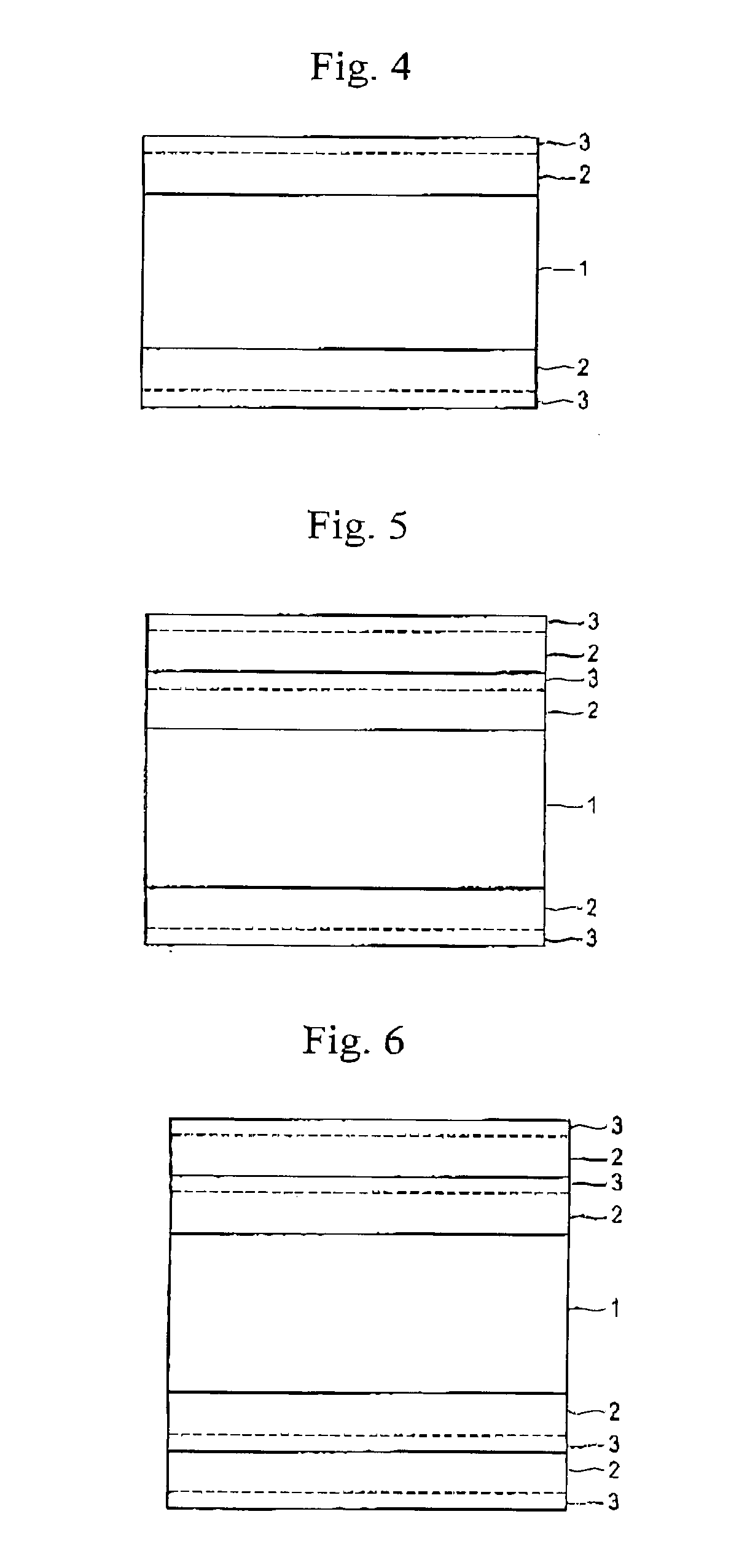

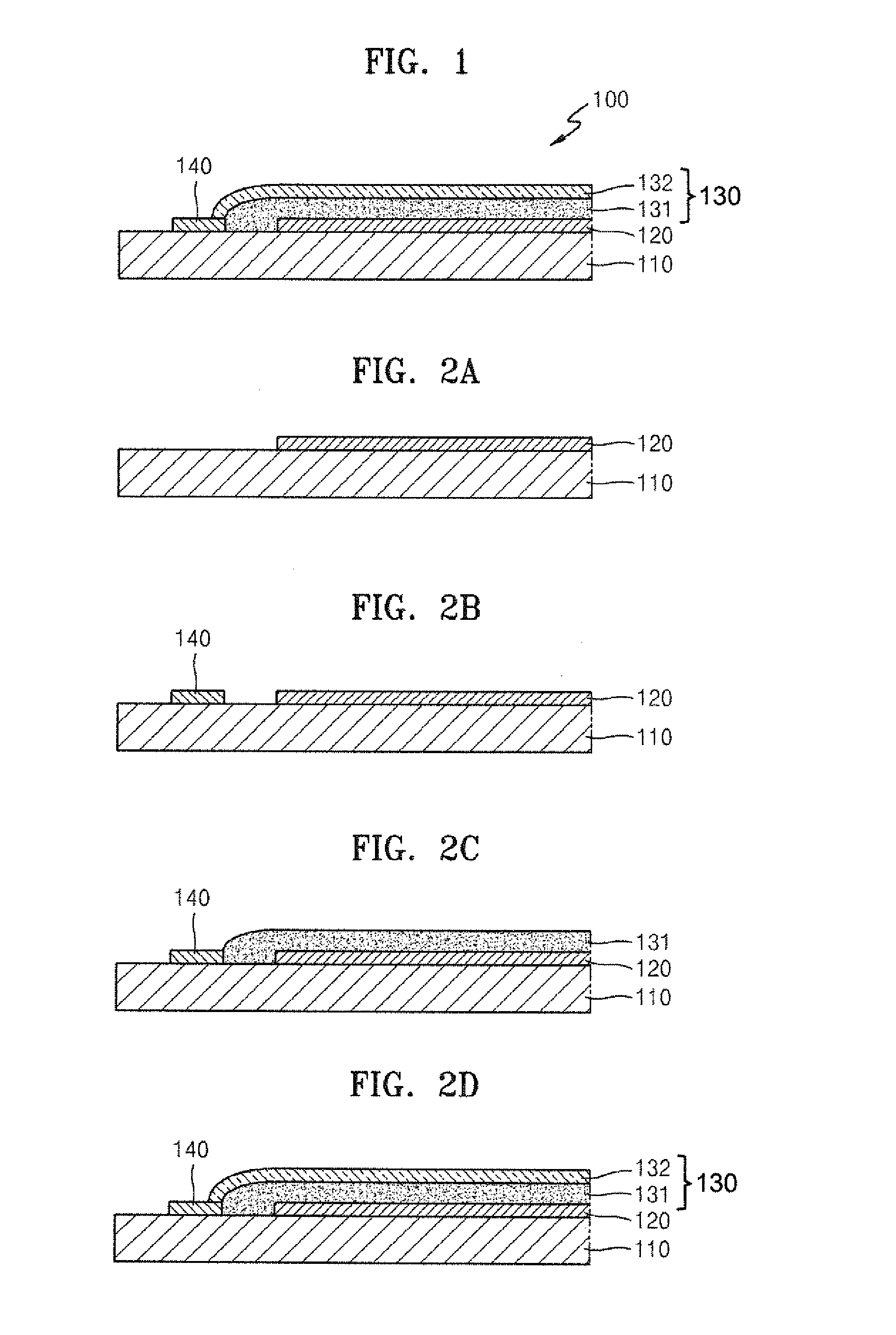

Method for fabrication of transparent gas barrier film using plasma surface treatment and transparent gas barrier film fabricated thereby

InactiveUS20100285319A1Excellent gas barrier performanceEconomical and simple methodSynthetic resin layered productsPretreated surfacesOptoelectronicsInorganic layer

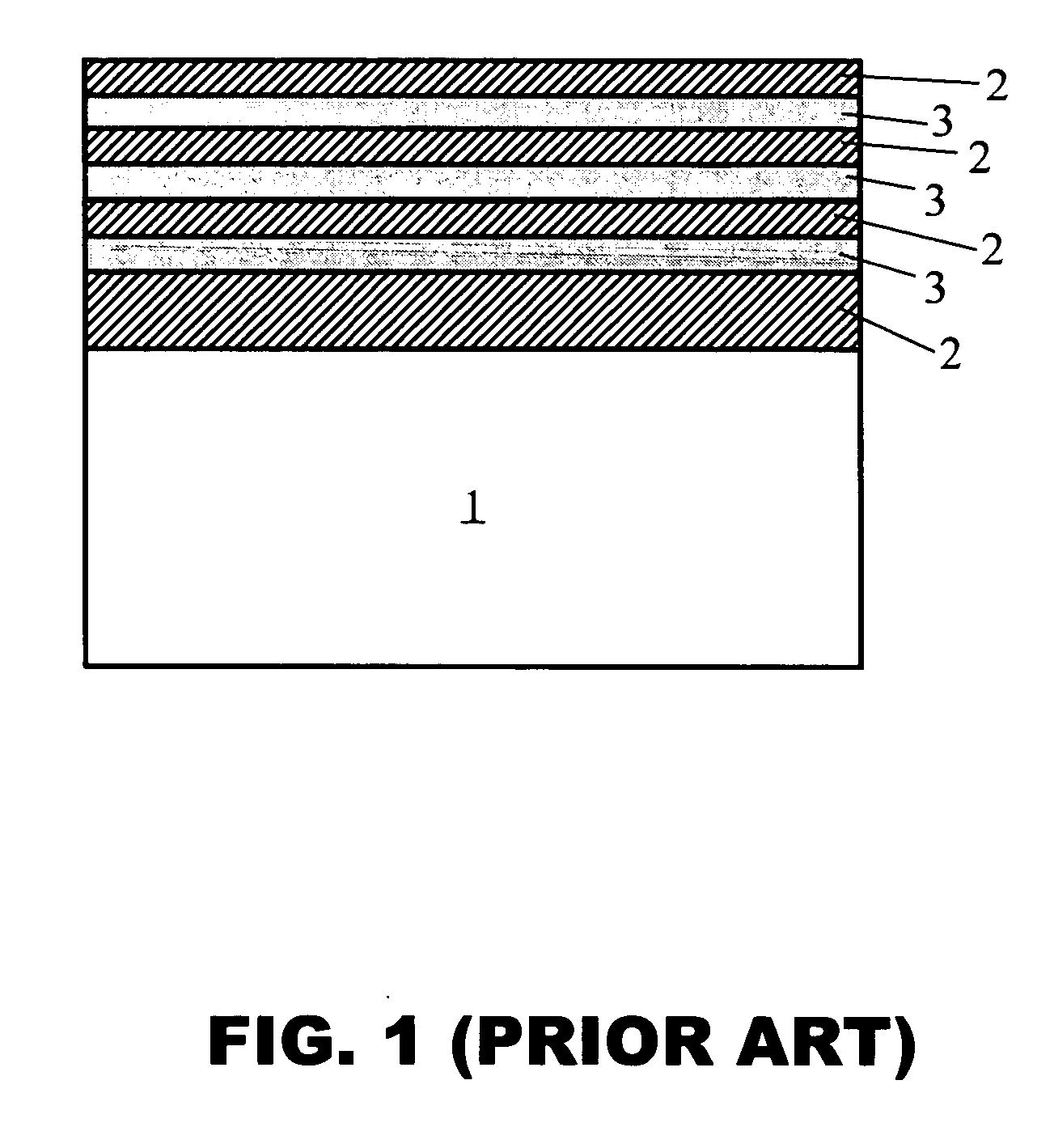

The present invention relates to a method of fabricating a transparent gas barrier film by using plasma surface treatment and a transparent gas barrier film fabricated according to such method which has an organic / inorganic gradient interface structure at the interface between an organic / inorganic hybrid layer and an inorganic layer. Since the method of the present invention is capable of fabricating a gas barrier film by plasma surface treatment instead of deposition under high vacuum, it can mass-produce a transparent gas barrier film with excellent gas barrier properties in an economical and simple manner. Further, since the transparent gas barrier film fabricated according to the method of the present invention shows excellent gas barrier properties and is free of crack formation and layer-peeling phenomenon, it can be effectively used in the manufacture of a variety of display panels.

