Patents

Literature

40 results about "Slip coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

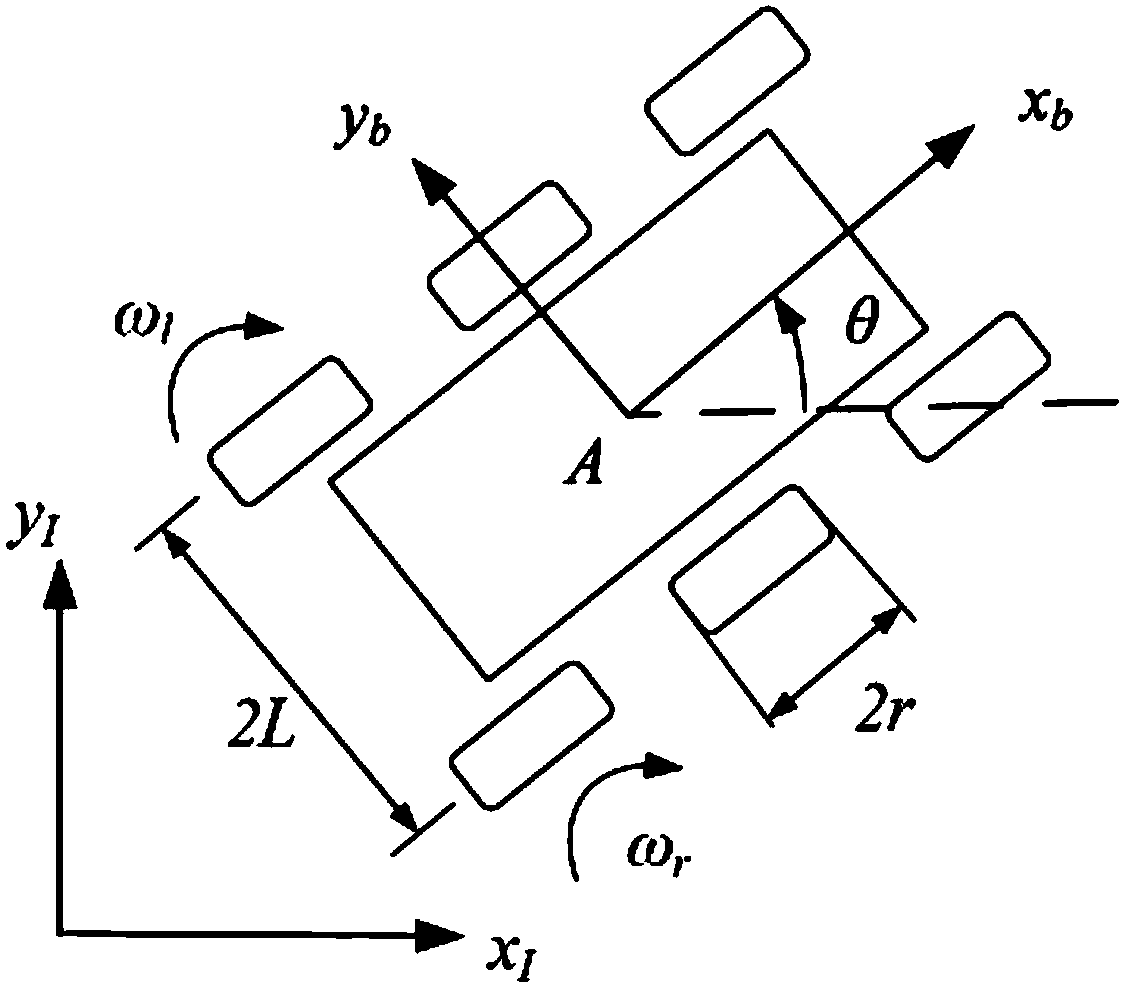

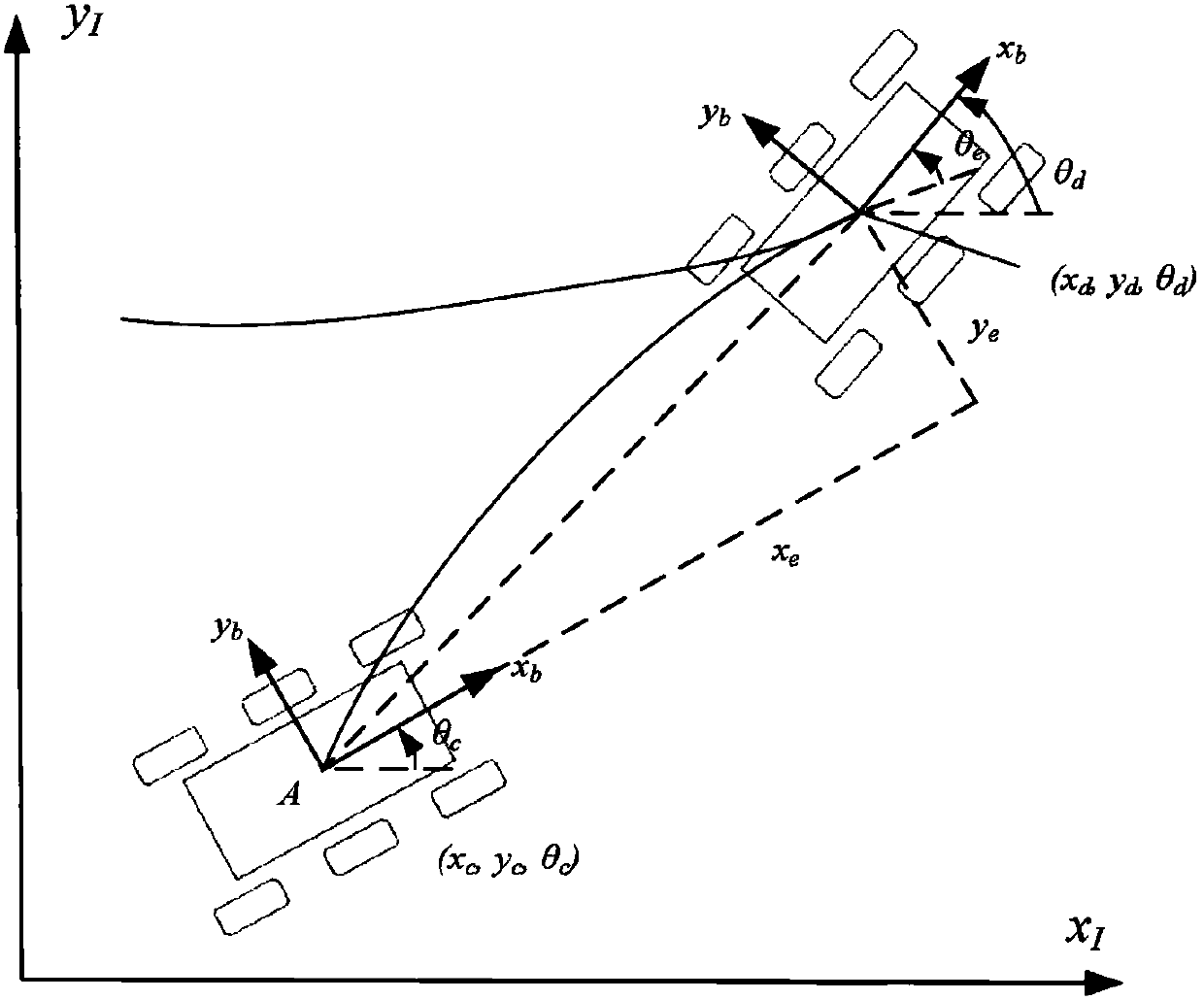

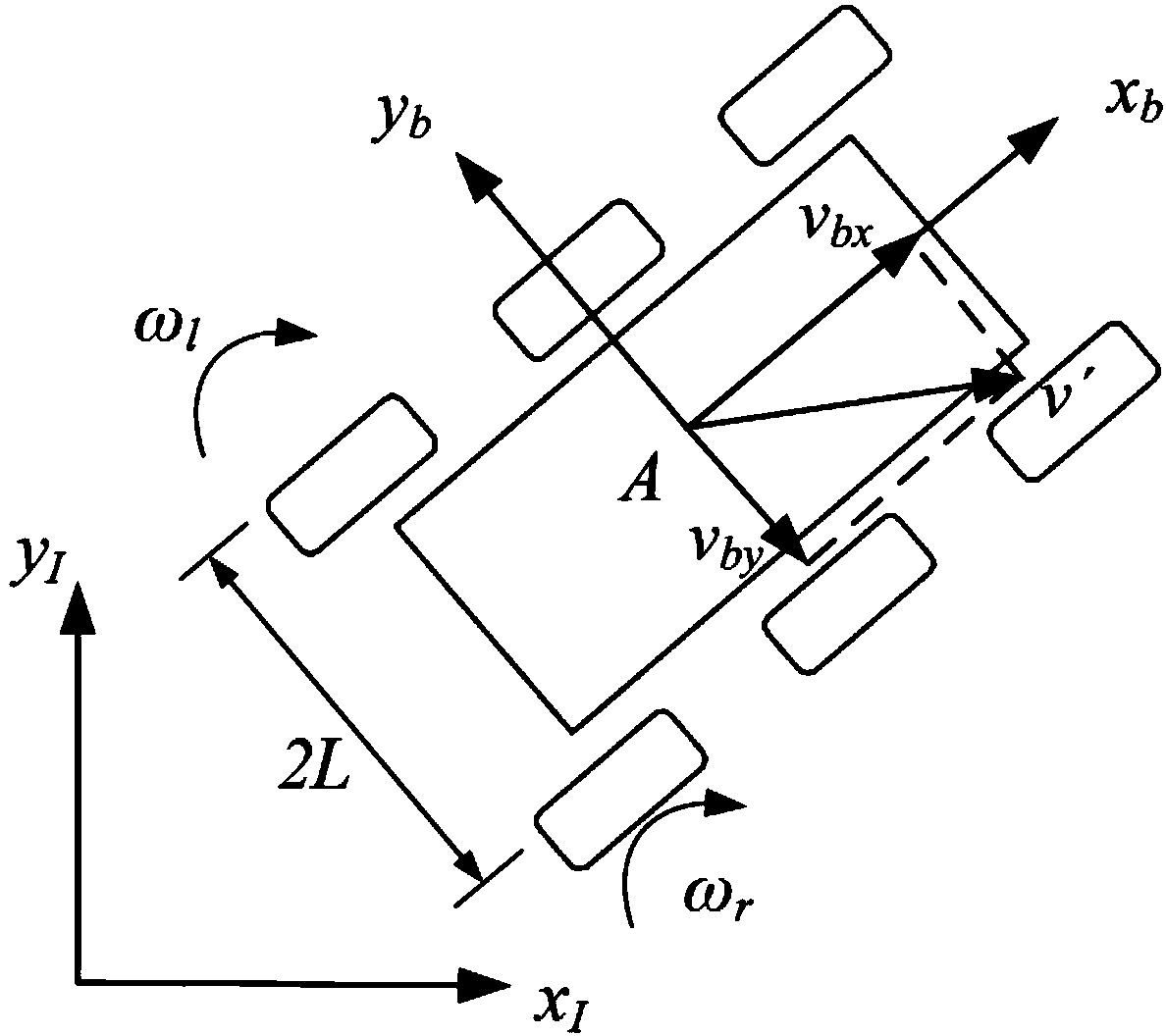

Mobile robot trace tracking control method

InactiveCN108098770AAccurate descriptionAccurate representationProgramme controlProgramme-controlled manipulatorMathematical modelSlip coefficient

The invention discloses a mobile robot trace tracking control method. The mobile robot trace tracking control method comprises the steps of calculating the numerical values of a slip coefficient and the slip rate according to motion mathematical model formulas of the slip coefficient and the slip rate and data detected by A GPS-INS and the information of the expected path, the expected speed and the expected yaw velocity given by a mobile robot decision layer; substituting the numerical values into a kinematic model of a mobile robot and compensating for and calculating the rotating speed of wheels achieving trace tracking to achieve the purpose of accurately tracking an expected trace. The mobile robot trace tracking control method has the advantages that the slippage rate can be calculated at any time; the actual motion state of the mobile robot can be described and represented more truly and accurately; accordingly, the expected trace can be tracked effectively and accurately.

