Patents

Literature

3108results about How to "Avoid stress concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

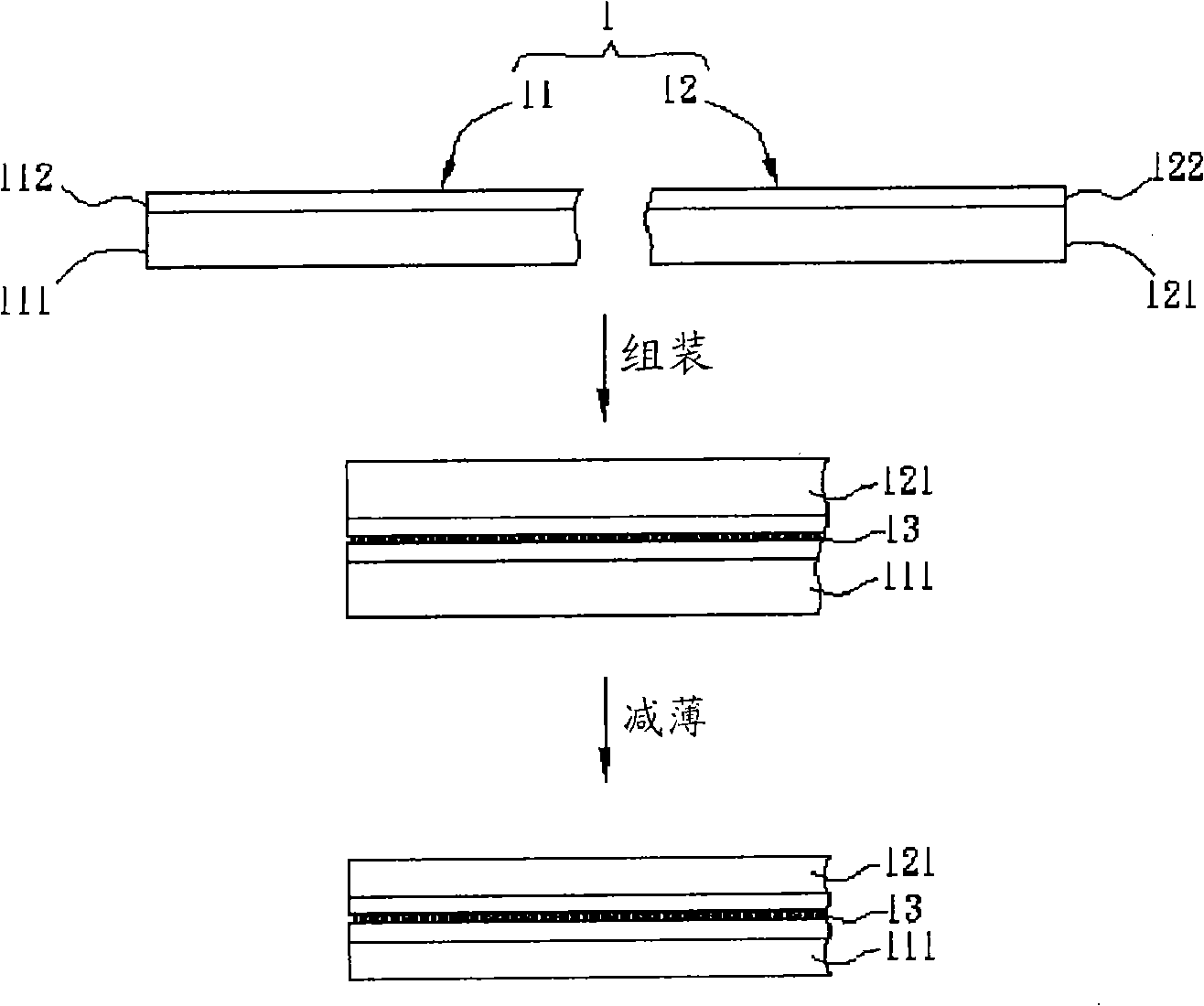

Display device and method of fabricating the same

InactiveUS20050070038A1Reduce weightAvoid stress concentrationSolid-state devicesSemiconductor/solid-state device manufacturingDriver circuitLiquid-crystal display

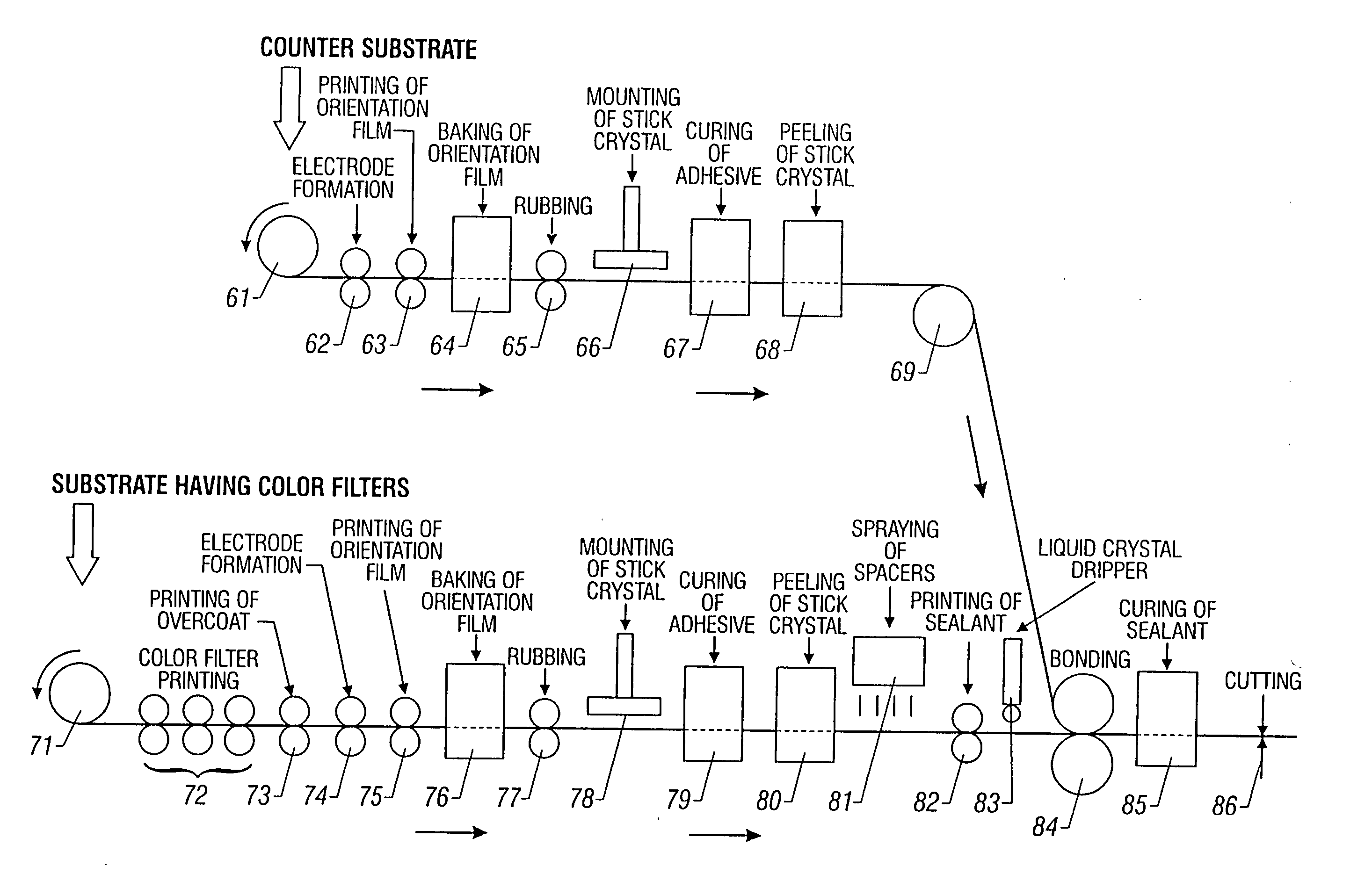

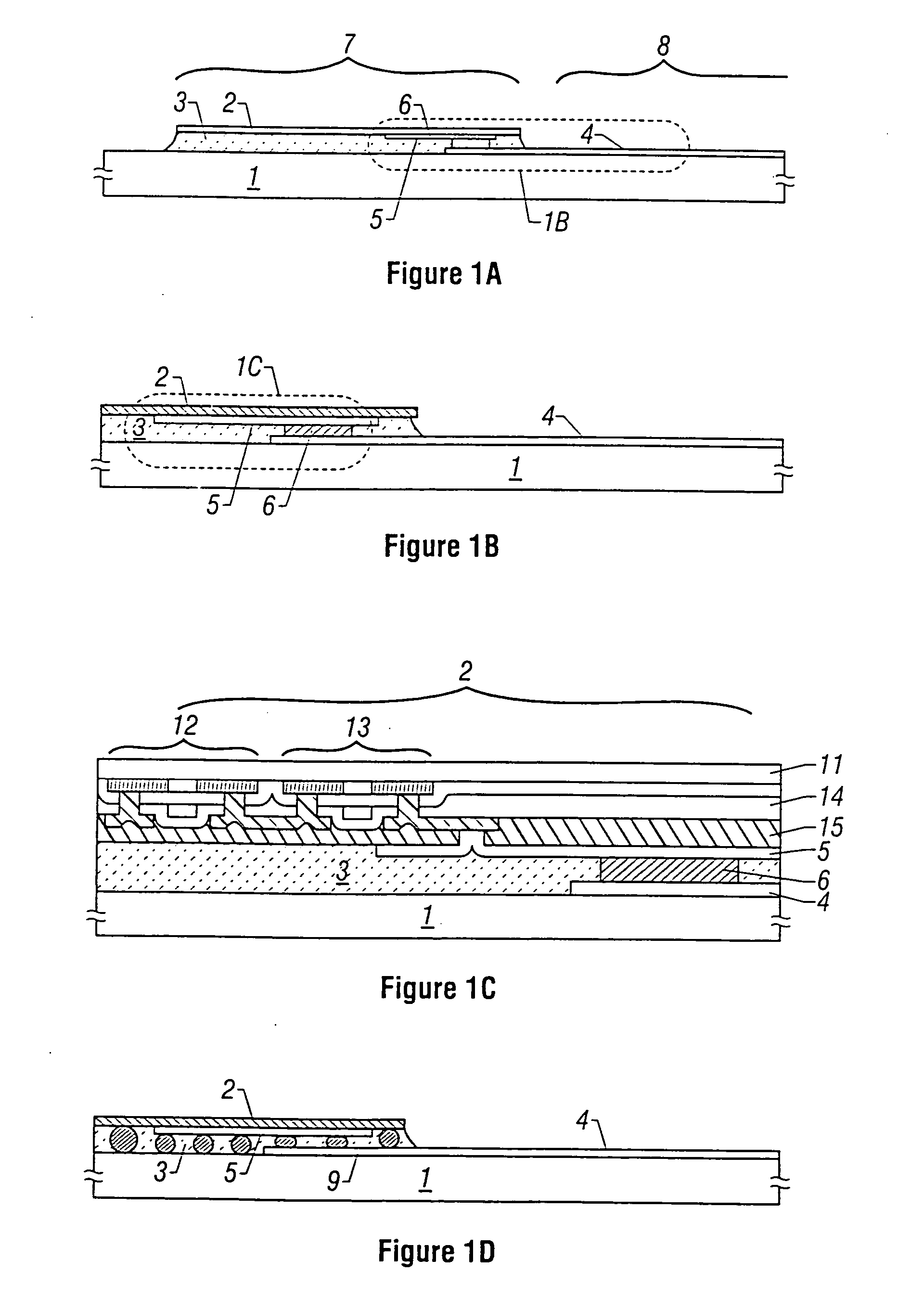

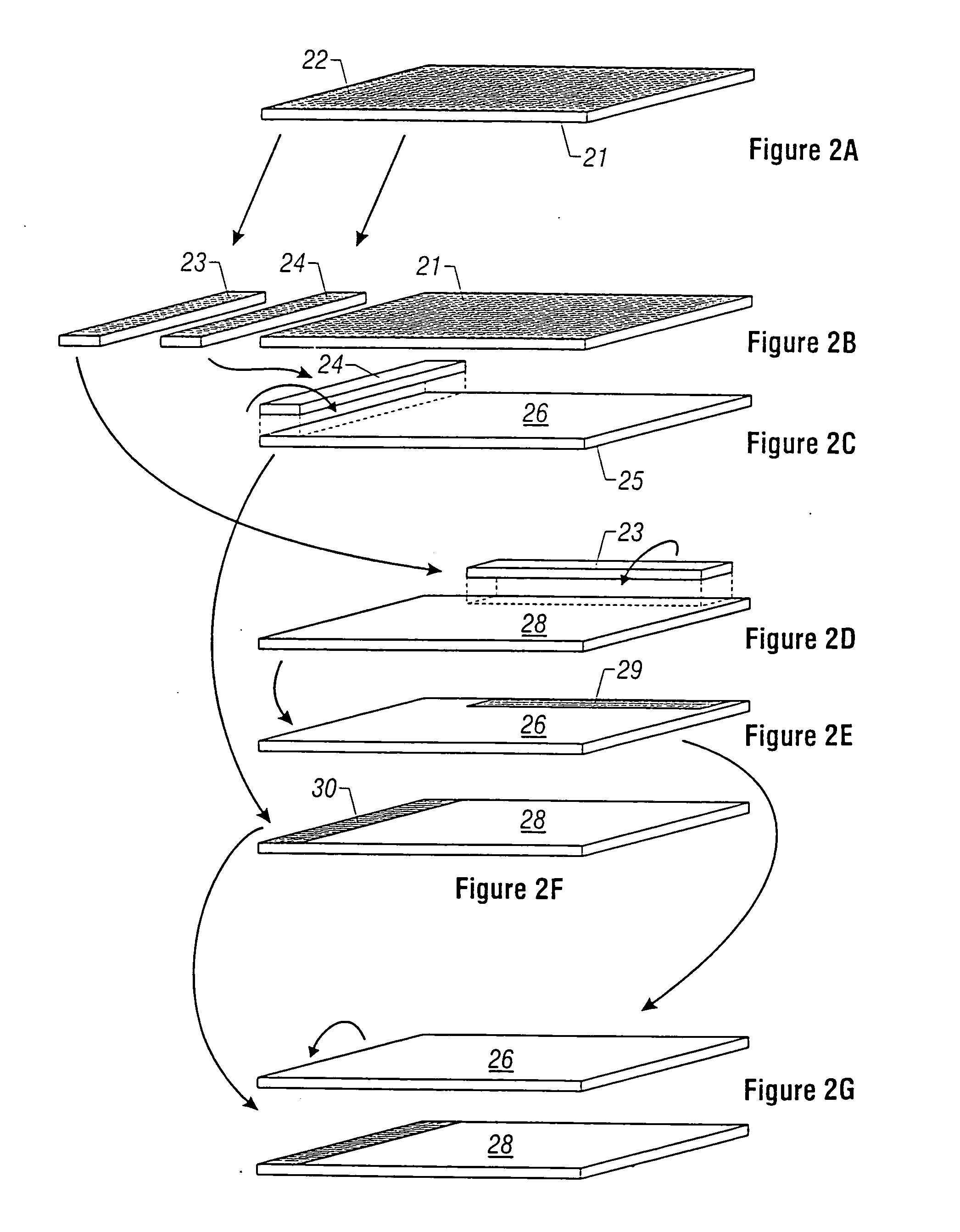

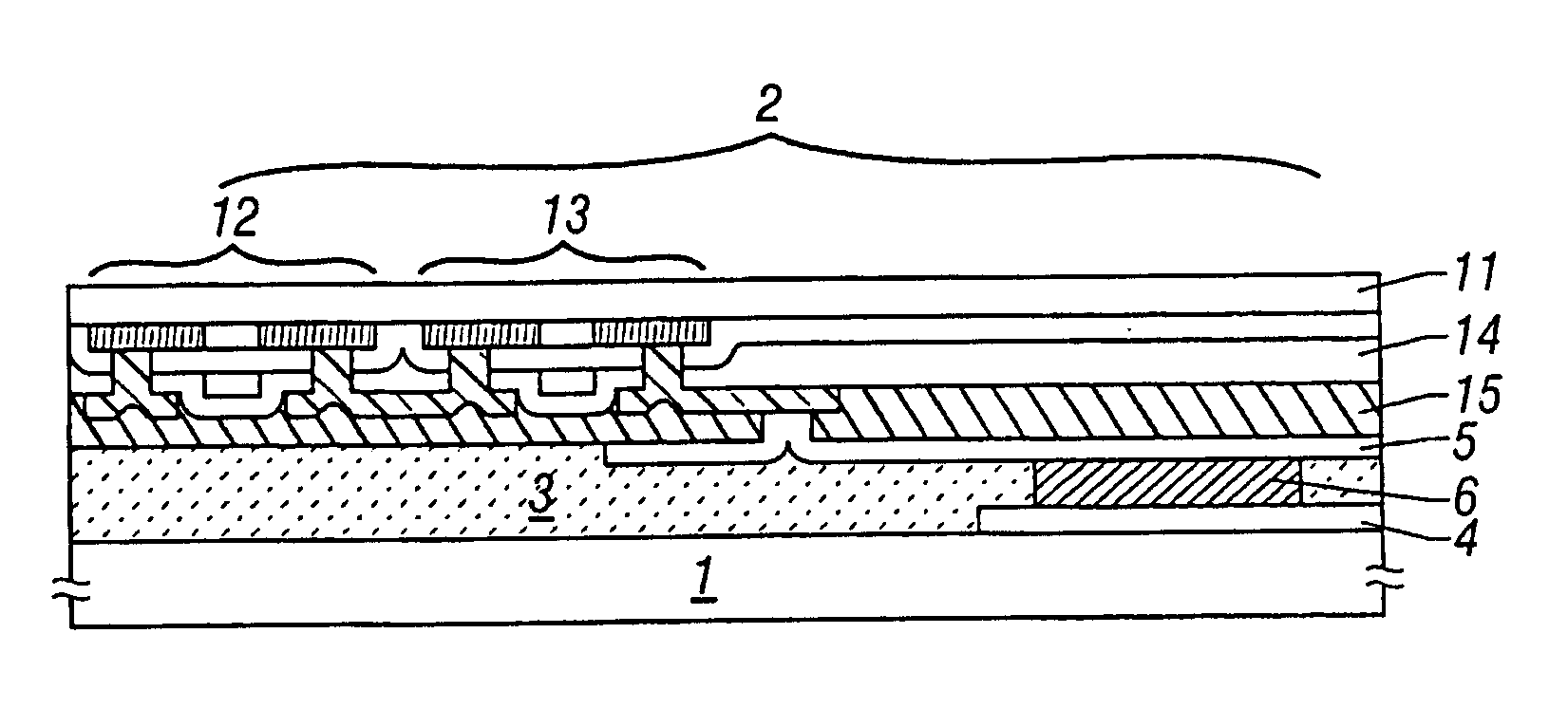

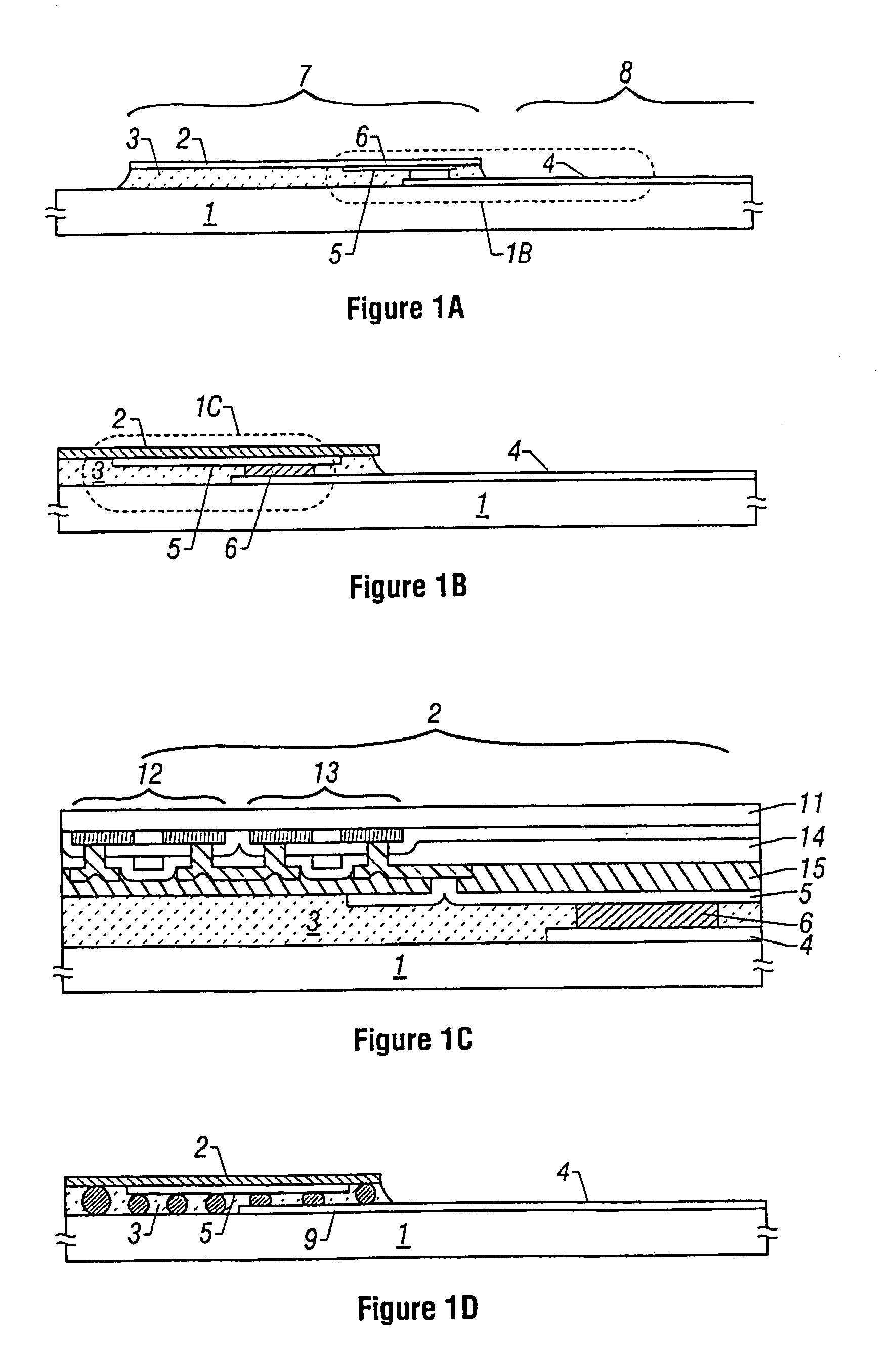

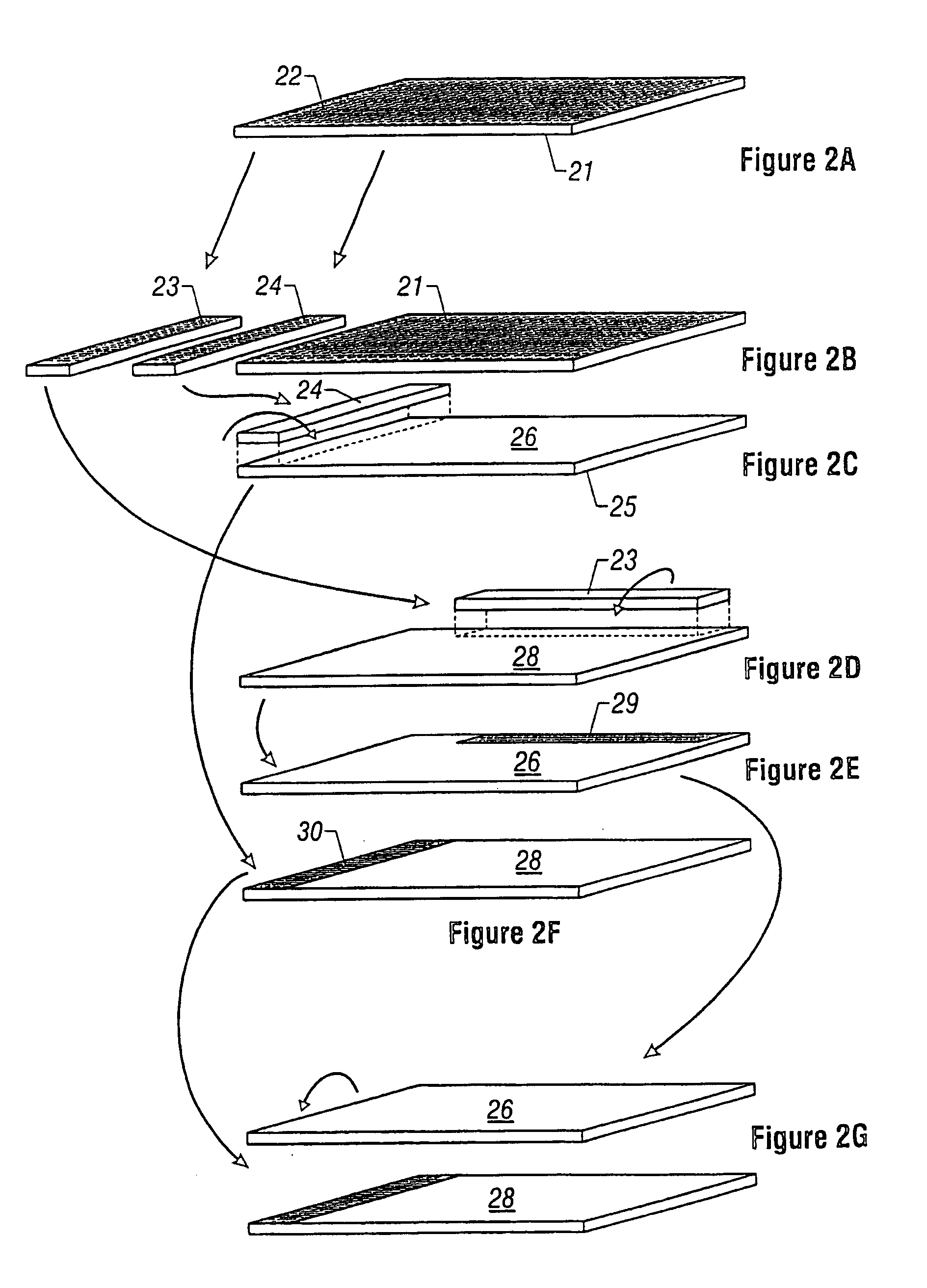

A method of fabricating a driver circuit for use with a passive matrix or active matrix electrooptical display device such as a liquid crystal display. The driver circuit occupies less space than heretofore. A circuit (stick crystal) having a length substantially equal to the length of one side of the matrix of the display device is used as the driver circuit. The circuit is bonded to one substrate of the display device, and then the terminals of the circuit are connected with the terminals of the display device. Subsequently, the substrate of the driver circuit is removed. This makes the configuration of the circuit much simpler than the configuration of the circuit heretofore required by the TAB method or COG method, because conducting lines are not laid in a complex manner. The driver circuit can be formed on a large-area substrate such as a glass substrate. The display device can be formed on a lightweight material having a high shock resistance such as a plastic substrate. Hence, a display device having excellent portability can be obtained.

Owner:YAMAZAKI SHUNPEI +3

Method of manufacturing a display device having a driver circuit attached to a display substrate

InactiveUS7050138B1Reduce weightAvoid stress concentrationSolid-state devicesSemiconductor/solid-state device manufacturingDriver circuitLiquid-crystal display

Owner:SEMICON ENERGY LAB CO LTD

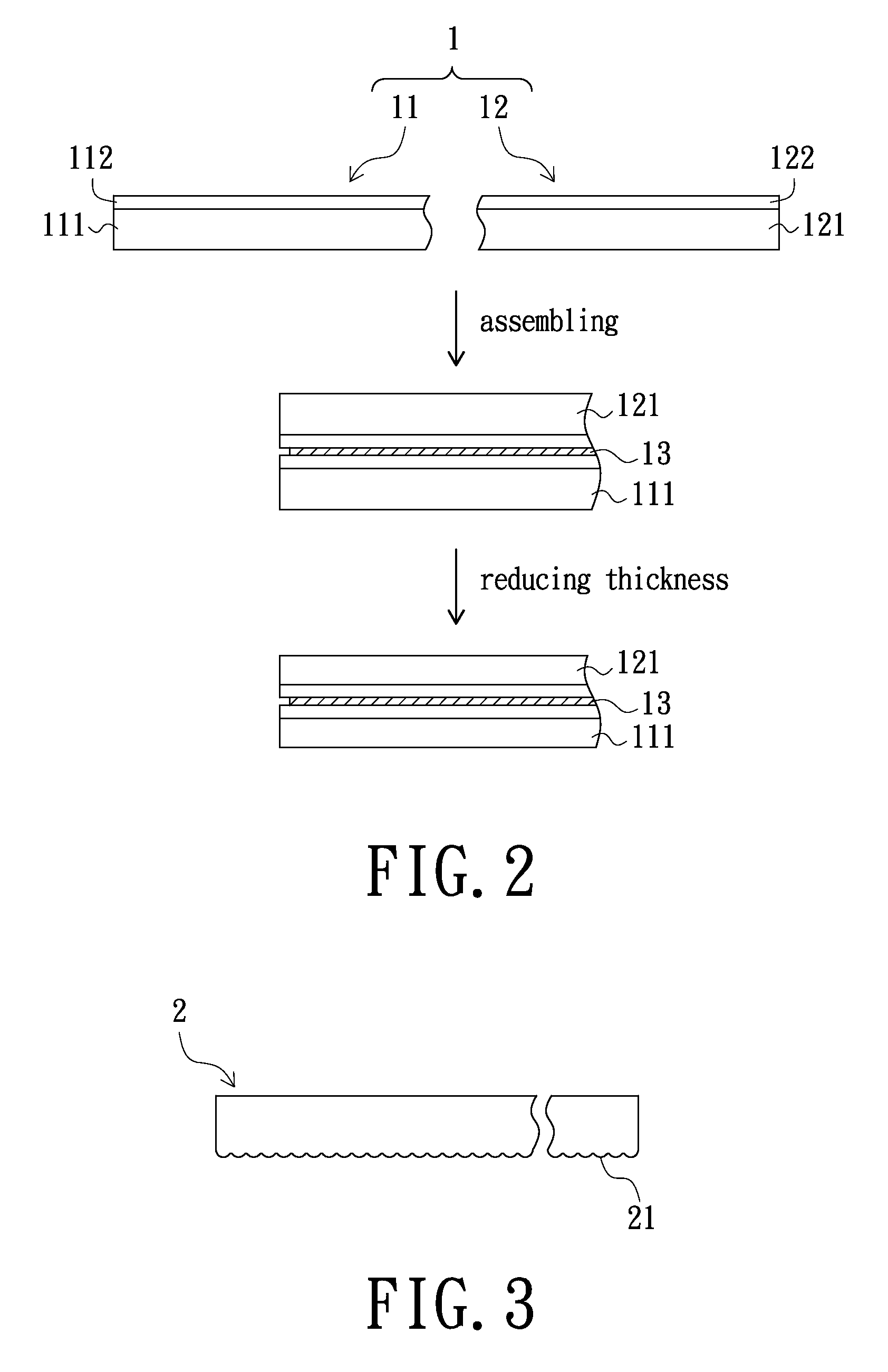

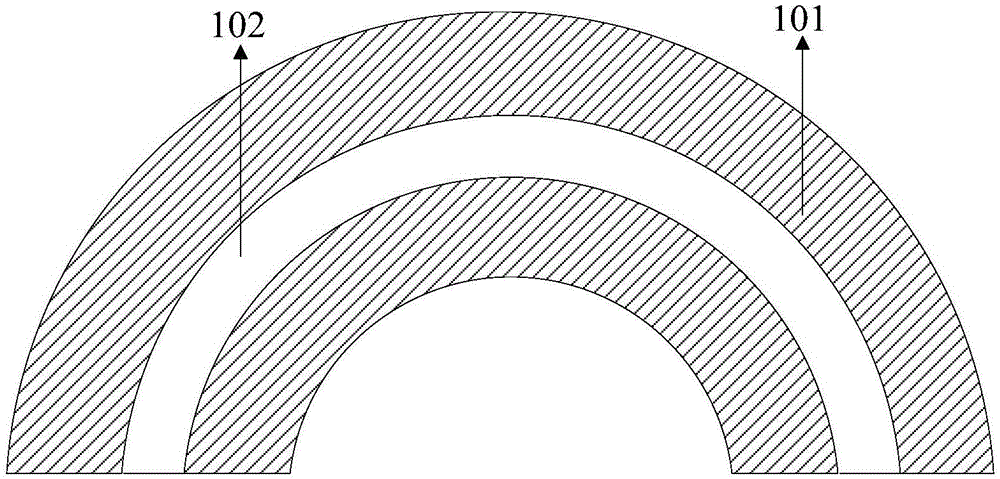

Curved display panel and method for manufacturing the same

ActiveUS8305743B2Improve production yieldIncrease stickinessDisposition/mounting of recording headsDigital data processing detailsEngineeringGlass sheet

Owner:OPTRONIC SCI LLC

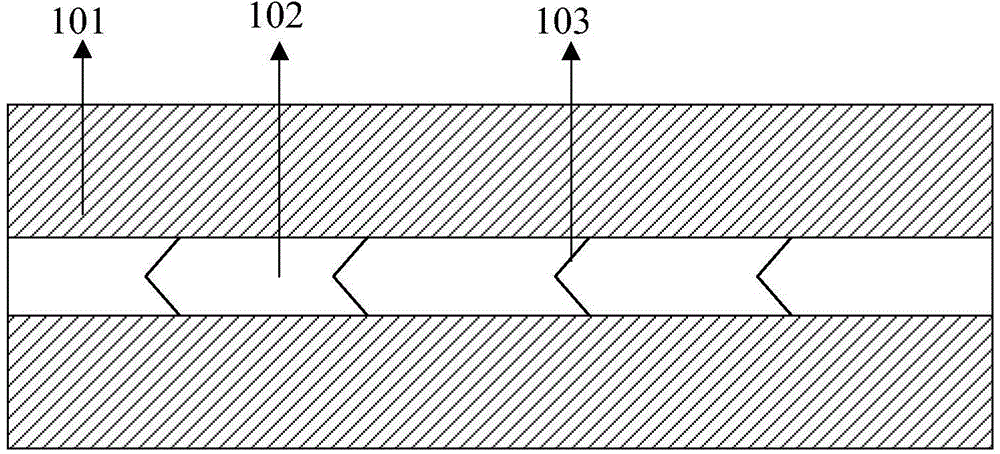

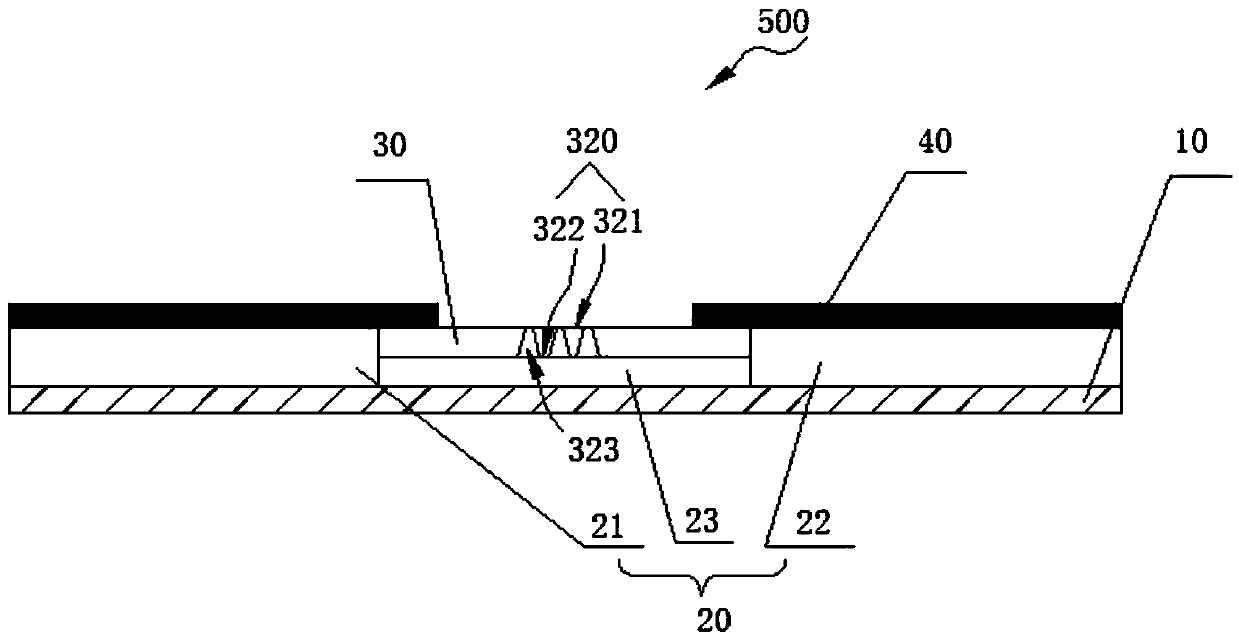

Barrier film, manufacturing method thereof and display device

ActiveCN104538425AAvoid stress concentrationReduced risk of breakageSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmStress concentration