Owner:KOREA INST OF SCI & TECH

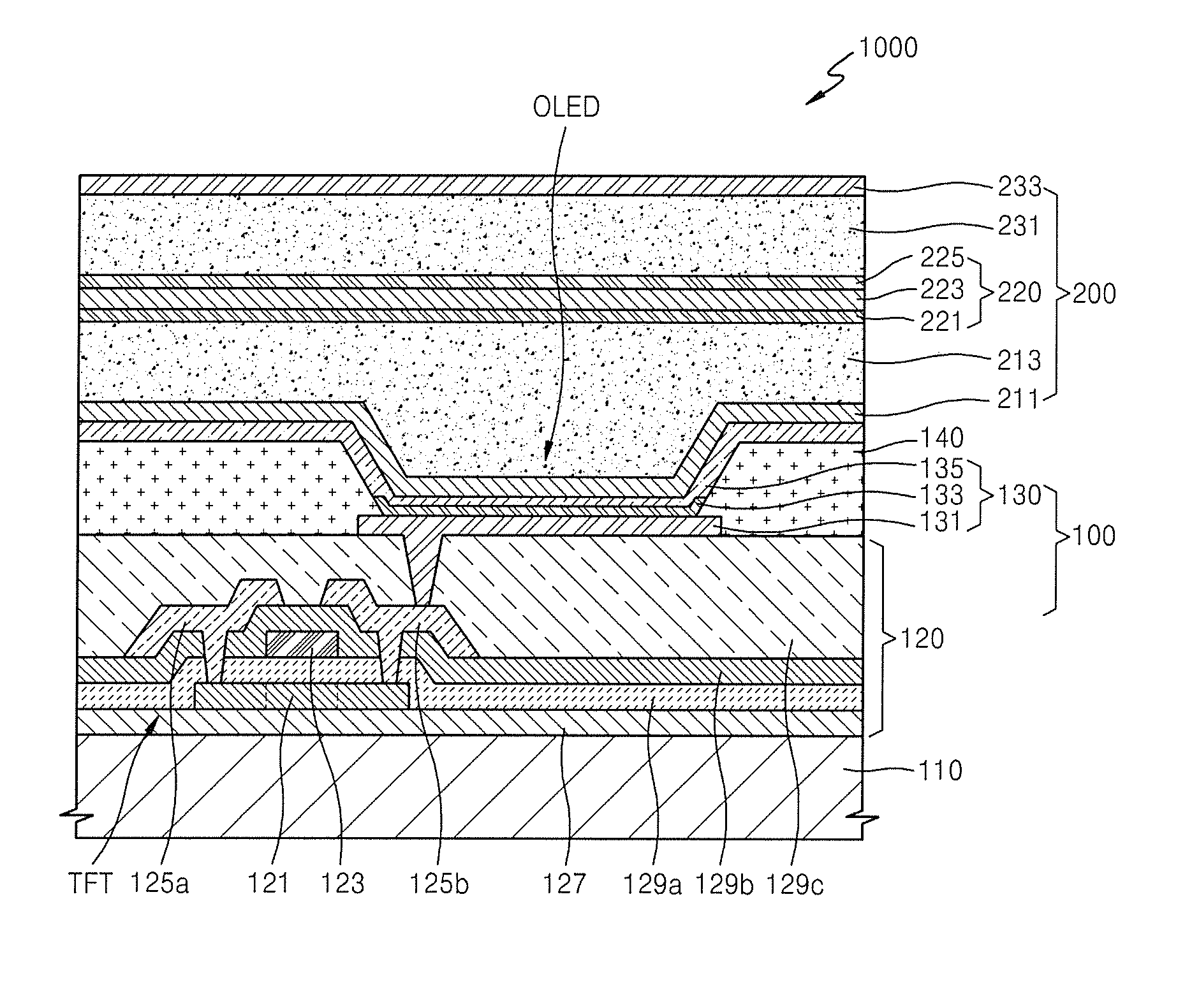

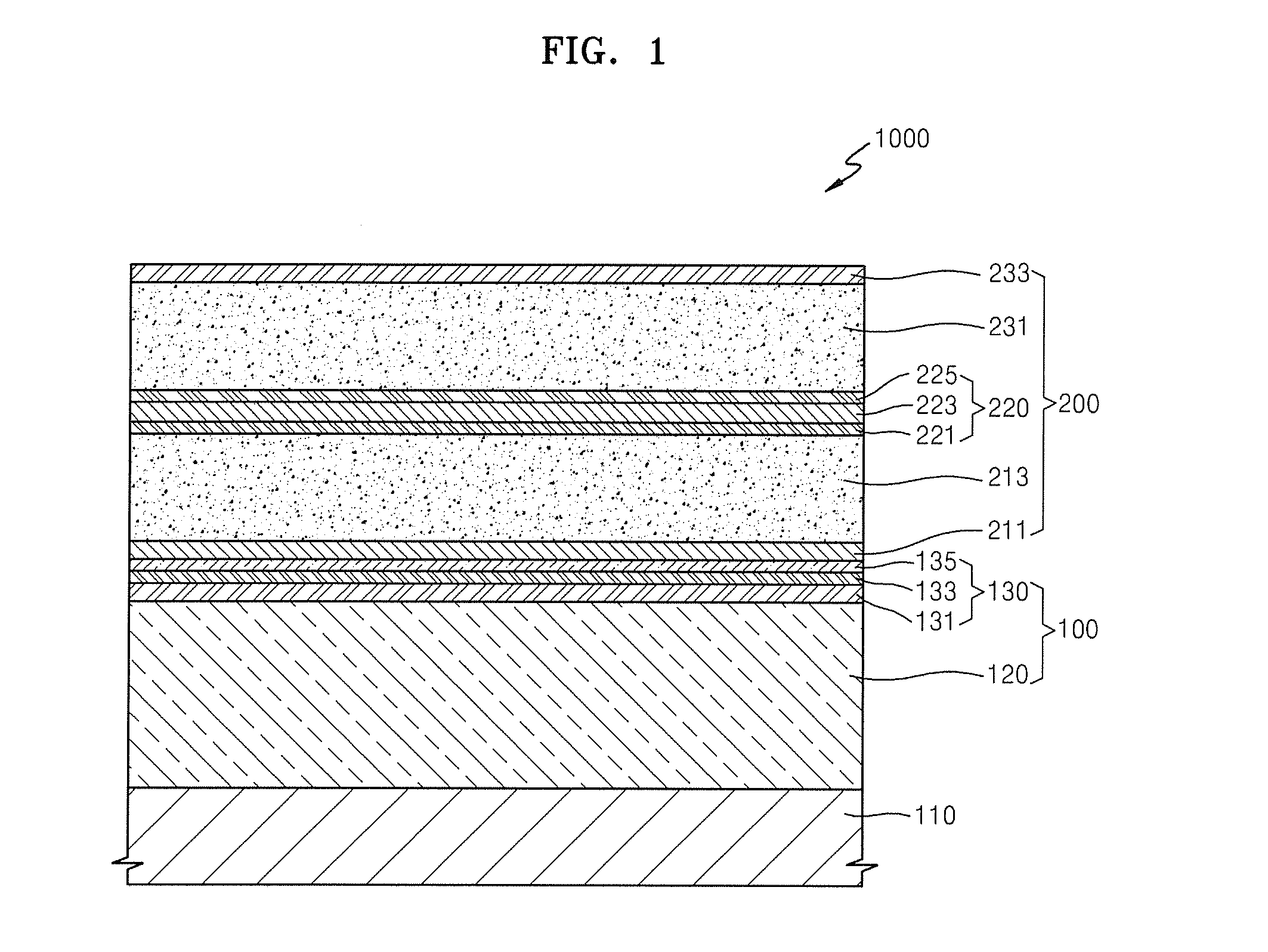

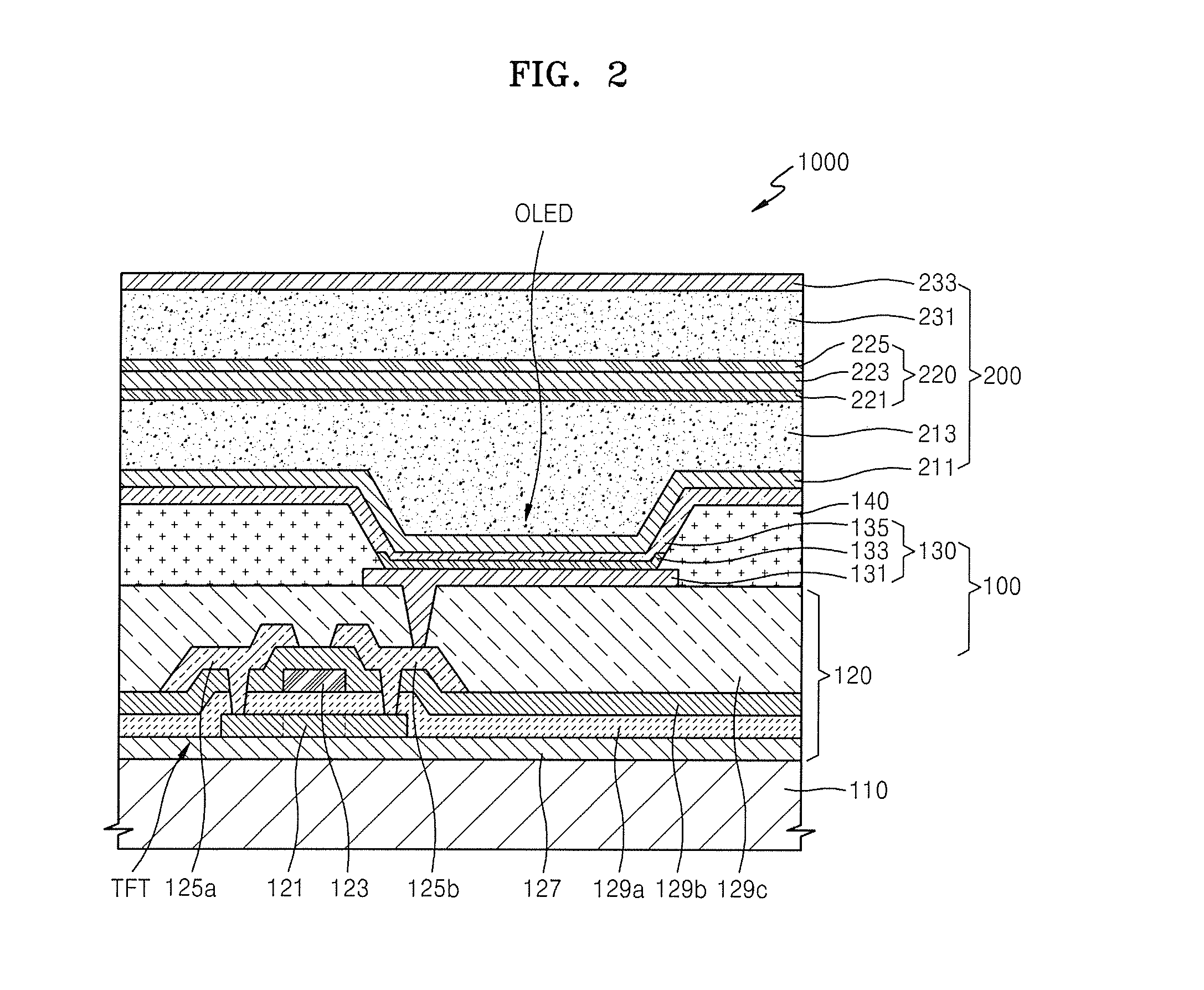

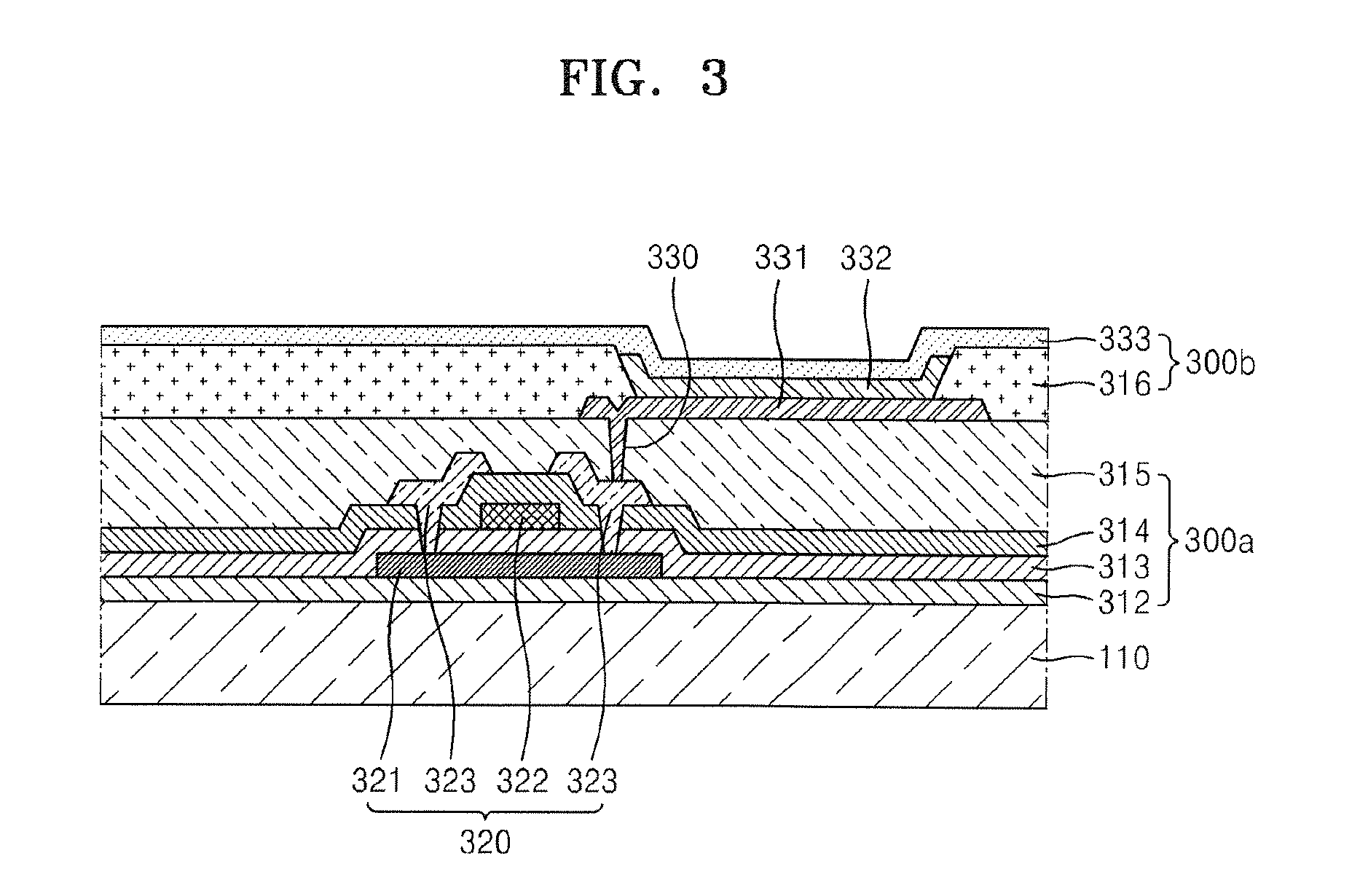

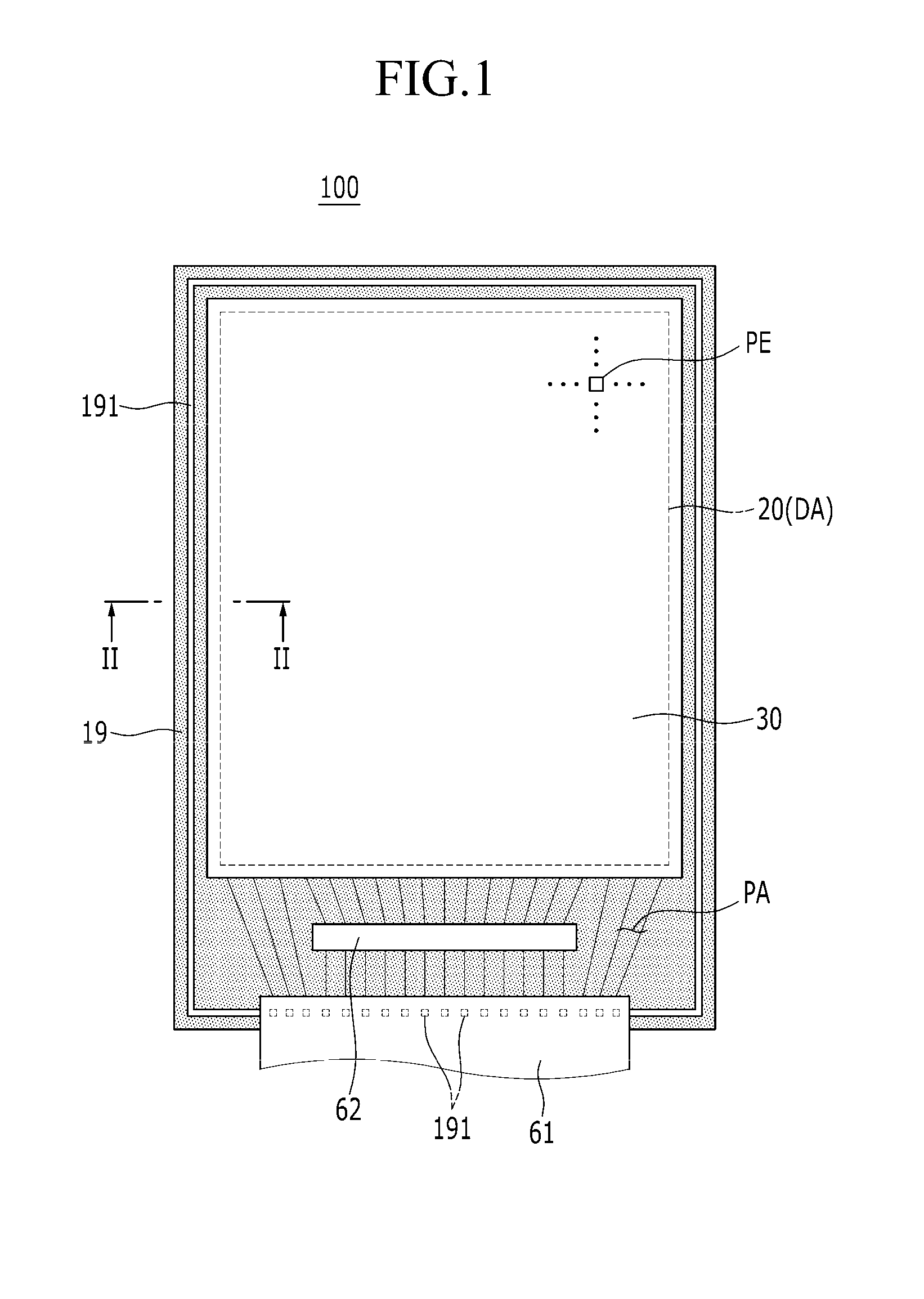

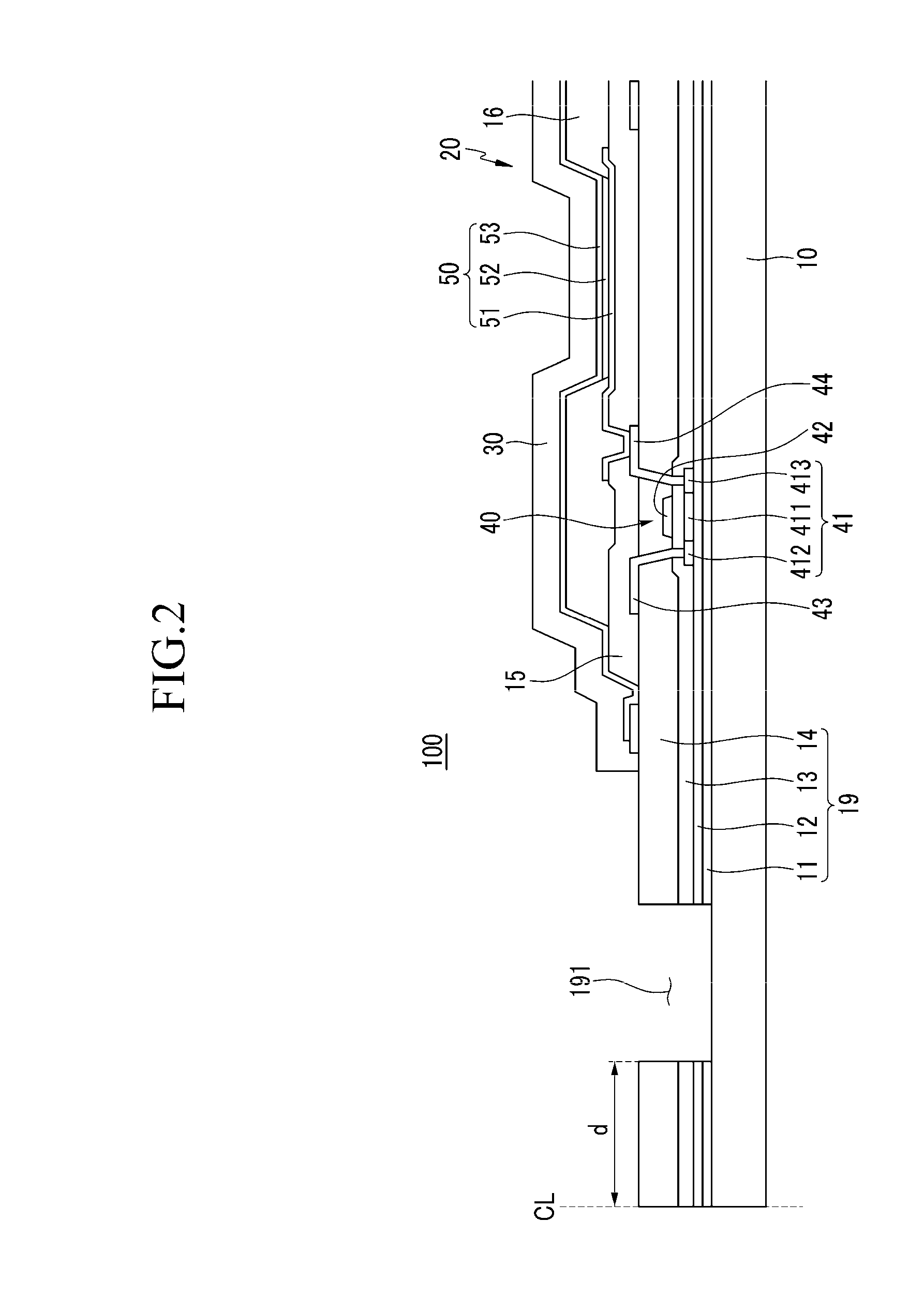

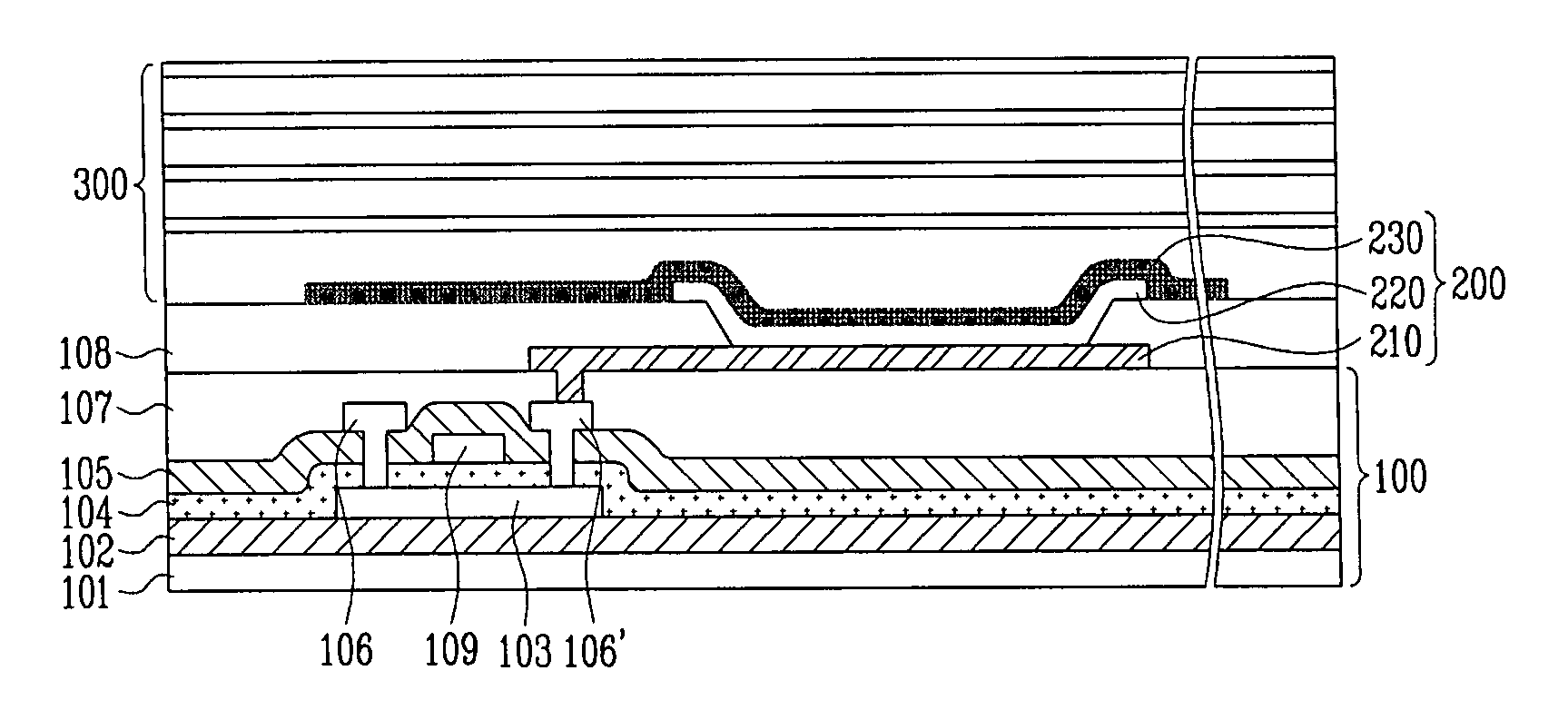

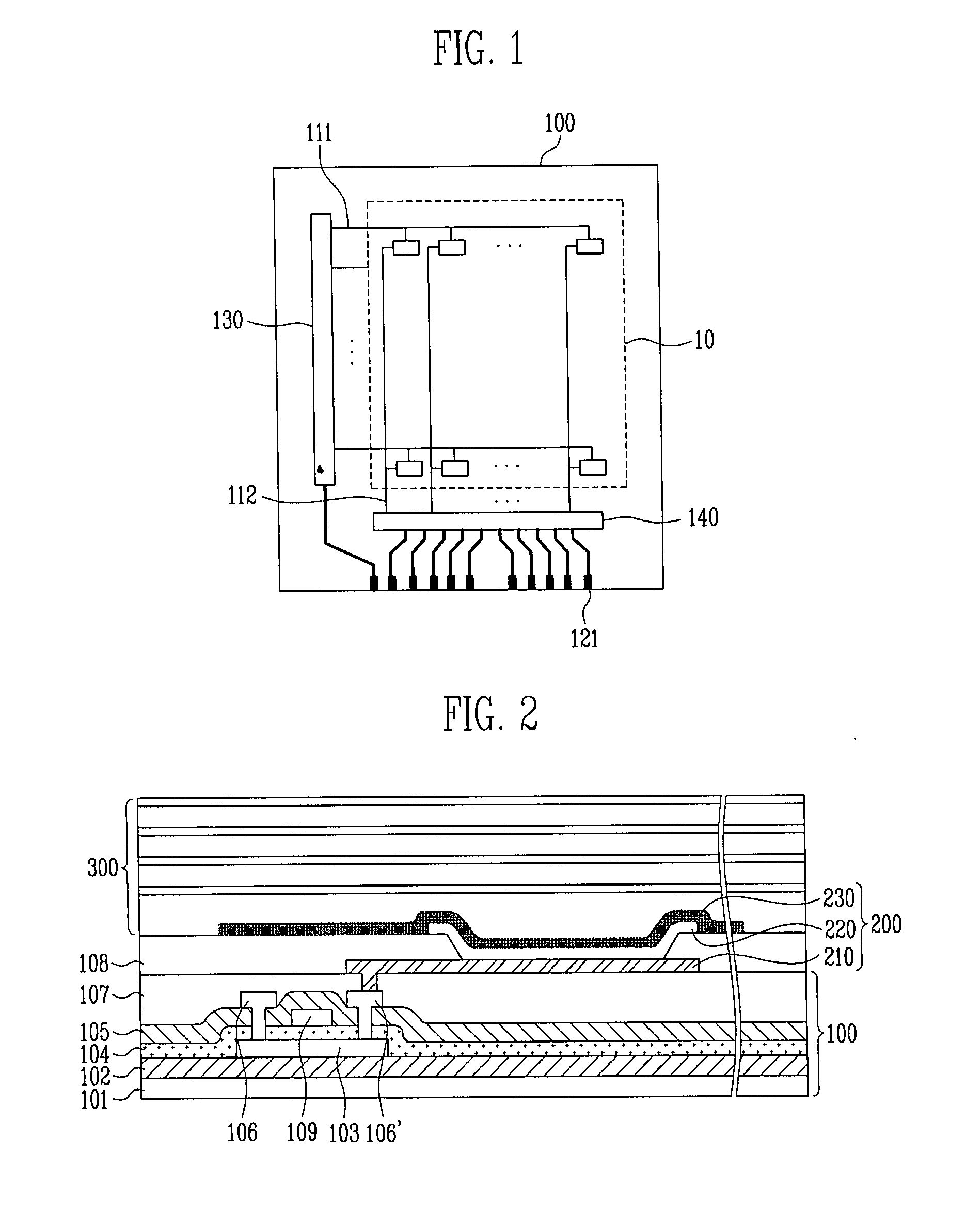

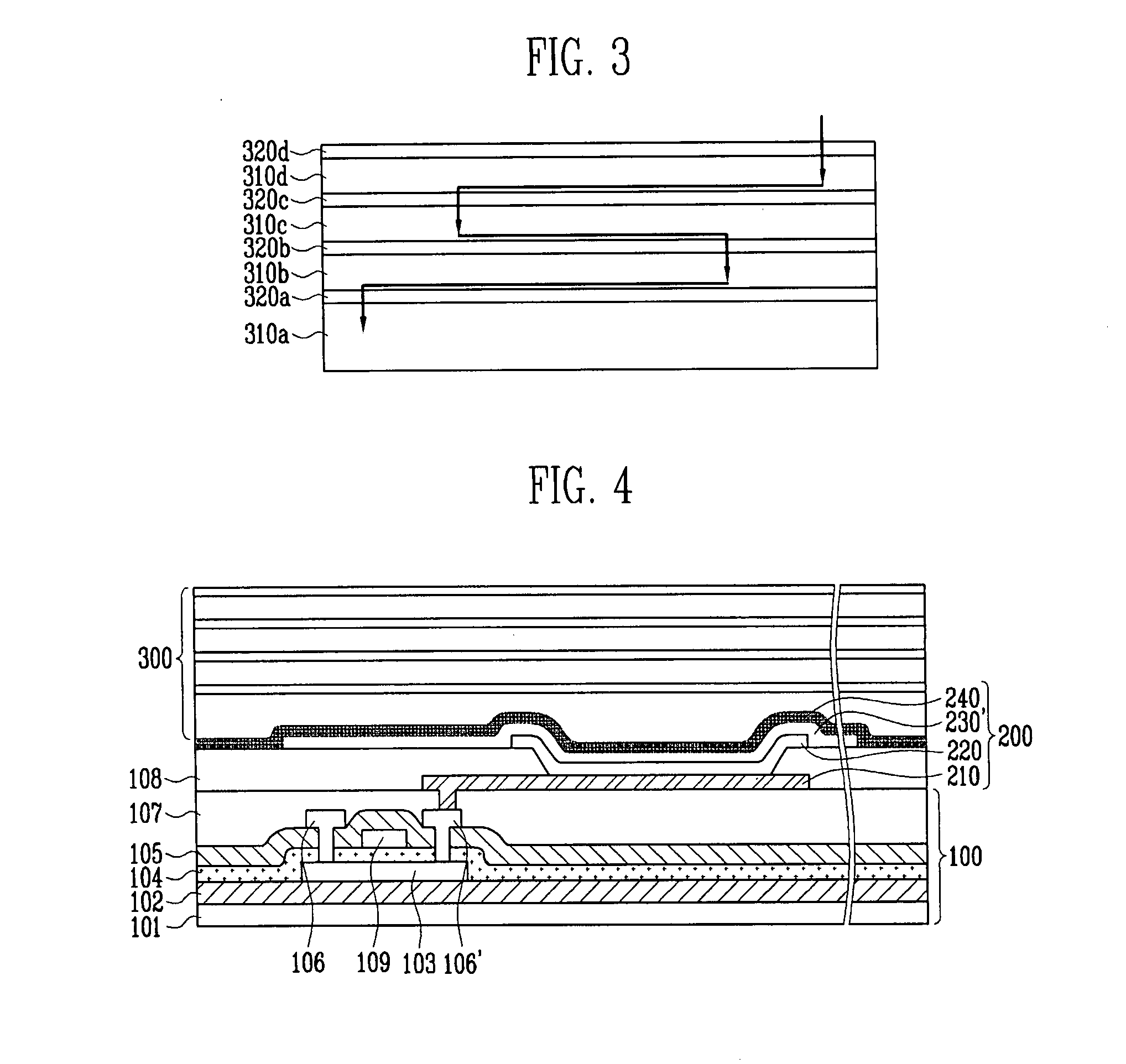

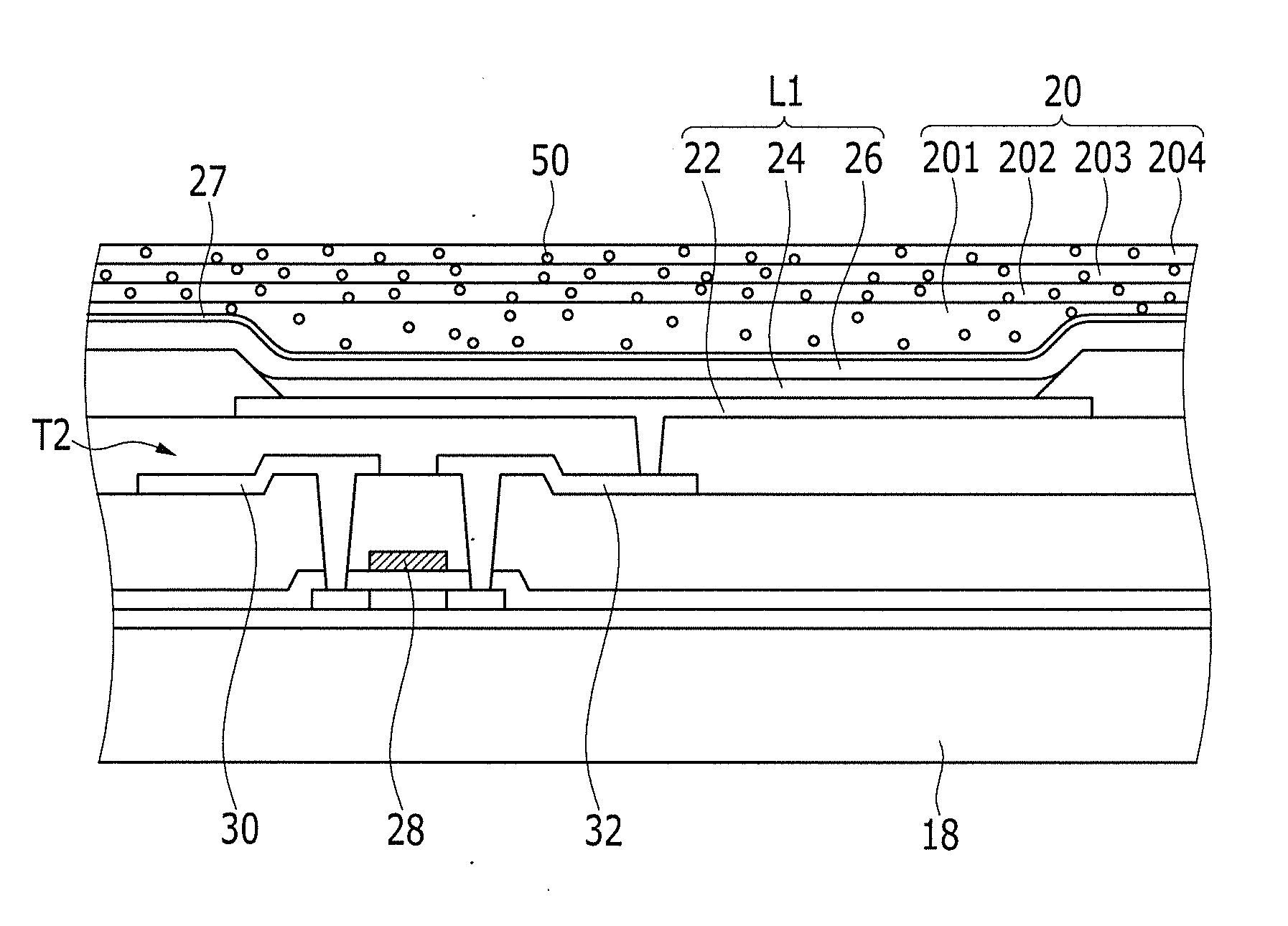

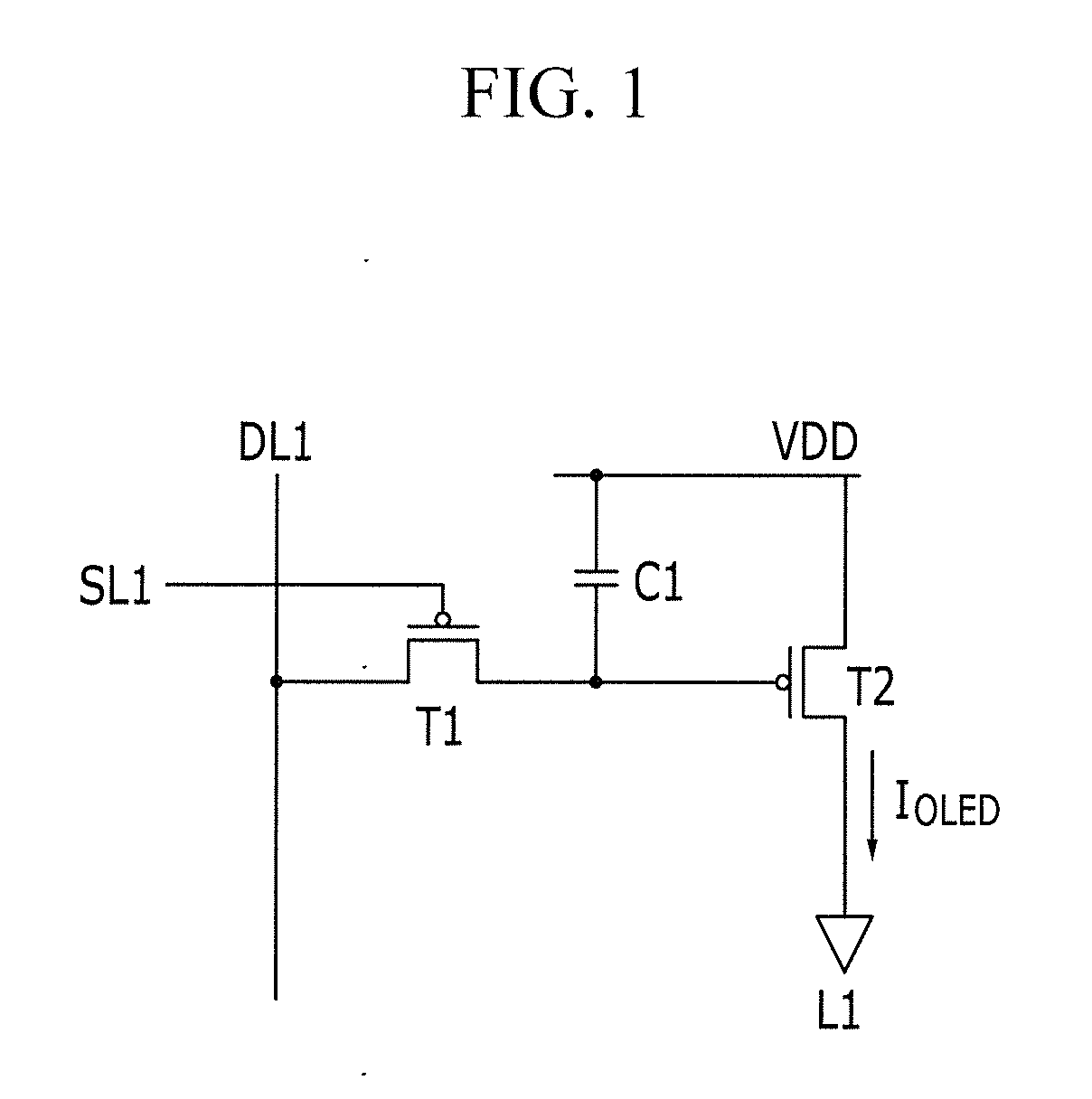

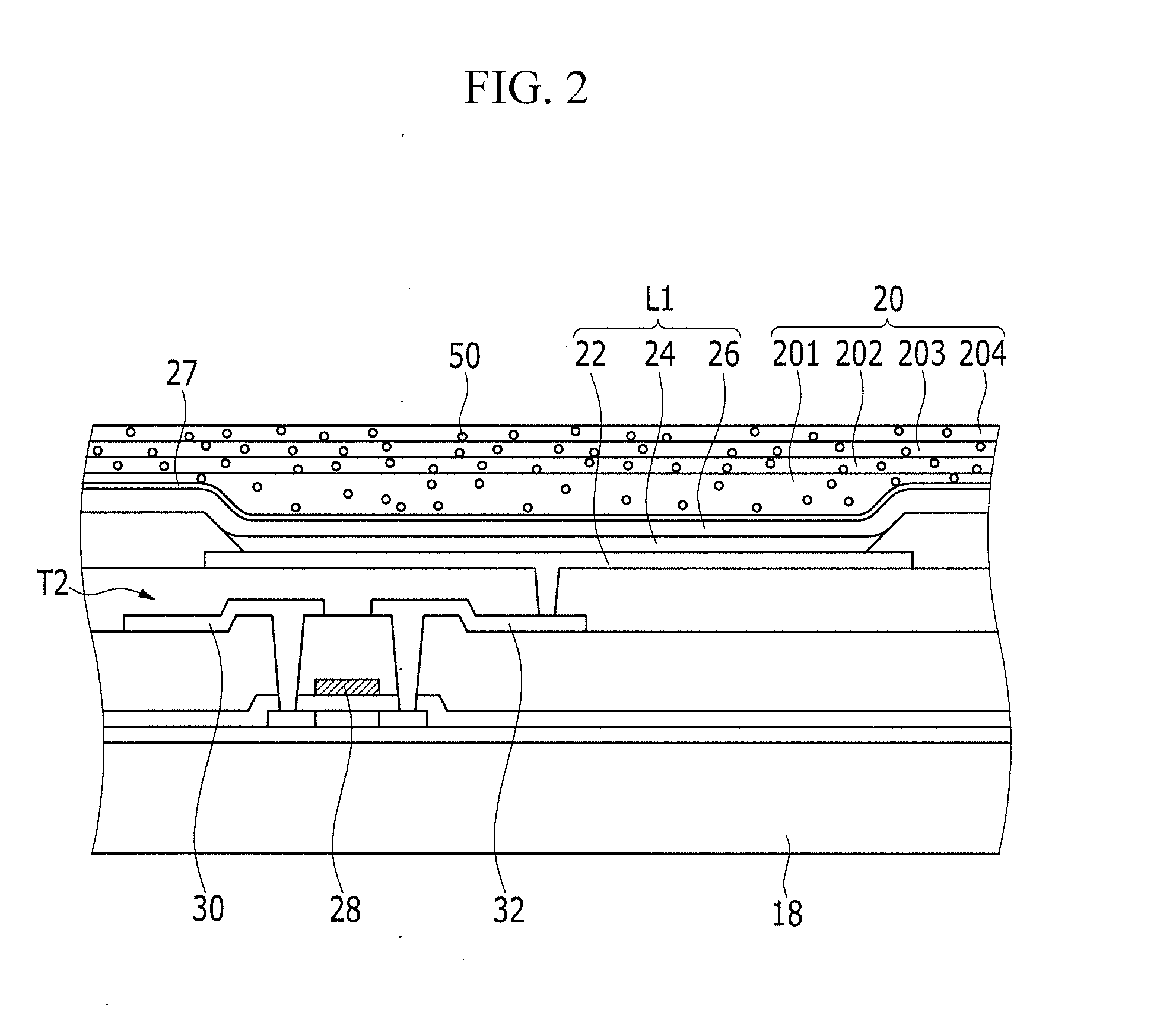

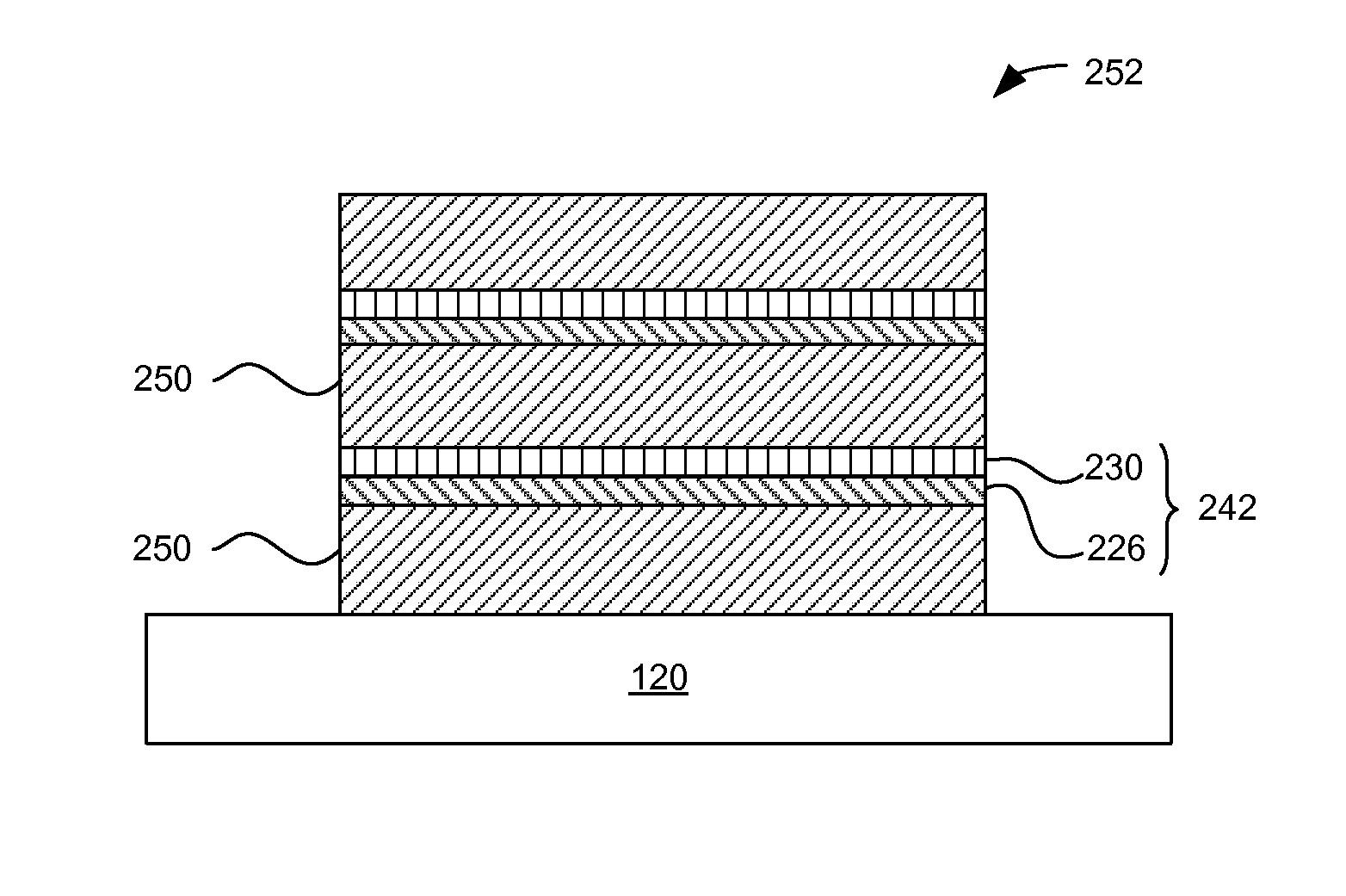

Organic light emitting display apparatus and method of manufacturing the same

ActiveUS20140145979A1Electrical apparatusElectroluminescent light sourcesTouch SensesLight-emitting diode

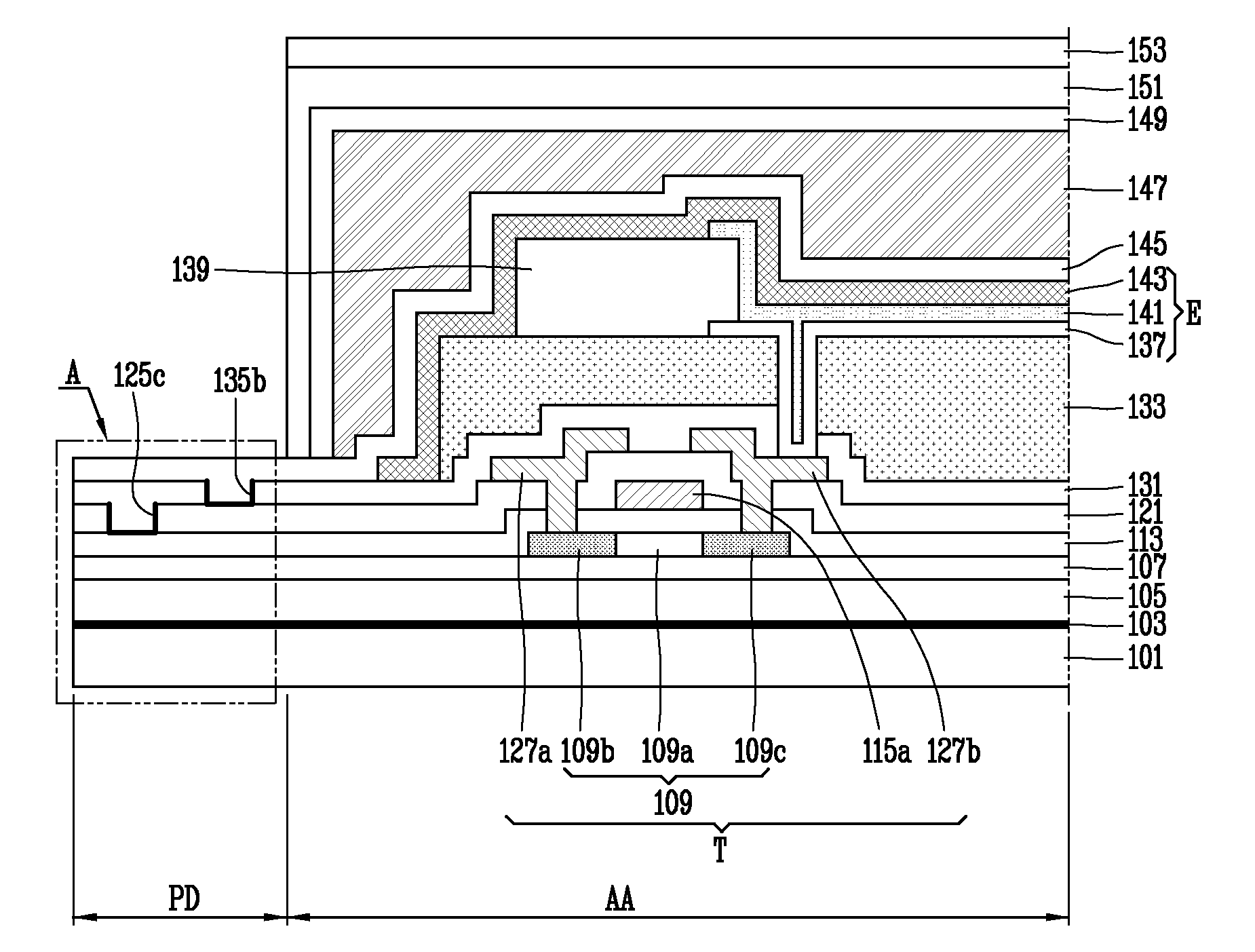

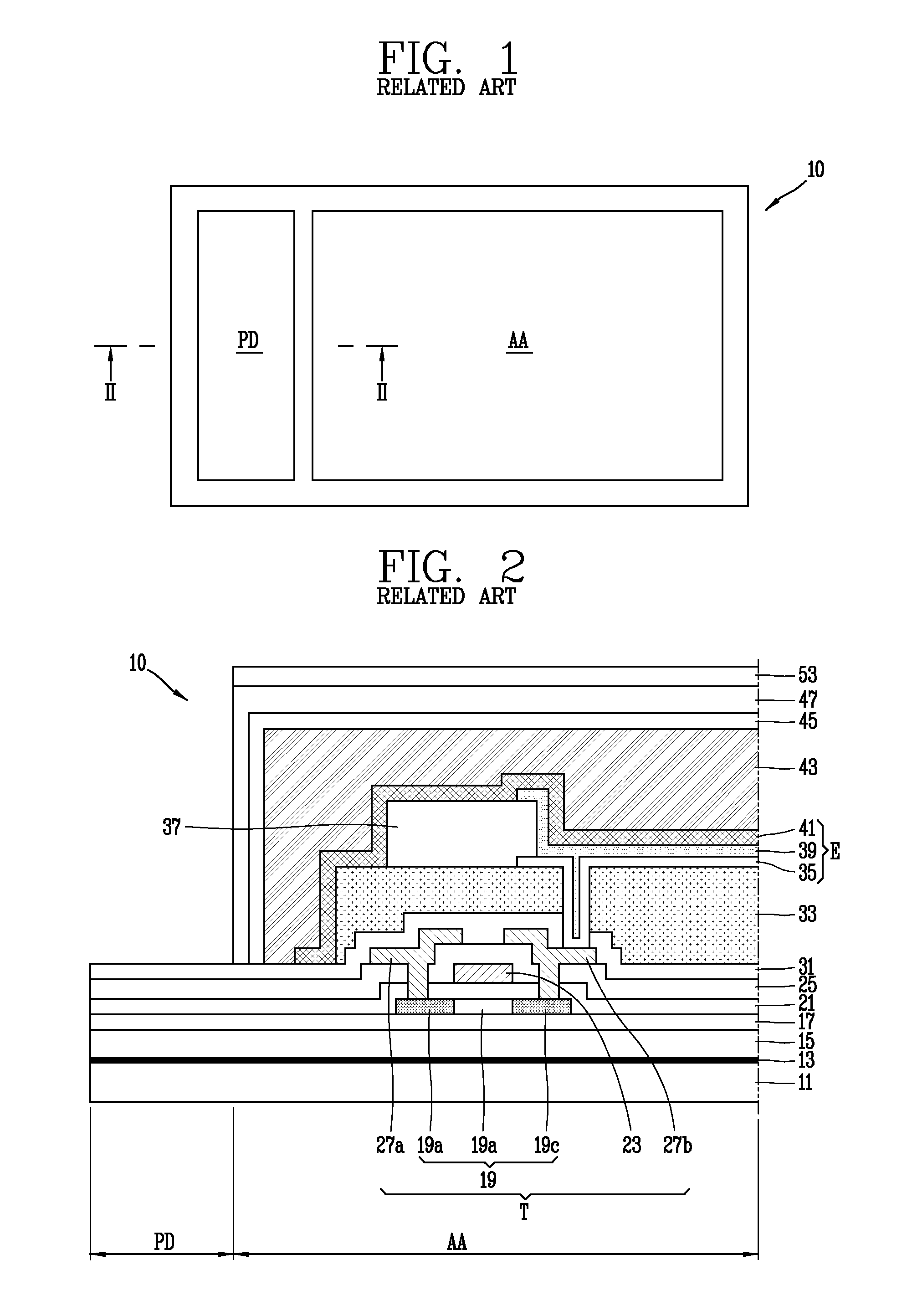

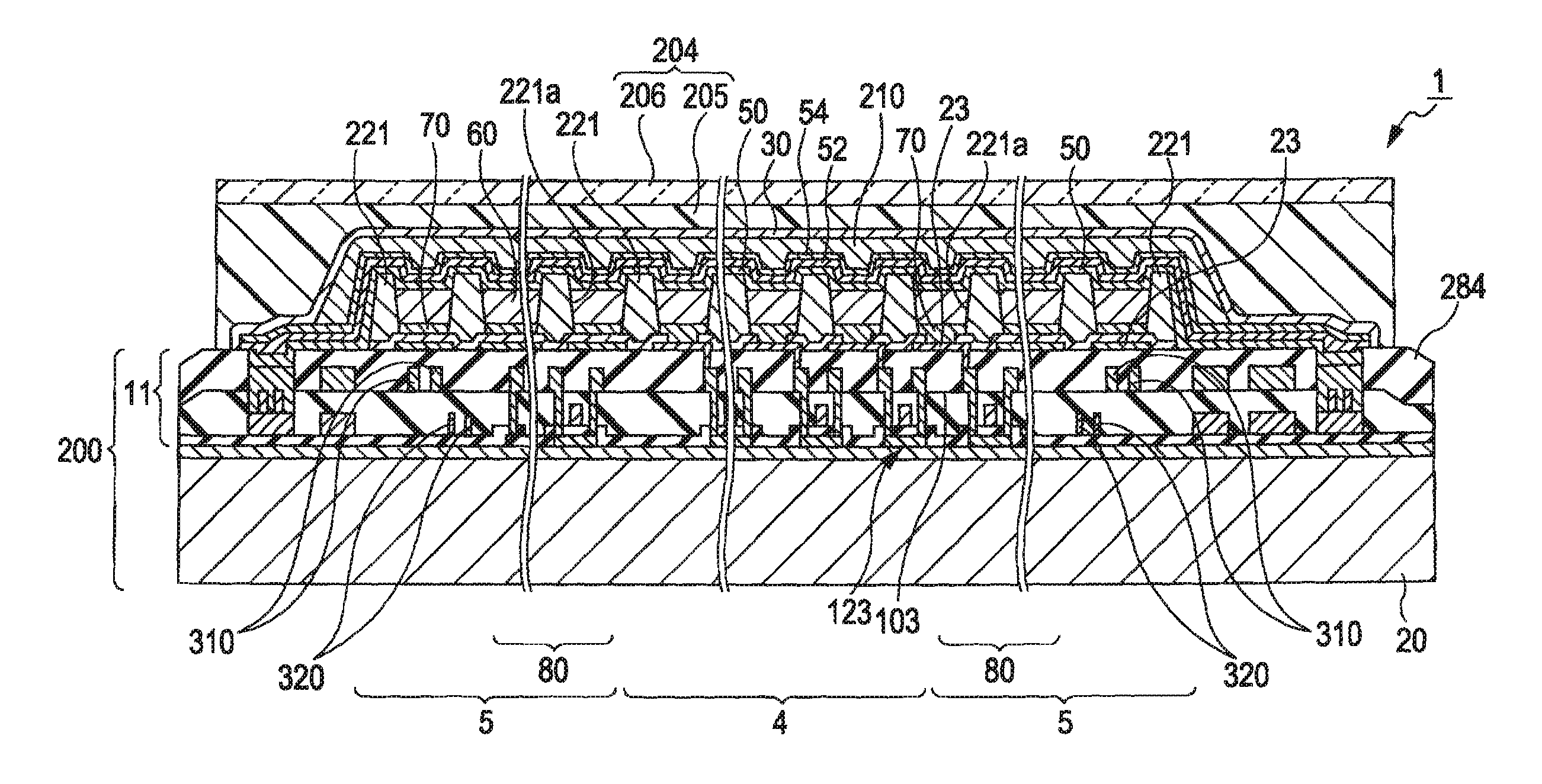

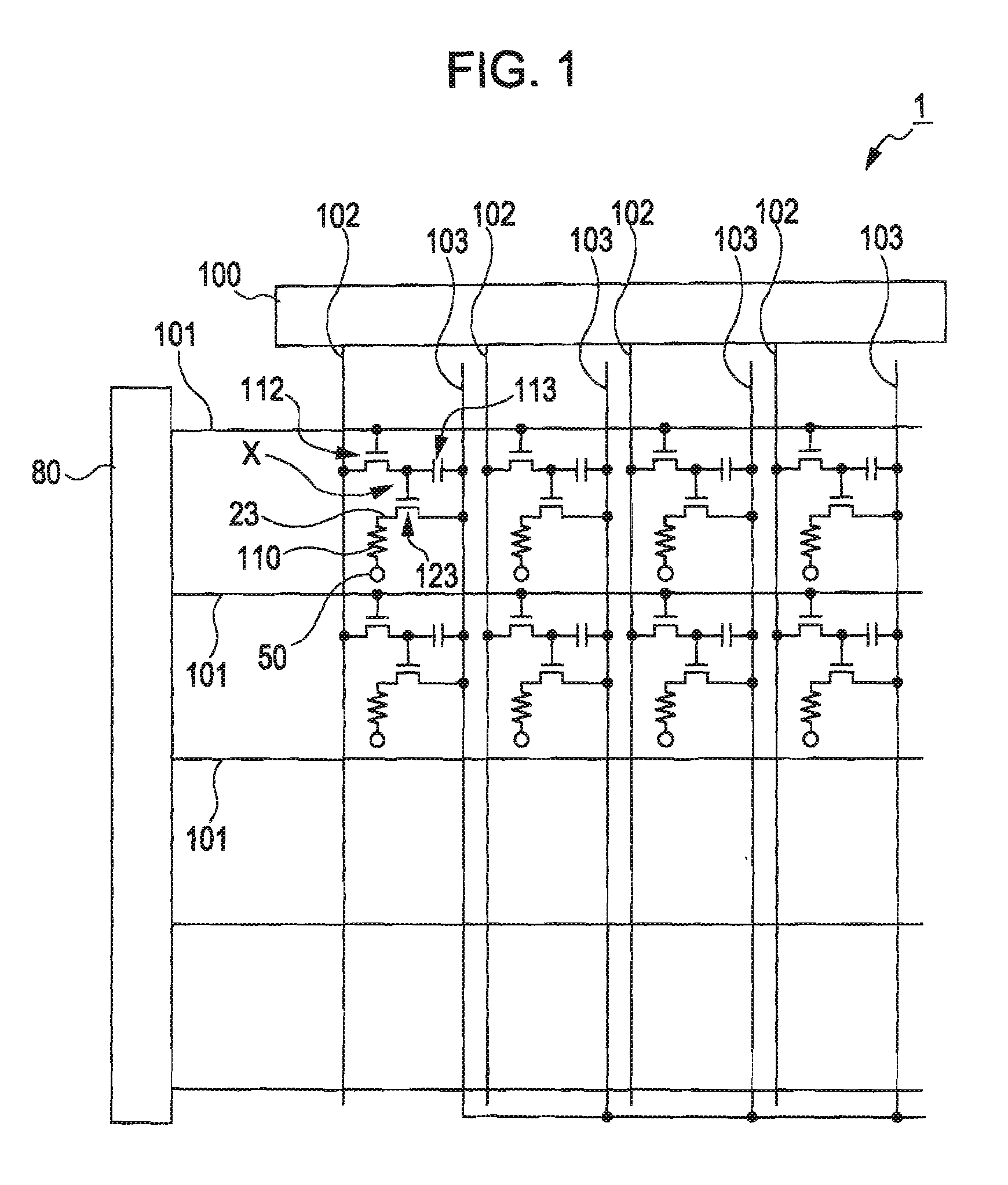

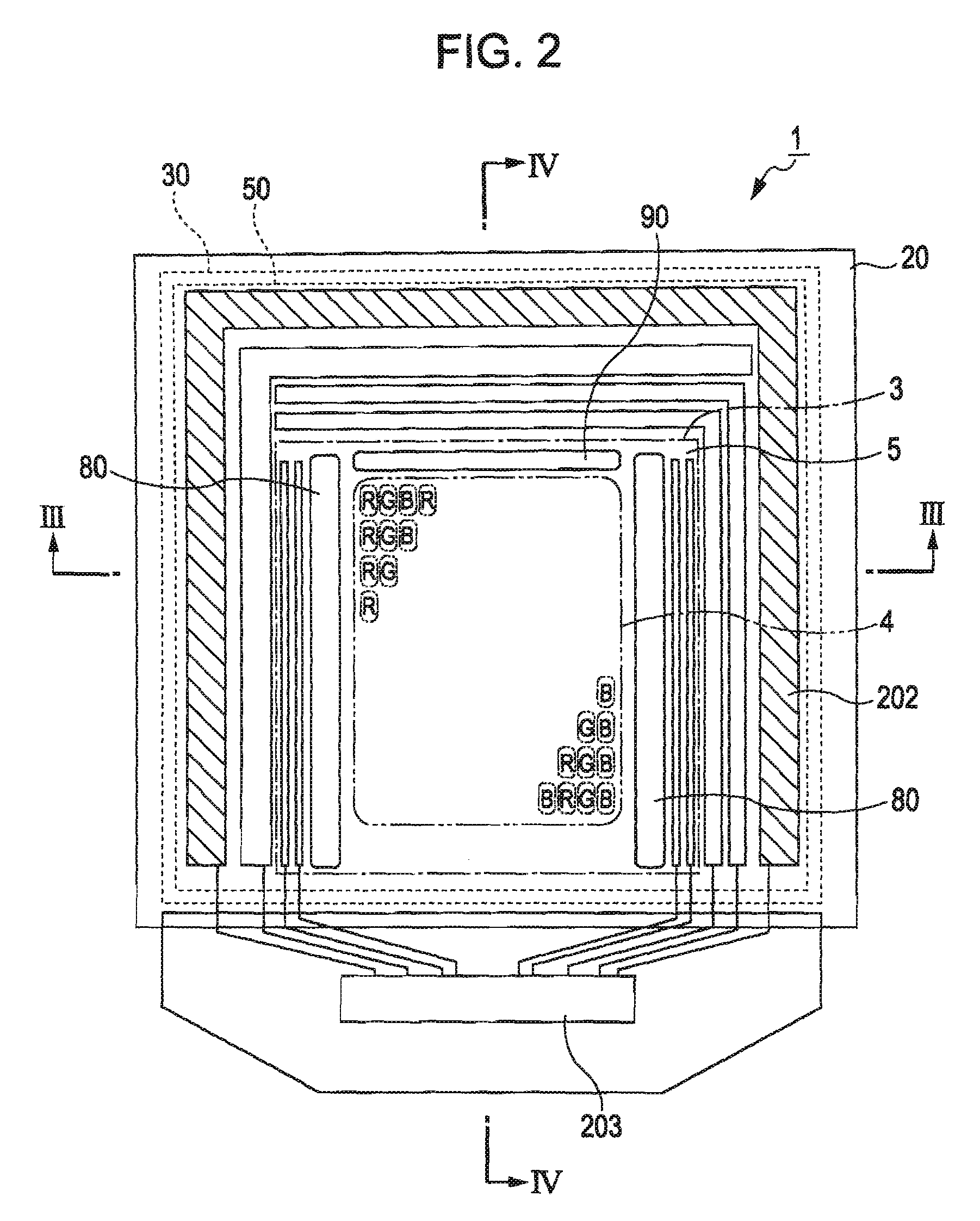

An organic light emitting display apparatus including a thin film encapsulation layer having a touch screen structure. The organic light emitting display apparatus includes a substrate; an organic light emitting diode (OLED) layer on the substrate; a thin film encapsulation layer on the OLED layer, and comprising a plurality of inorganic layers and a plurality of organic layers that are alternately stacked; and a touch sensing layer in the thin film encapsulation layer, wherein the touch sensing layer includes: a first touch conductive layer; a touch inorganic layer on the first touch conductive layer; and a second touch conductive layer on the touch inorganic layer, wherein the touch inorganic layer is one of the plurality of inorganic layers included in the thin film encapsulation layer.

