Patents

Literature

5775results about "Door leaves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

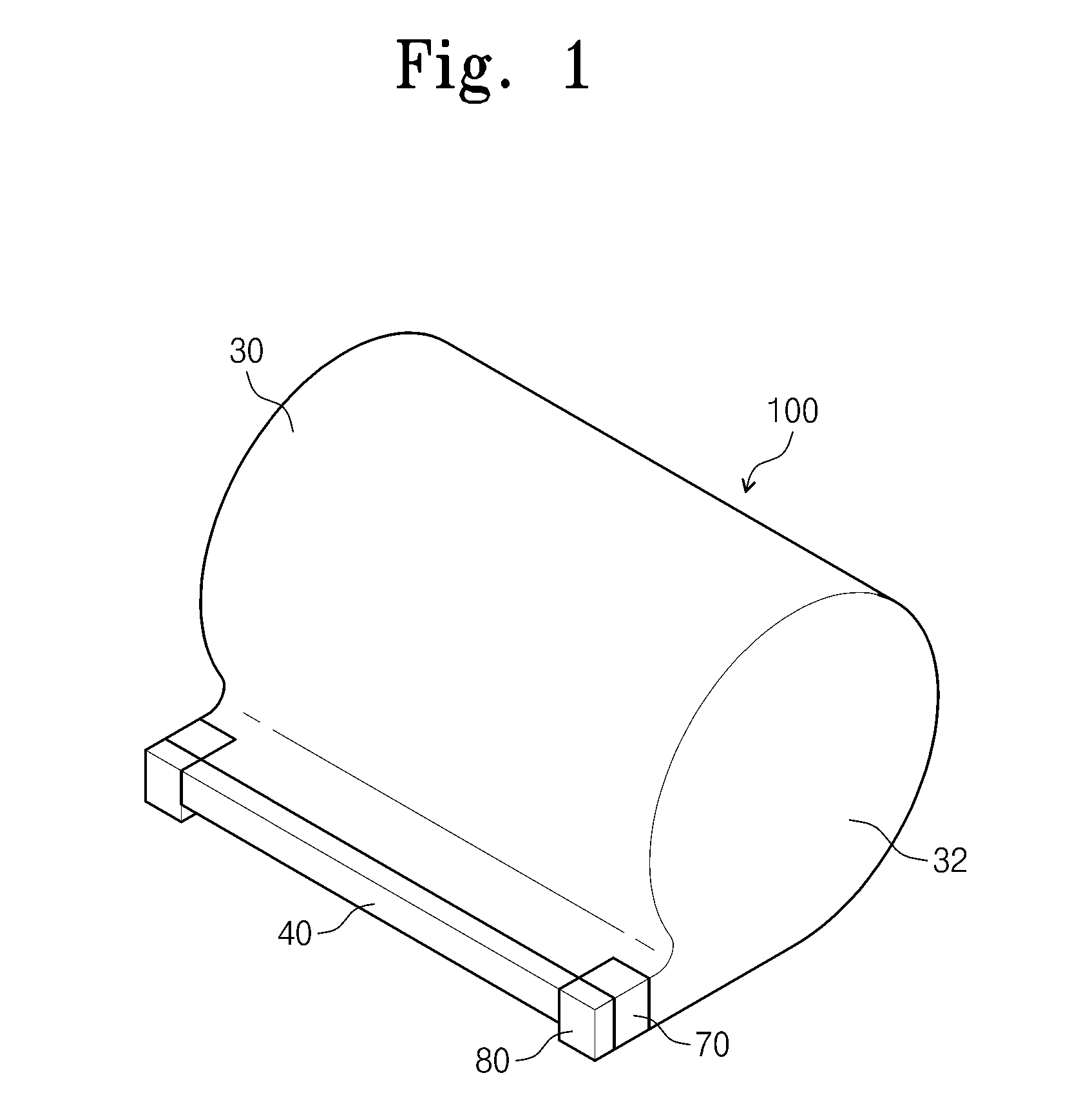

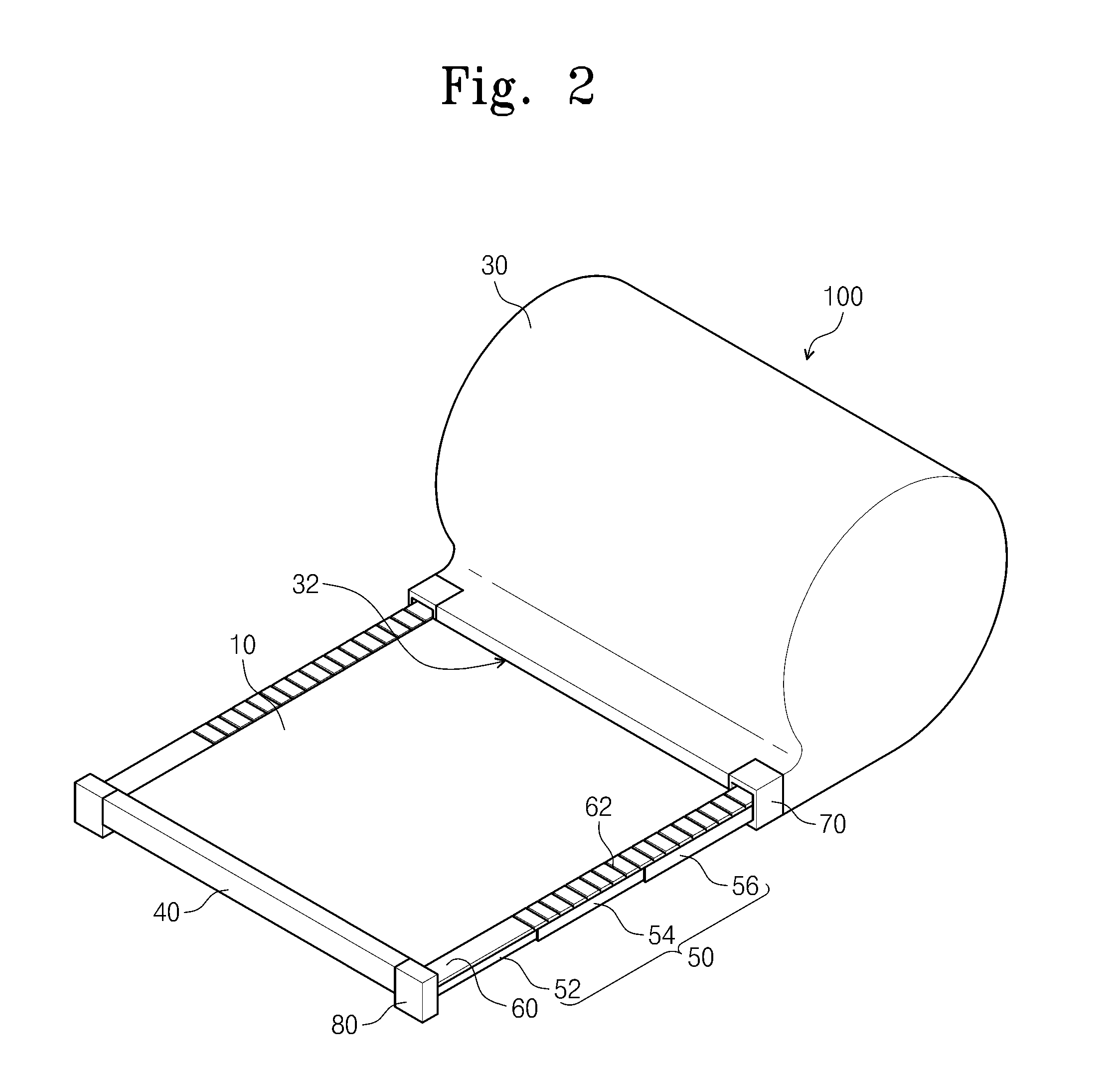

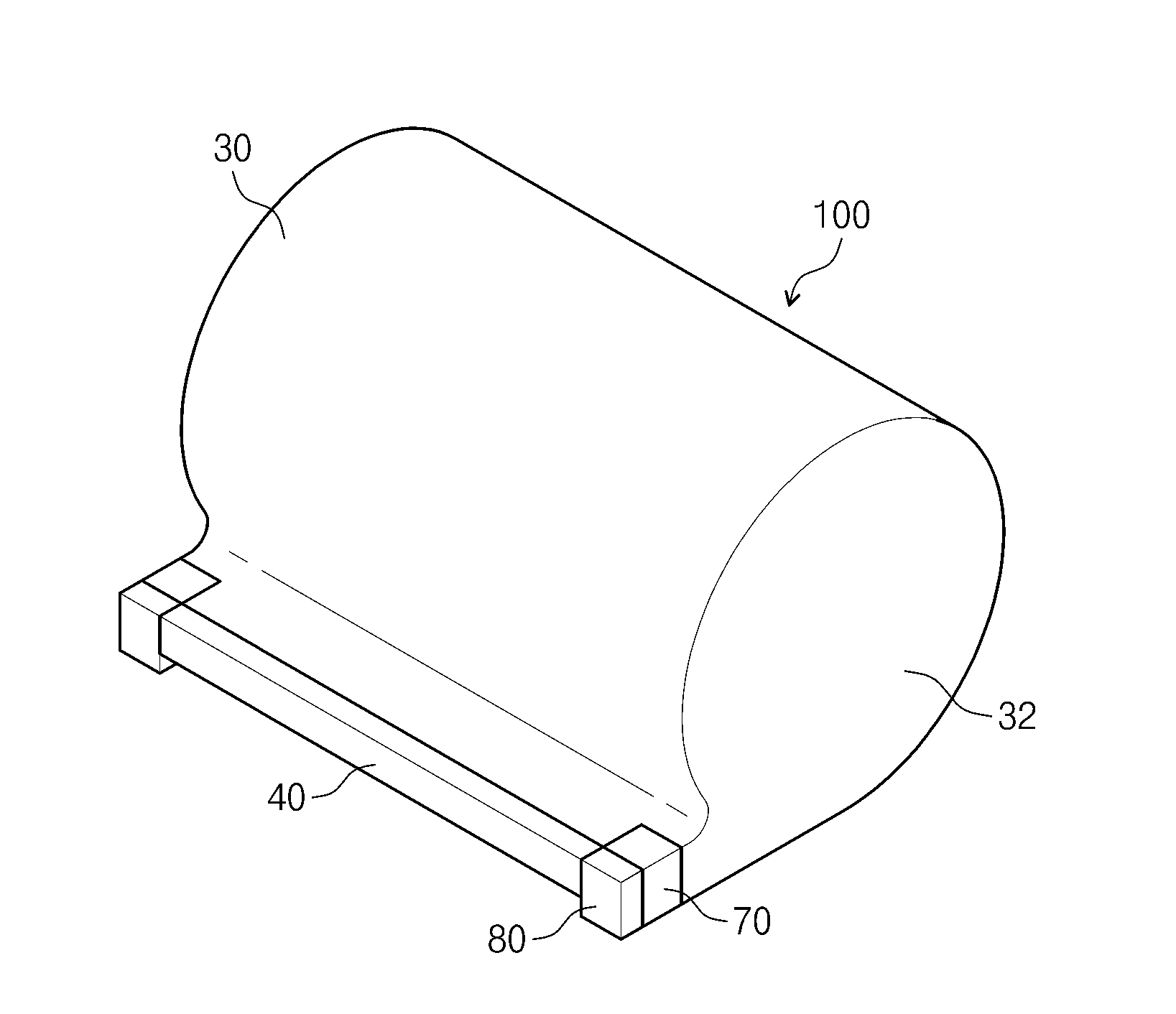

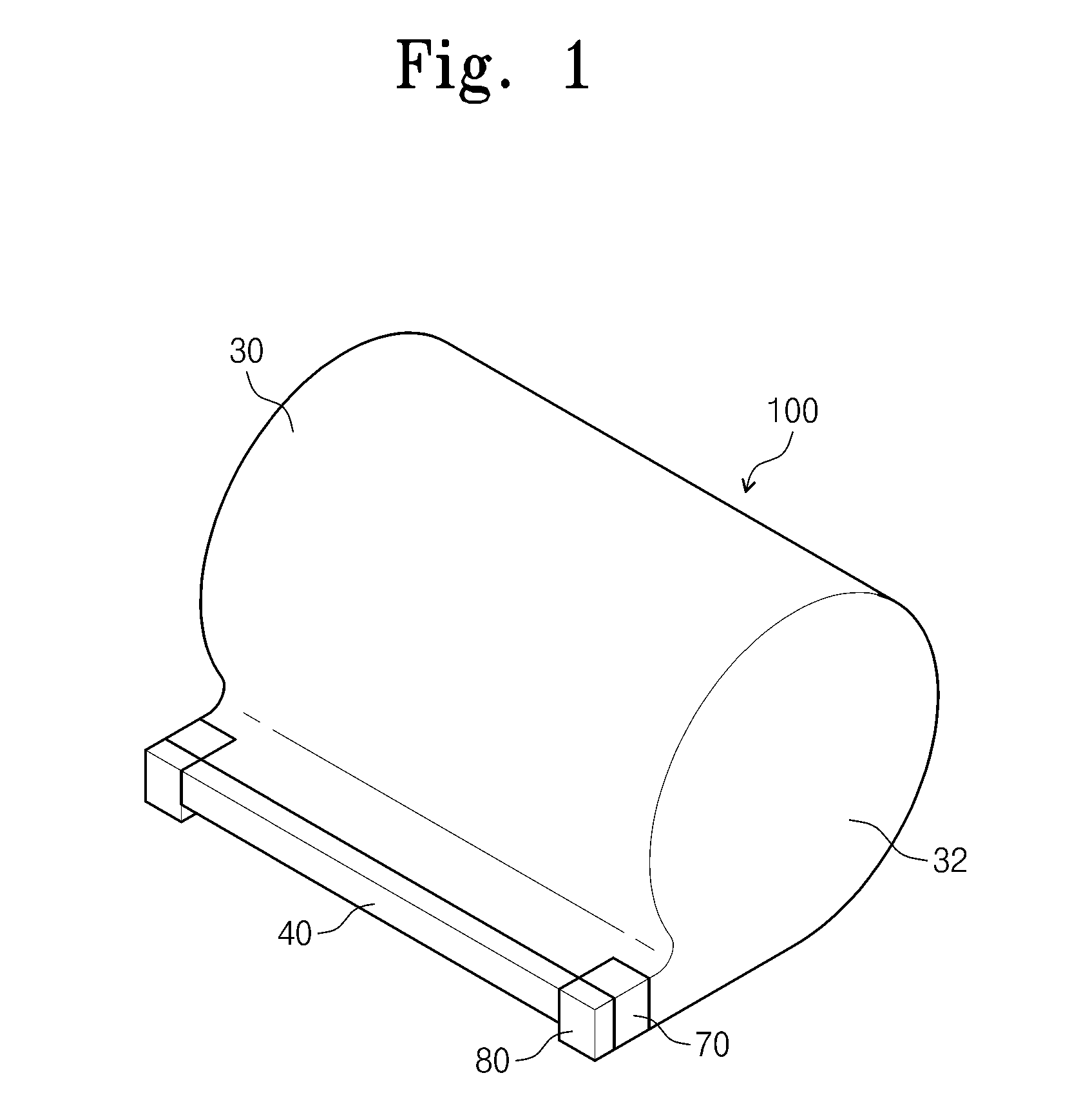

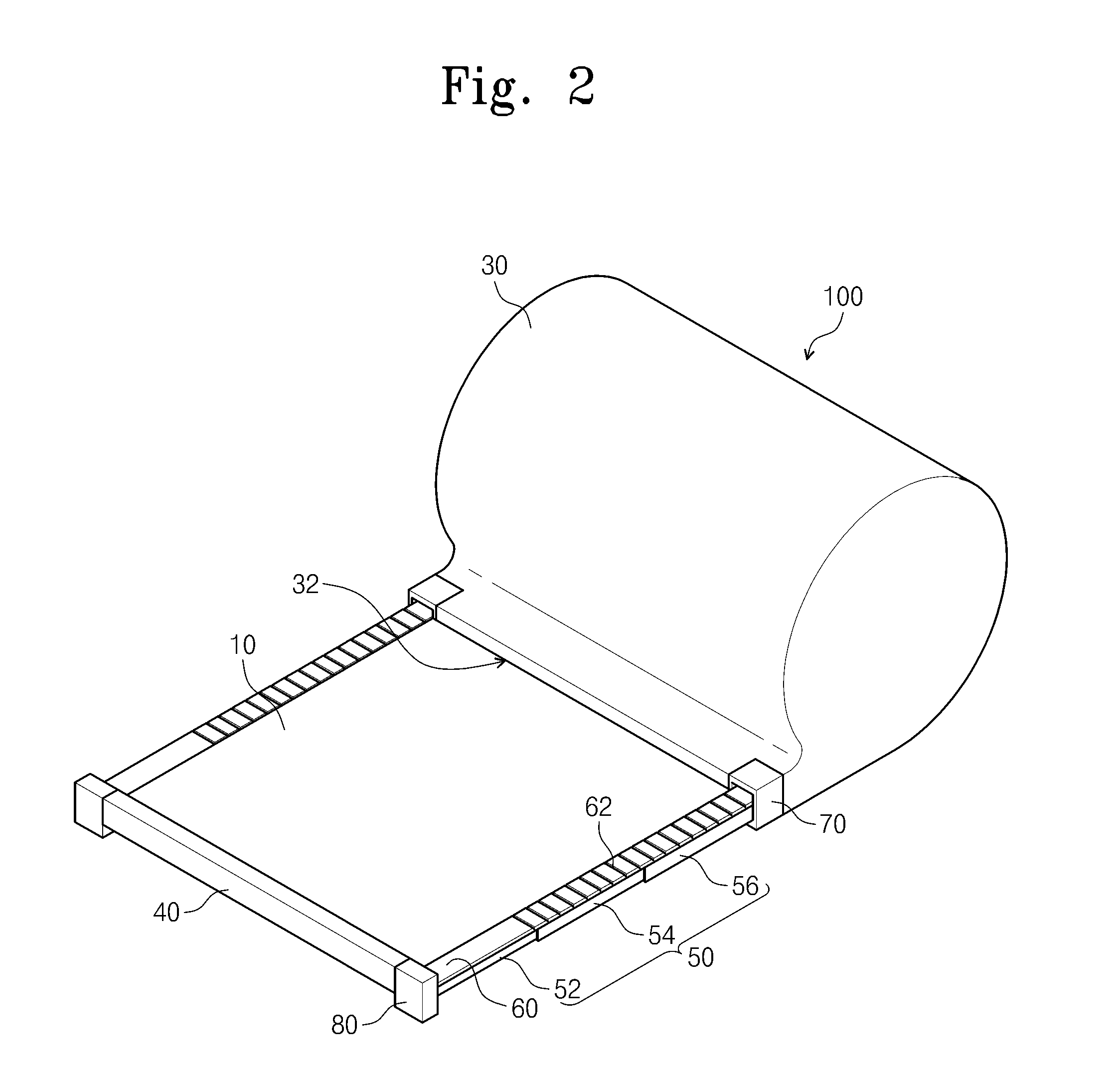

Flexible display apparatus

InactiveUS20120204453A1Easily rolled and unrolledScreensShutters/ movable grillesEngineeringFlexible display

Provided is a flexible display apparatus that includes: a flexible display apparatus including: a flexible display panel; a housing including an opening through which the flexible display panel enters and exits the housing; a cylinder disposed within the housing to coil and uncoil the flexible display panel; and a stretcher that selectively extends from the opening to support the flexible display panel, such that the flexible display panel is substantially planar when the flexible display panel is extended outside of the housing.

Owner:SAMSUNG DISPLAY CO LTD

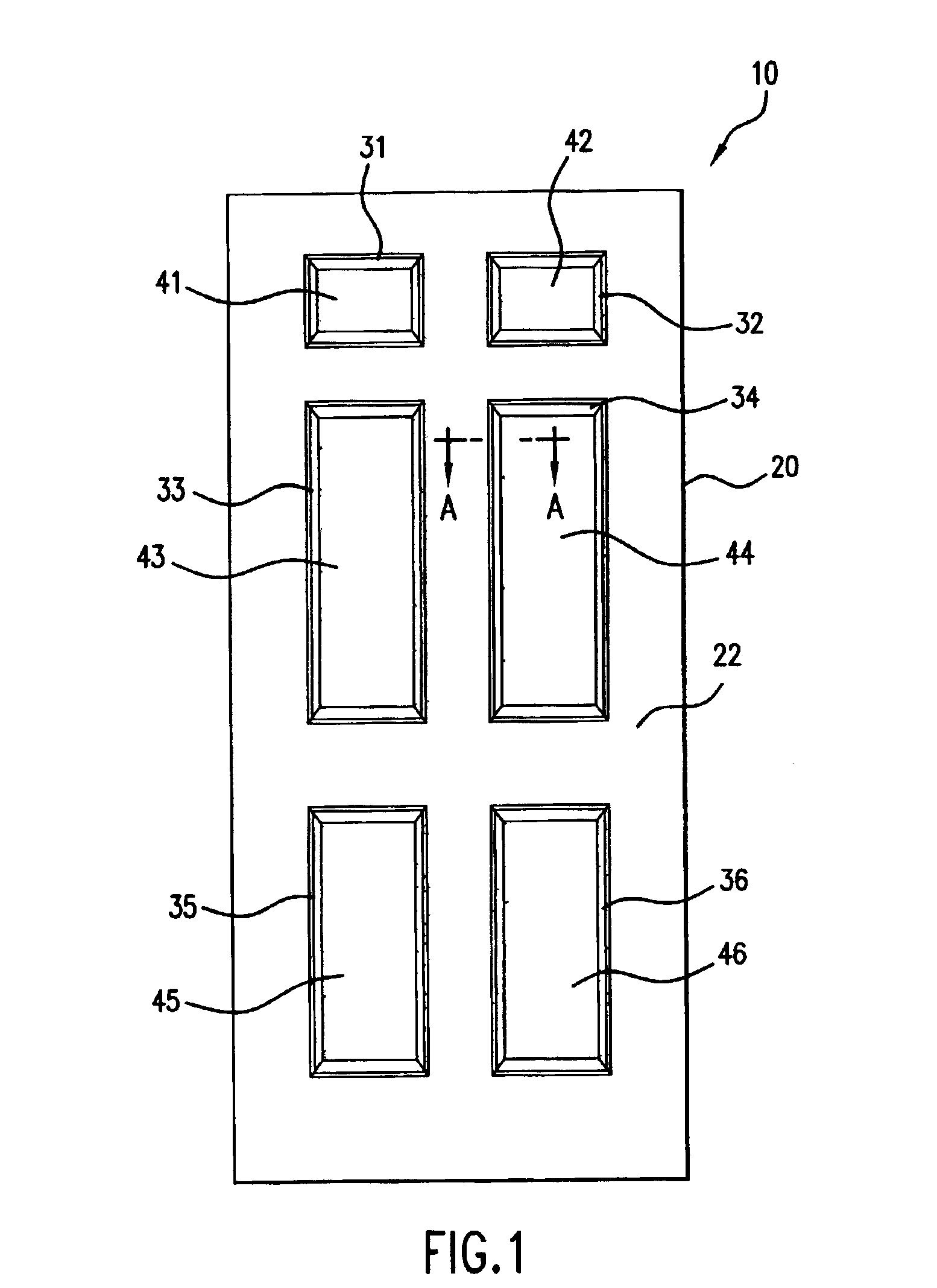

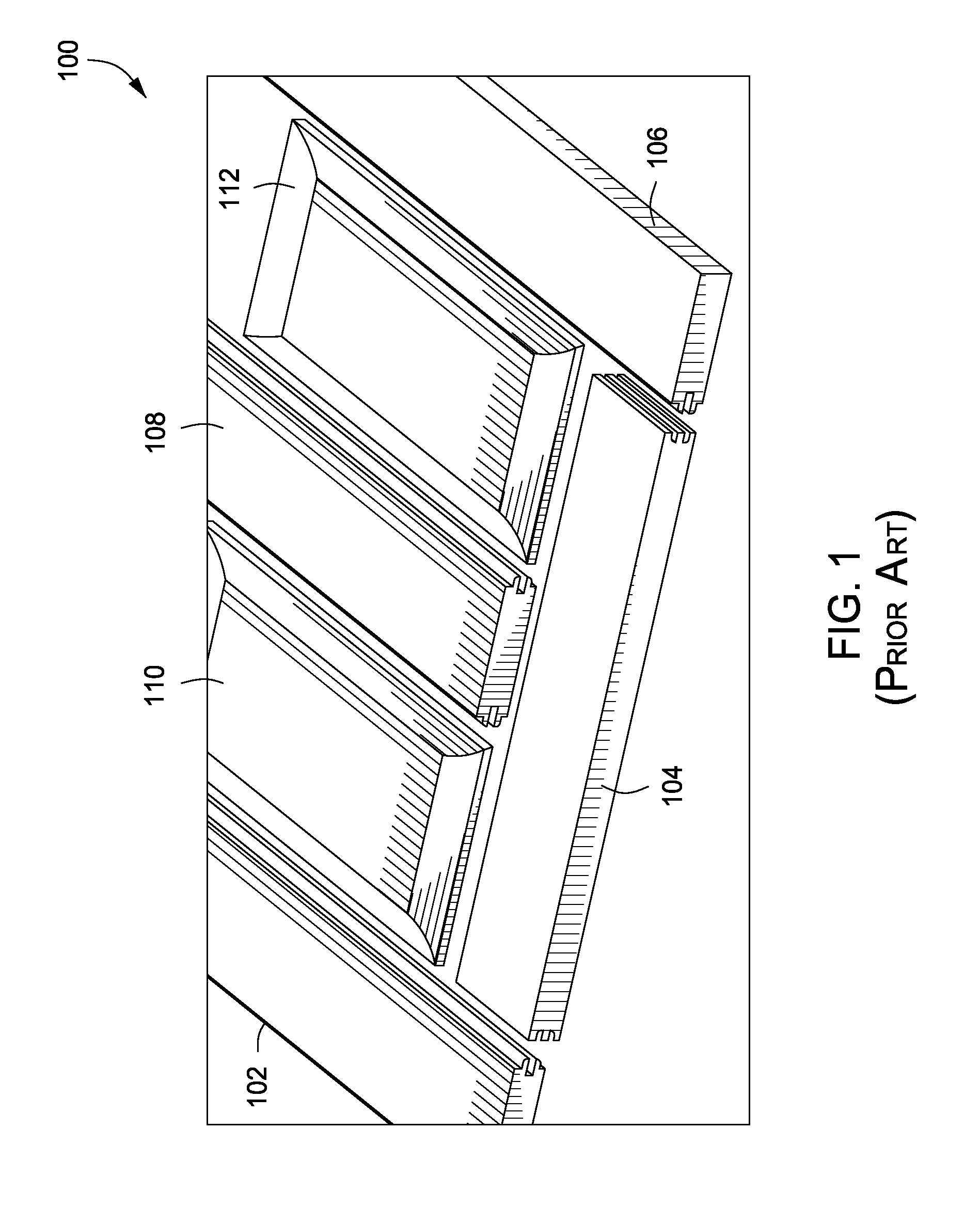

Fire retardant wooden door with intumescent materials

InactiveUS6745526B1Prevent the spread of fireEasy to installFireproof doorsDoor leavesTongue and grooveEngineering

A fire retardant wooden door that prevents the spread of fire through the door during a fire. The fire retardant wooden door has at least one door panel connected to stiles and rails by tongue and groove joints, and the tongue and groove joints have intumescent material therein. Each of the tongue and groove joints includes a tongue section having the intumescent material along a distal edge of the tongue section which expands upon exposure to heat or fire to seal the tongue and groove joints in order to prevent the heat or fire from passing through the door during a fire. Each of the tongue sections includes an interior channel extending along the axis of the tongue section, and the interior channel extends into the door panel. The interior channel has the intumescent material embedded therein which expands upon exposure to heat or fire to further seal the tongue and groove joints in order to prevent the heat or fire from passing through the door during a fire.