The embodiment of the invention discloses a barrier film, a manufacturing method thereof and a display device. The barrier film comprises a first organic film layer and a second organic film layer, a first groove is formed in the first organic film layer, at least one inorganic film layer is arranged on the first organic film layer, the first groove is filled with the inorganic film layer, and the thickness of the inorganic film layer is smaller than or equal to the depth of the first groove; the second organic film layer is arranged on the inorganic film layer and is a flattened layer. Due to the fact that the thickness of the inorganic film layer is smaller than or equal to the depth of the first groove, an inorganic layer is discontinuous and does not located in the same layer, the phenomenon of stress concentration can be avoided in the bending process, and the risk that the inorganic layer is cracked is lowered.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

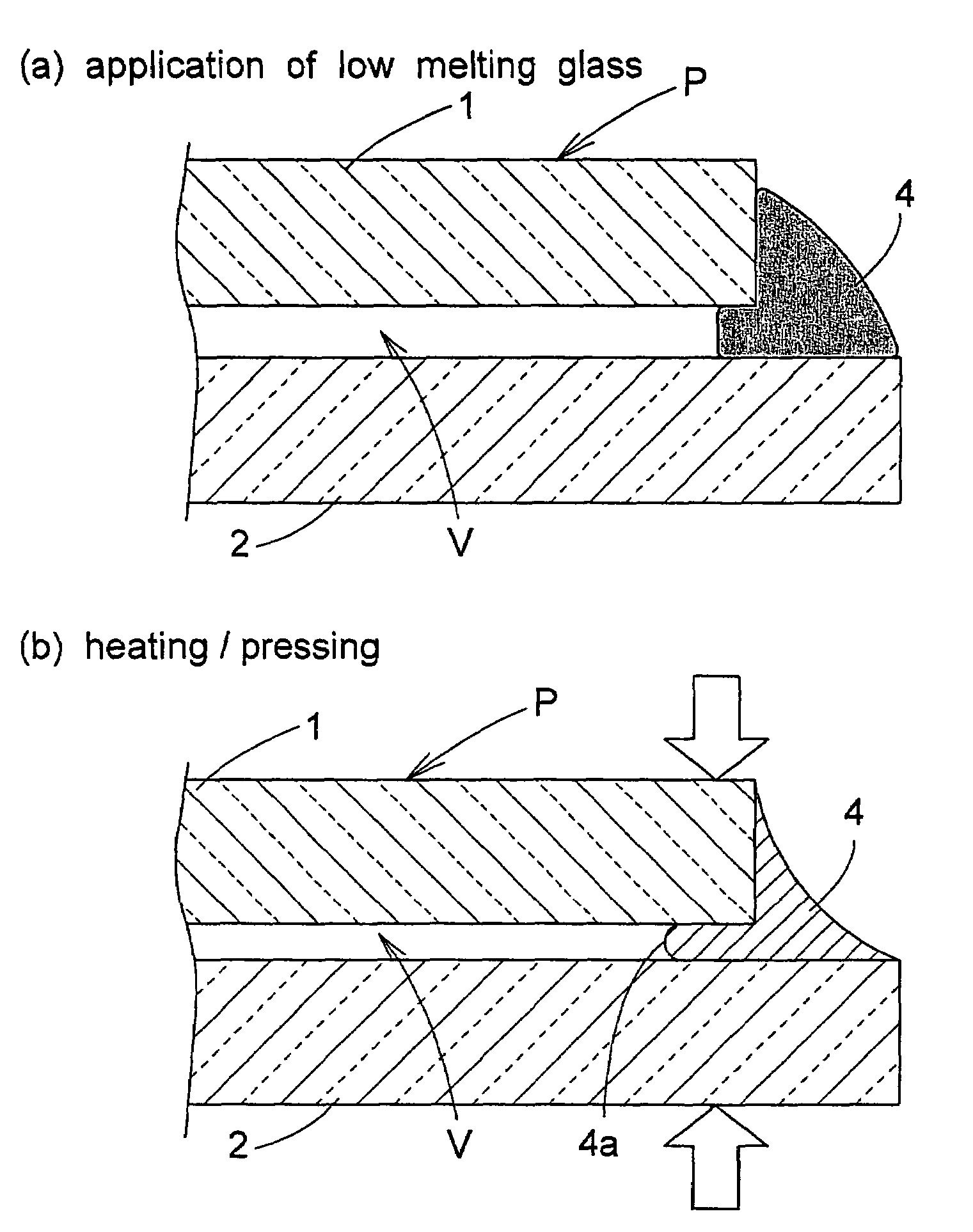

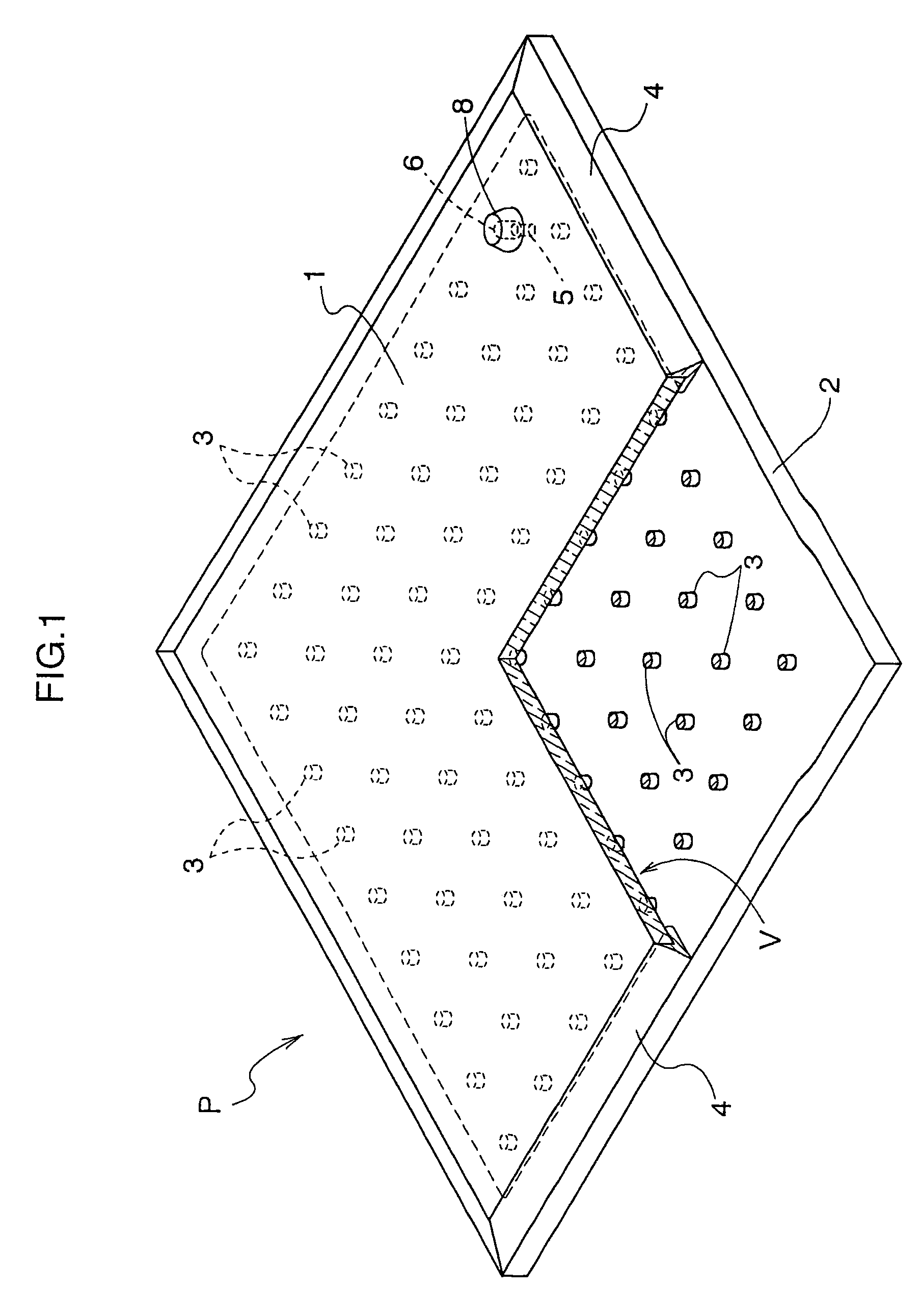

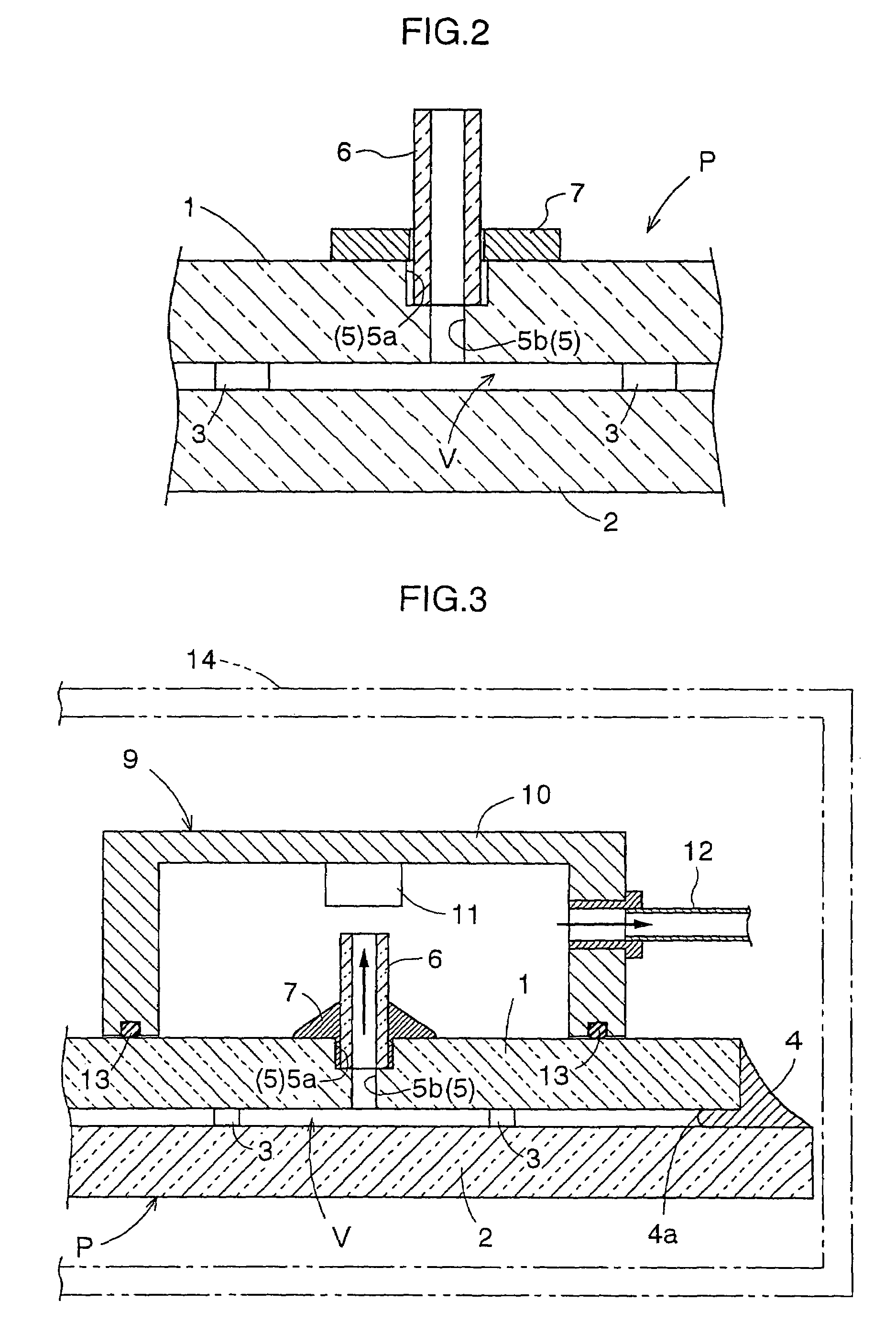

Glass panel

InactiveUS7244480B2Improve insulation effectHigh strengthDoors/windowsClimate change adaptationGlass sheetElectrical and Electronics engineering

A glass panel comprising: a pair of glass sheets (1), (2) disposed in opposition to each other via a gap (V) therebetween, peripheral edges of the two glass sheets (1), (2) being bonded with low melting glass (4) for sealing the gap (V);wherein in a cross section substantially normal to faces of the two glass sheets, (1), (2), an adjacent face (4a) of the low melting glass (4) adjacent the gap (V) has a center portion thereof between the two glass sheets (1), (2) bulging toward the gap (V).

Owner:NIPPON SHEET GLASS CO LTD +1

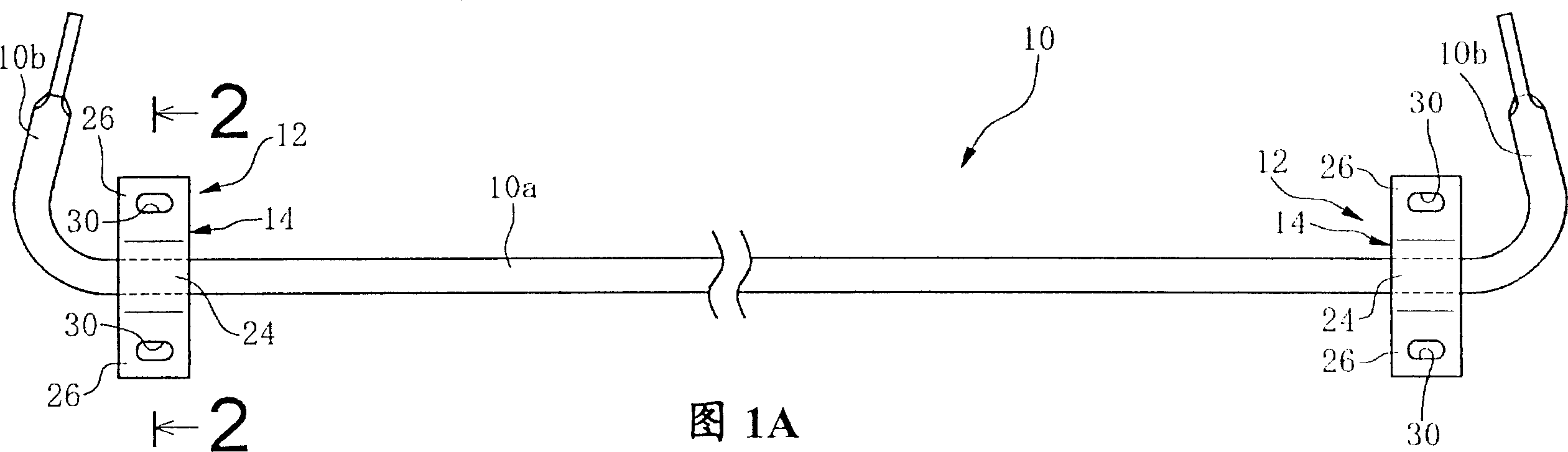

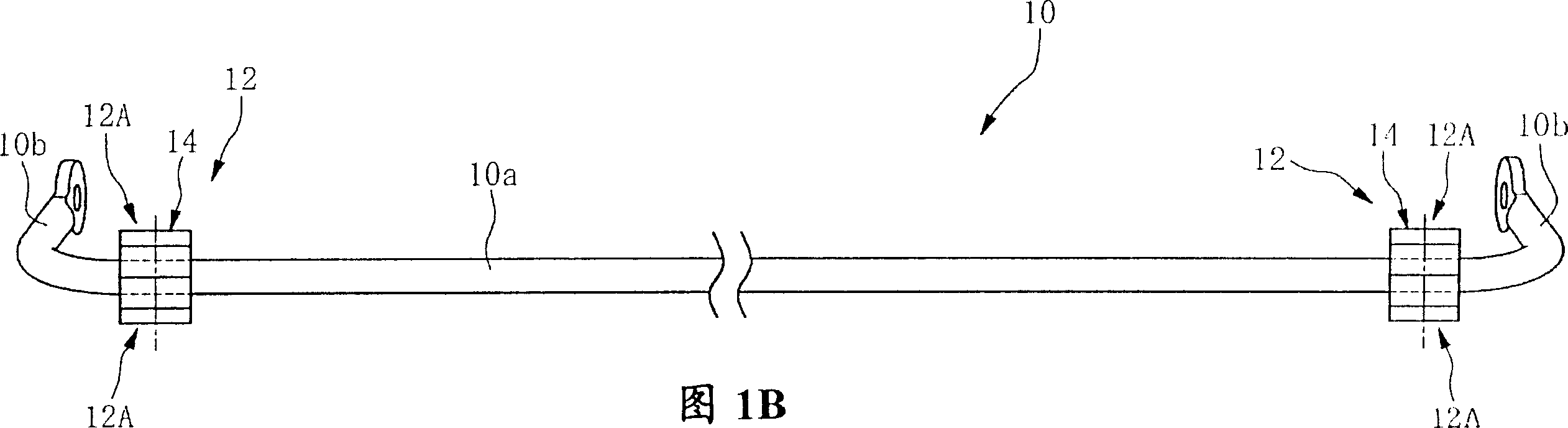

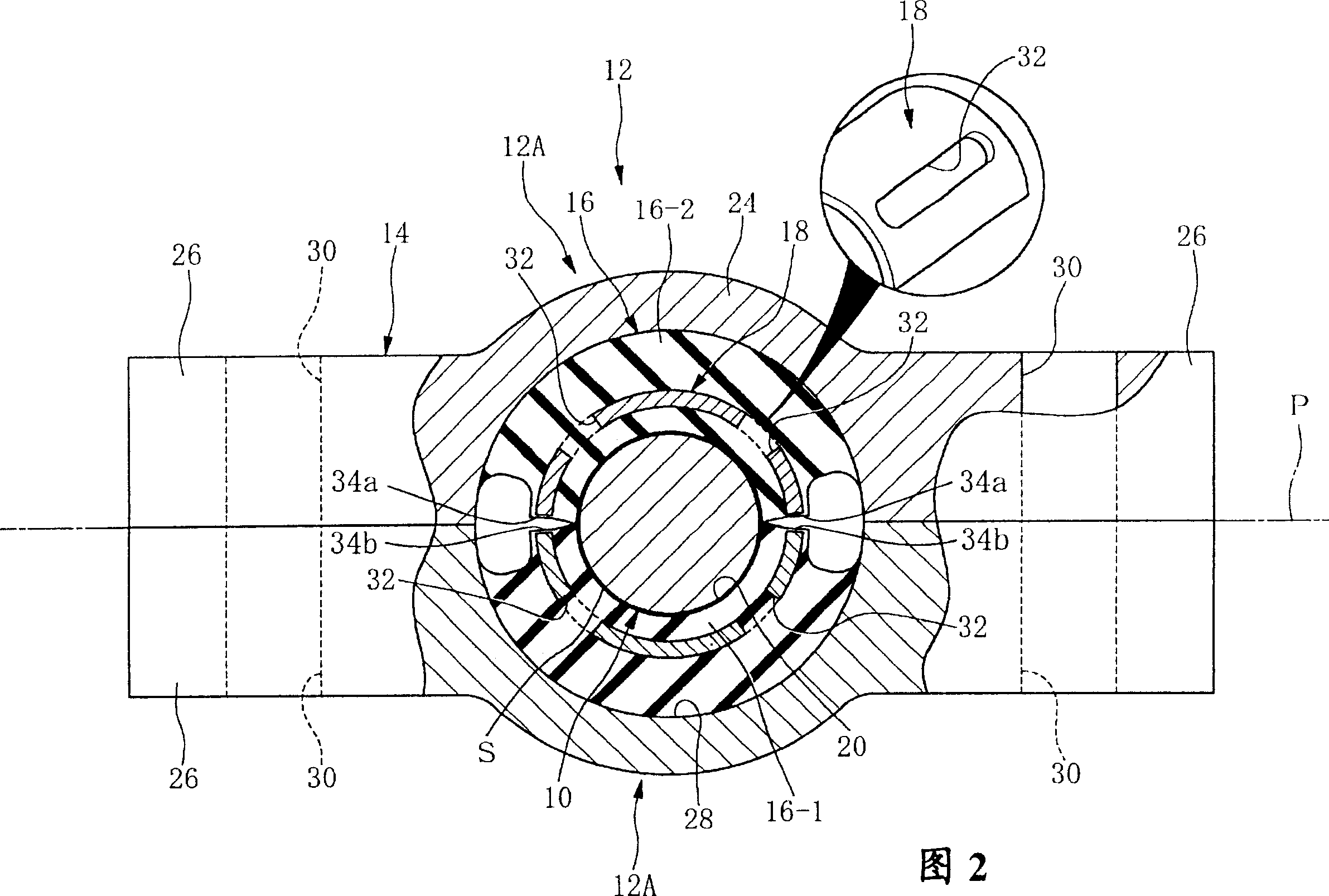

Stabilizer bushing

InactiveCN1766362AReduce axial flowReduce stress concentrationInterconnection systemsRubber-like material springsElastomerAdhesive

The invention relates to a stabilizer bar bushing (12), comprising a rubber elastic body (16); a bracket (14) and a middle part embedded in the rubber elastic body along the axis vertical direction so as to extend substantially the entire axial direction of the rubber elastic body An intermediate plate (18) extending in length, whereby the rubber elastic body is divided by the intermediate plate into an inner rubber layer (16-1) and an outer rubber layer (16-2) with a spring constant smaller than the inner rubber layer. The stabilizer bar bushing is composed of two circumferential divisions (12A, 12A), wherein the bracket and the middle plate are integrally vulcanized with the divisions, and the divisions are assembled together to clamp the stabilizer bar along the vertical direction of the axis ( 10) and withstand the compression along the vertical direction of the axis, so that the inner surface of the through hole (20) is bonded to the outer peripheral surface of the stabilizer bar through the adhesive (S).

Owner:TOYOTA JIDOSHA KK +1

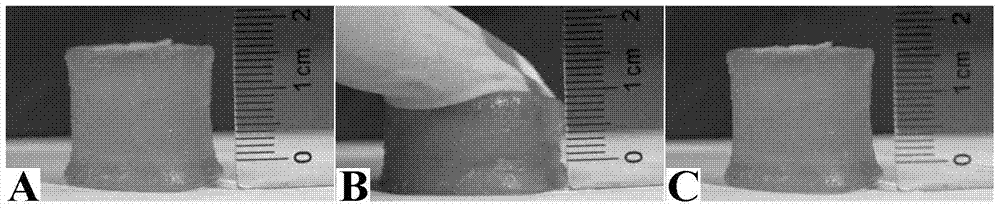

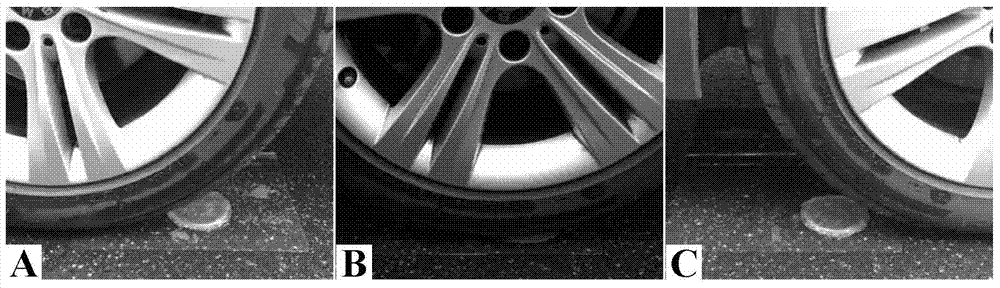

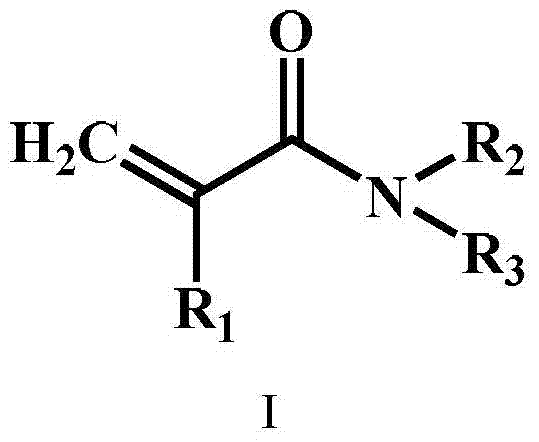

High-strength chemical-physical dual-network hydrogel with self-recovery capability, and preparation method and application of hydrogel

The invention discloses high-strength chemical-physical dual-network hydrogel with self-recovery capability, and a preparation method and application of the hydrogel. The high-strength chemical-physical dual-network hydrogel with the self-recovery capability is prepared from a first chemical network formed by the polymerization of hydrophilic monomers or by enabling hydrophilic macromolecules to be mixed and have a reaction, and a second physical network formed by carrying out physical crosslinking on polysaccharide and derivatives thereof, wherein the first chemical network and the second physical network are arranged in a way of being interspersed with each other. The dual-network hydrogel has high compressive strength and tensile strength, high toughness as well as good self-recovery property and fatigue resistance, and can maintain higher tensile strength and breakage elongation under the condition of having a notch. The prepared hydrogel has good mechanical property and biocompatibility, can be widely applied to the field of biological medicine, and can be used as a surface coating of a scaffold for tissue engineering, medical sponge or a medical implant.

Owner:INST OF CHEM CHINESE ACAD OF SCI

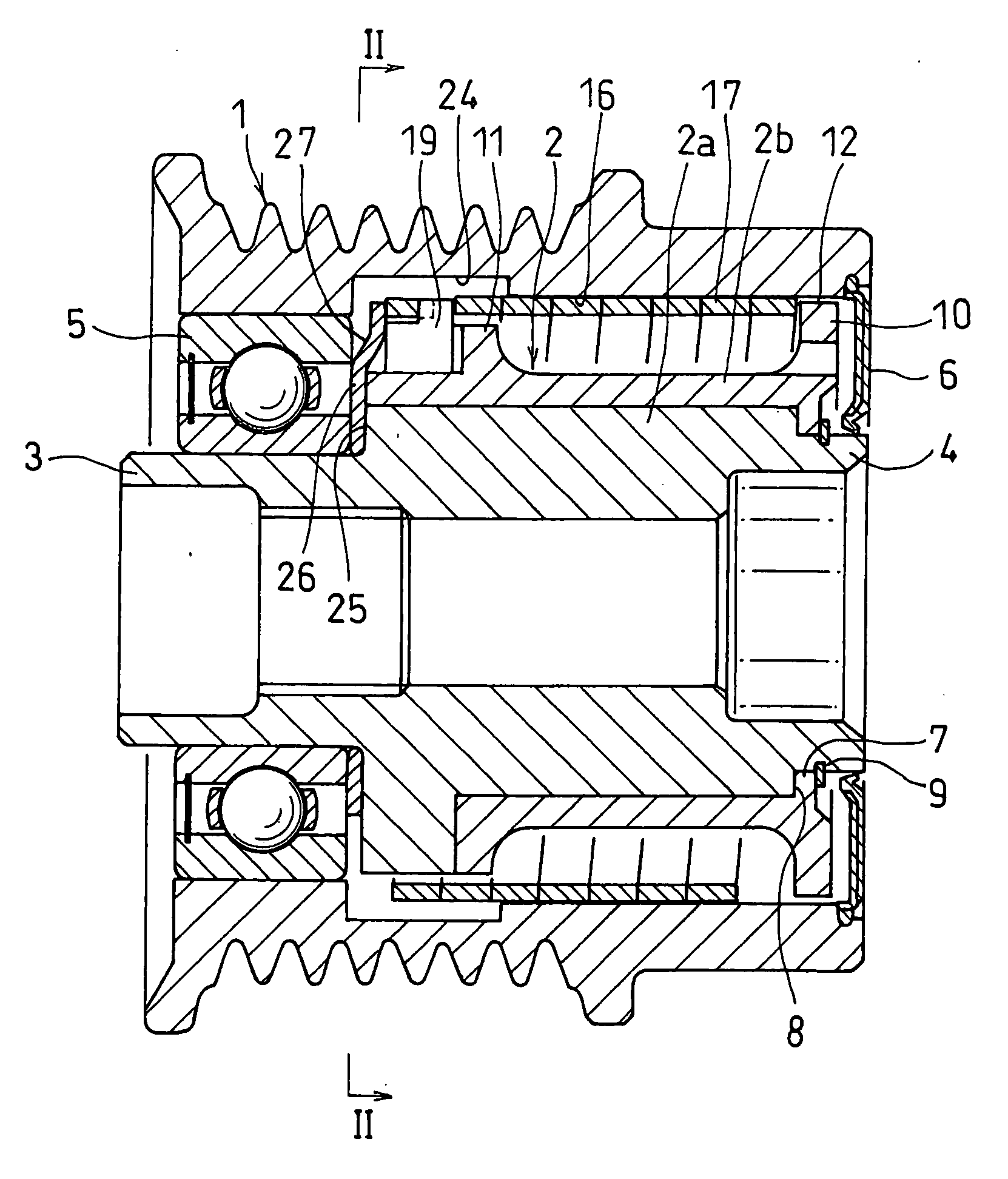

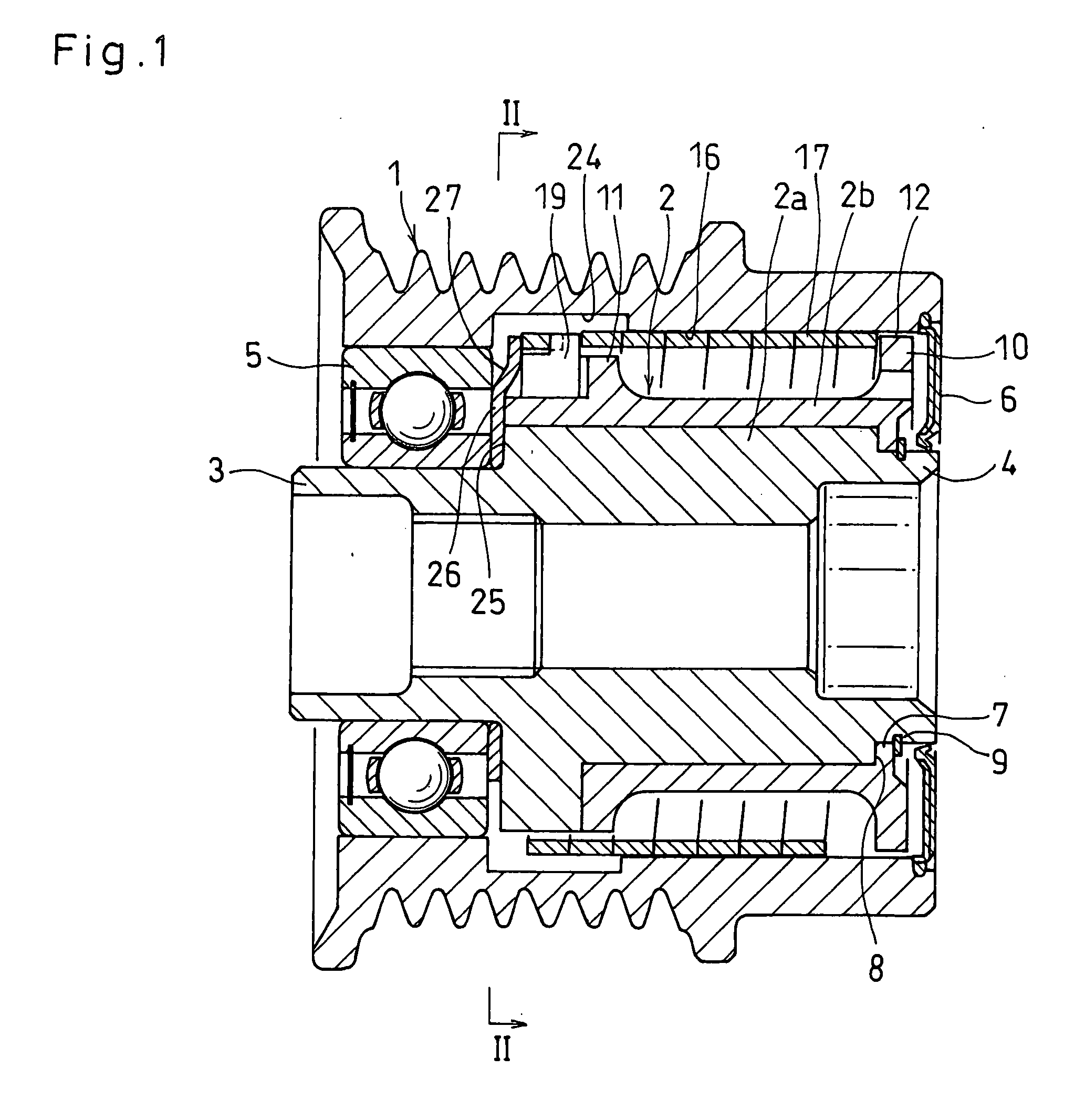

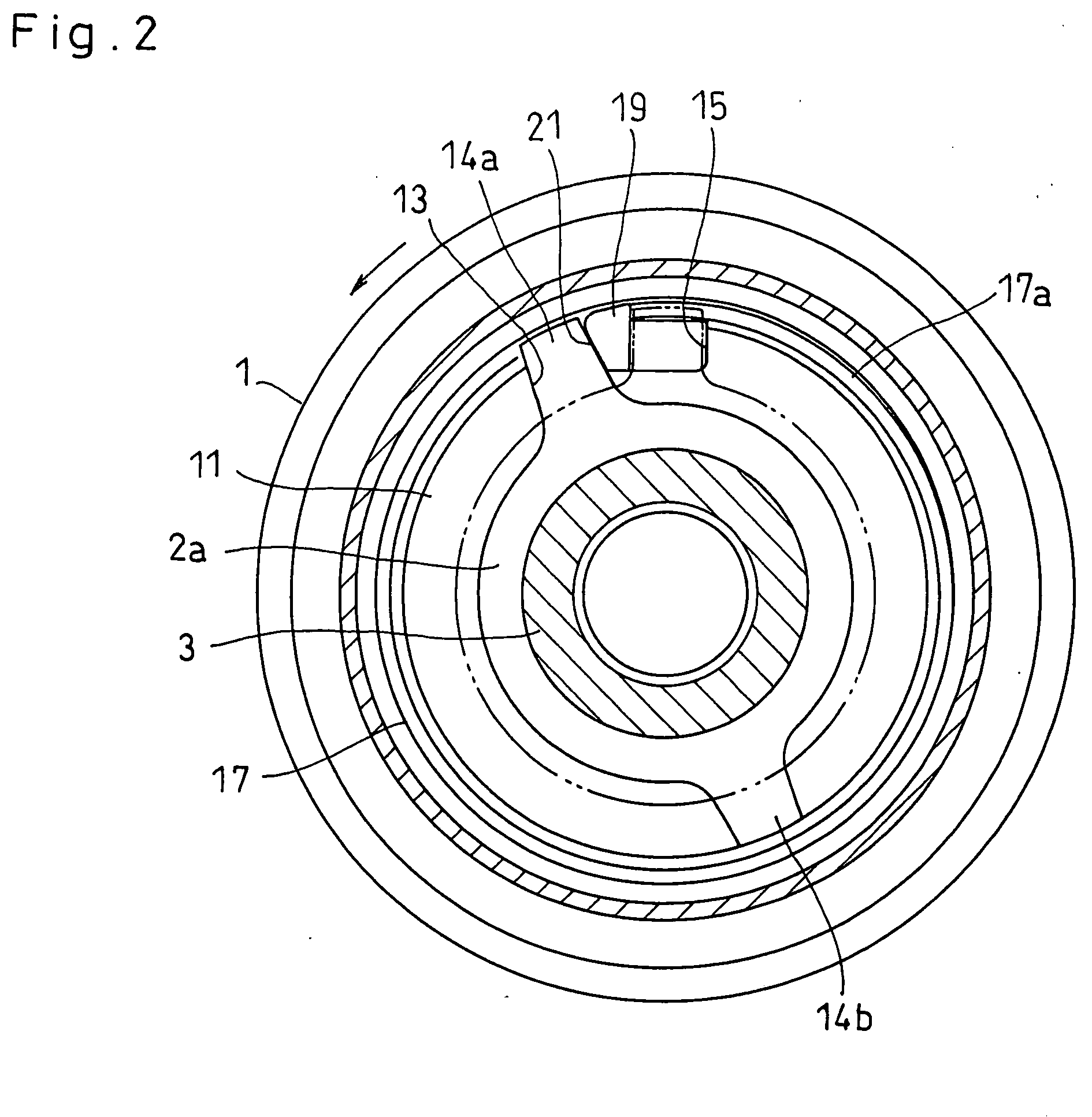

Spring Clutch

InactiveUS20070240964A1Increases percentage of absorptionImprove rigidityFriction clutchesFreewheel clutchesStress concentrationTorque transmission

A spring clutch is provided which has improved durability by preventing a clutch spring from breaking due to fatigue. A cylindrical clutch spring made from a wire having a square section is mounted between a pulley and a pulley hub mounted in the pulley. An end of the clutch spring is coupled to the pulley hub. A clutch surface is formed on the inner periphery of the pulley and is formed with a large-diameter recess at a position opposite to the end portion of the clutch spring including the torque transmission end. When the pulley rotates in one direction, the clutch spring expands. At this time, the end portion of the clutch spring including the torque transmission end expands in the large-diameter recess, thus relaxing sharp torque produced in the clutch. This prevents local stress concentration on the clutch spring and breakage of the clutch spring and improves the durability of the clutch.

