Patents

Literature

1007 results about "Horizontal force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The horizontal force depends on what the situation is that the skater is in. For example, if they were to use their foot to push the skateboard along, then this pushing force is the forward horizontal force, which acts against a horizontal friction force. Similarly, if they were to stand on a skateboard and get pushed by somebody,...

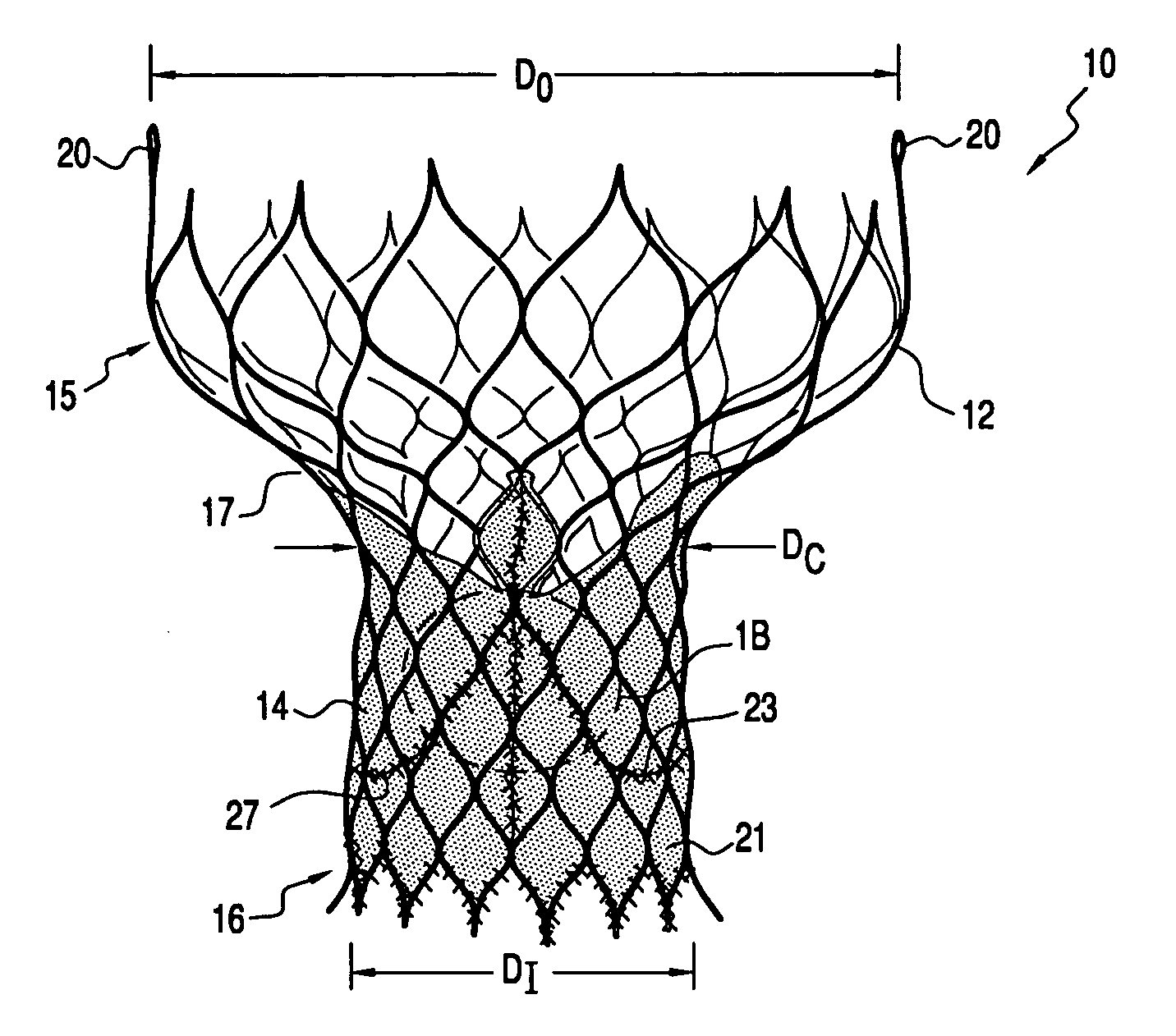

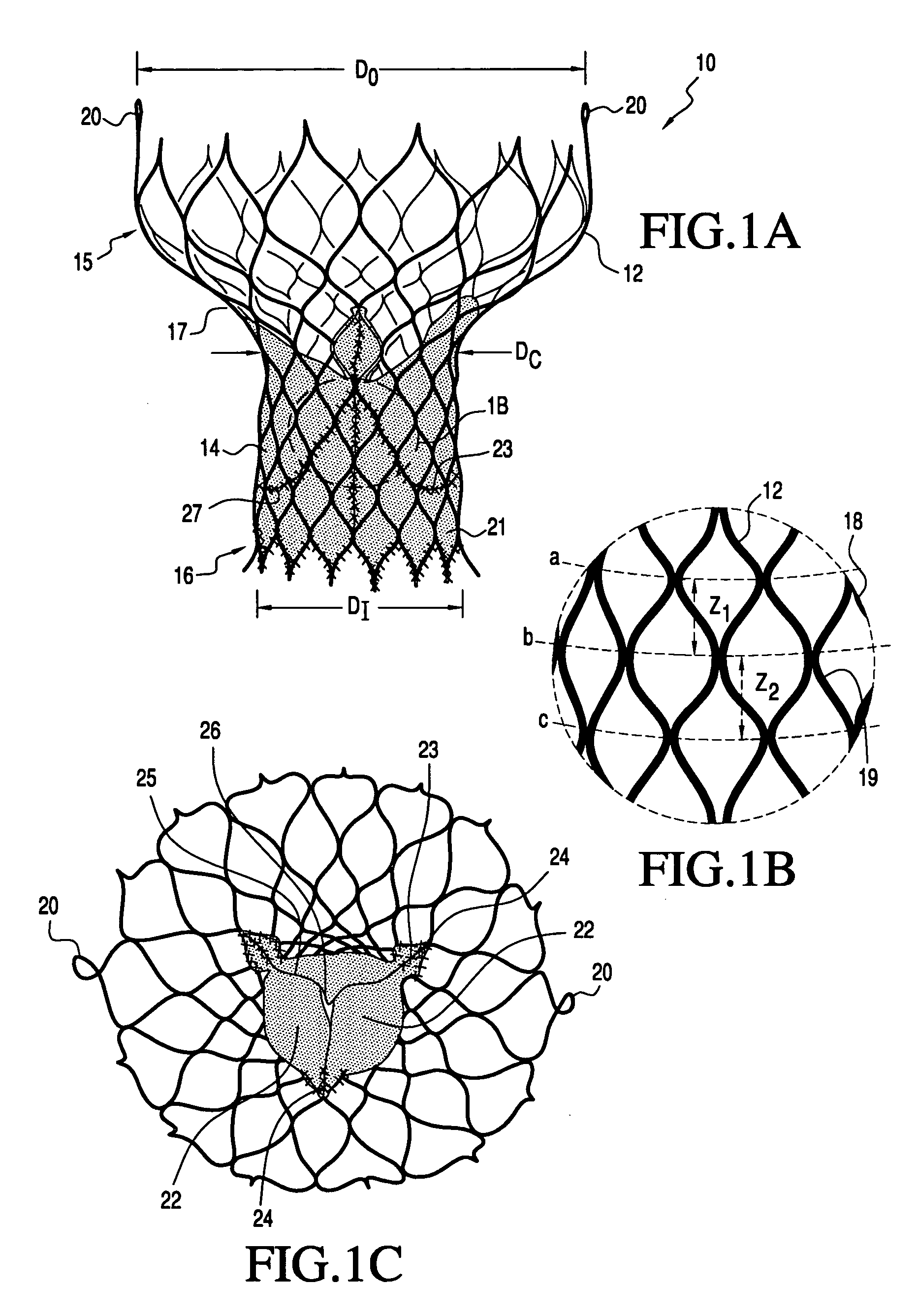

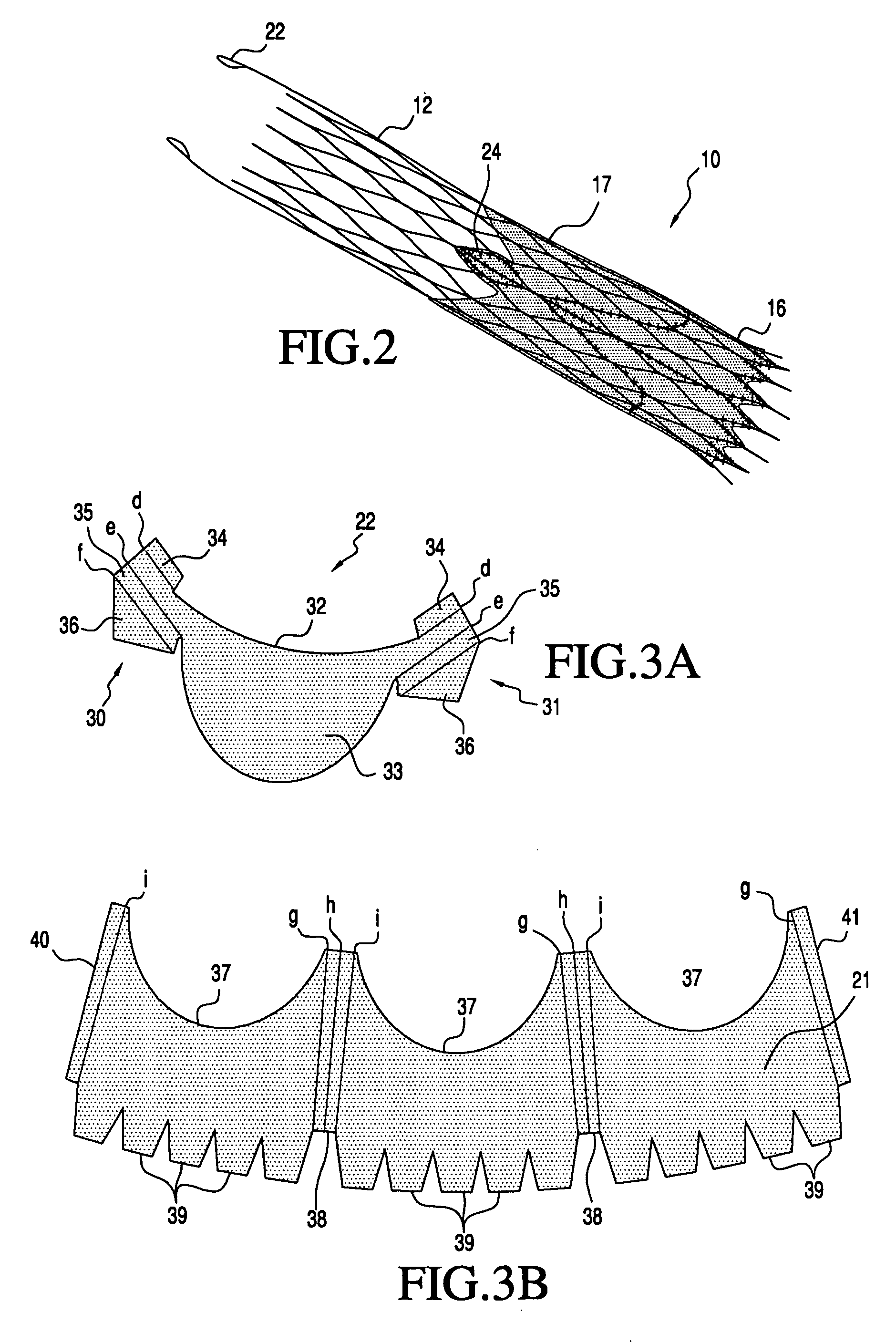

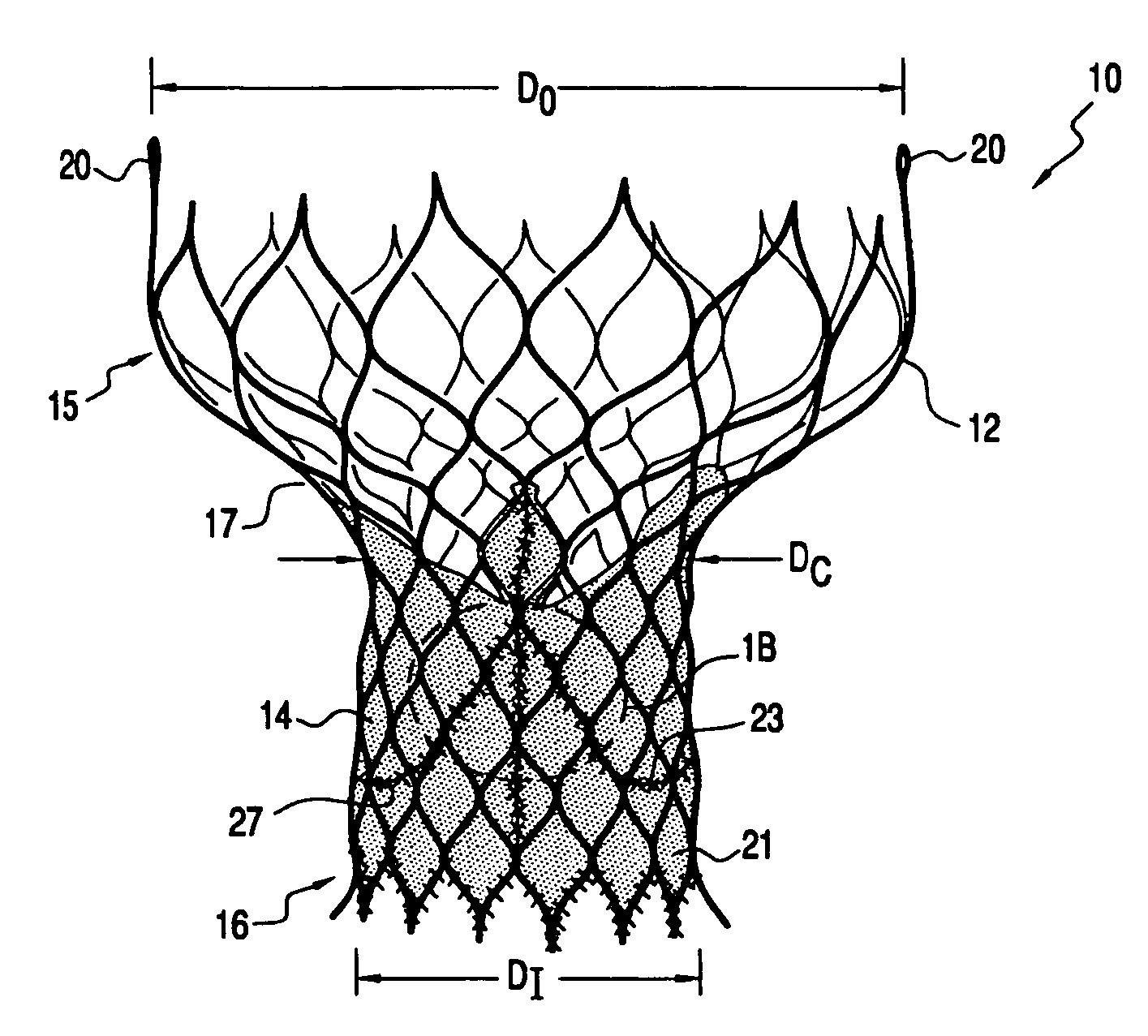

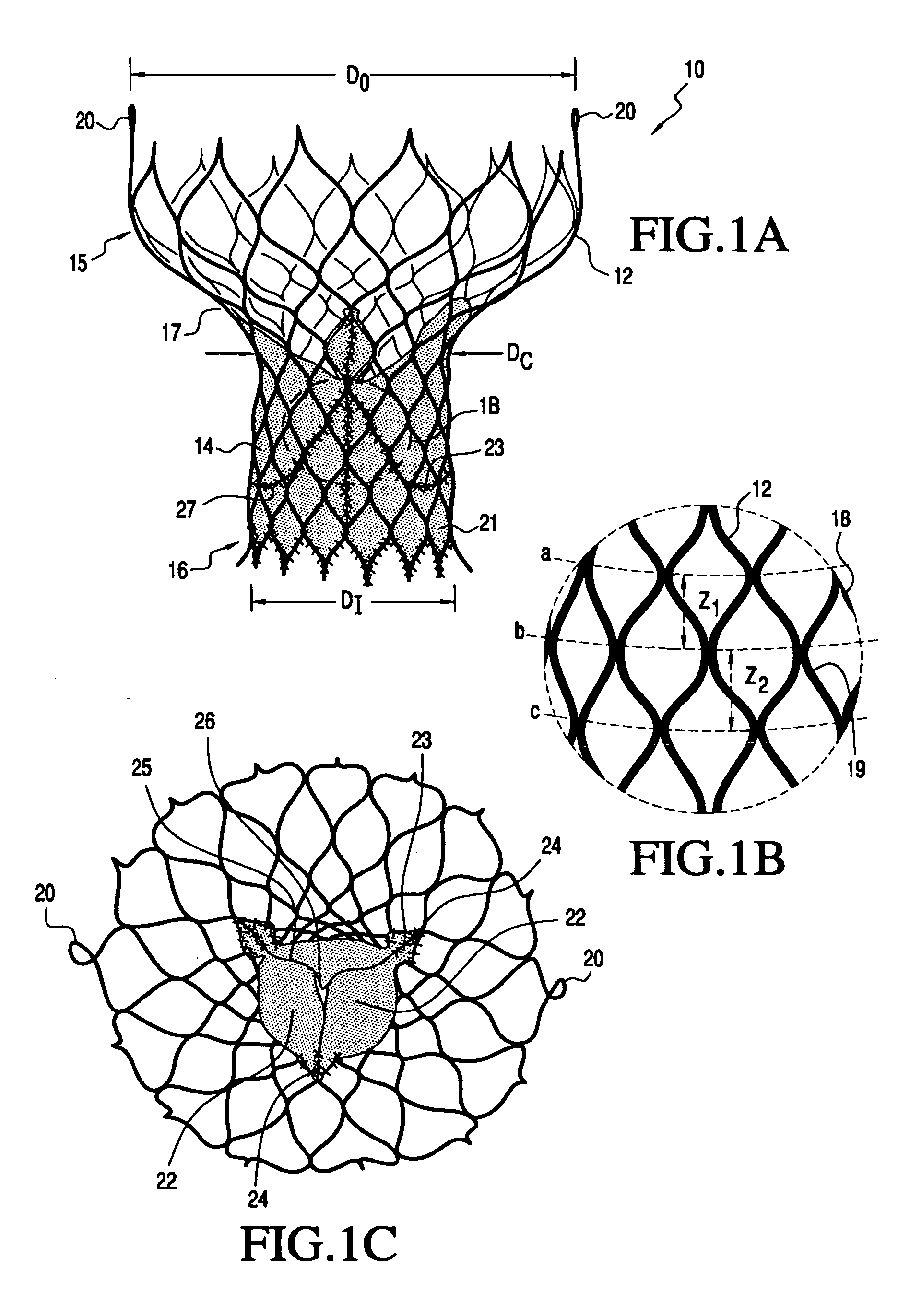

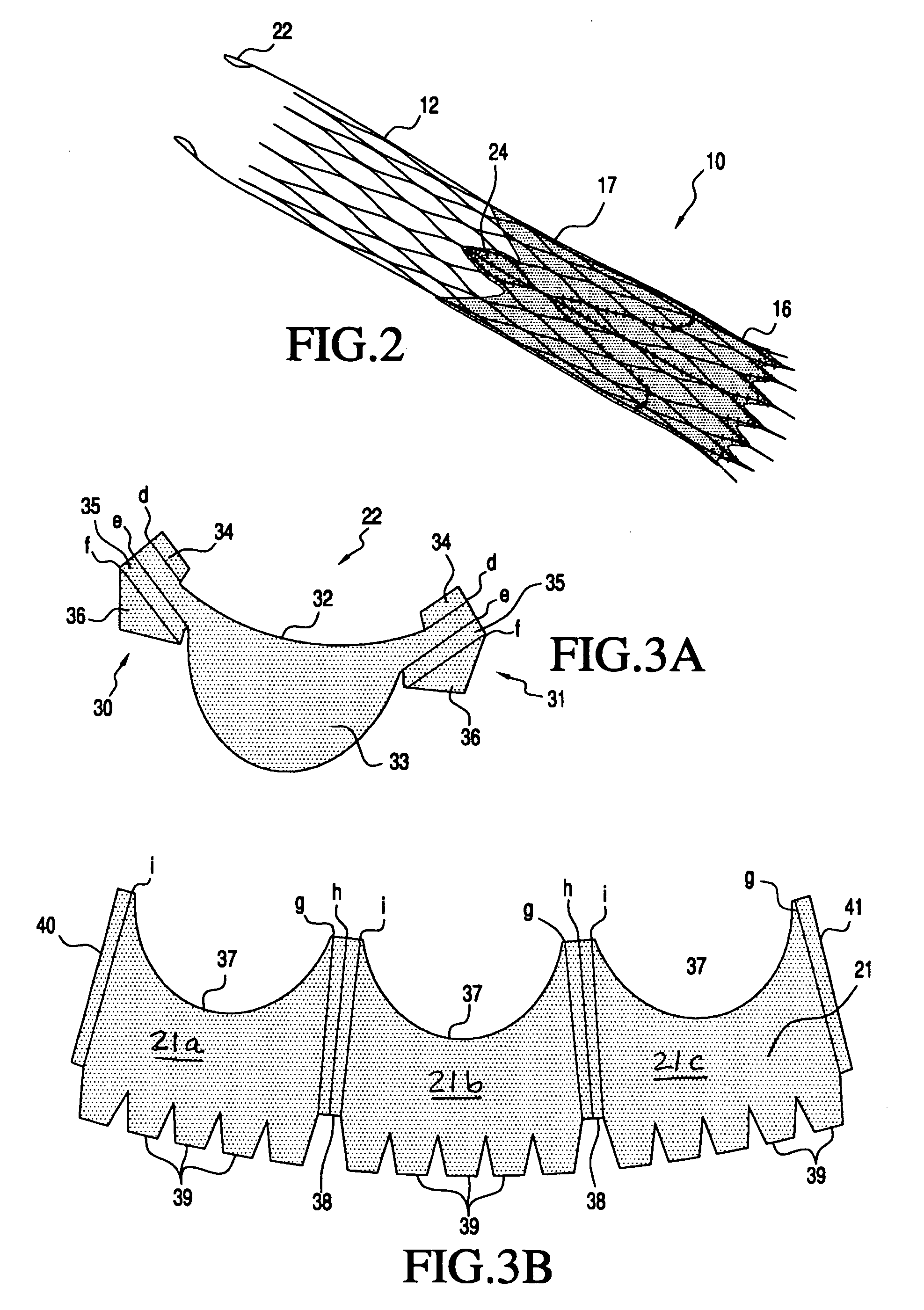

Heart valve prosthesis and methods of manufacture and use

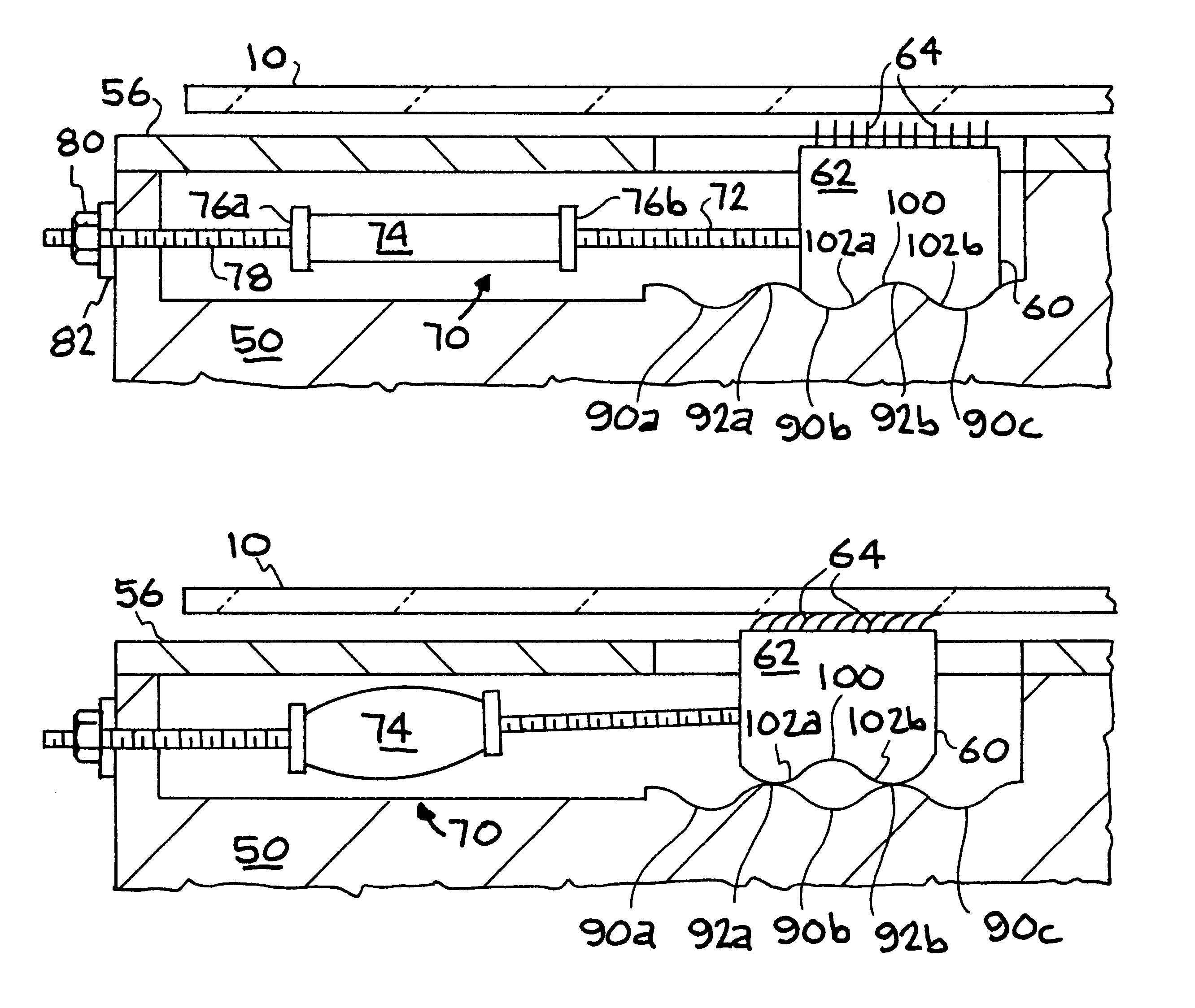

ActiveUS20060259136A1Overcomes drawbackReduce riskHeart valvesBlood vesselsHorizontal forceHourglass

A heart valve prosthesis is provided having a self-expanding multi-level frame that supports a valve body comprising a skirt and plurality of coapting leaflets. The frame transitions between a contracted delivery configuration that enables percutaneous transluminal delivery, and an expanded deployed configuration having an asymmetric hourglass shape. The valve body skirt and leaflets are constructed so that the center of coaptation may be selected to reduce horizontal forces applied to the commissures of the valve, and to efficiently distribute and transmit forces along the leaflets and to the frame. Alternatively, the valve body may be used as a surgically implantable replacement valve prosthesis.

Owner:MEDTRONIC ARDIAN LUXEMBOURG SARL

Heart valve prosthesis and methods of manufacture and use

ActiveUS20060265056A1Reduce risk of damageEfficient configurationHeart valvesHorizontal forceHourglass

A heart valve prosthesis is provided having a self-expanding multi-level frame that supports a valve body comprising a skirt and plurality of coapting leaflets. The frame transitions between a contracted delivery configuration that enables percutaneous transluminal delivery, and an expanded deployed configuration having an asymmetric hourglass shape. The valve body skirt and leaflets are constructed so that the center of coaptation may be selected to reduce horizontal forces applied to the commissures of the valve, and to efficiently distribute and transmit forces along the leaflets and to the frame. Alternatively, the valve body may be used as a surgically implantable replacement valve prosthesis.