Owner:AUTOVINO ENRICO

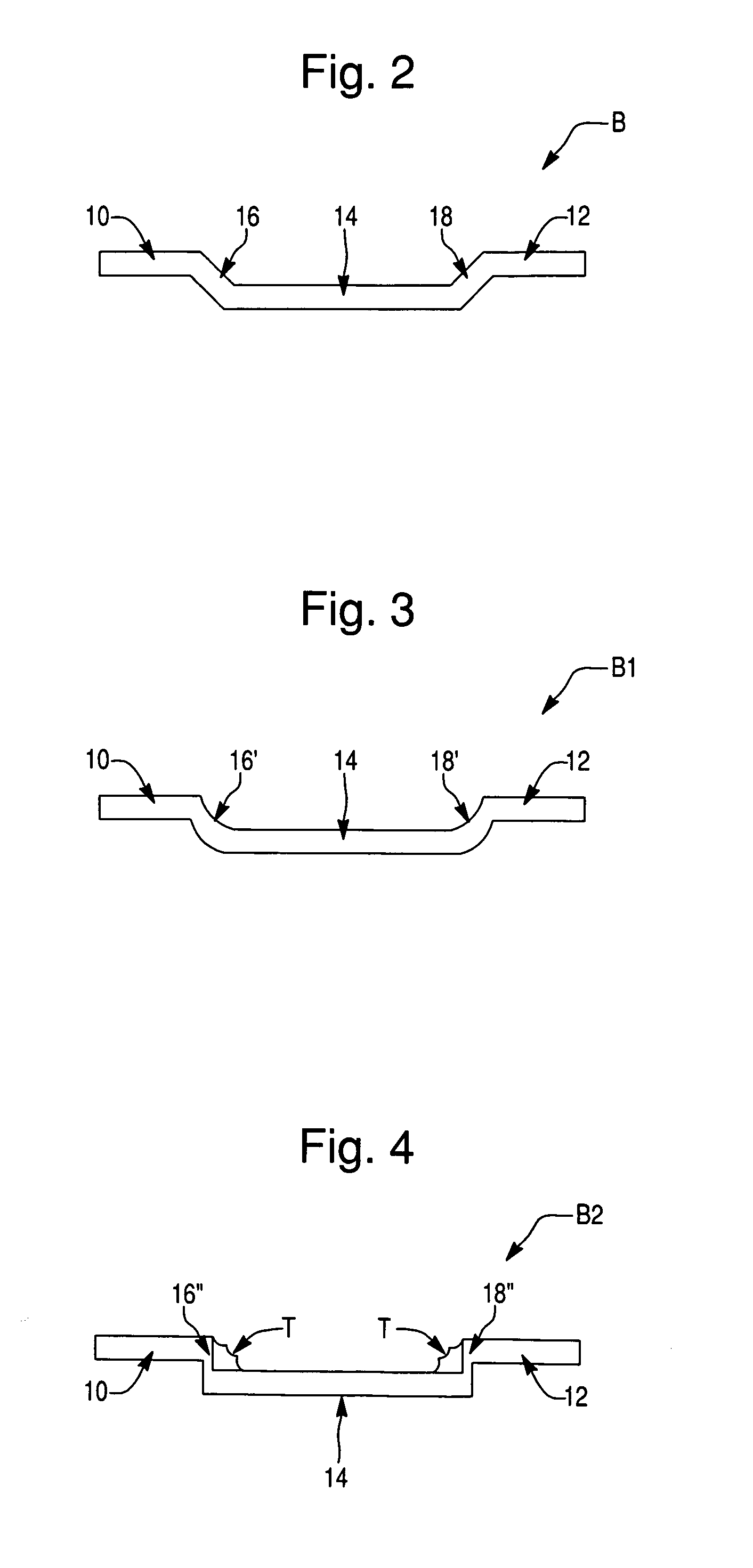

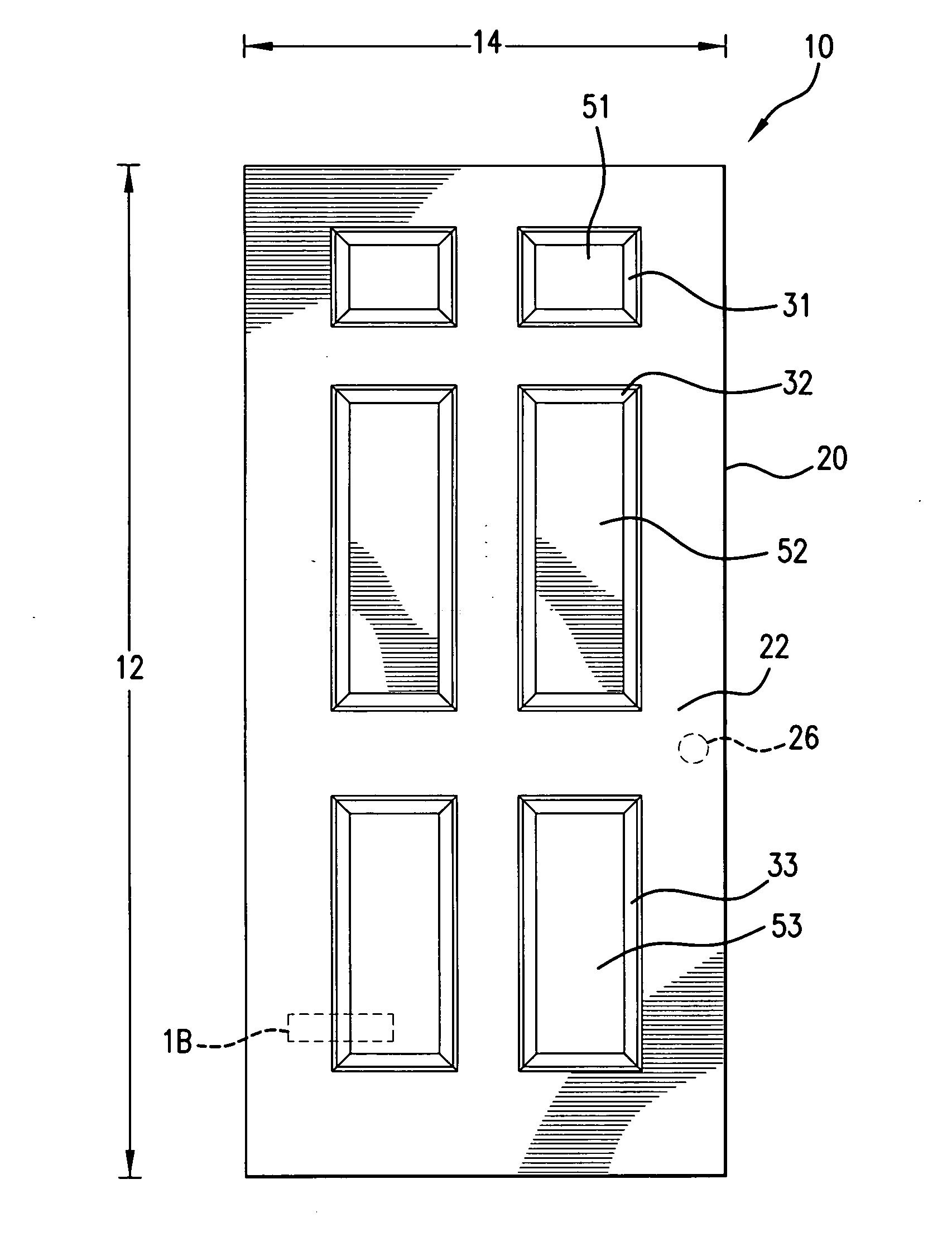

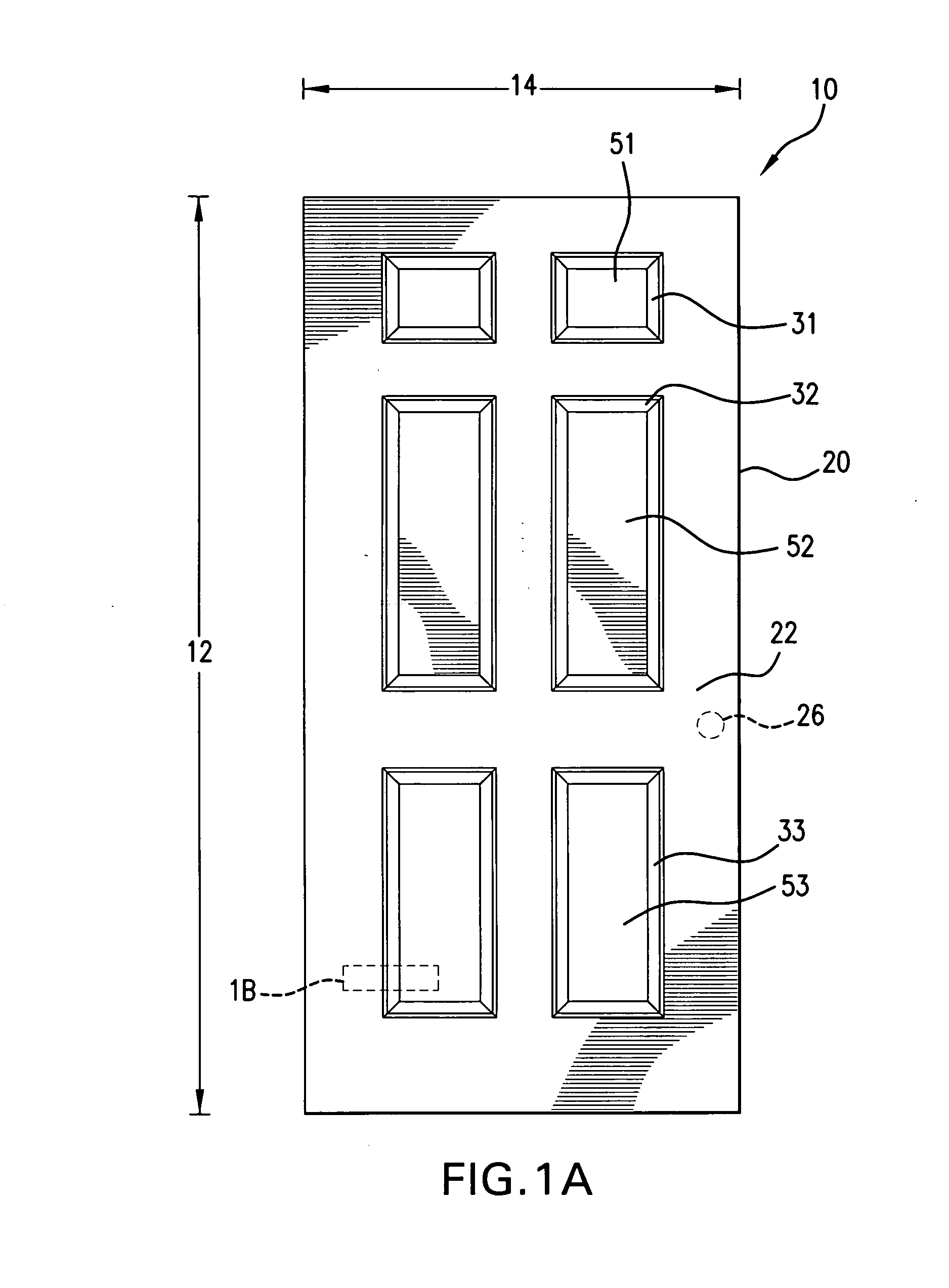

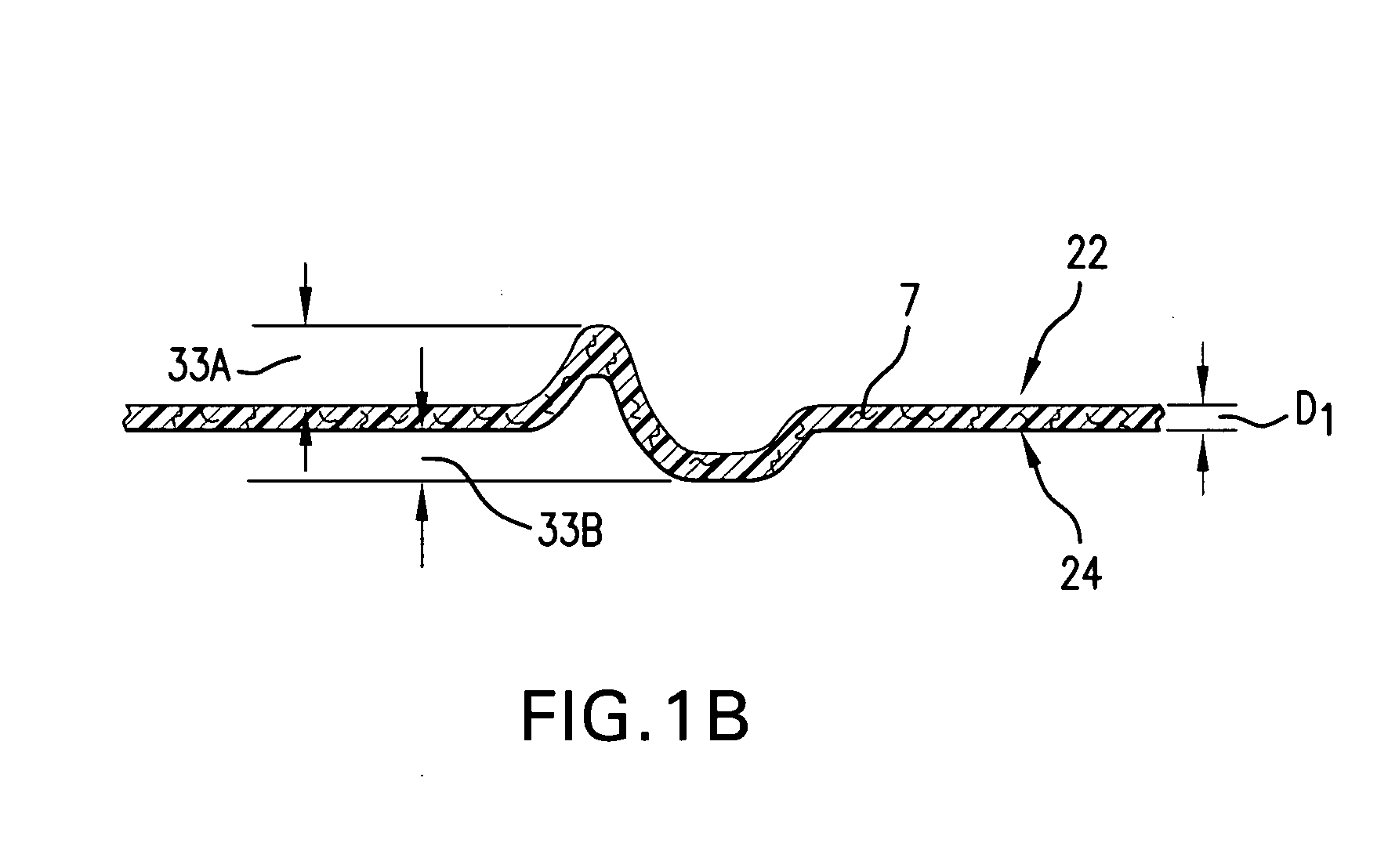

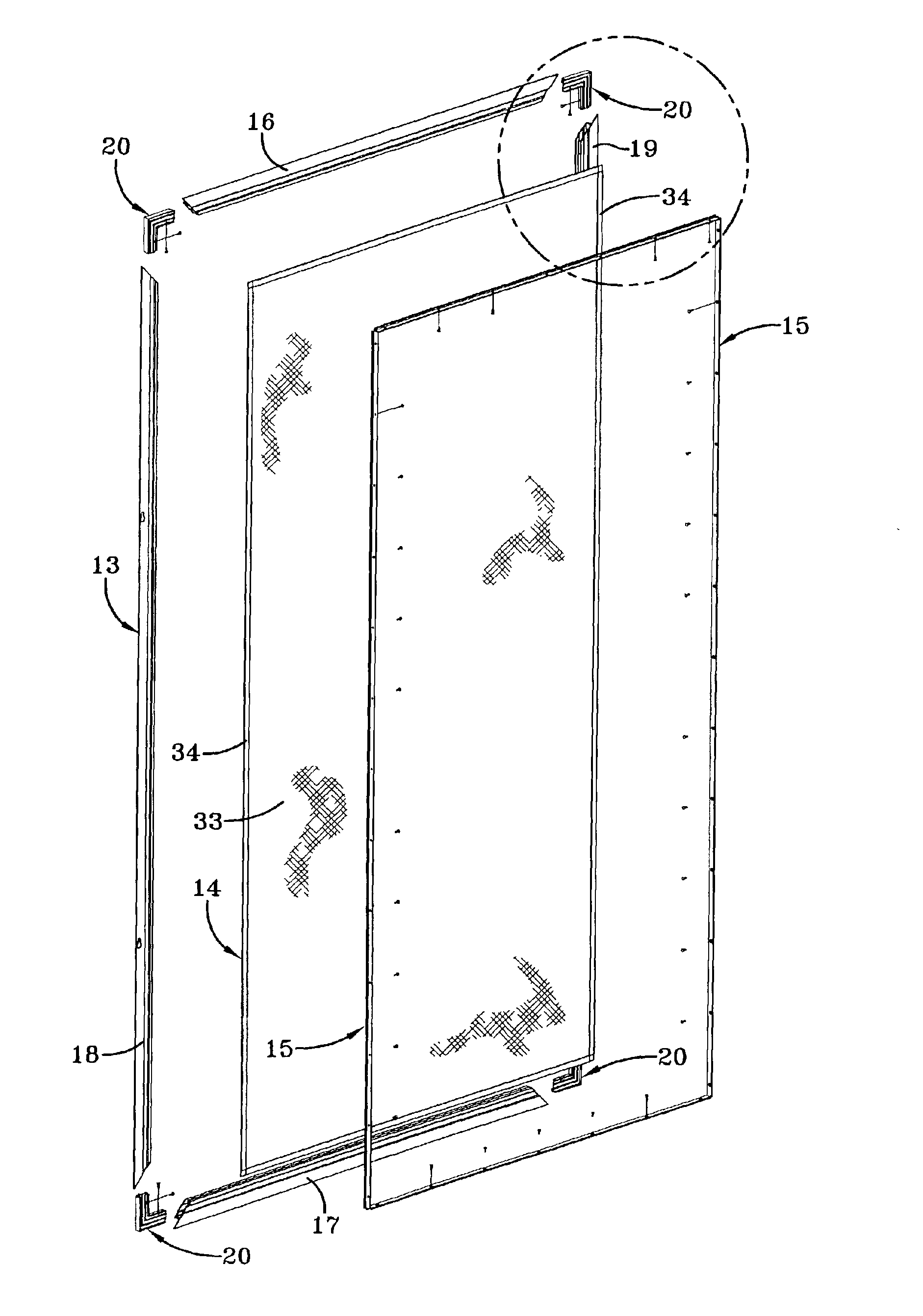

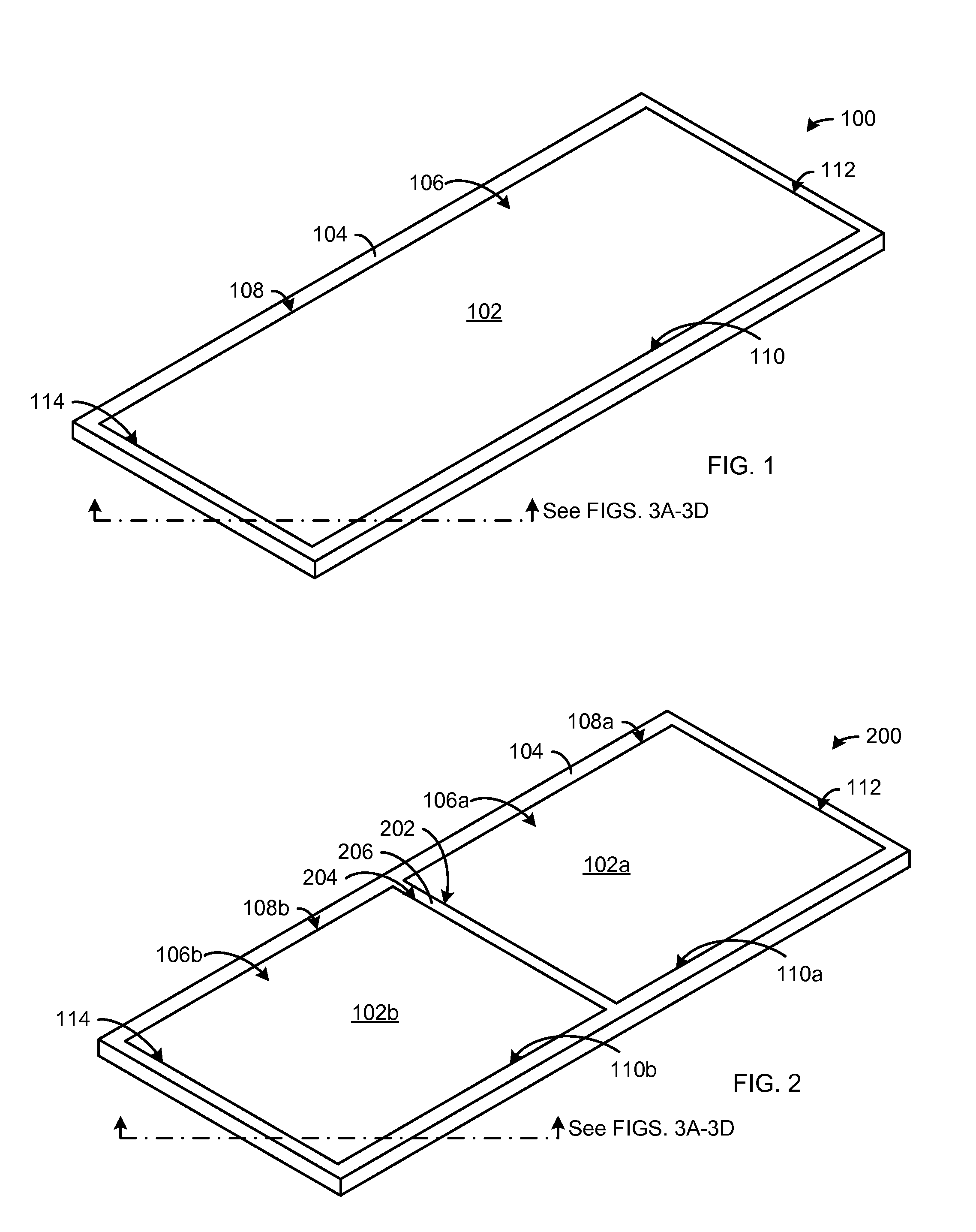

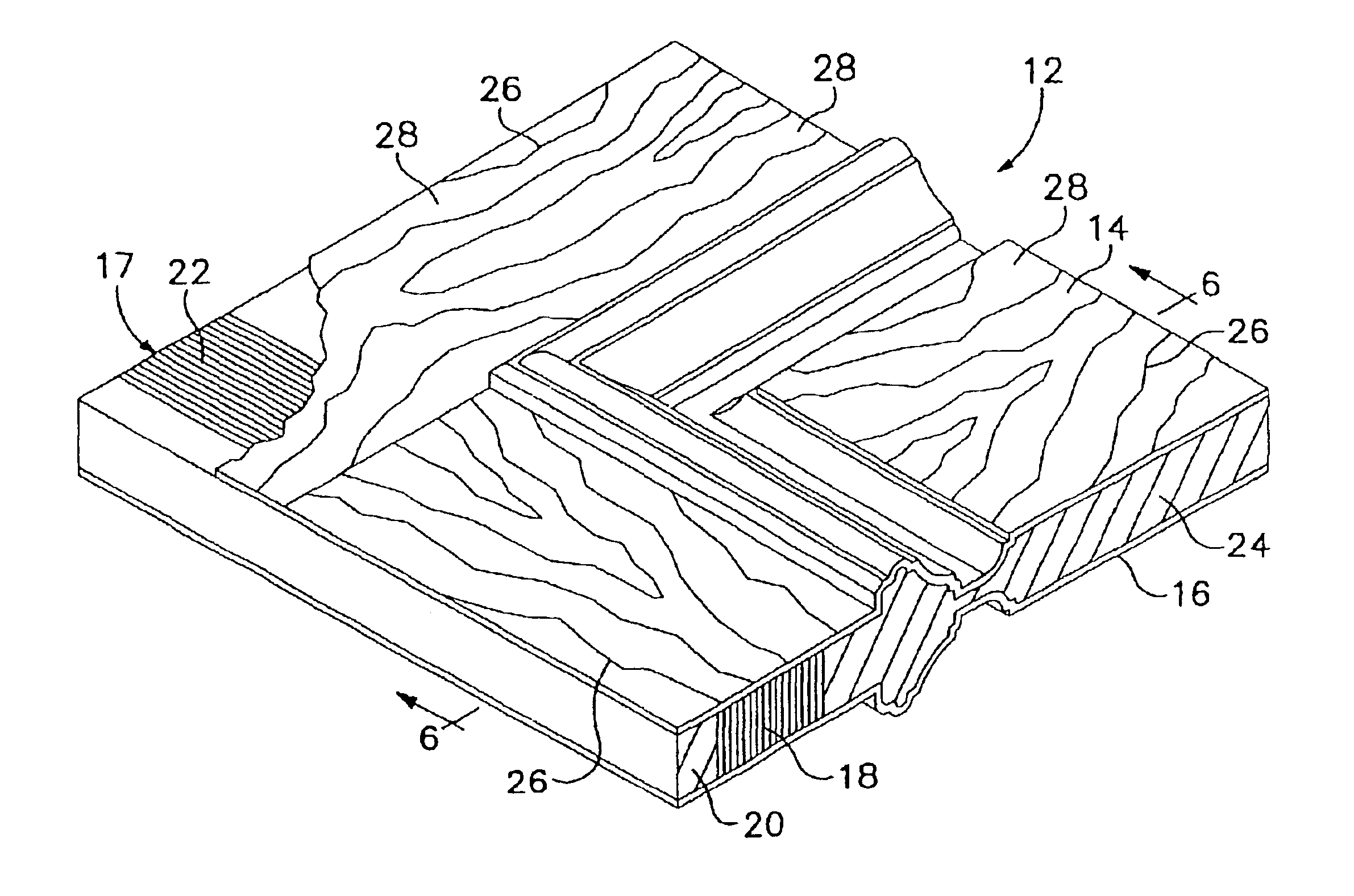

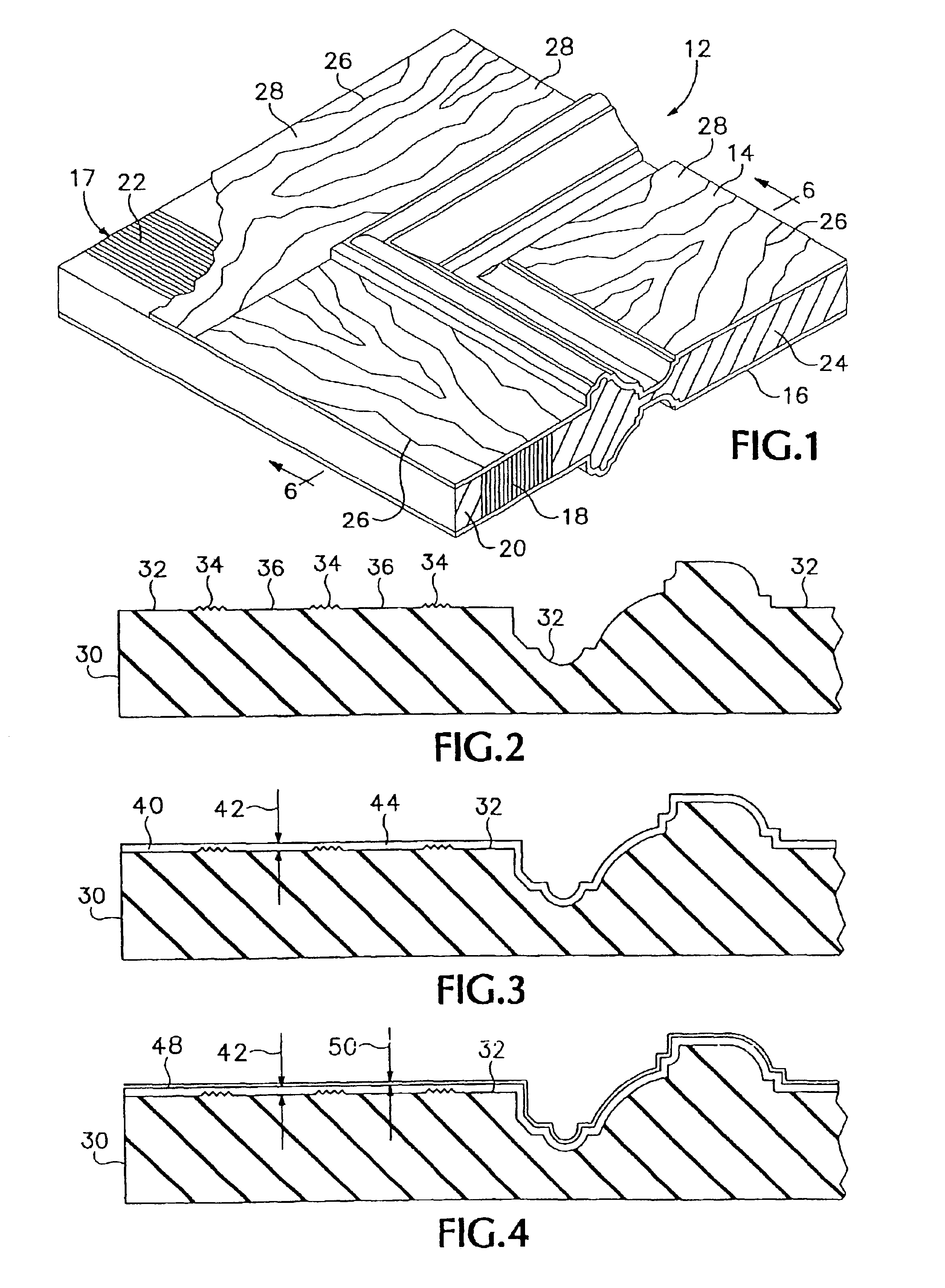

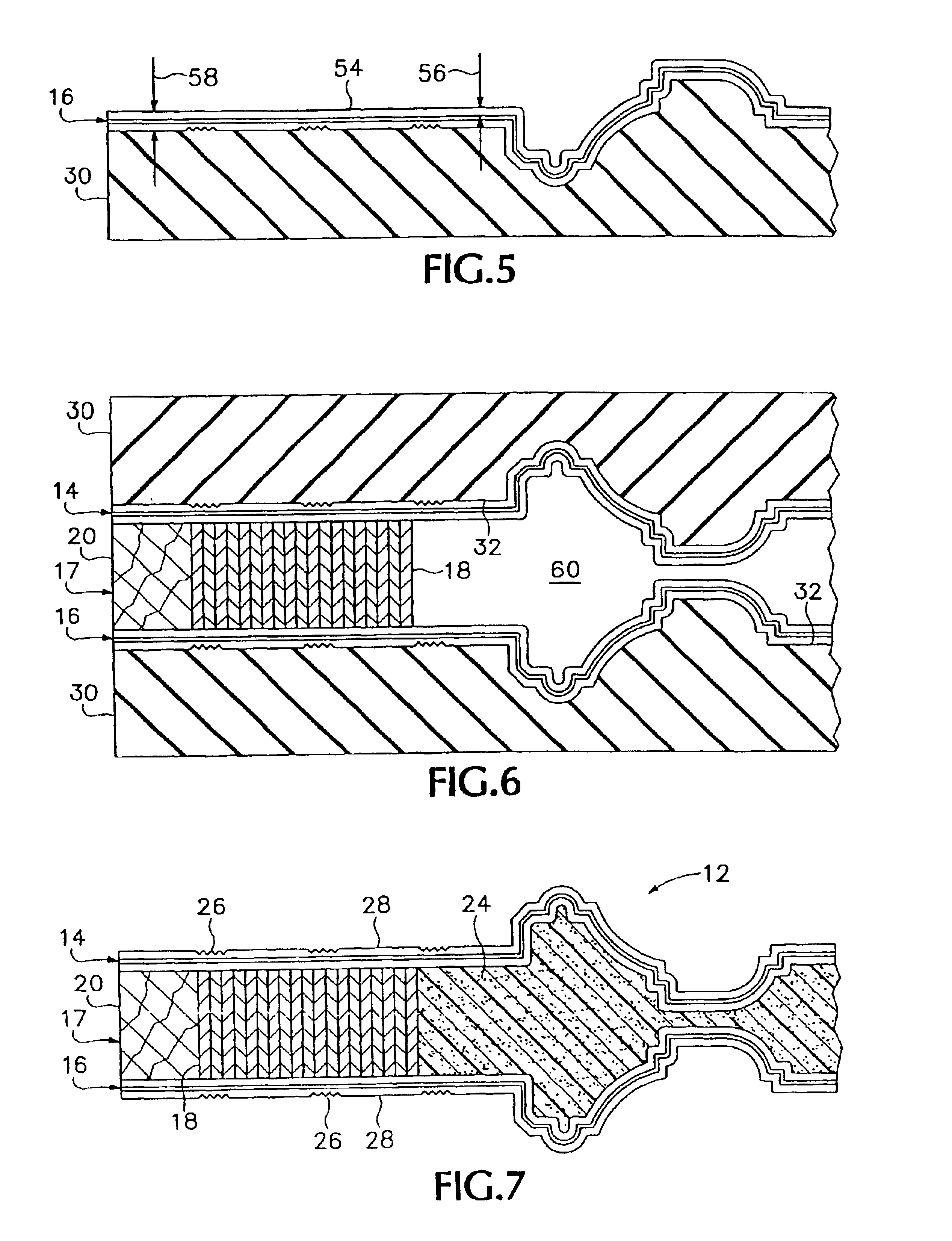

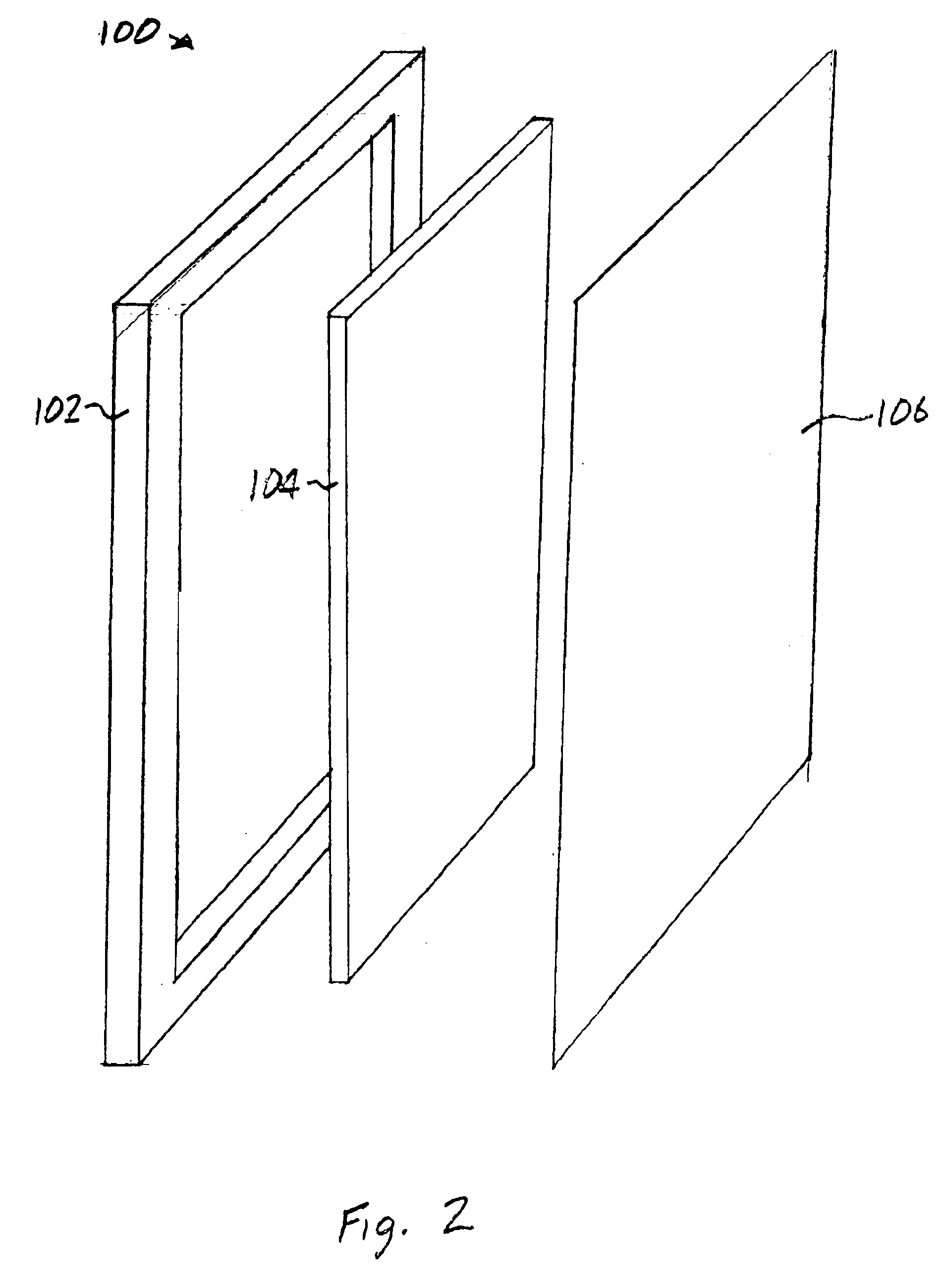

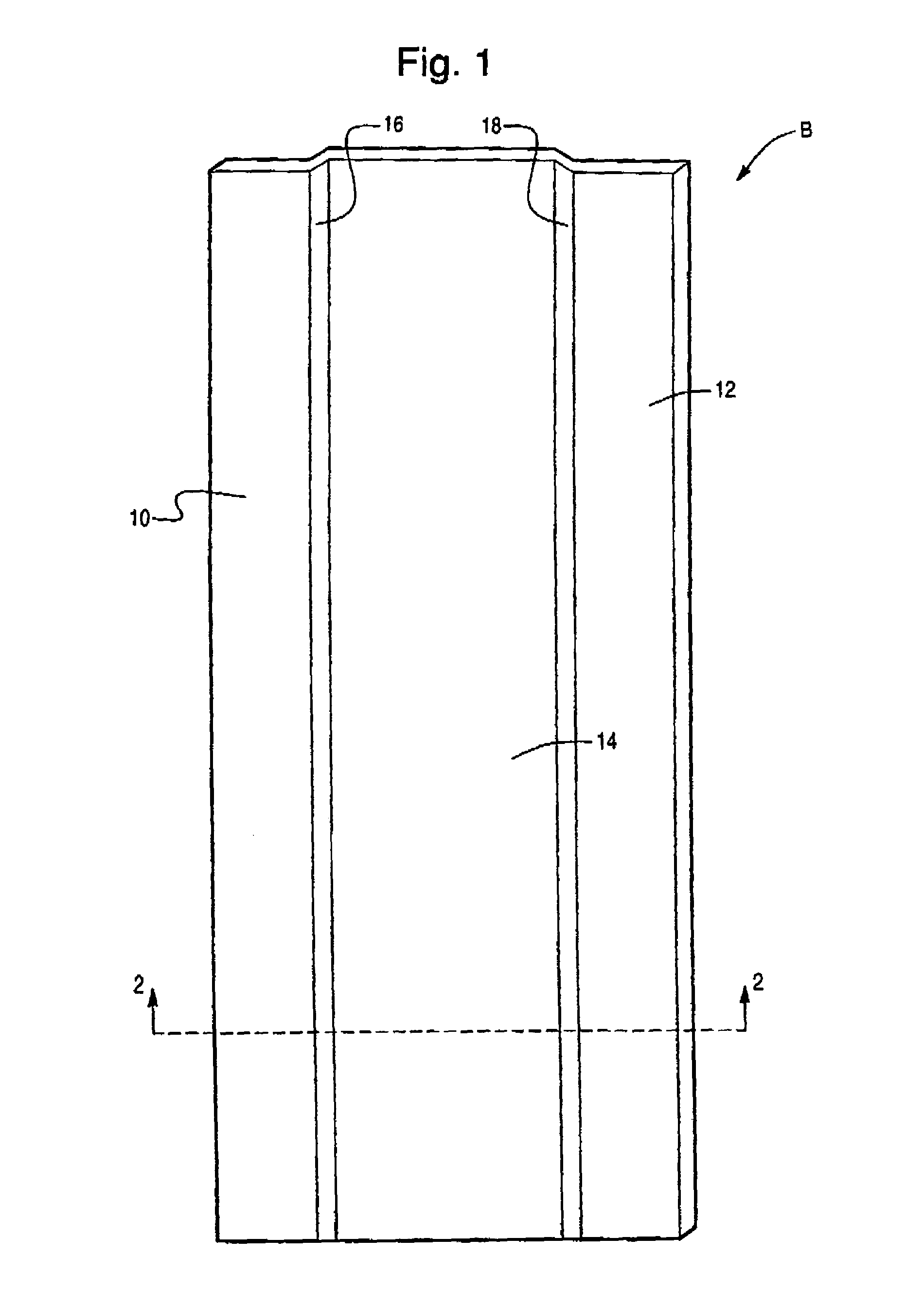

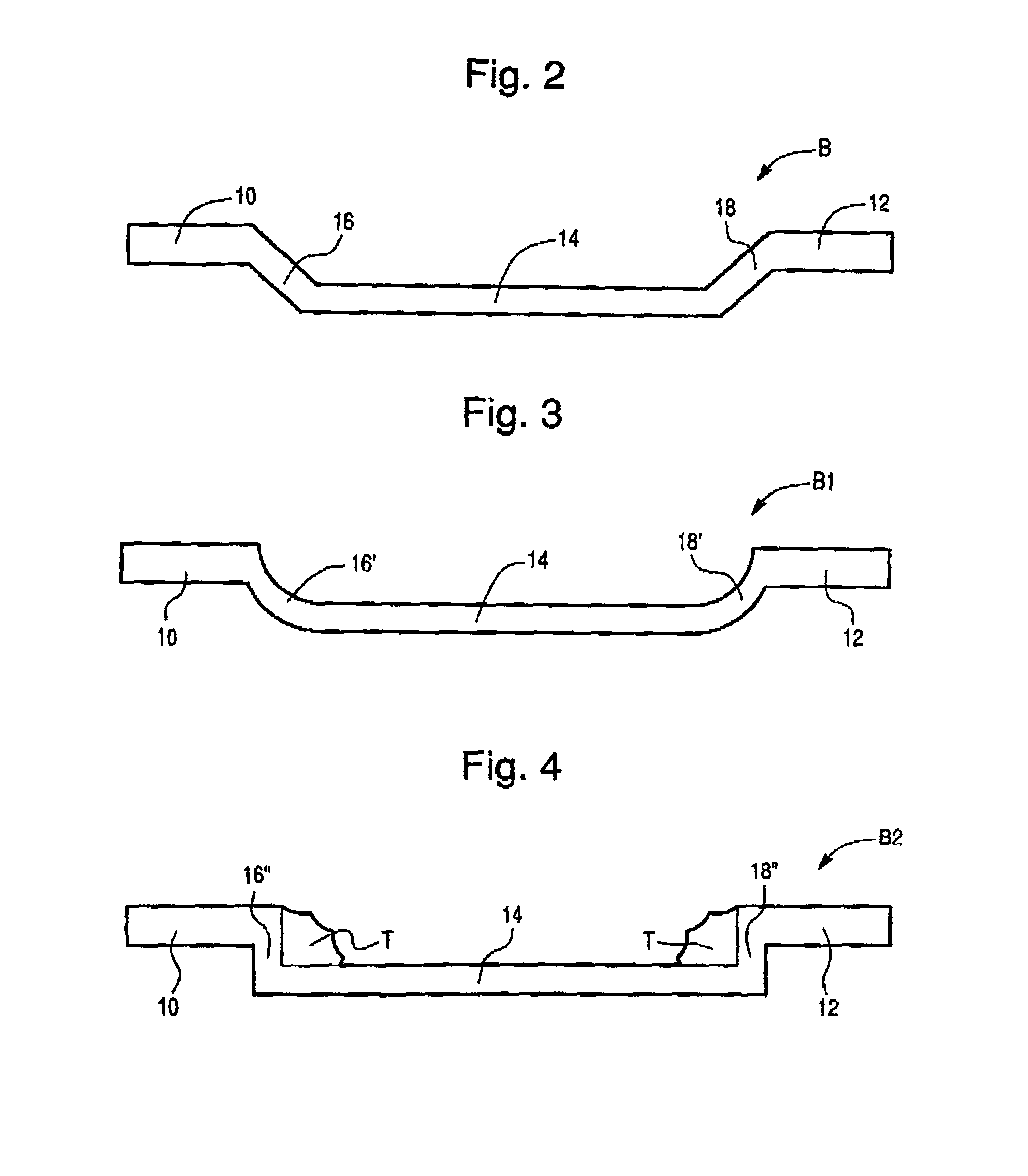

Universal door skin blank and door produced therefrom

InactiveUS7137232B2Building repairsBuilding material handlingEngineeringElectrical and Electronics engineering

A universal door skin blank comprises an exterior side and an interior side for securing to a frame member, first and second molded, spaced stiles, and a flat planar portion disposed between the stiles and lying on a plane spaced from the plane of the stiles. An interface portion is disposed between and contiguous with the stiles and the flat planar portion. The invention also relates to a door having at least one universal door skin blank, with at least two separately formed rails secured to the planar portion of the blank at opposite ends thereof.

