Patents

Literature

35results about How to "High R-value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

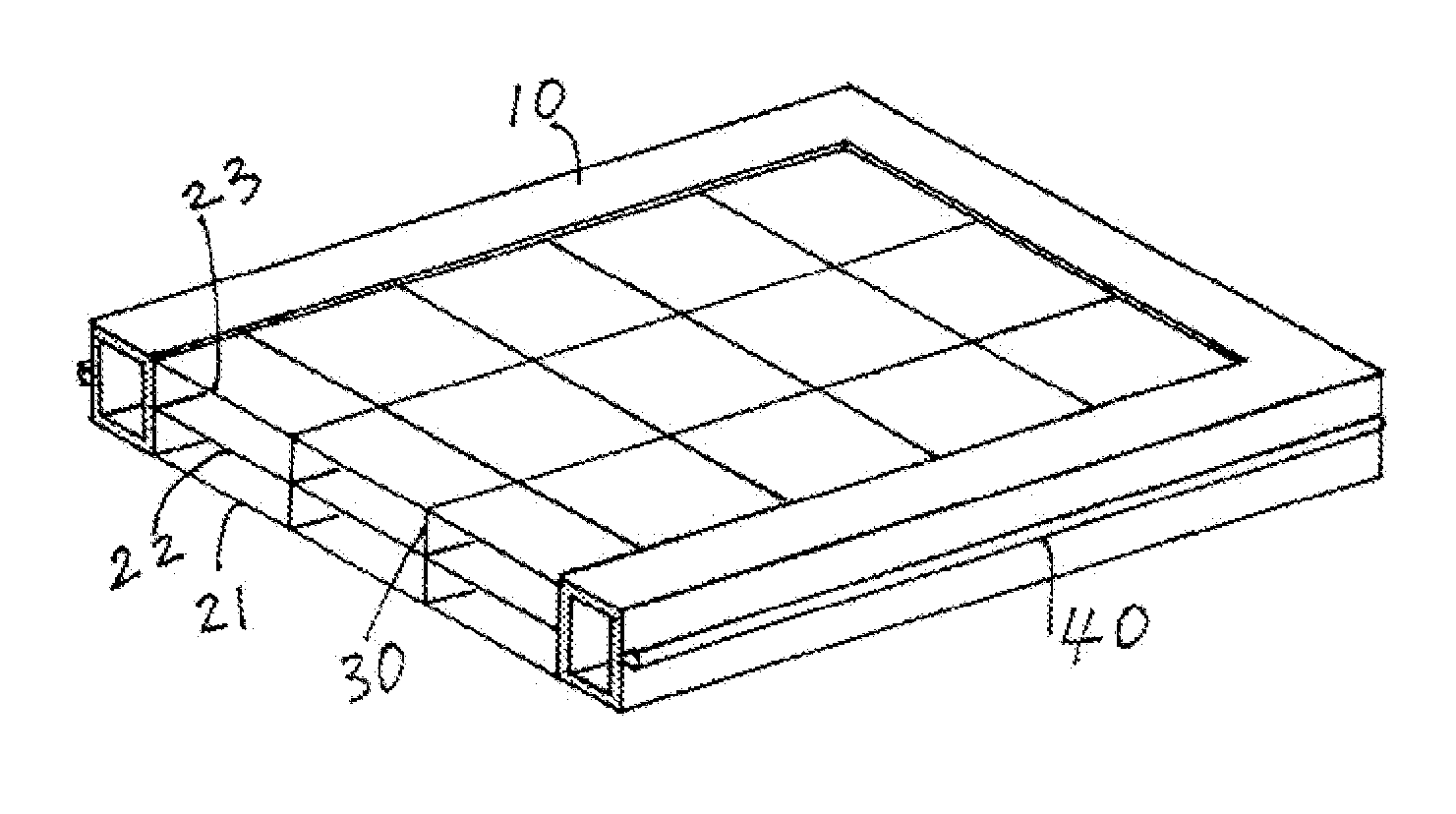

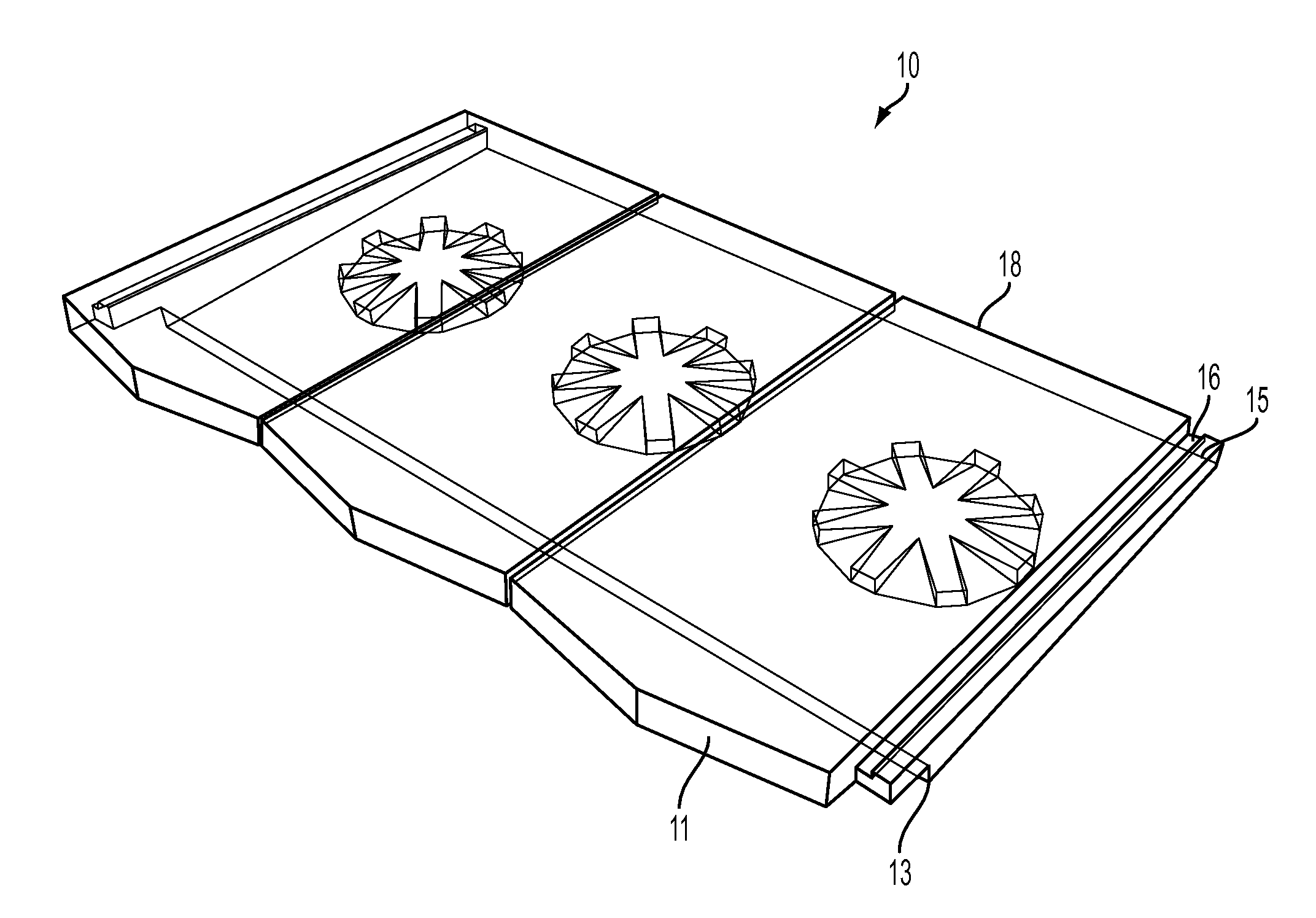

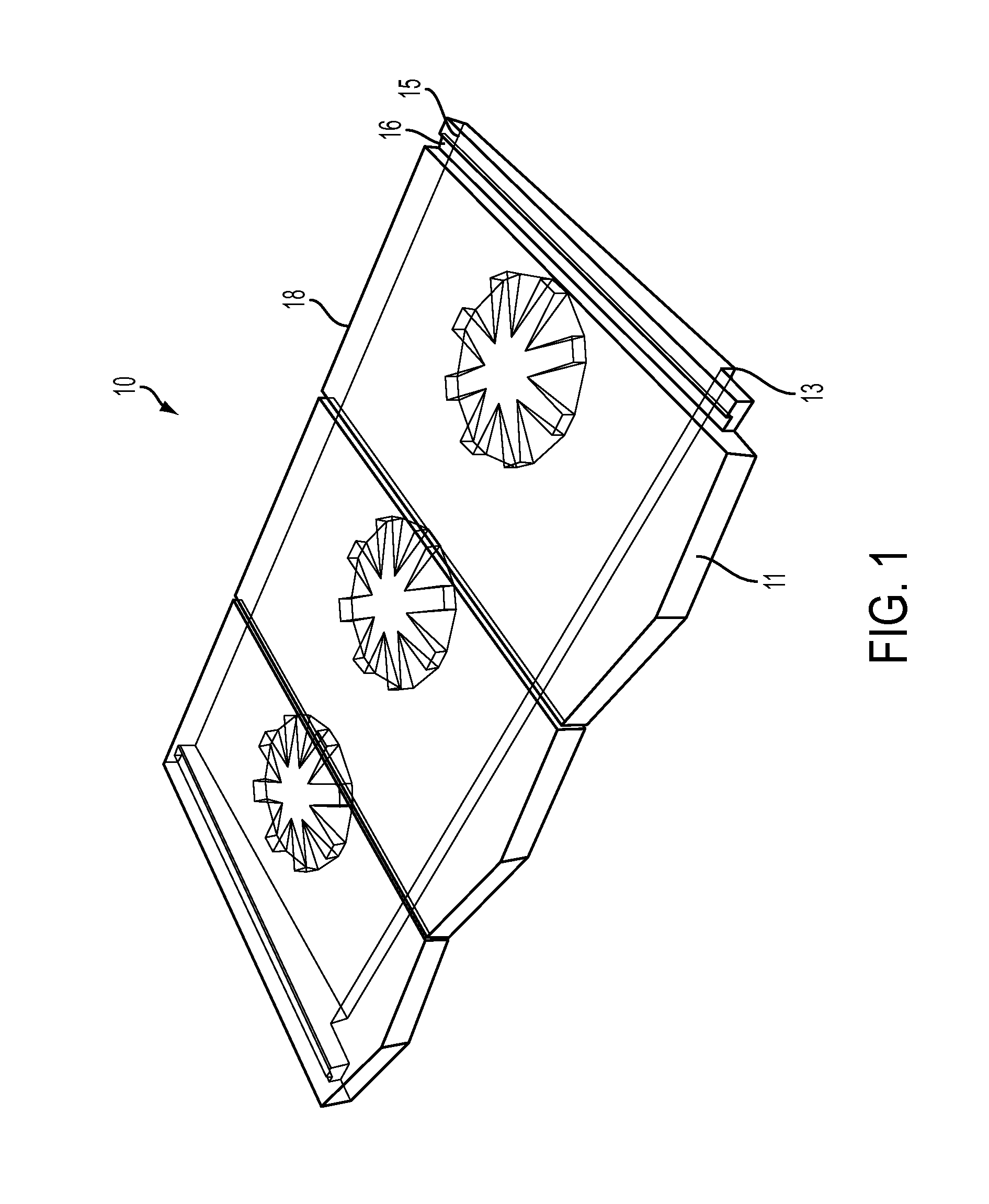

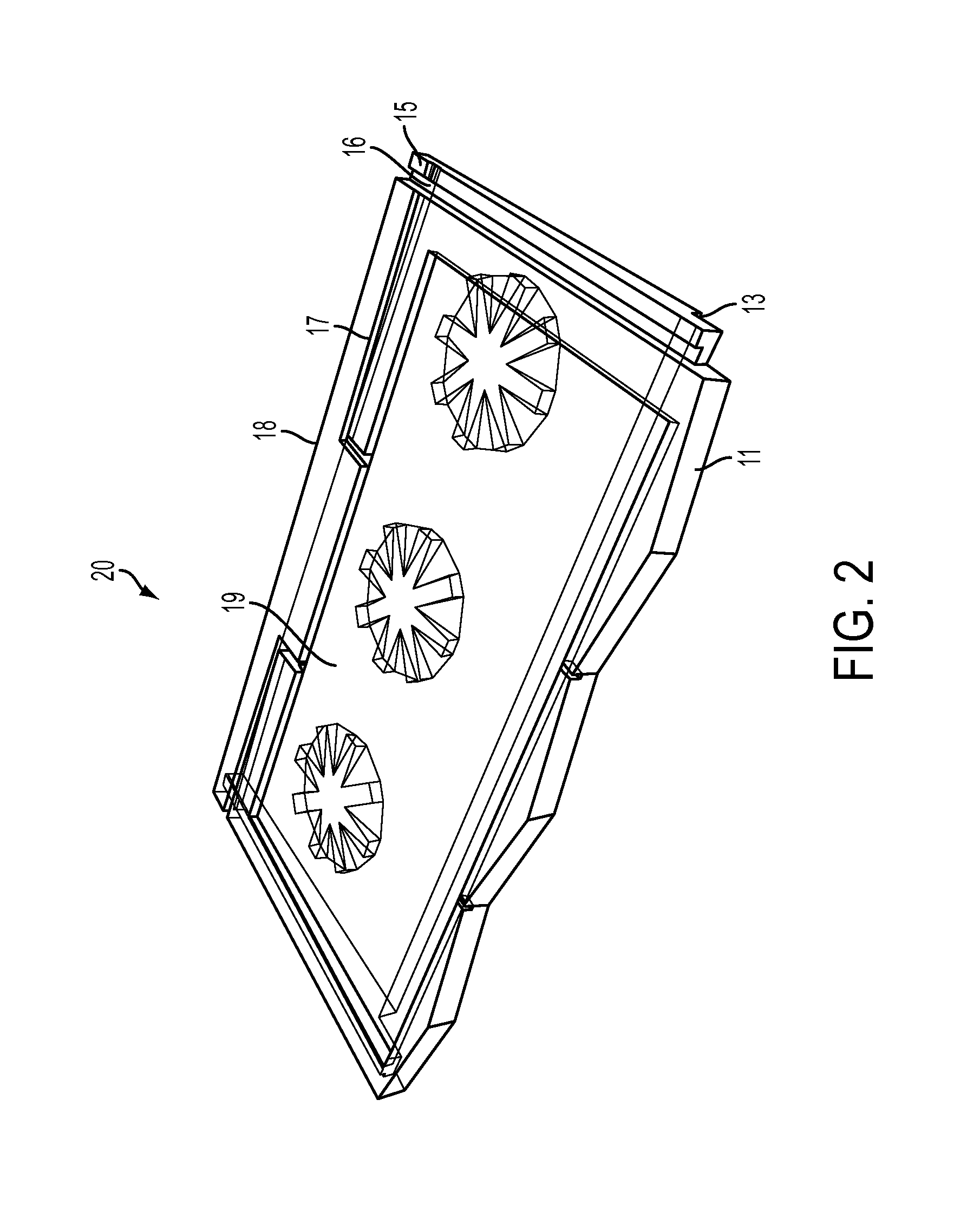

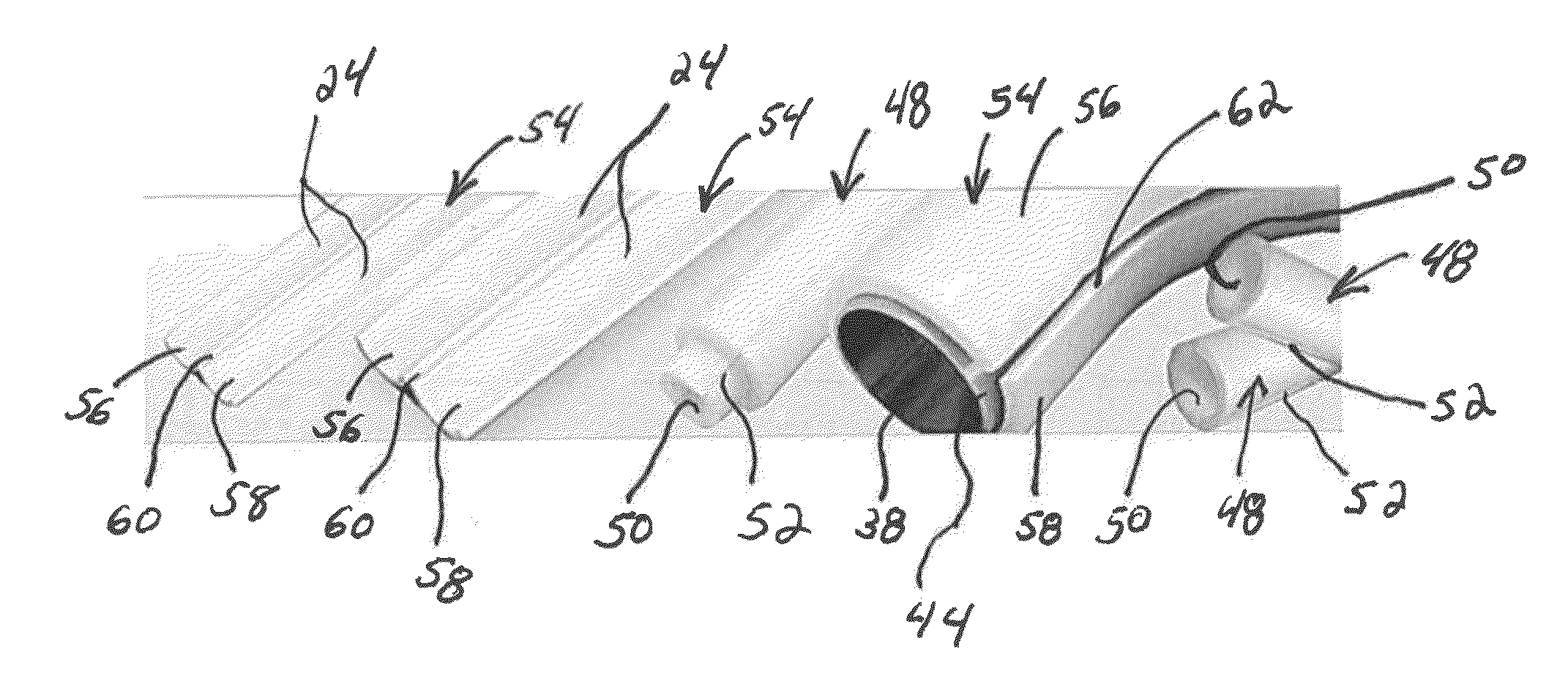

High R-value window unit

ActiveUS20070148379A1Decrease U-valueIncrease R-valueClimate change adaptationWindows/door improvementEngineeringAir space