Owner:MEDTRONIC ARDIAN LUXEMBOURG SARL

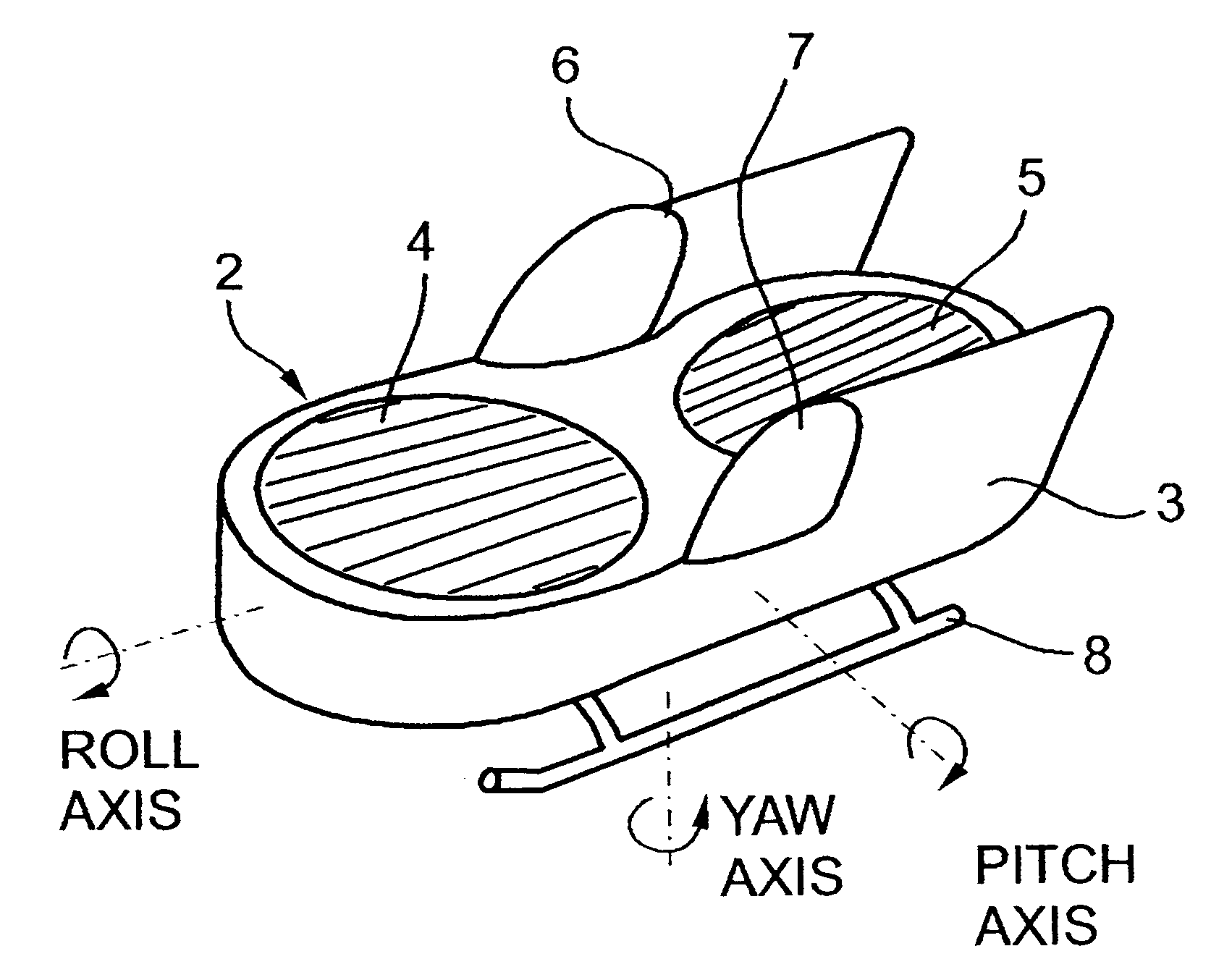

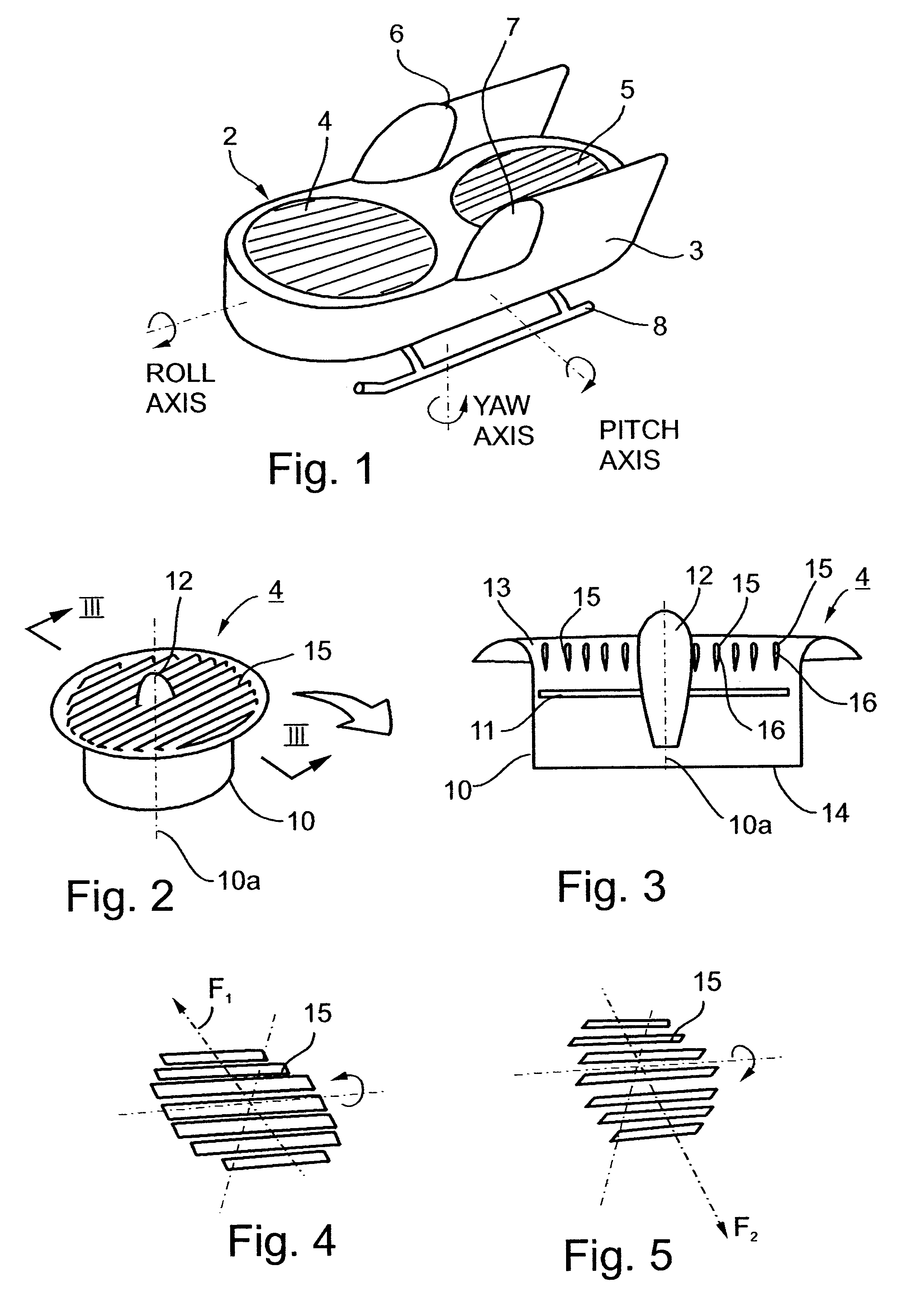

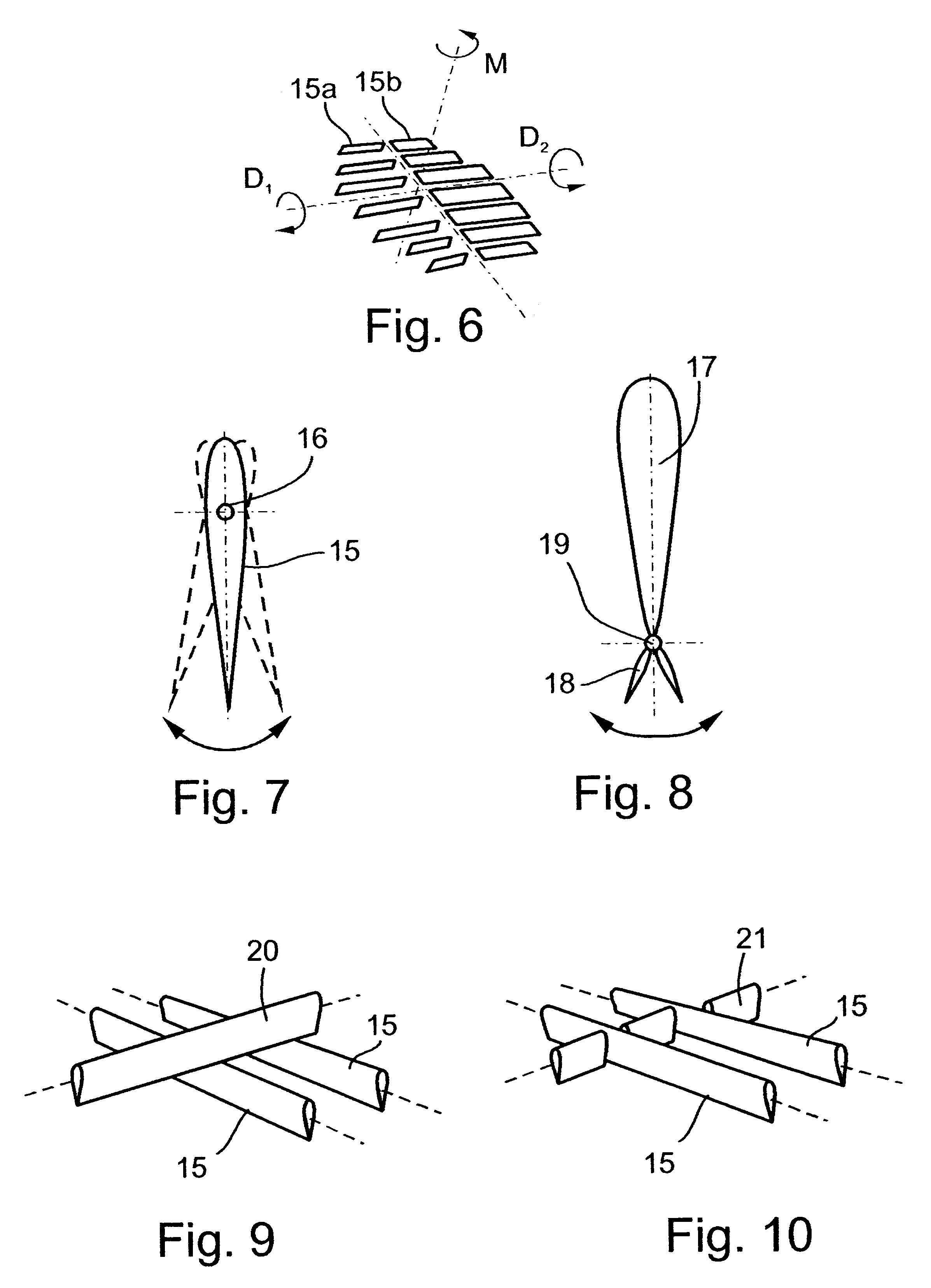

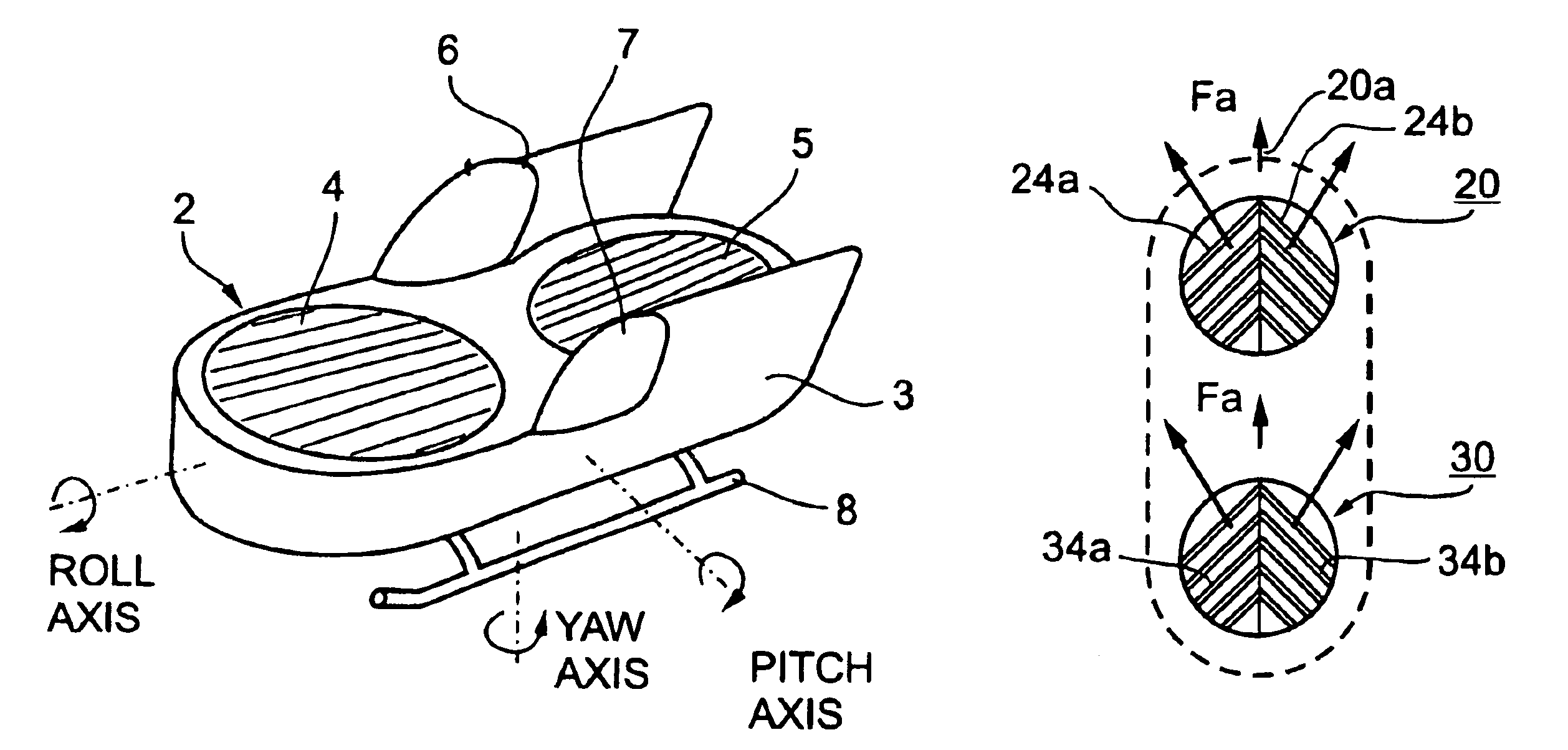

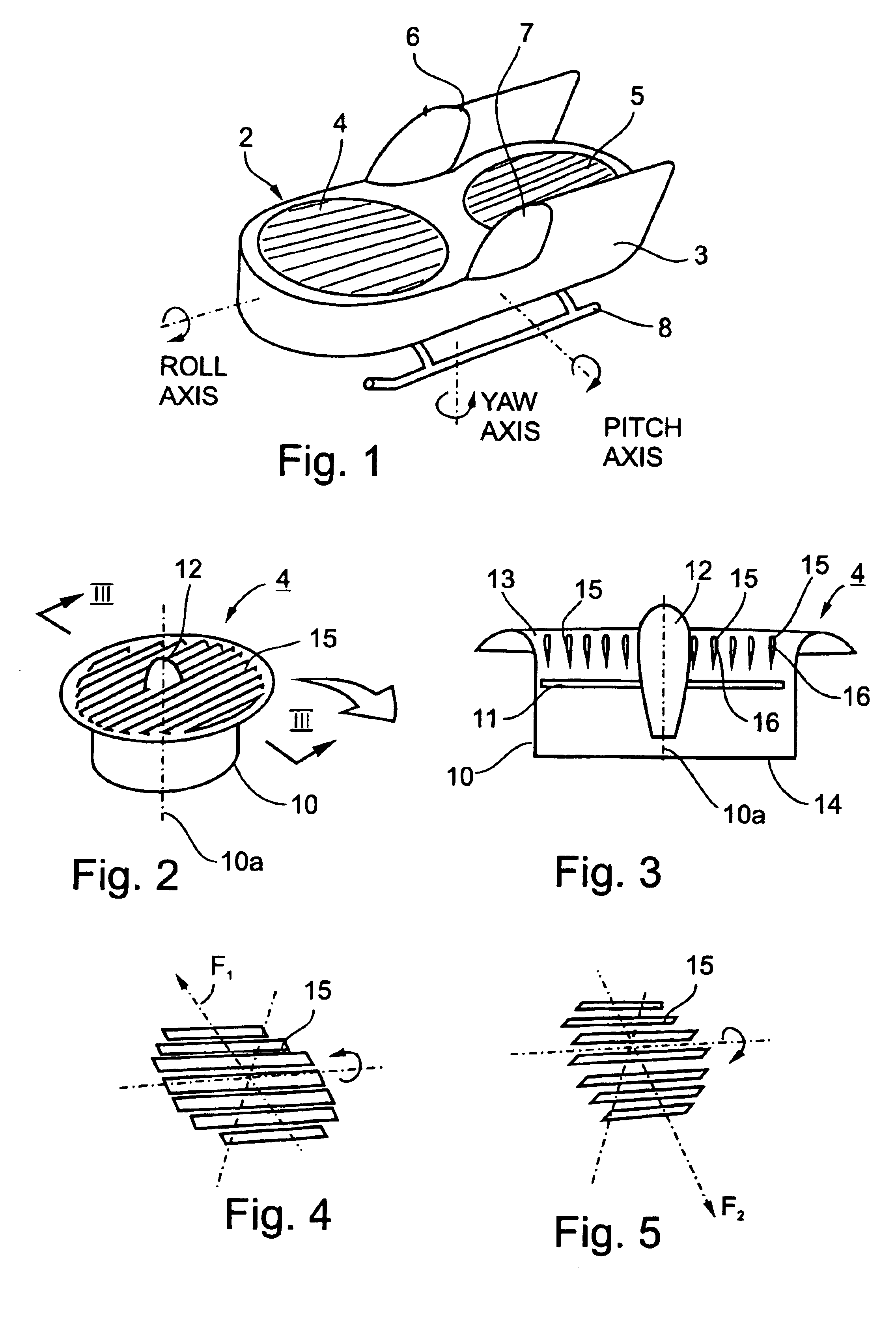

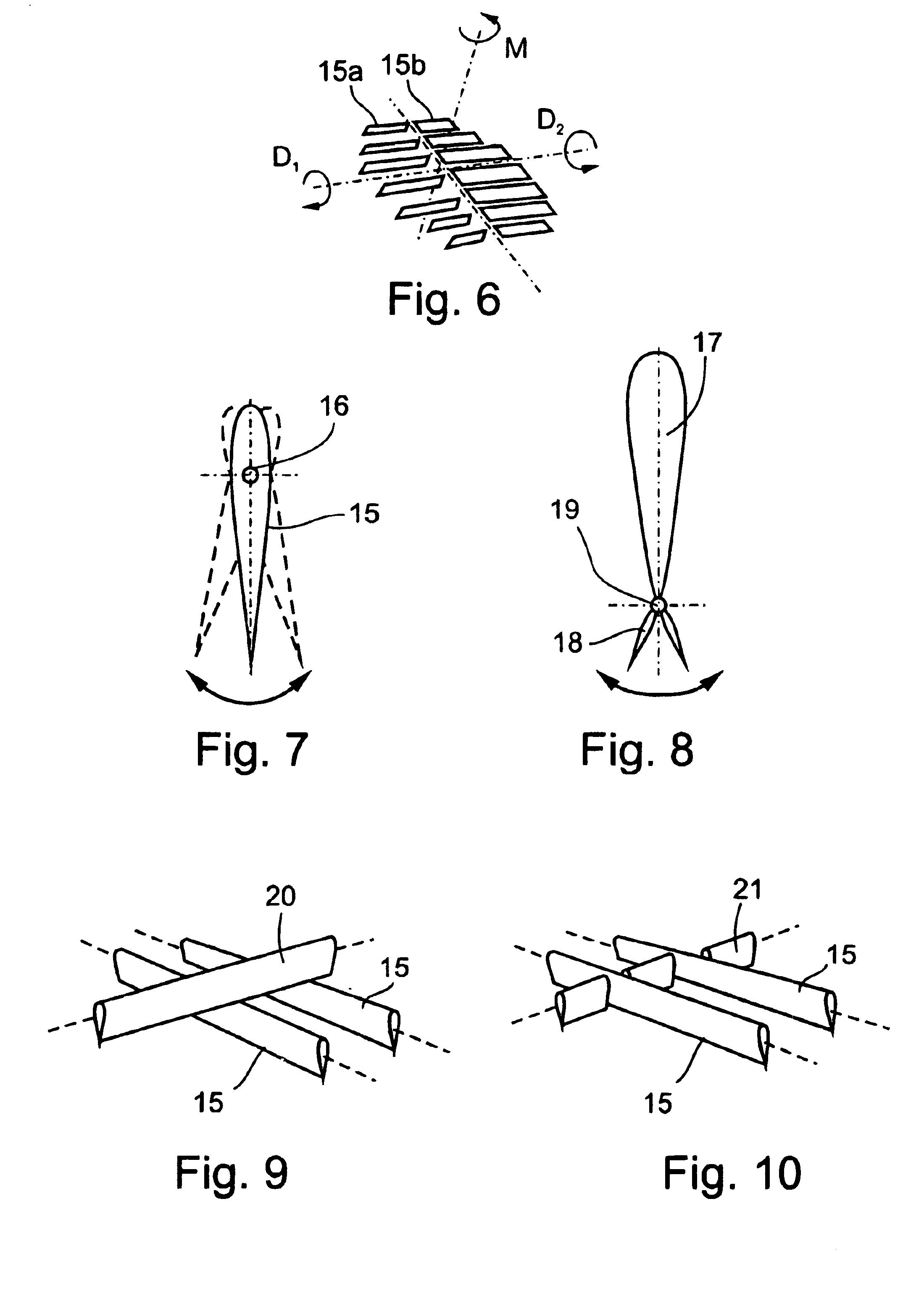

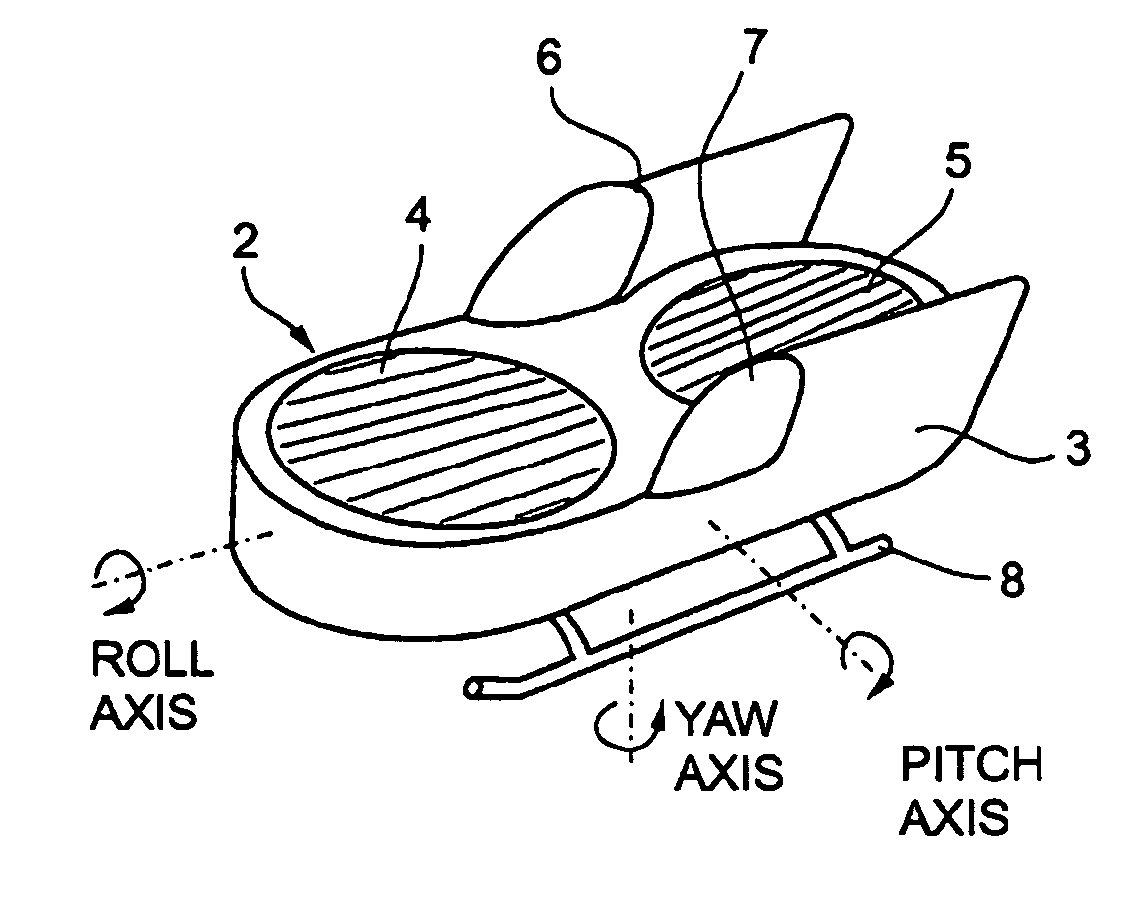

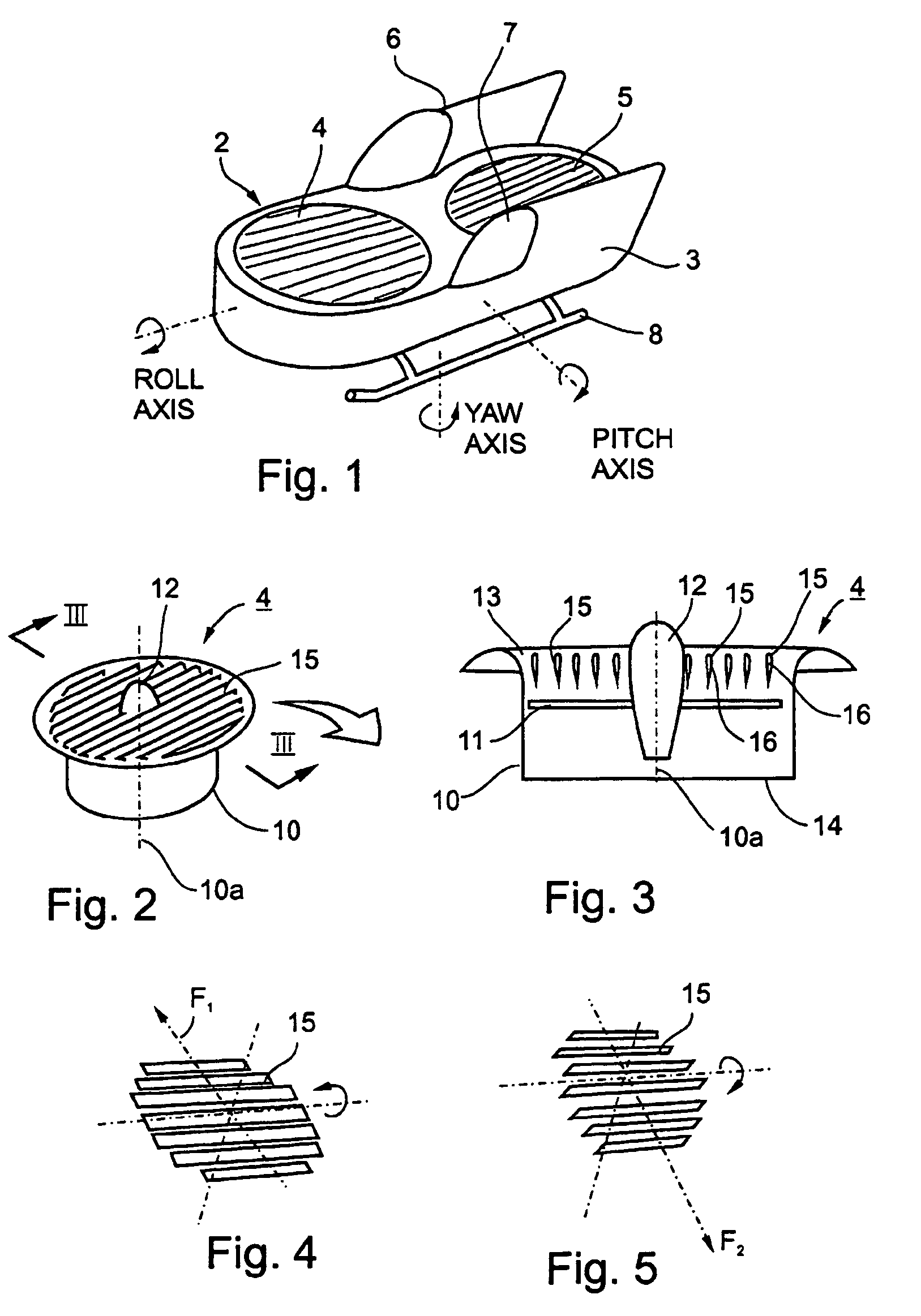

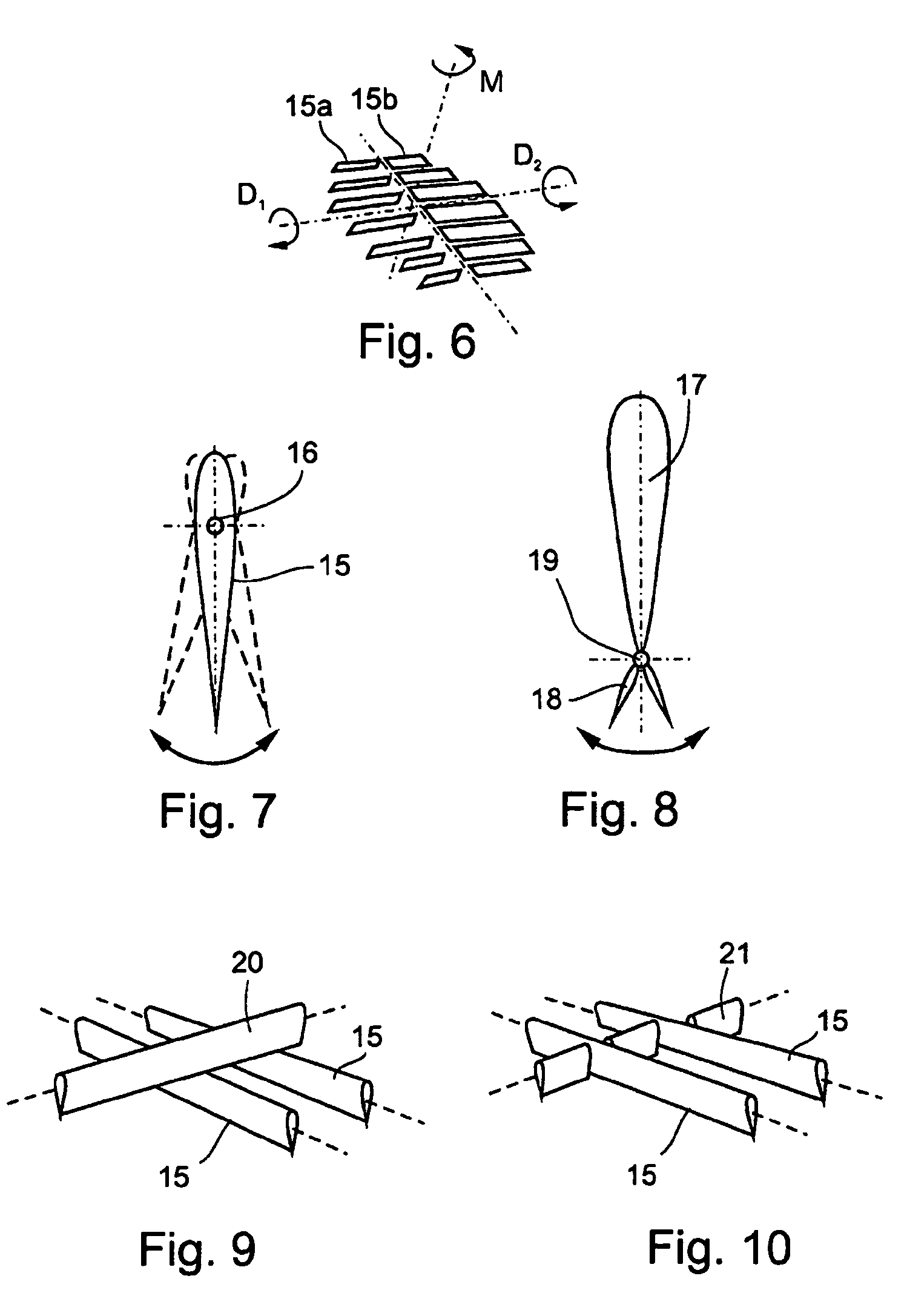

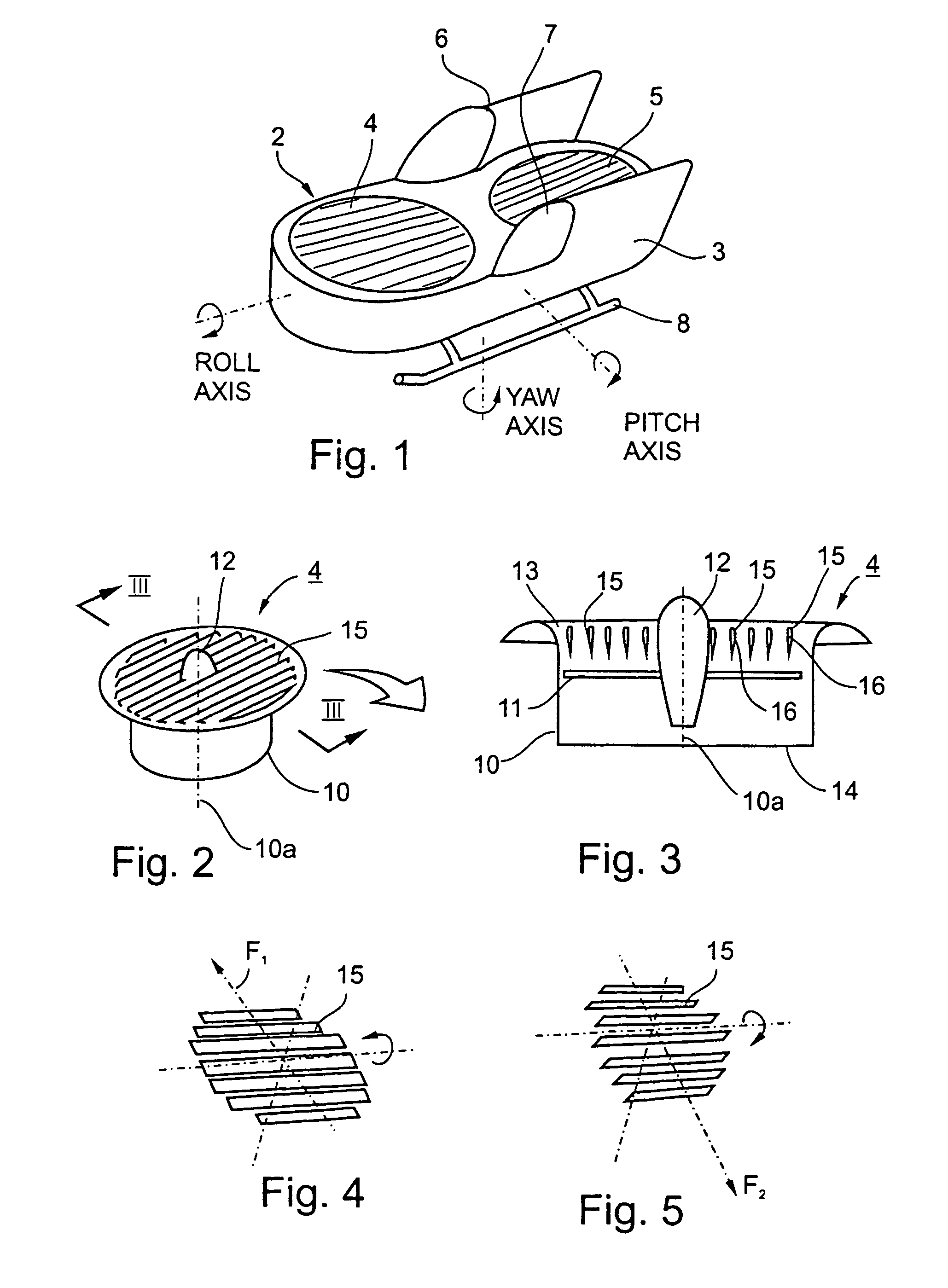

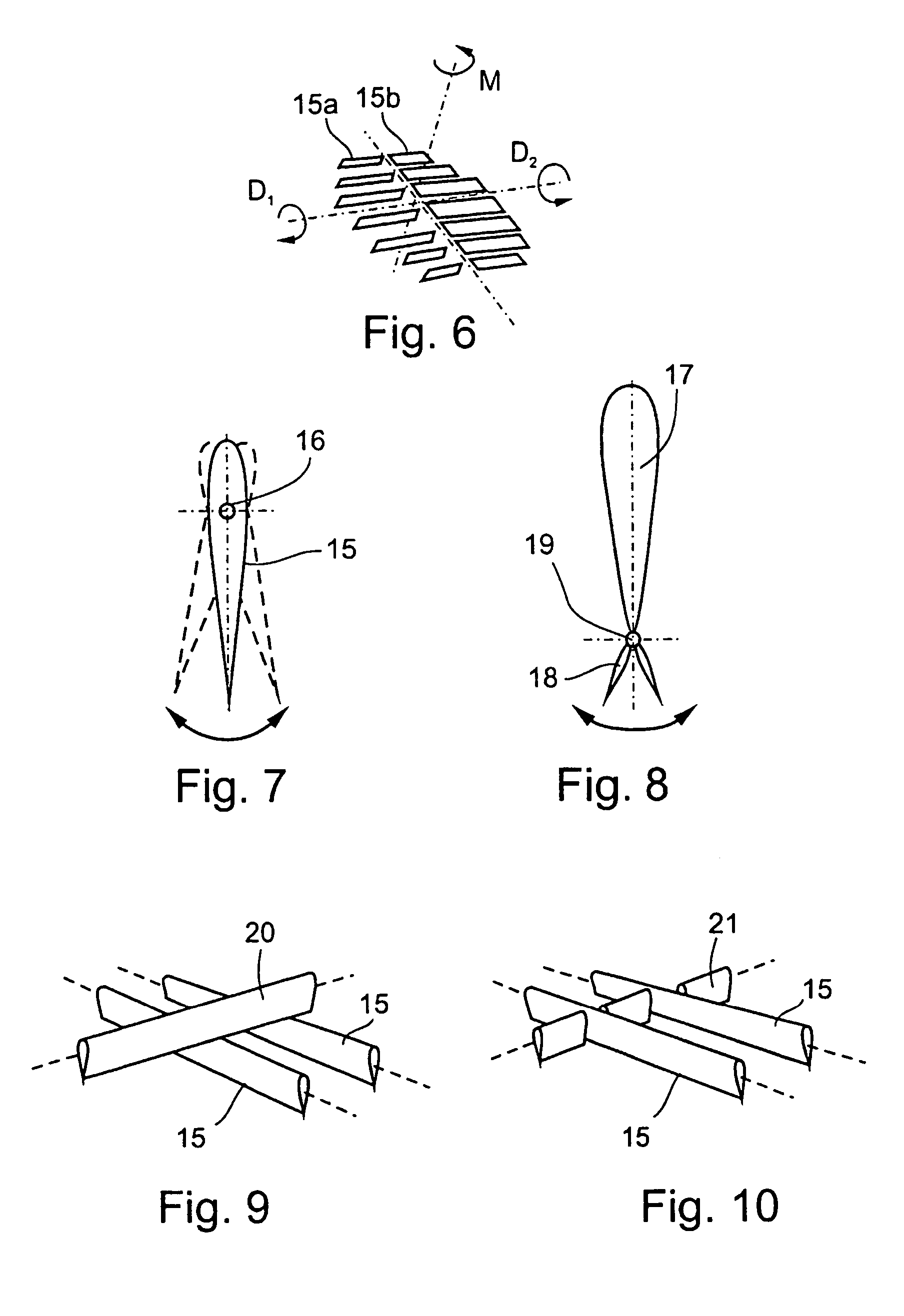

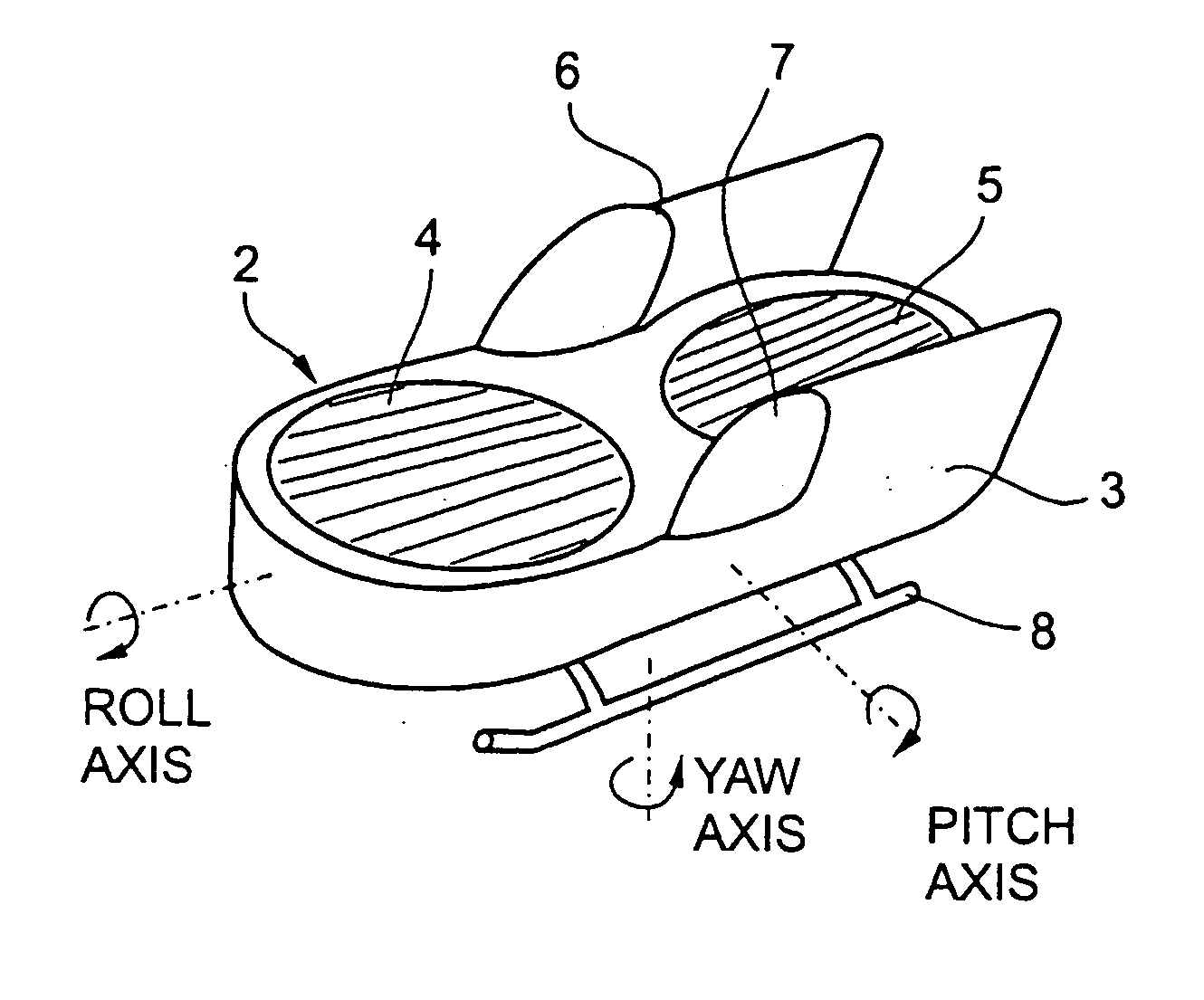

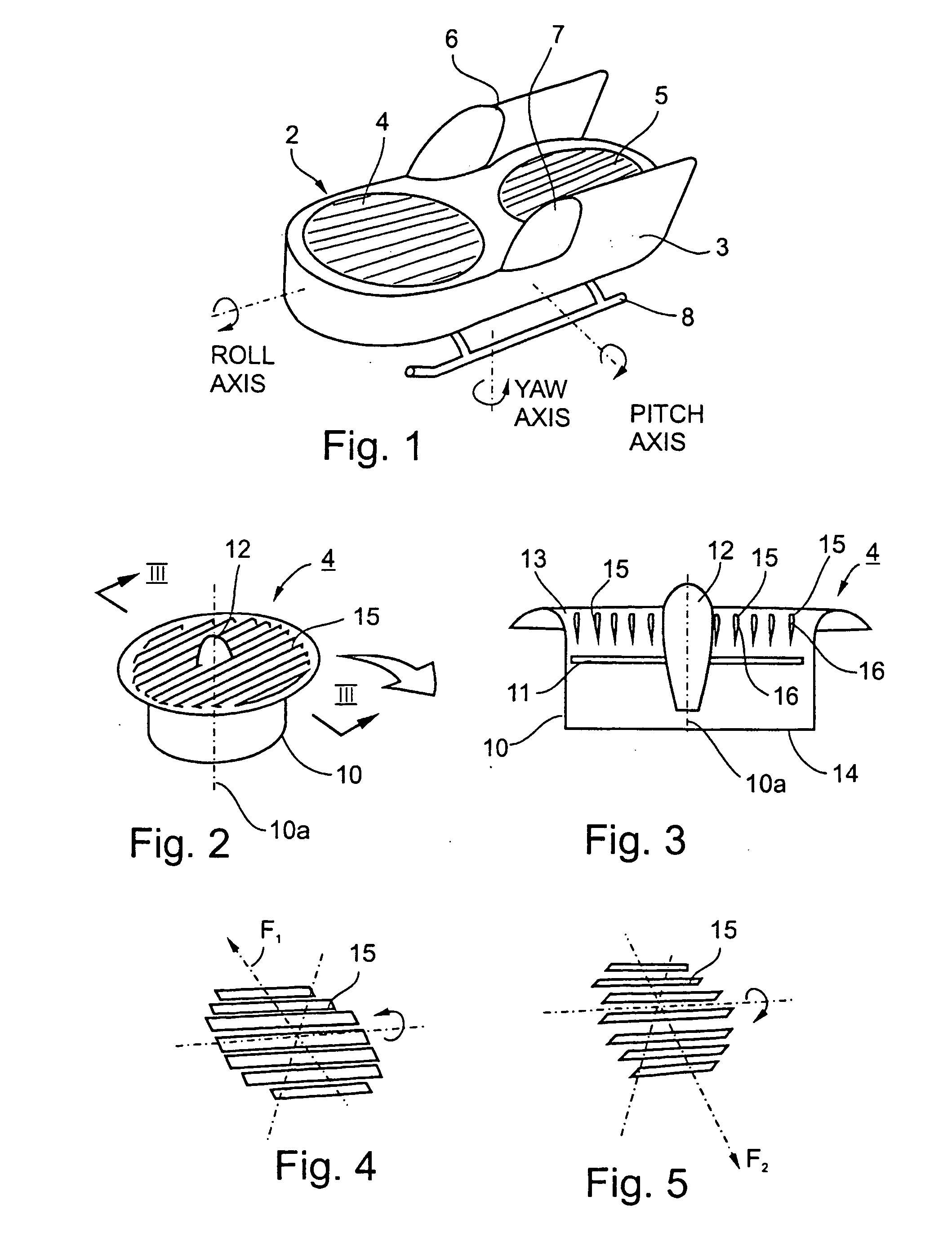

Ducted fan vehicles particularly useful as VTOL aircraft

InactiveUS6464166B1Easy to controlAircraft navigation controlVertical landing/take-off aircraftsHorizontal forceJet aeroplane

A vehicle, particularly a VTOL air vehicle, includes a duct carried by the vehicle frame with the longitudinal axis of the duct perpendicular to the longitudinal axis of the vehicle frame; a propeller rotatably mounted within the duct about the longitudinal axis of the duct to force an ambient fluid, e.g. air, therethrough from its inlet at the upper end of the duct through its exit at the lower end of the duct, and thereby to produce an upward lift force applied to the vehicle; and a plurality of parallel, spaced vanes pivotally mounted to and across the inlet end of the duct about pivotal axes perpendicular to the longitudinal axis of the duct and substantially parallel to the longitudinal axis of the vehicle frame. The vanes are selectively pivotal to produce a desired horizontal force component to the lift force applied to the vehicle. Various vane arrangements are disclosed for producing side, roll, pitch and yaw movements of the vehicle.

Owner:URBAN AERONAUTICS

Ducted fan vehicles particularly useful as VTOL aircraft

InactiveUS6817570B2Easy to controlAircraft navigation controlVertical landing/take-off aircraftsHorizontal forceVehicle frame

A vehicle, including a vehicle frame, a duct carried by the vehicle frame with the longitudinal axis of the duct perpendicular to the longitudinal axis of the vehicle frame, a propeller rotatably mounted within the duct about the longitudinal axis of the duct to force an ambient fluid therethrough from its inlet at the upper end of the duct through its exit at the lower end of the duct, and thereby to produce an upward lift force applied to the vehicle, and a plurality of parallel, spaced vanes pivotally mounted to and across the inlet end of the duct about pivotal axes perpendicular to the longitudinal axis of the duct and substantially parallel to the longitudinal axis of the vehicle frame, the vanes being selectively pivotal about their axes to produce a desired horizontal force component to the lift force applied to the vehicle.