Owner:NTN CORP

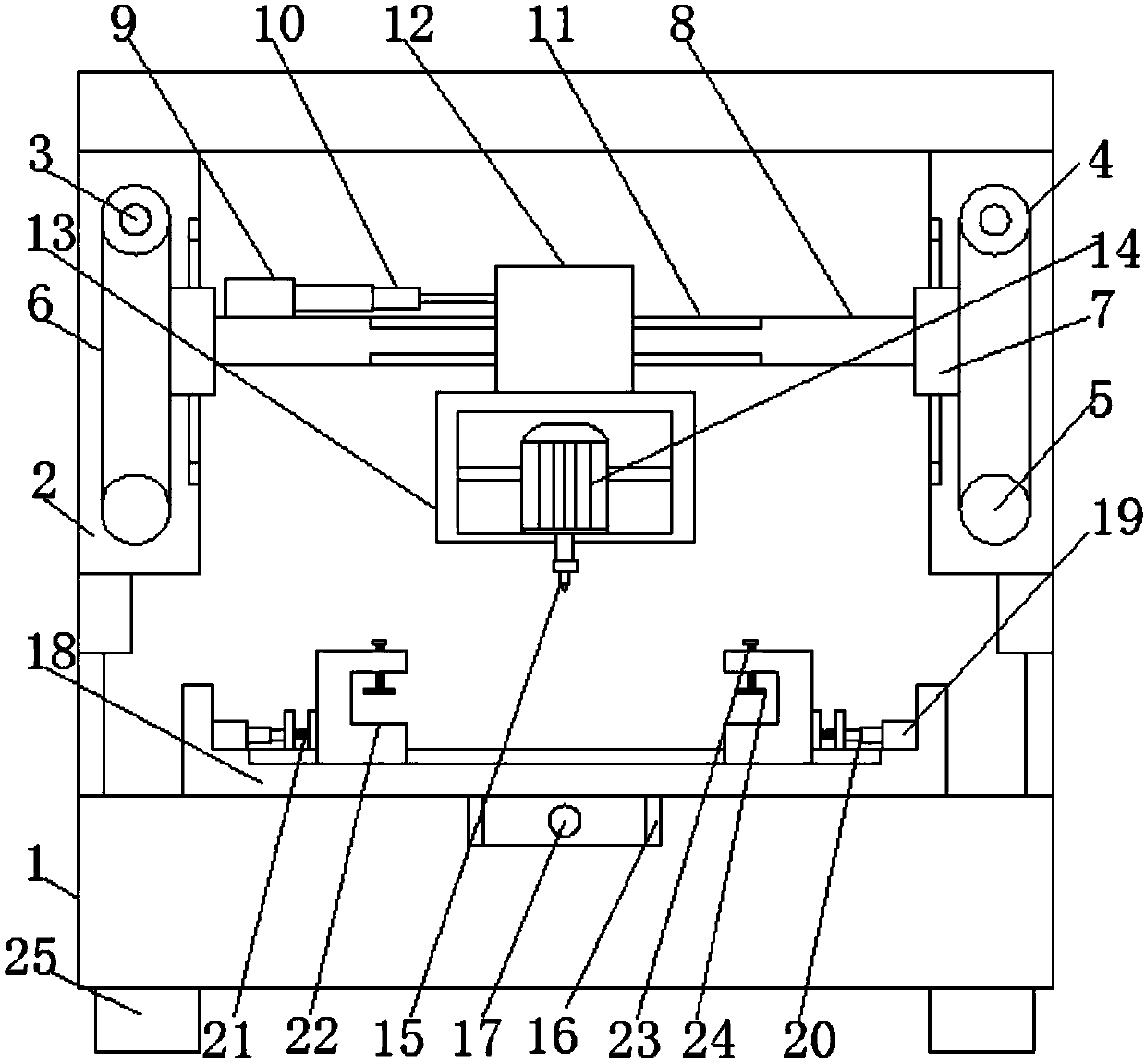

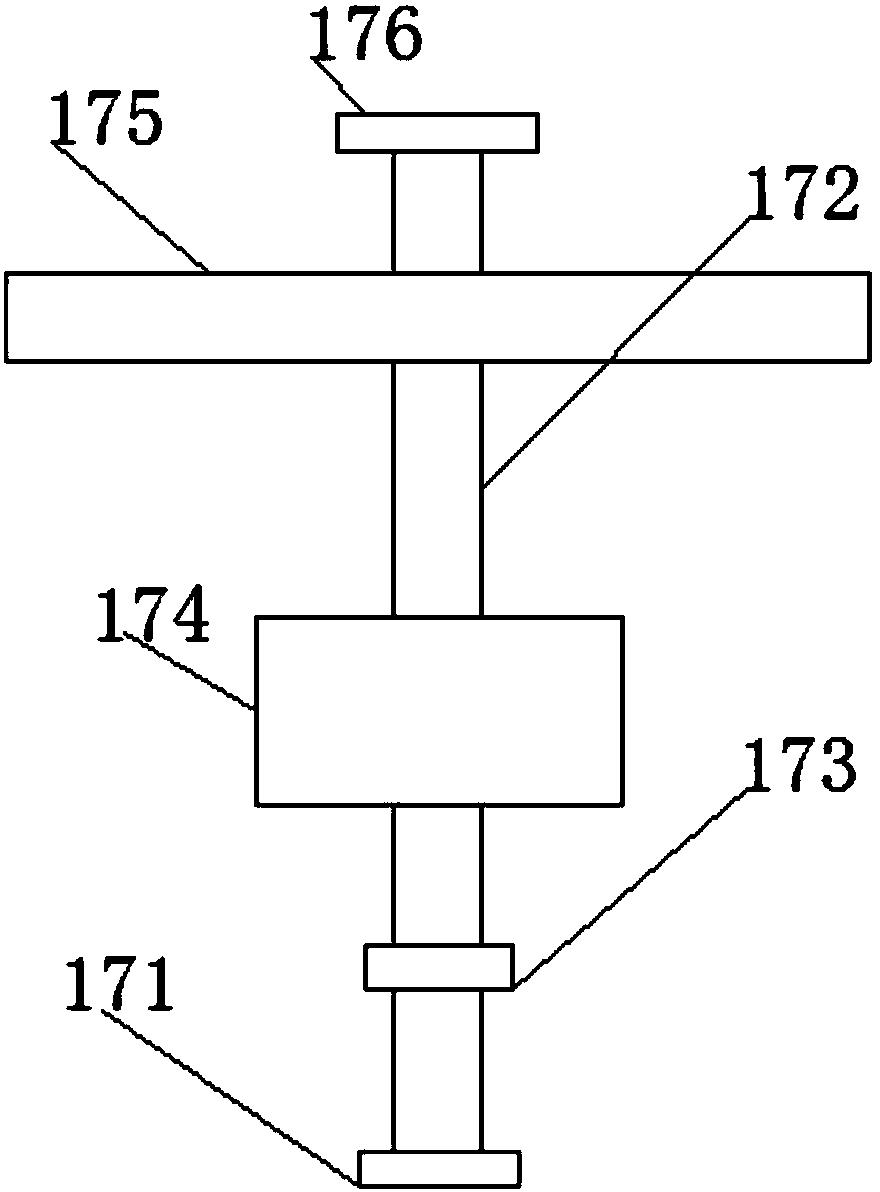

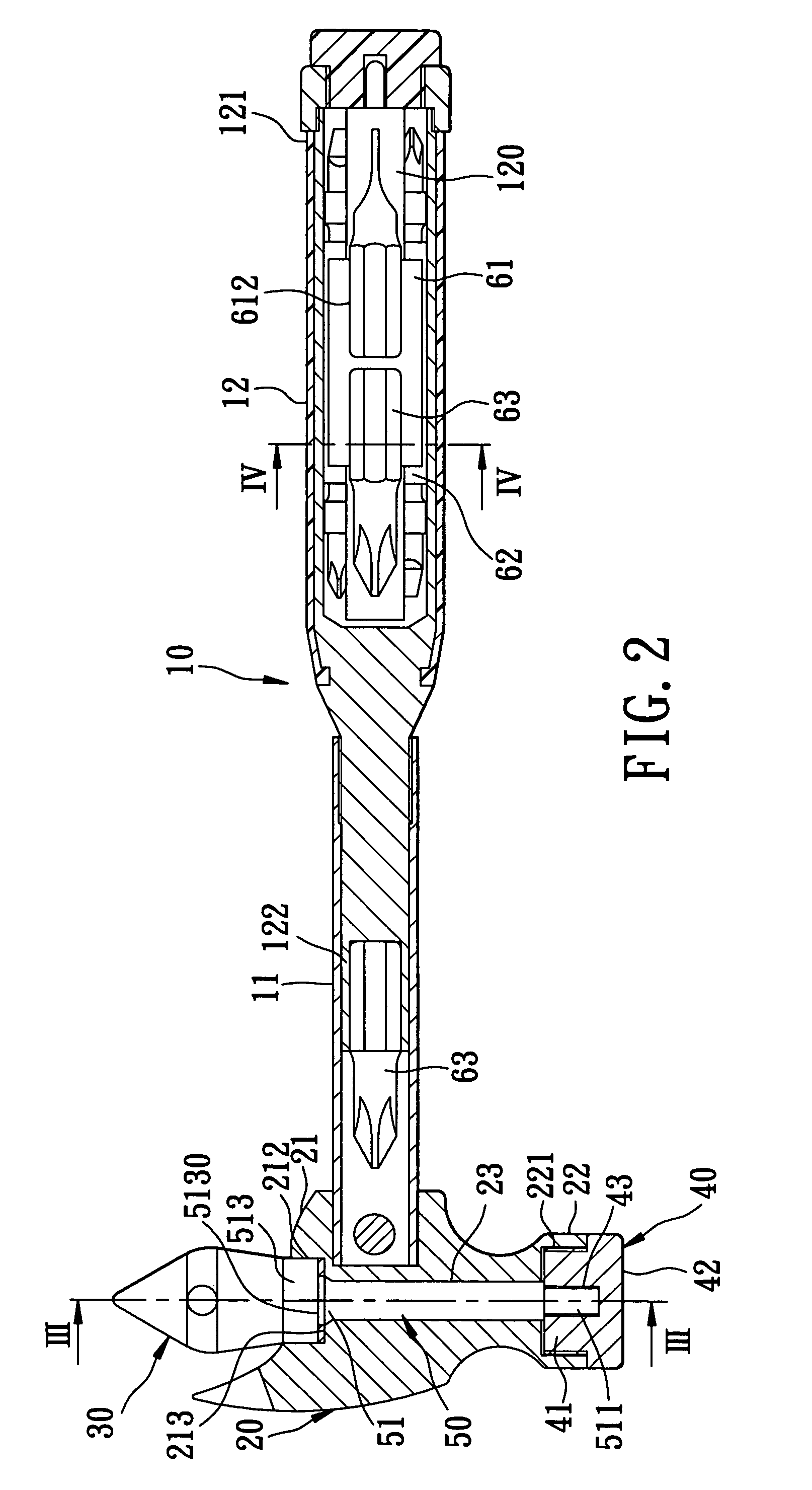

Steel structure drilling device

InactiveCN107824828AAvoid distortionAvoid stickingFeeding apparatusPositioning apparatusDrive wheelArchitectural engineering

The invention discloses a drilling device for a steel structure, which comprises a machine body. Both sides above the inner wall of the machine body are provided with organic casings. One motor, the output shafts of the two first motors are fixedly sleeved with driving wheels, the inner chambers of the two casings are provided with driven wheels, and belts are movably connected between the two driving wheels and the driven wheels, and the two belts Both of them are fixedly connected with fixed blocks, and the two fixed blocks are slidably connected to the inner wall of the through groove, and a support frame is fixedly connected between the two fixed blocks, and the left side of the top of the support frame is provided with a first cylinder. The invention solves the problem that the drill cannot be displaced laterally by adding a device for lateral movement to the drill, and achieves the purpose of the clamp device being able to move forward and backward by setting the turntable and the screw rod, and solves the problem that the existing steel structure drilling cannot be clamped at one time Problem with drilling multiple times.

Owner:余骆杨

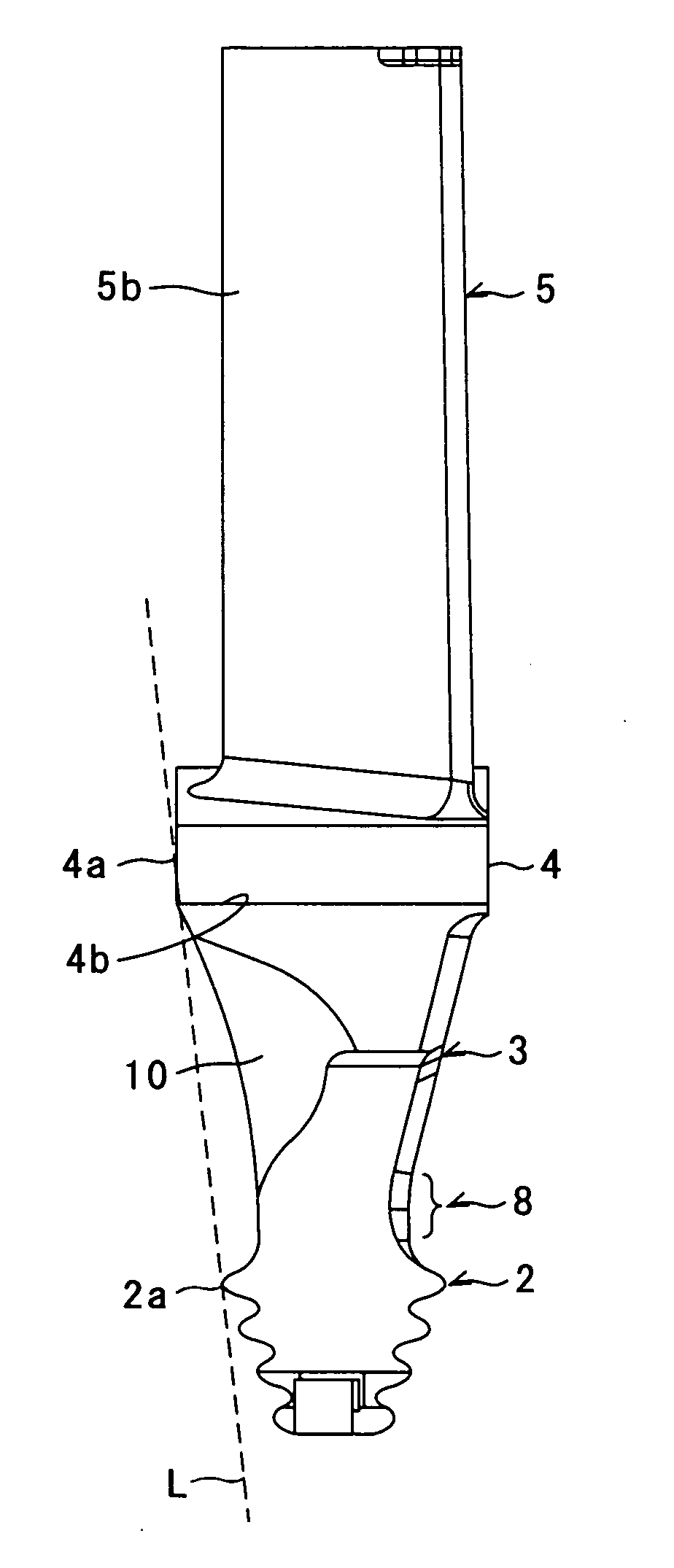

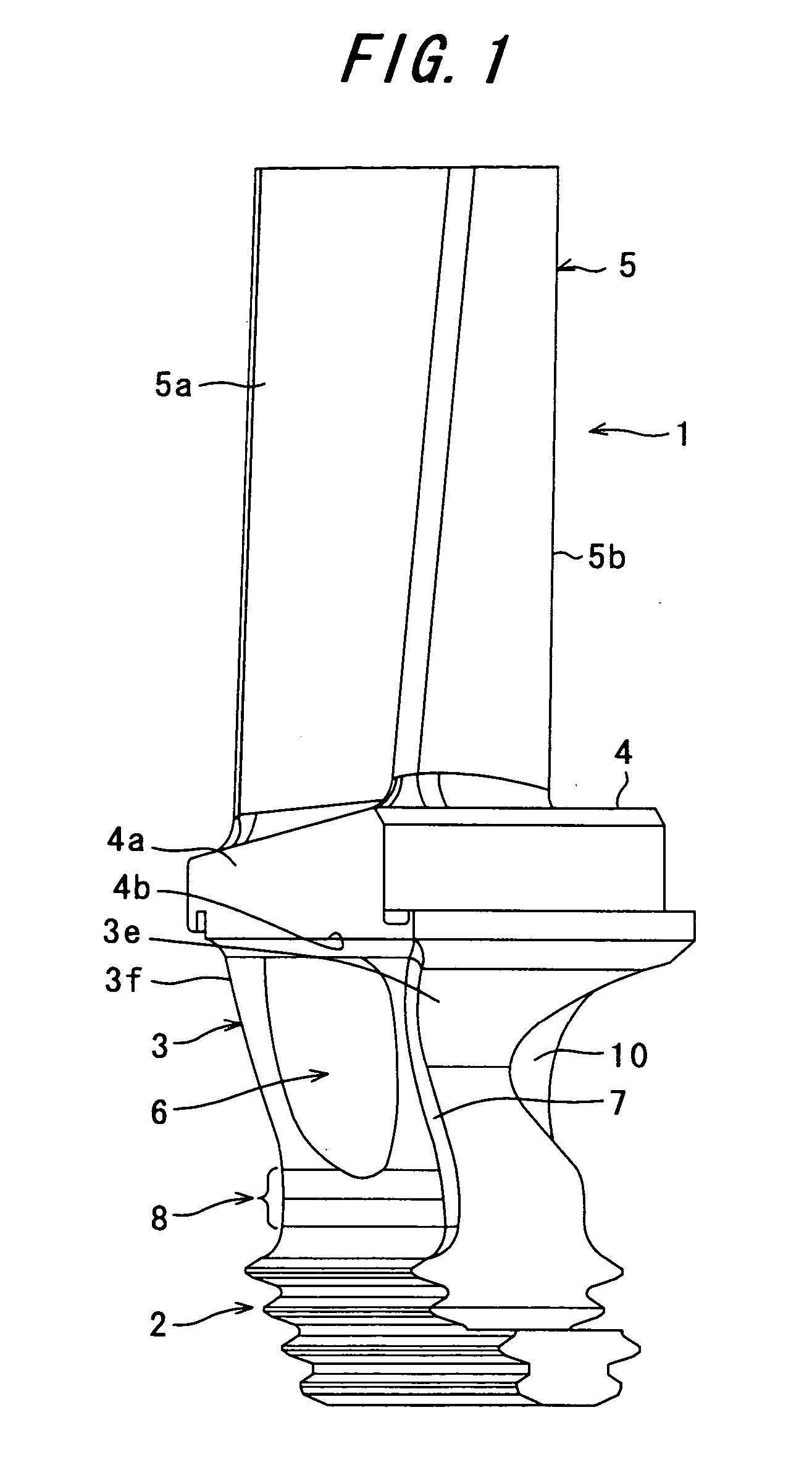

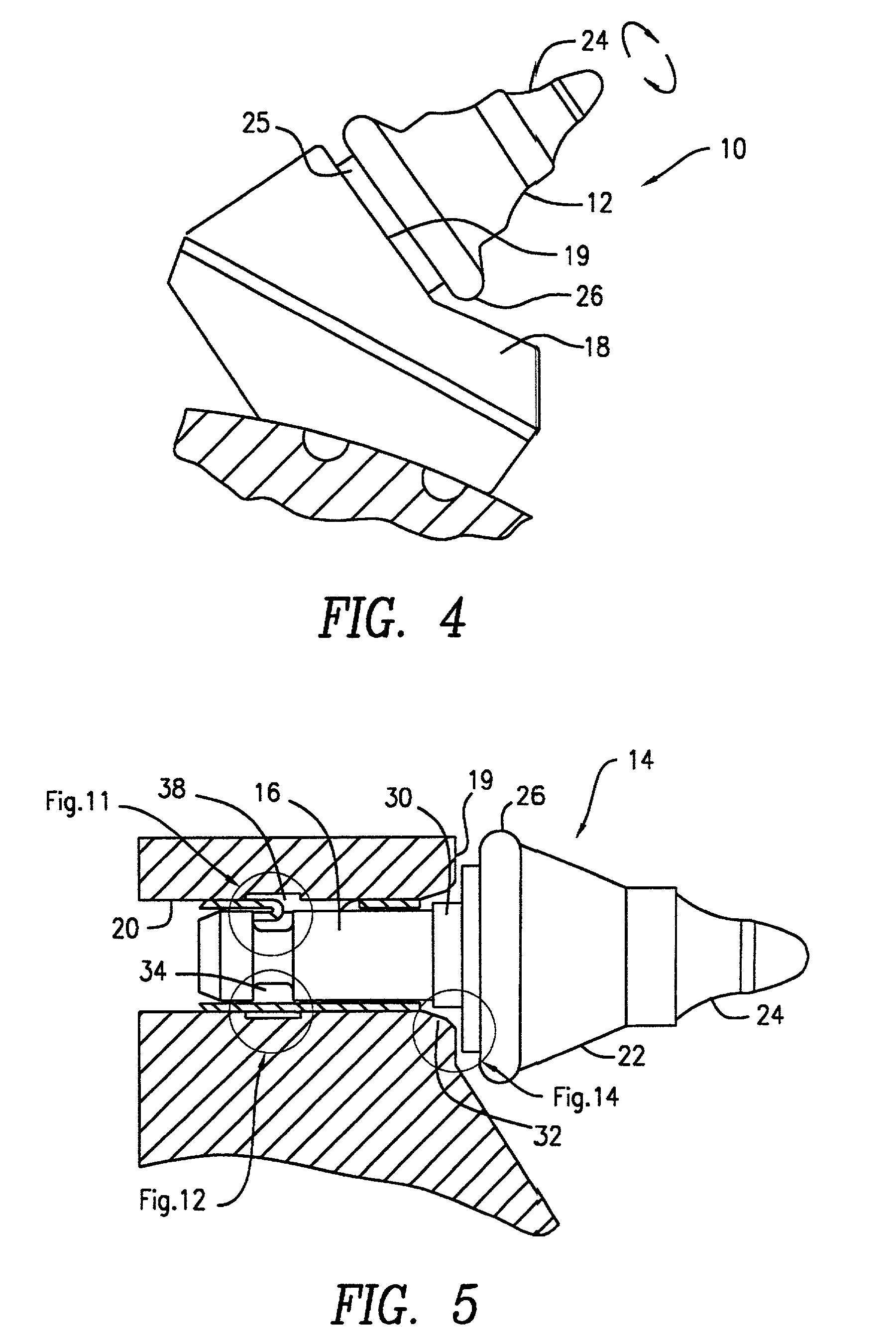

Moving blade and gas turbine using the same

ActiveUS20050186074A1Avoid stress concentrationUniform intensity distributionRotating vibration suppressionRotary propellersGas turbinesSpring system

In a gas turbine having a plurality of moving blades provided on a rotary shaft in a circumferentially adjoining condition, a seal pin is provided in a spacing between the shanks of the adjacent moving blades for preventing leakage of cooling air from a blade root portion side to an airfoil side; an arcuately depressed portion is formed on the shank of each of the moving blades; and vibration of each of the moving blades is suppressed in such a manner that the seal pin serves as a spring system while the airfoil portion, the platform, the shank, and the blade root portion serve as a mass system.

Owner:MITSUBISHI HEAVY IND LTD

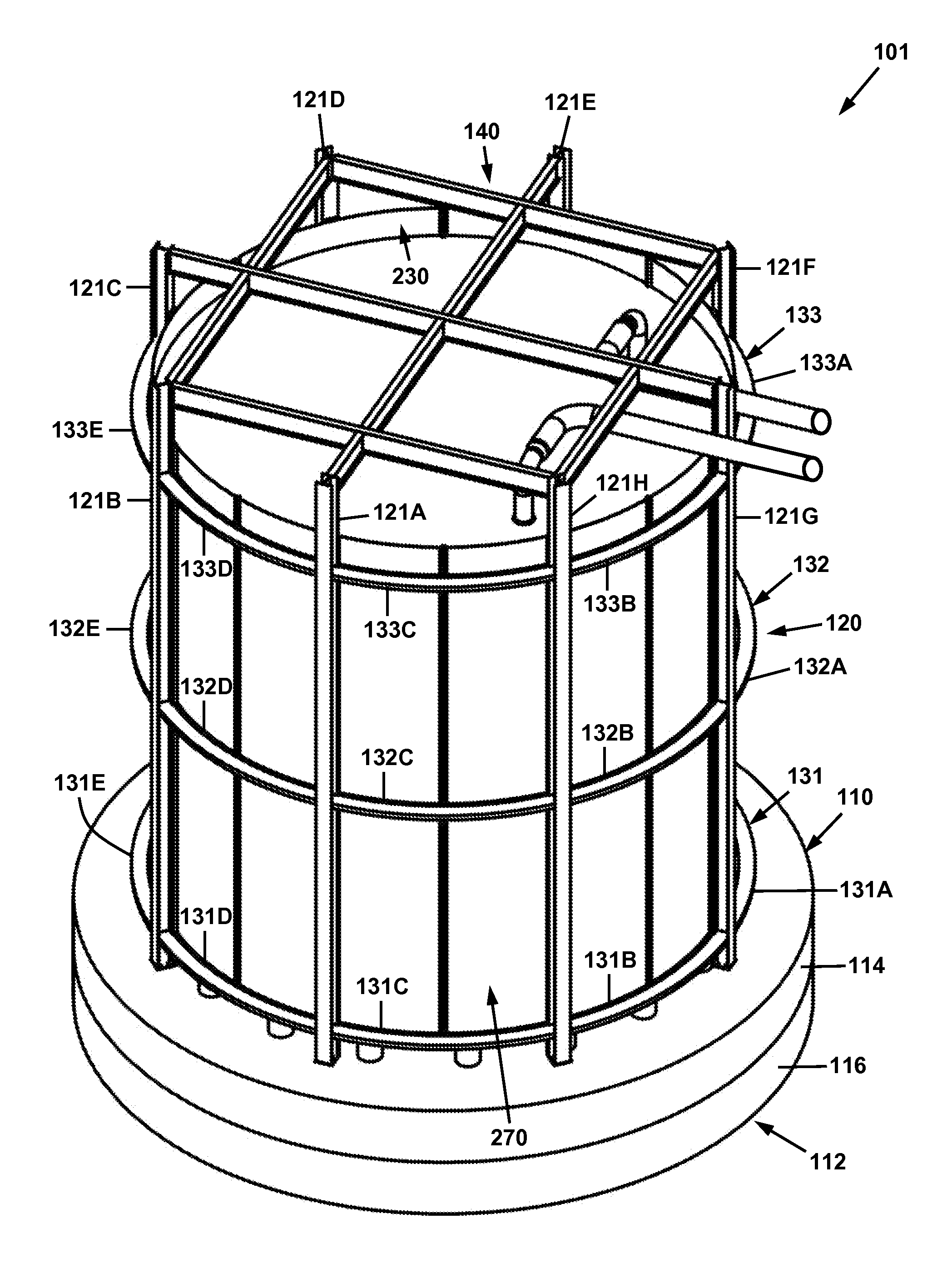

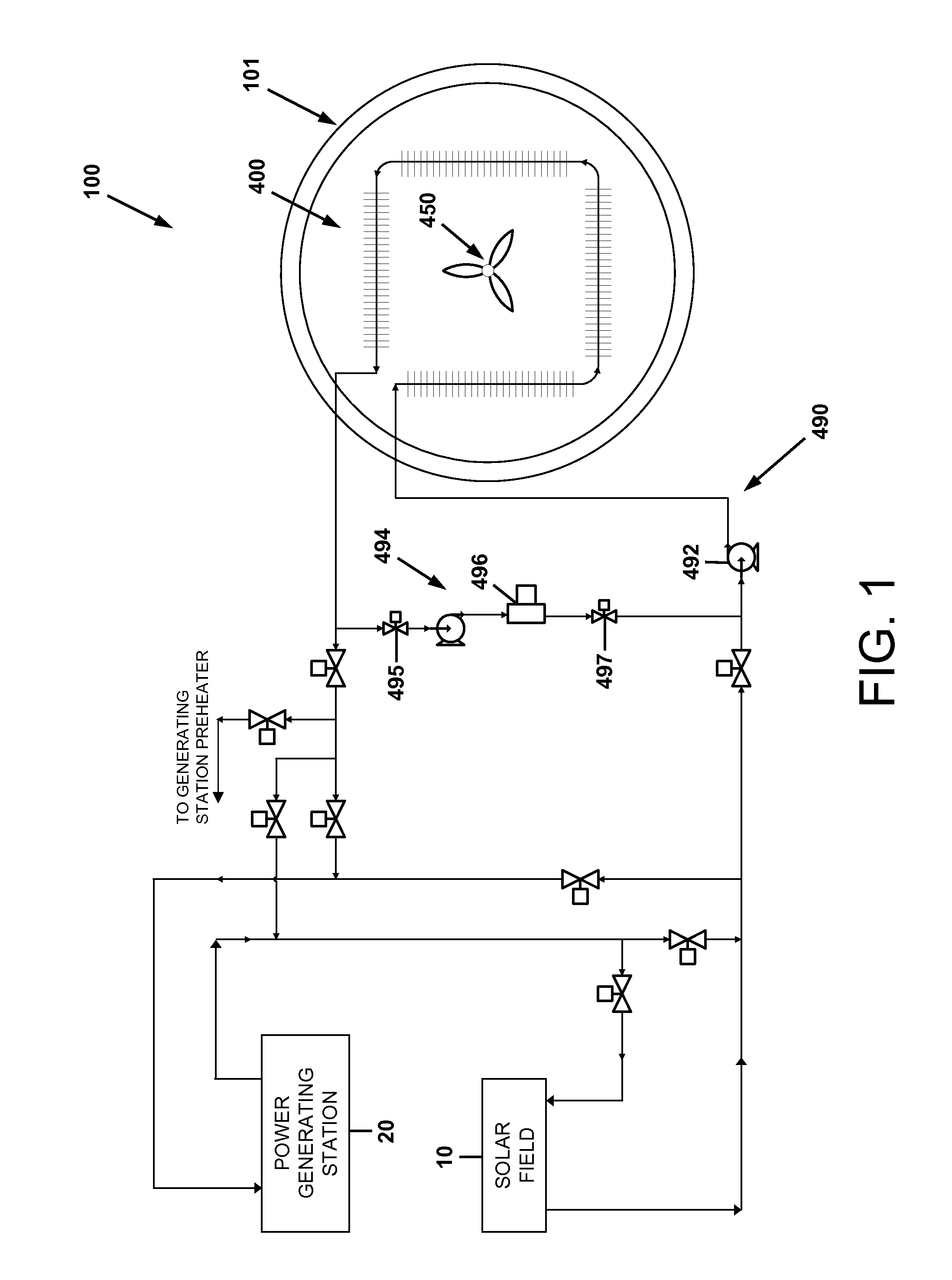

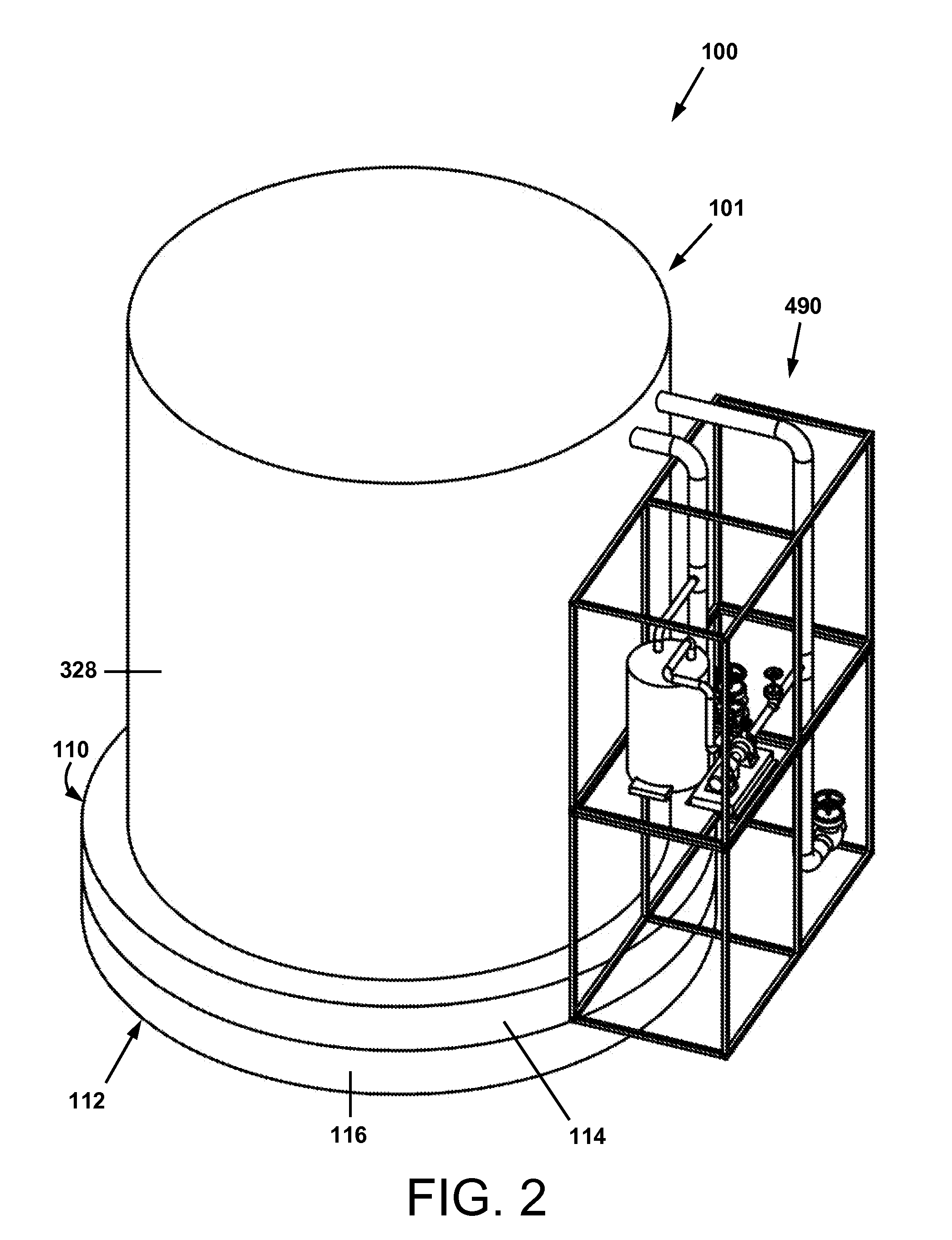

Energy storage vessel, systems, and methods

InactiveUS20110226780A1High R-valueSolve the real problemDomestic cooling apparatusHeat storage plantsEngineeringThermal energy storage system

A vessel for a thermal energy storage system comprising a bottom wall joined to a surrounding side wall, and an inner liner disposed within the bottom wall and side wall and comprising an inner liner bottom and an inner liner side wall. One aspect of the inner liner bottom and side wall is that they are configured to repeatedly expand and contract during the thermal cycling of the storage system. A thermal energy storage system comprising the containment vessel and an array of heat exchangers is also disclosed. The heat exchangers are disposed in the vessel, and arranged so as to enclose a volume within the vessel. Each of the heat exchangers is suspended by a suspension assembly. The assembly may be comprised of a central support hanger, a spring loaded upper hanger, and a lower hanger.