Owner:张辉

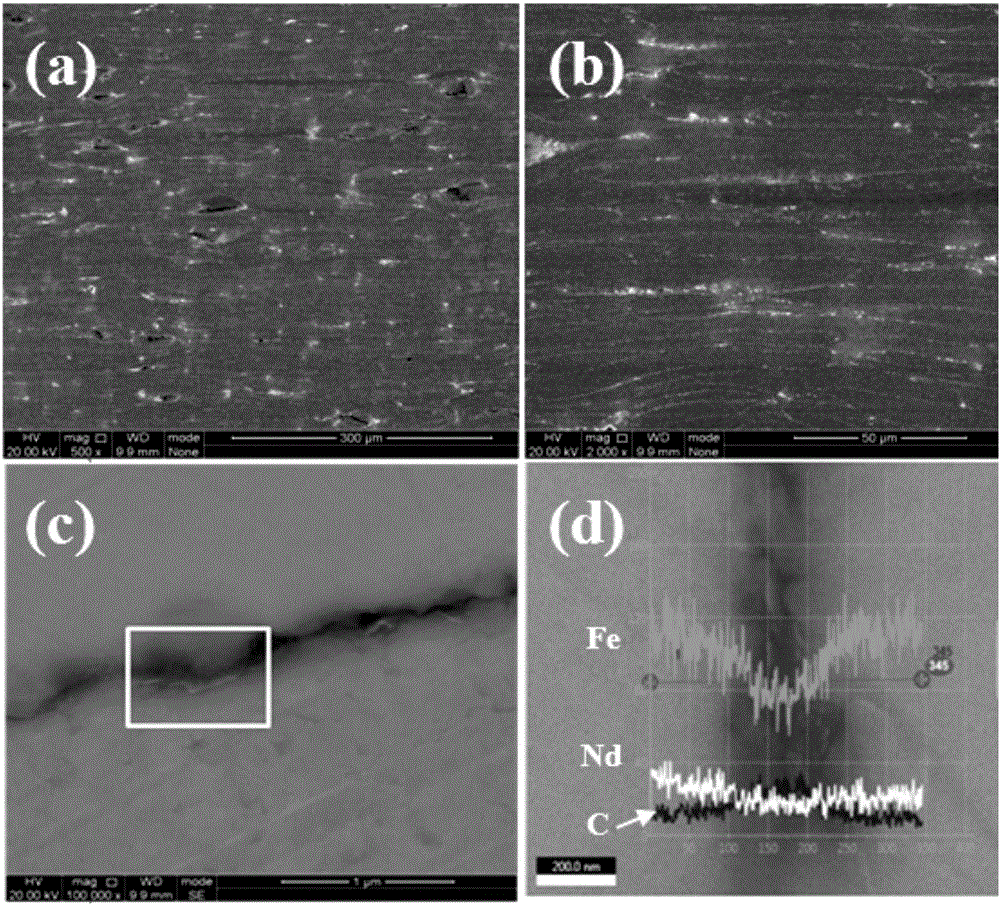

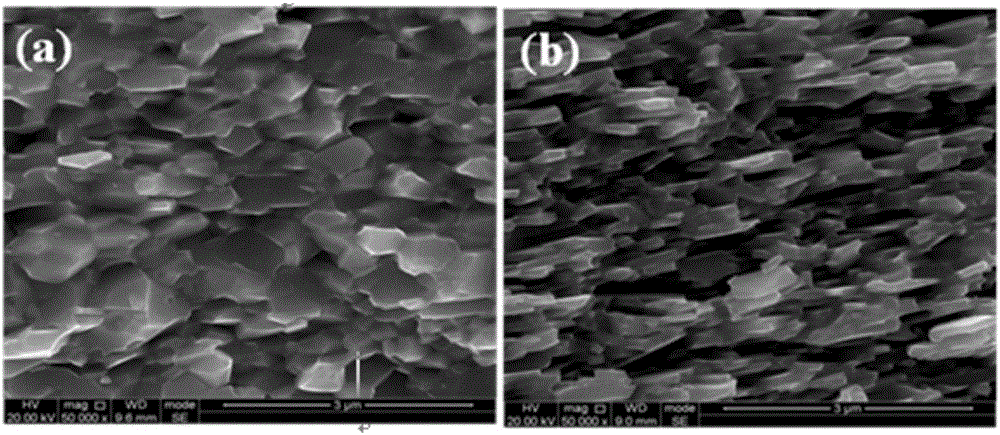

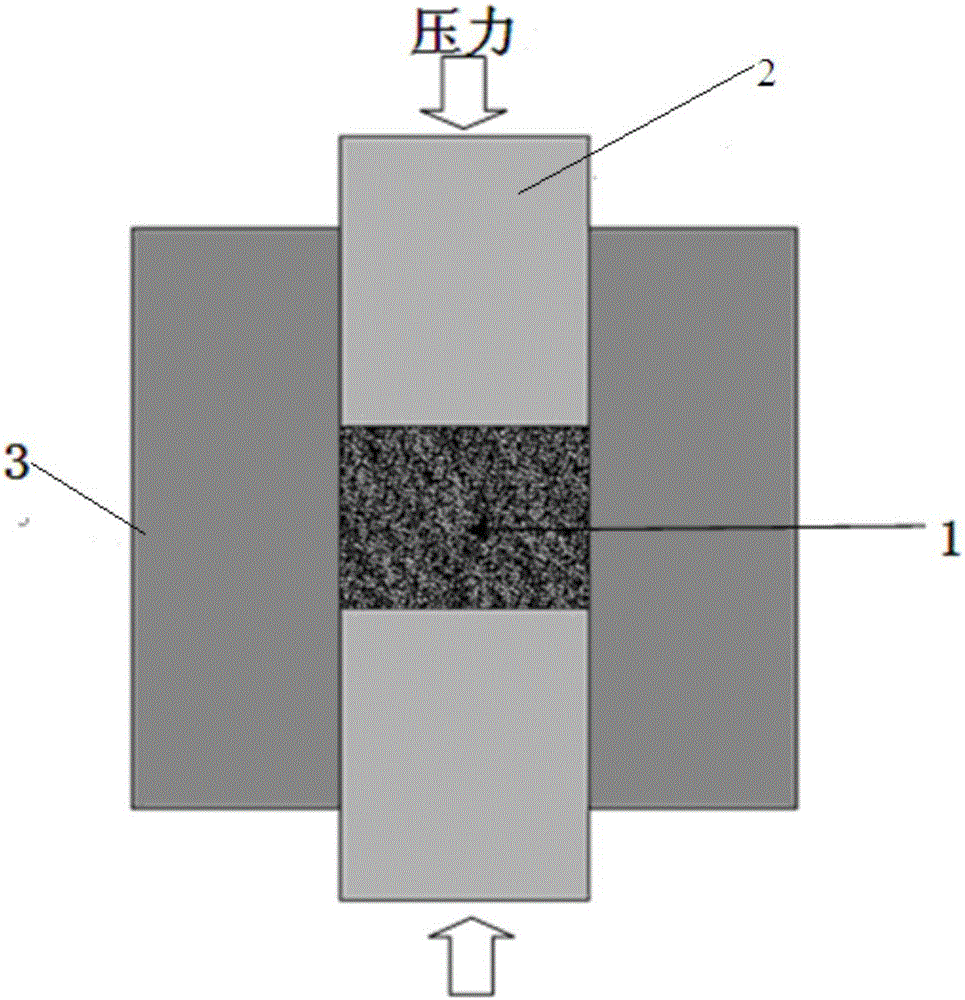

Anisotropic nanocrystalline rare earth permanent magnet and preparation method therefor

ActiveCN106448986ARich typeImprove microstructureInductances/transformers/magnets manufactureMagnetic materialsMetallurgySlip coefficient

The invention discloses an anisotropic nanocrystalline rare earth permanent magnet. The anisotropic nanocrystalline rare earth permanent magnet consists of nanocrystalline with the chemical formula of REFe<100-a-b-c>BTM<c> and graphene / or graphene microchips, wherein the content of the graphene / or graphene microchips is 0.01-1wt%; in the chemical formula of REFe<100-a-b-c>BTM<c>, a is greater than or equal to 28 and less than or equal to 33; b is greater than or equal to 0.9 and less than or equal to 1.35; c is greater than or equal to 0.15 and less than or equal to 7; RE is at least one of Ce, Nd, Pr or Dy; and TM is at least one of Ga, Co, Cu, Nb, Al, Zr, V, Si or Ti. The invention also provides a preparation method for the anisotropic nanocrystalline rare earth permanent magnet. The shortcomings of relatively low magnet slip coefficient of the rare earth permanent magnet material RE-Fe-B, harsh conditions of a contact surface of magnetic powder, difficulty in plastic deformation and the like are overcome; and the magnetic performance of the rare earth permanent magnet material is further improved.

Owner:SICHUAN UNIV

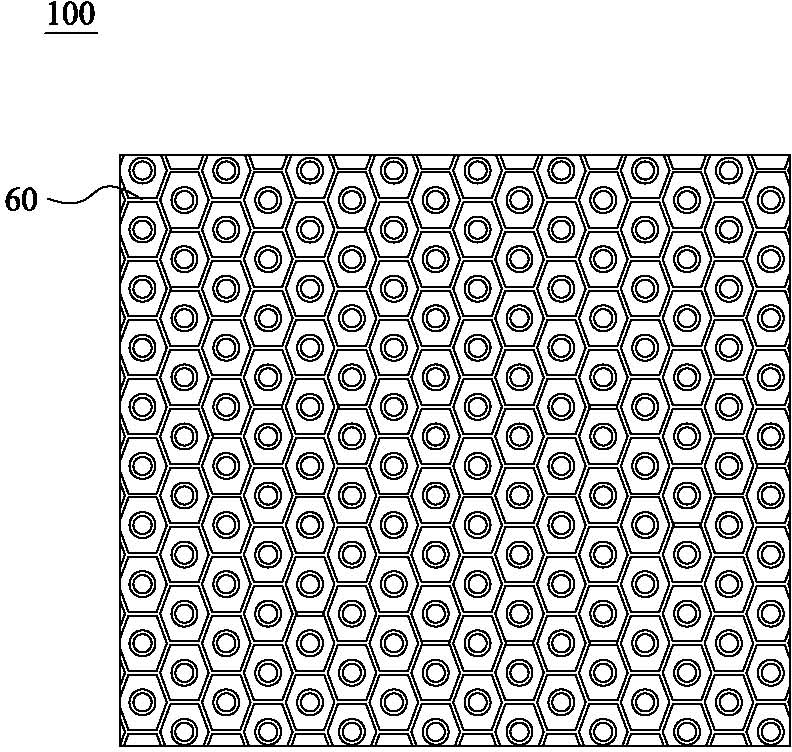

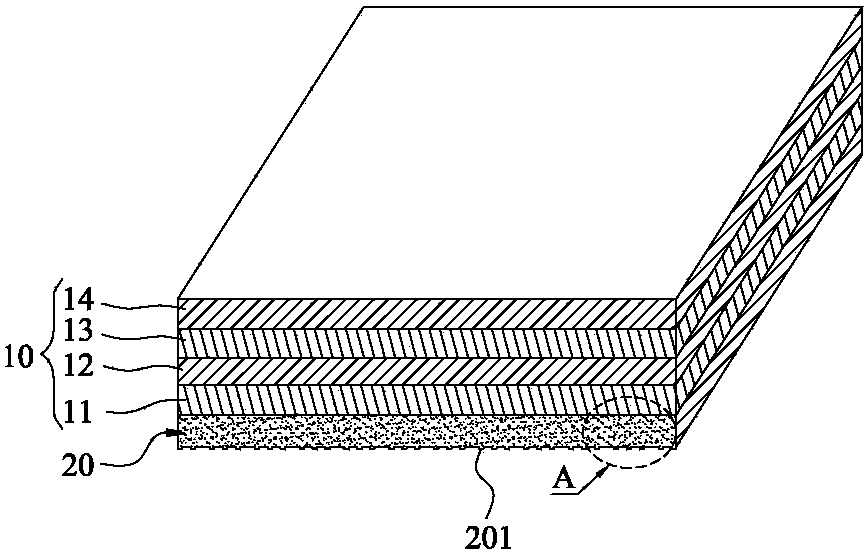

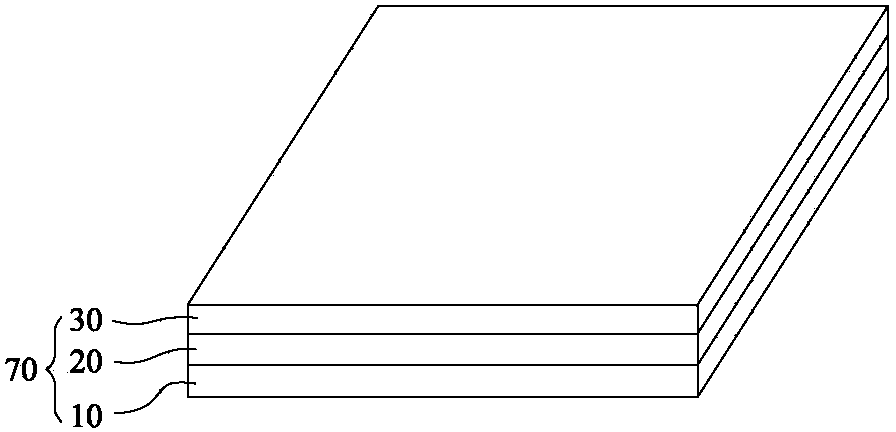

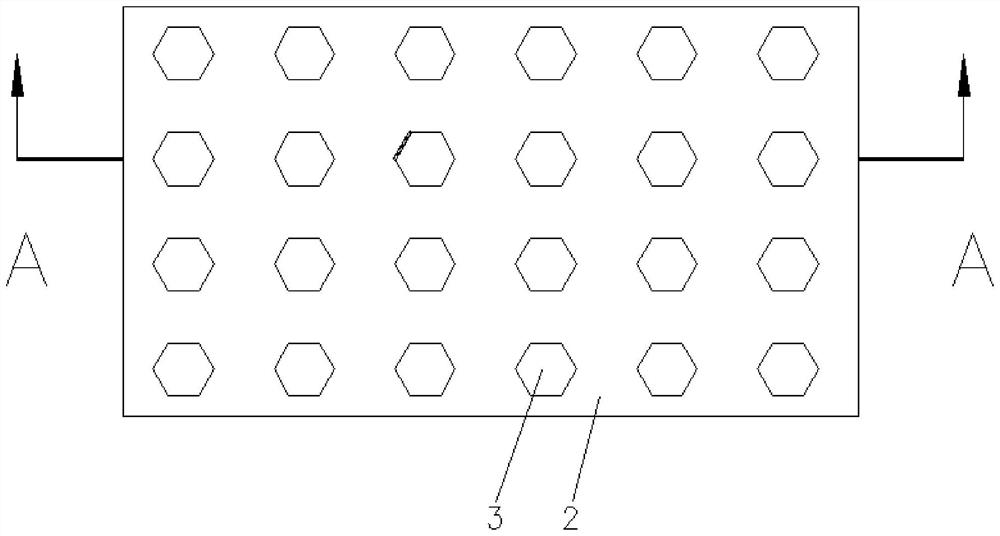

Glue-free PVC (polyvinyl chloride) limited slip floor tile of ring structure and preparation method thereof

ActiveCN102561657AImprove anti-slip performanceRemove security concernsFlooringSlip lineSlip coefficient

The invention discloses a glue-free PVC (polyvinyl chloride) limited slip floor tile of a ring structure and a preparation method thereof. as for the limited slip floor tile, a flexible thermocompression line is formed on the bottom surface of a PVC limited slip layer in a thermocompression manner; the thermocompression line comprises a plurality of seal hexagon protruding ribs which are continuously and repetitively connected and seal round protruding ribs which are positioned in each hexagon protruding rib; the material formulation of the PVC limited slip layer comprises the following components by weight: 58.5%-63.5% of PVC with polymerization degree of 1000, 34.9-39% of plasticizing agent, 0.95%-2.1% of stabilizing agent, 0.5%-0.69% of toner, and 0.06%-0.08% of calcium carbonate of 800 molybdenum; and the required softness obtained by using particular formulation dosage of the limited slip layer is combined with the limited slip line which is composed of non-hexagon of particular size and shape and the round protruding ribs to enable the limited slip coefficient to be more than 1.5, thereby overcoming the bottle neck of improving the limited slip performance in the industry of plastic floor tiles.