Owner:URBAN AERONAUTICS

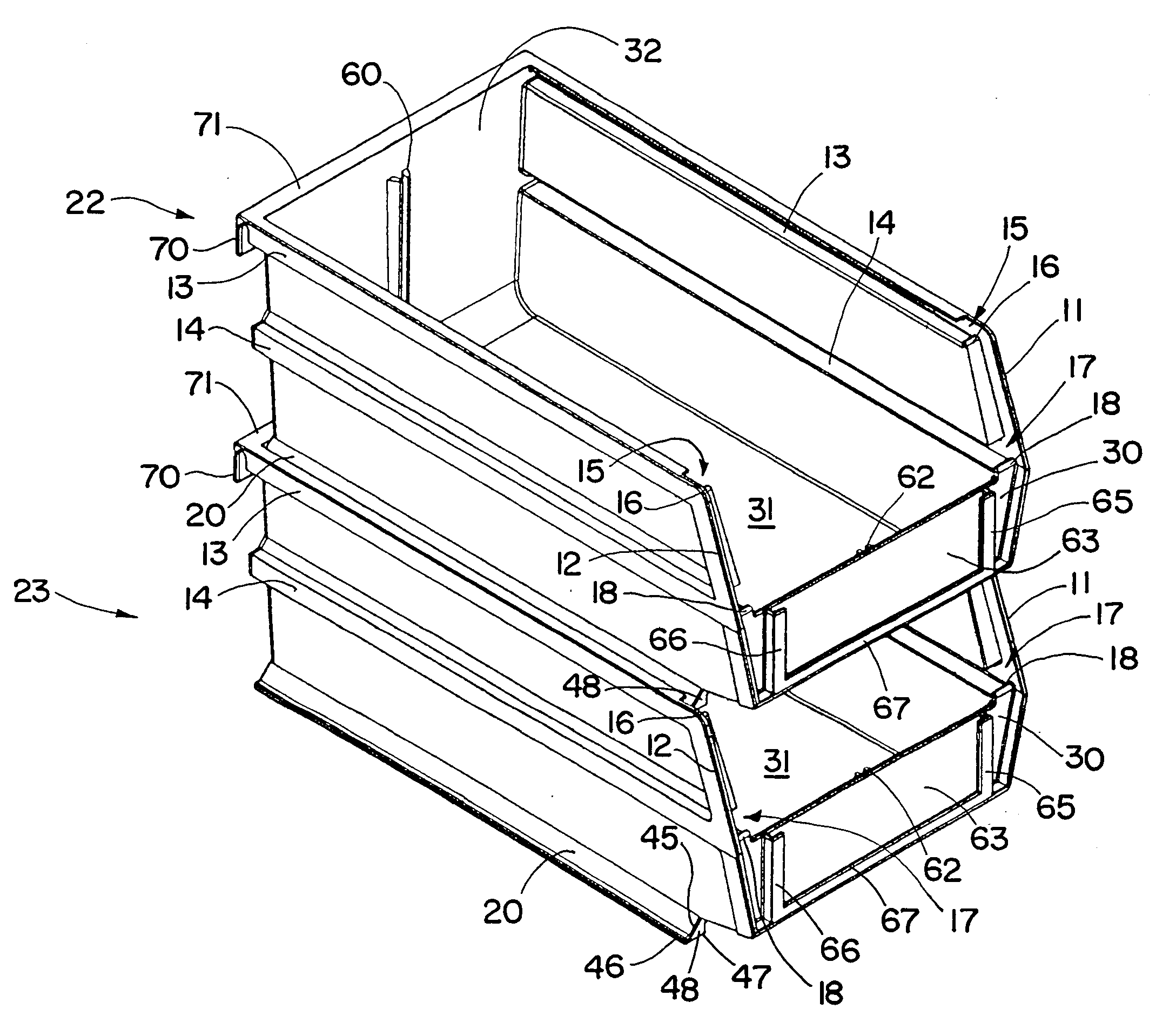

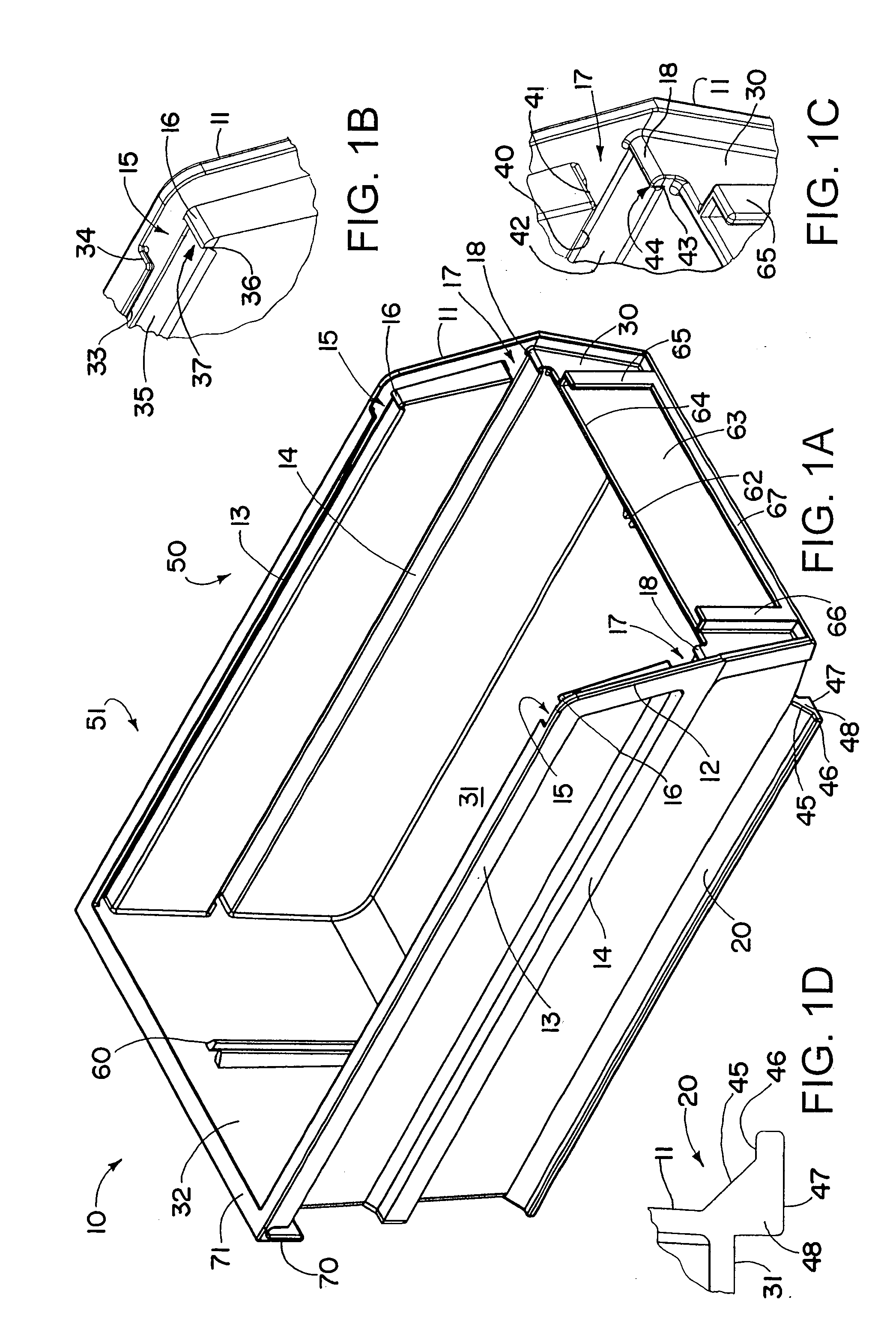

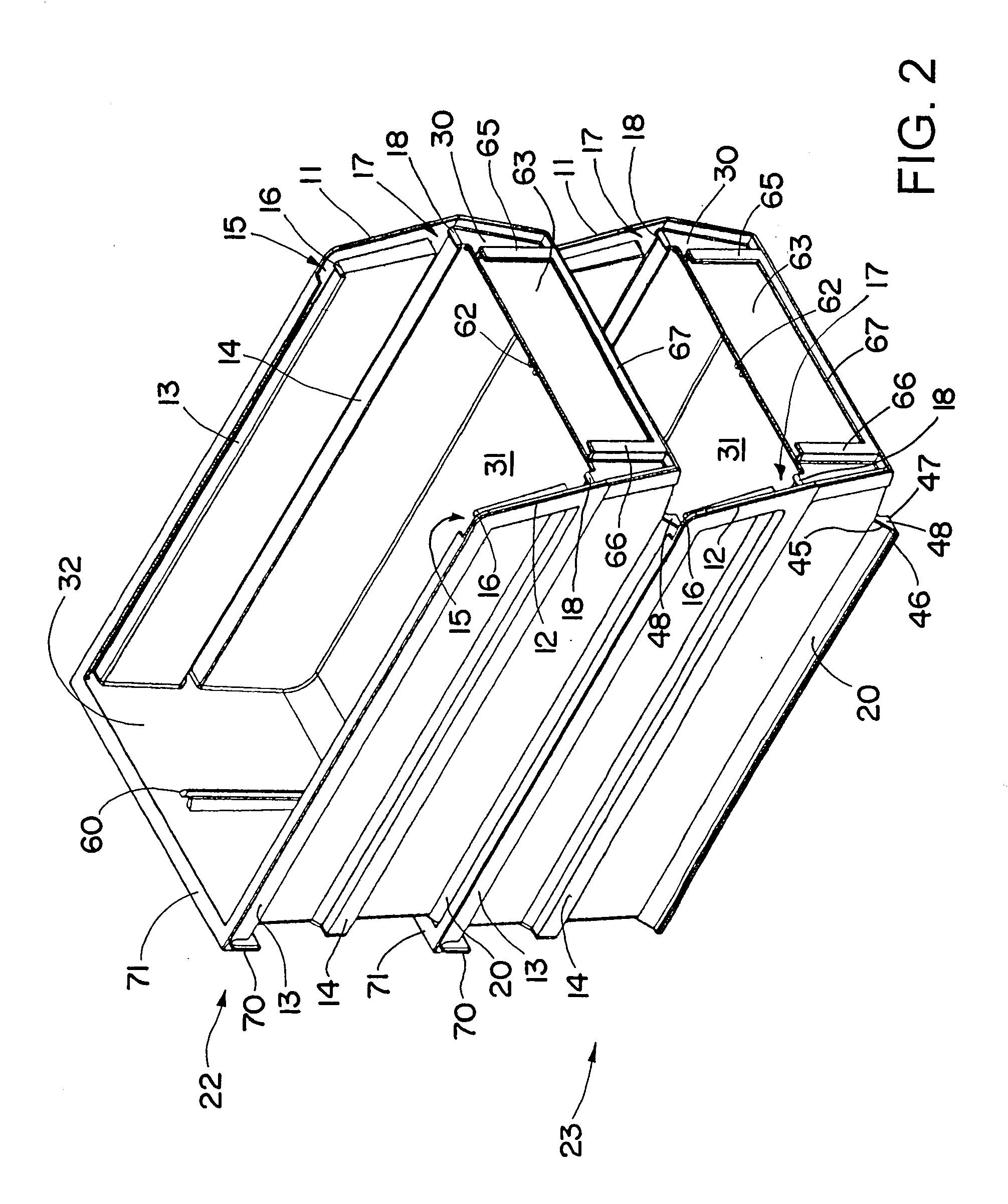

Multi-function storage bin

InactiveUS20090178989A1Limit horizontal movementShow cabinetsKitchen equipmentHorizontal forceEngineering

A storage bin having two side walls, each having an upper channel and a lower channel. The upper and lower channels have a point of entry that is partially blocked by a tab. The storage bin also has a pair of feet, which are insertable into the upper channels to stack the bins, or the lower channels to nest the bins. The tabs partially block the points of entry and act as a barrier to inhibit removal of the feet from the channels. Removal of the feet from the channels generally requires a vertical force to lift the feet over the tab and a horizontal force to slide the feet out of the channel. The channel and tab configuration therefore reduces the risk that the bins will fall into one another, tip over and separate or crack from placing unnecessary stress on the side walls of the bin when inserting and removing the feet from the channel. These as well as other features of the storage bin, are described more fully below.

Owner:TRITON PROD

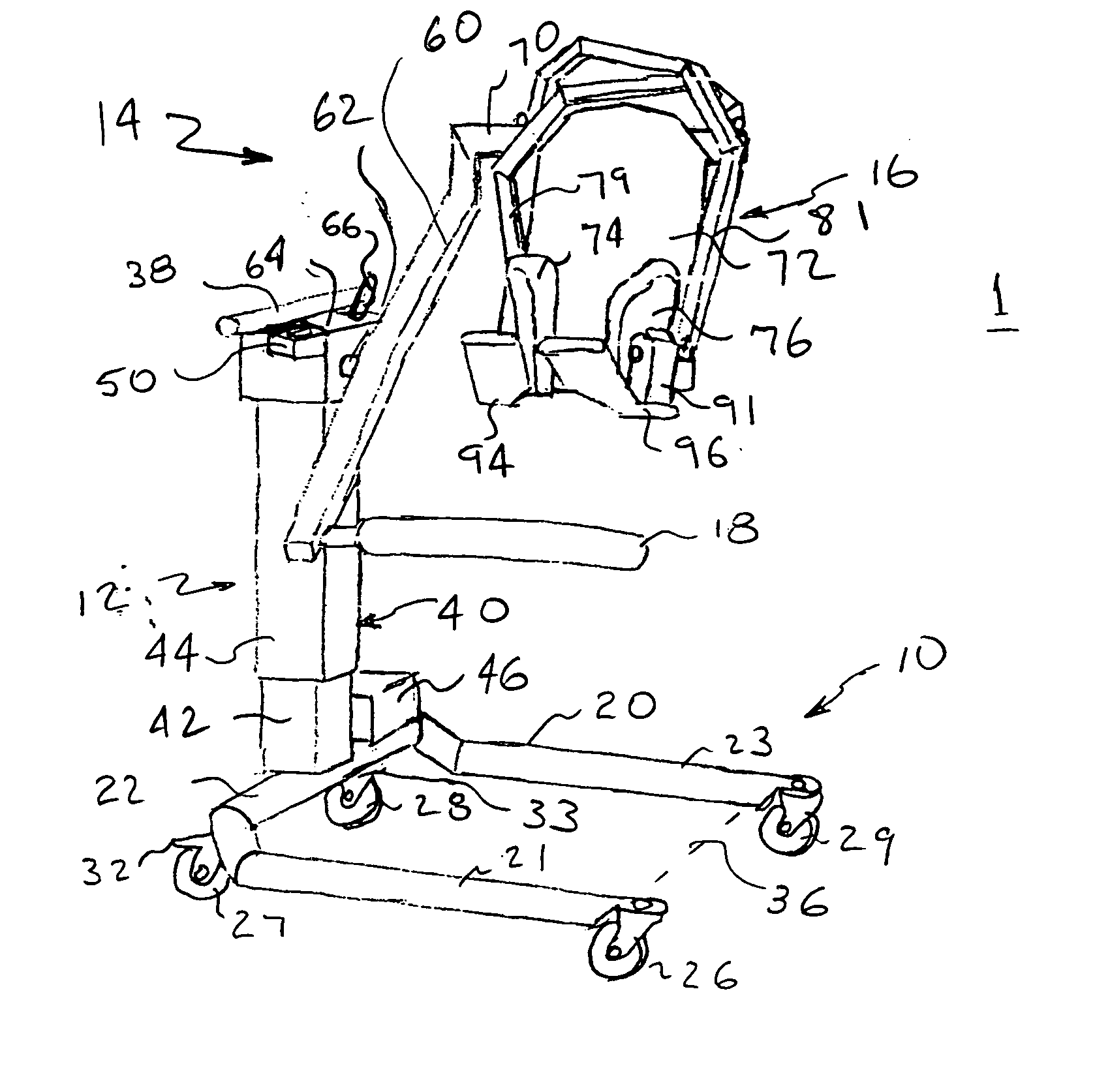

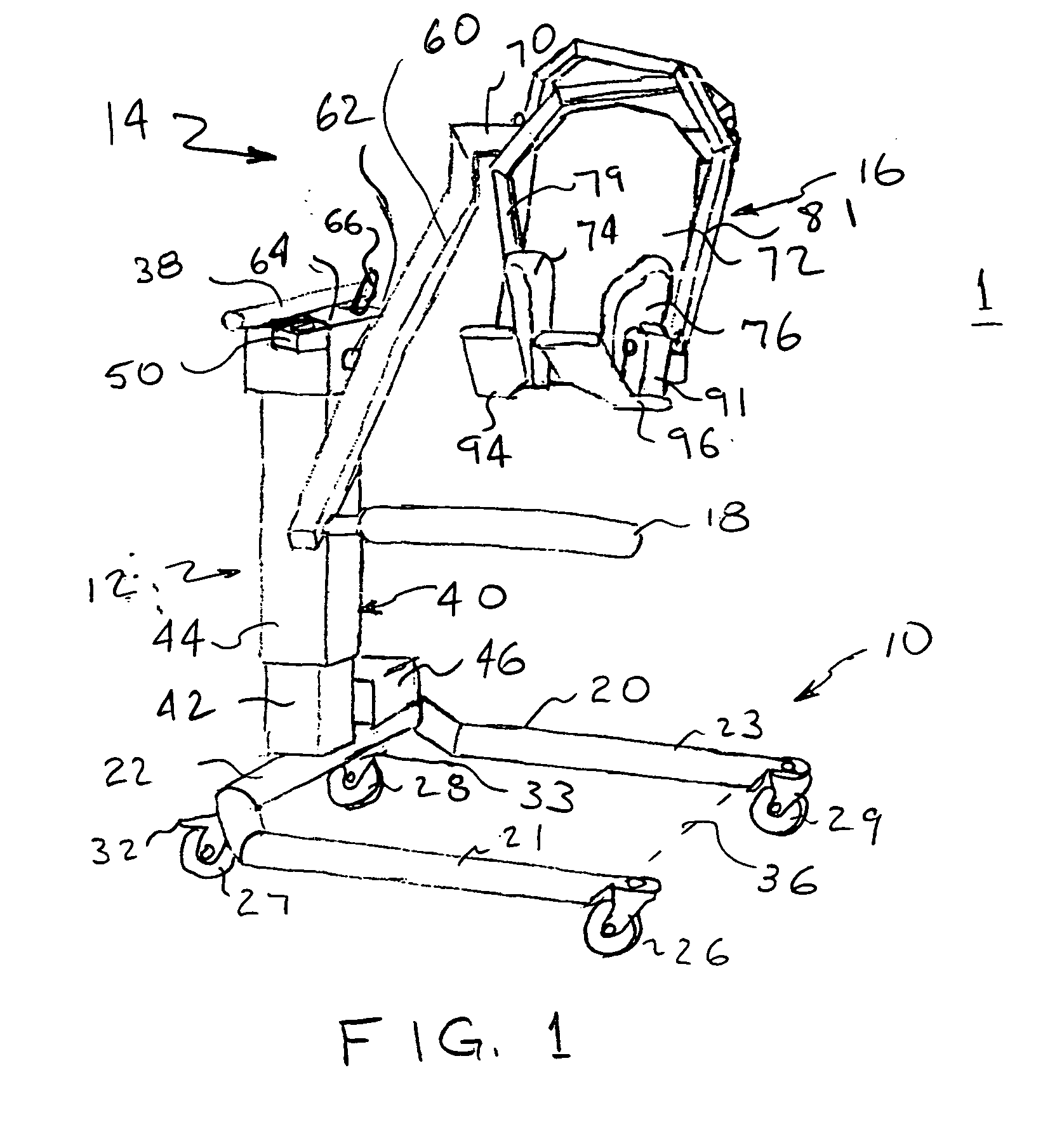

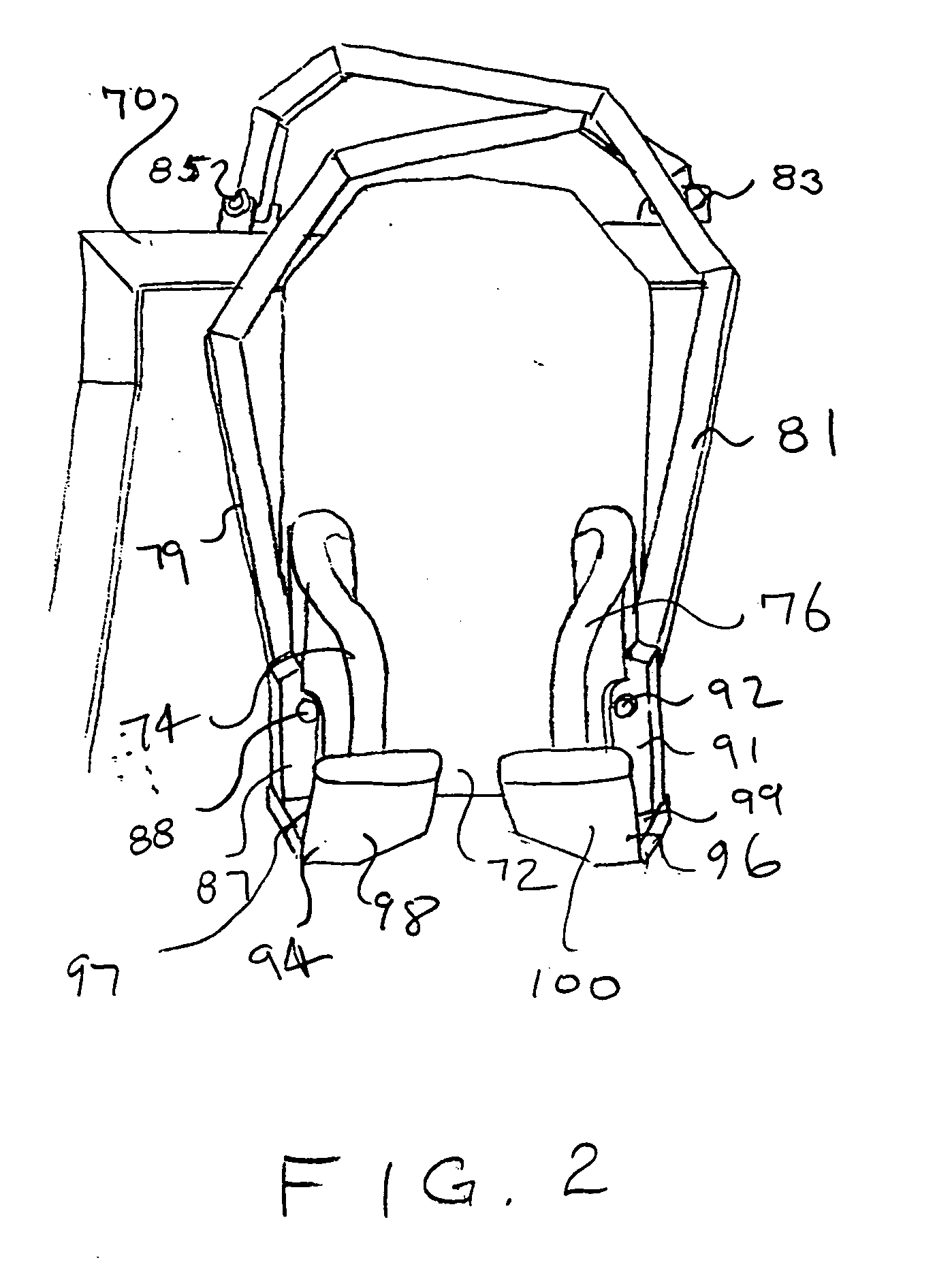

Patient lift and transfer device and method

InactiveUS20050217024A1Minimal manipulationHigh level of comfortWheelchairs/patient conveyanceNursing bedsHorizontal forceBariatric patient

In a lift and transfer device and method, a patient support assembly supported on a lift on a wheeled platform includes a main support arm pivoted to the lift. First and second transversely extending support arms respectively carrying a back support section and a leg support are cantilevered from the main support arm. The main support arm is positioned for lifting the patient from a bed. The main support arm is rotated from a first to a second angular position for lowering a patient to a wheelchair. First and second pivot arms each have an upper end pivotally supported to the back support section and a lower end having a torso grip pad positioned adjacent one side of the patient. Horizontal force applied by each torso grip pad and friction provide patient support. Further device forms are provided for bariatric patients and for use with other types of lifts.

Owner:AARESTAD JEROME K

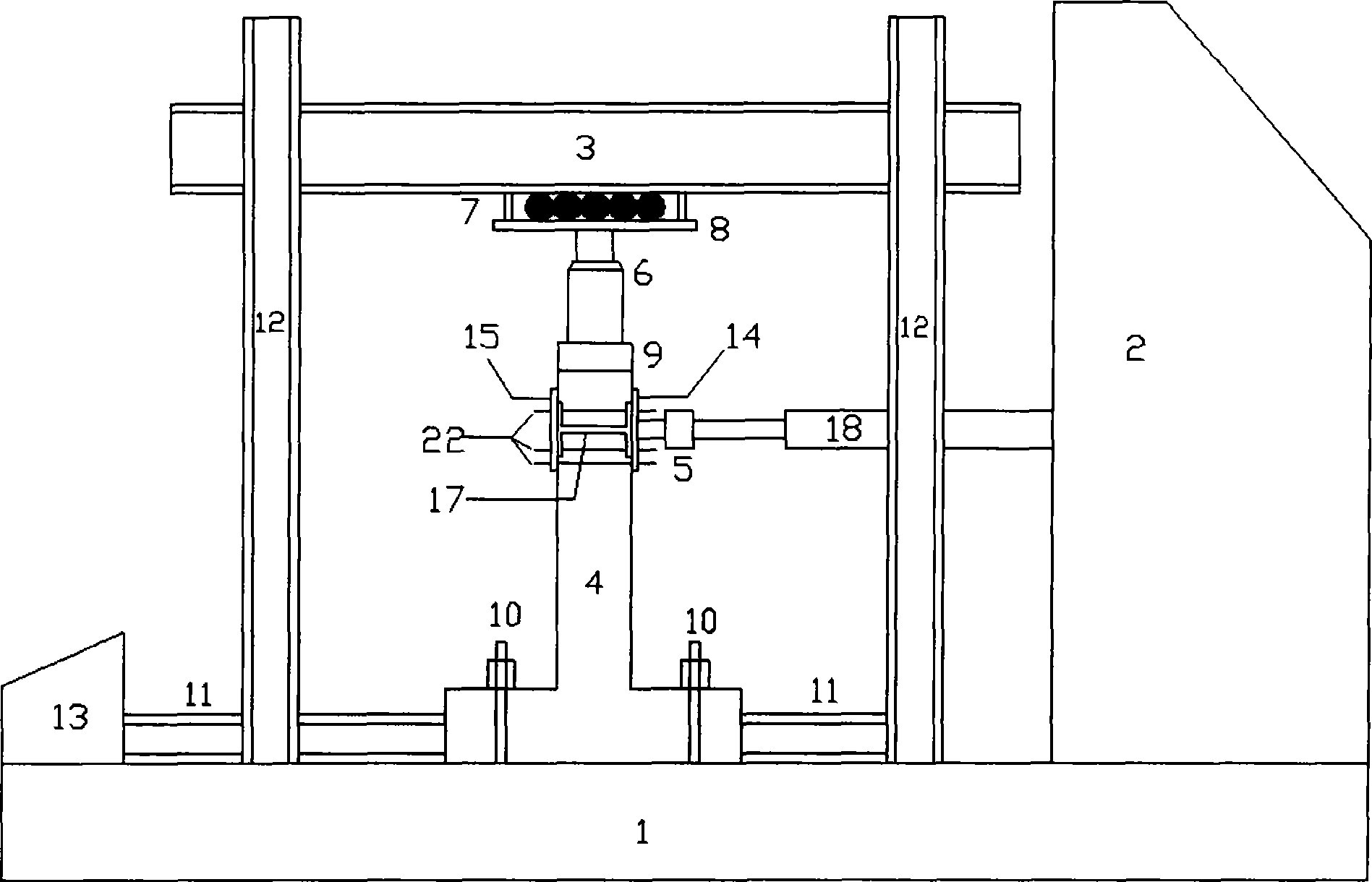

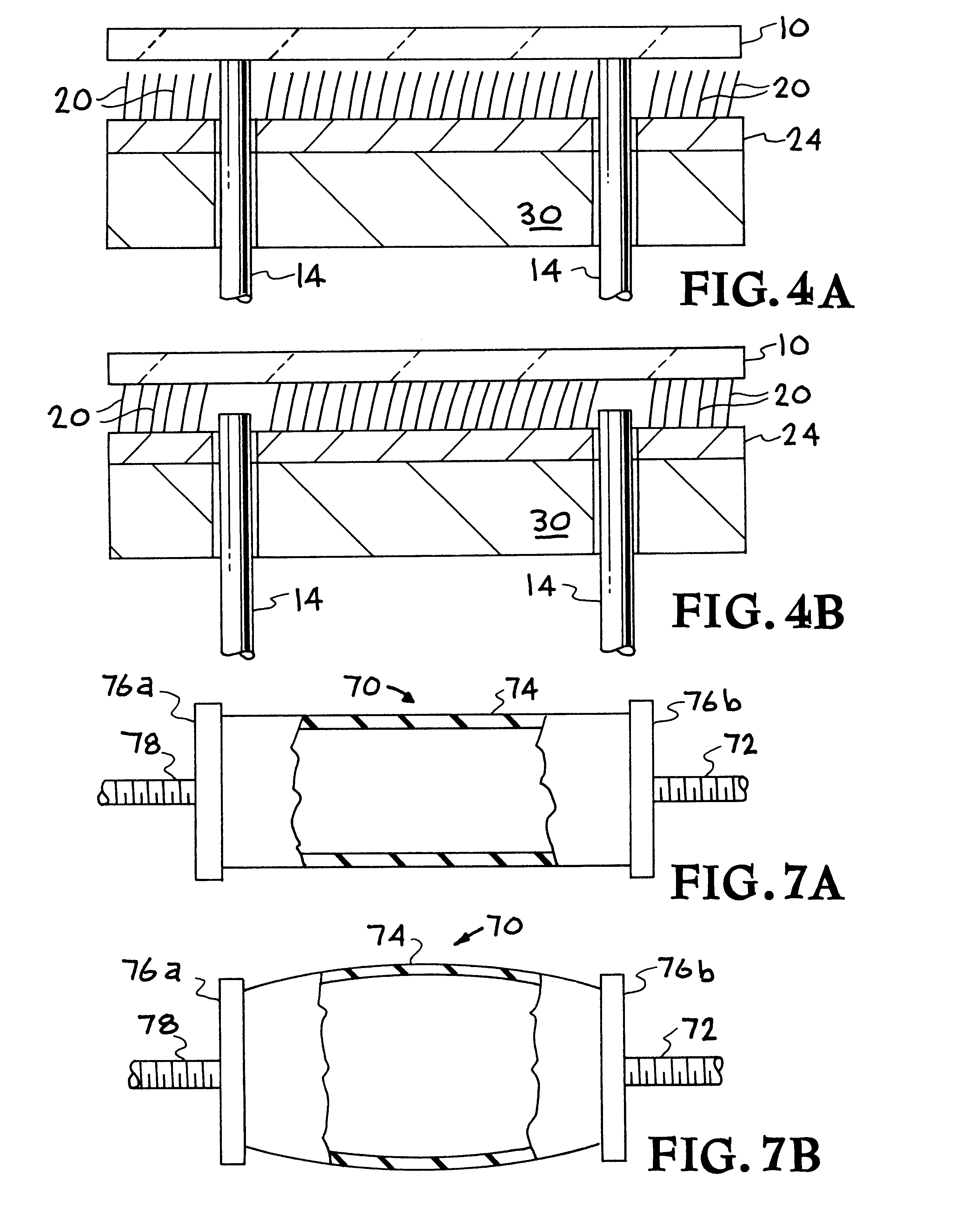

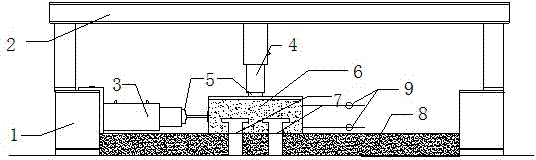

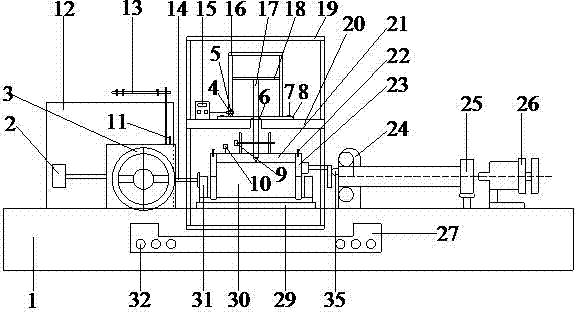

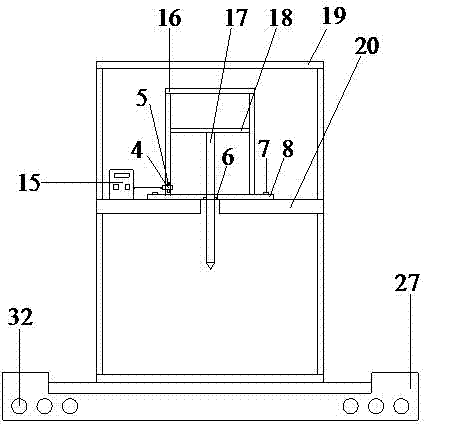

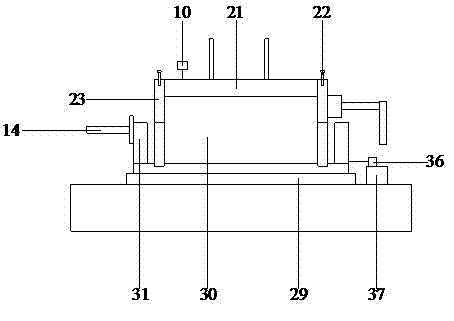

Component pressing and twisting experimental device and method thereof

InactiveCN101498625AObservation forceEasy to measureStructural/machines measurementMaterial strength using steady torsional forcesHorizontal forceAxial pressure

The invention relates to a device and a method for component compression-torsion testing, belonging to the technical field of architecture structure test. The device comprises a pedestal, a reaction beam, a reaction wall, a vertical force jack, a front clamp plate, a back clamp plate, a pure torsion loading beam, a loading beam and a horizontal force jack, wherein a component is fixed on the pedestal; the vertical force jack is connected at the lower surface of the reaction beam and corresponds to the component in position; the top of the component is tightly clamped between the front clamp plate and the back clamp plate; the loading beam is fixedly connected with the front clamp plate and the back clamp plate; one end of the pure torsion loading beam is articulated with the front clamp plate and the other end is fixedly connected with the reaction wall; one end of the horizontal force jack is articulated with the loading beam by a force sensor and the other end is fixedly connected with the reaction wall. In a test, the vertical force jack applies axial pressure to the component and the horizontal force jack applies horizontal force to the component to form the torque to the component. The device for component compression-torsion testing has simple structure and convenient assembly, can be used instantly after the assembly and can be used repeatedly.

