Patents

Literature

116results about How to "Reduce lateral deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

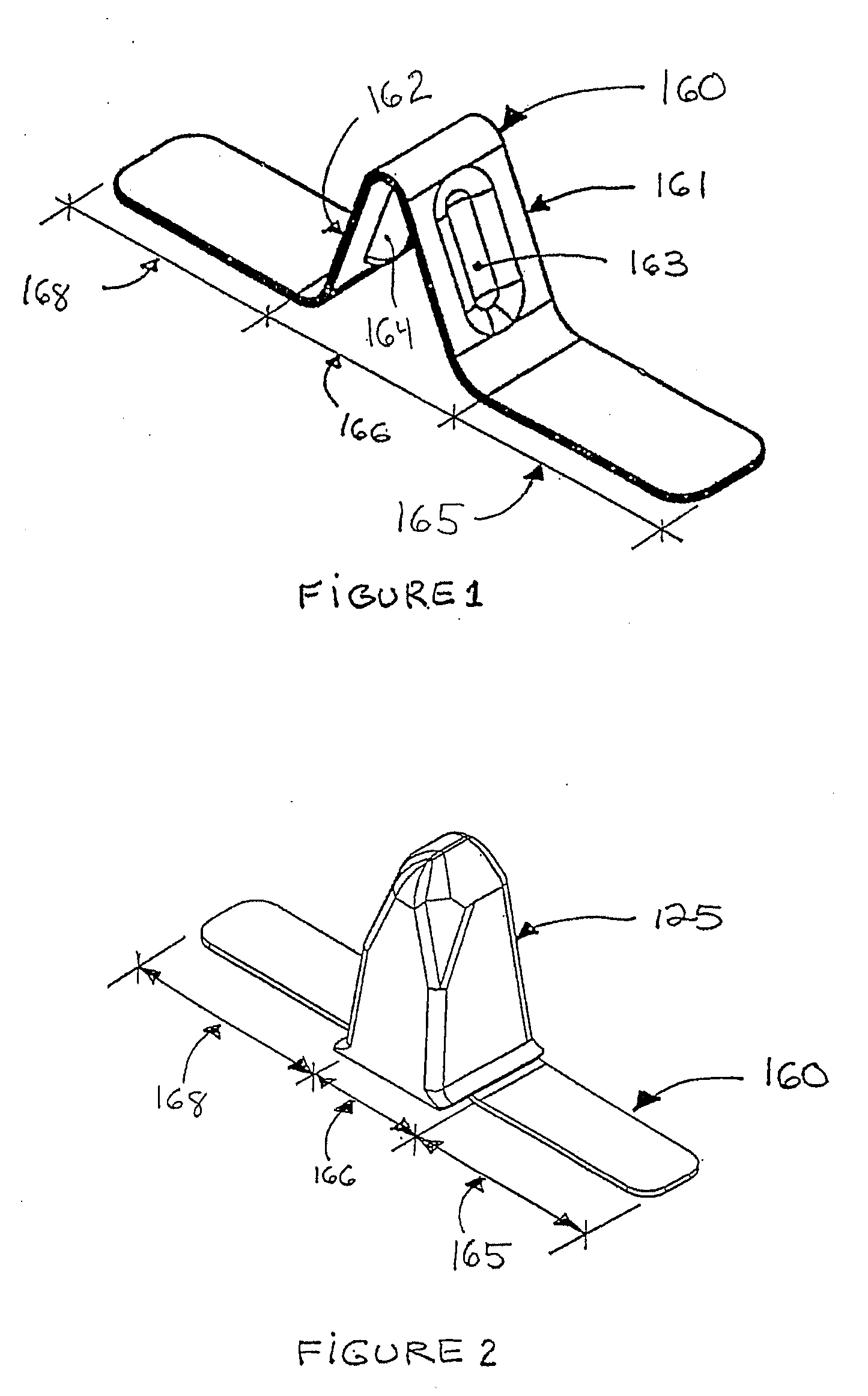

Elastomeric track with guide lug reinforcements

ActiveUS7784884B2Enhance lateral rigidity and resiliencyReduce lateral deformationEndless track vehiclesEngineeringMechanical engineering

Owner:SOUCY INT

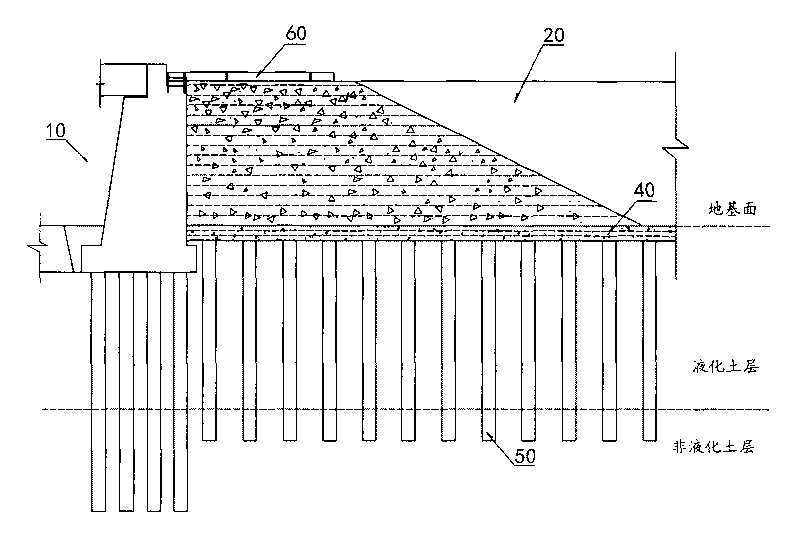

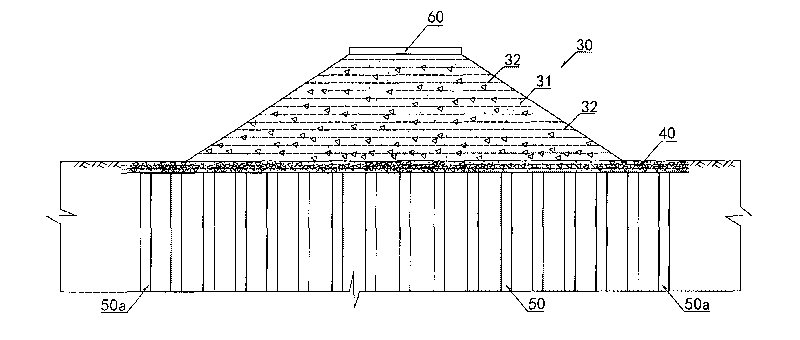

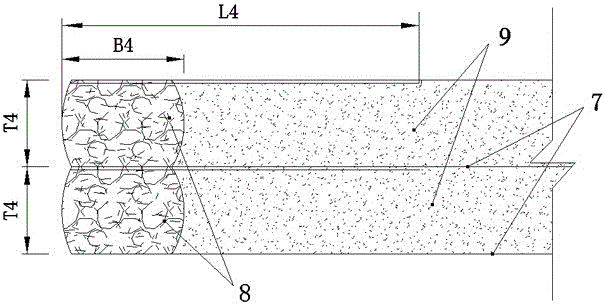

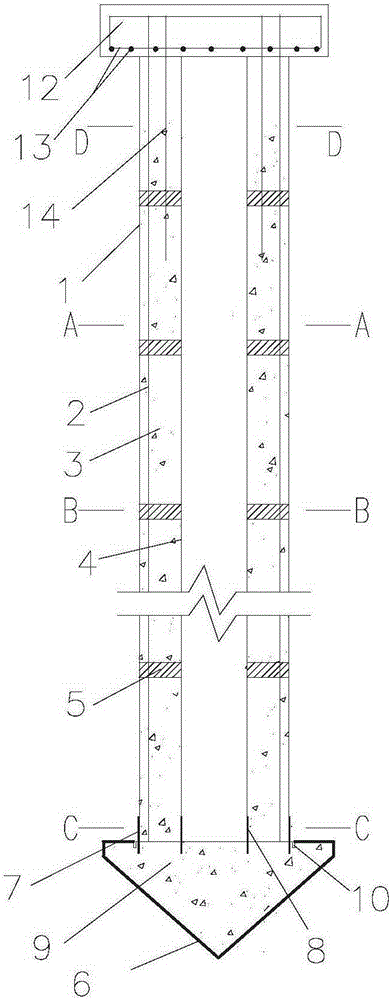

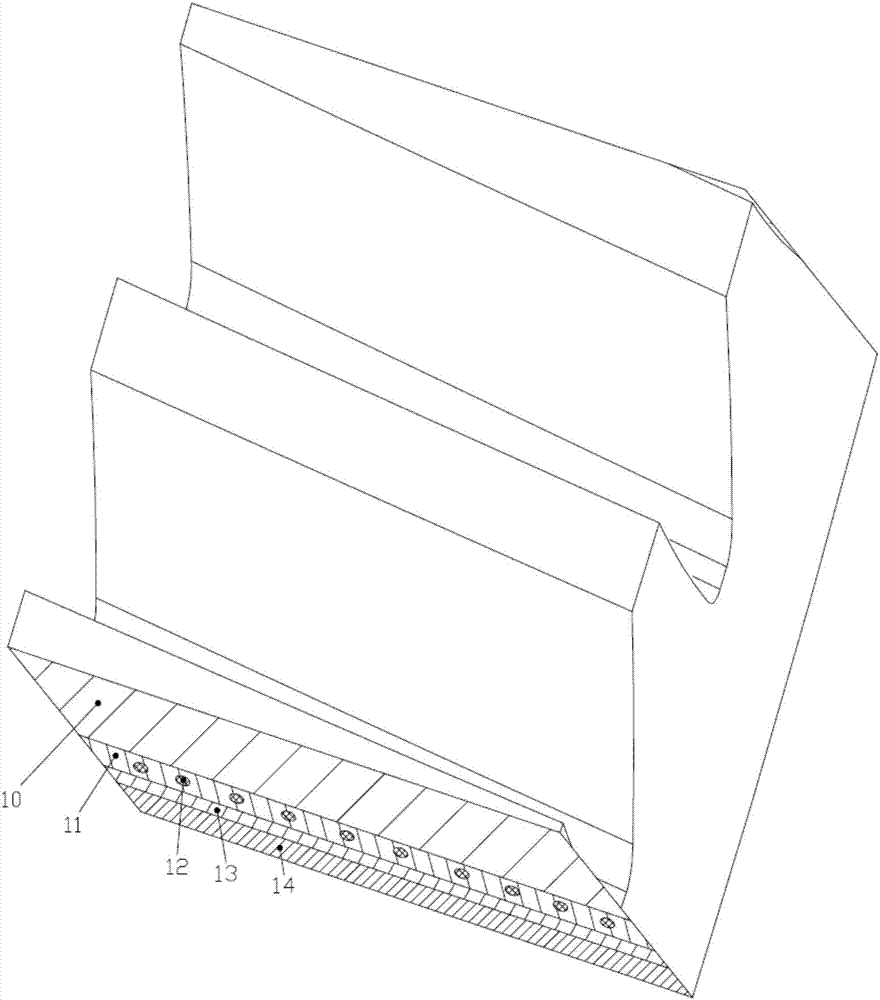

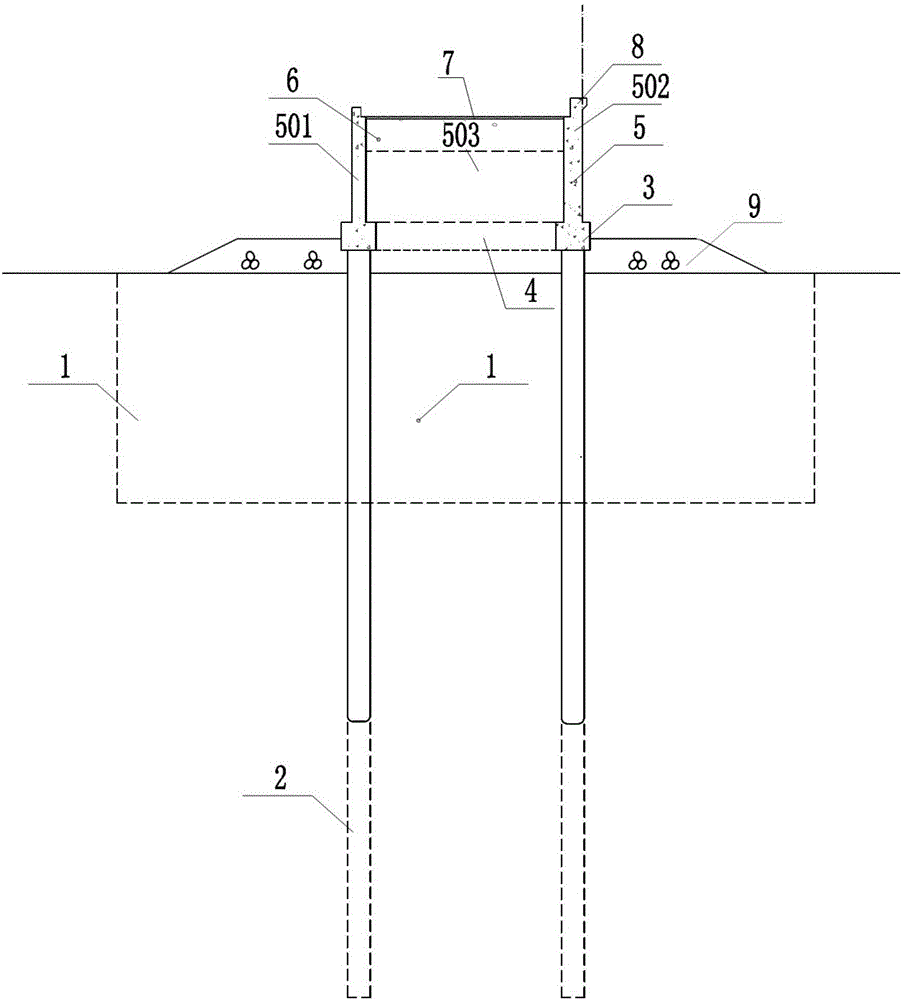

Liquefied soil foundation quake-proof road-bridge transition section structure of ballastless track of high-speed railway

InactiveCN101691724ALower fill longitudinalReduce lateral deformationRailway tracksBridge structural detailsReinforced concreteCrushed stone

The invention discloses a liquefied soil foundation quake-proof road-bridge transition section structure of a ballastless track of a high-speed railway, and aims to improve the stability and the integrity of the roadbed at the transition section and meet the quake-proof design requirements of lines. The structure comprises a concrete bridge abutment (10) and a soil roadbed (20). A reinforced grading gravel transition section (30) is arranged between the concrete bridge abutment (10) and the soil roadbed (20), wherein the longitudinal section of the transition section is wedge-shaped and the transverse section of the transition section is right trapezoidal. Rows of reinforcing piles (50) are arranged in the liquefied soil foundation at intervals along the longitudinal and transverse directions under the transition section (30). The pile ends of the reinforcing piles (50) pass through the liquefied soil layer of the foundation and enter a non-liquefied soil layer. A cement grading gravel reinforced cushion layer (40) is paved between the foundation surface and the pile top of the reinforcing pile (50). A reinforced concrete lap plate (60) is arranged on the top surface of the reinforced grading gravel transition section (30). One end of the reinforced concrete lap plate (60) is simply supported or fixedly supported on the concrete bridge abutment (10), while the other end is placed on the soil roadbed (20).