Owner:DONGGUAN PULONG PLASTIC PRODS

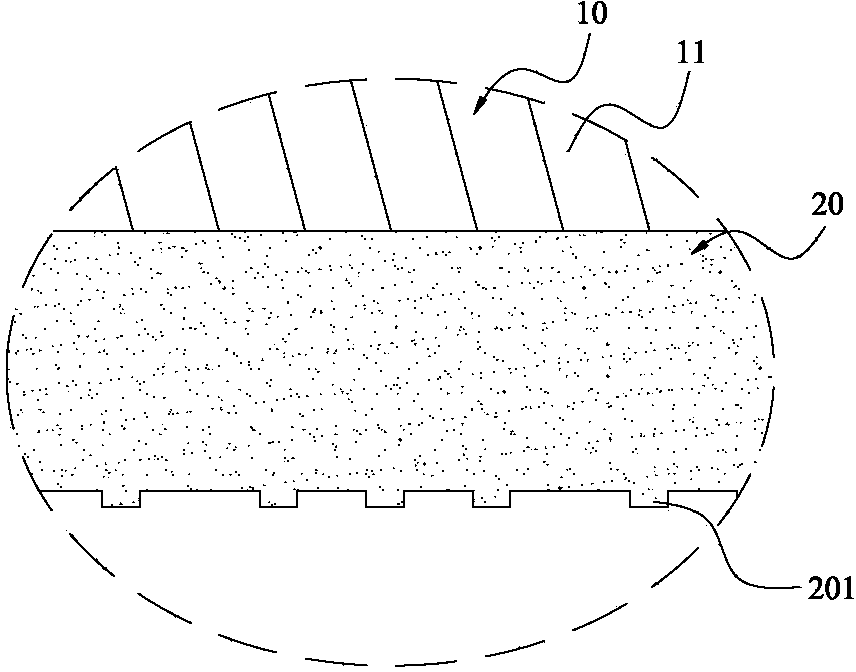

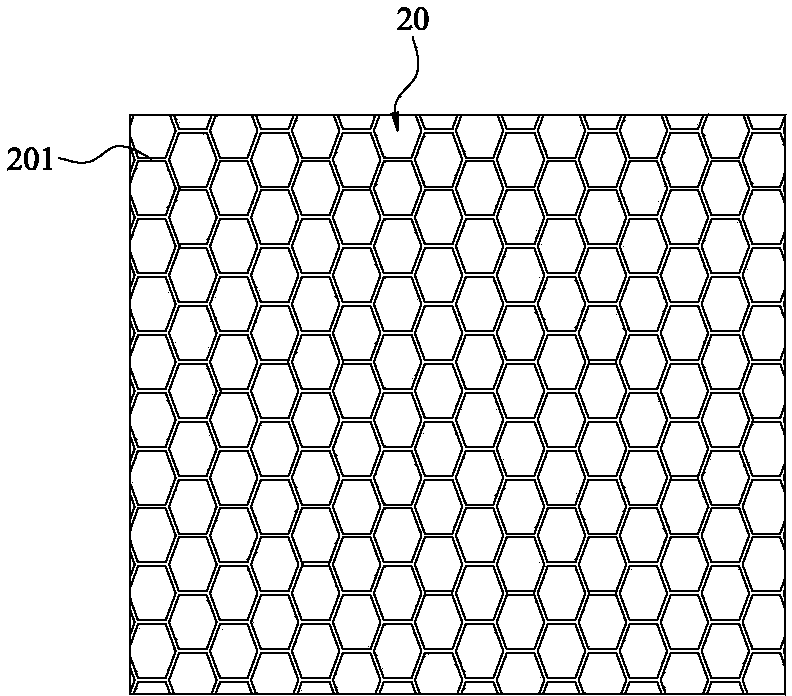

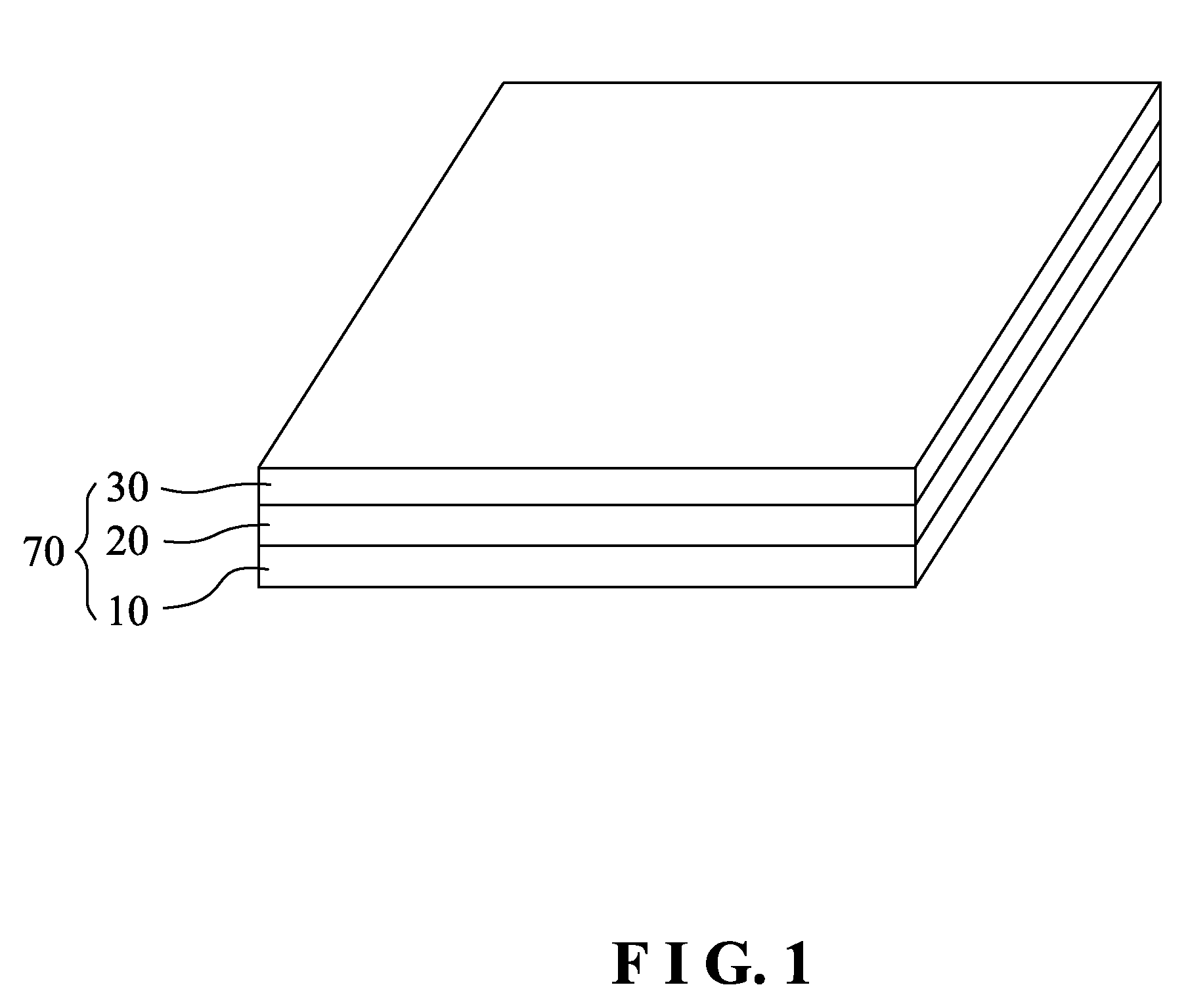

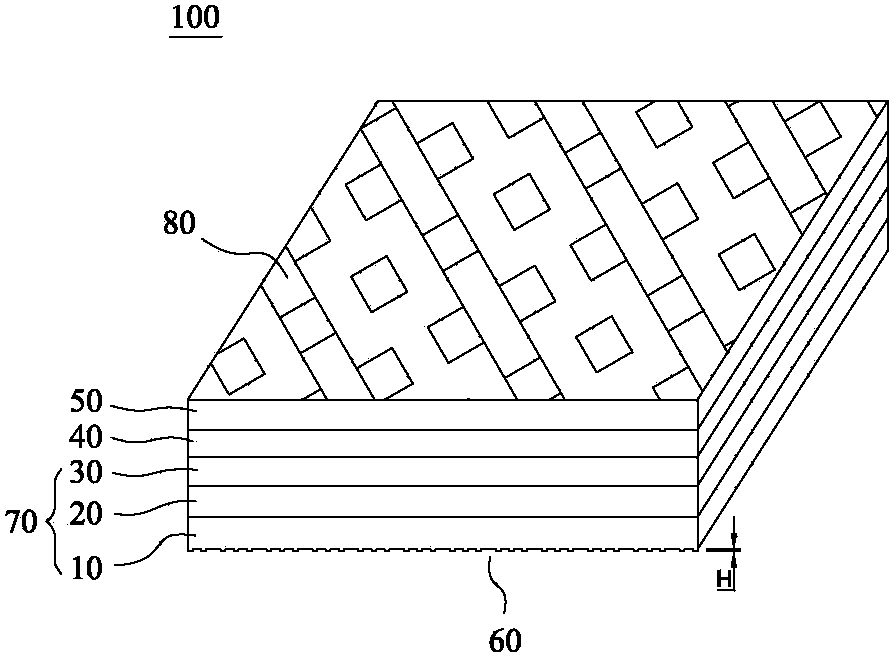

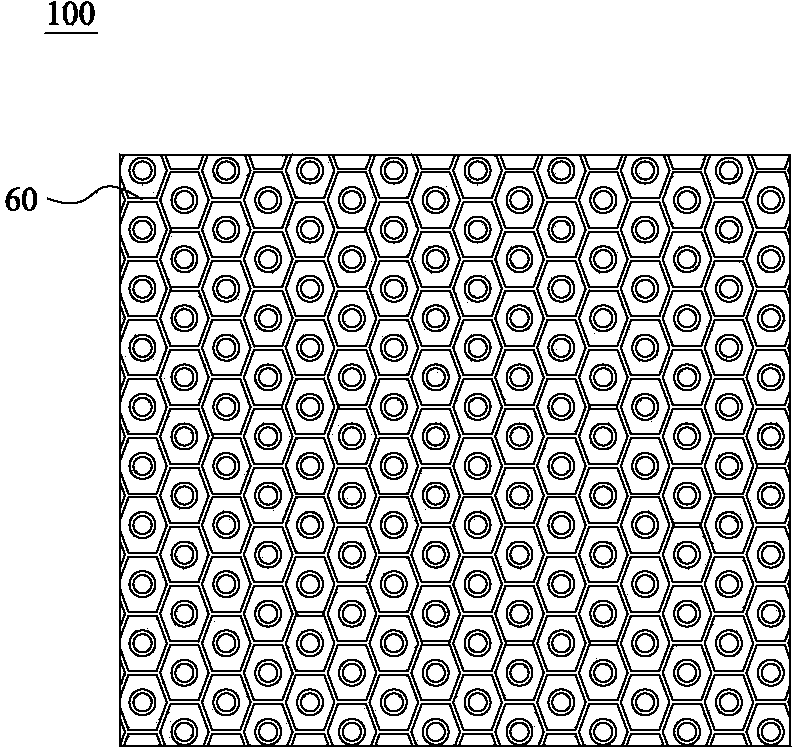

Non-slip floor

ActiveCN103410296ARemove security concernsEasy to installSynthetic resin layered productsFloor coveringsSlip coefficientPressure sense

The invention discloses a non-slip floor. The non-slip floor comprises a body, a pasting layer is arranged on the bottom surface of the body in a combined and stacked mode, a plurality of protruding ribs are arranged on the bottom surface, in contact with the ground, of the pasting layer in a convex mode, a plurality of closed cavity type suckers are formed by the protruding ribs in an enclosing mode, and the pasting layer is made of pressure-sensing thermosensitive gel. According to the material formula, the pasting layer comprises, by weight, 35-55% of tackifying resin, 10-20% of softener, 2-5% of antioxidant, 10-20% of butyl rubber and 5-10% of naphthenic oil, and the sum of the total amounts of all the above substances is 100%. Thus, the non-slip floor can be used repeatedly, easy to install and convenient to detach by the utilization of the characteristic of being capable of being used repeatedly of the pressure-sensing thermosensitive gel; the non-slip floor can be pasted to the ground through the pasting layer, therefore, the non-slip performance of the non-slip floor is greatly promoted, the non-slip floor has very good self-pasting and absorption effects, the non-slip coefficient of the bottom can reach 1.7-2.0, and safety concerns about the old and children can be relieved in terms of home mat formation.

Owner:DONGGUAN MEI JER PLASTIC PROD CO LTD

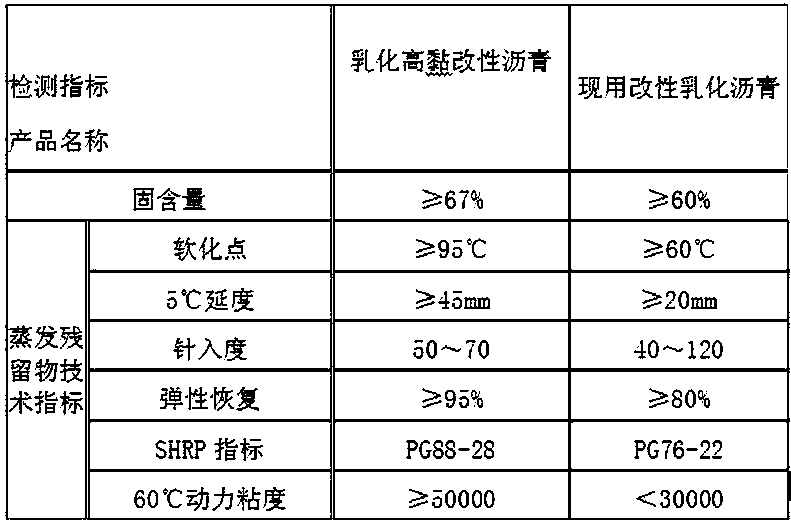

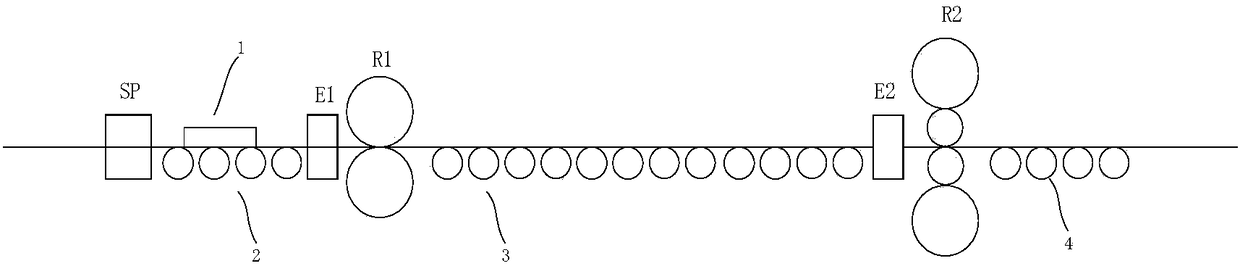

Hot-rolled edge quality control method for low-temperature and high-magnetic-inductance oriented silicon steel

ActiveCN109590339AImprove edge qualityReduce the degree of oxidationMetal rolling arrangementsProfile control deviceSlip coefficientQuality control

The invention discloses a hot-rolled edge quality control method for low-temperature and high-magnetic-inductance oriented silicon steel. The control method comprises the steps of in the process of heating the low-temperature and high-magnetic-inductance oriented silicon steel by a heating furnace high-temperature section, controlling an air-fuel ratio of an upper secondary heating section to an upper soaking section of the low-temperature and high-magnetic-inductance oriented silicon steel to be less than or equal to a first preset value, and controlling an air-fuel ratio of a lower secondaryheating section to a lower soaking section of the low-temperature high-magnetic-inductance oriented silicon steel to be less than or equal to a second preset value, wherein the first preset value isgreater than the second preset value; reducing the temperature of the heating furnace high-temperature section by 10-20 DEGC; and performing three pass of rough rolling on the low-temperature and high-magnetic-inductance oriented silicon steel by a first vertical roll and a second vertical roll, wherein the rolling speed in each pass in rough rolling is controlled at 2.6-4.8 m / s, and the best slope matching speed and backward slip coefficient between the vertical rollers E2 and R2 in each pass. The hot-rolled edge quality control method solves the technical problem of high occurrence rate of 'cake brittleness' defect at the edge of the strip.

Owner:武汉钢铁有限公司

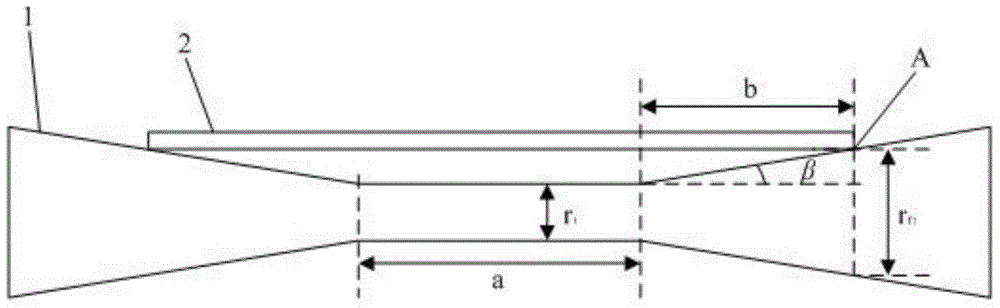

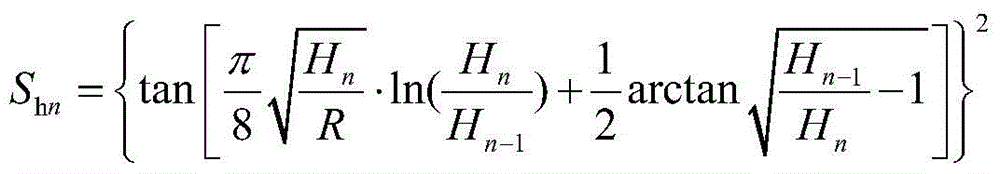

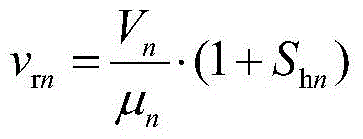

Speed cooperative control method for heavy and medium plate mill and conical roller beds

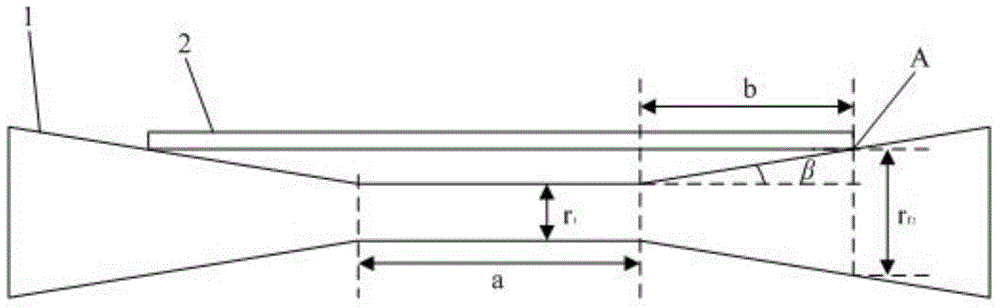

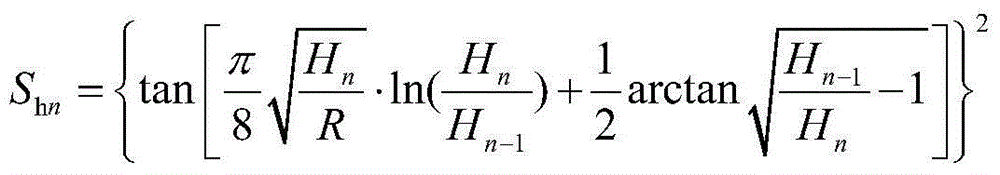

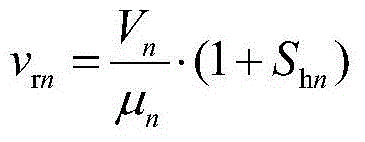

ActiveCN104942014AExtended service lifeNot easy to stainMetal rolling arrangementsRoll speed control deviceSlip coefficientEngineering

The invention discloses a speed cooperative control method for a heavy and medium plate mill and conical roller beds and relates to the technical field of metal pressure working. The speed cooperative control method for the heavy and medium plate mill and the conical roller beds includes the following steps that according to a roller bed rolling parameter of a plate, a forward slip coefficient in a plate rolling process is calculated, and the roller bed rolling parameter is obtained from a rolling mill two-stage process model set system; speeds of the plate rolled in the roller bed at the inlet position and the outlet position of a rolling mill are calculated through the rotating speed of a roller of the rolling mill and the obtained forward slip coefficient; the rotating speeds of the rolling mill at the inlet and the outlet conical roller beds are calculated respectively according to the inlet speed and the outlet speed of the plate, the width of the plate and the geometrical shape parameters of the conical roller beds, the calculated rotating speed values are sent to a roller bed motor transmission system for execution, and therefore speed setting is conducted respectively for the front and the rear conical roller beds of the rolling mill. The speed cooperative control method for the heavy and medium plate mill and the conical roller beds solves the problems that the contact portion of the plate and the conical roller beds is poor in linear speed, and the surface quality of the plate and the service life of the roller beds are seriously affected.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