Owner:BEIJING UNIV OF TECH

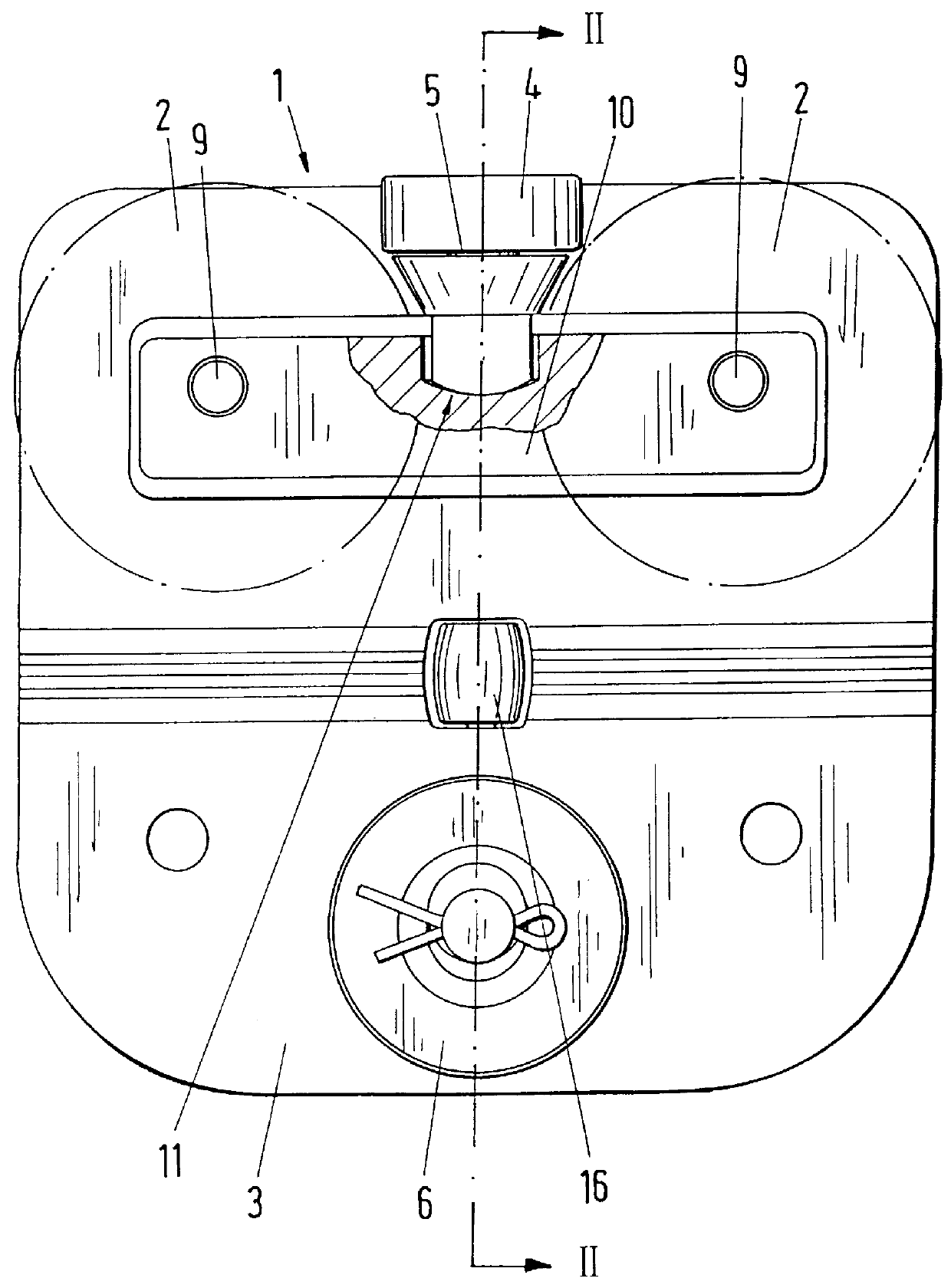

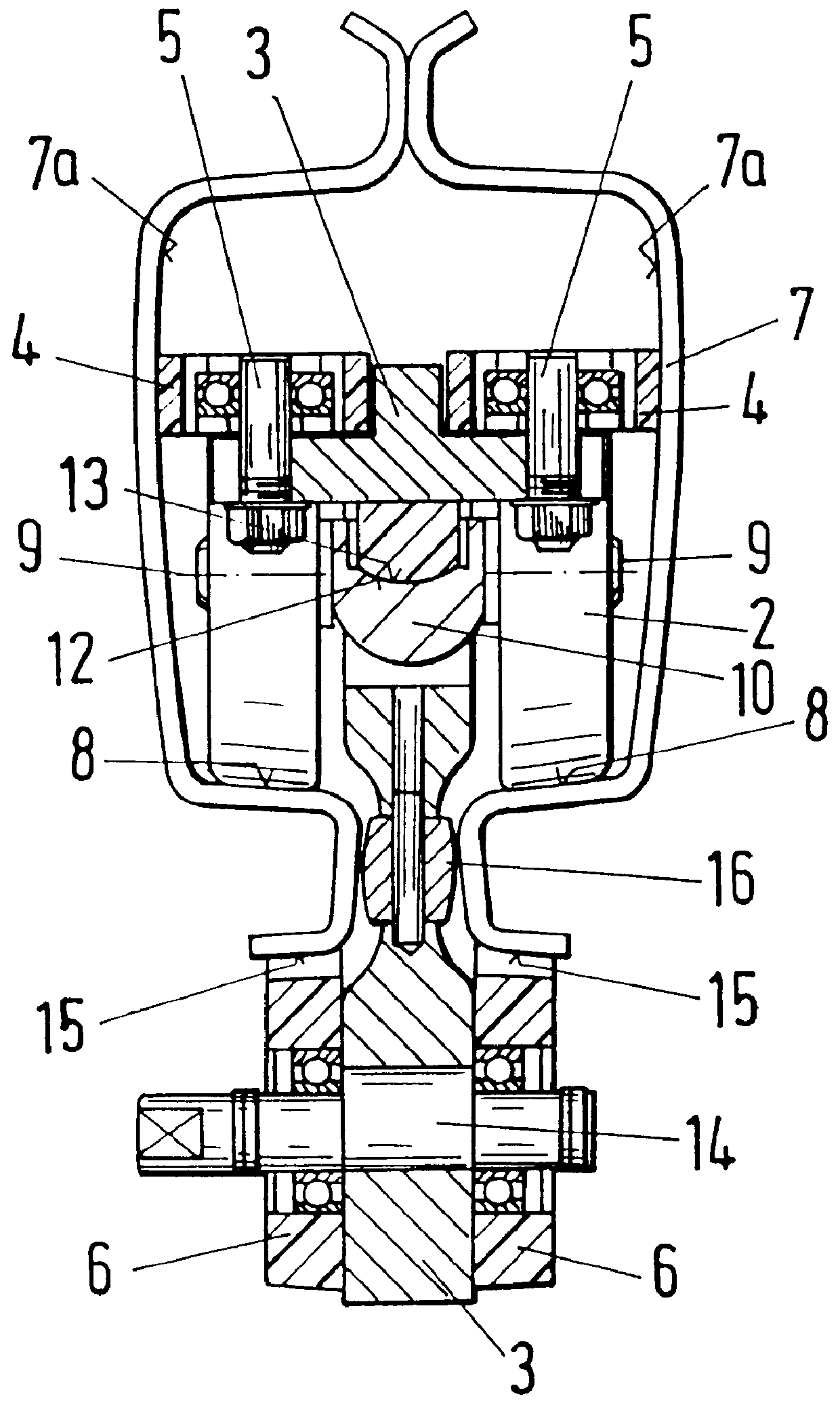

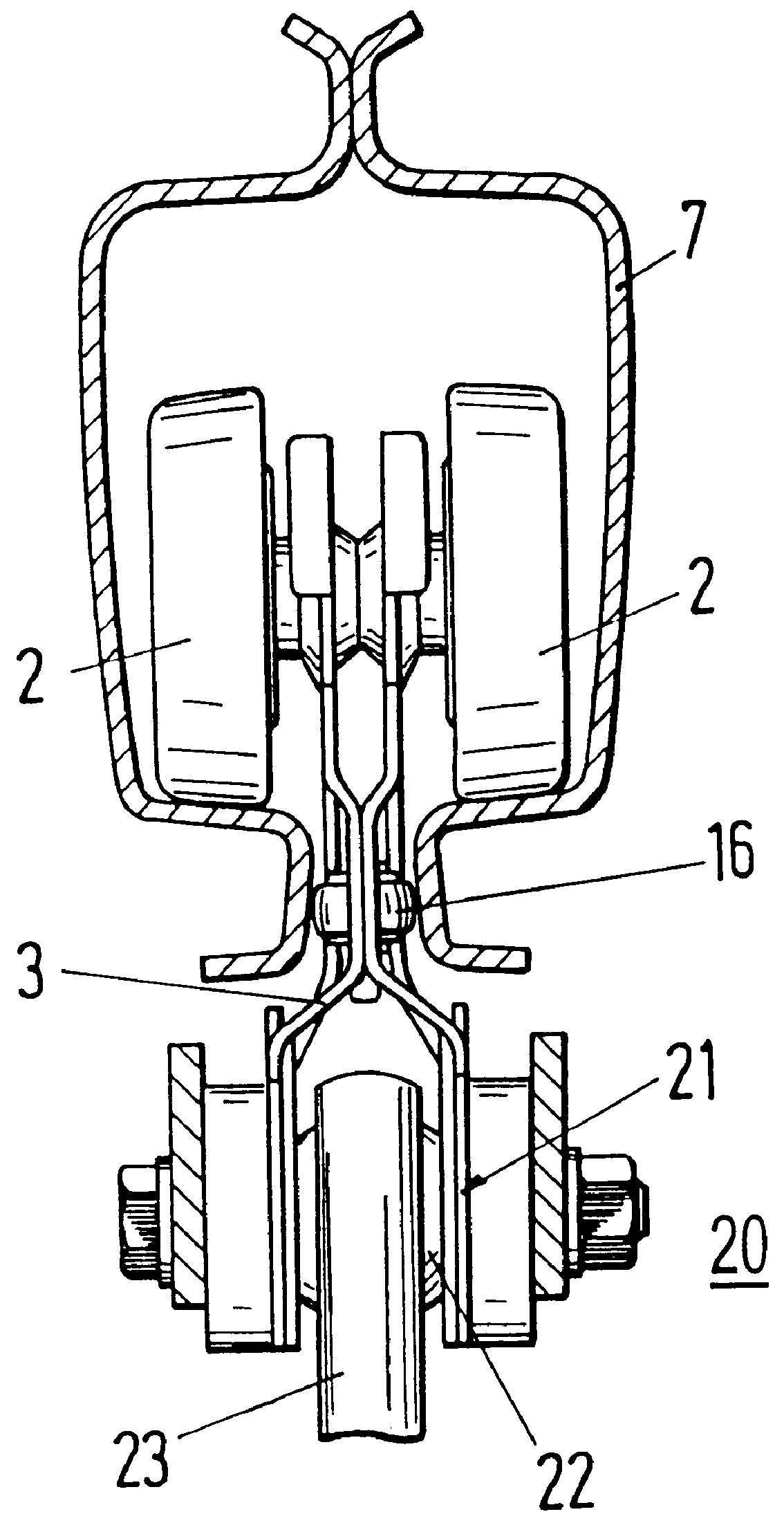

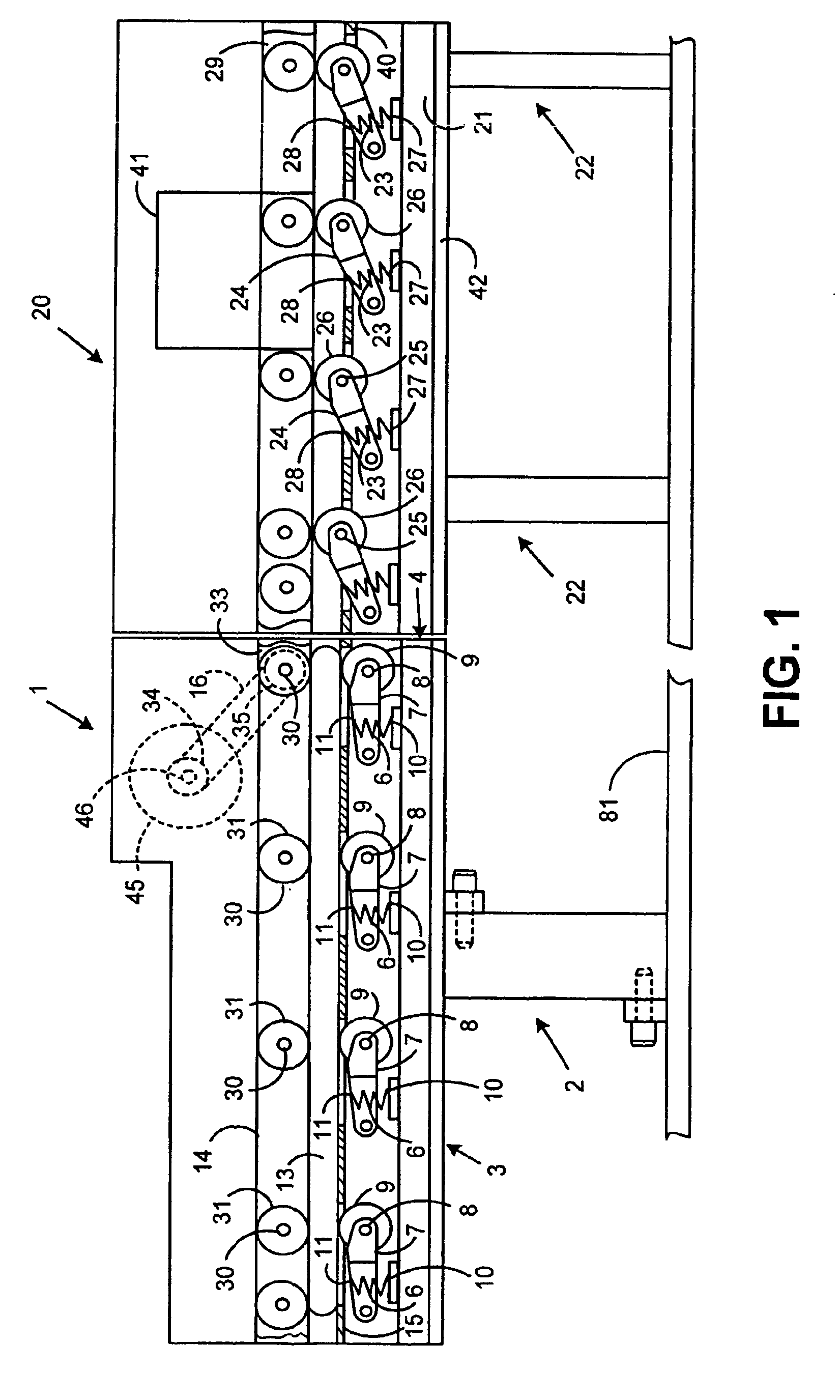

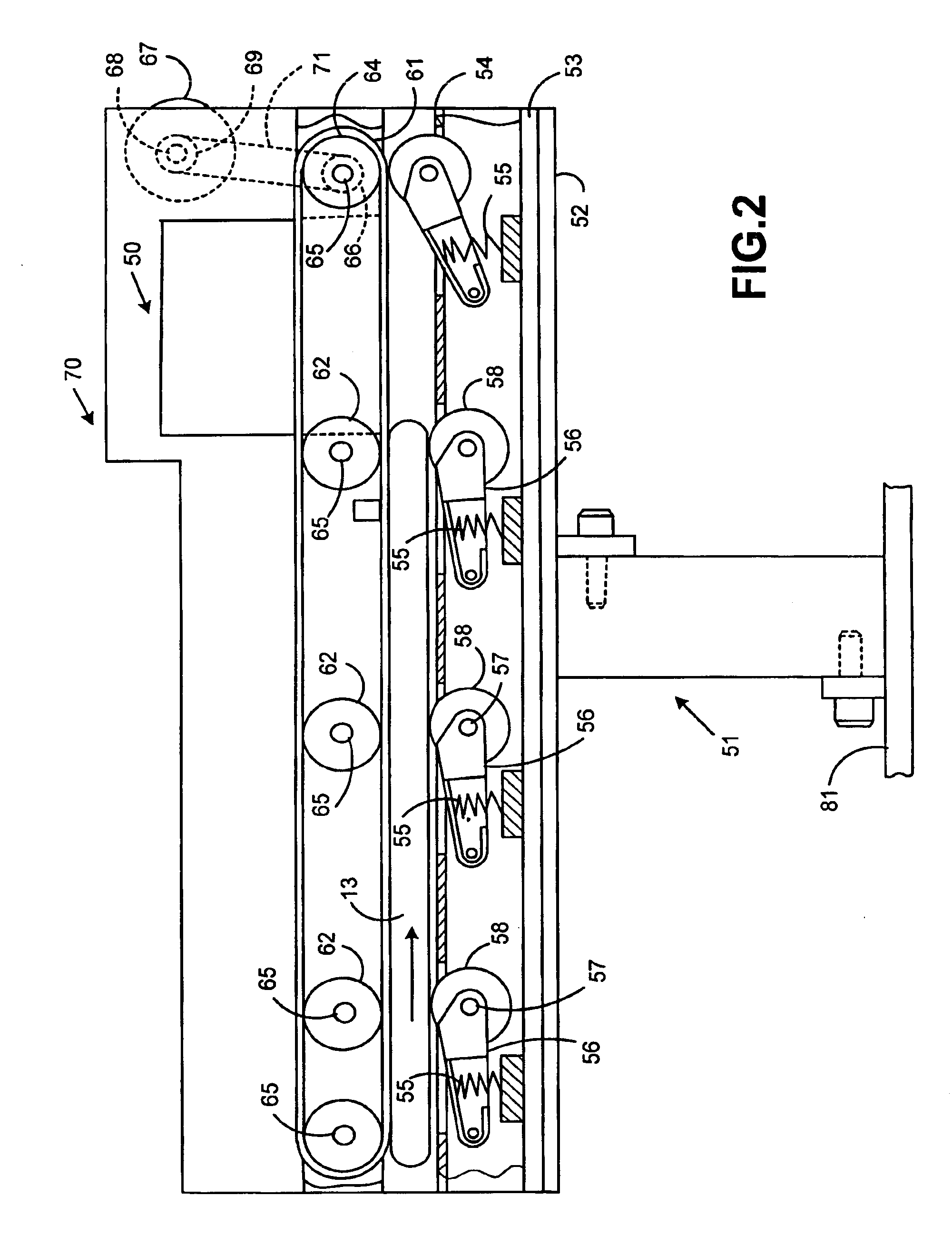

Traveling mechanism in a lifting arrangement which is moveable on rails

InactiveUS6058849AGuaranteed uptimeAvoid destructionMonorailsRailway componentsHorizontal forceFree rotation

A traveling mechanism for a lifting device, especially for a lifting device having a laterally cantilevering boom, is movable on rails with at least two running wheels. A connection element for attaching a load to said traveling mechanism is supported in the rail by the running wheels which are arranged on both sides of the connection element. The connection element has, at the region projecting down out of the rail, at least one running roller which is freely rotatable about a horizontal axis and rolls on a horizontal outer running surface of the rail. To effectively divert horizontal forces and uniformly distribute the vertical forces to the running wheels, running wheel axles are rigidly connected with a running wheel carrier, and the running wheel carrier and connection element are swivelably connected by a universal type joint. In addition, at least one support roller is rotatably mounted at the connection element in the interior of the rail. The support roller freely rotates about a vertical axis and rolls along at least one of the side surfaces to transmit horizontal forces to the rail.

Owner:TEREX MHPS

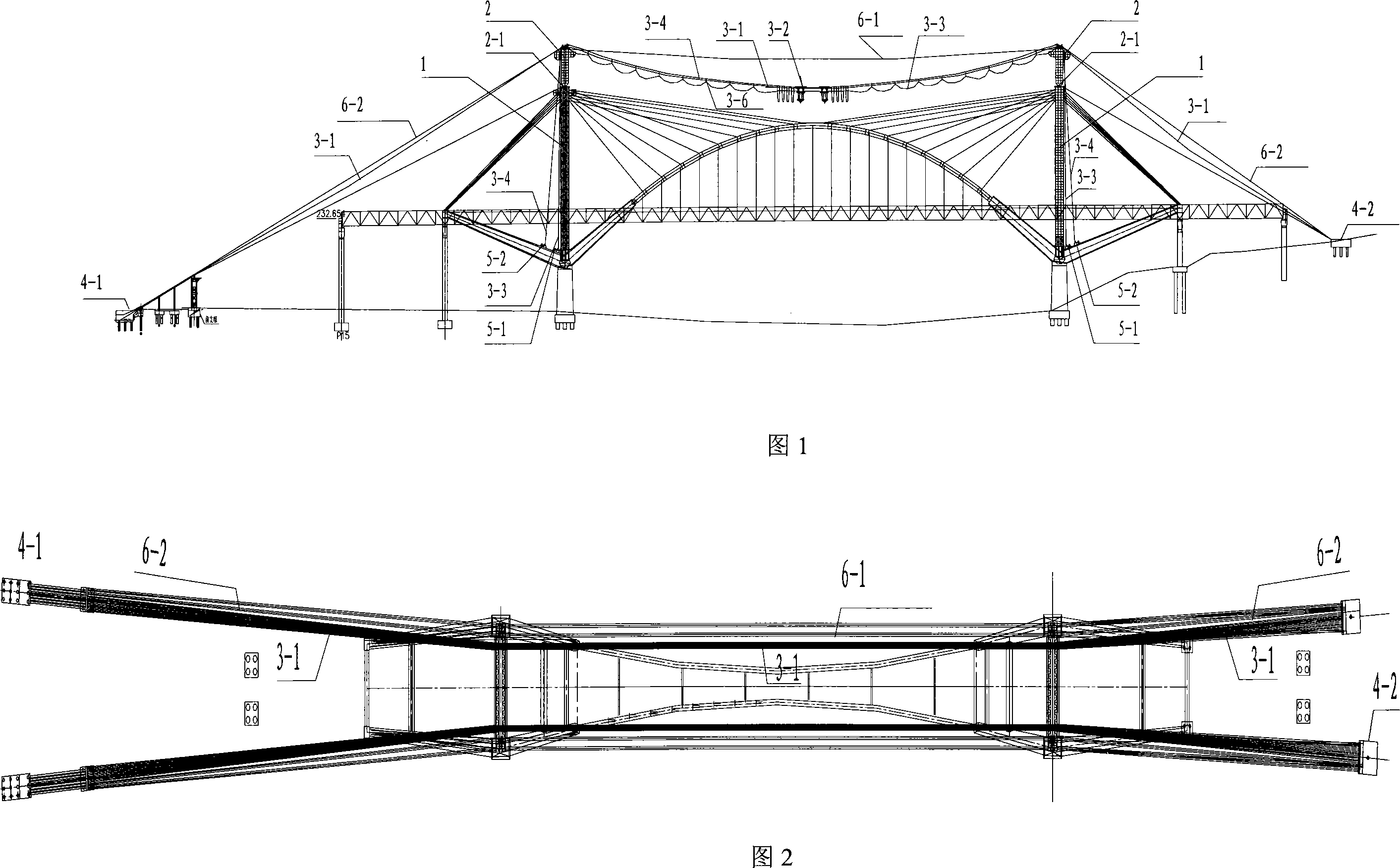

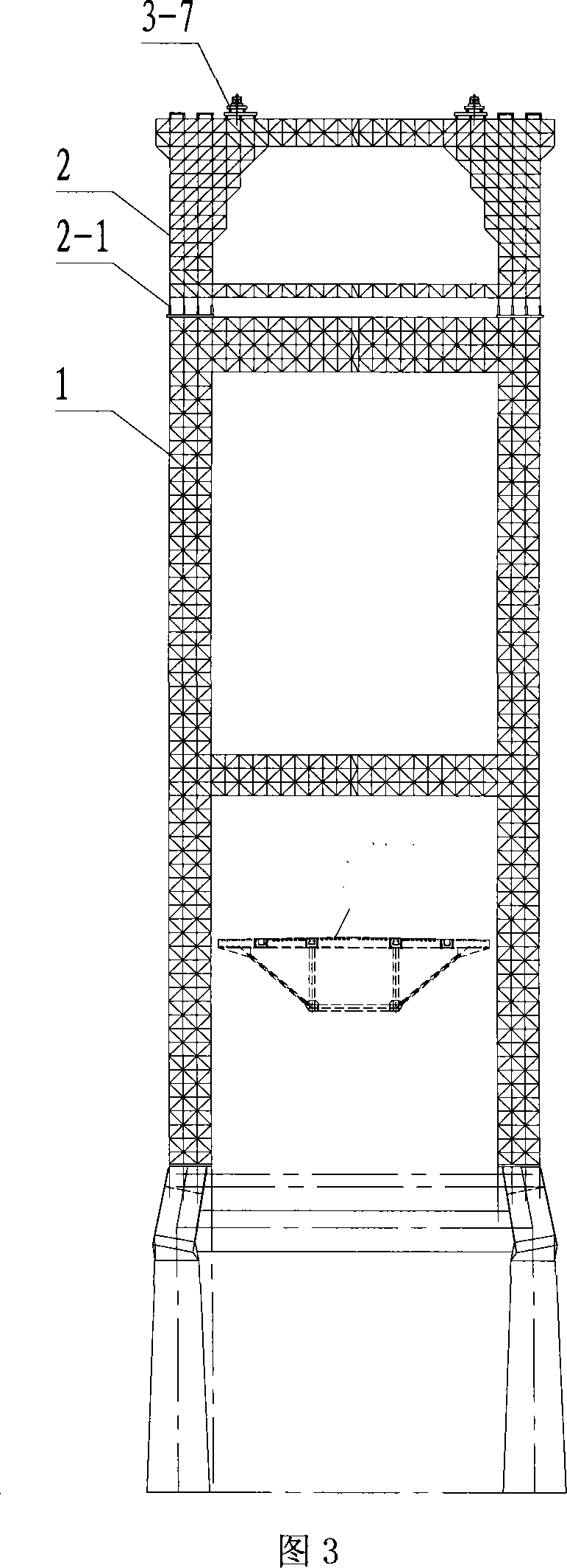

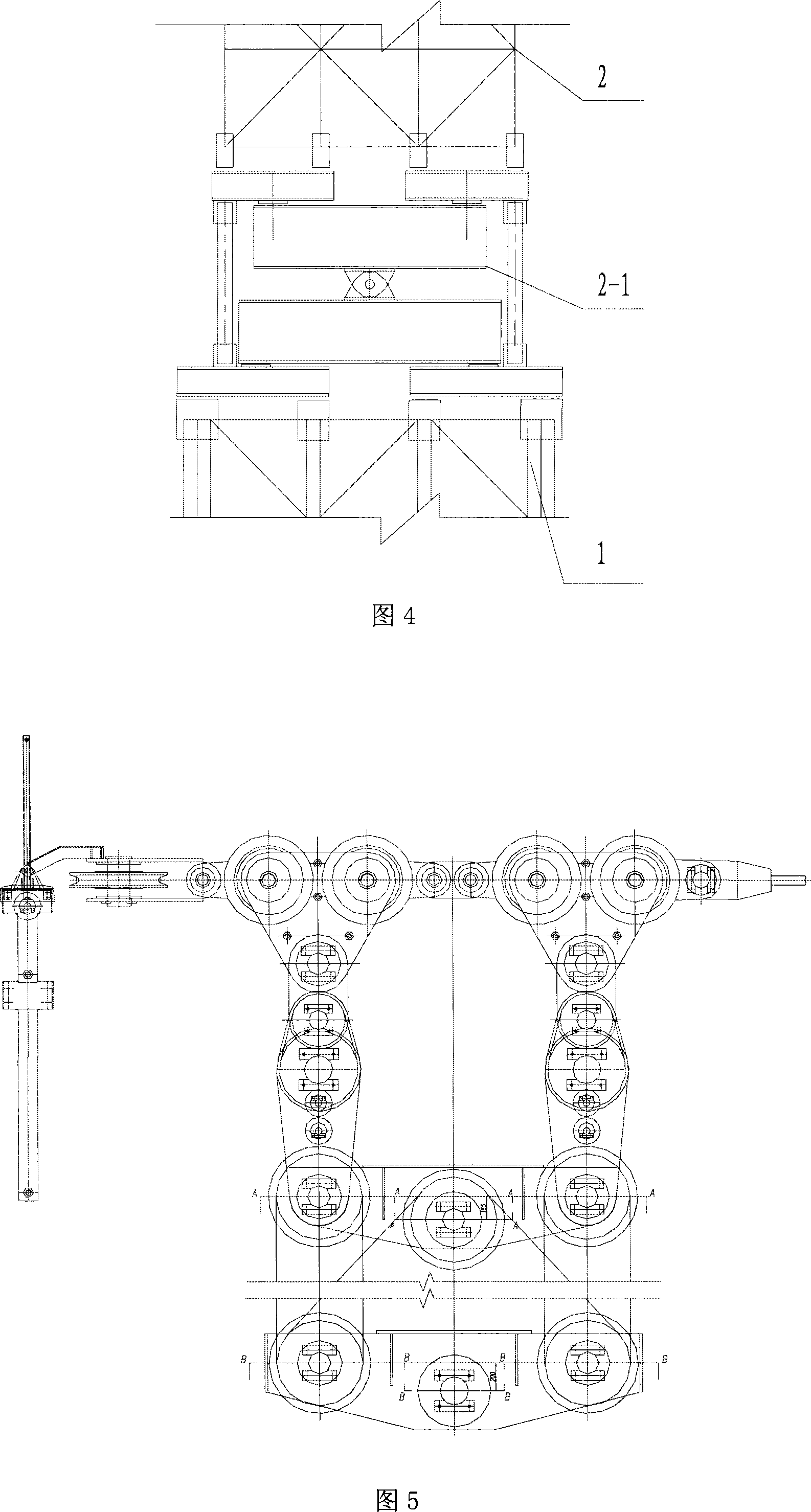

Long-span load-carrying cable lifting machine and mounting method therefor

InactiveCN101224856AReduce the impactReduce misalignmentBridge erection/assemblyCable carsHorizontal forceTraction system

The invention provides a long-span over loading cable crane and an installation method thereof which relates to a cable crane used in bridge construction and consists of a guy rope tower 1, a cable tower 2, a main cable and a hoisting traction system 3, an anchoring system 4, an electromechanical system 5 and a wind cable system 6. The tower of the cable crane consists of the guy rope tower 1 and the cable tower 2 which is hinged on the top of the guy rope tower 1 and fixedly connected with the bottom of the guy rope tower 1. The invention adopts the techniques of the parallel bearing of a plurality of main cables, the wind cables connected in series, the joint construction of the cable towel and the guy rope tower, etc., thereby greatly improving the loading capability of the long-span cable crane and lowering the manufacturing cost as much as possible. The invention can reduce the influence of the unbalanced horizontal force on the top of the cable tower 2 on the guy rope tower 1 and greatly save the construction cost of the guy rope tower 1. The loading cable crane has strong load-carrying capability, wide loading range and high economic performance.

Owner:CHINA MAJOR BRIDGE ENG

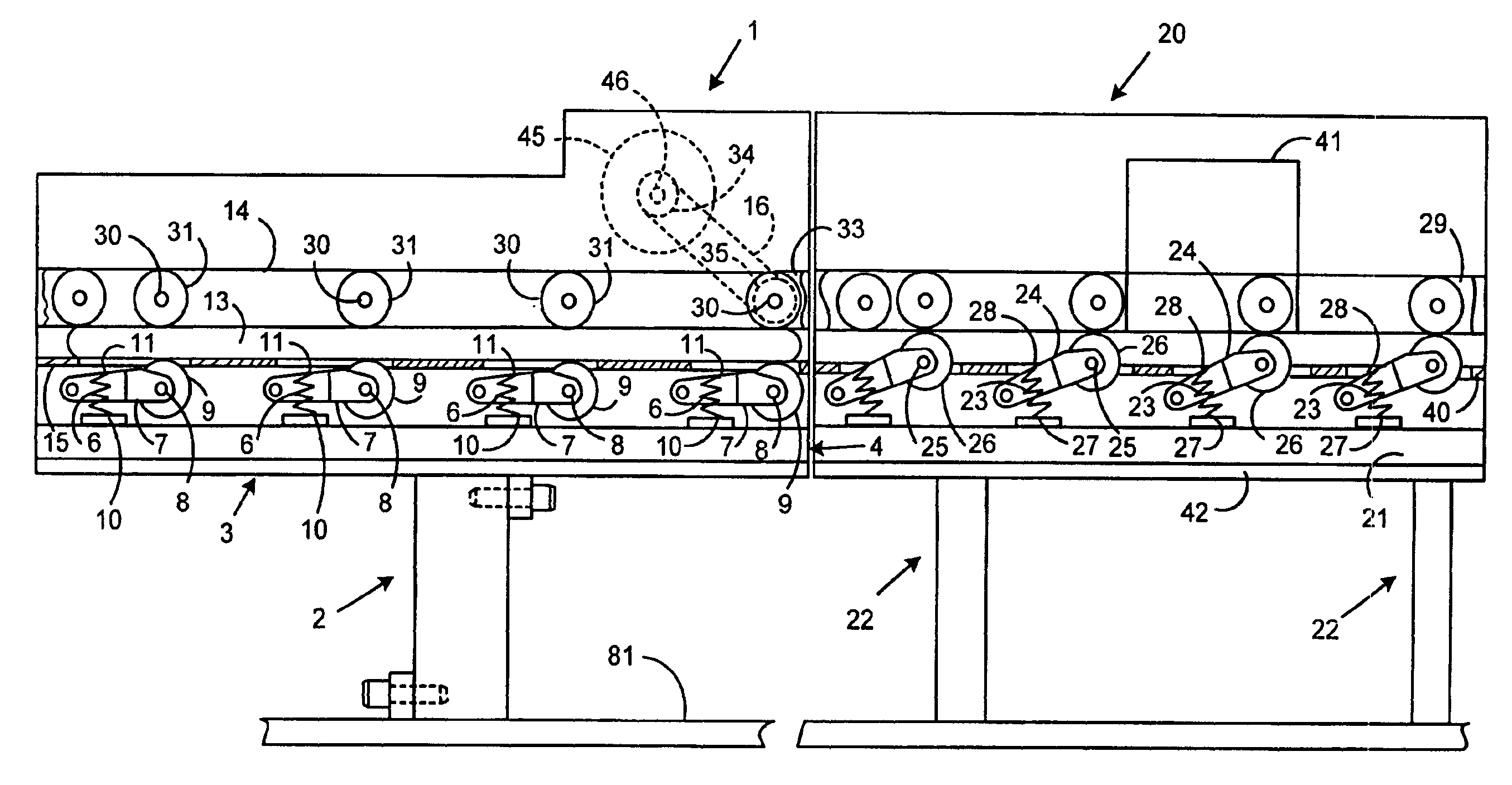

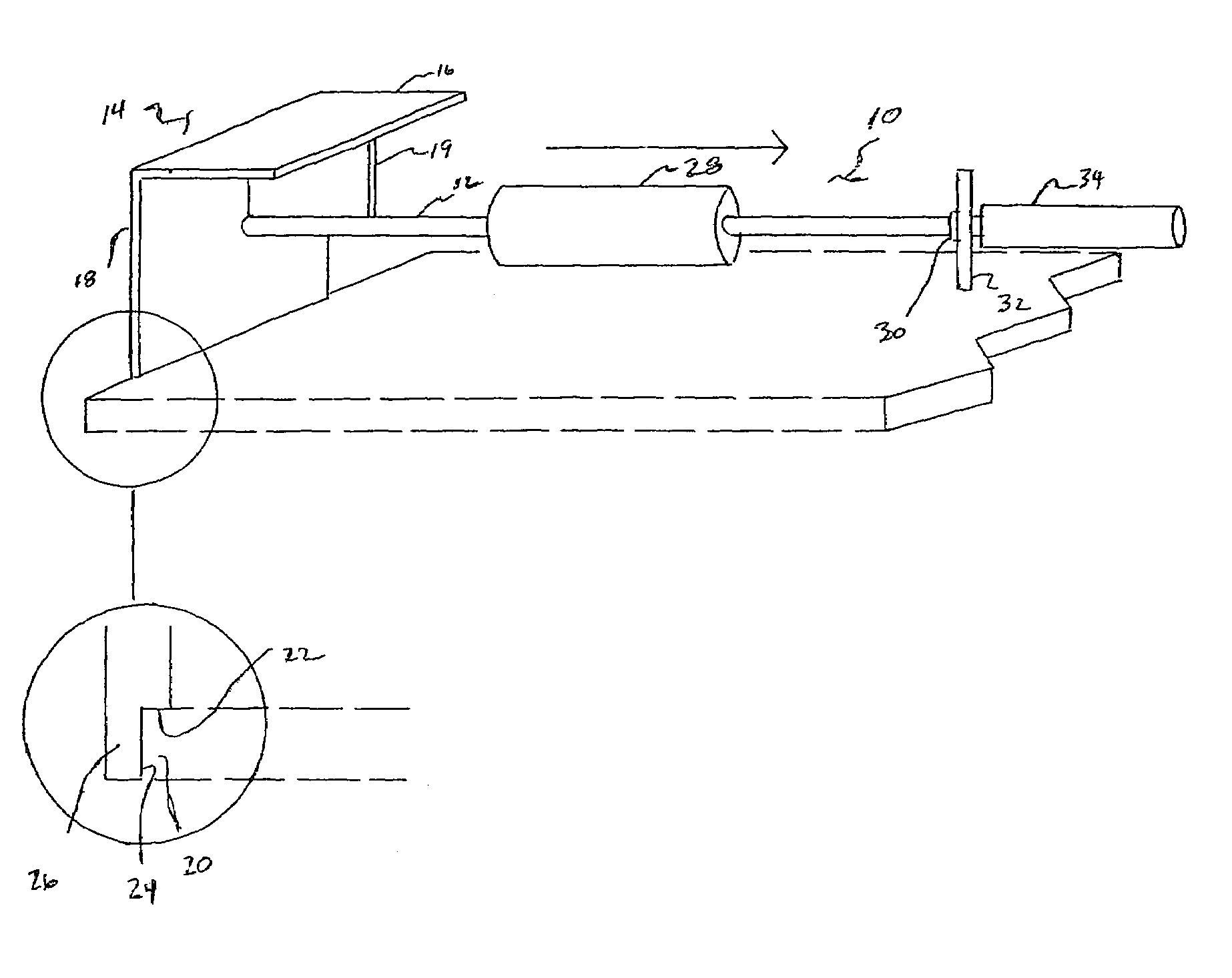

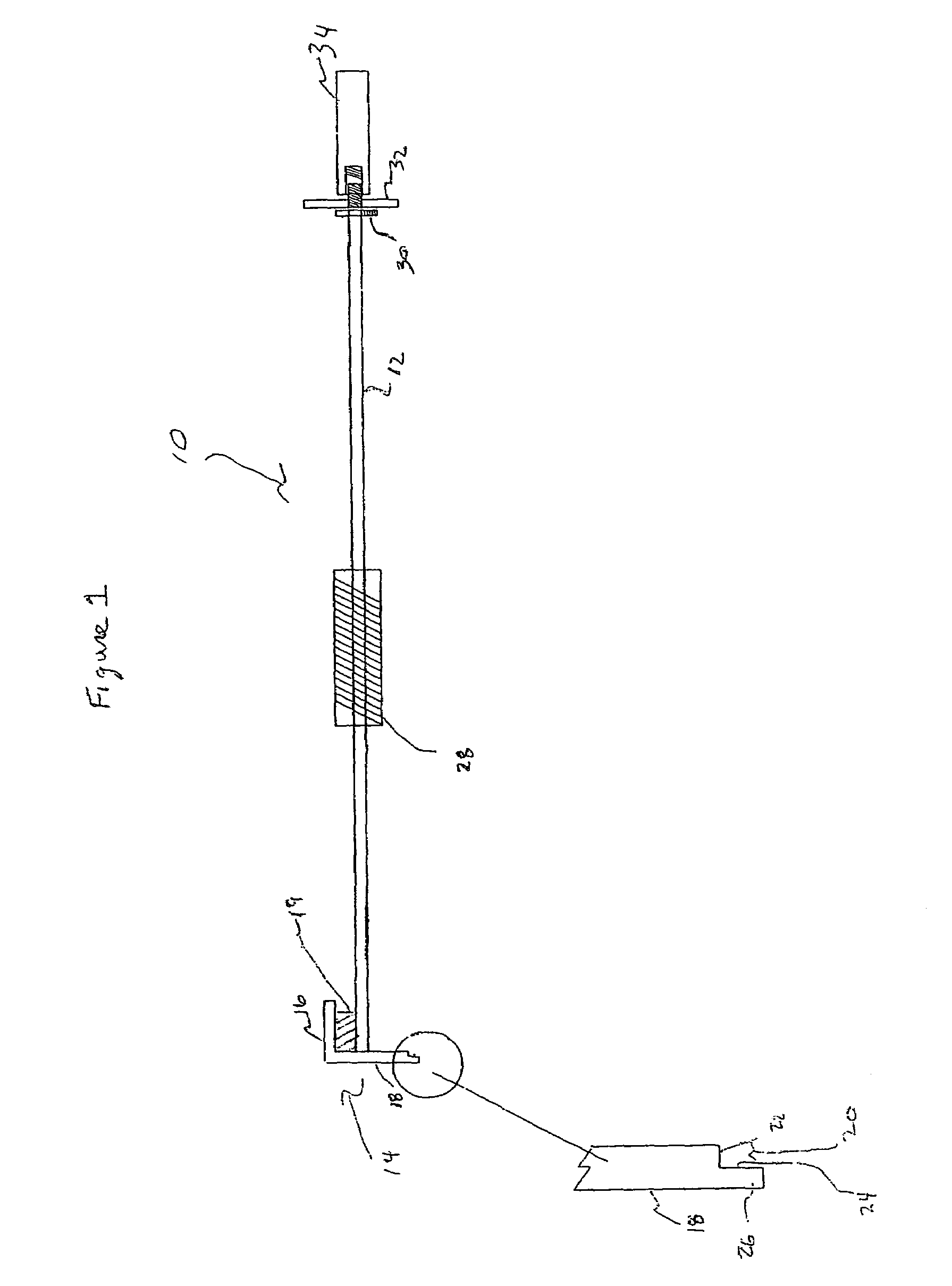

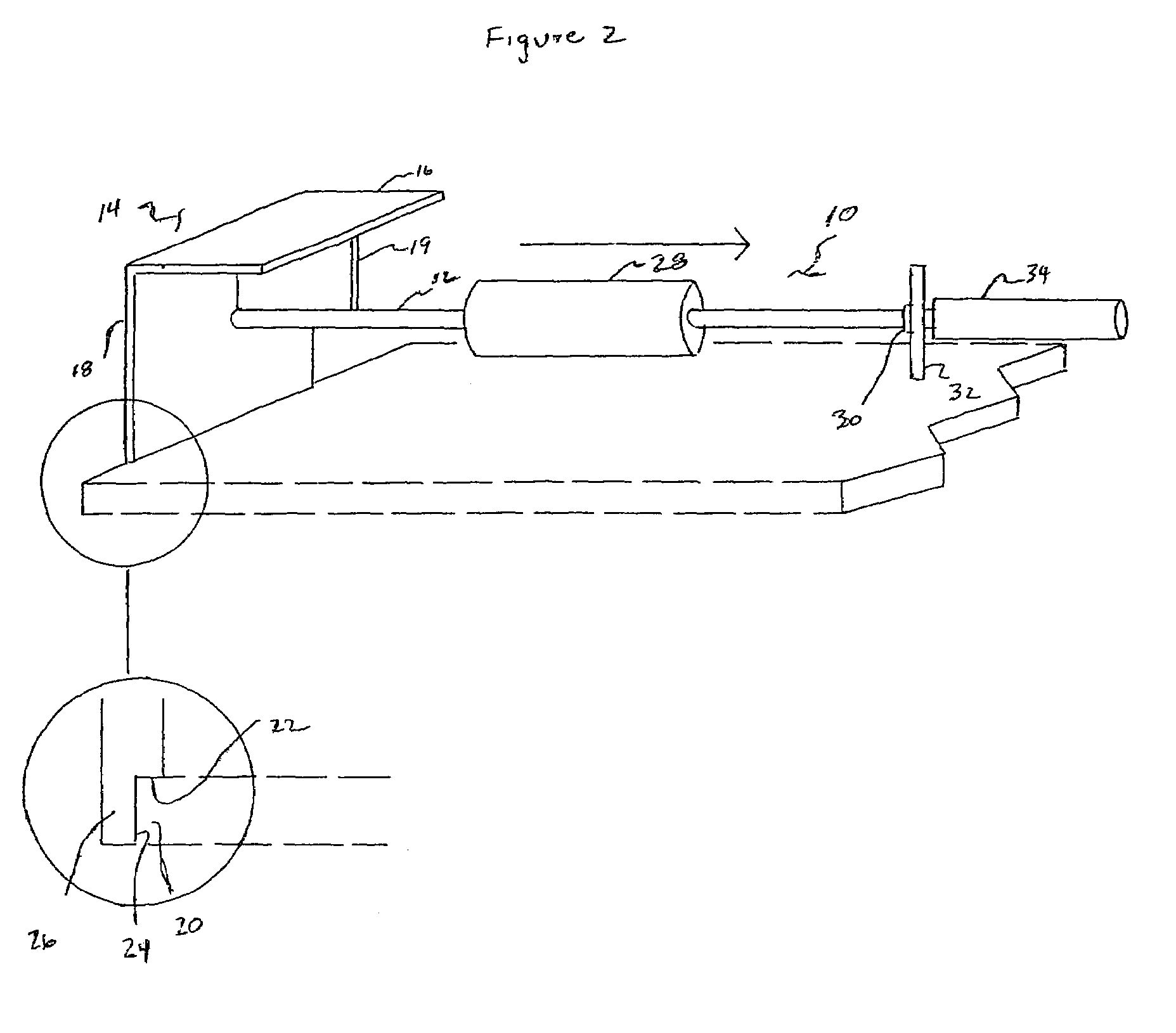

Method and apparatus for determining the mass of an article using a load cell

A method of determining the mass of an article using a load cell. An article whose mass is to be determined is transported across a platform without stopping or slowing the article. A load cell measures the horizontal force applied to the load cell by the transported article. This horizontal force, along with the acceleration of the article, allows a determination of the mass of the article.