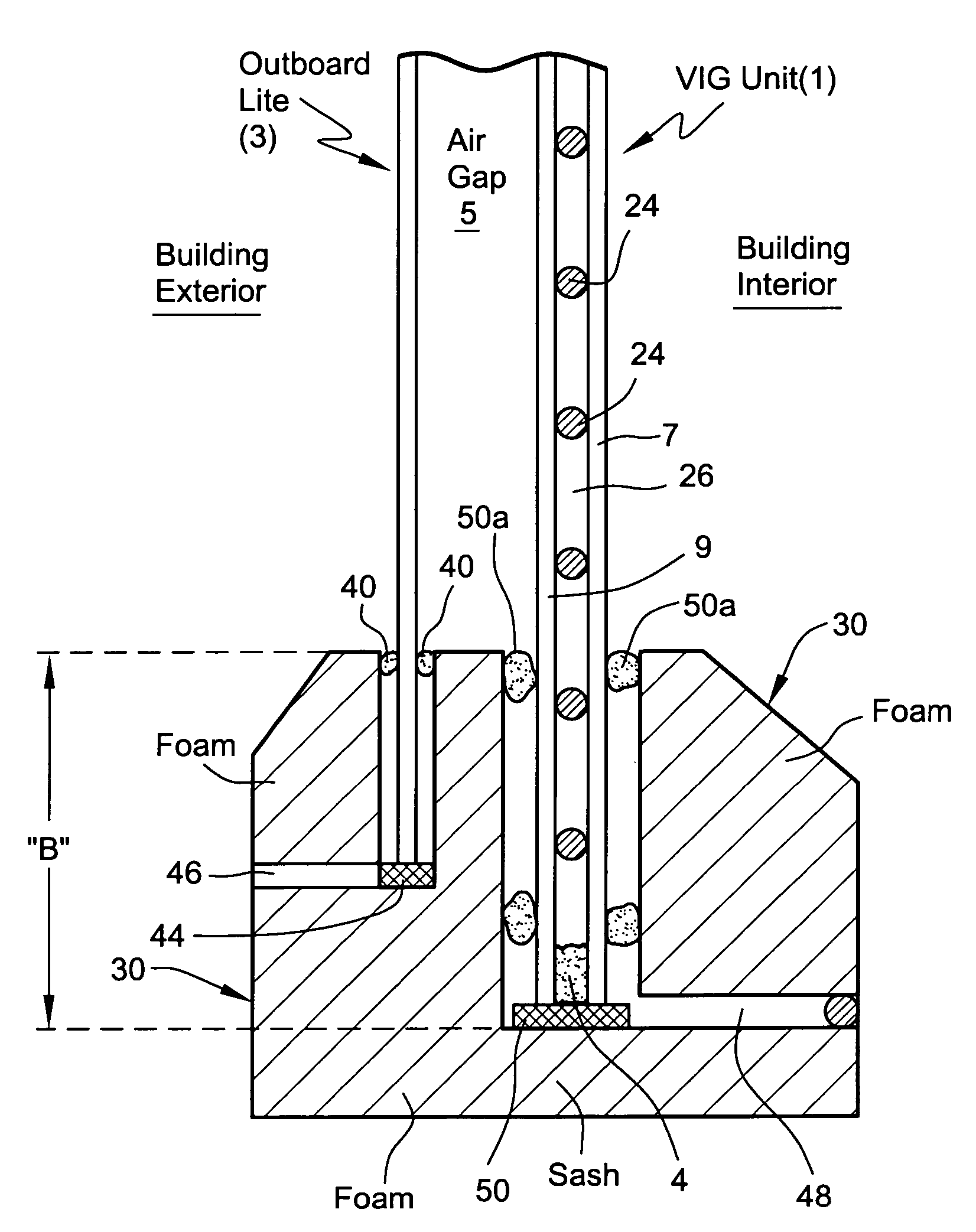

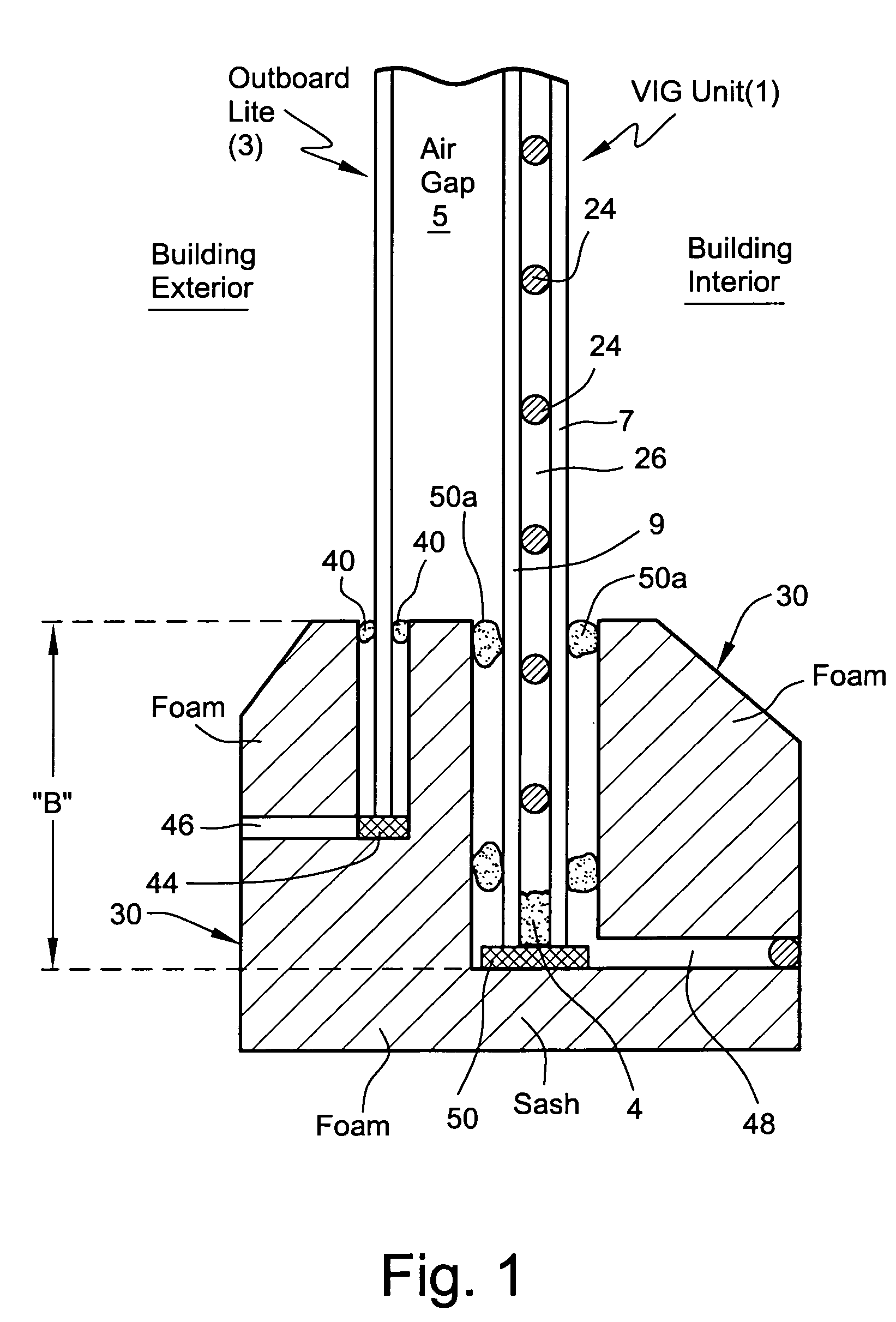

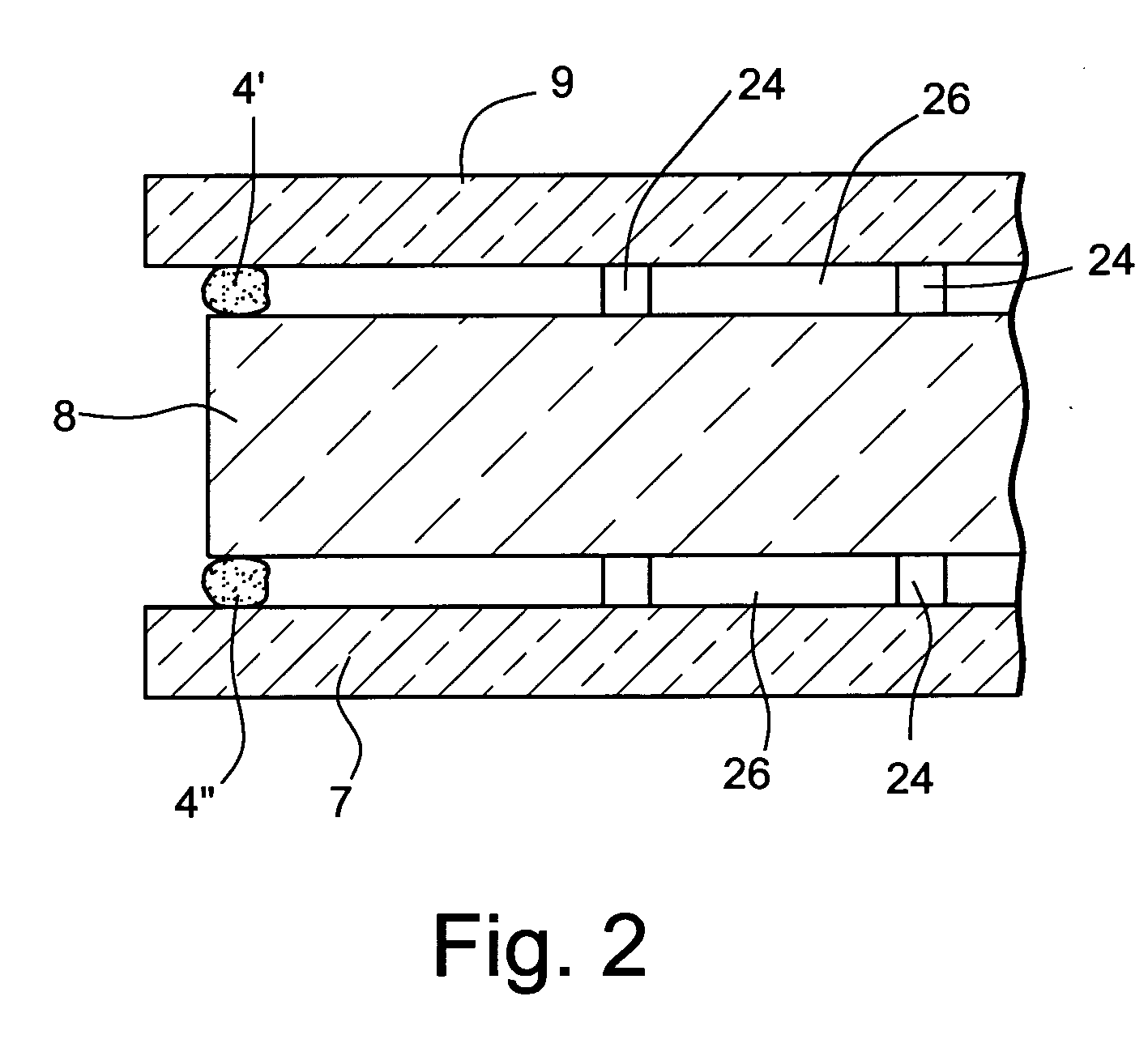

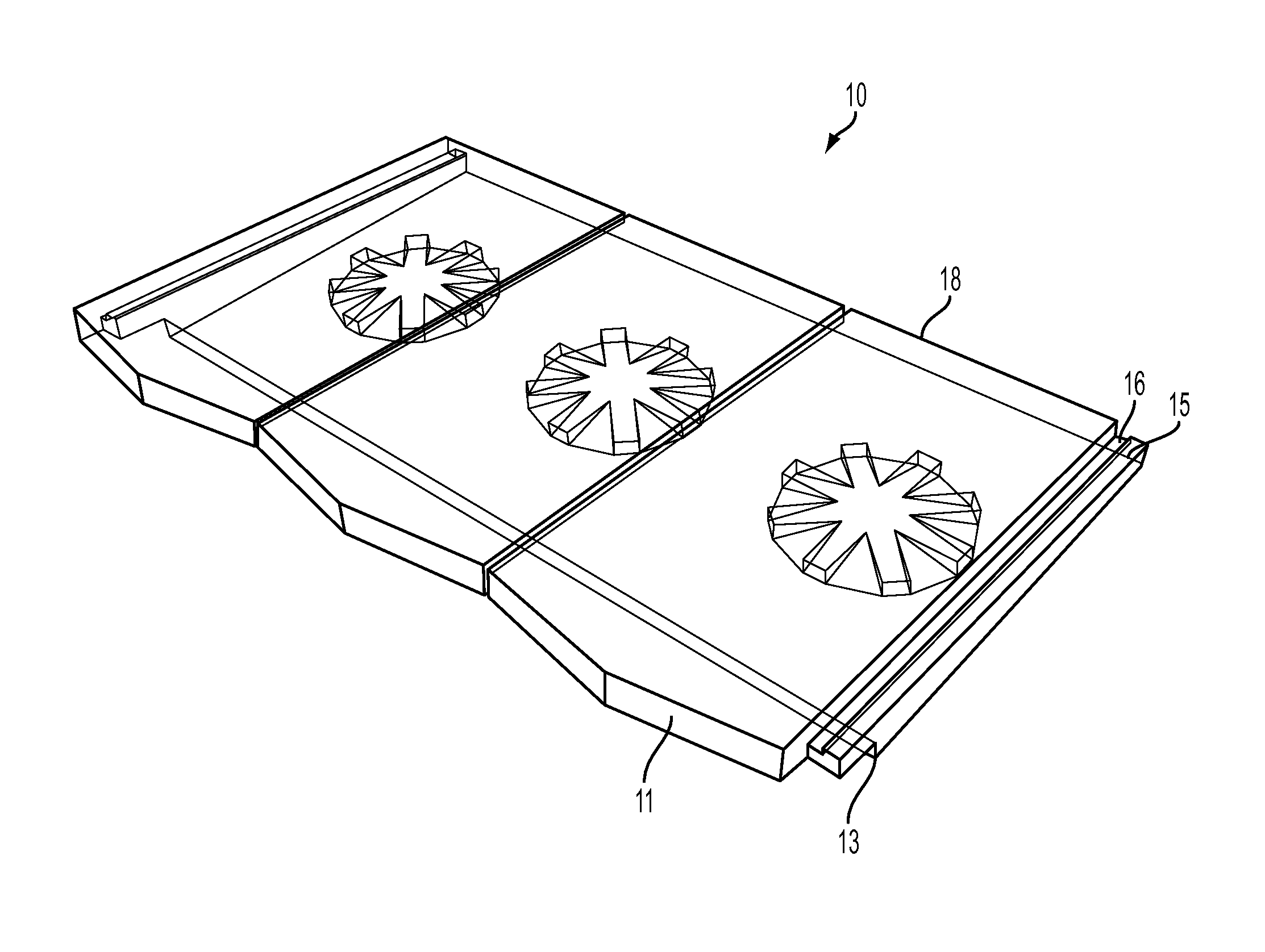

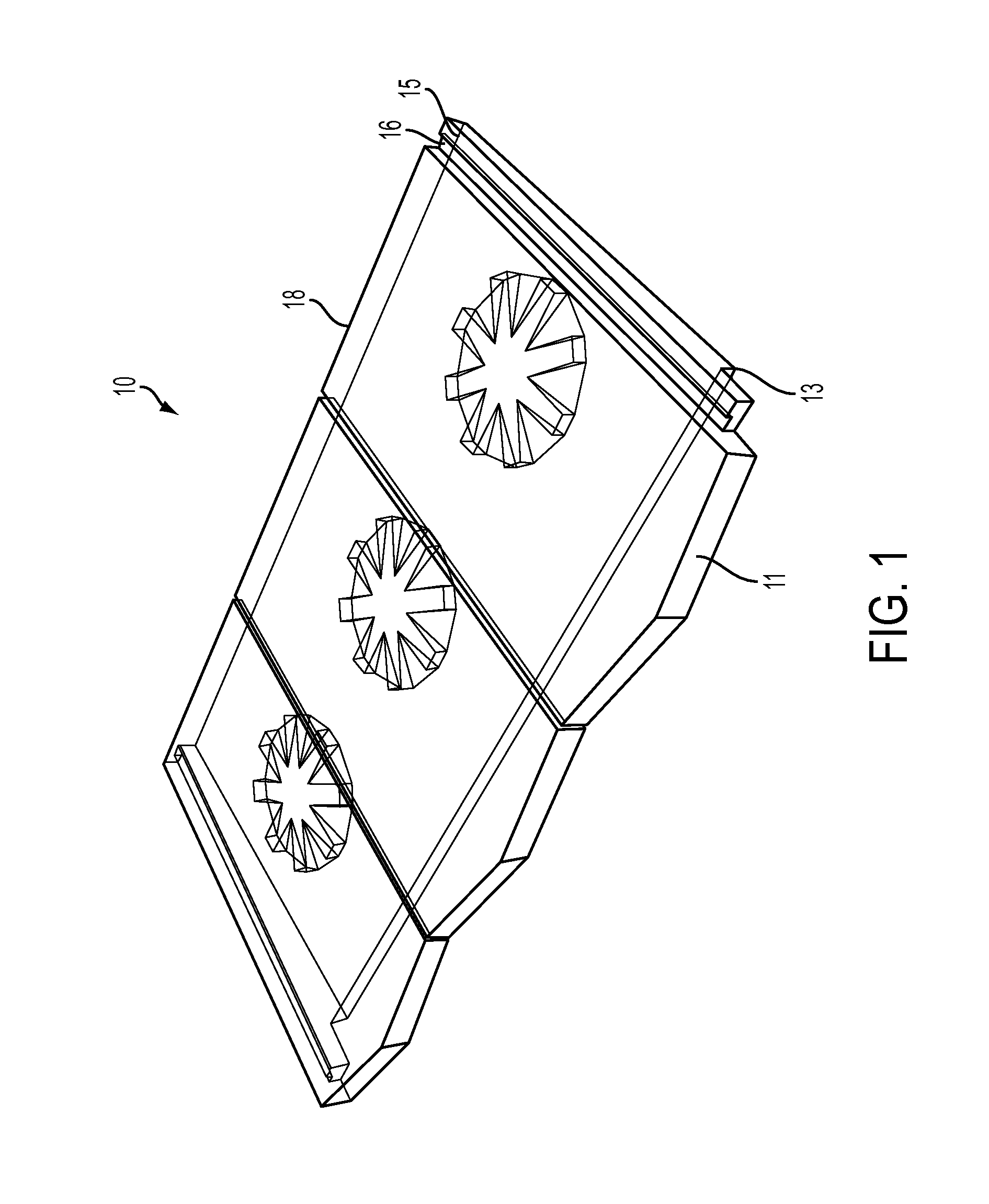

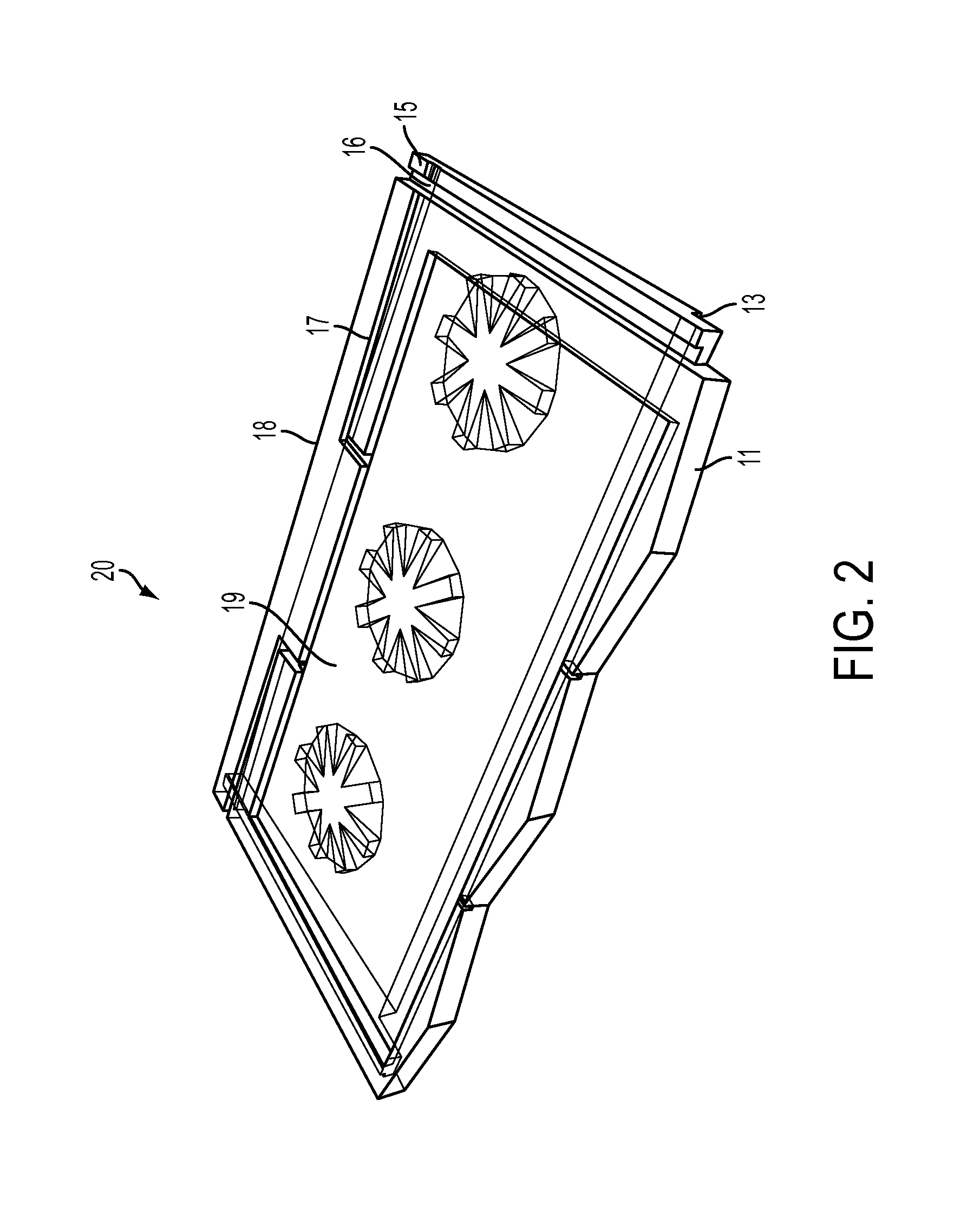

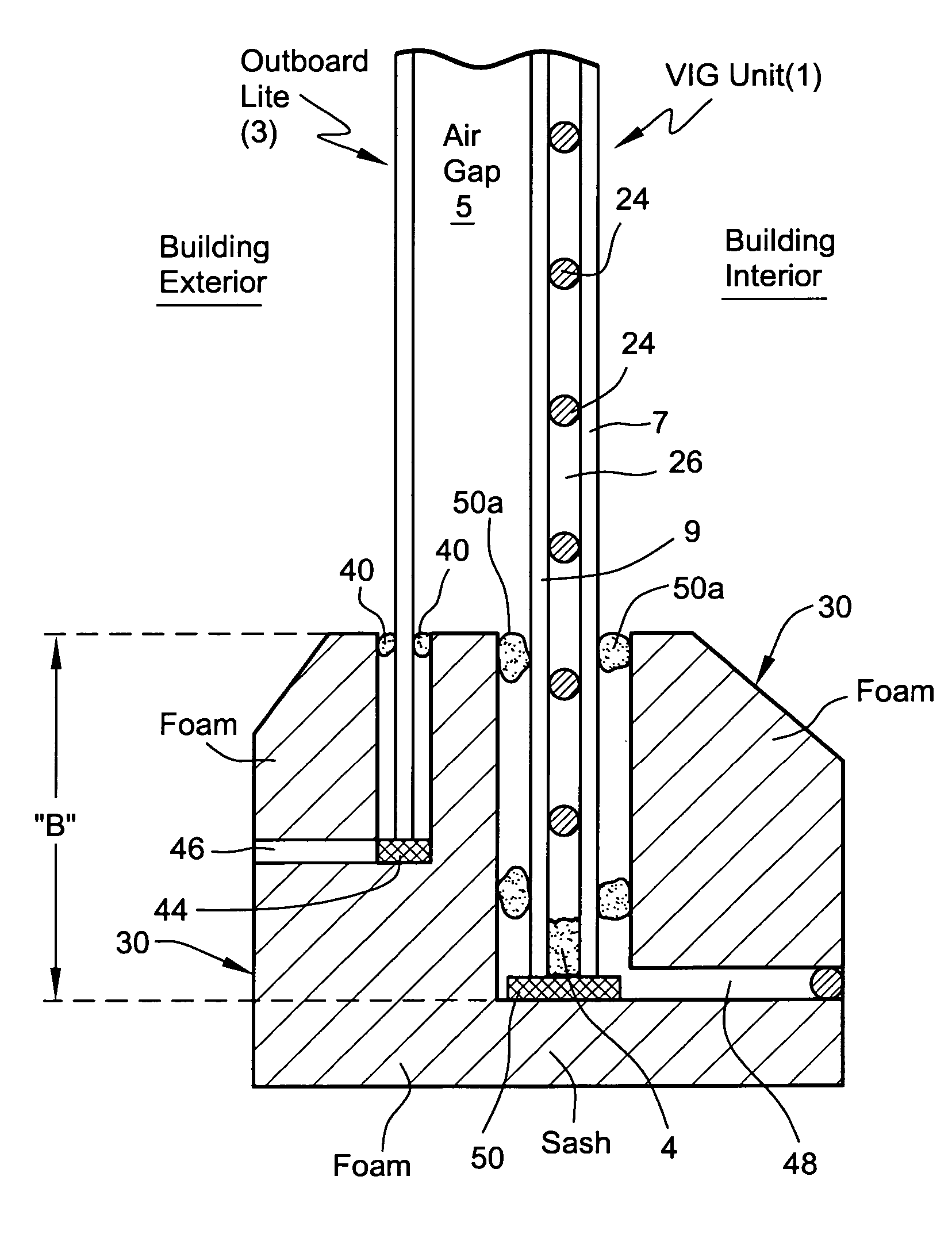

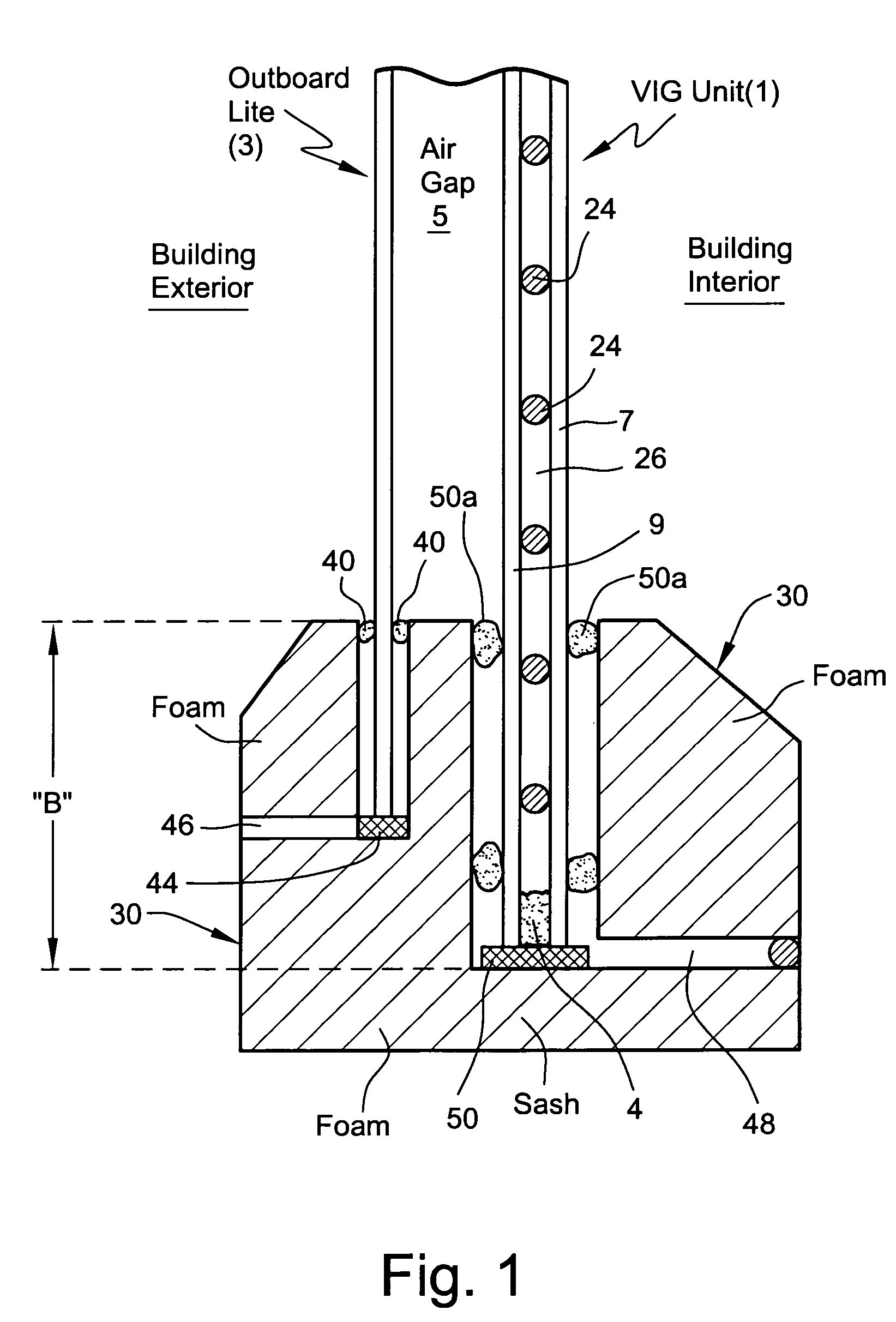

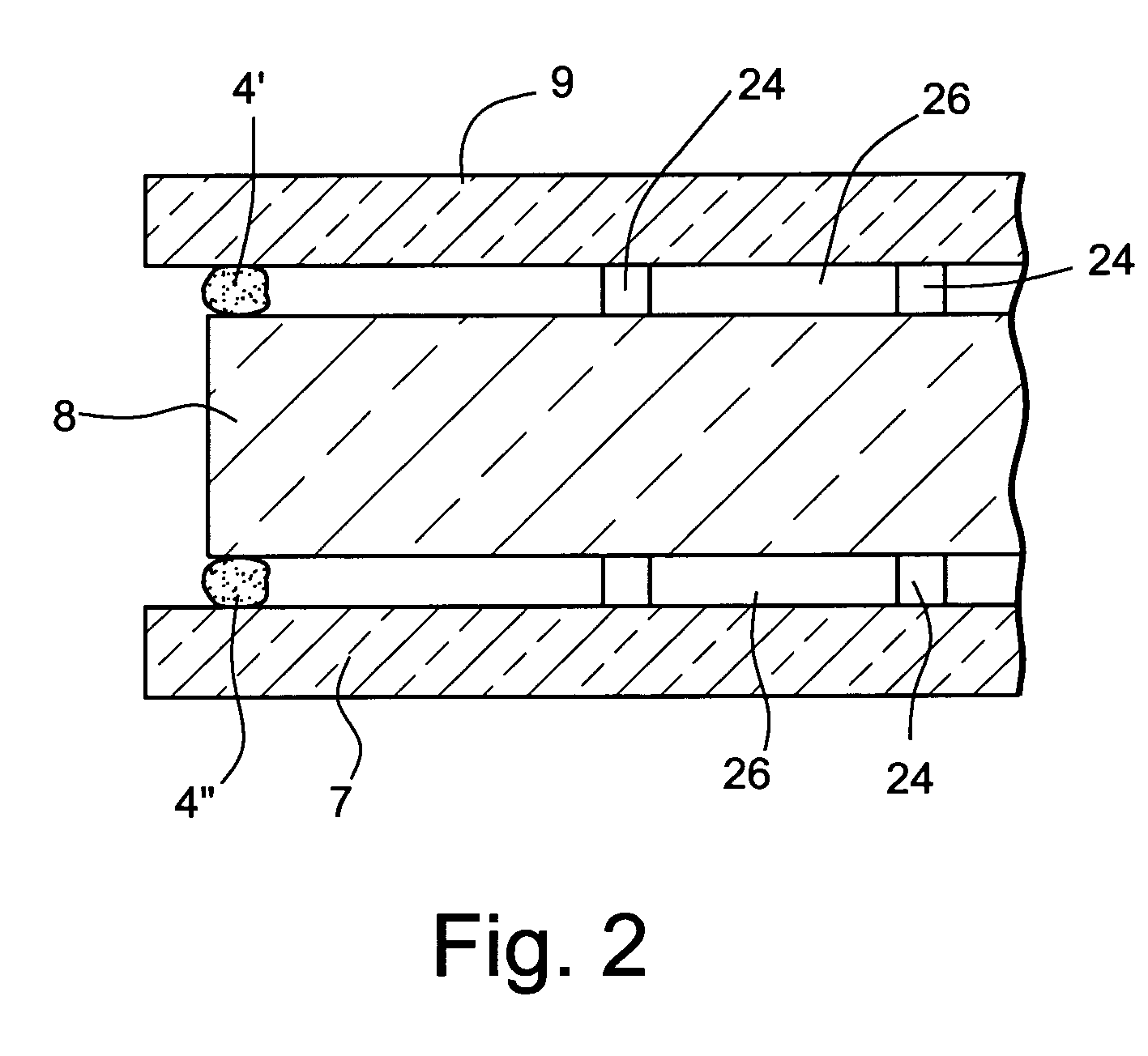

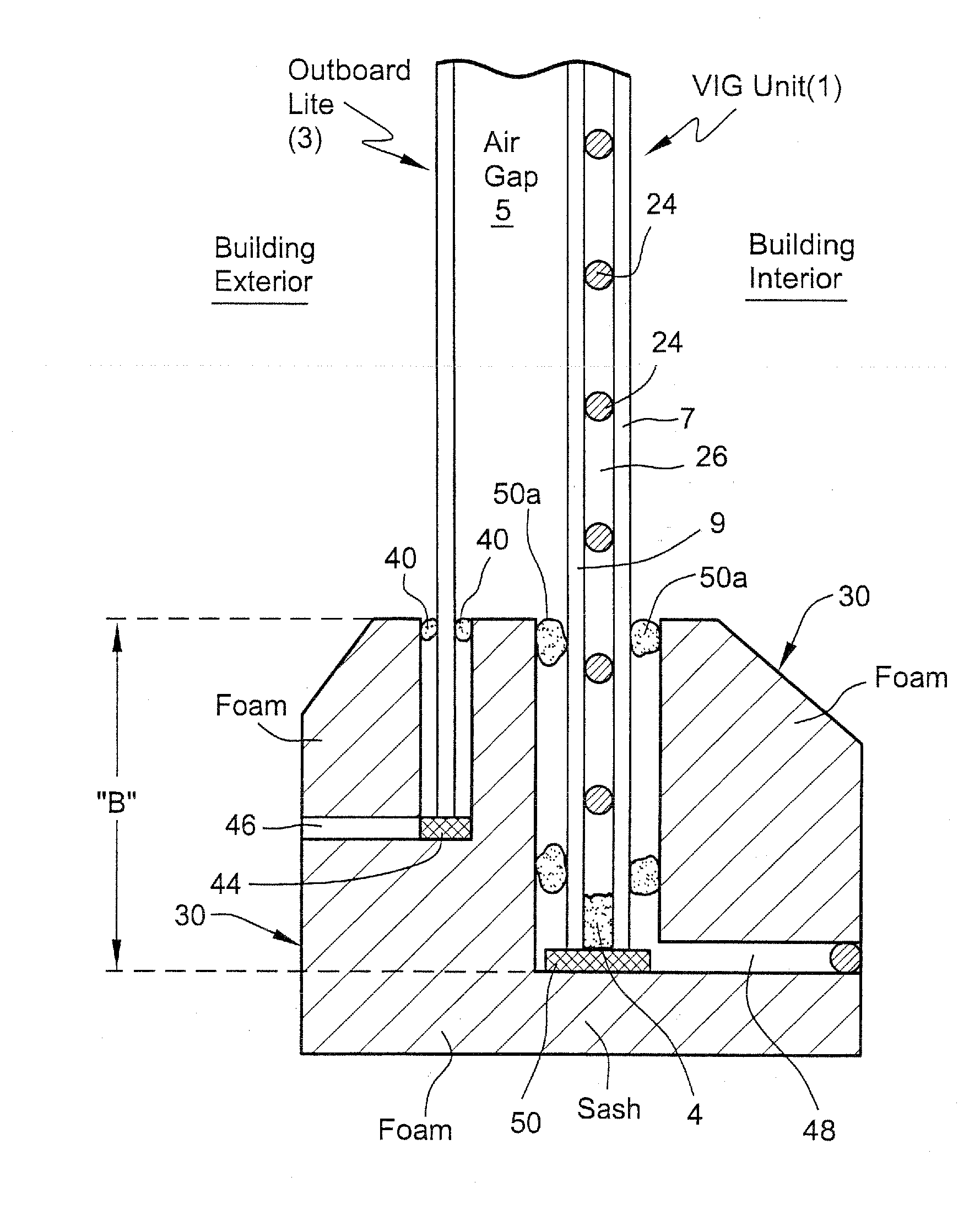

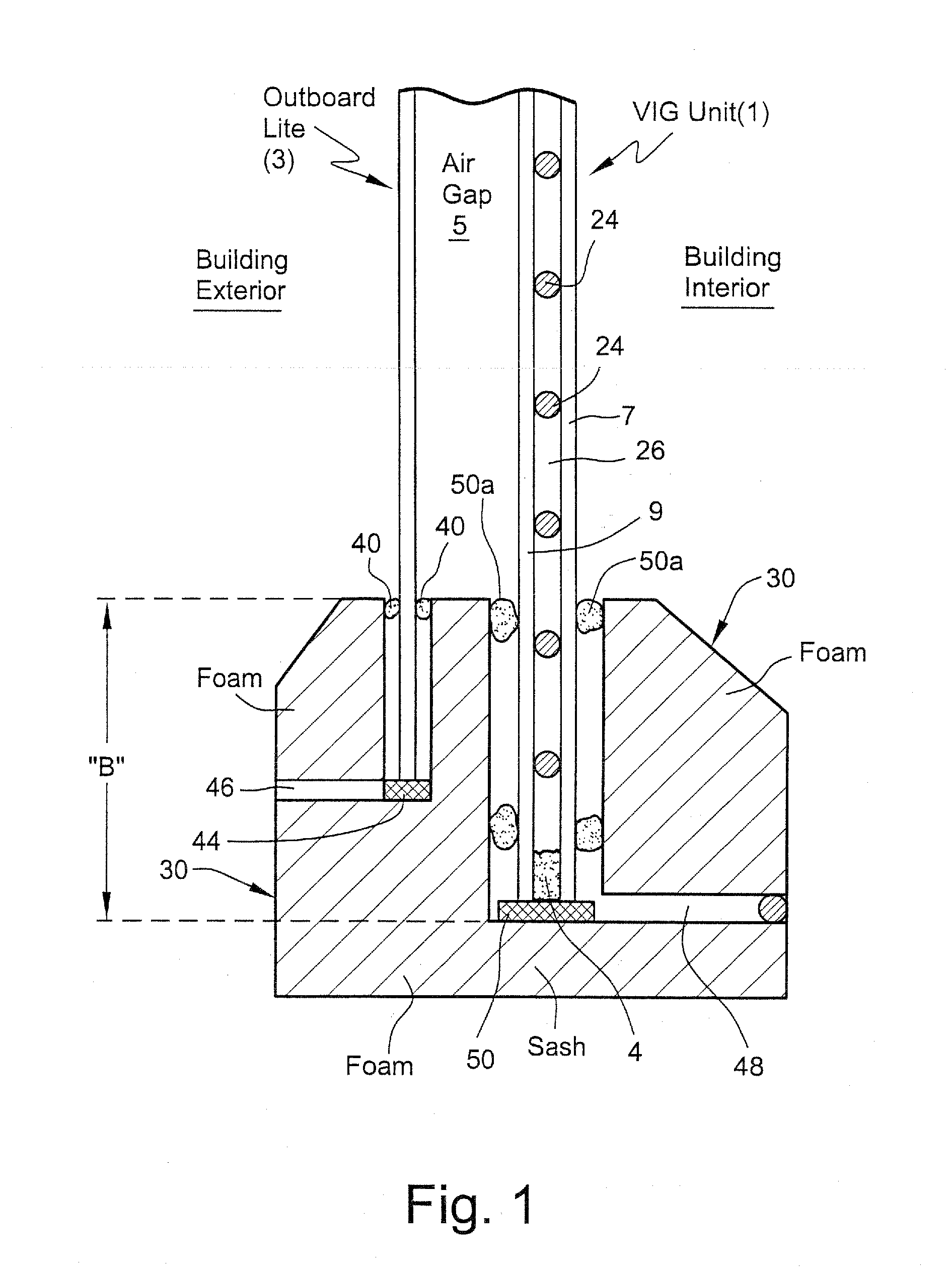

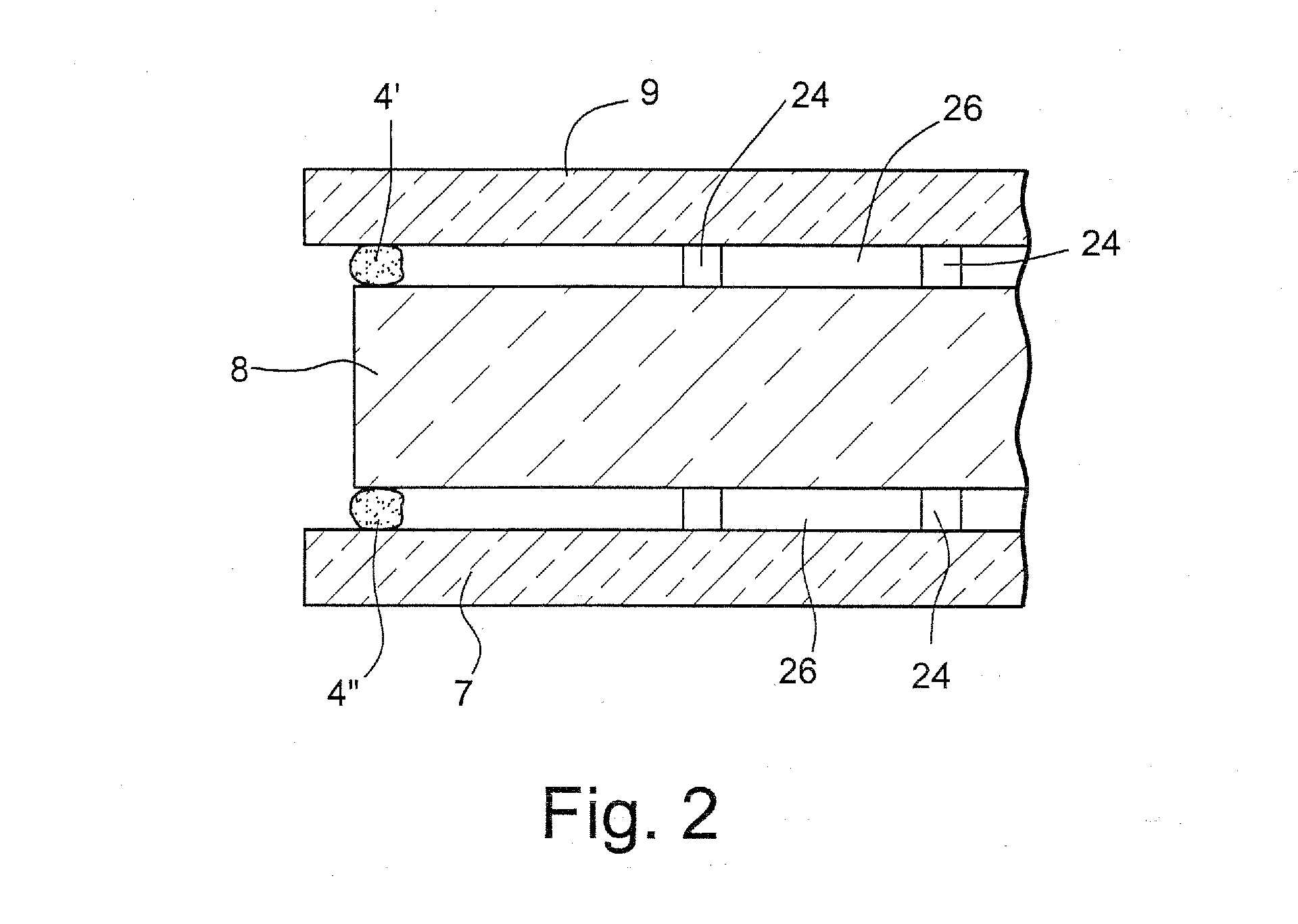

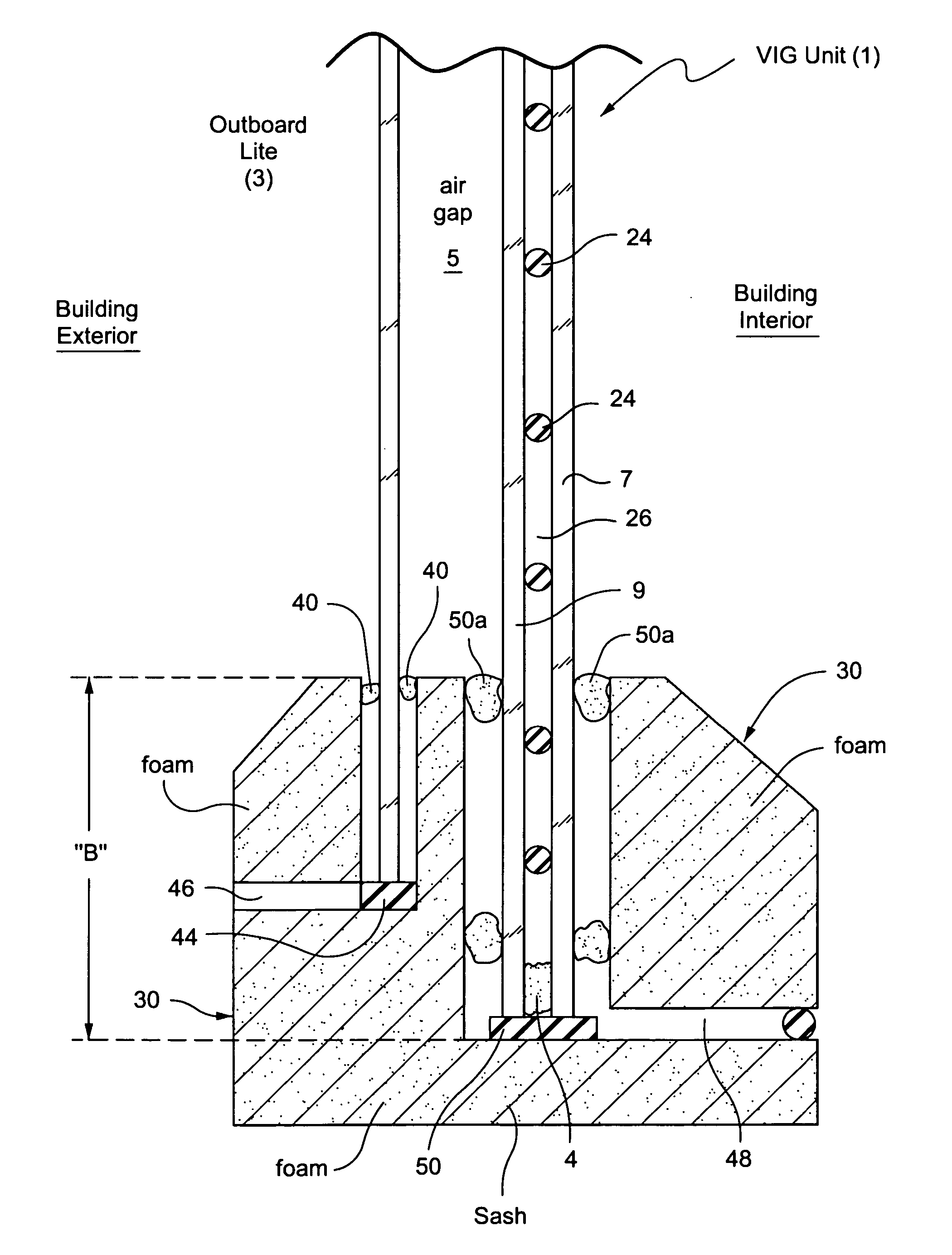

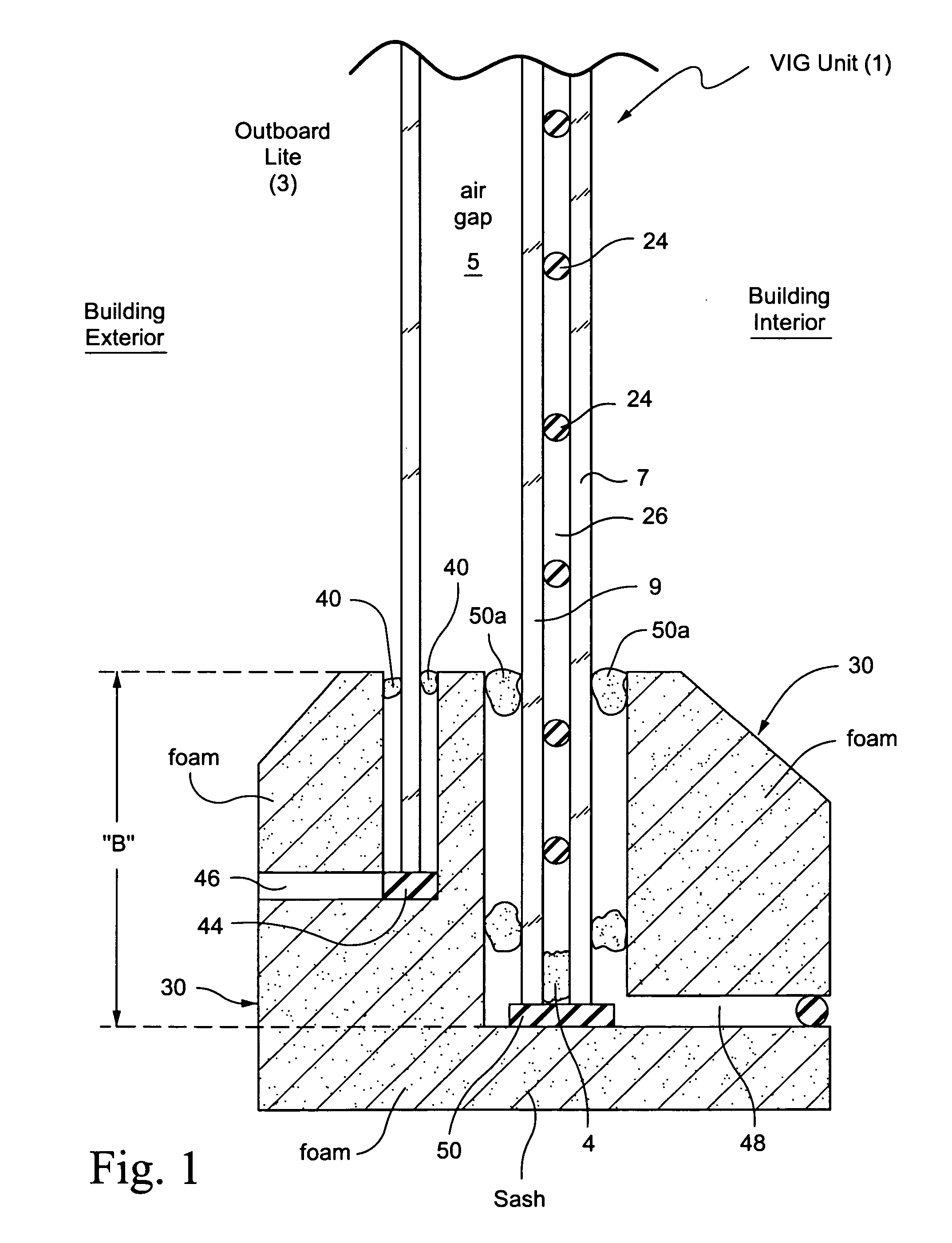

In certain example embodiments of this invention, a window unit may include a vacuum IG (VIG) unit as an inboard lite and a monolithic lite (e.g., with an optional low-E coating thereon) as an outboard lite. A dead air space may separate the inboard and outboard lites. A highly insulated frame may be used to support the inner and outer lites. The VIG unit may be partially embedded or supported in the insulative frame, so that the insulating frame separates the VIG unit inboard lite from the outboard lite thereby reducing conductivity around the edges of the window unit so that R-value can be increased (and U-value decreased). In certain example embodiments, the total R-value of the window unit is at least about R-8, and more preferably at least about R-10 (compared to the much lower R-values of conventional IG units).