Owner:MASONITE CORP

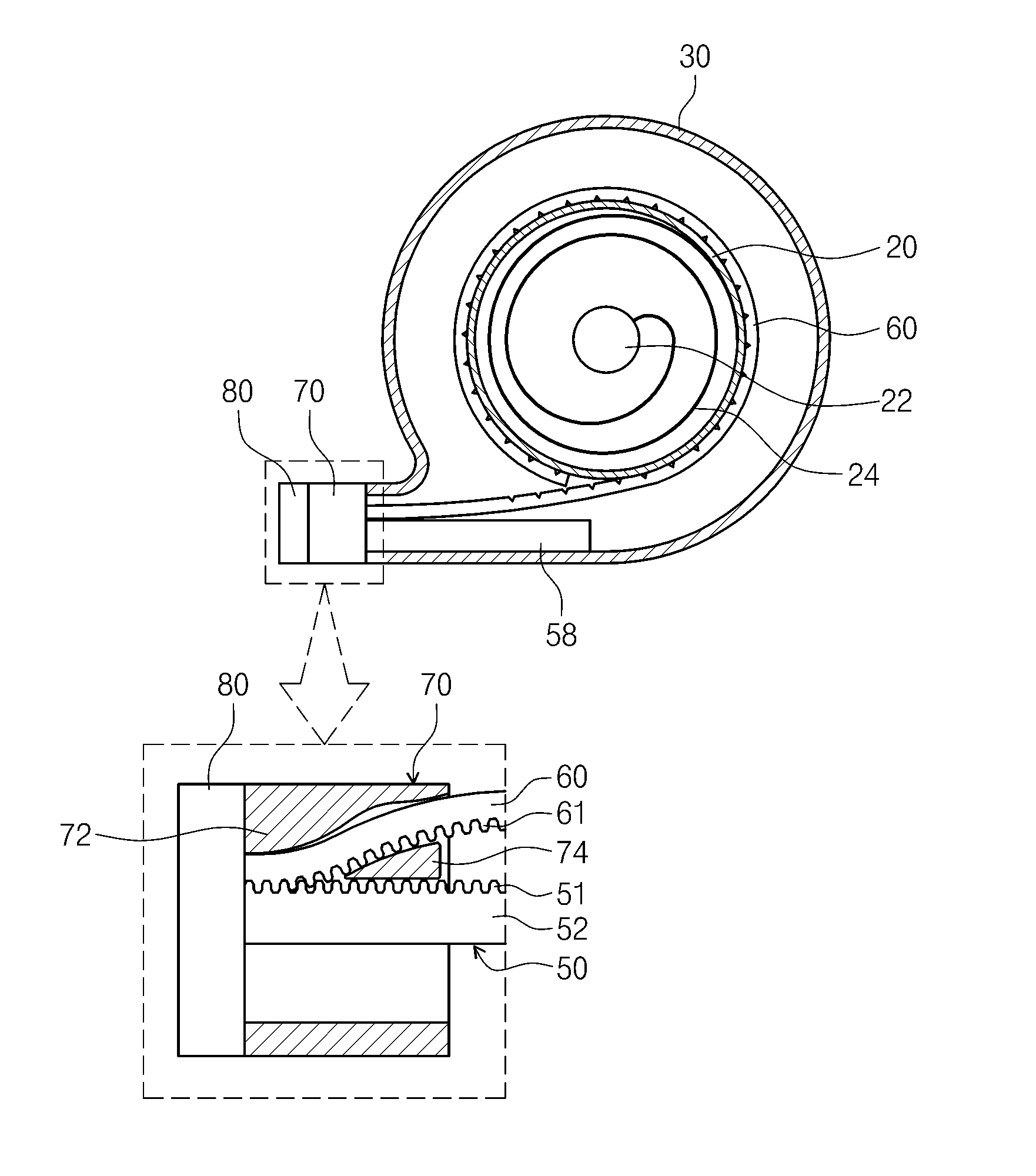

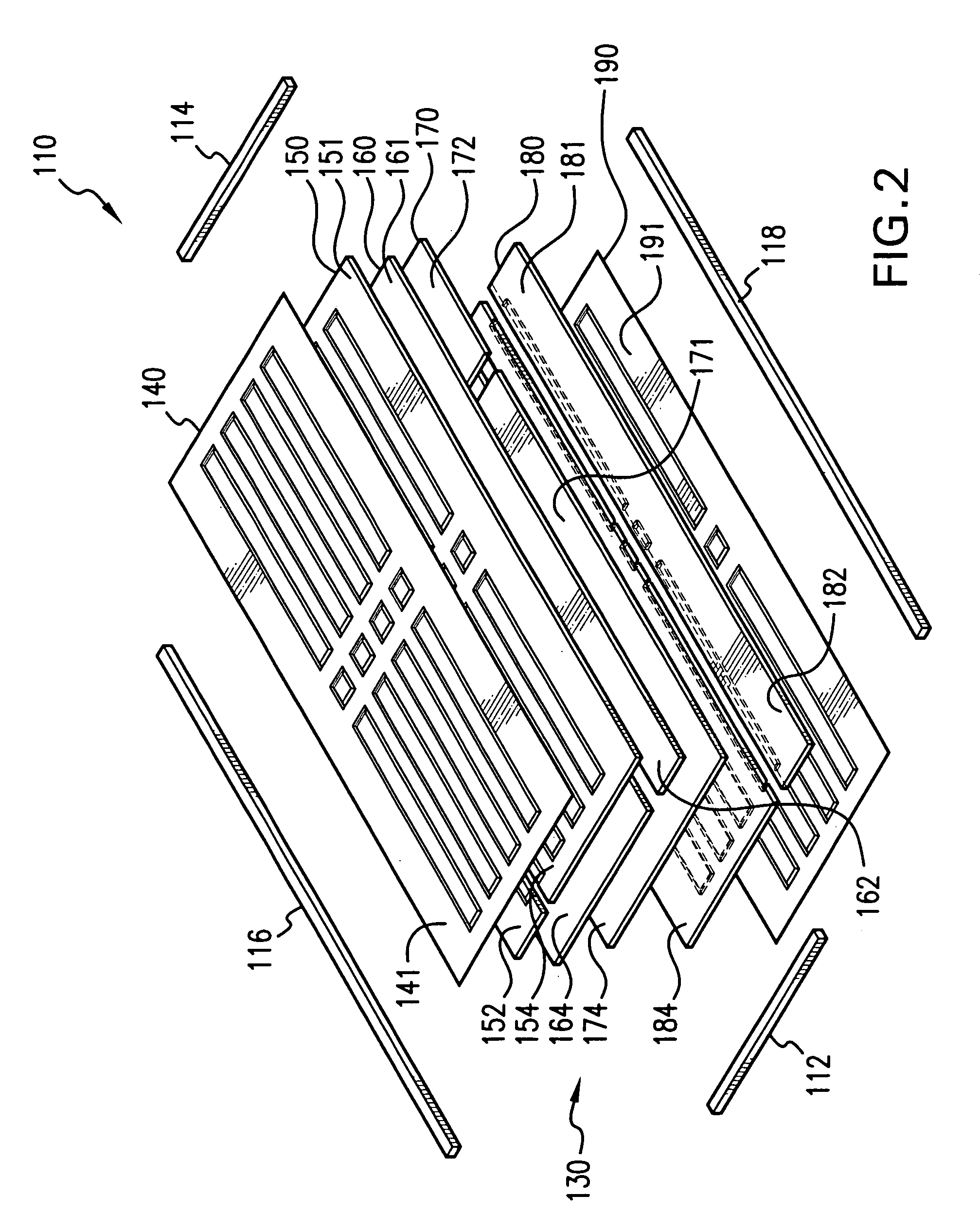

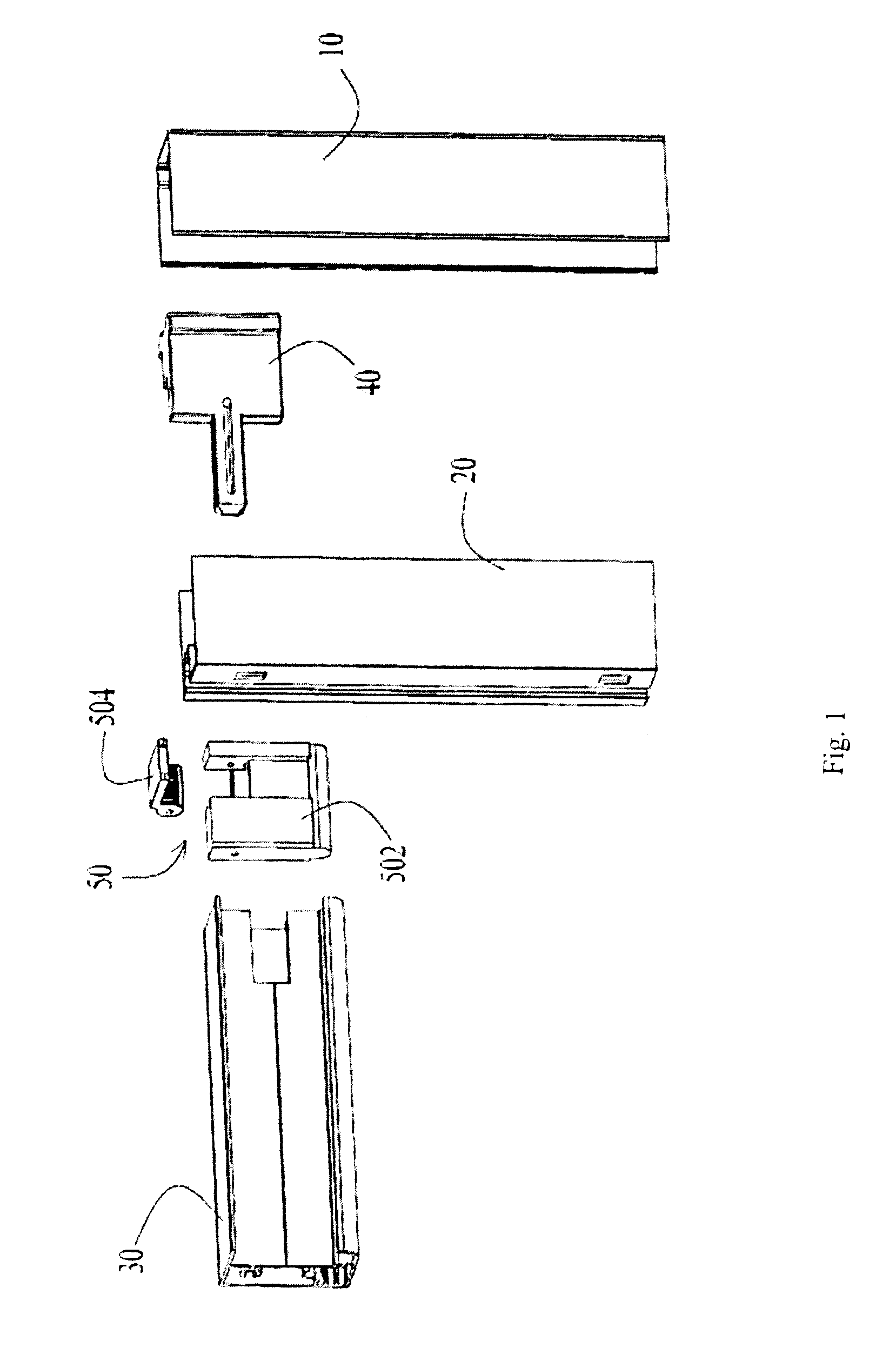

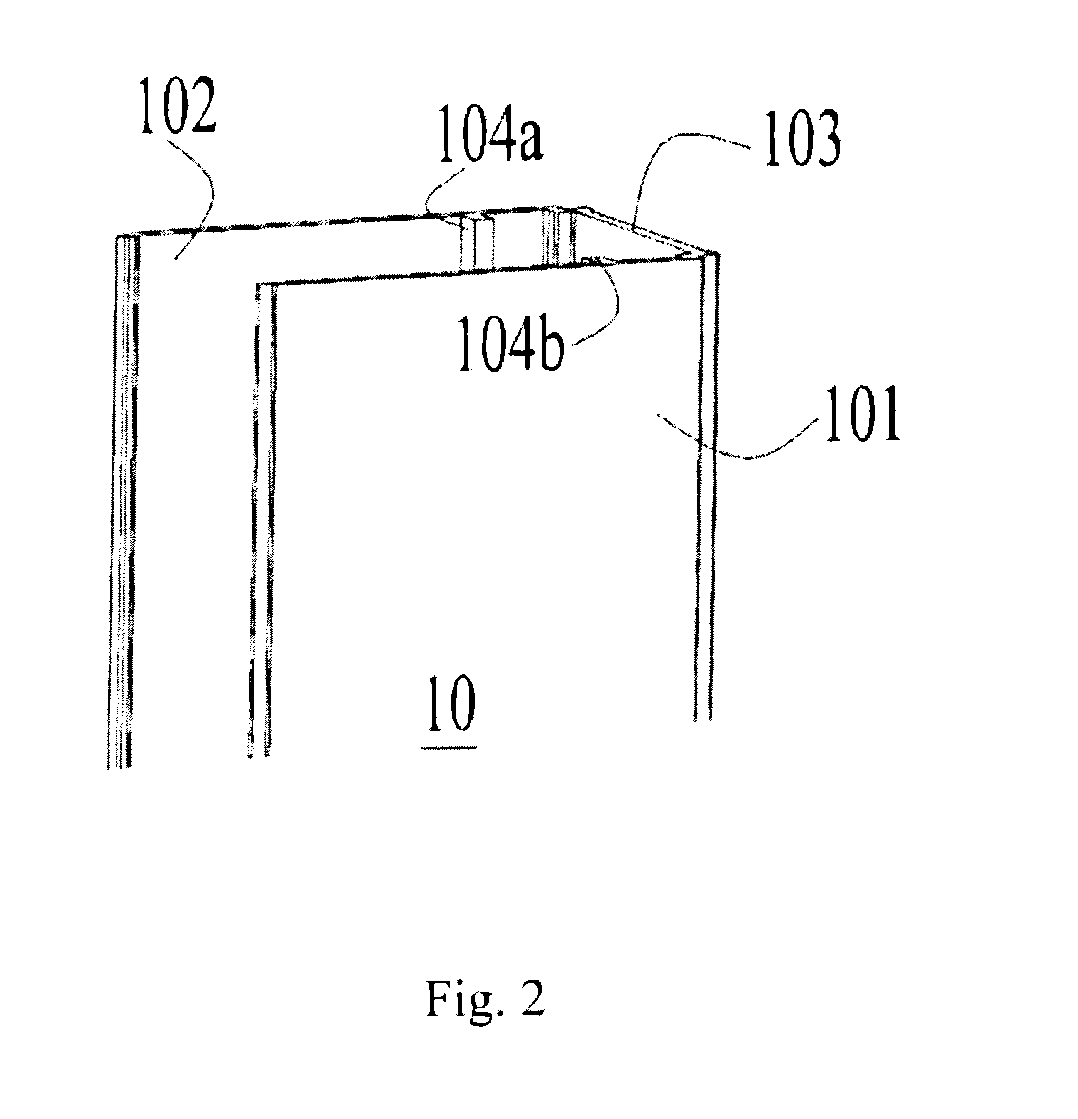

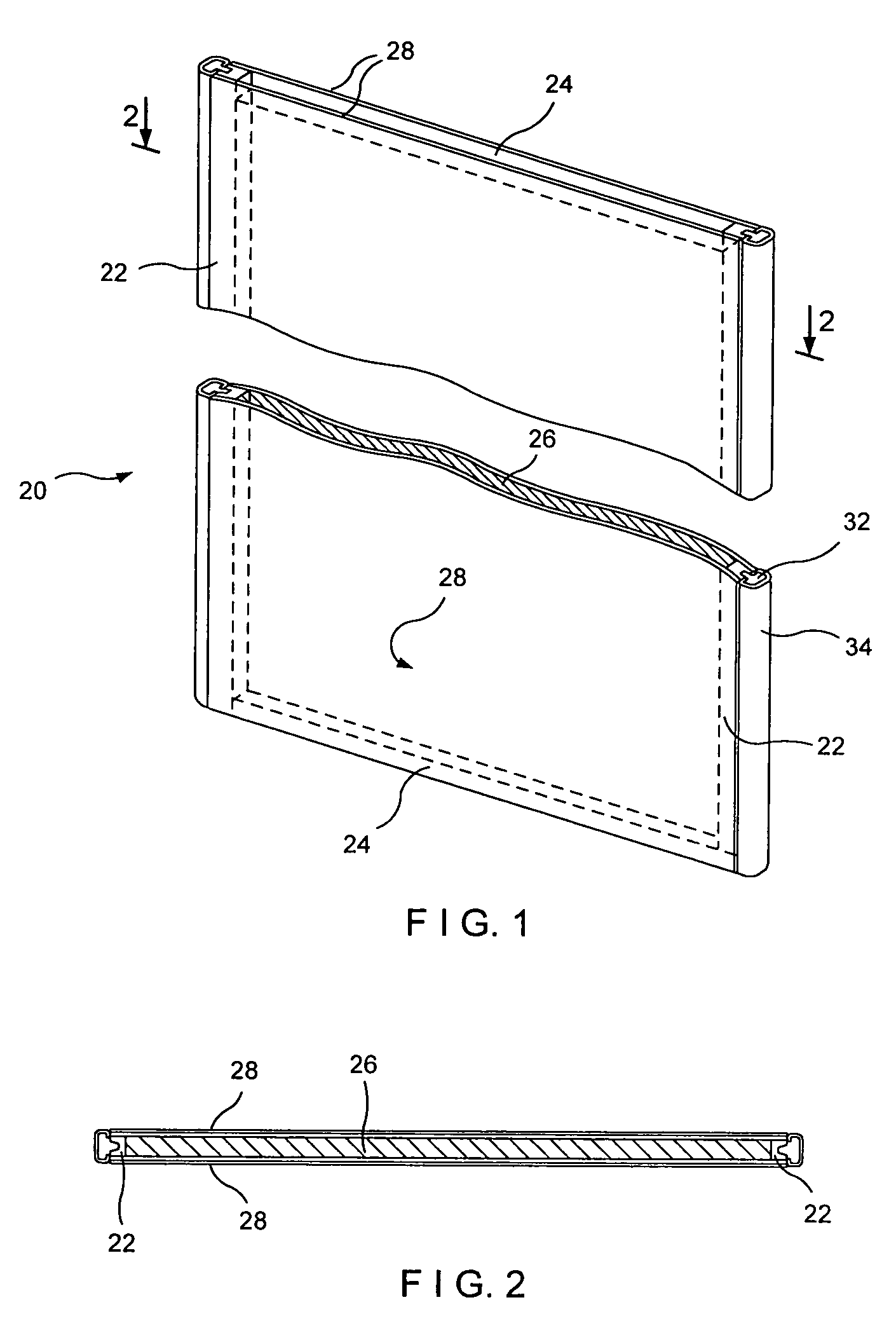

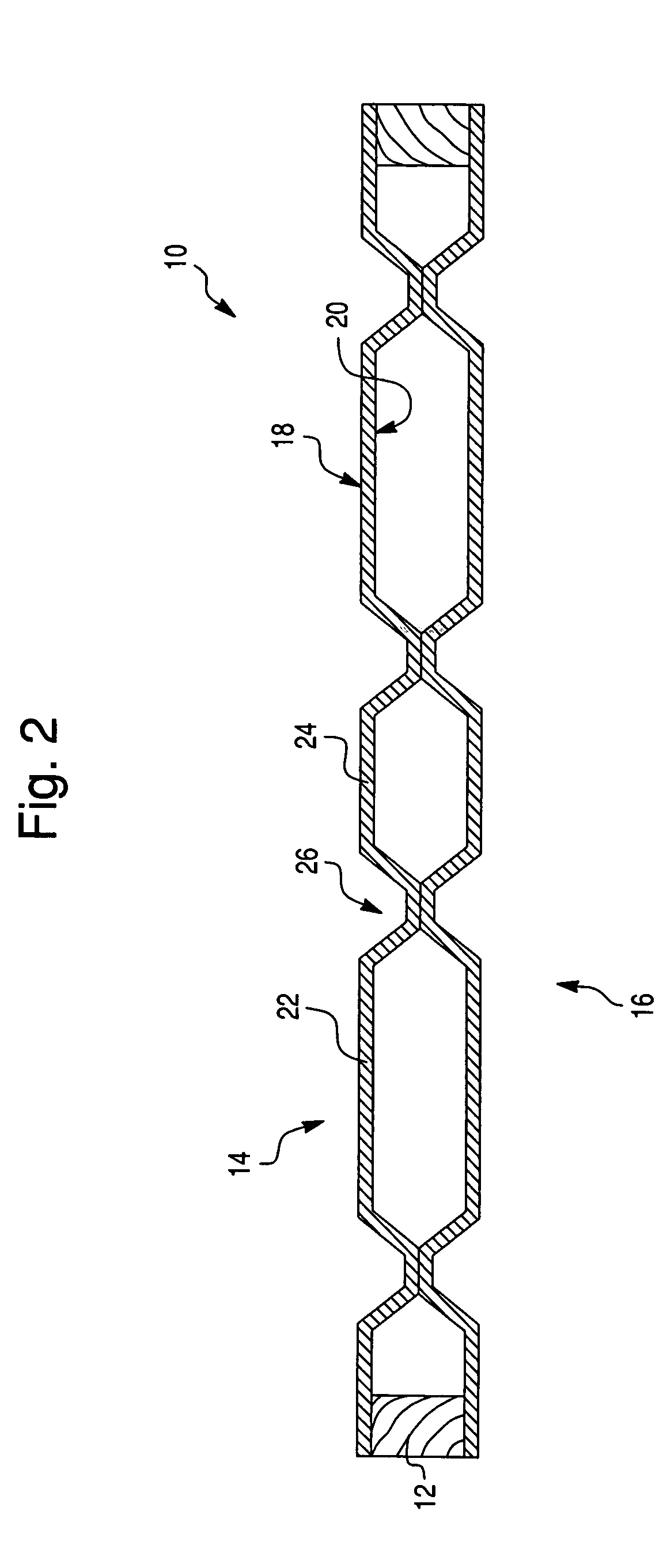

Flexible display apparatus

InactiveUS8516728B2Easily rolled and unrolledScreensShutters/ movable grillesEngineeringFlexible display

Provided is a flexible display apparatus that includes: a flexible display apparatus including: a flexible display panel; a housing including an opening through which the flexible display panel enters and exits the housing; a cylinder disposed within the housing to coil and uncoil the flexible display panel; and a stretcher that selectively extends from the opening to support the flexible display panel, such that the flexible display panel is substantially planar when the flexible display panel is extended outside of the housing.

Owner:SAMSUNG DISPLAY CO LTD

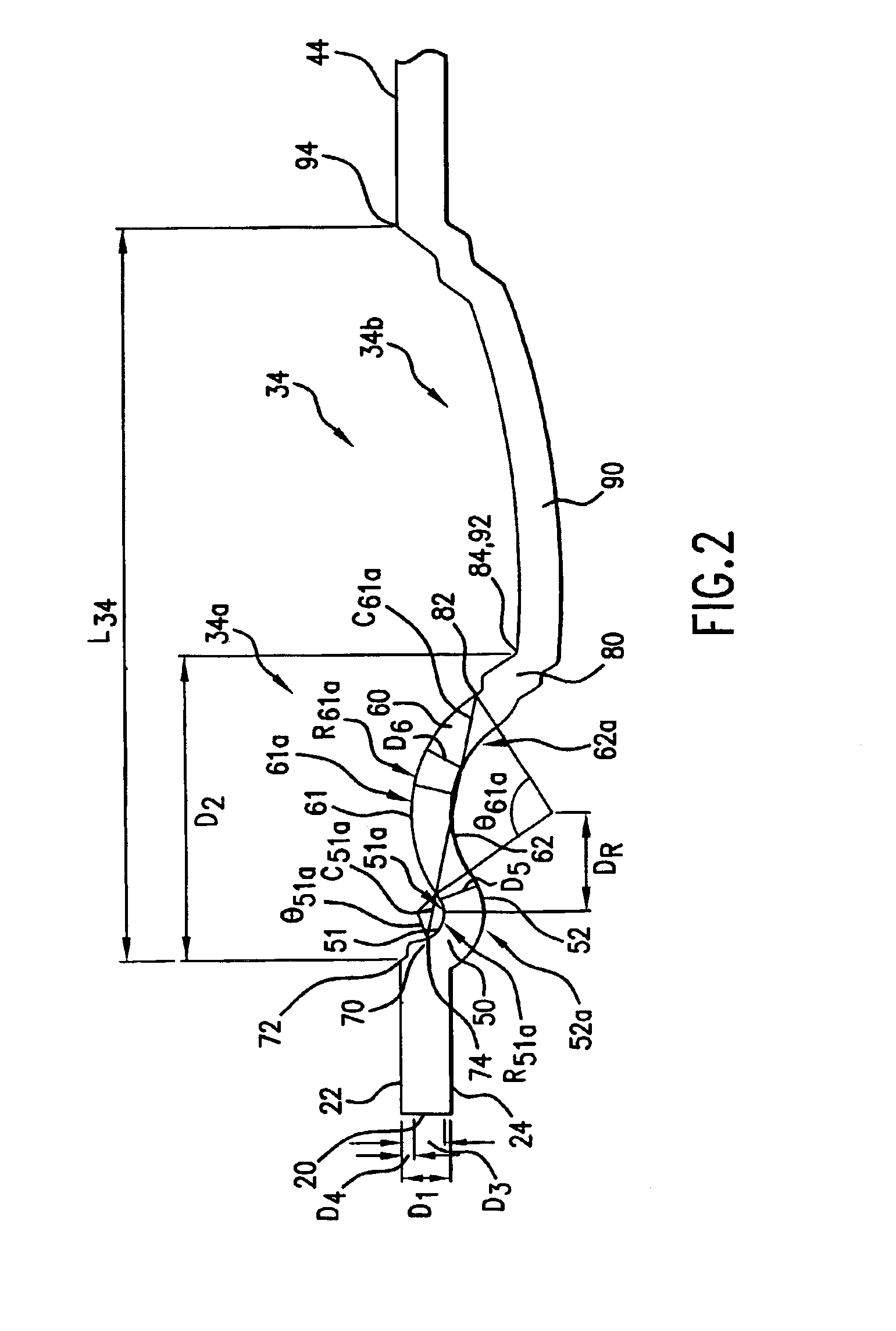

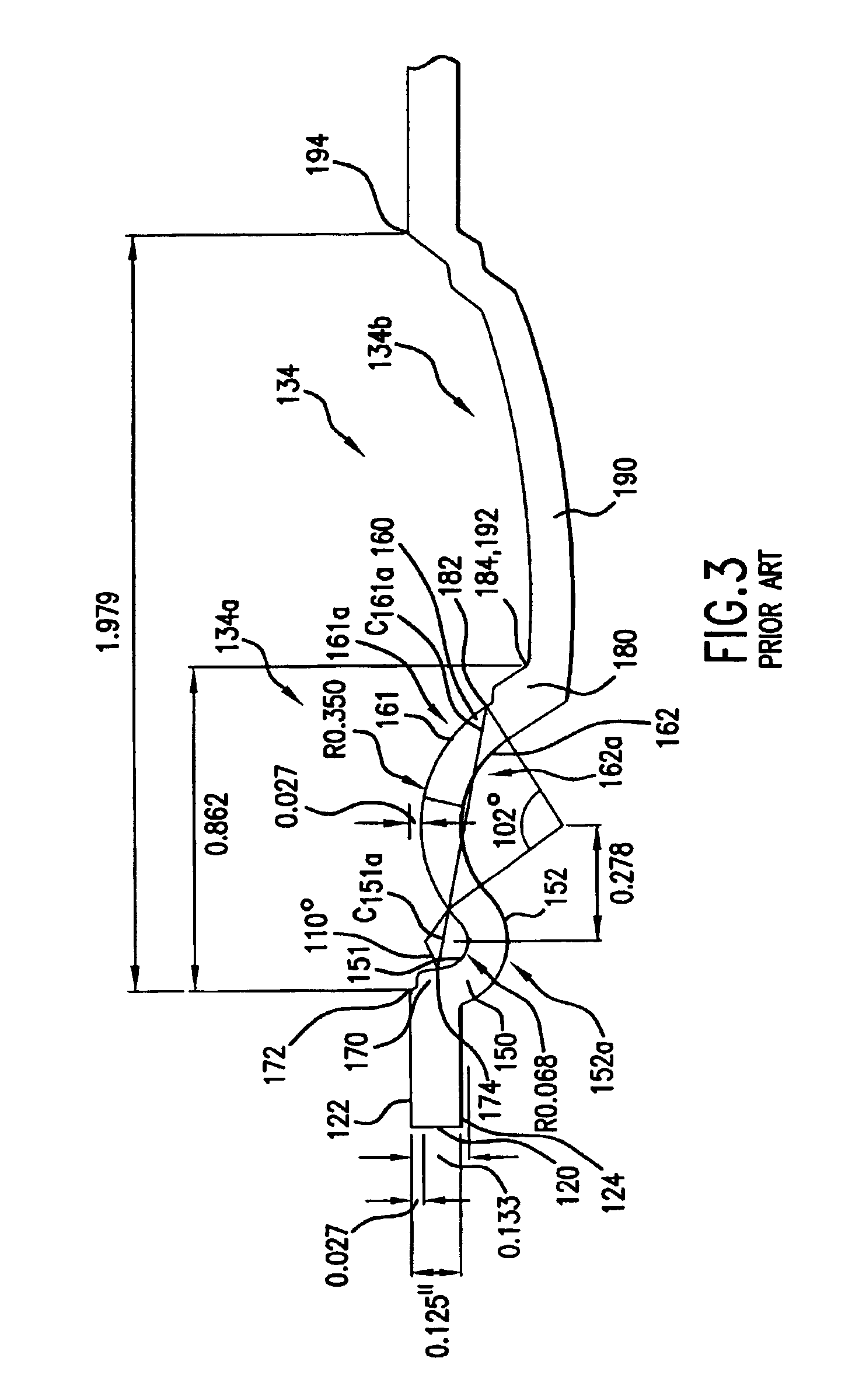

Molded skin with curvature

InactiveUS7022414B2Density is accurateUniform appearanceCeramic shaping apparatusWood layered productsEngineeringSheet material

Molded skins and methods of making molded skins are disclosed. An embodiment of a skin includes a sheet having first and second surfaces, a first arcuate portion integral with the sheet, and a second arcuate portion integral with the sheet and adjacent to the first arcuate portion. The sheet includes a cellulosic material. The first arcuate portion includes a first surface and a second surface, each having an arc. The second arcuate portion includes a first surface and a second surface, each having an arc. An angle forming the arc of the first surface of the first arcuate portion is greater than 110 degrees and an angle forming the arc of the first surface of the second arcuate portion is less than 102 degrees.