Owner:PITNEY BOWES INC

Ducted fan vehicles particularly useful as VTOL aircraft

InactiveUS7275712B2Easy to controlAircraft navigation controlVertical landing/take-off aircraftsHorizontal forceVehicle frame

A vehicle, including a vehicle frame, a duct carried by the vehicle frame with the longitudinal axis of the duct perpendicular to the longitudinal axis of the vehicle frame, a propeller rotatably mounted within the duct about the longitudinal axis of the duct to force an ambient fluid therethrough from its inlet at the upper end of the duct through its exit at the lower end of the duct, and thereby to produce an upward lift force applied to the vehicle, and a plurality of parallel, spaced vanes pivotally mounted to and across the inlet end of the duct about pivotal axes perpendicular to the longitudinal axis of the duct and substantially parallel to the longitudinal axis of the vehicle frame, the vanes being selectively pivotal about their axes to produce a desired horizontal force component to the lift force applied to the vehicle.

Owner:URBAN AERONAUTICS

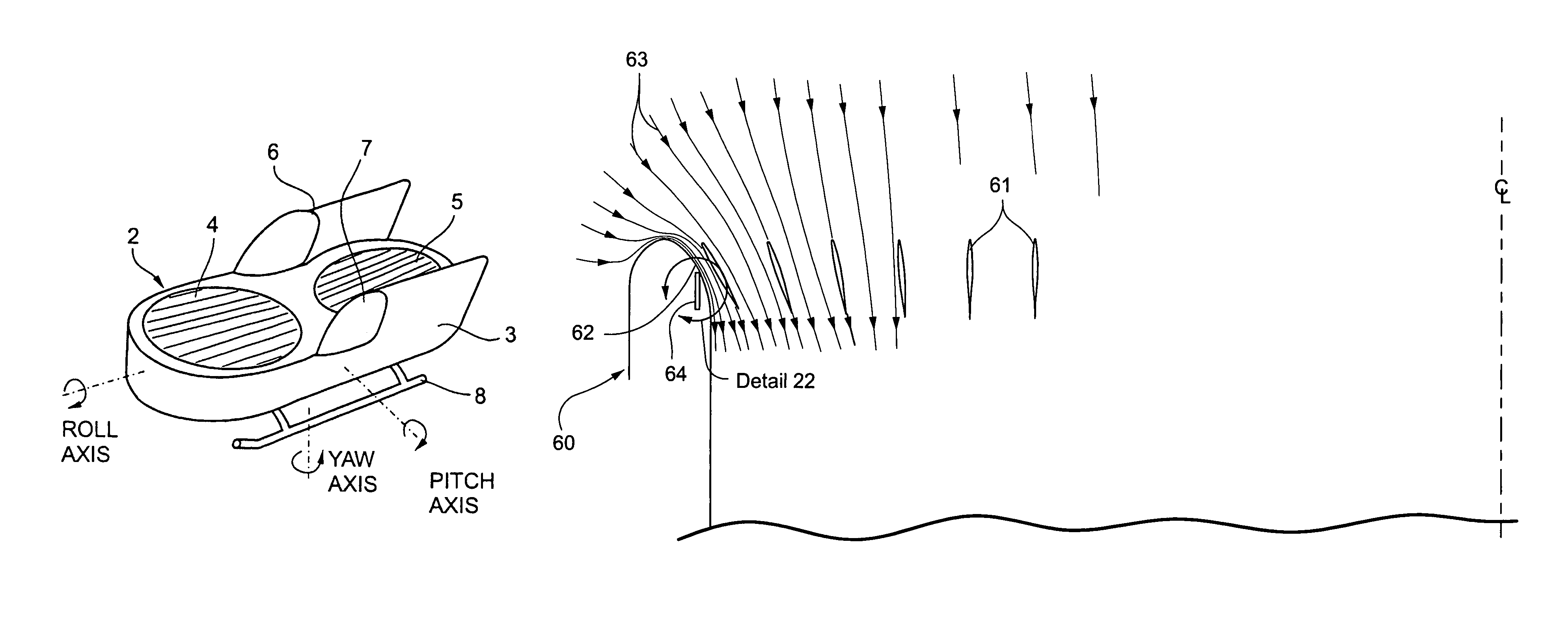

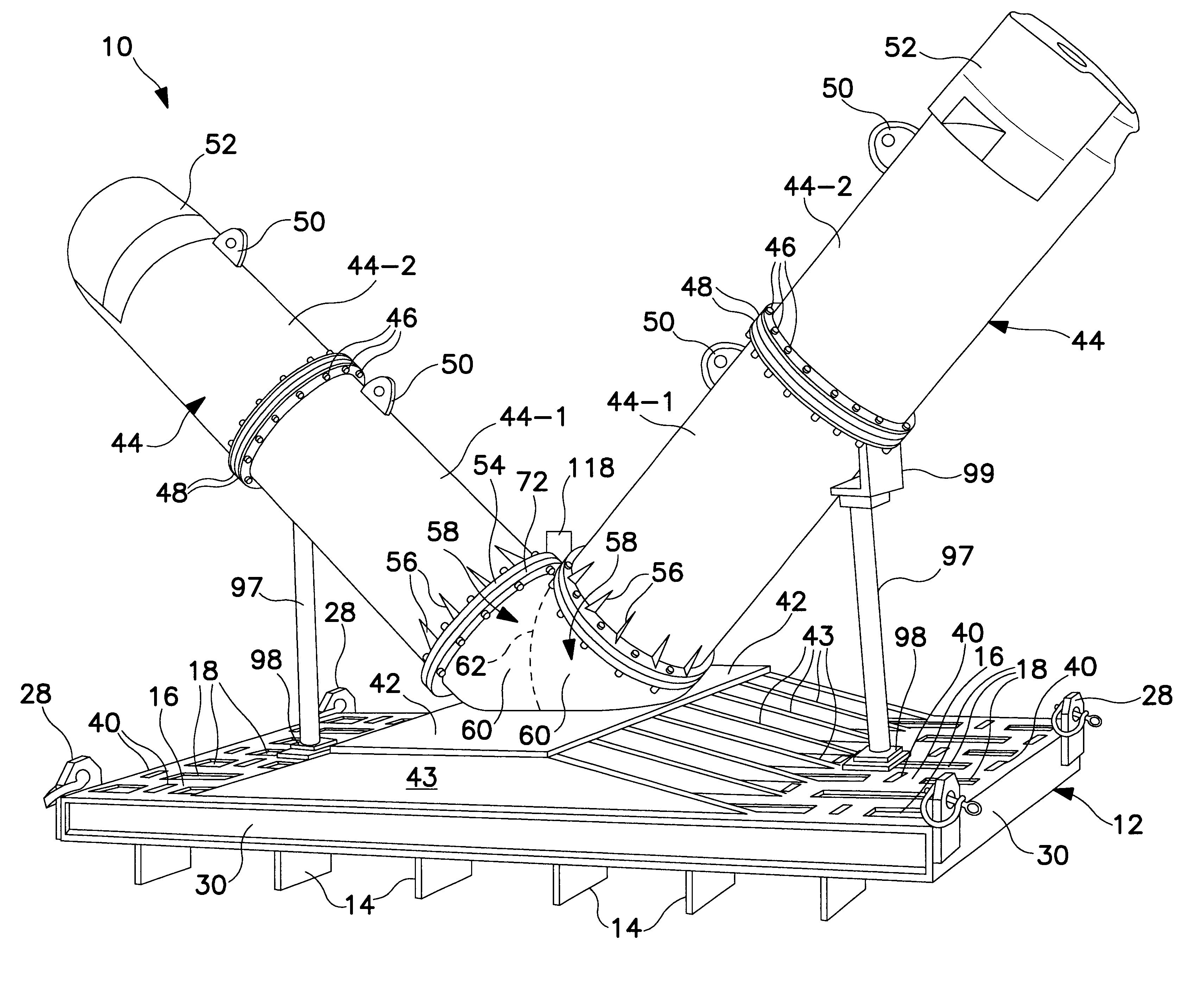

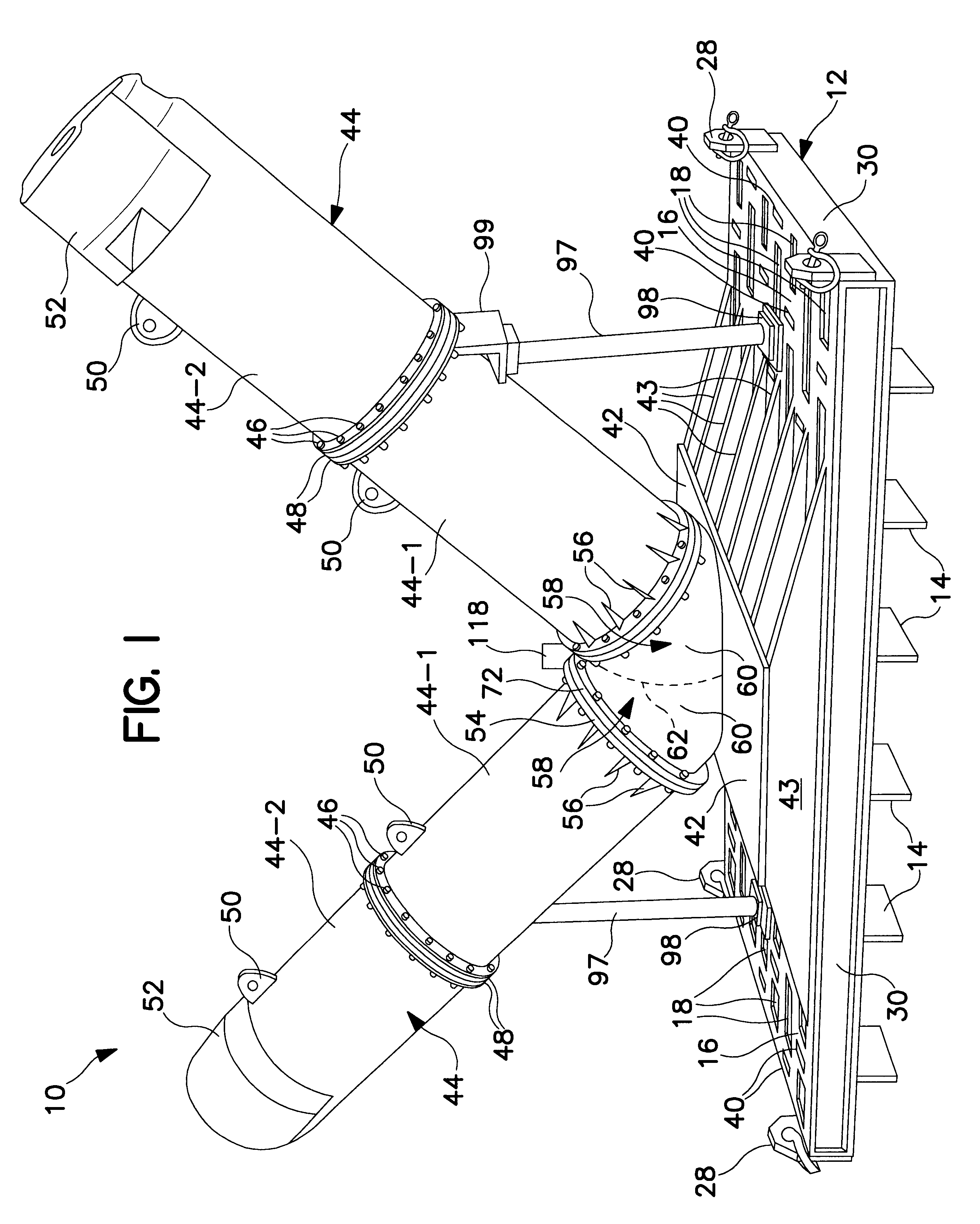

Apparatus for generating horizontal forces in aerial vehicles and related method

ActiveUS7717368B2Easy to controlAvoid separationVertical landing/take-off aircraftsRotocraftHorizontal forceVehicle frame

A vehicle, comprising: a vehicle frame; a duct carried by the vehicle frame with the longitudinal axis of the duct perpendicular to the longitudinal axis of the vehicle frame; a propeller rotatably mounted within the duct about the longitudinal axis of the duct to force an ambient fluid through from an inlet at the upper end of the duct through an exit at the lower end of the duct, and thereby produce an upward lift force applied to the vehicle; a first plurality of substantially parallel, spaced vanes non-pivotally mounted across at least the inlet end of the duct; and fluidic means for affecting the ambient fluid flow around the vanes to generate horizontal force components to the lift force applied to the vehicle.

Owner:URBAN AERONAUTICS

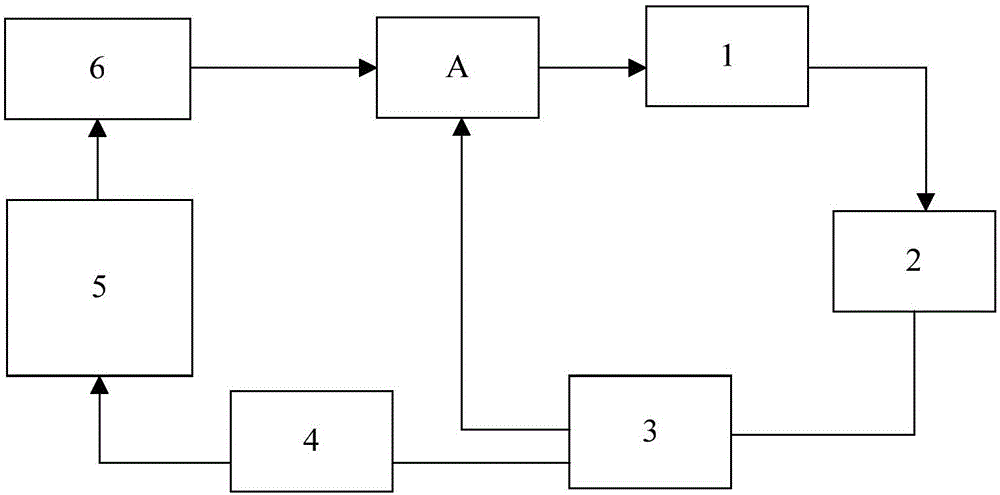

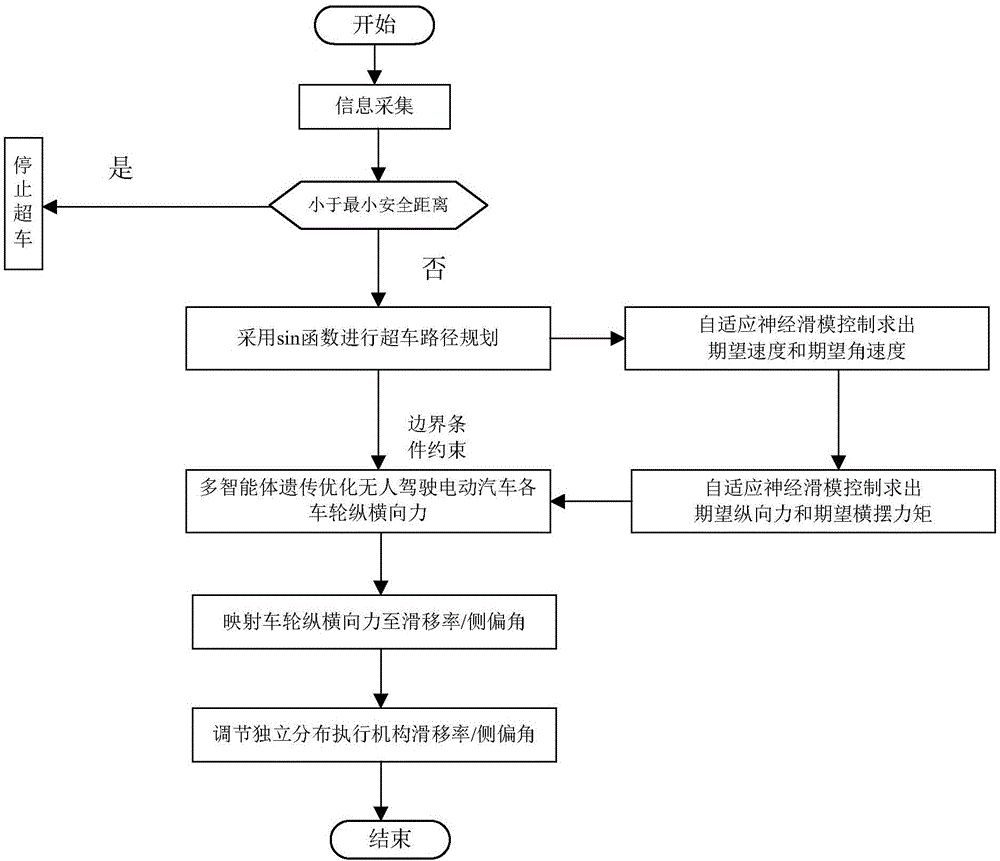

Multi-intelligent agent based unmanned electric car automatic overtaking system and method

ActiveCN106671982ARealize dynamic coordinationImplement executive controlExternal condition input parametersFuzzy sliding mode controlSimulation

The invention relates to a multi-intelligent agent based unmanned electric car automatic overtaking system and method. The automatic overtaking system includes a vehicle-mounted sensor for acquiring front traffic information of an unmanned electric car. The automatic overtaking method includes: establishing a minimize safe distance model on the basis of feature information of a car and a surround environment thereof extracted by a vehicle-mounted sensing system and a V2X communication system; setting a sine function form as a base function of an automatic overtaking desired path, and dynamically planning an automatic overtaking desired track of the unmanned electric car in real time; adopting a self-adaption fuzzy slide mode control technique to solve the desired speed and the desired yaw velocity of overtaking of the unmanned electric car on the basis of a deviation between the desired overtaking path and an actual path; adopting a multi-intelligent agent genetic optimization algorithm to calculate out the required longitudinal and horizontal force of each wheel of the unmanned electric car; and establishing a mapping model from the longitudinal and horizontal forces of the wheels of the unmanned electric car to the desired slip angle and slip rate, and achieving execution control of the longitudinal and horizontal force of tires the unmanned electric car.

Owner:XIAMEN UNIV

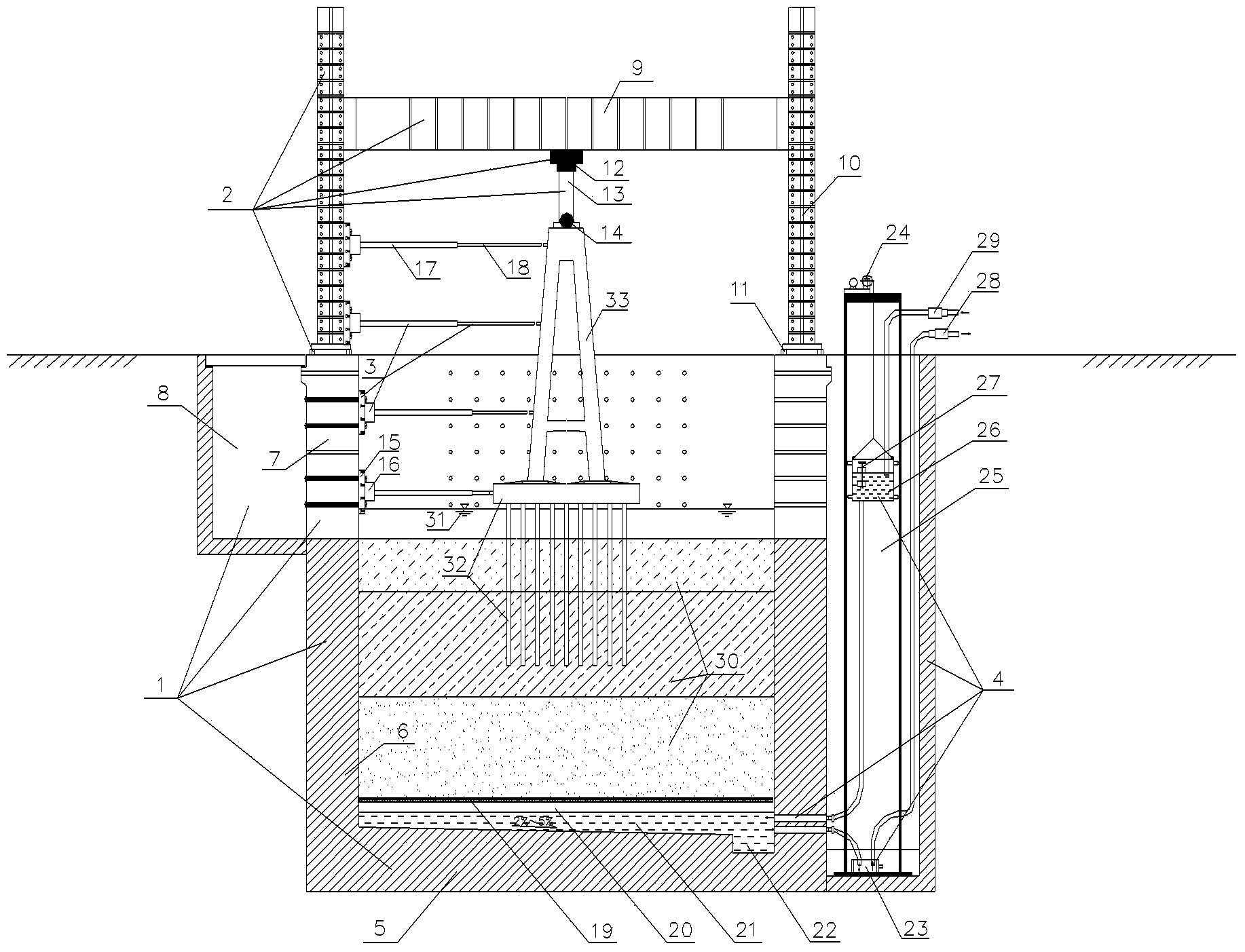

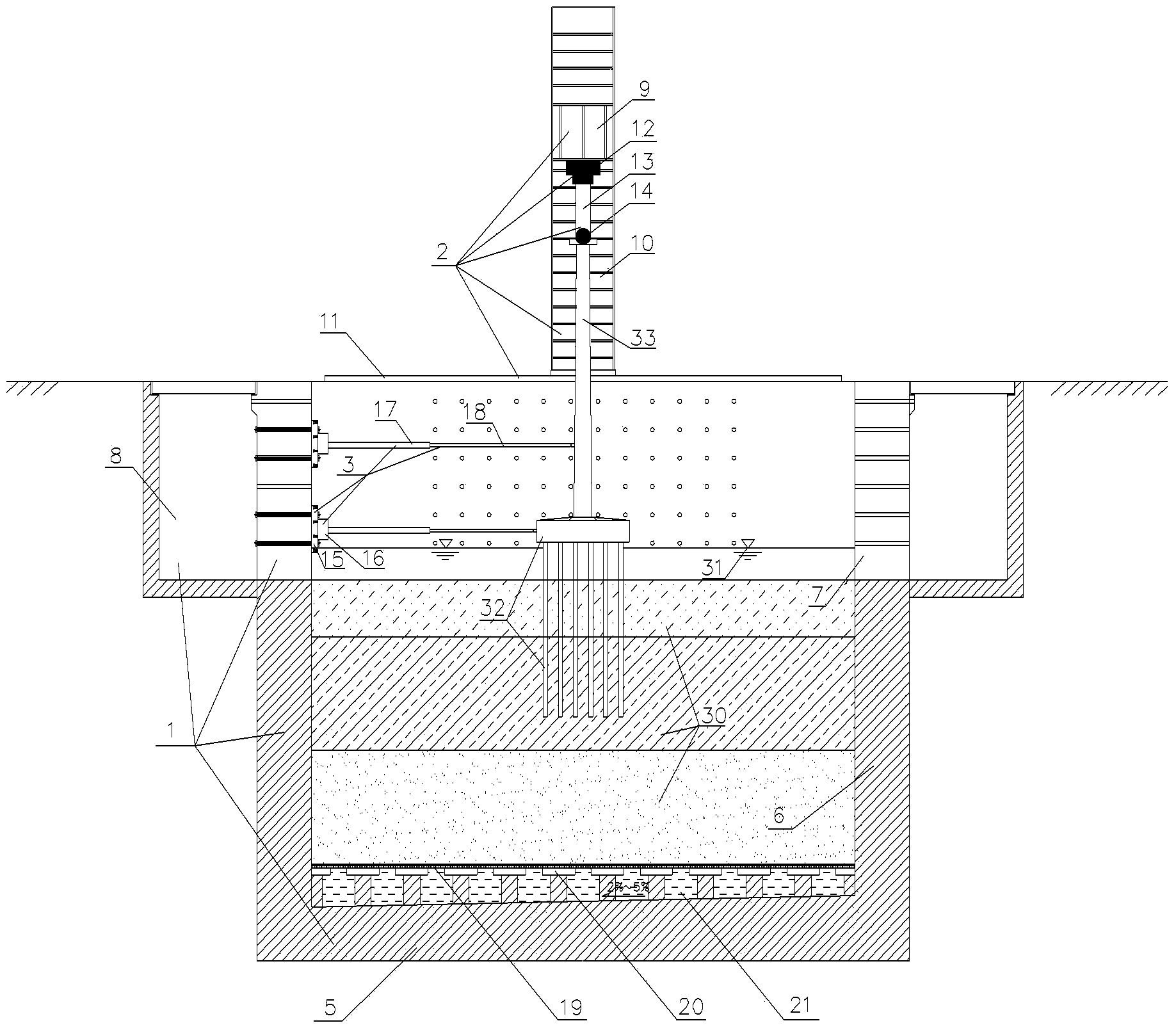

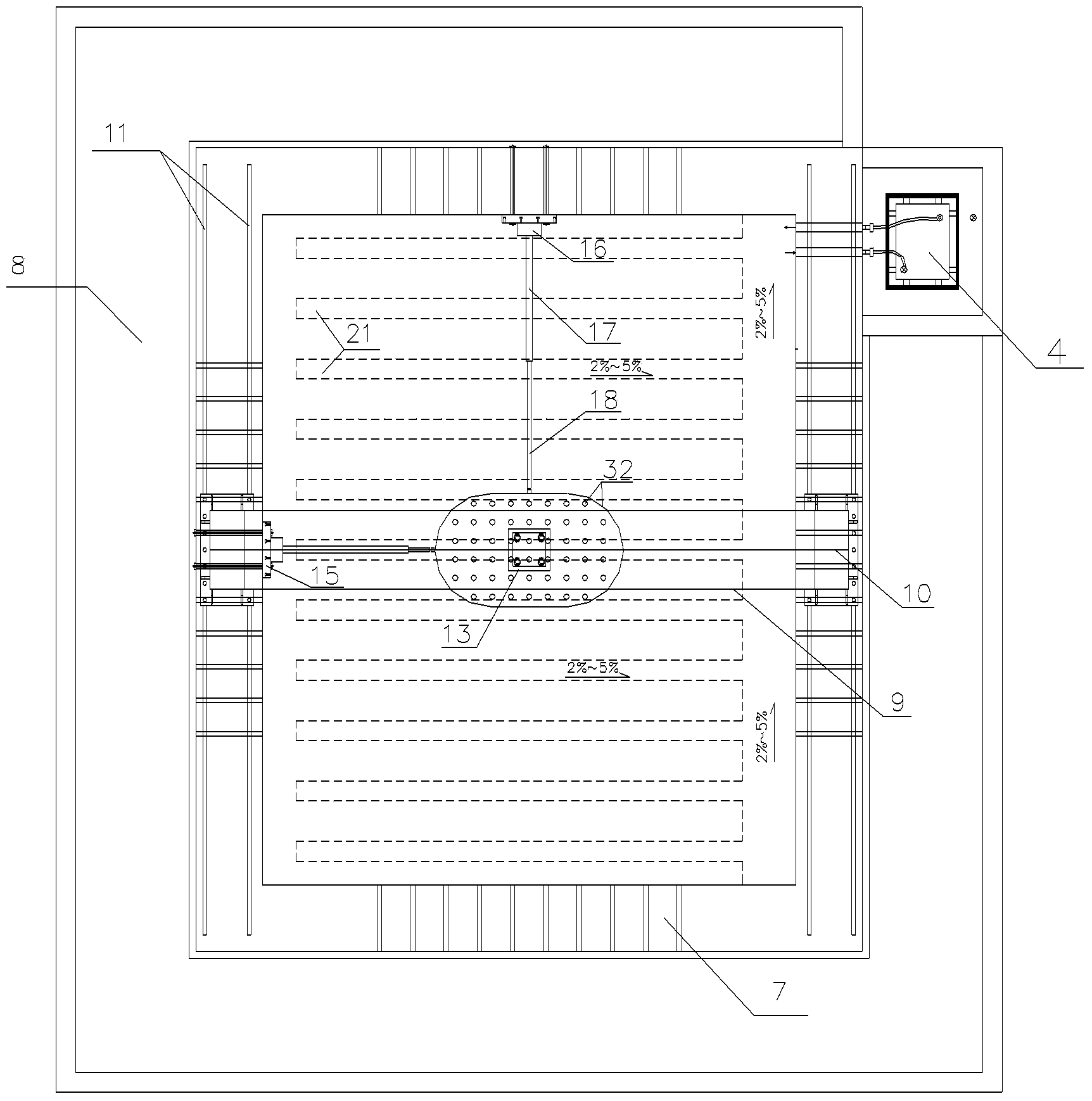

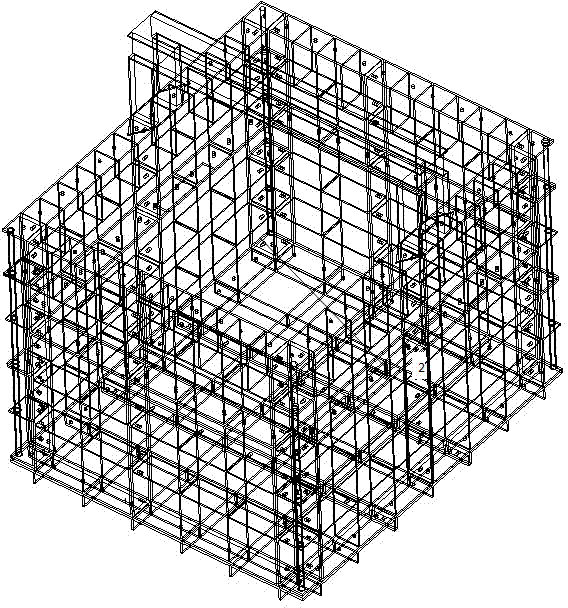

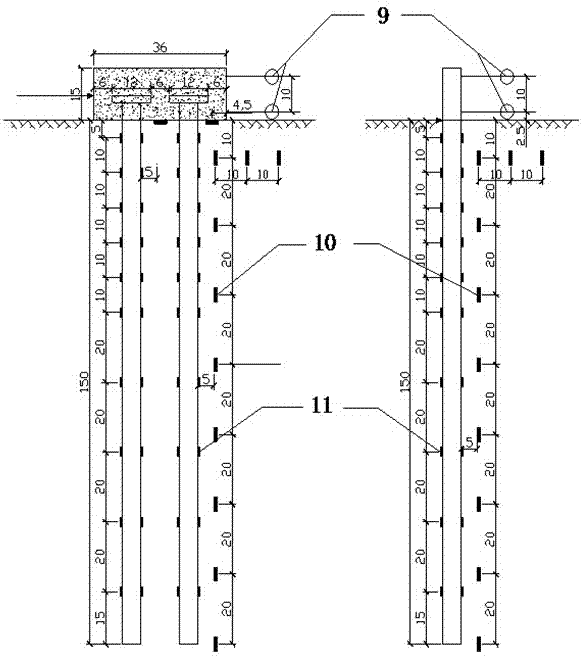

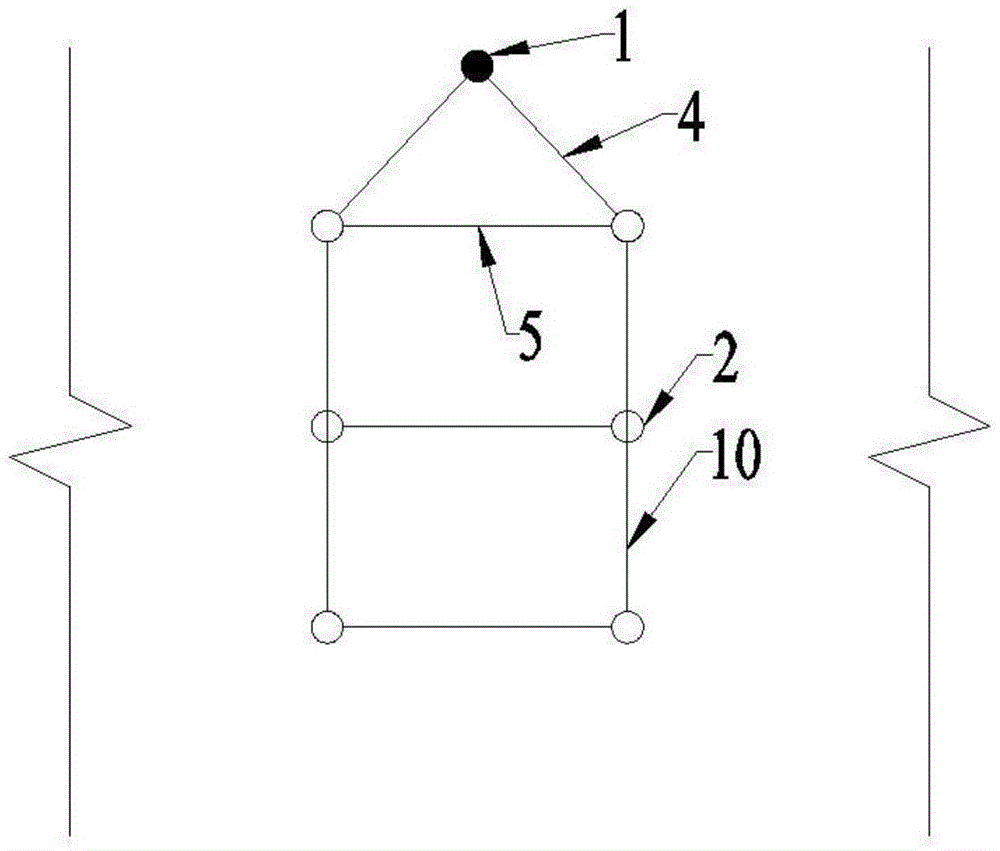

Three-directional static and dynamic loading model test platform for deep water foundations of bridges

ActiveCN103510551ASolve the technical problem of vertical loading influenceSmall sizeFoundation testingHorizontal forceTower

The invention discloses a three-directional static and dynamic loading model test platform for deep water foundations of bridges. The three-directional static and dynamic loading model test platform comprises a test foundation trench, a vertical loading system, a horizontal bi-directional loading system and a water level simulating system. The test foundation trench is used for arrangement of foundation soil, water and models. The vertical loading system used for applying vertical static and dynamic action on the models is installed at the top of the test foundation trench, the horizontal bi-directional loading system used for applying two or more horizontal static and dynamic actions on each model is installed on the upper portion of the inner side wall of the test foundation trench, and the water level simulating system used for water feeding and draining and test water level control in the test foundation trench is installed on the bottom and the outer side of the outer side wall of the test foundation trench. Test and research on the models of bridge deep water foundations such grouped piles, sink shafts, caissons and compound foundations and bridge towers (piles) under three-directional static and dynamic actions such as the vertical static and dynamic action and the horizontal bi-directional static and dynamic action can be carried out by the test platform, and the test platform solves problems about simulation of static and dynamic mutual action of the foundation soil-water-bridge deep water foundation-bridge tower (pile) under the combined working conditions of vertical force, horizontal force, bending moment, torque and the like.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT

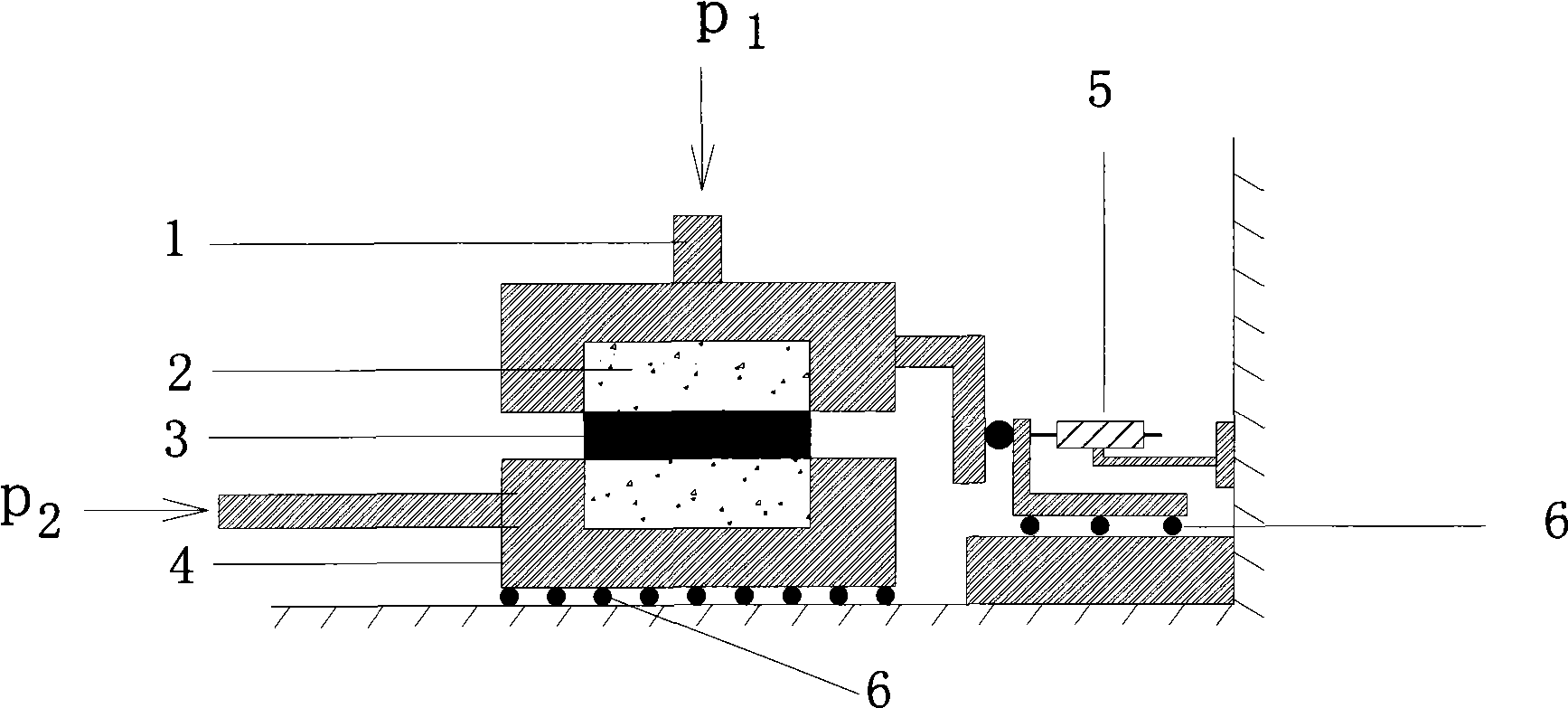

Interface shearing strength test method for adhesive bonding sample of sealant and substrate

InactiveCN101509868AStrong guidanceEasy to operateUsing mechanical meansMaterial strength using steady shearing forcesHorizontal forcePositive pressure

The invention discloses a testing method of the shearing resistance between a sealing gum and a stuck sample interface of a stuck base material, which manufactures the stuck base material into two samples, and a cavity with specified size is reserved in the middle for injecting the sealing gum, thus integrating the stuck base material and the sealing gum into a whole stuck sample which is placed in the environment with the temperature of 20 DEG C minus or plus 2 DEG C and the relative humidity of 65 percent minus or plus 5 percent for being conserved for 28 days, and the samples are respectively placed into an upper shearing box and a lower shearing box, positive pressure P1 is exerted on an upper part, and horizontal force P2 is exerted simultaneously. The shearing force exerted on the samples is measured by a dynamic meter 5. The shearing force P2 is exerted with specified loading rate, and until a shearing surface between the stuck base material and the sealing gum is destroyed, and the largest force measured by the dynamic meter 5 is the shearing resistant force. The value obtained by dividing the shearing resistant force by the area of the stuck sample interface is the shearing resistance between the bonding interfaces of the stuck base material and the sealing gum under the positive pressure P1. The testing method of the shearing resistance between the sealing gum and the stuck sample interface of the stuck base material has simple operation, convenient use and favorable popularization, has no need of new additional equipments, and has strong guidance to specific industrial practices.

