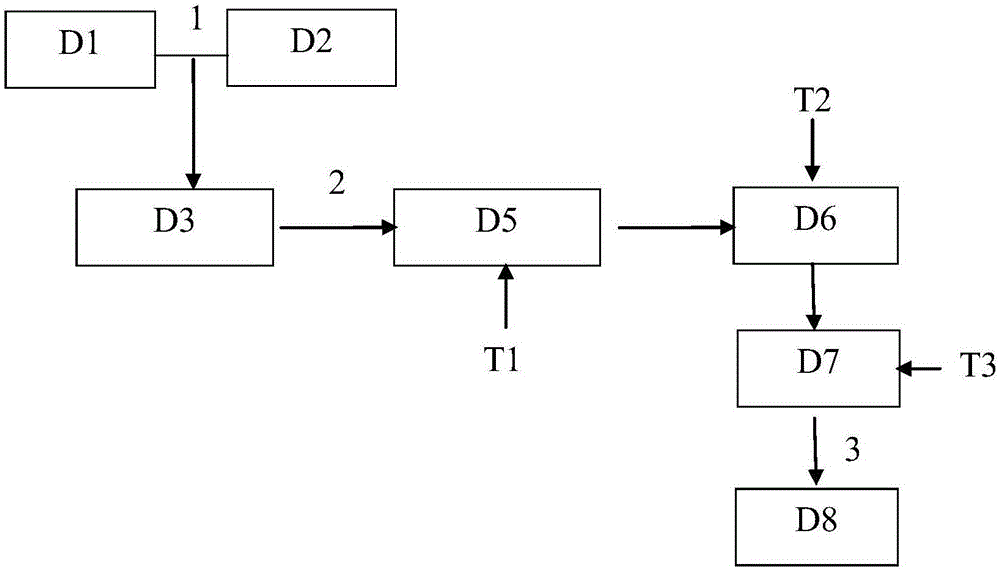

Patents

Literature

290results about How to "Improve slip resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

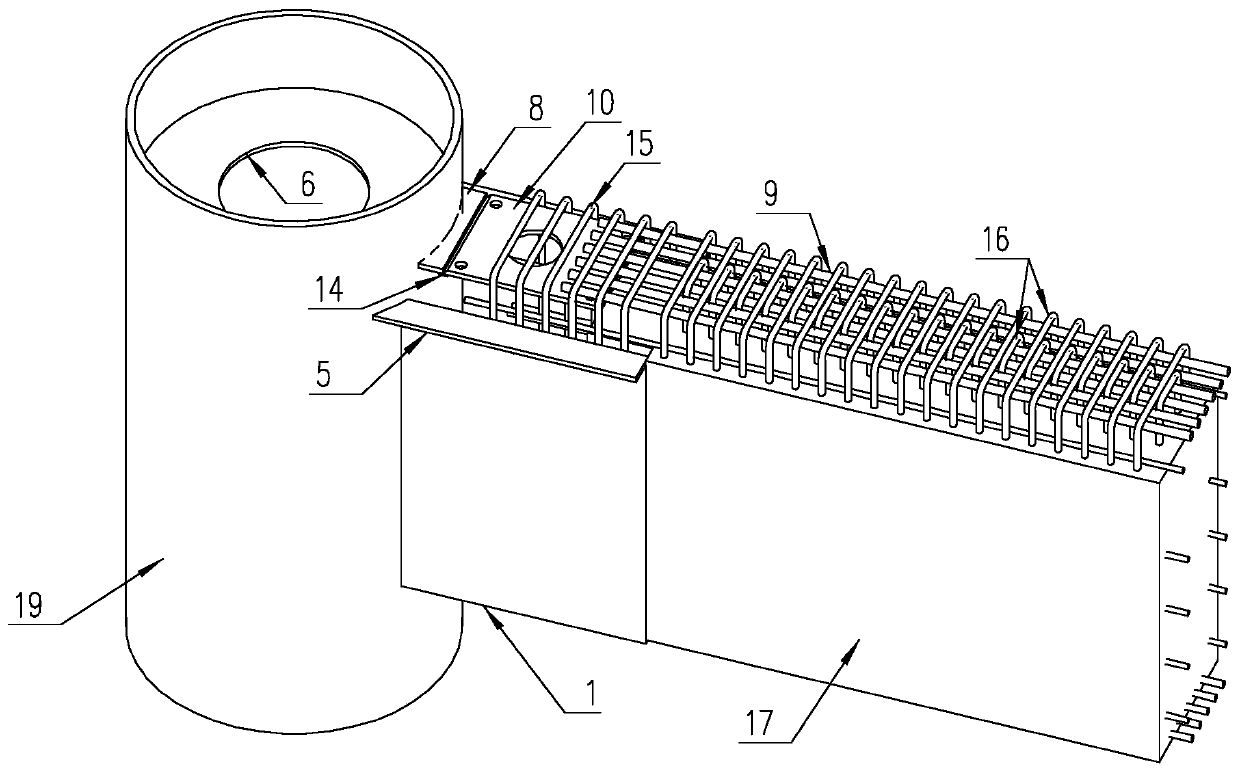

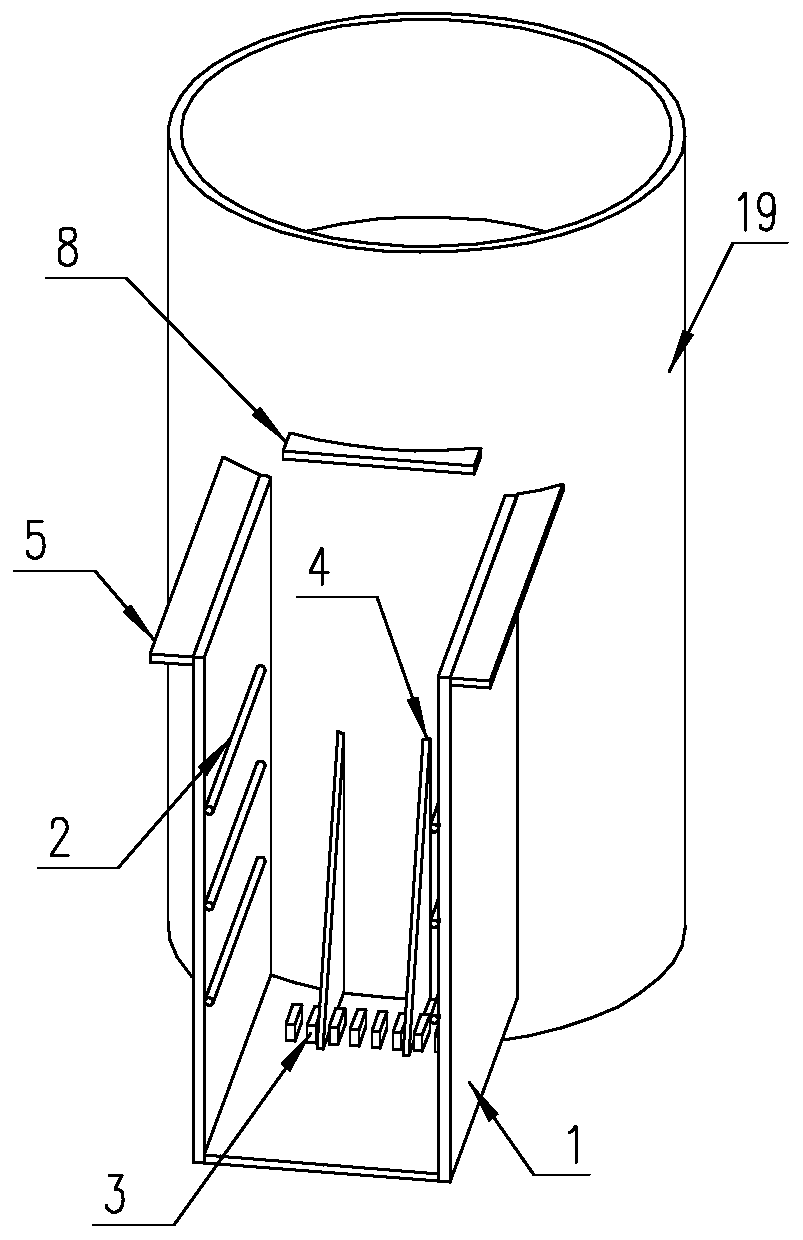

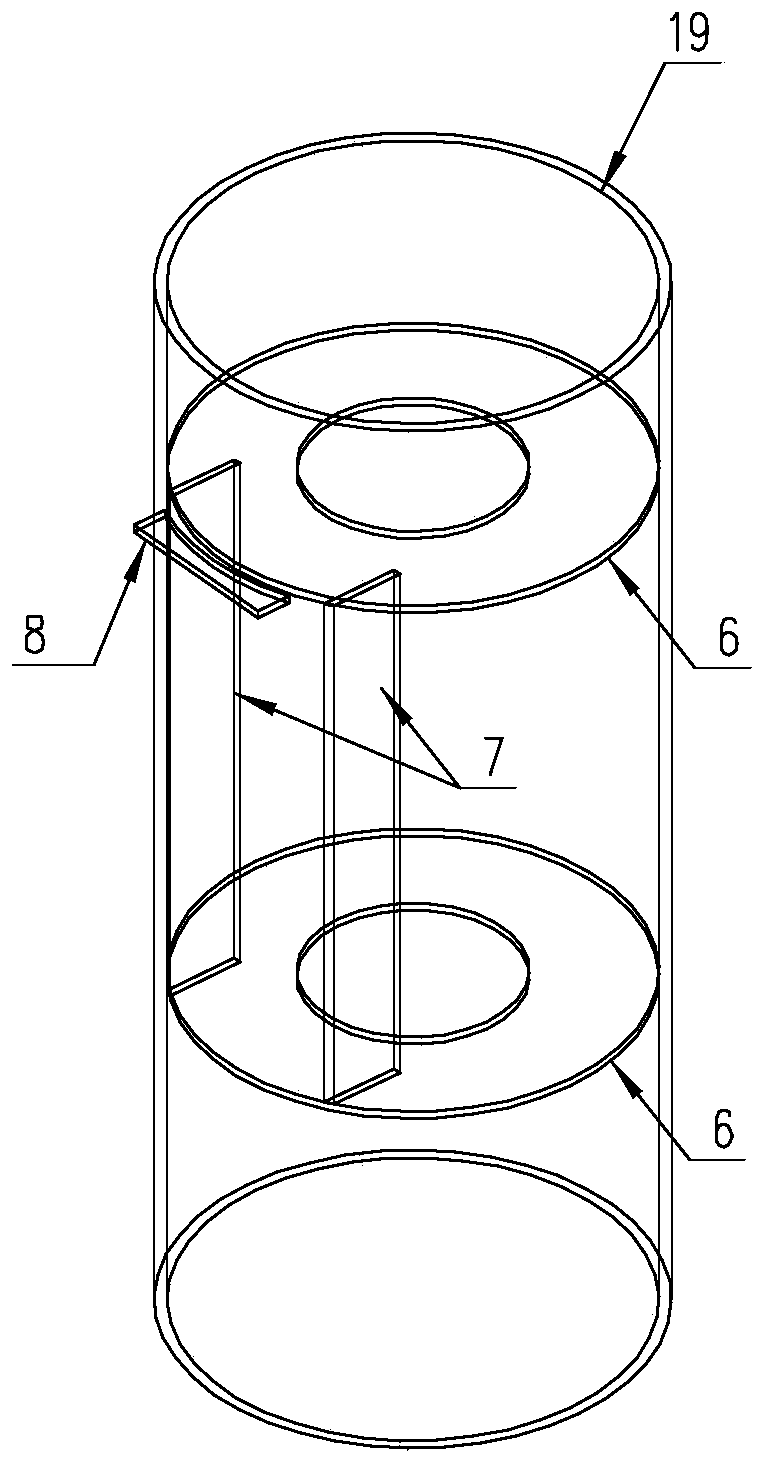

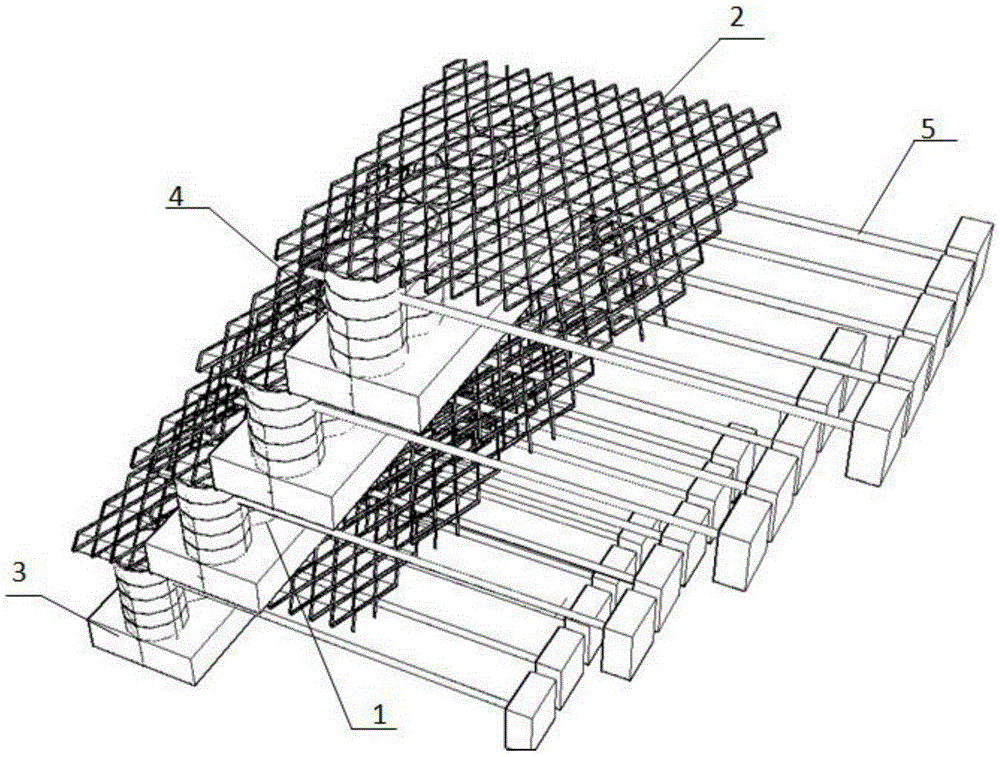

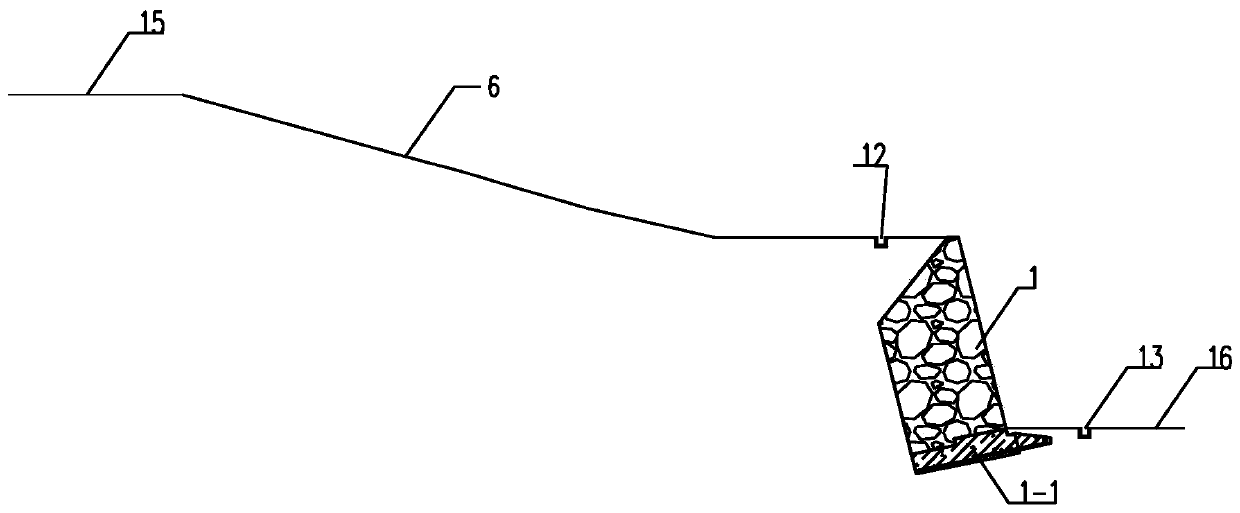

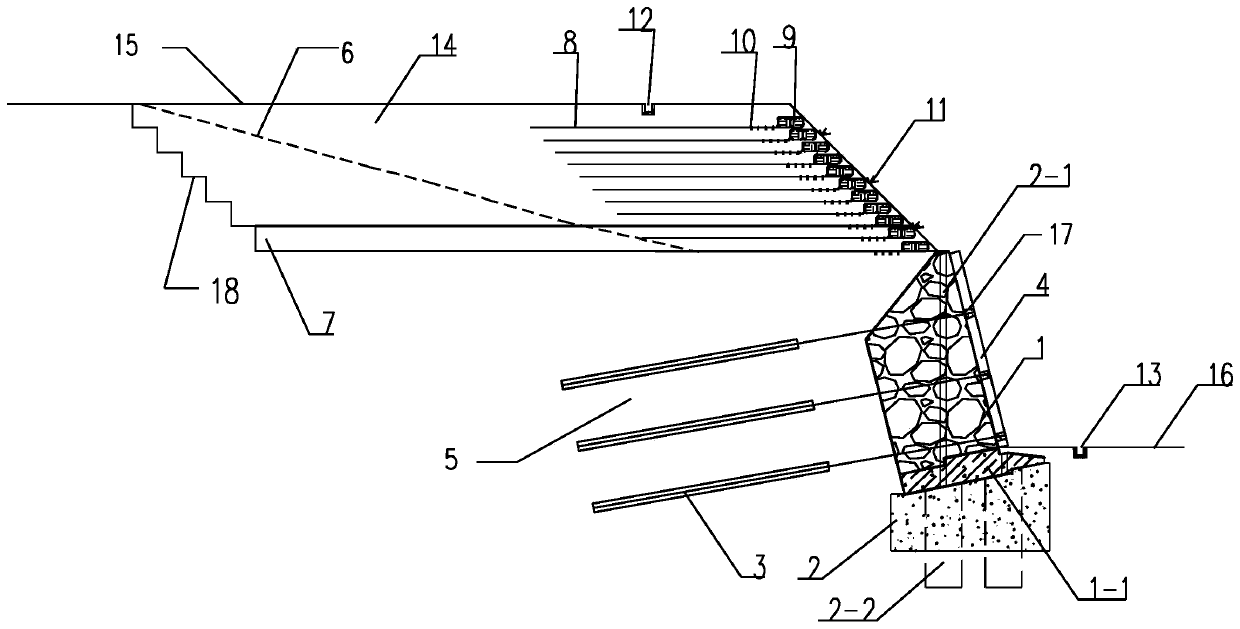

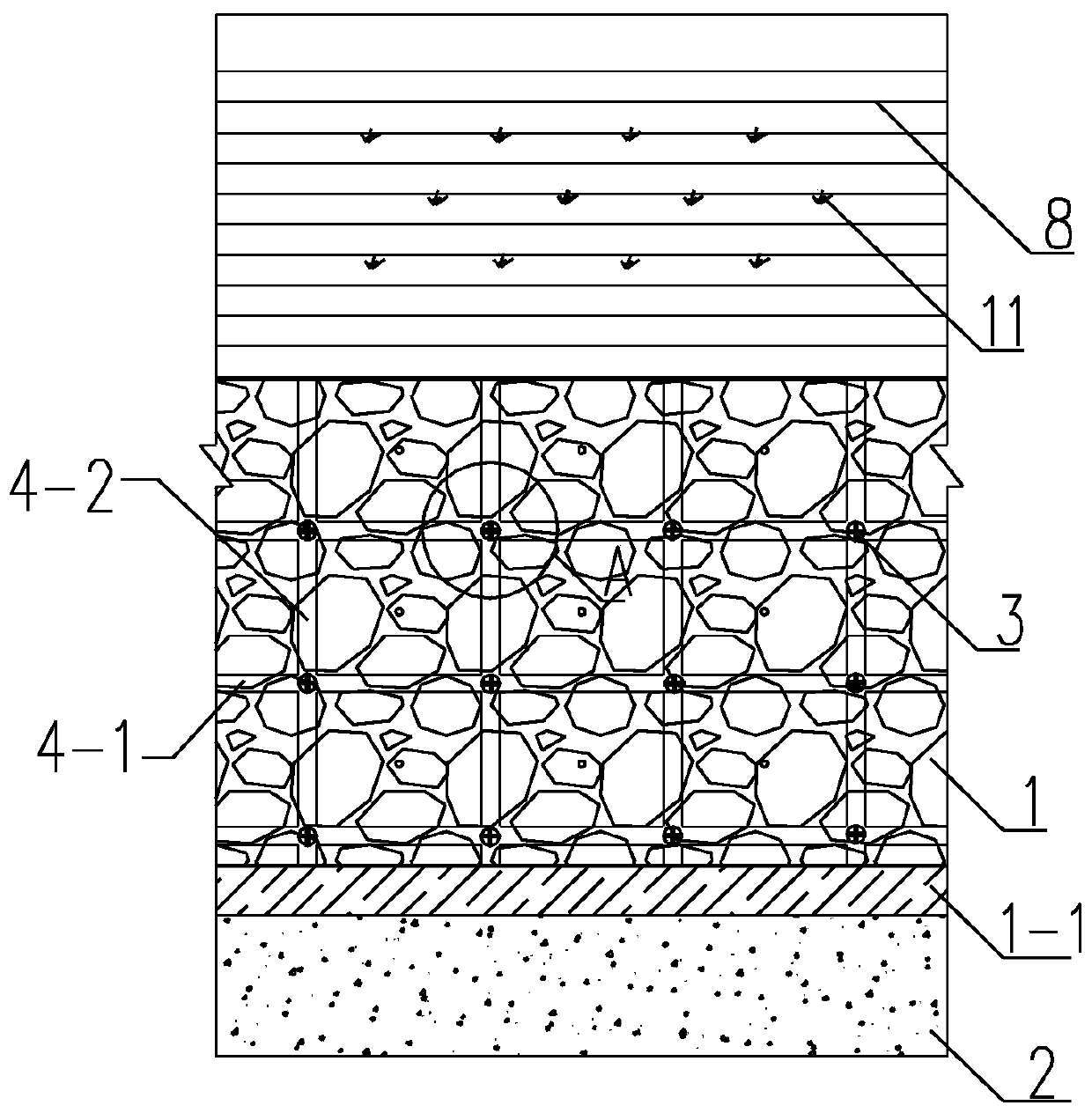

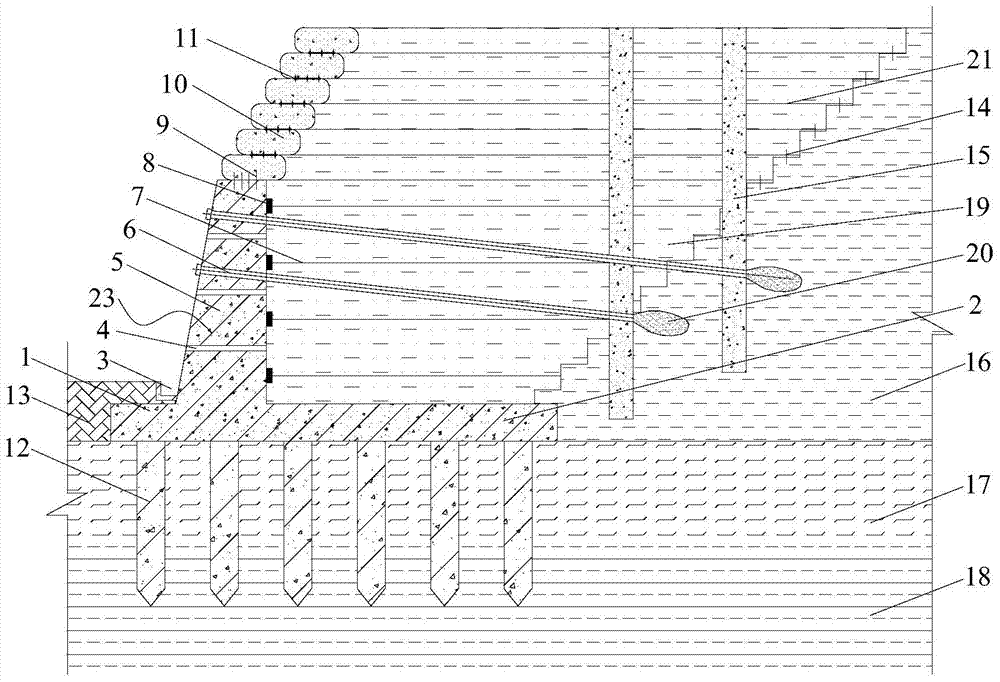

Three-dimensional reinforced rigid-soft composite ecological retaining wall and construction method