Owner:SAMSUNG DISPLAY CO LTD

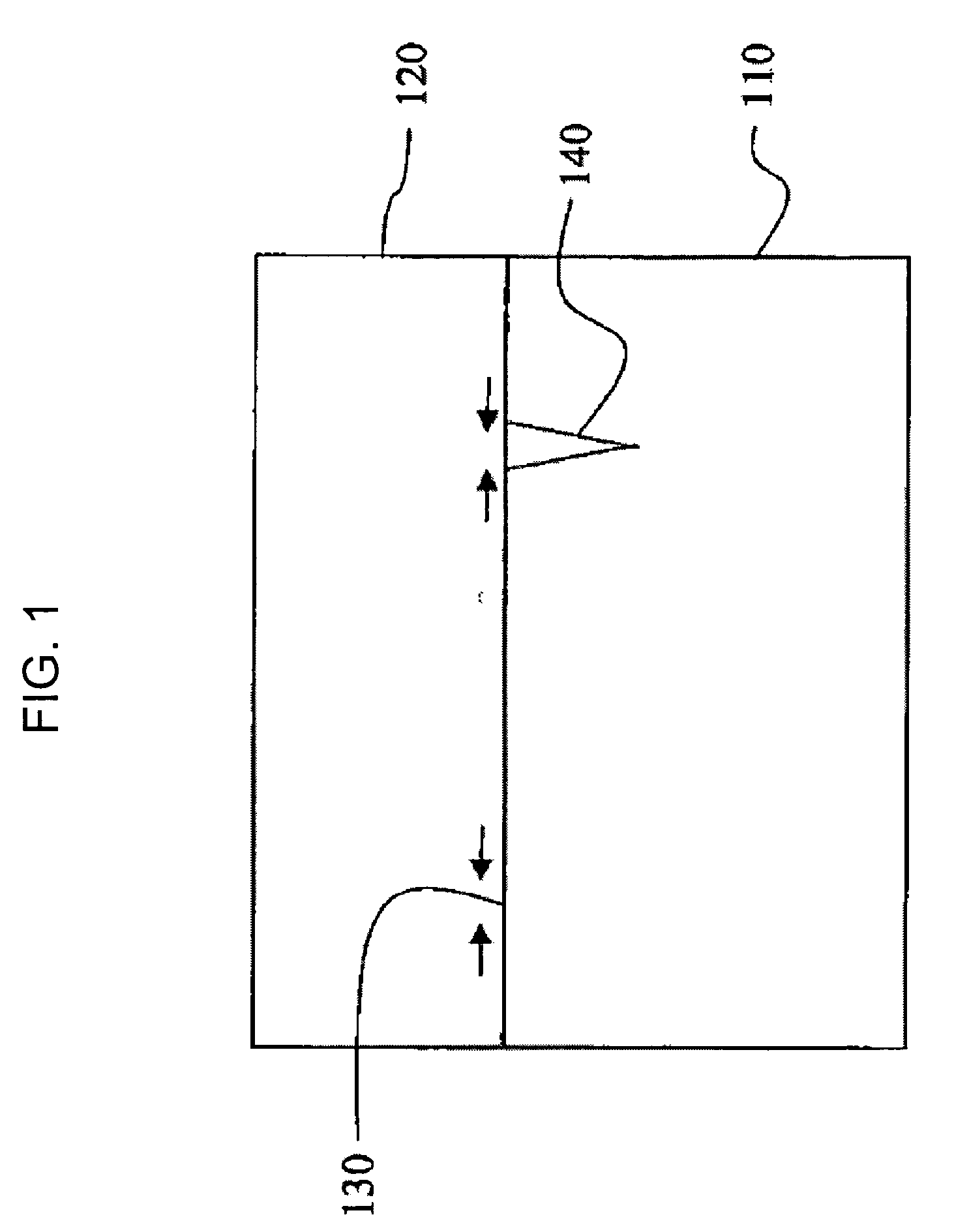

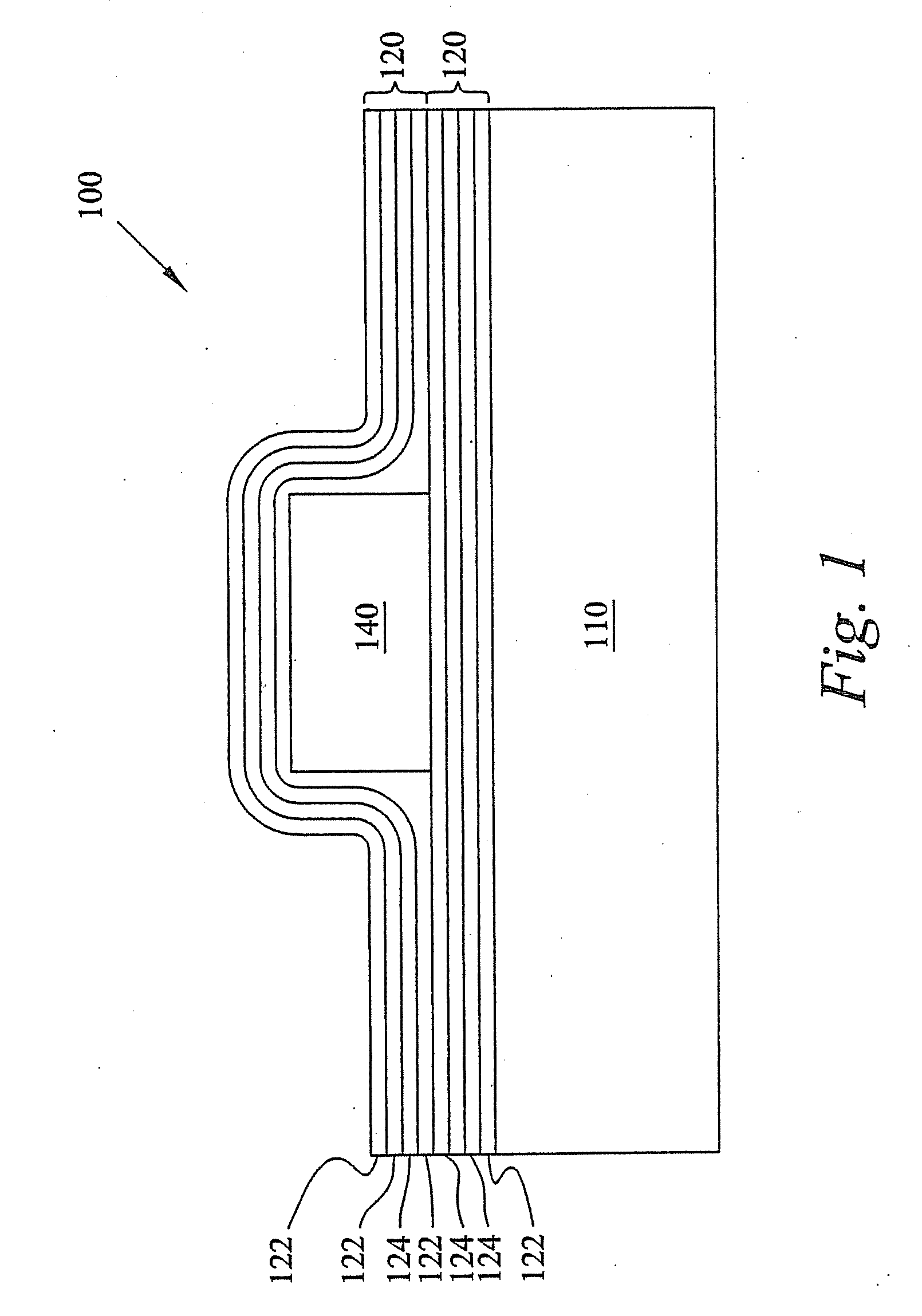

Deformable organic devices

InactiveUS20060169989A1Circuit bendability/stretchabilityDischarge tube luminescnet screensOrganic devicesBiaxial strain

A device is provided. The device includes a substrate, an inorganic layer disposed over the substrate, and an organic layer disposed on the inorganic conductive or semiconductive layer, such that the organic layer is in direct physical contact with the inorganic conductive or semiconductive layer. The substrate is deformed such that there is a nominal radial or biaxial strain of at least 0.05% relative to a flat substrate at an interface between the inorganic layer and the organic layer. The nominal radial or biaxial strain may be higher, for example 1.5%. A method of making the device is also provided, such that the substrate is deformed after the inorganic layer and the organic layer are deposited onto the substrate.