Owner:GUARDIAN GLASS LLC

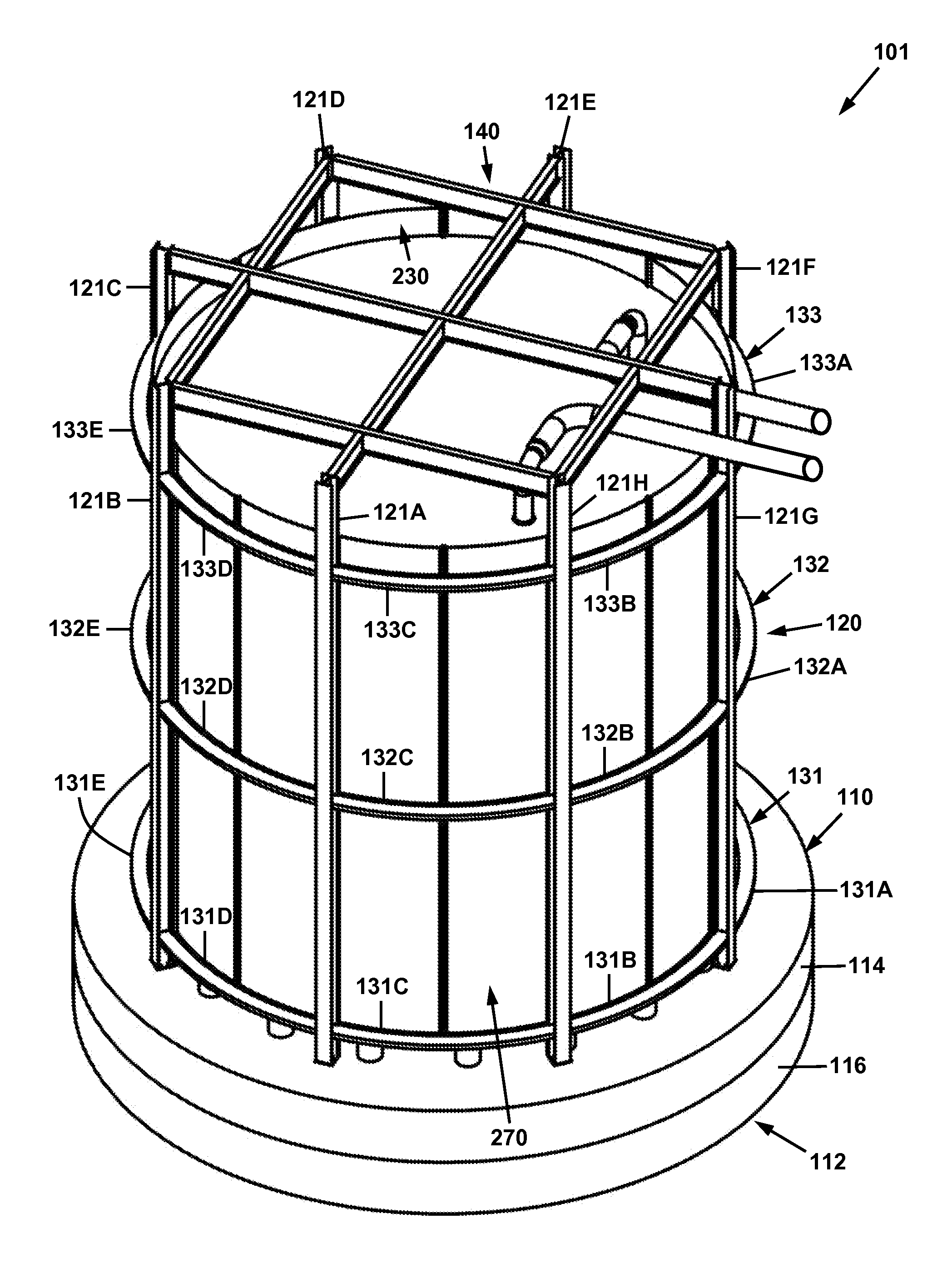

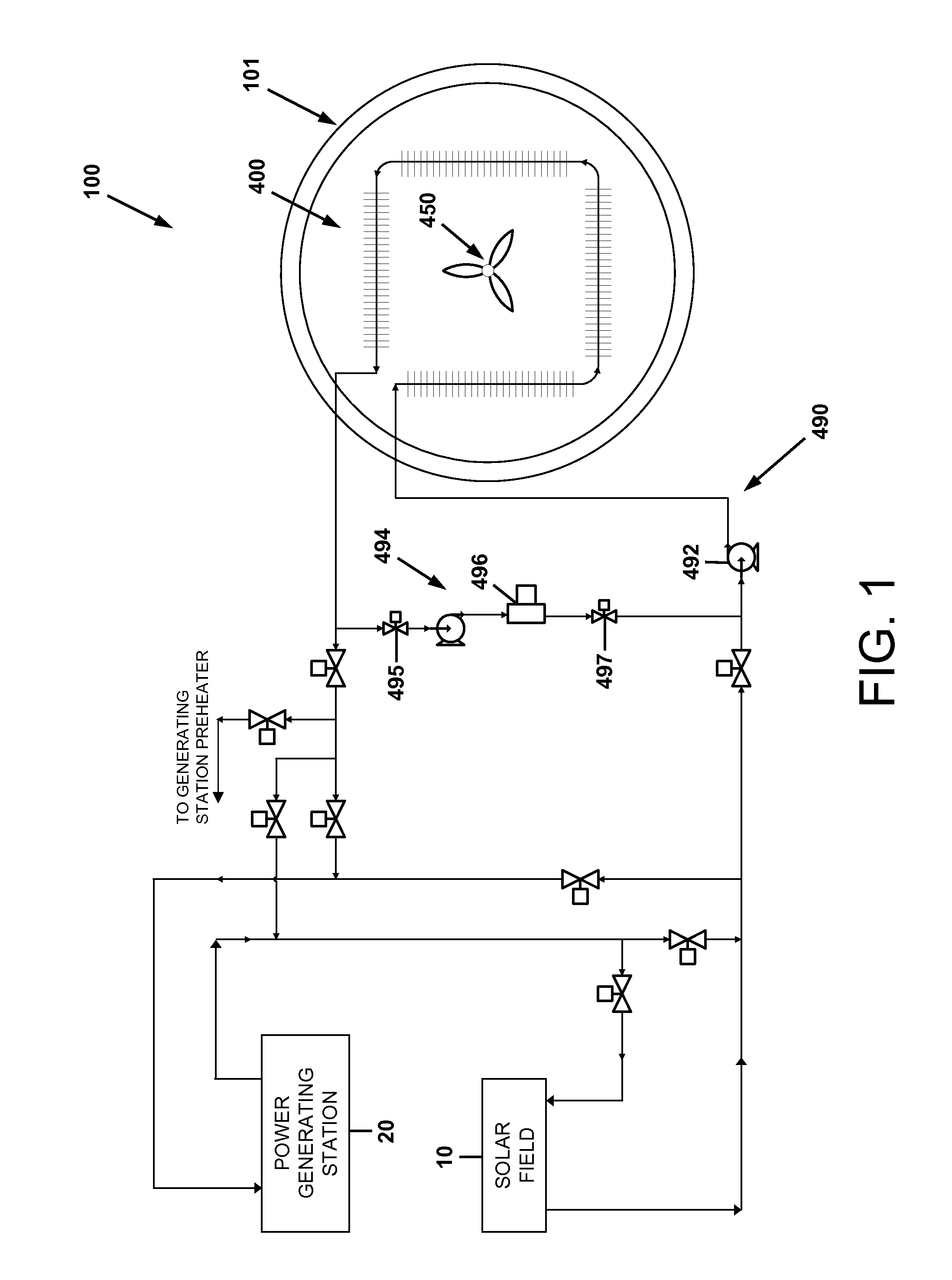

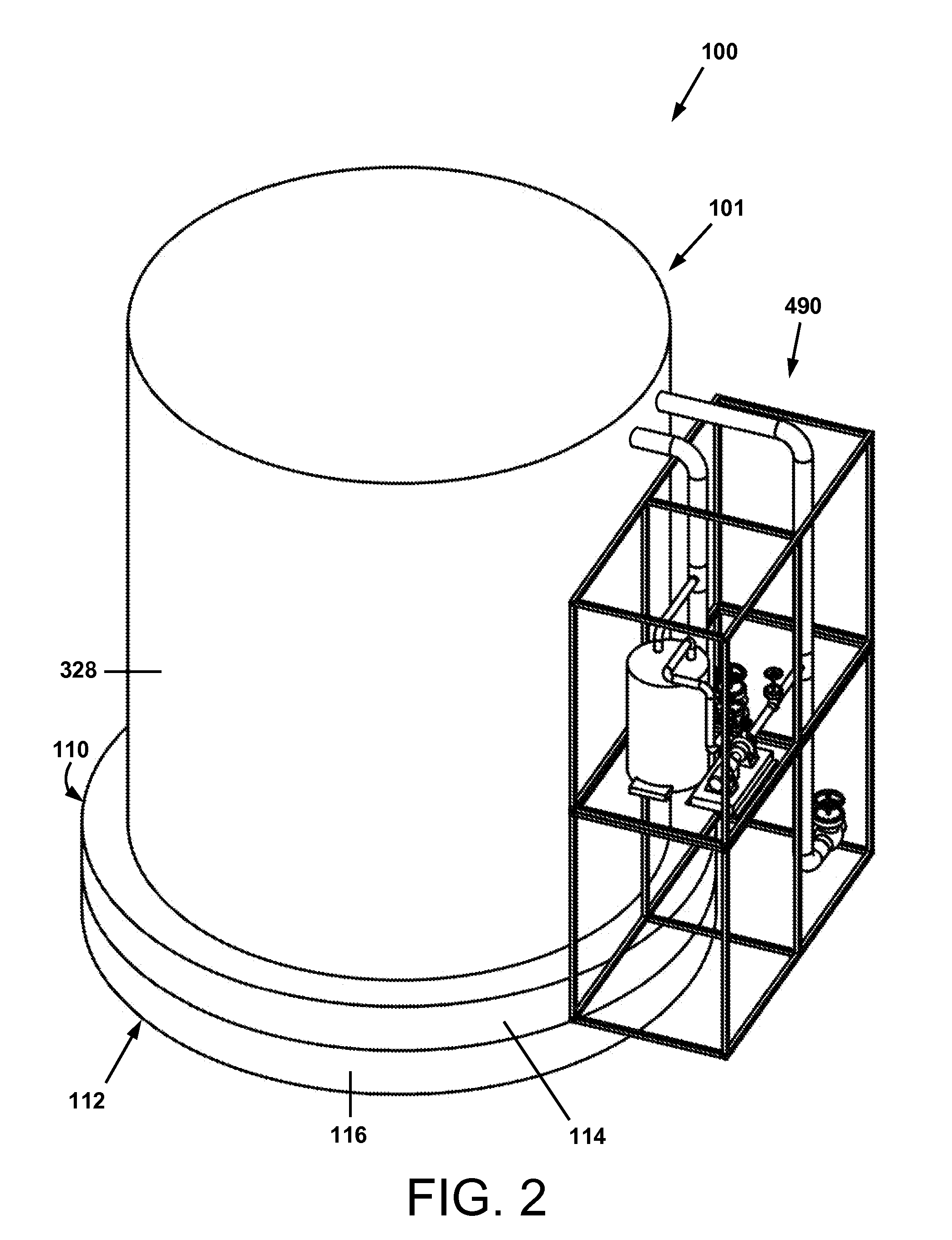

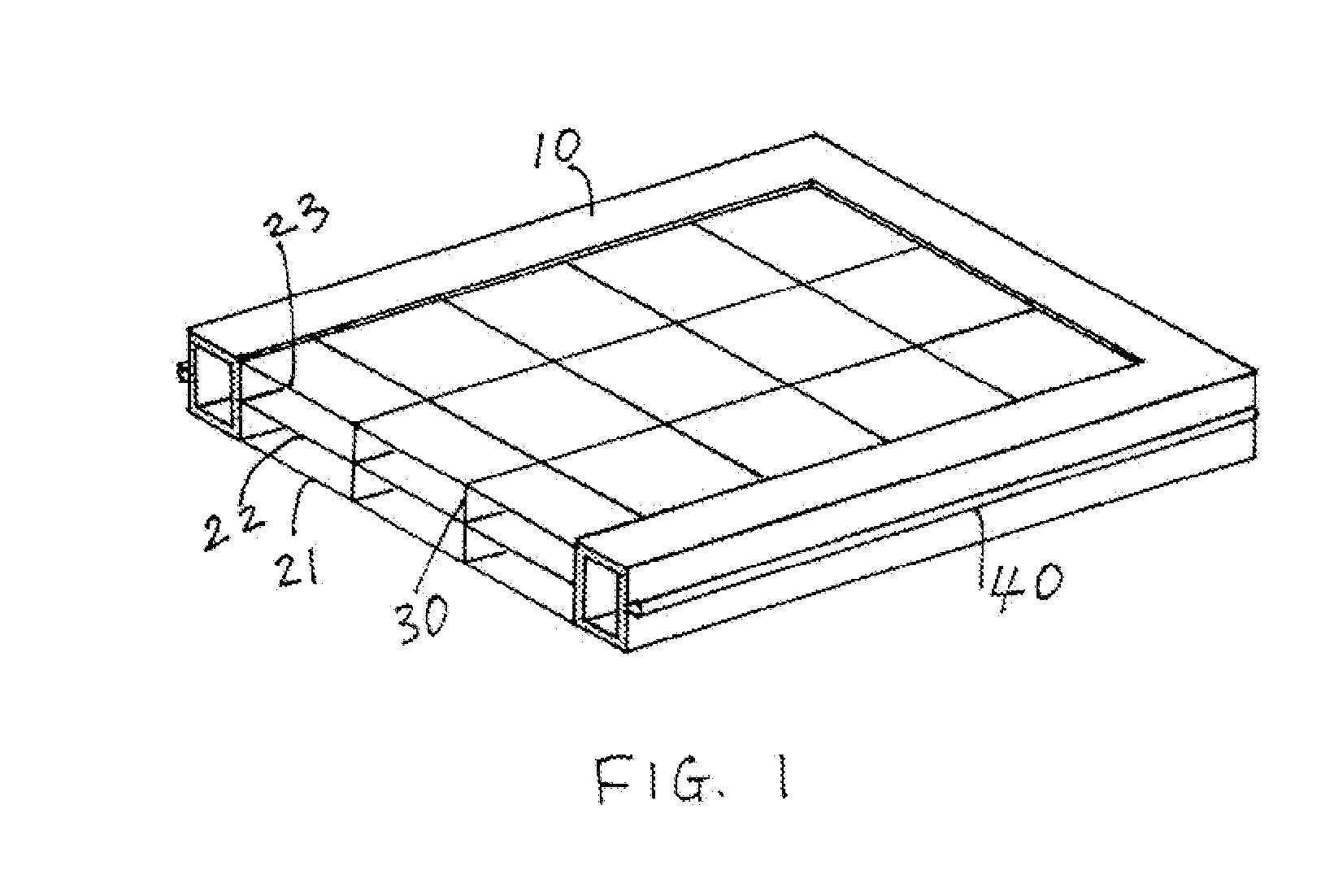

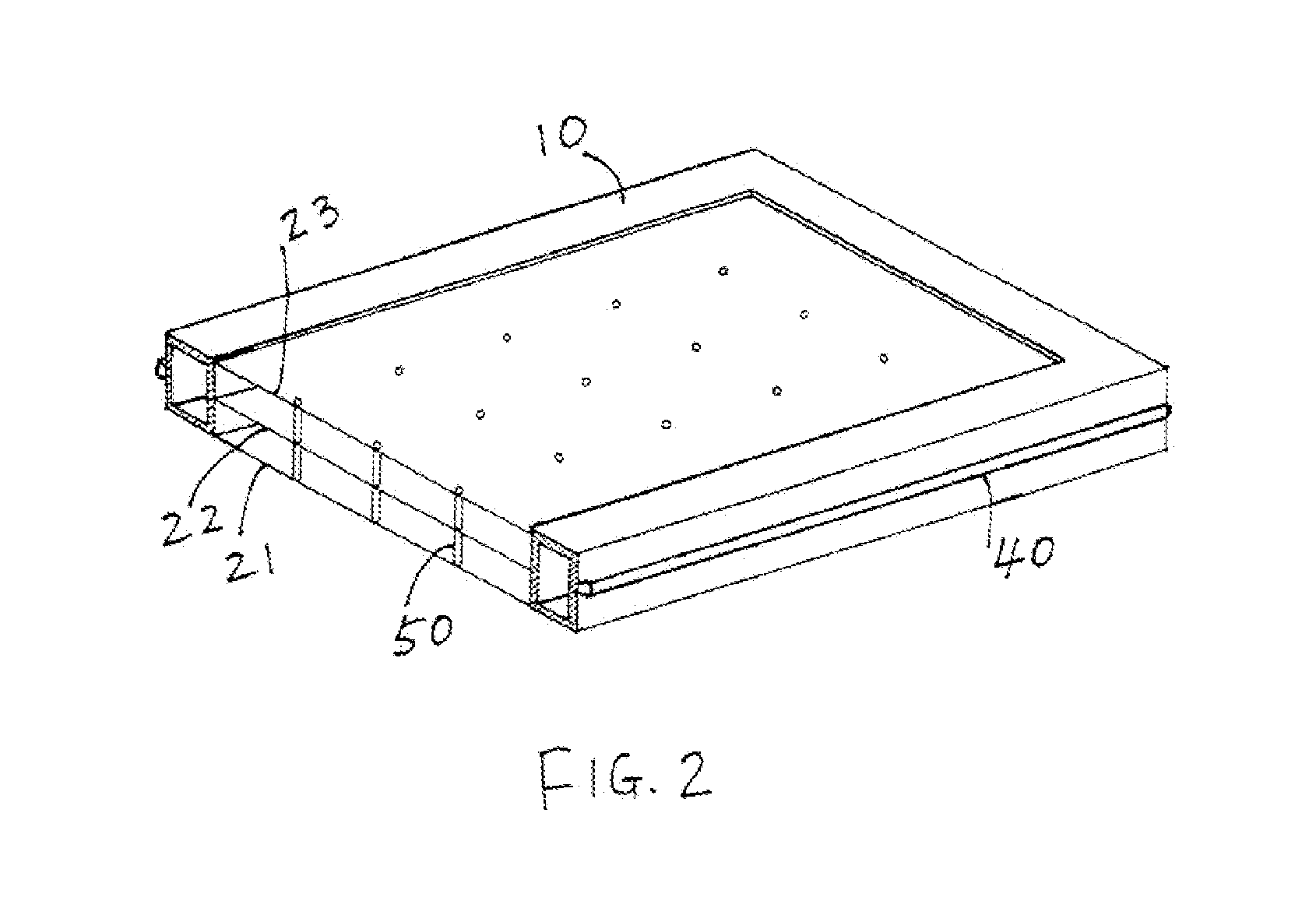

Energy storage vessel, systems, and methods

InactiveUS20110226780A1High R-valueSolve the real problemDomestic cooling apparatusHeat storage plantsEngineeringThermal energy storage system

A vessel for a thermal energy storage system comprising a bottom wall joined to a surrounding side wall, and an inner liner disposed within the bottom wall and side wall and comprising an inner liner bottom and an inner liner side wall. One aspect of the inner liner bottom and side wall is that they are configured to repeatedly expand and contract during the thermal cycling of the storage system. A thermal energy storage system comprising the containment vessel and an array of heat exchangers is also disclosed. The heat exchangers are disposed in the vessel, and arranged so as to enclose a volume within the vessel. Each of the heat exchangers is suspended by a suspension assembly. The assembly may be comprised of a central support hanger, a spring loaded upper hanger, and a lower hanger.