ActiveCN103410167AHigh strengthAchieve reorganizationArtificial islandsUnderwater structuresFilling materialsEngineering

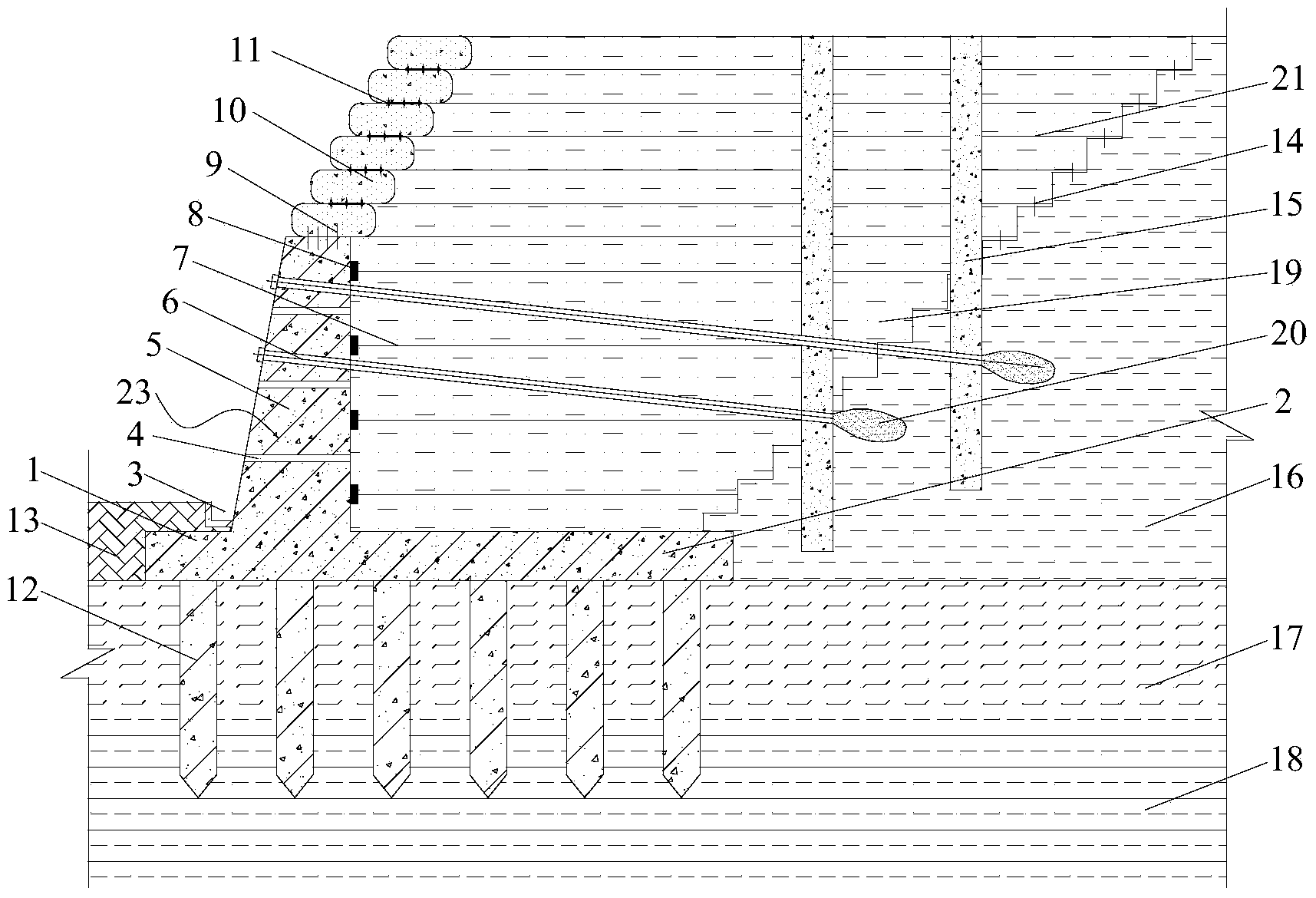

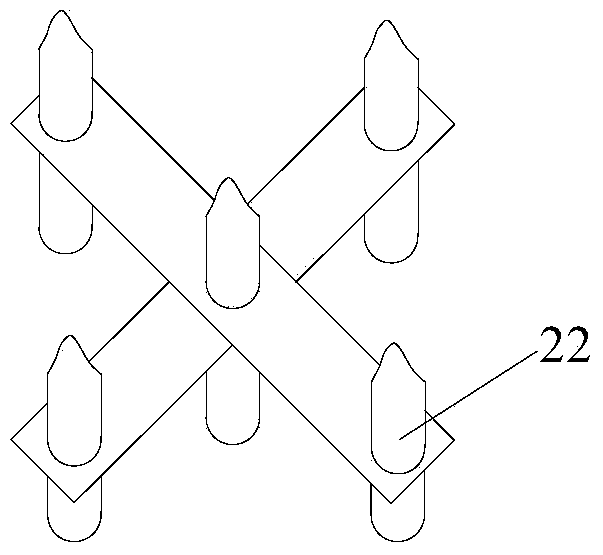

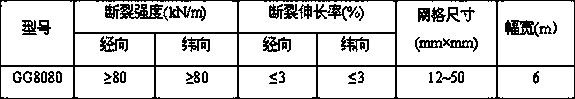

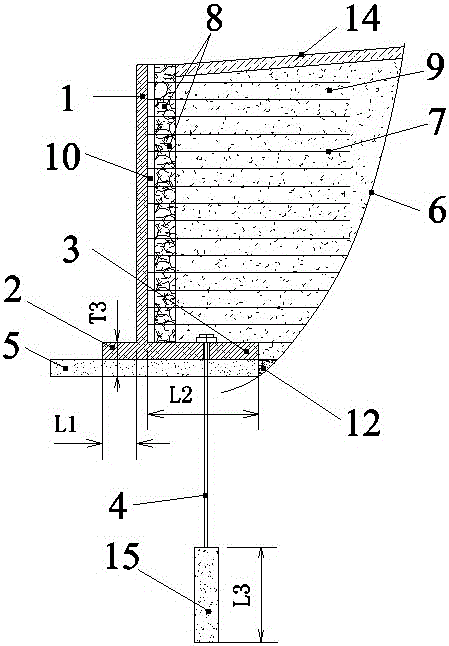

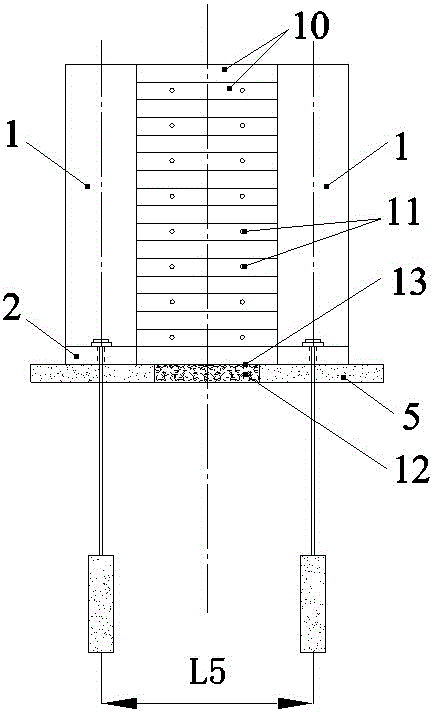

The invention relates to a three-dimensional reinforced rigid-soft composite ecological retaining wall and a construction method. The retaining wall is characterized by comprising an upper portion soft ecological retaining wall body and a lower rigid retaining wall body, wherein the upper portion soft ecological retaining wall body and the lower rigid retaining wall body are connected through anchor bars. All layers of filling materials of the upper portion soft ecological retaining wall body are connected through connecting buckle parts, and water draining pipes, the connecting and fixing ends of horizontal ribbing bodies and inclined tie bars are evenly arranged on the lower rigid retaining wall body. A wall heel of a foundation of the retaining wall extends backwards to the edge of a stable soil body, vertical reinforcing piles are arranged at the bottom of the retaining wall, the horizontal ribbing bodies are laid in the filling materials behind the retaining wall, the wall toe of the retaining wall is filled back with a wall foot pressing soil body, and vertical ribbing bodies are vertically arranged at the connection position between the filling materials behind the retaining wall and an original soil body. The retaining wall structurally combines the advantages of a rigid retaining wall and the advantages of a soft retaining wall, achieves ecological slope protection, reduces pressure of soil behind the retaining wall, enhances structural integrity and has good technical and economical benefits.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

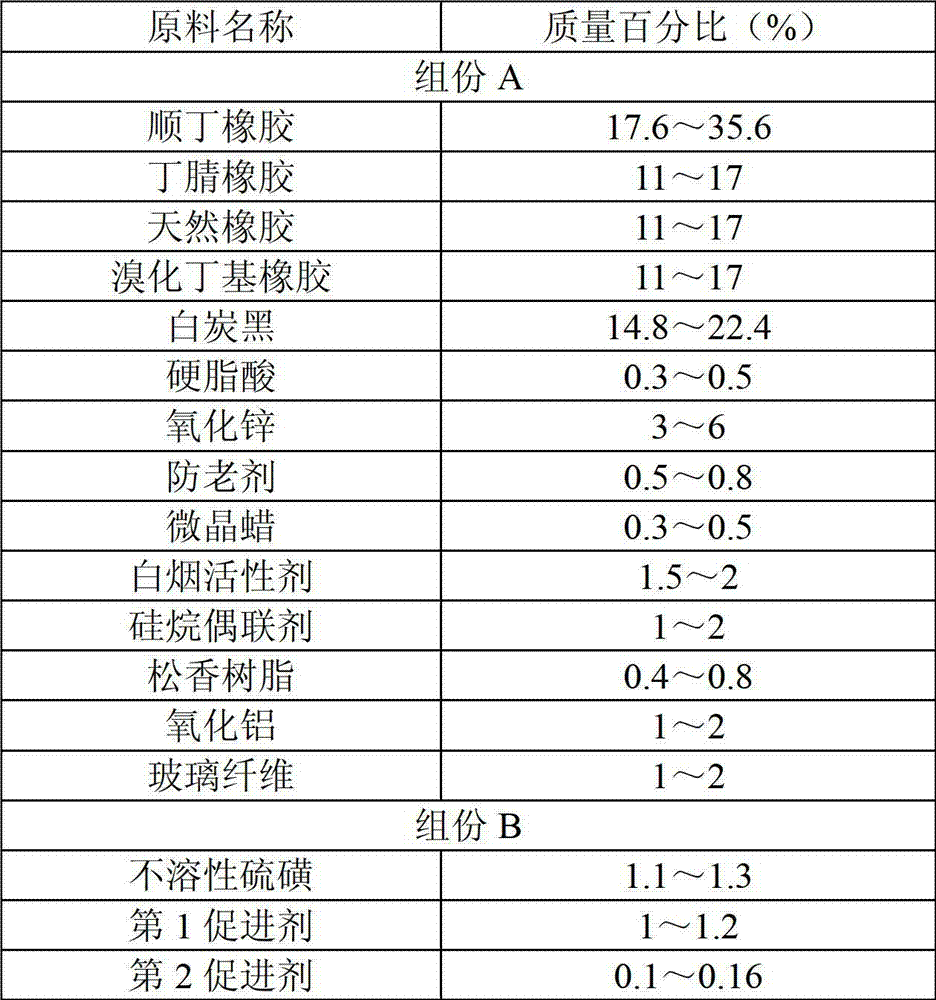

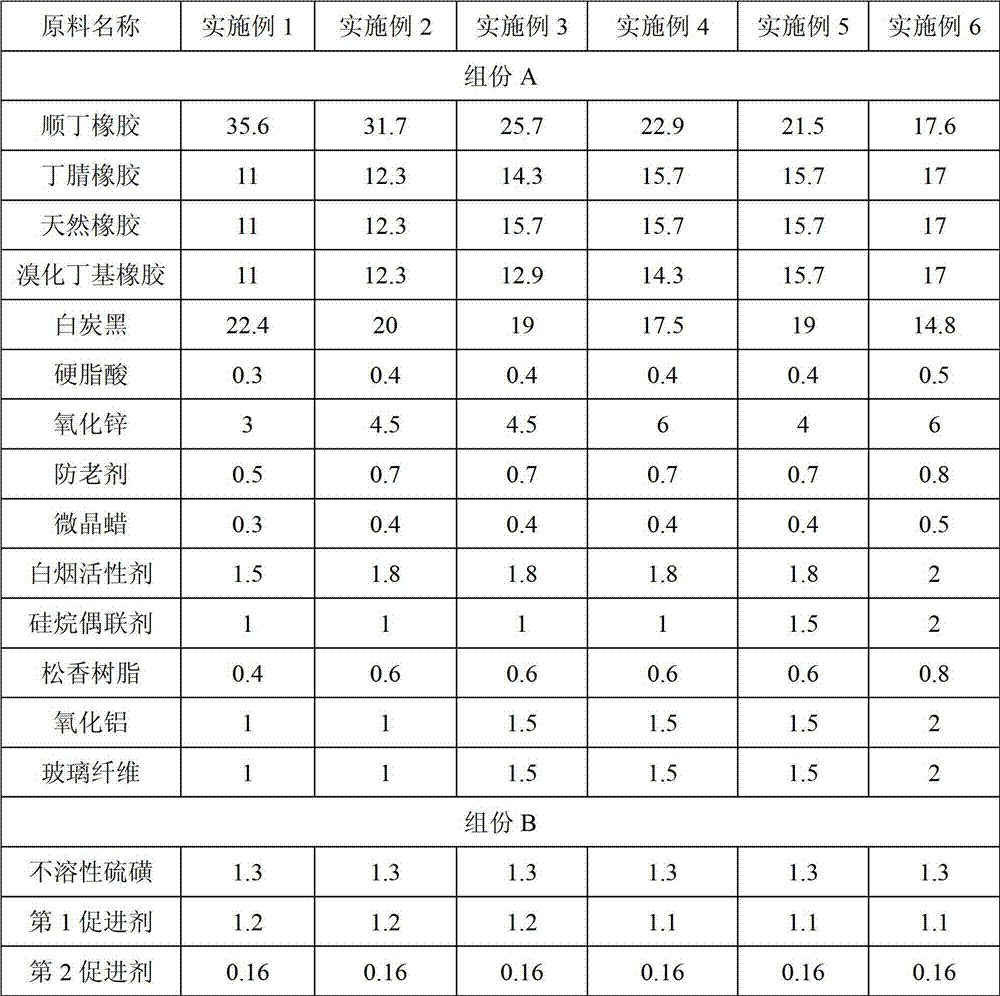

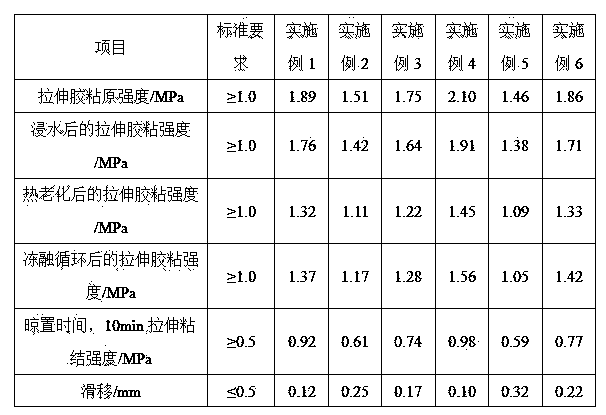

Ice surface anti-slip rubber sports shoe soles and manufacturing method thereof

The invention and relates to a pair of soles and discloses a pair of ice surface anti-slip rubber sports shoe soles which has a good anti-slip effect on road surface interfaces of thin ice, snowfield and tundra and long service life and a manufacturing method thereof. The raw materials of the ice surface anti-slip rubber sports shoe soles include components A and components B, wherein the component A consists of butadiene rubber, nitrile rubber, natural rubber, brominated butyl rubber, white carbon black, stearic acid, zinc oxide, anti-aging agent, microcrystalline wax, white smoke active agent, silane coupling agent, rosin resin, alumina and glass fiber; and the component B consists of insoluble sulfur, a first accelerant, a second accelerant. The manufacturing method comprises the following steps of: weighing the materials, banburying, open milling, dosing, measuring a vulcanization curve and oil-pressure forming.

Owner:ANQING TAIYA SHOES CO LTD

Desulfurization gypsum-based thermal insulation mortar and preparation method thereof

The invention relates to a desulfurization gypsum-based thermal insulation mortar and a preparation method of the mortar, belonging to the technical fields of solid waste comprehensive utilization and building material. The desulfurization gypsum-based thermal insulation mortar comprises the components in parts by weight: 1000 parts of desulfurization gypsum, 3-10 parts of white cement, 350-450 parts of glass beads, 5-15 parts of redispersible latex powder, 1-5 parts of wood fiber, 5-25 parts of sepiolite fiber, 1.5-5 parts of polypropylene (PP) fiber, 1-8 parts of polyvinyl alcohol, 1-5 parts of hydrophobic agent, 0.4-3 parts of retarder, 1-5 parts of water reducing agent and 2-6 parts of thickening agent. The desulfurization gypsum-based thermal insulation mortar is convenient to transport and has very strong thermal insulation performance and fireproof performance.

