Patents

Literature

112 results about "Slip rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The slip rate is rate of motion when the amount of distance travelled is divided by the time interval. The slip rate is measured in millimeter per year or meters per thousand years. Slip rate of a fault can be calculated by the recurrence interval of the fault.

Slip ratio estimating device and slip ratio control device

InactiveUS20090210128A1Accurate estimateQuick implementationSpeed controllerElectric motor controlMeasuring instrumentRotation velocity

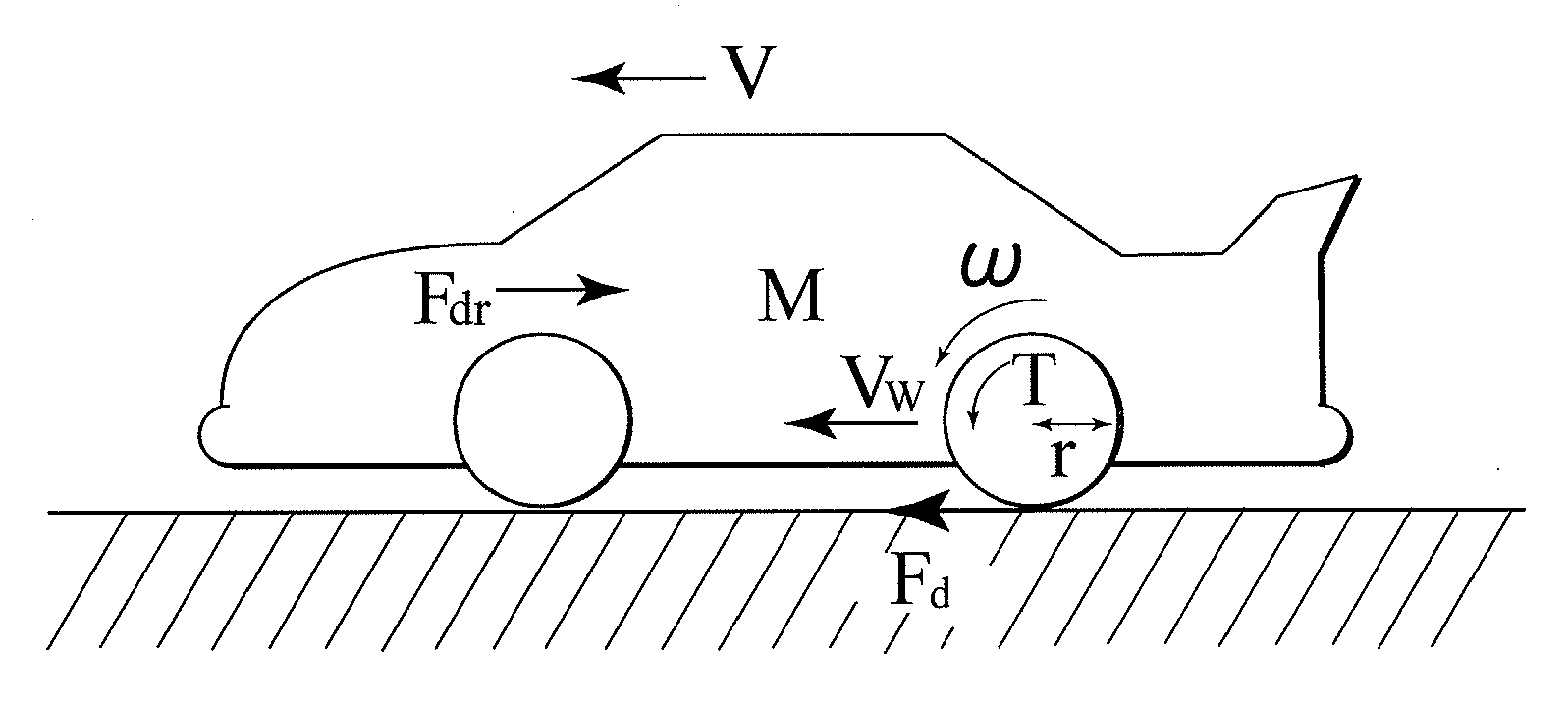

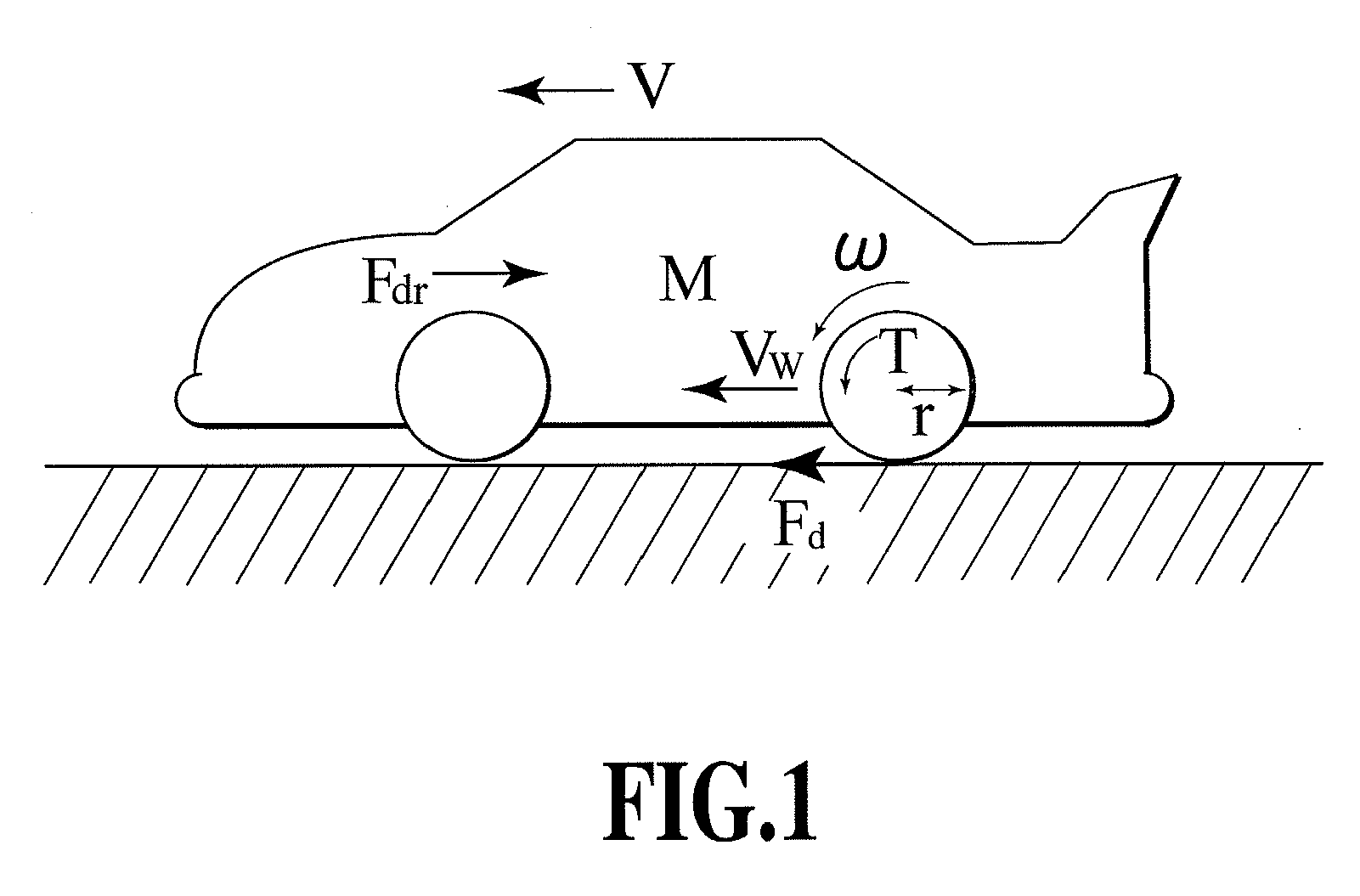

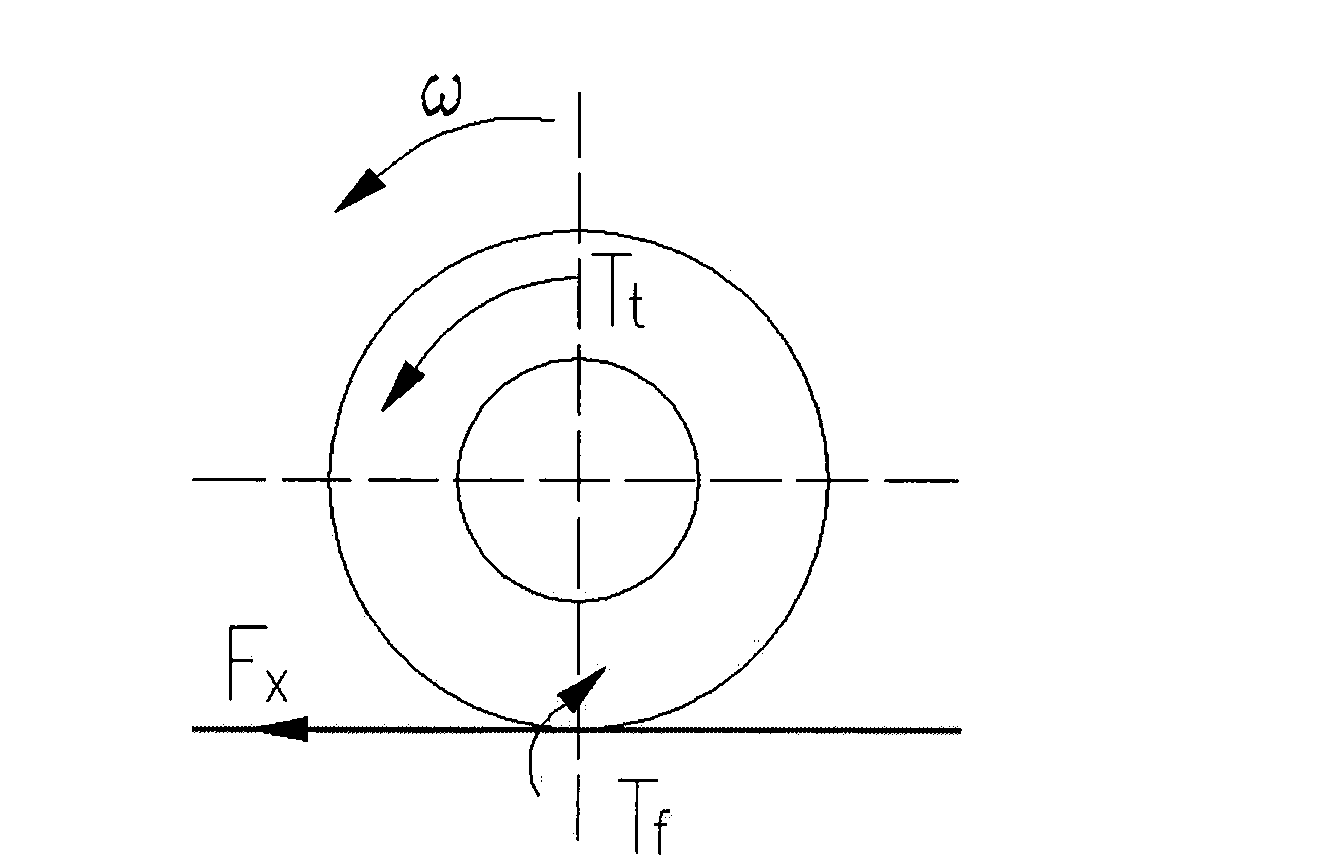

The present invention provides a slip rate estimating device measuring a slip ratio without the need for a body speed and a slip ratio control device using the slip ratio estimating device. A motor torque measured by a torque measuring instrument is input to each of a vehicle model (601) and an SRE (602) that performs calculations including time differentiation of the slip ratio. The vehicle model (601) derives a wheel rotation speed, a wheel rotation acceleration, and a body speed. The vehicle model (601) outputs the wheel rotation speed and the wheel rotation acceleration to the SRE (602). The SRE (602) outputs the slip ratio based on the motor torque, the wheel rotation speed, and the wheel rotation acceleration.

Owner:NAT UNIV CORP YOKOHAMA NAT UNIV

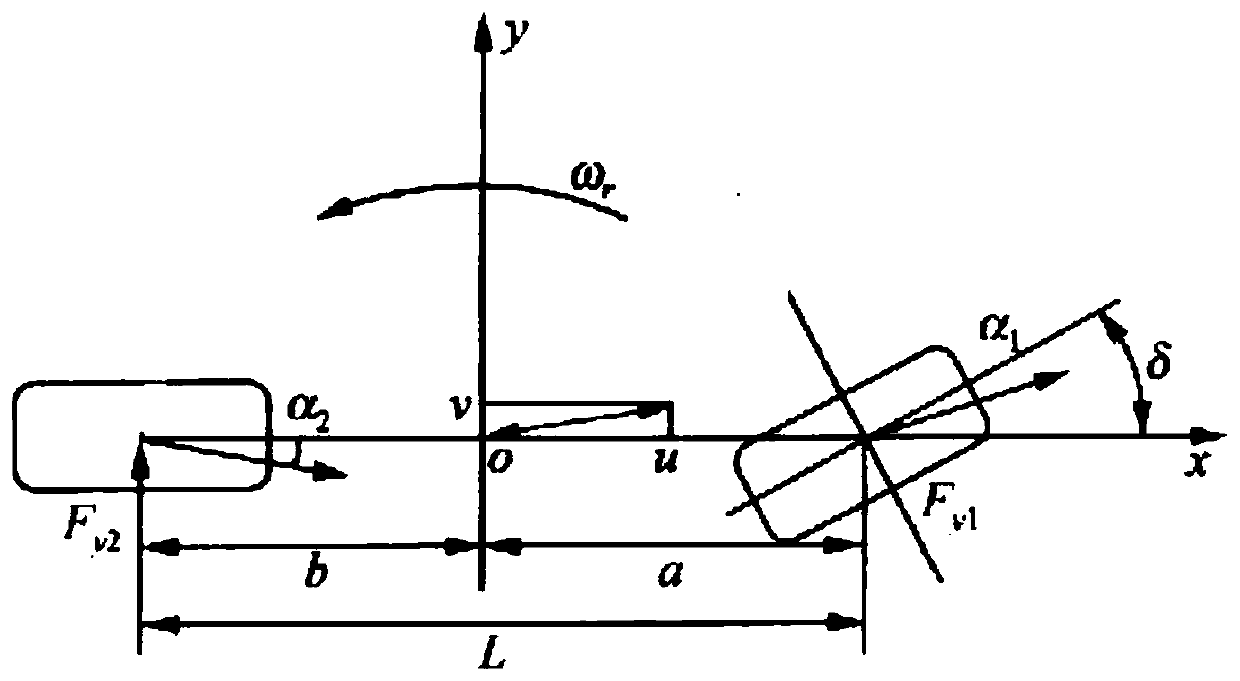

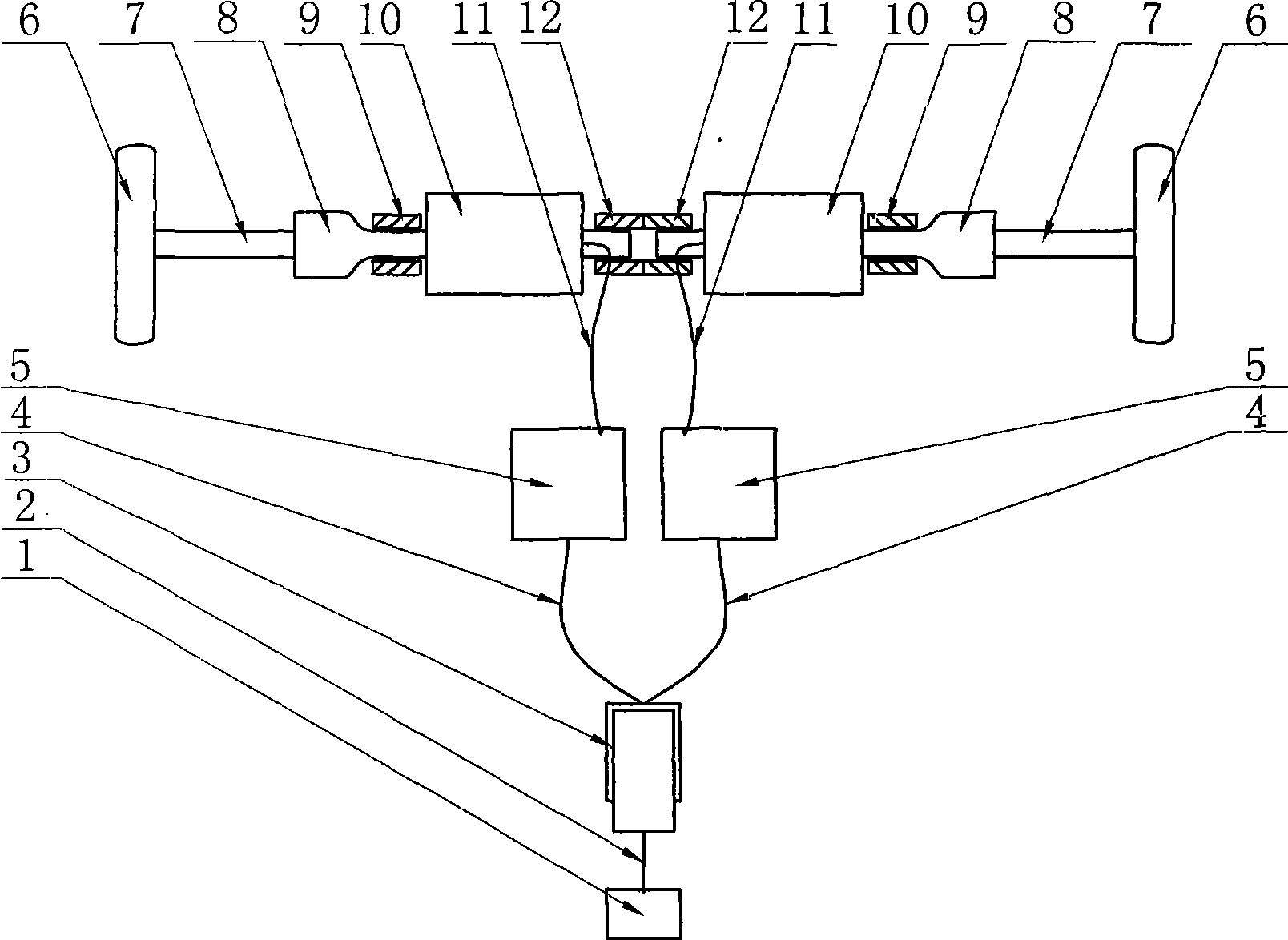

Electric motor car differential steeling control method based on slip rate control

InactiveCN101574979AImprove driveabilityImprove steering performanceSpeed controllerSteering linkagesWheel speed sensorSteering control

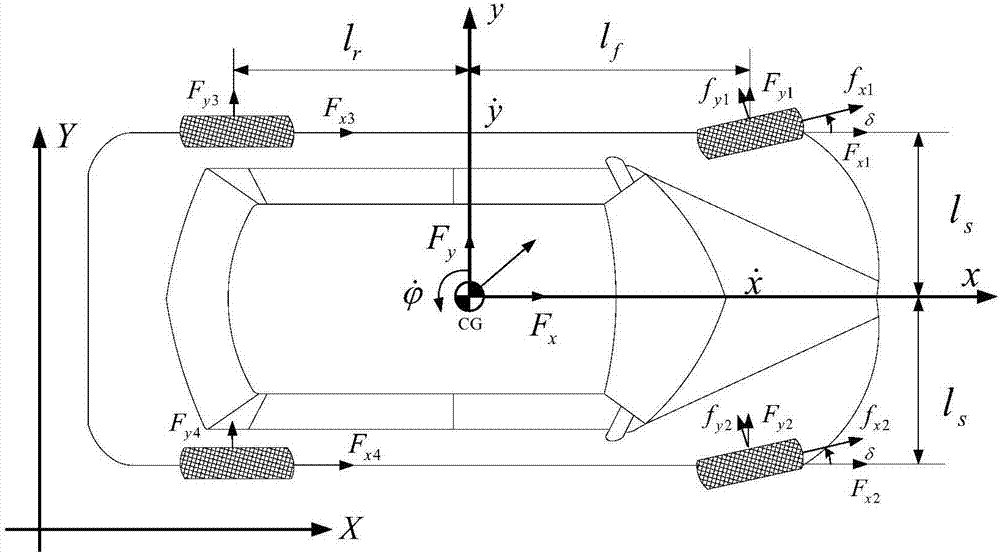

The invention provides an electric motor car differential steeling control method based on slip rate control. The method comprises the following steps of: (1) measuring the back wheel speed of the electric motor car, the actual output torque of a drive motor and the side speed of the car according to a wheel sped sensor; and (2) calculating the side speed and the heading angle peed of the electric motor car according to two freedom steering models, and then calculating the slip angles of four wheels, thereby calculating the rotational speed of the four wheels; and using a special arithmetic to realize the control on the electric differential steeling of a hub electric motor car. The electric motor car differential steeling control method based on slip rate control combines the calculation of torque distribution with the slip rate of the wheels to lead a designed electric differential steeling mechanism to have the effect of differential lock simultaneously when having the differential and also have the functions of reducing the speed and increasing the torque, thus greatly improving the running trafficability characteristic and the steering performance of the electric motor car, not only achieving the effect of a mechanical differential mechanism on the aspect of function, but also improving the transmission efficiency and reducing the complexity of a mechanical system.

Owner:CHONGQING UNIV

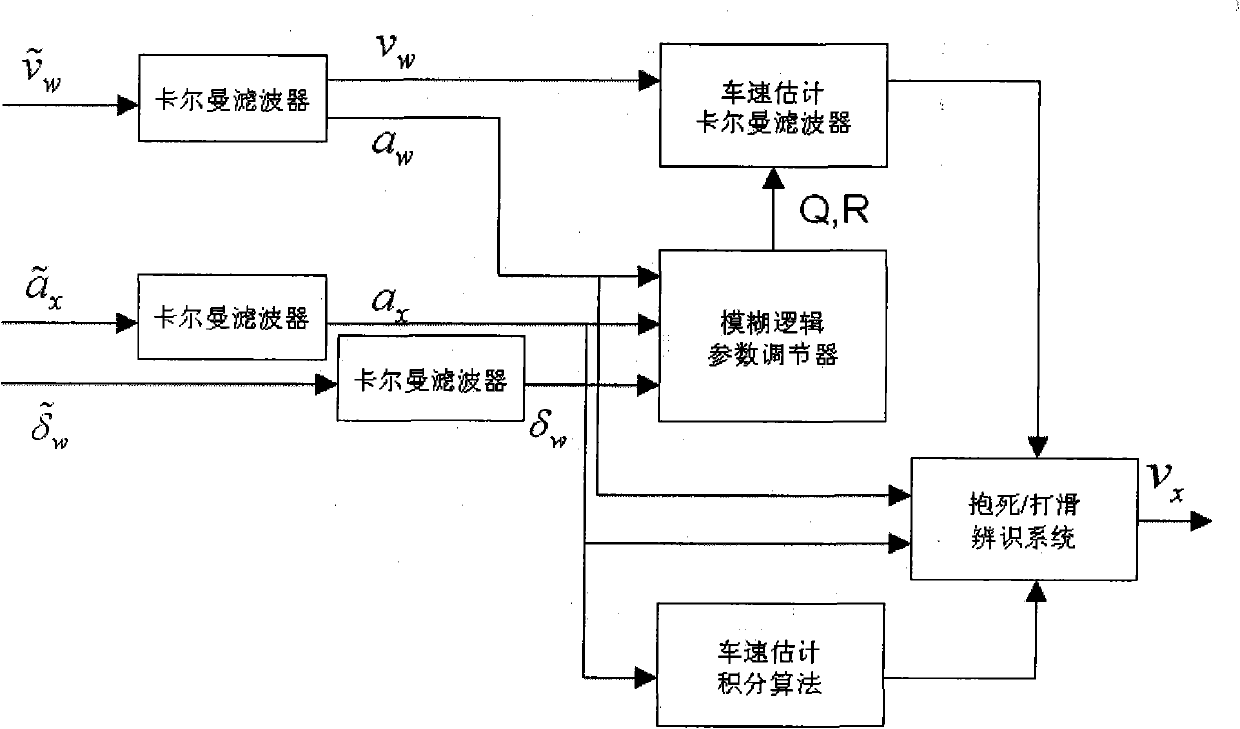

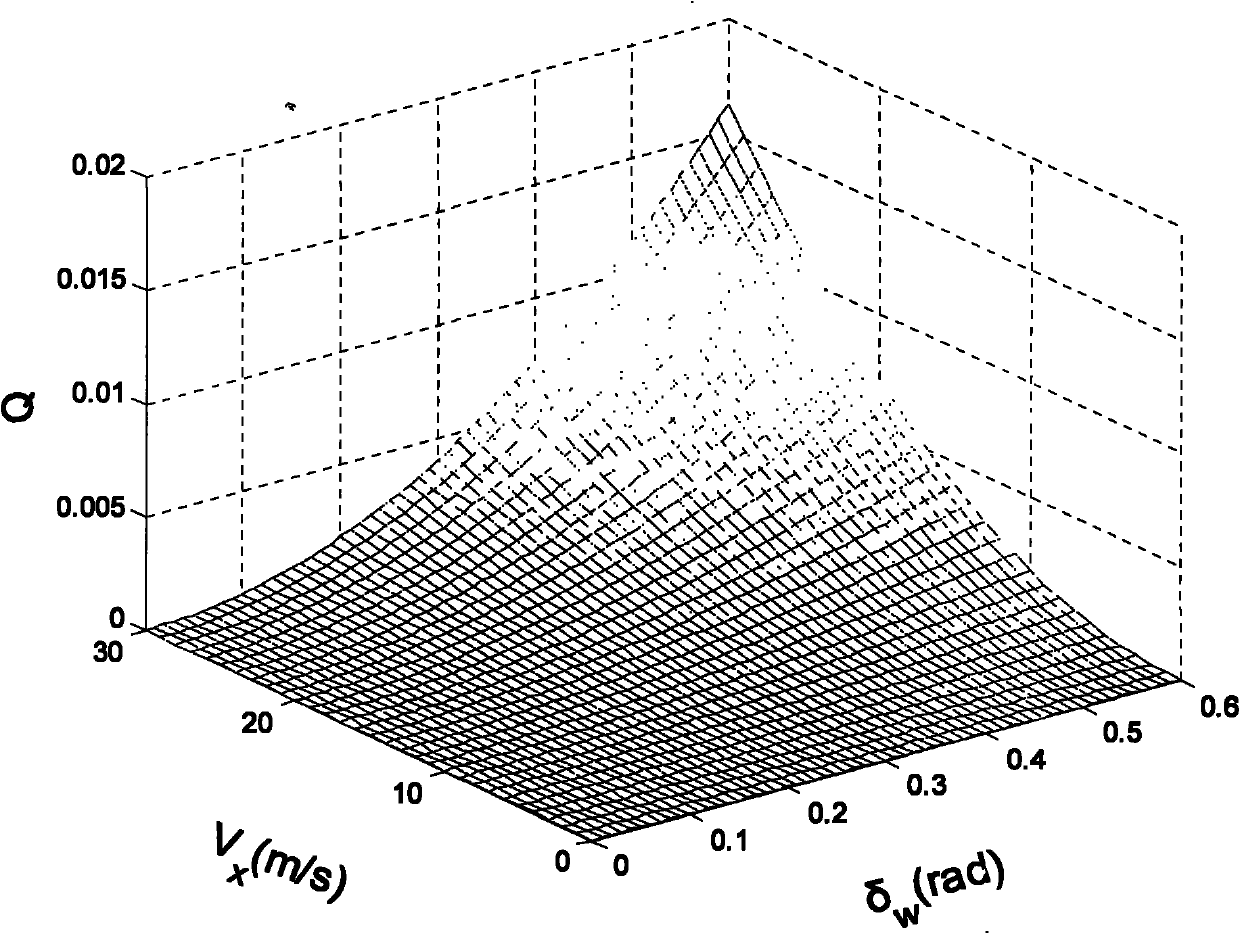

Longitudinal speed evaluation method of full-wheel electrically-driven vehicle

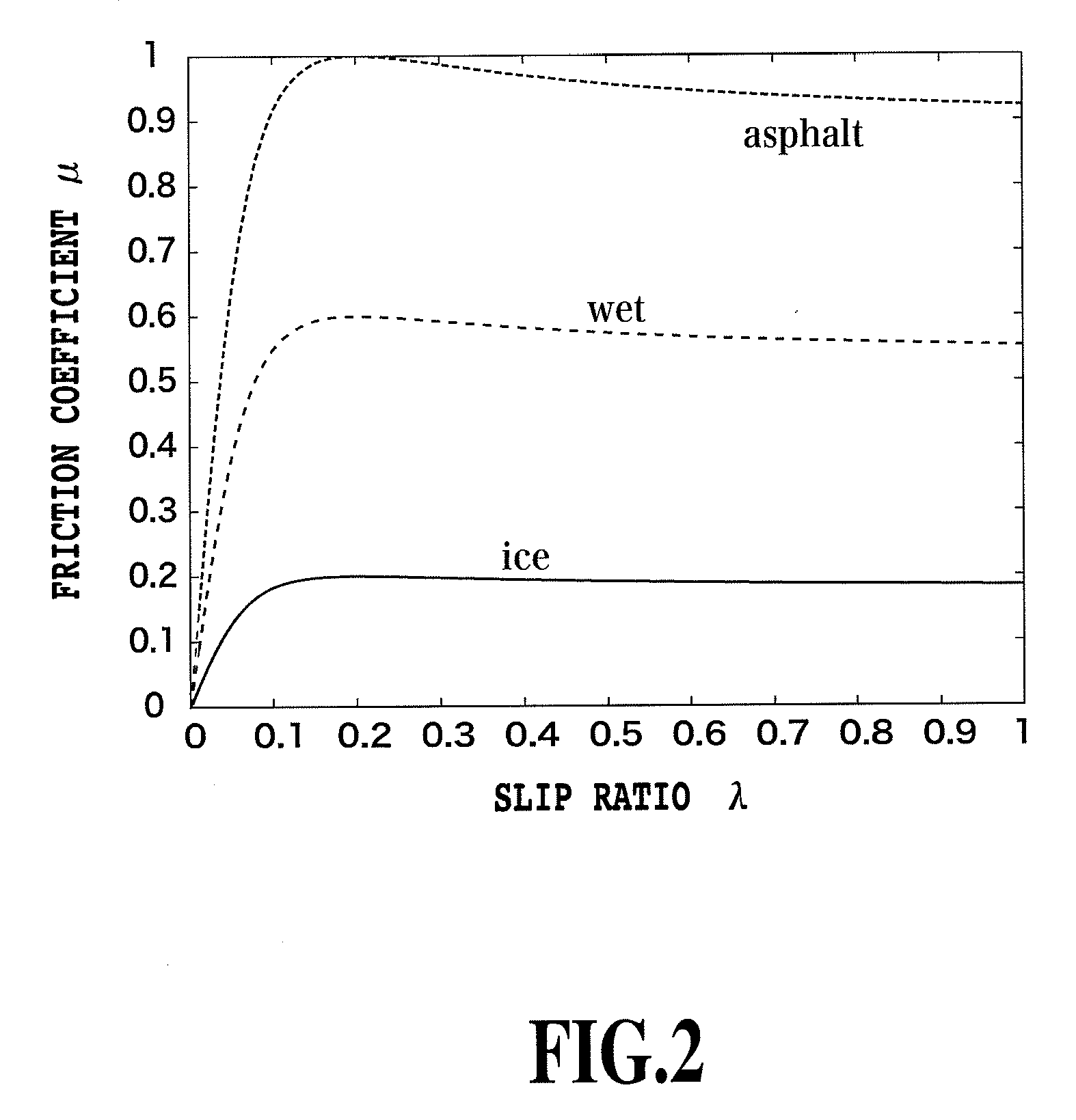

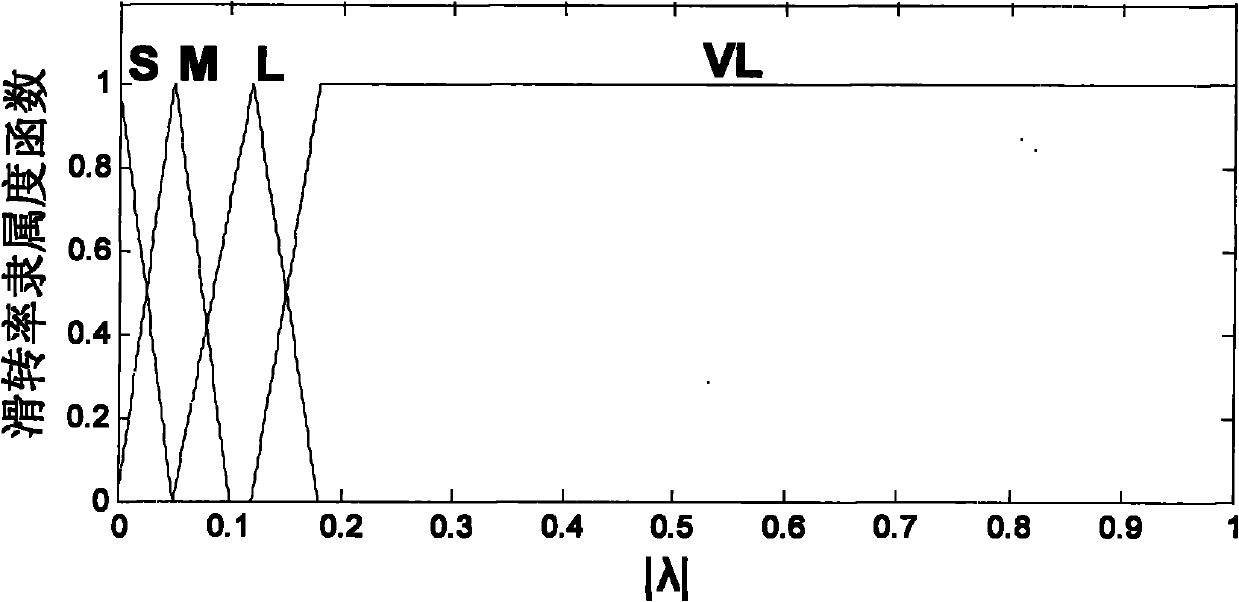

The invention relates to a longitudinal speed evaluation method of a full-wheel electrically-driven vehicle. The method comprises the following steps: 1) configuring a speed measuring system; 2) collecting signals shown in the specification in real time; 3) carrying out filtering treatment on the collected signals in a Kalman filtering mode; 4) establishing a speed evaluation formula based on a Kalman filter space equation structure and a speed evaluation formula based on integrated acceleration; and 5) switching discretion by using a speed evaluation algorithm: setting a threshold value for the absolute value of the trackslip / slip rate lambda as epsilon, when the absolute value of lambda is less than the epsilon, adopting the speed evaluation formula based on the Kalman filtering, and when the absolute value of lambda is more than or equal to the epsilon, adopting the speed evaluation formula based on the integrated acceleration. The method provided by the invention is suitable for online speed evaluation of the full-wheel electrically-driven vehicle, comprising exact observation for the longitudinal speed when the wheel is subject to excessive trackslip / slippage and even locking.