Owner:SOUTHWEST JIAOTONG UNIV +1

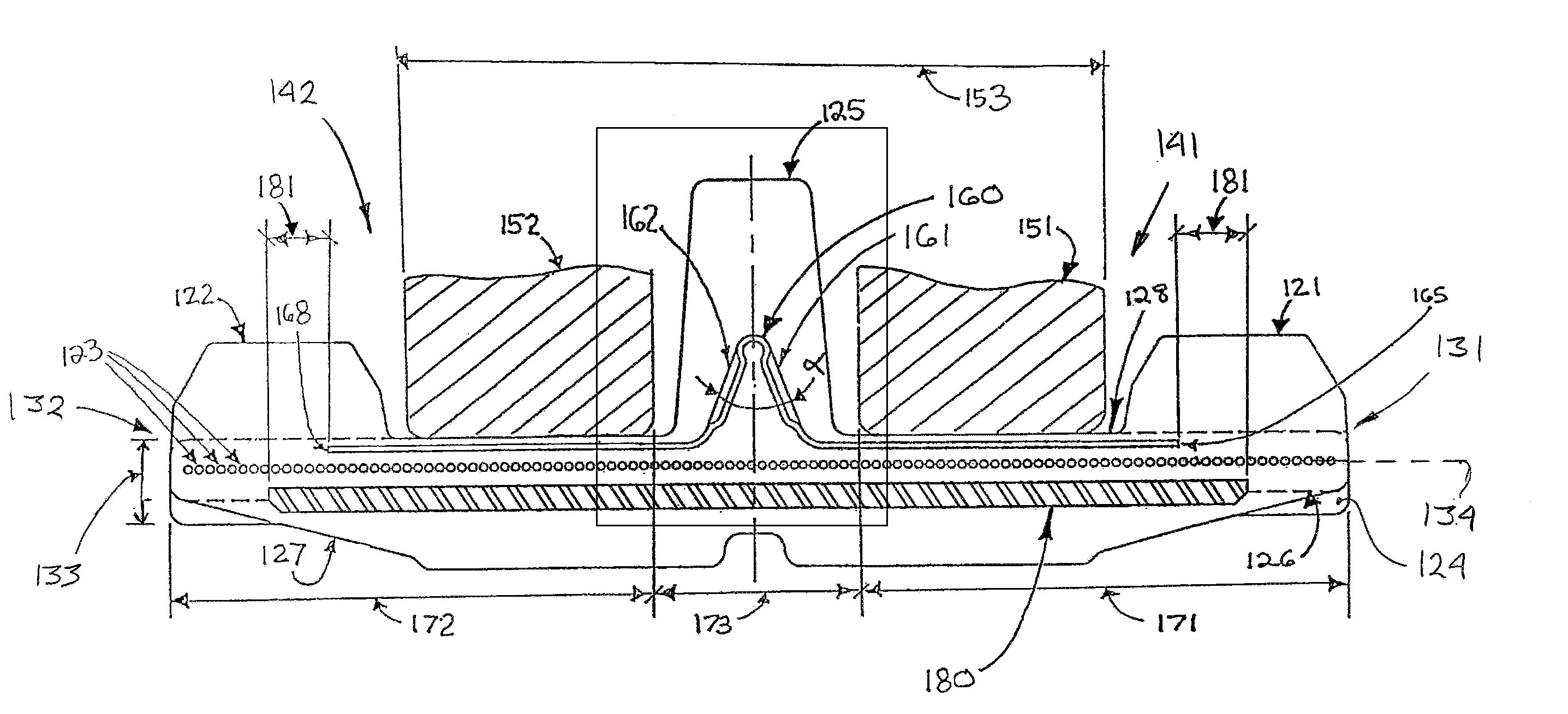

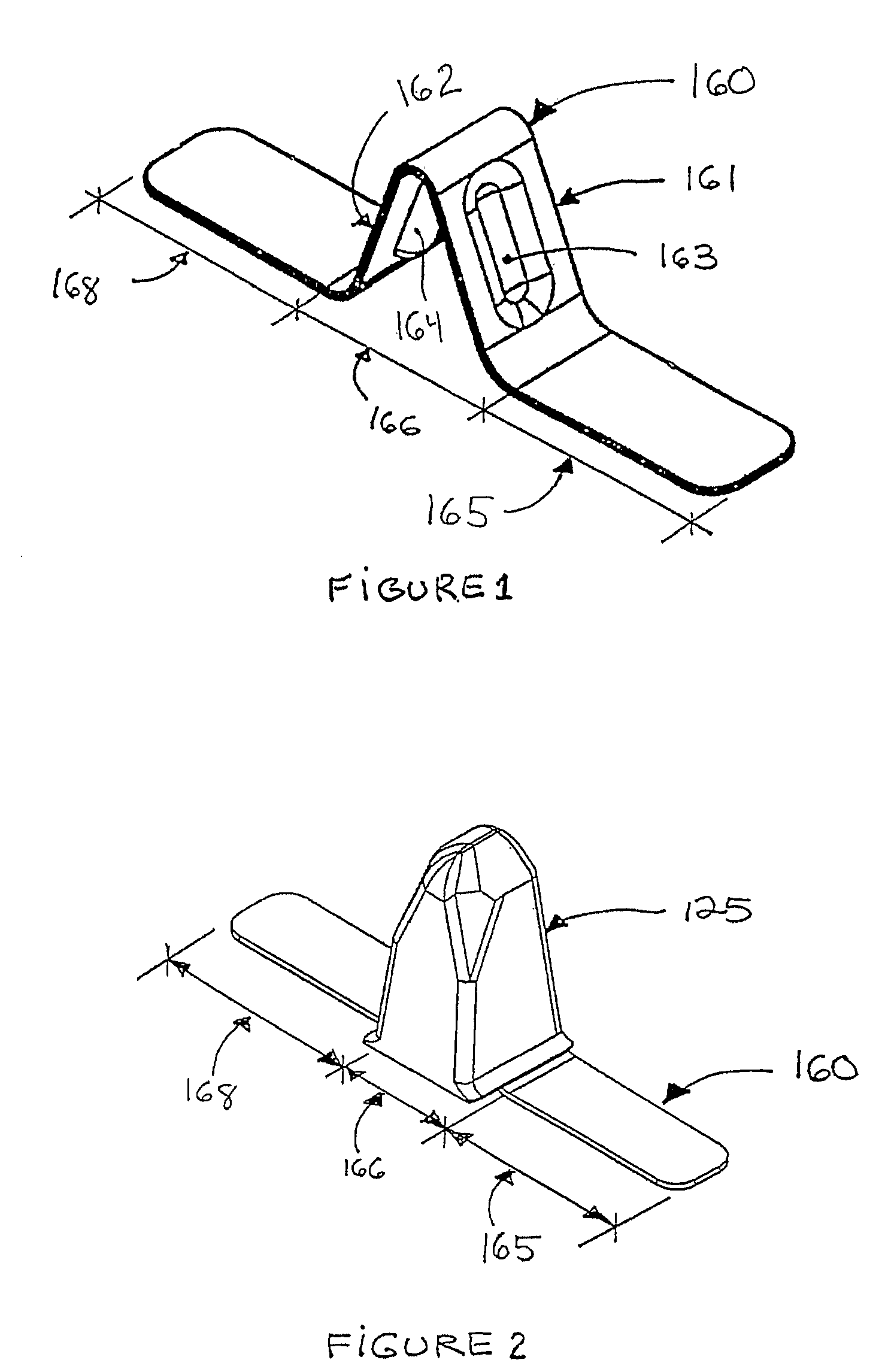

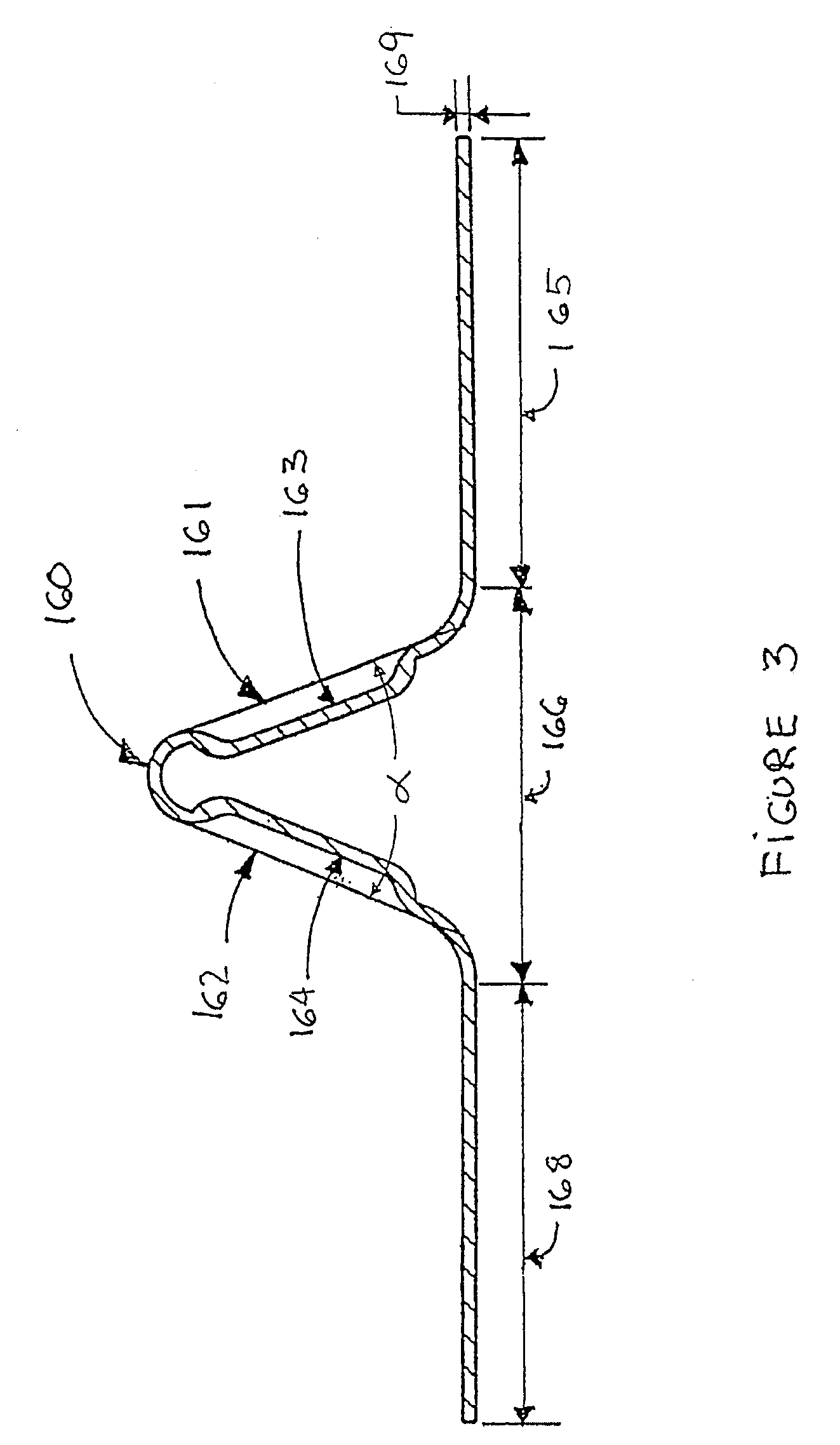

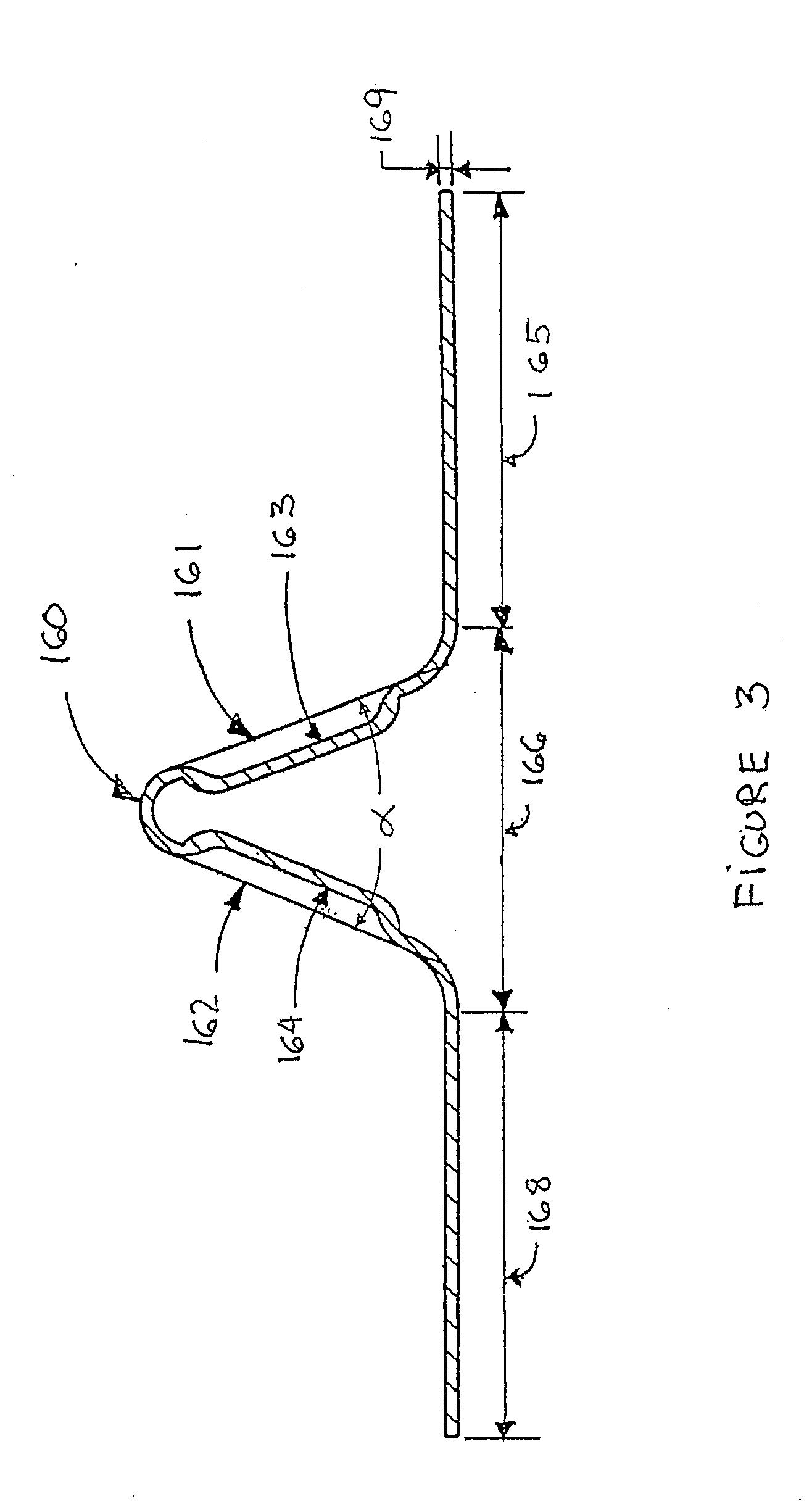

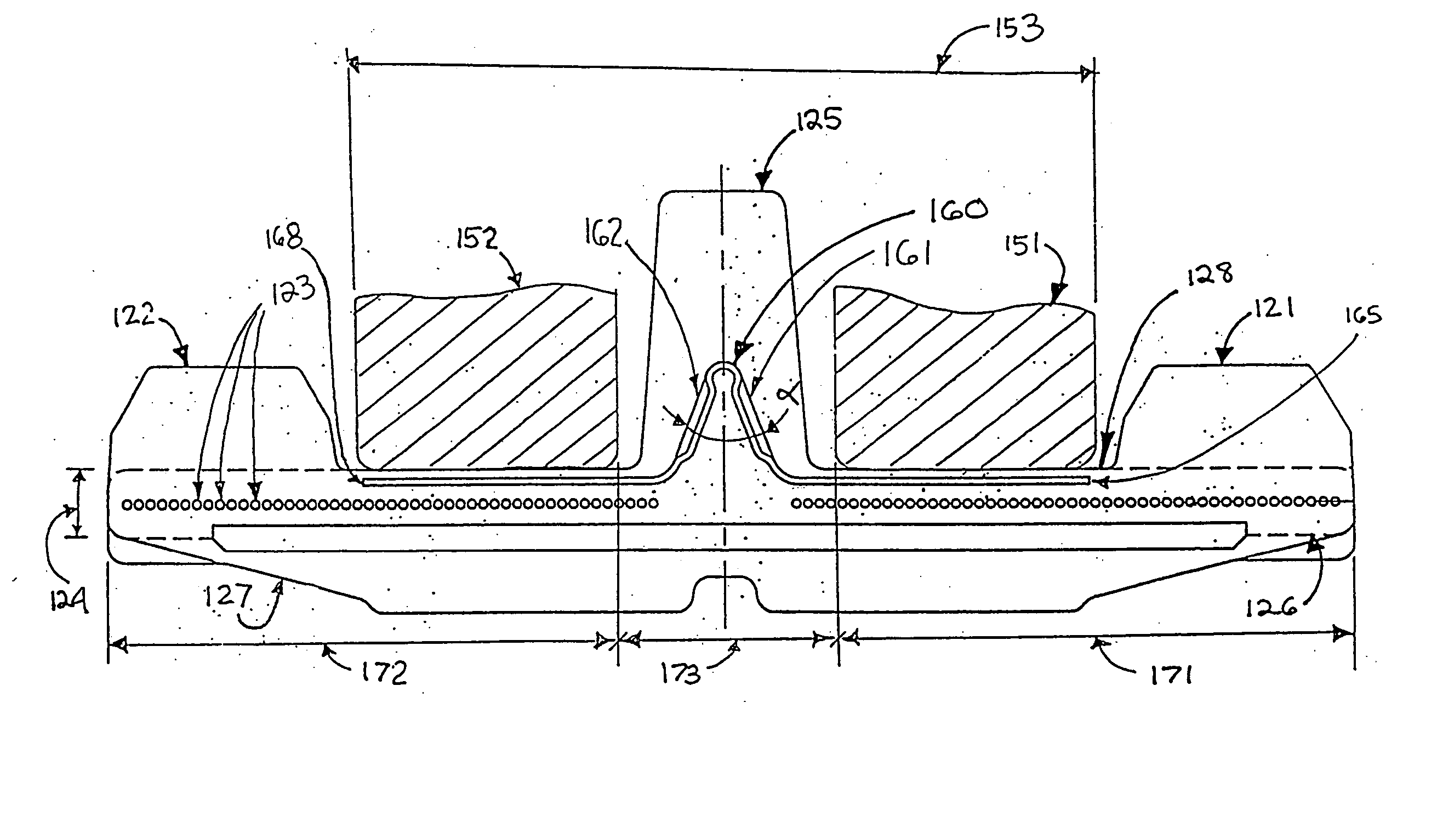

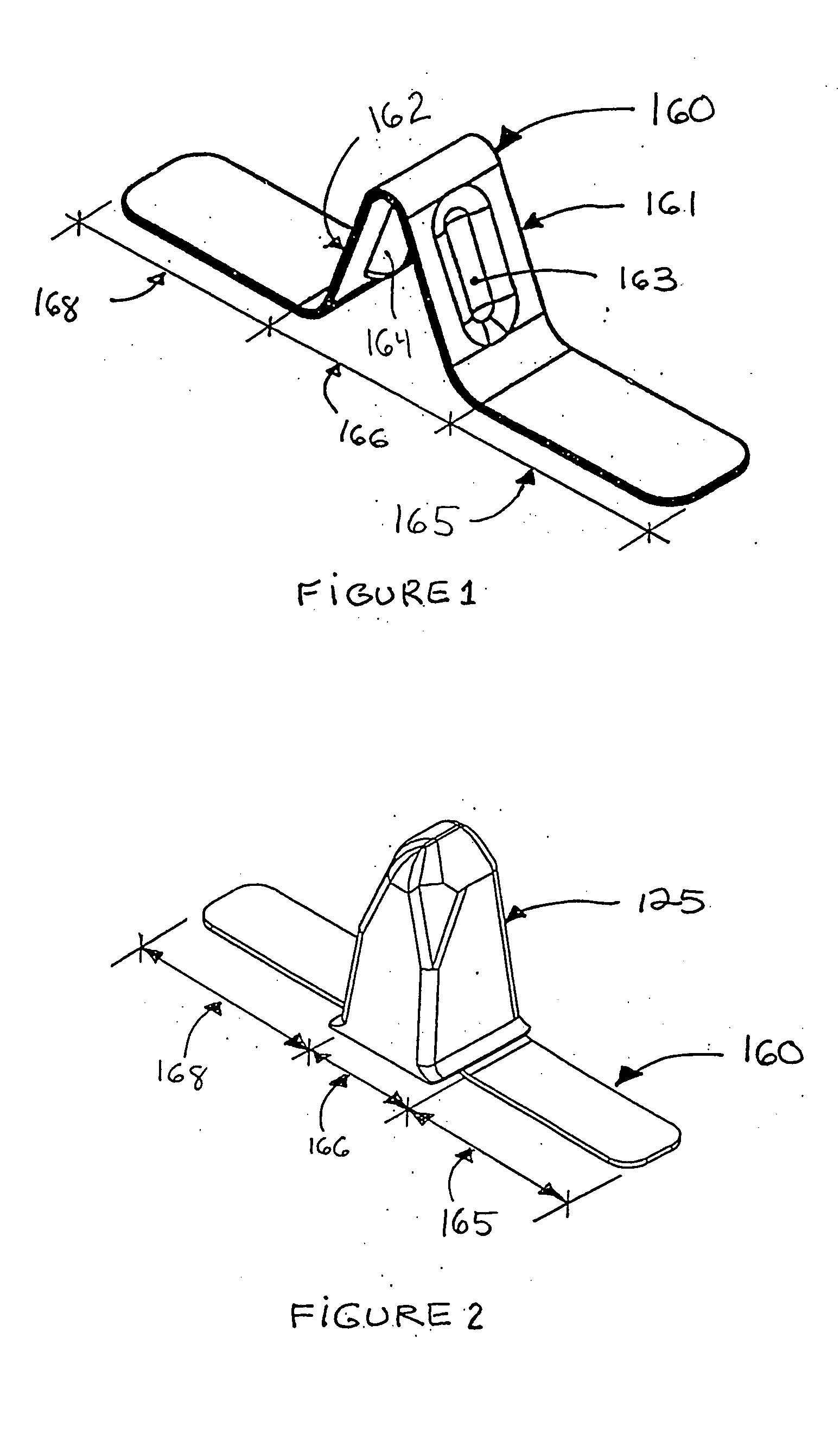

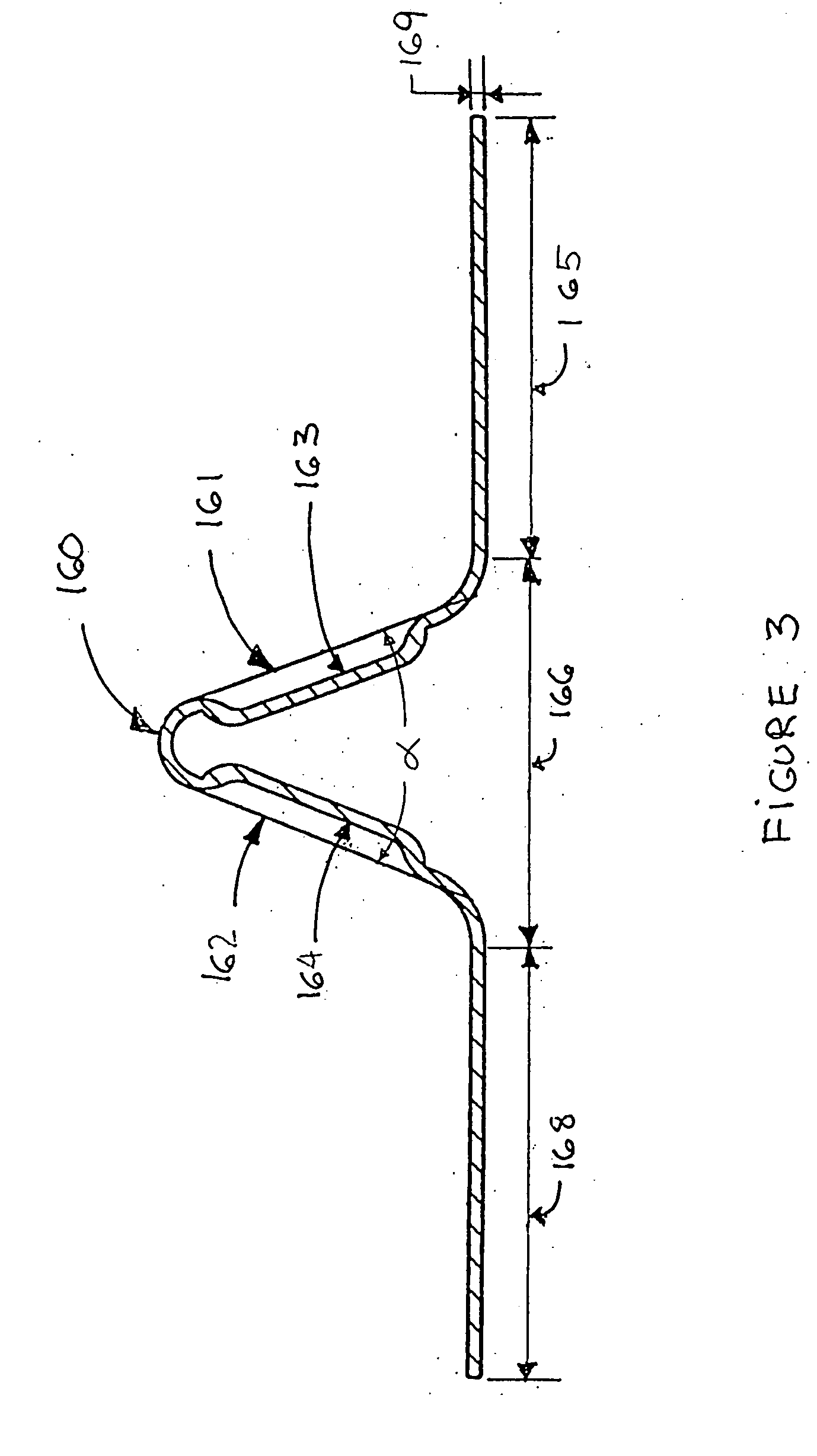

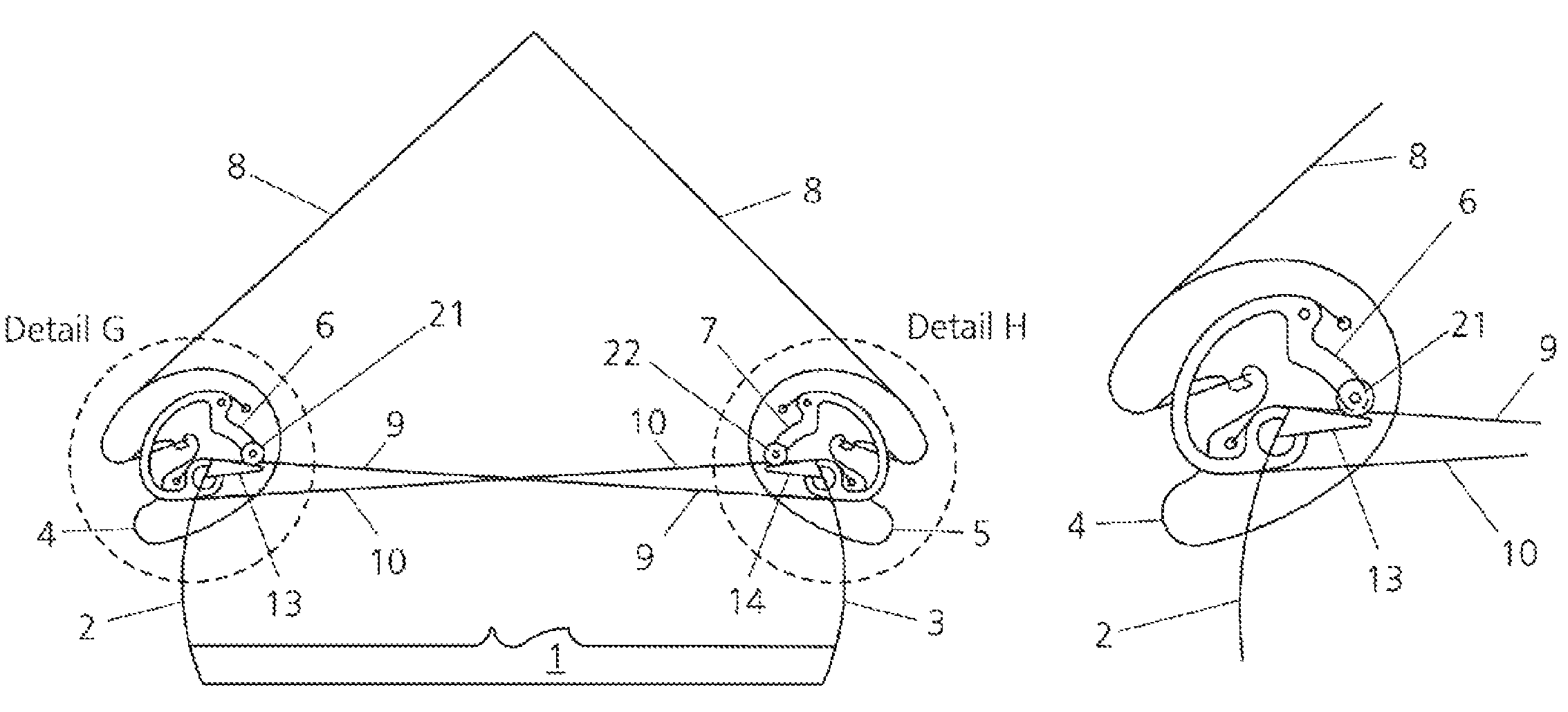

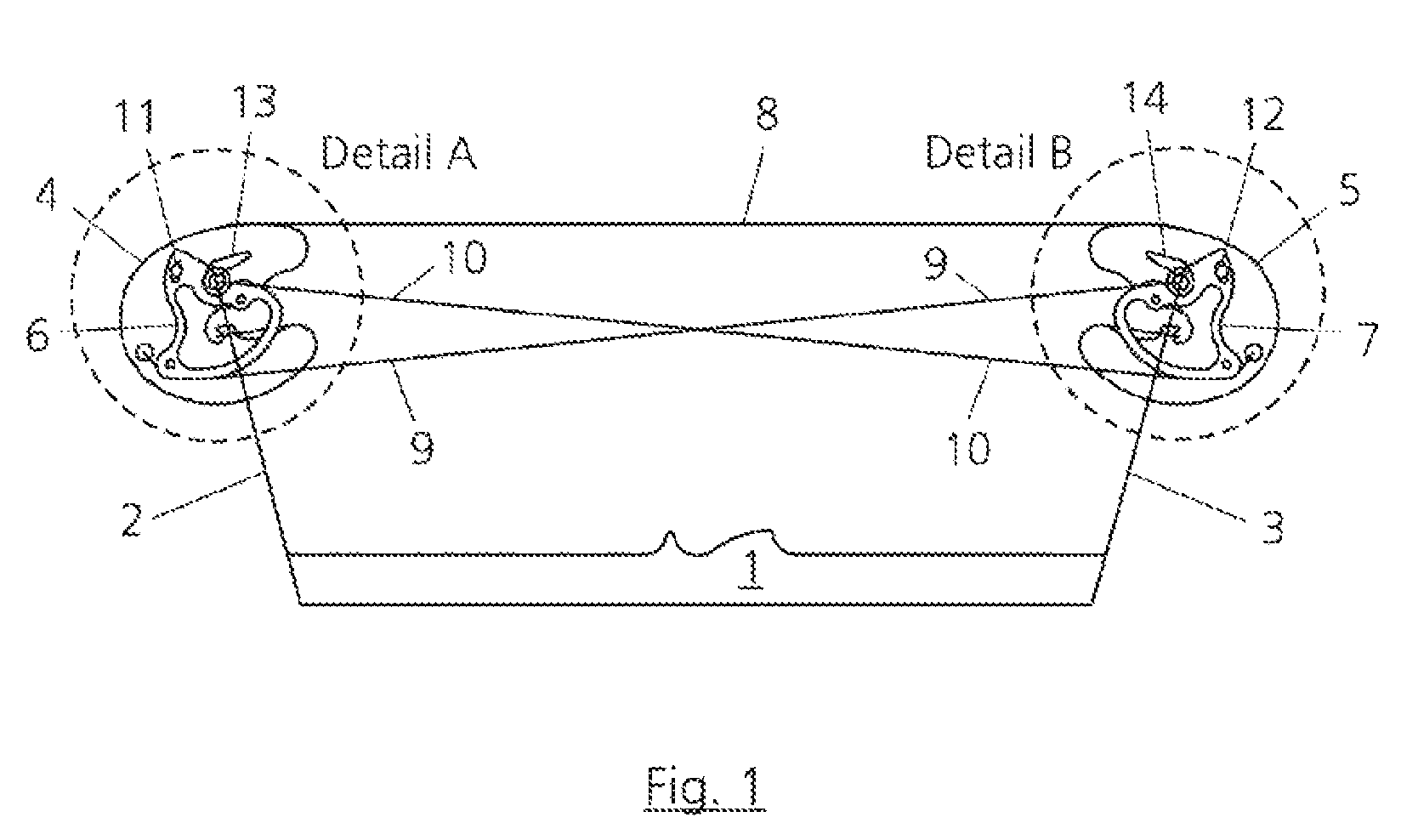

Elastomeric Track with Guide Lug Reinforcements

ActiveUS20080100134A1Enhance lateral rigidity and resiliencyReduce lateral deformationEndless track vehiclesMechanical engineeringClassical mechanics

