260MPa-grade hot-dip galvanized high-strength IF steel and preparation method thereof

A hot-dip galvanizing, high-strength technology, applied in the field of steel manufacturing, can solve the problems of poor resistance to secondary processing brittleness of high-strength IF steel, and achieve the effects of excellent resistance to secondary processing brittleness, cost reduction, and excellent resistance to secondary brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

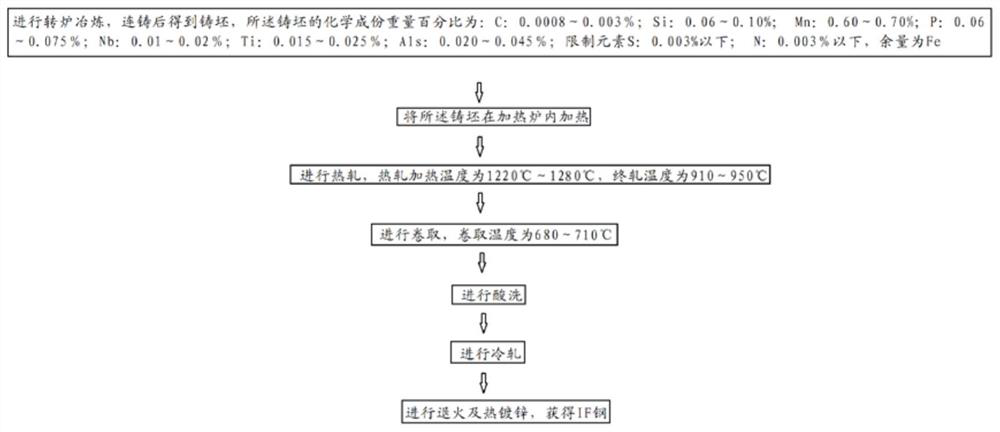

[0030] Based on the same inventive concept, the application also provides a preparation method of 260MPa grade hot-dip galvanized high-strength IF steel comprising the following steps:

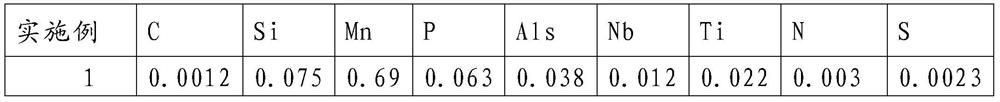

[0031] Converter smelting is carried out, and cast slabs are obtained after continuous casting. The weight percentages of the chemical components of the cast slabs are: C: 0.0008-0.003%; Si: 0.06-0.10%; Mn: 0.60-0.70%; P: 0.06-0.075%; Nb: 0.01-0.02%; Ti: 0.015-0.025%; Als: 0.020-0.045%; restricted element S: 0.003% or less; N: 0.003% or less, the balance being Fe;

[0032] The cast strand is heated in a heating furnace.

[0033] Carry out hot rolling, the hot rolling heating temperature is 1220 ℃~1280 ℃, and the final rolling temperature is 910~950 ℃.

[0034] Carry out coiling, coiling temperature is 680~710 ℃.

[0035] Perform pickling.

[0036] Perform cold rolling.

[0037] Perform annealing and hot-dip galvanizing to obtain IF steel.

[0038] On the one hand, Nb and Ti are added alon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com