Owner:BELL INDEPENDENT POWER CORP

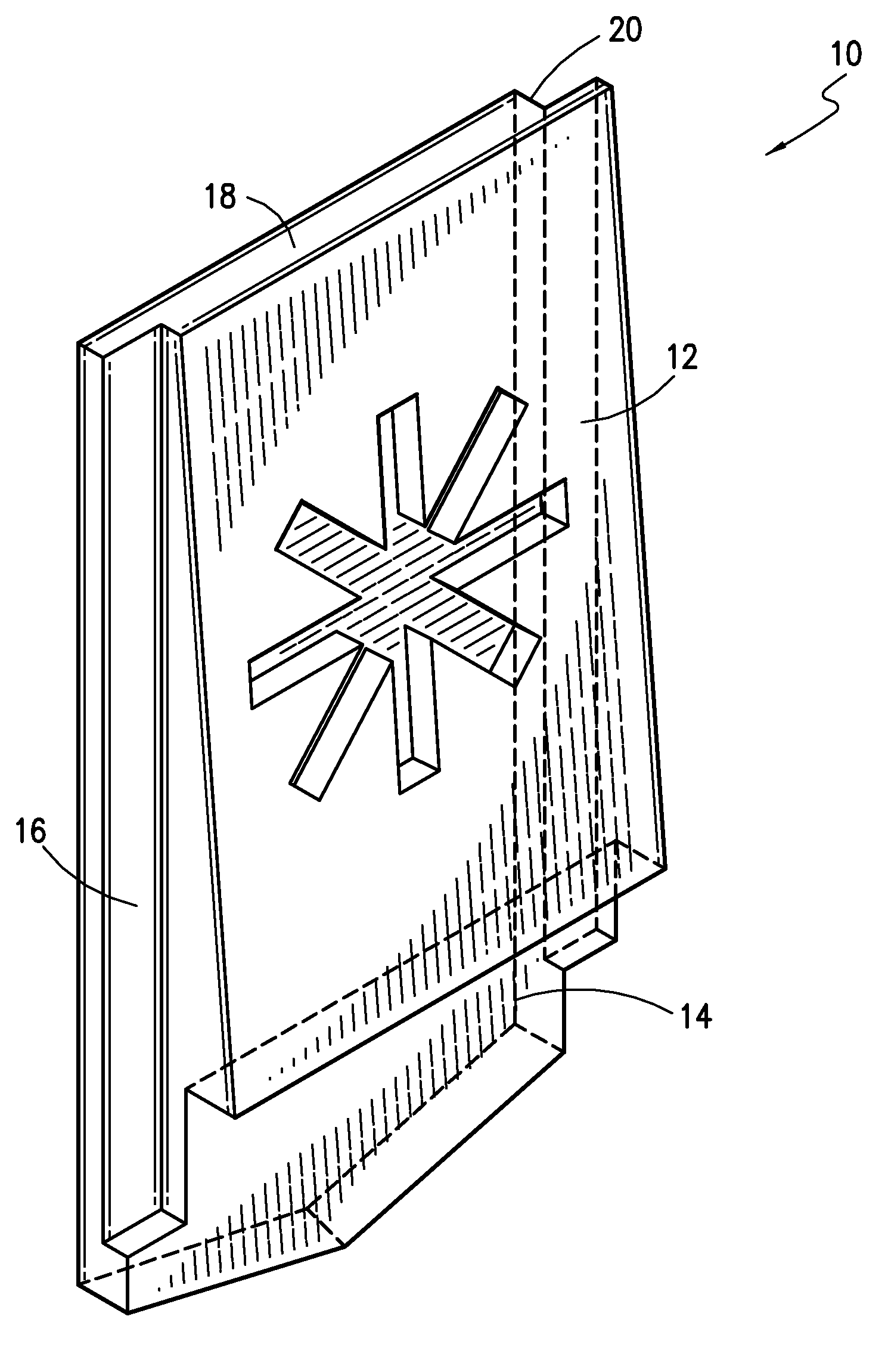

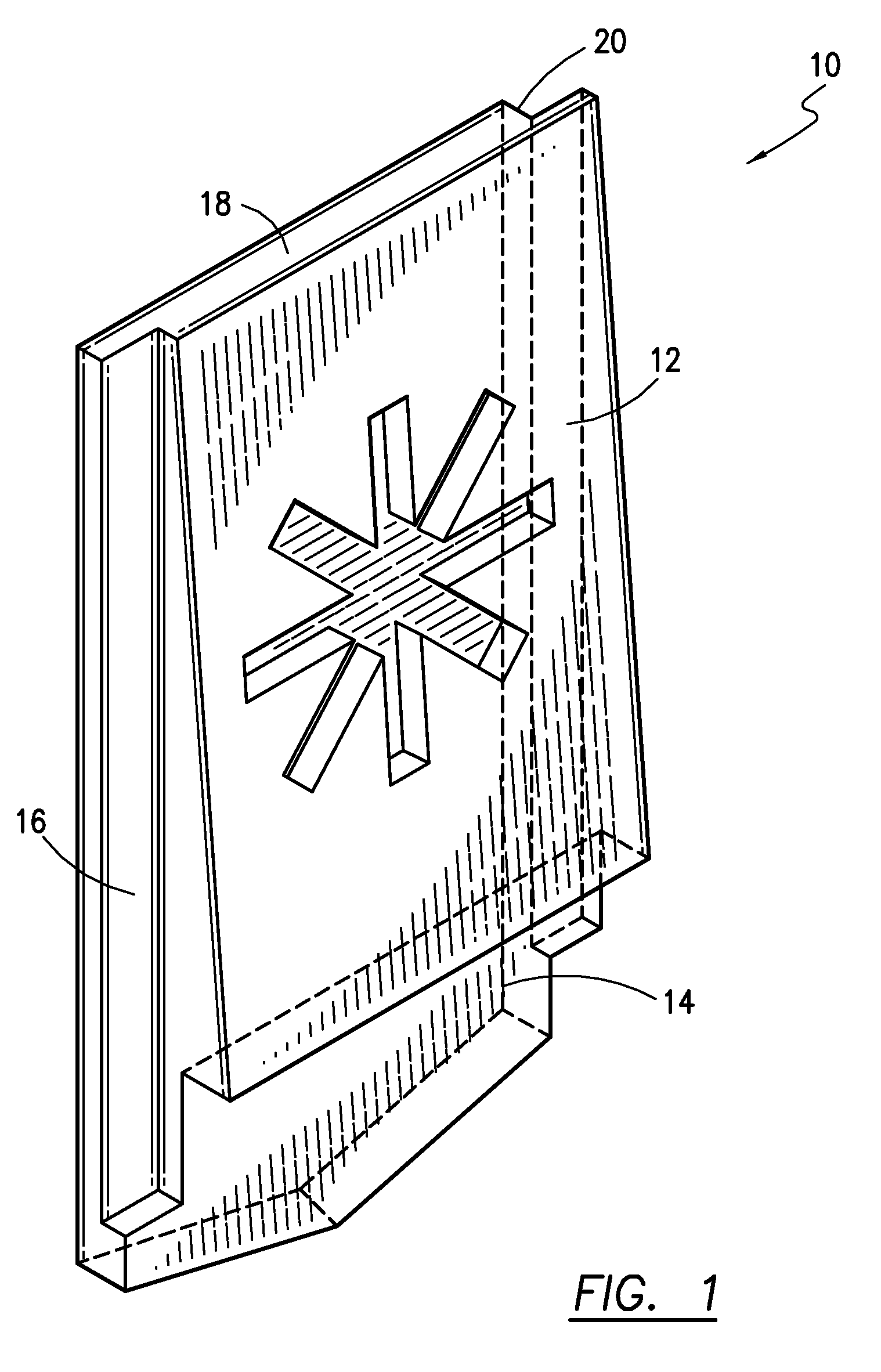

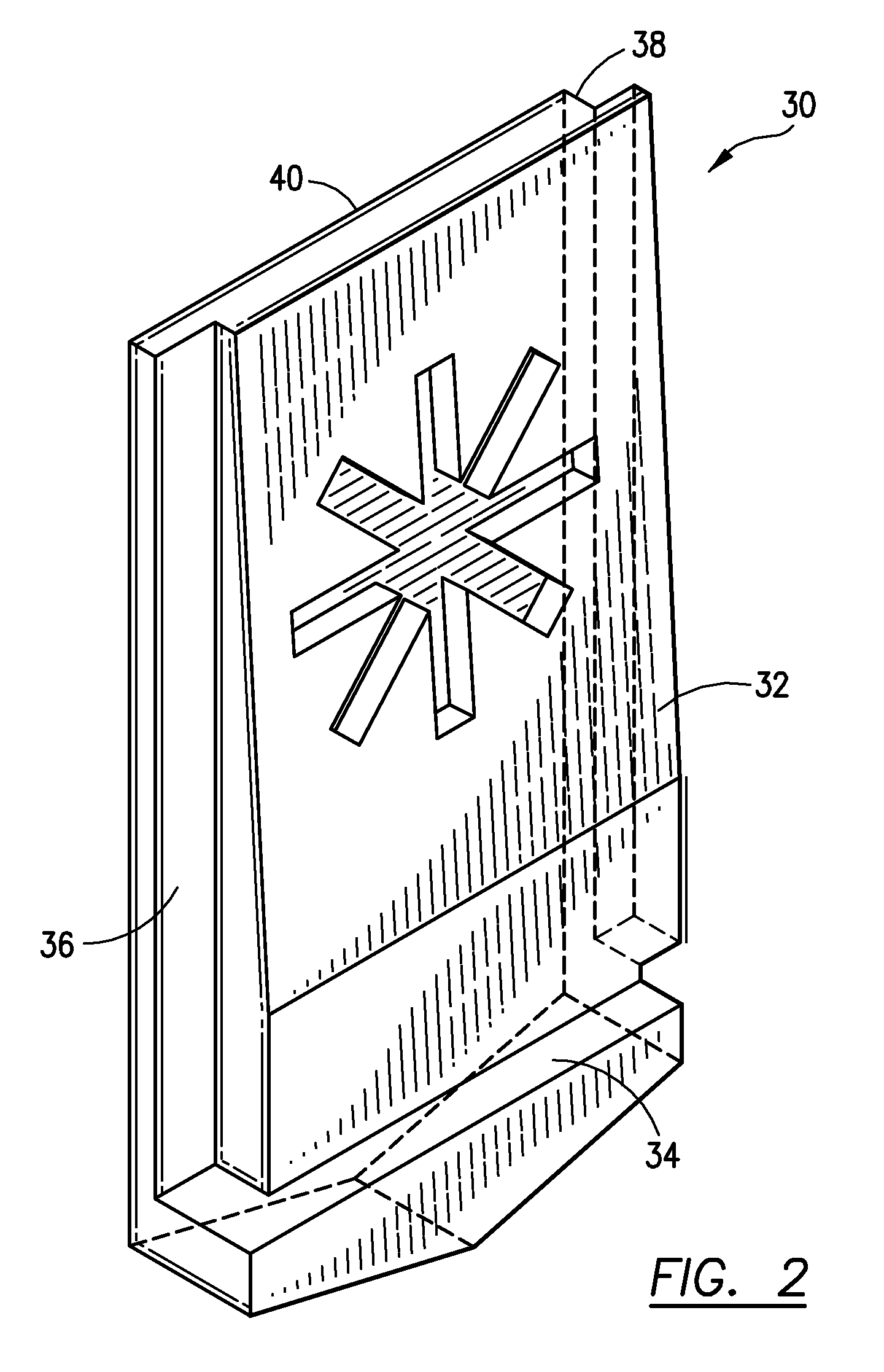

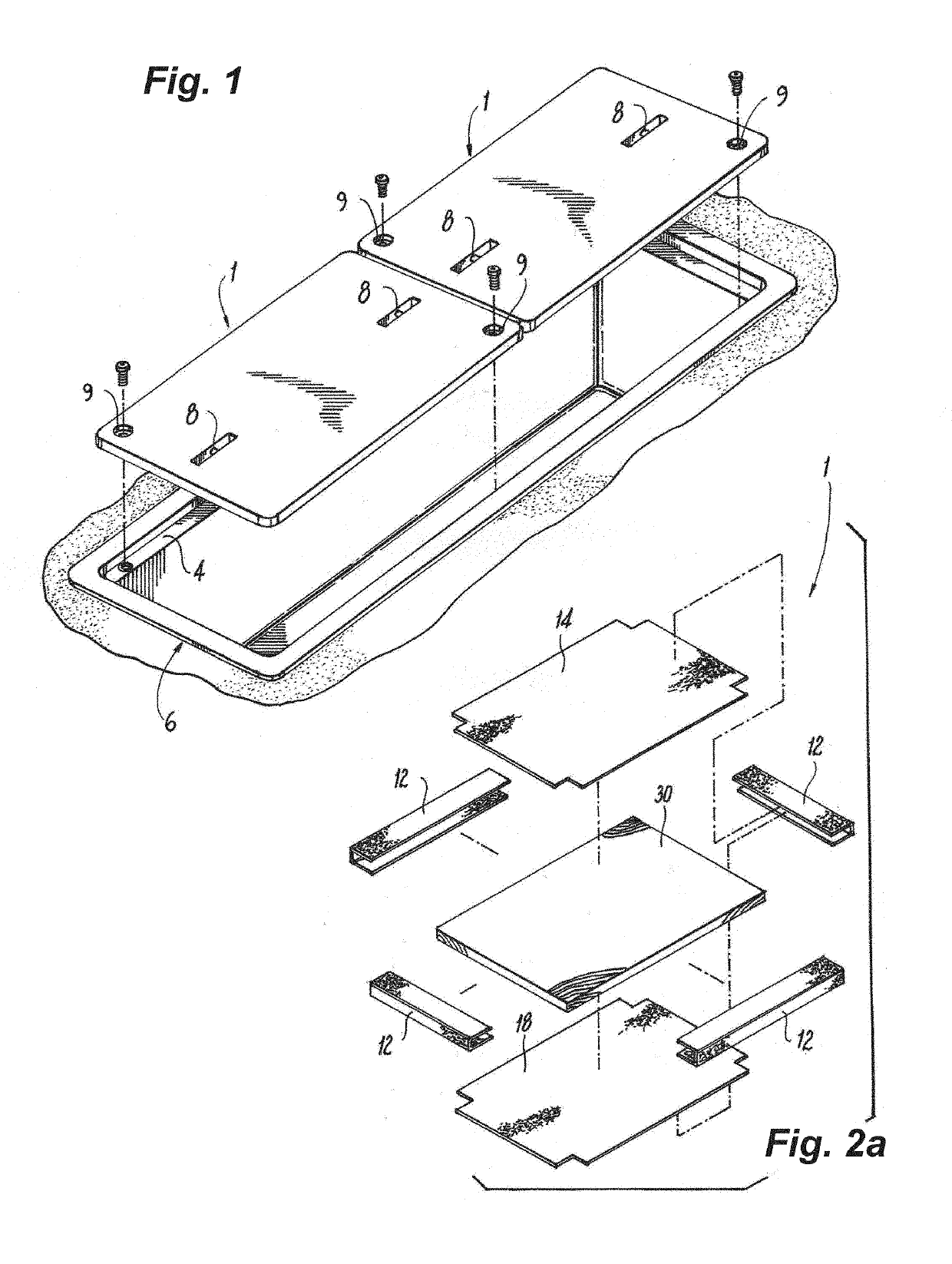

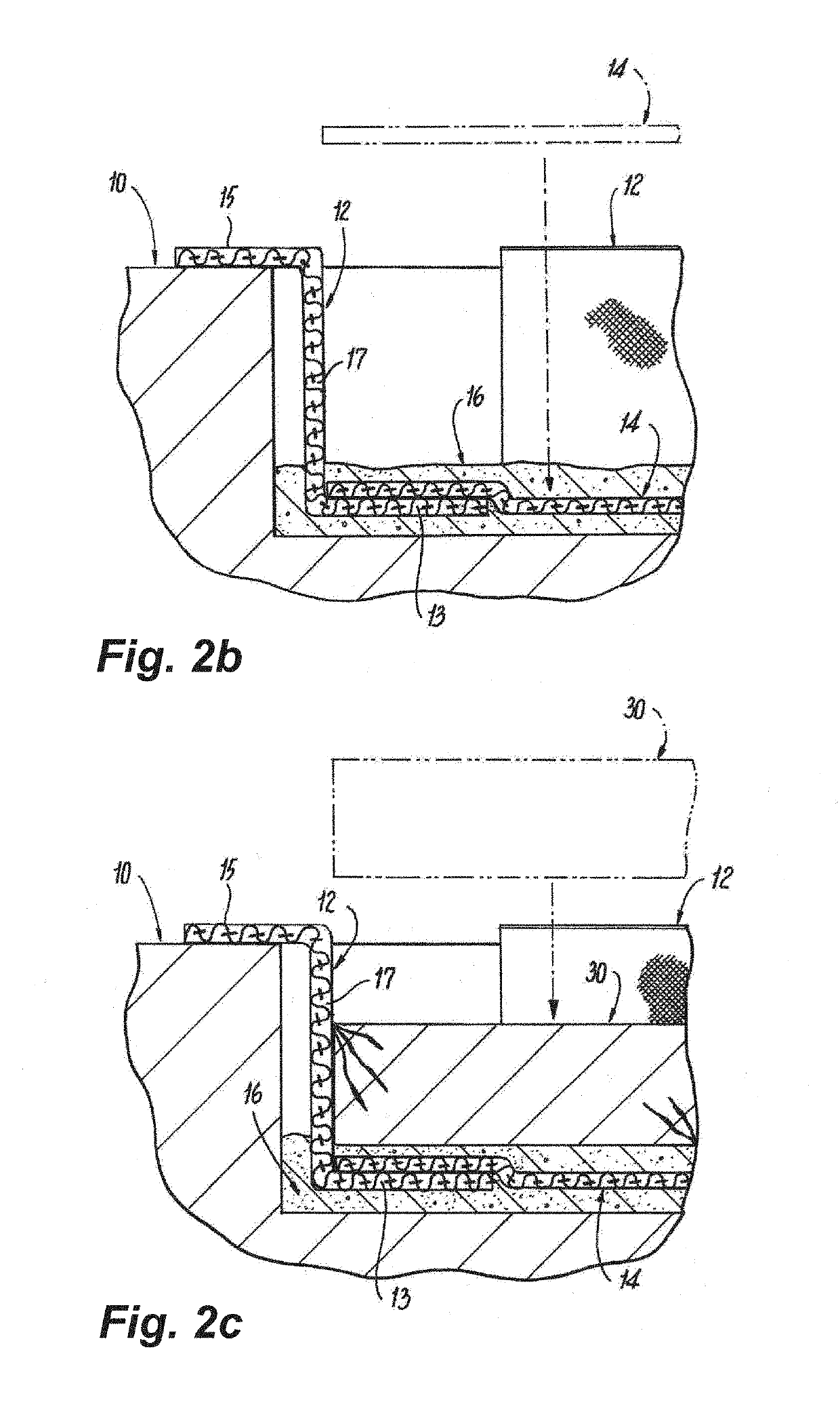

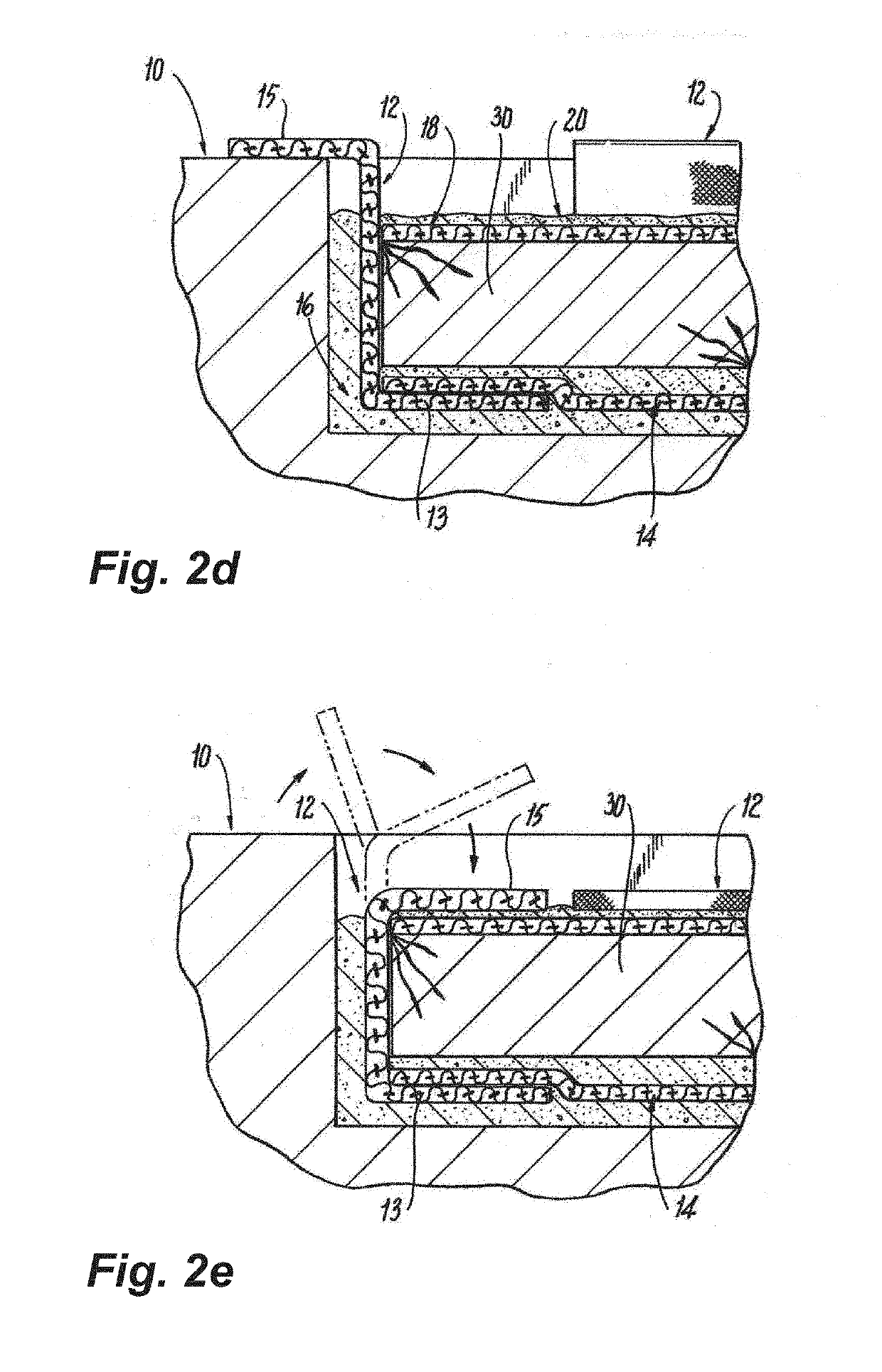

High R-value window unit with vacuum IG unit and insulating frame

ActiveUS7845142B2Higher andImproved R-value for the window unitFixed grillesClimate change adaptationEngineeringMechanical engineering

In certain example embodiments of this invention, a window unit may include a vacuum IG (VIG) unit as an inboard lite and a monolithic lite (e.g., with an optional low-E coating thereon) as an outboard lite. A dead air space may separate the inboard and outboard lites. A highly insulated frame may be used to support the inner and outer lites. The VIG unit may be partially embedded or supported in the insulative frame, so that the insulating frame separates the VIG unit inboard lite from the outboard lite thereby reducing conductivity around the edges of the window unit so that R-value can be increased (and U-value decreased). In certain example embodiments, the total R-value of the window unit is at least about R-8, and more preferably at least about R-10 (compared to the much lower R-values of conventional IG units).

Owner:GUARDIAN GLASS LLC

Light weight molded roof tile with integrated solar capabilities

InactiveUS9038330B2Easy to transportEasy to installPhotovoltaic supportsRoof covering using slabs/sheetsUv protectionPhosphate

An improved building roof tile for a sloping roof including a polyurethane foam tile that includes outer coating layers that are made of a uniquely fire resistant or retardant layered system that includes a first outer fire resistant layer of 100% solid aliphatic polyurea material and a second inner layer of an 100% solid intumescent non-halogenated phosphate material, said inner layer forming a fire blocking partition and said outer layer offering UV protection, featherweight, category 5 hurricane proof, yields a high R-value, offer low thermal transference into attic space, will retrofit any sloped roof without structural build-up, can be molded into single or triple units, cannot break under foot or when extreme pressures are applied, can produce upgradable solar energy, is easy to transport and install and can molded to look like slate, wood, flat roll tile or most other historical tiles.

Owner:BELLAVIA CARMEN

High R-value window unit

ActiveUS8377524B2Higher andImproved R-value for the window unit(s)Climate change adaptationWindows/door improvementEngineeringAir space

Owner:GUARDIAN GLASS LLC

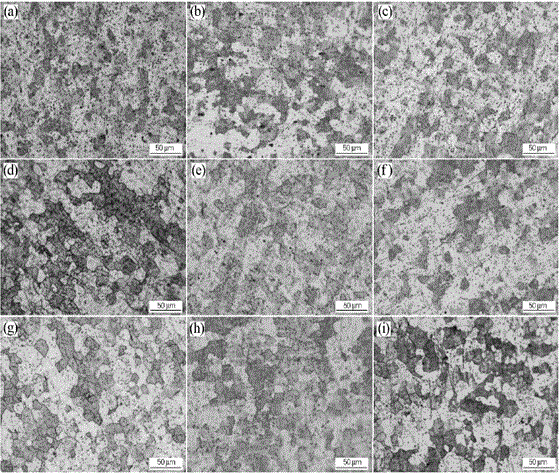

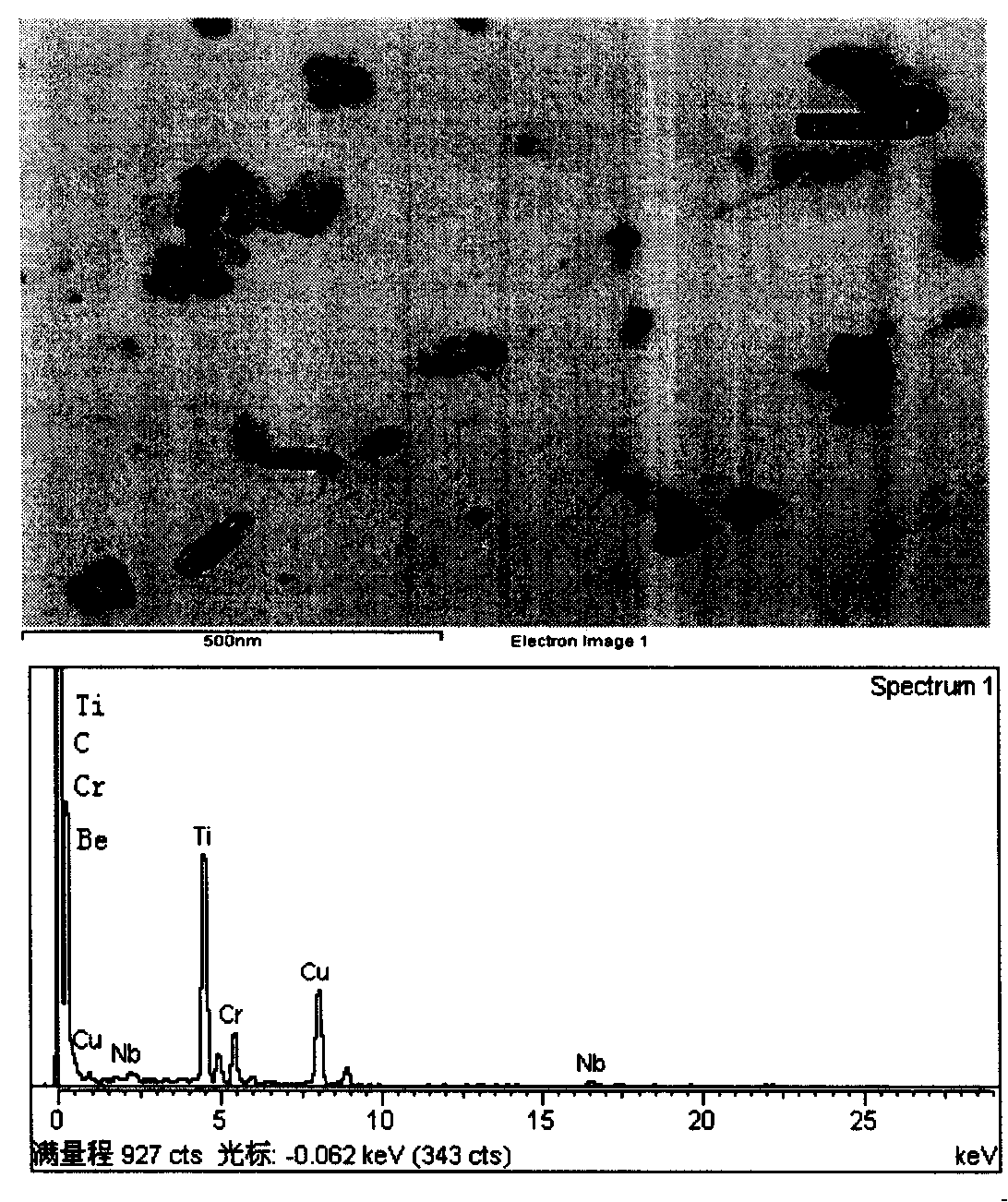

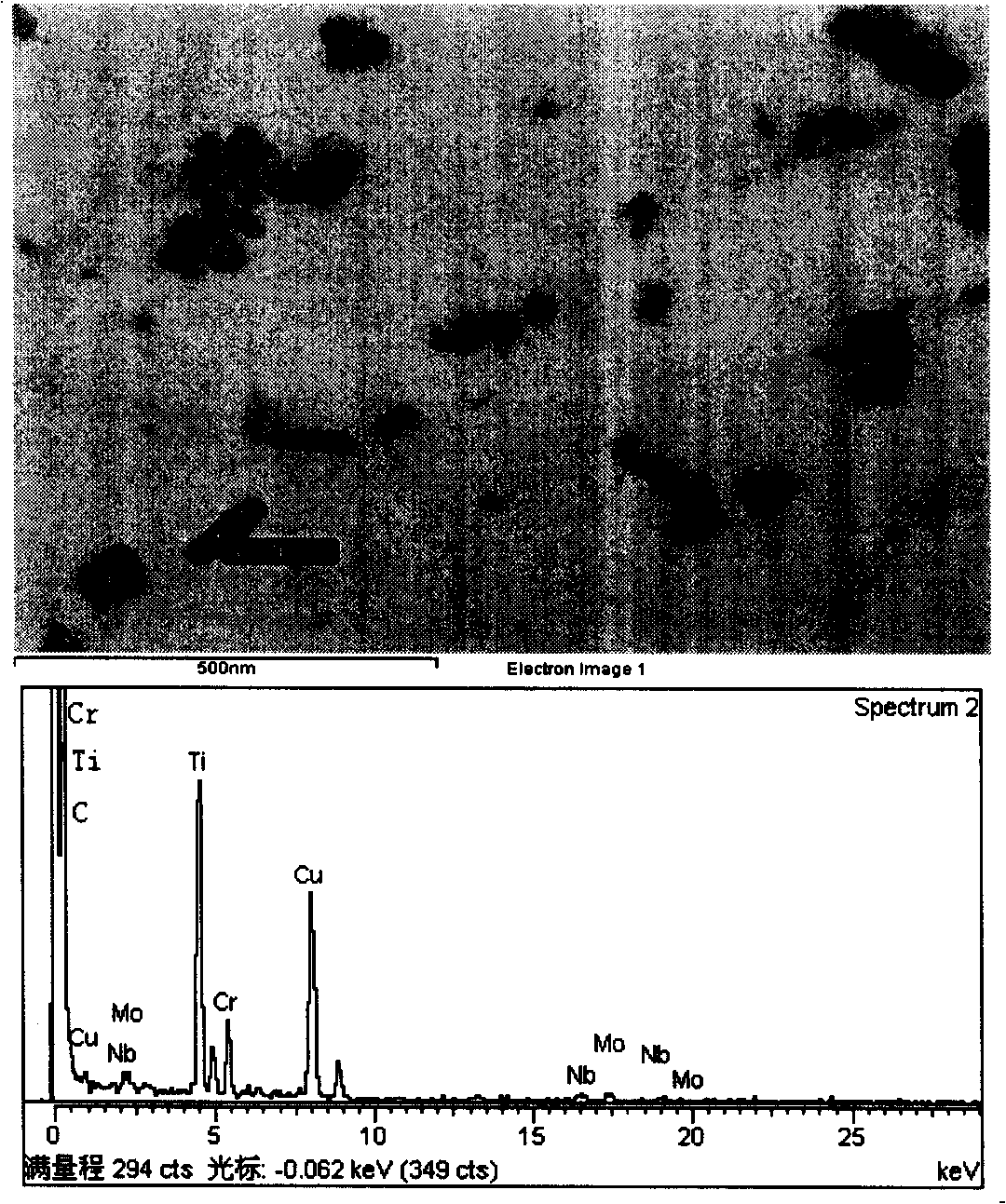

Heat-resistant cold rolled ferritic stainless steel sheet, hot rolled ferritic stainless steel sheet for cold rolling raw material, and methods for producing same

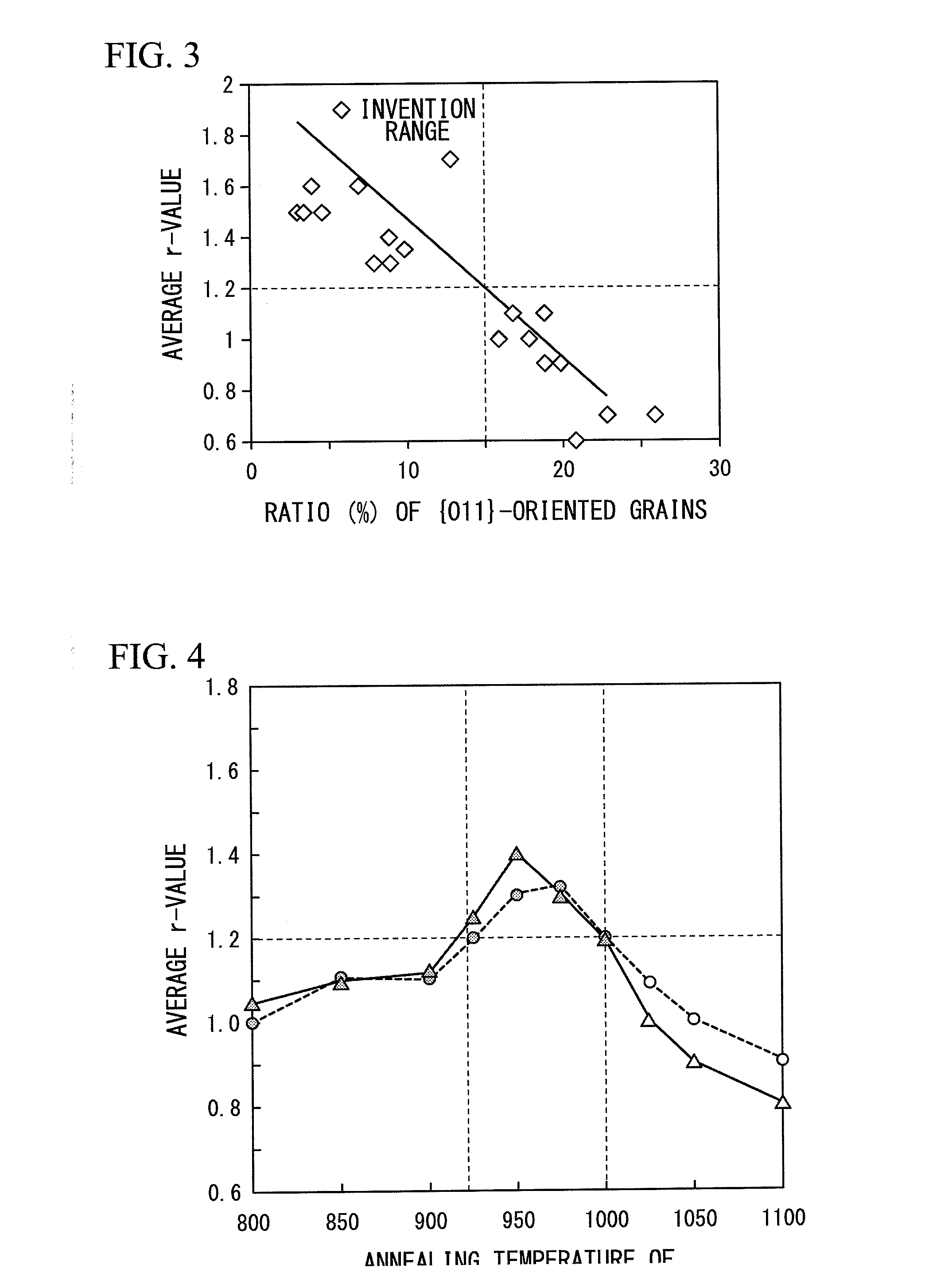

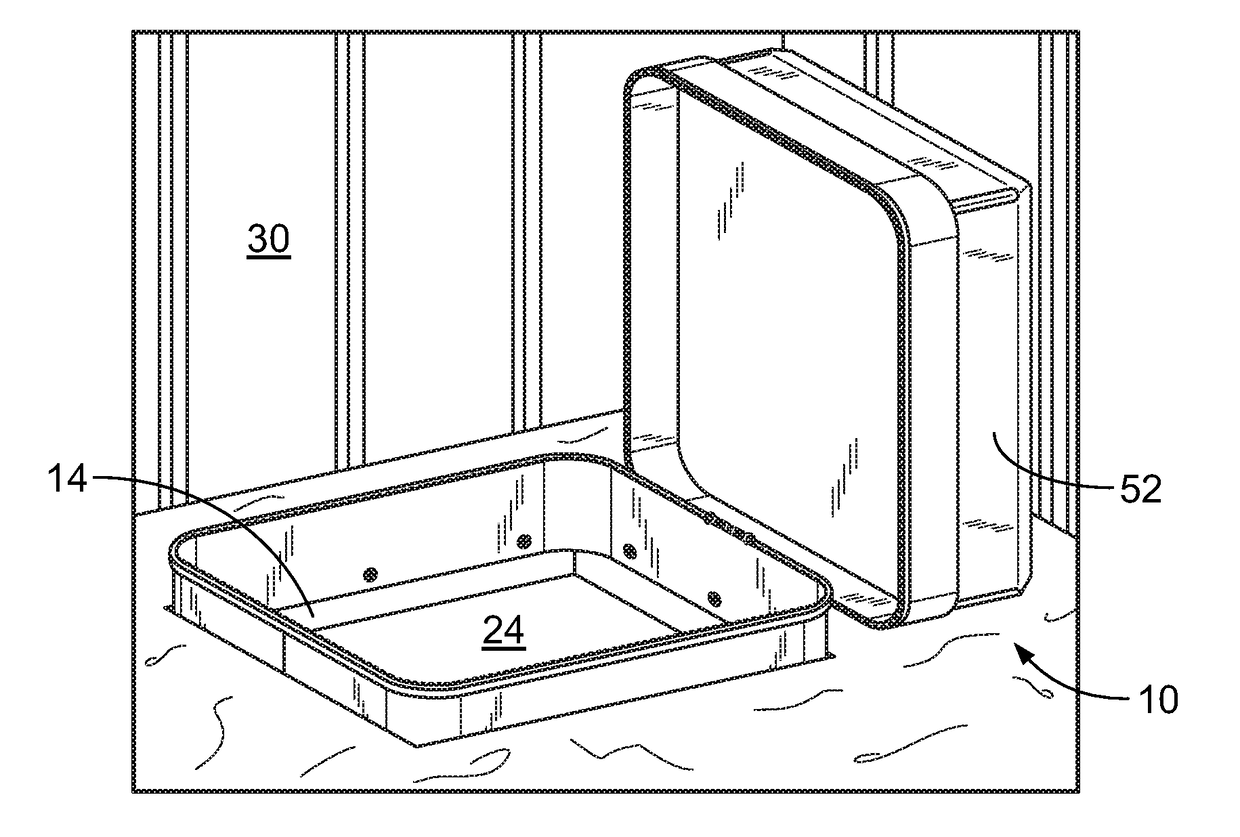

InactiveUS20150020933A1Secure high r-valueIncrease R-valueFurnace typesHeat treatment furnacesSurface layerArea ratio