Owner:TSINGHUA UNIV

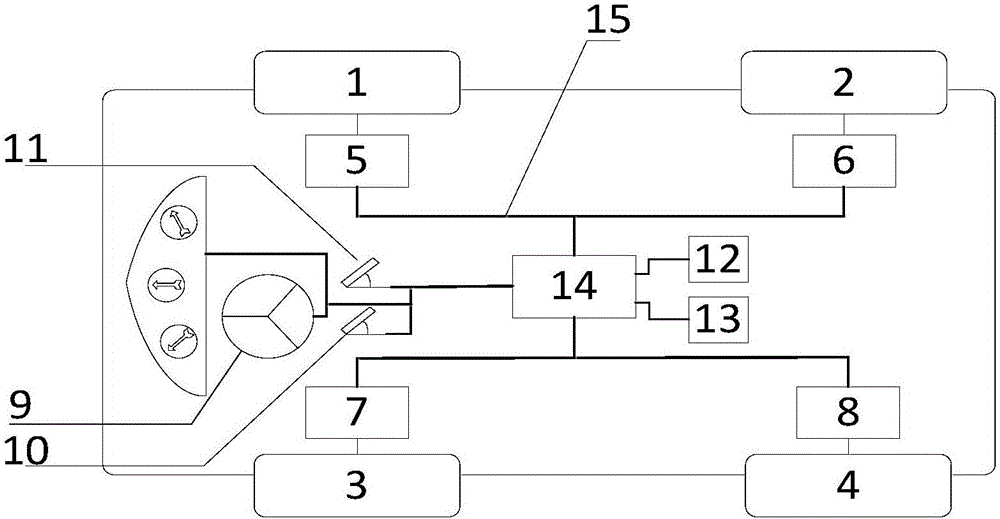

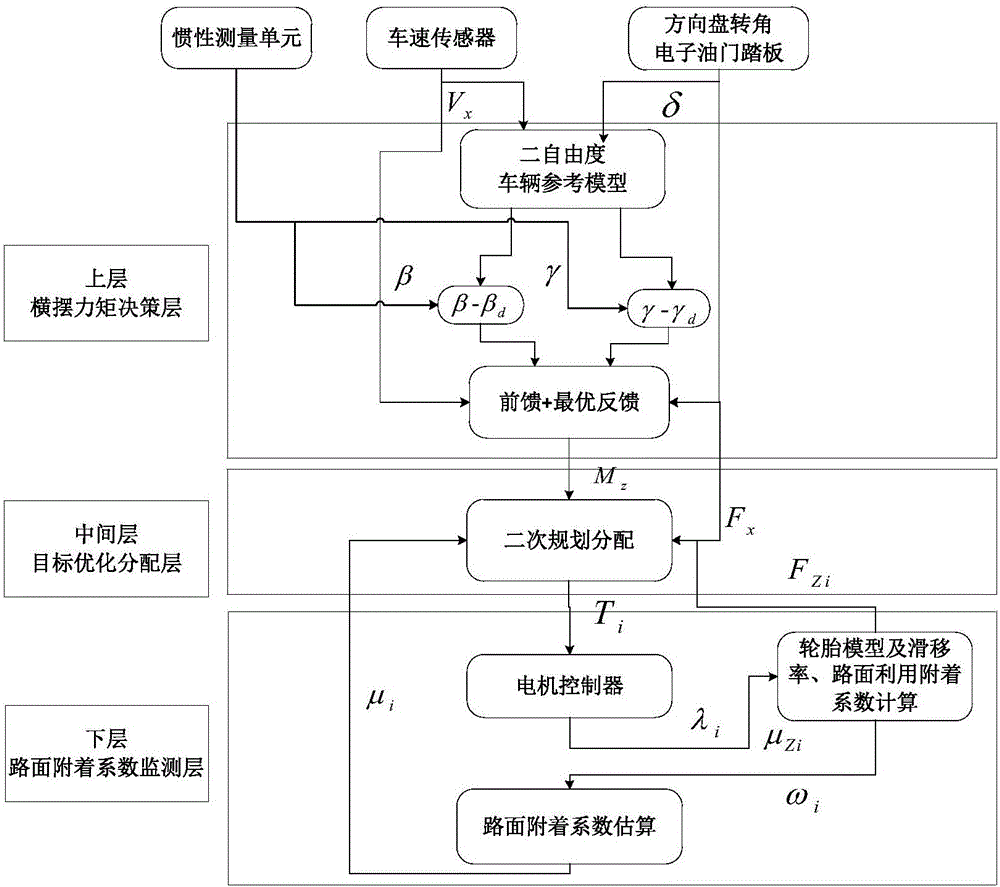

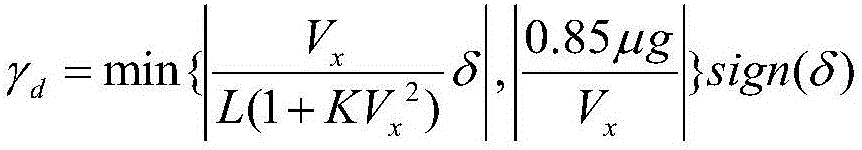

Hierarchical system used for four-wheel-hub motor-driven electric automobile, and control method

InactiveCN106585425AImprove stabilityImprove maneuverabilitySpeed controllerElectric devicesRoad surfaceEngineering

The invention discloses a hierarchical system used for a four-wheel-hub motor-driven electric automobile, and a control method. First of all, yaw moment is calculated as a yaw moment decision-making layer according to a vehicle speed sensor, a steering wheel rotary angle transmitter, an electronic throttle sensor and an inertia measurement unit; then according to automobile longitudinal force constraints, yaw moment constraints, a maximum adhesion force which can be provided by a pavement and restrictions of motor maximum output moment, target torque of each wheel hub motor is calculated as a target optimization analysis layer; and finally, degrees of similarity to six standard pavements are obtained by inputting two parameters, i.e., an adhesion coefficient and a wheel slip rate into a pavement adhesion coefficient estimation fuzzy controller by means of a current pavement, and an adhesion coefficient estimated value of the current pavement is obtained as a pavement adhesion coefficient monitoring layer after weighted averaging is performed. According to the invention, whole-vehicle stability is taken as a control target, motor torque is reasonably distributed according to operation working conditions, and the controllability, the stability and the economic property of vehicles are improved.

Owner:XI AN JIAOTONG UNIV

Antiskid control system and method for electromobile

ActiveCN101088818AReduce the probability of slippageImprove acceleration performanceWheel speed sensorControl system

The present invention discloses one kind of antiskid control system for electromobile. The antiskid control system includes wheel speed sensors for detecting the real-time speeds of the wheels, wheel brakes for braking the wheels separately, one motor for driving the electromobile, and one ABS / ASR integrated control unit connected to all the sensors, the brakes and the motor. When it receives an acceleration signal, the ABS / ASR integrated control unit regulates the real-time output torque of the motor based on the wheel slip rate; and when it receives a braking signal, it regulates the real-time braking force based on the wheel slip rate. The present invention can reduce the slip rate of electromobile effectively and raise its running stability.

Owner:BYD CO LTD

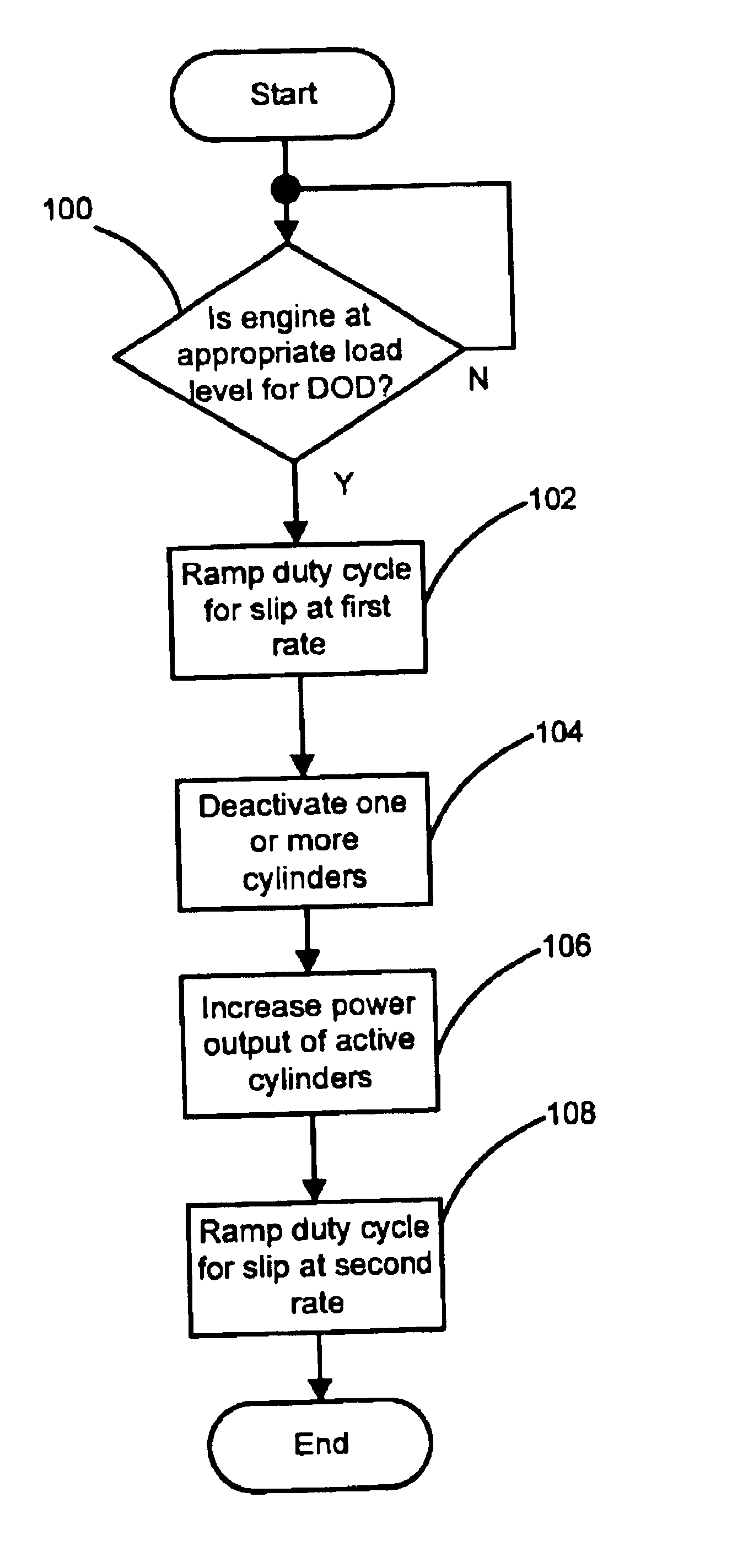

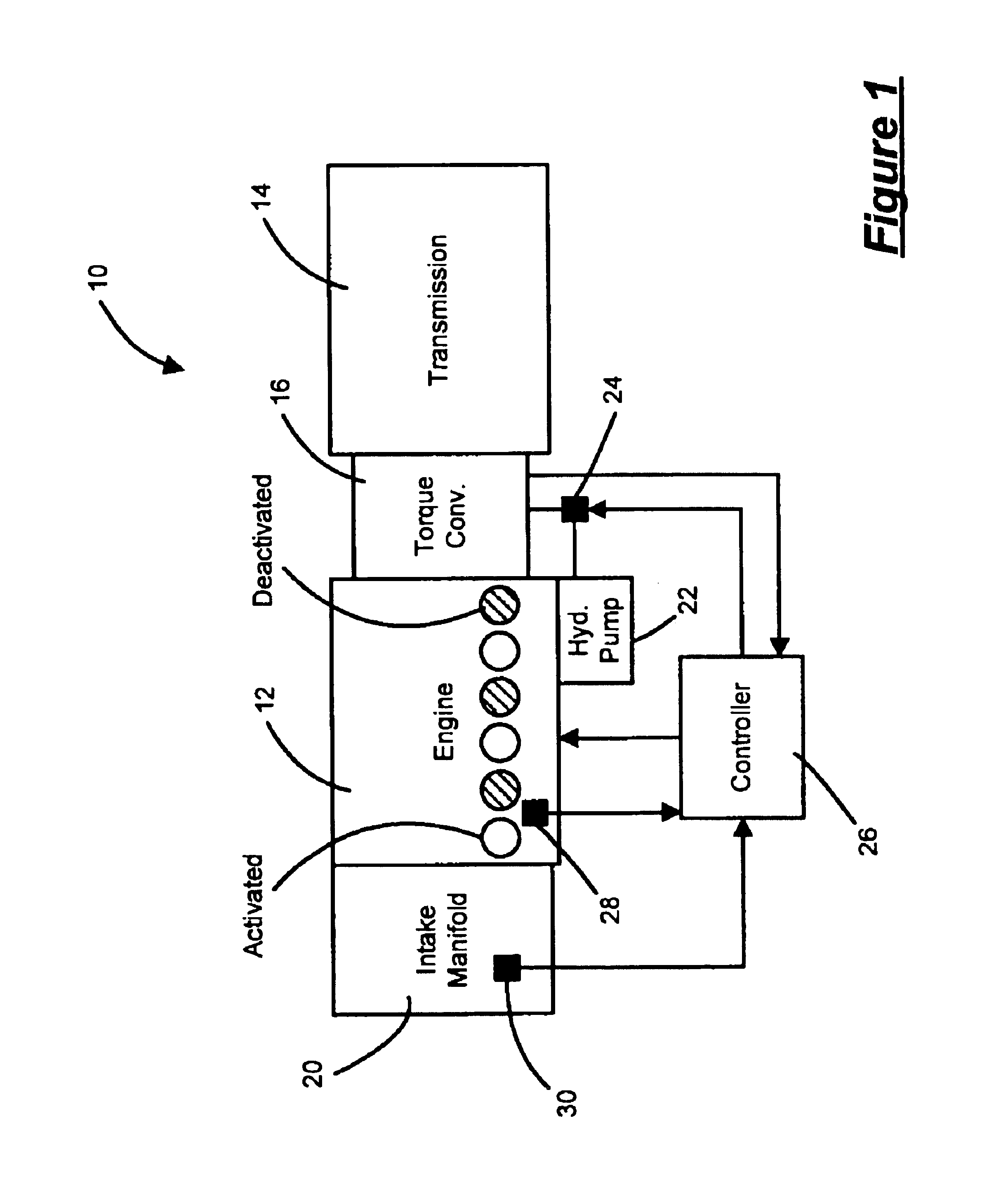

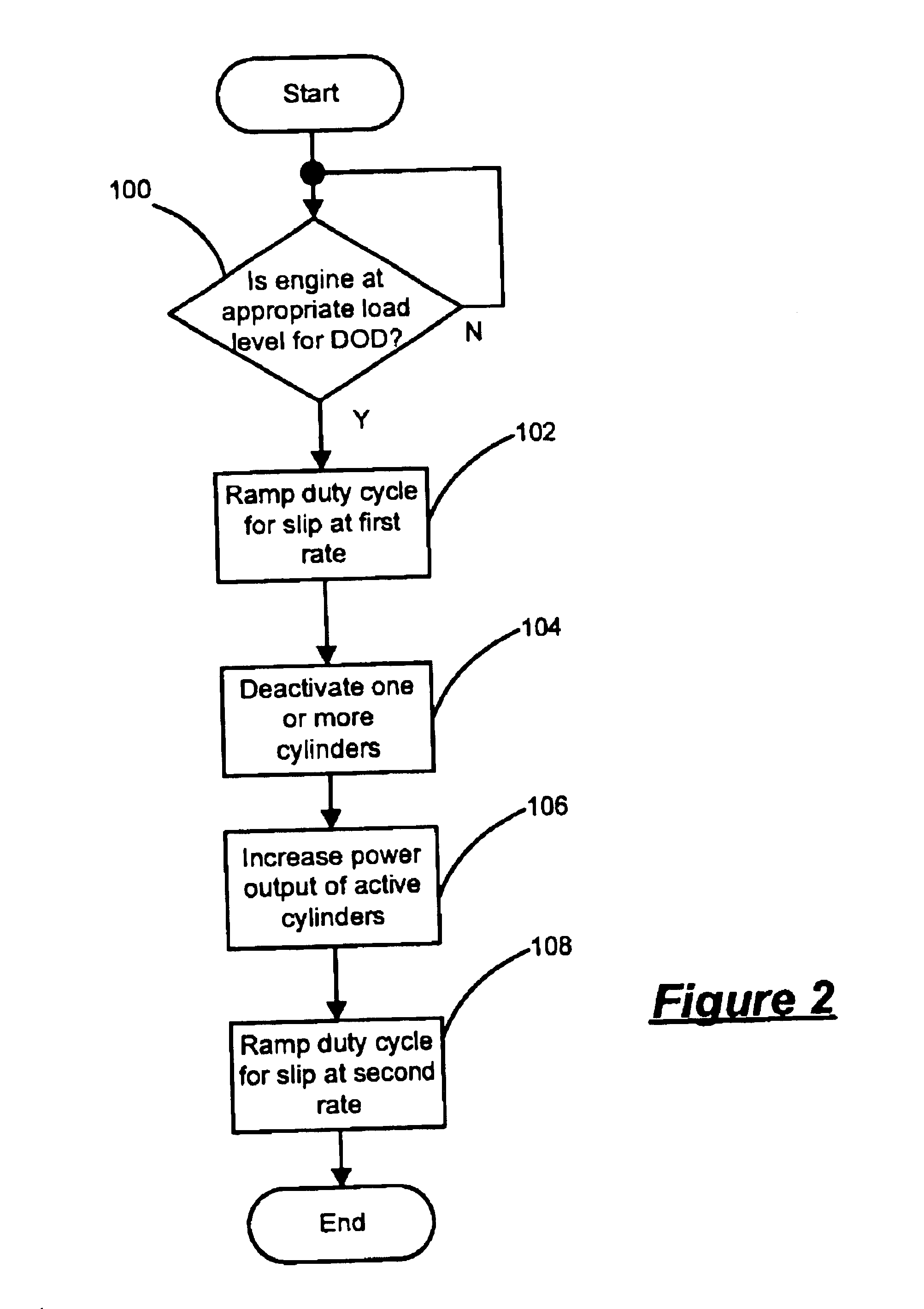

Torque converter slip control for displacement on demand

A torque smoothing system for a displacement on demand engine includes an engine having a plurality of cylinders and a torque converter. A controller adjusts a slip rate of the torque converter to a first rate and deactivates one or more of the cylinders. The controller then adjusts the slip rate to a second rate.

Owner:GM GLOBAL TECH OPERATIONS LLC

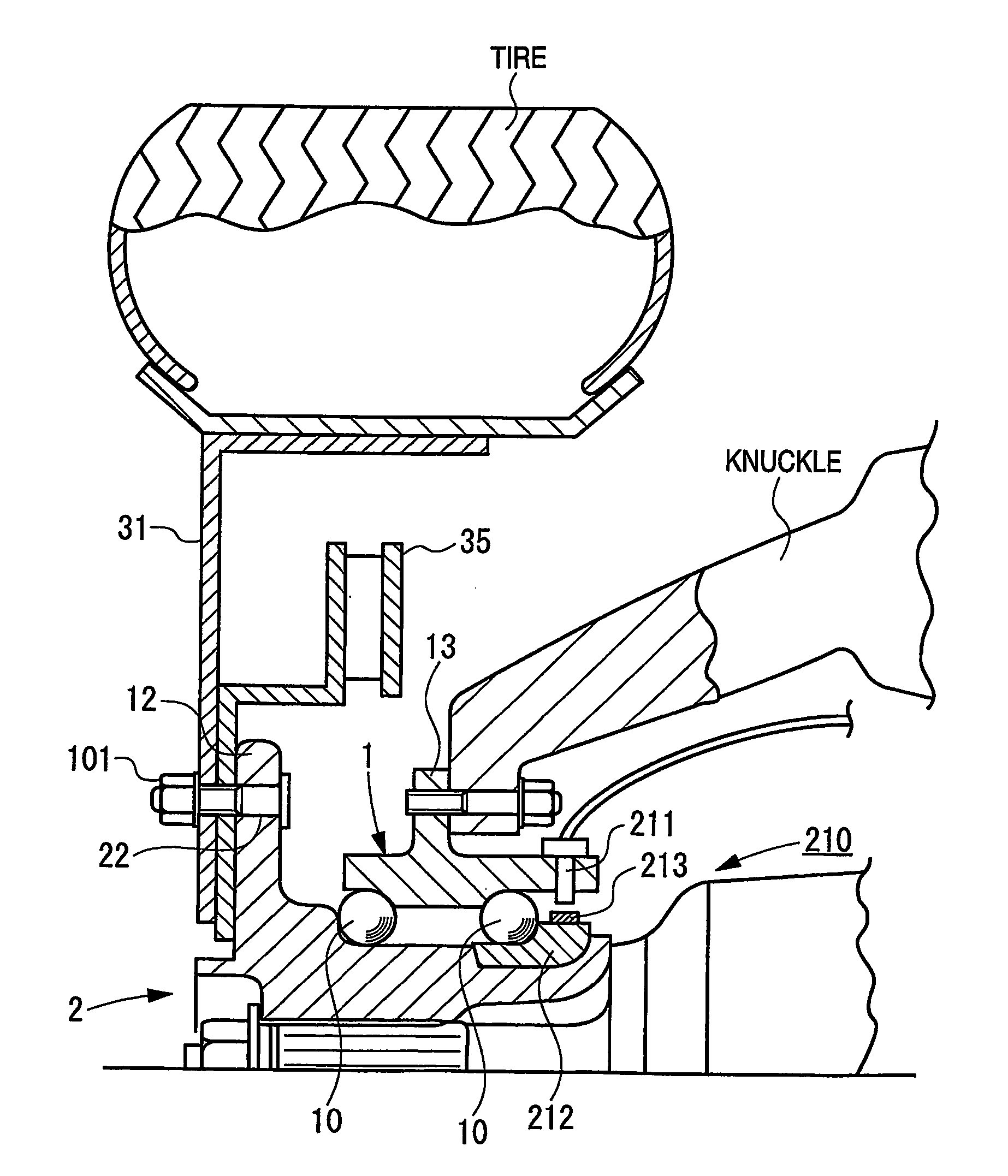

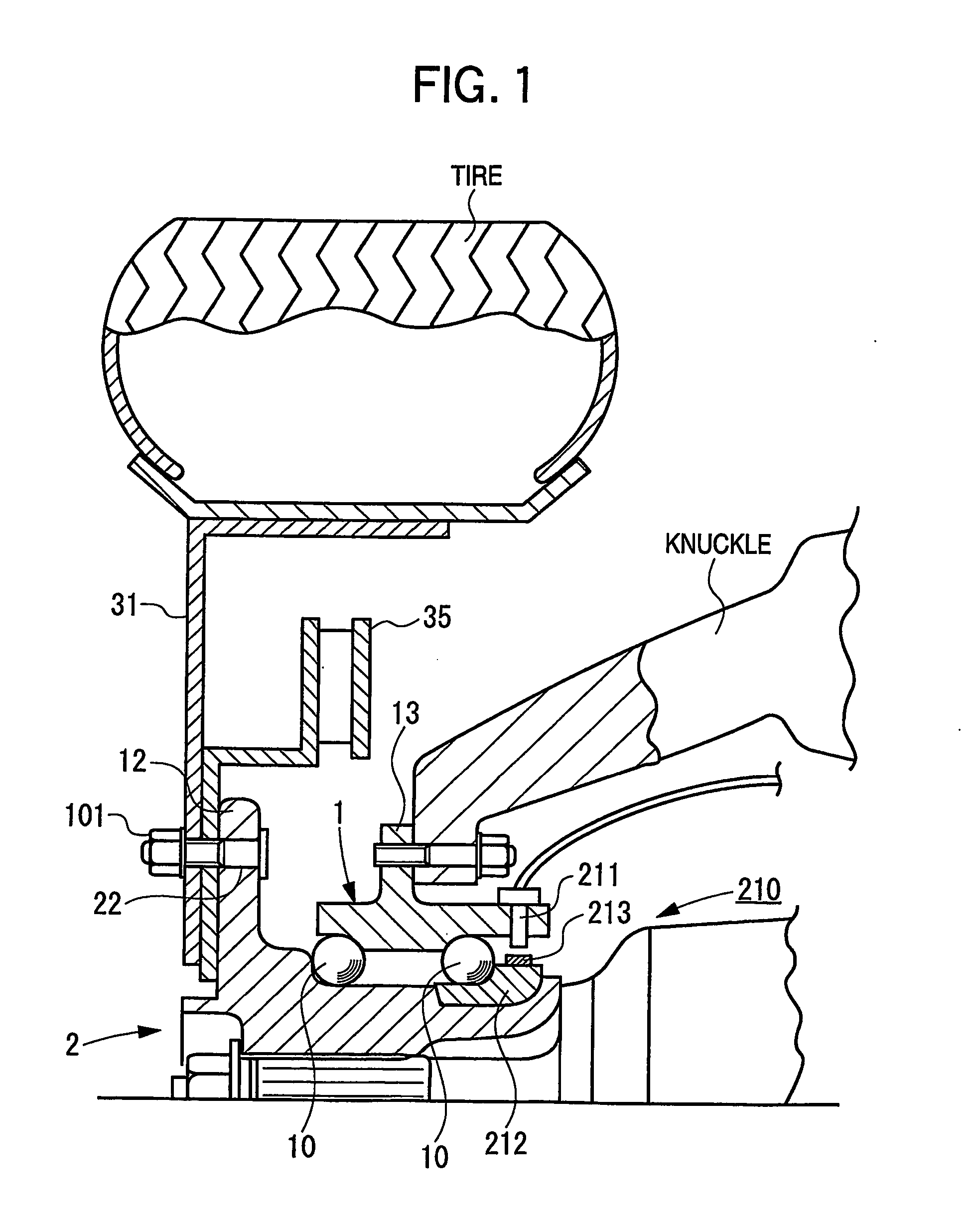

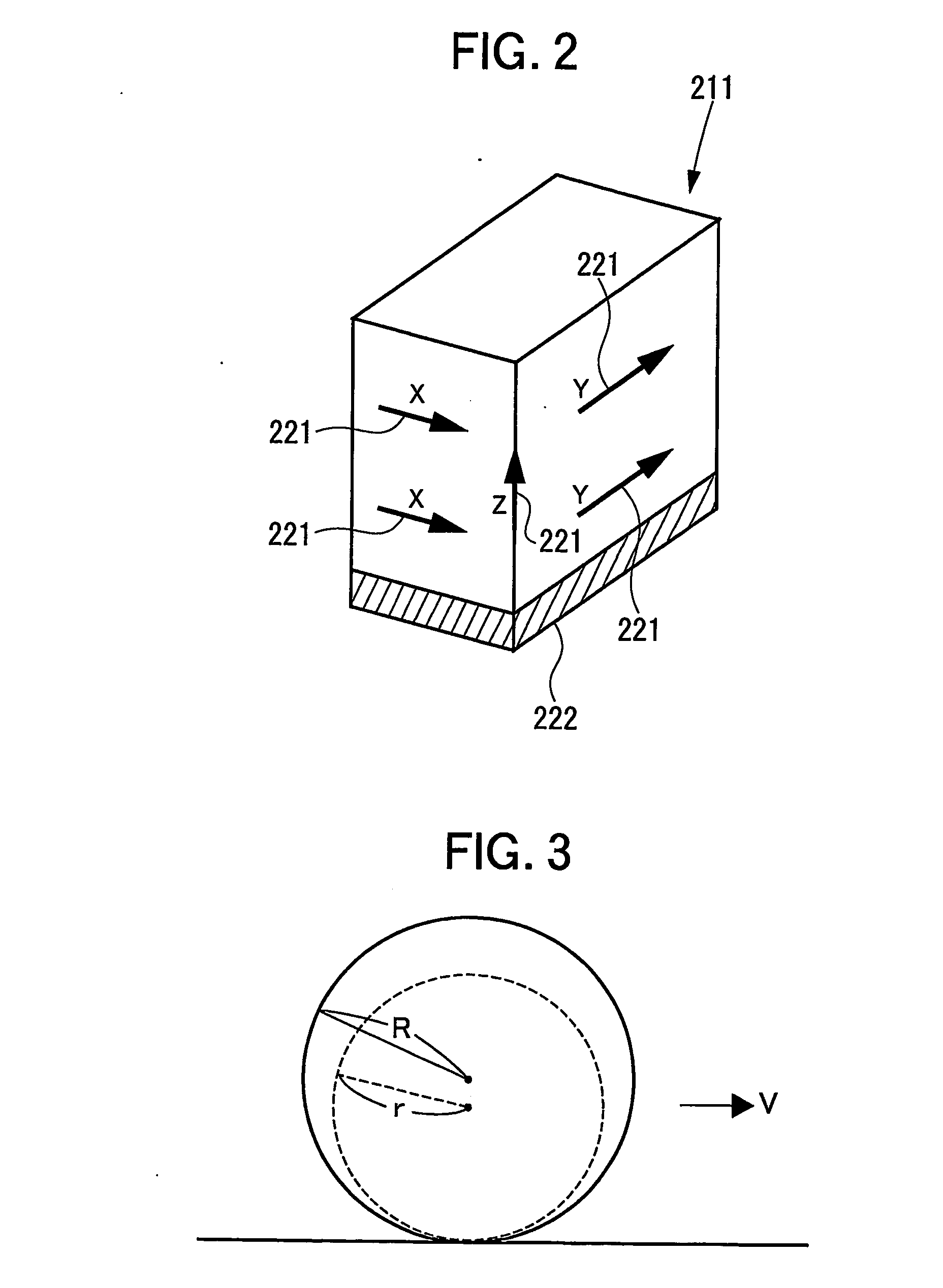

Axle unit with slip sensor and slip meansurement method

InactiveUS20060108170A1Improve accuracyStable controlBearing assemblyPedestrian/occupant safety arrangementRolling-element bearingRunning time

An axle unit 210 including a rolling bearing unit attached to a knuckle of a wheel support member has a slip sensor (211) including acceleration sensors and a rotation sensor in one piece. The slip sensor (211) has the rotation sensor placed on the base face, and the rotation sensor is placed facing an encoder (213) attached to a rotation member (212). At the vehicle running time, the traveling acceleration in the traveling direction of the wheel and the rotation angular speed are detected and at the vehicle running time, the ground speed of each wheel, the tire radius of each wheel, and the slip ratio of each wheel are found.

