Patents

Literature

78 results about "Muntin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

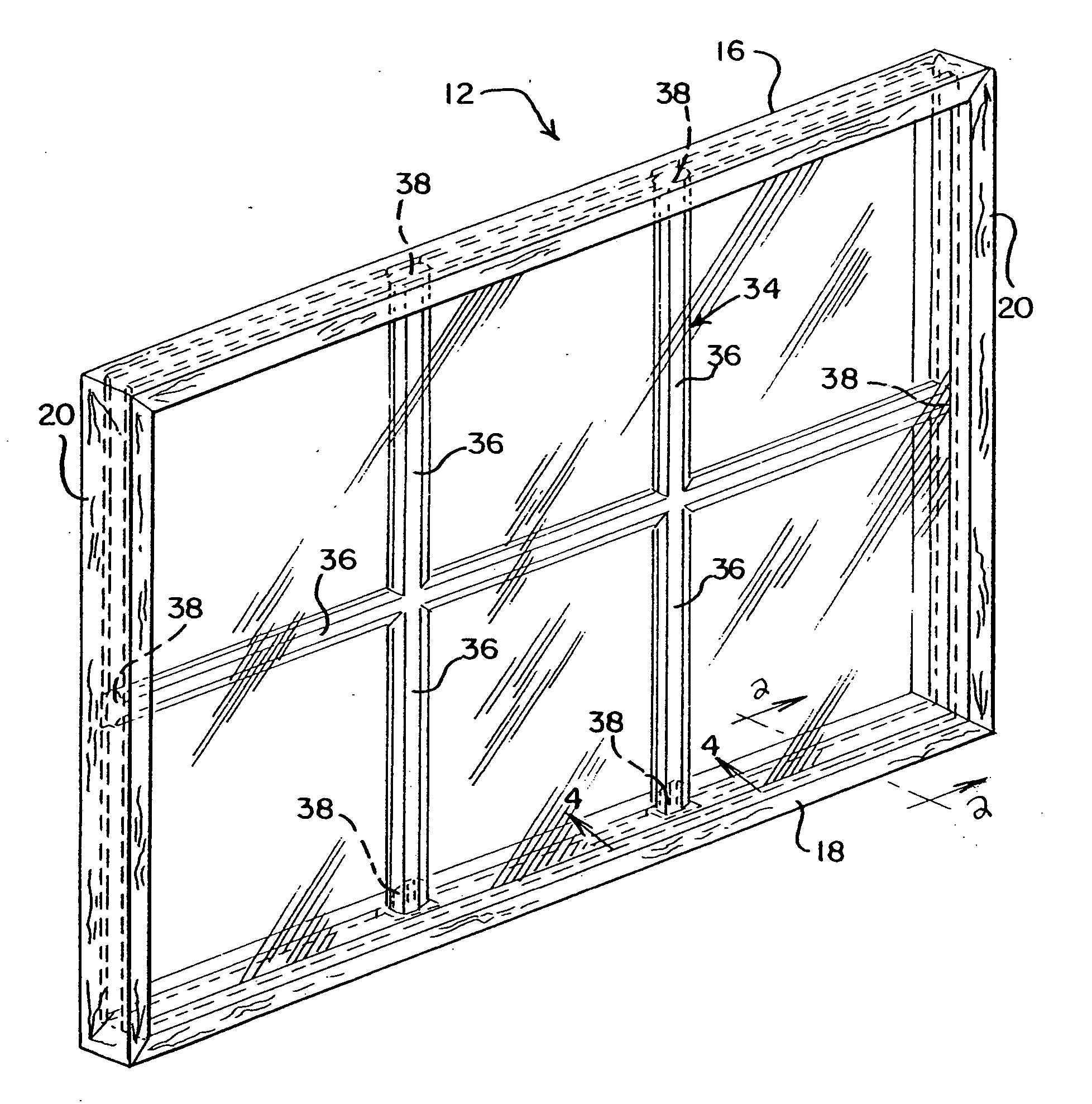

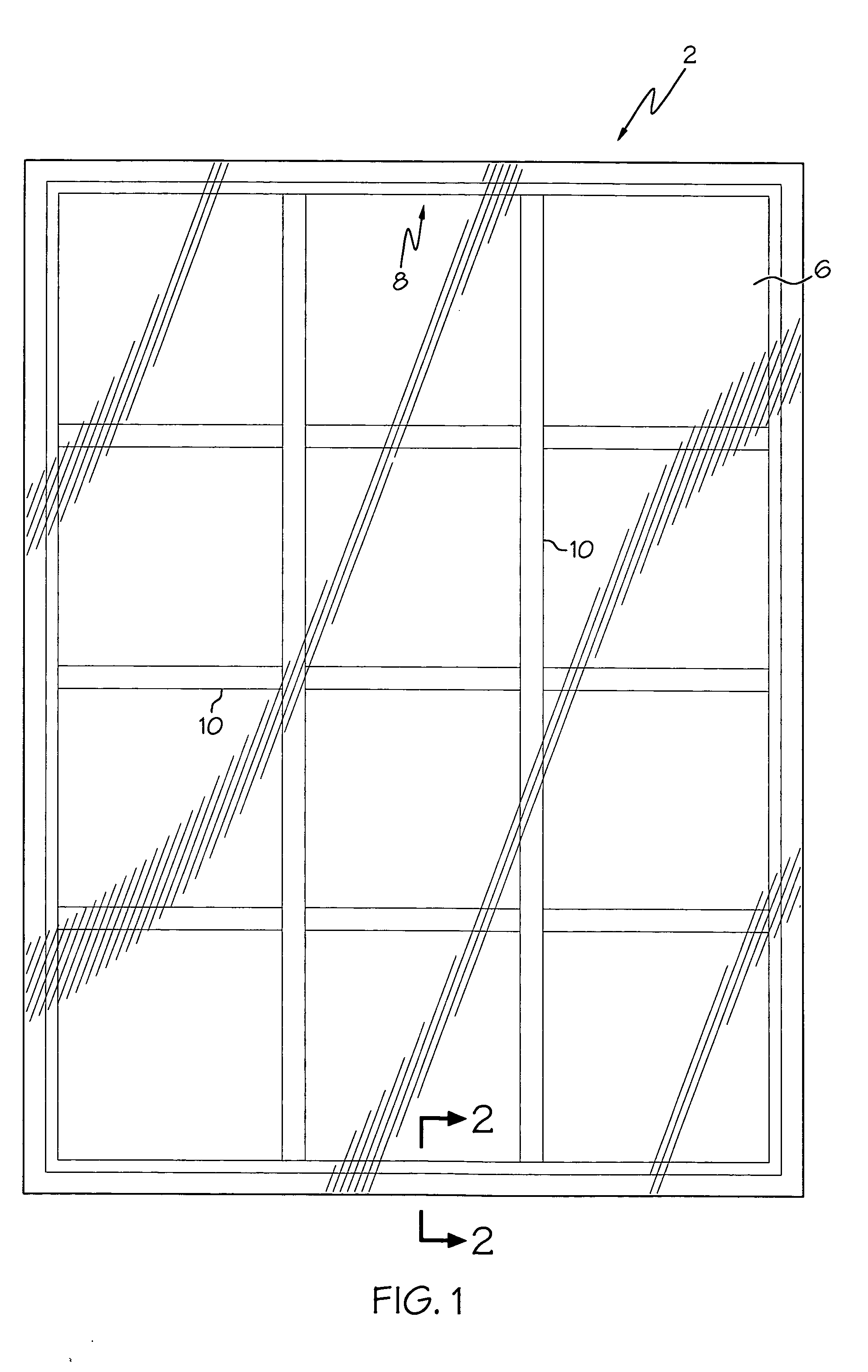

A muntin (US), muntin bar, glazing bar (UK) or sash bar is a strip of wood or metal separating and holding panes of glass in a window. Muntins can be found in doors, windows and furniture, typically in western styles of architecture. Muntins divide a single window sash or casement into a grid system of small panes of glass, called "lights" or "lites".

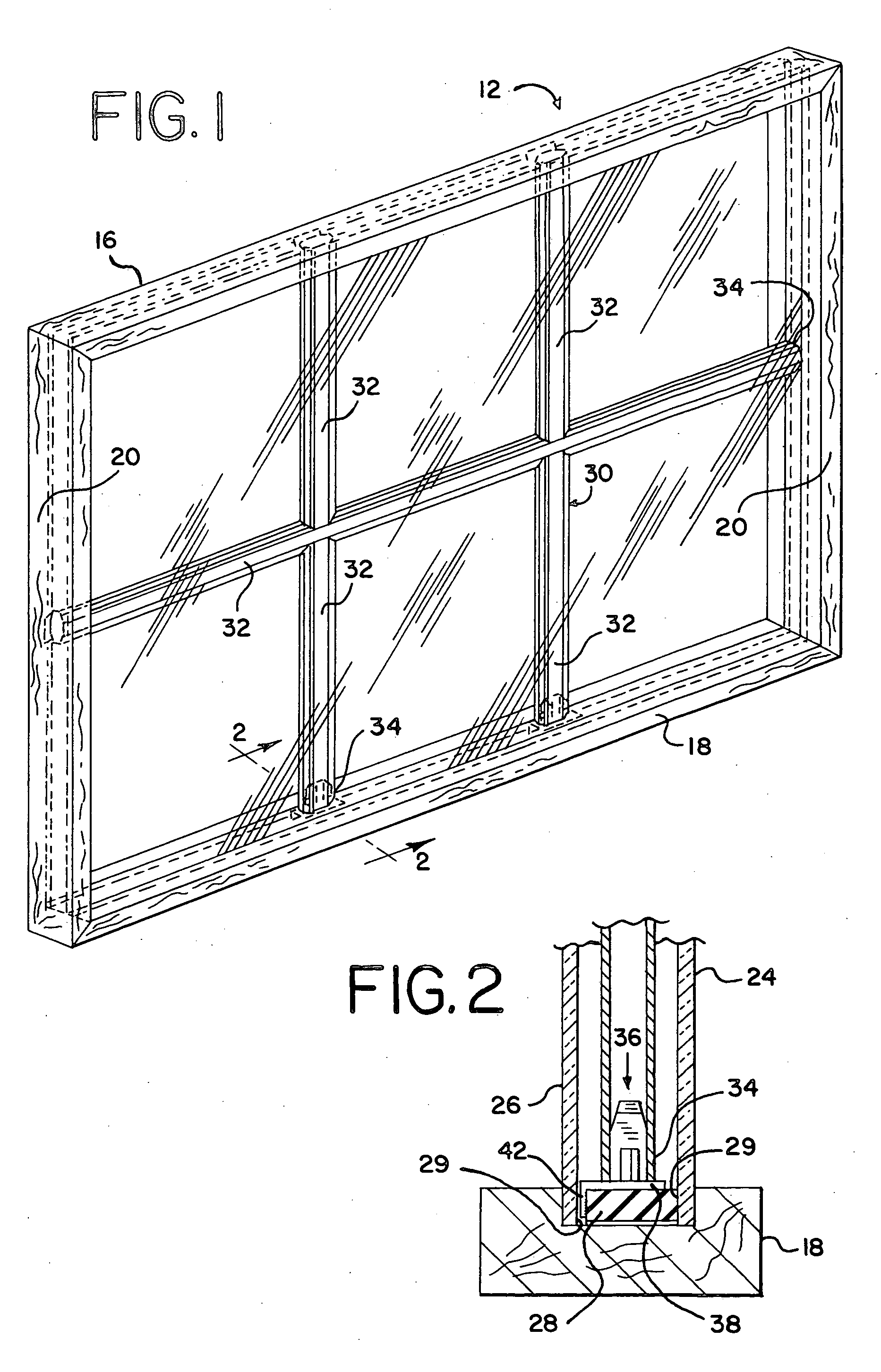

Muntin bar connector with positioning tabs

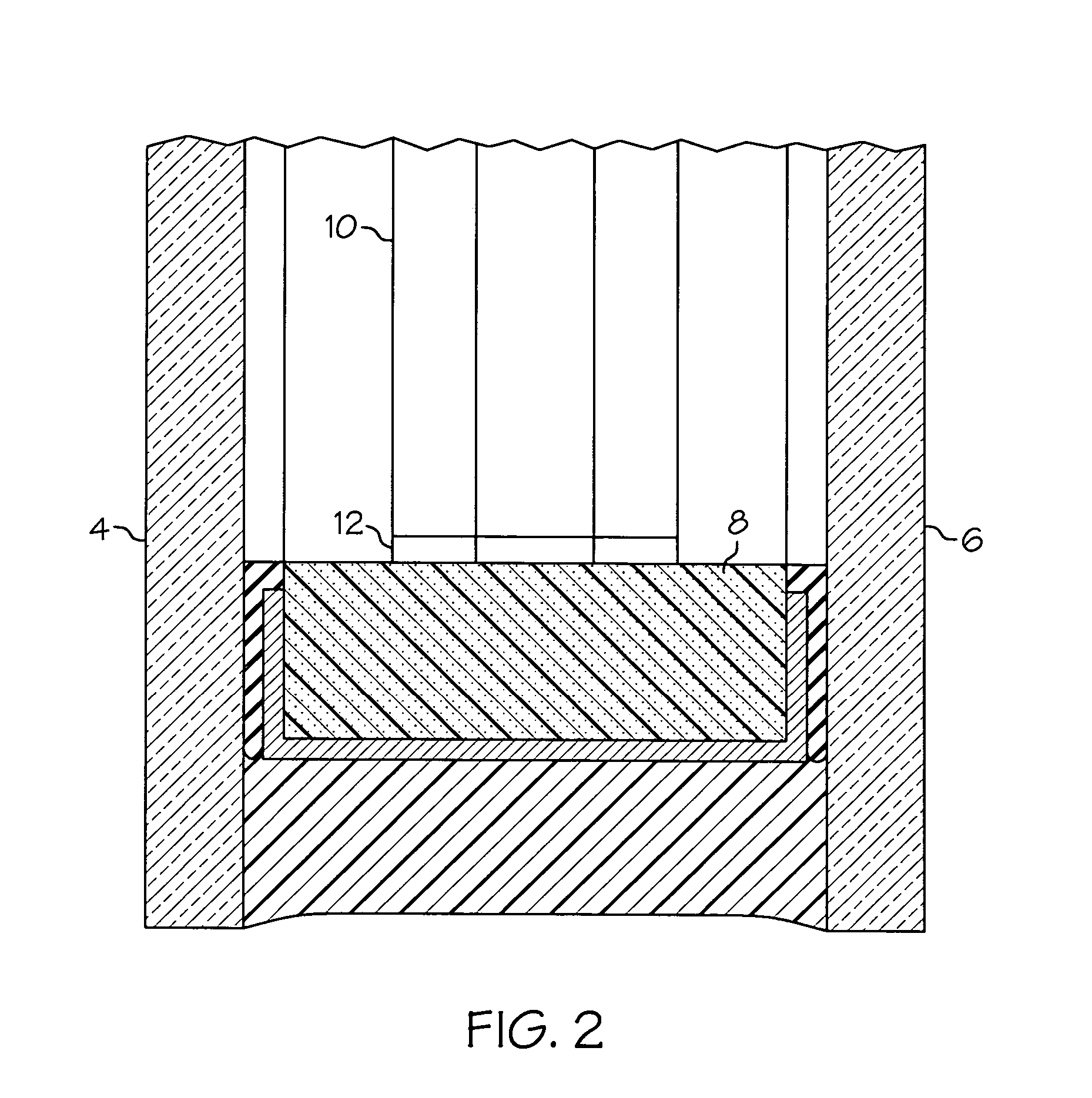

A connector for holding an internal muntin assembly away from a perimeter spacer of an insulating glass assembly until the assembler is ready to affix the muntin bar to the perimeter bar using an attachment device. The connector includes a positioning tab for holding the muntin bar away from the perimeter spacer to allow positioning of the muntin bar assembly until the positioning tab is moved relative to a baseplate so that the attachment device, such as thick double stick tape, is pressed to the perimeter spacer.

Owner:PELLA

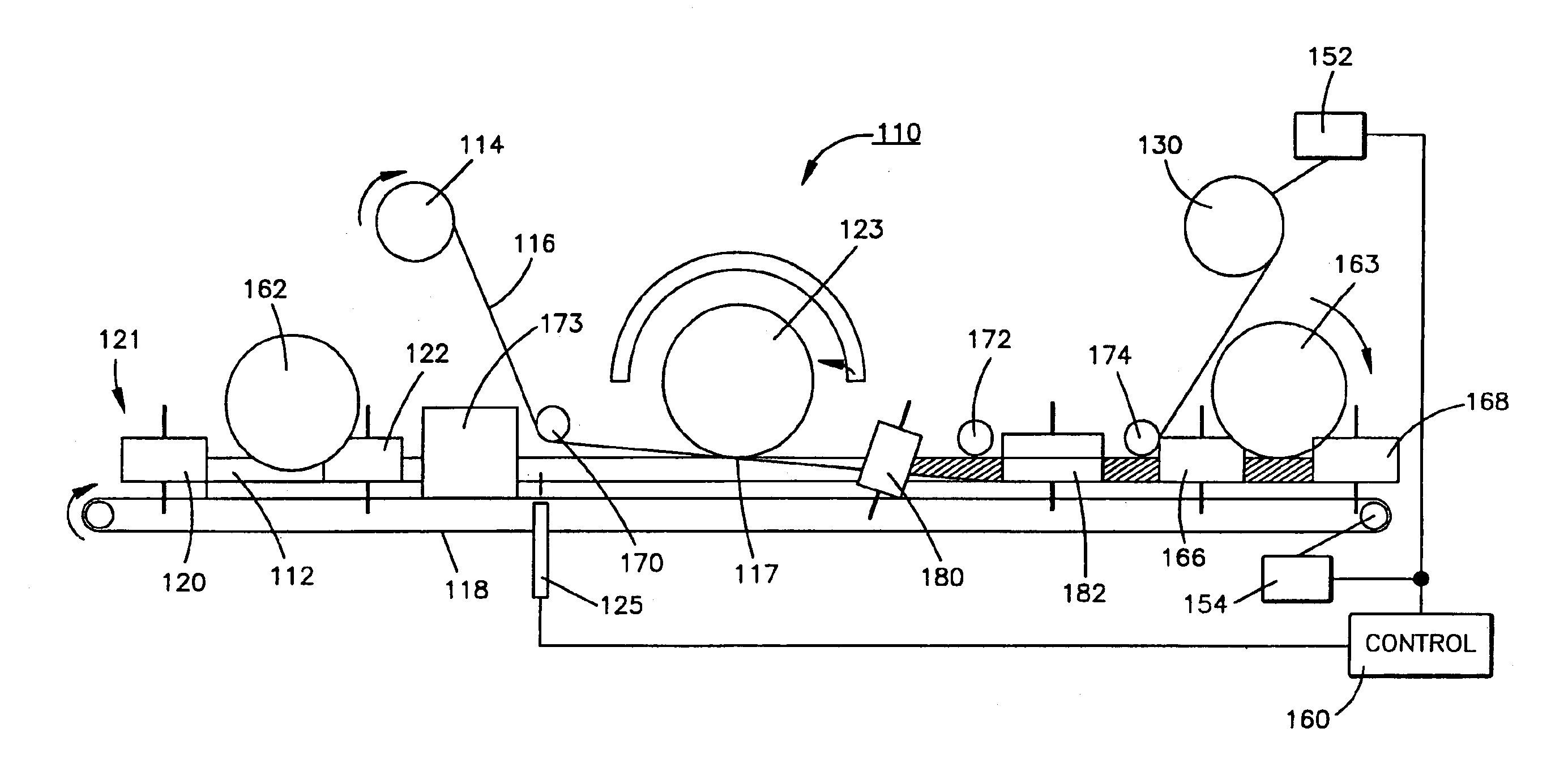

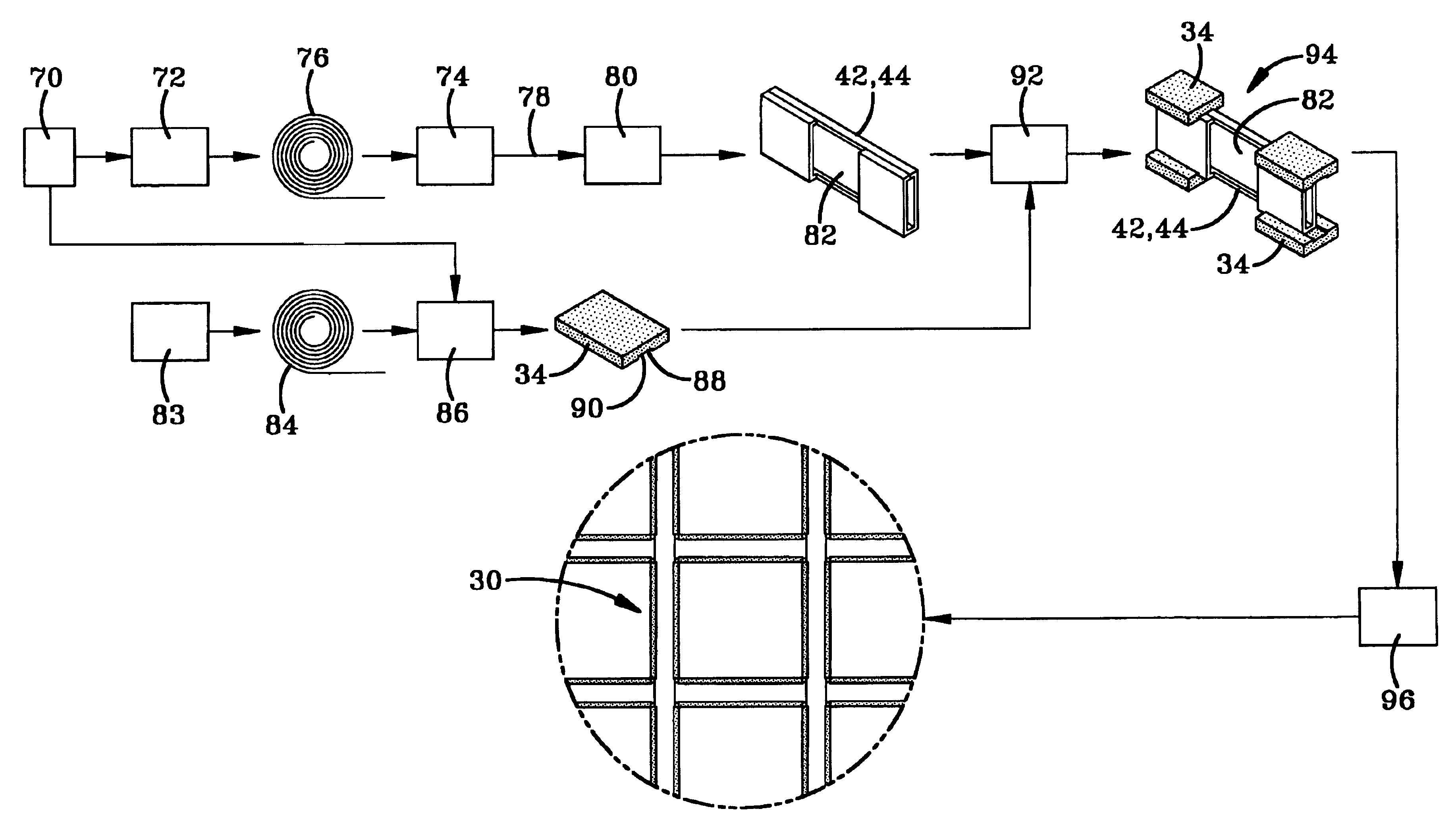

Process for making laminating preformed muntin bars

InactiveUS6889416B2Low costShorten the timeLamination ancillary operationsDecorative surface effectsAdhesiveBiomedical engineering

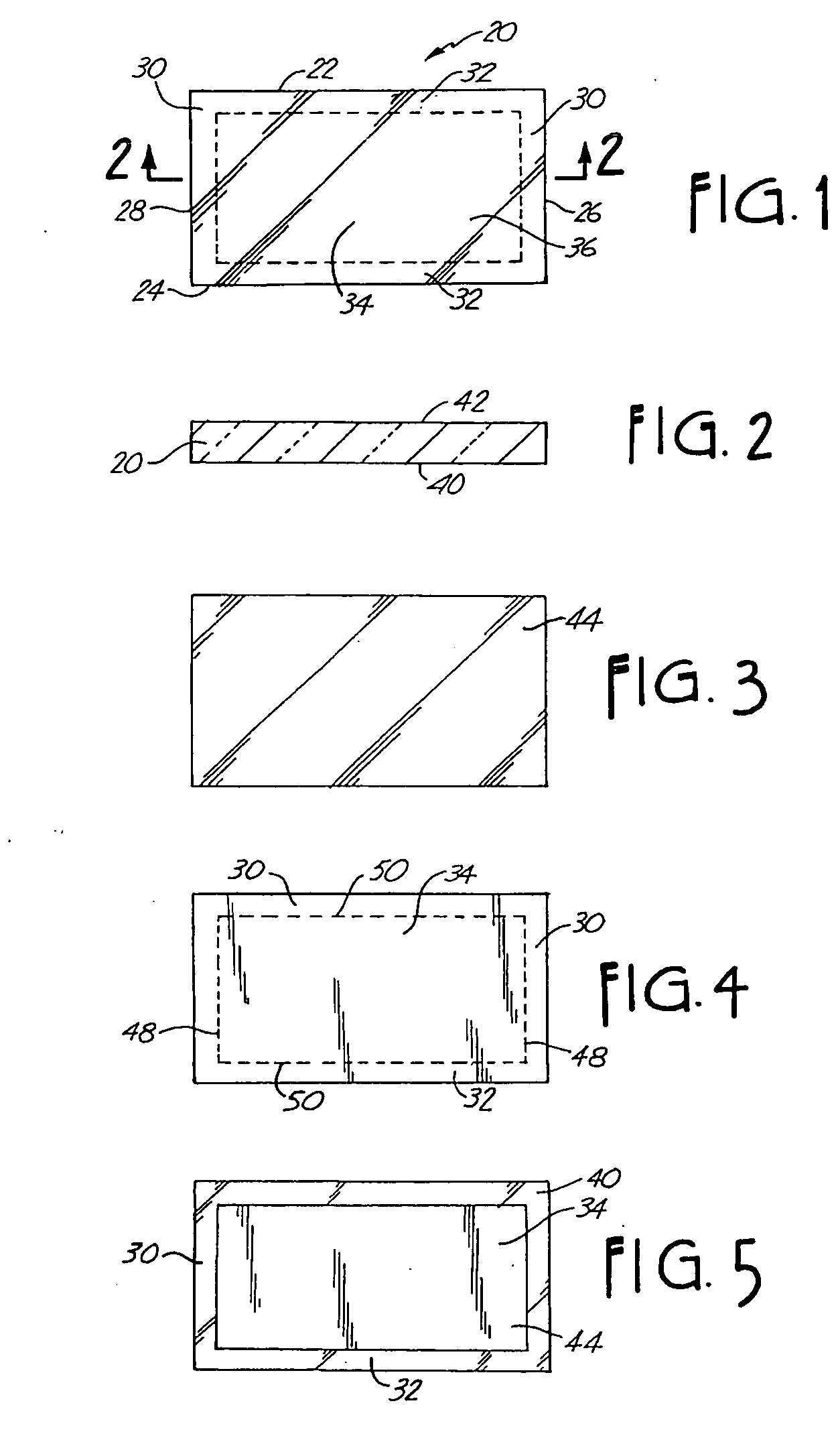

An exemplary embodiment of the invention concerns a process for forming two tone muntin bars. Method and apparatus of the invention uses an elongated preformed muntin bar member that has a treated portion of an exposed surface of the muntin bar member. An elongated strip of covering material is provided for controlled application onto a specified portion of the treated portion of the muntin bar material. The elongated strip of covering material includes an adhesive that causes the covering material to adhere to the muntin bar member. The muntin bar member and the covering material are brought into contact with each other to cause the covering material to overlie and adhere to the muntin bar member.