Owner:SOUCY INT

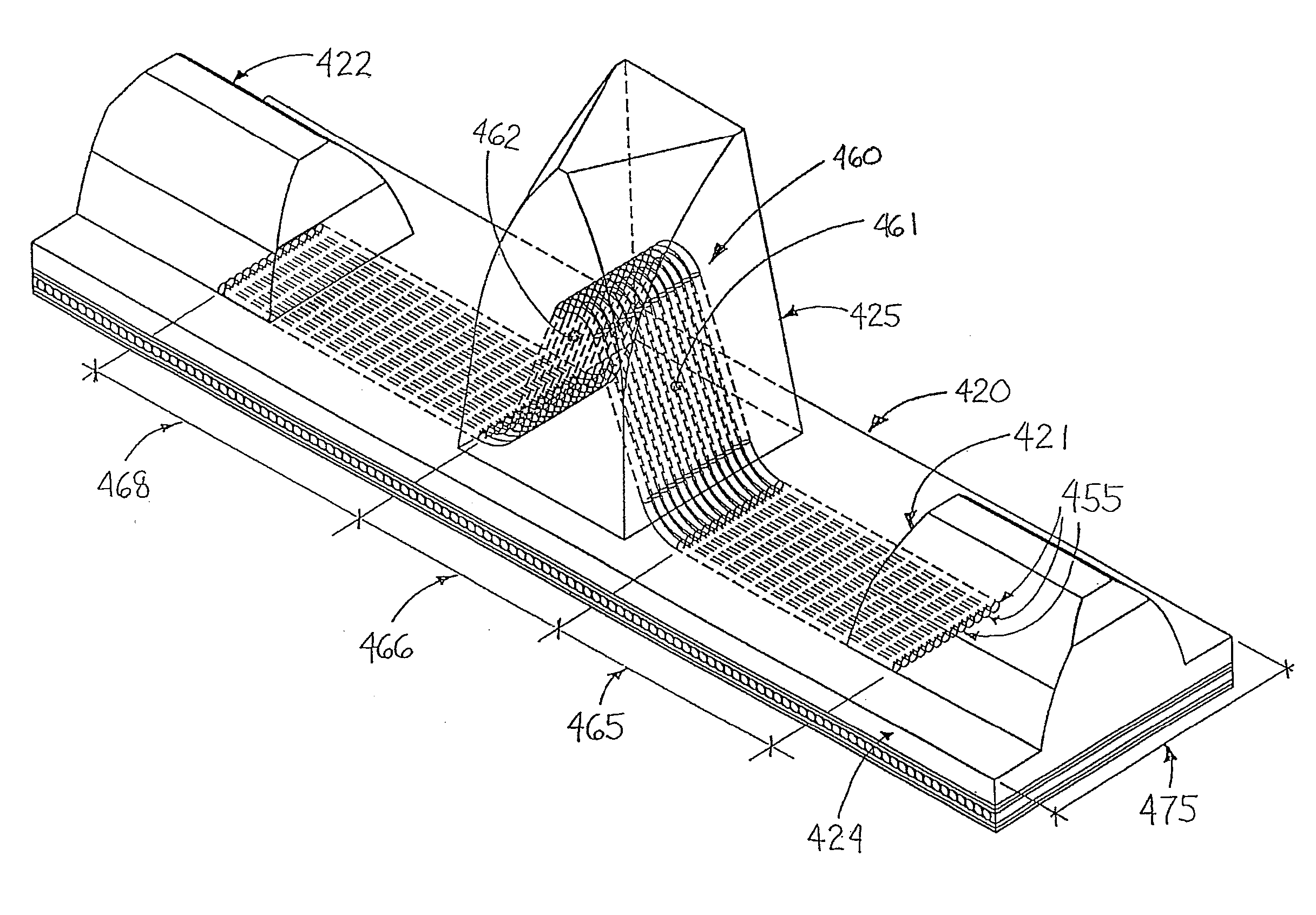

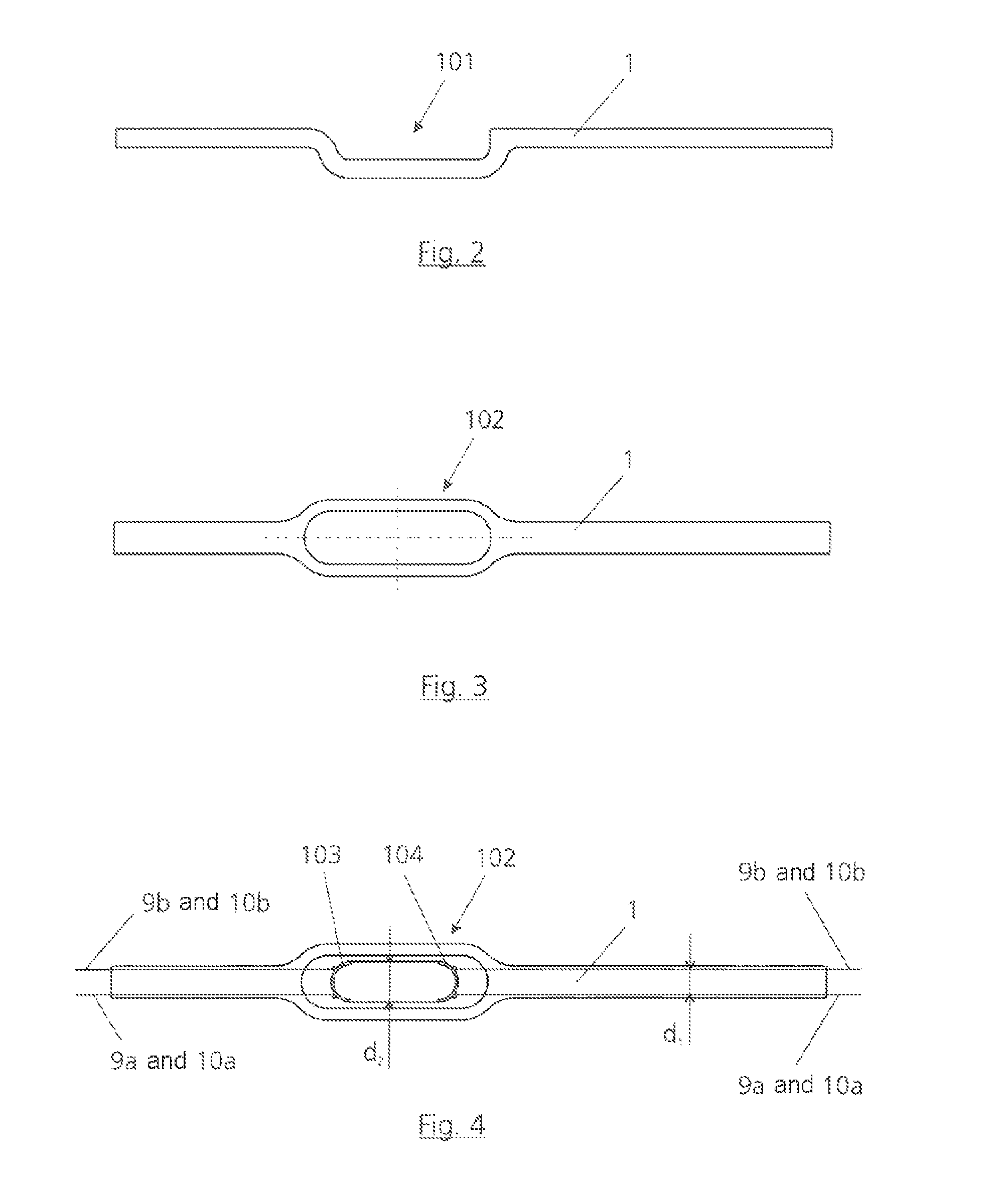

Elastomeric traction band with lug reinforcements

InactiveUS20040222697A1Increase lateral stiffnessReduce lateral deformationDriving beltsAlighting gearEngineeringTractor

This invention relates to an endless elastomeric traction band that is used to propel tracked vehicles [i.e., vehicles which use endless traction bands rather than tires to contact the terrain over which they are driven, e.g., tractors, tanks, bulldozers, etc.] and, more particularly, to the inner surface of such a traction band where lug reinforcements are inserted to laterally reinforce the guide lugs and minimize de-tracking occurrences.