Owner:NSK LTD

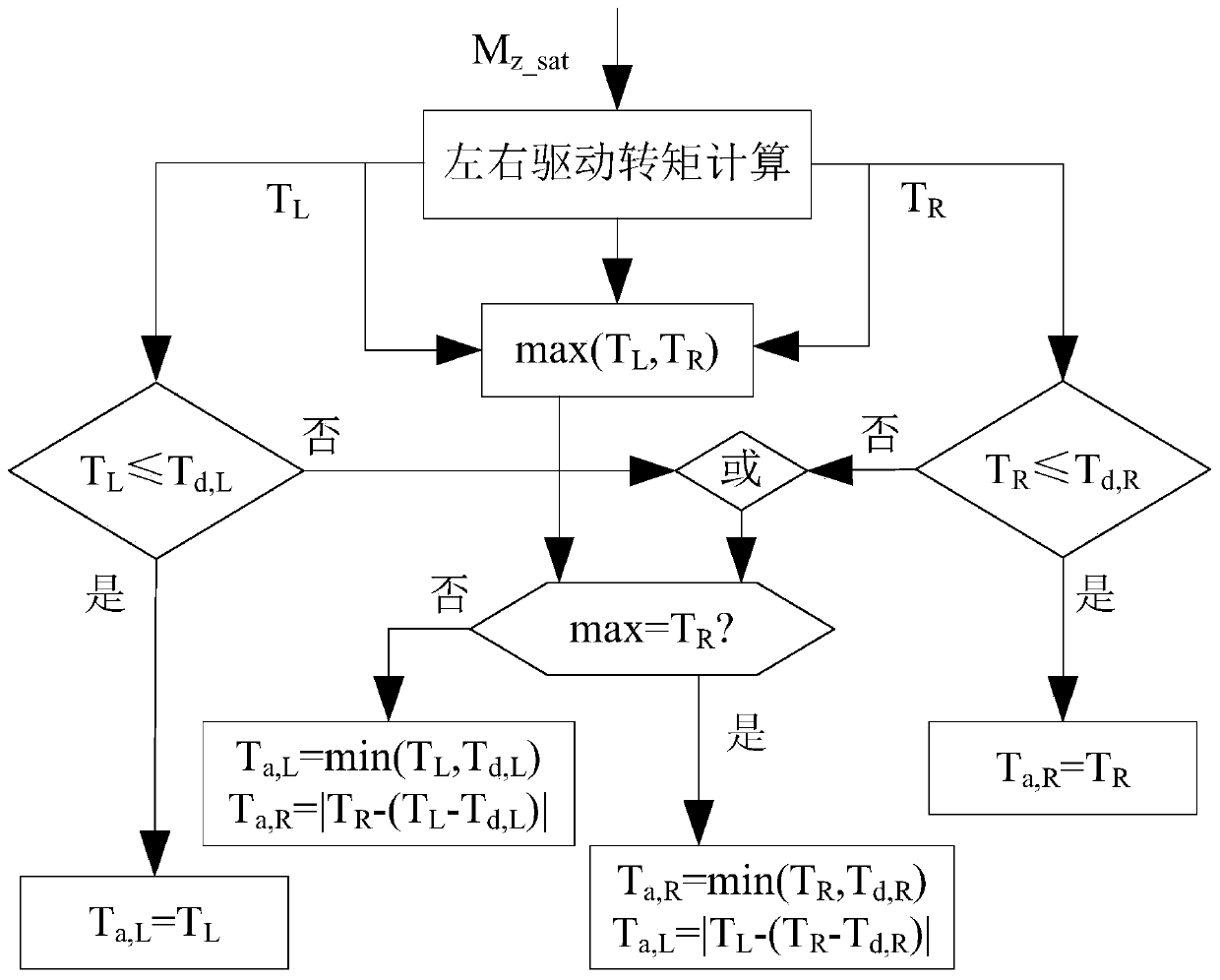

Vector distribution control method for torque of distributed-driven electric automobile

ActiveCN109747434AInhibition of difficult steering problemsImprove driving stabilitySpeed controllerElectric energy managementBrake torqueStable state

The invention discloses a vector distribution control method for torque of a distributed-driven electric automobile. Through the relation between vehicle driving state stability and the expected yaw velocity under a vehicle dynamical model, an ideal motion state of a vehicle under generalized additional yawing moment is worked out, and control stability of a system is judged and analyzed through the expected yaw velocity so as to determine whether yawing moment control is required or not; a tyre longitudinal slip rate is set as a specific value in a stable state, and driving torque is precisely distributed under the condition that a coefficient of road adhesion is met. Through reasonable distribution of driving or braking torque of front and back axles, the response speed to the expected yaw velocity can be remarkably increased, so that the vehicle has an ideal motion state when passing a curve, the problem of difficult steering of the vehicle when acceleration is not enough is effectively restrained, curve passing efficiency is improved, vehicle driving stability and smoothness are improved, control burden of the driver is remarkably reduced, and driving safety is improved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

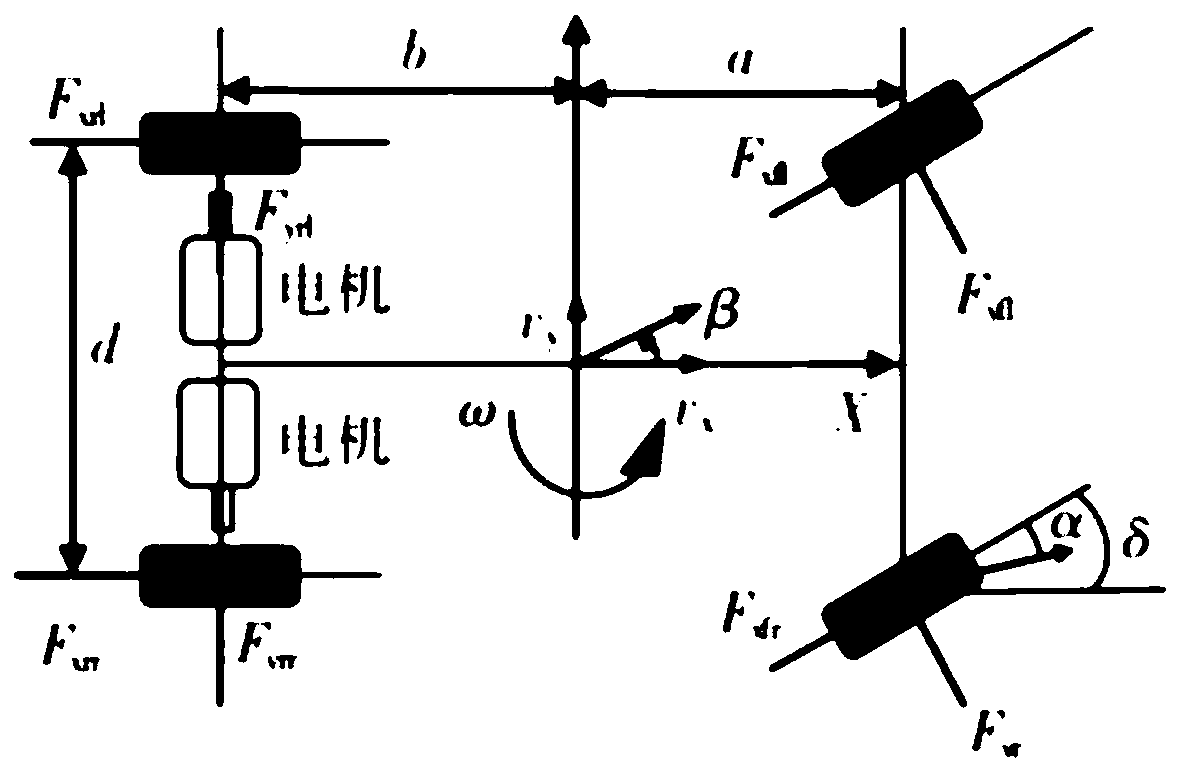

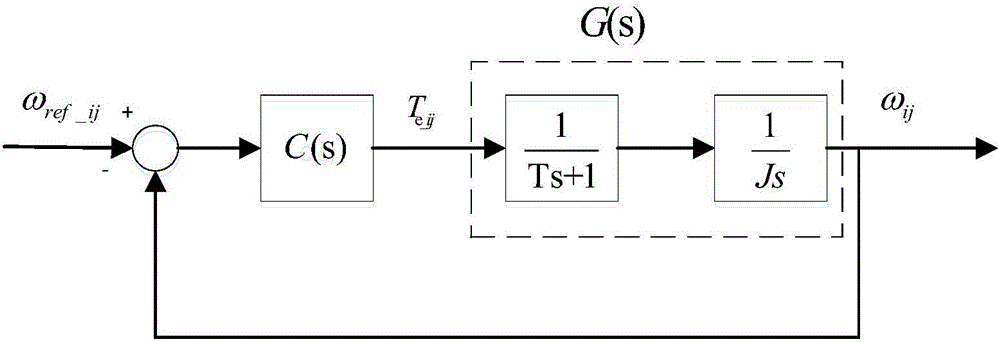

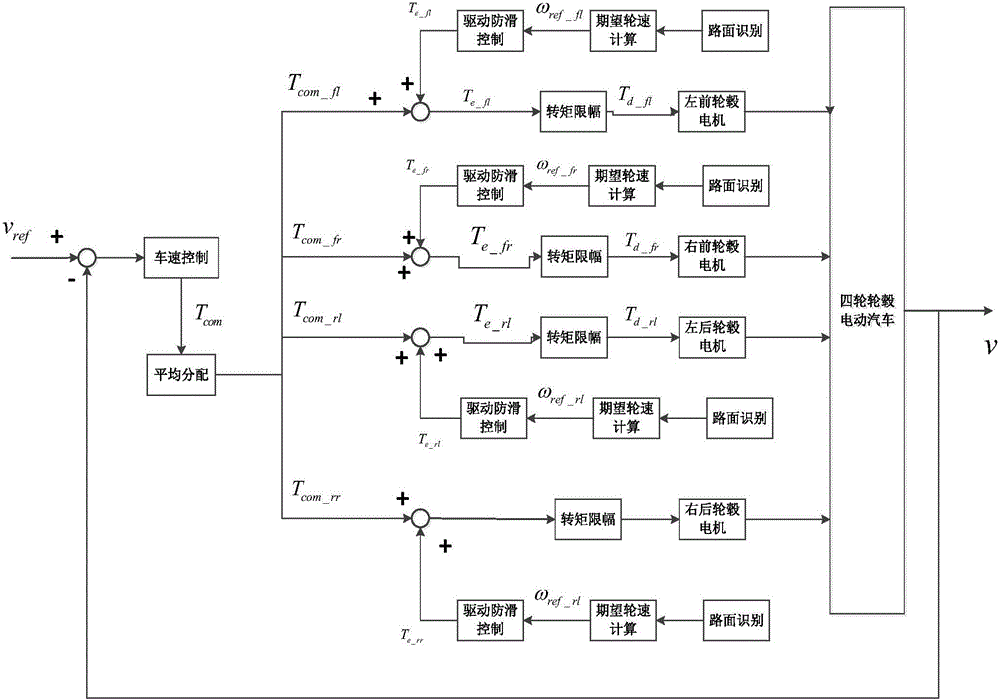

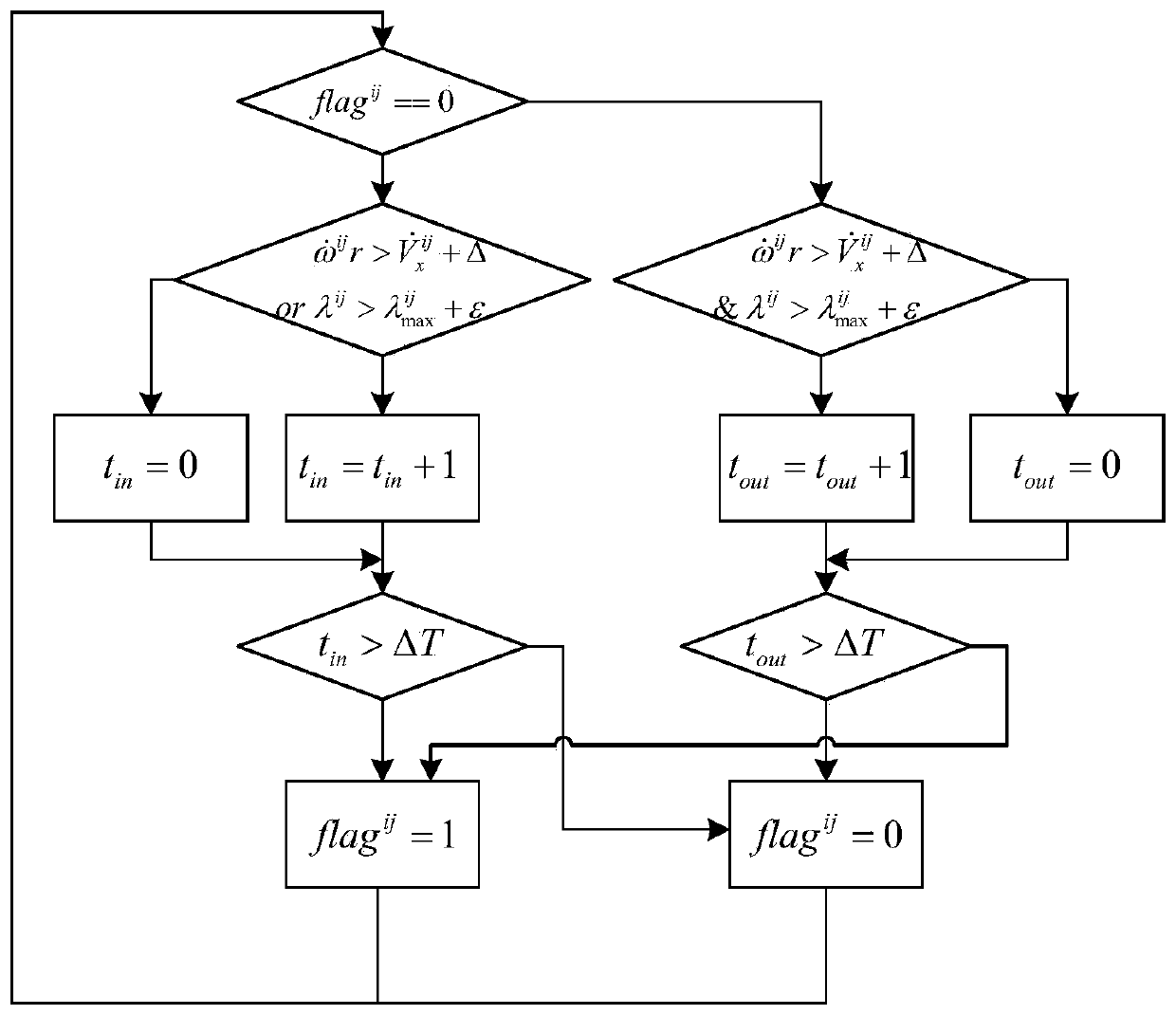

Antiskid control method for electric automobile with four wheels and hubs

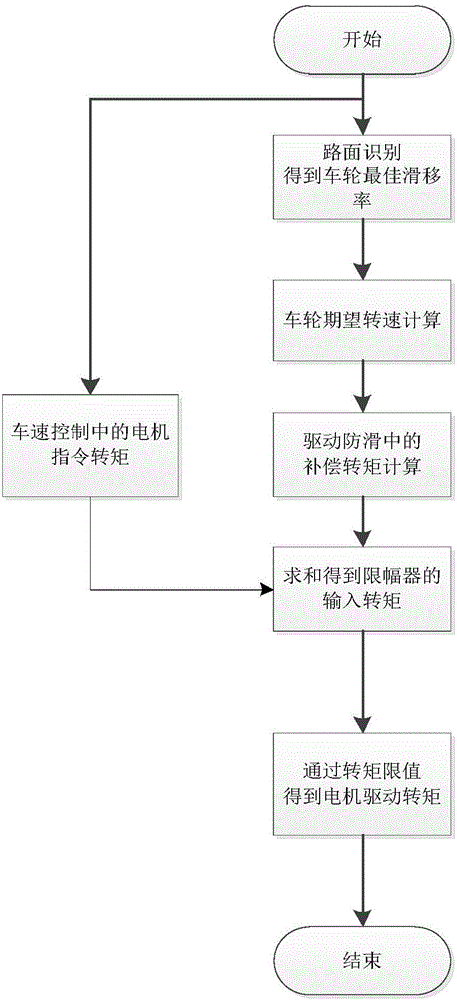

InactiveCN105751919AGuaranteed uptimeImprove stabilitySpeed controllerElectric devicesControl objectiveElectric machine

The invention discloses an antiskid control method for an electric automobile with four wheels and hubs. The antiskid control method includes that the optimal slip rates of the wheels are computed in real time by the aid of road surface identification algorithms, and expected rotational speeds of the wheels are computed by the aid of the optimal slip rates of the wheels; compensating torque of the wheels is computed according to states of the wheels, to be more specific, expected wheel speeds of the wheels are used as control targets if the wheels slip, the compensating torque is computed by the aid of a PID (proportion, integration and differentiation) controller for wheel speeds of the wheels, or the compensating torque is zero if the wheels do not slip; expected automobile speeds are used as control targets for automobile speed control, and instruction torque of motors is computed according to an automobile speed controller; the compensating torque and the instruction torque are added with each other to obtain a sum, and the sum is inputted into the motors so as to carry out drive antiskid control on the electric automobile with the four wheels and the hubs.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

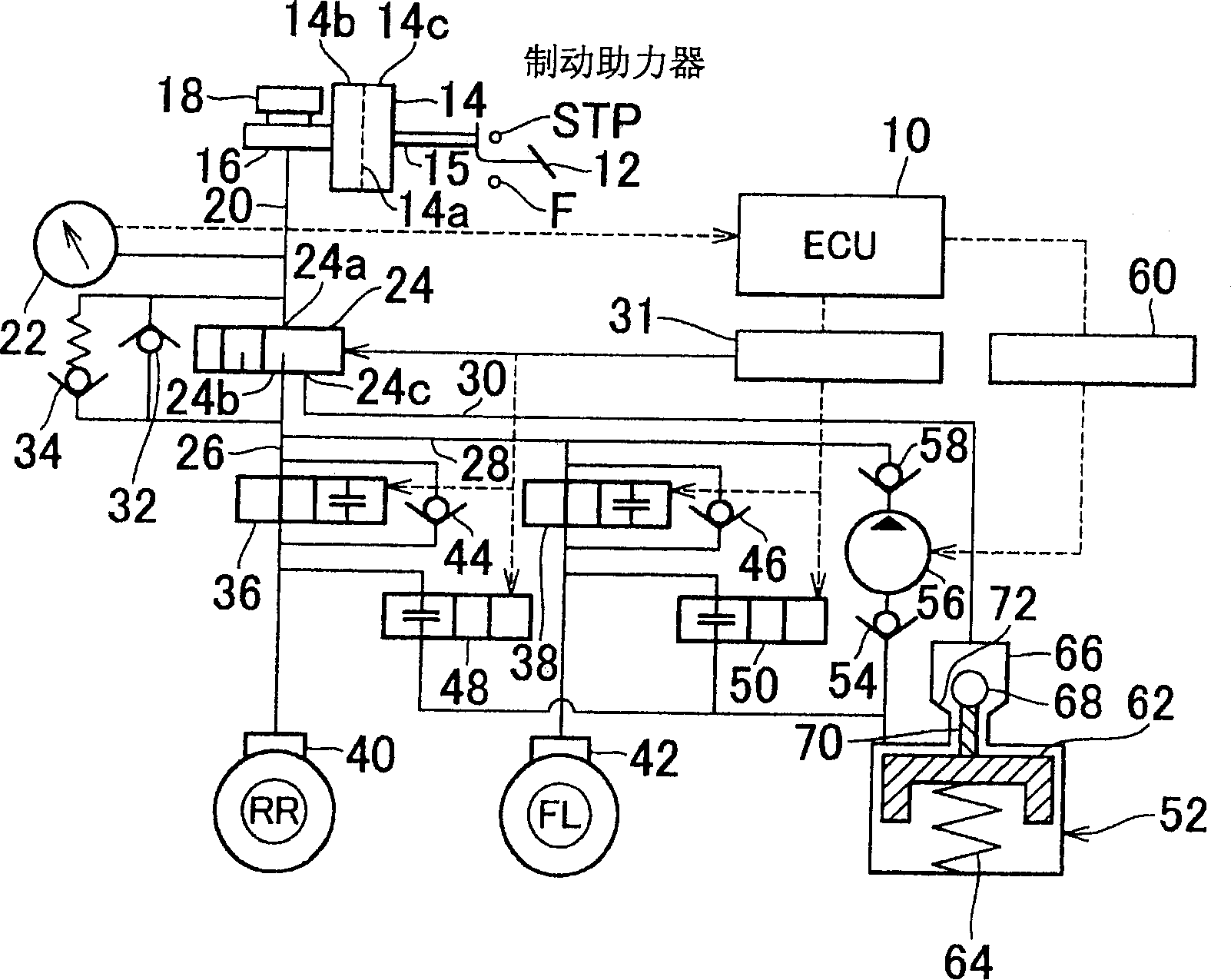

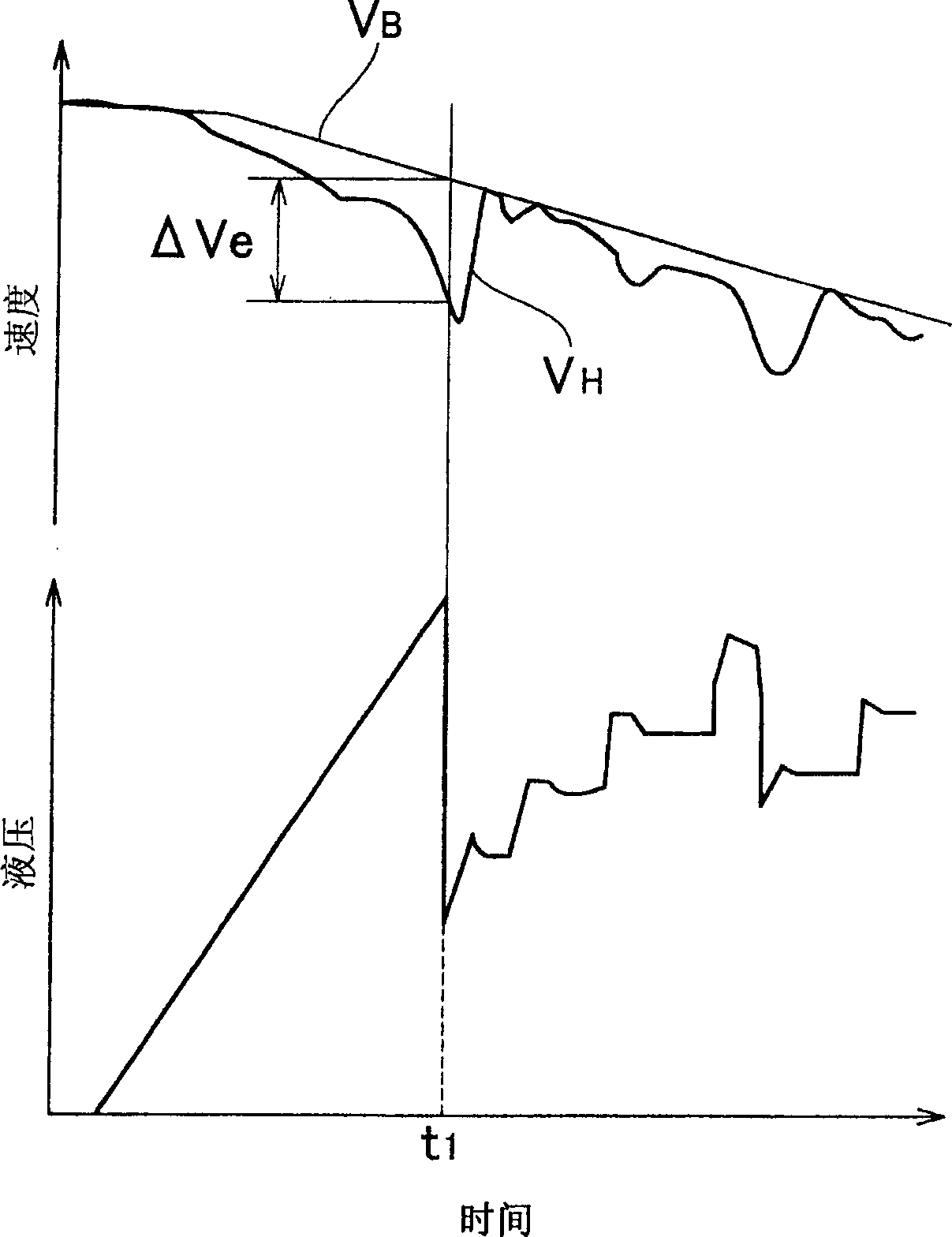

Vehicle brake system, and method of controlling such brake system

The brake system of the invention, during the ABS control mode, corrects the target slip rate in accordance with the turning of the vehicle, and determines whether the vehicle is running on a poor surface road. If the vehicle is running on a poor surface road, the system sets a target slip rate that provides a greater longitudinal force than the aforementioned target slip rate.

Owner:TOYOTA JIDOSHA KK +1

Detecting method for full wheel driven electric driving vehicle movement parameter

InactiveCN101051004AEliminate estimation errorAvoid measurement errorsVehicle testingLinear/angular speed measurementElectricitySteering wheel

A method for testing movement parameter of electrically driven vehicle in all wheel driving type includes using wheel speed and motor torque signals to calculate ground longitudinal force and vehicle speed, using rotary speed and track-slip rate as well as drift rate of non-steering wheel to present vehicle speed, calculating out track-slip rate of non-steering wheel by integration calculation in order to reverse-derive out vehicle speed then calculating track-slip rate of steering wheel.

Owner:TSINGHUA UNIV

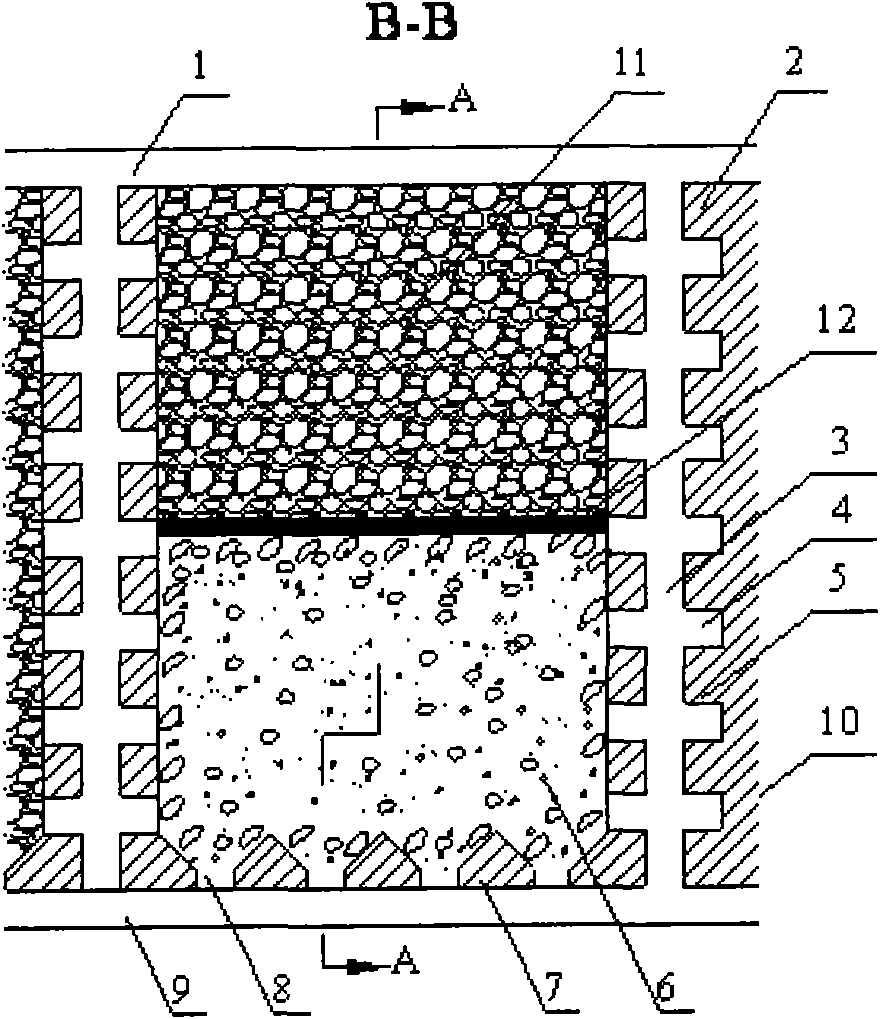

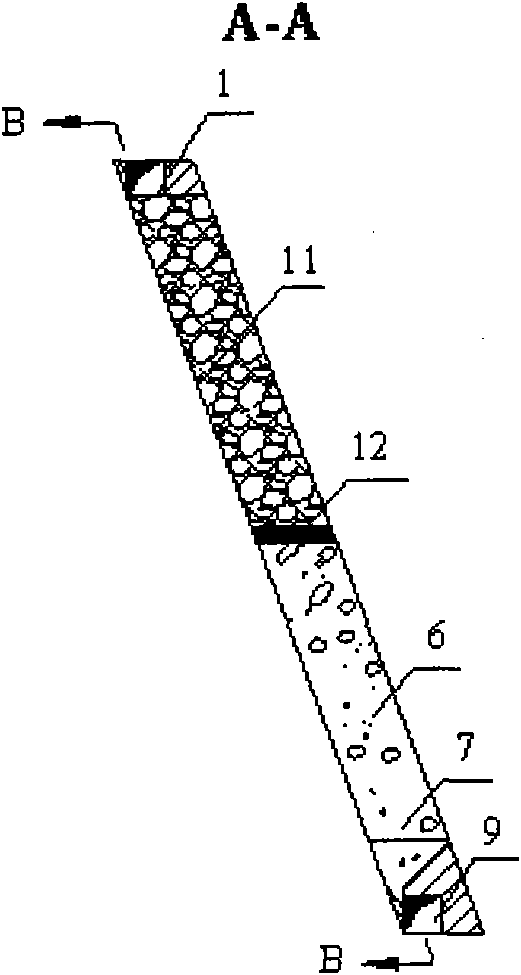

Great ore drawing simultaneous filling non-top column shrinkage mining method

InactiveCN101864957AControl exposure areaAvoid mass movementUnderground miningSurface miningLoss rateEarth surface

The invention relates to a great ore drawing simultaneous filling non-top column shrinkage mining method which comprises the following steps of: dividing a steep dipping ore body with thin steadiness to medium thick steadiness of surrounding rock above medium steadiness into stages and dividing ore blocks in the stages; stoping ore together with a top column layer by layer from bottom to top according to a traditional shrinkage method in an ore room without retaining the top column; laying an isolating layer on the surface of a shrinkage pile in advance before great ore drawing; drawing dry type paddings with proper lumpiness from an air return tunnel during great ore drawing and carrying out flat field operation in a manual way or an electric scraper way; controlling an ore slipping rate and a padding drawing rate by a vibratory ore-drawing machine matching with weight ore drawing; and simultaneously and uniformly sinking the paddings and the ore and controlling the exposure area of the surrounding rock till the ore is completely drawn. The invention prevents the surrounding rock from greatly scaling and mixing into the ore, controls the dilution rate and the loss rate of the ore, improves the recovery rate of the ore and limits subsidence of the earth surface.

