Glue-free PVC (polyvinyl chloride) limited slip floor tile of ring structure and preparation method thereof

A ring-shaped structure and floor tile technology, applied in the field of plastic flooring, can solve the problems of low anti-slip coefficient of plastic flooring, no further improvement, unreasonable texture design and combination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of PVC non-slip floor tile comprises the following steps:

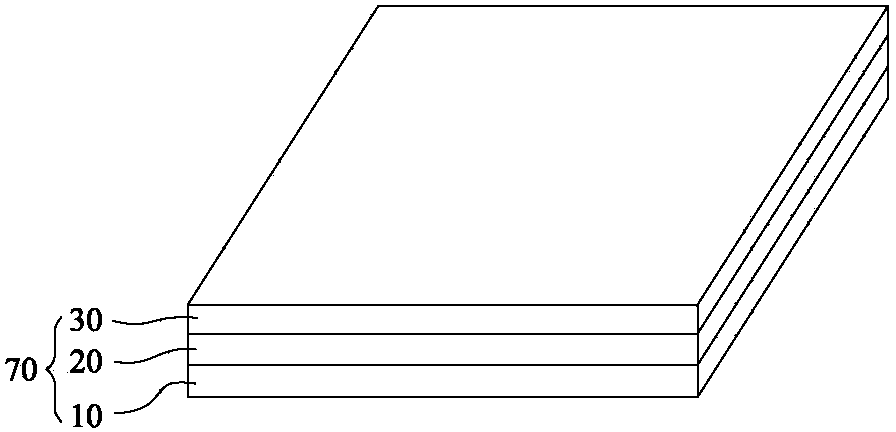

[0026] (1) The first hot pressing combination process: if figure 1 1. The PVC anti-slip layer 10, the PVC base material layer 20, and the PVC middle material layer 30 are stacked sequentially from bottom to top, and then hot-pressed to form a support body 70. The hot pressing process adopts segmented pressurization, and its specific pressurization parameters are as follows:

[0027]

[0028] The heating temperature is 130° C. for 24 minutes.

[0029] Among them, the material formula of the PVC anti-slip layer is: in parts by weight, including: 58.5% of PVC with a degree of polymerization of 1000, 38.8% of plasticizer, 2.1% of stabilizer, 0.52% of toner, and 0.08% of calcium carbonate of 800 mesh , the sum of the total amount of the aforementioned substances is 100%;

