Anti-seepage seawall with pile foundation framework rib plate structures

A rib plate and frame technology, applied in the field of light anti-seepage seawall, can solve problems affecting the progress of the project, affecting the safety of buildings such as bridge piers, and lateral deformation, so as to protect the safety of people's lives and property, improve the service life of the project, reduce The effect of lateral deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

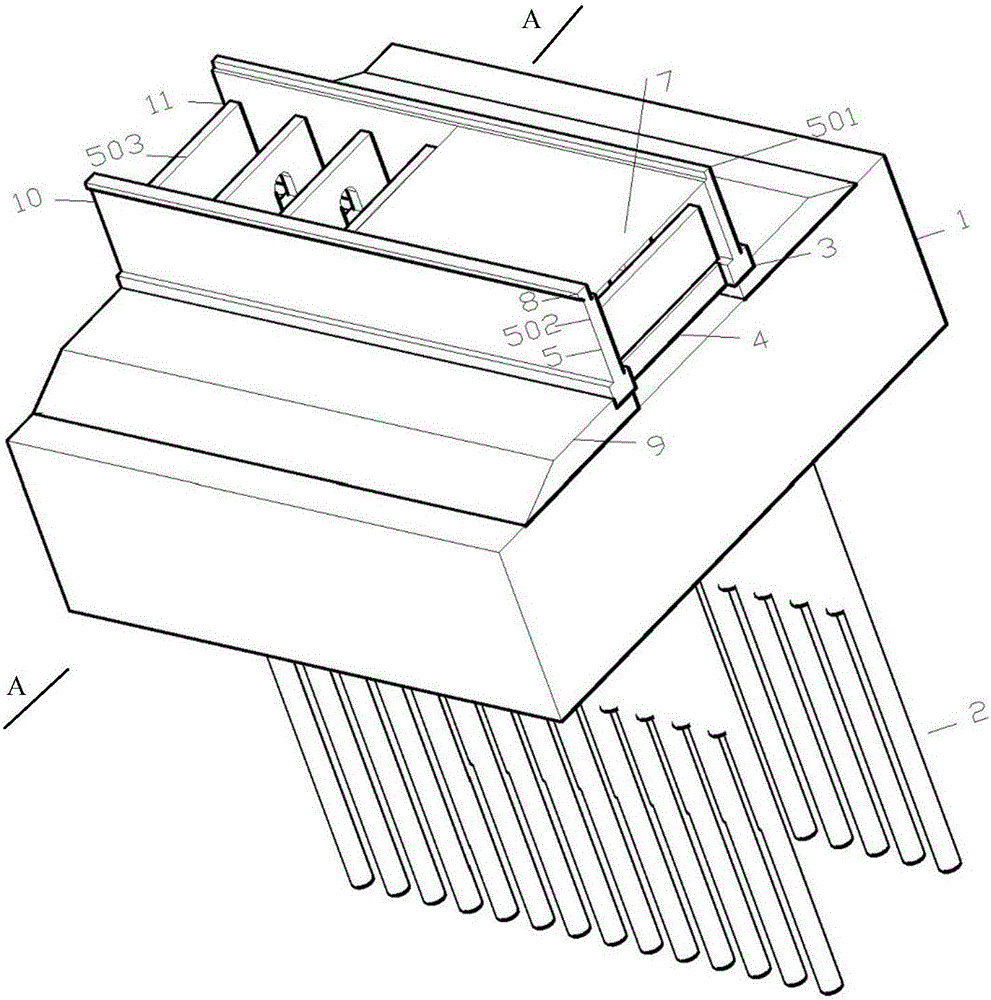

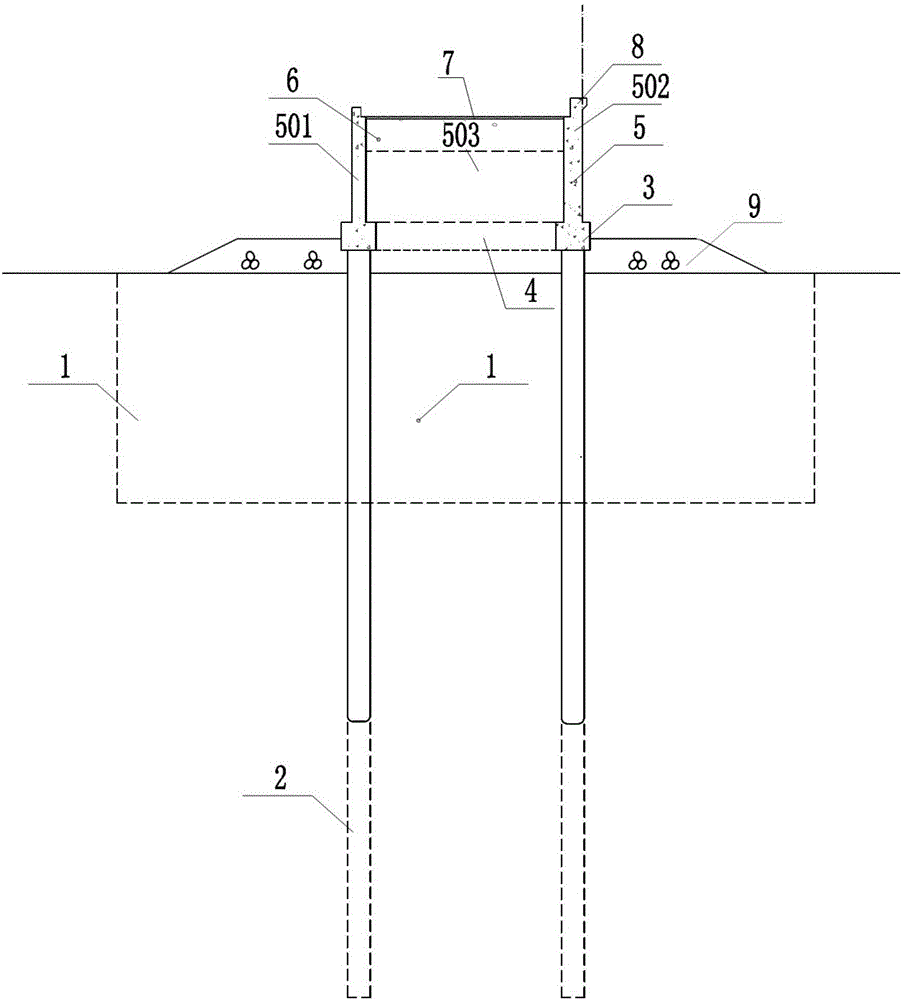

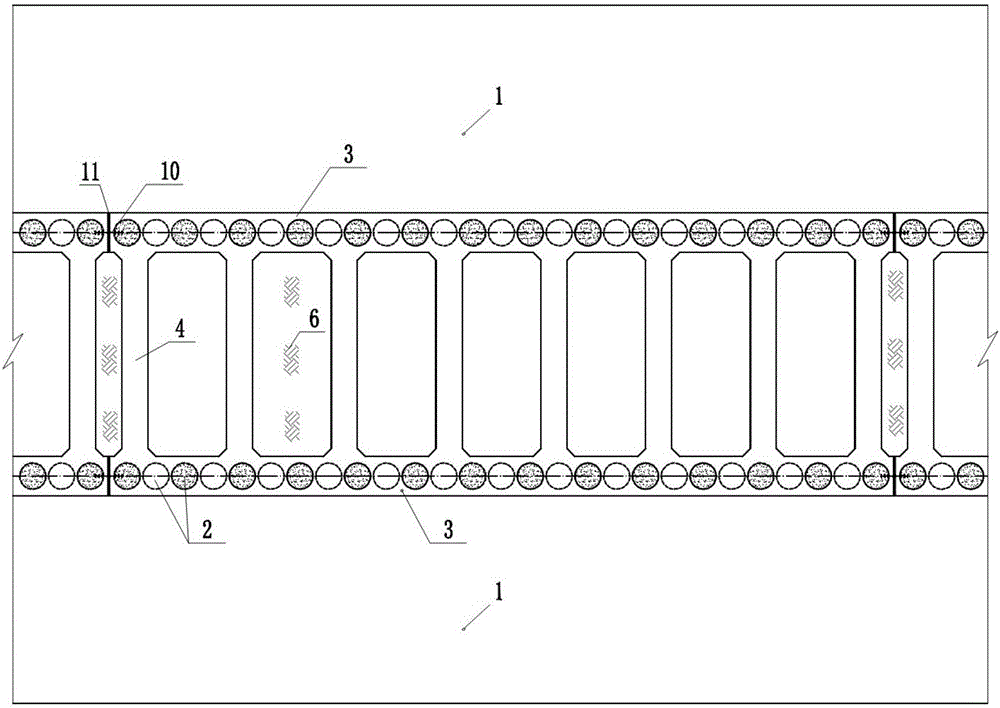

[0020] Such as Figure 1 ~ Figure 3 Shown, a kind of anti-seepage seawall with pile foundation frame rib structure of the present invention includes pile foundation structure 2, pile top crown beam 3, connecting beam 4, frame rib structure 5, solidified air-tight earthwork 6, anti-seepage The wave wall 8 and the anti-scouring structure 9, the pile foundation structure 2 are arranged in the foundation 1 after the pretreatment, the top of the pile foundation structure 2 in the same row is provided with a pile top crown beam 3, and there is a connection between the pile top crown beams 3 The tie beam 4 and the frame rib structure 5 are placed on the pile top crown beam 3 and the tie beam 4, and the frame rib structure 5 is filled with solidified air-tight earthwork 6, which is placed on the pre-treated foundation 1 and is close to the frame Anti-scouring structures 9 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com