Owner:THE TRUSTEES FOR PRINCETON UNIV

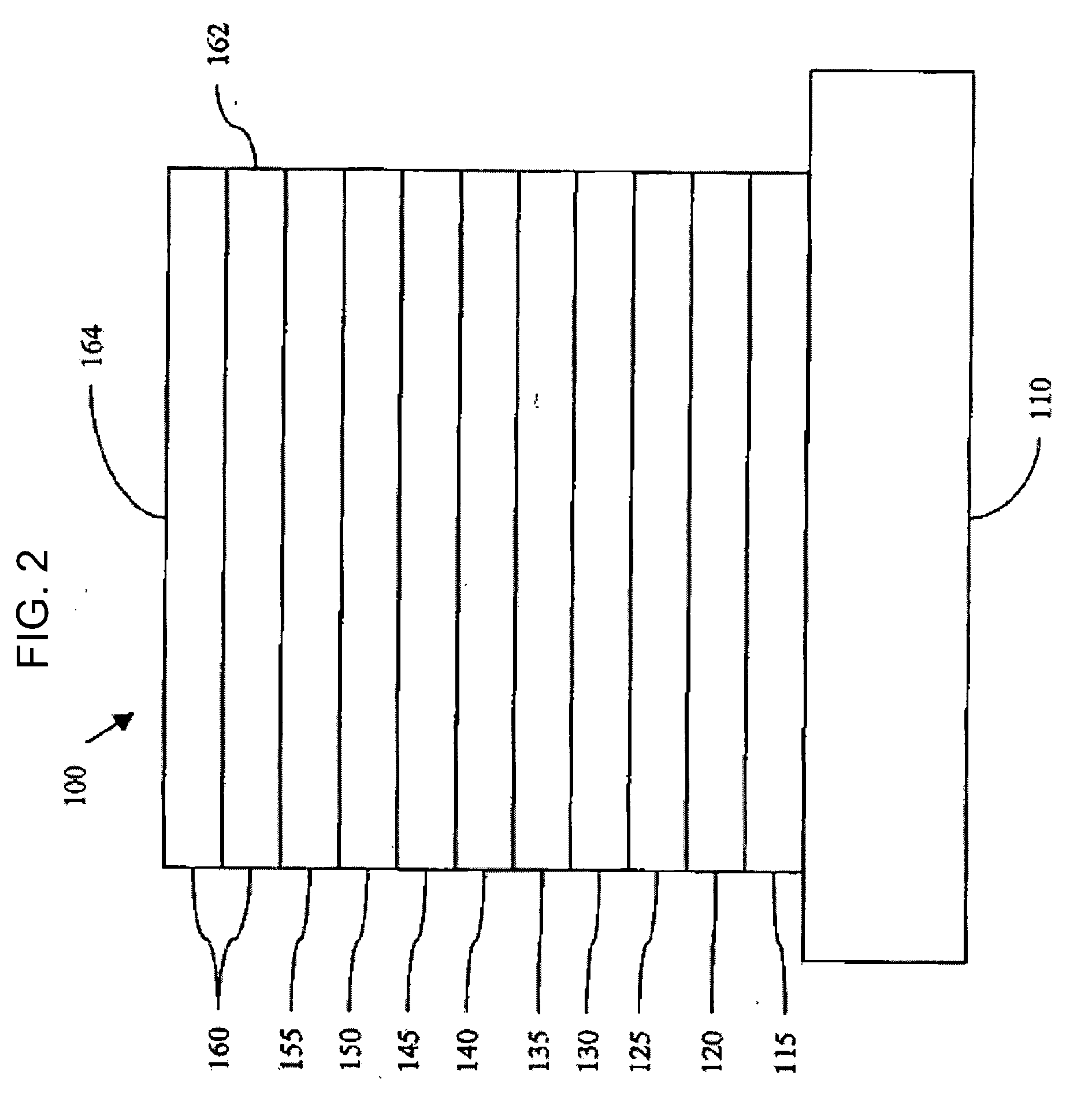

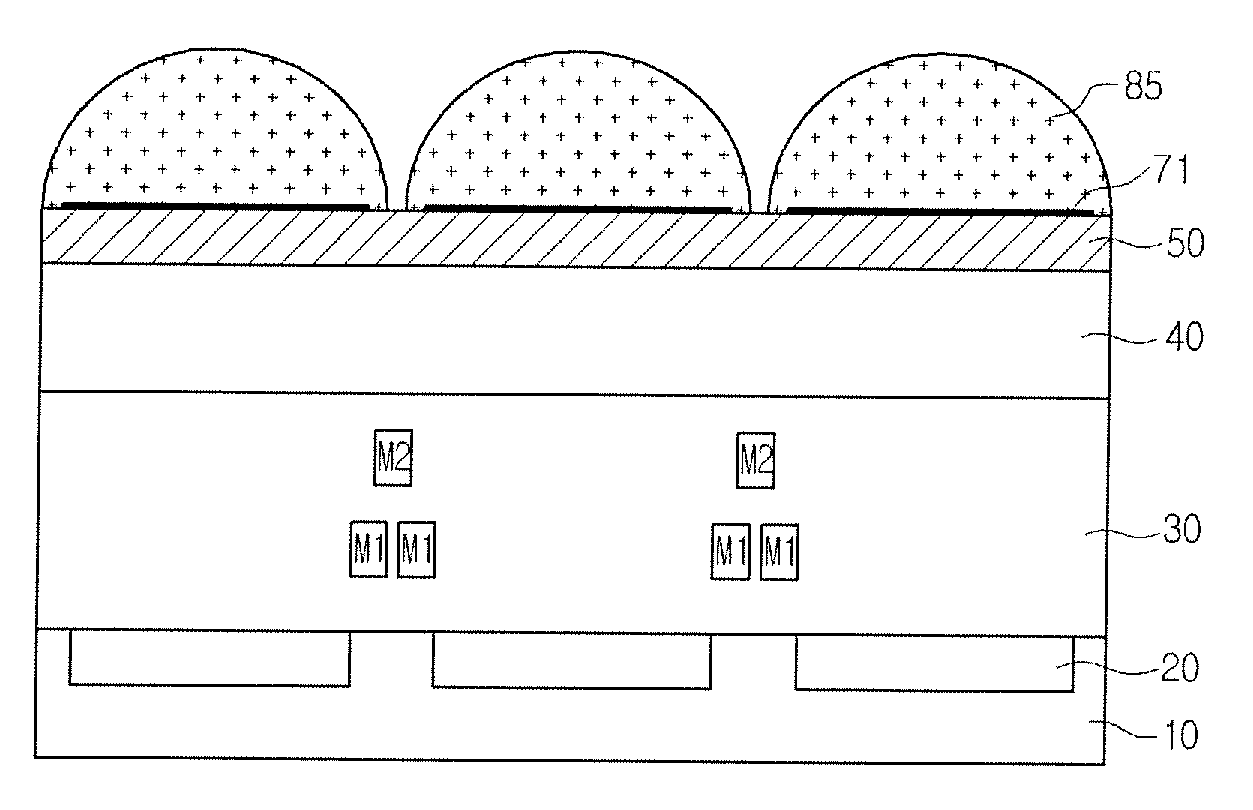

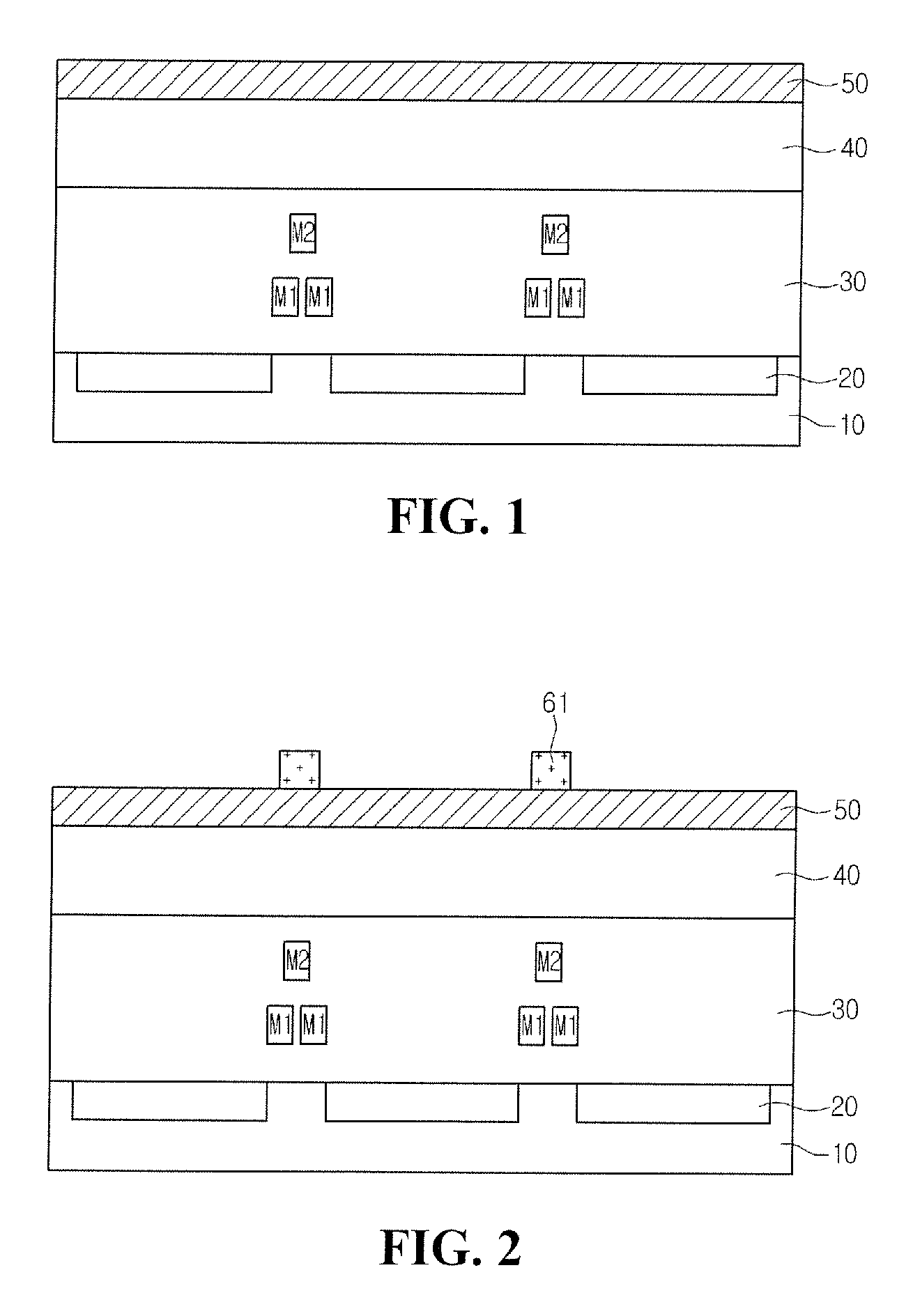

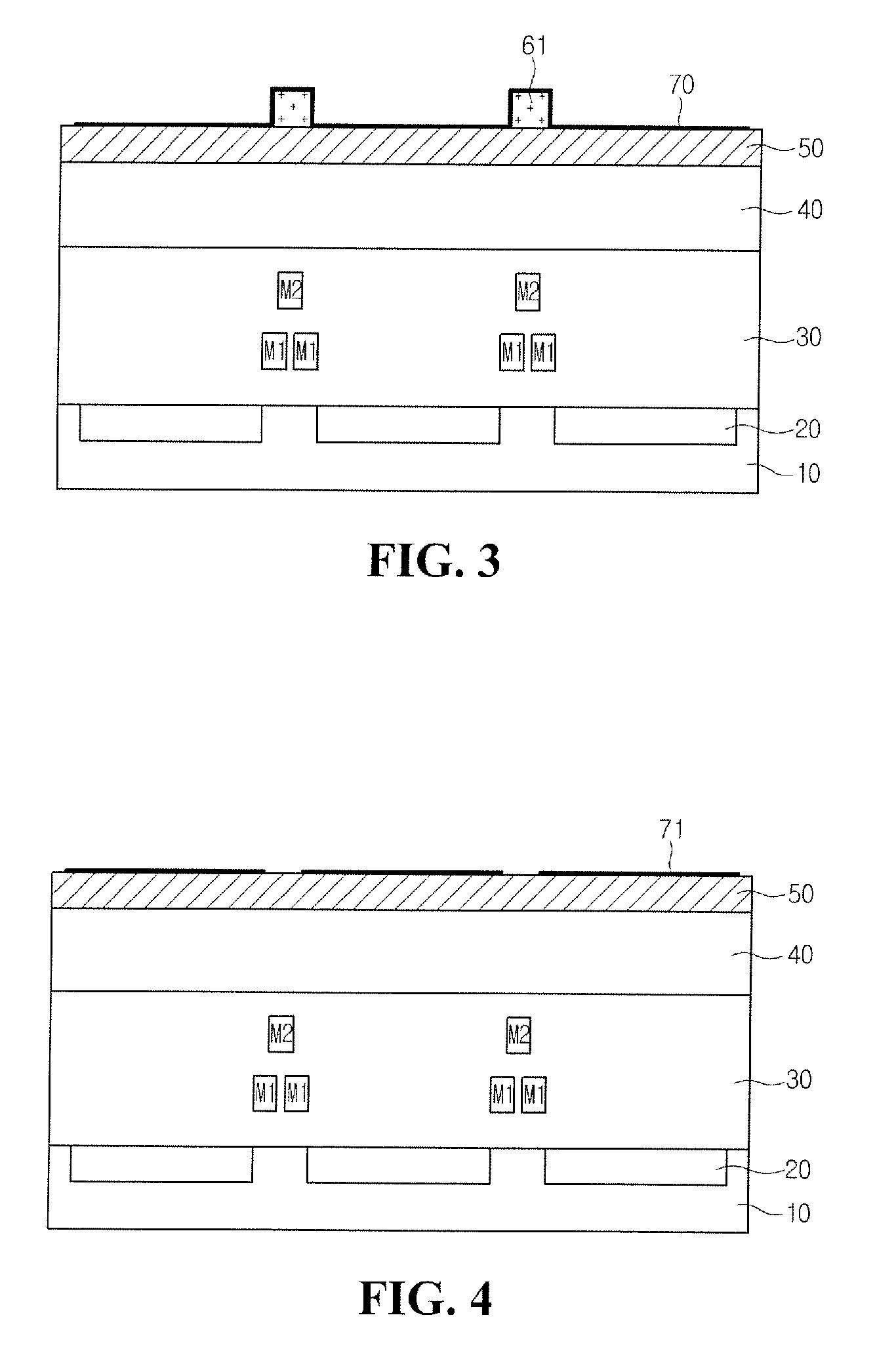

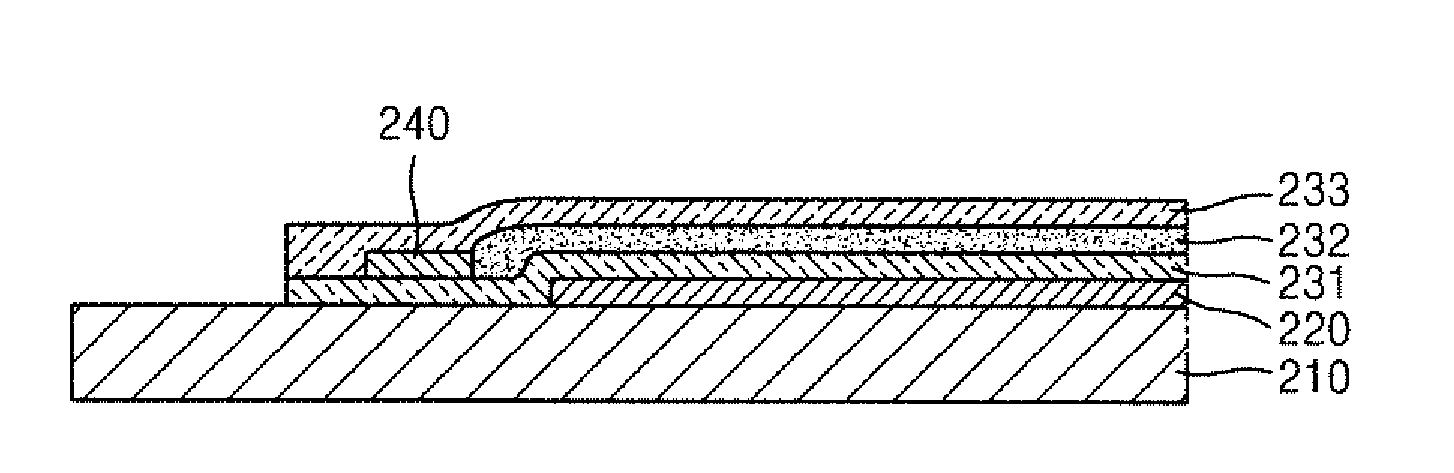

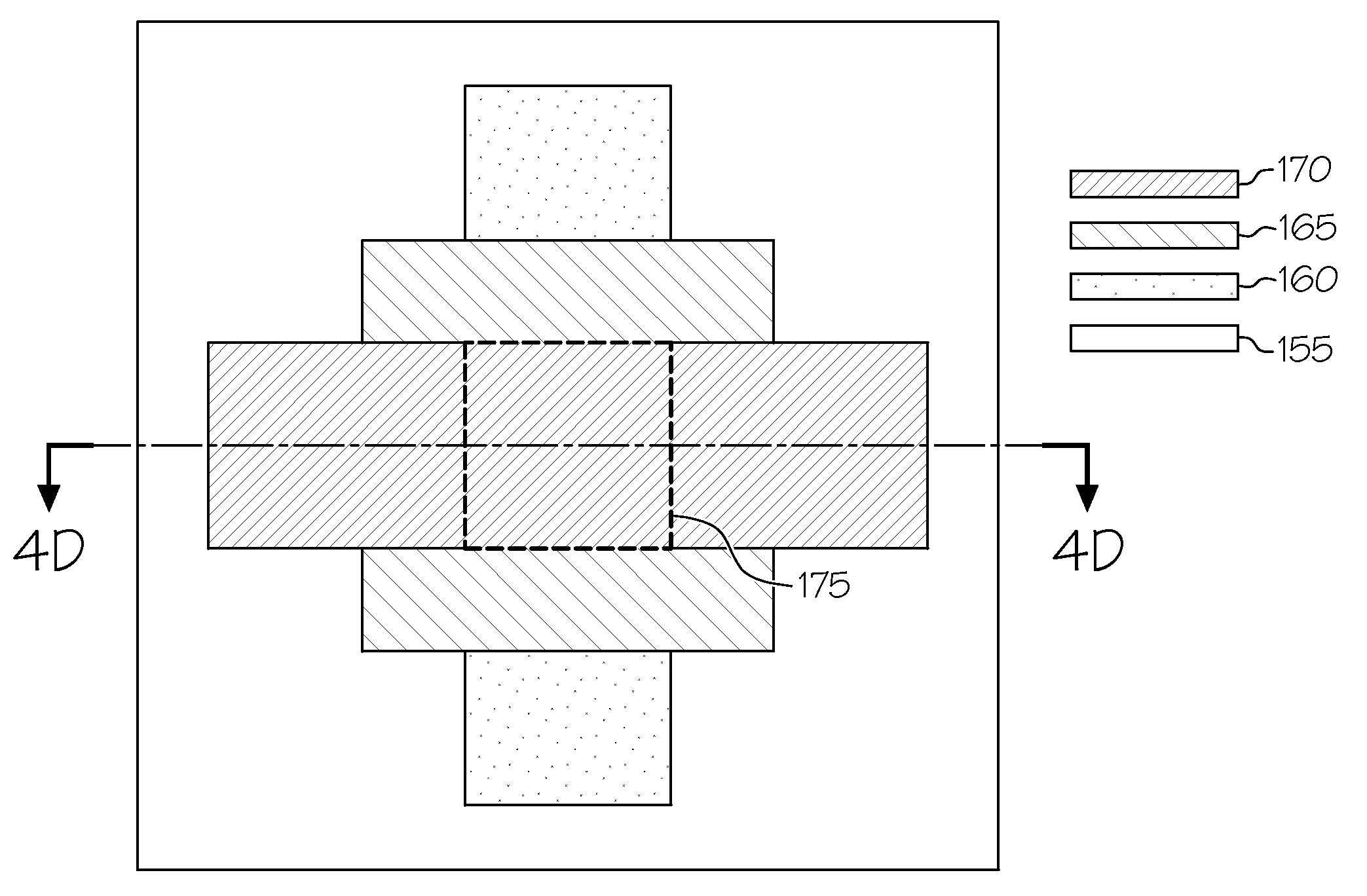

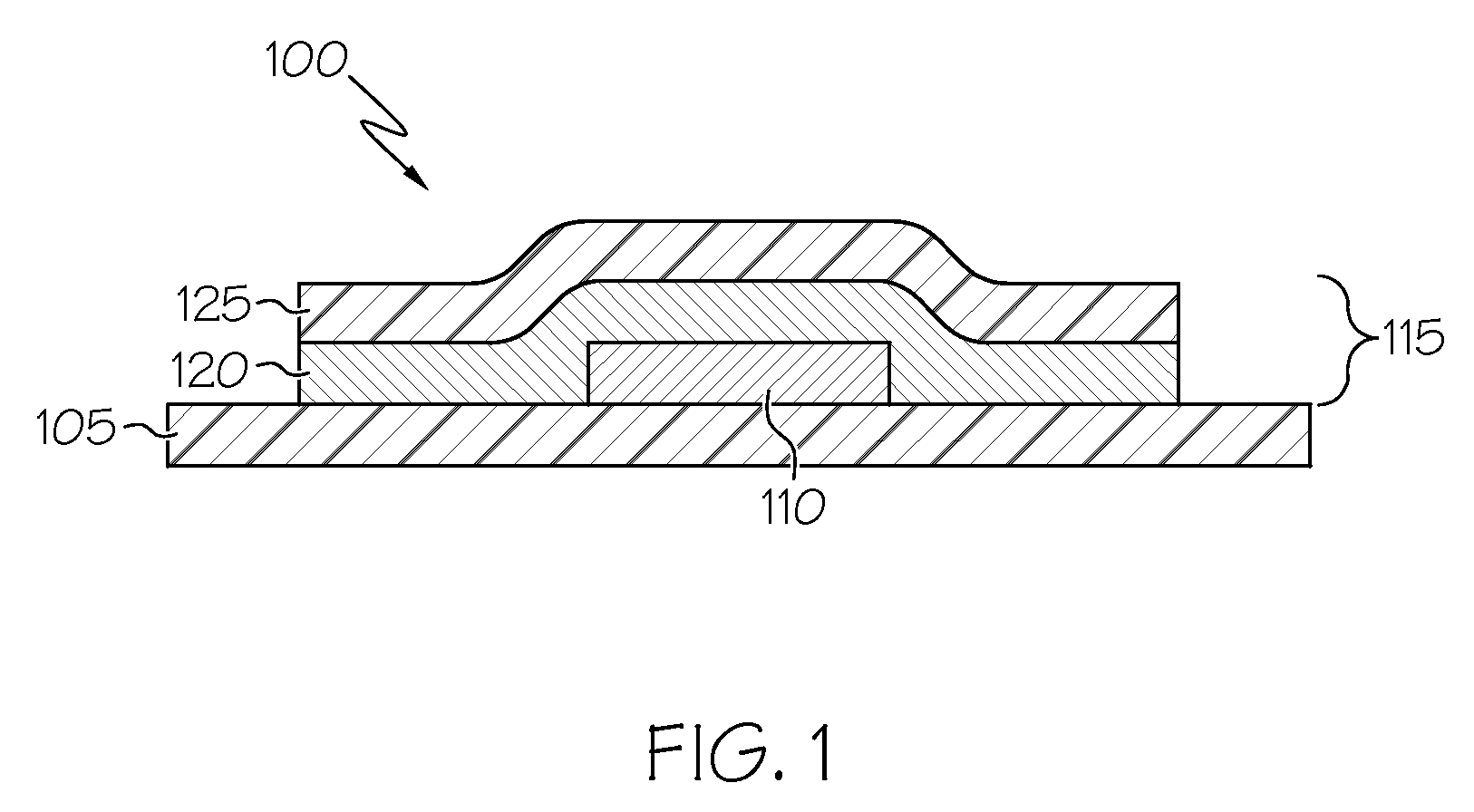

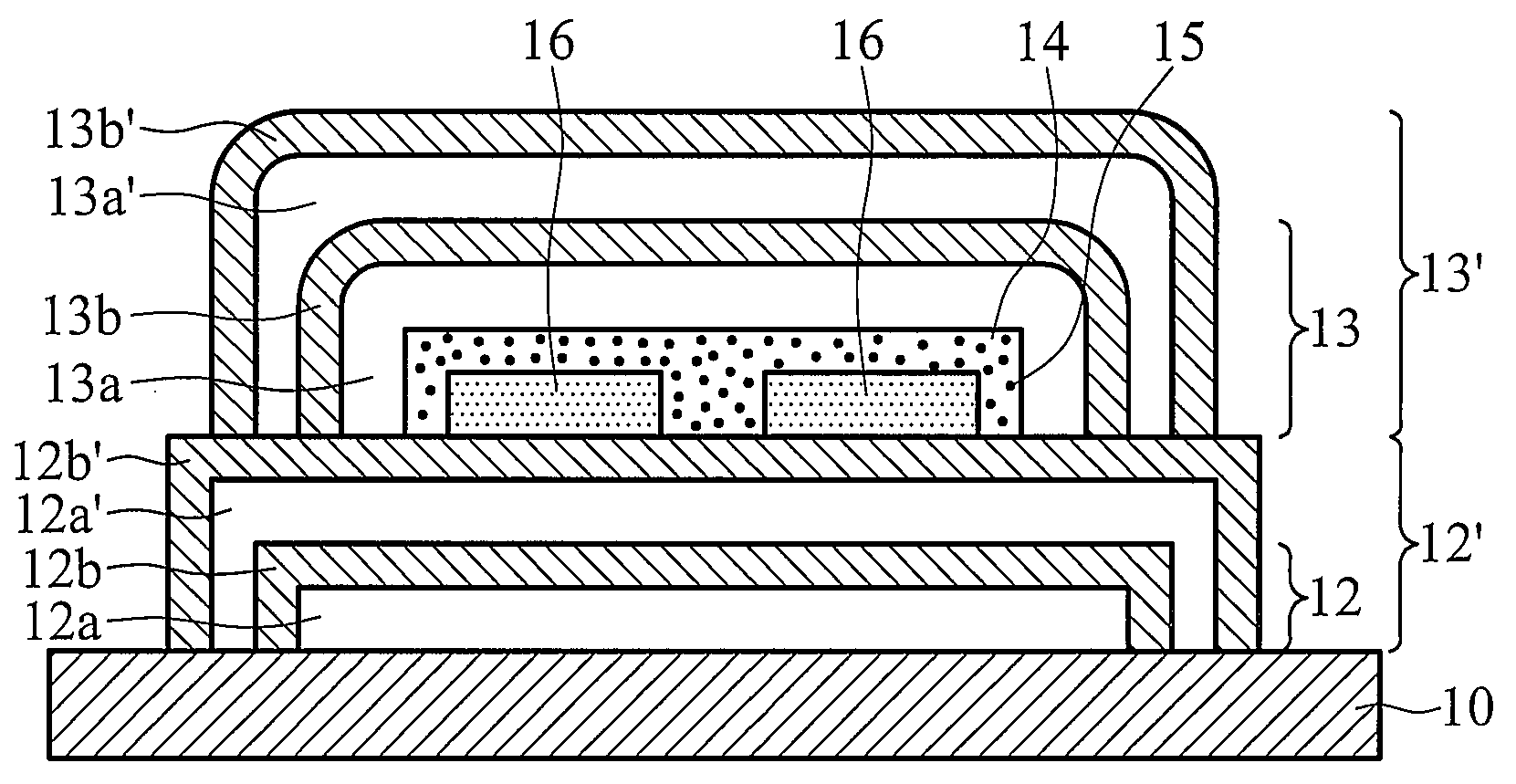

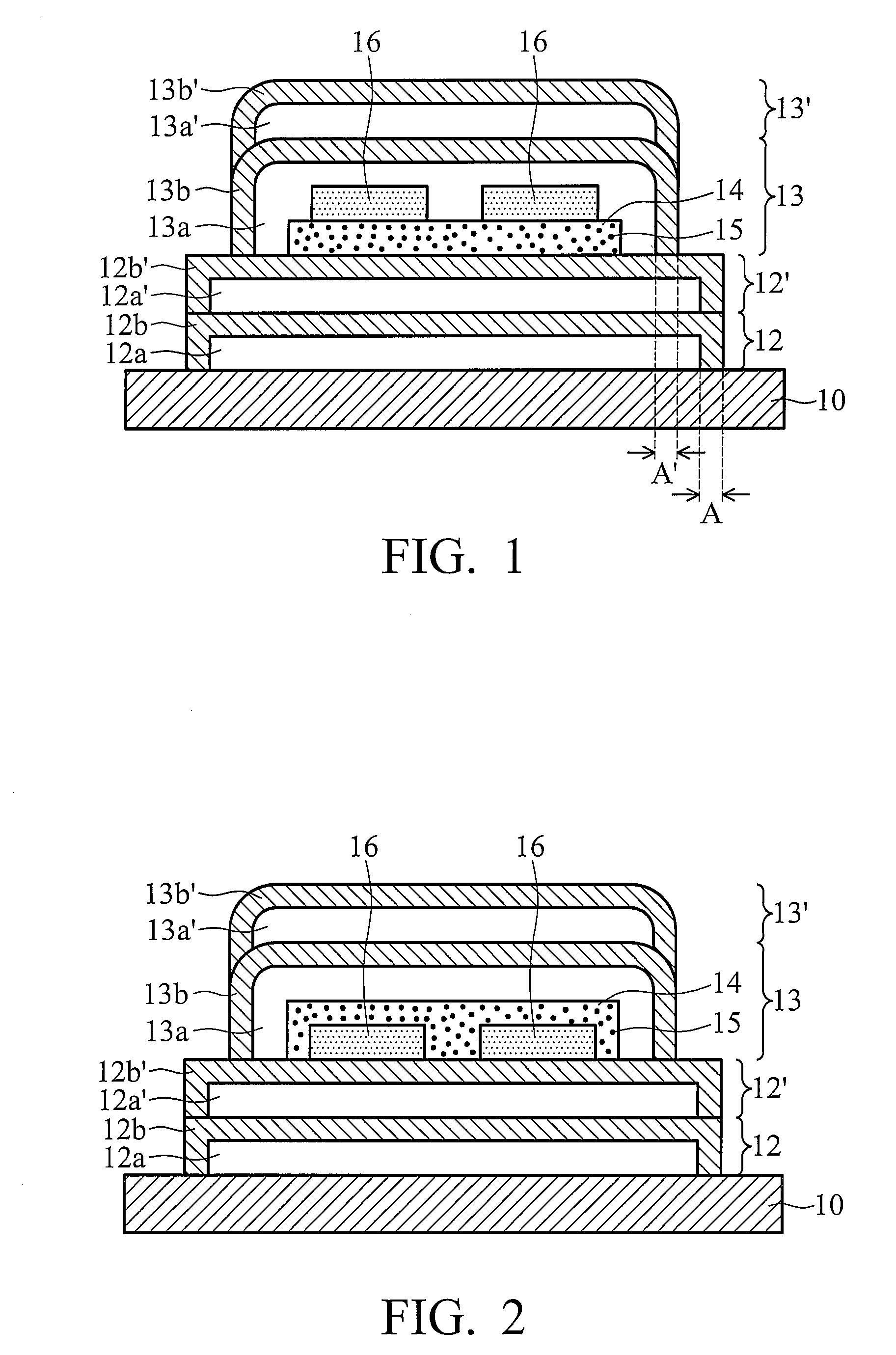

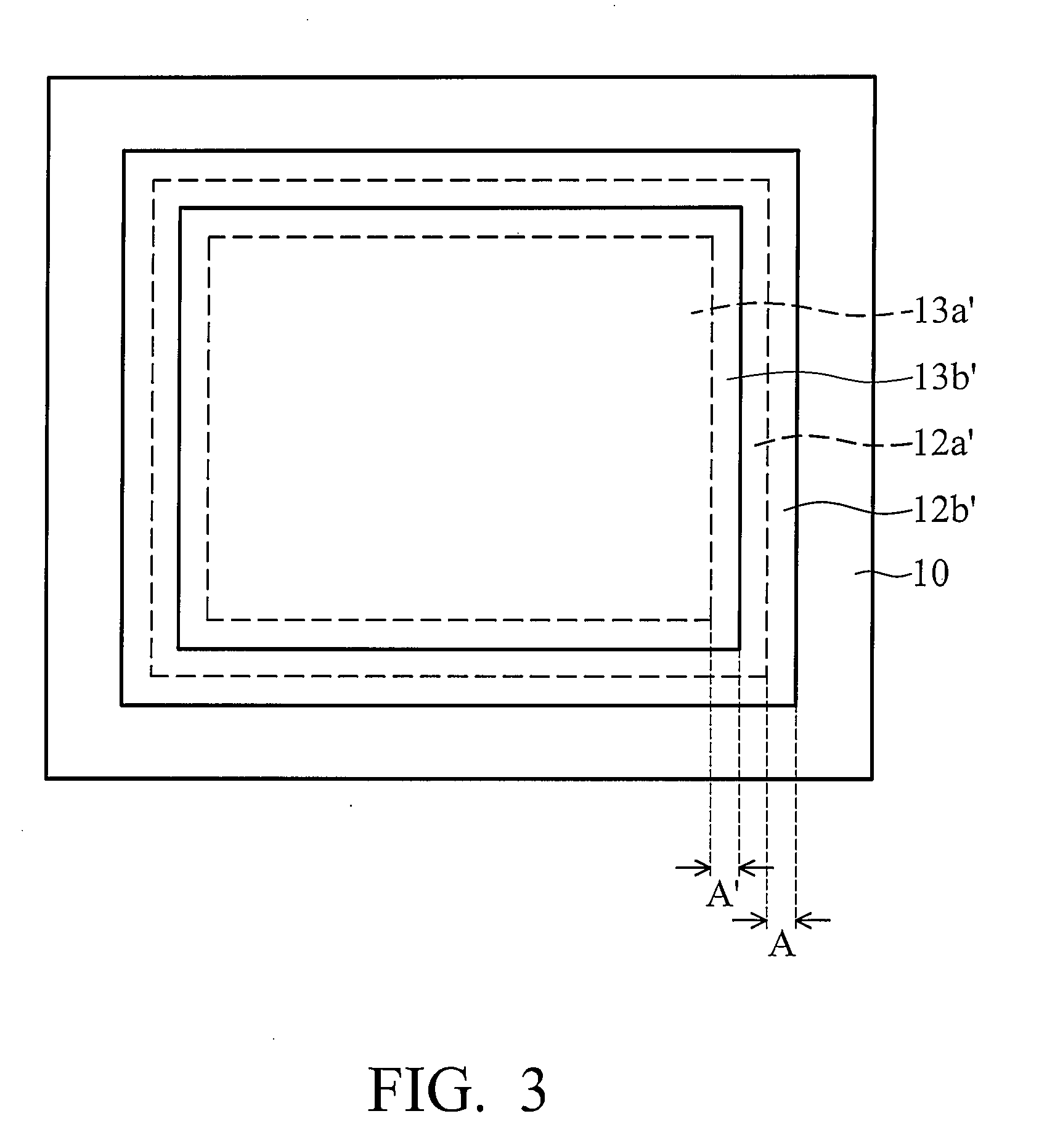

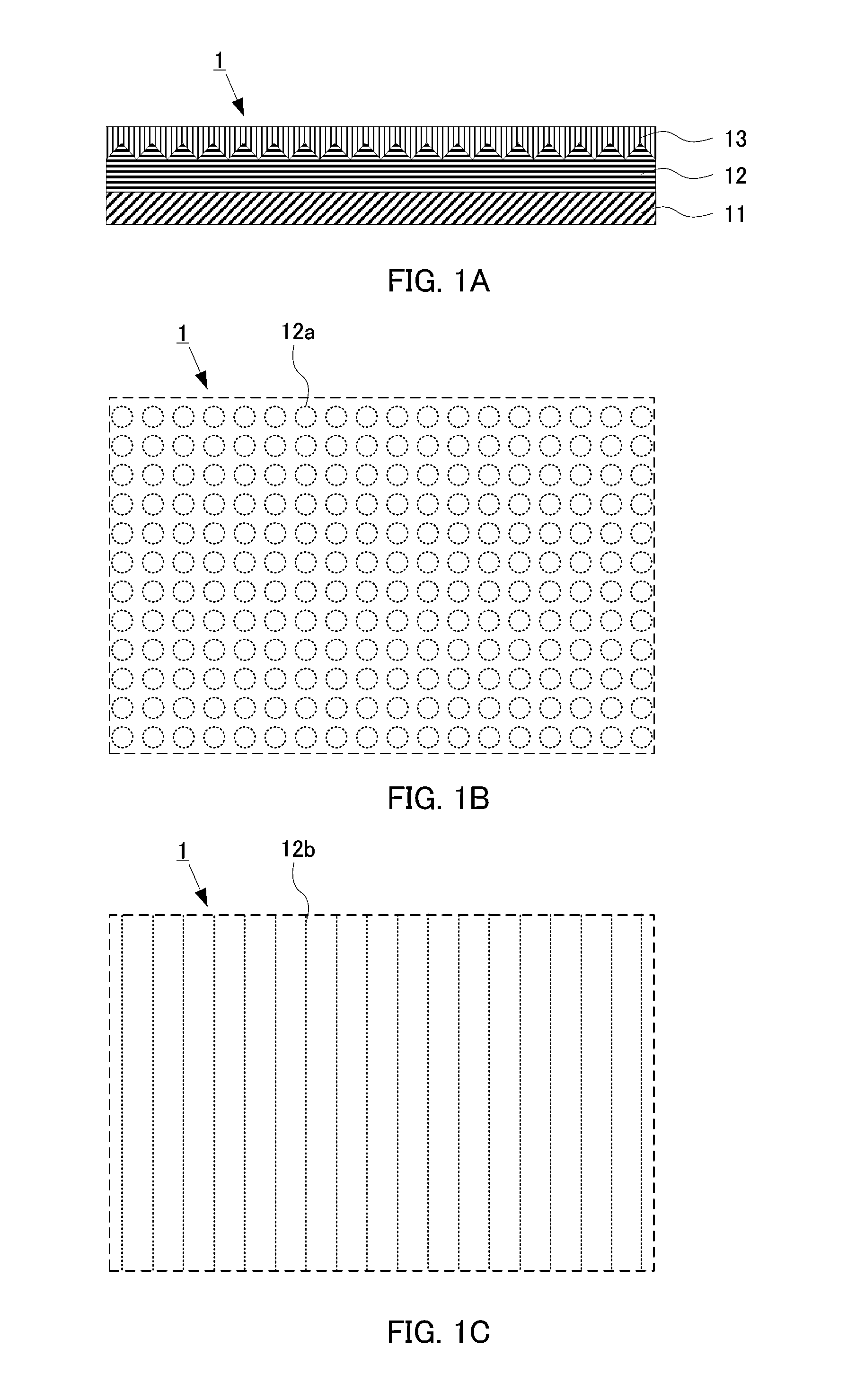

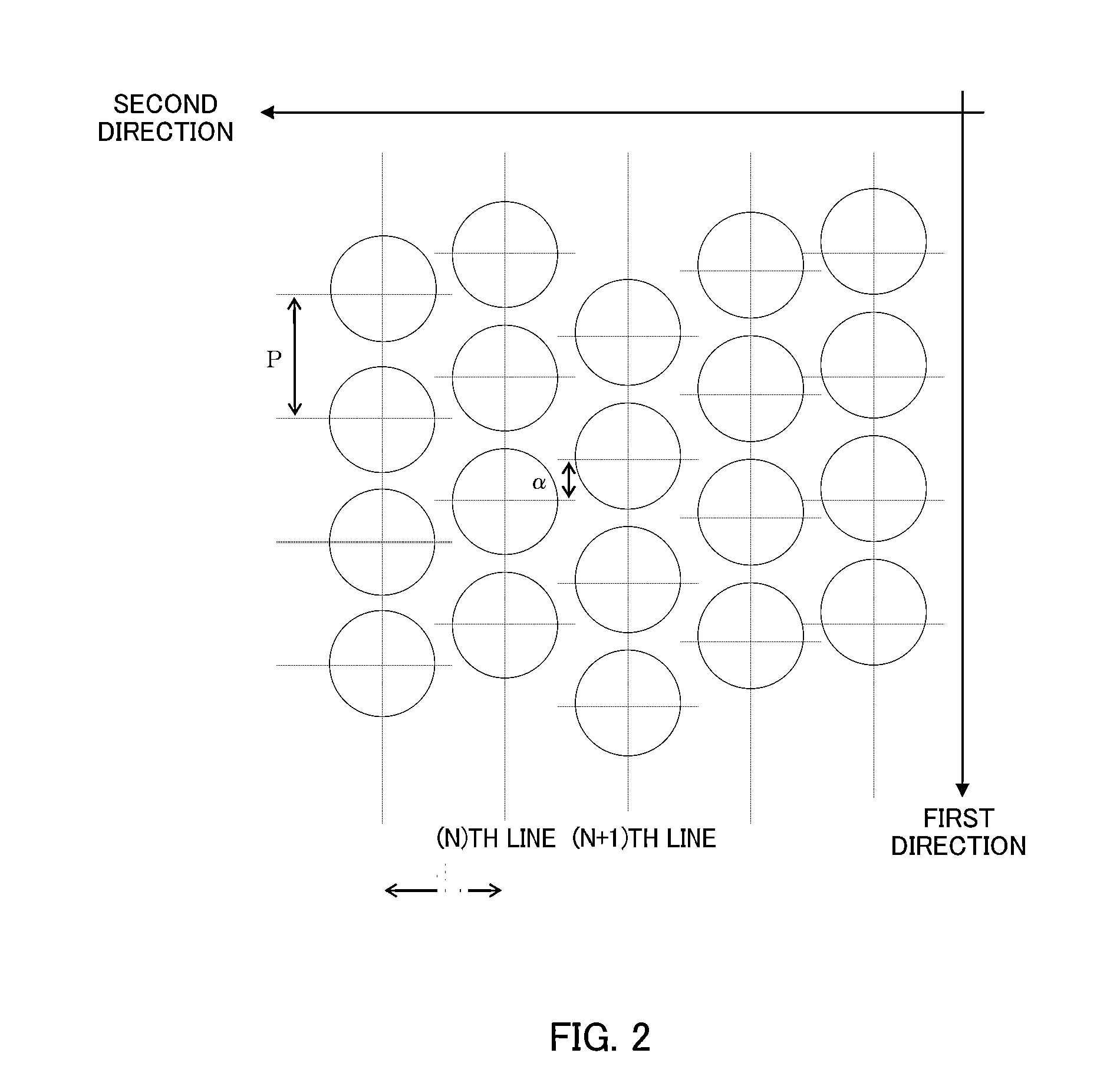

Image sensor and method of manufacturing the same

ActiveUS20080272416A1Gap minimizationAvoid formingSolid-state devicesSemiconductor/solid-state device manufacturingInterconnectionOptoelectronics

Provided is an image sensor and method of manufacturing the same. The image sensor can include a semiconductor substrate, a metal interconnection layer, an inorganic layer, lens seed patterns, and microlenses. The semiconductor substrate can include unit pixels. The metal interconnection layer can be disposed on the semiconductor substrate to provide signal and poser connections to the unit pixels. The inorganic layer can be disposed on the metal interconnection layer. The lens seed patterns are selectively disposed on the inorganic layer and are formed of an organic material. The microlenses are formed on the lens seed patterns.

Owner:DONGBU HITEK CO LTD

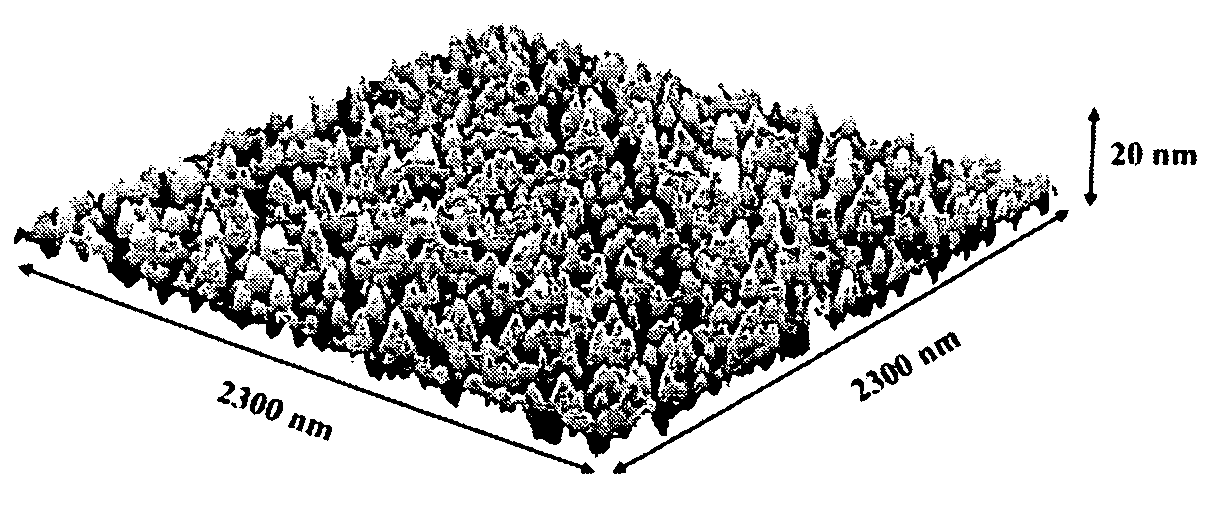

Medical devices having coatings for controlled therapeutic agent delivery

According to an aspect of the invention, medical devices are provided, which include a nanoparticle-derived inorganic layer disposed over a least a portion of structure that includes a substrate, and optionally, a therapeutic-agent-containing layer disposed over at least a portion of the substrate. In some embodiments, the inorganic layer is a nanoporous inorganic layer. Other aspects of the invention comprise methods for forming such medical device.

Owner:BOSTON SCI SCIMED INC

Nanophase multilayer barrier and process

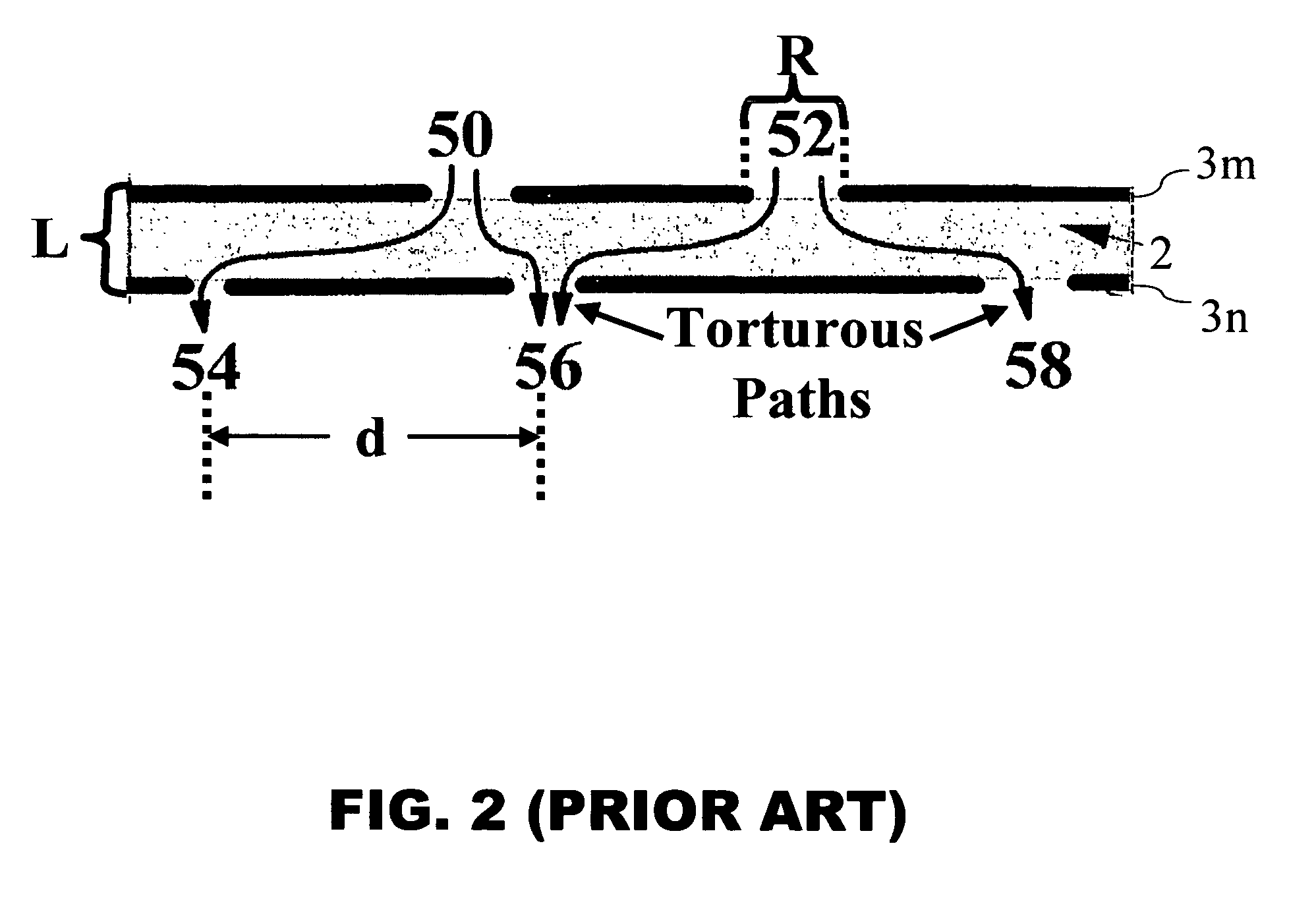

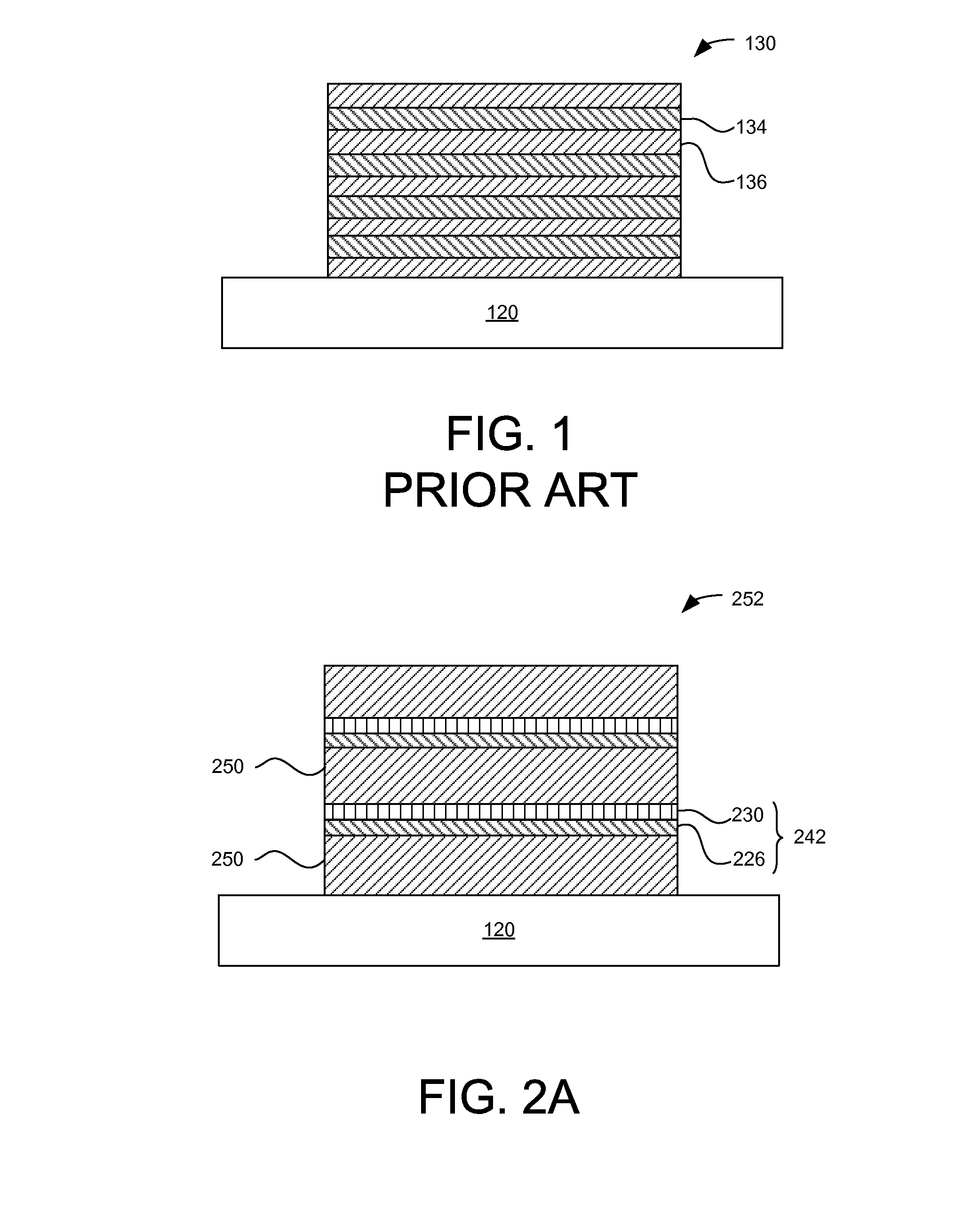

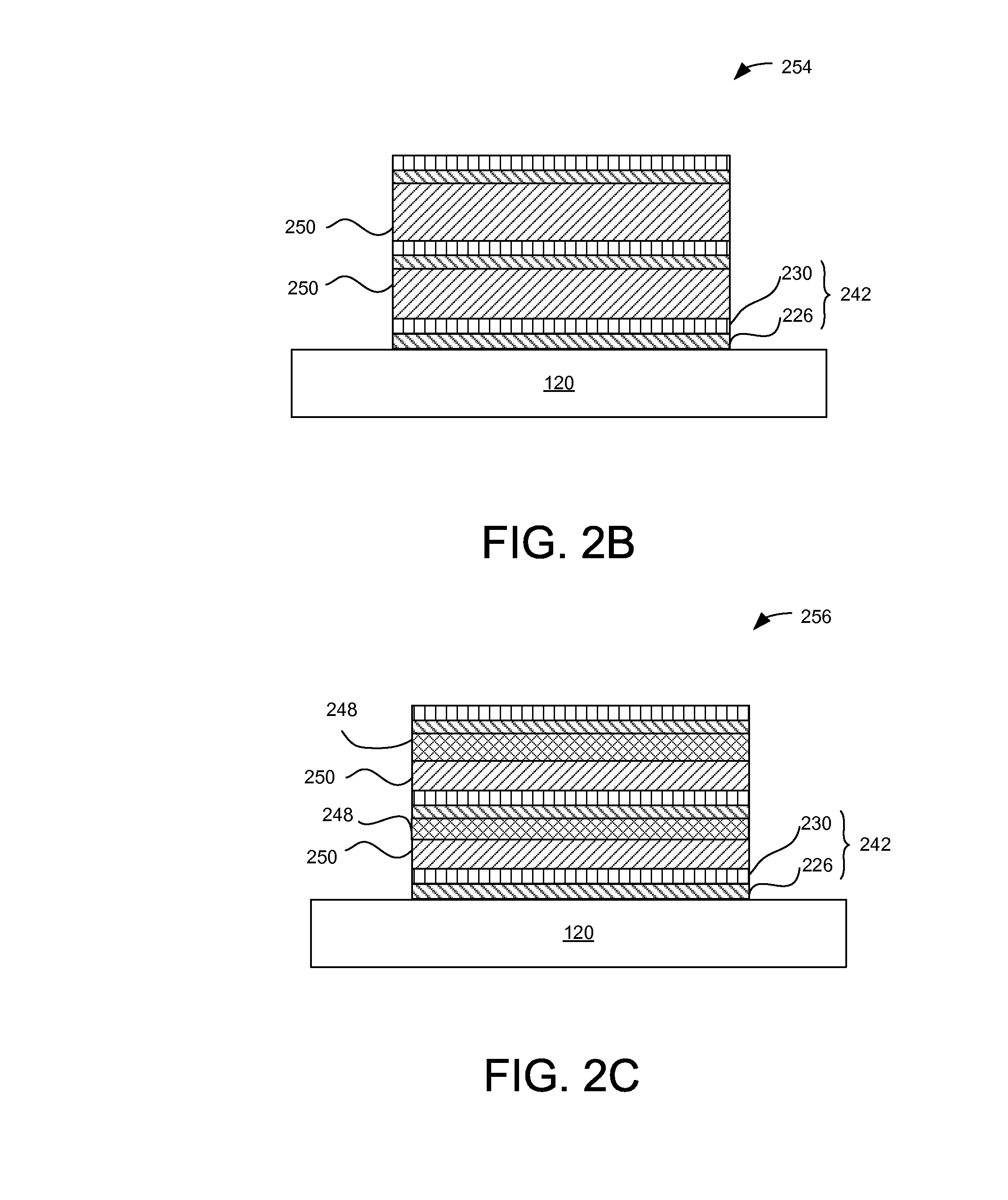

InactiveUS20050051763A1Improve toughnessHigh fracture-resistanceSolid-state devicesSemiconductor/solid-state device manufacturingPliabilityEngineering

A thin film barrier structure and process is disclosed, which is seen as particularly useful for use in devices that require protection from such common environmental species as oxygen and water. The disclosed barrier structure is of particular utility for such devices as implemented on flexible substrates, such as may be desirable for OLED-based or LCD-based devices. The disclosed barrier structure provides superior barrier properties, flexibility, as well as commercial-scale reproducibility, through the use of a novel organic / inorganic nanocomposite structure formed by infiltration of a porous inorganic layer by an organic material. The composite structure is produced by vacuum deposition techniques in the first preferred embodiment.

Owner:HELICON RES

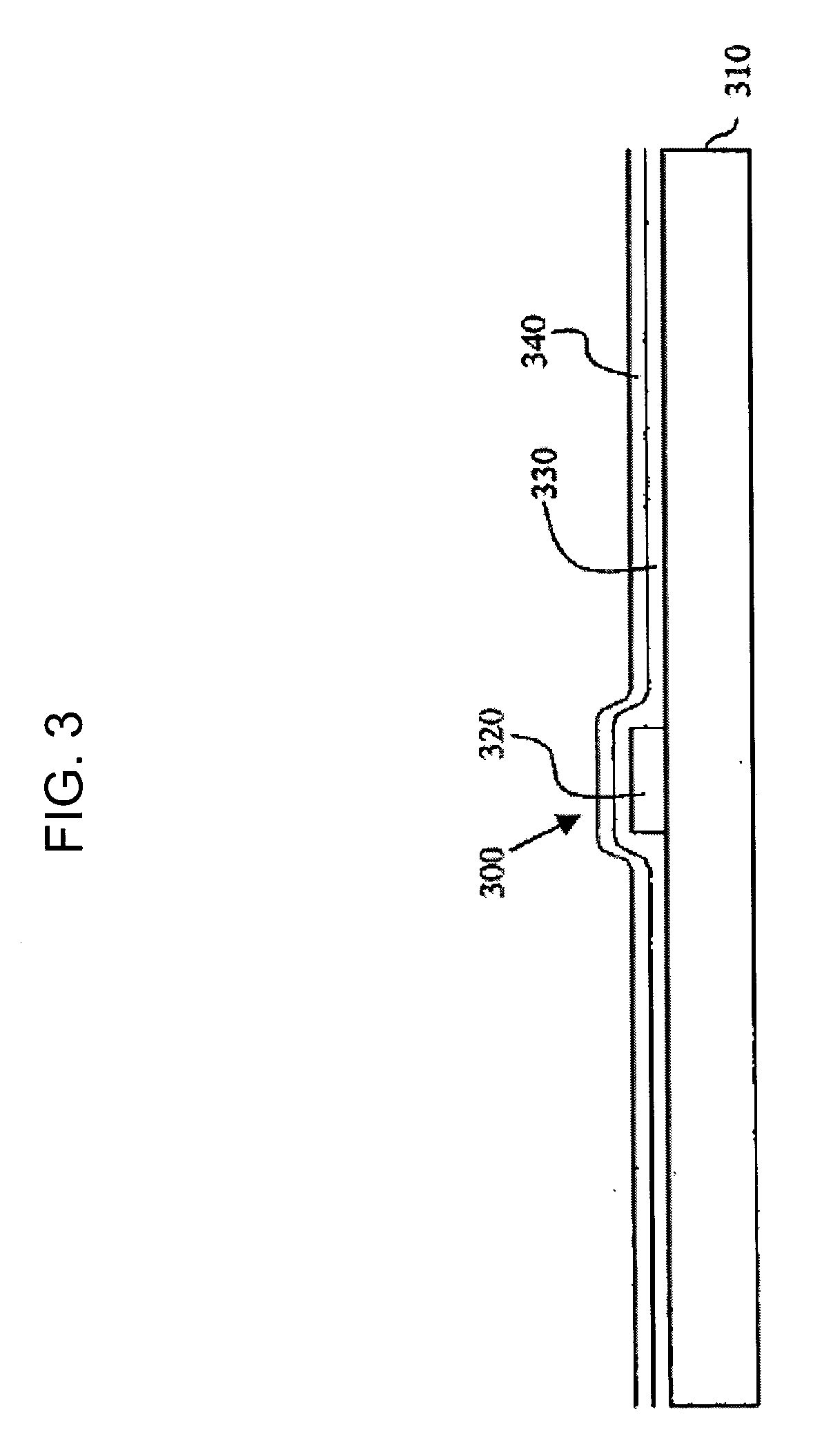

Flexible organic electroluminescent device and method for fabricating the same

ActiveUS20150060778A1Minimize damageMinimizing damageSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceFlexible electronics

Provided is a flexible organic electroluminescent device and a method for fabricating the same. In the flexible electroluminescent device, line hole patterns are formed on surfaces of a plurality of inorganic layers positioned in a pad region in which a flexible printed circuit board is connected to prevent a path of cracks caused by repeated bending and spreading of the organic electroluminescent device from spreading to the interior of the device.

Owner:LG DISPLAY CO LTD

Flat Panel Display Device and Method of Manufacturing the Same

ActiveUS20120133275A1Prevent penetrationInhibition formationDischarge tube luminescnet screensElectric discharge tubesEngineeringFlat panel display

In a flat panel display device and a method of manufacturing the same, the flat panel display device is manufactured by forming a display unit on a substrate, forming a hydrophobic barrier layer for preventing a material of an organic layer from flowing around the display unit, and forming a thin film sealing layer by alternately stacking an inorganic layer and the organic layer on the display unit. Accordingly, formation of an edge tail of the organic layer is prevented, thereby preventing penetration of external moisture.