Owner:SOUCY INT

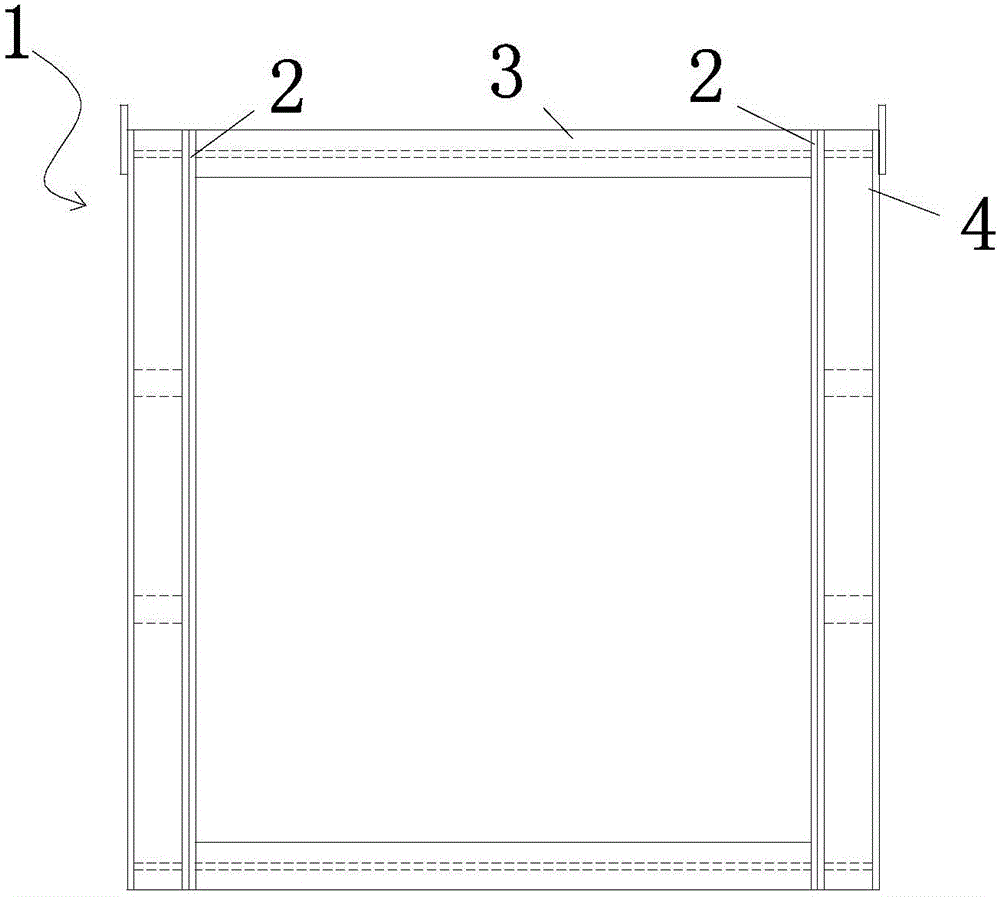

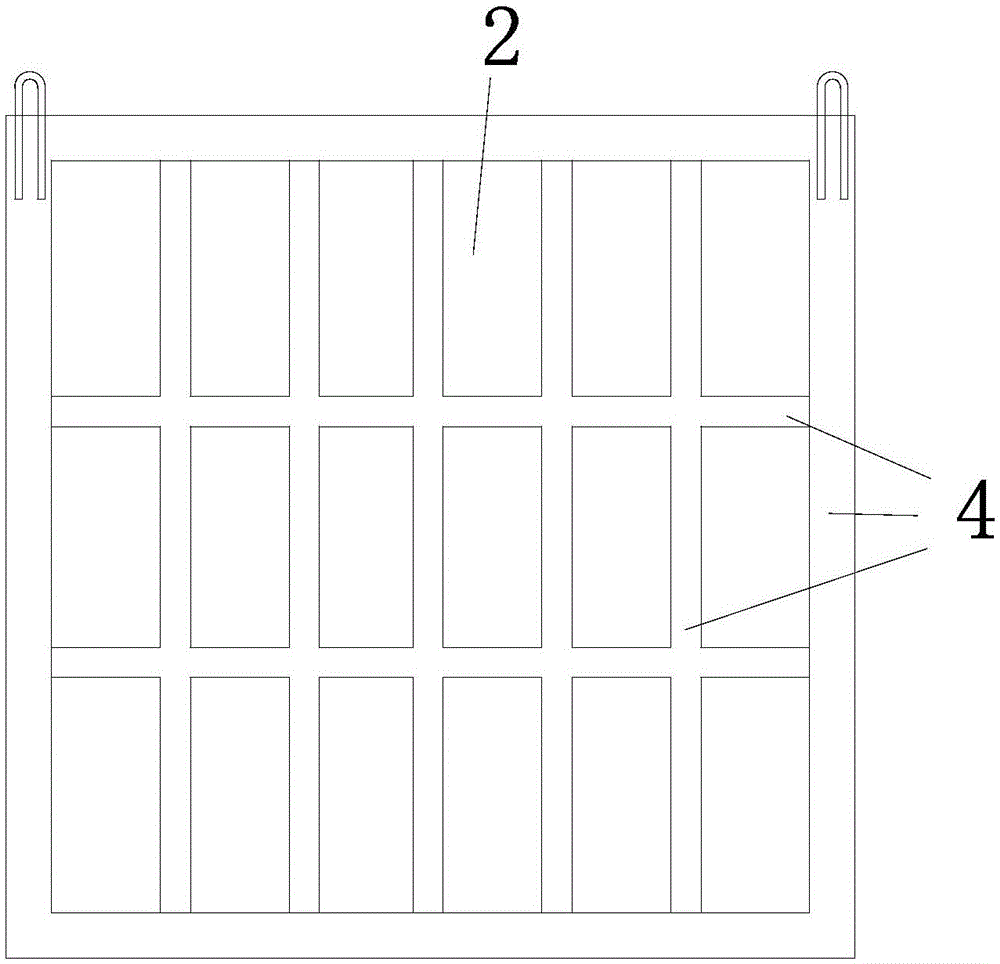

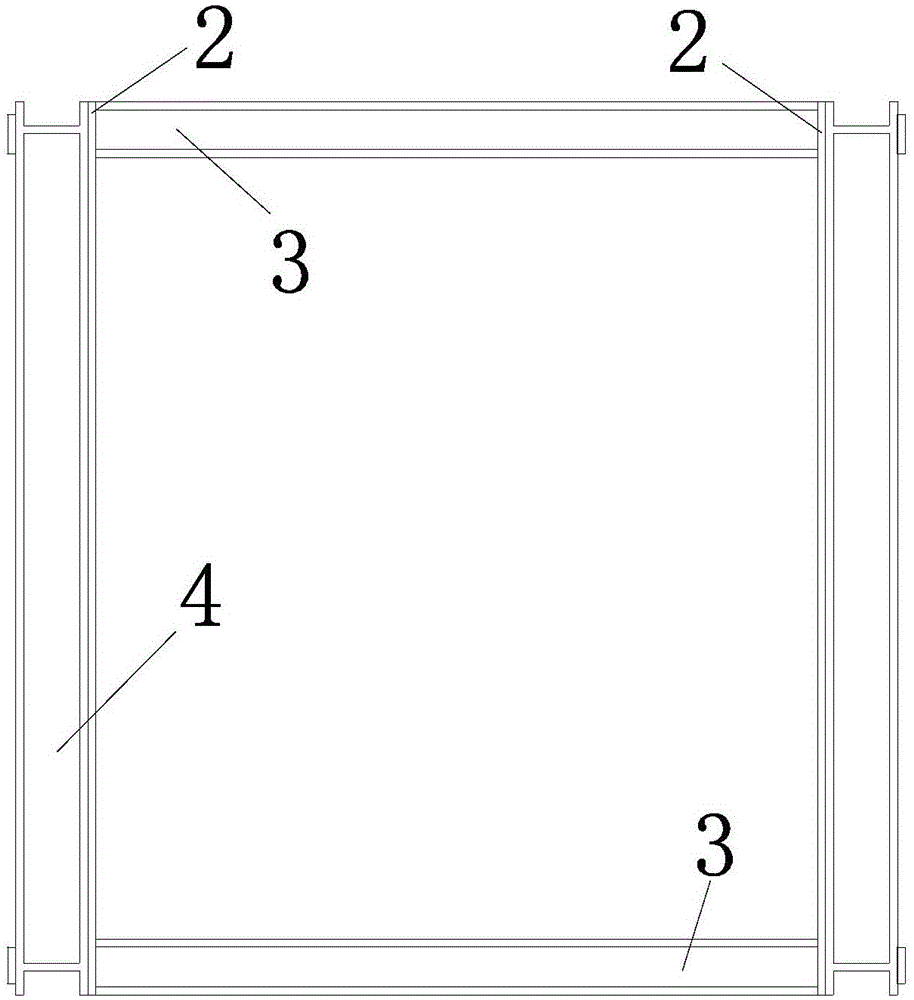

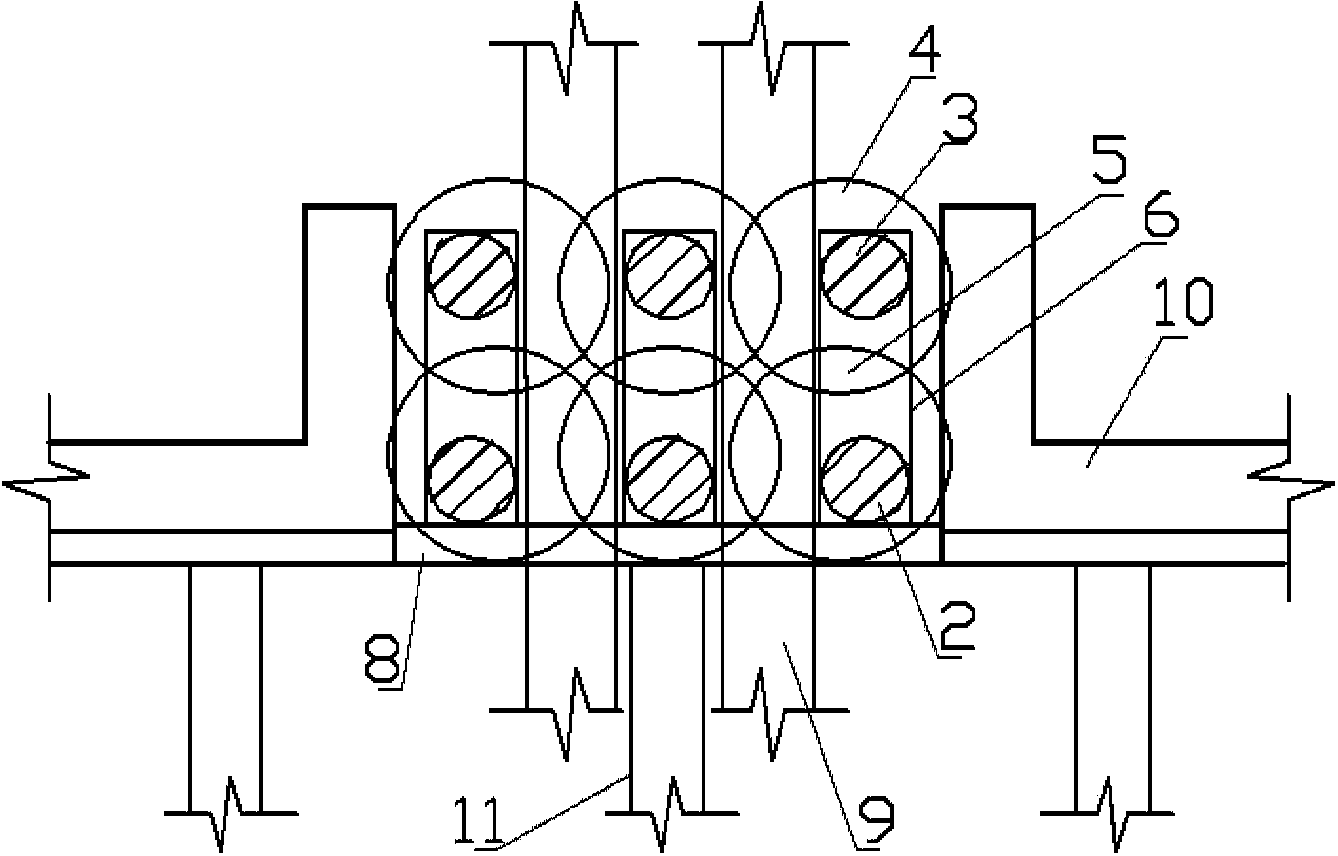

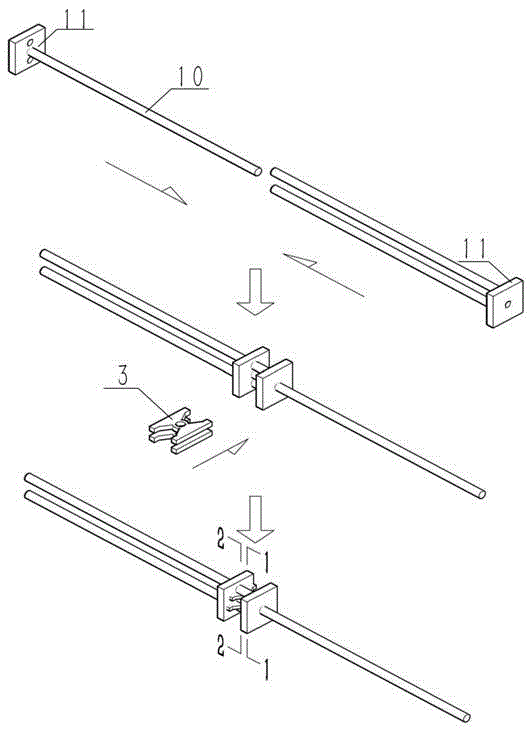

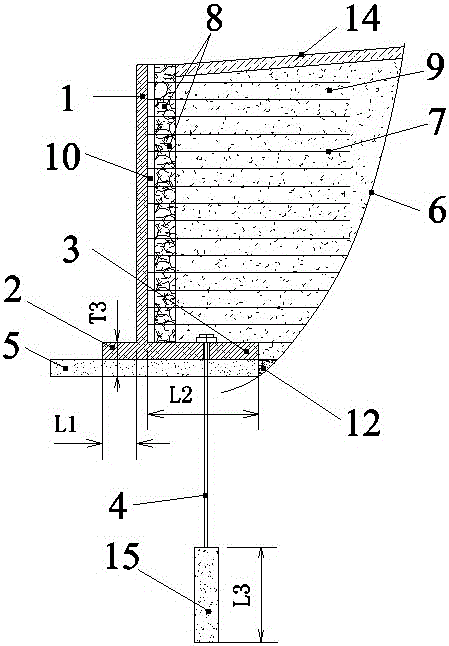

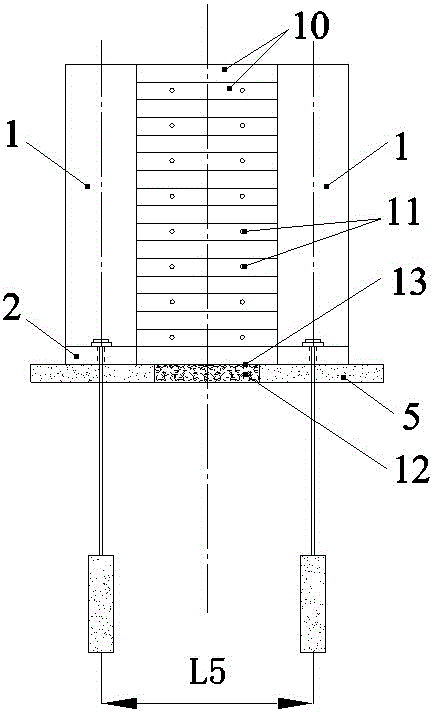

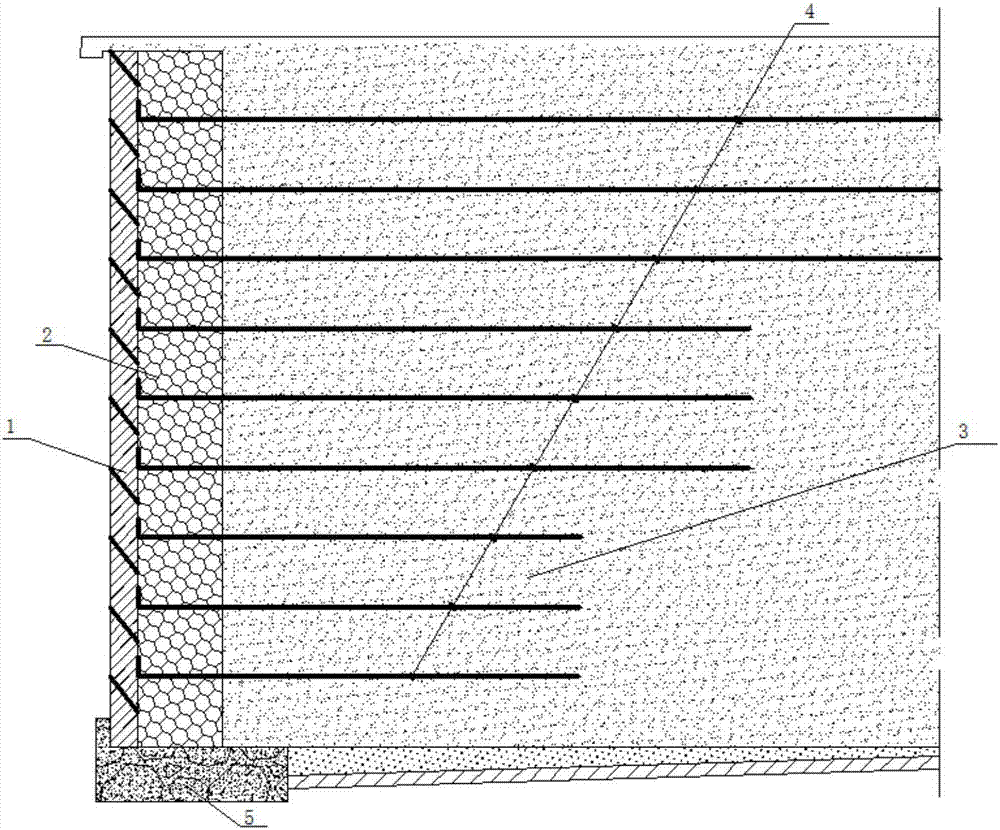

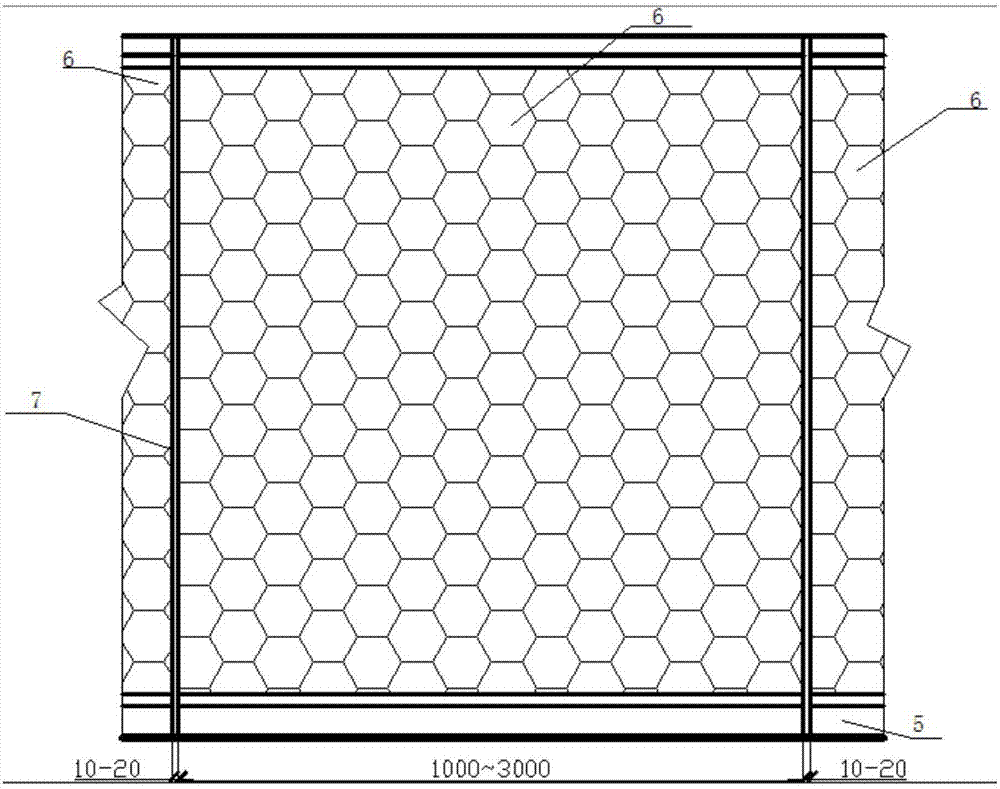

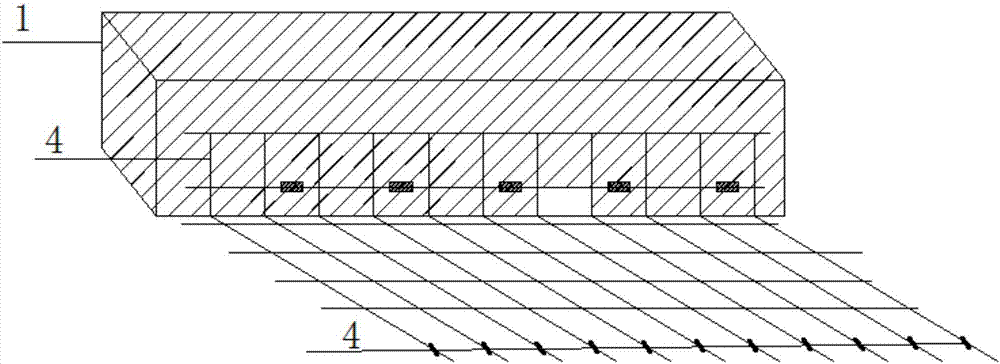

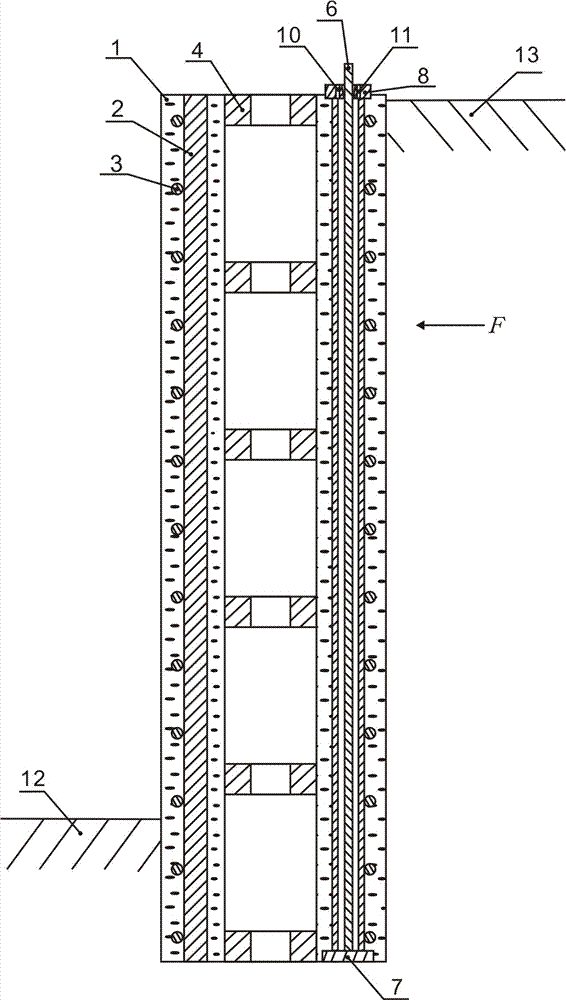

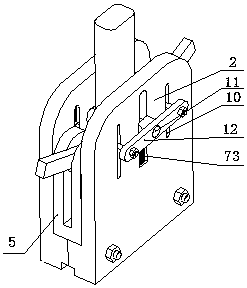

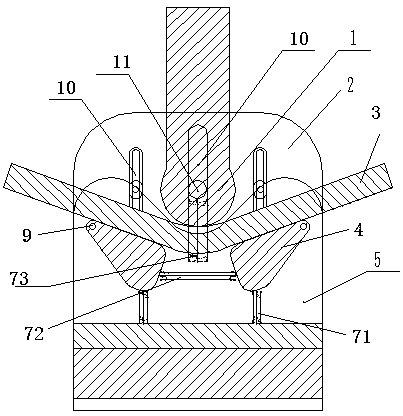

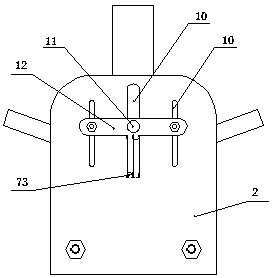

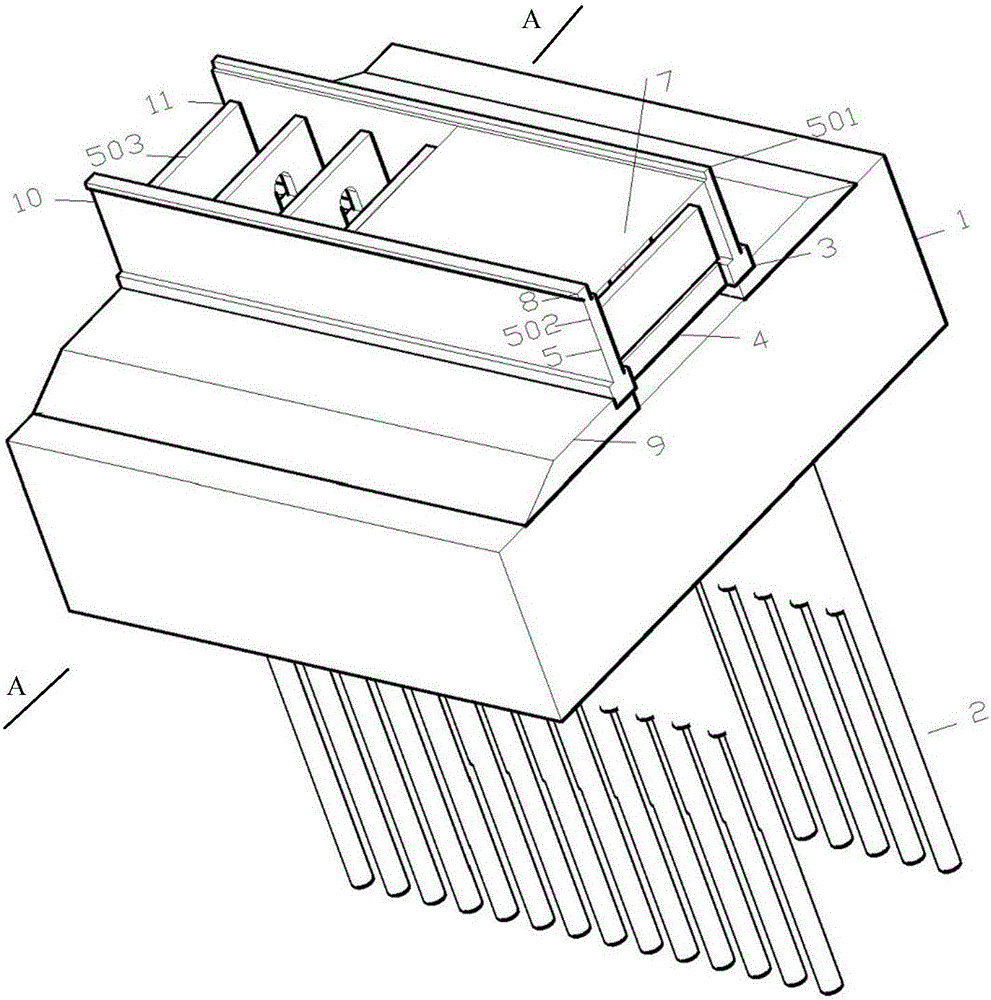

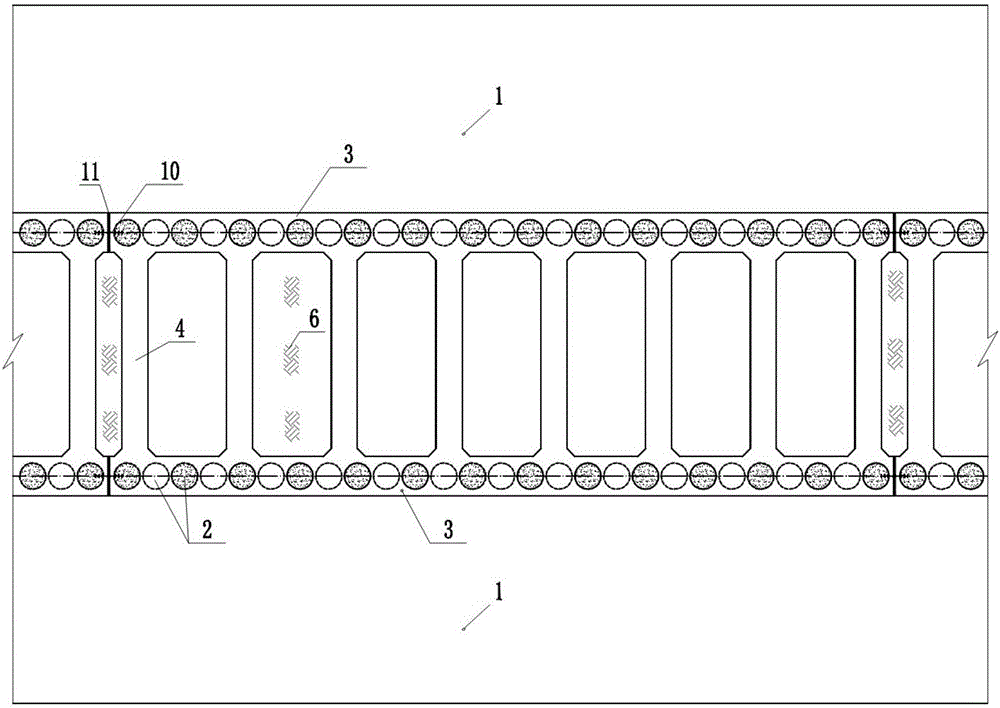

Reinforced earth retaining wall model test apparatus and method

ActiveCN105113555AMeasure the forceMeasured characteristicsFoundation testingFilling materialsVolumetric Mass Density

The invention discloses a reinforced earth retaining wall model test apparatus and method. The apparatus includes: a model case (1), a retaining wall panel (5), filling materials (7), a vertical load loading system (10) and a testing system. The filling materials (7) are put inside the model case (1). The retaining wall panel (5) is arranged in front of the model case (1). The vertical load loading system (10) is arranged above the model case (1) and applies vertical pressure to a model. According to the invention, the filling materials (7) are made of mixed cast-steel shots which have a density between 5.2g / cm<3> to 7.0g / cm<3> and an internal friction angle between 28 DEG to 35 DEG. The density of the mixed cast-steel shots is 3-4 times greater than that of ordinary sand filling materials, and the internal friction angle of the mixed cast-steel shots is similar to that of ordinary sands. A stress field is made equivalent by increasing the density of the filling materials, so that the stress state of the filling materials of a retaining wall is made to be equivalent, and the stress and deformation characteristics of the model can be measured effectively. The filling materials can be used repeatedly for many times, which significantly reduces the cost of the testing.

