Wheel type loading machine tire longitudinal force dynamic estimation method

A wheel loader and dynamic estimation technology, which is applied in the field of wheel loader tire longitudinal force dynamic estimation, front and rear axle independent electric drive wheel loader, can solve the problem that the change of tire radial stiffness value cannot be ignored, wheel loading It is difficult to obtain a good estimation accuracy of the longitudinal force of the tire, and the vertical force of the tire varies greatly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0064] In order to further elaborate the technical solution described in the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0065] The wheel loader tire longitudinal force dynamic estimation method of the present invention is briefly described as follows:

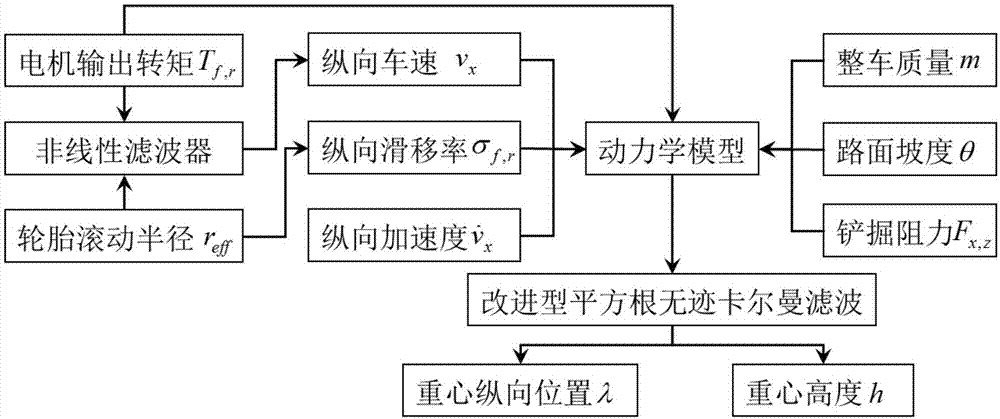

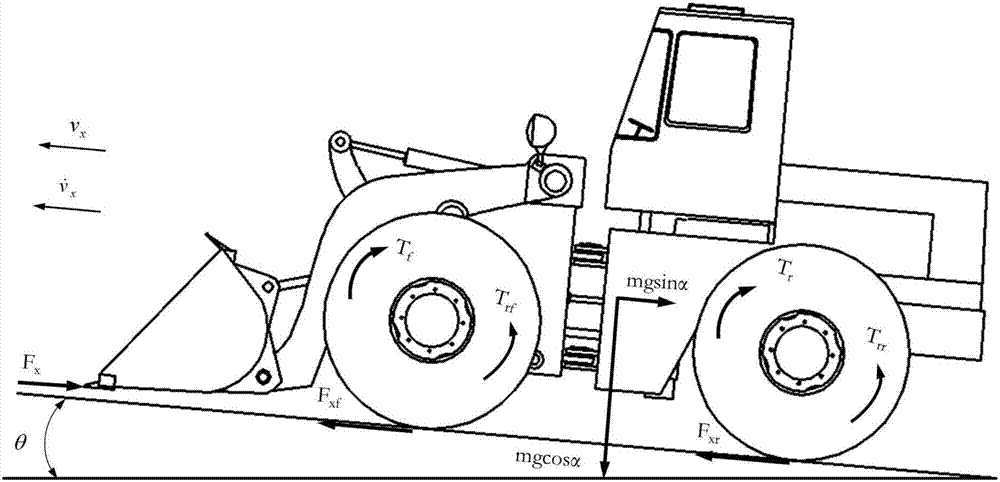

[0066] Based on the real-time output torque T of the front and rear motors of the wheel loader with independent electric drive on the front and rear axles f,r and the measured tire rolling radius r eff , the longitudinal velocity v is estimated by a nonlinear filter x ;According to the longitudinal acceleration measured by the sensor and slope θ, the estimated longitudinal velocity v x , The calculated front and rear tire slip ratio σ f,r And the mass m of the whole vehicle and the longitudinal component force F of the excavation resistance obtained by looking up the table or calculation x , build the state equation and measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com