Owner:GED INTEGRATED SOLUTIONS

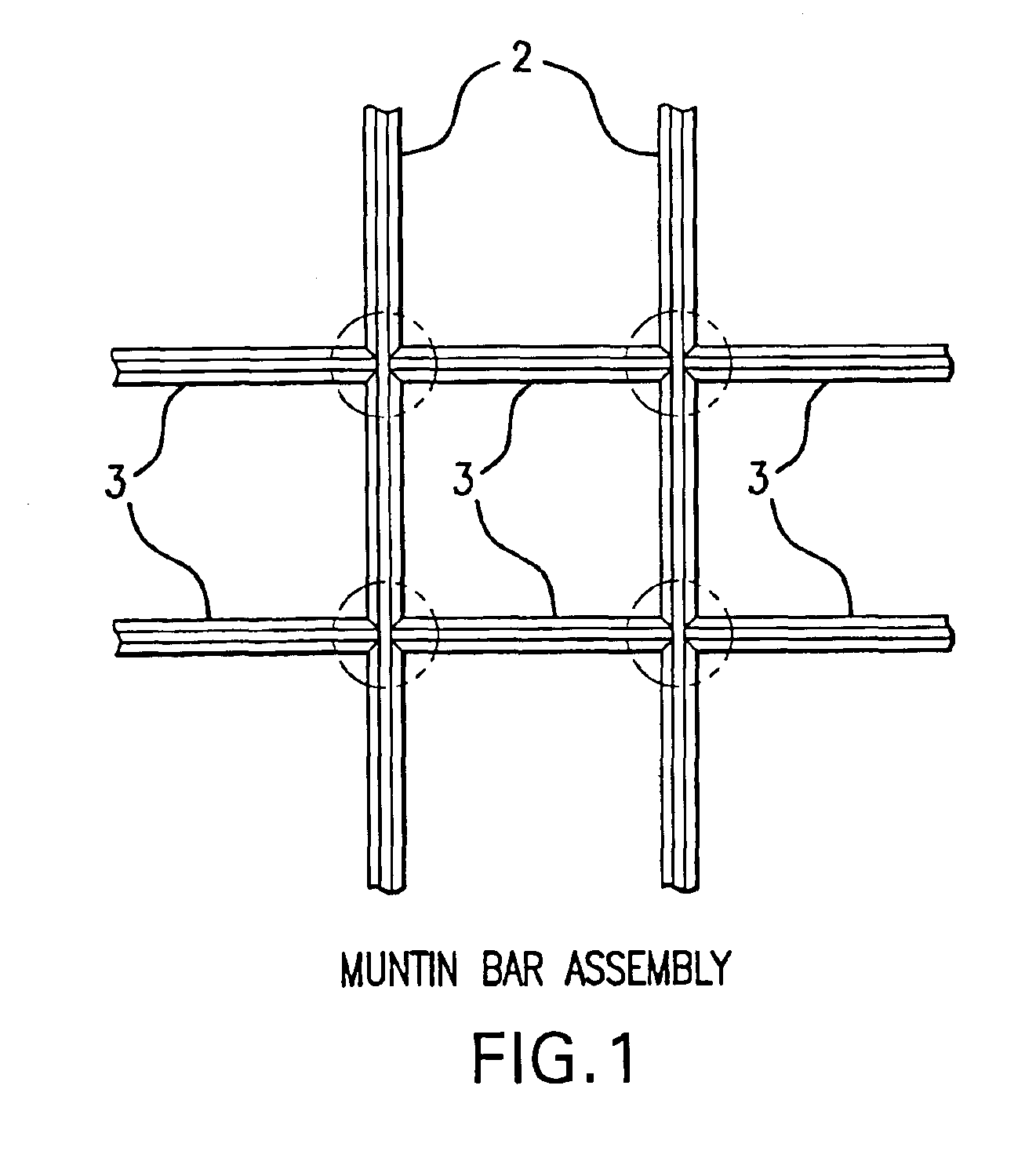

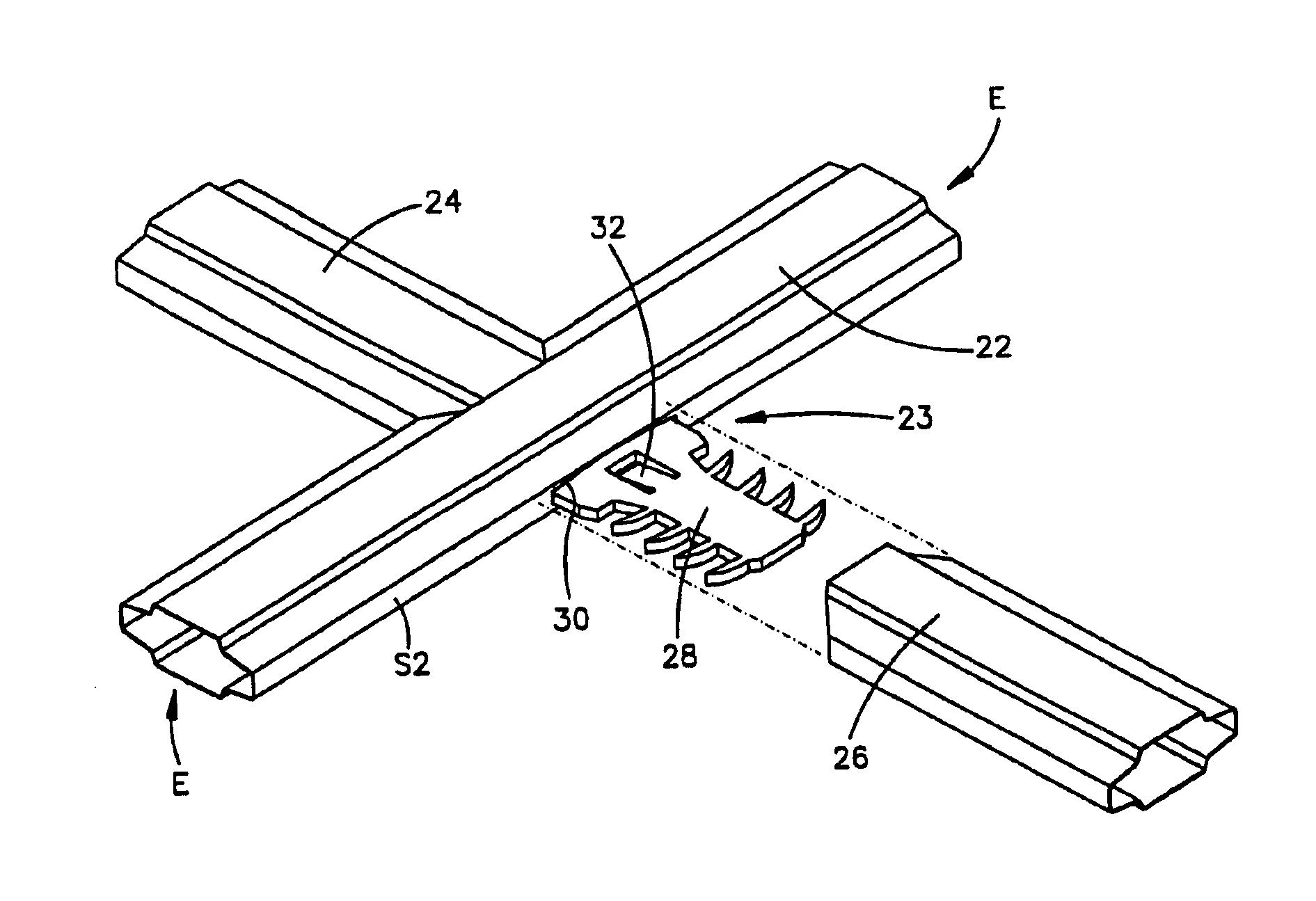

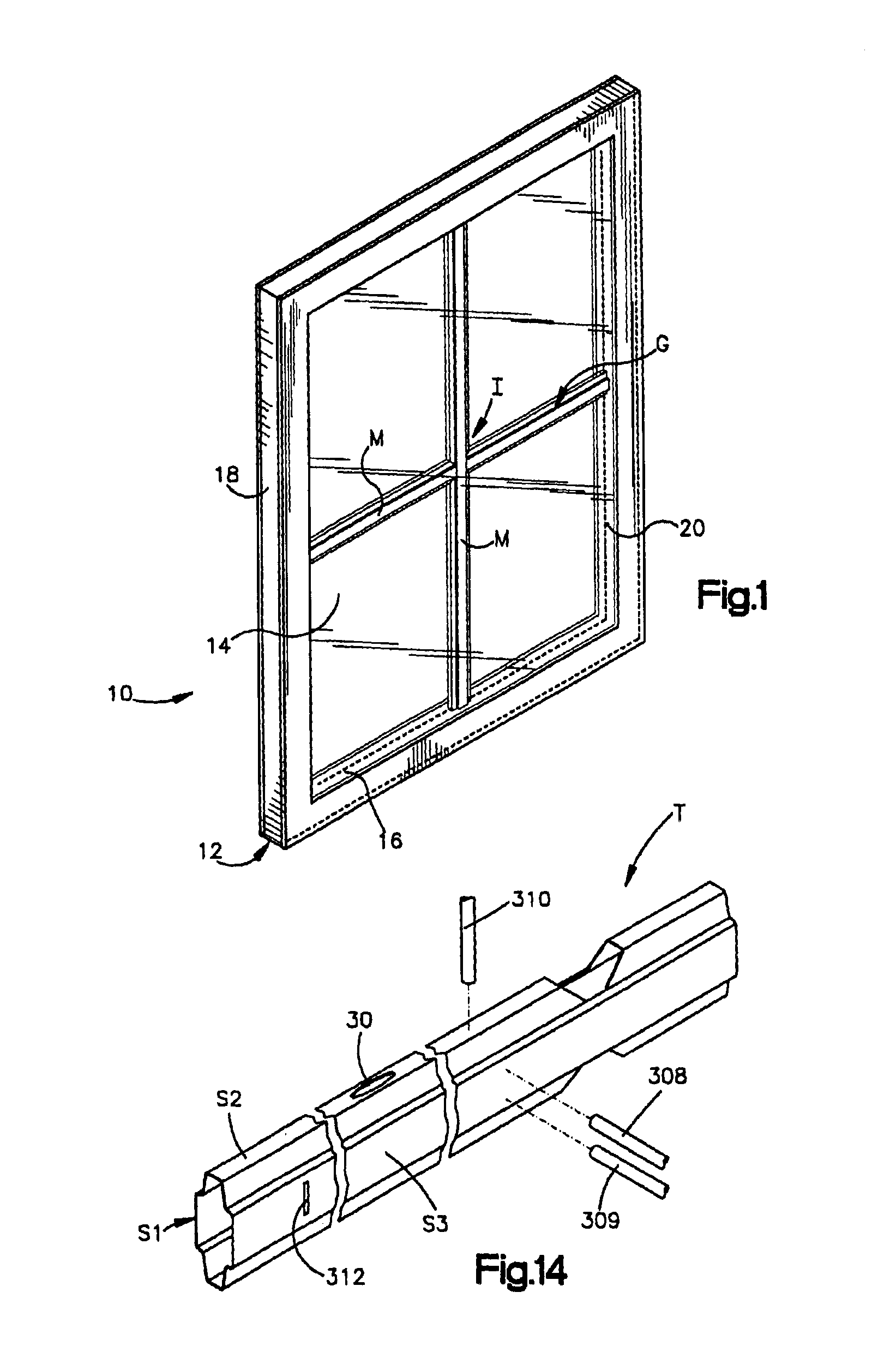

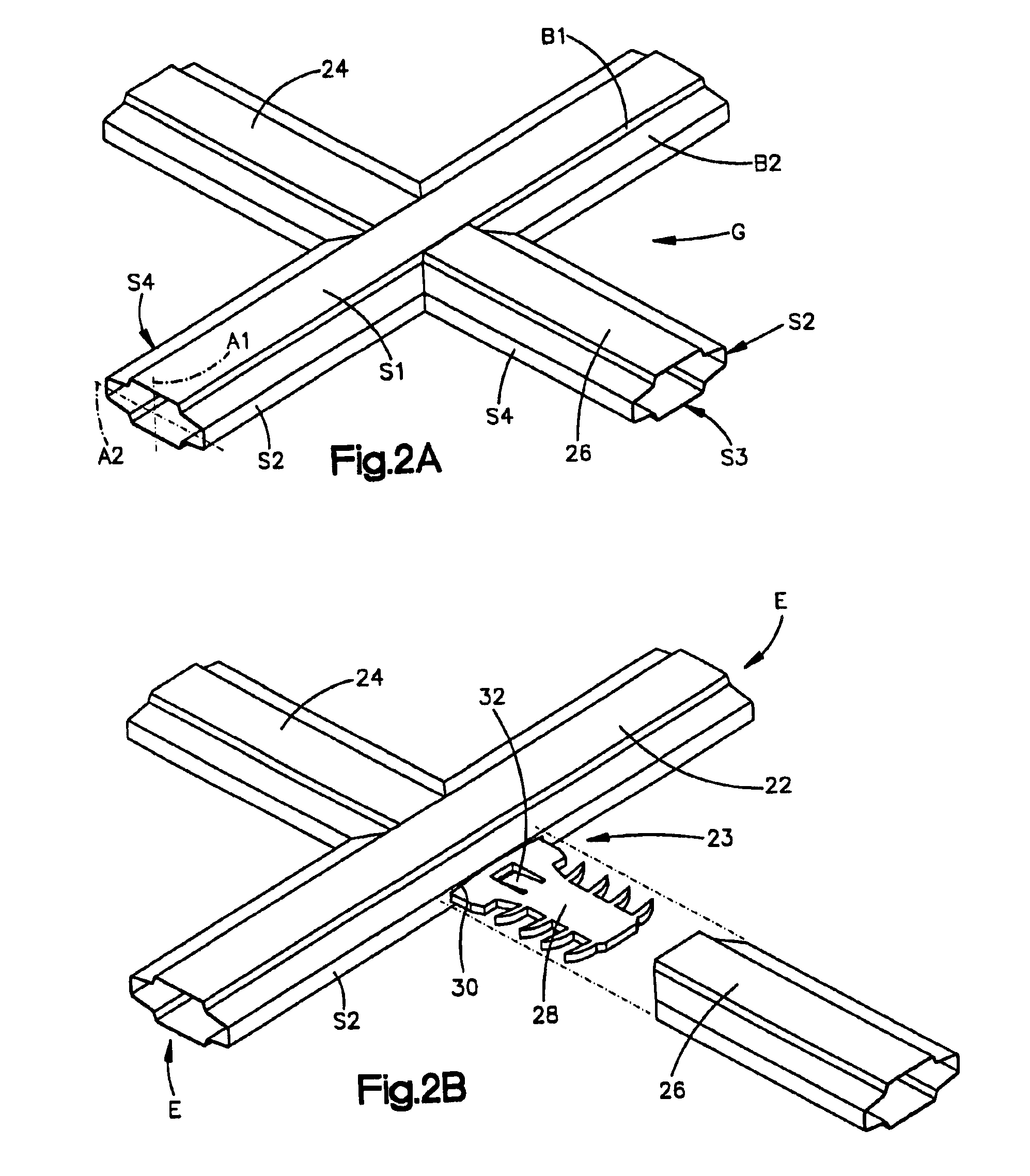

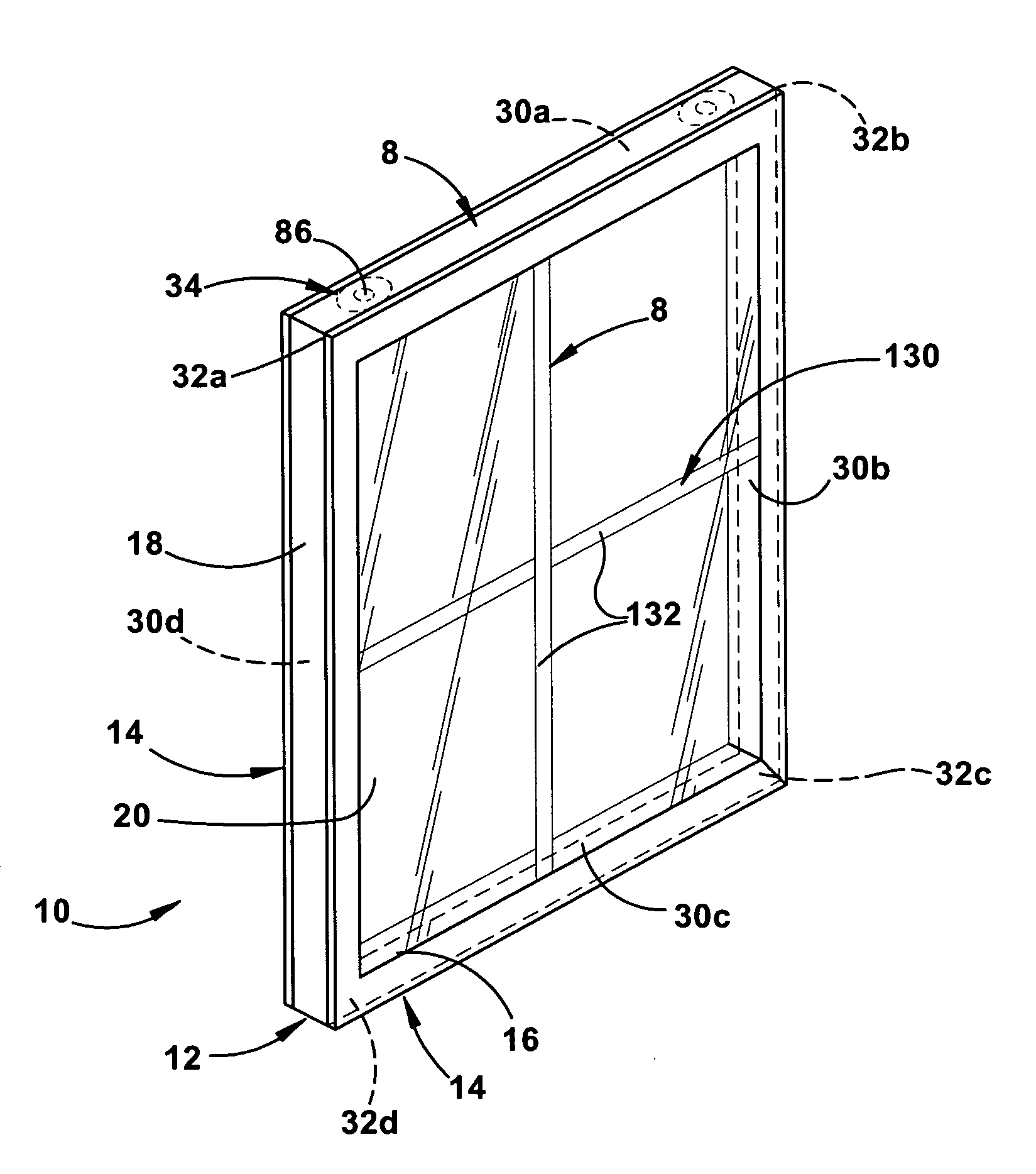

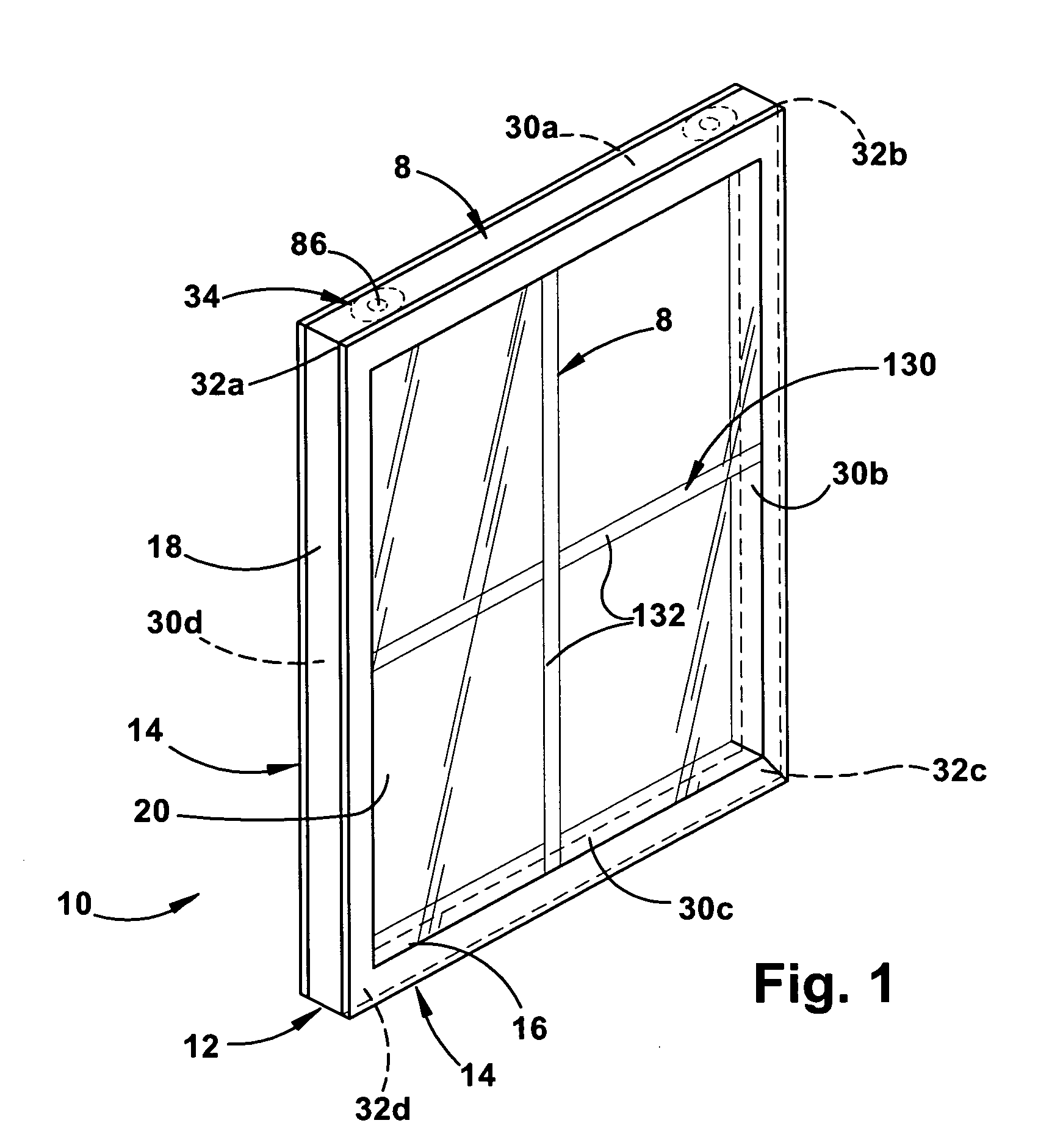

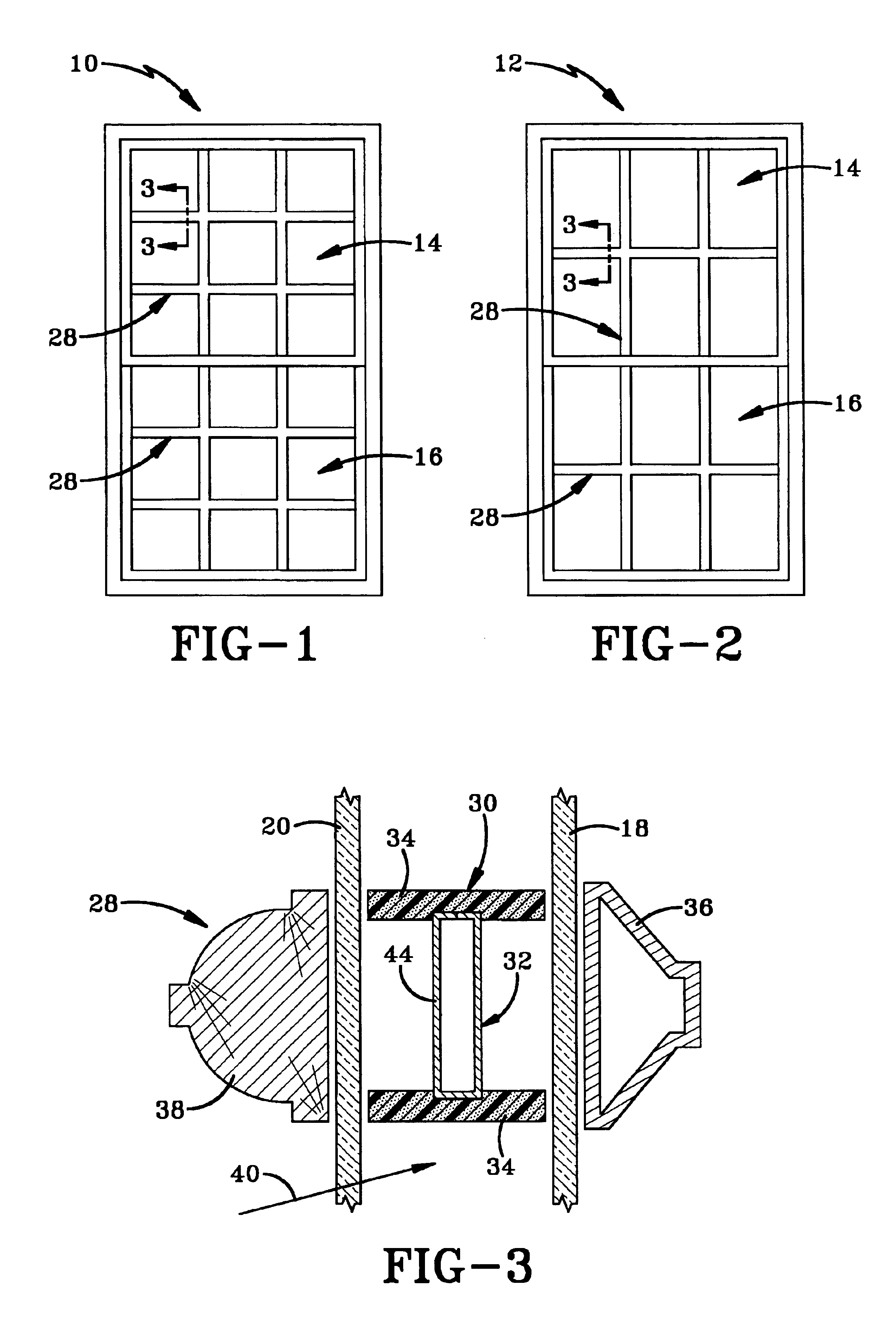

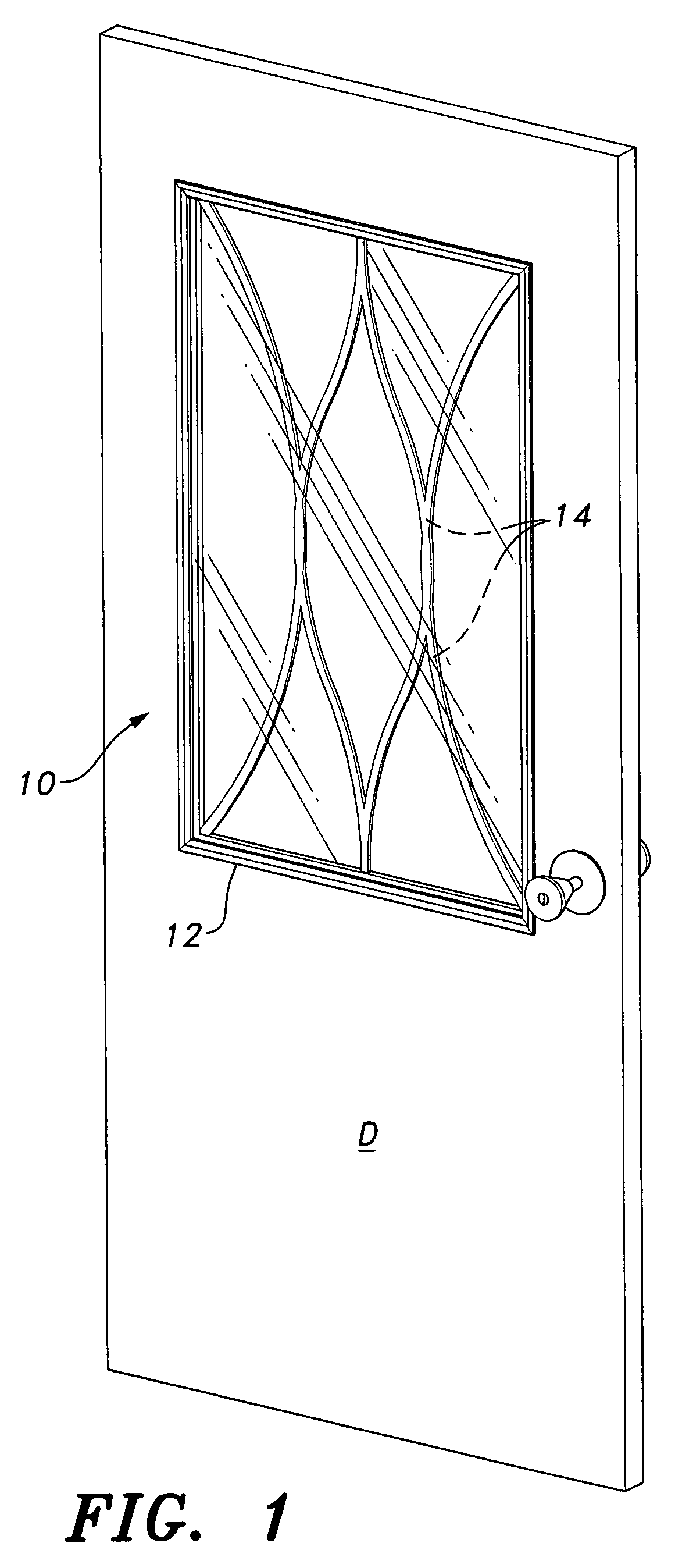

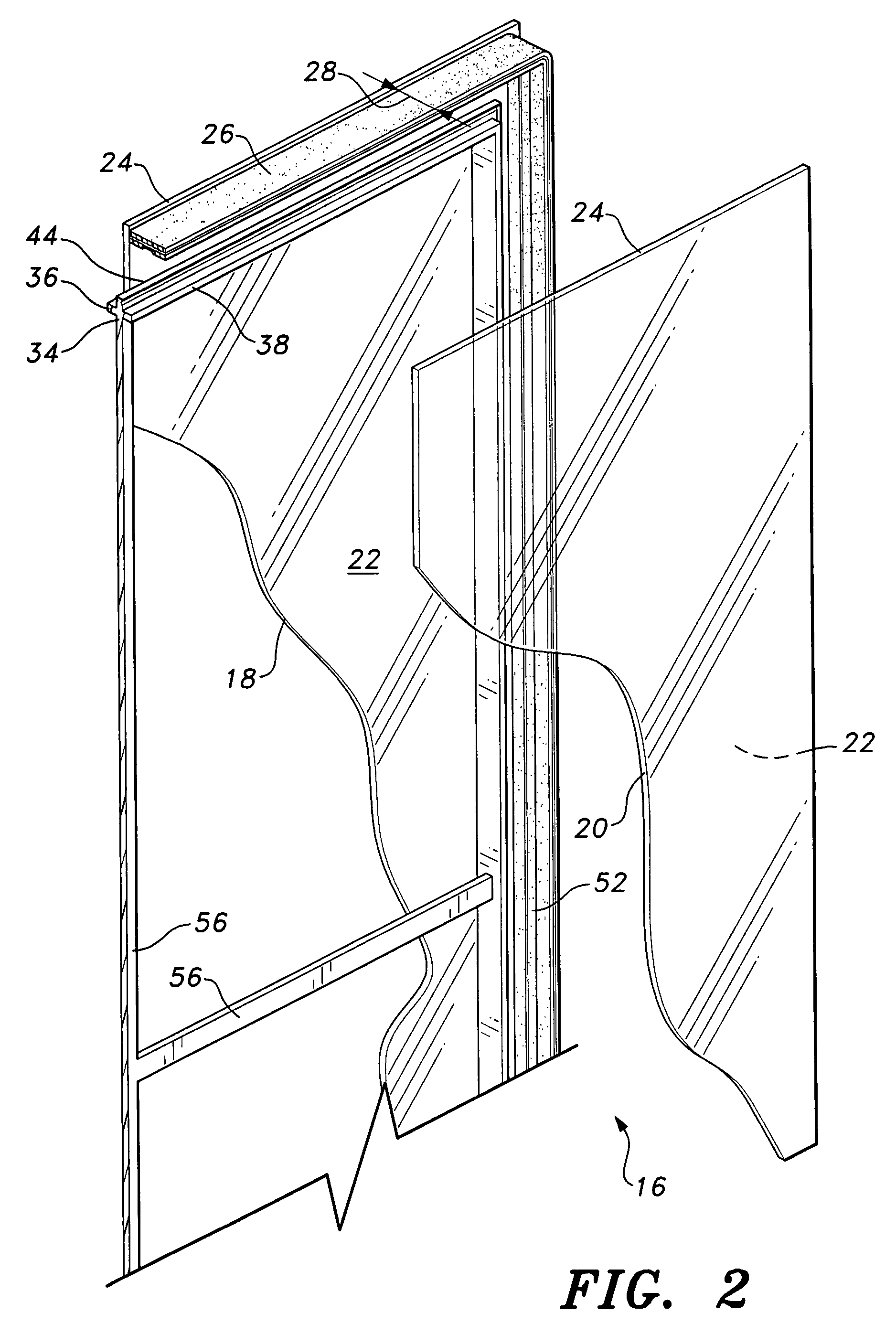

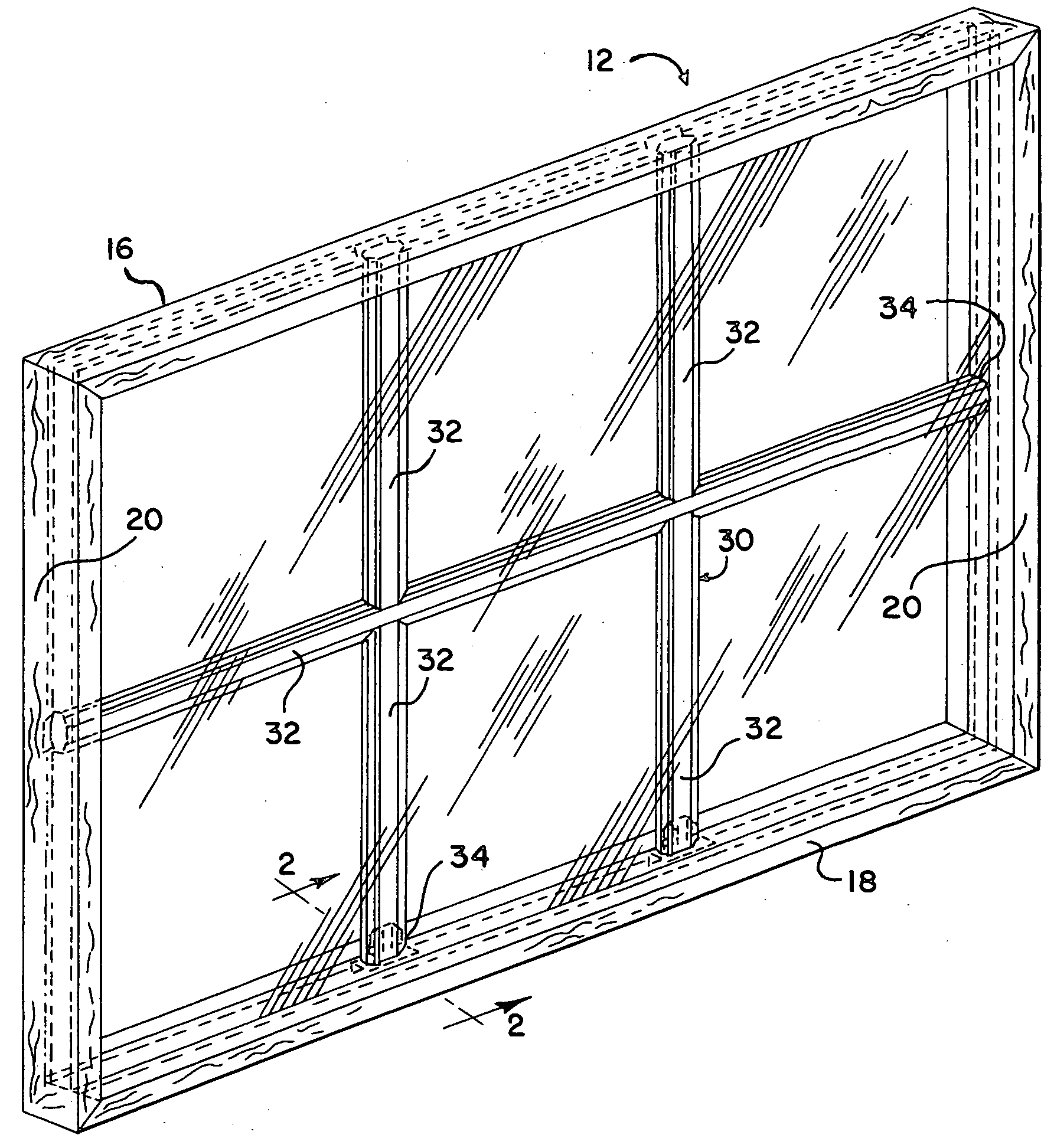

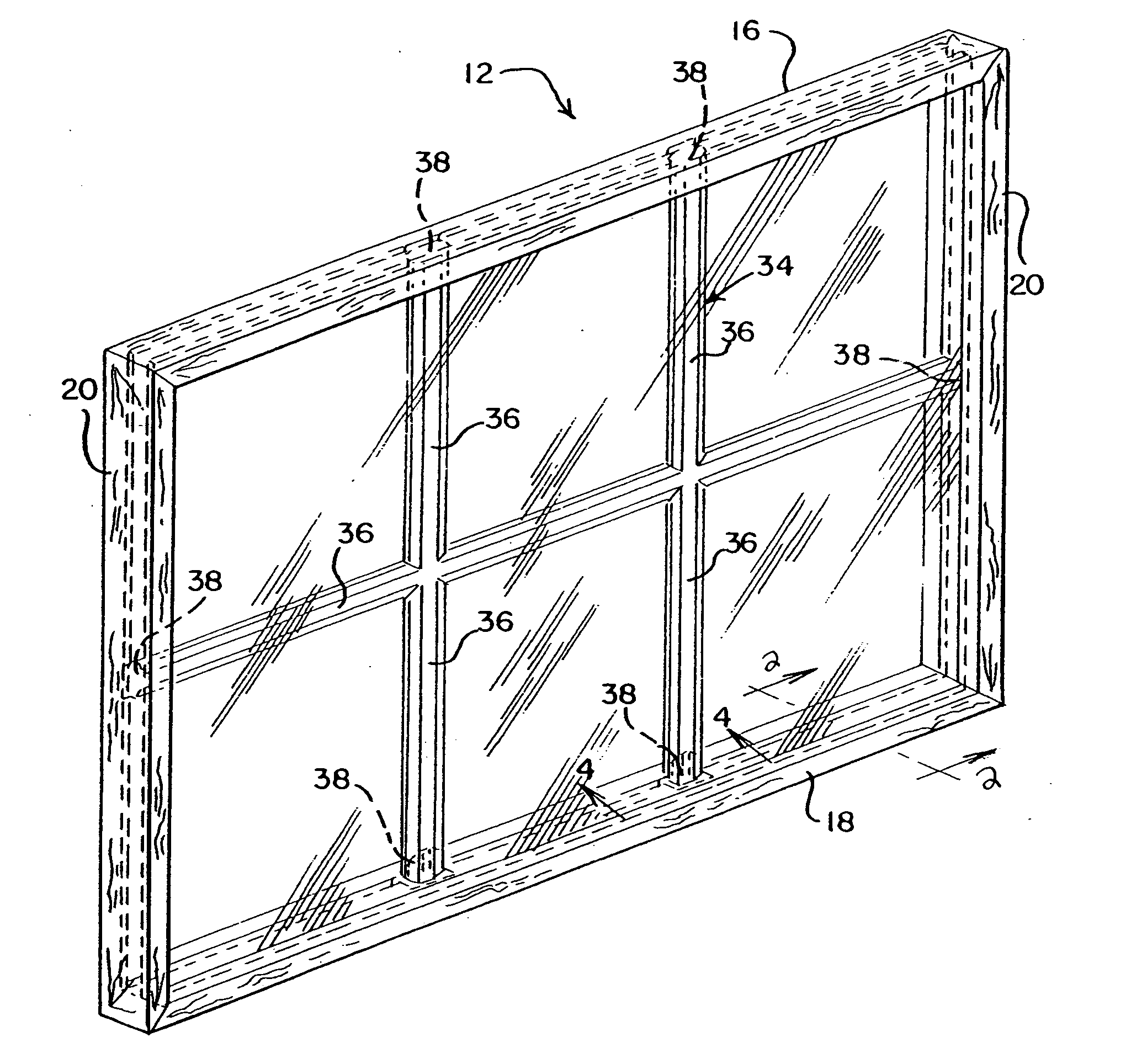

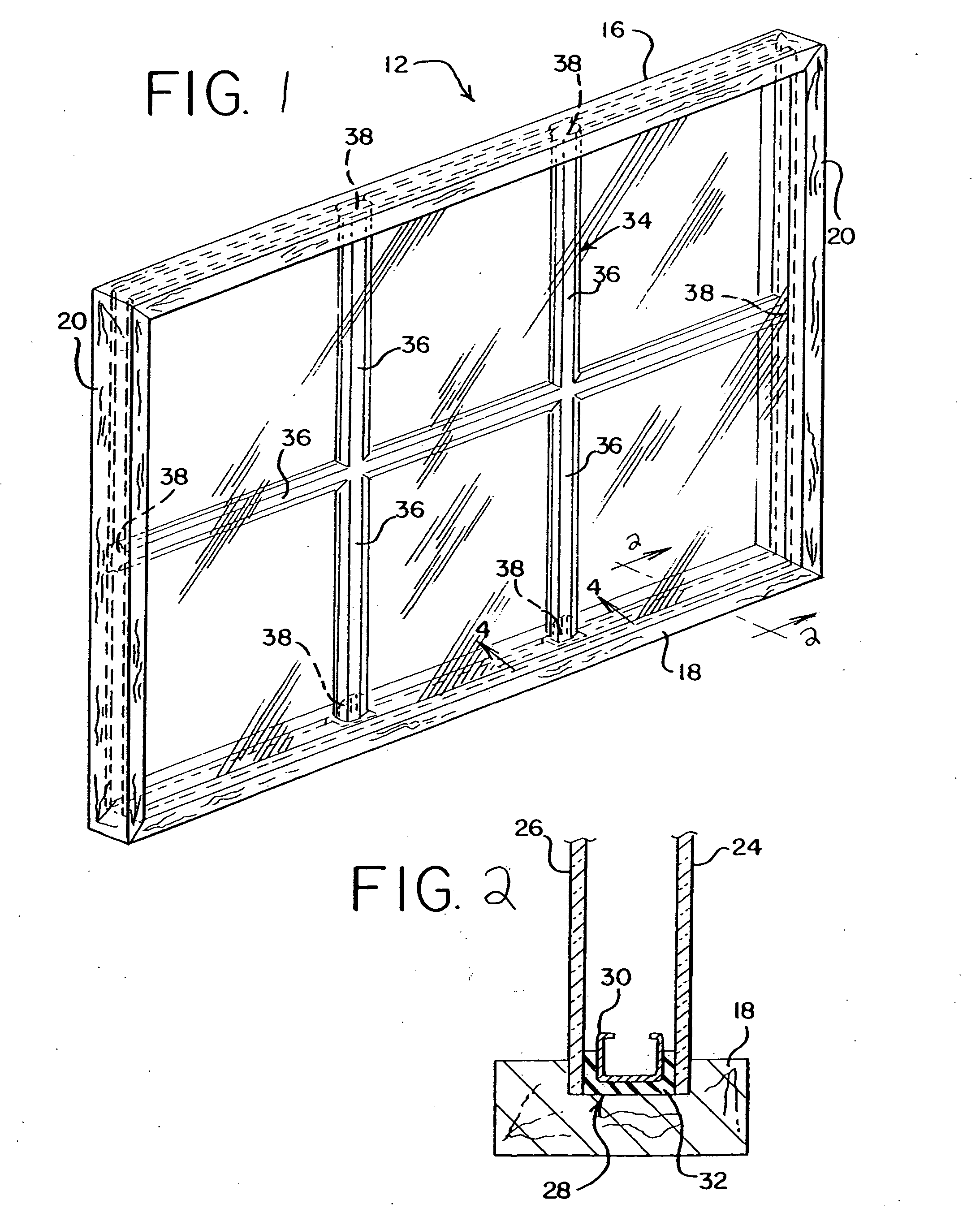

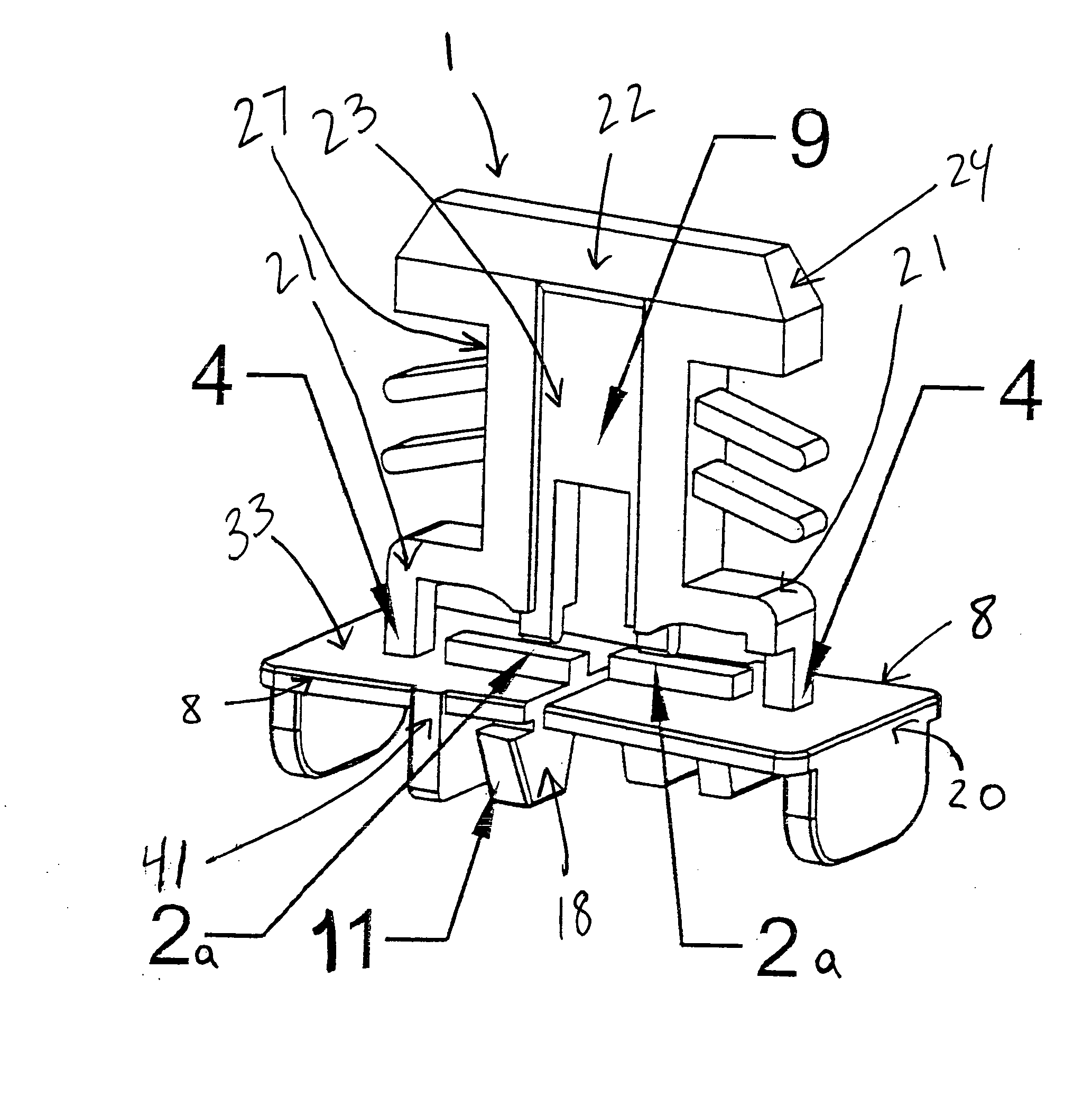

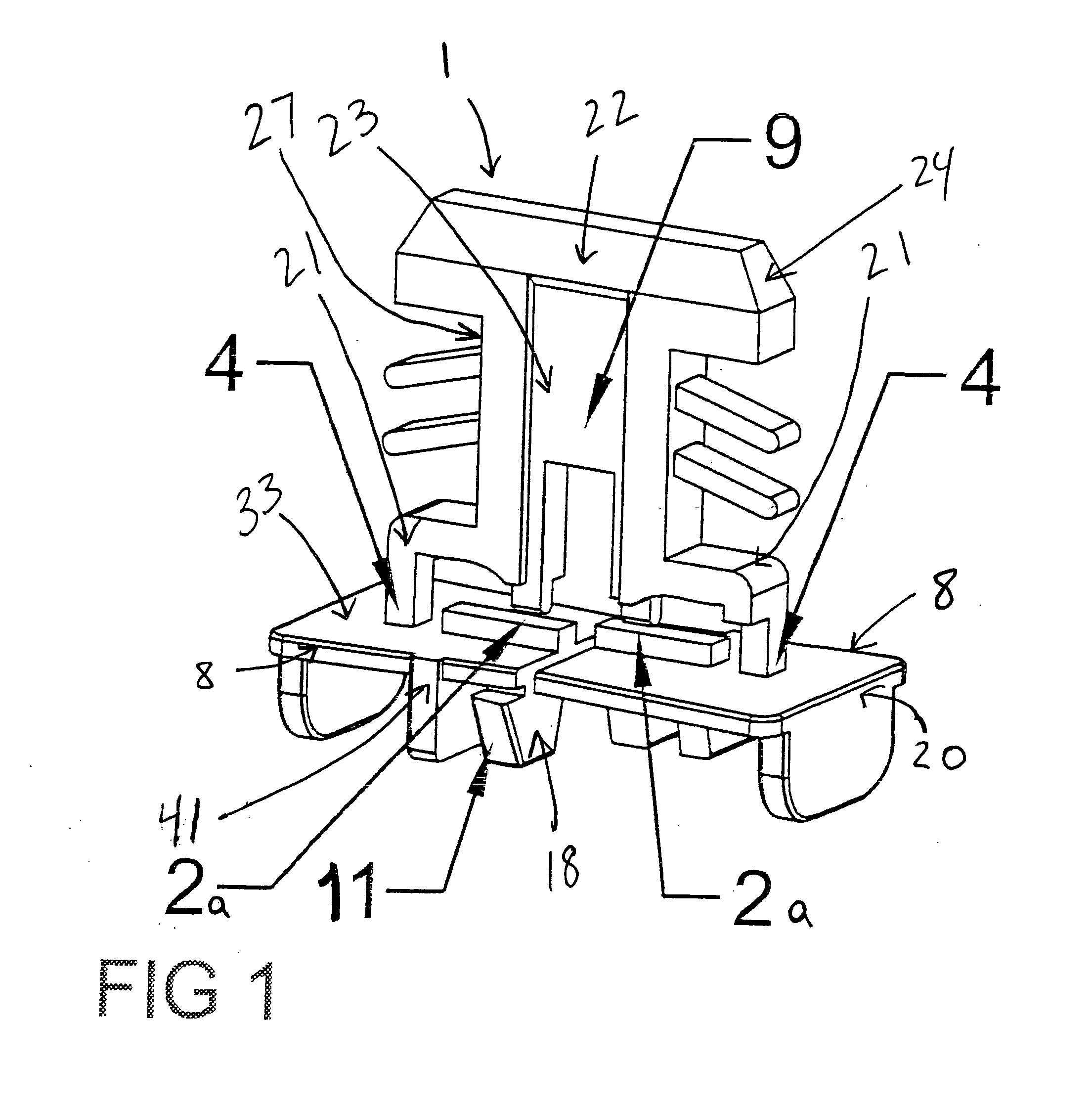

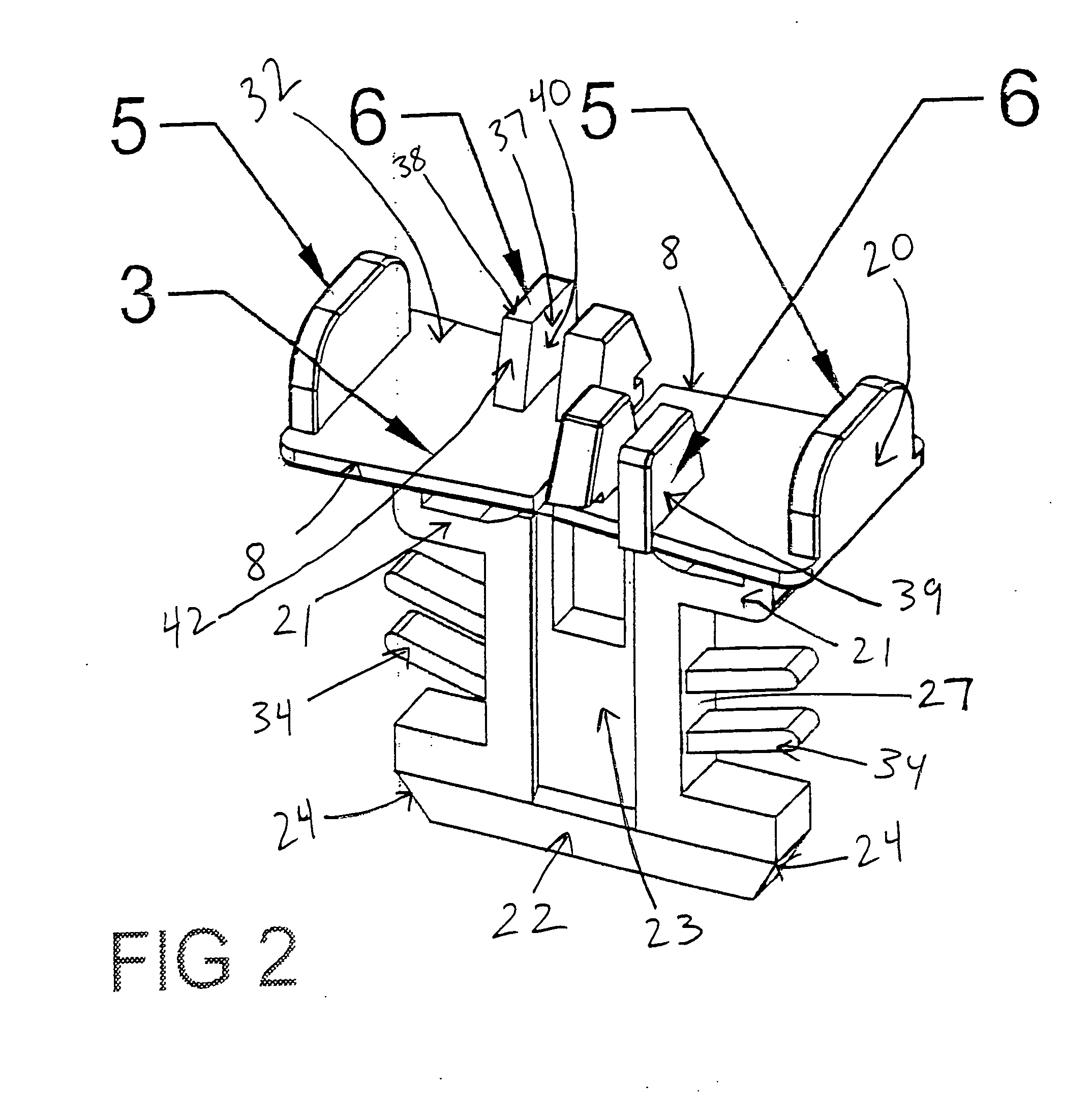

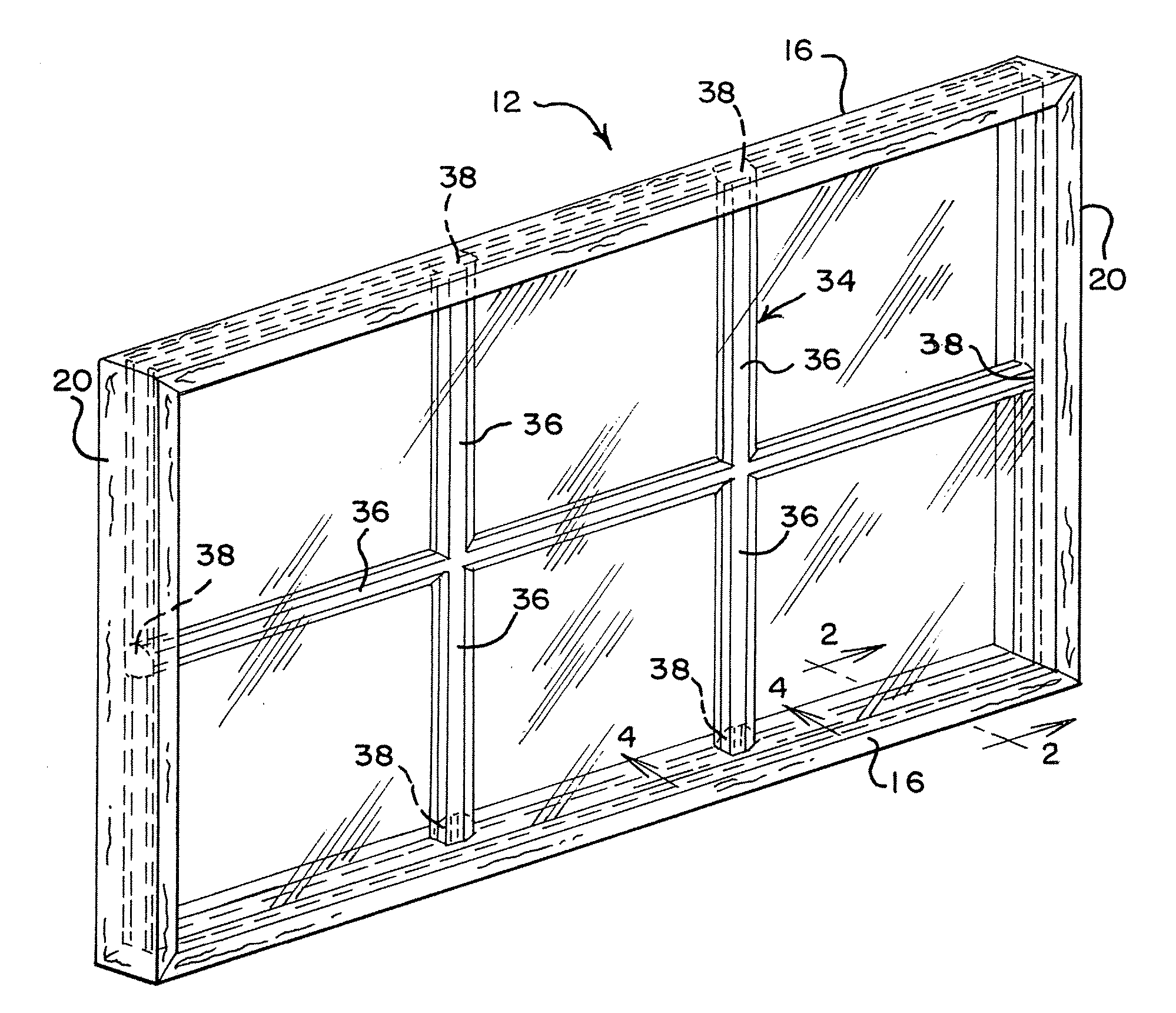

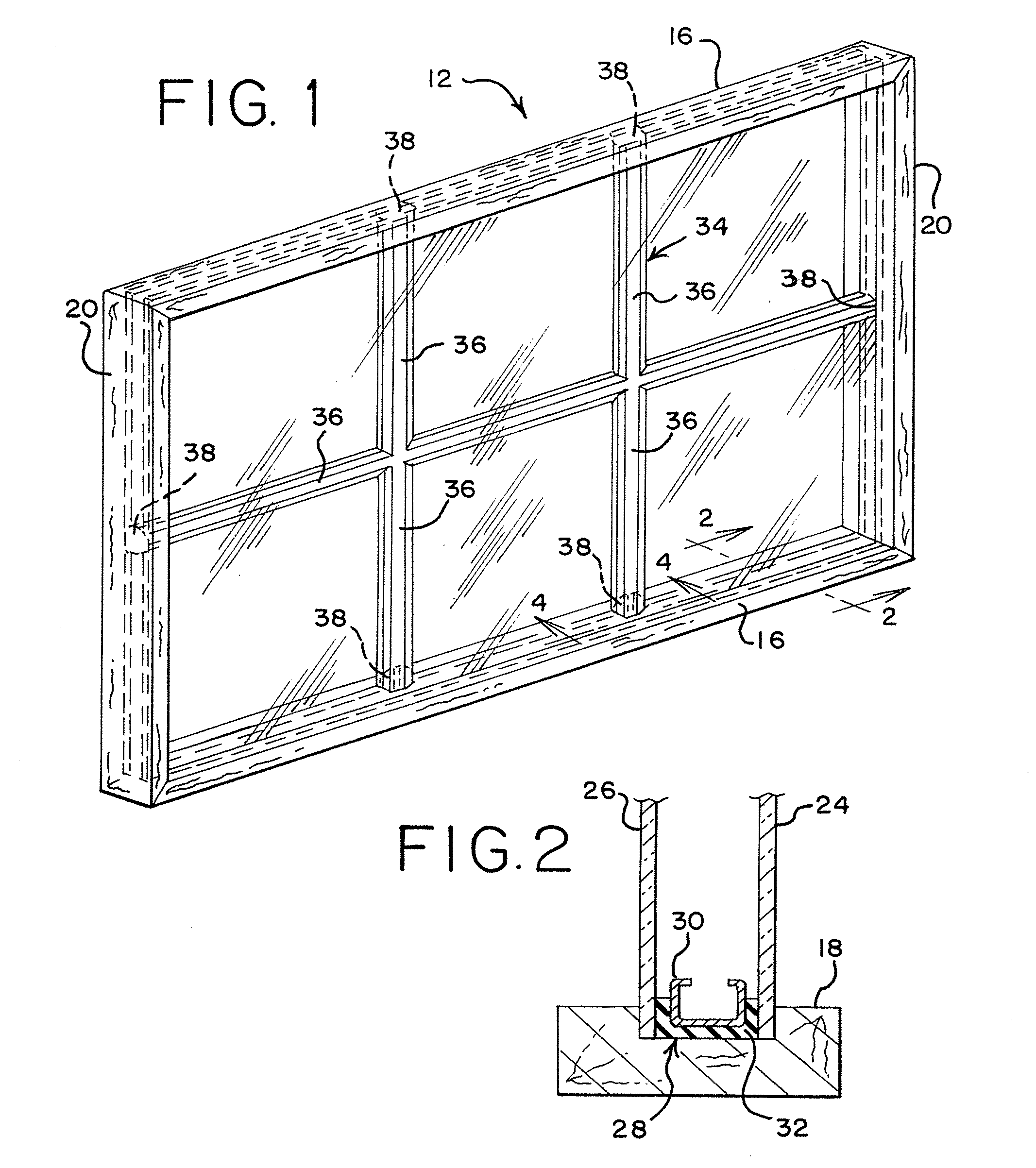

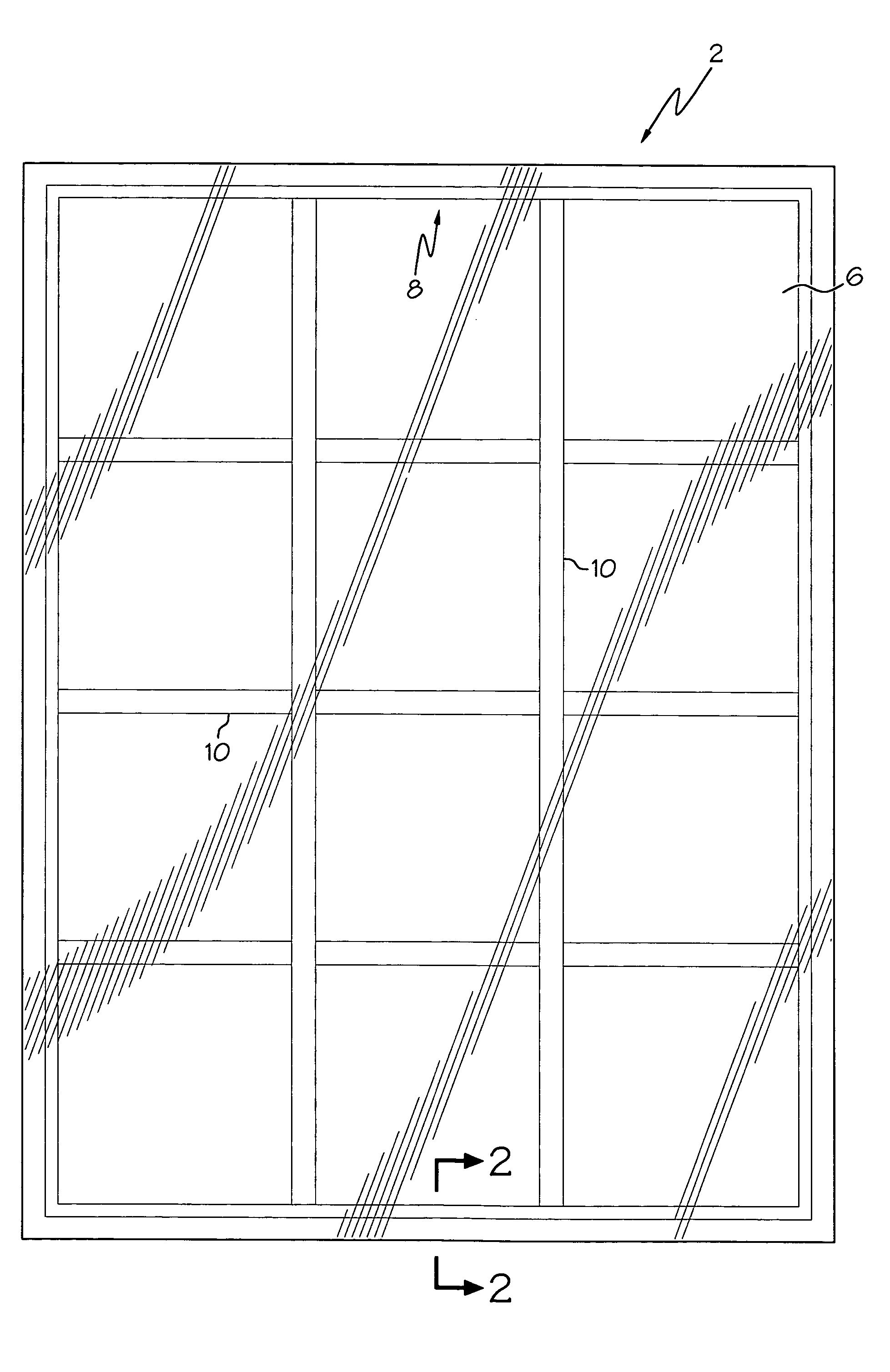

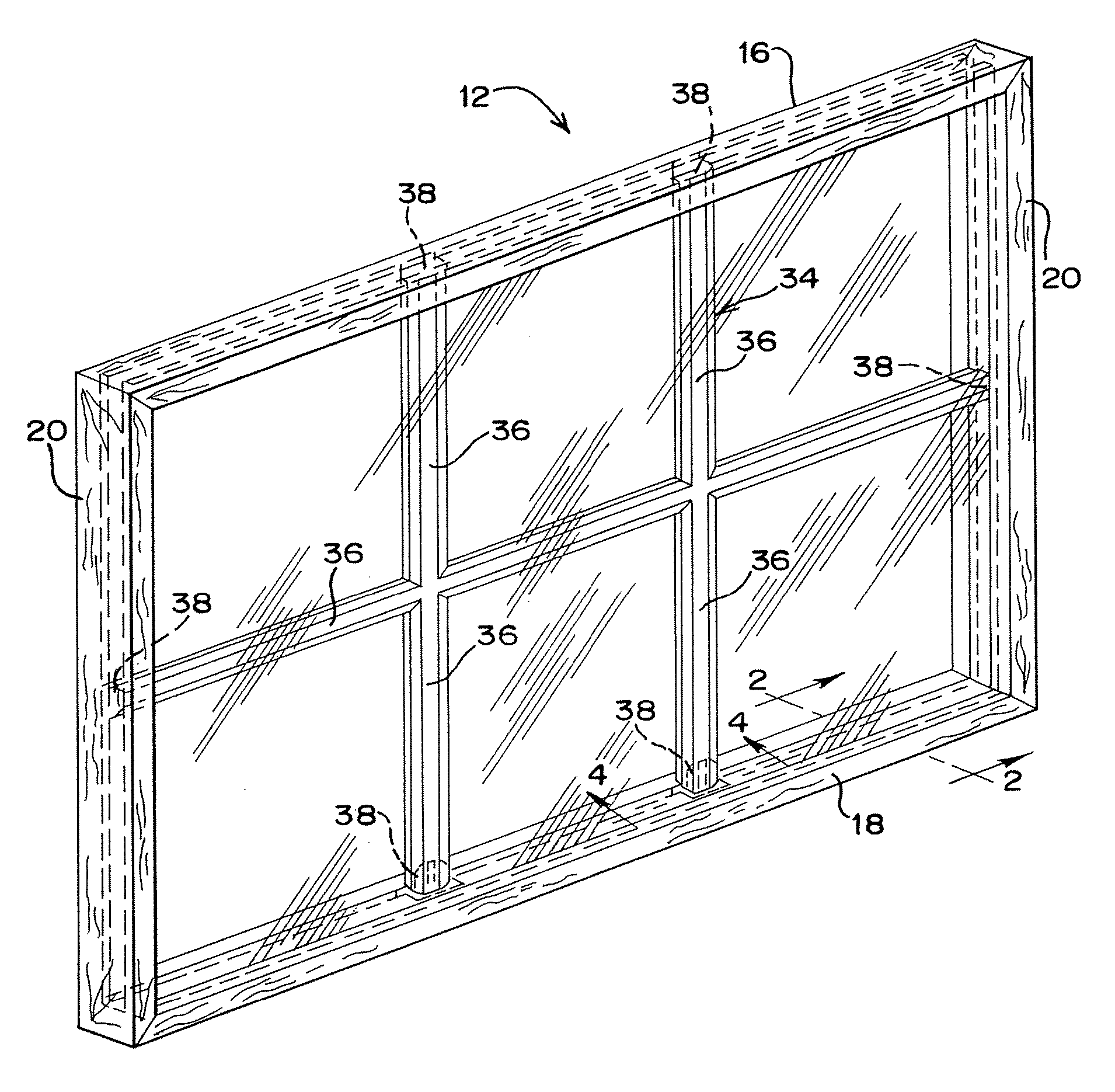

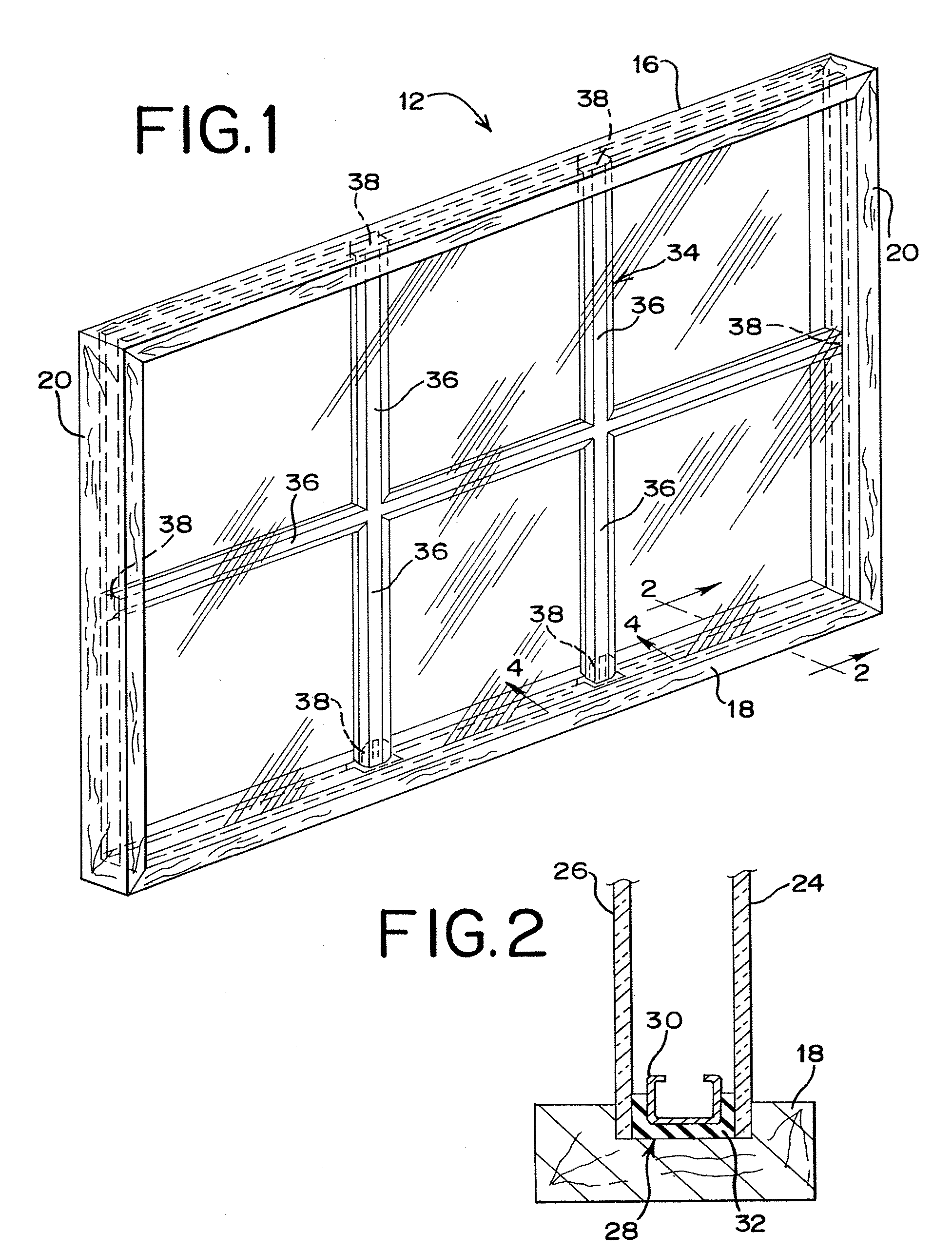

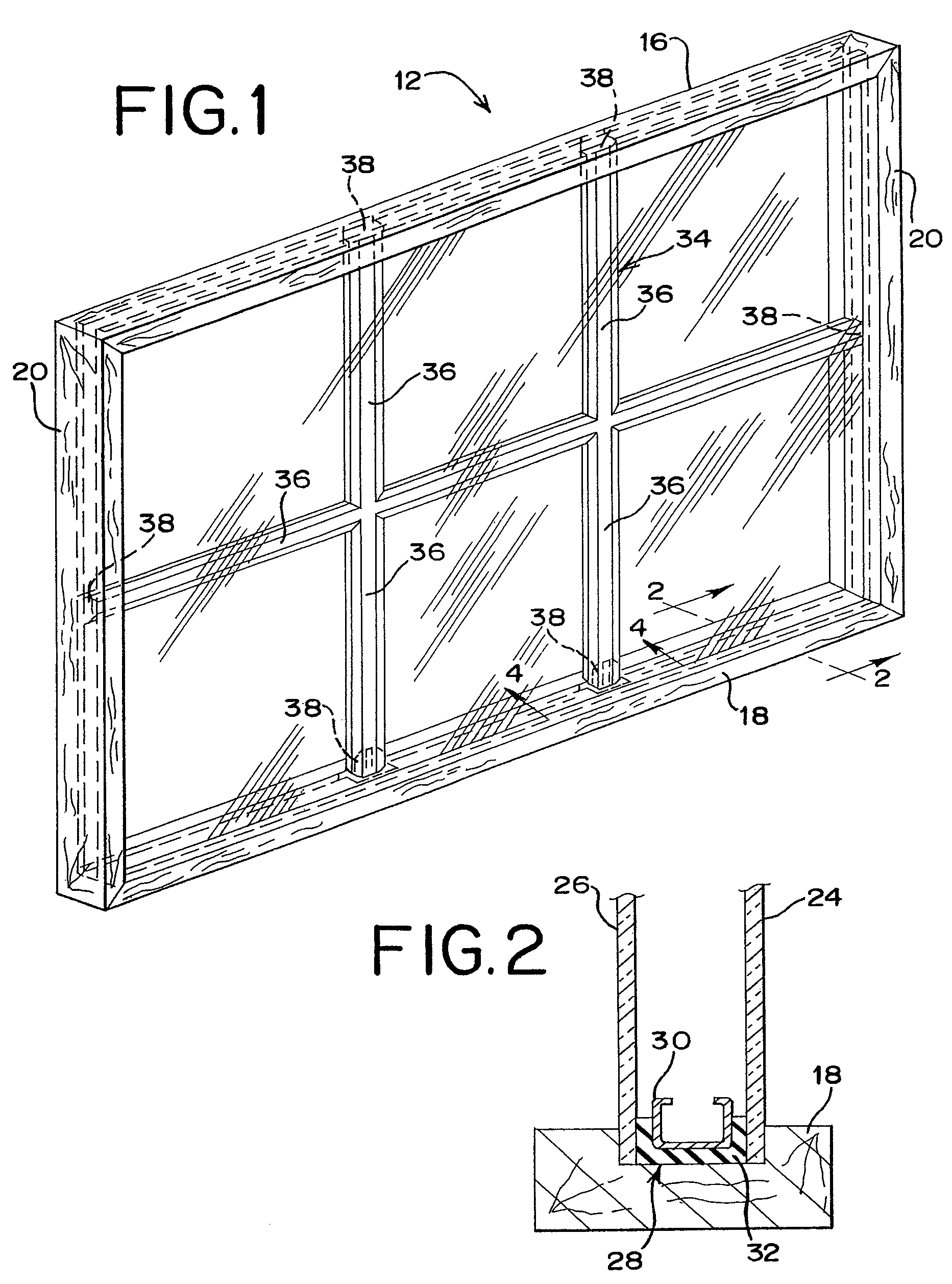

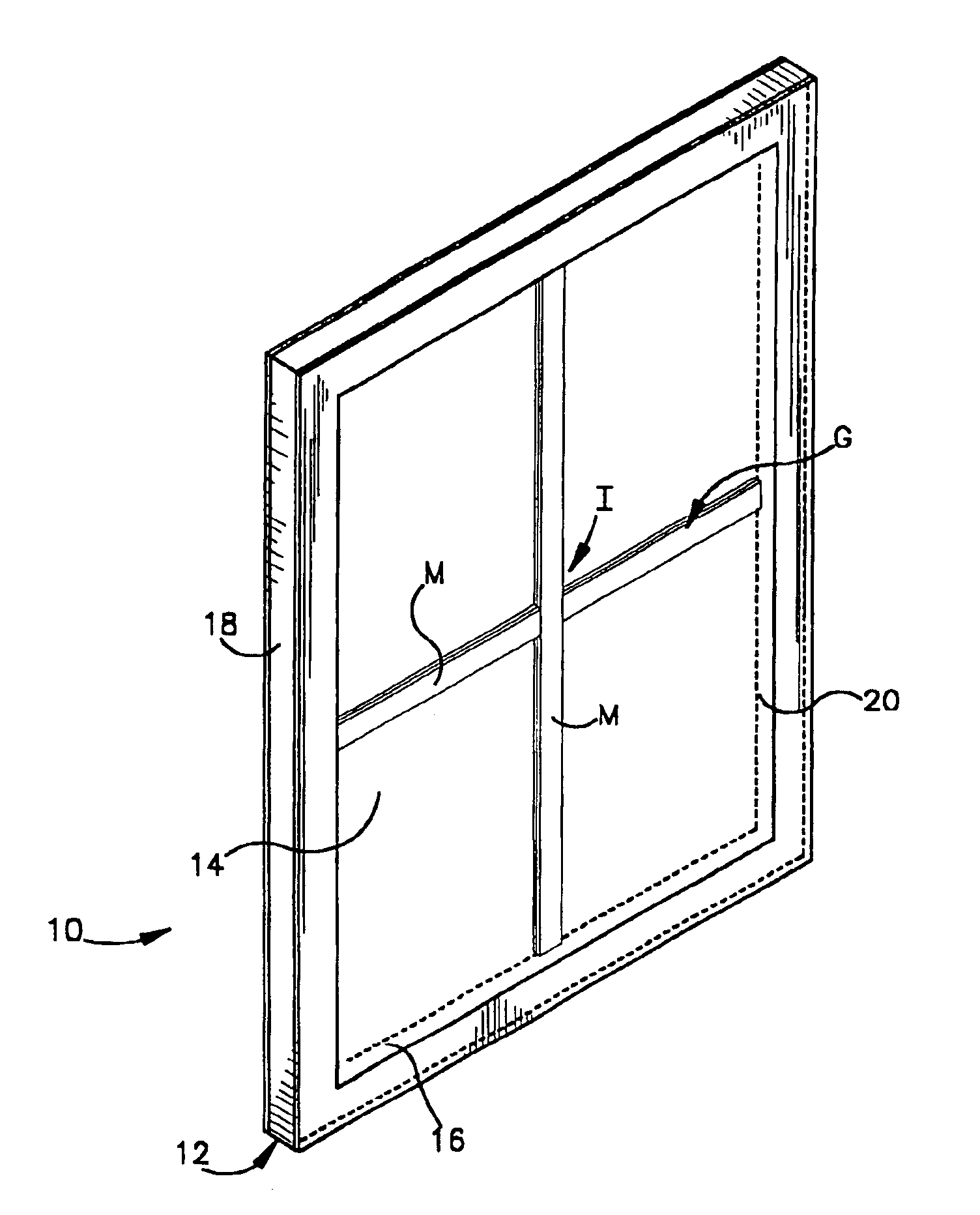

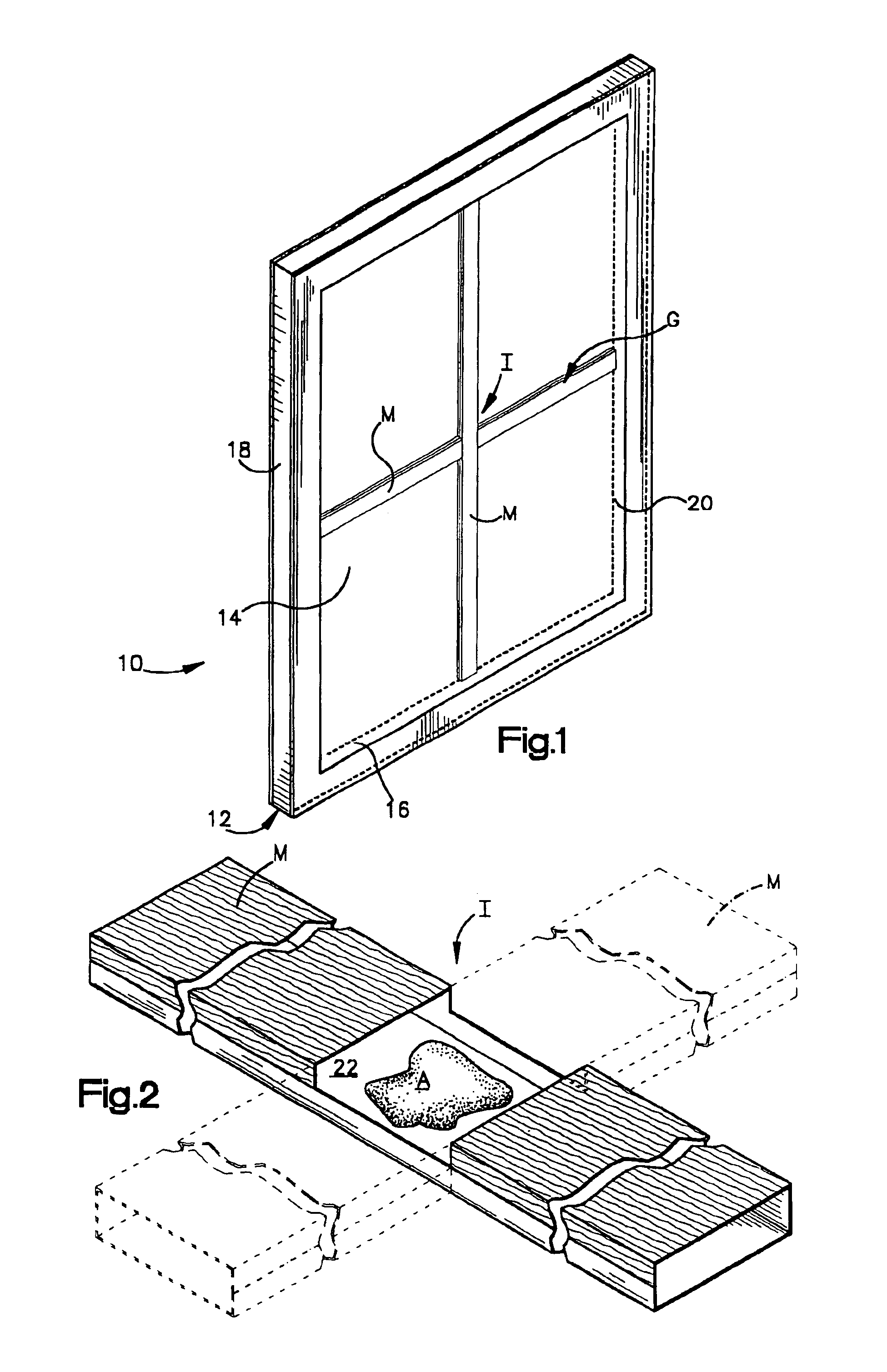

Muntin grid assembly and mounting system

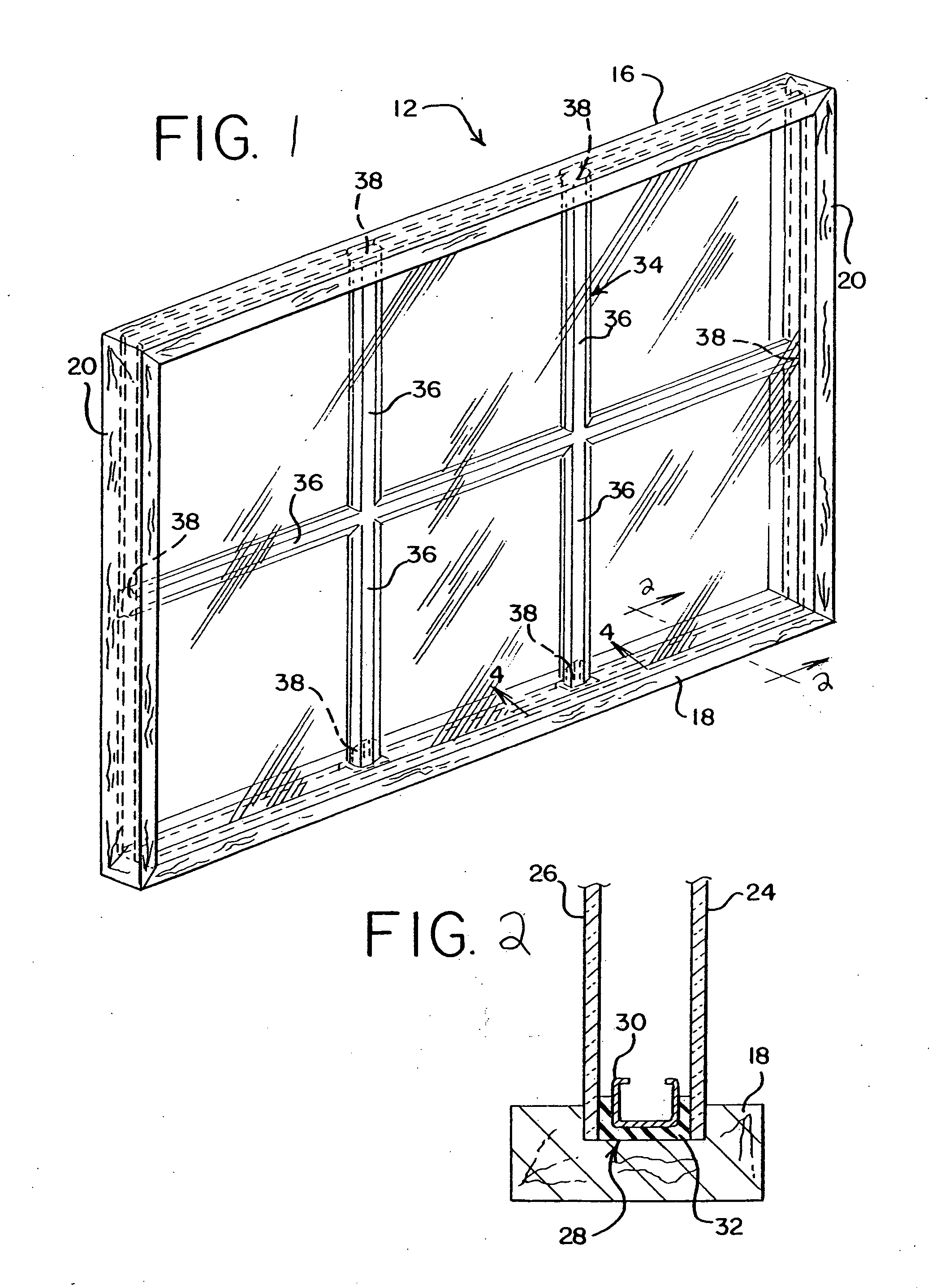

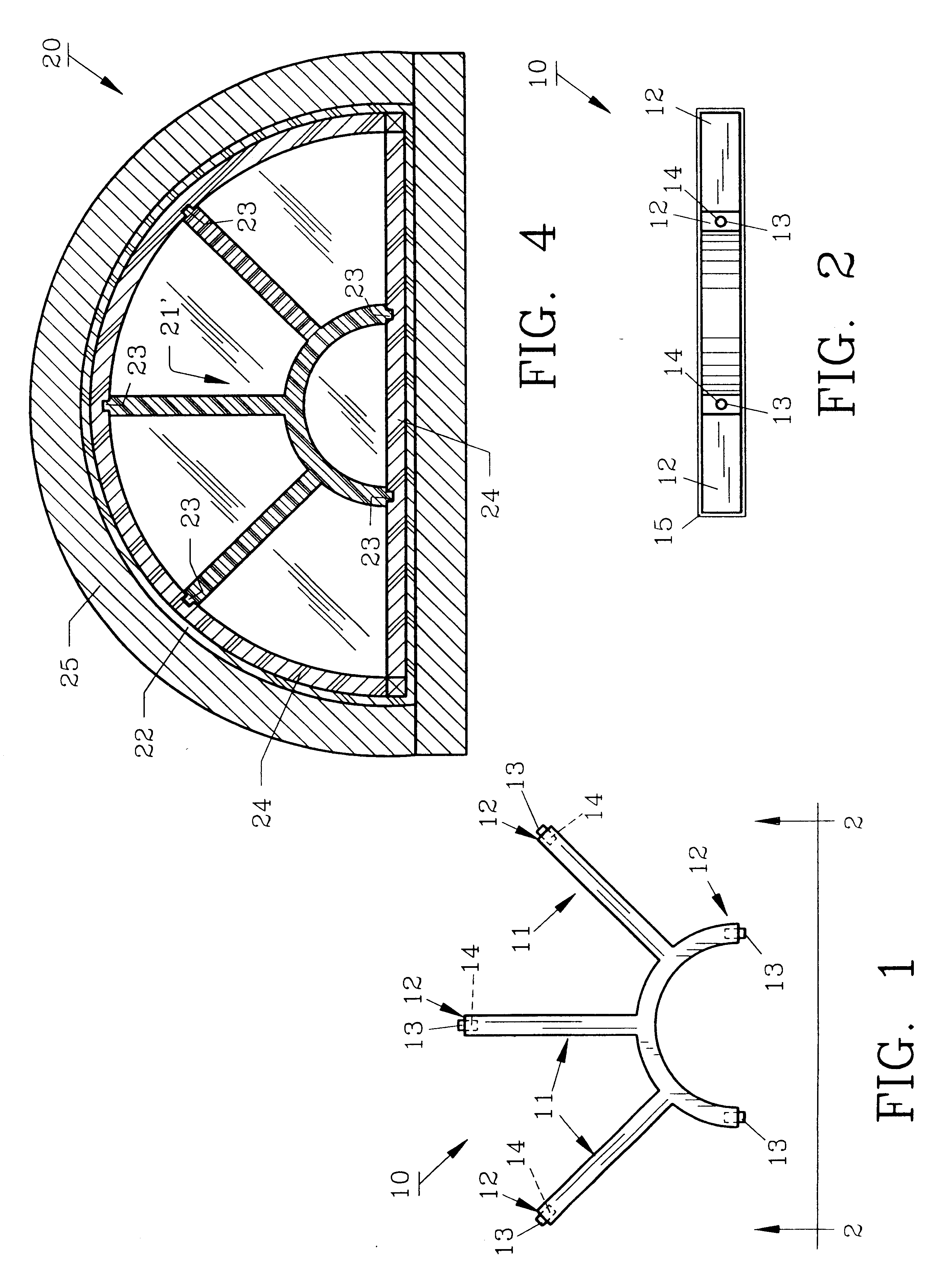