Owner:SAMSUNG DISPLAY CO LTD

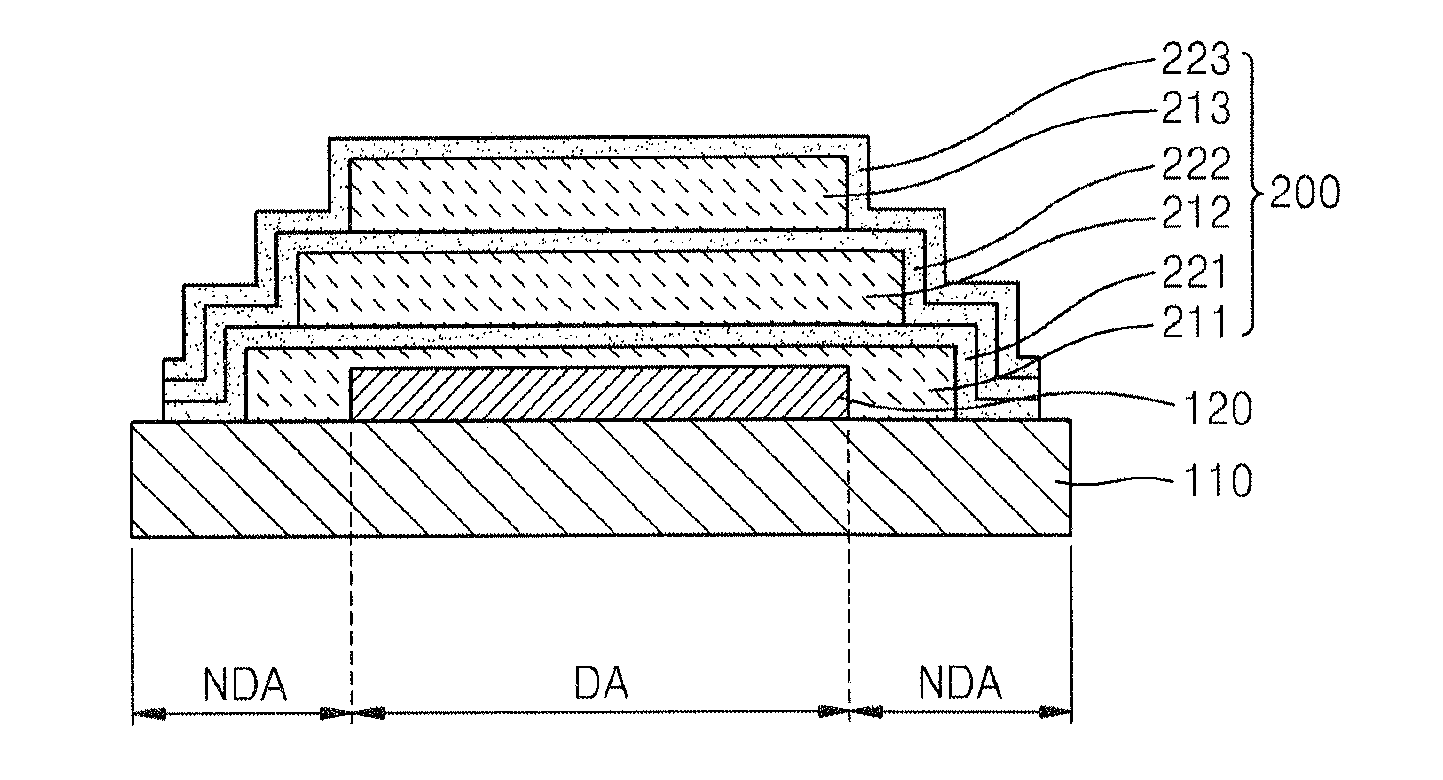

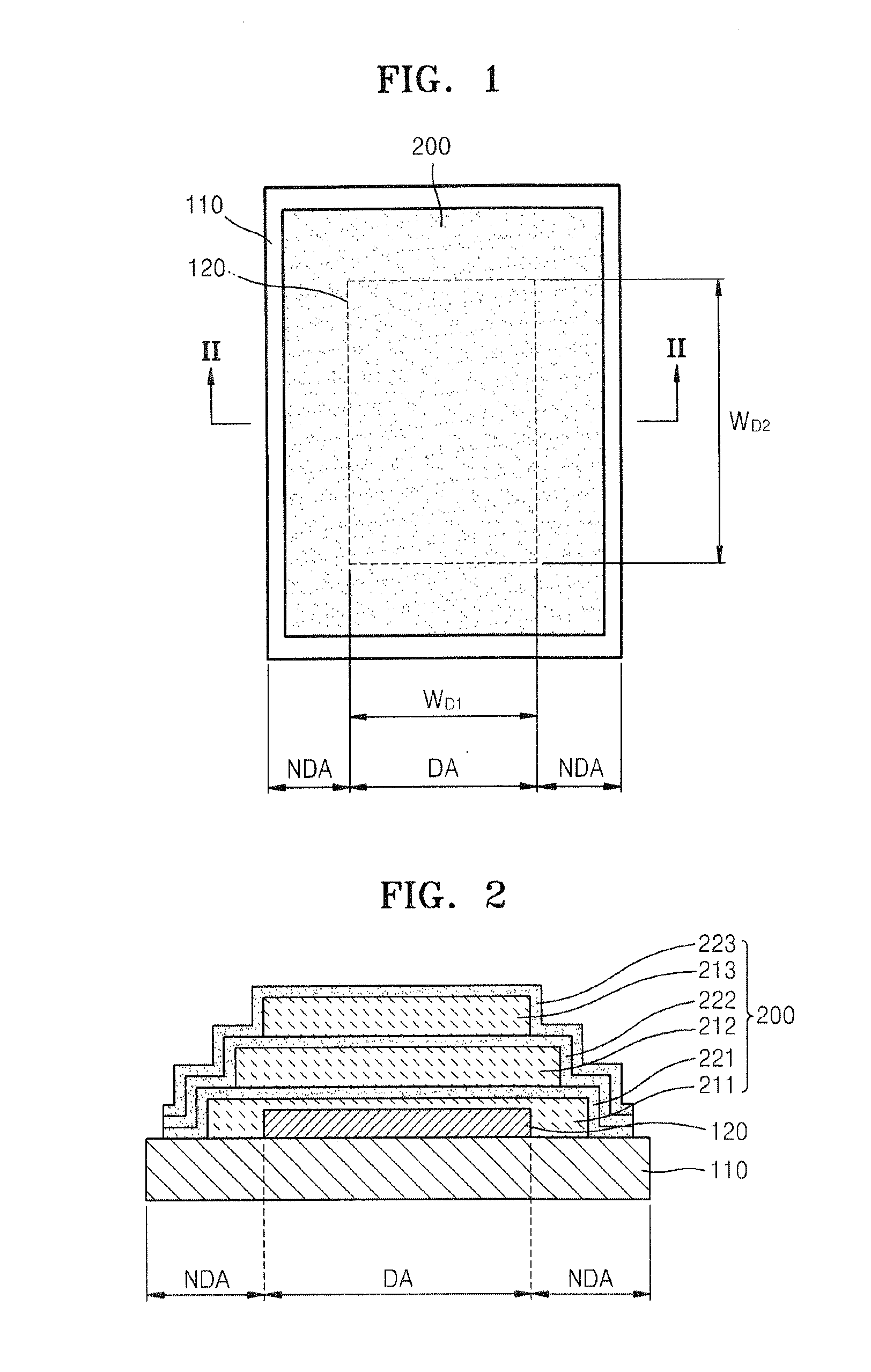

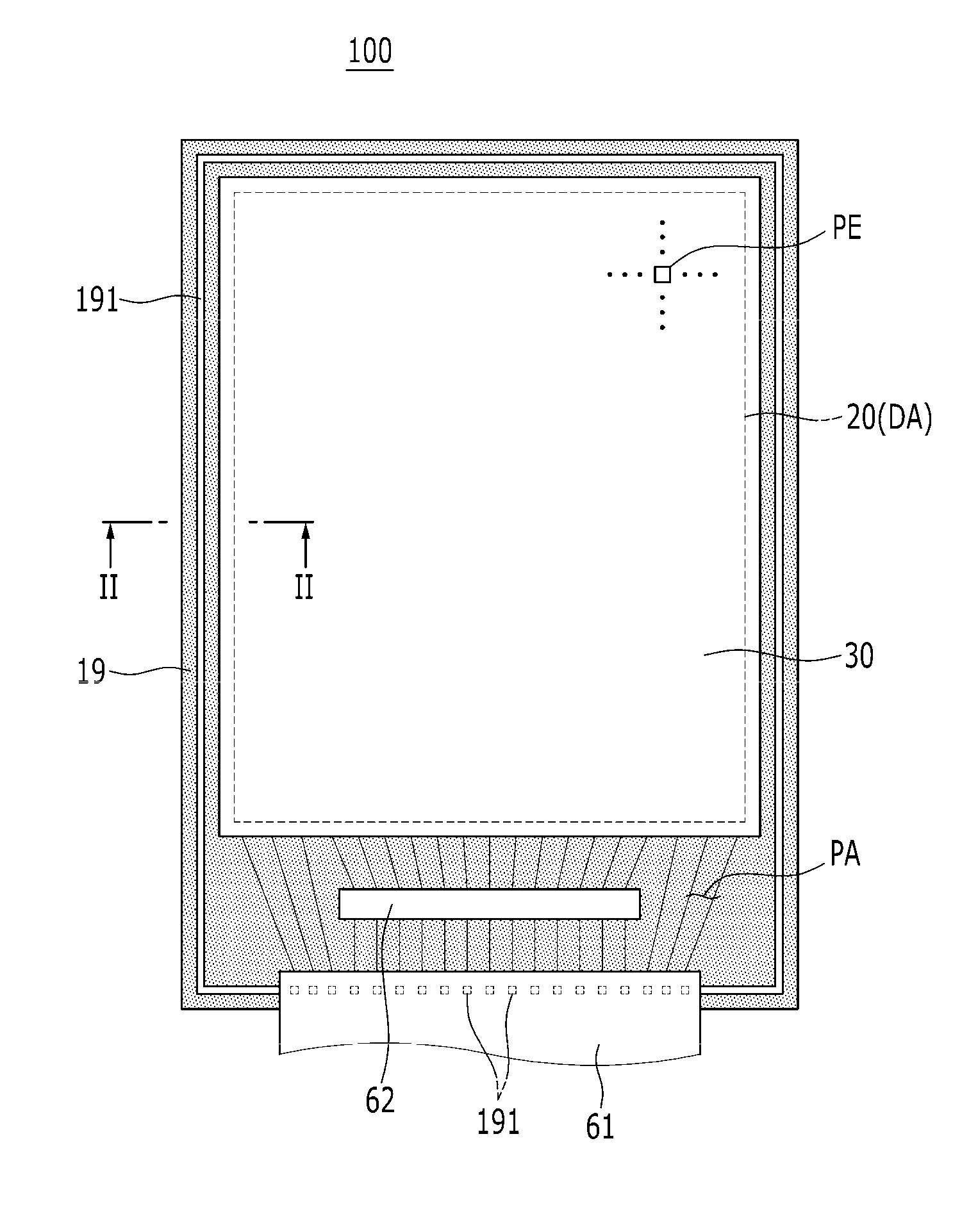

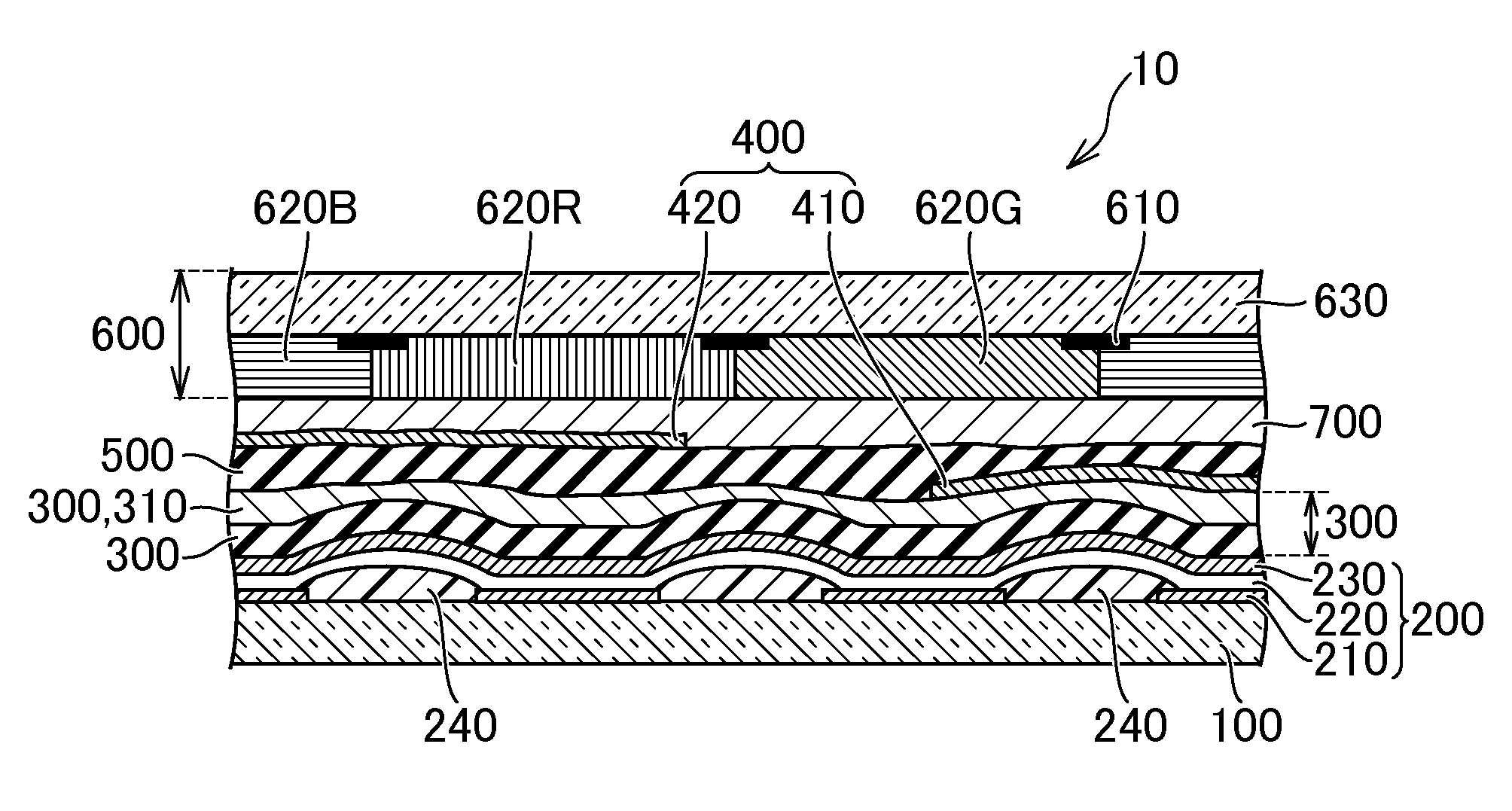

Organic light-emitting display apparatus and method of manufacturing the same

ActiveUS20120146492A1Reduce defective rateImprove moisture resistanceDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringInorganic layer

In an organic light-emitting display apparatus and a method of manufacturing the same, the organic light-emitting display apparatus comprises: a substrate; a light-emitting unit formed on the substrate; and an encapsulation film, which covers the light-emitting unit on the substrate, and which includes a plurality of organic layers and a plurality of inorganic layers which are alternately stacked.

Owner:SAMSUNG DISPLAY CO LTD

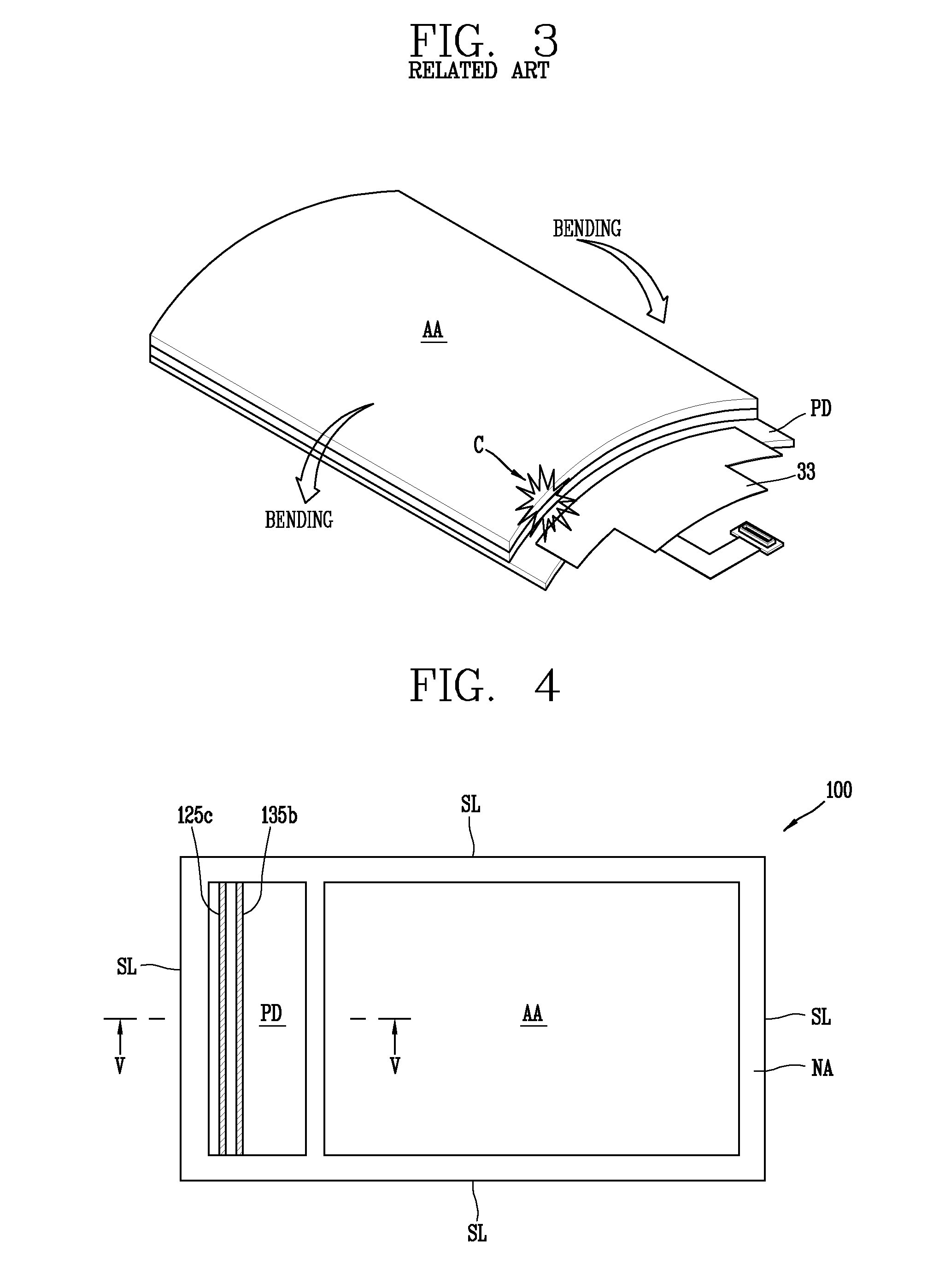

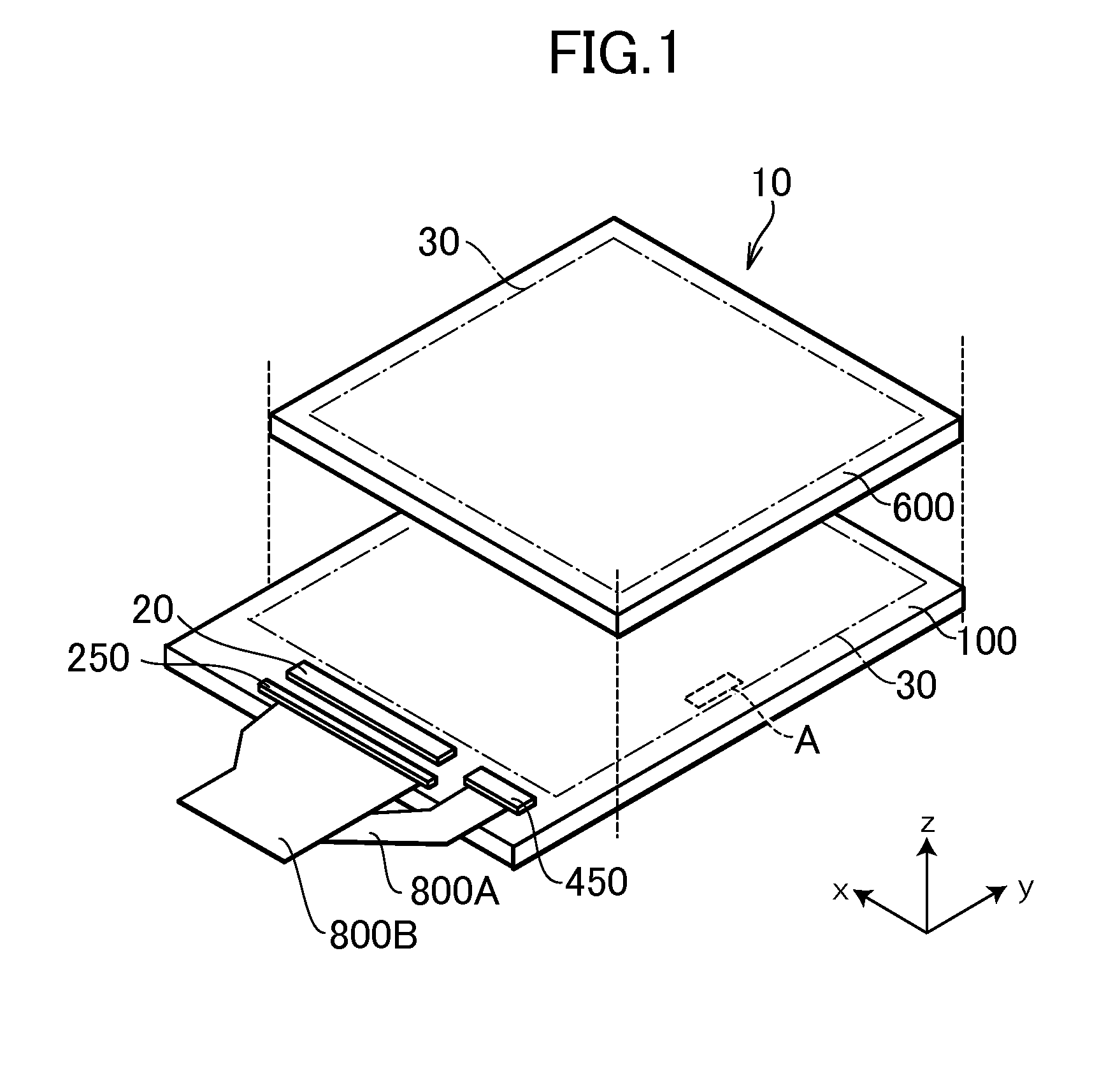

Flexible display device

ActiveUS20150036299A1Improve production yieldSuppressing panel shrinkageFinal product manufactureFlexible printed circuitsFlexible displayComputer science

A flexible display device that can suppress spread of cracks of an inorganic layer is provided. A flexible display device includes a flexible substrate including a display area and a periphery surrounding the display area, an inorganic layer formed on the flexible substrate, a display unit formed on the display area, and a thin film encapsulation layer covering the display unit. The inorganic layer includes an opening disposed on a periphery between edges of the flexible substrate and the thin film encapsulation layer.

Owner:SAMSUNG DISPLAY CO LTD

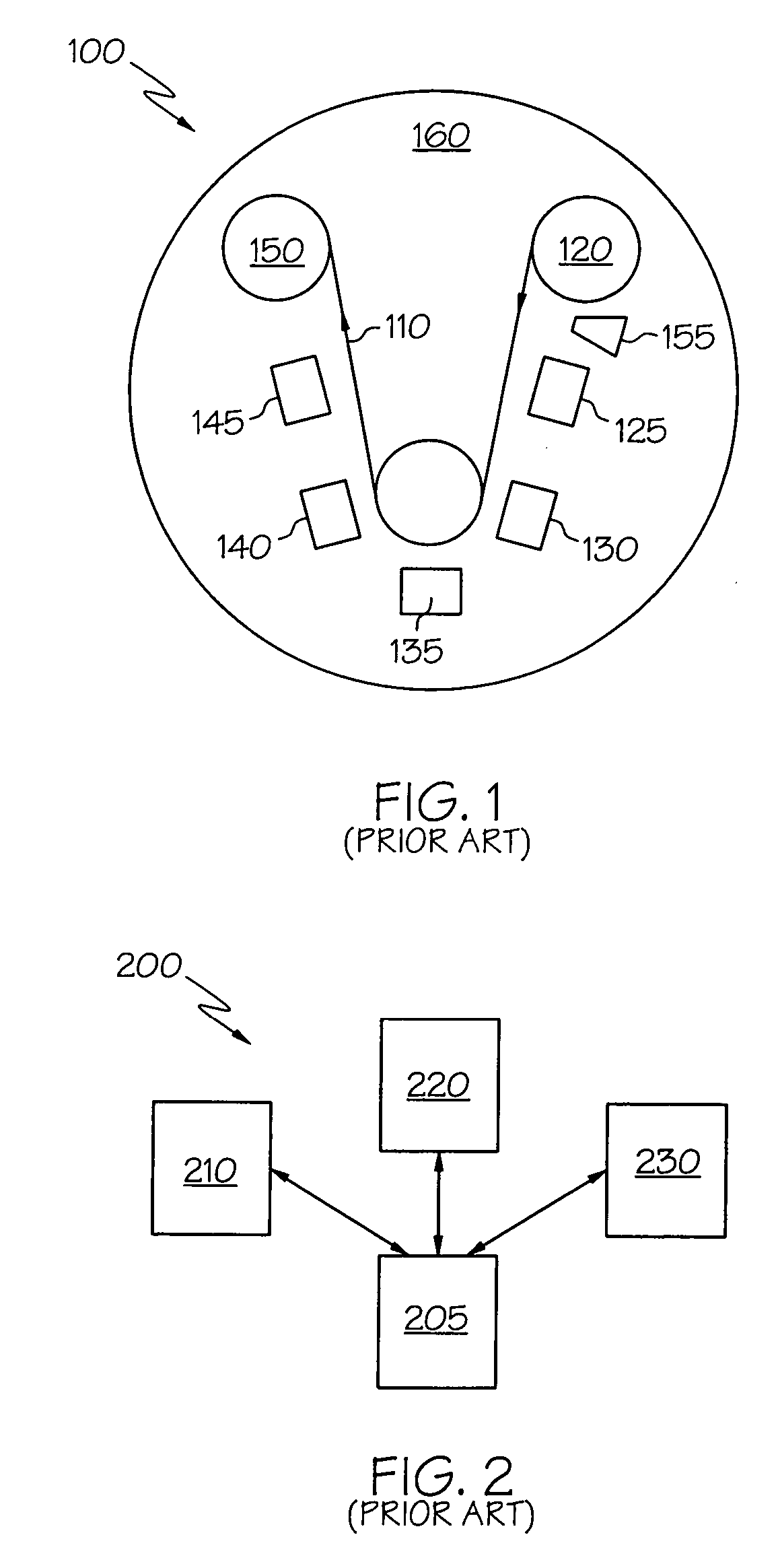

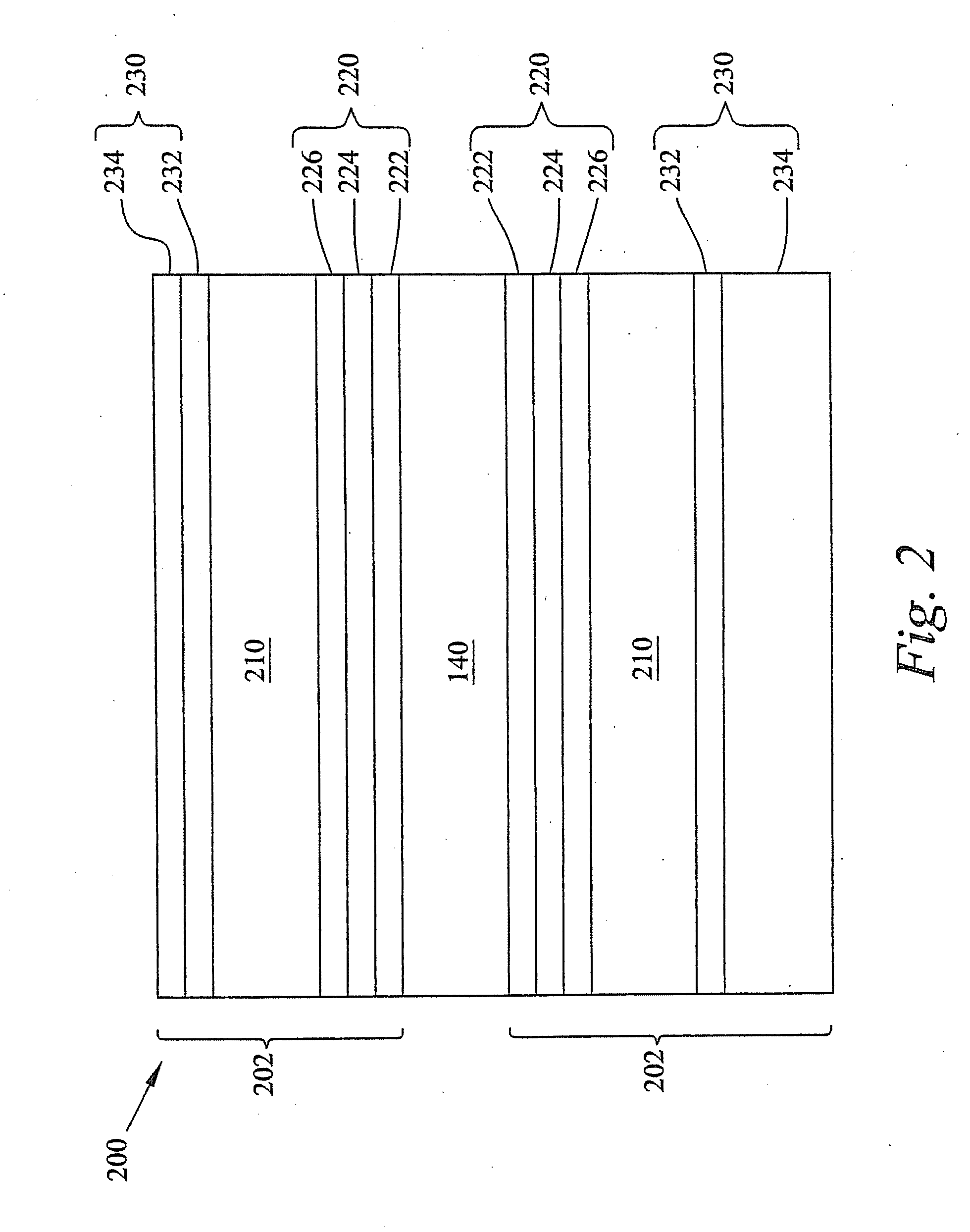

Apparatus for depositing a multilayer coating on discrete sheets

ActiveUS20050239294A1Reduce downtimeEasy to operateSolid-state devicesVacuum evaporation coatingTemperature controlEngineering

A tool for depositing multilayer coatings onto a substrate. In one configuration, the tool includes a includes an in-line organic material deposition station operating under at least one of a pressure or temperature controlled environment. In another, it further is of a hybrid design that incorporates both in-line and cluster tool features. In this latter configuration, at least one of the deposition stations is configured to deposit an inorganic layer, while at least one other deposition station is configured to deposit an organic layer. The tool is particularly well-suited to depositing multilayer coatings onto discrete substrates, as well as to encapsulating environmentally-sensitive devices placed on the flexible substrate.

Owner:SAMSUNG DISPLAY CO LTD

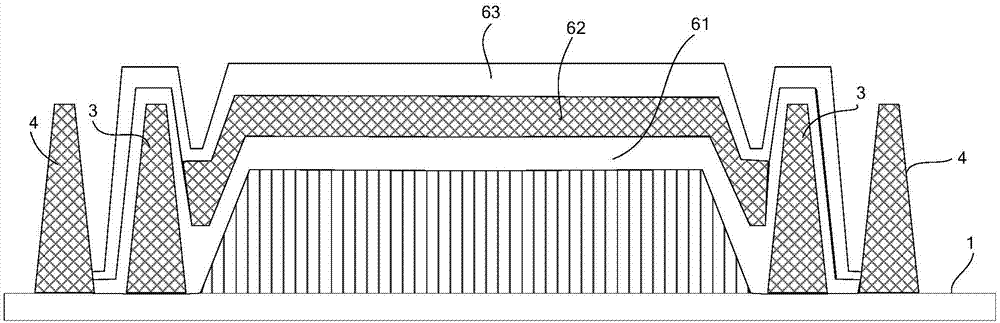

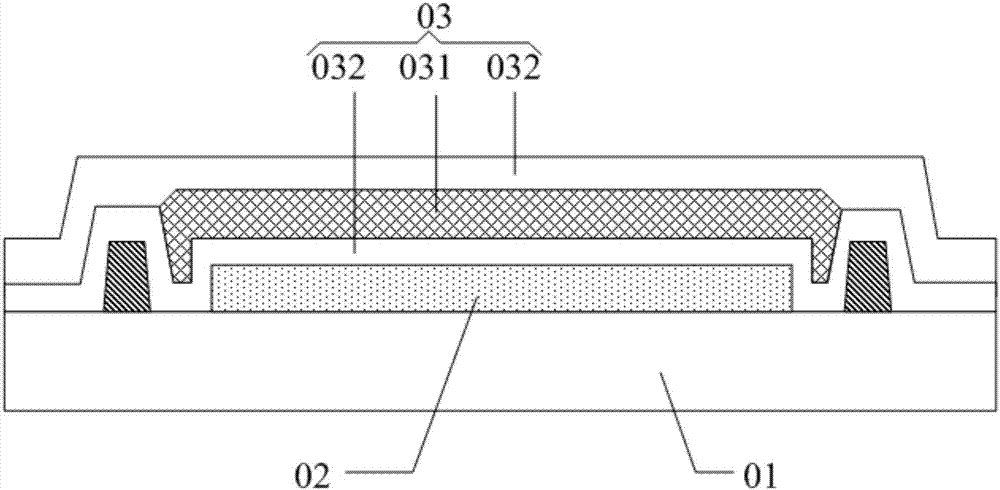

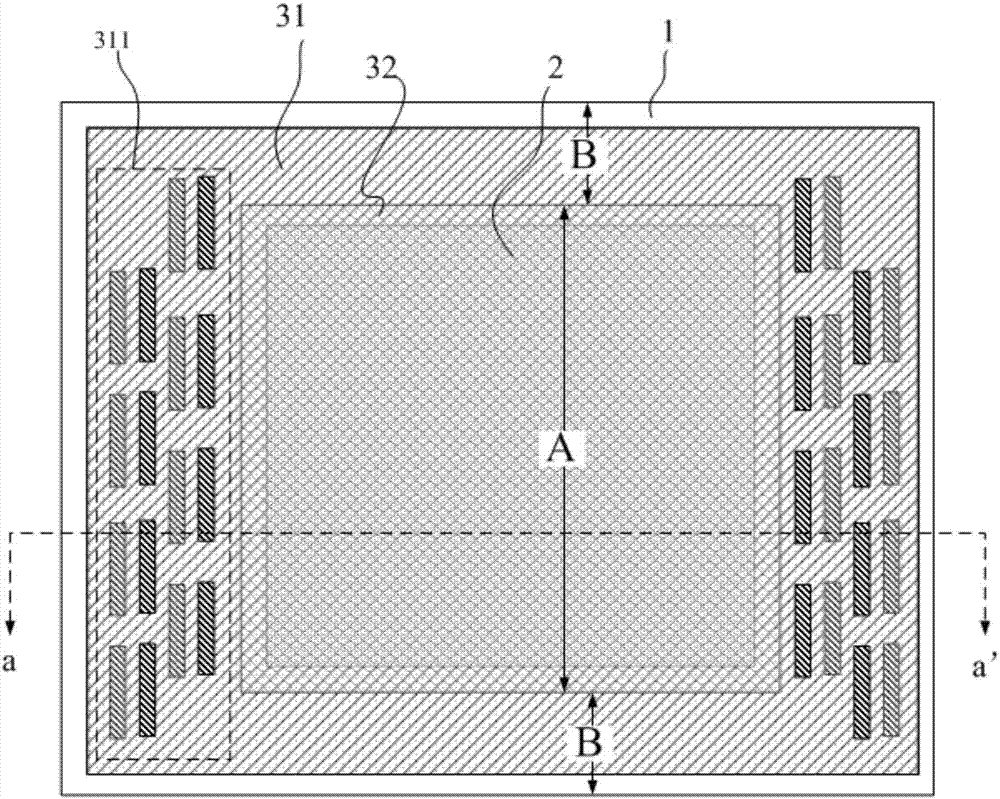

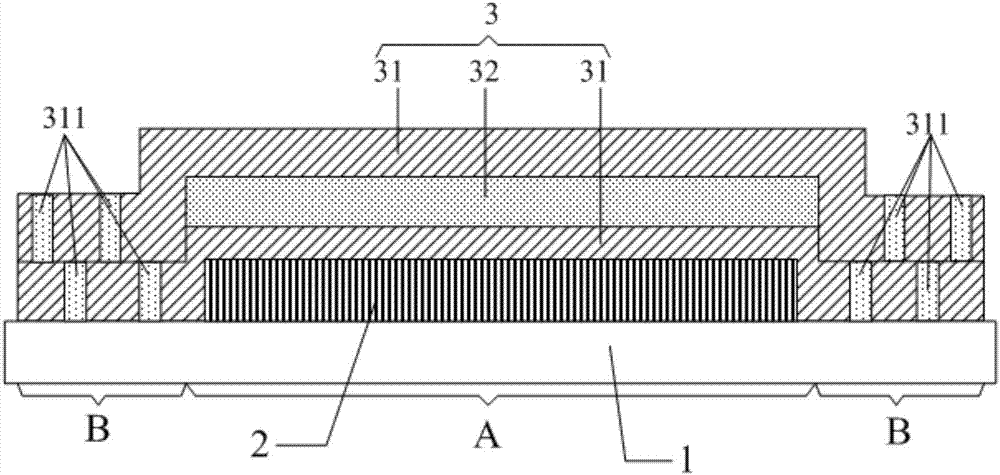

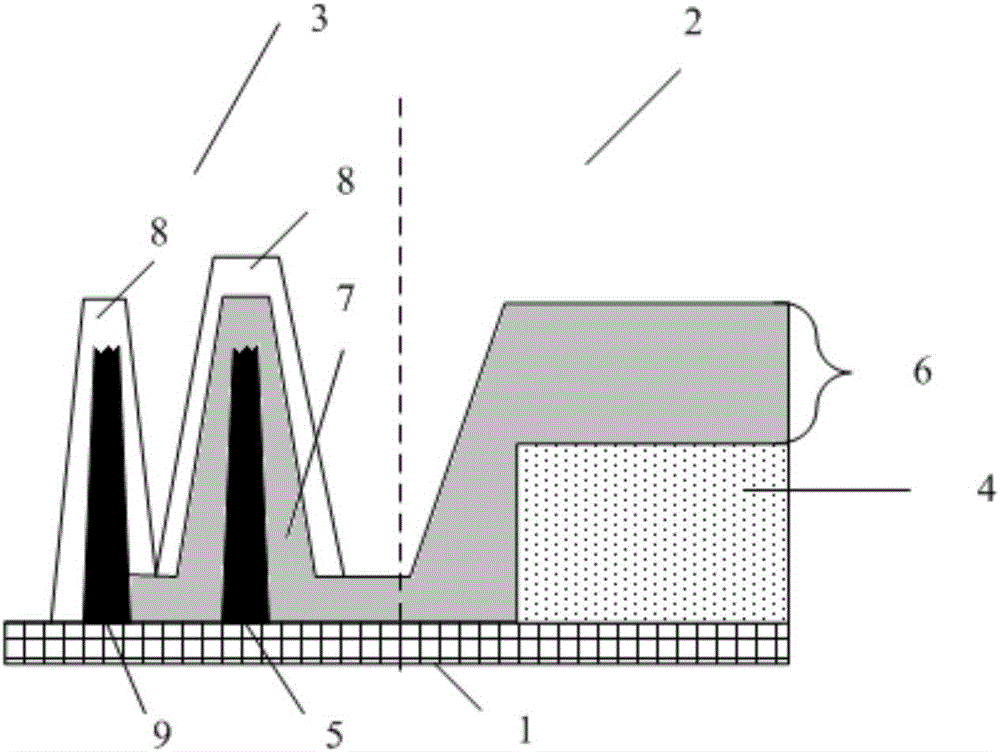

Flexible organic light emitting diode display panel, display device and fabrication method of flexile organic light emitting diode display panel

ActiveCN106981584AEffectively absorb or buffer stressAbsorb or buffer stressSolid-state devicesSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodeOrganic light emitting device