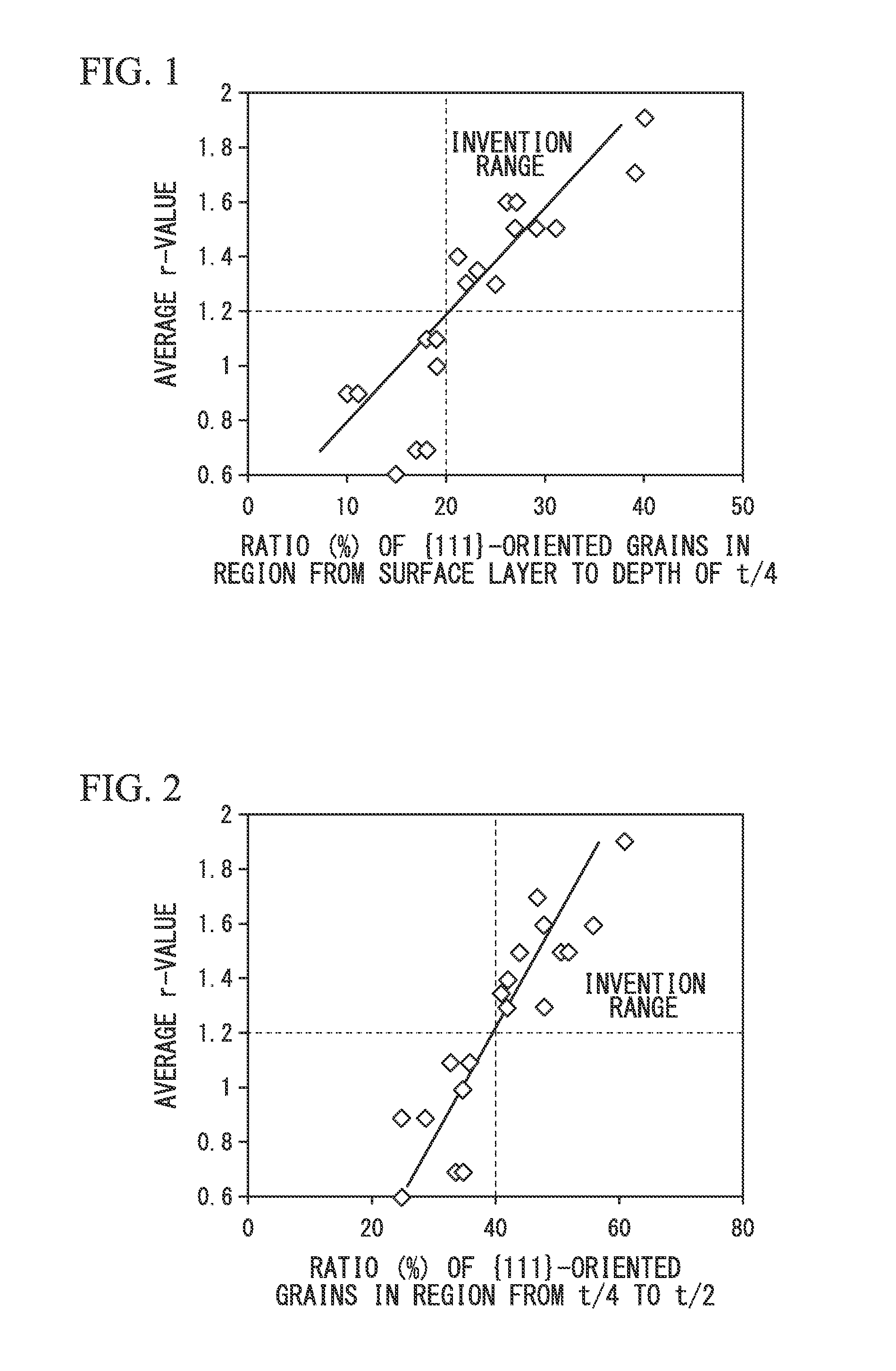

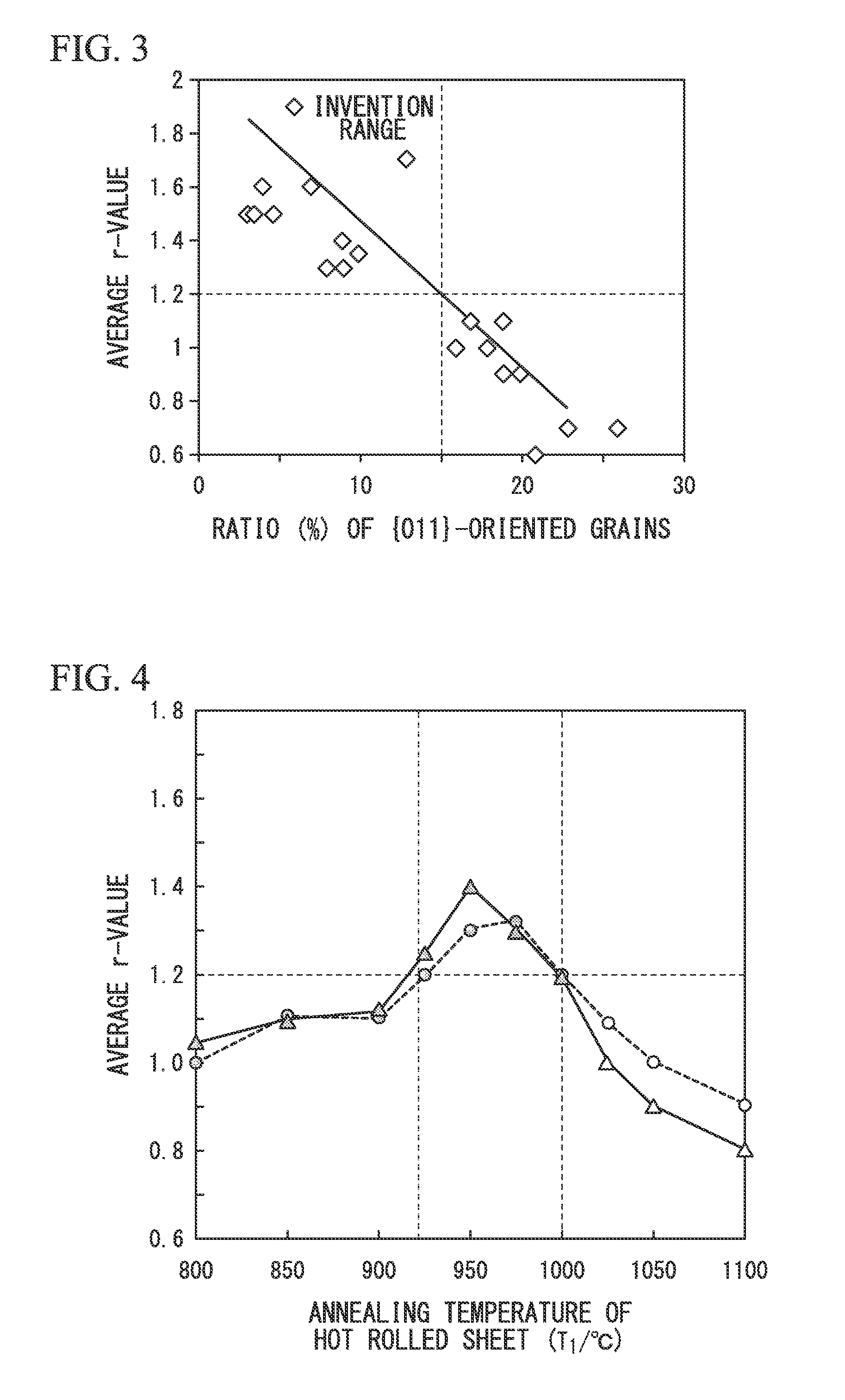

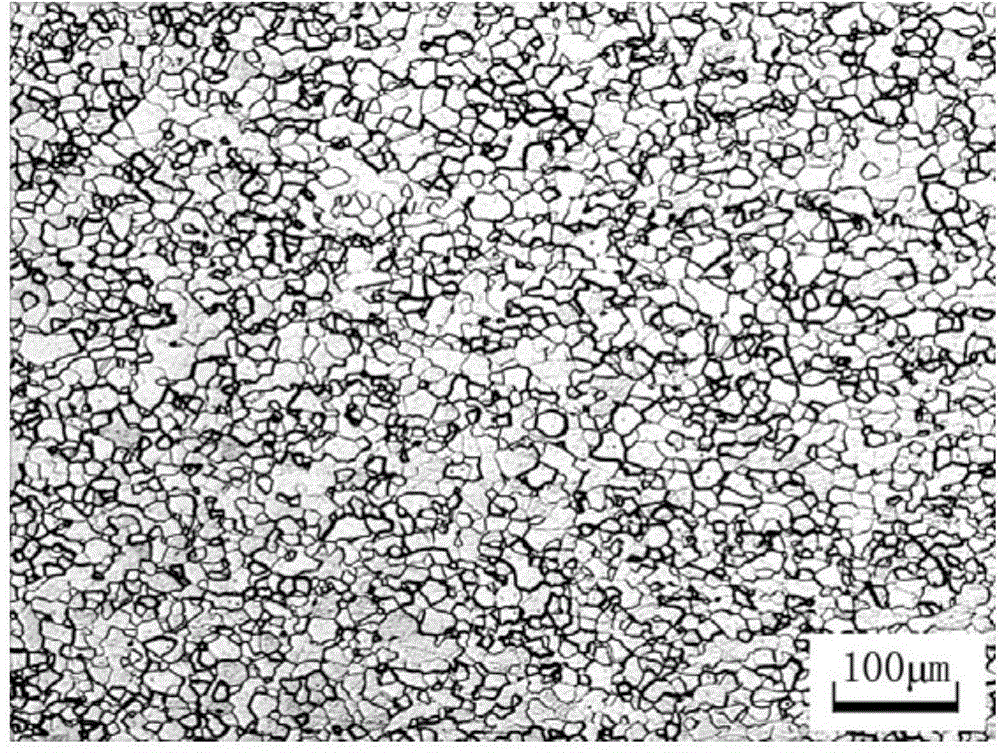

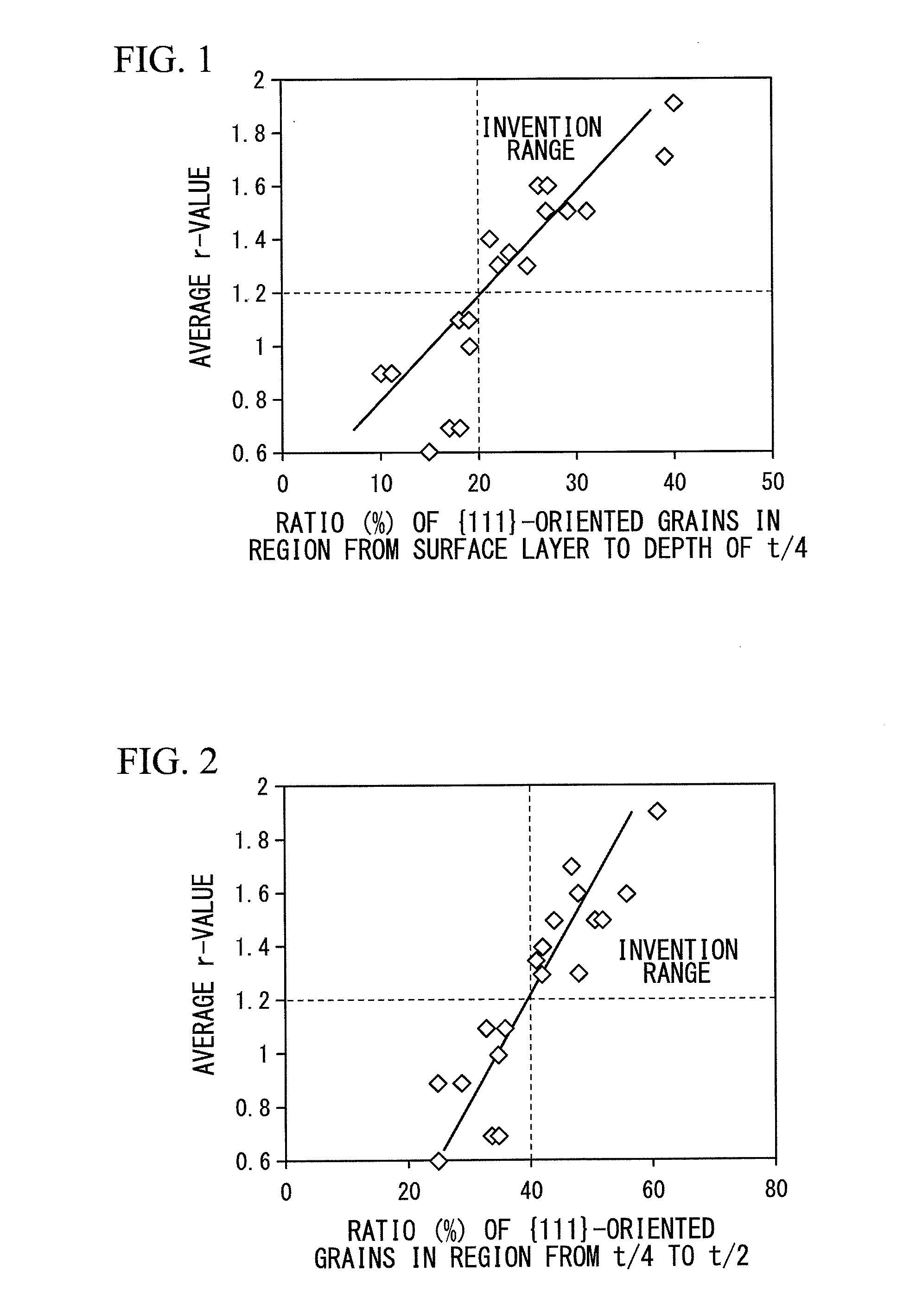

Provided is a heat-resistant cold rolled ferritic stainless steel sheet containing, in terms of mass %, 0.02% or less of C, 0.1% to 1.0% of Si, greater than 0.6% to 1.5% of Mn, 0.01% to 0.05% of P, 0.0001% to 0.0100% of S, 13.0% to 20.0% of Cr, 0.1% to 3.0% of Mo, 0.005% to 0.20% of Ti, 0.3% to 1.0% of Nb, 0.0002% to 0.0050% of B, 0.005% to 0.50% of Al, and 0.02% or less of N, with the balance being Fe and inevitable impurities, in which {111}-oriented grains are present at an area ratio of 20% or greater in a region from a surface layer to t / 4 (t is a sheet thickness), {111}-oriented grains are present at an area ratio of 40% or greater in a region from t / 4 to t / 2, and {011}-oriented grains are present at an area ratio of 15% or less in the entire region in a thickness direction.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

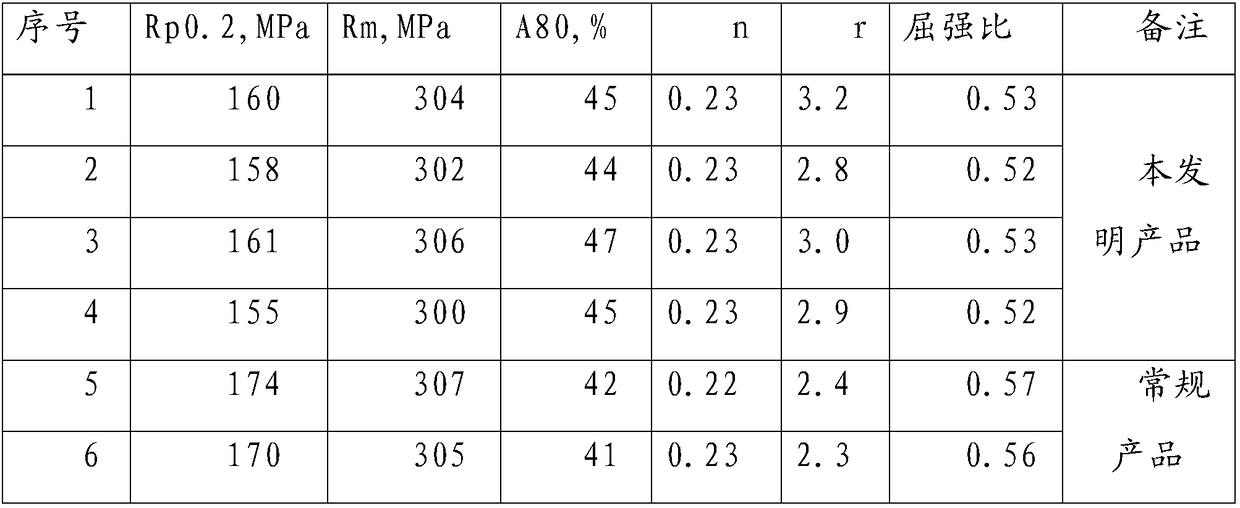

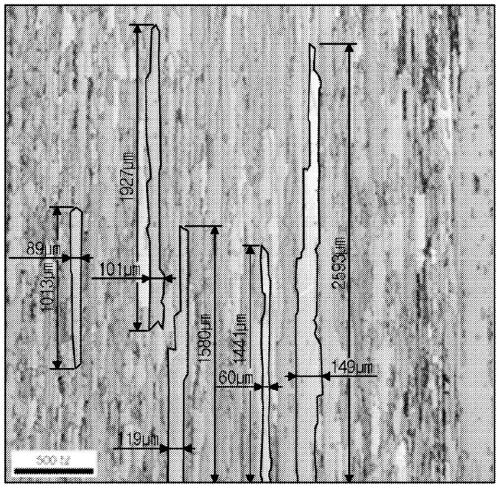

High strength galvanized steel sheet having excellent deep drawability and stretch flangeability and method for manufacturing the same

ActiveUS20130292010A1Improve deep drawing performanceHigh R-valueHot-dipping/immersion processesFurnace typesMartensiteMaterials science

A high-strength galvanized steel sheet contains C: 0.010% or more and 0.06% or less, Si: more than 0.5% and 1.5% or less, Mn: 1.0% or more and 3.0% or less, P: 0.005% or more and 0.1% or less, S: 0.01% or less, sol.Al: 0.005% or more and 0.5% or less, N: 0.01% or less, Nb: 0.010% or more and 0.090% or less, and Ti: 0.015% or more and 0.15% or less, on a mass percent basis. The Nb and C contents of the steel satisfy the relation of (Nb / 93) / (C / 12)<0.20. C* satisfies 0.005≦C*≦0.025. Ferrite constitutes 70% by area ratio or more of the steel sheet. Martensite constitutes 3% by area ratio or more of the steel sheet. C*=C−(12 / 93)Nb−(12 / 48){Ti−(48 / 14)N}, wherein C, Nb, Ti, and N denote the C, Nb, Ti, and N contents of the steel.