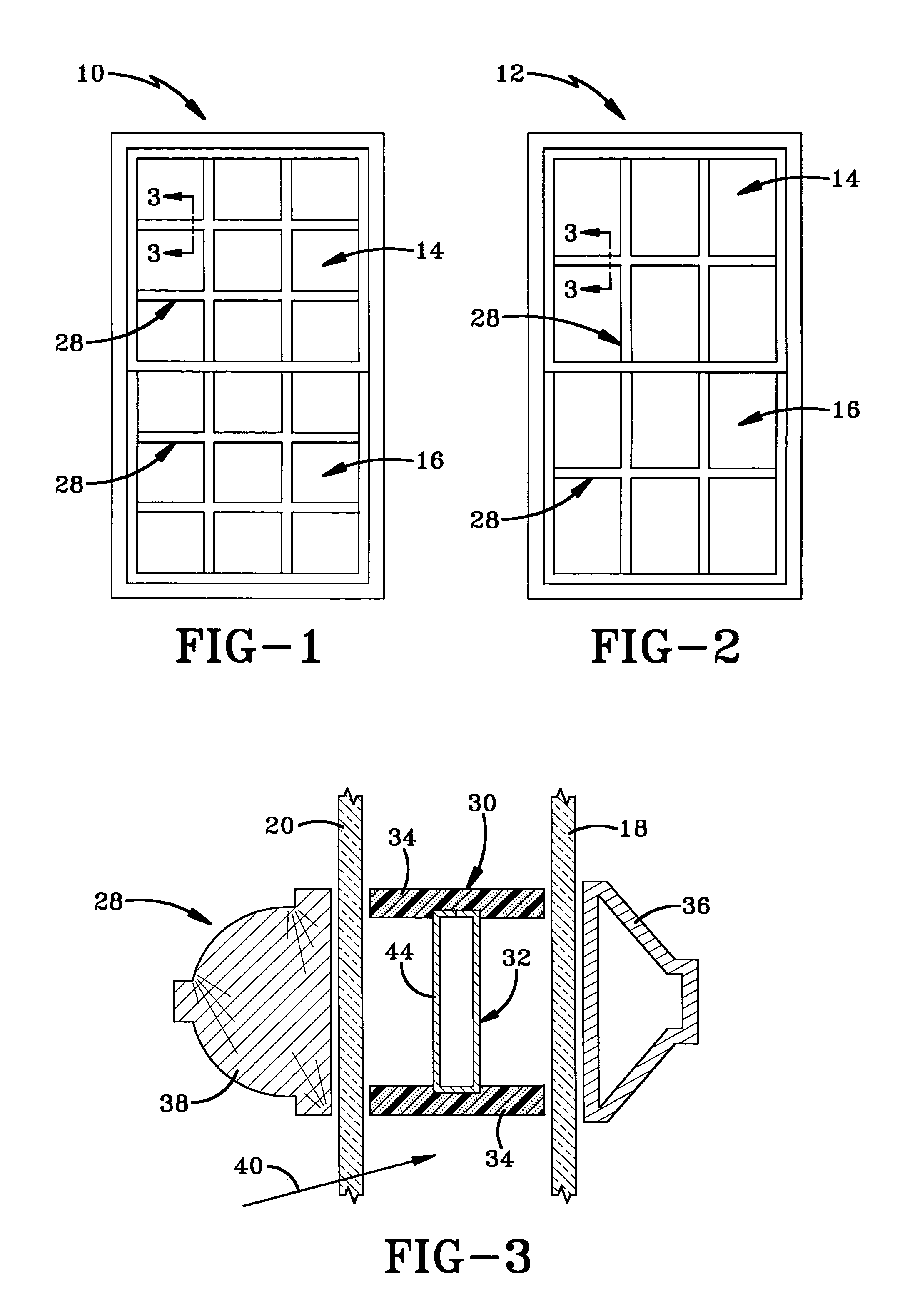

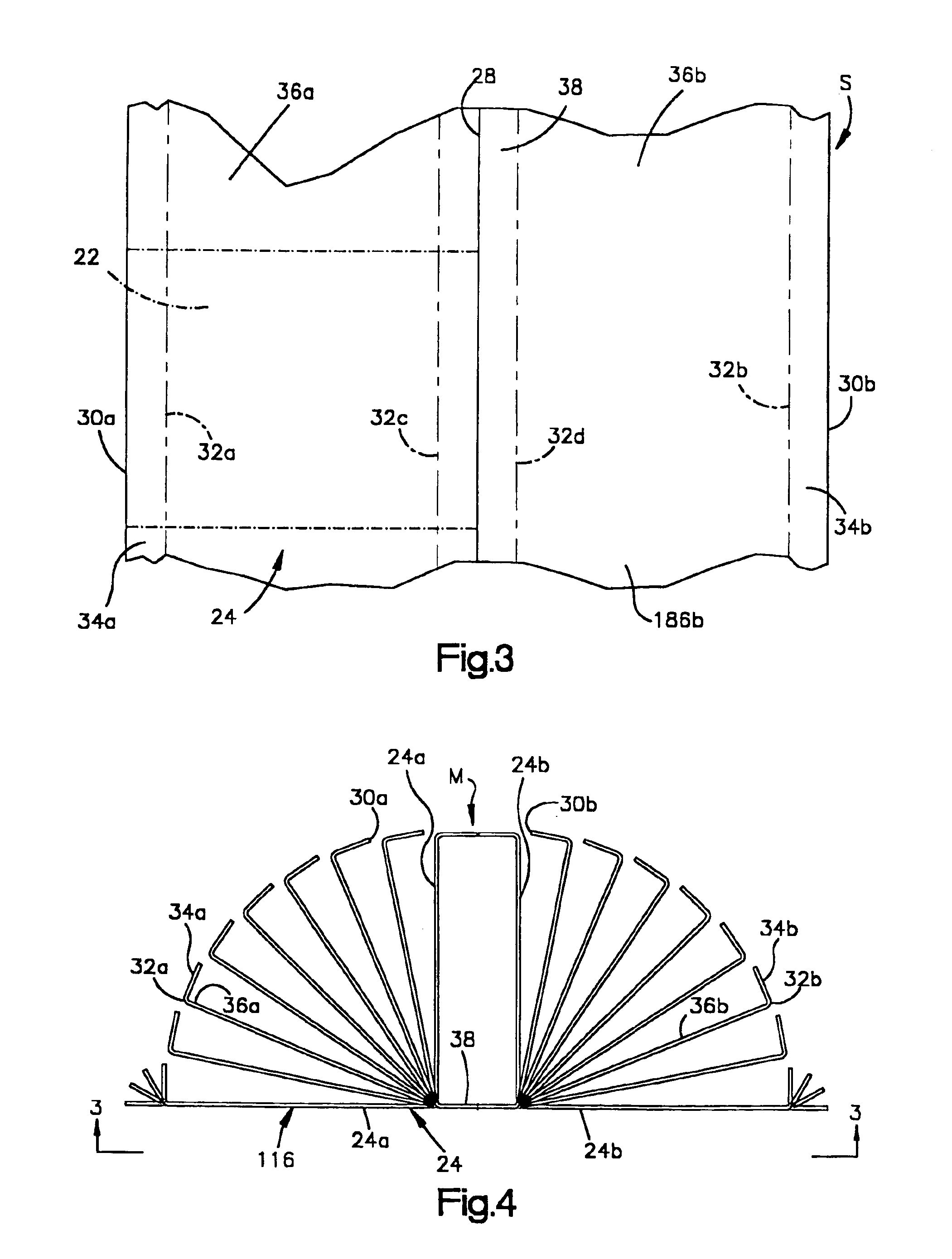

A muntin bar assembly for a window or door including a peripheral frame; a continuous surface contained within the frame; at least one continuous muntin bar and at least two discontinuous muntin bars on at least one side of the surface. The continuous muntin bar and discontinuous muntin bars both contain a continuous recessed portion on their underside and are connected together using an intersection clip having a spring-type arrangement which forms an intersection of the bars. The intersection clip has a raised central section that fits within the recessed portion of the continuous muntin bar; and further has two extensions positioned at opposite sides from the central portion which permit engagement of the discontinuous muntin bars to form the muntin assembly. An end clip is also included for attachment and alignment of the inner and outer assembly muntin bar ends and has a U-shape that fits over the edges of the surface for aligning and attaching the inner and outer assembly muntin bars.