Owner:GUANGXI UNIV

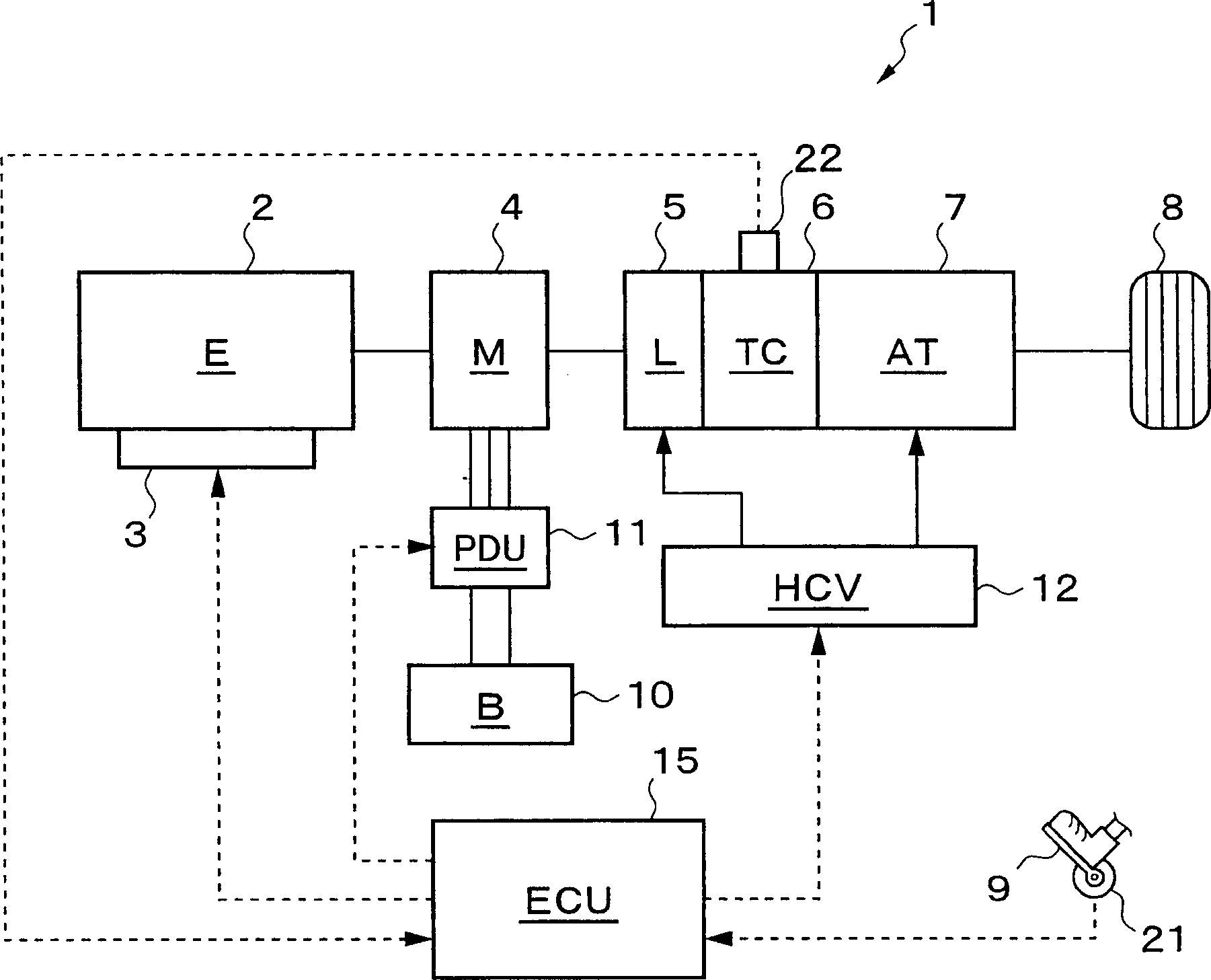

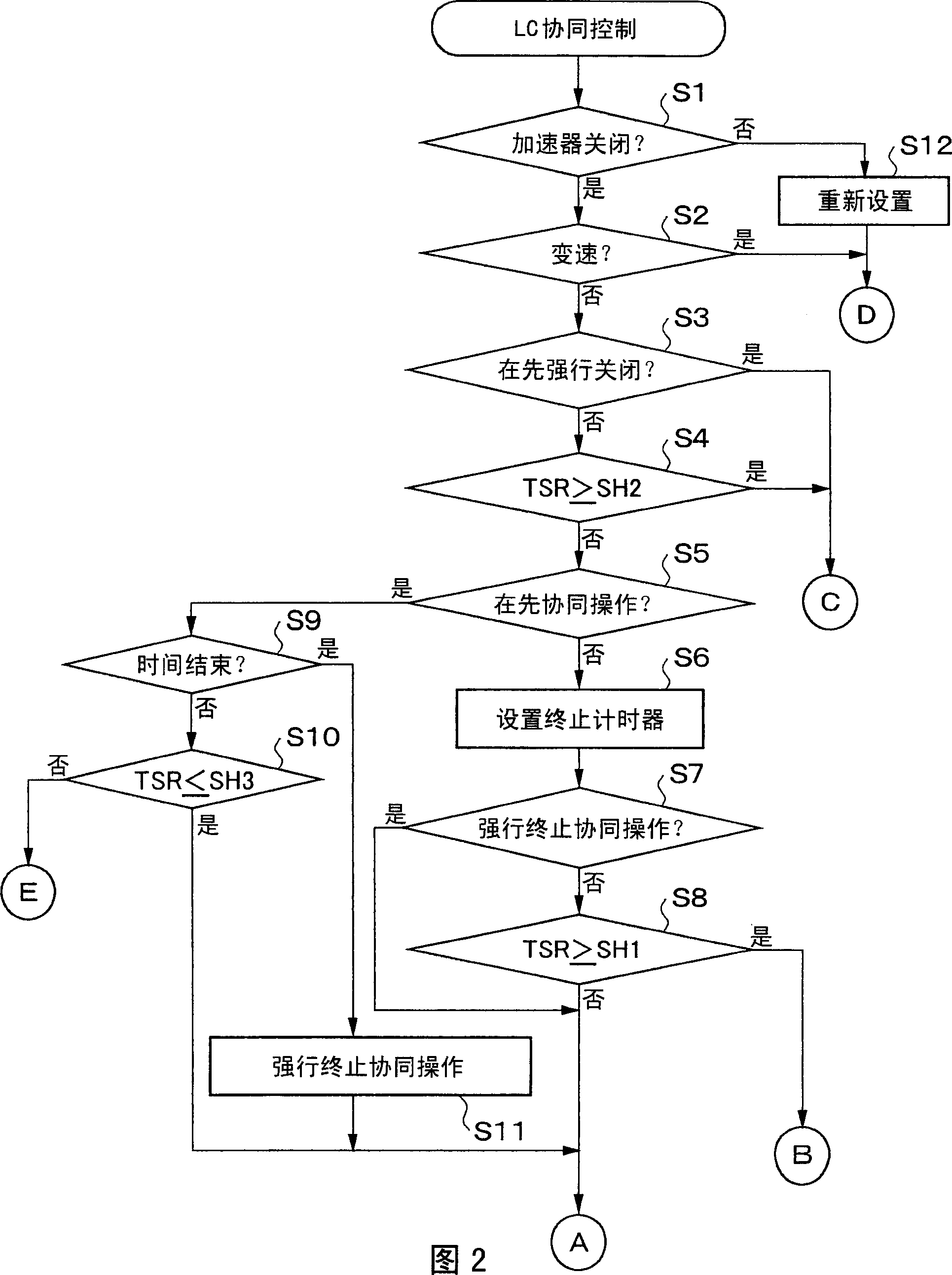

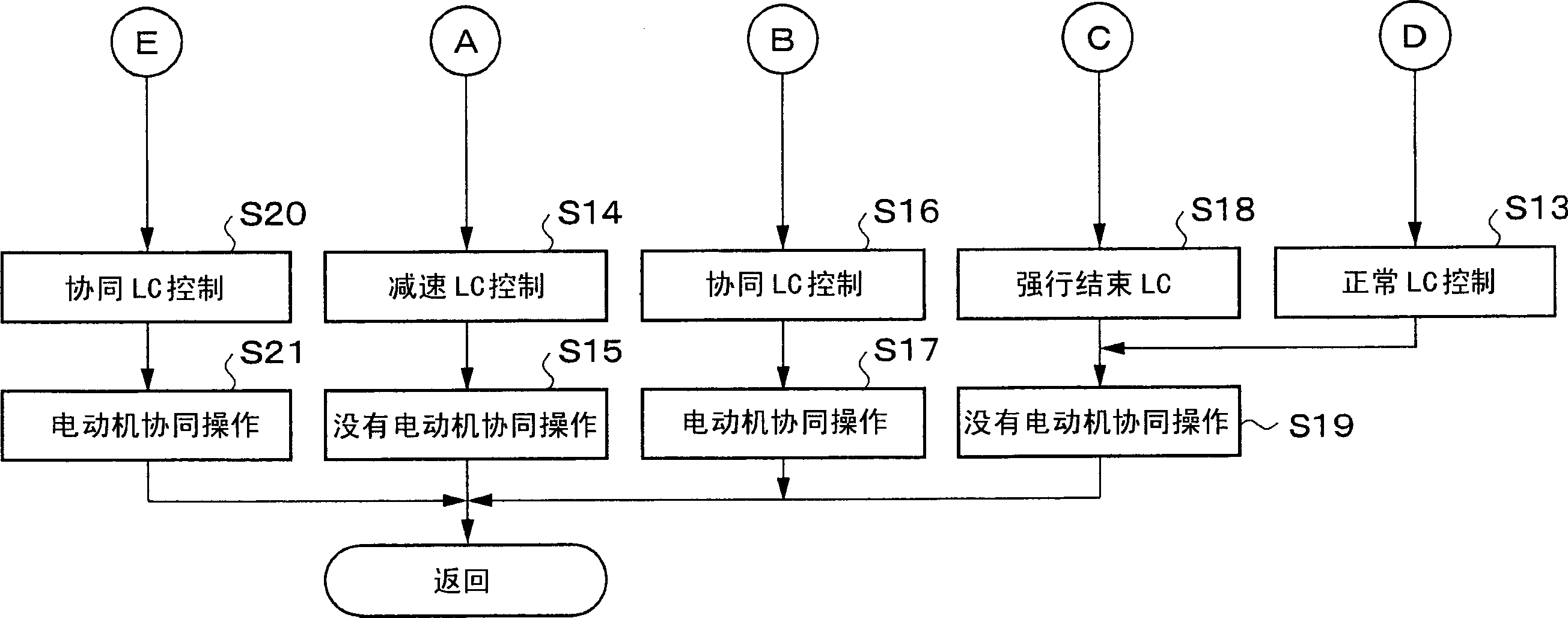

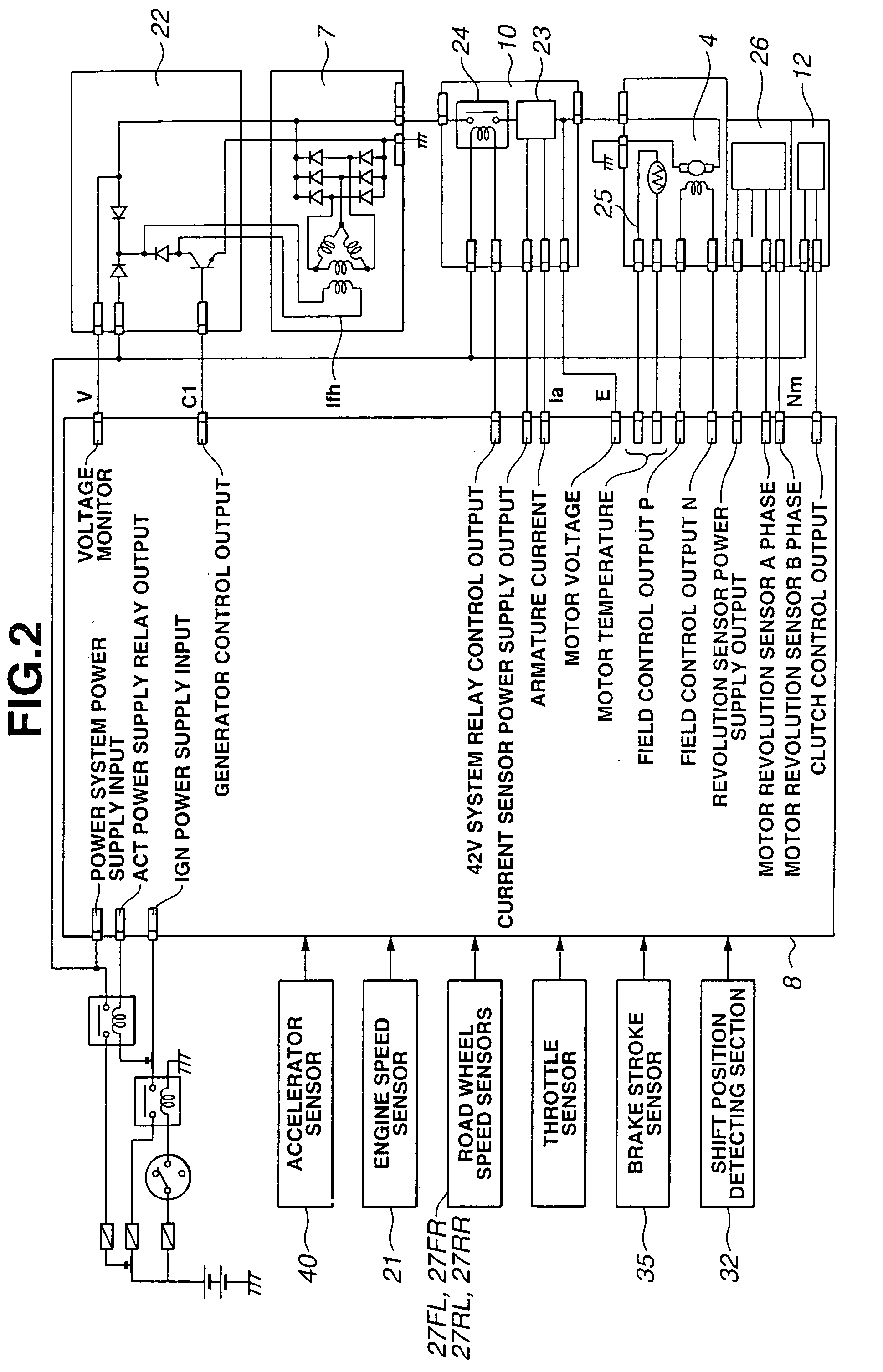

Control system for hybrid vehicle

InactiveCN1781789AAvoid volatilityNo sense of incongruityHybrid vehiclesGas pressure propulsion mountingControl systemHybrid vehicle

A hybrid vehicle includes an engine 2 , a motor generator 4 , a torque converter 6 with a lock-up clutch 5 and a ratio change mechanism 7 . The control system of the hybrid vehicle includes a rotational sensor 22 that detects the slip ratio of the torque converter and a hydraulic control valve 12 that controls engagement of the lockup clutch. When the vehicle moves as the accelerator pedal is released from the step-down state, driving force from the wheels is transmitted to the motor generator 4 to recover energy. The lockup clutch engagement is only controlled if the slip ratio of the torque converter is equal to or less than the first threshold. However, if the slip ratio is between the first threshold and the second threshold, the motor-generator is additionally cooperatively controlled.

Owner:HONDA MOTOR CO LTD

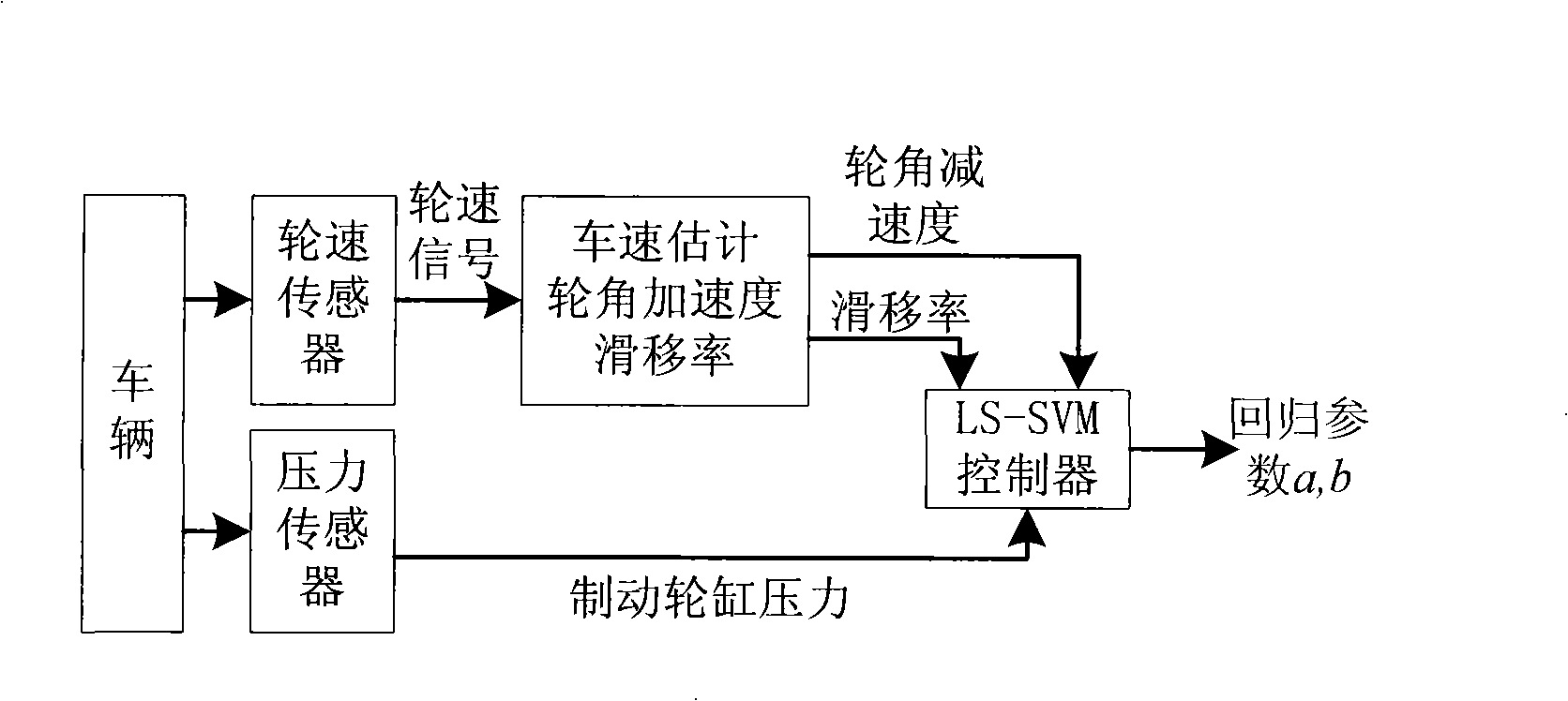

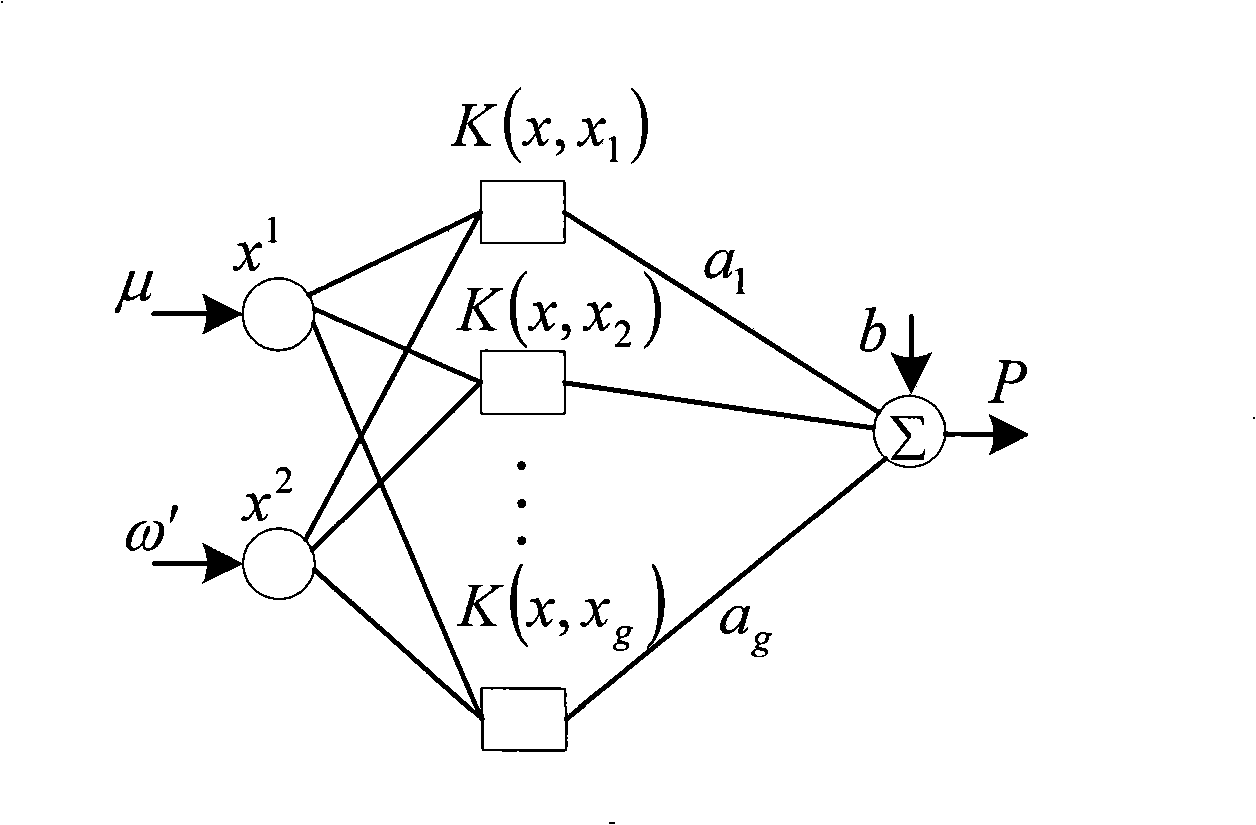

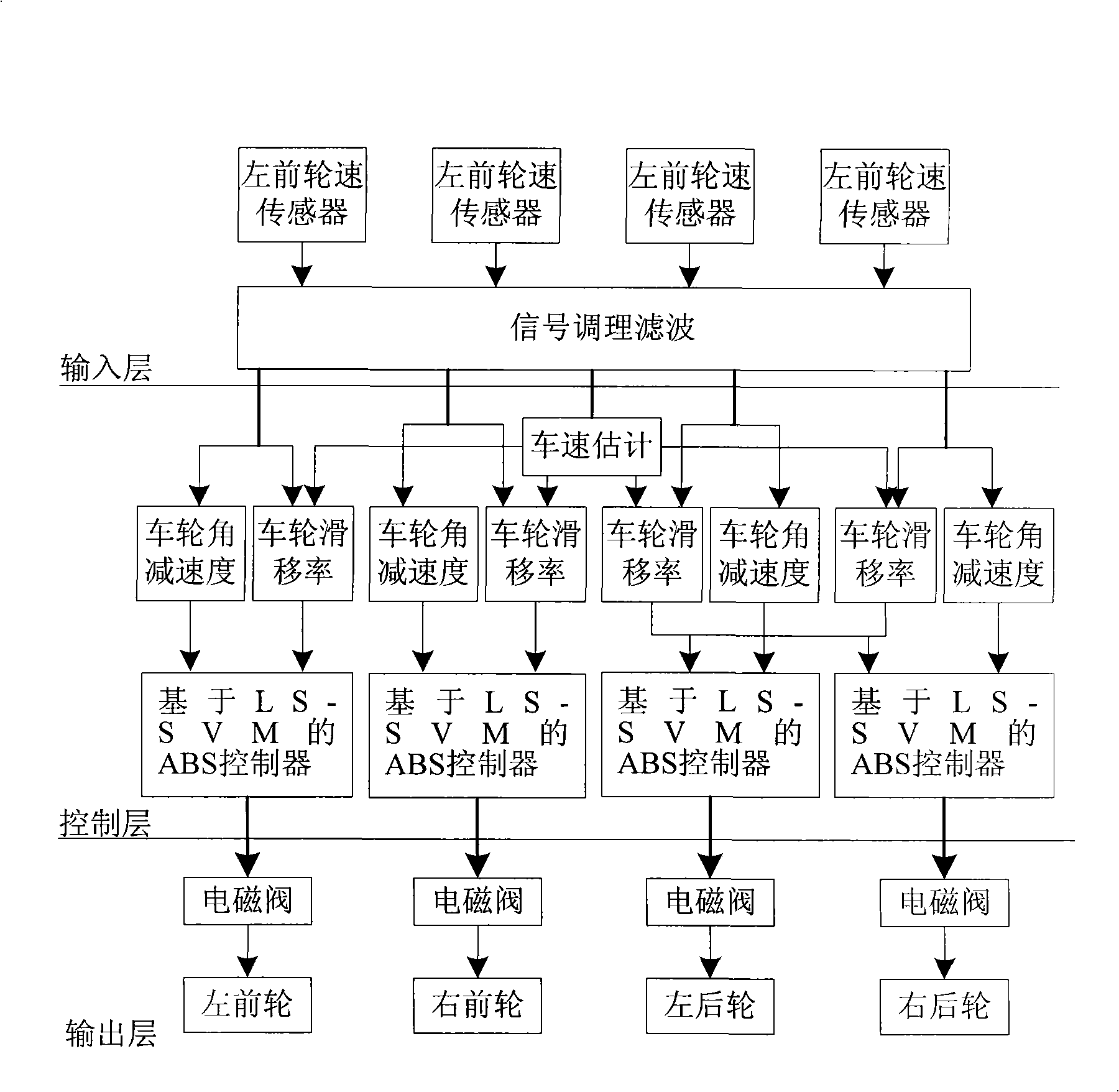

Vehicle anti-lock brake control method based on least squares support vector machine

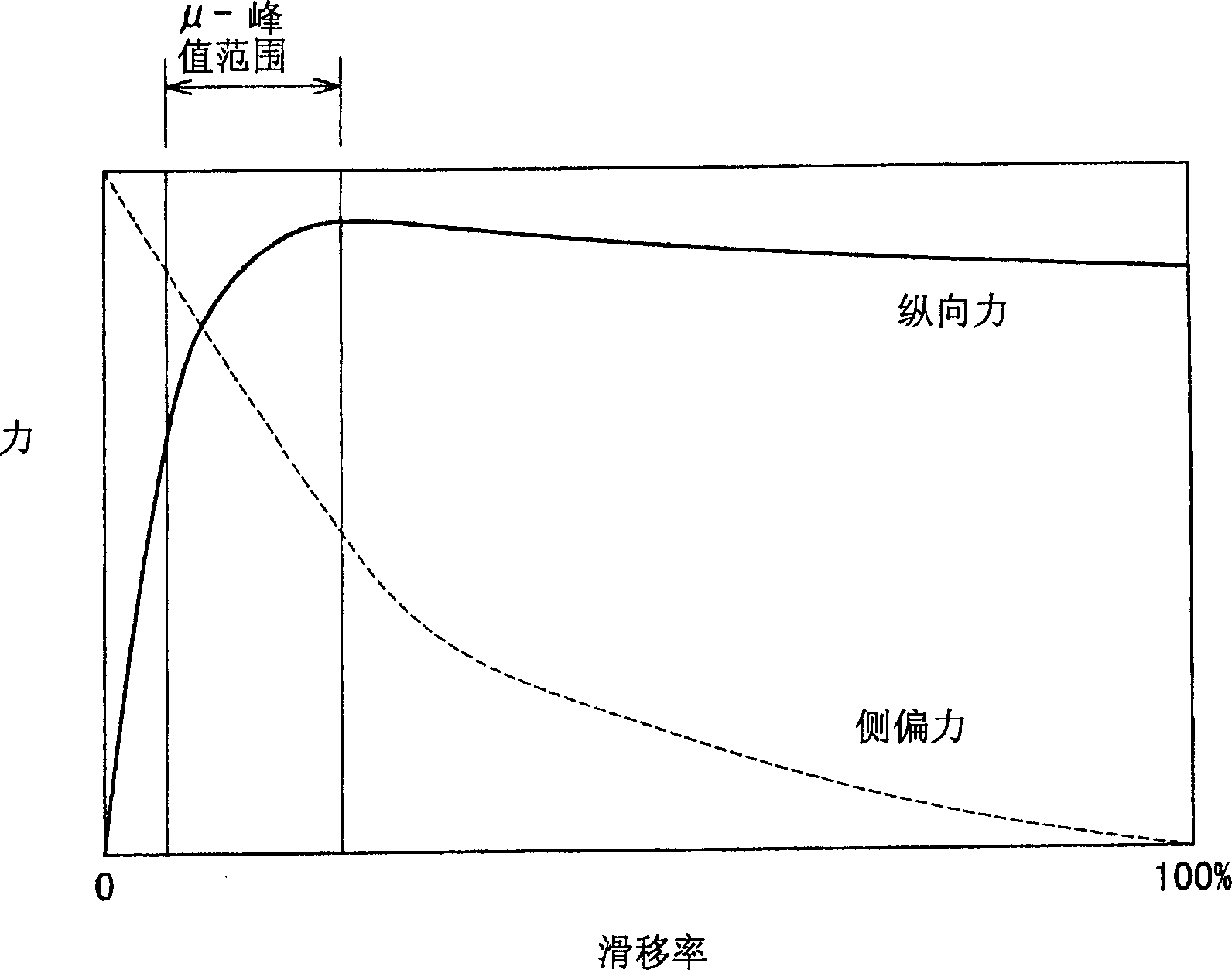

InactiveCN101311047AReduce development costsLow costAdaptive controlBraking systemsLeast squares support vector machinePeak value

The invention discloses a method for controlling an anti-lock braking system of automobiles, which bases on least squares support vector machines (LS-SVM) and relates to the technical filed of the electronic control of the automobiles. The controlling method estimates automobile body deceleration according to the wheel velocity peak values of four wheels; the automobile body reference speed is calculated according to the automobile body deceleration and then the reference slip rate of the wheels is obtained by calculation; the angular deceleration of the wheels is calculated according to the angular speed of the wheels; the angular speed and reference slip rate of every wheel are respectively taken as input to construct a controller of the least squares support vector machines; the expected brake pressure of every wheel is calculated; according to the expected brake pressure, a pulse width modulation method is adopted to control the on / off time of an electromagnetic valve, thus controlling the brake pressure and realizing safety braking. The method is applicable to controlling the anti-lock braking system (ABS) of automobiles.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Method and system for adaptively compensating closed-loop front-wheel steering control

InactiveUS20070213902A1Digital data processing detailsSteering initiationsVehicle dynamicsSteering wheel

An active front-wheel vehicle steering control system that employs closed-loop control includes an adaptive compensation sub-system that compensates for changes in vehicle dynamic parameters. The control system includes a dynamic parameter estimation sub-system that provides an estimated front cornering compliance and rear cornering compliance based on a steering wheel angle signal, a vehicle lateral acceleration signal, a vehicle yaw rate signal and a vehicle speed signal. The closed-loop control includes active gain for each of vehicle yaw rate, yaw acceleration, side-slip and side-slip rate, all based on the vehicle speed and vehicle dynamic parameter changes for use in generating a steering angle control signal to the front wheels of the vehicle.