Owner:BELL INDEPENDENT POWER CORP

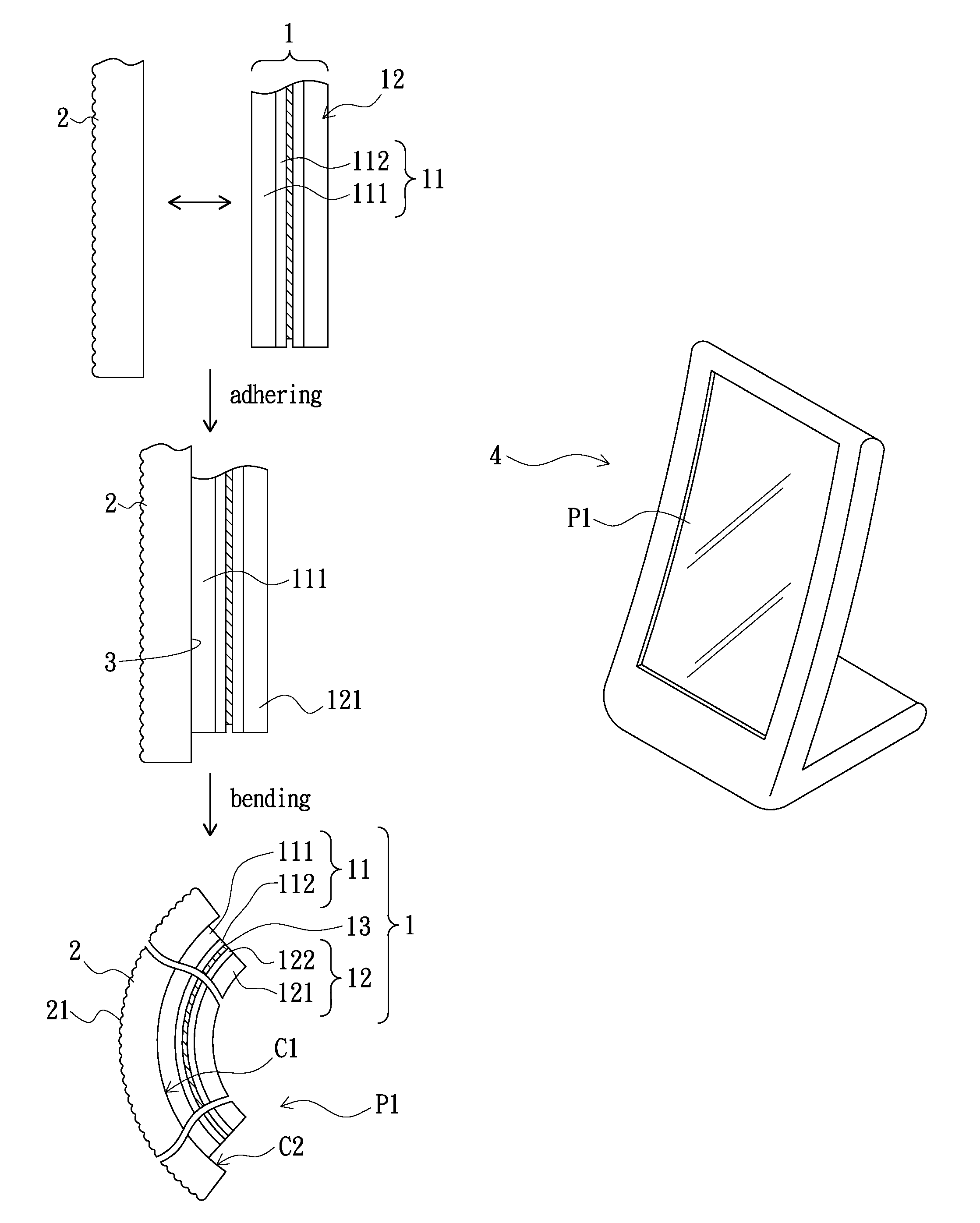

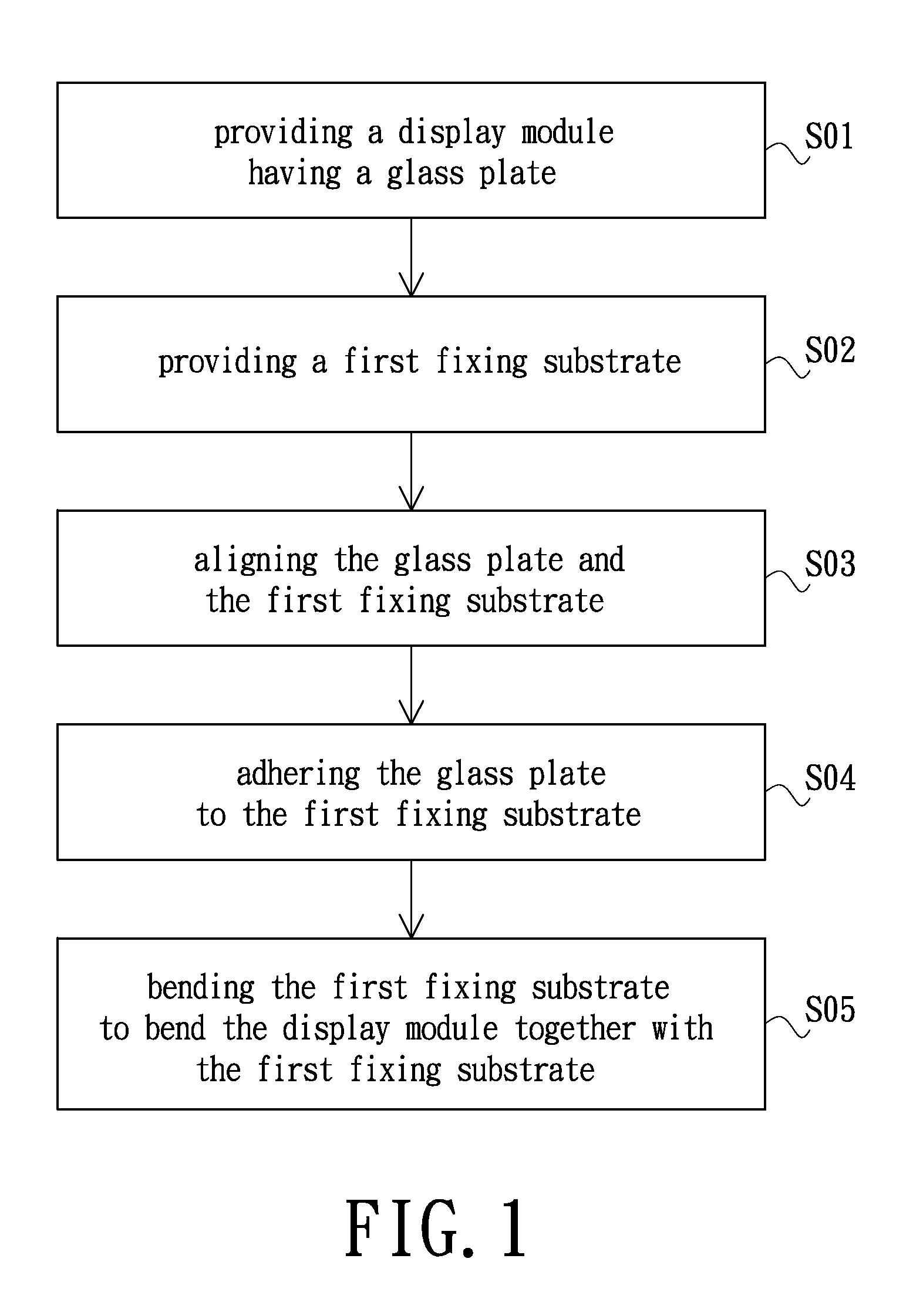

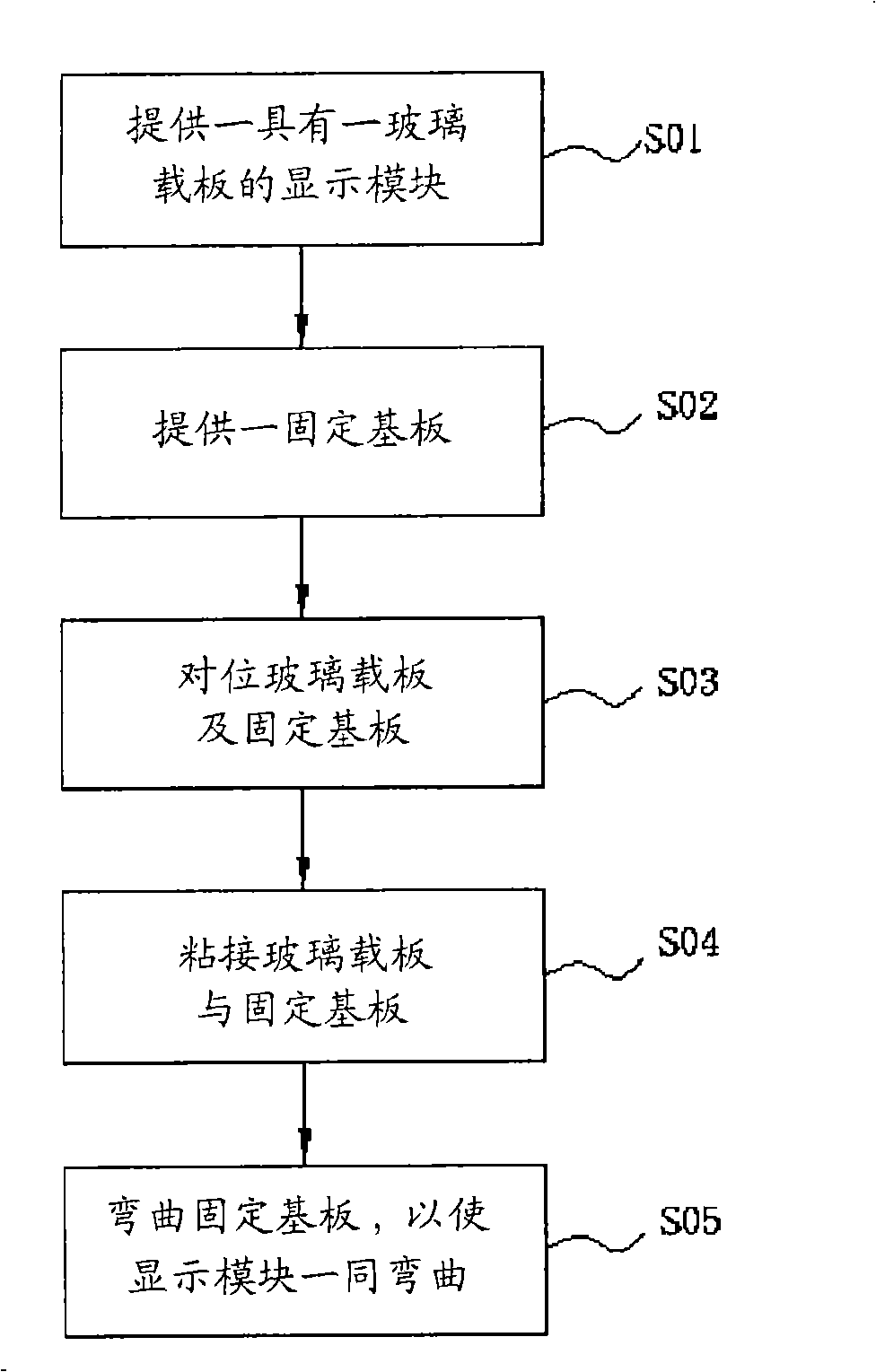

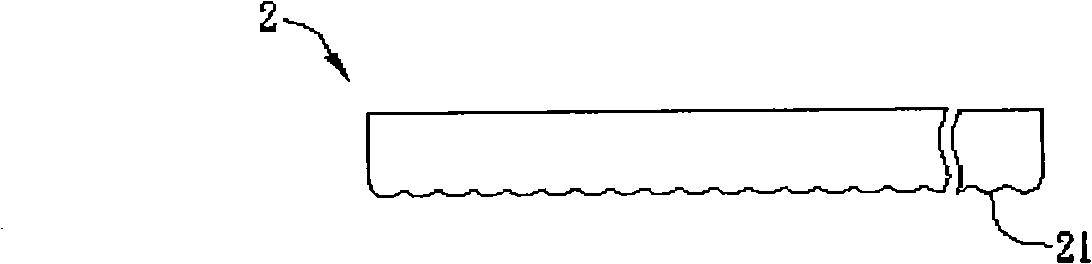

Curved face display panel and method of manufacture

InactiveCN101290445AAvoid stress concentrationImprove yieldStatic indicating devicesSolid-state devicesComputer moduleEngineering

The invention discloses a curved display panel and a method for making the same. The curved display panel comprises a display module, a fixed substrate and an adhesive material, wherein, the display module has a glass support plate provided with a first curved surface; the fixed substrate has a second curved surface arranged opposite to the first curved surface; and the adhesive material is used for bonding the first curved surface and the second curved surface.

Owner:AU OPTRONICS CORP

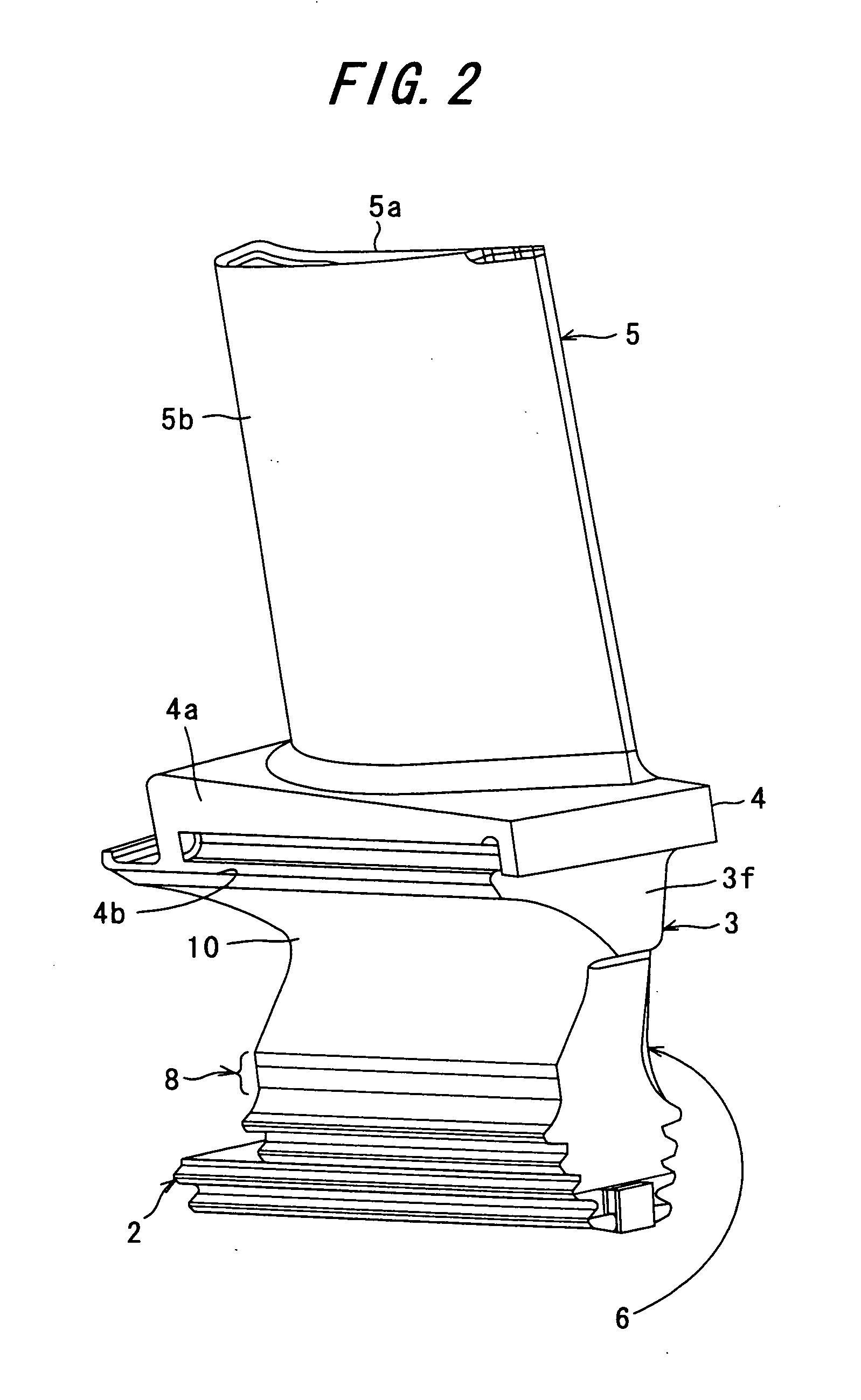

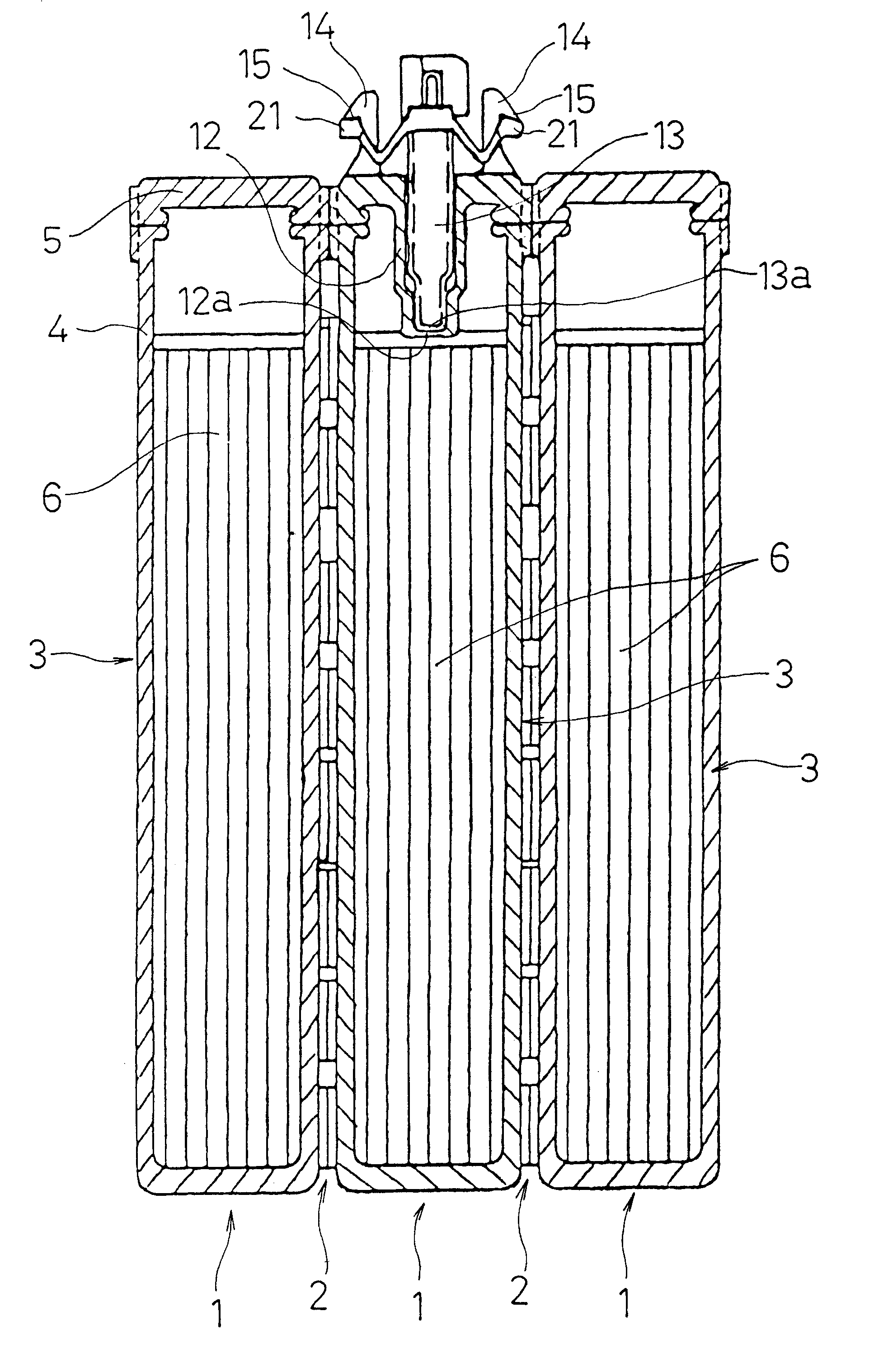

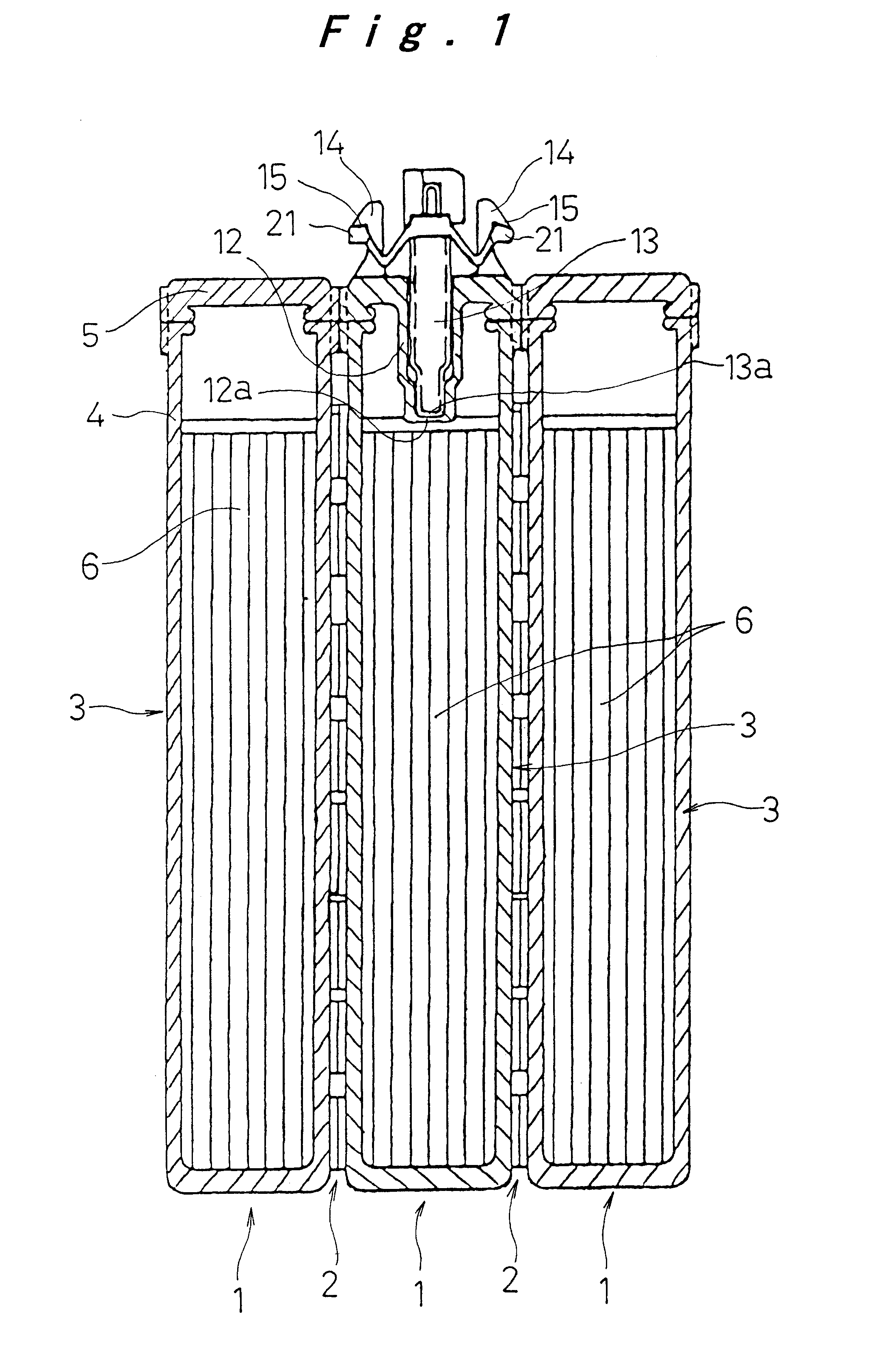

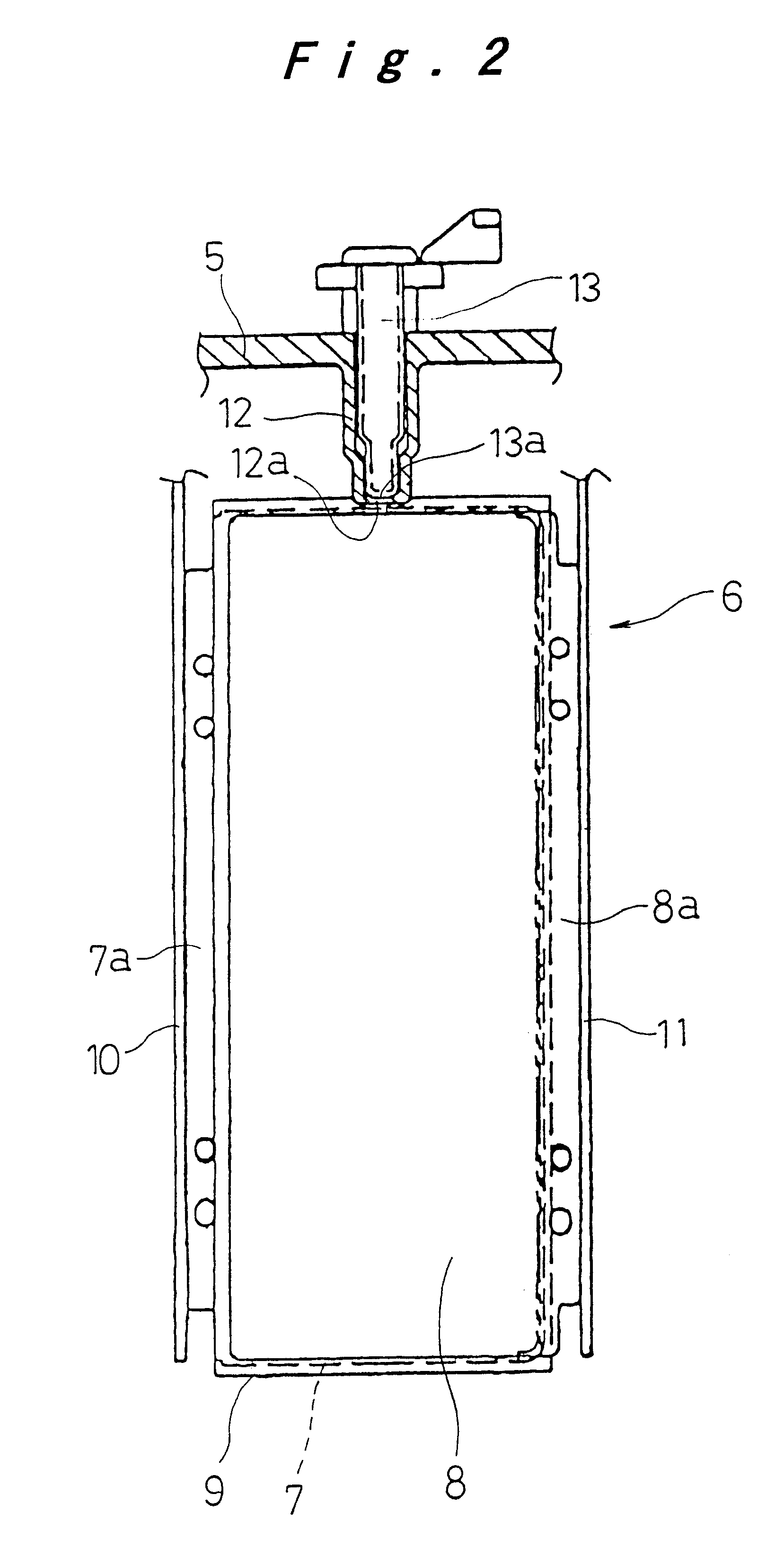

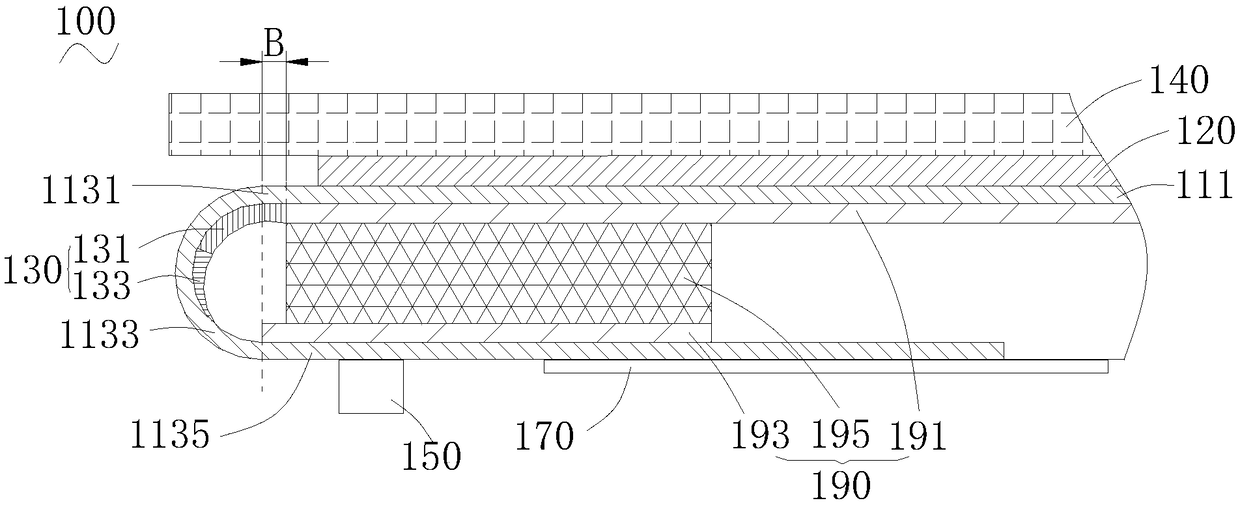

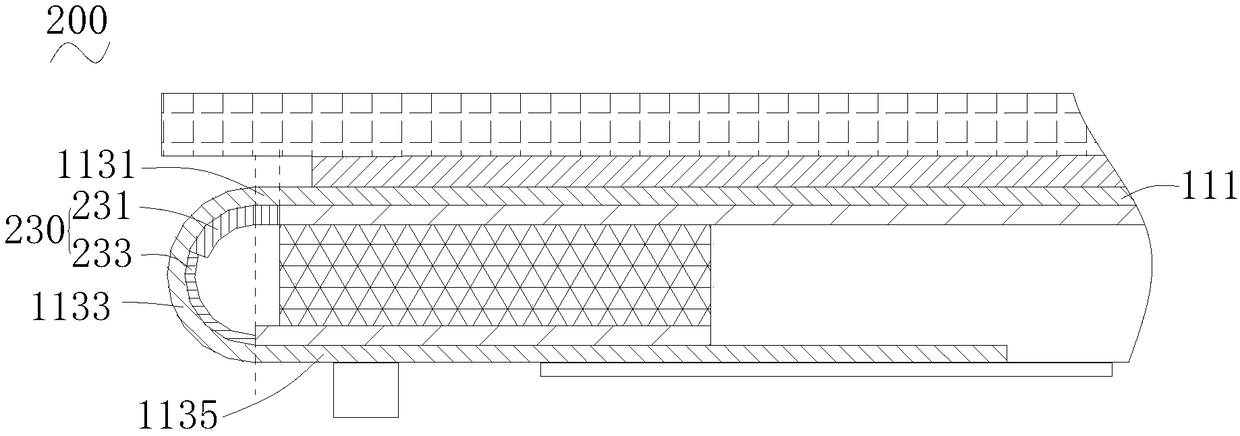

Mounting structure for temperature detecting member in rechargeable battery

InactiveUS6610439B1High precisionImprove responseThermometer detailsCell temperature controlEngineeringRechargeable cell

A temperature detection hole 12 having a bottom, which is sealed against the inside of the battery case 3 while being open to the outside, is formed in the battery case. The bottom wall 12a of the temperature detection hole is in contact with or in close proximity to the elements for electromotive force. Engaging hooks 14 are formed on lateral portions of the temperature detection hole 12 of the battery case 3, while a temperature sensor 13 is provided with elastically deformable engaging flanges 21. When the temperature sensor 13 is mounted removably in the temperature detection hole 12, the elastic restorative force of the engaging flanges 21 that are engaged in elastic deformation with the engaging hooks 14 is applied to the temperature sensor 13. The sensor end 13a of the temperature sensor 13 is thereby pressed against the bottom wall 12a of the temperature detection hole 12.

Owner:PANASONIC CORP +1

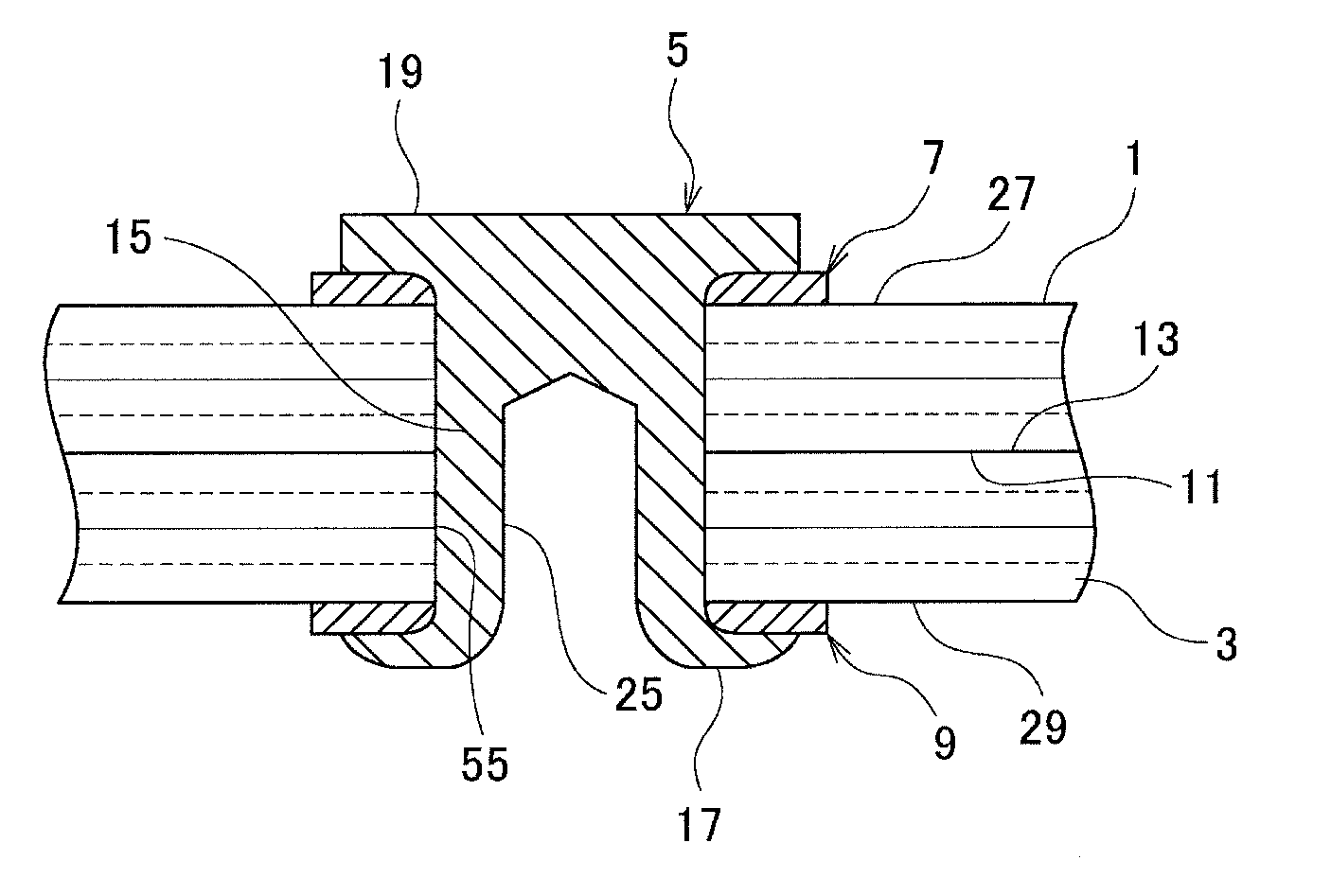

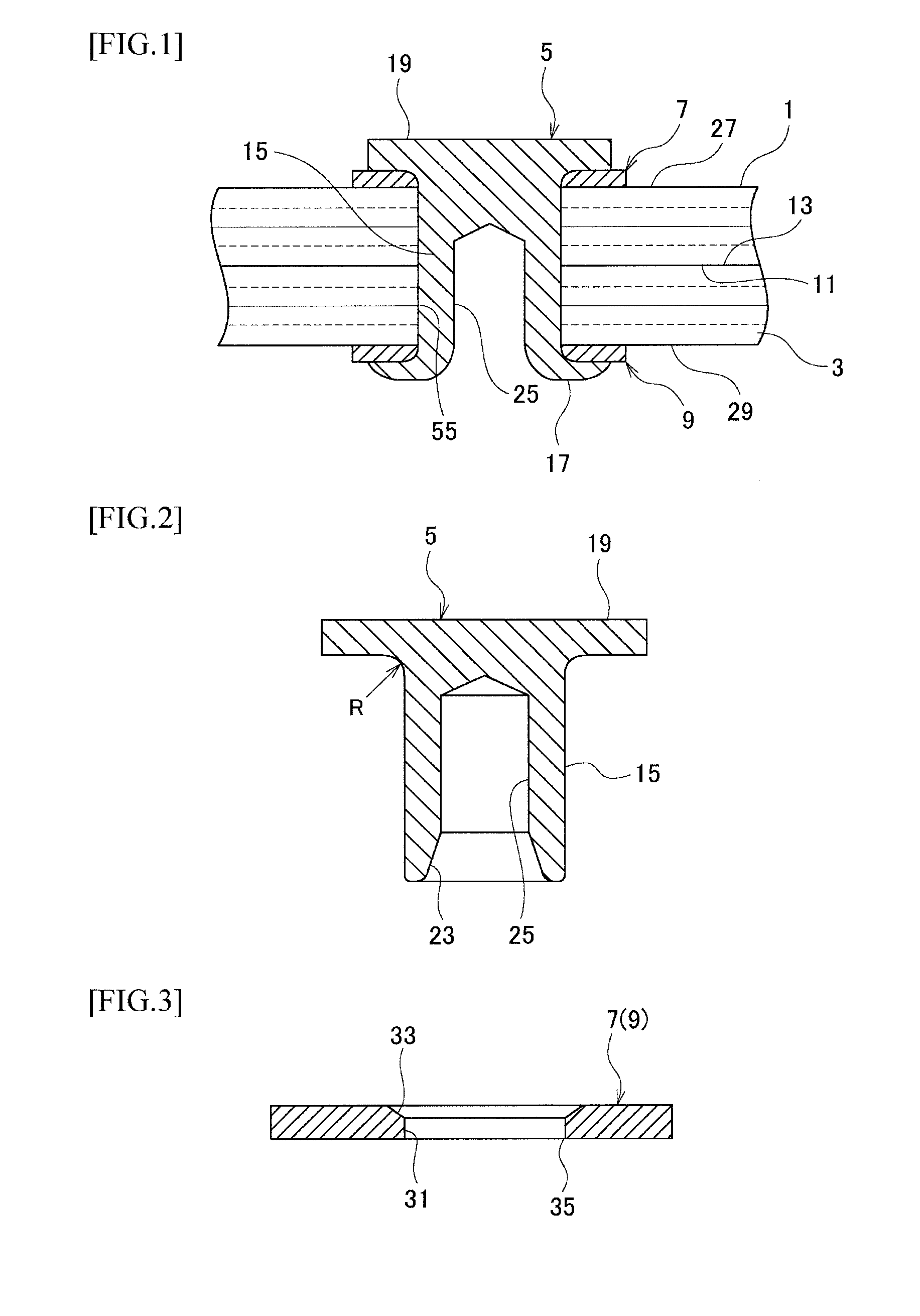

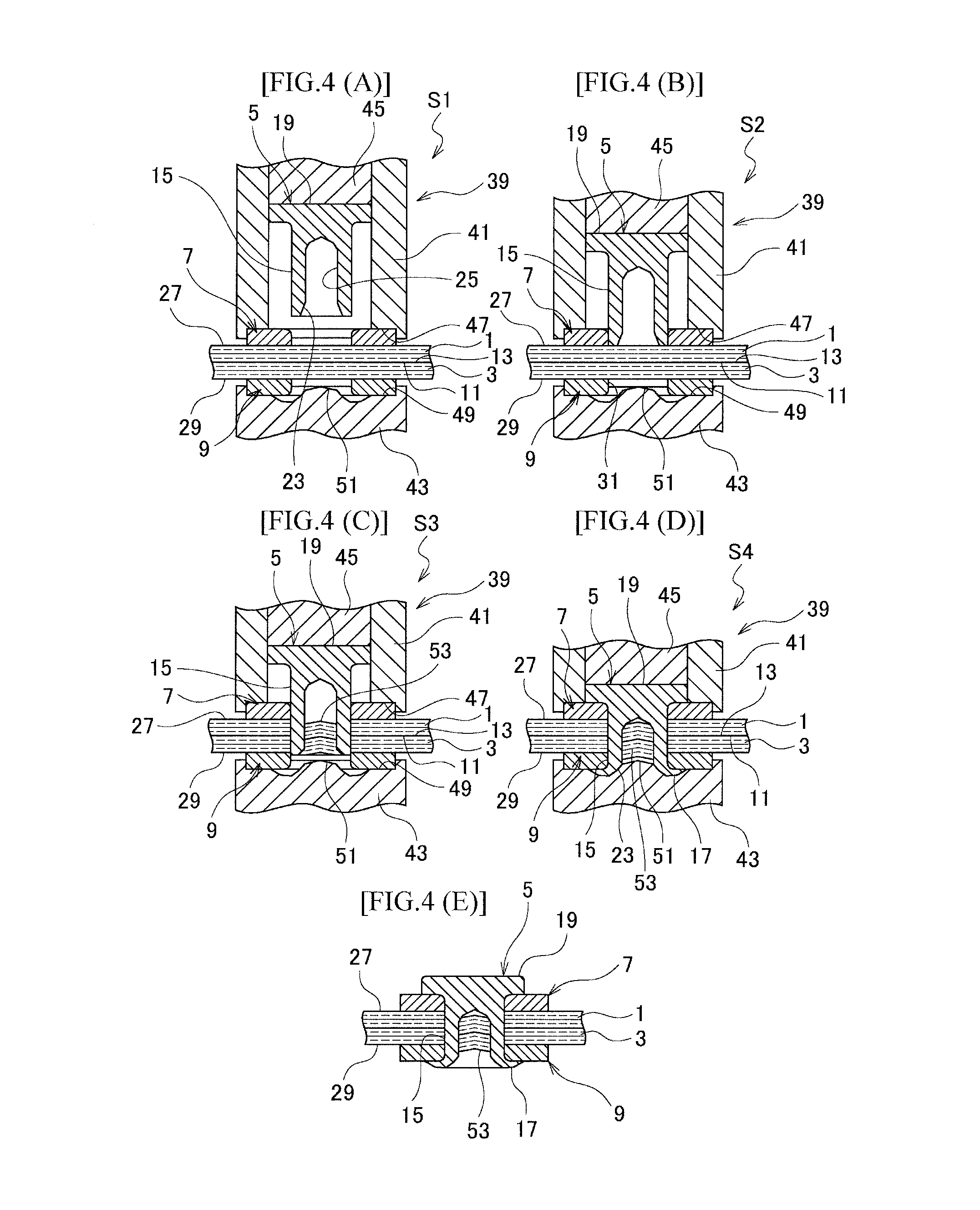

Substrate joining method using rivet, and joining structure

InactiveUS20130340239A1Avoid stress concentrationSuppresses separationRivetsSheet joiningPunchingRivet

A joining method includes punching respective laminated plate materials by a rivet shaft portion of a SPR, forming a crimp portion at the front end of the rivet shaft portion, and fastening and joining the laminated plate materials between the rivet head portion and the crimp portion. Washers are laid on and brought into contact with respective opposite surfaces relative to joining surfaces of the laminated plate materials, the washers each having an inner hole through which the rivet shaft portion is allowed to pass, the washers are used as jigs at the time of the punching, the punching by means of the rivet shaft portion is performed along the inner holes of the washers, and the joining is performed so that the washers left between the rivet head and the crimp portion and the opposite surfaces.