Owner:上海复培新材料科技有限公司

Low-alkalinity tile glue

The invention discloses a low-alkalinity tile glue, which comprises the following components in parts by weight: 30 to 45 parts of cement, 40 to 60 parts of fine aggregate, 8 to 15 parts of filling material, 0.2 to 0.5 part of water-retaining and thickening agent, 0 to 0.1 part of starch ether, 1 to 3 parts of redispersable latex powder, 0.1 to 0.3 part of water reducer, 0.1 to 0.3 part of retarder, 0.1 to 0.4 part of salt-petering resisting agent, 0.1 to 1.0 part of fiber, and 15 to 22 parts of water. The tile glue has the advantages of low alkalinity, salt-petering resistance, good construction performance, high adhesive strength, cavity and cracking resistance, and slippage resistance.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

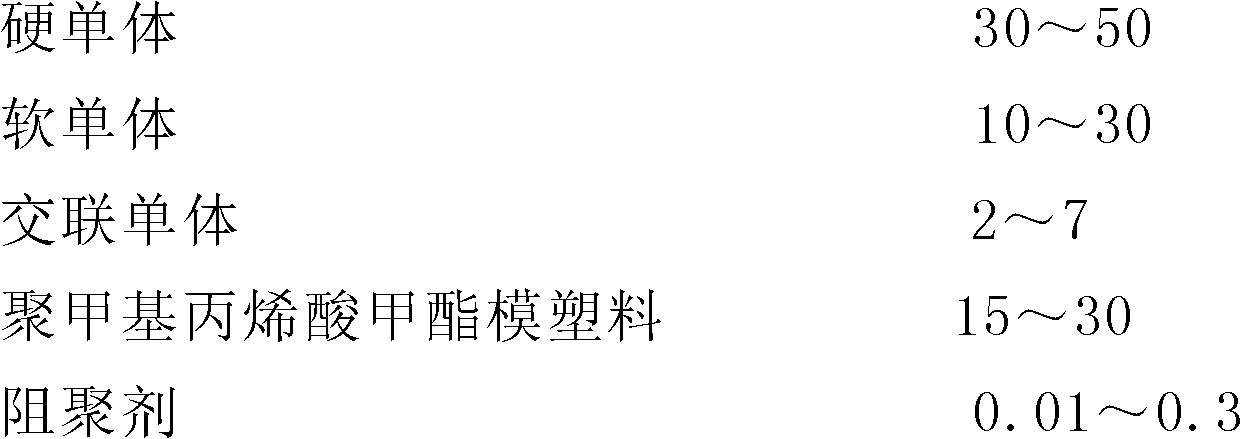

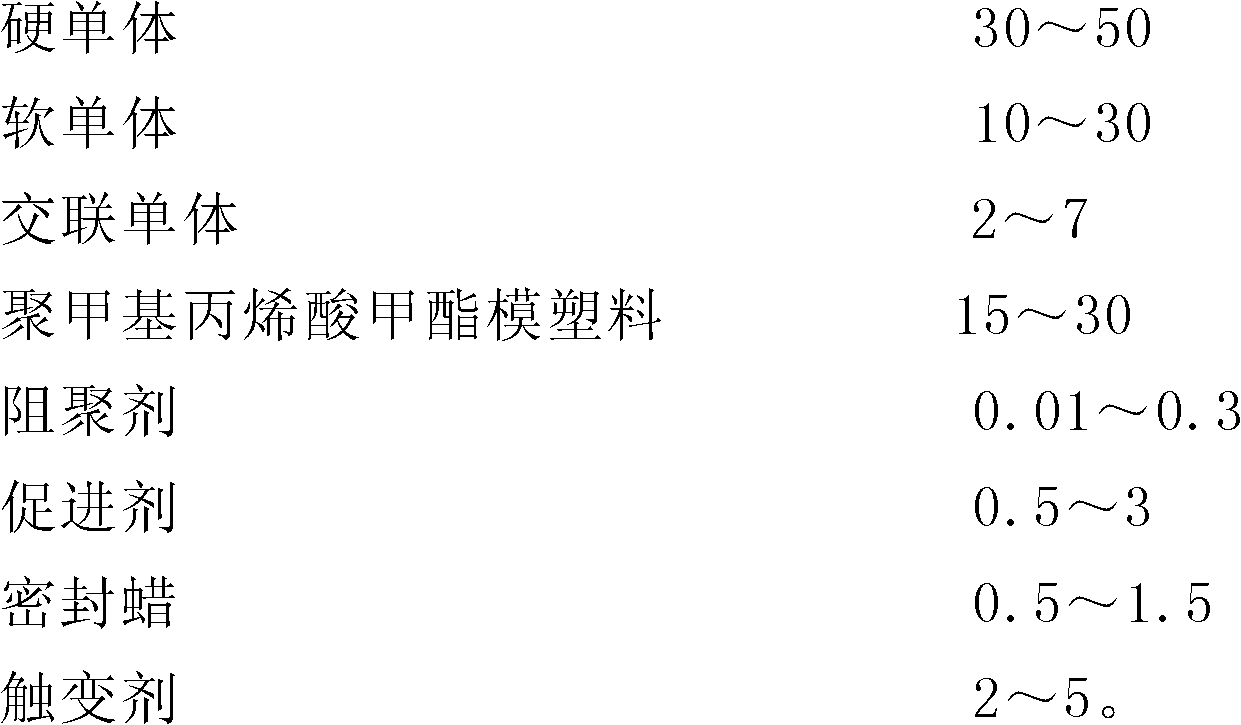

Polymethylmethacrylate waterproof paint and preparation method thereof

The invention relates to a polymethylmethacrylate waterproof paint and a preparation method thereof. The waterproof paint consists of components A and B, wherein the component A is a methacrylic acid resin liquid generated by reaction based on methyl methacrylate (MMA) utilized as a main composition, and the component B is an initiator. When the component A is prepared, a hard monomer, a soft monomer and a cross-linking monomer are put in a reaction kettle and evenly stirred, and then heating is carried out; polymethylmethacrylate moulding plastic is put, and then reaction is carried out for 1-6 hours at the temperature of 70-90 DEG C; cooling is carried out until the temperature is 50-65 DEG C, a polymerization inhibitor, an accelerator, sealing wax and a thixotropic agent are added and evenly stirred; and cooling is carried out until the temperature is 30-45 DEG C, and filtration and packaging are carried out so as to prepare the component A resin liquid. The components A and B are evenly stirred and mixed in a proper proportion, then coated, and finally solidified into a film. The waterproof paint has the characteristics of good strength, good elasticity, low temperature hardness, excellent weather resistance and the like, is simple and convenient for construction, can be solidified rapidly, and can be used for waterproof work of rapid transit railway bridge surfaces and super highway subgrades.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

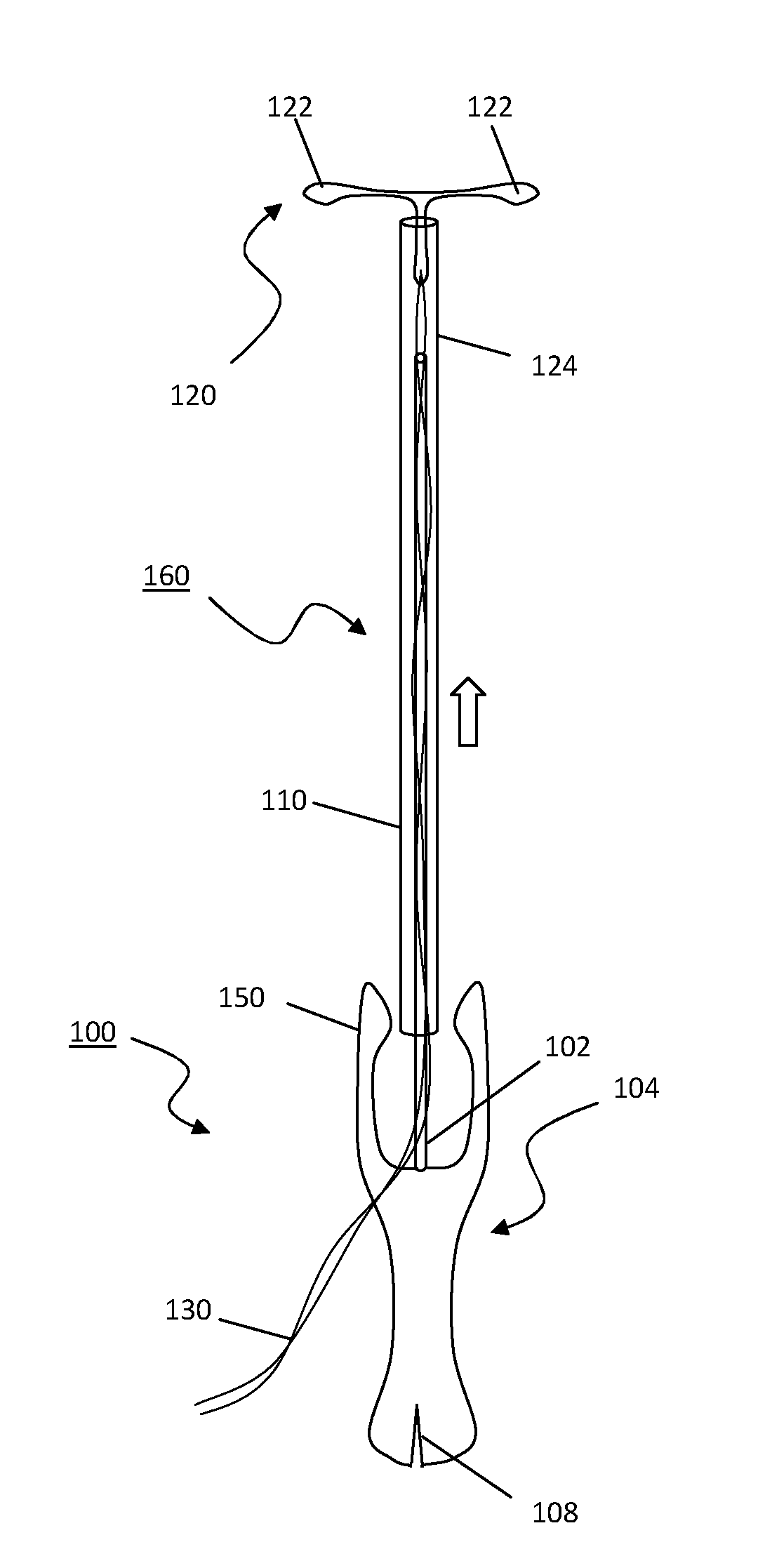

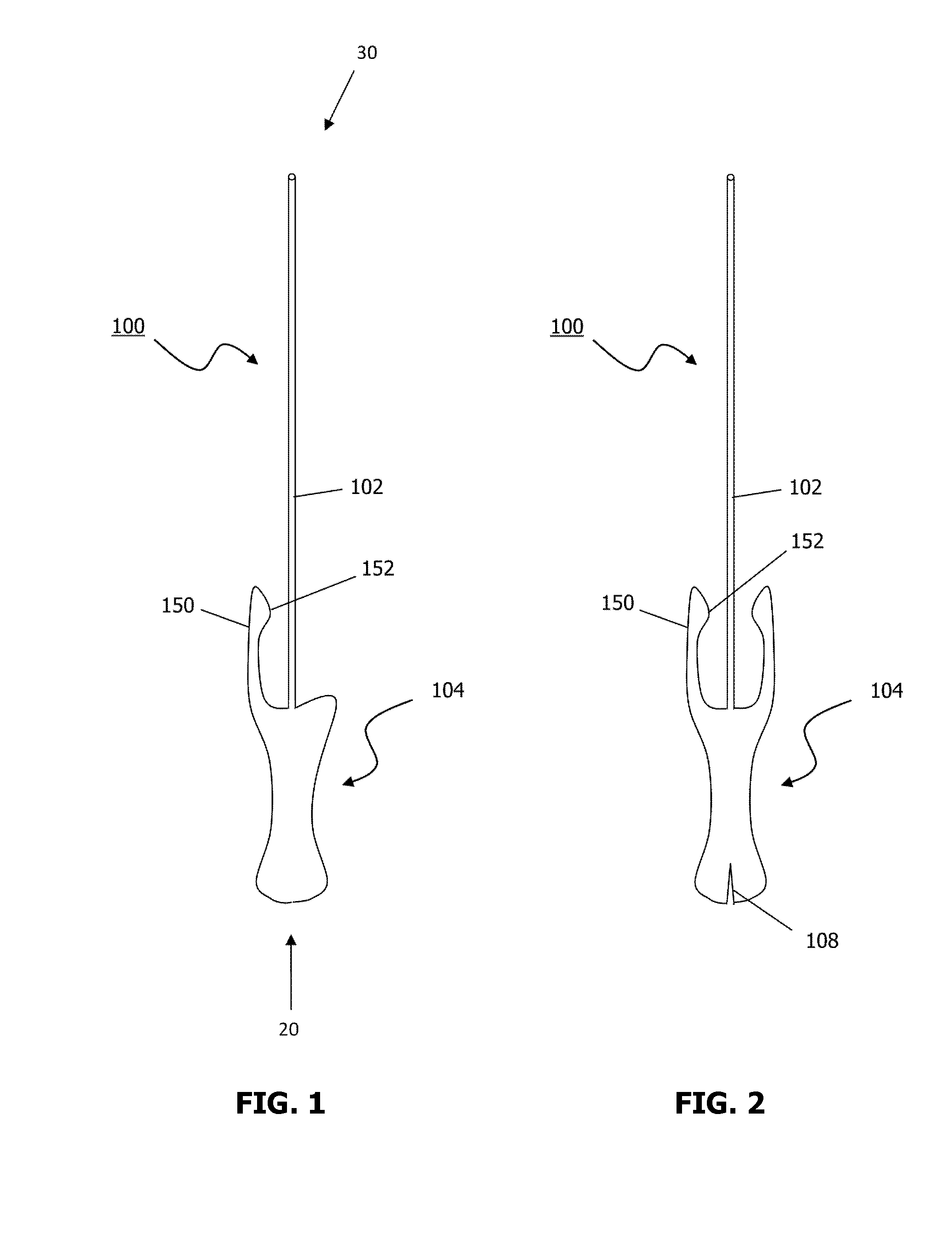

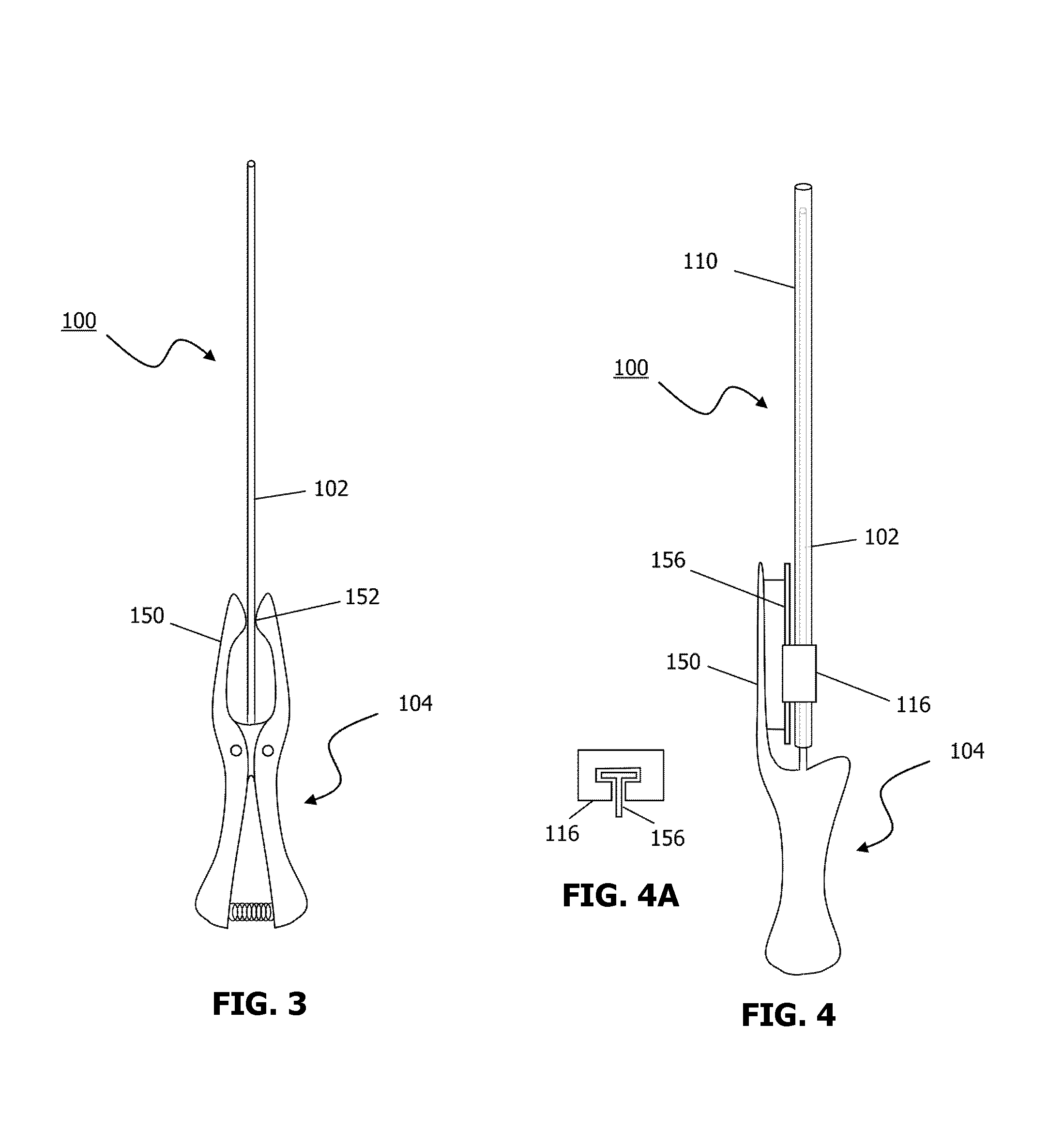

Intra-uterine insertion device

ActiveUS20130213406A1Improve the immunityImprove slip resistanceFemale contraceptivesOcculdersIntra-uterine deviceEngineering

The present invention relates to an inserter (100), having a proximal (20) and distal (30) end, for inserting and positioning an intra-uterine device (IUD) (120), which is attached to a withdrawal string (130), said inserter (100) comprising: a) a plunger (102), having a central longitudinal axis, configured for slidable mounting of a hollow protective tube (110), the distal (30) end of the plunger (102) being configured for dismountable connection with the IUD (120), which protective tube (110) is configured to slidably cover the IUD (120); b) a handle (104), which is attached to the proximal (20) end of the plunger (102); and c) a longitudinal member (150) that forms part of the handle (104), which extends in the distal (30) direction with respect to the plunger (102), which longitudinal member (150) contains a friction contact surface (152) against which the protective tube (110) can frictionally engage, wherein the frictional engagement of the friction contact surface (152) against the protective tube (110) is manually actuatable and wherein the frictional engagement of the friction contact surface (152) against the protective tube (110) increases resistance to sliding of the protective tube (110) relative to the plunger (102).

