Process for producing high-strength interstitial-free (IF) steel with high plastic strain ratio (r) value

A production process and high-strength technology, applied in the field of high-strength IF steel, can solve the problems of prolonging the production cycle, restricting practical application, and high production cost, and achieving the effect of increasing the r value, being easy to implement, and improving the deep drawing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

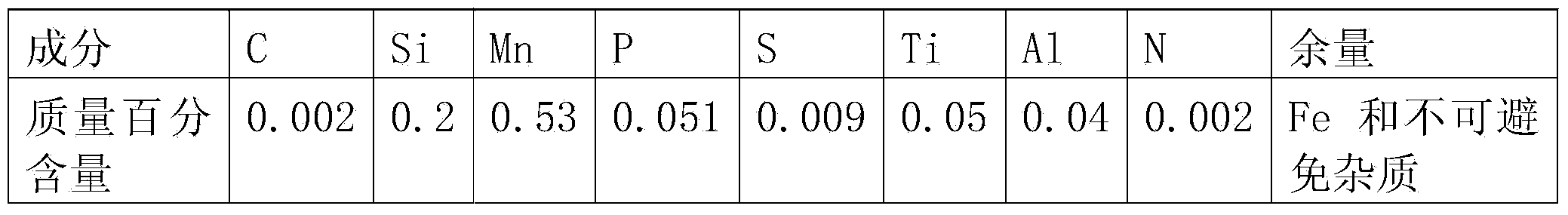

[0018] The composition of the high-strength IF steel implemented in the present invention is shown in Table 1.

[0019] Table 1 The chemical composition (wt%) of the steel of the specific embodiment of the present invention

[0020]

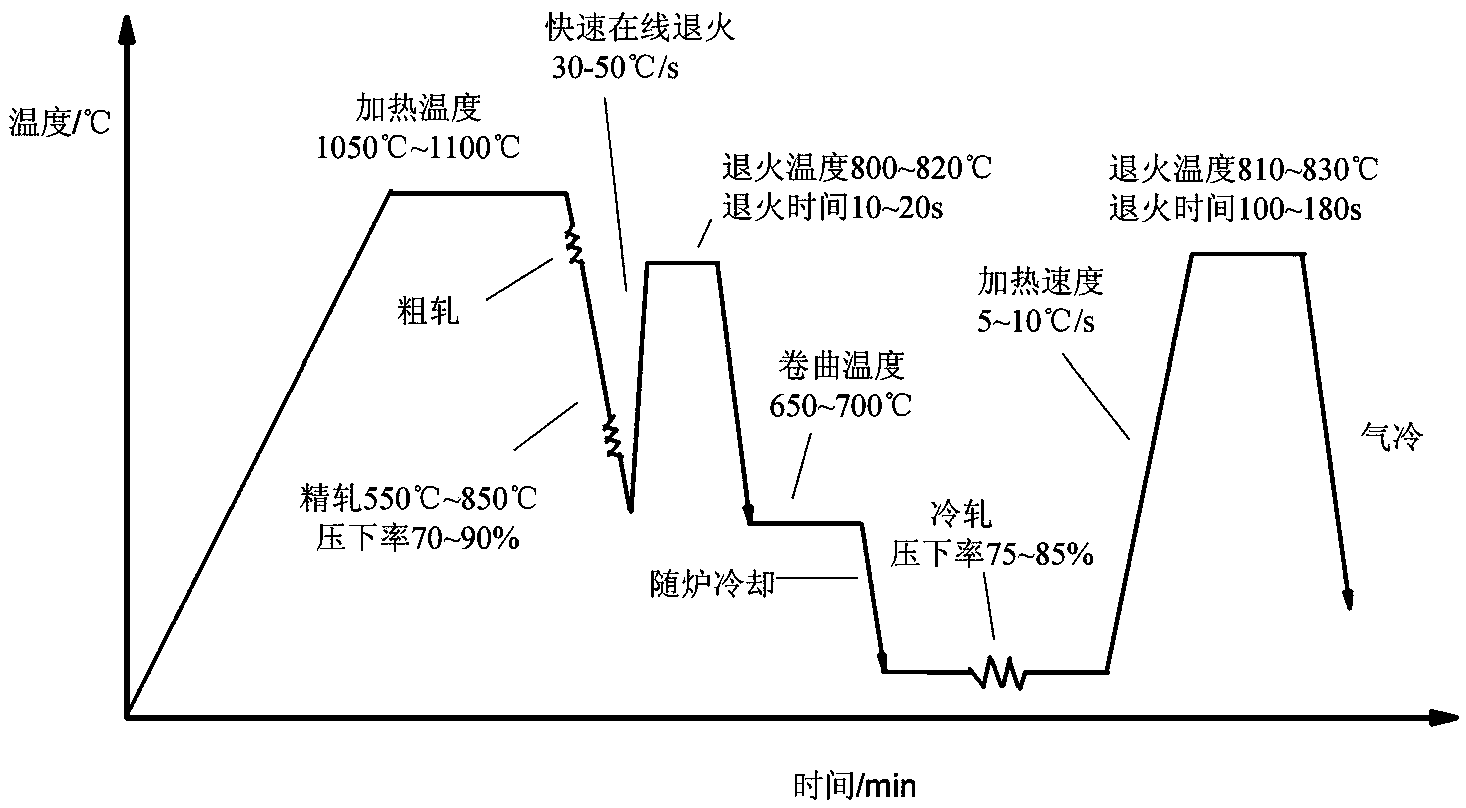

[0021] Carry out smelting, casting and forging according to the composition in Table 1, heat the forging billet to 1100°C, keep it warm for 2 hours, and carry out hot rolling on a 350mm hot rolling mill with the starting temperature of 1050°C, after 2 passes of rough rolling and 4 passes of finishing Rolling, the final thickness is 2.5mm, wherein the finish rolling start temperature is 850°C, the finish rolling reduction rate is 75%, the last two passes of finish rolling start rolling temperature is 650°C, the final rolling temperature is 550°C, two passes The cumulative reduction rate is 45%. After rolling, it directly enters the online rapid annealing furnace and is rapidly heated to an online annealin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com