Owner:JELD-WEN

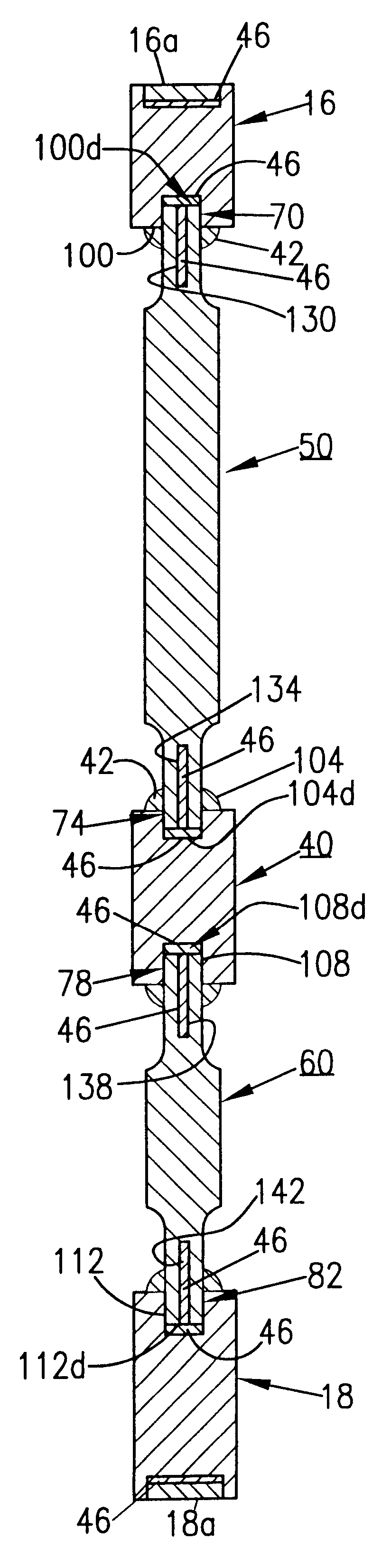

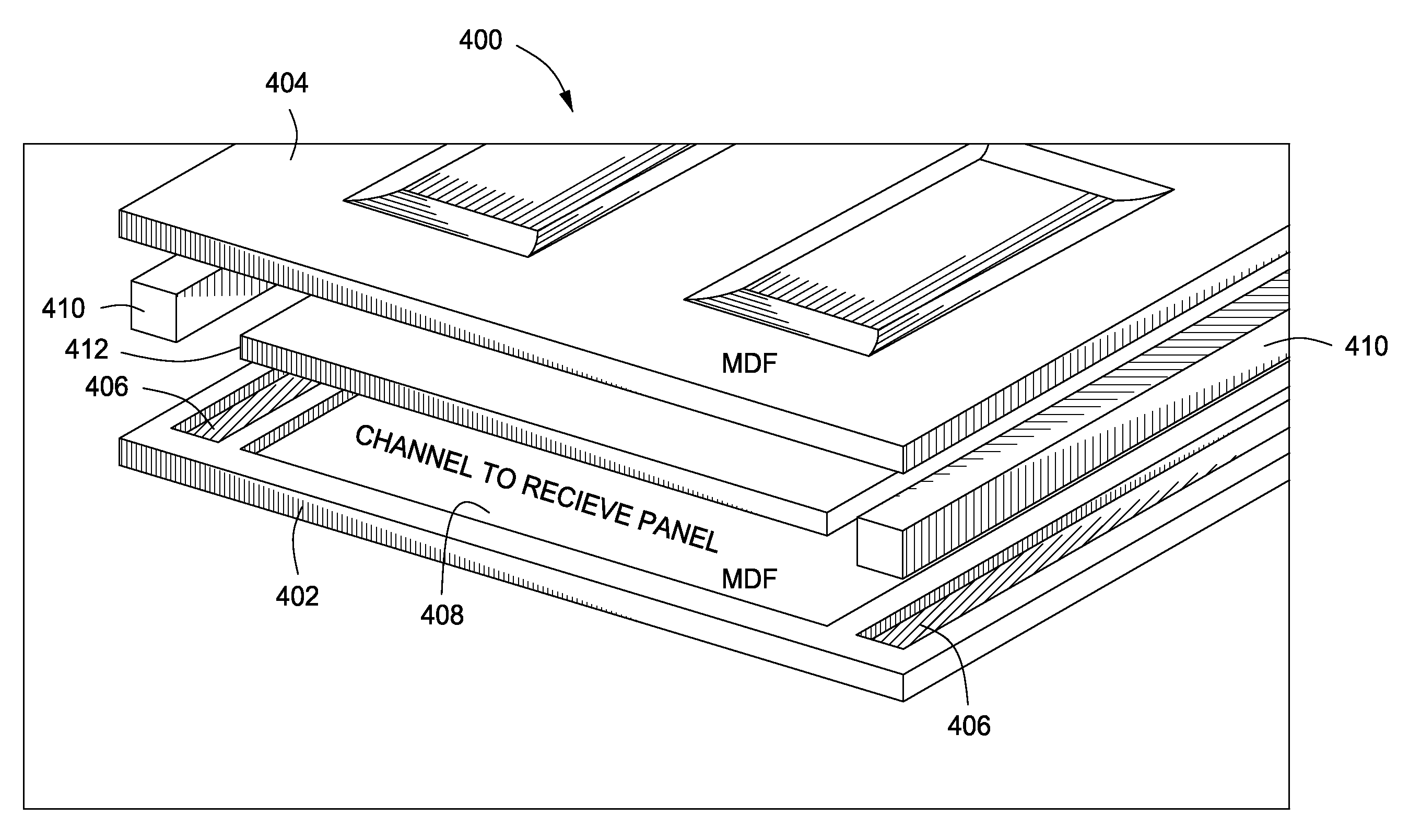

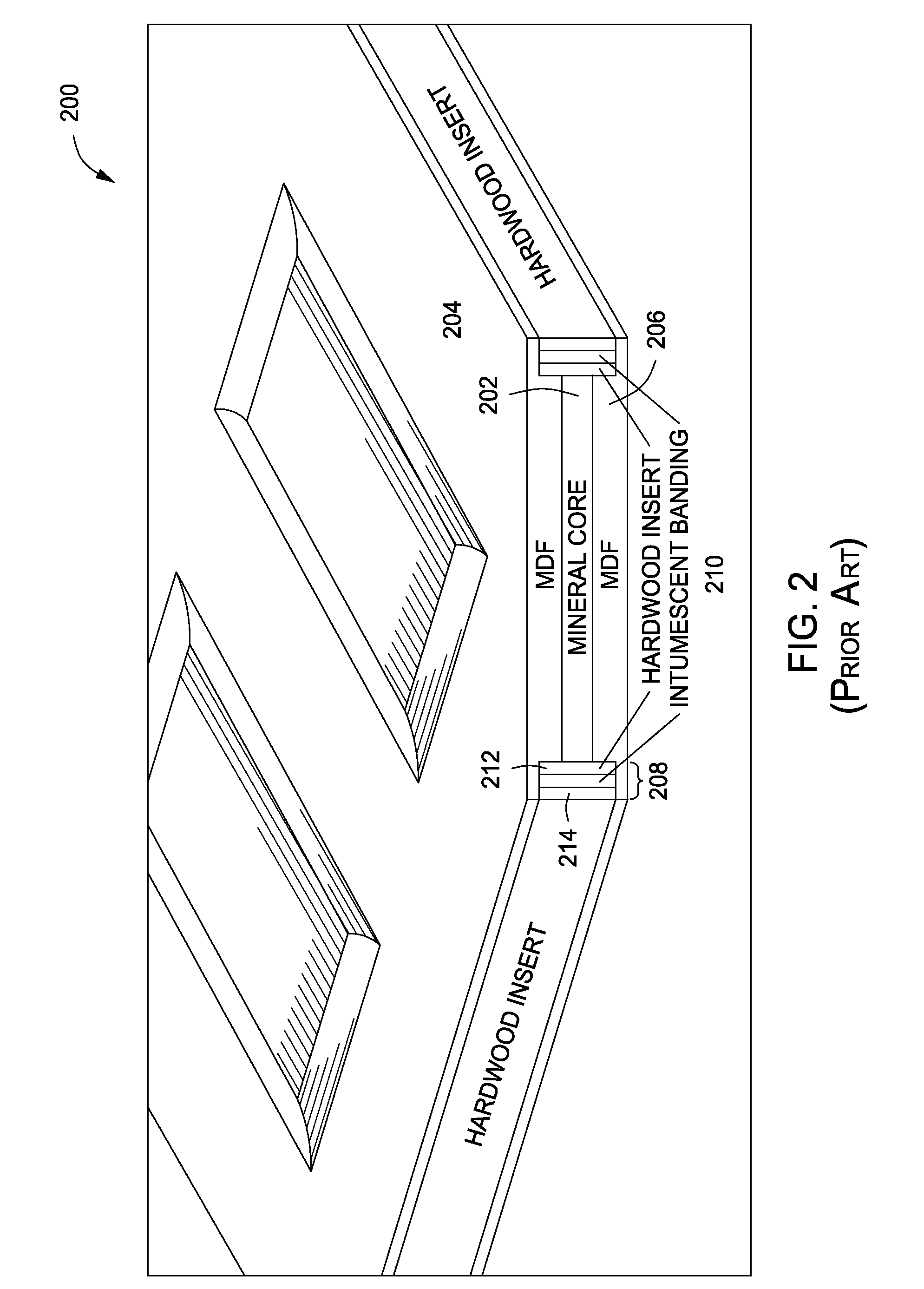

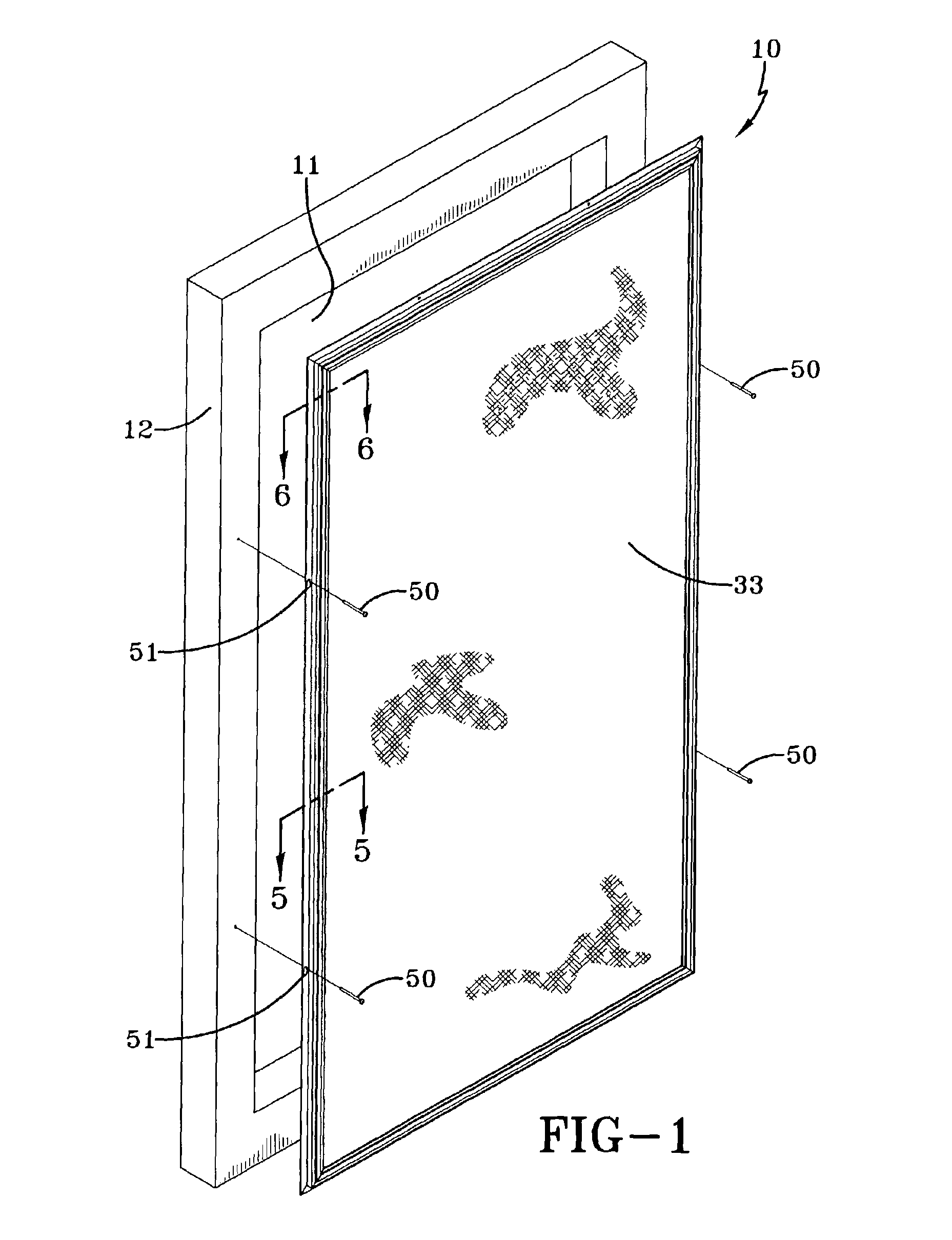

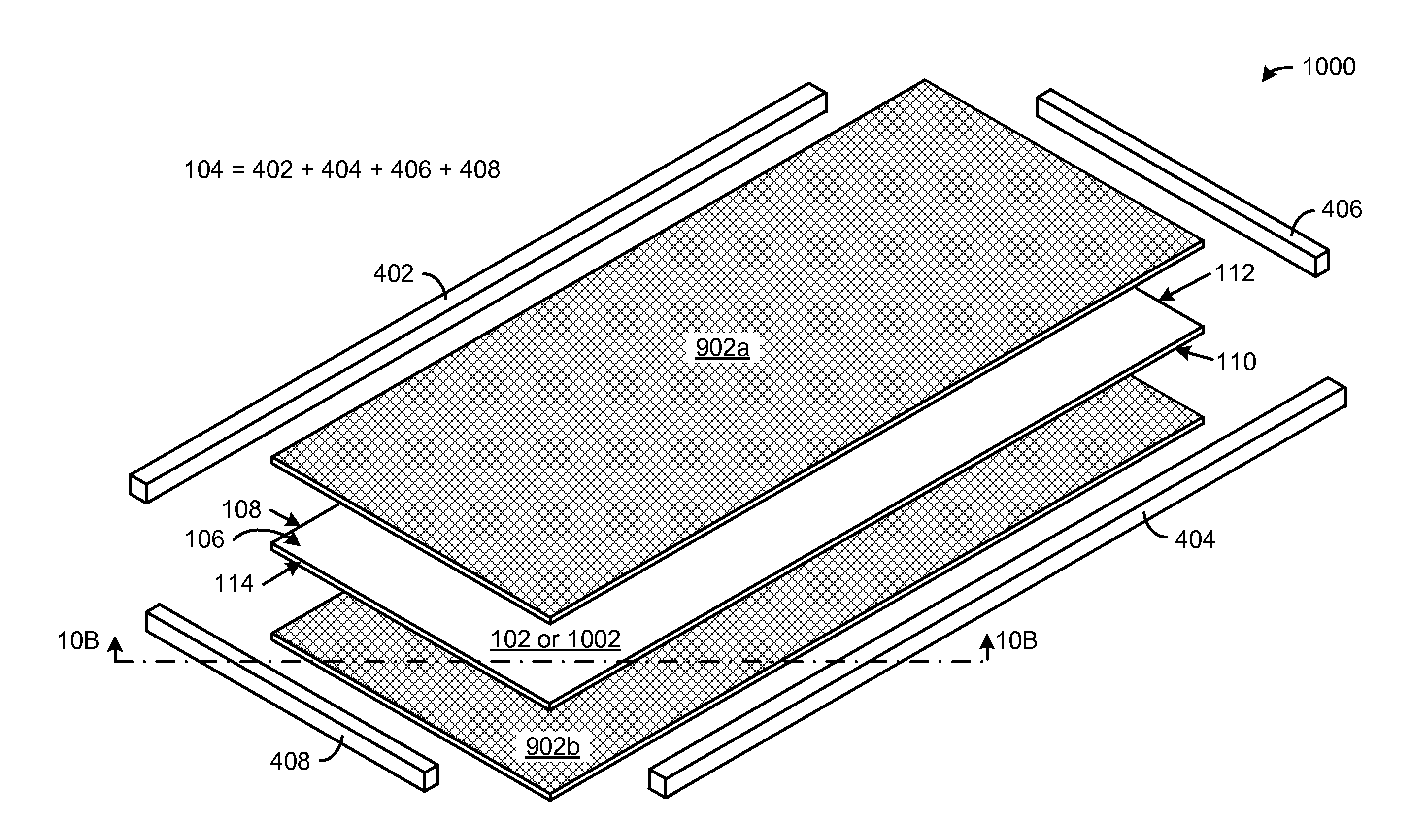

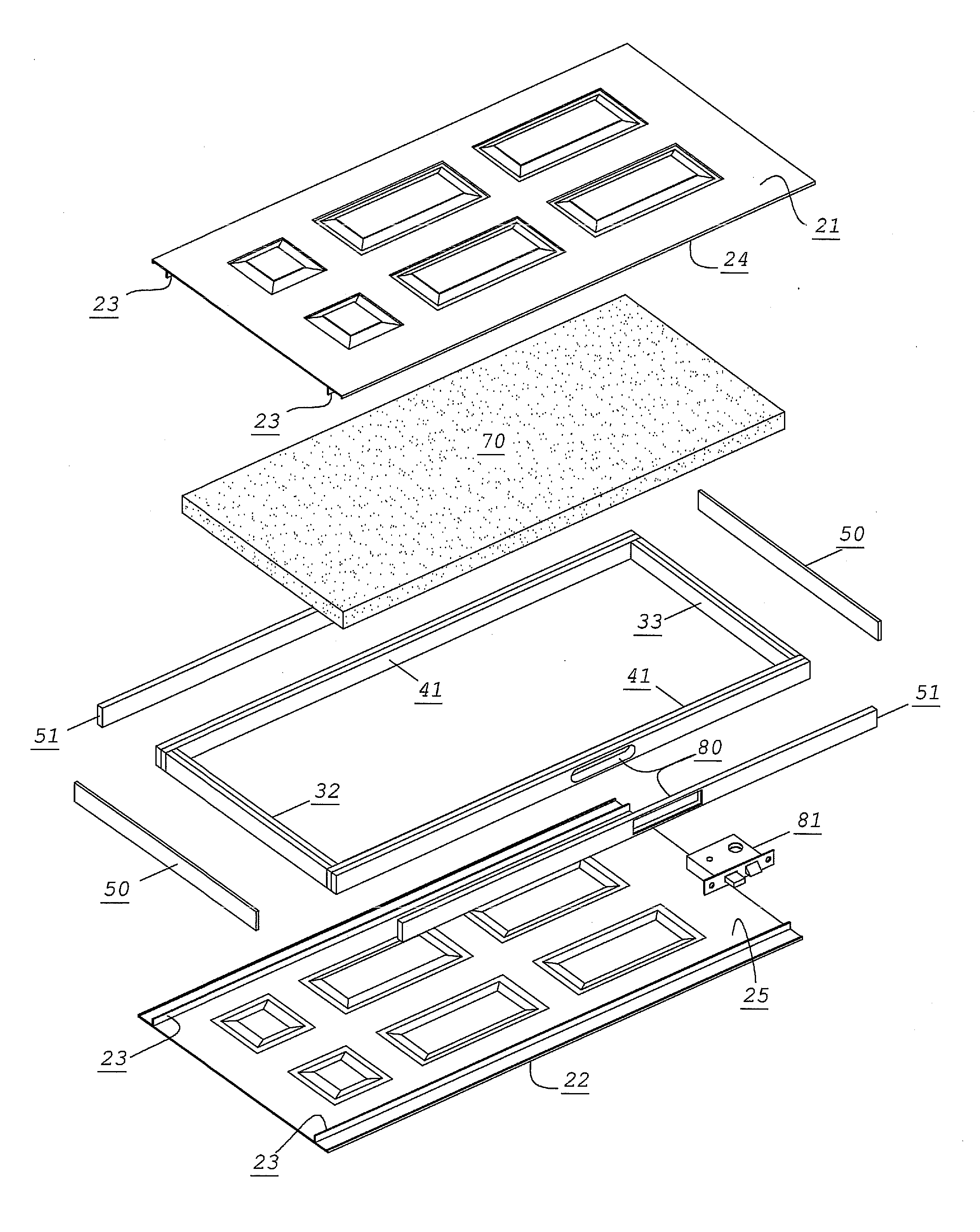

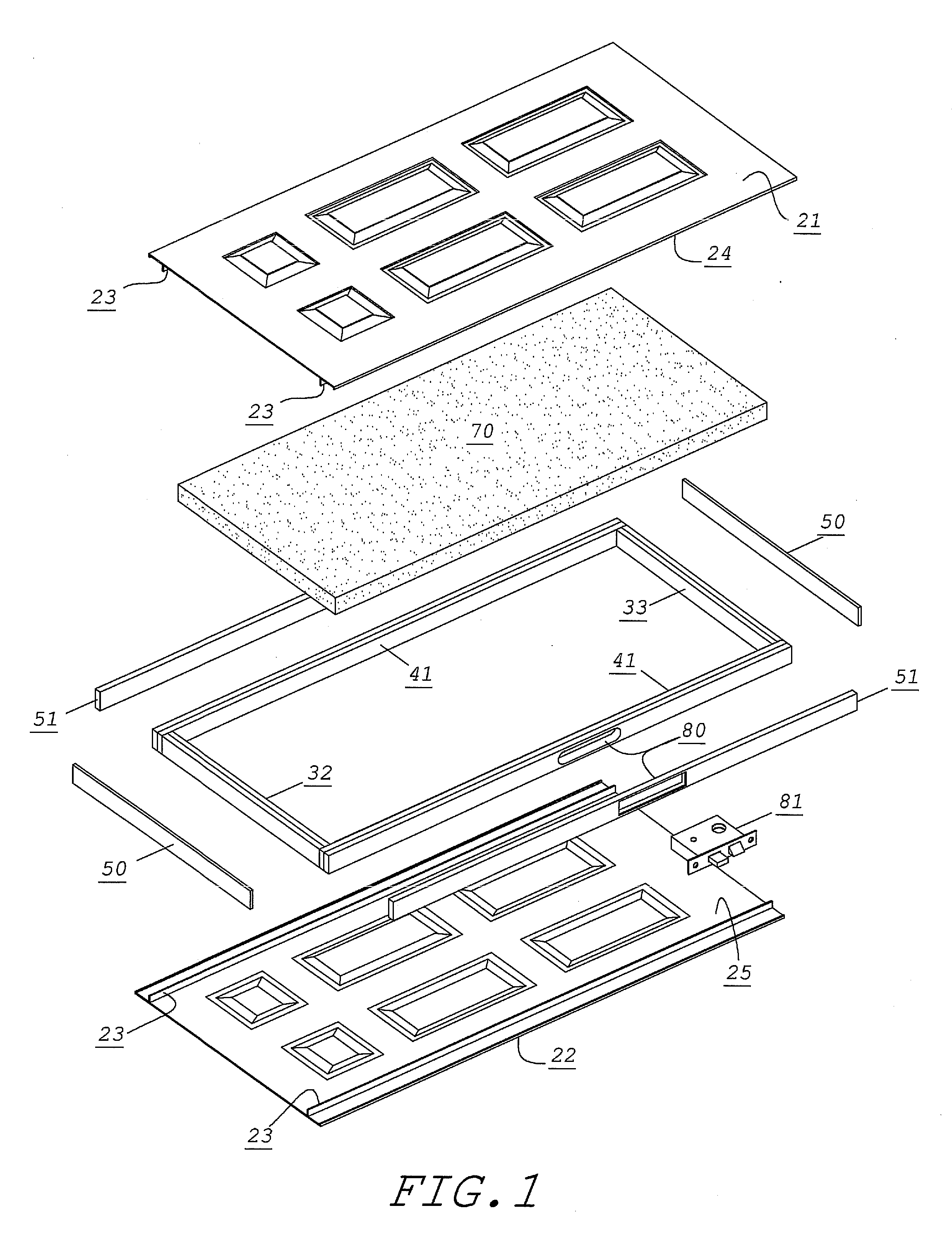

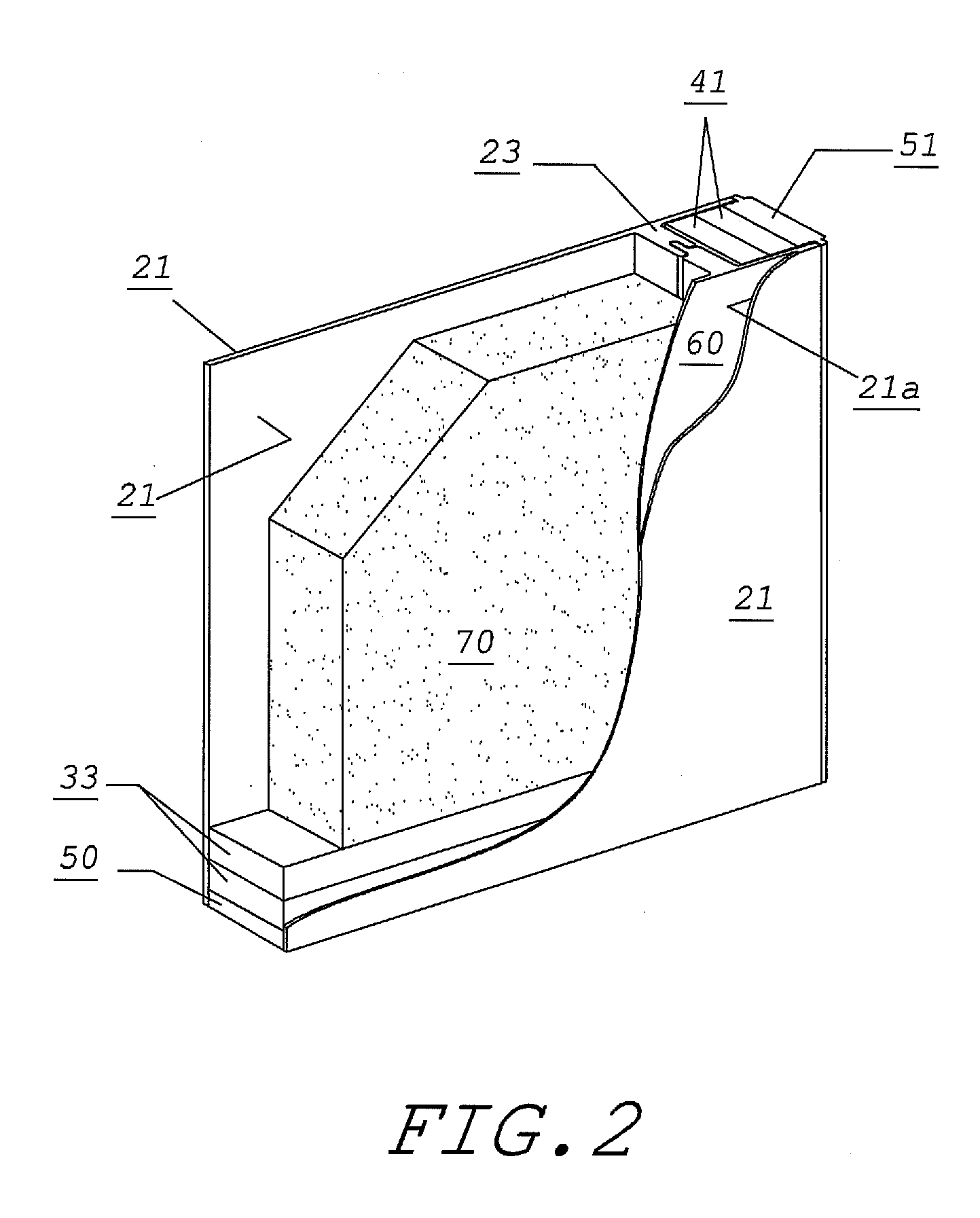

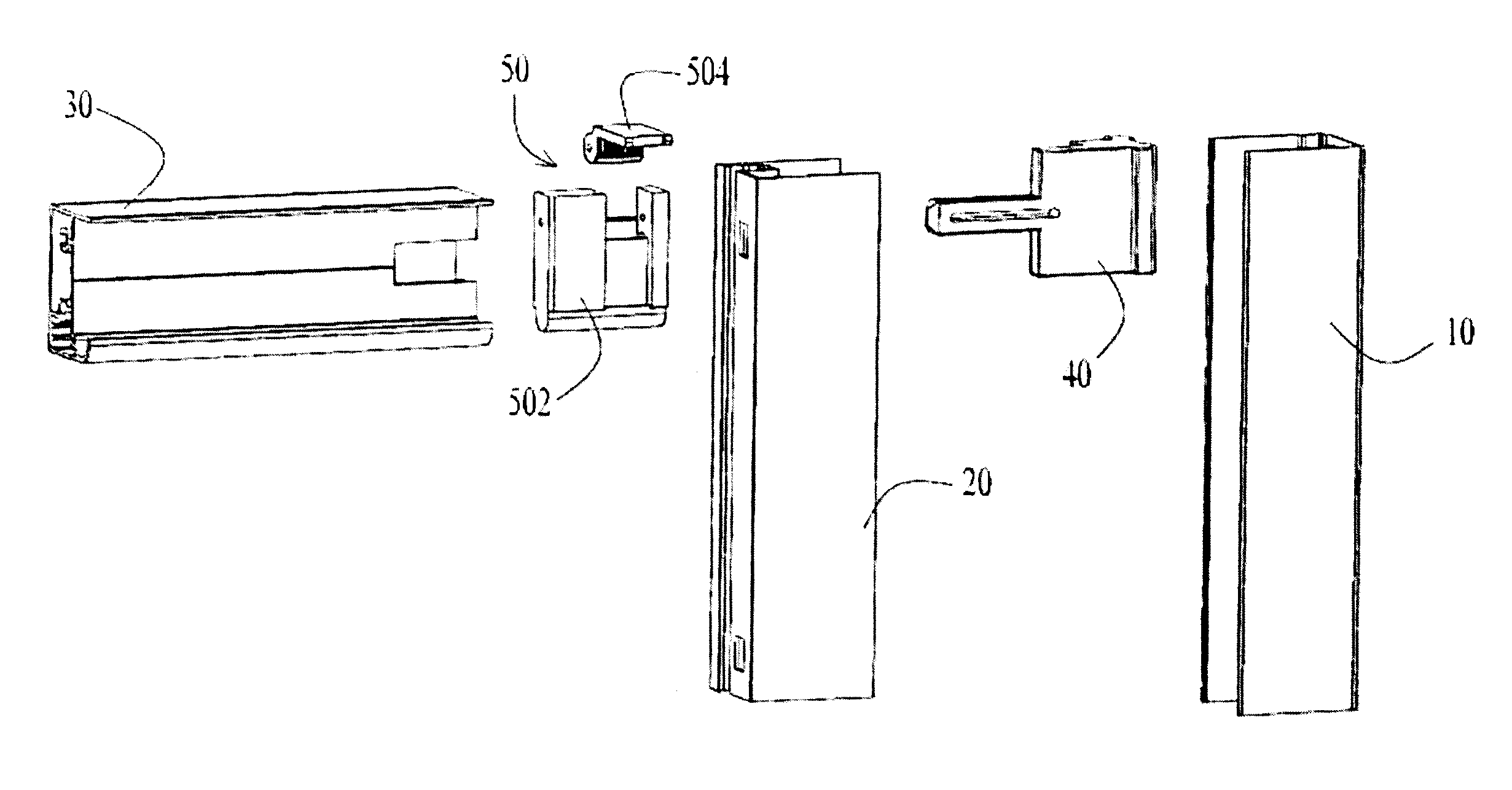

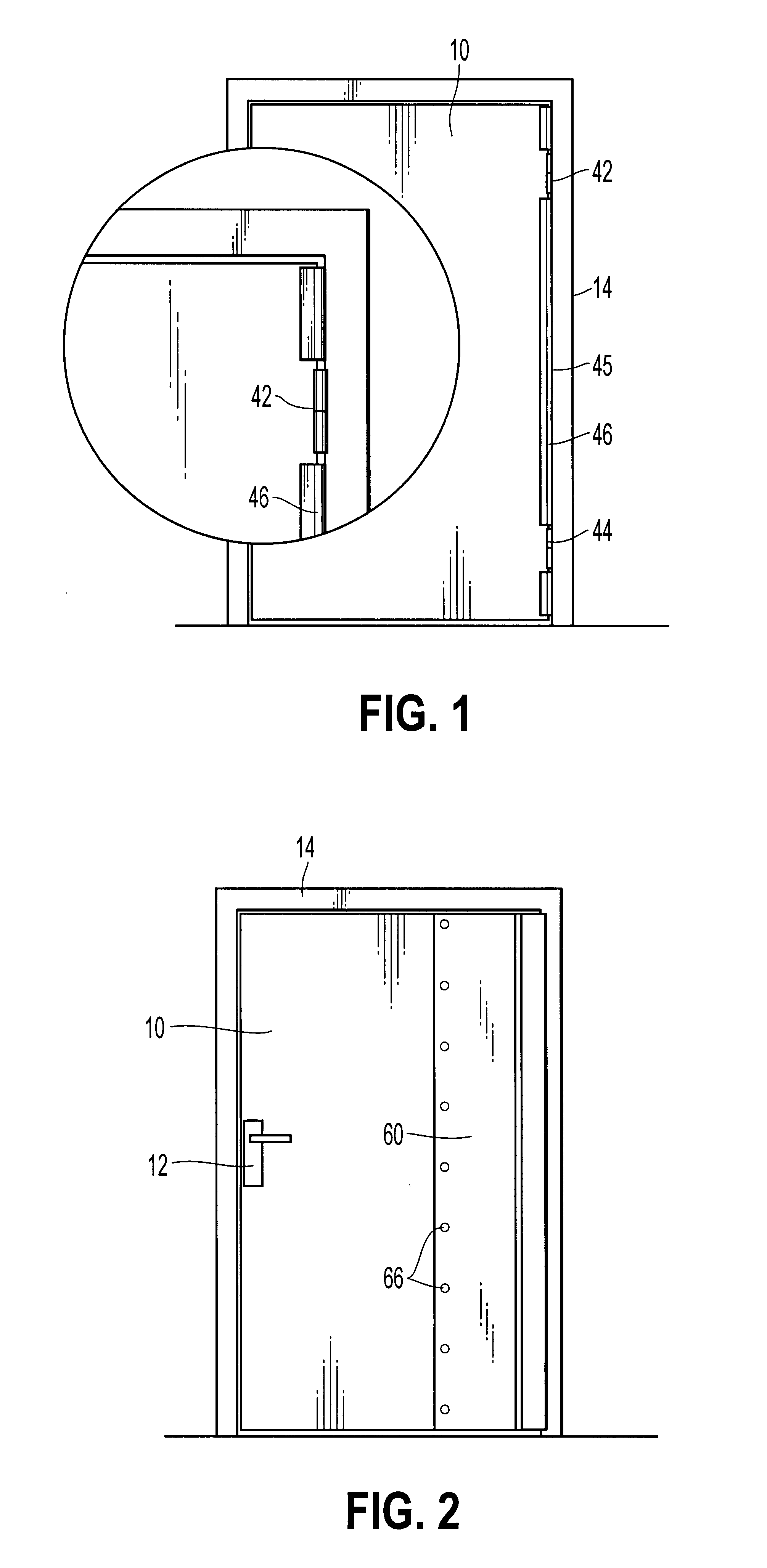

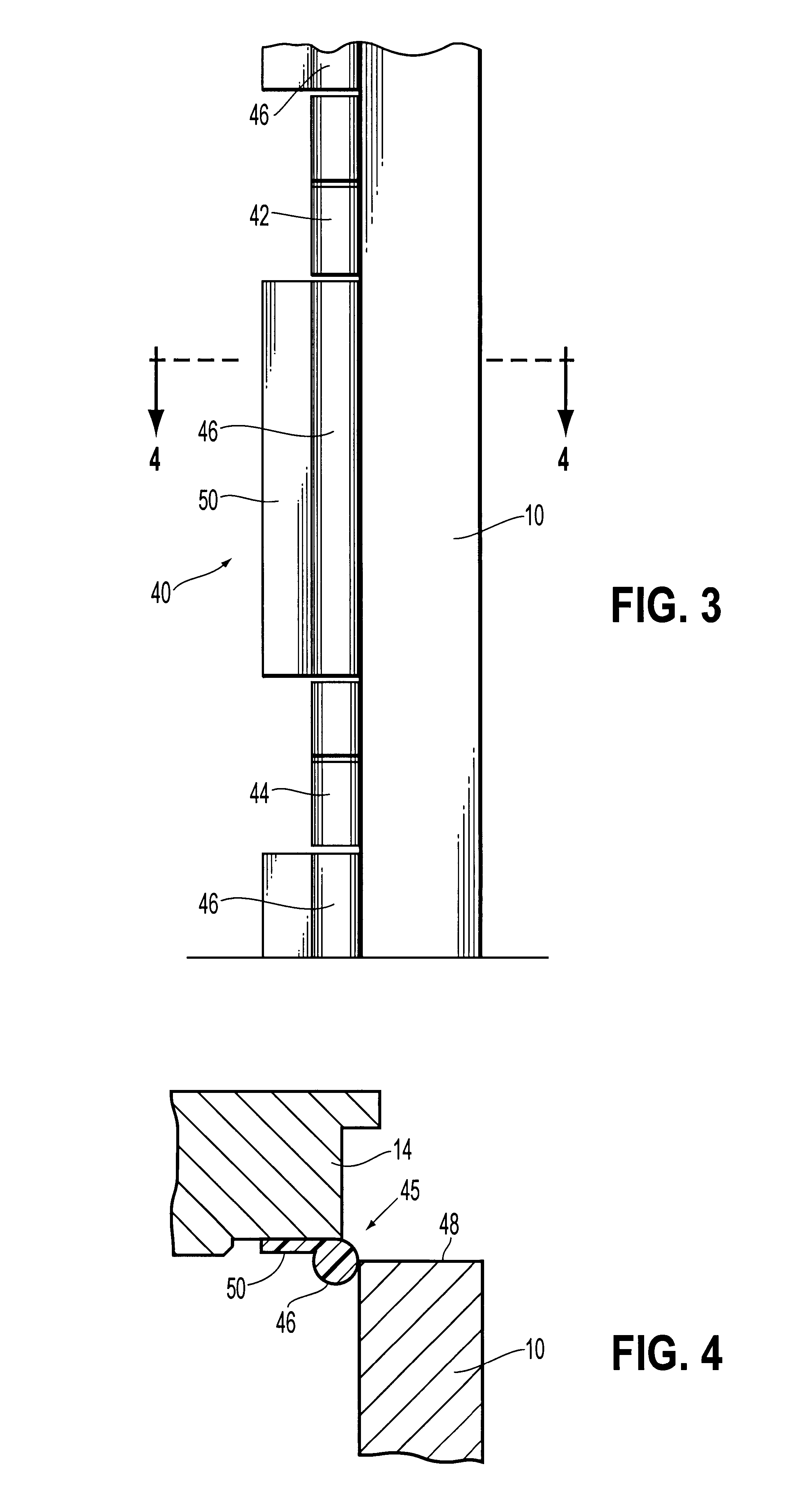

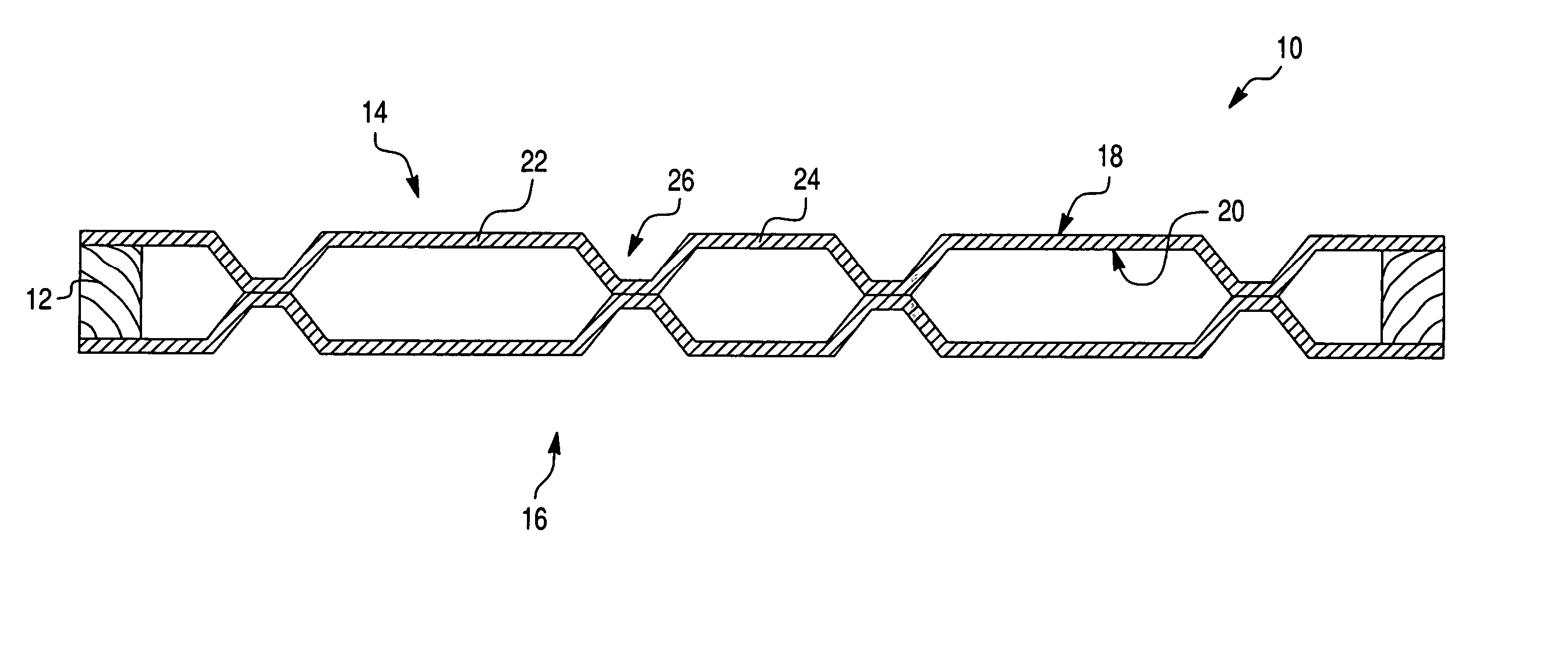

System, Method and Apparatus for Producing Fire Rated Doors

ActiveUS20070193220A1High strengthRaise the gradeFireproof doorsDoor leavesEngineeringUltimate tensile strength

The present invention provides a system, method and apparatus for producing fire rated doors having added strength, better finishing and low cost manufacturing flexibility. The fire rated doors are made from two panels “sandwiched” together. An optional interior layer (e.g., fire resistant material, lead sheeting, steel or Kevlar) can be added between the door panels for various purposes. Splines, stiles or sticks are inserted in longitudinal channels in the door panels to provide assistance in aligning the door panels and greater hardware holding strength. An intumescent banding material concealed by a banding material around the perimeter of the door seals the door within its frame during a fire. The door design and the automated manufacturing process provide greater design choice, reduced cost and faster fabrication.

Owner:POLYMER WOOD TECH

Multi-layered fire door and method for making the same

InactiveUS7185468B2Reduce complexityLow costFireproof doorsSynthetic resin layered productsPorous layerEngineering

A door has a core that includes a porous layer having a thickness and two opposing major surfaces. In one construction, the core also includes three fire-retardant layers, and two of the fire-retardant layers are separated by the porous layer. The porous layer and the fire-retardant layers are coupled together. Other constructions include one or more fire-retardant layers in balanced or unbalanced placement around the porous layer.