Owner:NIHON UNIVERSITY

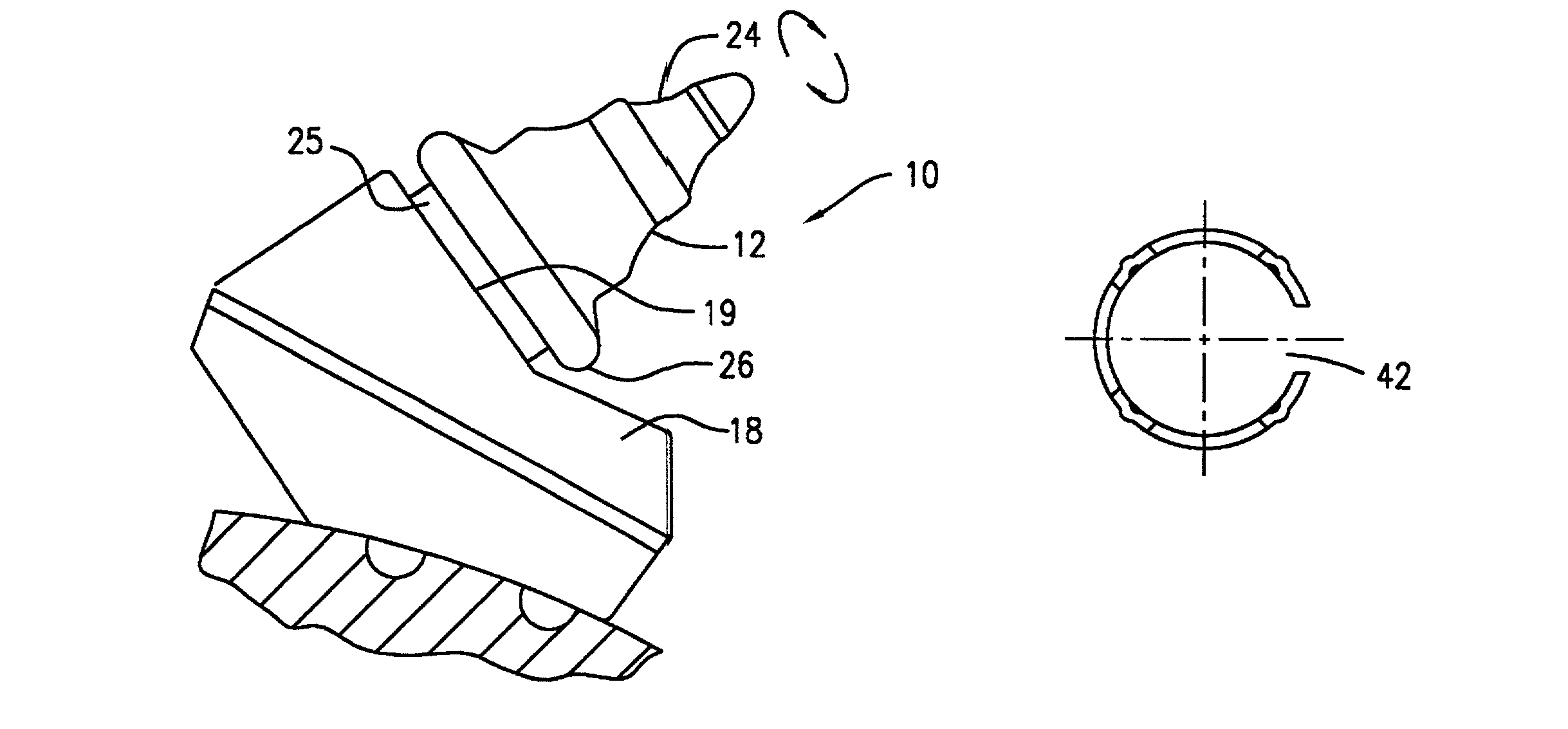

Rotatable cutting tool having retainer with dimples

ActiveUS7380888B2Hinders its propagationAvoid stress concentrationSlitting machinesCutting machinesShear lineEngineering

A cutting tool assembly including a cutting bit having a head and a cylindrical shank portion of substantially constant diameter depending from the head as well as a bit holder including a cylindrical bore for receiving the cylindrical shank portion of the cutting bit. The shank portion includes an annular recessed groove. The cutting tool assembly further includes a retainer sleeve disposed between the shank portion of the cutting bit and the bore of the bit holder and which closely conforms about the shank portion while allowing the shank portion to rotate within the bore. The retainer sleeve includes at least one inwardly folded over stop tab that cooperates with the recessed groove to axially position the shank within the retainer. The retainer includes stop tabs that are bent around beyond the shear cut lines of the tab opening so that the hub portions of the shank do not transmit a force against these weakened shear cut areas of the retainer. The shank hub is positioned so that the hub rotates against only those portions of the retainer that are not weakened by shear line openings.

Owner:KENNAMETAL INC

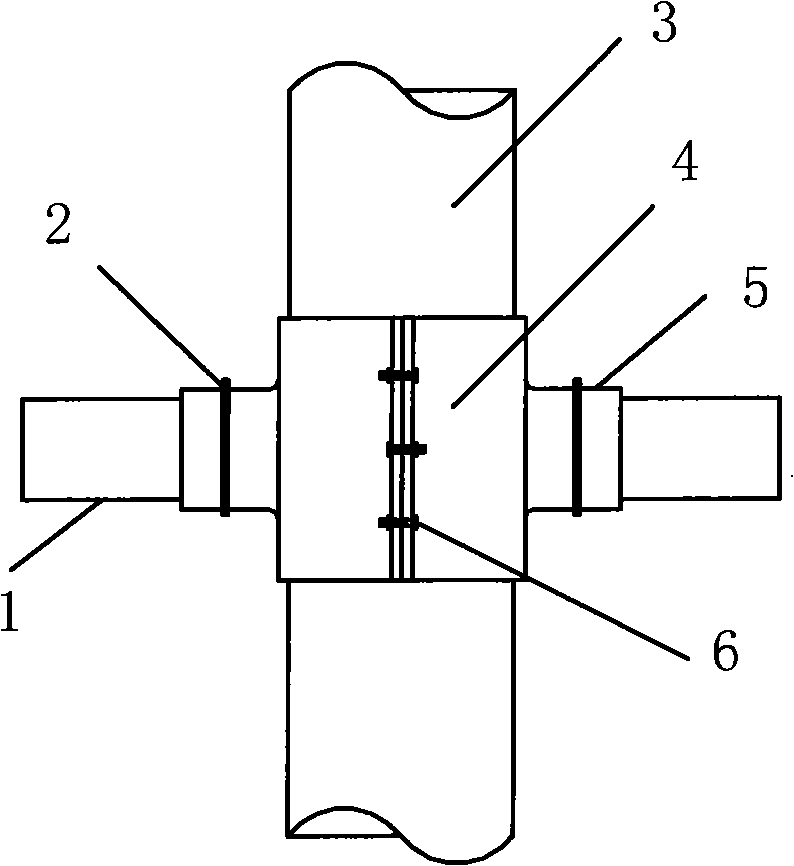

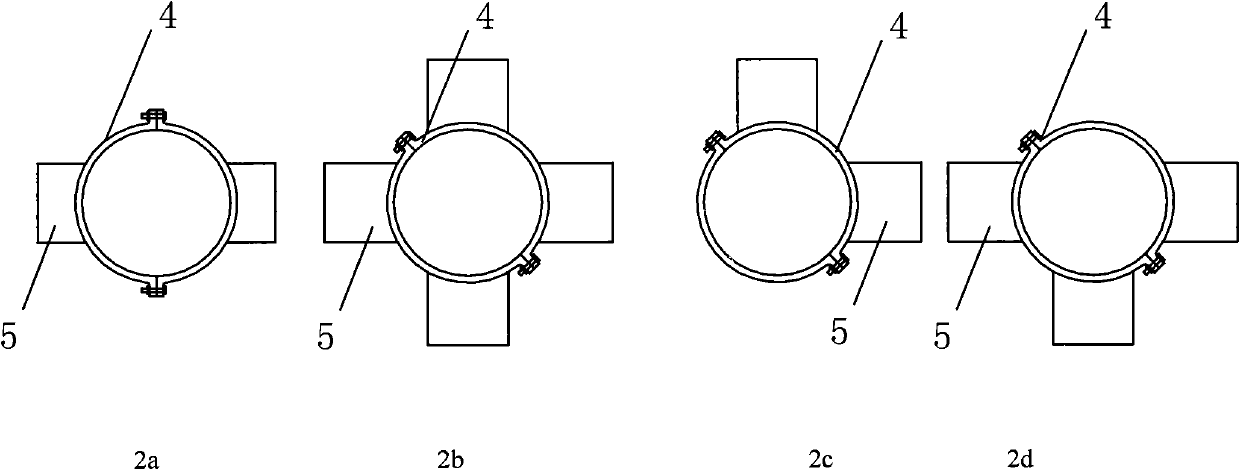

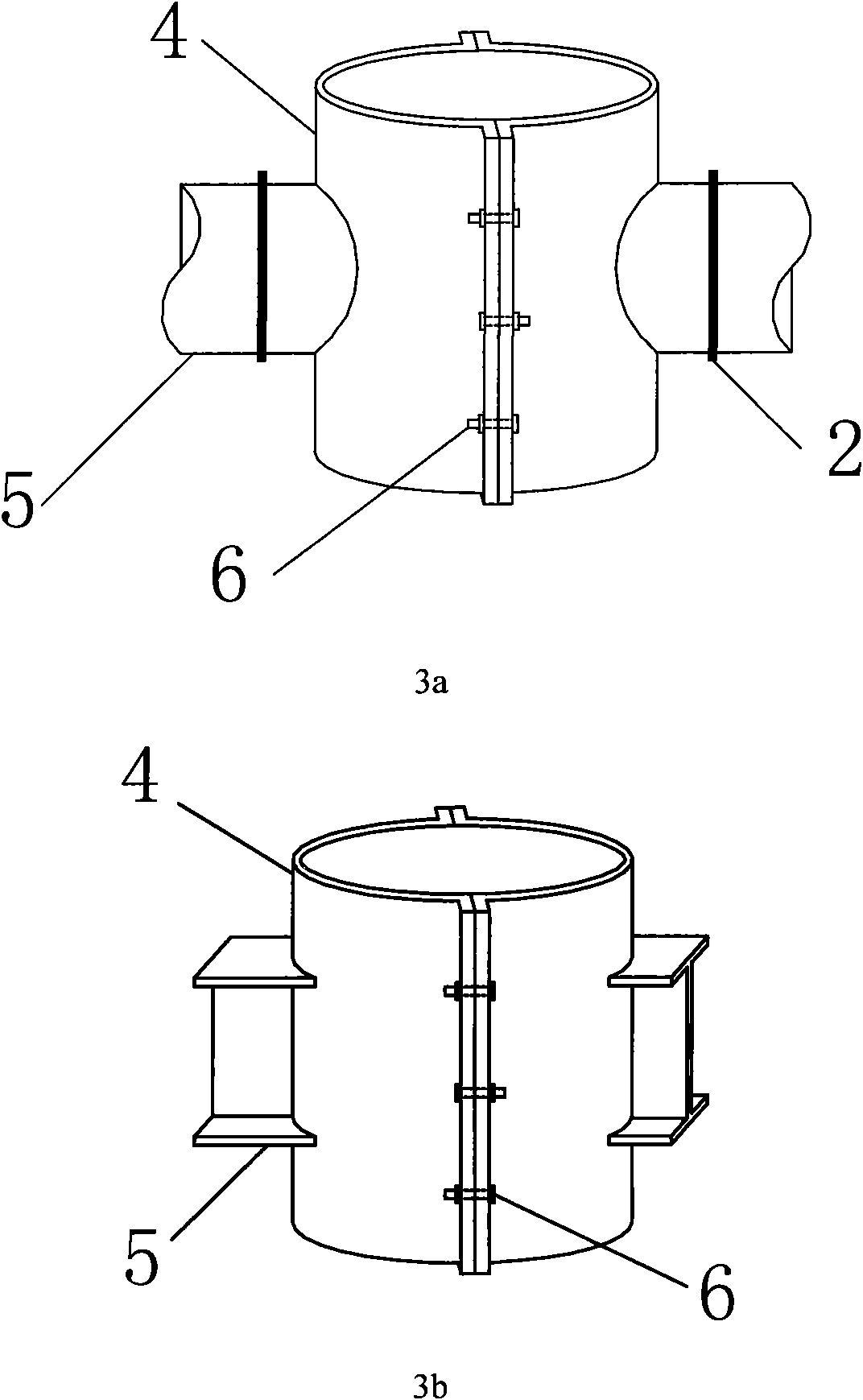

Circular steel tube concrete column and beam node connecting structure

InactiveCN101769011AFirmly connectedNode structure is simpleBuilding constructionsConcrete beamsEngineering

The invention discloses a circular steel tube concrete column and beam node connecting structure, which is characterized in that: the connecting structure comprises a node fastener, a bolt, a circular steel tube concrete column and a beam; the node fastener is composed of two sections of fastening rings and a joint, and the joint is in sleeve type and horizontally H-shaped type, the circular steel tube concrete column penetrates in the fastening rings and is fastened by the bolt, and the beam is connected by the joint on the fastener; the field installation is convenient without welding and the construction is rapid; the fastener is composed of two sections and is connected by the bolt after being fixed, and the circular steel tube concrete column is fixed by tightening force of the fastener; the circular steel tube concrete column is inserted in the sleeve type joint and is fixedly connected with the sleeve type joint by the bolt, and a concrete beam steel bar and a steel girder are welded with the horizontally H-shaped type joint; besides welding of the concrete beam steel bar and the horizontally H-shaped type joint, in the whole process, welding and complex distributed steel do not need, the construction is simple and rapid.

Owner:HOHAI UNIV

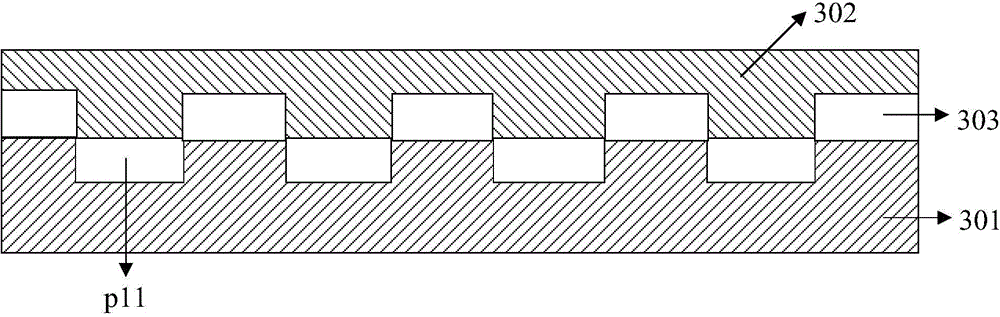

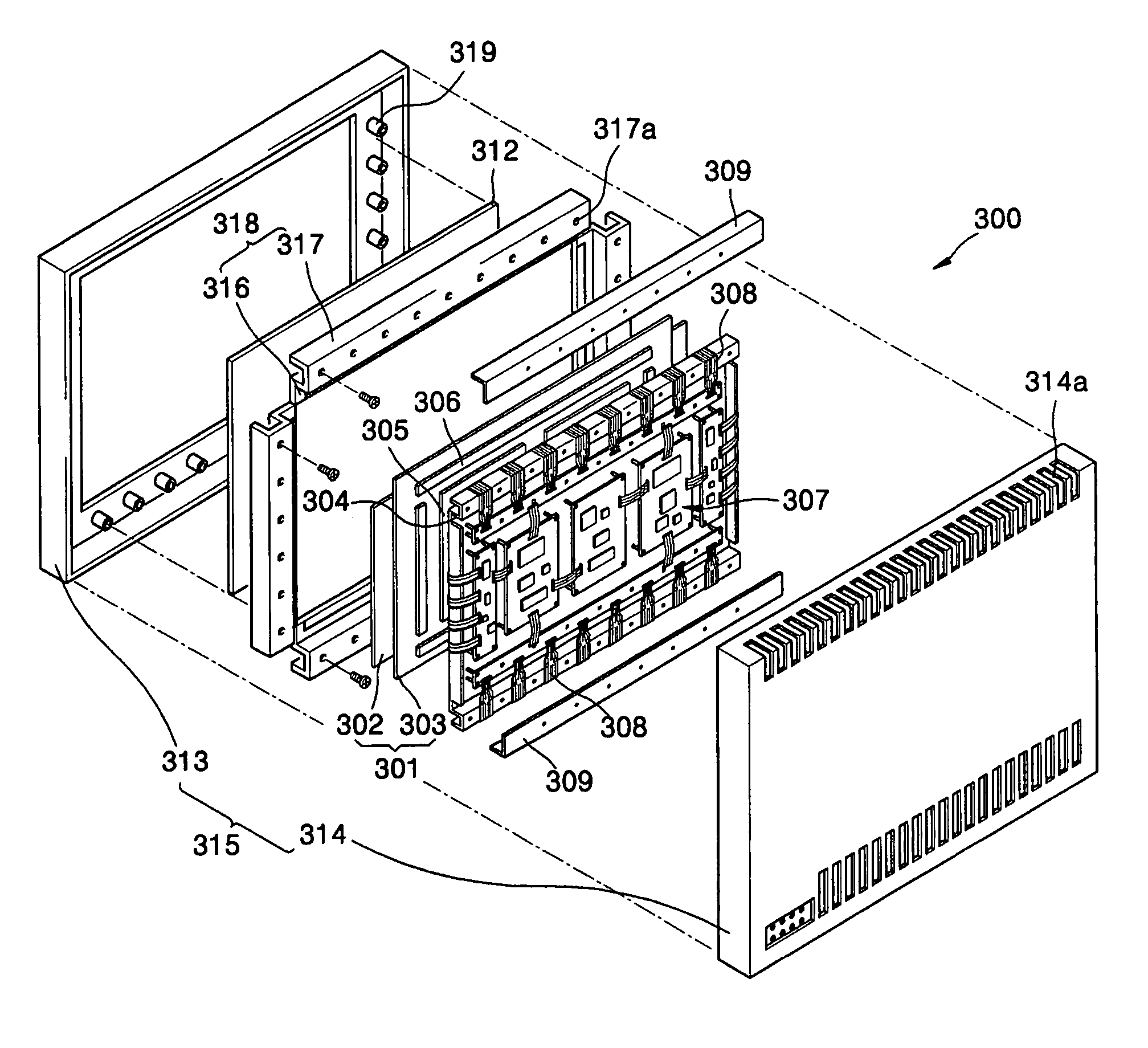

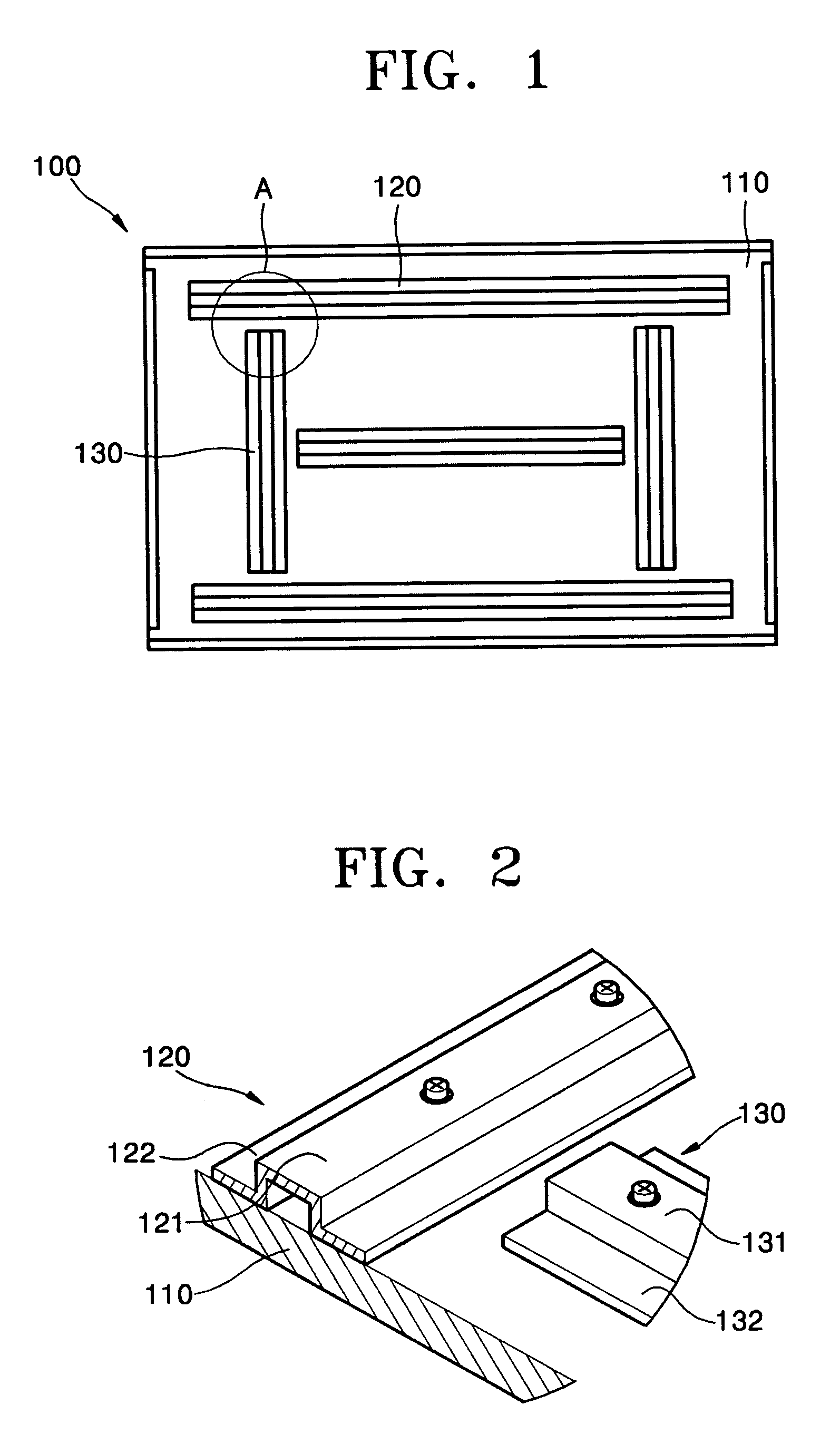

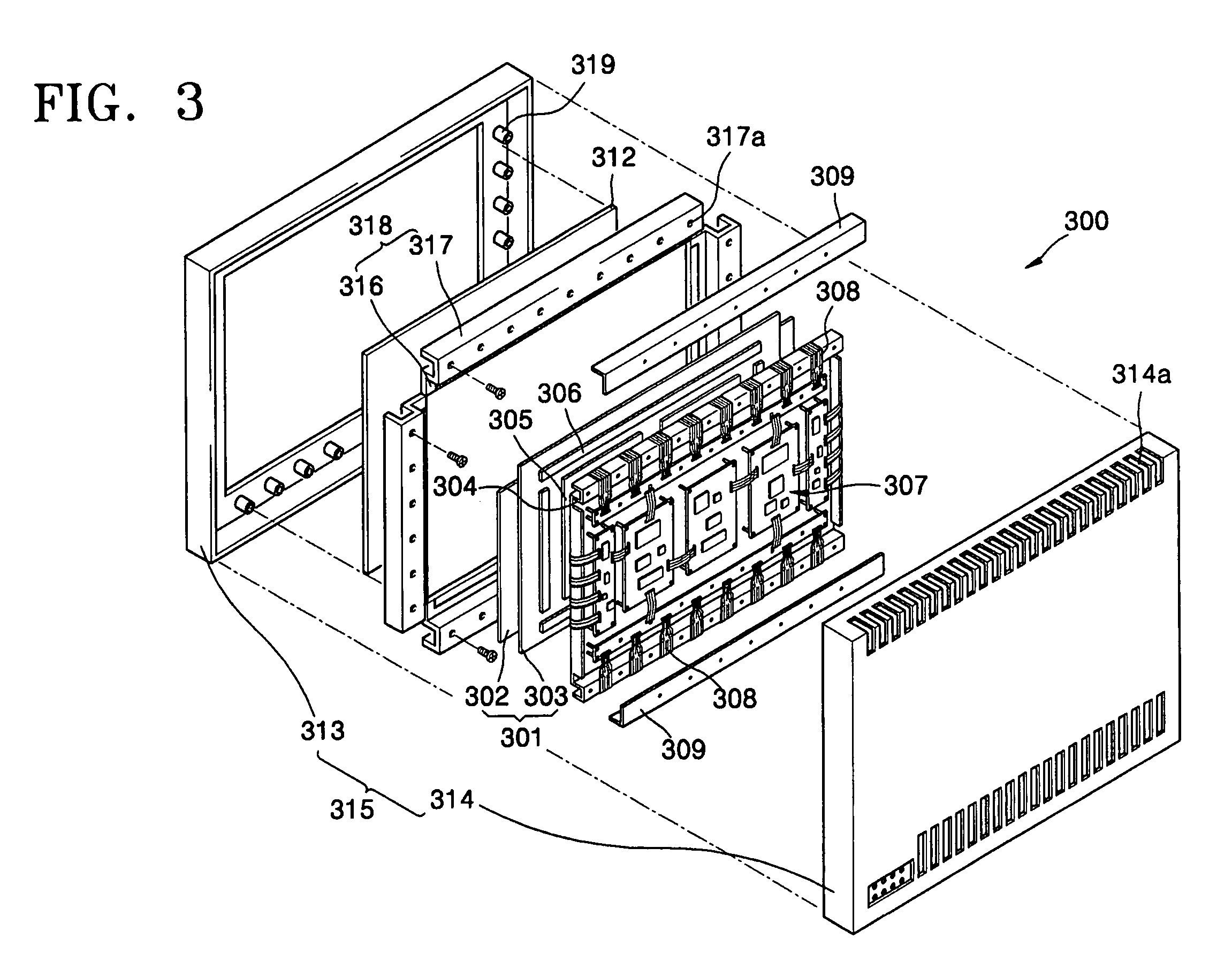

Chassis base assembly, method of manufacturing the chassis base assembly and plasma display panel (PDP) assembly using the chassis base assembly

InactiveUS20060133017A1High strengthAvoid stress concentrationDigital data processing detailsTube contructional detailsStress concentrationEngineering

In a chassis base assembly, a method of manufacturing the chassis base assembly, and a Plasma Display Panel (PDP) assembly, the method includes: preparing a raw flat panel for forming the chassis reinforcing member; forming ribs having a predetermined depth by processing the raw flat panel for forming the chassis reinforcing member using a drawing process; and forming an outer shape of the chassis reinforcing member using a notching process. There are no disconnections at corners where the horizontal and vertical reinforcing members meet to each other since the chassis reinforcing members are formed as a unitary body by a drawing process. Accordingly, stress concentrations at corners of the chassis reinforcing members are prevented, thereby increasing the strength of the chassis base assembly.

Owner:SAMSUNG SDI CO LTD

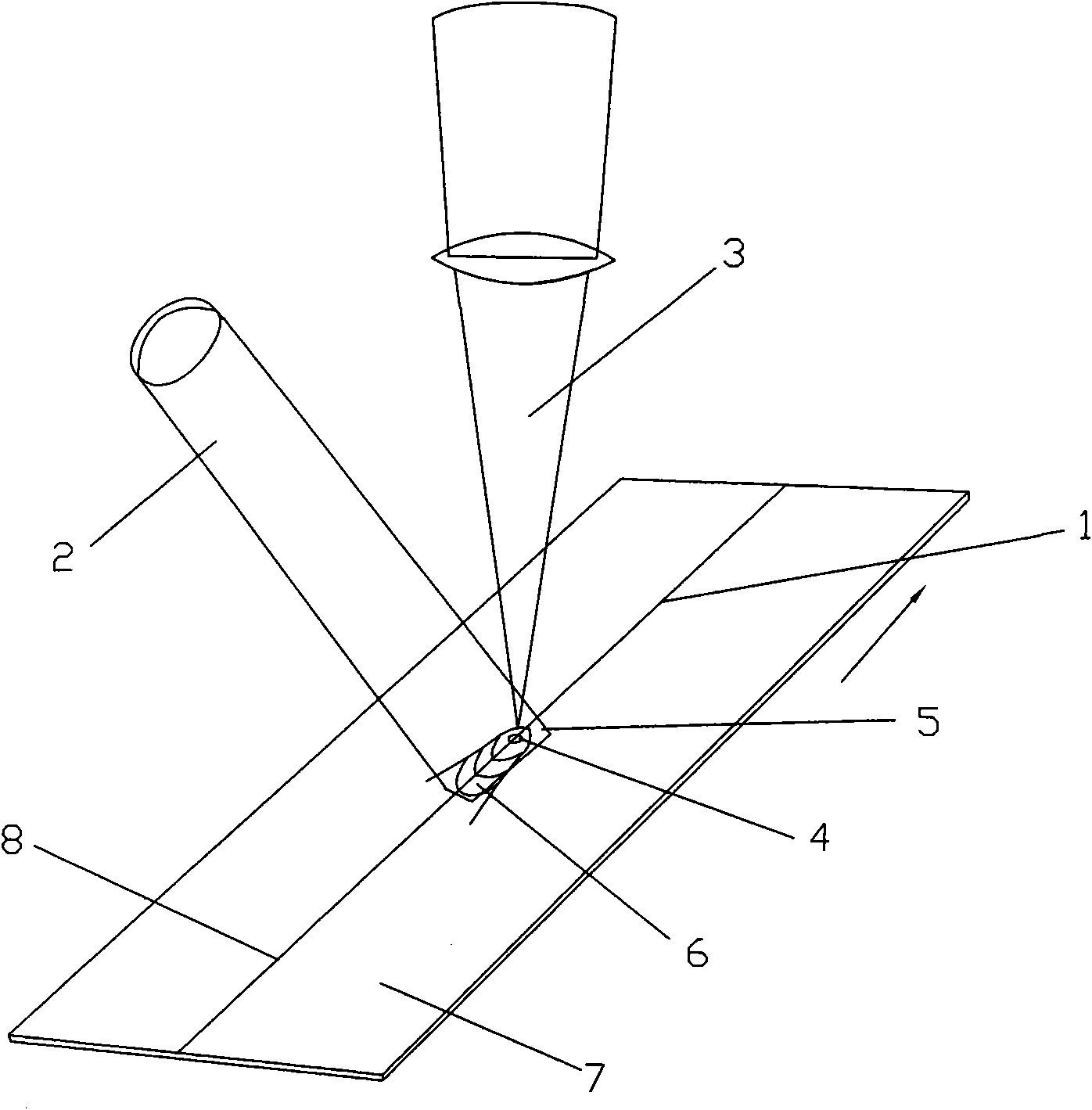

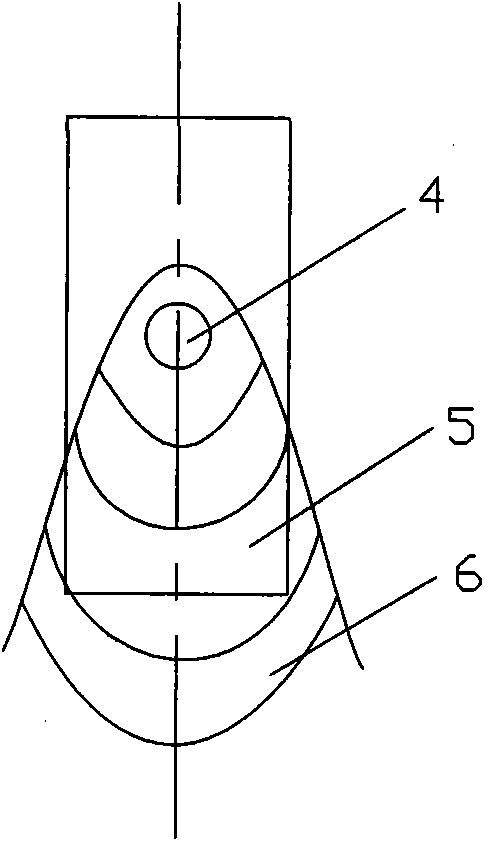

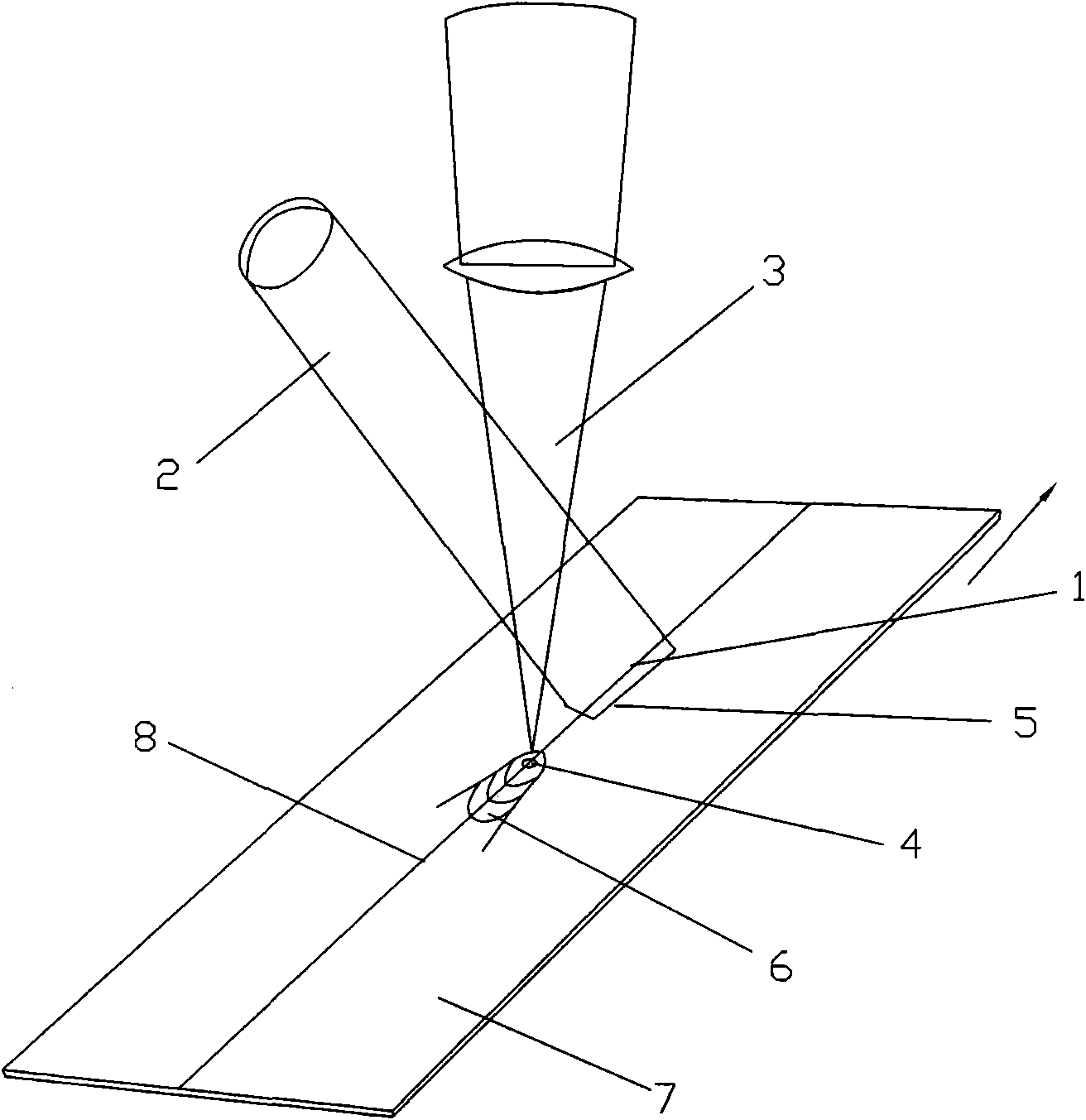

Compound welding method by using semiconductor laser and CO2 laser

InactiveCN101564799AFast preheating and homogenizationReduce temperature gradientLaser beam welding apparatusThermal treatmentCo2 laser

A compound welding method by using semiconductor laser and CO2 laser comprises the steps: using a semiconductor laser and a CO2 laser to be positioned on one side of a welding line of welded metals in a certain angle, adjusting a focusing position of the CO2 laser to cause a light spot of the CO2 laser to be positioned in the light spot of the semiconductor laser so that the welding direction is consistent with the slow axis direction of the semiconductor laser; using the semiconductor laser to pre-heat the welded metals, heating the part to be welded entering into the light spot of the semiconductor laser to 200-400 DEG C, using the CO2 laser to weld, and performing a post-welding thermal treatment to the welded metals by using the semiconductor laser for the welded parts of the welded metals welded by the welding of the CO2 laser. Due to synchronous pre-heating and post-heating treatments to the welding process, the invention can effectively solve the problem of cold cracking in high-strength steel welding and improve the quality of high-strength steel laser welding.