Owner:HUNAN UNIV

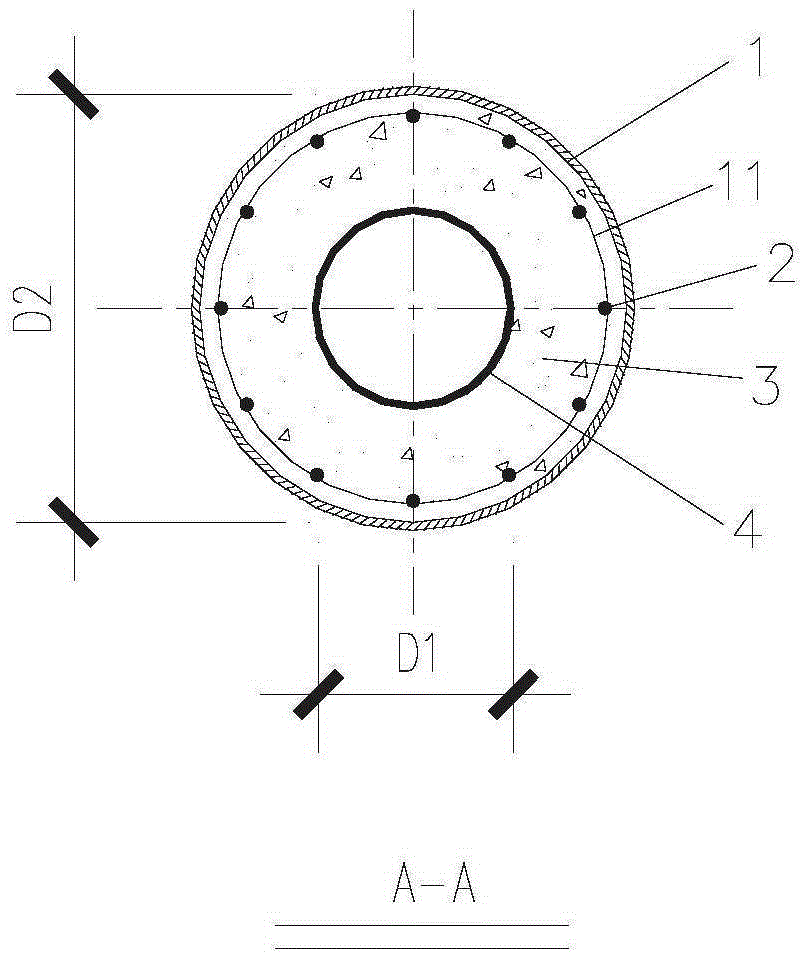

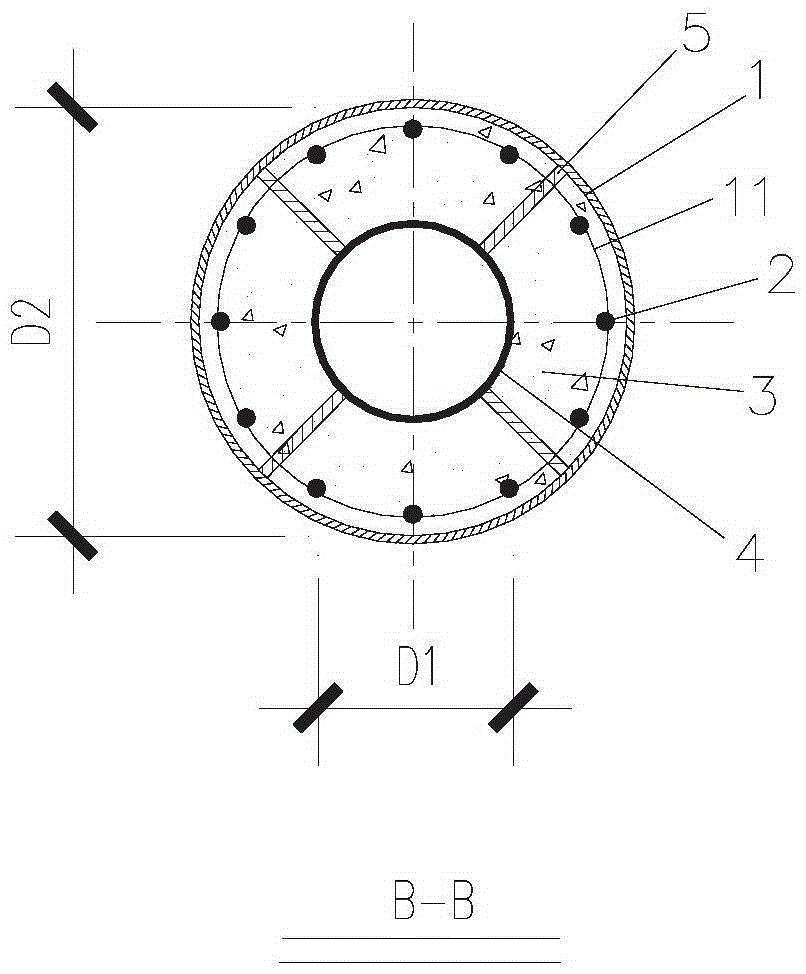

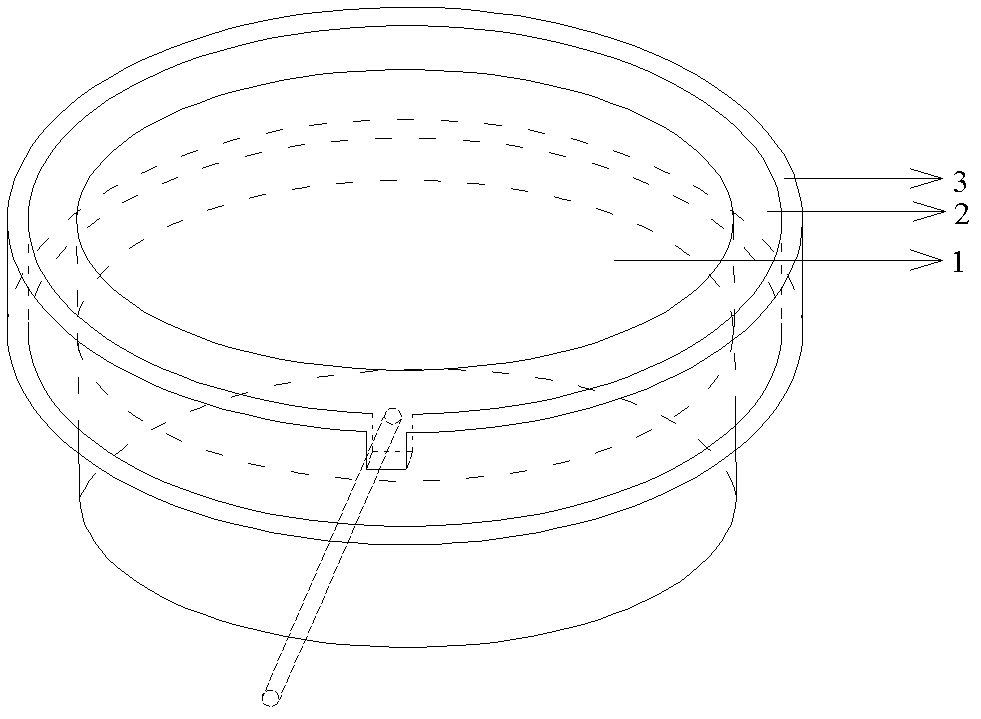

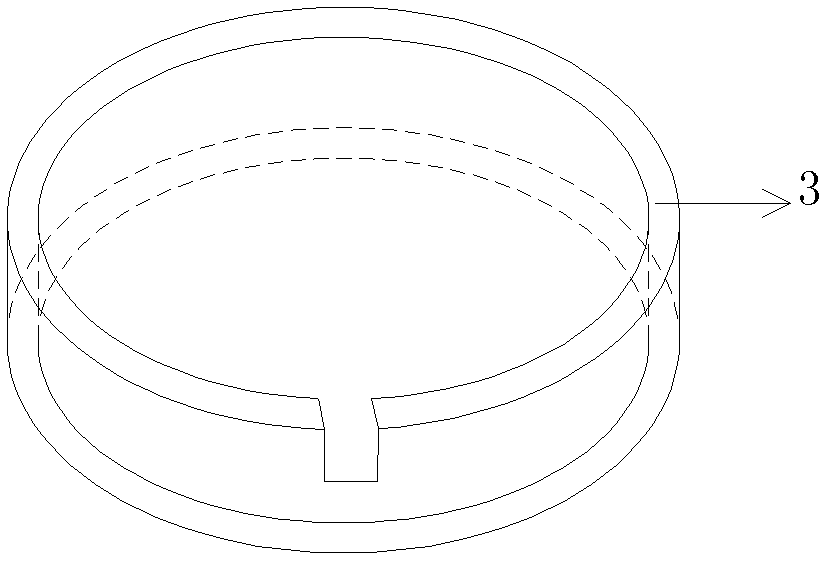

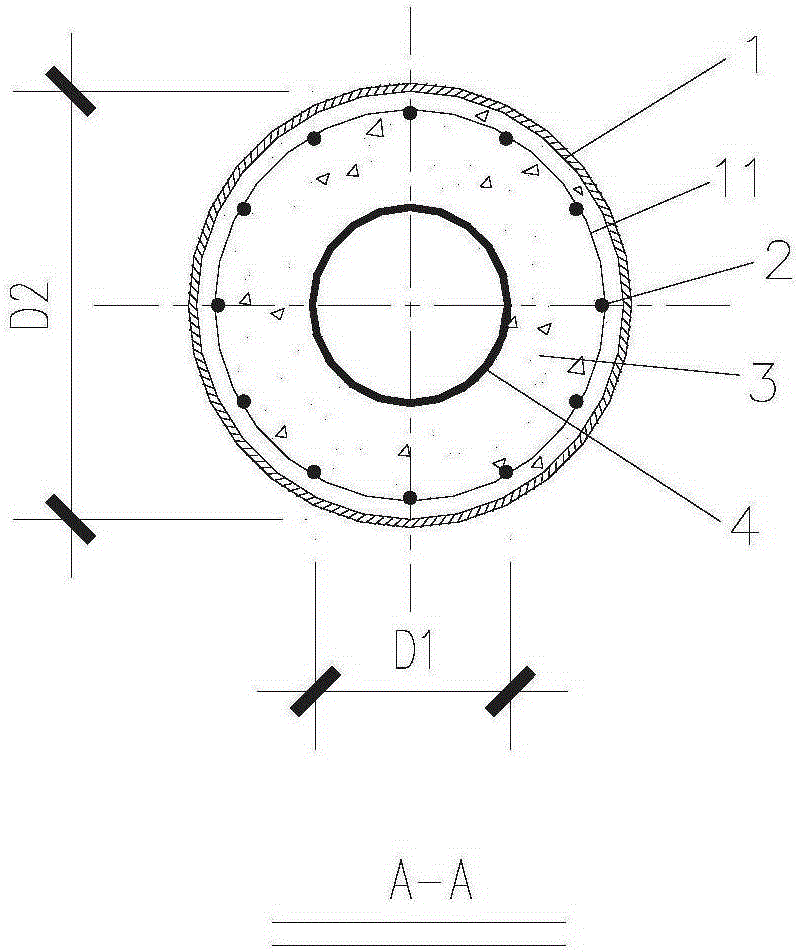

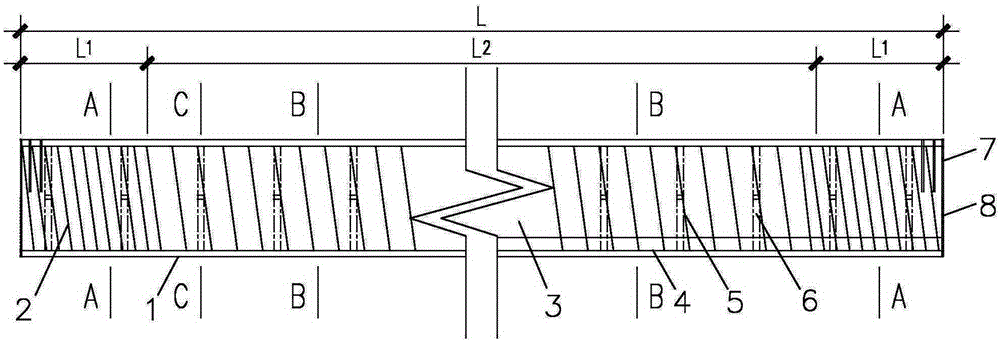

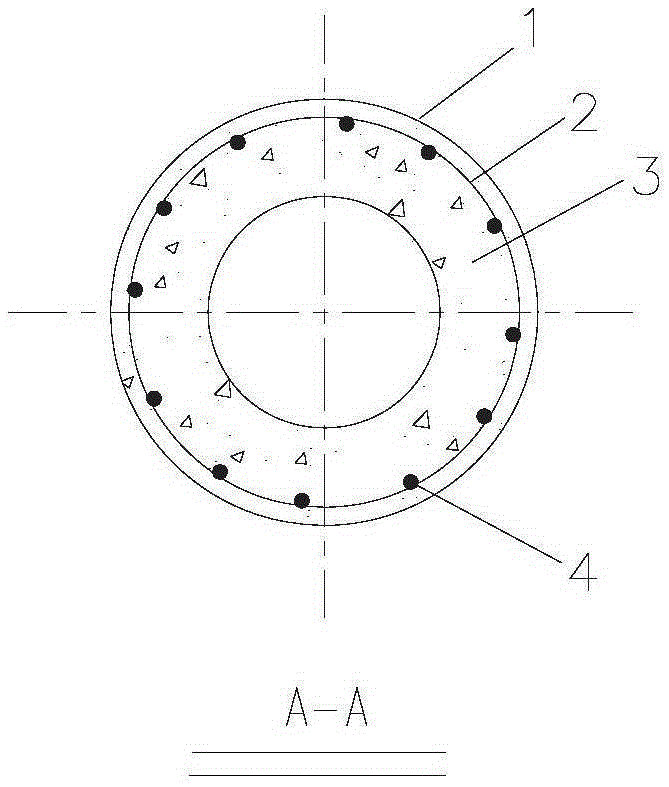

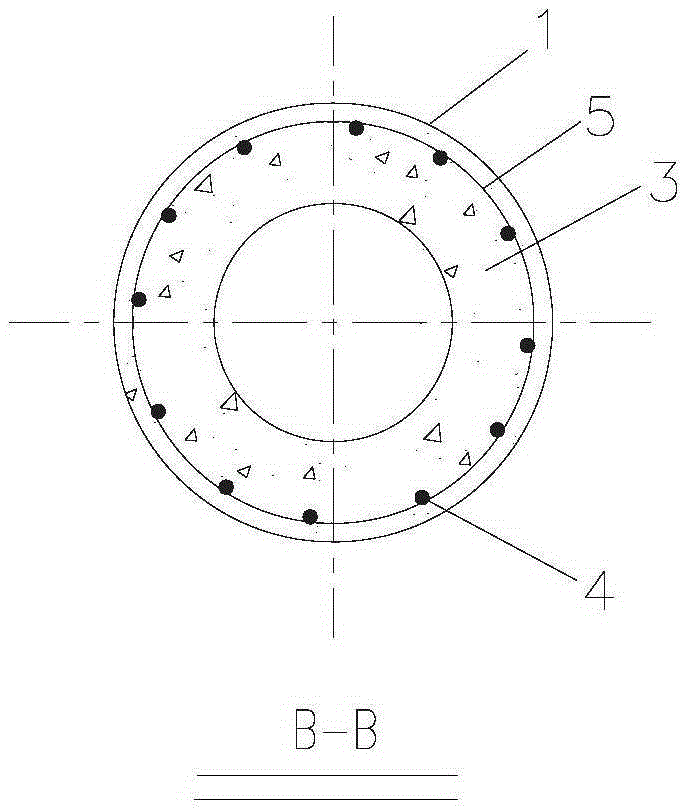

FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile

InactiveCN105386443AStop erosionInhibit deteriorationBulkheads/pilesThick wallFoundation engineering

The invention discloses an FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile which is mainly formed by an FRP pipe, a round reinforcement cage framework, a thick-wall steel pipe and recycled concrete. The round reinforcement cage framework and the thick-wall steel pipe are arranged in the FRP pipe, and the round reinforcement cage framework, the thick-wall steel pipe and the FRP pipe are arranged concentrically. The recycled concrete is poured in annular space between the FRP pipe and the thick-wall steel pipe. The bearing capacity and deformation resisting capacity of the single pile can be greatly improved through the built-in thick-wall steel pipe. The wrapping FRP pipe can effectively prevent a pile body from being corroded, and the durability of the pile body is improved. Meanwhile, the FRP pipe and spiral stirrups are combined to restrain the inner recycled concrete, and the bearing force of the compounding pile is further improved. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated. In a word, the compounding hollow recycled concrete pile has the advantages of being good in pile forming quality, high in bearing force, good in deformation resisting capacity and durability, small in influence on the environment, high in construction speed and the like.

Owner:GUANGXI UNIV

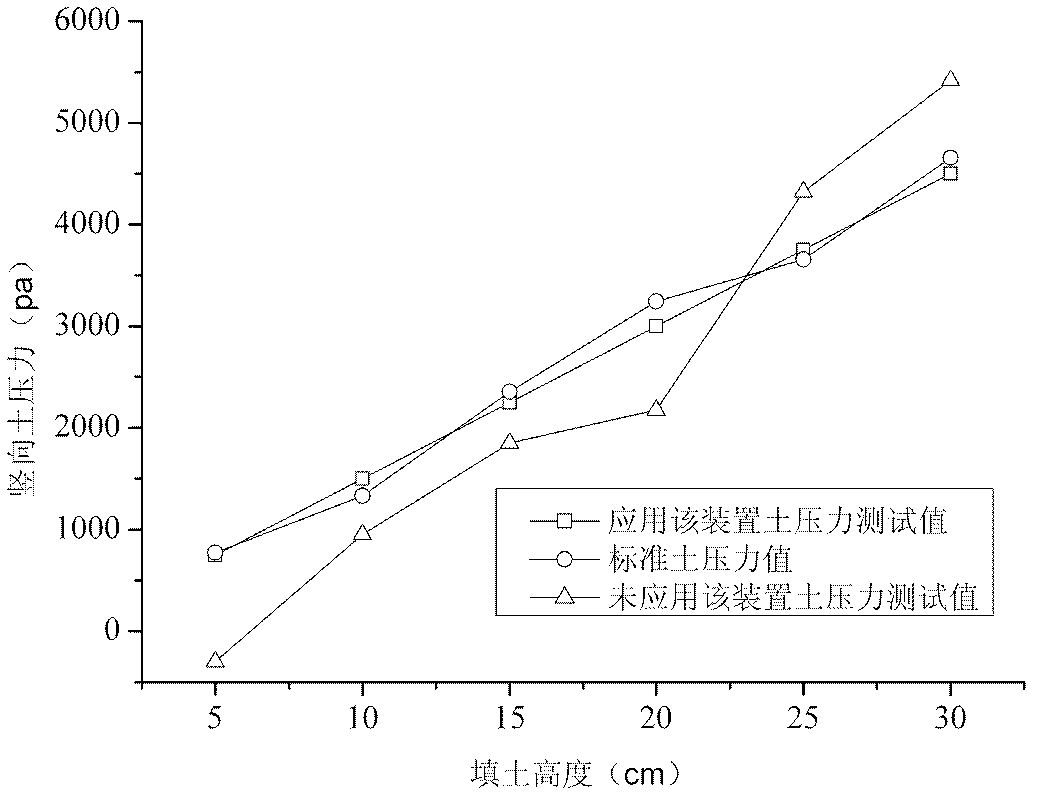

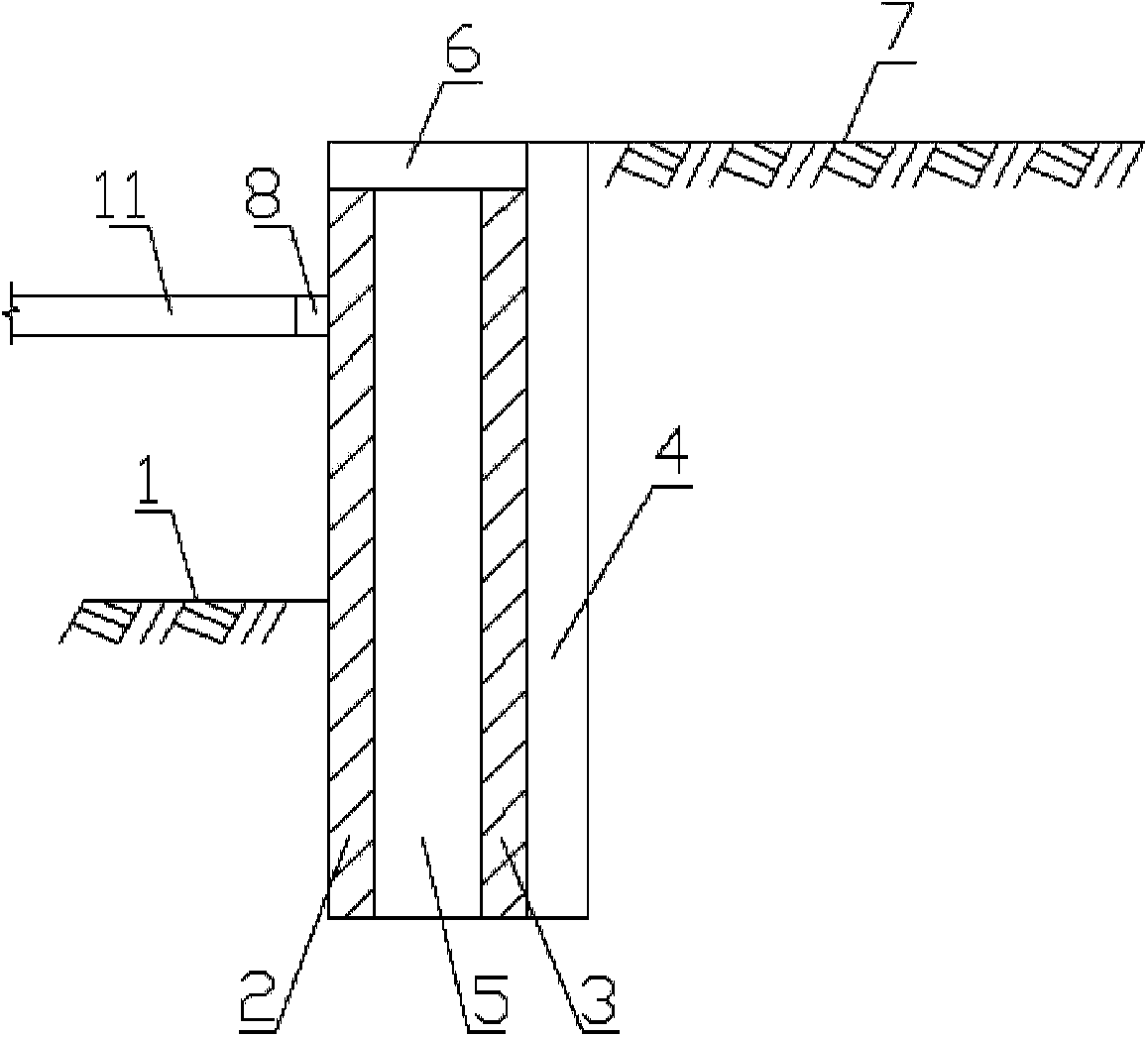

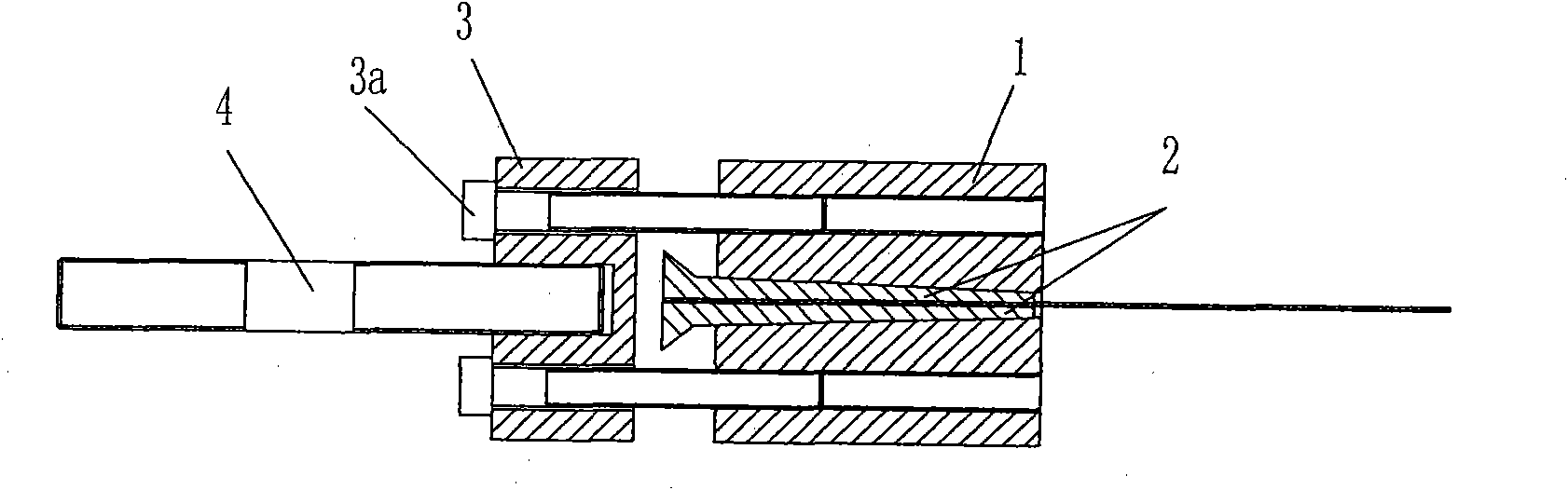

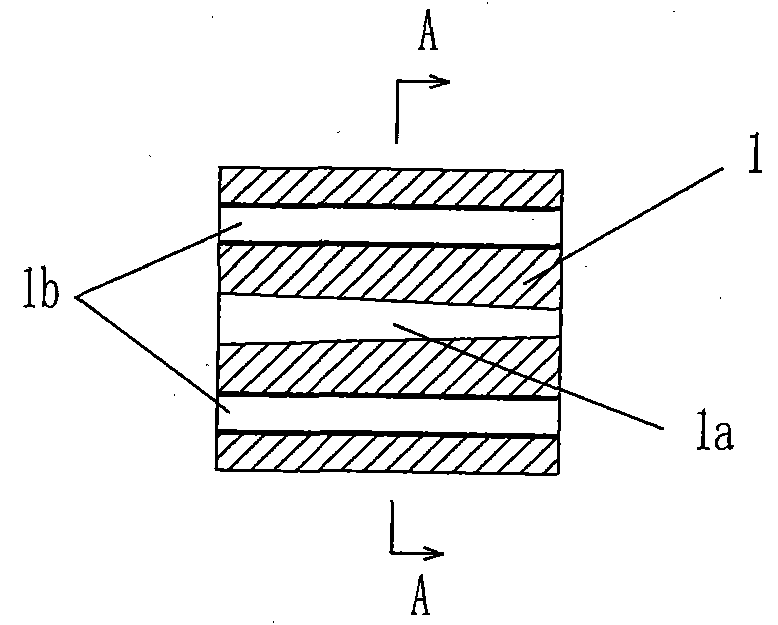

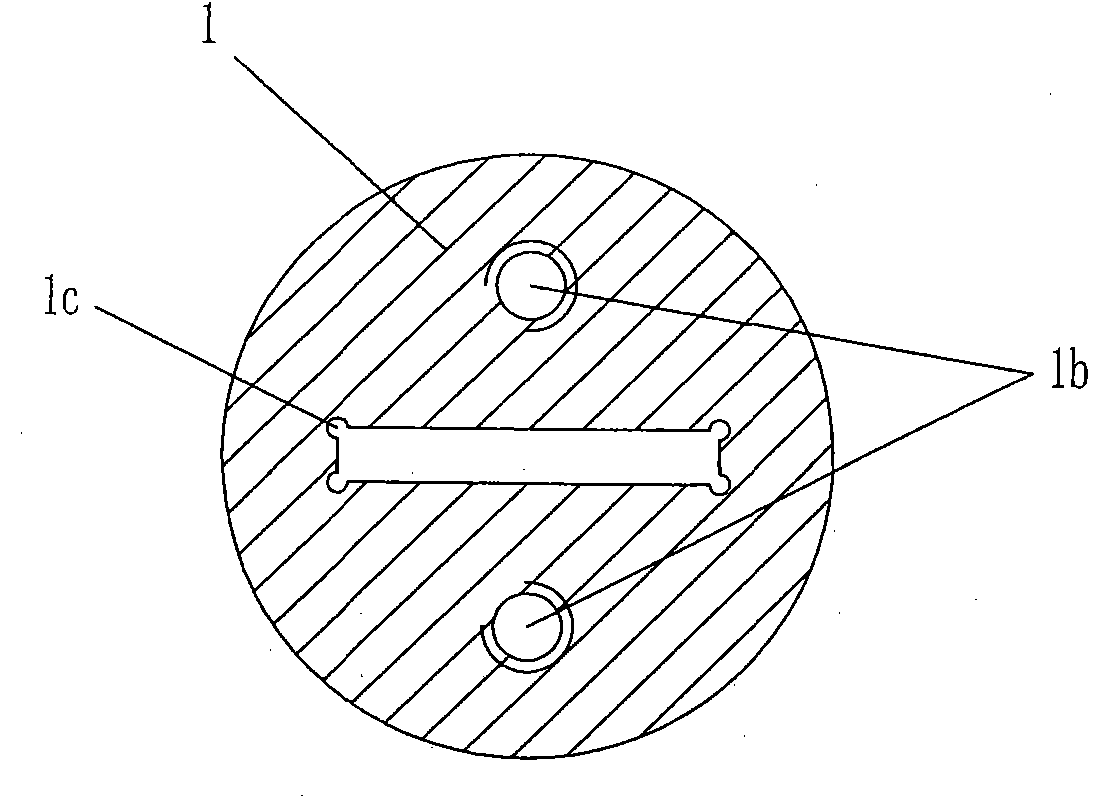

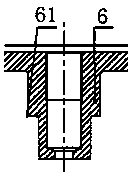

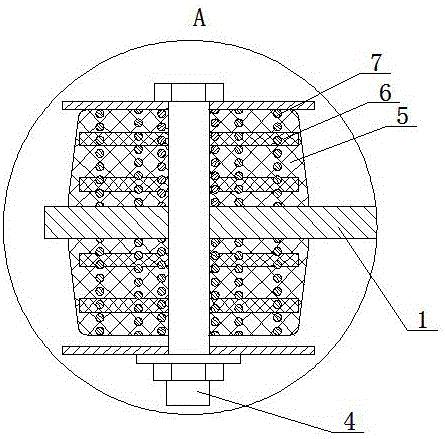

Device used in rock and soil test for improving testing accuracy of micro earth pressure cell

InactiveCN102589756AReduce lateral deformationImprove test accuracyForce measurementPressure cellPressure measurement

The invention belongs to the technical field of civil engineering, and particularly relates to a device used in the rock and soil test for improving the testing accuracy of a micro earth pressure cell. The device includes a micro earth pressure cell, a sponge ring and a steel ring, wherein the micro earth pressure cell (1) is provided with a data line; a side notch of the steel ring is used for leading out and fixing the data line of the micro earth pressure cell (1); the sponge ring (2) is sleeved on the outer side surface of the micro earth pressure cell (1); the steel ring (3) is sleeved on the outer side surface of the sponge ring (2); and the micro earth pressure cell, the sponge ring and the steel ring are connected through a binder. The device solves the problem of inaccuracy in earth pressure measurement during the civil engineering construction process, and has the characteristics of high accuracy, simple operation and good economical efficiency.

Owner:BEIJING UNIV OF TECH

Supporting structure of foundation pit

The invention discloses a supporting structure of a foundation pit. The supporting structure comprises jet grouting piles and a double-row pile structure which is inserted in the jet grouting piles, wherein the jet grouting piles are high-strength cement-soil pile bodies formed on a soil body around the foundation pit, and the multiple jet grouting piles are in mutual lap joint to form a reinforcing region; the double-row pile structure comprises a first row of cast-in-place piles, a second row of cast-in-place piles and connecting beams, the connecting beams are connected with the tops of the first row of cast-in-place piles and the tops of the second row of cast-in-place piles, and the first row of cast-in-place piles, the second row of cast-in-place piles and the connecting beams are all of a reinforced concrete structure. According to the scheme, the supporting structure aims to brace the deep foundation pit under the complicated geological condition with rich water and soft soil and under the condition that complicated barriers cut through the upper portions of the foundation pit; when the barriers such as cables cut through the upper portion of the foundation pit, the intervals between the cast-in-place piles can be flexibly adjusted to avoid the barriers; the large-diameter high-pressure jet grouting piles are in mutual lap joint, can effectively stop water and can control horizontal displacement of the soil body outside the pit along with the double rows of cast-in-place piles; the supporting structure formed by the cast-in-place piles is constructed in the large-diameter jet grouting piles, and therefore construction sites outside the foundation pit are saved.

Owner:CCCC HIGHWAY CONSULTANTS +1

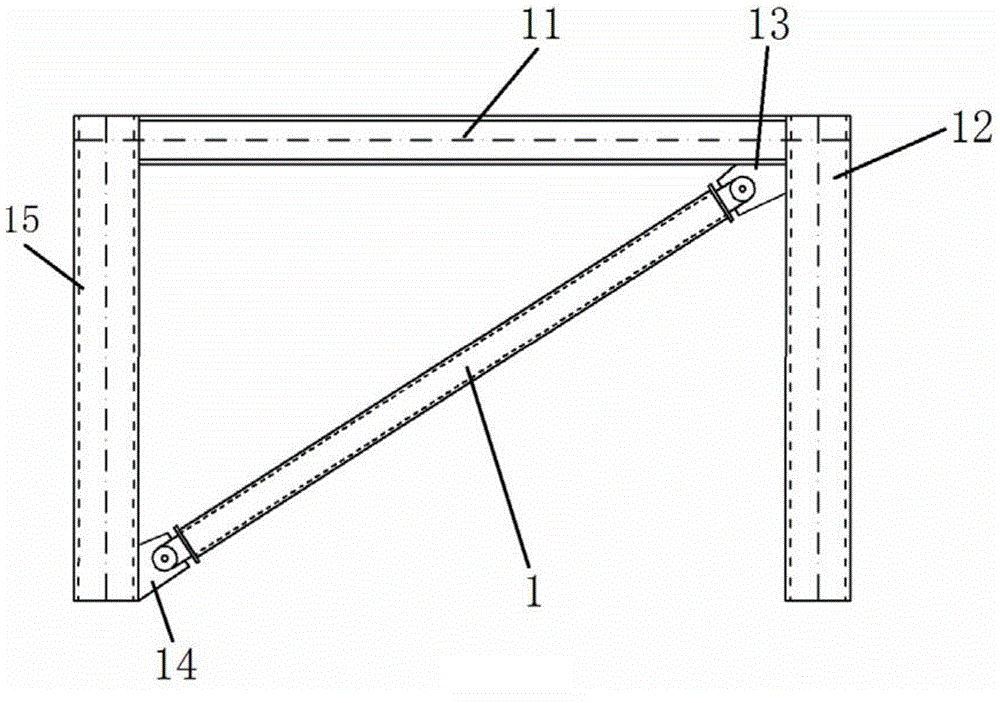

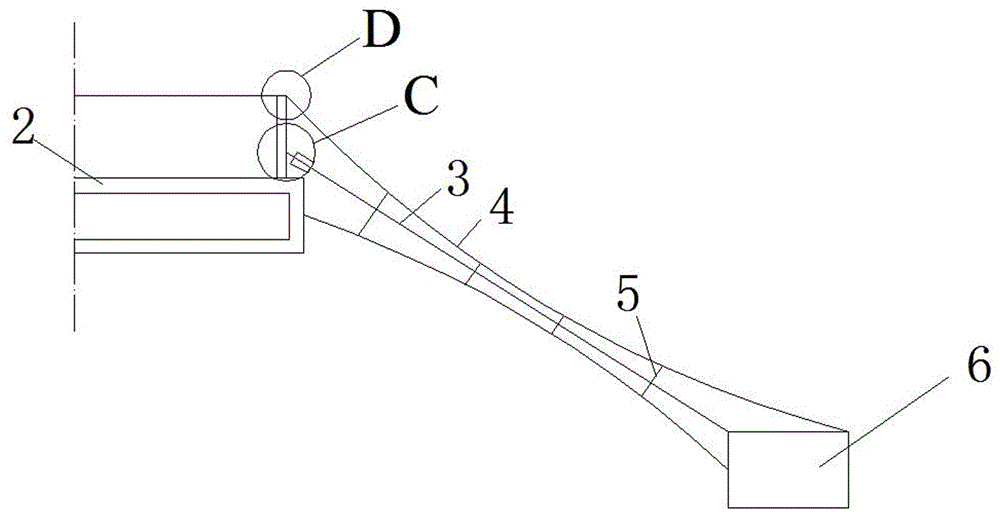

Self-resetting soft steel energy dissipating brace

InactiveCN105421610AReduce lateral deformationReduce maintenanceBridge structural detailsShock proofingResidual deformationStructural engineering

The invention relates to a self-resetting soft steel energy dissipating brace, which mainly consists of a brace component, a prestress device, an energy dissipating device and a plurality of fixed connecting components, wherein soft steel is connected with end plates through force transmission devices; one end of an inner sleeve is provided with a groove; a projected connecting plate can penetrate into the groove to be welded with the inner sleeve; an outer sleeve covers the inner sleeve; arc-shaped welding splicing plates are symmetrically welded on the outer surface of one end of the outer sleeve; the outwards extending part of each arc-shaped splicing plate is welded with a combined connecting plate; the end plates are positioned at two ends of the sleeves; resetting bars are arranged in the inner sleeve; and the two ends of the resetting bars are connected with the end plates through anchor devices. The self-resetting soft steel energy dissipating brace has the advantages that the soft steel is used to be stressed in the plane; greater initial rigidity is provided for a structure; the earthquake design level of no damage in minor earthquake is achieved; when medium or great earthquake occurs, the energy is dissipated through the plastic deformation of the soft steel; after the earthquake action stops, the soft steel is reset by using the recovery force of the resetting bars, so that the residue deformation of the structure is eliminated; and the earthquake design level of reparability after medium earthquake and falling prevention in great earthquake is achieved.