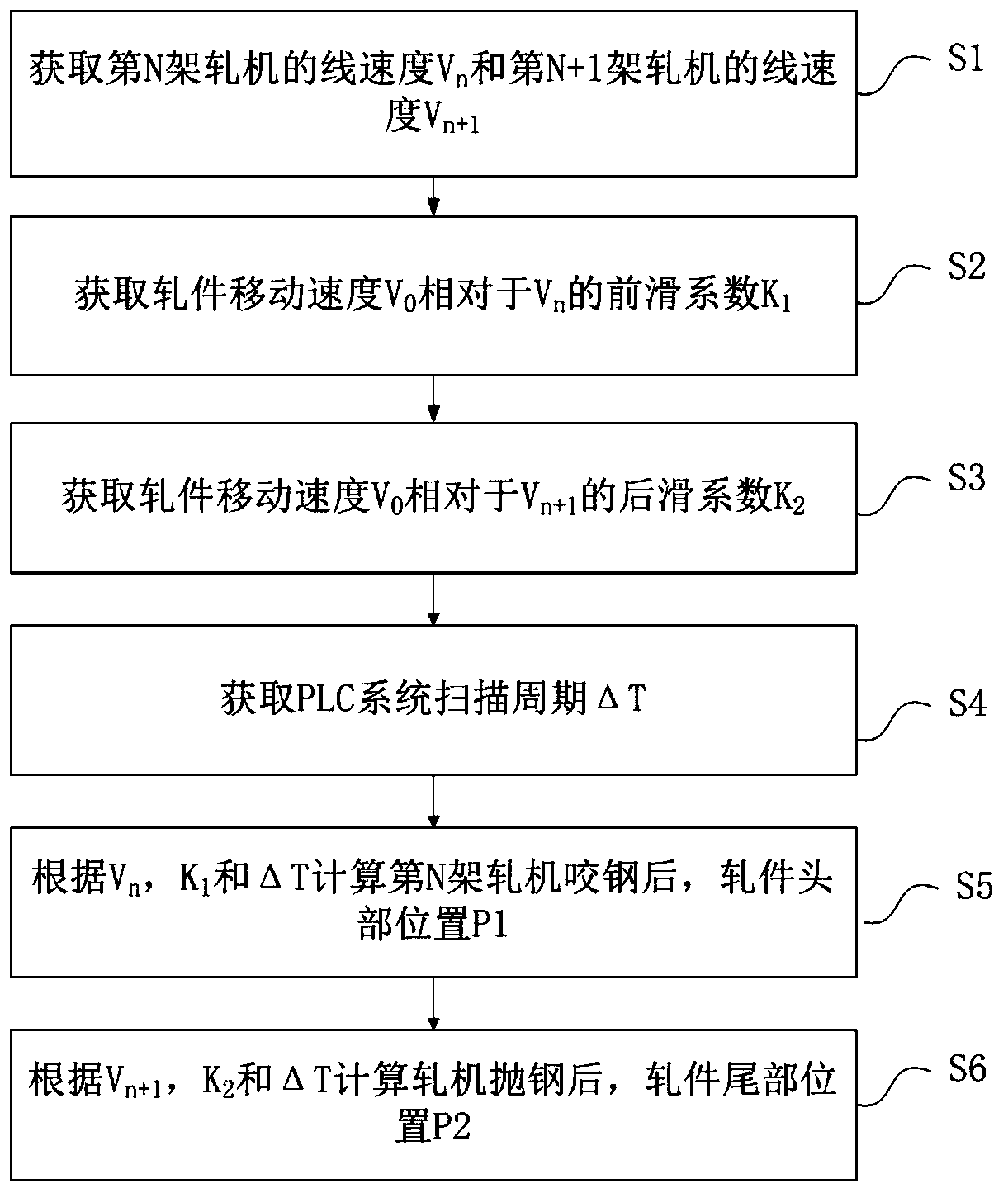

Intelligent steel rolling accurately-rolled piece tracking and handling method

InactiveCN110280608AMeet needsHigh precisionRare end control deviceMeasuring devicesProgrammable logic controllerSlip coefficient

The invention relates to an intelligent steel rolling accurately-rolled piece tracking and handling method. The intelligent steel rolling accurately-rolled piece tracking and handling method comprises the steps that the linear speedVn of an Nth rolling mill and the linear speed Vn+1of an N+1th rolling mill are acquired; the forward slip coefficientK1of the rolled piece movement speed V0 relative to Vn is acquired; the backward slip coefficient K2of the rolled piecemovement speedV0 relative to Vn+1 is acquired; the scanning perioddelta T of a programmable logic controller (PLC) system is acquired; according to Vn, K1 and delta T, the rolled piece head position P1 is calculated after steel enters the Nth rolling mill; and according to Vn+1, K2 and delta T,the rolled piece tail position P2is calculated when steel is thrown by the rolled mill. By means of the technical scheme of the intelligent steel rolling accurately-rolled piece tracking and handling method, the tracking accuracy of the rolled piece is improved greatly; and requirements for intelligent steel rolling control can be satisfied.

Owner:北京宇轩智能科技有限公司

Ceramic floor tile slip preventing agent and preparation method thereof

InactiveCN107141852AHigh anti-slip coefficientImprove durabilityAntifouling/underwater paintsPaints with biocidesWaxMetallurgy

The invention discloses a ceramic floor tile slip preventing agent. The ceramic floor tile slip preventing agent comprises the following components in percent by weight: 12% of tartaric acid, 10% of citric acid, 15% of sodium dodecyl sulfate, 0.8% of a defoaming agent, 6% of sodium chloride, 3.2% of an emulsifying agent, 6% of a stain remover, 4% of a wax remover and 43% of deionized water. The ceramic floor tile slip preventing agent is non-toxic, harmless, high in non-slip coefficient and high in durability and has relatively high stain removing performance.

Owner:上海地宝防滑防护科技有限公司

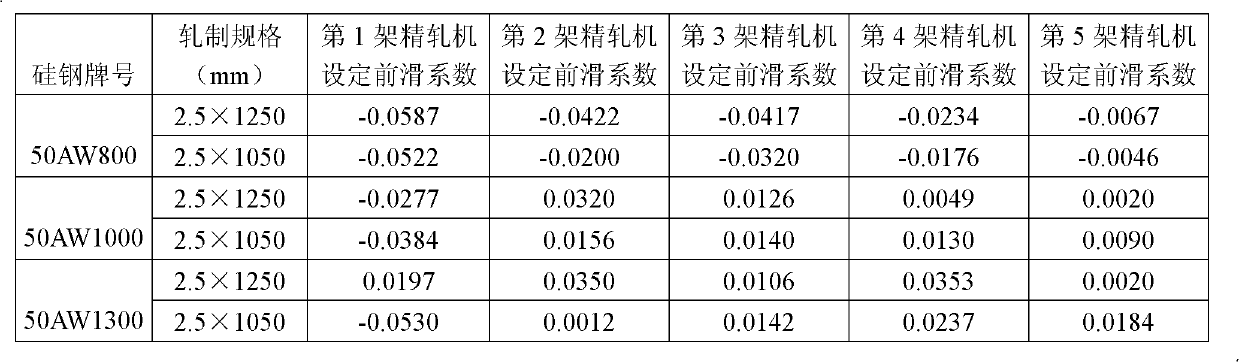

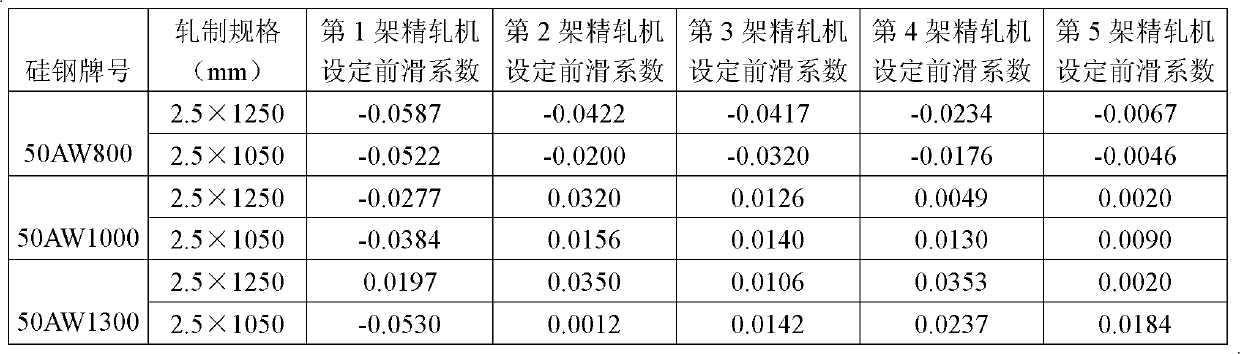

Control method for forward slipping coefficient of hot rolled silicon steel

ActiveCN102553934AImprove adaptabilitySolve the problem of rolling instabilityRoll mill control devicesMetal rolling arrangementsSlip coefficientModel control

The invention provides a control method for forward slipping coefficient of hot rolled silicon steel. The method comprises steps of additionally arranging a forward slipping control module in a finish rolling model control program, determining the set forward slipping coefficient of each finishing mill according to silicon steel marks and rolling specifications, learning and adjusting the forward slipping coefficients according to actual rolling conditions and loop states, and automatically recovering the forward slipping coefficients after being adjusted in a next rolling period so as to cause the forward slipping coefficient of each finishing mill to be more suitable for features and rolling characteristics of the silicon steel, therefore, the adaptability of the forward slipping coefficient is improved, the possibility of loop accumulation and quality accidents can be reduced, the problem of unstable rolling in silicon steel rolling, in particular to an initial stage of each roller changing period is solved, and the production is ensured to be carried out smoothly.

Owner:ANGANG STEEL CO LTD

Control method of head shearing speed of flying shears for hot continuously rolled band steel

InactiveCN106077805AEnsure consistencySolve the effect of actual speedShearing control devicesSlip coefficientEngineering

The invention provides a control method of the head shearing speed of a pair of flying shears for hot continuously rolled band steel and belongs to the technical field of metallurgy. The control method comprises the steps that firstly, an HMD60 hot metal detector is installed at the position 3 meters away from the flaying shears; secondly, the head shearing speed of the flying shears is set to be 0.8 m / s- 1.5 m / s; thirdly, no band steel exists in the area of the flying shears, the speed of a roller way in the area of the flying shears is 0.8 m / s- 1.5 m / s; and fourthly, when the band steel passes through the area of the flying shear, the speed of the roller way in the area of the flying shear is the product of the F0 machine frame speed actual value and the F0 machine frame backward slip coefficient. By the adoption of the control method of the head shearing speed of the pair of flying shears for the hot continuously rolled band steel, the influence of frequent change of the speed of the roller way on the actual band steel speed is eliminated, and the problem of the influence of faults of a laser velocimeter on production operation is also solved; and the stability of band steel head shearing control is achieved, and fault time is shortened.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Anti-skid and anti-electric shock sole and manufacturing method thereof

The invention provides an anti-skid and anti-electric shock sole and a manufacturing method thereof. According to the formula, the anti-skid and anti-electric shock sole is prepared from polyisoprenerubber, styrene-butadiene rubber of solution polymerization, acrylonitrile-butadiene-styreneterpolymer, mineral oil, zinc oxide, vulkanox, activated calcium carbonate, bis(2-ethylhexyl)adipate, tackifying resin, stearic acid, polyethylene glycol, a silane coupler, polyethylene wax, insoluble sulfur powder, vulcanization accelerators and antiskid auxiliary agent. The acrylonitrile-butadiene-styreneterpolymer are added to the sole formula, the anti-electric shock performance of the sole is enhanced, after repeated tests, the maximum leakage current at 18kVA voltage does not exceed 0.5mA, is farbeyond the industry standard, and can enhance the protection of users; the added antiskid auxiliary agent effectively improves the antiskid performance of the sole, measured by a plurality of tests,the anti-slip coefficient increases to 0.88, and so as to safety risks are further reduced when users work on the electricity.

Owner:TIANJIN TIANXING KESHENG LEATHER PROD

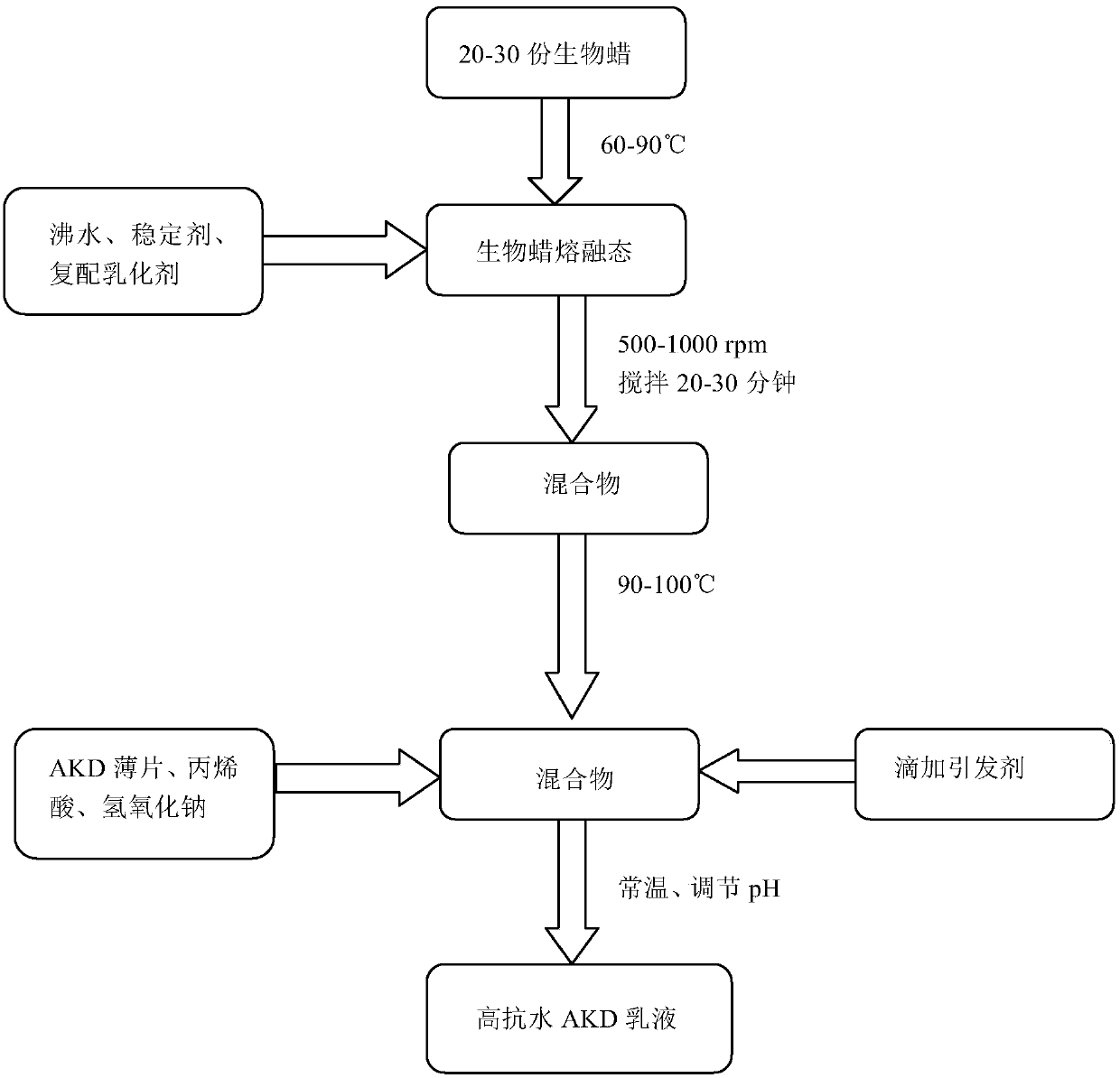

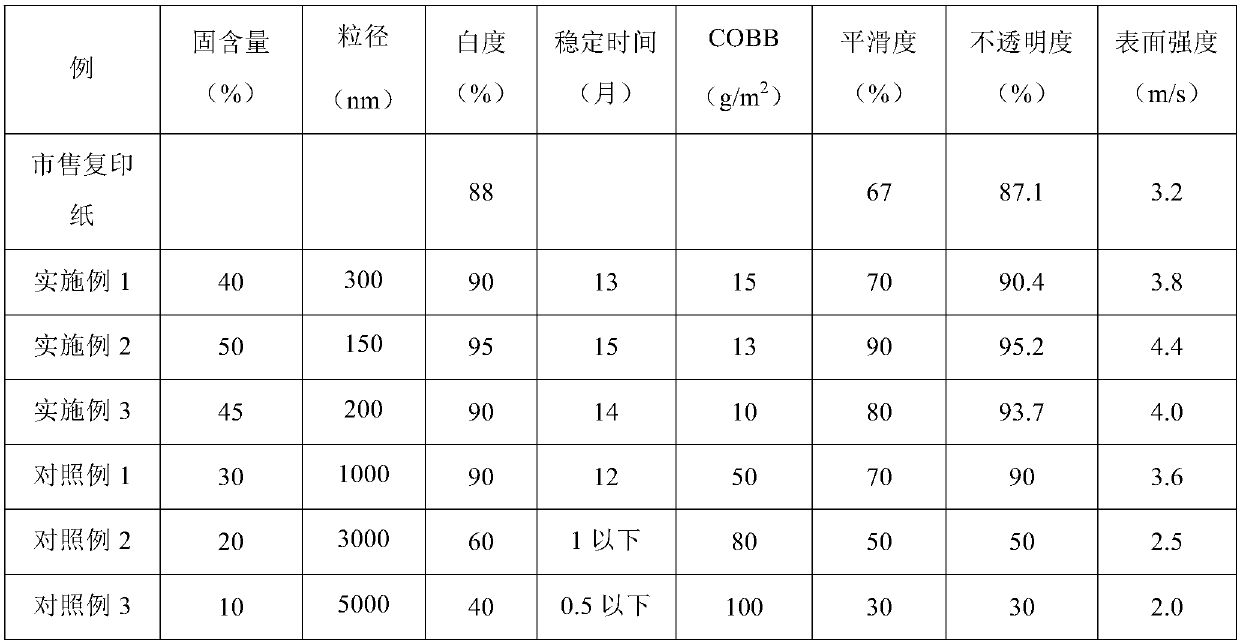

High-water-resistance alkyl ketene dimer (AKD) emulsion and preparation method thereof