Owner:BAOSHAN IRON & STEEL CO LTD

Display panel and display device

PendingCN108766246AAvoid stress concentrationAchieve protectionCircuit bendability/stretchabilityCasings with display/control unitsStress concentrationDisplay device

The invention relates to a display panel. The display panel comprises a flexible screen body and buffer layers, wherein the flexible screen body comprises a first region and a second region, the second region comprises a bending transition area, a bending area and an extending area which are arranged in sequence, the extending area comprises the side, away from the first region, of the bending area, the bending transition area is connected to the bending area and the first region, and the bending transition area and the first region are coplanar; the buffer layers are arranged on the inner surface of the bending transition area and the inner surface of the bending area of the flexible screen body, and the buffer layers are of different hardness. According to the display panel, the buffer layers are of different hardness, the hardness of the buffer layer near an initial bending position can be set to be greater so as to support the region, near the initial bending position, of the flexible screen body, the phenomenon of stress concentration caused by over bending in the initial bending position of the flexible screen body is prevented, and the protection for the initial bending position of the flexible screen body is realized. The invention also relates to a display device.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

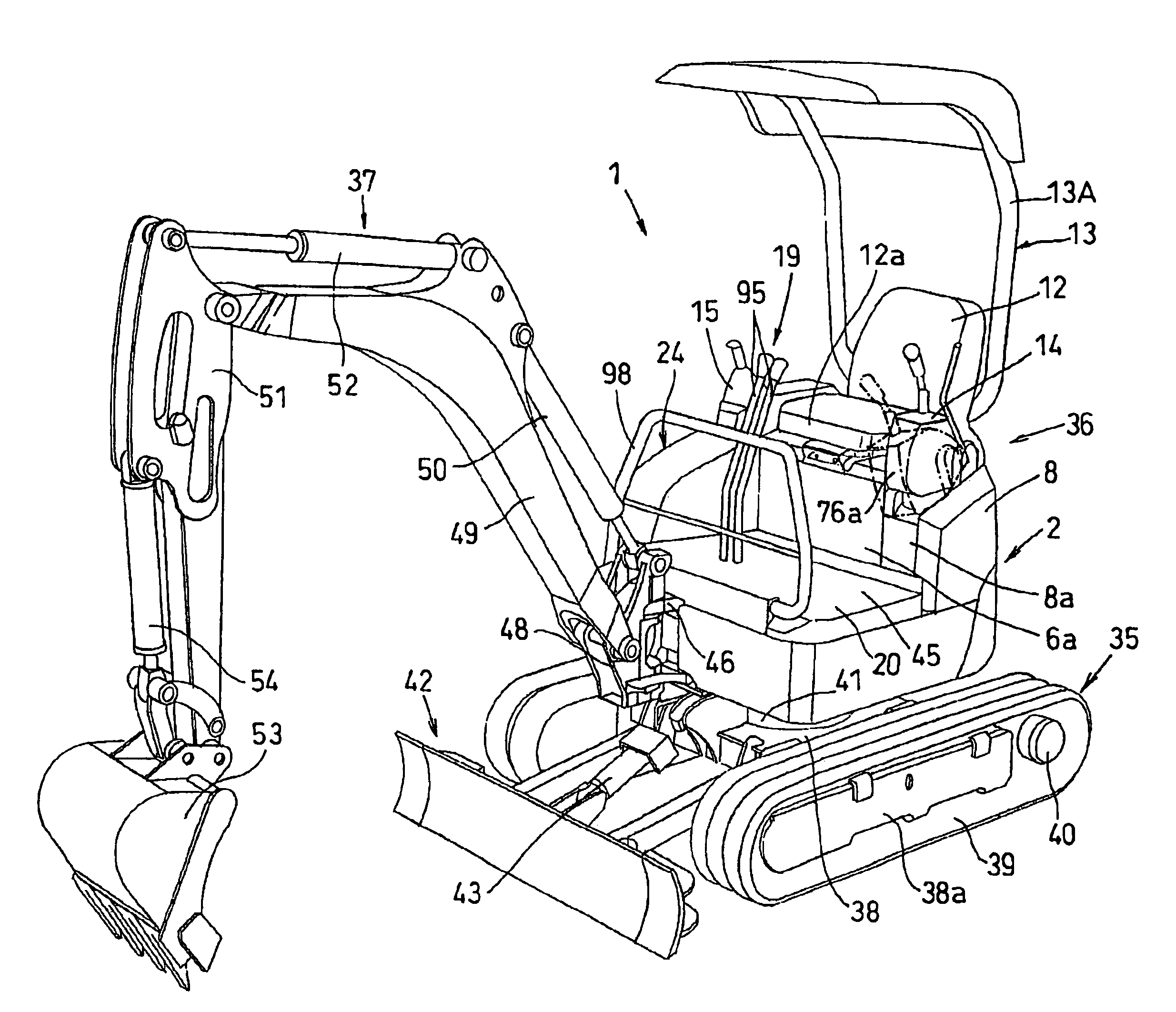

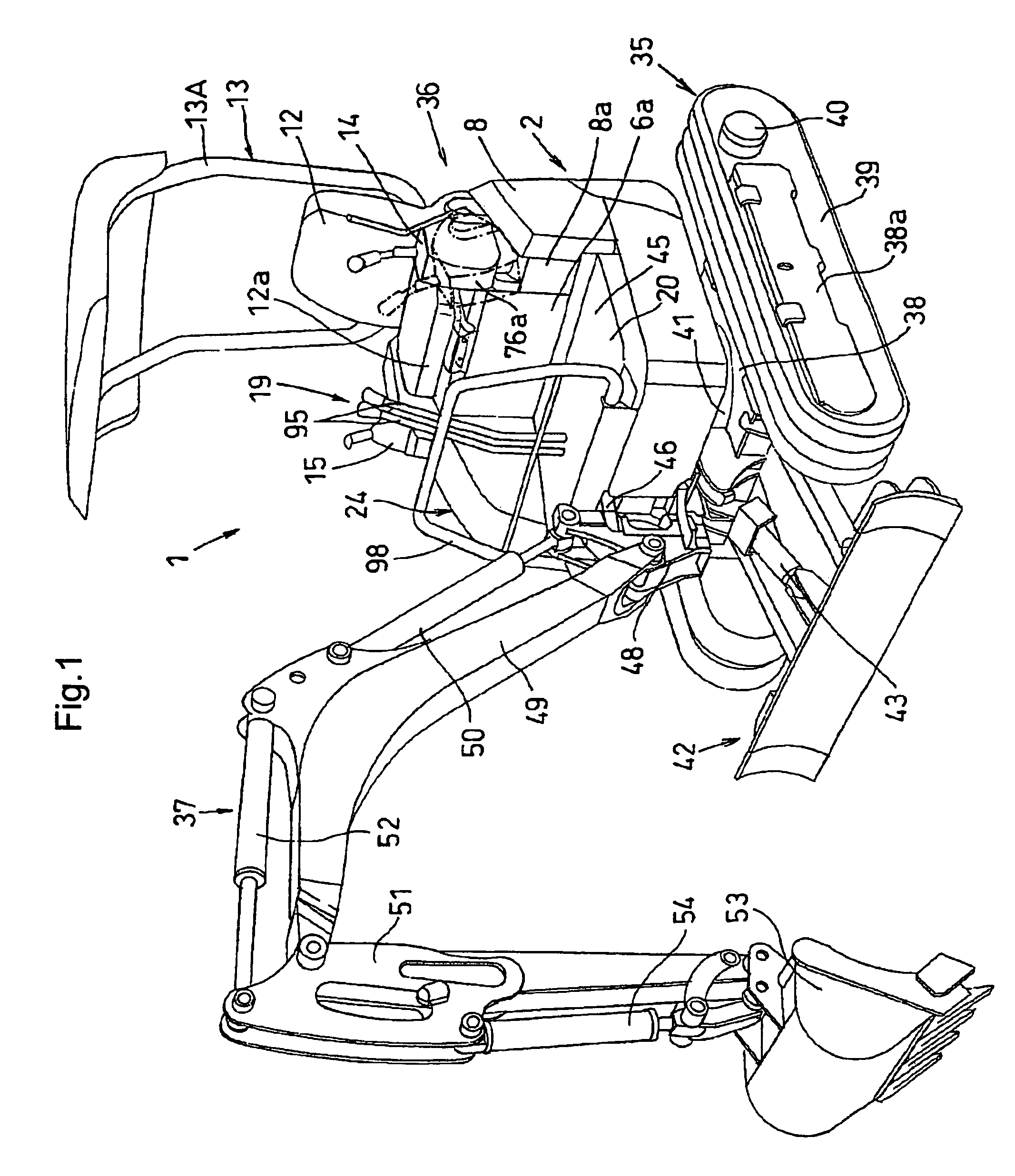

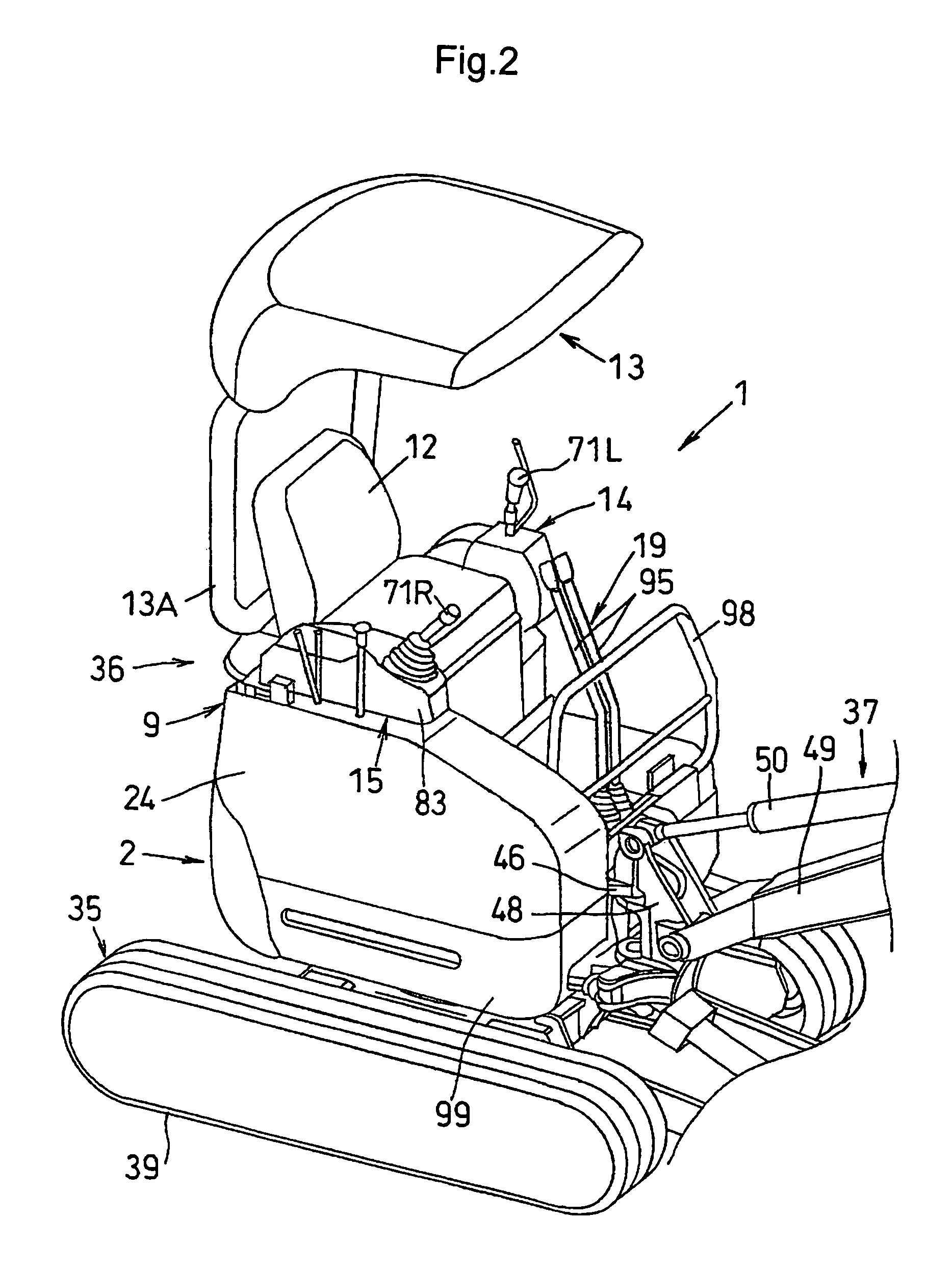

Swiveling work machine

ActiveUS7481289B2Avoid stress concentrationEasy to manufactureVehicle arrangementsMechanical machines/dredgersEngineeringMechanical engineering

A swiveling work machine includes a swivel deck, an engine and an operator's seat which are mounted on the swivel deck and a protector for the operator's seat mounted erect on the swivel deck. The swivel deck mounts, at a rear portion thereof, a support frame having four post portions disposed around the engine. Two rear post portions of the support frame have upper ends thereof connected via a rear beam member. The rear beam member includes an attaching portion for the operator's seat protector to which portion the protector is attached.

Owner:KUBOTA CORP

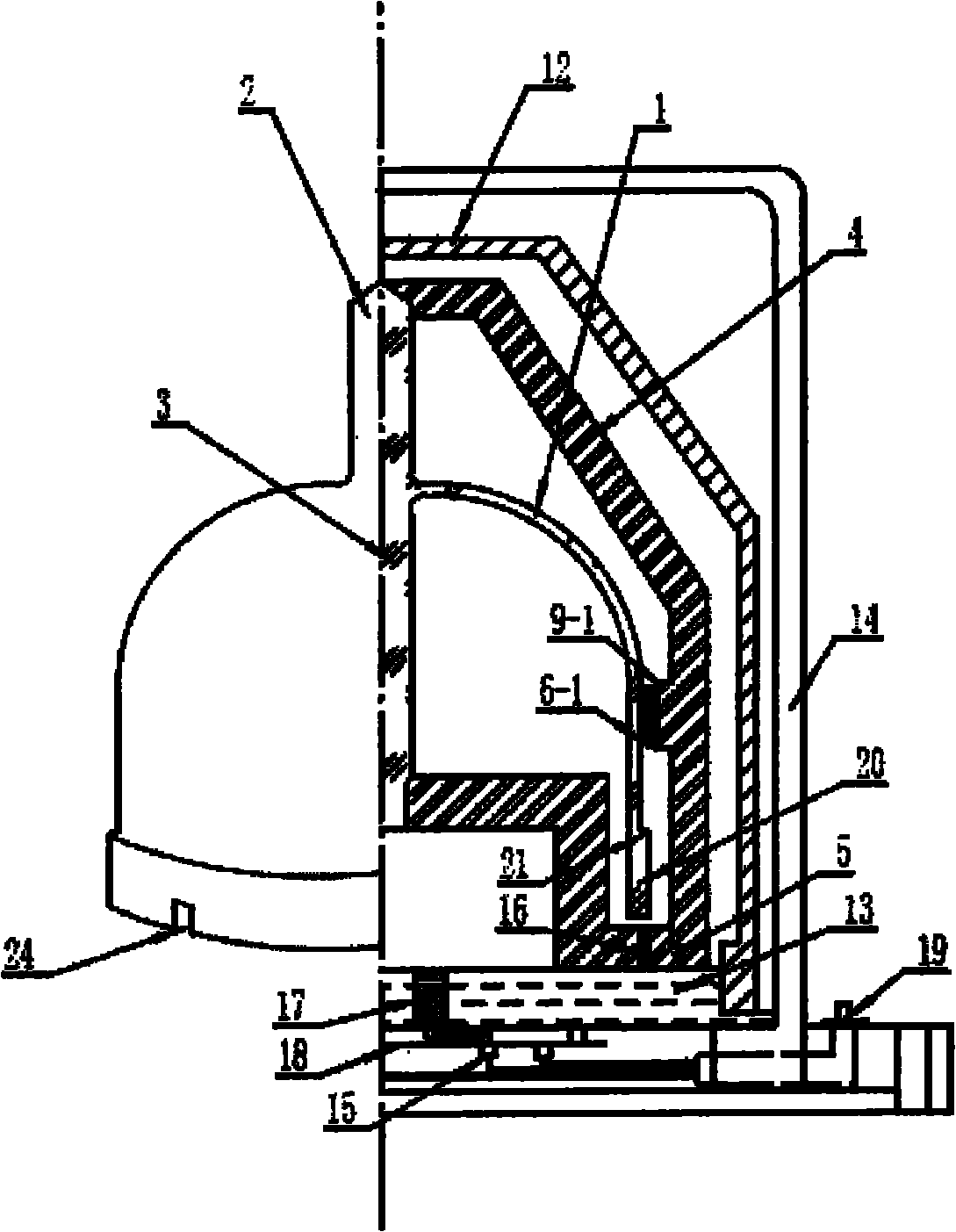

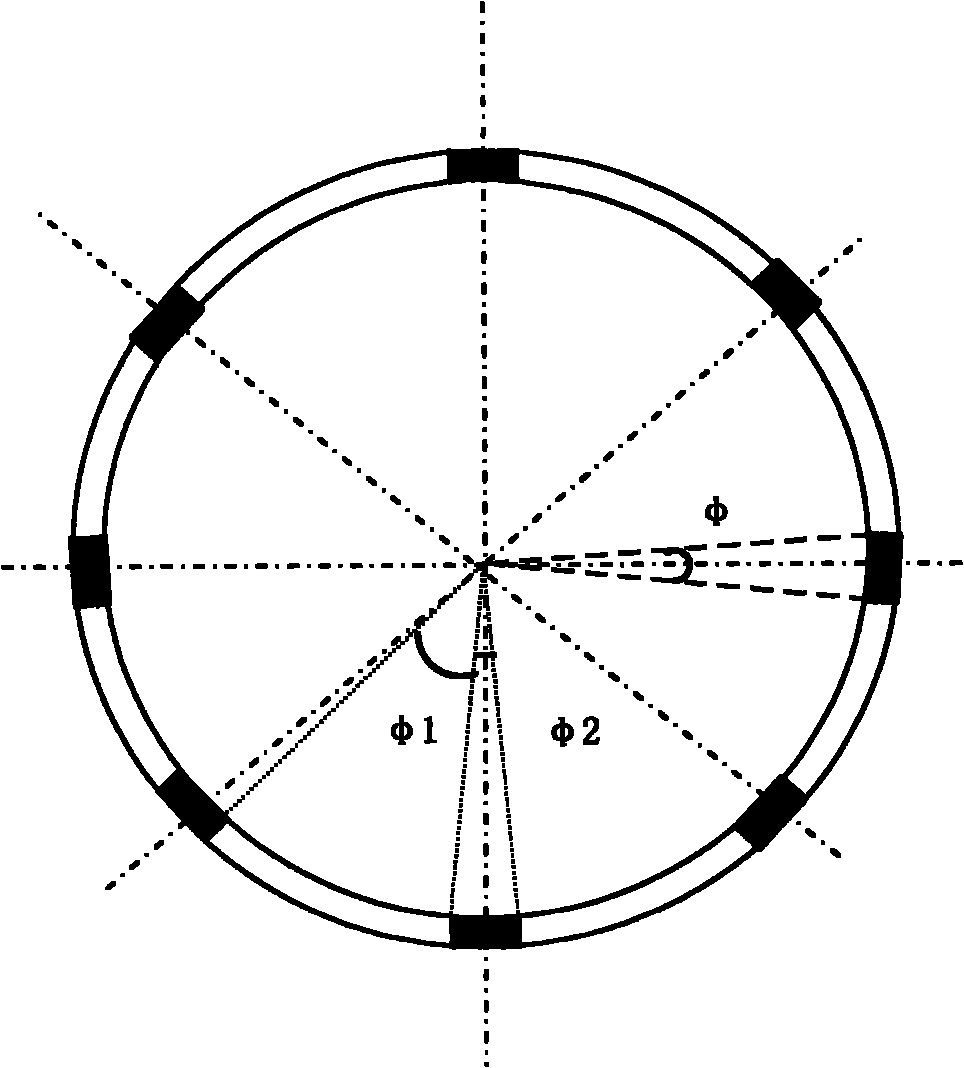

Campaniform oscillator type angular rate gyroscope

InactiveCN101968359AHigh quality factorImprove structural strengthSpeed measurement using gyroscopic effectsTurn-sensitive devicesInterior spaceVariable thickness

The invention relates to an angular rate gyroscope which has the variable-thickness axisymmetric multi-curved surface fusion structural feature and takes an oscillator with a campaniform structure as a sensitive element. The angular rate gyroscope consists of the oscillator, an oscillator support structure, an airtight cover, a cylindrical outer frame and a system circuit, wherein the oscillator is made of a quartz material and is machined integrally for forming with a phi-shaped support rod; the upper and the lower ends of the support rod are respectively fixed to the top end of a support cover and the central position of a support base plate; a driving electrode and a vibration mode stable electrode are attached to the support cover; a detection electrode is arranged in the inner space of the campaniform oscillator; the airtight cover and the cylindrical outer frame are sequentially arranged outside a support structure; and the system circuit is positioned between the bottom of the airtight cover and the outer frame. The angular rate gyroscope is suitable for the application field of measuring medium and low-precision angular rate in the high dynamic environment, and the oscillator with the campaniform structure has the high quality factors and high overload capacity resistance and has the characteristics of hold facility during power failure, simple structure, suitability for batch production and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

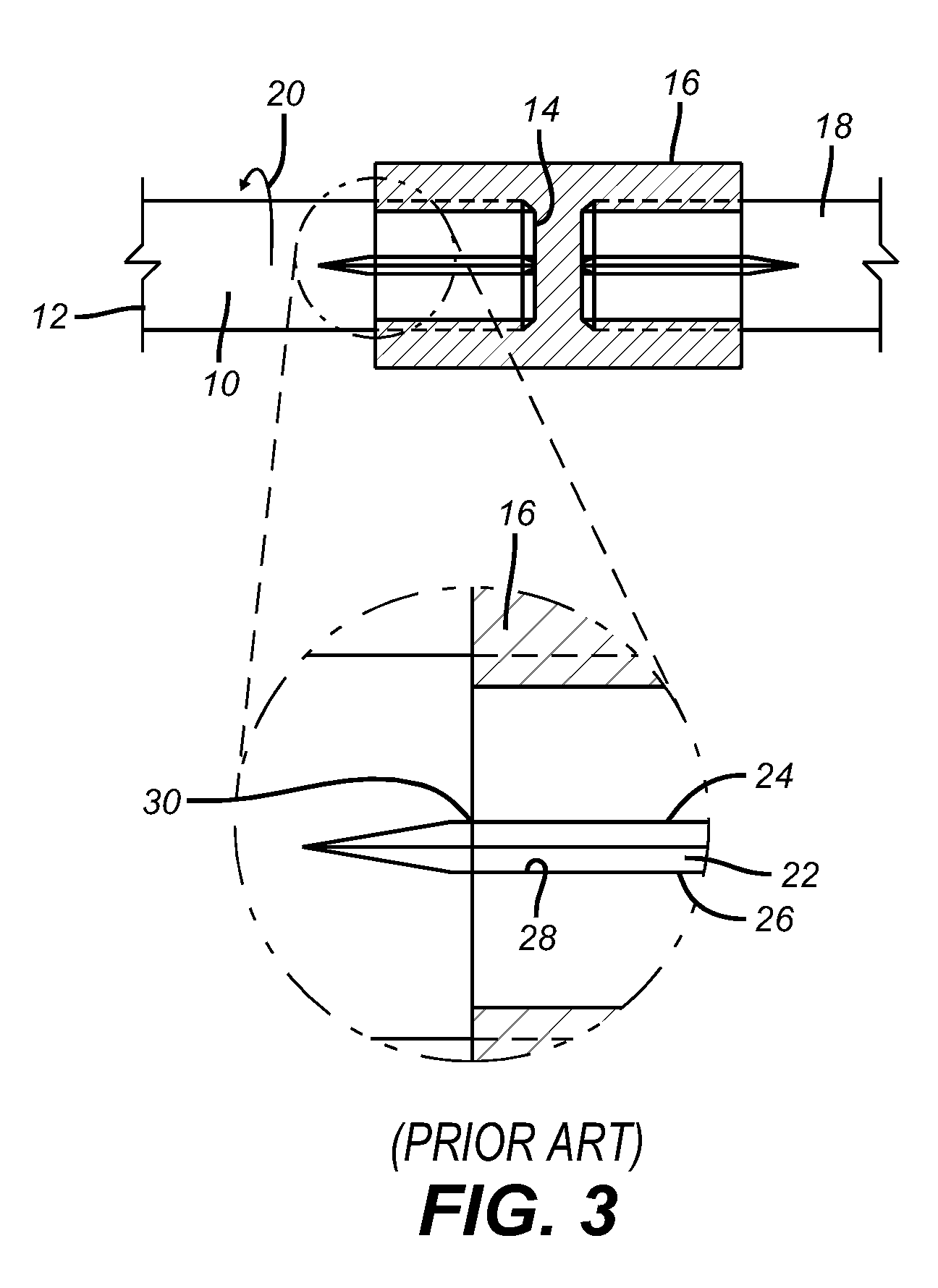

Spline Stress Distribution

InactiveUS20100303537A1Relieve pressureReduce stress concentrationYielding couplingRopes and cables for vehicles/pulleyStress distributionStress concentration

A connection between a shaft and a coupling that preferably involves involute shaped splines is designed to reduce stress from torque applied to the shaft by a drive motor. To avoid stress concentration at the mouth of the coupling on startup, the shaft splines are made to taper from the shaft end down to the spline end. As a result, the initial contact with the coupling splines occurs within the coupling and removed from it mouth. The shaft is allowed to elastically twist in response to the applied torque as the contact area increases with shaft twisting and the contact line moves toward the mouth of the coupling. Stress concentration that formerly occurred at the coupling mouth is alleviated as some shaft elastic twist occurs without adding stress to the shaft splines until coupling contact is made.

Owner:BAKER HUGHES INC

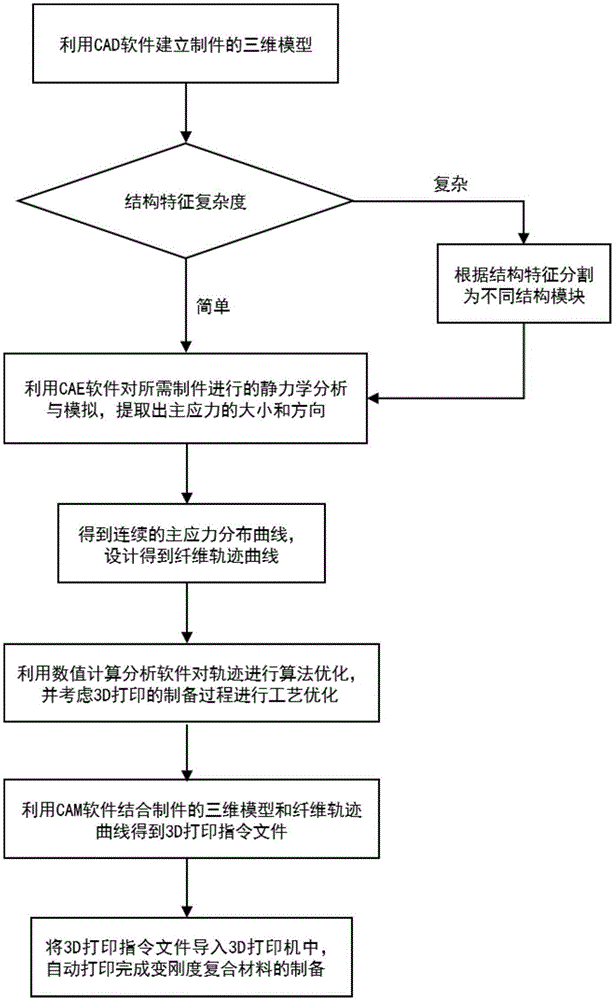

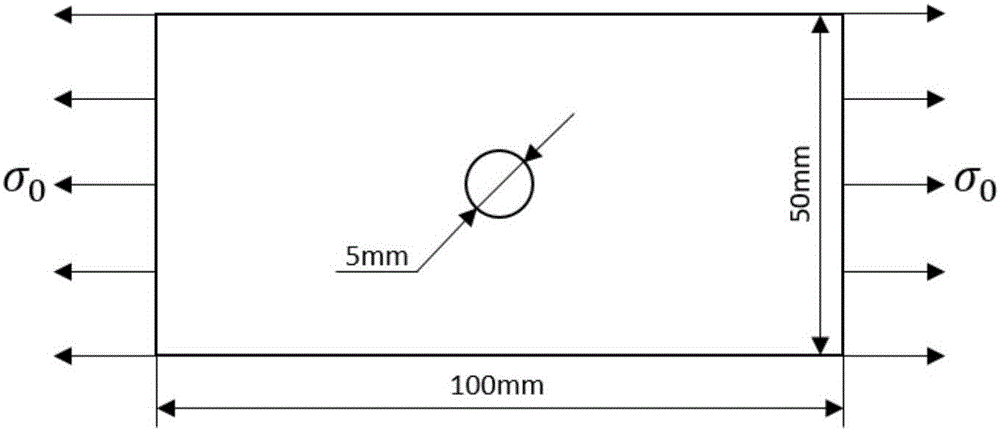

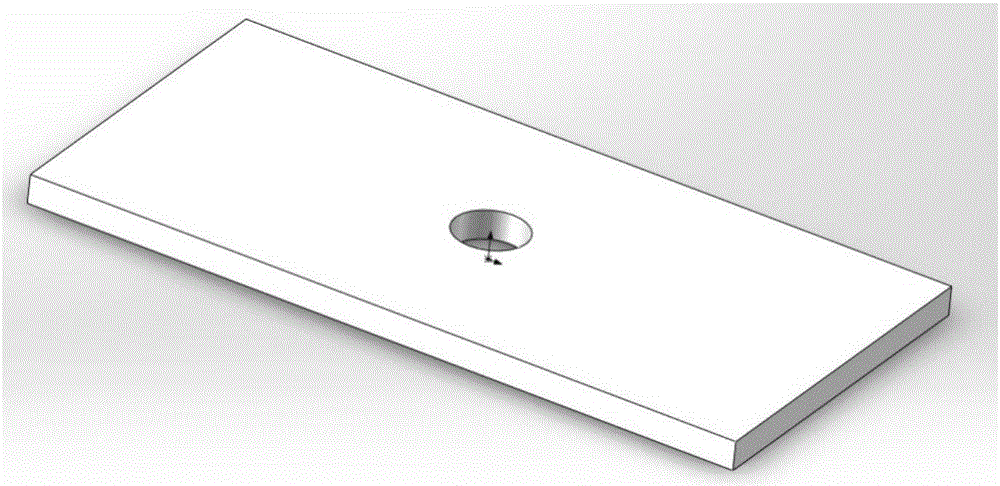

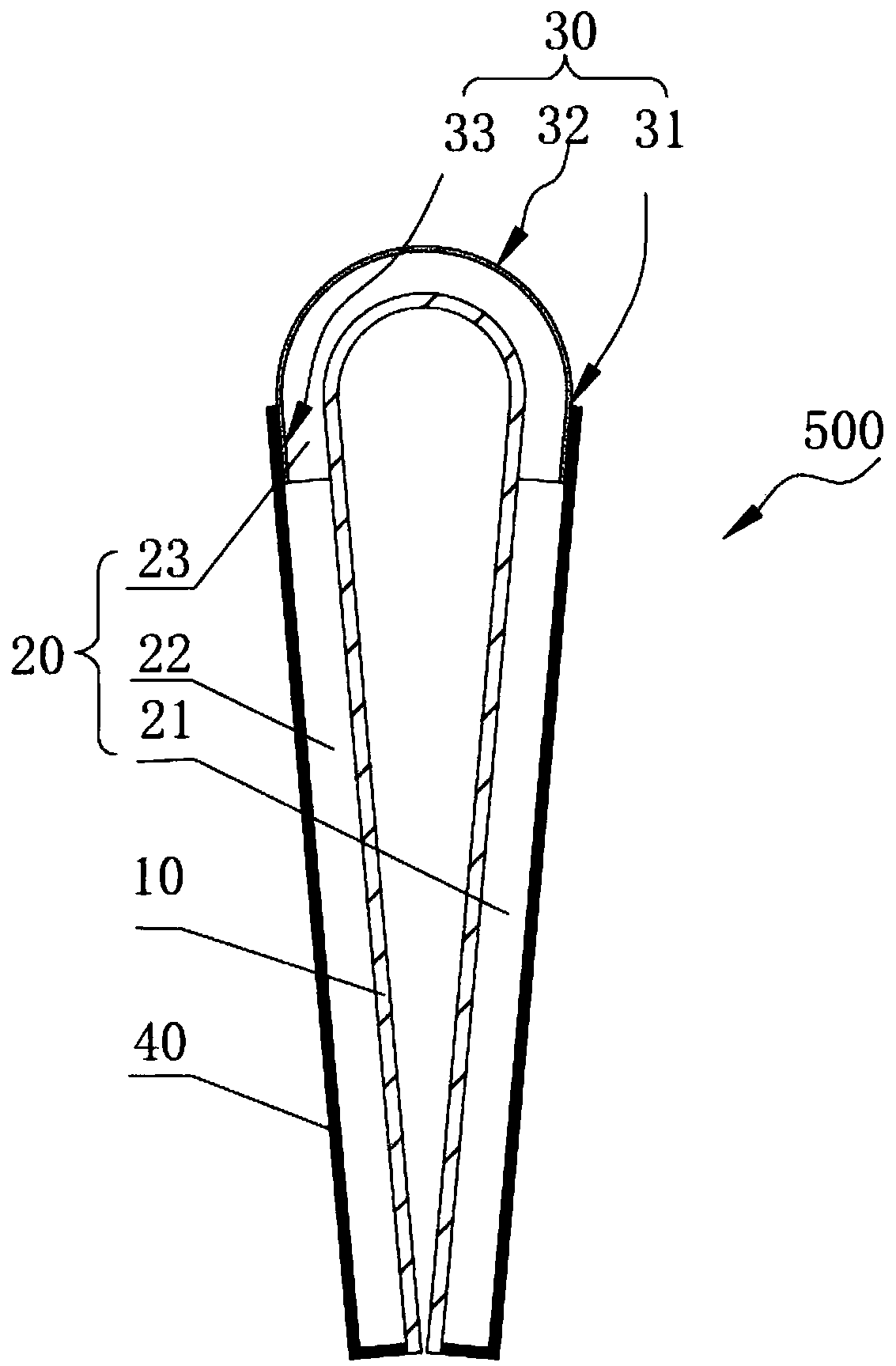

Function regulation and control structure production method based on continuous fiber composite material 3D printing