Owner:ODYSSEA PHARMA S P R L

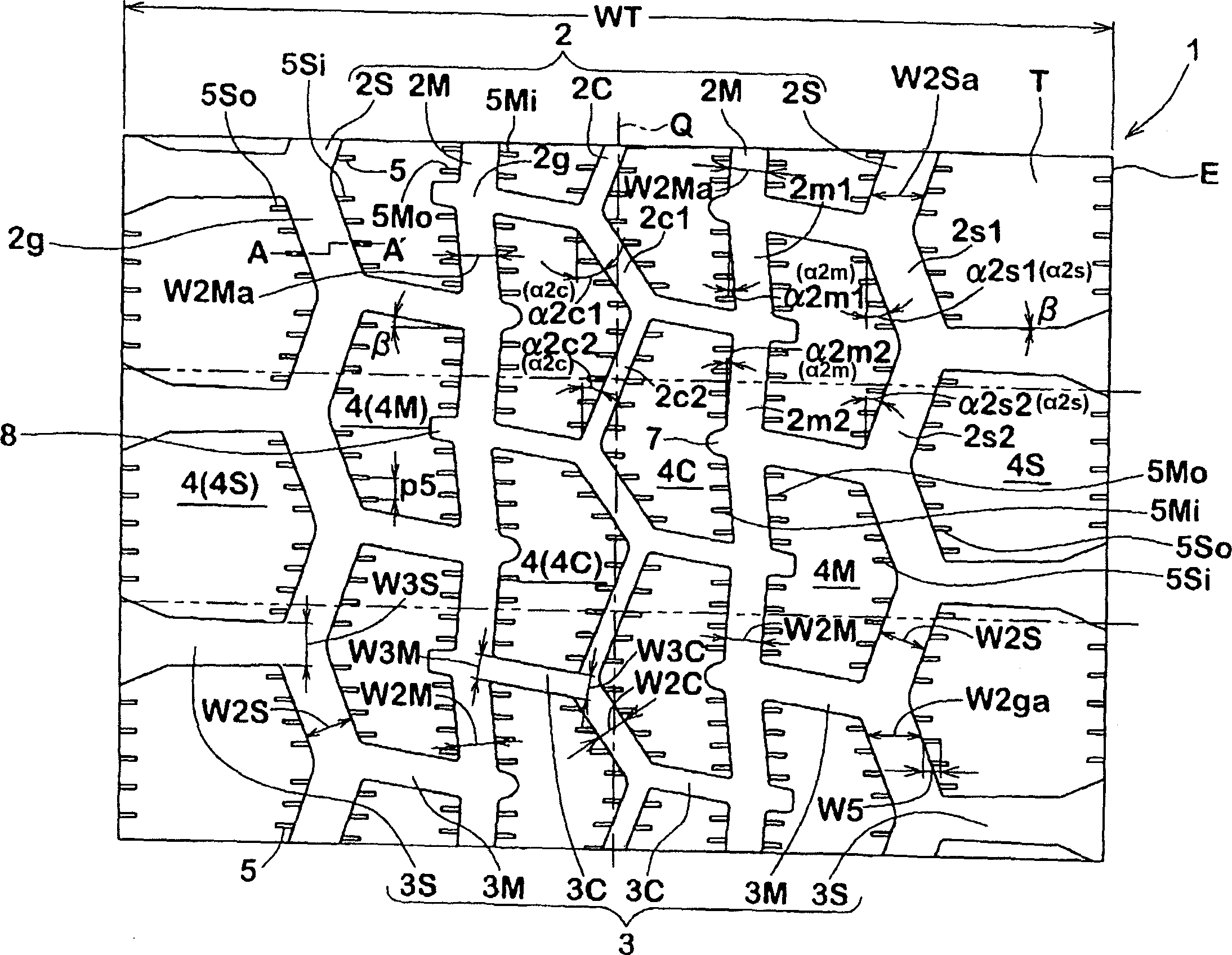

Heavy-load pneumatic tire

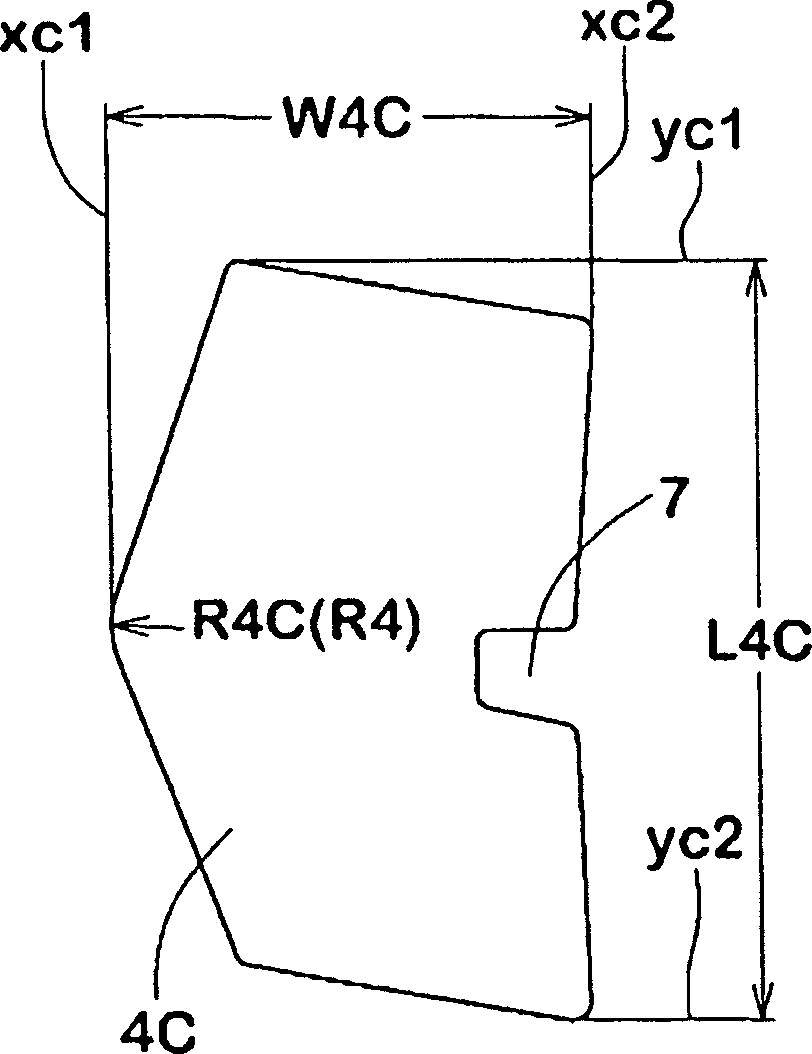

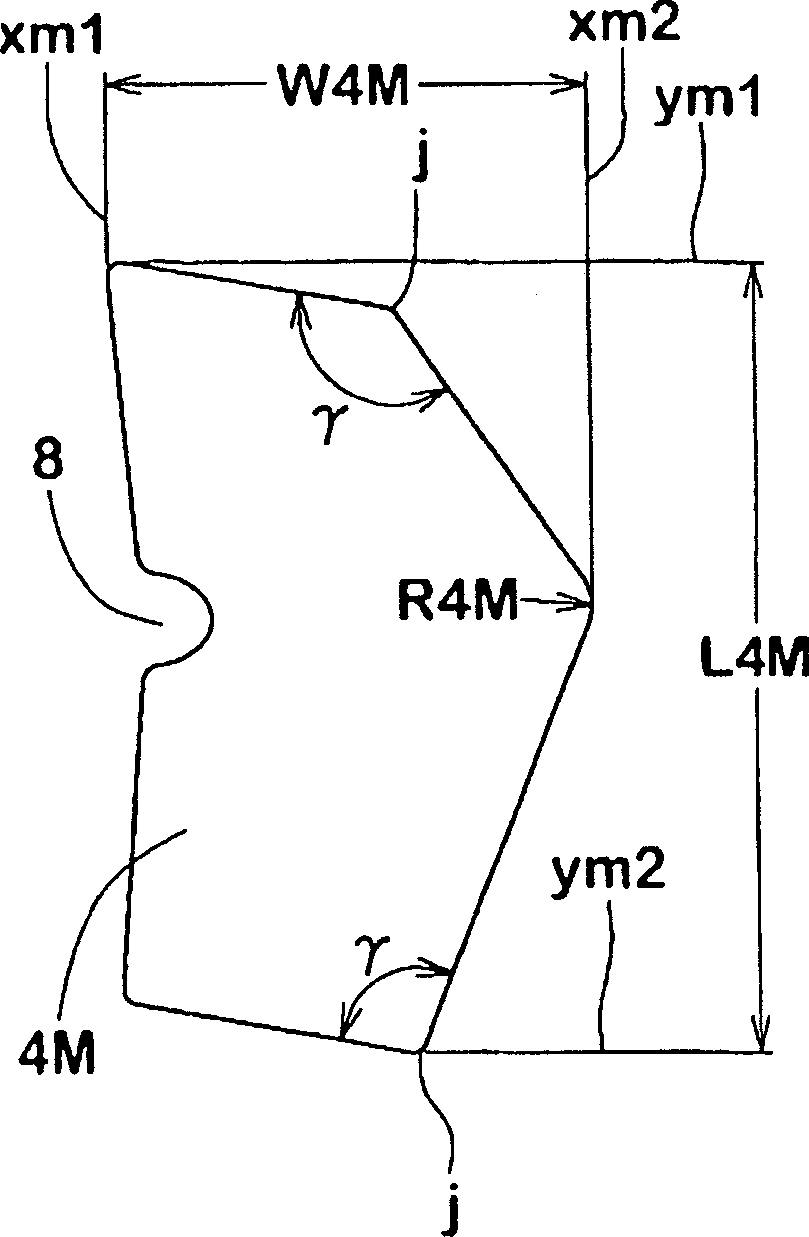

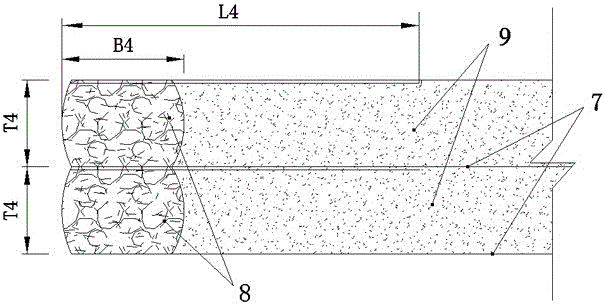

To provide a tread pattern of a pneumatic tire for heavy load enhancing both low noise performance and on-snow performance. Longitudinal length L4C of a central block, longitudinal length L4M of an intermediate block and longitudinal length L4S of an outer block, i.e., circumferential distances of respective tires between the most projecting end points on both sides of a tire circumferential direction of the central, intermediate and outer blocks (4) are defined; and lateral length W4C of the central block, lateral length W4M of the intermediate block and lateral length W4S of the outer block, i.e., tire axial distances between the most projective terminals at both sides in a tire axial direction of the respective central, intermediate and outer blocks (4) are defined. A longitudinal length ratio of the respective blocks is made to (L4S / W4S)<(L4M / W4M)<(L4c / W4C), 1.50 B60C 11 / 117 4 15 2 2006 / 7 / 31 1907738 2007 / 2 / 7 100473547 2009 / 4 / 1 2009 / 4 / 1 2009 / 4 / 1 Sumitomo Rubber Industries, Ltd. Japan Takahashi Nobugo xu qian luo yunpo 11227 Japan 2005 / 8 / 4 2005-226922

Owner:SUMITOMO RUBBER IND LTD

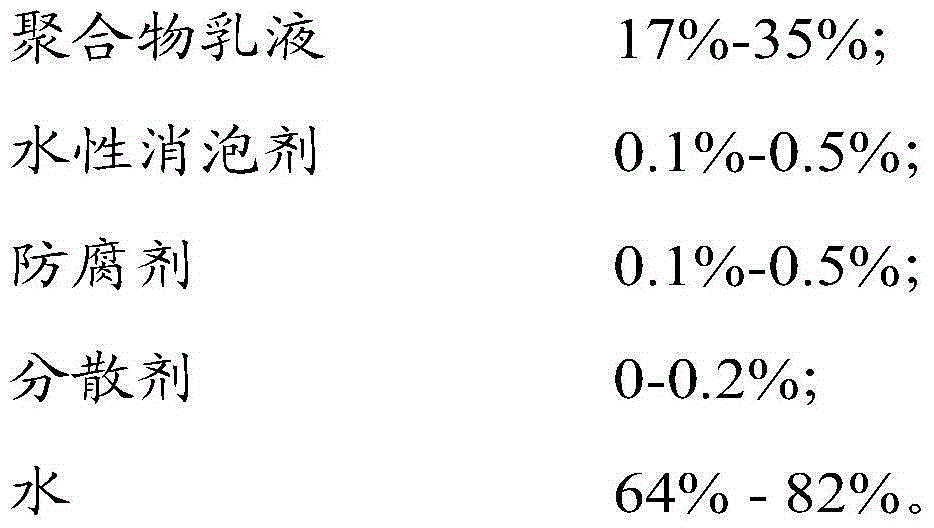

Adhesion agent as well as preparation method and application thereof

InactiveCN104446251APrevent peelingCounteract and absorb deformation stressWater basedMaterials science

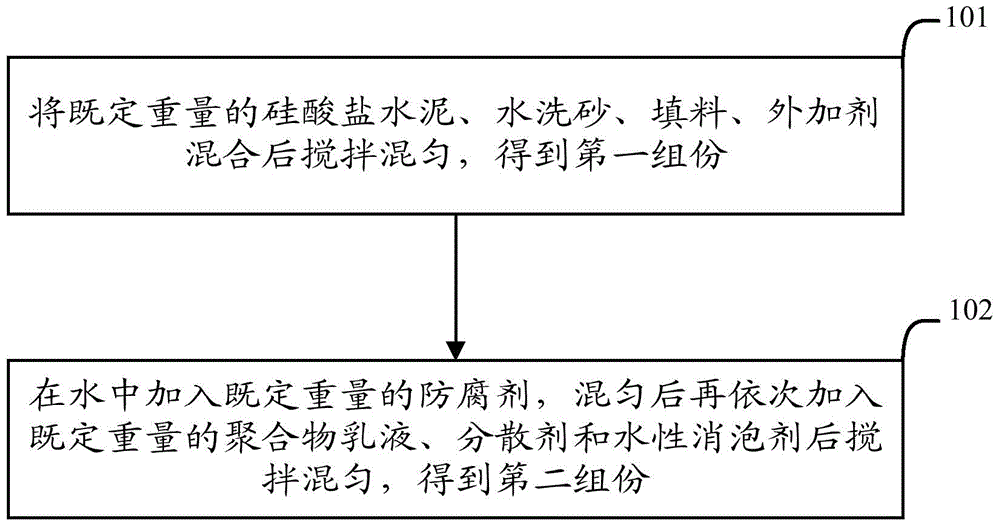

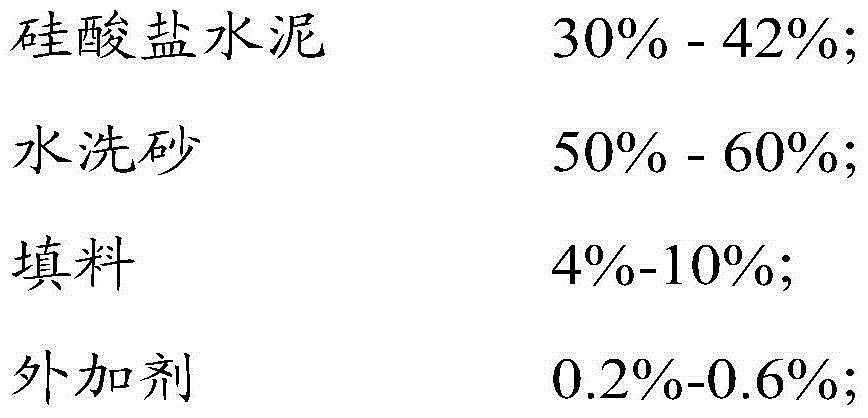

The invention provides an adhesion agent as well as a preparation method and application thereof, and relates to the technical field of building materials. Raw material components of the adhesion agent comprise a first component and a second component, wherein the first component comprises raw materials in percentage by weight: 30-42% of Portland cement, 50-60% of washed sand, 4-10% of stuffing and 0.2-0.6% of additives; the second component comprises raw materials in percentage by weight: 17-35% of polymer emulsion, 0.1-0.5% of water-based defoamer, 0.1-0.5% of corrosion remover, 0-0.2% of dispersing agents and 64-82% of water. The adhesion agent has the advantages of high adhesive strength, good water resistance, good heat resistance, good weather resistance, good vertical-flowing resistance, good anti-sliding performance, low cost and the like.

Owner:JIUZHU ENERGY SAVING TECH TIANJIN

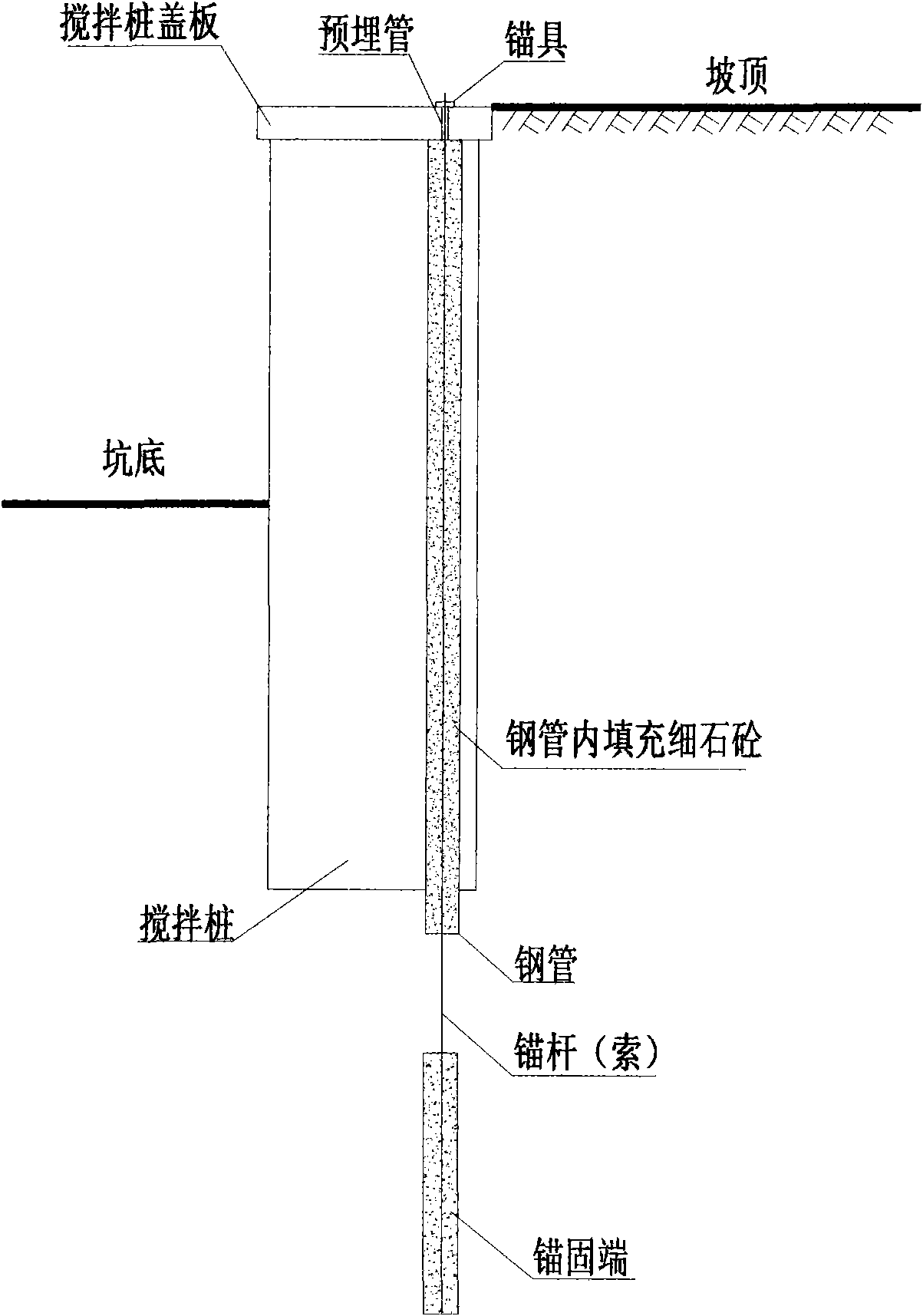

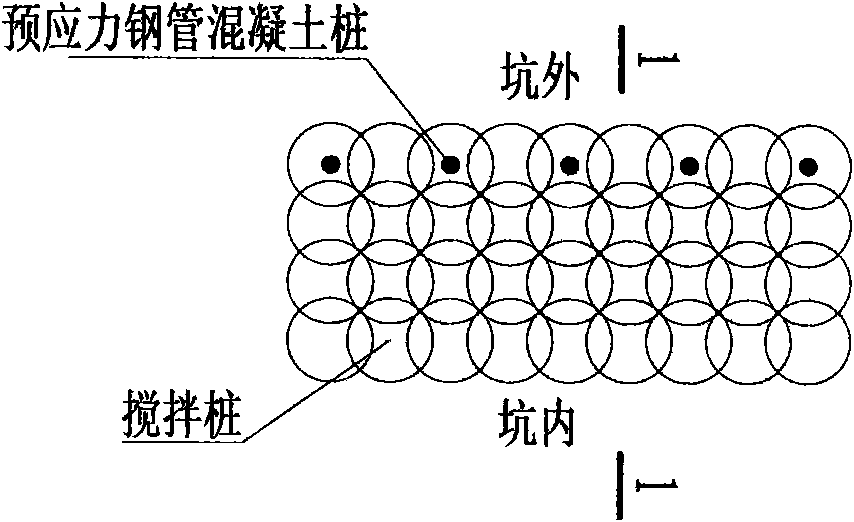

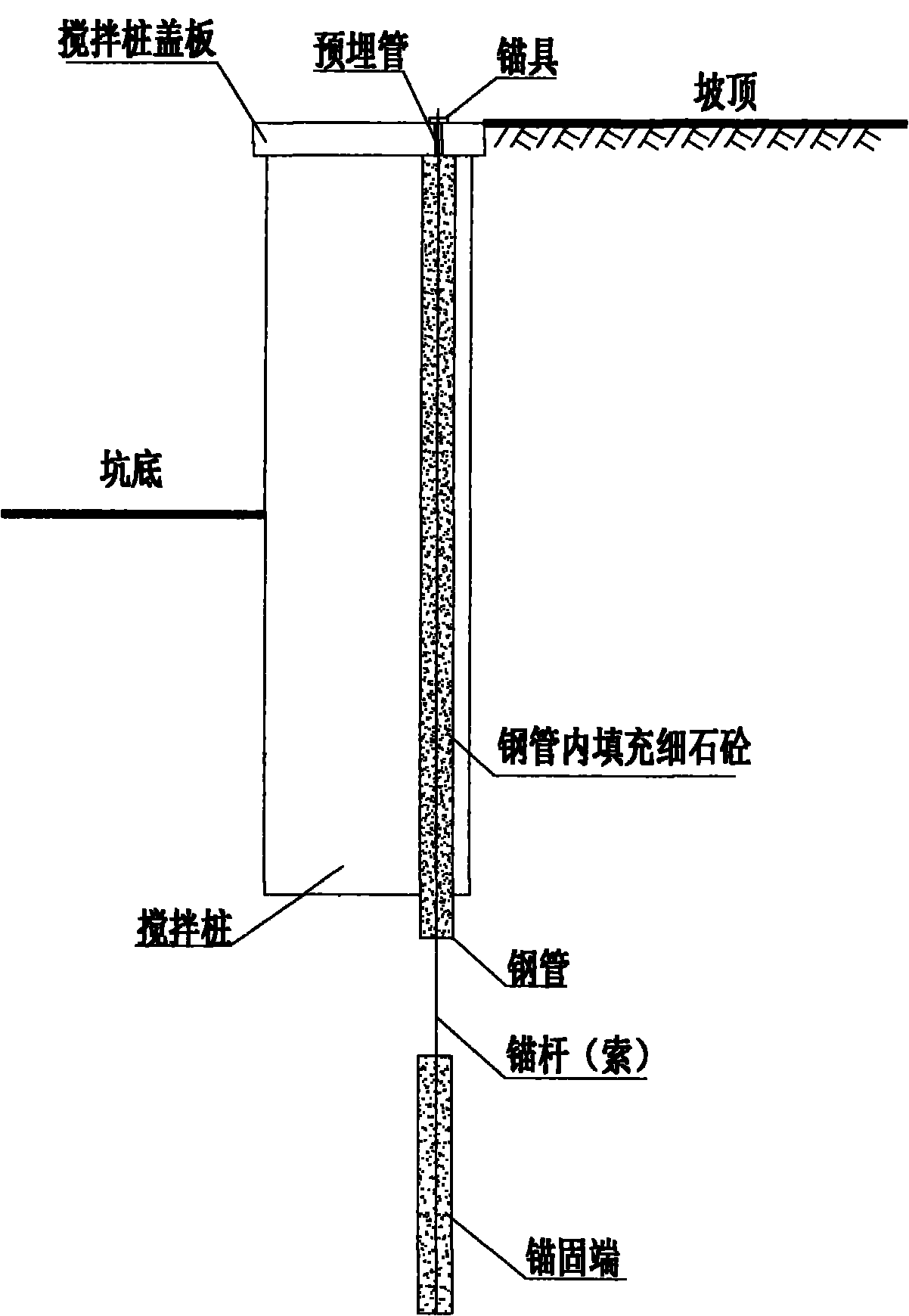

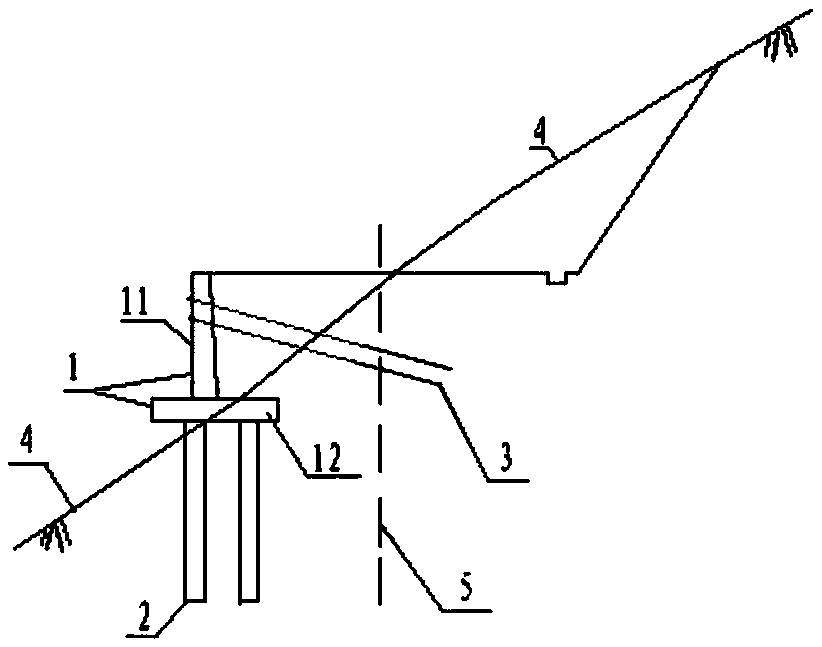

Deep mixing pile-micro pre-stressed steel pipe concrete pile-vertical anchor rod composite foundation pit support method

InactiveCN101851925AImprove overturning resistanceImprove slip resistanceExcavationsBulkheads/pilesLow noisePre stress

The invention provides a deep mixing pile-micro pre-stressed steel pipe concrete pile-vertical anchor rod composite foundation pit support method. The method comprises the following steps: (1) constructing the deep mixing pile; (2) grouting at an anchoring end; and (3) forming the micro pre-stressed steel pipe concrete pile. The method has the advantages that as the deep mixing pile is equipped with the micro pre-stressed steel pipe pile and an anchor rod or an anchor rope, the bending and shearing bearing capacity thereof is improved; the antidumping and anti-slip capability of the wall body of the mixing pile is improved under the condition of not exceeding a land red line; and meanwhile the combined support method has the advantages of short construction period, low noise, no pollution and no soil squeezing and is very beneficial to environmental protection during the construction process, thus being a novel combined support member and a method which are worth to be popularized and applied.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