Owner:GM GLOBAL TECH OPERATIONS LLC

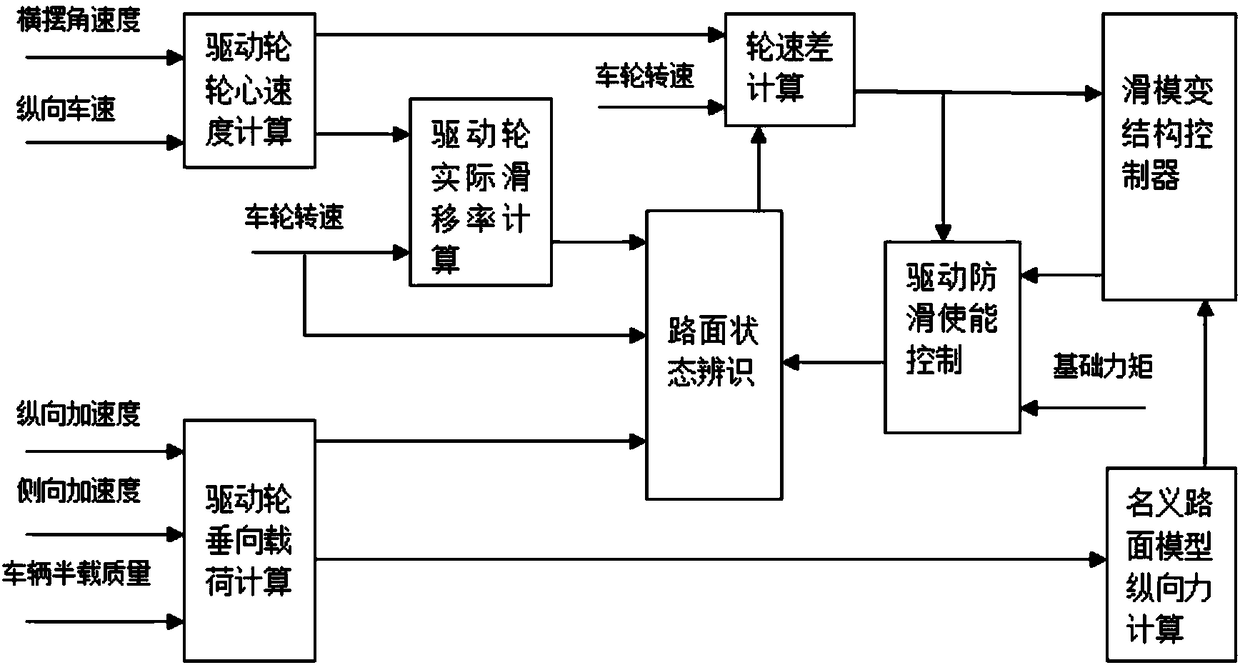

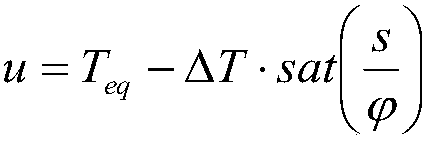

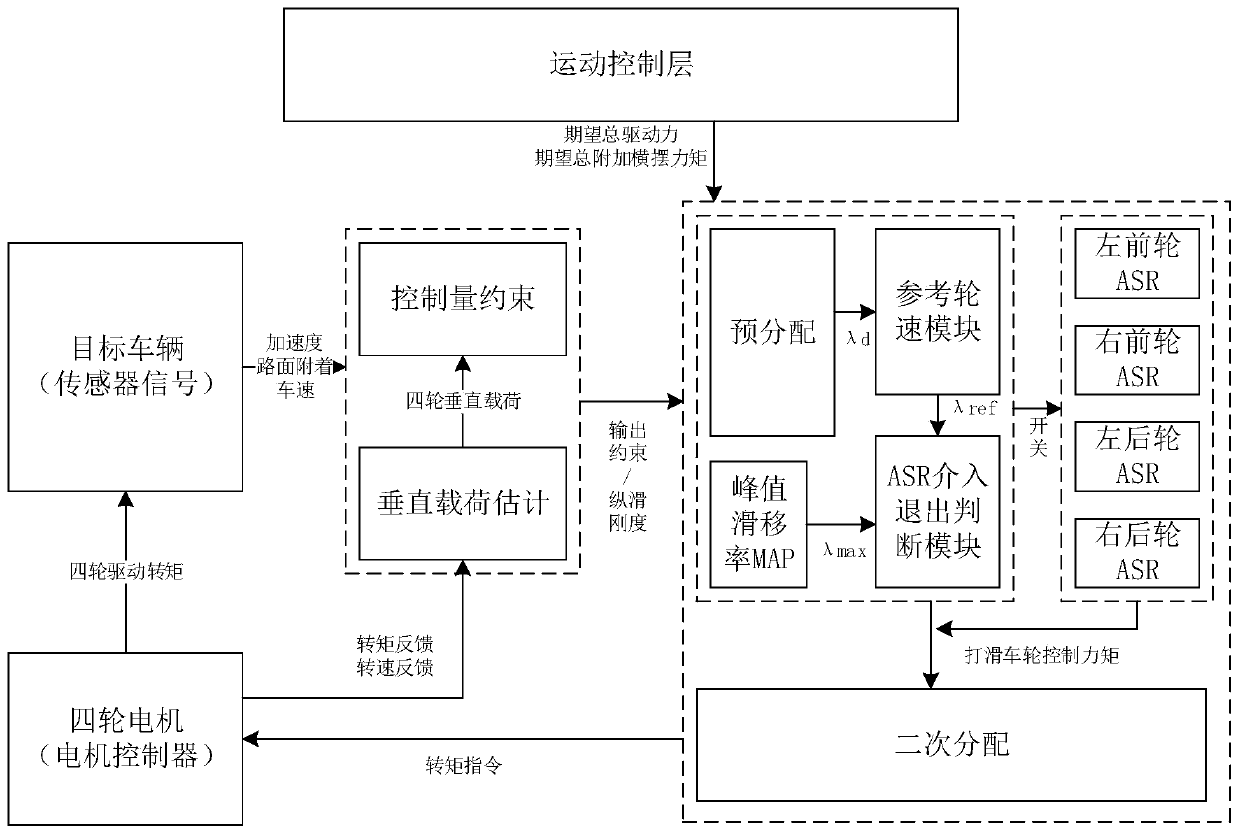

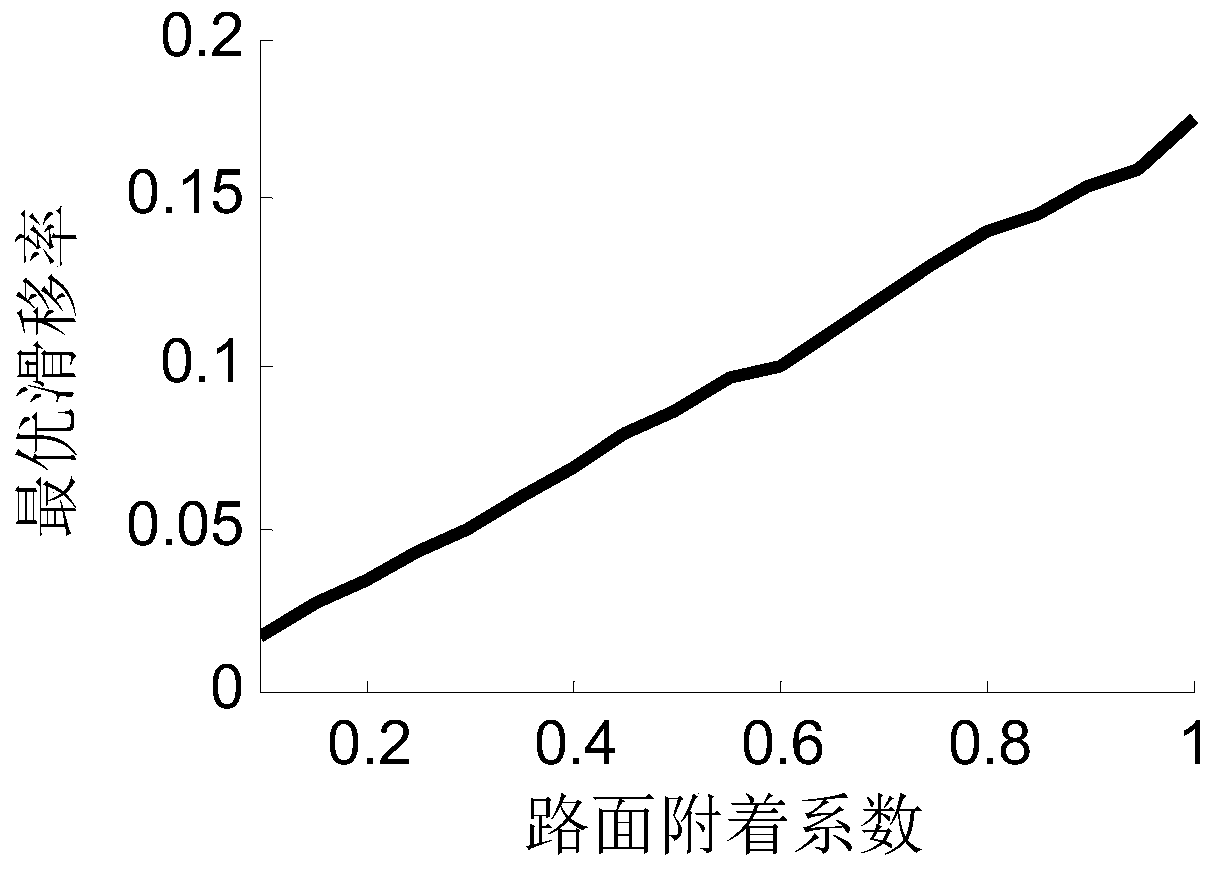

Road surface self-adaptive driving anti-skid control method and system of distributed driving electric automobile

ActiveCN109421552AAchieving Adaptive ControlEliminate static errorsSpeed controllerOperating modesAdhesion coefficientRoad surface

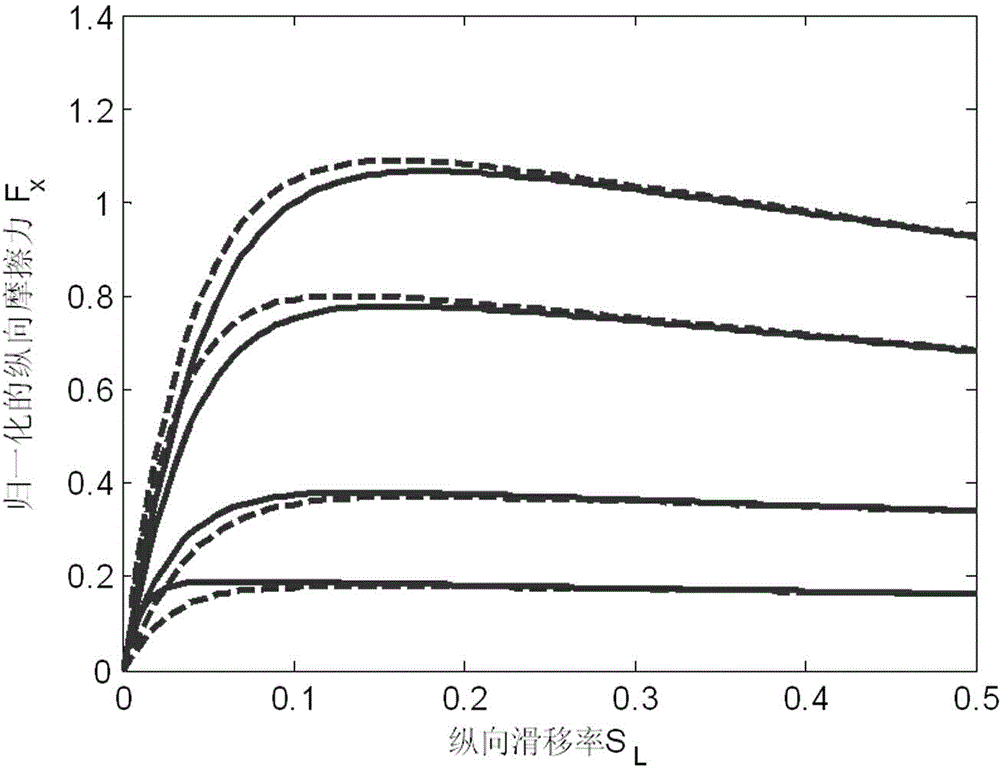

The invention relates to a road surface self-adaptive driving anti-skid control method and system of a distributed driving electric automobile and belongs to the technical field of vehicle control. According to the road surface self-adaptive driving anti-skid control method of the distributed driving electric automobile, by estimating a current road surface peak adhesion coefficient in real time,a current road surface optimal slip rate is obtained according to a corresponding linear relation between the current road surface peak adhesion coefficient and the current road surface optimal slip rate; by combining a current wheel center speed, a current wheel reference wheel speed is determined; a difference between an actual wheel speed and the reference wheel speed is calculated; according to the wheel speed difference, the moment of a wheel, which slips in a driving state, is controlled by using a sliding mode variable structure controller; and therefore, it is guaranteed that the wheelslip rate is controlled to the current road surface optimal slip rate. According to the road surface self-adaptive driving anti-skid control method of the distributed driving electric automobile, thewheel slip rate is controlled to the current road surface optimal slip rate to realize self-adaptive control of anti-skid driving of the wheel.

Owner:ZHENGZHOU YUTONG BUS CO LTD

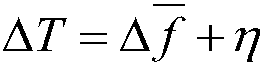

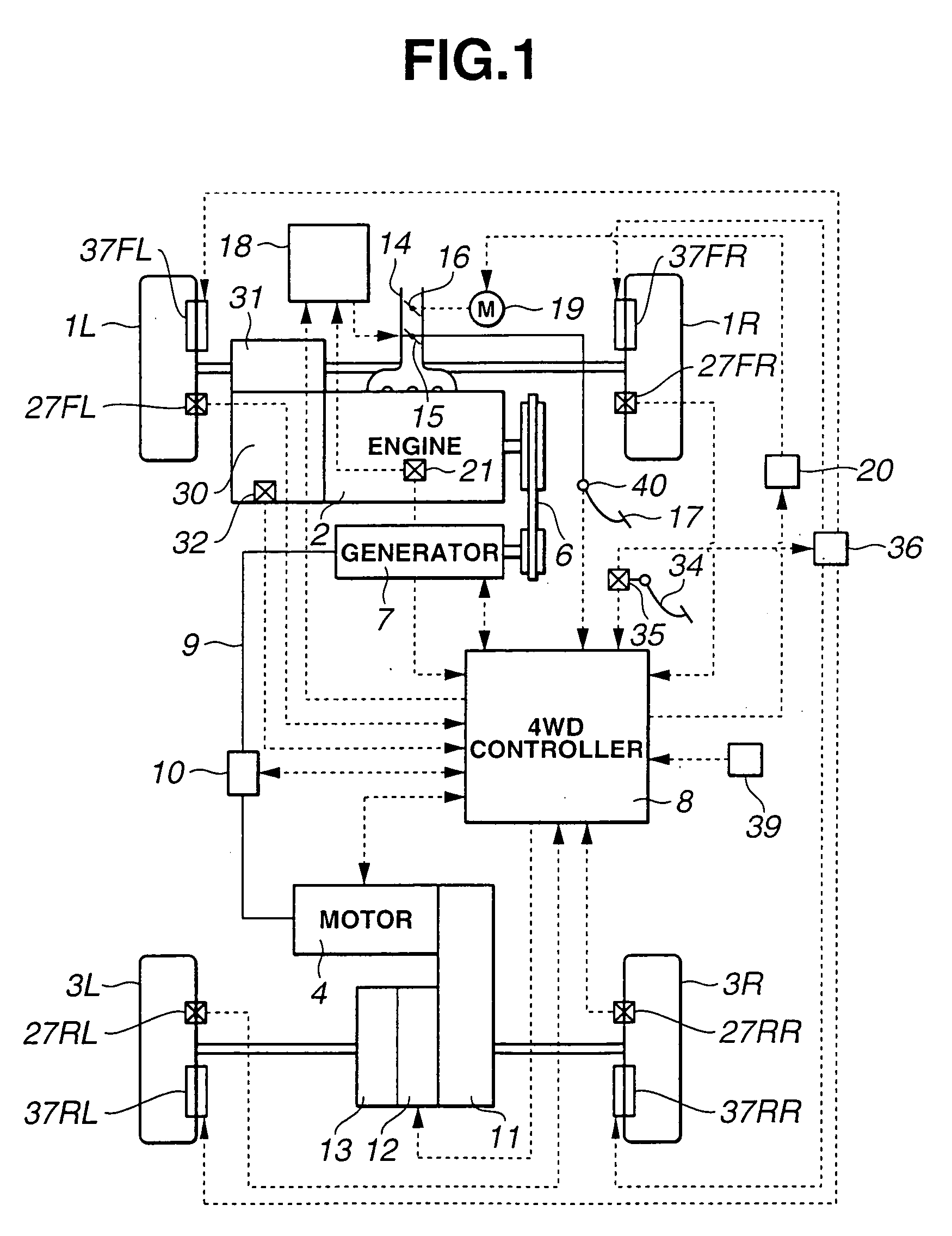

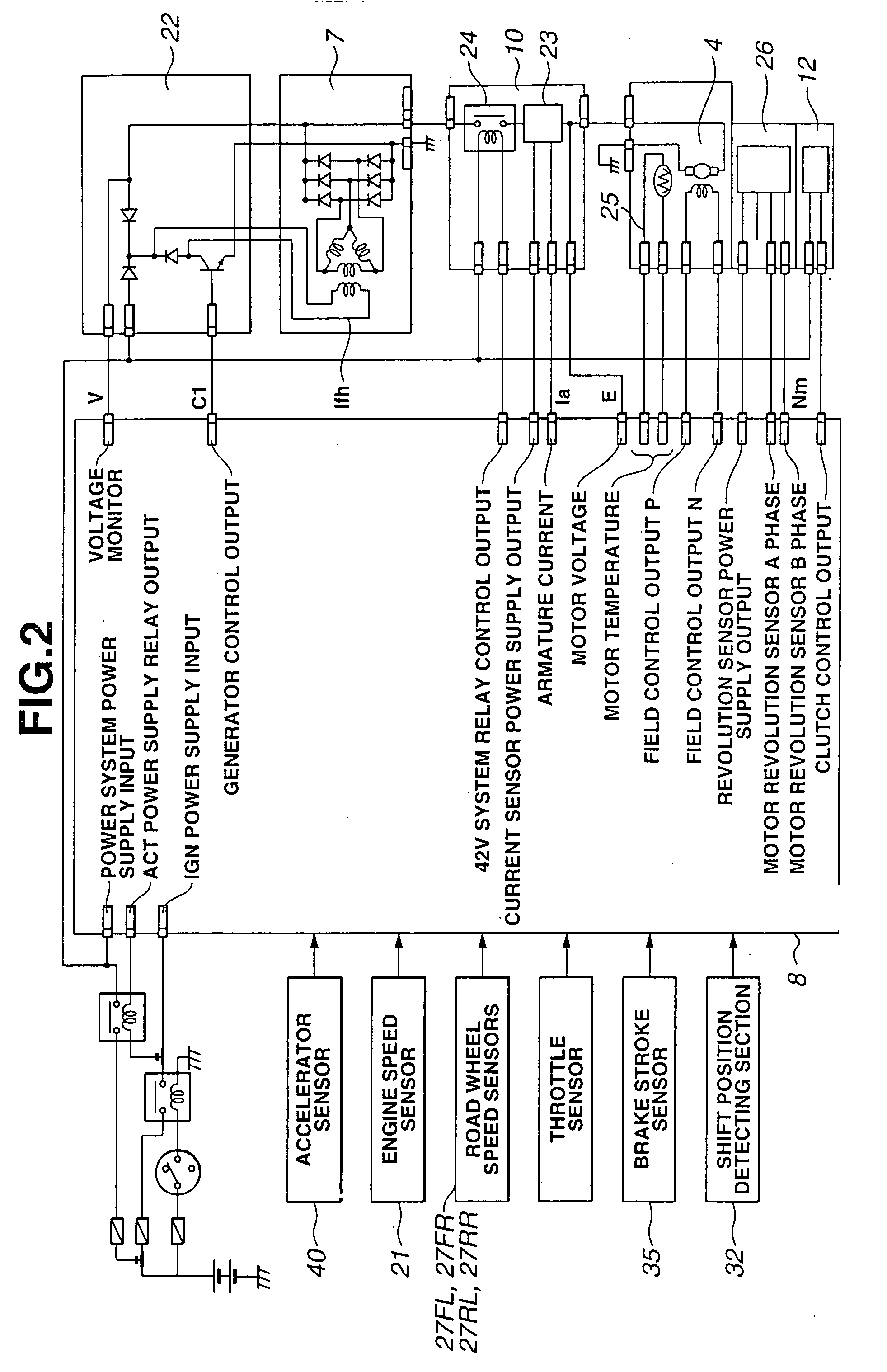

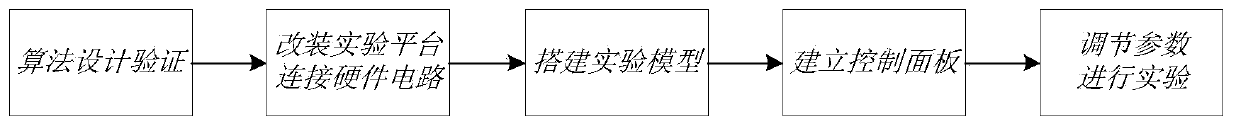

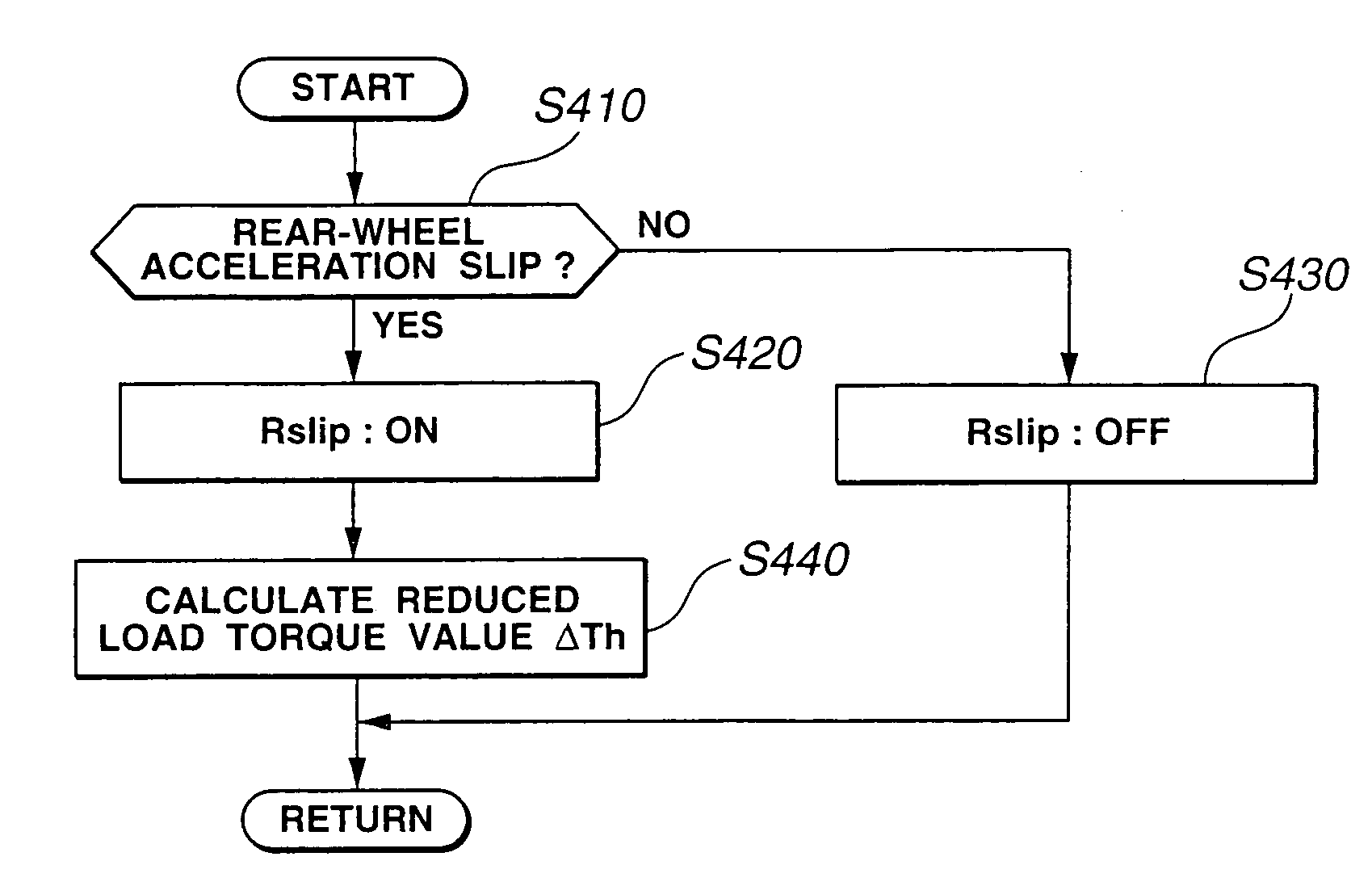

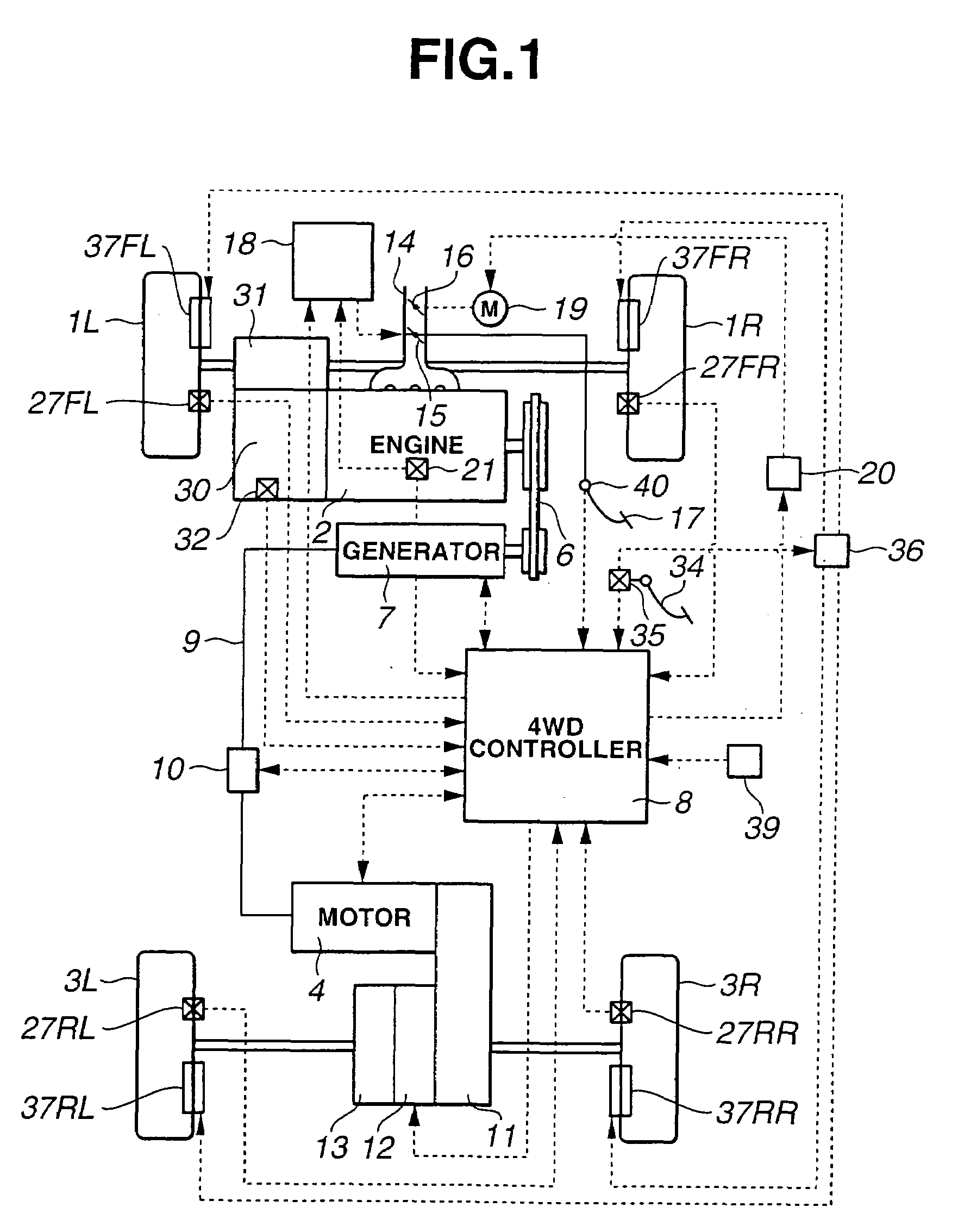

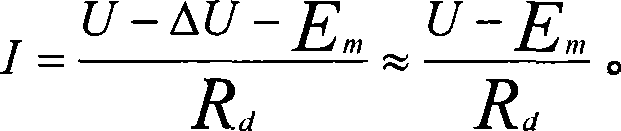

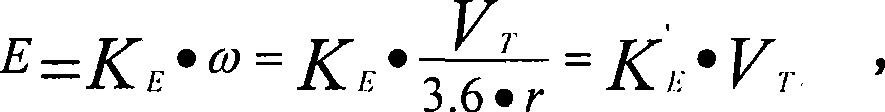

Driving force control apparatus for automotive vehicles

InactiveUS20050278104A1Effectively suppressing acceleration slipWithout convergence performanceSpeed controllerDigital data processing detailsMobile vehicleMotor drive

In a driving force control apparatus for an automotive vehicle employing an engine that drives a main drive wheel, a generator driven by the engine, and a motor driven by an electric power output generated by the generator to drive a subsidiary drive wheel, a subsidiary-drive-wheel acceleration slip estimation circuitry is provided to estimate a subsidiary-drive-wheel acceleration slip rate. An electric power output suppression circuitry is provided to suppress the electric power output of the generator when the estimated subsidiary-drive-wheel acceleration slip rate exceeds a predetermined slip rate. Also provided is a subsidiary-drive-wheel acceleration-slip period engine output torque reduction circuitry that reduces an engine output torque responsively to suppressing the electric power output.