ActiveCN109608597AUnique craftLarge specific surface areaWater-repelling agents additionPaper coatingNitrogen gasPhotochemistry

The invention discloses a high-water-resistance alkyl ketene dimer (AKD) emulsion and a preparation method thereof. The preparation method comprises the following steps: (1) adding 20-30 parts of biological wax into a reaction kettle, carrying out heating to 60-90 DEG C, adding 80-100 parts of boiling water, 1-3 parts of a stabilizer and 3-5 parts of a compound emulsifier in a nitrogen protectiveatmosphere after the biological wax is melted, and carrying out stirring for 20-30 minutes at a stirring speed of 500-1000 rpm; (2) carrying out heating to 90-100 DEG C after the solution is completely and uniformly mixed, adding 40-50 parts of AKD sheets, 5-10 parts of acrylic acid and 7-9 parts of sodium hydroxide, slowly and dropwise adding 3-5 parts of an initiator, and carrying out stirring for 5-10 hours at a stirring speed of 1000-1500 rpm; and (3) carrying out cooling to the normal temperature after the reaction is finished, and adjusting the pH value of the solution by using a diluteacid to enable the emulsion to be neutral, so that the high-water-resistance AKD emulsion can be obtained. According to the high-water-resistance AKD emulsion provided by the invention, the preparation process is simple and mature, production cost is low, environment friendliness is achieved, and operation is easy to control. The obtained high-water-resistance AKD emulsion is high in sizing efficiency, high in curing speed and low in slip coefficient, energy consumption and the environmental pollution can be reduced, and water resistance effect is excellent.

Owner:山东同创精细化工有限公司

Method for producing special fibers of large bright sewing thread from polyester bottle waste material

ActiveCN102732993ASmooth feedingWith matting effectNew-spun product collectionPlastic recyclingPolyesterDrum drying

The present invention relates to a method for producing special fibers of large bright sewing thread from a polyester bottle waste material. The method of the present invention is the improvement of the chopped fiber regeneration process in the prior art. The method comprises: carrying out a vacuum drum drying treatment, wherein the water content in the material is less than 80 ppm; adding additives of an OB-1 brightening agent, barium sulfate and zinc stearate to the material according to a certain ratio, wherein per ton of the material is added with 25-50 g of the OB-1 brightening agent, 500-2000 g of the barium sulfate, and 50-200 g of the zinc stearate; uniformly mixing the material and the additives, and carrying out melting extruding with a screw extruder. According to the method, fiber whiteness can be increased with the OB-1 brightening agent; a slipping coefficient of crushed sheets can be increased with the zinc stearate, such that uniform material feeding of the screw extruder can be ensured so as to reduce reflux degradation of the melt, and uniform material conveying in the dry bin can be provided so as to reduce moisture regaining due to long time staying; the spinning performance and the drafting performance can be improved with the barium sulfate; and the additives are added to the material, and the production process is appropriately adjusted, such that the produced product can meet requirements of the special fibers of the large bright sewing thread.

Owner:广东源辉环保纤维有限公司

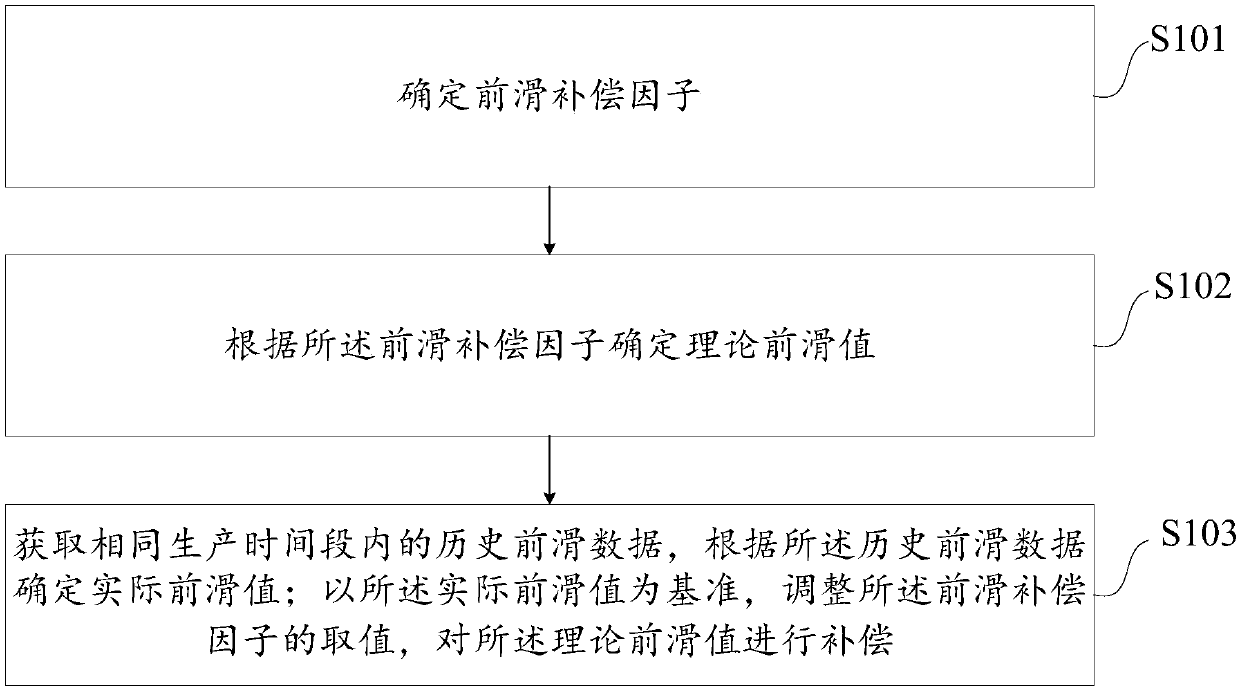

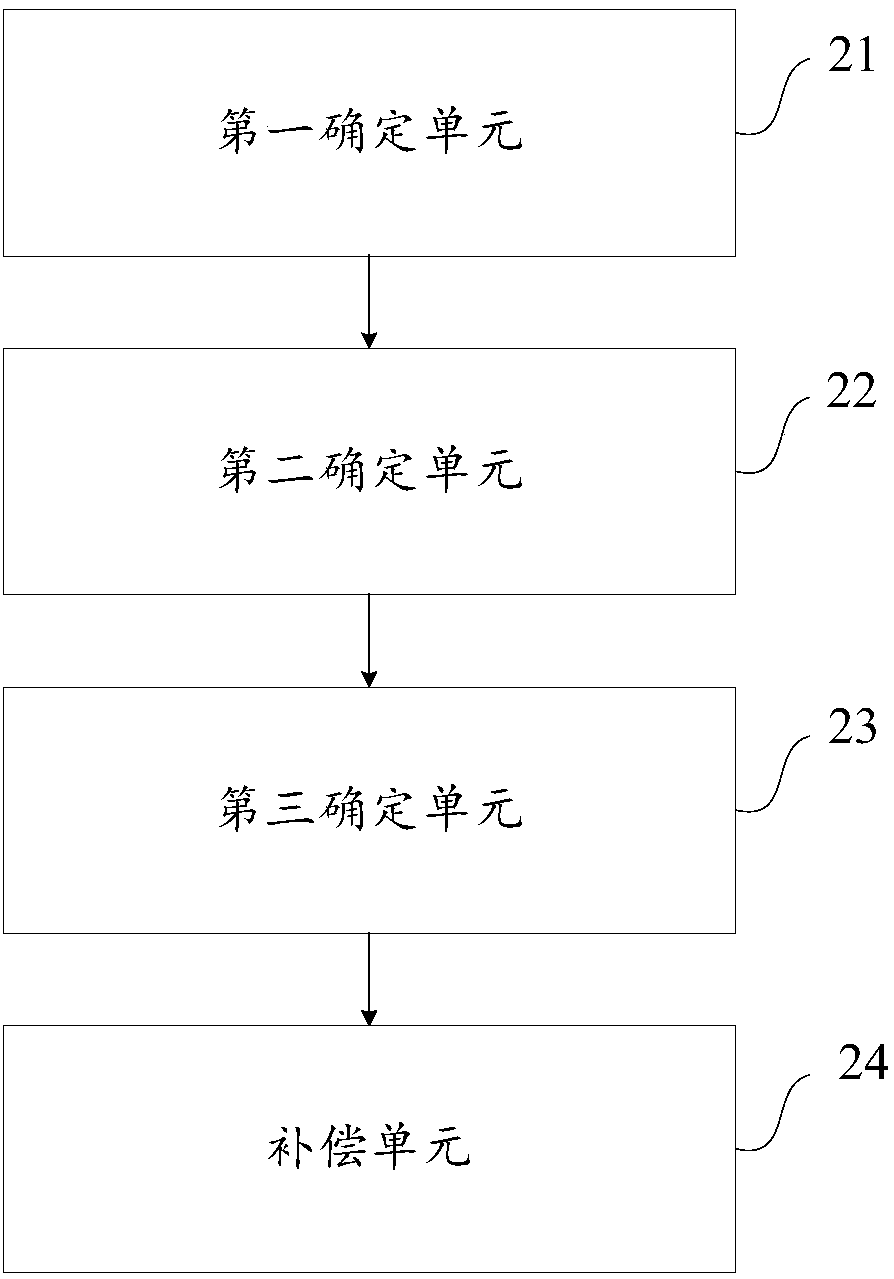

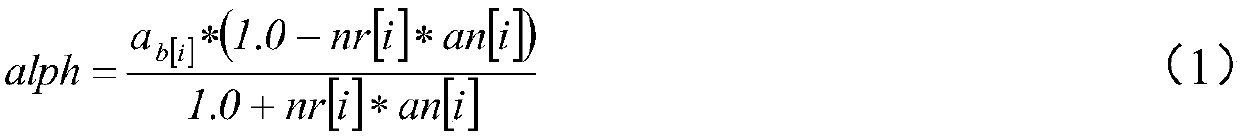

Method and device for compensating cold continuous rolling forward slip value

ActiveCN107583959AImprove calculation accuracyGuarantee product qualityRoll mill control devicesMetal rolling arrangementsSlip coefficientStrip steel

The embodiment of the invention provides a method and device for compensating a cold continuous rolling forward slip value. The method comprises the steps that a forward slip compensation factor is determined, wherein the forward slip compensation factor comprises a cardinal number of all rack forward slip coefficients and an adjustment factor of the number of rolling coils; according to the forward slip compensation factor, a theoretical forward slip value is determined; historical forward slip data in a same production time interval is acquired; according to the historical forward slip data,an actual forward slip value is determined; based on the actual forward slip value, the value of the forward slip compensation factor is adjusted so that the theoretical forward slip value can be compensated. Therefore, the forward slip compensation factor is introduced into the calculation process of the forward slip value, and the value of the forward slip compensation factor is adjusted in real time according to the historical actual production data, so that the calculation precision of the forward slip value is improved, then the rolling stability is guaranteed, and the quality of strip steel products is guaranteed.

Owner:BEIJING SHOUGANG CO LTD

Super-hard anti-slip terrace material

InactiveCN109370388AEasy to mix and applyImprove skid resistanceAnti-corrosive paintsEpoxy resin coatingsPolyamideSalicylic acid

The invention particularly relates to a super-hard anti-slip terrace material which comprises a component A and a component B. The component A comprises, by weight, 40-50 parts of bisphenol-A epoxy resin, 1-5 parts of color paste, 15-20 parts of 600-mesh heavy calcium powder, 15-20 parts of 600-mesh quartz powder, 5-10 parts of 600-mesh mica powder, 5-10 parts of phenyl glycidyl ether, 5-10 partsof butyl glycidyl ether, 0.5-3 parts of salicylic acid, 0.1-0.5 part of 300-mesh zirconium dioxide, 0.1-0.3 part of EFKA 2040, 0.2-0.5 part of EFKA 3650 and 0.2-0.6 part of EFKA 4330. The component Bcomprises, by weight, 40-50 parts of modified polyamide and 1-3 parts of methyl diethanolamine. The terrace material is not easily caked, good in compatibility and rapid in surface drying time, and has ultra-high hardness and anti-slip coefficient.

Owner:FUZHOU ROYAL FLOOR

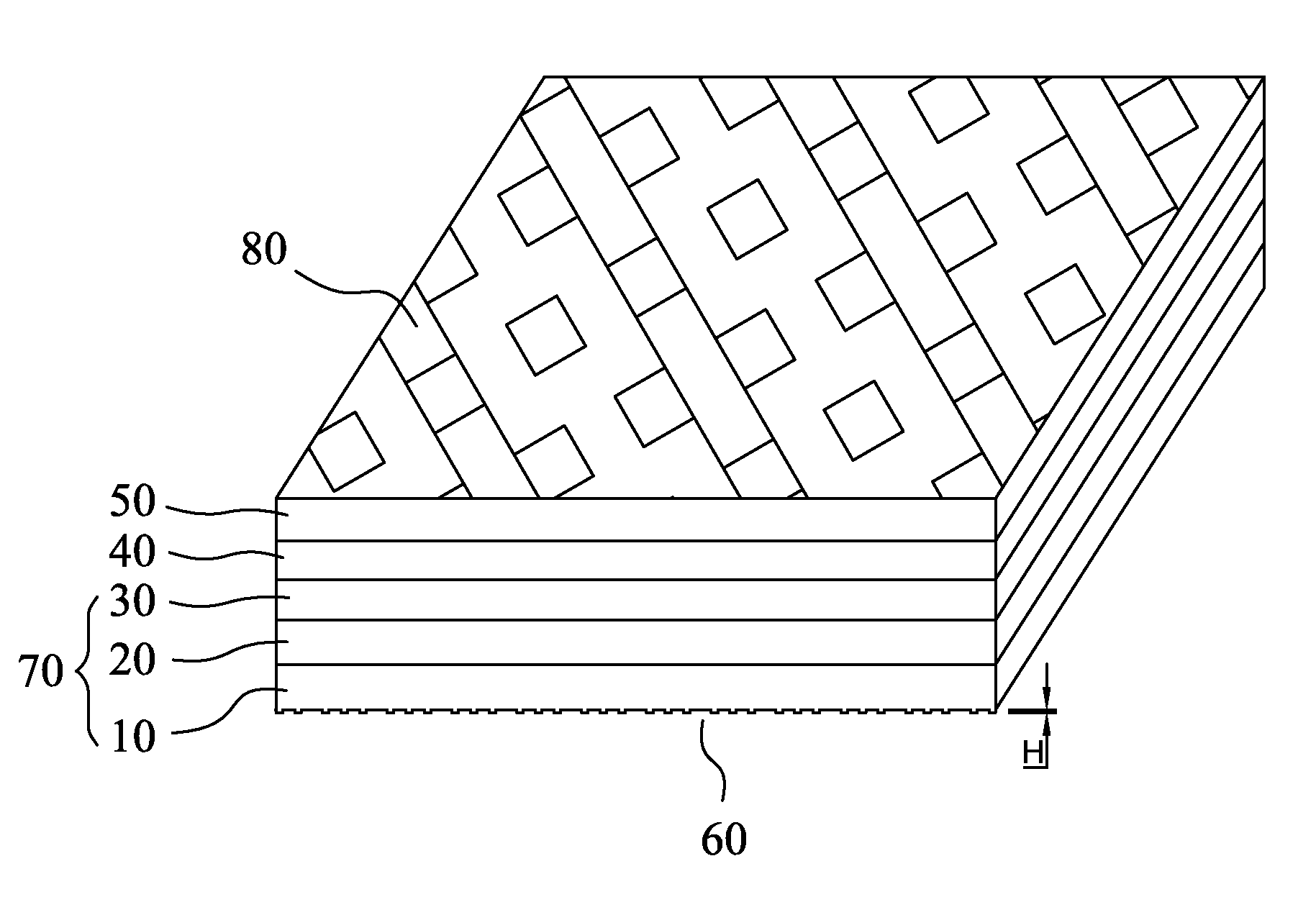

Factory-prefabricated self-adhesive water-sealing anti-slip and anti-crack pavement sticker and preparation and construction method of the same

InactiveCN109056452AGuaranteed water seepage coefficientReduce driving noisePaving detailsRoad surfacePermeability coefficient

The invention discloses a factory-prefabricated self-adhesive water-sealing anti-slip and anti-crack pavement paste and a preparation and construction method thereof, belonging to the technical fieldof highway maintenance. The invention comprises an isolation paper layer, a self-adhesive adhesive layer, an anti-crack cloth layer, a lower binder layer, an aggregate layer, an upper binder layer anda surface protection layer. The surface protective layer is sprayed with thermosetting polymer binder. 15 DEG C pull-out t >= 0. 5MPa; The binder completely covers the aggregate and forms a continuous bonding material layer to ensure that the water permeability coefficient is 0; Multi-texture surface structure and surface protective film ensure the anti-slip coefficient BPN >= 55 and the drivingnoise is low; The longitudinal and transverse fracture strength is high, and the reflection crack is delayed. The pavement sticker of the invention is directly applied to the tortoise-shaped cracks ofthe local pavement network which needs to be repaired or the whole pavement is corrected and pre-cured, is convenient to use, can quickly open the traffic, has long service life, and has remarkable social and economic benefits.