Owner:TONGJI UNIV

Construction method of combined supporting and retaining structure

ActiveCN106638673AReduce excavationReduce lateral deformationArtificial islandsUnderwater structuresReinforced concretePre stress

The invention discloses a construction method of a combined supporting and retaining structure, and relates to the technical field of civil construction. The method includes the steps of surveying and setting-out, mountain slope treatment, manufacturing of prefabricated reinforced concrete breast boards, foundation surface cleaning and replacement filling, construction of a cast-in-place concrete foundation, construction of a cantilever type structure, construction of pre-stressed anchor cables, masonry installation of the prefabricated reinforced concrete breast boards, and construction of a wrapped face reinforced soil structure and a covering layer. By using the vertical pre-stressed anchor cables, the workload can be reduced, the construction period can be shortened, the anti-overturning capacity and anti-slippage capacity of the combined supporting and retaining structure can be improved, and the overall stability and anti-lateral-deformation capacity of the whole combined supporting and retaining structure can be improved; by adopting the prefabricated reinforced concrete breast boards, the construction progress can be accelerated, and the project quality can be ensured; by using the wrapped face reinforced soil structure, the strength and integrity of a filling part can be improved, and the lateral soil pressure on the panel of the supporting and retaining structure can be reduced. By means of the method, the overall stability is improved, occupation of land is reduced, construction is simplified, and the construction cost is reduced; the method is especially suitable for roadbed construction in mountainous and hilly regions.

Owner:SOUTHWEST JIAOTONG UNIV +4

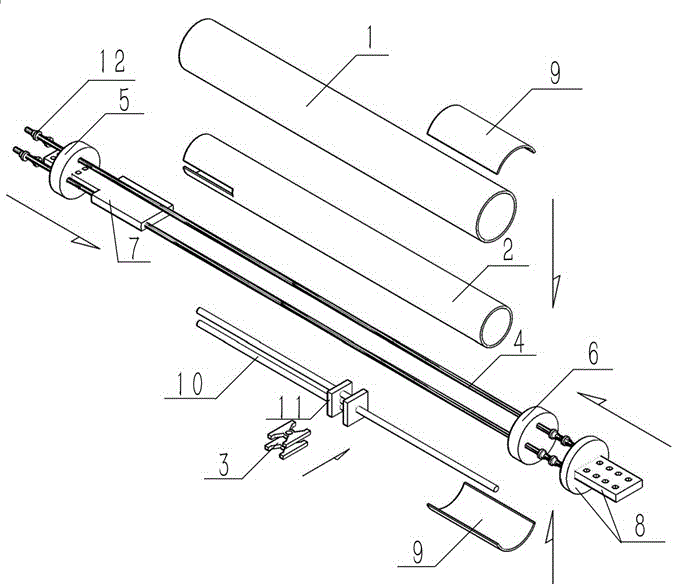

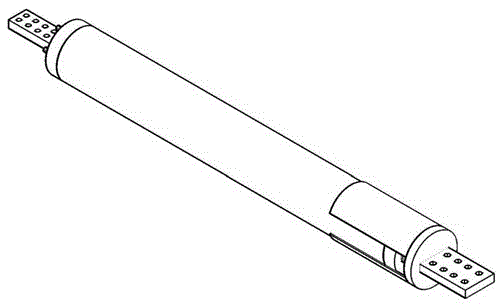

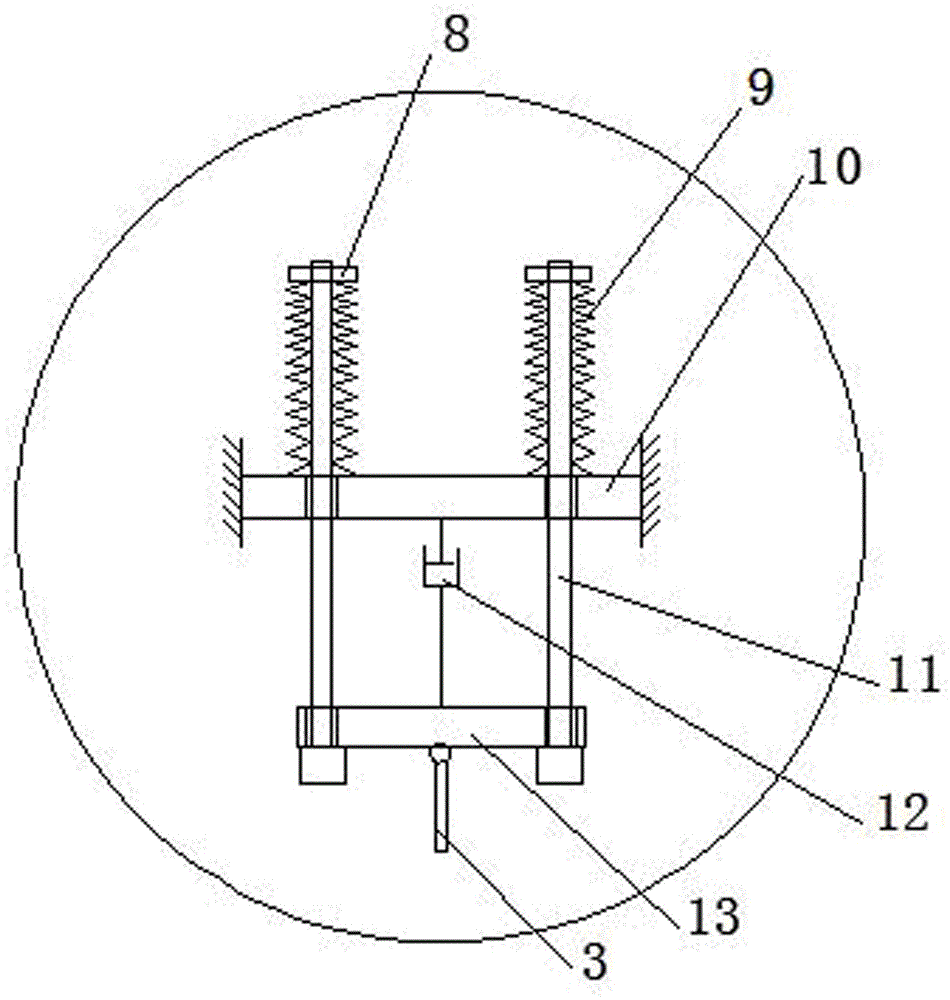

Opposite pulling type anchor rods for gob-side entrydriving small coal pillar and support method thereof

ActiveCN105804776ARange of compensationMake up for the shortcoming of easy breakage and failure due to miningAnchoring boltsEngineeringLarge deformation

The invention discloses opposite pulling type anchor rods for a gob-side entrydriving small coal pillar and a support method thereof. A middle pull rod body of each opposite pulling type anchor rod is sleeved with two rubber pulp stopping valves in a spaced mode, and one of the rubber pulp stopping valves is provided with a pulp pouring hole; large deformation devices with the same structure, trays and nuts are symmetrically connected to the two ends of each middle pull rod body, and the trays and the nuts are matched with one another; each large deformation device comprises a sleeve, a high-strength compression spring, a fastening bolt and a connection piece, wherein one end of the sleeve is a seal bottom with a through hole, and the other end of the sleeve is an opening end; each opening end is in threaded connected with the corresponding connection piece, and each connection piece is in threaded connection with the corresponding middle pull rod body; and each high-strength compression spring is installed in the corresponding sleeve, and after each fastening bolt penetrates through the corresponding high-strength compression spring, the threaded head of the fastening bolt is exposed out of the corresponding sleeve seal bottom through hole. When the opposite pulling type anchor rods are used for supporting the small coal pillar, a support mode that the pulp is poured in the middle, and the two ends are pre-tightened is formed, large deformation of the coal pillar is adapted, and meanwhile the safety and stability of the coal pillar are ensured.

Owner:SHANDONG UNIV OF SCI & TECH

Wrapping type reinforcement solidification method for roadbed of high filled embankment

A wrapping type reinforcement solidification method for a roadbed of a high filled embankment is implemented as follows: solidified soil material making, concretely, the solidified soil material is made by uniformly stirring a soil curing agent and filler soil; reinforcement laying, concretely, reinforcements are horizontally crosswise arranged and completely paved on the surface of a lower bearing layer after being leveled in full width, a fixed geogrid is inspected and aligned while being pulled and paved forwards, and the reinforcements are flattened and straightened; solidified soil material paving, concretely, the solidified soil material is paved on the geogrid layer by layer, each layer is ground and formed after being paved uniformly, and grinding is conducted till the filling elevation of wrapping reinforcement solidified soil is reached; wrapping and reinforcement stretching, concretely, the reinforcements of the preserved reinforcement sections at the both sides are inflected upwards to wrap the outer side of the solidified soil material by certain length, and the inflected reinforcements at the both sides are connected by reinforcement stretching strips and paved longitudinally at an equal interval, to form a reinforced solidification wrapping body; and curing and molding, concretely, field soil covers or geomembrane caps the upper parts of the reinforced solidification wrapping bodies for 7-14 days for curing. According to the invention, the light reinforced structure with good deformation compatibility is provided, the dead-weight can be reduced, and thus the load borne by a foundation is effectively decreased.

Owner:四川天宜石油化工工程有限公司

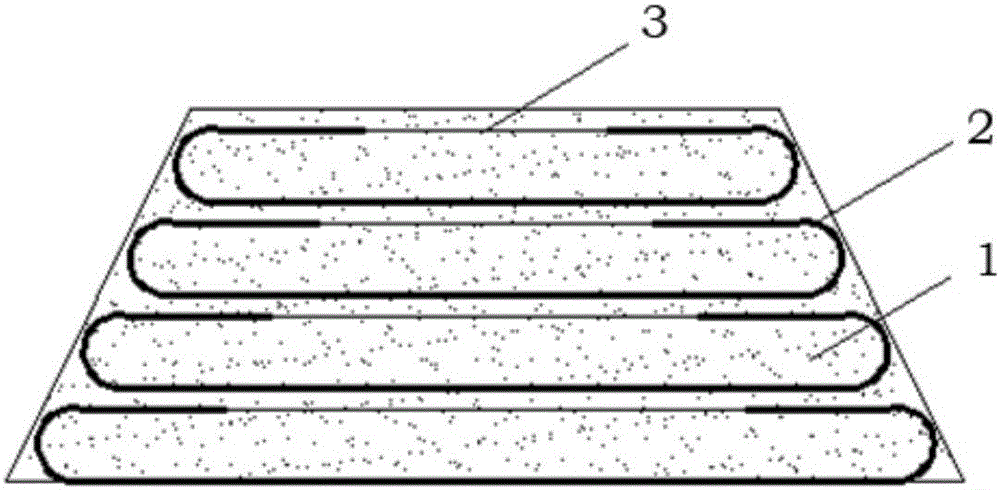

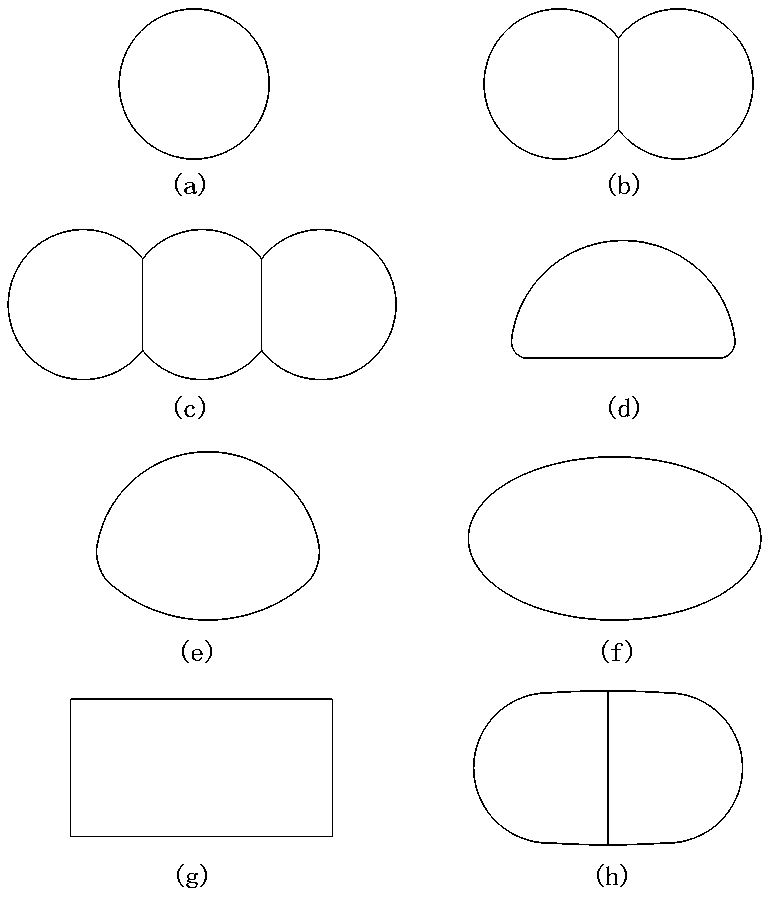

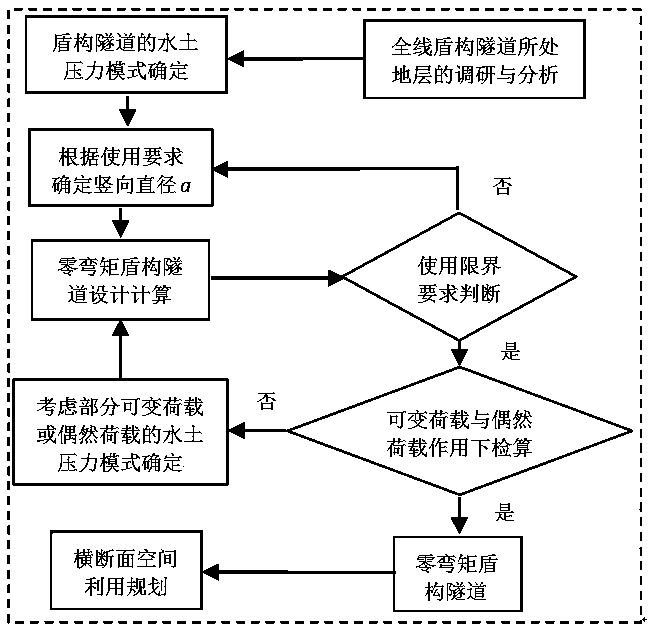

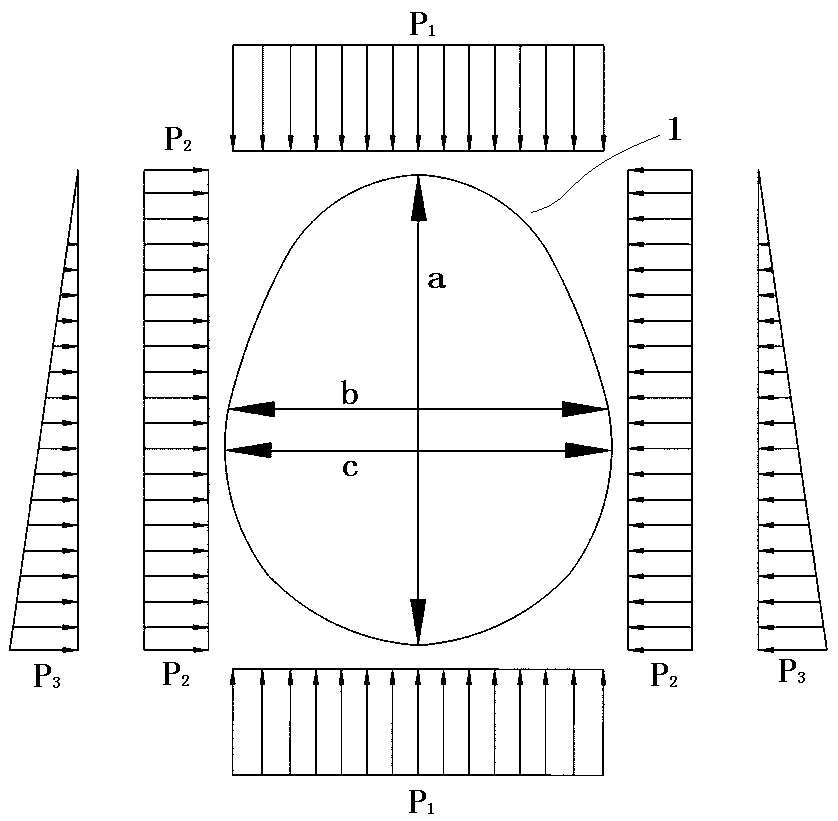

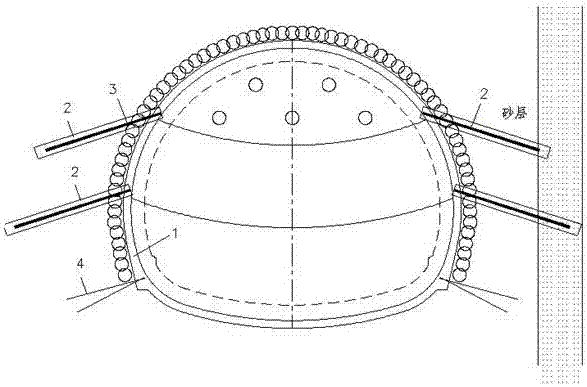

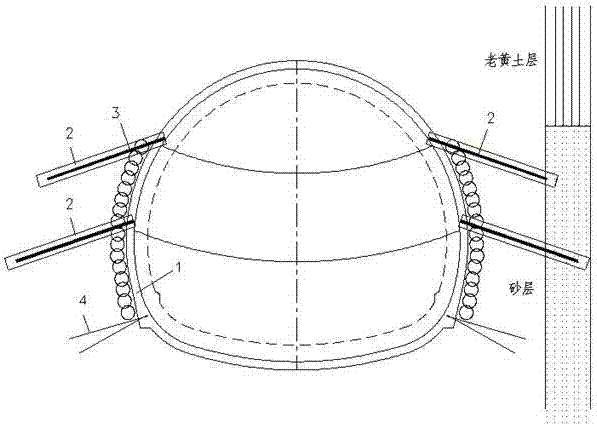

Design and calculation method of zero bending moment shield tunnel cross section

ActiveCN107247851AReduce bending momentReduce lateral deformationGeometric CADDesign optimisation/simulationWater tableWater level

The invention discloses a design and calculation method of a zero bending moment shield tunnel cross section. In the method, overall buried depth conditions, surrounding water and soil mechanical properties, underground water level conditions and the like of the top of a shield tunnel are analyzed according to formation conditions of the shield tunnel, the designed water and soil pressure mode of the shield tunnel is determined after comprehensive analysis, in this way, the rational axis and key parameters of shield tunnel cross section are designed, the cross section of the shield tunnel is of an egg-shaped structure which is small in the top and big in bottom, and the cross section theoretical bending moment of the shield tunnel cross section is zero under the effect of the designed water and soil pressure. The design and calculation method of the zero bending moment shield tunnel cross section has the advantages that the design and calculation method is simple and easy to operate, compared with a traditional shield tunnel, on the condition that the project cost is not basically increased, the bending moment of the designed zero bending moment shield tunnel is reduced to the greatest extent, therefore the cross section deformation of the shield tunnel and the expansion deformation of a pipe sheet longitudinal joint connector are avoided, breakage and water seepage of the pipe sheet longitudinal joint connector are prevented, and the using quantity of steel bars in a pipe sheet is reduced.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Reinforced fly ash soil retaining wall and construction method

The invention discloses a reinforced fly ash soil retaining wall and a construction method. The reinforced fly ash soil retaining wall is composed of three parts including padding, reinforcing ribs arranged in the padding and a wall face plate. The method includes the steps that firstly, a retaining wall base groove is excavated on a to-be-constructed ground, foundation construction is conducted, the wall face plate is built on a foundation through building blocks, a settlement joint and an expansion joint are arranged when the wall face plate is built, and geogrids are built between the building blocks of the wall face plate at certain intervals; then, an EPS foam plastic plate is stuck to the wall face plate and is polished; and finally, the saponification residual slag-fly ash-soil light padding is used for backfilling, the performance of the padding should meet the design requirement in the compaction process during filling, manual spreading is adopted close to the EPS foam plastic plate, the rest of the parts are spread, ground and compacted through a machine till each layer of geogrid rib materials are spread and the padding is spread and compacted, and construction of the reinforced fly ash soil retaining wall is completed. The reinforced fly ash soil retaining wall has good performance that the structure is simple, construction is convenient, durability is good, and ageing resistance is achieved.

Owner:HUBEI UNIV OF TECH

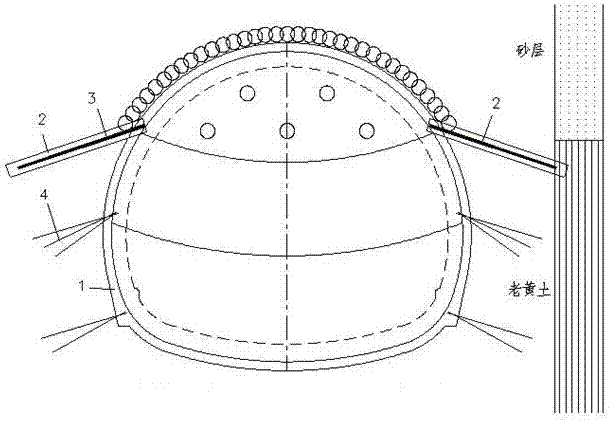

Lock foot pile support structure for controlling tunnel initial support settlement convergence

PendingCN106979027ASimple processLess impact from process changeoverUnderground chambersTunnel liningArchitectural engineeringSteel frame

The invention discloses a lock foot pile support structure for controlling tunnel initial support settlement convergence. The structure comprises an initial support in the tunnel grotto. A tilted lock foot pile is arranged at the outer wall of the initial support; the lock foot pile comprises a rotary jetting pile body, and the rotary jetting pile body is connected to an L-shaped steel core material. The other end of the L-shaped steel core material is connected with a connecting steel bar. The connecting steel bar is connected to an I beam steel frame of the initial support. The lock foot pile support structure for controlling the tunnel initial support settlement convergence has the advantages that the technical process is simple; the effected interference to the process conversion is less, the operation is convenient; the work efficiency is improved; the problems that the excavations of middle and lower steps cause the arch foot to be vacant, the side wall of the tunnel is unstable or the slippage and the grouting and anchorage effect of lock foot are poor are overcome; the stability of the palm surface, the deformation and settlement of the control cavern and the mechanized construction are achieved.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Carbon fiber board prestress tension clamp

The invention discloses a carbon fiber board prestress tension clamp which comprises a clamping sleeve with a wedge-shaped through hole, a wedge-shaped clamping piece used for clamping a carbon fiber plate, a connecting plate detachably fixedly arranged at the big opening end of the wedge-shaped through hole, and a tension rod fixedly arranged on the connecting plate, wherein the wedge-shaped clamping piece is used for clamping the carbon fiber plate and then is wedged into the clamping sleeve to be matched with the wedge-shaped through hole. The carbon fiber board prestress tension clamp is characterized in that the wedge angle of the wedge-shaped clamping piece is more than that of the wedge-shaped through hole, which can lighten the stress concentration at the small end of the wedge-shaped clamping piece, is beneficial to transferring the tension force inside the clamp and prevents the carbon plate from being broken during the tesnion. The cylindrical clamping sleeve is adopted to ensure that the thickness of the clamping sleeve at the middle along the width direction of the wedge-shaped clamping piece is biggest, which can reduce the transverse deformation of the clamping sleeve, is beneficial to the uniform force of the carbon fiber plate in the width direction and prevents carbon fibers at the side of the carbon fiber plate from being broken, therefore, the clamp has better clamping property. A pre-ejecting and ejecting-retreating device is matched with the clamp, therefore, the prestress tension operation with high-quality and high speed and efficiency of the carbon fiber plate can be realized.