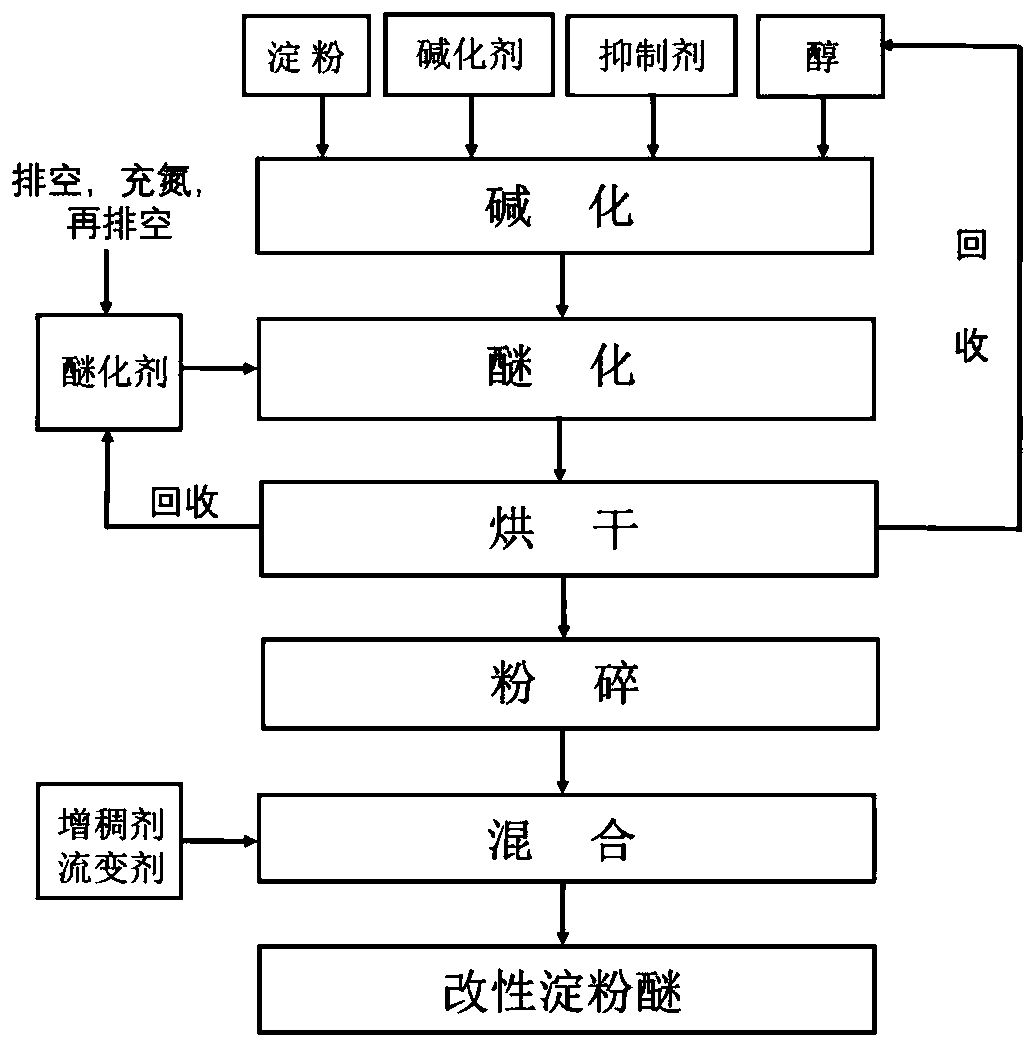

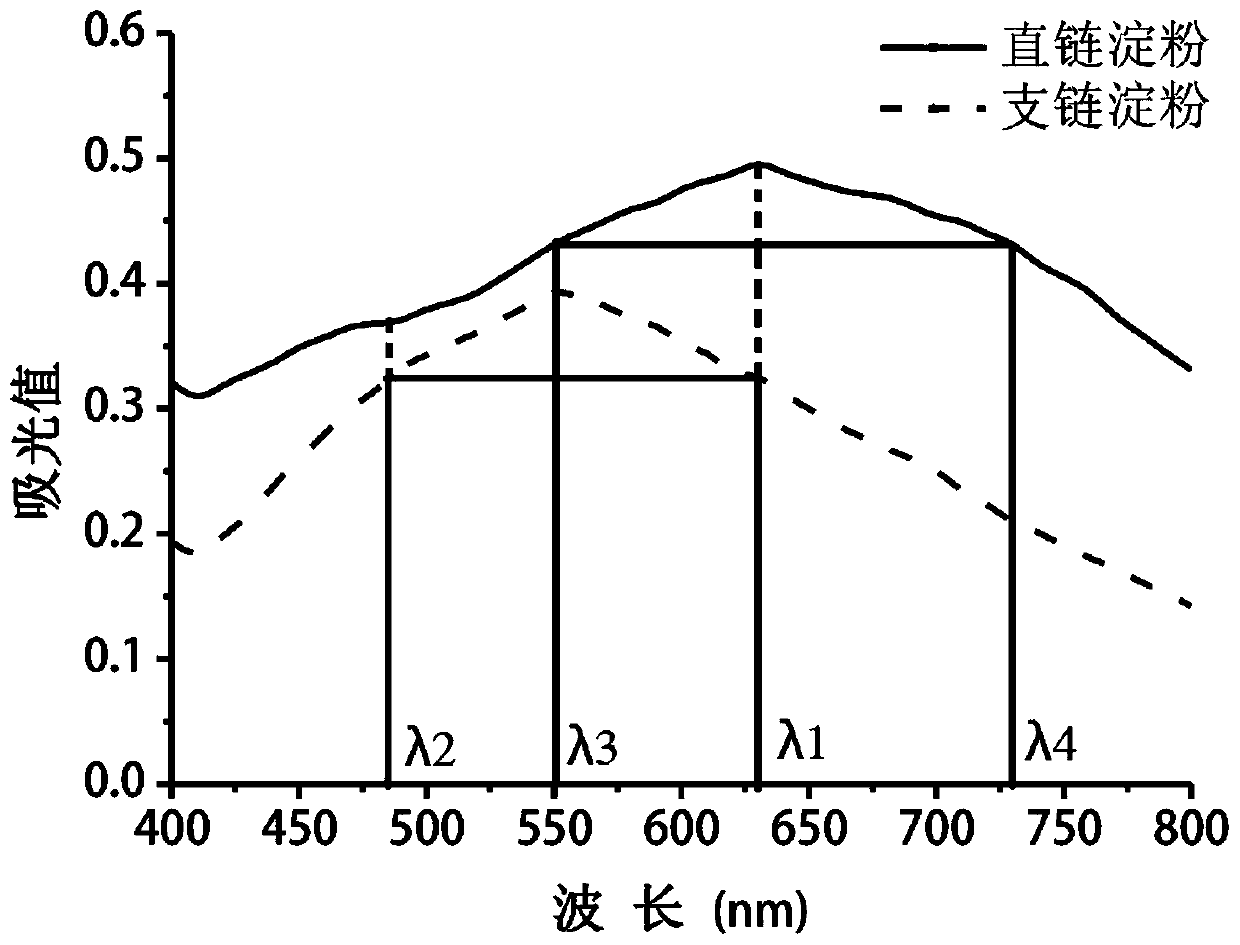

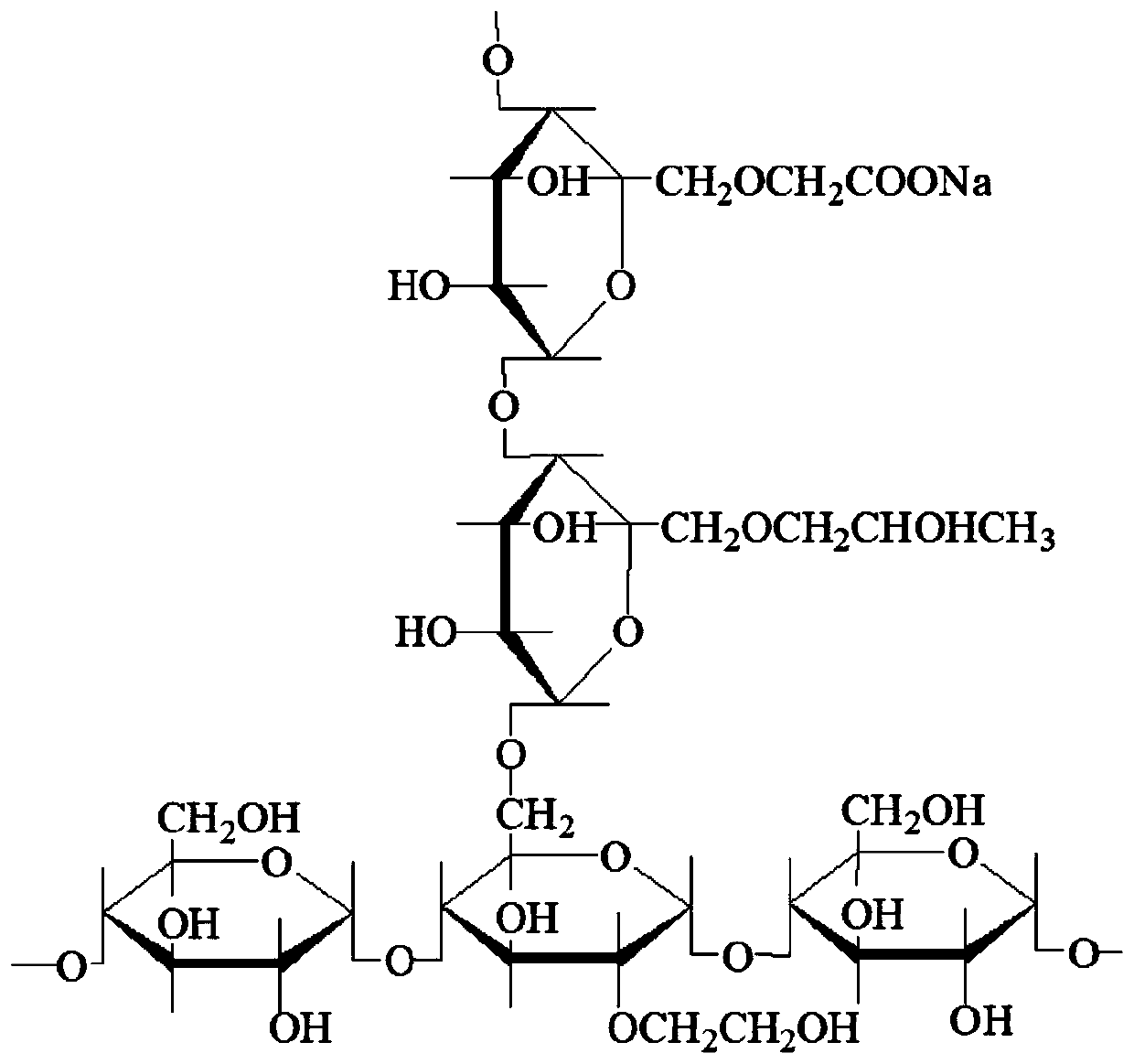

Preparation method of modified starch ether for improving slip performance of ceramic tile glue

ActiveCN110590966AImprove sliding performanceImprove slip resistanceStarch derivtive adhesivesMacromolecular adhesive additivesChemical treatmentEther

The invention relates to the technical field of building additives, in particular to a preparation method of a modified starch ether for improving slip performance of ceramic tile glue. The preparation method comprises the following steps: carrying out one-step etherification chemical treatment modification on starch to obtain starch ether, and carrying out physical modification treatment. According to the preparation method, the complex operation of multi-step etherification in existing modified starch ether preparation process is changed, a starch ether modified product with better performance can be obtained only by one-step simultaneous etherification, and when the obtained product is used for the ceramic tile glue, the slippage performance of ceramic tile glue can be remarkably improved because of adoption of the physical modification treatment; meanwhile, compared with the prior art, the operation conditions of one-step simultaneous etherification treatment are obviously different.

Owner:SHANDONG YITENG NEW MATERIAL CO LTD

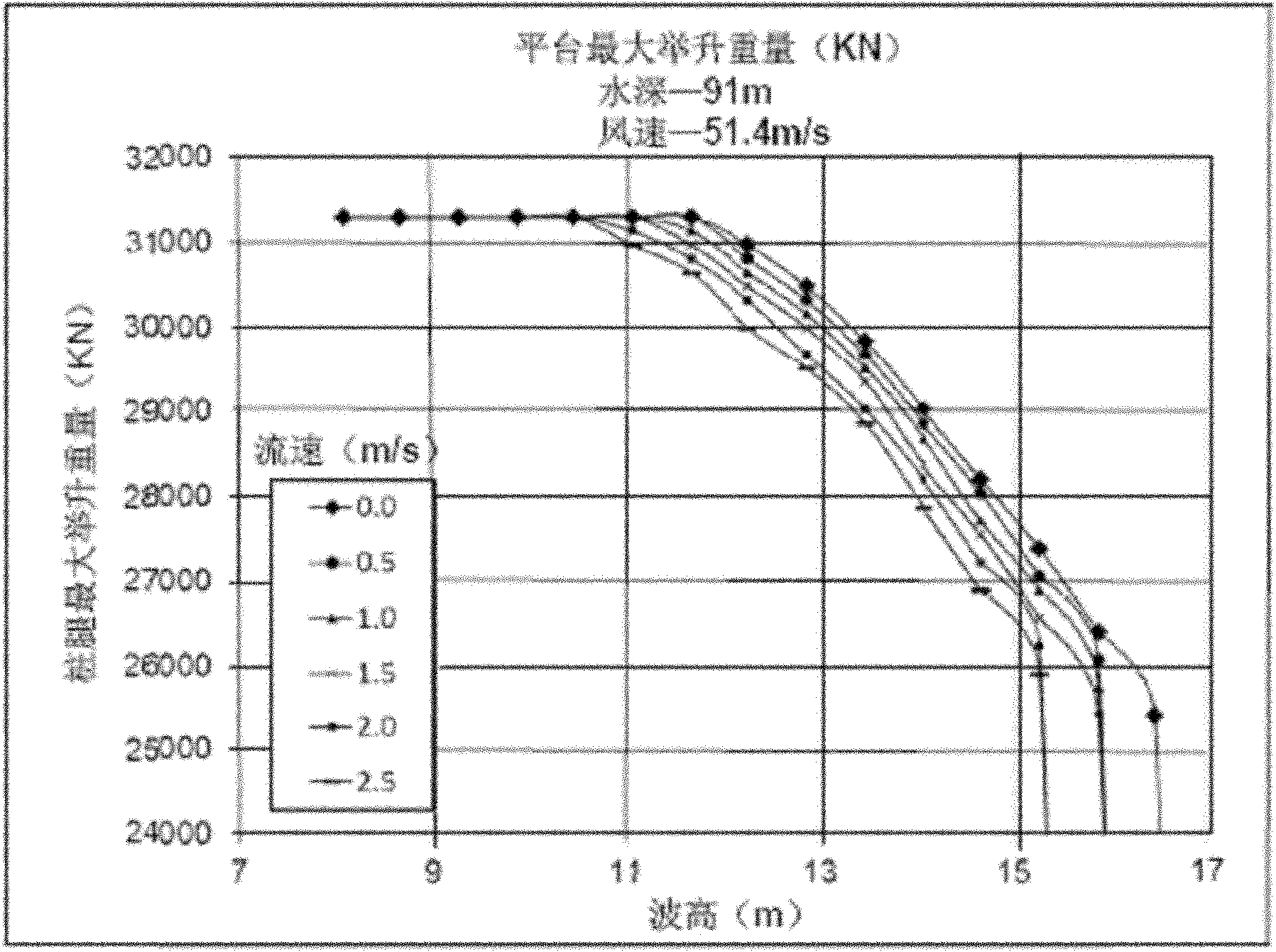

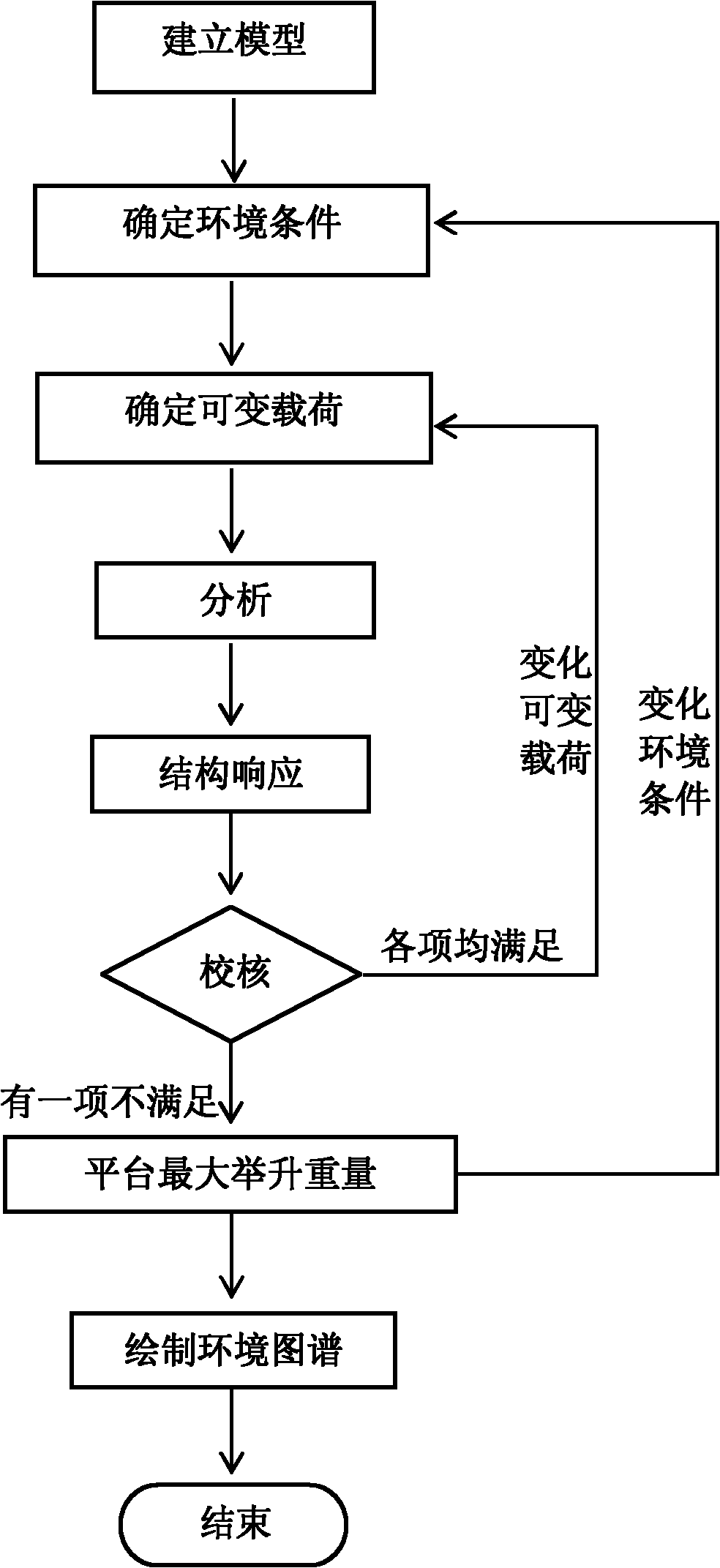

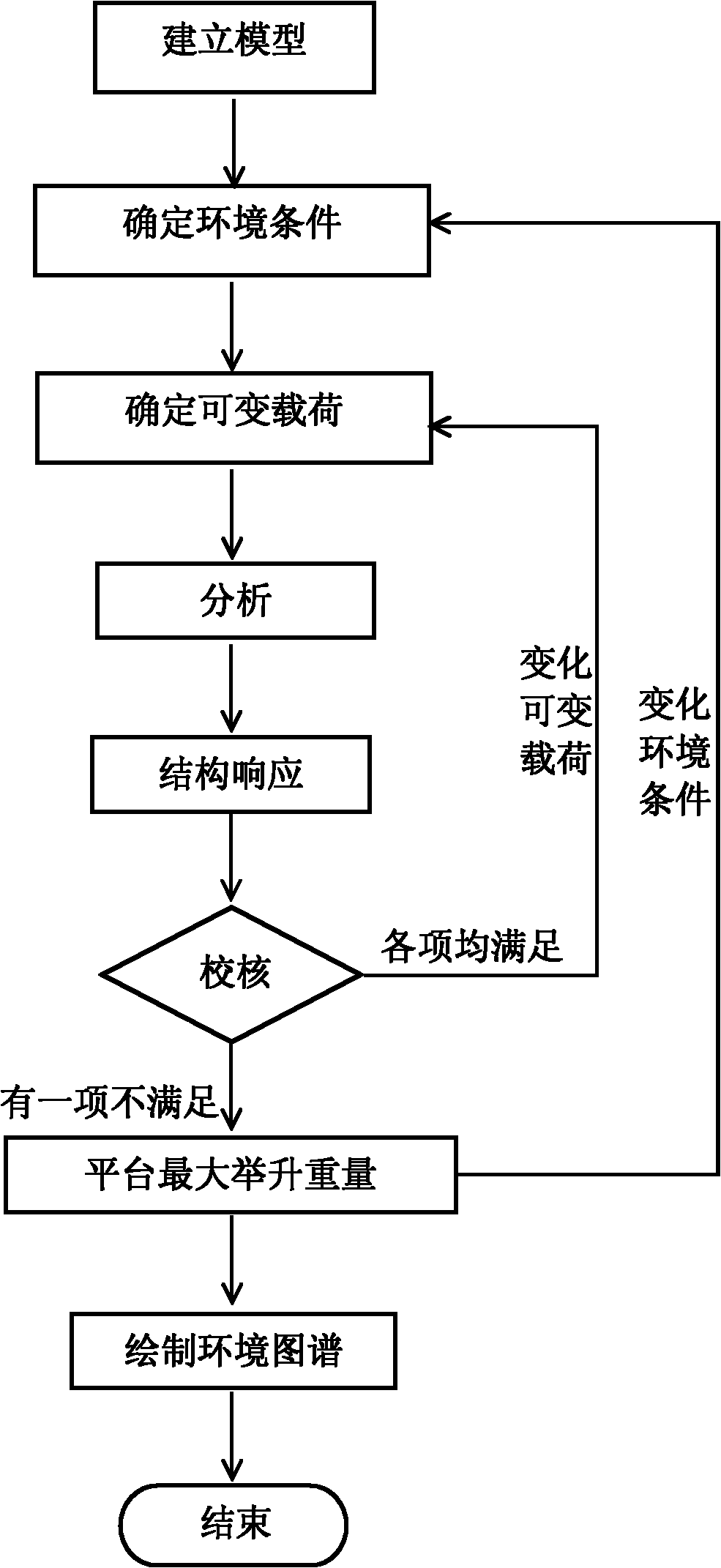

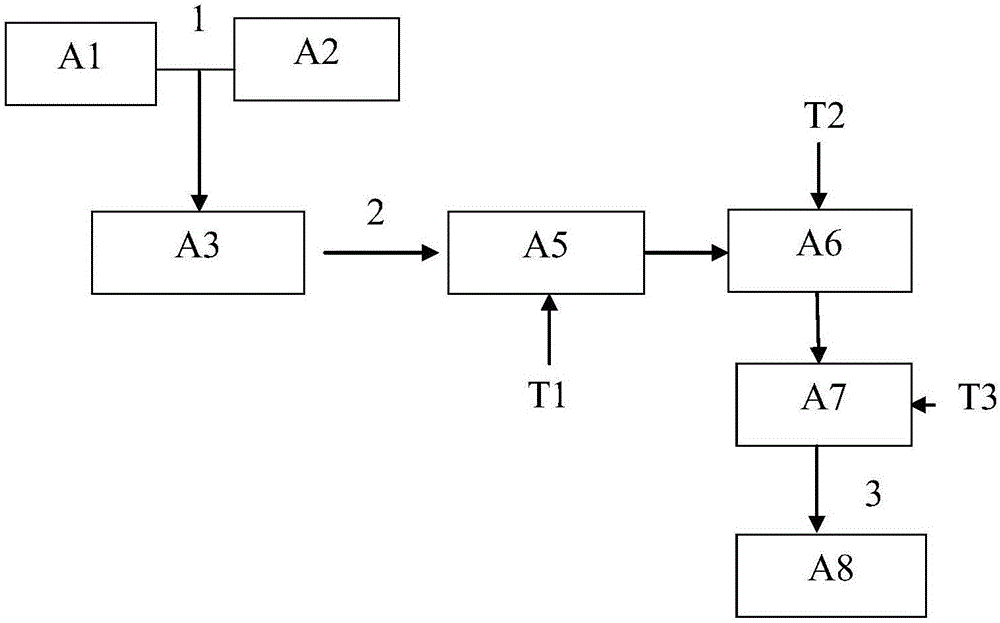

Analysis and computation method for structural strength of elevating drilling platform

ActiveCN102043881AImprove carrying capacityImprove slip resistanceSpecial data processing applicationsLifting capacityElement model

The invention discloses an analysis and computation method for the structural strength of an elevating drilling platform, comprising the following steps: building a finite element model according to the structure point of a drilling platform; determining an environment condition according to the operational sea area of the drilling platform; determining a variable load; combining different environmental working conditions with the variable load to obtain different computation working conditions; analyzing and calculating each computation work condition; after each computation working condition is calculated, checking the computation result from seven aspects according to relevant standards; drawing the environmental map of the drilling platform by taking the environment condition and the maximum lifting capacity as parameters; and inquiring the map to obtain the true state of the drilling platform under the practical use condition. The method has the outstanding characteristics of more computation working conditions, more manpower and time are consumed if people manually operate to finish the computation, but the dedicated program software which is compiled by the method and is dedicated for the environmental map can finish all computations within short time. Meanwhile, the software supports parallel computation so as to further shorten computation time.