Owner:NORTHWEST A & F UNIV

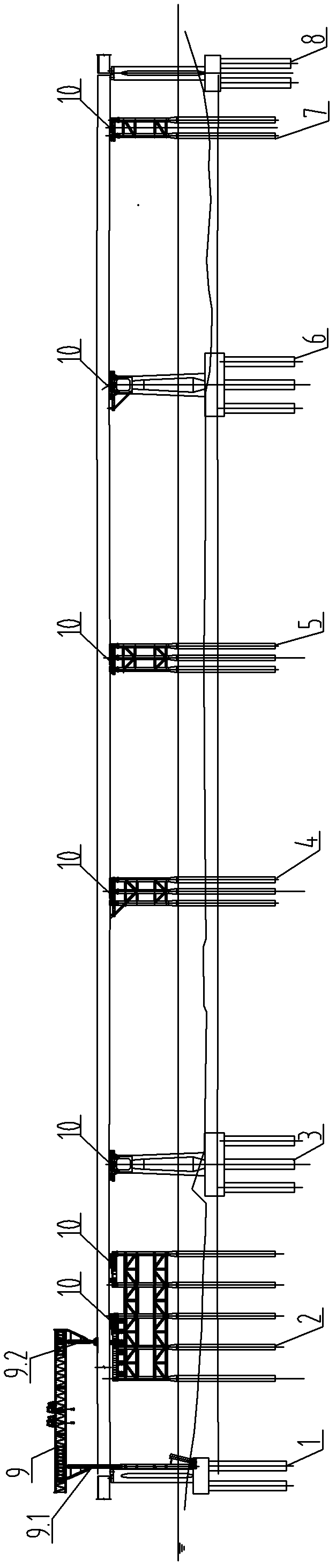

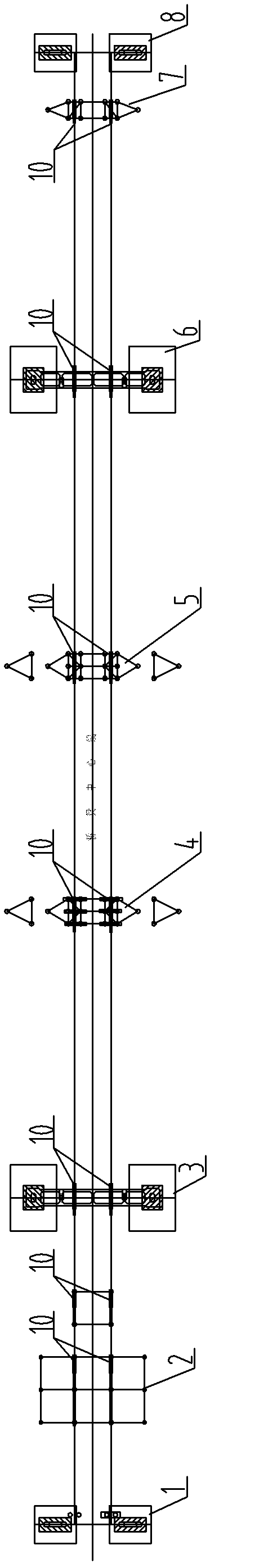

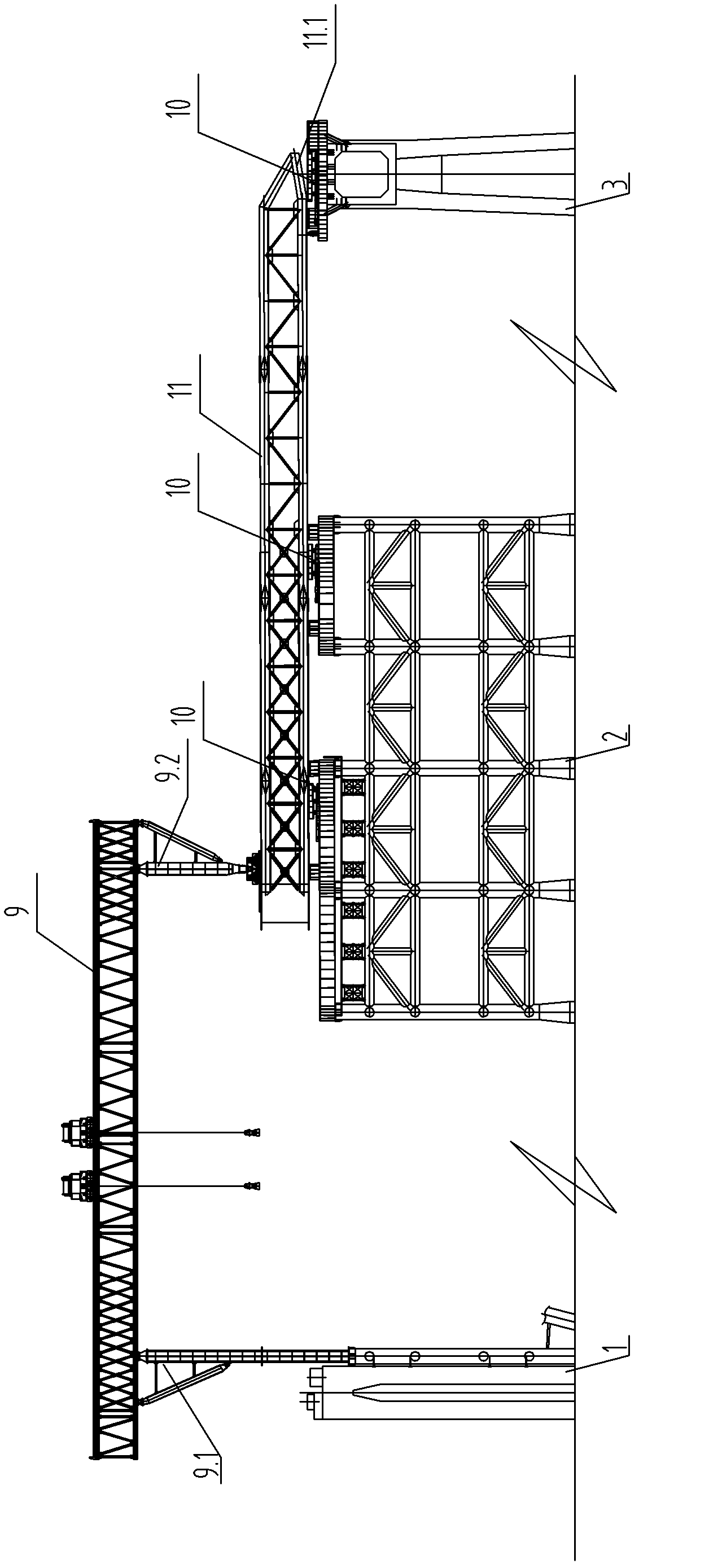

Walking type multipoint pushing construction method and walking type multipoint pushing construction system for steel box girder

ActiveCN102587291ASolve the shortcomings of conventional processesReduce stress valueBridge erection/assemblyHorizontal forceSteel box girder

The invention discloses a walking type multipoint pushing construction method for a steel box girder, which is an improved optimized scheme for improving the disadvantages of a pulling type pushing method. The optimized scheme comprises the steps of installing pushing devices at assembly platforms, temporary mounds, main mounds and other points, firstly jacking the steel box girder with a vertical jack to separate the steel box girder from a girder laying frame, then pushing the steel box girder for a stroke in the longitudinal direction by a pushing jack, lowering the steel box girder to the girder laying frame, retracting the pushing jack for a next stroke of pushing, and keeping the circulation of the work until the installation of the steel box girder is finished. The pushing construction method for the steel box girder provided by the invention adopts a multipoint walking type pushing system, which not only can avoid disadvantages in the process in prior arts, but also has the advantages that the horizontal force at the mound top is greatly reduced; the structure of the temporary mound is simplified; the damage to the steel box girder is small; the construction cost is low and the like.

Owner:THE FIRST ENG OF CCCC FOURTH HARBOR ENG

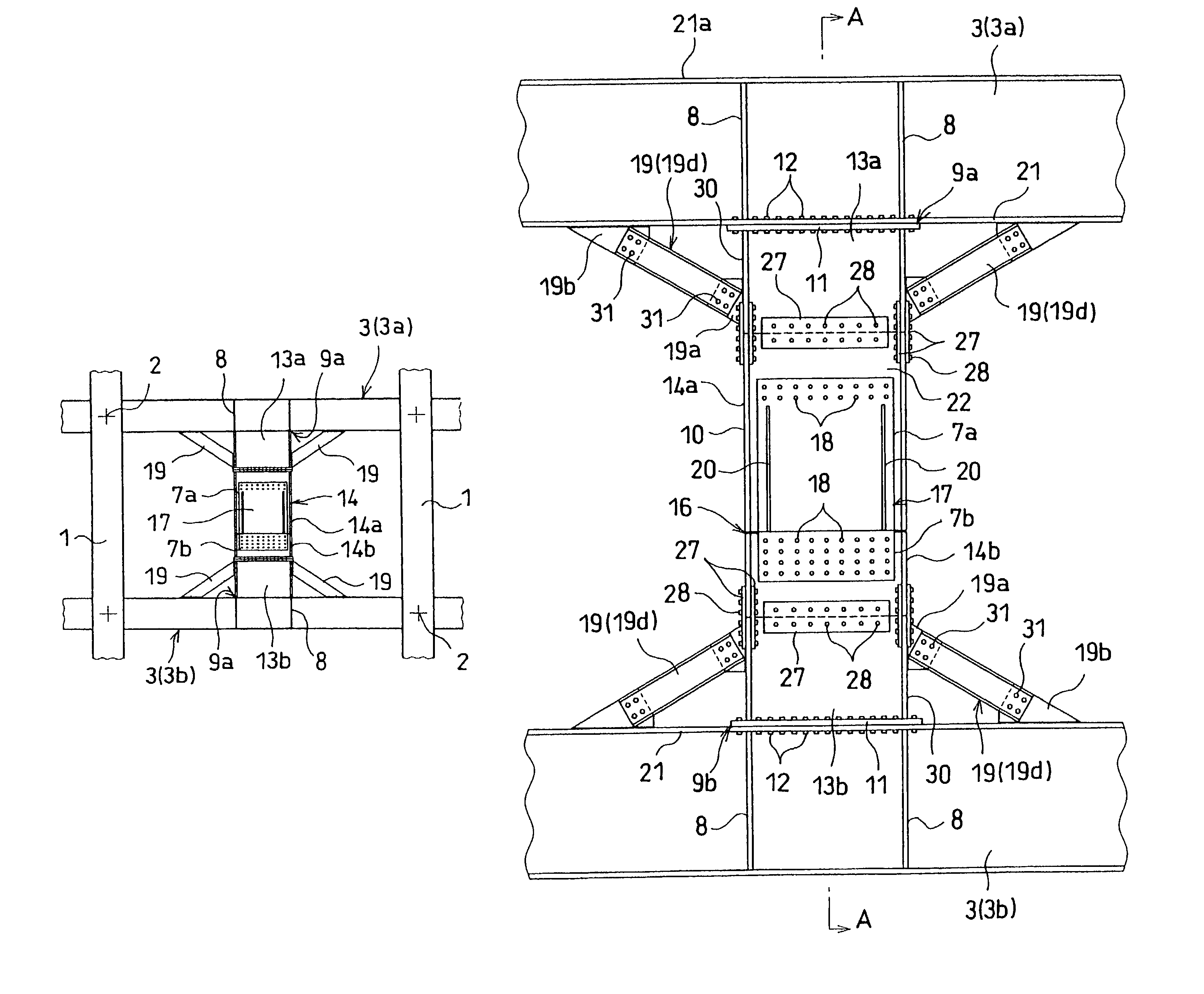

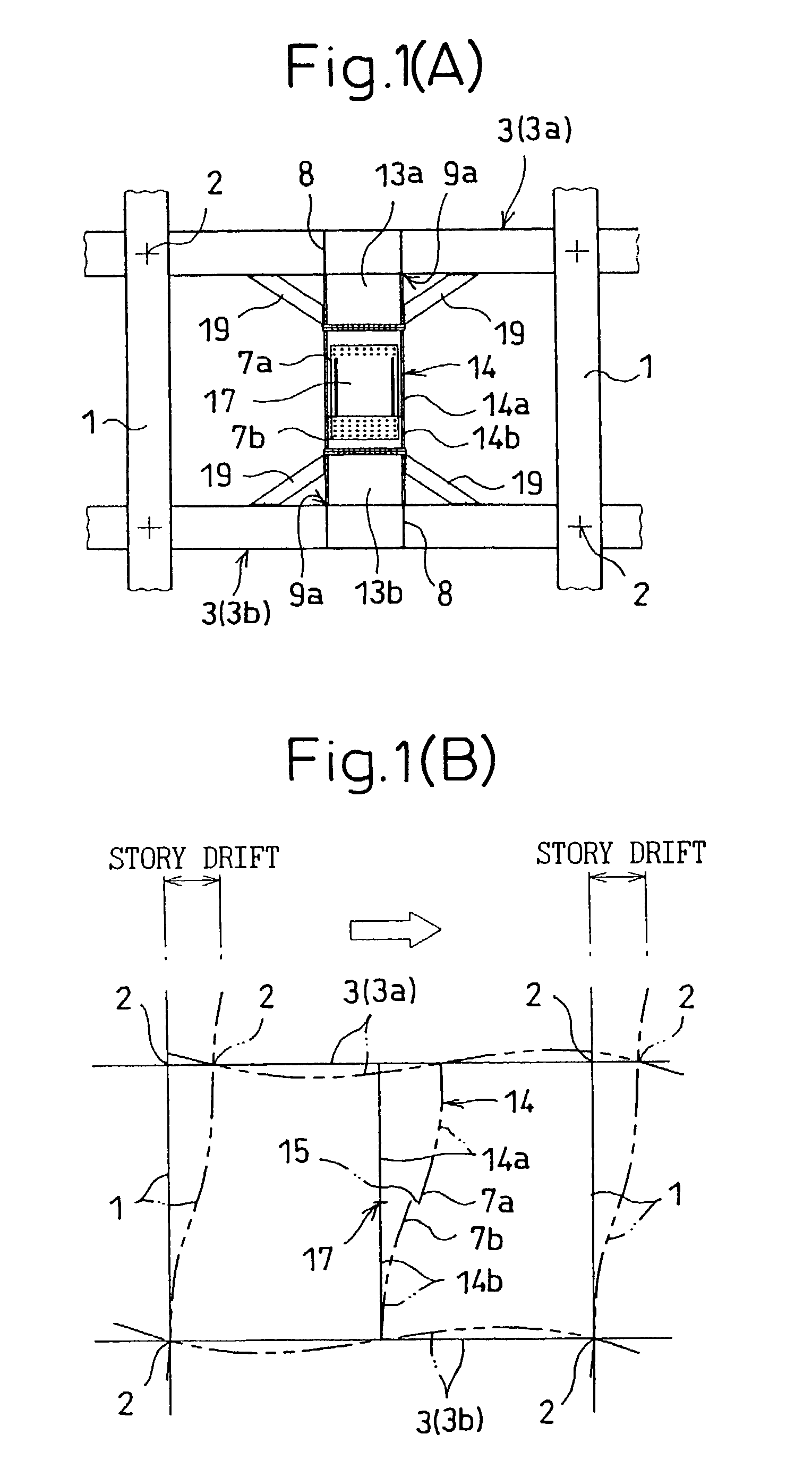

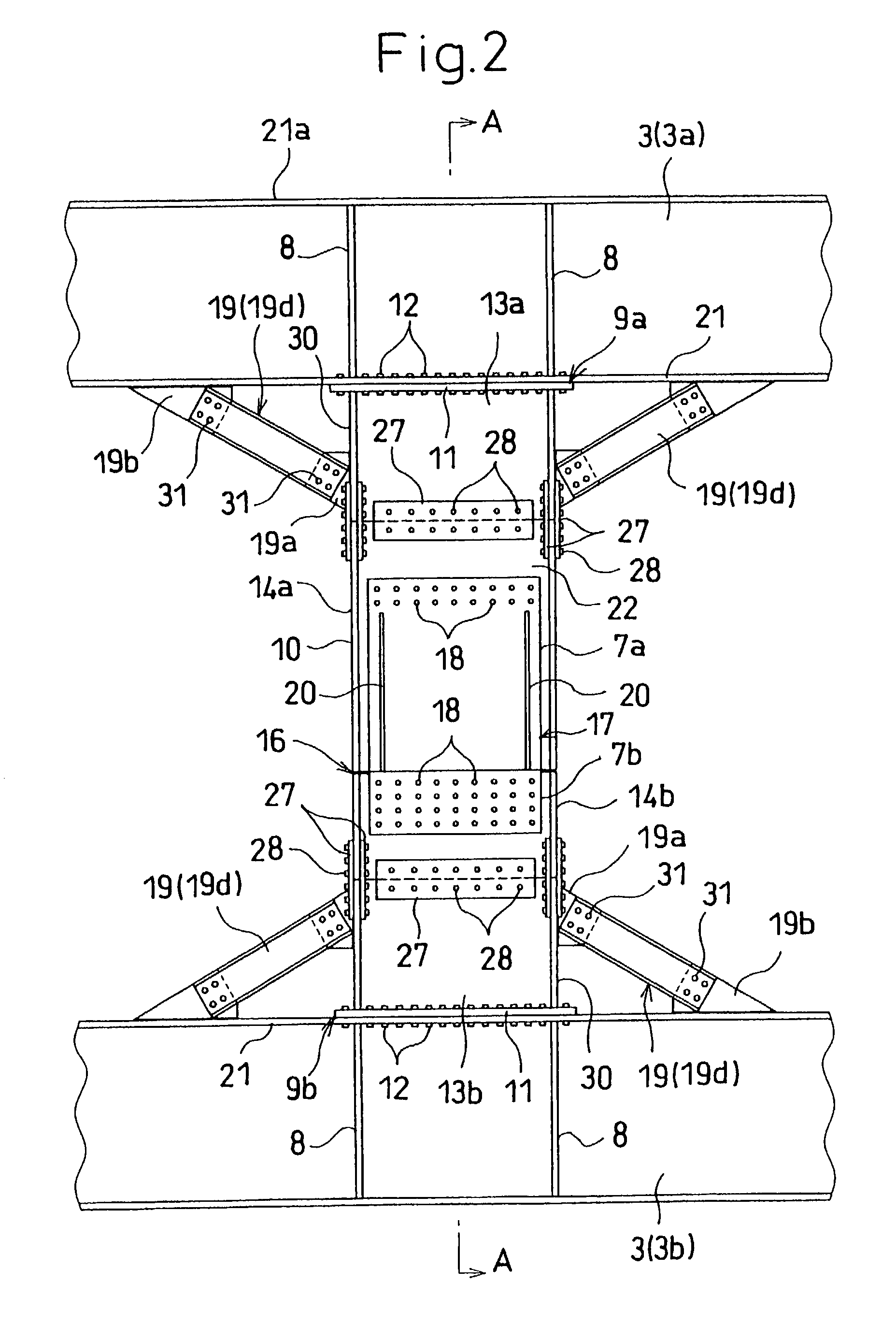

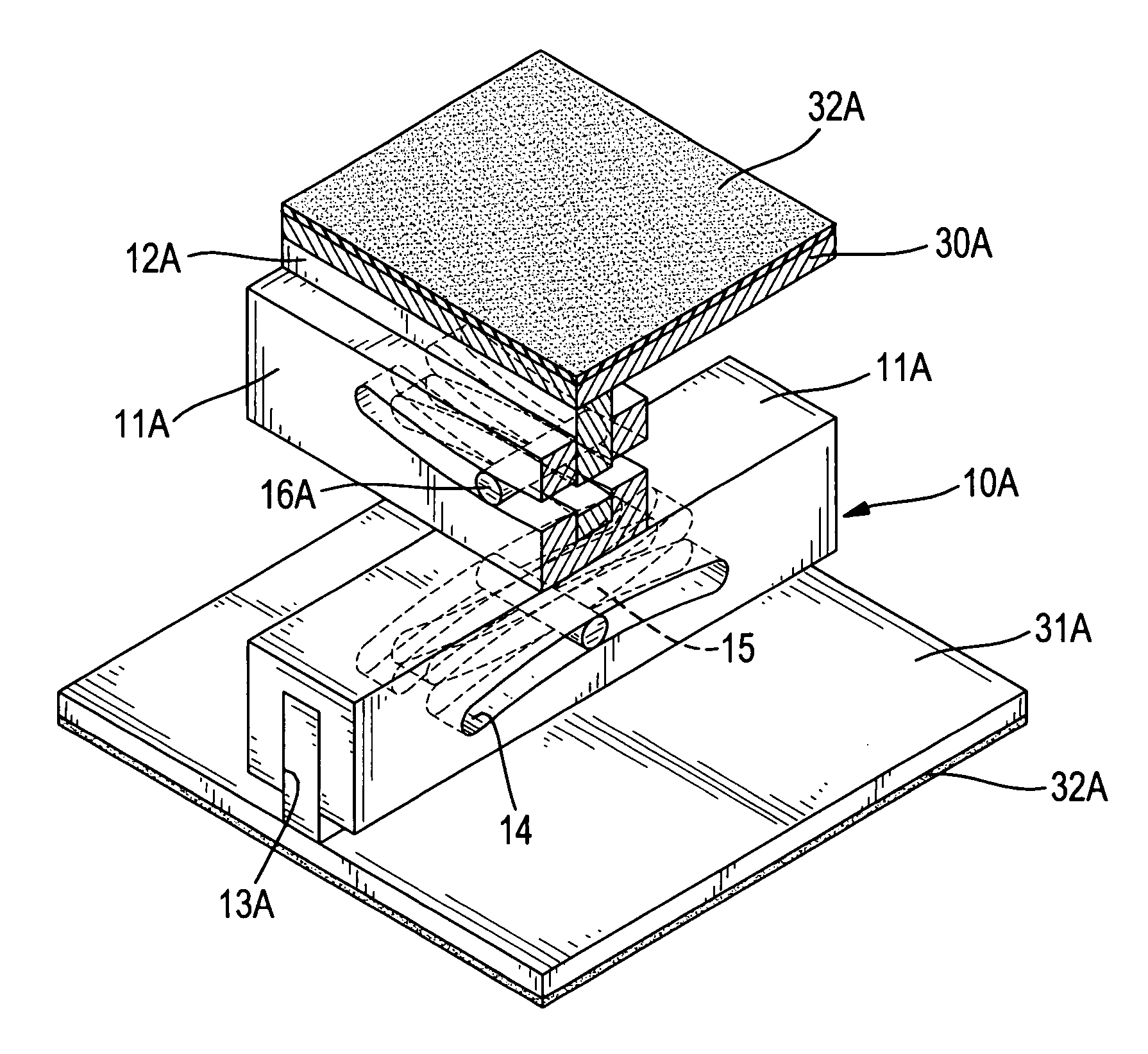

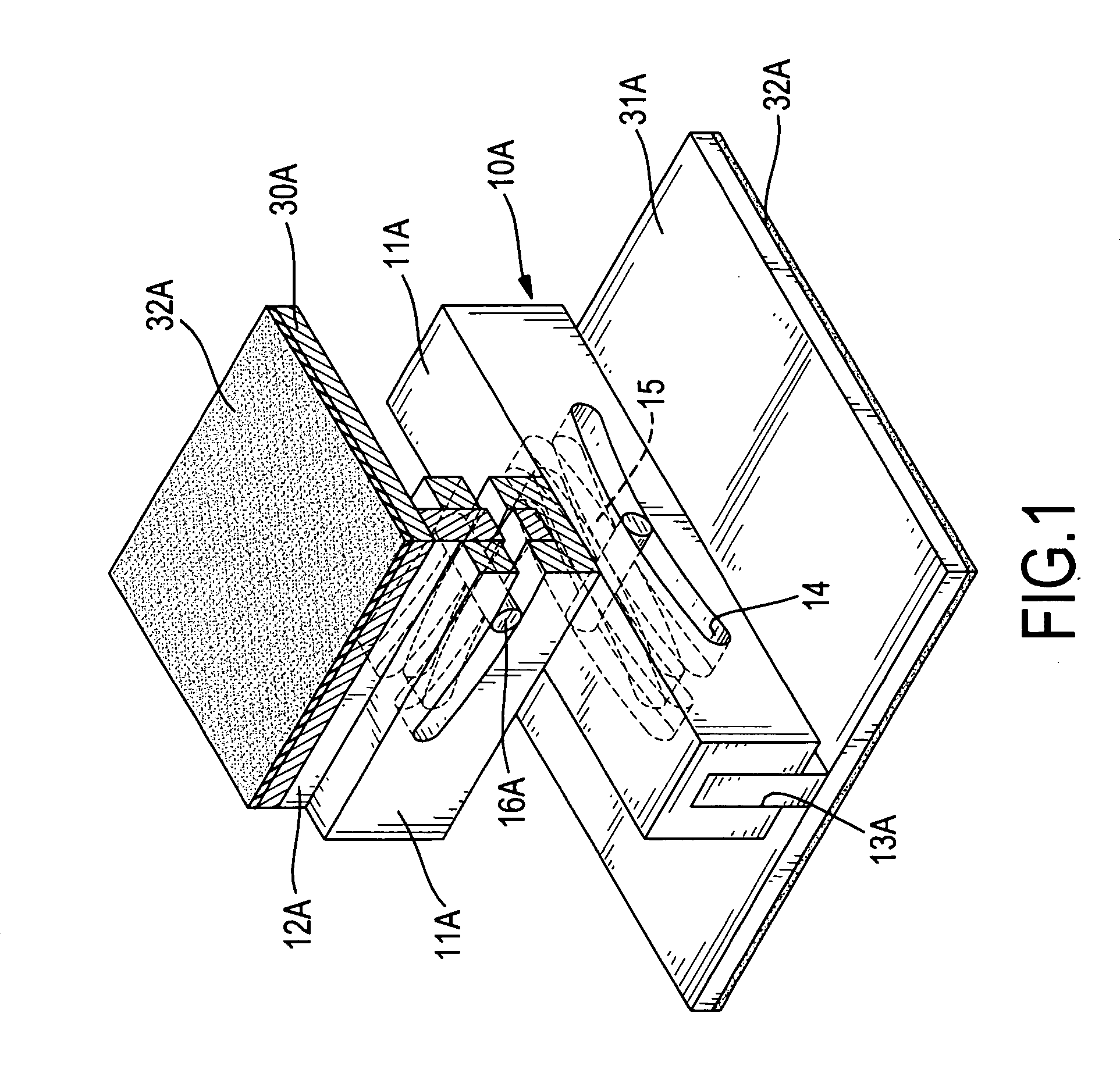

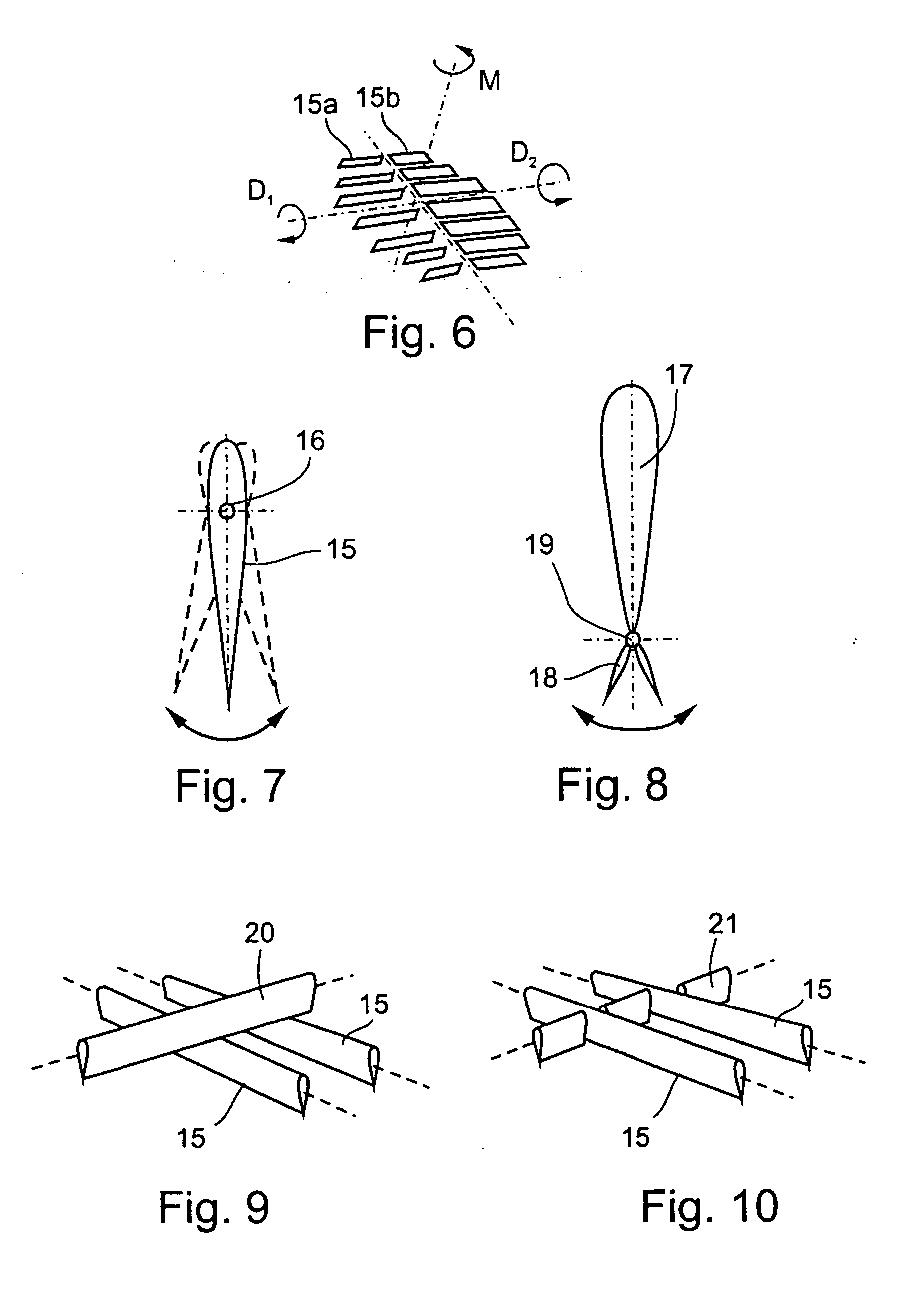

Damping intermediate pillar and damping structure using the same

InactiveUS7076926B2High strengthIncrease shear deformationNon-rotating vibration suppressionProtective buildings/sheltersHorizontal forceViscoelastic damping

A damping intermediate pillar, which can exhibit a sufficient resistance against the horizontal force of a strong earthquake by reinforcing the joins between the damping intermediate pillar and the upper and lower beams, is disclosed. A damping intermediate pillar 14, used for a building or a structure configured of pillars 1 and beams 3, is divided into upper and lower damping intermediate pillar portions 14a, 14b of H shape steel, and includes a plurality of inner steel plates 7b fixed on the damping intermediate pillar portion 14b and a plurality of outer steel plates 7a fixed on the other damping intermediate pillar portion 14a. The inner and outer steel plates are arranged alternately in a single or a plurality of layers, between which a viscoelastic member 15 is held to make up a viscoelastic damper 17. The coupling end surfaces of the intermediate pillar portions 14a, 14b directed vertically are fixed on the upper and lower floor beams 3a, 3b. Further, one or both sides of each of the damping intermediate pillar portions 14a, 14b (i.e. the coupling members 13a, 13b) and the upper and lower floor beams 3a, 3b are coupled to each other by knee braces 19.