The invention discloses a flexible organic light emitting diode display panel, a display device and a fabrication method of the flexile organic light emitting diode display panel. The flexible organic light emitting diode display panel comprises a substrate, an organic light emitting device, a package thin film and at least retaining wall structures and also comprises an organic dielectric layer, wherein the substrate contains a display region and a non-display region, the organic light emitting device is arranged on the display region of the substrate, the package thin film covers the organic light emitting device and comprises an organic layer and at least one inorganic layer, the at least two retaining wall structures are arranged on the non-display region of the substrate, two adjacent retaining wall structures are arranged at intervals, the at least one part of retaining wall structures are covered by the package thin film, and the organic dielectric layer is arranged between the at least two adjacent retaining wall structures, is arranged on the substrate and is covered by the at least one inorganic layer. Since the inorganic layer and the organic dielectric layer are filled between the retaining wall structures, the stress generated by the inorganic layer during bending for many times can be effectively absorbed by the organic dielectric layer, and a crack is prevented from being generated between the retaining wall structures.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

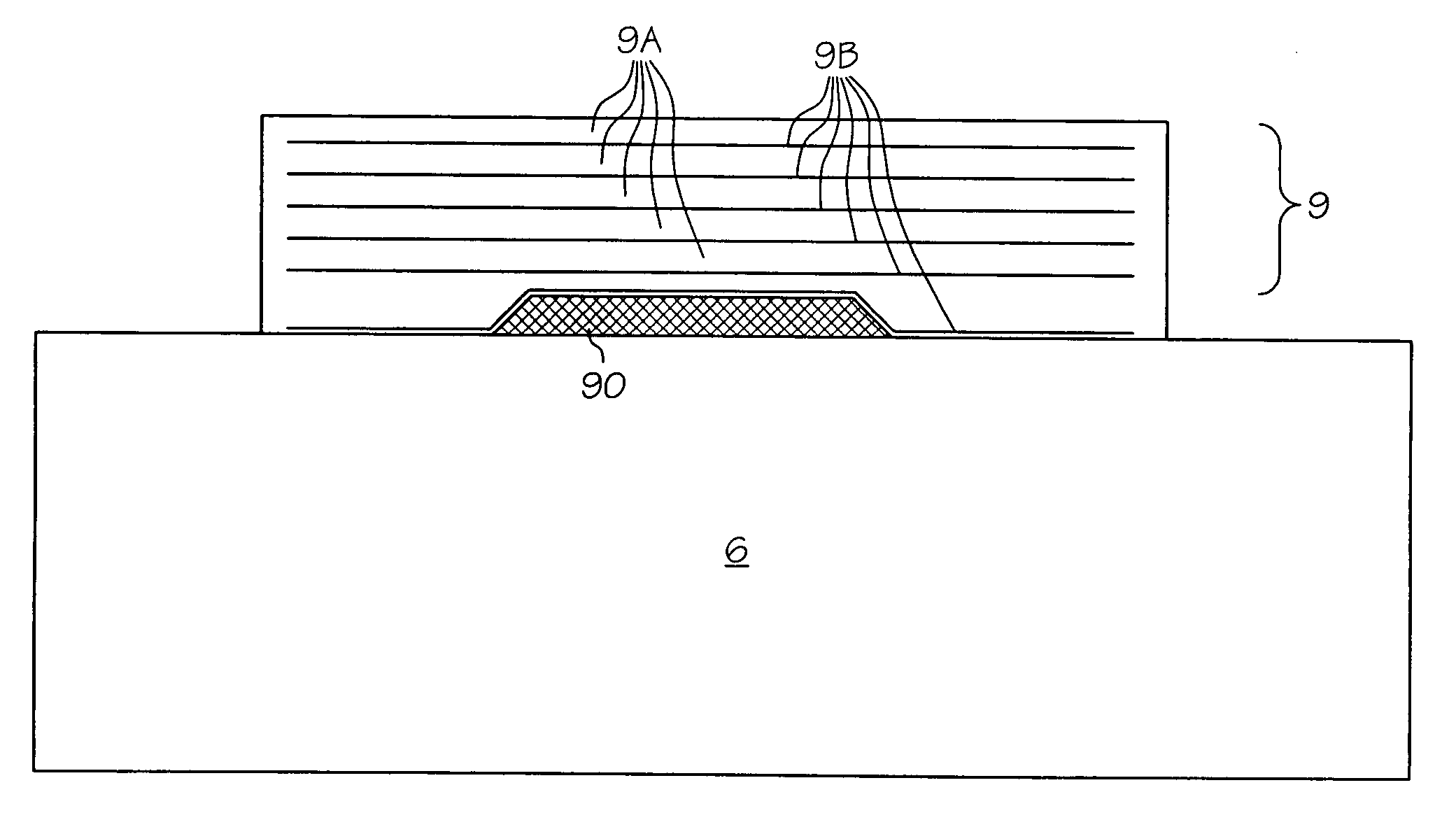

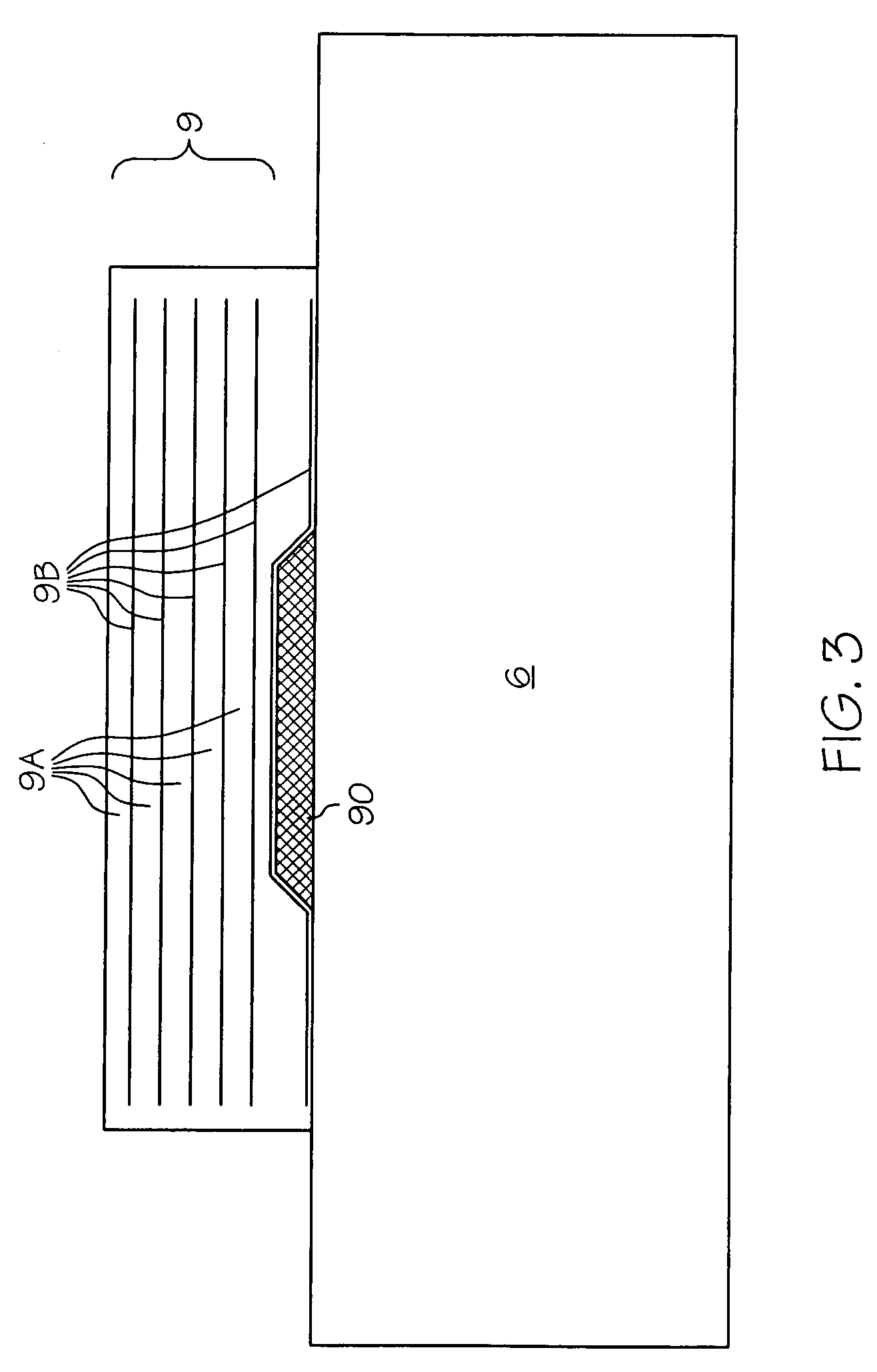

Donor substrate for laser induced thermal imaging and method of fabricating organic light emitting diode using the same

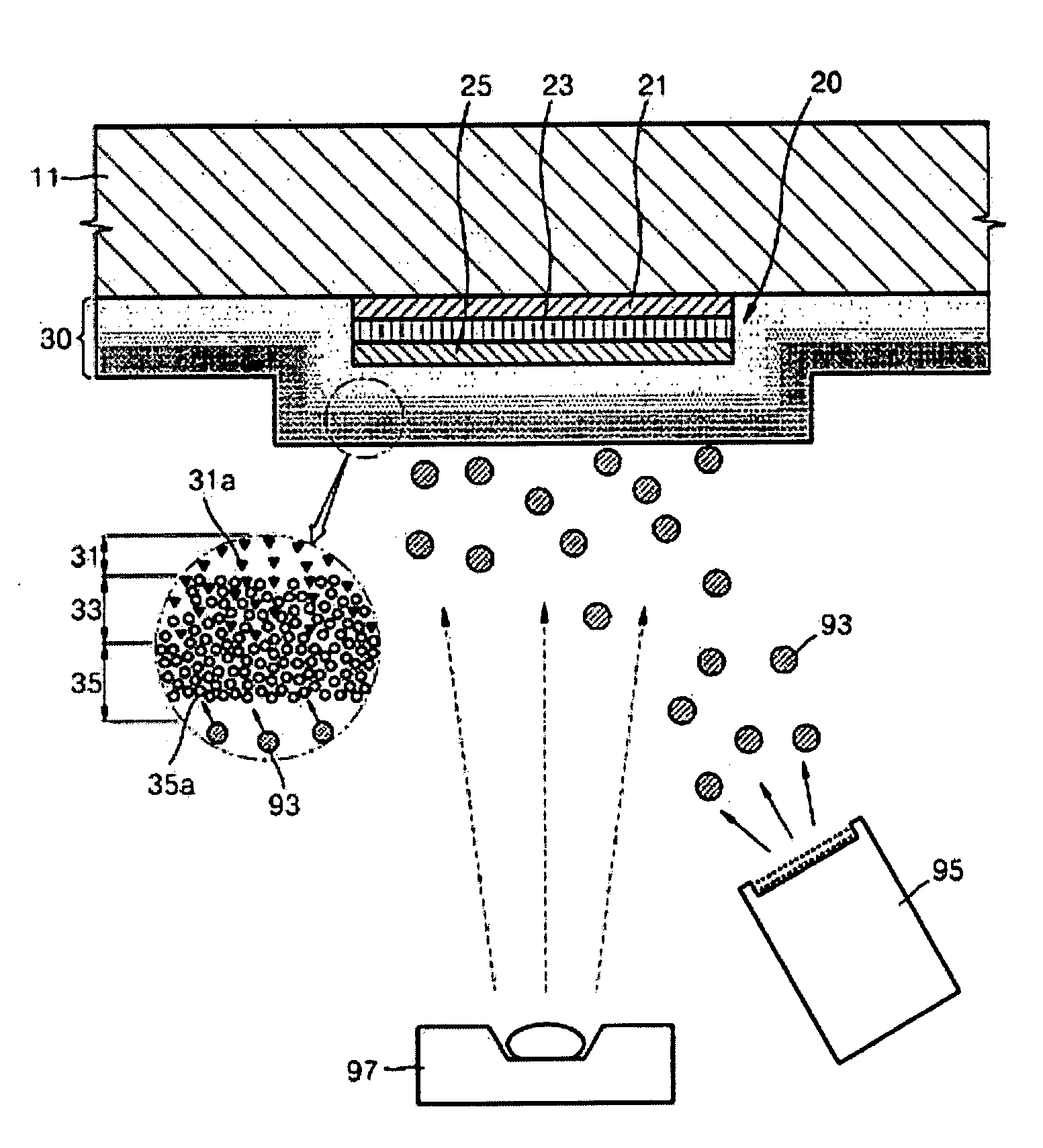

ActiveUS8486857B2Possible to selectAvoid damageElectroluminescent light sourcesSolid-state devicesMolecular orbital energyLight-emitting diode

Provided are a donor substrate for laser induced thermal imaging (LITI) and a method of fabricating an organic light emitting diode (OLED) using the same, which can prevent a transferred emission layer from being damaged by heat and thus prevent wrinkles from forming on the surface thereof. The donor substrate includes a base layer, a light-to-heat conversion layer disposed on the base layer, a first transfer layer disposed on the light-to-heat conversion layer and including an organic layer, an inorganic layer, or a double layer thereof, and a second transfer layer disposed on the first transfer layer and including an emission layer. The first transfer layer has an absolute value of lowest unoccupied molecular orbital energy level of 2.6 to 3.0 eV and a band gap energy of 2.8 to 3.4 eV.

Owner:SAMSUNG DISPLAY CO LTD

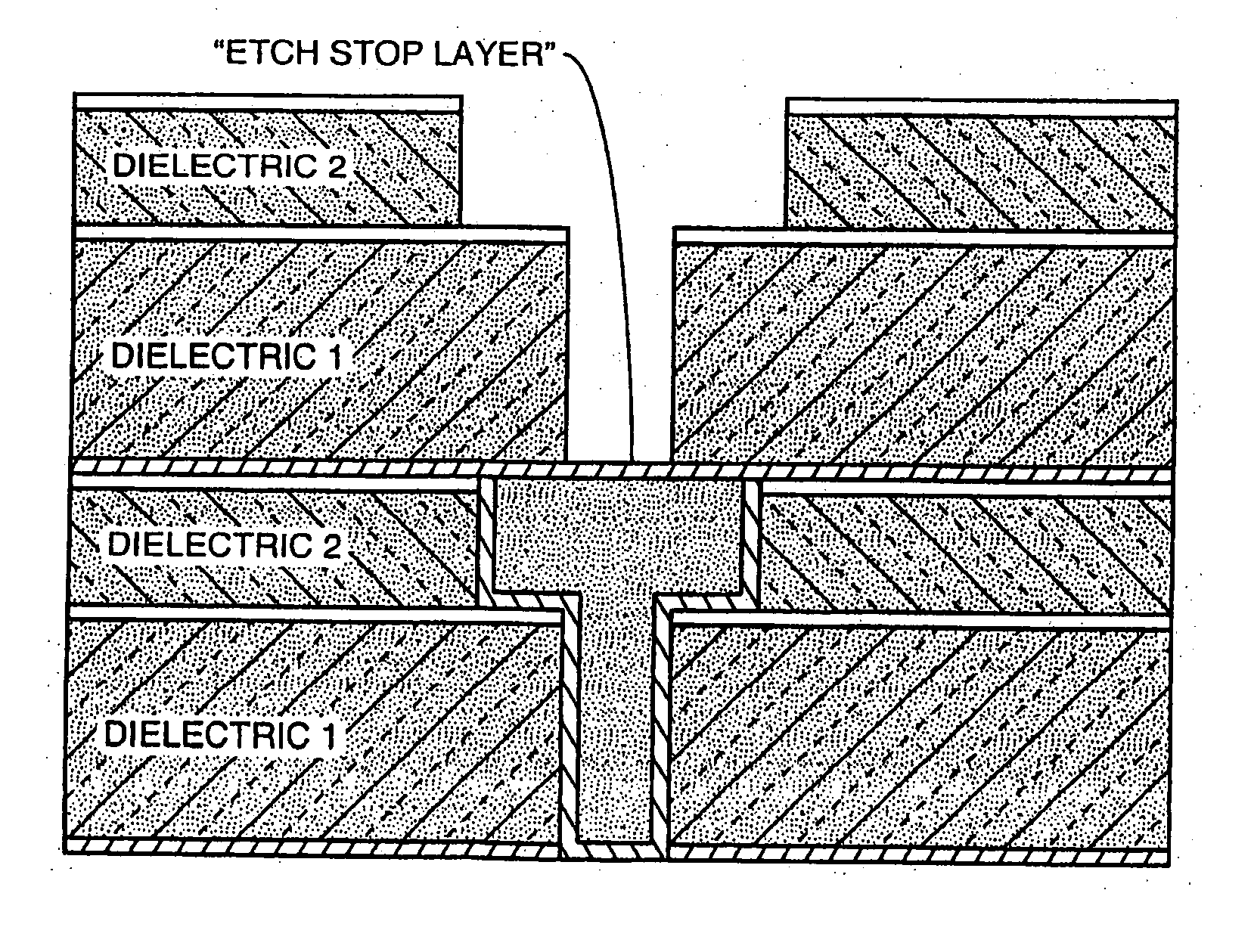

Remover compositions for dual damascene system

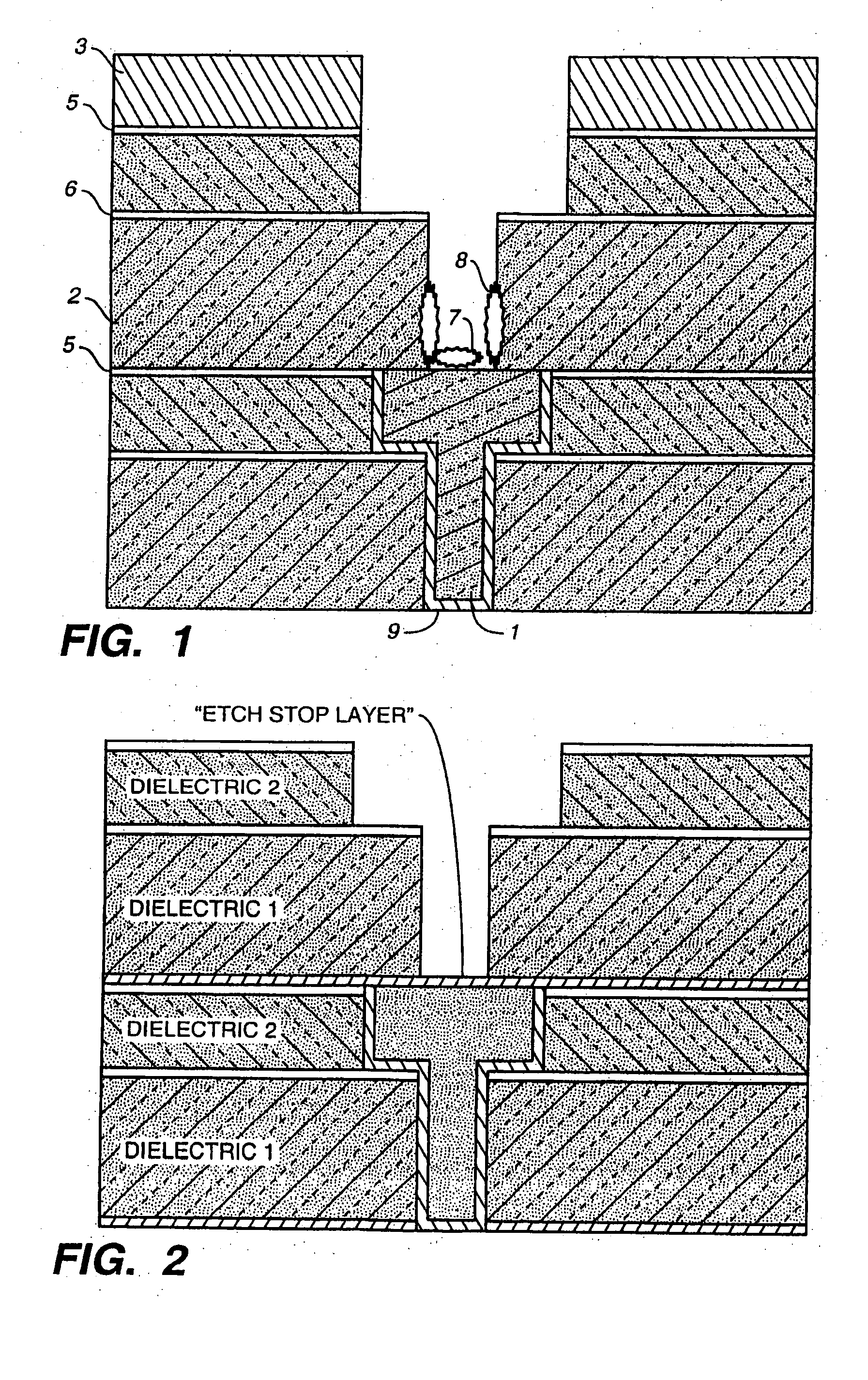

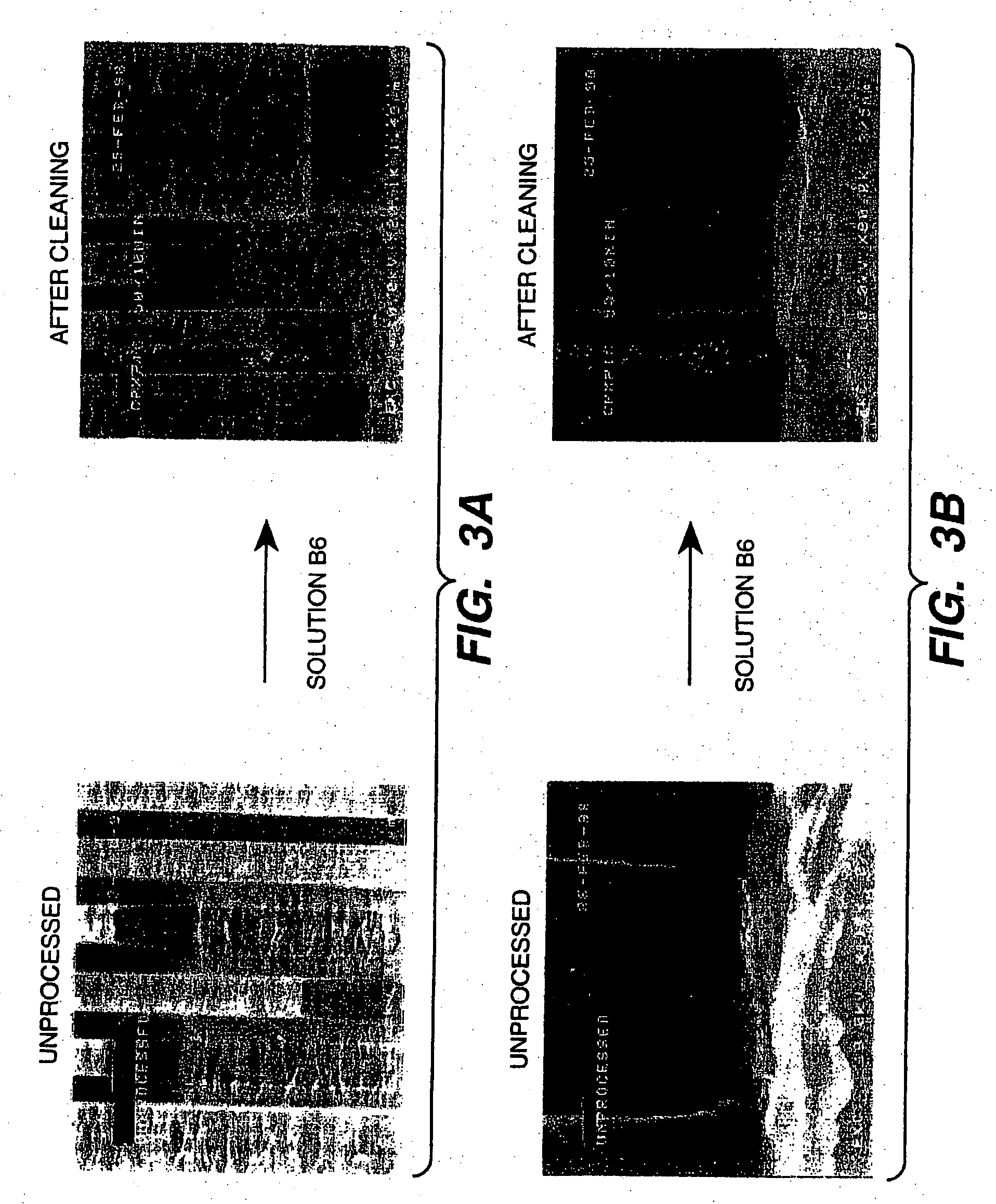

InactiveUS20050266683A1Avoid corrosionAvoid inhibitionNon-surface-active detergent compositionsSemiconductor/solid-state device manufacturingDielectricAnti-reflective coating

A new remover chemistry based on a choline compound, such as choline hydroxide, is provided in order to address problems related to removal of residues, modified photoresists, photoresists, and polymers such as organic anti-reflective coatings and gap-fill and sacrificial polymers from surfaces involved in dual damascene structures without damaging the dielectrics and substrates involved therein. An etch stop inorganic layer at the bottom of a dual damascene structure may or may not be used to cover the underlying interconnect of copper. If not used, a process step of removing that protective layer can be avoided through a timed etch of the via in trench-first dual damascene processes.

Owner:EKC TECH

Emissive device, process for producing emissive device, and electronic apparatus

ActiveUS20070132381A1Avoid crackingIncrease productivityDischarge tube luminescnet screensElectroluminescent light sourcesOptoelectronicsElectron

An emissive device includes a substrate; a plurality of first electrodes; pixel banks having a plurality of openings each corresponding to the position of a corresponding one of the first electrodes; organic function layers disposed in at least the openings; a second electrode disposed so as to cover the pixel banks and the organic function layers; a first inorganic layer disposed over the second electrode; a second inorganic layer disposed over the first inorganic layer; an organic buffer layer disposed over the second inorganic layer; and a gas barrier layer disposed over the organic buffer layer.

Owner:SEIKO EPSON CORP

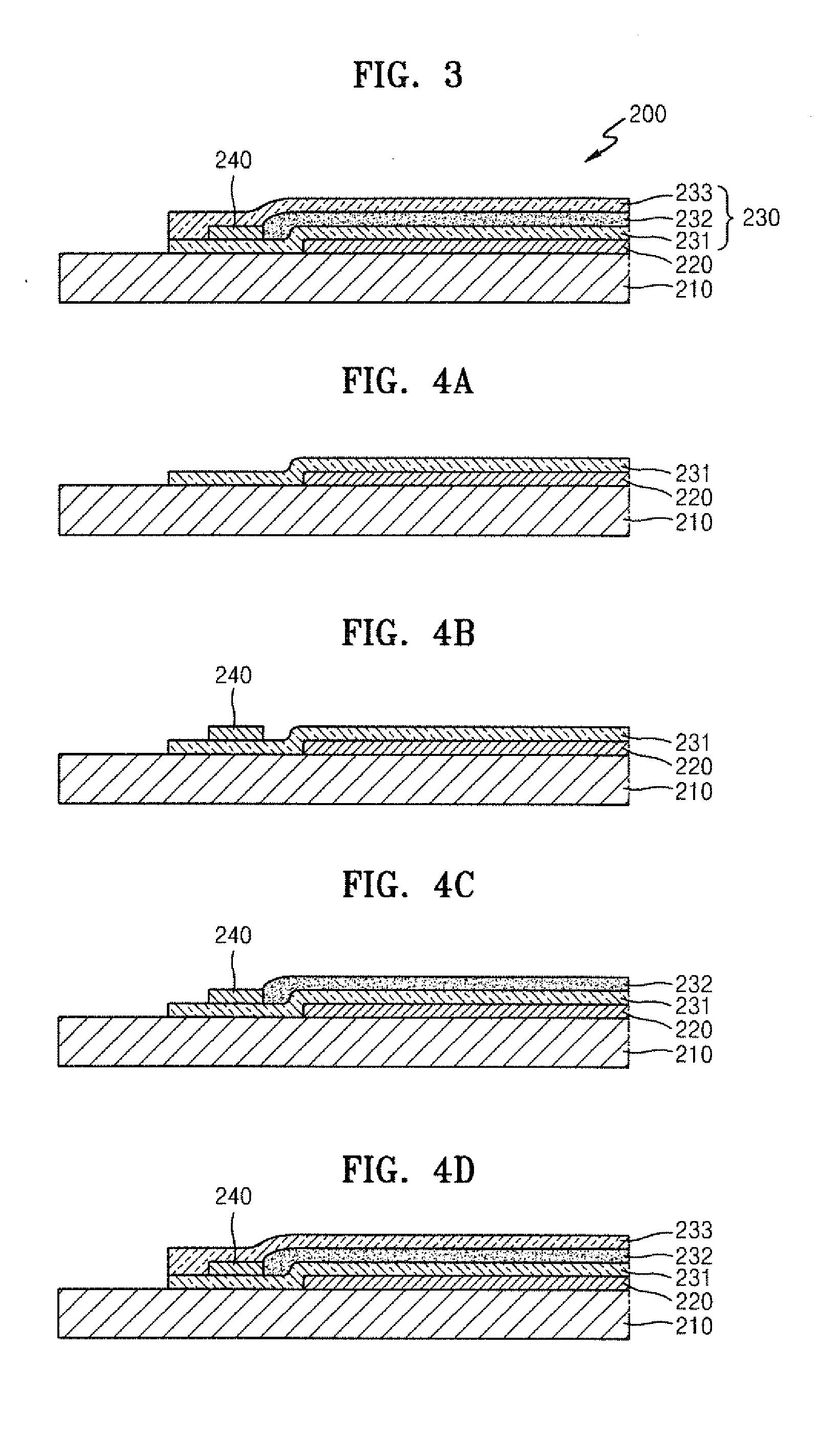

Organic light emitting device and method of manufacturing the same

InactiveUS20080305360A1Avoid problemsElectroluminescent light sourcesVacuum evaporation coatingOrganic light emitting deviceLight-emitting diode

An organic light emitting device includes an organic light emitting diode on a substrate and an encapsulation layer covering the organic light emitting diode. The encapsulation layer includes an organic layer, an inorganic layer on the organic layer, and an intermixing region between the organic layer and the inorganic layer, the organic layer includes an organic material, the inorganic layer includes an inorganic material, and the intermixing region includes the organic material and the inorganic material.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

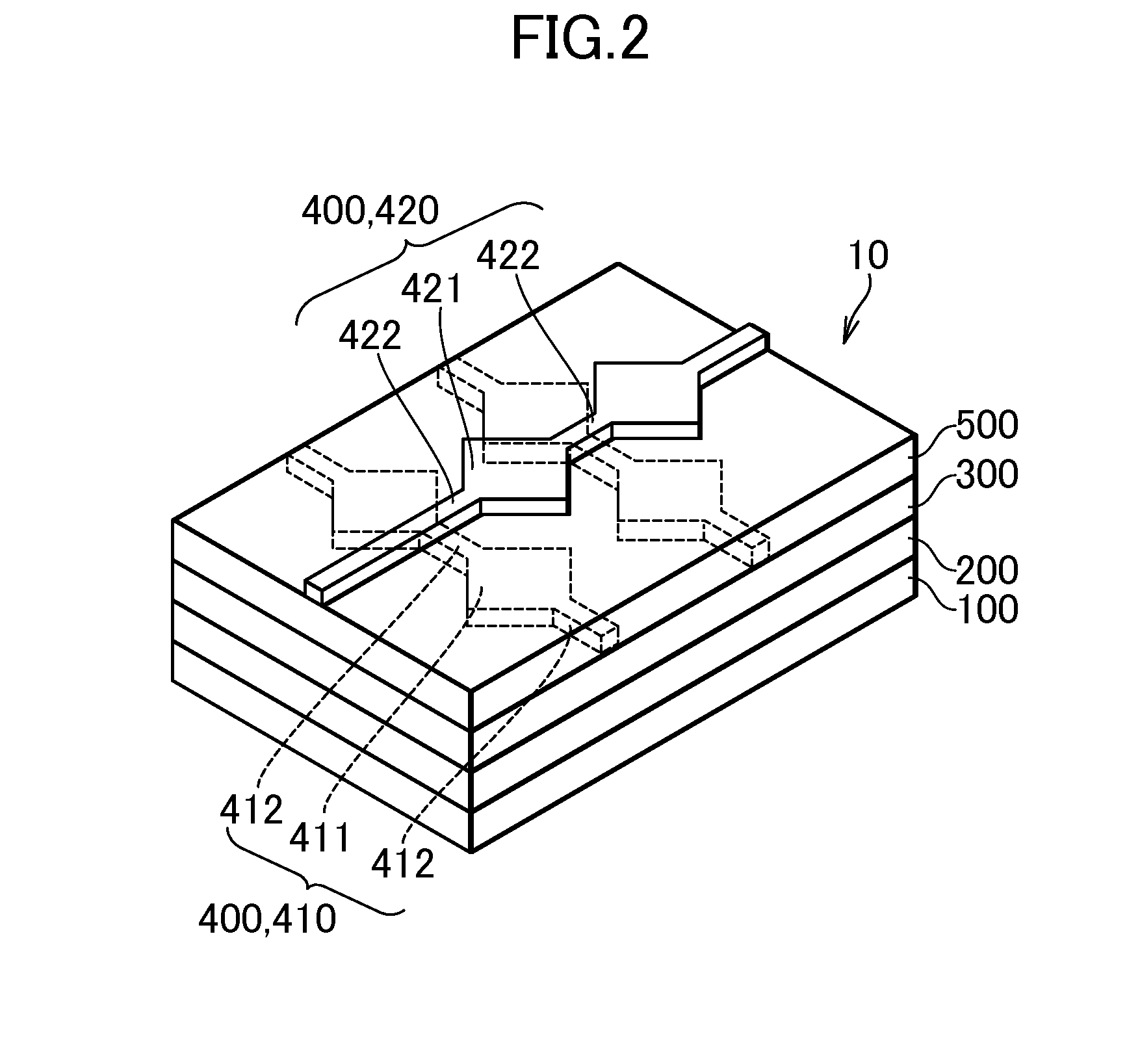

Display device

ActiveUS20150060817A1Solid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

An organic electroluminescent device with a touch sensor including: a first substrate; a second substrate arranged opposite to the first substrate; an organic EL element layer arranged above the first substrate; a first sealing film arranged toward the second substrate of the organic EL element layer, covering the organic EL element layer, and including a first inorganic layer; plural first detection electrodes extending in one direction, and arranged in parallel toward the second substrate of the first sealing film; a second sealing film arranged toward the second substrate of the first detection electrodes, and including a second inorganic layer; plural second detection electrodes extending in another direction different from the one direction, and arranged in parallel toward the second substrate of the second sealing film; and a touch sensor control unit controlling a potential to detect a touch with a display surface.