Owner:DALIAN UNIV OF TECH

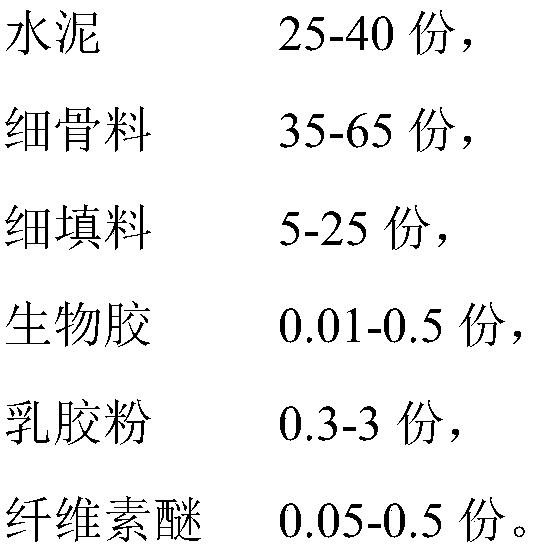

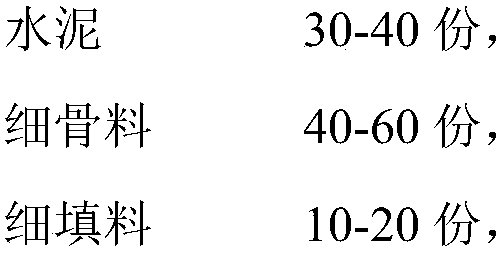

Ceramic tile adhesive and preparation method thereof

The invention discloses a ceramic tile adhesive and a preparation method thereof, and relates to the field of building materials. The ceramic tile adhesive comprises the following raw materials in parts by weight: 25-40 parts of cement, 35-65 parts of fine aggregate, 5-25 parts of a fine filler, 0.01-0.5 parts of biological glue, 0.3-3 parts of latex powder and 0.05-0.5 part of cellulose ether. The ceramic tile adhesive has relatively high bonding strength and excellent anti-slippage performance, is suitable for construction ways of thick-layer paving, thin-layer paving, and paving from top tobottom, and can avoid slippage to guarantee the construction quality.

Owner:VASA MORTAR CO LTD

Ceramic tile adhesive

The invention discloses ceramic tile adhesive, comprising the following components according to parts by weight: 300-400 parts of ordinary Portland cement, 50-100 parts of heavy calcium, 200-250 parts of 40-mesh to 70-mesh quartz sand, 350-400 parts of 70-mesh to 100-mesh quartz sand, 10-20 parts of redispersible emulsion powder, 4-8 parts of organosilicon water repellent, 2-3.5 parts of cellulose, 1-1.5 parts of lignocellulose and 1-2 parts of polyvinyl alcohol. The ceramic tile adhesive has high adhesive powder and low plasticity, is good in constructability and is resistant to aging.

Owner:江苏蓝圈新材料股份有限公司

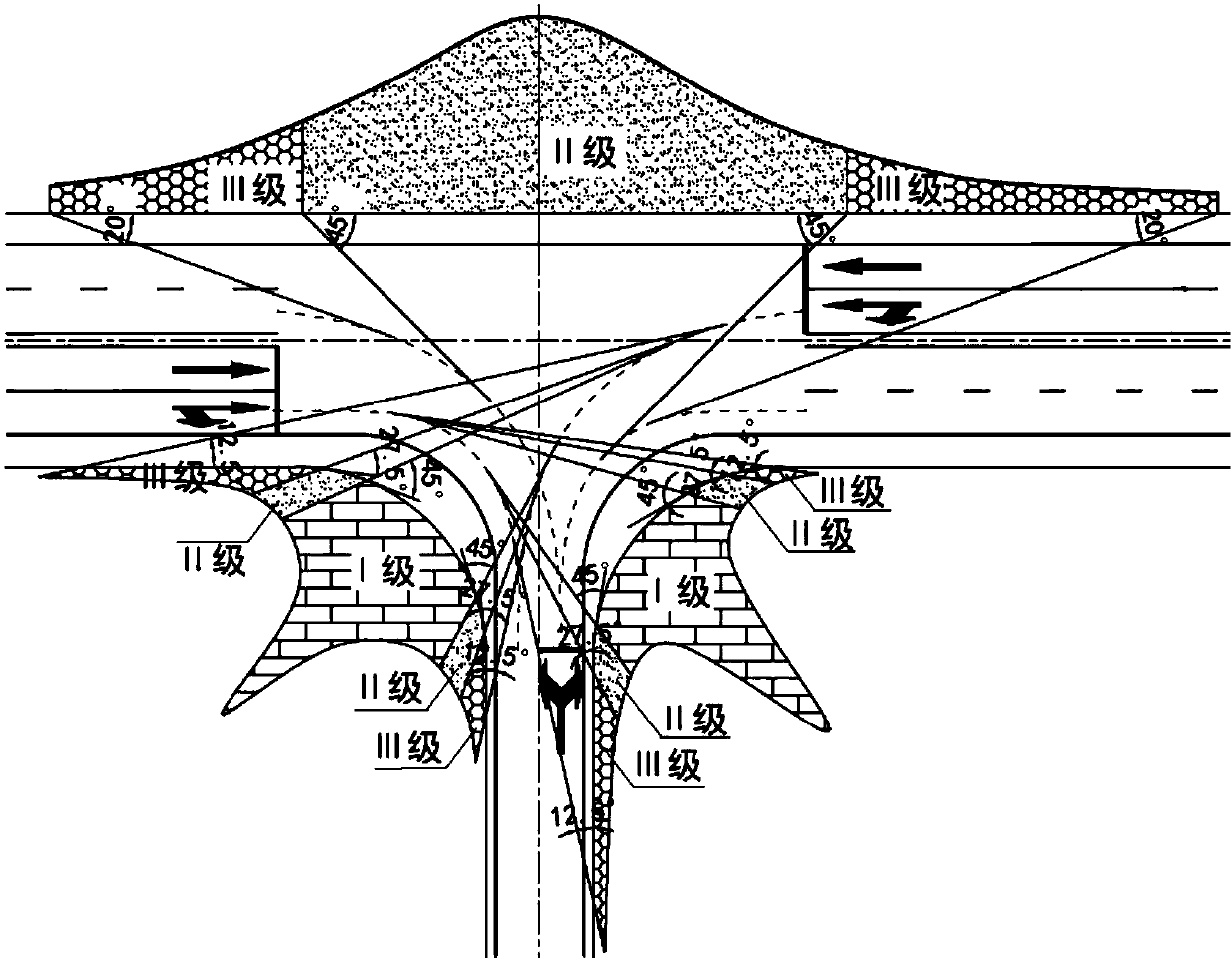

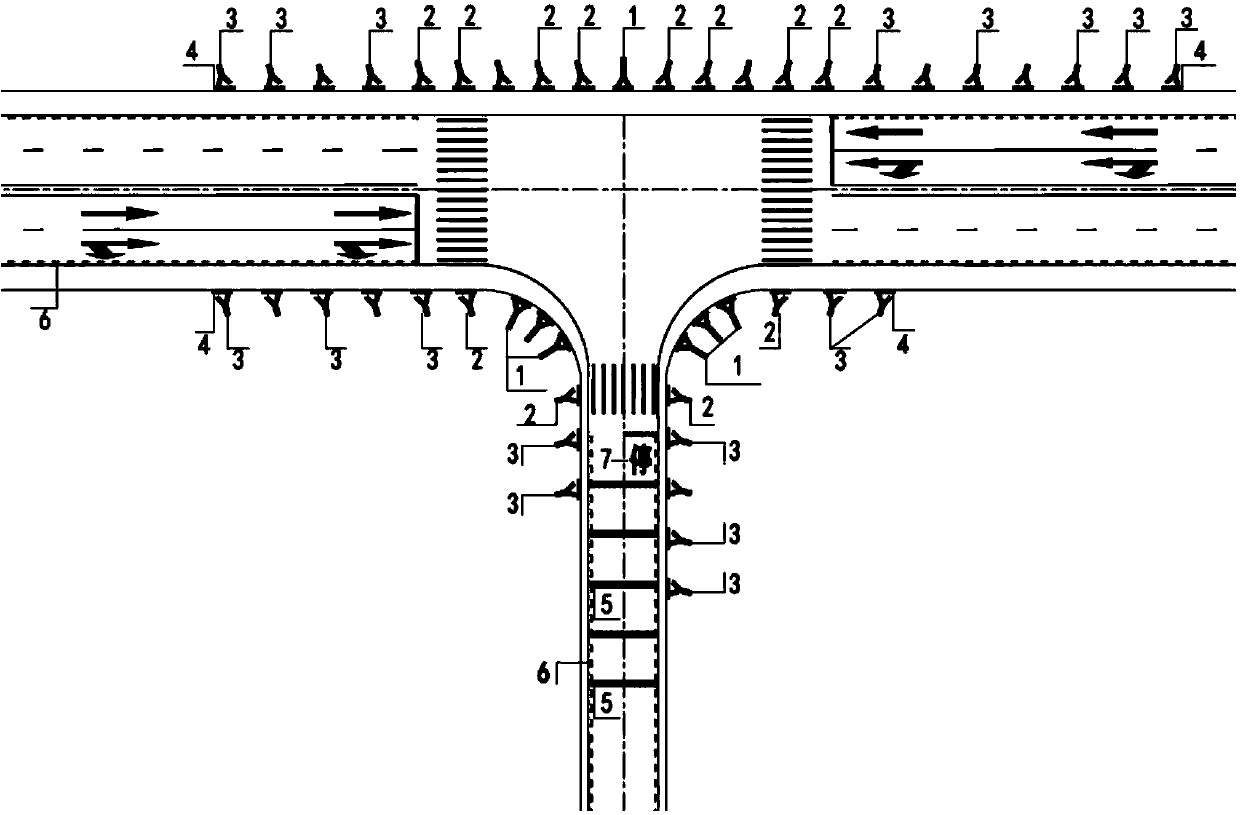

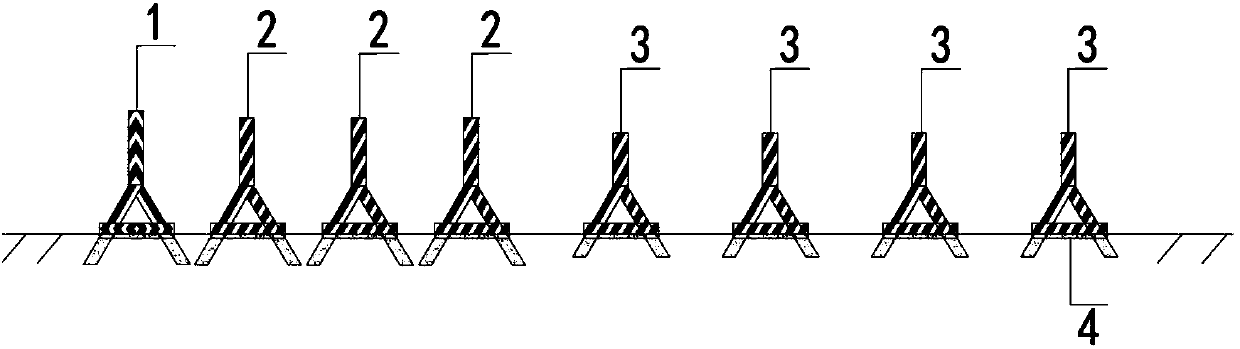

Design method of T-shaped intersection of arterial highway in mountain area for traffic safety

InactiveCN103437255ALow occlusion heightGood permeabilityRoadway safety arrangementsSafety designVisibility

The invention relates to a design method for a T-shaped intersection of an arterial highway in a mountain area for traffic safety. Roadside protections are graded according to the collision energy of vehicles steering at the roadside of the intersection, and corresponding novel concrete guard bar structures are arranged; guard bars comprise herringbone collision posts and independent concrete short bases, the requirements of different protection levels of the roadside at the intersection are met by regulating the spaces, sizes and the depth embedded into a roadbed of the herringbone collision posts, and the purpose of protecting the vehicles steering at the intersection is achieved; the included angle between the herringbone collision posts and the edge line of a lane is 5-15 degrees, so that the protection area for steering vehicles is increased; PVC (poly vinyl chloride) pipes are sheathed on the outer layers of the collision posts, red-and-white retroreflection vertical face mark lines are arranged on both the collision posts and the concrete short bases, so that the visibility of the intersection is improved; 3-4 groups of vibration deceleration zones are arranged on the crossed road 3-6m away from the intersection; vibration side lines are additionally arranged at the roadside in the range of 30-50m in all the directions of the intersection. The design method is applicable to controlling the T-shaped intersection in the mountain area without signal control, and the primary road is a second-class highway or a first-class highway.

Owner:WUHAN UNIV OF TECH

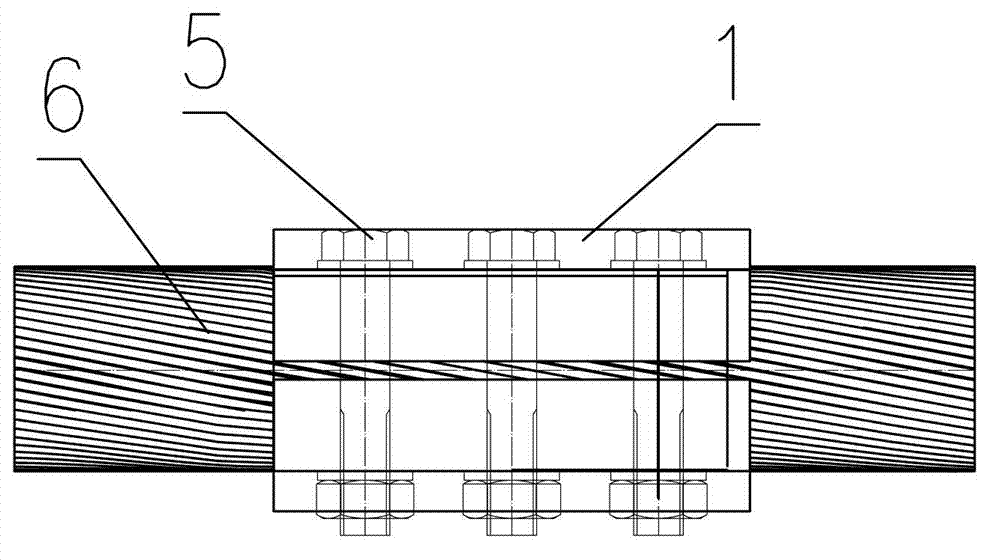

Steel pipe concrete column-precast concrete superposed beam assembly type building connection node

The invention discloses a steel pipe concrete column-precast concrete superposed beam assembly type building connection node. The steel pipe concrete column-precast concrete superposed beam assembly type building connection node comprises a steel pipe concrete column and a precast concrete superposed beam, wherein the outer wall of the steel pipe concrete column is provided with a U-shaped steel tank and a prewelded outer ring steel plate in a welded manner, the prewelded outer ring steel plate is horizontally arranged and located above the U-shaped steel tank, the U-shaped steel tank is provided with a bottom plate and side plates, the bottom plate is provided with bottom steel bar clamping buckle devices, and the tops of the side plates are provided with upper flanges being folded outwards; and the precast concrete superposed beam is installed inside the U-shaped steel tank in an inserted manner, the bottom of the precast concrete superposed beam is connected with the bottom steel bar clamping buckle devices in a clamped manner, the top of the precast concrete superposed beam is welded to the prewelded outer ring steel plate, a mutual plug-in mounting area of the precast concretesuperposed beam and the U-shaped steel tank is a superposed area, and concrete is poured into the superposed area after lap joint and assembly of the precast concrete superposed beam. The steel pipeconcrete column-precast concrete superposed beam assembly type building connection node is convenient and fast to install without bolts and mold supporting, and the production and construction efficiency can be effectively improved.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

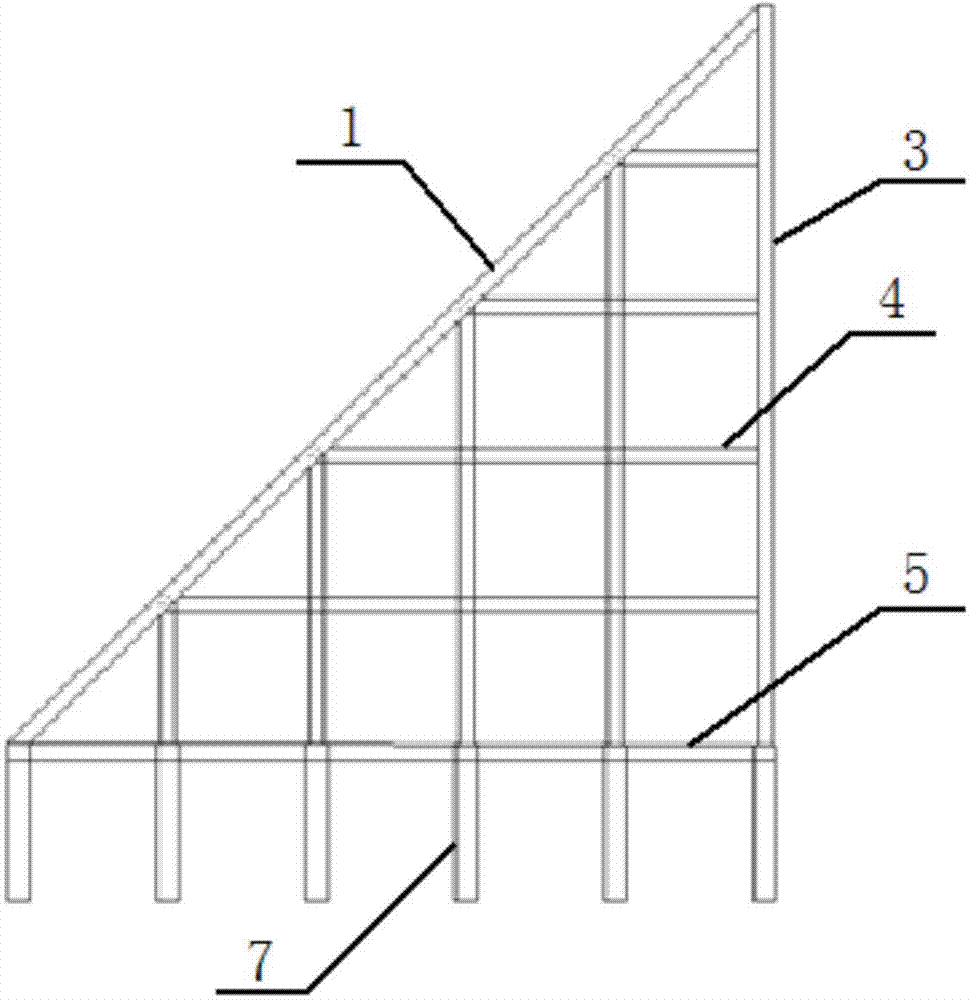

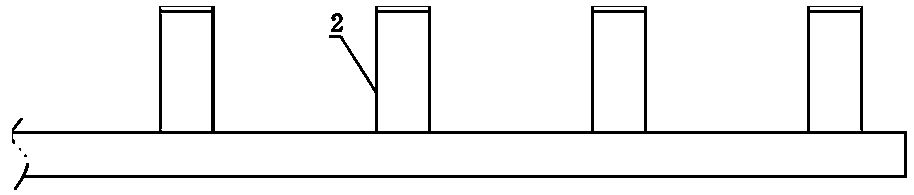

Three-dimensional continuous frame type reinforced concrete structure retaining wall

ActiveCN103485363AIncreased local pressureEnsure stabilityArtificial islandsExcavationsReinforced concreteShear capacity

The invention belongs to the field of construction engineering, and relates to a three-dimensional continuous frame type reinforced concrete structure retaining wall. The three-dimensional continuous frame type reinforced concrete structure retaining wall comprises piles which are fixedly connected through a ground beam. Columns are fixedly connected to a base plate, the columns are in rigid connection through girders so that a frame can be formed, and a shingle is arranged on the outer vertical face of the frame. The three-dimensional continuous frame type reinforced concrete structure retaining wall is simple in structure, the frame type structure is adopted, a frame body is rooted into a stable foundation supporting layer, the lateral pressure of a side slope soil layer is dispersed through the girders and the columns, the overlarge local pressure of a wall body can be avoided, anti-sliding capacity, shear capacity and bearing capacity are enhanced, the stability and the durability of the retaining wall are guaranteed, the potential risks of engineering can be greatly reduced, and the three-dimensional continuous frame type reinforced concrete structure retaining wall is suitable for enclosing and retaining side slope soil mass in loose sandy soil, recent fill and soil piling and filling areas which can not be closely grained easily.