Owner:KAZUHIKO KASAI +1

Inductrack configuration

InactiveUS7096794B2Improve rendering capabilitiesLittle strengthLinear bearingsRailway vehiclesHorizontal forceLevitation

A simple permanent-magnet-excited maglev geometry provides levitation forces and is stable against vertical displacements from equilibrium but is unstable against horizontal displacements. An Inductrack system is then used in conjunction with this system to effect stabilization against horizontal displacements and to provide centering forces to overcome centrifugal forces when the vehicle is traversing curved sections of a track or when any other transient horizontal force is present. In some proposed embodiments, the Inductrack track elements are also employed as the stator of a linear induction-motor drive and braking system.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

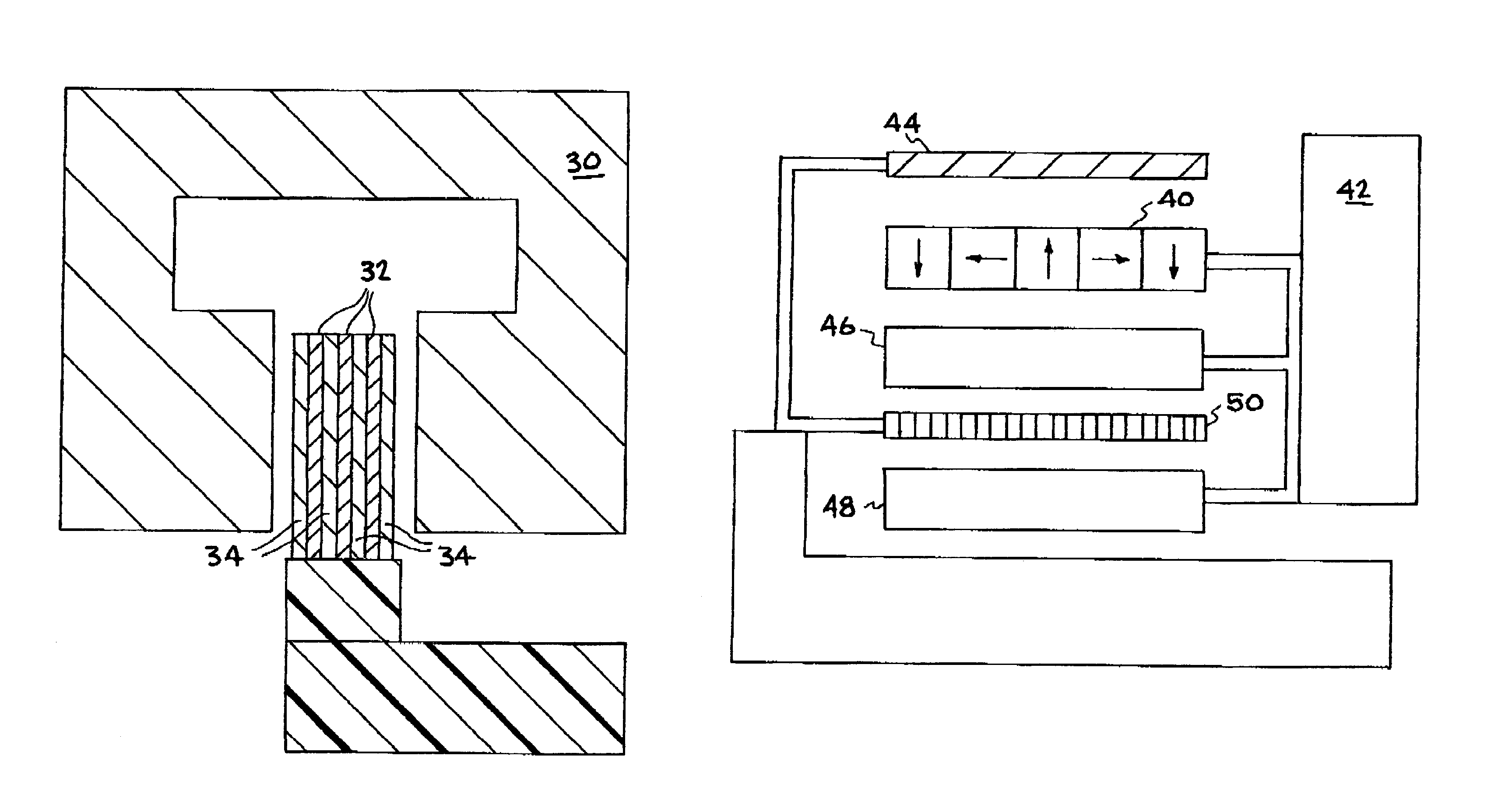

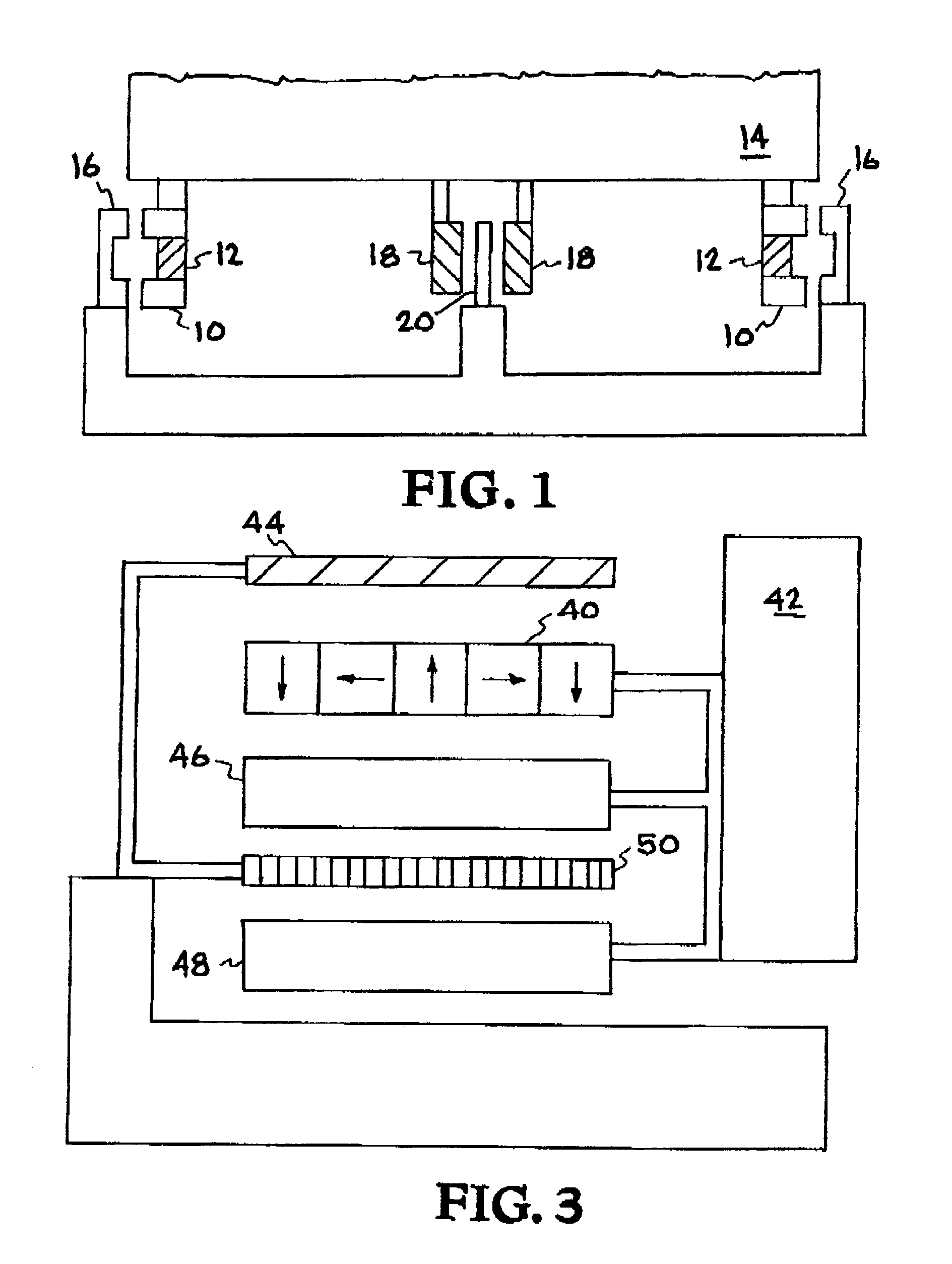

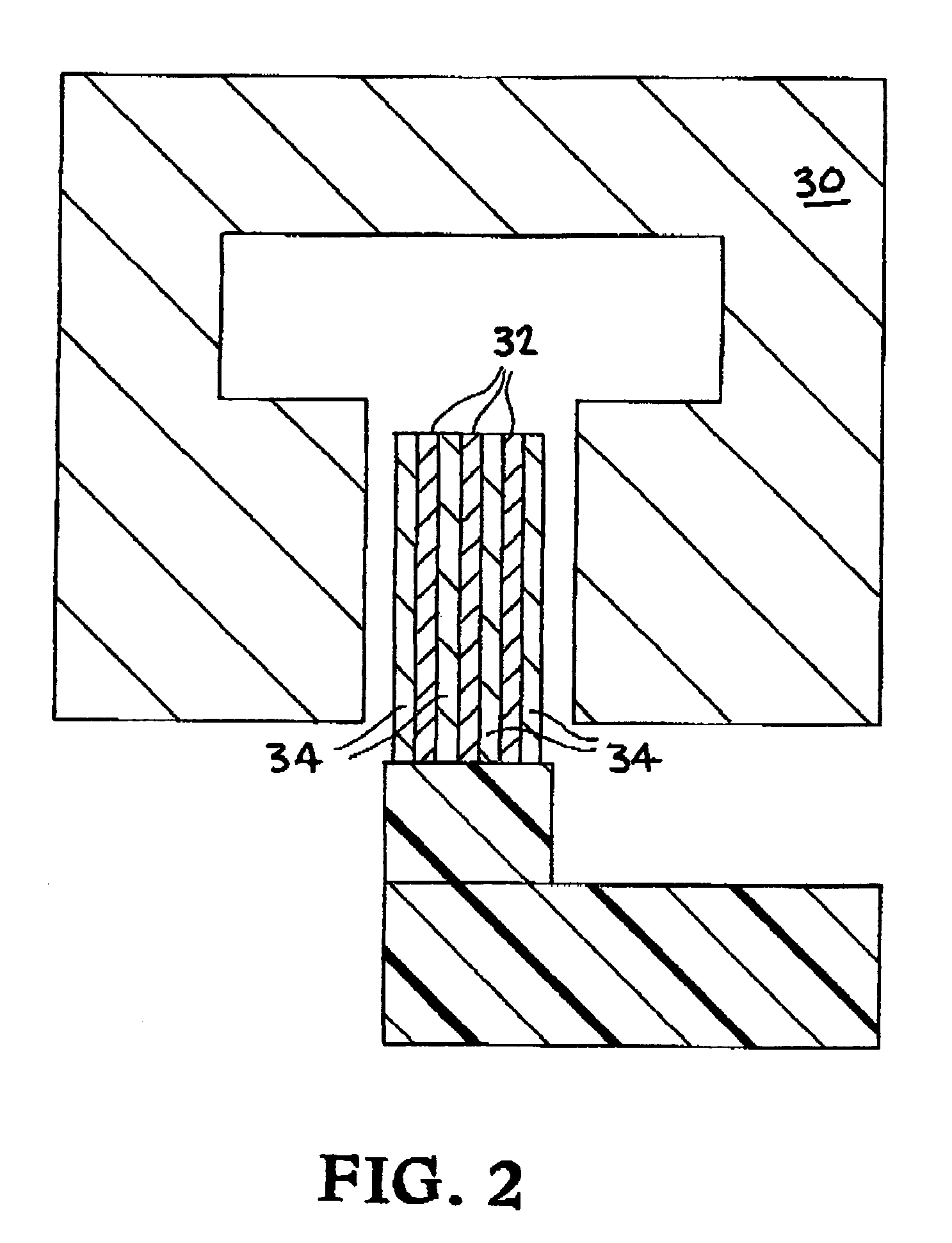

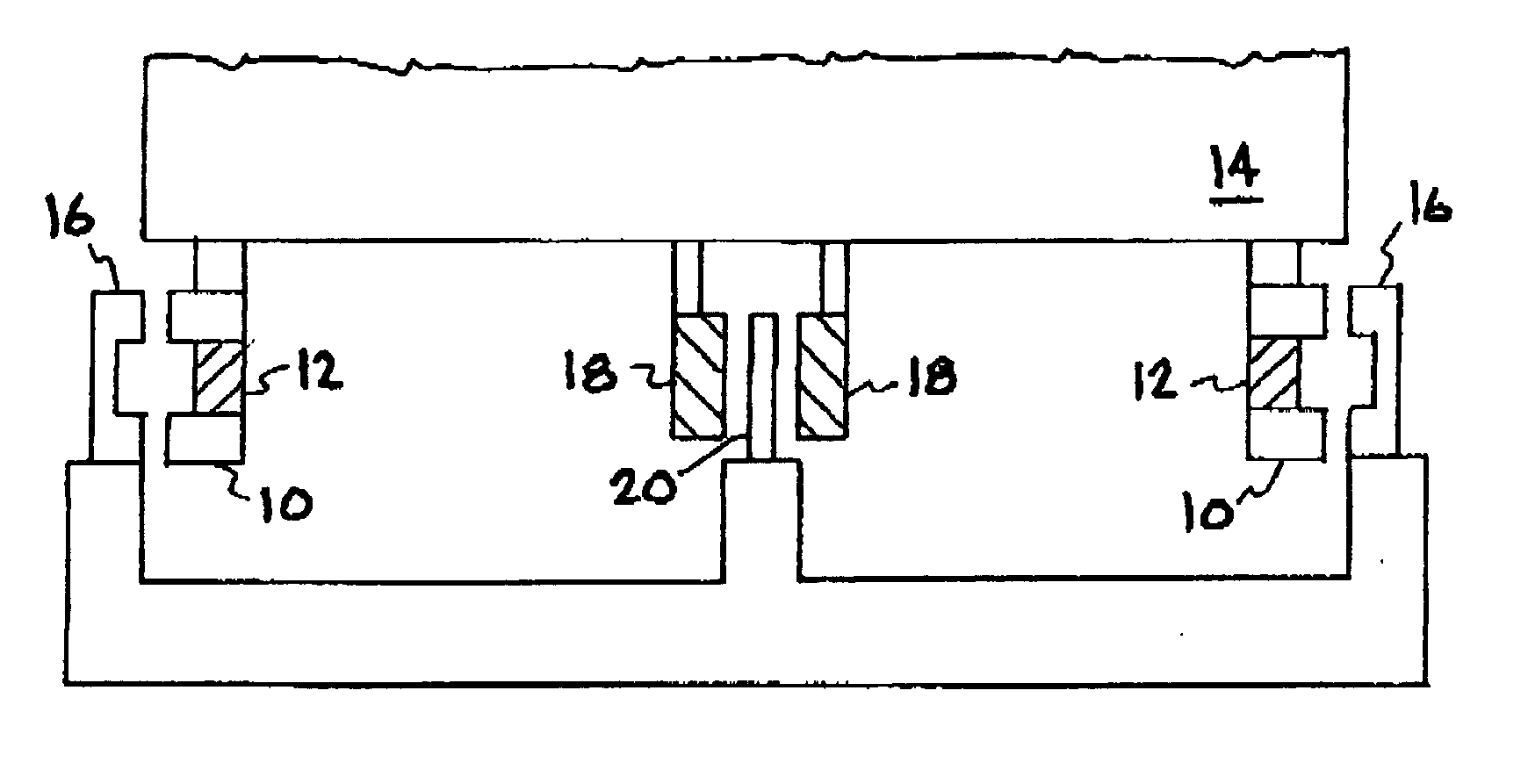

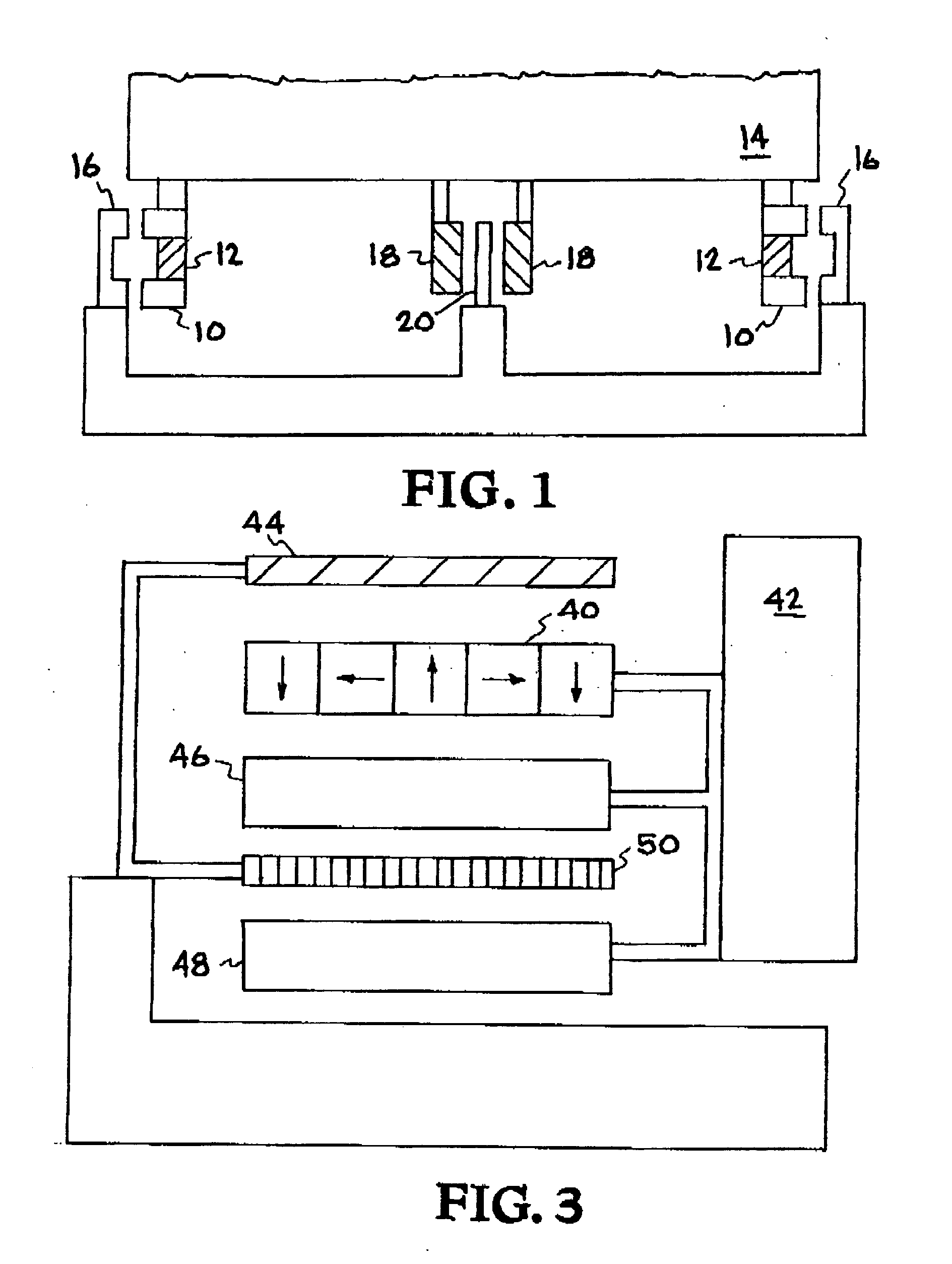

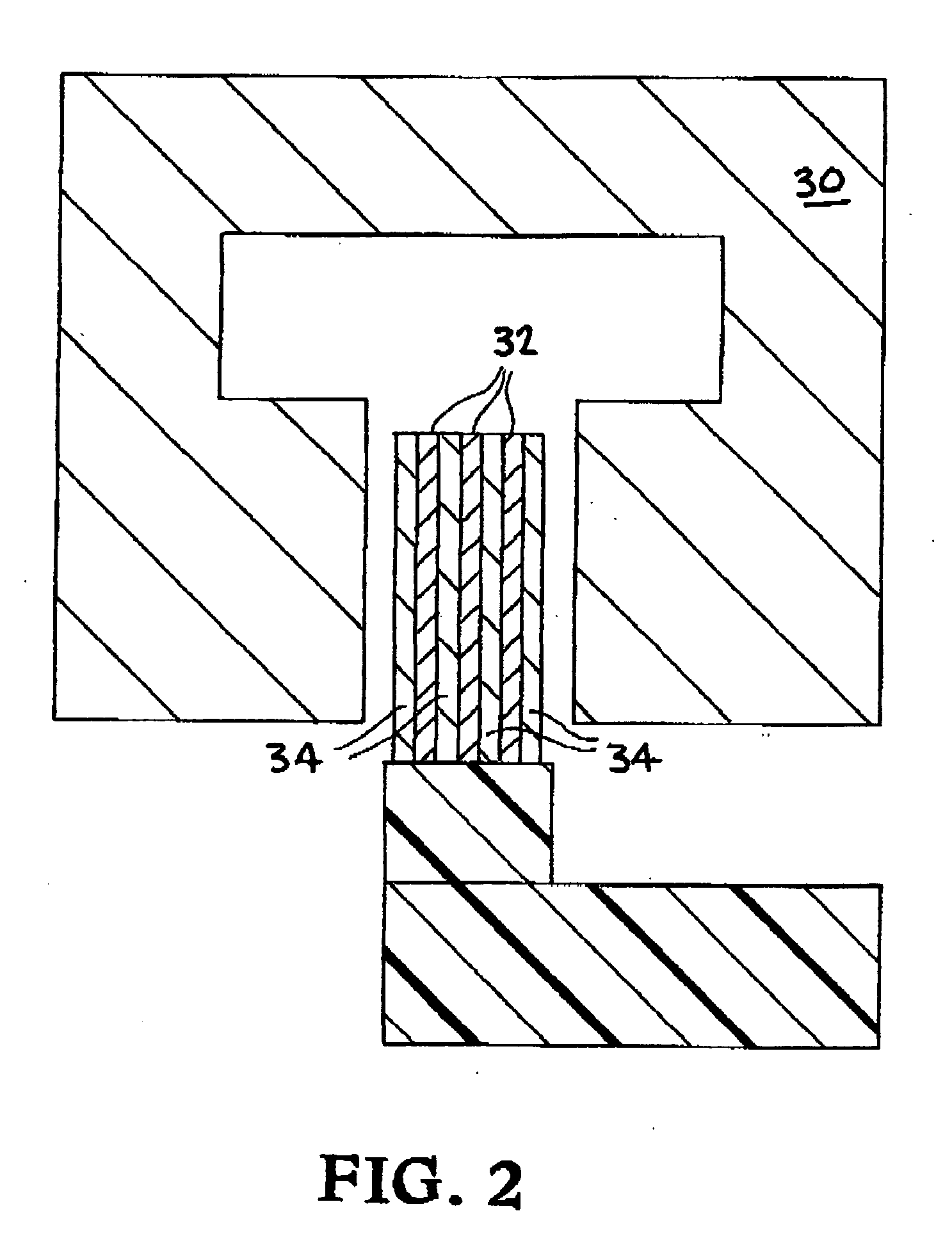

Apparatus and method for removably adhering a semiconductor substrate to a substrate support

A process and apparatus is disclosed capable of removably adhering a semiconductor substrate to a substrate support in a sub-atmospheric environment using a plurality of individual fibers, each mounted at one end adjacent the substrate support, and each having a loose end. When the portions of the fiber adjacent the loose fiber ends are each brought into contact with the under surface of the substrate, Van der Waals forces are exerted between the substrate and the fibers to urge the substrate toward the underlying substrate support. In a preferred embodiment, the substrate and portions of the fiber adjacent the loose fiber ends are first vertically brought into physical contact with one another, and then a horizontal force is applied to horizontally move, with respect to one another, the substrate and the portions of the fibers adjacent the loose fiber ends. After application of the horizontal force, a vertical force is applied between the substrate and the fibers of sufficient strength to urge the substrate and the fibers away from one another without breaking contact between the substrate and the portions of the fiber adjacent the fiber ends to thereby place tension on the substrate to urge the substrate to lie flat against the underlying substrate support.

Owner:KLA TENCOR TECH CORP

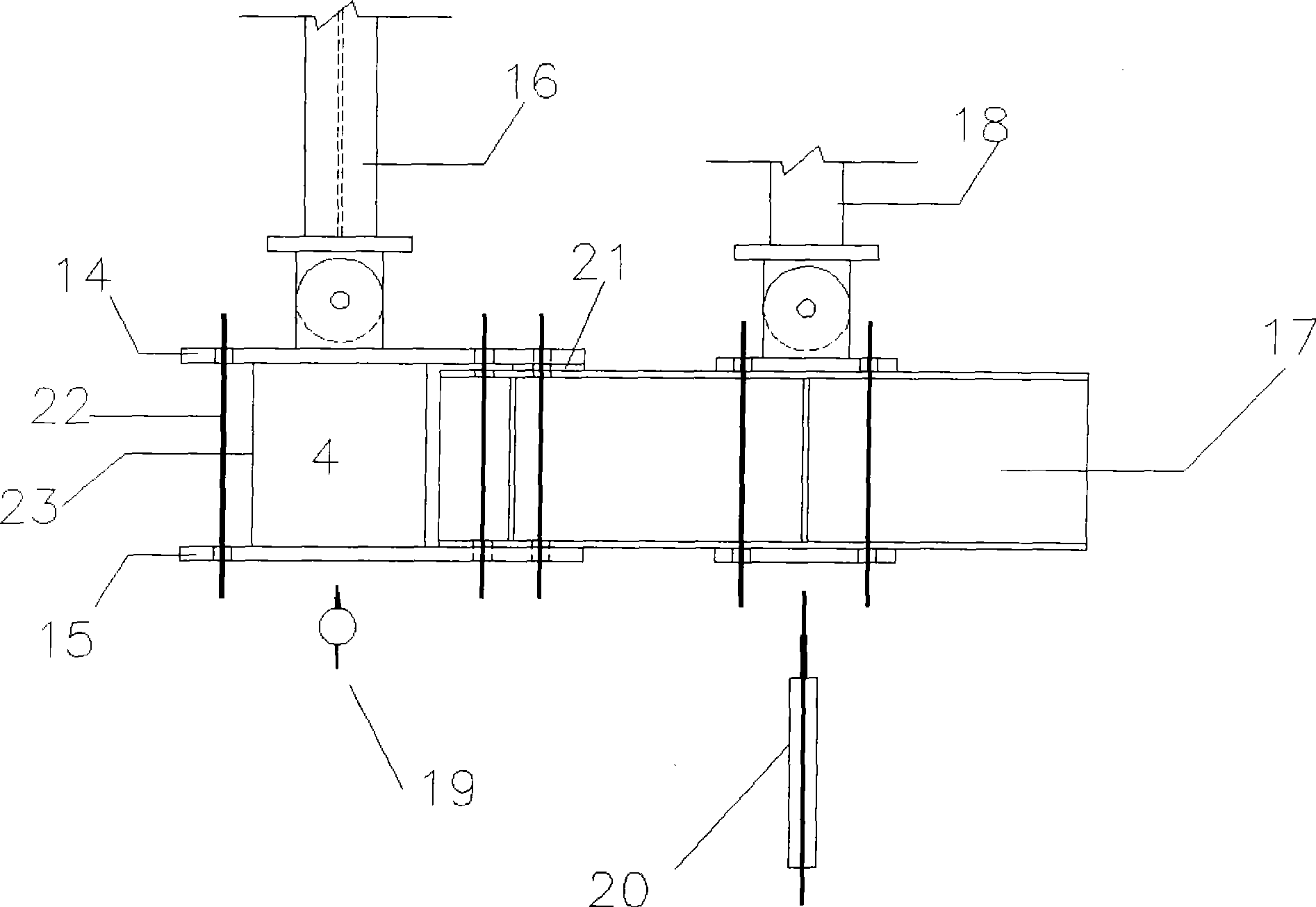

Prestressed concrete pipe pile horizontal bearing characteristic test model and test method

ActiveCN103882894ASimple and fast operationHighly adjustableFoundation testingMaterial strength using tensile/compressive forcesHorizontal forcePre stress

The invention discloses a prestressed concrete pipe pile horizontal bearing characteristic test model and a test method. The prestressed concrete pipe pile horizontal bearing characteristic test model comprises a model groove, a bearing table used for bearing a model pile is arranged in the model groove, and the upper end of the model pile is embedded into the bearing table. A vertical pneumatic loading system exerting vertical force on the bearing table and connected with a counter force frame is arranged above the model groove. The inner side of the model groove is provided with a horizontal pneumatic loading system exerting horizontal force on the bearing table and connected with the model groove. Monitoring devices are arranged on the bearing table, the model pile and the loading system. The invention provides a test device which can well meet the requirement for load conditions of a pile foundation load test, simulate the practical working conditions of the pile foundation more truly and detect the bearing characteristics of a single pipe pile and group pipe piles under the action of horizontal loads.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

Anti-shock device

InactiveUS20070125930A1Eliminate vibrationSmall sizePortable framesLiquid springsHorizontal forceVertical vibration

An anti-shock device has at least two sliding members placed in at least two layers. Each sliding member is comprised of a slotted seat, an inner seat, and a rolling shaft. The slotted seat has a slot defined longitudinally in a face and has outer curved rails defined in two sidewalls. The inner seat mounted slidably in the slot has an inner curved rail defined therein, corresponding to and curving in the opposite direction of the outer curved rails. The rolling shaft is mounted rotatably through the outer curved rails and the inner curved rail. When subjected to vibration, the anti-shock device converts the horizontal forces into vertical forces. In addition, an energy dissipation member is provided in the anti-shock device that eliminates vertical vibrations.

Owner:TSAI CHONG SHIEN

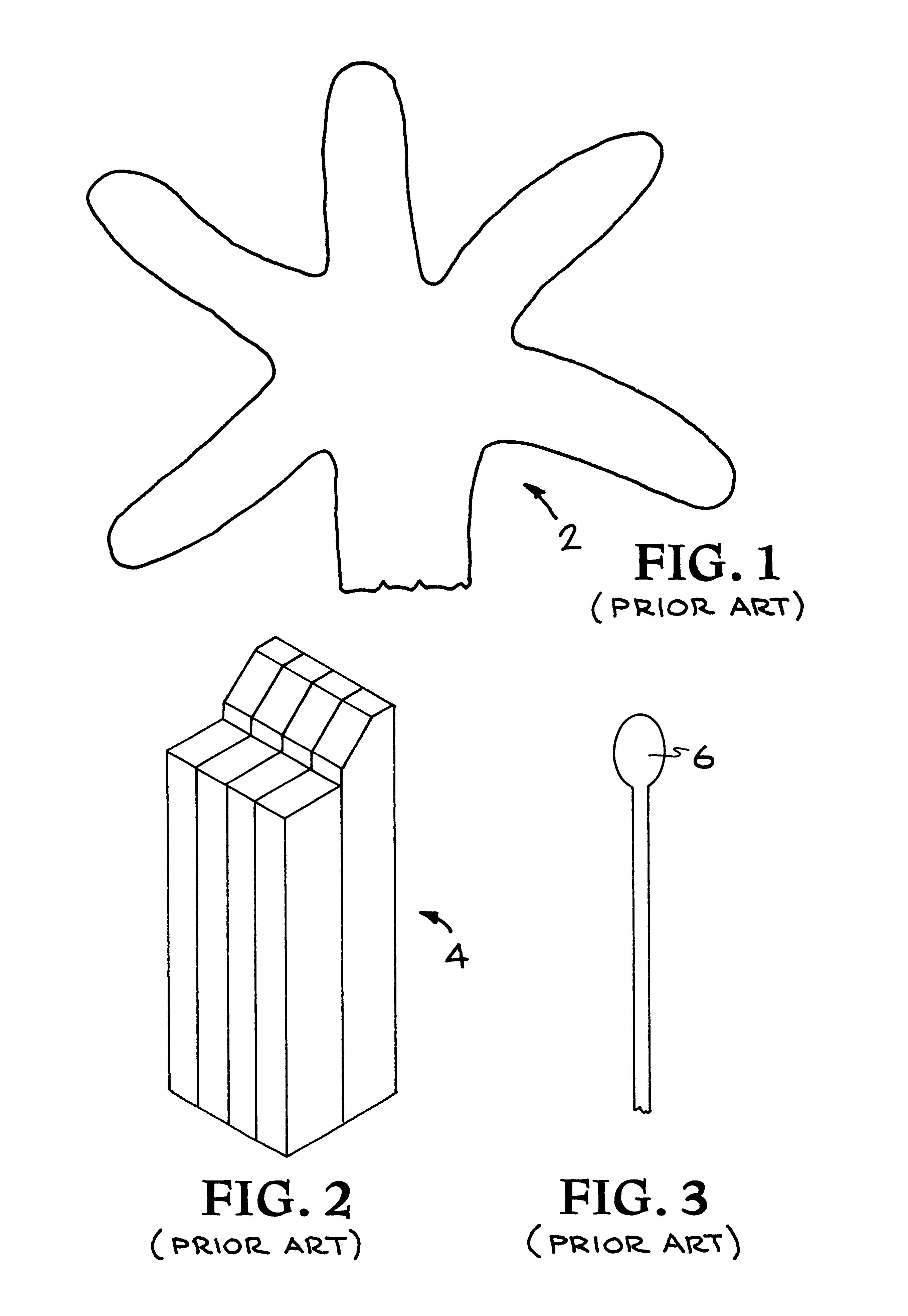

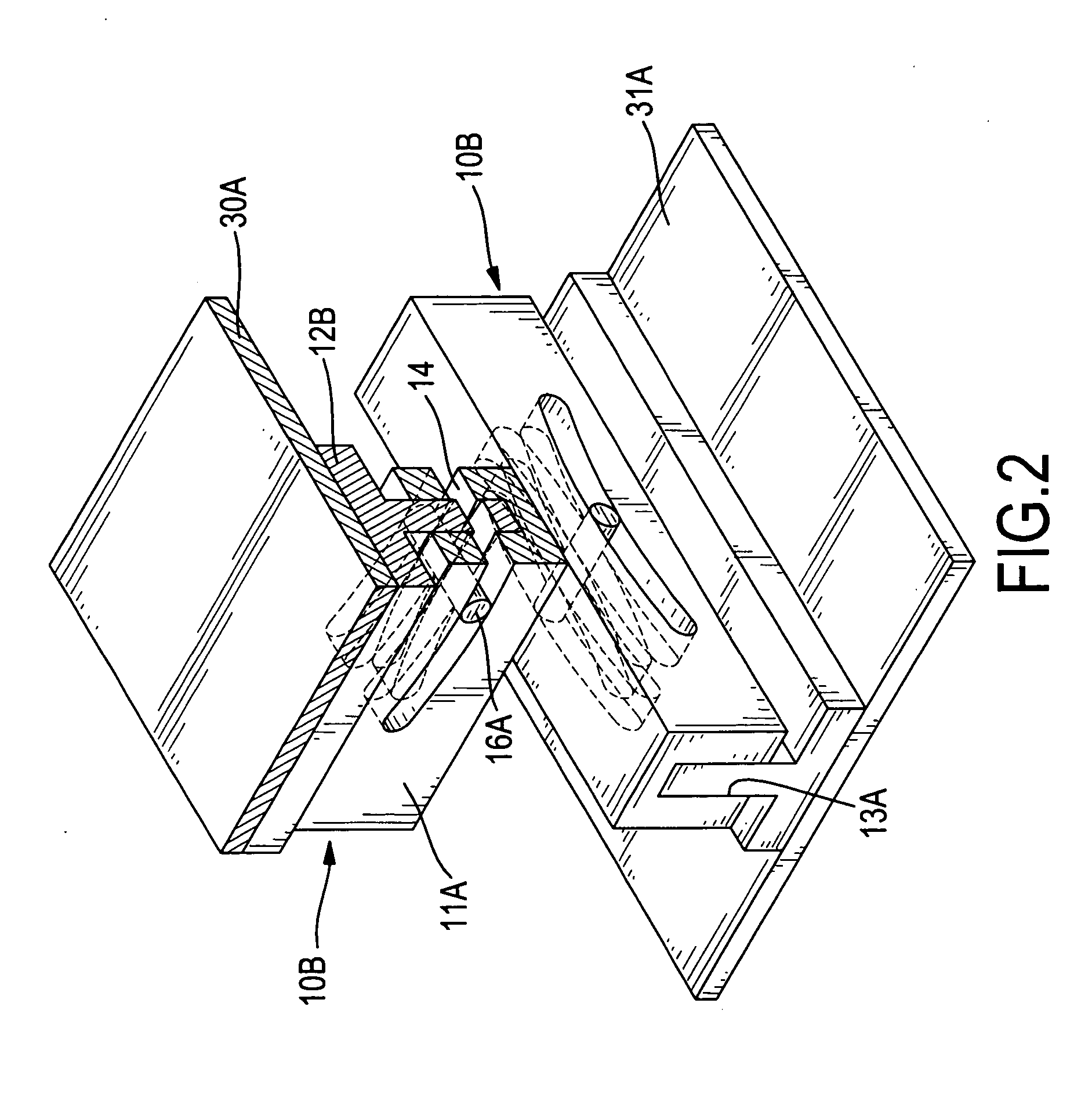

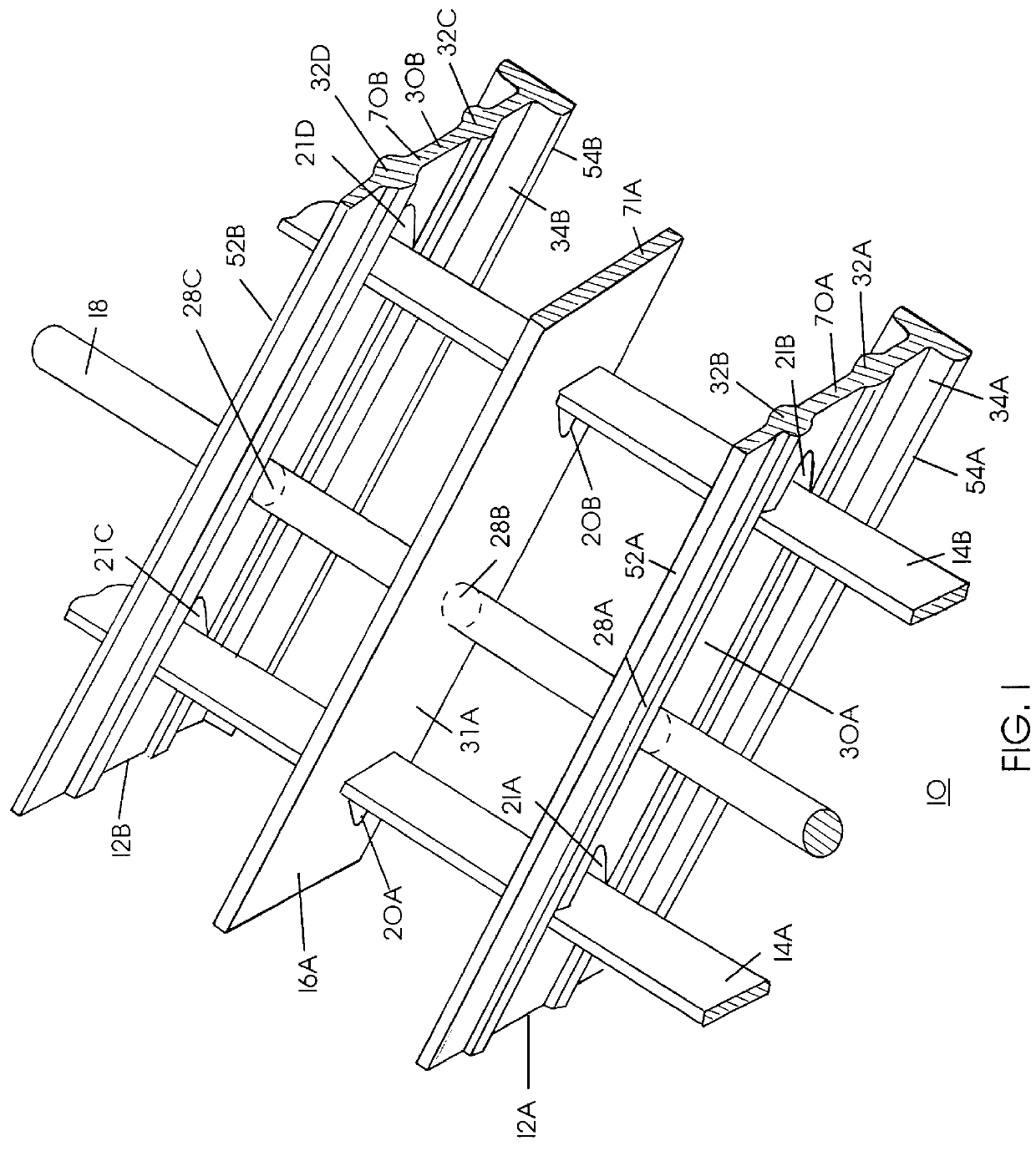

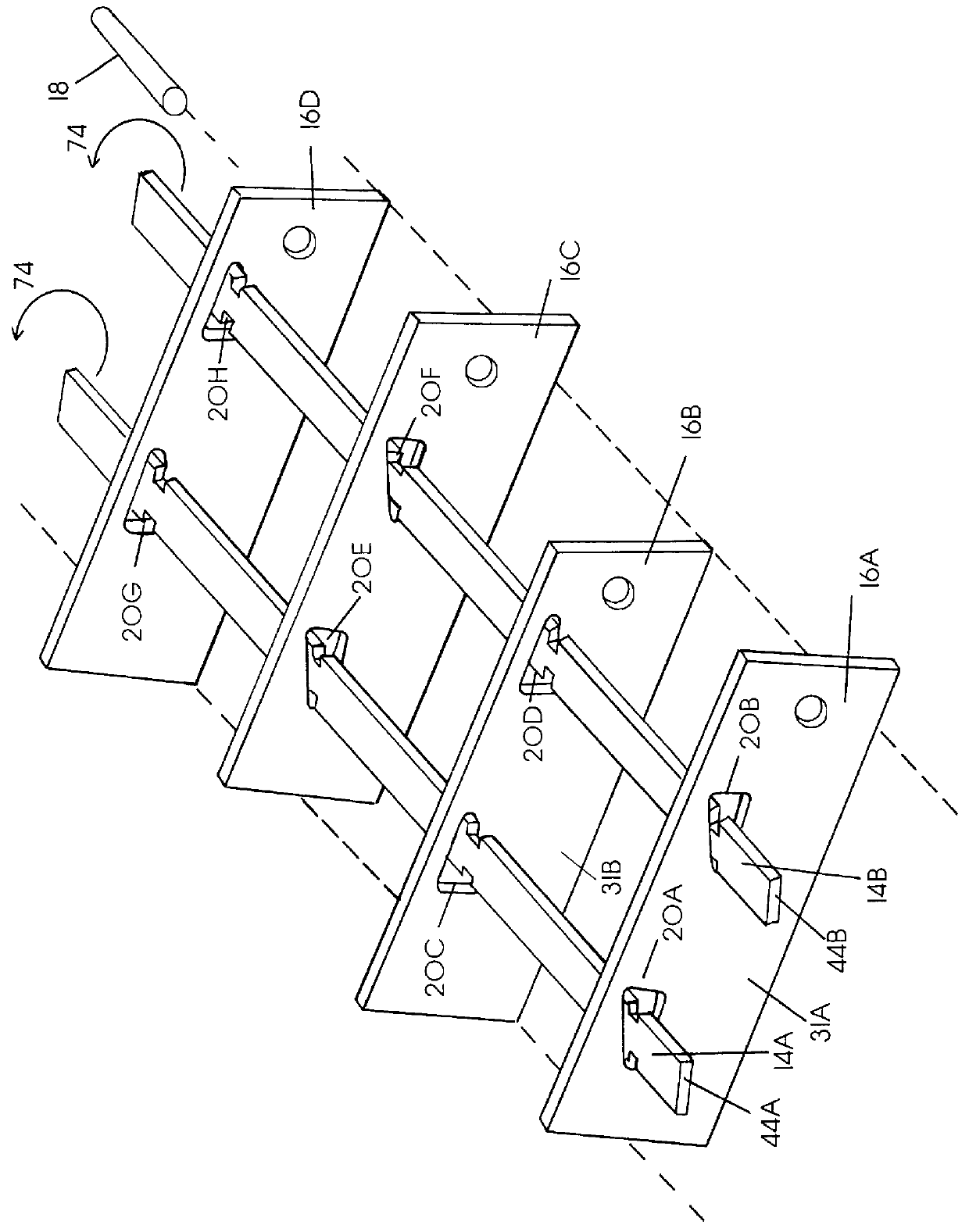

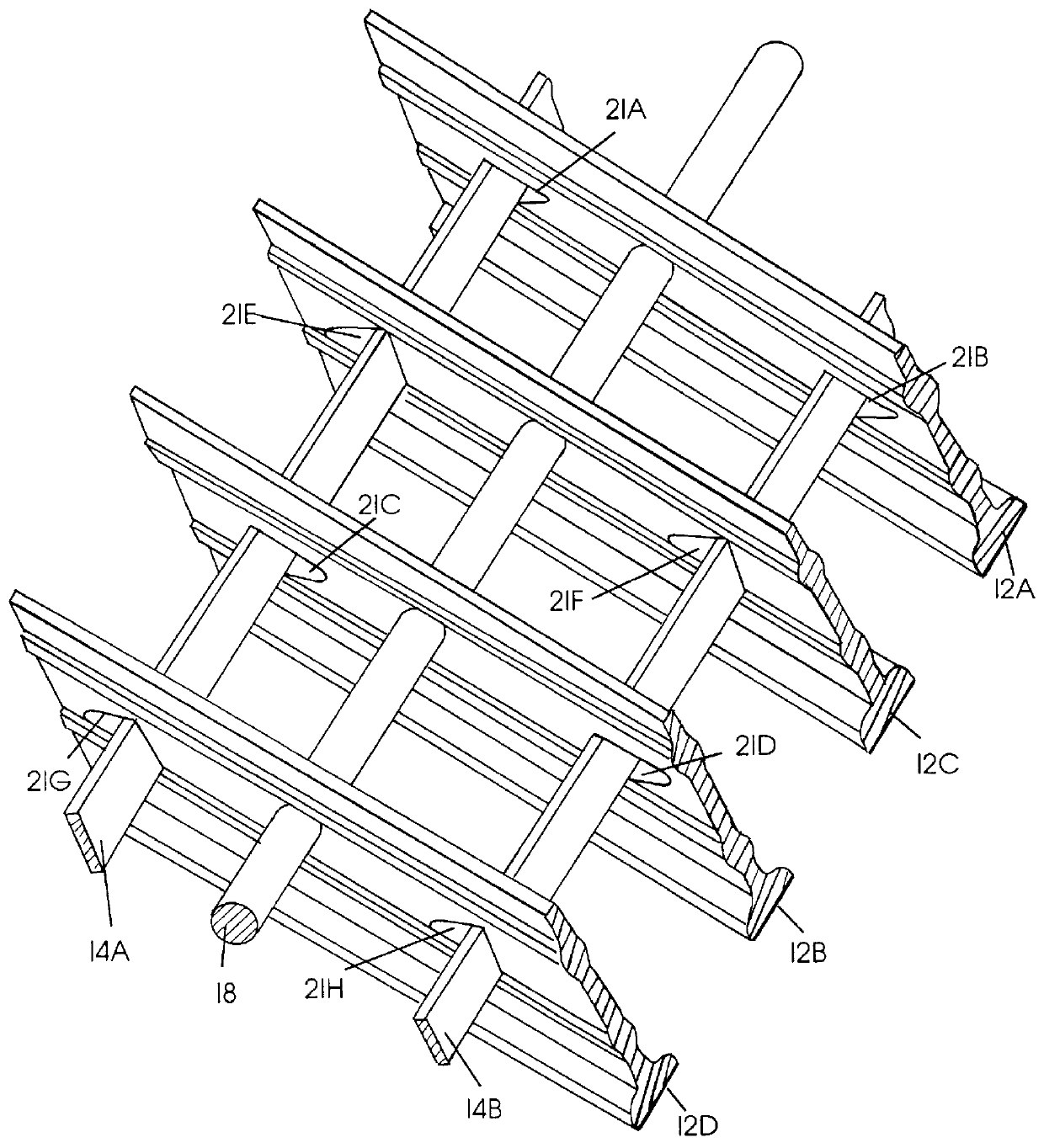

Automated weldless inter-locking grating assembly for bridge decks and like structures