Owner:FOLSOM PETER +1

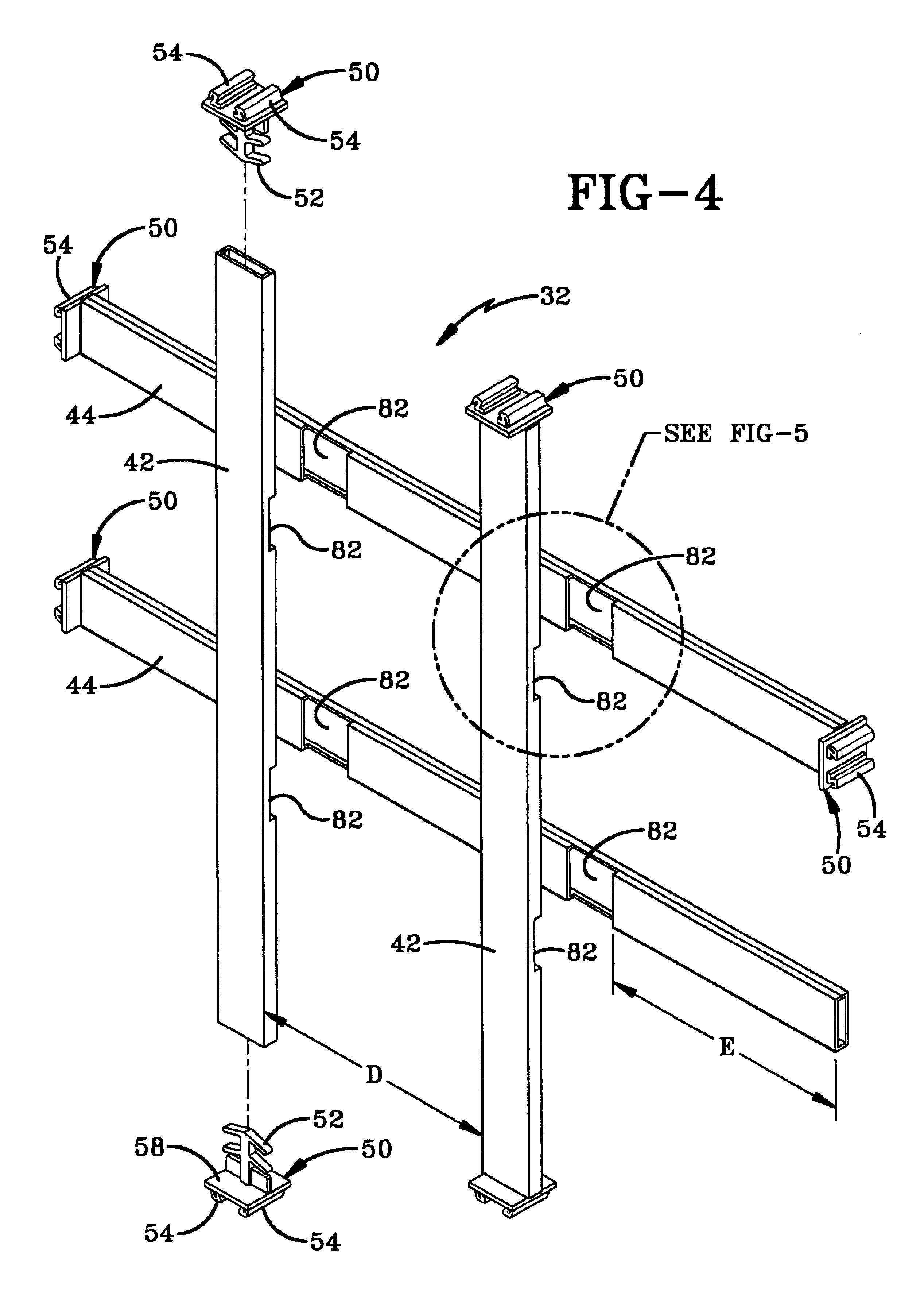

Muntin bars

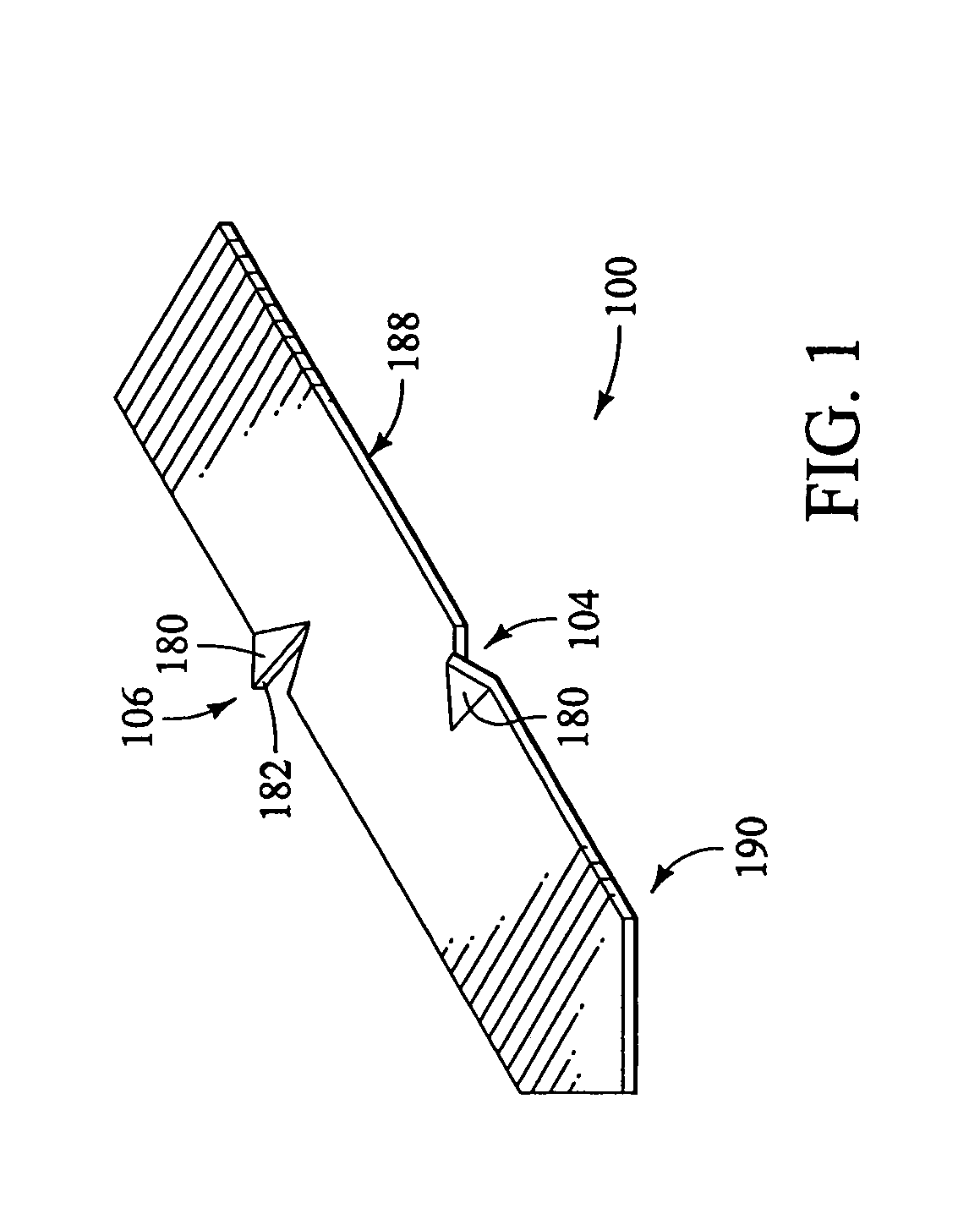

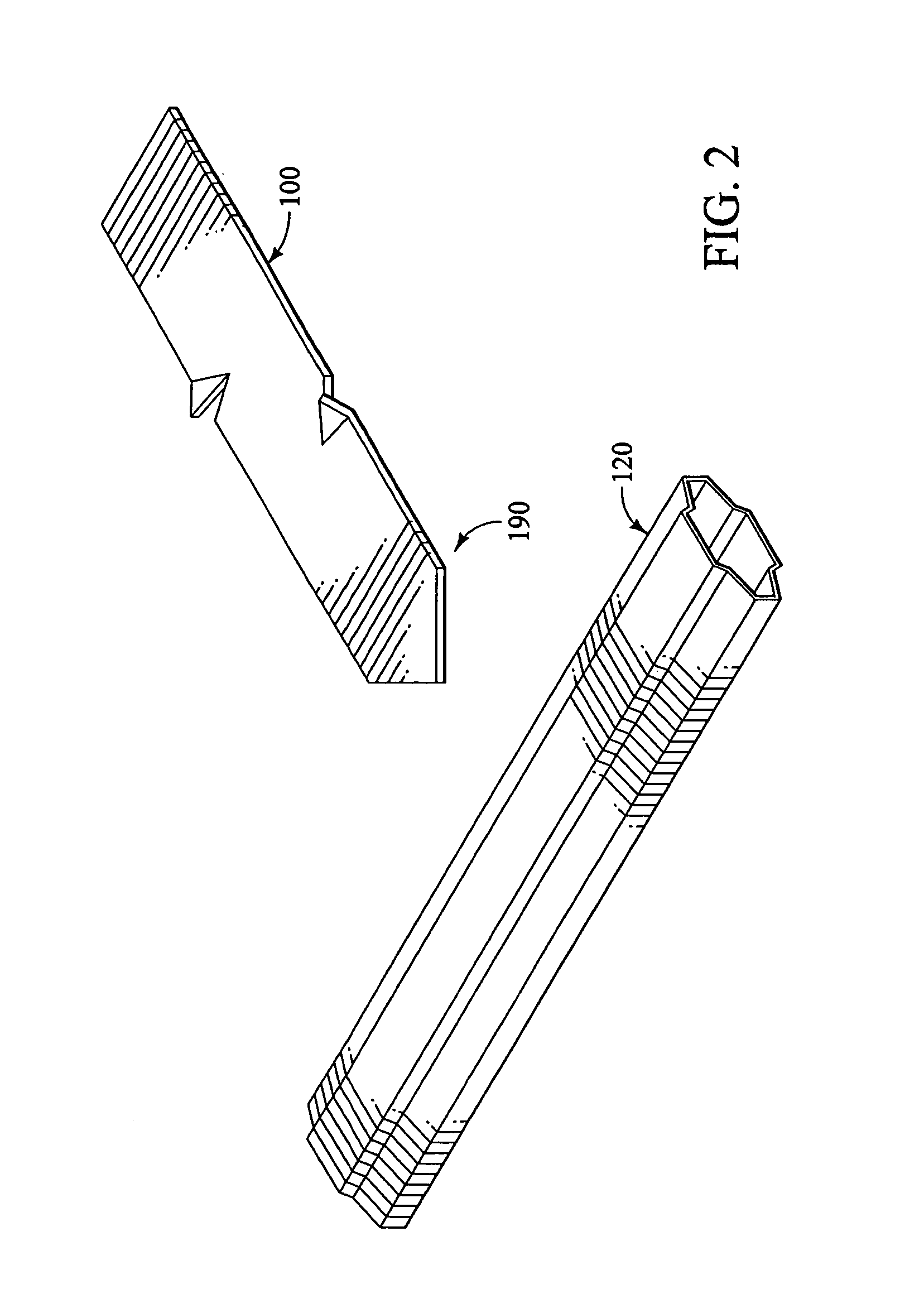

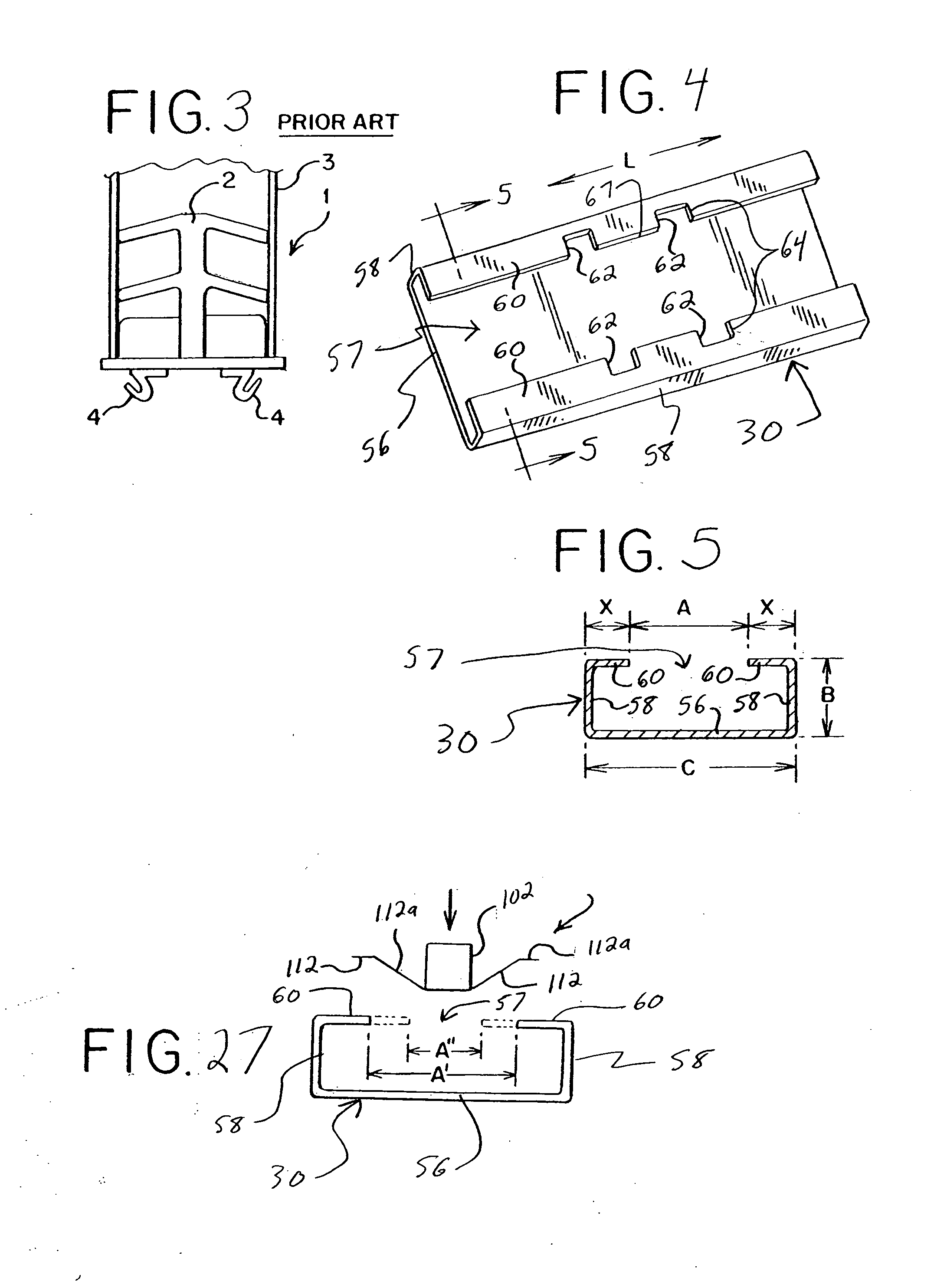

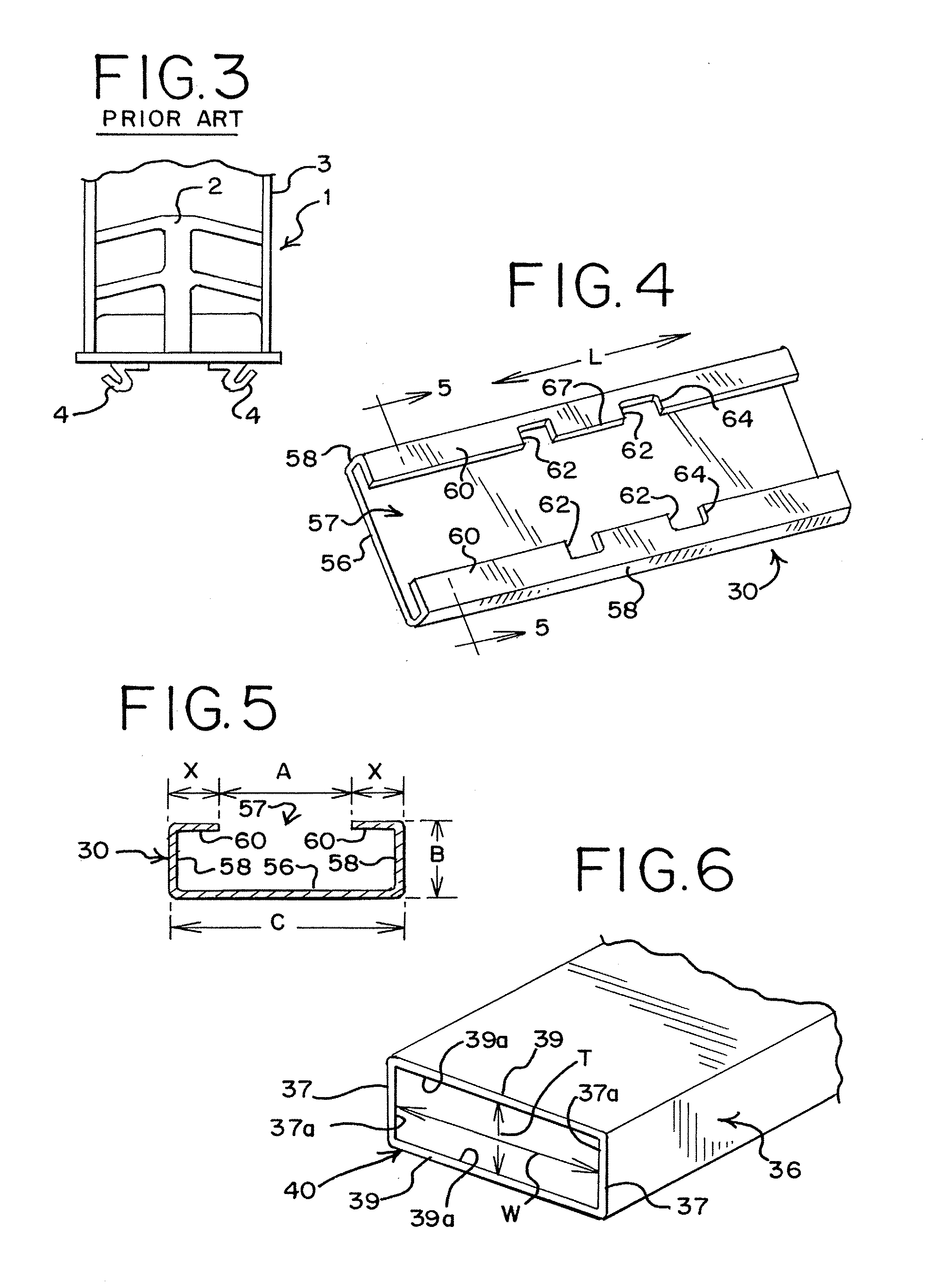

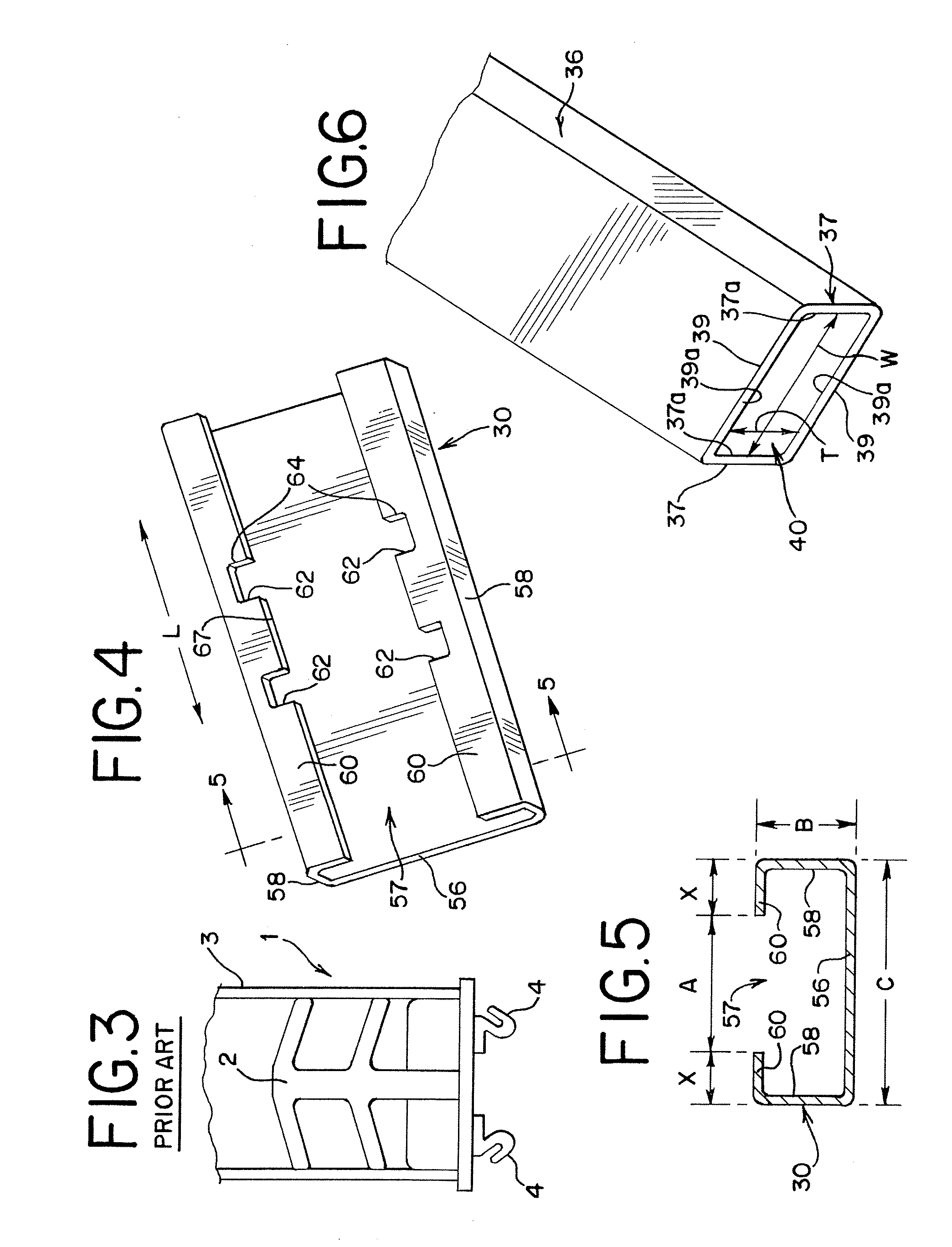

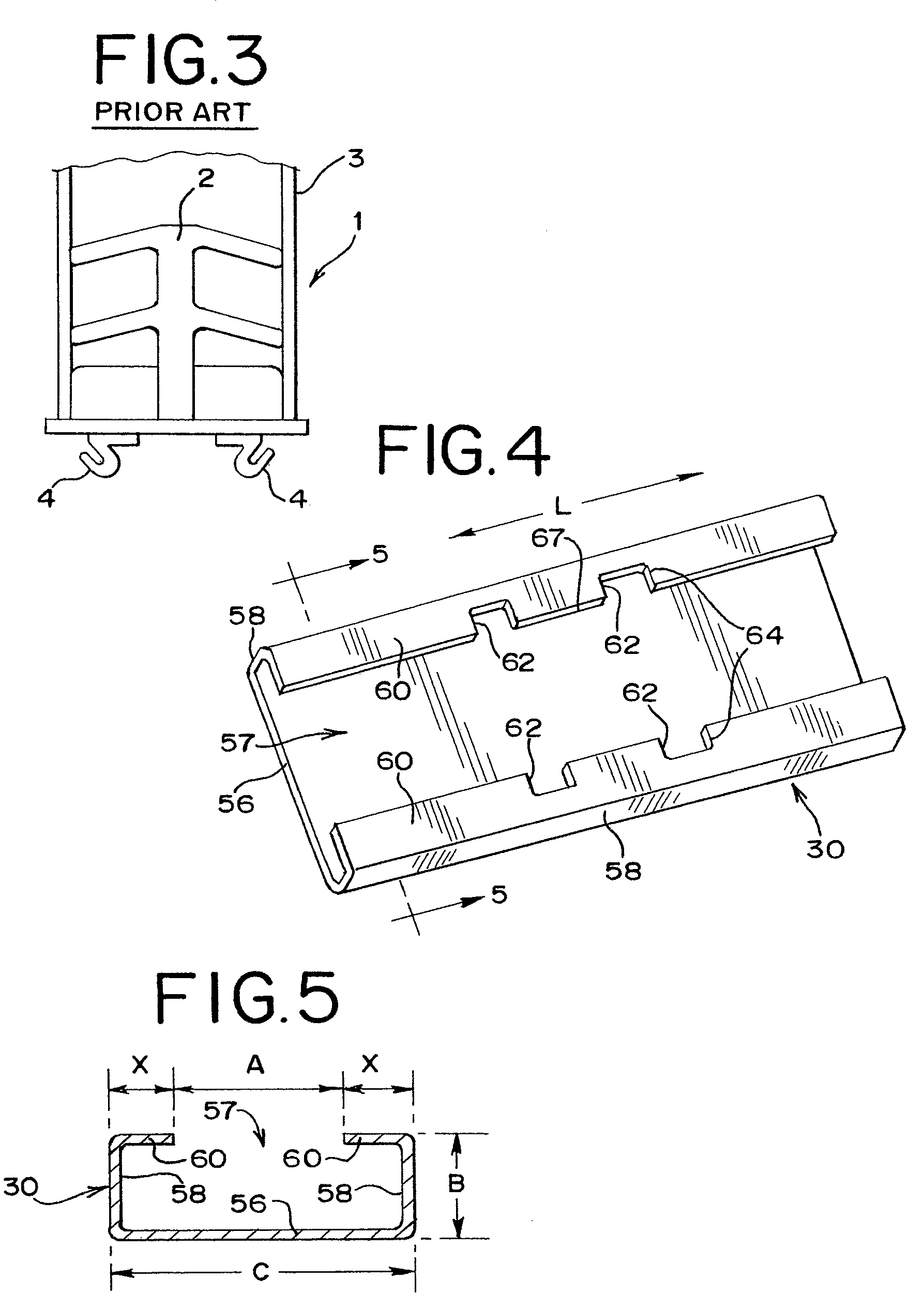

InactiveUS6883278B2Rapid productionEasy to useLayered productsThin material handlingPunchingEngineering

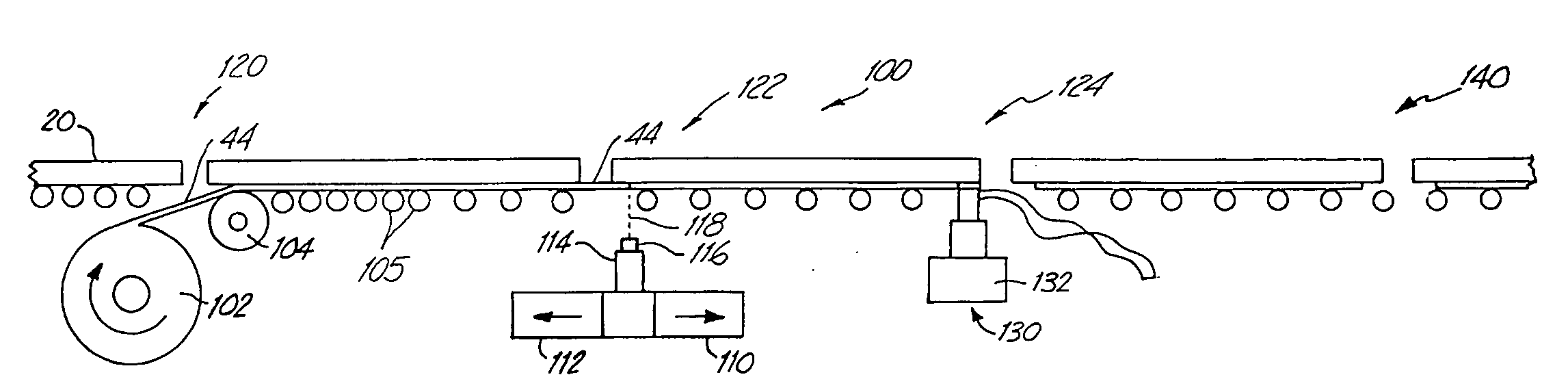

Method and apparatus for making a contoured muntin bar. A supply of sheet material having a finished surface on at least one side in the form of a coiled ribbon is unwound and fed along a strip path of travel to a punch station. At the punch station a ribbon punching mechanism punches the ribbon at a precisely predetermined locations along the ribbon to form one of a plurality notch patterns that define a portion of a contoured muntin bar. Downstream along the travel path from the punch station the ribbon is fed through a forming station having a succession of forming rolls that define a succession of forming roll nips to bend the ribbon and form a generally closed cross-sectional tube. The rolls form a number of bending stages to produce a muntin bar tube having a contoured shape with raised sides to provide an attractive appearance to a muntin grid.

Owner:GED INTEGRATED SOLUTIONS

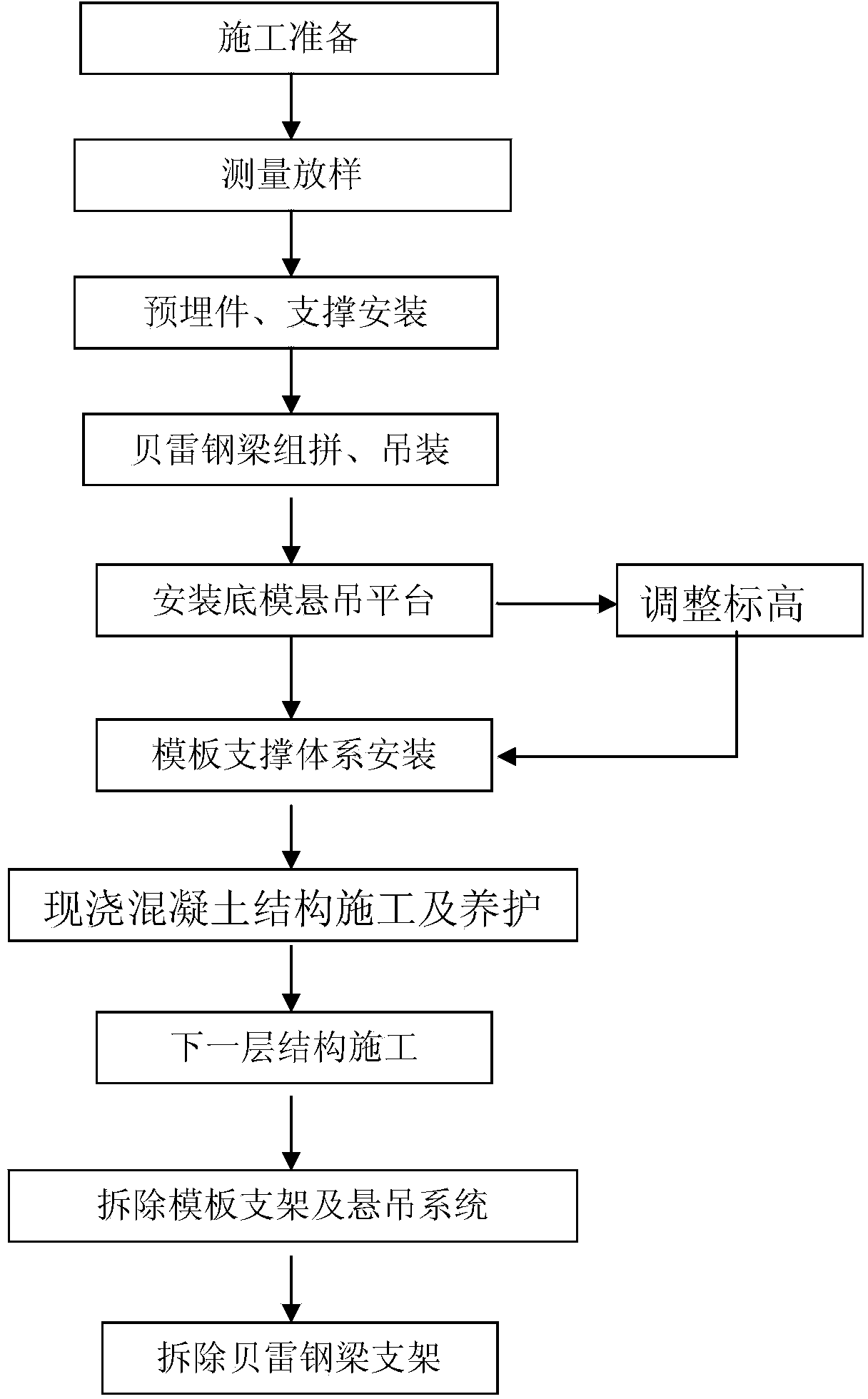

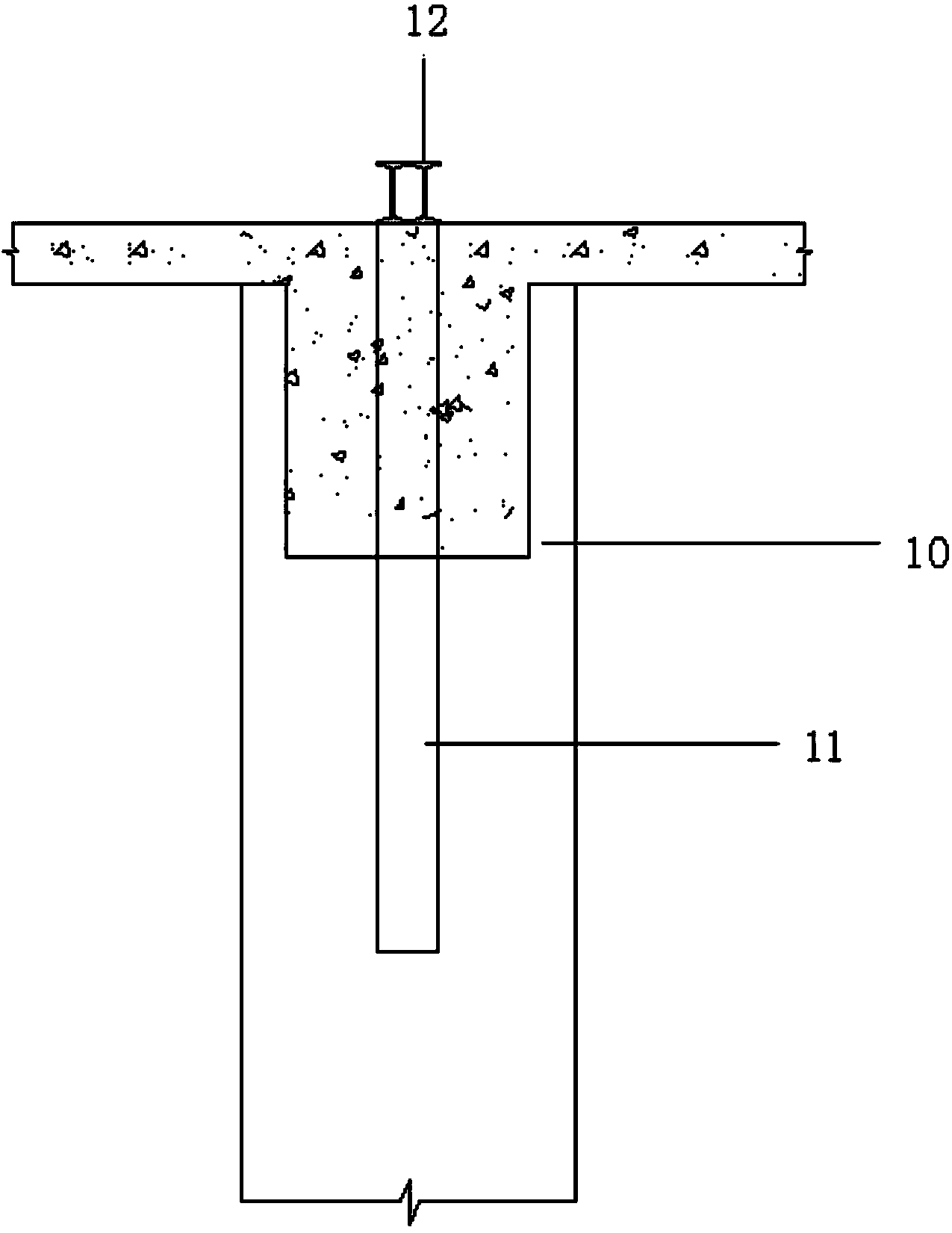

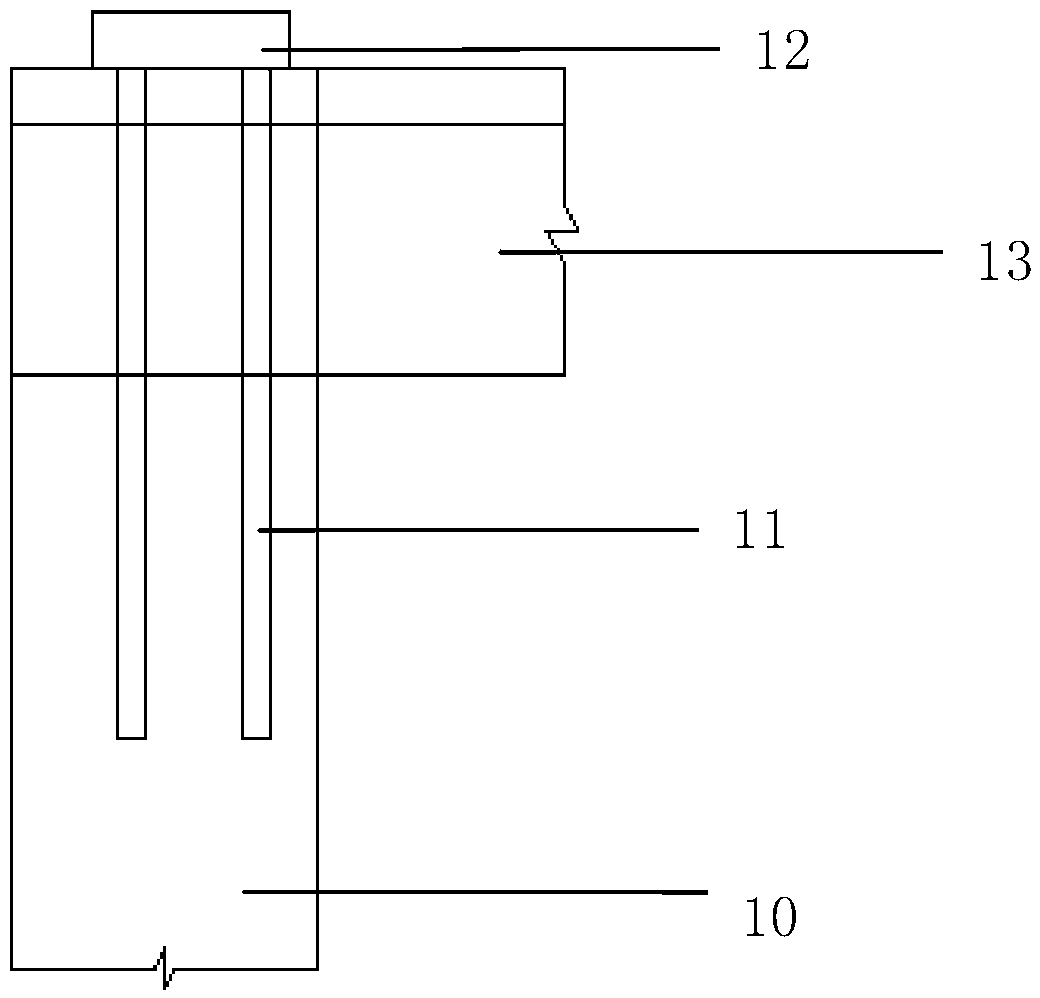

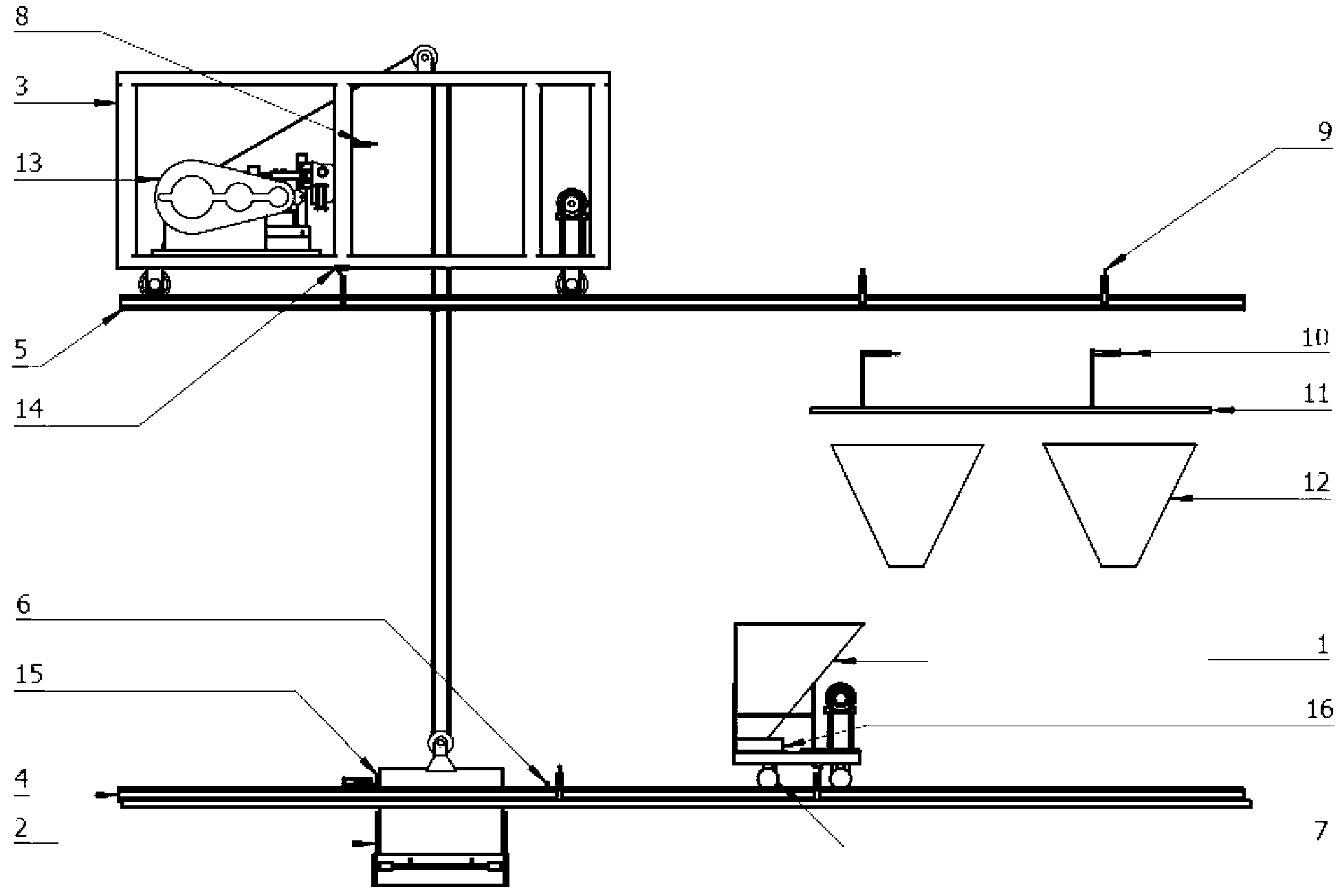

Bailey beam suspension formwork supporting system and construction method thereof

ActiveCN104141383ASimple structureEasy to transportForms/shuttering/falseworksBuilding material handlingFalseworkSupporting system

The invention discloses a bailey beam suspension formwork supporting system and a construction method thereof. The bailey beam suspension formwork supporting system comprises longitudinal and transverse stress trusses (2) consisting of bailey beams (1); suspenders (5) are arranged on transverse bailey beams (3) and the suspenders penetrate through a concrete layer structure bottom formwork (6) for suspending a bidirectional I-shaped steel load-bearing platform (7); a steel pipe scaffolding formwork supporting system (8) is arranged above the platform, the transverse bailey beams are perpendicularly arranged above the longitudinal bailey beams (9) according to spacing, and the longitudinal bailey beams (9) are supported on a framework structure or temporary supports (10). The construction method of the bailey beam suspension formwork supporting system comprises the following steps: erecting a bailey beam formwork supporting system suspension system at the upper part of an additionally constructed layer in advance, and laying a formwork support operating platform below. The bailey beam suspension formwork supporting system and the construction method thereof have the advantages that the construction site is not occupied, the system and the method are suitable for cast-in-situ concrete construction of aerial connecting corridors, high and large muntin and transfer layer engineering of reinforced concrete or section steel combined structures, are particularly suitable for additionally constructed engineering which does not have a stress relationship with original structures, and have unique advantages.