Owner:SHANDONG DASHAN ROAD & BRIDGE ENG

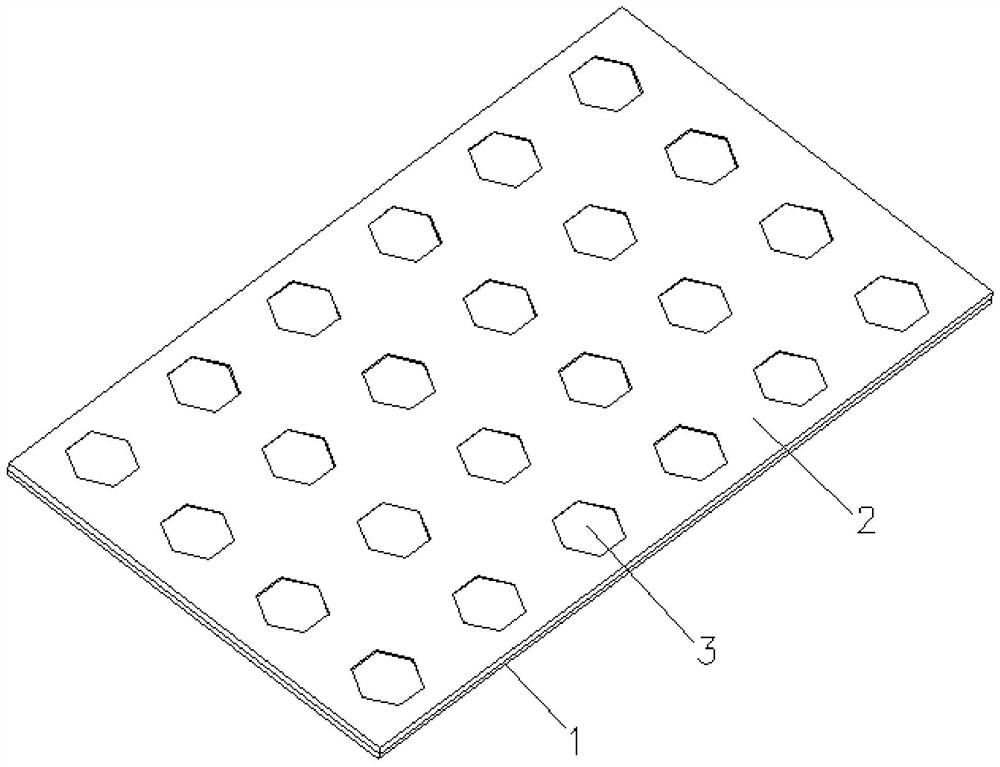

Glue-free anti-slip polyvinyl chloride floor brick and preparing method thereof

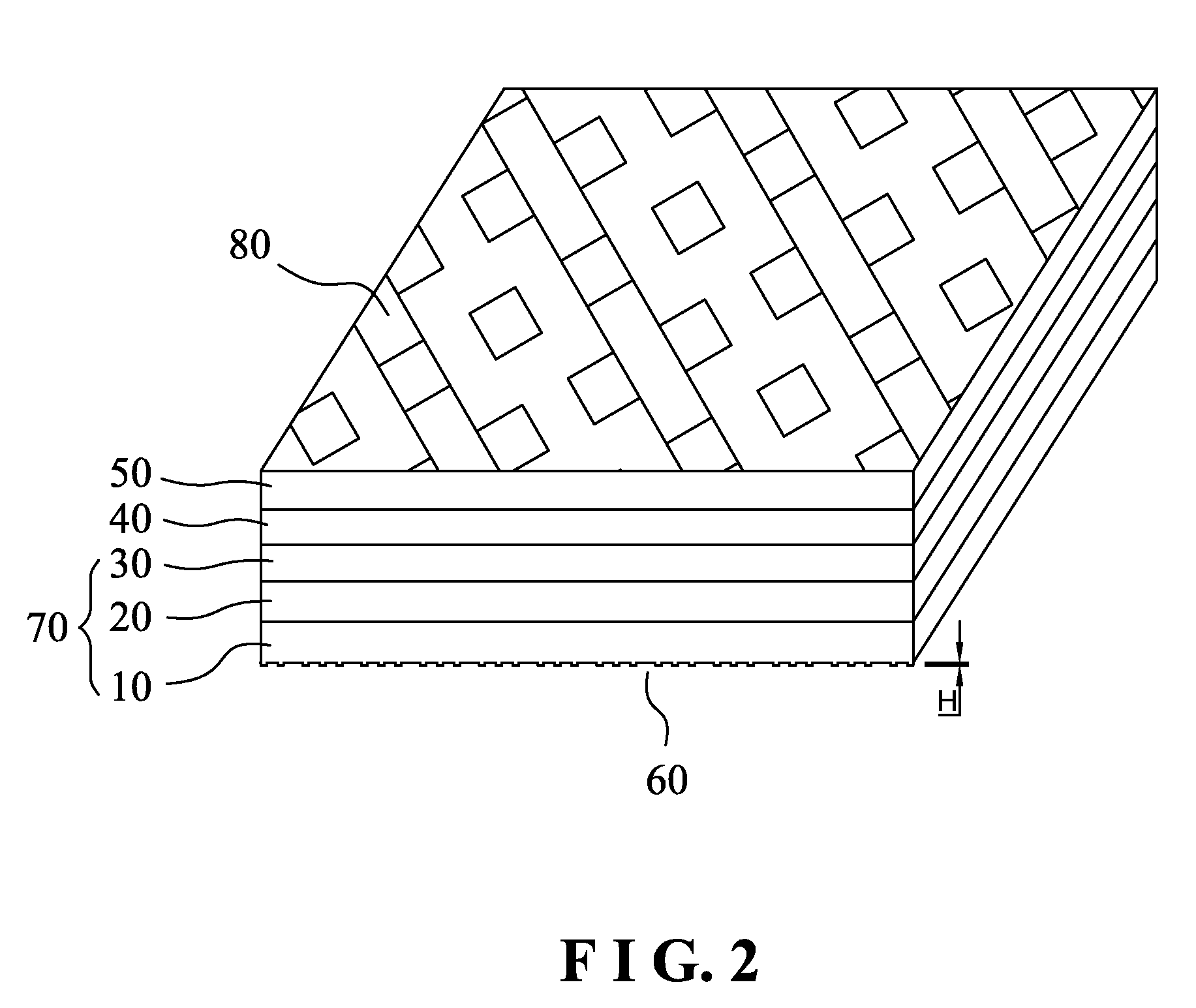

ActiveUS8822014B2Improve skid resistanceImprovement factorMechanical working/deformationFloorsBrickPolyvinyl chloride

The present invention discloses a glue-free anti-slip polyvinyl chloride floor brick which includes a polyvinyl chloride anti-slip layer having a bottom surface formed with a flexible thermal-pressed pattern by thermal pressing. The thermal-pressed pattern includes a plurality of continuously and repetitively connected, closed and non-equilateral hexagonal protruded ribs, which are characterized with a required flexibility by utilizing a special ingredient amount of the anti-slip layer and provided with an anti-slip coefficient of 1.5 by incorporating with non-equilateral hexagonal anti-slip patterns with special sizes and shapes, thereby enhancing the slip resistance of the floor brick to overcome the bottlenecks in plastic floor brick industries.

Owner:DONGGUAN MEI JER PLASTIC PROD CO LTD

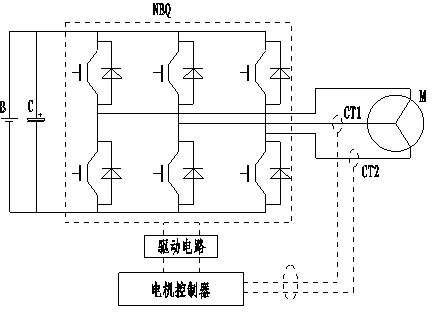

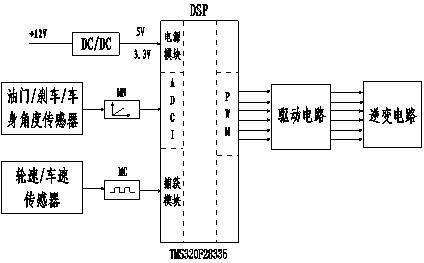

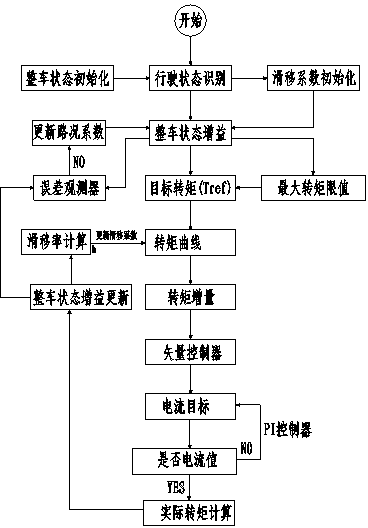

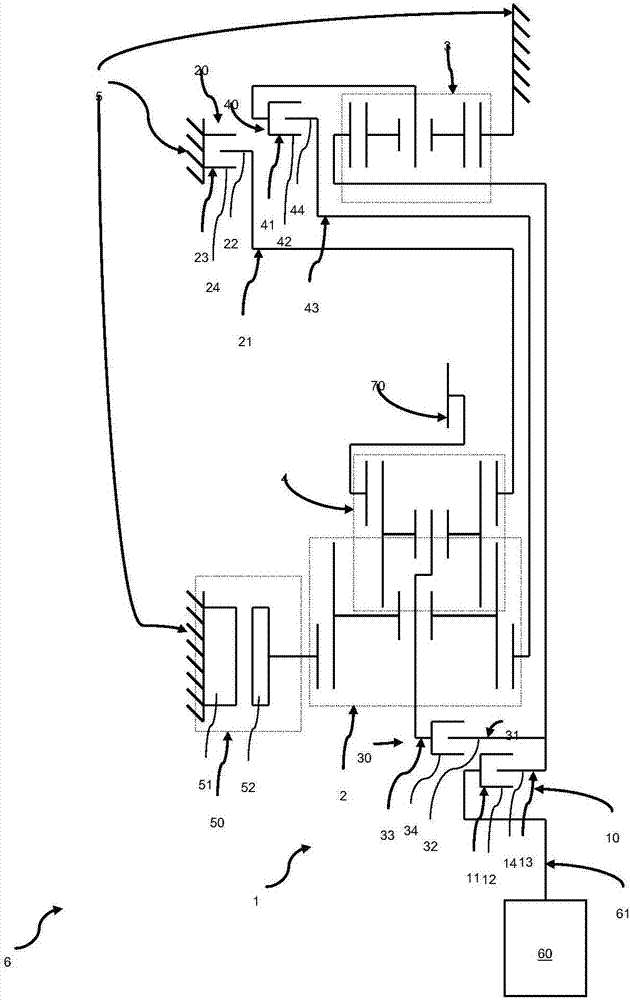

Method for controlling traction of electric vehicle

InactiveCN102501779BImprove acceleration performanceImprove lateral stabilitySpeed controllerElectric energy managementElectric machineSlip coefficient

The invention discloses a method for controlling the traction of an electric vehicle. A motor is driven by one controller; and the controller is internally provided with a finished vehicle status gain calculator, a vector controller, an error observer and an optimal slip ratio tracker. When a system operates, the finished vehicle status gain calculator analyzes the intention of a driver according to initialized vehicle information and real-time read finished vehicle status information and determines a torque gain curve, a vehicle acceleration curve and a vehicle desired speed; then the vector controller controls the motor to be up to a preset torque; next, the error observer compares the error between an actual value and a calculated value of the speed and adjusts a road condition resistance coefficient; and the optimal slip ratio tracker calculates the real-time slip ratio of the vehicle and adjusts a slip coefficient in a torque equation according to the calculated value so that the vehicle keeps in an optimal slip ratio state. By using the method, the phenomenon of slip is effectively prevented, and the acceleration performance and the side stability of the electric vehicle are improved.

Owner:GREAT WALL MOTOR CO LTD

Anti-skid flame-retardant insole

InactiveCN105367926AImprove flame retardant performanceHigh anti-slip coefficientInsolesFiberEngineering

The present invention discloses an anti-skid flame-retardant insole. The insole comprises the following raw material components in parts by weight: 12-15 parts of chlorinated polyethylene rubber, 5-8 parts of butyl rubber, 5-8 parts of staple fibers, 12-15 parts of white carbon, 2-4 parts of an environmental-protection flame retardant, 1-2 parts of stearic acid, 3-5 parts of an anti-skid agent, 2-4 parts of paraffin oil, 4-6 parts of bis-silane tetrasulfide, 3-5 parts of sulfur (S), 2-4 parts of an antioxidant 1076, 3-5 parts of a filler and 1-3 parts of an accelerant DM. According to anti-skid flame-retardant insole provided by the present invention, the filler and the anti-skid agent work collaboratively, can be used for a nature rubber system to improve the flame retardant of the material. The anti-skid agent can increase non-slip coefficient of the insole to ensure safety in sports, people do not readily fall, and the insole is particularly suitable for mountaineering. The prepared insole has good elasticity, formability, recovery, ventilation and water absorption. The natural components are used as main raw materials, so that environmental pollution is little, the materials are easy to degrade and recycle, the loss index is low, the wear capacity and the tear resistance are high, and the insole has a broad market application prospect.