ActiveCN107433713AImprove mechanical propertiesStrong applicabilityAdditive manufacturing apparatus3D object support structuresThree dimensional modelComputer Aided Design

Owner:深圳协同创新高科技发展有限公司

Mobile terminal

ActiveCN105516409AExtended service lifeAvoid stress concentrationTelephone set constructionsWrinkle skinStress concentration

The invention provides a mobile terminal comprising a flexible display screen, a folding body, and an elastic plate. The flexible display screen is stacked on the surface of the folding body. The folding body comprises a first body, a second body, and a bent portion. The bent portion is connected with the first body and the second body in order that the first body is bent relative to the second body. The elastic plate comprises a first extended portion, a fixed portion, and a second extended portion which are successively disposed. The fixed portion is fixed to a side, far from the flexible display screen, of the bent portion. The first extended portion and the second extended portion may slide relative to the folding body. Stress concentration due to the wrinkle of the elastic plate can be prevented when the mobile terminal is unfolded and a technical effect of prolonging the service life of the flexible display screen is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

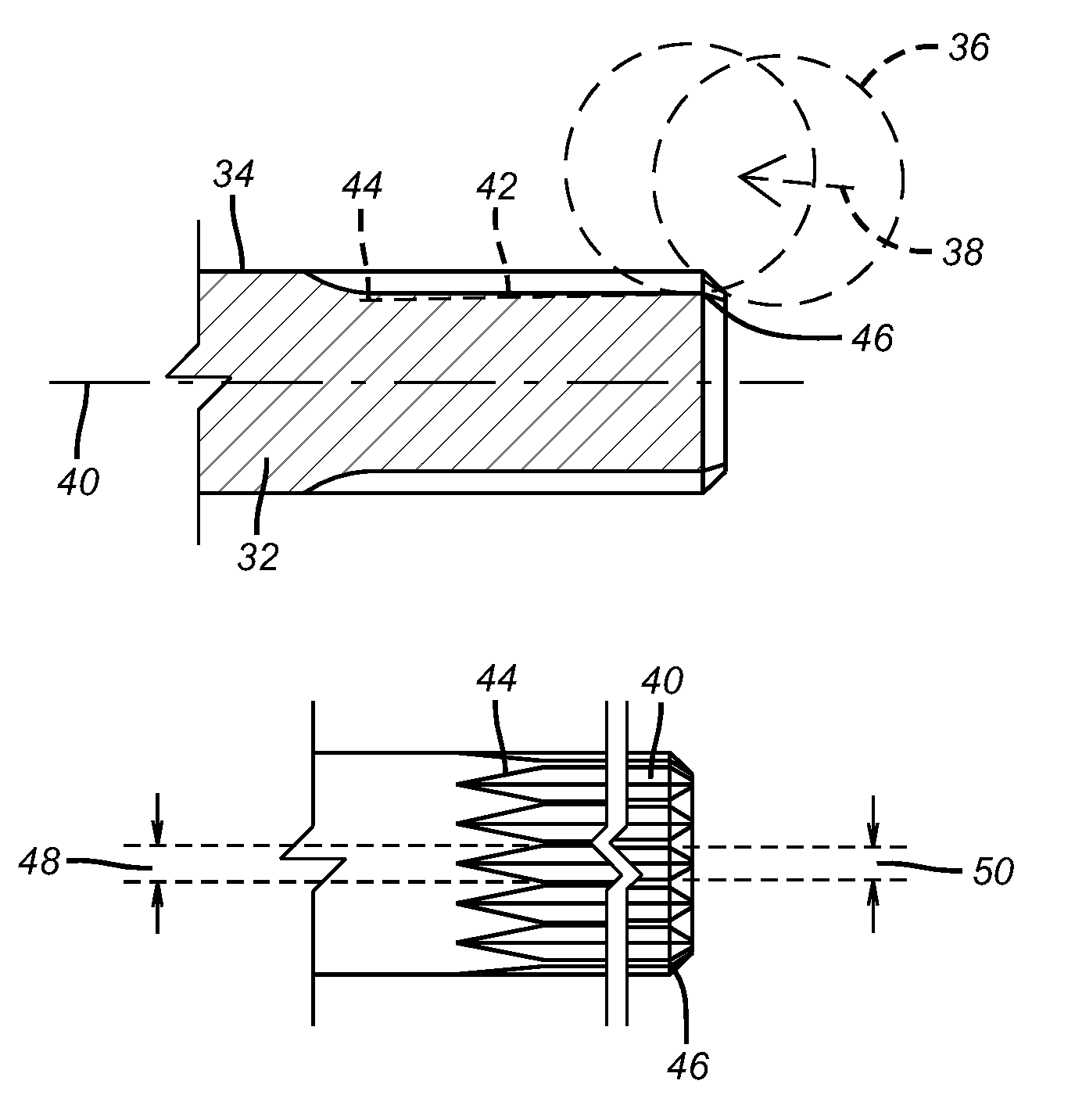

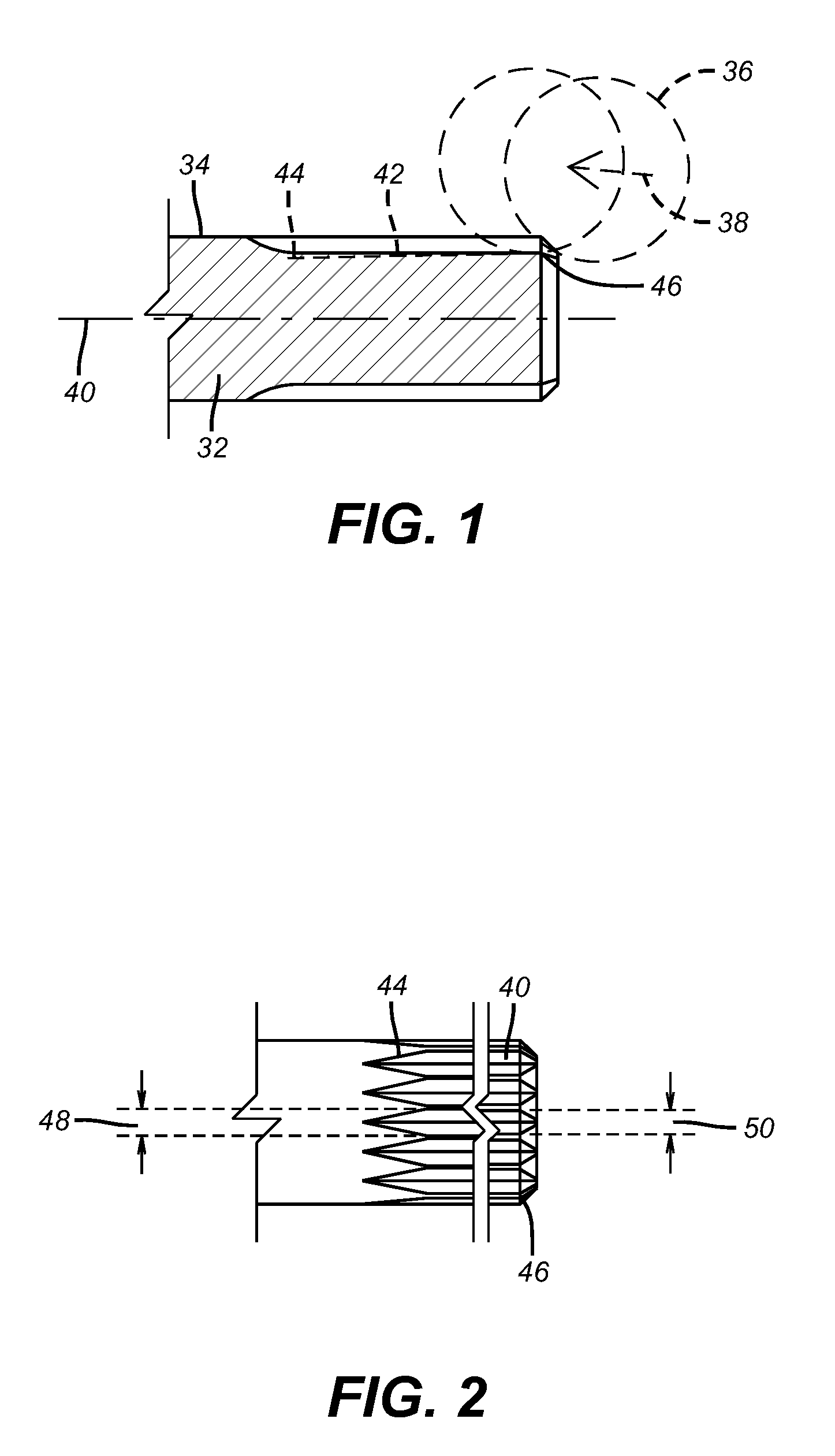

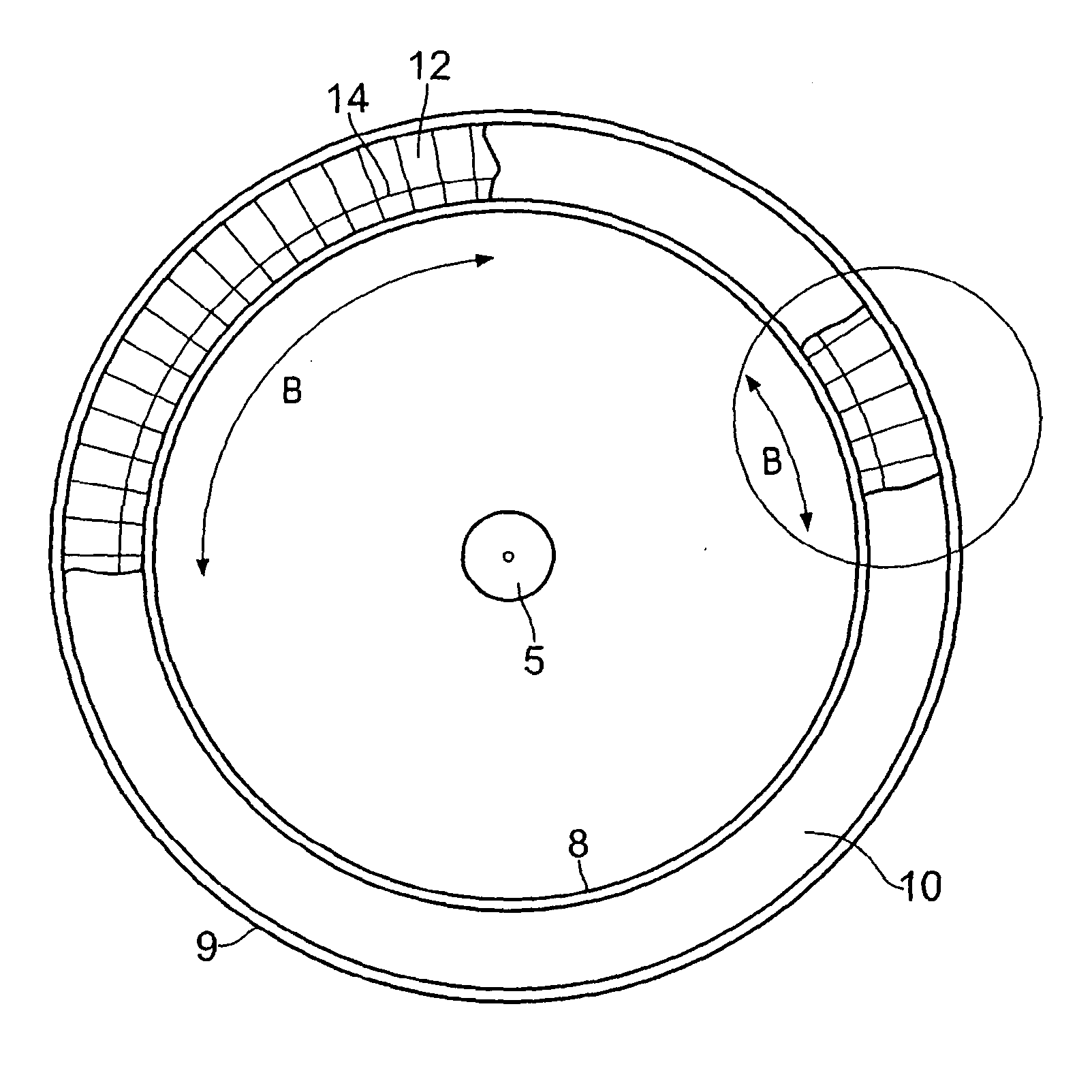

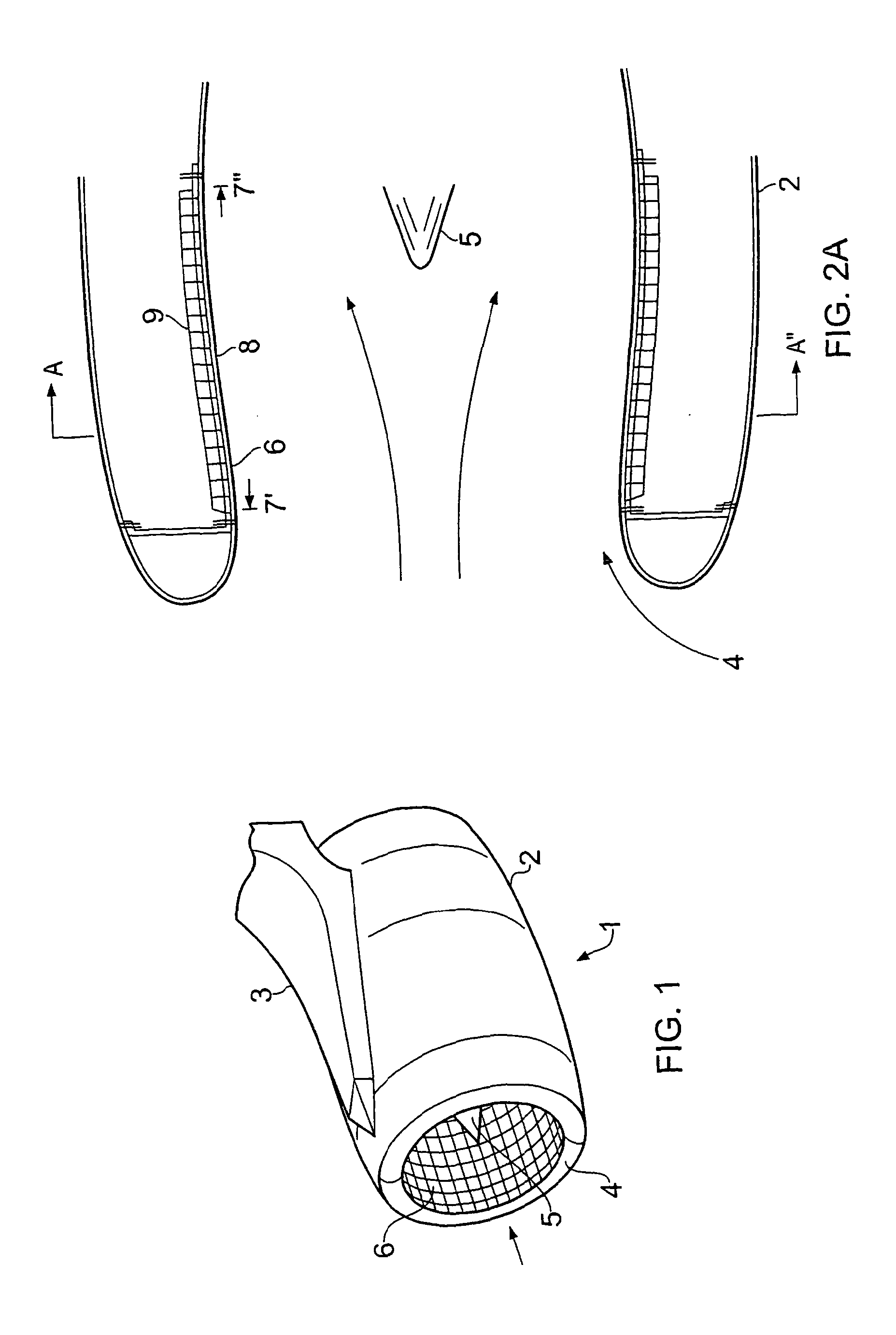

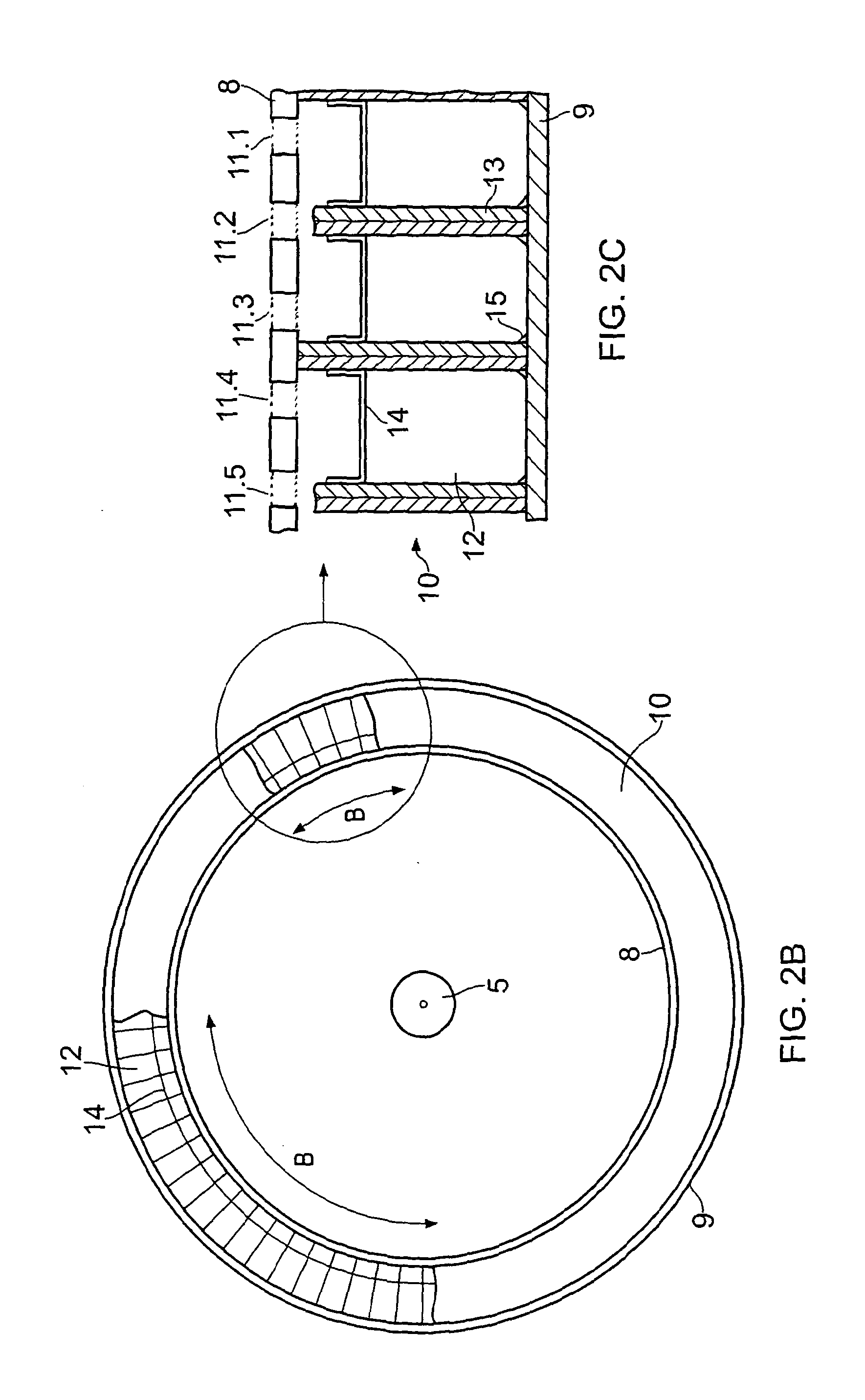

Seamless acoustic liner

ActiveUS20130075193A1Add partsAvoid introducingCeilingsTurning machine accessoriesEngineeringTurbine

The invention relates to a method of manufacturing a composite acoustic panel employed in an inlet passage of a gas turbine engine (1). The acoustic panel comprises a permeable face-layer (8), an impermeable backing sheet (9) and a sound absorbing layer (10) disposed therebetween. The method comprises a double polymerisation process for the face-layer and the remainder of the acoustic panel and finally a perforation step to perforate the face-layer according to a pre-determined perforation distribution (11.1, 11.2, 11.3, 11.4, 11.5).

Owner:GKN AEROSPACE SERVICES LTD

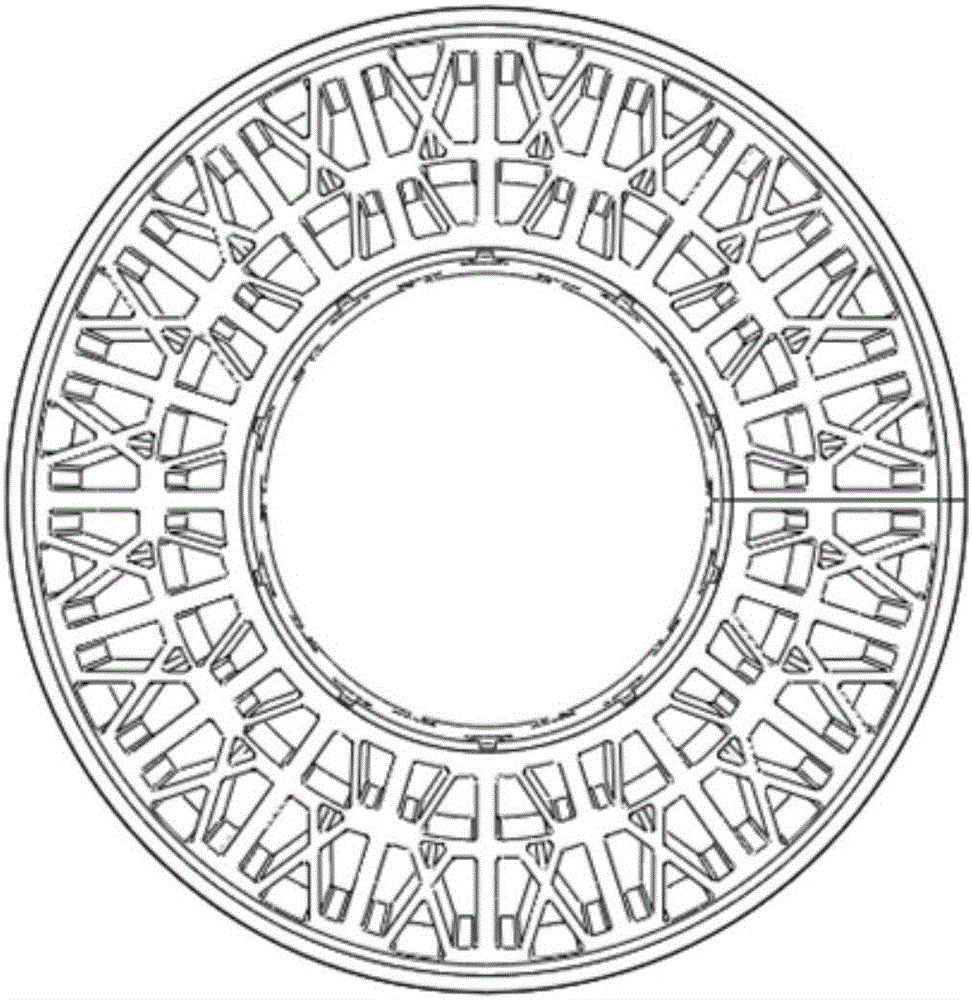

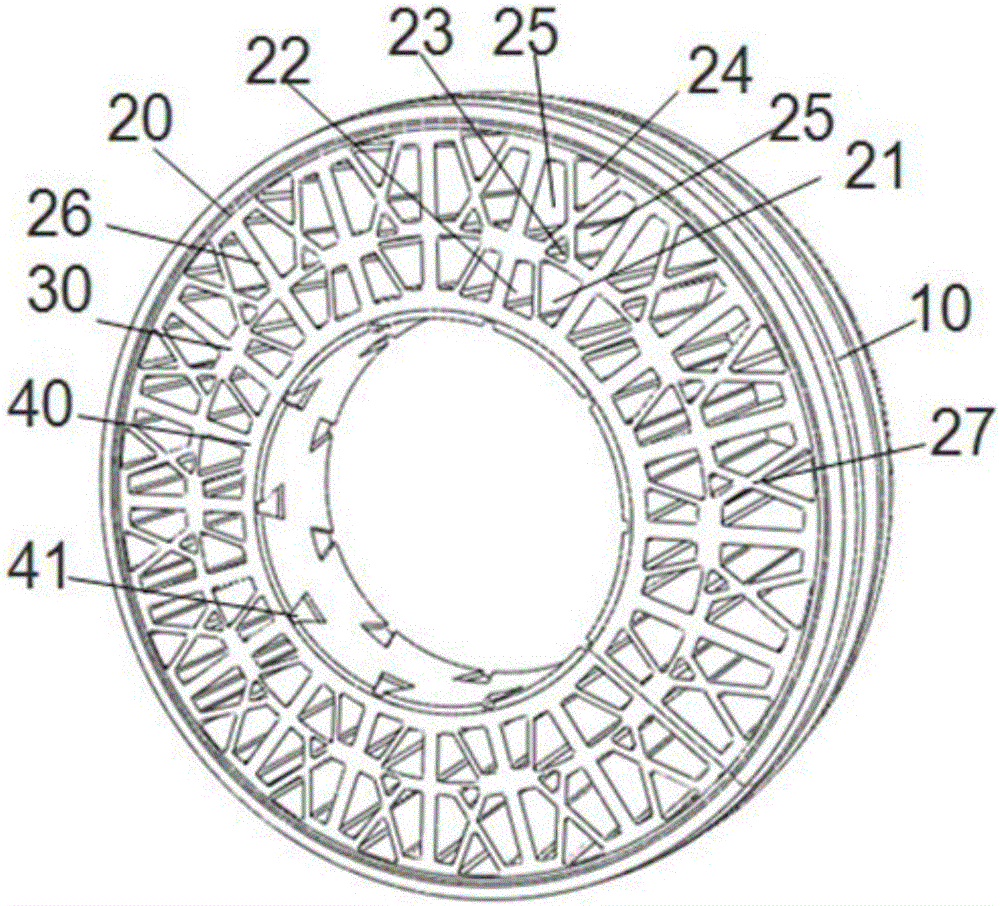

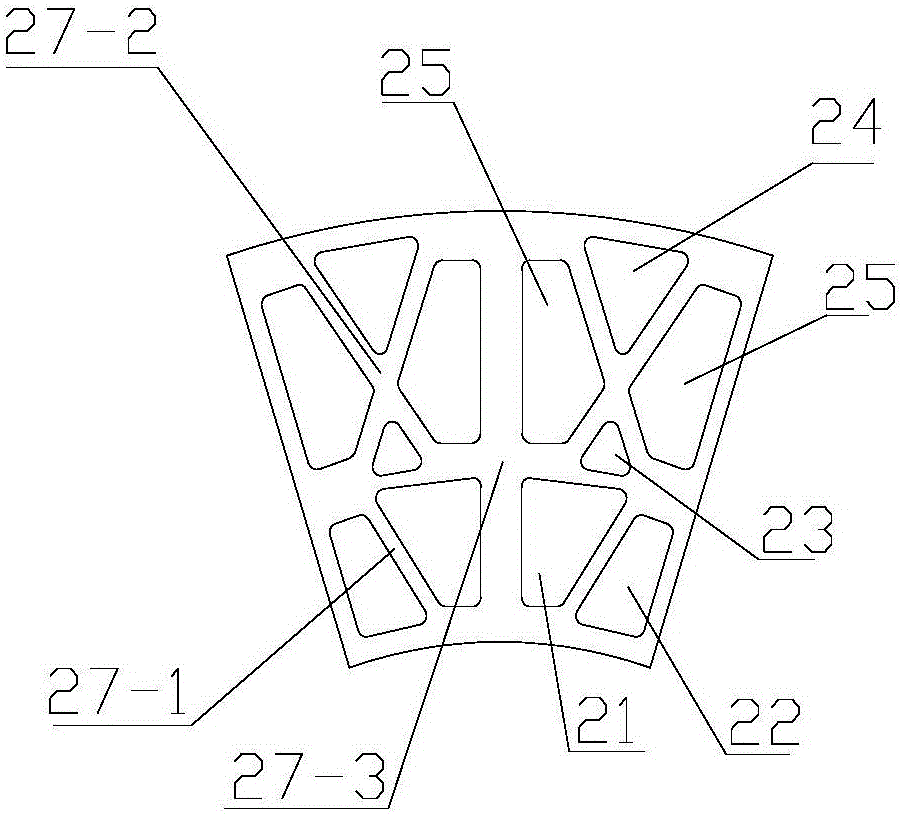

Non-pneumatic safety tire

The invention provides a non-pneumatic safety tire, which comprises a tread, an outer ring, a support body and an inner ring from the outside to the inside in order. The tread is bonded or vulcanized on the outer ring, the support body is arranged between the inner ring and the outer ring along the radial direction and circumferential direction from the outer ring, multiple groups of damping units and support ribs, each group of damping unit consists of two sets of damping structures, and two sets of damping structures are circumferentially disposed with the radial direction as the symmetric axis. The non-pneumatic tire provided by the invention has good bearing capacity, and by means of wheel disk thickening and multiple damping hole diameter change, the bearing capacity of the tire can be enhanced. The non-pneumatic safety tire not only has the carrying capacity and static rigidity characteristics of pneumatic tyres, but also has rationally distributed ground pressure, the abrasion resistance and trip distance of the tire are increased, especially the reasonable distribution of multiple damping holes and support ribs in the radial and circumferential direction can enhance the carrying capacity of the tire and also can improve the static rigidity of the tire.