Owner:JELD-WEN

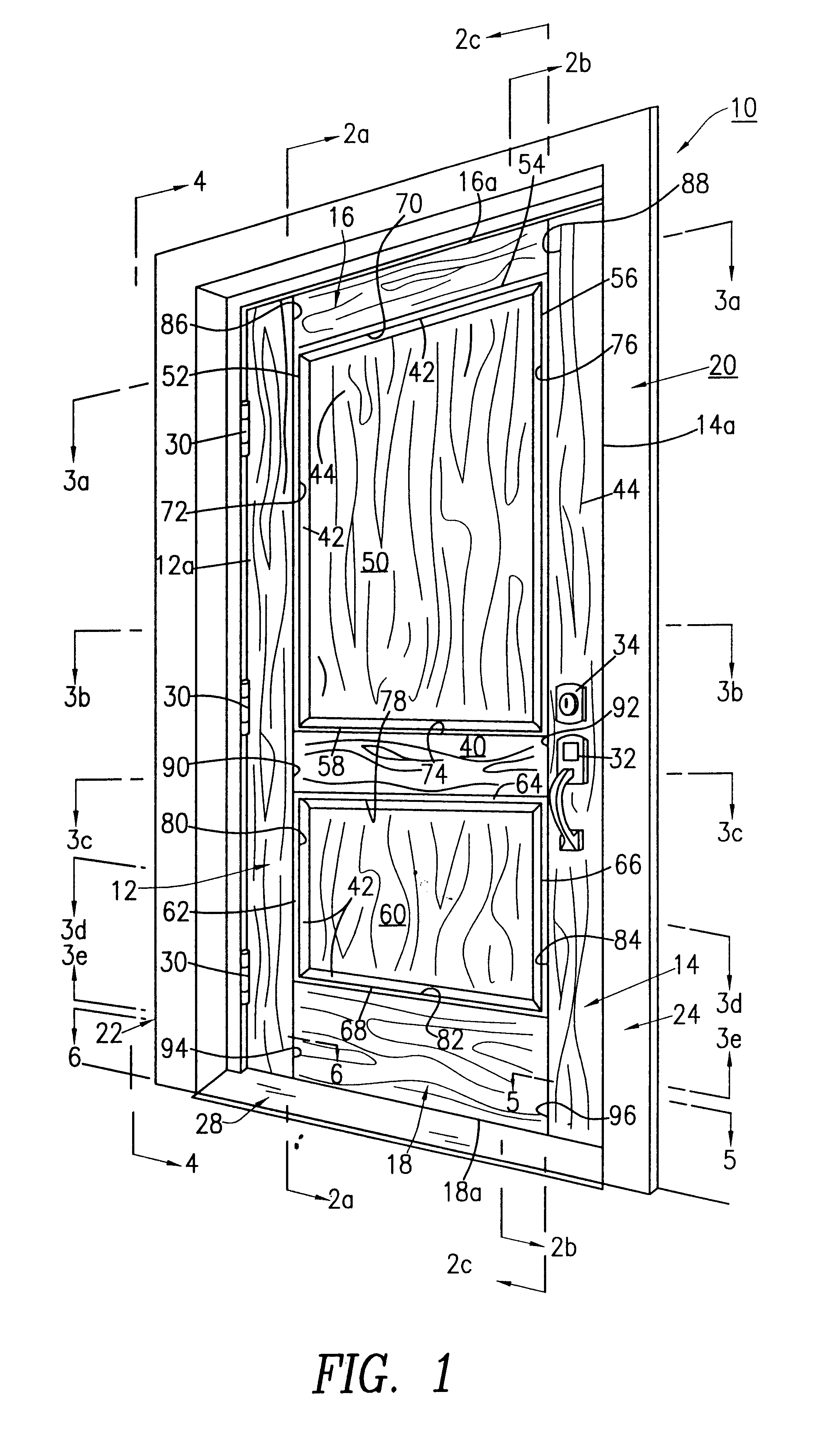

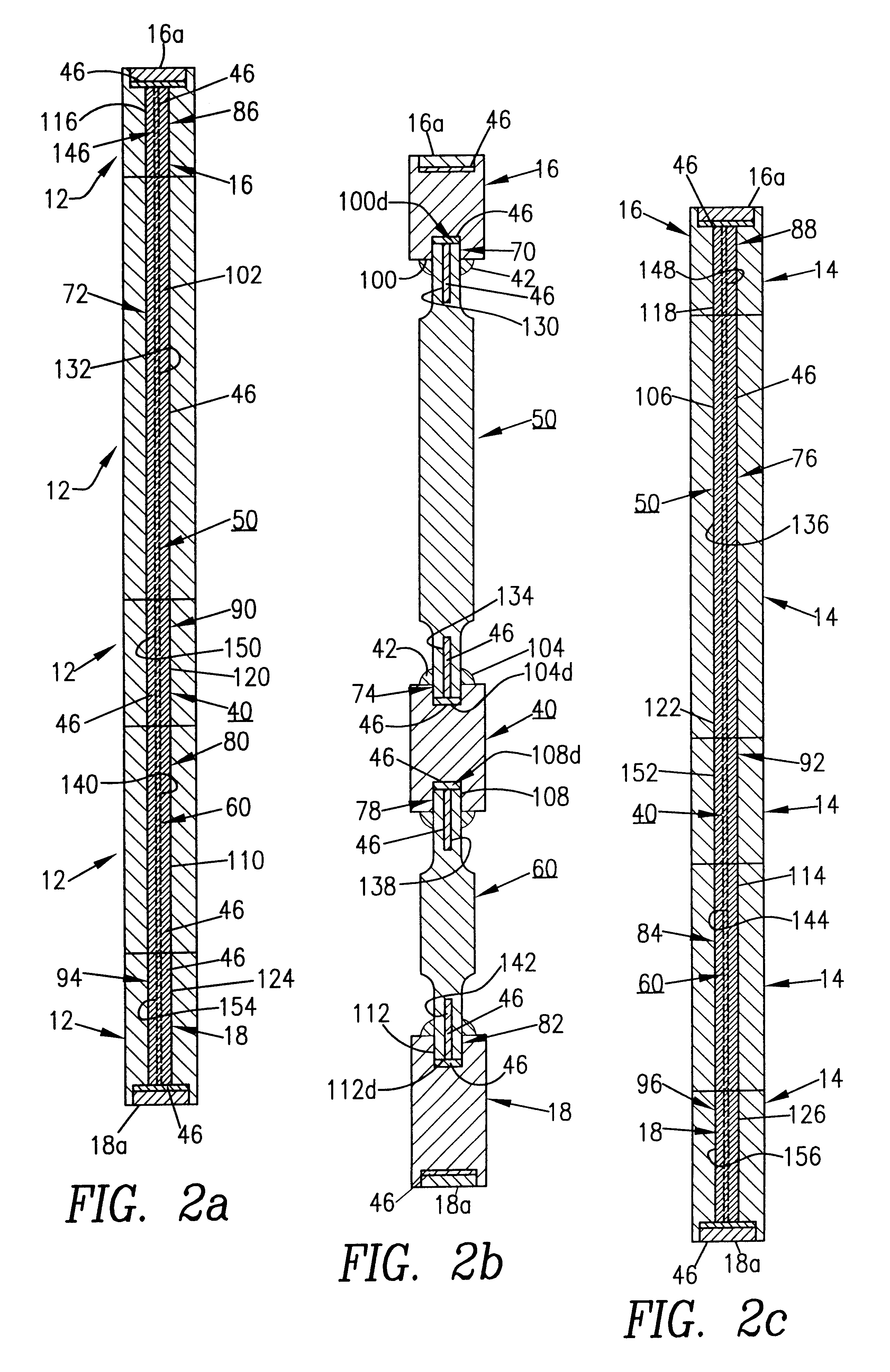

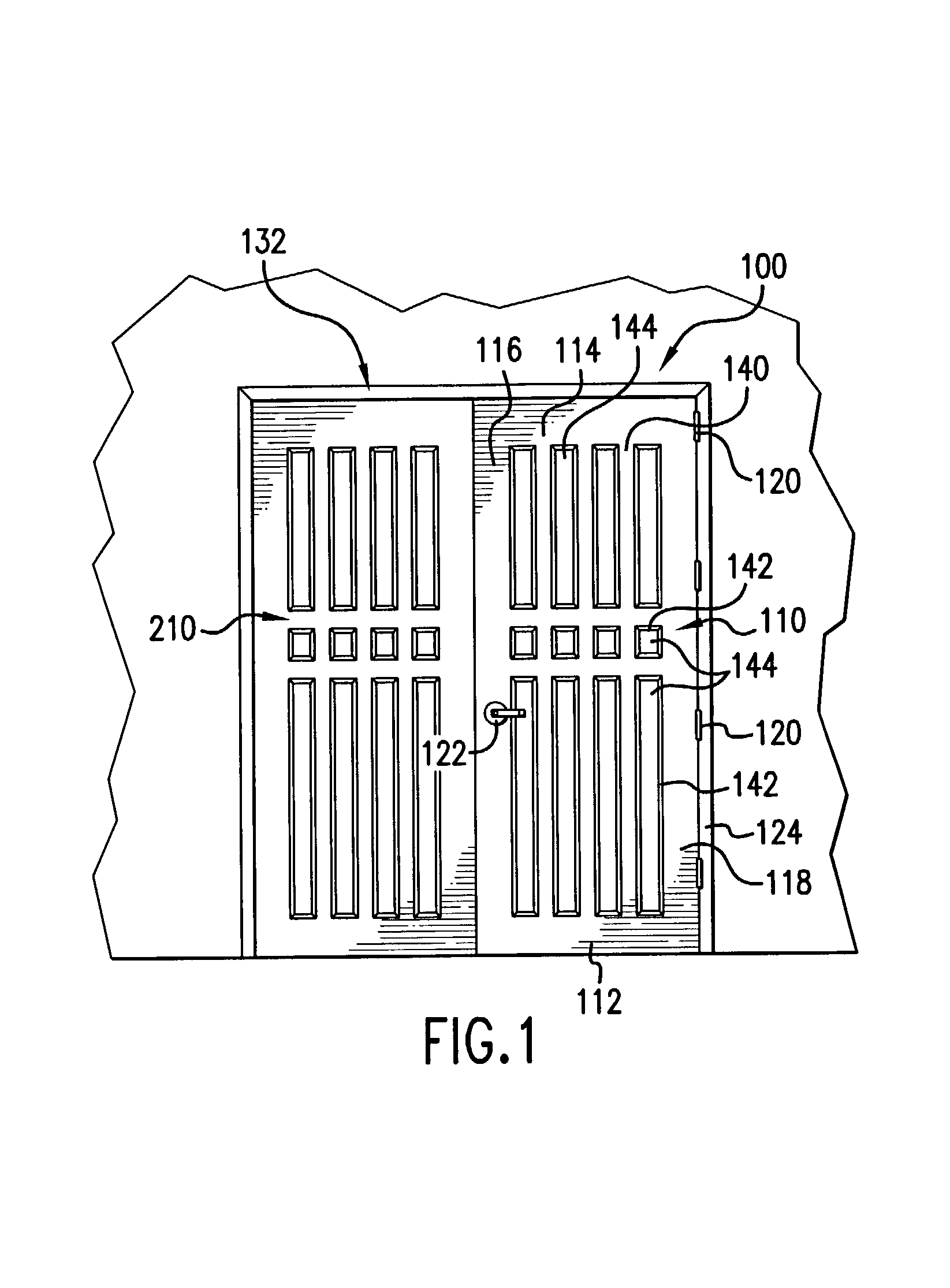

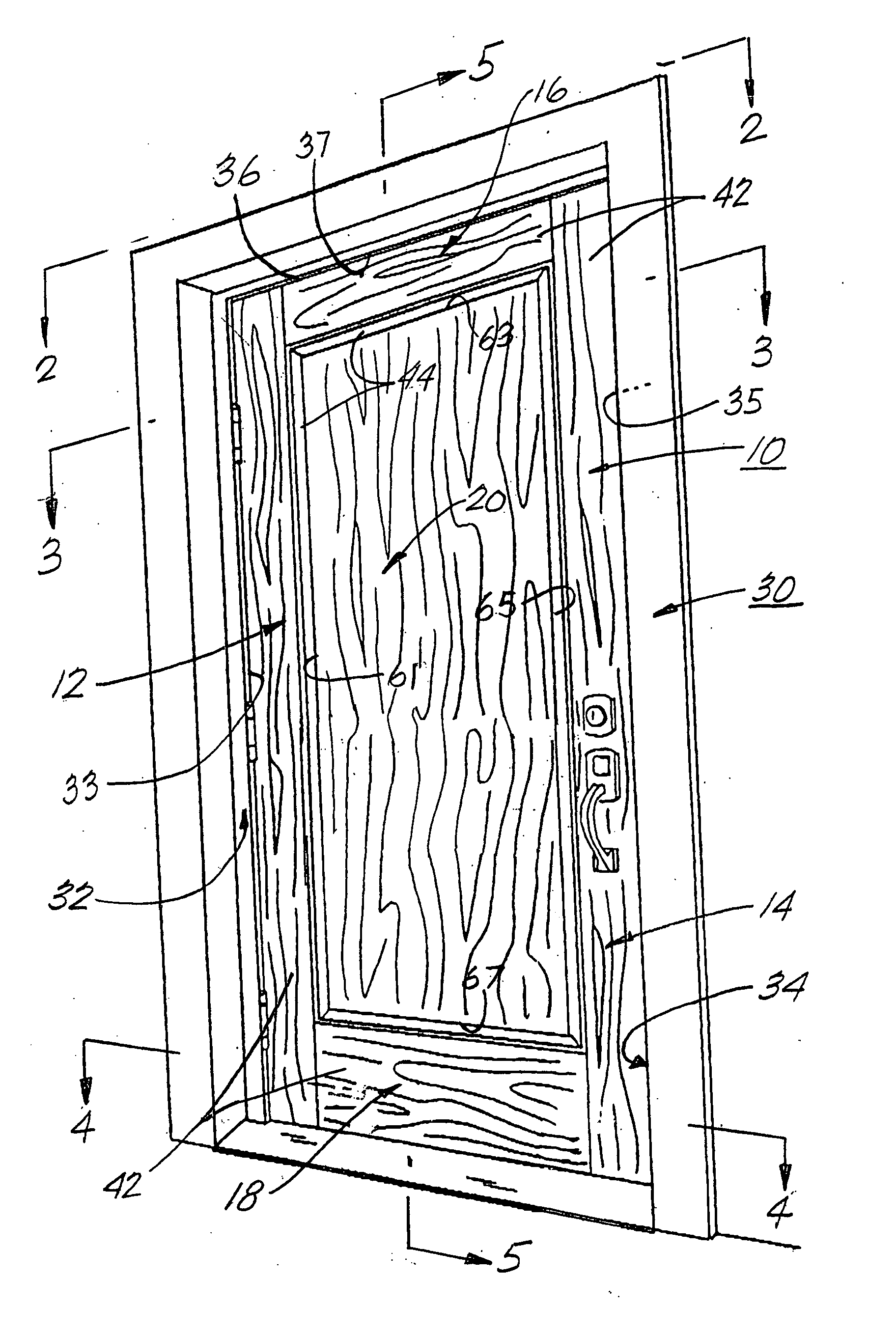

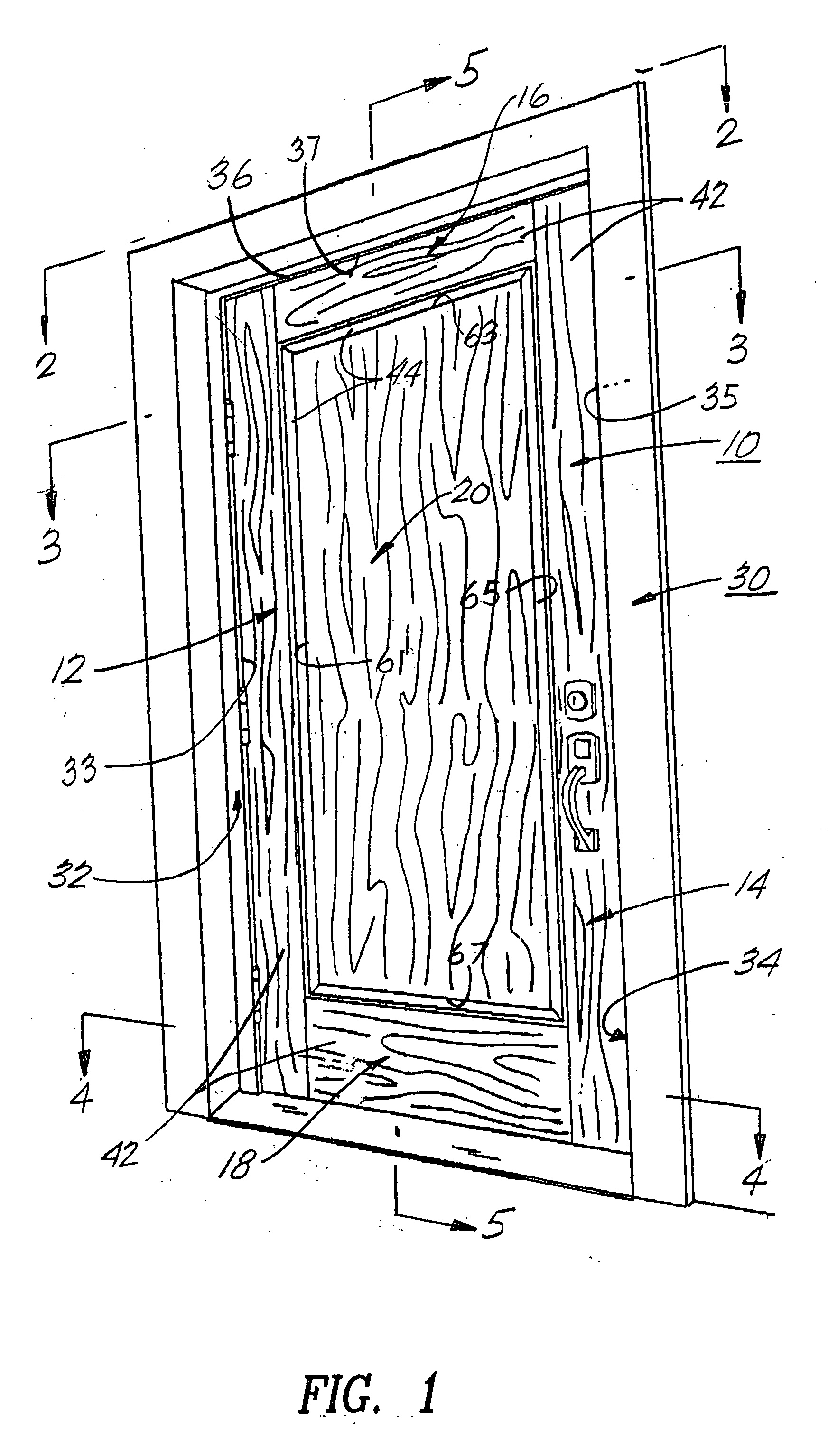

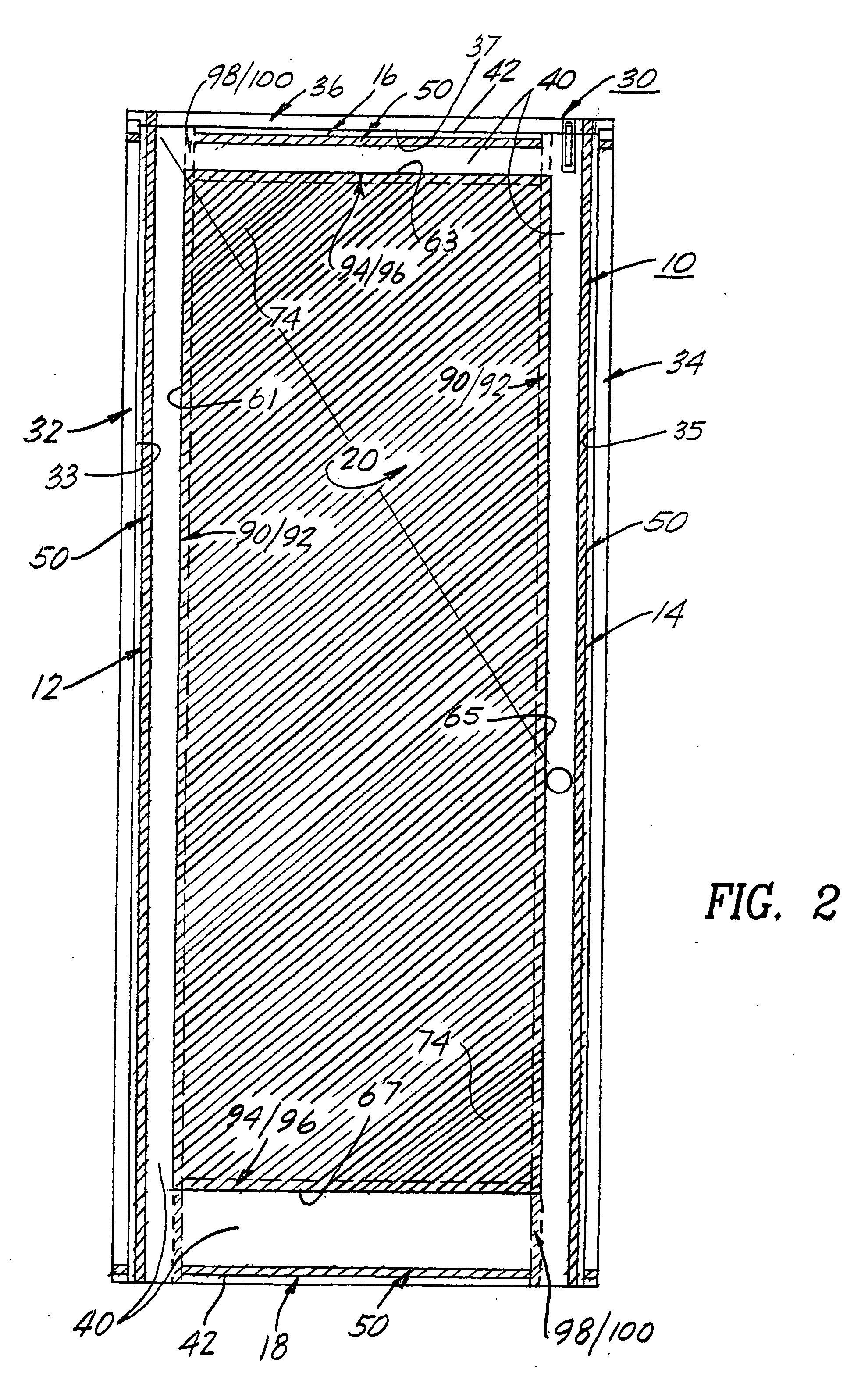

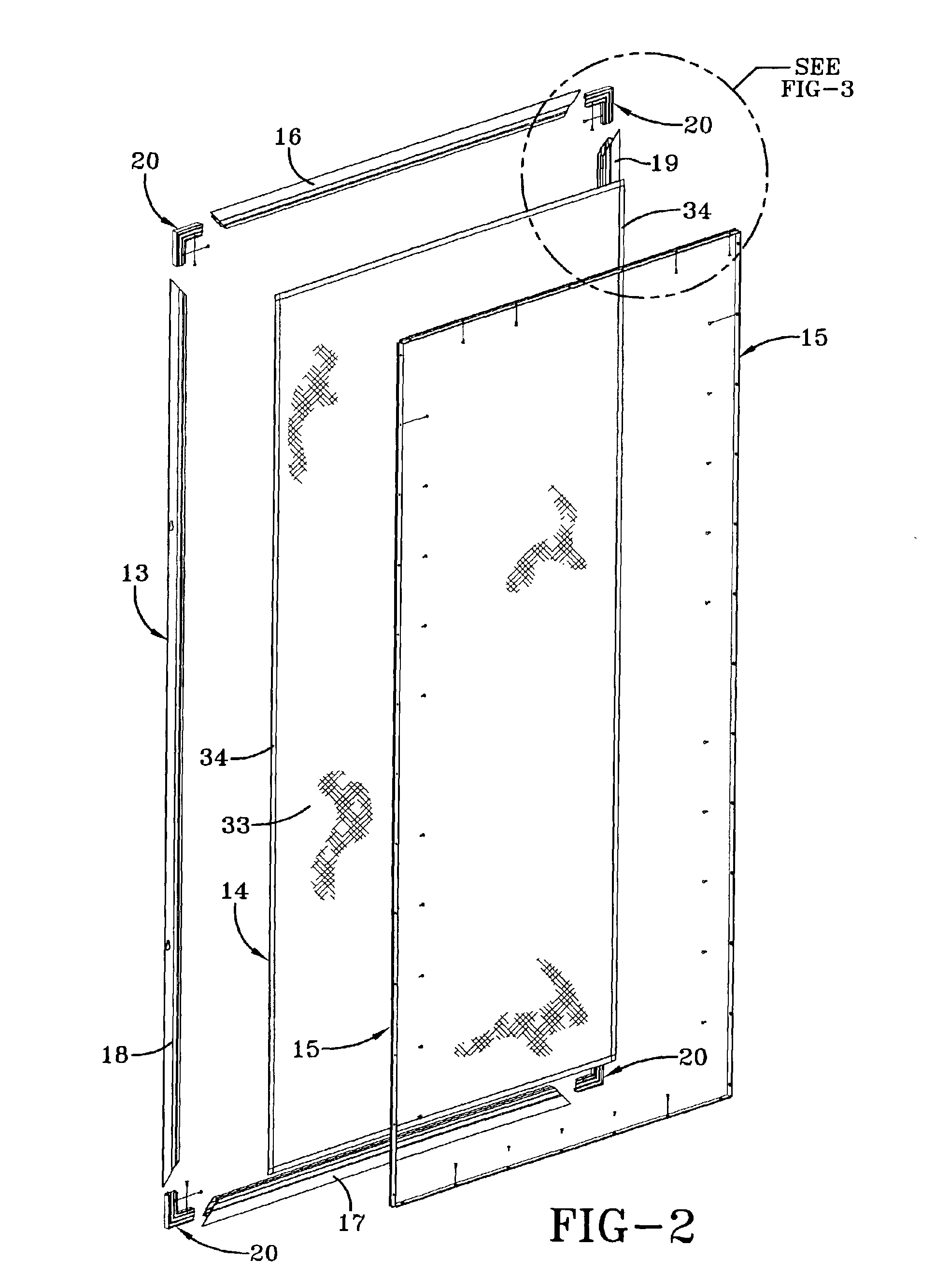

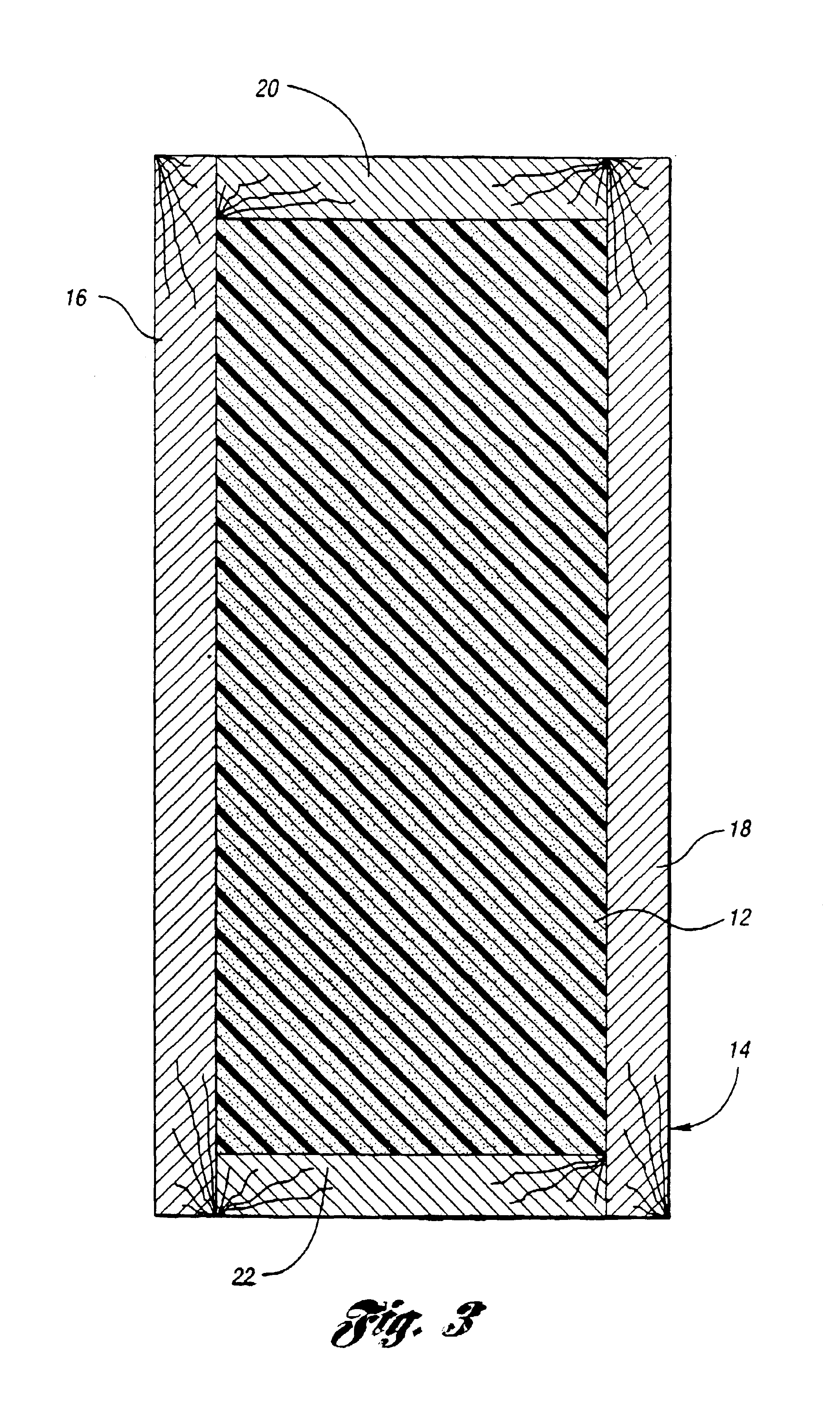

Fire retardant panel door and door frame having intumescent materials therein

InactiveUS20050284030A1Prevent the spread of fireFireproof doorsBuilding locksComposite laminatesRefractory

A fire retardant panel door and door frame that prevents the spread of fire through the door during a fire. The fire retardant panel door has at least one door panel and stiles and rails. The door panel includes an interior center composite section formed by a first plurality of layers of intumescent materials and a first plurality of layers of fire resistant materials disposed between and laminated to a pair of outer sections formed of wood for enclosing the interior center composite section to form a composite laminated door panel. Each of the stiles includes a first center core formed of wood enclosed by a second plurality of layers of intumescent materials and a second plurality of layers of fire resistant materials; and the second layers of intumescent and fire resistant materials are enclosed by a first applique layer formed of wood to form a composite laminated stile. Each of the rails includes a second center core formed of wood enclosed by a third plurality of layers of intumescent materials and a third plurality of layers of fire resistant materials; and the third layers of intumescent and fire resistant materials are enclosed by a second applique layer formed of wood to form a composite laminated rail. The first, second, and third plurality of layers of intumescent materials are activated to expand upon exposure to heat and / or fire to prevent the heat and / or fire from passing through at least one door panel, the stiles and the rails of the panel door during a fire for at least 90 minutes. At least one door panel is connected to the panel door by tongue and groove joints; and the tongue and groove joints have a fourth plurality of layers of intumescent materials and a fourth plurality of layers of fire resistant materials in the tongue and groove joints; and wherein the fourth plurality of layers of fire resistant materials in the tongue and groove joints are activated to expand upon exposure to heat and / or fire to seal the joints in order to prevent the heat and / or fire from passing through the panel door during a fire for at least 90 minutes.

Owner:ATRISTIC DOORS & WINDOWS

Polyvinyl chloride antistatic dust-proof modified window section bar and producing method thereof

The invention discloses a kind of window PCE shaped material with antistatic and dustproof function and its manufacturing method. It raw materials are composes of PVC resin powder, antistatic agent, impact modifier, stabilizer, filler and processing aid in accordance with the weight ratio of 100:0.2-20:1-10:2-8:5-20:1-10. Then it heats and stirs the raw materials at a temperature of 100 ~ 130deg.C in the high-speed mixer, and then it slowly cools the mixture to room temperature and transfers the materials to the extruder, finally it achieves the shaped material through extrusion molding mold, vacuum cooling, traction and cutting.

Owner:LG HAUSYS TIANJIN

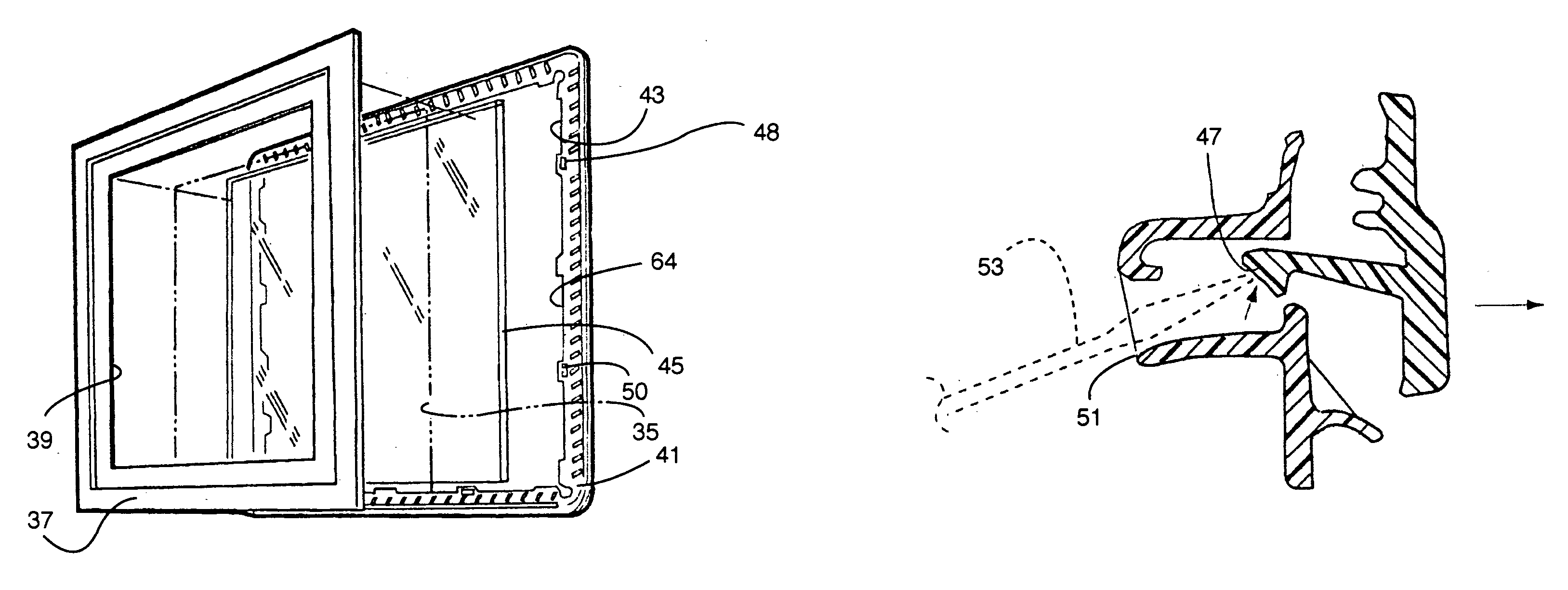

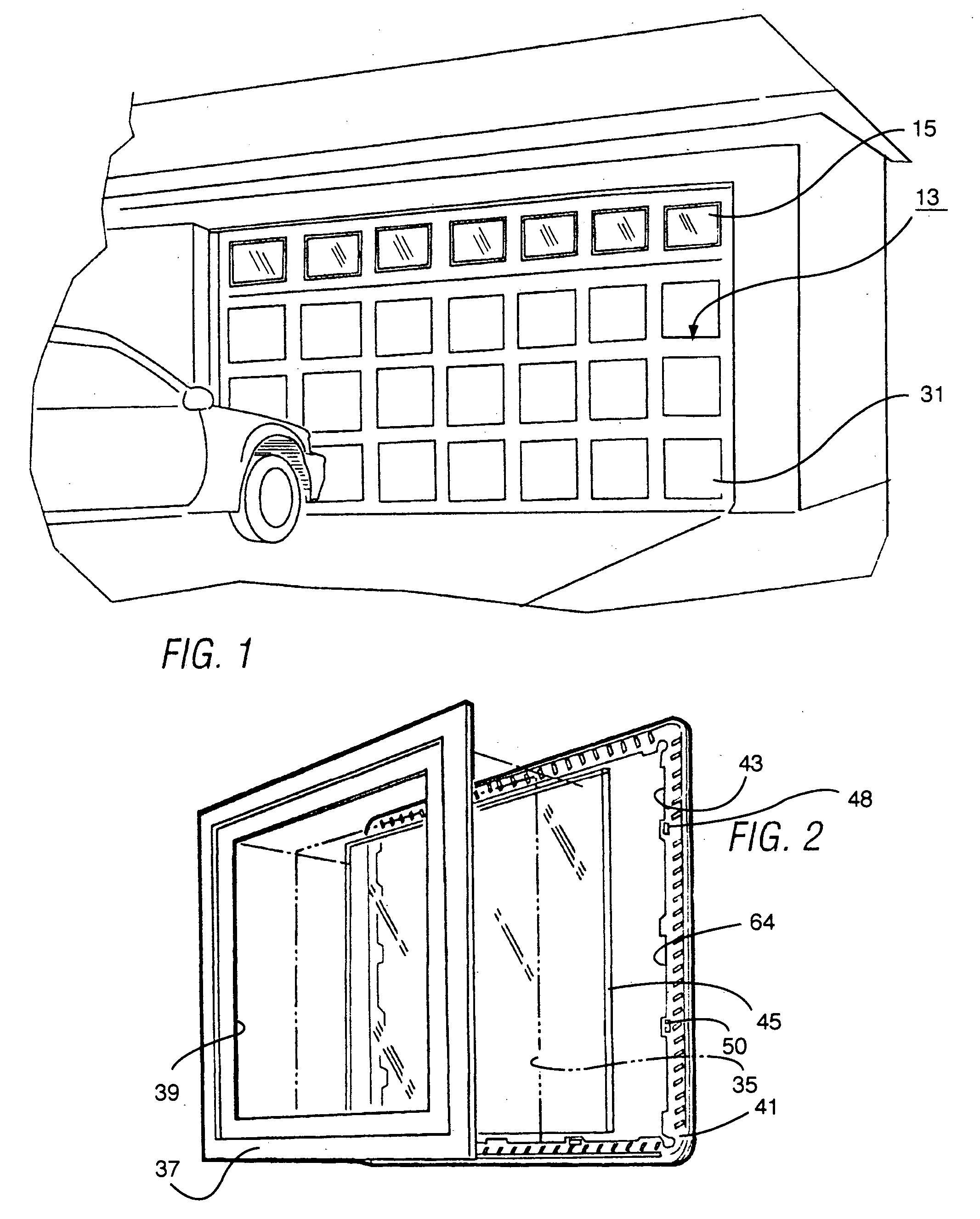

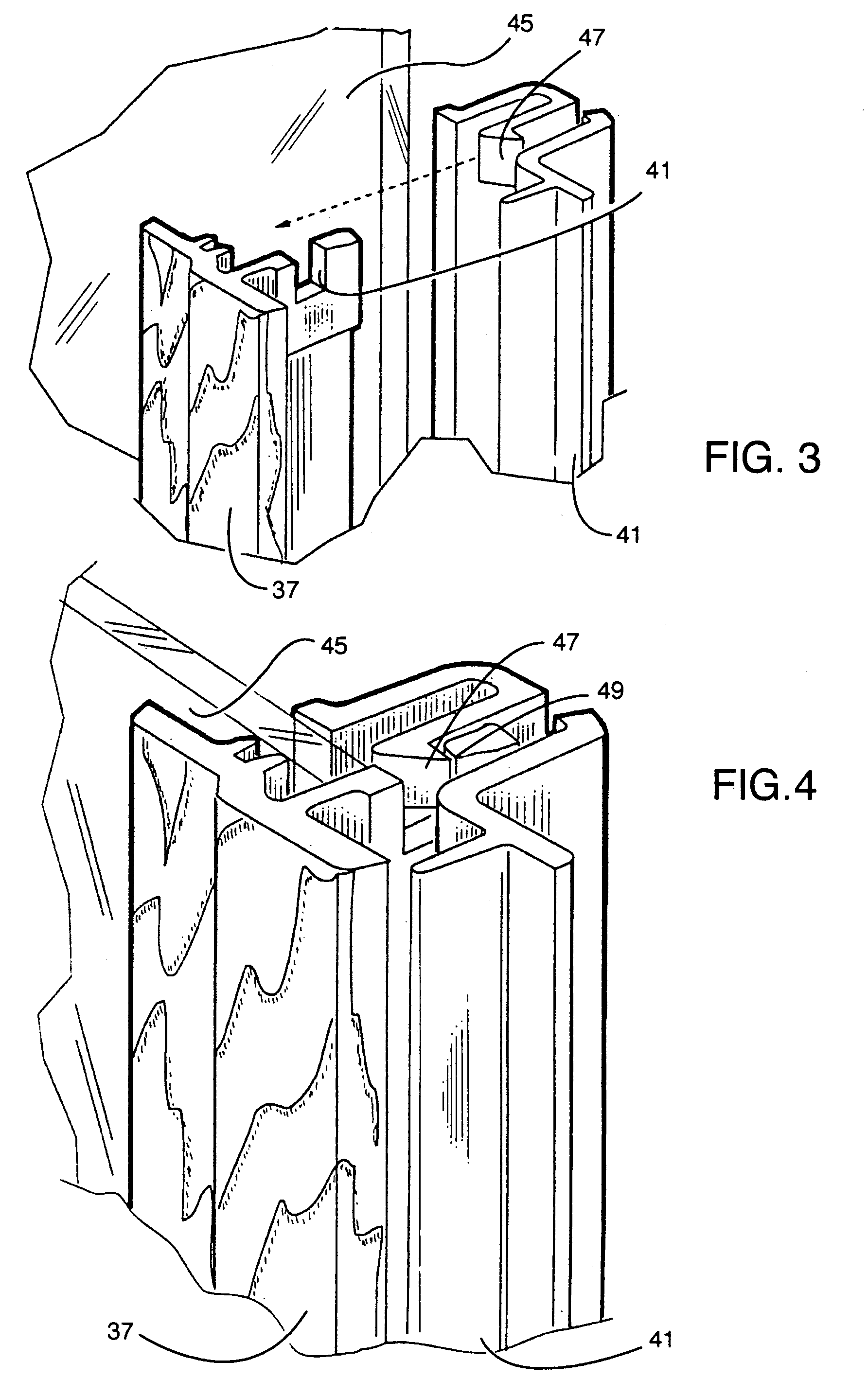

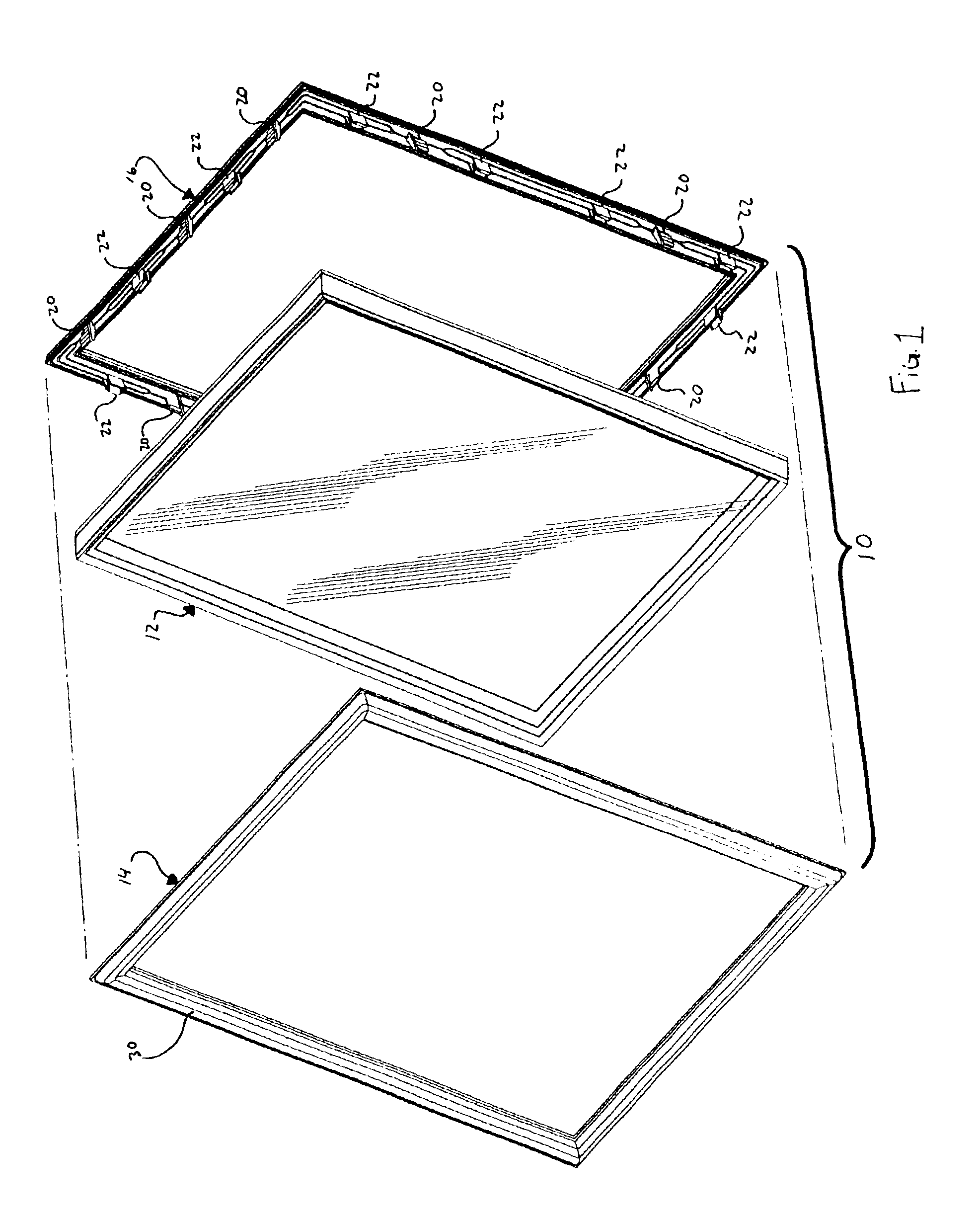

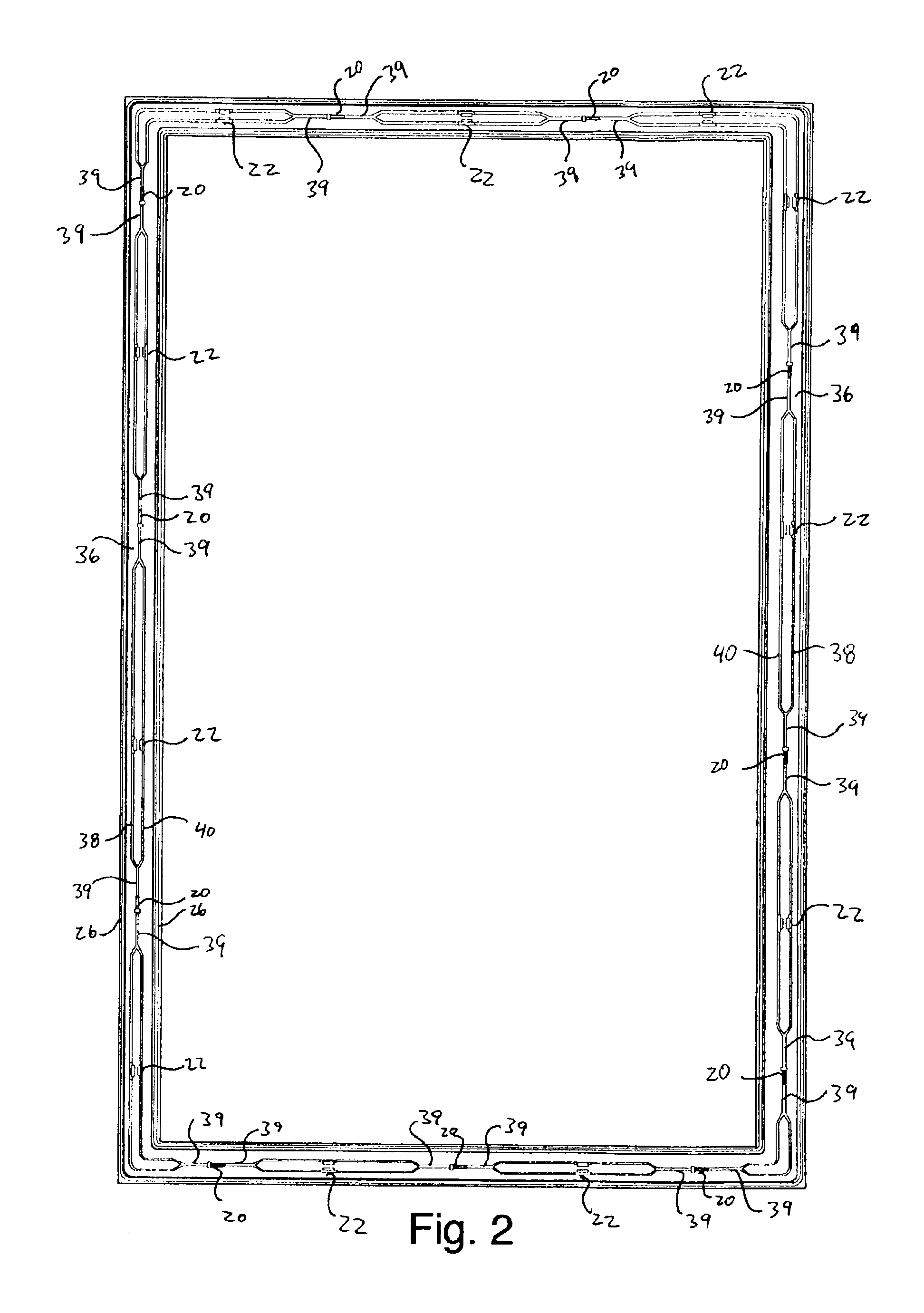

Garage door window frame and method of installation

ActiveUS7107736B2Easy to disassemblePromote repairWindow/door framesBuilding repairsWindow openingEngineering

A window frame assembly for installation within a garage door having front and rear exposed surfaces and one or more window openings. The assembly includes front and rear window frame members of injection molded plastic which are installed within the door opening on the front and rear exposed surfaces. The window frame members have engagement elements located about their peripheries which snap together in mating fashion to mount the frame members within the window opening. The engagement elements are also disenageable with a hand tool to separate the frame members and remove the members from the window opening.

Owner:NAT DOOR INDS

Fiber-reinforced composites and building structures comprising fiber-reinforced composites

InactiveUS20050266222A1Overcome disadvantagesEnhanced advantageConstruction materialWindow/door framesGlass fiberFiber-reinforced composite

The present invention provides fiber-reinforced composites, and components for buildings, such as door skins, that include fiber-reinforced composites. Also provided are methods and systems for manufacturing fiber-reinforced composites that may be used in building structures. In an embodiment, the present invention provides a fiber-reinforced composite comprising long fibers of fiberglass and polyurethane produced using long-fiber injection (LFI) technology.

Owner:JELD-WEN

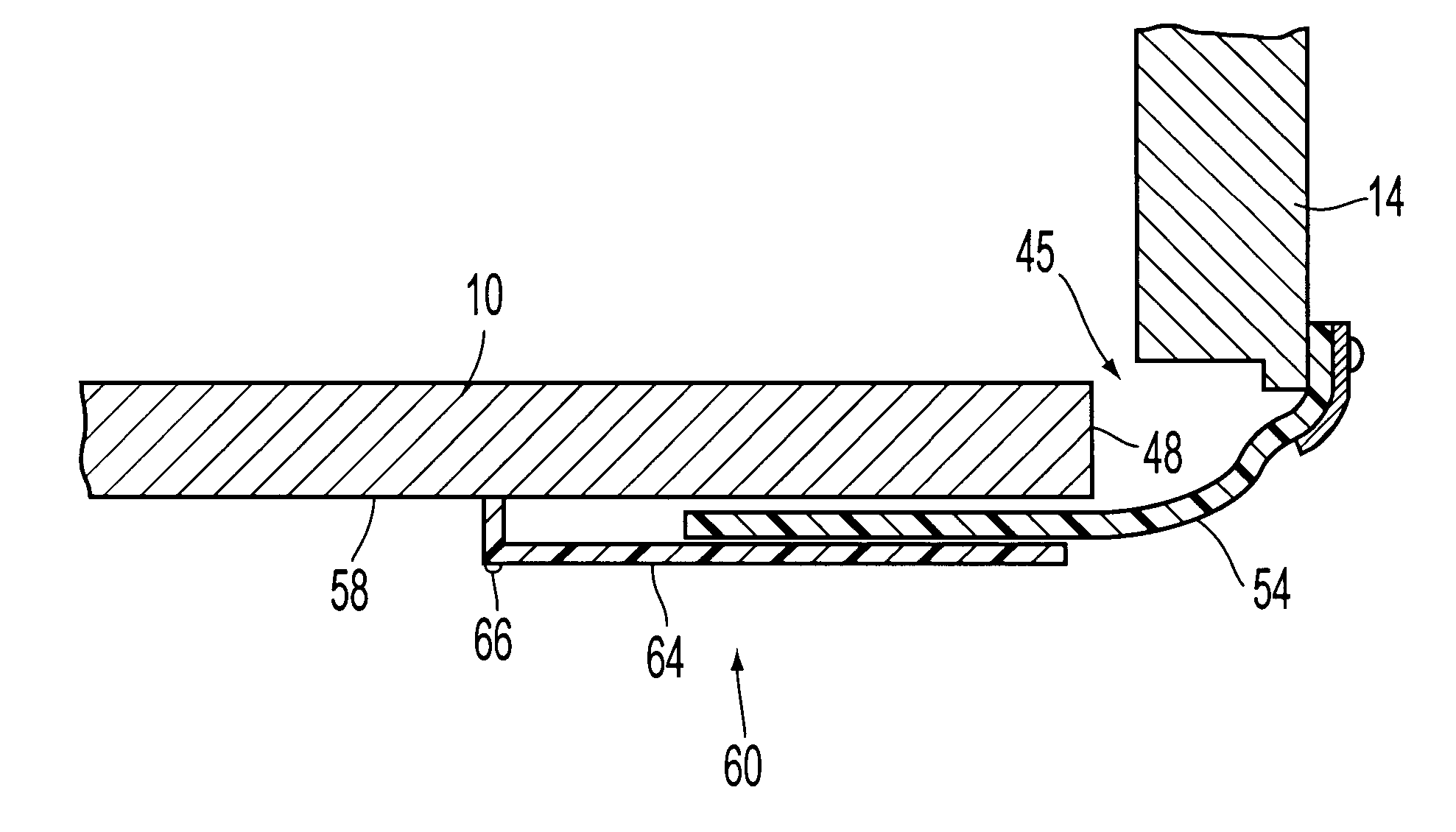

Tensioned fabric storm protection panel

InactiveUS6886300B2Easy and fast assemblyEasy to installScreensHurricane shuttersEngineeringMechanical engineering

Owner:OVERHEAD DOOR

Gypsum Composites used in Fire Resistant Building Components

A composite product includes gypsum in an amount of 70 to 90% by weight, fibers in an amount of 1.5 to 26% by weight substantially homogeneously distributed through the composite, and a rheology-modifying agent in an amount of 0.5 to 6% by weight. The composite is caused or allowed to cure to form a cured composite. The cured composite is a fire resistant component used in a fire-rated door core, a fire-rated door or a fire-rated building panel. The fire resistant component may include a building panel, a door panel, a door core, a door rail, a door stile, a door lock block, a door border, or a door insert.

Owner:THE INTELLECTUAL GORILLA

Synthetic door with improved fire resistance

Using integrally formed stiles on skins of sheet molded plastics (thermosetting) employed to form the exterior surfaces of a synthetic door having sheets of reinforcing materials adhered to the inner surface of each of the skins, the skins can be connected through the integral stiles and slats of a fire proof materials can be affixed to these stiles and rails closing the top and bottom opening between the skins to increase the fire resistance of the resulting door when the core is filled with a phenolic foam. The structure described reduces the weight of the resulting door and places the fire resistant materials around the door edges which are the most susceptible to failure during a fire while structurally tying the slats together through the sheets of carbon fiber or fiberglass disposed on the inner surfaces of the skins whereby failure (disintegration) of the skins during a fire will not lead to a collapse of the door as with some prior art door structures. A slat of polyvinyl chloride can be employed to cover the fire proof slats so the door edges can be trimmed so it will fit into the door frame and the edges will be pleasingly attractive.