Owner:NISSAN MOTOR CO LTD

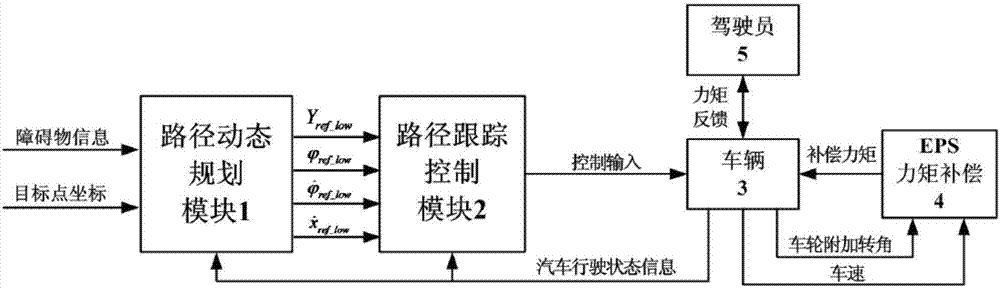

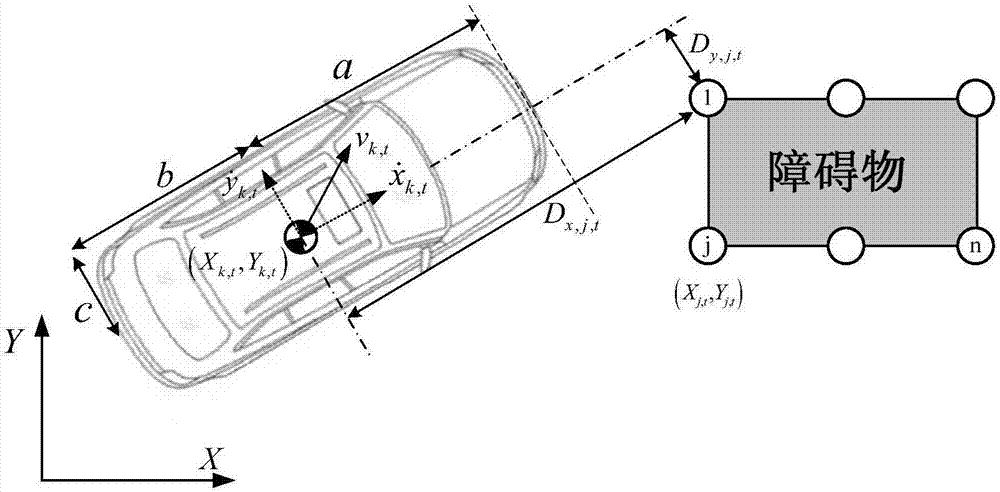

Automobile emergency collision avoidance hierarchical control method considering human-machine cooperation

InactiveCN107885932AImprove real-time performanceSolve real-timeGeometric CADElectrical steeringDynamic planningSteering wheel

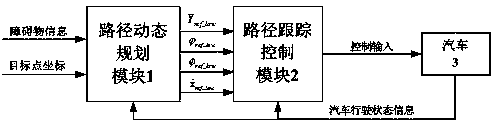

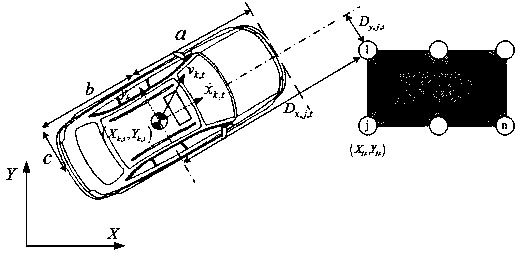

The invention discloses an automobile emergency collision avoidance hierarchical control method considering human-machine cooperation and relates to the field of automobile assisted driving technology. According to the method, a lateral displacement reference value, a yaw angle reference value, a yaw velocity reference value and a longitudinal velocity reference value of a desired trajectory are obtained through real-time optimization through a path dynamic planning module according to barrier information, target point coordinates and automobile travel state information collected in real time,and the values are input into a path tracking control module; meanwhile, current automobile travel state information is collected through the path tracking control module, a front wheel rotating angle and slip rates of four wheels of an automobile are obtained through real-time optimization, and the automobile is controlled to realize collision avoidance; and in the collision avoidance control process, a compensation control moment is determined according to the velocity and a front wheel additional rotating angle through an EPS moment compensation module, the steering wheel sudden change moment is controlled to be within an ideal range, and automobile emergency collision avoidance with human-machine cooperation is realized. Through the method, path dynamic planning and real-time trackingduring emergency collision avoidance are realized, and safe optimal collision avoidance is realized.

Owner:CHANGCHUN UNIV OF TECH

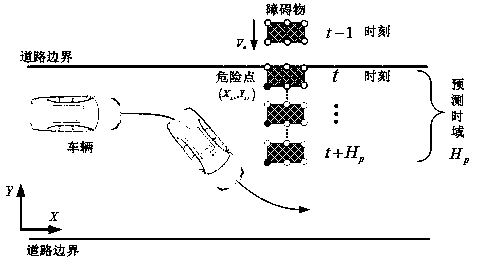

Automobile emergency collision-avoidance layered control method taking moving obstacles into account

InactiveCN107867290ASolve real-timeTroubleshoot movement barriersExternal condition input parametersPosition/course control in two dimensionsTurn angleDynamic planning

The invention relates to an automobile emergency collision-avoidance layered control method taking moving obstacles into account. The automobile emergency collision-avoidance layered control method taking the moving obstacles into account is characterized by including the steps that through a path dynamic planning module, according to obstacle information, coordinates of target points and automobile driving state information which are collected in real time, a lateral displacement reference value, a yaw angle reference value, a yaw angular velocity reference value and a longitudinal velocity reference value of an expected trajectory are obtained by real-time optimization and are input into a path tracking control module, at the same time, through the path tracking control module, current automobile driving state information is collected, turning angles of front wheels and the slip rate of four wheels of an automobile are obtained by real-time optimization, and the automobile is controlled to avoid collision.

Owner:CHANGCHUN UNIV OF TECH

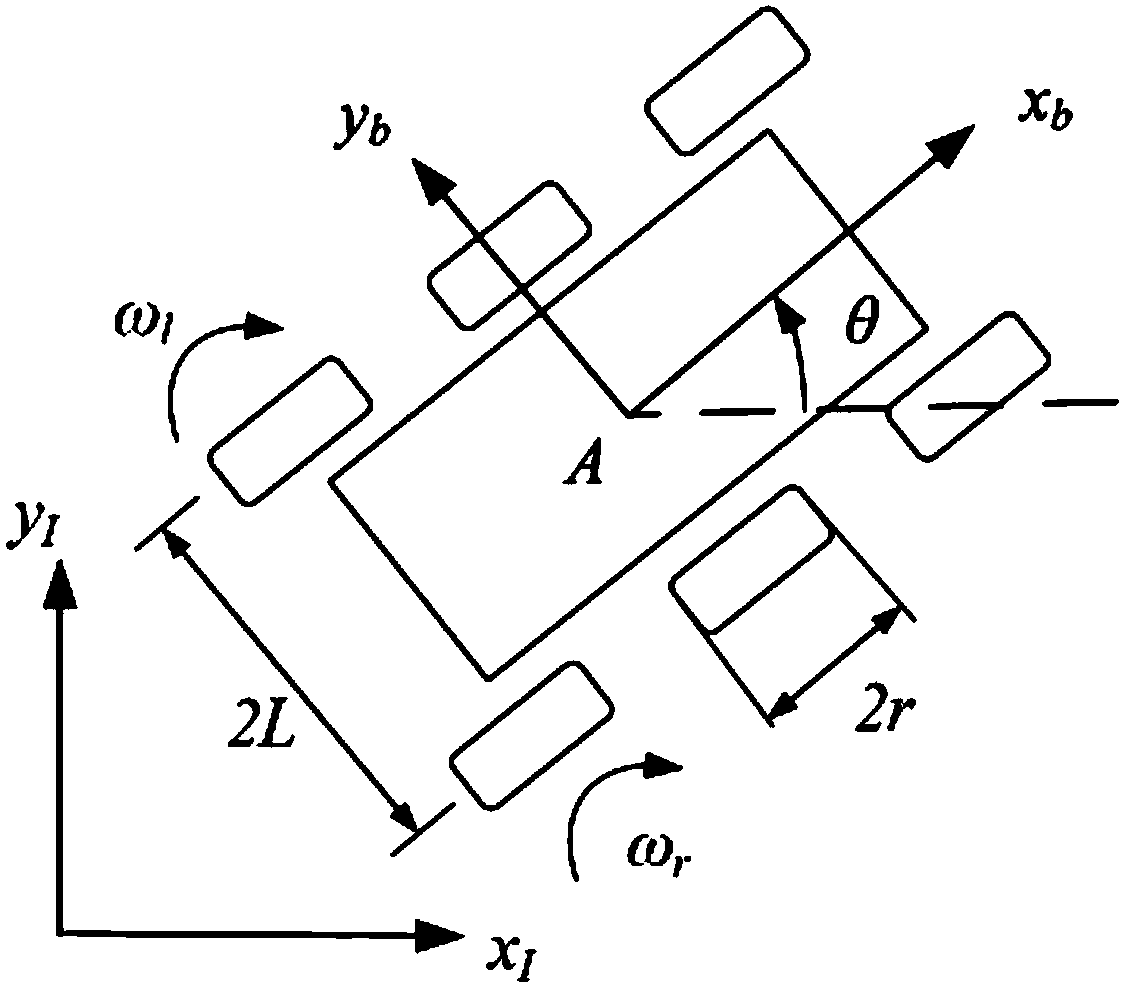

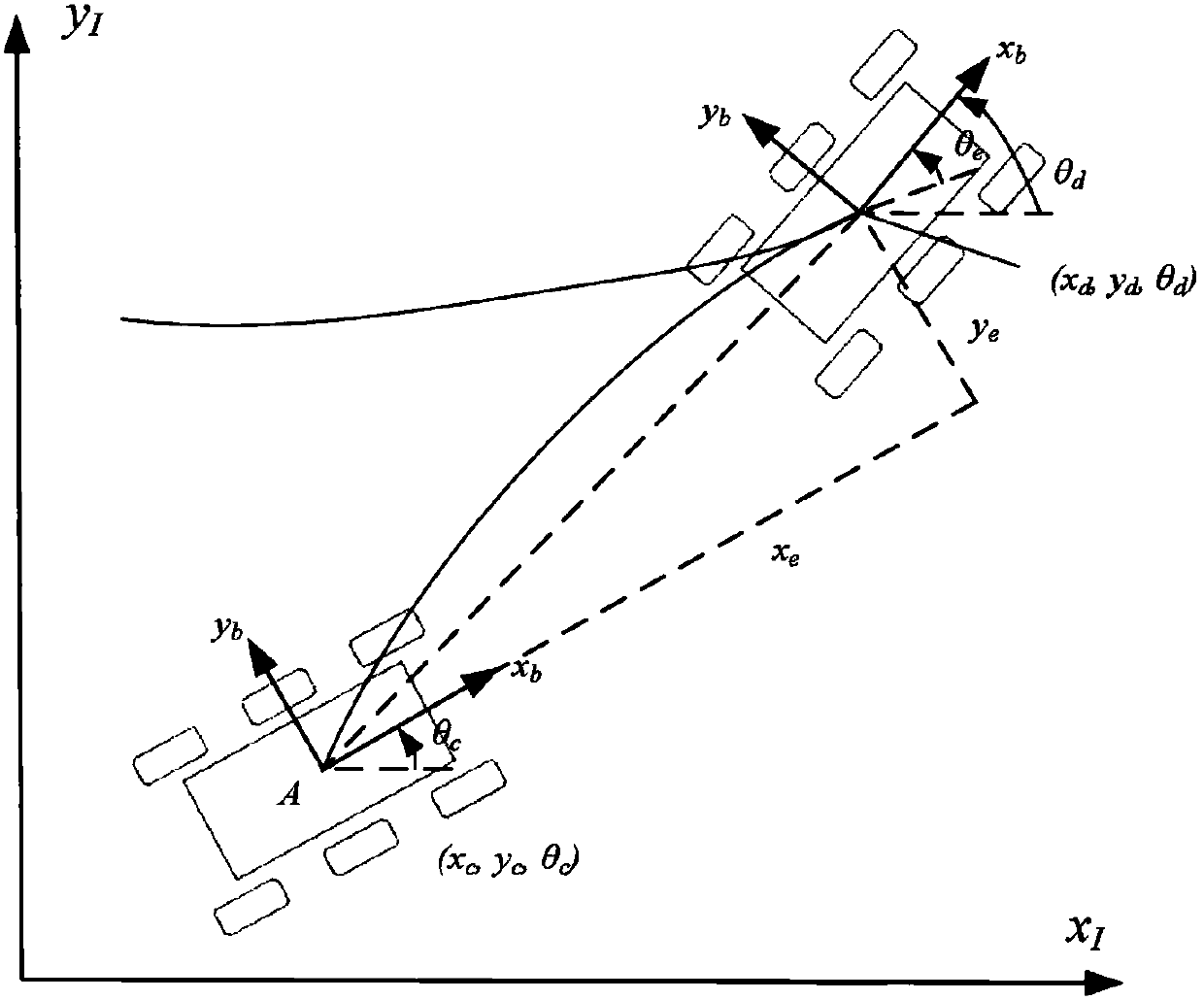

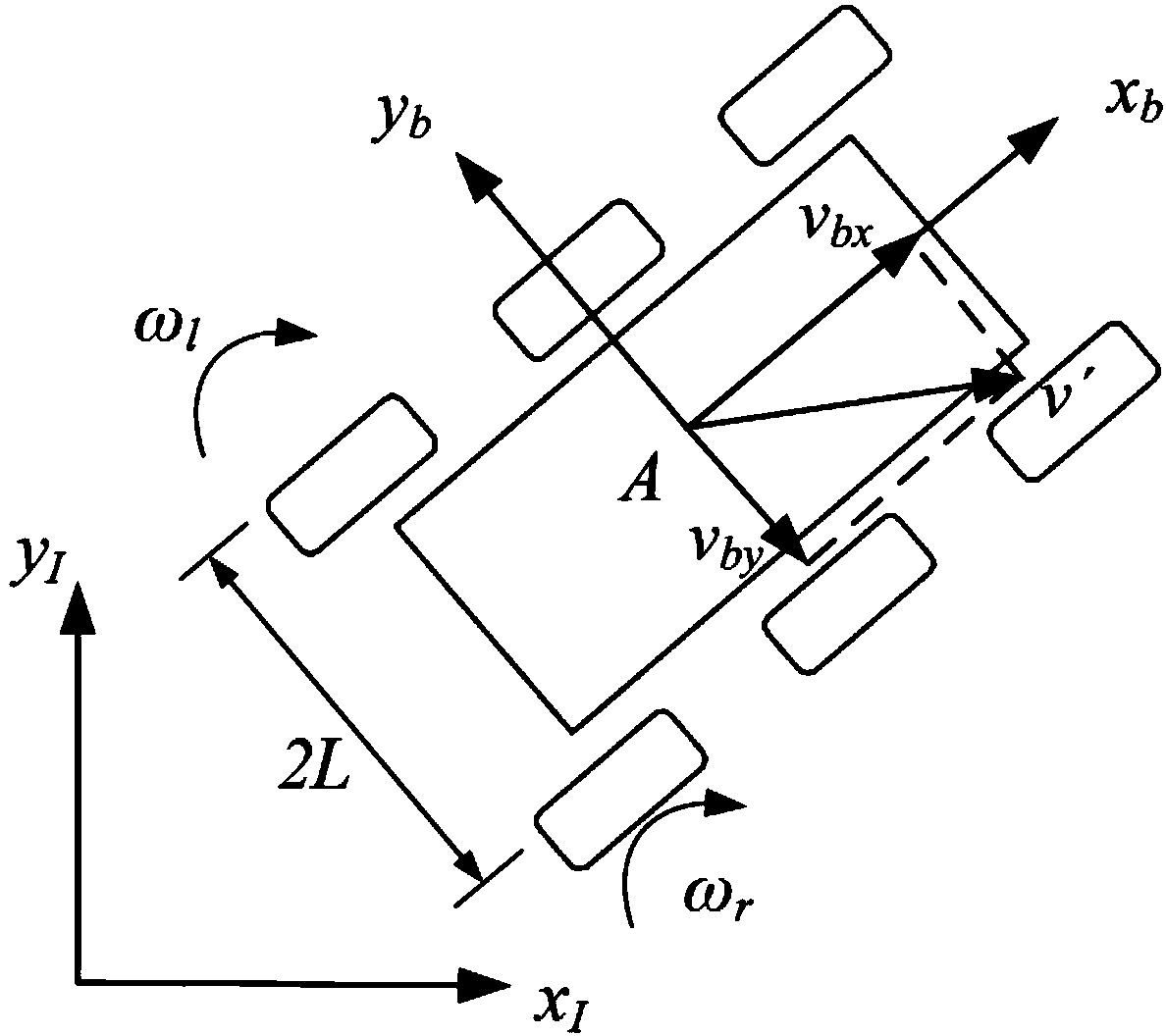

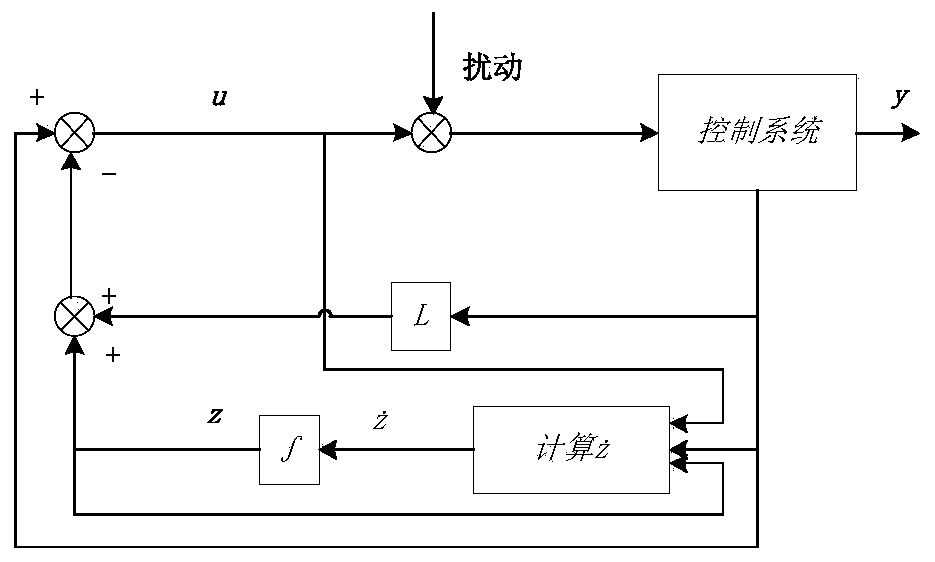

Mobile robot trace tracking control method

InactiveCN108098770AAccurate descriptionAccurate representationProgramme controlProgramme-controlled manipulatorMathematical modelSlip coefficient

The invention discloses a mobile robot trace tracking control method. The mobile robot trace tracking control method comprises the steps of calculating the numerical values of a slip coefficient and the slip rate according to motion mathematical model formulas of the slip coefficient and the slip rate and data detected by A GPS-INS and the information of the expected path, the expected speed and the expected yaw velocity given by a mobile robot decision layer; substituting the numerical values into a kinematic model of a mobile robot and compensating for and calculating the rotating speed of wheels achieving trace tracking to achieve the purpose of accurately tracking an expected trace. The mobile robot trace tracking control method has the advantages that the slippage rate can be calculated at any time; the actual motion state of the mobile robot can be described and represented more truly and accurately; accordingly, the expected trace can be tracked effectively and accurately.

Owner:张辉

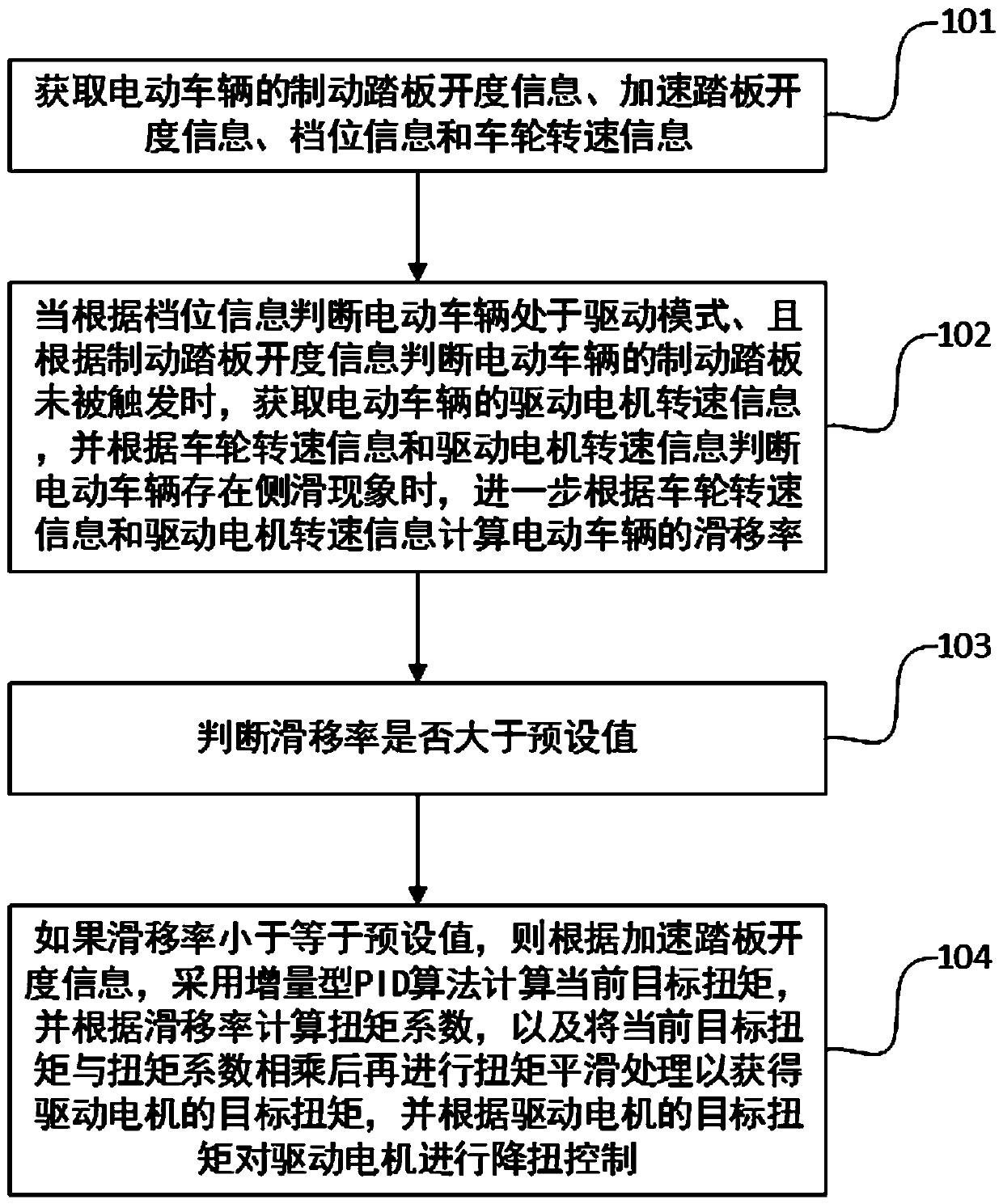

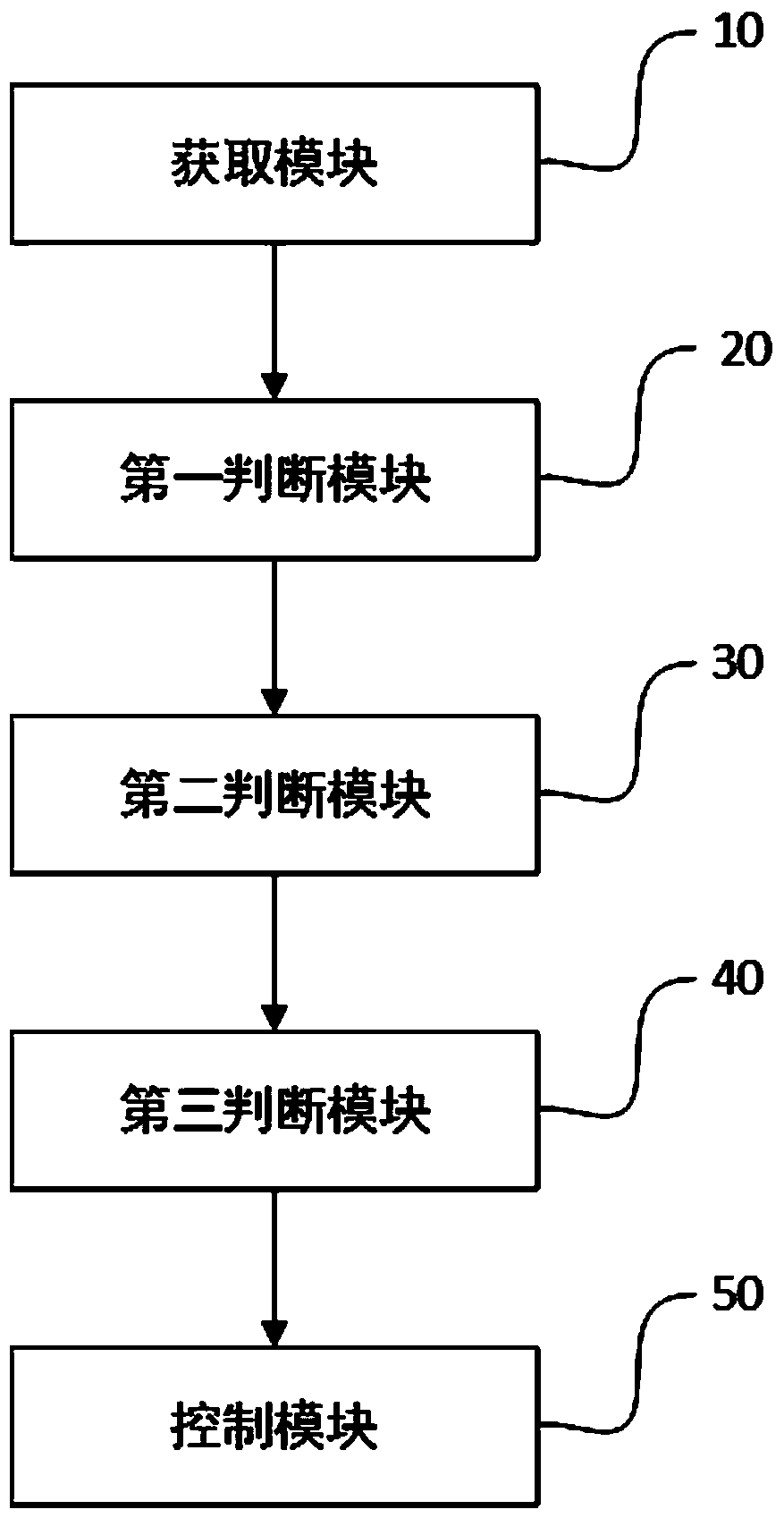

Driving anti-slip control method and control device for electric vehicle, medium and vehicle control unit

The invention discloses a driving anti-slip control method and control device of an electric vehicle, a medium, a vehicle control unit. The method comprises the following steps of acquiring vehicle information of an electric vehicle; when the electric vehicle is in a driving mode and a brake pedal is not triggered, acquiring the rotating speed information of the driving motor, and further calculating the slip rate when judging that the electric vehicle has a sideslip phenomenon; if the slip rate is smaller than or equal to the preset value, calculating a current target torque, calculating a torque coefficient according to the slip rate, carrying out torque smoothing processing to obtain a target torque of the driving motor, and carrying out torque reduction control on the driving motor according to the target torque of the driving motor. The motor torque can be intervened with through cooperation between the vehicle control unit and the motor controller, driving antislip control over the electric vehicle can be completed through the combination of a common PID algorithm and a torque smoothing algorithm, the process is simple and easy to implement, and it is possible that an ASR system can be widely applied to the electric vehicles.

Owner:厦门金龙汽车新能源科技有限公司

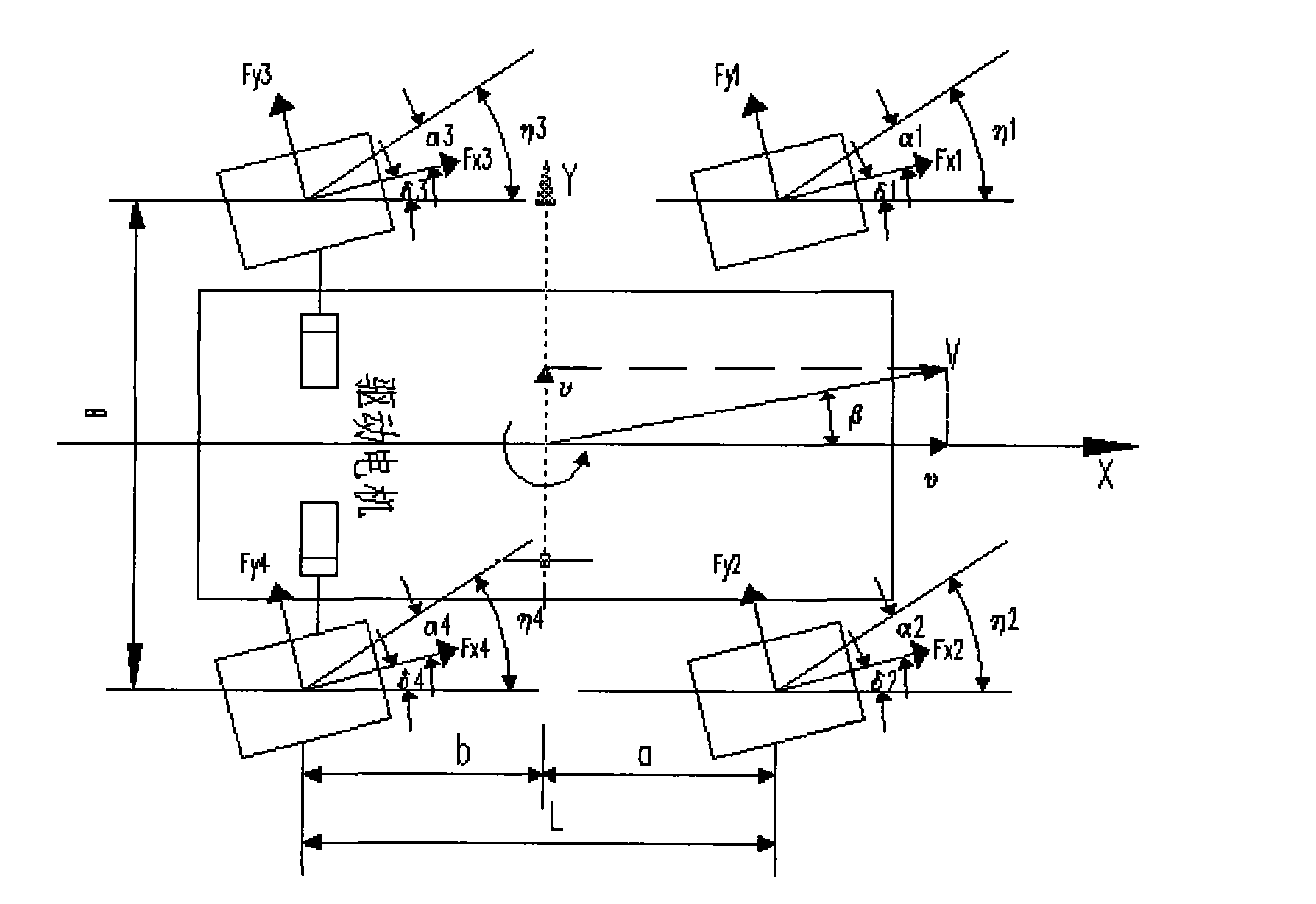

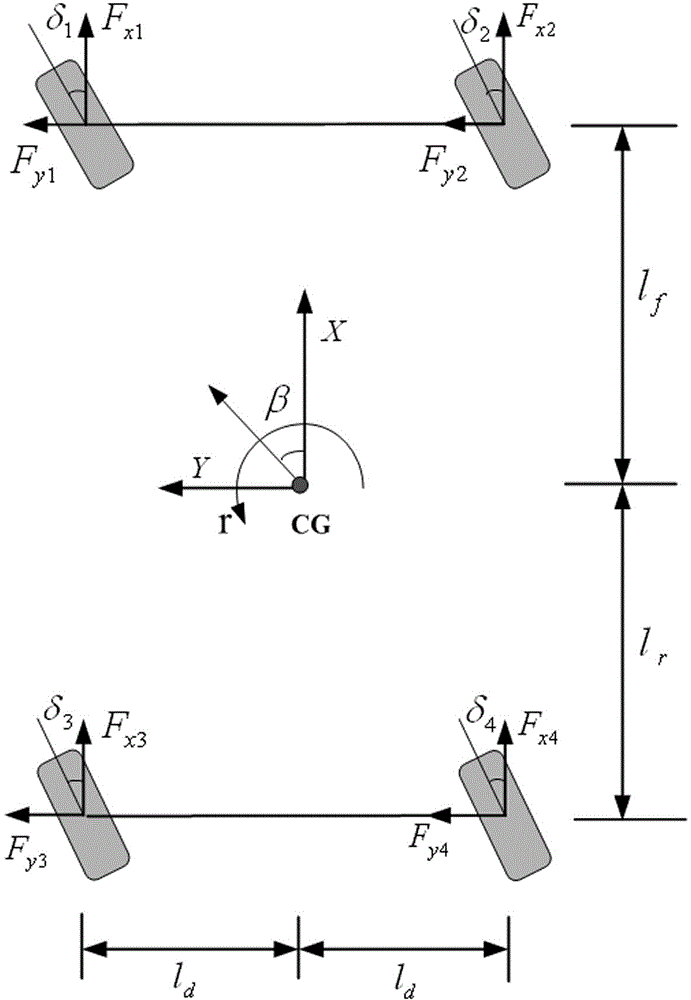

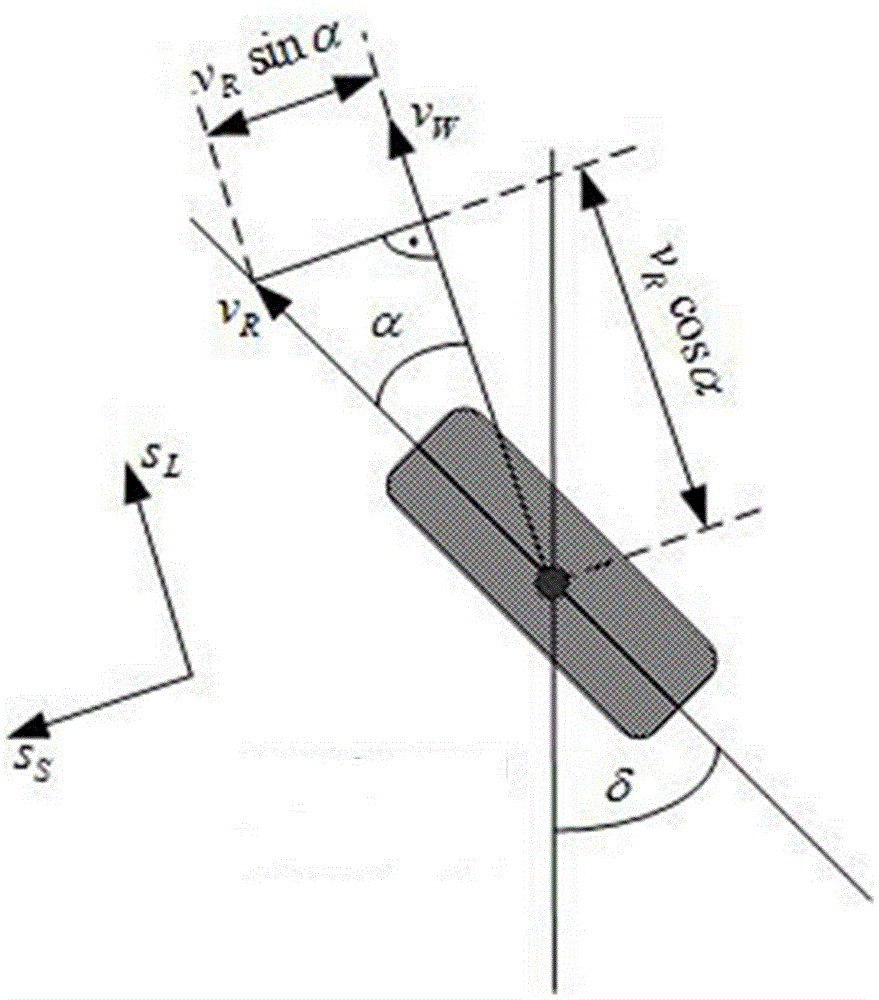

Speed estimation and friction identification method of four-wheel turning/driving vehicle