Owner:北京万兴建筑集团有限公司

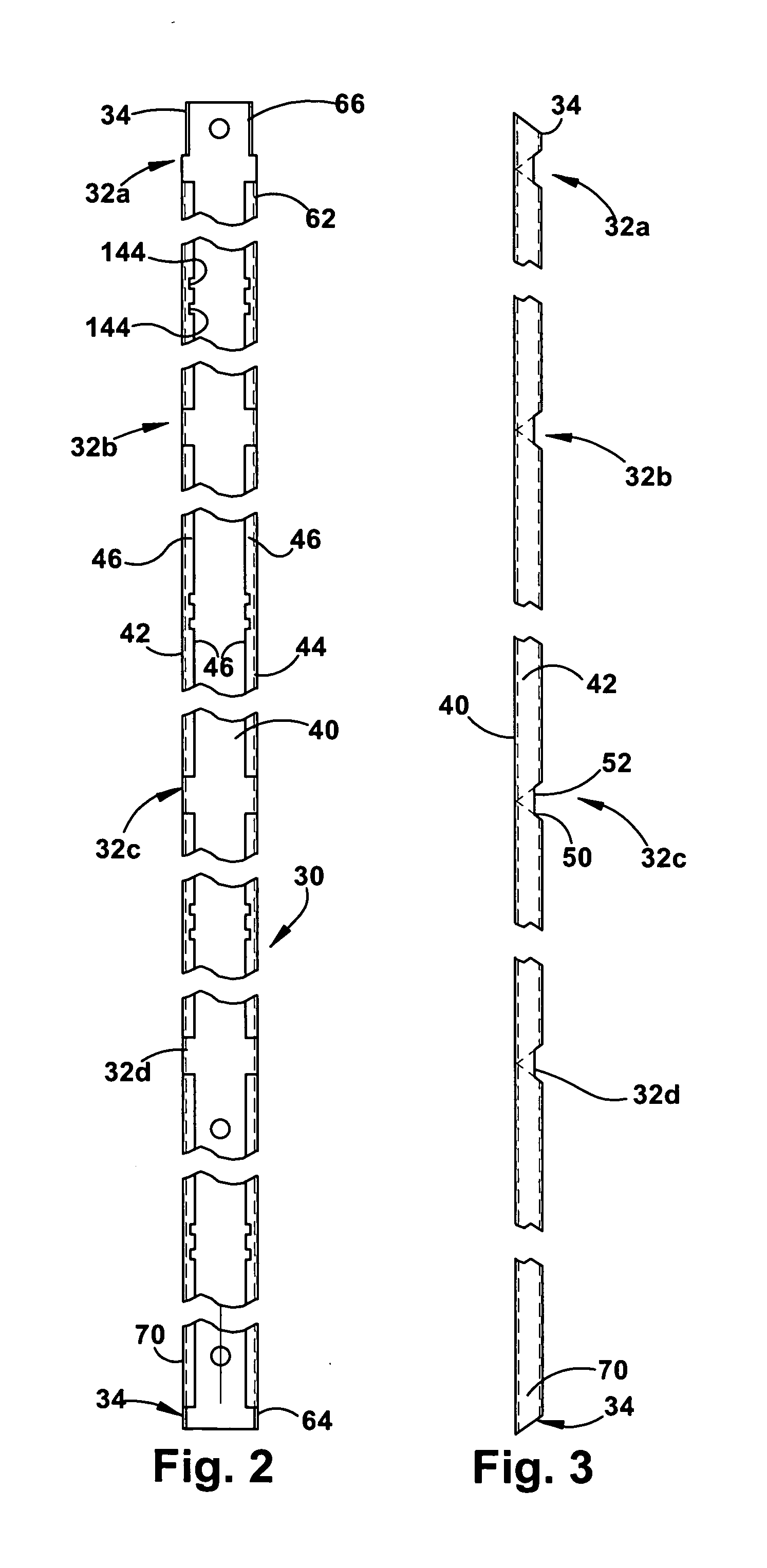

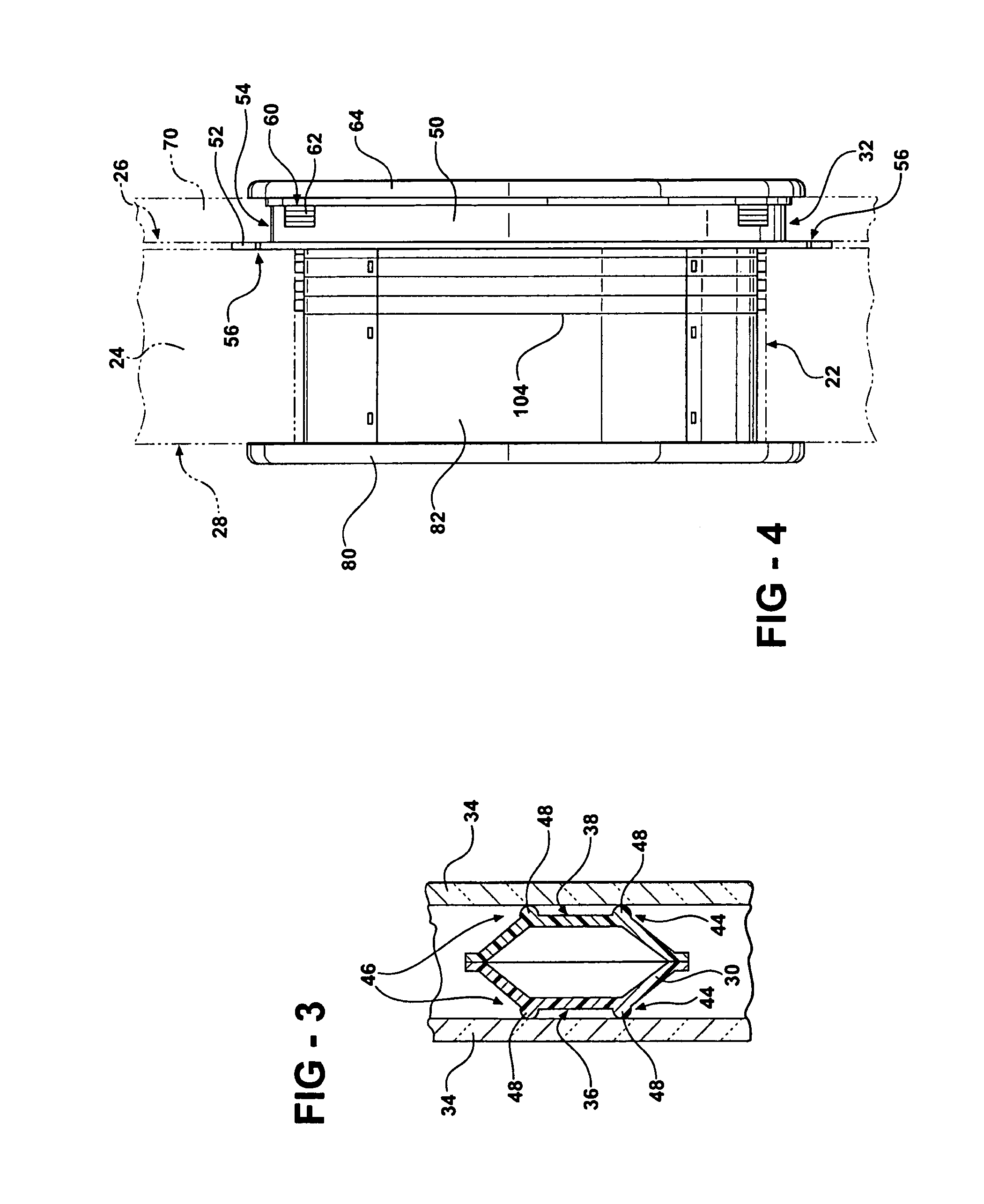

Apparatus for manufacturing muntin bar assemblies

InactiveUS7076927B2Avoid relative motionCorner/edge jointsCondensed water formation preventionFlangeMuntin

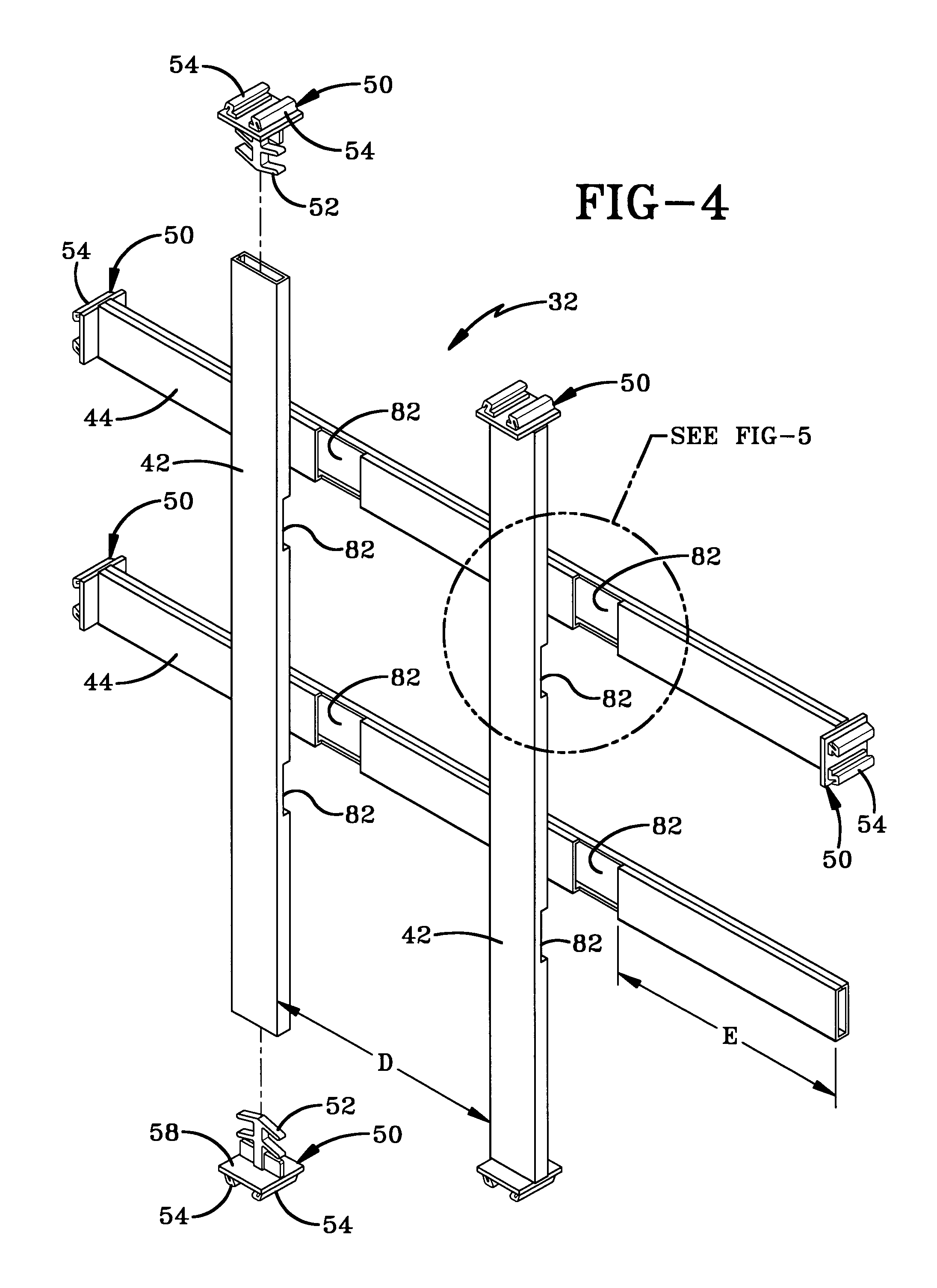

Methods and apparatus for assembling muntin bar lattices and spacer frames for use in insulating glass units are disclosed. One method of assembling a muntin bar lattice in accordance with the present invention comprises the steps of providing a muntin bar segment and a keeper dimensioned for piercing a wall of the muntin bar segment. A keeper in accordance with an exemplary embodiment of the present invention comprises an elongate body including a tip portion that is dimensioned for piercing a wall of the muntin bar segment to create an opening therein. A spacer for the separation of panes in an insulating glass unit in accordance with one exemplary embodiment of the present invention may include a tubular member comprising a wall defining a lumen and a mounting flange defining a plurality of mounting holes.

Owner:CARDINAL CG

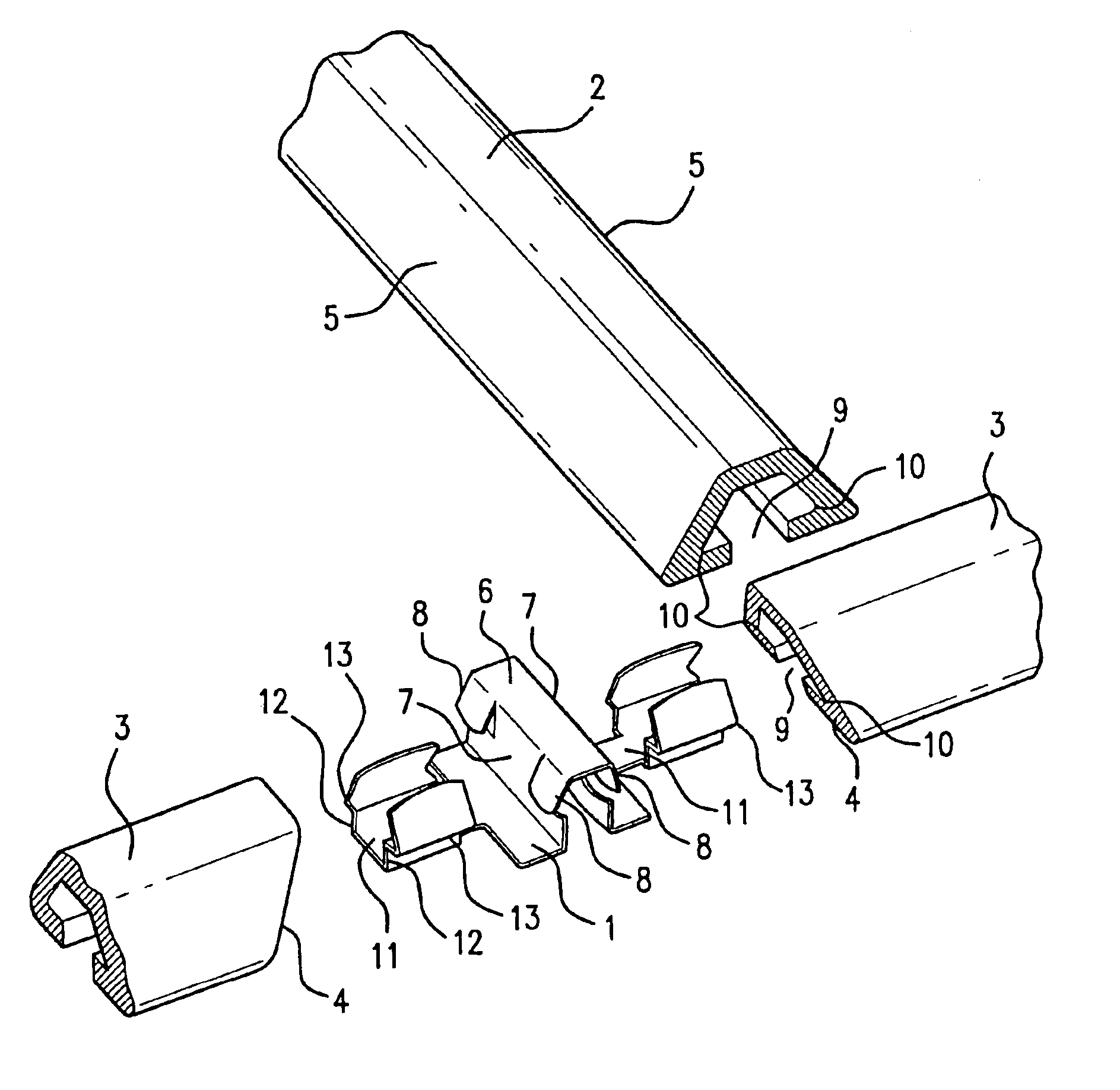

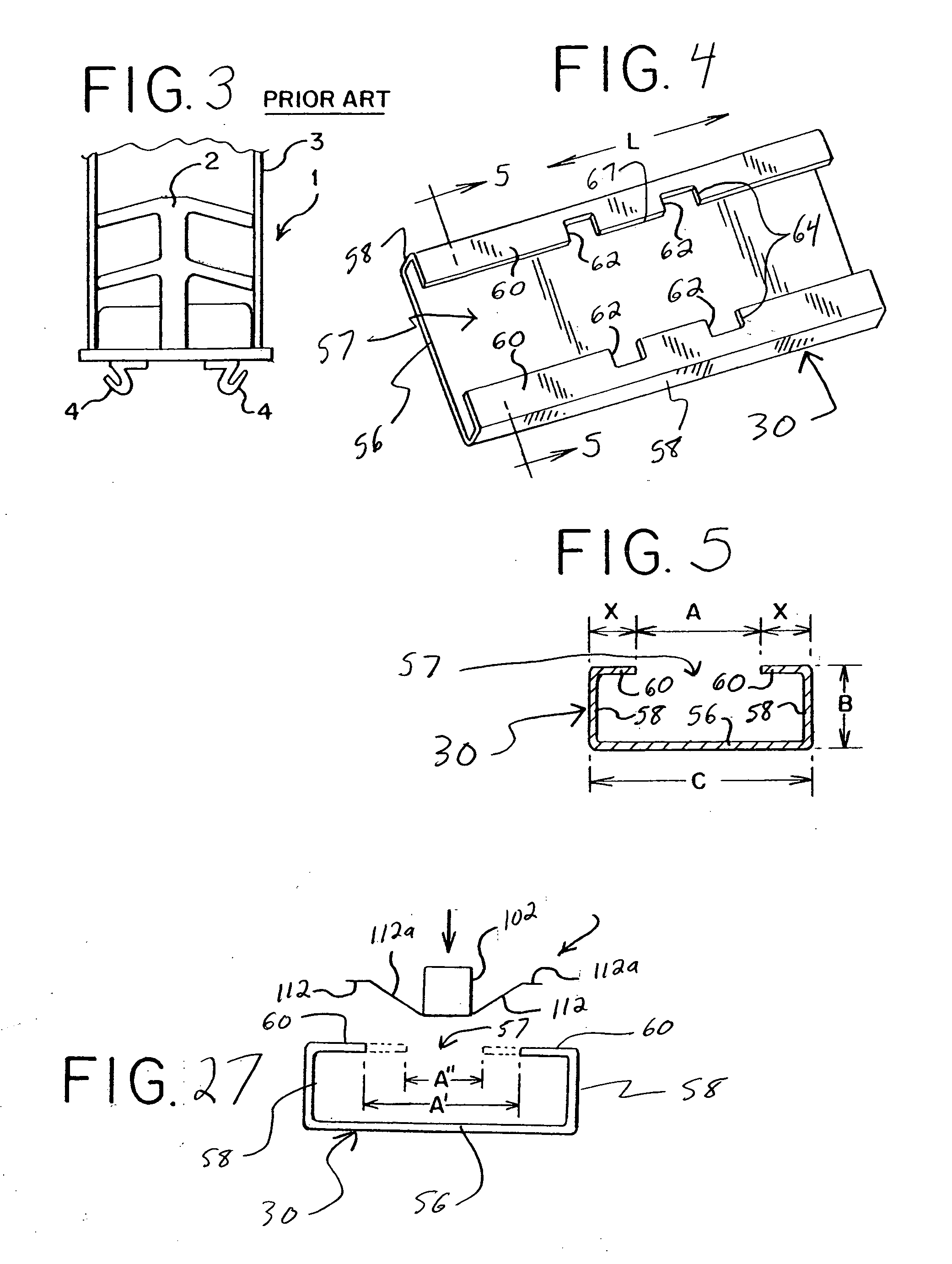

Flexible clip

A muntin clip for use with a spacer frame or window sash having an elongated channel extending around an inner periphery of the frame. The disclosed muntin clip has a spacer frame or sash engaging body for insertion into a channel of the spacer frame. A flexible body portion flexes from a first configuration to a second configuration as the clip is pushed into the spacer frame to exert an outward force against walls of the spacer frame bounding the frame channel. The disclosed clip also includes a muntin bar engaging body attached to the spacer frame engaging body that includes a flexible portion that flexes as the muntin bar engaging body is pushed into the muntin bar to frictionally engage the muntin bar.

Owner:GED INTEGRATED SOLUTIONS

Method of fabricating muntin bars for simulated divided lite windows

InactiveUS6868596B2Avoid stretchingAvoid layeringAutomatic control devicesAssembly machinesAdhesiveEngineering

A method for fabricating muntin grid pieces includes steps that attach a pair of material strips to opposed edges of the muntin bar element. The material strips may be provided in side-by-side strips that may be separated an simultaneously applied to the opposite sides of the muntin bar element. The connection between the material strips and the muntin bar element may be made with an adhesive or a mechanical connection. The method allows the material strips to be connected to the muntin grid pieces before the muntin grid pieces are assembled into a muntin bar grid for a window.

Owner:QUANEX IG SYST INC

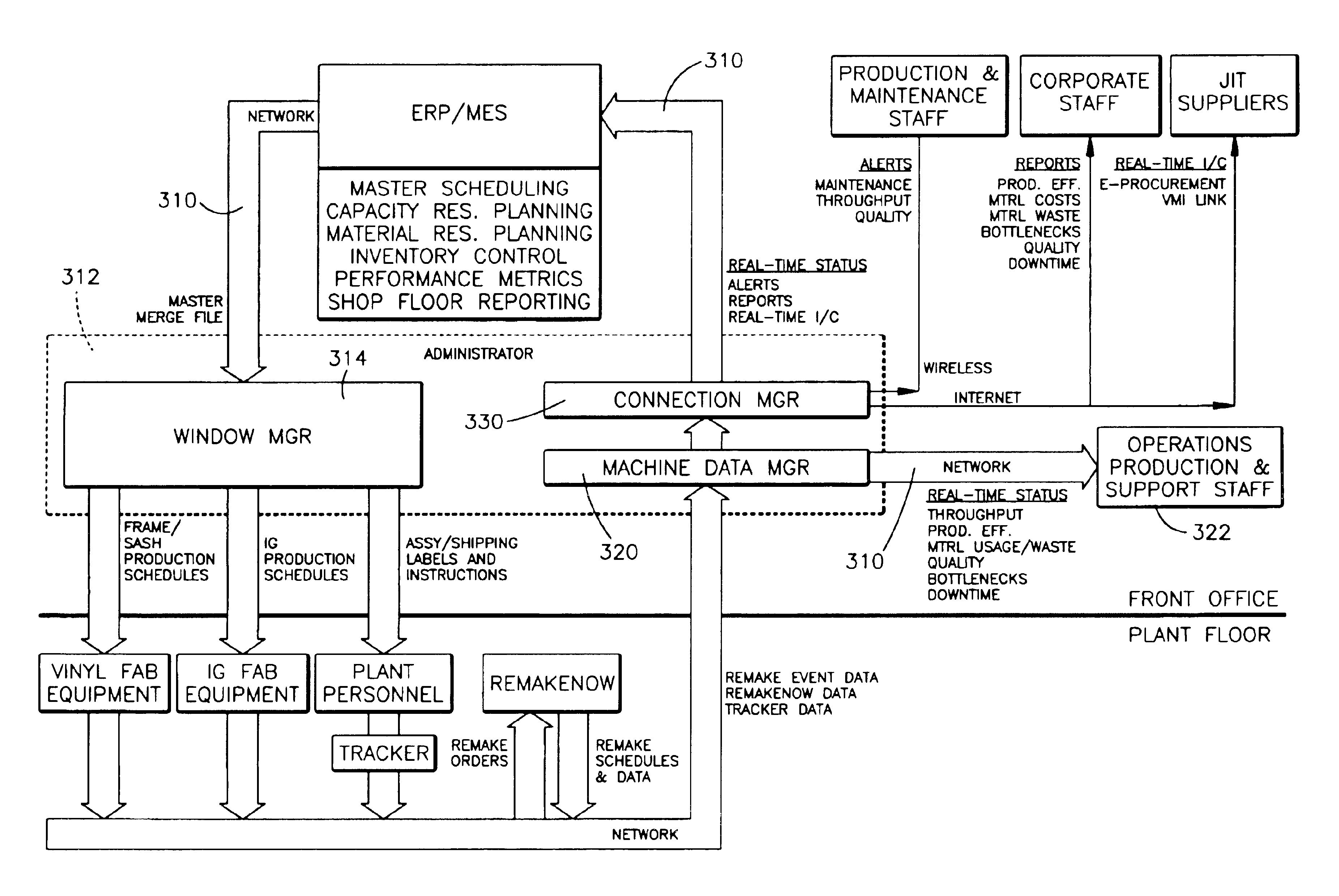

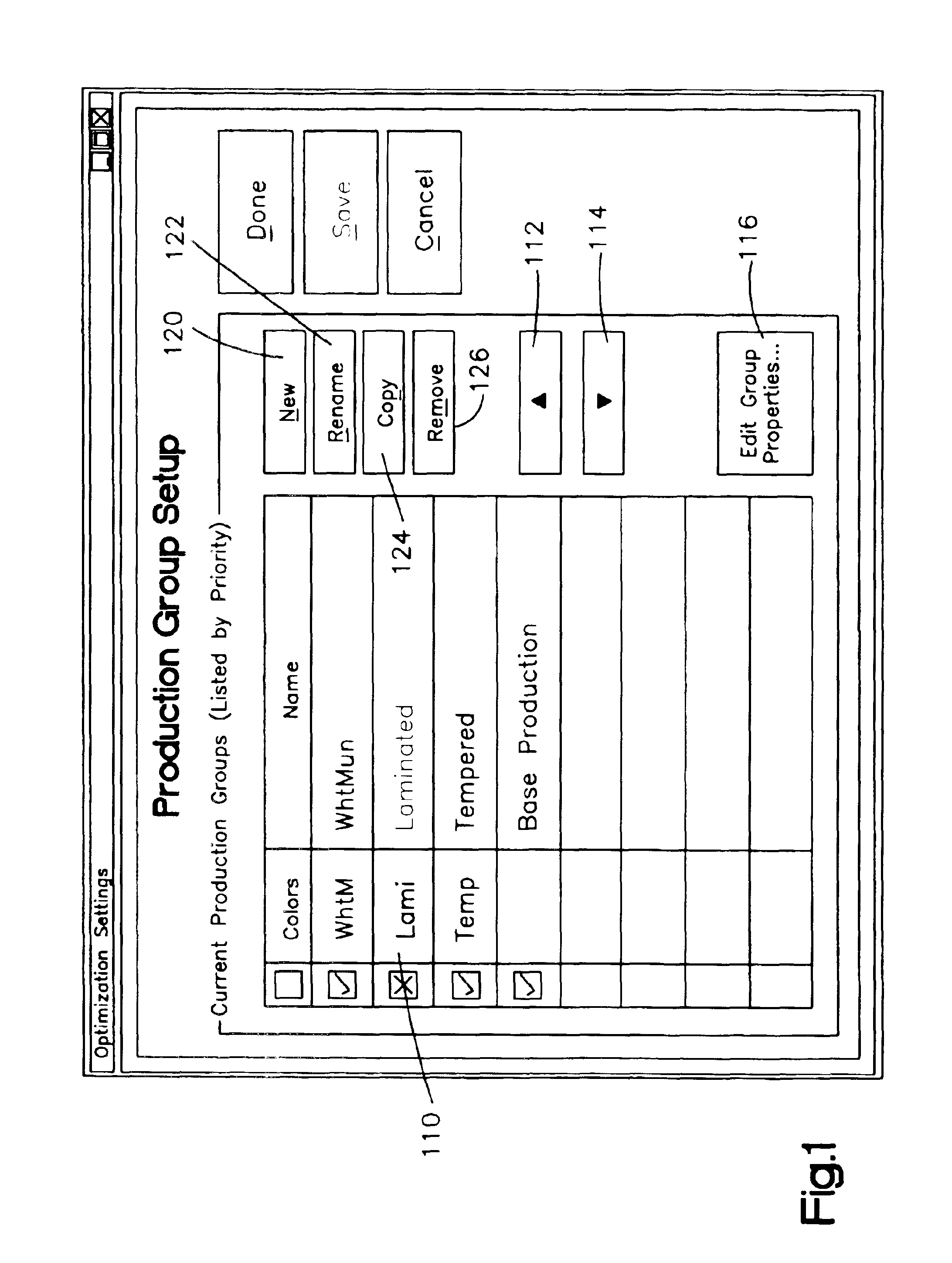

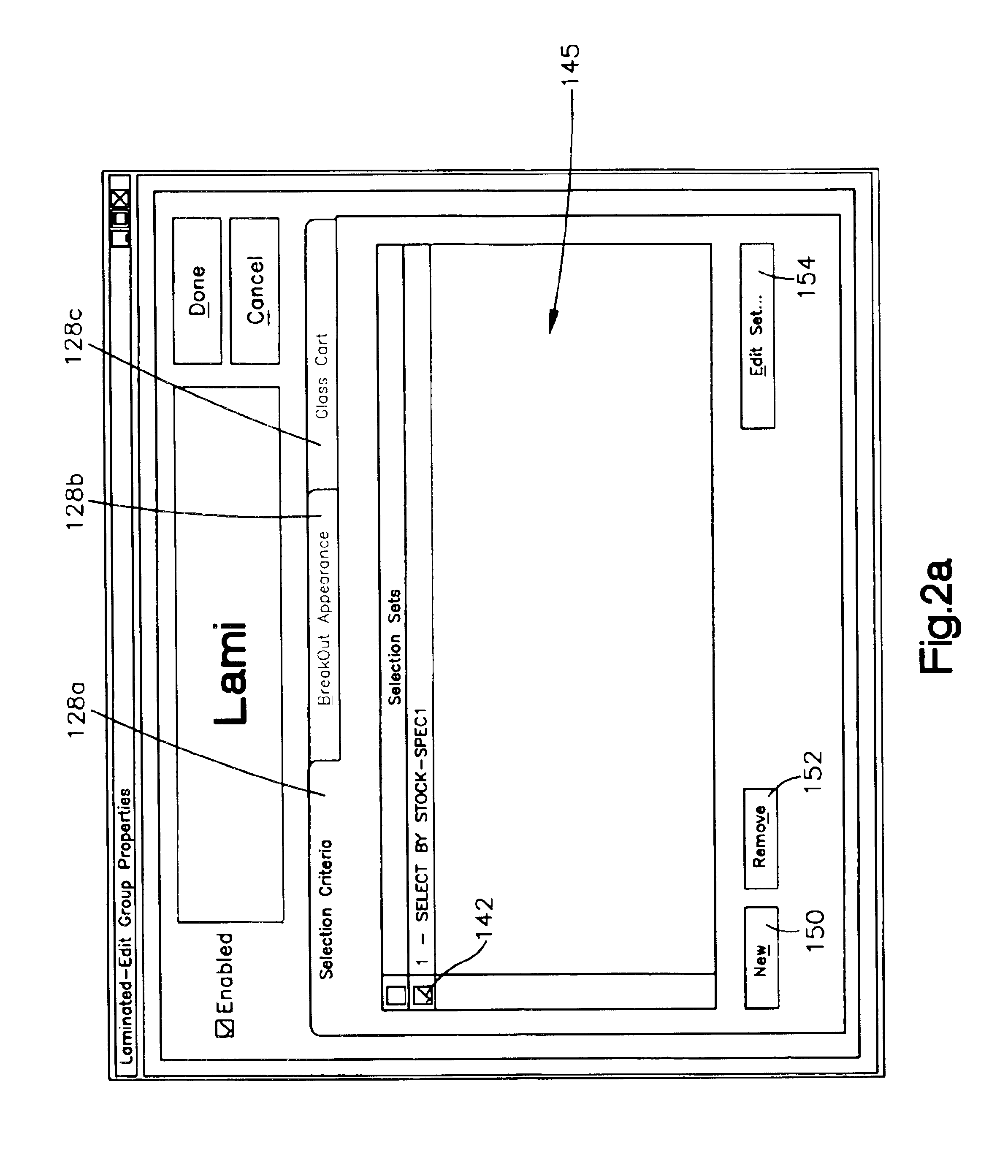

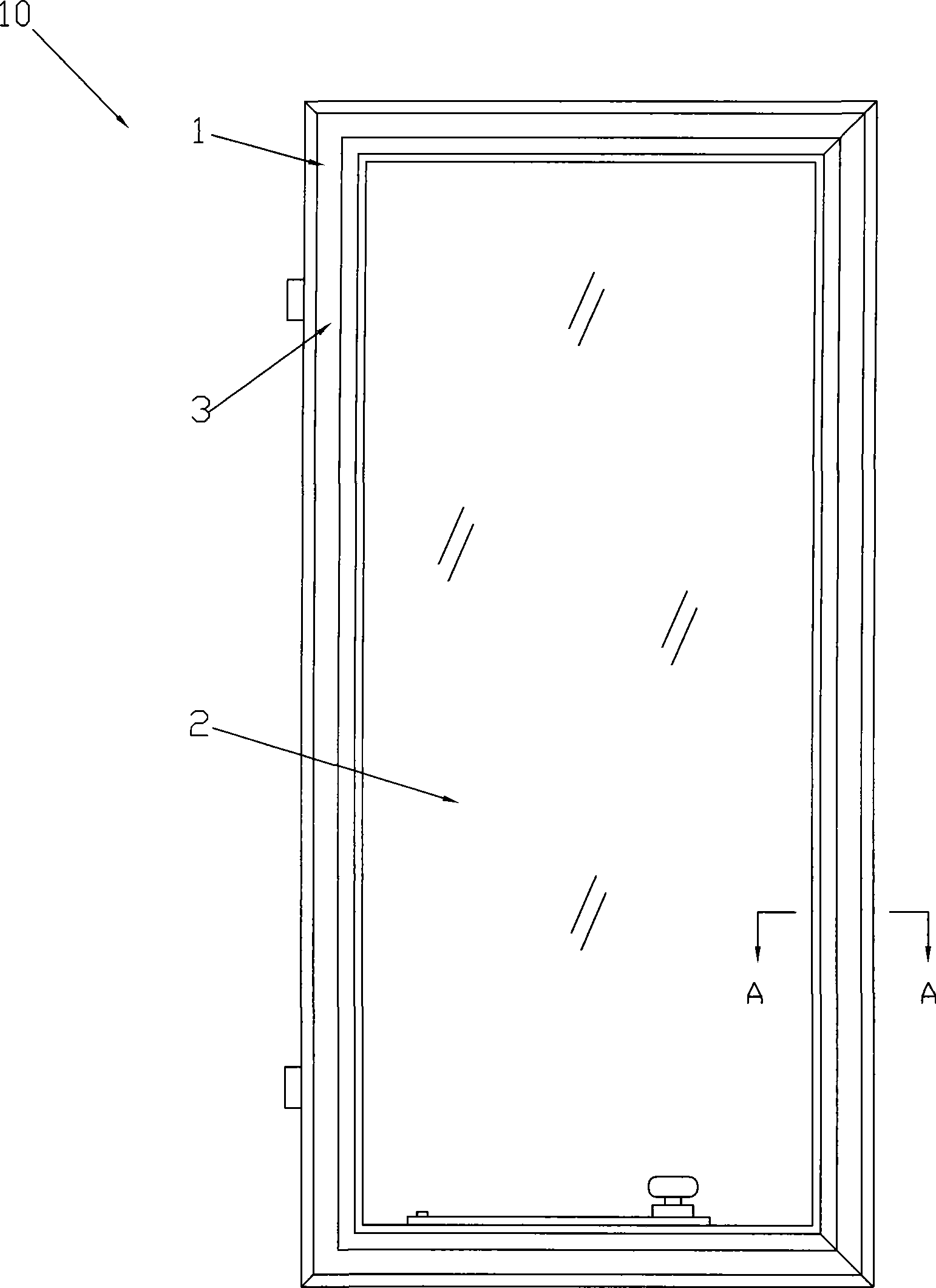

Window or door manufacturing method and apparatus

InactiveUS6954676B2Facilitates setting up and identifyingEasy to set upTotal factory controlSpecial data processing applicationsEngineeringSoftware

An exemplary embodiment of the invention concerns a method of manufacturing a window or a door. Different groups of components are defined. These components combine to form a window or door. The components that make up a group are monitored on a viewing screen during movement of those components through a manufacturing or assembly location. Practice of the invention facilitates setting up and identifying standard and custom groups for the Window and Door Industry. These groups include but are not limited to the following items, Glass, IG Units, Muntins, Gas, Frames, Sashes, Windows Lines and Window Styles. Such visual software helps set up a window manufacturing sequence criteria used for processing the various groups. It allows the set up of various multiple sort levels and sort criteria within the Groups.