Owner:JFE STEEL CORP

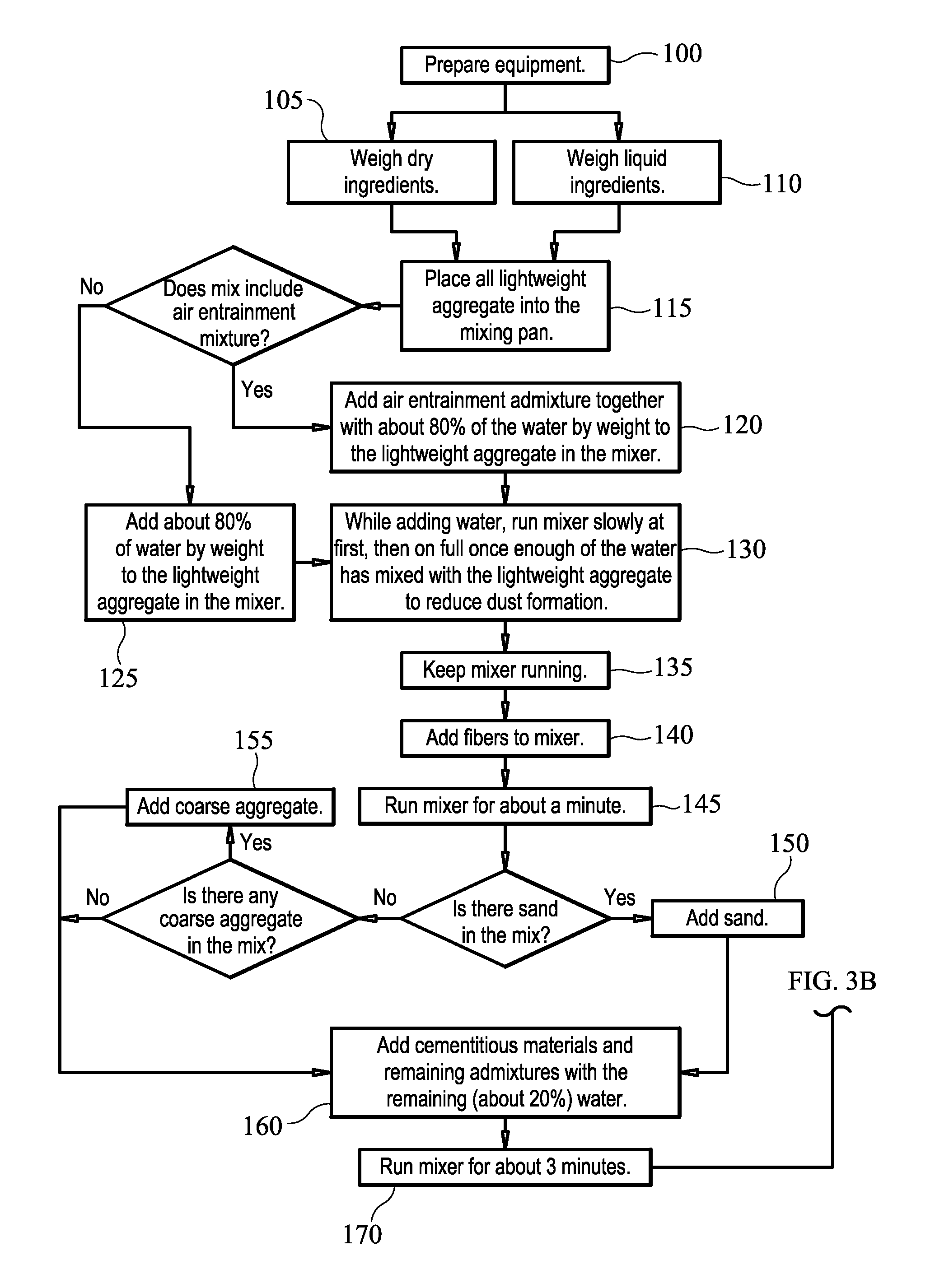

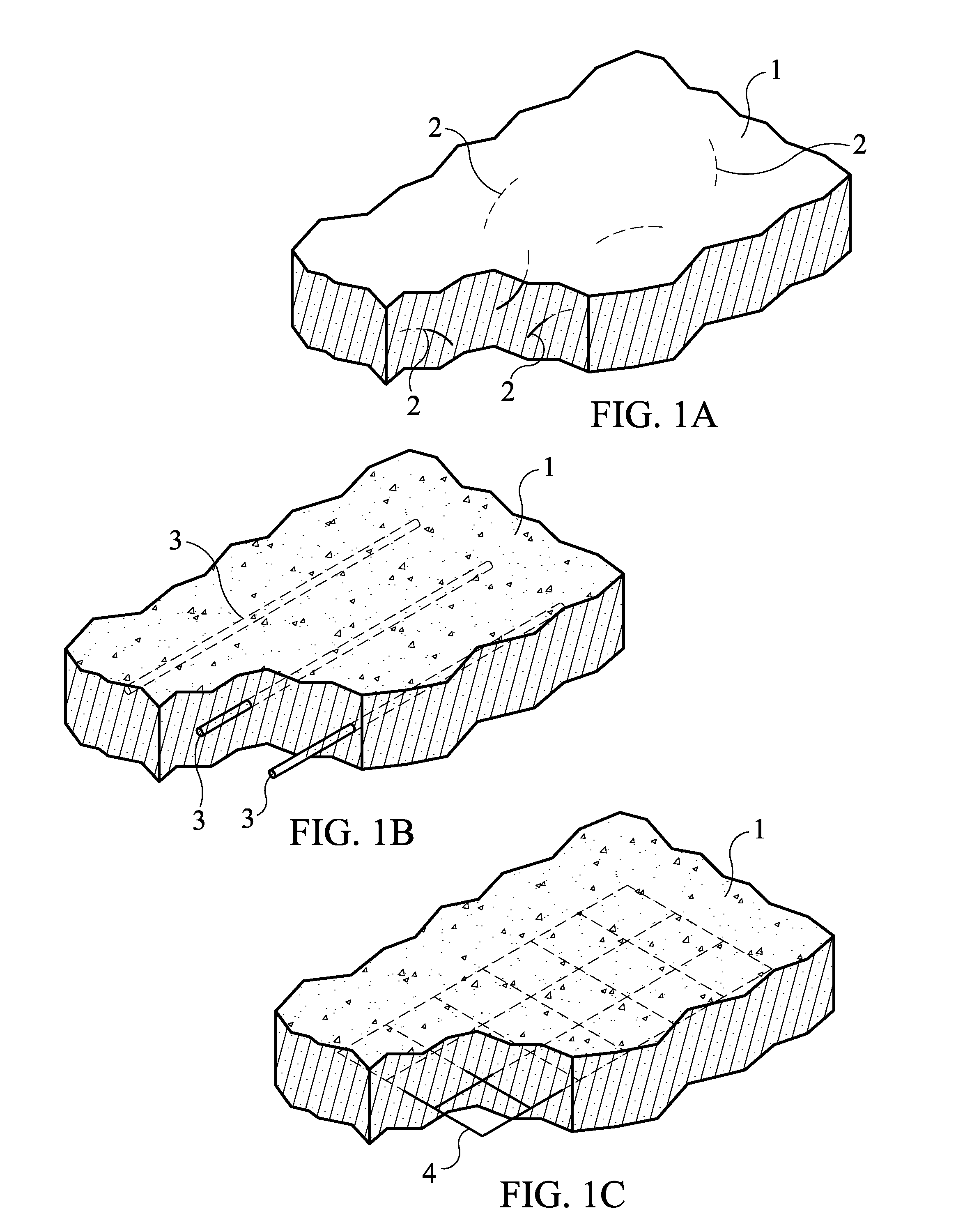

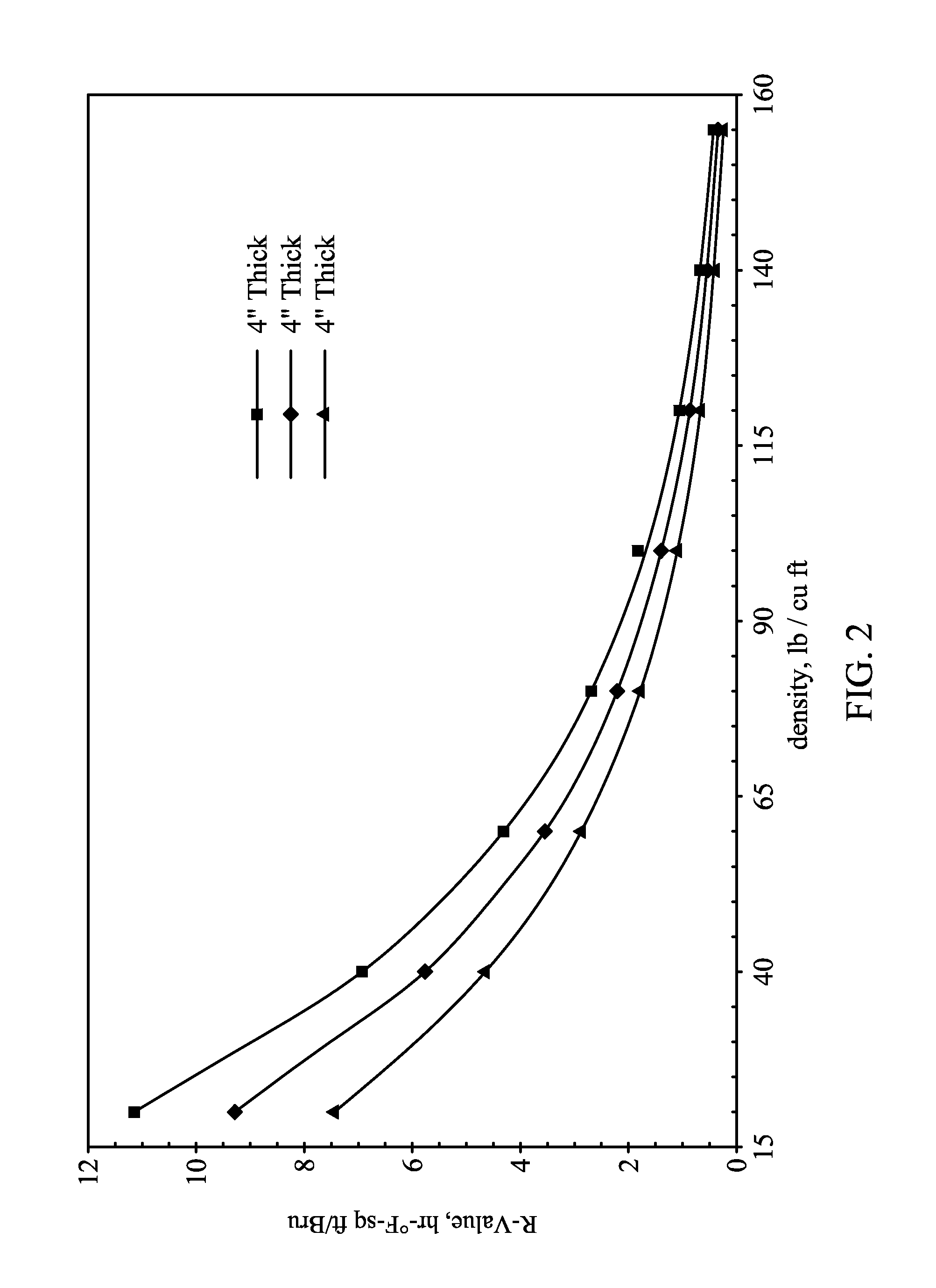

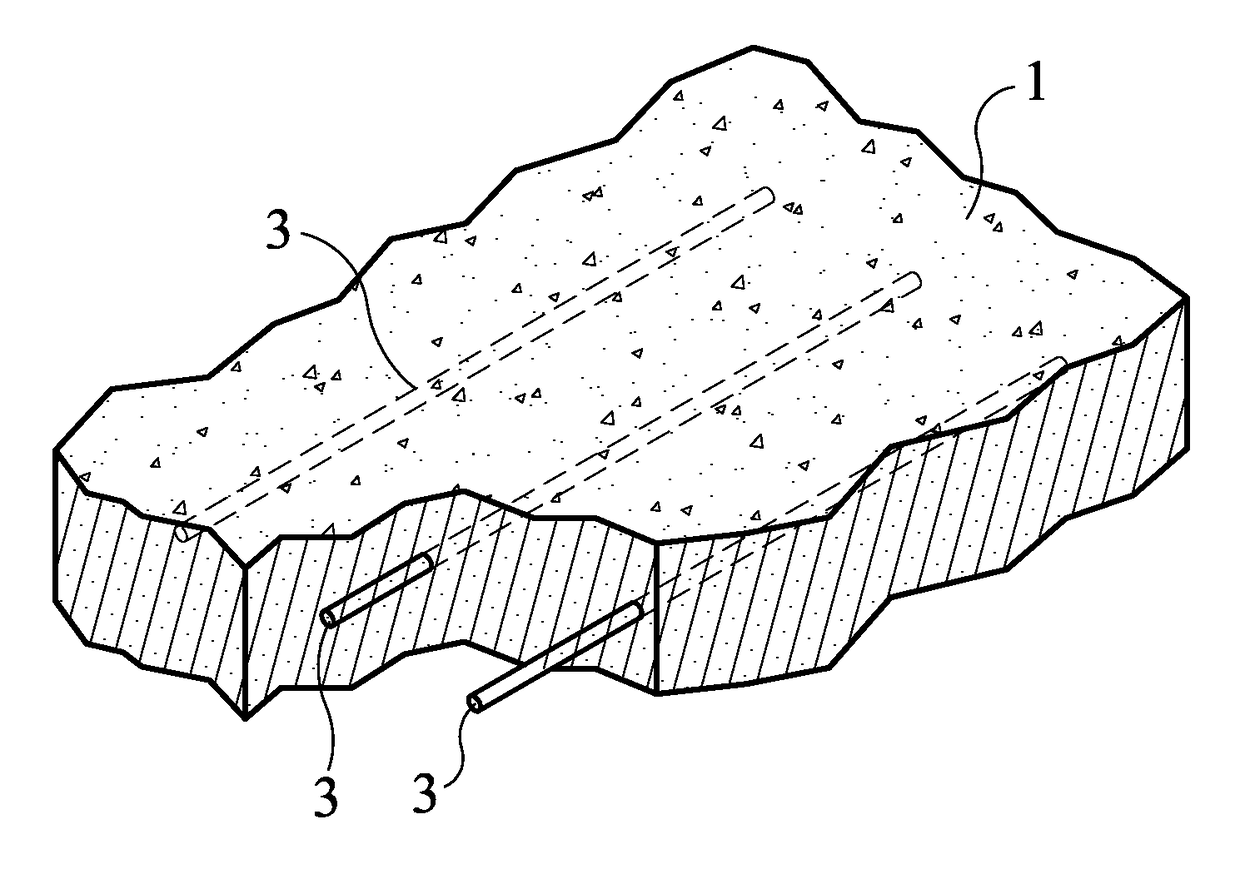

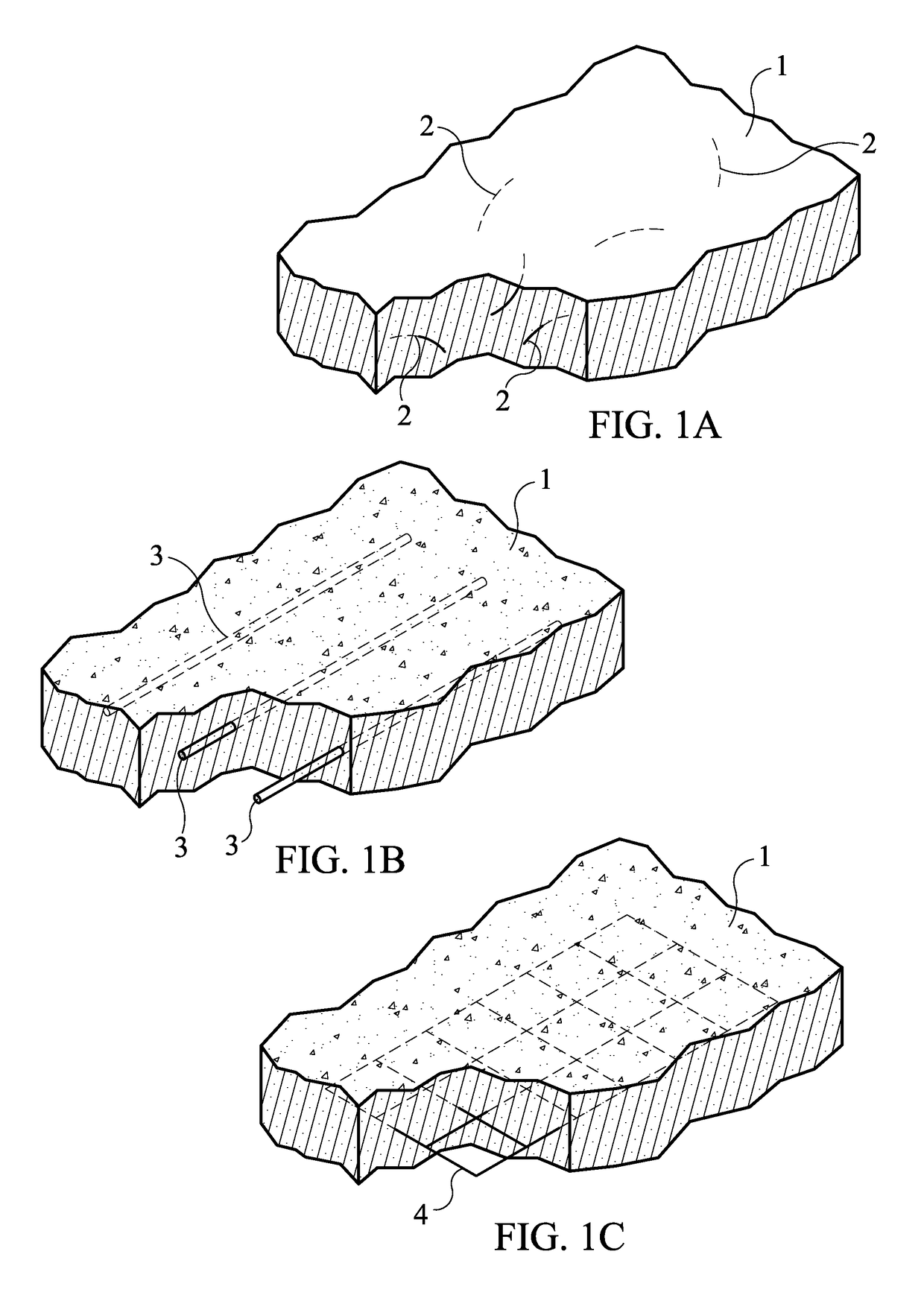

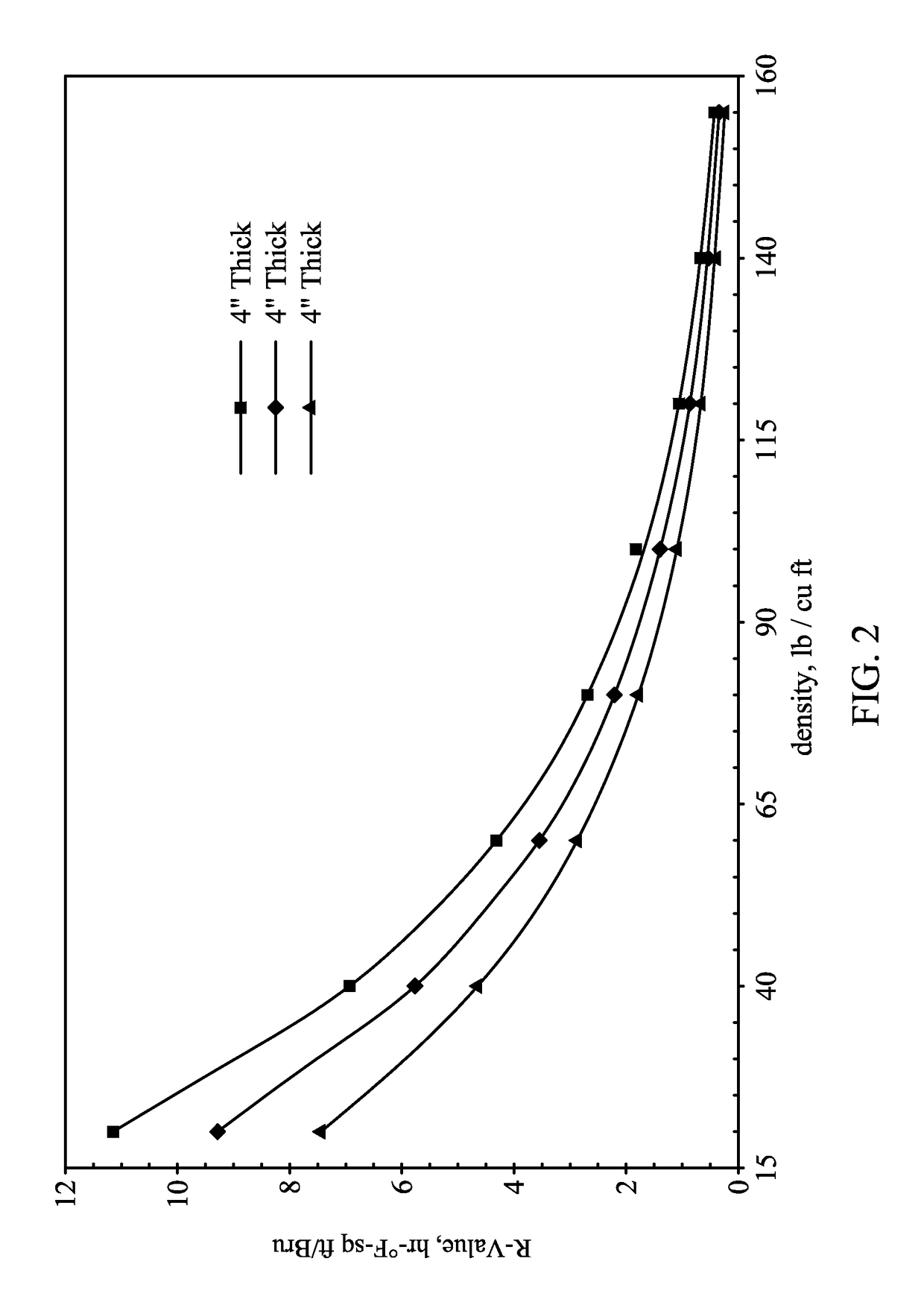

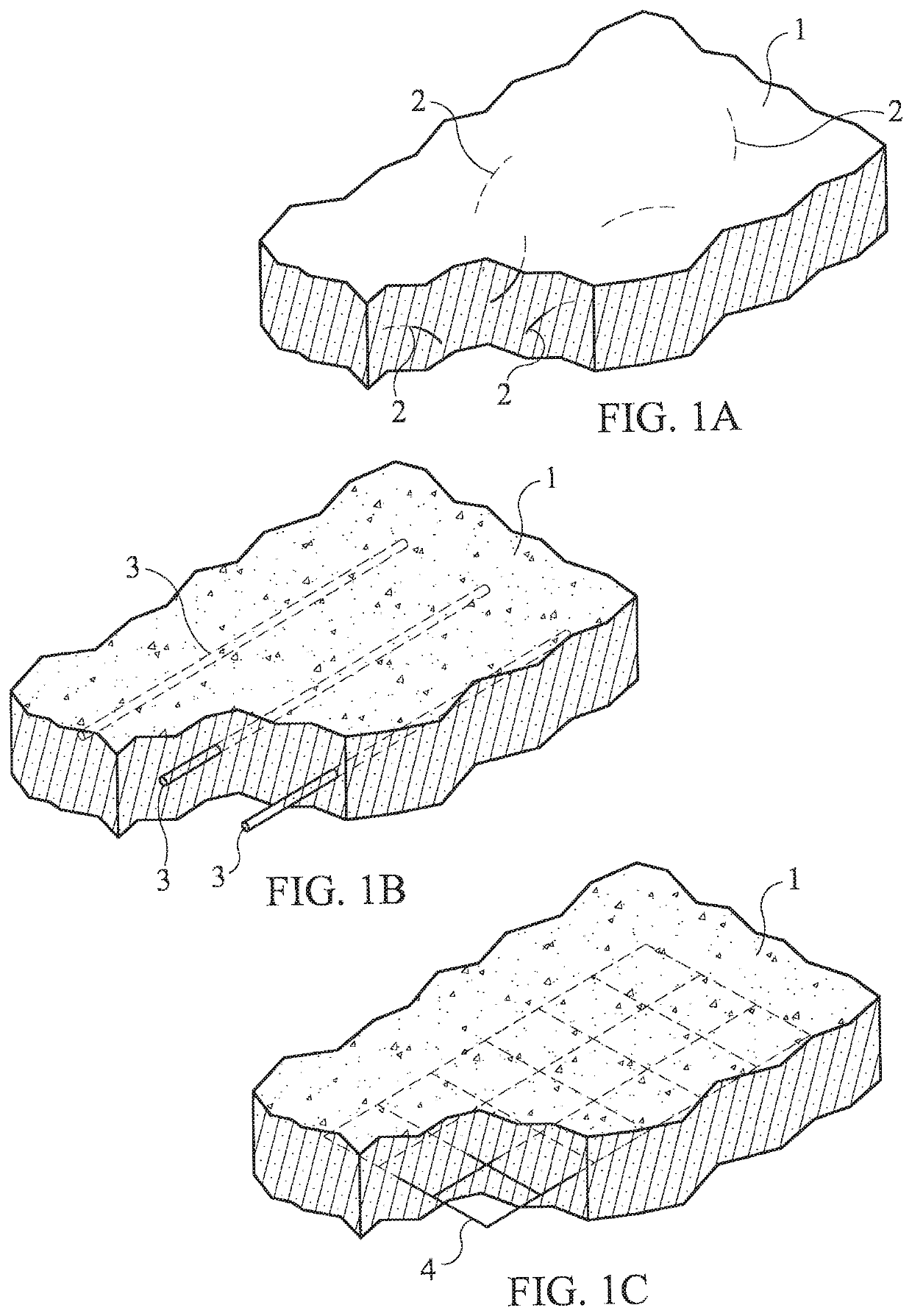

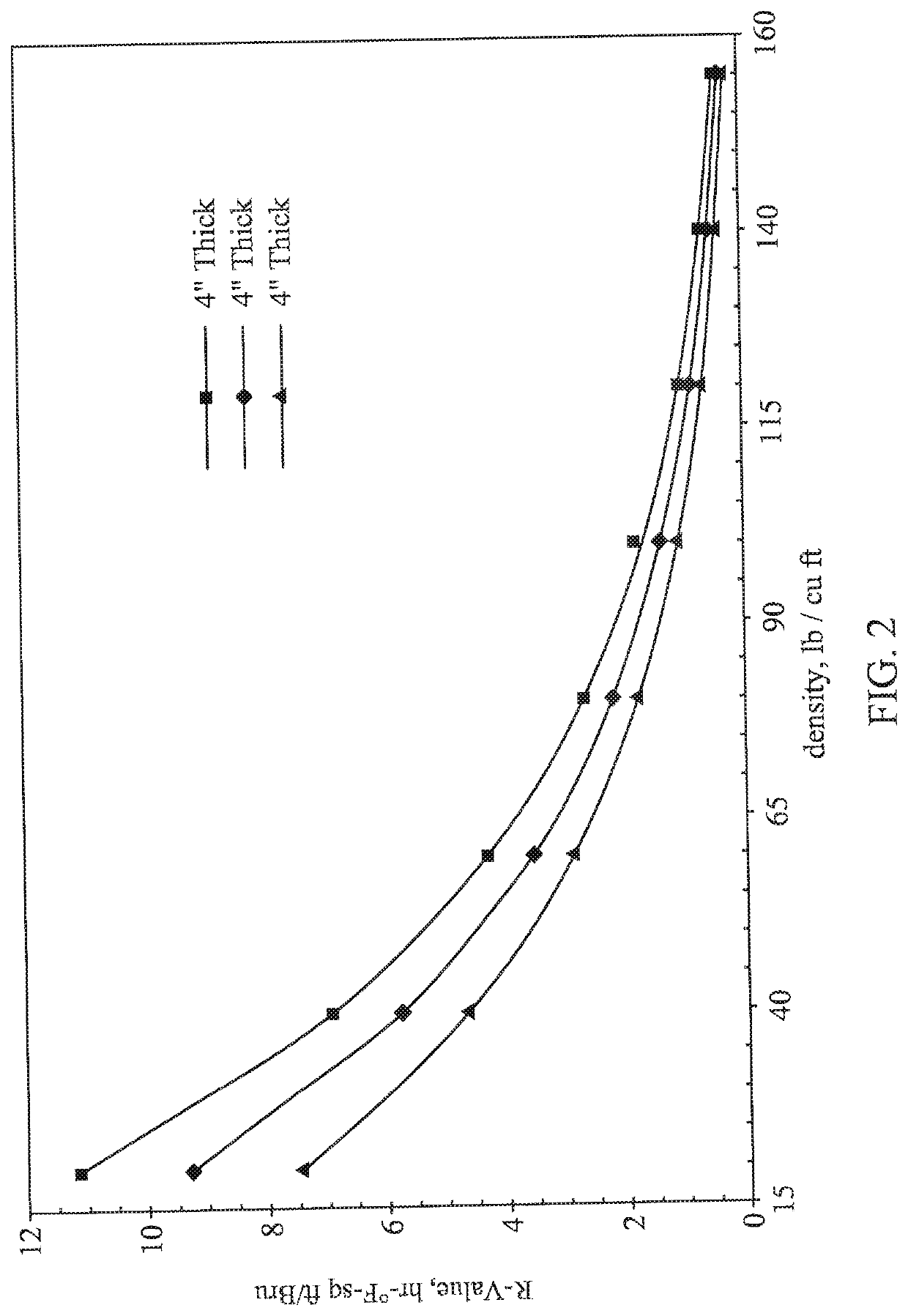

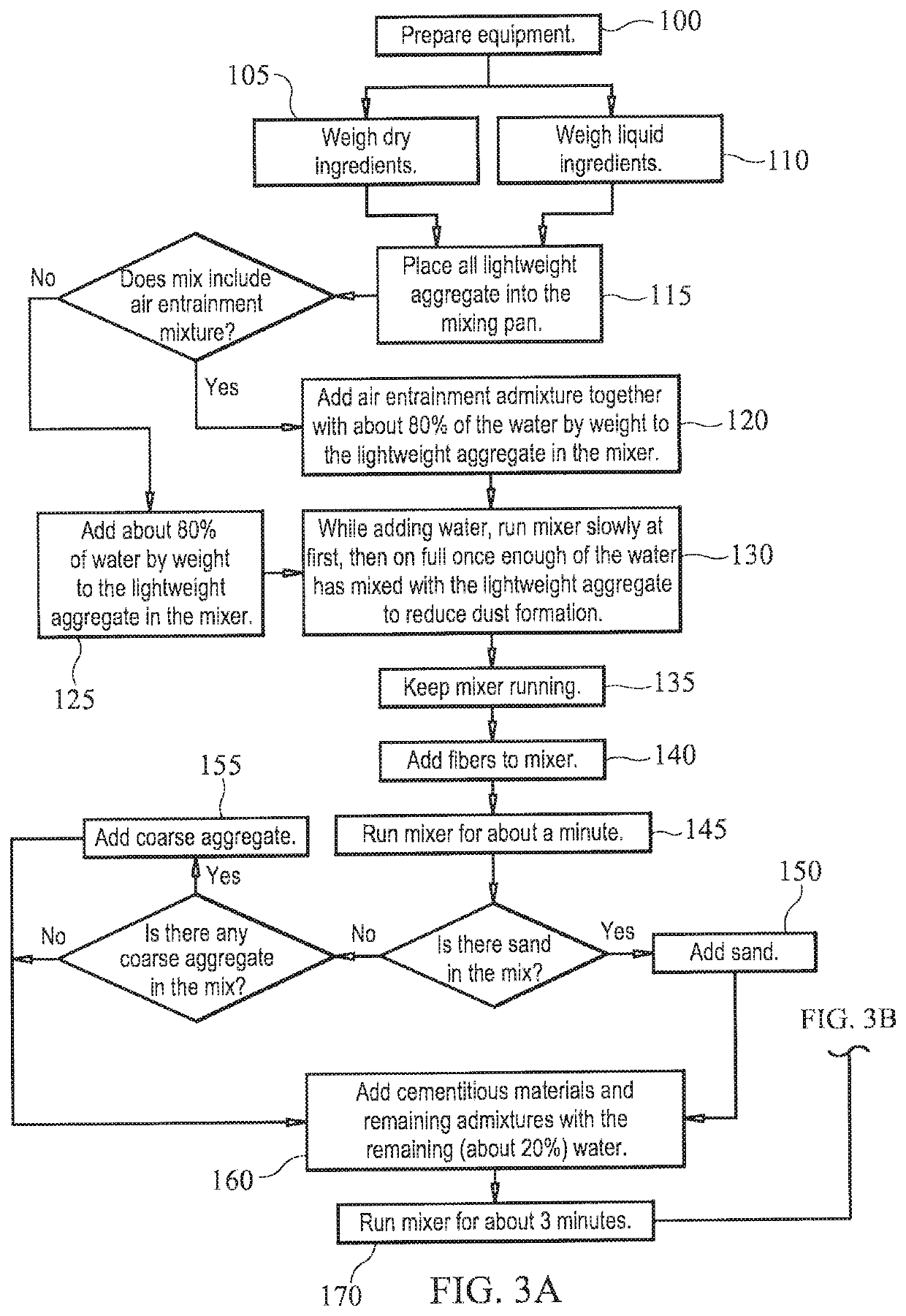

Low-density high-strength concrete and related methods

ActiveUS20160060169A1Low densityRaise the ratioSolid waste managementControl apparatusHigh strength concreteDensity ratio

A low-density, high-strength concrete composition that is both self-compacting and lightweight, with a low weight-fraction of aggregate to total dry raw materials, and a highly-homogenous distribution of a non-absorptive and closed-cell lightweight aggregate such as glass microspheres or copolymer polymer beads or a combination thereof, and the steps of providing the composition or components. Lightweight concretes formed therefrom have low density, high strength-to-weight ratios, and high R-value. The concrete has strength similar to that ordinarily found in structural lightweight concrete but at an oven-dried density as low as 40 lbs. / cu.ft. The concrete, at the density ordinarily found in structural lightweight concrete, has a higher strength and, at the strength ordinarily found in structural lightweight concrete, a lower density. Such strength-to-density ratios range approximately from above 30 cu.ft / sq.in. to above 110 cu.ft / sq.in., with a 28-day compressive strength ranging from about 3400 to 8000 psi.

Owner:SEBASTOS TECH

High R-Value, Removable and Transparent Window Insulation Panels

InactiveUS20120324806A1Light weightEasy to installCondensed water formation preventionEngineeringPlastic film

The structures and preparations of high R-value, low-cost, light-weight, durable, removable, and transparent window insulation panels are disclosed. The panels are made of spaced and parallel double or multiple layers of transparent plastic sheets, air-tightly mounted on to a frame of plastic, wood, aluminum or other materials. The frame of the panels has seals on the sides for air-tight fitting into the interior structure of the windows, and has different shapes, colors and styles, if necessary, to match the design of the windows. The panels can also be designed to fit into the interior structure of glass doors to provide supplementary insulations. The panels can increase the R-value of double pane windows or glass doors from current about 3 to up to 8 or more, dramatically reducing energy losses.

Owner:CHEN FANGREN

Light weight molded roof tile

InactiveUS20110094169A1High R-valueEasy to installPhotovoltaic supportsRoof covering using slabs/sheetsThermal insulationIsocyanate compound

An improved roof tile that is composed of a polymeric isocyanate and water blown component, mineral fiber or fiberglass, said roof tile being molded producing a roof tile with a high R-value thermal insulation and being very light weight. Each tile includes a flat bottom surface including a groove of a predetermined pattern that receives poly foam adhesive for attaching each tile to a roof substrate.

Owner:BELLAVIA CARMEN

Lightweight molded cover

PendingUS20190284778A1High R-valueArtificial islandsSynthetic resin layered productsGlass fiberFiber

Disclosed is a cover for a utility vault and a method for making such covers. The cover is formed from fiberglass reinforcement layers, a low-density core, and a polymer mix matrix. The reinforcement layers include a bottom reinforcement layer, one or more edge reinforcement layers, and a top reinforcement layer. A first portion of the edge reinforcement layer overlaps a portion of the bottom reinforcement layer and a second portion of the edge reinforcement layer overlaps a portion of the top reinforcement layer. The core is positioned between the top and bottom reinforcement layers. The reinforcement layers are formed from fiberglass fabric and may include fiberglass layers whose fibers are oriented quadraxially. The polymer mix impregnates the fabric layers, encases the core, and binds the components together. The polymer matrix includes a thermoset polymer resin.

Owner:HUBBELL INC

Low-density high-strength concrete and related methods

A low-density, high-strength concrete composition that is both self-compacting and lightweight, with a low weight-fraction of aggregate to total dry raw materials, and a highly-homogenous distribution of a non-absorptive and closed-cell lightweight aggregate such as glass microspheres or copolymer polymer beads or a combination thereof, and the steps of providing the composition or components. Lightweight concretes formed therefrom have low density, high strength-to-weight ratios, and high R-value. The concrete has strength similar to that ordinarily found in structural lightweight concrete but at an oven-dried density as low as 40 lbs. / cu.ft. The concrete, at the density ordinarily found in structural lightweight concrete, has a higher strength and, at the strength ordinarily found in structural lightweight concrete, a lower density. Such strength-to-density ratios range approximately from above 30 cu.ft / sq.in. to above 110 cu.ft / sq.in., with a 28-day compressive strength ranging from about 3400 to 8000 psi.

Owner:SEBASTOS TECH

Light weight molded roof tile with integrated solar capabilities

ActiveUS20150089887A1Save time and moneyGood bondingPhotovoltaic supportsRoof covering using slabs/sheetsPolyureaIntumescent

An improved building roof tile for a sloping roof including a polyurethane foam tile that includes outer coating layers that are made of a uniquely fire resistant or retardant layered system that includes a first outer fire resistant layer of 100% solid aliphatic polyurea material and a second inner layer of an 100% solid intumescent non-halogenated phosphate material, said inner layer forming a fire blocking partition and said outer layer offering UV protection, featherweight, category 5 hurricane proof, yields a high R-value, offer low thermal transference into attic space, will retrofit any sloped roof without structural build-up, can be molded into single or triple units, cannot break under foot or when extreme pressures are applied, can produce upgradable solar energy, is easy to transport and install and can molded to look like slate, wood, flat roll tile or most other historical tiles.

Owner:BELLAVIA CARMEN

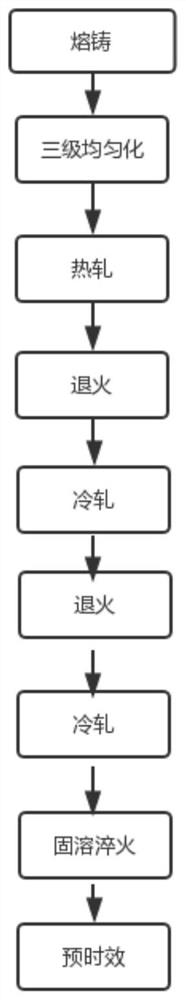

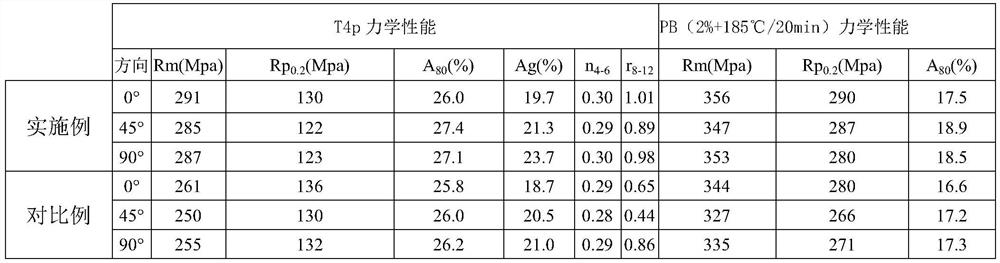

Preparation process of high-formability 6111 aluminum alloy automobile plate

The invention belongs to the technical field of metal materials, and relates to a preparation process of a high-formability 6111 aluminum alloy automobile sheet. The process comprises the following steps: casting, three-stage homogenization, hot rolling, annealing, cold rolling, annealing, cold rolling, solid solution quenching and pre-aging. An intermediate annealing process in the cold rolling process is carried out on a continuous annealing line, and the annealing schedule is 480 DEG C / 20 s. Through mutual cooperation of hot rolling, medium annealing and cold rolling processes, An r value excellent in three directions is obtained, the solid solution quenching and pre-aging processes are combined with an existing continuous annealing production line, the process is more suitable for actual industrial production, and finally the high-formability 6111 aluminum alloy automobile plate material capable of being applied to industrial production is obtained.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Low-density high-strength concrete and related methods

ActiveUS10759701B1Low densityRaise the ratioSolid waste managementCement productionPolymer scienceMicrosphere

A low-density, high-strength concrete composition that is lightweight and self-compacting or non-self-compacting, with a low weight-fraction of aggregate to total dry raw materials, and a highly-homogenous distribution of a non-absorptive and closed-cell lightweight aggregate such as glass microspheres or copolymer polymer beads or a combination thereof, and the steps of providing the composition or components. Lightweight concretes formed therefrom have low density, high strength-to-weight ratios, and high R-value. The concrete has strength similar to that ordinarily found in structural lightweight concrete but at a lower density, such as an oven-dried density as low as 40 lbs. / cu.ft. Such strength-to-density ratios range approximately from above 30 cu.ft / sq.in. to above 110 cu.ft / sq.in., with a 28-day compressive strength ranging from about 3400 to 8000 psi.

Owner:SEBASTOS TECH

High r-value window unit

ActiveUS20130129944A1Higher andImproved R-value for the window unit(s)Climate change adaptationWindows/door improvementEngineeringAir space

In certain example embodiments of this invention, a window unit may include a vacuum IG (VIG) unit as an inboard lite and a monolithic lite (e.g., with an optional low-E coating thereon) as an outboard lite. A dead air space may separate the inboard and outboard lites. A highly insulated frame may be used to support the inner and outer lites. The VIG unit may be partially embedded or supported in the insulative frame, so that the insulating frame separates the VIG unit inboard lite from the outboard lite thereby reducing conductivity around the edges of the window unit so that R-value can be increased (and U-value decreased). In certain example embodiments, the total R-value of the window unit is at least about R-8, and more preferably at least about R-10 (compared to the much lower R-values of conventional IG units).

Owner:GUARDIAN GLASS LLC

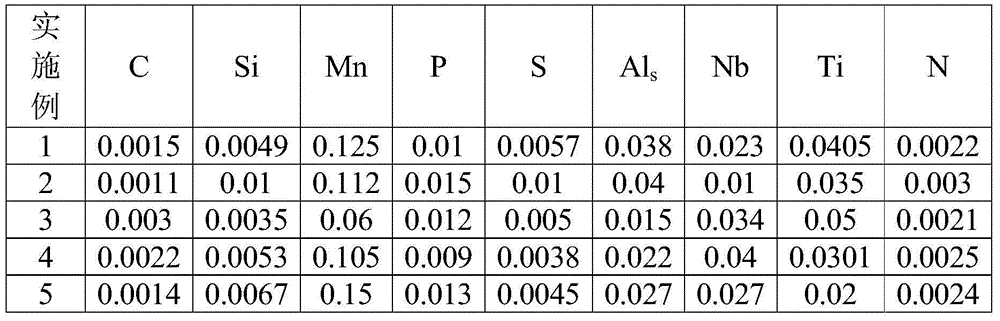

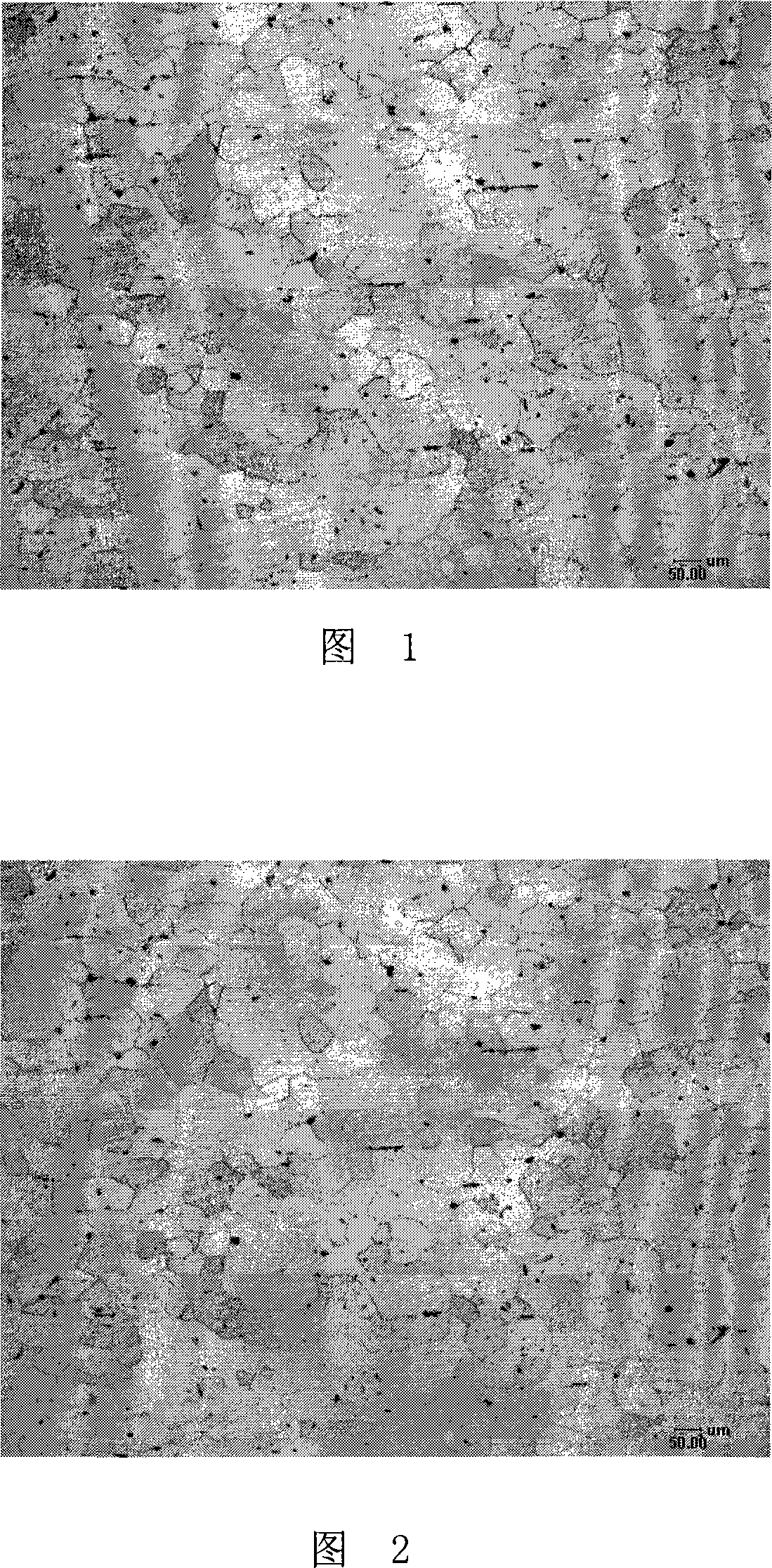

Niobium-containing alloying hot-galvanizing steel for automobile outer cover part and manufacturing method of steel

The invention discloses niobium-containing alloying hot-galvanizing steel for an automobile outer cover part. The steel comprises the chemical components by weight percentage: smaller than or equal to 0.003 percent of C, smaller than or equal to 0.01 percent of Si, 0.06 percent to 0.15 percent of Mn, smaller than or equal to 0.015 percent of P, 0.01 percent to 0.04 percent of Nb, 0.02 percent to 0.05 percent of Ti, 0.015 percent to 0.04 percent of Als, smaller than or equal to 0.01 percent of S, smaller than or equal to 0.003 percent of N and the rest of Fe and unavoidable impurities. Besides, the invention also provides a corresponding manufacturing method. The produced steel for the outer cover part has low strength and very high deep drawability, meanwhile has a lower deltar value and better coating quality, and has good isotropy and excellent welding performance.