ActiveCN104442830AAccurate estimateReal-time identificationExternal condition input parametersKinematics equationsDynamic equation

The invention discloses a velocity estimation and friction identification method of a four-wheel turning / driving vehicle. The velocity estimation and friction identification method comprises the steps that firstly, a vehicle body coordinate system O-XY is established; secondly, a vehicle kinetic equation is established; thirdly, a wheel kinetic equation is established; fourthly, a wheel velocity equation is established; fifthly, a wheel slip rate equation is established; sixthly, the longitudinal force and lateral force of a wheel are obtained; seventhly, a friction model is parameterized; eighthly, a kinematical equation describing the relation of the vehicle velocity, the yaw velocity and the acceleration is established; ninthly, an observer is designed under the situation that detectable signals z comprise the longitudinal acceleration ax, the lateral acceleration ay, the yaw velocity r, the wheel angular velocity wj and the steering wheel rotation angle delta i; tenthly, persistent excitation conditions are defined. According to the velocity estimation and friction identification method, the nonlinearity self-adaptation observer for estimating the vehicle longitudinal velocity and the lateral velocity is established, the tire road surface friction parameters are established in real time according to the change of road surface conditions, and the velocity is estimated more accurately.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

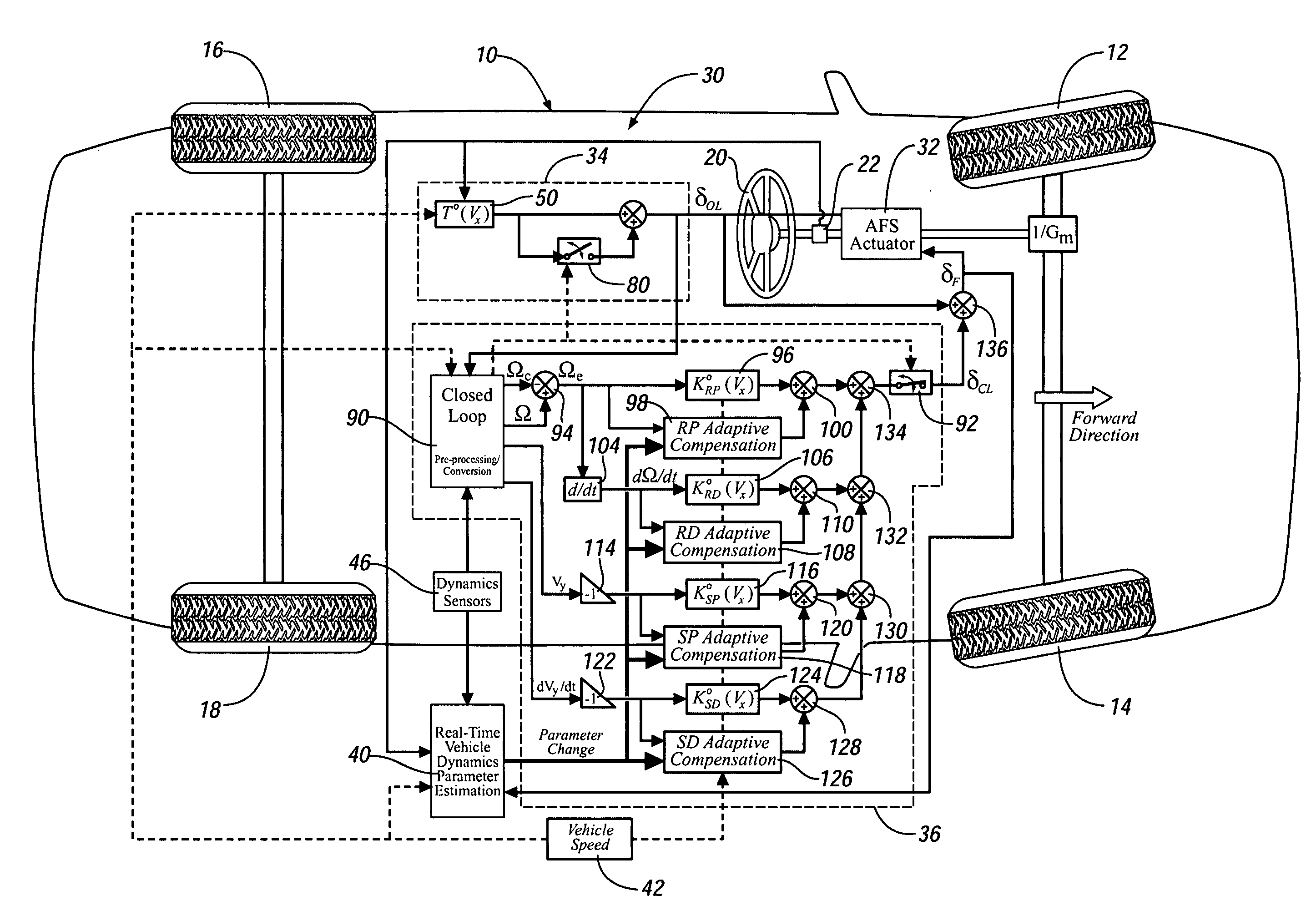

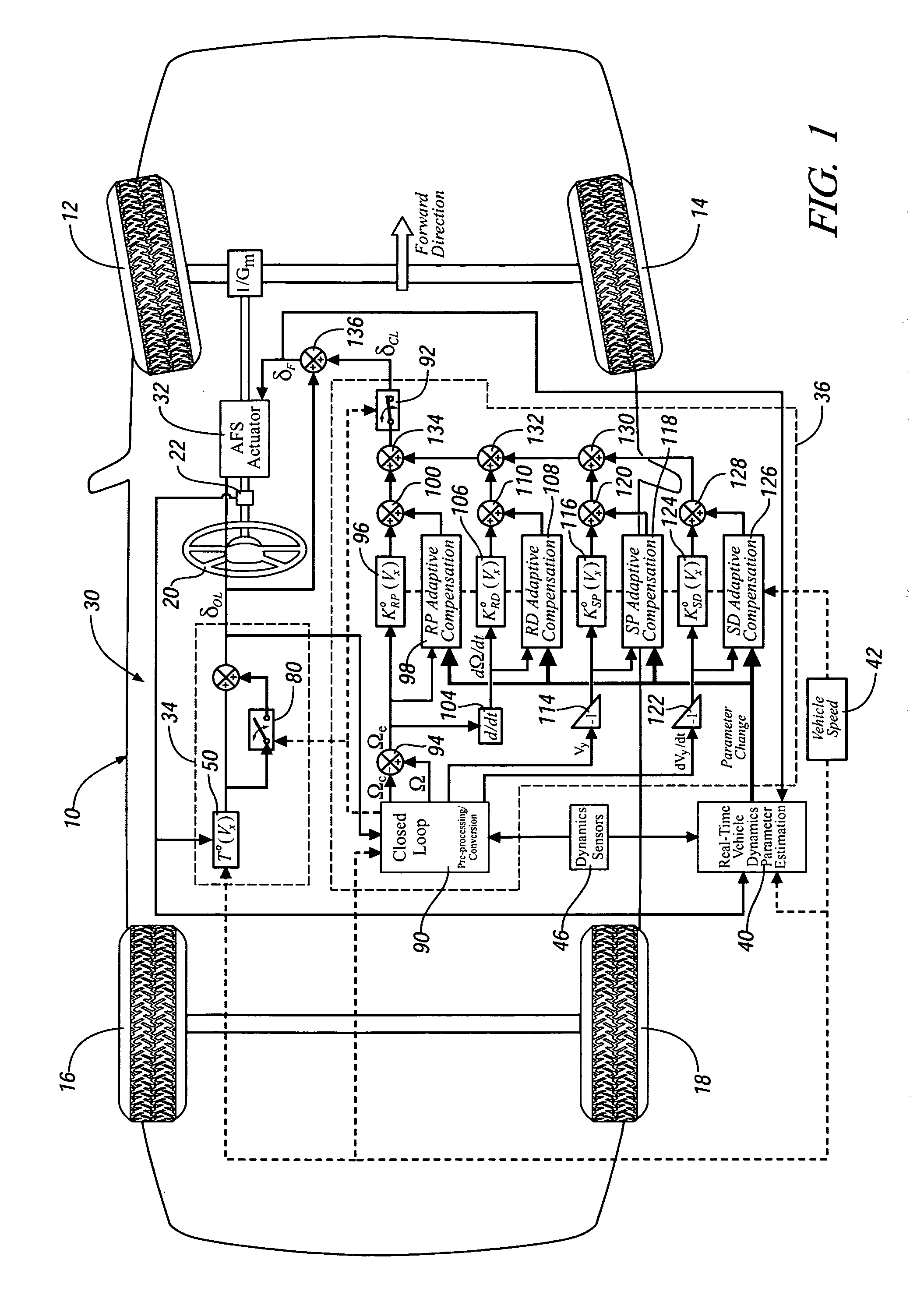

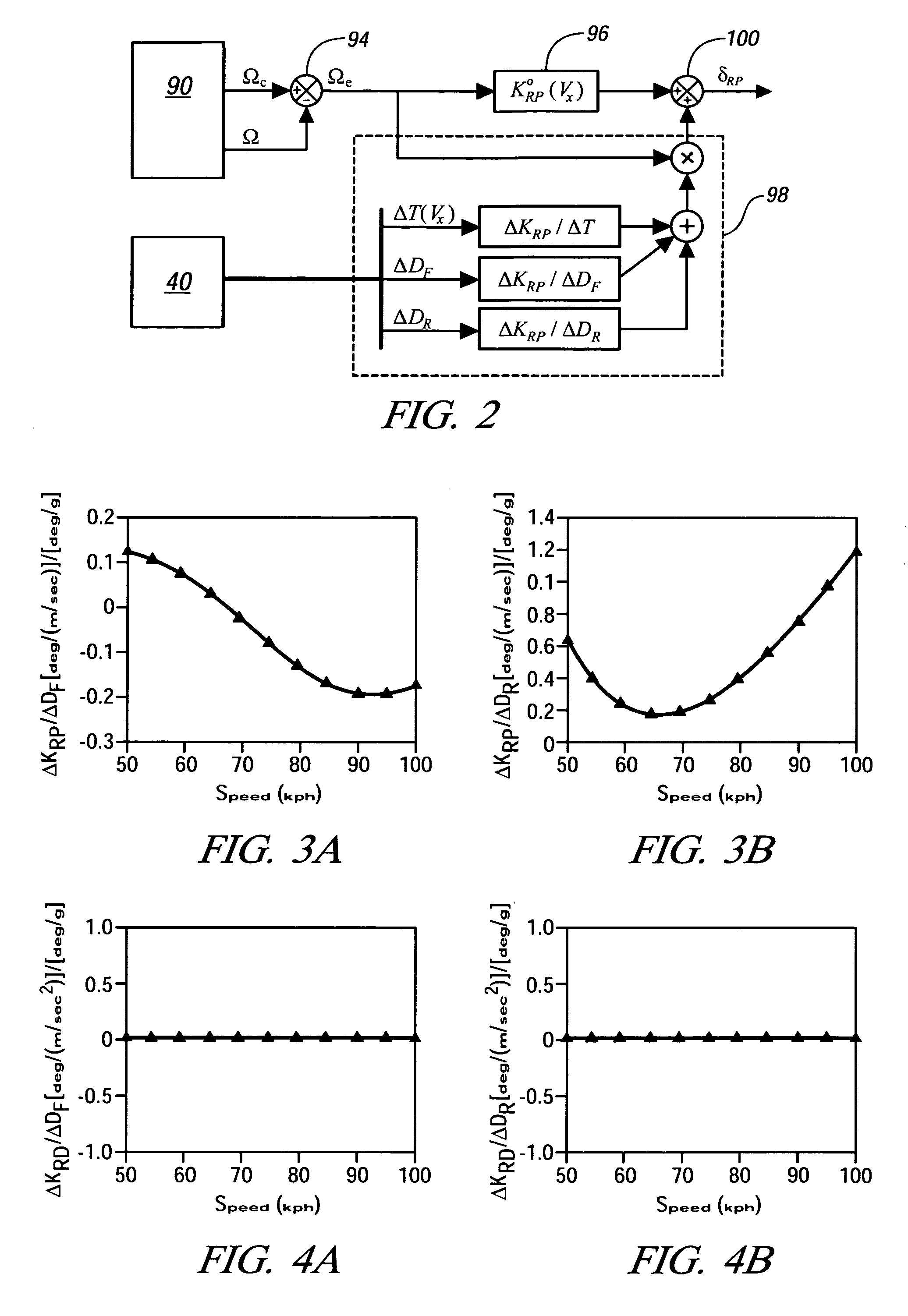

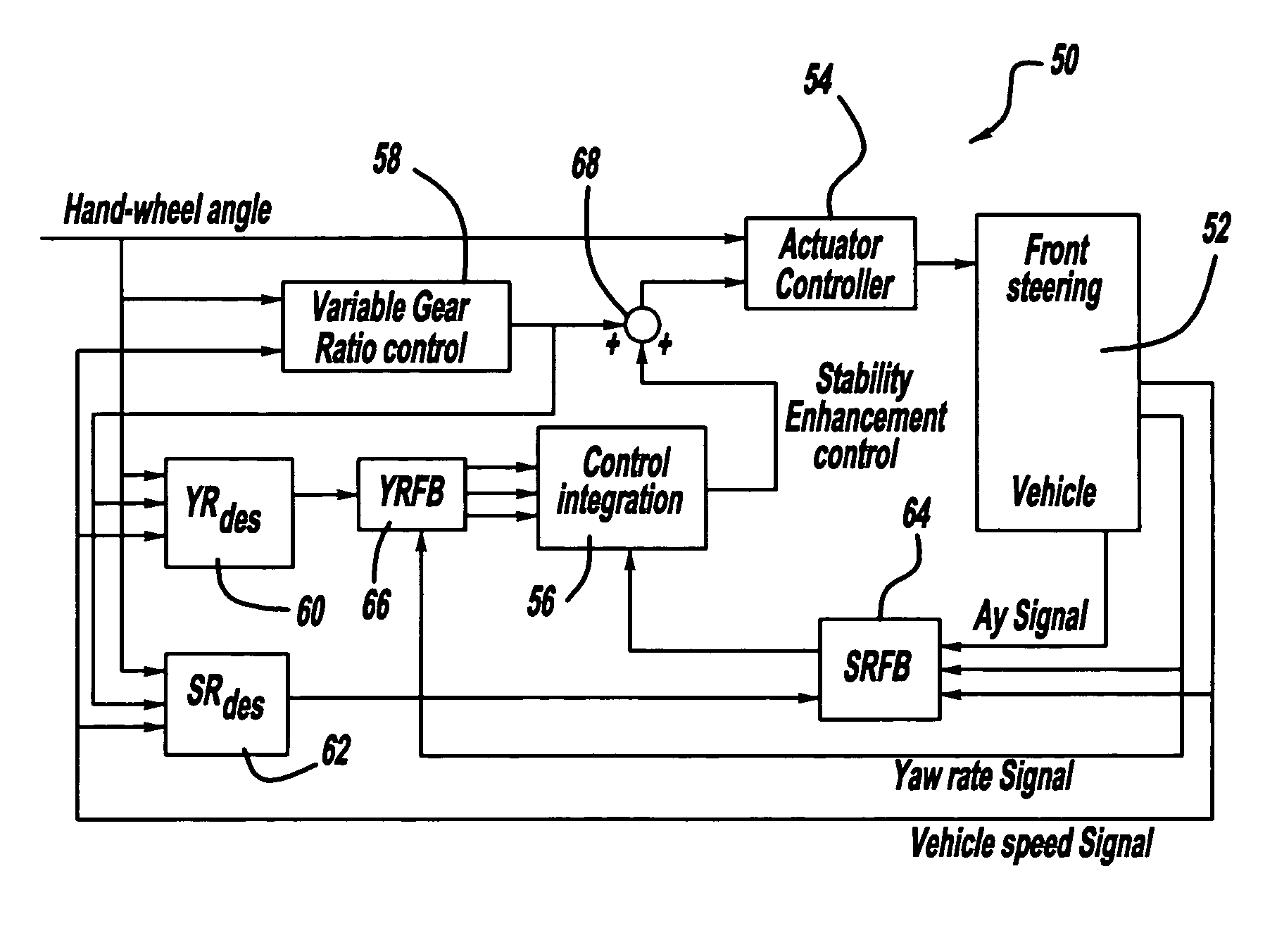

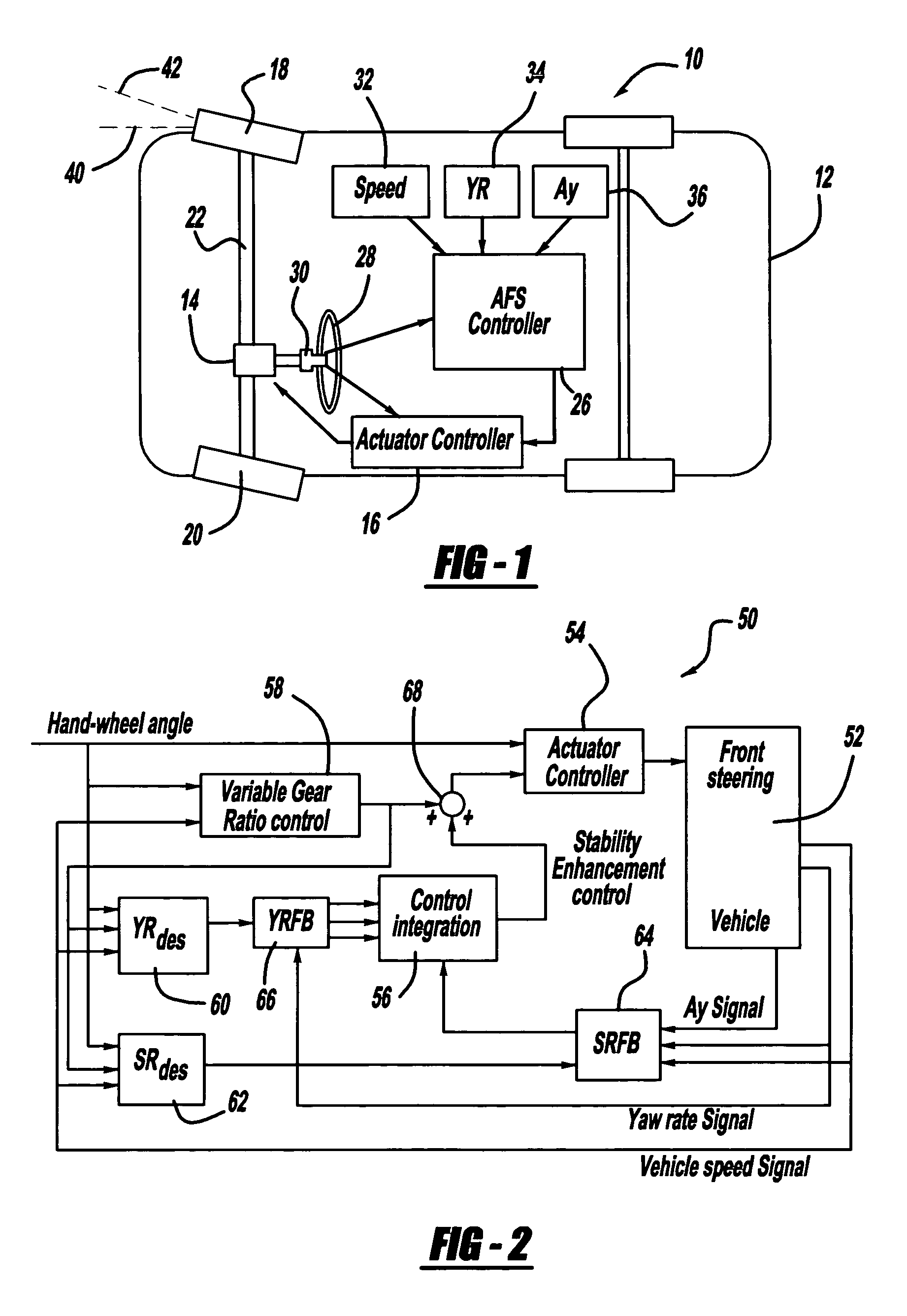

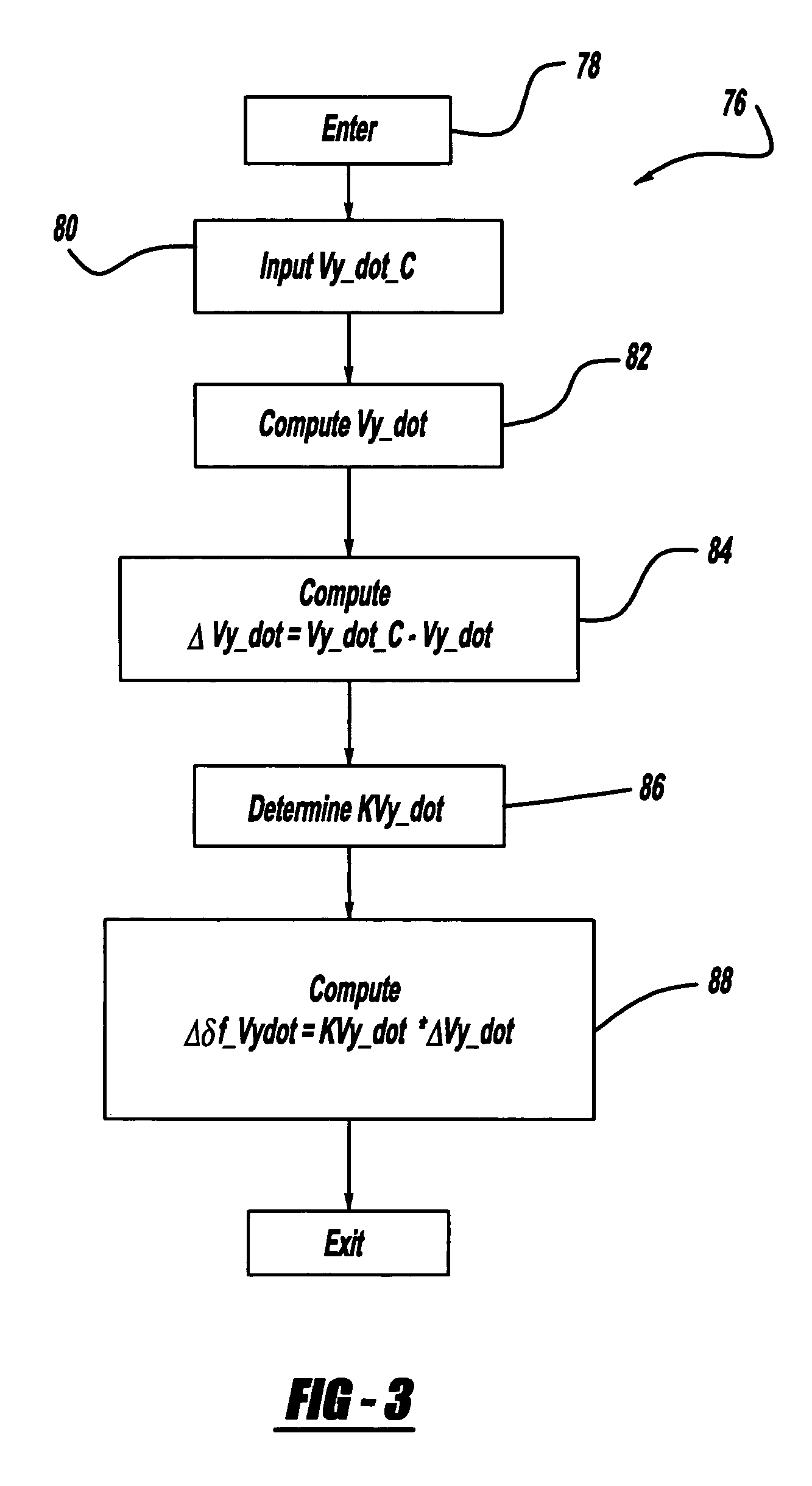

Active front steer control for vehicle stability enhancement

InactiveUS7181326B2Digital data processing detailsAutomatic steering controlControl signalControl system

An AFS control system that combines and weights yaw rate feedback and side-slip rate feedback to provide increased vehicle stability enhancement control. The AFS system includes a yaw rate sub-system that generates a desired yaw rate signal. The AFS system also includes a side-slip rate sub-system that generates a desired side-slip rate feedback signal. The AFS system further includes a side-slip rate feedback sub-system that generates a side-slip rate feedback signal. The AFS system also includes a yaw rate feedback sub-system that generates a yaw rate feedback signal. The yaw rate feedback signal and the side-slip rate feedback signal are integrated in a control integration sub-system that generates a stability enhancement control signal. The control integration sub-system determines whether the vehicle is in an oversteer or understeer condition, and weights the desired yaw rate feedback signal accordingly based on the vehicle condition.

Owner:GM GLOBAL TECH OPERATIONS LLC

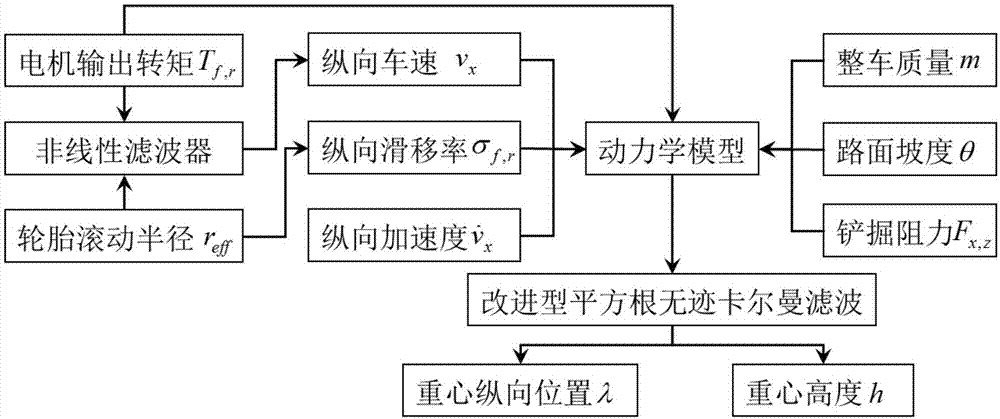

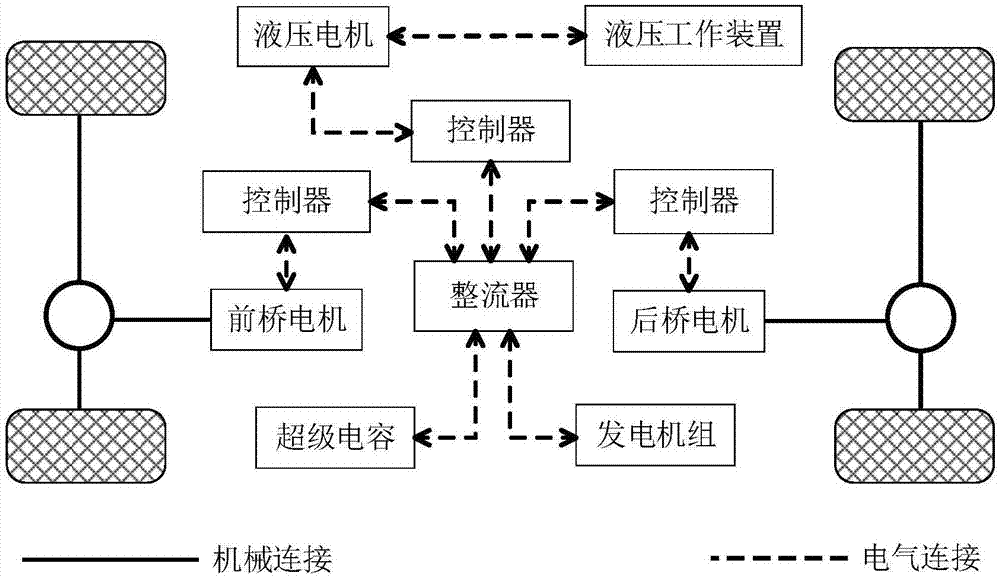

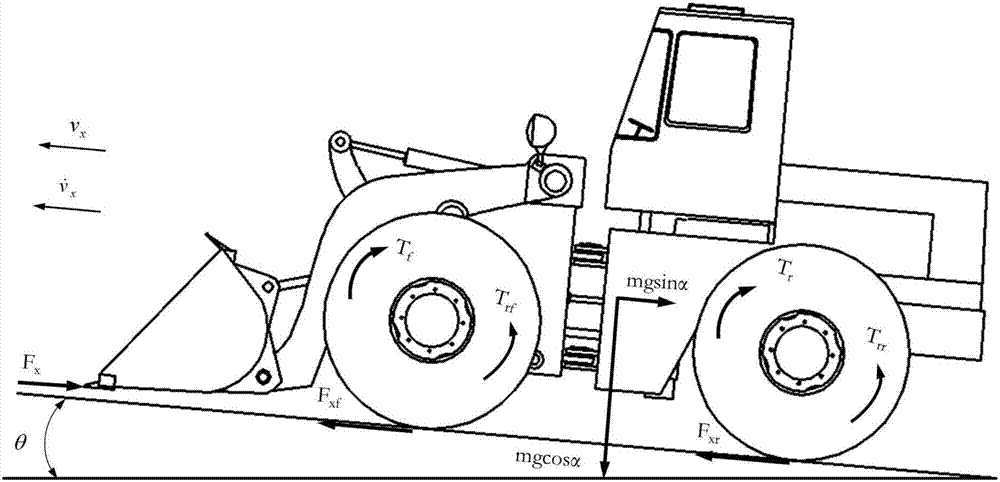

Wheel type loading machine tire longitudinal force dynamic estimation method

The invention provides a wheel type loading machine tire longitudinal force dynamic estimation method. The method comprises the steps of firstly, based on motor output torque capable of being known inreal time of a front motor and a rear motor of a wheel type loading machine independently electrically driven by a front axle and a rear axle and the measured tire rolling radius, and through estimation of a nonlinear filter, obtaining the longitudinal speed; then, constructing a state equation and a measurement equation according to the longitudinal acceleration and slope obtained through measurement of a sensor and the estimated longitudinal speed and through the calculated front tire and rear tire slip rate and the whole vehicle mass and the spading resistance obtained by looking up a table or conducting calculation; finally, estimating dynamic front wheel longitudinal force and rear wheel longitudinal force through extended Kalman filter. By means of the method, accurate tire longitudinal force dynamic parameters are provided for wheel type loading machine intellectualized dynamics control independently electrically driven by the front axle and the rear axle, and the whole-vehiclecontrol precision and performance are improved. The method is applicable to wheel type loading machine of longitudinal motion in all working conditions, less sensors are utilized, and the price is low.