Owner:GED INTEGRATED SOLUTIONS

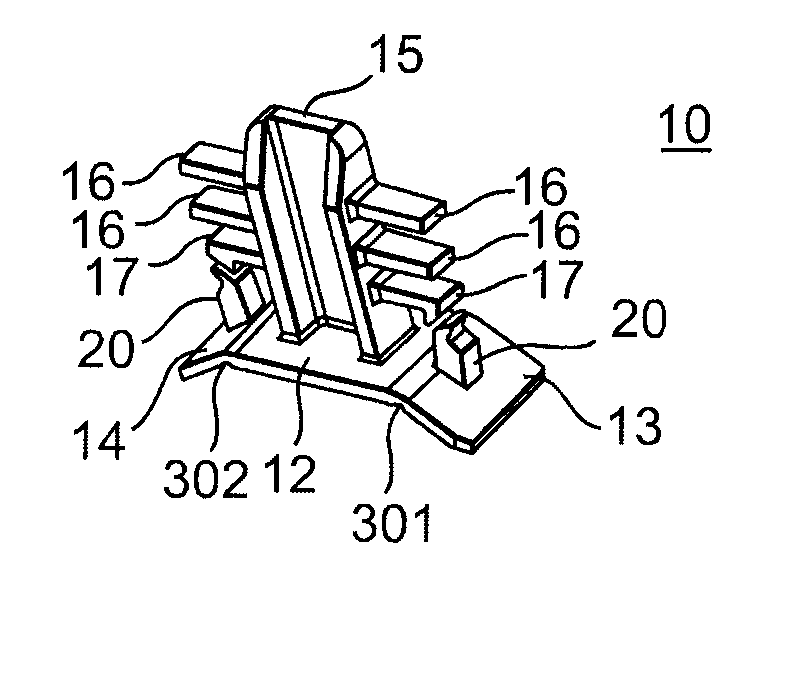

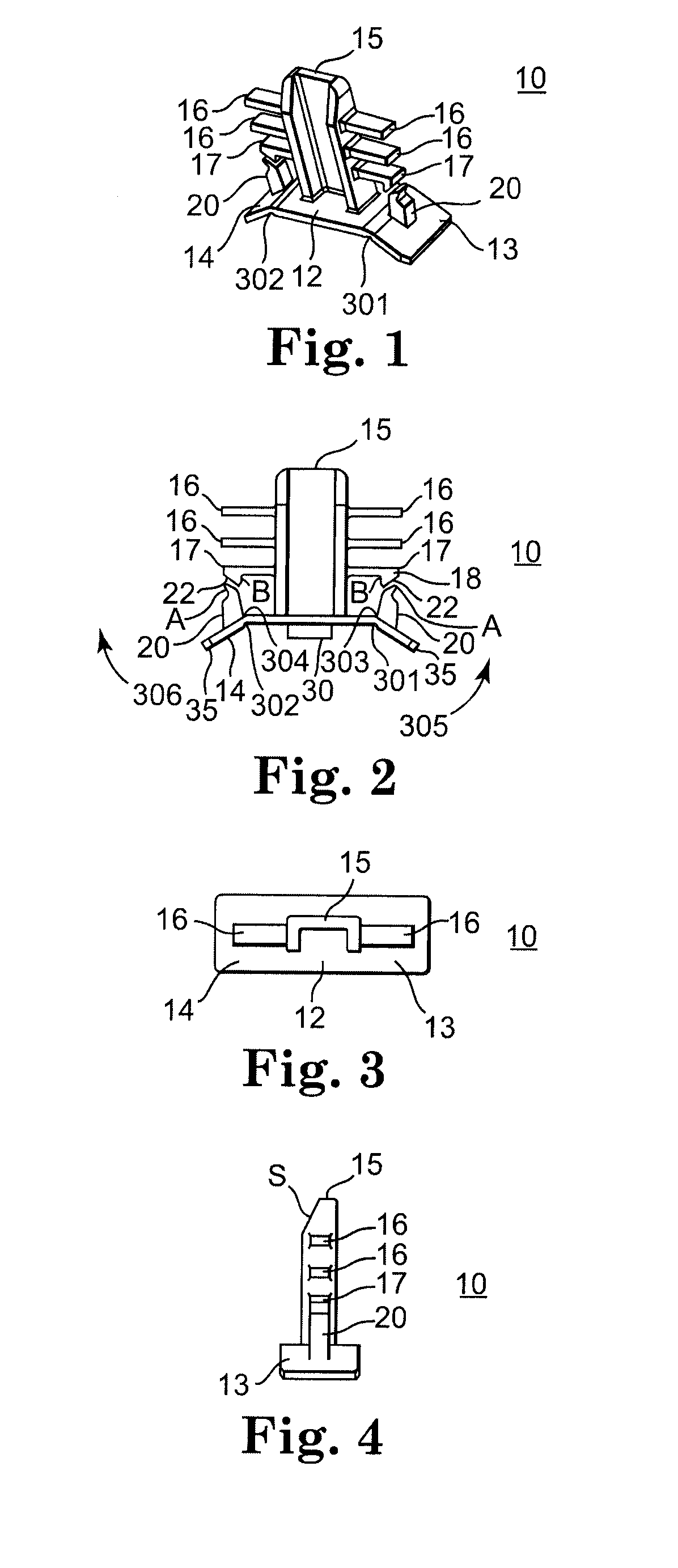

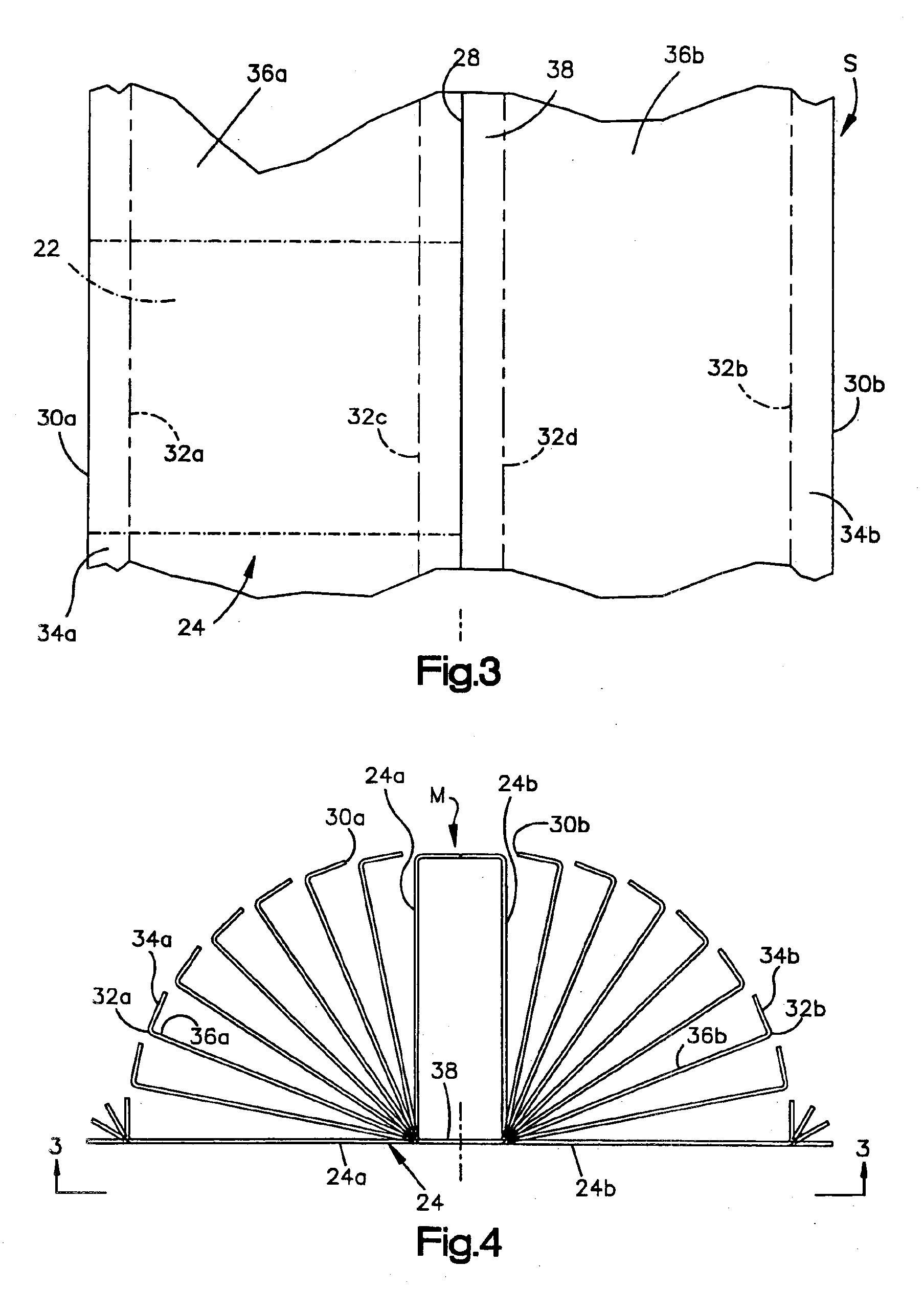

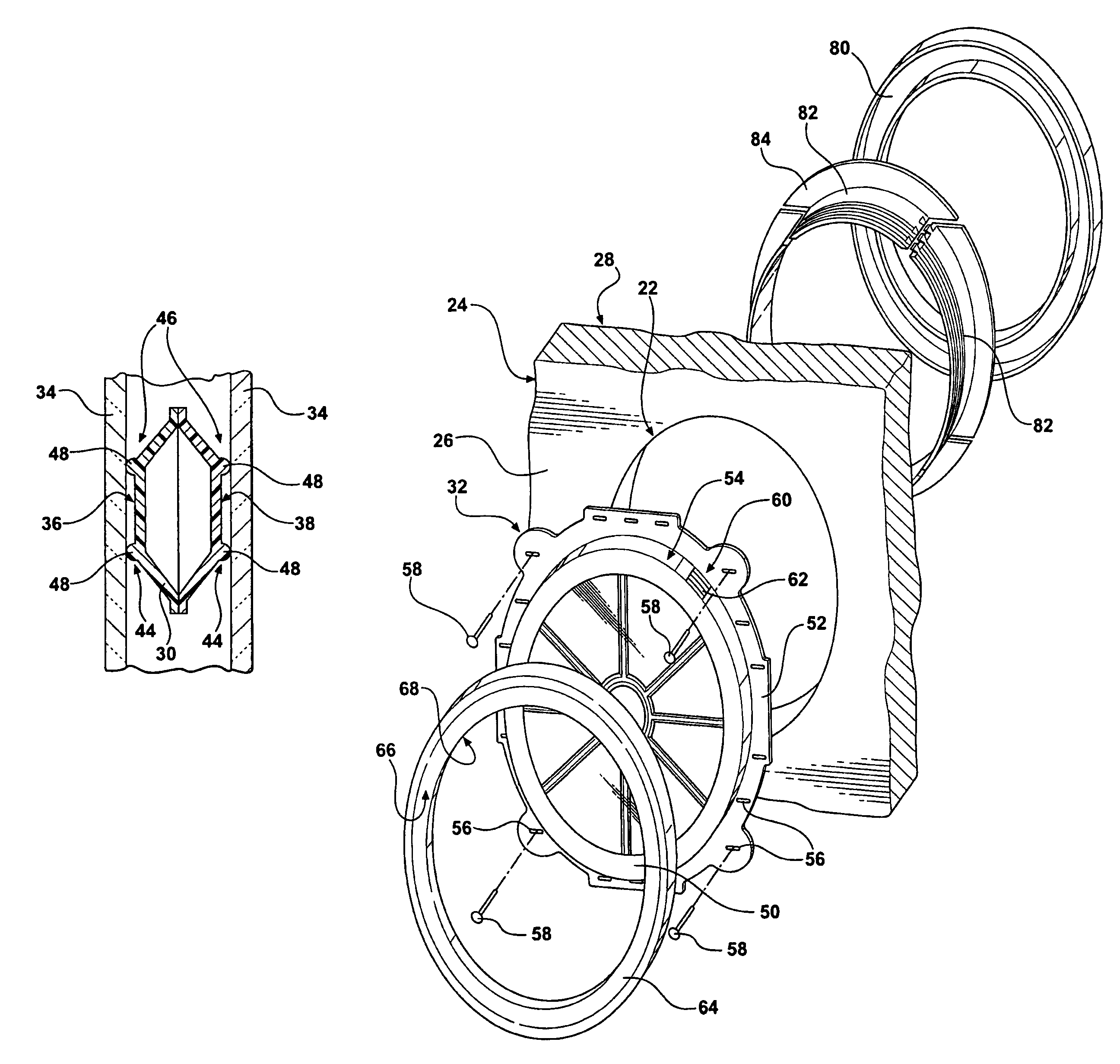

Muntin clip

A muntin clip has a bar support adapted to be connected to a muntin bar end and a base member adapted to be connected to a spacer frame. The bar support has a plurality of flexible support members attached thereto, which are adapted to contact the opposed interior walls of the muntin bar end and deform in response to such contact. The base member has two flexible members forming a flexible latching structure which is adapted to deform when inserted into the spacer frame. The muntin clip to be used with muntin bars and spacer frames having a range of different dimensions and configurations.

Owner:ASHLAND HARDWARE LLC

Window, muntin and method

InactiveUS6415579B1Improve energy savingEasy to manufactureFixed grillesLaminationPolystyreneEngineering

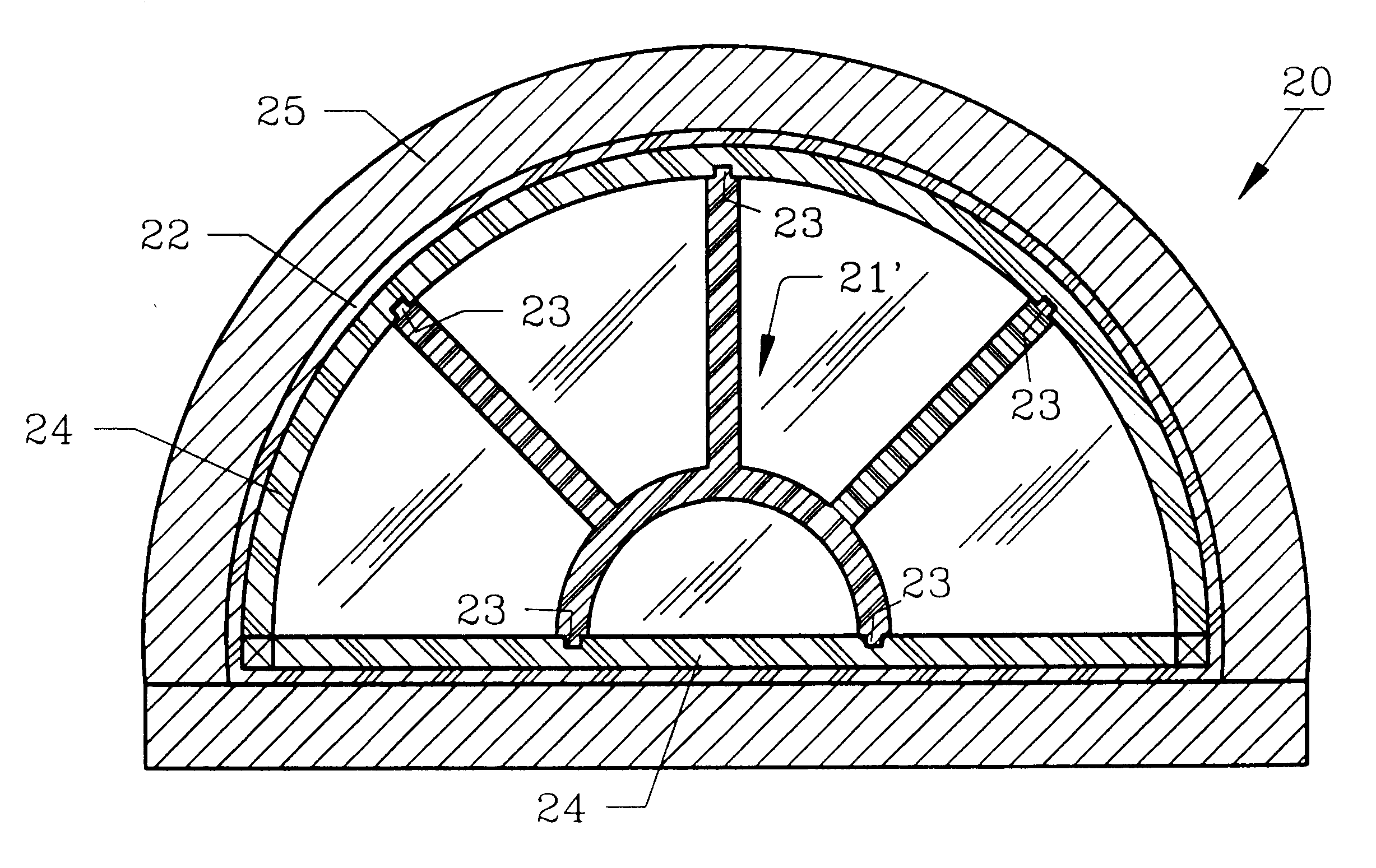

A non-metal window muntin formed from plastic or wood is described for use in hermetically sealed insulated glass windows. The process for forming the muntin includes machining polystyrene sheets which are painted with a latex pain and baked prior to use between sealed glass of the window.

Owner:CUSTOM GLASS PRODS OF CAROLINA

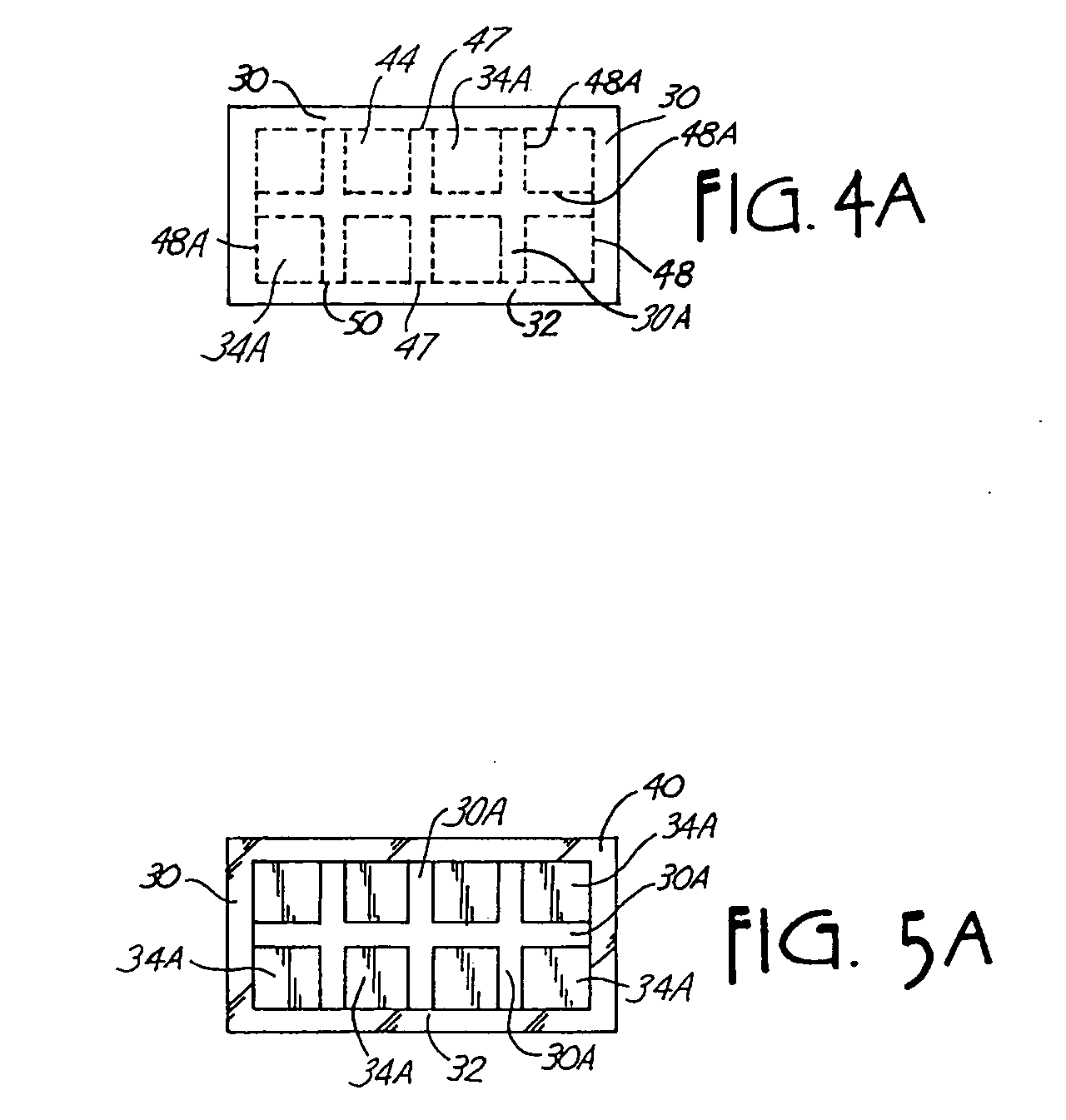

Glass block assembly

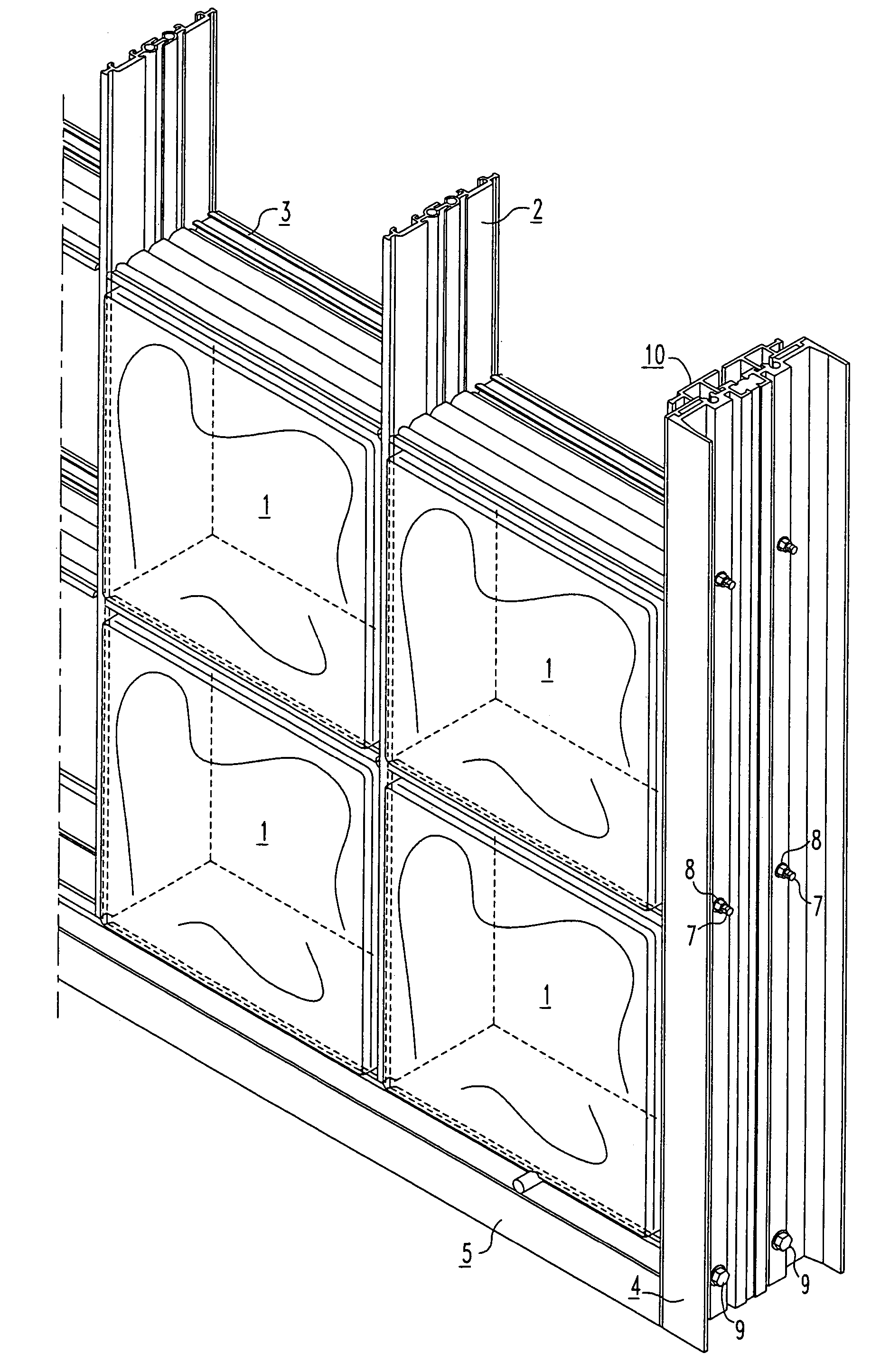

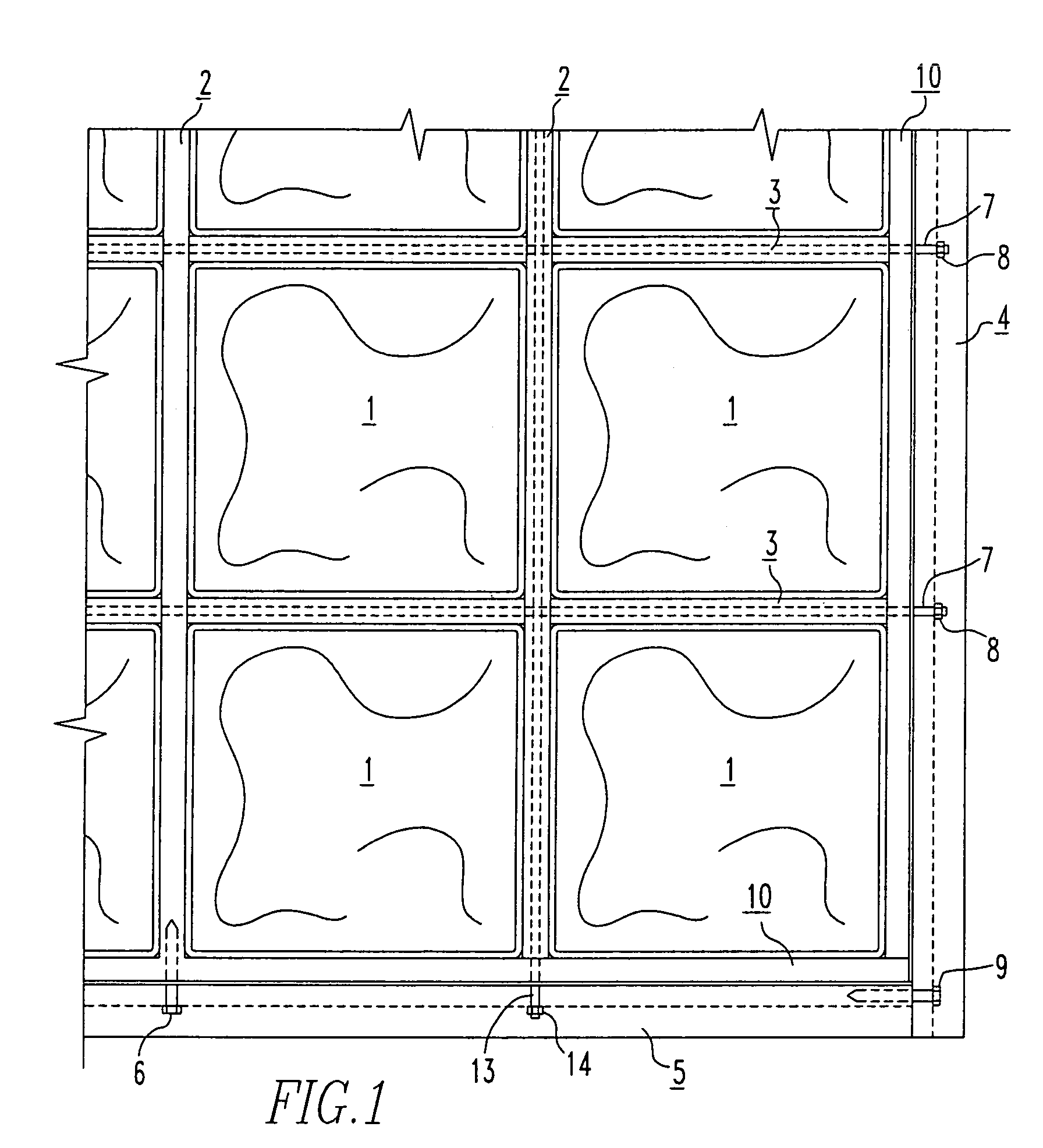

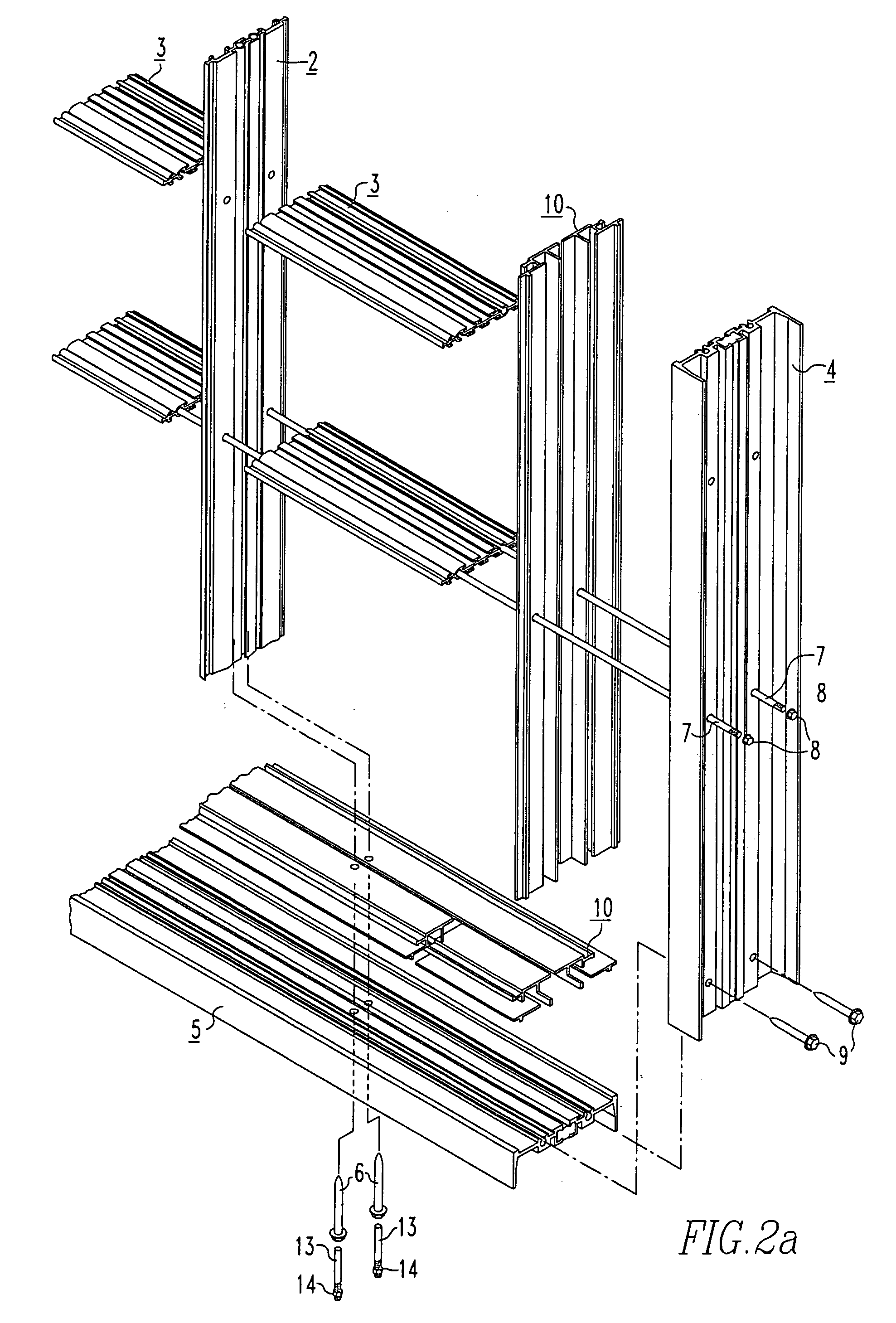

InactiveUS7373763B2Improve structural strengthImprove securityConstruction materialFloorsEngineeringElectrical and Electronics engineering

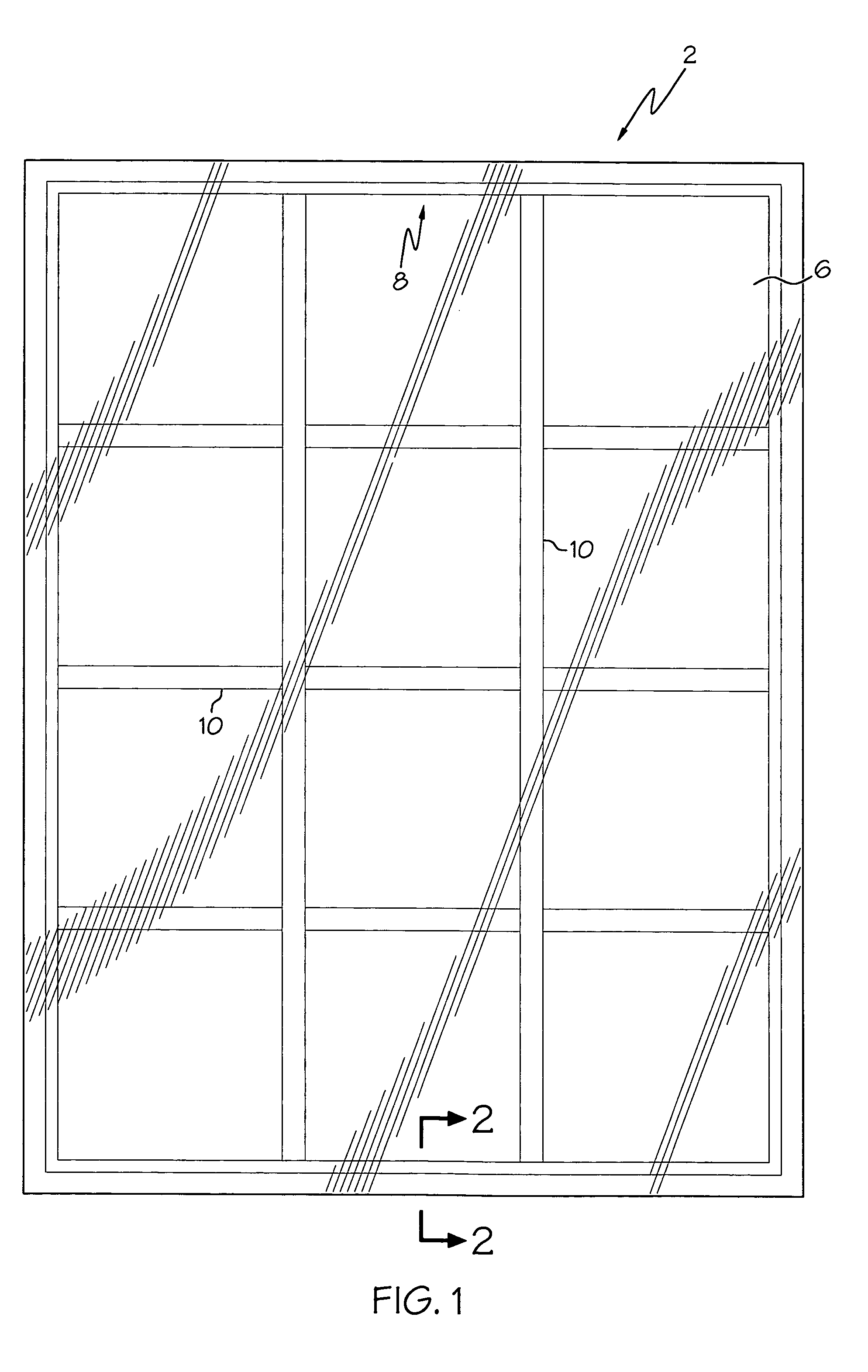

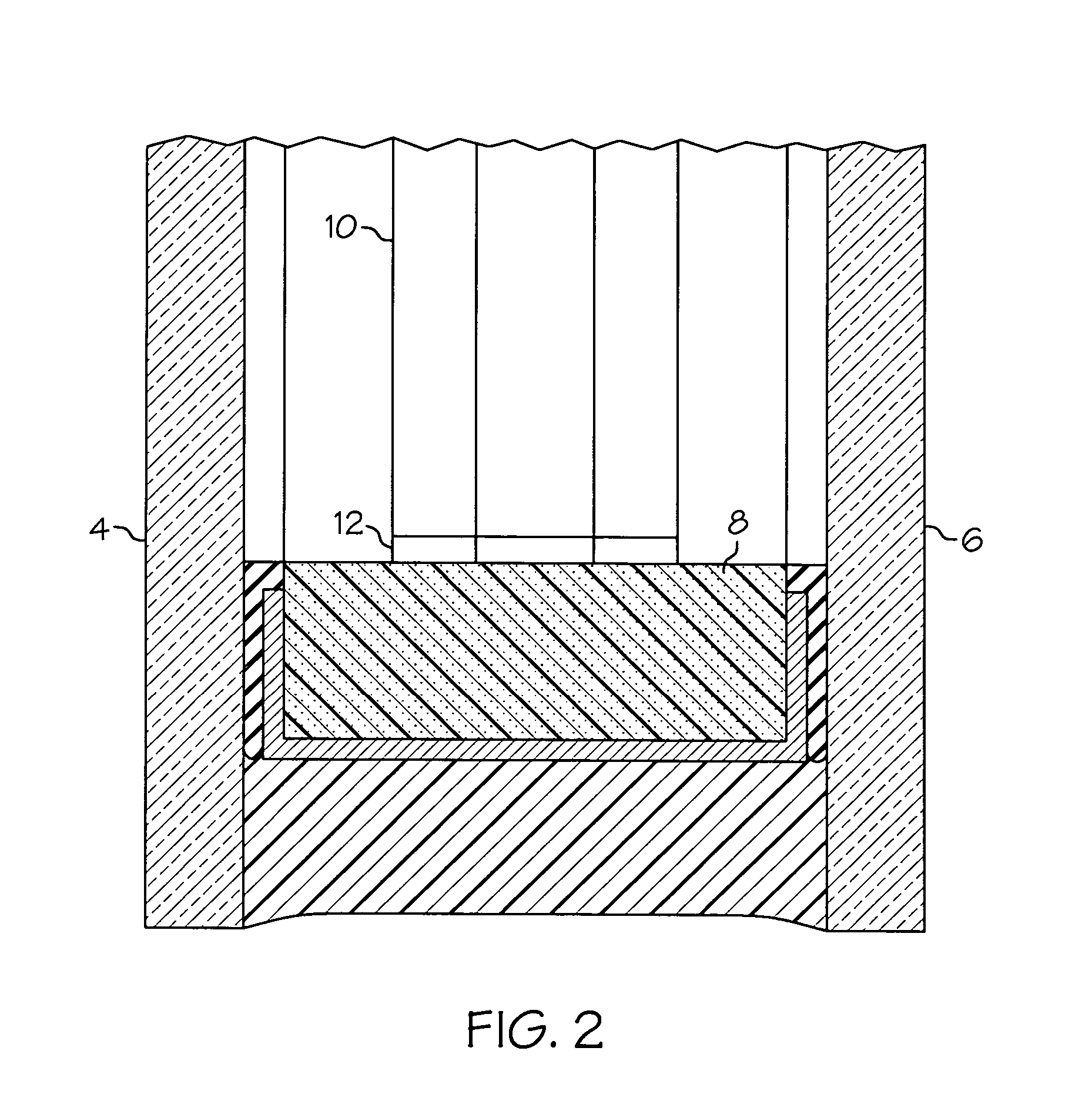

An assembly of glass blocks held in a structural frame comprises a plurality of glass blocks, a rectangular structural perimeter frame, a plurality of primary muntins, each said primary muntin comprising an elongate web, the primary muntins extending entirely across the structural perimeter frame, a plurality of extruded secondary muntins, and a plurality of structural rods inserted through the secondary muntins and extending entirely across the structural perimeter frame, such that the primary and secondary muntins form a matrix within the structural perimeter frame with openings for receiving the plurality of glass blocks.

Owner:EXTECH EXTERIOR TECH

Double pane window construction

The double pane window construction includes an inner peripheral surround captured between two panes of glass immediately adjacent the outer peripheral seal of the assembly. The surround has a width sufficient to conceal the inner surface of the seal from the view when the interior of the assembly is viewed at an acute angle through the glass, but includes a circulation gap between each edge thereof and the adjacent glass pane to allow the air or gas entrapped between the panes to communicate with the seal and any dessiccant material therewith. The surround includes a seal attachment flange for attachment to the seal, and may have a faux muntin pattern formed integrally therewith. The surround and faux muntin grid may be formed of plastic or other suitable material in any practicable size and pattern. The assembly is particularly well suited as a door lite.

Owner:SOLTESIZ JOSEPH R +1

Muntin clip

A muntin clip is provided for use with a sash window. The muntin clip is for use with a muntin grid located between panes of glass of a sash window separated by a pane separator. The muntin clip includes a base having a first surface frictionally engaging the separator and a connector extending from the base and adapted to engage the grid.