InactiveUS6018833AEasy and fast assemblySubstantial rigidityPaving reinforcementsSingle unit pavingsHorizontal forceGrating

An automated weldless inter-locking grating assembly for bridge decks and the like which includes a plurality of primary load-bearing members located laterally, a plurality of transverse secondary load-bearing members and a plurality of trimorphic load-bearing members. Secondary load-bearing structural members are inserted sideways into apertures of primary load-bearing members and trimorphic load-bearing members. Thus, when a horizontal force is applied to alternate primary or trimorphic load-bearing members or any combination thereof, rotation of secondary load-bearing member or members occur to efficiently and automatically lock secondary load-bearing member or members into primary and trimorphic load-bearing member or members completing assemblage thereof into a rigid structural form.

Owner:STARGRATE SYST IN

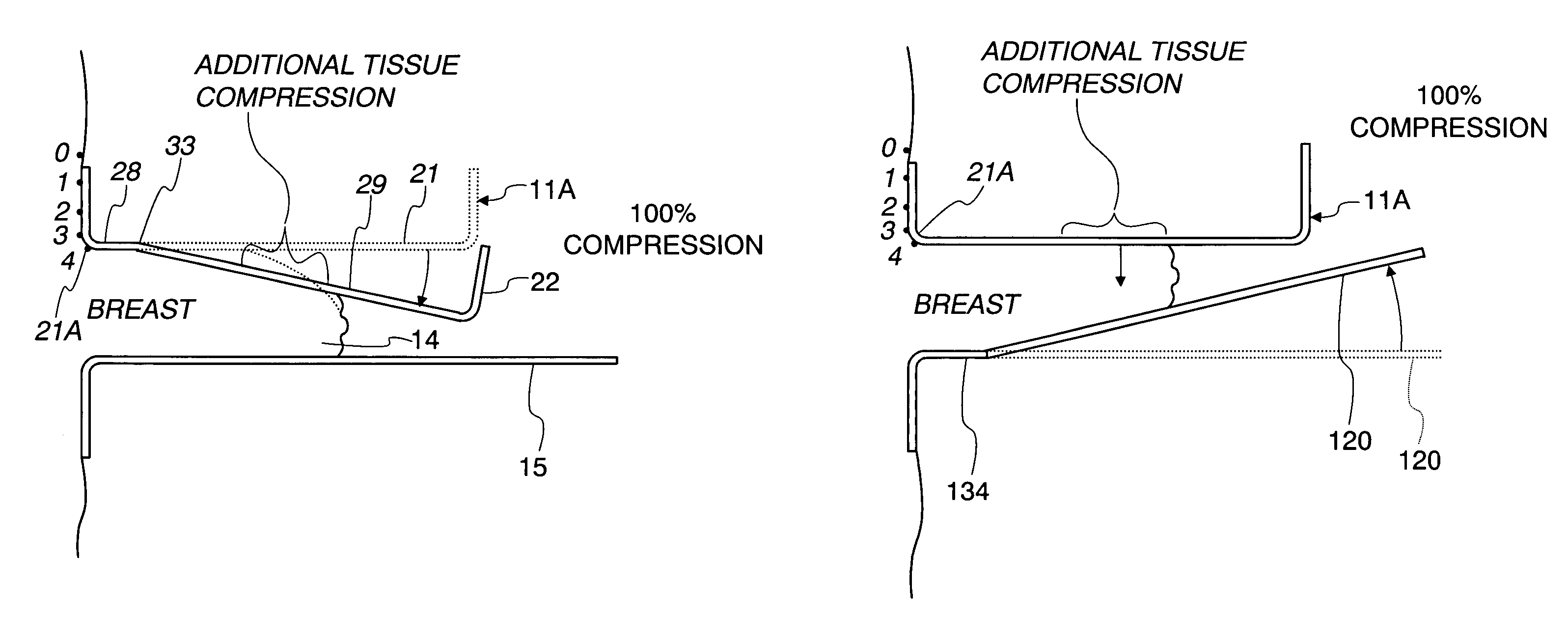

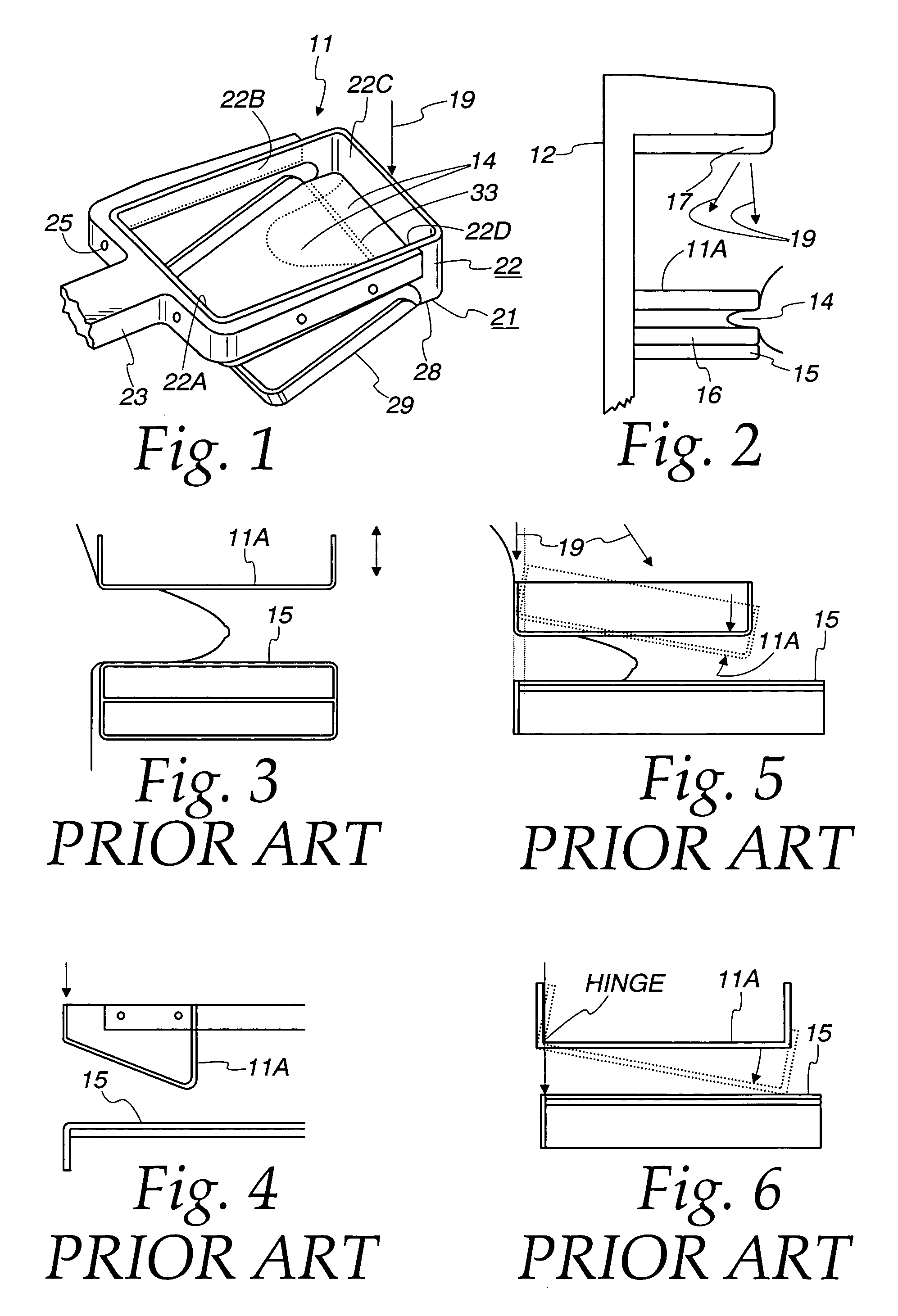

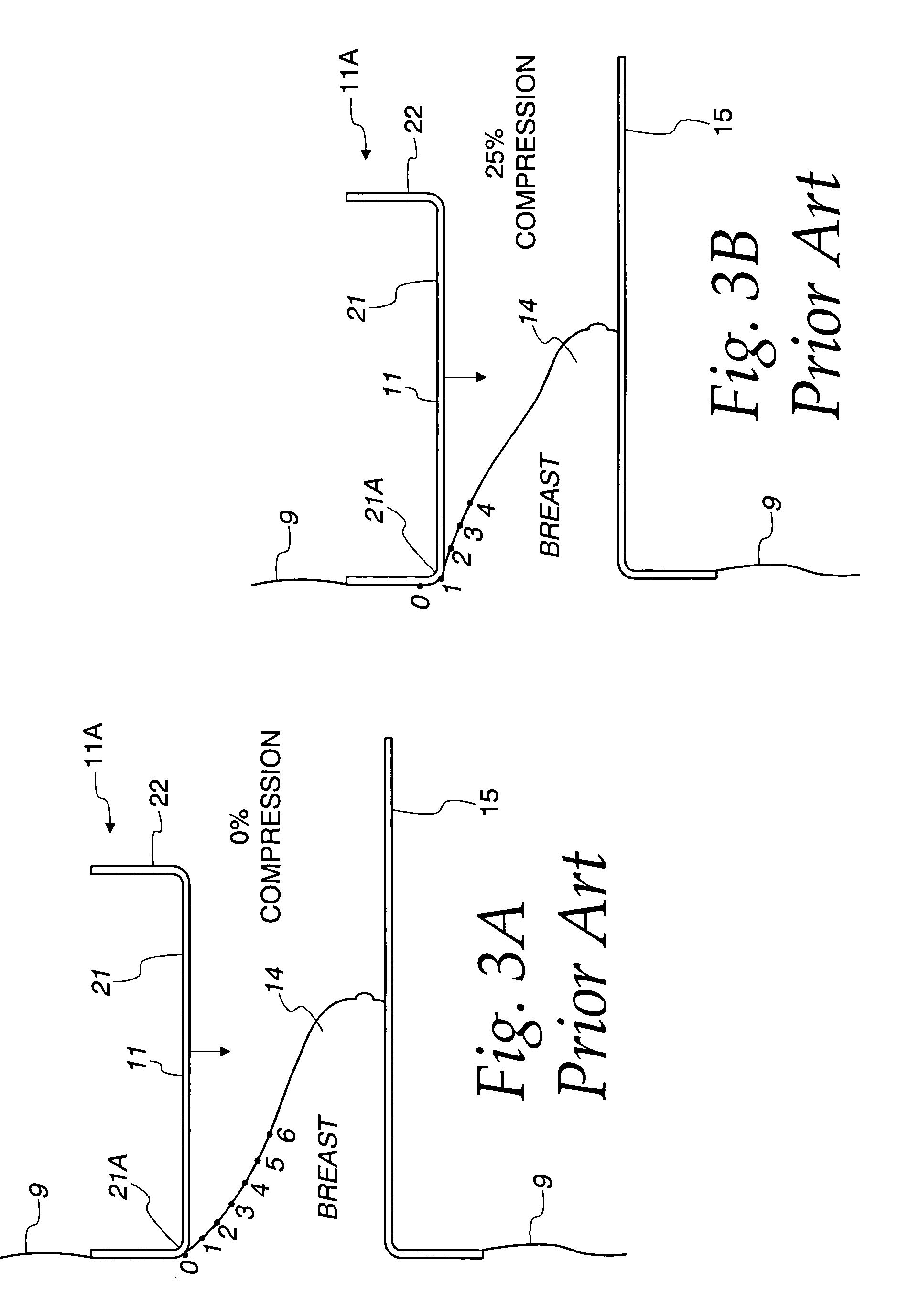

Method and apparatus for x-ray mammography imaging

InactiveUS6999553B2Relieve anxietySignificant compressionPatient positioning for diagnosticsMammographyImage detectionX-ray

Owner:ADVANTAGE IMAGING

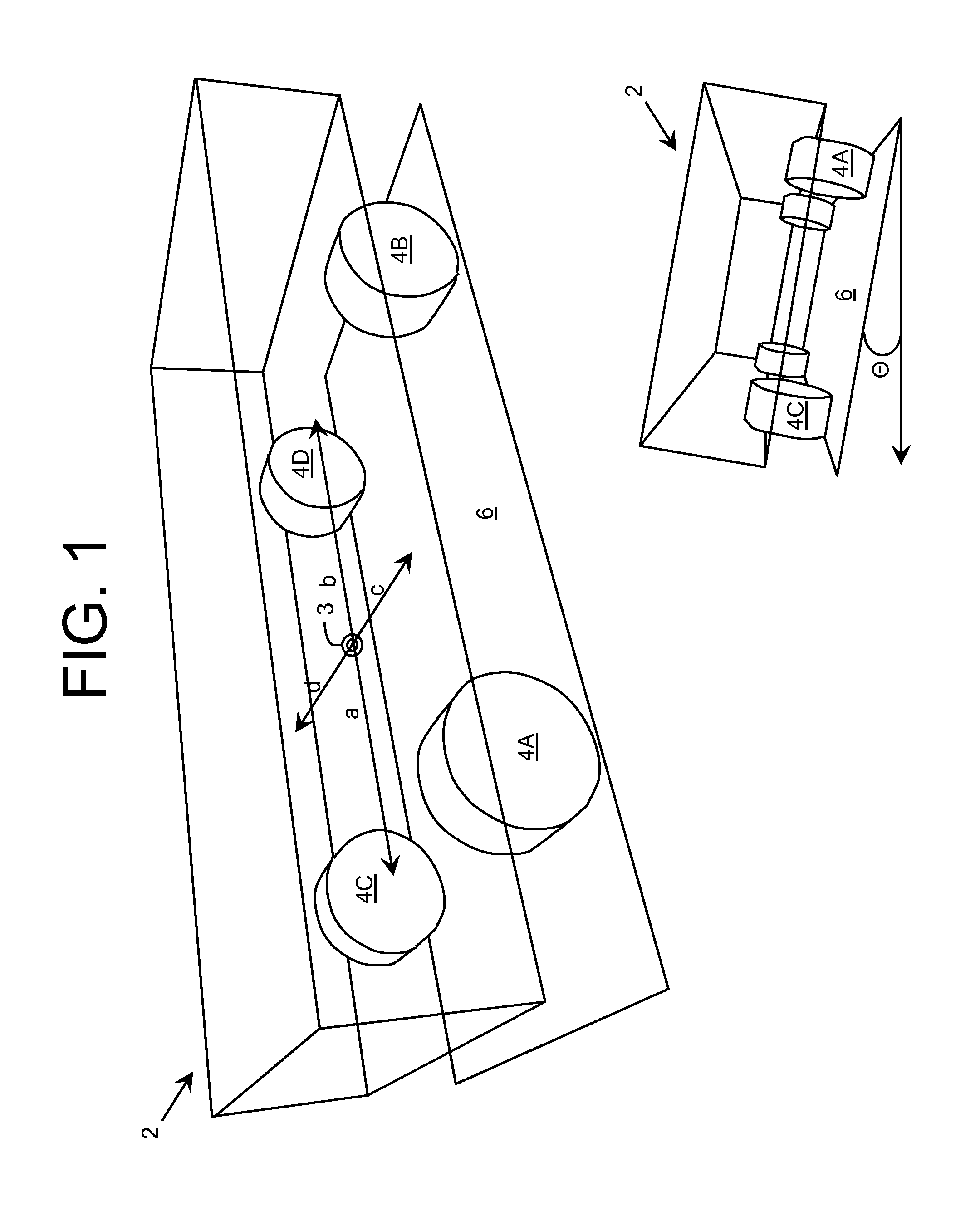

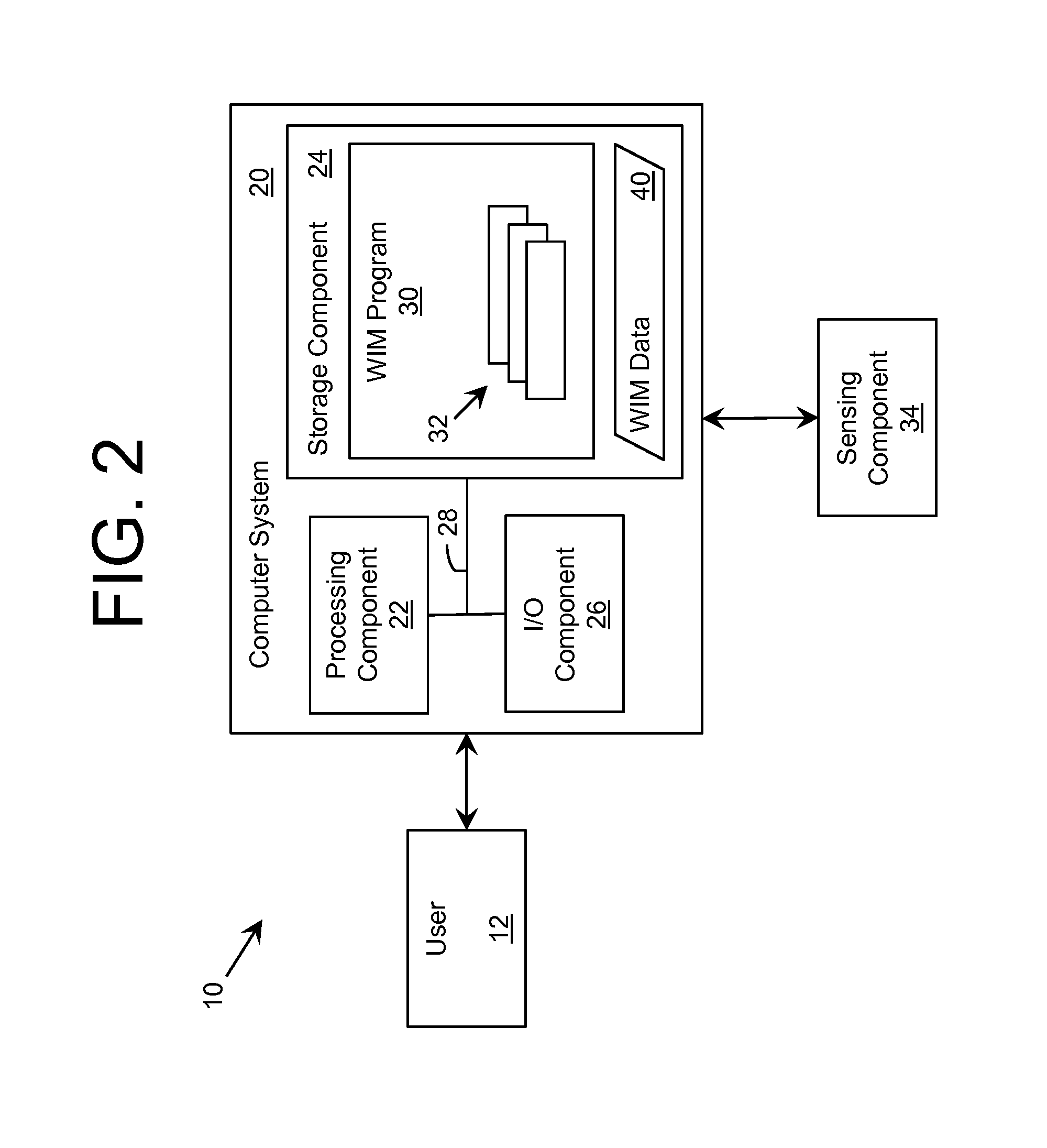

Object evaluation accounting for motion-related dynamic forces

ActiveUS9121747B2Weighing auxillary devicesSpecial purpose weighing apparatusHorizontal forceEngineering

A solution for evaluating an object, which accounts for various motion-related dynamic forces is provided. In an embodiment, the object is a vehicle and the evaluation includes determining a set of static weights corresponding to the vehicle as it moves through a sensing element. The sensing element can include a load plate with vertical force sensing devices and horizontal force sensing devices located below the load plate. Analysis of measurement data acquired by the force sensing devices can enable calculation of the set of static weights corresponding to the vehicle.

Owner:INT ELECTRONICS MACHINES

Method and apparatus for laying floors

ActiveUS7398628B2Avoid liftingThe equipment is easy to operateLifting devicesRoof toolsHorizontal forceEngineering

A tool and method for abutting an individual floor panel which is near an obstruction, such as a wall, to the assembled floor. The tool and method provide a rod having a flanged member at one end. The flanged member has a notch in its vertical flange which contacts the floorboard to be abutted, requiring a minimal amount of space between the obstruction and floorboard to be set. A sliding weight mounted on a rod can then be slid toward an impact surface resulting in a horizontal force being applied to the individual floorboard thereby abutting or setting that floorboard with respect to the assembled floor. An especially useful application for the device and method is in the installation of a tongue-in-groove laminate floor in which the individual floorboards have a tongue and groove connection on their ends.

Owner:VAN HORNE JR JEFFERSON

Apparatus for generating horizontal forces in aerial vehicles and related method

ActiveUS20070095971A1Straighten and improve flowInhibition of flow separationVertical landing/take-off aircraftsRotocraftHorizontal forceVehicle frame

A vehicle, comprising: a vehicle frame; a duct carried by the vehicle frame with the longitudinal axis of the duct perpendicular to the longitudinal axis of the vehicle frame; a propeller rotatably mounted within the duct about the longitudinal axis of the duct to force an ambient fluid through from an inlet at the upper end of the duct through an exit at the lower end of the duct, and thereby produce an upward lift force applied to the vehicle; a first plurality of substantially parallel, spaced vanes non-pivotally mounted across at least the inlet end of the duct; and fluidic means for affecting the ambient fluid flow around the vanes to generate horizontal force components to the lift force applied to the vehicle.

Owner:URBAN AERONAUTICS

Strain-control type tension-shearing direct shear apparatus

ActiveCN104713788AHigh precisionReduce frictionMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesHorizontal forcePull force

The invention particularly provides a strain-control type tension-shearing direct shear apparatus. The strain-control type tension-shearing direcot shear apparatus comprises a base and a bracket, wherein the base is provided with a horizontal-force applying device, a measuring device, an upper shearing box and a lower shearing box; the bracket is provided with an axial-tension loading device; the horizontal-force applying device consists of a pushing seat, a speed changing box, a sliding frame II, a force-measuring ring bearing, a force-measuring ring part and a locking nut; the measuring device comprises a force measuring ring, a horizontal displacement meter and a vertical displacement meter; and the axial-tension loading device mainly comprises a pneumatic control adjusting device, an air-pressure chamber, a force transferring rod, a piston and a connecting seat. The strain-control type tension-shearing direct shear apparatus provided by the invention has the advantages that the modes of electric-control horizontal loading and axial loading of the air-pressure transferring force are adopted; by a horizontal-force applying device, the measuring device and the axial-tension loading device, stable-force application on a test sample is realized; and the structure is simple, the operation is convenient, the control is stable and the data is reliable.

Owner:XIAN CHANGQING TECH ENG

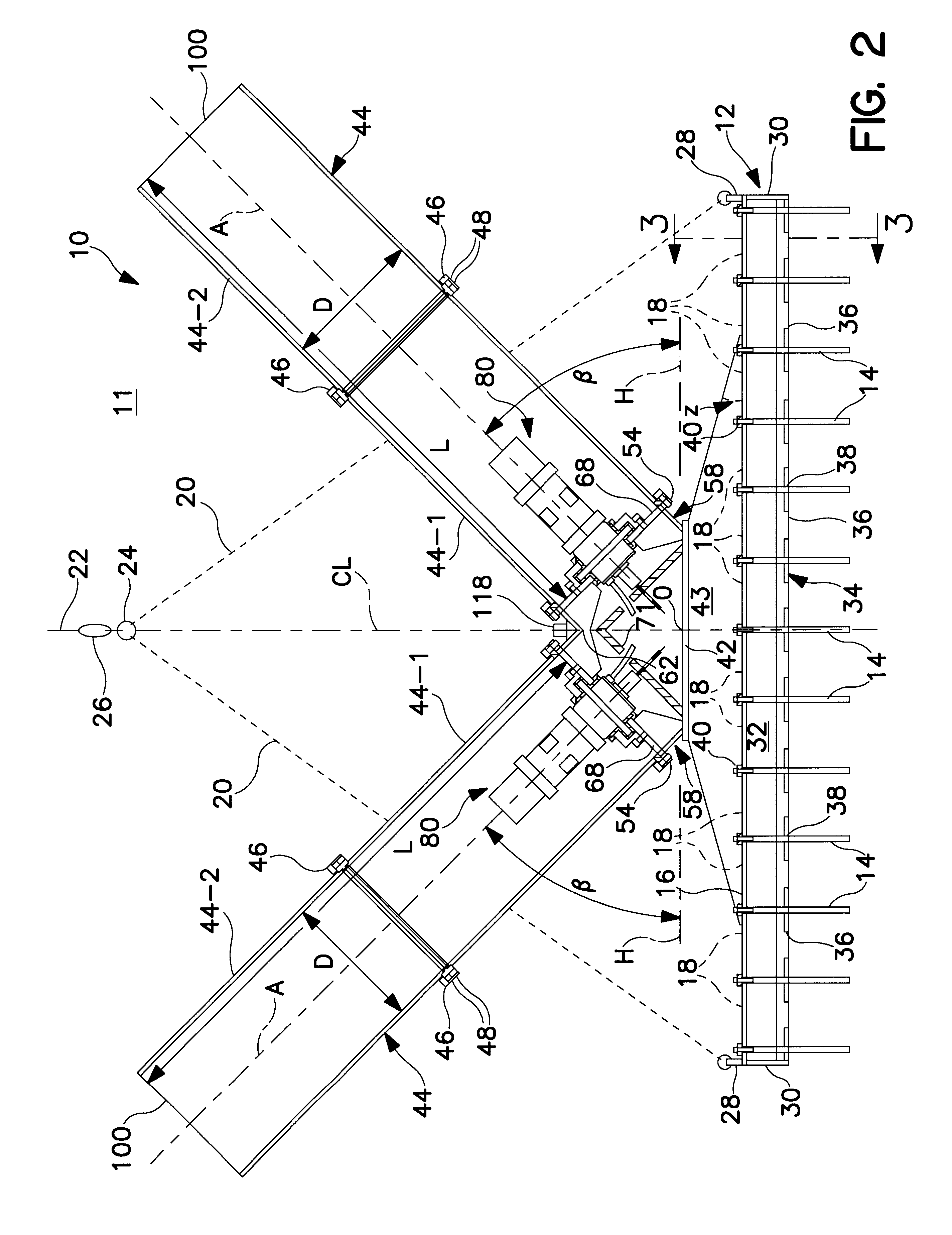

Controlled-polarization marine seismic shear-wave source

InactiveUS6612396B1Turn easilySeismic energy generationSeismology for water-covered areasOcean bottomAcute angle

Controlled-polarization marine seismic shear-wave source has a base suitable for positioning on a seafloor, beneath a water body. Twin water-blast tubes (seismic-impulse-generation thrusters) are mounted on the base, aimed upwardly, outwardly in opposite directions at equal acute angles beta relative to the base. These blast tubes are positioned symmetrically on opposite sides of vertical centerline CL of the source. When submerged, water enters open mouths at upper ends of the tubes. The base has multiple downwardly projecting blade-like teeth for penetrating into the seafloor. Firing a compressed-air discharger mounted in a lower end of a water-blast tube hurls a powerful slug of water upwardly along the tube, producing a powerful reaction impulse acting downwardly generally parallel with the tube axis. These blade-like teeth, engaging with seafloor material, couple into the seafloor horizontal force components of reaction impulses, thereby propagating simultaneously into the body of the seafloor horizontally-polarized shear waves (SH-Waves) and vertically-polarized shear waves (SV-Waves). Firing one blast tube produces SH-Waves and SV-Waves of first polarities. Firing the other tube produces SH-Waves and SV-Waves of second polarities, respectively opposite to the first polarities. Both tubes are fired simultaneously for propagating compressional P-Waves. While lifting slightly by a swivel cable, azimuthal orientations of the source and resulting shear-wave orientations are controllably changeable by simultaneously firing pneumatic thrusters aimed outwardly from diagonally opposite corners of the base.

Owner:BOLT TECH CORP

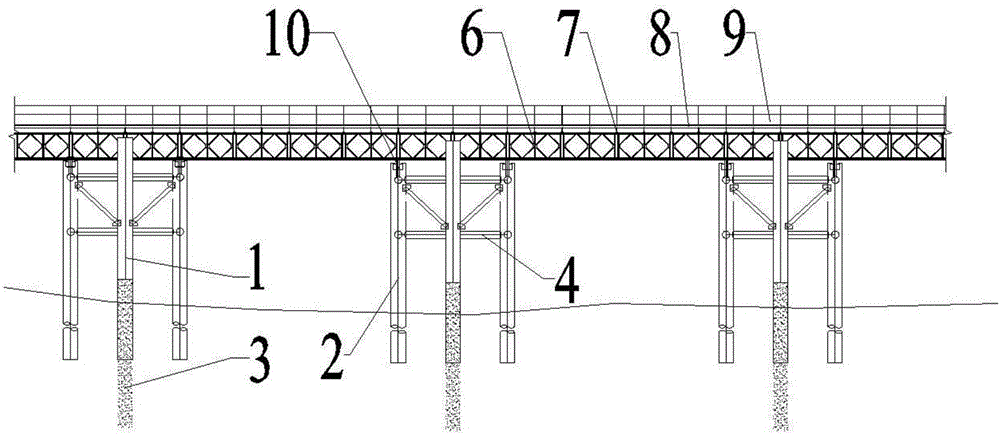

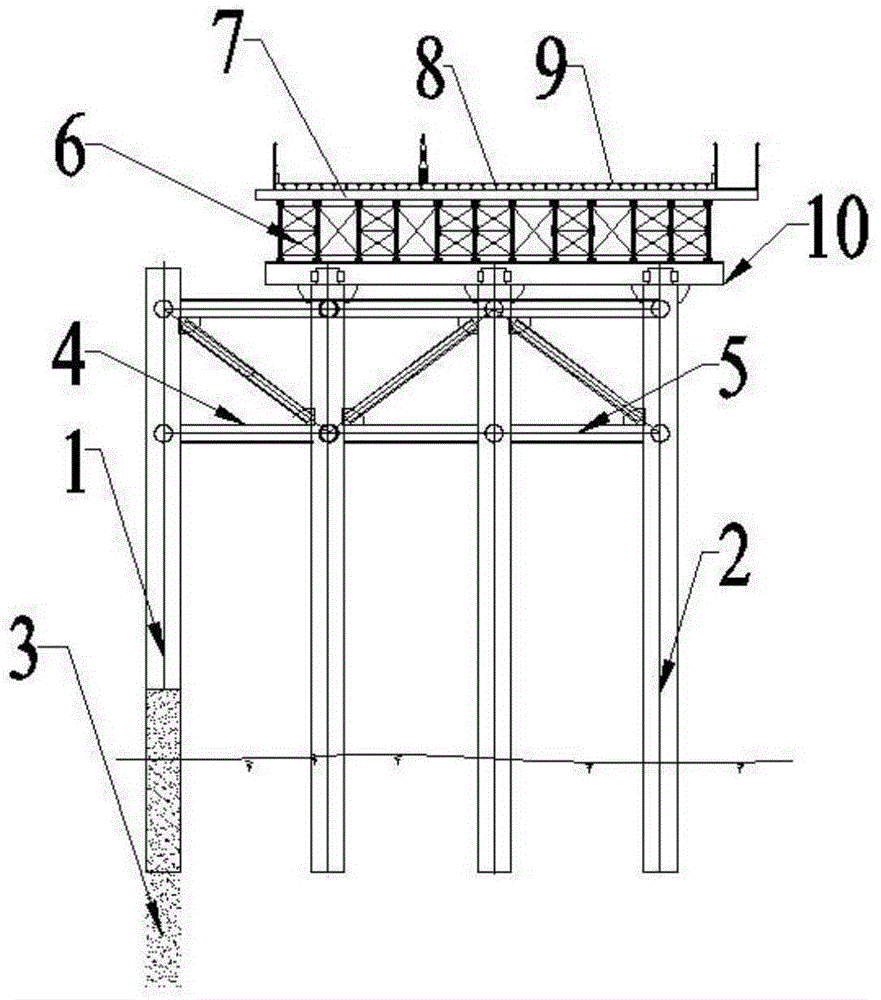

Steel trestle provided with steel anchor pile and construction method of steel trestle

InactiveCN104404861AMake up for the lack of poor stabilityImprove structural stabilityTruss-type bridgeBridge erection/assemblyHorizontal forceReinforced concrete

The invention relates to the field of bridge buildings, in particular to a steel trestle provided with a steel anchor pile and a construction method of the steel trestle. The steel trestle comprises a steel pipe support structure and the steel anchor pile, wherein the steel anchor pile is of a cylindrical and hollow tubular structure, reinforced concrete is poured in the steel anchor pile, the lower end of the reinforced concrete is fixed on a riverbed, and the steel anchor pile is connected to the steel pipe support structure through a first truss structure; a bailey truss which is arranged along the bridge direction, a transverse distributive girder which is arranged along the transverse bridge direction, and a longitudinal distributive girder and a bridge panel which are arranged along the bridge direction are fixed on the upper end of the steel pipe support structure from bottom to top in sequence. According to the steel trestle provided with the steel anchor pile and the construction method of the steel trestle, the horizontal force borne by a steel pipe pile is resisted by utilizing the steel anchor pile, so that stability of the steel pipe pile is effectively enhanced, furthermore, through drilling in the steel anchor pile, the depth for vibration sink of the steel anchor pile is reduced and the construction difficulty is reduced. The problem of difficulty in construction of the steel pipe pile with large flow speed in a cobblestone area is effectively solved, meanwhile, structural stability of the steel trestle is effectively improved, and the promotion value is great.

Owner:CCCC SECOND HARBOR ENG

Inductrack configuration

InactiveUS20050204948A1Little strengthImprove propertiesLinear bearingsRailway vehiclesHorizontal forceLevitation

A simple permanent-magnet-excited maglev geometry provides levitation forces and is stable against vertical displacements from equilibrium but is unstable against horizontal displacements. An Inductrack system is then used in conjunction with this system to effect stabilization against horizontal displacements and to provide centering forces to overcome centrifugal forces when the vehicle is traversing curved sections of a track or when any other transient horizontal force is present. In some proposed embodiments, the Inductrack track elements are also employed as the stator of a linear induction-motor drive and braking system.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com