Owner:王威淞

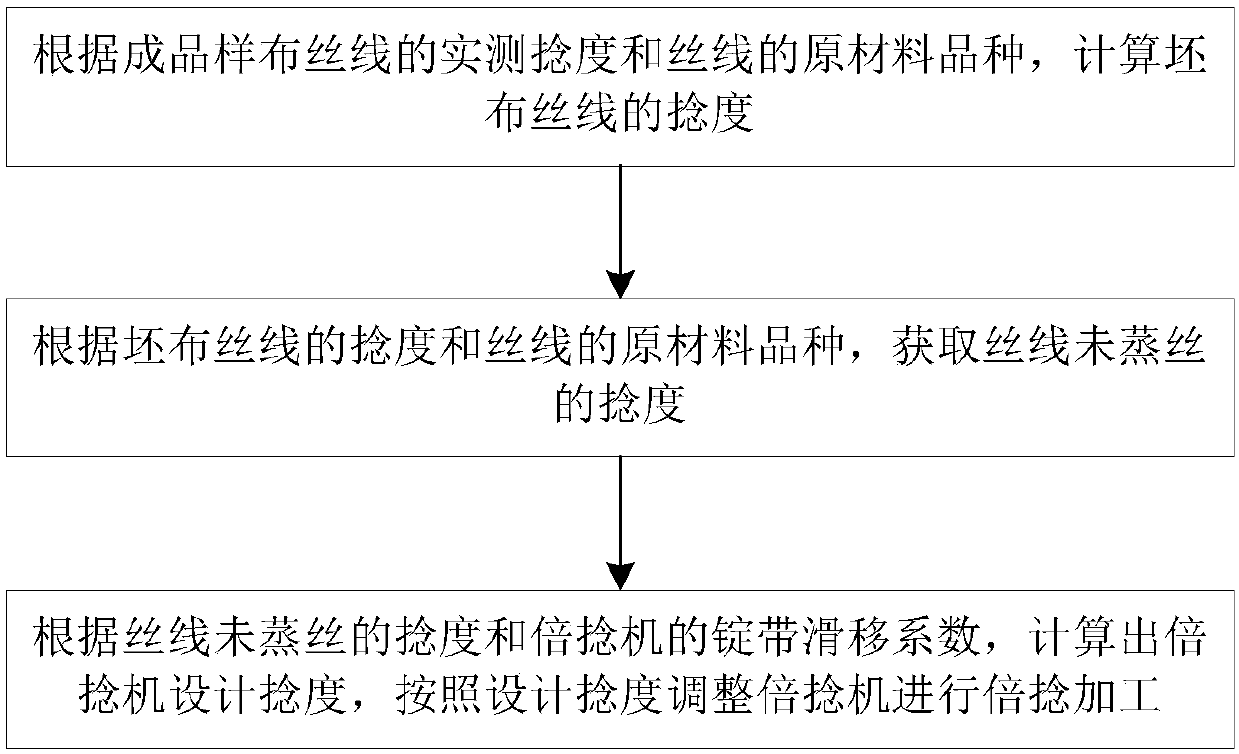

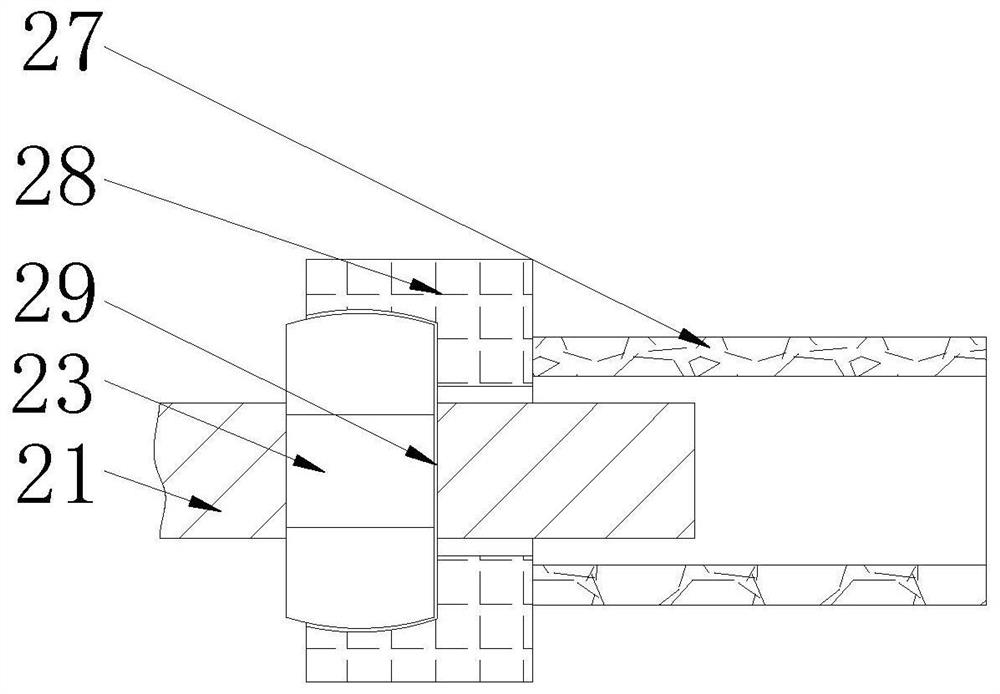

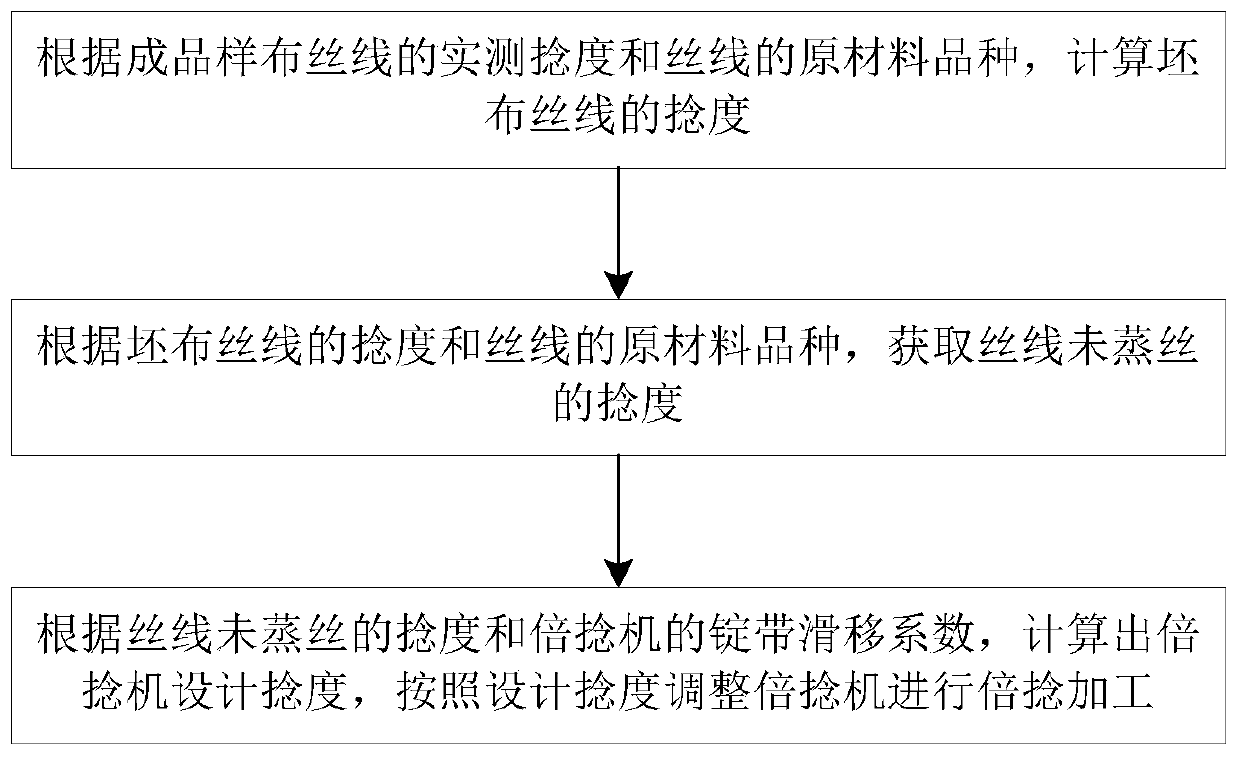

Method for processing silk threads through two-for-one twister

InactiveCN108560083AMeet or design requirementsTextile testingContinuous wound-up machinesShrinkage rateSlip coefficient

The invention discloses a method for processing silk threads through a two-for-one twister. The method for processing the silk threads through the two-for-one twister comprises the following steps that firstly, according to the actually measured twist of finished product sample fabric silk threads and the raw material variety of the silk threads, the twist of gray fabric silk threads is calculated; secondly, the twist of the non-steamed silk threads is obtained according to the twist of the gray fabric silk threads and the raw material variety of the silk threads; finally, according to the twist of the non-steamed silk threads and the spindle tape slip coefficient of the two-for-one twister, the design twist of the two-for-one twister is calculated, and the two-for-one twister is adjustedaccording to the design twist to conduct two-for-one twisting processing. According to the method, the steam shrinkage rate and the printing and dyeing shrinkage rate of the silk threads and the spindle tape slip coefficient of the two-for-one twister are considered, and the design twist of the two-for-one twister is calculated; processing is carried out according to the design twist, the twist ofa manufactured finished product fabric is consistent with that of a finished product sample fabric, and the requirements of clients or design are well met.

Owner:SHAOXING UNIV YUANPEI COLLEGE +1

Coordinated Speed Control Method of Plate Mill and Conical Roller Table

ActiveCN104942014BExtended service lifeNot easy to stainMetal rolling arrangementsRoll speed control deviceSlip coefficientCo operative

The invention discloses a speed cooperative control method for a heavy and medium plate mill and conical roller beds and relates to the technical field of metal pressure working. The speed cooperative control method for the heavy and medium plate mill and the conical roller beds includes the following steps that according to a roller bed rolling parameter of a plate, a forward slip coefficient in a plate rolling process is calculated, and the roller bed rolling parameter is obtained from a rolling mill two-stage process model set system; speeds of the plate rolled in the roller bed at the inlet position and the outlet position of a rolling mill are calculated through the rotating speed of a roller of the rolling mill and the obtained forward slip coefficient; the rotating speeds of the rolling mill at the inlet and the outlet conical roller beds are calculated respectively according to the inlet speed and the outlet speed of the plate, the width of the plate and the geometrical shape parameters of the conical roller beds, the calculated rotating speed values are sent to a roller bed motor transmission system for execution, and therefore speed setting is conducted respectively for the front and the rear conical roller beds of the rolling mill. The speed cooperative control method for the heavy and medium plate mill and the conical roller beds solves the problems that the contact portion of the plate and the conical roller beds is poor in linear speed, and the surface quality of the plate and the service life of the roller beds are seriously affected.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

Glue-free PVC (polyvinyl chloride) limited slip floor tile of ring structure and preparation method thereof

ActiveCN102561657BImprove anti-slip performanceRemove security concernsFlooringSlip lineSlip coefficient

The invention discloses a glue-free PVC (polyvinyl chloride) limited slip floor tile of a ring structure and a preparation method thereof. as for the limited slip floor tile, a flexible thermocompression line is formed on the bottom surface of a PVC limited slip layer in a thermocompression manner; the thermocompression line comprises a plurality of seal hexagon protruding ribs which are continuously and repetitively connected and seal round protruding ribs which are positioned in each hexagon protruding rib; the material formulation of the PVC limited slip layer comprises the following components by weight: 58.5%-63.5% of PVC with polymerization degree of 1000, 34.9-39% of plasticizing agent, 0.95%-2.1% of stabilizing agent, 0.5%-0.69% of toner, and 0.06%-0.08% of calcium carbonate of 800 molybdenum; and the required softness obtained by using particular formulation dosage of the limited slip layer is combined with the limited slip line which is composed of non-hexagon of particular size and shape and the round protruding ribs to enable the limited slip coefficient to be more than 1.5, thereby overcoming the bottle neck of improving the limited slip performance in the industry of plastic floor tiles.

Owner:DONGGUAN PULONG PLASTIC PRODS

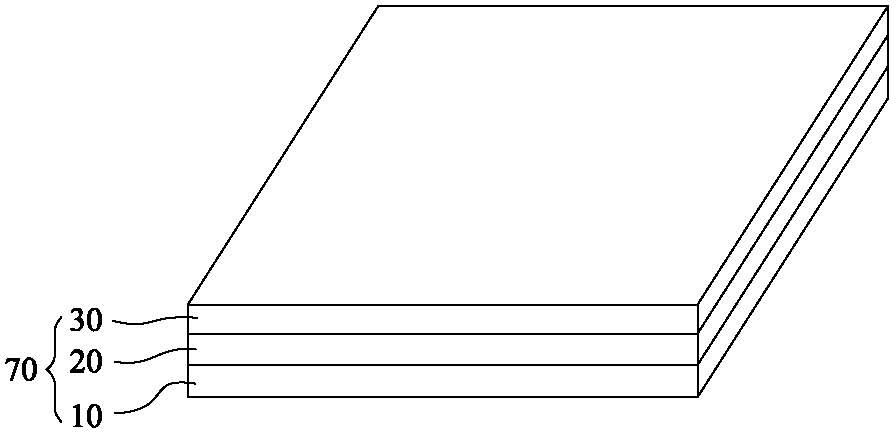

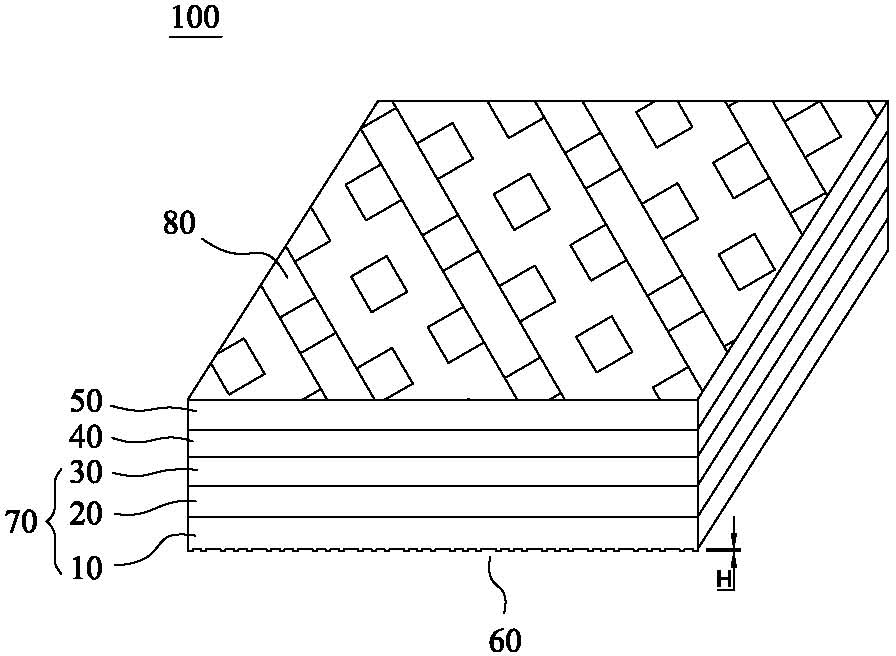

Material with variable non-slip coefficient and application thereof

PendingCN113542468AImprove skid resistancePrevent slippingWriting connectorsTelephone set constructionsSlip coefficientEngineering

The invention provides a material with a variable non-slip coefficient and application thereof. The material comprises a bottom layer, first contact blocks and second contact blocks. The first contact blocks and the second contact blocks are arranged at the top of the bottom layer in a staggered mode. The second contact block comprises a water swellable material. The friction coefficient of the top surface of the first contact block is smaller than that of the top surface of the second contact block. The top surface of the first contact block is higher than the top surface of the second contact block, and when the second contact block absorbs water and swells, the top surface of the first contact block is lower than or equal to the top surface of the second contact block; or, the top surface of the first contact block is equal to the top surface of the second contact block, and when the second contact block absorbs water and swells, the top surface of the first contact block is lower than the top surface of the second contact block. According to the material provided by the invention, the anti-slip capacity of a use surface can be improved when the material is wet or meets water, so that the material can adapt to different use occasions or scenes.