Owner:NEWELL OPERATING COMPANY

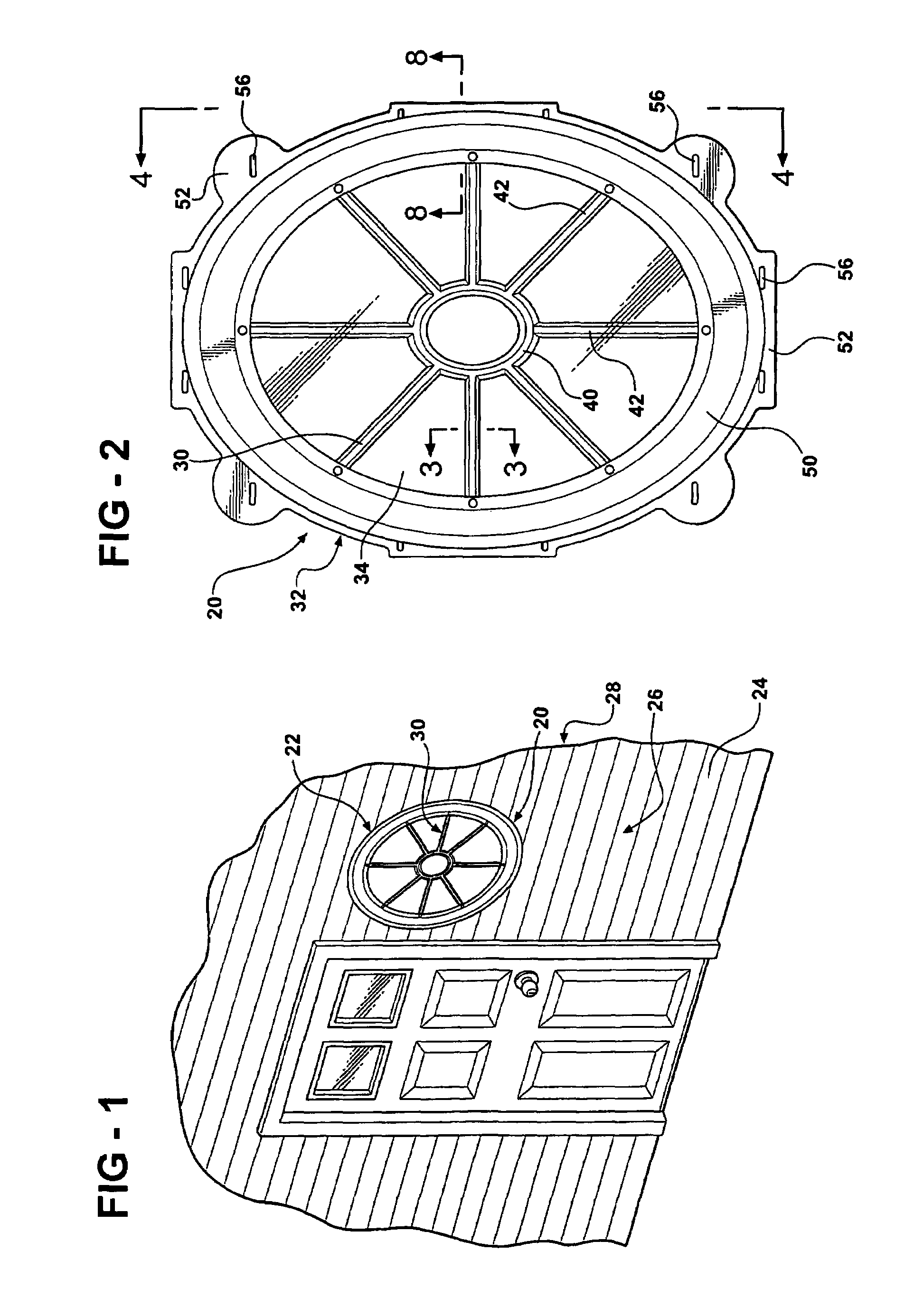

Plastic window assembly

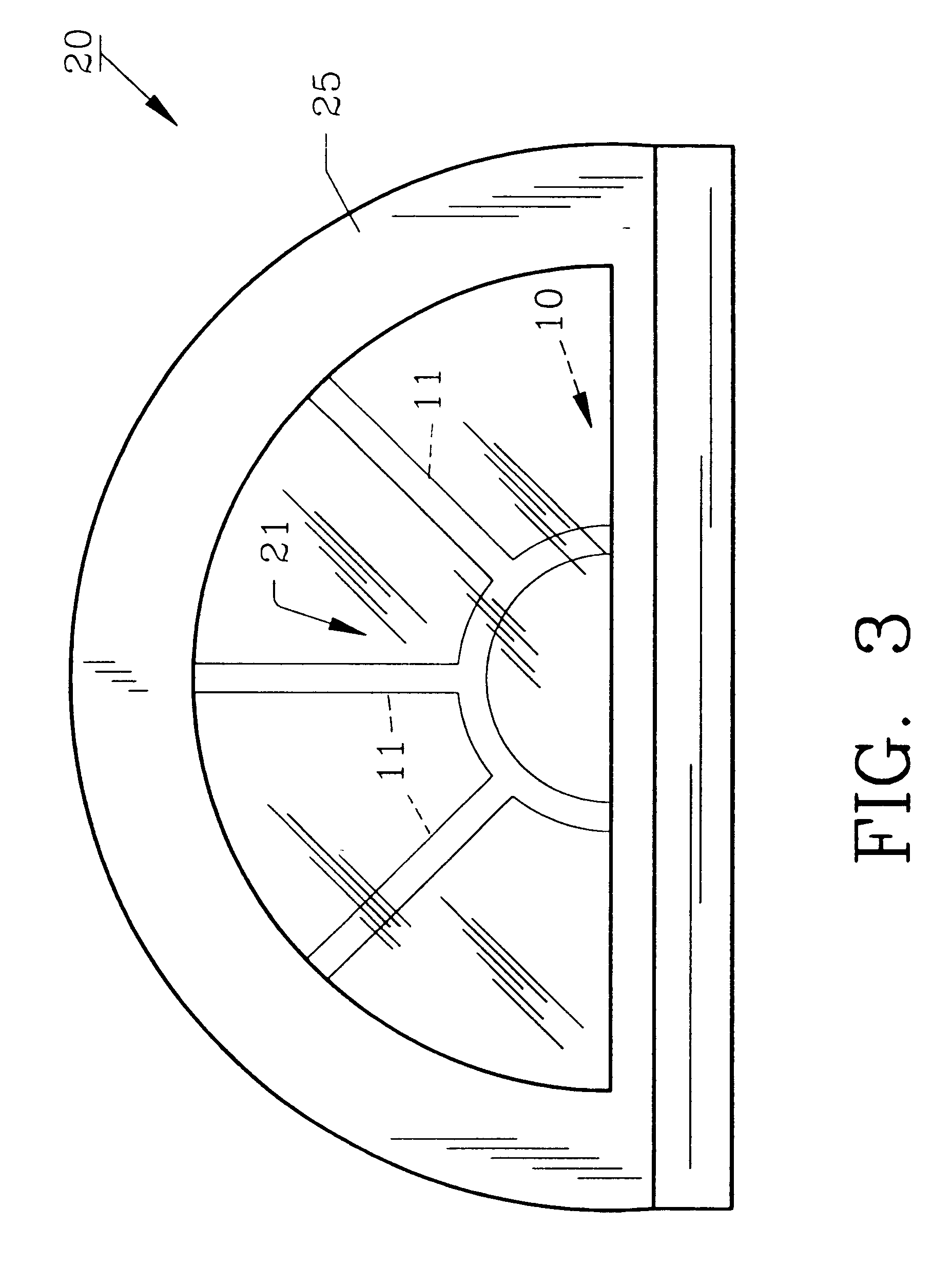

InactiveUS7024830B2Easy low cost installationEliminate damageNatural patternsFixed grillesEngineeringVisor

A plastic window assembly is adapted to be mounted in an opening defined by a structure. The plastic window assembly is oval-shaped with a decorative plastic window muntin. A plastic frame supports parallel window panes. The window muntin is disposed between the parallel window panes. Flat surfaces of the window muntin have a first edge and a second edge and include a ridge disposed along each of the edges. Marring of the window panes is prevented because the ridge provides for line contact between the window muntin and the window panes. The window muntin may also be integrally molded to a plastic pane disposed between the parallel panes of glass. The plastic pane includes a surface texture that simulates frosted glass. The plastic window assembly includes a plurality of liner panels that extend through the opening from an interior of the structure. The window assembly includes a flange having aperture throughwhich fasteners are inserted to secure the window assembly to the structure. An exterior trim ring attaches to the outside of the window assembly and over siding on the structure. An interior trim ring attaches to a flange in the liner panel to give a finished appearance. All exposed surfaces include a surface texture that simulates wood grain.

Owner:HEADWATERS INC AS GRANTOR +4

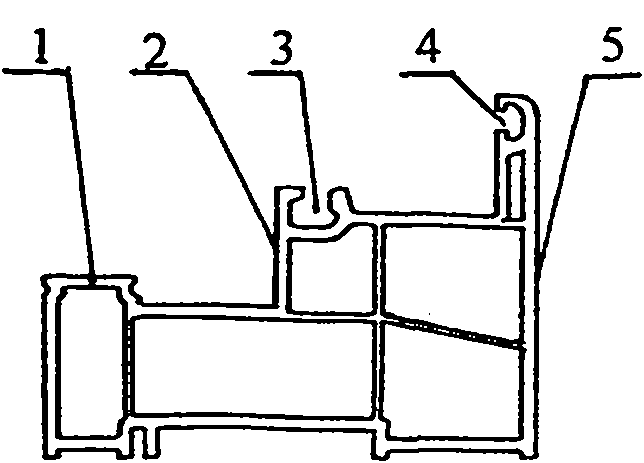

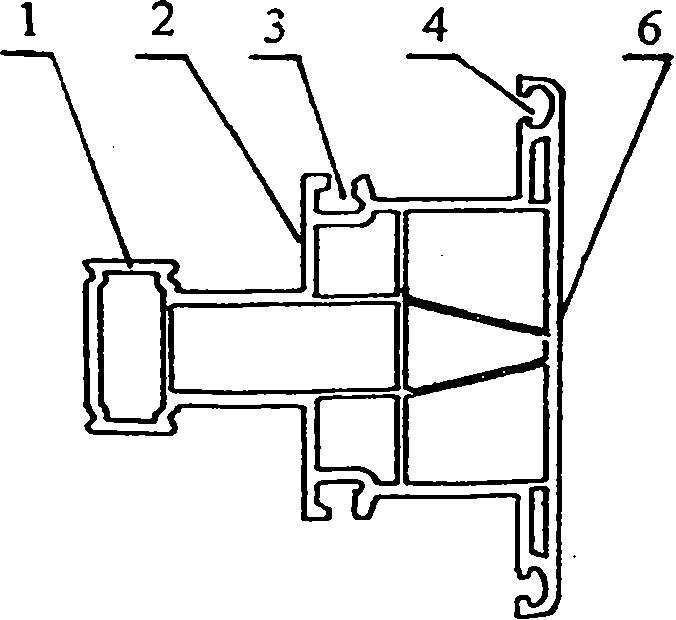

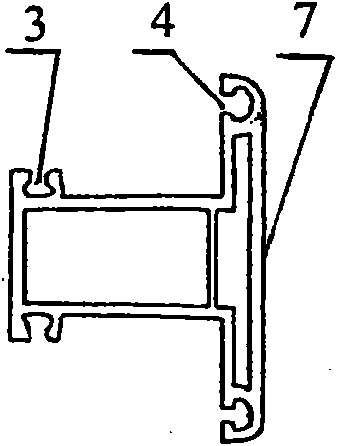

Window frame section integrally welded with single push-pull window frame

InactiveCN101787836AHigh strengthImprove sealingDoor/window protective devicesWing arrangementsPush pullUltimate tensile strength

The invention belongs to a window section for buildings, in particular to a window frame section integrally welded with a single push-pull window frame. The window frame section comprises a frame section (5), a muntin frame section (6), small-medium sections (7) and sealing strips (8), wherein the frame section (5) and the muntin frame section (6) are provided with section vertical surfaces (2) on which the small-medium sections (7) are welded; foundation slideways (1) are arranged on the frame section (5) and the muntin frame section (6) and are connected with a slideway heightening strip (11) and slideway sealing strips (12) in sequence; adhesive tapes (9) of the sealing strips and wood top ports (10) are arranged on the sealing strips (8); an adhesive tape port (4) is connected with screen window cloth (19) with the adhesive tapes; and the frame section (5) and the muntin frame section (6) are also provided with heat-insulating curtain connecting grooves (20). The window frame section integrally welded with the single push-pull window frame not only improves the integral strength and the grade for resisting wind pressure, but also improves the sealing effect and has low cost and favorable performance.

Owner:李光

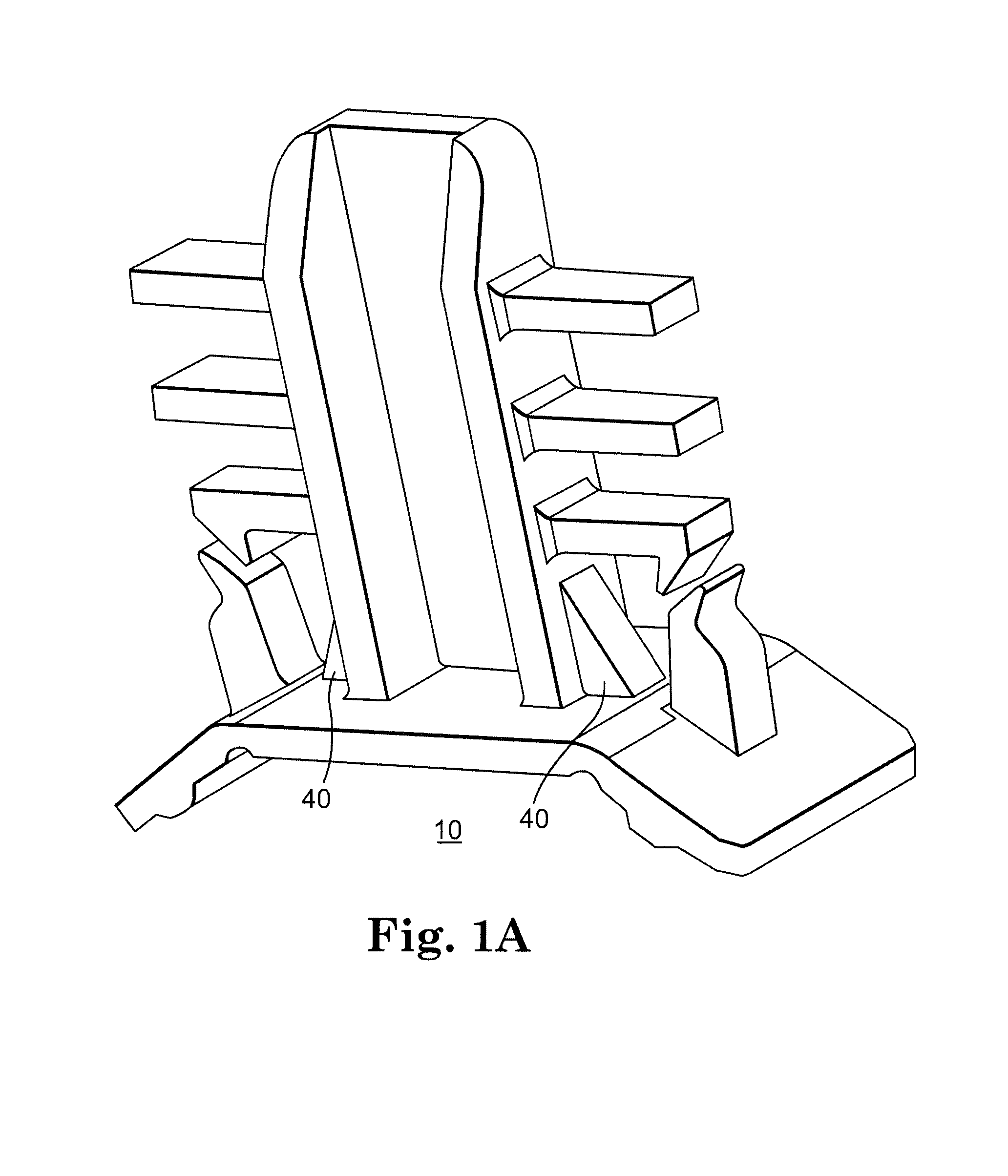

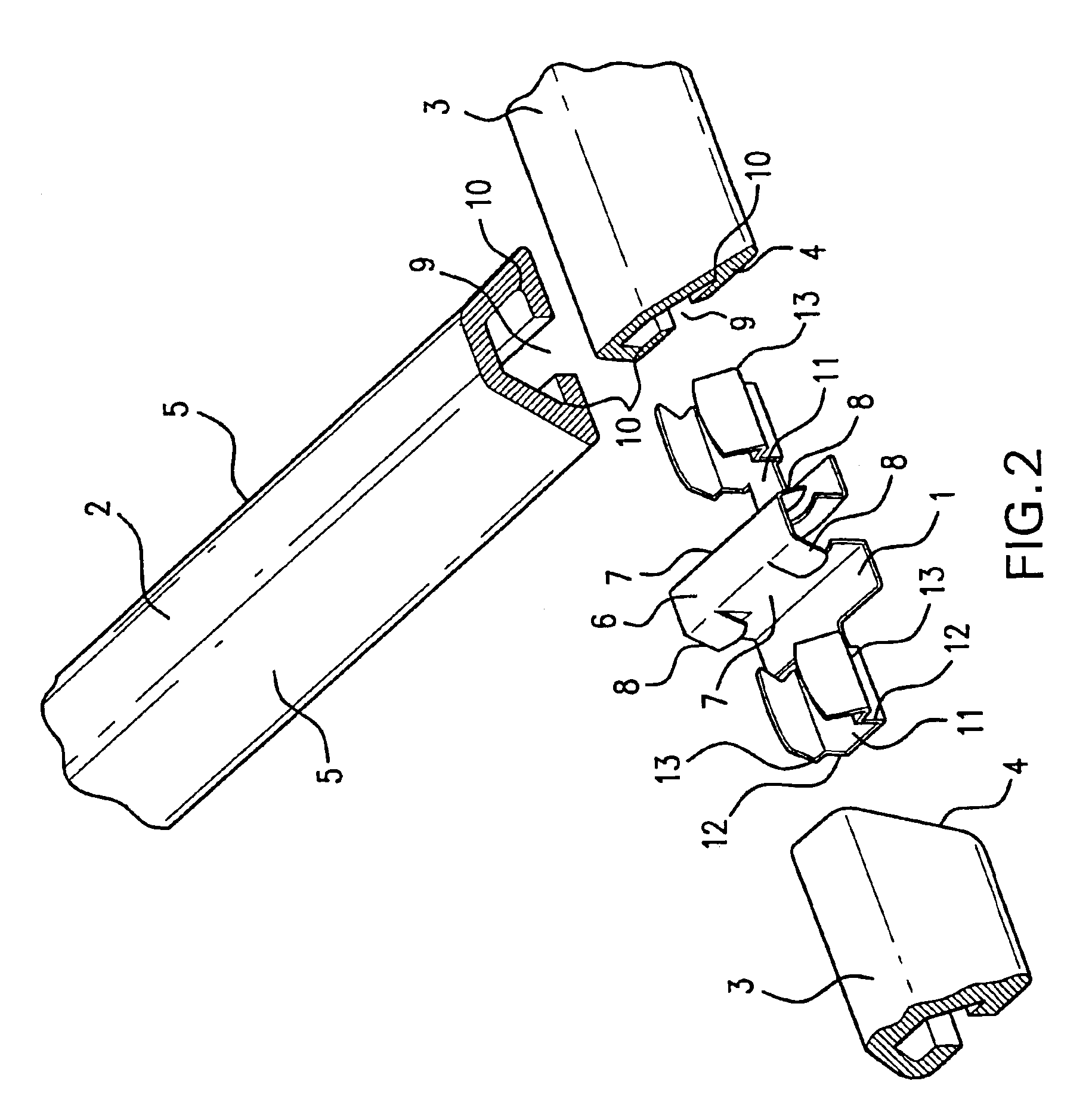

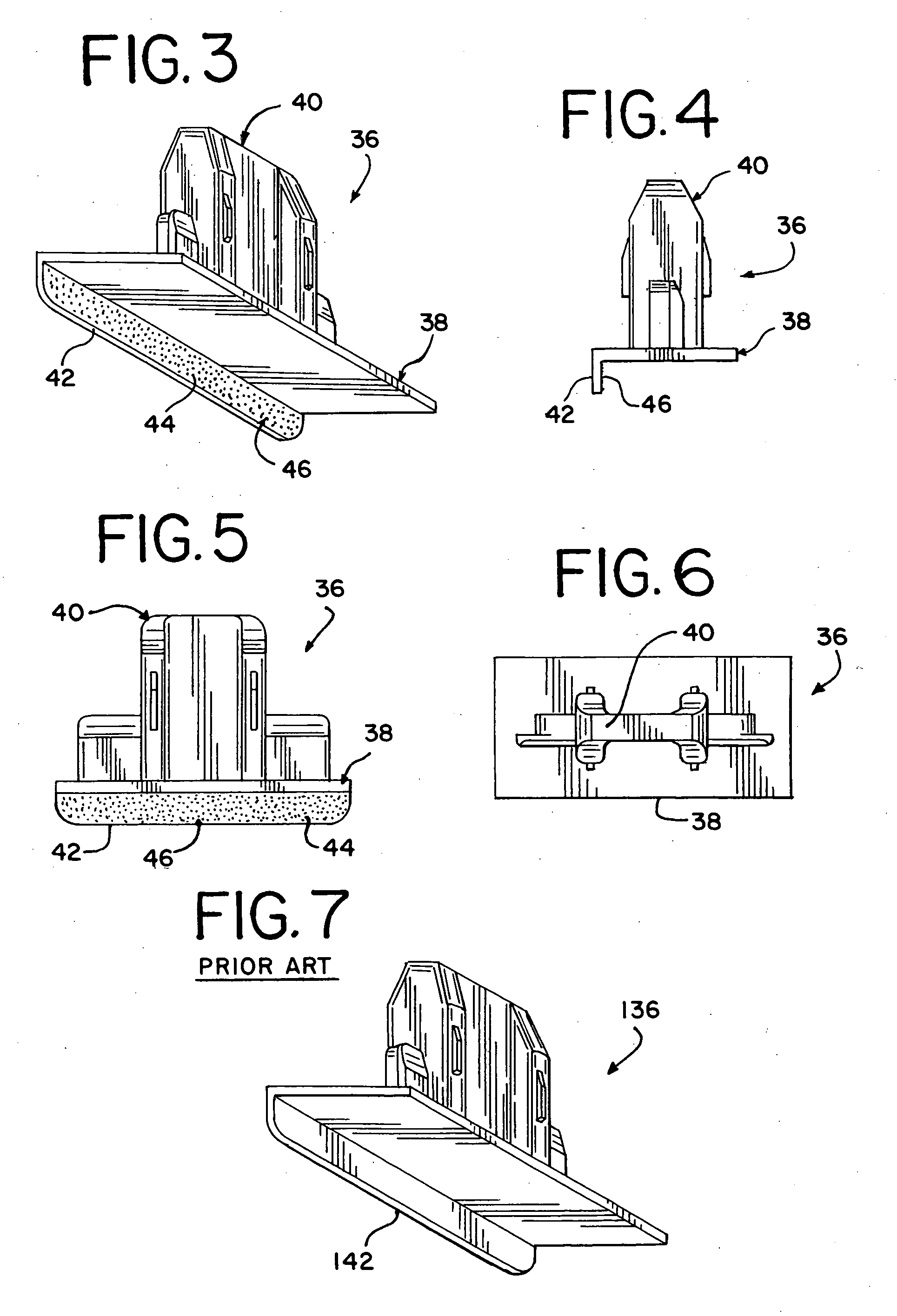

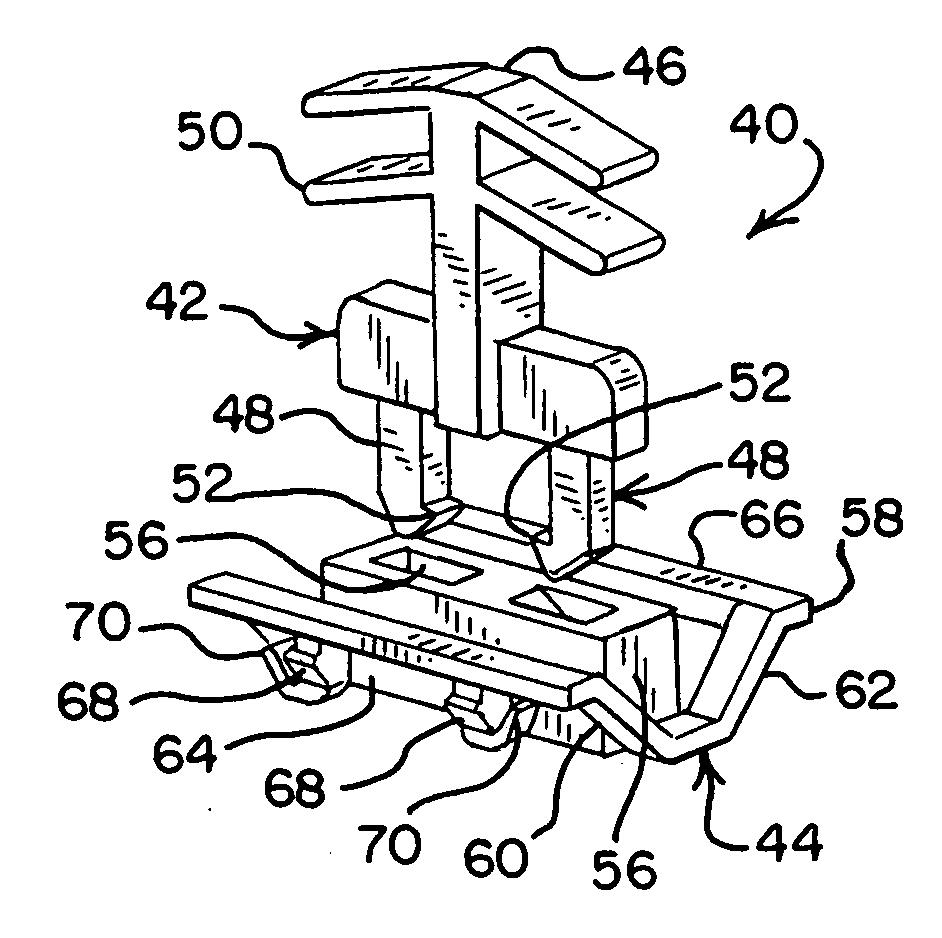

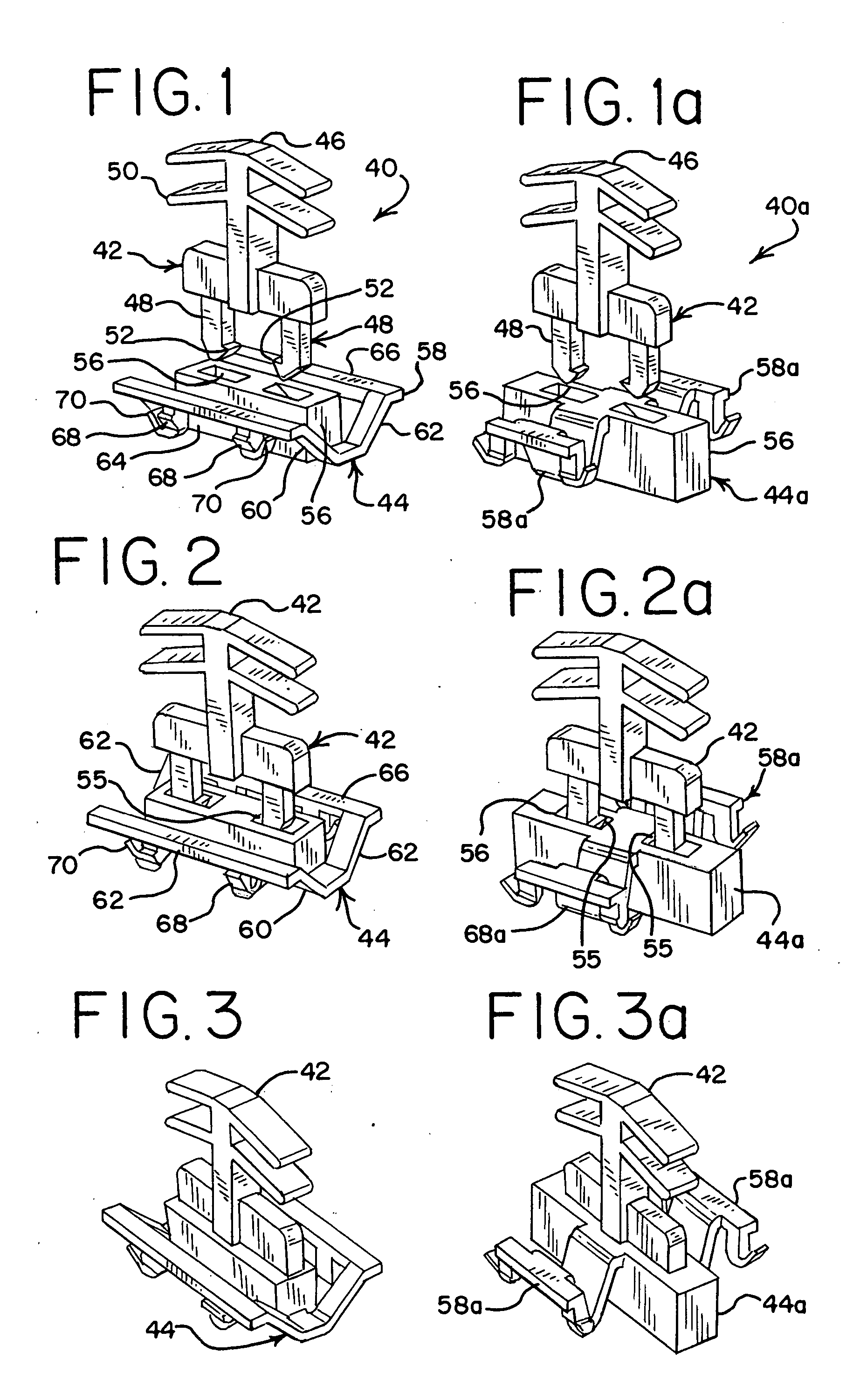

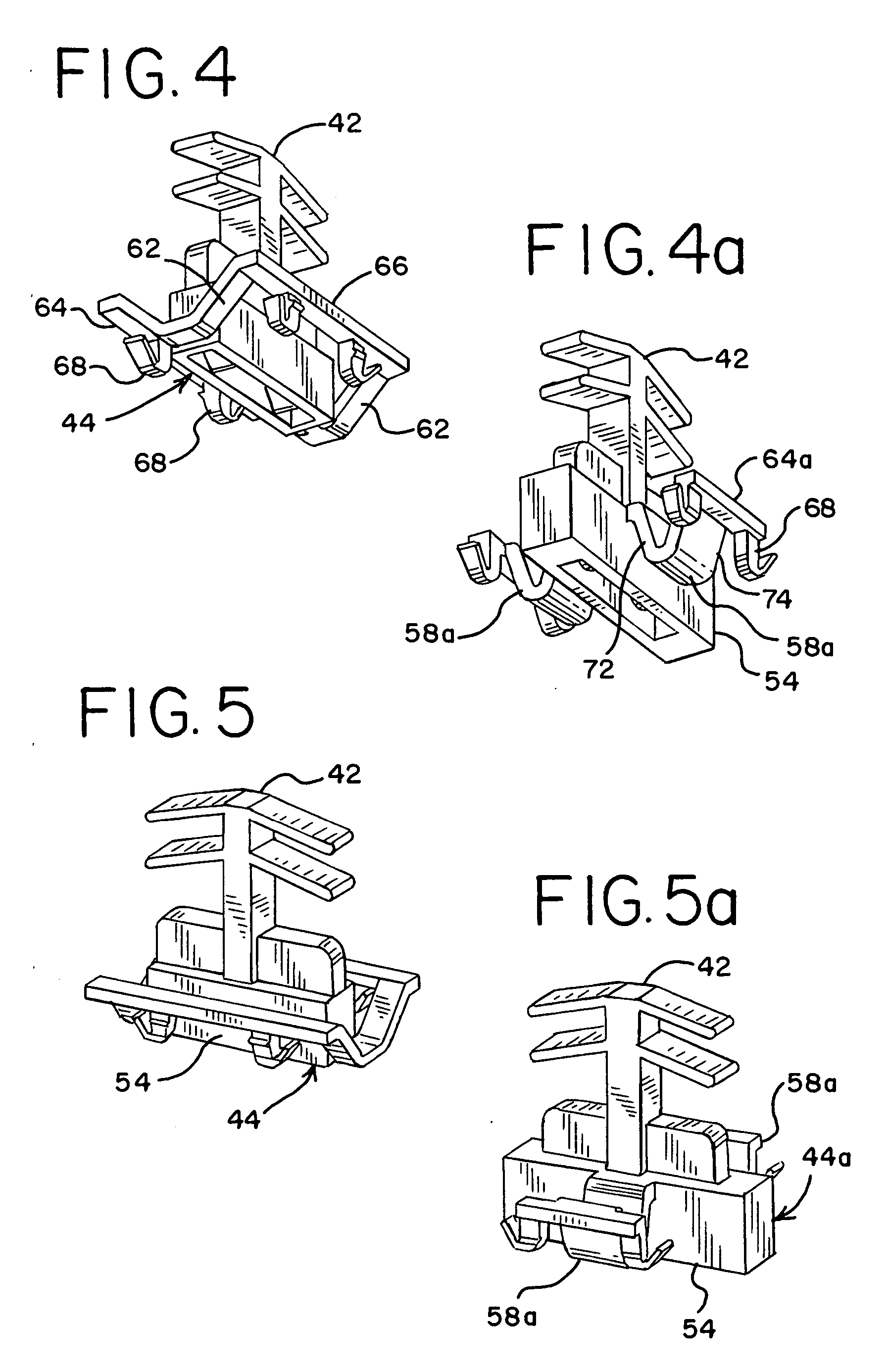

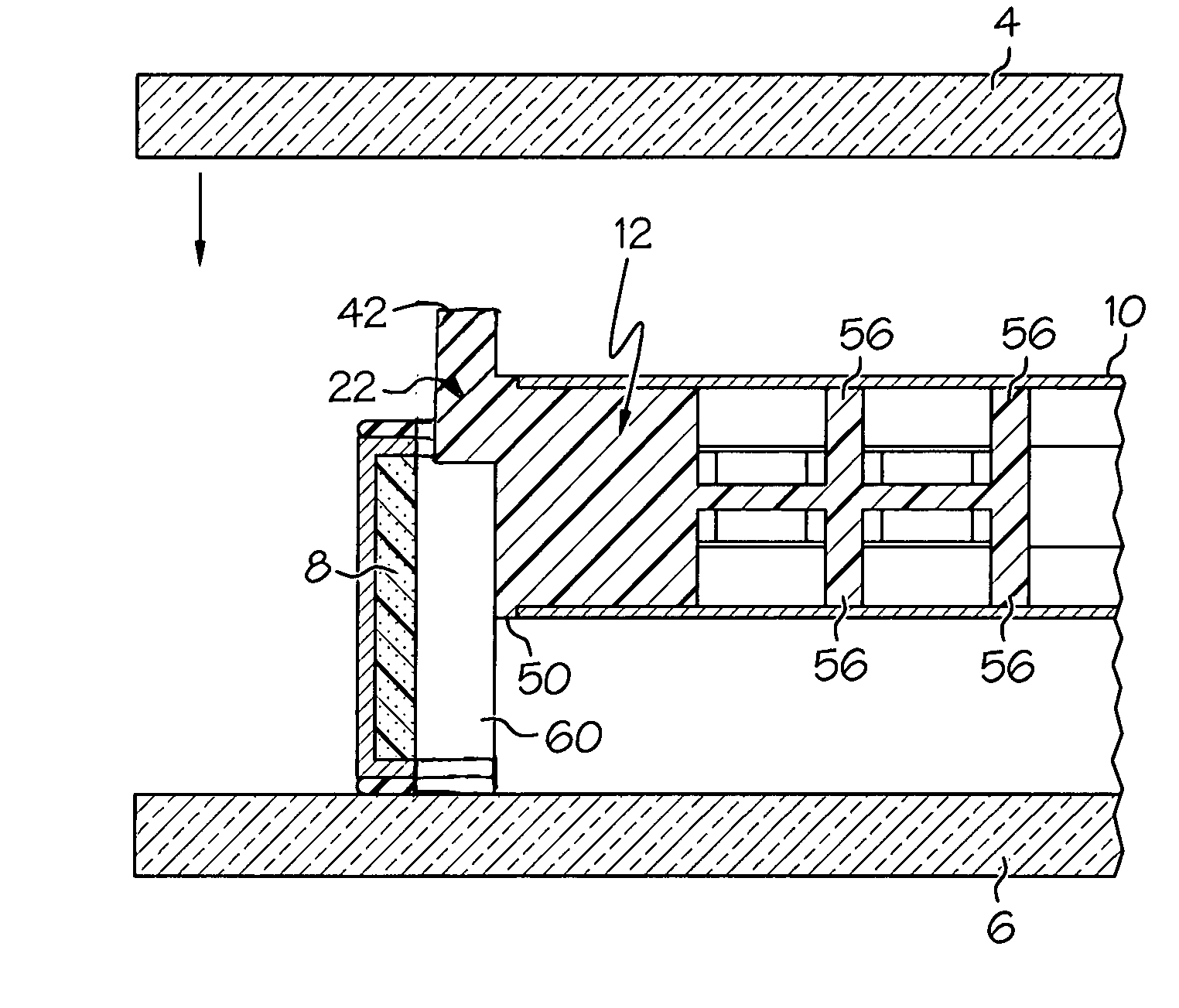

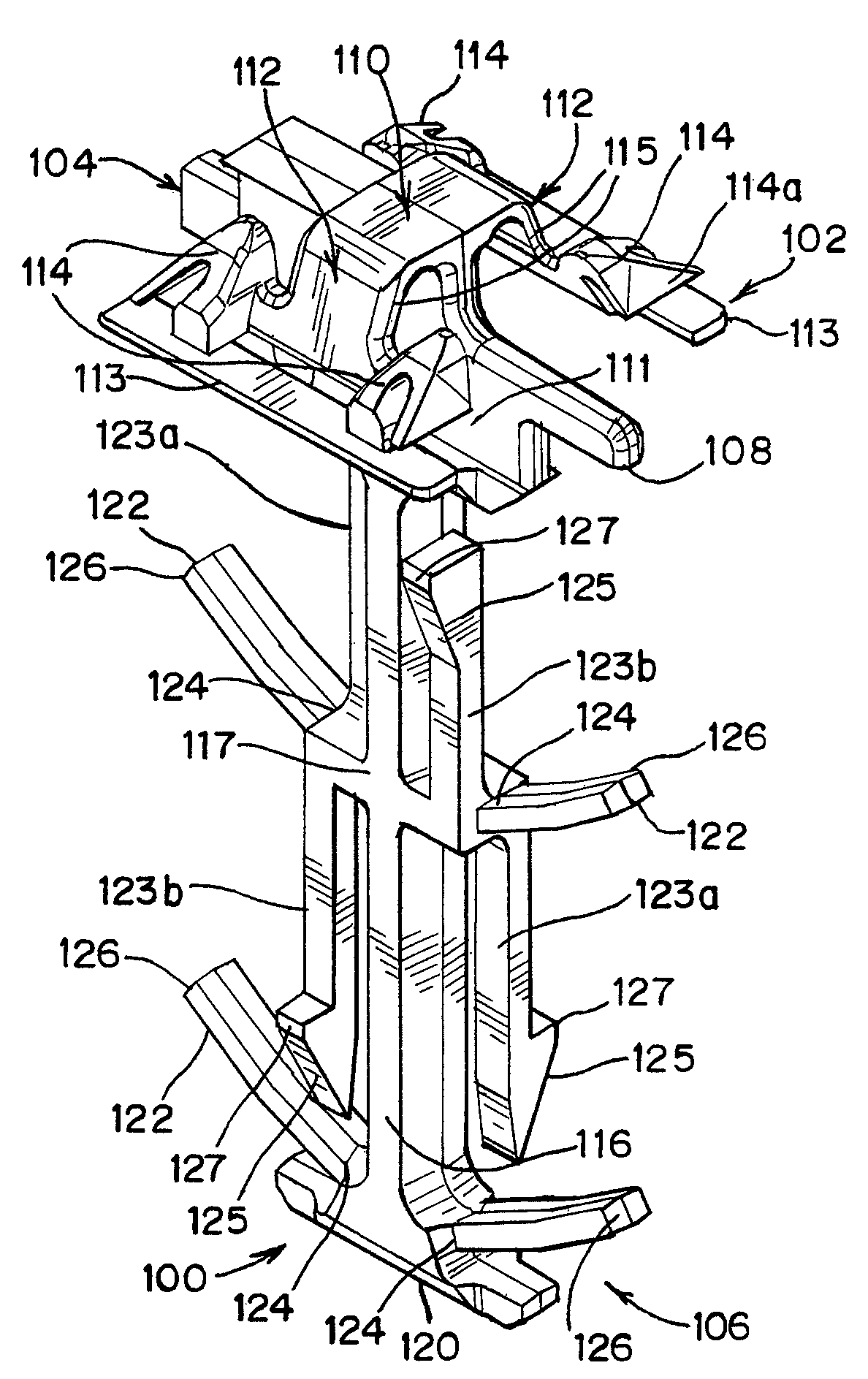

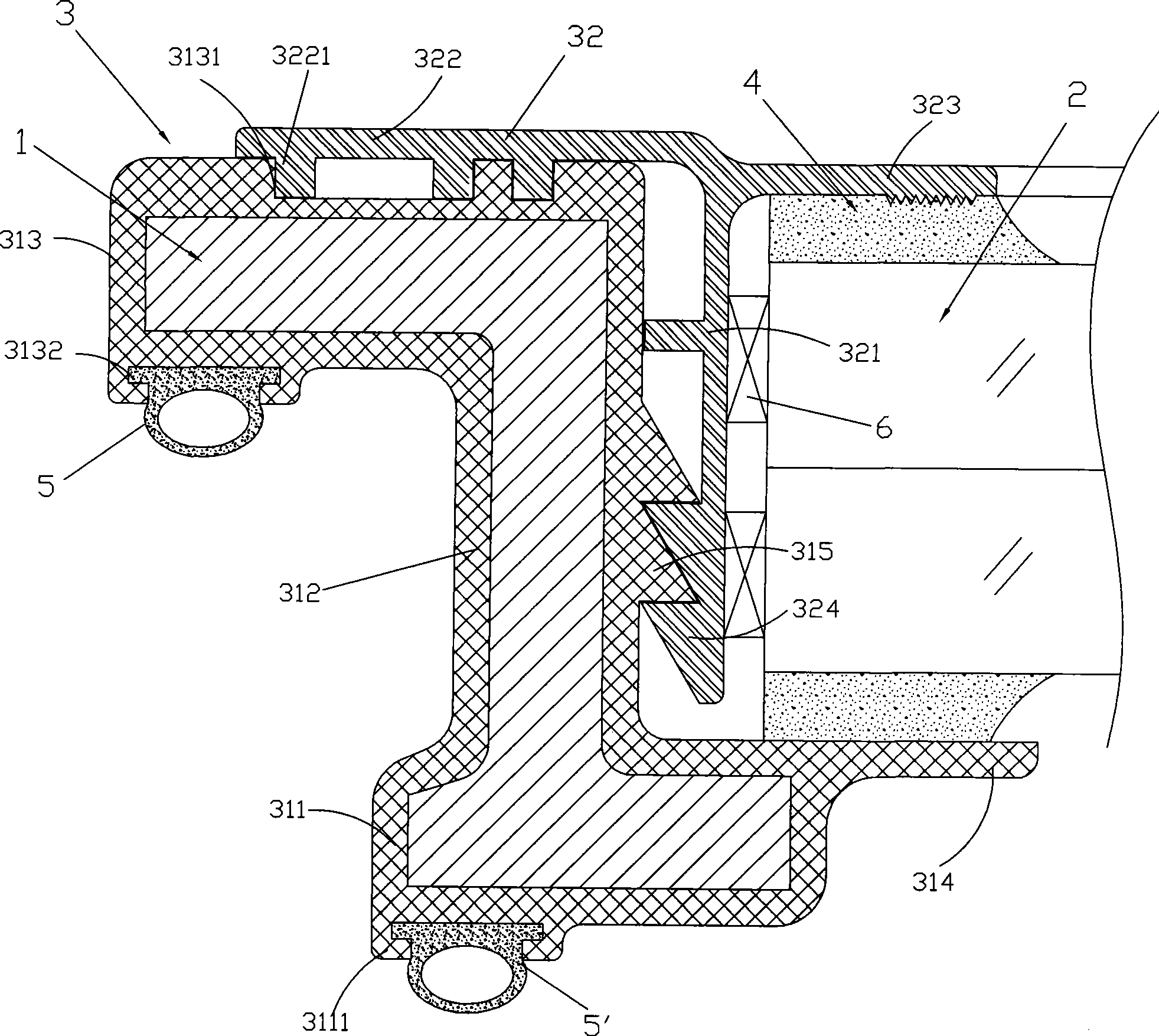

Muntin clip assembly

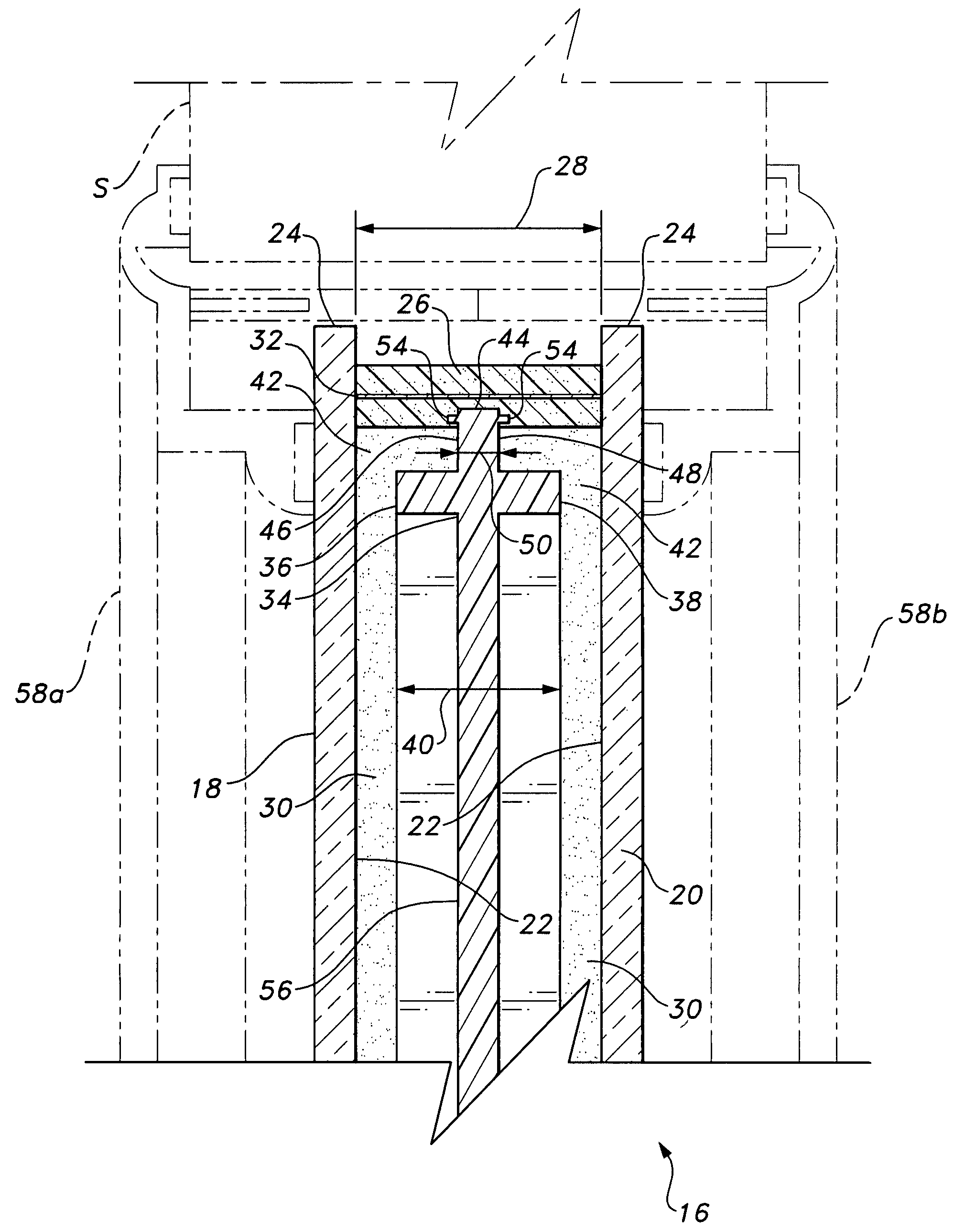

A muntin clip assembly (40) is provided for connecting a muntin bar (36) having a muntin bar end (38) to a spacer frame (30). The assembly includes a bar support (42) having a tree (46) adapted to be connected to the muntin bar end (38) and a flexible leg (48). The assembly also includes a base member (44) having a slot (56) for receiving the leg (48) and a flexible wing (58) adapted to be connected to the shoulders (35) of the spacer frame (30).