Owner:JAPAN DISPLAY INC

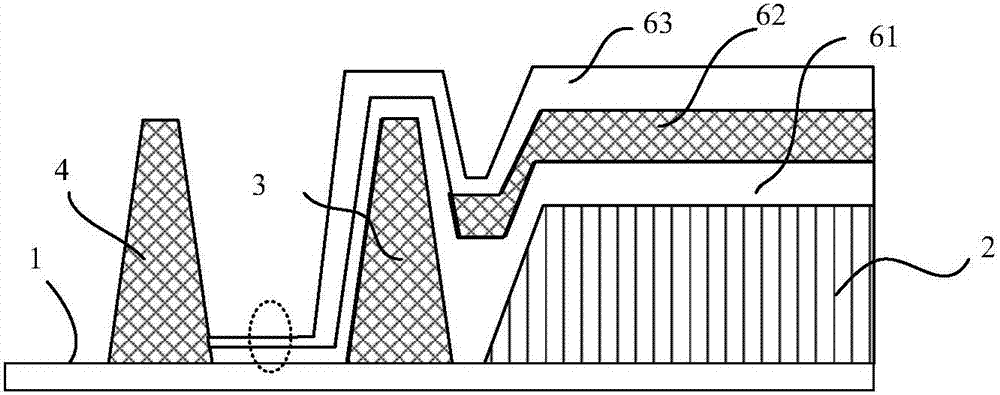

Flexible display panel and display device

ActiveCN106997930AIncrease contactAvoid crackingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOrganic electroluminescence

The invention discloses a flexible display panel and a display device. The flexible display panel comprises a substrate which is defined as a display area and a non-display area surrounding the display area, an organic electroluminescent structure which is located in the display area, and an encapsulating film layer which is located in the display area and the non-display area to cover the organic electroluminescent structure. The encapsulating film layer comprises at least two inorganic layers and an organic layer arranged between two inorganic layers. In the non-display area, the inorganic layers are directly laminated with each other. Each inorganic layer located in the non-display area is provided with a groove filled with an organic filler, and the orthographic projections of the organic fillers in different inorganic layers do not overlap on the substrate. Cracks of the inorganic layer edge are avoided when the flexible display panel is bent, and the path of the cracks expanding to the display area is blocked. By using non-overlapping organic fillers, the diffusion path of water-oxygen in adjacent inorganic layers is increased.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

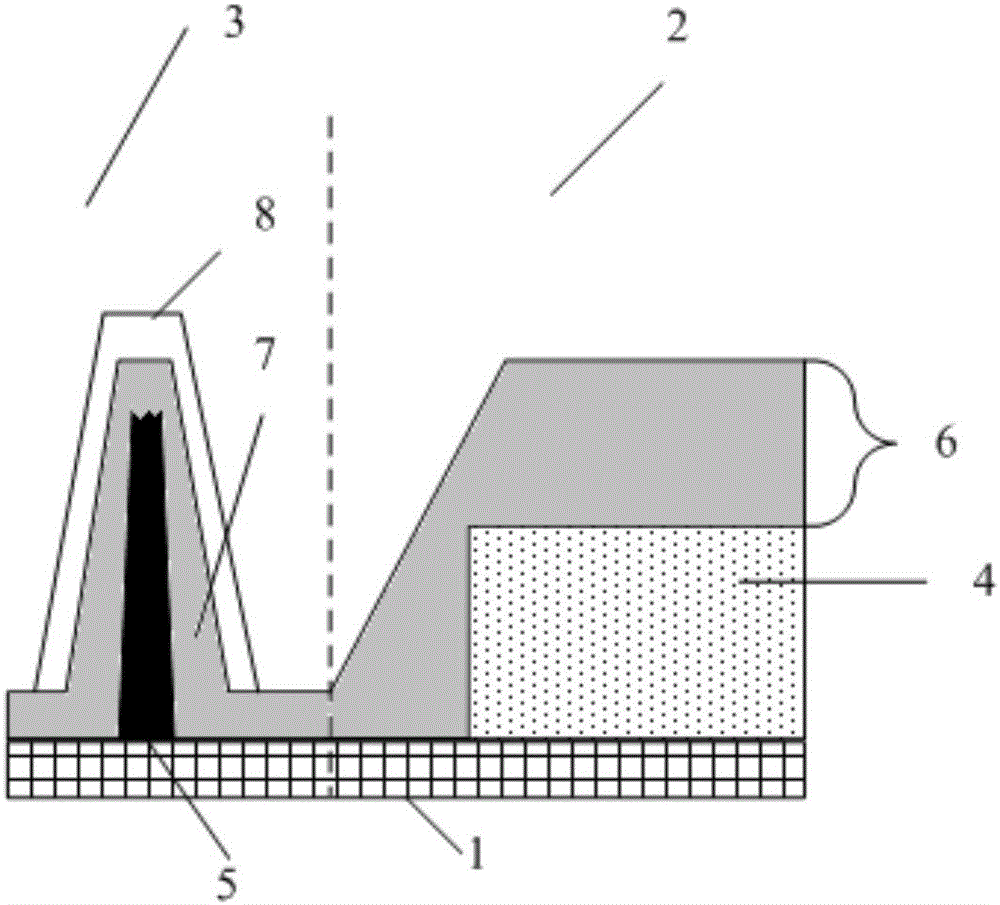

Organic light-emitting diode display panel and display

ActiveCN106816456AInhibit growthImprove sealingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides an organic light-emitting diode display panel and a display. A protection layer additionally disposed on an inorganic layer on a retaining wall is used to prevent an inorganic layer crack from continuously growing, and therefore product sealing performance is improved, and product bending performance is improved. The organic light-emitting diode comprises a display area and an adjacent peripheral area. The display panel comprises a substrate, a display function layer, and a packaging layer. The display area comprises a display function layer, and the peripheral area comprises a first retaining wall, which is disposed around the display area. The packaging layer comprises at least one inorganic layer, which is vertical to the direction of the substrate, and is used to cover the first retaining wall. The display panel comprises the protection layer, which is vertical to the direction of the substrate, and is used to cover the at least one inorganic layer on the upper part of the first retaining wall.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

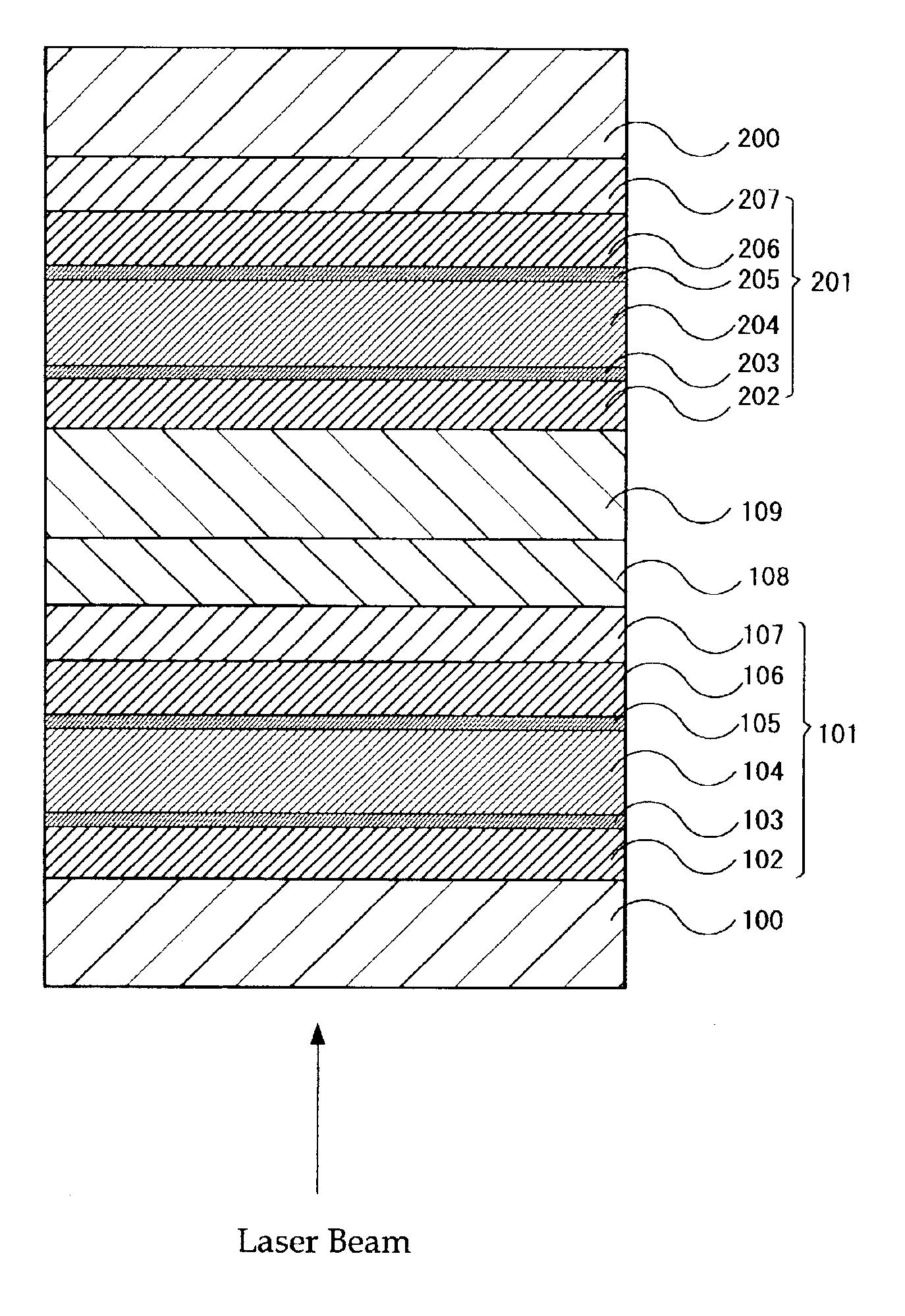

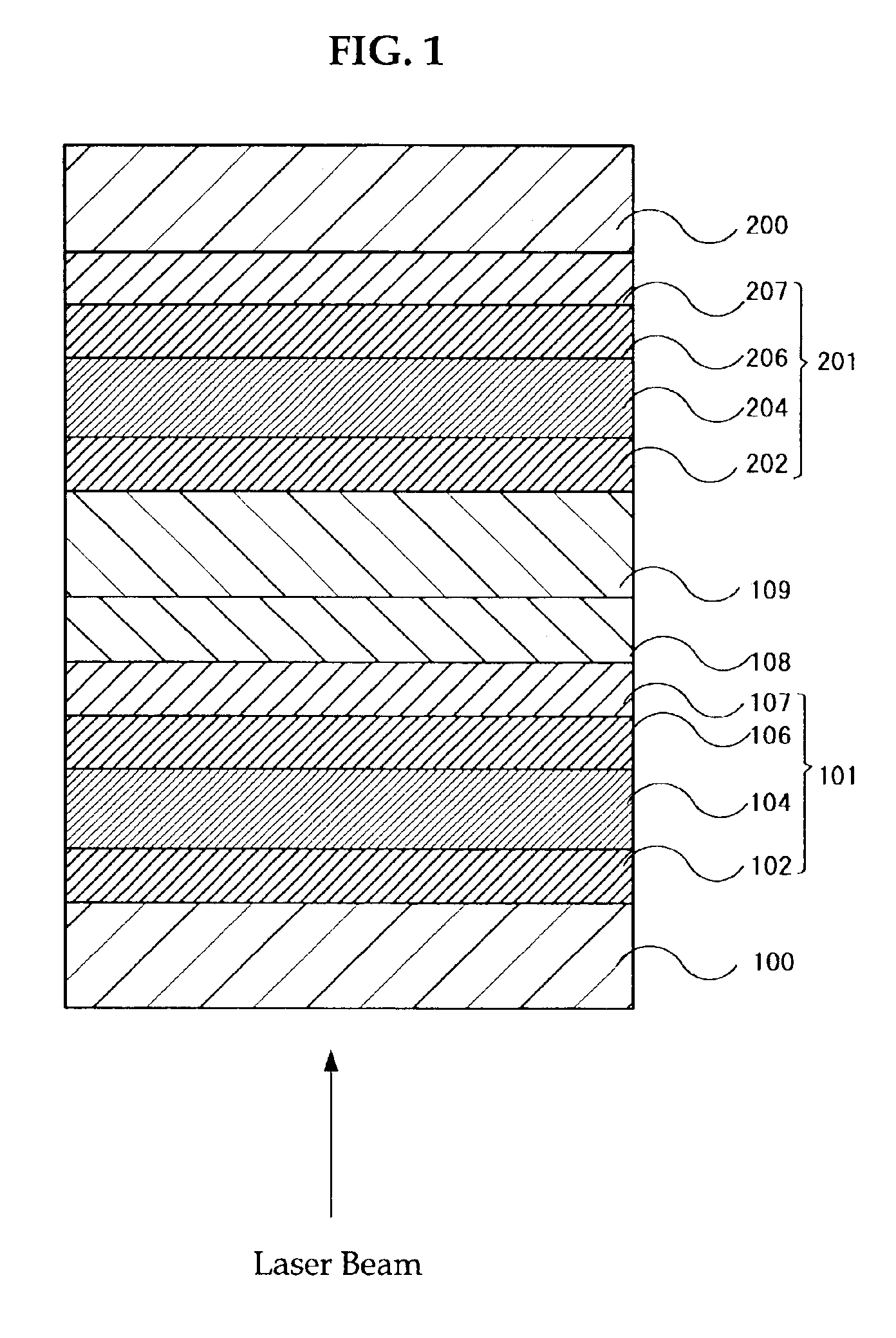

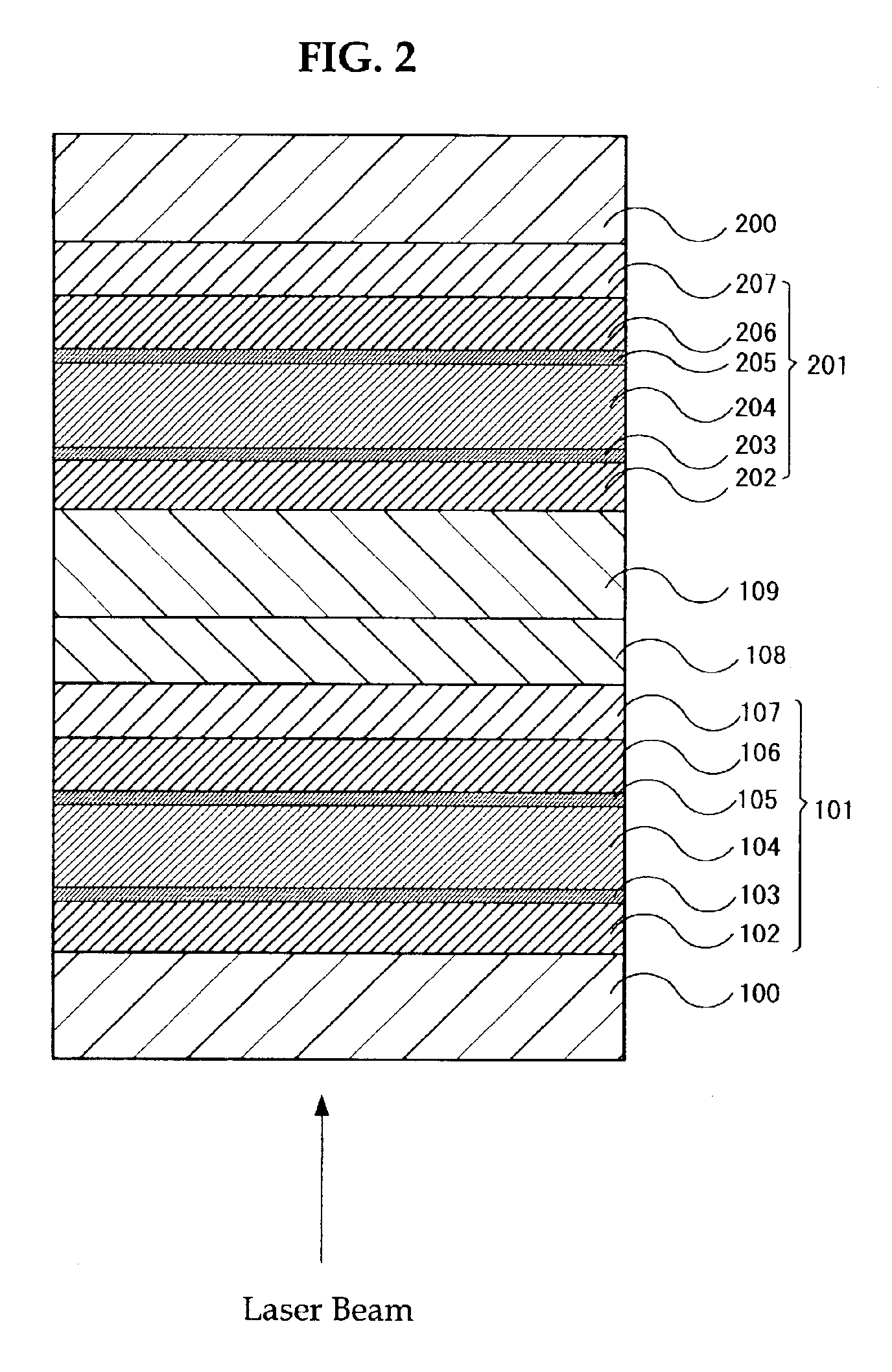

Optical recording medium and optical recording process using the same

InactiveUS7012878B2Twice more recording capacityImprove propertiesMechanical record carriersRecord information storageInter layerOptical recording

An optical recording medium having two recording layer structures which includes a cover substrate, a grooved substrate, a first recording layer structure, an intermediate layer, a separation layer, and a second recording layer structure. In the optical recording medium, the two recording layer structures include a first recording layer structure, and a second recording layer structure between the substrates, the first recording layer structure includes, in this order, a first protective layer, a first recording layer, a second protective layer, a first inorganic layer, the second recording layer structure includes, in this order, a third protective layer, a second recording layer, a forth protective layer, a second inorganic layer, and a ratio of a thickness of the first recording layer structure and a thickness of the intermediate layer is 0.2 to 1.0.

Owner:RICOH KK

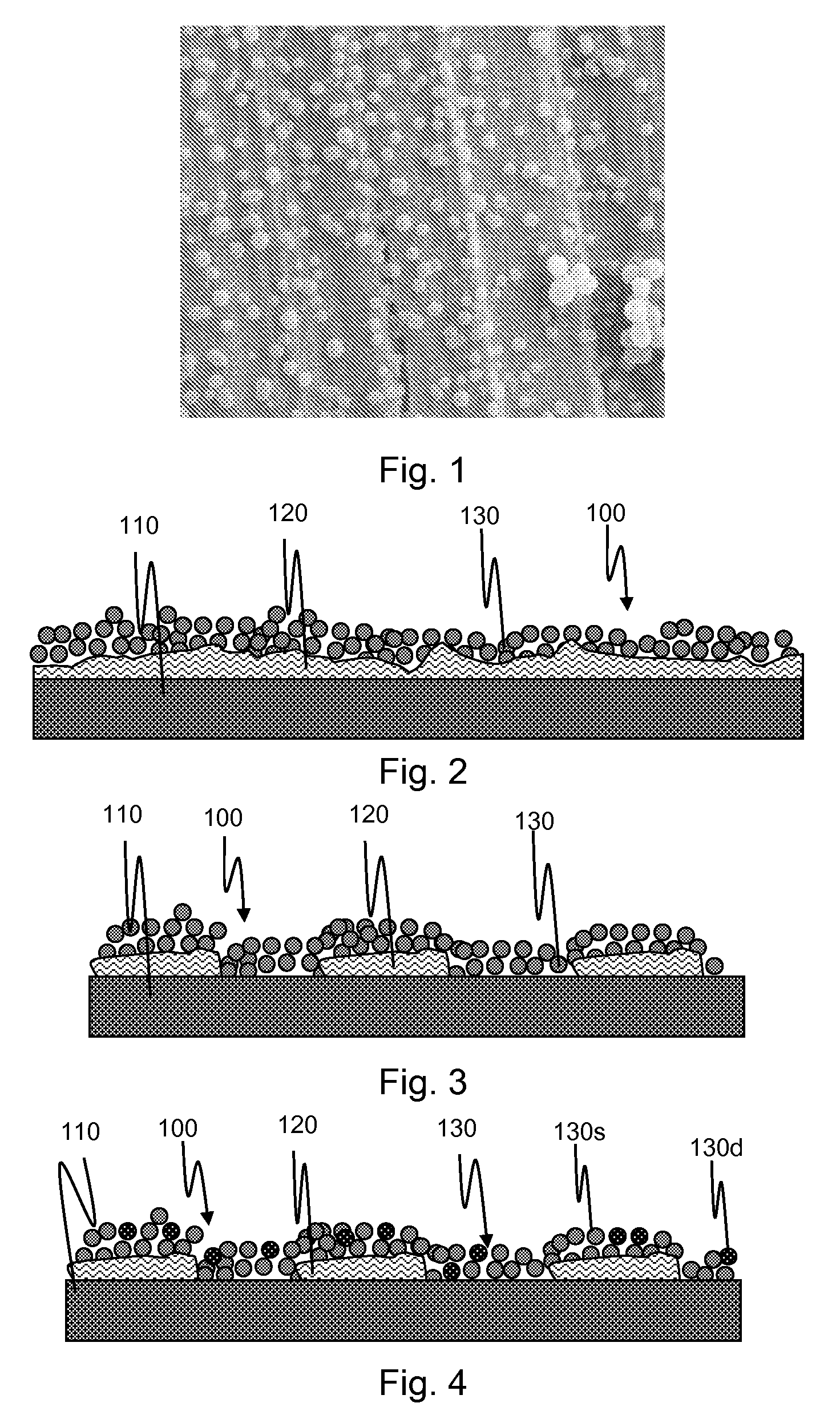

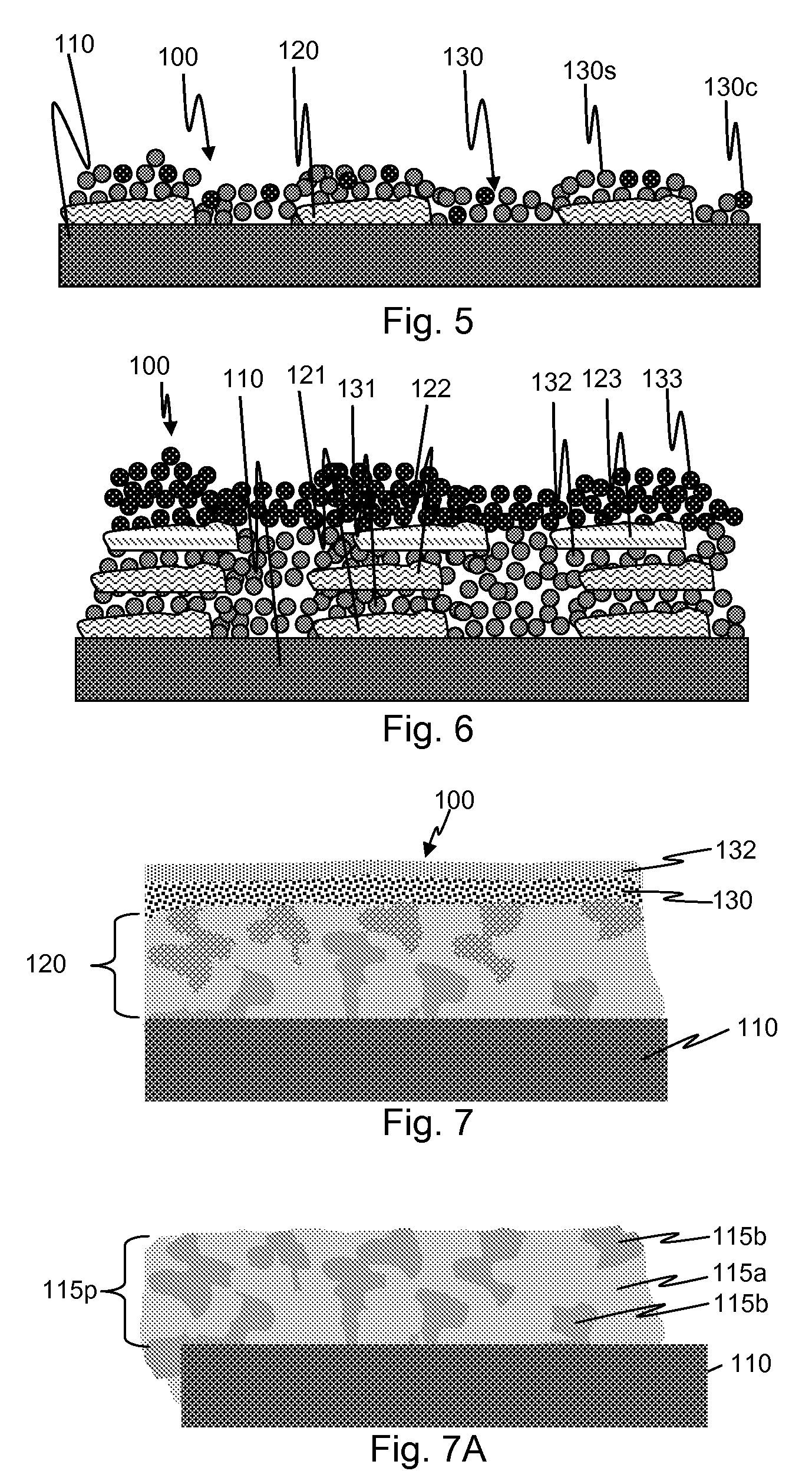

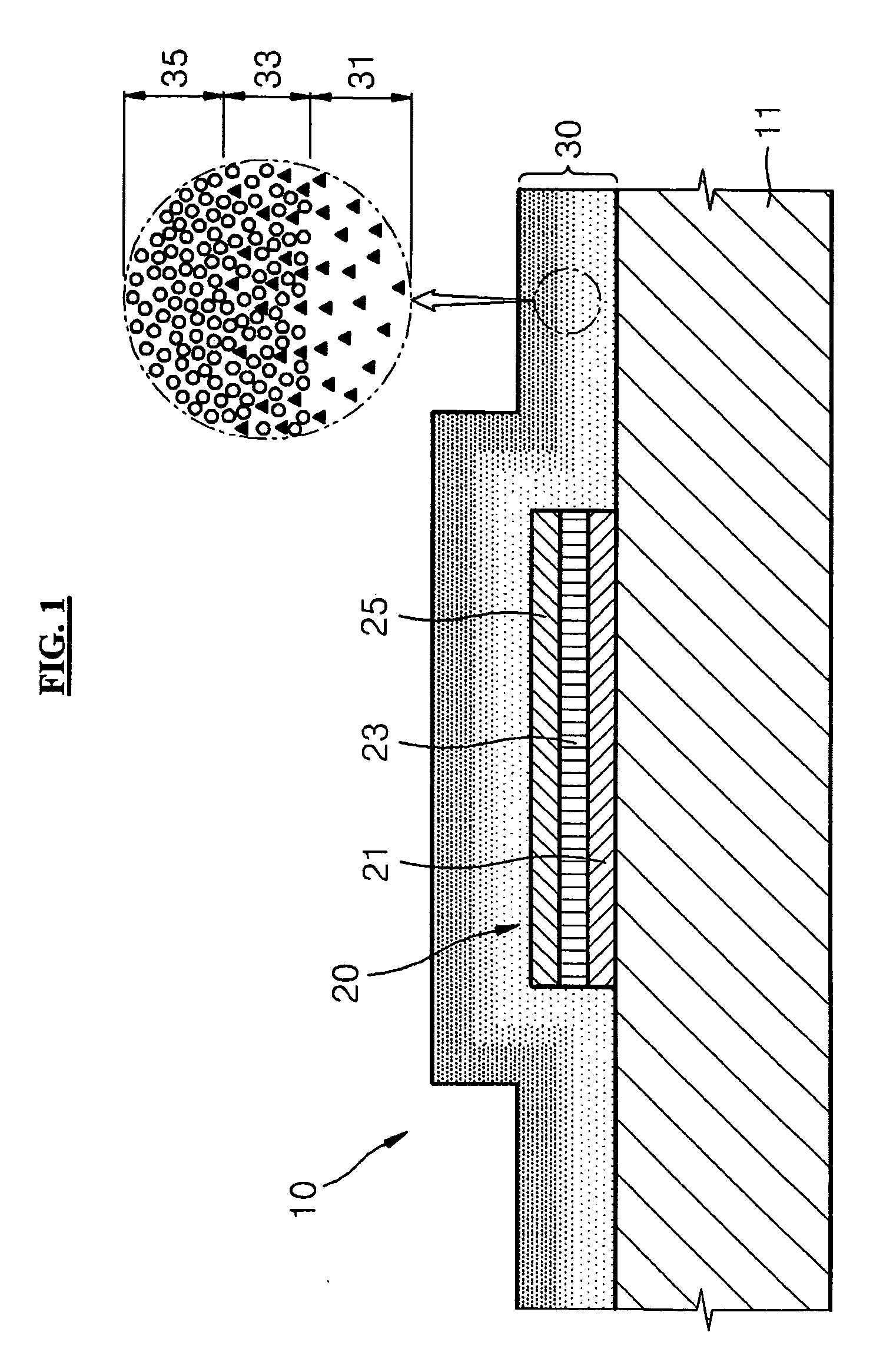

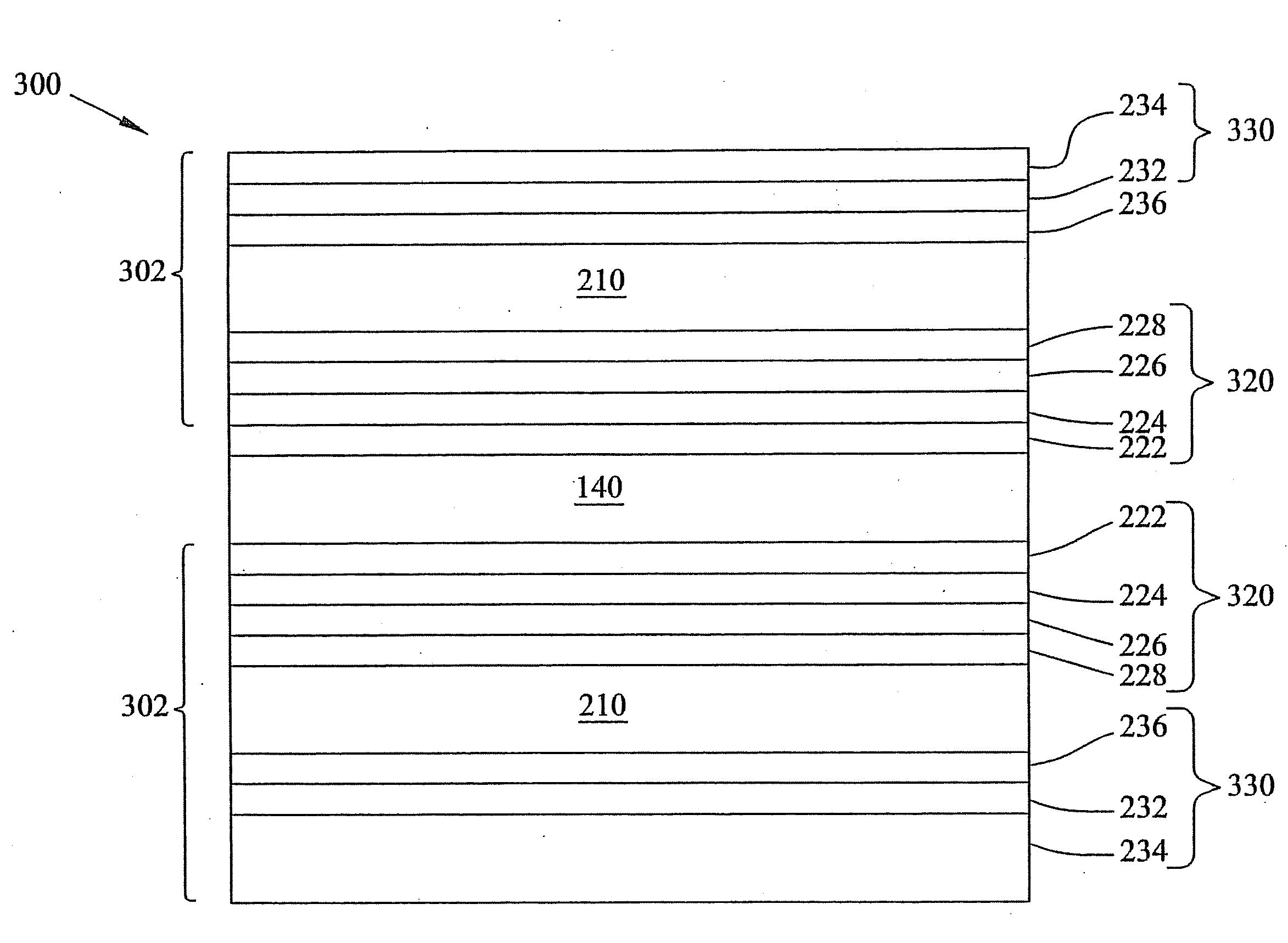

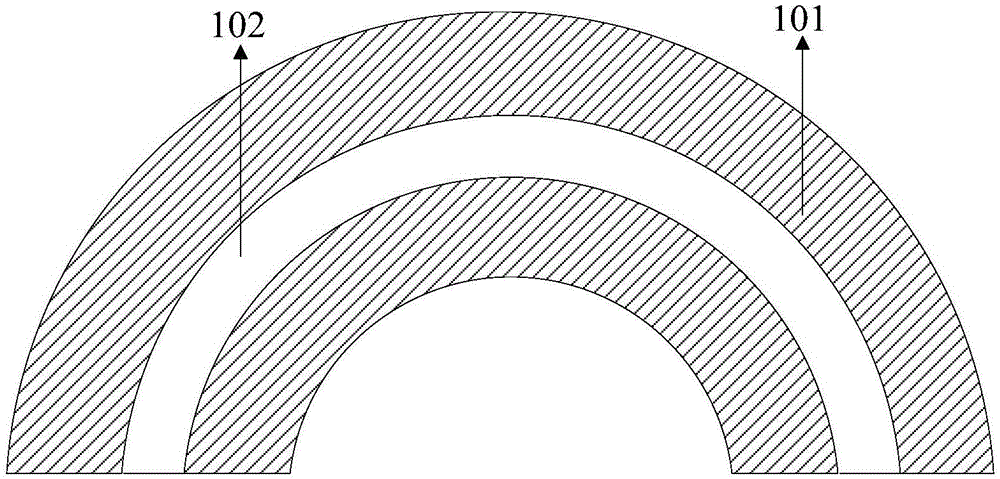

Multilayer barrier stacks and methods of making multilayer barrier stacks

InactiveUS20070281174A1Reduce harmAvoid damageFinal product manufactureVacuum evaporation coatingPolymerInorganic layer

An improved barrier stack. The barrier stack is made by the process of depositing the polymeric decoupling layer on a substrate; depositing a first inorganic layer on the decoupling layer under a first set of conditions wherein an ion and neutral energy arriving at the substrate is less than about 20 eV so that the first inorganic layer is not a barrier layer, wherein a temperature of the substrate is less than about 150° C.; and depositing a second inorganic layer on the first inorganic layer under a second set of conditions wherein an ion and neutral energy arriving at the substrate is greater than about 50 eV so that the second inorganic layer is a barrier layer. Methods of reducing damage to a polymeric layer in a barrier stack are also described.

Owner:SAMSUNG DISPLAY CO LTD

Multilayer coating package on flexible substrates for electro-optical devices

An electro-optical device having at least one base and a multilayer coating surface disposed on at least one surface of the base. The at least one base may comprise either an optically or electronically active portion or a flexible polymeric material. The multilayer coating set comprises at least one organic layer and at least one inorganic layer. The base and multilayer coating set are transparent. The multilayer coating set provides a barrier to moisture and oxygen and provides chemical resistance. The multilayer coating set is also mechanically flexible and thermally stable up to a glass transition temperature of the base.

Owner:BOE TECH GRP CO LTD

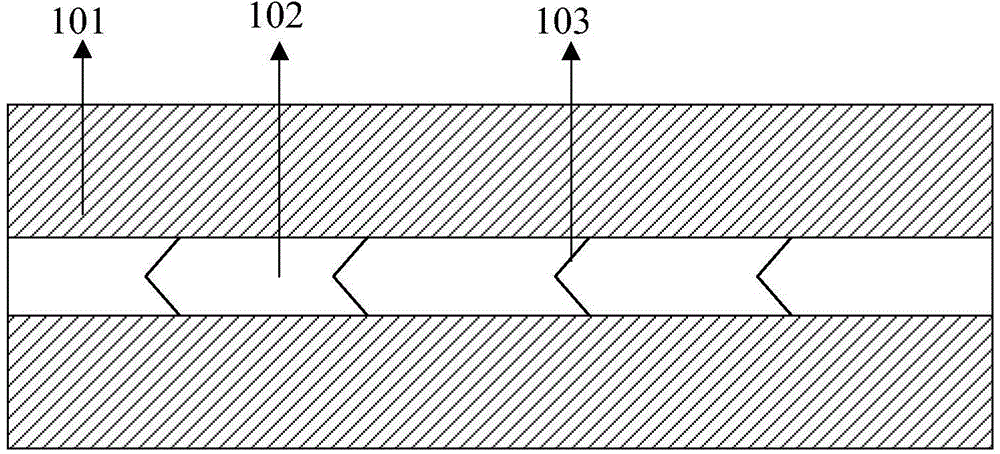

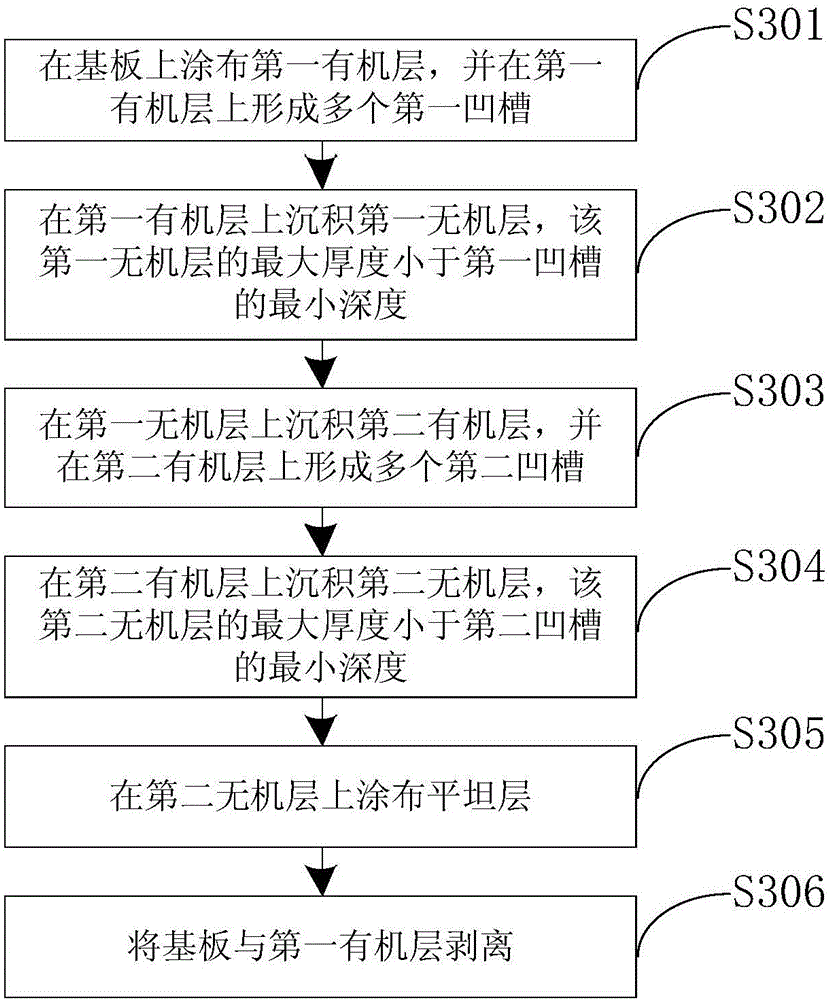

Barrier film, manufacturing method thereof and display device

ActiveCN104538425AAvoid stress concentrationReduced risk of breakageSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmStress concentration

The embodiment of the invention discloses a barrier film, a manufacturing method thereof and a display device. The barrier film comprises a first organic film layer and a second organic film layer, a first groove is formed in the first organic film layer, at least one inorganic film layer is arranged on the first organic film layer, the first groove is filled with the inorganic film layer, and the thickness of the inorganic film layer is smaller than or equal to the depth of the first groove; the second organic film layer is arranged on the inorganic film layer and is a flattened layer. Due to the fact that the thickness of the inorganic film layer is smaller than or equal to the depth of the first groove, an inorganic layer is discontinuous and does not located in the same layer, the phenomenon of stress concentration can be avoided in the bending process, and the risk that the inorganic layer is cracked is lowered.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Organic light emitting display device and method for manufacturing the same

ActiveUS20070267973A1Minimizing UV light damageEffective shieldingDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceInorganic materials

An organic light emitting display device, includes a substrate, at least one organic light emitting diode on the substrate, a functional layer including an opaque material and a light transmitting inorganic material, and an encapsulation layer on the organic light emitting diode, the encapsulation layer including at least one inorganic layer and at least one organic layer.

Owner:SAMSUNG DISPLAY CO LTD

Organic electroluminescent device

ActiveUS20080157656A1Effectively hinder moisture and oxygen from permeating through the sidewallsMaterial nanotechnologyDischarge tube luminescnet screensOxygenOrganic electroluminescence

An organic electroluminescent device. The organic electroluminescent device comprises a first barrier layer disposed on a substrate; organic electroluminescent elements disposed over the first barrier layer and encapsulated with a second barrier layer; and a getter layer disposed between the first and second barrier layers. Each of the first and second barrier layers includes an organic layer and an inorganic layer covering the top and sidewall surfaces of the organic layer, thus providing stacked inorganic sidewalls to hinder moisture and oxygen.