Owner:HUAMAO (XIAMEN) WEAVING DYEING & FINISHING CO LTD

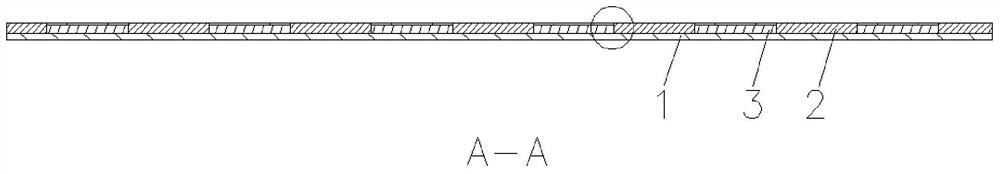

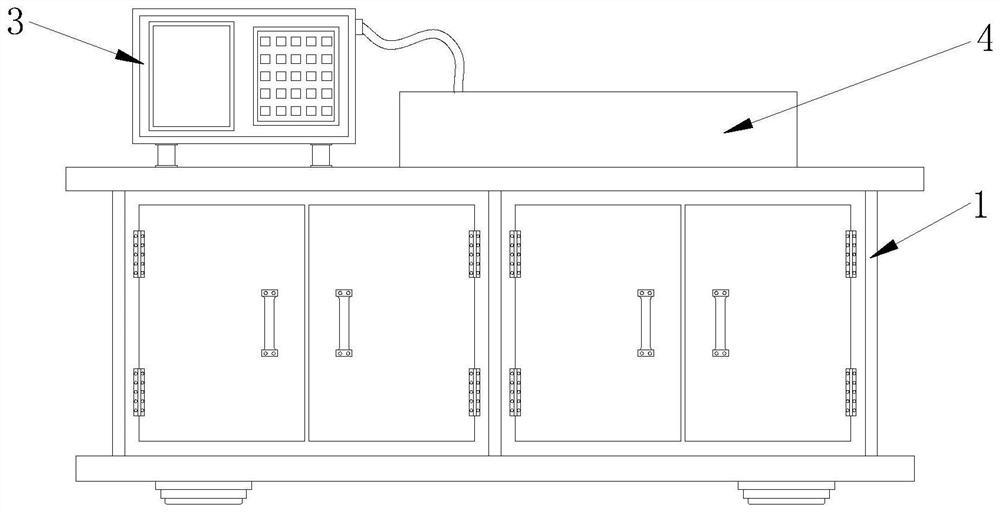

Anti-slip coefficient detector and working method thereof

PendingCN111912780ARealize tightening and fixingImprove practicalityUsing mechanical meansMaterial analysisFixed frameDisplay device

Owner:湖北科规检测有限公司

A method of thread processing using a two-for-one twister

InactiveCN108560083BMeet or design requirementsTextile testingContinuous wound-up machinesShrinkage rateSlip coefficient

The invention discloses a method for processing silk threads through a two-for-one twister. The method for processing the silk threads through the two-for-one twister comprises the following steps that firstly, according to the actually measured twist of finished product sample fabric silk threads and the raw material variety of the silk threads, the twist of gray fabric silk threads is calculated; secondly, the twist of the non-steamed silk threads is obtained according to the twist of the gray fabric silk threads and the raw material variety of the silk threads; finally, according to the twist of the non-steamed silk threads and the spindle tape slip coefficient of the two-for-one twister, the design twist of the two-for-one twister is calculated, and the two-for-one twister is adjustedaccording to the design twist to conduct two-for-one twisting processing. According to the method, the steam shrinkage rate and the printing and dyeing shrinkage rate of the silk threads and the spindle tape slip coefficient of the two-for-one twister are considered, and the design twist of the two-for-one twister is calculated; processing is carried out according to the design twist, the twist ofa manufactured finished product fabric is consistent with that of a finished product sample fabric, and the requirements of clients or design are well met.

Owner:SHAOXING UNIV YUANPEI COLLEGE +1

A method for testing the reaction time constant of the main servomotor of a hydroelectric generating set

ActiveCN105022286BRealize simulationHigh precisionSimulator controlElectric power systemWater turbine

The invention discloses a test method for the reaction time constant of a main servomotor of a water turbine generator set. The method comprises that safe operation conditions are determined; grid-connection operation of a speed regulator is simulated and set in an automatic manner; the proportion amplification multiple of the regulator is set as the minimum, the integration amplification multiple as the minimum, and the differential amplification multiple as the minimum, and a permanent slip coefficient is set as 0; the manual rotating speed and opening degree dead zones of the speed regulator of a water turbine are both set as 0; the minimal displacement in the close direction of main distribution, the maximal displacement in the open direction of main distribution, the minimal open degree of a guide vane, the maximal open degree of the guide vane and a middle position z of main distribution are determined; an open-degree feedback signal of the guide vane is modified to a fixed value; the displacement of main distribution and a curve of open-degree change of the guide vane are determined; the curve is fit; and the reaction time constant of the main servomotor is calculated. The method can be used to solve the problems that the reaction time constant of the main servo motor of the water turbine generator set cannot be effectively measured by speed regulator test of the hydroelectric generating set, and the stability of the power system and the calculation accuracy are influenced.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

Method for operating a transmission and a transmission with at least two shifting devices

InactiveCN105531510BReduce or avoid stick-slipImproved shift qualityGearing controlSlip coefficientEngineering

Owner:AVL LIST GMBH

Factory-prefabricated water-sealed anti-slip anti-crack pavement sticker and preparation and construction method thereof

InactiveCN109056454AWater permeability coefficient 0Reduce driving noisePaving detailsRoad surfacePrice ratio

The invention discloses a water-sealing anti-slip and anti-crack pavement paste made in a factory, a preparation method and a construction method thereof, belonging to the field of highway maintenance. The invention comprises an isolation paper layer, an anti-crack cloth layer, a lower binder layer, an aggregate layer, an upper binder layer and a surface protection layer. The surface protective layer is sprayed with thermosetting polymer binder. The pavement sticker of the invention completely wraps the aggregate and forms a continuous adhesive material layer to ensure that the water permeability coefficient is 0; Multi-texture surface structure and surface protective film ensure the anti-slip coefficient BPN >= 55 and the driving noise is low; The longitudinal and transverse fracture strength is high, and the reflection crack is delayed. The pavement paste of the invention is directly applied to the tortoise-shaped cracks of the local pavement network which needs to be repaired or thewhole pavement is corrected and pre-cured when the pavement is used after the pavement is brushed and the binder is coated. The pavement paste of the invention is convenient to use, can quickly openthe traffic, has long service life, high performance-price ratio, is green, low-carbon, energy-saving and environment-friendly, and has remarkable social and economic benefits.

Owner:SHANDONG DASHAN ROAD & BRIDGE ENG

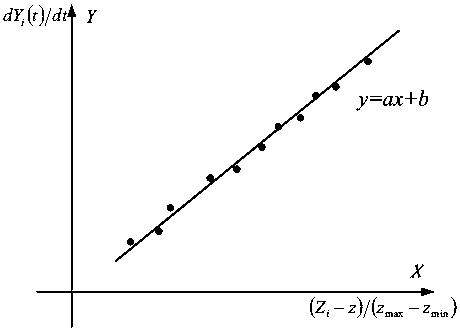

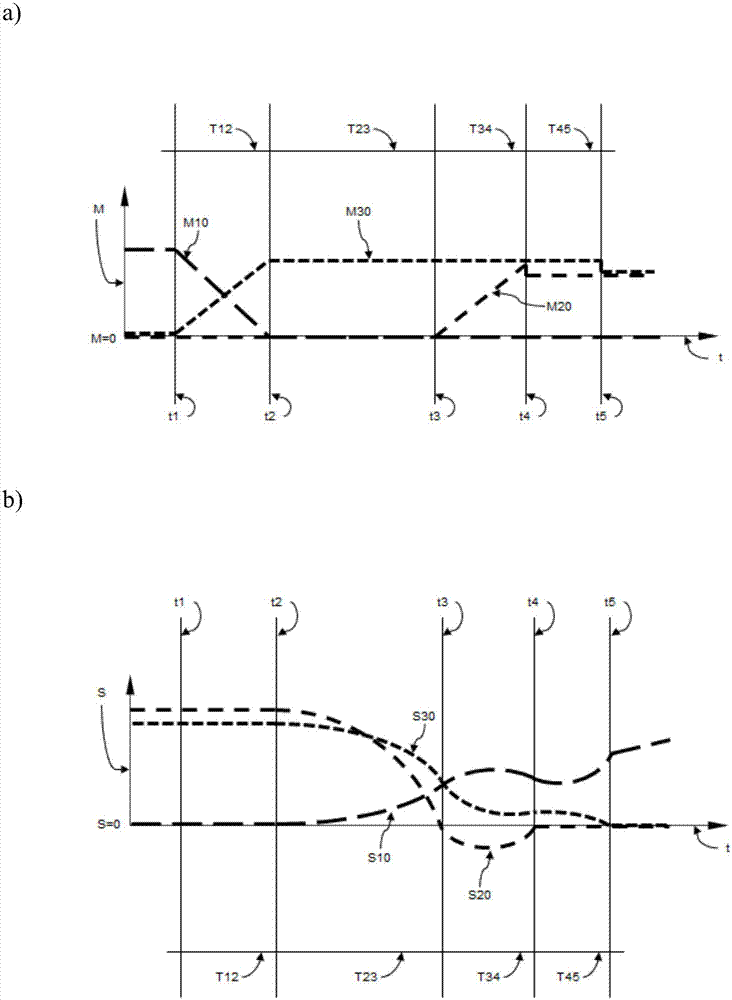

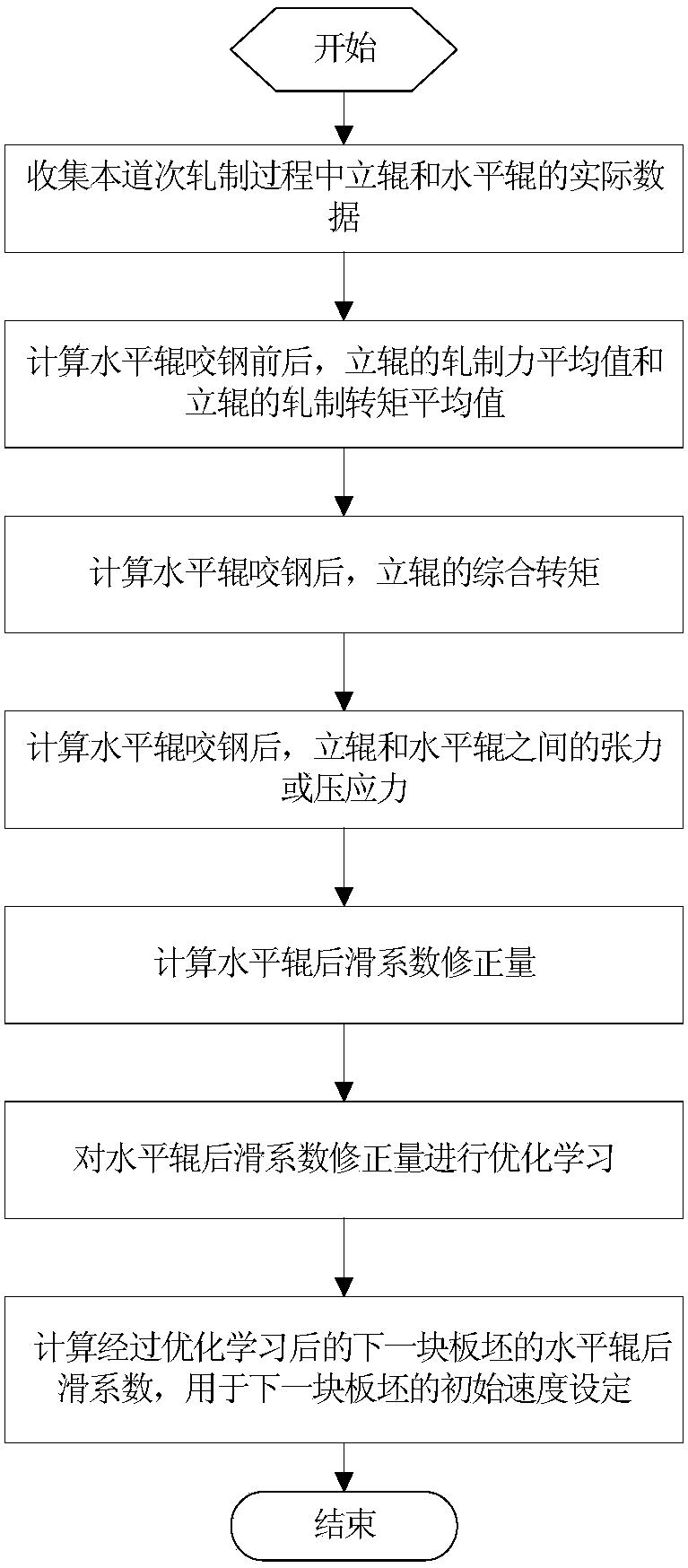

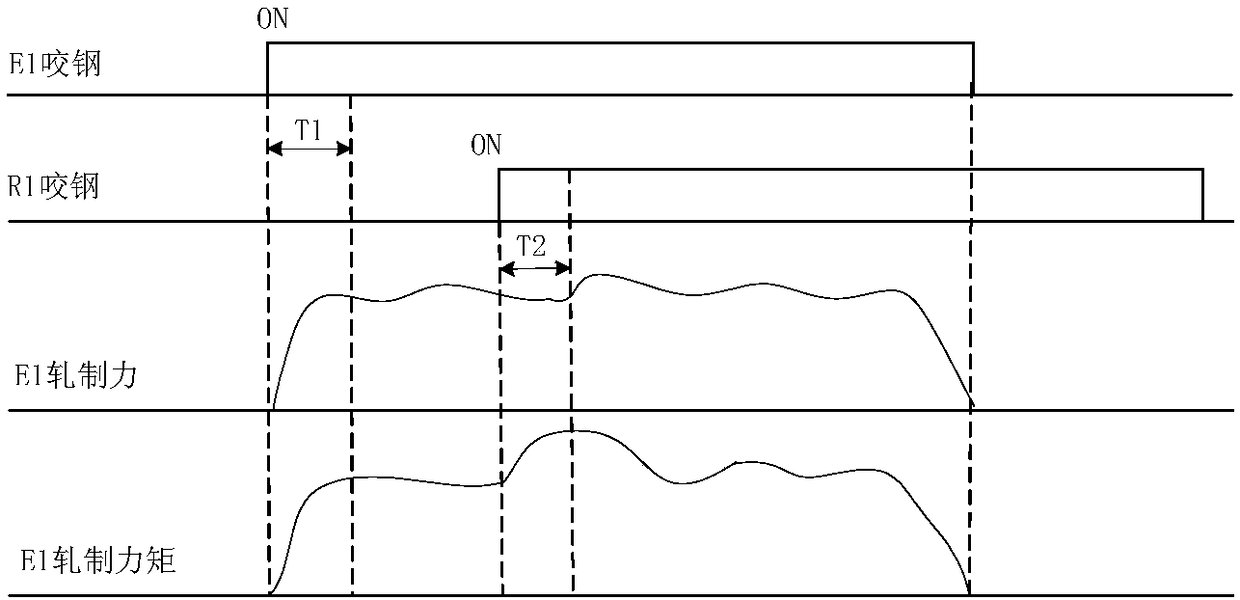

Optimizing setting method for speed of vertical roll in hot continuous rolling and rough rolling forward pass rolling process

ActiveCN108941210AImprove initial setup speedPrevent electric shock or even motor damage accidentsRolling mill drivesMetal rolling arrangementsSlip coefficientControl theory

The invention relates to an optimizing setting method for the speed of a vertical roll in the hot continuous rolling and rough rolling forward pass rolling process. The method comprises the steps that(1) actual data are collected; (2) the rolling force average value and the rolling torque average value of the vertical roll before and after steel biting of a horizontal roll are calculated; (3) thecomprehensive torque of the vertical roll before and after steel biting of the horizontal roll is calculated; (4) the backward slip coefficient correction of the horizontal roll is calculated; (5) optimizing study of the backward slip coefficient correction is carried out; and (6) the backward slip coefficient correction of a horizontal roll of a next plate blank is calculated and is used for setting the initial speed of the next plate blank. According to the method, the initial speed matching degree of the vertical roll and the horizontal roll is improved during steel biting, the failures such as tripping of a vertical roll rolling mill or the phenomenon of plate blank edge cracking caused by steel pulling is avoided, and the production stability or product quality is improved. The problem that in the existing steel plate hot rolling process, due to the fact that the influence of impact quick decrease exists after steel biting of the horizontal roll, the failures such as tripping ofthe vertical roll rolling mill or the phenomenon of plate blank edge cracking caused by steel pulling is prone to being caused is solved.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing special fibers of large bright sewing thread from polyester bottle waste material

ActiveCN102732993BSmooth feedingWith matting effectNew-spun product collectionPlastic recyclingPolyesterDrum drying

The present invention relates to a method for producing special fibers of large bright sewing thread from a polyester bottle waste material. The method of the present invention is the improvement of the chopped fiber regeneration process in the prior art. The method comprises: carrying out a vacuum drum drying treatment, wherein the water content in the material is less than 80 ppm; adding additives of an OB-1 brightening agent, barium sulfate and zinc stearate to the material according to a certain ratio, wherein per ton of the material is added with 25-50 g of the OB-1 brightening agent, 500-2000 g of the barium sulfate, and 50-200 g of the zinc stearate; uniformly mixing the material and the additives, and carrying out melting extruding with a screw extruder. According to the method, fiber whiteness can be increased with the OB-1 brightening agent; a slipping coefficient of crushed sheets can be increased with the zinc stearate, such that uniform material feeding of the screw extruder can be ensured so as to reduce reflux degradation of the melt, and uniform material conveying in the dry bin can be provided so as to reduce moisture regaining due to long time staying; the spinning performance and the drafting performance can be improved with the barium sulfate; and the additives are added to the material, and the production process is appropriately adjusted, such that the produced product can meet requirements of the special fibers of the large bright sewing thread.

Owner:广东源辉环保纤维有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com