Owner:CHEN KUEI YUNG WANG

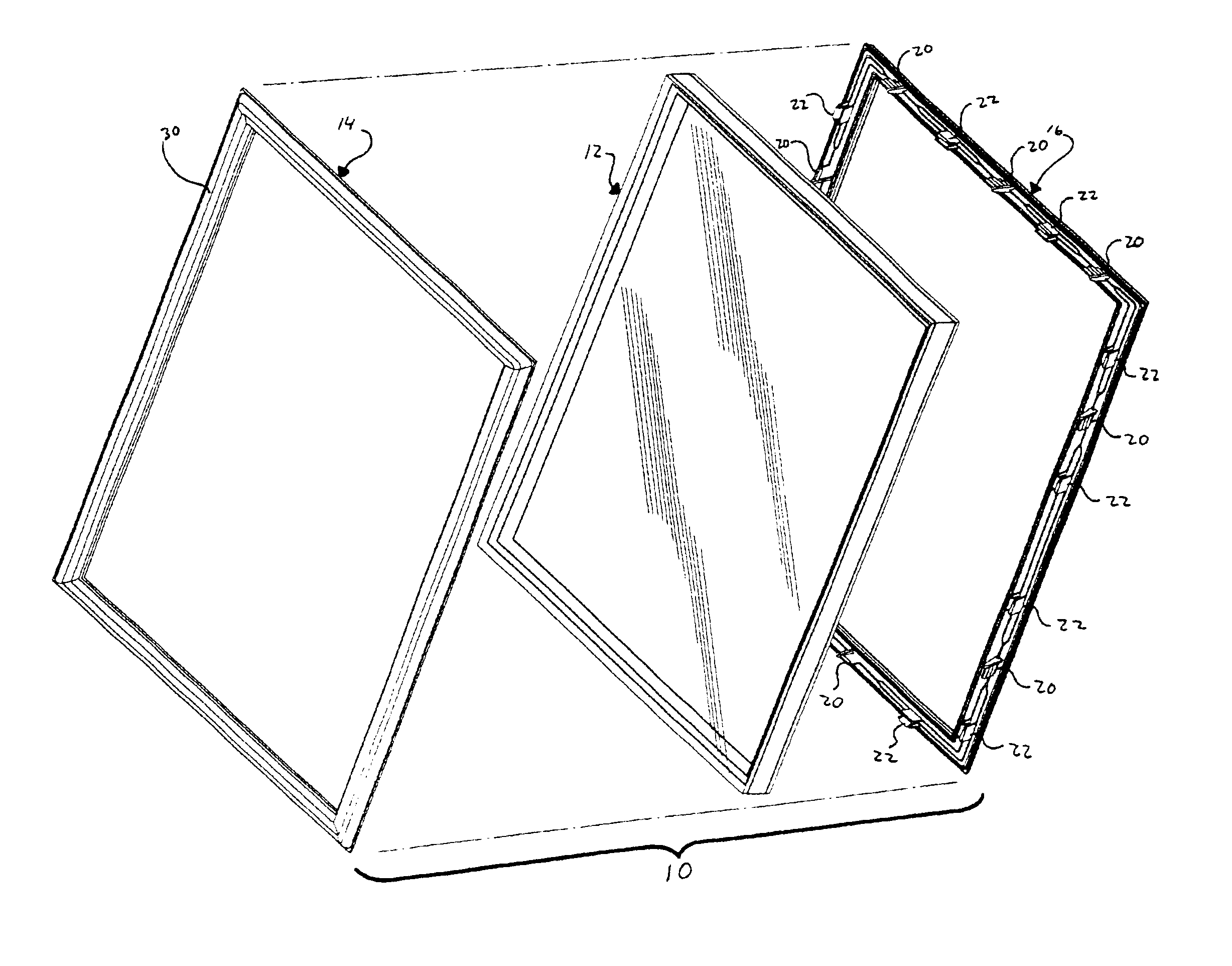

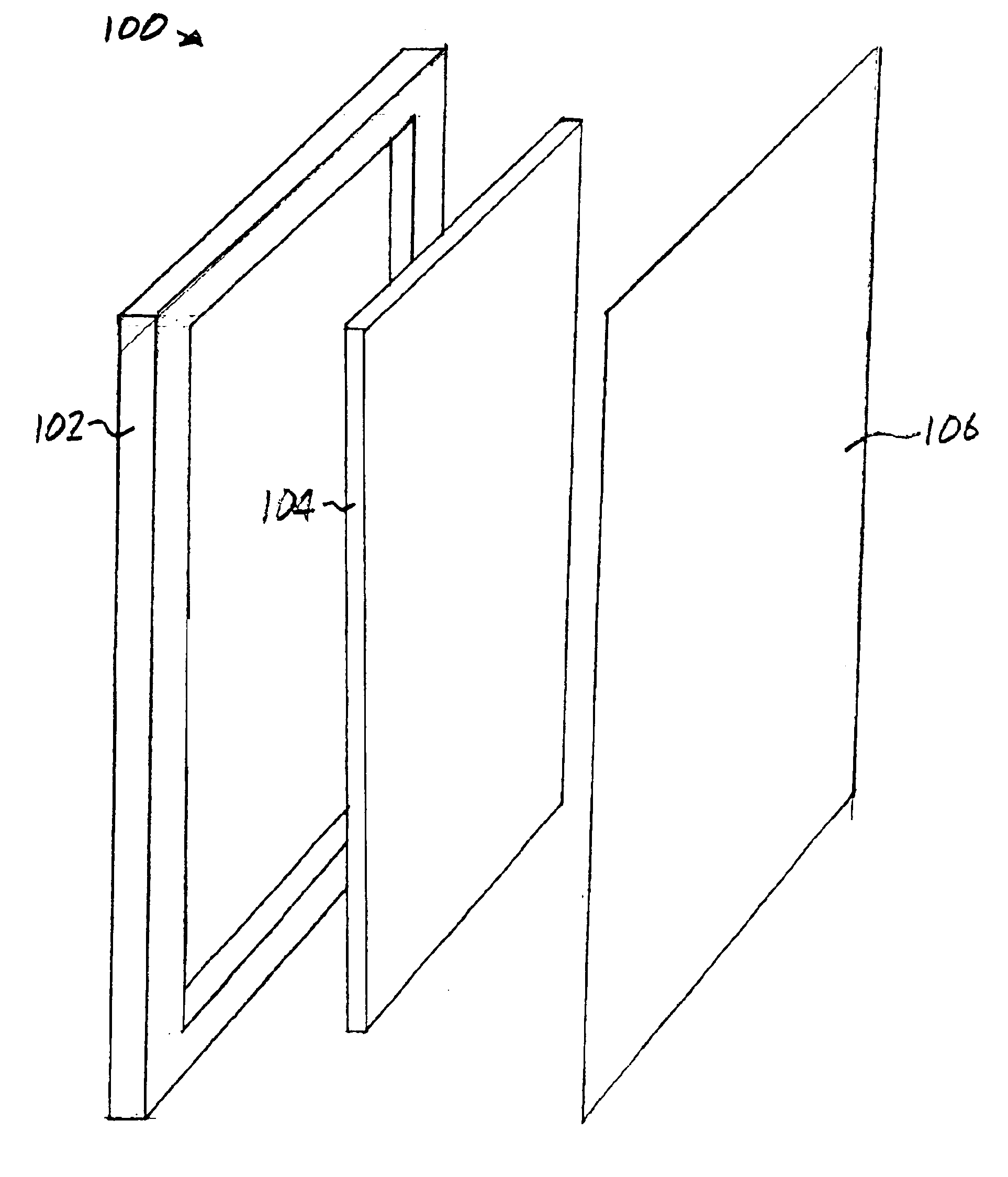

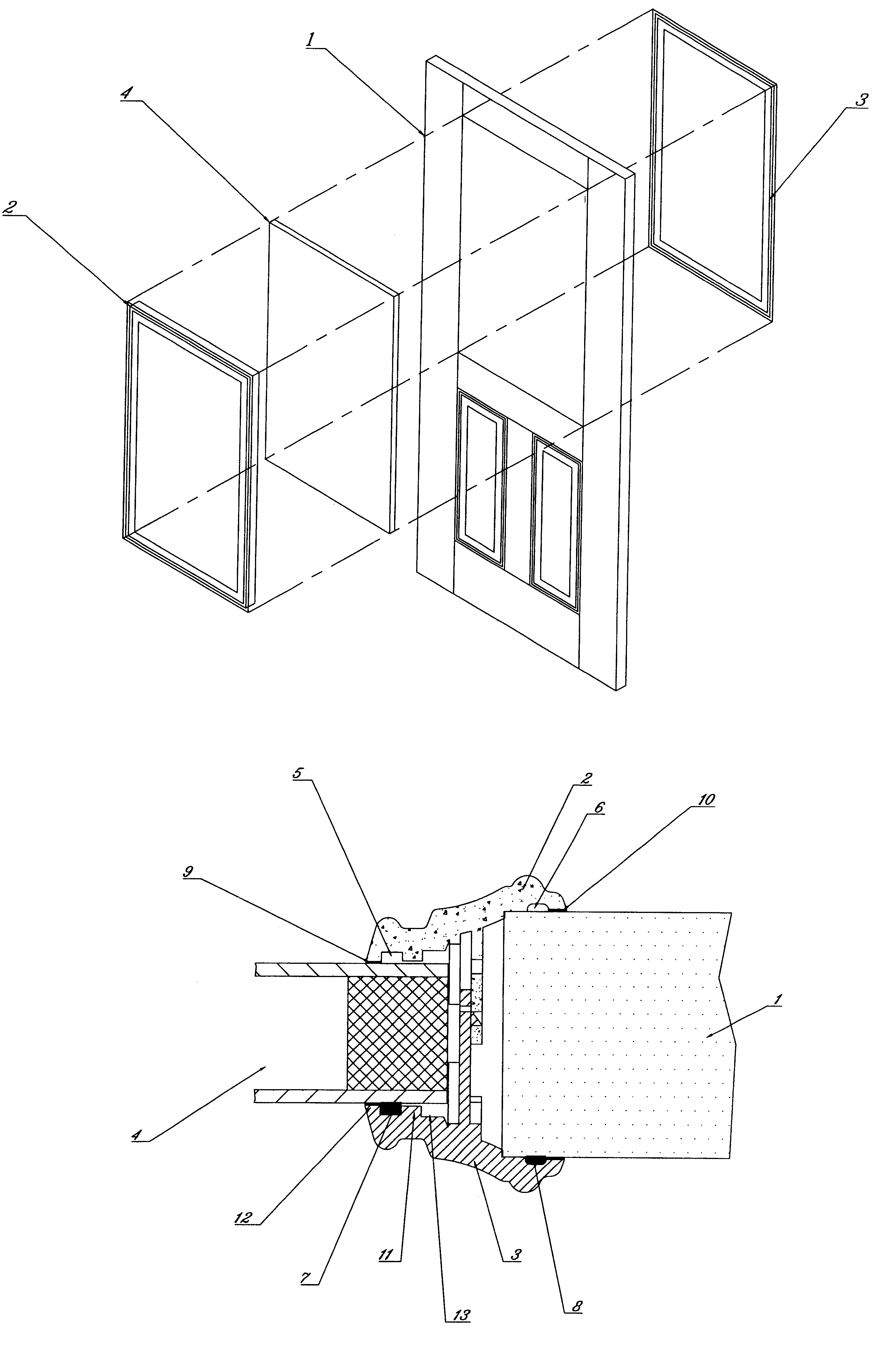

Screwless window frame assembly

InactiveUS6925767B2Easily and securely alignedEasily and securely and interconnectedWindow/door framesGlass pane fixingEngineeringFastener

A window frame including a pair of frame halves having integral fasteners for interconnecting the frame halves. The fasteners include mating barbed connectors that interfit with one another to permanently intersecure the frame halves. The fasteners further include integral cooperating alignment pins and receivers for aligning the fasteners and hence the frame halves. The alignment pins and receivers are laterally offset from the fasteners.

Owner:ODL

Compression molded door assembly

A door member comprising a frame having a first side and a second side, opposite the first side, a core positioned within the frame, and a molded skin attached to the first side of the frame. The skin is prepared from a molding compound which, when molded, has a shrinkage of between about −0.0003 to about +0.0015. The molding compound comprises a resin system comprising a curable polyester resin, a co-curable unsaturated monomer, and at least two low profile additives. The molding compound also comprises at least about 30 percent by weight, based on the weight of the molding compound, of filler material, and fibrous reinforcement in an amount of less than about 35 weight percent, based on the weight of the molding compound.

Owner:THERMA TRU

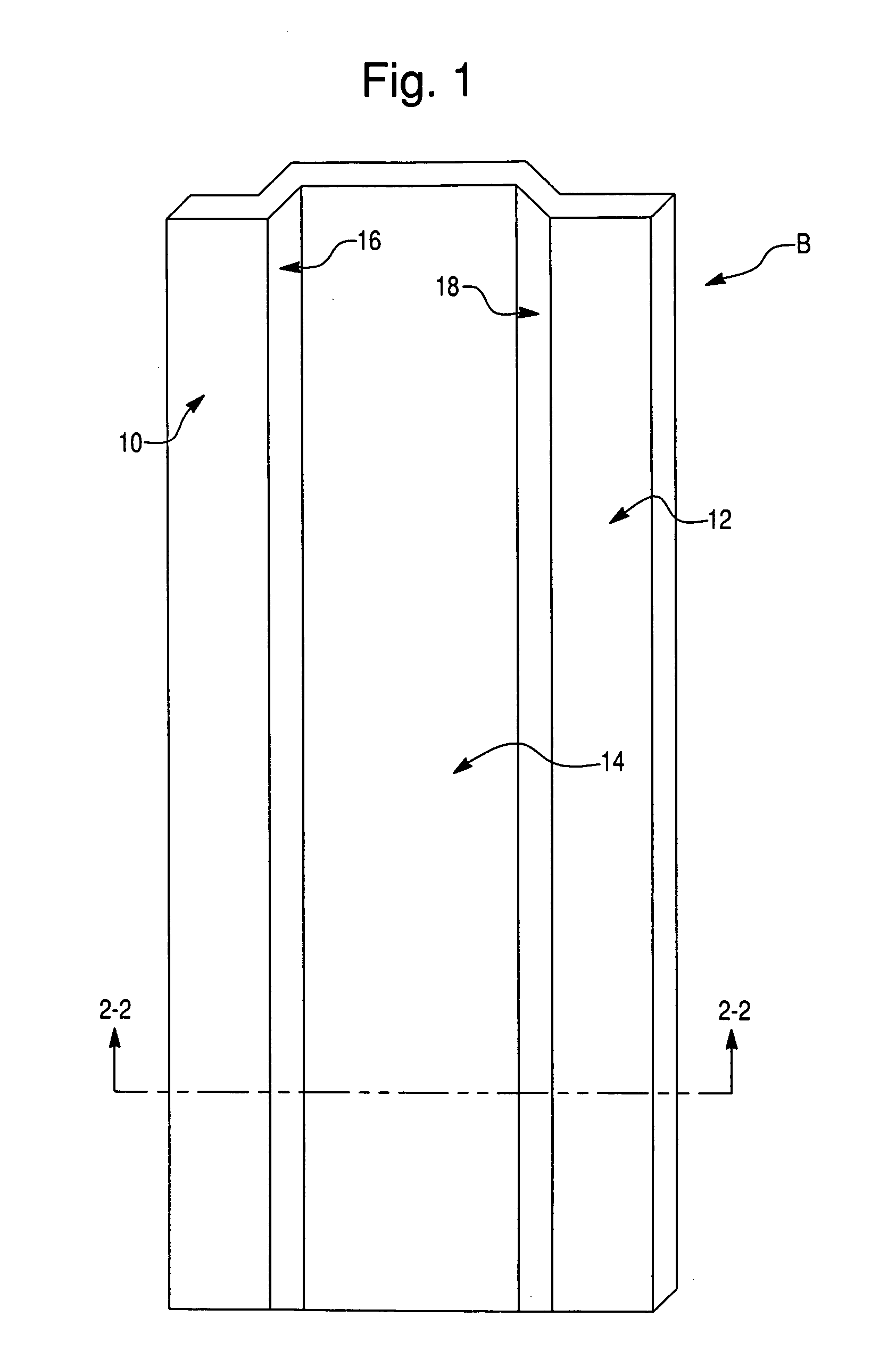

Reinforced door stile

In combination with a door in which the door includes two spaced apart solid plastic stiles and at least two spaced apart solid plastic rails and in which the two solid plastic stiles and the at least two solid plastic rails are connected together to form a rectangle having an opening defined by the distances between an inner edge of the solid plastic rails and the solid plastic stiles. At least one of a screen and a glass are dimensioned to cover such opening. Further, there is a means for fastening the screen and / or glass in a position to cover the opening. The improvement comprises at least one of the two solid plastic stiles and / or two rails having a lengthwise void formed at a predetermined location therein. A non-plastic reinforcing member is fitted in the lengthwise void.

Owner:SFPD +1

Articles of composite structure having appearance of wood

A door or other entryway component of synthetic resin composite construction and closely resembling the appearance of stained real wood. Skin portions of doors and other structures have a surface layer of clear gel coat resin molded to include the texture of a wood grain surface. A subsurface layer adjacent the clear gel coat layer is of pigmented gel coat resin. A structural support layer of the skin is of reinforced resin. Skins of a door or similar article are mounted on frames, and dense micro porous resin foam is provided between the skins to form a solid structure such as a door. Moldings retaining glass panels in openings defined in the door or similar structure are attached to the skins by adhesively fastening the moldings to the skins. Fasteners mounted in the moldings so that there are no plugged holes in the exterior surfaces of the moldings are used to locate the moldings properly with respect to the skins by inserting the fasteners into predrilled holes in the skins. The assembled doors and other structures can be finished by staining and coating with a finish system such as a urethane varnish to provide an appearance closely resembling real wood.

Owner:JELD-WEN

Fire-resistant material and method of manufacture

InactiveUS6886306B2Improve fire resistanceImprove the level ofConstruction materialClimate change adaptationCelluloseZinc borate

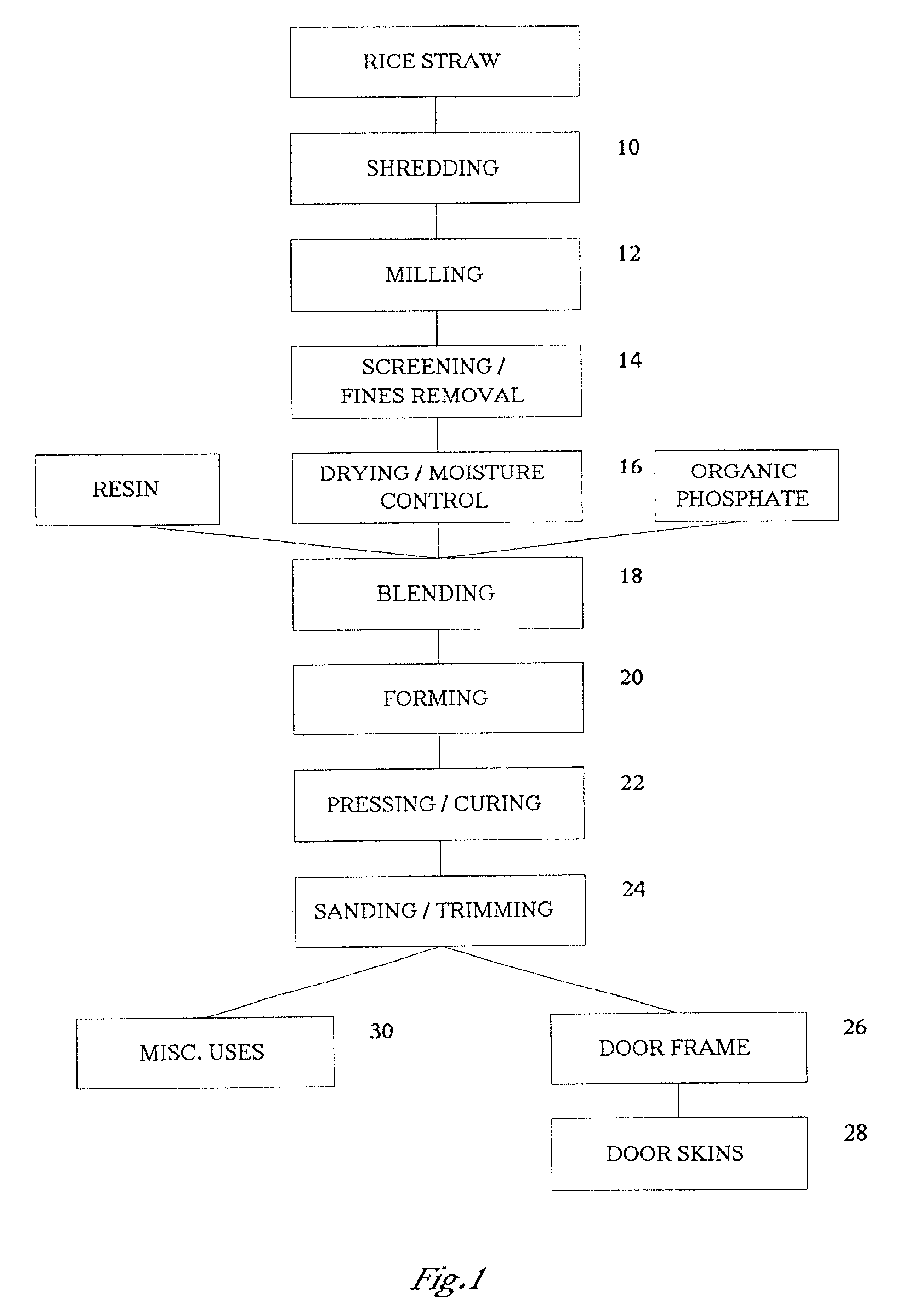

The present invention provides a building material derived from straw, such as rice straw, that has significantly improved fire-resistance properties over traditional cellulose-based materials. In one embodiment, the invention provides a method of fabricating a board from milled rice straw. The milled rice straw is blended with a binder to form a mixture. The mixture is then formed into a mat with sufficient size to achieve a predetermined board thickness and density. The mat is then pressed into the board. In another embodiment, the present invention provides a fire resistant board that includes milled rice straw, a resin binder, and a fire retardant material such as an organic phosphate, zinc borate, aluminum trihydrate, sodium silicate, or even rice hulls.

Owner:GREENCOR COMPOSITES

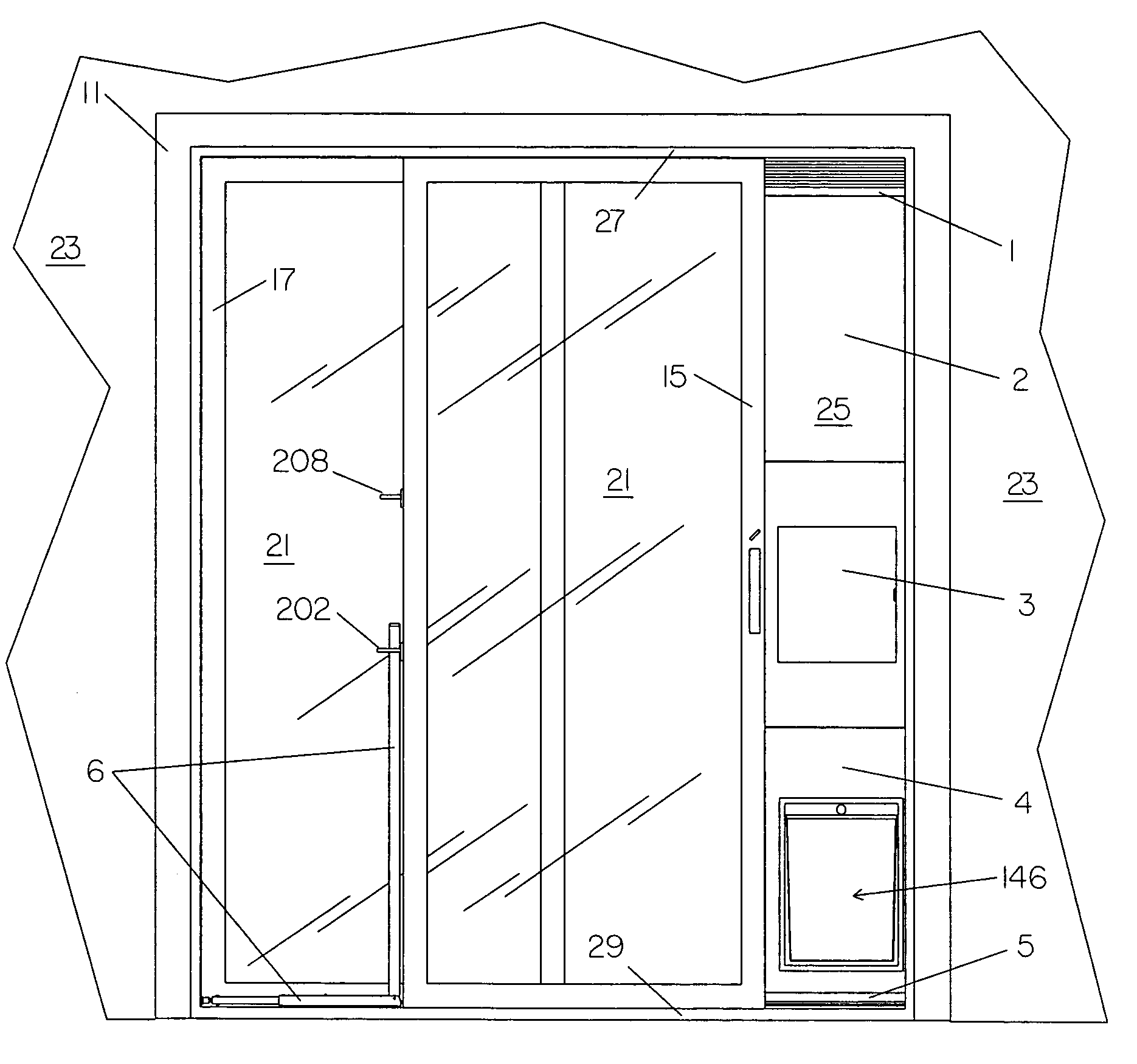

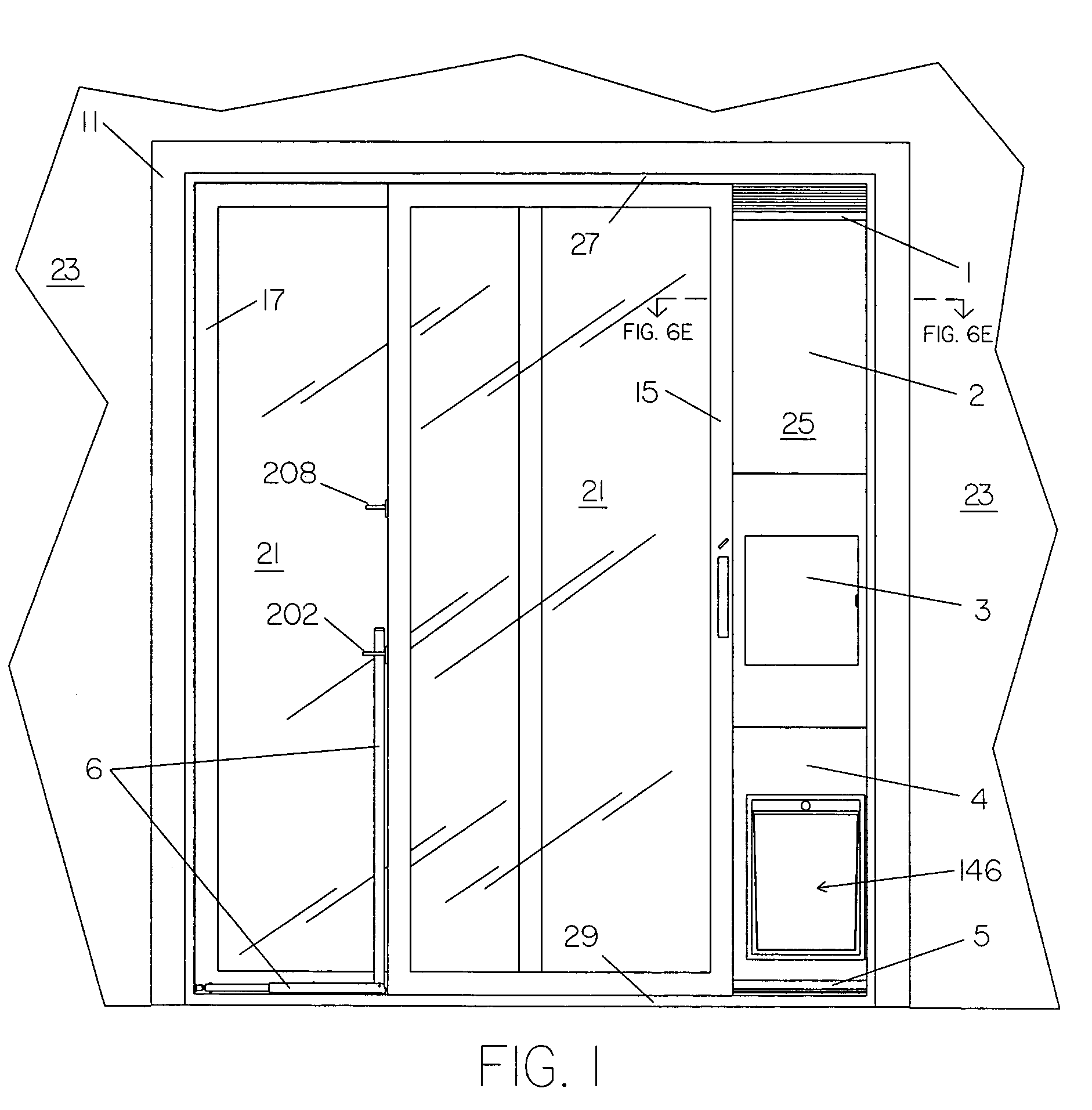

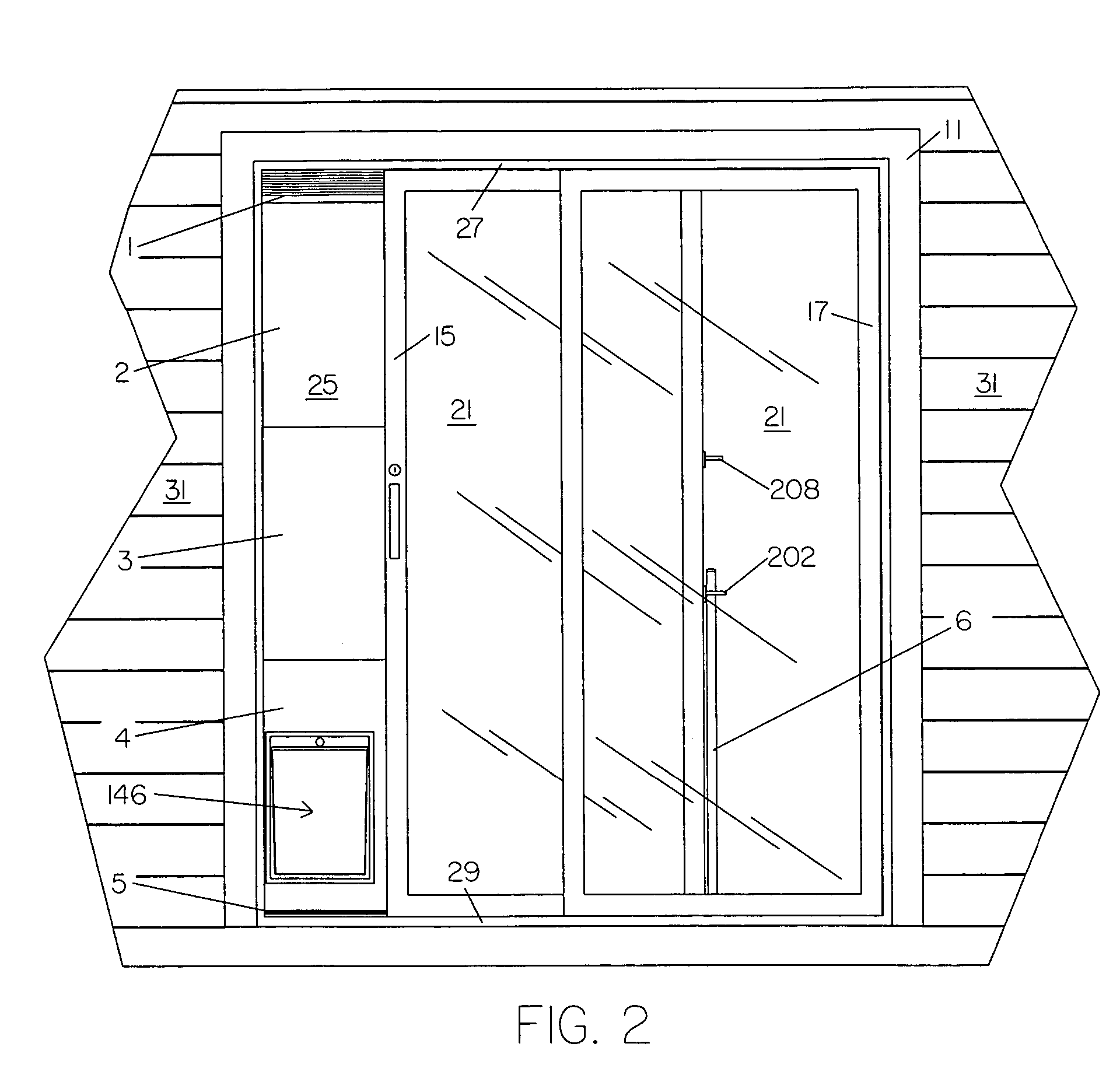

Sliding door insert for portable pet portal

ActiveUS7207141B2Facilitating transportation opportunityImprove portabilityMan-operated mechanismWing fastenersTongue and grooveCam

A portable pet portal insert for a sliding patio door includes separate top, center, and bottom modules that can be assembled together through use of tongue and groove fittings therebetween, with the bottom module having a cutout portion adapted for receiving a pet portal, the pet portal including a pivotal flap, a cam operated lock for preventing movement of the flap away from an associated frame, and a weather seal mechanism.

Owner:ACCESSION

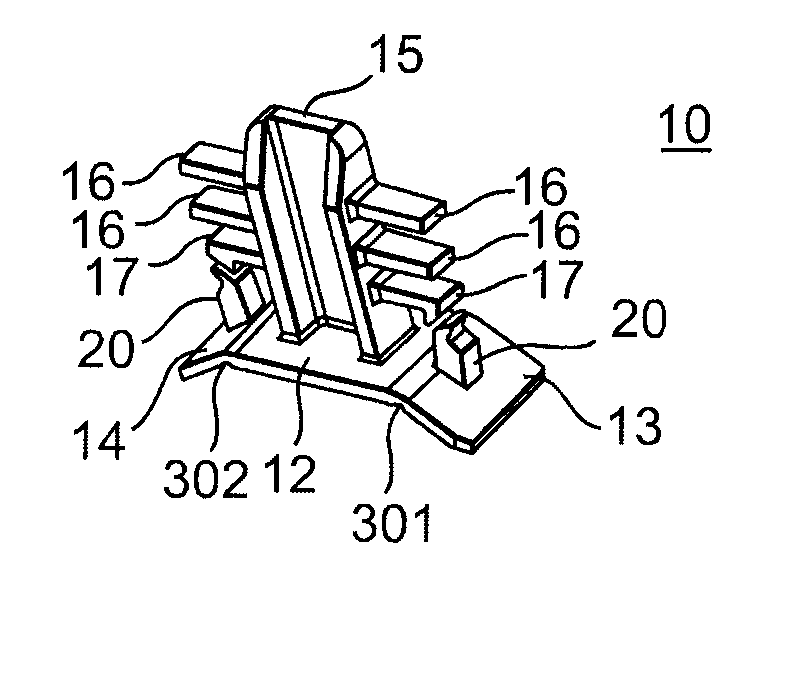

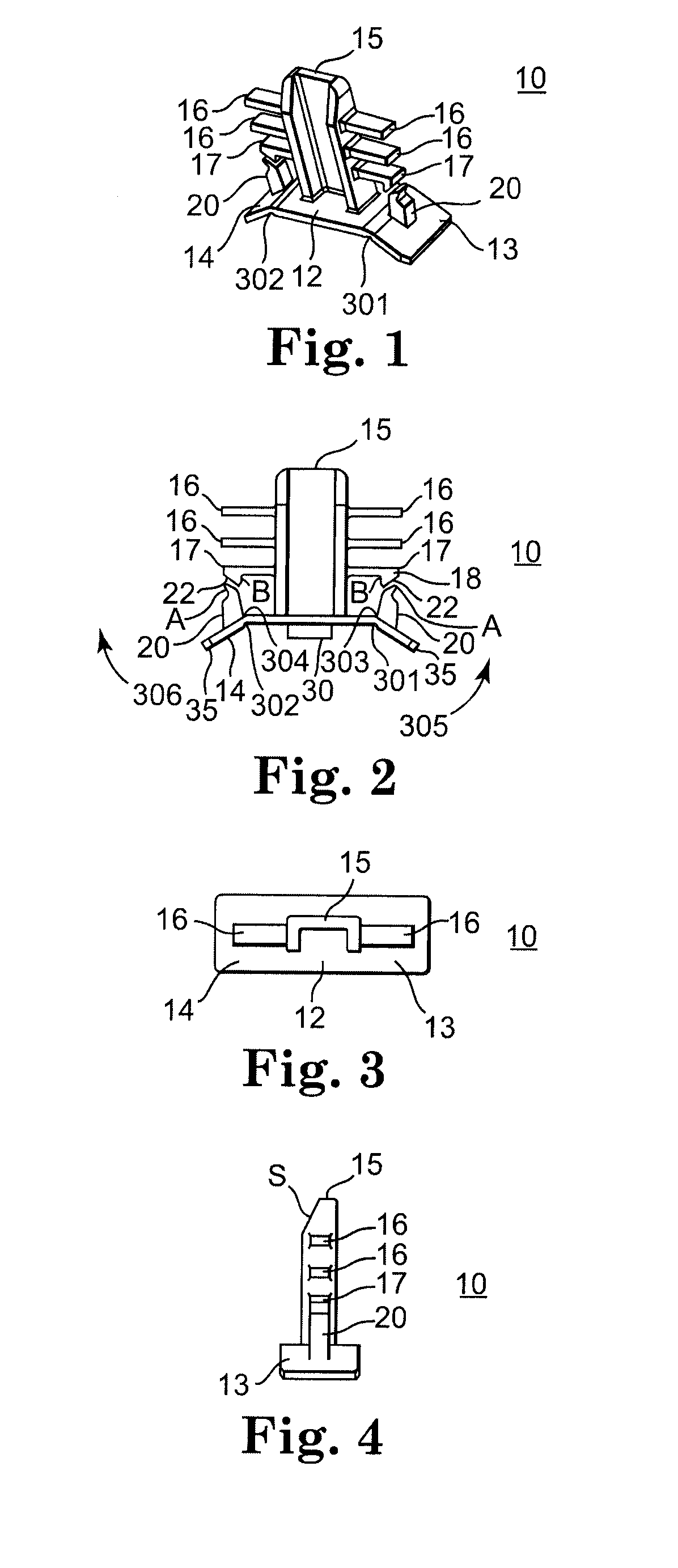

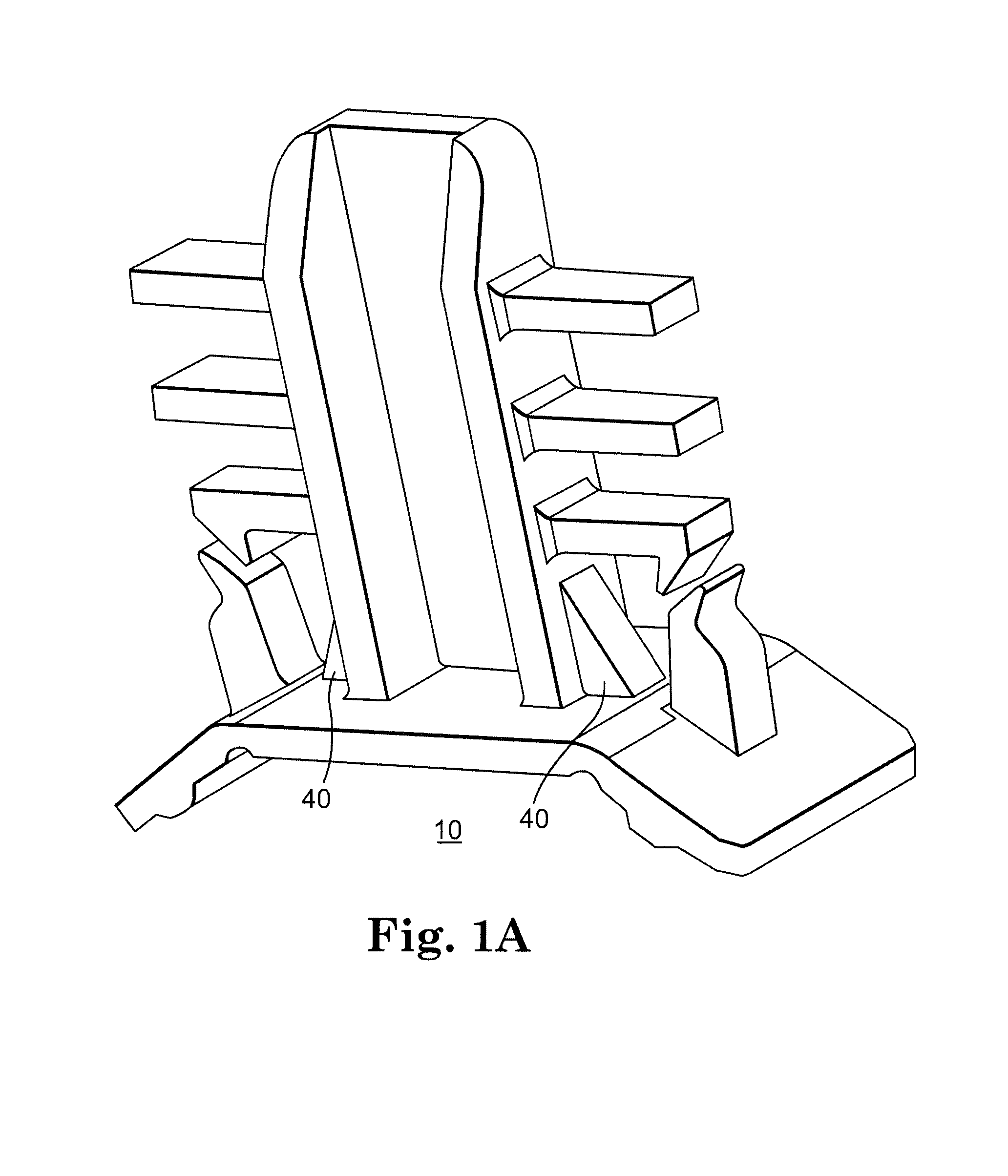

Muntin bar connector with positioning tabs

A connector for holding an internal muntin assembly away from a perimeter spacer of an insulating glass assembly until the assembler is ready to affix the muntin bar to the perimeter bar using an attachment device. The connector includes a positioning tab for holding the muntin bar away from the perimeter spacer to allow positioning of the muntin bar assembly until the positioning tab is moved relative to a baseplate so that the attachment device, such as thick double stick tape, is pressed to the perimeter spacer.