Owner:WUHAN IRON & STEEL (GROUP) CORP

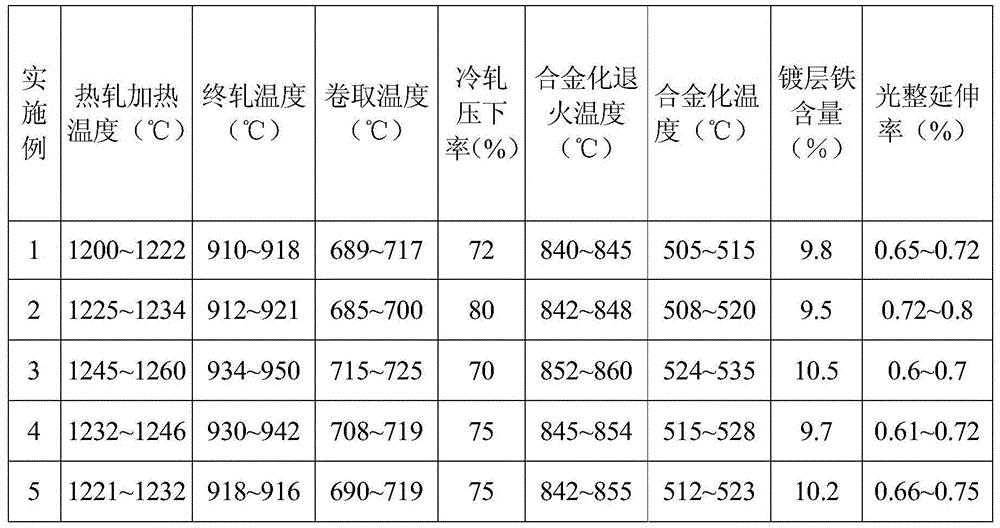

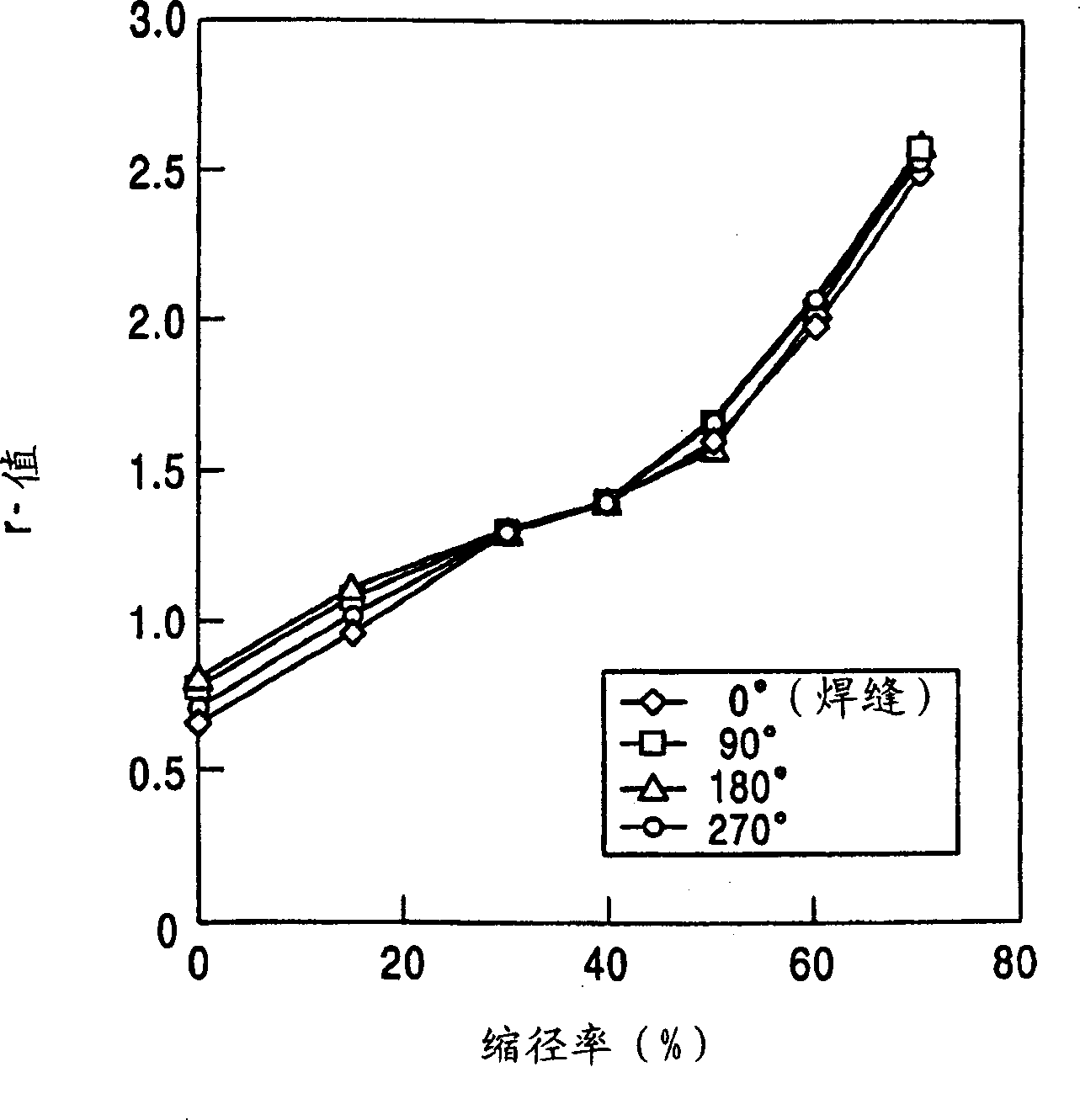

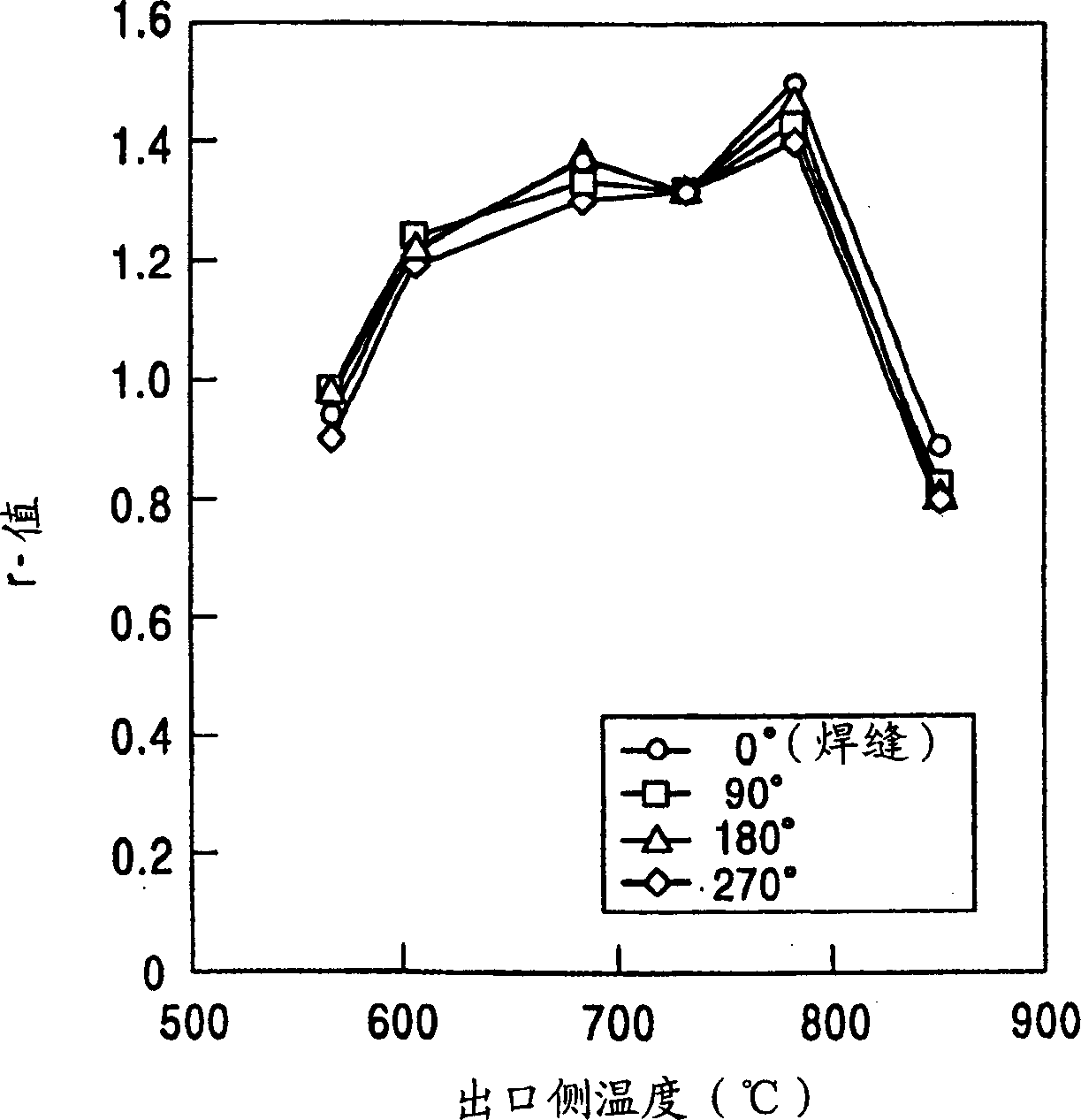

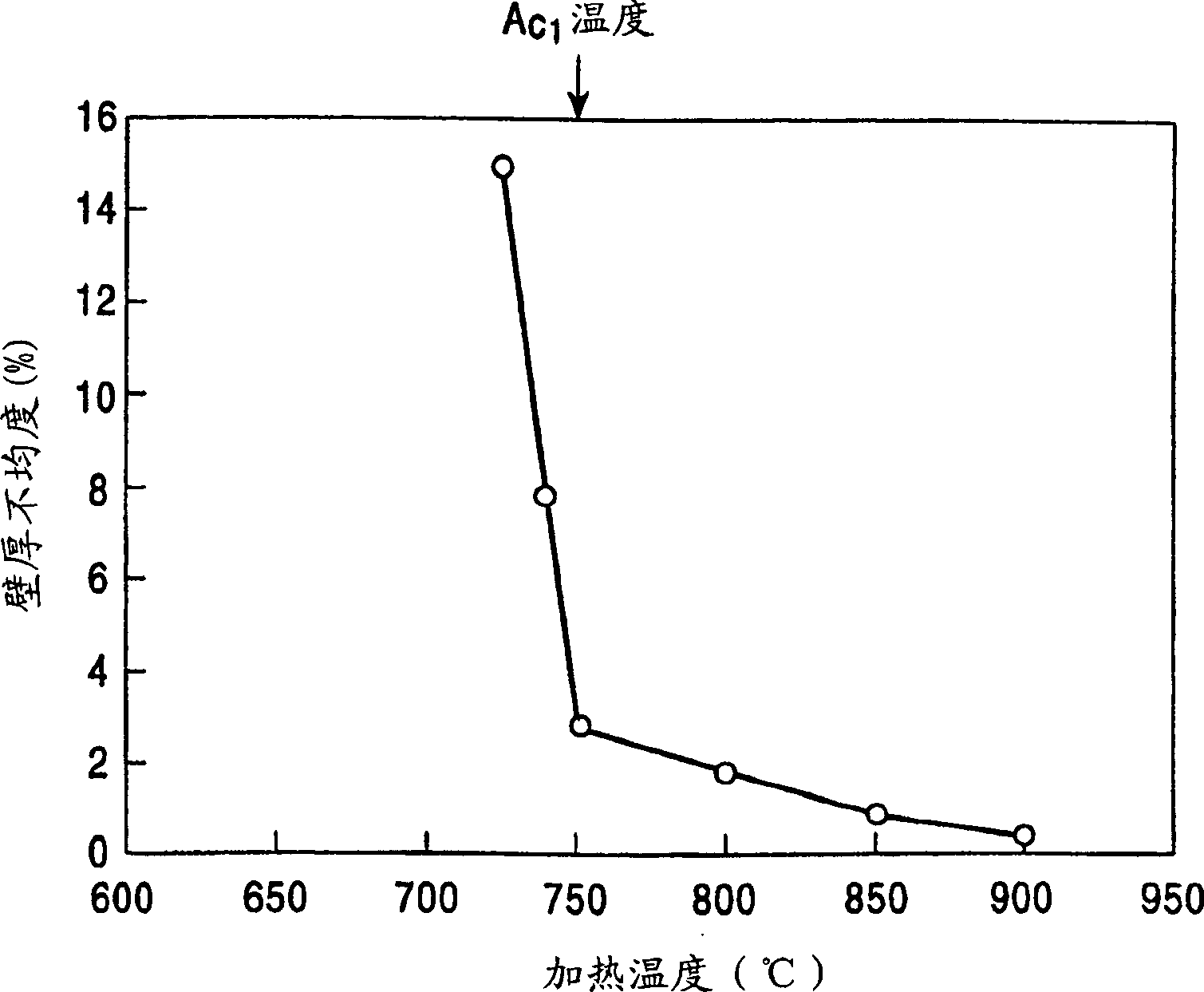

Steelpipe having high formability and method for production thereof

InactiveCN1426489AHigh r valueFurnace typesMetal rolling arrangementsStrip steel% diameter reduction

A steel pipe having high formability which has an r value in the longitudinal direction of 1.2 or more, preferably 1.6 or more over the whole region of perimeter direction containing a seamed portion; and a method of producing the steel pipe which comprises heating a steel pipe prepared by the electric welding of steel hoops to an Ac1 temperature or higher and subjecting the heated pipe to a stretch reducing of a diameter reduction percentage of 30% or more in a temperature region of 600 deg or higher and up to an Ac1 temperature, and optionally heating again the pipe during or after completion of cooling after said reduction to a temperature of 600 to 900 deg and holding it at the temperature for 1 second or longer.

Owner:JFE STEEL CORP

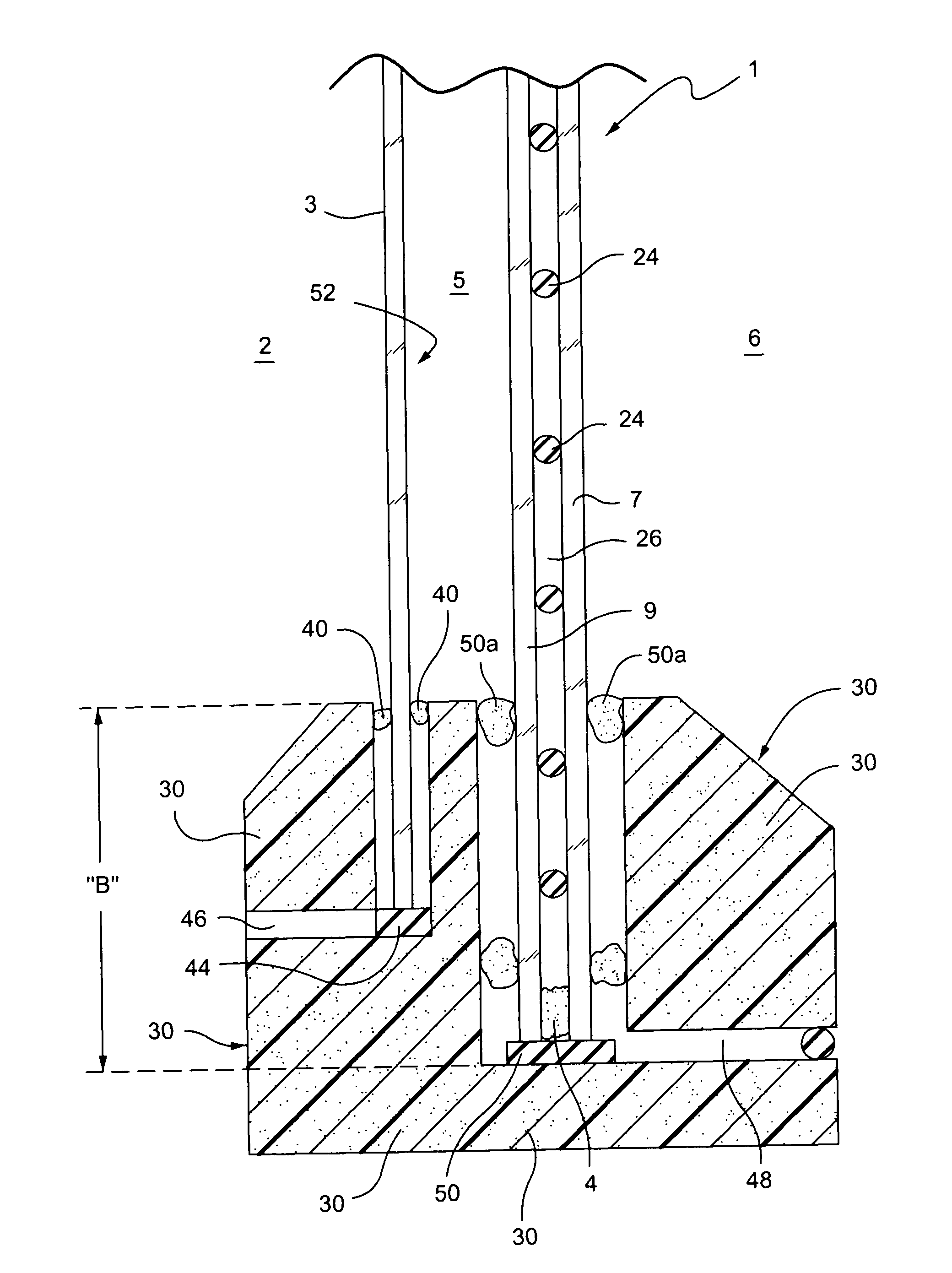

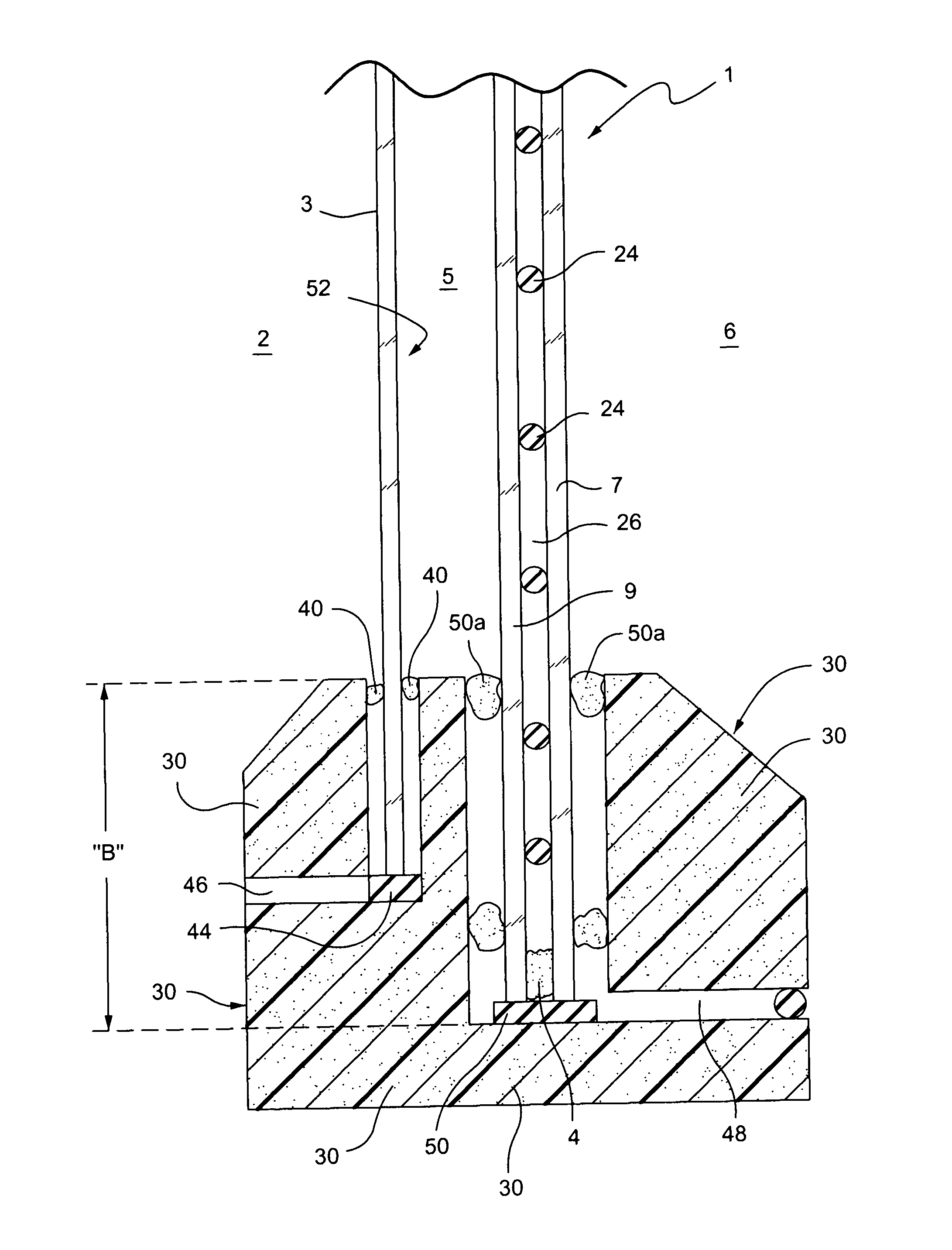

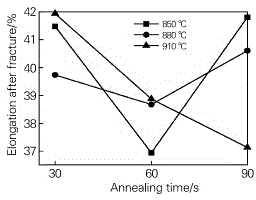

High R-value window unit with vacuum IG unit and insulating frame

ActiveUS20070144085A1Decrease U-valueIncrease R-valueFixed grillesClimate change adaptationEngineeringAir space

In certain example embodiments of this invention, a window unit may include a vacuum IG (VIG) unit as an inboard lite and a monolithic lite (e.g., with an optional low-E coating thereon) as an outboard lite. A dead air space may separate the inboard and outboard lites. A highly insulated frame may be used to support the inner and outer lites. The VIG unit may be partially embedded or supported in the insulative frame, so that the insulating frame separates the VIG unit inboard lite from the outboard lite thereby reducing conductivity around the edges of the window unit so that R-value can be increased (and U-value decreased). In certain example embodiments, the total R-value of the window unit is at least about R-8, and more preferably at least about R-10 (compared to the much lower R-values of conventional IG units).

Owner:GUARDIAN GLASS LLC

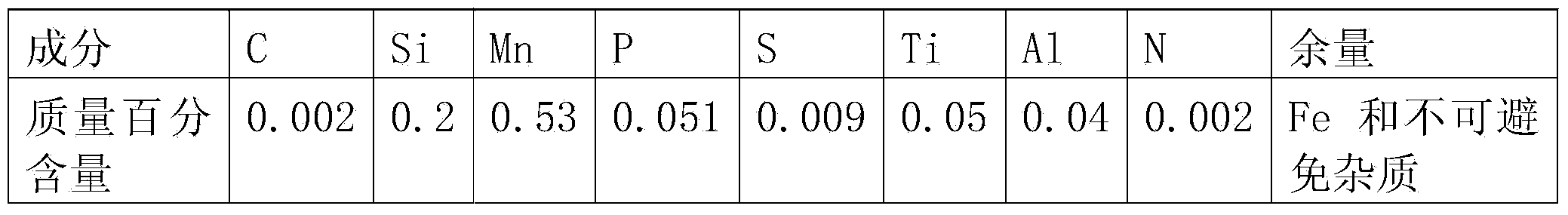

A kind of IF steel and preparation method thereof

Owner:SHOUGANG CORPORATION

Ferrite stainless steel with excellent ridging property and surface quality and manufacturing method therefor

ActiveCN110073022ASuppression of wrinkle defectsHigh surface glossFurnace typesHeat treatment furnacesImpurityArea ratio

Disclosed are ferrite stainless steel having an excellent ridging property and surface quality of a final product by changing a microstructure of a central portion of a cross section by further performing cold rolling before a heat treatment of hot-rolling annealing, and a manufacturing method therefor. Austenitic stainless steel according to the present invention comprises, in percentage by weight: 0.005 to 0.1% of C; 0.01 to 2.0% of Si; 0.01 to 1.5% of Mn; 0.05% or less of P; 0.005% or less of P; 10 to 30% of Cr; 0.005 to 0.1% of N; 0.005 to 0.2% of Al; and the balance being Fe and other unavoidable impurities, in which max is 20% or more and less than 50%, and a fine groove area ratio of a surface is 2.0% or less.

Owner:浦项股份有限公司

Attic entrance insulation cover

Owner:SOUTHEAST ENERGY SOLUTIONS INC

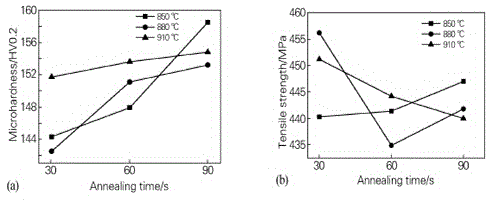

Annealing process for improving performance of 410 stainless steel

The invention discloses an annealing process for improving performance of 410 stainless steel. The 410 ferritic stainless steel comprises chemical components, by mass percentage: 0.065 of C, 0.179 of Si, 0.725 of Mn, 16.7 of Cr, 0.152 of V, P less than 0.005, and S less than 0.005, with the balance being Fe. The annealing process is characterized in that the hot rolling finishing temperature of a rolling plate is 850 DEG C; and cold rolling is performed after annealing, wherein heat preservation is carried out at 850-910 DEG C for 30-90s for annealing. The annealing temperature is 910 DEG C, and the heat preservation time for annealing is 30s.

Owner:王美

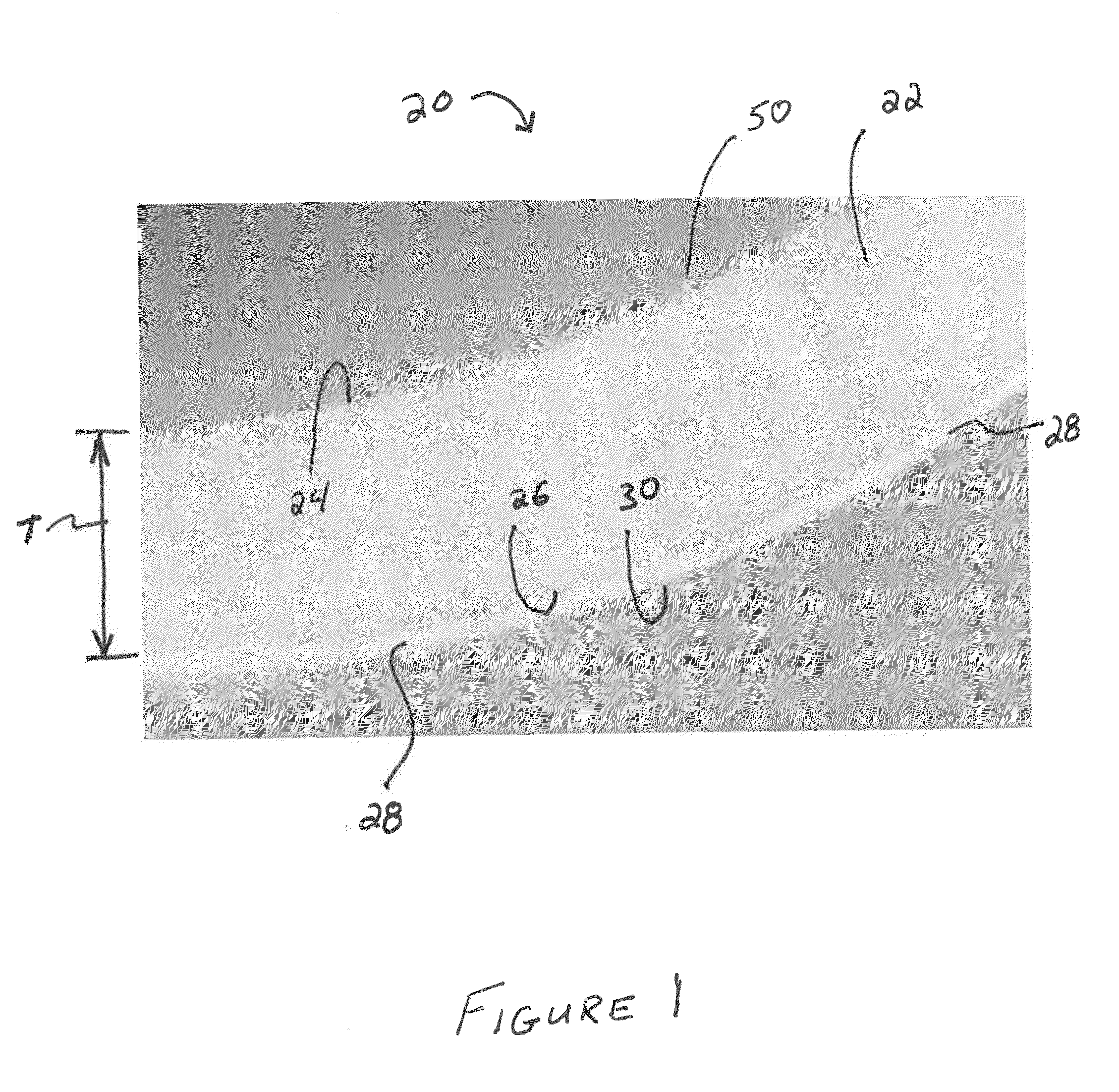

Insulating member for covering a conduit in a clean room

InactiveUS20130071593A1Reduce volumeResists mold growthThermal insulationClosuresFluoropolymerBiomedical engineering

This disclosure provides an insulating member for covering a conduit in a clean room. The insulating member typically has a length and defines a cavity extending along the length. The cavity is sized and shaped to receive the conduit. The insulating member typically includes an innermost layer that may be a closed cell fluoropolymer foam and is disposed to contact the conduit. The insulating member also typically includes an outermost layer that is disposed on the innermost layer and that may be a second fluoropolymer.

Owner:UFP TECHNOLOGIES

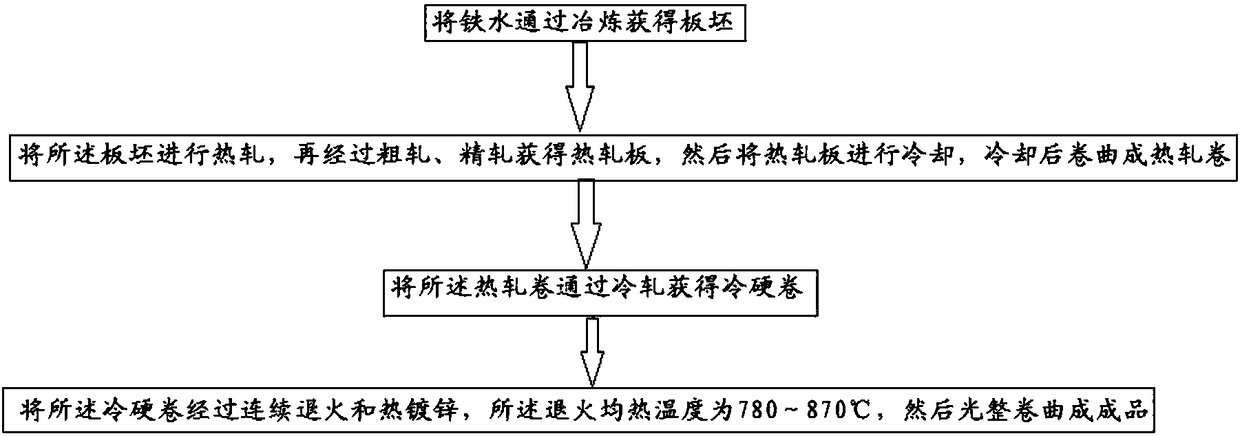

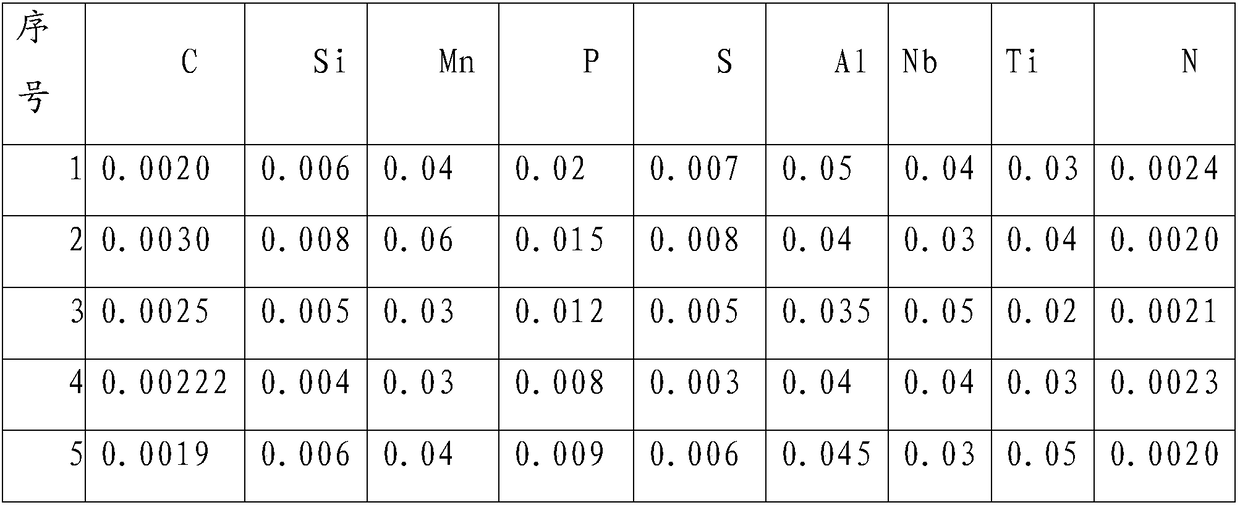

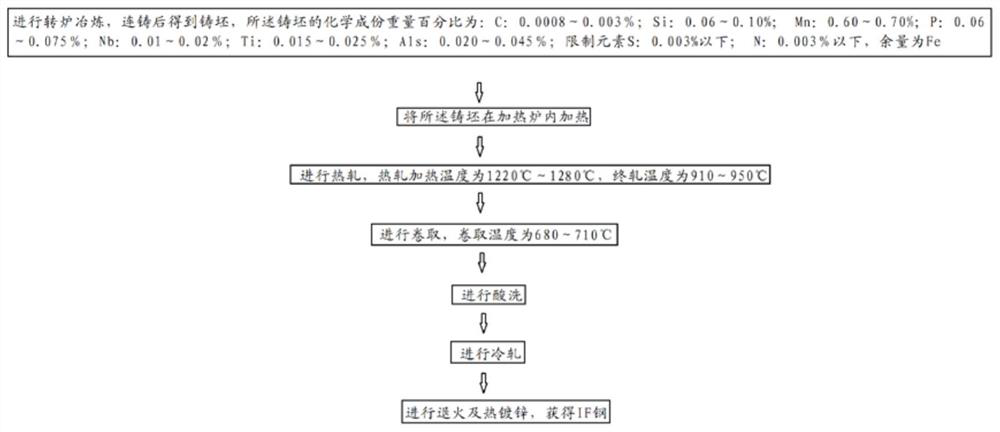

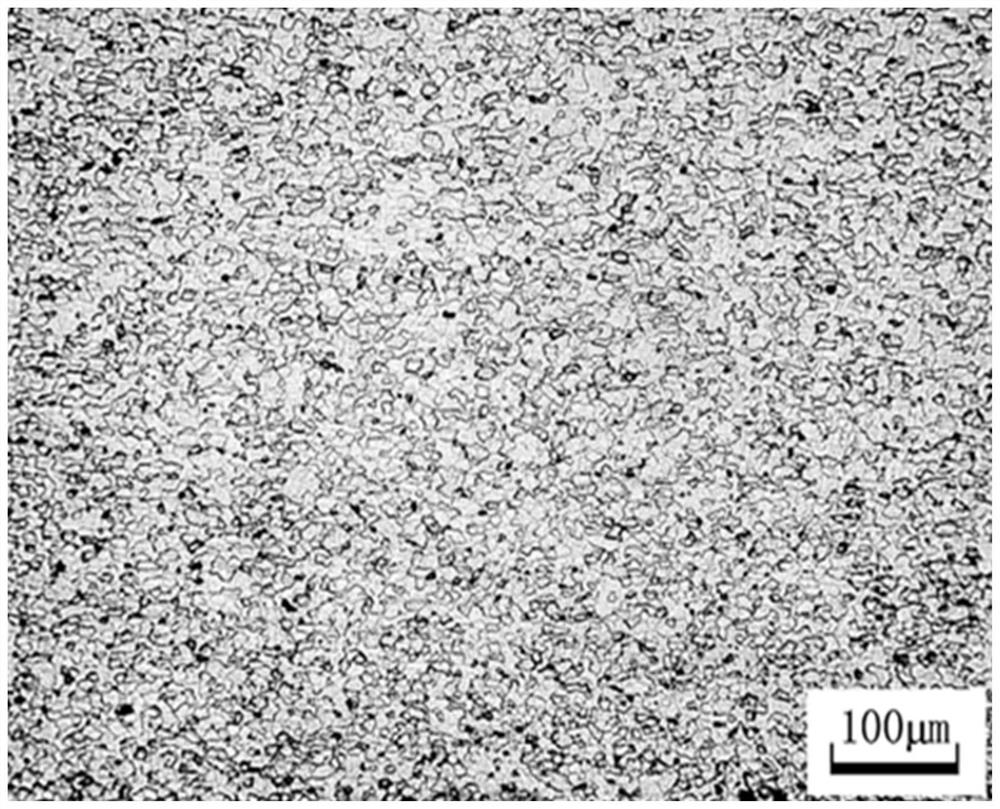

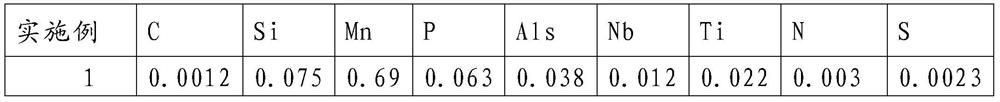

260MPa-grade hot-dip galvanized high-strength IF steel and preparation method thereof

InactiveCN113106330AHigh strengthGood formabilityHot-dipping/immersion processesMachiningBrittleness

The invention discloses 260MPa-grade hot-dip galvanized high-strength IF steel and a preparation method thereof, and belongs to the technical field of steel manufacturing. The IF steel comprises the following chemical components in percentage by weight of 0.0008 to 0.003% of C, 0.06 to 0.10% of Si, 0.60 to 0.70% of Mn, 0.06 to 0.075% of P, 0.01 to 0.02% of Nb, 0.015 to 0.025% of Ti, 0.020 to 0.045% of Als, less than 0.003% of a limiting element S, less than 0.003% of N, and the balance being Fe. According to the 260MPa-grade hot-galvanized high-strength IF steel and the preparation method thereof, the 260MPa-grade hot-galvanized high-strength IF steel has higher strength, good forming performance and excellent secondary machining brittleness resistance, and the cost is reduced.