Owner:CHONGQING UNIV

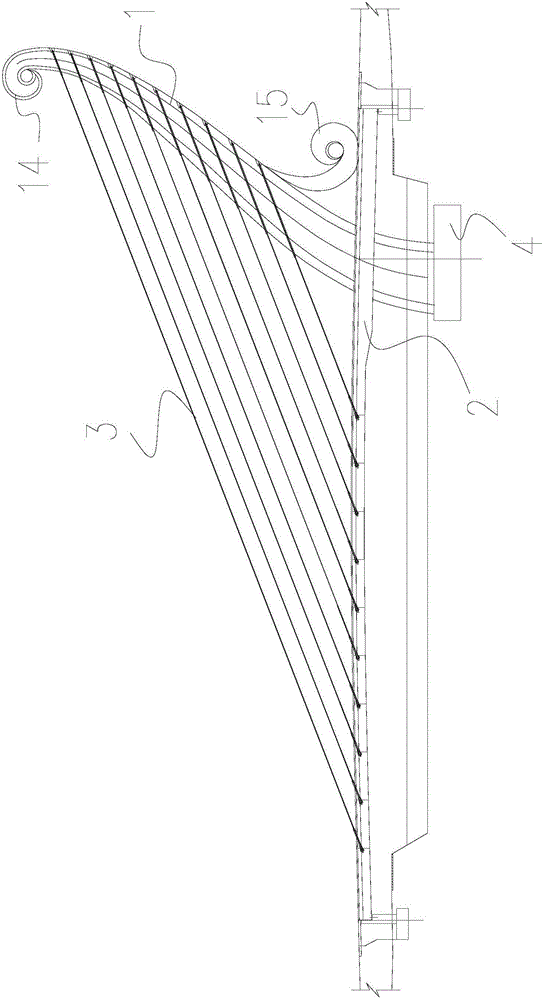

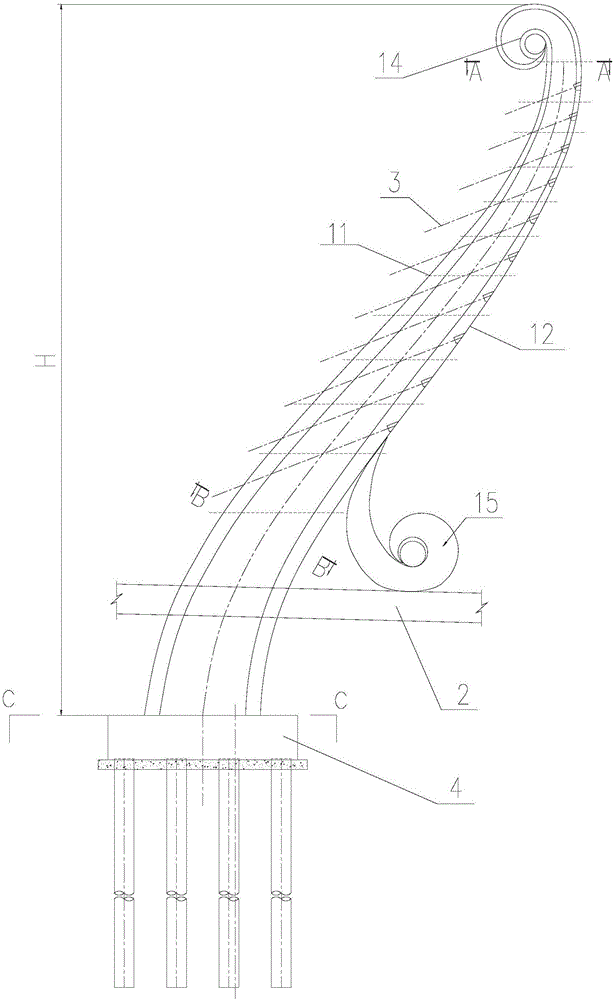

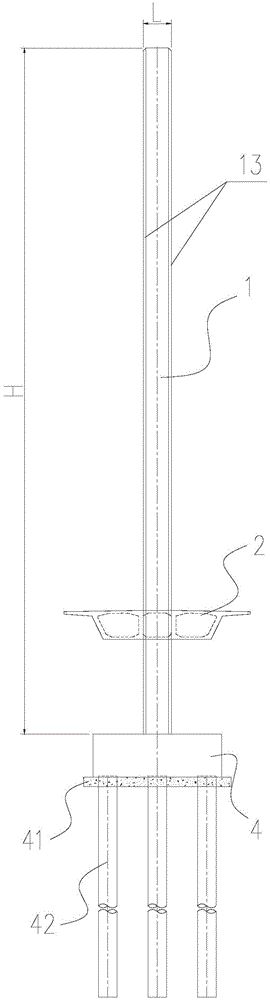

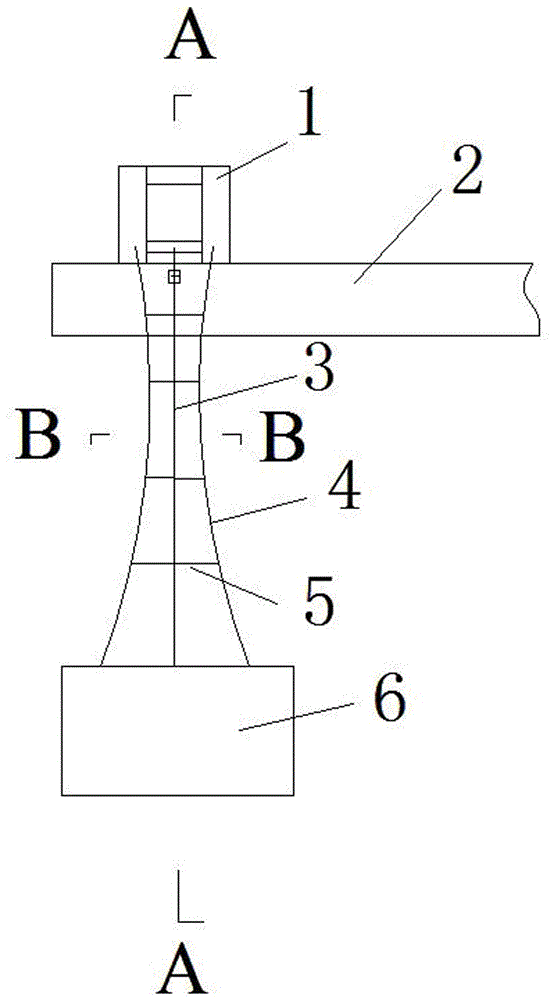

Cable-stayed bridge provided with curved single pylon with double cable planes

ActiveCN105839511AImprove carrying capacityImprove construction convenienceCable-stayed bridgeBridge structural detailsCable stayedSlant angle

The invention discloses a cable-stayed bridge provided with curved single pylon with double cable planes. The bridge comprises a main pylon, a main beam, stay cables and a cushion cap, wherein the cable facing plane and the cable backing plane of the main pylon are cambered surfaces with variable curvature and unchangeable width, longitudinal slant angles are different and change section by section along with construction of the main pylon, the longitudinal slant angle in the middle section of the main pylon is at least 50 degrees, and the longitudinal slant angles at the bottom and the top of the pylon are about 90 degrees; two side surfaces of the main pylon are planes, the widths of the two sides surface of the main pylon gradually get smaller from bottom to top, and accordingly, the cross sections of the main pylon gradually linearly get smaller from the bottom to the top of the pylon in the height direction; the main pylon is a solid section with four chamfered sides, the lengths of chamfers of the main pylon are gradually linearly changed from 150 cm to 50 cm from the bottom to the top of the pylon in height direction, and the widths of the chamfers are all 30 cm; the main beam and the main pylon are integrated through concrete pouring; ten pairs of stay cables are arranged between the main pylon and the main beam. The cable-stayed bridge is reasonable in structure, attractive in appearance and strong in stress sense and gives people a unique visual feeling.

Owner:CCCC THIRD HARBOR ENG +2

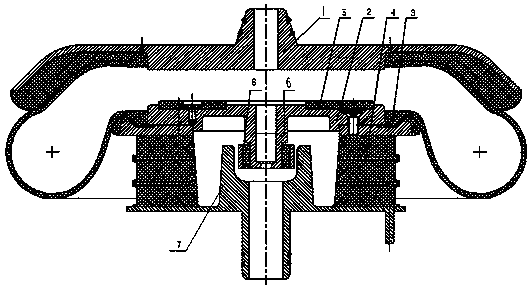

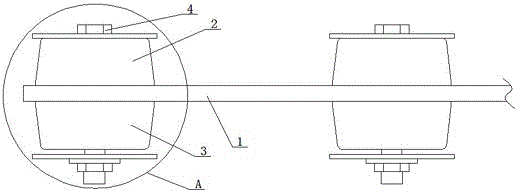

Nonlinear air spring and transverse rigidity design method thereof

ActiveCN110836239AMeet comfort requirementsEnsure security requirementsSpringsShock absorbersAir springEngineering

The invention discloses a nonlinear air spring. The nonlinear air spring comprises an upper cover plate, a support plate, air bags, an annular rubber pile and an abrasion plate; the support plate is coaxially arranged below the upper cover plate, upper and lower sub-openings are arranged at the air bags on the upper cover plate and the support plate, the annular rubber pile is coaxially bonded atthe bottom of the support plate, and the abrasion plate is fixed to the top surface of the support plate; the center position of the support plate is provided with a limiting projection that projectsdownwardly into an inner cavity of the annular rubber pile, the center position of a bottom plate of the annular rubber pile is provided with a limiting stop which protrudes upwards, the top surface of the limiting stop is a groove shape to form a limiting groove, the limiting protrusion extends into the limiting groove along the central axis and is not in contact with the limiting groove, the nonlinear air spring is characterized in that the limiting protrusion is sleeved with an elastic stop, and the elastic stop extends into the limiting groove and is not in contact with the limiting groove. The three-stage transverse nonlinear rigidity is realized, various line conditions are better adapted, and the safety requirement of a vehicle is guaranteed. The invention further provides a transverse rigidity design method of the nonlinear air spring.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

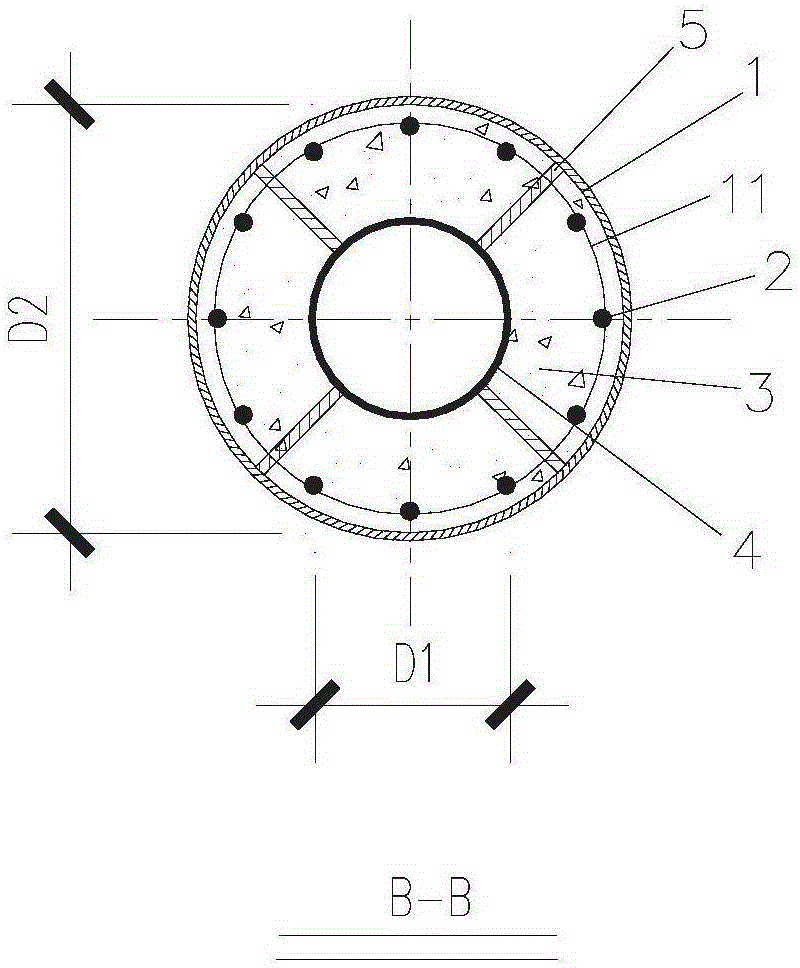

PVC pipe and thick wall steel tube composite hollow recycled concrete pile

InactiveCN105200983AStop erosionInhibit deteriorationBulkheads/pilesThick wallFoundation engineering

The invention discloses a PVC pipe and thick wall steel tube composite hollow recycled concrete pile, which is mainly prepared from PVC pipes, a round reinforcement cage framework, thick wall steel tubes and recycled concrete, wherein the round reinforcement cage framework and the thick wall steel tubes are arranged in PVC pipes, and the three are concentrically arranged; recycled concrete is poured into the PVC pipes and the thick wall steel tubes; the built-in thick wall steel tubes are capable of improving single-pile bearing capacity and non-deformability by a large margin; the externally covered PVC pipes are capable of effectively preventing pile bodies from being corroded and improving pipe body durability; at the same time, the recycled concrete inside can be jointed restrained by the PVC pipes and spiral stirrups, thus further enhancing composite pile bearing capacity; and waste concrete can be used as recycled aggregate, thus being favor of popularization and application of recycled concrete in building foundation engineering. In short, the PVC pipe and thick wall steel tube composite hollow recycled concrete pile has the advantages of good pile formation quality, high bearing capability, good non-deformability, good durability, small environment influence, quick construction speed and the like.

Owner:GUANGXI UNIV

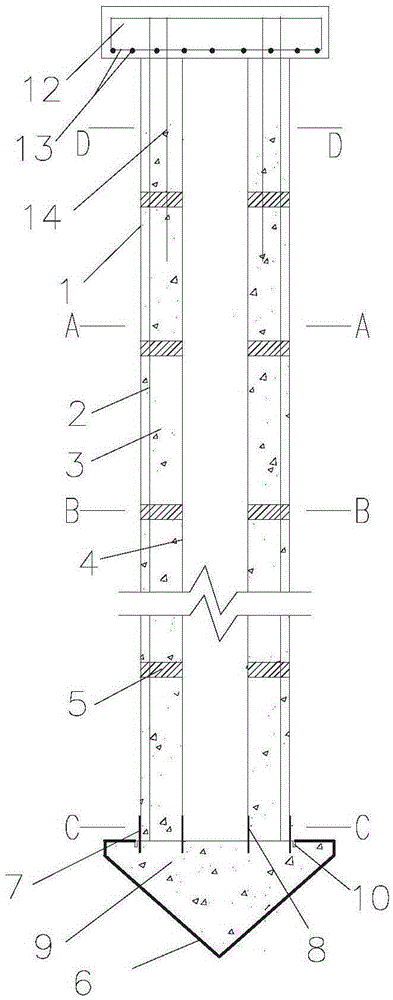

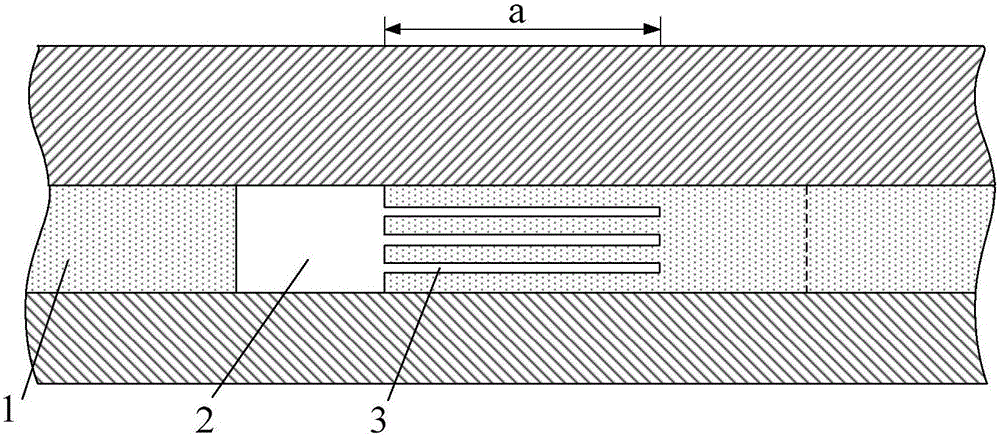

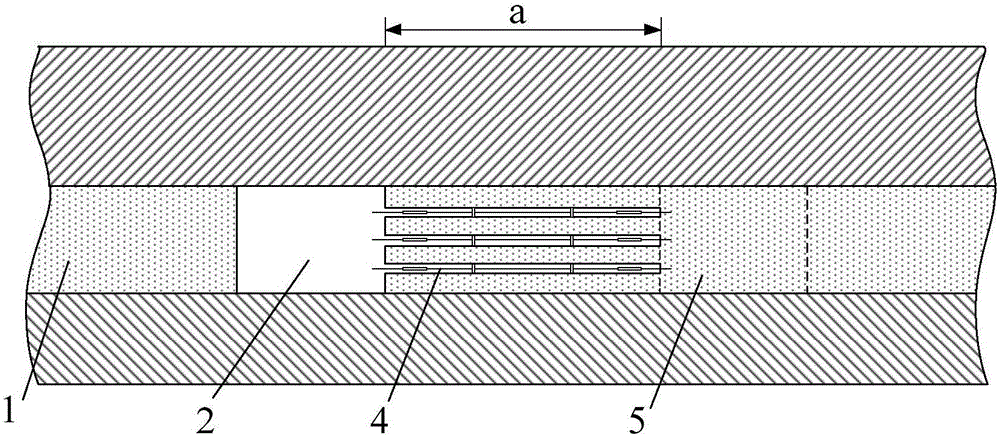

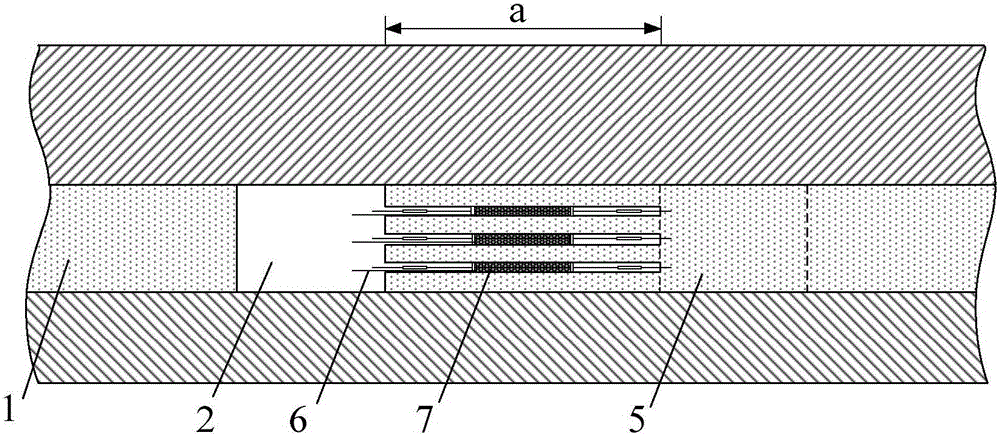

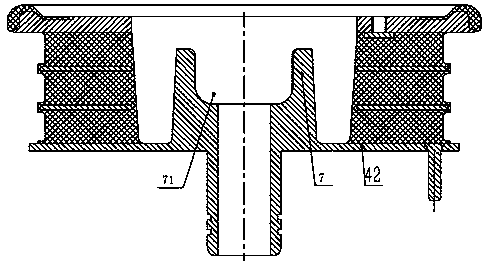

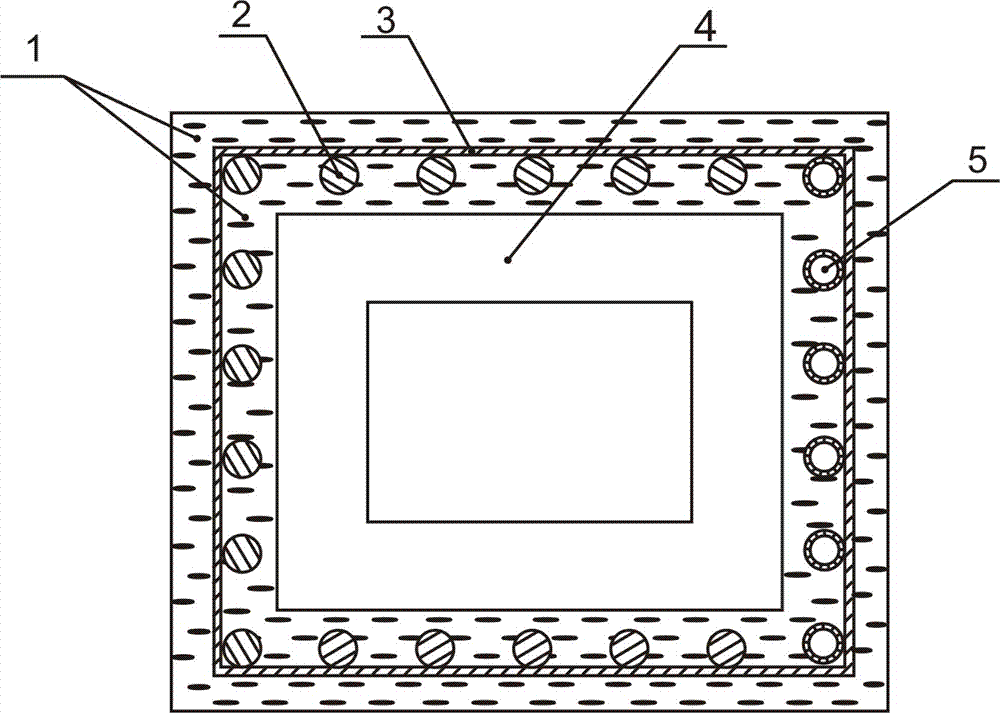

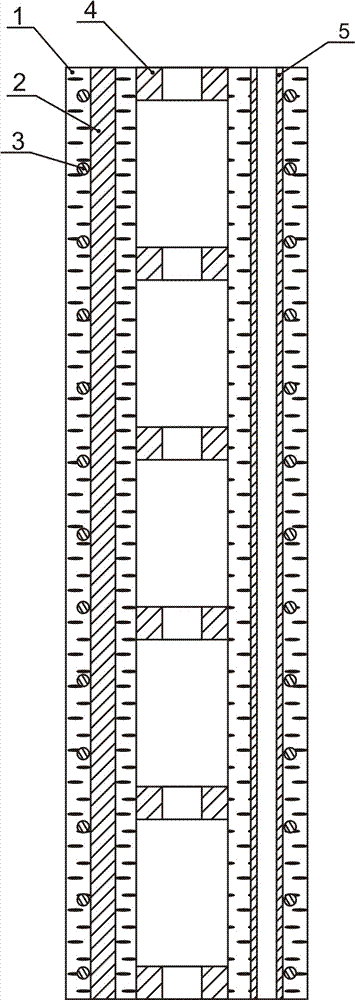

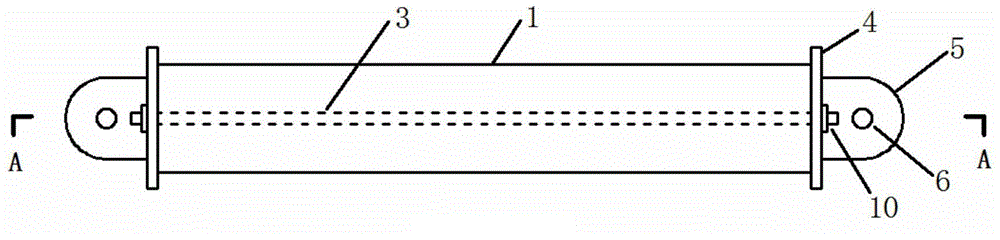

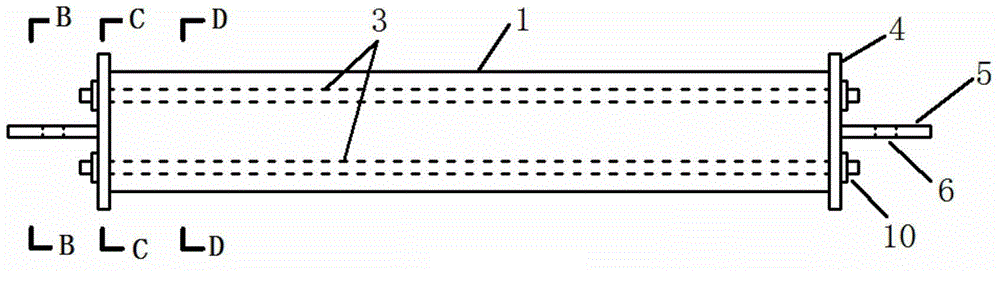

Post-tensioned prestressing rectangular hollow foundation pit support pile

InactiveCN103031841AGood containmentReduce lateral deformationBulkheads/pilesPre stressBottom pressure

The invention relates to a post-tensioned prestressing rectangular hollow foundation pit support pile. The support pile comprises a rectangular stabilizing ring rib, a rectangular steel reinforcement framework, concrete, a bottom pressure bearing plate and a locking anchorage device, wherein reinforcing steel bars are respectively arranged on a rectangular steel reinforcement framework inner side which is close to a foundation pit and the two adjacent sides of the rectangular steel reinforcement framework, an isolation pipe is arranged outside the foundation pit, a steel strand or a high tensile reinforcing steel bar is arranged in the isolation pipe, a reinforcement stirrup is used to fix the reinforcing steel bar and the isolation pipe to form a rectangular framework structure, the pressure bearing plate is arranged on the bottom end of the pile of the isolation pipe, the pile bottom pressure bearing plate is fixedly connected with one end of the steel strand or the high tensile reinforcing steel bar, the steel strand or the high tensile reinforcing steel bar penetrates through the isolation pipe, the locking anchorage device is used to lock a pile top, meanwhile, a grouting hole and a vent hole are formed in the locking anchorage device on the pile top, and the rectangular stabilizing ring rib is arranged in a rectangular hollow support pile. By the pile, a function in supporting the foundation pit is enhanced, the side deformation of a supporting structure and the adverse influence of the foundation pit to the periphery environment are reduced, the use amounts of the reinforcing steel bars and the concrete are reduced, and the building cost is saved.