Owner:PELLA

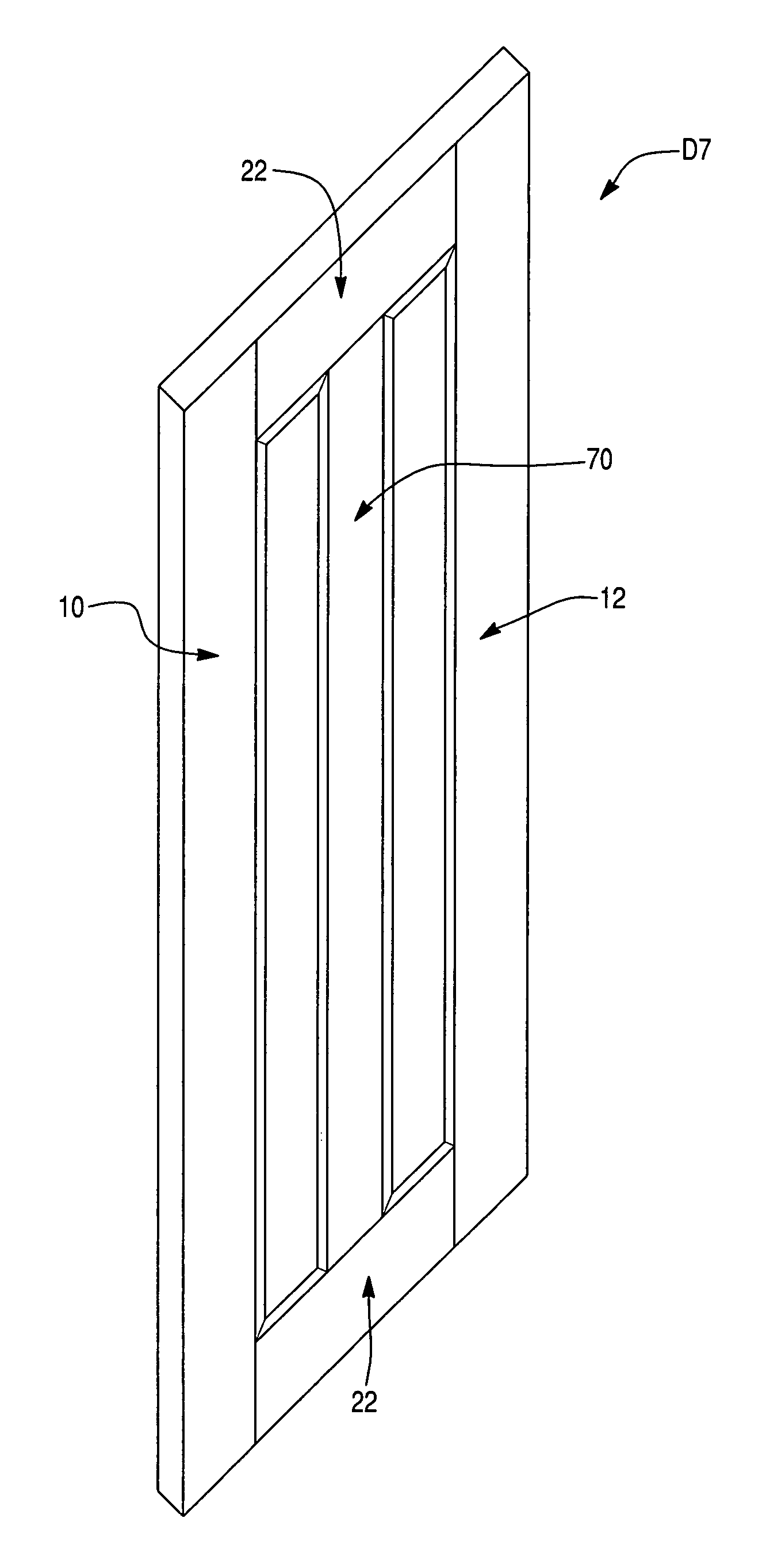

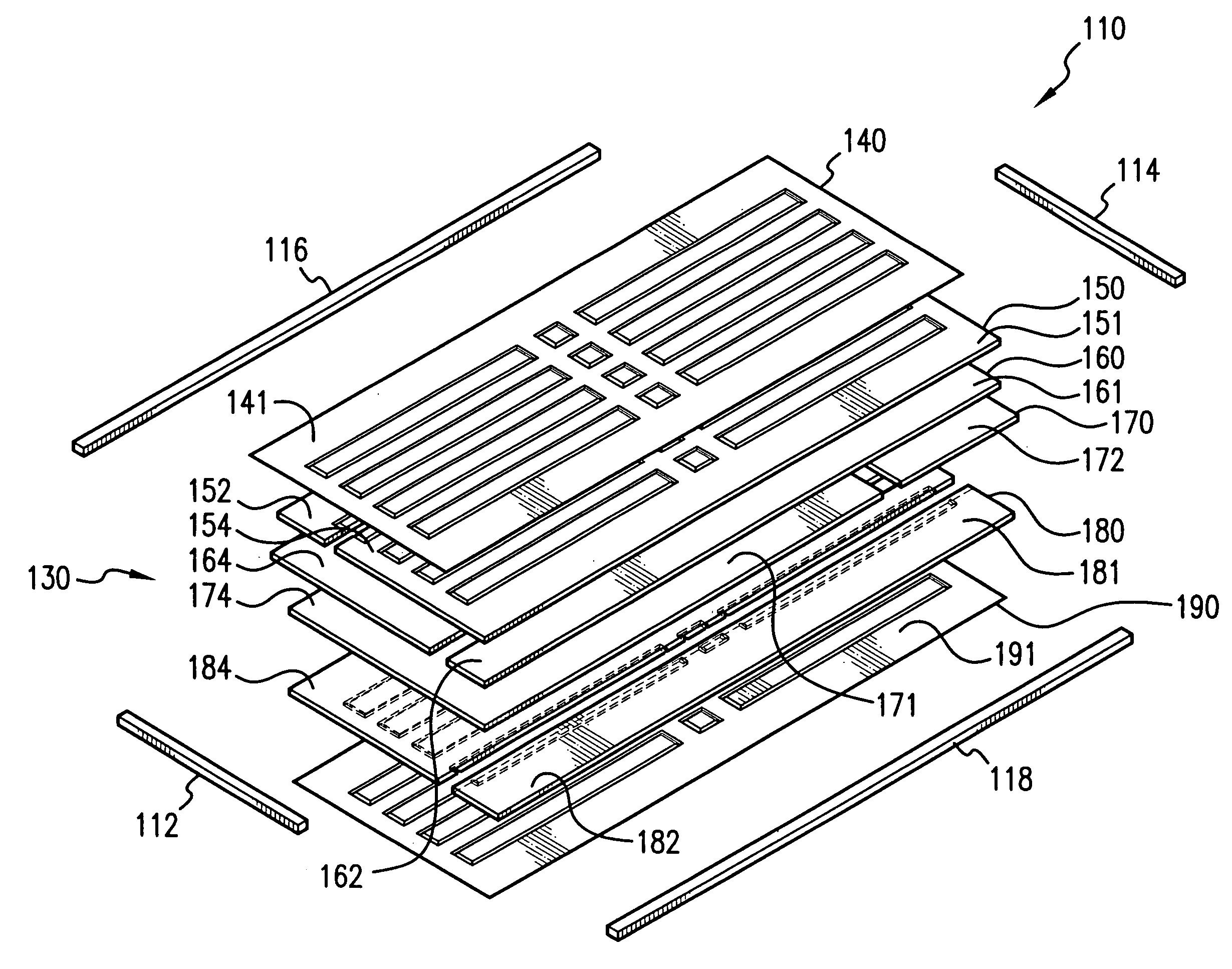

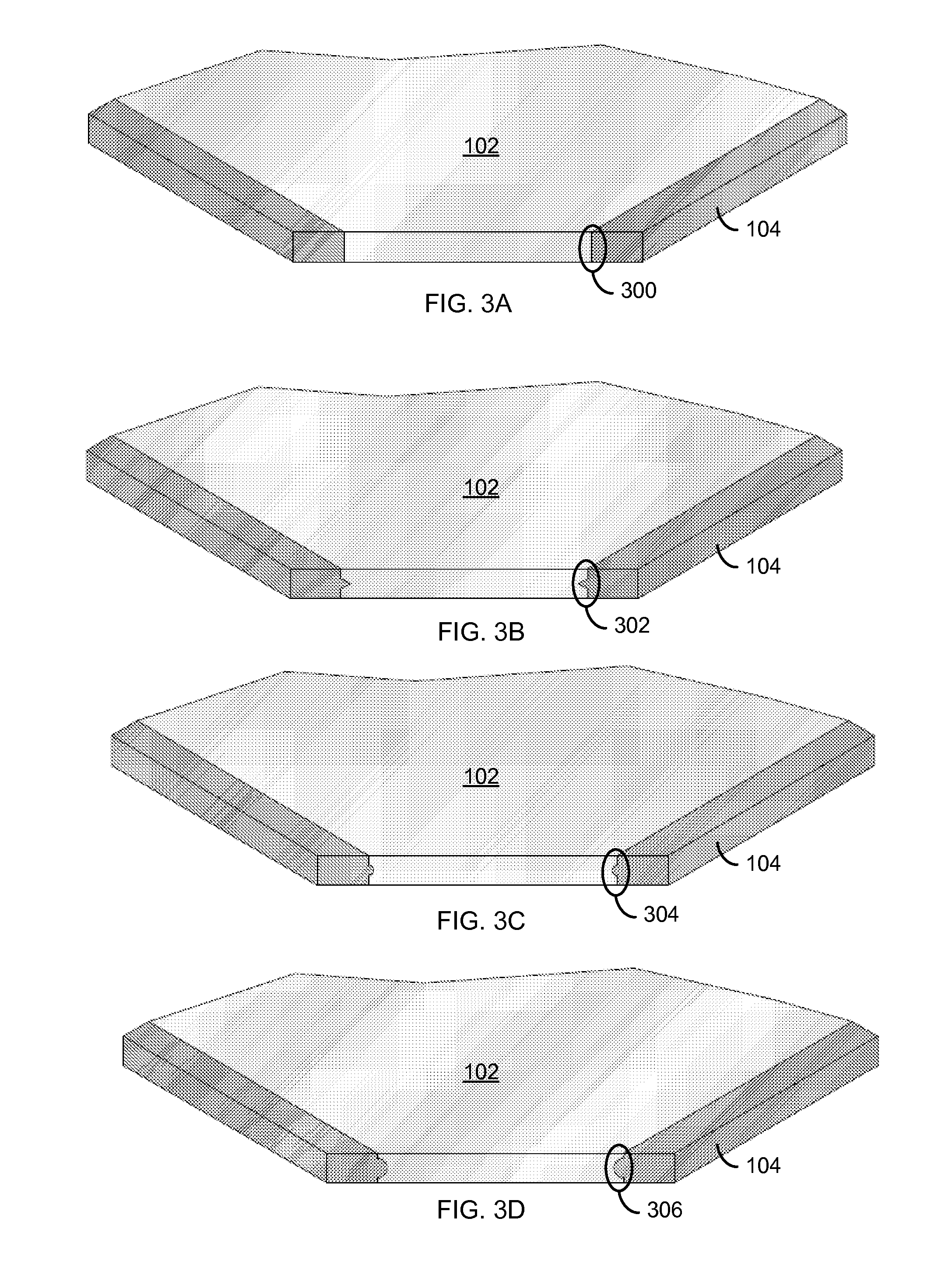

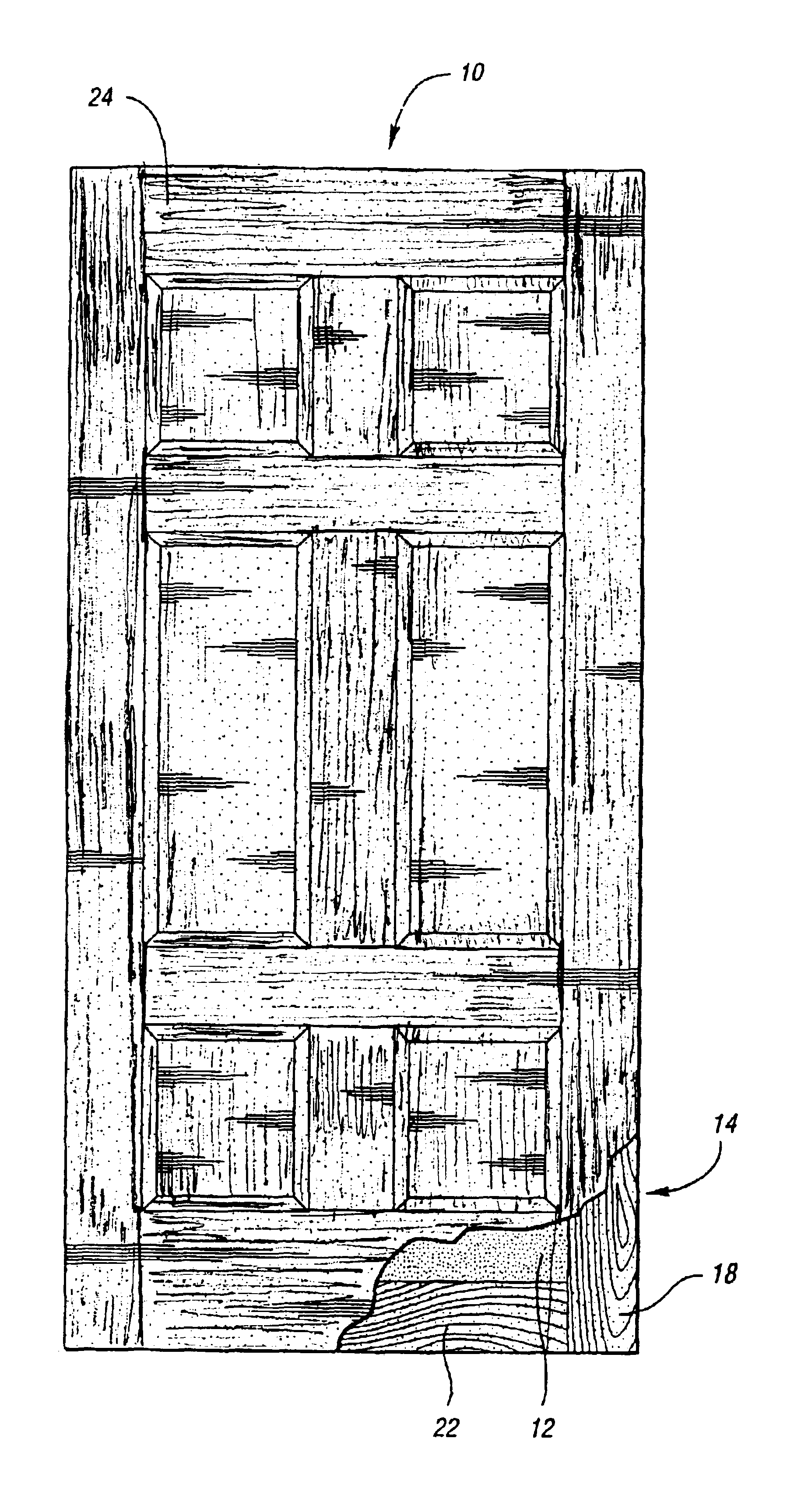

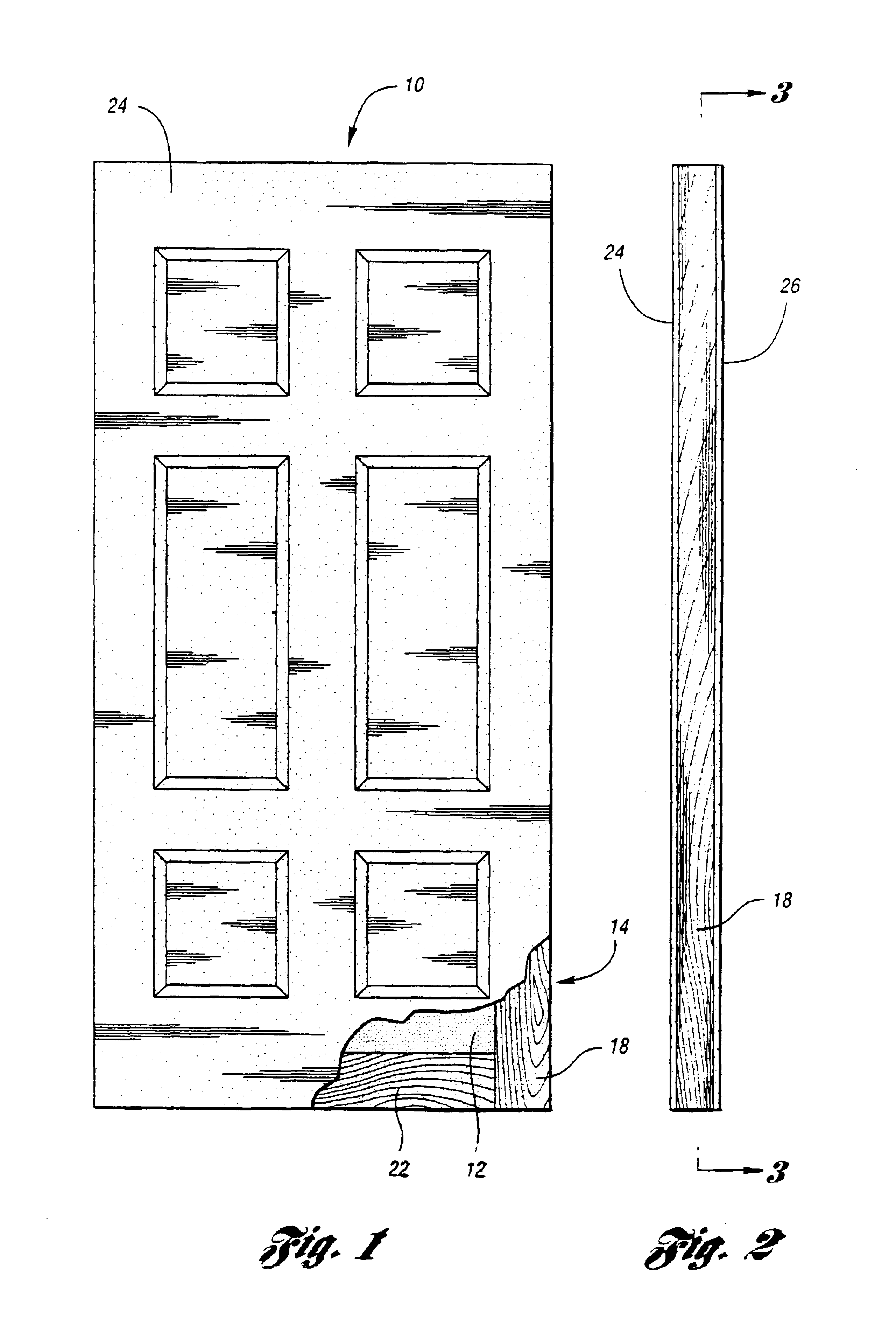

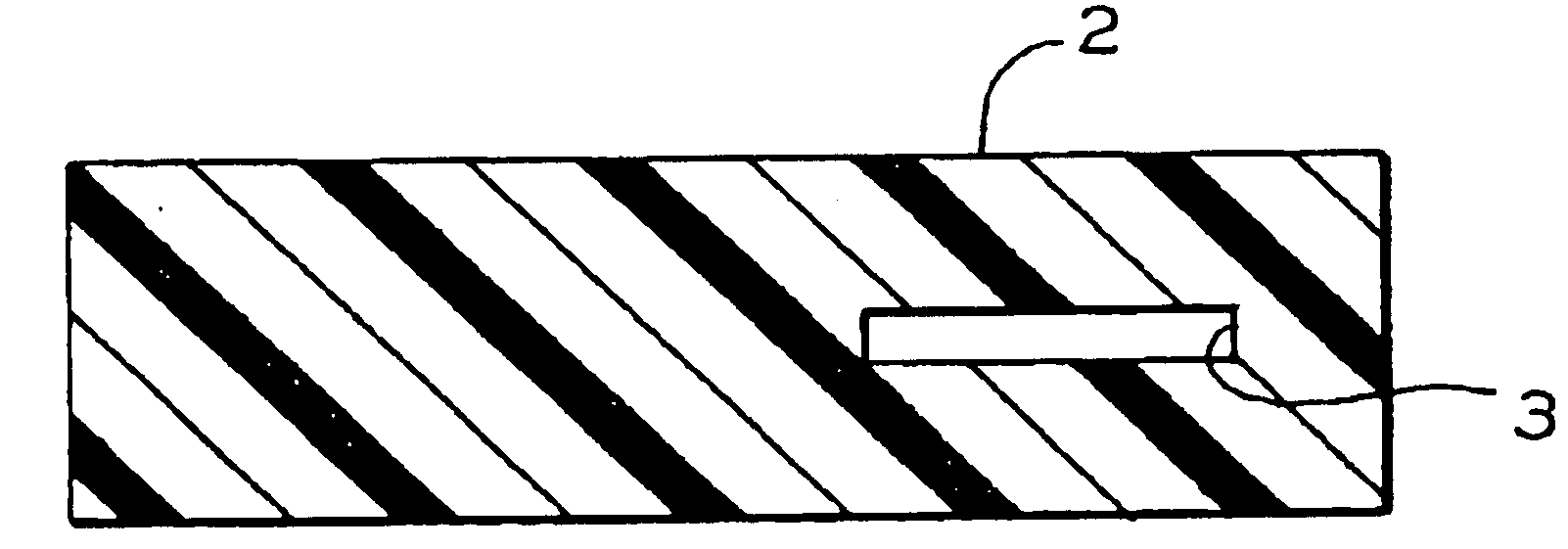

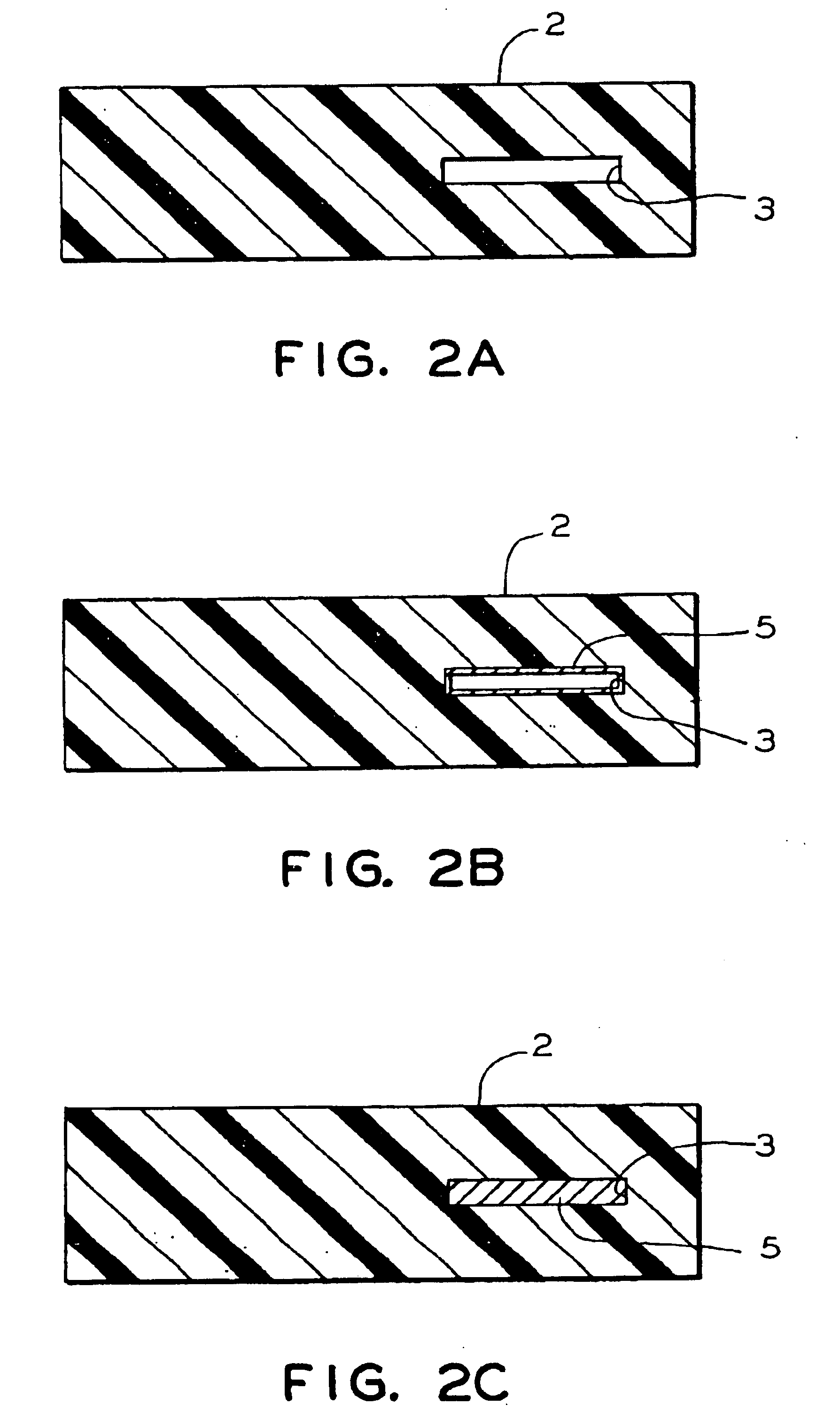

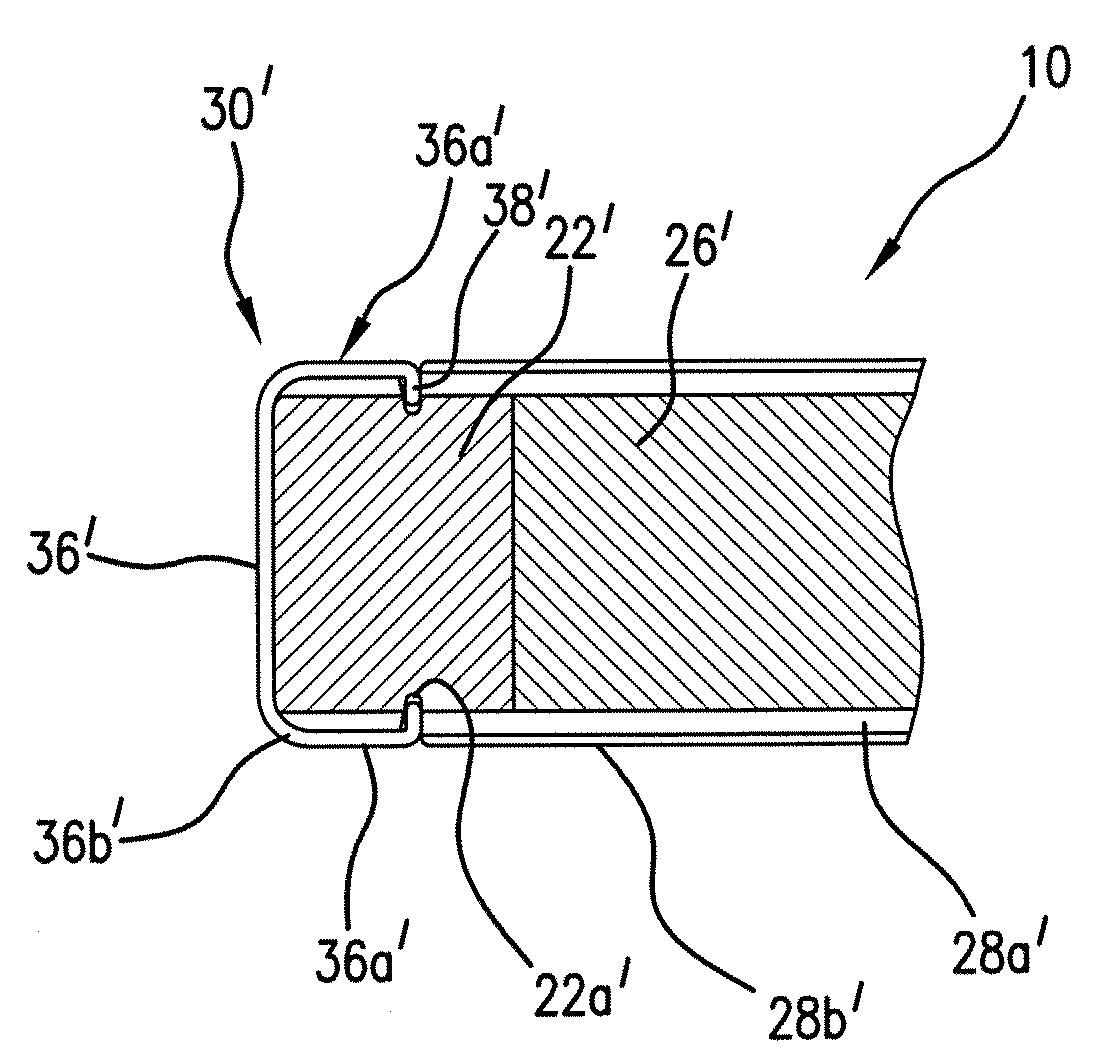

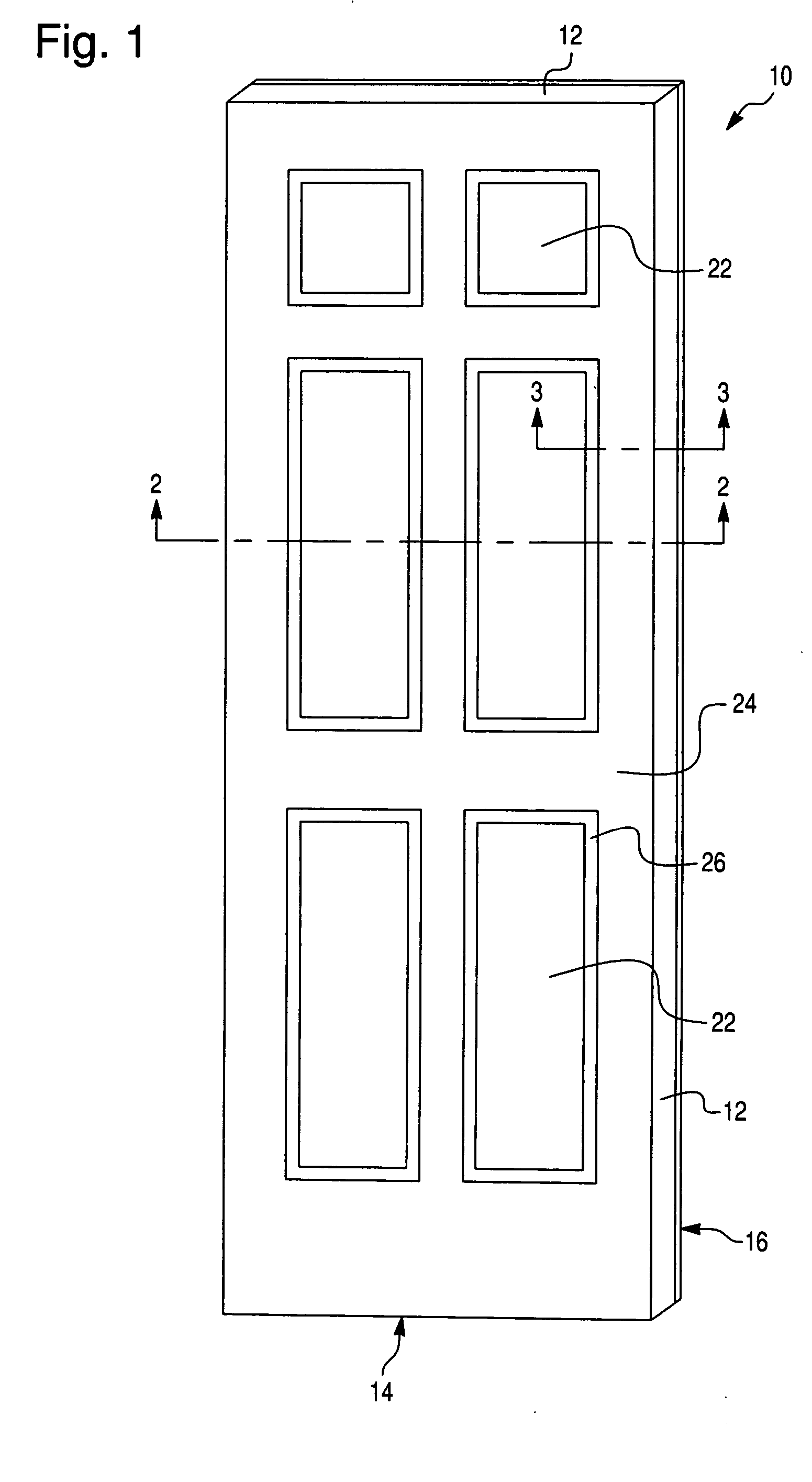

Door skin, method of manufacturing a door produced therewith, and door produced therefrom

A door skin comprises an exterior side and an interior side for being secured to a frame member. First and second molded, spaced stiles lie on a first plane. A flat planar portion is disposed between the stiles and lies on a second plane spaced from the first plane. A first interface portion is disposed between and contiguous with the stiles and the flat planar portion. First and second integrally molded, spaced rails lie on a third plane, wherein the third plane is intermediate the first and second planes.

Owner:MASONITE CORP

Shower door assembly

ActiveUS20140250795A1Simple structureQuickly and conveniently installedBathsDouchesFixed frameEngineering

A shower door assembly is disclosed comprising a stationary frame, a movable frame having a window, an upper frame, and an adjusting assembly. The adjusting assembly further comprises an adjusting block and a fixing block. The adjusting block is disposed between the stationary frame and the movable frame and at least partially received in the stationary frame, and the adjusting block further includes an extension portion on a surface of which a first engaging element is disposed. The fixing block is received in the upper frame and includes an eccentric rotary block having a second engaging element and a base portion having a passage for receiving the extension portion. The eccentric rotary block is rotatable about the base portion.

Owner:FOSHAN IDEAL

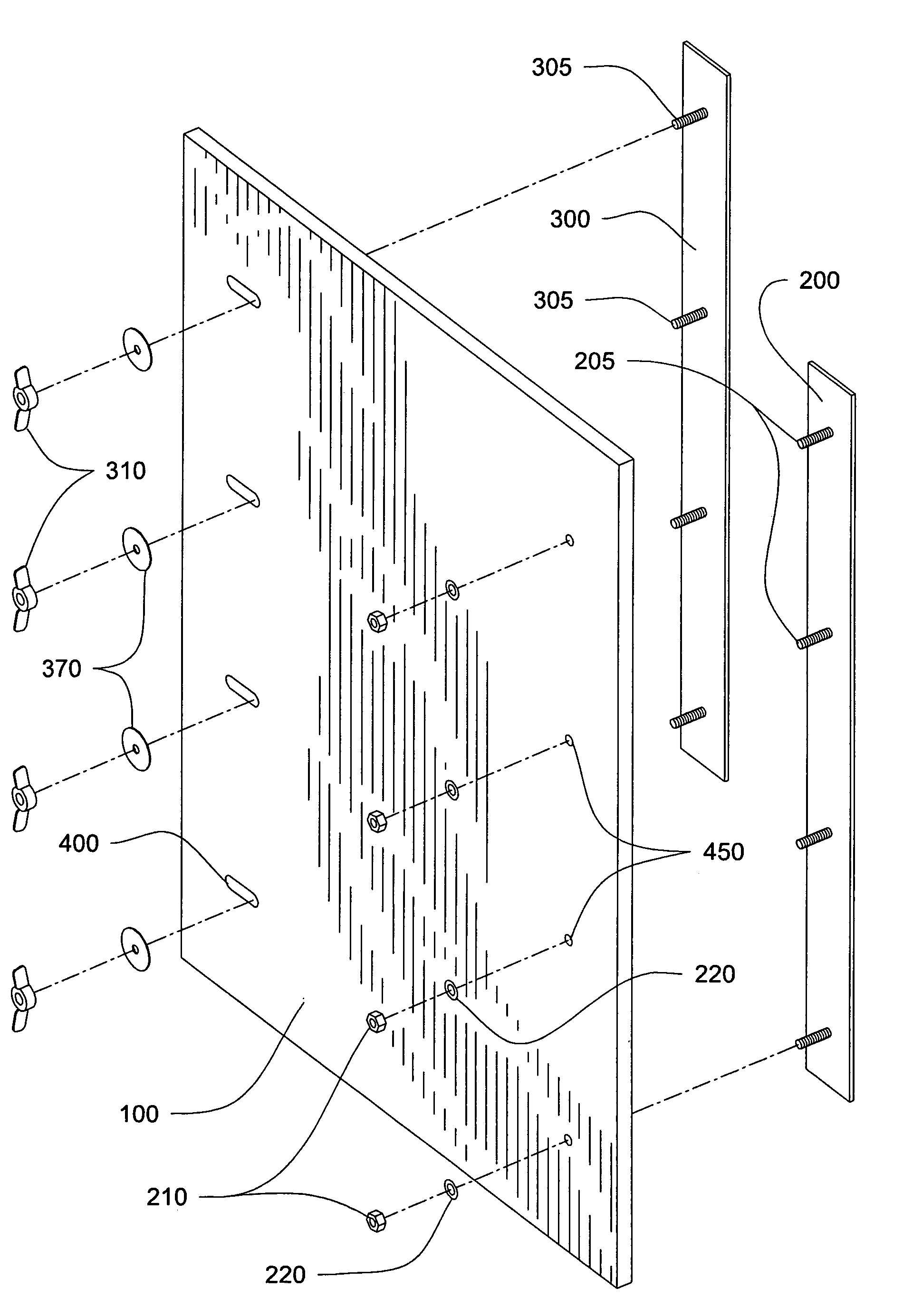

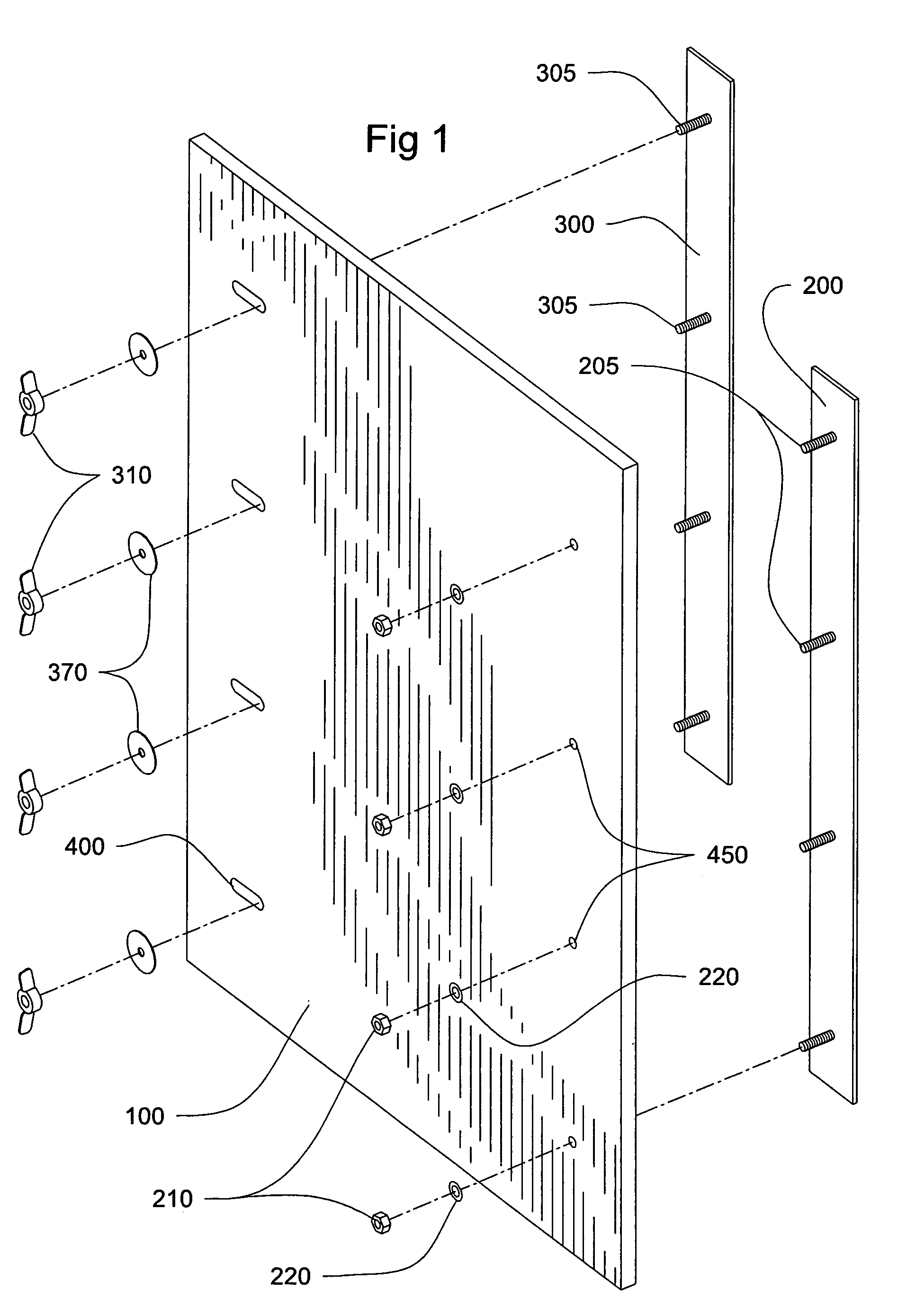

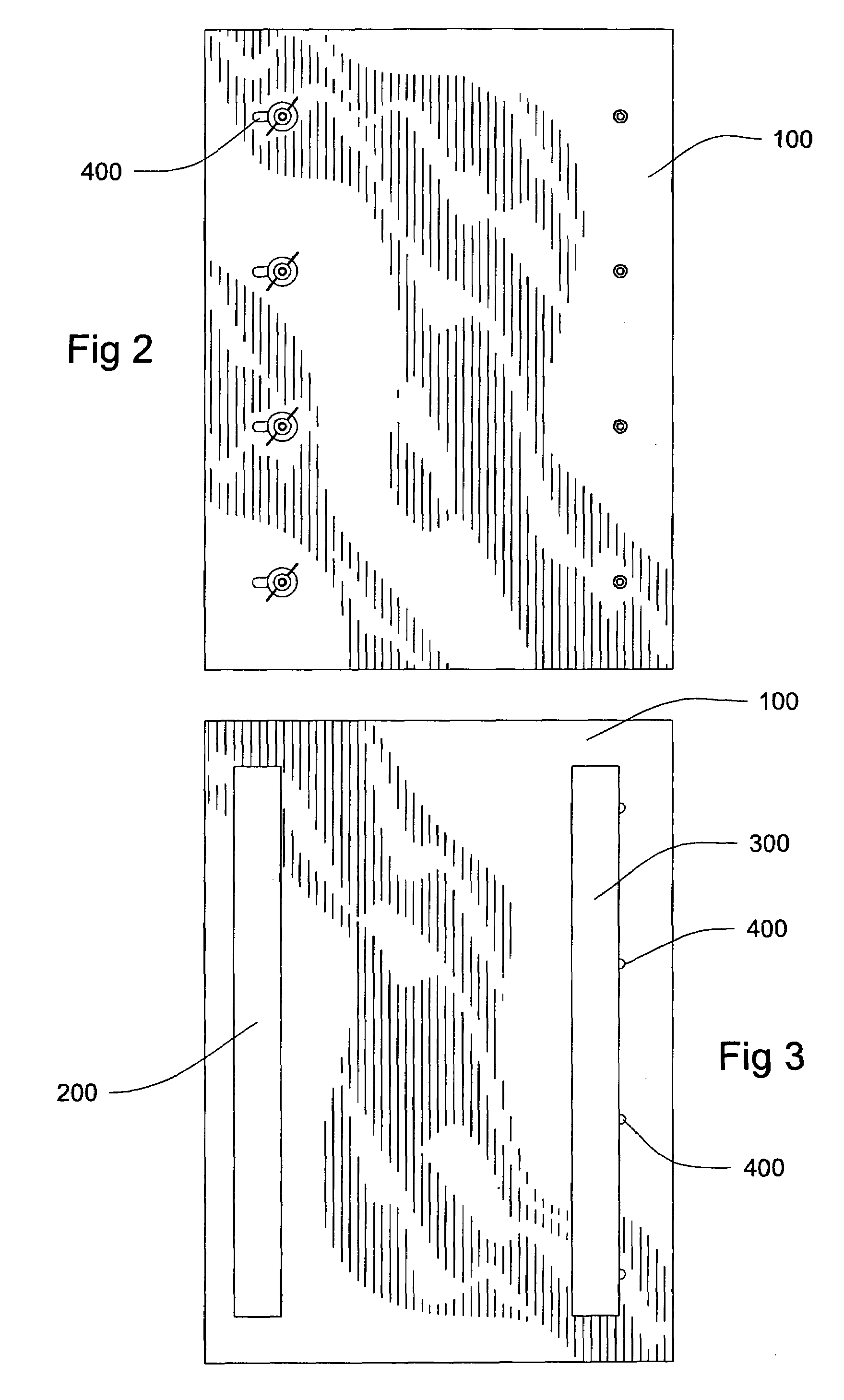

Storm shutter system

InactiveUS6978579B1Easy to installEasy to removeCeilingsShutters/ movable grillesWindow shutterFixed position

The embodiment of this invention is disclosed, which describes a storm shutter system, which allows easy installation and removal by the homeowner. This invention does not add anything to the window and does not require the homeowner to change the window or drill holes into the home in order to install this device. The device is installed in a temporary fashion using the existing screen track of the existing window. One side of the device used a bar, which remains, in a fixed position and the other side uses a bar with slots to allow lateral movement to insure custom fit of the device.