Owner:JIANGHAN UNIVERSITY

Process for producing high-strength interstitial-free (IF) steel with high plastic strain ratio (r) value

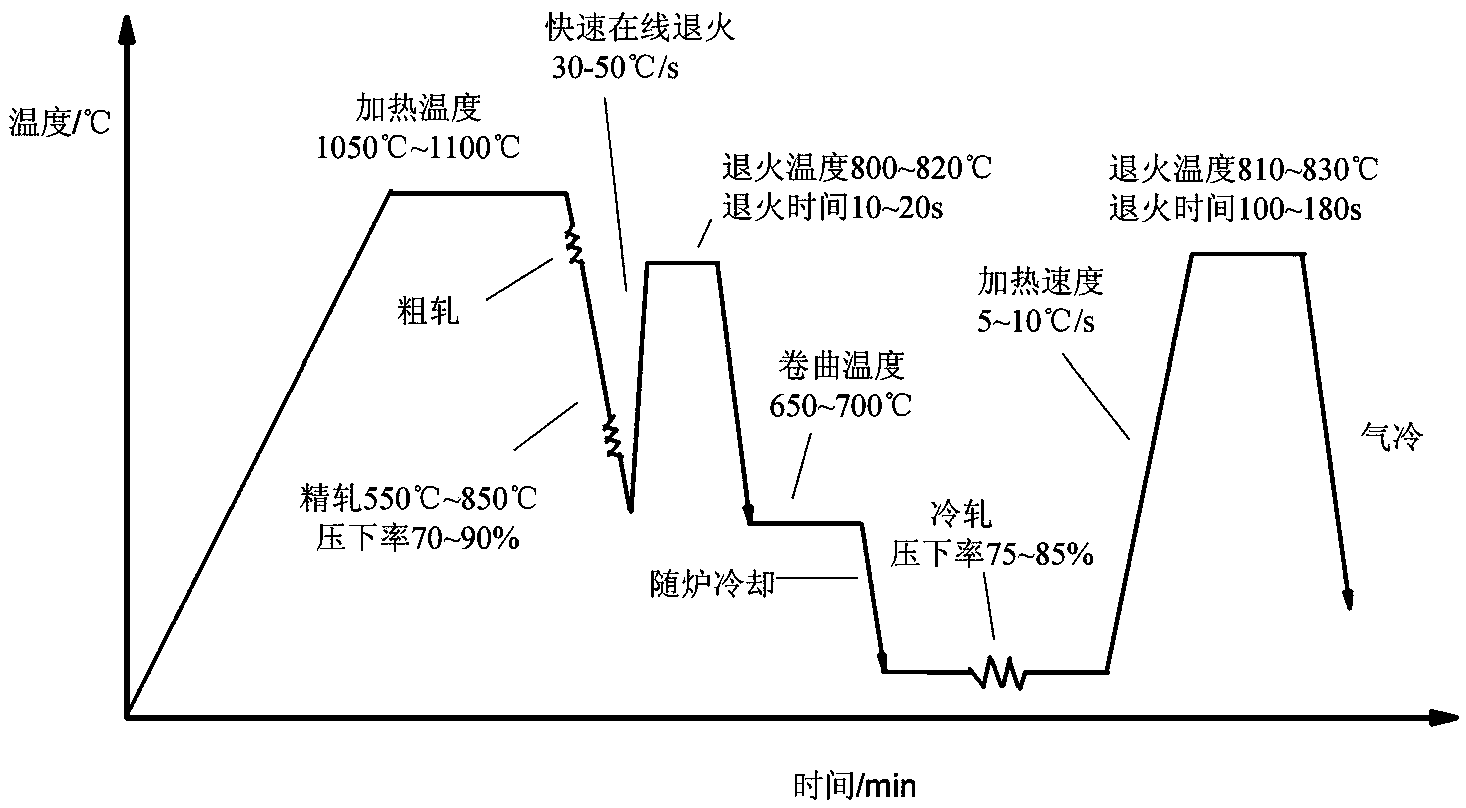

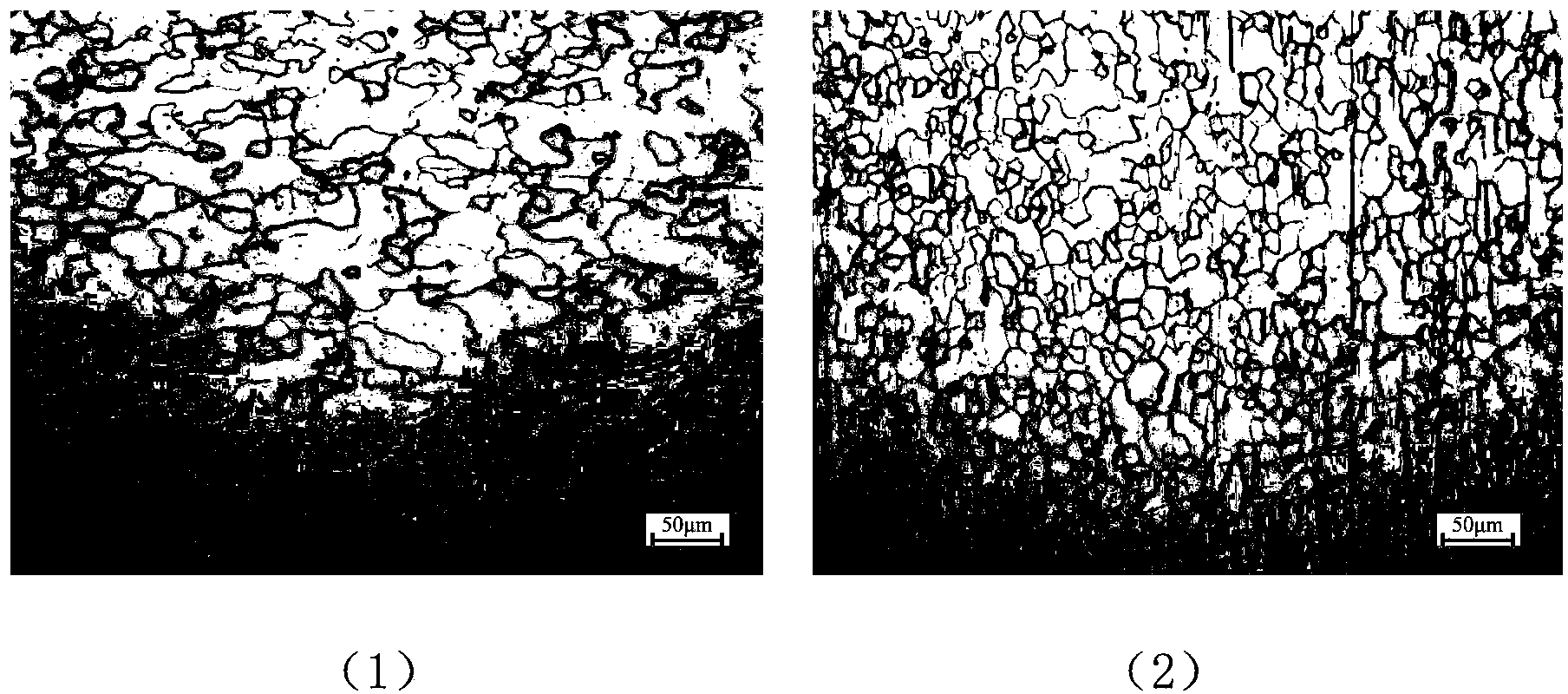

The invention relates to the technical field of the auto sheet production process, and relates to a process for producing high-strength IF steel with a high r value. A P-Mn compound added 340 MPa high-strength IF steel is utilized, and the process comprises hot rolling, low-temperature finish rolling, direct online rapid annealing by using the rolled high temperature, rapid cooling till the temperature reaches the coiling temperature, and cold rolling and annealing to obtain a steel plate with 355 MPa extension strength and a 2.75 rolling direction r value. The temperature for hot rolling and finish rolling ranges from 550 DEG C to 850 DEG C, the finish rolling reduction rate is between 70% and 90%, the temperature of the finish rolling phase is below 650 DEG C, the finish rolling phase comprises more than two rolling passes, and the accumulated reduction rate is larger than 40%; the online annealing heating speed is between 30 DEG C / s and 50 DEG C / s, the annealing temperature is in a range of 800 DEG C to 820 DEGC, the heating time is between 10s and 20s, the coiling temperature is between 650 DEGC and 700 DEG C, the cold rolling reduction amount is in a range of 75% to 85%, the heating speed of the continuous annealing process is between 5 DEG C / s and 10 DEG C / s, the heat preservation temperature ranges from 810 DEG C to 830 DEG C, and the heat preservation time is between 100s and 180s.

Owner:UNIV OF SCI & TECH BEIJING

Heat-resistant cold rolled ferritic stainless steel sheet, hot rolled ferritic stainless steel sheet for cold rolling raw material, and methods for producing same

ActiveUS20160097114A1High R-valueImprove machinabilityFurnace typesHeat treatment furnacesSurface layerHot rolled

A heat-resistant cold rolled ferritic stainless steel sheet containing, in mass %, 0.02% or less of C, 0.1% to 1.0% of Si, greater than 0.6% to 1.5% of Mn, 0.01% to 0.05% of P, 0.0001% to 0.0100% of S, 13.0% to 20.0% of Cr, 0.1% to 3.0% of Mo, 0.005% to 0.20% of Ti, 0.3% to 1.0% of Nb, 0.0002% to 0.0050% of B, 0.005% to 0.50% of Al, 0.02% or less of N, with the balance being Fe and inevitable impurities, in which {111}-oriented grains are present at an area ratio of 20% or greater in a region from a surface layer to t / 4 (t is a sheet thickness), {111}-oriented grains are present at an area ratio of 40% or greater in a region from t / 4 to t / 2, and {011}-oriented grains are present at an area ratio of 15% or less in the entire region in a thickness direction.

Owner:NIPPON STEEL STAINLESS STEEL CORP

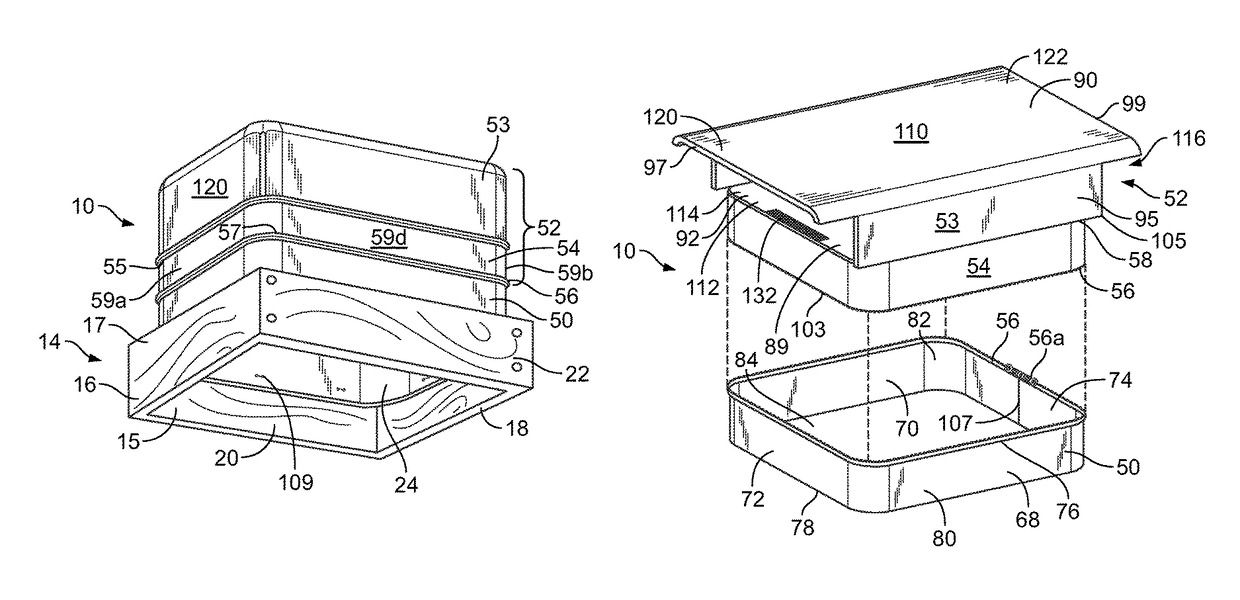

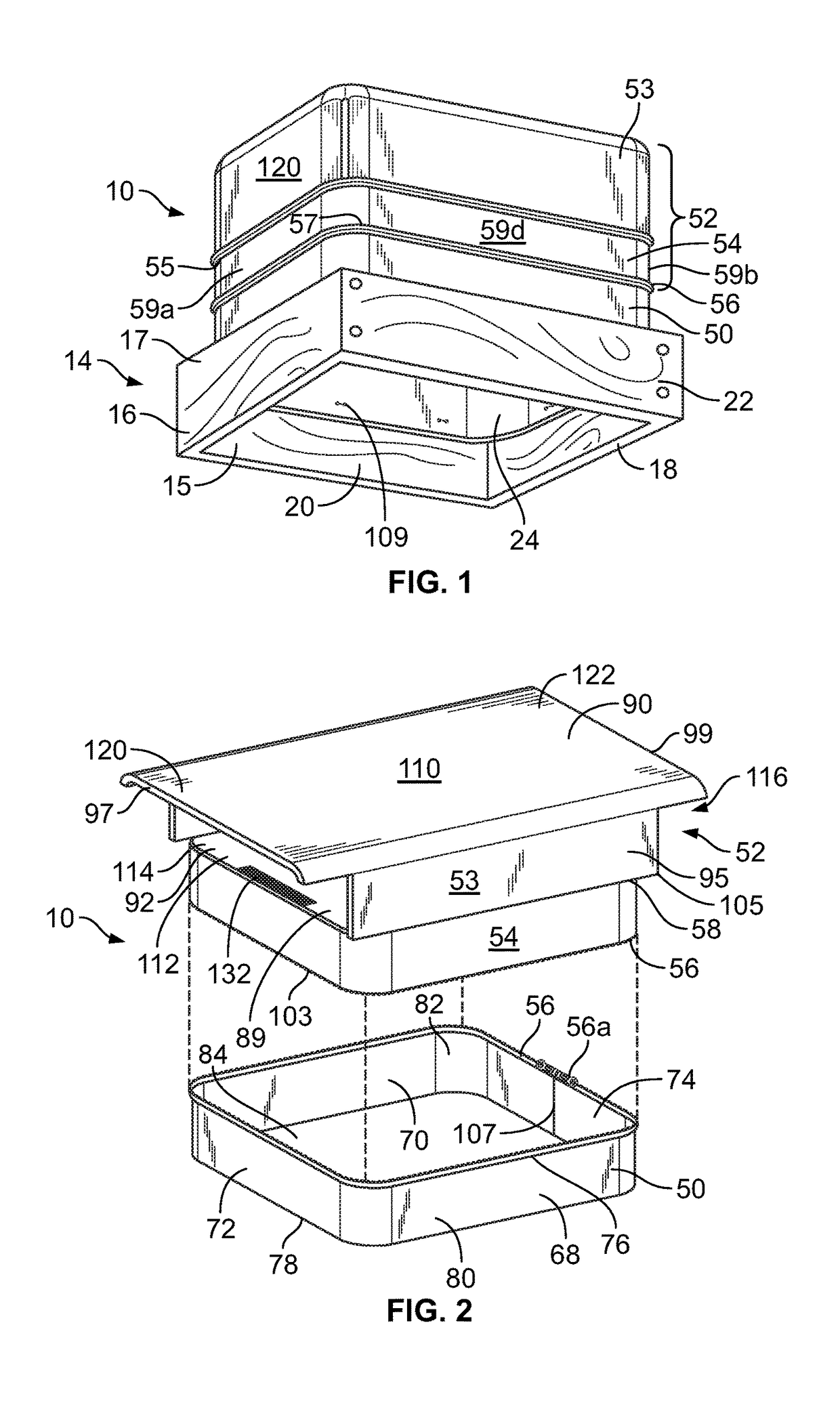

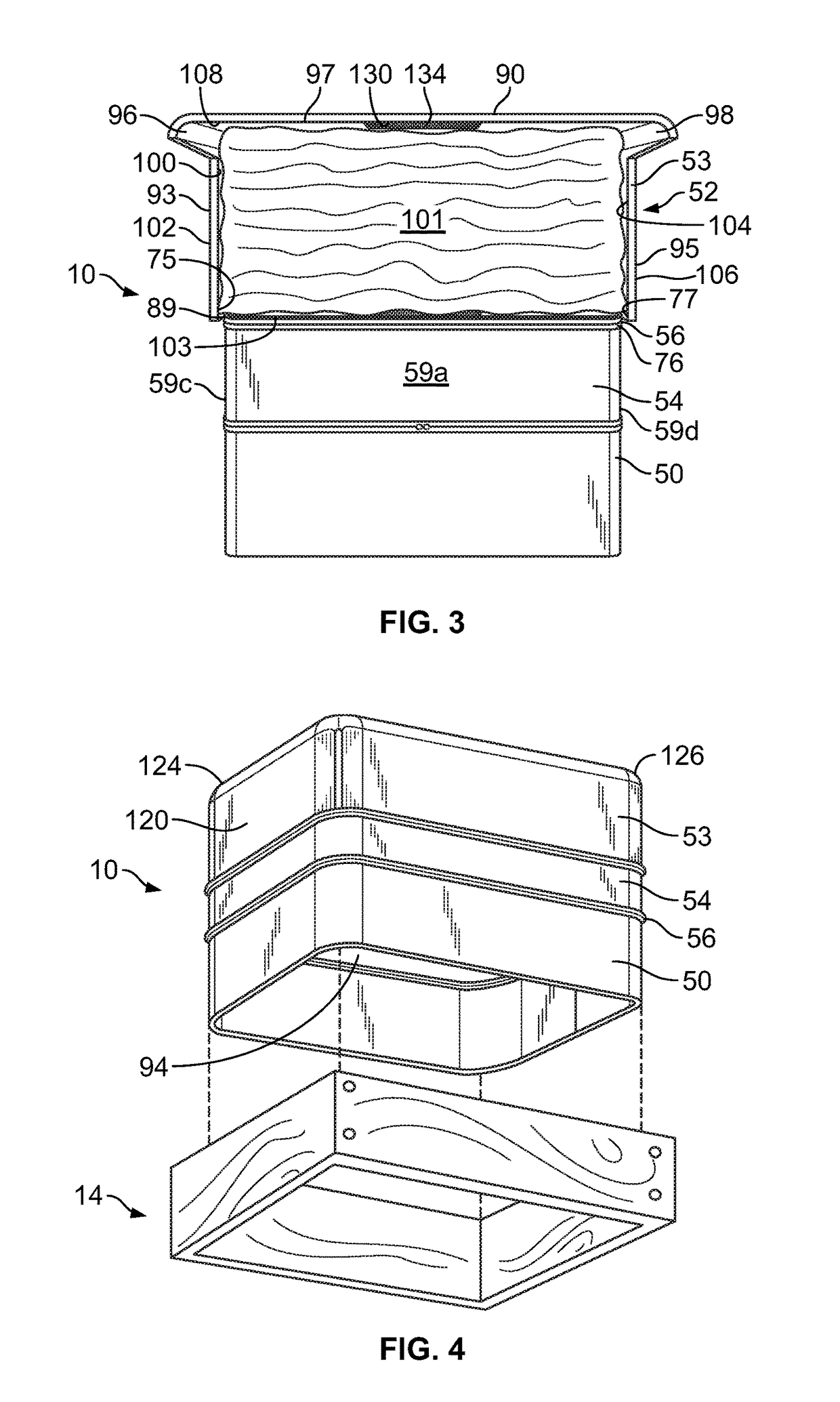

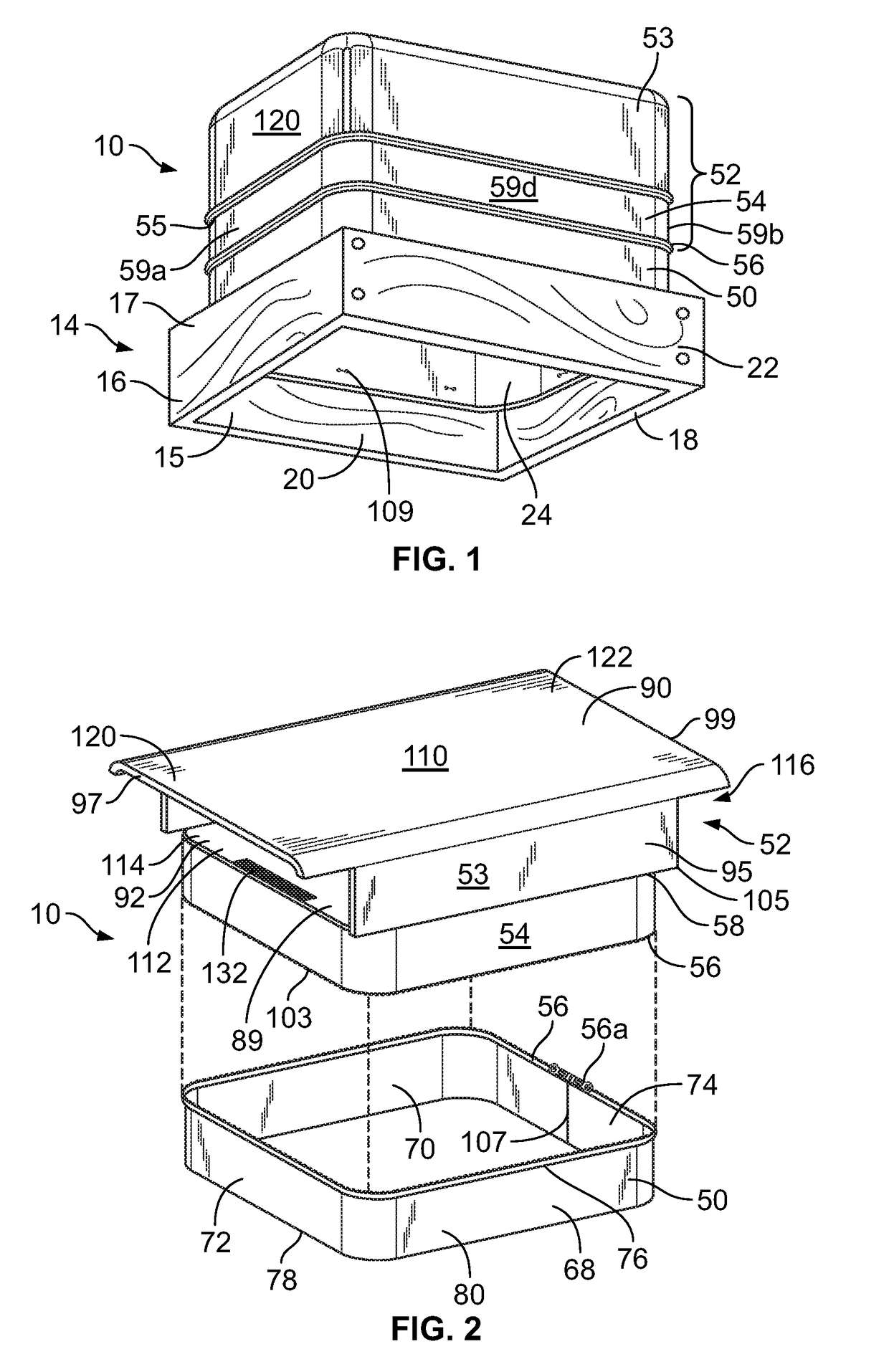

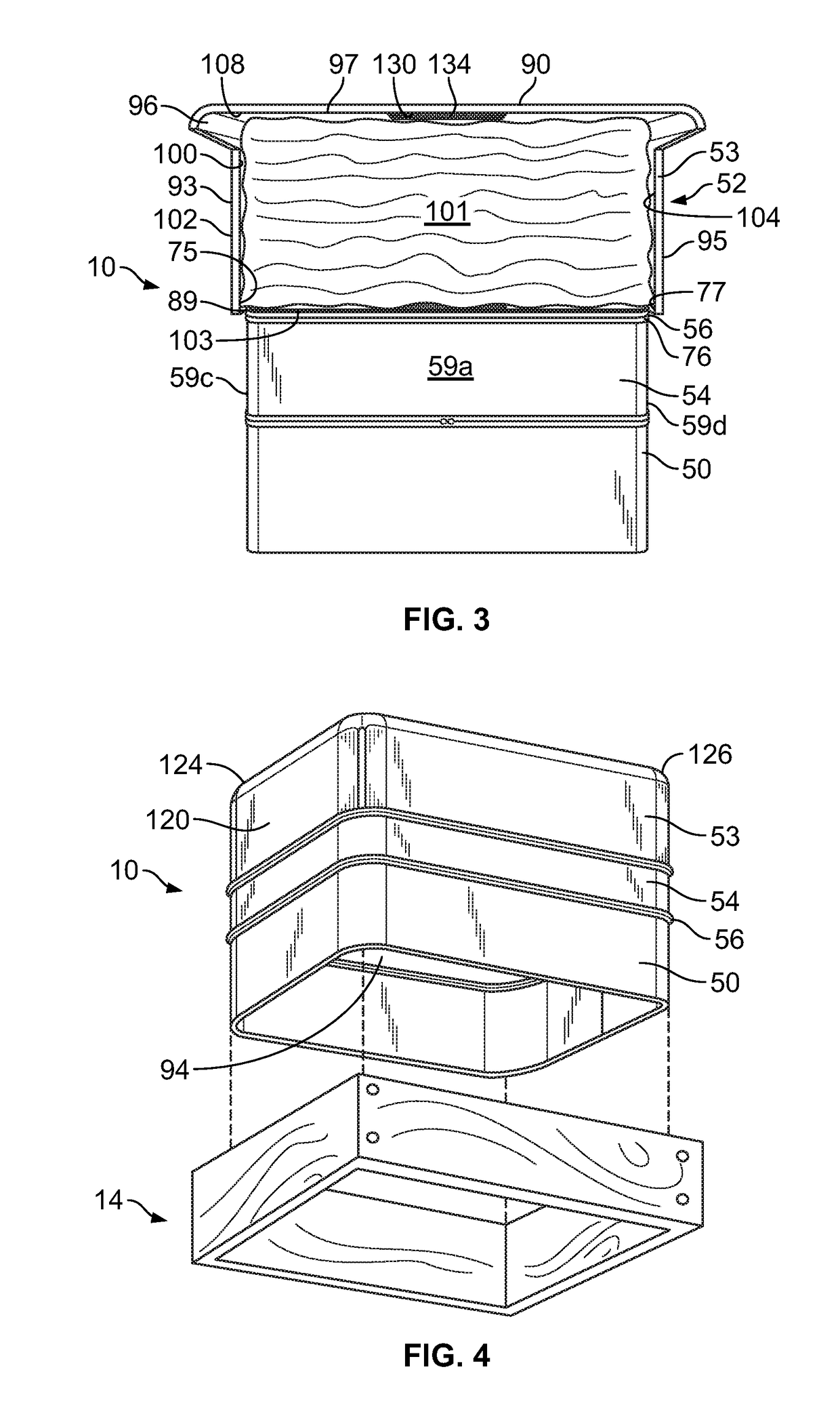

Attic entrance insulation cover

An attic-insulation cover designed to cover access doors leading into attic spaces, such as scuttle holes and vertical attic doors includes an attic insulation flange or border for placement over the attic opening frame, the attic insulation flange having a first top end and a second bottom end, an attic insulation jacket having a top wall, parallel side walls, parallel end walls and a bottom panel; and a closure device at the second bottom end of the attic-insulation flange for connecting the attic insulation flange and the attic insulation jacket.

Owner:SOUTHEAST ENERGY SOLUTIONS INC

High chromium content ferrite stainless steel and manufacturing method thereof

InactiveCN101381842BImprove nodulationImprove surface qualityWork treatment devicesRoll mill control devicesDie castingContinuous annealing

The invention discloses high chromium ferritic stainless steel and a manufacturing method thereof. The high chromium ferritic stainless steel is characterized in that the high chromium ferritic stainless steel comprises chemical elements according to the following weight percentage: less than or equal to 0.015 percent of C, less than or equal to 0.020 percent of N, less than or equal to 1.0 percent of Si, less than or equal to 1.0 percent of Mn, less than or equal to 0.035 percent of P, less than or equal to 0.010 percent of S, 20 to 25 percent of Cr, 0.30 to 0.50 percent of Cu, less than or equal to 0. 5 percent of Ti and Nb, and the balance being Fe, wherein (Ti / 48+Nb / 93) / (C / 12+N / 14) is more than 1.5. The manufacturing method comprises the: 1) a step of continuous casting or die casting, in which raw materials are primarily rolled into steel billets after the die casting; 2) a step of rolling, in which the final rolling temperature of steel plates is between 800 and 950 DEG C, and the gradual cooling is performed after the rolling; 3) a step of continuous annealing, in which the temperature is between 850 and 950 DEG C; 4) a step of the removal of oxide coating; 5) a step of cold rolling; and 6) a step of continuous annealing after the recrystallization. The ferritic stainless steel has the advantages of stronger corrosion resistance, higher plasticity and good deep drawability.

Owner:BAOSHAN IRON & STEEL CO LTD

High strength galvanized steel sheet having excellent deep drawability and stretch flangeability and method for manufacturing the same

ActiveUS9598755B2Improve deep drawing performanceHigh R-valueHot-dipping/immersion processesFurnace typesMartensiteGalvanization

A high-strength galvanized steel sheet contains C: 0.010% or more and 0.06% or less, Si: more than 0.5% and 1.5% or less, Mn: 1.0% or more and 3.0% or less, P: 0.005% or more and 0.1% or less, S: 0.01% or less, sol.Al: 0.005% or more and 0.5% or less, N: 0.01% or less, Nb: 0.010% or more and 0.090% or less, and Ti: 0.015% or more and 0.15% or less, on a mass percent basis. The Nb and C contents of the steel satisfy the relation of (Nb / 93) / (C / 12)<0.20. C* satisfies 0.005≦C*≦0.025. Ferrite constitutes 70% by area ratio or more of the steel sheet. Martensite constitutes 3% by area ratio or more of the steel sheet. C*=C−(12 / 93)Nb−(12 / 48){Ti−(48 / 14)N}, wherein C, Nb, Ti, and N denote the C, Nb, Ti, and N contents of the steel.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com