Owner:IND TECH RES INST

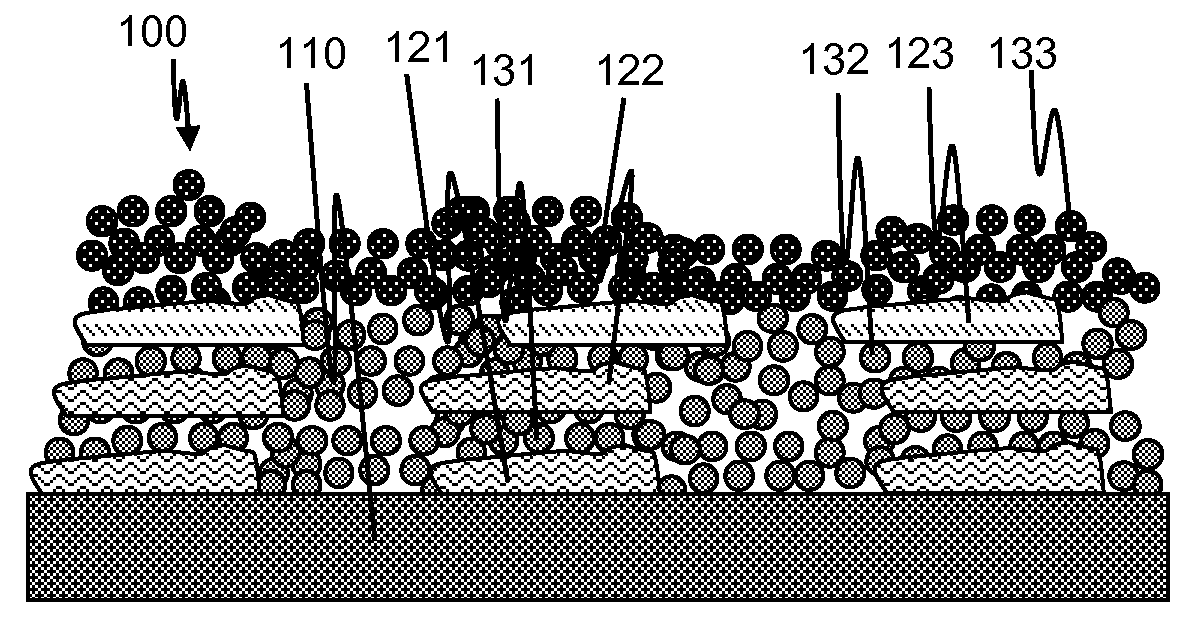

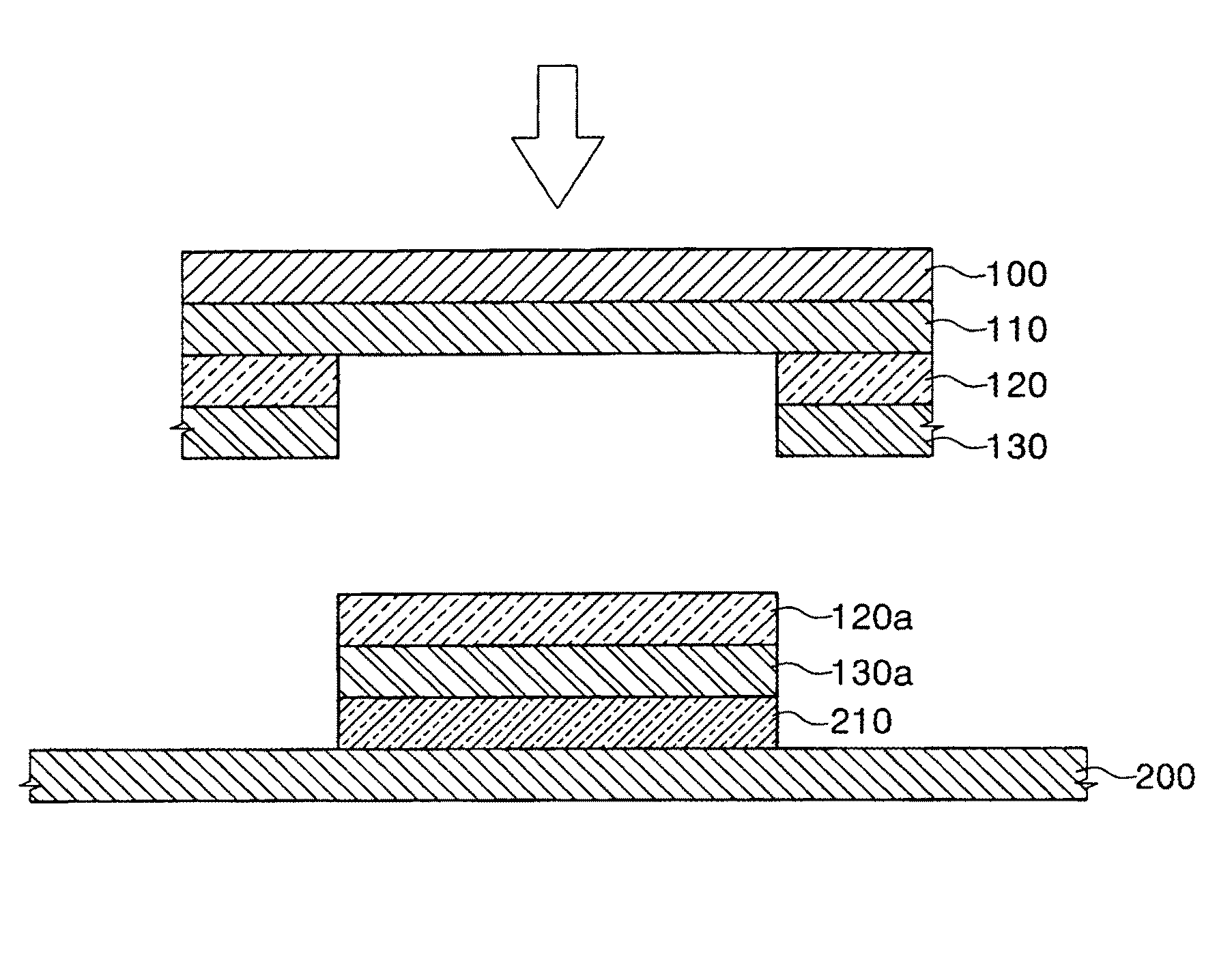

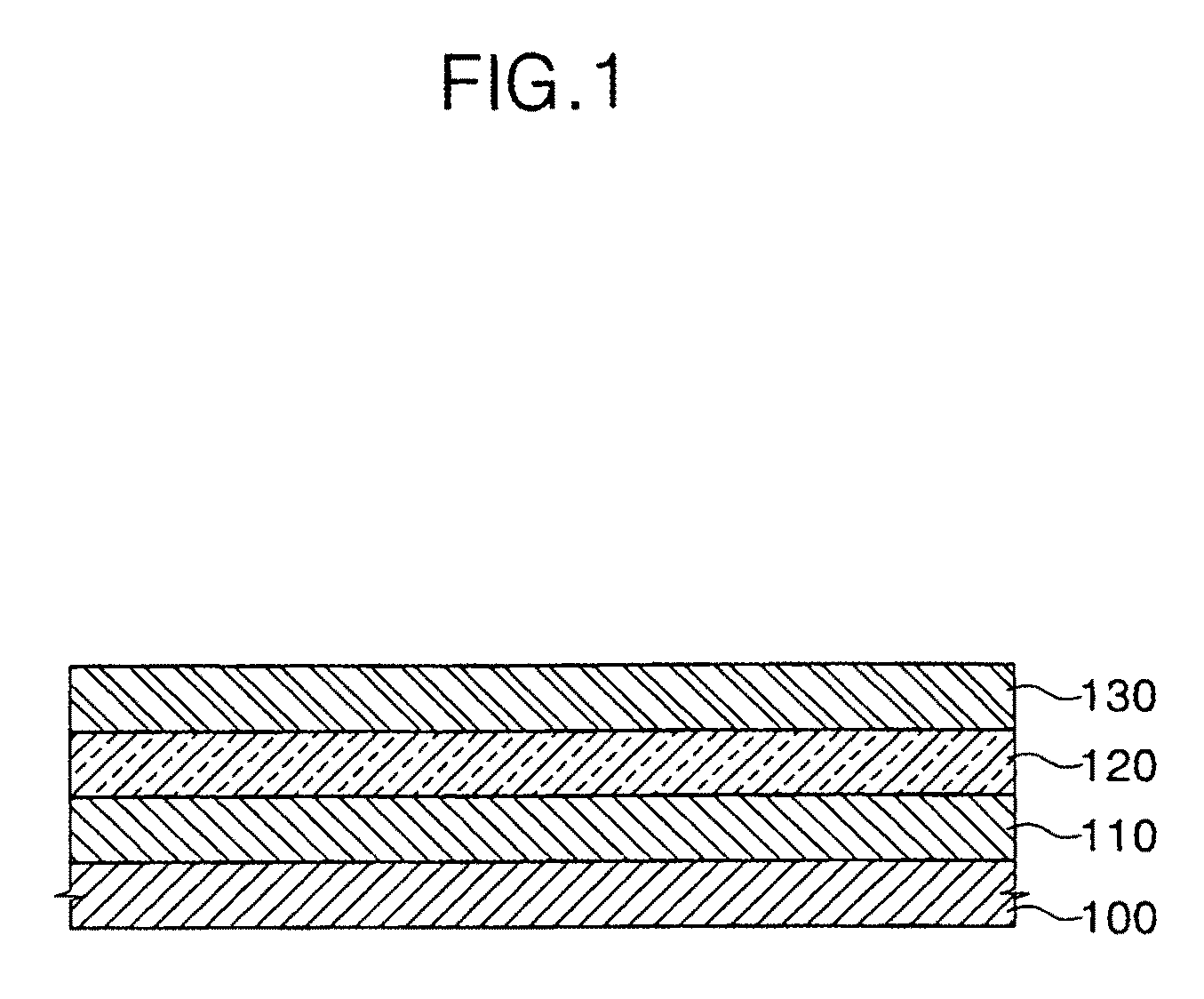

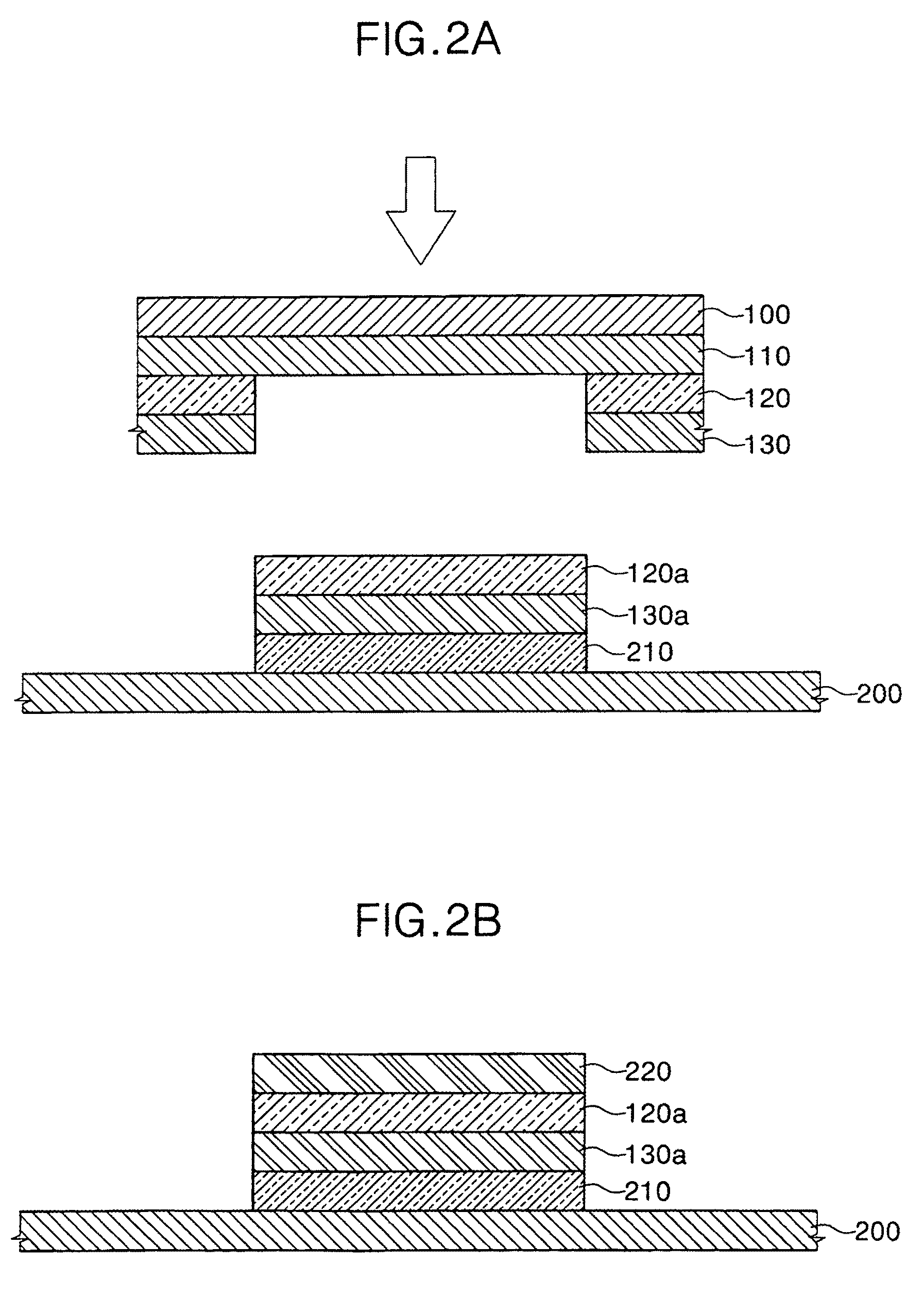

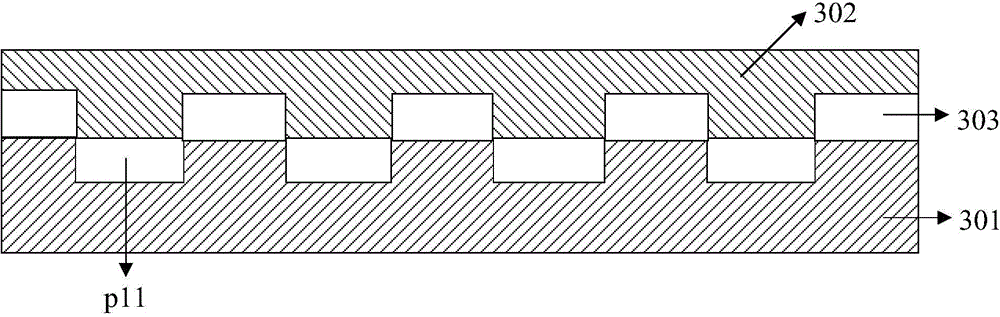

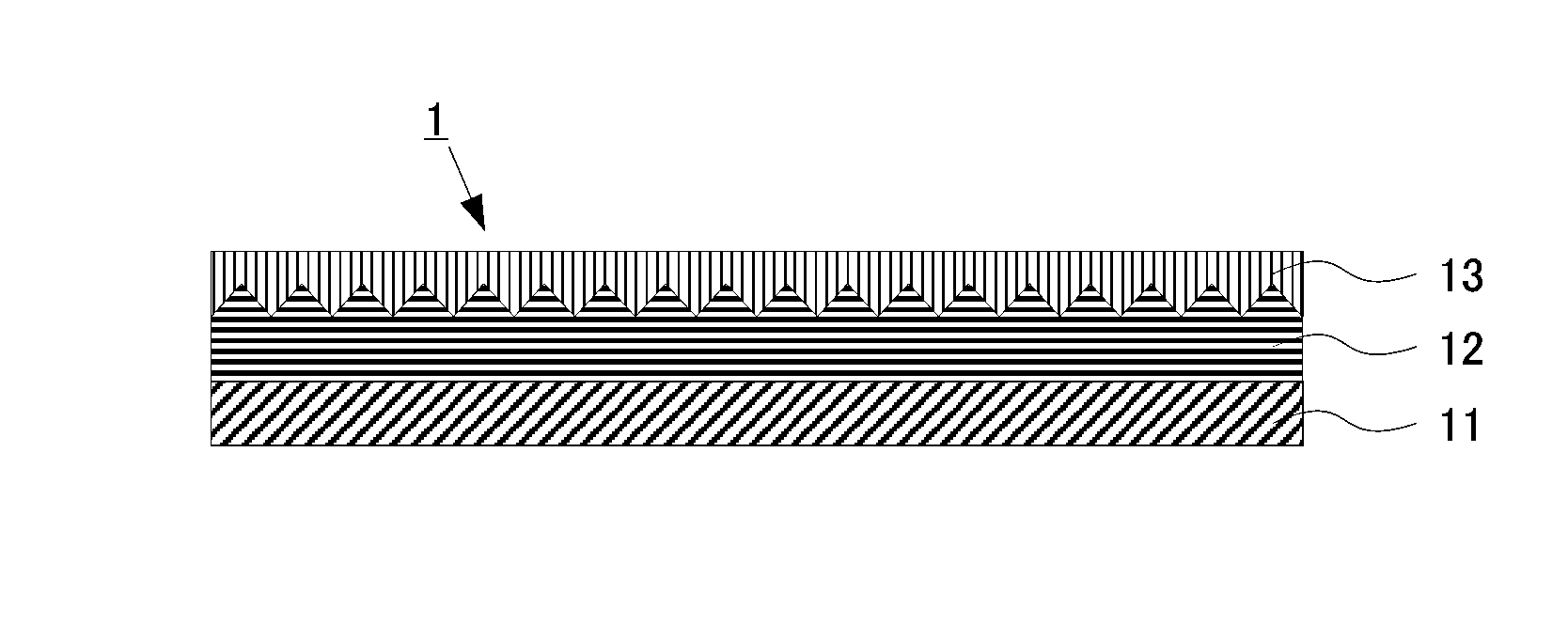

Fine-structure layered product, preparation method of the fine-structure layered product and manufacturing method of a fine-structure product

InactiveUS20130319522A1Increase resistanceImprove stabilitySynthetic resin layered productsSemiconductor/solid-state device manufacturingConvex structureWeather resistance

To provide a fine-structure layered product, and a preparation method of a fine-structure layered product using the fine-structure layered product for enabling a fine concavo-convex structure excellent in environmental resistance, weather resistance and long-term stability to be formed with a large area and high productivity, and provide a manufacturing method of a fine-structure product for enabling a large area to be made with high productivity, a fine-structure layered product of the invention is provided with a substrate, a resin layer that is formed on one main surface of the substrate and that has a fine concavo-convex structure on its surface, and an inorganic layer that is provided on the fine concavo-convex structure of the resin layer and that contains a sol-gel material having a fine concavo-convex structure in a shape associated with the fine concavo-convex structure of the resin layer, where a fluorine element concentration (Es) in a region on the inorganic layer side of the resin layer is higher than an average fluorine concentration (Eb) in the resin layer.

Owner:ASAHI KASEI KK

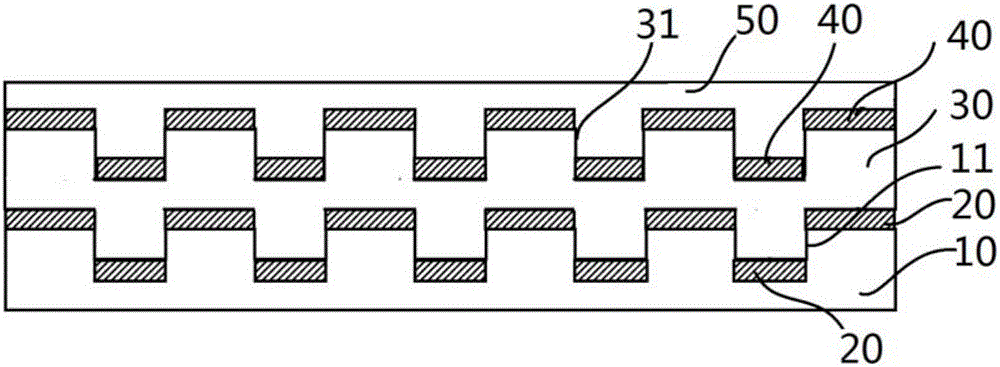

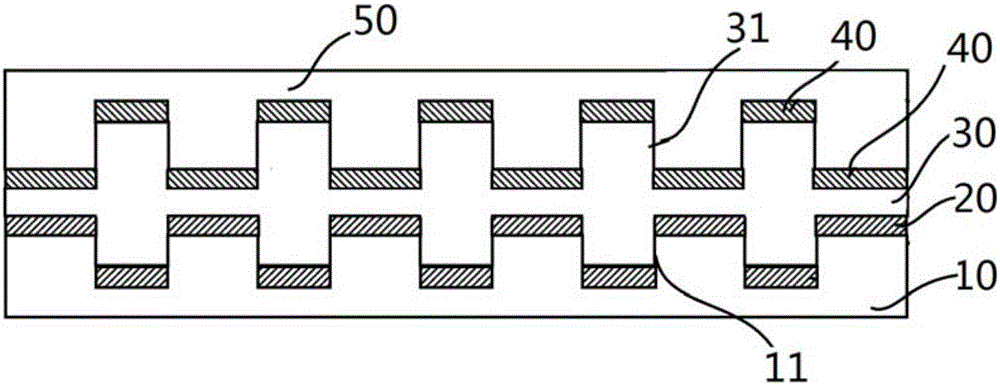

Laminated flexible substrate and production method

InactiveCN105702624AGood flexibilityImprove adhesionFinal product manufactureSynthetic resin layered productsOptoelectronicsInorganic layer

The invention provides a laminated flexible substrate and a production method. The production method comprises the following steps of coating a first organic layer on a substrate, and forming a plurality of first grooves on the first organic layer; depositing a first inorganic layer on the first organic layer, wherein the maximum thickness of the first inorganic layer is smaller than the minimum depth of the first grooves; depositing a second organic layer on the first inorganic layer, and forming a plurality of second grooves on the second organic layer; depositing a second inorganic layer on the second organic layer, wherein the maximum thickness of the second inorganic layer is smaller than the minimum depth of the second grooves; coating a flat bed on the second inorganic layer; and stripping the substrate from the first organic layer. According to the laminated flexible substrate and the production method which are provided by the invention, an adhesive force between the organic layers is increased, the possibility that a film surface falls off in the subsequent product process is reduced, and the probability that stresses are accumulated when the laminated flexible substrate is bent is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Organic light emitting diode display

ActiveUS20120256218A1Improve lighting efficiencyDiffusing elementsSolid-state devicesRefractive indexDisplay device

An organic light-emitting diode (OLED) display according to an exemplary embodiment may include: a substrate and an organic light emitting element on the substrate; a thin film encapsulation layer on the substrate and covering the organic light emitting element; and one or more scattering materials dispersed in the thin film encapsulation layer. According to the exemplary embodiment, light efficiency may be improved by dispersing scattering materials in at least one of an organic layer or an inorganic layer forming a thin film encapsulation layer with a large refractive index difference.

Owner:SAMSUNG DISPLAY CO LTD

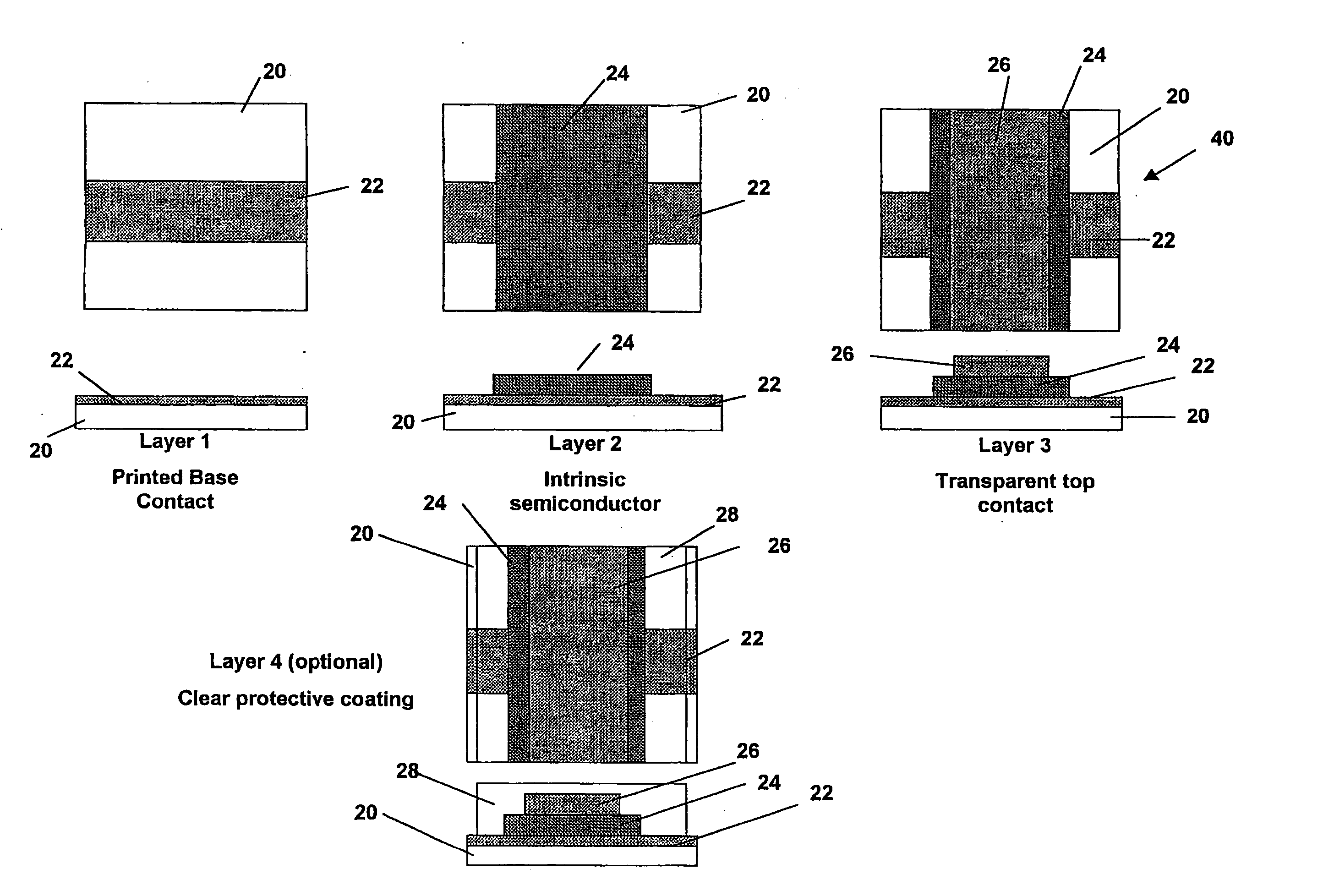

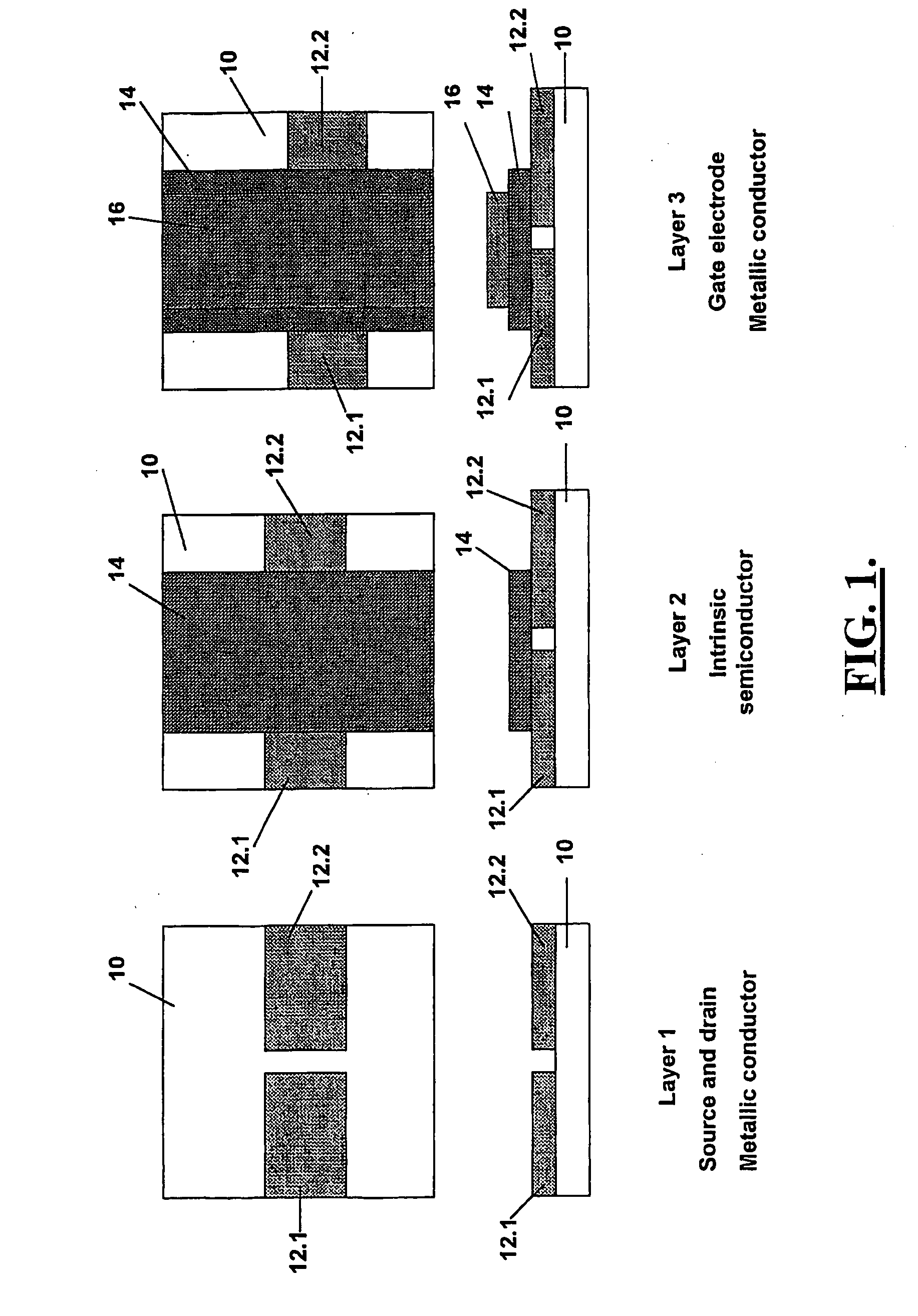

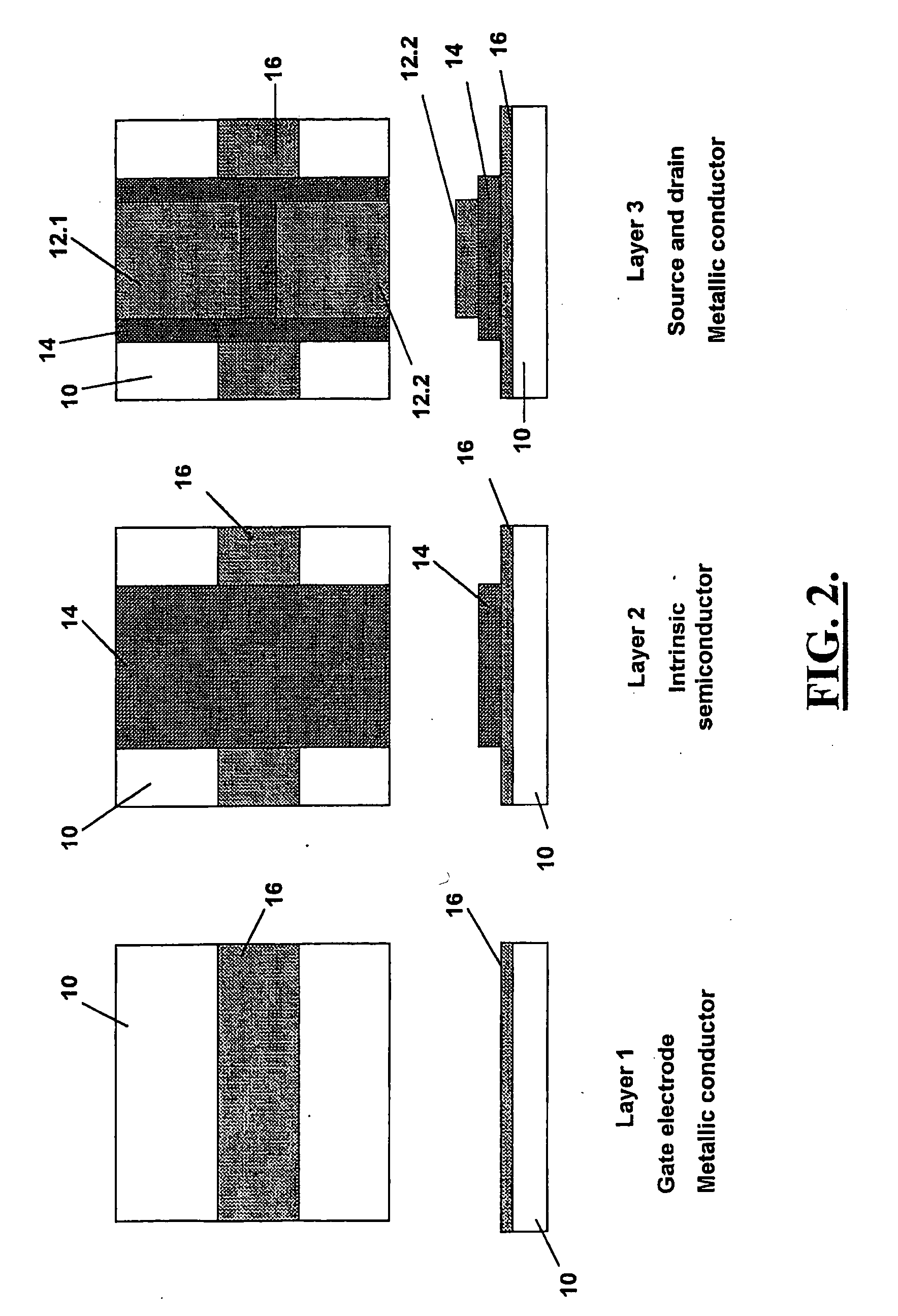

Thin film semiconductor device and method of manufacturing a thin film semiconductor device

A thin film semiconductor in the form of a metal semiconductor field effect transistor, includes a substrate 10 of paper sheet material and a number of thin film active inorganic layers that are deposited in layers on the substrate. The active layers are printed using an offset lithography printing process. A first active layer comprises source 12.1 and drain 12.2 conductors of colloidal silver ink, that are printed directly onto the paper substrate. A second active layer is an intrinsic semiconductor layer 14 of colloidal nanocrystalline silicon ink which is printed onto the first layer. A third active layer comprises a metallic conductor 16 of colloidal silver which is printed onto the second layer to form a gate electrode. This invention extends to other thin film semiconductors such as photovoltaic cells and to a method of manufacturing semiconductors.

Owner:PST SENSORS

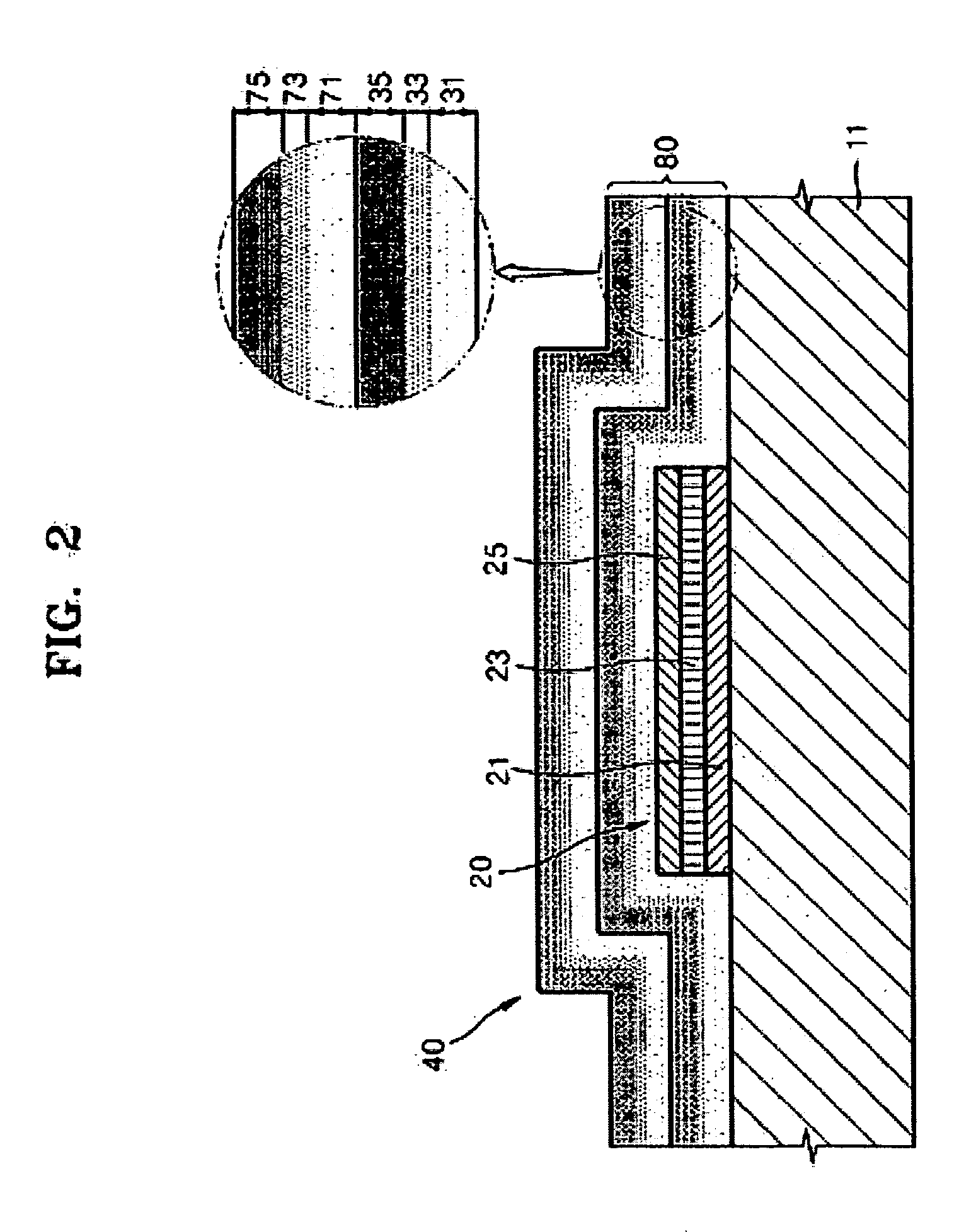

Deposition of non-isostructural layers for flexible substrate

InactiveUS20150159271A1Increase deposition rateImprove responseLayered productsChemical vapor deposition coatingReagentInorganic layer

A plurality of non-isostructural layers are deposited onto a substrate. An inorganic layer is deposited onto the substrate by adsorbing metal atoms to the substrate. The inorganic layer on the substrate is exposed to a hydrocarbon-containing source precursor to deposit a first hydrocarbon-containing layer by adsorbing the hydrocarbon-containing source precursor onto the inorganic layer. The first hydrocarbon-containing layer on the substrate is exposed to a reactant precursor to increase reactivity of the first hydrocarbon-containing layer on the substrate, and a second hydrocarbon-containing layer is deposited onto the first hydrocarbon-containing layer on the substrate. The process may be repeated to deposit the plurality of layers. The second hydrocarbon-containing layer may have higher hydrocarbon content and may be deposited at a higher deposition rate than the first hydrocarbon-containing layer.

Owner:VEECO ALD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com