Owner:NEWELL OPERATING COMPANY

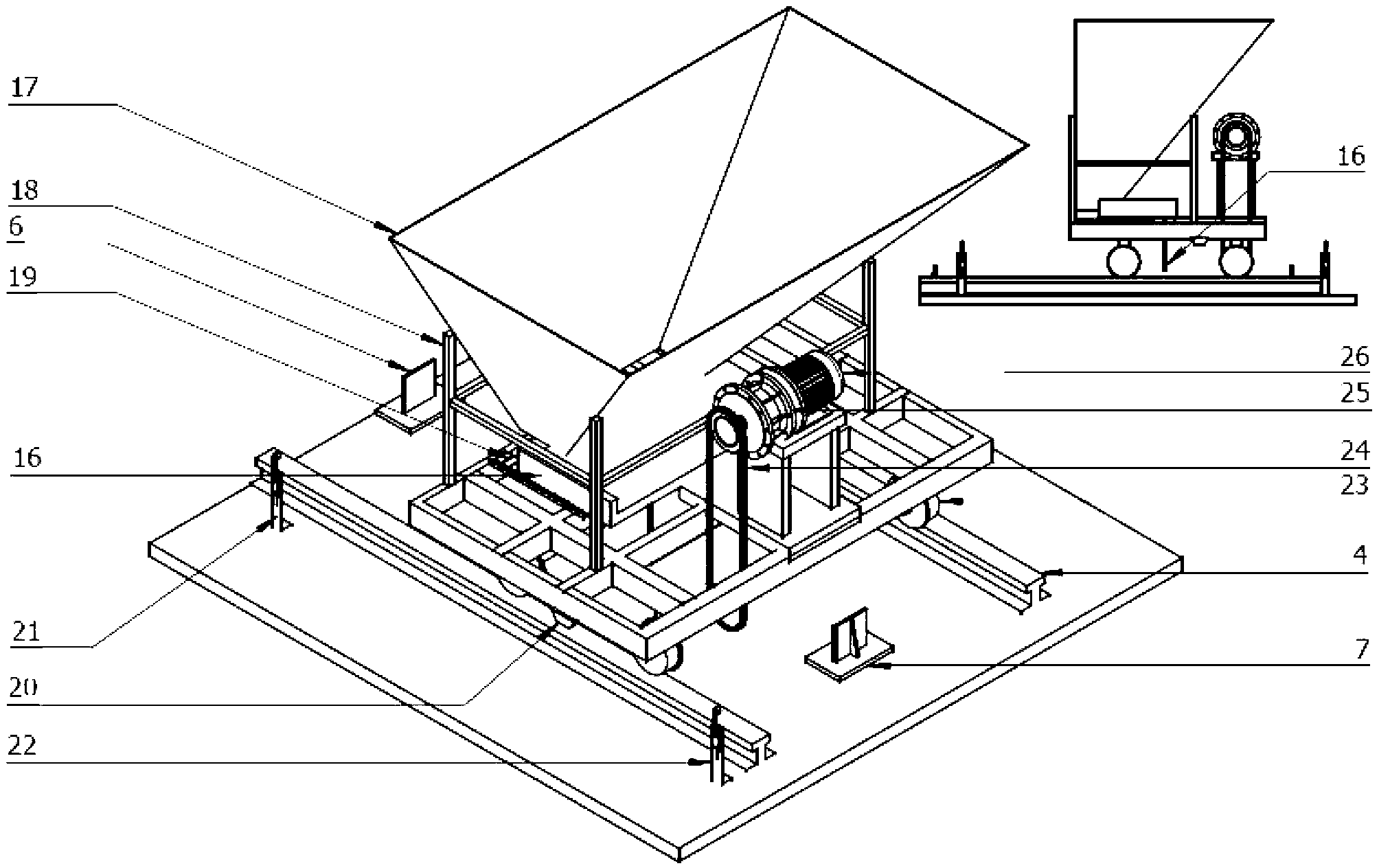

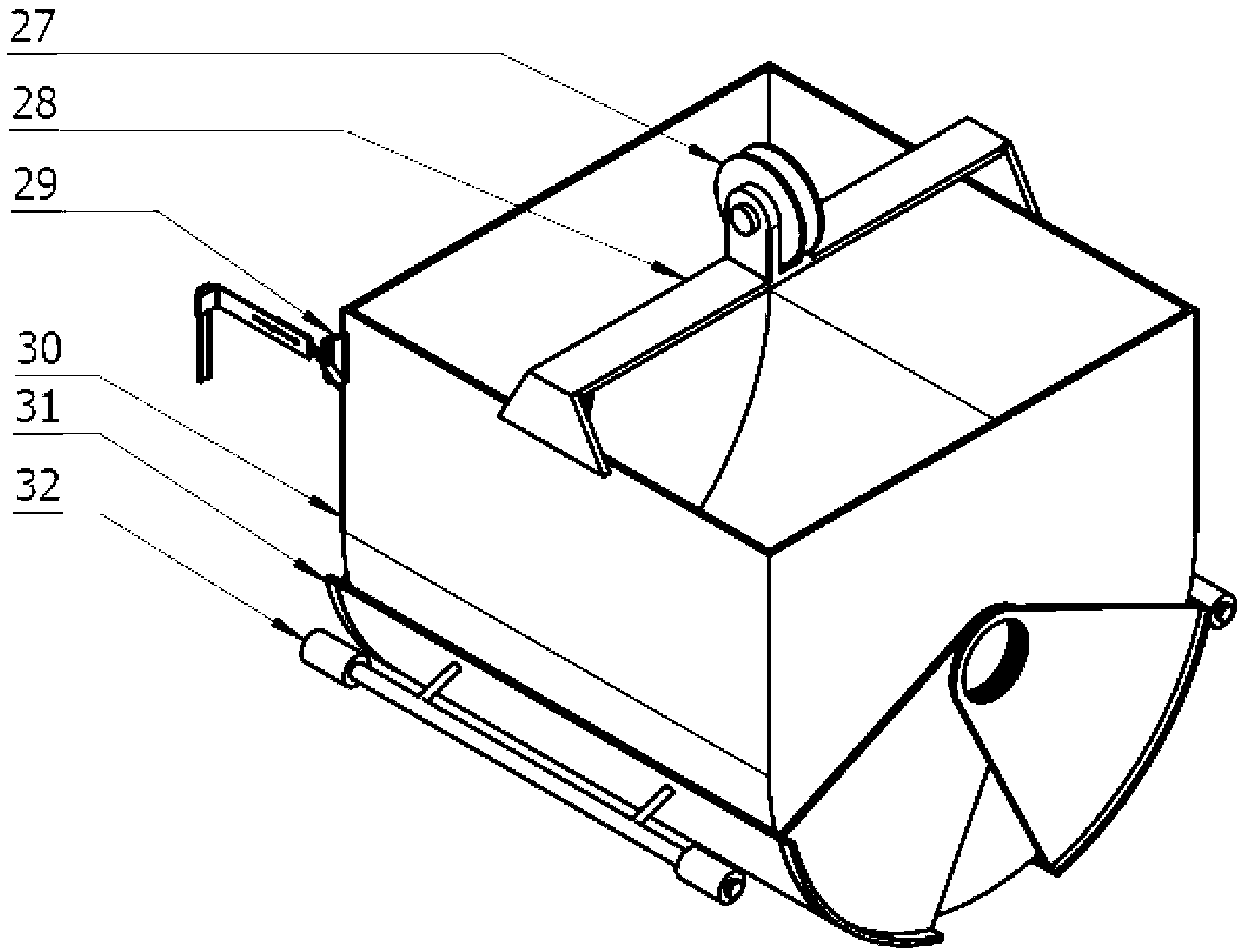

Multi-station full-automatic ore conveying equipment

The invention discloses multi-station full-automatic ore conveying equipment which belongs to the technical field of smelting. The multi-station full-automatic ore conveying equipment is characterized by consisting of a multi-station ore conveying mechanical system and a full-automatic electric control system. A self-gravity opening and closing hopper in the multi-station ore conveying mechanical system comprises a moving pulley, a lifting frame, a wedge-shaped baffle, a hopper main body, hopper doors and rolling stop levers; when the hopper descends to the horizontal height where a muntin is located, the rolling stop levers on the hopper doors receive upward resistance, so that the hopper doors are opened smoothly; and when the hopper ascends, two hopper doors are automatically closed under the action of gravity. According to the electric control system, a winding motor on a ferry push car is connected with a transducer and a brake resistor, and the output frequency of the transducer can be controlled by a programmable controller. The multi-station full-automatic ore conveying equipment has the beneficial effects that ore can be conveyed to a plurality of stations, the ore is not scattered, the occupied area is saved, and the equipment not only is applicable to the conveying of ore with the diameter of 60mm to 100mm in the fused magnesium smelting industry, but also is applicable to the conveying of the ore in other smelting industries.

Owner:DALIAN UNIV OF TECH

Muntin clip

A muntin clip has a bar support adapted to be connected to a muntin bar end and a base member adapted to be connected to a spacer frame. The bar support has a plurality of flexible support members attached thereto, which are adapted to contact the opposed interior walls of the muntin bar end and deform in response to such contact. The base member has two flexible members forming a flexible latching structure which is adapted to deform when inserted into the spacer frame. The muntin clip to be used with muntin bars and spacer frames having a range of different dimensions and configurations.

Owner:ASHLAND HARDWARE LLC

Muntin clip and method of using the same

Owner:QUANEX IG SYST INC

Muntin bar clip for colonial and other-style windows

InactiveUS20090158677A1Prevents inadvertent dislodgingIncrease pressureDoors/windowsEngineeringAir space

An improved muntin bar clip for ease of installing bars to the air space of a double-paned window in order to achieve the colonial style window appearance. The clip is configured for one end to be inserted into the frame which provides separation between the lights. The opposite end of the clip points toward the center of the window and provides a quick and easy means of mounting the bars.

Owner:LIANG LUKE +2

Method of fabricating muntin bars for simulated divided lite windows

A method for fabricating muntin grid pieces includes steps that attach an outer muntin grid element to an inner muntin grid element to form a two piece muntin grid piece. The outer muntin grid element surrounds at least three sides of the inner muntin grid element and may be held to the outer muntin grid element without connectors such as adhesive. The outer muntin grid element may be a slit tube that is spread open to be positioned over the inner muntin grid element.

Owner:QUANEX IG SYST INC

Glass masking method using lasers

InactiveUS20060127612A1Method is fastPrecise definitionLamination ancillary operationsLayered product treatmentEngineeringGlass sheet

Methods and apparatus for masking glazing panels while leaving a peripheral region free of masking material. The method can include providing a masking material and applying the masking material to at least one major surface of the glazing panel. The glazing panel can be either a single glass pane or a multi-pane insulating glass unit. After application to at least one major surface, a laser can be used to describe a closed path on the major surface, thereby cutting or scoring the masking material through to the glass major surface. The path demarcates a central, masked region from a peripheral masked region of the glazing panel. In one method, the laser cuts a muntin bar pattern having several central regions. The laser power can be selected and / or adjusted such that the masking material is burned through, without damage to the underlying glass material and any coatings on the glass material. After cutting through the masking material to define the peripheral masked region, the peripheral masked region can be peeled or stripped off from the masked glazing panel. The remaining panel thus has a protective mask about the central region while leaving the peripheral region unprotected. The resultant masked glazing panel may be assembled into a window unit by mounting window frame members about the four sides of the glazing panel. The window frame members may thus have a tight and durable fit directly to the glass in the peripheral region, while the central region of the glazing panel remains protected by the masking material.

Owner:LARSEN JAMES E

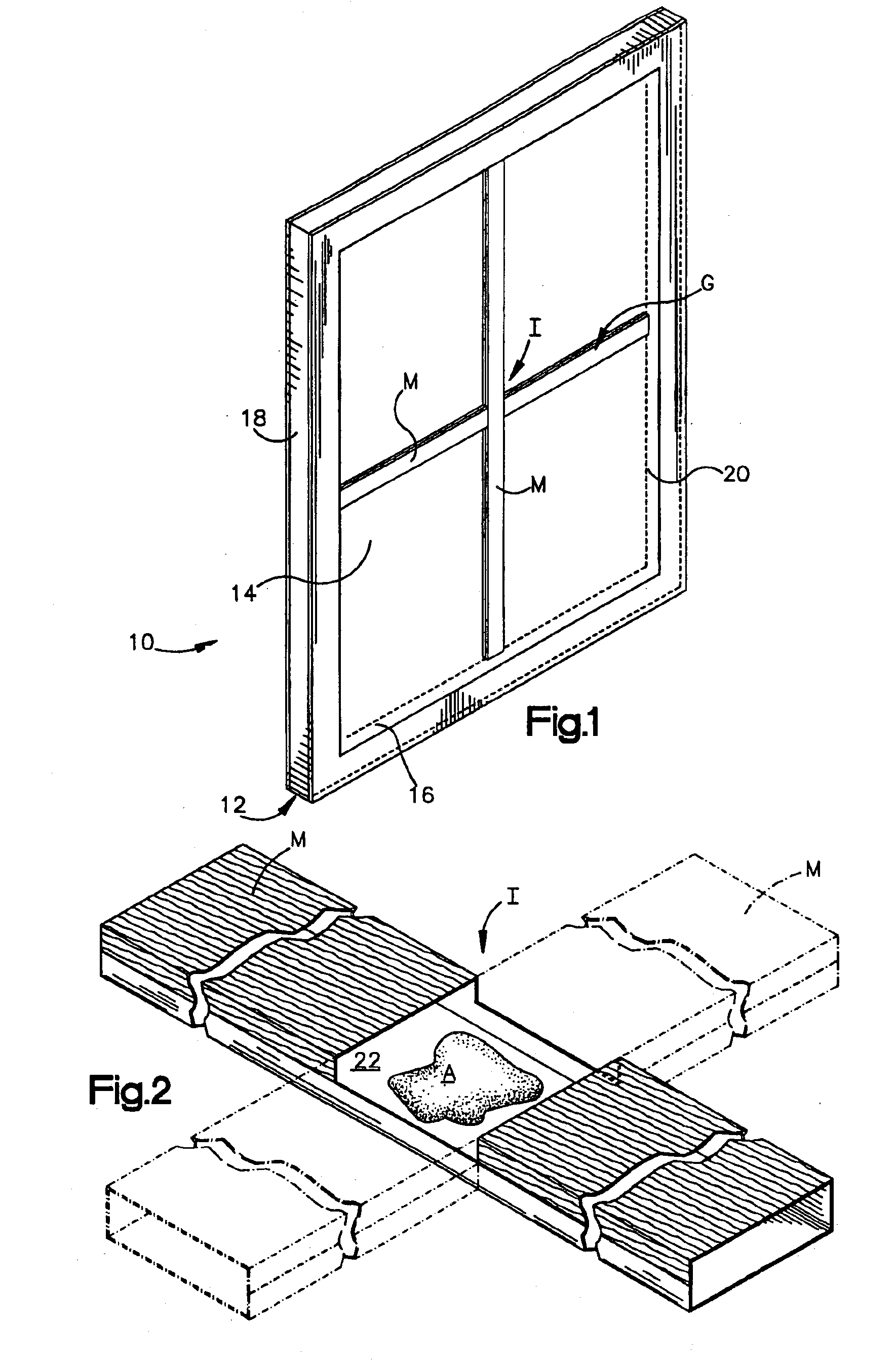

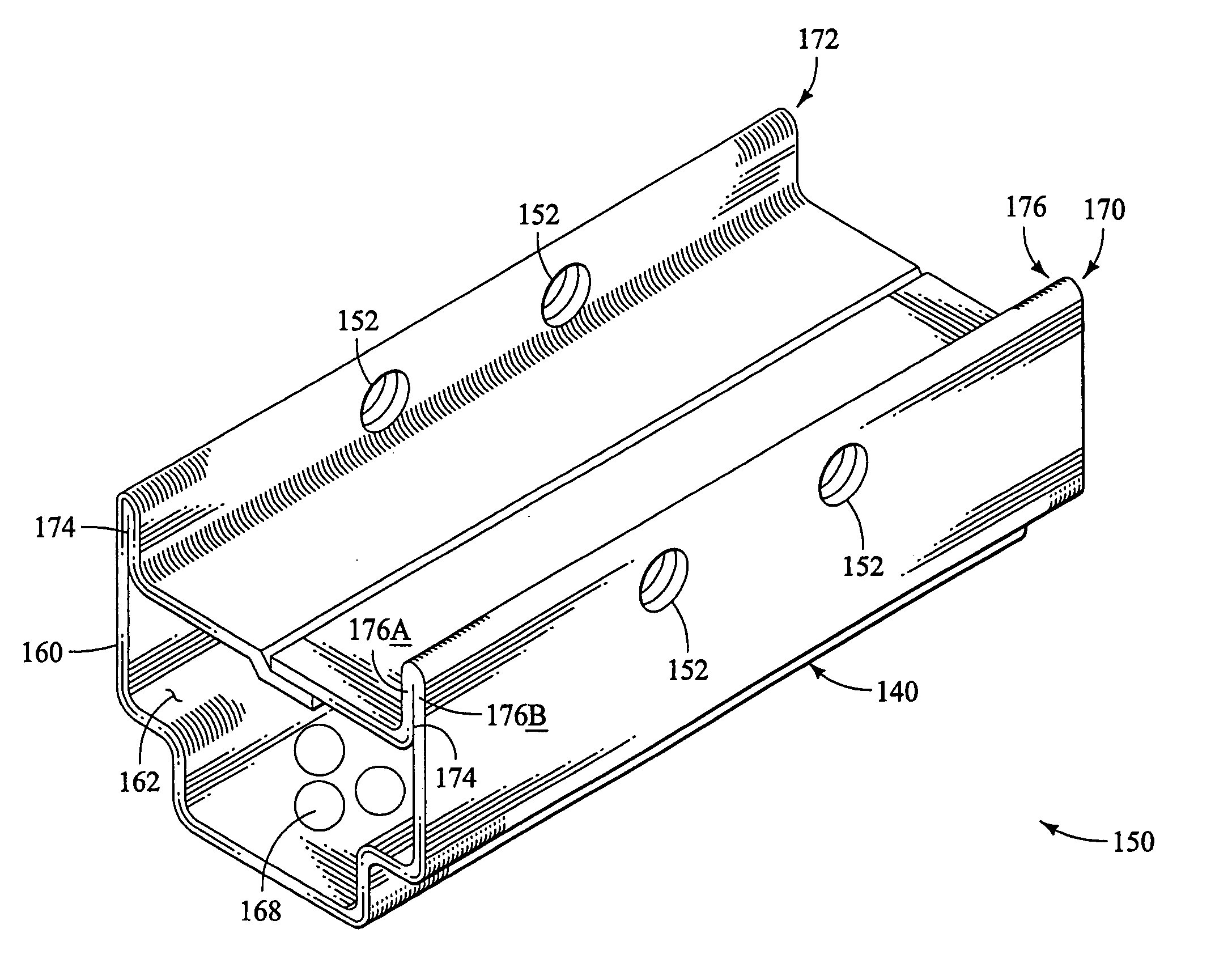

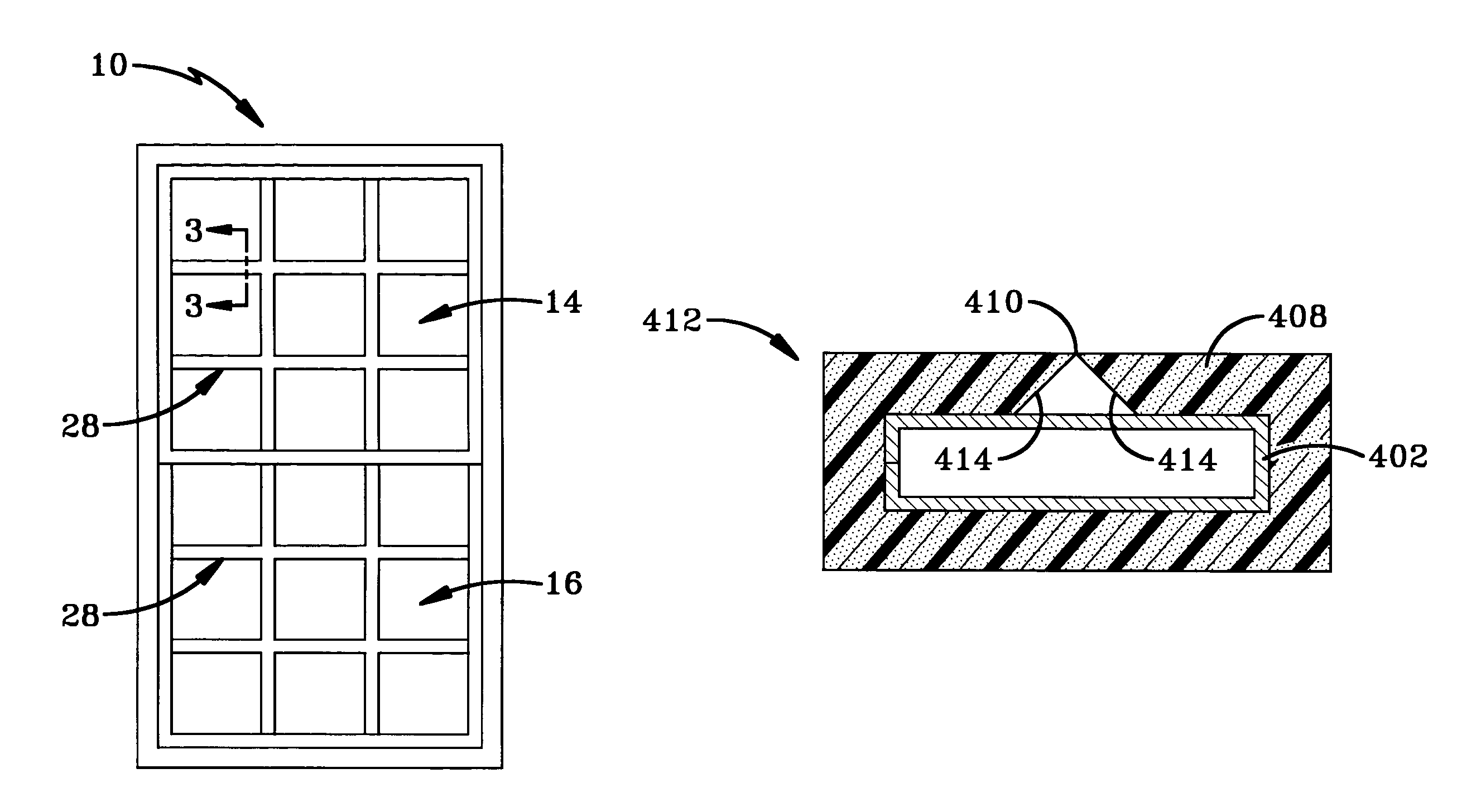

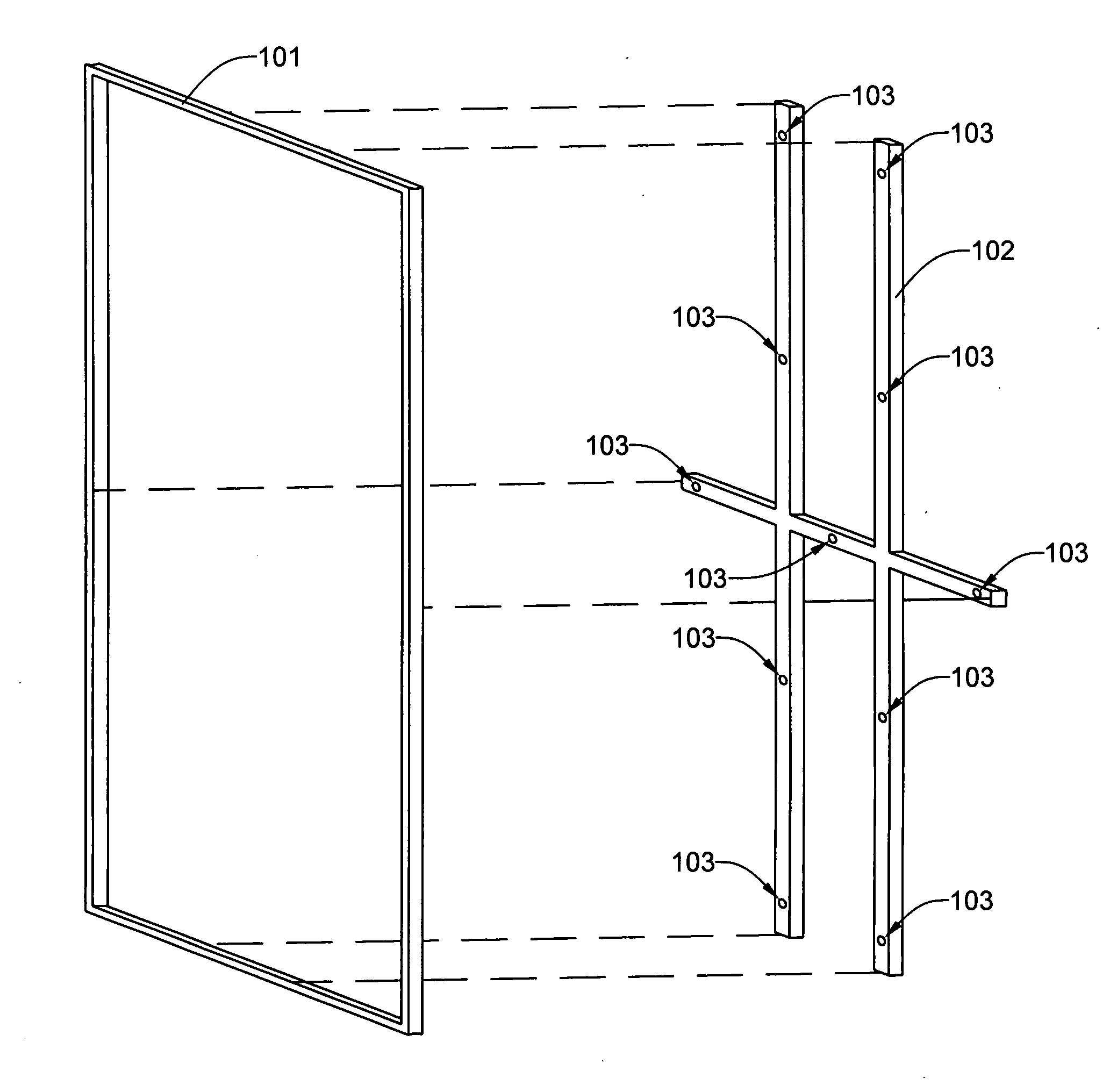

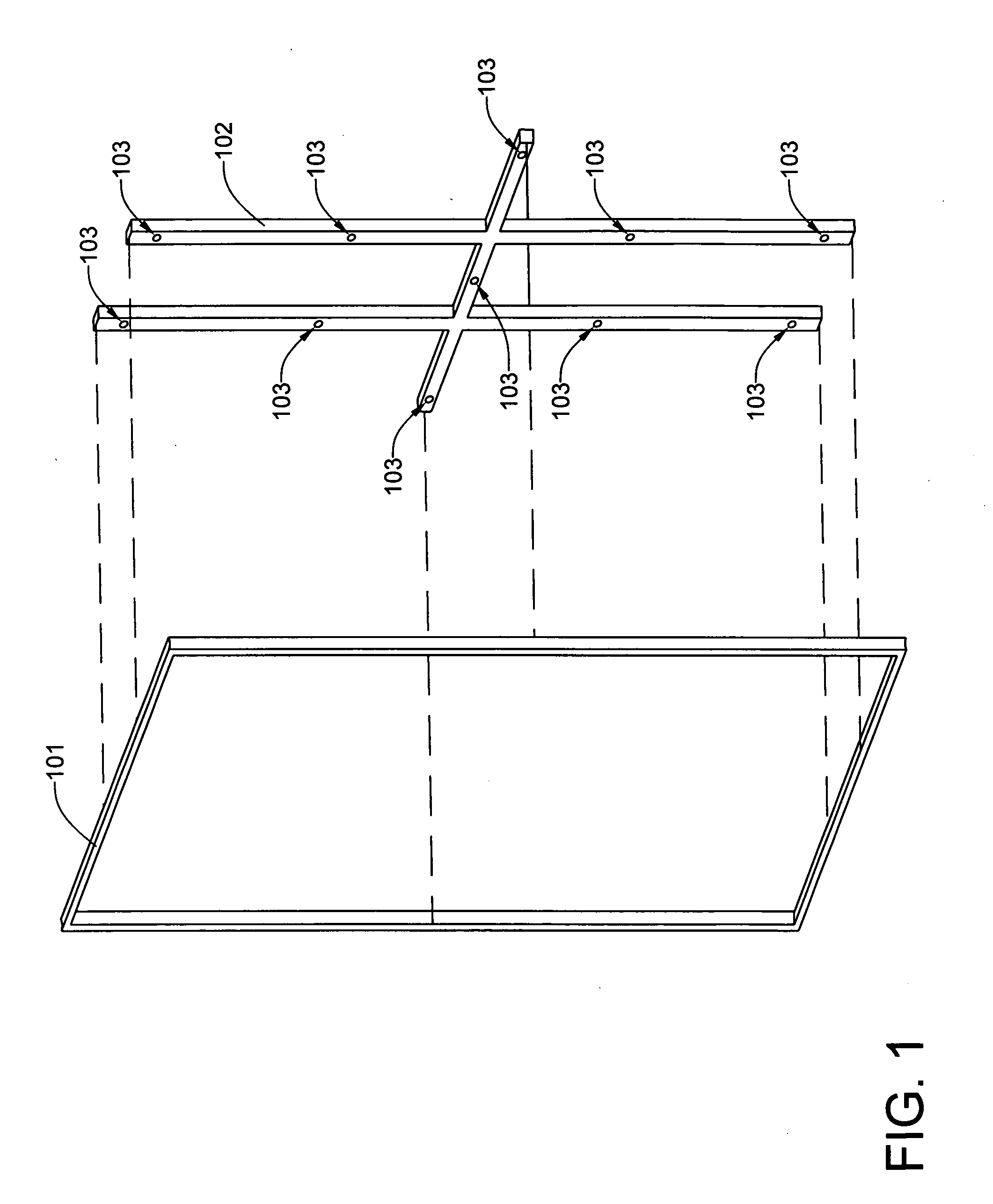

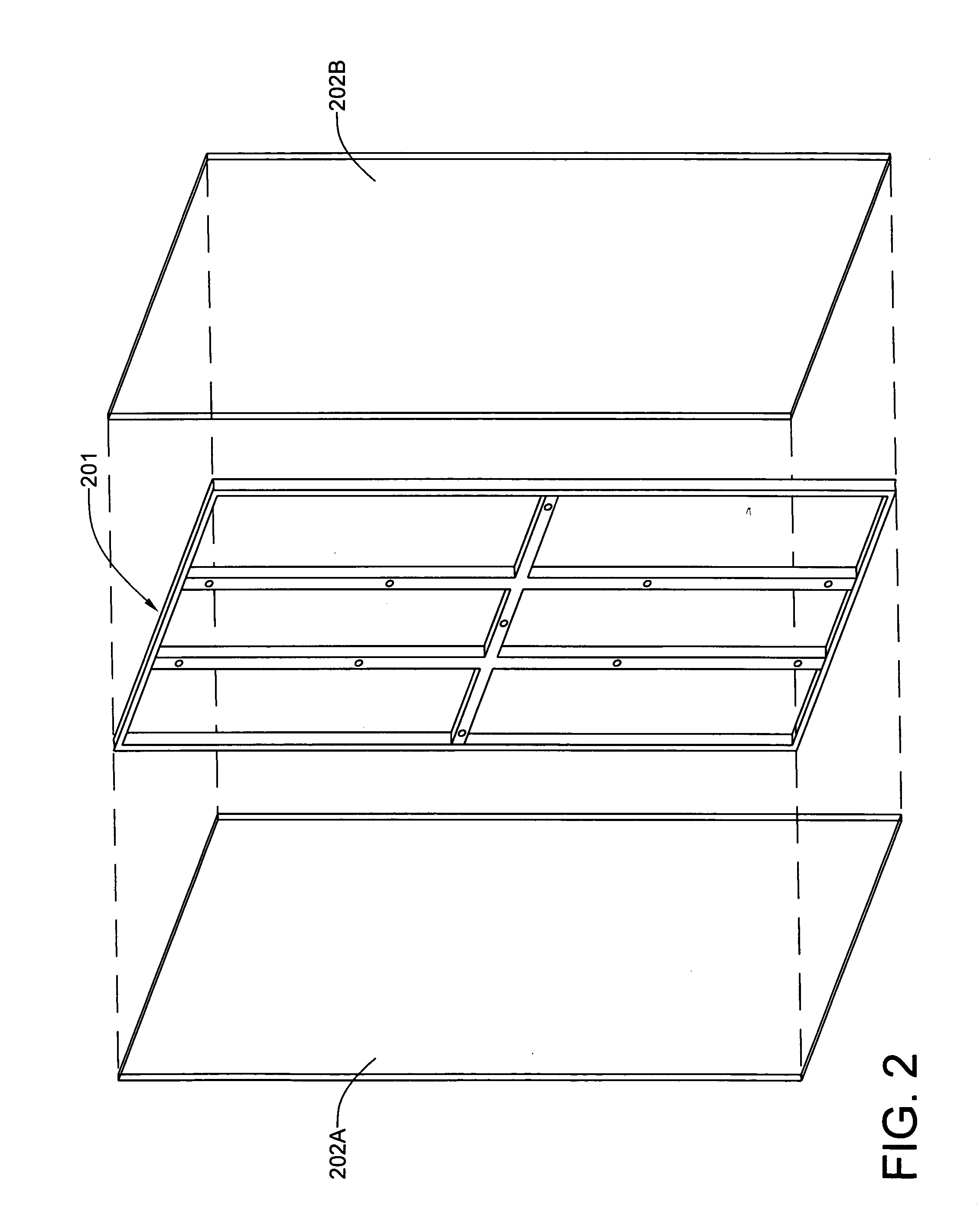

Divided light windows having magnetically-attached grids

An improved simulated authentic divided-light windows, includes an internal muntin grid structure sandwiched between the panes of a double-glazed sealed window pane, and an external muntin grid removably attached to each side of the sealed window pane. The internal grid is equipped with multiple neodymium magnets, which are embedded in the grid structure at regular intervals, while the back side of each of the outer muntin grid structures is equipped with multiple steel or iron inserts which align with the neodymium magnets when the outer grids are positioned, as intended, on the sash. Outer grids used on the inside of a building can be made of wood or plastic. Outer grids used on the exterior of building are preferably made of extruded aluminum or other weather resistant material. The steel or iron inserts are threadably secured or adhesively bonded to apertures in the back side of the grid.(150)

Owner:PARKER ROBERT FLOYD

Muntin Clip

A muntin clip is adapted to be connected to a muntin bar end and a spacer frame. The muntin clip includes a base member adapted for connection to the spacer frame and a bar support adapted for connection to the muntin bar end. The base member has a first segment, a second segment, and a mount structure. The bar support extends from the base member and has a first segment extending from the first segment of the base member and a second segment extending from the second segment of the base member. A flexible hinge member connects the first segment of the bar support to the second segment of the bar support, allowing the muntin clip assembly to move between an unfolded position and a folded position. A tension mechanism exerts outward force on the first and second segments of the base member when the muntin clip assembly is in the folded position.

Owner:NEWELL OPERATING COMPANY

Muntin clip and method of using the same

A muntin clip supports a muntin grid inside an insulating glazing unit. The clip includes a positioning arm that allows the clip to be positioned with respect to the spacer. In one embodiment, the clip has a flat base adapted to be positioned on the inwardly facing surface of the spacer. The positioning arm extends from one side of the plate with the muntin-engaging body extending from the other side of the plate. The arm has an outer end that projects beyond the outer edge of the plate. A method for using the clip includes the step of using one of the glass sheets to engage and position the positioning arm of the muntin clip. Stops may be provided to limit the insertion of the clip into the spacer.

Owner:QUANEX IG SYST INC

Muntin Bar Joiner

InactiveUS20080066411A1Improve connection characteristicsDoor leavesEngineeringMechanical engineering

A muntin bar joiner is adapted to be connected to a first muntin bar and a second muntin bar. The muntin bar joiner has a base adapted to be connected to a first muntin bar. The base has a cap sized to extend beyond a first opening in the first muntin bar. The muntin bar joiner also has a bar support extending from the base member and adapted for connection to a second muntin bar.

Owner:NEWELL OPERATING COMPANY

Muntin clip

A muntin clip has a bar support adapted to be connected to a muntin bar end and a base member adapted to be connected to a spacer frame. The bar support has a plurality of flexible support members attached thereto, which are adapted to contact the opposed interior walls of the muntin bar end and deform in response to such contact. The base member has two flexible members forming a flexible latching structure which is adapted to deform when inserted into the spacer frame. The muntin clip to be used with muntin bars and spacer frames having a range of different dimensions and configurations.

Owner:ASHLAND HARDWARE LLC

Laminated muntin bar method

An exemplary embodiment of the invention concerns a process for forming an elongated strip for use in making two tone muntin bars. An elongated strip of muntin bar material is provided that has been treated on at least a portion of one side to define an exposed surface of a completed muntin bar fabricated from the muntin bar material. An elongated strip of covering material is also provided for controlled application onto a specified portion of a surface of the muntin bar material. The elongated strip of covering material includes an adhesive for adhering the covering material to the muntin bar material. The muntin bar material and the covering material are brought into contact with each other thereby causing the covering material to overlie and adhere to the muntin bar material.

Owner:GED INTEGRATED SOLUTIONS

Steel plastic integral composite energy-saving environment protection window and manufacturing method thereof

InactiveCN101435306AOvercoming airtightnessOvercoming thermal insulationSealing arrangementsWing framesEngineeringInjection moulding

The invention discloses a manufacturing method of an energy-conserving and environment-protective window, comprising the following steps of: a) moulding a metal window sash frame of the window; b) manufacturing a mould and opening the mould according the structural shapes of a window sash profile base and a cover plate; c) putting the metal window sash frame into the mould for injection moulding; d) placing glass at the inner side of the profile base for covering; and buckling the cover plate on the base and the glass; e) coating sealing gum among the base, the cover plate and the glass for fixing and sealing, and finishing the manufacturing of the window sash by now; f) moulding the metal window sash frame into an I-shaped structure by welding; g) sheathing window frame plastic profiles on an upper section bar, a lower section bar, a left section bar and a right section bar of the I-shaped frame except muntins; h) forming the window frame structure; and i) mounting right-angle steel plates at the corners of the window frame by screw nails for fixing and connecting, and finishing manufacturing the window frame of the energy-conserving and environment-protective window by now; and mounting hardware fittings, and finishing the manufacturing of the energy-conserving and environment-protective window by matching with the window sash.

Owner:朱明 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com