Owner:QINGDAO UNIV OF SCI & TECH

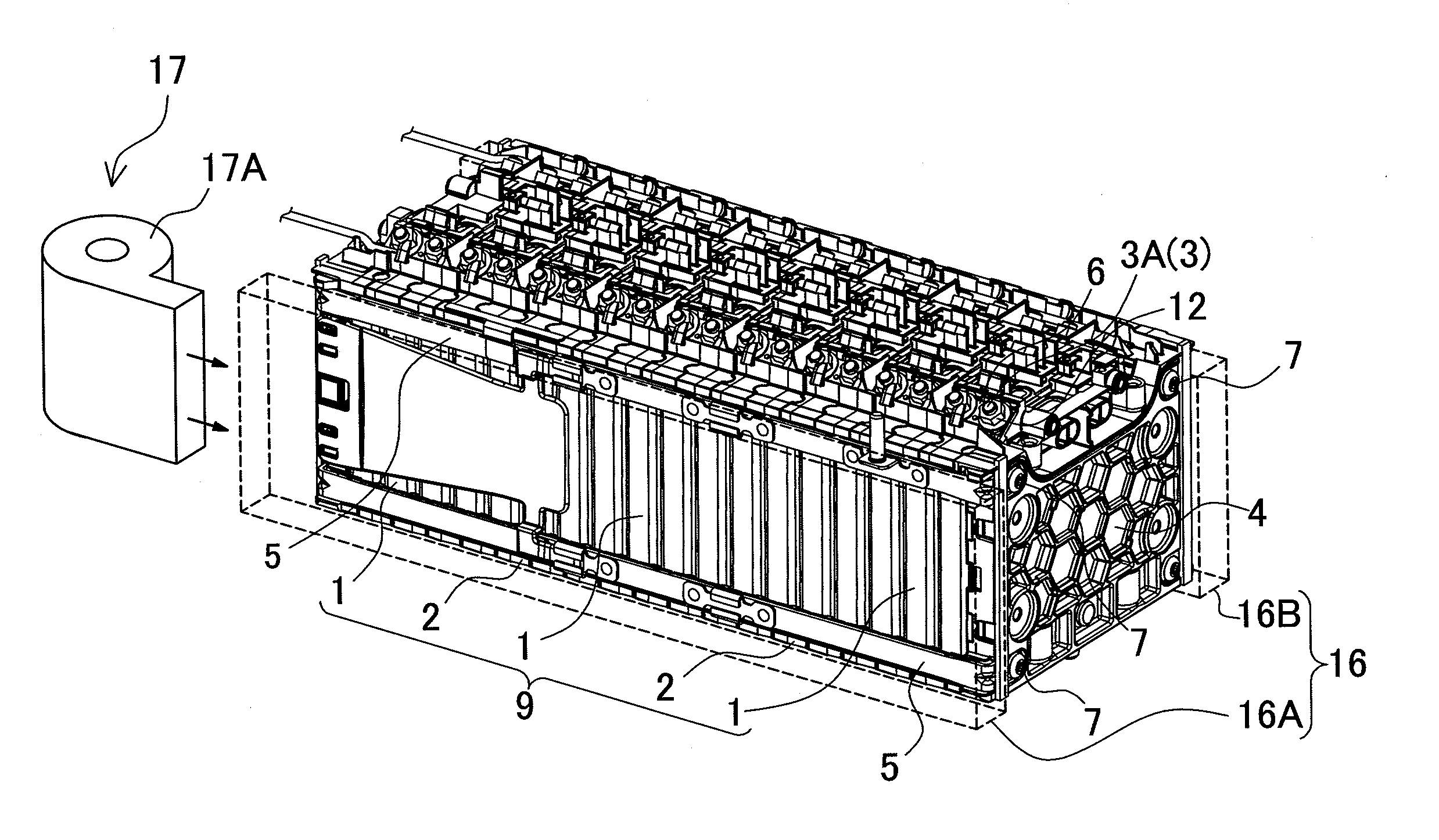

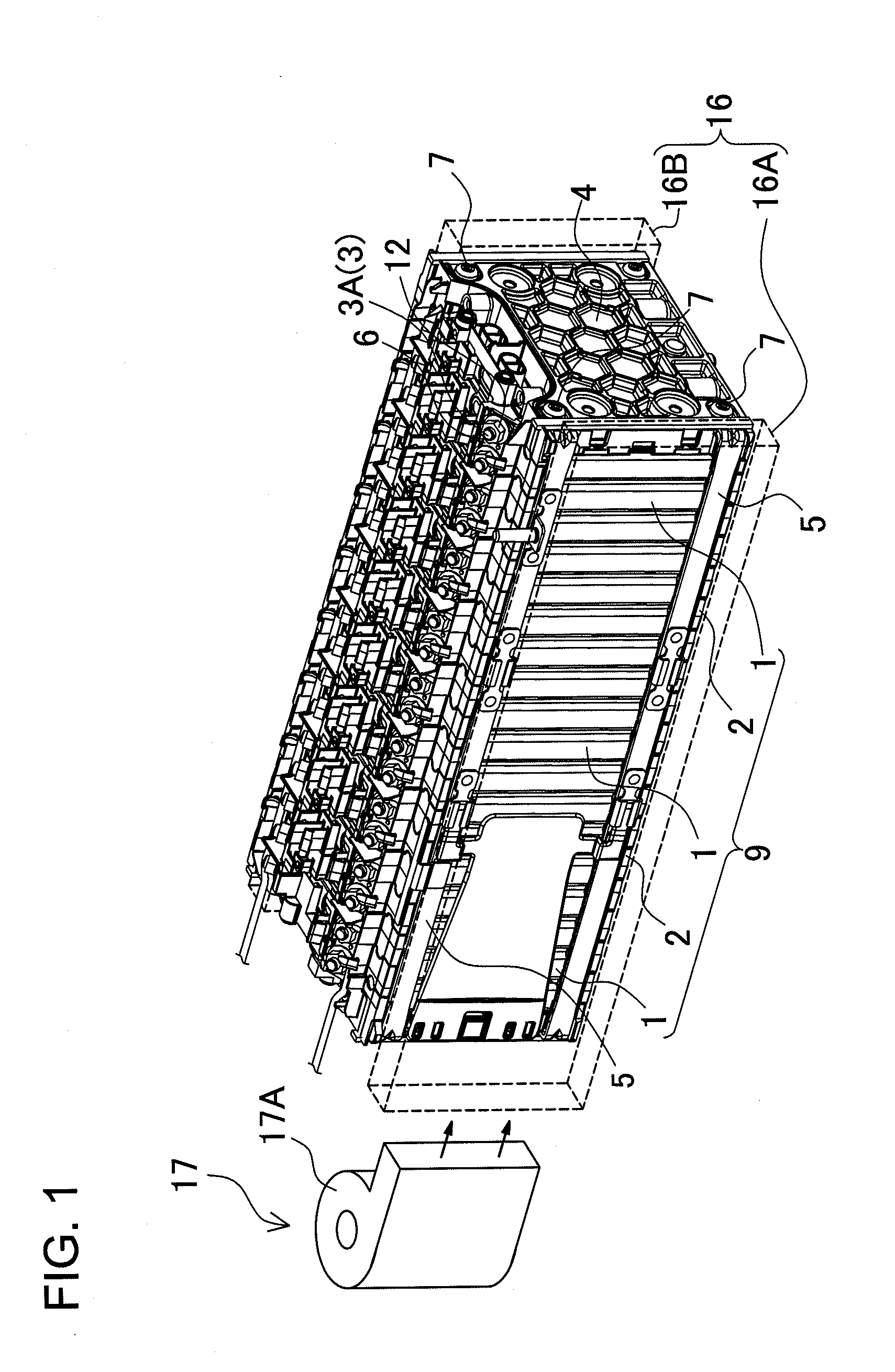

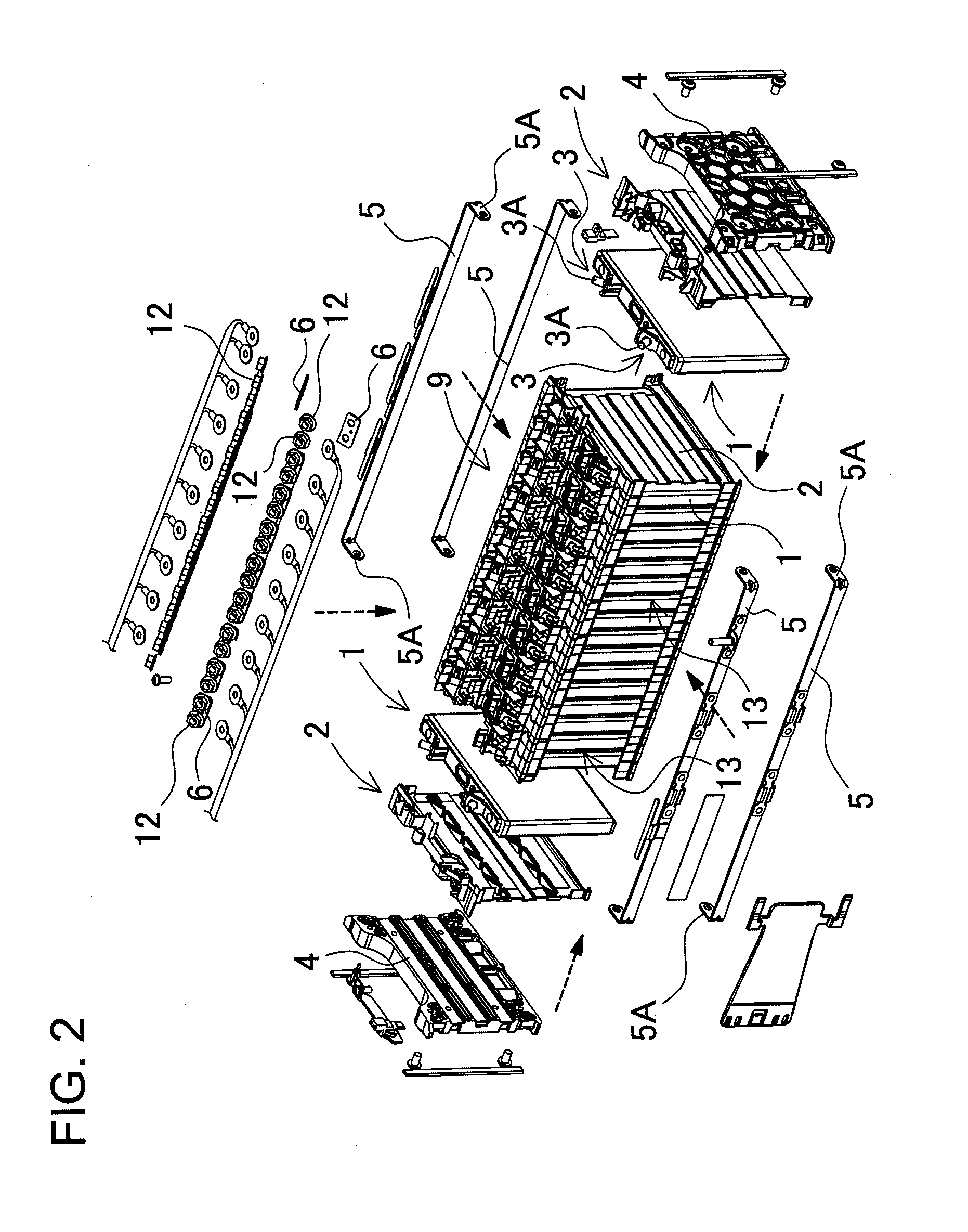

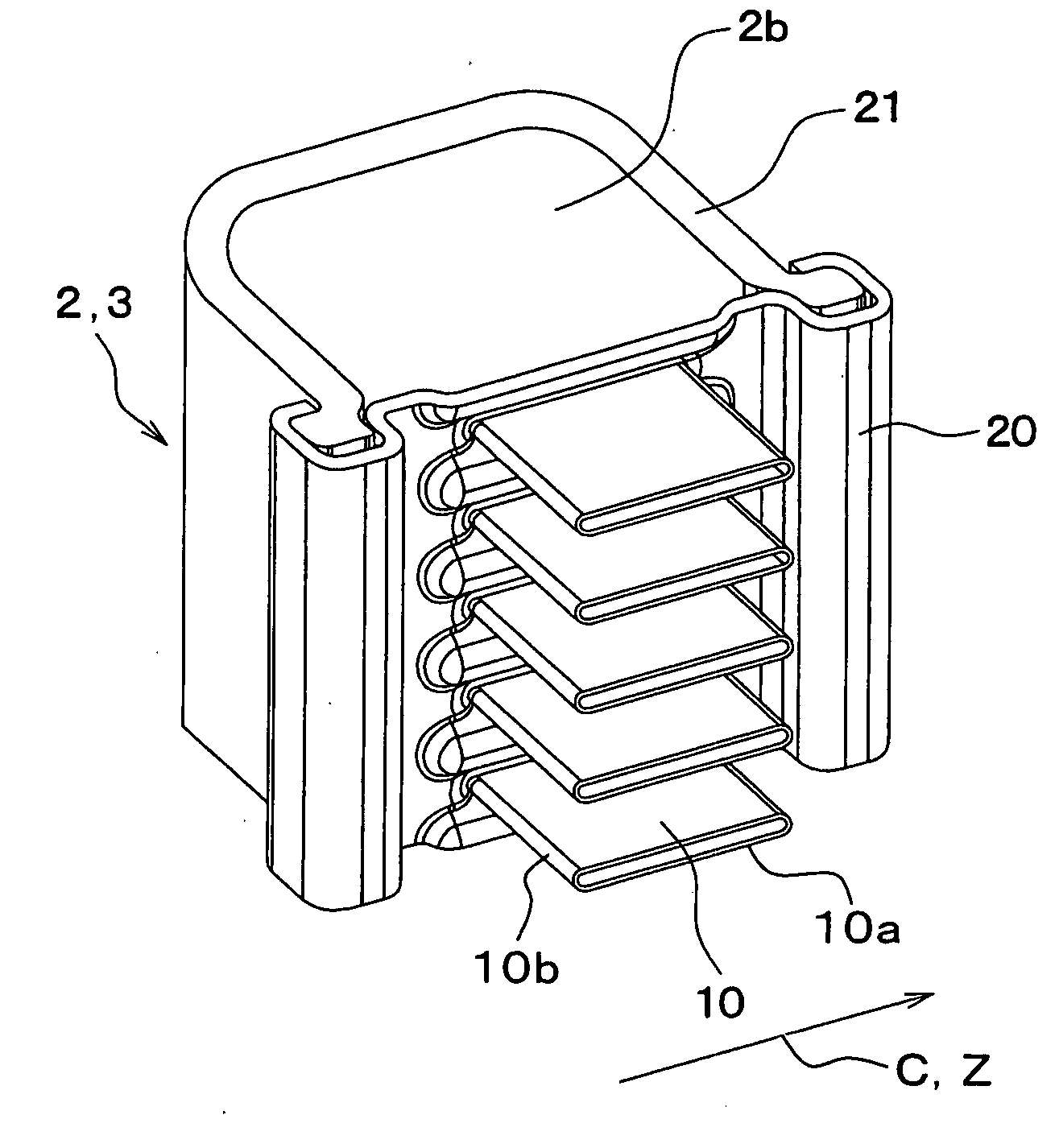

Battery array, battery separator, and vehicle equipped with battery array

InactiveUS20130260197A1Avoid damage and deformationAvoid stress concentrationSecondary cellsPropulsion by batteries/cellsEngineeringBattery cell

Owner:SANYO ELECTRIC CO LTD

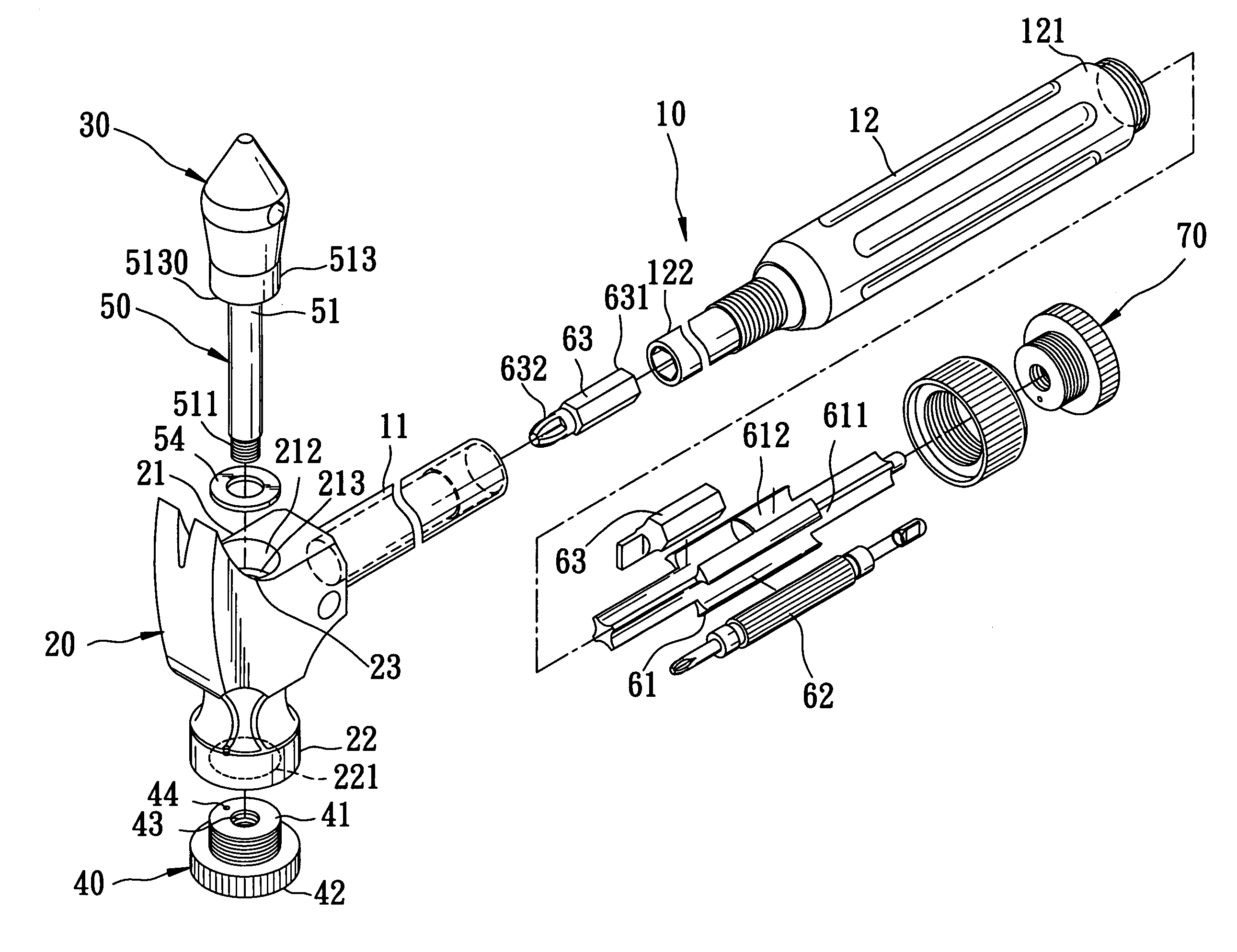

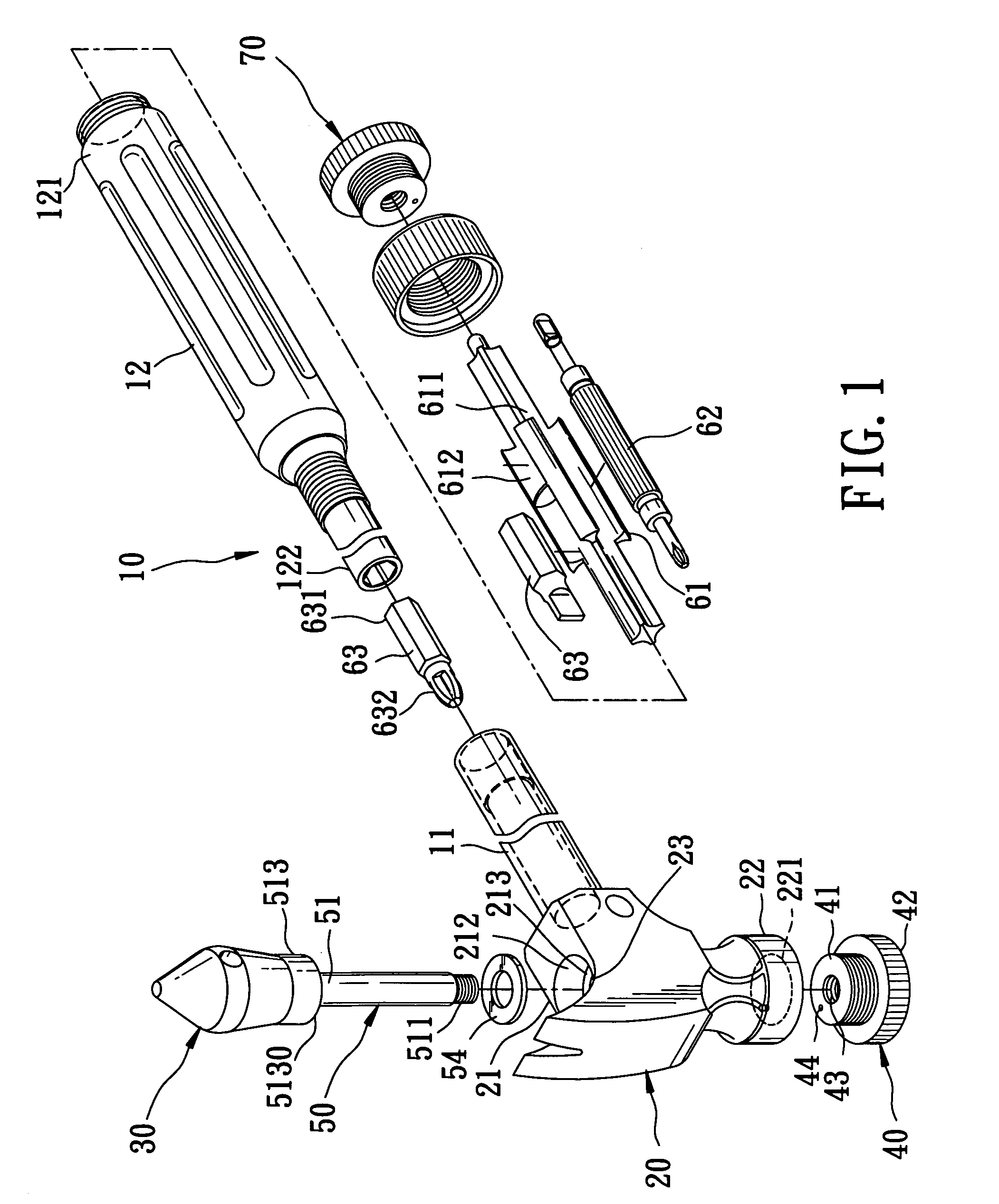

Striking head-interchangeable hammer with a stress-distributable fastener

A striking head-interchangeable hammer includes a handle, a head body connected securely to the handle and formed with a through-hole and upper and lower bores, a striking body having a connecting portion that is received fittingly in the lower bore, and a stress-distributable fastener including a connecting rod that extends through the through-hole and the upper and lower bores in the head body to engage threadedly the striking body, and that is formed with an abutting flange received fittingly in the upper bore and anchored on and abutting against an abutting face of a bore-defining wall of the upper bore upon tightening of the connecting rod onto the striking body.

Owner:LIN MING HSUAN

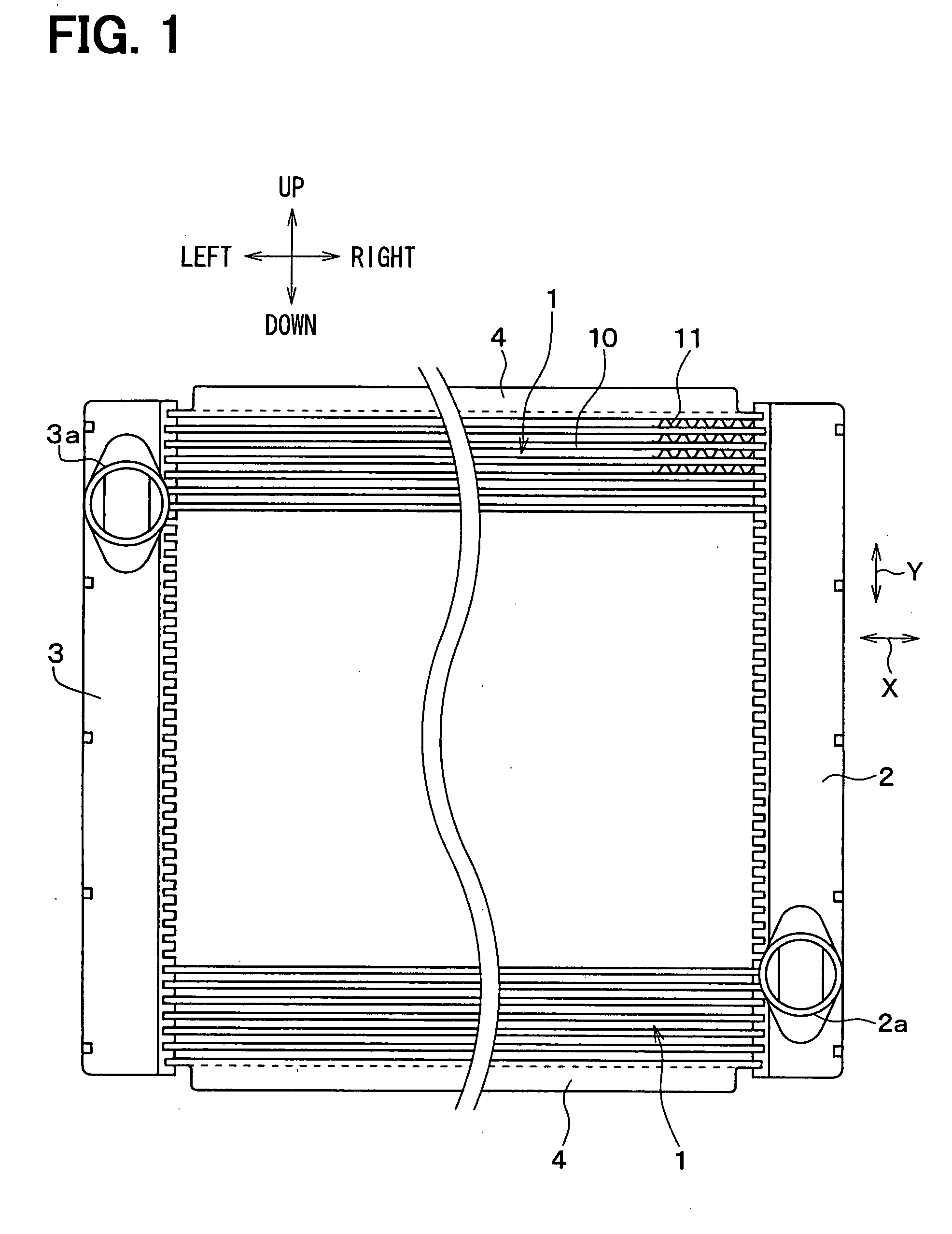

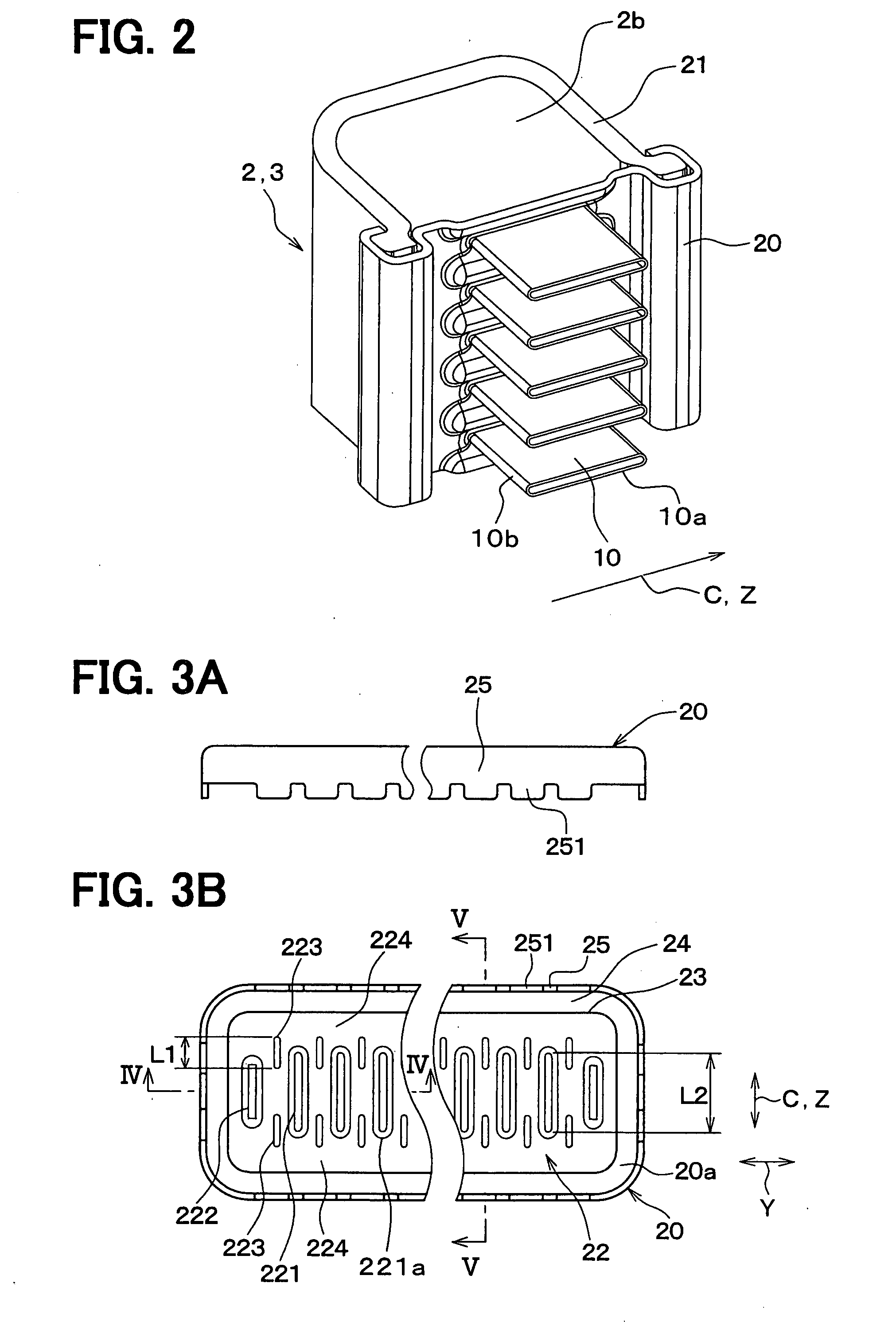

Heat exchanger

ActiveUS20080000626A1Good molding effectAvoid stress concentrationReinforcing meansStationary conduit assembliesMechanical engineeringRib cage

A heat exchanger includes tubes and a tank. The tubes extend in a first direction, and are stacked in a second direction. The tank has a tube insertion plate part, and is arranged at an end portion of the tubes. The tube insertion plate part has tube holes in which the tubes are inserted, and ribs extending in a third direction that is approximately perpendicular to the first direction and the second direction. The tube hole has end portions in the third direction. The rib are arranged to overlap with the end portion of the tube hole in the second direction, and to provide a deformable part to be deformable in the first direction. The deformable part is located in the tube insertion plate part outside of the ribs in the third direction.

Owner:DENSO CORP

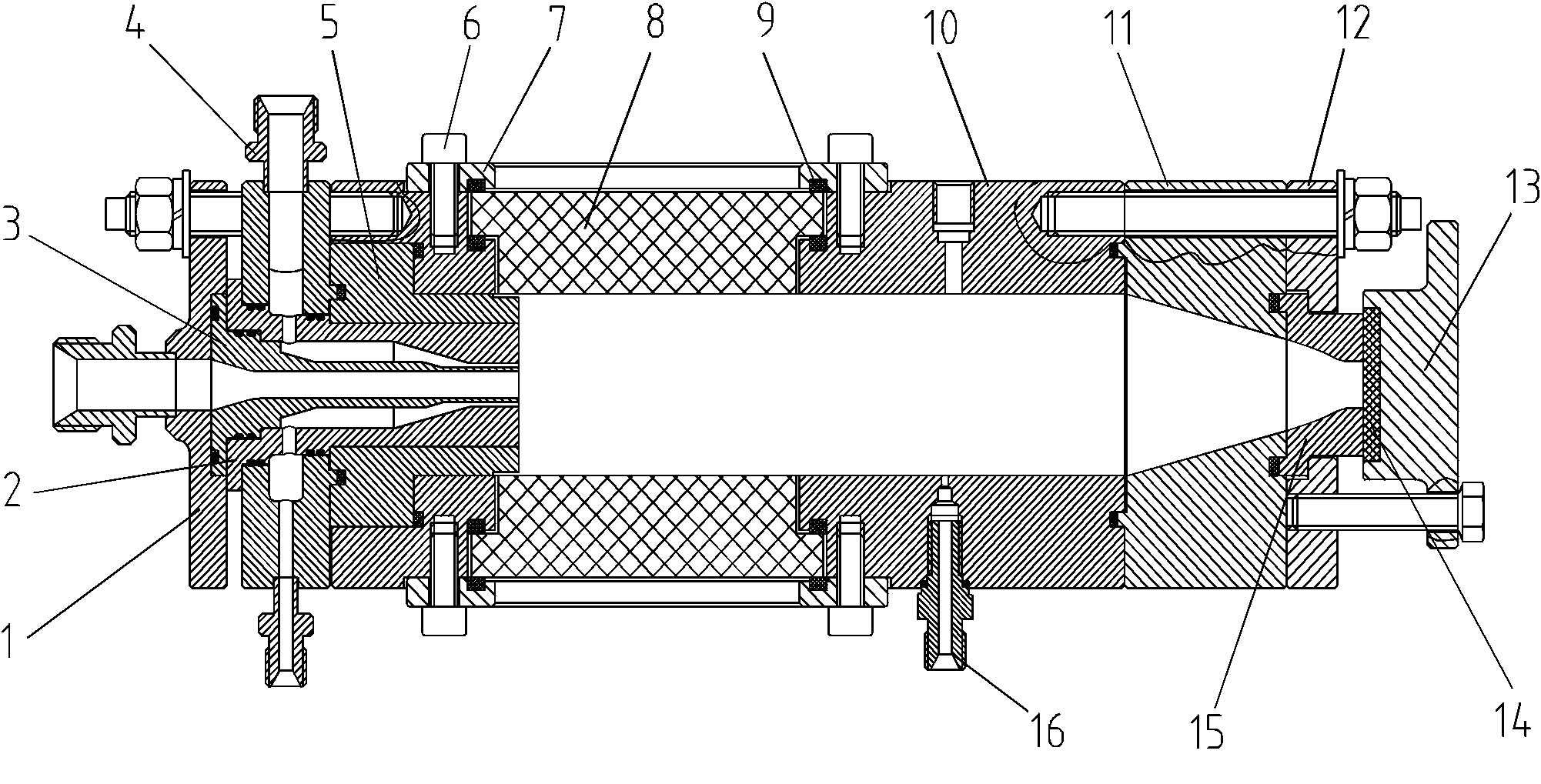

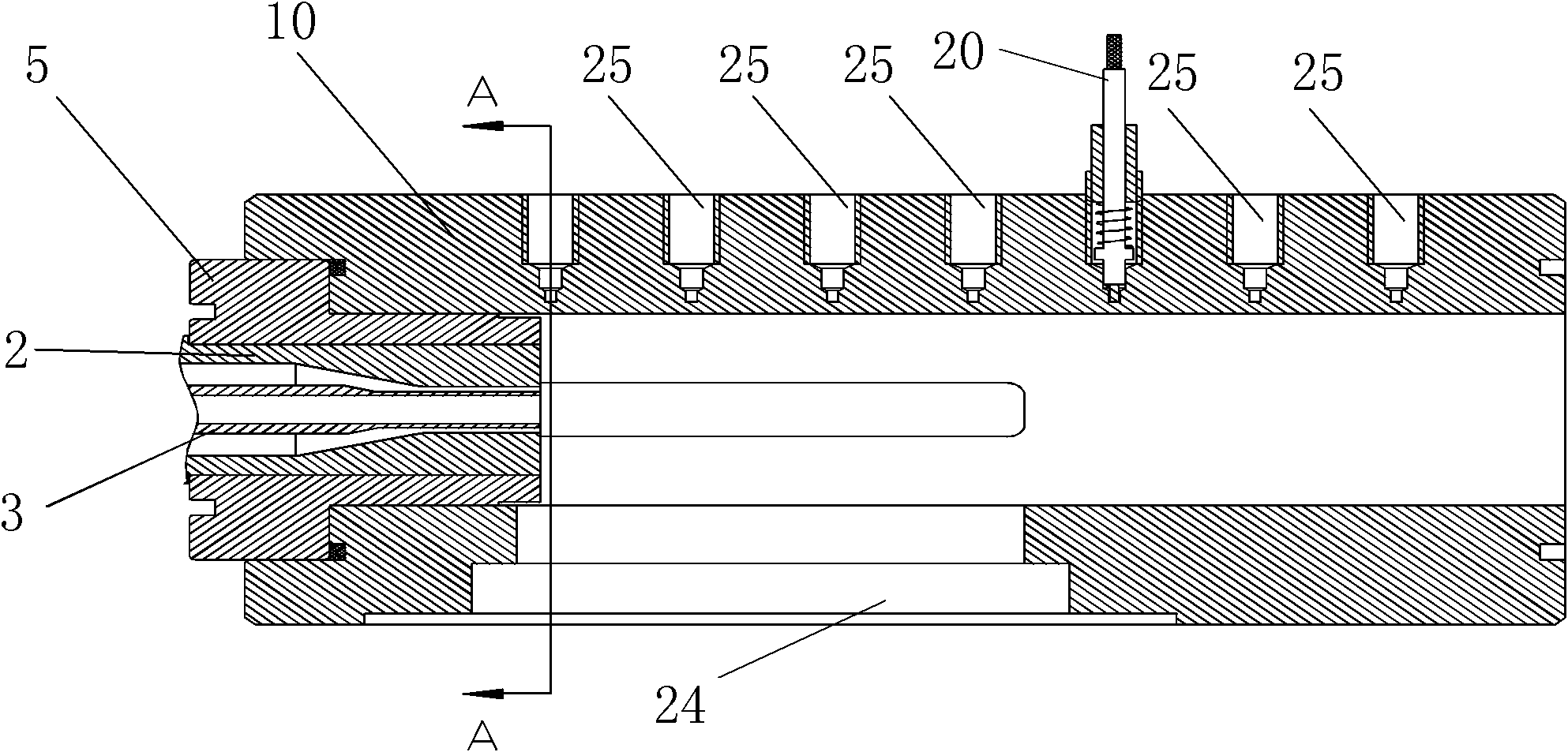

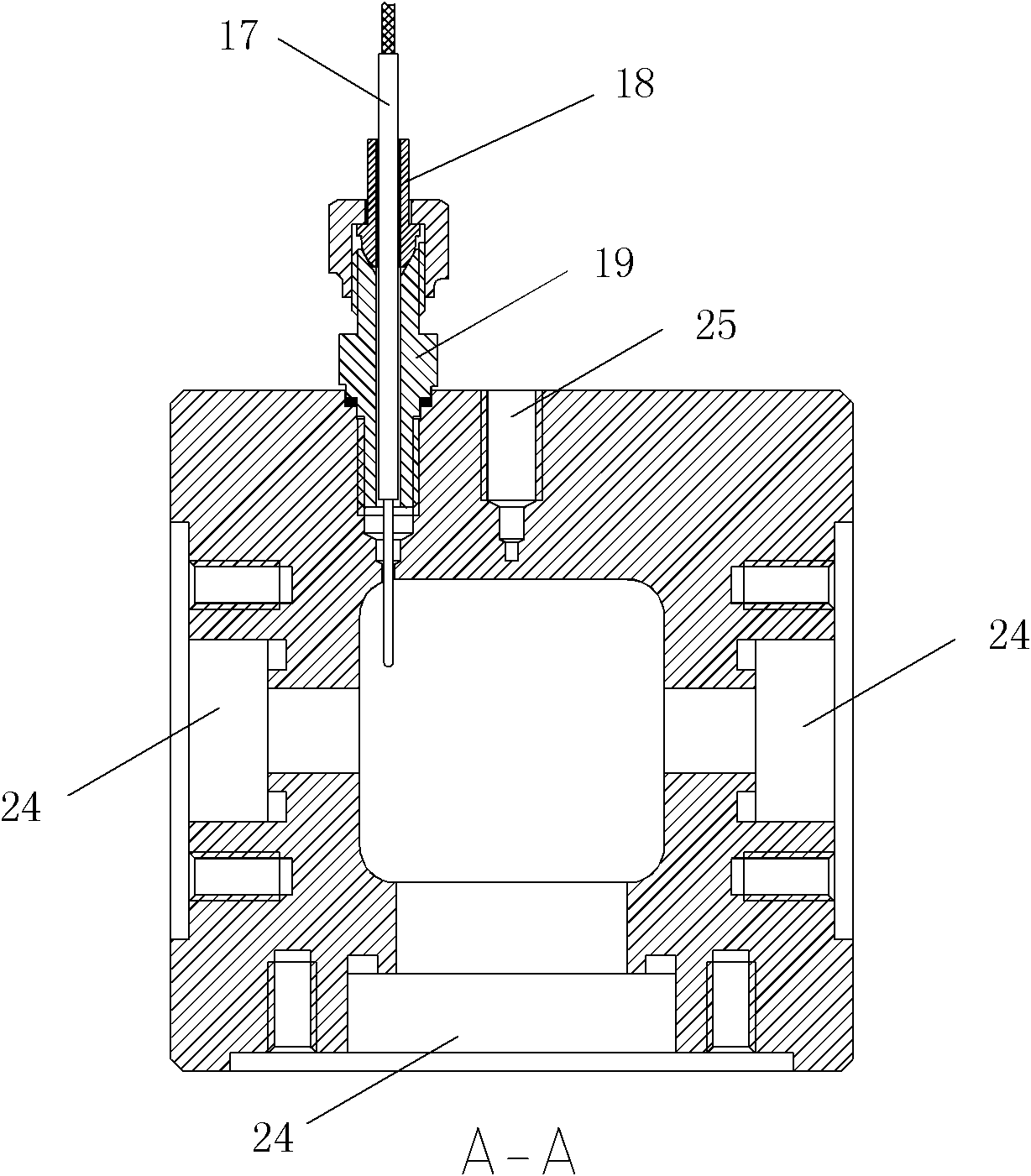

Transparent combustion chamber with square interior passage

InactiveCN102062020APromise not to touchReduce distractionsRocket engine plantsStress concentrationCombustion chamber

The invention discloses a transparent combustion chamber with a square interior passage, belonging to the field of the design of transparent combustion chambers for liquid-propellant rocket engines. The transparent combustion chamber comprises a head mechanism, a combustion chamber body mechanism, an observation window mechanism and a guiding mechanism; wherein the head mechanism comprises an oxidant cavity, a fuel nozzle, an oxygen nozzle and a fuel cavity; the combustion chamber body mechanism comprises a combustion chamber body substrate and a pressure-measuring filler neck; the observation window mechanism comprises an observation window cover plate and quartz glass; and the guiding mechanism comprises an head guiding slot and a tail guiding flange. In the invention, the observation window cover plate, the quartz glass and the combustion chamber substrate are mutually sealed with square graphite which expands to fill gaps among the observation window cover plate, the quartz glass and the combustion chamber substrate, so that glass can be ensured to be contactless with metal so as to play the role of protecting the quartz glass. The design of the square interior channel of the combustion chamber is favorable for leveling a quartz glass sheet to the inner wall surface of the combustion chamber and reducing the disturbance to an inner flow field of the combustion chamber; and four corners of the square interior channel are transitioned by adopting large circular arcs so as to prevent stress concentration.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com