Owner:SOUTHWESTERN ARCHITECTURAL DESIGN INST

Steel bar prestressed steel pipe concrete supporter

The invention discloses a steel bar prestressed steel pipe concrete supporter, belongs to a building structure component, and particularly relates to a steel-concrete combined structure support component. By aiming at solving the problems of serious post-earthquake structure damage and too great lateral displacement of a framework structure under the horizontal earthquake effect and simultaneously overcoming the defect of great steel consumption of a steel structure supporter, the invention provides the steel bar prestressed steel pipe concrete supporter. On the basis of a steel pipe concrete supporter, ordinary steel bars are embedded in concrete; the two ends of the ordinary steel bars are anchored onto steel pipe end plates; prestress is applied onto the concrete by a post-tensioning method, so that the steel pipe concrete supporter can simultaneously bear great pressure and tension under the effect of a horizontal earthquake load. A building structure using the steel bar prestressed steel pipe concrete supporter has excellent anti-earthquake performance and high material utilization efficiency, and can sufficiently achieve the advantages that the mechanical property is good; the construction is convenient; and economy and reasonableness are realized.

Owner:CHONGQING UNIV

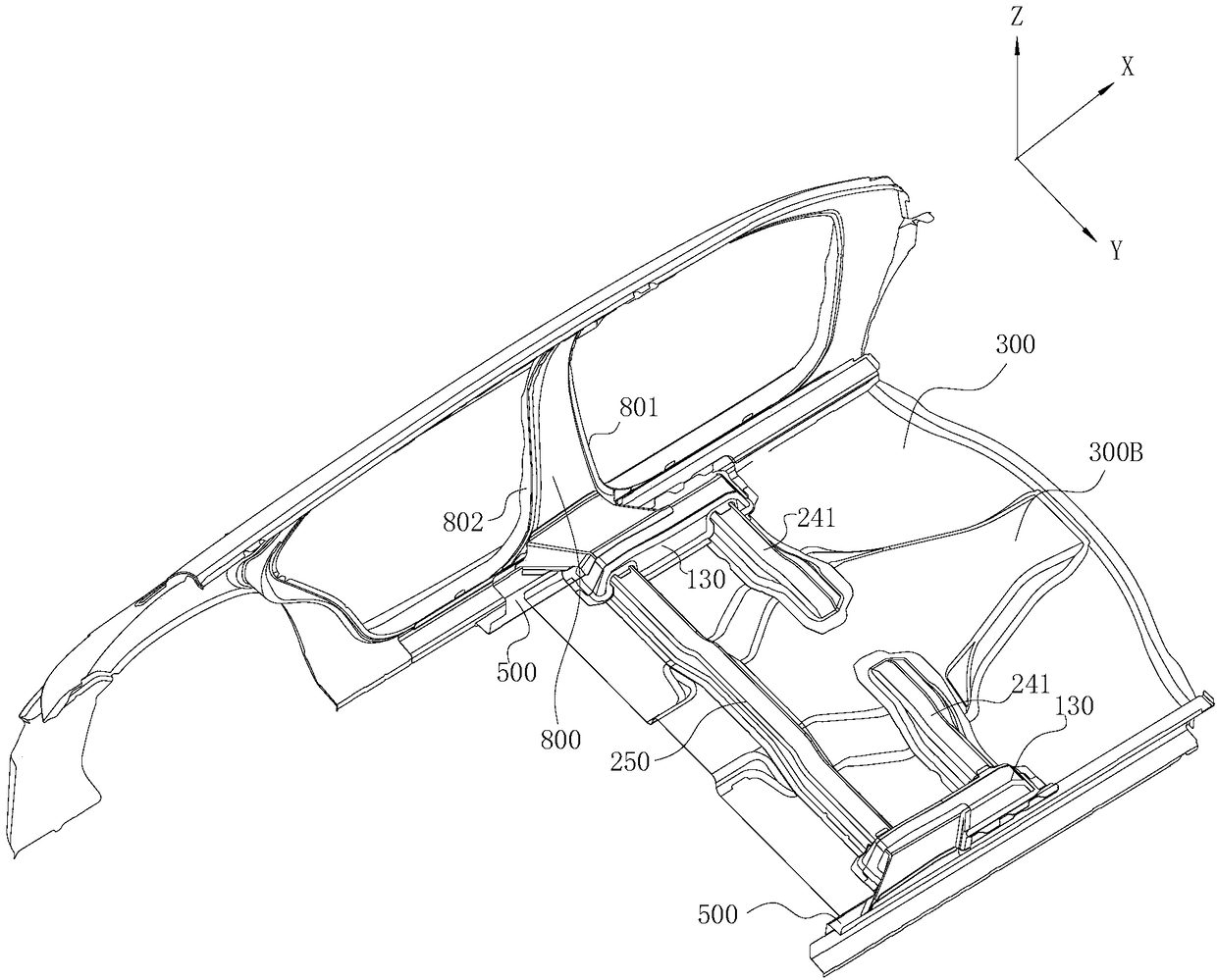

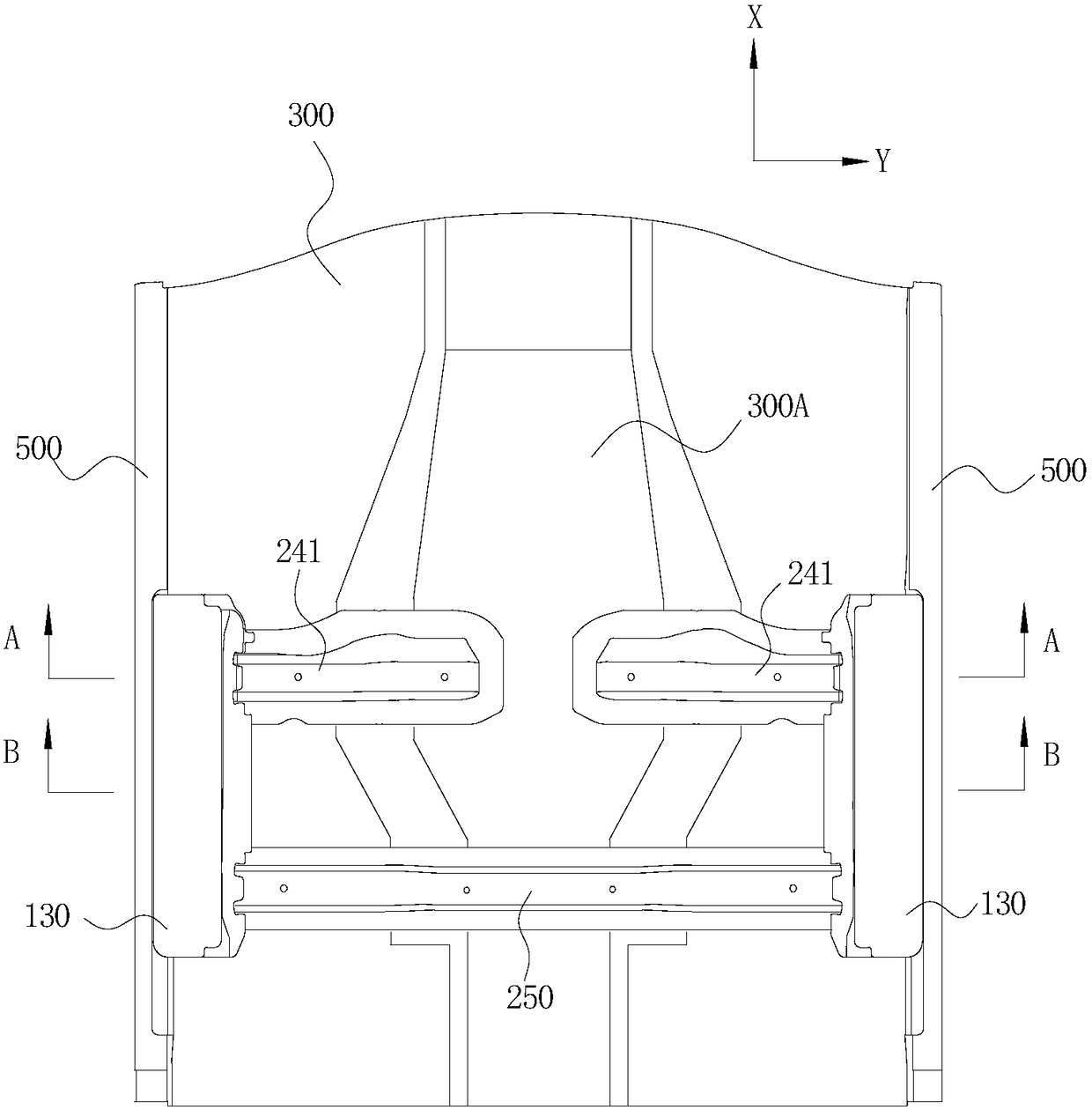

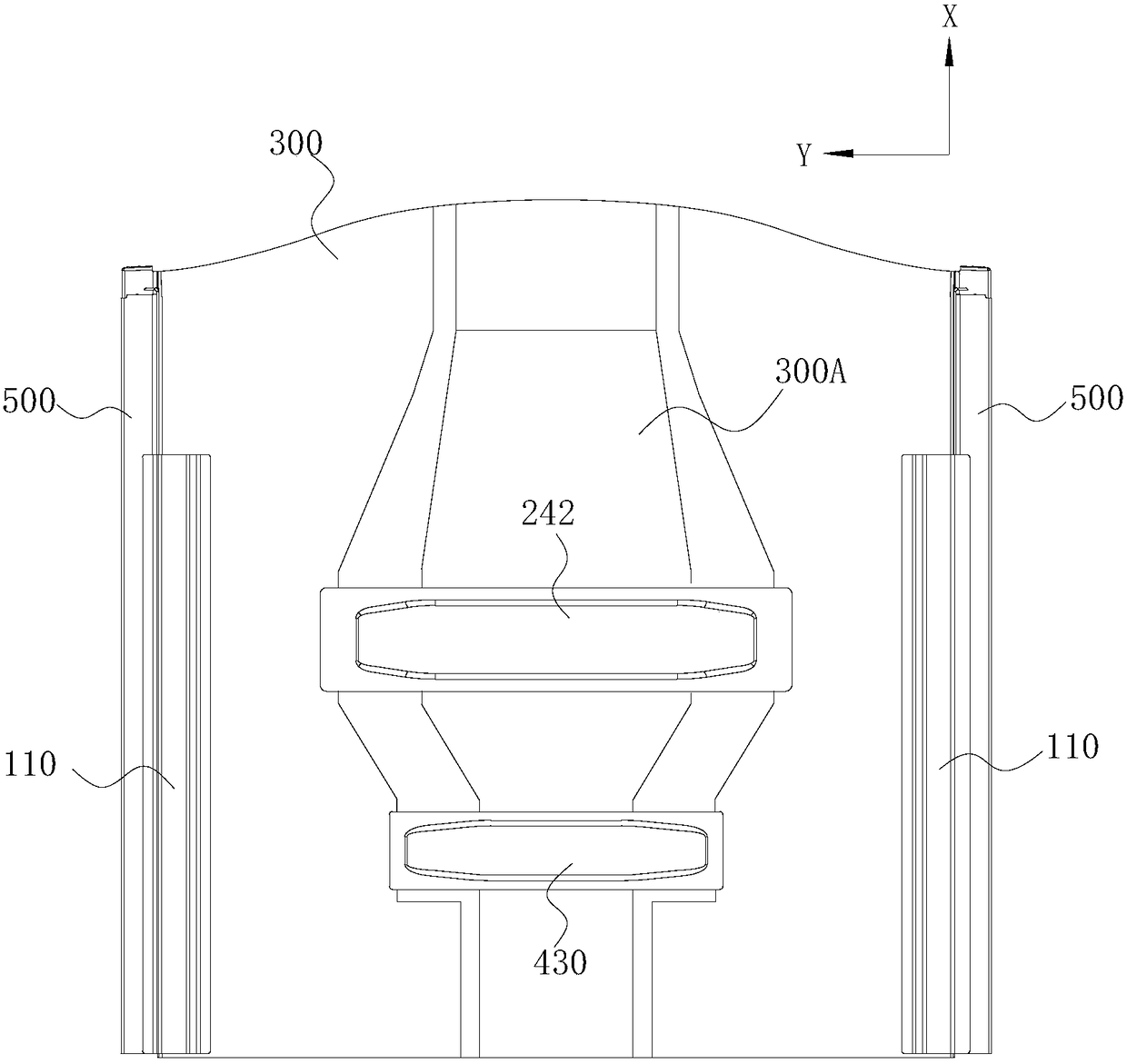

Body structure and vehicle

ActiveCN109204491AExtended cruising distanceReduce flip distortionUnderstructuresSuperstructure subunitsEngineeringPreventing injury

The present disclosure relates to a body structure and a vehicle. The body structure includes a bearing frame, a battery tray, two reinforcing longitudinal beams, and at least one reinforcing cross member, the battery tray being mounted on the bearing frame, the bearing frame comprising at least a front mounting cross member of the battery pack, a rear mounting cross member of the battery pack, and two door sill inner panels, each reinforcing longitudinal member being connected to a corresponding door sill inner panel, and each reinforcing cross member being connected to two reinforcing longitudinal members. Through the sill support structure formed by the reinforcing cross member and the reinforcing longitudinal member, the side impact force can be transmitted directly from the sill innerpanel on one side to the sill inner panel on the other side, significantly reducing the lateral deformation of the floor panel and the sill inner panel, preventing injury to occupants and damage to the battery pack. Through the structural design of the load-bearing frame, not only can the overall strength of the body structure be increased, but also the batteries can be arranged as much as possible under the floor panel, which is conducive to ensuring that the vehicle has as long a range as possible.

Owner:BYD CO LTD

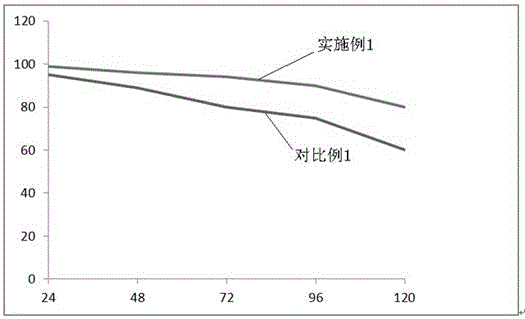

Production technology of oblique tooth-shaped edge-cut triangular belt

InactiveCN107266751AGood elongation resistanceReduce lateral deformationV-beltsVegetal fibresPressure loadEngineering

The invention discloses a production technology of an oblique tooth-shaped edge-cut triangular belt. The production technology comprises viscose blending according to technical requirements, mixing, calendaring, reversing splicing, molding, oblique tooth-shaped rubber sleeve preparation, vulcanization, cutting and grinding. The base rubber layer is prepared from an oriented nylon fiber-rubber compound and a nylon fiber group is transversely and orientedly arranged in a triangular belt compressed layer so that the lateral rigidity and resistance to side pressure load of the triangular belt are obviously improved, the load is uniformly distributed on the whole strengthening layer and the dynamic mechanical properties of the triangular belt are improved. The oriented nylon fibers are added into the base rubber layer so that hardness and impact strength of the base rubber layer are improved. The oriented nylon fiber-rubber compound can effectively prevent early damage of the surface of the triangular belt, improve wear resistance, improve holding power between the triangular belt and a grooved wheel, reduce transmission noise and satisfy maintenance-free technical requirements.

Owner:浙江保尔力橡塑股份有限公司

Bending die

InactiveCN108580685AReduce lateral deformationIncrease productivityShaping toolsEjection devicesMechanical engineeringEngineering

The invention relates to a bending die. The bending die comprises a male die body and a female die body. Supporting shafts which are used for supporting and bending a copper bar and matched with the male die body are arranged on the female die body. A first guide face for preventing the side wall of the copper bar from deforming and a second guide face corresponding to the first guide face are arranged on the female die body. An ejecting mechanism for ejecting the copper bar from the portion between the first guide face and the second guide face is arranged between the first guide face and thesecond guide face. The ejecting mechanism comprises swinging arms which are arranged on the supporting shafts in a sleeving manner and can rotate around the supporting shafts. According to the die, the groove matched with the copper bar for positioning is formed in the female die body. When the copper bar is bent, the first guide face and the second guide face can support the side wall of the copper bar, longitudinal bending and deformation of the copper bar are reduced effectively, and the copper bar is ejected upwardly through the ejecting mechanism after the copper bar is bent, so that thecopper bar can be formed at a time, the production efficiency is improved, the quality of products is guaranteed, and the safety is improved as well.

Owner:HENAN SENYUAN ELECTRIC CO LTD

Multi-cable compounded damping cable

InactiveCN106638311AIncrease the itineraryAchieving shock resistanceBridge structural detailsEngineeringAbsorption effect

The invention discloses a multi-cable compounded damping cable. The technical key point lies in that the multi-cable compounded damping cable comprises a main cable and at least one secondary cable distributed around the main cable, and the at least one secondary cable is located on the upper portion of the main cable. The lower ends of the main cable and the secondary cables are connected with a concrete anchor fixed to the ground. The upper end of the main cable is connected with an upper anchoring end stand column fixedly connected with a structure through a main cable shock absorption device. The upper ends of the secondary cables are connected with the upper anchoring end stand column fixedly connected with the structure through a secondary cable shock absorption device. Hanging rods are arranged between the main cable and each secondary cable as well as between the secondary cables. According to the multi-cable compounded damping cable, the multi-cable compounded damping cable can be installed between two structures which are at a long distance and move relatively, and has the energy dissipation and shock absorption effects basically equal to those of a damper installed between two structures very close to each other.

Owner:HUNAN UNIV OF SCI & TECH

Acid-resistant pipeline steel and pipe making method

The invention discloses acid-resistant pipeline steel and a pipe making method, and relates to the field of steel and iron materials. The acid-resistant pipeline steel comprises the chemical compositions of, by mass, 0.014%-0.024% of C, 0.10%-0.35% of Si, 0.60%-0.80% of Mn, less than or equal to 0.012% of P, less than or equal to 0.0010% of S, 0.030%-0.070% of Nb, 0.006%-0.020% of Ti, 0.10%-0.30%of Ni, 1.00%-1.10% of Cr, 0.15%-0.20% of Mo, 0.10%-0.30% of Cu, 0.010% of V, 0.015%-0.050% of Al, and the balance Fe and impurities. According to the acid-resistant pipeline steel and the pipe makingmethod, unique composition design is adopted, pipe making is carried out through edge milling, prebending, forming, welding, flaw detection, hole enlargement and hydraulic testing and other processesto meet the pipe making requirements of the acid-resistant pipeline steel.

Owner:NANJING IRON & STEEL CO LTD

Shock absorber of engine

ActiveCN106188714AReduce lateral deformationHigh strengthJet propulsion mountingInternal combustion mountingRubber elasticityEngineering

The invention discloses a shock absorber of an engine. Upper shock absorbing pads are arranged above a support plate, and lower shock absorbing pads are arranged below the support plate; each of the upper shock absorbing pads and the lower shock absorbing pads comprises a rubber block, plastic reinforcing plates and springs are embedded in the rubber block, and the springs penetrate the plastic reinforcing plates respectively; fixing holes are formed in the middle of the upper shock absorbing pads and the lower shock absorbing pads, through holes are formed in the support plate, and the upper shock absorbing pads and the lower shock absorbing pads are arranged on the support plate through fixing bolts; each fixing bolt penetrates the fixing hole of the corresponding upper shock absorbing pad, the corresponding through hole in the support plate and the fixing hole of the corresponding lower shock absorbing pad sequentially. By means of the plastic reinforcing plates, the strength and the stiffness of each shock absorbing pad are improved; besides, the plastic reinforcing plates are integrally connected by the springs, the strength and the stiffness of the shock absorbing pads are improved, and deformation of the shock absorbing pads is reduced; further, the energy storage effect of the springs is better, the rubber elasticity is better, and vibration isolation and better comfort can be guaranteed through combination of the springs and the rubber.

Owner:河南恒发新能源汽车减振技术研究院有限公司 +1

PVC pipe wrapped inner supporting cross prestress recycled concrete tubular pile

The invention discloses a PVC pipe wrapped inner supporting cross prestress recycled concrete tubular pile mainly formed by a PVC pipe, a round reinforcement cage framework, cross steel ribs and recycled concrete. The round reinforcement cage framework and the cross steel ribs are arranged in the PVC pipe, and a round inner cavity is formed in the PVC pipe by the recycled concrete. The round reinforcement cage framework is formed by welding longitudinal prestressed tendons and spiral stirrups. A PVC pipe wrapped pile body resistant to corrosion, light and high in strength can be effectively prevented from being corroded, the corrosion problem of the tubular pile is solved, and the durability of a pile foundation is improved. The inner supporting cross steel ribs can fully achieve the respective advantages of steel, prestressed reinforcement and concrete, the stress performance of the recycled concrete is improved, the bearing capacity and stability of the single pile are improved, the lateral rigidity of the pile body is increased, and transverse deformation is reduced. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated.

Owner:GUANGXI UNIV

Compound bow with rigid deflecting stop

Bow having a centerpiece, two flexurally elastic limbs, a string, at least one string pulley, mounted in one end of a limb and intended for accommodating the string, and at least two cable pulleys, connected rigidly to the string pulley and intended for accommodating and guiding compensating cables, and in each case at least one cable pulley is arranged on both sides of the string pulley, and the subassembly made up of the string pulley and cable pulleys is mounted in a rotatable manner in each case, and at least one deflecting stop is present for the purpose of limiting the deflection of the string, and this deflecting stop, when the string is deflected, strikes against a limb or against a stop element connected rigidly to the limb.

Owner:OKUPNIAK CHRISTOPH

Anti-seepage seawall with pile foundation framework rib plate structures

InactiveCN106049350AReduce lateral deformationProtect life and property safetyBreakwatersQuaysLand utilizationSeawall

The invention provides an anti-seepage seawall with pile foundation framework rib plate structures. Pile foundation structures of the anti-seepage seawall are arranged in a preprocessed foundation; a pile top crown beam is arranged on the tops of the same row of pile foundation structures; the pile top crown beams are connected into a whole through connecting and tying beams; framework rib plate structures are arranged on the pile top crown beams and the connecting and tying beams; the interior of the framework rib plate structures are filled with solidification closure earthwork; the portions, on the two sides of each framework rib plate structure, of the preprocessed foundation are provided with anti-scouring structures; and under the joint effect of the preprocessed foundation and the pile foundation structures, adverse effects of common large seawall settlement and large horizontal displacement on adjacent buildings are avoided. The anti-seepage seawall with the pile foundation framework rib plate structures guarantees the safety of the adjacent buildings to the maximum extent, engineering investment is saved, the construction progress is accelerated, the environment interference is reduced, and the land utilization rate is increased.

Owner:浙江省水利水电勘测设计院有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com