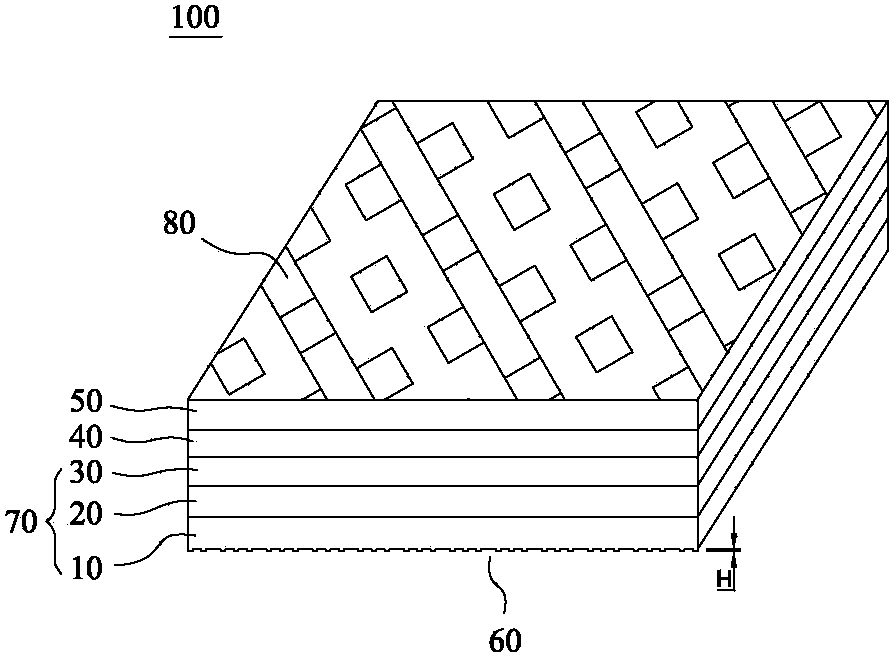

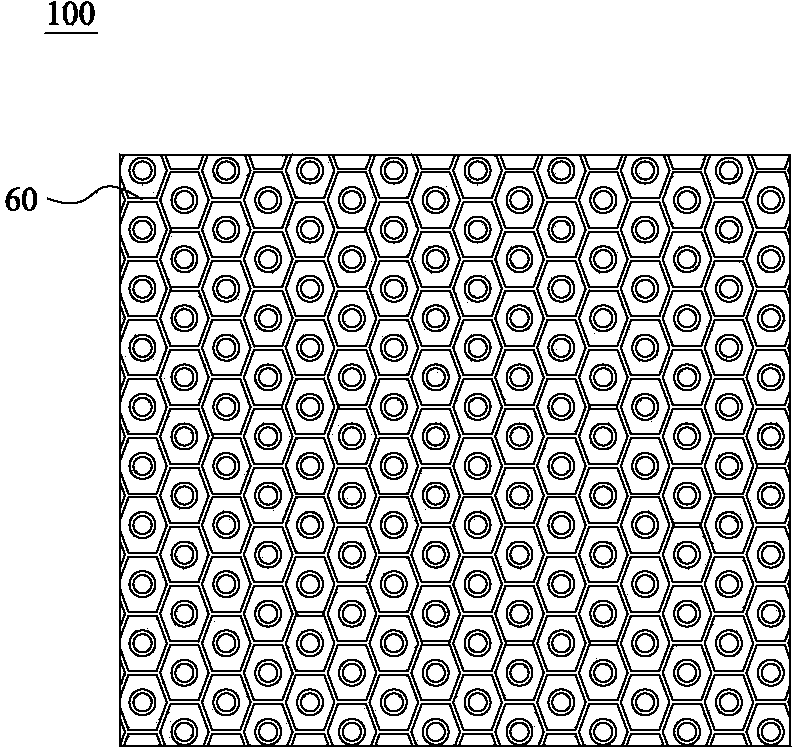

[0030] (2) Secondary hot embossing texture process: such as figure 2 , the PVC wear-resistant layer 50 and the PVC...

Embodiment 2

[0038] The preparation method of PVC non-slip floor tile comprises the following steps:

[0039] (1) The first hot pressing combination process: if figure 1 1. The PVC anti-slip layer 10, the PVC base material layer 20, and the PVC middle material layer 30 are stacked sequentially from bottom to top, and then hot-pressed to form a support body 70. The hot pressing process adopts segmented pressurization, and its specific pressurization parameters are as follows:

[0040]

[0041] The heating temperature is 130° C. for 24 minutes.

[0042] Among them, the material formula of the PVC anti-slip layer is: in parts by weight, including: 63.5% of PVC with a degree of polymerization of 1000, 34.9% of plasticizer, 1.0% of stabilizer, 0.54% of toner, and 0.06% of calcium carbonate of 800 mesh , the sum of the total amount of the aforementioned substances is 100%;

[0043] (2) Secondary hot embossing texture process: such as figure 2 , the PVC wear-resistant layer 50 and the PVC...

Embodiment 3

[0051] The preparation method of PVC non-slip floor tile comprises the following steps:

[0052] (1) The first hot pressing combination process: if figure 1 1. The PVC anti-slip layer 10, the PVC base material layer 20, and the PVC middle material layer 30 are stacked sequentially from bottom to top, and then hot-pressed to form a support body 70. The hot pressing process adopts segmented pressurization, and its specific pressurization parameters are as follows:

[0053]

[0054] The heating temperature is 130° C. for 24 minutes.

[0055] Among them, the material formula of the PVC anti-slip layer is: in parts by weight, including: 61.5% of PVC with a degree of polymerization of 1000, 36.5% of plasticizer, 1.3% of stabilizer, 0.64% of toner, and 0.06% of 800-mesh calcium carbonate , the sum of the total amount of the aforementioned substances is 100%;

[0056] (2) Secondary hot embossing texture process: such as figure 2 , the PVC wear-resistant layer 50 and the PVC pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com