Owner:THE LUBRIZOL CORP

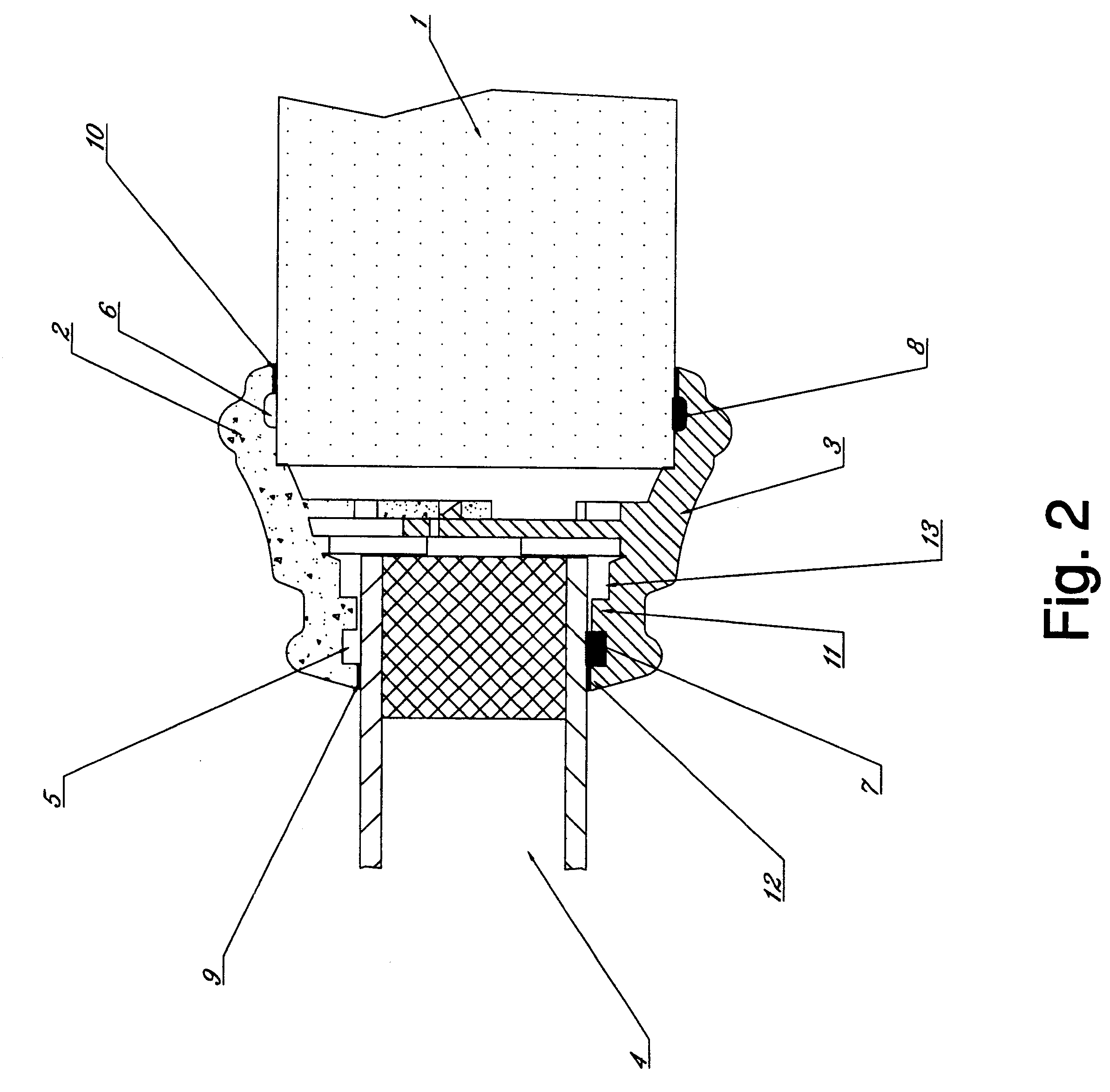

Opposite inserted structure for injecting frame of door leaf with glass

A door assembly structure with glass according to this invention is formed from one door leaf, which is rectangular shape with an opening for glass installed therein; two identical glass injected-frames, which is provided with inside frame and outside frame which is at a position bevel to inside frame, and which outside frame has a flat surface inside on which has a recess, and at inside frame an inner rib with flat surface is formed along its inner edge and a middle rib with flat surface is also formed at a distance parallel to inner rib so that a recess formed in between inner rib and middle rib and a space formed beside middle rib, wherein at a certain distance to middle rib several tenons and several slot mortises in interval with symmetrical position is formed so that by tenon and slot mortise joint one of two identical glass injected-frames may be jointed to the other which is turned in half circle; and at least one piece of glass, which size is smaller than opening of said door leaf and which appearance is similar to that of said opening of said door leaf.Without using any general screws to assemble a door assembly structure with glass of this invention but by use of tenon and slot mortise joint. This invention is completely assembled as a whole door assembly structure with glass much more easily than before does and capably reduce cost without wasting working time.

Owner:NANYA PLASTICS CORP

Mechanical safety device for a door pivotally mounted on a frame

InactiveUS6298605B1Reliable and reliableEasy to installHingesSealing arrangementsVertical alignmentEngineering

A safety device for a door is arranged to prevent access to the vertical gap situated on the side where the hinges are located between the frame and the rear edge of the door. The safety device comprises a protection unit having at least one tubular element fitted in the gap in vertical alignment with the hinges, and a strip made of flexible or semi-rigid material arranged on the side opposite the tubular element. The fixing part for fixing the strip onto the frame comprises a rounding unit for rounding the strip over the whole height thereof so as to perform preliminary bending of the strip at a predetermined angle. The strip and the plate extending down to the bottom of the door to achieve total protection.

Owner:DELEFOSSE BRUNO +2

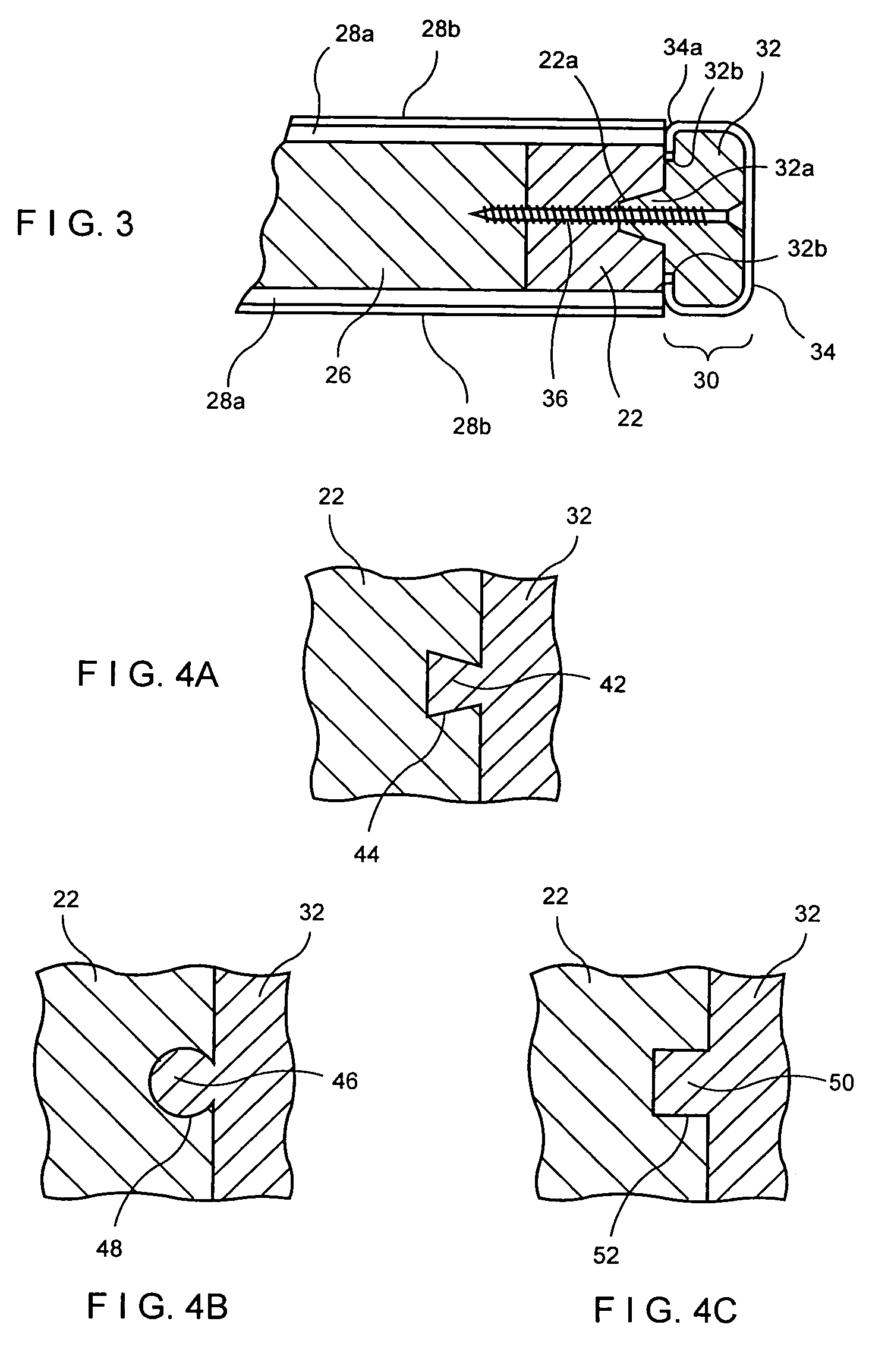

Door edge construction

InactiveUS7886501B2Simply and inexpensively restoredMinimize necessityFireproof doorsDoor leavesCouplingEngineering

A door is constructed with a separate member joined to the door edge by a tongue-and-groove coupling and screws so as to be readily removable and replaceable. The separate member sustains the impacts imparted to the door by carts or wagons pushed past the door and can be readily replaced when damaged, thus avoiding replacement of the entire door. A flexible cover snaps over the outer surface of the separate member to add impact resistance and aesthetic appeal. Intumescent strips may be inserted inside or outside of the cover to enhance sealing between the door, and as adjacent door or door frame, thereby improving the fire resistance rating of the door. Accent strips or reveals of contrasting or complementary colors may be incorporated to add to the aesthetic appeal of the door. The door construction is of particular utility in schools, health care facilities and other institutions.

Owner:CONSTR SPECIALTIES

Door, deep draw molded door facing, and methods of forming door and facing

InactiveUS20050217206A1Satisfactory stretch factorNatural patternsLayered productsEngineeringMechanical engineering

The present invention relates to a wood composite panel having a major planar portion, at least one panel portion, and an inwardly extending contoured portion surrounding the panel portion and interconnecting the major planar portion and the panel portion. The contoured portion defines an inter-relationship between a vector angle and a deep draw depth that achieve a satisfactory stretch factor. The present invention also relates to a door having the disclosed wood composite door facings, and methods of forming the facing and door.

Owner:MASONITE CORP

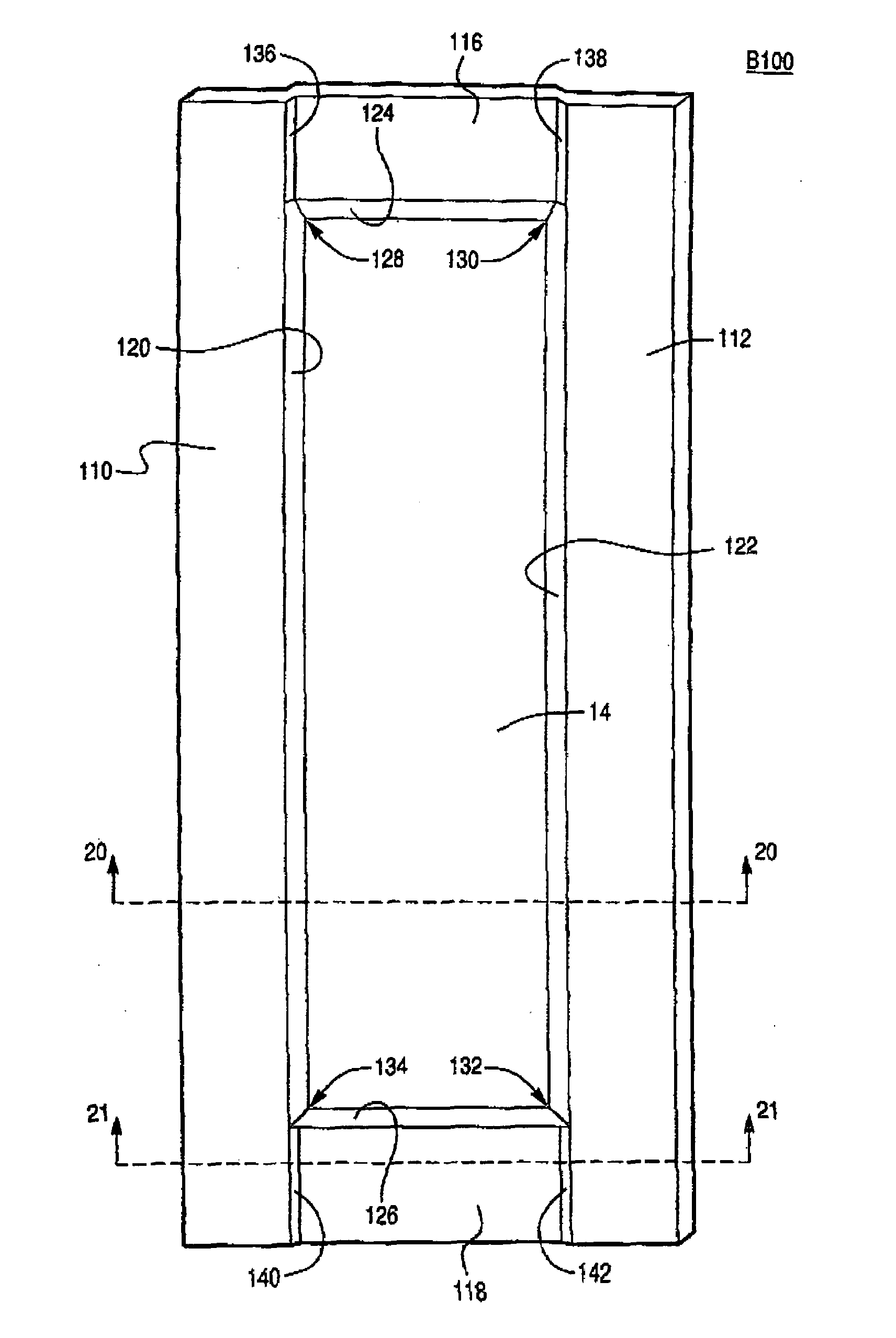

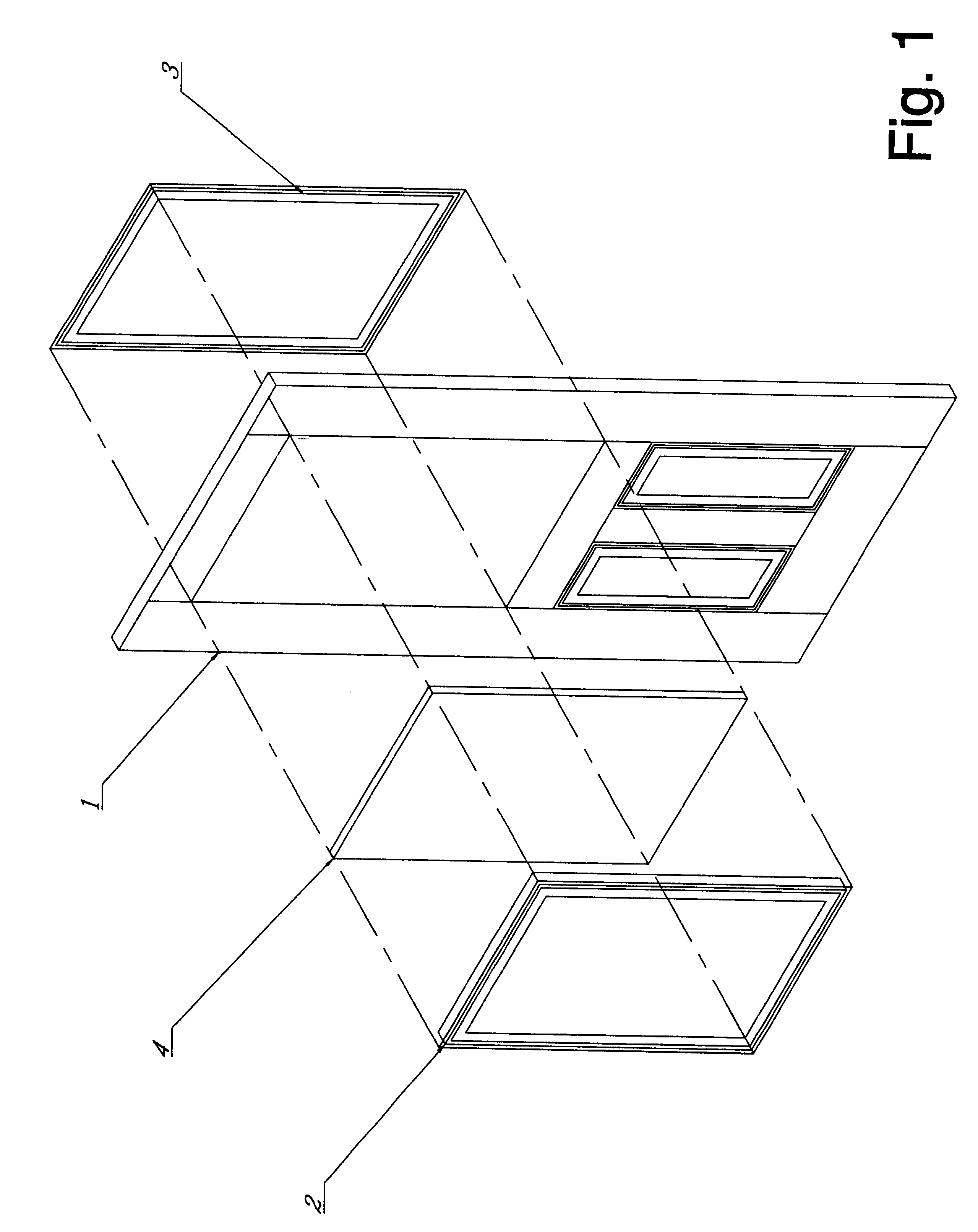

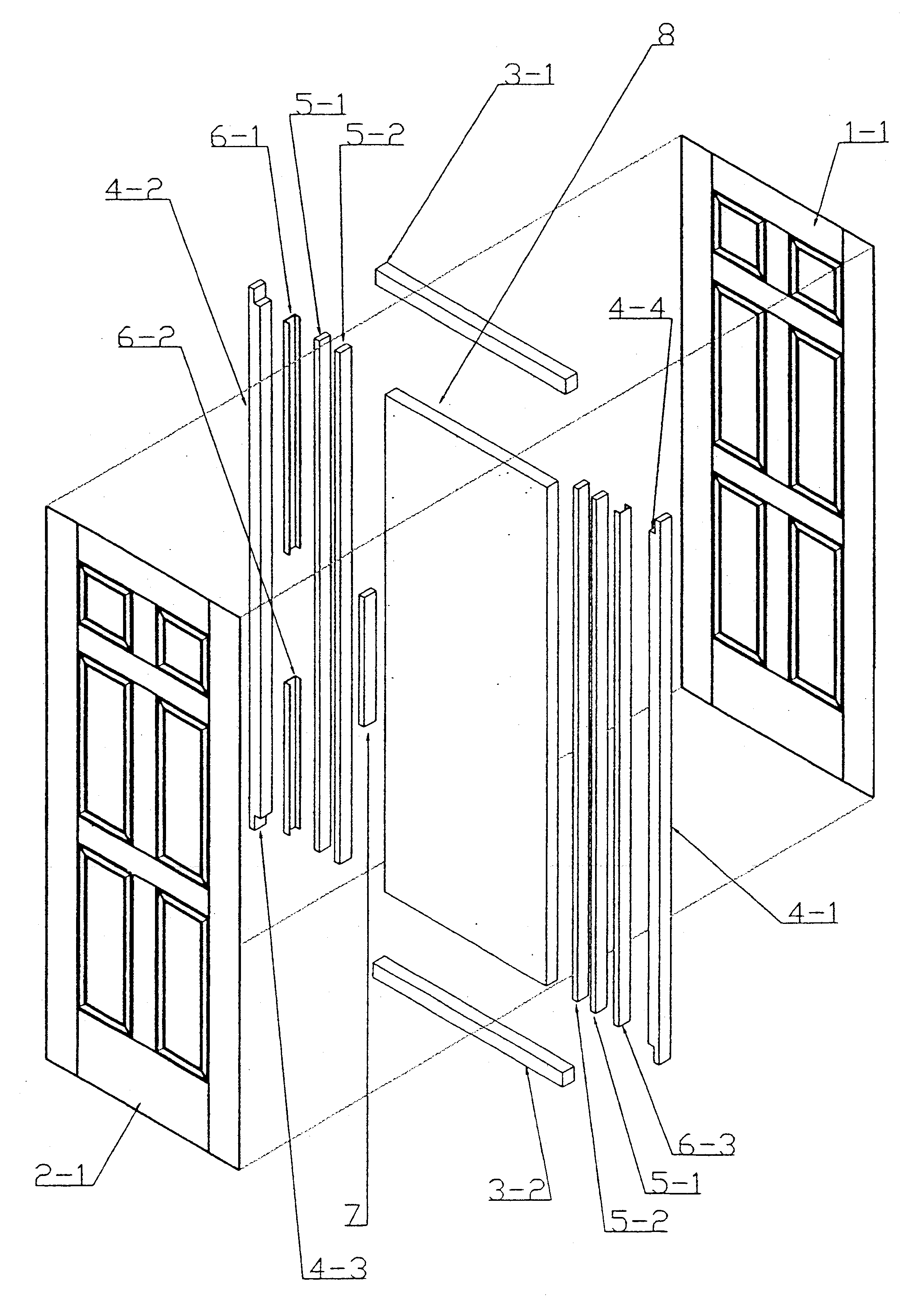

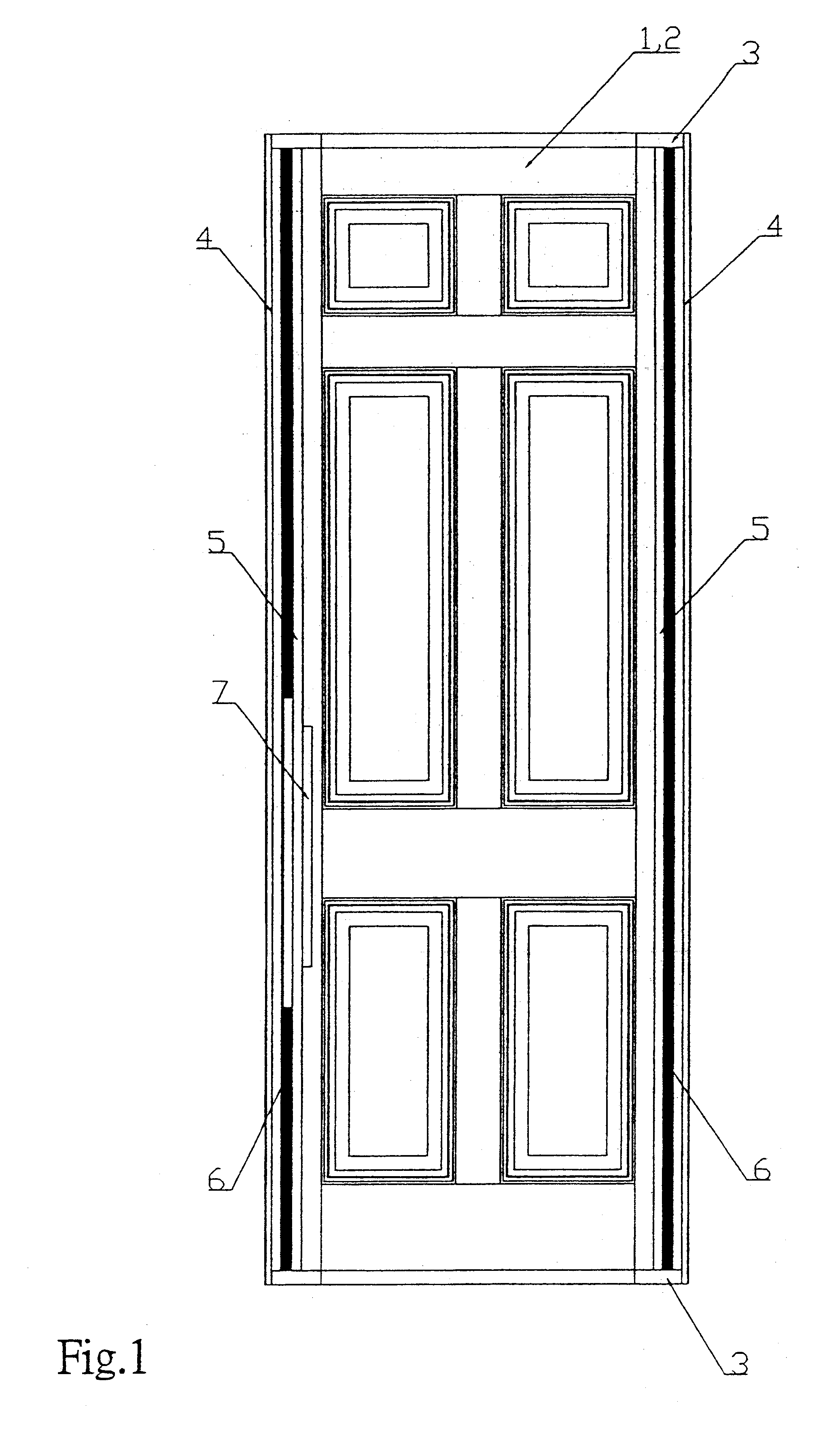

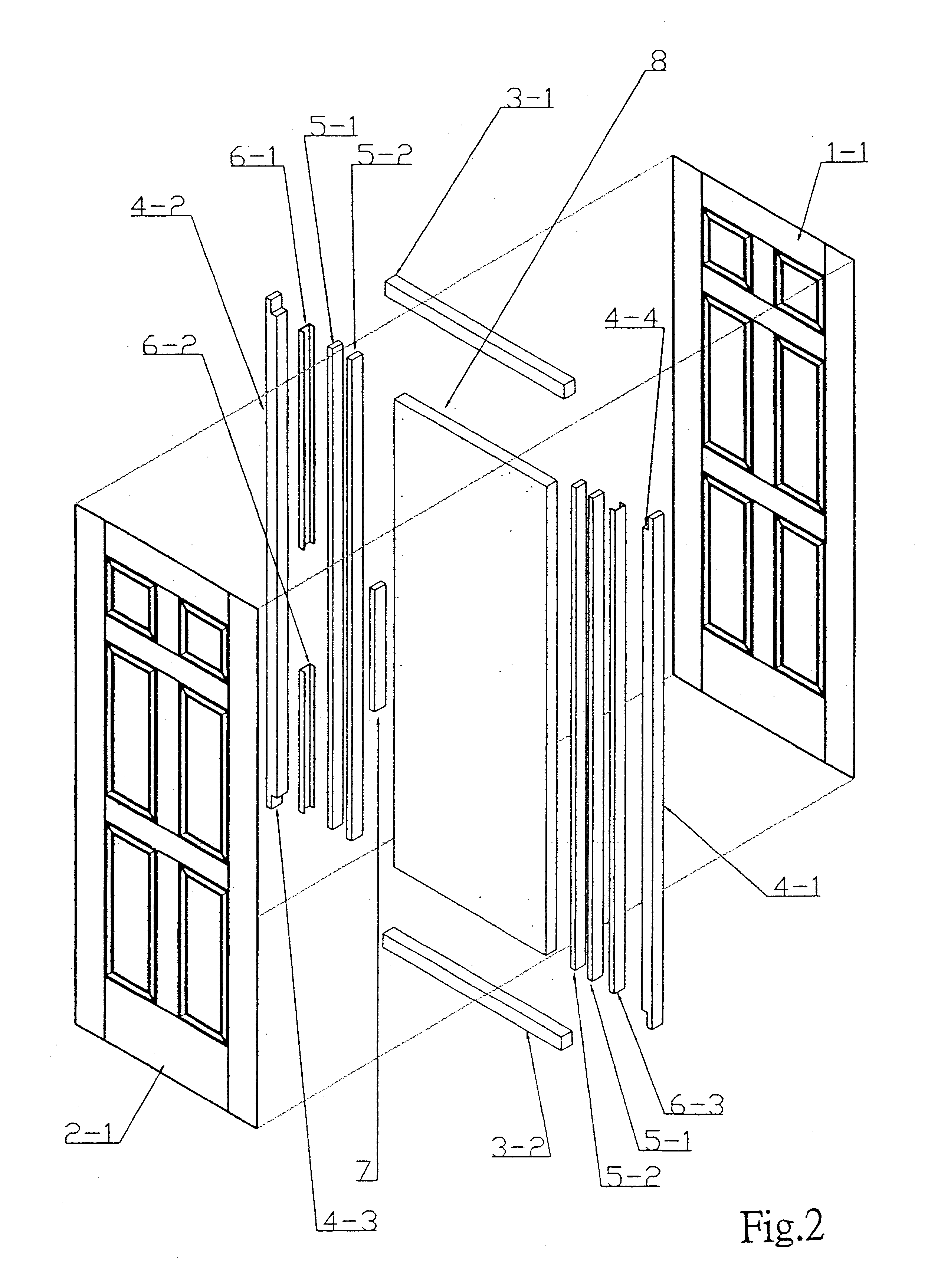

Super high door structure

InactiveUS6619010B2Optimize assembly structureImprove assembly structure and firmnessDoor leavesEngineeringAssembly structure

An assembly structure of a super-high door includes two hubbed door skins and top, bottom, left and right edge-sealing angle bars. The door skins are positioned by flange ribs of the left angle bar. The top and bottom bars are positioned by notches at the top and the bottom ends of the left and right angle bars. The inner side of a first upper longer region (above the handle) of the left angle bar and the inner side of a second lower shorter region (below the handle) of the left angle bar are respectively inlaid with two U-shaped reinforcing irons having a length corresponding to that of the first and second regions. A wood strip with a length shorter than that of the left angle bar is inserted into the inner of the two reinforcing irons and is then closely joined to another wood strip of which the handle position is inlaid with a reinforcing angle bar. The inner side of the right angle bar is inlaid with a reinforcing iron having a length shorter than that of the right angle bar, and a wood strip with a length corresponding to that of the reinforcing iron is inserted thereto and closely joined to another wood strip. After assembly, the structure is filled with ammonium polyester foamed plastic.

Owner:NANYA PLASTICS CORP

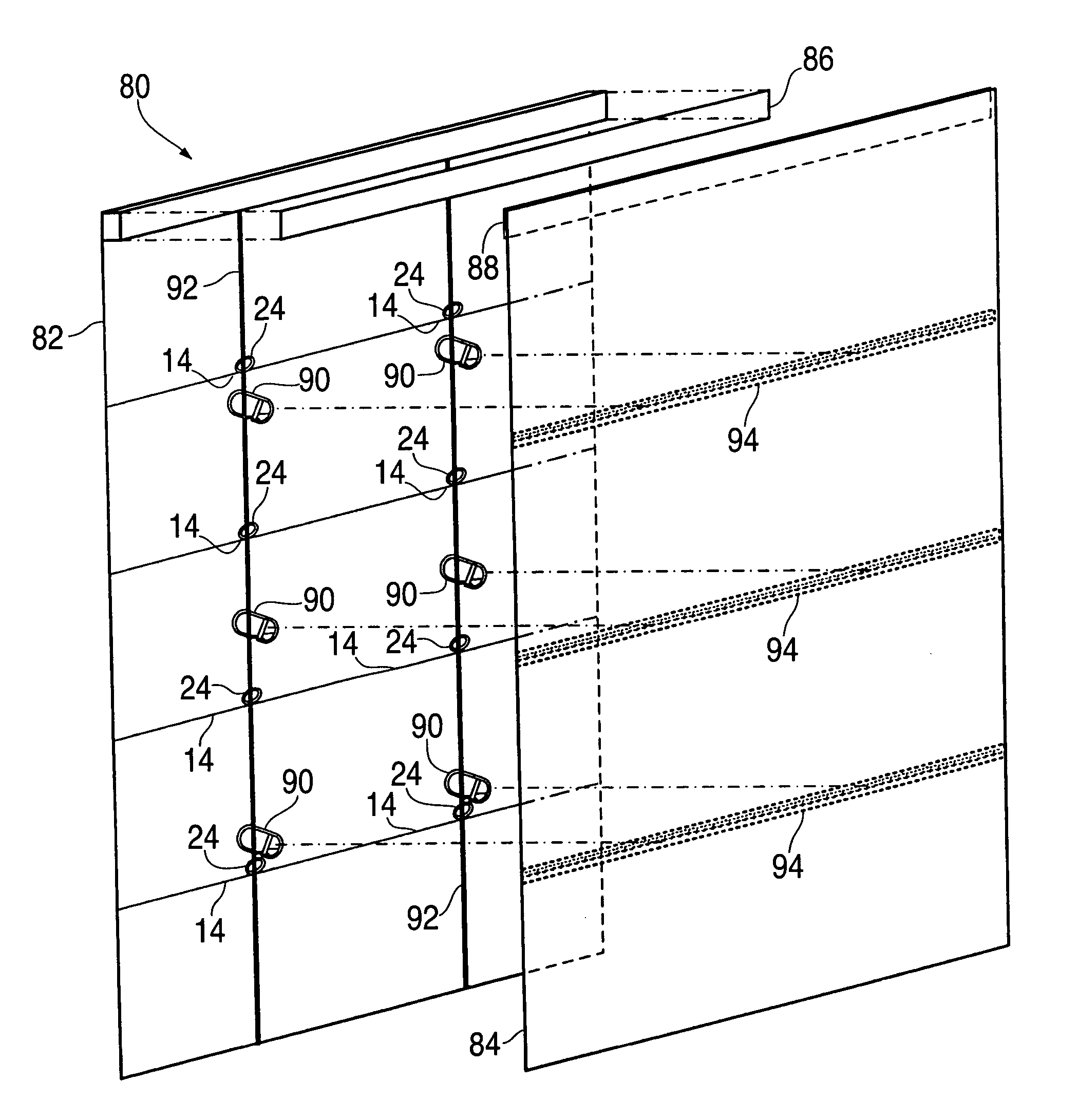

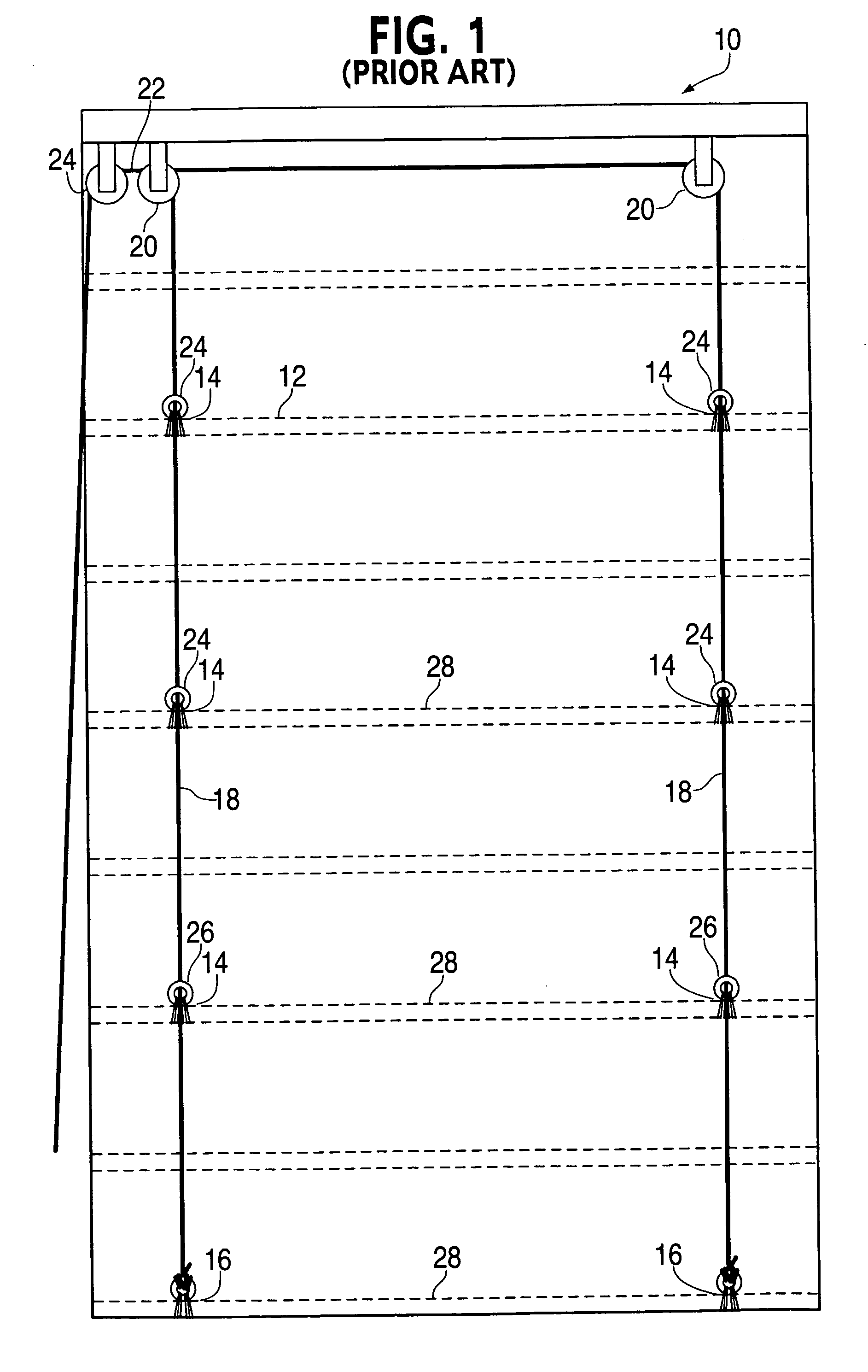

Window shade liner method and apparatus

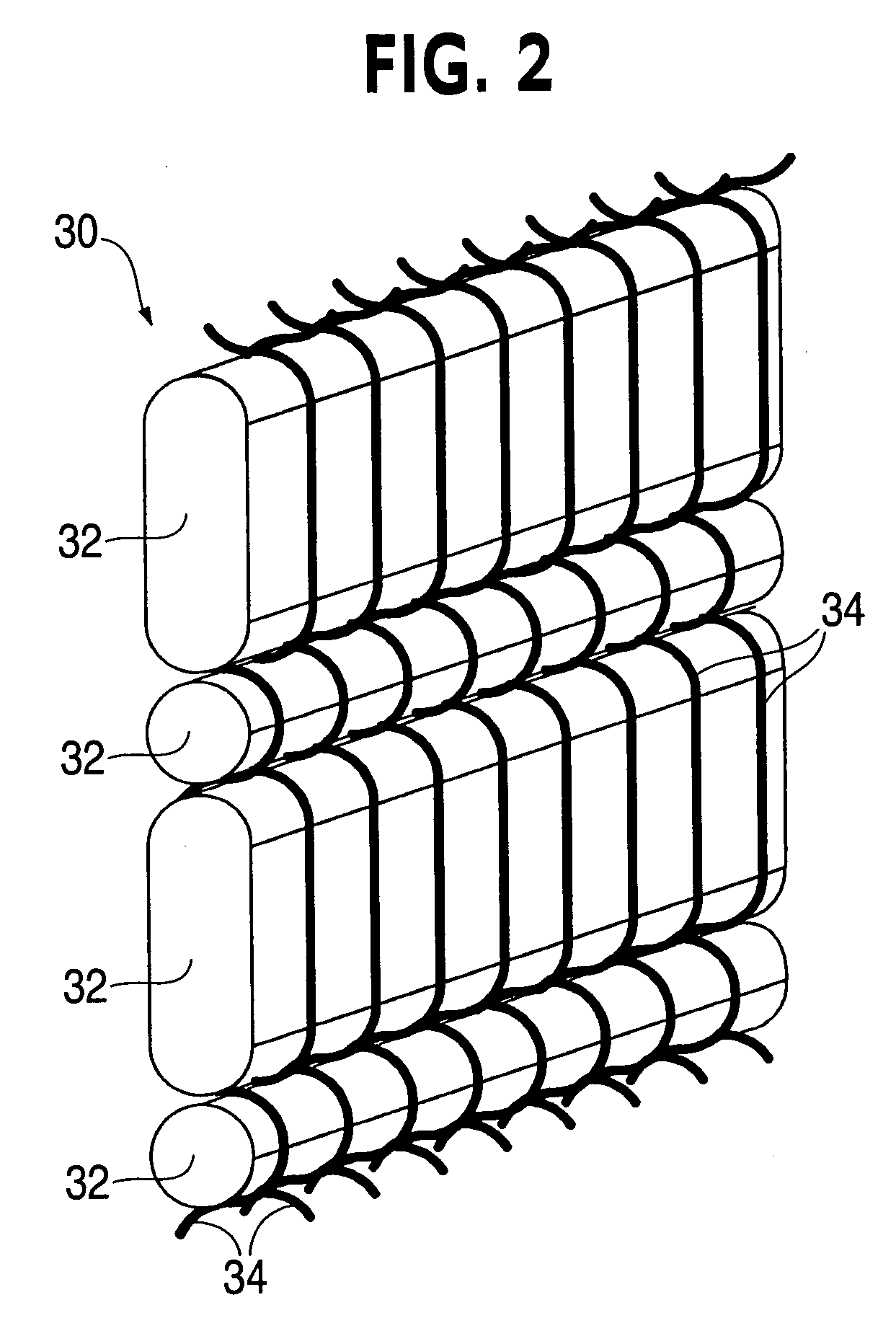

A universal removable liner attaches to a Roman shade to block sunlight and provide privacy. The shade retraction mechanism draws the shade up in tiers with one or more lift cords. The liner links to the shade across the top of the shade and at the lift cords, with the tiers formed in the shade lifting the liner in tiers as well. Links between the lift cords and the liner at the shade tier tops are closable loops. A hook-and-loop tape is preattached to the top edge of the liner, while a separate strip of adhesive-backed, mating hook-and-loop tape is furnished for user attachment to the top edge of substantially any tier-lift shade. Once the user joins the shade and liner at the tier tops, the liner forms tiers mirroring the tiers of the shade as the two are raised together.

Owner:LEWIS HYMAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com