Owner:JILIN UNIV

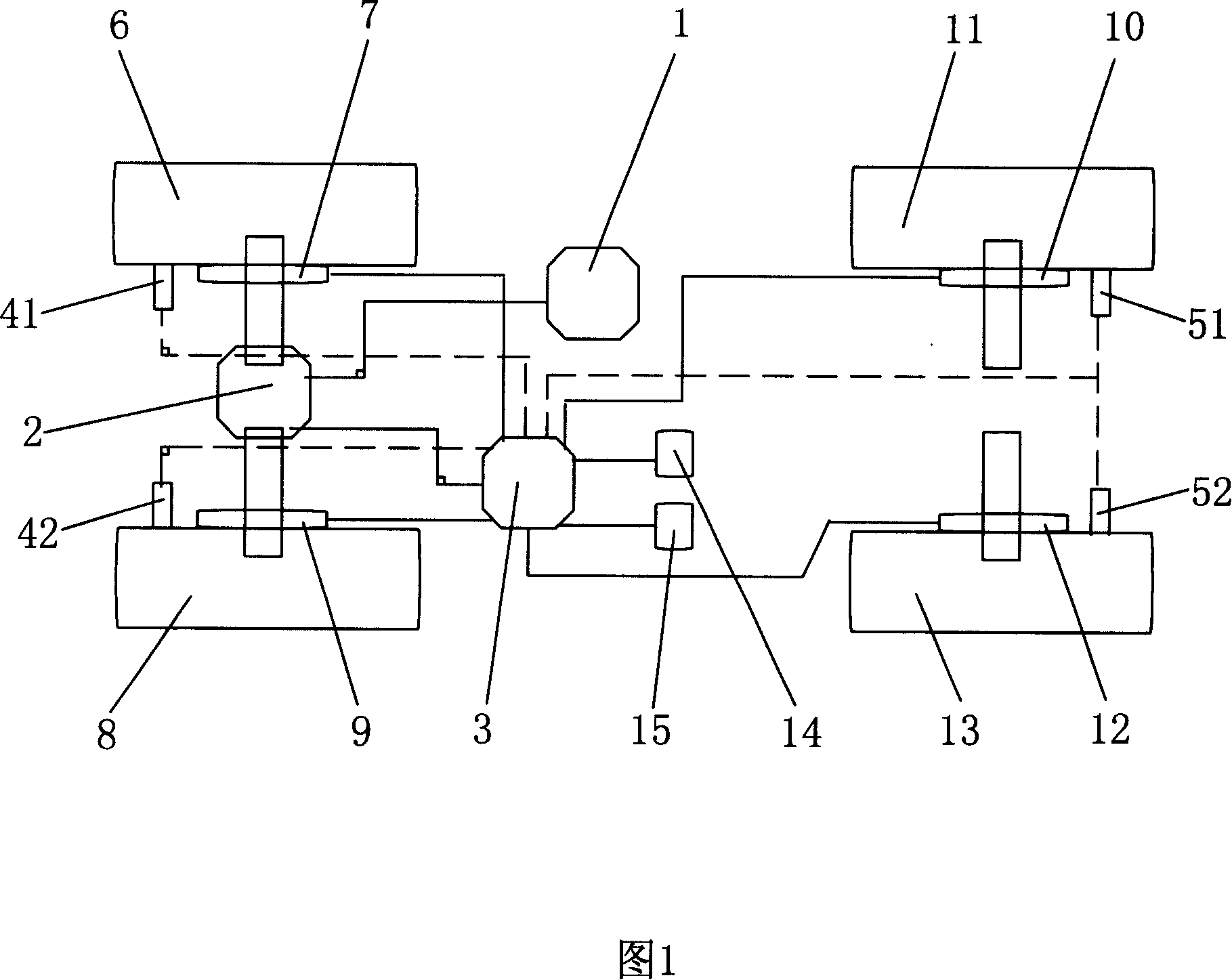

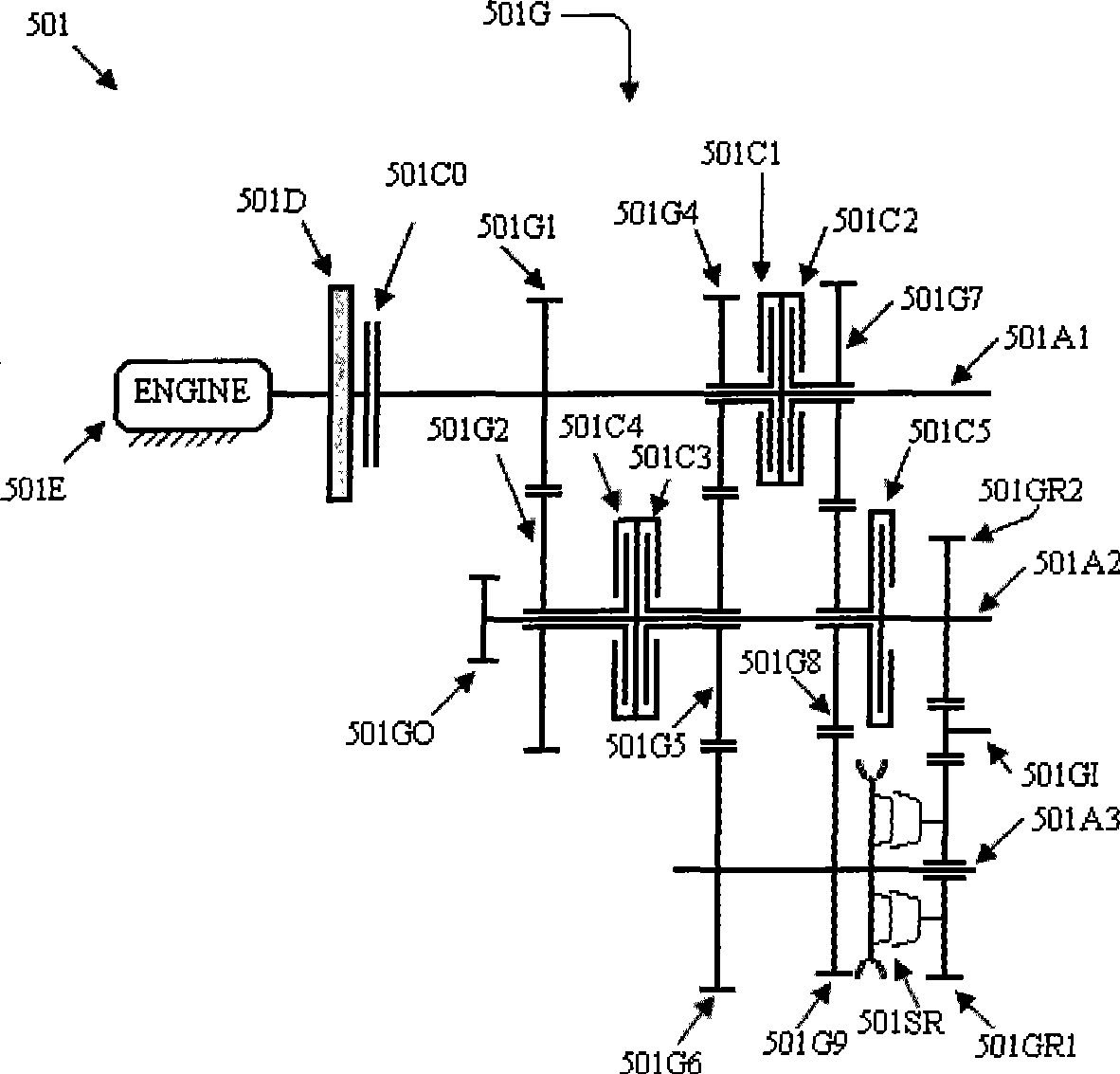

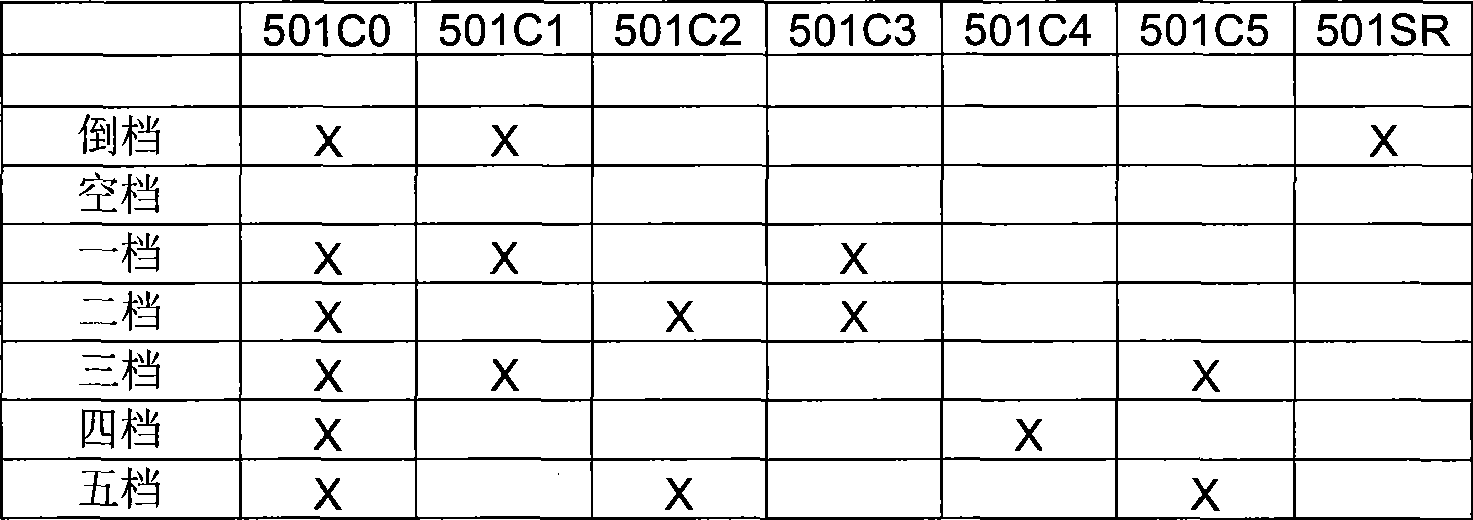

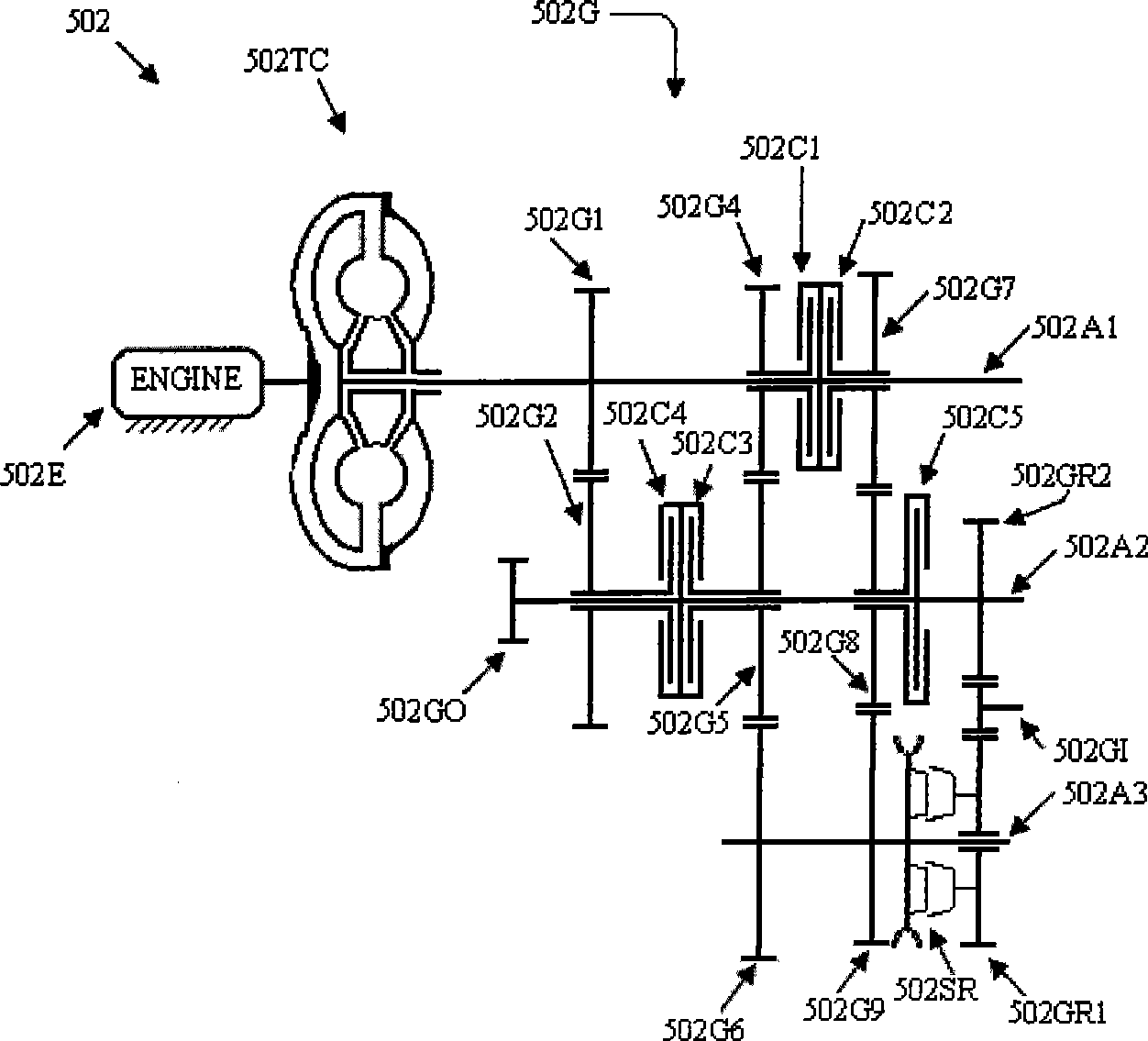

Parallel shaft-type automatic gearbox series

InactiveCN101532552AHigh slip rateReduce the probability of slippingToothed gearingsAutomatic transmissionGear wheel

The invention relates to a novel parallel shaft-type automatic transmission gearbox series, which is applied in the fifth, the sixth, the seventh, the eighth and the ninth gear of an automotive transmission system. Three types of automatic transmission gearboxes are produced according to the design concept, namely, an automatic transmission gearbox without a hydraulic torque converter, an automatic transmission gearbox with the hydraulic torque converter and an automatic manual transmission gearbox. By the optimized arrangement of a gear, a clutch and a synchronizer, when a plurality of clutches are used for gear shifting, the defaults of the high slip rate of the clutch of a dual-clutch automatic transmission, and high material requirement, high transient heating and complex control caused by the high slip rate are overcome, so that the slip rate of the clutch is reduced to a level within the allowed range of a traditional automatic transmission clutch material, thus simplifying the entire system. The default of using excessive forward gears in the dual-clutch automatic transmission and the traditional automatic transmission is overcome, and the invention permits using less forward gear, thereby reducing the cost, the weight and the volume of the gearbox.

Owner:杨庆民 +3

Torque distribution control system for considering coordination of maneuverability and wheel stability, and method

ActiveCN110103963AHigh control precisionEffective anti-slipSpeed controllerElectric energy managementDistribution controlRoad surface

The invention relates to a torque distribution control system for considering coordination of maneuverability and wheel stability, and a method. The method comprises the following steps that (1) the range constraint of wheel output torque is obtained; (2) generalized force demands for a motion control layer are pre-distributed; (3) the peak slip rate corresponding to a road surface adhesion coefficient and the reference wheel speed of each wheel are obtained, and the working mode of each wheel is determined; (4) an anti-saturation integral slip-mode variable-structure controller is built, anda difference value between the actual wheel speed and the reference wheel speed serves as input to obtain control torque; (5) the non-slip wheels serve as a control variable of secondary distribution,the weighted sum of the minimum generalized force tracking error and the minimum adhesion utilization rate serves as a target function, and optimization solution is conducted; and (6) finally, a torque instruction of a driving anti-slip control unit and a torque instruction of a four-wheel torque distribution control unit are combined to be output to a motor controller. Compared with the prior art, the torque distribution control system for considering coordination of maneuverability and wheel stability, and the method have the advantages of secondary distribution, effective slip preventing,comprehensive consideration, precise control and the like.

Owner:TONGJI UNIV

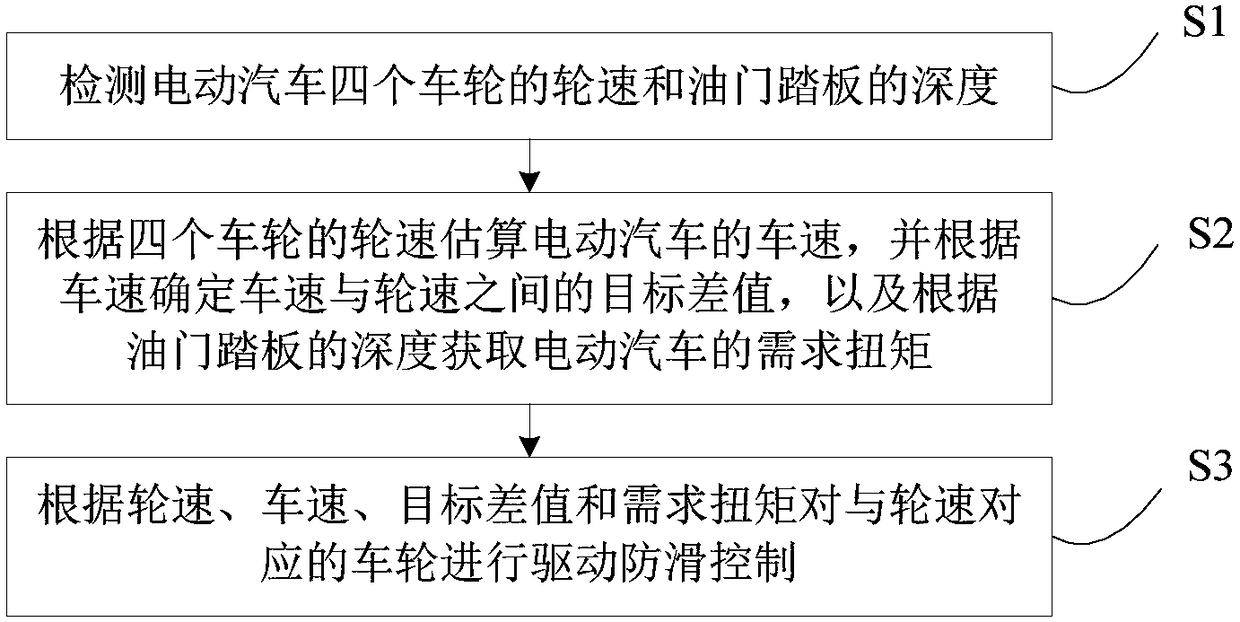

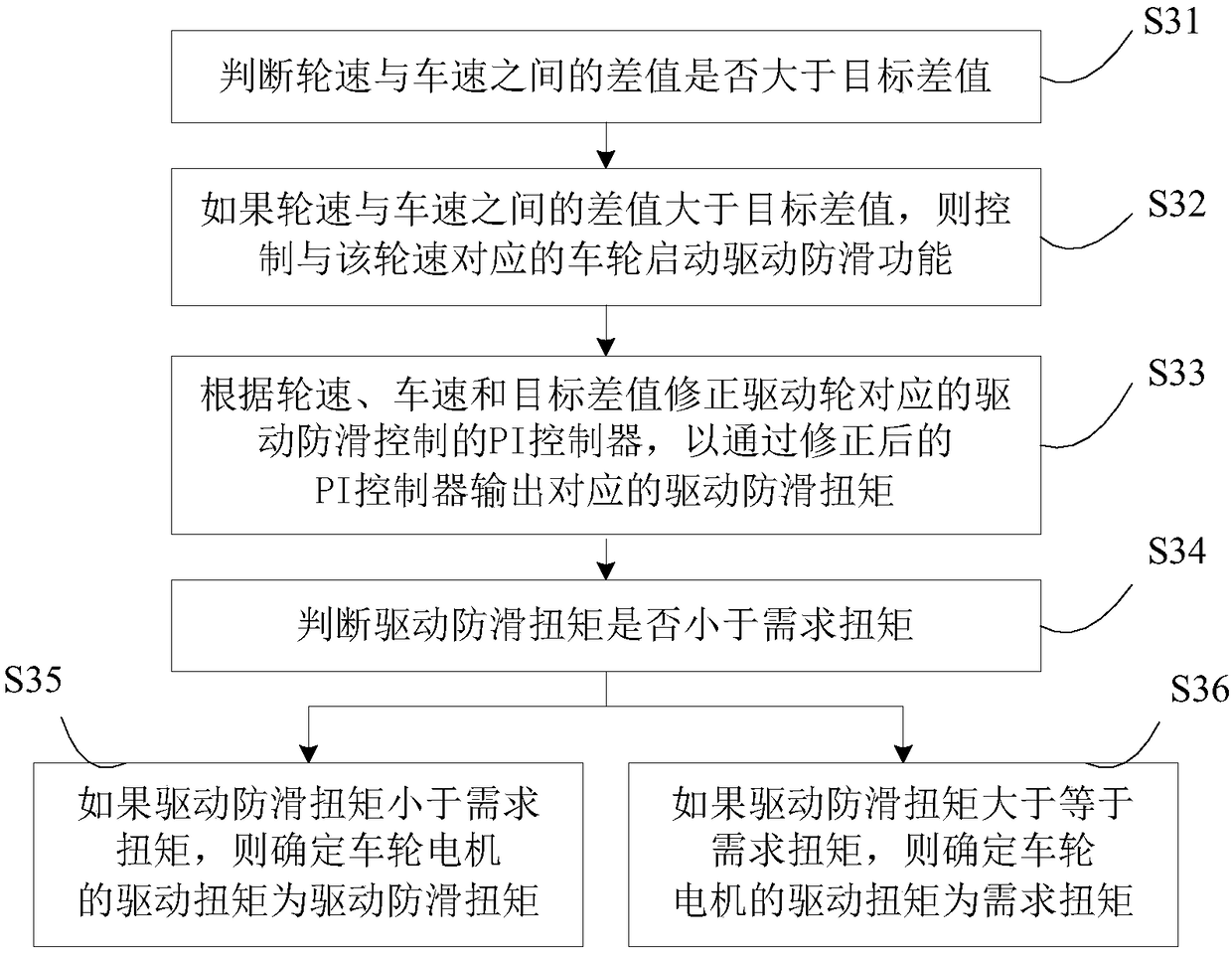

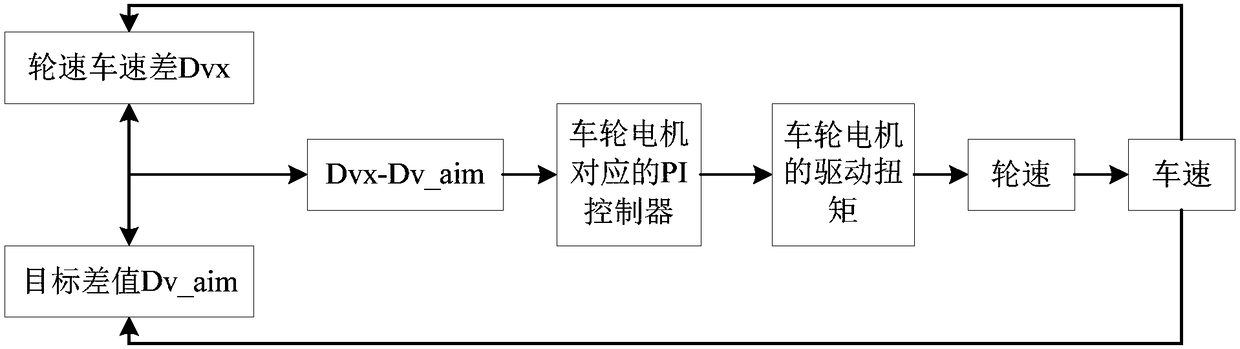

Driving anti-slip control method and device of four-drive electric vehicle

ActiveCN108248449ASolve technical problemsSuitable slip ratioSpeed controllerElectric devicesRoad surfaceElectric vehicle

The invention discloses a driving anti-slip control method and device of a four-drive electric vehicle. The method comprises the following steps of detecting wheel speeds of four vehicle wheels of theelectric vehicle and the depth of an accelerator pedal; according to the wheel speeds of the vehicle wheels, estimating the vehicle speed of the electric vehicle, determining a target difference value of the vehicle speed and the wheel speeds according to the vehicle speed, and obtaining needed torque of the electric vehicle according to the depth of the accelerator pedal; according to the wheelspeeds, the vehicle speed, the target difference value and the needed torque, conducting driving anti-slip control over the vehicle wheels corresponding to the wheel speeds. Therefore, the differencevalue of the wheel speeds and the vehicle speed can be stabilized within a corresponding target difference range to maintain a proper slip rate; meanwhile, pavement identification is not needed, therefore the error caused by the pavement identification is reduced, and the driving anti-slip control method and device have practical value.

Owner:BYD CO LTD

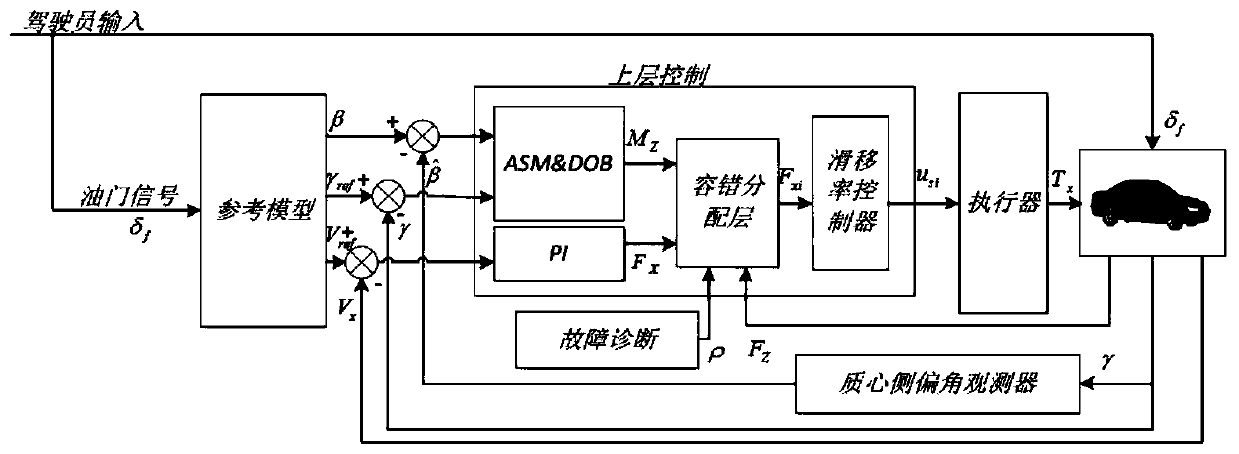

Robust adaptive fault-tolerant control method for four-wheel independently driven electric vehicle based on disturbance observation

ActiveCN110481334AImprove securityHas fault-tolerant distribution effectsSpeed controllerElectric devicesVehicle dynamicsControl layer

The invention discloses a robust adaptive fault-tolerant control method for a four-wheel independently driven electric vehicle based on disturbance observation. The method mainly comprises the following steps of 1, establishing a vehicle dynamics model in combination with a disturbance observer; 2, constructing a side slip angle observer of the vehicle according to the yaw velocity of the vehicleand a two-degree-of-freedom model of the vehicle; 3, designing an upper-layer controller based on an adaptive sliding mode control theory to obtain a virtual control quantity; 4, designing a fault-tolerant distribution layer based on the fault information to distribute the motor control signals to the normally driven motors so as to ensure the stability of the vehicle in case of a fault; and 5, establishing a slip rate control layer, and controlling the slip rates of the wheels within a reasonable range. The method has the advantages that the failure condition of the 4WID-EV driving motor is considered, a fault factor is introduced to redistribute a lower-layer signal, the disturbance observer is established to compensate the disturbance of the vehicle, the robustness of the system is improved by adopting the adaptive sliding mode control, and the slip rate is controlled to prevent the unreasonable slip of the wheels.

Owner:JIANGSU UNIV

Driving force control apparatus for automotive vehicles

InactiveUS7634344B2Effectively suppressing acceleration slipWithout convergence performanceSpeed controllerVehicle fittingsMobile vehicleDrive wheel

In a driving force control apparatus for an automotive vehicle employing an engine that drives a main drive wheel, a generator driven by the engine, and a motor driven by an electric power output generated by the generator to drive a subsidiary drive wheel, a subsidiary-drive-wheel acceleration slip estimation circuitry is provided to estimate a subsidiary-drive-wheel acceleration slip rate. An electric power output suppression circuitry is provided to suppress the electric power output of the generator when the estimated subsidiary-drive-wheel acceleration slip rate exceeds a predetermined slip rate. Also provided is a subsidiary-drive-wheel acceleration-slip period engine output torque reduction circuitry that reduces an engine output torque responsively to suppressing the electric power output.

Owner:NISSAN MOTOR CO LTD

Self-adjusting electric speed differential

InactiveCN101380908ASpeed controllerElectric propulsion mountingDrive wheelElectronic control system

The invention relates to a self-regulating electronic differential mechanism which is an electronic control system of an electric car and is mainly applied to a dual-motor independent driving mode electric car. Two driving wheels are respectively driven by two motors directly. The driving motors are respectively controlled by two controllers with the same specification. The dual-motor independent and direct driving mode is realized and the self-regulating function of the electric differential is realized. The two controllers are controlled by an accelerator so that the two motors work under the same power and voltage. Due to the characteristics of the motors, the electric differential self-regulating function is realized through the regulation of different slipping rates and the flow limiting function of the controllers. As the driving torque of an internal driving wheel is larger than the external driving torque, therefore, different slipping rates appear and understeer is represented.

Owner:ZAOZHUANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com