Owner:HAINAN HENGXIN CIVIL ENG CONSTR

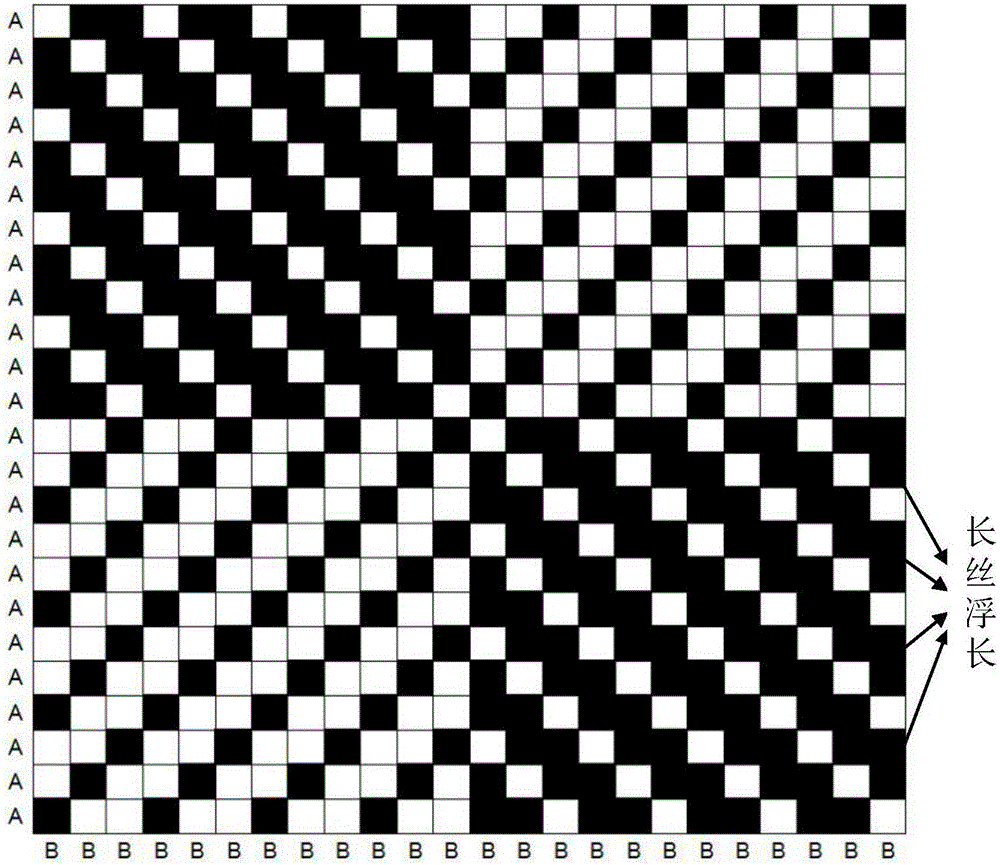

Comfortable anti-flaming fabric and manufacturing method thereof

InactiveCN106592064AFlame retardant permanentComfortable foreverHeat resistant fibresHeating/cooling textile fabricsEngineeringFire resistance

The invention discloses a comfortable anti-flaming fabric. The comfortable anti-flaming fabric is characterized by being formed by vertically interweaving first yarns and second yarns, wherein the first yarns are made from staple fibers with anti-flaming property; the second yarns are made from anti-flaming filament yarns; after the fabric is padded, a firm fibroin sericin film is formed on the surface. The comfortable anti-flaming fabric has the advantage that the fire resistance and the comfort property are effectively combined so that the fabric has permanent flame retardance, wet-absorbing and breathable properties, skin-friendly and smooth properties, anti-pilling property, shrink-proof and anti-wrinkle properties, and the like.

Owner:北京邦维普泰防护纺织有限公司

Construction method of combined supporting and retaining structure

ActiveCN106638673AReduce excavationReduce lateral deformationArtificial islandsUnderwater structuresReinforced concretePre stress

The invention discloses a construction method of a combined supporting and retaining structure, and relates to the technical field of civil construction. The method includes the steps of surveying and setting-out, mountain slope treatment, manufacturing of prefabricated reinforced concrete breast boards, foundation surface cleaning and replacement filling, construction of a cast-in-place concrete foundation, construction of a cantilever type structure, construction of pre-stressed anchor cables, masonry installation of the prefabricated reinforced concrete breast boards, and construction of a wrapped face reinforced soil structure and a covering layer. By using the vertical pre-stressed anchor cables, the workload can be reduced, the construction period can be shortened, the anti-overturning capacity and anti-slippage capacity of the combined supporting and retaining structure can be improved, and the overall stability and anti-lateral-deformation capacity of the whole combined supporting and retaining structure can be improved; by adopting the prefabricated reinforced concrete breast boards, the construction progress can be accelerated, and the project quality can be ensured; by using the wrapped face reinforced soil structure, the strength and integrity of a filling part can be improved, and the lateral soil pressure on the panel of the supporting and retaining structure can be reduced. By means of the method, the overall stability is improved, occupation of land is reduced, construction is simplified, and the construction cost is reduced; the method is especially suitable for roadbed construction in mountainous and hilly regions.

Owner:SOUTHWEST JIAOTONG UNIV +4

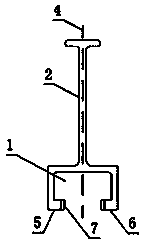

High-strength aluminum alloy pre-burie channel and molding process thereof

The invention discloses a high-strength aluminum alloy pre-buried channel and a molding process thereof, comprising a pre-buried channel body, wherein the pre-buried channel body is composed of a C-shaped groove and an anchor rod fixedly connected to the back surface of the C-shaped groove bottom; The anchor rod and the C-shaped groove are an integral structure of extrusion forming, the notch of the C-shaped groove is two inner flanging structures symmetrical to the middle line of the C-shaped groove, and the opposite sides of the two inner flanging edges are rack structures. As that high-strength aluminum alloy material is adopt for the pre-buried channel through the extrusion die to be extruded into the pre-buried channel body profile, the strength and load capacity of the pre-buried channel are greatly improved, the consumption of materials is less than that of the prior pre-buried channel unde the same load, and the manufacturing cost is lower than that of the prior pre-buried channel. The meshing teeth engaged with the T-shaped bolt are arranged on opposite sides of the two inner flanges of the C-shaped notch, so that the tooth area is large, the tooth profile is clear, the load level of the tooth force-bearing part is high, and the anti-sliding ability of the tooth is greatly improved.

Owner:河南厚德电力科技有限公司

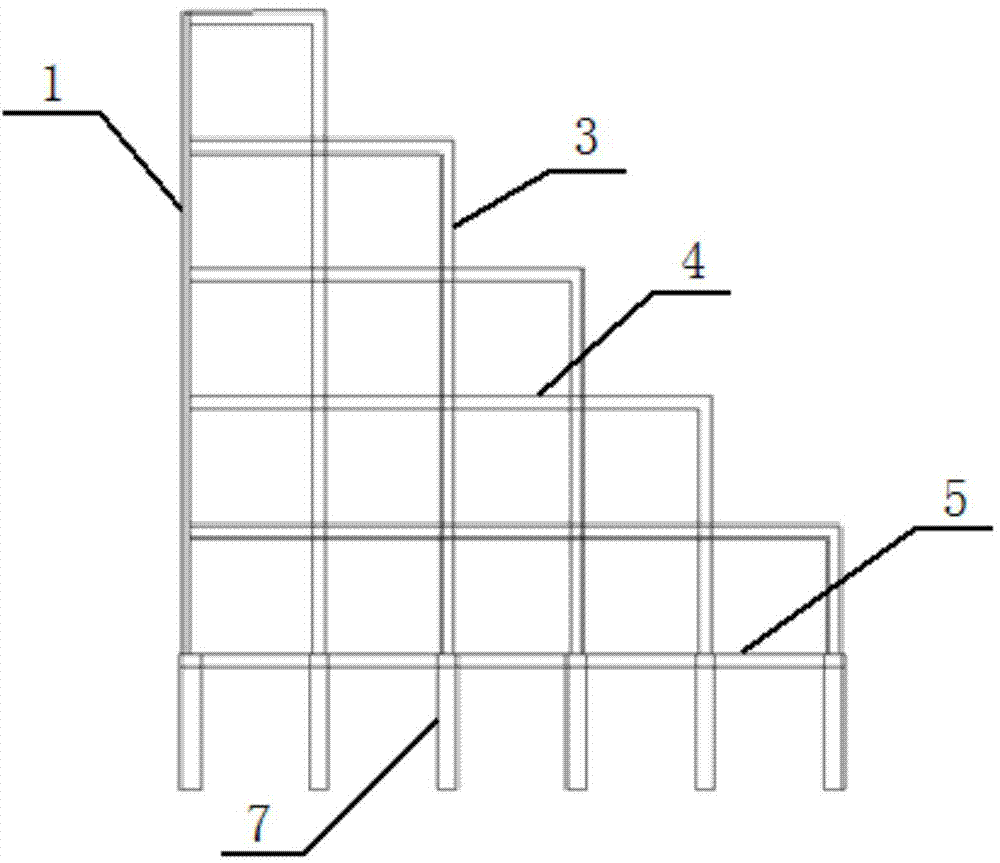

Waste tire gabion units, gabion anchor plate earth-retaining wall and construction method

ActiveCN105256824AEasy to fixImprove slip resistanceArtificial islandsUnderwater structuresUltimate tensile strengthRetaining wall

The invention discloses waste tire gabion units, a gabion anchor plate earth-retaining wall and a construction method. The earth-retaining wall comprises a plurality of earth-retaining unit layers arranged in a step shape. Each earth-retaining unit layer comprises a horizontally-arranged base. A groove is formed in each base. The corresponding gabion units arranged in multiple rows and columns are arranged in each groove. A reinforcing rib structure is horizontally fixed onto the gabion units on each upmost row. The waste tire gabion units, the gabion anchor plate earth-retaining wall and the construction method have the beneficial effects that waste tires are arranged in the grooves in the bases, and finally the grooves and the waste tires are grouted, so that the waste tires are fixed stably, and the anti-capsizing capacity and anti-sliding capacity of the whole earth-retaining wall are enhanced; the earth-retaining wall composed of the waste tires and construction waste is not only high in structural strength but also easy and convenient to construct, and meanwhile environmental protection and resource recycling are facilitated.

Owner:SHANDONG UNIV

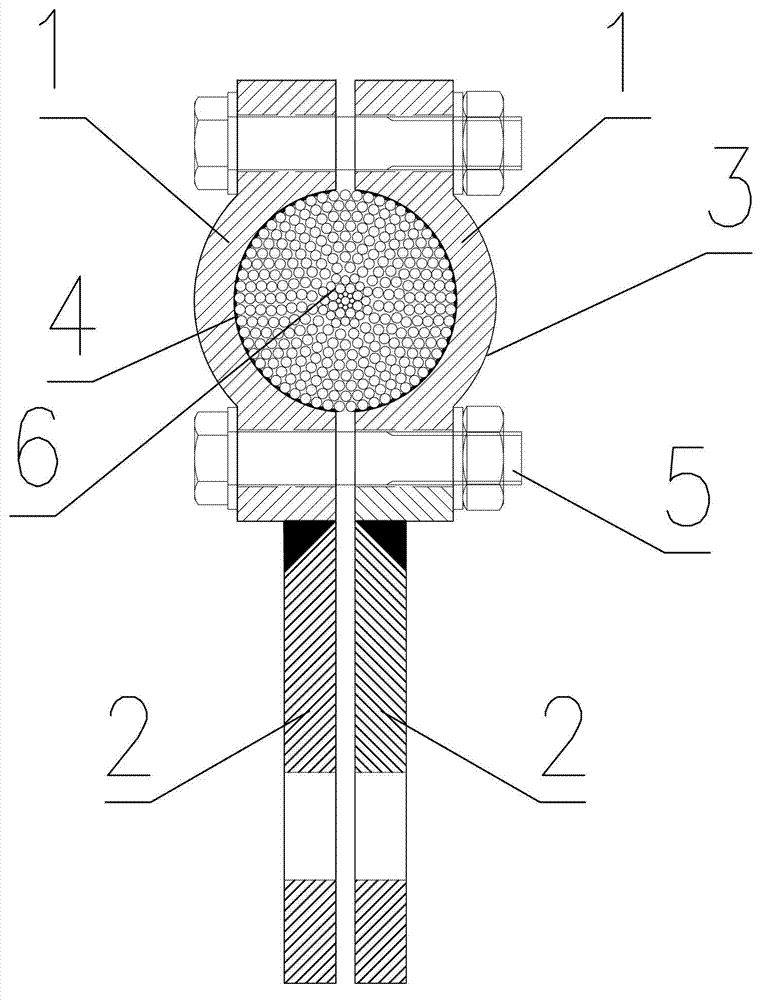

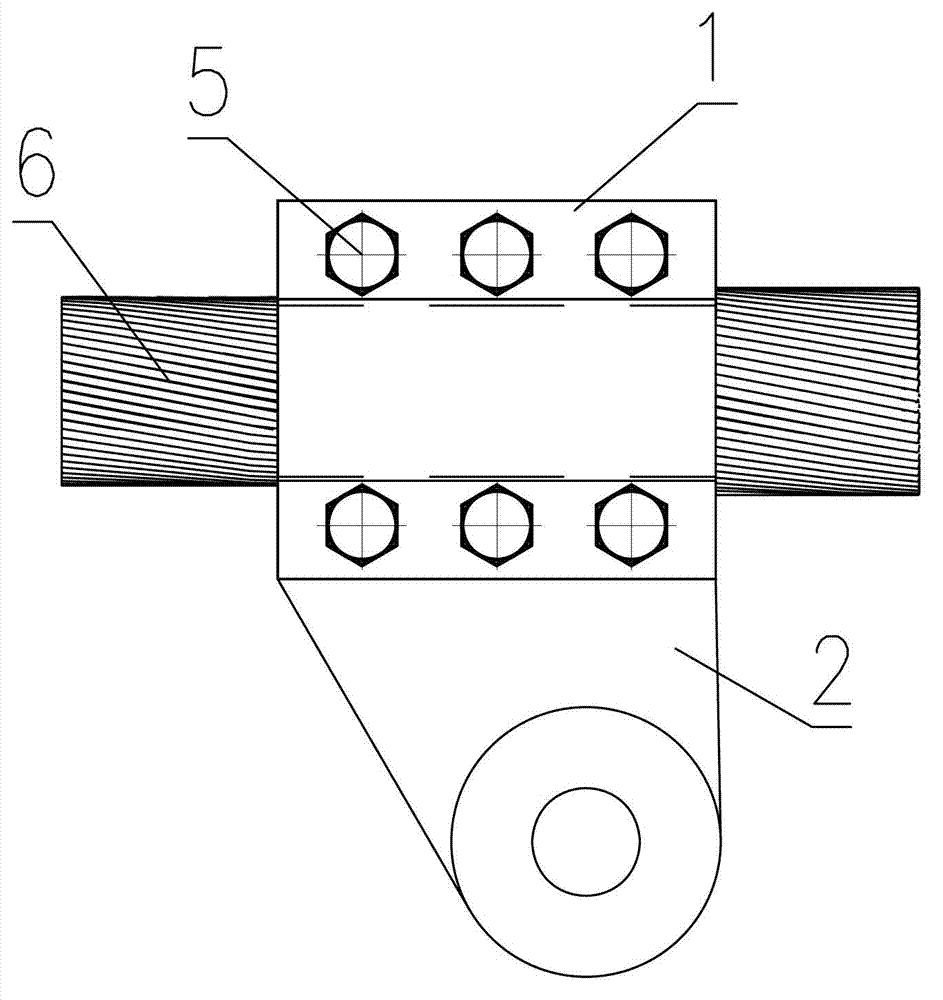

High-vanadium round wire tendon rope clamp as well as manufacturing process and design method thereof

ActiveCN102888896APower transmission is simpleReasonable forceBuilding constructionsPre stressingZinc

The invention discloses a high-vanadium round wire tendon rope clamp which comprises clamp bodies, connecting ear plates, an anticorrosion zinc layer, an anti-sliding metal layer and a high-strength bolt. According to the rope clamp, two rope clamp bodies which are symmetry in shape are integrally connected through the high-strength bolt so as to tightly clamp a high-vanadium round wire tendon rope body; the anti-sliding metal layer is filled at the contact part of the rope clamp bodies and the rope body; and the rope clamp bodies are subjected to hot galvanizing anticorrosion treatment. The invention also provides a manufacturing process of the rope bodies and a design method of shape and size. The rope bodies are machined by using high-strength steels, so that the problems of high manufacturing cost, quality defects and the like caused by the fact that cast steel joints are adopted are avoided. The rope clamp joint is simple in structure, convenient to manufacture and construct and economic and reasonable; the performance of the joint is verified through tests, so that the rope clamp joint is applicable to connection joints in a stretch-draw type rope rod beam pre-stress spatial structure. By adoption of the rope clamp, the force bearing performance of the high-vanadium rope body is effectively improved, the anticorrosion plated layer on the surface of the steel wire is protected, the anti-sliding ability of the rope clamp and the rope bodies is improved, so that the rope clamp is beneficial for the high-vanadium round wire tendon to be popularized and applied in China.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

Low-carbon environment-friendly flexible large-plate ceramic tile adhesive

The invention discloses a low-carbon environment-friendly flexible large-plate ceramic tile adhesive. The adhesive is prepared from the following components in parts by weight: 10 to 25 parts of pII52.5 ordinary Portland cement; 15 to 30 parts of mineral powder; 20 to 35 parts of coarse quartz sand; 15 to 33 parts of fine quartz sand, 1 to 2 parts of negative ion powder, 2 to 15 parts of modifiedredispersible latex powder, 2 to 15 parts of VAE redispersible latex powder, 0.3 to 0.9 part of modified cellulose ether, 0.04 to 0.08 part of starch ether, 0.5 to 1 part of an early strength agent, 0.6 to 1.5 parts of a thixotropic lubricant and 1 to 5 parts of an excitant. The carbon emission of the ceramic tile adhesive is reduced, the adhesion firmness of large plates and heavy ceramic tiles are improved and the adhesive is an environment-friendly ceramic tile adhesive.

Owner:佛山市德堡建材有限公司

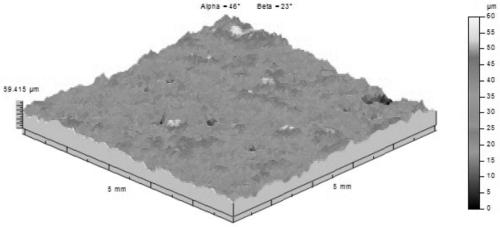

Filler for clear rubber

Provided is a filler for a clear rubber, which can be handled easily and comprises a wet type silica giving excellent transparency and abrasion resistance to the clear rubber prepared. The filler for the clear rubber comprises the wet type silica having a specific surface area of 100-250m<2> / g, a ratio (V / S) of an oil absorption (V;cc / 100g) to the specific surface area (S;m<2> / g) of not less than 1.05 and an average particle diameter of 5-10[mu]m. One hundred pts.wt. of a rubber component consisting of a butadiene rubber and a styrene-butadiene rubber of a solution-polymerizing type as major components is incorporated with 20-50 pts.wt. of the above filler comprising the wet type silica. The clear rubber with a thickness of 2 mm exhibits a total light transmission rate of 70% or more.

