Bailey beam suspension formwork supporting system and construction method thereof

A formwork support, Bailey beam technology, applied in formwork/formwork/work frame, on-site preparation of building components, construction, etc. problem, to achieve the effect of large load, less material waste and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

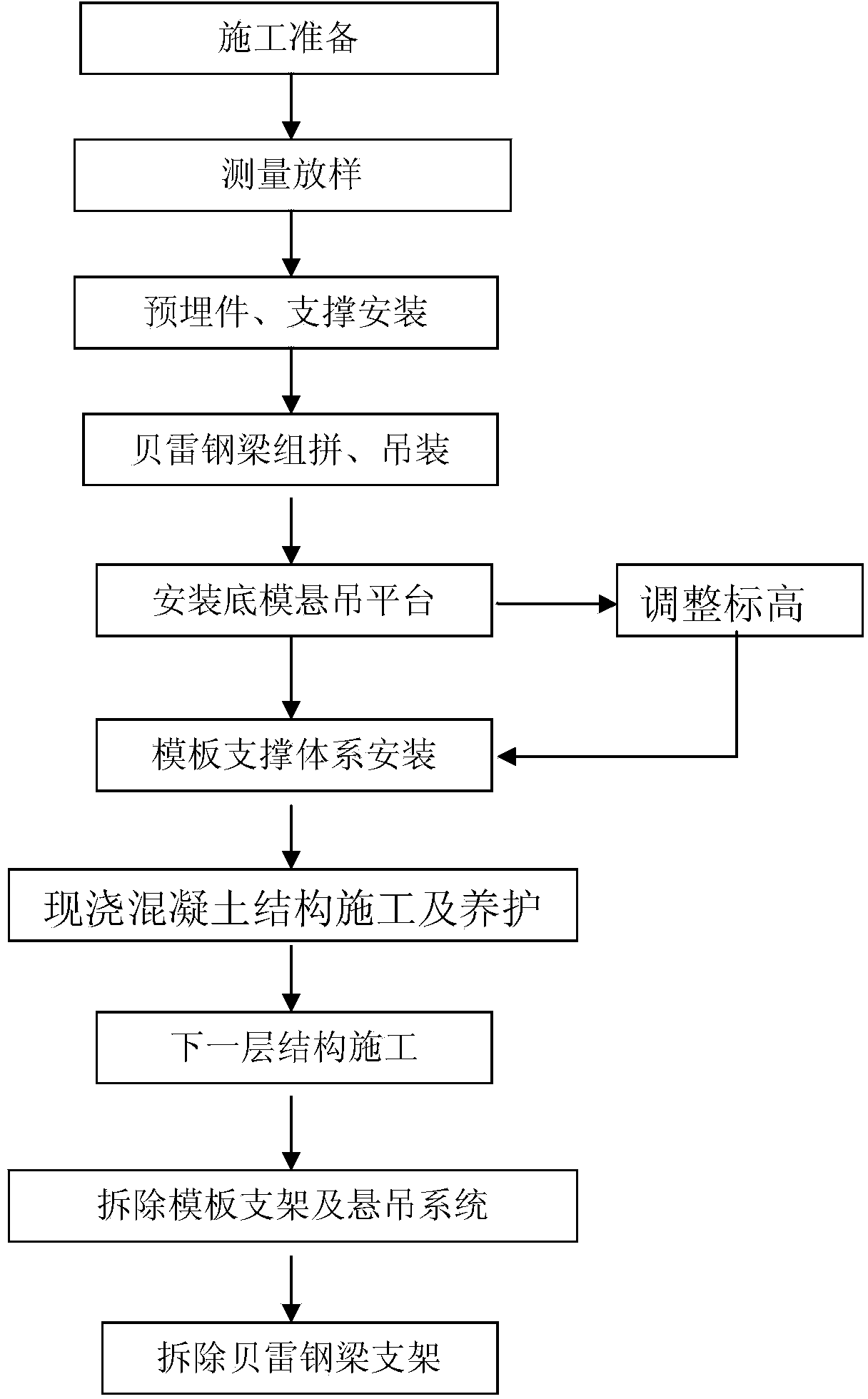

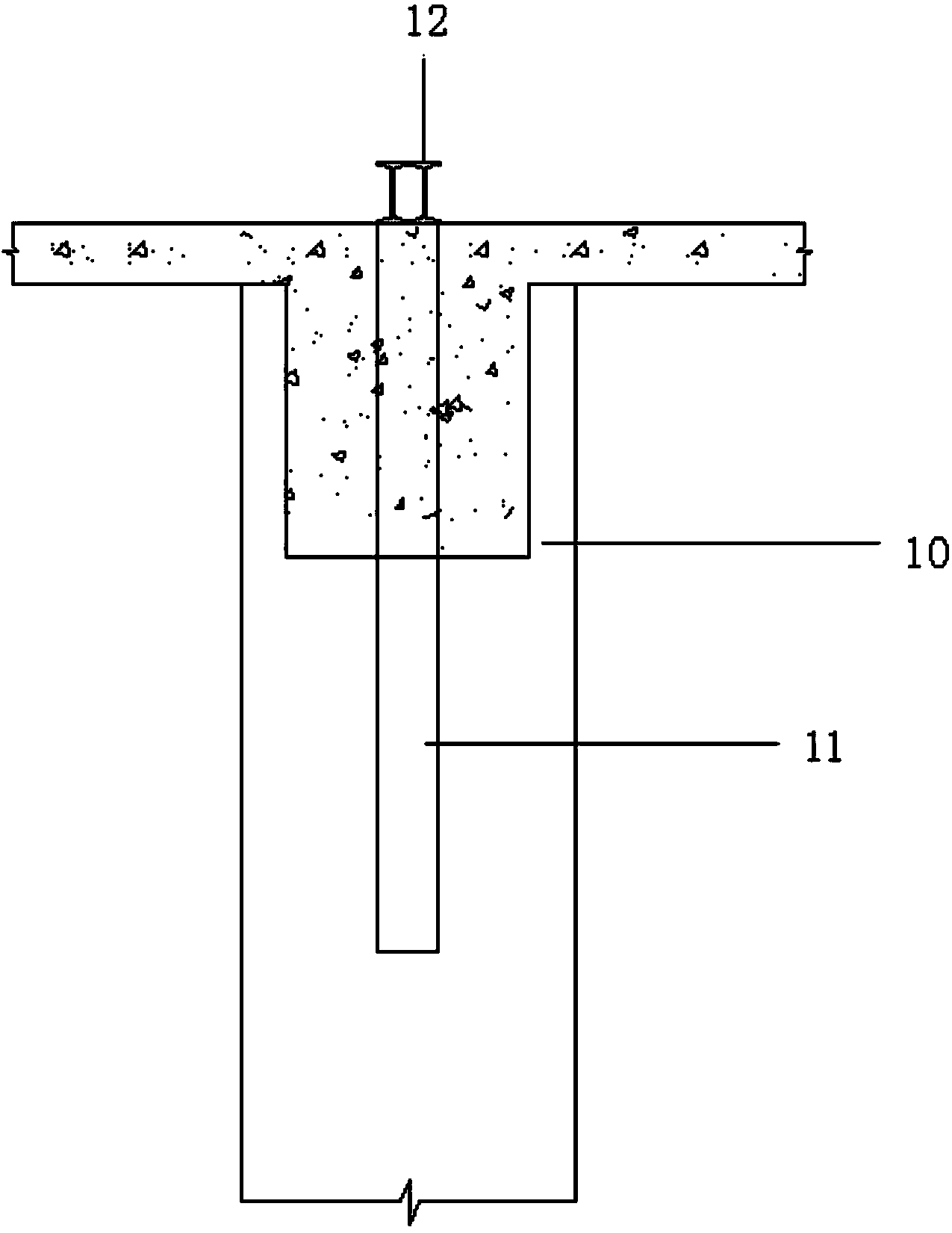

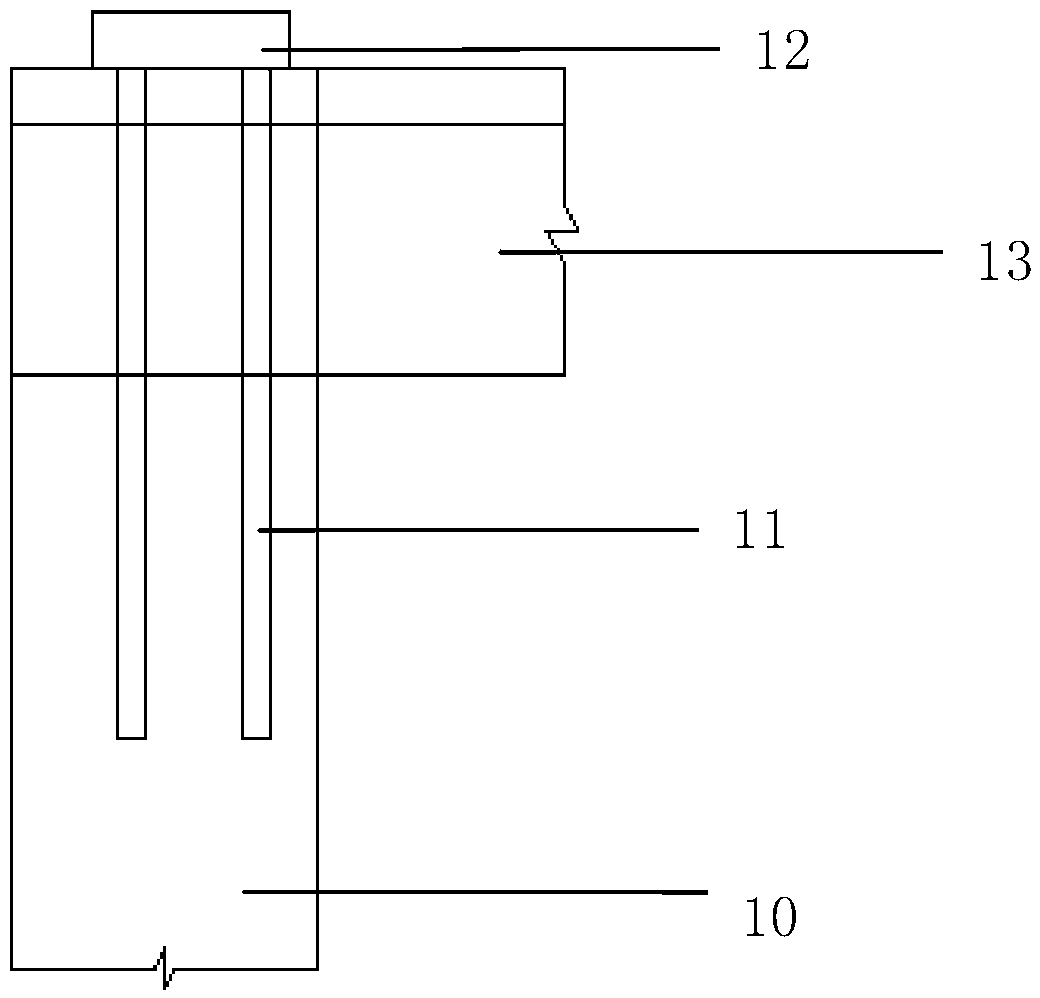

[0045] Such as Figure 2-1 to Figure 4-2 The Bailey beam suspension formwork support system shown is composed of a single-layer or multi-layer Bailey beam 1 to form a vertical and horizontal force truss 2, and a fine-rolled rebar suspender 5 is installed on the lower chord 4 of the transverse Bailey beam 3; Described suspender is covered with PVC pipe, passes through concrete layer structure bottom formwork 6 and hangs two-way I-beam load-bearing platform 7, above described platform supports steel pipe scaffold formwork support system 8 as usual, can adjust the length of described suspender The elevation and flatness of the load-bearing platform form a suspended formwork support system. The transverse Bailey beams 3 are vertically arranged on the longitudinal Bailey beams 9 according to the designed spacing, and use their own allowable stress to bear the construction load generated by pouring concrete. The longitudinal Bailey beams are supported on existing frame structures o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com