Owner:TOKUYAMA CORP

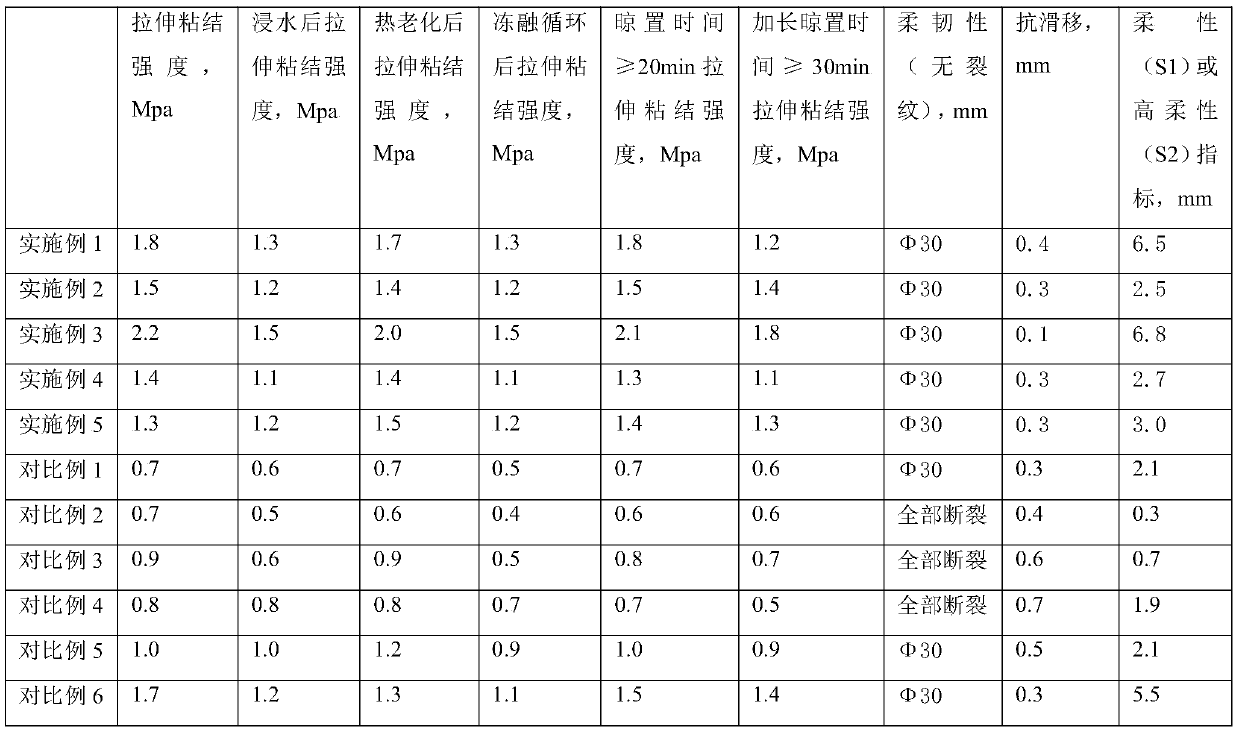

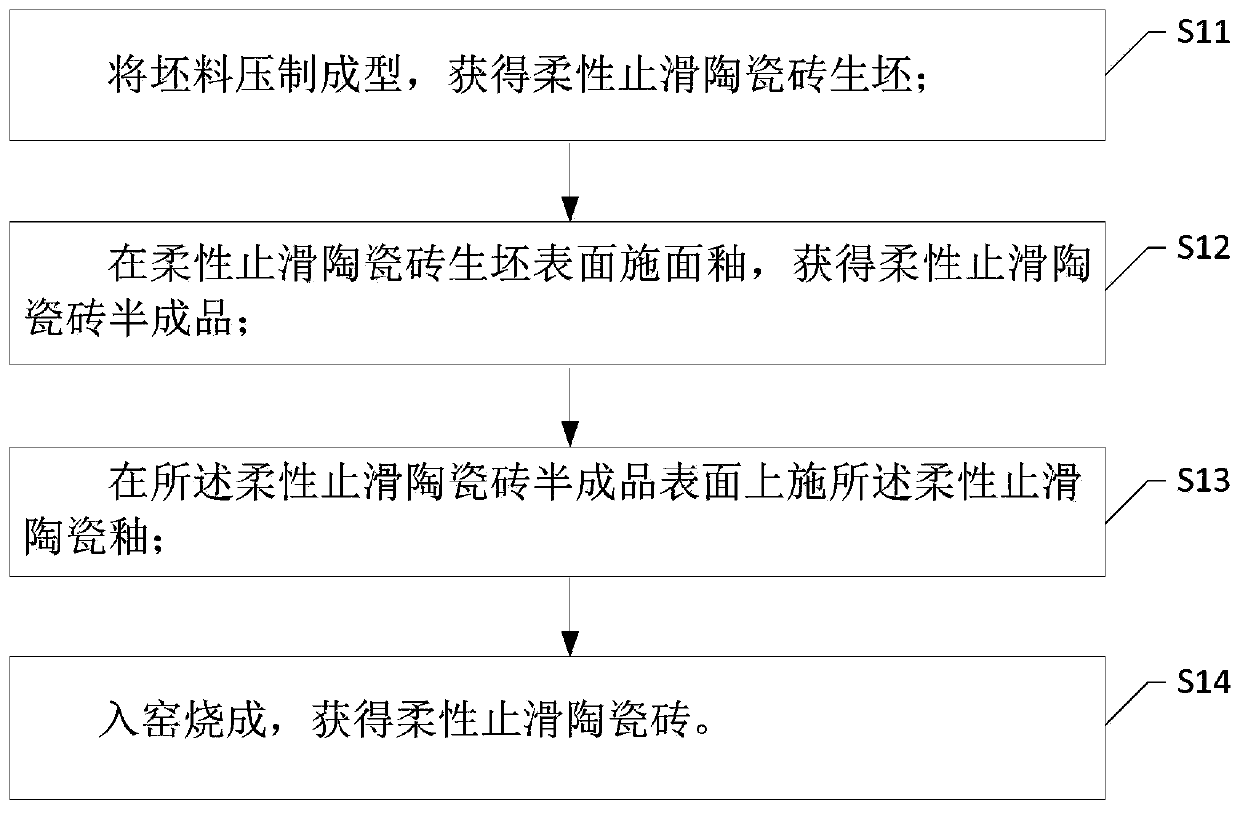

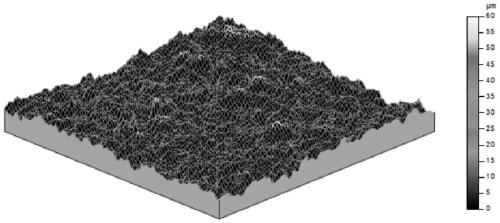

Flexible non-slip ceramic glaze, flexible non-slip ceramic tile and preparation method of flexible non-slip ceramic tile

The invention discloses flexible non-slip ceramic glaze, a flexible non-slip ceramic tile and a preparation method of the flexible non-slip ceramic tile. The flexible non-slip ceramic glaze comprisesthe following chemical components in percentage by mass: 21-54% of SiO2; 22%-25% of Al2O3; 0% to 0.29% of Fe2O3; 6%-8% of CaO; 2%-3% of MgO; 2%-4% of K2O; 0 to 1% of Na2O; 2%-4% of ZnO; 0 to 0.01% ofTiO2; 6%-8% of BaO; and 1%-5% of SrO. The loss on ignition ranges from 0 to 0.1%. The flexible non-slip ceramic glaze and the flexible non-slip ceramic tile provided by the invention have excellent wear resistance and slip resistance after being sintered at high temperature.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +2

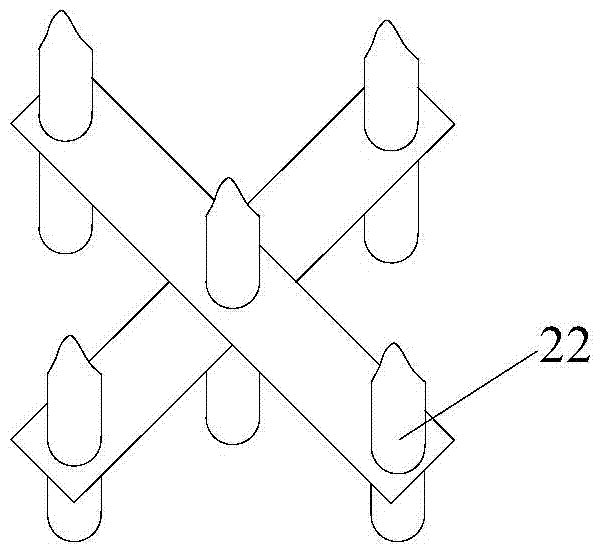

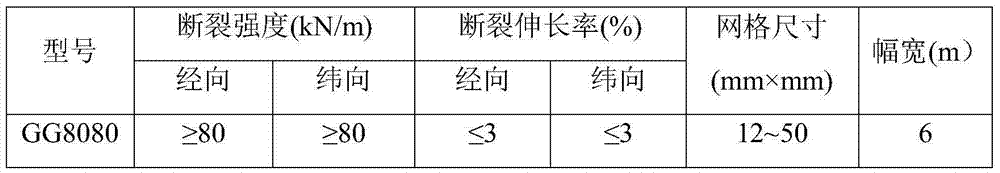

Fill side slope gravity type retaining wall reinforcing structure and construction method thereof

PendingCN110847224AImprove reliabilityLow costArtificial islandsUnderwater structuresGeogridRetaining wall

The invention provides a fill side slope gravity type retaining wall reinforcing structure and a construction method thereof. The reinforcing structure comprises an original gravity type retaining wall, a fill side slope above the retaining wall, a high-pressure rotary spraying reinforcement body constructed in the retaining wall foundation, a lattice anchor cable supporting structure constructedon the retaining wall and a slope reinforcing structure constructed on the soil filling side slope. According to the reinforcing structure, the original retaining wall foundation is subjected to high-pressure rotary jet reinforcement treatment, the bearing capacity of the retaining wall foundation is directly improved, the passive protection of the original retaining wall is changed into active protection of the lattice pressure type anchor cable, the anti-overturning, anti-slip and other stability of the original retaining wall is greatly improved, and the displacement of the retaining wall can be effectively controlled; and according to the upper fill side slope, a geogrid is laid in the filling soil, and the deformation condition of the soil body is improved and the engineering performance of the soil body is improved by utilizing the interaction between the geogrid and the filling soil of each layer, so that the stability of the upper fill side slope is guaranteed, and the adverseeffect of the upper filling soil on the original retaining wall can be effectively reduced.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

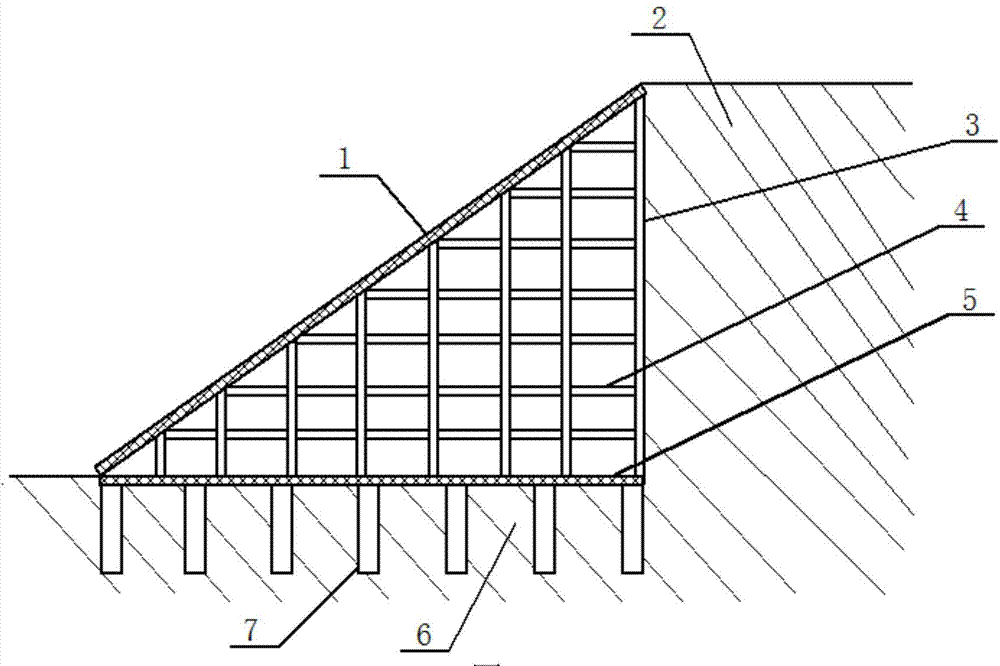

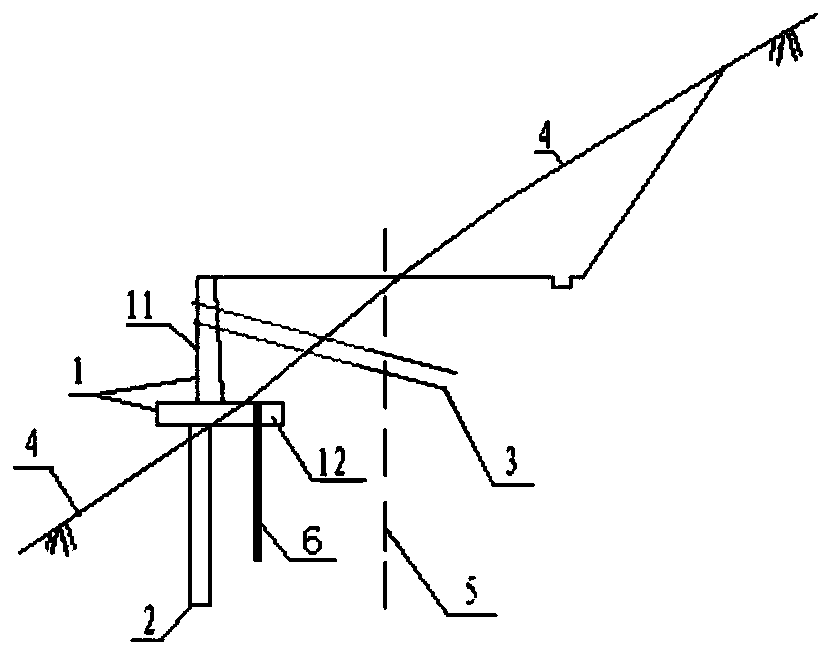

Steep slope embankment supporting and blocking structure and construction method thereof

PendingCN109403371AImprove anti-overturn performanceImprove slip resistanceArtificial islandsRoadwaysSteep slopeEngineering

The invention relates to the field of steep slope roads and discloses a steep slope embankment supporting and blocking structure and a construction method thereof. The steep slope embankment supporting and blocking structure comprises a cantilever-type soil retaining wall, a foundation pile and an anchor cable; and the cantilever-type soil retaining wall comprises a bottom plate and a vertical wall located on the bottom plate, the foundation pile is arranged on the lower part of the bottom plate, the bottom of the foundation pile is inserted into a slope body, a first anchor cable hole is formed in the vertical wall, one end of the anchor cable is connected with the vertical wall at the first anchor cable hole, and the other end of the anchor cable is inserted into a second anchor cable hole in the slope body and fixed into a stable soil layer or base rock of the slope body. According to the steep slope embankment supporting and blocking structure and the construction method thereof, apile foundation is arranged to support the cantilever-type soil retaining wall so that the problem of insufficient bearing capacity of a foundation can be solved, and the anti-overturning capabilityand the anti-sliding capability of the supporting and blocking structure are improved; and the anchor cable is arranged to connect the vertical wall with the slope body, the soil pressure of the wallback of the soil retaining wall can be partially counteracted, and the anti-overturning capability of the soil retaining wall and the overall stability of the supporting and blocking structure are further improved.

Owner:CHINA RAILWAY SIYUAN GRP SOUTHWEST SURVEY & DESIGN CO LTD +1

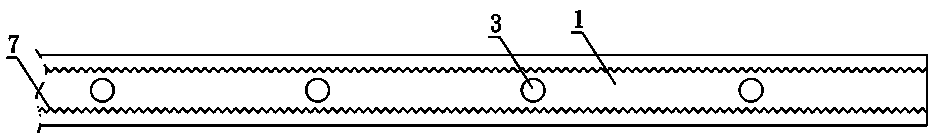

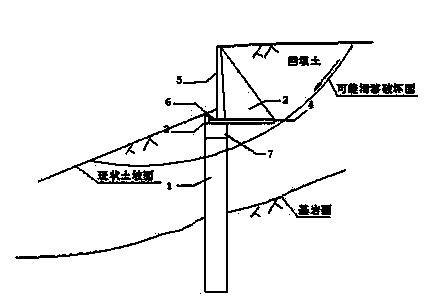

Pile top buttress type retaining wall supporting structure and construction method

PendingCN108277814AImprove slip resistanceImprove bearing capacityExcavationsTransverse pressureCut and fill

The invention discloses a pile top buttress type retaining wall supporting structure and a construction method. The pile top buttress type retaining wall supporting structure comprises a pile and a buttress type retaining wall, the pile is buried within the range which is 2 m below an existing soil slope surface, the buttress type retaining wall is formed at the top of the pile through a connection beam, wherein a shingle of the buttress type retaining wall is vertically arranged on the connection beam, and a wall heel plate transversely extends towards the backfill soil side. The supporting structure combines the advantages of the pile and the buttress type retaining wall, the self stability against overturning of the supporting structure can be improved when the bearing capacity of the top edge of a slope or the bearing capacity of foundation soil is low, moreover, transverse pressure of slope high backfill soil to the supporting structure can be borne, and deformation and slippage are resisted.

Owner:王凯 +1

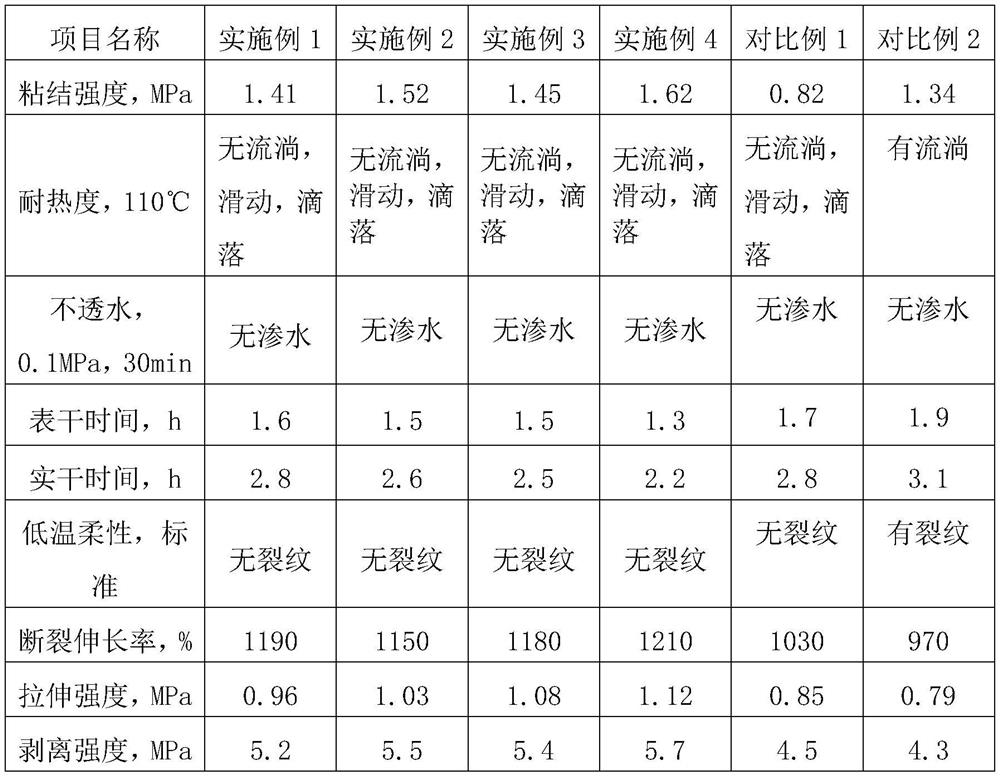

High-viscosity water-based asphalt waterproof coating and preparation method thereof

ActiveCN113667404AHigh bonding strengthHigh tensile strengthAntifouling/underwater paintsPaints with biocidesPolymer scienceBituminous waterproofing

The invention relates to a high-viscosity water-based asphalt waterproof coating and a preparation method thereof. The high-viscosity water-based asphalt waterproof coating comprises the following raw materials in parts by weight: 50-70 parts of anionic emulsified asphalt, 10-30 parts of an acrylic emulsion, 5-25 parts of neoprene latex, 1-2 parts of a defoaming agent, 1-3 parts of a thickening agent, 0.5-1 part of a sterilizing agent, 3-5 parts of a wetting agent, 1-3 parts of a dispersing agent, 10-30 parts of filler, 1-2 parts of a cosolvent and 5-15 parts of water. The thickening agent is prepared from water-based associated polyurethane, silica gel and polyhydroxy polyacrylamide according to a mass ratio of 1:(0.45-0.68):(0.6-0.9). The coating has high bonding strength, high tensile strength, high elongation rate and excellent low-temperature flexibility, and solves the problem of blistering during construction.

Owner:河北三棵树涂料有限公司

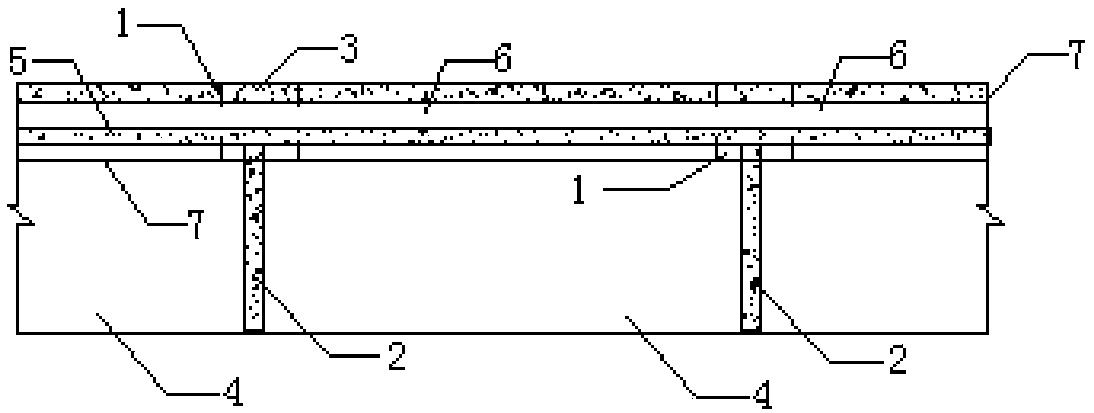

Three-dimensional reinforced rigid-soft composite ecological retaining wall and construction method

ActiveCN103410167BHigh strengthAchieve reorganizationArtificial islandsUnderwater structuresFilling materialsRebar

The invention relates to a three-dimensional reinforced rigid-soft composite ecological retaining wall and a construction method. The retaining wall is characterized by comprising an upper portion soft ecological retaining wall body and a lower rigid retaining wall body, wherein the upper portion soft ecological retaining wall body and the lower rigid retaining wall body are connected through anchor bars. All layers of filling materials of the upper portion soft ecological retaining wall body are connected through connecting buckle parts, and water draining pipes, the connecting and fixing ends of horizontal ribbing bodies and inclined tie bars are evenly arranged on the lower rigid retaining wall body. A wall heel of a foundation of the retaining wall extends backwards to the edge of a stable soil body, vertical reinforcing piles are arranged at the bottom of the retaining wall, the horizontal ribbing bodies are laid in the filling materials behind the retaining wall, the wall toe of the retaining wall is filled back with a wall foot pressing soil body, and vertical ribbing bodies are vertically arranged at the connection position between the filling materials behind the retaining wall and an original soil body. The retaining wall structurally combines the advantages of a rigid retaining wall and the advantages of a soft retaining wall, achieves ecological slope protection, reduces pressure of soil behind the retaining wall, enhances structural integrity and has good technical and economical benefits.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

Formula and preparation process of easily degradable natural material for shoes

The invention relates to a footwear mixed natural material, and a formula and a preparation process thereof, and provides the footwear mixed natural material which can effectively shorten the degradation time of a footwear EVA material, and the formula and the preparation process thereof, wherein the footwear EVA material has a certain slip resistance. The footwear mixed natural material formula comprises the components calculated by weight: 10 parts to 20 parts of EVA, 30 parts to 40 parts of polyoxyethylene, 10 parts to 15 parts of a filling agent, 30 parts to 40 parts of natural particles, 0.5 part to 5.5 parts of a cross-linking agent, 2.0 parts to 3.0 parts of zinc oxide, 0.8 part to 5.8 parts of a foaming agent, and 10 parts to 20 parts of stearic acid. All the raw materials are put into an internal mixer for seal mixing; the seal mixed materials are subjected to open mixing in an open mill; the open mixed sheets are put into a granulator for granulating; and the obtained particles are put into a foaming mold for forming.

Owner:张子亮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com